Humidification method of eddy flow spray and humidification tower

A technology of humidification and tower body, which is applied in the field of gas turbine device humidification, can solve the problems of unfavorable heat and mass transfer, reduce the contact area between gas and liquid phases, and the filler surface cannot be completely wetted, etc., and achieve the effect of economical selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

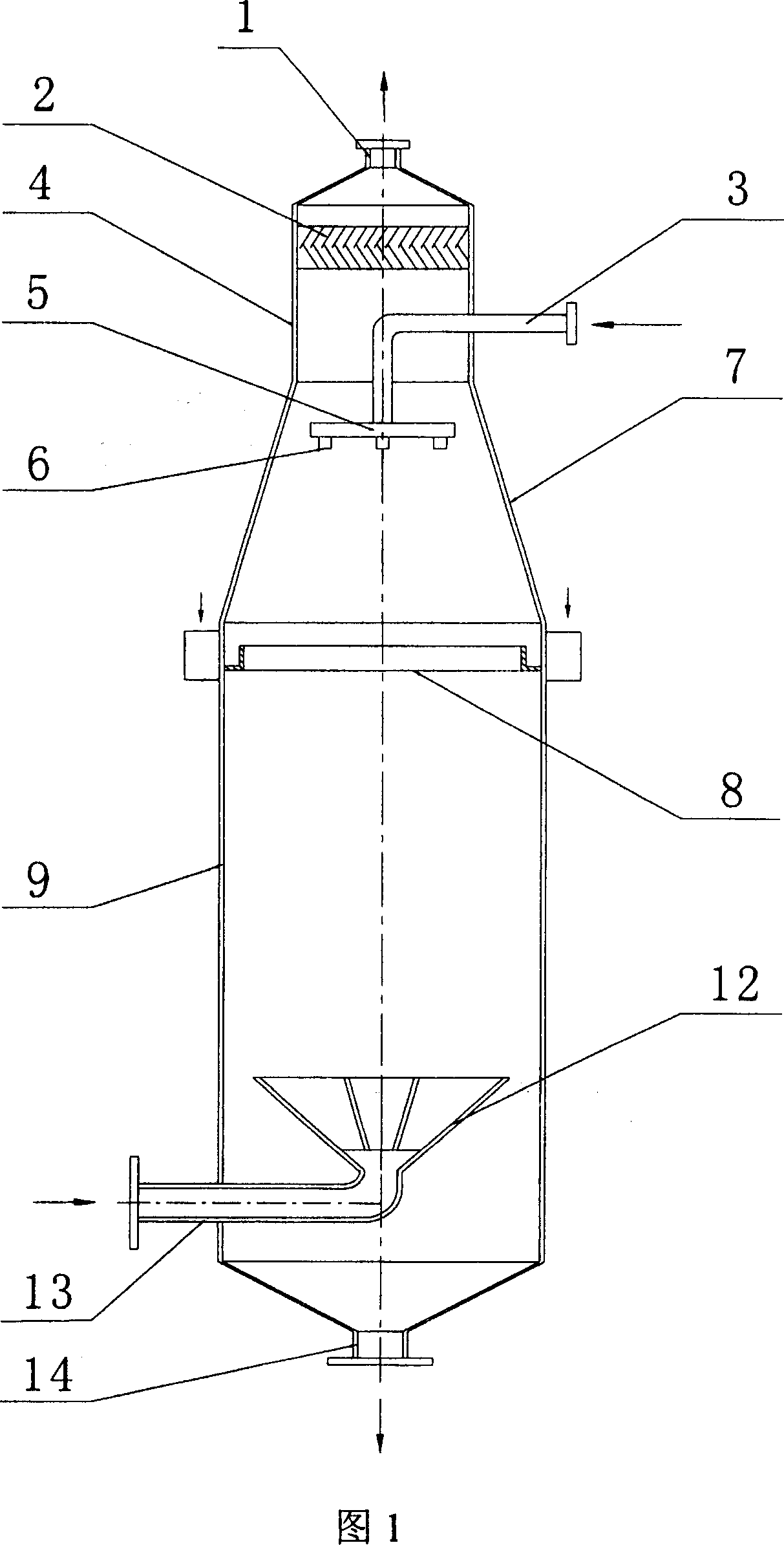

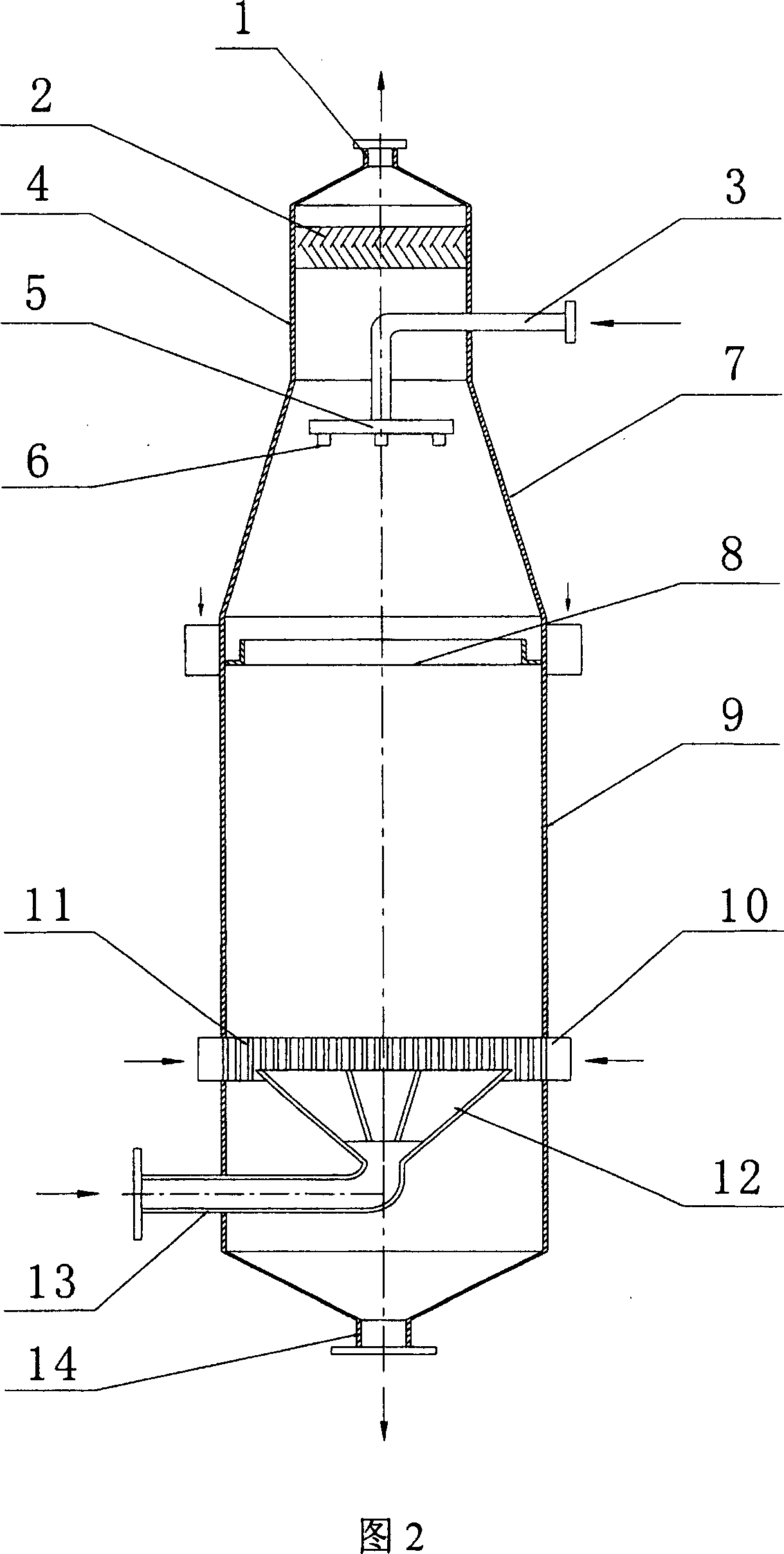

