Patents

Literature

191results about How to "High heat and mass transfer efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

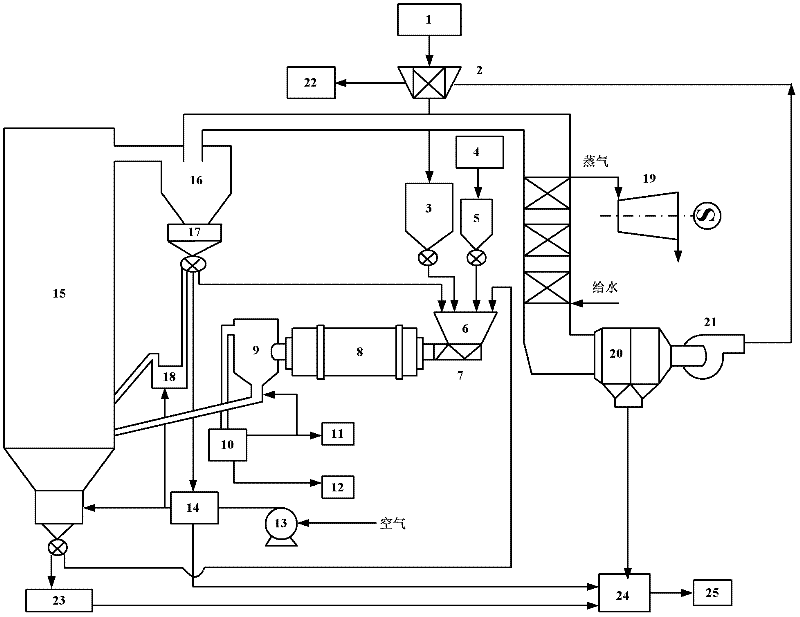

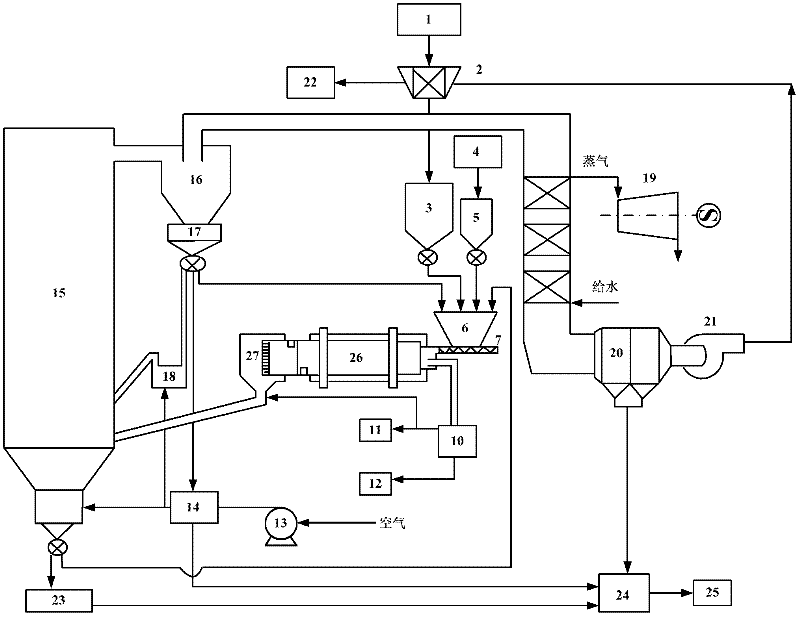

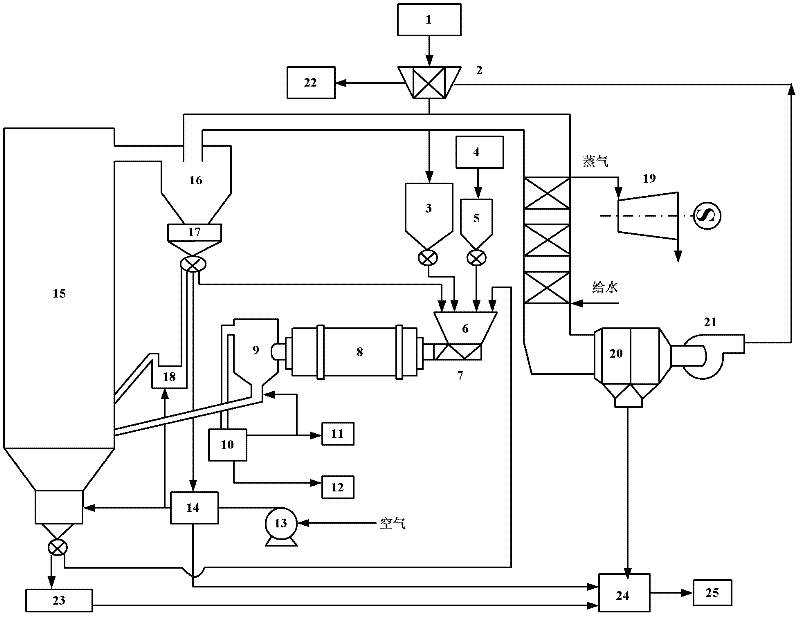

Oil shale rotary kiln dry distillation and circulating fluidized bed combustion process

InactiveCN102533296AImprove combustion efficiencyControl generationDirect heating destructive distillationBiofuelsBottom ashInternal combustion engine

An oil shale rotary kiln dry distillation and circulating fluidized bed combustion process makes organic combination of a rotary kiln dry distillation with a circulating fluidized bed; oil shale particles are mixed with thermal-cycle ash from a circulating fluidized bed boiler and part of circulating fluidized bed boiler bottom ash, and then are sent into a rotary kiln for dry distillation to prepare shale oil and dry distillation coal gas; the dry distillation coal gas has a high calorific value; a part of the coal gas is used as recycle wind of a semicoke material recycle device, and enters the circulating fluidized bed boiler with oil shale semicoke particles for combustion, and the residual part is delivered into an internal combustion engine for combustion generation. The invention can increase shale oil and coal gas quality, reduce energy loss and environment pollution, and improve the comprehensive utilization degree.

Owner:SHANGHAI JIAO TONG UNIV

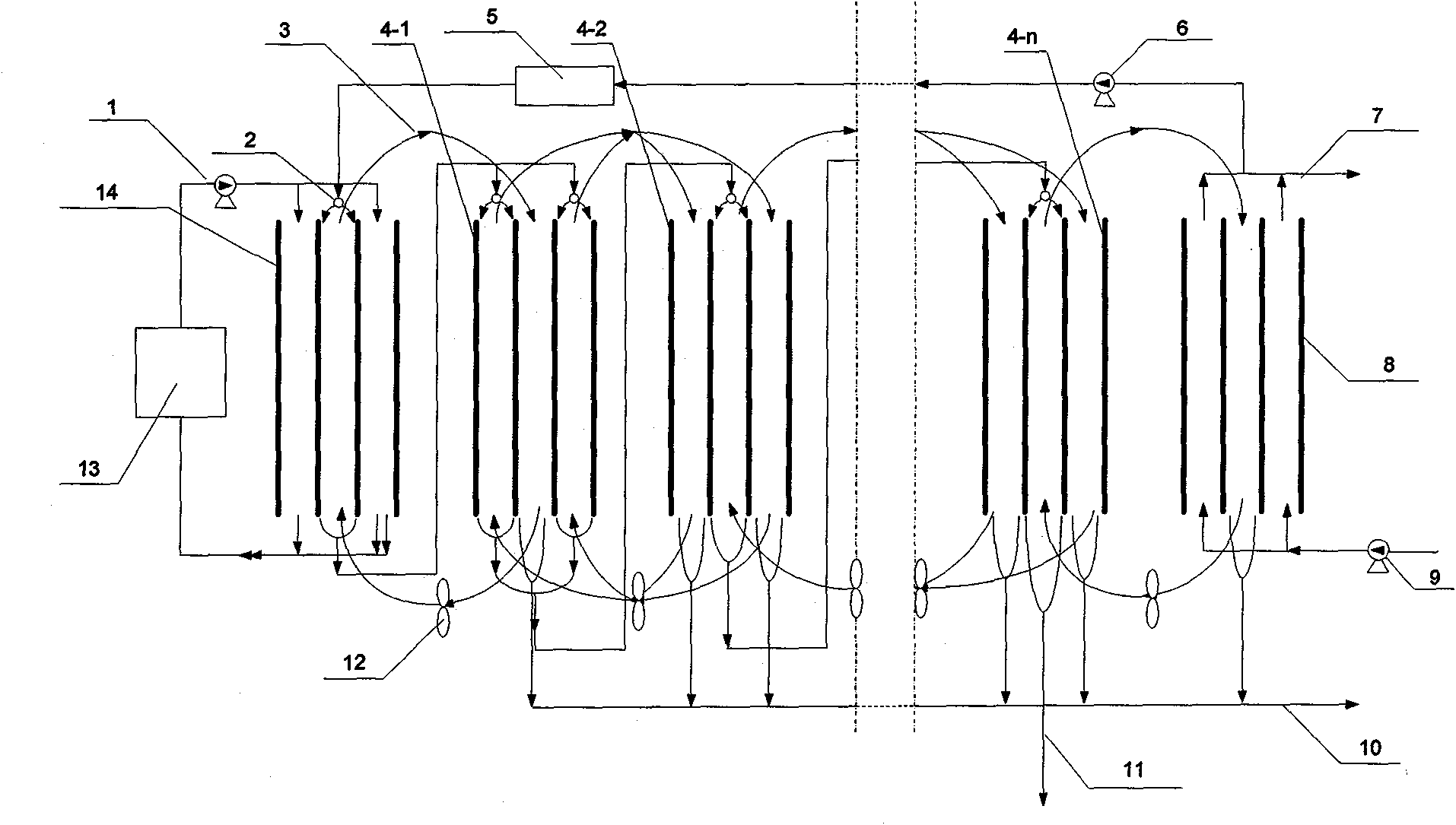

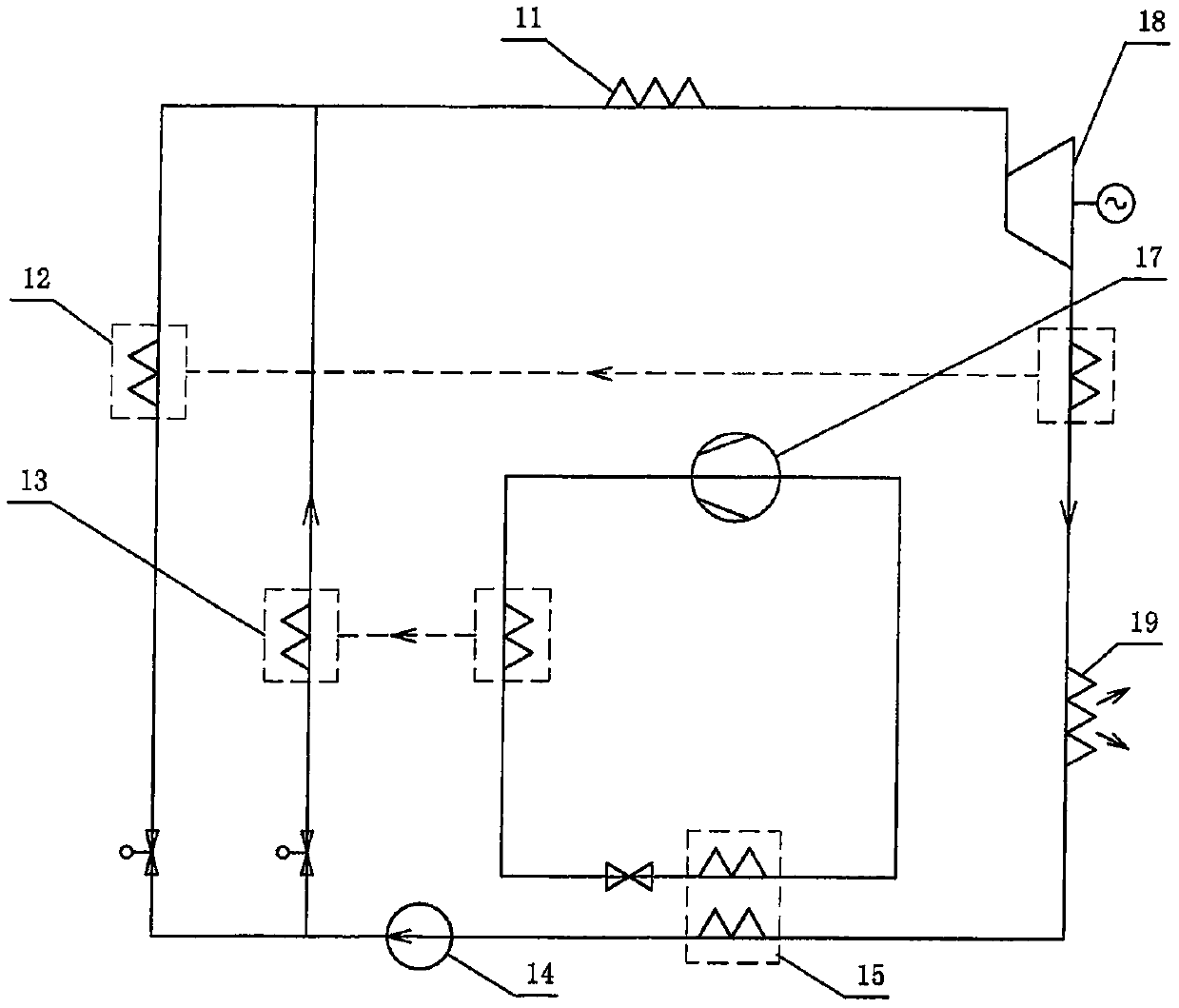

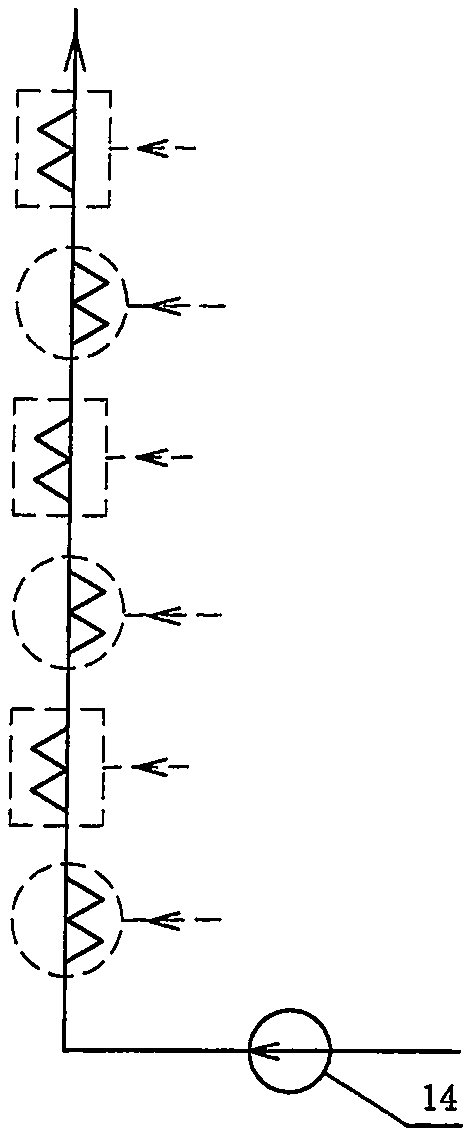

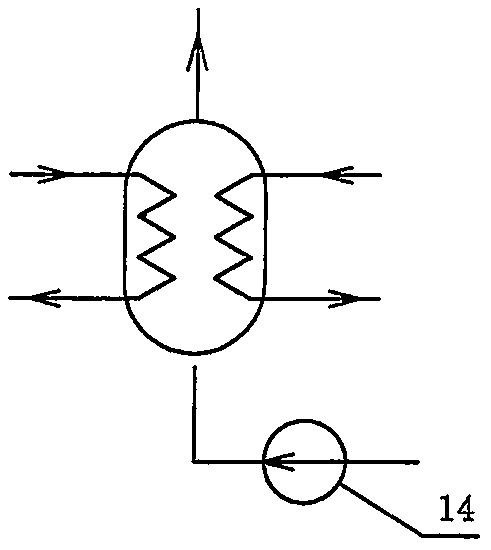

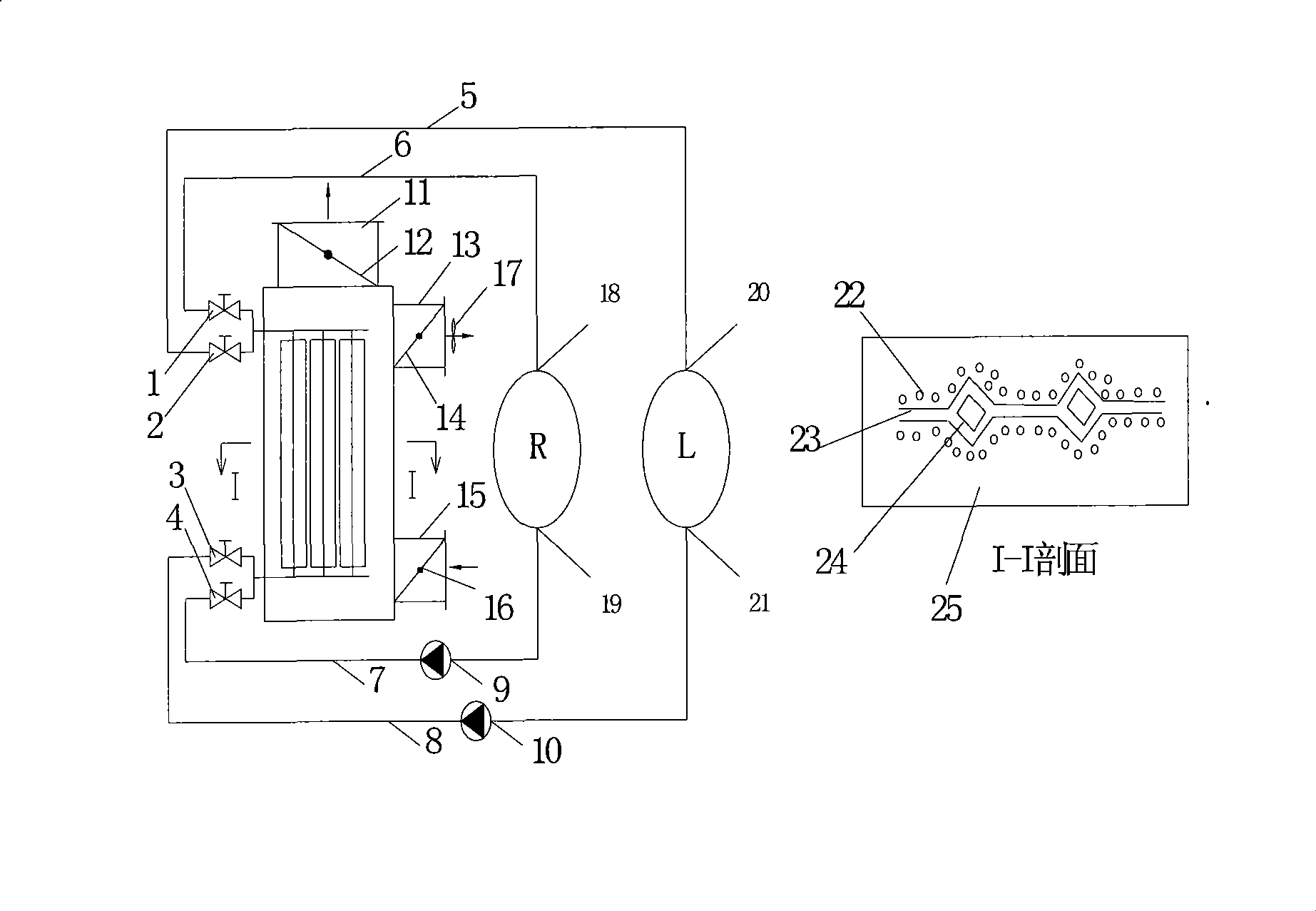

Constant-pressure multiple-effect evaporation condensation sea water desalination device with air medium

InactiveCN101921036AReduce consumptionImprove performanceSeawater treatmentMultistage water/sewage treatmentWater desalinationEnergy recovery

