Circulation mixer and application thereof

A technology of mixer and guide tube, applied in the direction of fluid mixer, mixer, chemical instrument and method, etc., can solve the problems of complex structure, complicated process flow, easy damage of shaft seal and bearing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The structure of the mixer

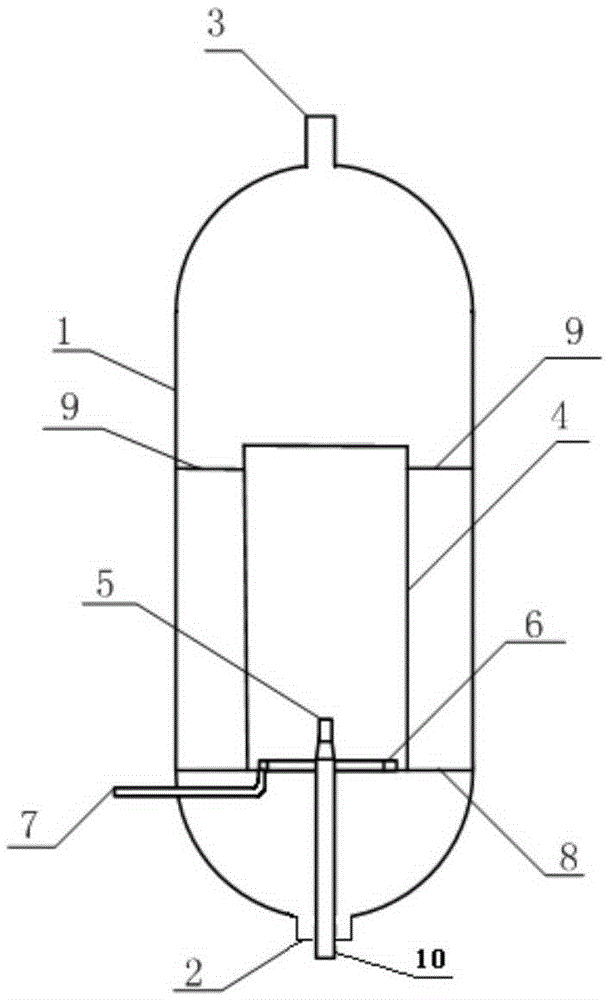

[0025] figure 1 The general structure of the loop mixer of the present invention is schematically shown.

