Patents

Literature

1339results about "Chemical/physical/physico-chemical nozzle-type rreactors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

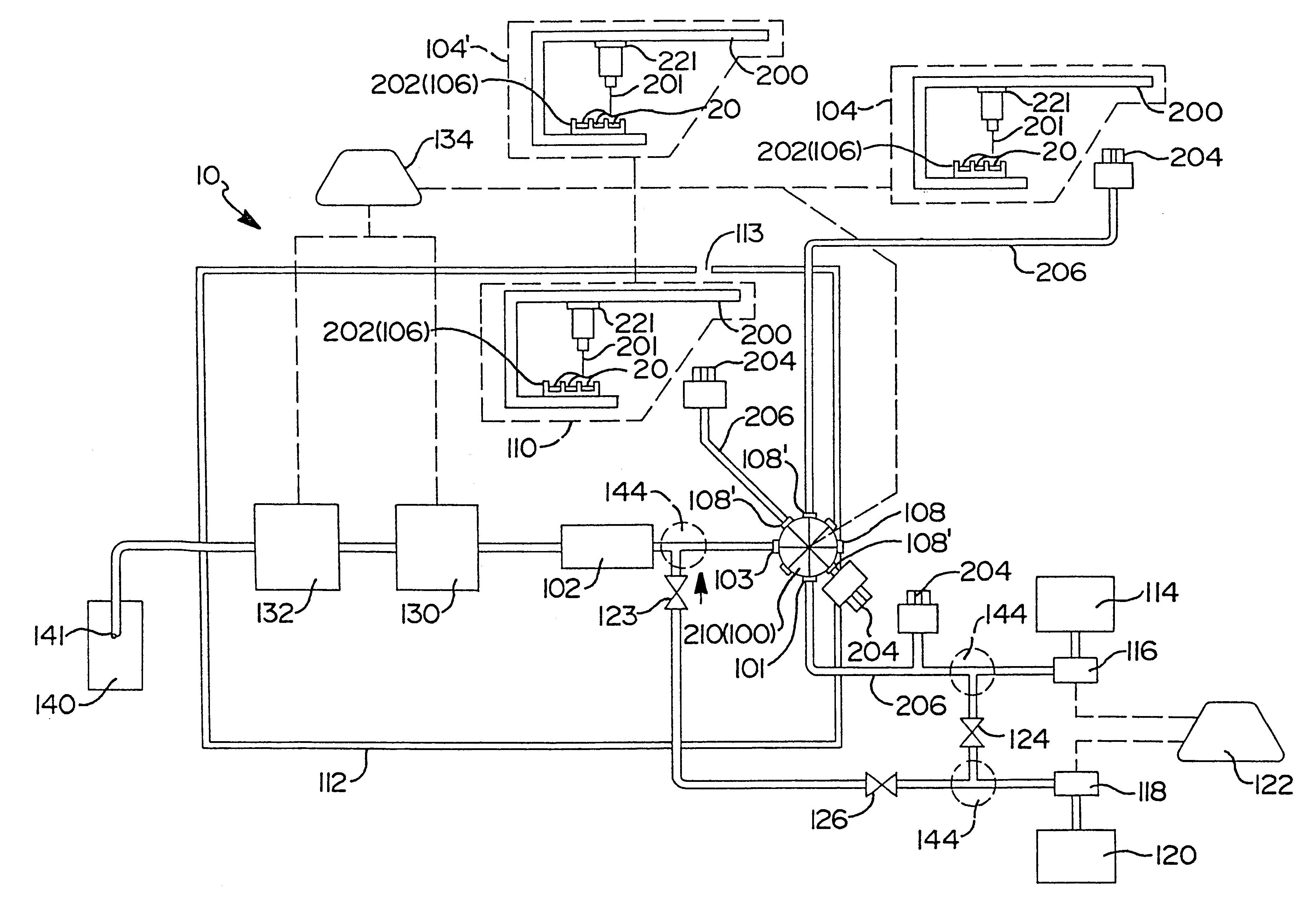

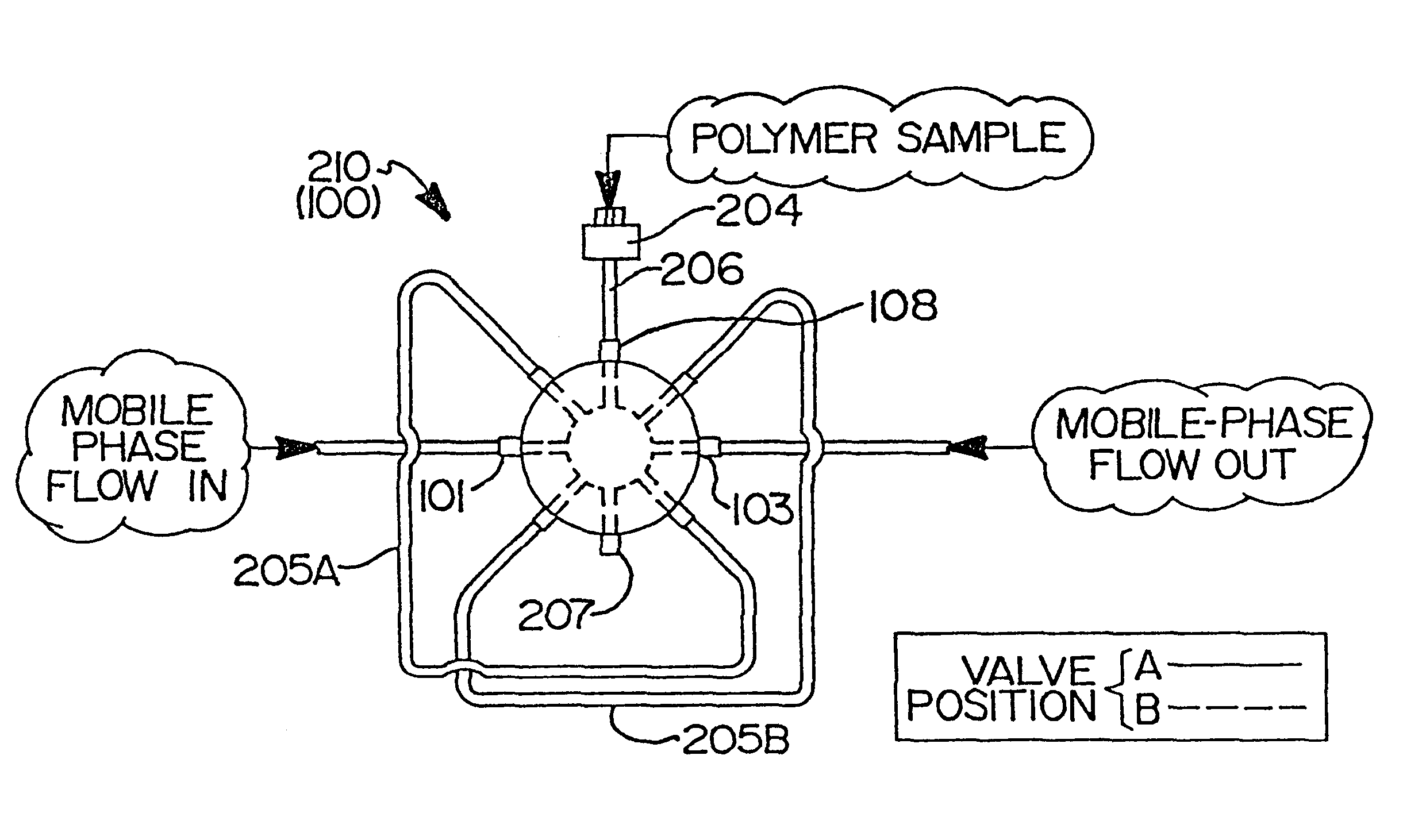

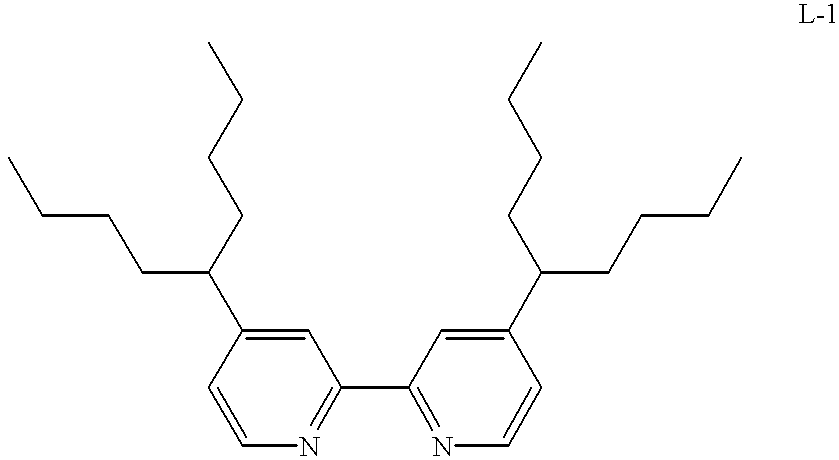

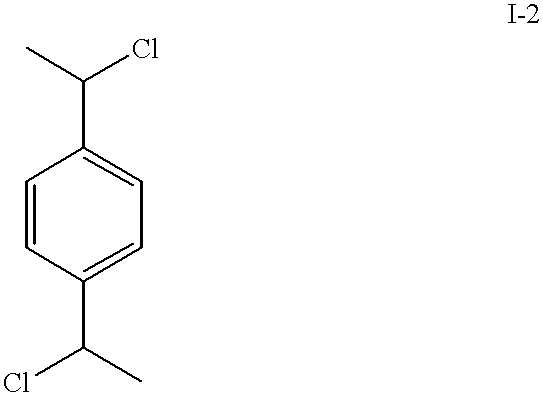

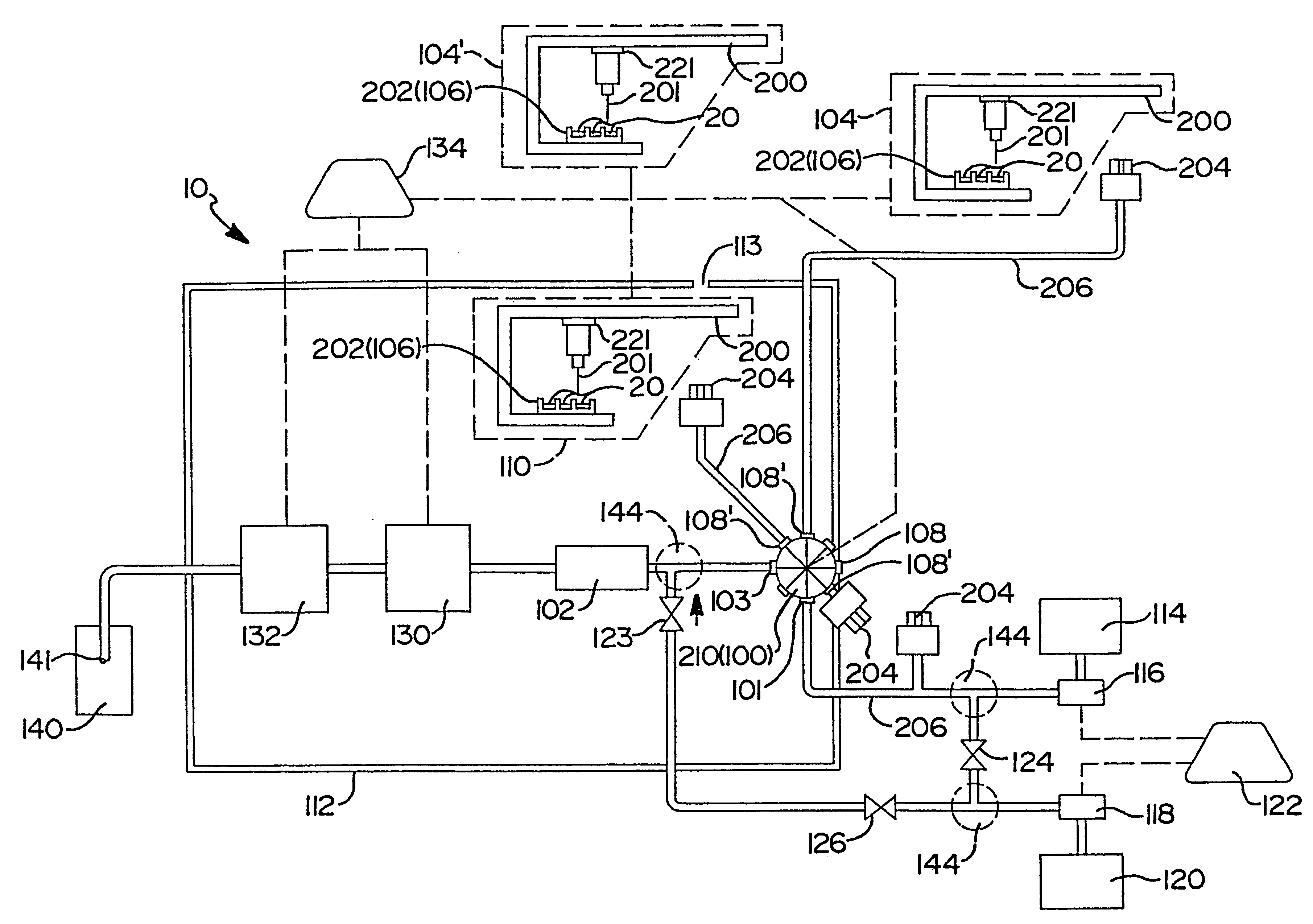

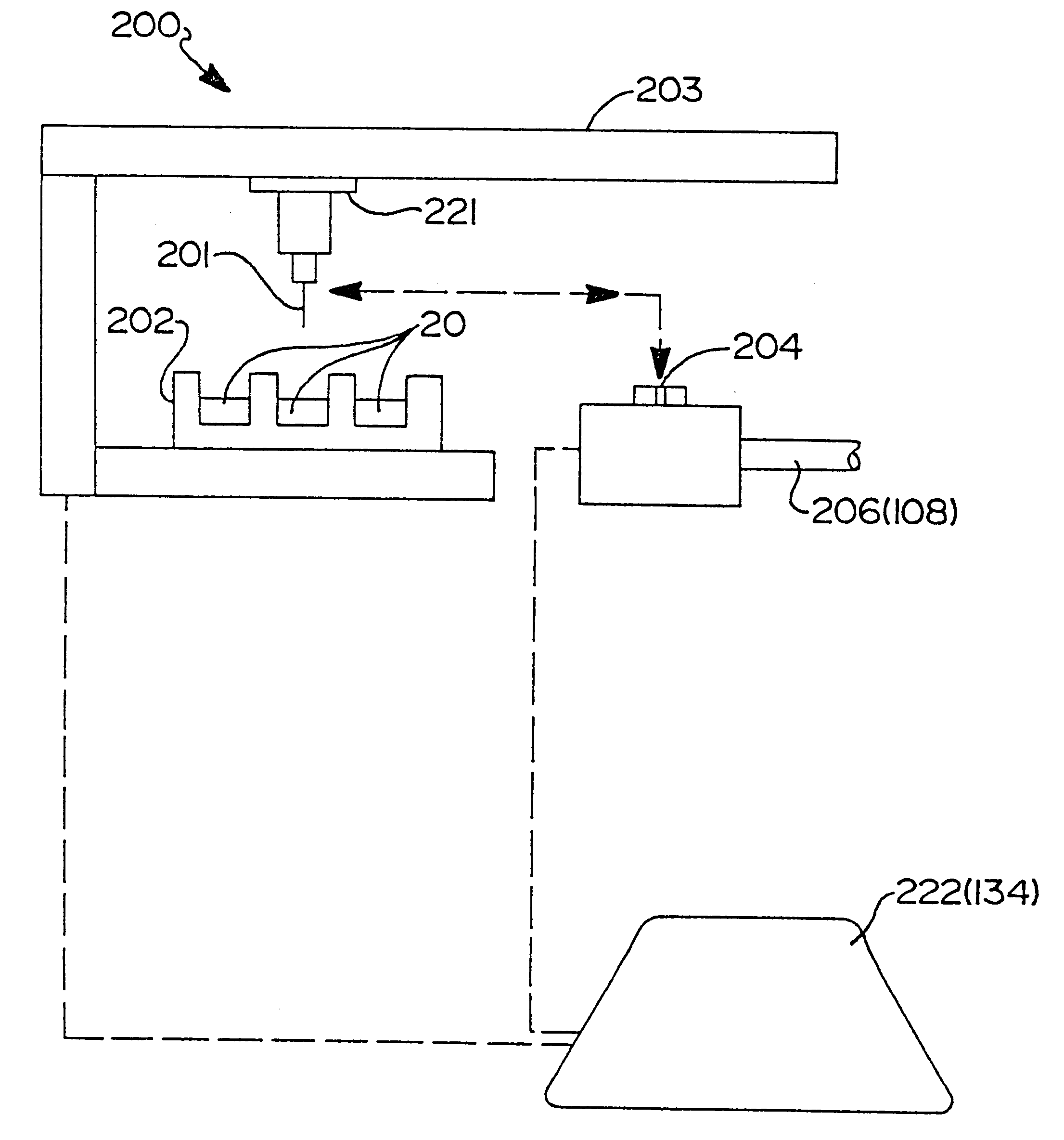

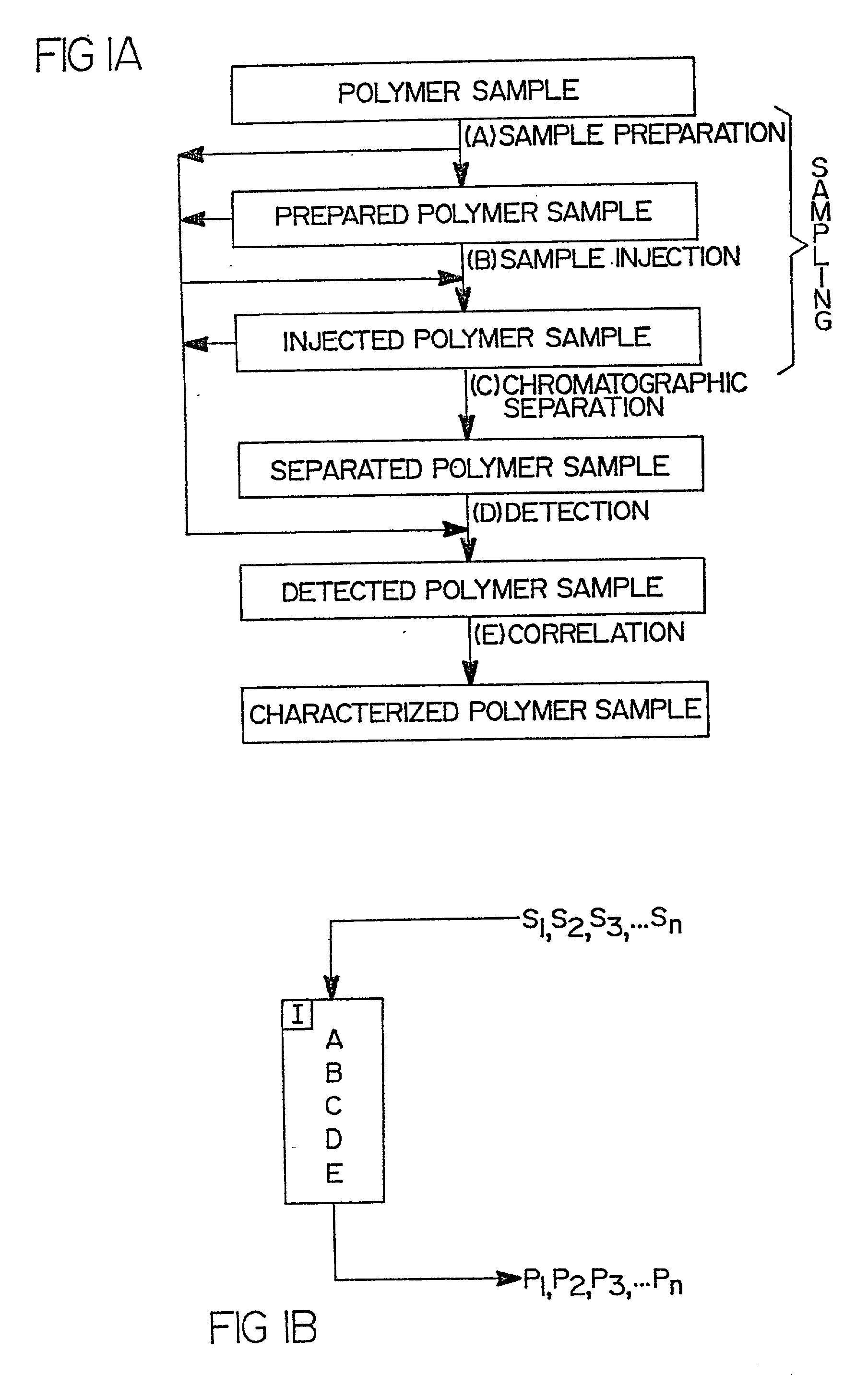

Flow-injection analysis and variable-flow light-scattering methods and apparatus for characterizing polymers

InactiveUS6175409B1Avoid backlogImprove throughputSequential/parallel process reactionsSamplingFlow injection analysisPolymer

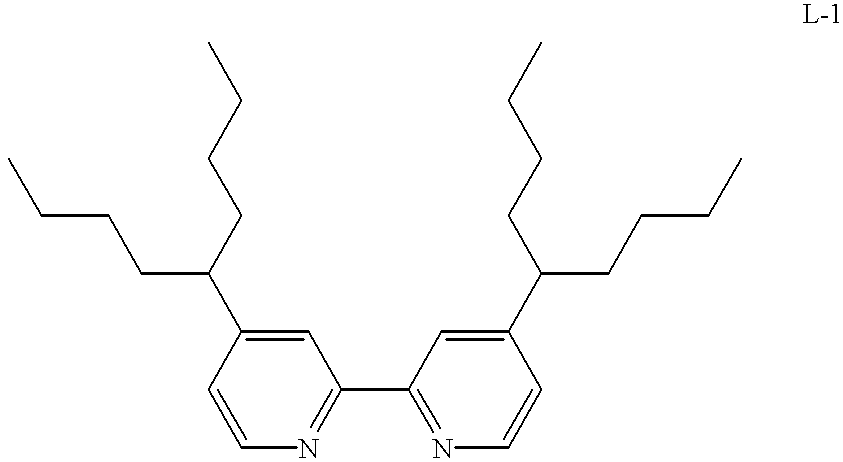

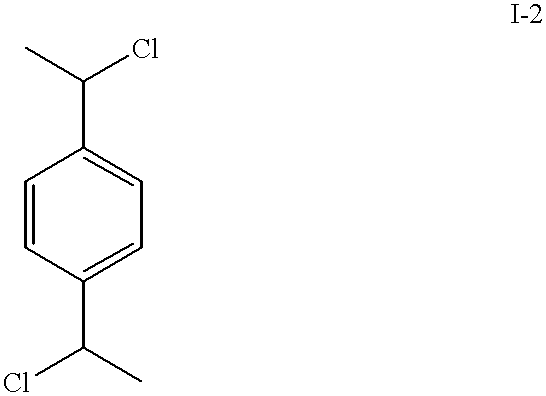

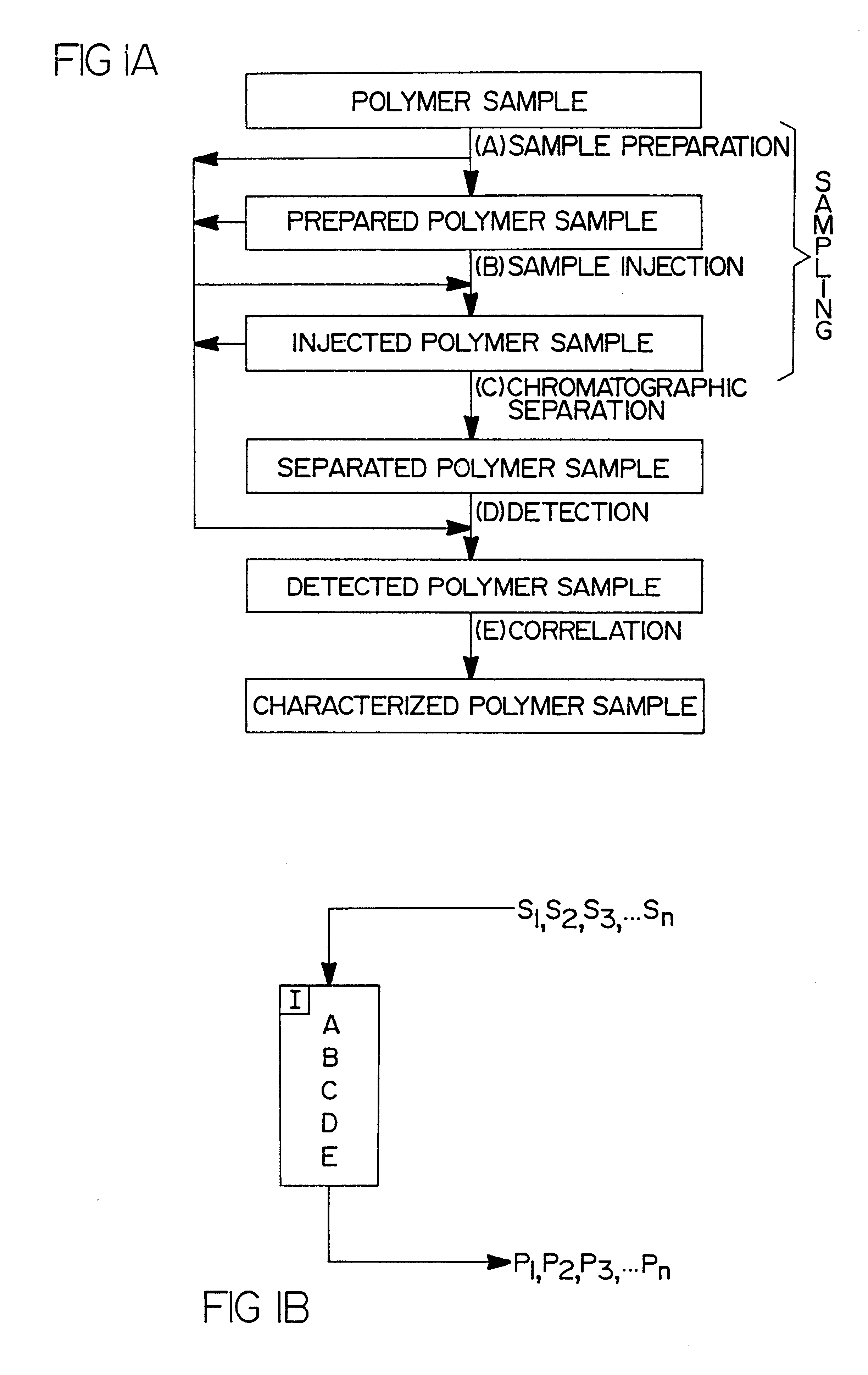

Rapid characterization and screening of polymer samples to determine average molecular weight, molecular weight distribution and other properties is disclosed. Rapid flow characterization systems and methods, including liquid chromatography and flow-injection analysis systems and methods are preferably employed. High throughput, automated sampling systems and methods, high-temperature characterization systems and methods, and rapid, indirect calibration compositions and methods are also disclosed. The described methods, systems, and devices have primary applications in combinatorial polymer research and in industrial process control.