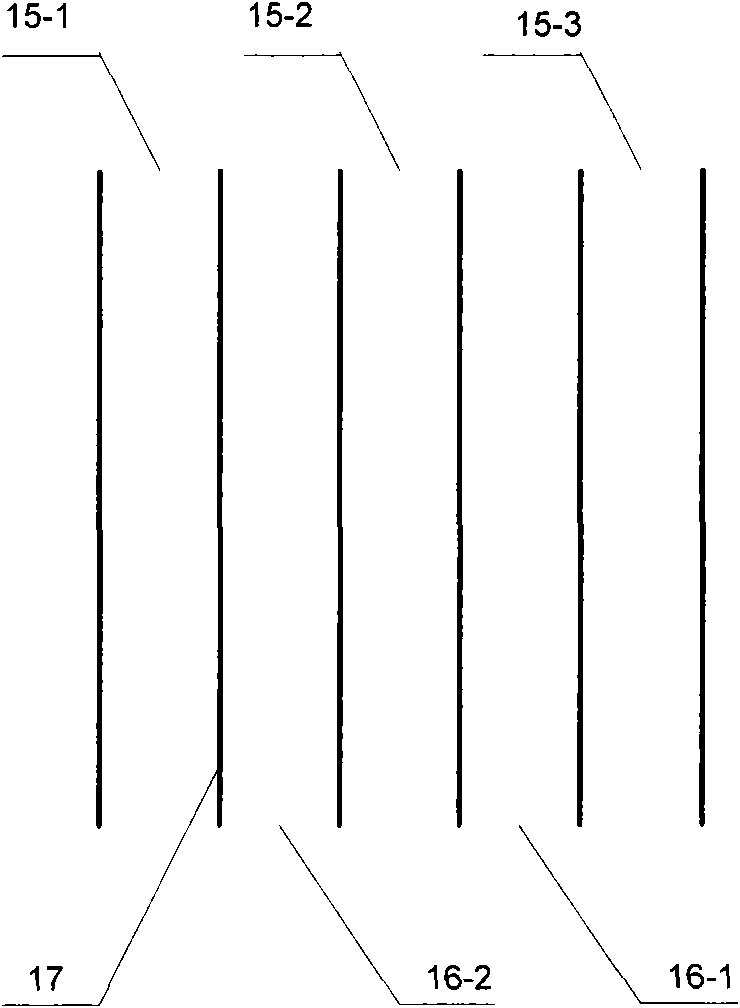

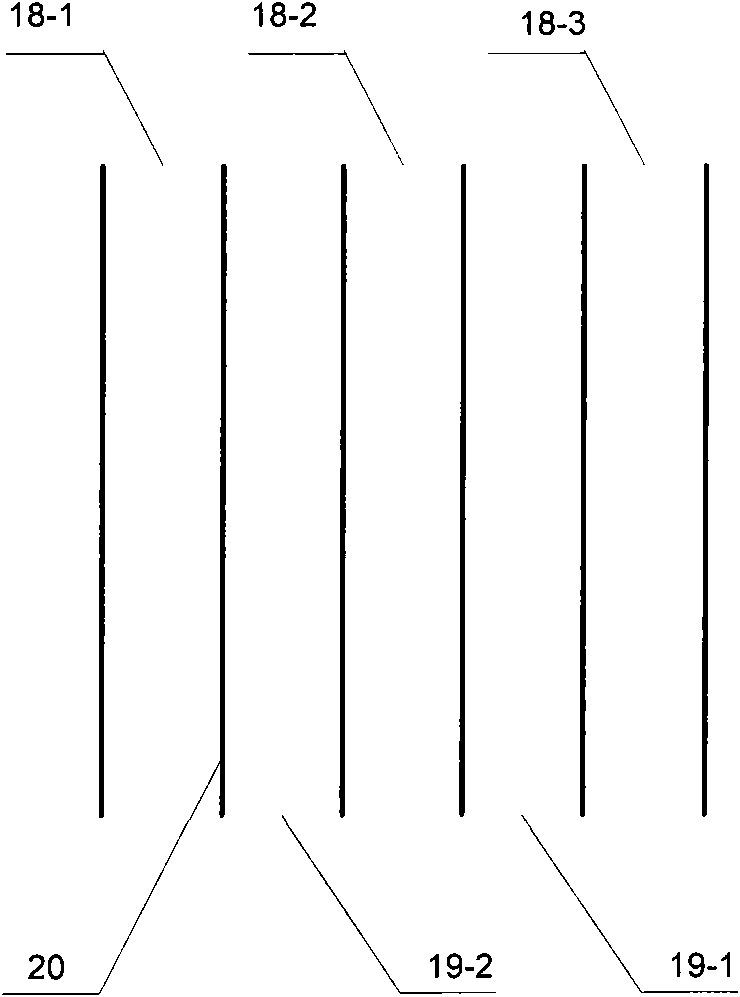

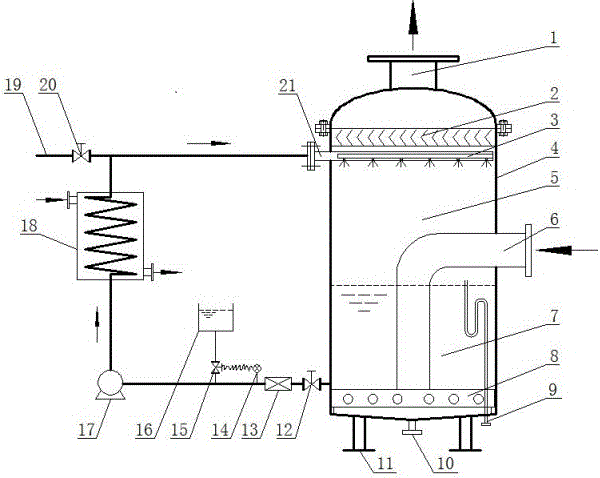

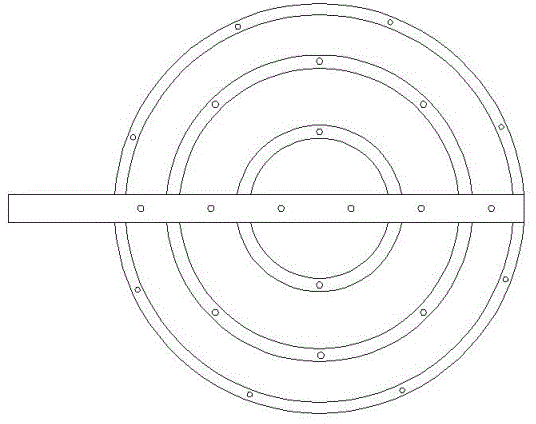

The invention discloses a constant-pressure multiple-effect evaporation condensation sea water desalination device with an air medium, which mainly comprises a low-and-medium temperature heat source (13), a first-stage heating evaporator (14), an evaporation condenser (4) and a last-stage condenser (8). The first-stage heating evaporator (14), the evaporation condenser (4) and the last-stage condenser (8) are installed in sequence closely, and the low-and-medium heat source (13) and the first-stage heating evaporator (14) are connected together. The first-stage heating evaporator (14), the evaporation condenser (4) and the last-stage condenser are all formed by combining a plurality of heat exchange plates which are arranged from left to right in sequence, and a gap is reserved between every two adjacent heat exchanging plates to form a flow channel for heat exchange fluid. By adopting the plate-type heat exchange principle, the sea water desalination device realizes multiple-effect air humidification and dehumidification evaporation and condensation for sea water desalination under constant pressure. Heat and moisture transfer is performed between sprayed sea water and overflowing air, and the condensation latent heat of fore effect heat and moisture air can be absorbed at the same time, and therefore, energy recovery is realized and the fore effect heat and moisture air can be condensed to obtain fresh water.

Owner:GUANGDONG FIVESTAR SOLAR ENERGY

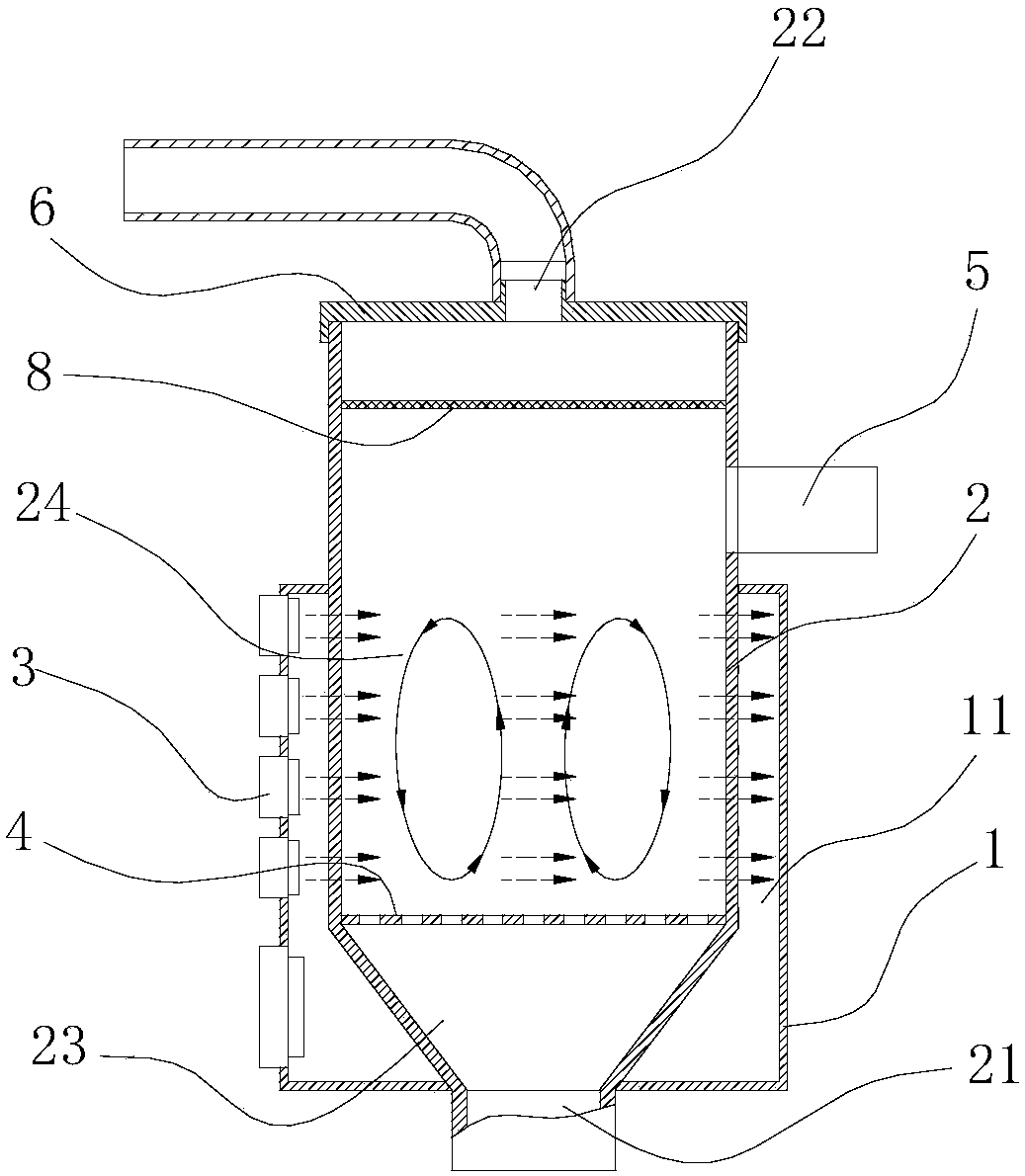

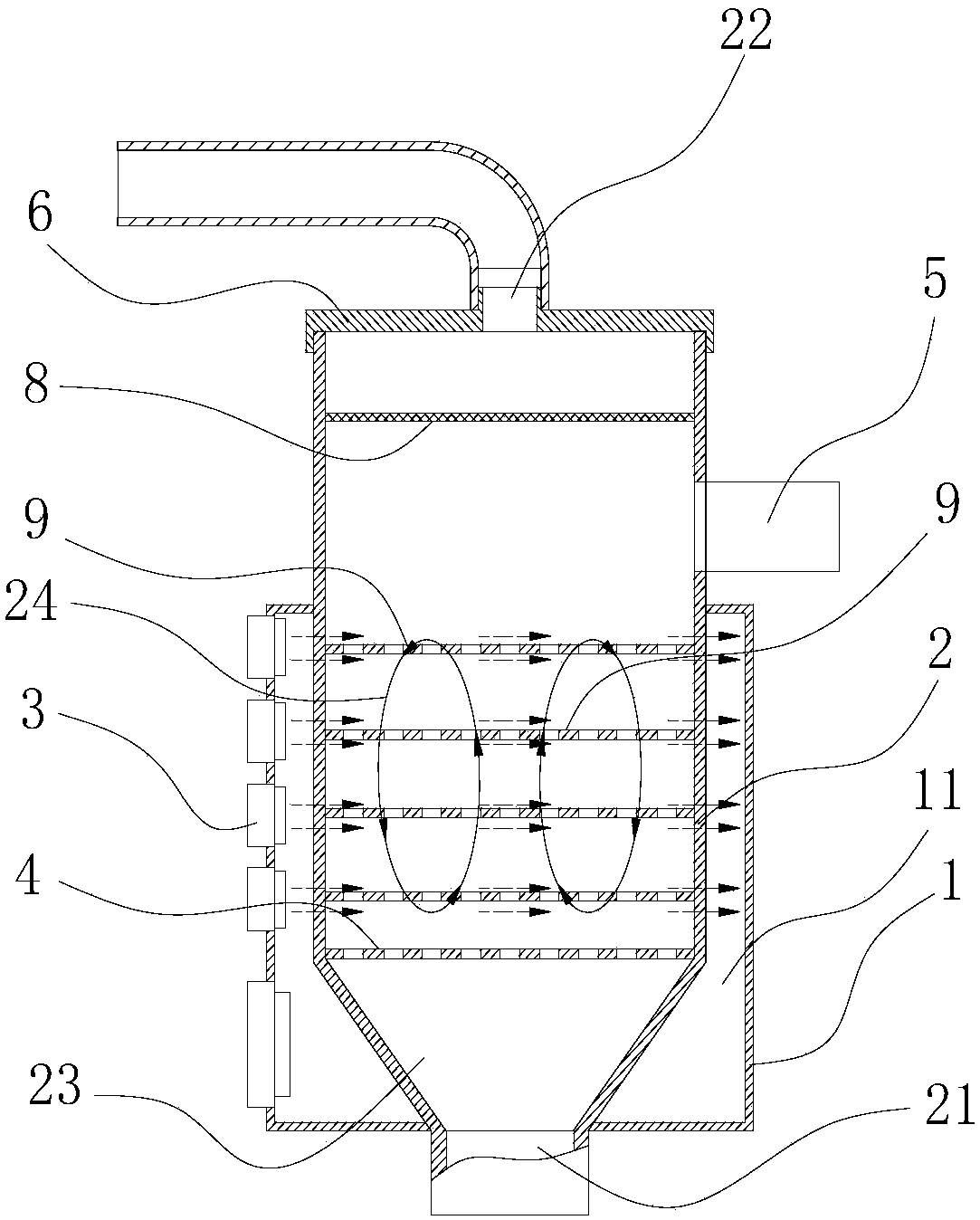

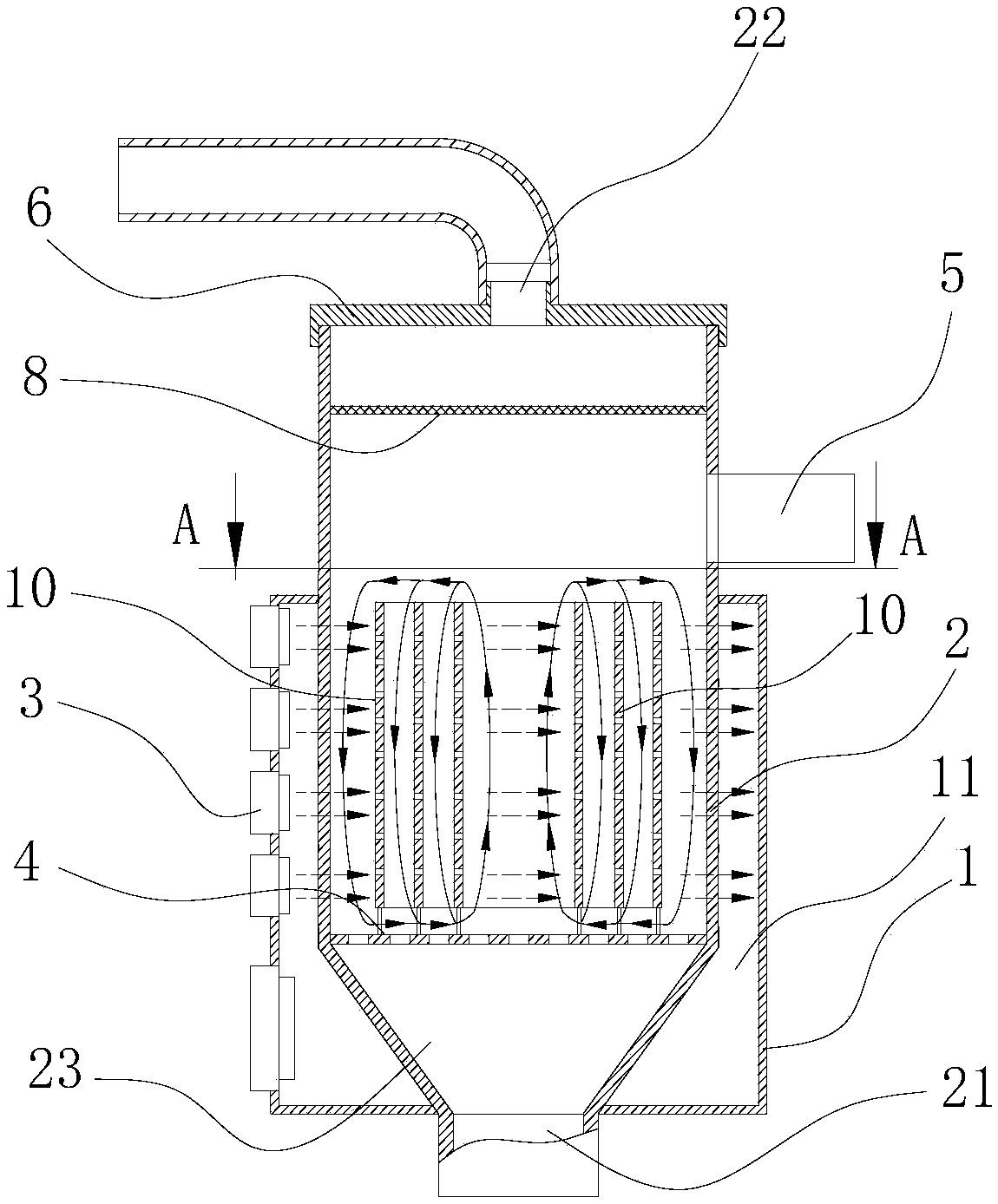

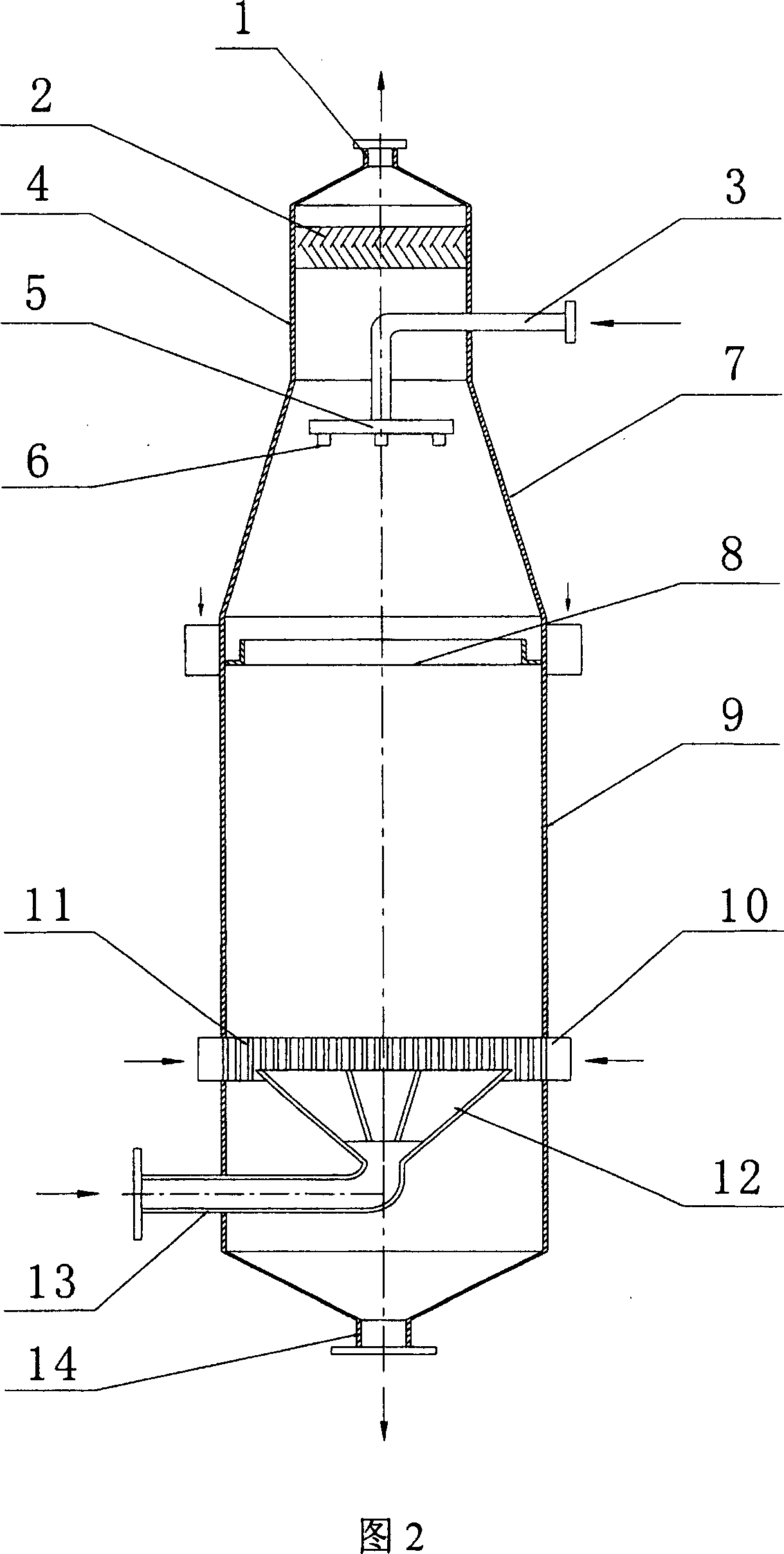

Heat supplying device for smoke purification and waste heat recovery

InactiveCN104791823AEvenly distributedReduce resistanceCombustion technology mitigationWater heatersThermal engineeringWaste heat recovery unit

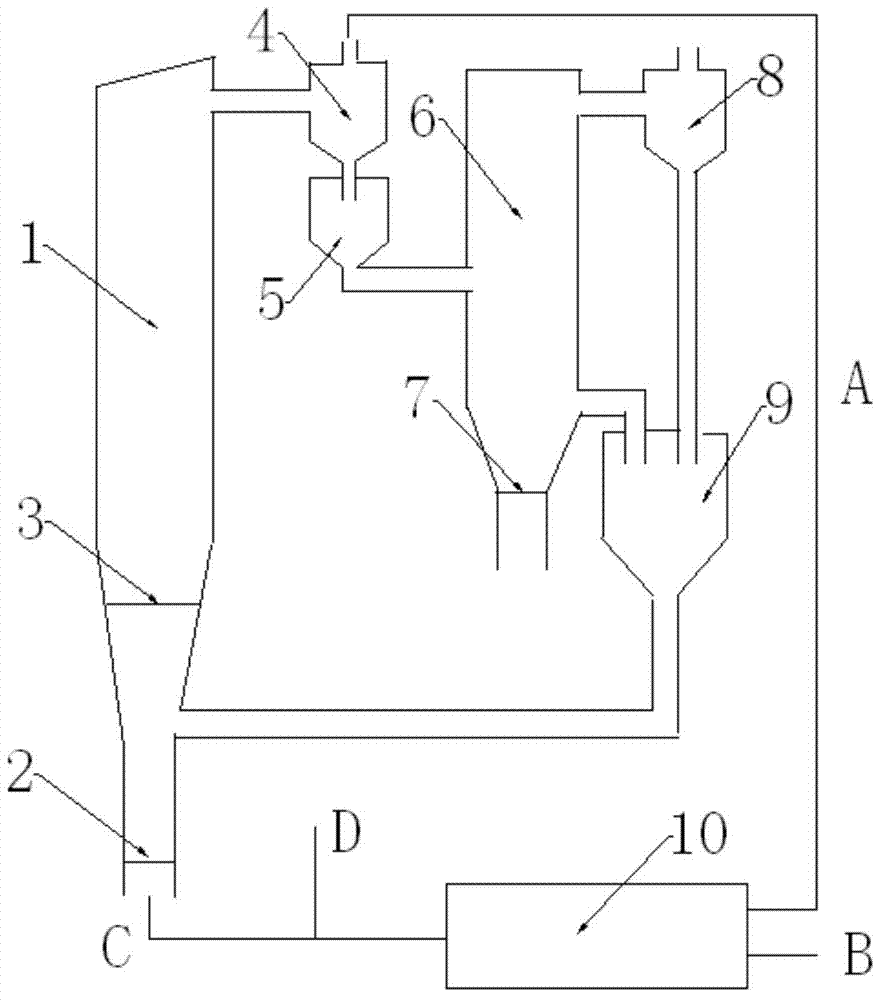

The invention discloses a heat supplying device for smoke purification and waste heat recovery. The heat supplying device comprises a direct contact type waste heat recovery device and a circulating water system and is characterized in that the direct contact type waste heat recovery device comprises a bubbler, a smoke inlet pipe, an overflow pipe, a cylinder, a bubbling section, a spraying section, a sprayer, a water inlet pipe, a demister and a smoke exhaust pipe. The high temperature smoke enters cooling water in the bubble form through the bubbler and carries out direct contact type heat and mass transfer in the bubbling section; smoke discharged from the cooling water enters the spraying section and is in direct contact with the cooling water sprayed out of the sprayer again to transfer heat and mass; the cooling water absorbing heat enters the circulating water system, and a heat medium is heated through a heat exchanger in the circulating water system so as to supply heat outwards; the purified and cooled smoke is exhausted from a chimney at the upper portion of the cylinder. Two-section type direct contact of the smoke and the cooling water is adopted in the heat supplying device to transfer heat and mass, so that the smoke is fully cooled and completely purified, and the heat supplying device is suitable for smoke purification and waste heat recovery of all gas thermal engineering equipment.

