Patents

Literature

944 results about "LNG storage tank" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A liquefied natural gas storage tank or LNG storage tank is a specialized type of storage tank used for the storage of Liquefied Natural Gas. LNG storage tanks can be found in ground, above ground or in LNG carriers. The common characteristic of LNG Storage tanks is the ability to store LNG at the very low temperature of -162 °C (-260 °F). LNG storage tanks have double containers, where the inner contains LNG and the outer container contains insulation materials. The most common tank type is the full containment tank. Tanks vary greatly in size, depending on usage.

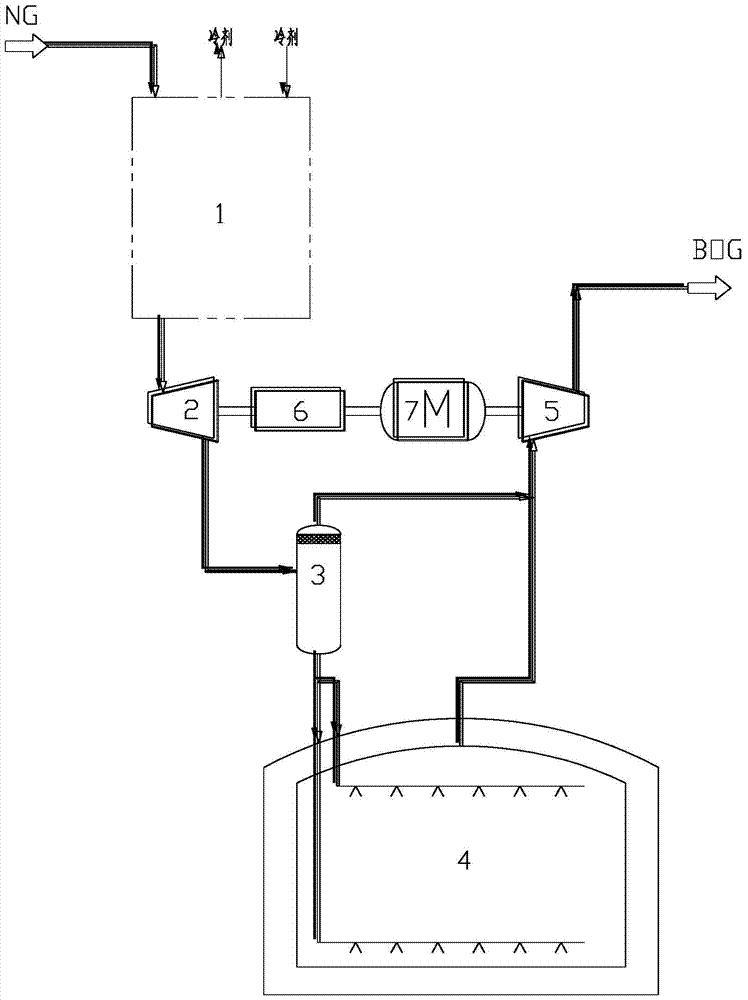

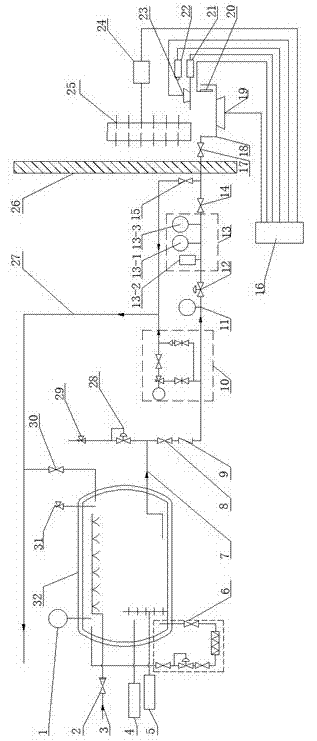

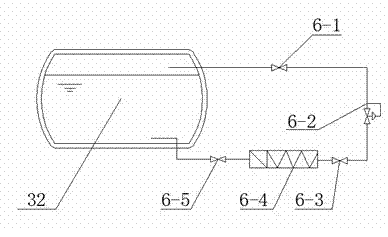

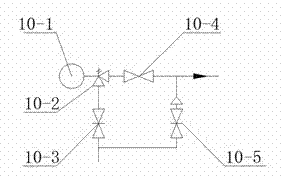

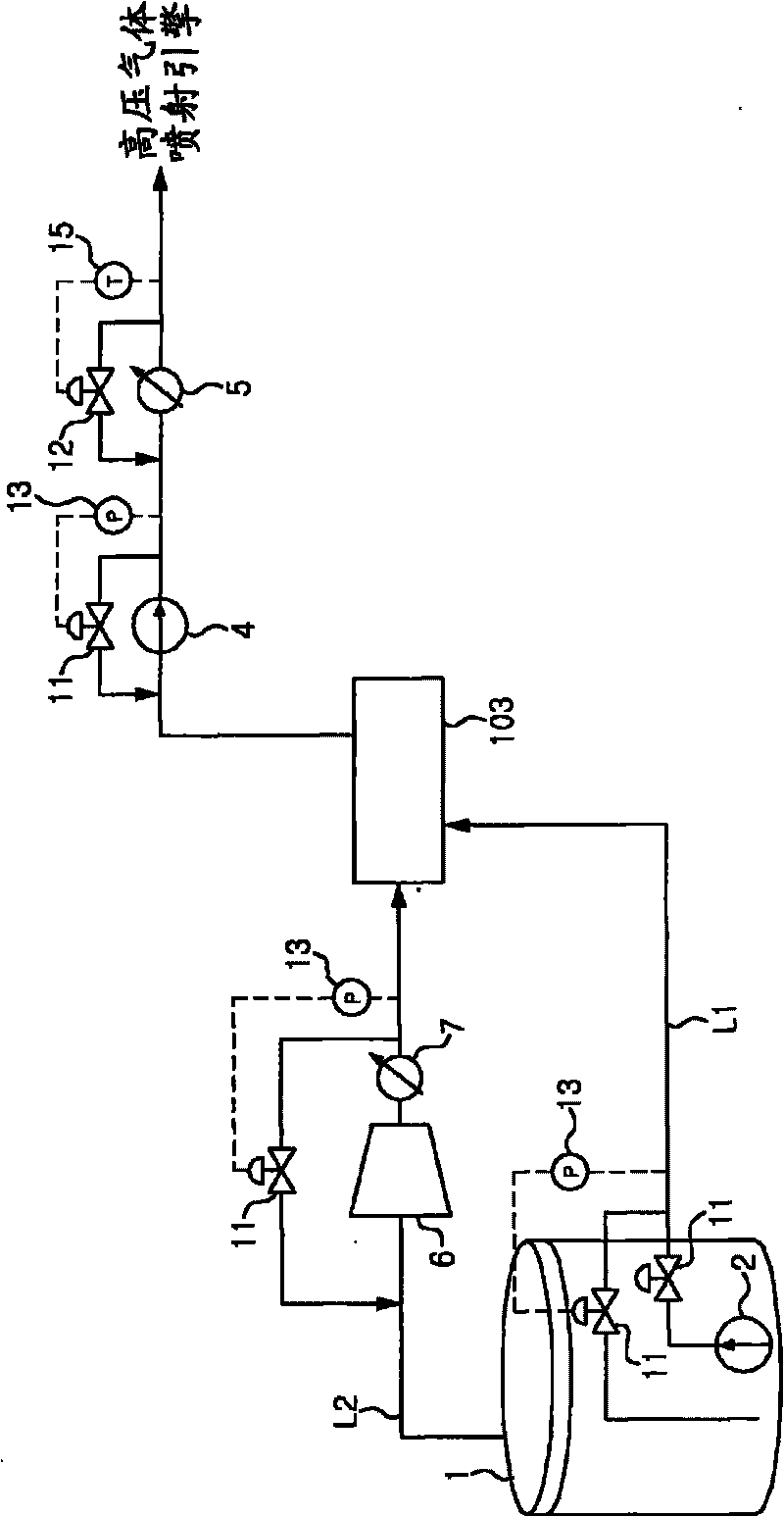

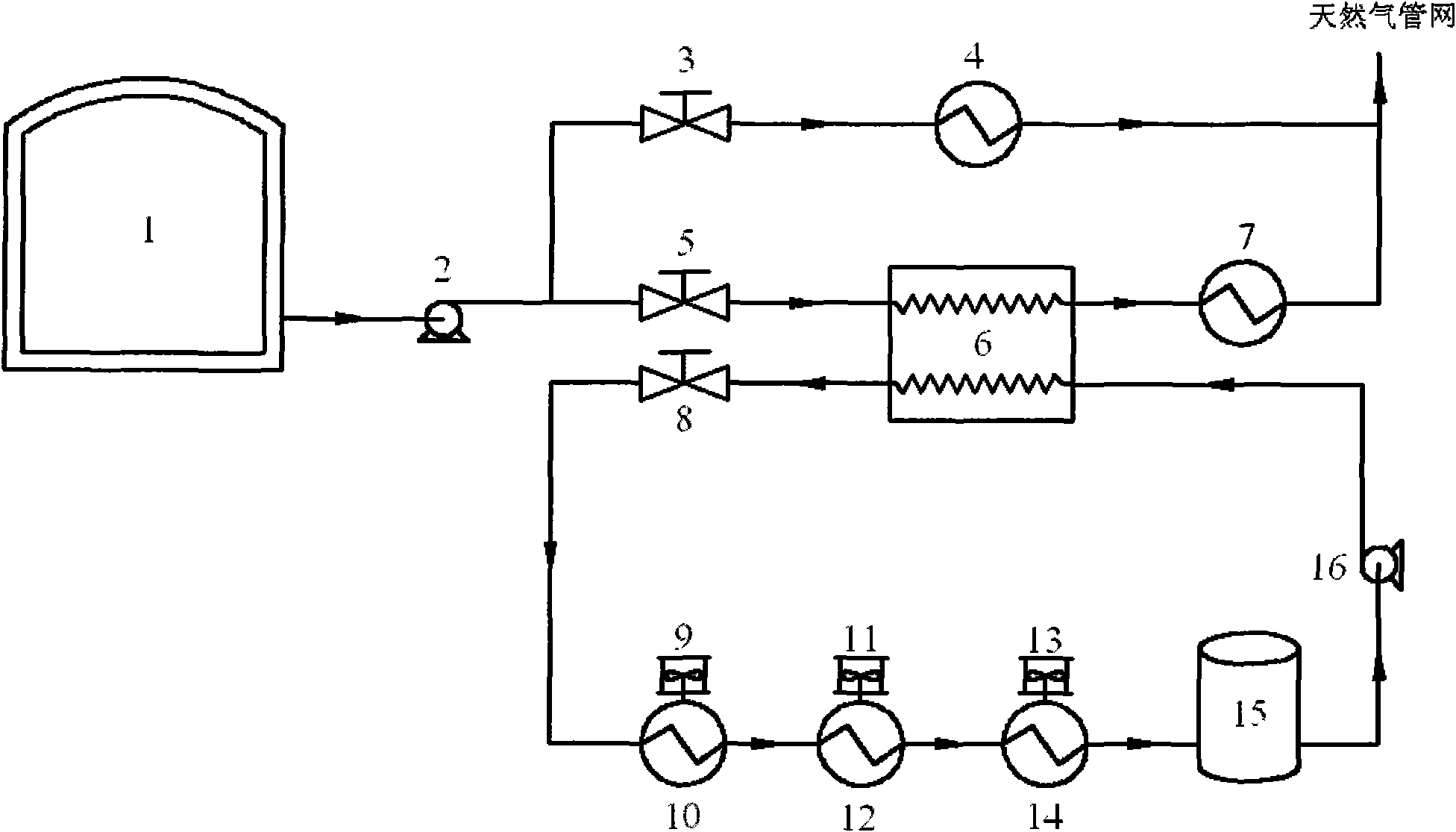

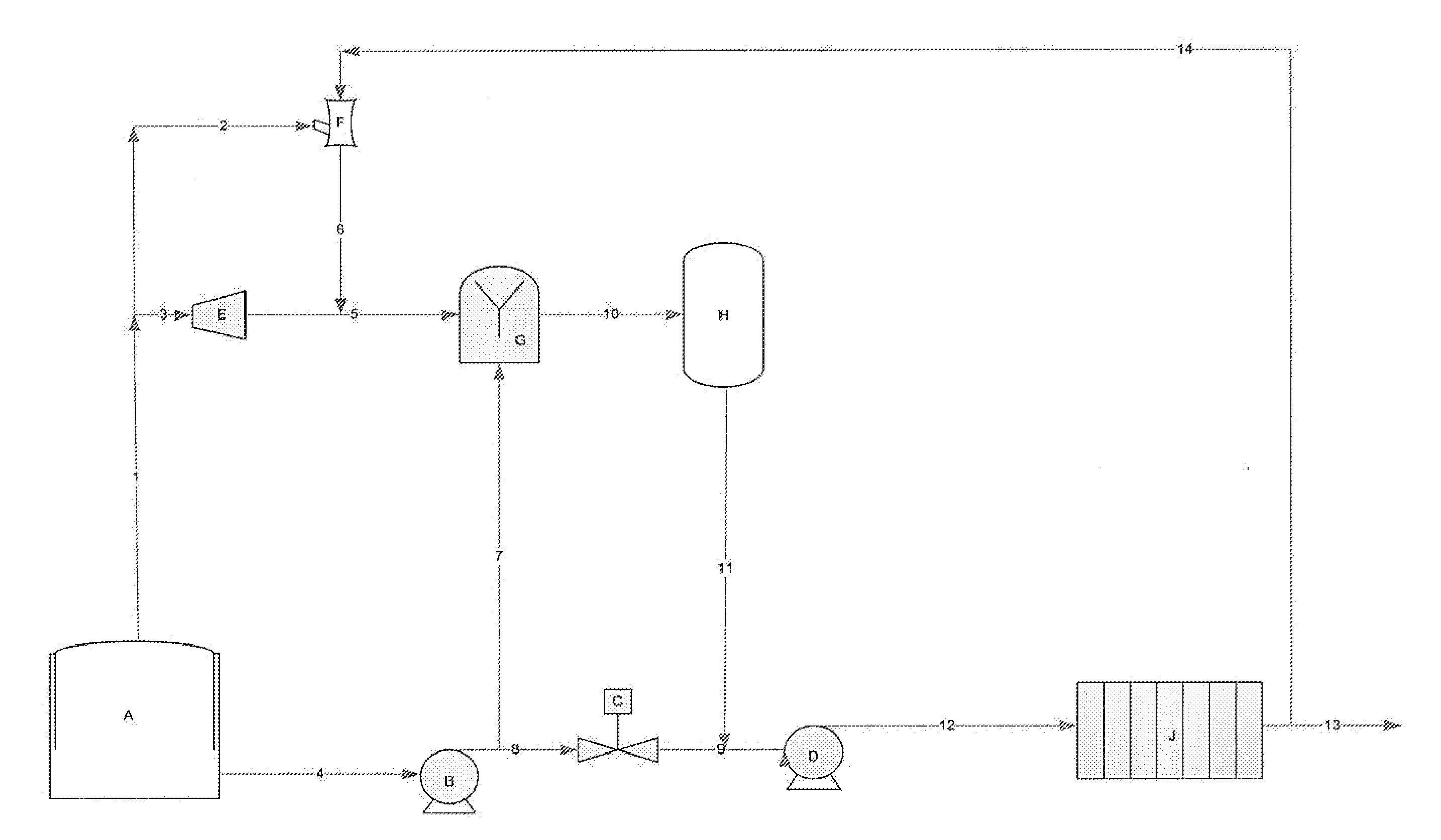

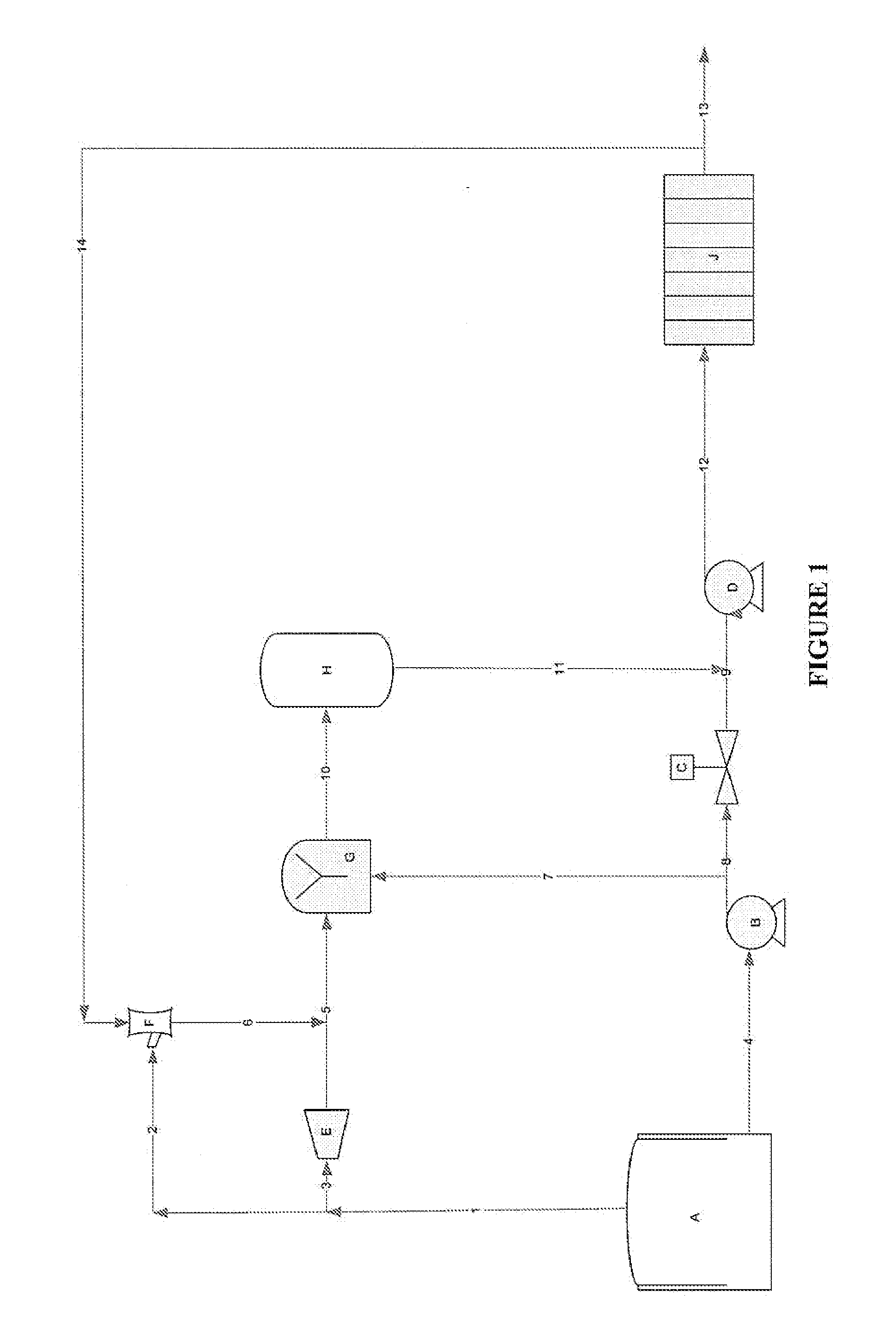

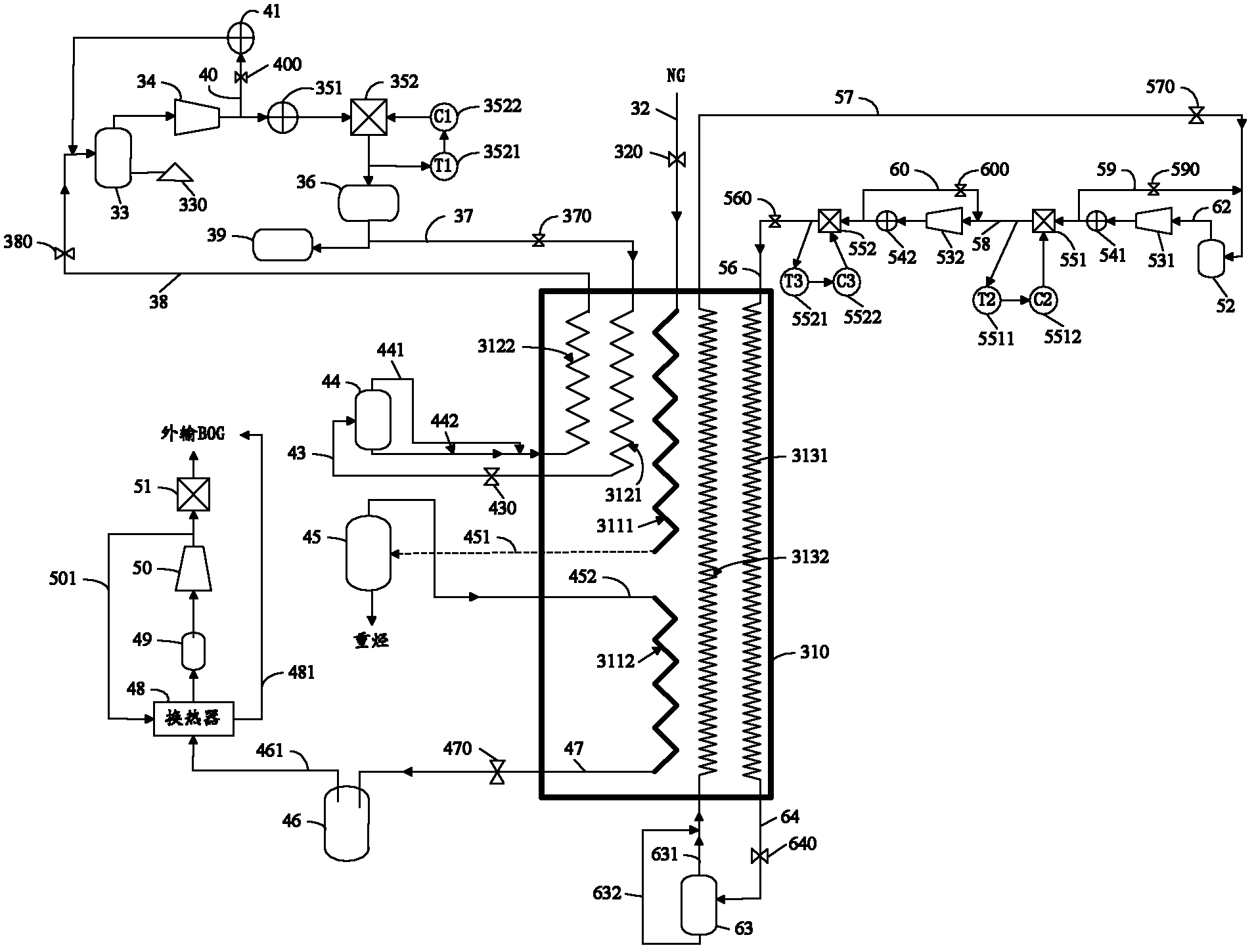

A kind of lng energy recovery process

ActiveCN105240064BReduce the temperatureIncrease productionSteam engine plantsGas phaseMechanical energy

The invention relates to the technical field of natural gas low temperature equipment, in particular to an LNG energy recovery process. By an LNG hydraulic turbine device (or expanding machinery in other forms), high pressure and low temperature LNG converts pressure energy to mechanical energy which is output by a supercharging end of the LNG hydraulic turbine device. Depressurized LNG is further cooled, a gas phase and a liquid phase generated in a depressurizing process are separated by a gas-liquid separation tank, the liquid LNG is charged to an LNG storage tank, and the gas phase BOG and BOG of the LNG storage tank are supercharged together by the supercharging end, namely, a BOG supercharger, of the LNG hydraulic turbine device. The LNG hydraulic turbine device replaces a J-T valve of the LNG product for expanding throttling, as the LNG is lower in temperature, output of the BOG is reduced, LNG yield is improved, and mechanical energy can be recovered by BOG supercharging of the BOG supercharging end.

Owner:SICHUAN HENGRI GAS ENG CO LTD

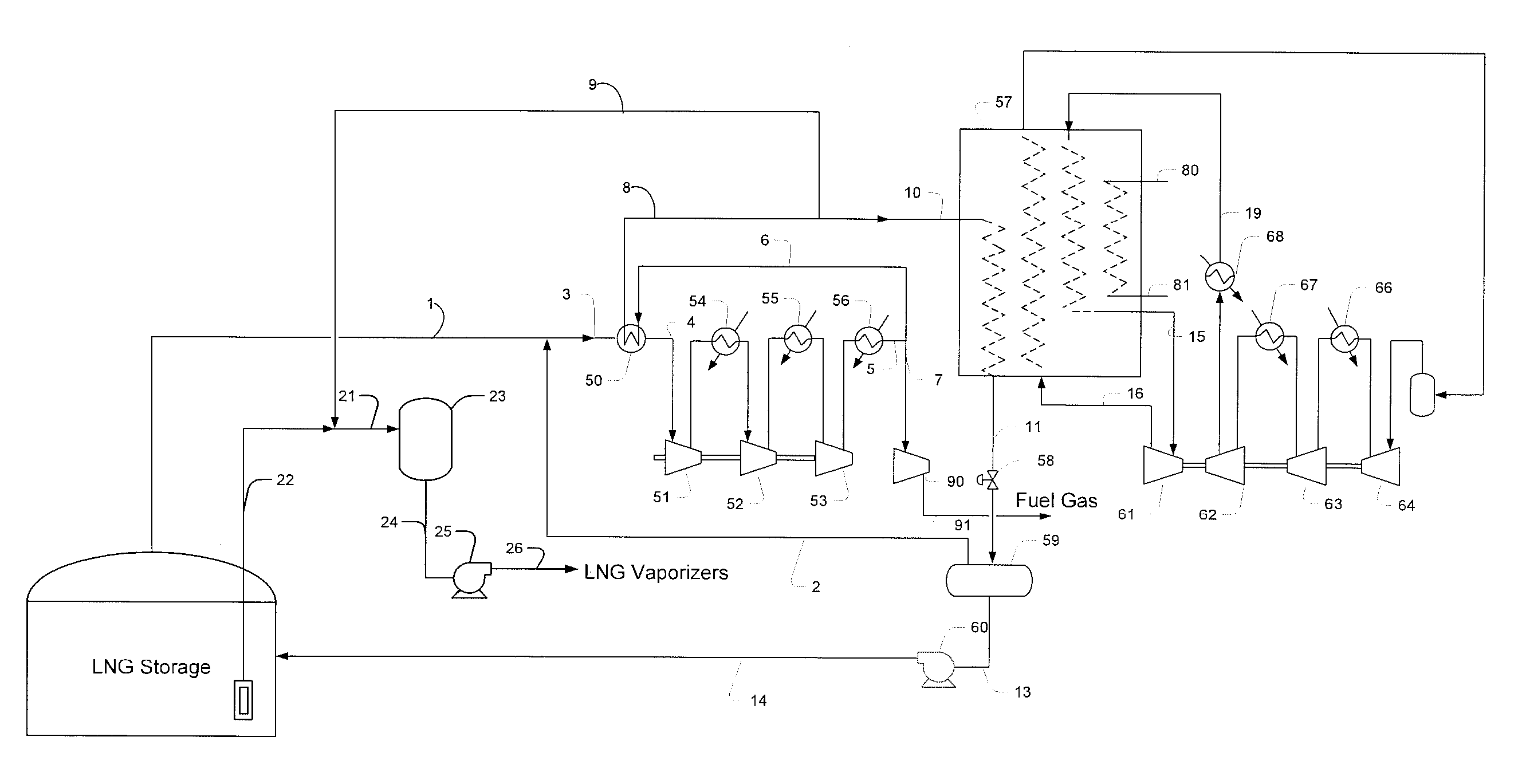

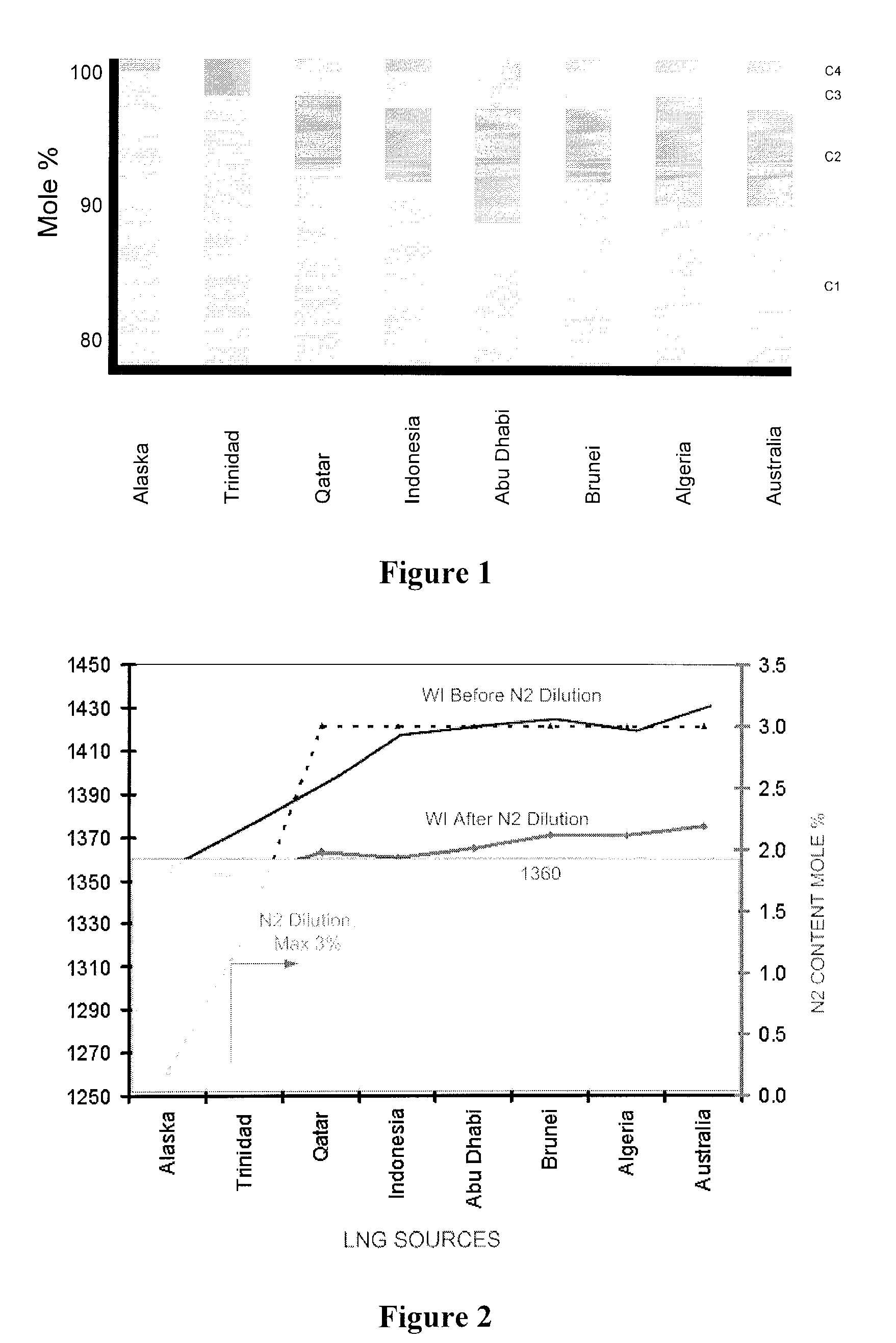

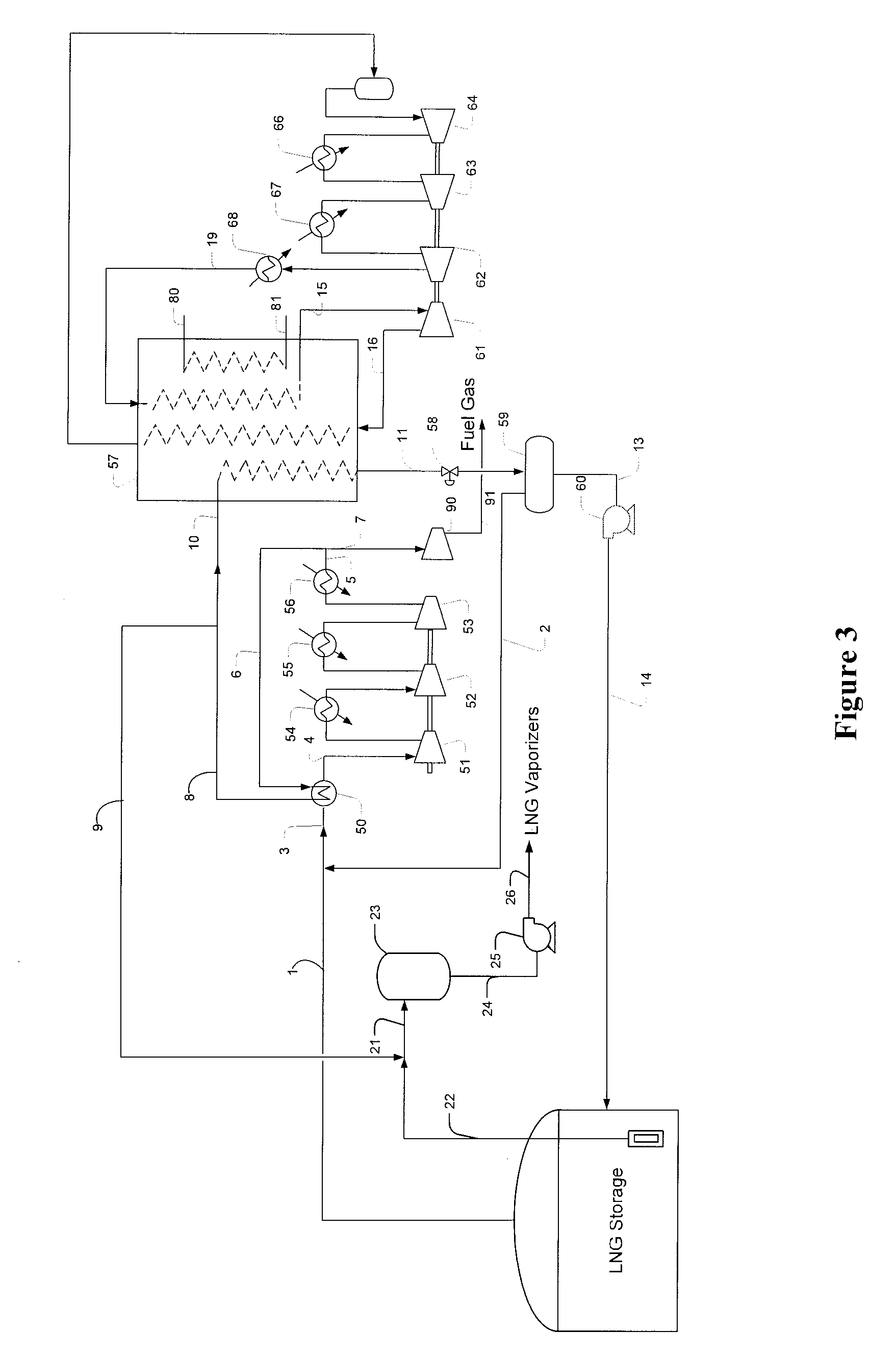

Methods and Configurations of Boil-off Gas Handling in LNG Regasification Terminals

InactiveUS20110056238A1Stable storage tank pressure controlStable controlSolidificationLiquefactionProcess engineeringWobbe index

A LNG storage and regasification plant includes a reliquefaction unit in which boil-off vapors from the storage tanks are re liquefied and recycled back to the LNG storage tanks for tank pressure and Wobbe index control. Preferably, LNG cold is used for reliquefaction and operational flexibility is achieved by feeding a portion of the pressurized boil-off gas to a fuel gas header and / or to be recondensed by the sendout LNG.