Owner:INTERMOLECULAR

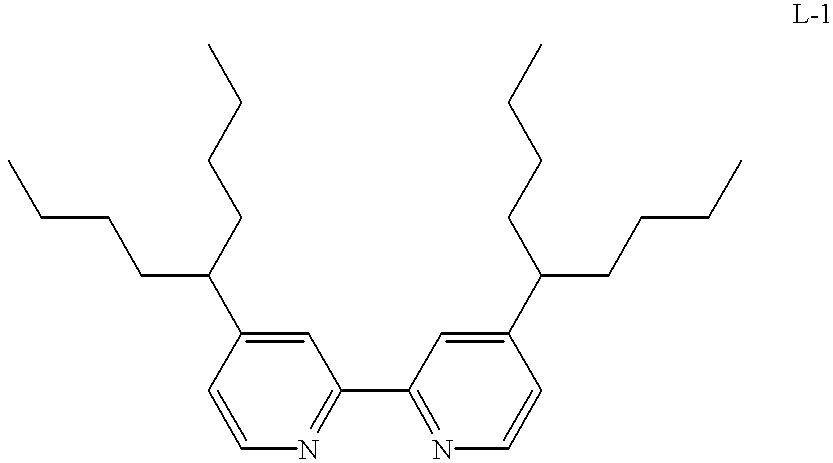

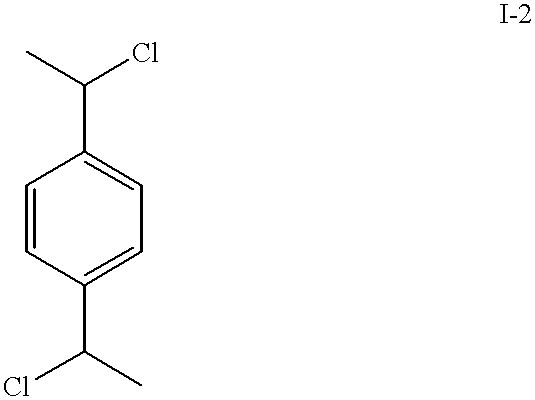

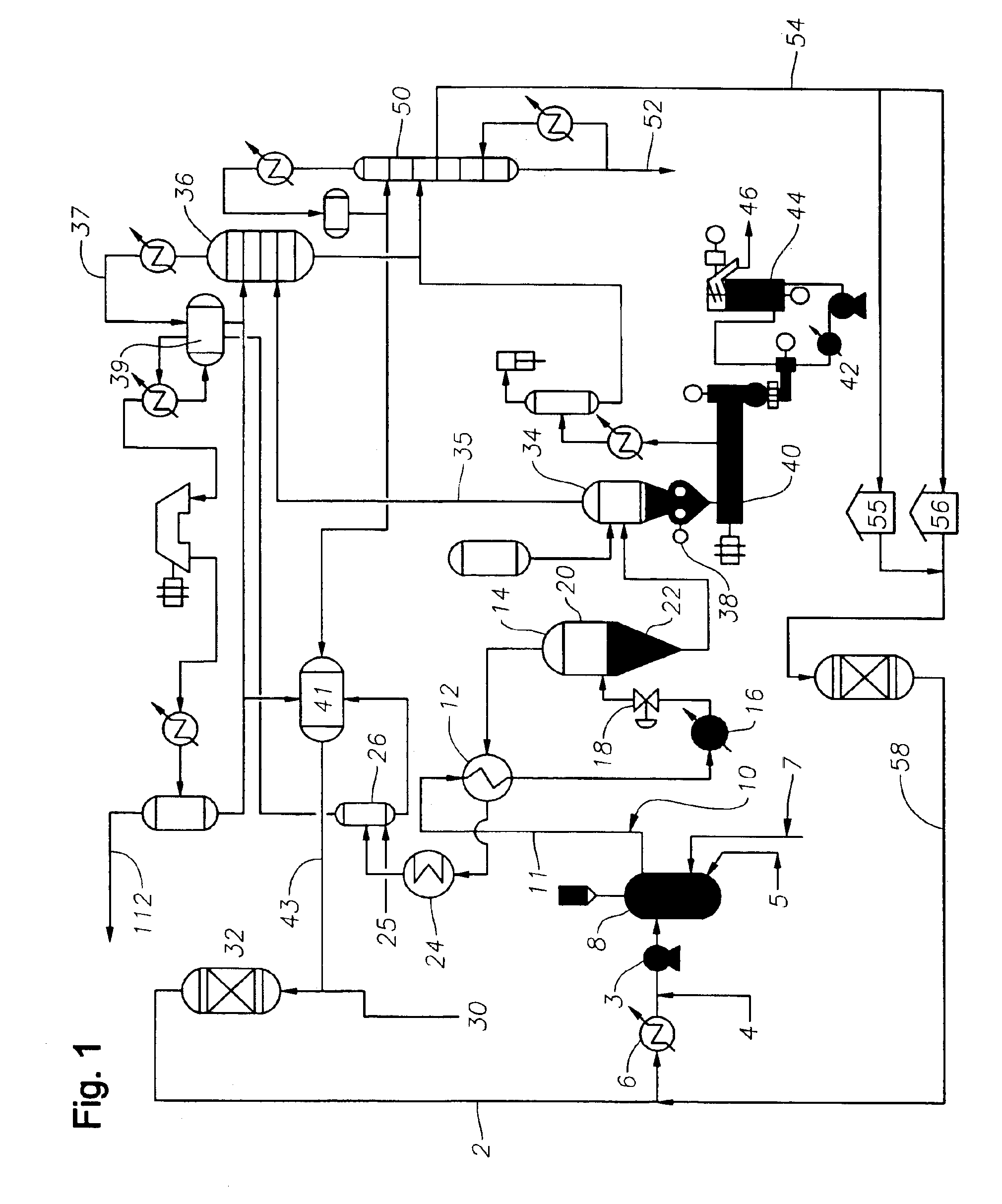

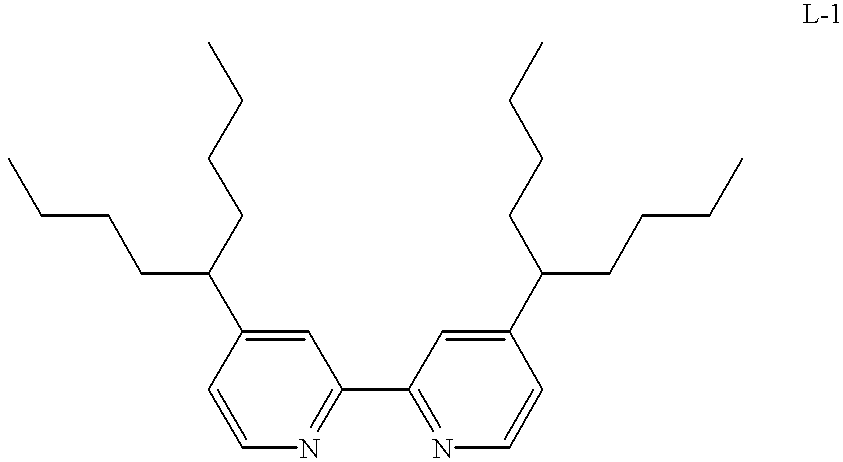

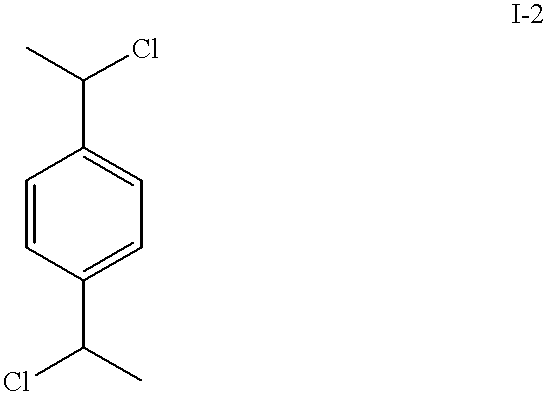

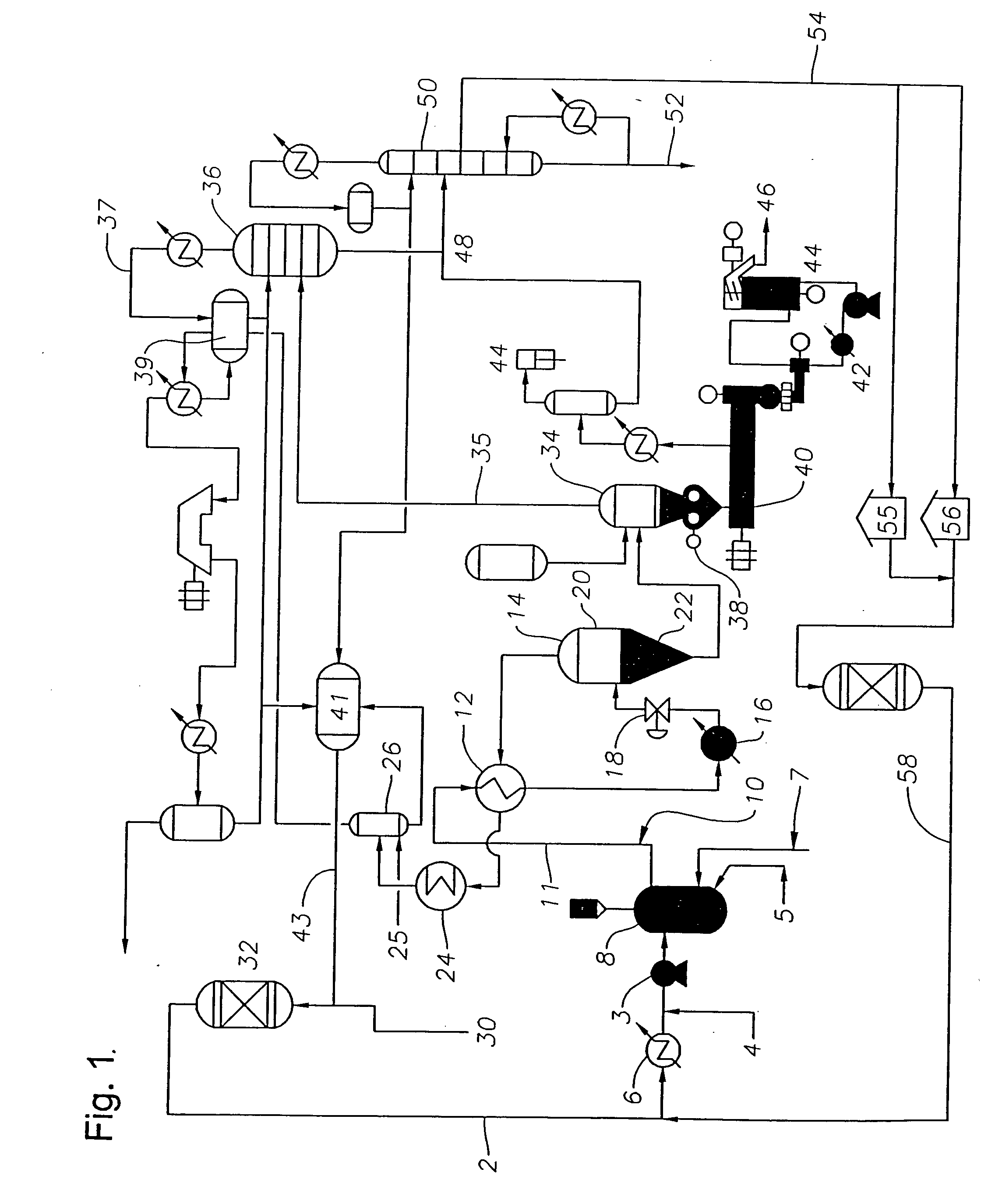

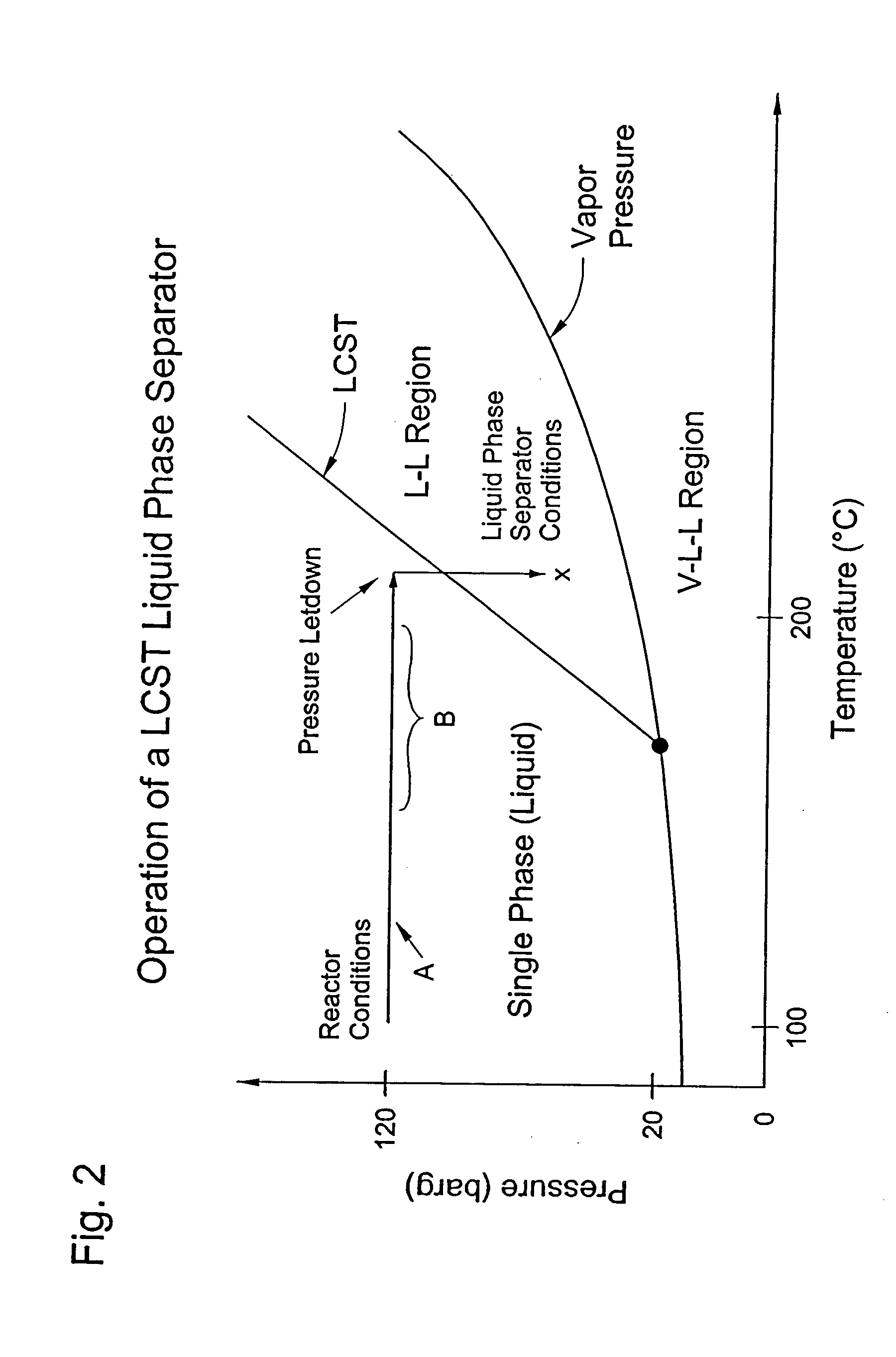

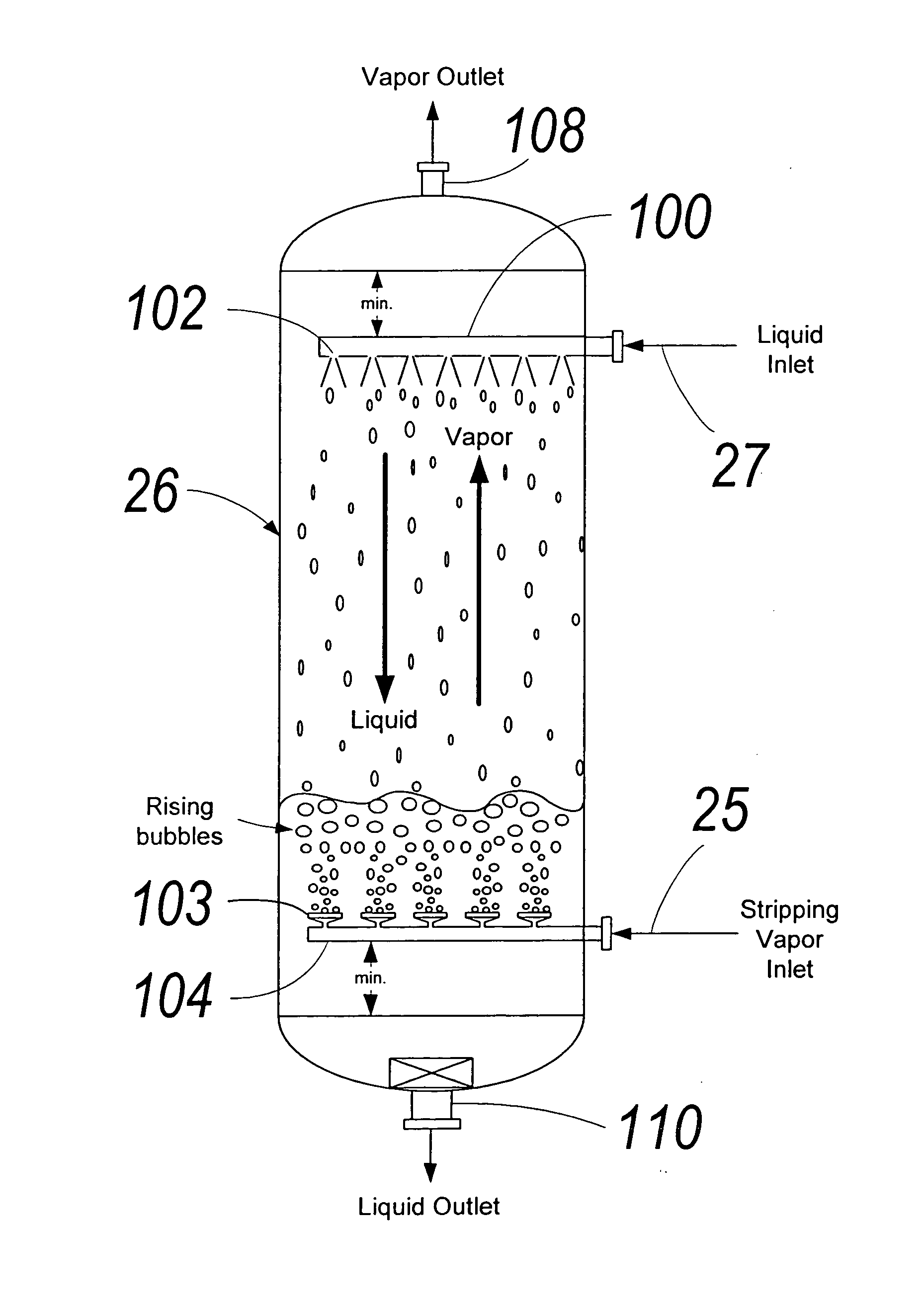

Processes and apparatus for continuous solution polymerization

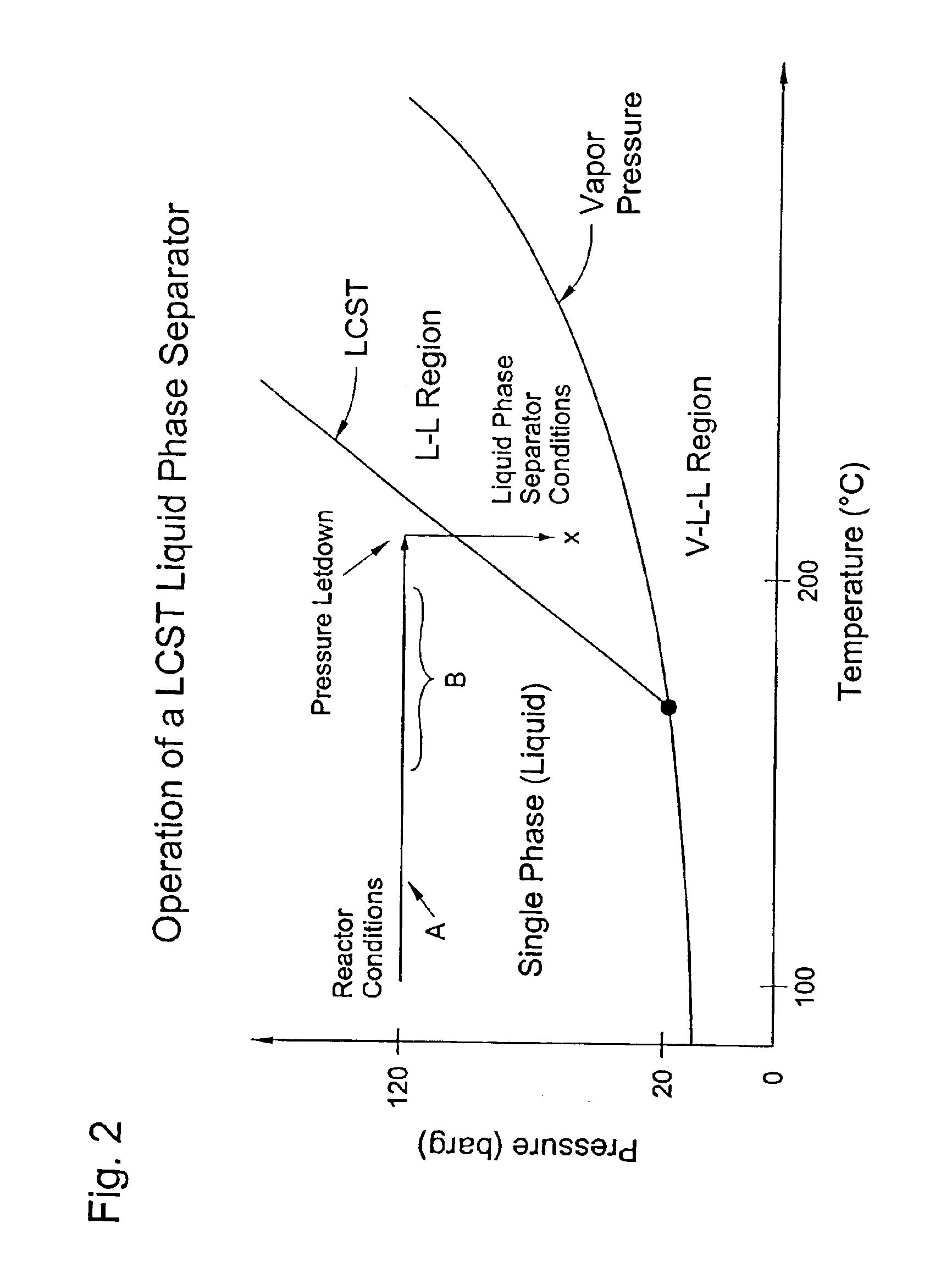

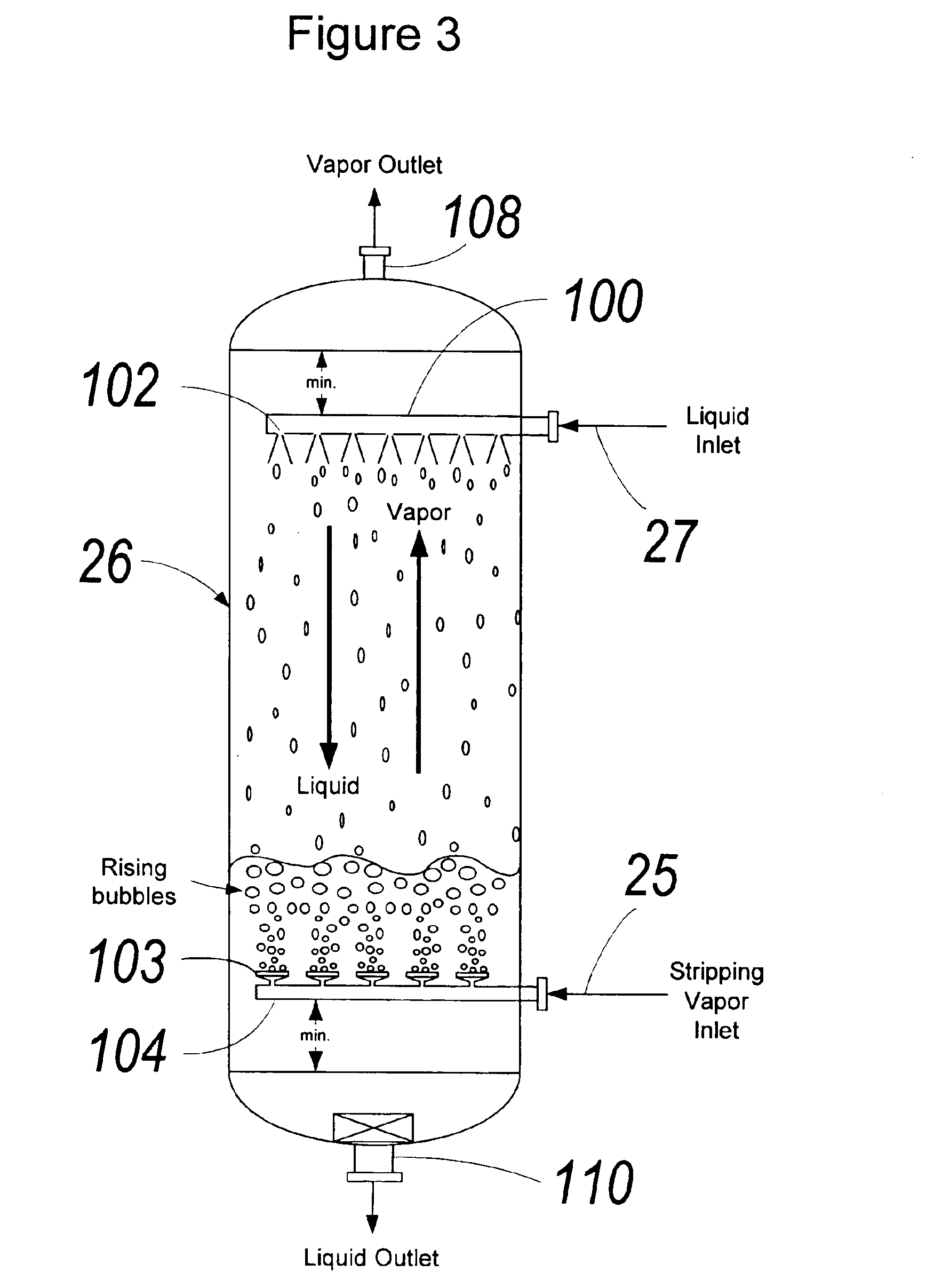

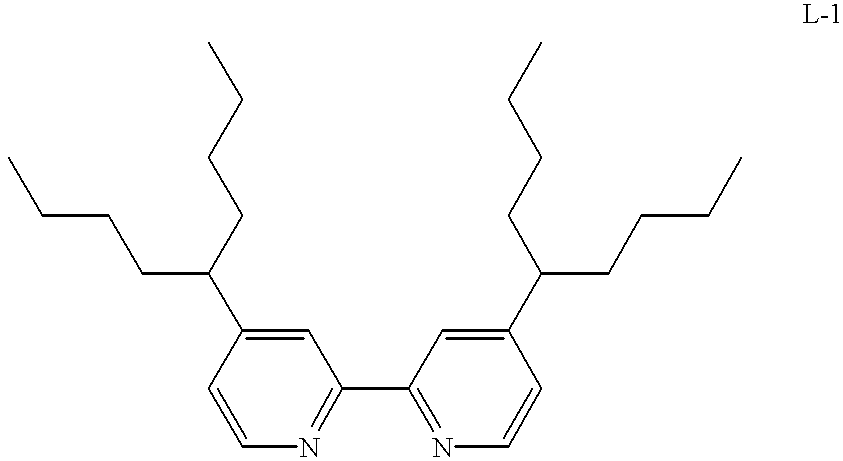

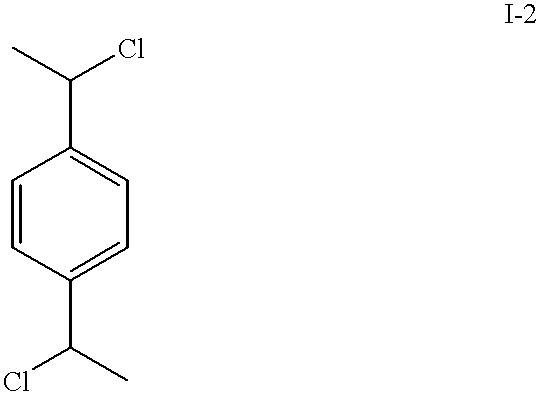

InactiveUS6881800B2Process control/regulationLiquid-gas reaction as foam/aerosol/bubblesSolution polymerizationProcess plant

The invention relates to processes and plants for continuous solution polymerization. Such plant and processes include a pressure source, a polymerization reactor, downstream of said pressure source, pressure let-down device, downstream of said polymerization reactor, and a separator, downstream of said pressure let-down device, wherein said pressure source is sufficient to provide pressure to said reaction mixture during operation of said process plant to produce a single-phase liquid reaction mixture in said reactor and a two-phase liquid-liquid reaction mixture in said separator in the absence of an additional pressure source between said reactor and said separator.

Owner:EXXONMOBIL CHEM PAT INC

High-temperature characterization of polymers

InactiveUS6260407B1Avoid backlogImprove throughputSequential/parallel process reactionsComponent separationElutionChromatography column

Rapid characterization and screening of polymer samples to determine average molecular weight, molecular weight distribution and other properties is disclosed. Rapid flow characterization systems and methods, including liquid chromatography and flow-injection analysis systems and methods are preferably employed. High throughput, automated sampling systems and methods, high-temperature characterization systems and methods, and rapid, indirect calibration compositions and methods are also disclosed. In preferred high-temperature embodiments, the polymer sample is maintained at a temperature of not less than about 75° C. during sample preparation, loading into a liquid chromatography or flow-injection analysis system, injection into a mobile phase of a liquid chromatography or flow-injection analysis system, and / or elution from chromatographic column. The described methods, systems, and device have primary applications in combinatorial polymer research and in industrial process control.

Owner:INTERMOLECULAR

Rapid characterization of polymers

InactiveUS6406632B1More separatedHigh sample throughputSequential/parallel process reactionsSamplingFluid phasePhysical chemistry

Rapid characterization and screening of polymer samples to determine average molecular weight, molecular weight distribution and other properties is disclosed. Rapid flow characterization systems and methods, including liquid chromatography and flow-injection analysis systems and methods are preferably employed. High throughput, automated sampling systems and methods, high-temperature characterization systems and methods, and rapid, indirect calibration compositions and methods are also disclosed. The described methods, systems, and devices have primary applications in combinatorial polymer research and in industrial process control.

Owner:INTERMOLECULAR

Indirect calibration of polymer characterization systems

InactiveUS6294388B1Avoid backlogImprove throughputIon-exchange process apparatusSamplingPolymer characterizationFlow injection analysis

Rapid characterization and screening of polymer samples to determine average molecular weight, molecular weight distribution and other properties is disclosed. Rapid flow characterization systems and methods, including liquid chromatography and flow-injection analysis systems and methods are preferably employed. High throughput, automated sampling systems and methods, high-temperature characterization systems and methods, and rapid, indirect calibration compositions and methods are also disclosed. The described methods, systems, and devices have primary applications in combinatorial polymer research and in industrial process control.

Owner:INTERMOLECULAR

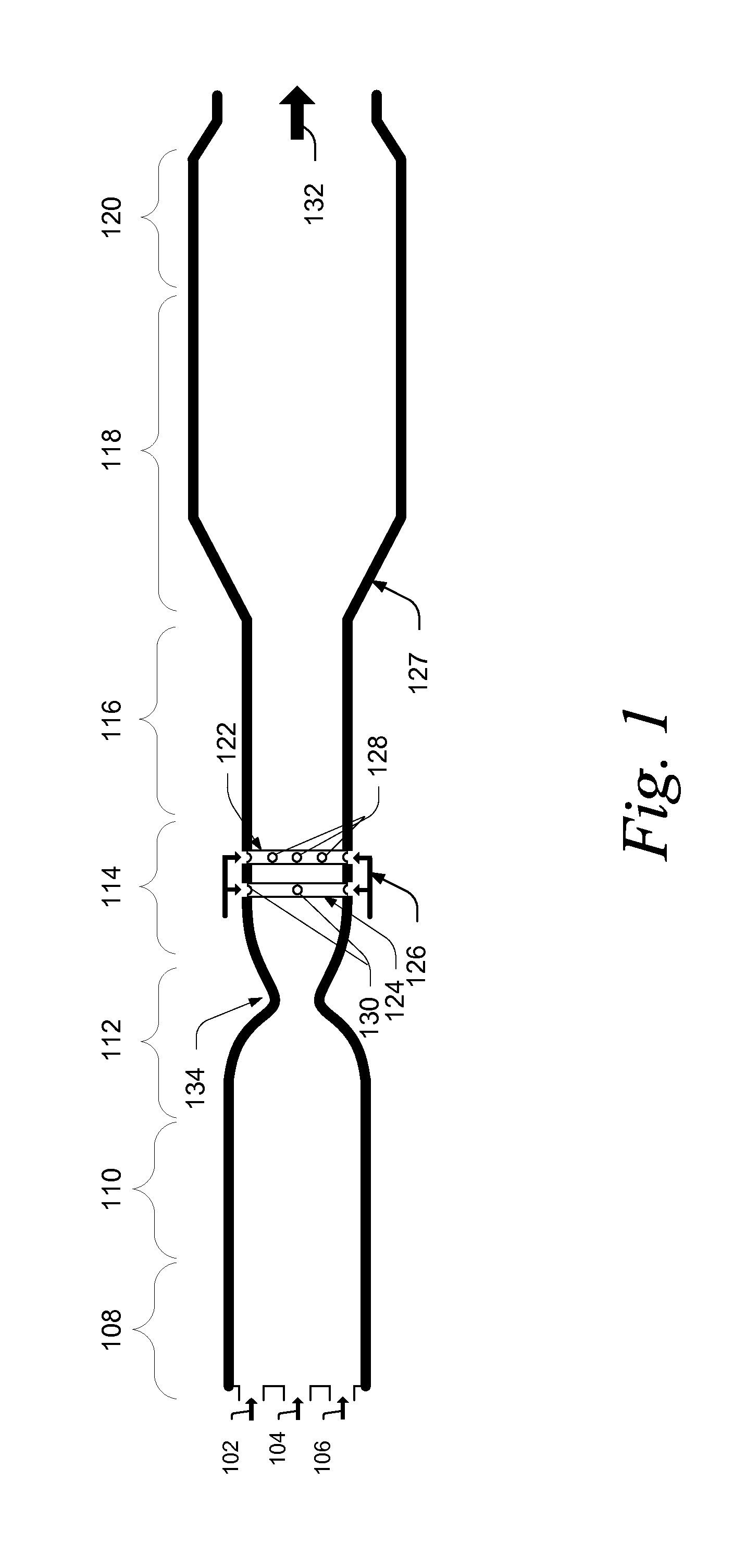

Pyrolytic reactor

A pyrolytic reactor comprising a fuel injection zone, a combustion zone adjacent to the fuel injections zone, an expansion zone adjacent to the combustion zone, a feedstock injection zone comprising a plurality of injection nozzles and disposed adjacent to the expansion zone, a mixing zone configured to mix a carrier stream and feed material and disposed adjacent to the feedstock injection zone, and a reaction zone adjacent to the mixing zone. The plurality of injection nozzles are radially distributed in a first assembly defining a first plane transverse to the feedstock injection zone and in a second assembly transverse to the feedstock injection zone.

Owner:UOP LLC

Process for producing single wall nanotubes using unsupported metal catalysts

InactiveUS6221330B1Continuous and efficient productionMaterial nanotechnologyFibre chemical featuresHydrogenGas phase

A process for producing hollow, single-walled carbon nanotubes by catalytic decomposition of one or more gaseous carbon compounds by first forming a gas phase mixture carbon feed stock gas comprising one or more gaseous carbon compounds, each having one to six carbon atoms and only H, O, N, S or Cl as hetero atoms, optionally admixed with hydrogen, and a gas phase metal containing compound which is unstable under reaction conditions for said decomposition, and which forms a metal containing catalyst which acts as a decomposition catalyst under reaction conditions; and then conducting said decomposition reaction under decomposition reaction conditions, thereby producing said nanotubes.