Owner:ZHENGZHOU UNIV

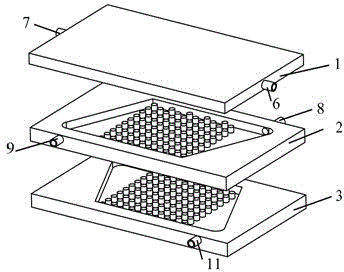

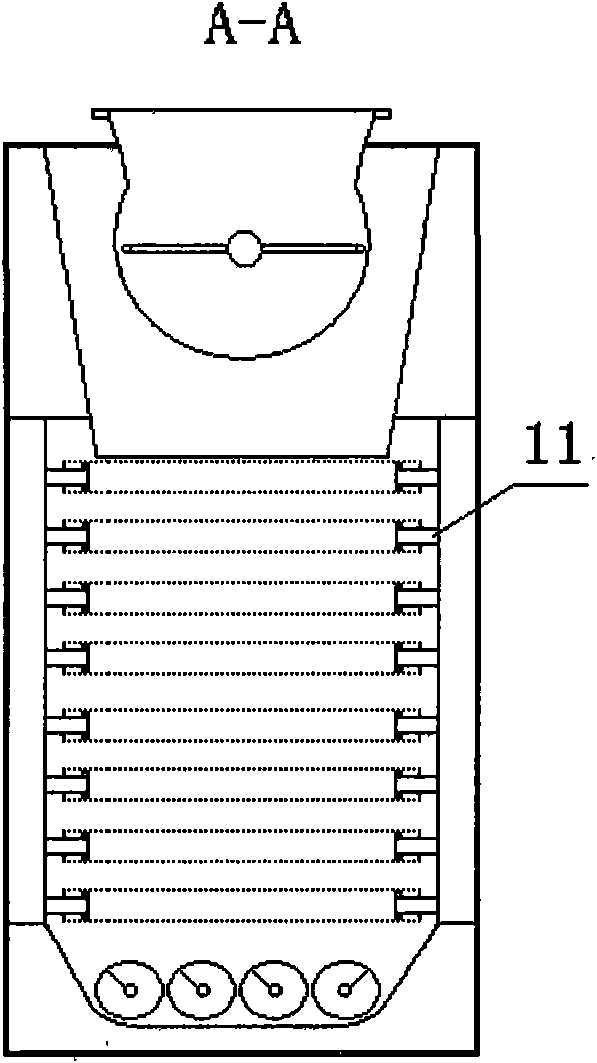

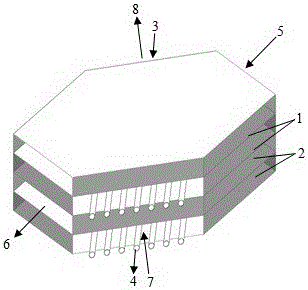

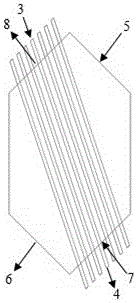

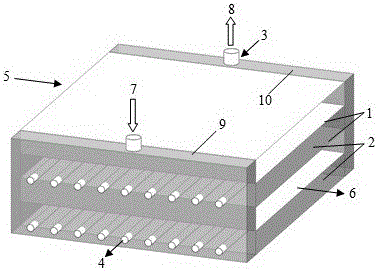

Self-heating staggered-arrangement micro-boss array type alcohol reforming device

InactiveCN103601151AEnhance heat and mass transferHigh heat and mass transfer efficiencyHydrogenHydrogen fuel cellHydrogen fuel

The invention discloses a self-heating staggered-arrangement micro-boss array type alcohol reforming device. The self-heating staggered-arrangement micro-boss array type alcohol reforming device comprises a hydrogen purification component, a reforming hydrogen production plate and a catalytic combustion plate sequentially from top to bottom. A reforming hydrogen production cavity is arranged in the reforming hydrogen production plate and loaded with a hydrogen production catalyst which is used for alcohol reformation so as to produce hydrogen; a catalytic combustion cavity is arranged in the catalytic combustion plate and loaded with a combustion catalyst which is used for alcohol combustion and heat supply. Heat is supplied for the reforming hydrogen production through alcohol combustion, so that the natural operation of the alcohol reforming device can be realized. Staggered-arrangement micro-boss array structures are arranged in the reforming hydrogen production cavity and the catalytic combustion cavity, so that the specific area is large and the heat transfer and mass transfer efficiency is high. In addition, the alcohol reforming device comprises the hydrogen purification component, so that the fuel conversion efficiency of the reforming hydrogen production cavity can be improved, and hydrogen at an outlet can be directly used for a hydrogen fuel battery. The self-heating staggered-arrangement micro-boss array type alcohol reforming device is compact in structure, convenient for catalysts to load, easy for the whole structure to assemble, and capable of being used in intermediate and small flow alcohol reforming hydrogen production situations.

Owner:ZHEJIANG UNIV

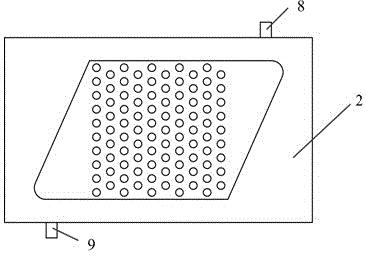

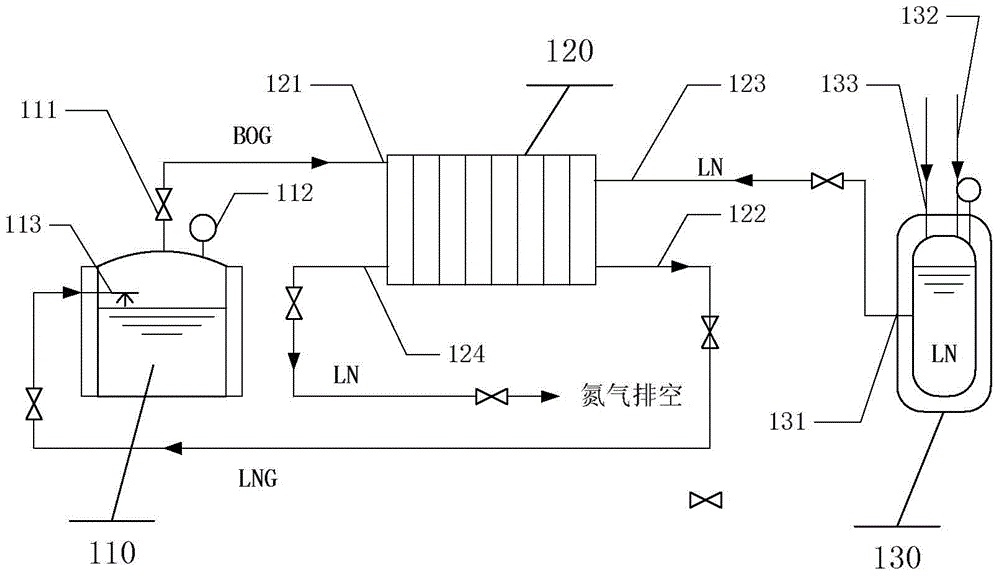

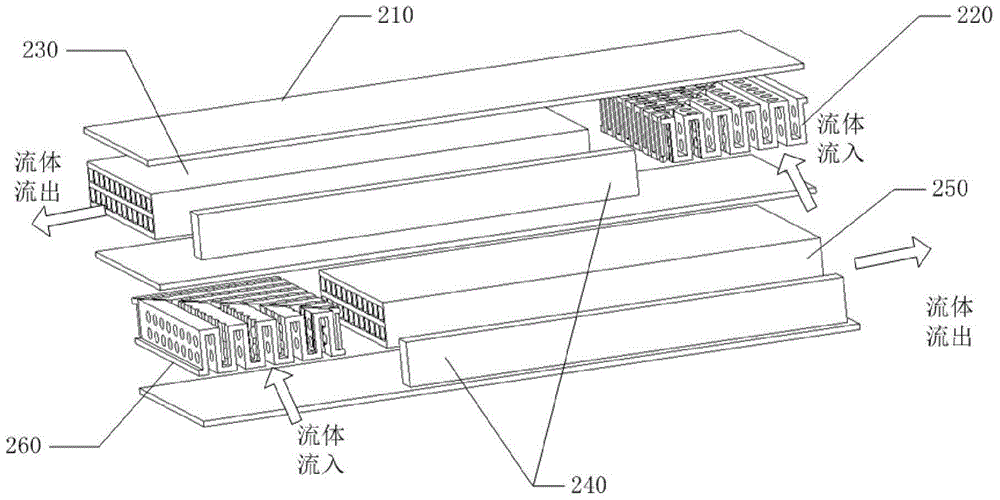

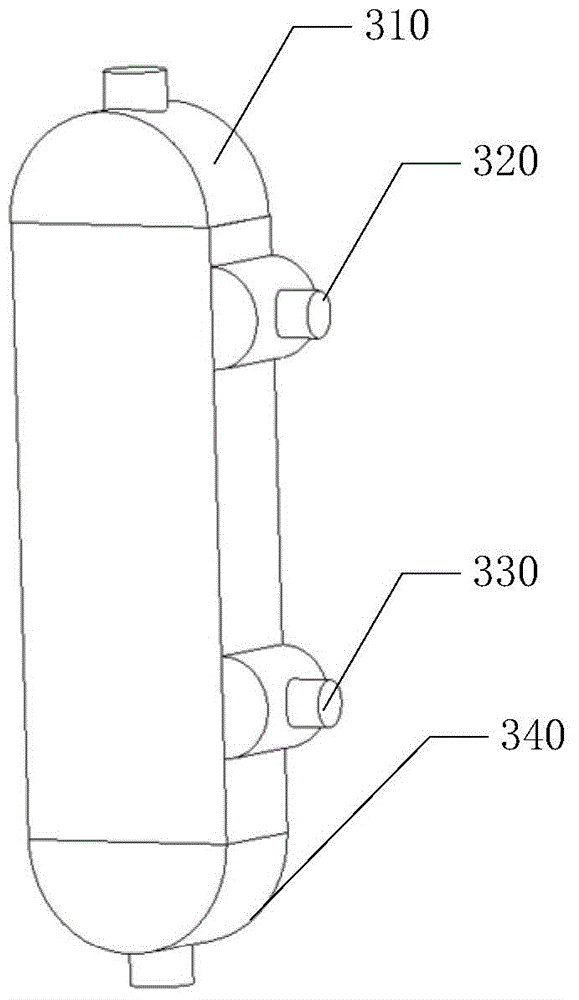

BOG recovering method and device

ActiveCN104390136AImprove throughputHigh heat and mass transfer efficiencyContainer filling methodsSteam/vapor condensersAutomatic controlNitrogen

The invention discloses a boil-off gas (BOG) recovering method, comprising a liquefied natural gas (LNG) storage tank, a double-row micro-channel harmonica-shaped tube condensation recovery device, a liquid nitrogen storage tank, an automatic control system and a plurality of auxiliary devices. In a recovering process, a compressor and a low-temperature pump are not utilized, and the self pressure of BOG gas and nitrogen is taken as a driving force of a fluid flowing in a pipeline. A BOG outlet of the LNG storage tank is directly connected with a BOG inlet receiver of the double-row micro-channel harmonica-shaped tube condensation recovery device through a pipeline, an outlet for the recovered LNG liquid is connected with the LNG storage tank through a pipeline, and the pipeline of the LNG storage tank is provided with a valve and a pressure detector; an outlet of the liquid nitrogen storage tank is connected with a liquid nitrogen inlet of the double-row micro-channel harmonica-shaped tube condensation recovery device through a pipeline, a nitrogen outlet of the condensation recovery device is divided into two paths, one path is directly connected with air, the other path is connected with the nitrogen inlet of the liquid nitrogen storage tank, and the pipeline of the liquid nitrogen storage tank is provided with a valve and a pressure detector.

Owner:溧阳德维透平机械有限公司

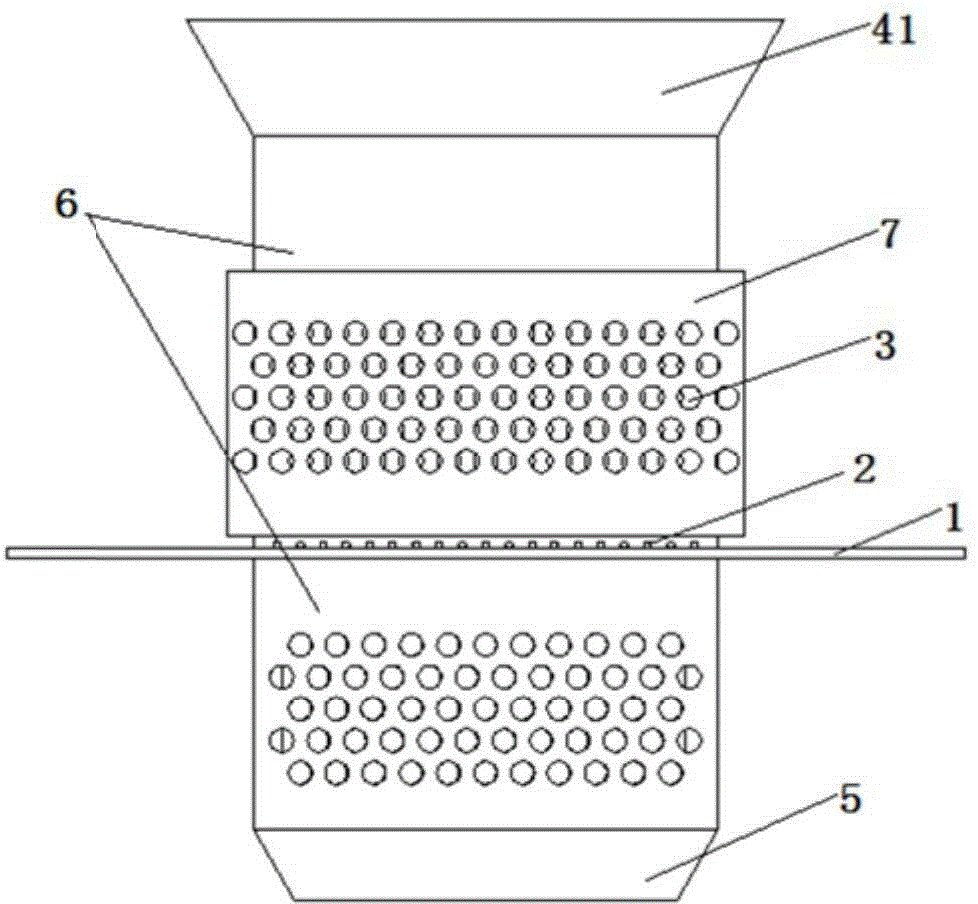

Device and process for preparing O2-CO2 mixed gas based on chemical-looping technology

InactiveCN103496672ALow costAbsolute selectivityCarbon compoundsOxygen preparationFluidized bedProcess engineering

The invention discloses a device and process for preparing O2-CO2 mixed gas based on a chemical-looping technology. The device comprises a fast fluidized bed reactor, a first air distribution plate, a distribution plate, a first cyclone separator, a first returning mechanism, a bubbling bed reactor, a second air distribution plate, a second cyclone separator, a second returning mechanism and an oxygen-enriched combustion device. The process comprises the steps of releasing oxygen in the fluidized bed reactor by using oxygen-carrying particles; separating the O2-CO2 mixed gas from the oxygen-carrying particles by using the first cyclone separator; adding the oxygen-carrying particles into the bubbling bed reactor for regeneration by using the first returning mechanism; separating the regenerated oxygen-carrying particles from oxygen-depleted gas by using the second cyclone separator; conveying the oxygen-carrying particles to the fluidized bed reactor by using the second returning mechanism to form a circulating system. The device and the process can realize continuous preparation of the O2-CO2 and has the advantages of stable operation, simple process and capability of performing continuous and high-efficiency production.

Owner:NANJING UNIV OF SCI & TECH

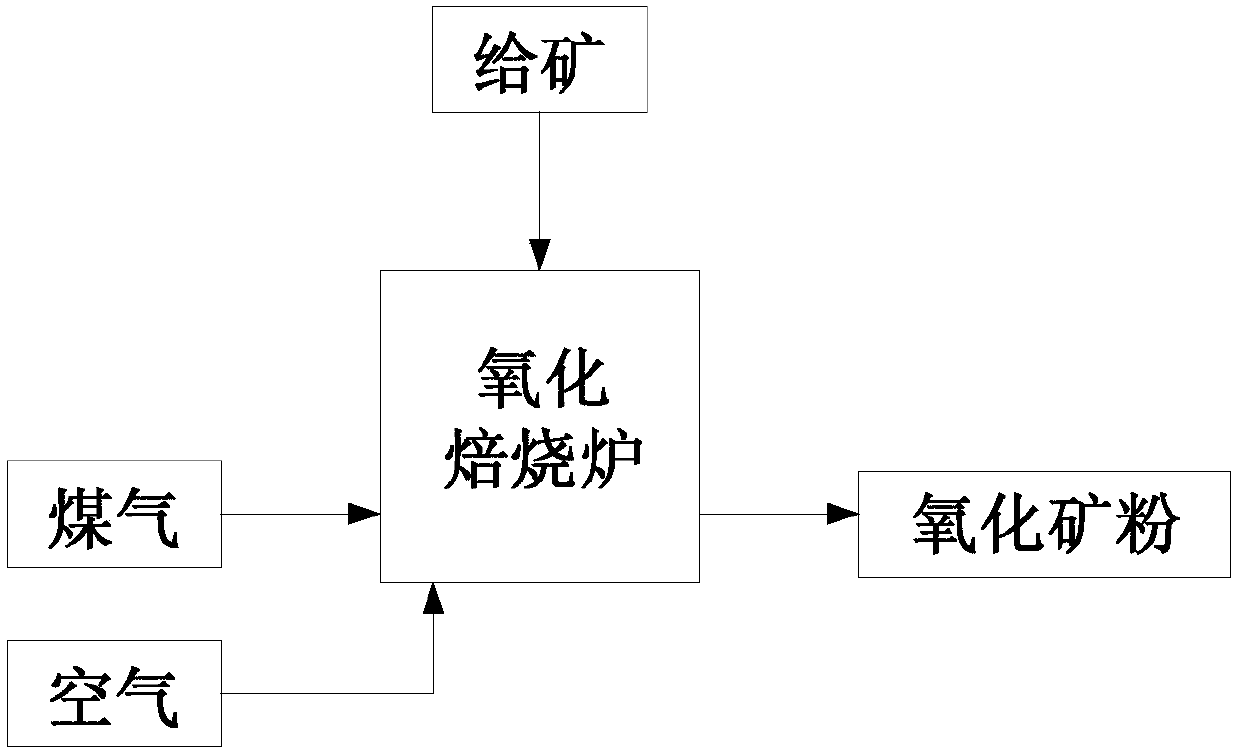

Preparation method for producing strong-magnetism magnetite through refractory weak-magnetism oxidized iron ore

The invention relates to the production techniques of iron ore concentrate of refractory ore, in particular to a preparation method for producing strong-magnetism magnetite through refractory weak-magnetism oxidized iron ore. The method comprises the following steps that firstly, the crushed iron ore is ground into fine ore; then the fine ore is subjected to low-temperature roasting, and during the low-temperature roasting, the fine ore is made to be in a roasting system to be preheated and roasted; the roasted ore enters a cooling system to be cooled; and then the cooled roasted ore is subjected to size mixing and sent to a magnetic separation system to be separated, and high-grade iron ore concentrate is obtained through separation. According to the method, the process is simple, the temperature and air flow are distributed uniformly, control is easy, the automation degree is high, the number of operation components of equipment is small, refractory siderite and limonite can be treated, the magnetizing roast efficiency of the refractory iron ore is high, heat is substantially recycled during roasting, the roasted ore is stable in quality and high in magnetic separation efficiency, and the technical indexes that the grade of the iron ore concentrate is larger than 60%, and the iron recycling rate is larger than 85% can be achieved.