Owner:FLUOR TECH CORP

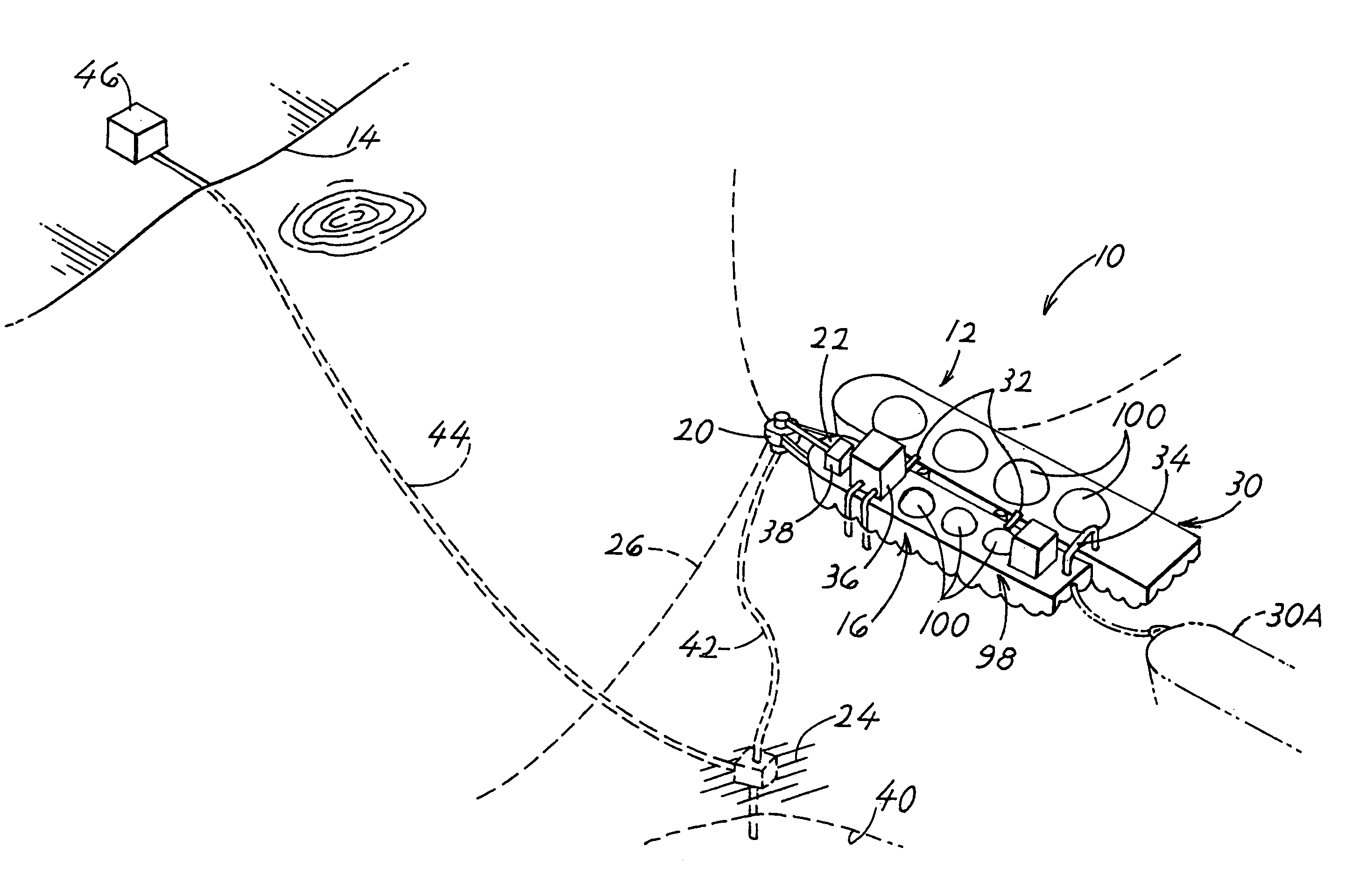

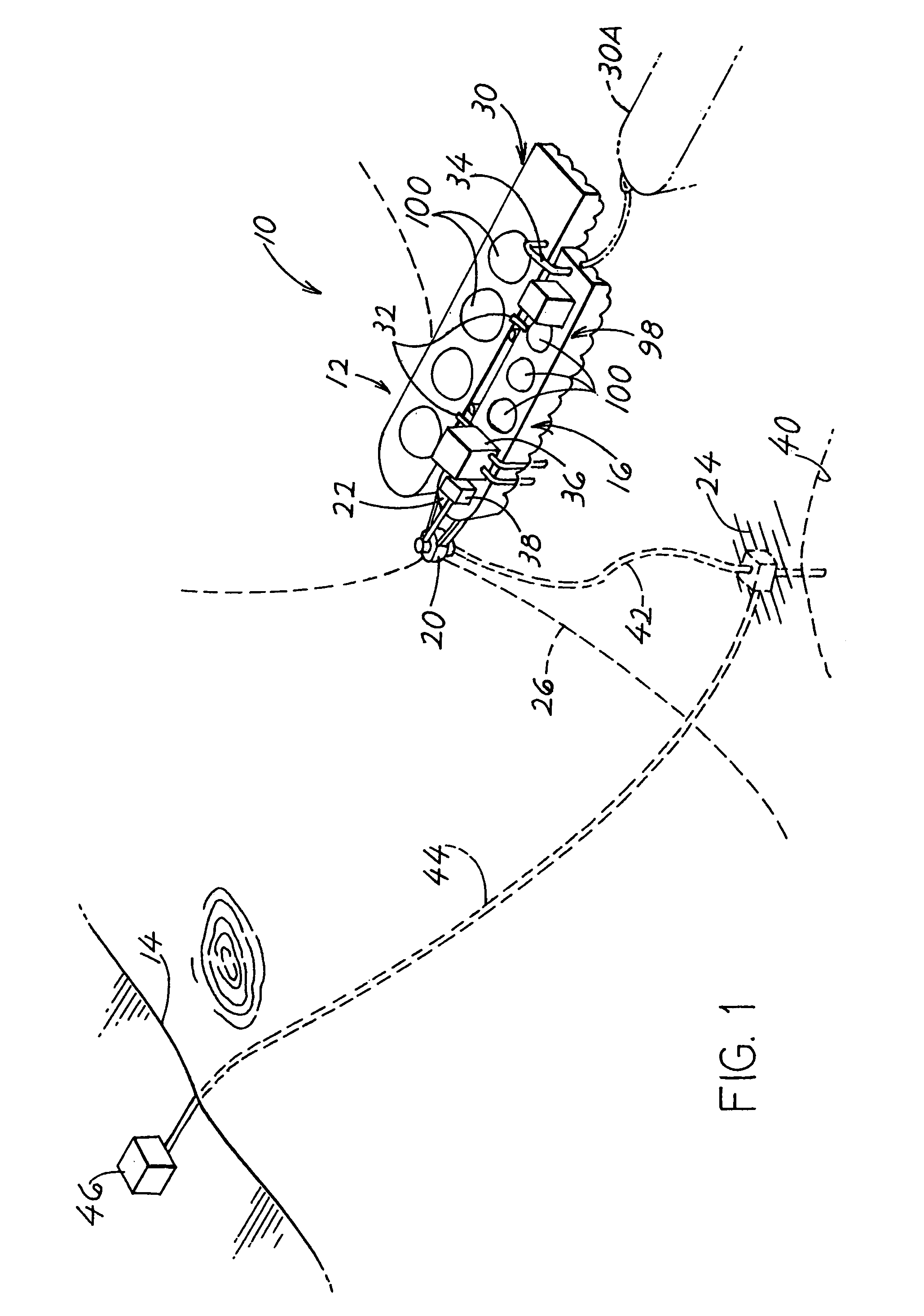

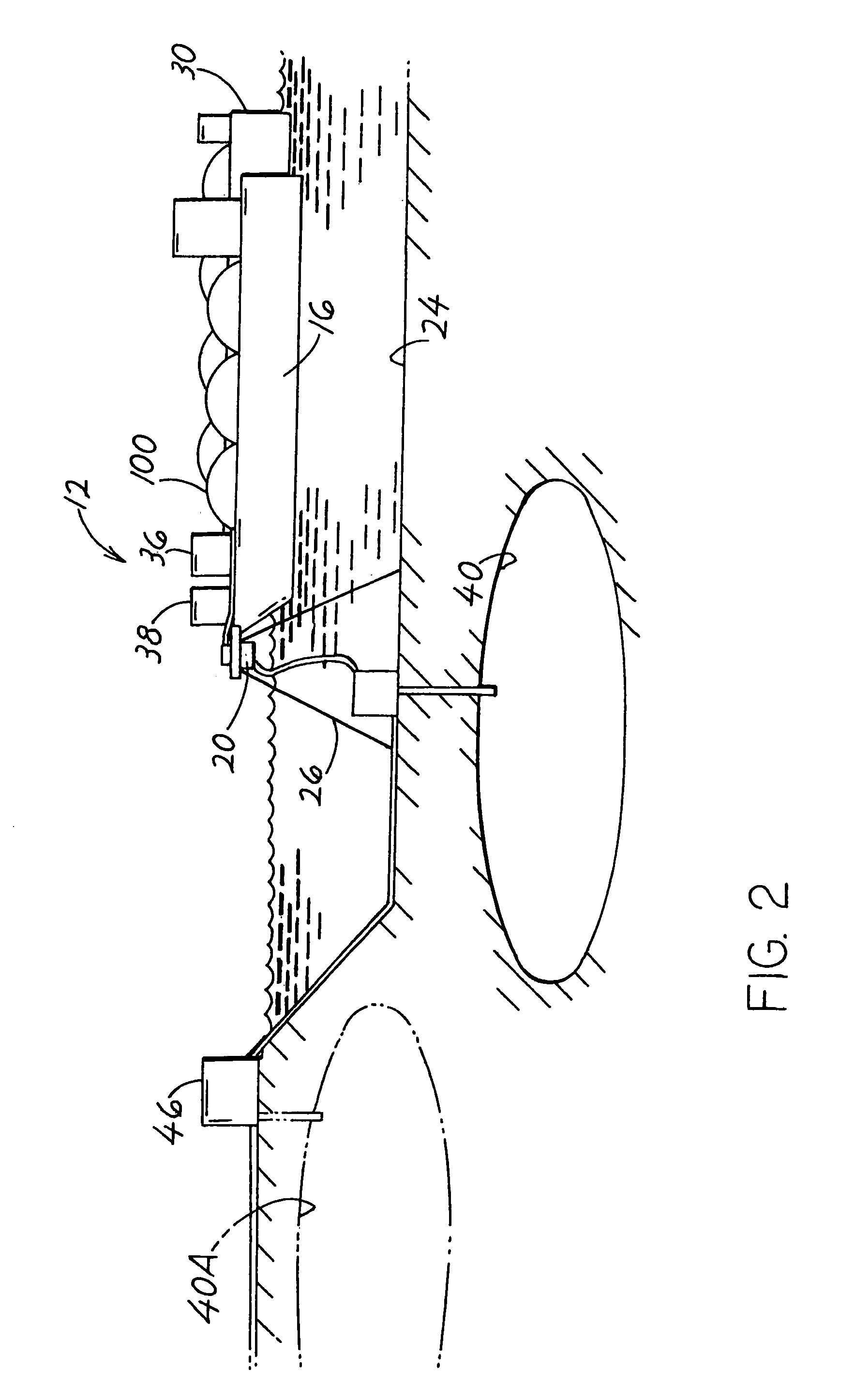

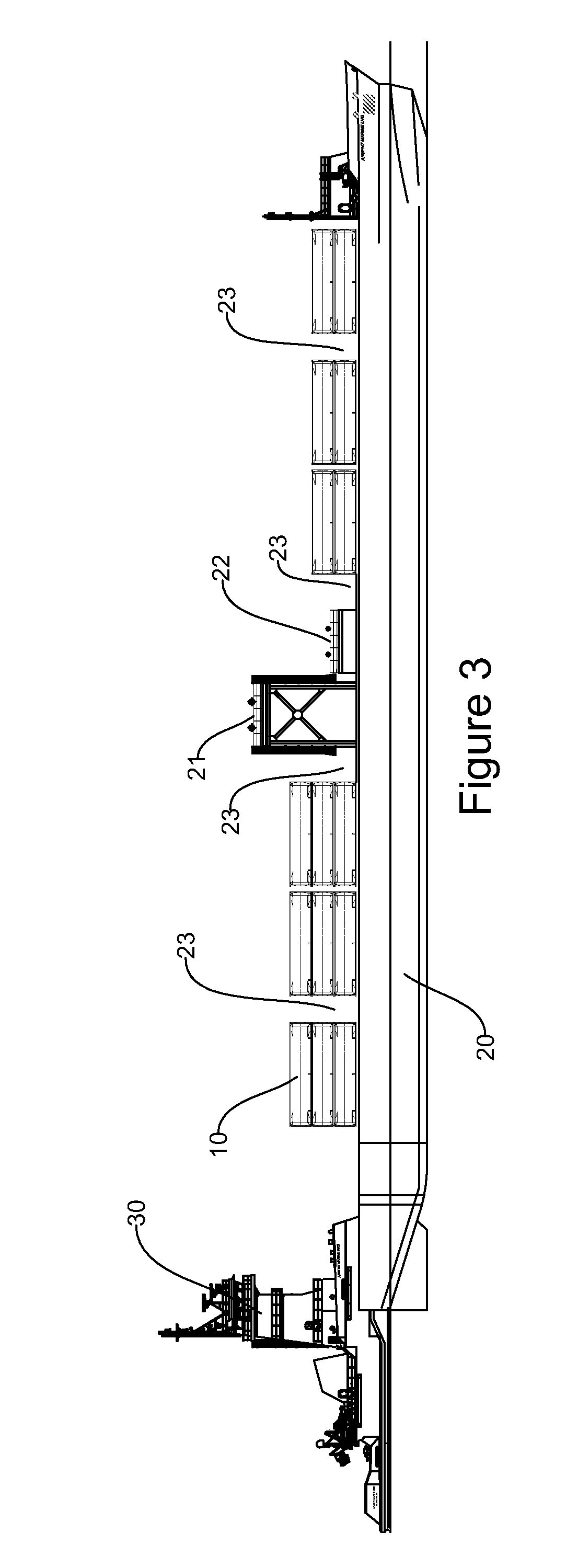

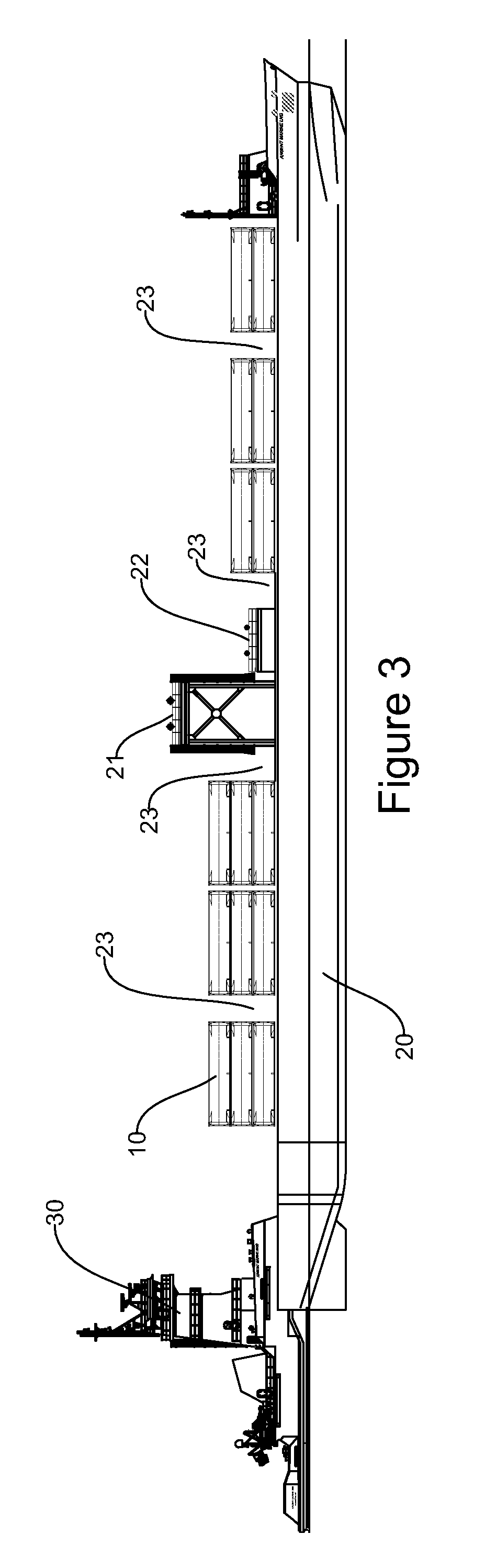

Quick LNG offloading

ActiveUS7080673B2Low costReceive quicklyGas handling applicationsGas handling/storage effectsProduct gasEngineering

A system of the type wherein LNG from a tanker (30) is offloaded to a moored vessel (16), which has a regas unit (36) which heats the LNG to transform it into gaseous hydrocarbons, and which has a pump unit (38) that pumps the gaseous hydrocarbons to a consumer (46) such as an onshore gas distribution facility. The system is constructed to enable more rapid tanker unloading so the tanker is released earlier to sail back to a pickup location. The moored vessel has a thermally insulated LNG storage facility such as LNG tanks (100), with a capacity to store all LNG not regassed during offloading of the tanker. The regas unit has sufficient capacity to regas all LNG received in one tanker load, before the tanker returns with another load of LNG.

Owner:SINGLE BUOY MOORINGS INC

Floating LNG regasification facility with LNG storage vessel

InactiveUS20080295526A1Well formedContainer filling methodsGas handling applicationsMarine engineeringSubmarine pipeline

An LNG terminal is disclosed which includes an offshore mooring turret, an LNG storage vessel operatively coupled to the mooring turret, the LNG storage vessel including at least one LNG storage tank for the storage of liquid natural gas and a regasification vessel operatively coupled to the LNG storage vessel. A method of operating an offshore LNG terminal is also disclosed which includes obtaining liquefied natural gas from at least one LNG storage tank on an LNG storage vessel that is operatively coupled to a mooring turret, regasifying the liquefied natural gas from the LNG storage vessel using a regasification vessel operatively coupled to the LNG storage vessel, and supplying the regasified gas to at least one subsea pipeline via the mooring turret.

Owner:SOFEC

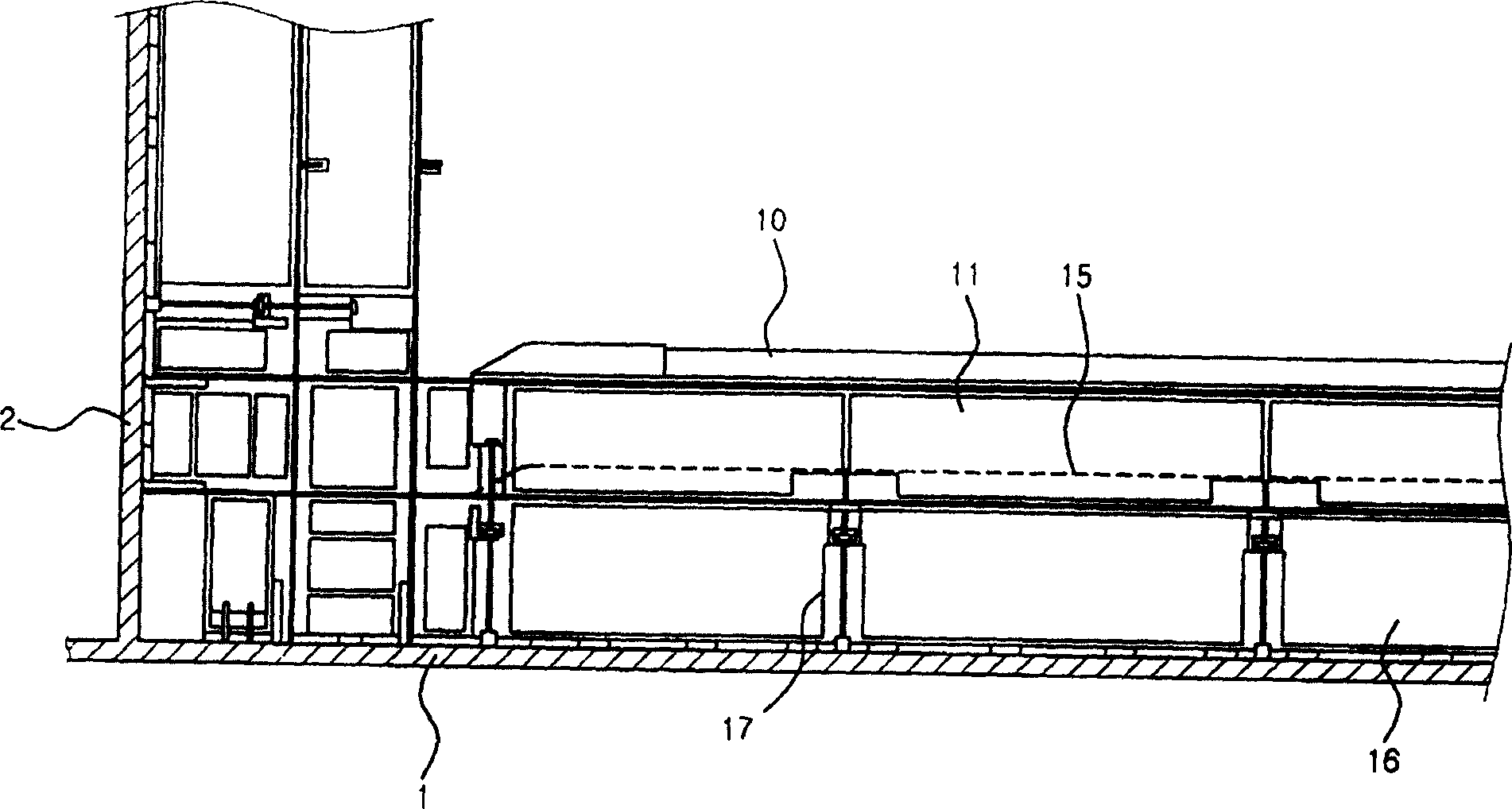

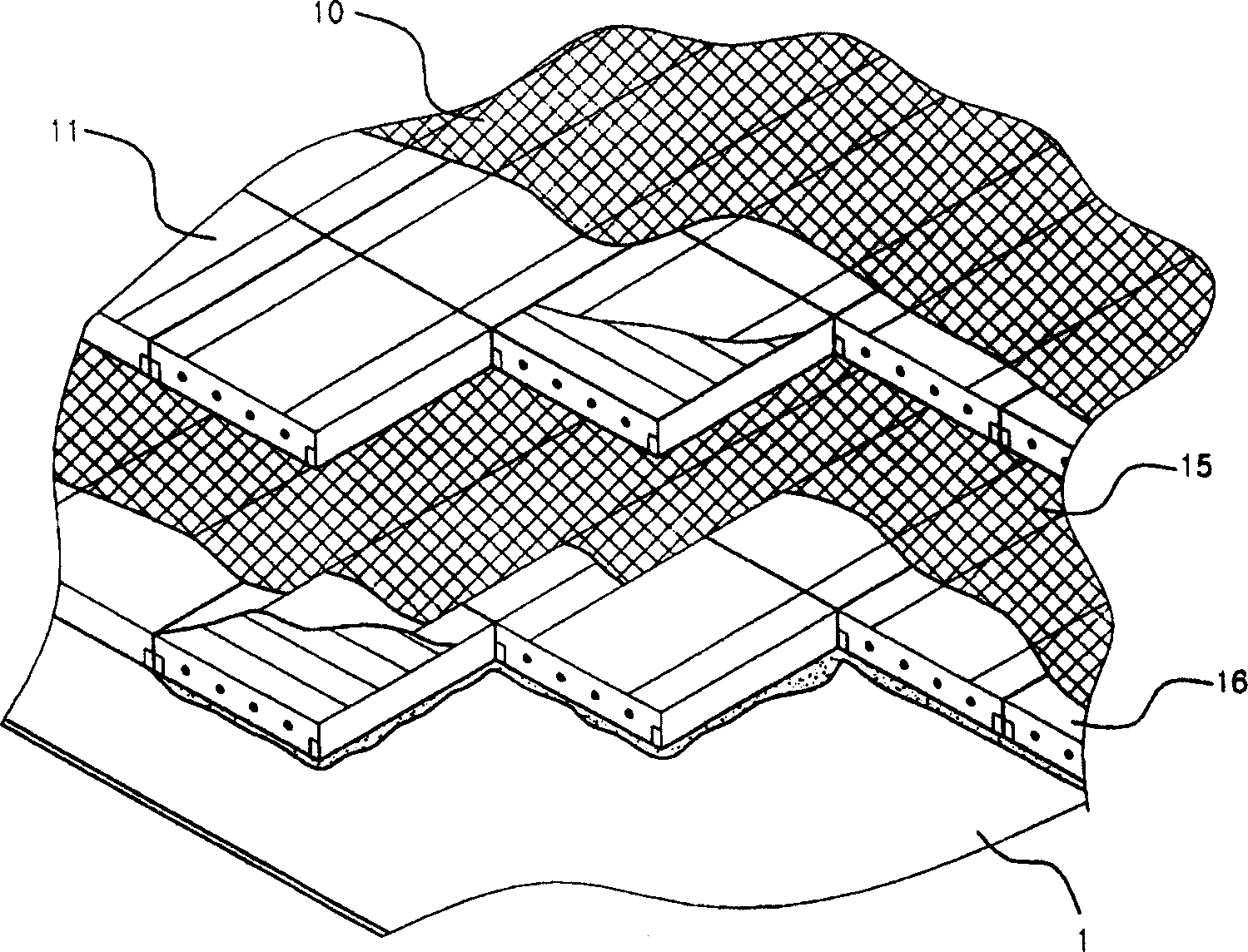

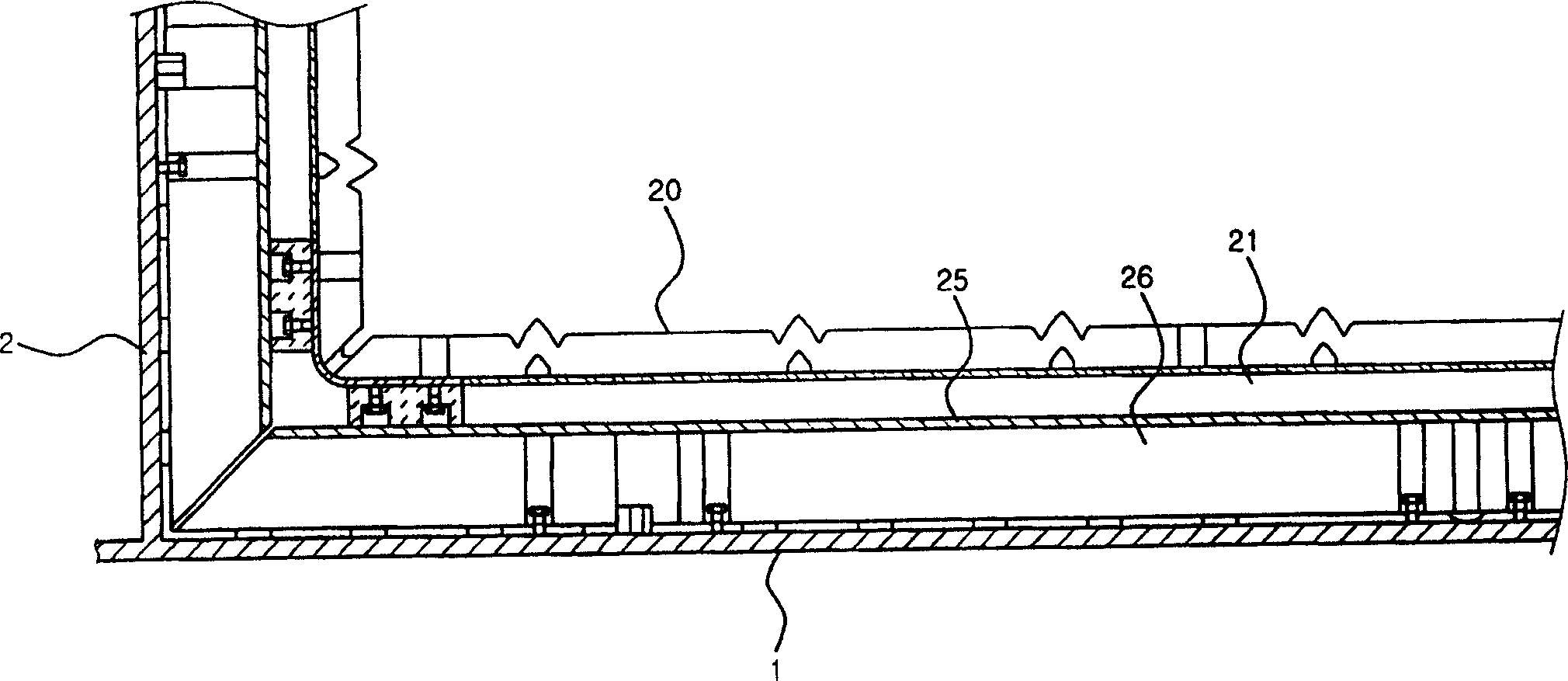

Lng storage tank and constructing method thereof

InactiveCN1898124AMaintain liquid-tight propertiesAvoid breakingContainer filling methodsRailway vehiclesEngineeringStructural engineering

Disclosed is a liquid container adapted to store liquefied natural gas (LNG). The LNG storage container include a sealing wall directly contacting liquid contained in the tank and a structural wall, which is an exterior wall or inner structure integrated with the exterior wall. The container further includes a plurality of connectors mechanically connecting the sealing wall and the structural wall and an intermediate wall structure positioned between the structural wall and the interior wall. The intermediate wall structure is configured to move relative to at least one of the interior wall and the structural wall.