Owner:HYPERION CATALYSIS INT

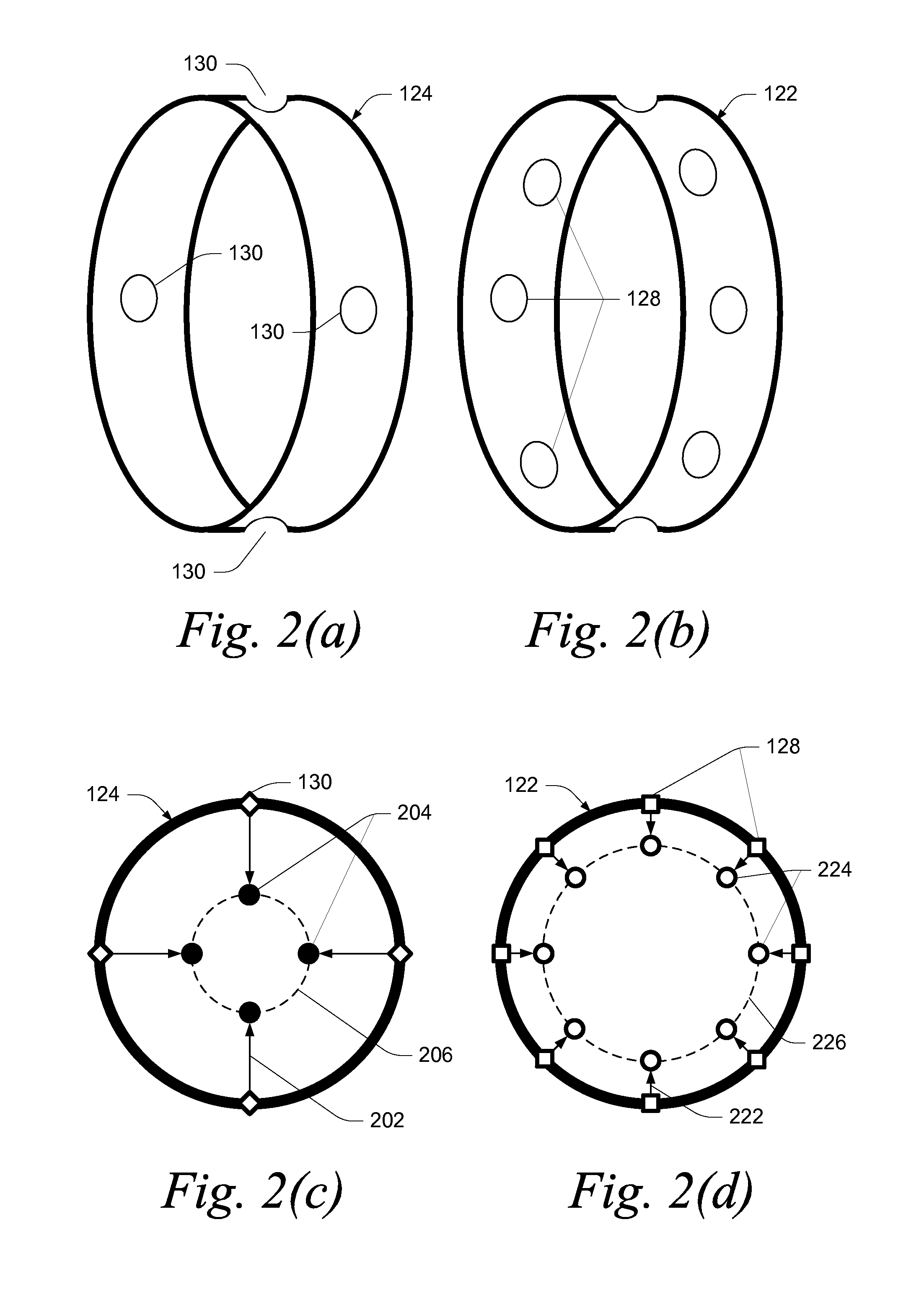

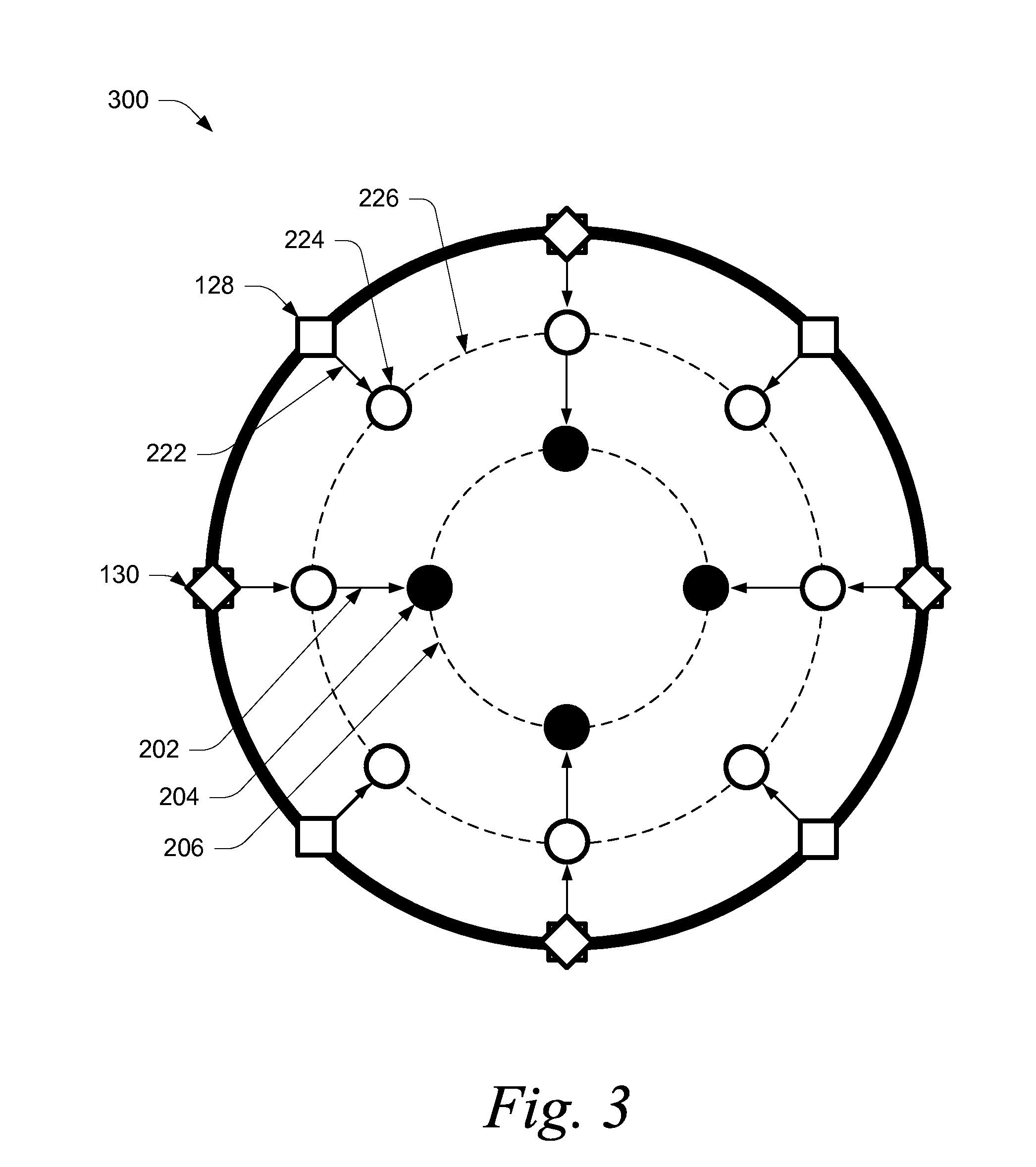

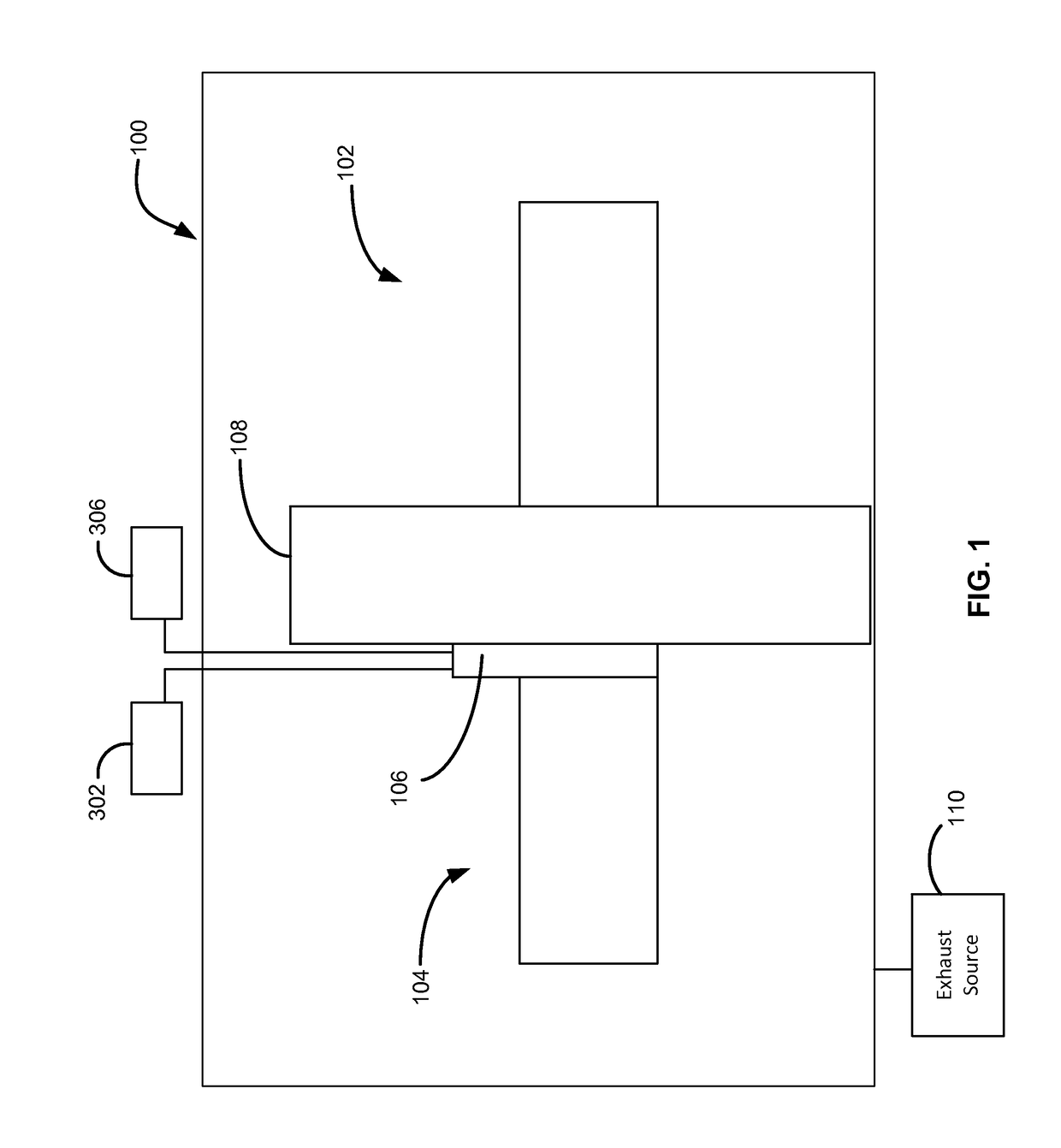

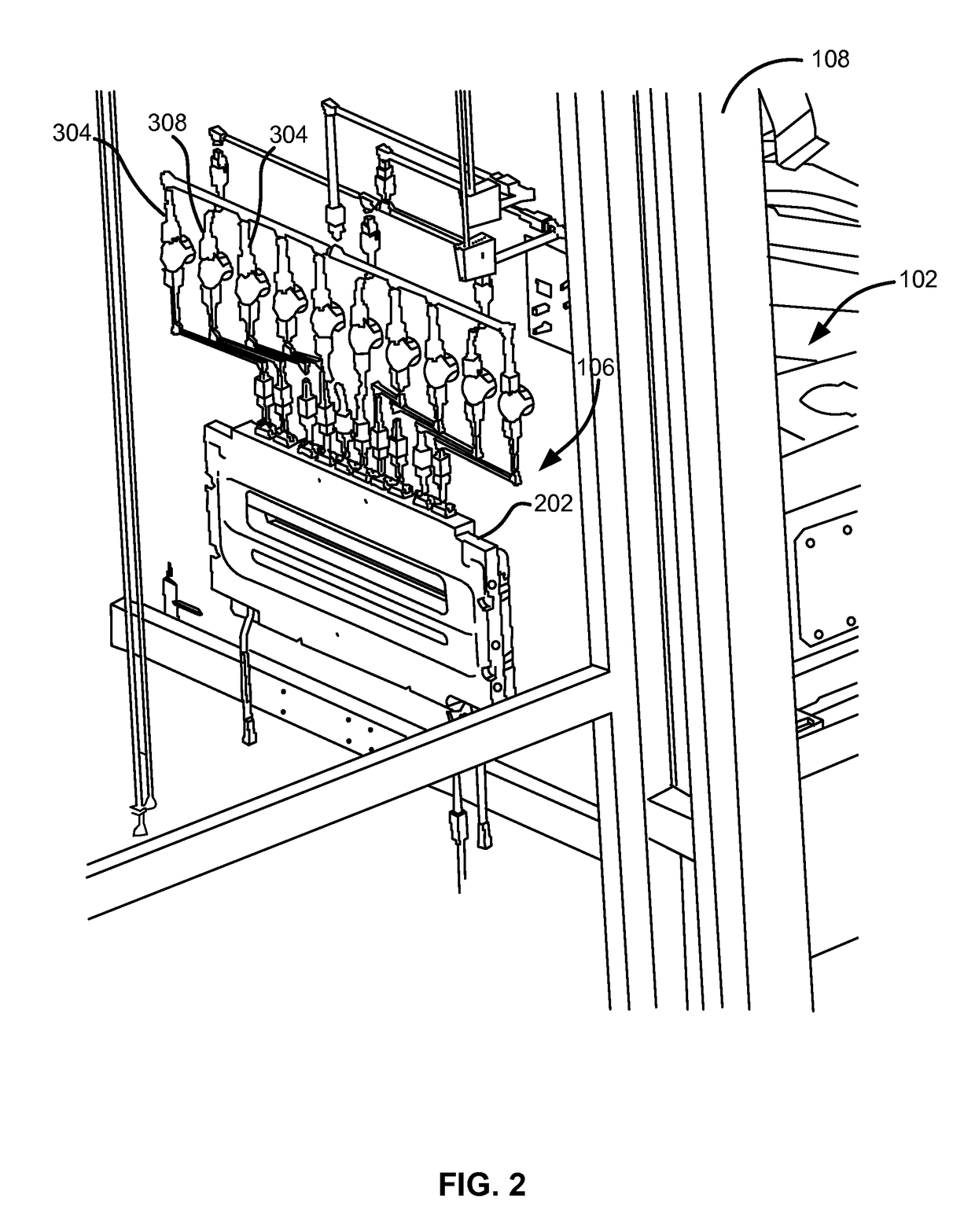

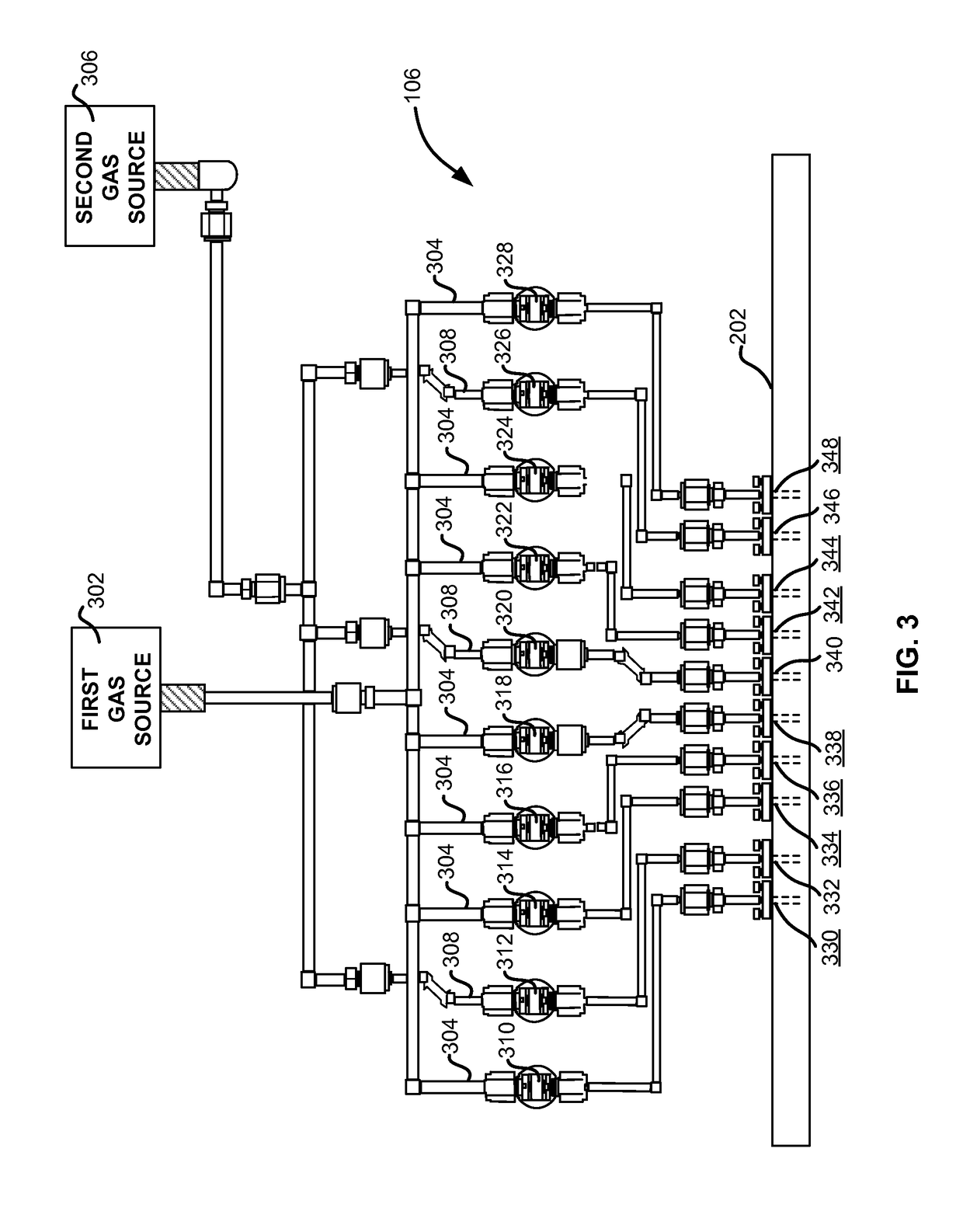

Gas distribution system, reactor including the system, and methods of using the same

ActiveUS10167557B2Facilitate localized mixingChemical/physical/physico-chemical nozzle-type rreactorsEnergy based chemical/physical/physico-chemical processesReactor systemGas phase

A gas distribution system, a reactor system including the gas distribution system, and method of using the gas distribution system and reactor system are disclosed. The gas distribution system can be used in gas-phase reactor systems to independently fine tune gas source locations and gas flow rates of reactants to a reaction chamber of the reactor systems.

