Methods and configuration of boil-off gas handling in LNG regasification terminals

一种燃气、再液化的技术,应用在容器排放的方法、气体处理/储存目的、流体处理等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

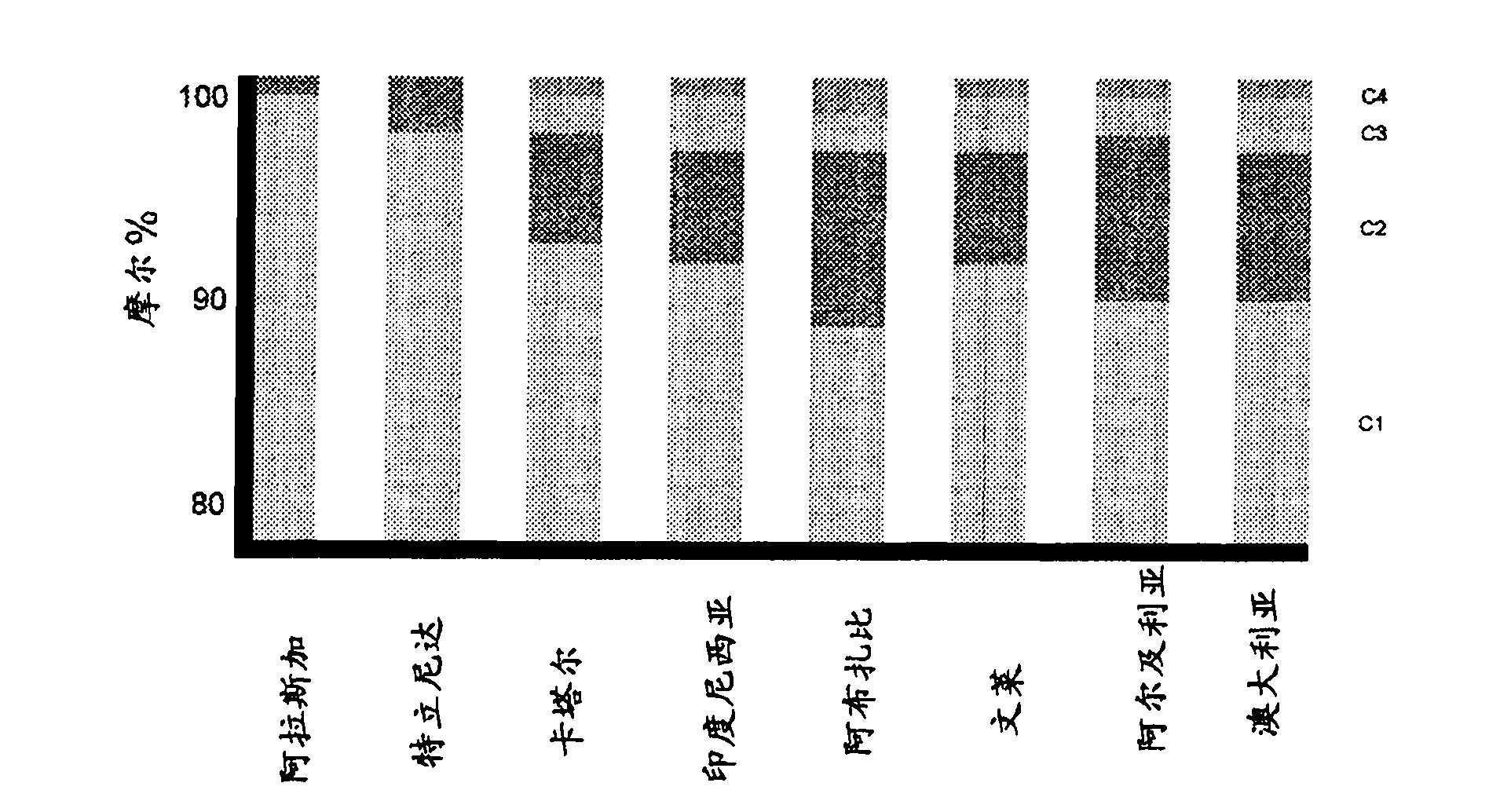

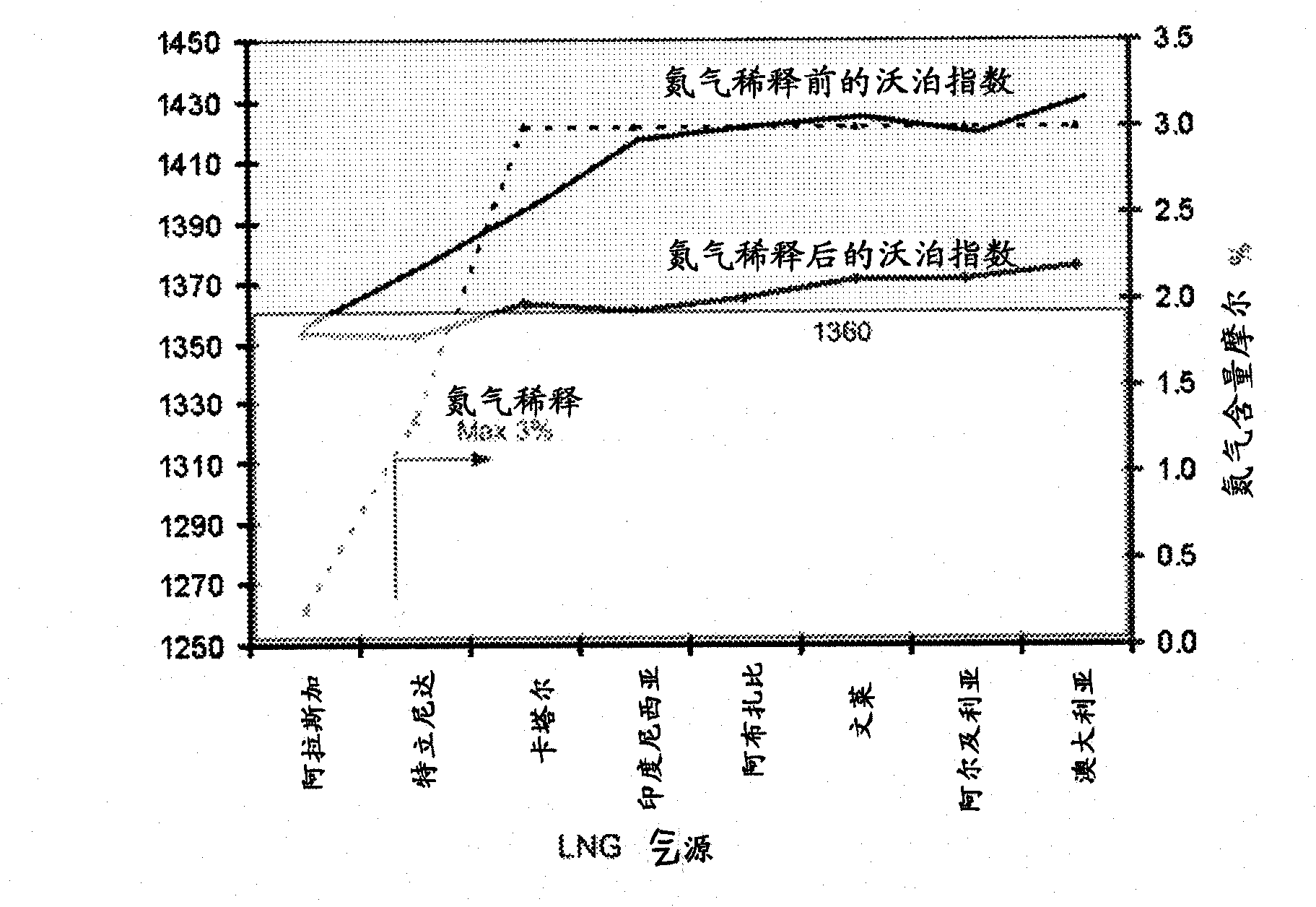

[0019] The inventors have found that, for situations where at least partially vaporized vapor is reliquefied during storage and at least partially condensed within the feed LNG, changes in the Wobbe Index due to aging in LNG storage tanks can be reduced and typically In some cases the change can be prevented entirely. Further flexibility is provided by routing at least another portion of the steam to a fuel manifold or other device utilizing lean natural gas.