Owner:KC LNG TECH CO LTD ENTIRE RIGHT

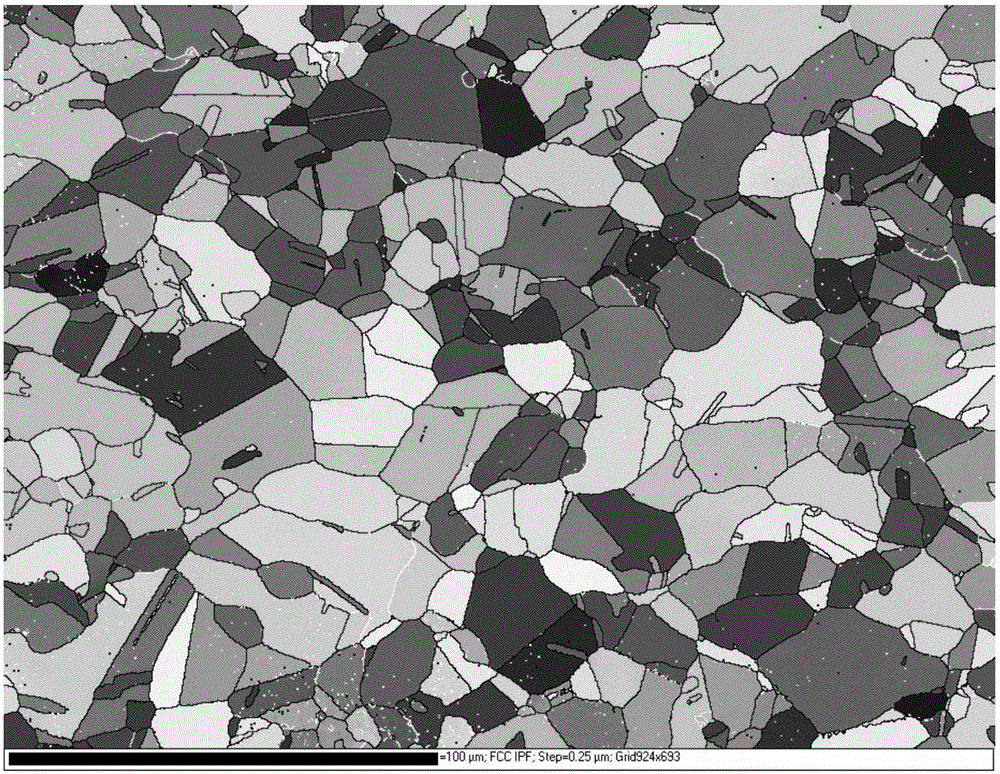

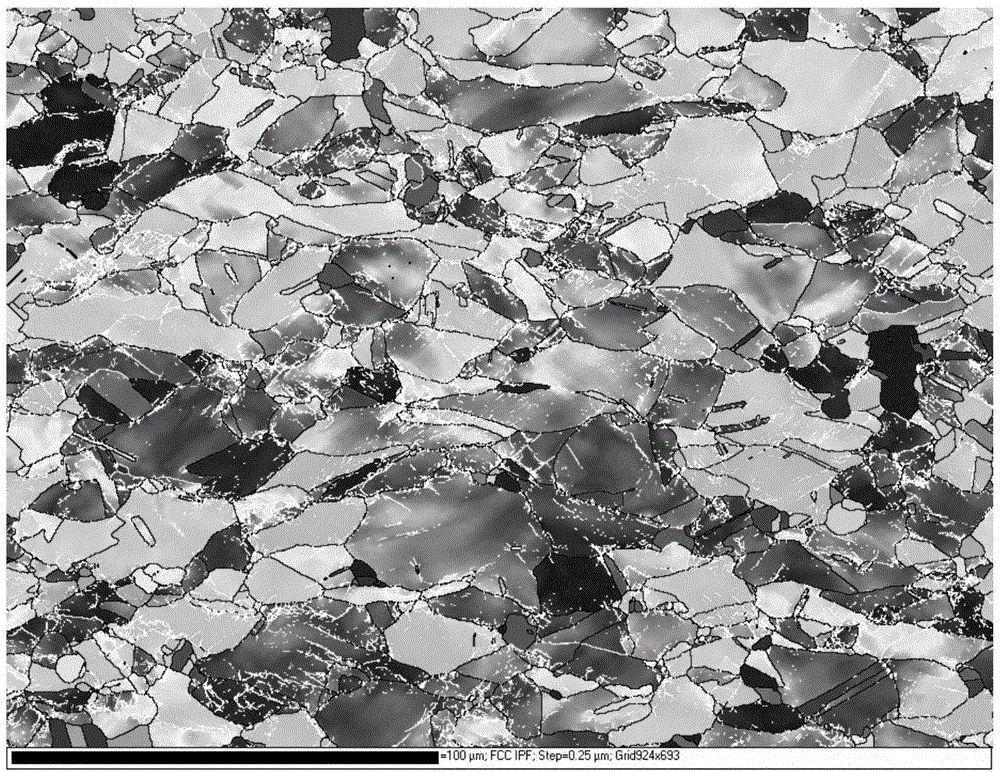

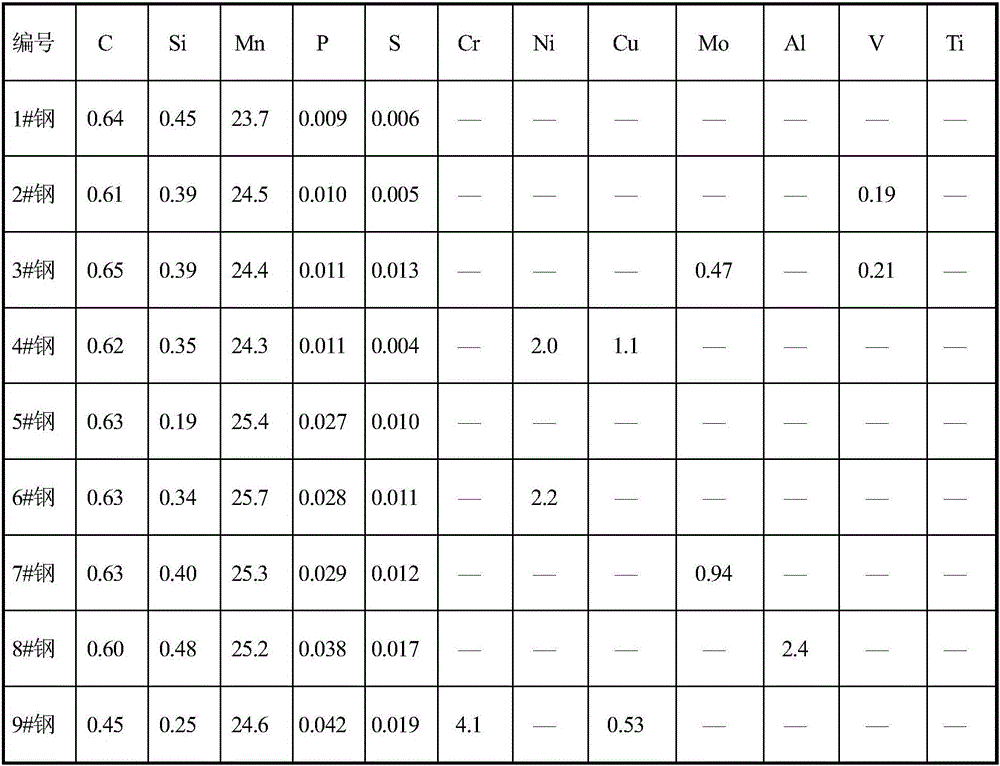

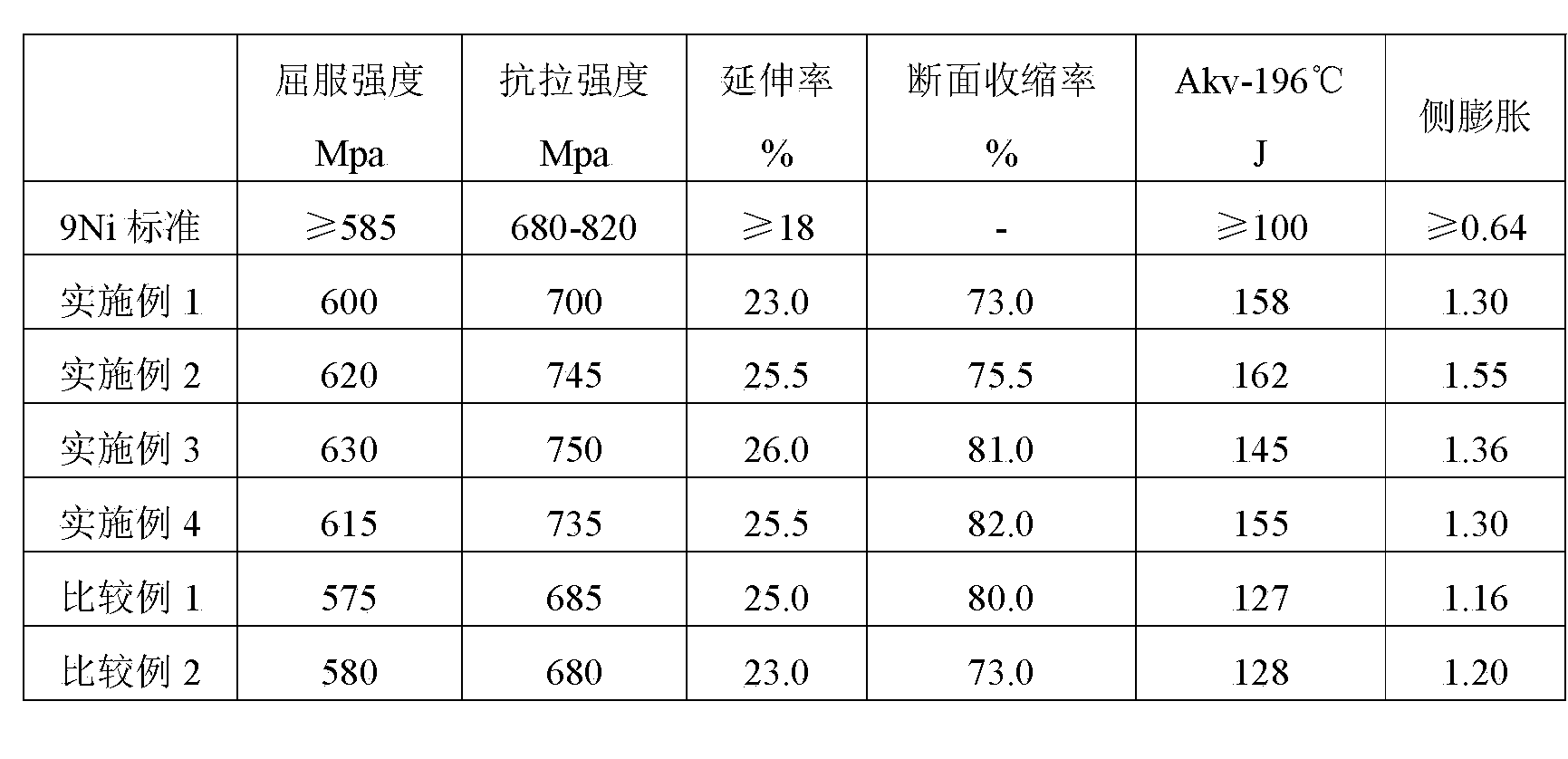

Design of high-manganese medium-thickness plate applied to LNG (Liquefied Natural Gas) storage tanks and production method thereof

ActiveCN107177786AImprove strong plasticityExcellent -196℃ ultra-low temperature impact toughnessChemical compositionImpurity

The invention relates to design of a high-manganese medium-thickness plate applied to LNG (Liquefied Natural Gas) storage tanks and a production method thereof and belongs to the field of steel materials. The high-manganese medium-thickness plate comprises the following chemical components in percentage by weight: 0.45-0.67% of C, 0.02-0.48% of Si, 23.70-27.20% of Mn, less than or equal to 0.051% of P, less than or equal to 0.02% of S, 0.00-2.20% of Ni, 0.00-4.13% of Cr, 0.00-1.10% of Cu, 0.00-0.94% of Mo, 0.00-0.21% of V, 0.00-4.64% of Al and the balance of Fe and inevitable impurities. The production method of the high-manganese medium-thickness plate comprises the steps of smelting, pouring, forging and rolling. The product obtains a single-phase austenite structure; the experiment steel has high plasticity, simultaneously obtains excellent impact toughness at ultralow temperature of 196 DEG C below zero and has potential for replacing 9% Ni steel; and the cost of the experiment steel is far lower than that of the 9% Ni steel.

Owner:NORTHEASTERN UNIV

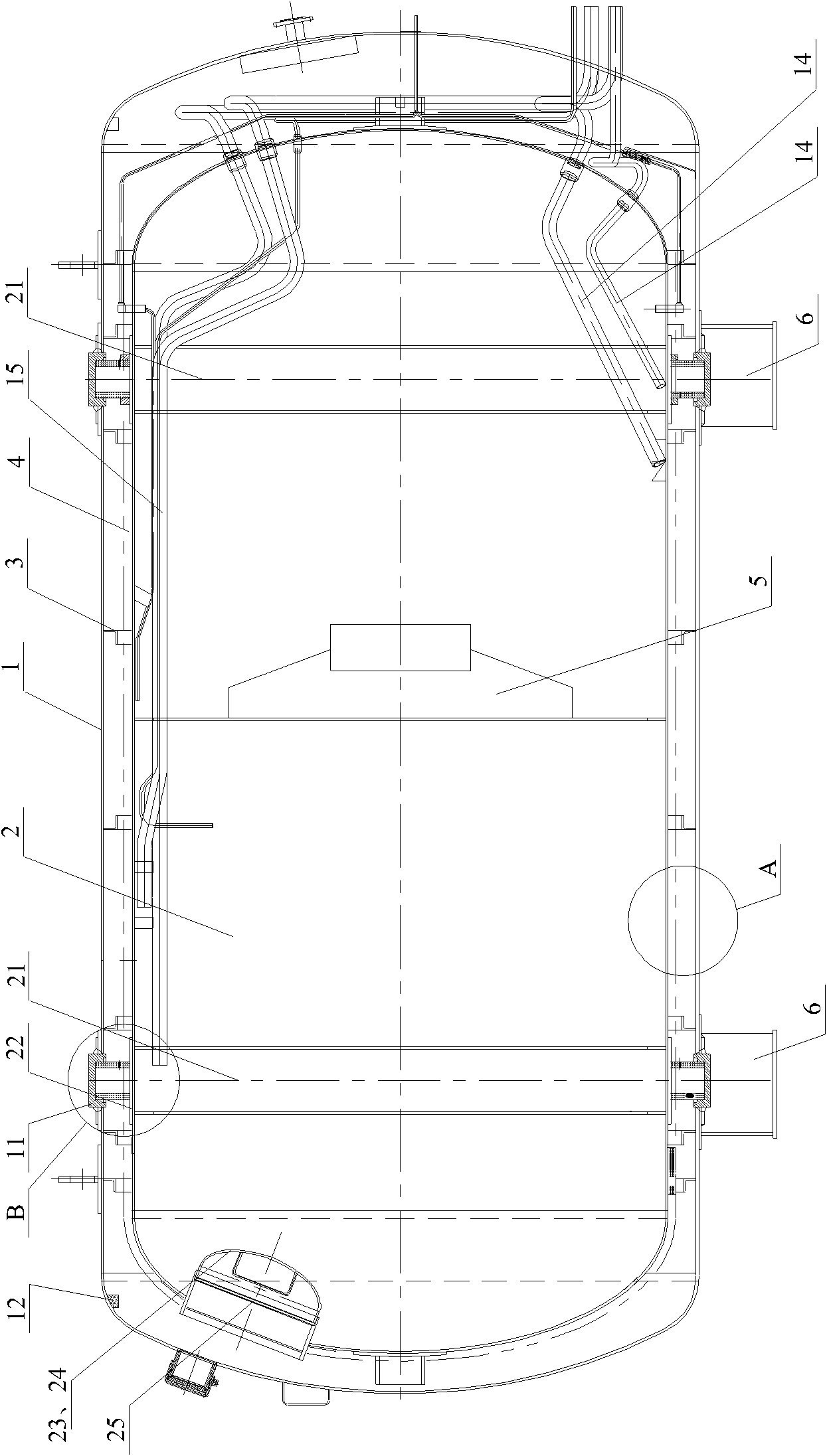

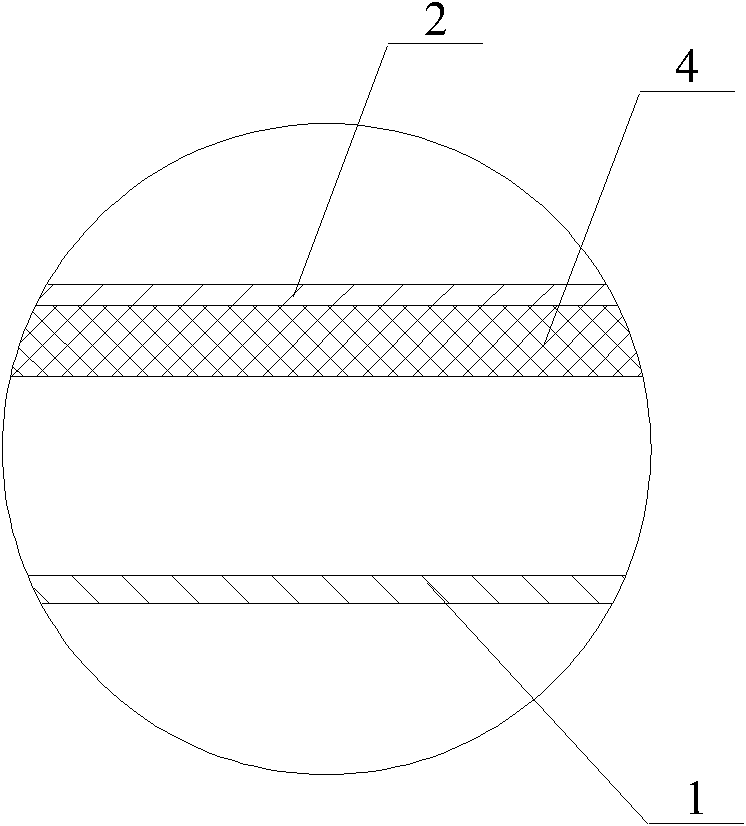

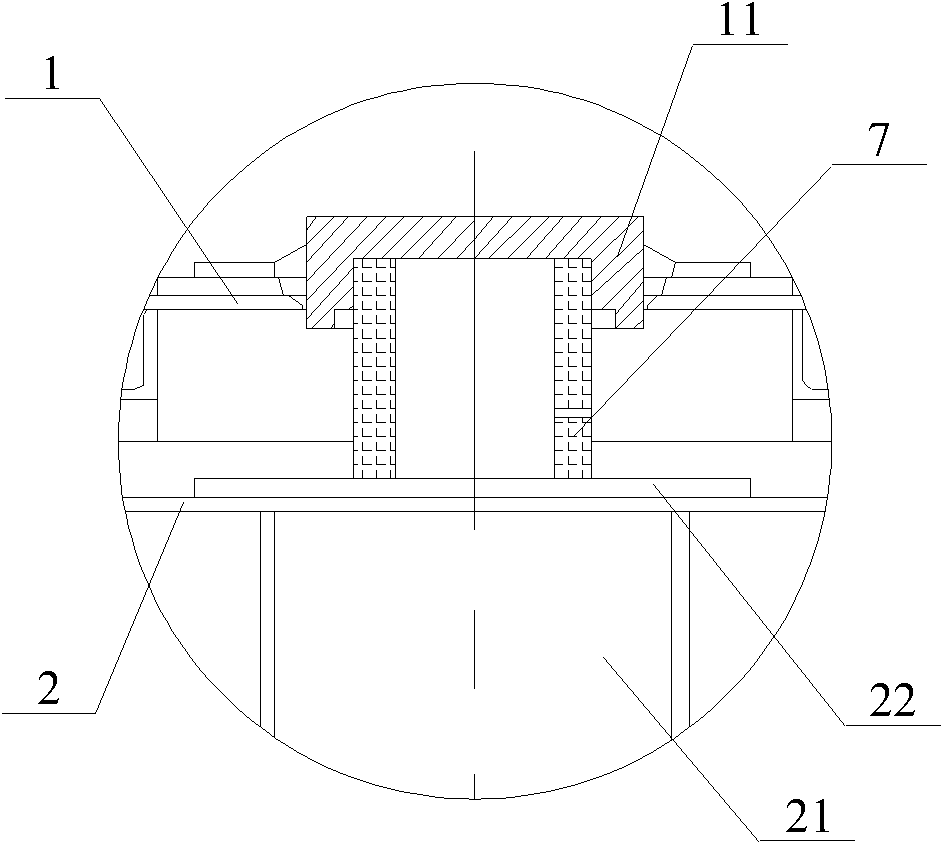

LNG storage tank for diesel-LNG hybrid power ship

ActiveCN101915356ASatisfy sailing requirementsReduce shockPressure vesselsInsulation layerEngineering

The invention discloses an LNG storage tank for a diesel-LNG hybrid power ship. The LNG storage tank comprises a sealed shell and a sealed inner container arranged in the shell, wherein the shell is provided with a first LNG filling pipe communicated with the bottom of the inner container; the inner container is supported in the shell through a plurality of glass steel pipe struts, and a heat insulation layer is wound on the inner container; an interlayer between the shell and the inner container is vacuum; the middle part of the inner container is provided with a wave-proof device; the wave-proof device comprises a central pipe and a support plate; the axis of the central pipe is superposed with the axis of the inner container; and the support plate is trumpet-shaped, an opening at the small end of the support plate is welded with the outer circumference surface of the central pipe, and an opening at the large end of the support plate is welded with the inner wall of the inner container. Because the wave-proof plate with a special structure is arranged in the inner container, impact and oscillation of liquid in the tank body in each direction when the ship runs are reduced, and the safety is ensured. Meanwhile, the LNG storage tank provides proper liquid storage volume and good heat insulation performance, and is fully suitable to be used in the ship.

Owner:孙加成 +1

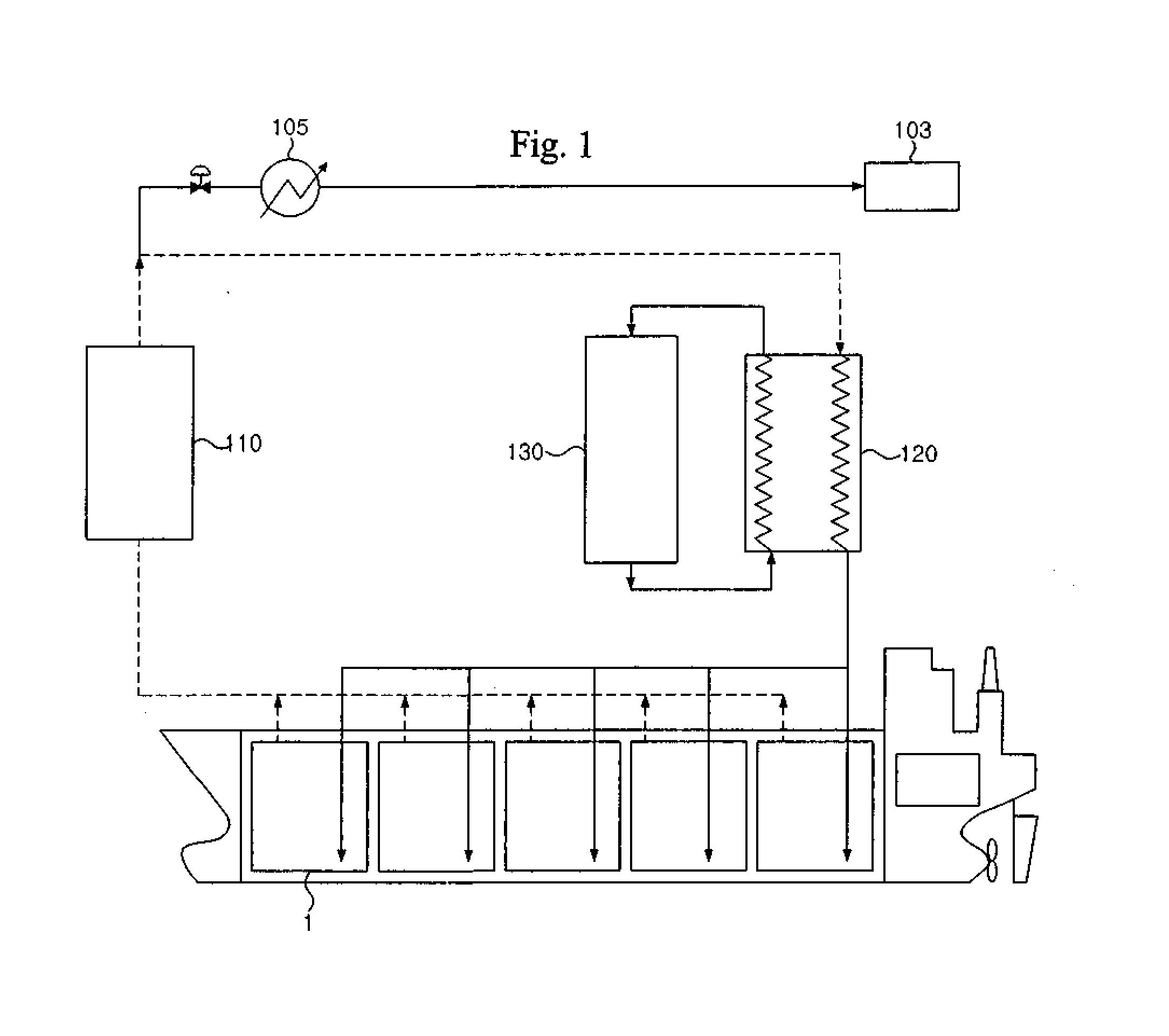

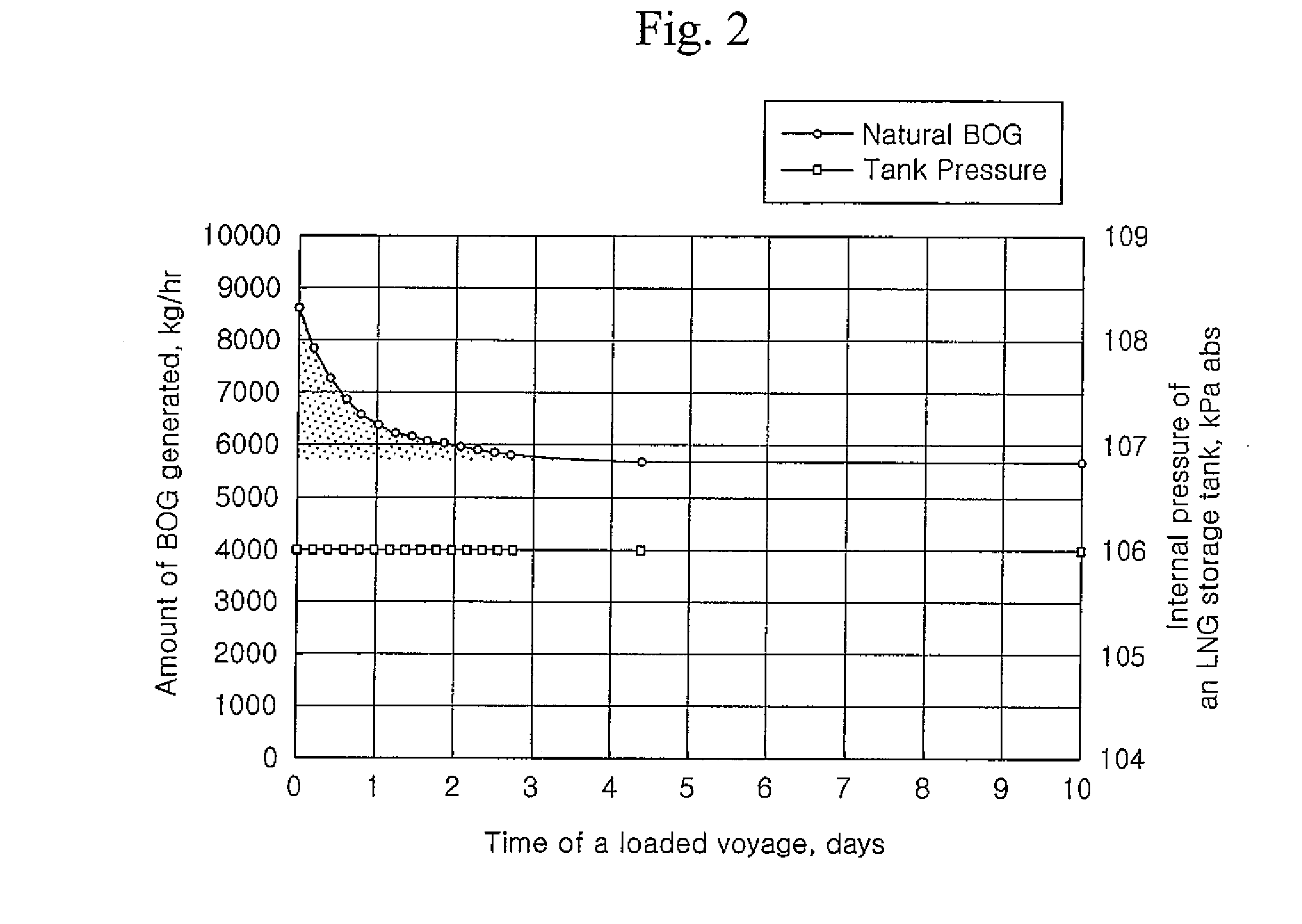

Method and Apparatus for Treating Boil-Off Gas in an LNG Carrier Having a Reliquefaction Plant, and LNG Carrier Having Said Apparatus for Treating Boil-Off Gas

InactiveUS20080308175A1Avoid wastingSave energyVessel mounting detailsWaterborne vesselsInternal pressureLiquid state

Disclosed are a method and an apparatus for treating boil-off gas generated in an LNG storage tank of an LNG carrier for transporting LNG in a cryogenic liquid state, the LNG carrier having a boil-off gas reliquefaction plant, wherein an amount of boil-off gas corresponding to a treatment capacity of the reliquefaction plant among the total amount of boil-off gas generated during the voyage of the LNG carrier is discharged from the LNG storage tank and reliquefied by the reliquefaction plant. The boil-off gas treating method and apparatus can maintain an amount of boil-off gas discharged from an LNG storage tank at a constant level by storing in the LNG storage tank, instead of discharging and burning, surplus boil-off gas which has not been returned to the LNG storage tank through the reliquefaction plant among the total amount of boil-off gas generated in the LNG storage tank, and can prevent waste of boil-off gas and save energy by allowing an internal pressure of the LNG storage tank to be increased.