Owner:湖北华方装备有限公司

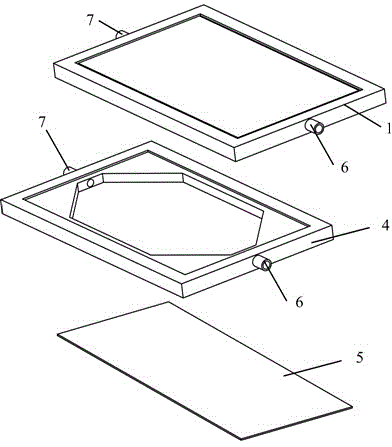

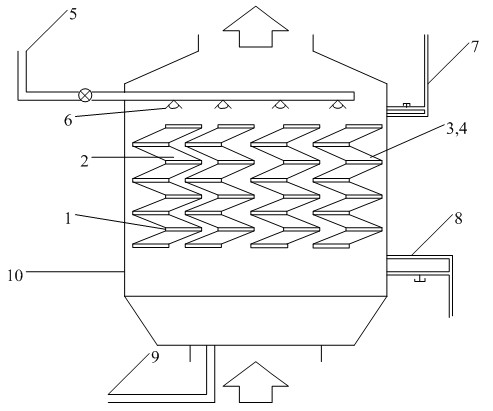

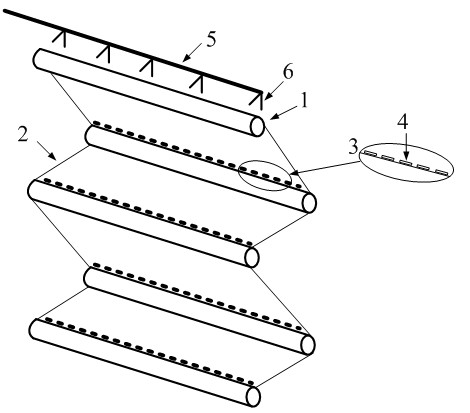

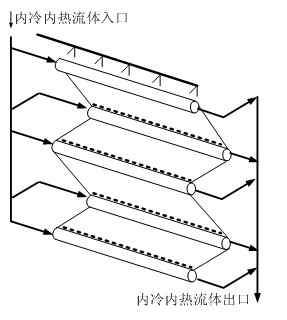

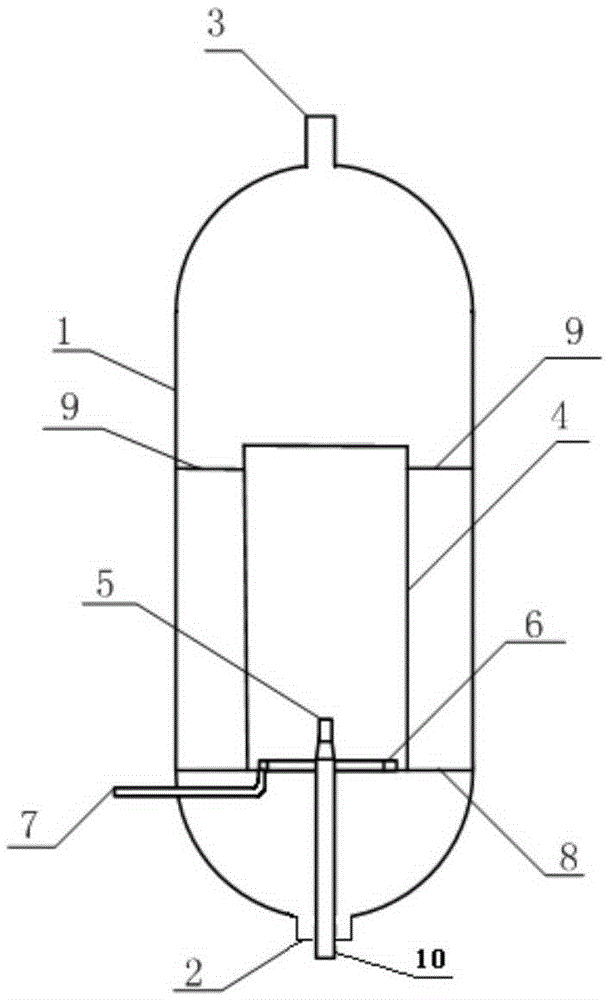

Solution dehumidifying and regenerating device

InactiveCN102147134ASolving Corrosion ProblemsReduce volumeLighting and heating apparatusAir conditioning systemsEngineeringMachining process

The invention discloses an internal cold / internal heat type solution dehumidifying and regenerating device. A plurality of zigzag connected heat and mass transfer units consisting of reducing templates (2) and internal cold / internal heat pipes (1) are arranged in a shell (10), an inlet pipe (7) is arranged above the shell, and an outlet pipe (8) is arranged below the shell; a dehumidifying solution inlet pipe (5) is arranged above the heat and mass transfer units, a solution distributor (6) is arranged on the dehumidifying solution inlet pipe (5), and the bottom of the shell (10) is provided with a dehumidifying and regenerating solution delivery pipe (9). A dehumidifying solution flows into a pipeline through a solution inlet header pipe and is sprayed to the reducing templates to be in direct contact with wet air for carrying out a heat and mass transfer process so that the purpose of air dehumidifying or solution regenerating is achieved; and internal heat / internal cold branch pipes play a role of strengthening the heat and mass transfer process, thus the solution dehumidifying and regenerating efficiency is greatly improved. The internal cold / internal heat type solution dehumidifying and regenerating device has the advantages of simple machining process, low cost and easiness in production and manufacture.

Owner:SOUTHEAST UNIV

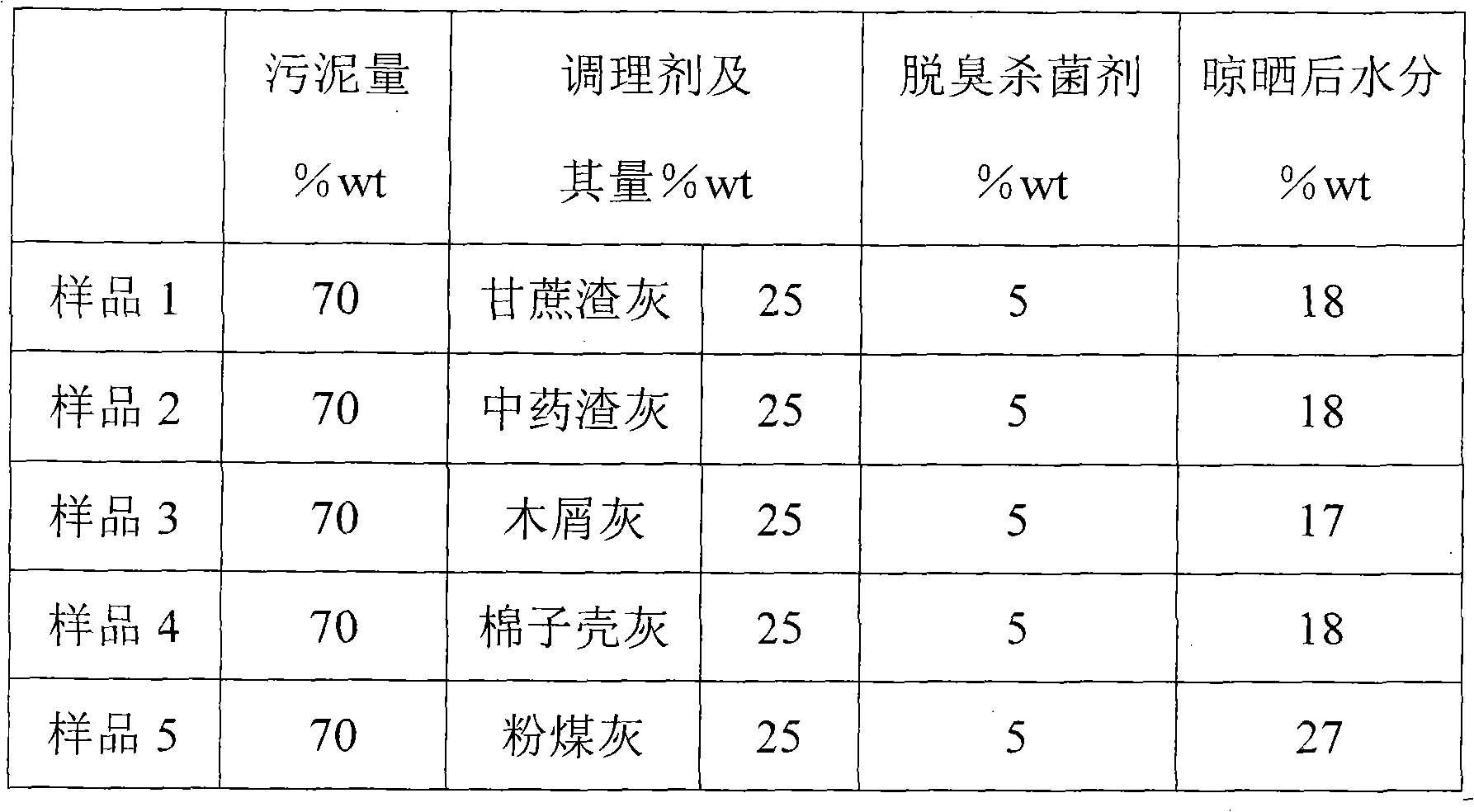

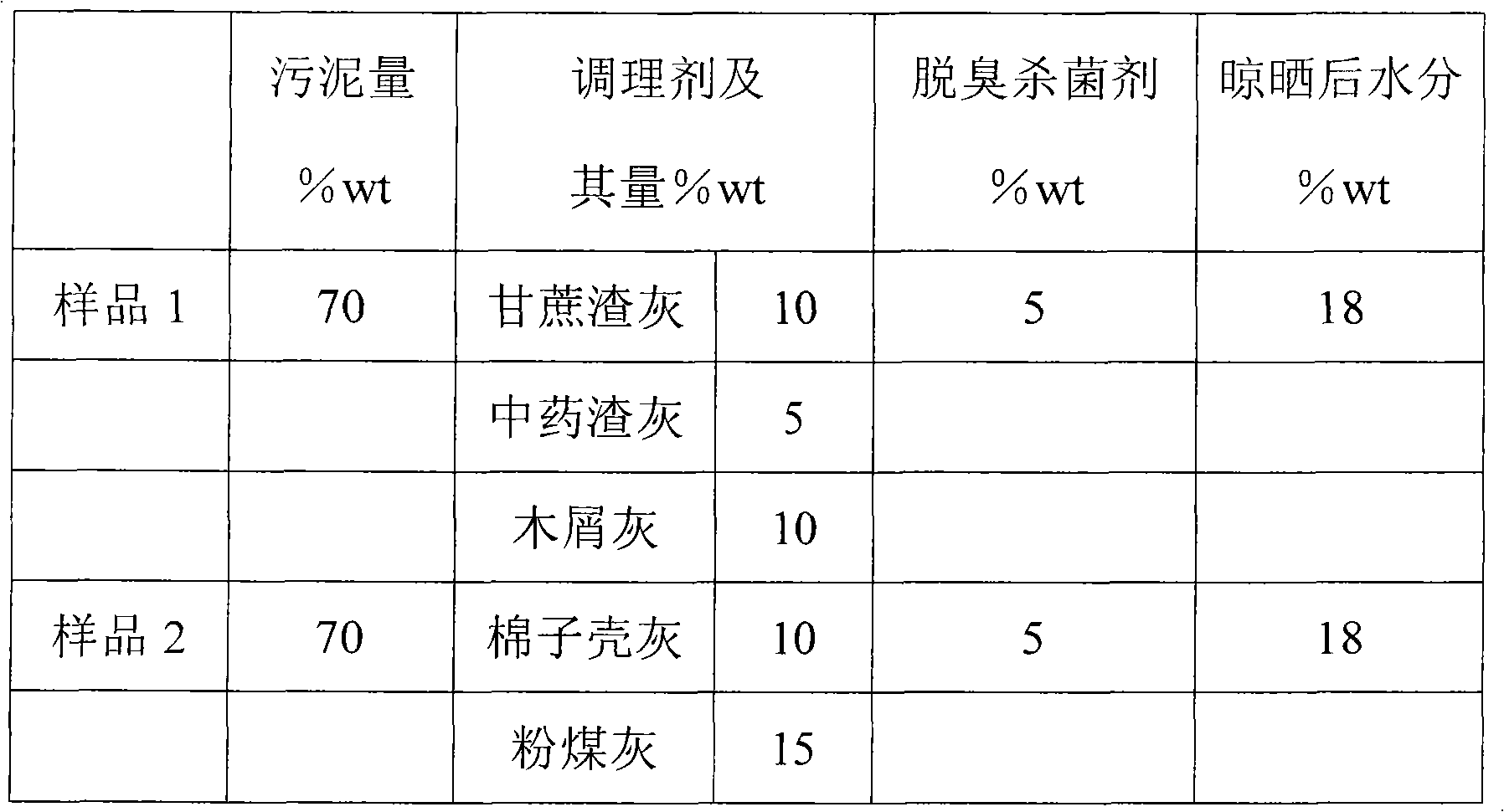

Sludge dry powder and preparation method thereof

InactiveCN101618934ADrying and dehydration is easyIncrease contact areaSludge treatment by de-watering/drying/thickeningBrickSolid fuel

The invention discloses a method for preparing dry powder by sludge, which comprises the following steps: uniformly mixing the following components in percentage by weight: 50-85 percent of sludge containing 40-98 percent of water, 14-40 percent of conditioner and 1-10 percent of deodorizing bactericide at room temperature; and then, drying the mixture through airing or afterheat and the like to acquire the sludge dry powder. The invention solves the problem of difficult municipal sludge treatment, greatly reduces the cost for sludge dehydration and drying, and prepares the sludge into dry powder. The sludge dry powder can be used for land utilization, used as solid fuel with a low combustion value, used as the raw material for producing clay or bricks or concrete and also used for direct sanitary landfills.