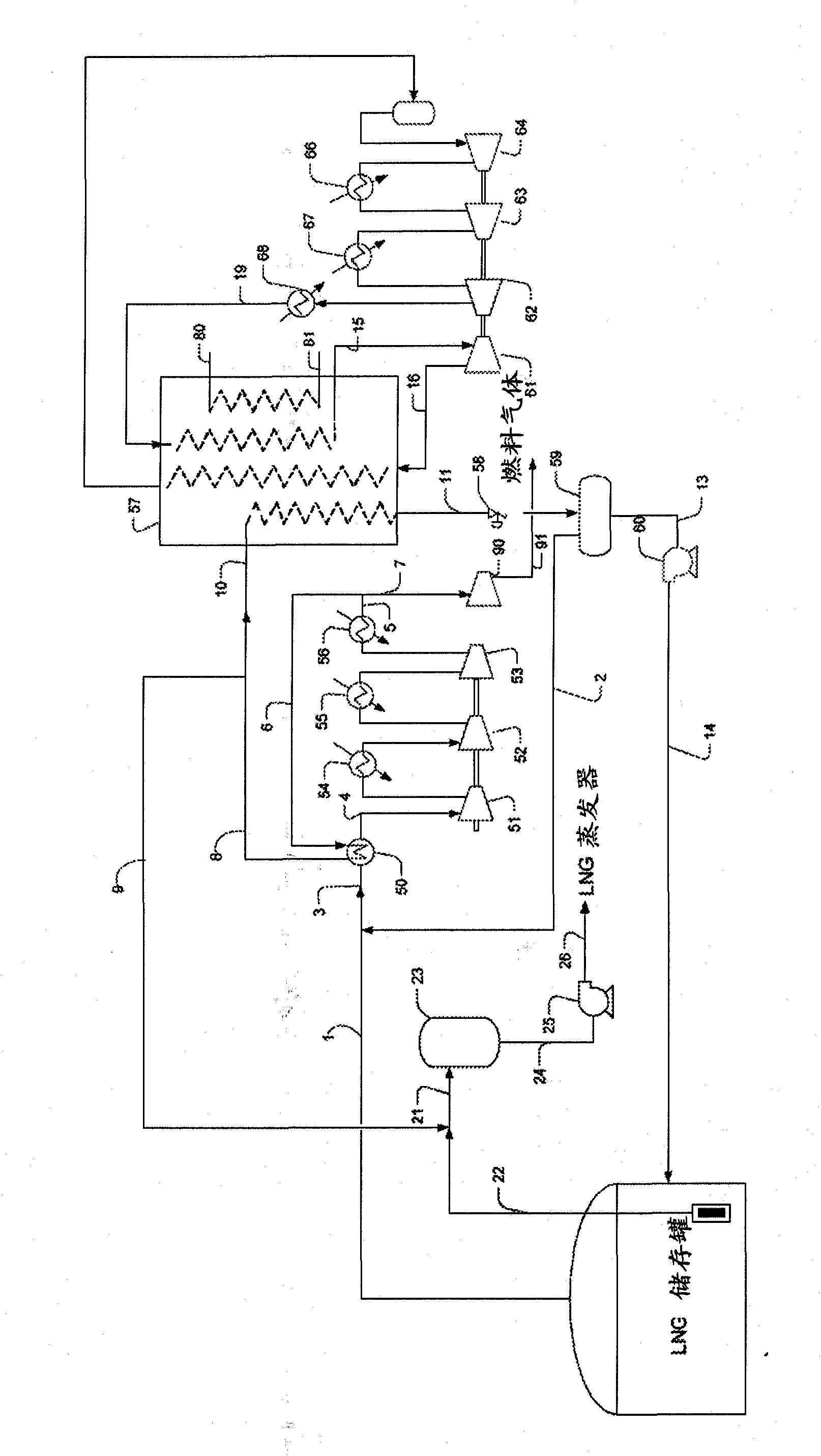

[0020] For example in a particularly preferred method, control of the Wobbe index of the LNG in the LNG storage tank (which is coupled to the regasification unit) can be achieved by means of a compression unit which compresses the cold boil-off gas from the tank, and The first stream of compressed boil-off gas is heat exchanged with cold boil-off gas or LNG to form cooled compressed boil-off gas. A portion of the cooled compressed boil-off gas is then mixed with LNG while another portion of the cooled compressed boil-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com