Owner:ASM IP HLDG BV

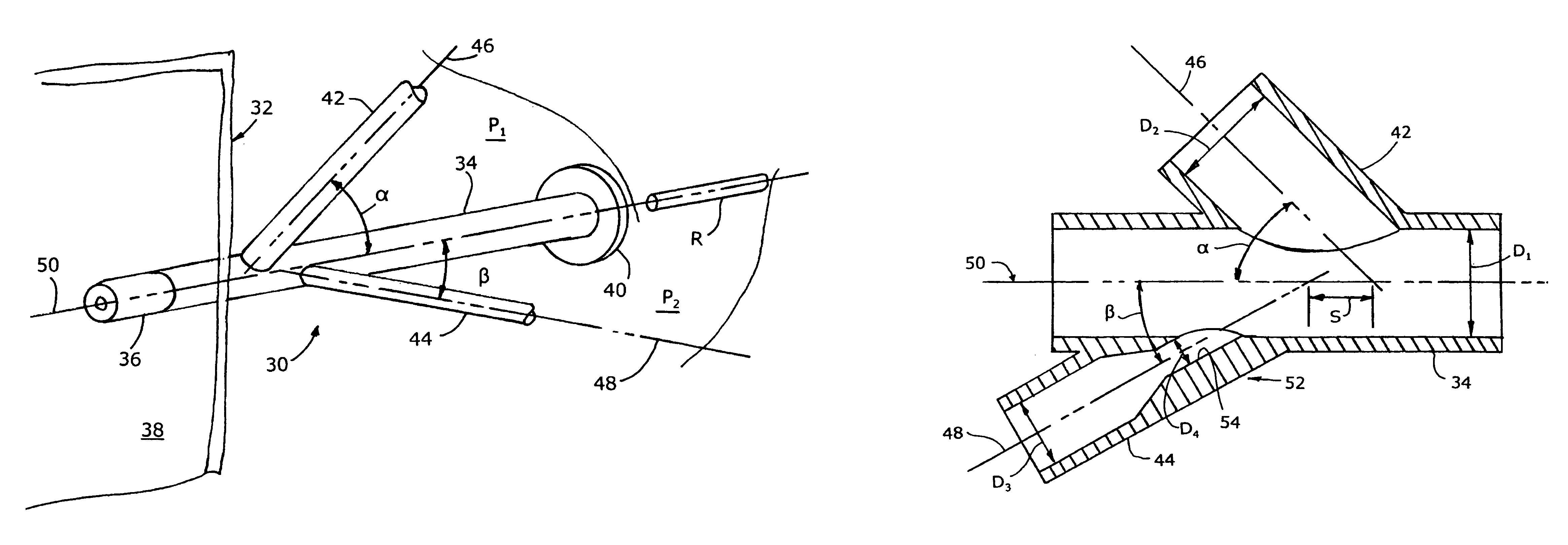

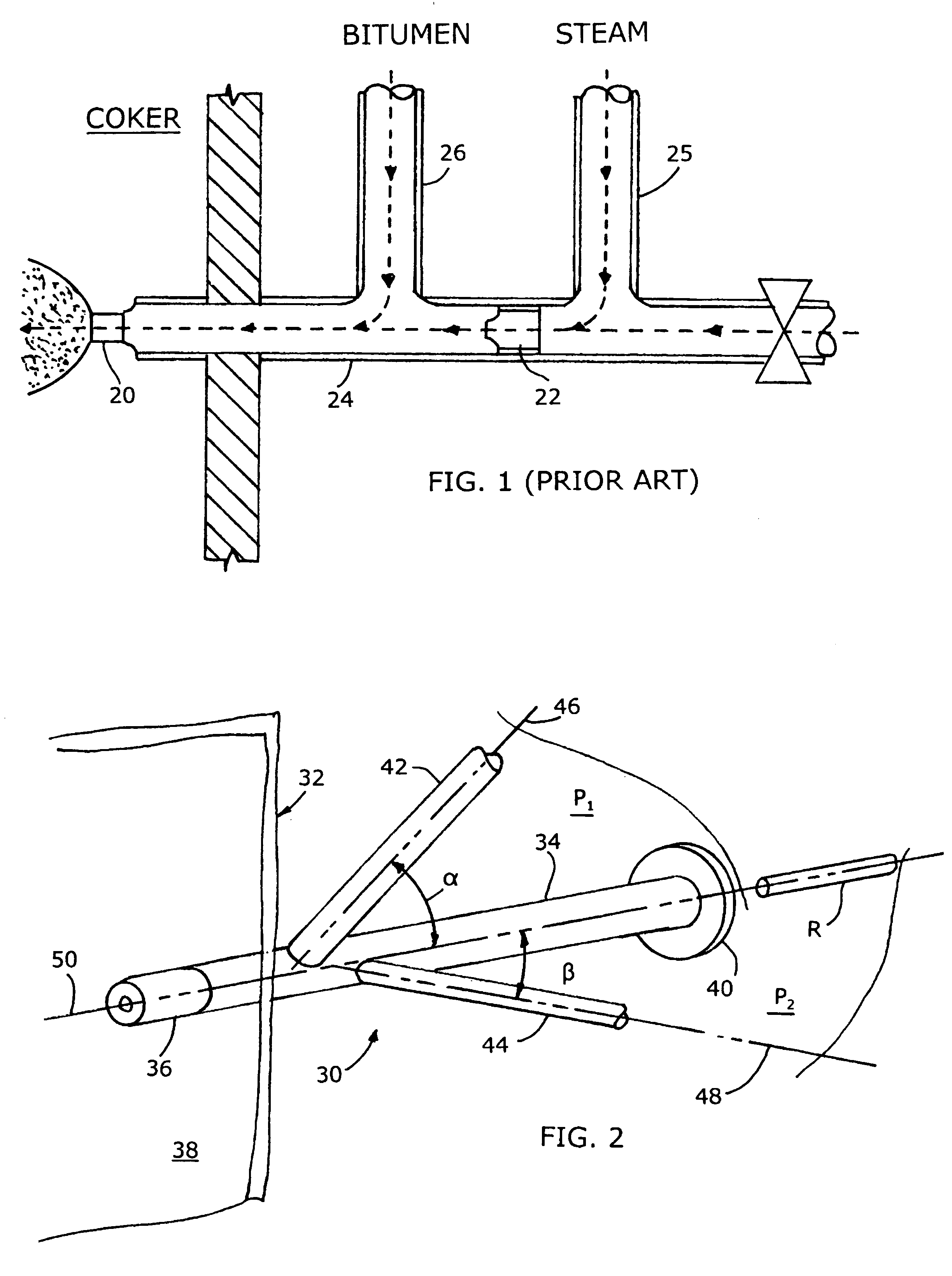

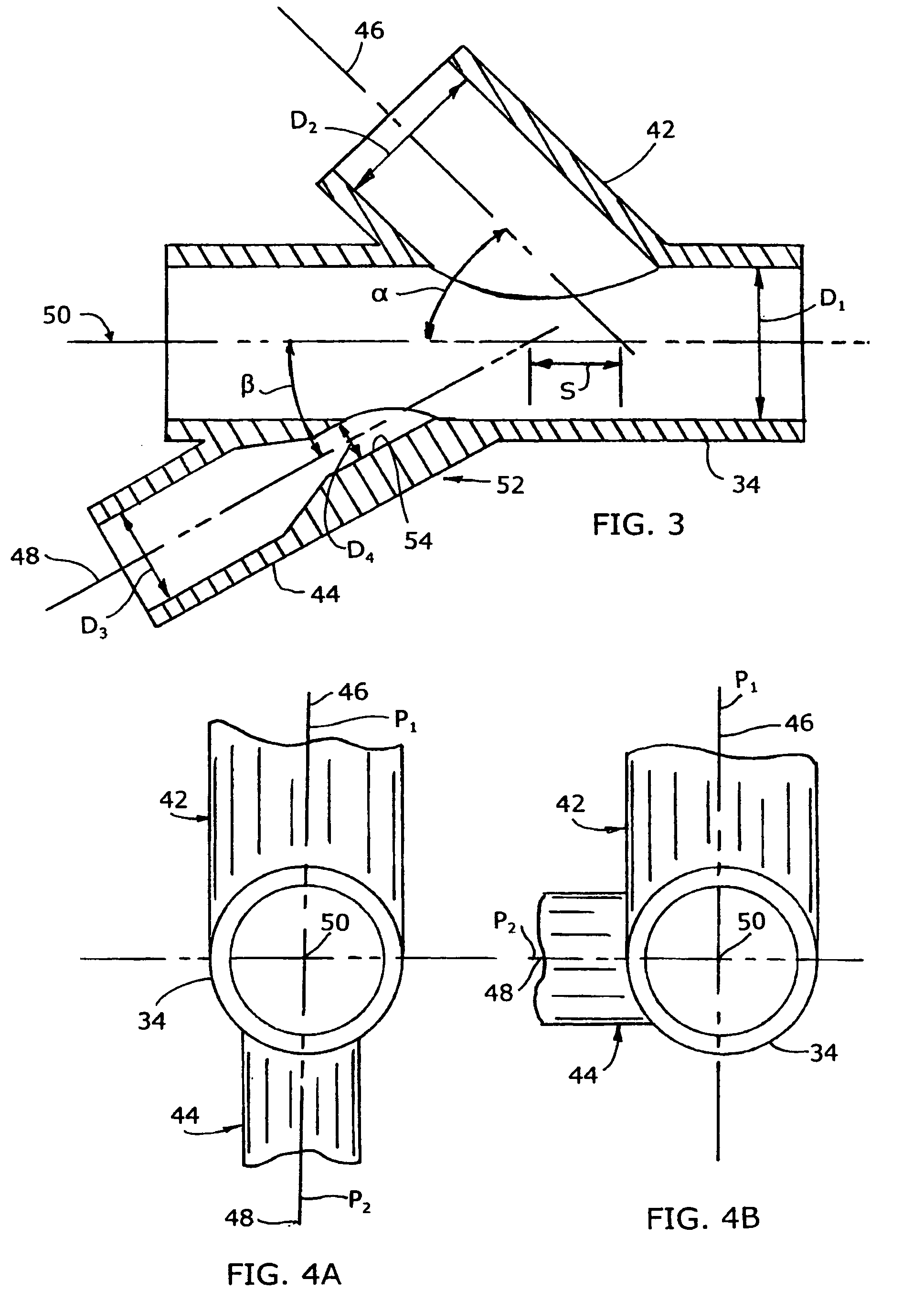

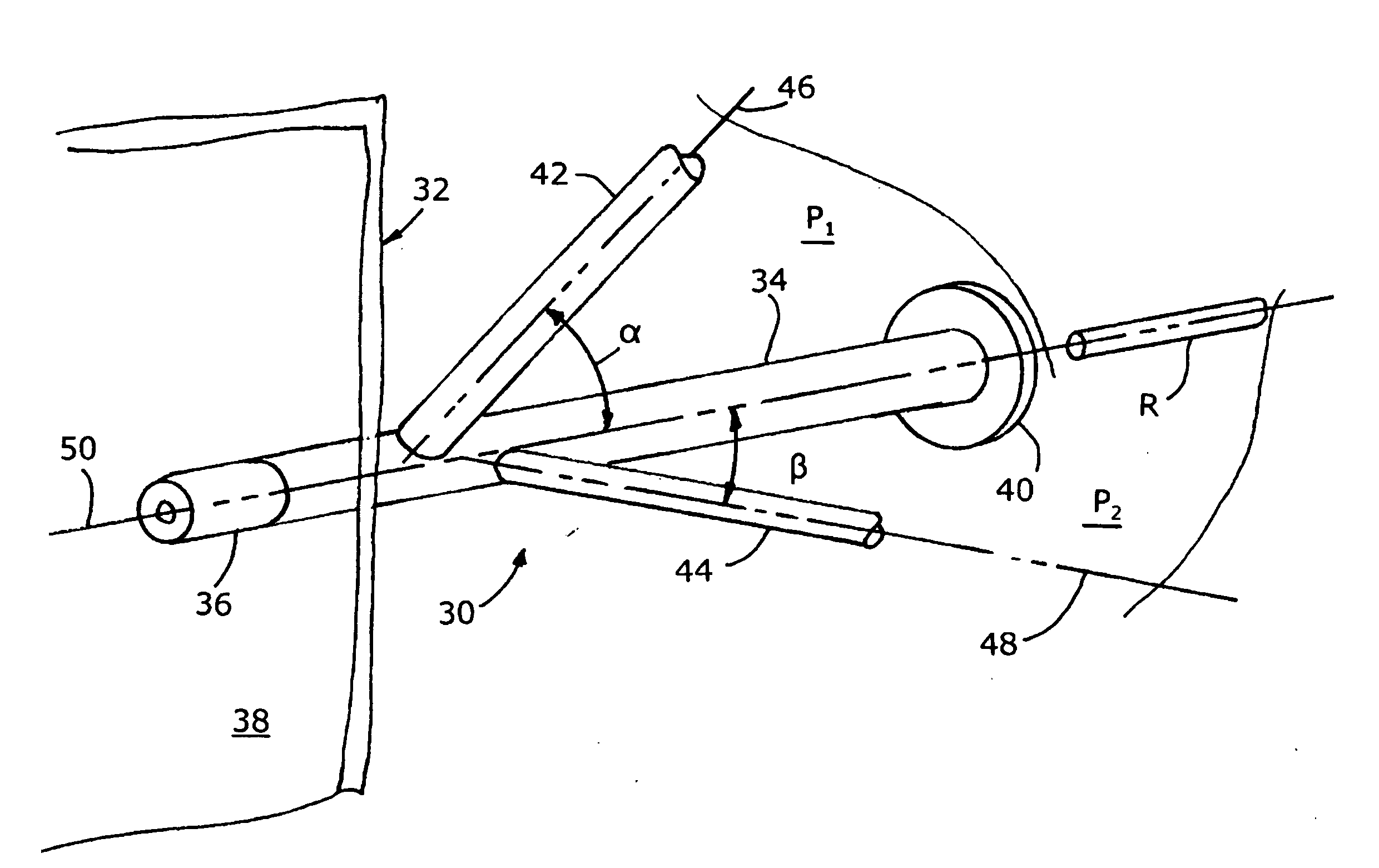

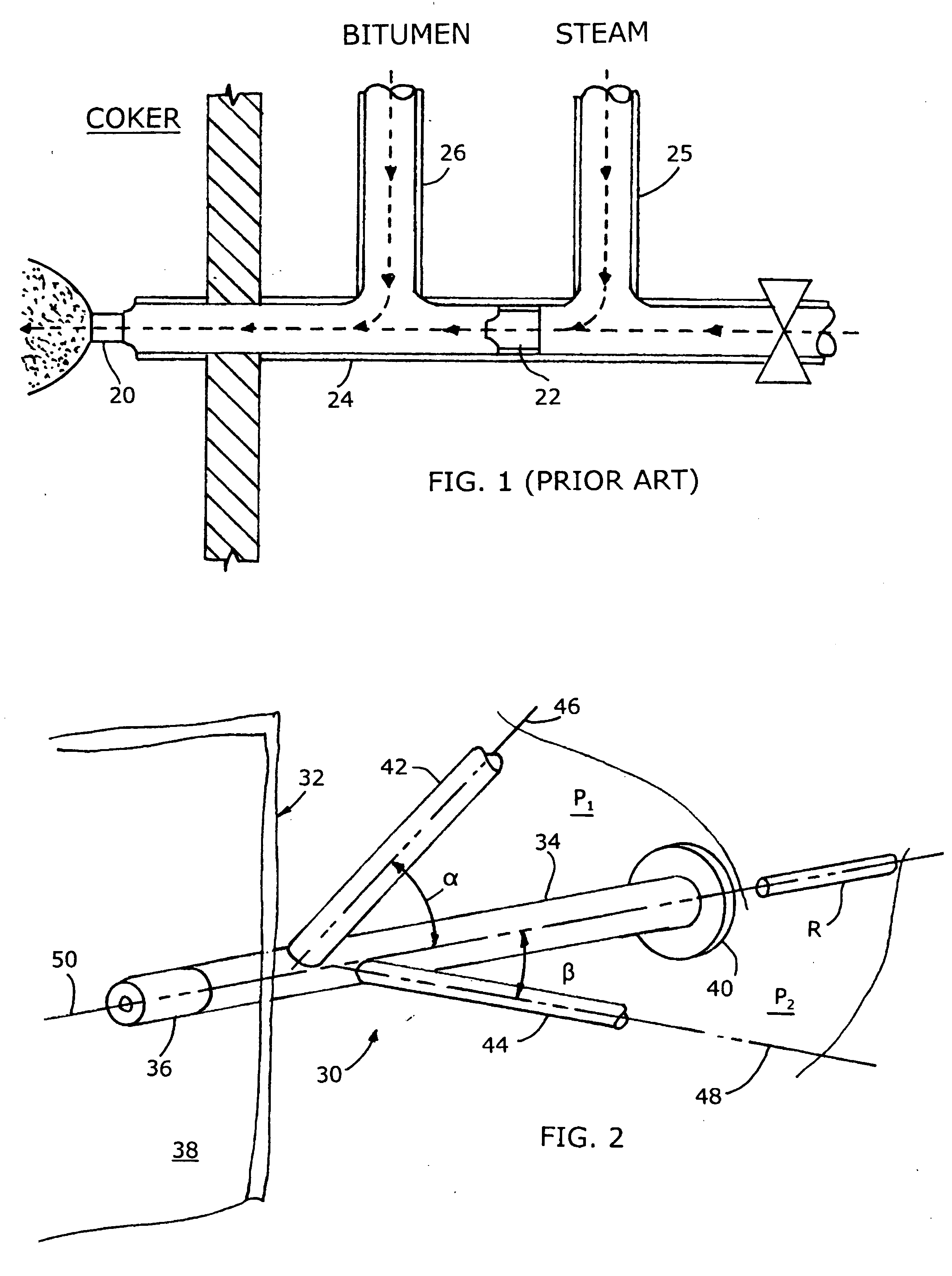

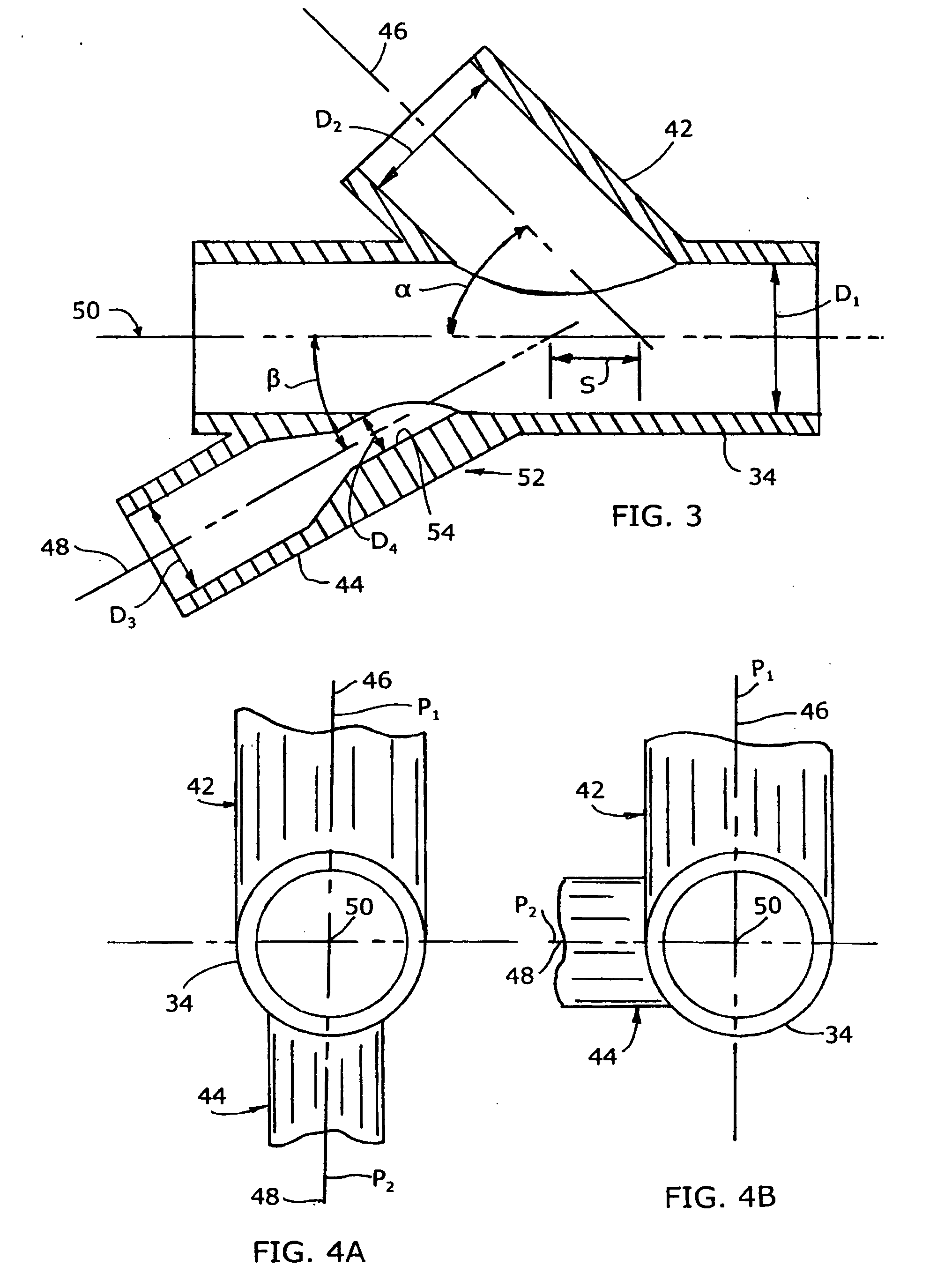

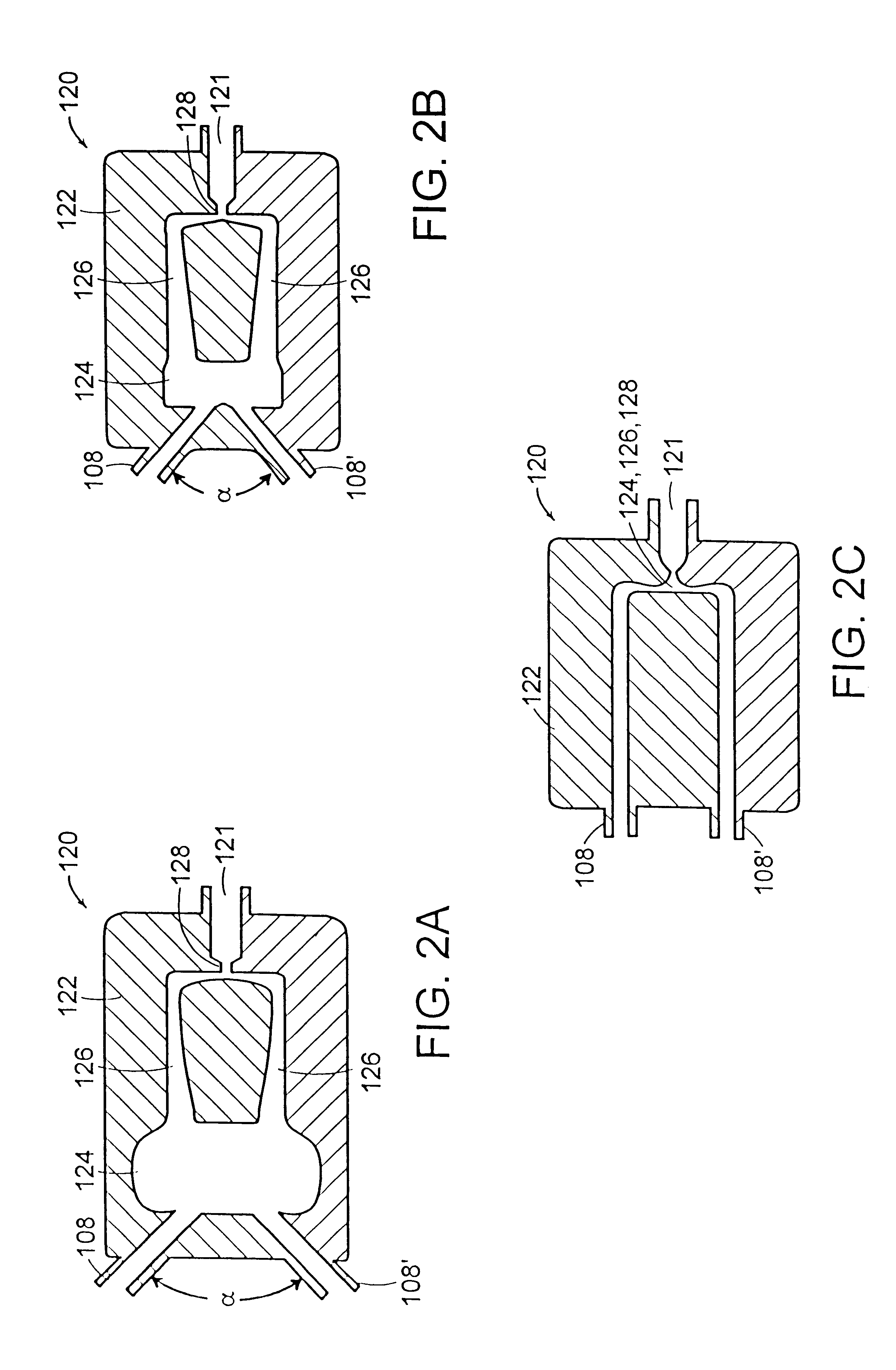

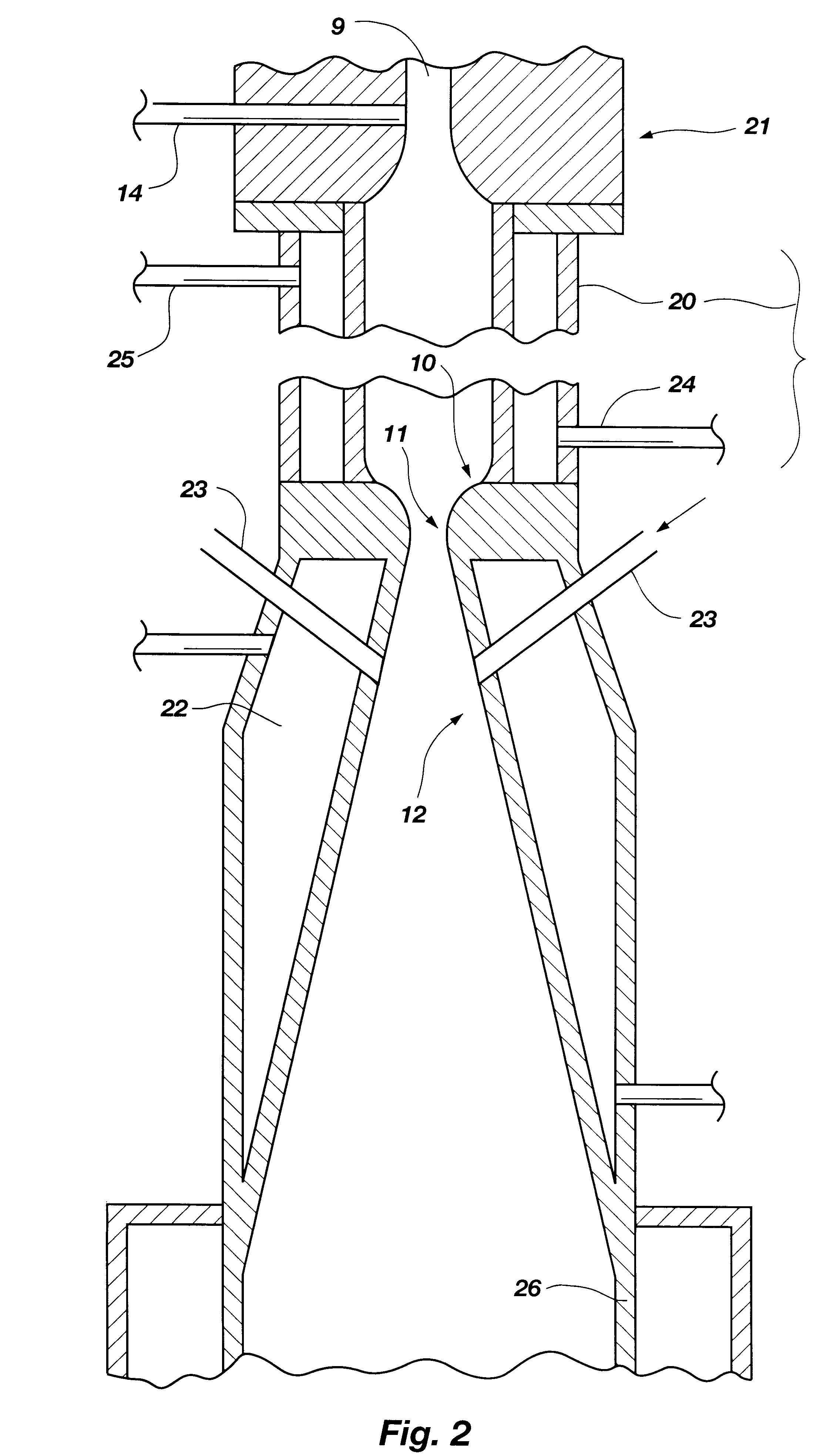

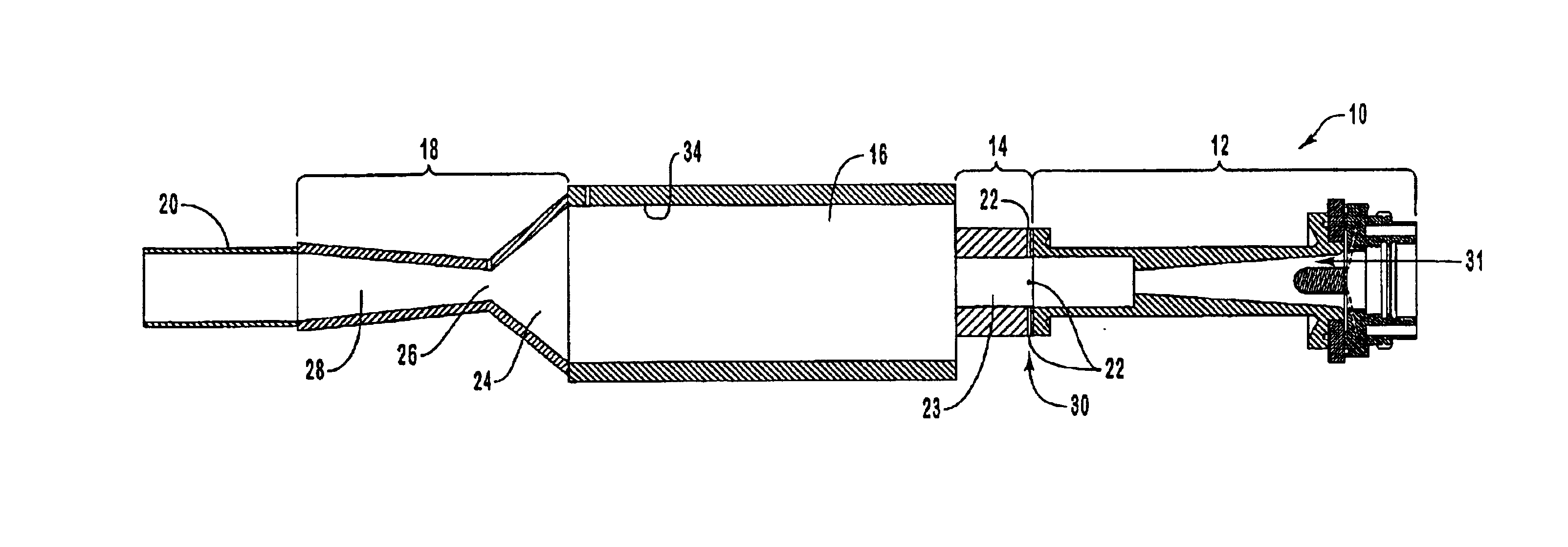

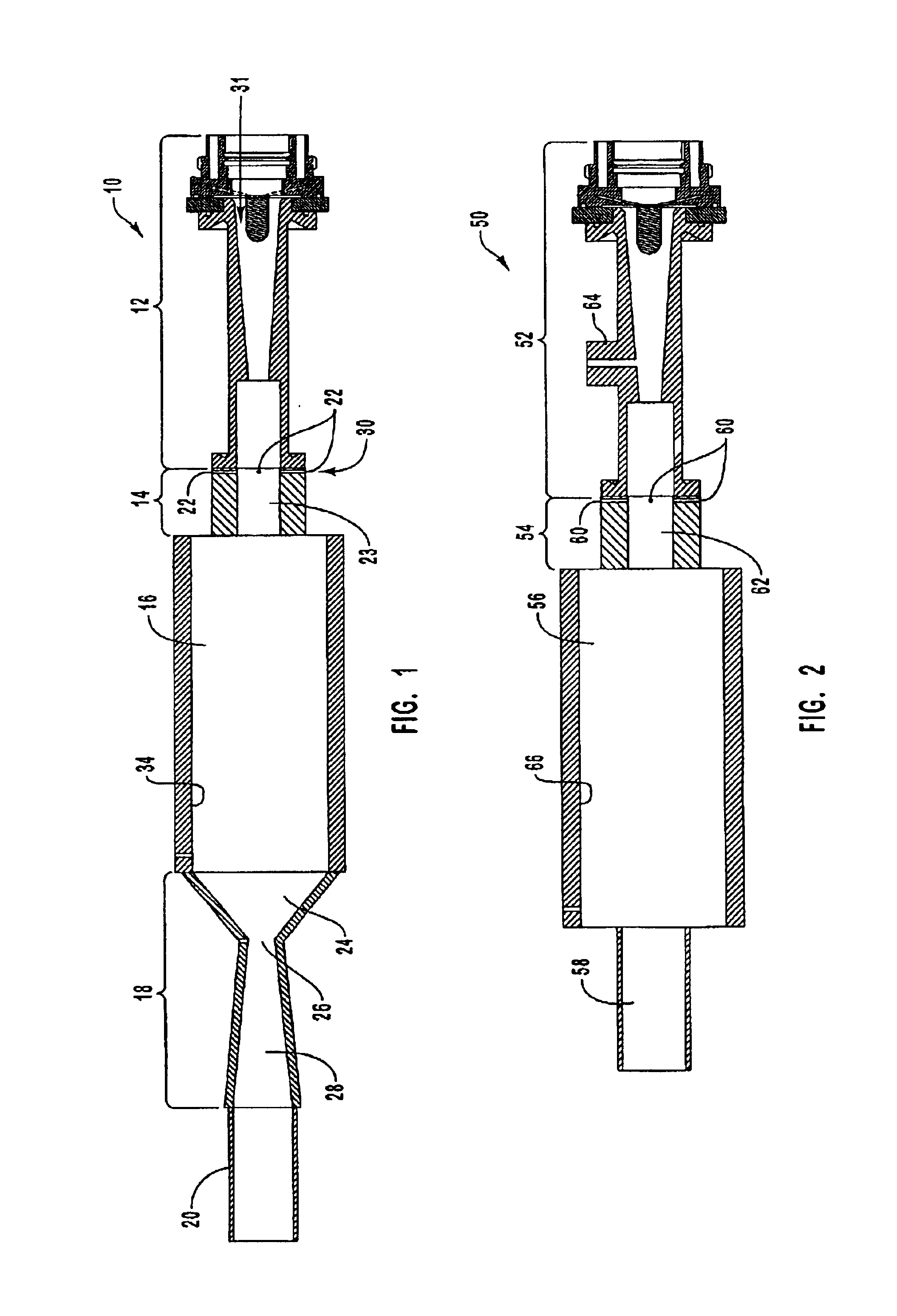

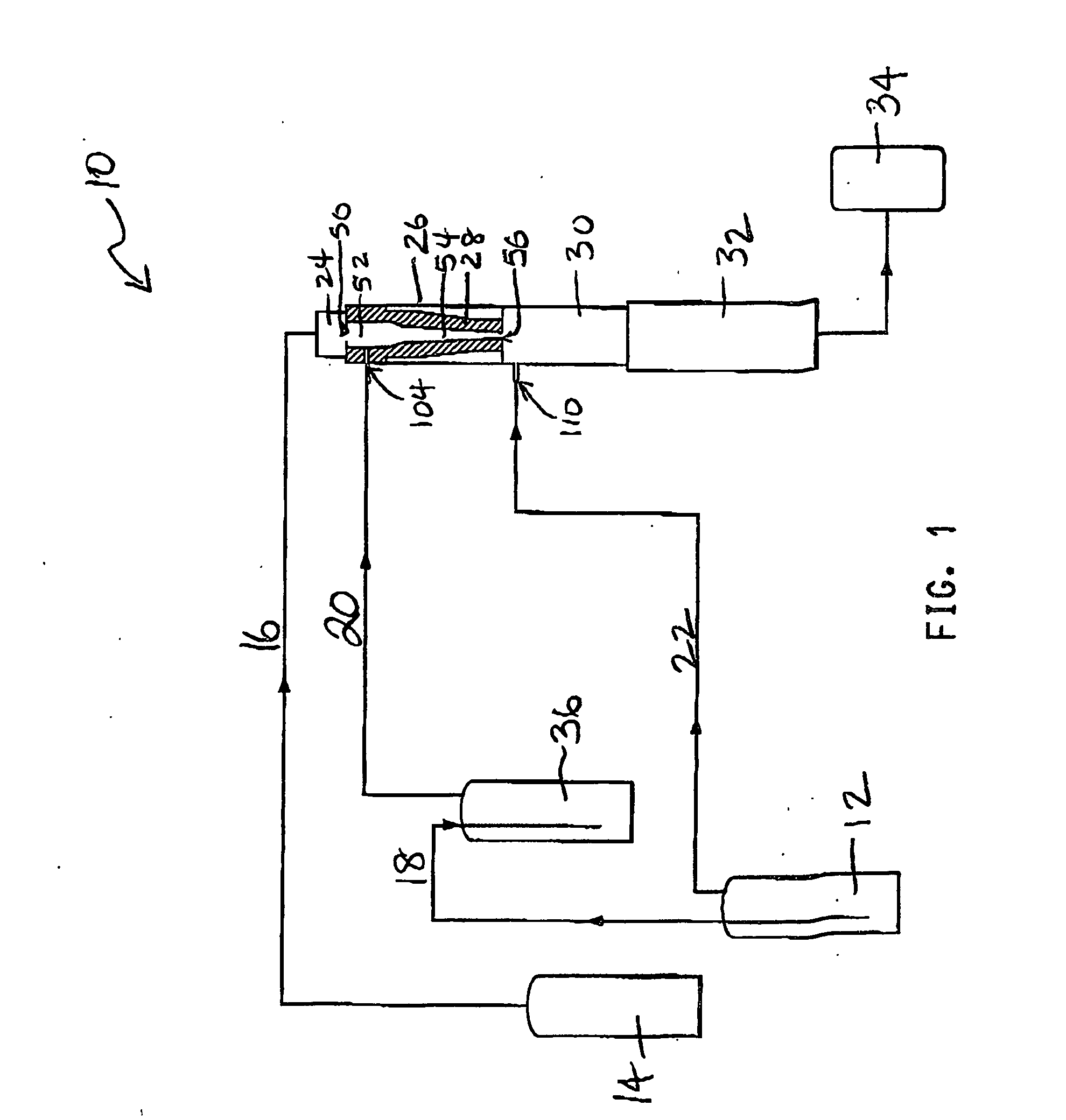

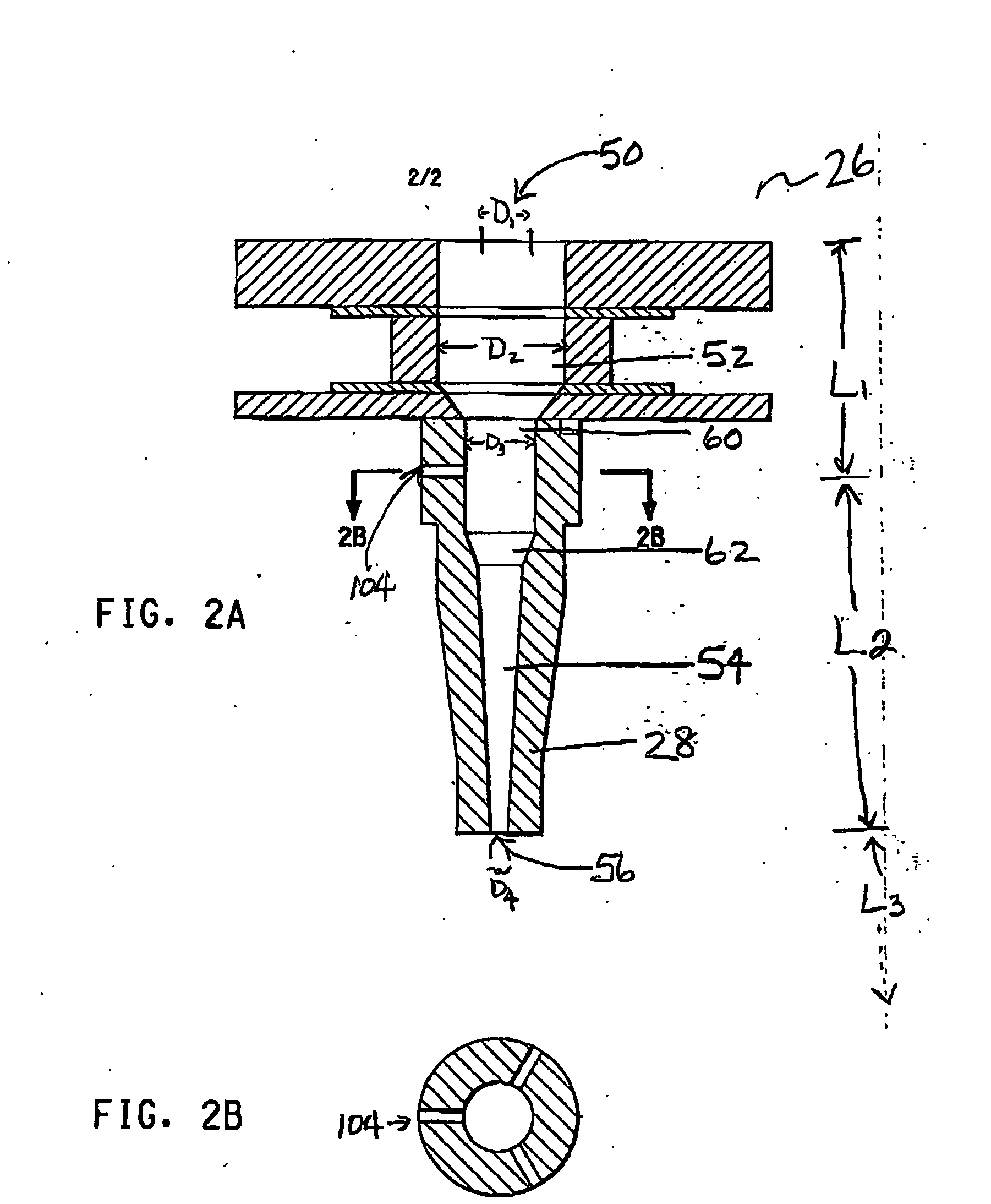

Mixing arrangement for atomizing nozzle in multi-phase flow

ActiveUS7140558B2Smooth transitionEasy to processCharging-discharging device combinationsFlow mixersAcute angleShortest distance

The invention relates to an improved mixing arrangement for, primarily, moving bitumen in steam from sources of such bitumen and steam to a reactor or coker for further processing of the bitumen into petroleum products. The invention provides a main conduit connected to an atomizing nozzle mounted in a wall of the reactor and first and second conduits for flowing bitumen and steam respectively into the main conduit. The first conduit is angled relative to the main conduit at an acute angle of about 45° and the second conduit is angled relative to the main conduit at an acute angle of about 30°. The second conduit is positioned upstream of the first conduit by a short distance of about 23 mm and may be angled radially relative to the first conduit by any angle, although a 90° angle is preferred. A flow accelerating nozzle is located in the second conduit adjacent the entrance therefrom into the main conduit The arrangement of the invention improves the flow characteristics of 2-phase material flowing to the atomizing nozzle, reducing pulsations in the main conduit and improving the resulting atomization of the bitumen in the reactor.

