BOG recovering method and device

A recovery method and technology of a recovery device, applied in the field of BOG recovery, can solve the problems of complex process, difficult realization by enterprises, and small scope of application, and achieve the effects of high heat and mass transfer efficiency, complex solution process, and wide application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples, but the implementation and protection of the present invention are not limited thereto.

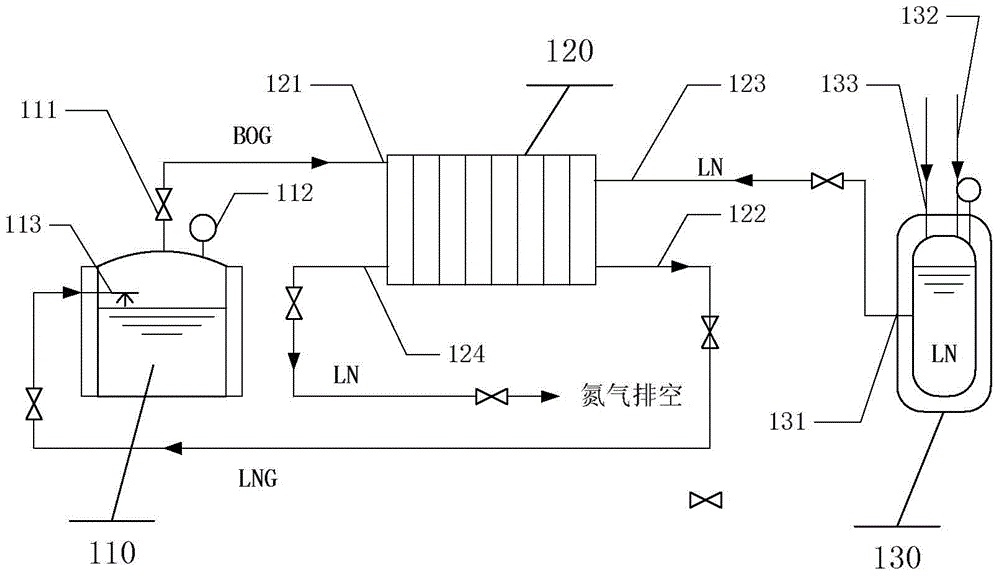

[0015] Such as figure 1 As shown, the device in this embodiment includes an LNG storage tank 110 , a condensation recovery device 120 , and a nitrogen storage tank 130 . Both the LNG storage tank 110 and the liquid nitrogen storage tank 130 are equipped with pressure detection device pressure gauges, and the inlet and outlet pipelines of the LNG storage tank 110, the condensate recovery device 120 and the nitrogen storage tank 130 are all equipped with check valves to control the flow direction of the fluid. . The pressure of the storage tank 110 increases with the continuous gasification of LNG. When the pressure is higher than the set value, the control system opens the one-way valve 111 at the outlet of the LNG storage tank 110, so that the BOG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com