Owner:WUHAN GLT ENERGY & ENVIRONMENTAL TECH CO LTD

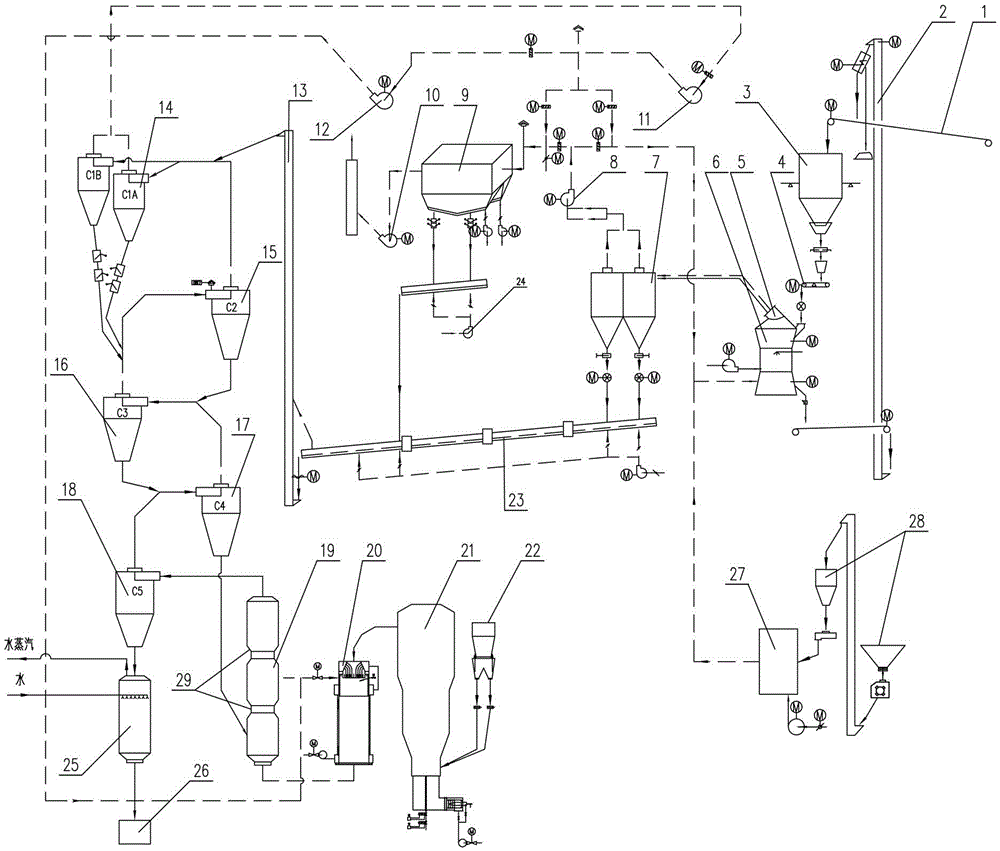

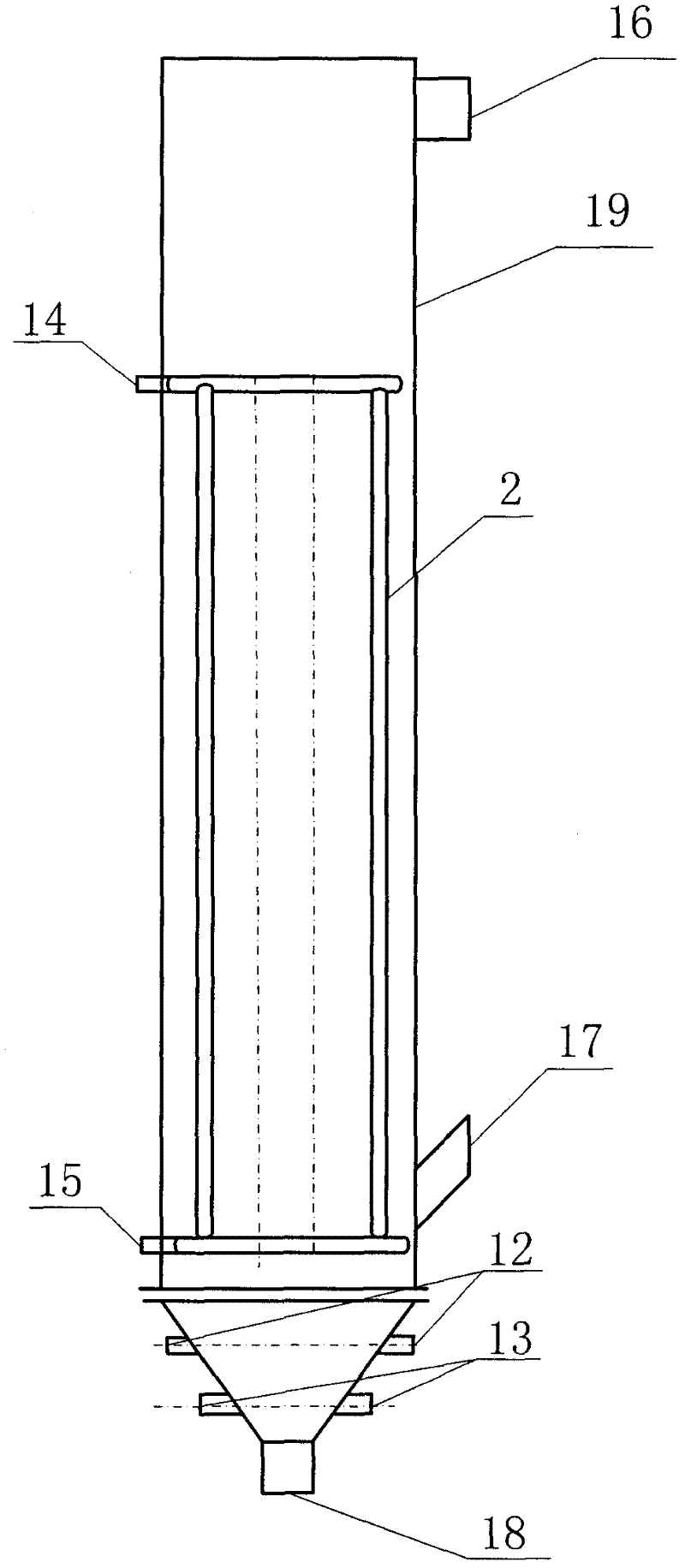

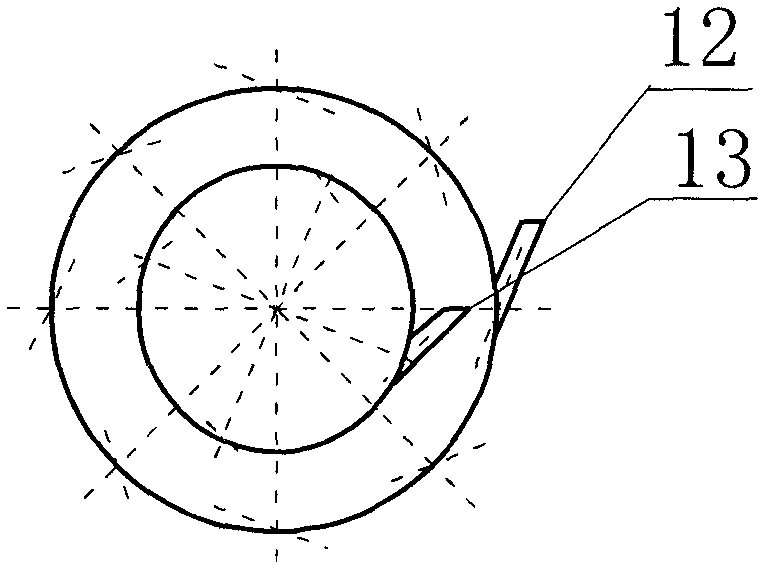

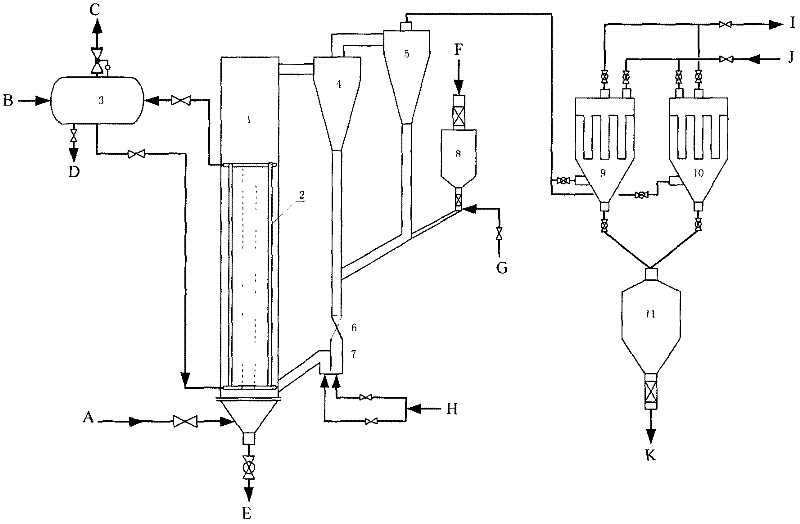

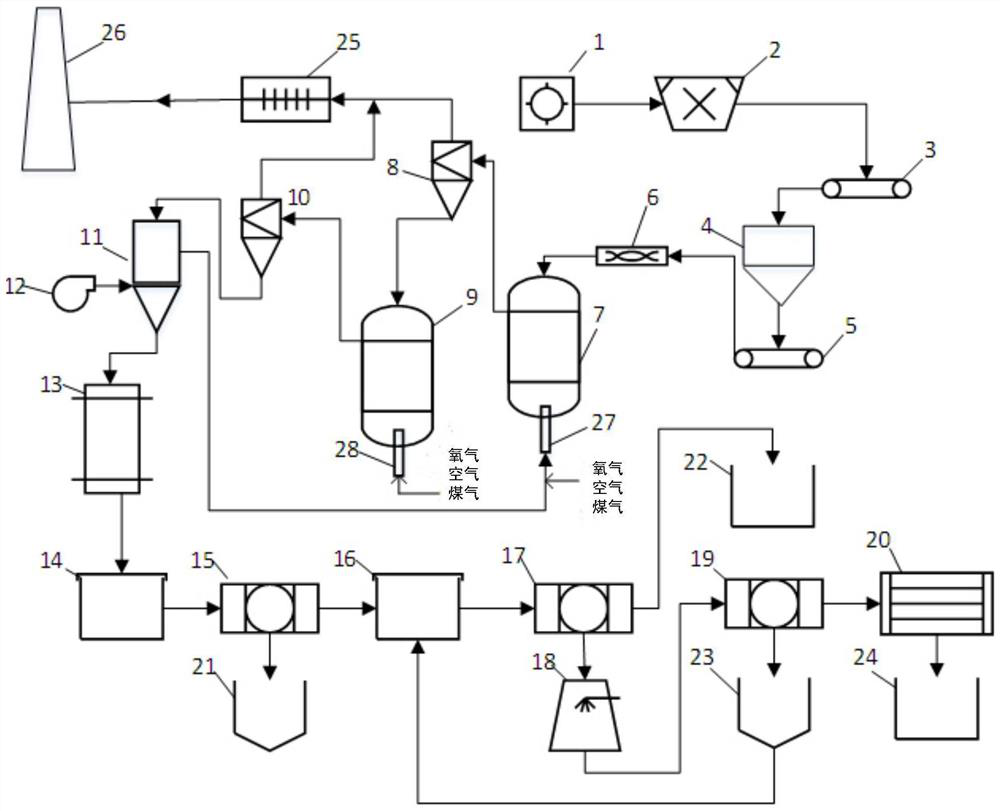

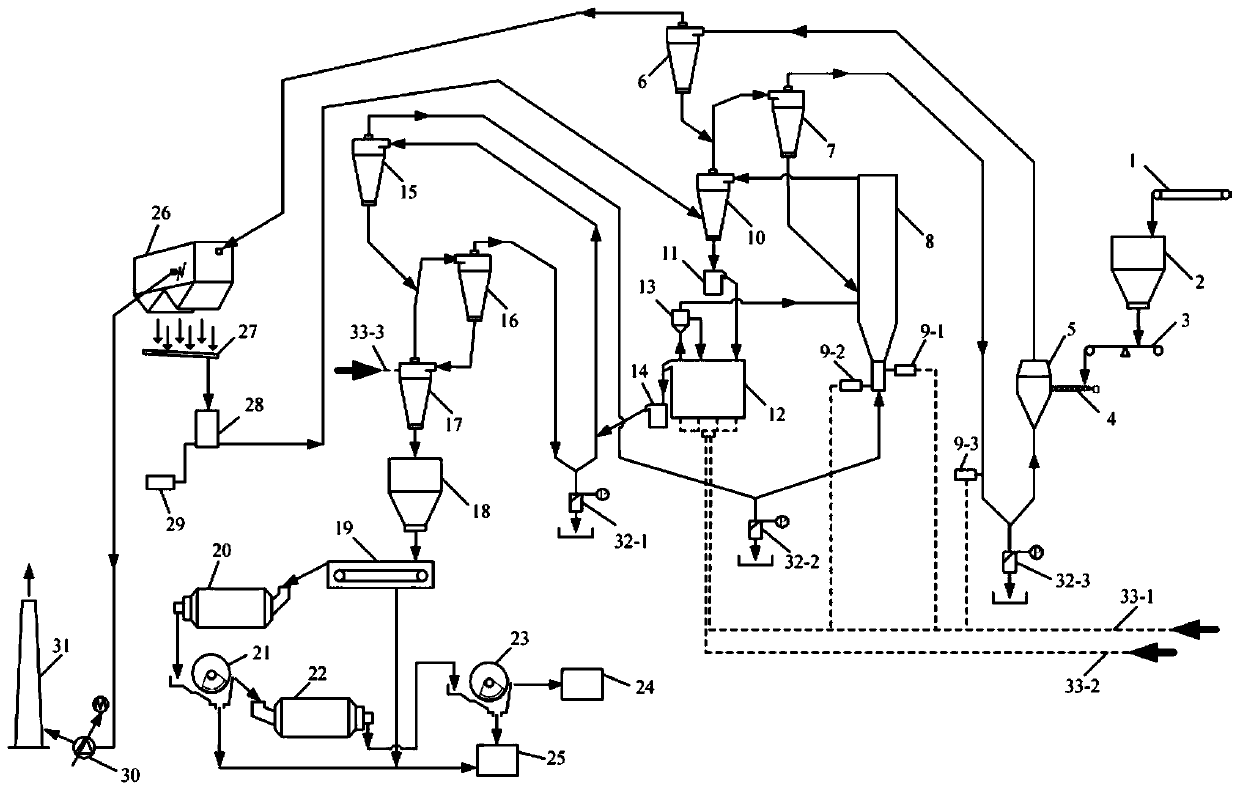

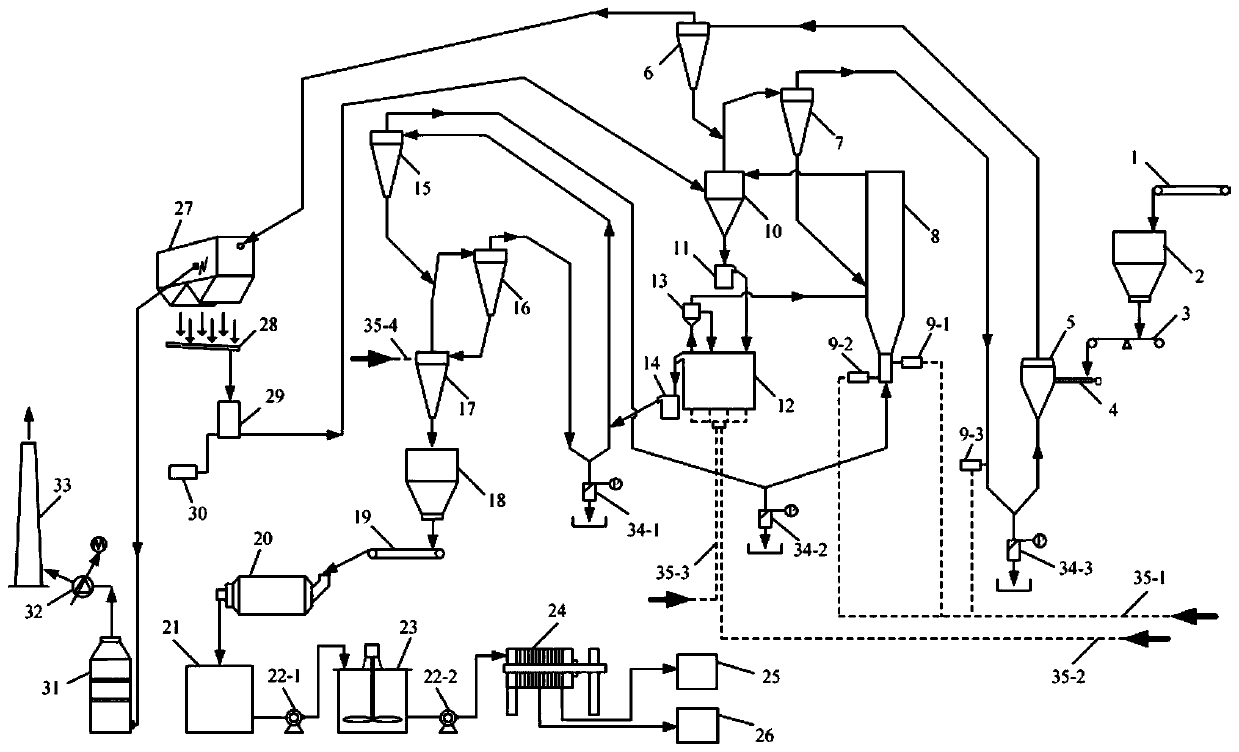

Suspension roasting system and method for industrially processing ferromanganese ore

The invention provides a suspension roasting system and method for industrially processing ferromanganese ore. The suspension roasting system comprises a feeding silo, a venturi dryer, a first cyclonepreheater, a second cyclone preheater, a pre-oxidation suspension roaster, a thermal separation cyclone, a suspension reduction roaster, a collection bin, an ore grinder, a magnetic separator and aninduced draft fan. The suspension roasting method comprises the steps that (1) the ferromanganese ore is crushed; (2) the ferromanganese ore is continuously transported to the venturi dryer; (3) the induced draft fan is started, negative pressure is generated in the system, and combustion flue gas in the venturi dryer is mixed with fine ore to remove adsorbed water; (4) the material enters the first cyclone preheater and the second cyclone preheater to be preheated and then enters the pre-oxidation suspension roaster; (5) after suspension roasting, the material enters the suspension reductionroaster through the thermal separation cyclone; (6) suspension reduction roasting is carried out at 500-650 DEG C; (7) the material enters the collection bin through a three-stage cooling cyclone; and(8) magnetic separation is carried out after ore grinding. The suspension roasting device and method have the advantages of high heat and mass transfer efficiency, low energy consumption, high adaptability to different types of ferromanganese ore, large processing capacity, suitability for large-scale industrial production and the like.

Owner:SHANGHAI MILESTONE TECH CO LTD

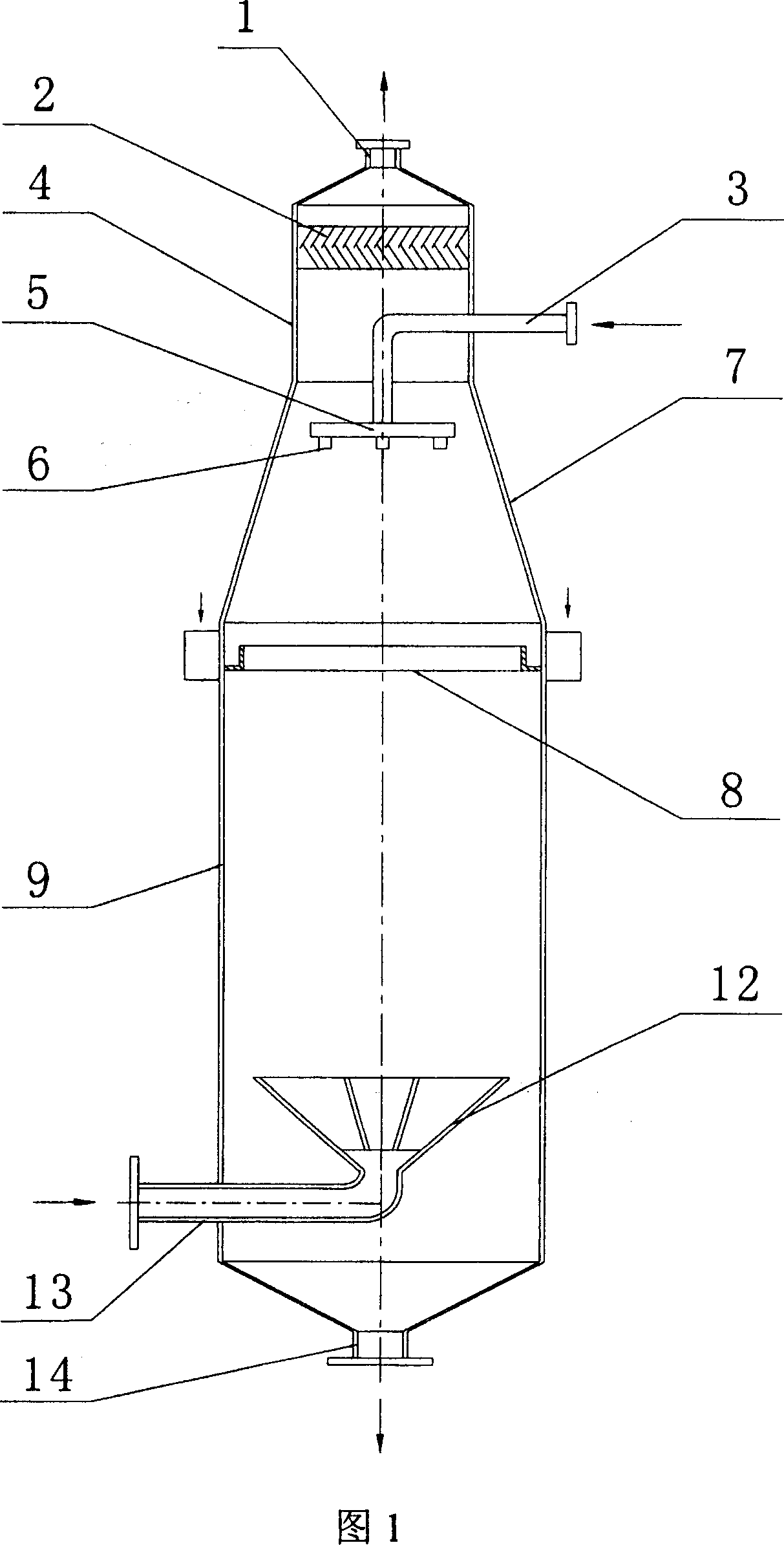

Fluidized bed catalytic deoxidation method and equipment for oxygen-containing coal bed gas

The invention relates to a fluidized bed catalytic deoxidation method for oxygen-containing coal bed gas. The fluidized bed catalytic deoxidation method comprises the following steps that: a fluidized bed deoxidation reactor is preheated to the temperature of 300-400 DEG C; the oxygen-containing coal bed gas is fed into the fluidized bed deoxidation reactor; deoxidation catalyst granules are loaded into a feed hopper and are added into the fluidized bed deoxidation reactor under the action of air blowing and supplying; methane and oxygen in the coal bed gas are subjected to low-temperature catalytic combustion reaction in the fluidized bed deoxidation reactor; the gas moves upwards with the carrying of part of solid catalyst granules and enters a one-stage cyclone separator and a two-stage cyclone separator from the top outlet of the fluidized bed deoxidation reactor, and the collected solid catalyst granules circularly enter the fluidized bed deoxidation reactor under the control of a feed back control valve and air blowing and supplying; and the deoxidated coal bed gas which is subjected to coarse dust removal by the cyclone separators is subjected to fine catalyst dust removal by a high-temperature filter, and then, is transferred to a follow-up system for use. The fluidized bed catalytic deoxidation method for the oxygen-containing coal bed gas has the advantages of good safety, low energy consumption, high deoxidation efficiency, long service life of catalyst and large processing capacity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

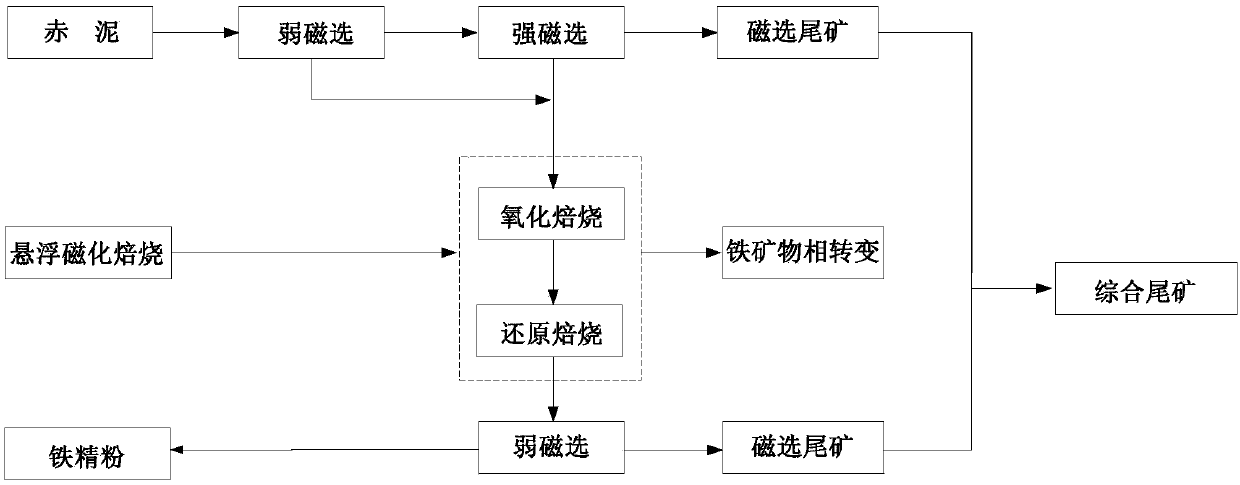

Method for preparing iron powder through red mud suspension roasting

The invention discloses a method for preparing iron powder through red mud suspension roasting, and belongs to the technical field of mineral processing. The method comprises following steps: firstly,red mud is subject to fine grinding and then subject to one-segment weak magnetic separation; secondly, one-segment weak magnetic separation tailings is subject to strong magnetic separation, and one-segment weak magnetic concentrate and strong magnetic concentrate are mixed to serve as preconcentration concentrate; thirdly, the preconcentration concentrate is placed in an oxidizing roaster, gasand air are led, and the preconcentration concentrate is subject to oxide roasting to obtain oxide powder ore; fourthly, the oxide powder ore is placed in a reduction roaster, nitrogen and reduction gas are led, and reduction roasting is carried out; fifthly, the roasted ore is subject to fine grinding, and then, second-segment weak magnetic separation is carried out. The method is simple in process flow, the equipment treatment amount is large, the product character is easily controlled, industrial application is achieved, the method is energy-saving and environment-friendly, and enlargementis easily achieved.

Owner:NORTHEASTERN UNIV LIAONING

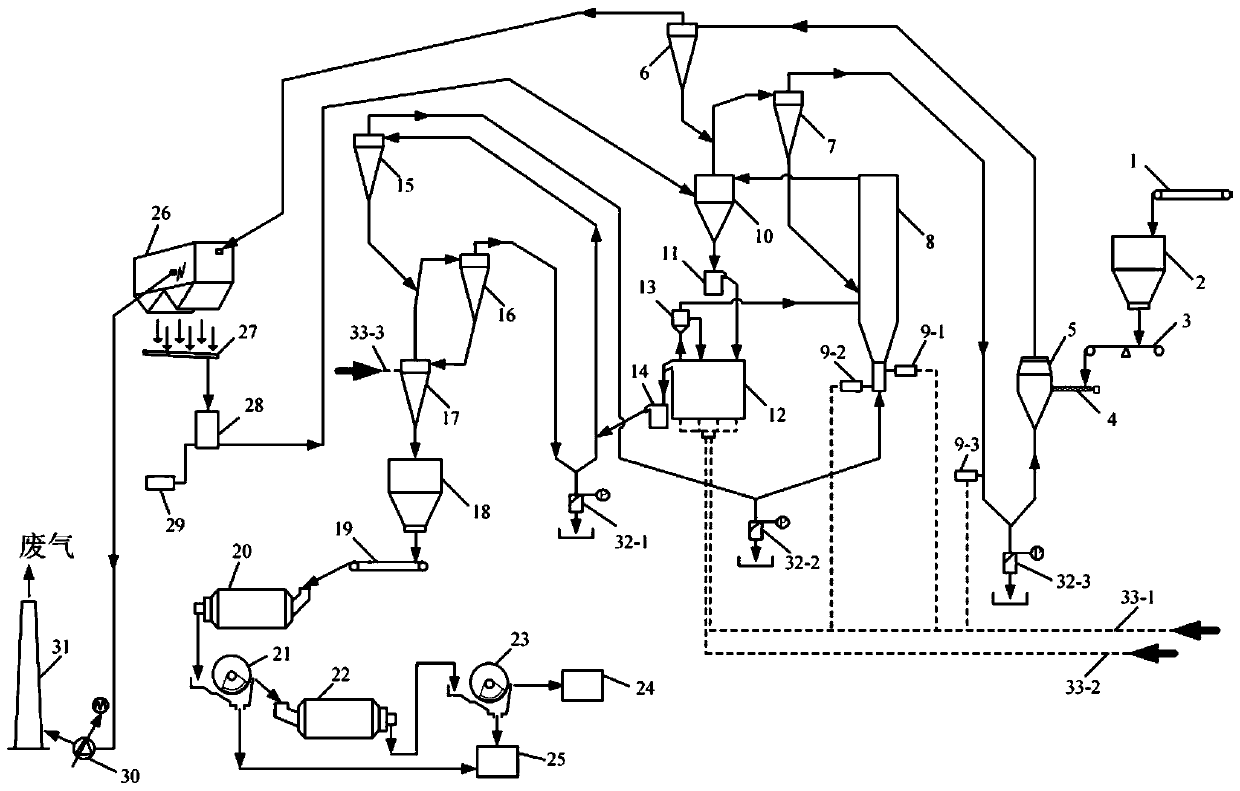

Suspension magnetizing roasting cyanide breakage-weak magnetic separation iron extraction device for high-iron cyanide tailings

ActiveCN111455165ADecompose thoroughlyHigh heat and mass transfer efficiencyMagnetic separationIron cyanideMagnetic separator

The invention discloses a suspension magnetizing roasting cyanide breakage-weak magnetic separation iron extraction device for high-iron cyanide tailings. A venturi dryer, two cyclone preheaters and apre-oxidation suspension roasting furnace communicate with one another in series. The pre-oxidation suspension roasting furnace comprises a combustor and air inlets. The upper portion of the pre-oxidation suspension roasting furnace communicates with a heat separation cyclone barrel through a pipeline, the heat separation cyclone barrel, a first flow sealing valve and a suspension reducing roasting furnace communicate with one another in series, and the suspension reducing roasting furnace communicates with a coal gas source and a nitrogen source. A discharging outlet of the suspension reducing roasting furnace, a second flow sealing valve, a first cooling cyclone barrel, a second cooling cyclone barrel, a third cooling cyclone barrel and a collecting bin communicate with one another in series. An outlet of the collecting bin cooperates with an inlet of a first-stage ore grinding machine, and the first-stage ore grinding machine, a first-stage weak magnetic separation machine, a second-stage ore grinding machine and a second-stage weak magnetic separation machine cooperate with each other in sequence. An air outlet of the first cyclone preheater communicates with a dust collectorand an induced draft fan in series. The suspension magnetizing roasting cyanide breakage-weak magnetic separation iron extraction device for the high-iron cyanide tailings has the advantages of beinghigh in heat transfer and mass transfer efficiency, thorough in cyanide decomposition, high in processing capacity and high in adaptability, being suitable for large-scale industrial production and the like.

Owner:上海逢石科技有限公司

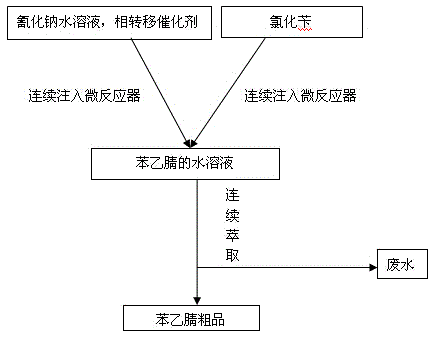

Method for synthesizing phenylacetonitrile by performing continuous reaction

ActiveCN105218401ARealize continuous productionIncrease productivityPreparation by cyanide reactionAutomatic controlBenzyl chloride

The invention discloses a method for synthesizing phenylacetonitrile by performing continuous reaction, and relates to the field of preparing a compound containing six-membered aromatic ring connected with cyano group by saturated carbon chain. The method comprises the following steps: adjusting the temperature of a micro-reactor to 80-400 DEG C; adding a mixture of a sodium cyanide aqueous solution and phase-transfer catalyst, and benzyl chloride in the micro-reactor continuously; reacting in the micro-reactor for 20-300 s to get a phenylacetonitrile aqueous solution. The method has rapid reaction speed, high production efficiency, low cost, good product quality, is easy to realize automatic control, is beneficial to subsequent post-treatment, and can raise the phenylacetonitrile yield, reduce the side reaction, and save labour.