Owner:NAT RES COUNCIL OF CANADA +1

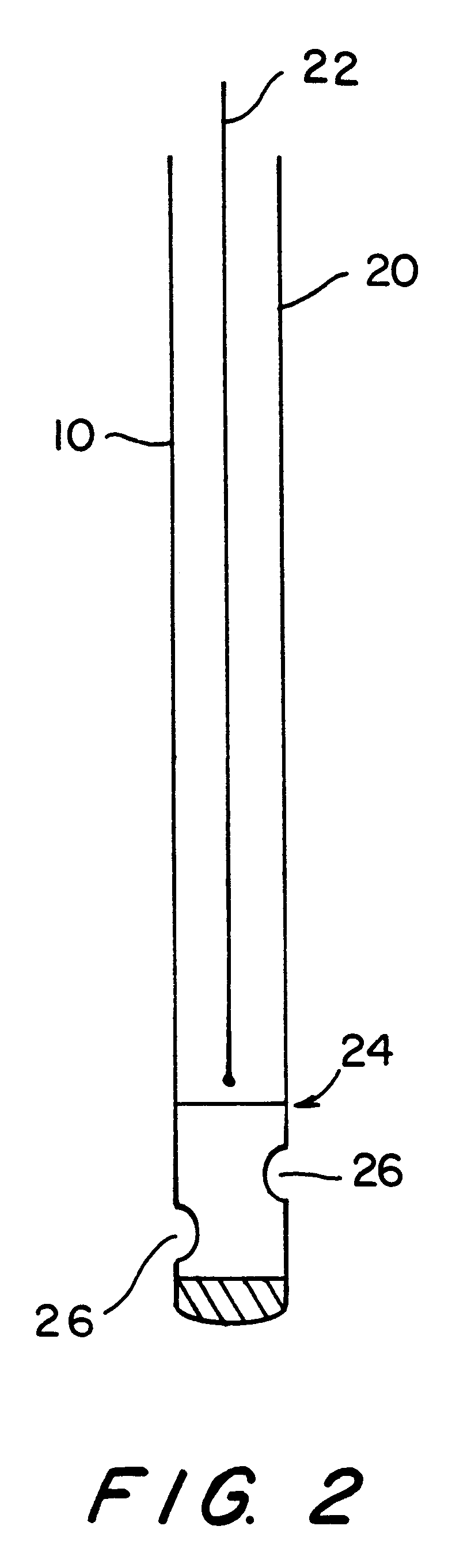

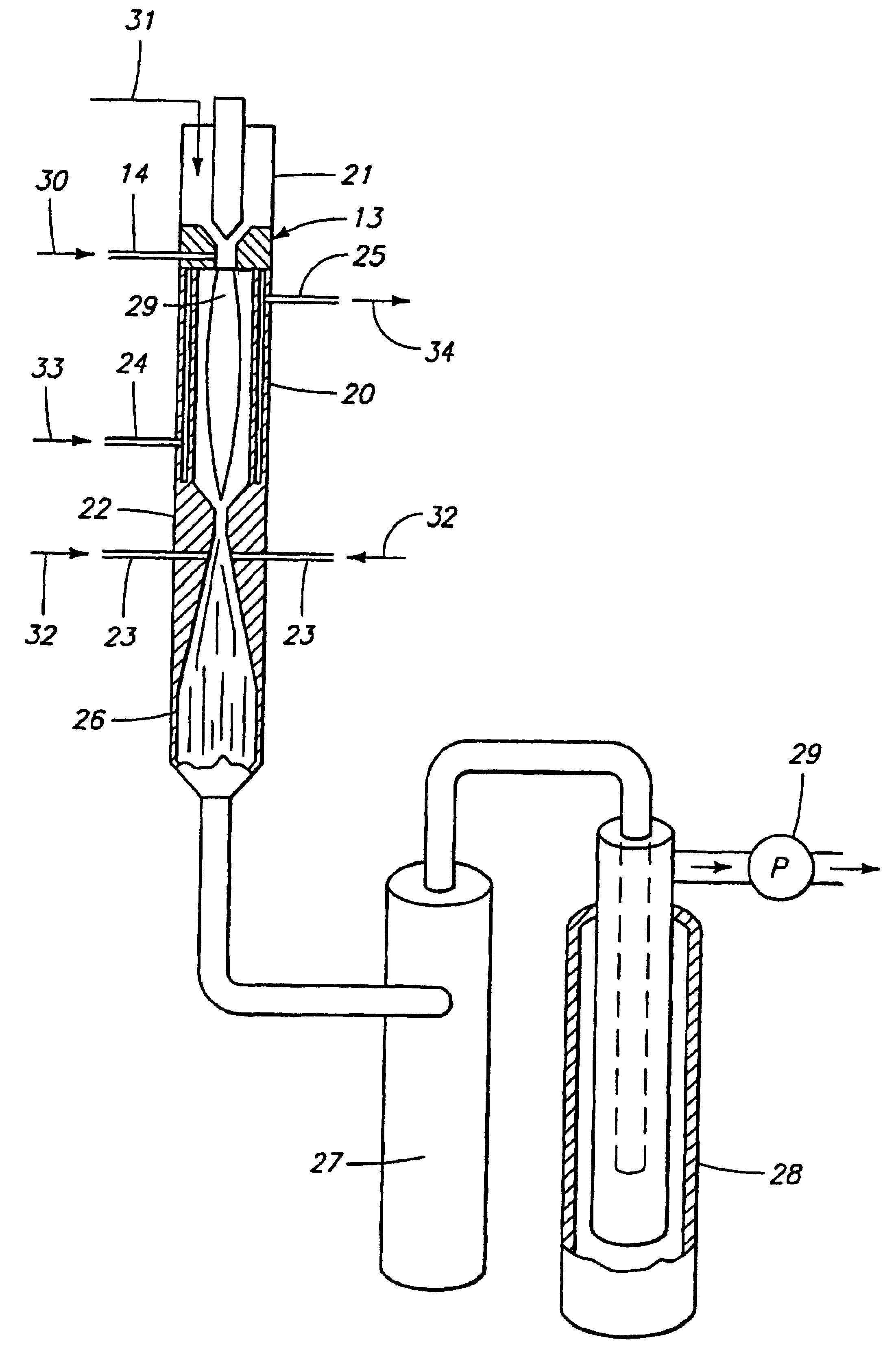

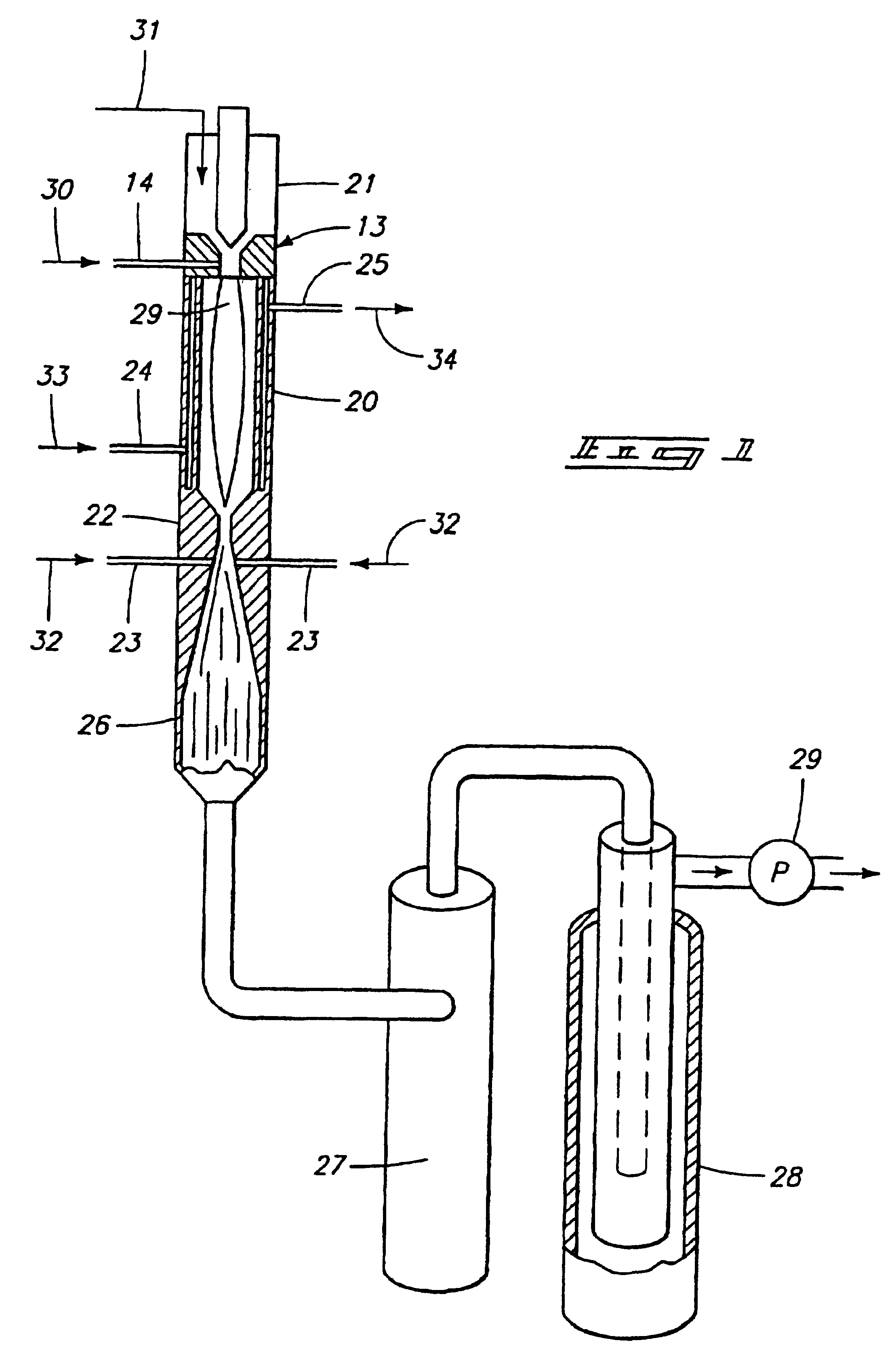

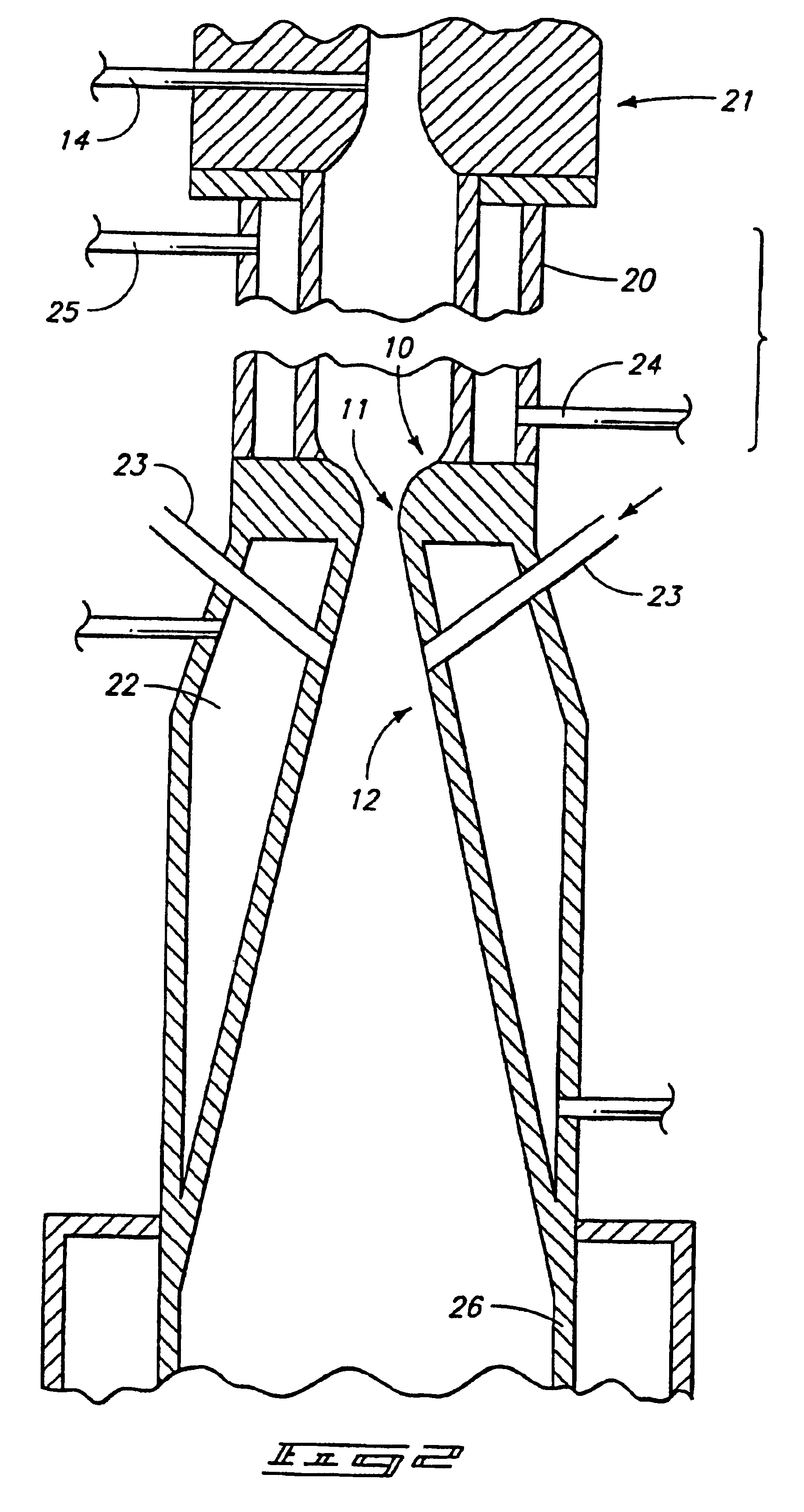

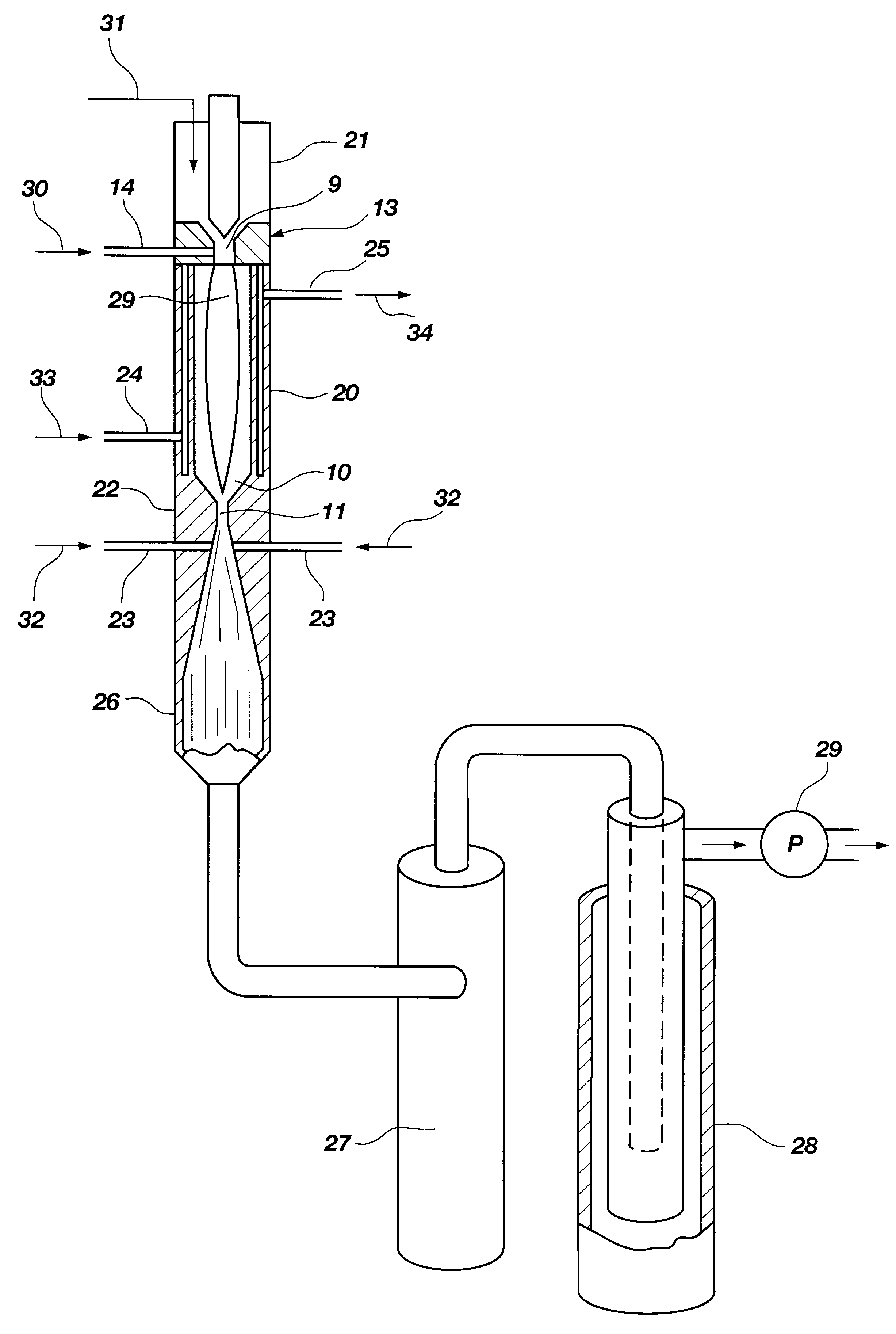

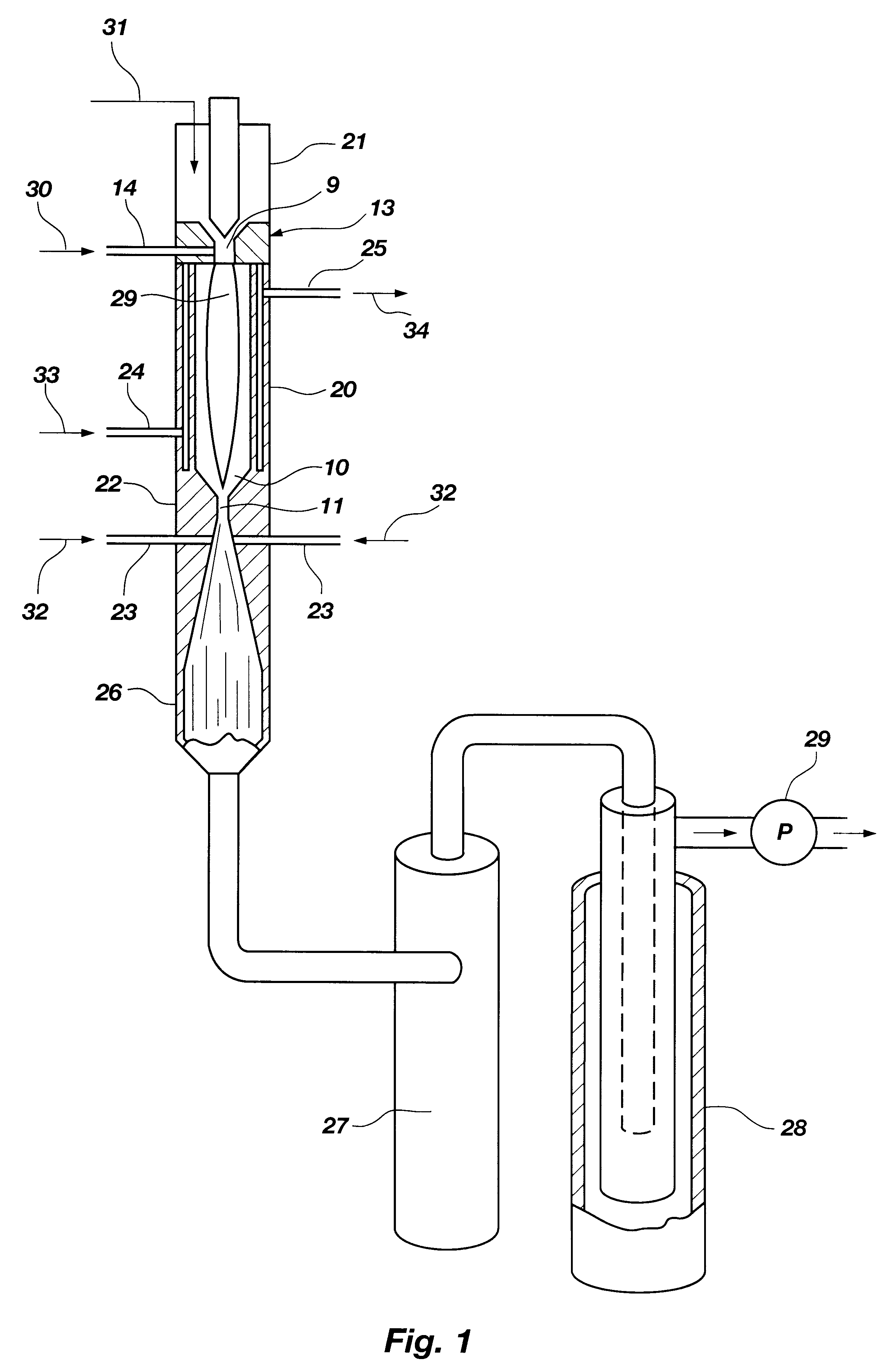

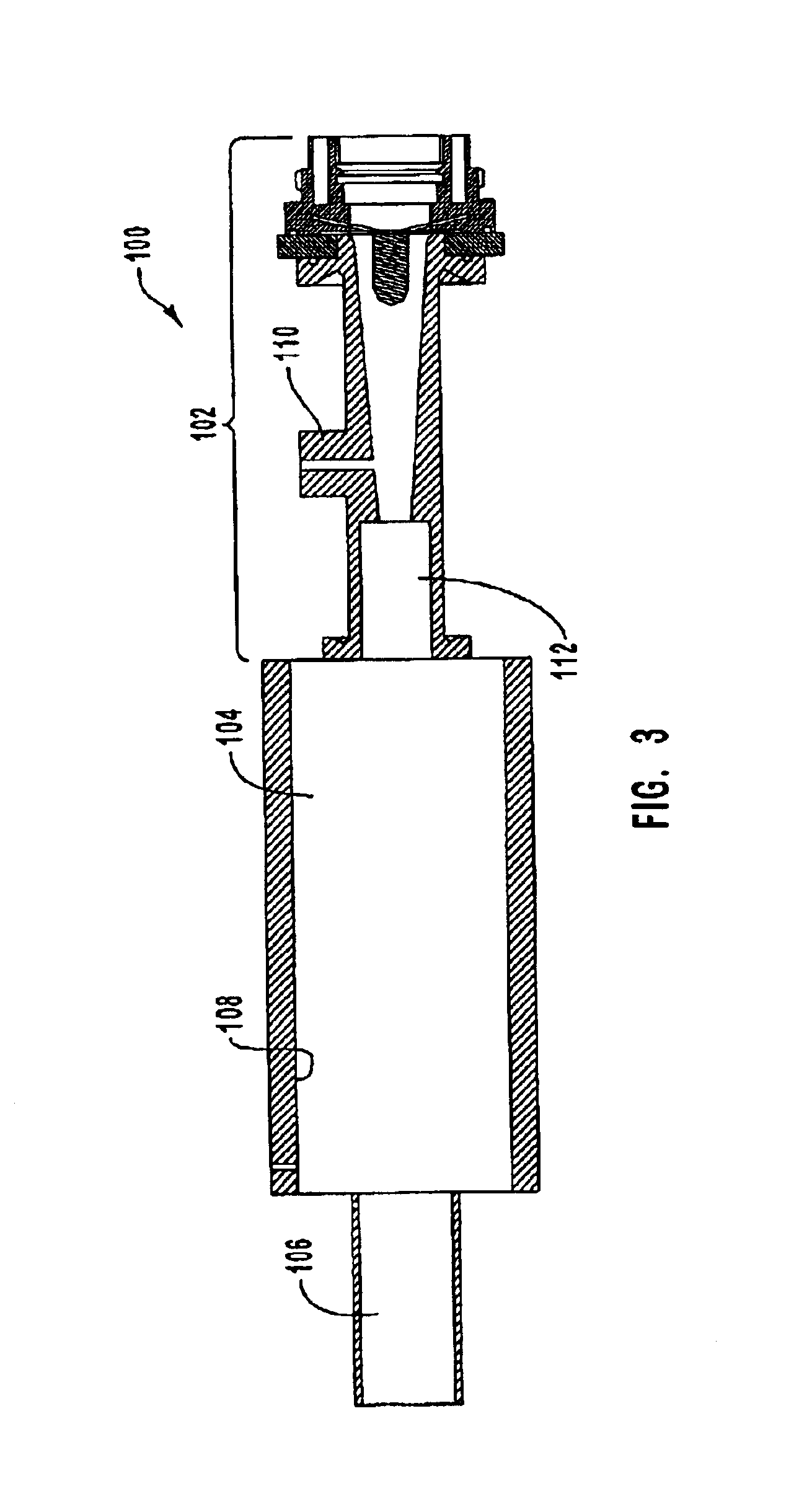

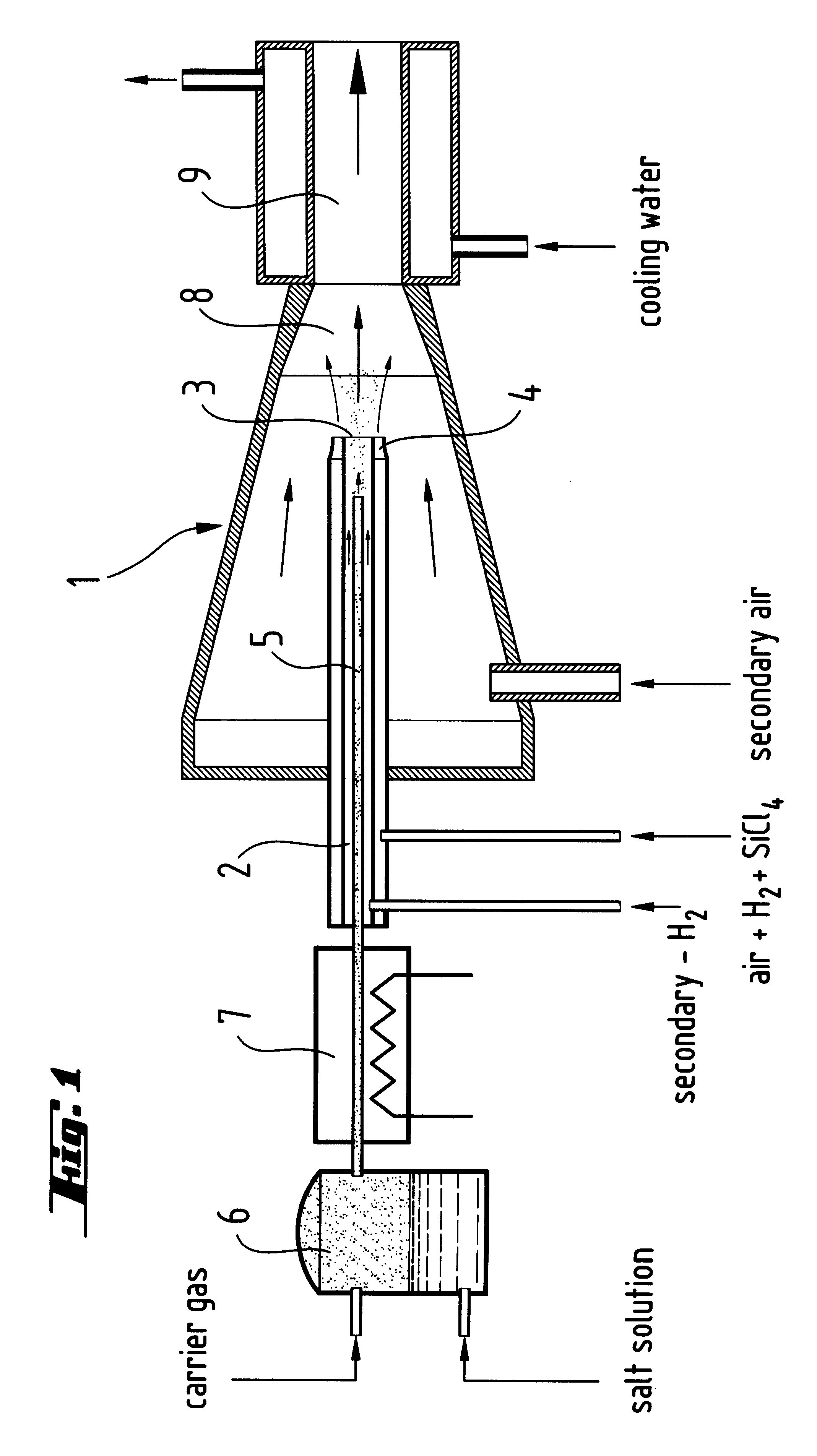

Fast quench reactor and method

InactiveUSRE37853E1Minimizing back reactionRapid coolingMaterial nanotechnologyIndirect heat exchangersThermodynamicsProcess engineering

A fast quench reaction includes a reactor chamber having a high temperature heating means such as a plasma torch at its inlet and a restrictive convergent-divergent nozzle at its outlet end. Reactants are injected into the reactor chamber. The resulting heated gaseous stream is then rapidly cooled by passage through the nozzle. This "freezes" the desired end product(s) in the heated equilibrium reaction stage.

Owner:BATTELLE ENERGY ALLIANCE LLC

Mixing arrangement for atomizing nozzle in multi-phase flow

ActiveUS20050001062A1Smooth transitionEasy to processCharging-discharging device combinationsFlow mixersAcute angleShortest distance

The invention relates to an improved mixing arrangement for, primarily, moving bitumen in steam from sources of such bitumen and steam to a reactor or coker for further processing of the bitumen into petroleum products. The invention provides a main conduit connected to an atomizing nozzle mounted in a wall of the reactor and first and second conduits for flowing bitumen and steam respectively into the main conduit. The first conduit is angled relative to the main conduit at an acute angle of about 45° and the second conduit is angled relative to the main conduit at an acute angle of about 30°. The second conduit is positioned downstream of the first conduit by a short distance of about 23 mm and may be angled radially relative to the first conduit by any angle, although a 90° angle is preferred. A flow accelerating nozzle is located in the second conduit adjacent the entrance therefrom into the main conduit. The arrangement of the invention improves the flow characteristics of 2-phase material flowing to the atomizing nozzle, reducing pulsations in the main conduit and improving the resulting atomization of the bitumen in the reactor.