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

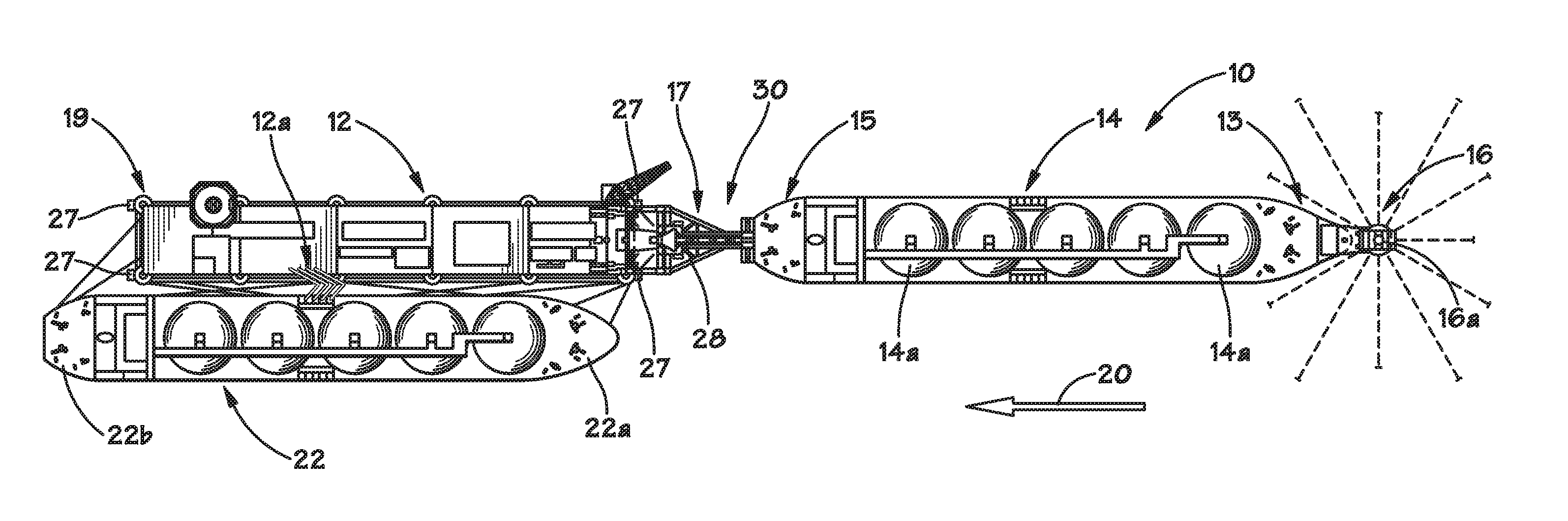

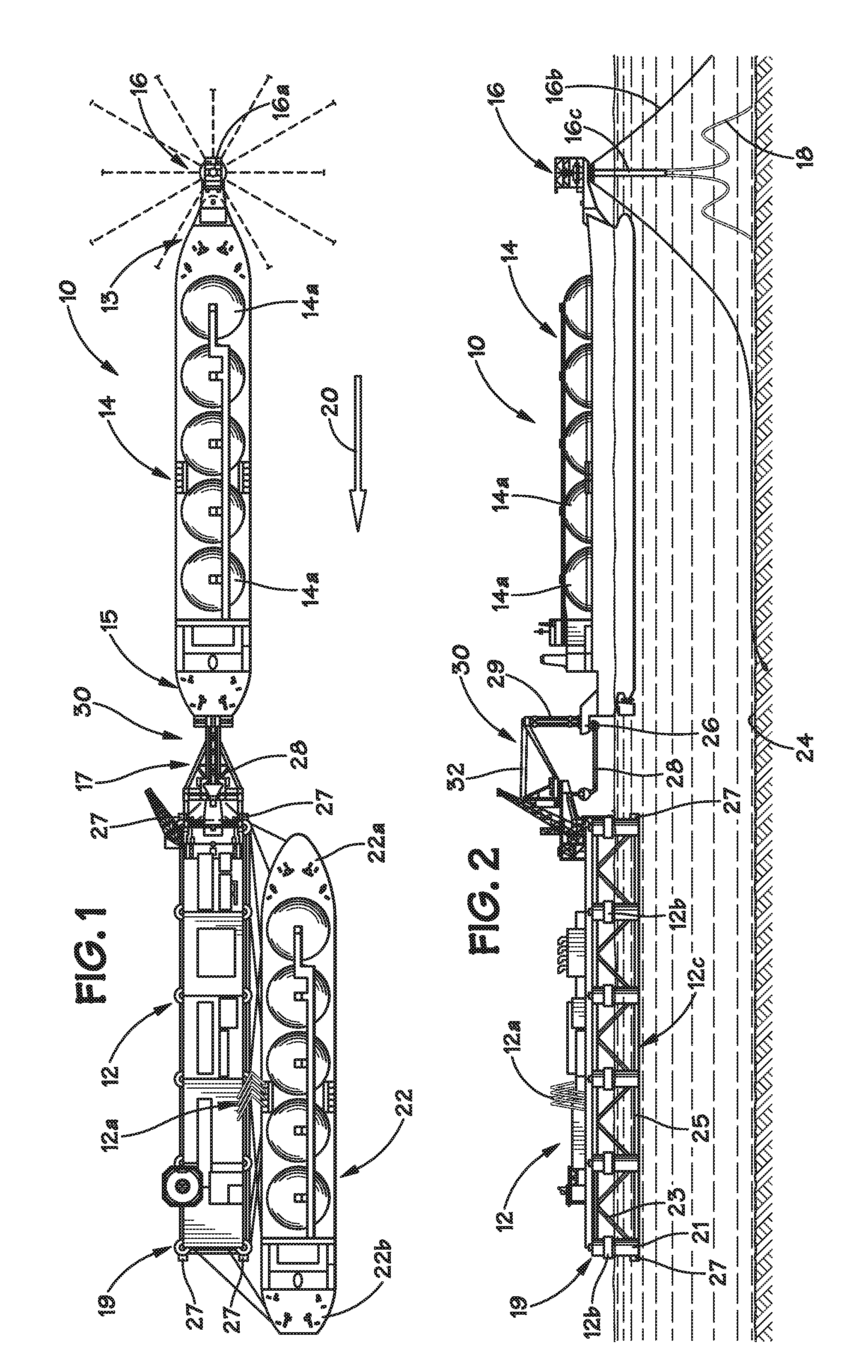

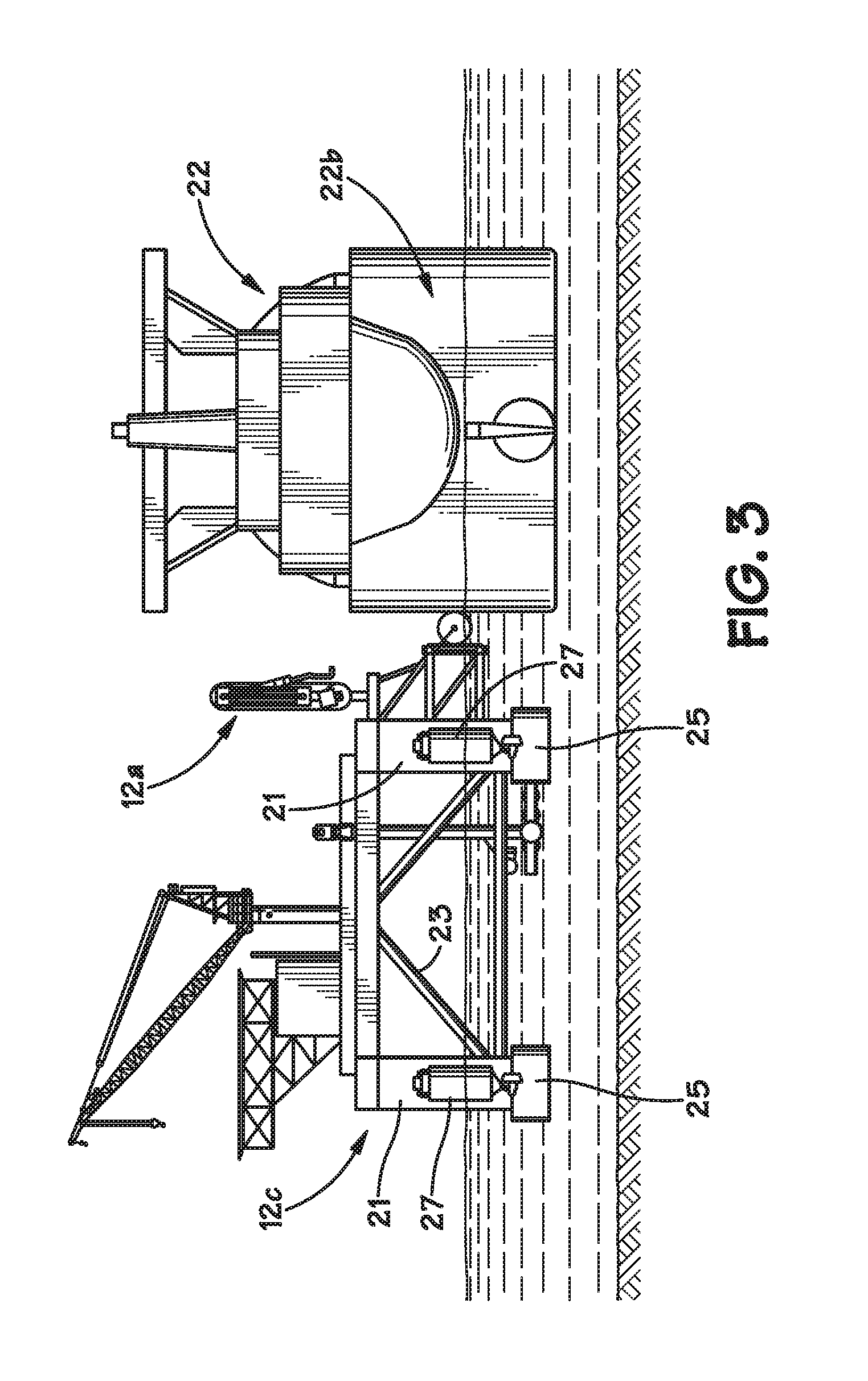

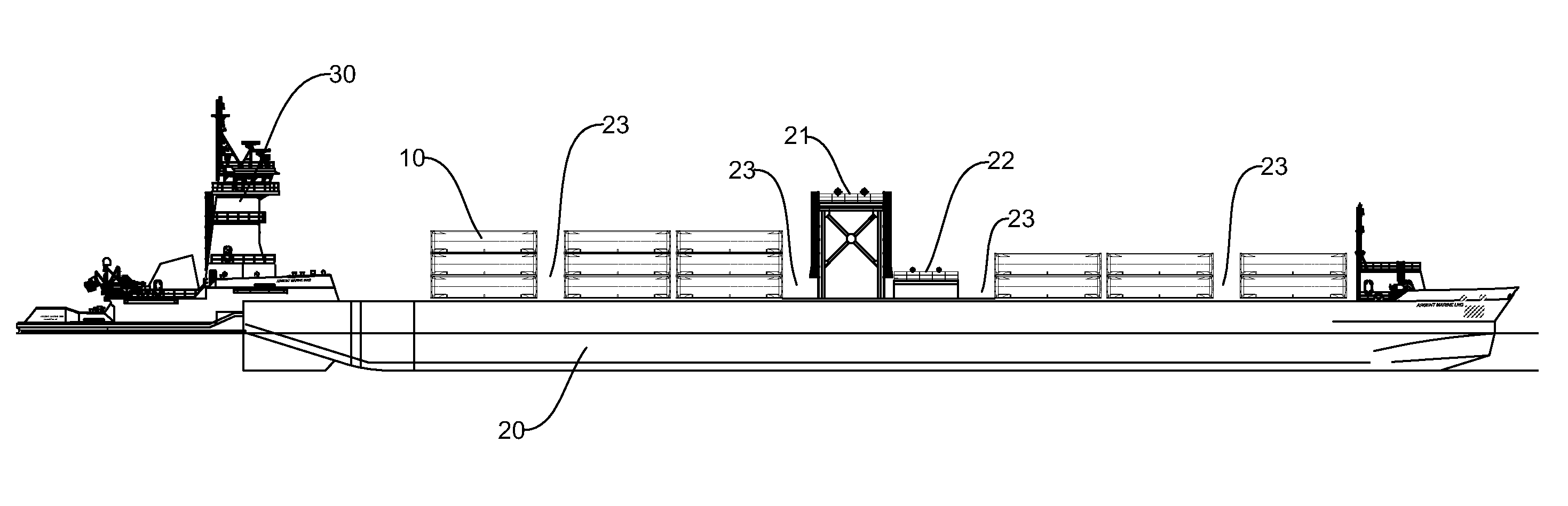

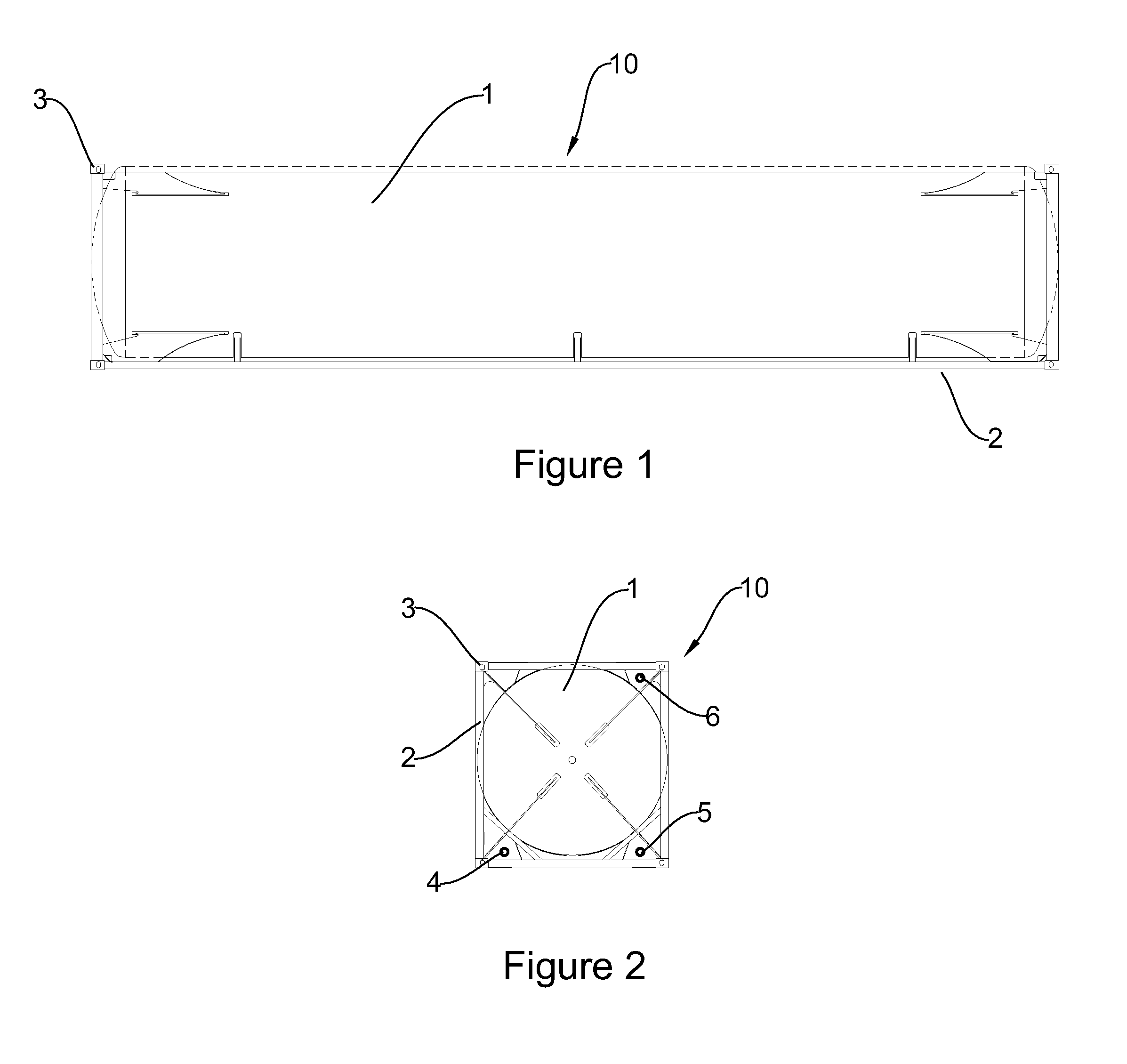

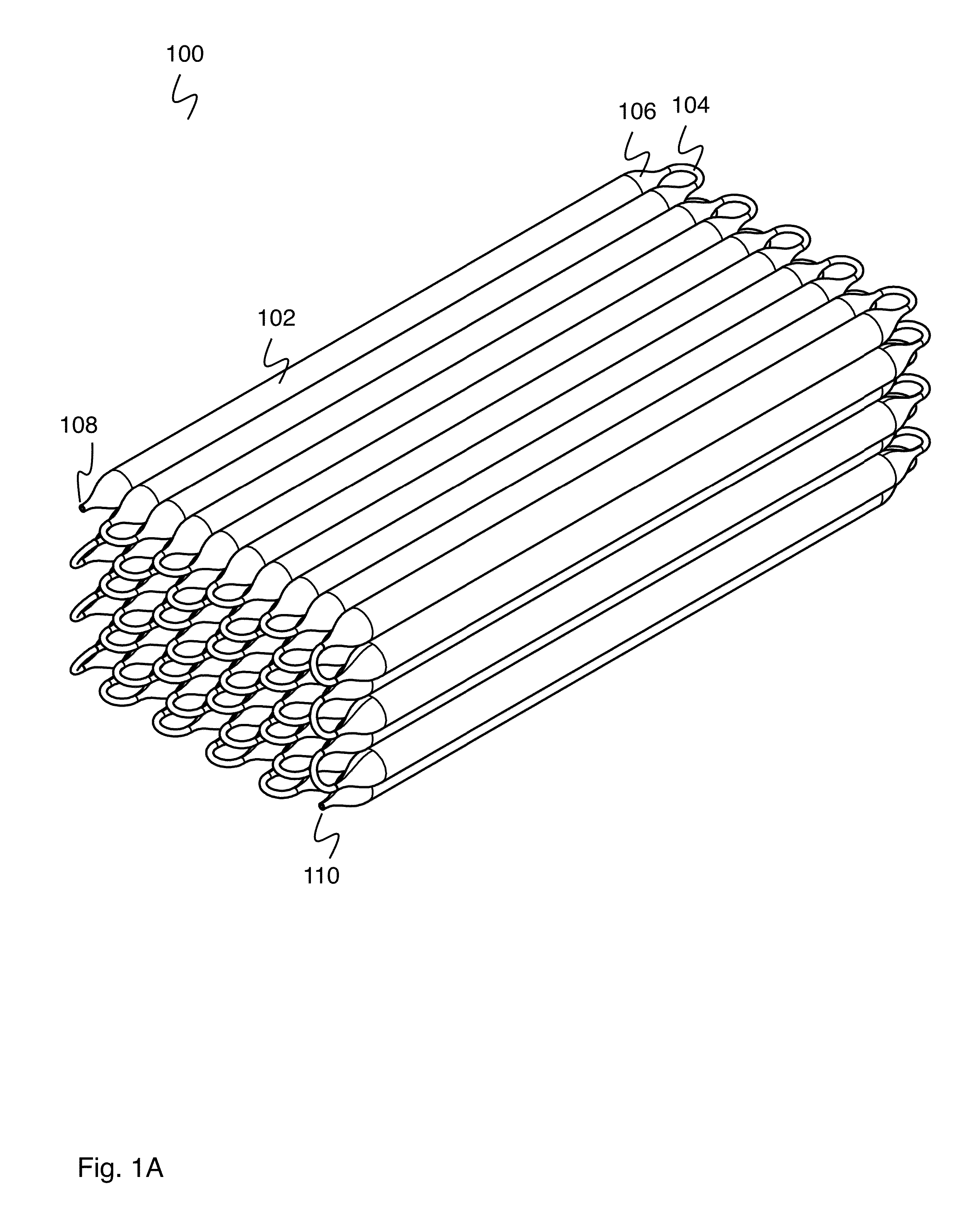

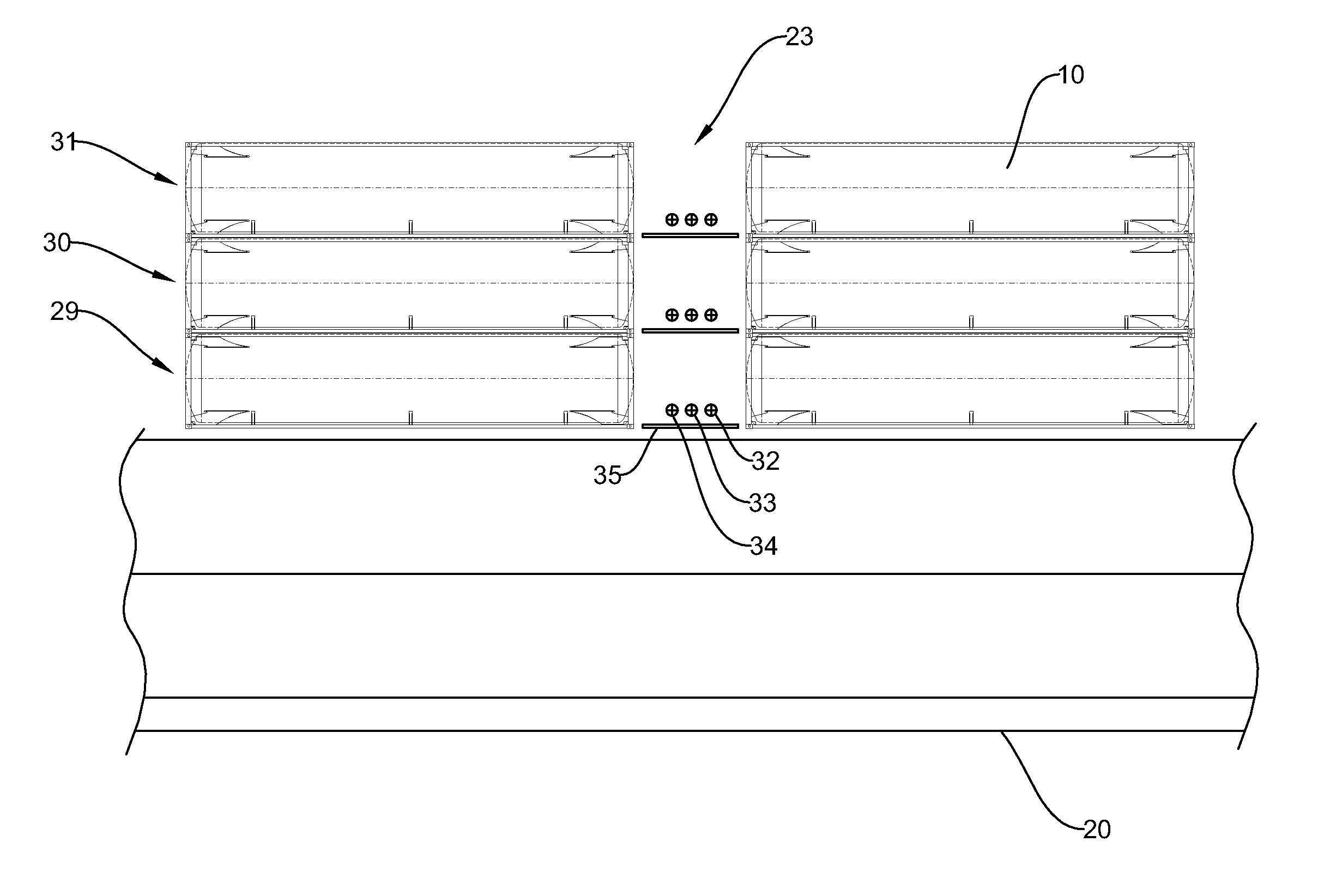

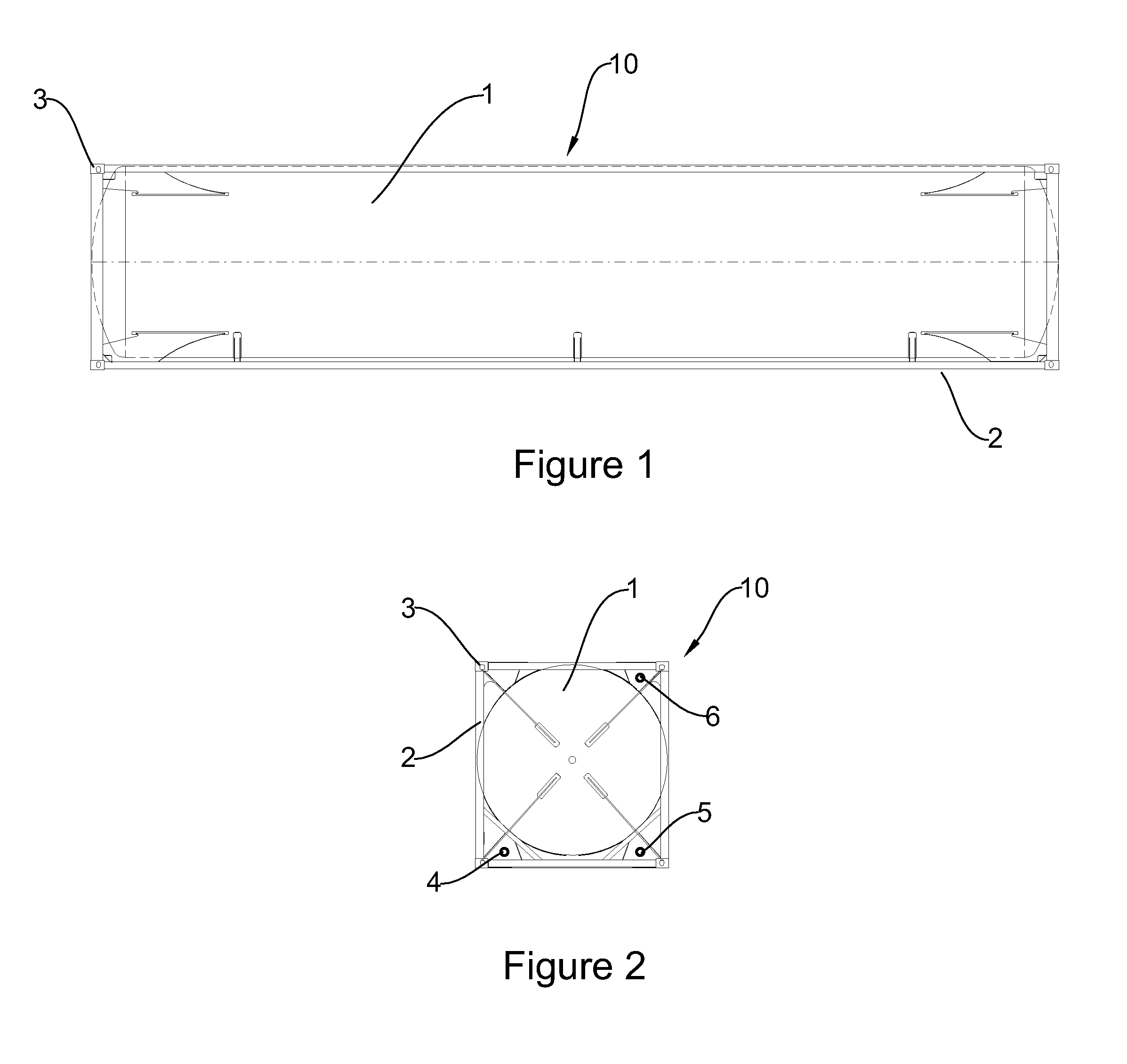

System and method for containerized transport of liquids by marine vessel

ActiveUS20120137955A1Efficient loadingSafely berthingLarge containersGaseous engine fuelsLiquid tankInterconnection

A marine vessel, and a system and method of using the marine vessel, to facilitate the introduction of bulk liquid commodities, such as LNG, into the established and extensive worldwide intermodal transportation system, which is based on containerized shipments. The marine vessel is a specialized vessel, of either ship or barge form, that is capable of holding a large number of ISO-sized intermodal LNG tanks and is configured so as to have at one and the same time characteristics of both a tanker vessel (e.g., a gas carrier) and a container vessel. The intermodal LNG tanks connect to a piping system of the marine vessel and are thereby interconnected in such a manner that allows the interconnected intermodal LNG tanks to behave as if they constitute a typical LNG vessel bulk liquid tank to facilitate efficient loading at a typical marine LNG terminal The containerized intermodal LNG tanks are capable of discharging liquids to a marine terminal as if in a bulk mode, or of being disconnected from the common interconnection system to allow lift-off discharge of the intermodal LNG tanks at a typical cargo container port so that the intermodal LNG tanks can enter the existing intermodal transportation system for further distribution to the end user by other marine vessels, over-the-road truck, or by rail.

Owner:ARGENT MARINE MANAGEMENT

Liquefied natural gas (LNG) drain diffusion and pool fire combustion simulated experimental platform and LNG drain diffusion and pool fire combustion simulated experimental method

ActiveCN102879305AAvoid suffocation damageAvoid cold damageSurface/boundary effectData acquisitionEngineering

The invention relates to a liquefied natural gas (LNG) drain diffusion and pool fire combustion simulated experimental platform and an LNG drain diffusion and pool fire combustion simulated experimental method. The platform comprises an experimental system, a testing system and a control system, wherein the experimental system consists of an LNG storage tank, heat-insulation pipes, experimental devices and an anti-explosion isolating wall; the testing system consists of an electronic balance, an ignition system, a methane concentration detector, a thermocouple tree, a data acquirer and a camera; and the control system consists of a programmable logic controller (PLC) system, various display instruments and a control valve. By designing an angle-adjustable LNG surface spreading experimental device with a changeable surface material, spreading and gasification diffusion experimental simulation of LNG on surfaces of different substances and at different flowing speeds can be carried out; and by matching the ignition system and the methane concentration detector, LNG gas cloud concentration change monitoring and gas cloud ignition can be realized, and data and images are acquired automatically. The platform has the advantages of short experimental time, low cost, high experimental efficiency and the like. By the design, experimental steps are less, experimental safety is guaranteed under the condition of severe monitoring and control, the platform is easy and convenient to operate, and experimental repeatability is high.

Owner:应急管理部天津消防研究所

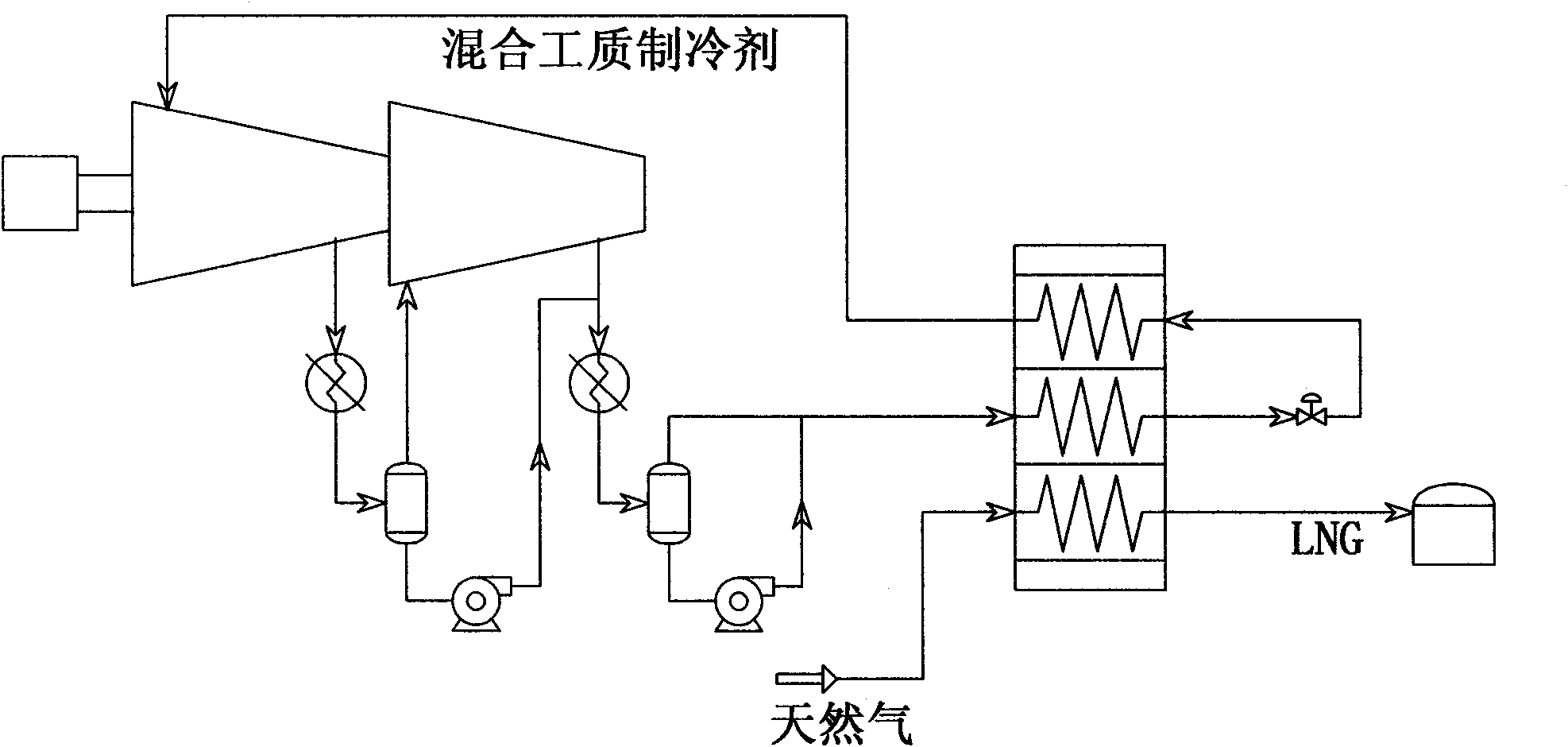

Method and device for liquefying natural gas via refrigeration of single mixed refrigerant

InactiveCN101967413AReduce power consumptionReduce the degree of impactSolidificationLiquefactionRefrigeration compressorVapor–liquid separator

The invention relates to a device for liquefying natural gas via the refrigeration of a single mixed refrigerant, comprising a motor-driven three-section mixed refrigerant compressor, three coolers, five gas-liquid separators, two liquid pumps, three throttling devices, three fin-type heat exchangers and one LNG (Liquefied Natural Gas) storage tank. According the device, the mixed refrigerant is compressed and separated step by step by using the three-section mixed refrigeration compressor, and the liquid separated in each step is pressurized by the liquid pumps and then directly enters the heat exchanger group for heat exchange, thereby reducing the power consumption of gas compression; the three-stage refrigeration cycle is adopted to ensure that the heat exchange curves of the cold fluid and the hot fluid in the whole heat exchange process are better matched, therefore, the flow of the mixed refrigerant is effectively decreased and the energy consumption of the device is finally reduced.