Owner:HEBEI CHENGXIN

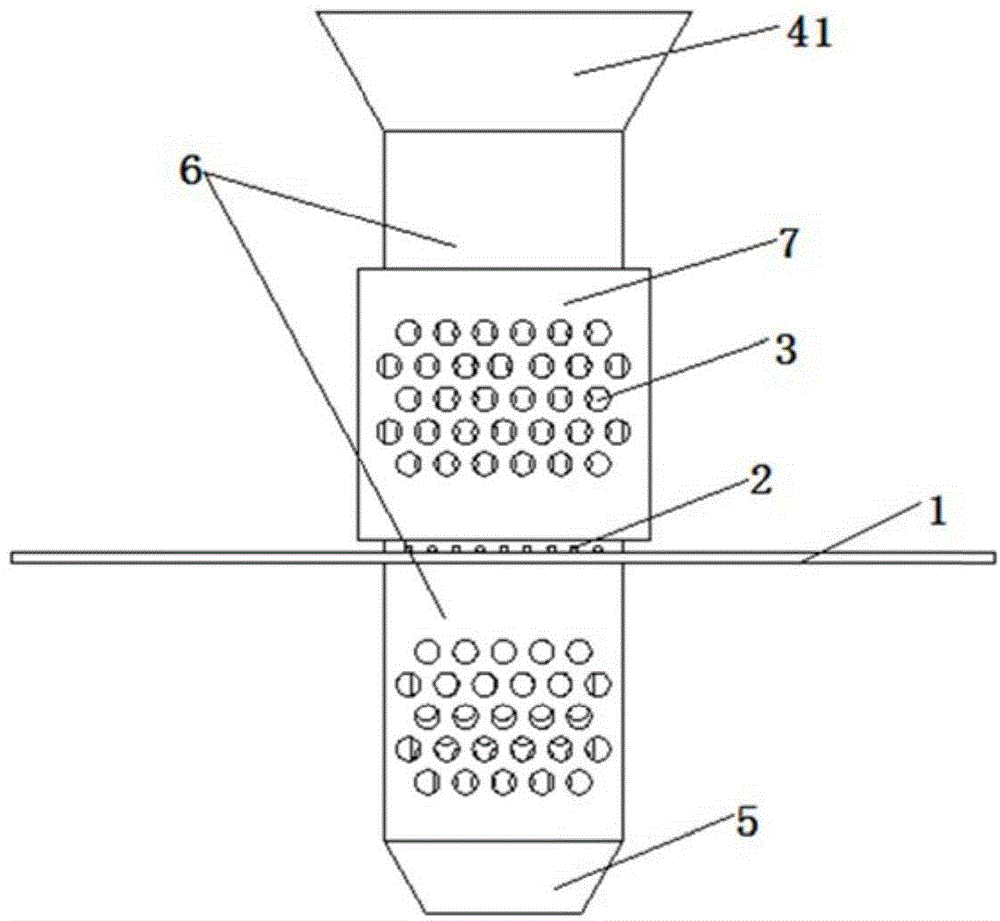

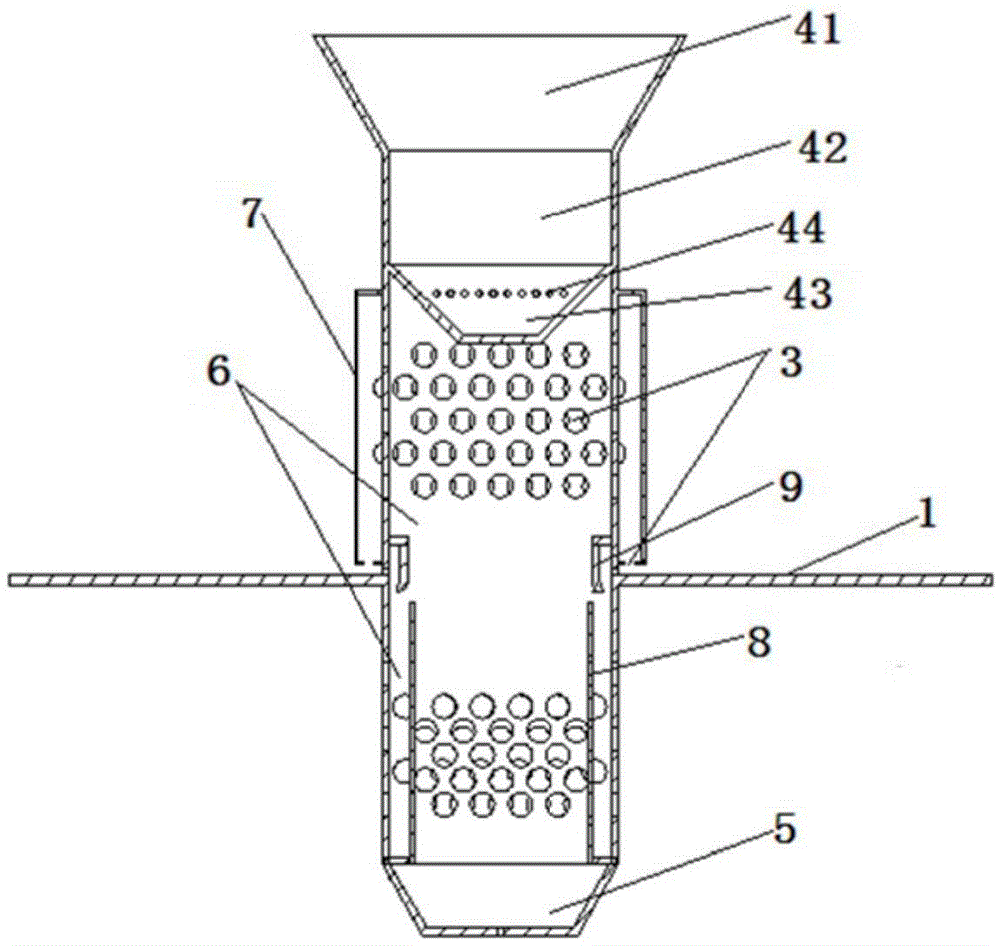

Stone coal vanadium ore oxidizing, crystal breaking, roasting and vanadium extracting comprehensive utilization system

ActiveCN111876616AHigh heat and mass transfer efficiencySolve problems such as secondary pollutionSilicaChemical industryDecarburizationCoal

The invention discloses a stone coal vanadium ore oxidizing, crystal breaking, roasting and vanadium extracting comprehensive utilization system. A crusher, a high-pressure roller mill, a first feeding belt, a feeding bin, a second feeding belt and a spiral feeder are sequentially matched with one another, and the discharging end of the spiral feeder is matched with a feeding port of a suspensiondecarburization roasting furnace; the suspension decarburization roasting furnace, a first cyclone separator, a suspension crystal breaking roasting furnace, a second cyclone separator and a cooler are sequentially communicated in series; a combustor and an air inlet are respectively arranged at the bottoms of the suspension decarburization roasting furnace and the suspension crystal breaking roasting furnace; an air inlet of the cooler is communicated with an air compressor; and a discharging hole in the bottom of the cooler is matched with a feeding hole of an acid mixing curing furnace; andthe acid mixing curing furnace, a first leaching tank, a first filtering device, a second leaching tank, a second filtering device, a pH value adjusting tank and a third filtering device are sequentially connected in series and matched with one another. The system provided by the invention is stable in operation, large in treatment capacity, low in energy consumption and cost of unit treatment capacity, and capable of easily controlling product properties and easily achieving large-scale equipment.

Owner:上海逢石科技有限公司

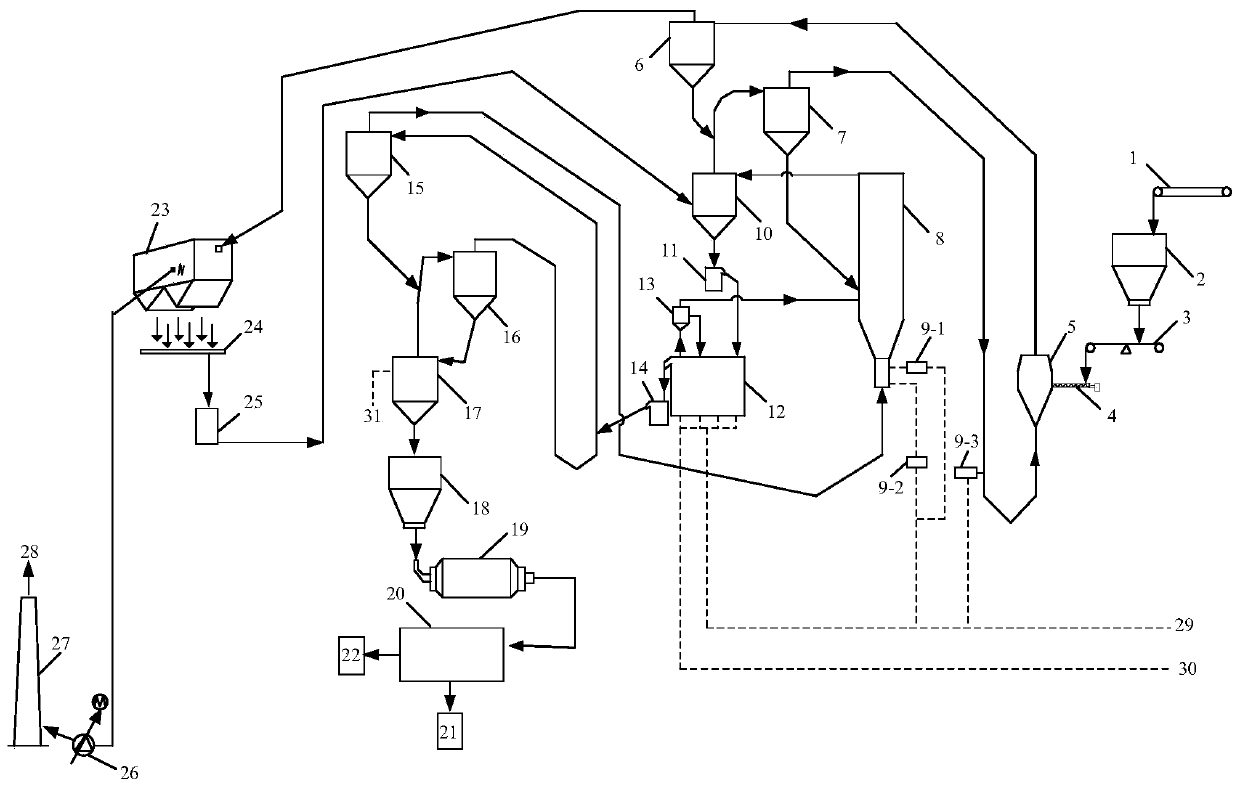

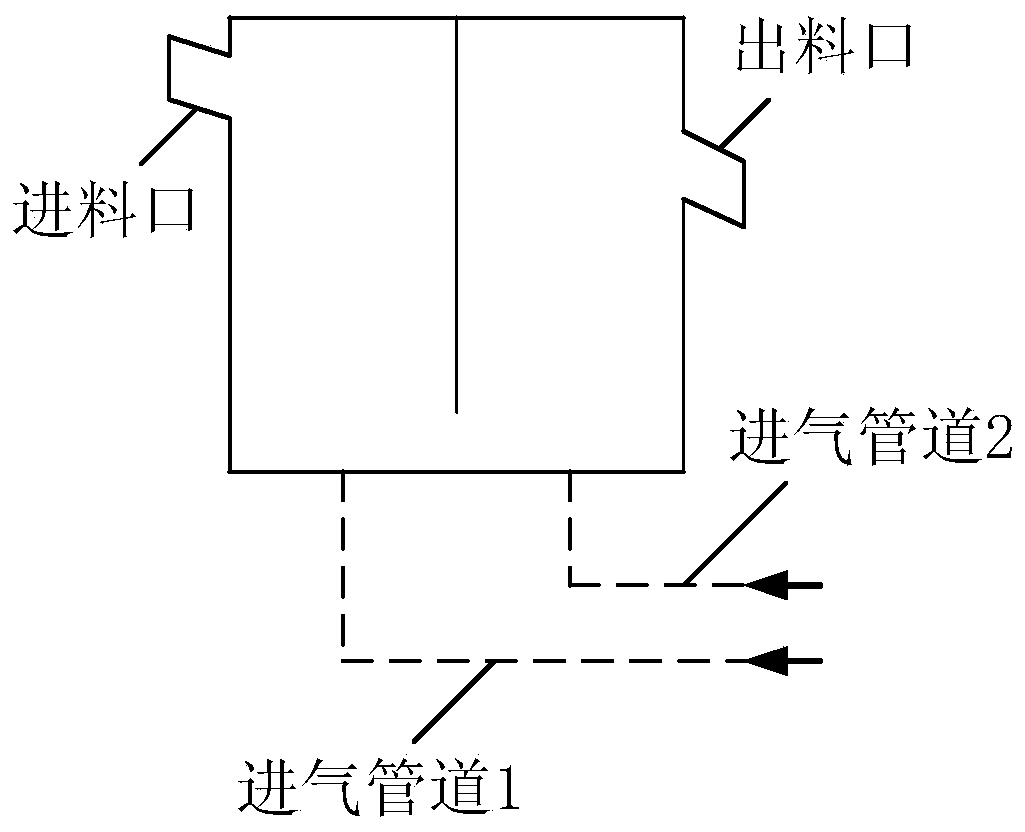

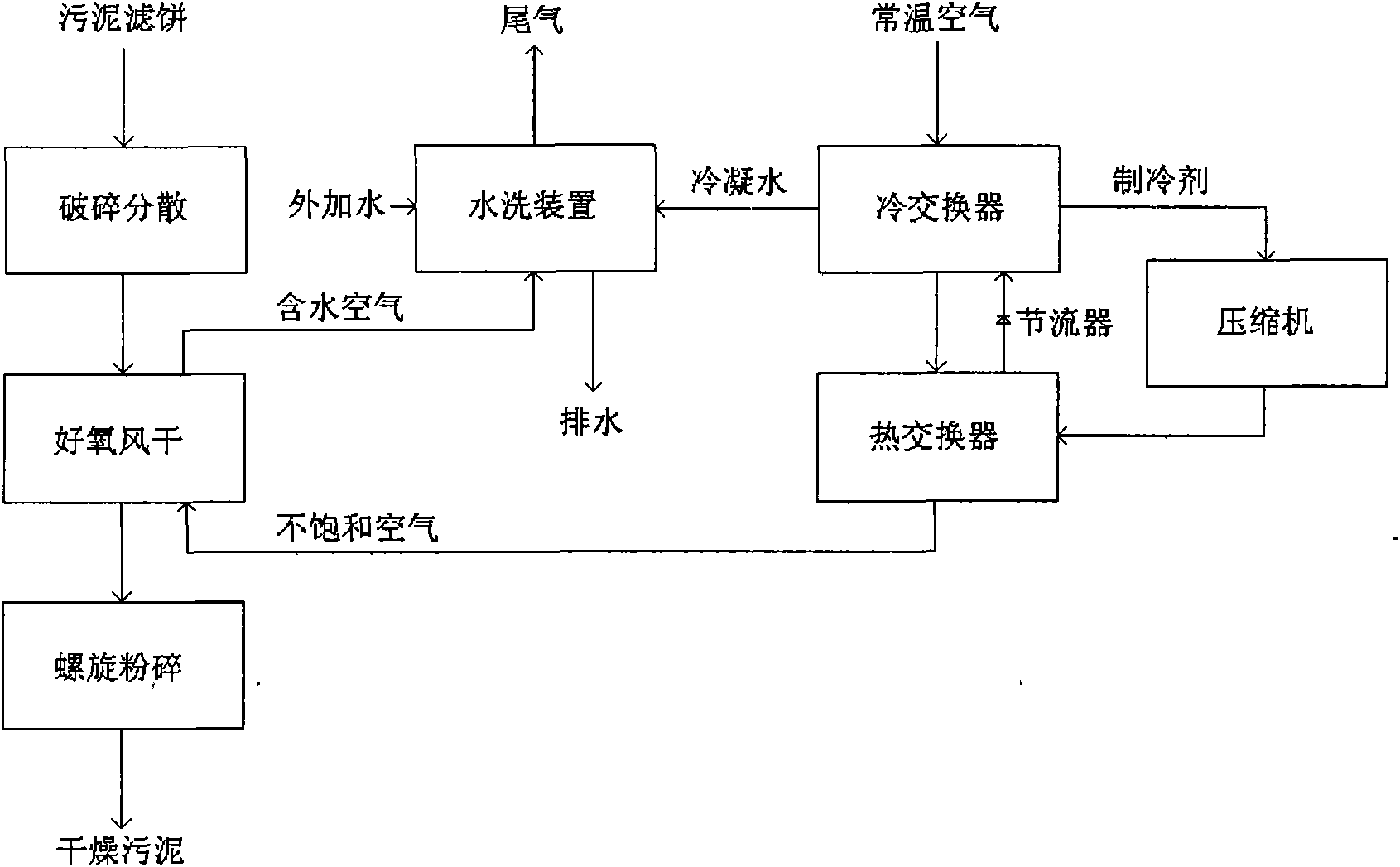

Method and device for sludge filter cake aerobic air drying

ActiveCN101671106ALarge specific surface areaPlay a role in deodorizationDrying solid materials with heatSludge processingSludgePositive pressure

The invention discloses a method and device for sludge filter cake aerobic air drying. The method mainly includes that: sludge filter cake is dispersed into granular layers and dry air at certain temperature is fed into slowly moving or overturning sludge granular layers at positive pressure; physical or chemical sterilization treatment is carried out on slowly moving or overturning sludge granules; tail gas containing sludge moisture is exhausted at negative pressure outside the sludge granular layer and is discharged after washing; and the dried sludge granules are further smashed in conveying process by a screw conveyor, thus meeting the requirement of reclamation utilization. The invention has the following advantages: firstly, heat transfer mass transfer efficiency in drying is high and drying energy consumption is low; secondly, drying is speeded up and deodorization effect is realized on the sludge; thirdly, the sludge granules are stable and safe in production in drying process; fourthly, the dried tail gas can be discharged by environmental protection standard after washing; and fifthly, the discharged sludge granules are loose, thus being convenient for reclamation utilization.

Owner:SWISON CREATIVE ENVIRONMENTAL SOLUTIONS CO LTD

Self-cooled thermodynamic cycle method

InactiveCN107605554AIncrease useUniversally applicableHeat pumpsSteam engine plantsCyclic processThermal energy

The invention discloses a self-cooled thermodynamic cycle method and belongs to the field of thermal energy power. The working medium of a thermodynamic system absorbs heat from a heat source to applywork after boosting. The self-cooled thermodynamic cycle method comprises the following steps: the boosting process of the working medium from the low-temperature state, the preheating process afterboosting, the heat absorption process from the heat source enabling the working medium to become a power air source, the expansion work applying process of the power air source after entering into anexpansion work-applying system, the further heat release and heat discharging process of the low-temperature air working medium after expansion work applying and the thermodynamic cycle realizing process; a thermodynamic cycle system adopts open cycle or closed cycle; the heat pump adopting process absorbs all or part of heat released by the working medium during the heat discharging process; thepreheating process directly or indirectly absorbs all or part of heat discharged during the heat pump process; a heat returning process can be adopted between the heat discharging process and the preheating process; and the thermodynamic system recycles all or part of heat discharged during the heat discharging process through the heat pump process and the heat returning process.

Owner:张玉良

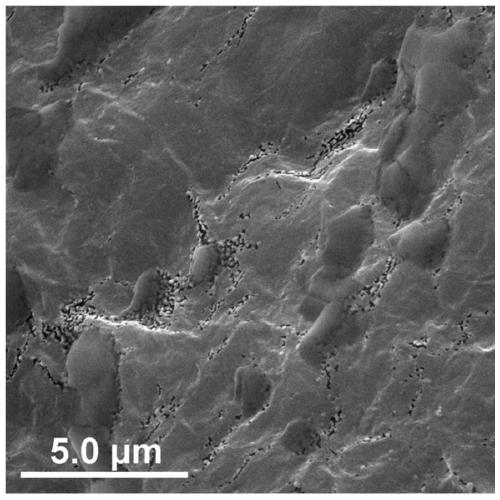

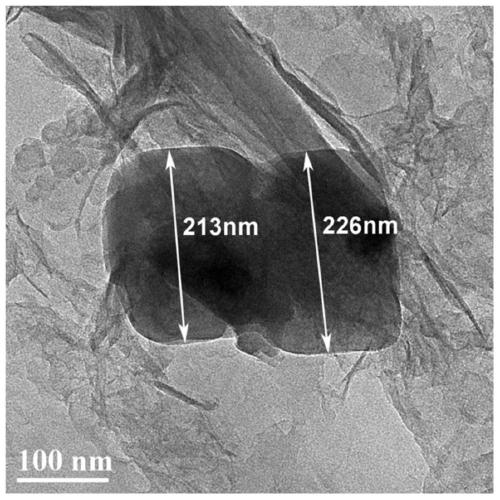

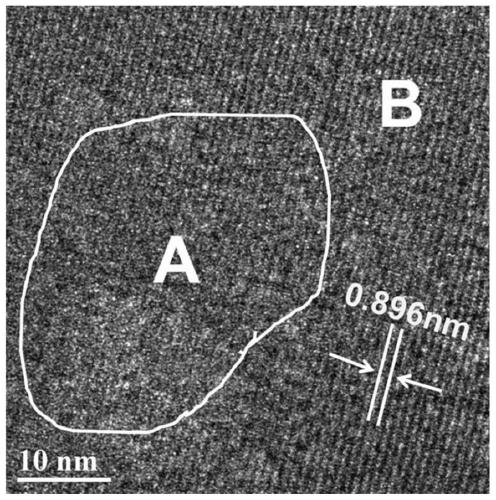

Graphene oxide aerogel thermochemical heat storage composite material and preparation method thereof

ActiveCN109929518AOvercome uneven distribution of hydrated inorganic saltsSolve reunionHeat-exchange elementsSelf-assemblyHigh energy

The invention relates to a graphene oxide aerogel thermochemical heat storage composite material and a preparation method thereof. The method comprises the following steps: 1) ultrasonically strippinga graphite oxide aqueous solution to obtain a graphene oxide aqueous solution; 2) uniformly mixing the graphene oxide aqueous solution with MgCl2.6H2O, and carrying out hydrothermal crosslinking self-assembly to obtain MgCl2.6H2O-graphene oxide hydrogel compound; and 3) carrying out vacuum drying treatment on the MgCl2.6H2O-graphene oxide hydrogel compound to obtain the graphene oxide aerogel thermochemical heat storage composite material. Compared with the prior art, graphene oxide aerogel is used as a carrier; a large specific surface area is provided for MgCl2.6H2O crystallization, so thatthe problem that hydrated inorganic salt is easy to agglomerate can be effectively solved, and the MgCl2.6H2O-graphene oxide hydrogel compound has the advantages of high energy storage density, adjustable reaction temperature, good dispersity and the like. The composite material has a huge application space in the field of medium and low temperature thermochemical heat storage.