Owner:NAT RES COUNCIL OF CANADA +1

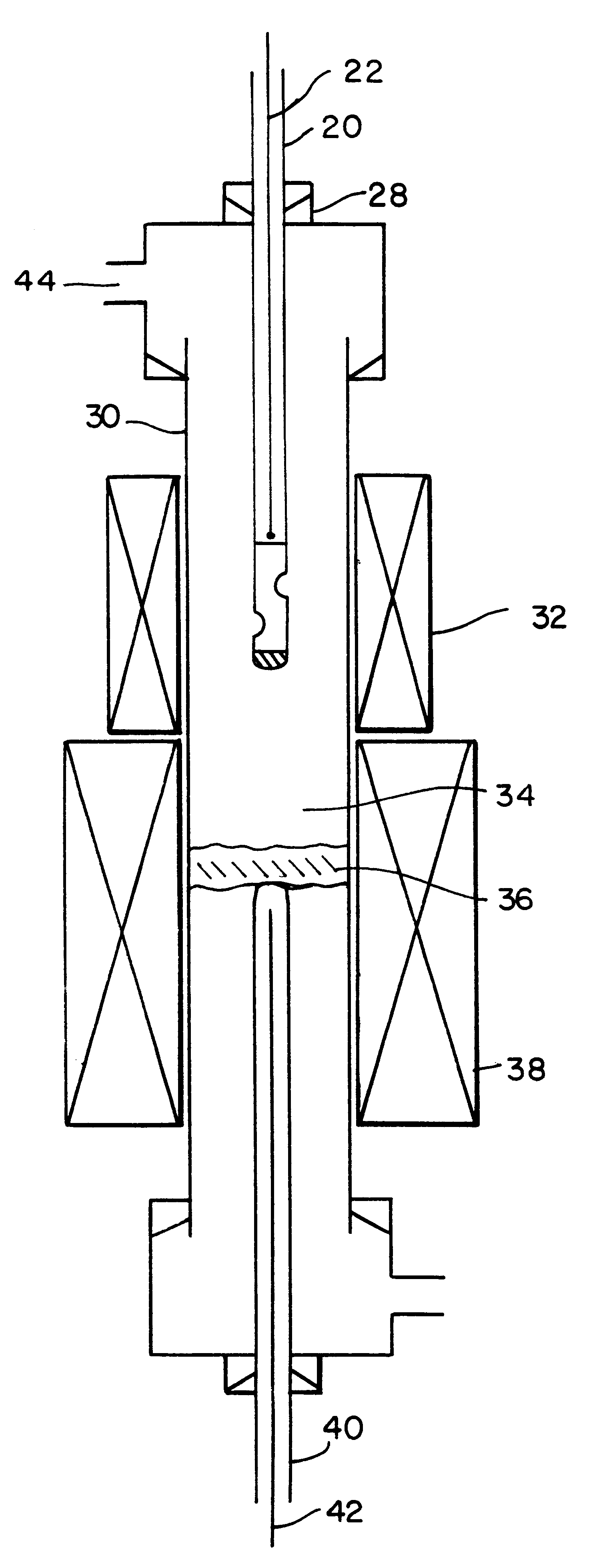

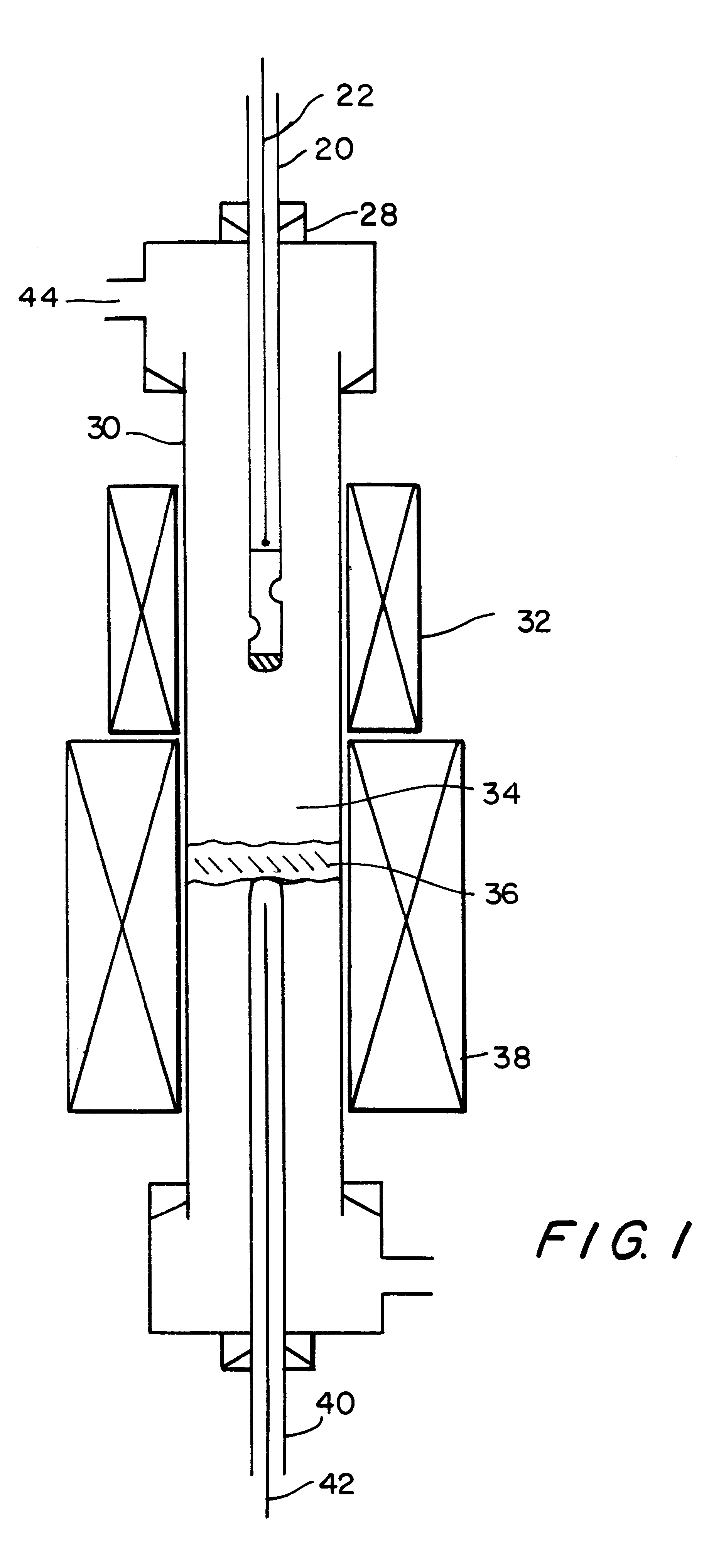

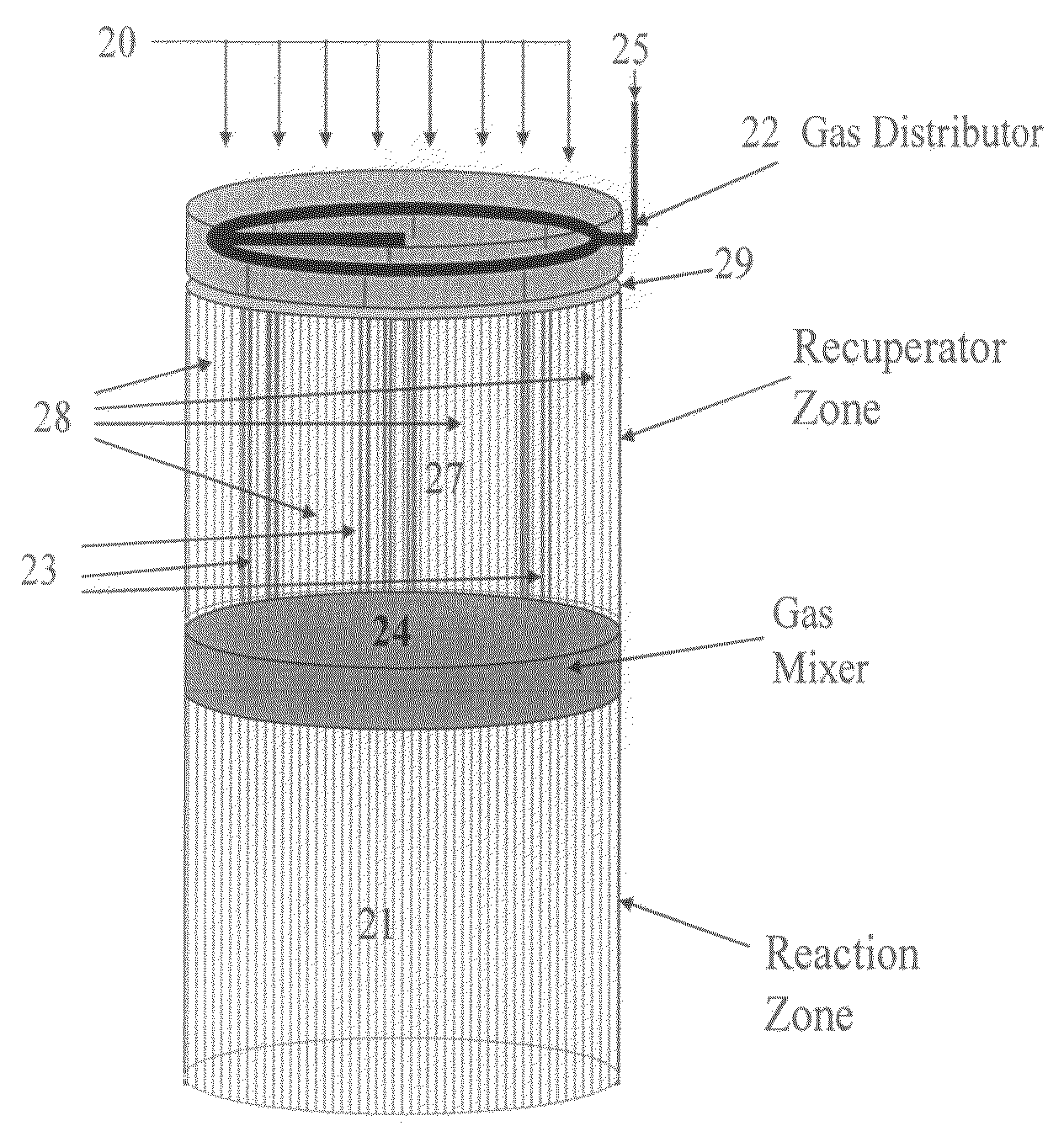

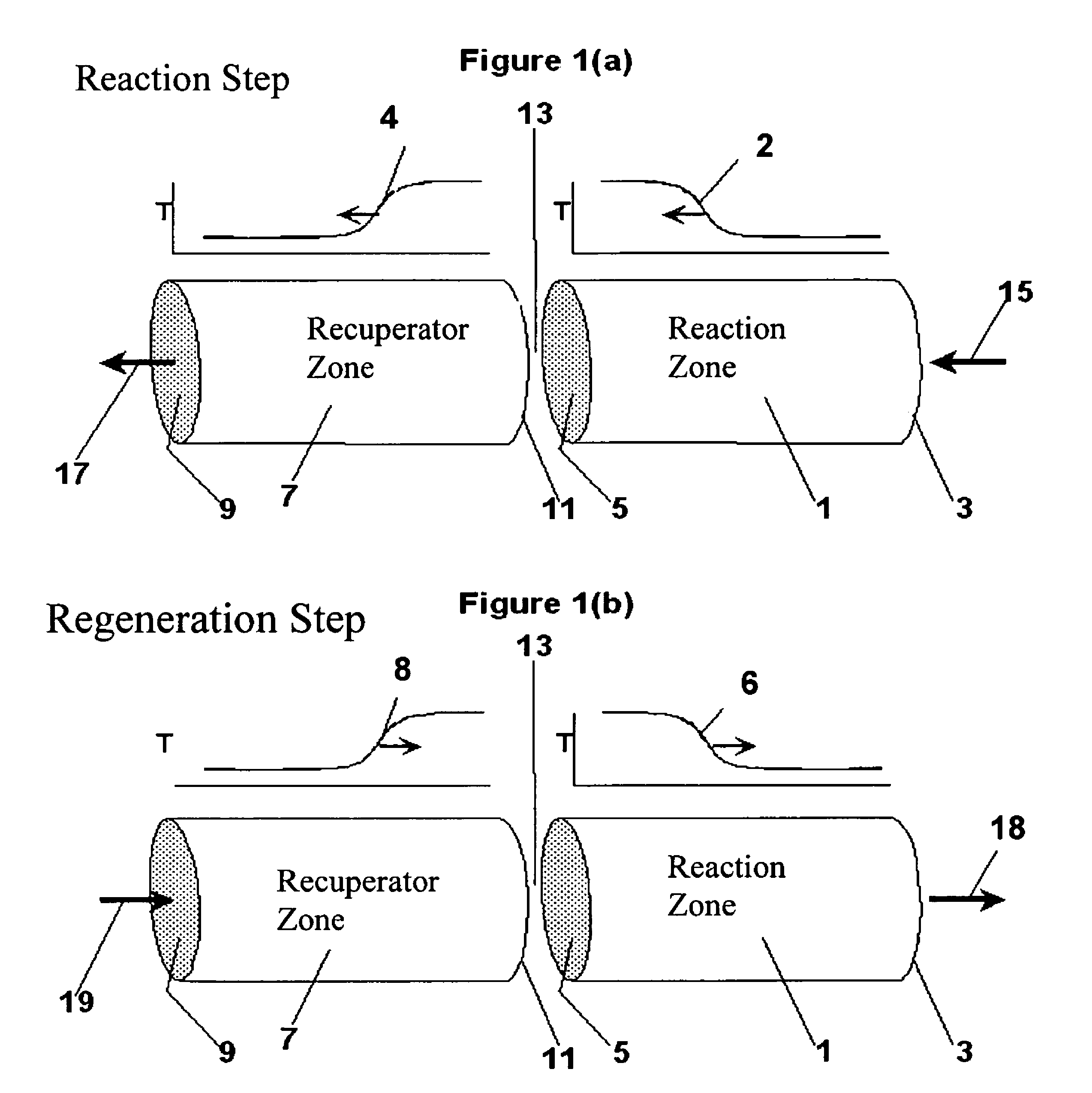

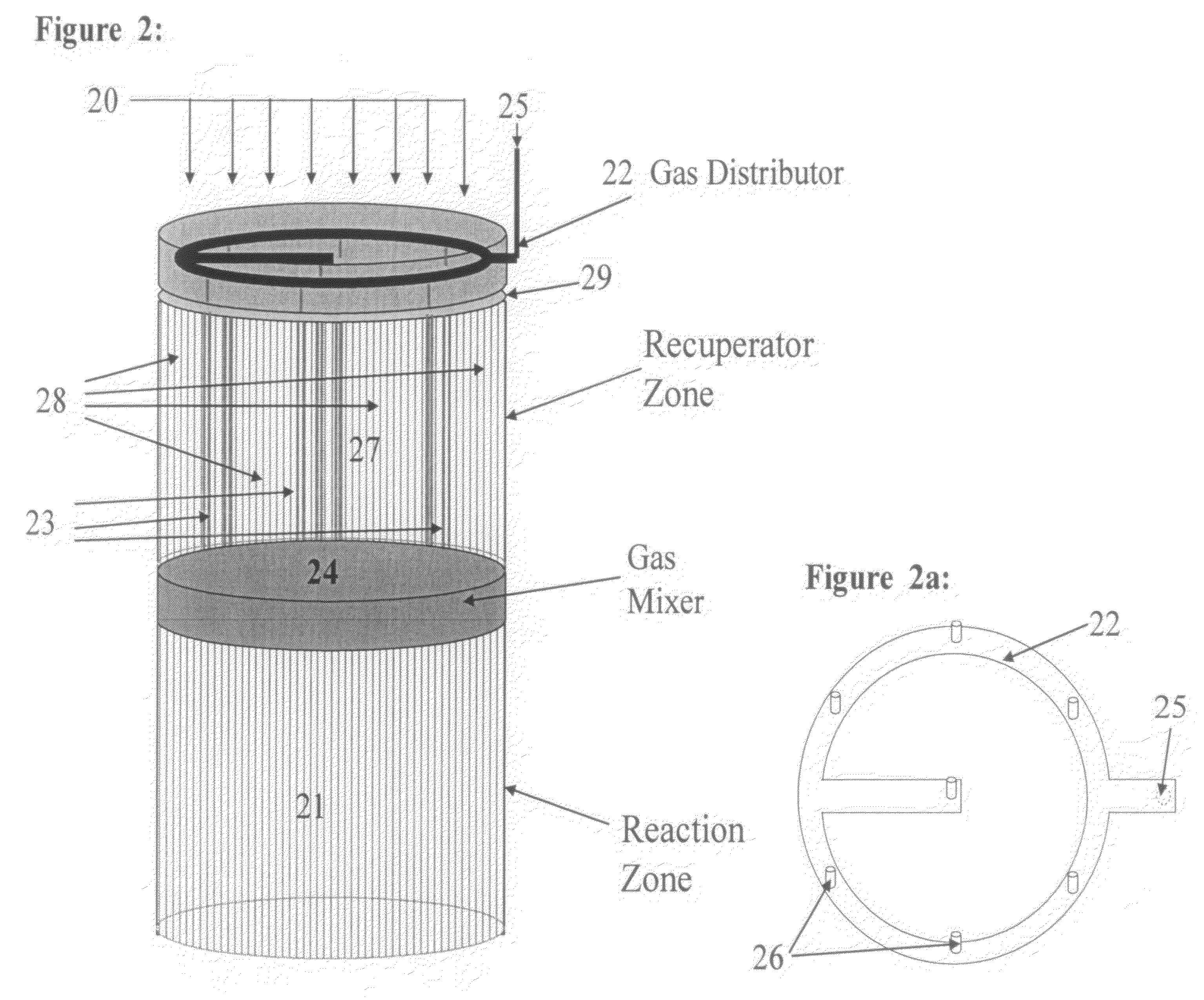

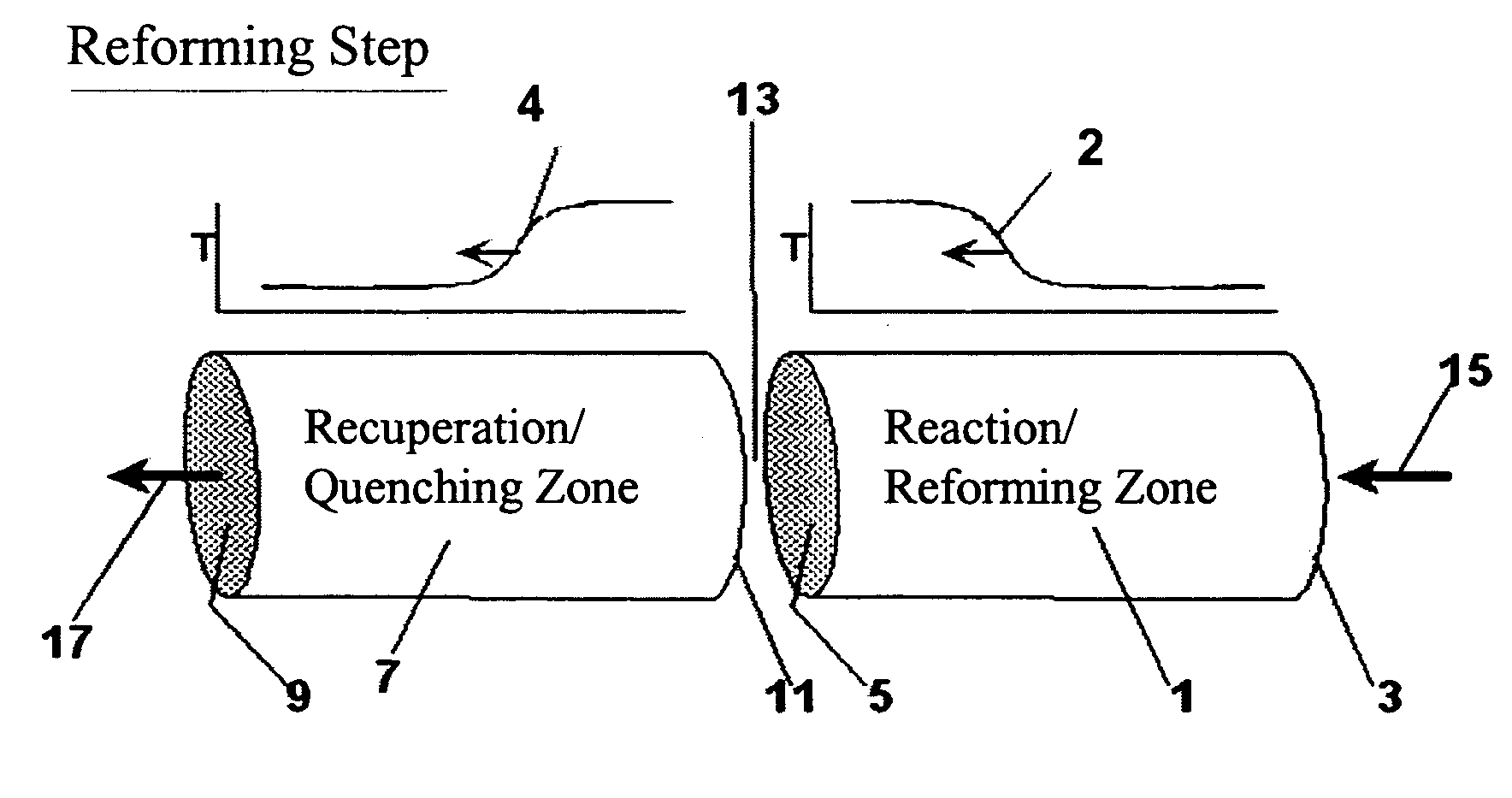

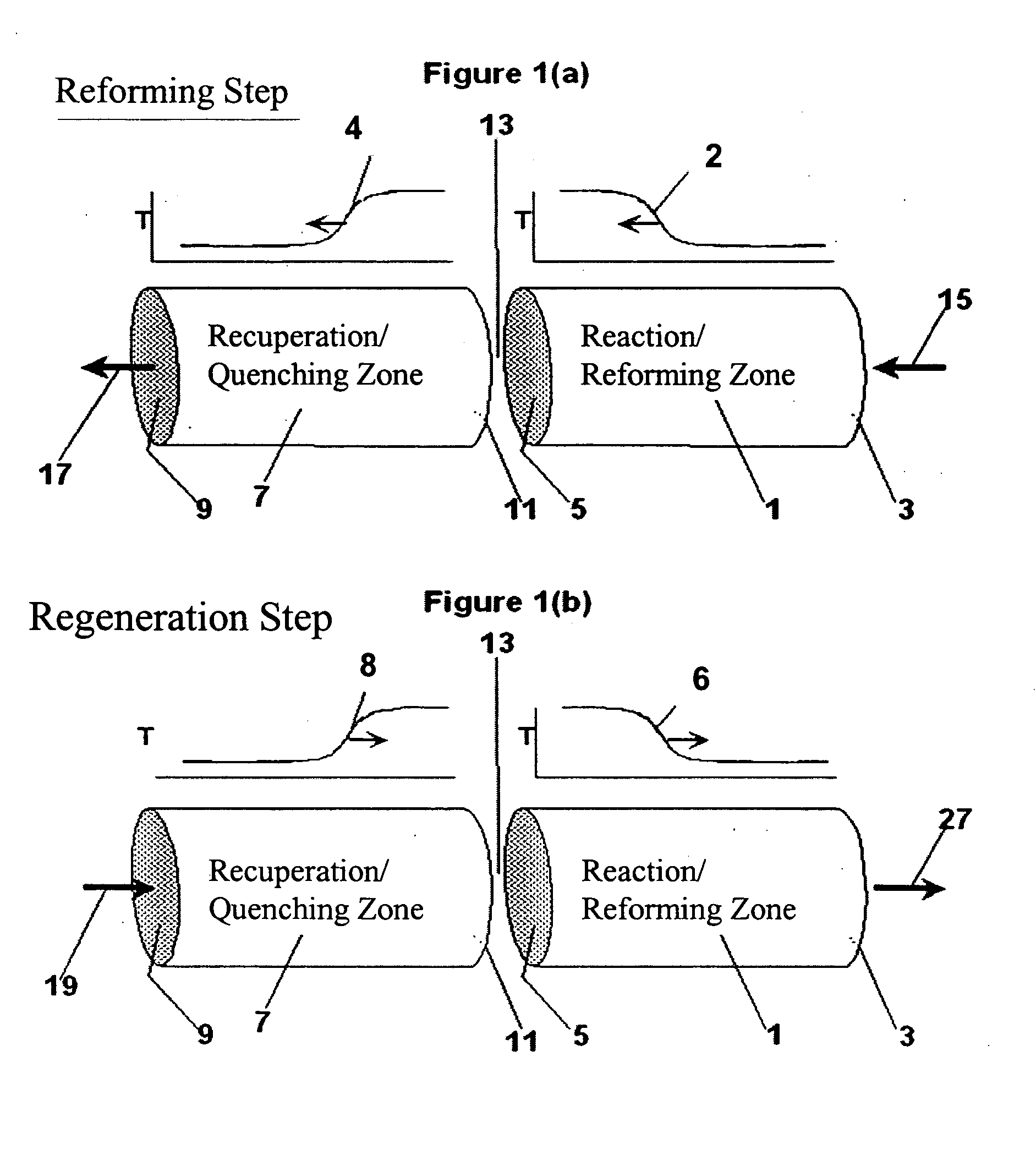

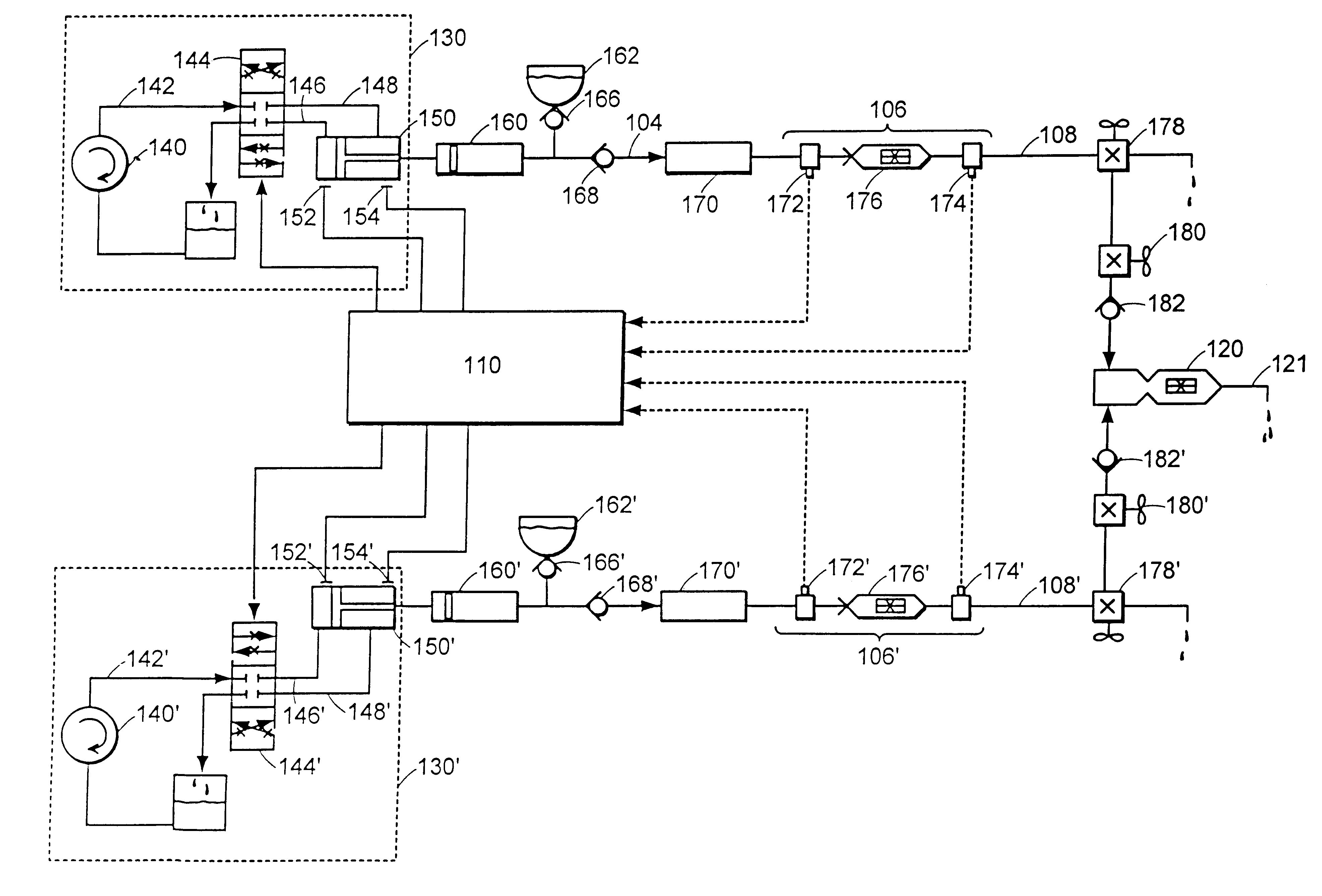

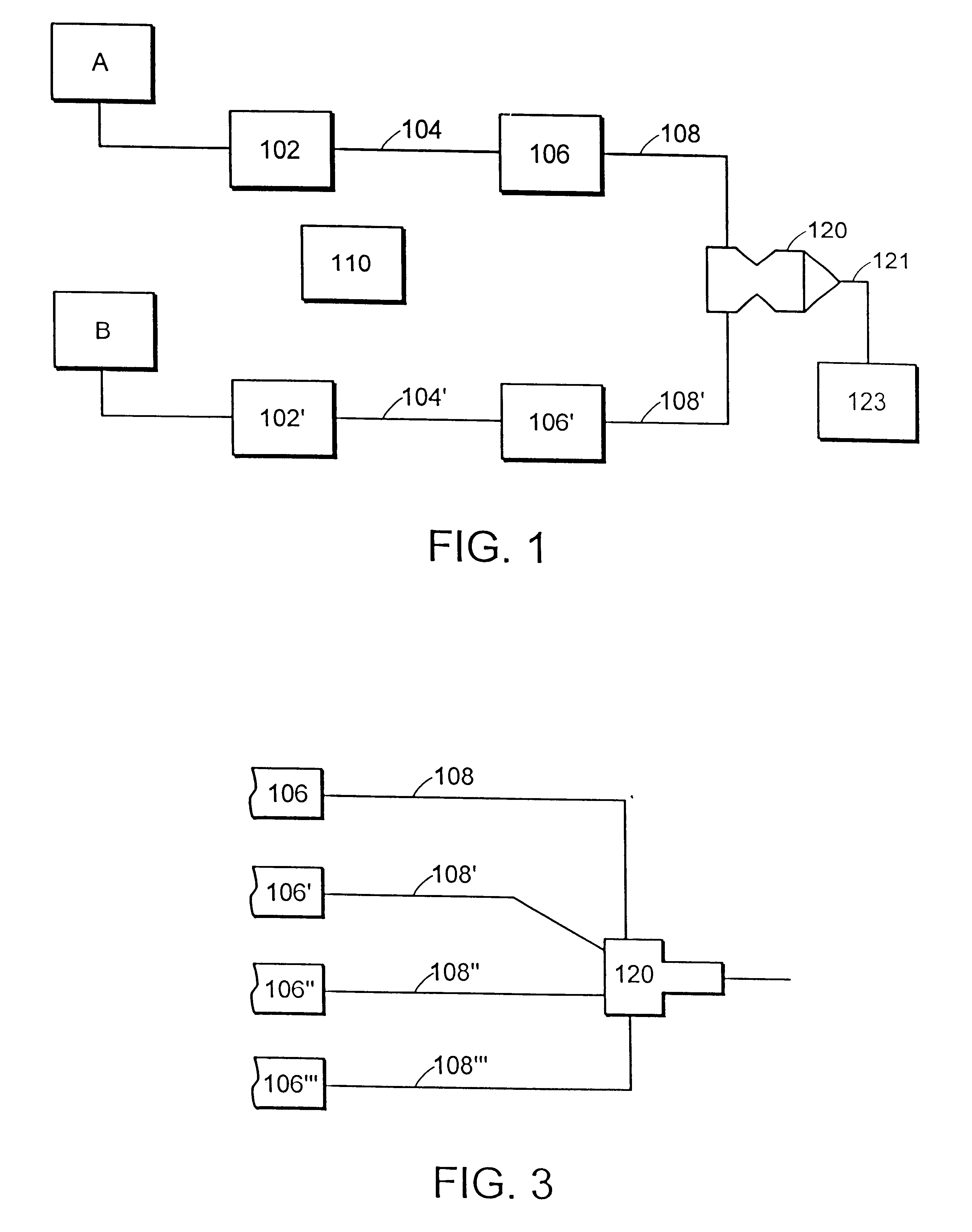

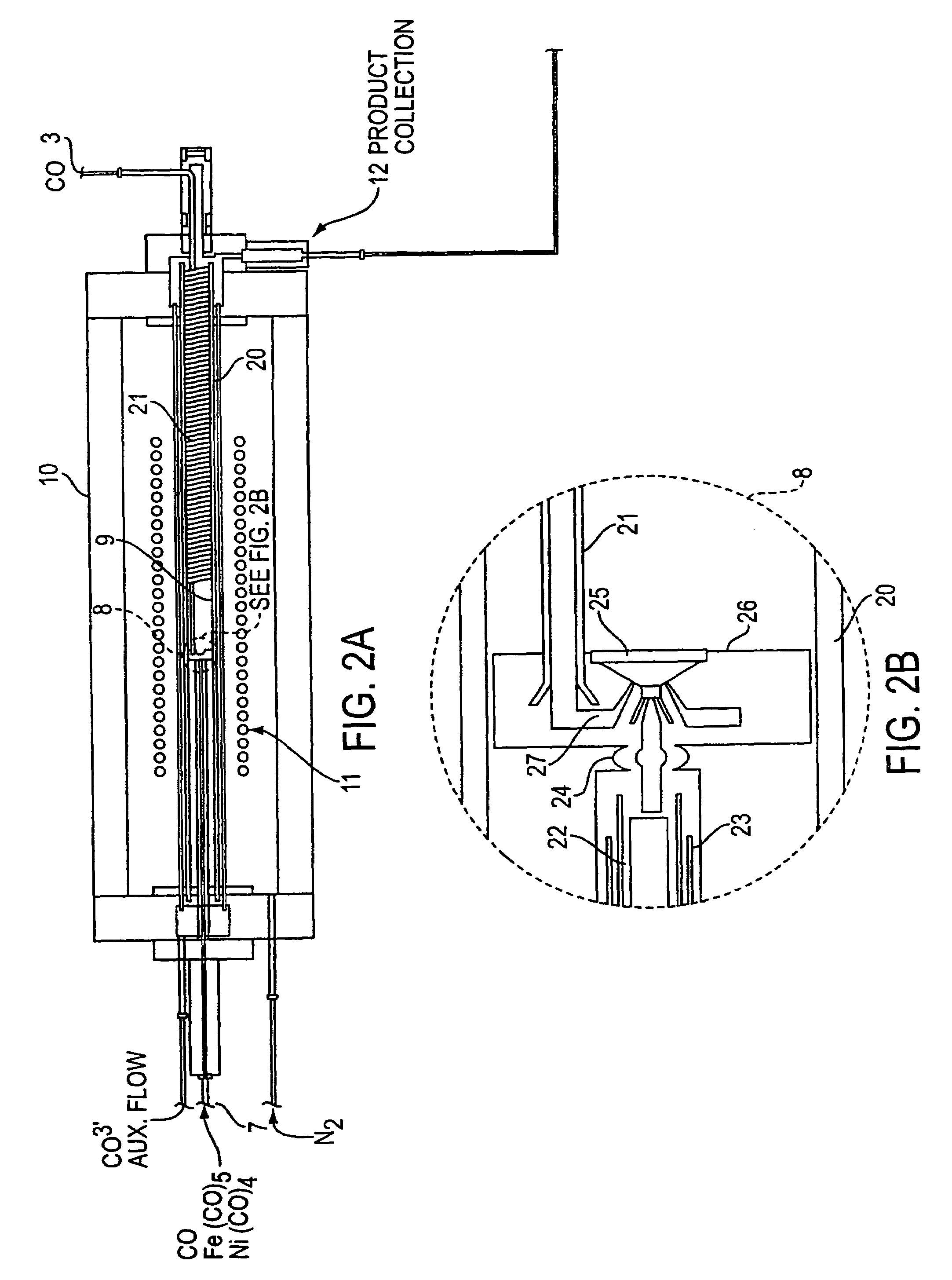

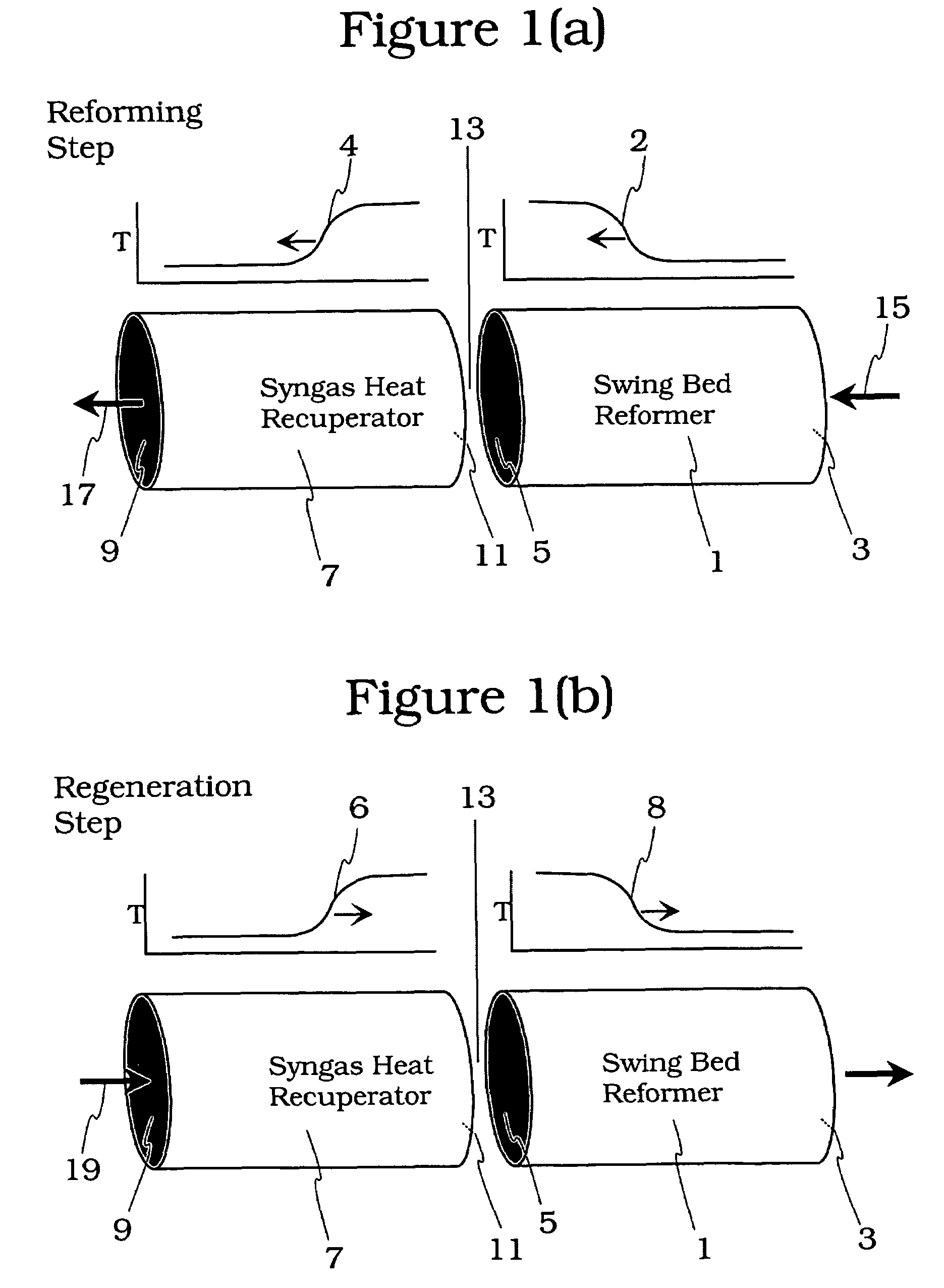

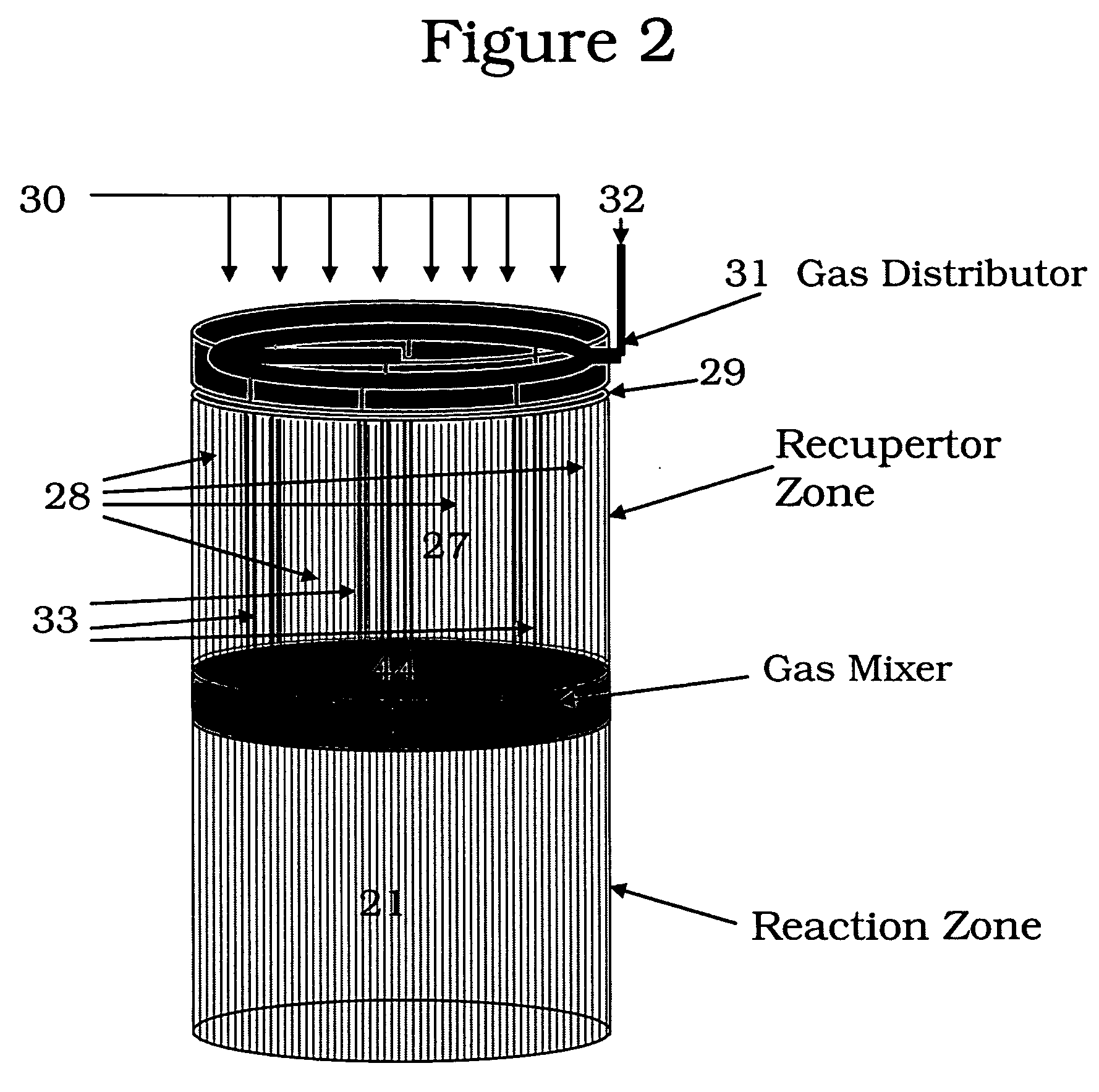

Controlled combustion for regenerative reactors with mixer/flow distributor

ActiveUS7815873B2Efficient transferEvenly distributedHydrocarbon by dehydrogenationFlow mixersReactor systemCombustion

The overall efficiency of a regenerative bed reverse flow reactor system is increased where the location of the exothermic reaction used for regeneration is suitably controlled. The present invention provides a method and apparatus for controlling the combustion to improve the thermal efficiency of bed regeneration in a cyclic reaction / regeneration processes. The process for thermal regeneration of a regenerative reactor bed entails(a) supplying the first reactant through a first channel means in a first regenerative bed and supplying at least a second reactant through a second channel means in the first regenerative bed,(b) combining said first and second reactants by a gas mixing means situated at an exit of the first regenerative bed and reacting the combined gas to produce a heated reaction product,(c) passing the heated reaction product through a second regenerative bed thereby transferring heat from the reaction product to the second regenerative bed.

Owner:EXXON RES & ENG CO

Methane conversion to higher hydrocarbons

ActiveUS20070191664A1Efficient preparationValid conversionGenerators with non-automatic water feedFlow mixersReactor systemReagent

The present invention provides a process for the manufacture of acetylene and other higher hydrocarbons from methane feed using a reverse-flow reactor system, wherein the reactor system includes (i) a first reactor and (ii) a second reactor, the first and second reactors oriented in a series relationship with respect to each other, the process comprising supplying each of first and second reactant through separate channels in the first reactor bed of a reverse-flow reactor such that both of the first and second reactants serve to quench the first reactor bed, without the first and second reactants substantially reacting with each other until reaching the core of the reactor system.

Owner:EXXONMOBIL CHEM PAT INC

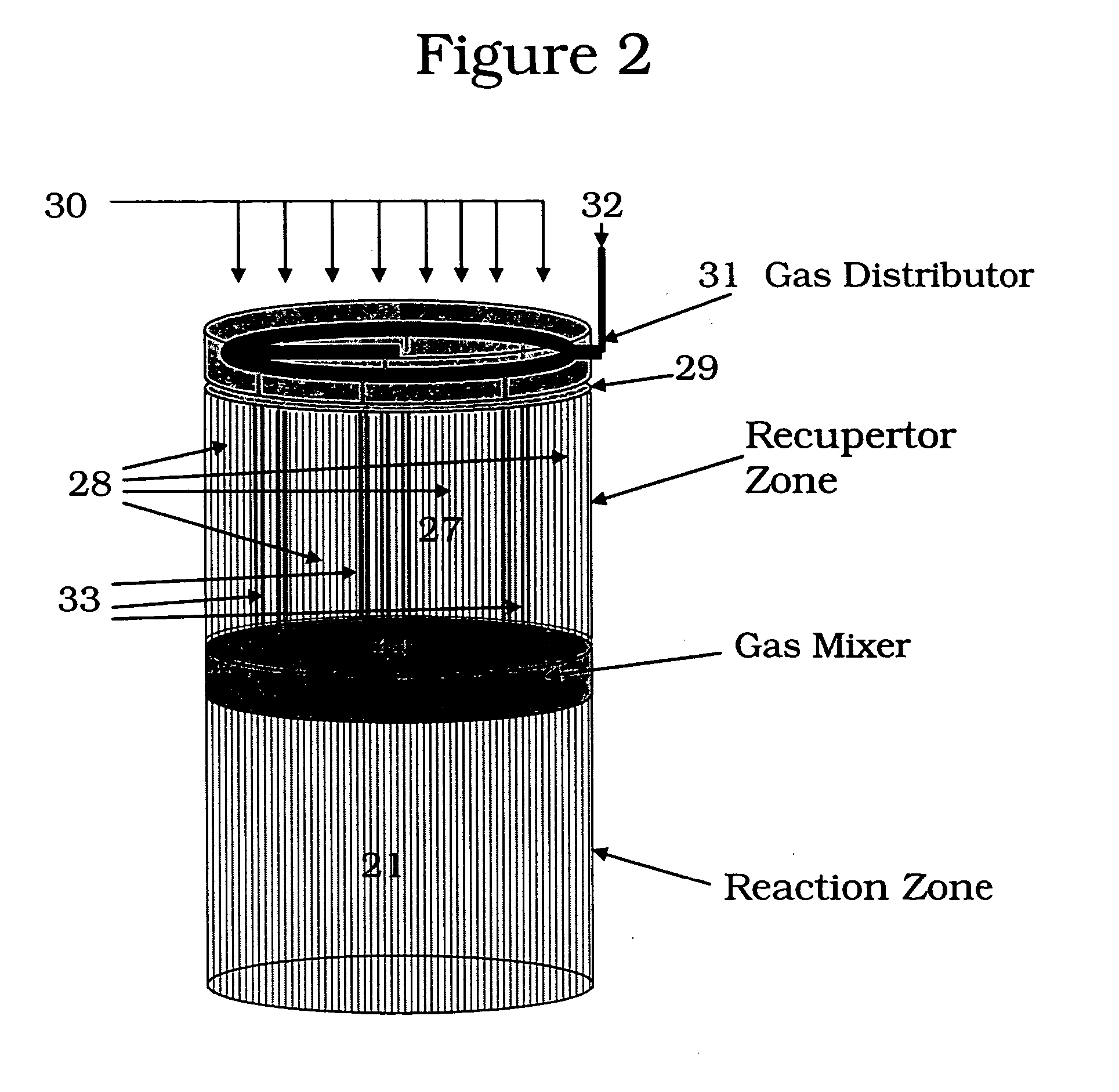

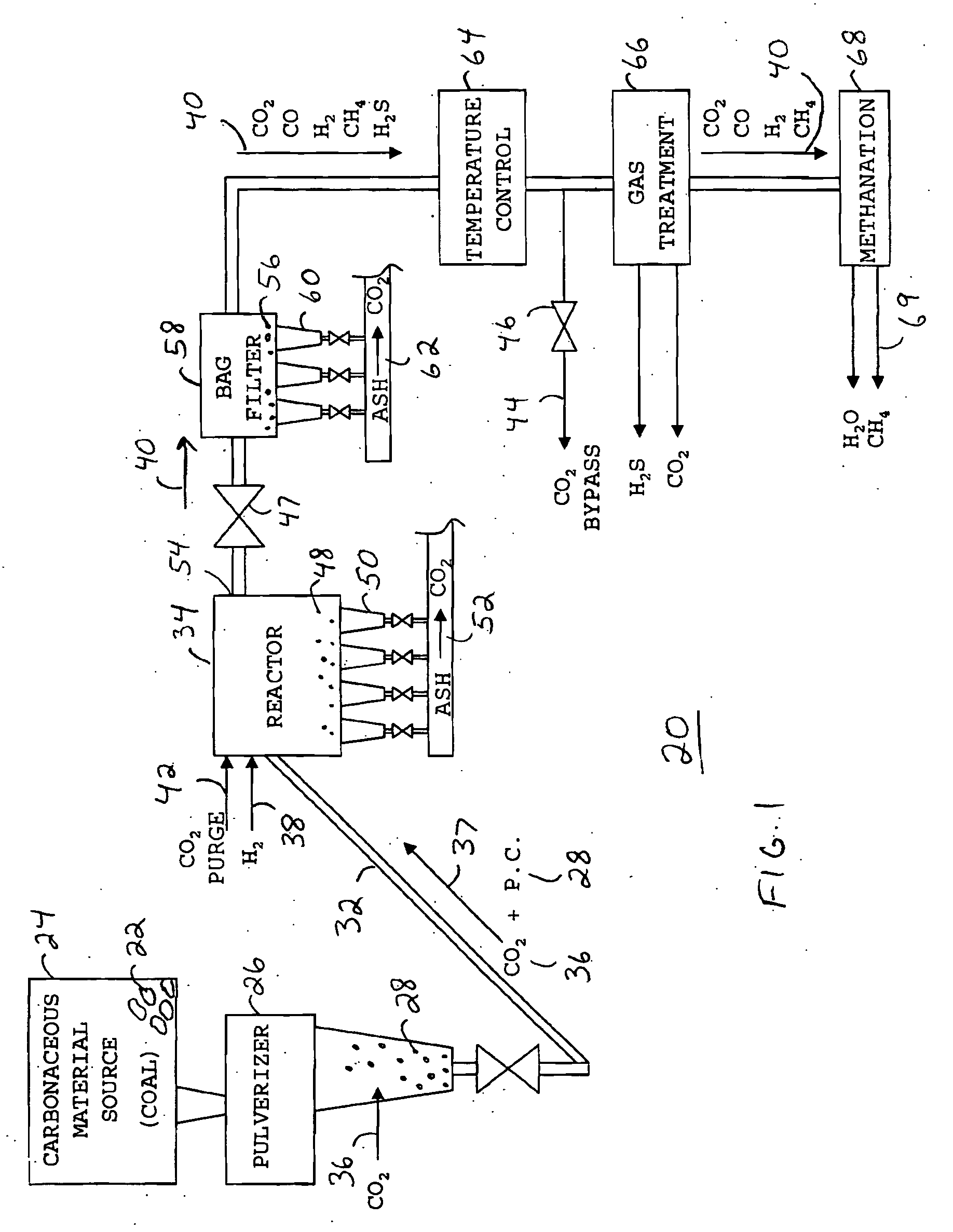

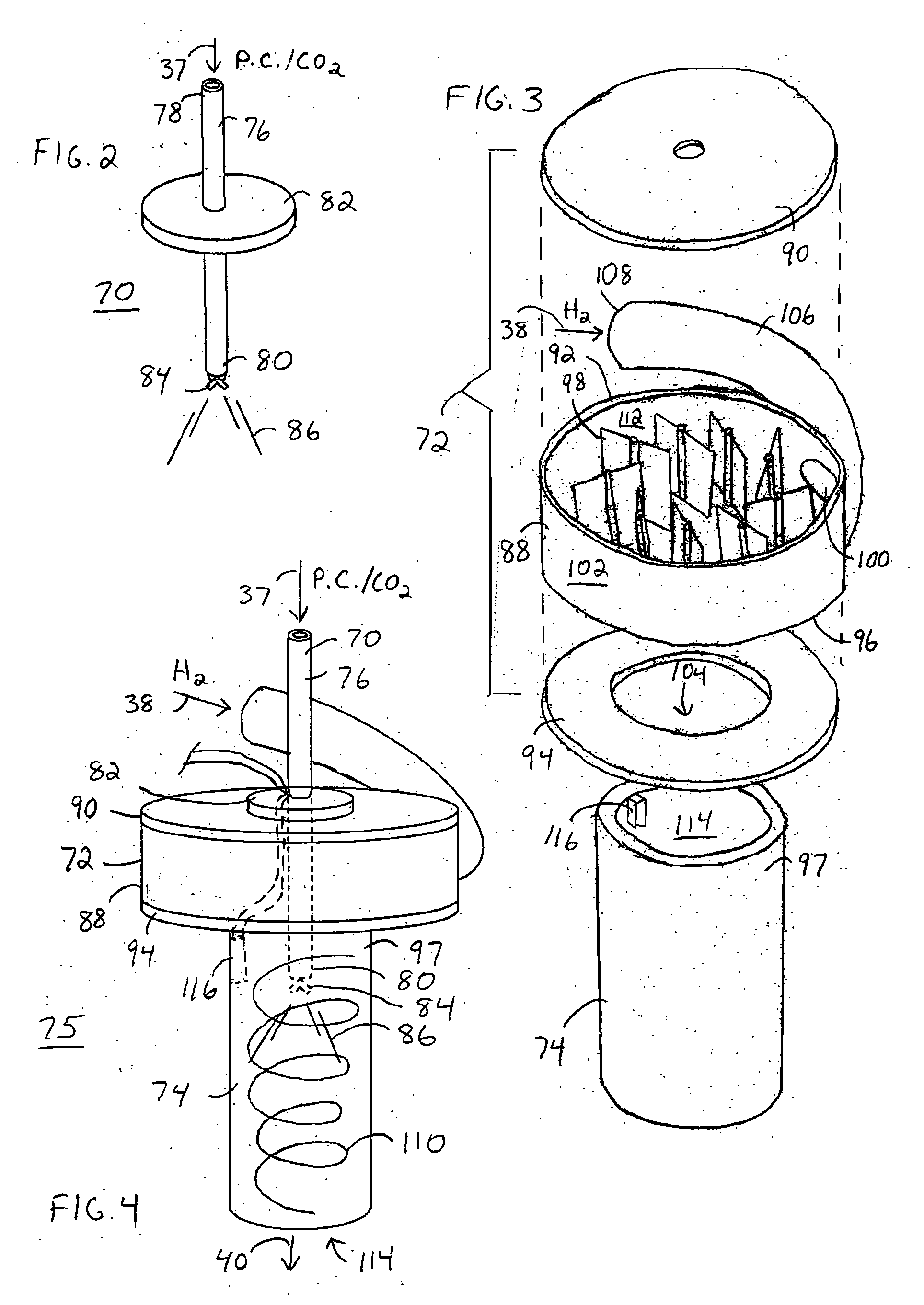

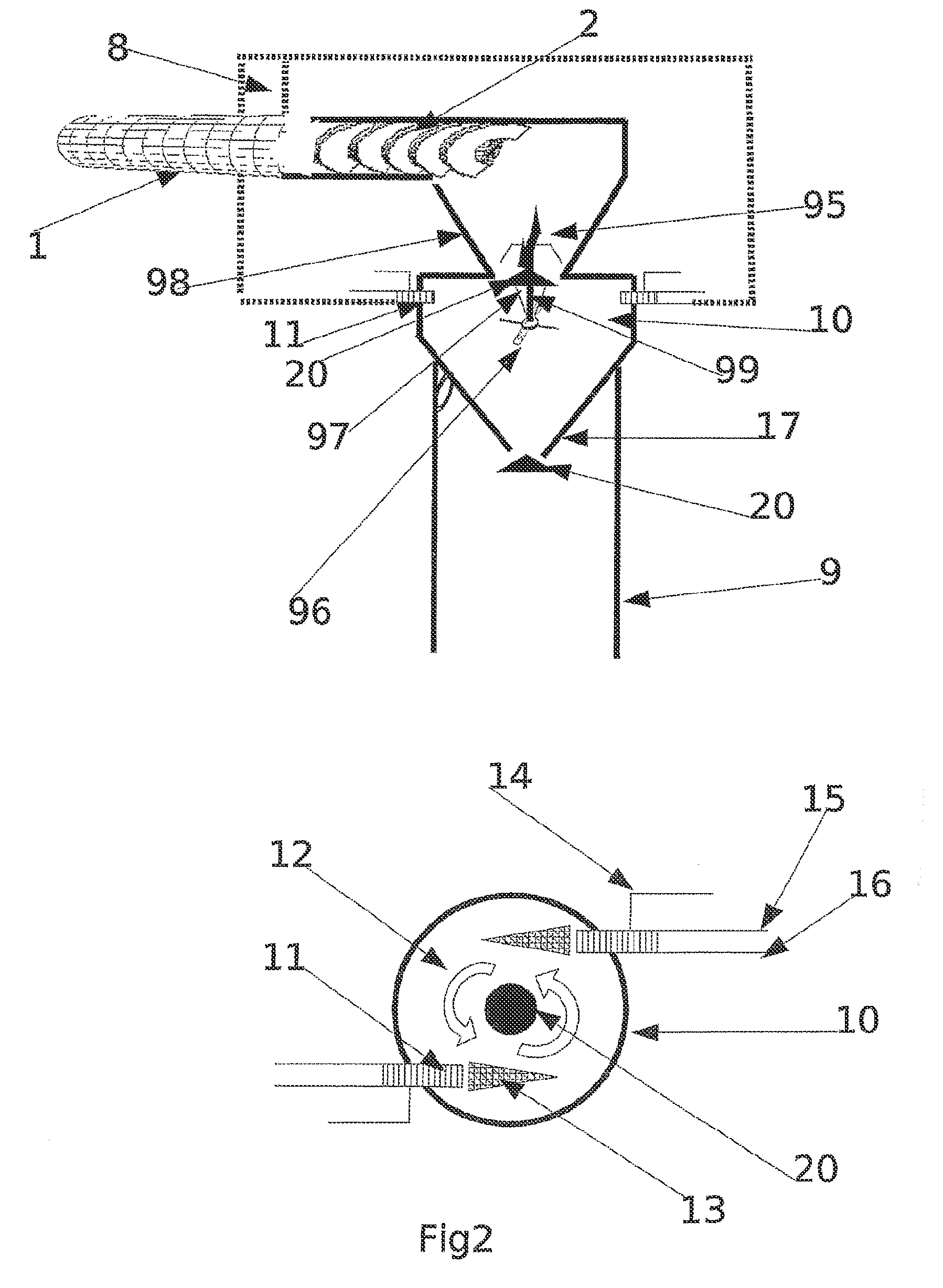

Method and apparatus for producing methane from carbonaceous material

InactiveUS20060265953A1Efficient productionEfficient deliveryHydrogen separationGaseous fuelsHydrogenReaction zone

A method for producing methane (69) from a carbonaceous (22) material includes conveying pulverized carbonaceous material (28) entrained in an inert carrier fluid, such as carbon dioxide (36), into a reactor (34). The reactor (34) includes a vortex region (72) for receiving hydrogen gas (38) and imparting a swirling motion to the hydrogen gas (38). The pulverized carbonaceous material (28) is exposed to the swirling stream of hydrogen gas (38) in a first reaction zone (114) within the reactor (34) to form an exit gas (40) that includes methane (69). Remaining unreacted carbonaceous material (28) is further exposed to the hydrogen gas (38) in a second, low velocity, reaction zone (120). The methane rich exit gas (40) is subsequently extracted from the reactor (34) for further processing.

Owner:ARIZONA PUBLIC SERVICE

Multiple stream high pressure mixer/reactor

InactiveUS6221332B1Improve reliabilityFew and less partCalcium/strontium/barium carbonatesPressurized chemical processStream flowLow density

Enhanced macromixing, mesomixing, and micromixing of multiple discrete reactant streams, particularly for precipitation reactions of low density pumpable fluids, are obtained by controlled continuous high pressure multiple reactant streams flowing into a chemical mixer / reactor. Individual reactant streams are pressurized to about 8,000 to 50,000 psi and achieve velocities up to about 250 meters / second in the final stage of the chemical mixer / reactor. Reactant flows are controlled by a combination of a fixed restriction and a variable driving pump.

Owner:MICROFLUIDICS INT

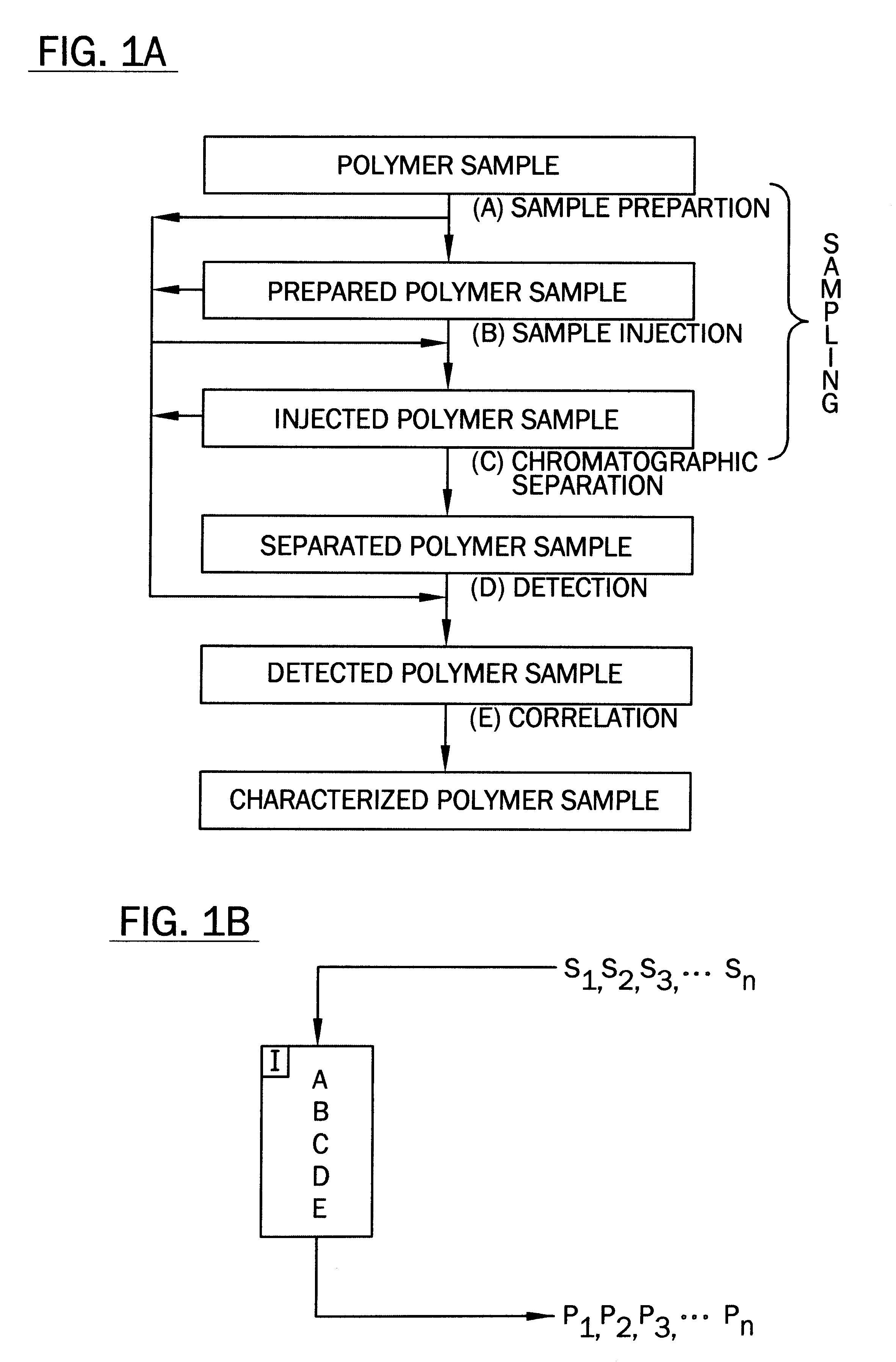

Automated sampling methods for rapid characterization of polymers

InactiveUS6265226B1Avoid backlogImprove throughputSequential/parallel process reactionsComponent separationFlow injection analysisPolymer

Rapid characterization and screening of polymer samples to determine average molecular weight, molecular weight distribution and other properties is disclosed. Rapid flow characterization systems and methods, including liquid chromatography and flow-injection analysis systems and methods are preferably employed. High throughput, automated sampling systems and methods, high-temperature characterization systems and methods, and rapid, indirect calibration compositions and methods are also disclosed. The described methods, systems, and devices have primary applications in combinatorial polymer research and in industrial process control.