Owner:HANGZHOU FORTUNE CRYOGENIC EQUIP CO LTD

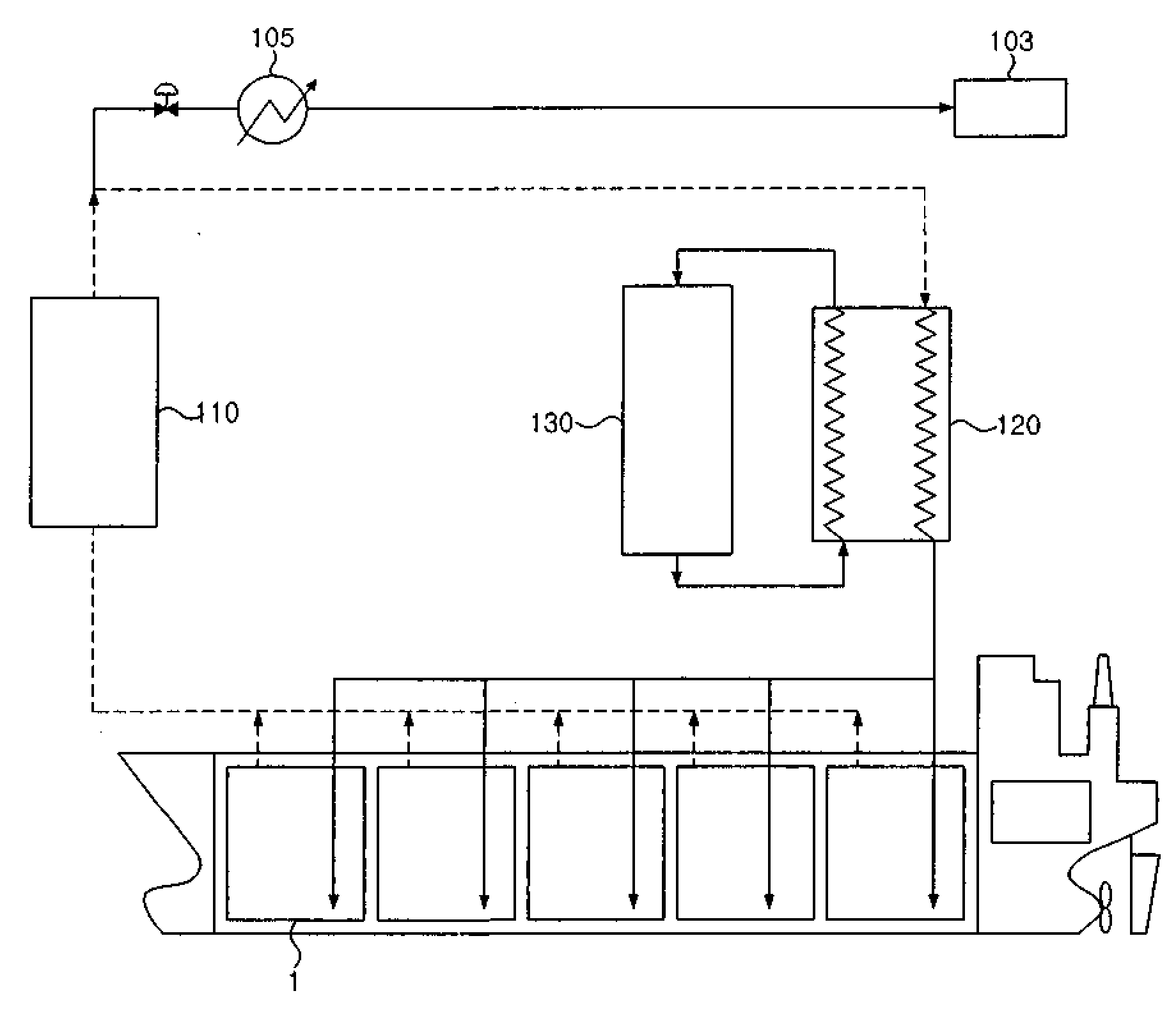

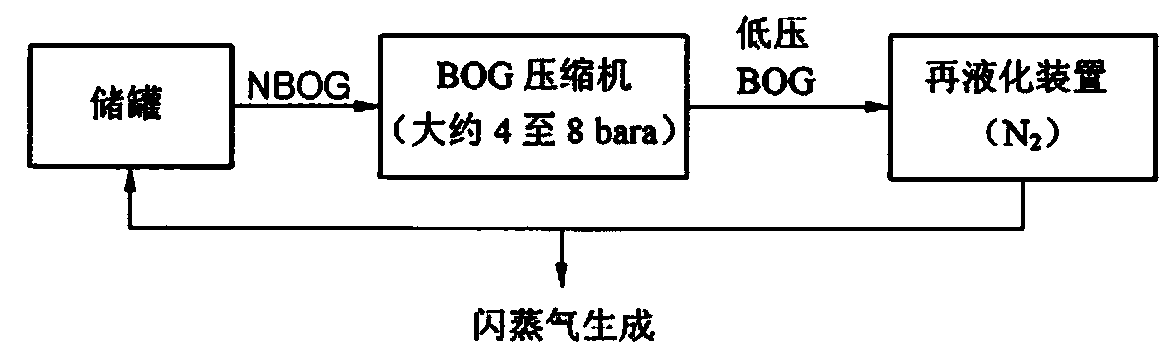

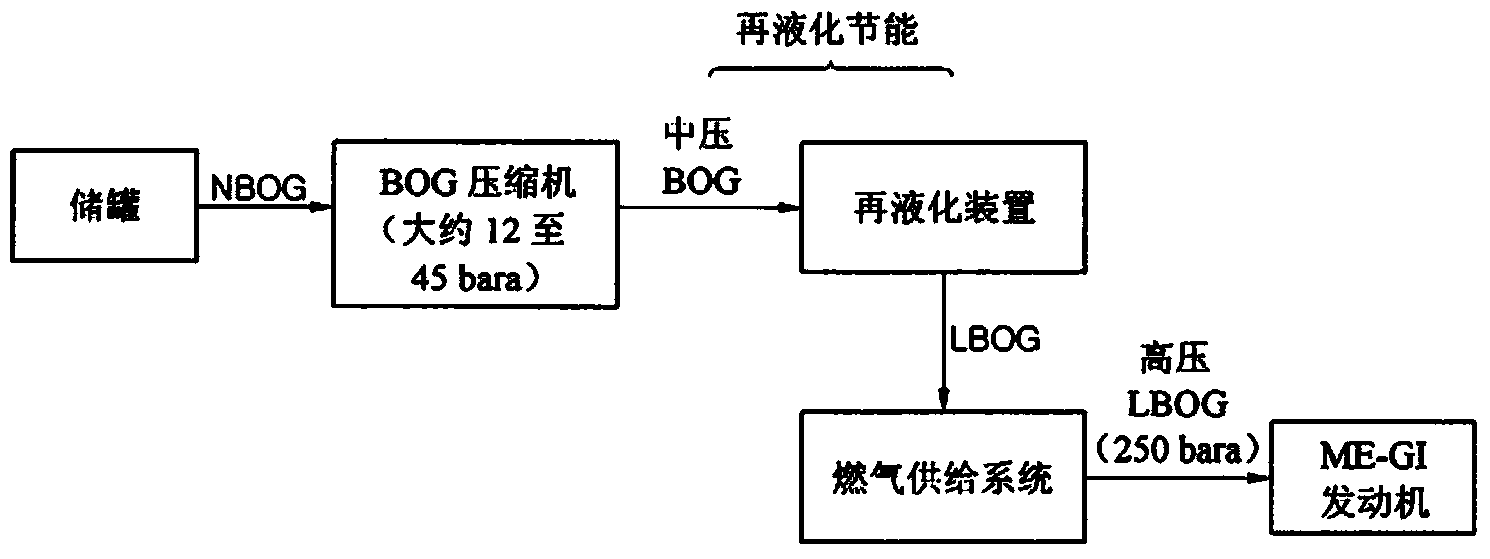

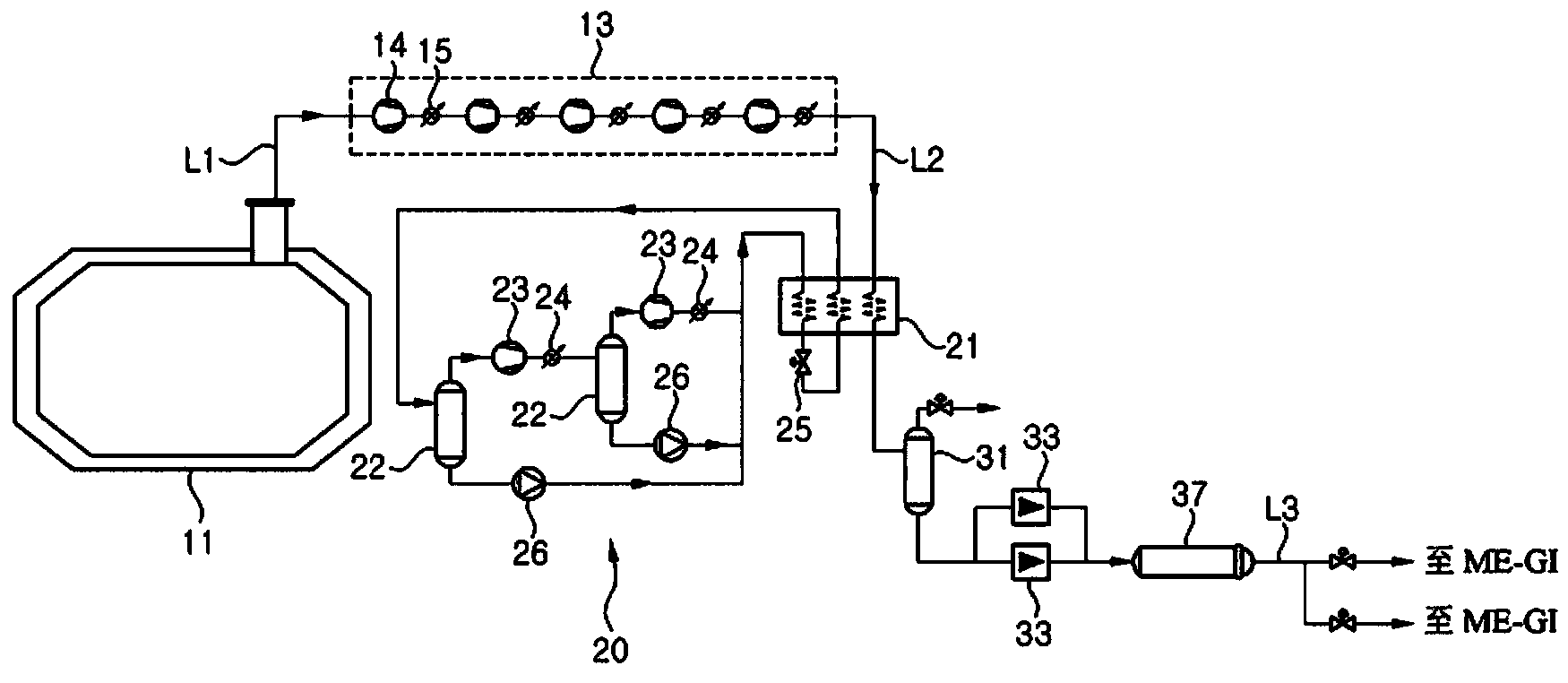

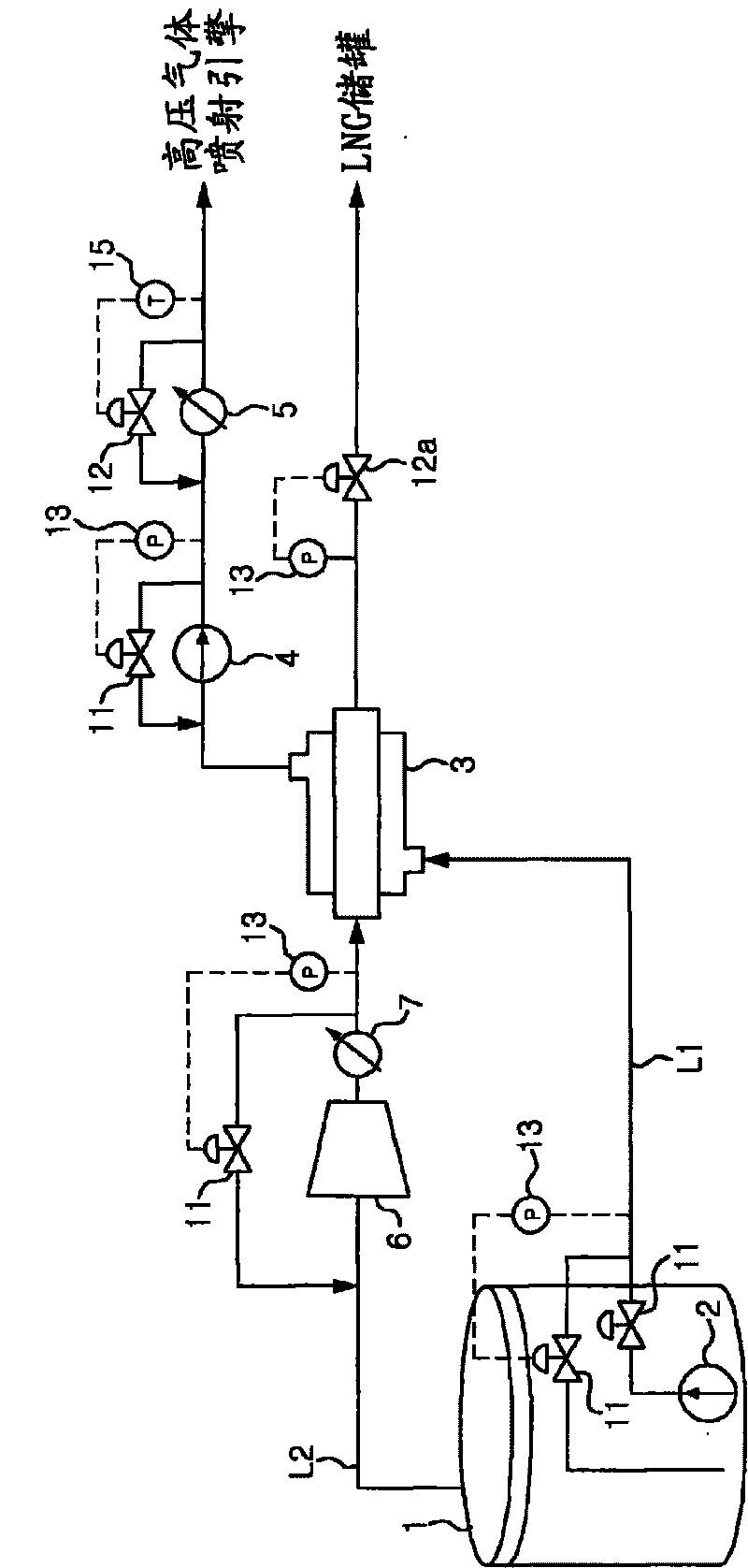

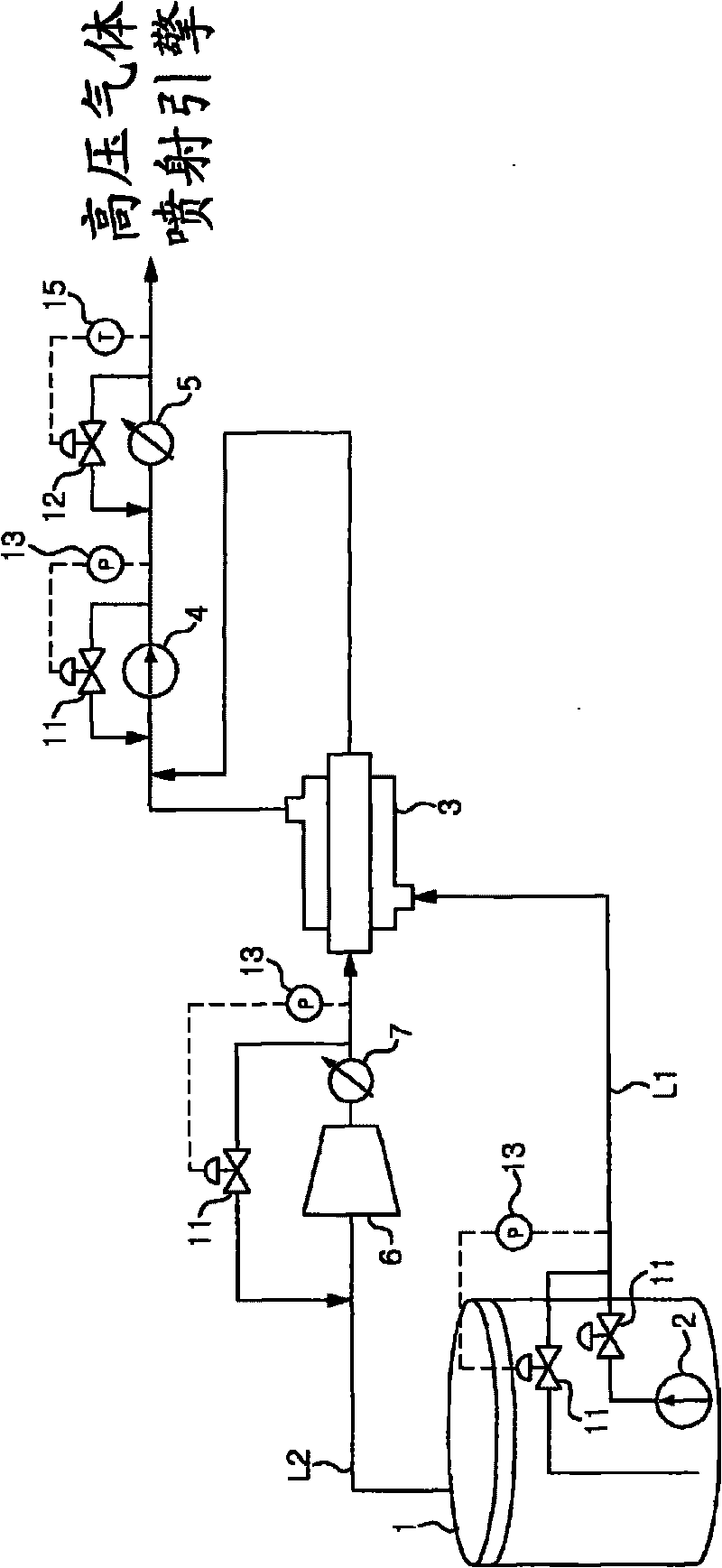

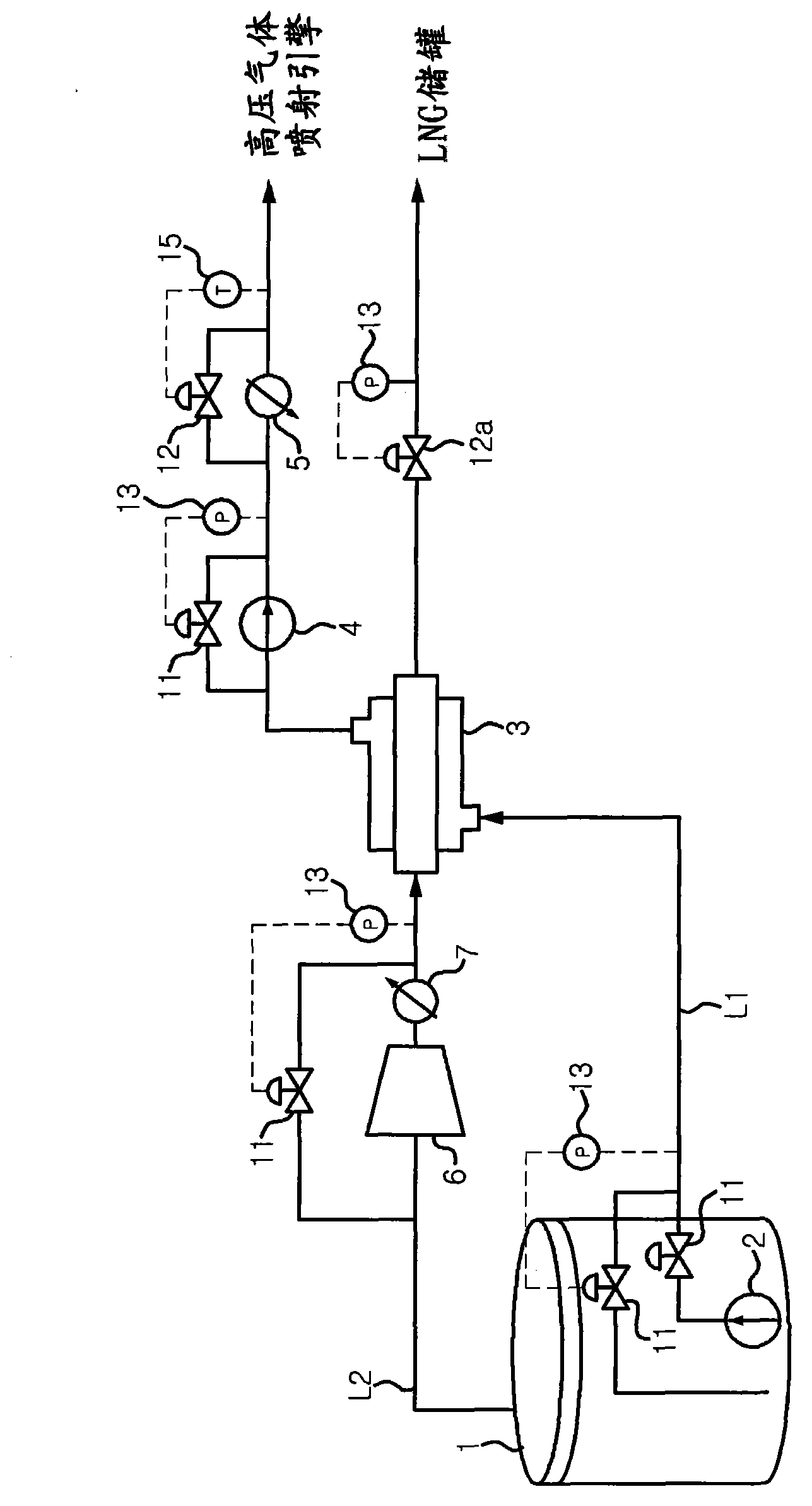

Method and system for supplying fuel to high-pressure natural gas injection engine

PendingCN103562536ALiquefaction Energy DecreasedReduce consumptionNon-fuel substance addition to fuelInternal combustion piston enginesGas compositionBuffer tank

Provided is a fuel supply system for a marine structure using a high-pressure natural gas injection engine, for example, an ME-GI engine, in which boil-off gas generated in an LNG storage tank is compressed to a medium pressure, reliquefied, compressed to a high pressure, gasified, and then supplied to the high-pressure natural gas injection engine. The fuel supply system for a high-pressure natural gas injection engine includes: a boil-off gas (BOG) compression unit configured to receive and compress BOG generated in a storage tank storing a liquefied gas; a reliquefaction apparatus configured to receive and liquefy the BOG compressed by the BOG compression unit; a buffer tank configured to receive the liquefied BOG from the reliquefaction apparatus and separate the reliquefied BOG into a gaseous component and a liquid component; a high-pressure pump configured to receive the liquid component from the buffer tank and compress the liquid component; and a high-pressure gasifier configured to gasify the liquid component compressed by the high-pressure pump and supply the gasified liquid component to the high-pressure natural gas injection engine. The liquid component supplied from the buffer tank to the high-pressure pump has a pressure of 12 to 45 bara (absolute pressure).

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

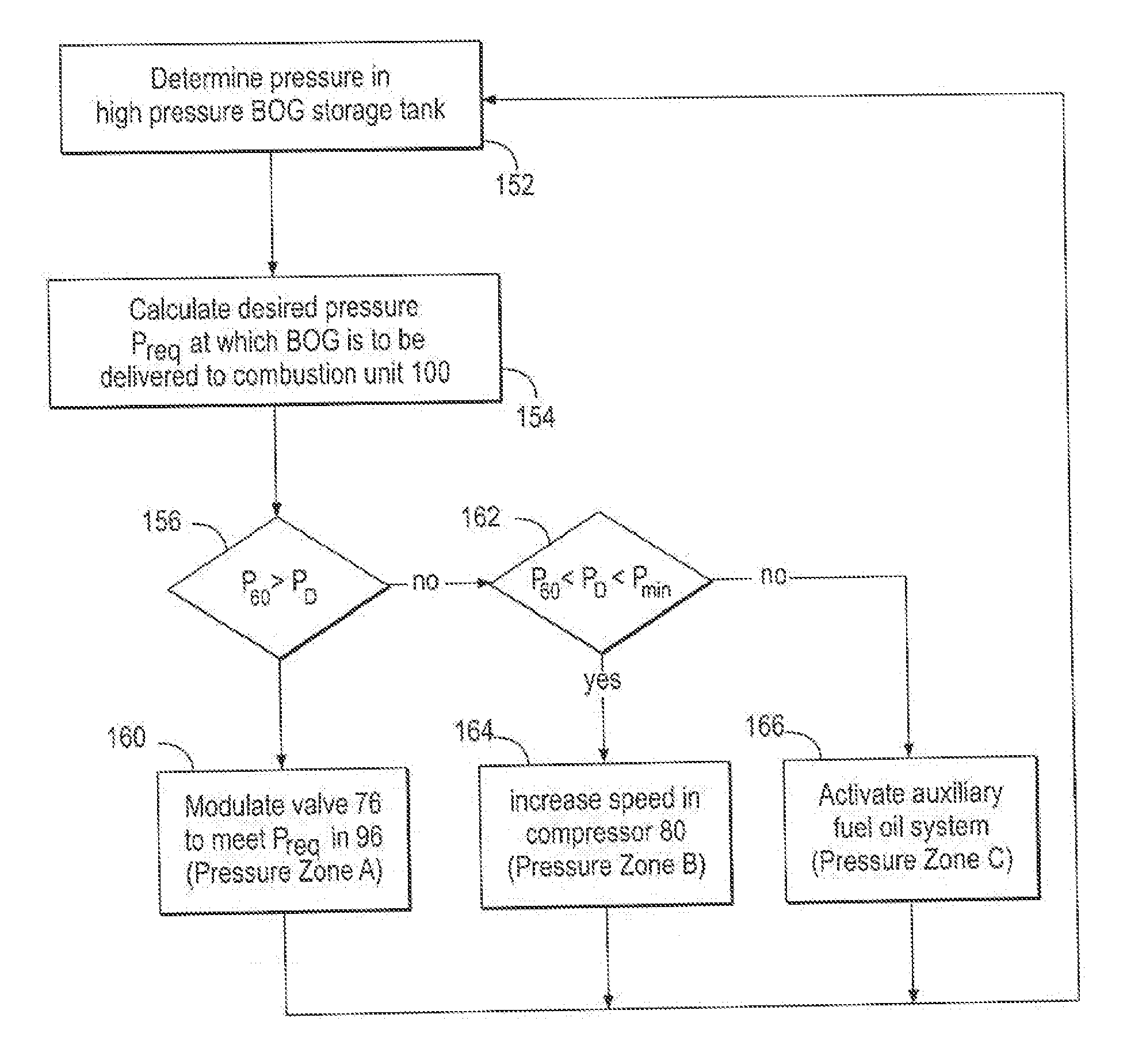

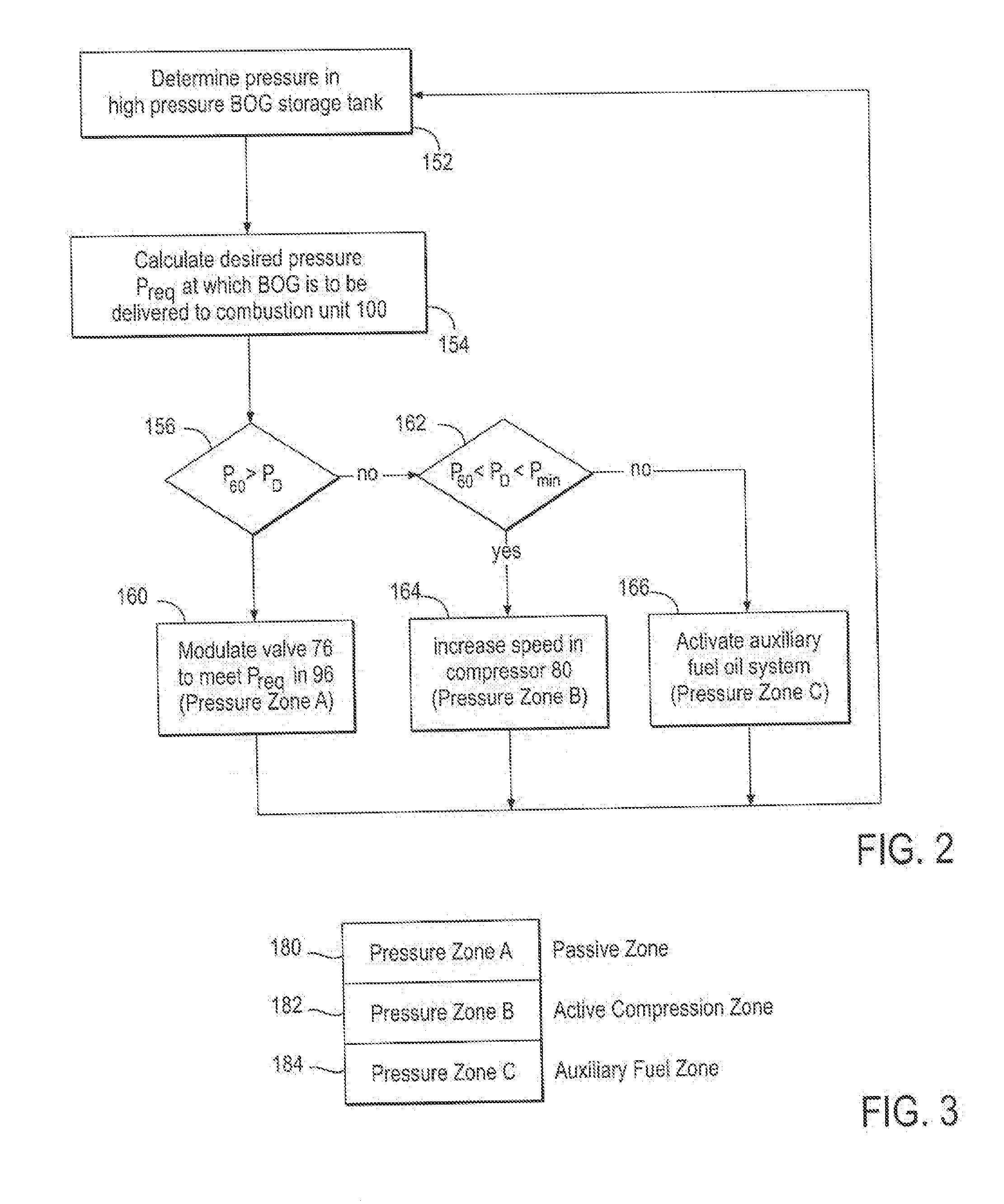

LNG transport vessel and method for storing and managing excess boil off gas thereon

InactiveUS20110302923A1Sufficient pressureReciprocating combination enginesFuel supply regulationCombustionHigh pressure

A liquefied natural gas (LNG) transport vessel for transporting liquefied natural gas (LNG) is disclosed which is capable of storing excess boil off gas BOG until needed for combustion in one or more combustion apparatus on the vessel. A method for managing the delivery of the BOG to the combustion apparatus is also described. The LNG vessel includes at least one insulated LNG storage tank which stores LNG. A first stage LNG receiver receives and stores BOG from the at least one LNG storage tank. A second stage or high pressure BOG storage tank receives compressed BOG from the receiver and stores the BOG as needed for combustion by one or more combustion apparatus of the vessel. A pressure regulator allows BOG gas to be delivered to the combustion apparatus if there is sufficient pressure in the high pressure storage tank to passively deliver the BOG at a predetermined delivery pressure. If the pressure in the high pressure BOG storage tank is insufficient to passively delivery the BOG to combustion apparatus, then a combustion apparatus compressor may be used to actively increase the pressure in BOG such that the BOG is delivered at the necessary delivery pressure. If there is still insufficient BOG in the high pressure BOG storage tank, then it may be necessary to supply supplemental auxiliary fuel to meet the needs of the combustion apparatus.