Owner:TONGJI UNIV

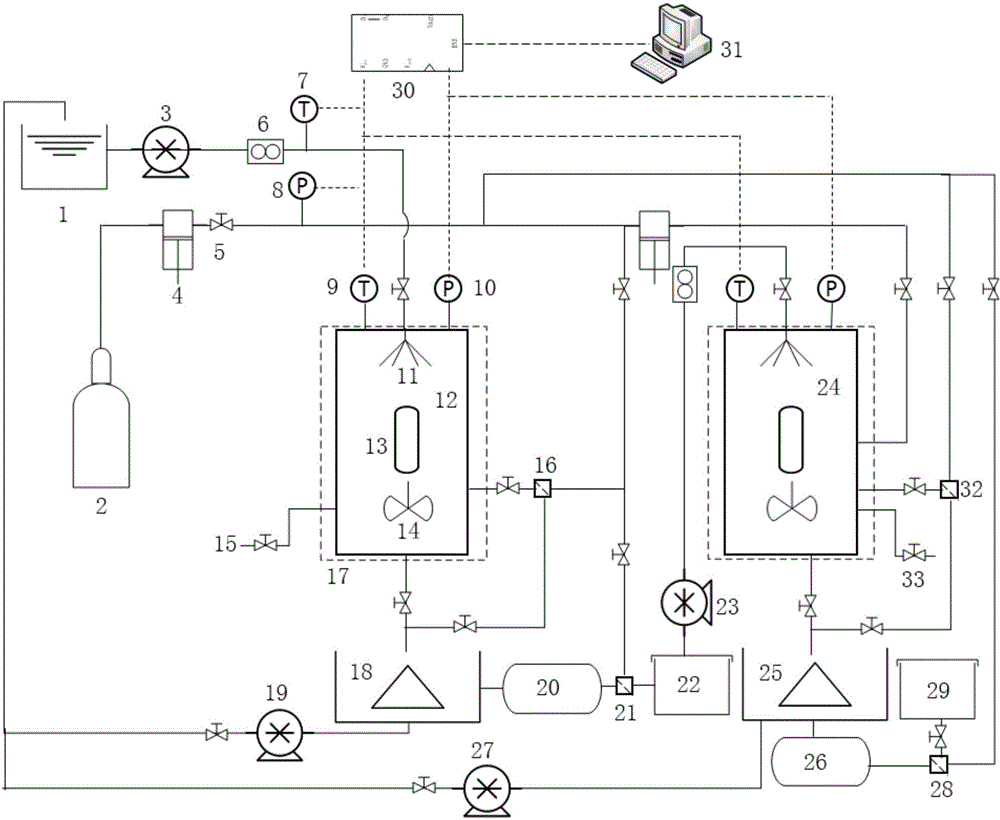

Gas hydrate method sewage treatment system

InactiveCN104591436AAchieve mutual circulationImprove the degree of purificationMultistage water/sewage treatmentIndustrial waste waterTreatments water

The invention relates to a gas hydrate method sewage treatment system belonging to the field of environmental science and engineering. The gas hydrate method sewage treatment system comprises two levels of treatment facilities and comprises a first-level treatment water mixture-sewage transportation unit, a first-level treatment hydrate generation decomposing unit, a secondary-level treatment water mixture-sewage transportation unit and a secondary-level hydrate generation decomposing unit. Hydrate decomposition water after first-level treatment is used as a raw material of secondary-level treatment, and pollutant removal efficiency is improved through two-level treatment. The gas hydrate method sewage treatment system is suitable for large-scale treatment of domestic wastewater and industrial wastewater, inorganic pollutant and organic pollutant can be effectively removed simultaneously, operating cost is reduced due to cyclic utilization of water mixture, heat and mass transfer of hydrate generation process is strengthened due to arrangement of a spray device and a stirrer, and the hydrate growth velocity is increased. The system and the method are reasonable and compact in structure, industrial production requirement is met, operation process is stable and reliable, cost is low, energy is saved and environment is protected.

Owner:DALIAN UNIV OF TECH

Inside cooling film dehumidifier and air dehumidification purification device using same

InactiveCN106377979AImprove performanceReduce the temperatureGas treatmentLighting and heating apparatusMoisture absorptionEngineering

The invention relates to the field of air sterilization purification and humidity control, in particular to an inside cooling film dehumidifier and an air dehumidification purification device using the same. The inside cooling film dehumidifier comprises a solution flow passage and an air flow passage in mutually parallel and alternate arrangement, wherein a cooling pipe is arranged inside the solution flow passage; cooling liquid or cooling gas is introduced into the cooling pipe, and is used for cooling the solution in the solution flow passage; the cooling pipe brings away the heat of the dehumidification solution; the temperature of the solution is lowered; the moisture absorption performance of the solution is improved; the cooling pipe is arranged inside the solution flow passage, so that the additional addition of the flow passage is not needed; the structure is compact; the solution flow passage dead regions are eliminated by controlling the pipe diameter size and the pipe space distribution; the heat transfer and mass transfer efficiency is improved, so that the performance of the film dehumidifier is improved.

Owner:DONGGUAN UNIV OF TECH

Microwave processing multi-phase fluidized bed reactor and process for treating phosphogypsum

ActiveCN108311066AIdeal flow patternHigh heat and mass transfer efficiencySulfur compoundsChemical/physical processesChemical reactionReaction rate

The invention discloses a microwave processing multi-phase fluidized bed reactor and a process for treating phosphogypsum, in the microwave processing multi-phase fluidized bed reactor, a reactor canbe heated divisionally, material flow fields in the reactor can be controlled, the reactor and microwave generators are separately arranged, the microwave processing multi-phase fluidized bed reactorcomprises the microwave-penetrable reactor and a microwave-reflecting shell sleeving the lower portion of the reactor, and the microwave generators, which are distributed from bottom to top and transmit microwave to a microwave-reflecting chamber, are arranged on the microwave-reflecting shell. The process for treating the phosphogypsum comprises the following steps: placing solid calcium sulfateparticles and liquid sulfur in a molar ratio of 1:1 to 1:10 in the reactor; heating the reactor through the microwave generators, controlling the pressure inside of the reactor to less than 1Mpa; andafter the reaction is completed, discharging a material. The microwave processing multi-phase fluidized bed reactor and the process for treating the phosphogypsum can enhance the heat and mass transfer efficiency among gas, liquid and solid three phases, reduce subsequent separation cost, save the process, and increase the chemical reaction rate.

Owner:SICHUAN UNIV

Circulation mixer and application thereof

InactiveCN106607004ASimple structureHigh heat and mass transfer efficiencyPreparation from carboxylic acid saltsFlow mixersSpray nozzleMass transfer

The invention especially relates to a circulation mixer, belonging to the technical field of mixers. The circulation mixer comprises a tank with at least one opening, a guide shell fixed in the tank in a suspension manner, a nozzle located below the guide shell, and a gas distributor fixedly arranged in the tank and located below the guide shell, wherein the nozzle is connected with a first conveyer pipe which penetrates the sidewall of the tank and extends to the interior of the tank, and the gas distributor is connected with a second conveyer pipe which penetrates the sidewall of the tank and extends to the interior of the tank. The circulation mixer is simple in structure; during mixing of equal amounts of raw materials, the circulation mixer achieves the purpose of liquid-liquid or gas-liquid mixed mass transfer or heat transfer through formation of circulation in the circulation mixer; the size of the mixer may be substantially reduced compared with mixers in the prior art; and in particular, when the mixer is used as a chemical reactor needing heating, and heat and mass transfer efficiency of the reactor is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device and method for extracting iron from iron tailings through suspension roasting

ActiveCN111589563AHigh heat and mass transfer efficiencyImprove production continuityVortex flow apparatusMagnetic separationCombustionFlue gas

The invention discloses a device and method for extracting iron from iron tailings through suspension roasting. The device comprises a feeding bin, a venturi dryer, a pre-oxidation suspension roastingfurnace, a suspension reduction roasting furnace, a collecting bin, a dry magnetic separator, a first-stage ore grinding machine, a first-stage low-intensity magnetic separator, a second-stage ore grinding machine, a second-stage low-intensity magnetic separator and an induced draft fan. The method comprises the following steps of (1), finely grinding the iron tailings; (2), conveying the ore fines to the vnturi dryer; (3), mixing and dehydrating combustion flue gas and ore fines in the venturi dryer; (4), preheating the ore fines and feeding the ore fines into the pre-oxidation suspension roasting furnace; (5), pre-oxidizing and roasting in a suspension state, and then feeding into the suspension reduction roasting furnace; (6), carrying out reduction roasting in a suspension state; (7),cooling and then feeding into the collecting bin; and (8), carrying out first-stage ore grinding and first-stage low-intensity magnetic separation after dry magnetic separation, and then carrying outsecond-stage ore grinding and second-stage low-intensity magnetic separation. The device and the method have the advantages of high heat and mass transfer efficiency, high production continuity, hightreatment capacity, high adaptability, easiness in realizing large-scale industrial production and the like.

Owner:上海逢石科技有限公司

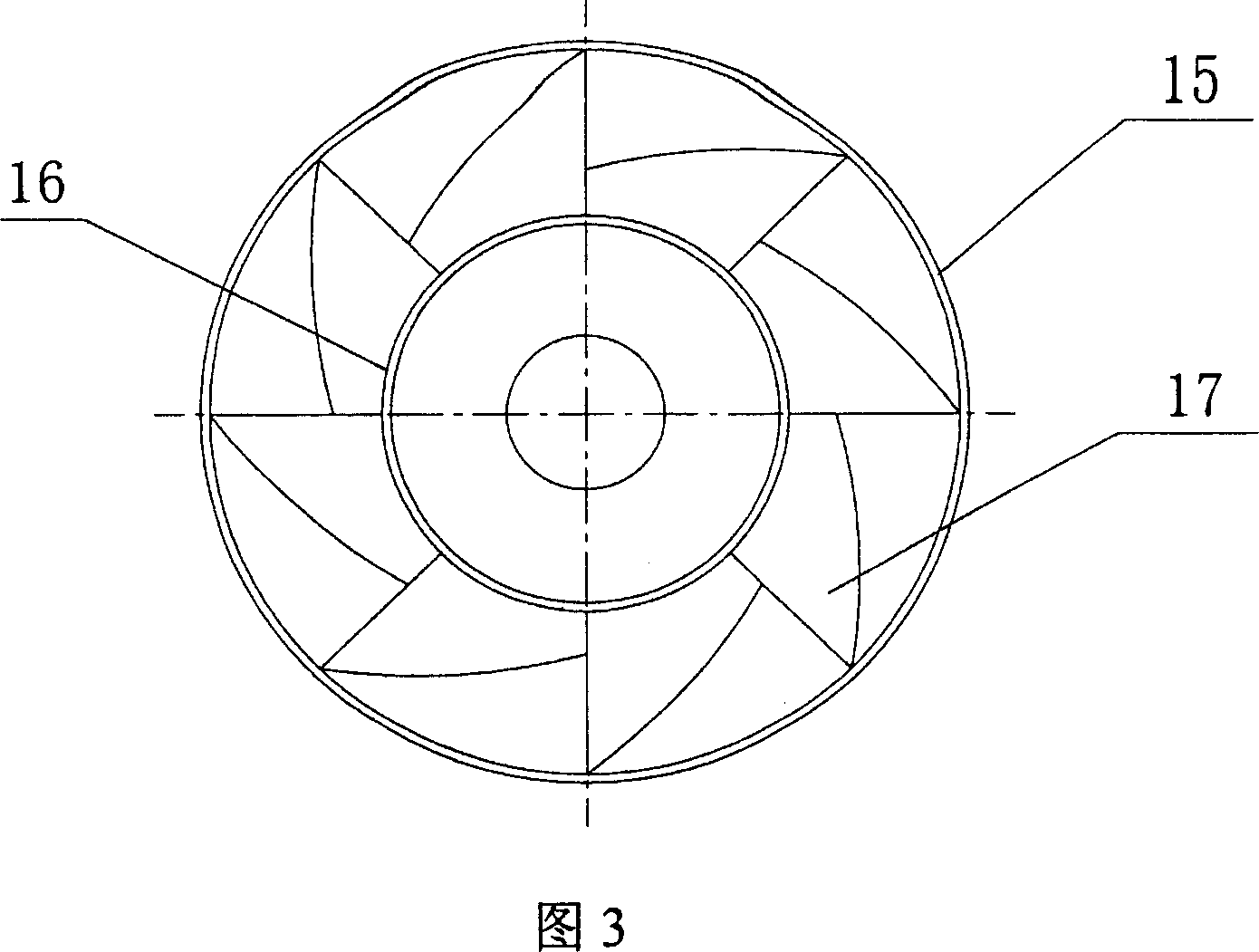

Humidification method of eddy flow spray and humidification tower

ActiveCN1959086AReduce manufacturing costHigh heat and mass transfer efficiencyTurbine/propulsion engine coolingGas turbine plantsCounter flowEngineering

A wetting method by spiral-flow atomizing includes leading low temperature air to bottom of wetting tower in counter-flow uniform mode, spraying high temperature water from top down to bottom then discharging said water out after it is heat and mass transferred with said low temperature air counter-flow forming air flow film at periphery of scattered water drop in said heat and mass transfer course then removing off small water drop rising-up in following air flow for finalizing the dewatering or deatomizing process. The wetting tower used for realizing said method is also disclosed.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