Owner:INTERMOLECULAR

Hydrogen and elemental carbon production from natural gas and other hydrocarbons

InactiveUS6395197B1High quench rateAddressing slow performanceHydrocarbon from carbon oxidesEnergy inputUnsaturated hydrocarbonHydrogen fuel

Diatomic hydrogen and unsaturated hydrocarbons are produced as reactor gases in a fast quench reactor. During the fast quench, the unsaturated hydrocarbons are further decomposed by reheating the reactor gases. More diatomic hydrogen is produced, along with elemental carbon. Other gas may be added at different stages in the process to form a desired end product and prevent back reactions. The product is a substantially clean-burning hydrogen fuel that leaves no greenhouse gas emissions, and elemental carbon that may be used in powder form as a commodity for several processes.

Owner:BATTELLE ENERGY ALLIANCE LLC

Thermal synthesis apparatus and process

InactiveUS6821500B2Improve efficiencyHigh yieldCarbon monoxideIndirect heat exchangersNuclear engineeringReaction zone

An apparatus for thermal conversion of one or more reactants to desired end products includes an insulated reactor chamber having a high temperature heater such as a plasma torch at its inlet end and, optionally, a restrictive convergent-divergent nozzle at its outlet end. In a thermal conversion method, reactants are injected upstream from the reactor chamber and thoroughly mixed with the plasma stream before entering the reactor chamber. The reactor chamber has a reaction zone that is maintained at a substantially uniform temperature. The resulting heated gaseous stream is then rapidly cooled by passage through the nozzle, which "freezes" the desired end product(s) in the heated equilibrium reaction stage, or is discharged through an outlet pipe without the convergent-divergent nozzle. The desired end products are then separated from the gaseous stream.

Owner:BATTELLE ENERGY ALLIANCE LLC

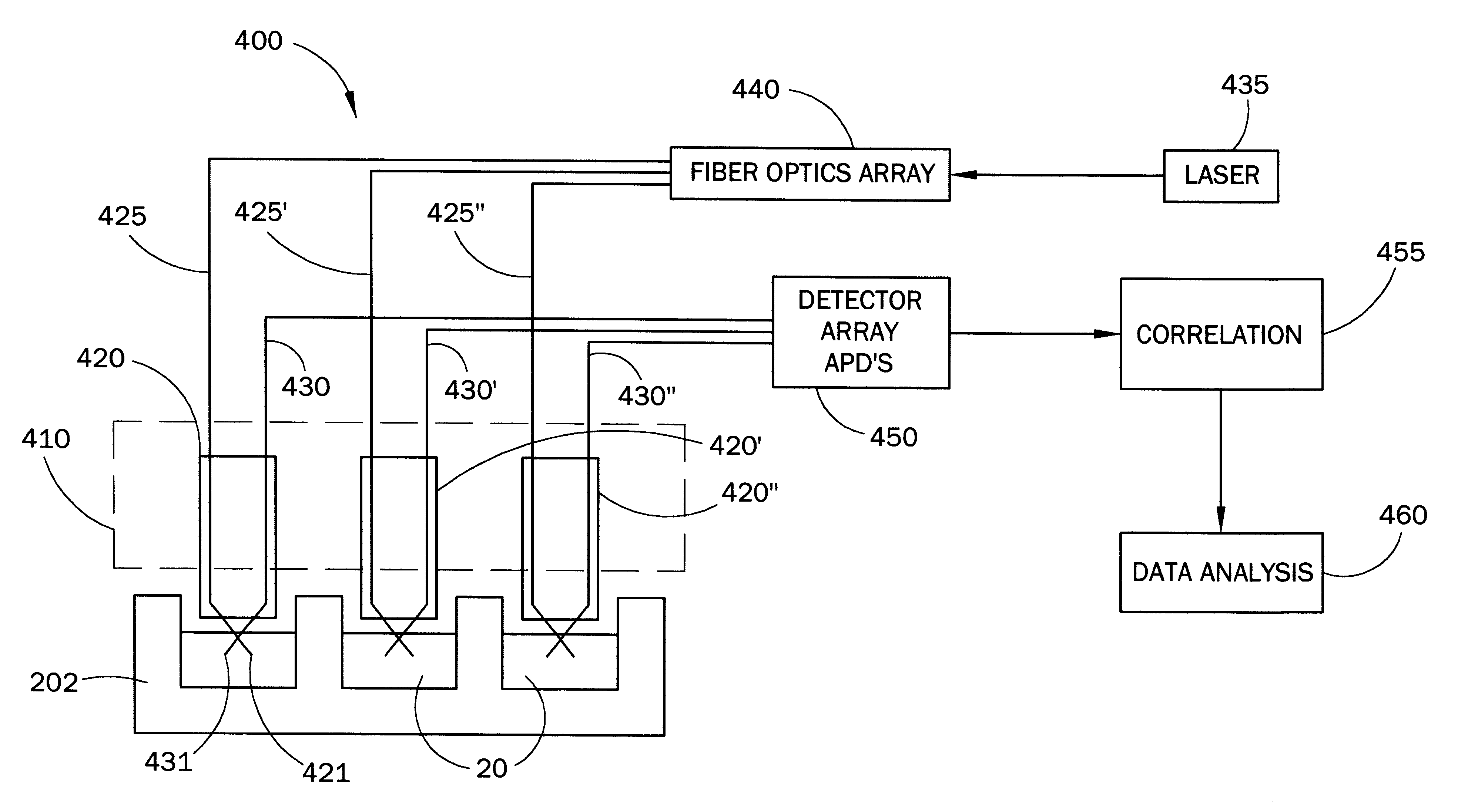

Fiber optic apparatus and use thereof in combinatorial material science

InactiveUS6519032B1Facilitate the discovery of commercially important polymericEffectively and efficiently characterizingSequential/parallel process reactionsComponent separationFiberHigh-Throughput Screening Methods

Methods, systems and devices are described for rapid characterization and screening of liquid samples to determine properties (e.g., particle size, particle size distribution, molar mass and / or molar mass distribution) thereof with static light scattering and / or dynamic light scattering. The liquid samples can be solutions, emulsions, suspensions or dispersions. One method, includes providing a vessel containing a liquid sample having an exposed surface that defines a gas-liquid sample interface, and analyzing the sample by light scattering methods that include transmitting light through the gas-liquid sample interface into the sample, and detecting light scattered from the sample or from a component thereof. Additional methods are directed to characterizing a plurality of liquid samples or components thereof. The methods, systems, and devices have applications in high-throughput screening, and particularly, in combinatorial materials research and in industrial process control.

Owner:WYATT TECH

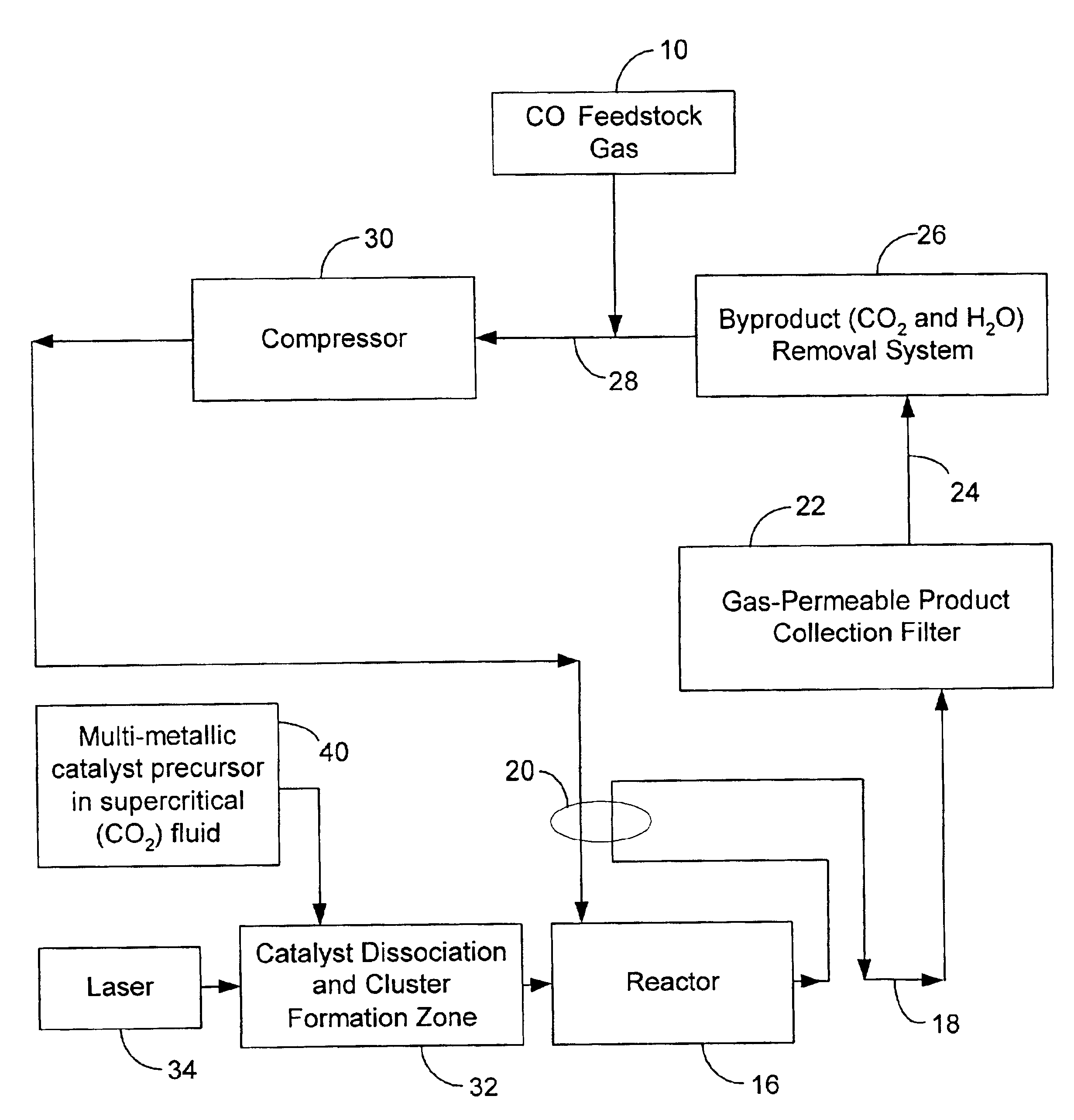

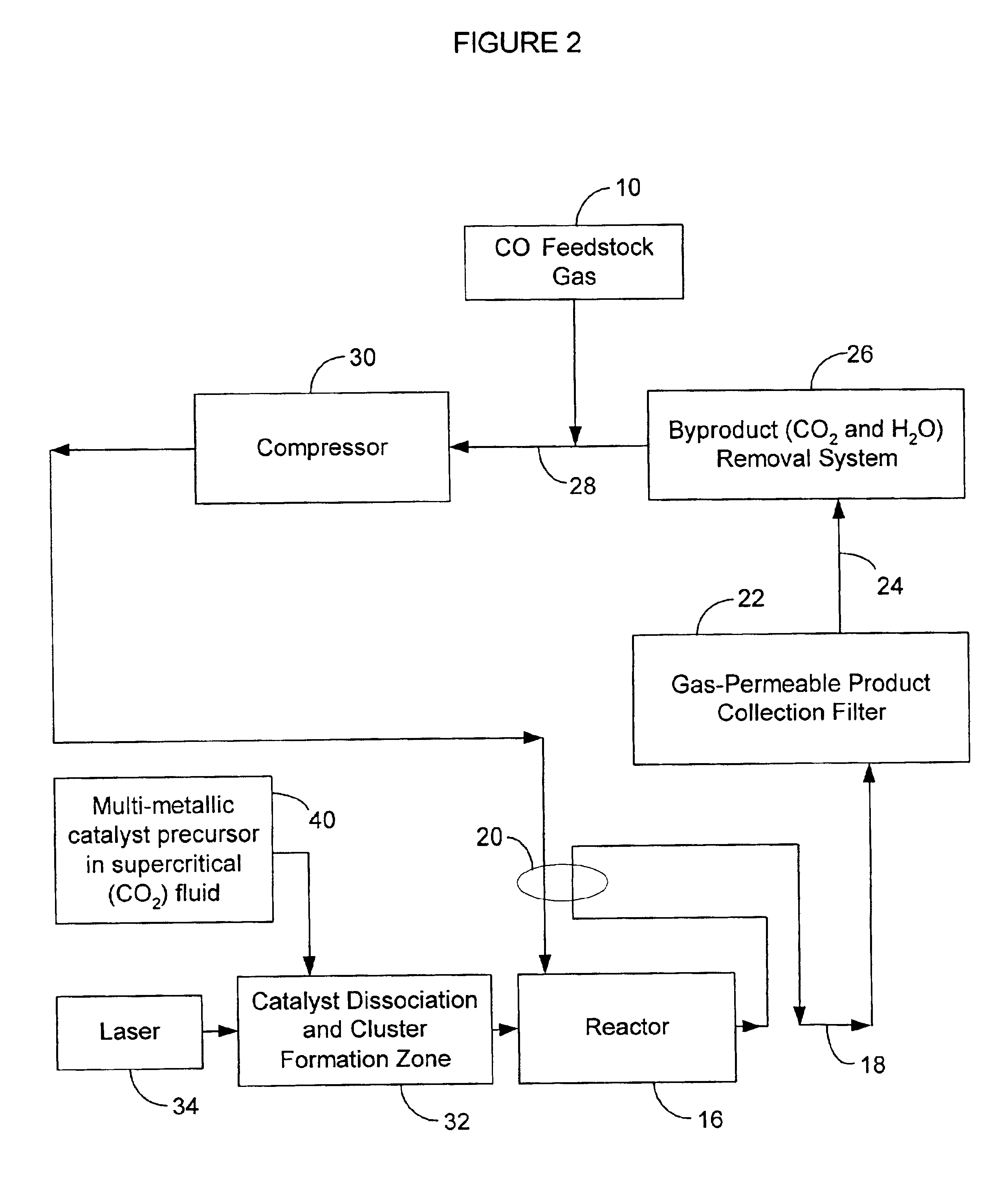

Process utilizing seeds for making single-wall carbon nanotubes

InactiveUS7052668B2Facilitates nucleation phaseFaster and more reproducible and stable clusteringMaterial nanotechnologyFullerenesMetal catalystGas phase

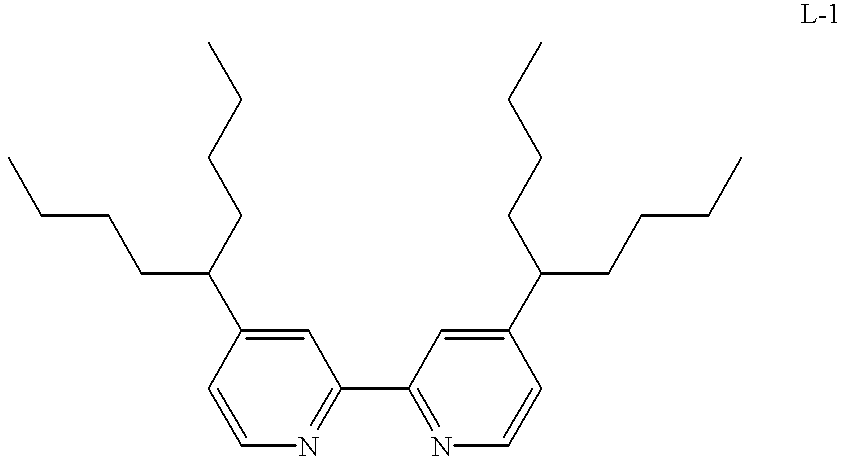

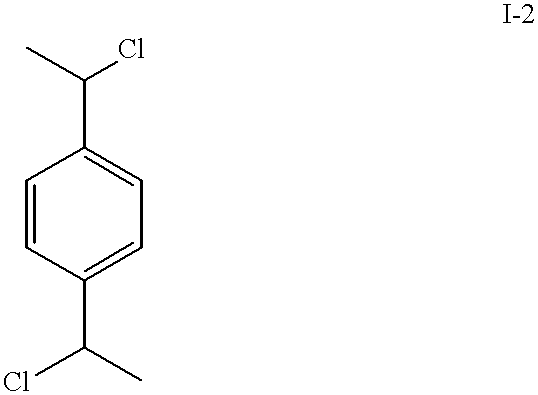

A gas-phase method for producing high yields of single-wall carbon nanotubes with high purity and homogeneity is disclosed. The method involves using preformed metal catalyst clusters to initiate and grow single-wall carbon nanotubes. In one embodiment, multi-metallic catalyst precursors are used to facilitate the metal catalyst cluster formation. The catalyst clusters are grown to the desired size before mixing with a carbon-containing feedstock at a temperature and pressure sufficient to initiate and form single-wall carbon nanotubes. The method also involves using small fullerenes and preformed sections of single-wall carbon nanotubes, either derivatized or underivatized, as seed molecules for expediting the growth and increasing the yield of single-wall carbon nanotubes. The multi-metallic catalyst precursors and the seed molecules may be introduced into the reactor by means of a supercritical fluid. In addition the seed molecules may be introduced into the reactor via an aerosol or smoke.

Owner:RICE UNIV

Processes and apparatus for continuous solution polymerization

InactiveUS20040024146A1Suppress further polymerizationProcess control/regulationLiquid-gas reaction as foam/aerosol/bubblesSolution polymerizationProcess plant

The invention relates to processes and plants for continuous solution polymerization. Such plant and processes include a pressure source, a polymerization reactor, downstream of said pressure source, pressure let-down device, downstream of said polymerization reactor, and a separator, downstream of said pressure let-down device, wherein said pressure source is sufficient to provide pressure to said reaction mixture during operation of said process plant to produce a single-phase liquid reaction mixture in said reactor and a two-phase liquid-liquid reaction mixture in said separator in the absence of an additional pressure source between said reactor and said separator.

Owner:EXXONMOBIL CHEM PAT INC

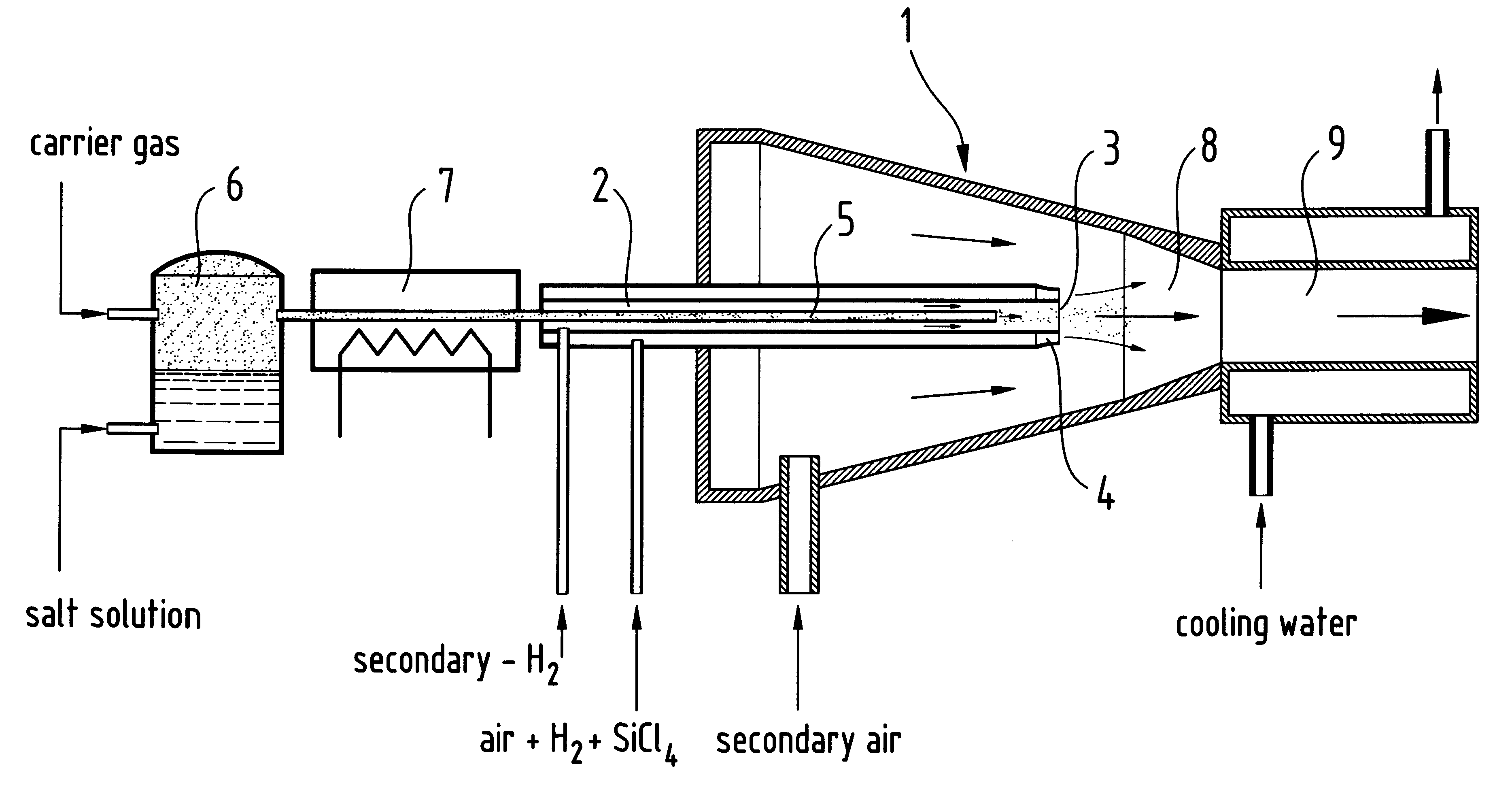

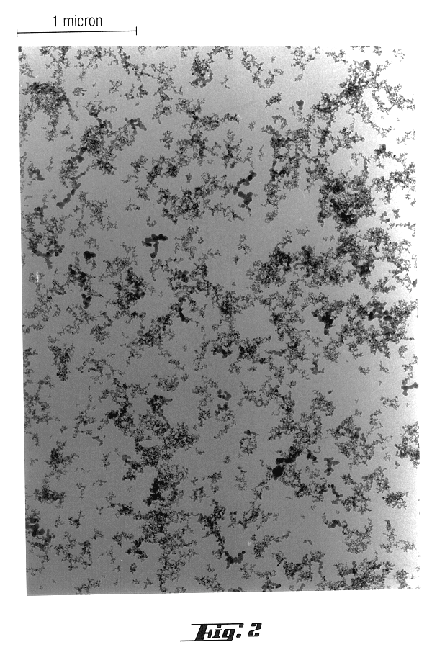

Doped, pyrogenically prepared oxides

InactiveUS6328944B1Germanium dioxidePipe protection by thermal insulationDoped oxideAqueous solution

Doped, pyrogenically prepared oxides of metals and / or non-metals which are doped with one or more doping components in an amount of 0.00001 to 20 wt. %. The doping component may be a metal and / or non-metal or an oxide and / or a salt of a metal and / or a non-metal. The BET surface area of the doped oxide may be between 5 and 600 m2 / g. The doped pyrogenically prepared oxides of metals and / or non-metals are prepared by adding an aerosol which contains an aqueous solution of a metal and / or non-metal to the gas mixture during the flame hydrolysis of vaporizable compounds of metals and / or non-metals.

Owner:EVONIK DEGUSSA GMBH

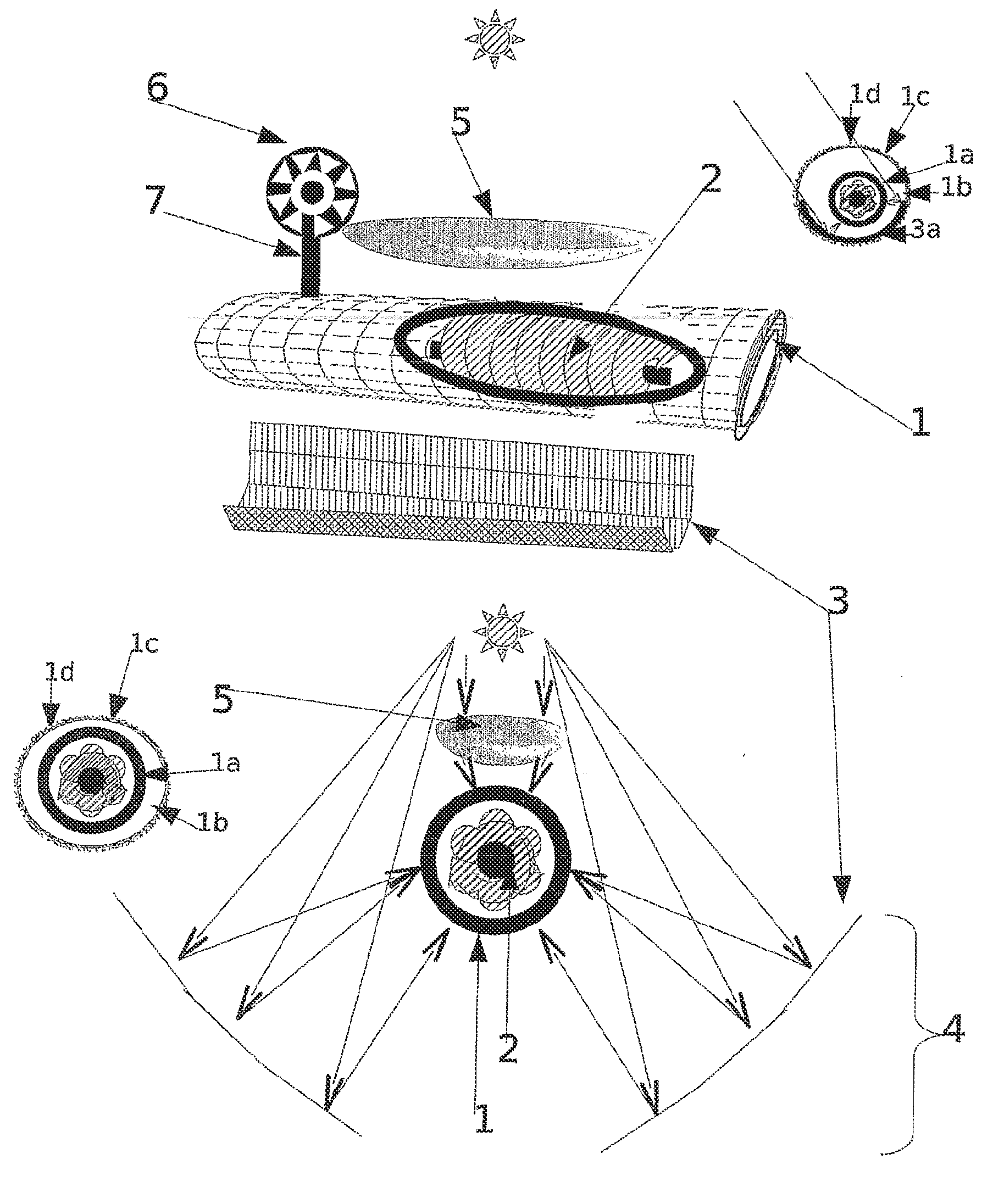

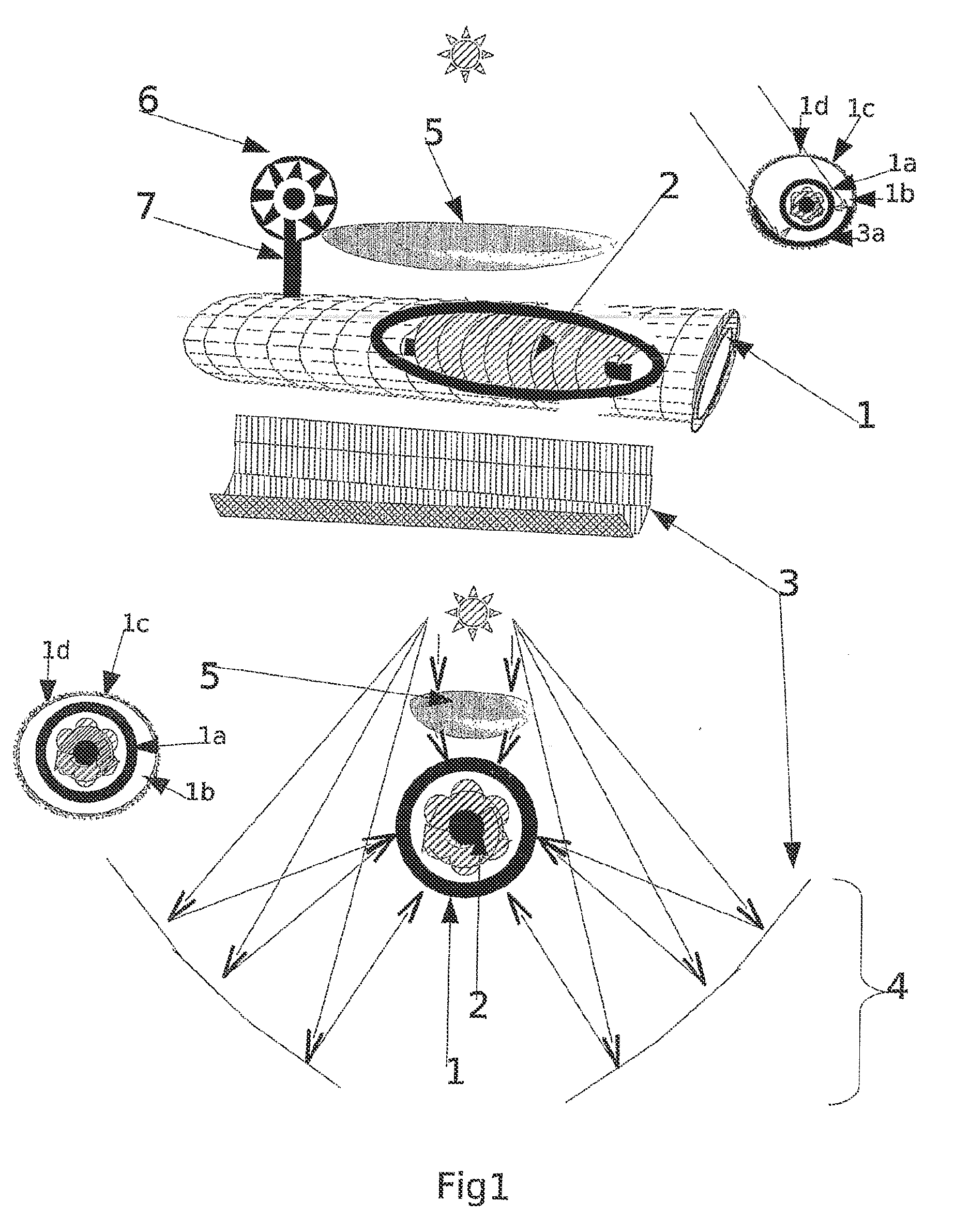

Method using solar energy, microwaves and plasmas to produce a liquid fuel and hydrogen from biomass or fossil coal

ActiveUS20100258429A1Promote gasificationImproving thermal inertiaElectrical coke oven heatingSolar heating energySludgeFractionating column

A system uses thermal solar energy coupled with microwaves and plasma for producing carbon monoxide (CO) and dihydrogen (H2) from carbonated compounds (biomass, domestic waste, sludge from waste water, fossil coal), wherein the obtained gaseous mixture yields, amongst others, hydrocarbon fuels (olefins, paraffin), esters, and alcohols via a Fischer-Tropsch synthesis. In a first step the carbonated compounds are roasted and pyrolized to produce char and dry coal, and a mixture of superheated gases containing CO2, steam, tars and non-condensable volatile materials. The method includes in a second step, and from the pyrolyis products (char or coal, gas mixture), generating a syngas substantially containing a mixture of carbon monoxide and dihydrogen, the mixture being used in Fischer-Tropsch synthesis units. After the Fischer-Tropsch step, the synthesis products are separated in a distillation column after heating in solar furnaces of mixed furnaces (solar / microwave).