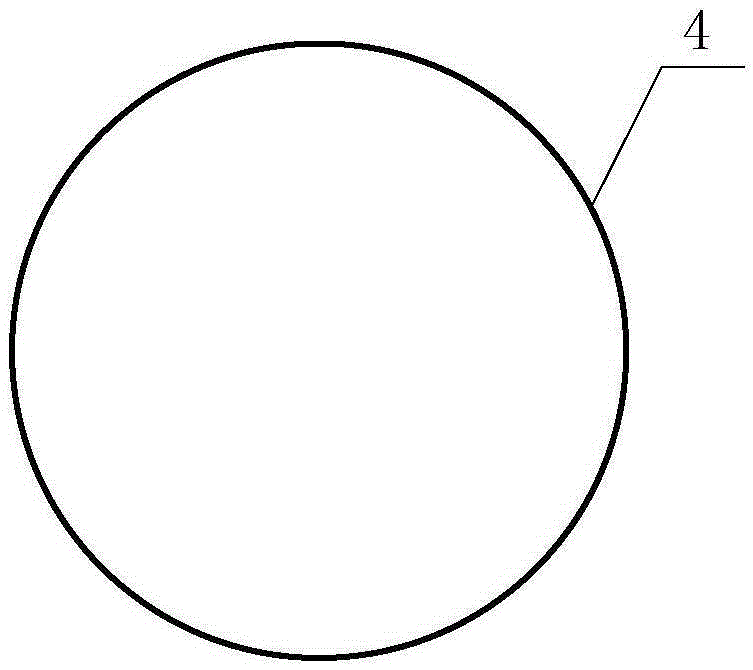

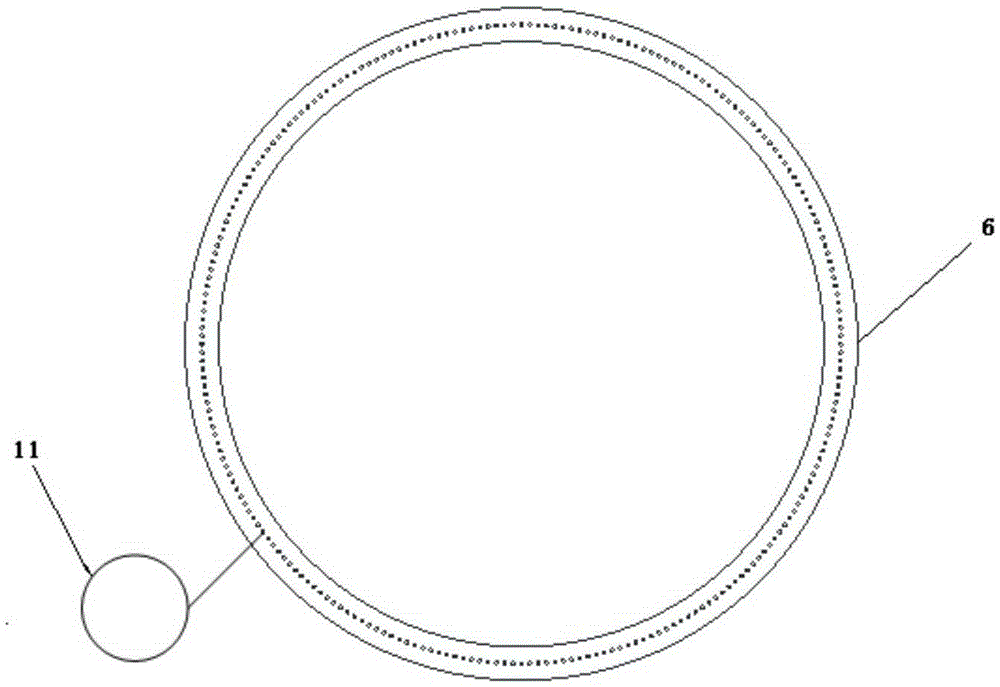

[0026] Above and below are defined in the description of the invention with the orientation of the annular mixer in the drawings. The circulating mixer includes a tank body 1, a first opening 2 at the lower part of the tank body 1 and a second opening 3 at the upper part, and a guide cylinder 4 suspended and fixed in the tank body 1, wherein the guide cylinder 4 is free from the upper and lower parts. Cylindrical structure of the lid. The interior of the tank body 1 also includes a gas distributor 6 fixed under the guide tube 4. For example, the gas distributor 6 can be fixed inside the tank body 1 through a bracket 8; The first delivery pipe 10 of the nozzle 5 leads from the lower end of the tank body 1 to the interior of the tank body 1 , that is to say, the first delivery pipe 10 can pass through the first opening 2 and its two en...

Embodiment 2

[0033] Utilize the mixer of the present invention to prepare acetic acid, the schematic flow diagram is shown in Figure 5. The material flow rate of 2316g / h of methanol and 2311g / h of CO is continuously fed into the 5L zirconium material tank 1, and will contain 200wtppm of Rh, 1500wtppm of Ir, 1500wtppm of Ru, 9wt% Methyl iodide, the water of 5.5 % by weight, the methyl acetate of 12 % by weight, all the other are the reaction solution of 528g of acetic acid (the volume of the reaction solution is 4L) and pass into the tank 1 and carry out carbonylation reaction, and the temperature of reaction is 195 ℃ °C, and the reaction pressure was 2.8 MPa. The mixture obtained after the reaction is sent to a flash tower through a pipeline connected to the first opening 2 for flash distillation, and a gas phase component containing acetic acid and an acetic acid solution containing Rh, Ir and Ru are obtained in the flash tower. The acetic acid solution containing Rh, Ir and Ru in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com