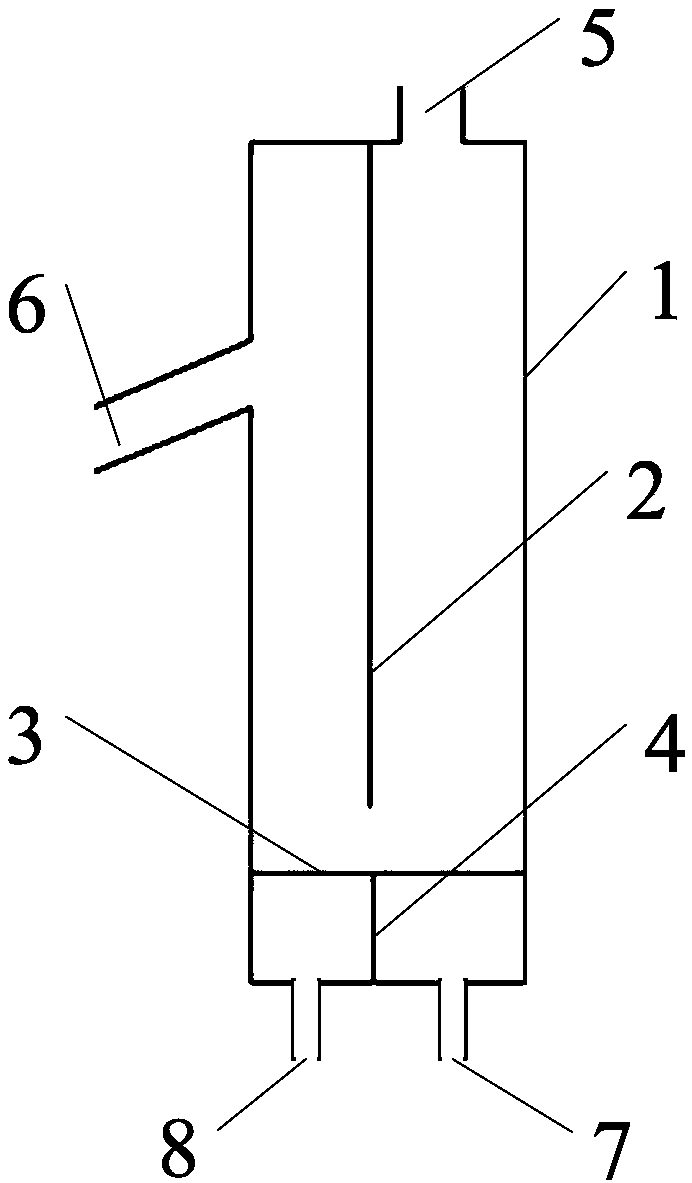

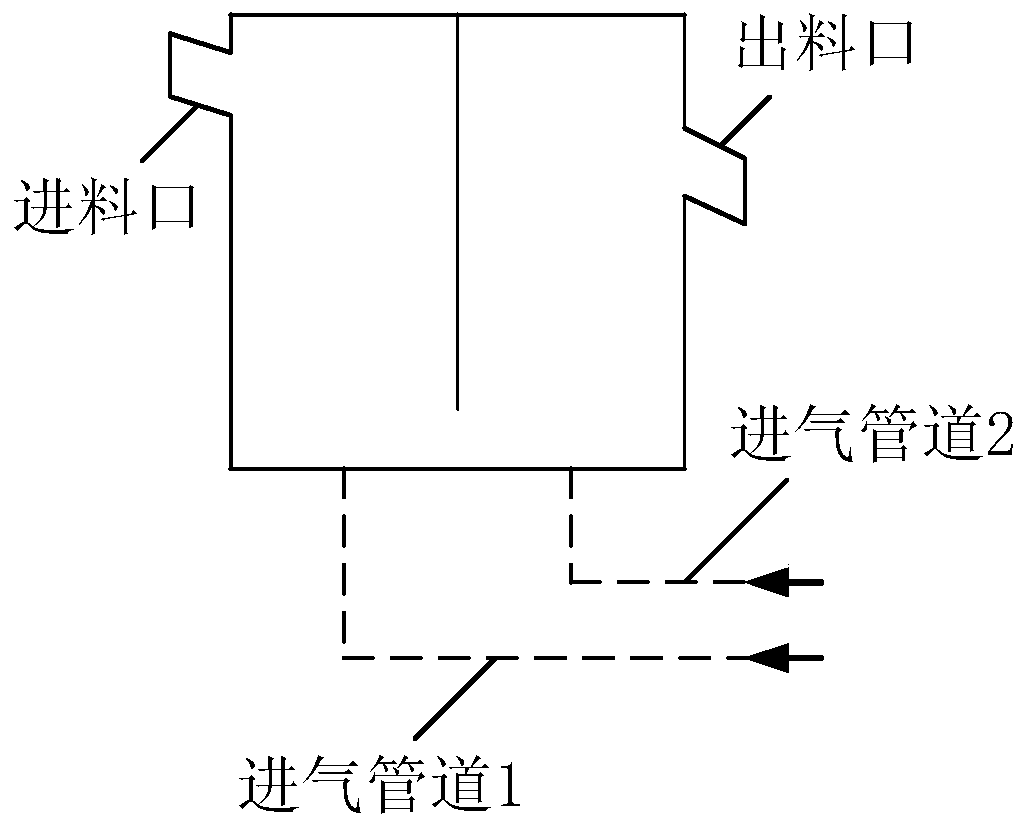

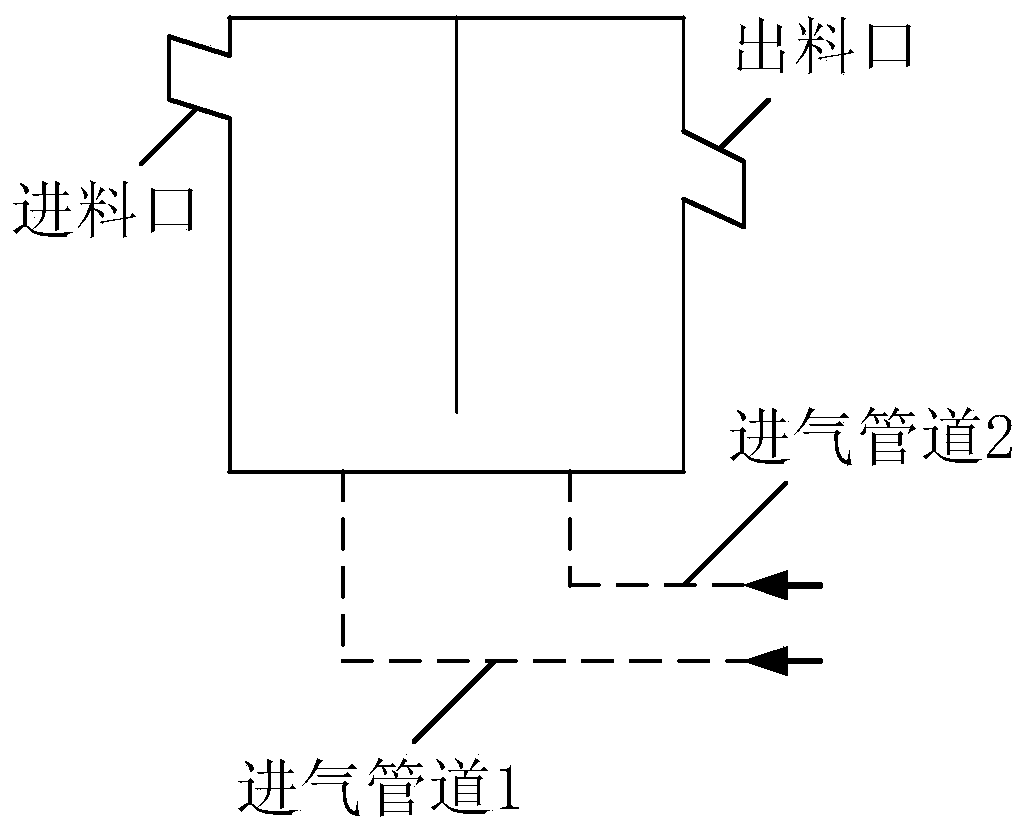

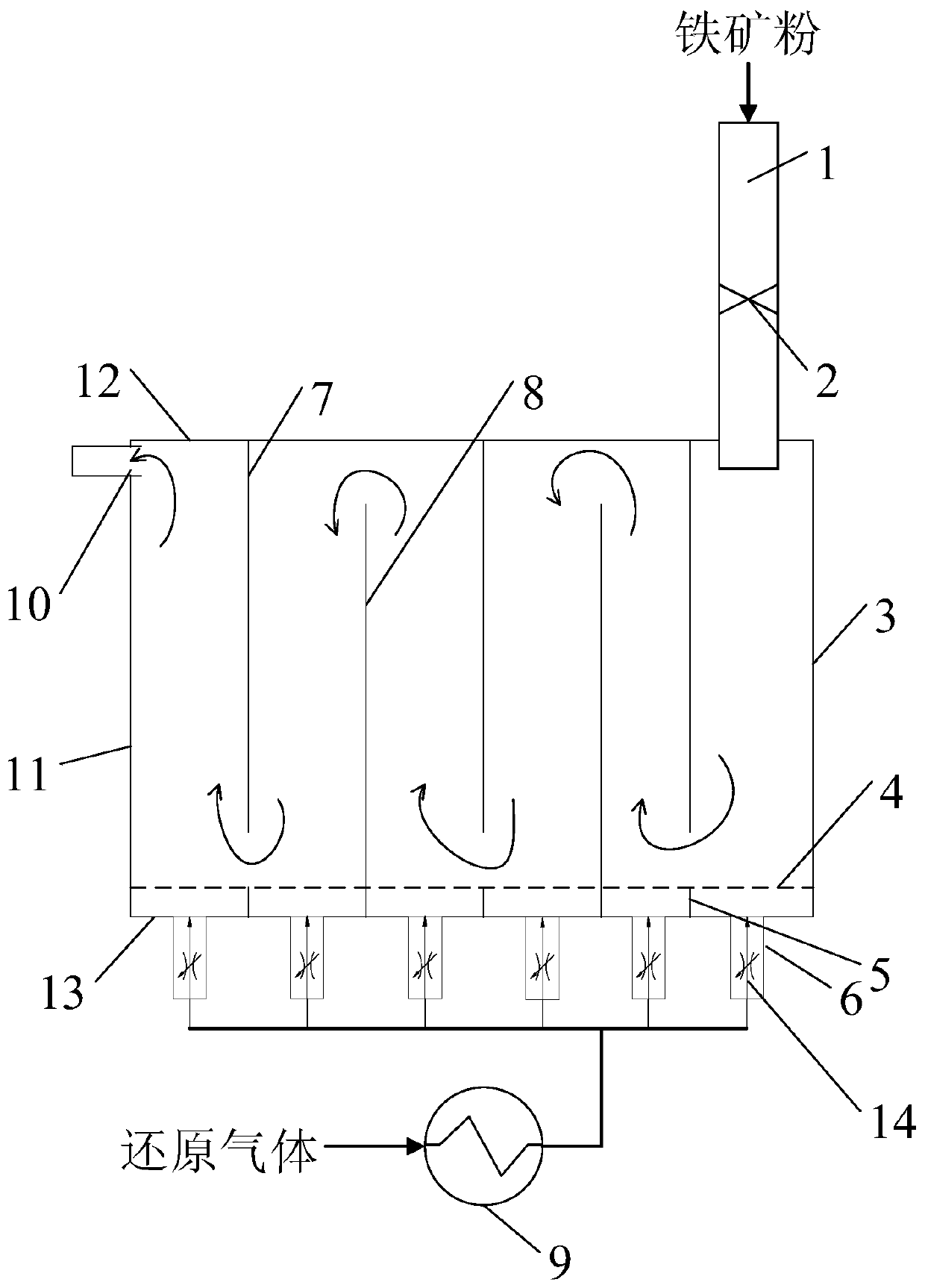

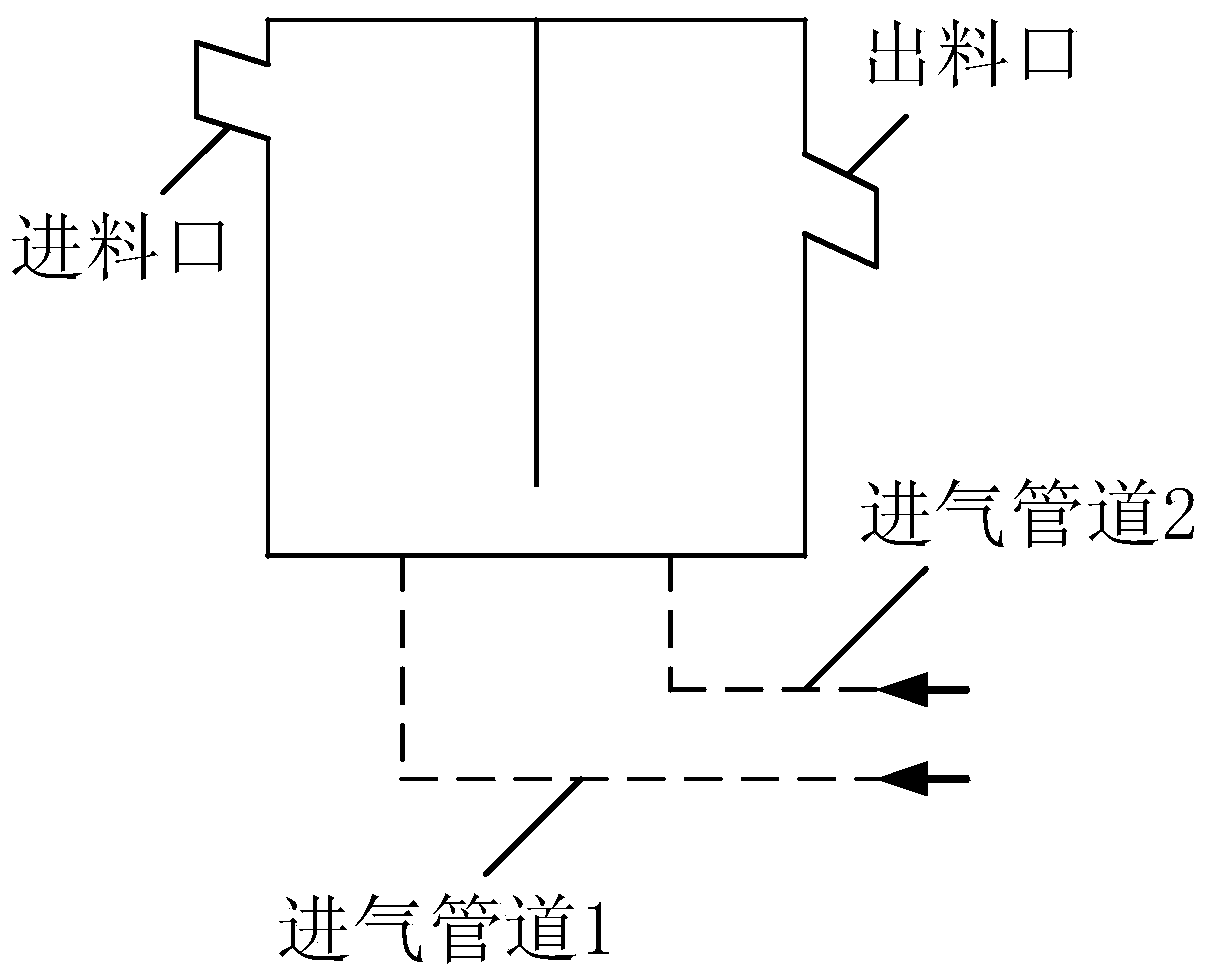

Iron ore powder multi-stage suspension state reduction roasting device and method

The invention discloses an iron ore powder multi-stage suspension state reduction roasting device and method. The device comprises a shell, a baffle plate group, a feeding pipe and an air inlet pipe group; a flap valve is arranged in the feeding pipe; the baffle group consists of N upper baffle plates and N-1 lower baffle plates, and one lower baffle plate is arranged between every two adjacent upper baffle plates; each upper baffle plate is opposite to one supporting plate, and the bottom surface of an airflow distribution plate is connected with the supporting plates; each air inlet pipe communicates with one air flow area; and the air inlet pipes simultaneously communicate with a gas heater. The method comprises the following steps: (1) heating the reducing gas to 500-900 DEG C and thenfeeding the reducing gas to each reaction chamber; (2) feeding iron ore powder into a feeding pipe, and opening the flap valve to feed the iron ore powder to the reaction chambers; (3) carrying out reduction reaction on the iron ore powder; and (4) discharging the iron ore powder from a discharge port after reduction reaction. The method has the advantages of high heat and mass transfer efficiency, high reaction speed and short reaction time in the reduction process, thereby greatly improving the production efficiency and reducing the energy consumption.

Owner:NORTHEASTERN UNIV

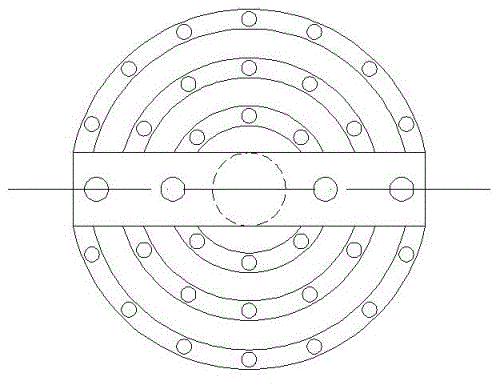

Low-resistance efficient column tray

ActiveCN104383709AHigh heat and mass transfer efficiencyLow flow resistanceDispersed particle separationDistillation separationOn columnEngineering

The invention provides a low-resistance efficient column tray. Cover hoods are welded on column plates; outer layer liquid blocking sieve plates with sieve holes are arranged at the peripheries of the outer parts of the side walls of the cover hoods above the column plates for secondary gas-liquid dispersion mass transfer; a row of small liquid distribution holes are formed in the side surfaces of the cover hoods, close to the column plates; a liquid collecting groove is formed above the cover hoods; the cover hoods protrude out of the plane of the column plates by a certain height so as to prevent solid substances from blocking the cover hoods and the sieve holes; an oblique plate is arranged at the part corresponding to the small liquid distribution holes in each cover hood; a narrow gap is formed between the oblique plate and the side walls of the cover hoods for distributing a liquid; a plurality of sieve holes are also formed in the side walls of the cover hoods at the lower parts of the column plates; meanwhile, an inner layer liquid blocking sieve plate is arranged in the side wall of the cover hood below the column plates for secondary gas-liquid dispersion mass transfer; a plurality of liquid exhaust holes are formed in the bottom of the cover hoods for liquid distribution and dropping, and meanwhile play a role of liquid sealing. The low-resistance efficient column tray has the advantages that the gas flow resistance is low; the gas-liquid contact effect is good; the antiblocking effect is good; the column plate efficiency is high; the manufacture and running costs are low; the column tray is convenient to overhaul.

Owner:TIANJIN AOZHAN XINGDA TECH

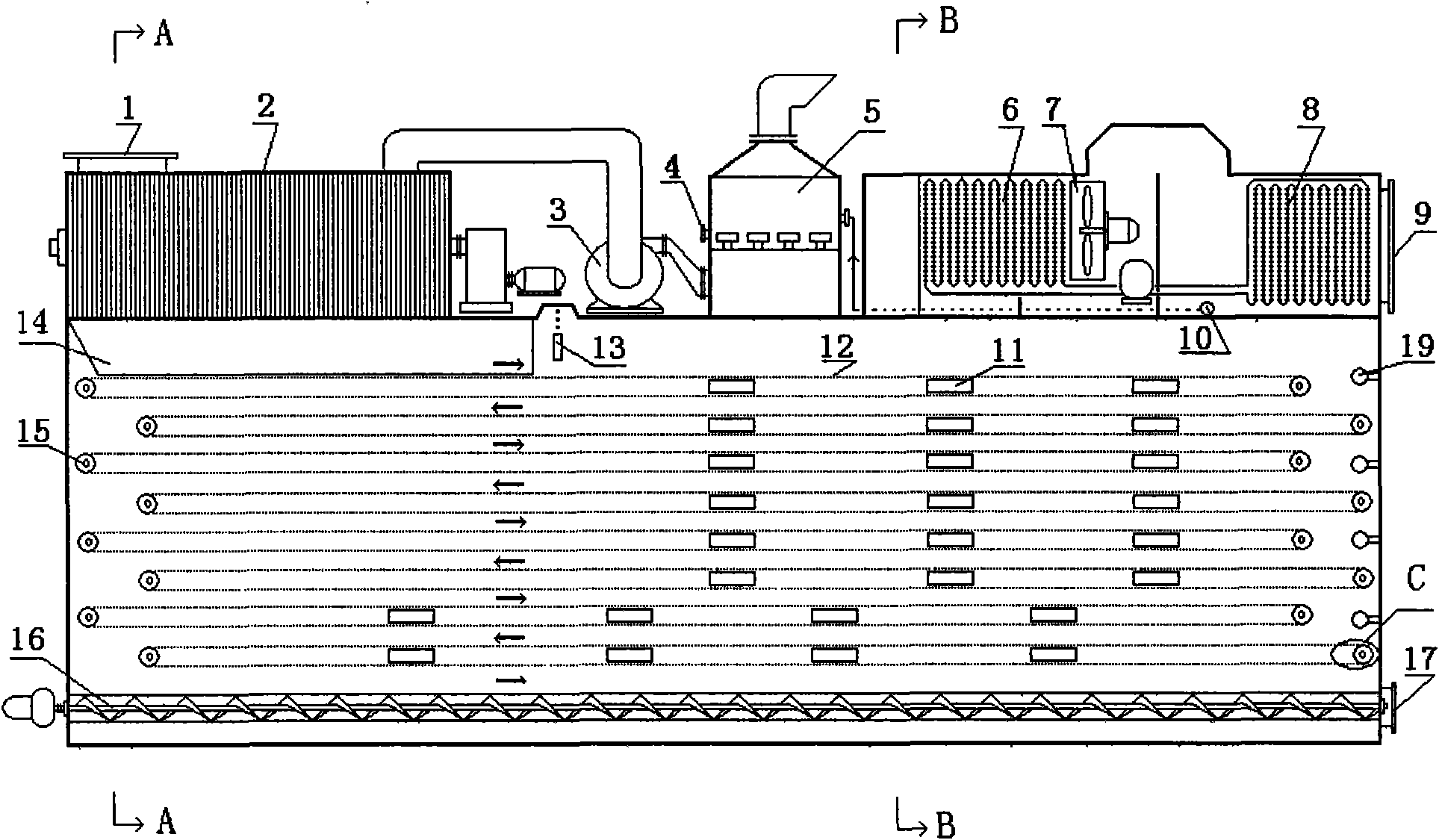

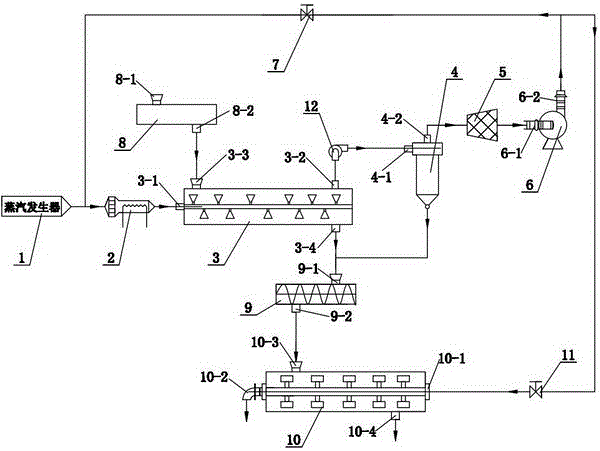

Sludge two-grade united energy-saving drying device and method

PendingCN106517727AFully recover latent heatFully recover part of the sensible heatSludge treatment by de-watering/drying/thickeningSludgePulp and paper industry

The invention relates to a sludge two-grade united energy-saving drying device and a sludge two-grade united energy-saving drying method. The sludge two-grade united energy-saving drying device includes a steam generator, a heater, a direct stirring dryer, a blower, a cyclone dust collector, a filter, a steam compressor, a valve, a sludge pump, an indirect sludge dryer and a spiral feeder. The sludge pump, the direct stirring dryer, the spiral feeder, and the indirect sludge dryer are formed to be a material access; the steam generator, the heater, the direct stirring dryer, the blower, the cyclone dust collector, the filter, the steam compressor, and the valve are formed to be a first-grade drying gas flow access; the valve and the indirect sludge dryer are formed to be a secondary-grade drying gas flow access. The invention has the beneficial effects of crossing through a sludge viscous zone through a two-grade drying method, and solving the viscous problem caused by high water content of sludge in indirect drying; besides, residual steam is used as the hot source for the next-grade drying, the potential heat and a part of sensible heat of the excessive steam can be generated during the recycling and drying processes, and thus the gradient utilization of energy can be realized.

Owner:NANCHANG HANGKONG UNIVERSITY

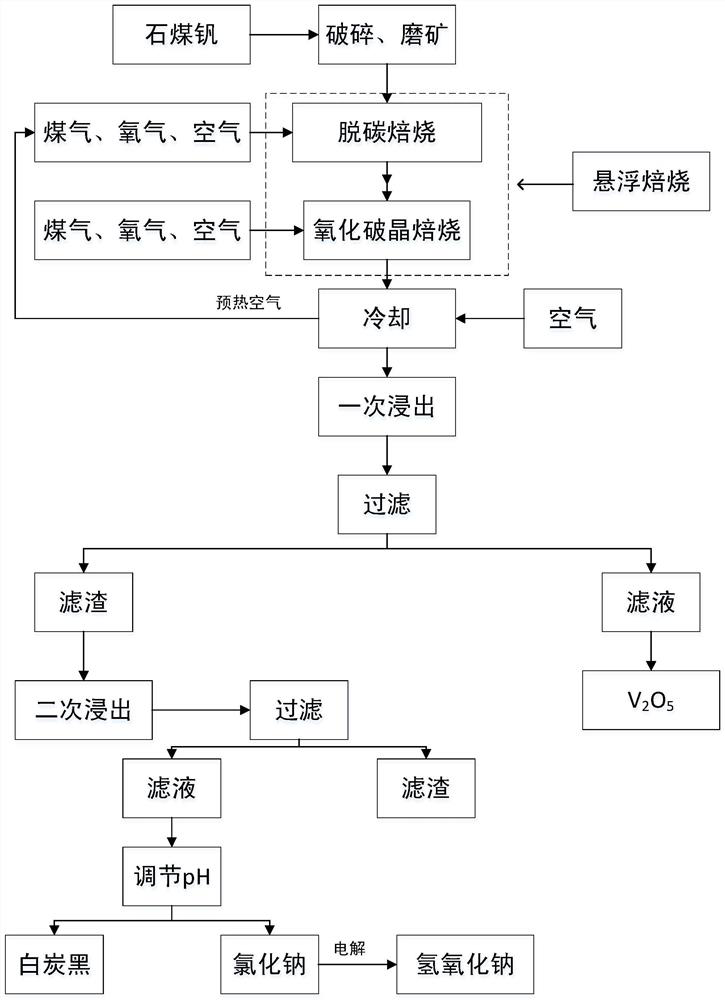

Stone coal vanadium ore oxidation grain breaking roasting comprehensive utilization method

ActiveCN111719054AHigh operating costsAdaptableSilicaProcess efficiency improvementPregnant leach solutionCyclonic separation

The invention discloses a stone coal vanadium ore oxidation grain breaking roasting comprehensive utilization method. The method is carried out according to the following steps (1) a stone coal vanadium ore is crushed and ground to obtain powder ore; (2) the power is delivered to a suspended decarburization roasting furnace for decarburization reaction; (3) a decarburized material is subjected tocyclone separation and then enters a suspended grain breaking roasting furnace to be subjected to a grain breaking oxidation reaction; (4) an oxidized material is discharged after cyclone separation;(5) cooling is conducted to 150-200 DEG C is conducted, acid mixing curing leaching, or directly leaching is conducted; (6) a leached material is filtered to obtain a V2O5 leaching solution; (7) filter residue is mixed with a sodium hydroxide solution for secondary leaching, and filtering is conducted to obtain a secondary filtrate; (8) hydrochloric acid is added into the secondary filtrate to generate white precipitate, and filtering is conducted to obtain third filter residue, and drying is conducted to obtain white carbon black. According to the method, sodium salt adding is not required byroasting, the problems of incomplete vanadium oxidation, low equipment processing amount, high operation cost and the like in a traditional process are solved, the process flow is simple, equipment and system operation are stable, and energy consumption and cost for unit processing amount are low.

Owner:NORTHEASTERN UNIV

Novel solid adsorption dehumidifier

InactiveCN101504174ALow regeneration temperature requirementHigh heat and mass transfer efficiencyOther heat production devicesSolar heat devicesWater sourceInlet valve

The invention relates to a solid adsorption dehumidifier, which is characterized in that a finned tube formed by closely combining a tube and a fin is used as a substrate. The surface of the substrate is stuck with a silica gel absorption substance which is arranged in an air channel; the upper part and the lower part of the finned tube are both connected with cold and hot water pipes and corresponding valves which are communicated with cold and hot water sources respectively; the upper end of the air channel is provided with an exhaust port, an exhaust port valve, an air outlet, an outlet valve and a fan; and the lower end of the air channel is provided with an air inlet and an air inlet valve. The solid adsorption dehumidifier has the advantages that: 1, the fin and the finned tube are used as the substrate, so the solid adsorption dehumidifier has simple structure, easy marketization, high heat transfer efficiency and bearing capacity; 2, silica gel is used as the absorption substance, so that the solid adsorption dehumidifier has low regeneration temperature, and can use solar energy and geothermal energy; and 3, the fan is used for driving humid air current to flow through the surface of a silica gel layer, so the solid adsorption dehumidifier has good heat calorie exchange and dehumidifying effect.

Owner:北京清华索兰环能技术研究所

Suspension roasting system for carbon-containing gold ore

ActiveCN111500852AAdaptableHigh heat and mass transfer efficiencyProcess efficiency improvementThermodynamicsEngineering

The invention provides a suspension roasting system for carbon-containing gold ore. A feeding bin is opposite to a screw feeder, and the screw feeder is opposite to a venturi dryer; the venturi dryer,a first cyclone preheater, a second cyclone preheater and a pre-oxidation suspension roaster are connected in series, the upper part of the pre-oxidation suspension roaster is connected with the thermal separation cyclone through a pipeline, the thermal separation cyclone, a first flow sealing valve and a strong oxidation suspension roaster are connected in series, and the strong oxidation suspension roaster communicates with an oxygen gas source and a nitrogen gas source; a discharging outlet of the strong oxidation suspension roaster, a second flow sealing valve, a first cooling cyclone, asecond cooling cyclone, a third cooling cyclone and a collection bin are connected in series; and a collection bin, an ore grinding machine, a collection tank, a first slurry pump, a leaching tank, asecond slurry pump and a filter press are matched in sequence. The suspension roasting system for the carbon-containing gold ore has the advantages of high heat and mass transfer efficiency, completeremoval of carbon materials, sulfur and arsenic, high efficiency high adaptability to different ores, easy realization of large-scale industrial production and the like.

Owner:SHANGHAI MILESTONE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com