Owner:CHEVROU USA INC

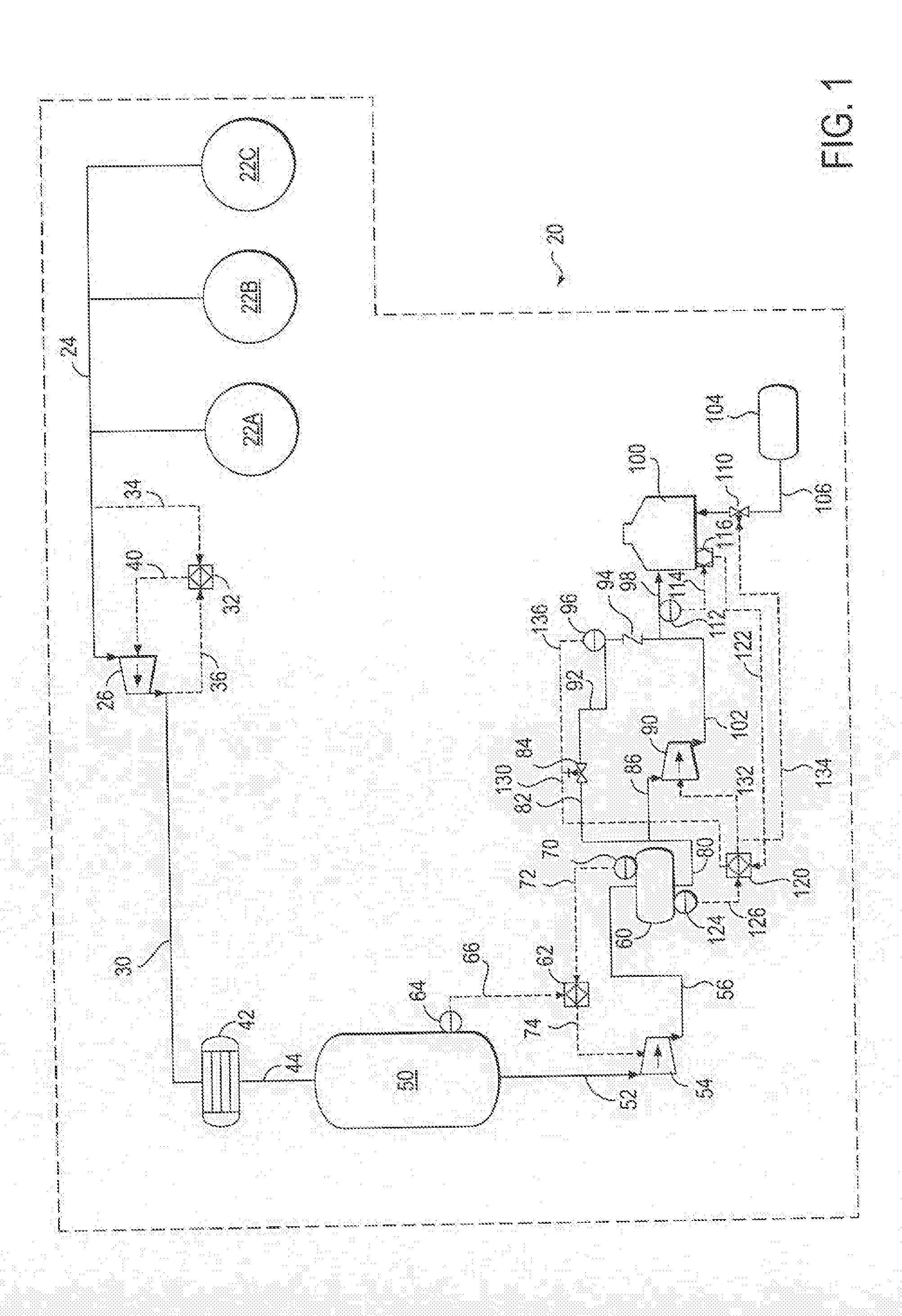

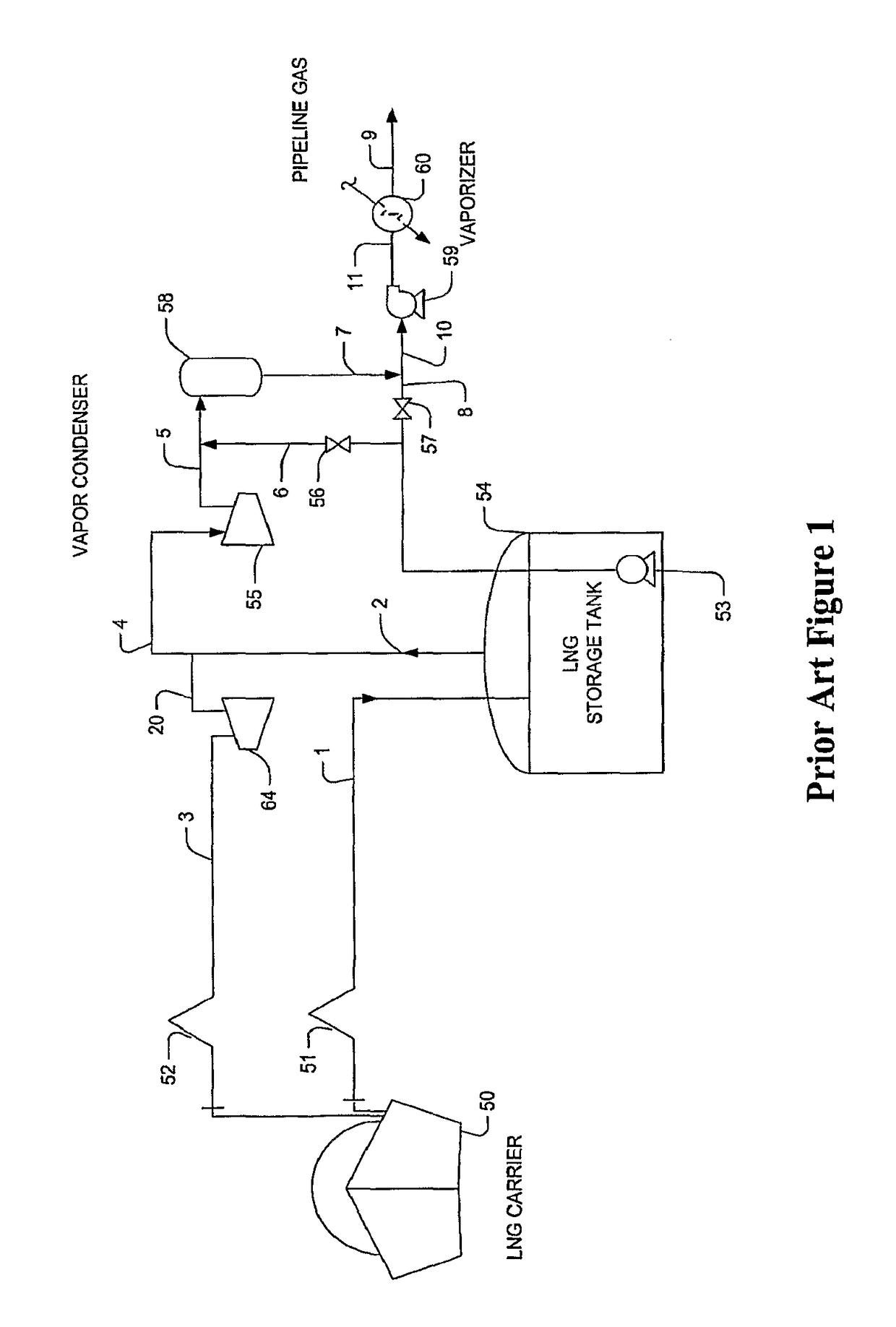

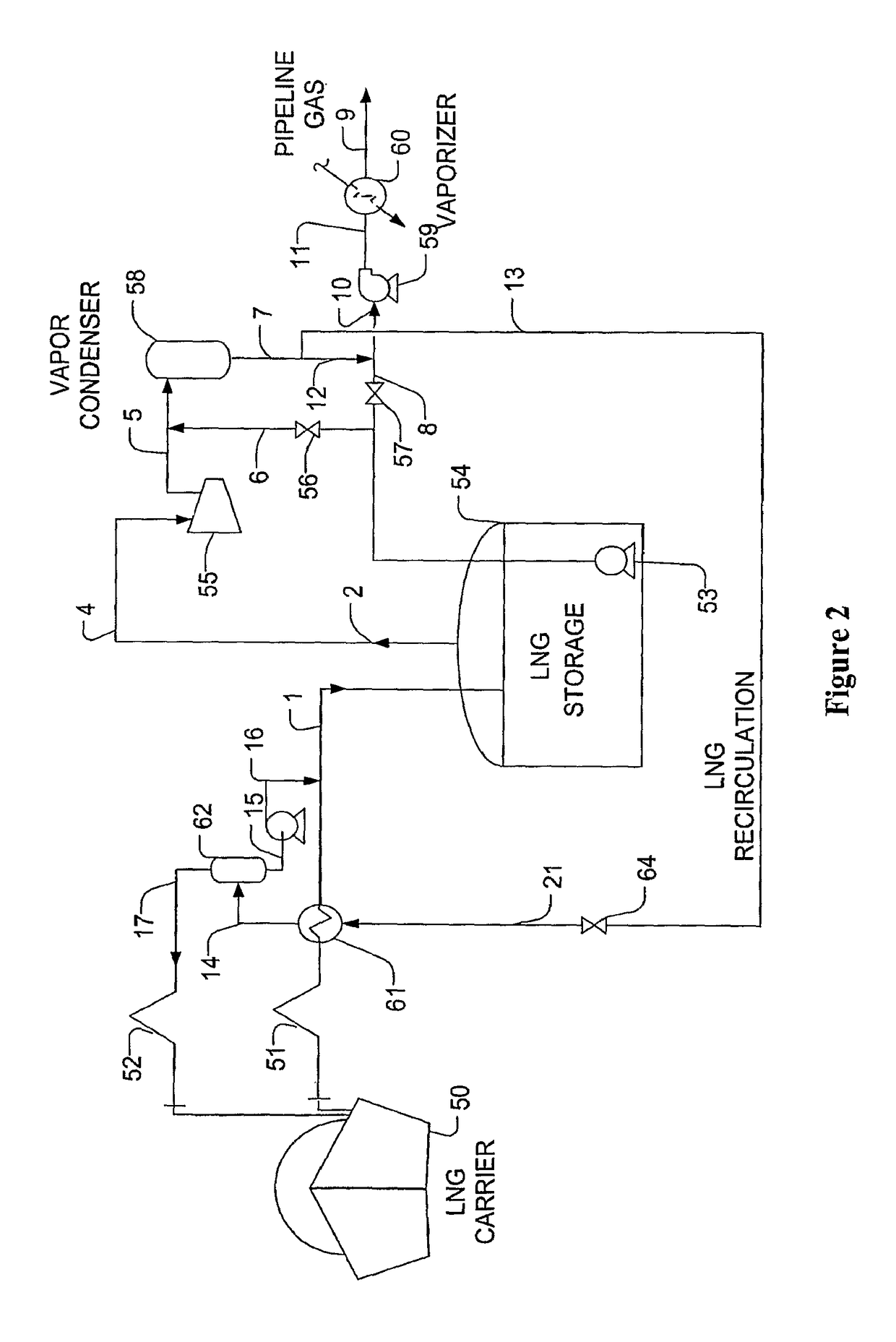

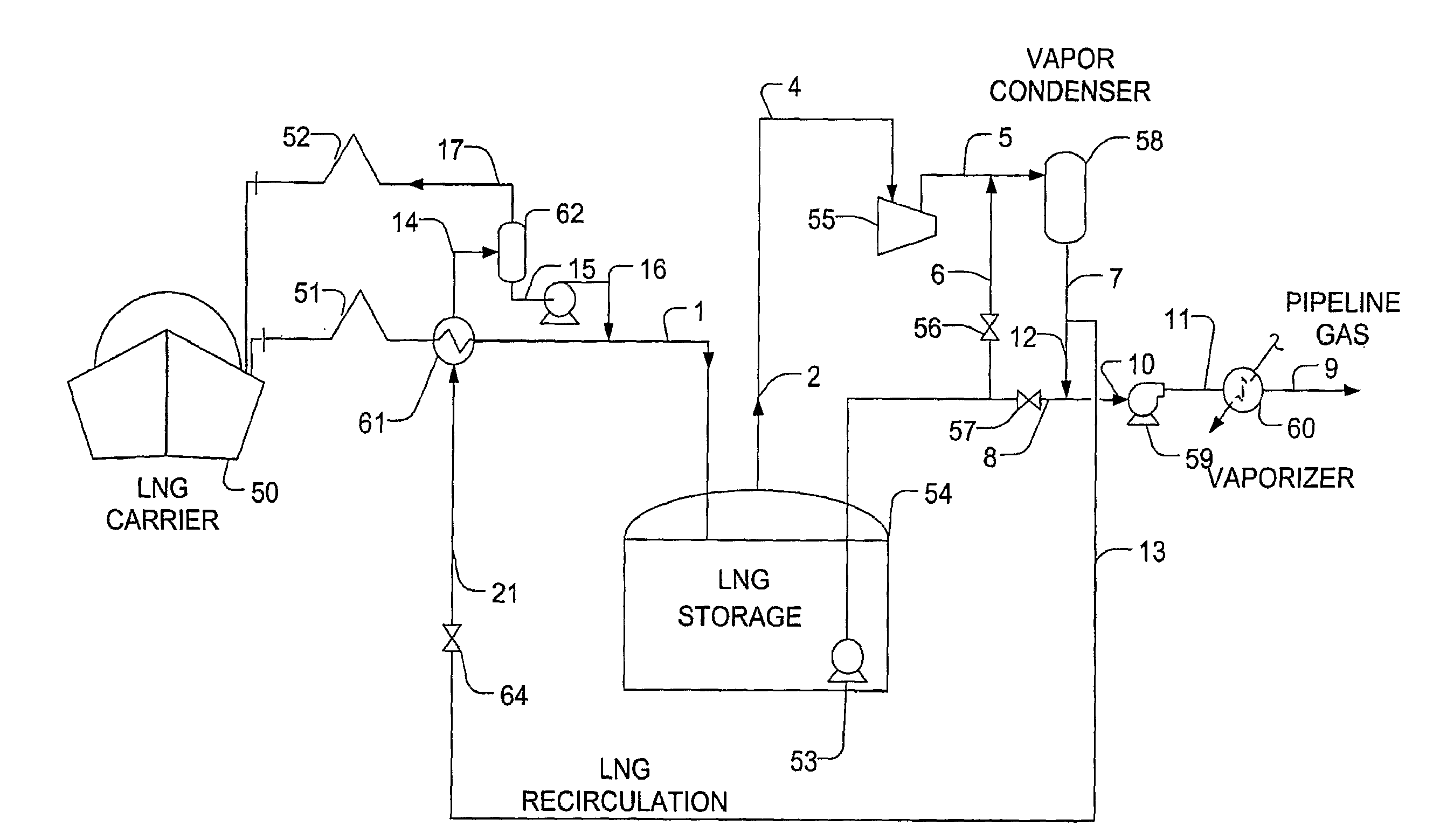

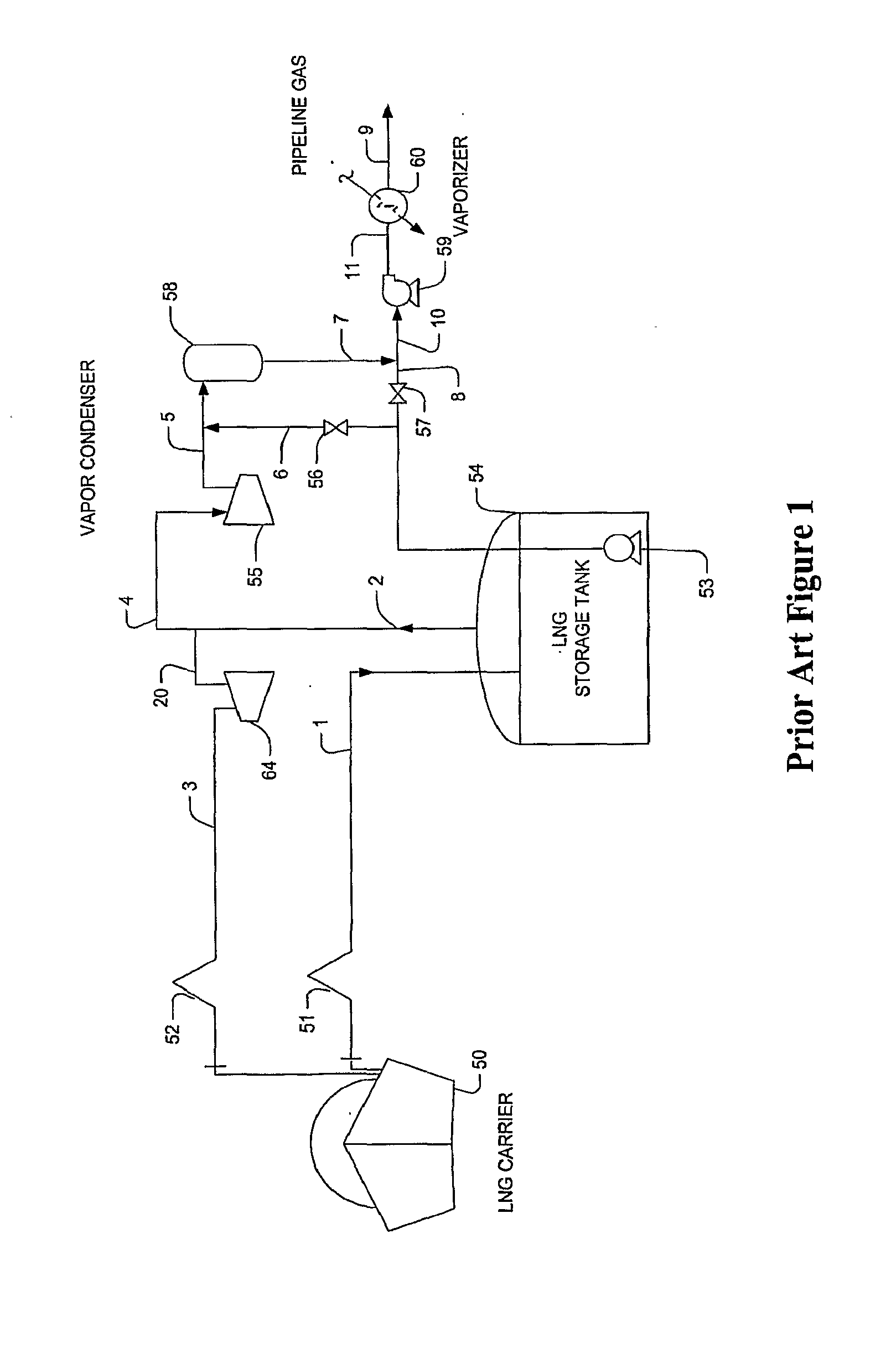

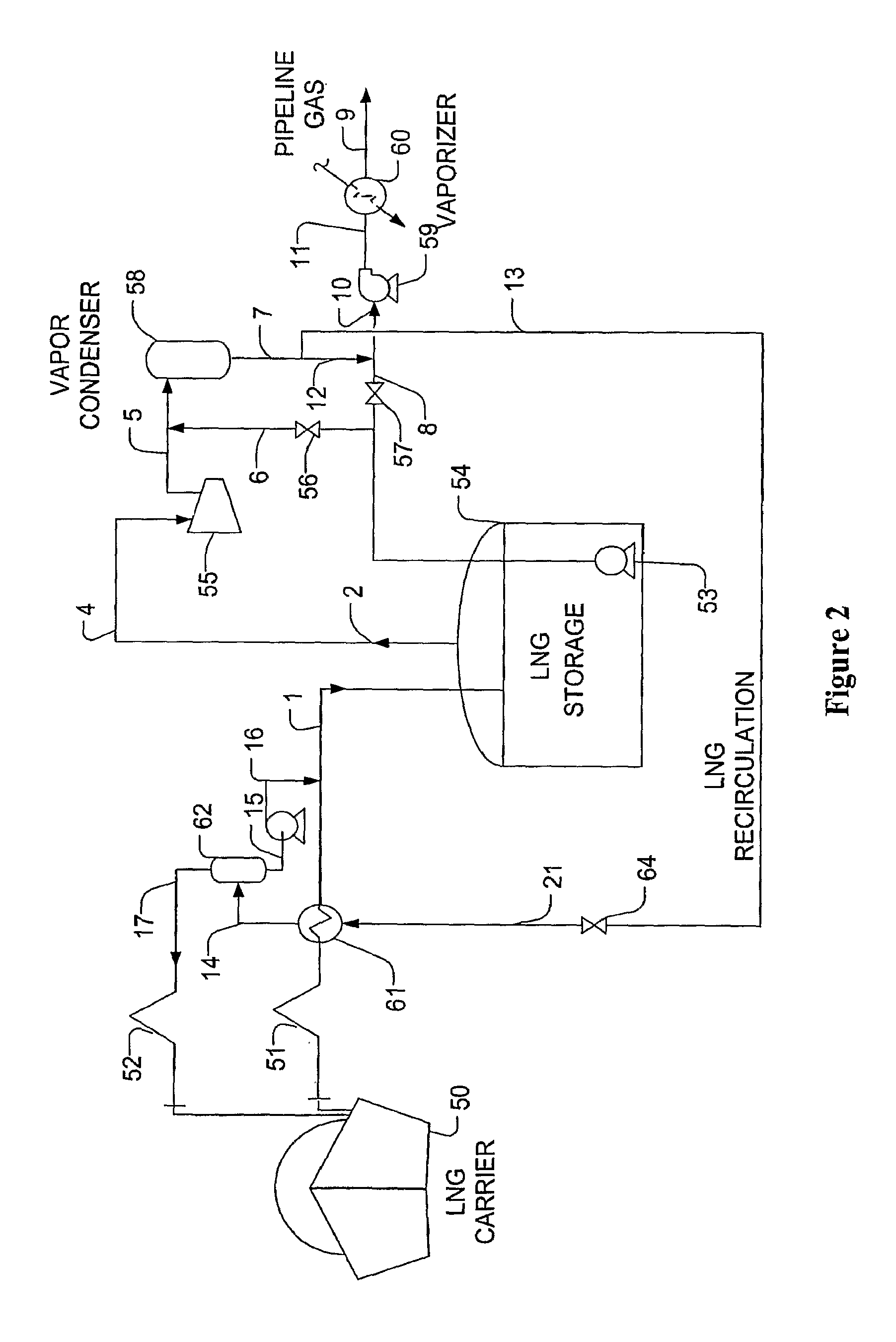

LNG vapor handling configurations and methods

InactiveUS8117852B2Reduce boil-off volumeEliminate needSolidificationLiquefactionProcess engineeringRefrigeration

LNG from a carrier is unloaded to an LNG storage tank in configurations and methods in which expansion of compressed and condensed boil-off vapors from the LNG storage tank provide refrigeration to subcool the LNG that is being unloaded. Most advantageously, such configuration and methods reduce the amount of boil-off vapors and eliminate the need for a vapor return line and associated compressor.

Owner:FLUOR TECH CORP

Full-automatic submerged-arc welding solid-core welding wire for high-manganese steel for preparing LNG storage tank

ActiveCN107052618AAvoid organizationAvoid performance changesArc welding apparatusWelding/cutting media/materialsUltimate tensile strengthToughness

The invention discloses a full-automatic submerged-arc welding solid-core welding wire for high-manganese steel for preparing an LNG storage tank. According to the technical scheme, the full-automatic submerged-arc welding solid-core welding wire comprises 0.25-0.45wt% of C, 23-26wt% of Mn, 6-8wt% of Ni, 3-5wt% of W, 0.02-0.04wt% of N, less than or equal to 0.02wt% of P, less than or equal to 0.001wt% of S and the balance of Fe and inevitable impurities. The full-automatic submerged-arc welding solid-core welding wire has the advantages that the price of adopted alloy elements is low, and an alloy component system is simple; and the low-temperature toughness of weld metal formed by the prepared full-automatic submerged-arc welding solid-core welding wire is excellent, the strength of the full-automatic submerged-arc welding solid-core welding wire is matched with the strength of the ultralow-temperature high-manganese steel for preparing the LNG storage tank, and the technical requirements for the strength and the ultralow-temperature toughness of the welded LNG storage tank can be met.

Owner:WUHAN UNIV OF SCI & TECH +1

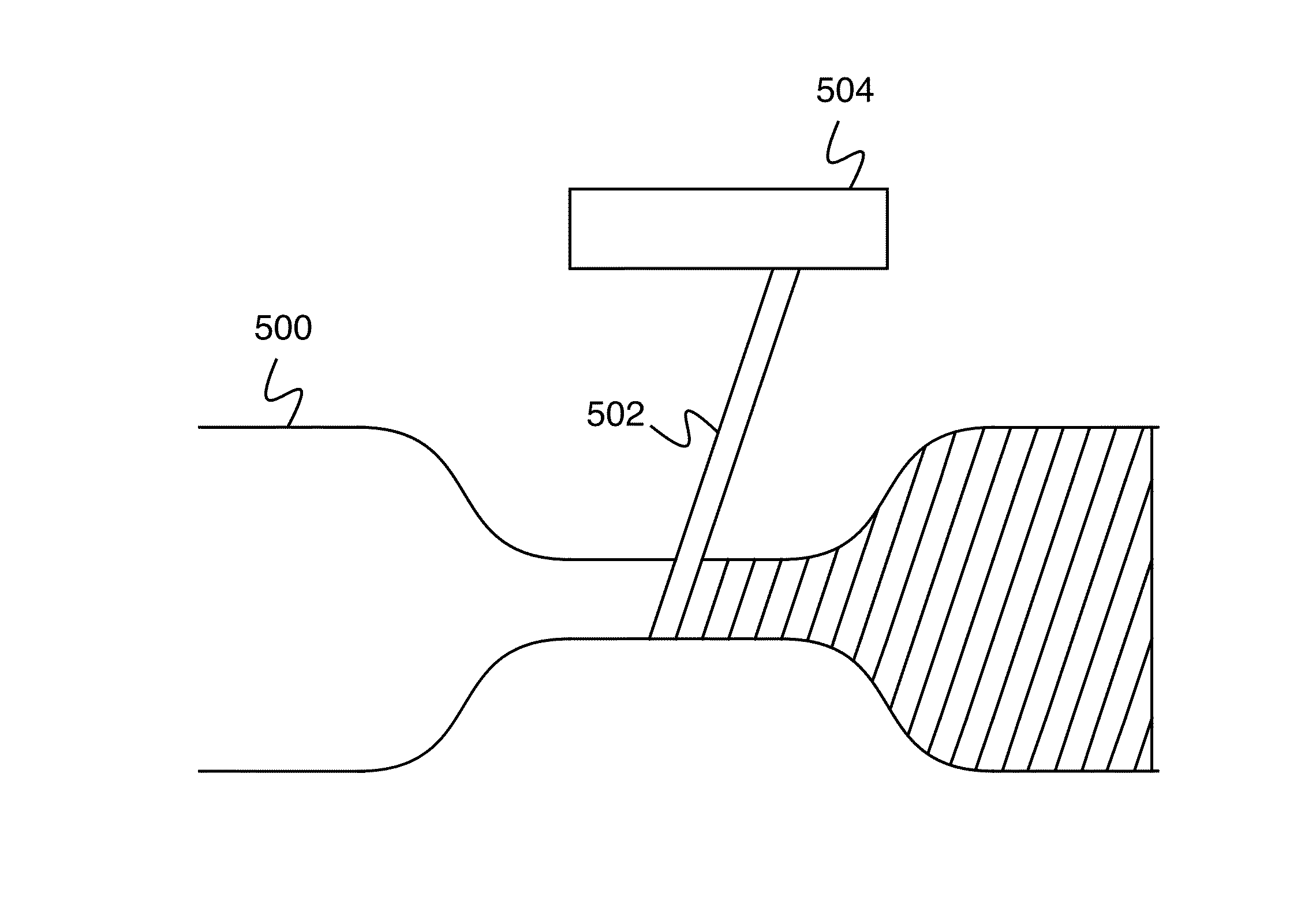

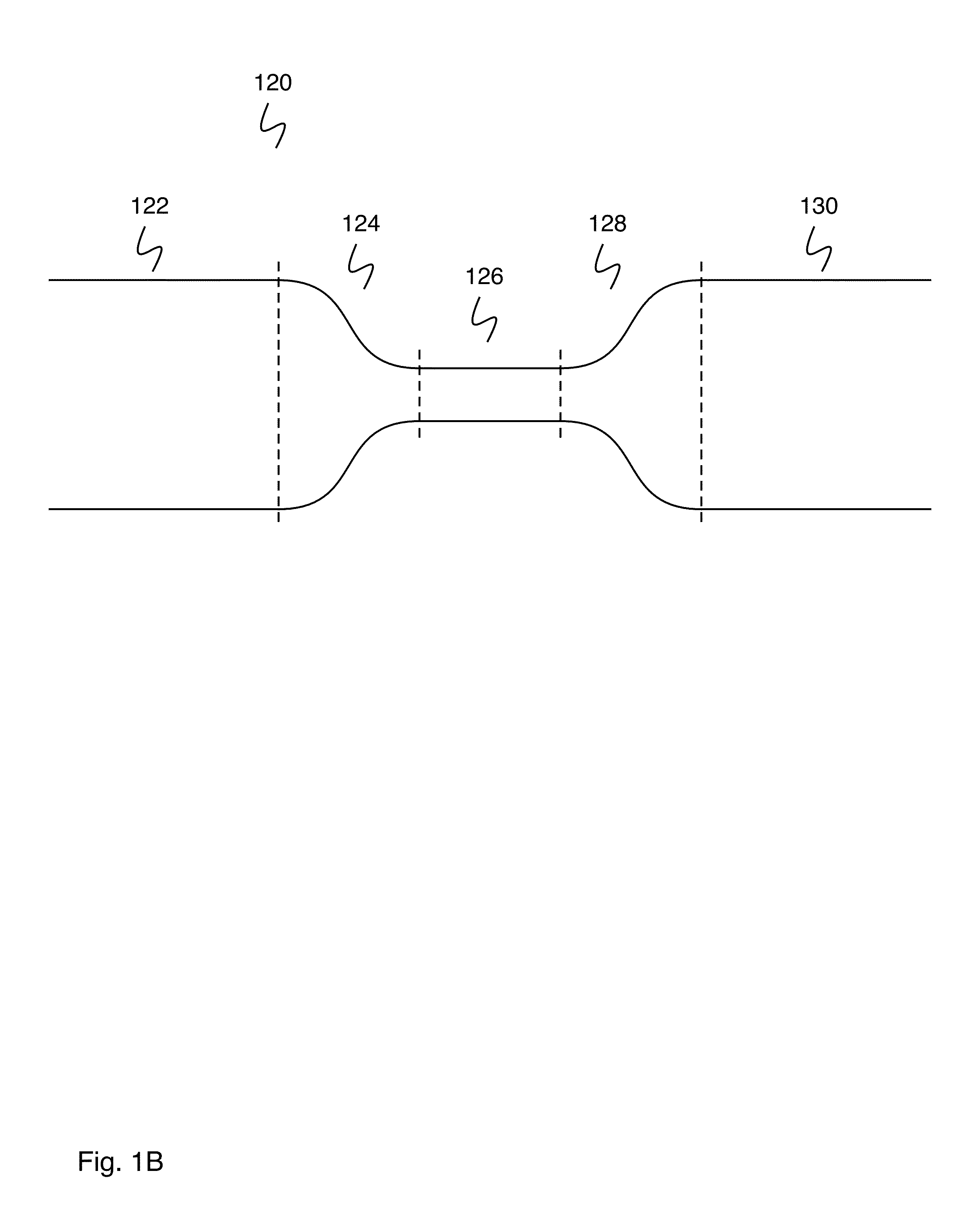

Natural gas intestine packed storage tank

ActiveUS20140305951A1Vessel mounting detailsVessel manufacturingReactor pressure vesselMarine engineering

A high-pressure pressure vessel for storing natural gas comprises a plurality of first vessel regions of first diameters, a plurality of couplers, and a fiber layer. A three dimensional volume is filled using at least in part the plurality of first vessel regions. Each coupler of the plurality of couplers couples each pair of first vessel regions of the plurality of first vessel regions. Each coupler of the plurality of couplers comprises a second vessel region of a second diameter and two third vessel regions that transition diameters between the first diameter and the second diameter. The three dimensional volume is filled using at least in part the plurality of couplers. The first vessel regions and the couplers comprise a material with low permeability to natural gas. The fiber layer surrounds the plurality of first vessel regions and the plurality of couplers.

