Graphene oxide aerogel thermochemical heat storage composite material and preparation method thereof

A graphene aerogel, graphene hydrogel technology, applied in chemical instruments and methods, heat exchange materials and other directions, can solve the problem of low load rate of hydrated inorganic salts and reduced energy storage density of thermochemical heat storage composite materials and other problems to achieve the effect of overcoming the uneven distribution of hydrated inorganic salts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of graphene oxide airgel thermochemical heat storage composite material, comprising:

[0034] Preparation of graphene oxide (GO) aqueous solution: graphite oxide was prepared by the improved Hummers method, and a graphite oxide aqueous solution with a concentration of 3-10 mg / mL was prepared, and 3-10 mg / mL was obtained after ultrasonic stripping at a frequency of 20-60 kHz for 1-2 hours. Graphene oxide aqueous solution;

[0035] Preparation of MgCl 2 ·6H 2 O-graphene oxide hydrogel composite: measure GO aqueous solution 30-60mL, press MgCl 2 ·6H 2 The different mass percentages of O in the complex are 50-90wt%, and the corresponding MgCl is weighed 2 ·6H 2 O, the two are mixed evenly, and the hydrothermal reaction is carried out at 50-100°C for 10-18 hours, and MgCl is obtained after cross-linking and self-assembly 2 ·6H 2 O-graphene oxide hydrogel composite (abbreviated as GOH-M);

[0036] Preparation of MgCl 2 ·6H 2 O-graphene oxide air...

Embodiment 1

[0040] Graphite oxide was prepared by the improved Hummers method, and a graphite oxide aqueous solution with a concentration of 5 mg / mL was prepared, and a 5 mg / mL graphene oxide aqueous solution was obtained after 40 kHz ultrasonic stripping for 2 hours. by MgCl 2 ·6H 2 The mass percentage of O in the composite is 50wt%, and the corresponding MgCl is weighed 2 ·6H 2 O was dispersed in 50 mL of GO aqueous solution, stirred evenly, poured into the reaction kettle, and heated at 90 °C for 12 h to obtain the GOH-M50 complex. GOH-M50 was pre-frozen at -45°C for 2 hours, and vacuum freeze-dried for 72 hours under the conditions of vacuum degree of 2Pa and cold hydrazine temperature of -45°C to obtain the GOA-M50 complex.

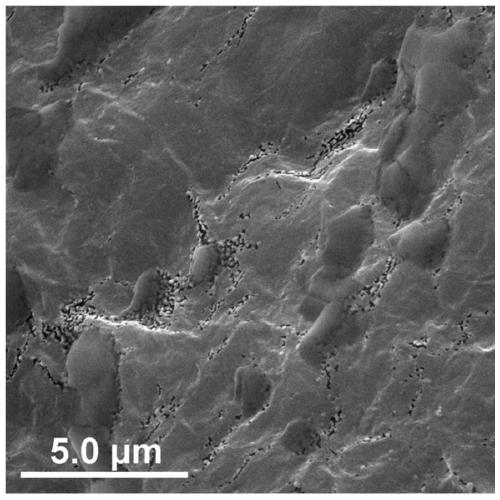

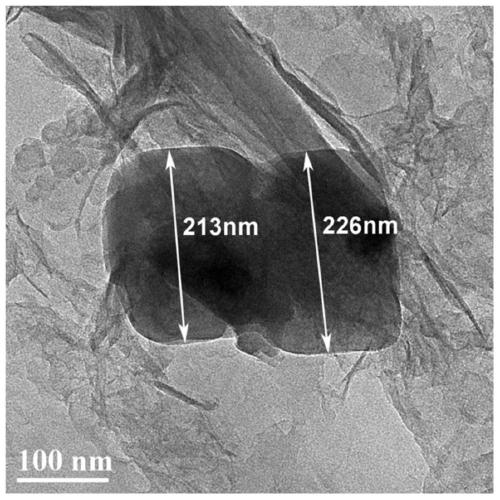

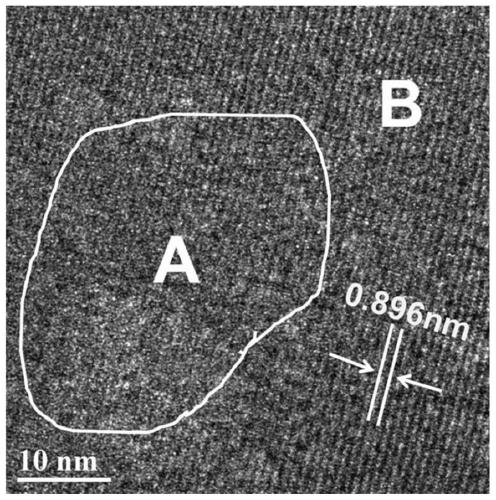

[0041] figure 1 and figure 2 They are the SEM image and TEM image of GOA-M50 respectively. It can be seen from the figure that MgCl 2 ·6H 2 O particles are uniformly dispersed on the GOA sheet, and the size reaches 200-300nm. image 3 MgCl in GOA-M50 2...

Embodiment 2

[0043] Graphite oxide was prepared by the improved Hummers method, and a graphite oxide aqueous solution with a concentration of 5 mg / mL was prepared, and a 5 mg / mL graphene oxide aqueous solution was obtained after 20 kHz ultrasonic stripping for 2 hours. by MgCl 2 ·6H 2 The mass percentage of O in the complex is 60wt%, and the corresponding MgCl is weighed 2 ·6H 2 O was dispersed in 50 mL GO aqueous solution, stirred evenly, poured into the reaction kettle, and heated at 80 °C for 12 h to obtain the GOH-M60 complex. GOH-M60 was pre-frozen at -40°C for 2 hours, kept at a vacuum of 2 Pa, and cooled to -45°C, and lyophilized in vacuum for 72 hours to obtain the GOA-M60 complex.

[0044] GO prepared in this example, MgCl 2 ·6H 2 The XRD diffraction pattern of O and GOA-M60 composite is as follows Figure 4 , where a represents the XRD diffraction pattern of GO, and the two curves in b are MgCl 2 ·6H 2 XRD diffraction pattern of O and GOA-M60 composite. It can be seen fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com