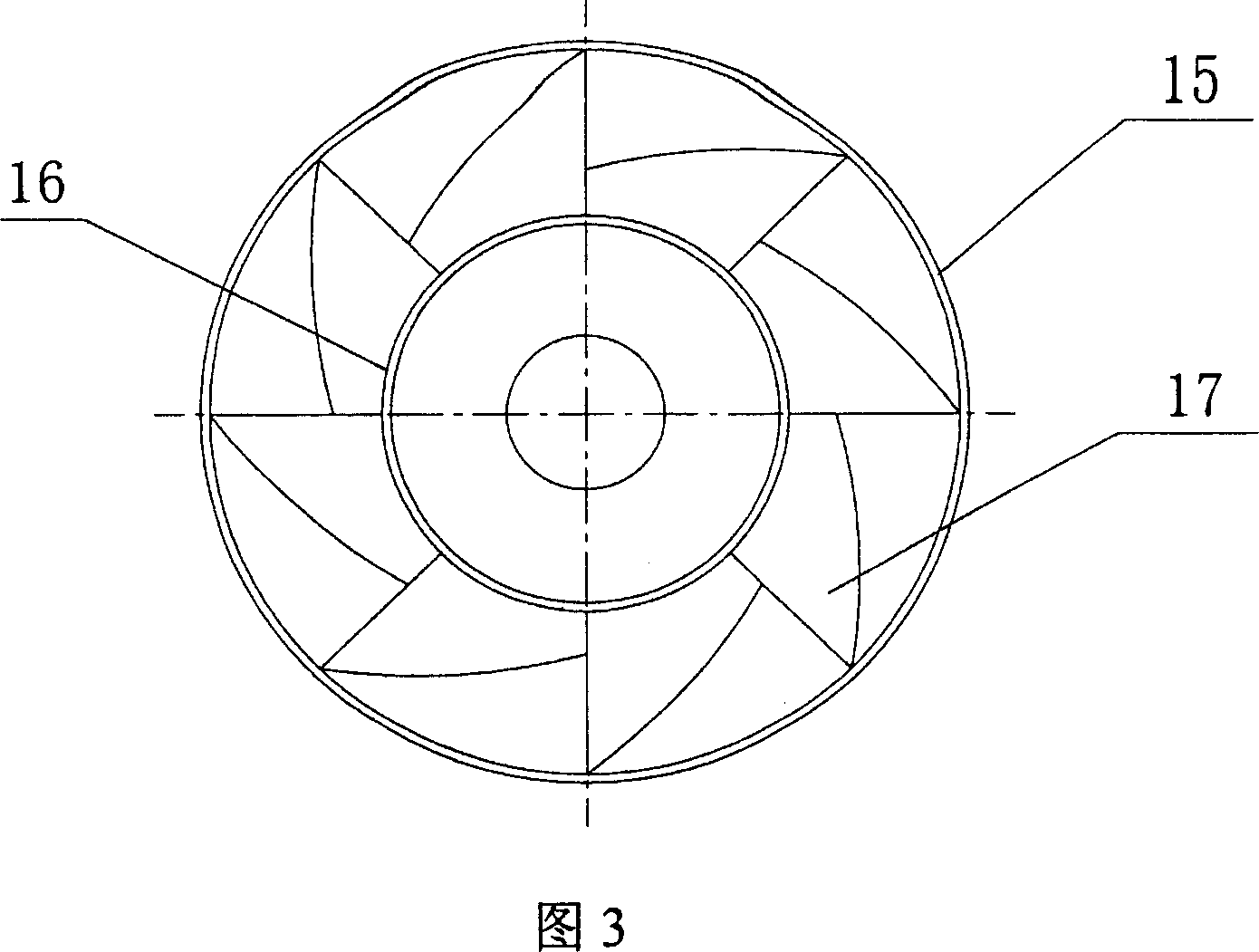

[0033] Please refer to FIG. 1 , which is a schematic structural diagram of a cyclone spray humidification tower provided by the present invention. mainly includes:

[0034] A tower body is composed of a cylindrical shell 9, a cylindrical transition section 4 and a conical shrinkage section 7. A drain pipe 14 is provided at the bottom of the tower body. At the same time, a water seal and a liquid seal are installed to control the pressure in the tower. The level control system can maintain a certain water level in the humidifier and realize pressure control (the liquid level control system is a known technology, not shown in the figure). An exhaust pipe 1 is opened on the top of the tower to discharge the heated and humidified high-pressure air. The upper part of the tower body 9 and below the exhaust pipe 1 is provided with a water inlet pipe 3, through which a liquid spraying device is connected, and the liquid spraying device is composed of a plurality of atomizing nozzles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com