Owner:OTHER LAB

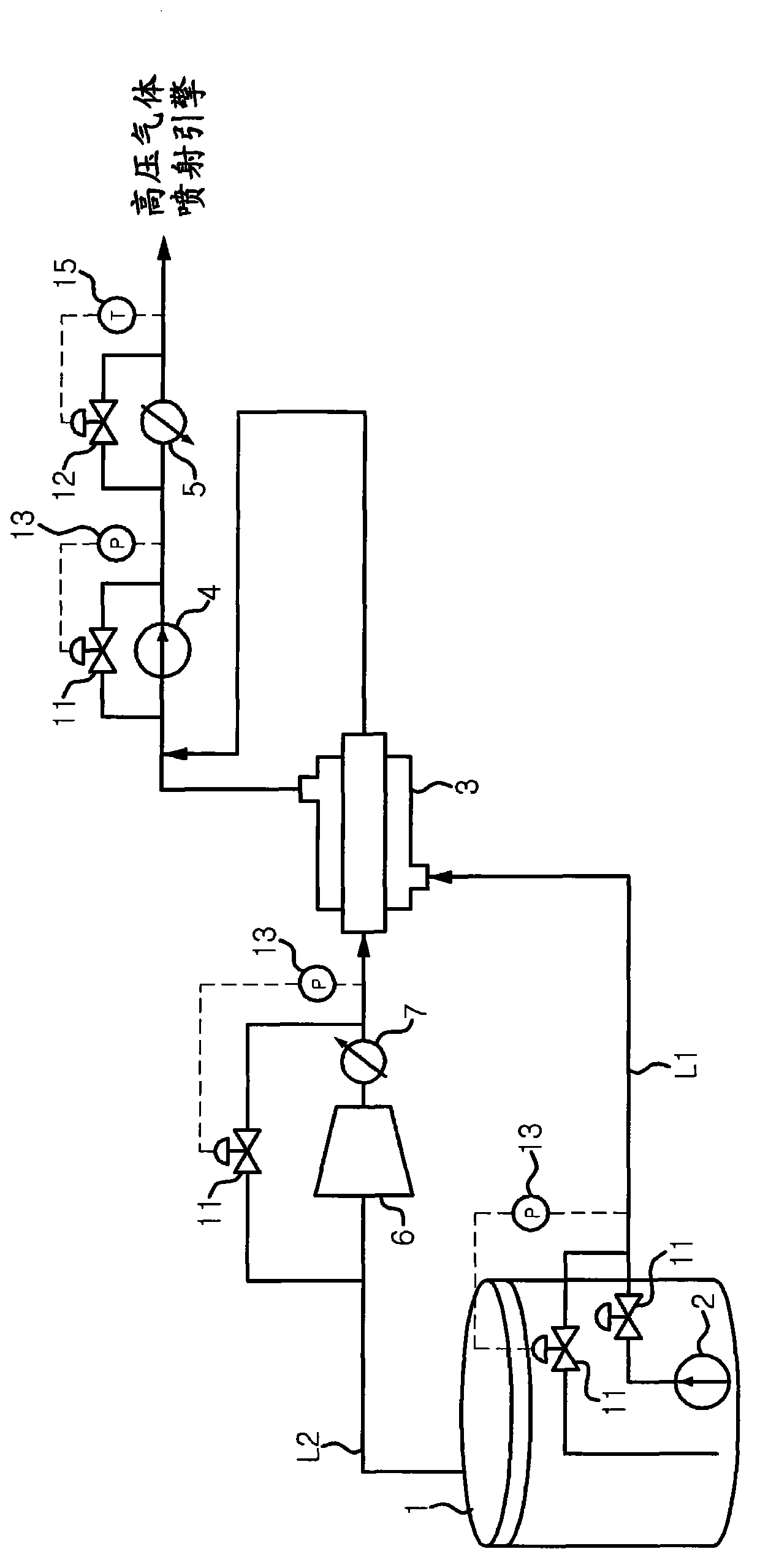

Fuel gas supply system and method of ship

ActiveCN101754897ASimple configurationReduced Power RequirementsPropulsion based emission reductionAuxillariesHigh pressureHigh pressure gas

A fuel gas supply system of a ship is provided for supplying fuel gas to a high-pressure gas injection engine of a ship, wherein LNG is extracted from an LNG tank of the ship, compressed at a high pressure, gasified, and then supplied to the high-pressure gas injection engine.

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

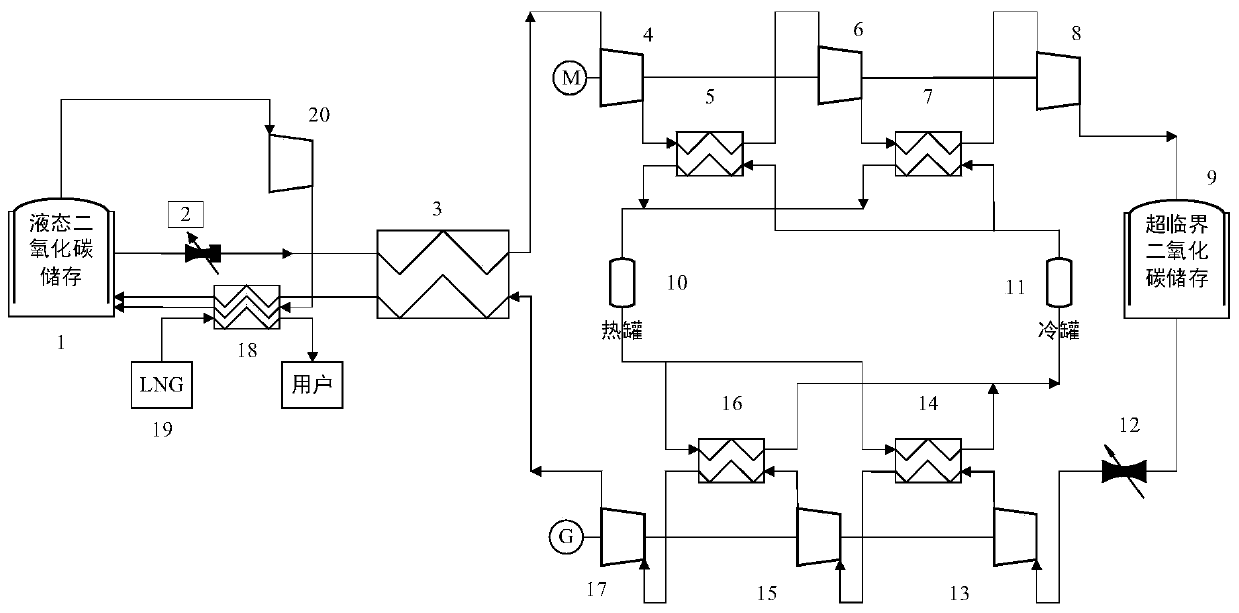

Cross-critical carbon dioxide energy storage system and method based on utilization of LNG cold energy utilization

ActiveCN110374838AReduce the temperatureReduce gasificationPositive displacement pump componentsSteam useElectricityMotor drive

The invention discloses a cross-critical carbon dioxide energy storage system and method based on utilization of LNG cold energy utilization. The system comprises a carbon dioxide circulation loop; the carbon dioxide circulating loop comprises a liquid carbon dioxide gas storage tank, a first heat exchanger, a second heat exchanger, a compression unit, a supercritical carbon dioxide storage tank and an expansion unit; the outlet of the liquid carbon dioxide storage tank is connected with the inlet of the supercritical carbon dioxide storage tank through the evaporation side of the first heat exchanger and the compression unit; the outlet of the supercritical carbon dioxide storage tank is connected with the inlet of the liquid carbon dioxide air storage tank sequentially through the expansion unit, the condensation side of the first heat exchanger and the condensation side of the second heat exchanger; the evaporation side inlet of the second heat exchanger is connected with an LNG storage tank, and the outlet of the second heat exchanger is connected with the user end to form an LNG utilization loop; and the liquefied carbon dioxide flowing out from the condensing side of the first heat exchanger is further condensed through LNG as a cold source; the compression unit is connected with a motor driven by an off-peak electric motor for energy storage; and the expansion unit is connected with a user through a power generator to carry out energy release.

Owner:XI AN JIAOTONG UNIV

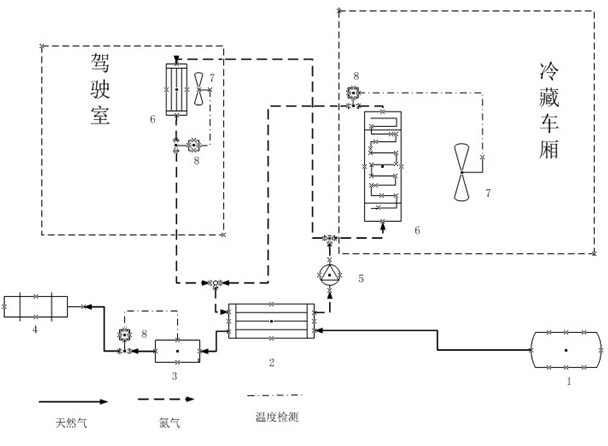

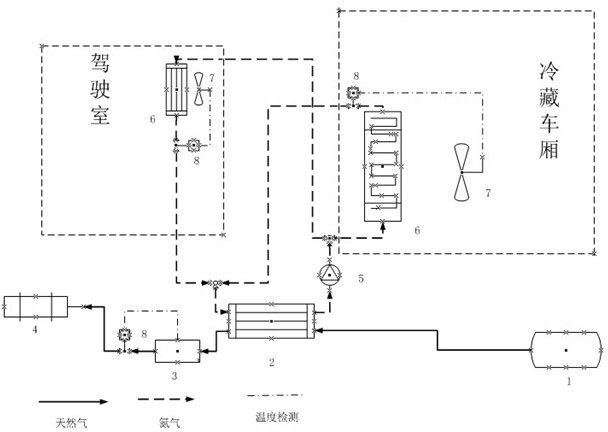

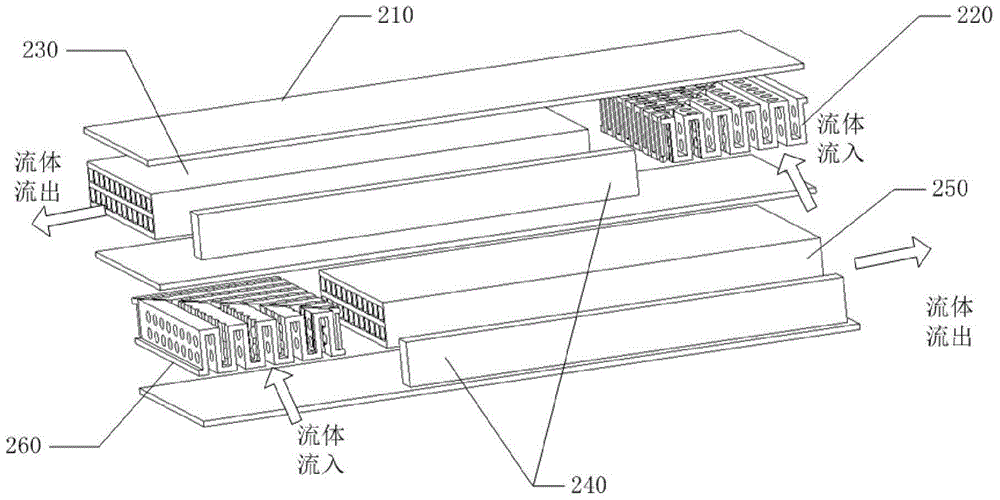

Cold energy utilizing device for liquefied natural gas refrigerator truck

InactiveCN102555733AImprove heat transfer efficiencyAvoid cloggingAir-treating devicesRefrigerated goods vehicleComing outEngineering

The invention discloses a cold energy utilizing device for a liquefied natural gas refrigerator truck. The device comprises a fuel gas system and a refrigerating system, wherein the fuel gas system comprises an LNG (liquefied natural gas) storage tank, a plate-fin heat exchanger and a water tank, wherein the LNG comes out of the storage tank, enters the plate-fin heat exchanger to exchange heat with nitrogen, further enters the water tank to exchange heat with the water, and enters an engine to act as the fuel gas. The refrigeration system comprises two coil pipes; the nitrogen is divided into two ways after coming out of the heat exchanger, wherein one nitrogen enters the coil pipe at a refrigeration carriage to exchange heat with the cold air, and the cold air subjected to the heat exchange provides cold energy to the carriage; and the other nitrogen enters the coil pipe in a cab to exchange heat with the air, so as to provide cold air. According to the cold energy utilizing device, the refrigerator truck is provided with the fuel gas, and at the same time the refrigeration carriage and the cab are provided with the cold air of better quality; and the waste of energy is reduced.

Owner:SOUTH CHINA UNIV OF TECH +1

Refrigerant phase transformation-free refrigerator for recovering liquefied natural gas (LNG) cold energy

InactiveCN101619914ARealize cold energy recoveryRealize cold energy utilizationDomestic cooling apparatusLighting and heating apparatusRefrigerator carLiquid state

The invention relates to a refrigerant phase transformation-free refrigerator for recovering liquefied natural gas (LNG) cold energy, which belongs to the technical fields of energy saving and refrigeration. The refrigerant phase transformation-free refrigerator for recovering LNG cold energy comprises an LNG storage tank, an LNG cryopump, an LNG carburetor, an LNG-refrigerant heat exchanger, a refrigerator heat exchanger, a refrigerator fan, a refrigerant low-temperature storage tank, a low-temperature refrigerant pump and various flow valves. R410A is selected as refrigerant to sequentially enter all refrigerators after obtaining refrigeration amount from LNG, the refrigerant releases the refrigeration amount step by step, and the step utilization of the cold energy is realized. The refrigerant is run in a complete liquid state in the whole process and does not generate phase transformation in heat exchangers of all the refrigerators; and the refrigeration amount transformation needed by the refrigerators is realized by adjusting the rotating speed of the fan and the flow of the refrigerant. The invention has the obvious effects of saving the energy and reducing the discharge.

Owner:SHANGHAI JIAO TONG UNIV

LNG Vapor Handling Configurations And Methods

InactiveUS20090217676A1Reduce boil-off volumeEliminate needSolidificationLiquefactionProcess engineeringRefrigeration

LNG from a carrier is unloaded to an LNG storage tank in configurations and methods in which expansion of compressed and condensed boil-off vapors from the LNG storage tank provide refrigeration to subcool the LNG that is being unloaded. Most advantageously, such configuration and methods reduce the amount of boil-off vapors and eliminate the need for a vapor return line and associated compressor.

Owner:FLUOR TECH CORP

Residual boil-off gas recovery from LNG storage tanks at or near atmospheric pressure

InactiveUS20080110181A1Gas handling/storage effectsNon-pressured vesselsEngineeringProcess engineering

A process is provided for recovering residual boil-off gas from LNG storage tanks at or near atmospheric pressure. Vaporized natural gas is recycled to an eductor to provide a motive force to withdraw residual boil-off gas in a container. The vapor is mixed with intermediate pressure LNG and sent to a vaporizer for down stream processing.

Owner:CHEVROU USA INC

High nickel steel for ultralow-temperature pressure vessel and manufacturing method thereof

The invention discloses high nickel steel for an ultralow-temperature pressure vessel and a manufacturing method thereof. The high nickel steel comprises the following chemical components, by weight, 0.01-0.08% of C, Si being less than or equal to 0.05%, 0.90-1.20% of Mn, 7.00-7.50% of Ni, 0.05-0.10% of Mo, 0.30-0.60% of Cr, 0.01-0.03% of Ti, S being less than or equal to 0.005%, P being less than or equal to 0.008% and the balance Fe and impurities. Two-stage controlled rolling is adopted. First-stage rolling temperature is greater than or equal to 1050 DEG C, secondary-stage rolling temperature is greater than or equal to 850 DEG C, finish rolling temperature is 750+ / -20 DEG C, and air cooling is carried out after rolling; thermal insulation is carried out for 2min / mm at 800-850 DEG C and quenching is carried out, thermal insulation is carried out for 2min / mm at 630-700 DEG C and quenching is carried out, thermal insulation is carried out for 4min / mm at 550-600 DEG C and tempering is carried out, and air cooling is finally carried out. The high nickel steel for an ultralow-temperature pressure vessel can replace 9% Ni steel. Thus, manufacturing cost of steel for an LNG storage tank is reduced, and direct economic benefit can be created.

Owner:ANGANG STEEL CO LTD

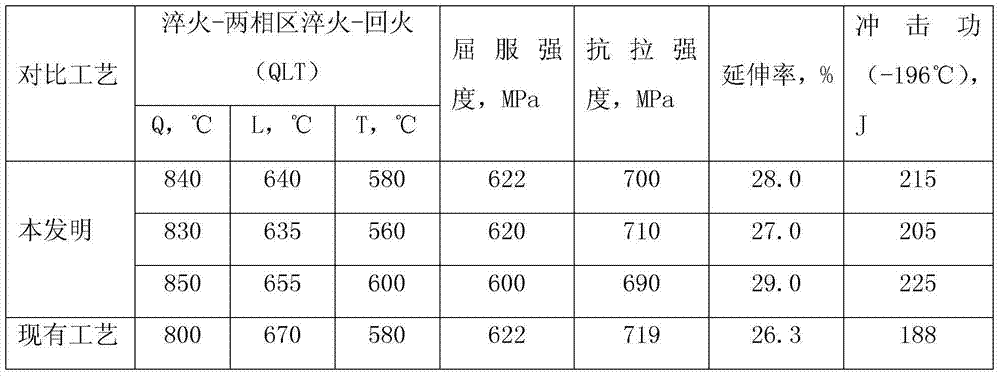

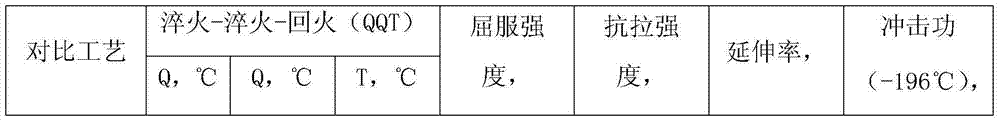

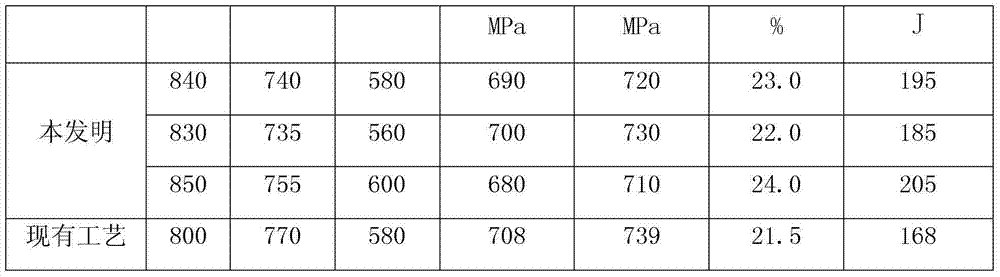

Heat treatment process capable of improving low temperature impact toughness of 9Ni steel

InactiveCN104745770ALarge temperature differenceImprove thermal stabilityQuenchingMechanical property

The invention discloses a heat treatment process capable of improving low temperature impact toughness of 9Ni steel. The heat treatment process are as follows: (a) quenching-dual-phase intercritical quenching-tempering (OLT) heat treatment process, wherein the quenching temperature is 830-850 DEG C, the intercritical quenching temperature is 635-655 DEG C and the tempering temperature is 560-600 DEG C; or (b) quenching-quenching-secondary tempering (QQT) heat treatment process, wherein the quenching temperature is 830-850 DEG C, the secondary tempering temperature is 735-755 DEG C, and the tempering temperature is 560-600 DEG C; or (c) normalizing-secondary normalizing-tempering (NNT) heat treatment process, wherein the normalizing temperature is 830-850 DEG C, the secondary normalizing temperature is 735-755 DEG C, and the tempering temperature is 560-600 DEG C; therefore, 9Ni steel with excellent low temperature impact toughness is obtained. The heat treatment process has the advantages that the low temperature impact toughness is improved greatly and the mechanical property of 9Ni steel is optimized while the strength of the 9Ni steel is reduced slightly, so that the 9Ni steel can completely meet the property requirement of large LNG storage cylinders.

Owner:NANJING IRON & STEEL CO LTD

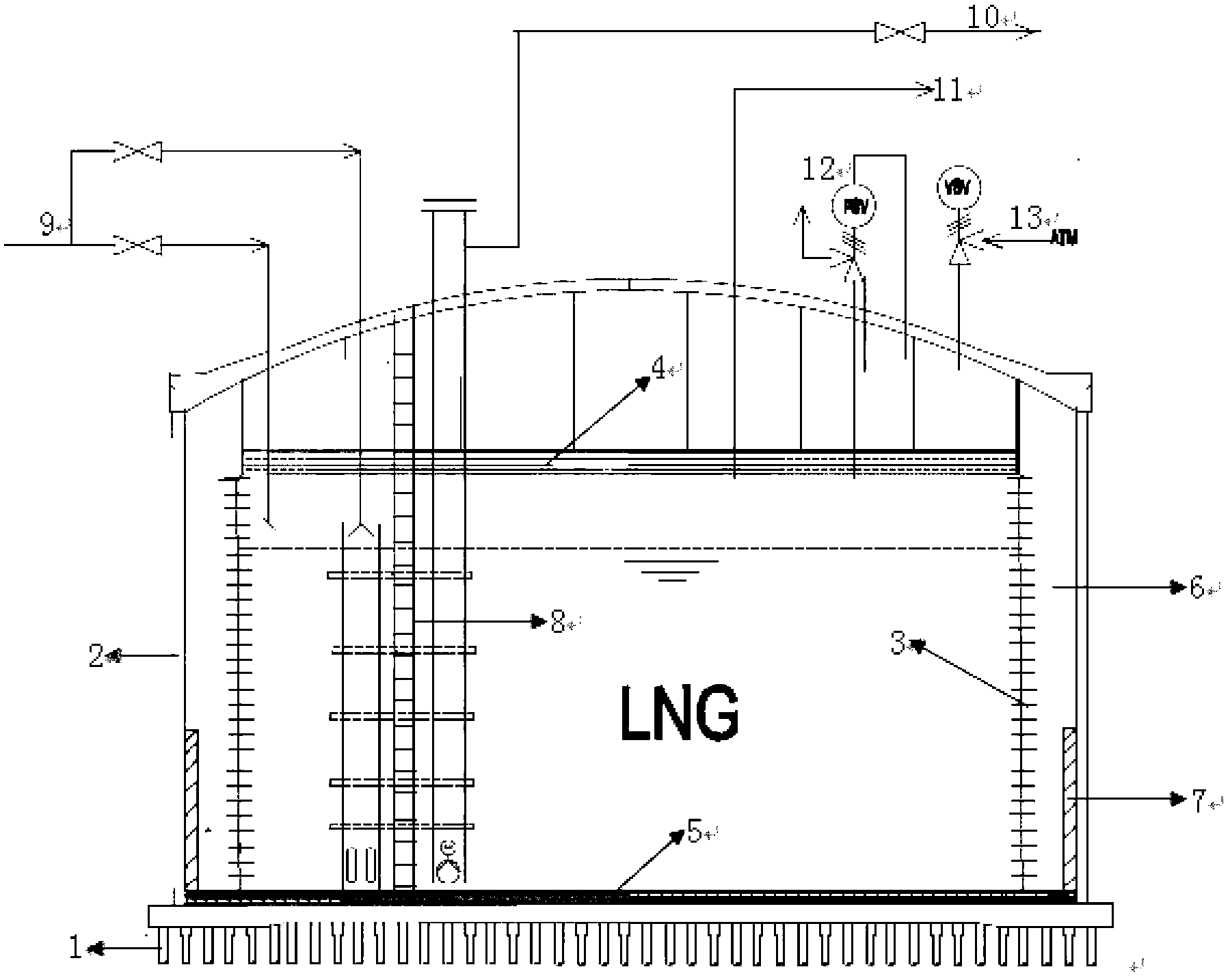

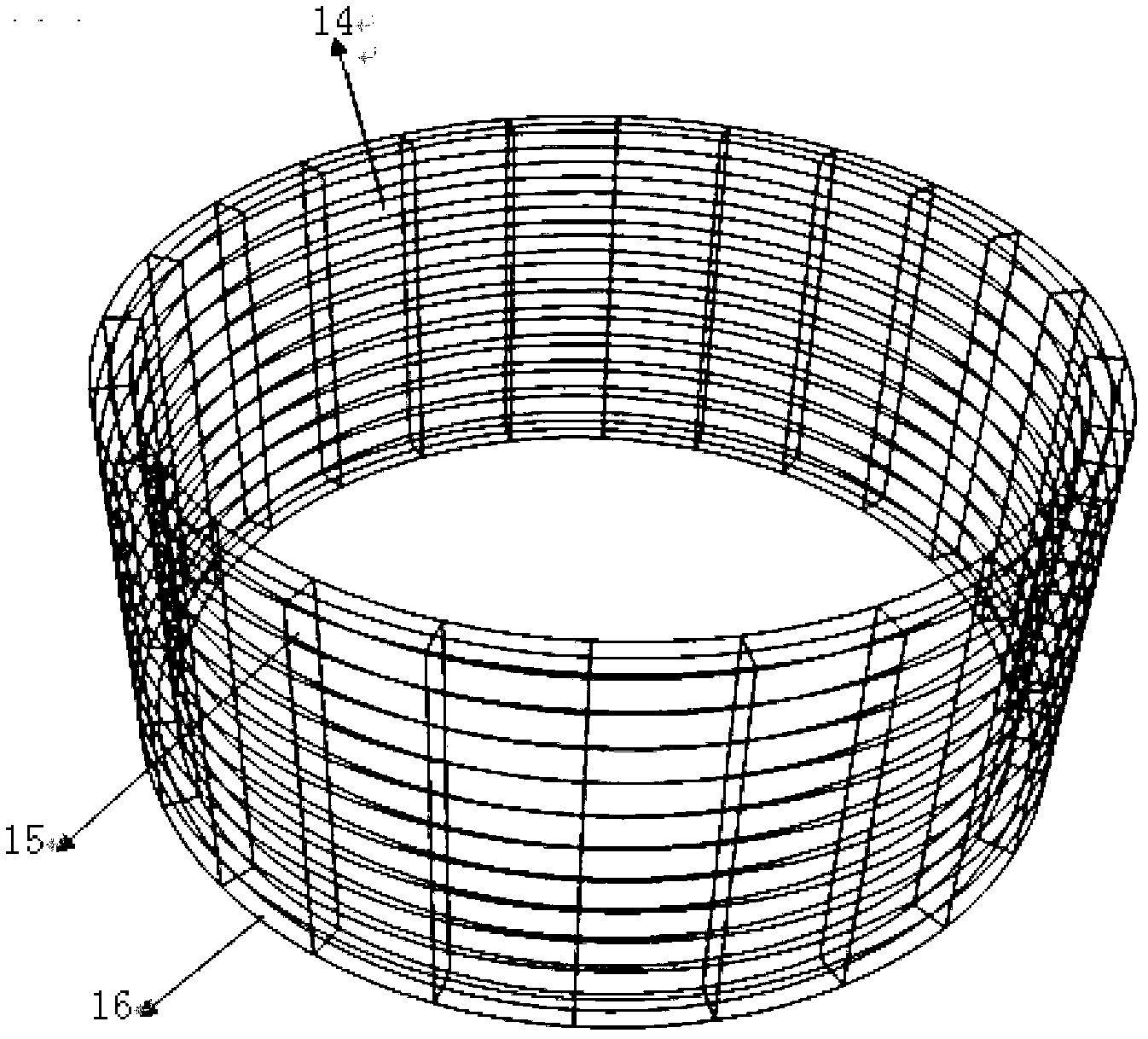

Self-supporting type LNG (Liquefied Natural Gas) storage tank

ActiveCN103162085AIncrease profitLow investment costContainer filling methodsPressure vesselsProtection systemWall plate

The invention discloses a self-supporting type LNG (Liquefied Natural Gas) storage tank which comprises a main storage tank body, wherein the main storage tank body is arranged on a pile foundation and comprises an outer concrete tank and an inner composite steel structure tank which is sleeved in the outer concrete tank; the outer concrete tank comprises a concrete bearing platform, a concrete tank wall and a concrete tank top; the concrete bearing platform is arranged on the pile foundation; and the tank top of the outer concrete tank is communicated with an LNG feeding pipeline, is communicated with an outward LNG transporting system and is also communicated with a pressure protection system. According to the storage tank, a wall plate of the inner tank can bear hydraulic pressures at different position heights by being densely added with rib piece and strengthening ring structures, so that the wall plate is thin, the composite structure can enable the material utilization rate to be high, and the investment cost of the LNG storage tank can be reduced to a great degree; the wall plate of the inner tank is thin, so that most of prefabricating and mounting processes of the wall plate of the inner tank, the rib piece and strengthening string composite structures can be finished in advance in a workshop or a site, and the high-altitude welding amount is reduced; and the compared with the conventional LNG storage tank, the LNG storage tank disclosed by the invention can be used for shortening the construction period.

Owner:CHINA NAT OFFSHORE OIL CORP +1

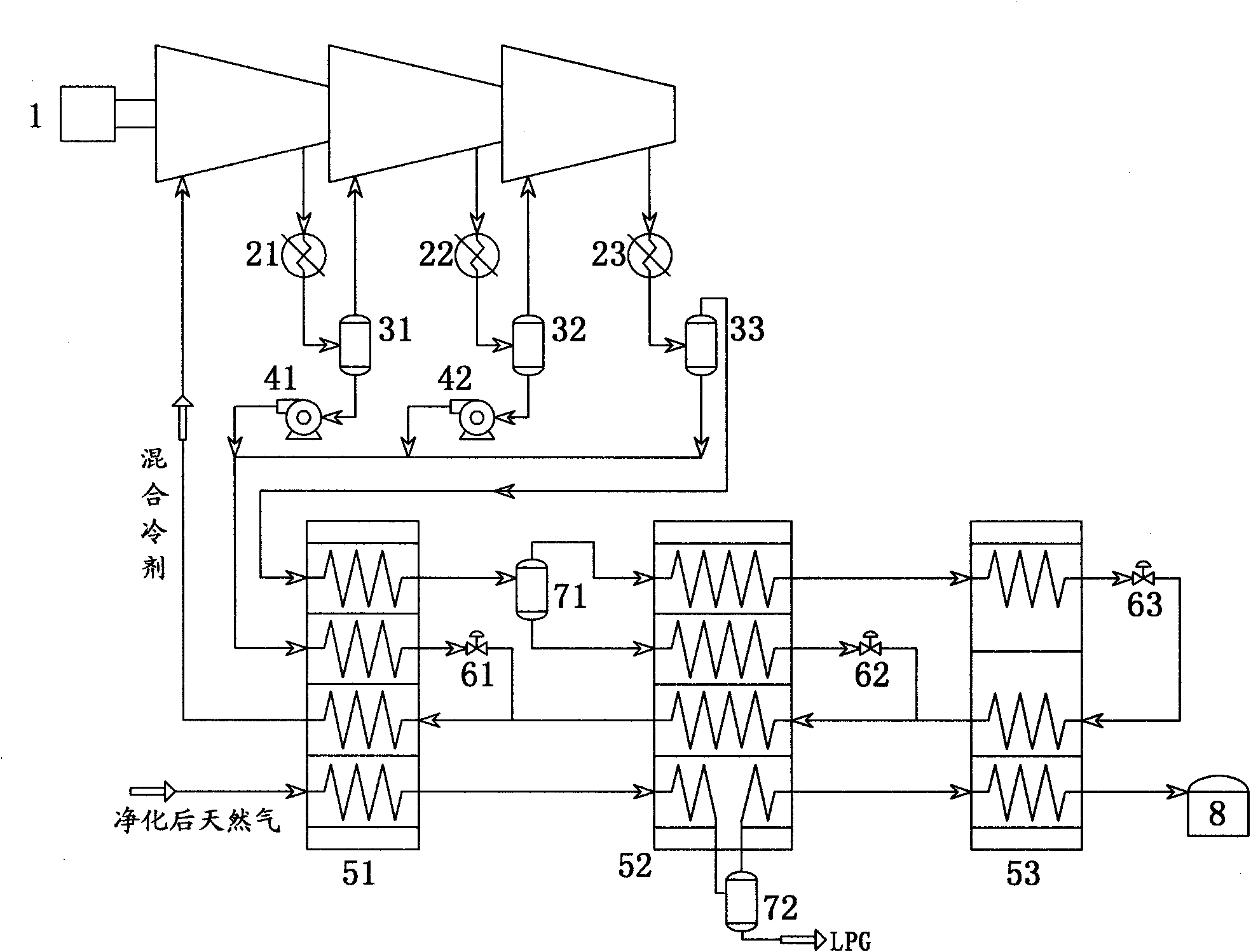

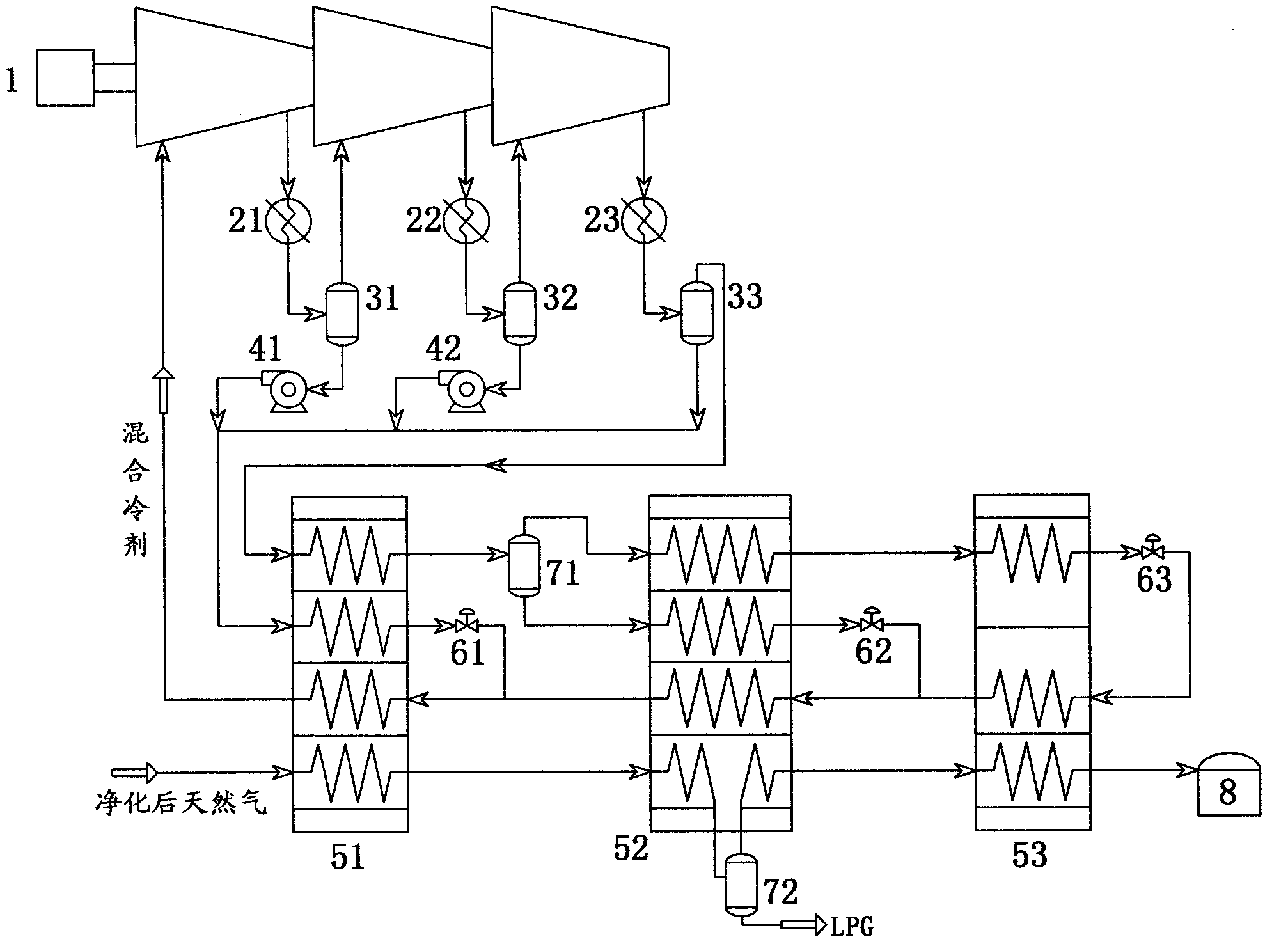

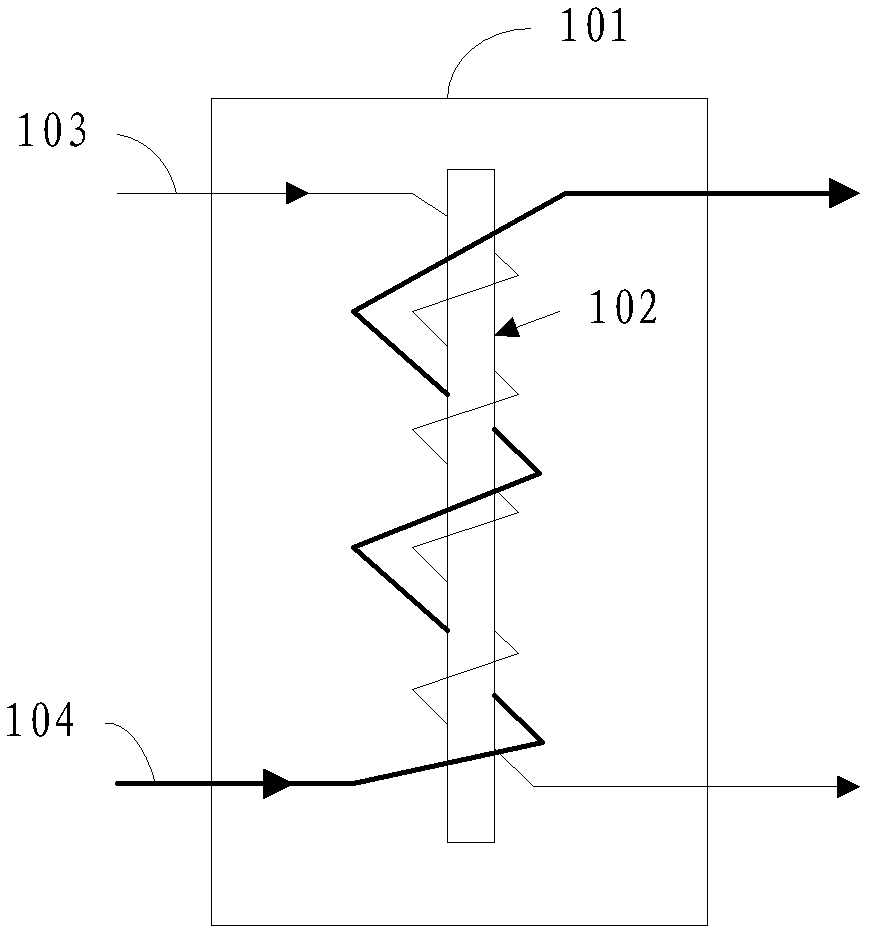

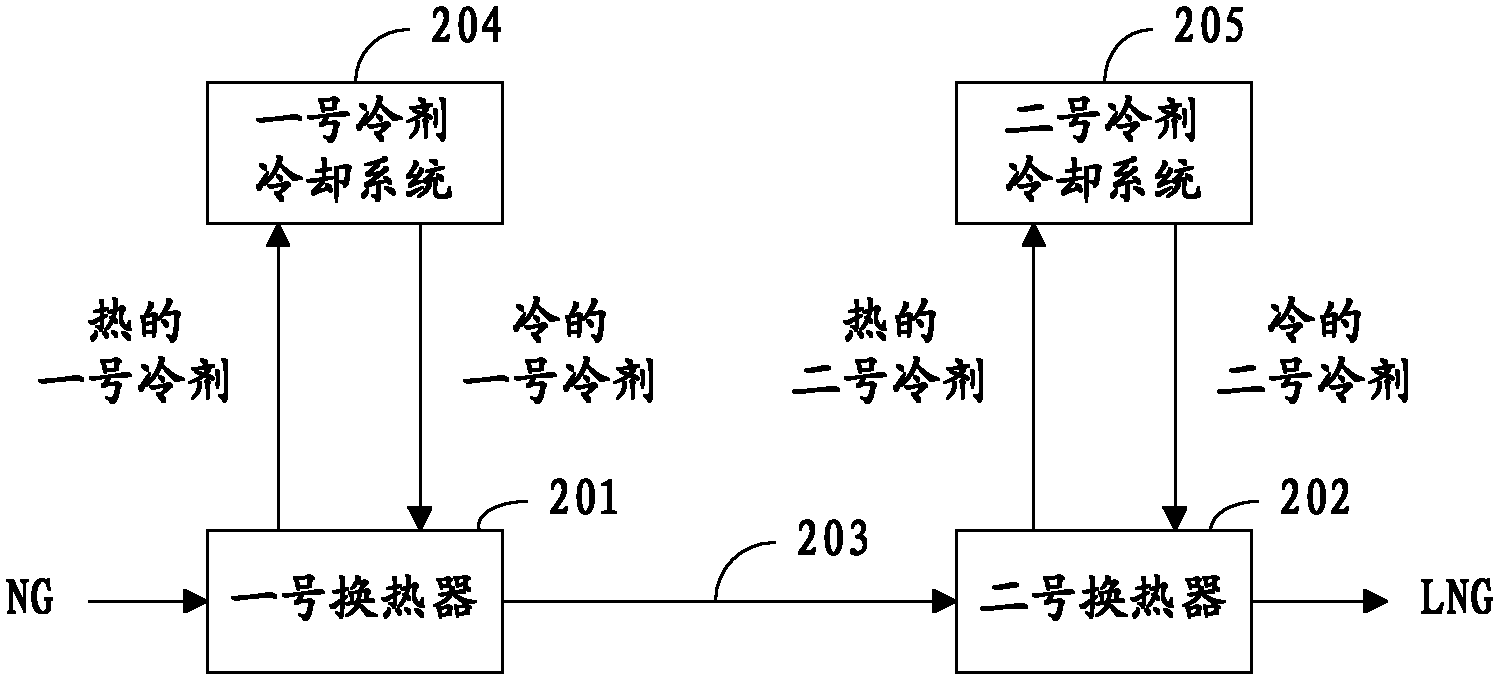

Liquefaction system and method for NG (Natural Gas)

ActiveCN103075868AImprove utilization efficiencyImprove cooling efficiencySolidificationLiquefactionEngineeringHigh pressure

The invention relates to a liquefaction system and a liquefaction method for NG (Natural Gas). The system comprises a cold box, a supply pipe for supplying the NG to the cold box, a No.1 refrigerant liquefaction subsystem, a No.2 refrigerant liquefaction subsystem, a No.1 refrigerant cooling subsystem, a No.2 refrigerant cooling subsystem, a heavy hydrocarbon separation tank which is used for conducting gas-liquid separation to liquid heavy hydrocarbon and gas light hydrocarbon, and an LNG (Liquefied Natural Gas) storage tank which is used for storing LNG obtained through liquefaction, wherein the cold box comprises an NG precooling passage which is connected with the heavy hydrocarbon separation tank and is used for supplying the NG; an NG deep cooling passage which is connected with the LNG storage tank and is used for supplying the gas light hydrocarbon; a No.1 refrigerant precooling passage and a No.2 refrigerant precooling passage which are used for respectively supplying and cooling high-pressure No.1 refrigerant and high-pressure No.2 refrigerant which are respectively supplied by the No.1 refrigerant liquefaction subsystem the No.2 refrigerant liquefaction subsystem, and are used for respectively supplying the cooled high-pressure No.1 refrigerant and the cooled high-pressure No.2 refrigerant to the No.1 refrigerant cooling subsystem and the No.2 refrigerant cooling subsystem; and a No.1 refrigerant cooling passage and a No.2 refrigerant cooling passage which are used for respectively supplying low-temperature No.1 refrigerant and low-temperature No.2 refrigerant which are respectively supplied by the No.1 refrigerant cooling subsystem and the No.2 refrigerant cooling subsystem to cool the NG, high-temperature No.1 refrigerant and high-temperature No.2 refrigerant. By adopting the technical scheme, the complexity and the energy consumption of the system can be reduced.

Owner:PETROCHINA CO LTD +1

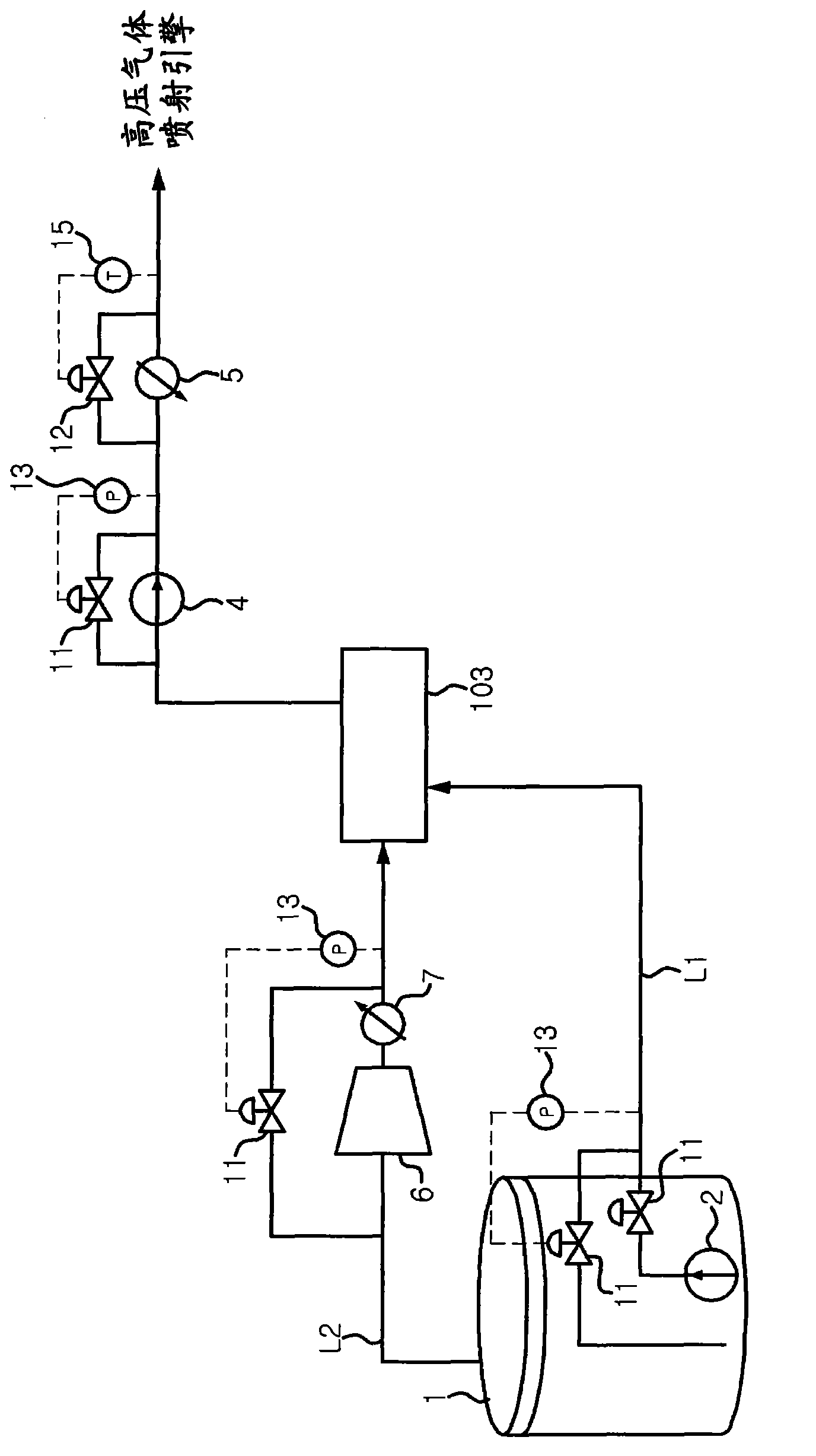

Fuel gas supply system and method of ship

InactiveCN103010447ASimple configurationReduced Power RequirementsPropulsion based emission reductionAuxillariesProcess engineeringProduct gas

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

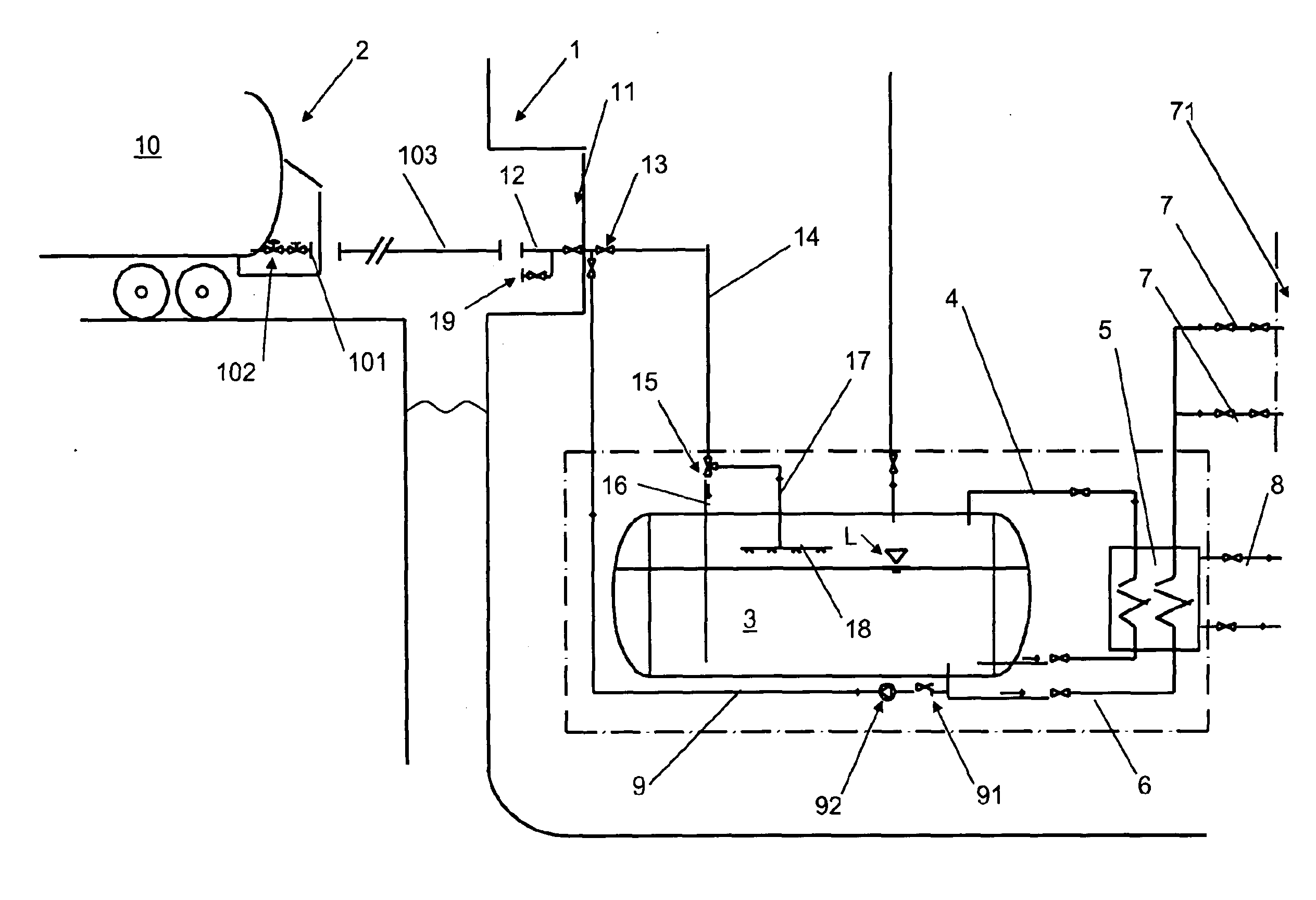

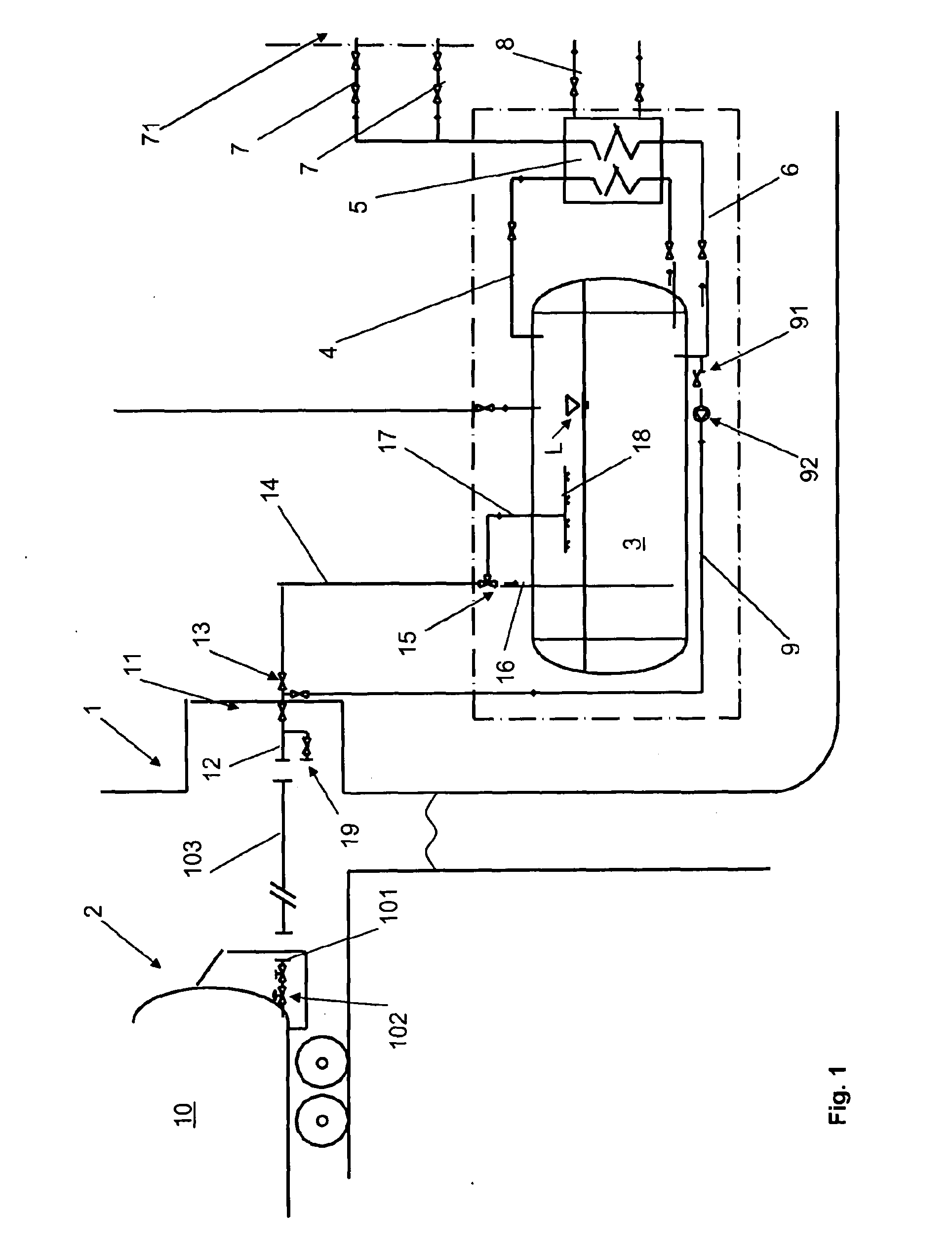

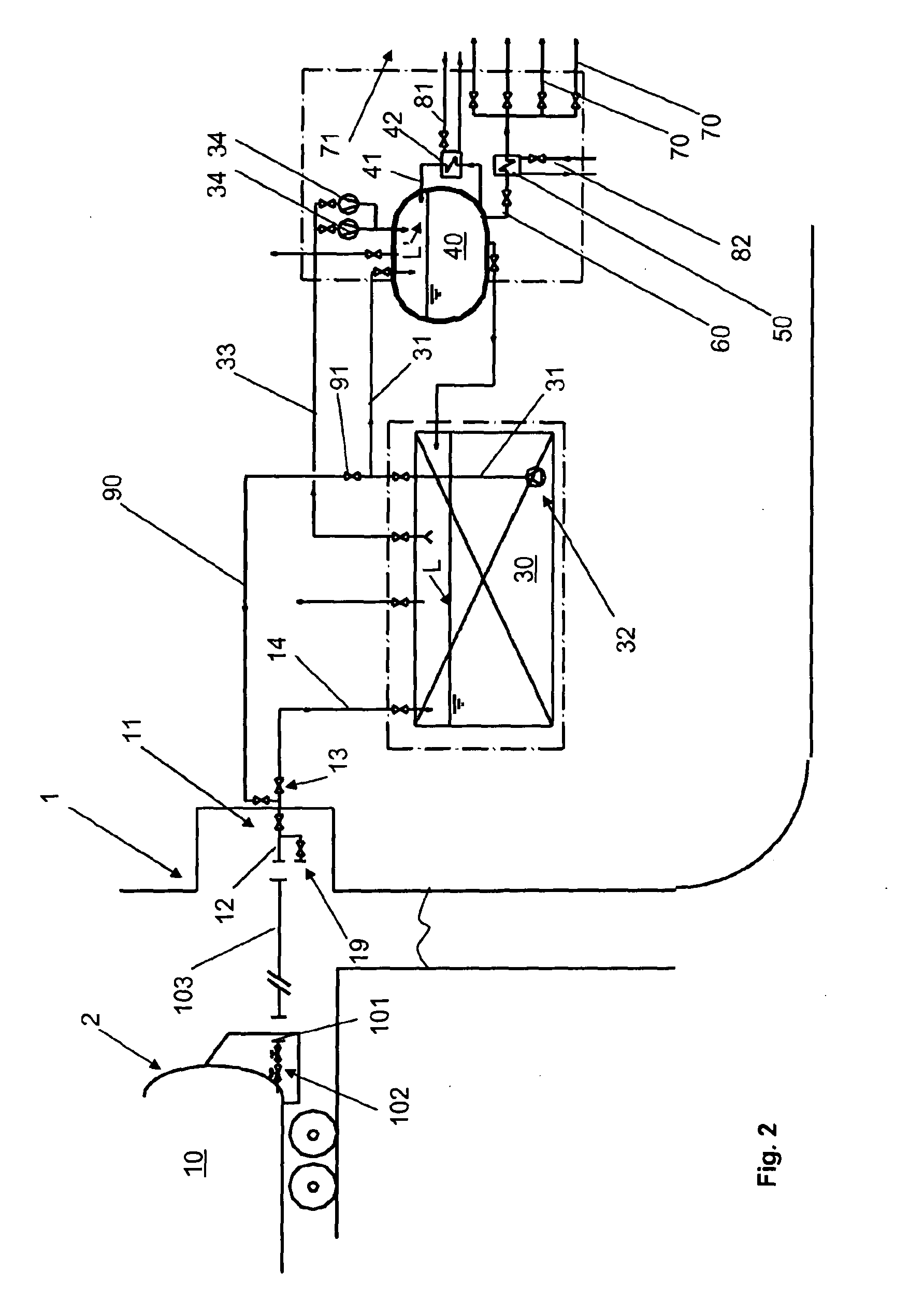

Method for operating a LNG fuelled marine vessel

InactiveUS20110179810A1Efficient transferRestricting fuel flowAuxillariesGas handling applicationsLine tubingMarine engineering

The invention relates to a method and system for operating a LNG fuelled marine vessel. The marine vessel (1) comprises a LNG storage tank (3) and a LNG fuelled power plant (71). LNG is stored in the LNG storage tank, and in connection with a bunkering operation the marine vessel is supplied with LNG by connecting a source of LNG to a bunkering line (14) of the marine vessel and subsequently supplying the marine vessel with LNG through the bunkering line. In order to achieve a faster bunkering operation the bunkering line (14) is cooled down prior to the bunkering operation.

Owner:WARTSILA FINLAND OY

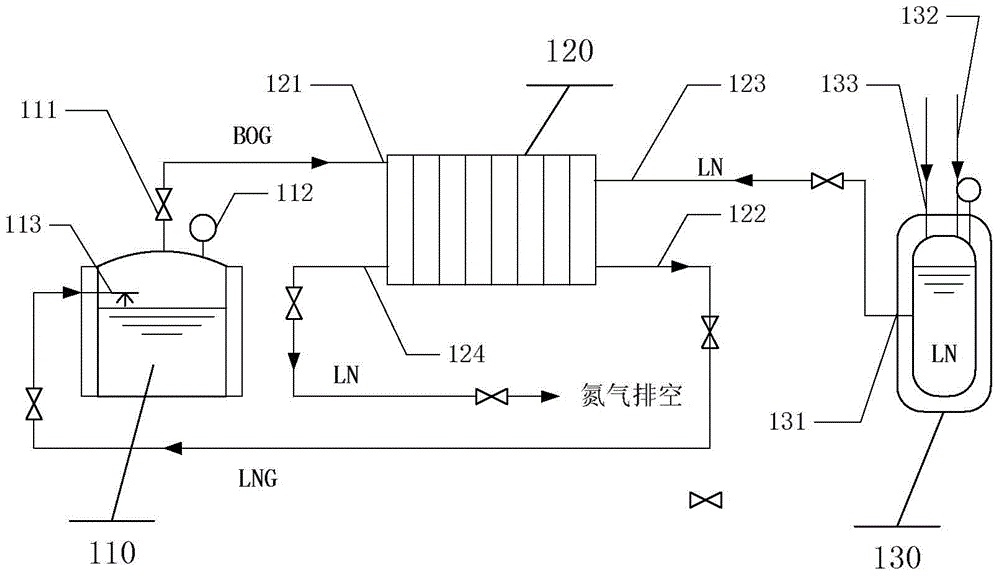

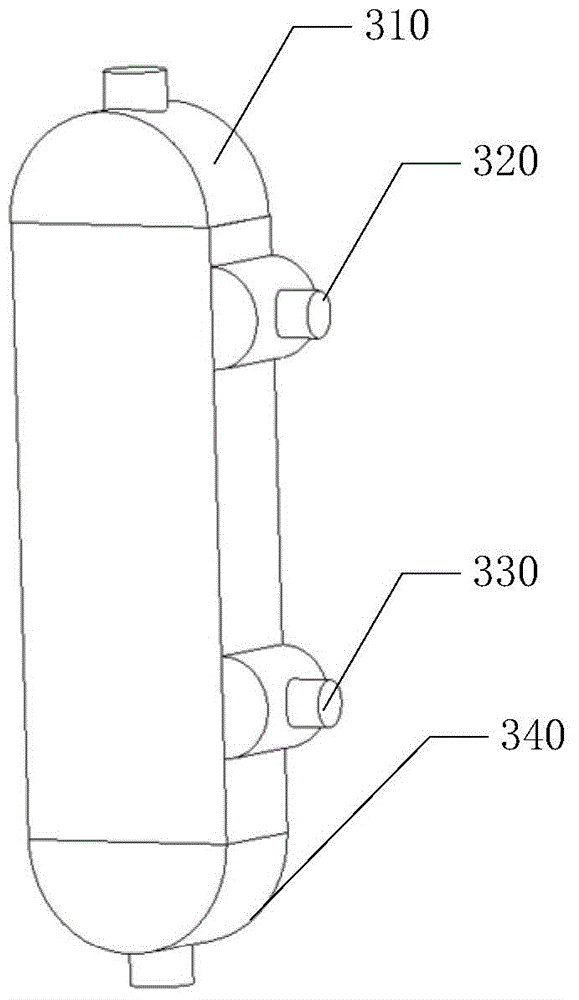

BOG recovering method and device

ActiveCN104390136AImprove throughputHigh heat and mass transfer efficiencyContainer filling methodsSteam/vapor condensersAutomatic controlNitrogen

The invention discloses a boil-off gas (BOG) recovering method, comprising a liquefied natural gas (LNG) storage tank, a double-row micro-channel harmonica-shaped tube condensation recovery device, a liquid nitrogen storage tank, an automatic control system and a plurality of auxiliary devices. In a recovering process, a compressor and a low-temperature pump are not utilized, and the self pressure of BOG gas and nitrogen is taken as a driving force of a fluid flowing in a pipeline. A BOG outlet of the LNG storage tank is directly connected with a BOG inlet receiver of the double-row micro-channel harmonica-shaped tube condensation recovery device through a pipeline, an outlet for the recovered LNG liquid is connected with the LNG storage tank through a pipeline, and the pipeline of the LNG storage tank is provided with a valve and a pressure detector; an outlet of the liquid nitrogen storage tank is connected with a liquid nitrogen inlet of the double-row micro-channel harmonica-shaped tube condensation recovery device through a pipeline, a nitrogen outlet of the condensation recovery device is divided into two paths, one path is directly connected with air, the other path is connected with the nitrogen inlet of the liquid nitrogen storage tank, and the pipeline of the liquid nitrogen storage tank is provided with a valve and a pressure detector.

Owner:溧阳德维透平机械有限公司

System and method for containerized transport of liquids by marine vessel

ActiveUS8375876B2Efficient loadingSafely berthingAuxillariesContainer filling methodsLiquid tankInterconnection

A marine vessel, and a system and method of using the marine vessel, to facilitate the introduction of bulk liquid commodities, such as LNG, into the established and extensive worldwide intermodal transportation system, which is based on containerized shipments. The marine vessel is a specialized vessel, of either ship or barge form, that is capable of holding a large number of ISO-sized intermodal LNG tanks and is configured so as to have at one and the same time characteristics of both a tanker vessel (e.g., a gas carrier) and a container vessel. The intermodal LNG tanks connect to a piping system of the marine vessel and are thereby interconnected in such a manner that allows the interconnected intermodal LNG tanks to behave as if they constitute a typical LNG vessel bulk liquid tank to facilitate efficient loading at a typical marine LNG terminal. The containerized intermodal LNG tanks are capable of discharging liquids to a marine terminal as if in a bulk mode, or of being disconnected from the common interconnection system to allow lift-off discharge of the intermodal LNG tanks at a typical cargo container port so that the intermodal LNG tanks can enter the existing intermodal transportation system for further distribution to the end user by other marine vessels, over-the-road truck, or by rail.

Owner:ARGENT MARINE MANAGEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com