Owner:UGOLIN NICOLAS

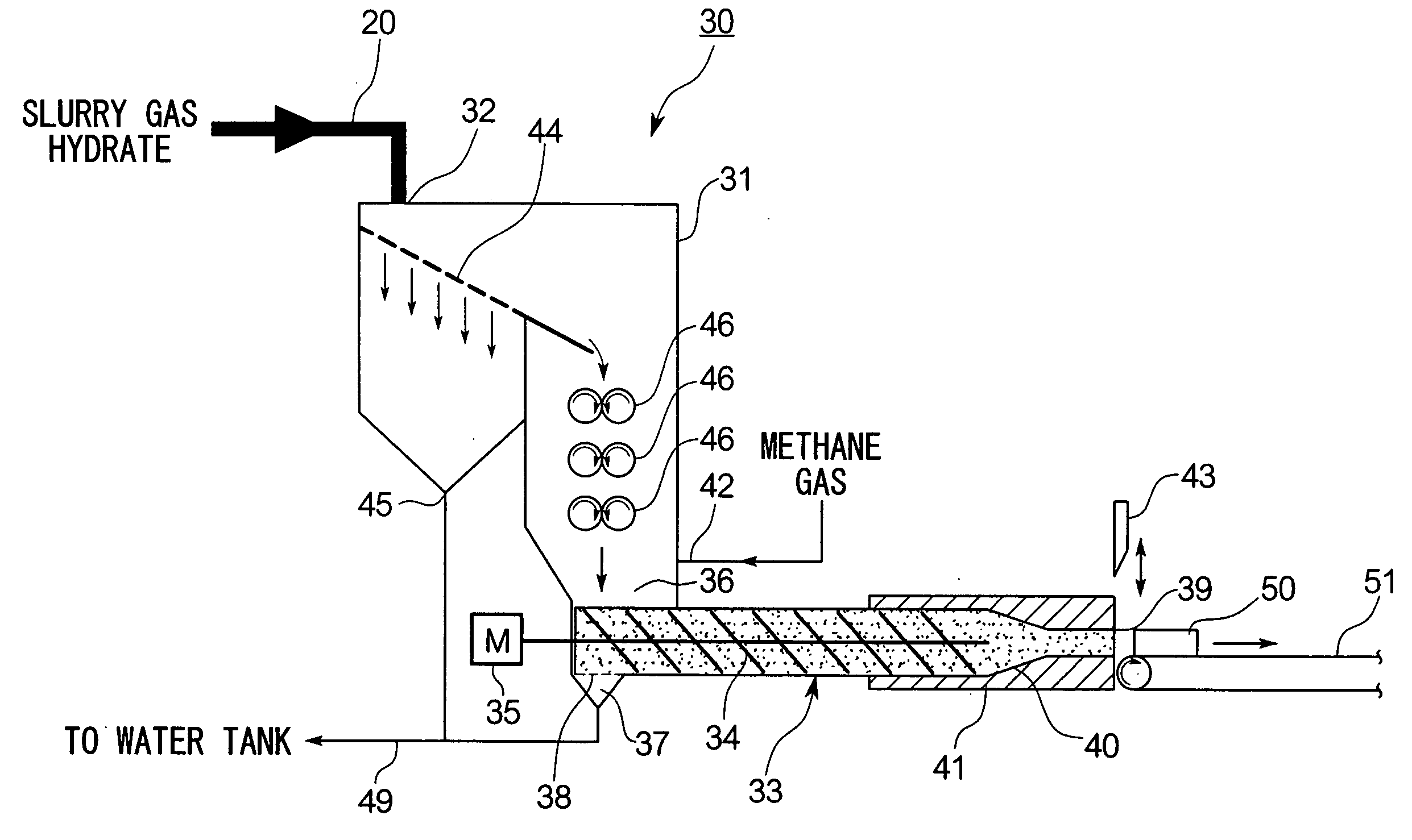

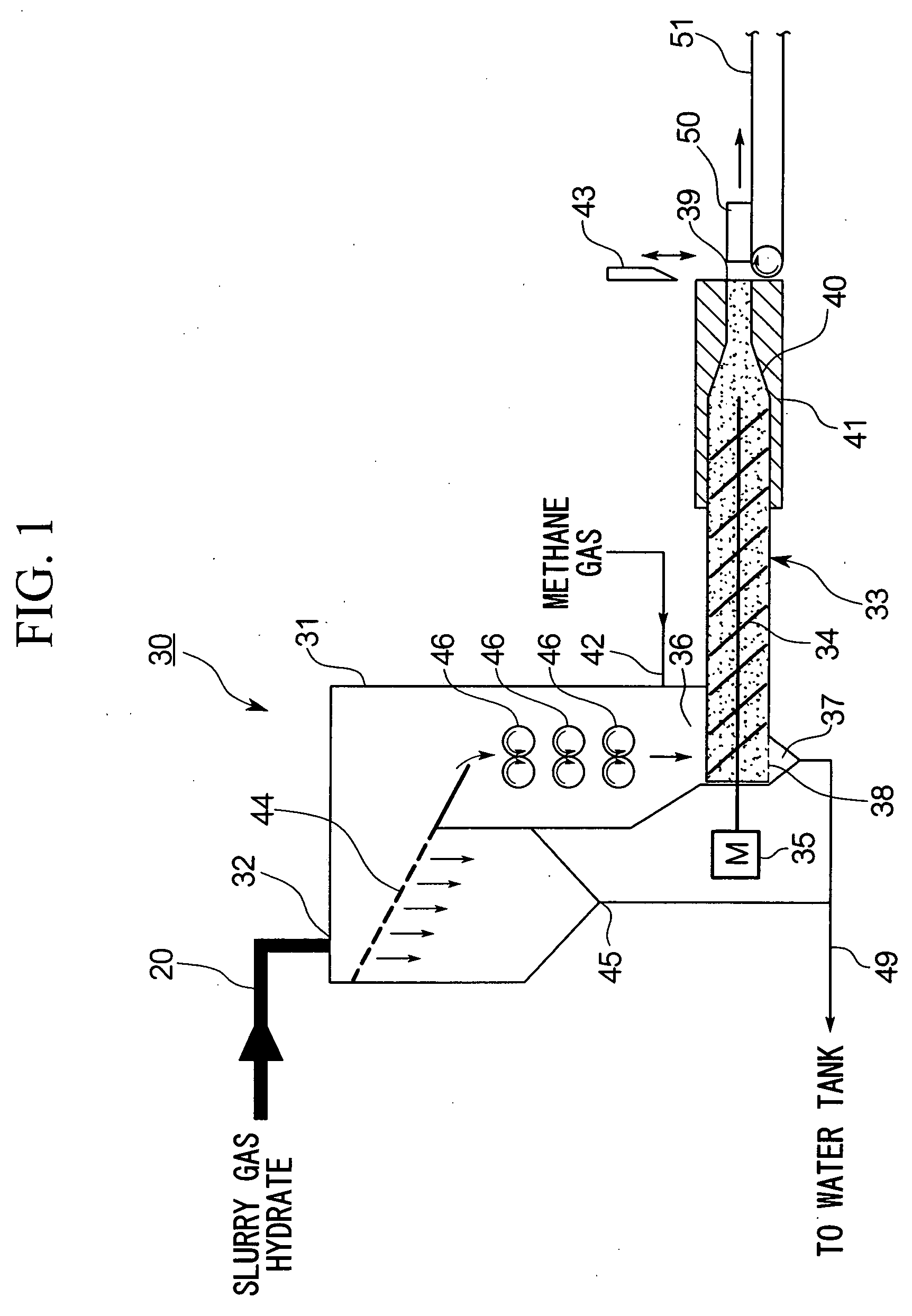

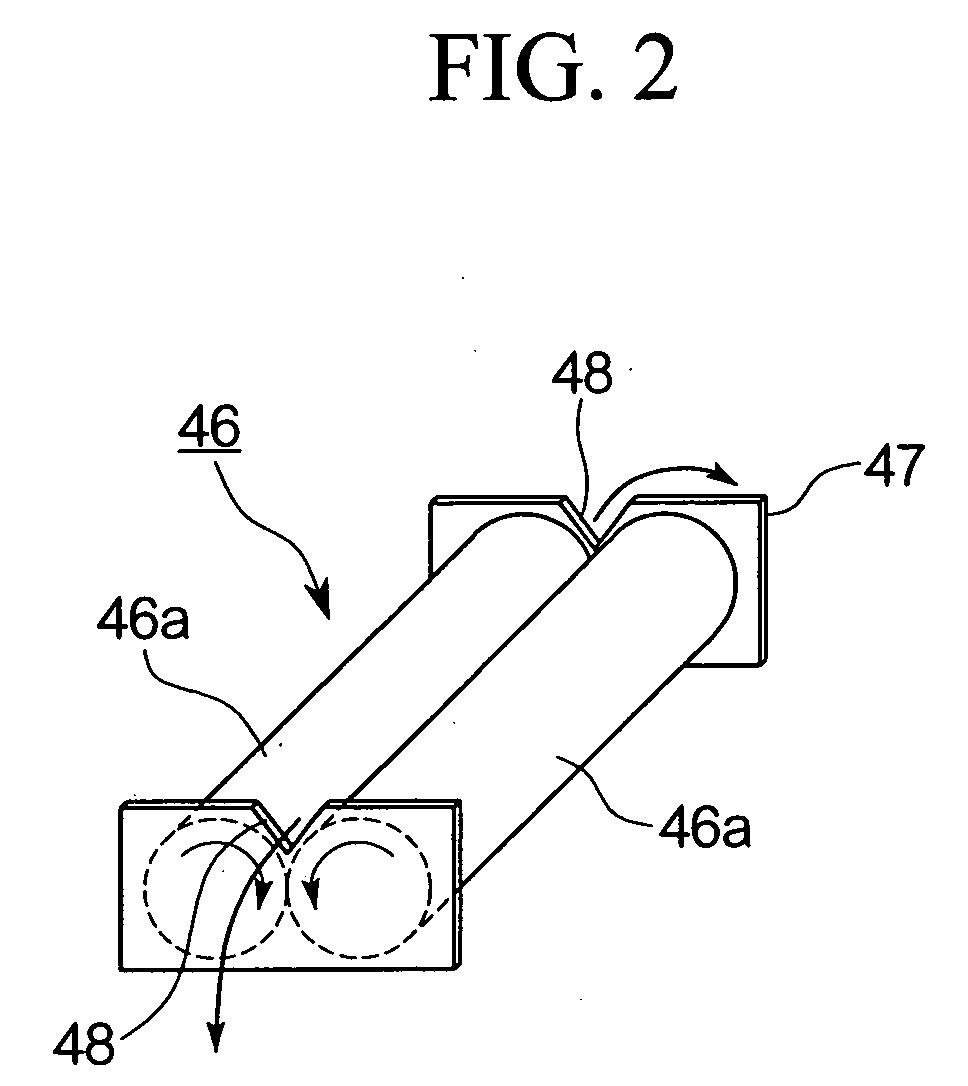

Gas hydrate production device and gas hydrate dehydrating device

InactiveUS20050107648A1Easy to implementSmall sizeOrganic chemistryDrying solid materials without heatAmbient pressureSlurry

The invention relates to a gas hydrate dewatering cooling and outputting apparatus which dewaters and solidifies gas hydrate slurry and takes out the solidified gas hydrate under ambient pressure. The apparatus comprises an output apparatus body 31 having a supply port 32 for the gas hydrate slurry on an upper part of a pressure vessel, a screw extruder 33 provided at a lower part inside the output apparatus body 31 and having a drain 37 and an outlet sealing device, and a cooling device 41 which cools the vicinity of the outlet 39 of the screw extruder 33. According to such a construction, slurry gas hydrate can be efficiently and continuously dewatered, cooled and solidified, and gas hydrate powder can be consolidated into blocks and taken out to the atmosphere.

Owner:MITSUBISHI HEAVY IND LTD

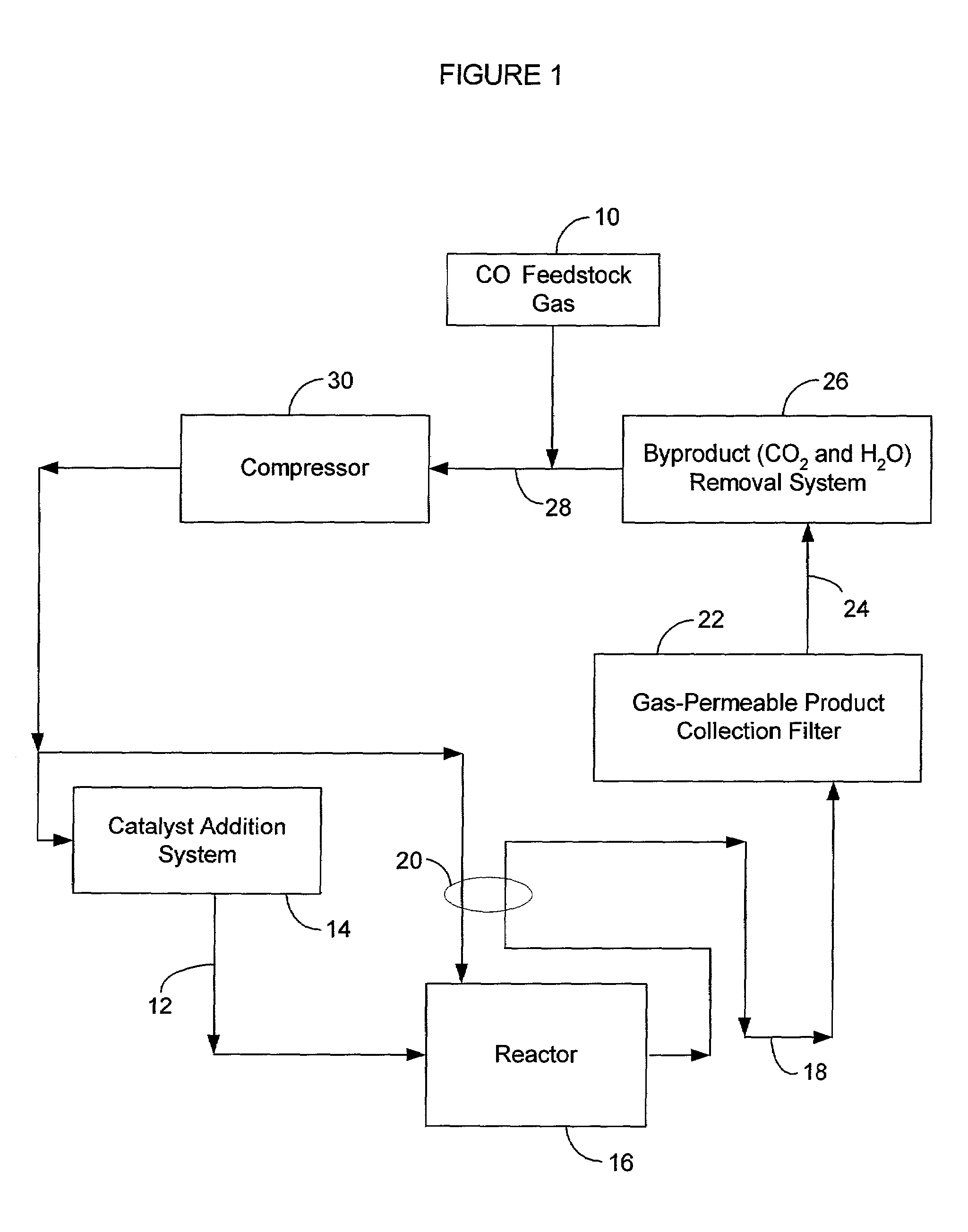

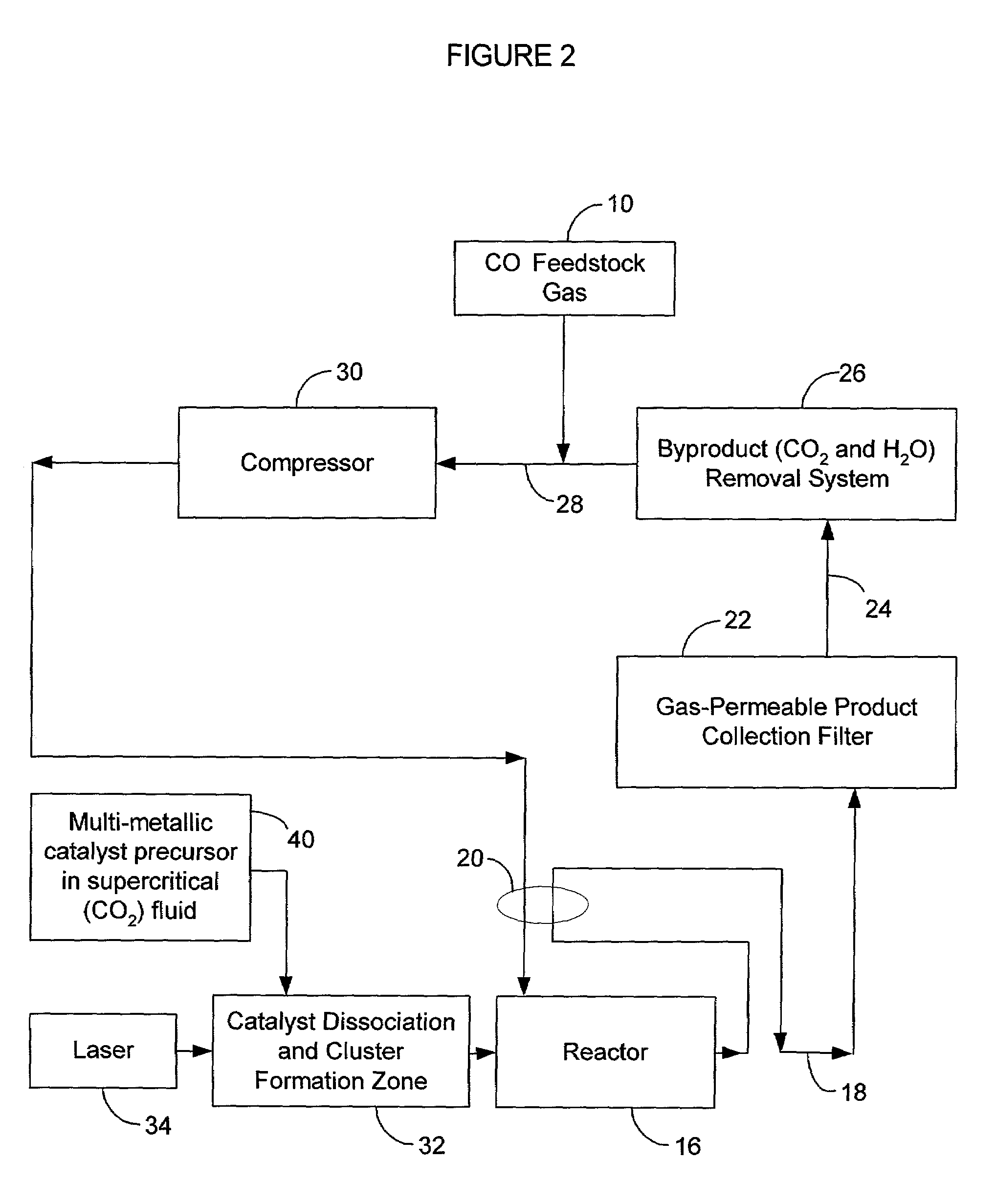

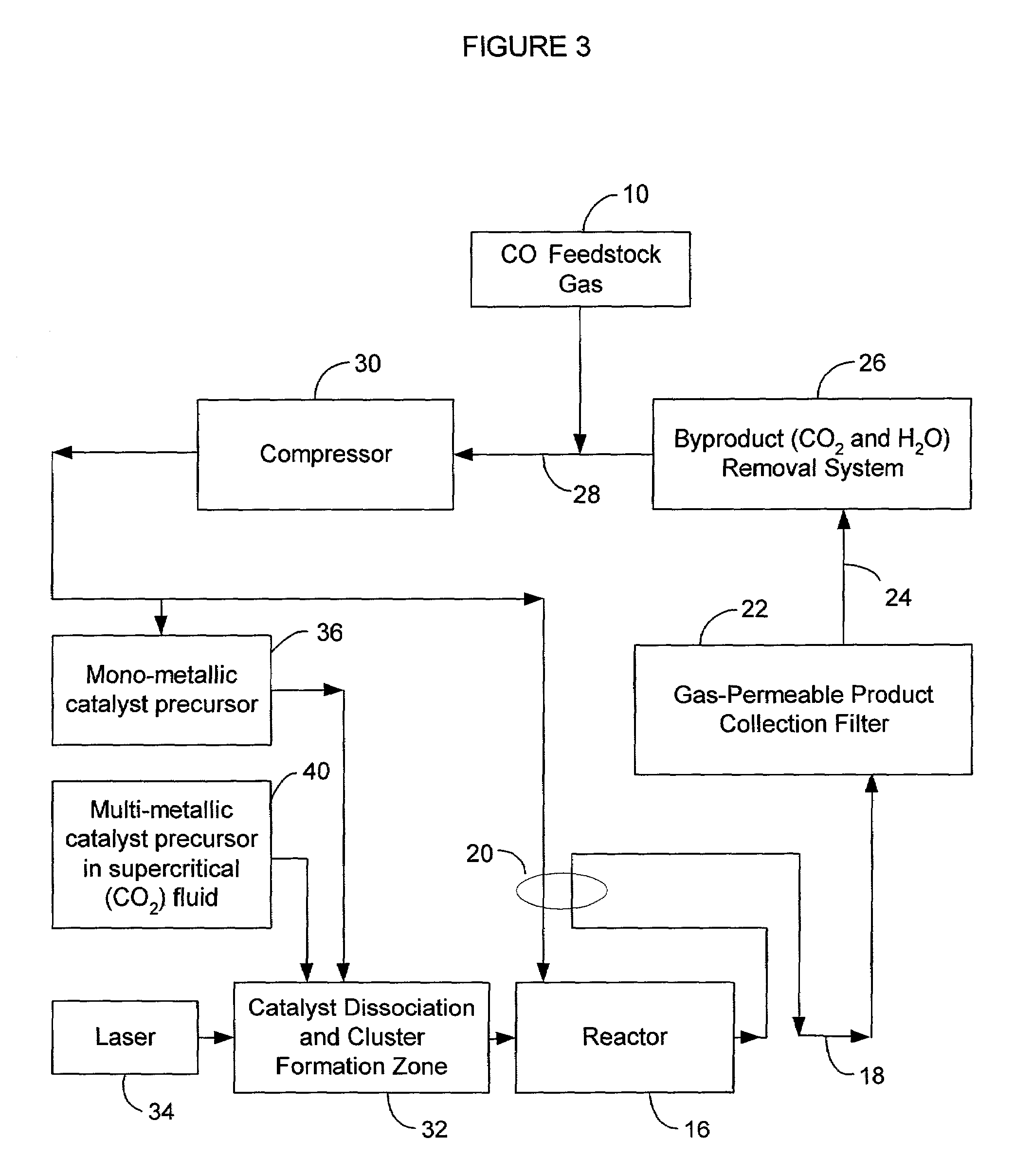

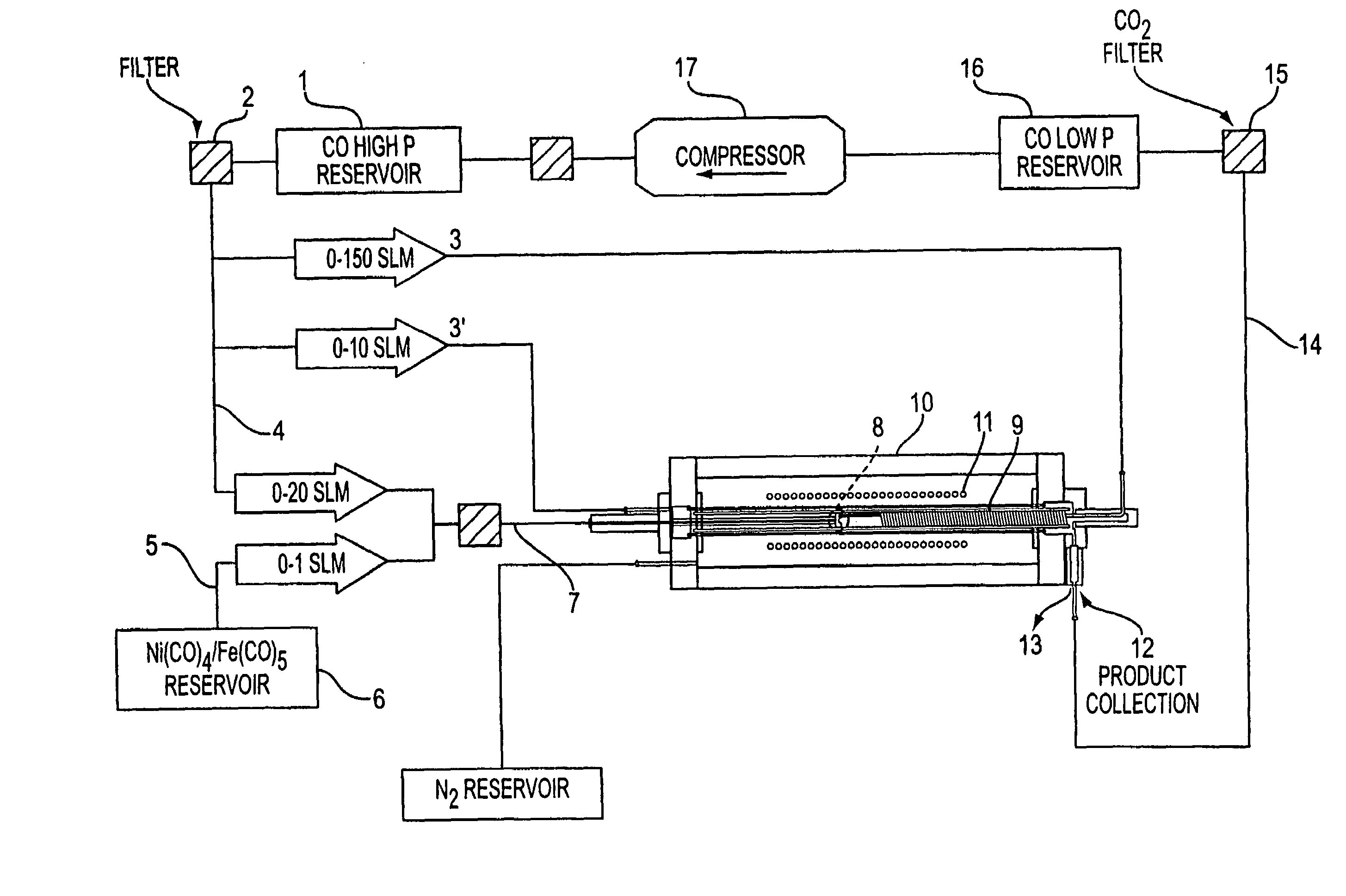

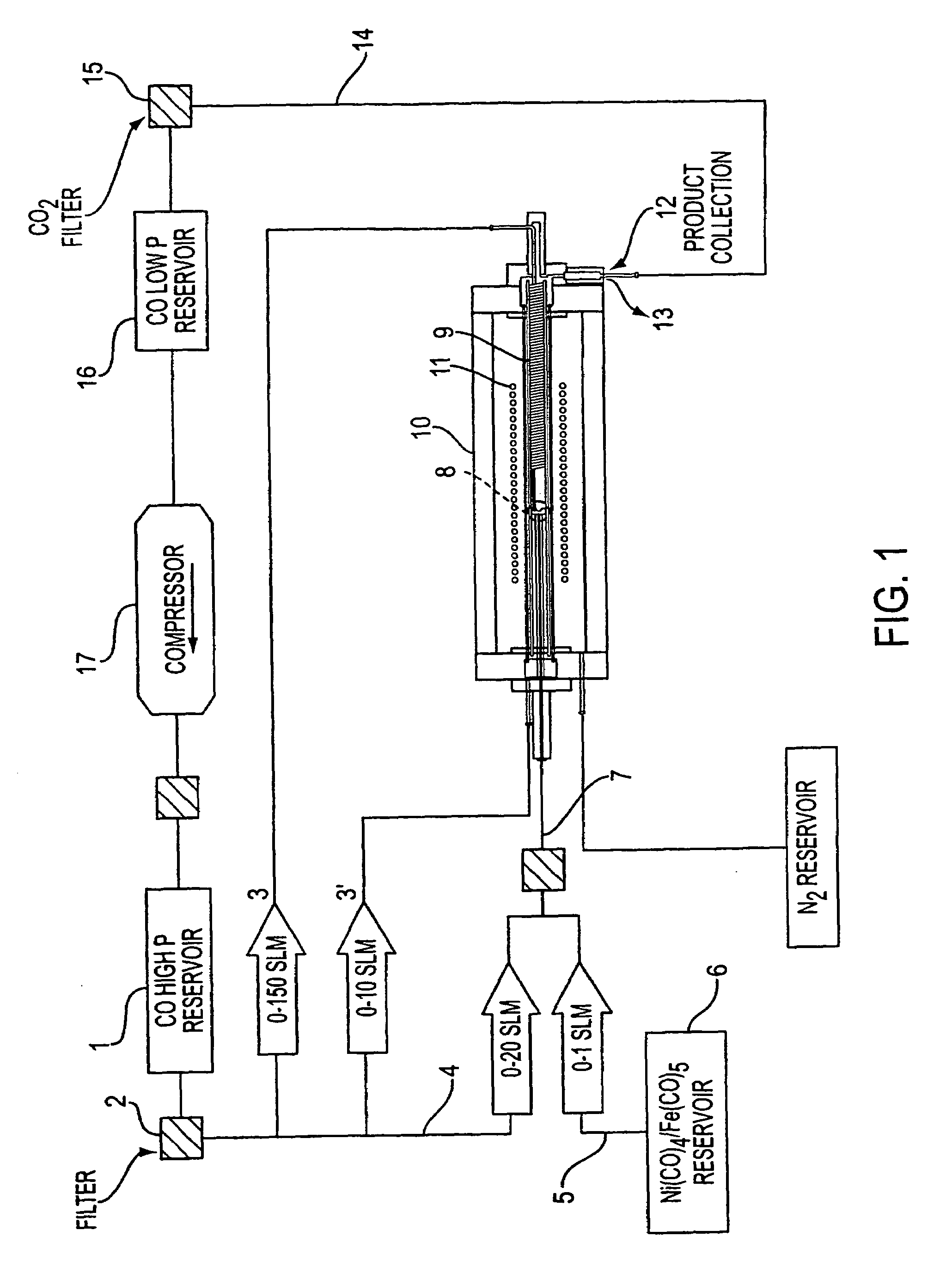

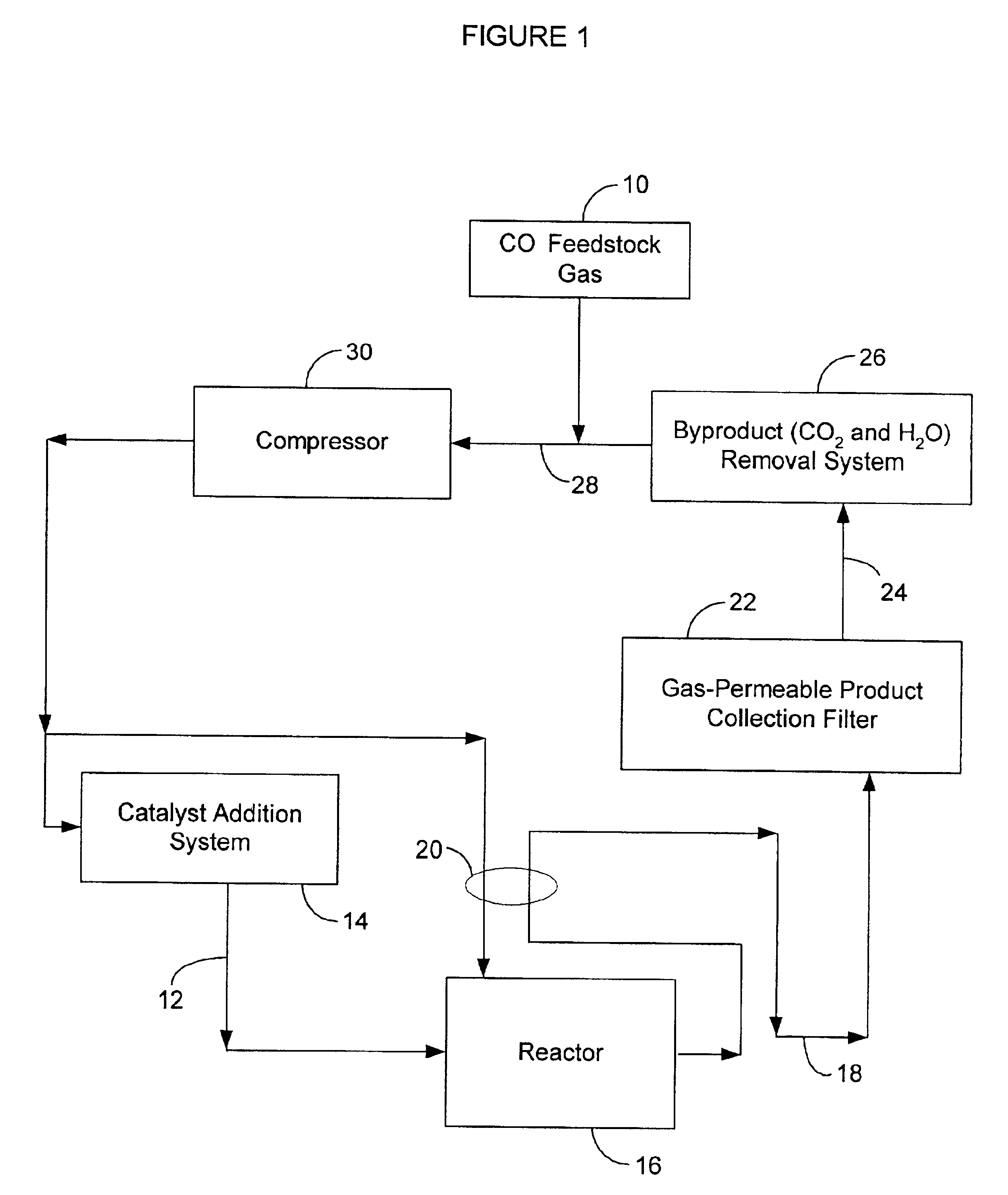

Single-wall carbon nanotubes from high pressure CO

InactiveUS7204970B2Promote rapid formationIncrease pressureMaterial nanotechnologyNanostructure manufactureDecompositionCarbon nanotube

The present invention discloses the process of supplying high pressure (e.g., 30 atmospheres) CO that has been preheated (e.g., to about 1000° C.) and a catalyst precursor gas (e.g., Fe(CO)5) in CO that is kept below the catalyst precursor decomposition temperature to a mixing zone. In this mixing zone, the catalyst precursor is rapidly heated to a temperature that results in (1) precursor decomposition, (2) formation of active catalyst metal atom clusters of the appropriate size, and (3) favorable growth of SWNTs on the catalyst clusters. Preferably a catalyst cluster nucleation agency is employed to enable rapid reaction of the catalyst precursor gas to form many small, active catalyst particles instead of a few large, inactive ones. Such nucleation agencies can include auxiliary metal precursors that cluster more rapidly than the primary catalyst, or through provision of additional energy inputs (e.g., from a pulsed or CW laser) directed precisely at the region where cluster formation is desired. Under these conditions SWNTs nucleate and grow according to the Boudouard reaction. The SWNTs thus formed may be recovered directly or passed through a growth and annealing zone maintained at an elevated temperature (e.g., 1000° C.) in which tubes may continue to grow and coalesce into ropes.

Owner:RICE UNIV

Controlled combustion for regenerative reactors

The overall efficiency of a regenerative bed reverse flow reactor system is increased where the location of the exothermic reaction used for regeneration is suitably controlled. The present invention provides a method and apparatus for controlling the combustion to improve the thermal efficiency of bed regeneration in a cyclic reaction / regeneration processes. The process for thermal regeneration of a regenerative reactor bed entails(a) supplying the first reactant through a first channel means in a first regenerative bed and supplying at least a second reactant through a second channel means in the first regenerative bed,(b) combining said first and second reactants by a gas mixing means situated at an exit of the first regenerative bed and reacting the combined gas to produce a heated reaction product,(c) passing the heated reaction product through a second regenerative bed thereby transferring heat from the reaction product to the second regenerative bed.

Owner:EXXON RES & ENG CO

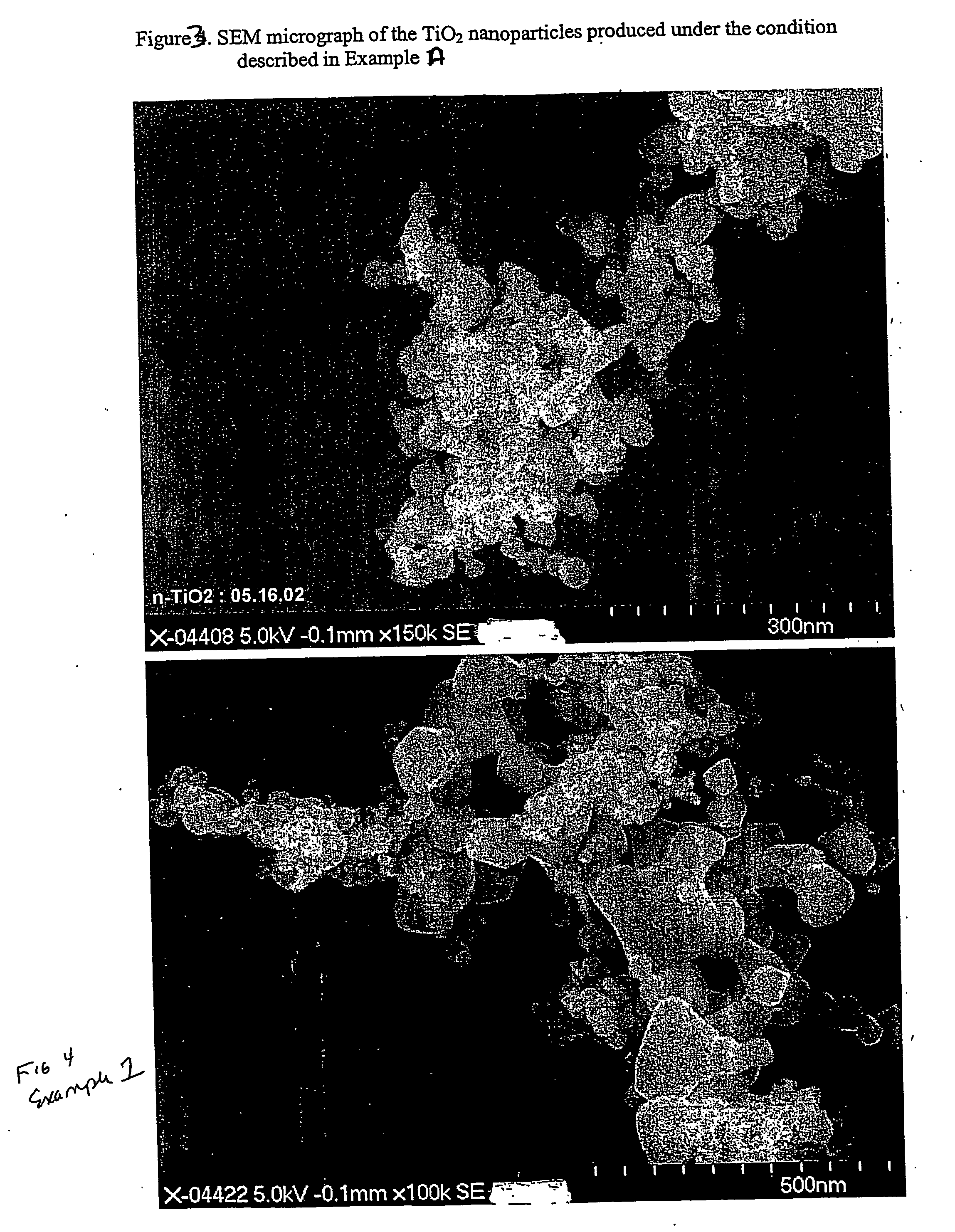

Method of producing nanoparticles using a evaporation-condensation process with a reaction chamber plasma reactor system

InactiveUS20060159596A1Reduce the temperatureMaterial nanotechnologyNanostructure manufactureNanoparticleReaction zone

The present invention provides a method and apparatus for the controlled synthesis of nanoparticles using a high temperature process. The reactor chamber includes a high temperature gas heated by means such as a plasma torch, and a reaction chamber. The homogenizer includes a region between the reactant inlets and the plasma (the spacer zone) to ensure that feeds from the reactant inlets are downstream of the recirculation zone induced by the high temperature gas. It also includes a region downstream of the reactant inlets that provides a nearly I dimensional (varying only in the axial direction) flow and concentration profile in the reaction zone to produce nanoparticles with narrow size distribution.

Owner:EI DU PONT DE NEMOURS & CO

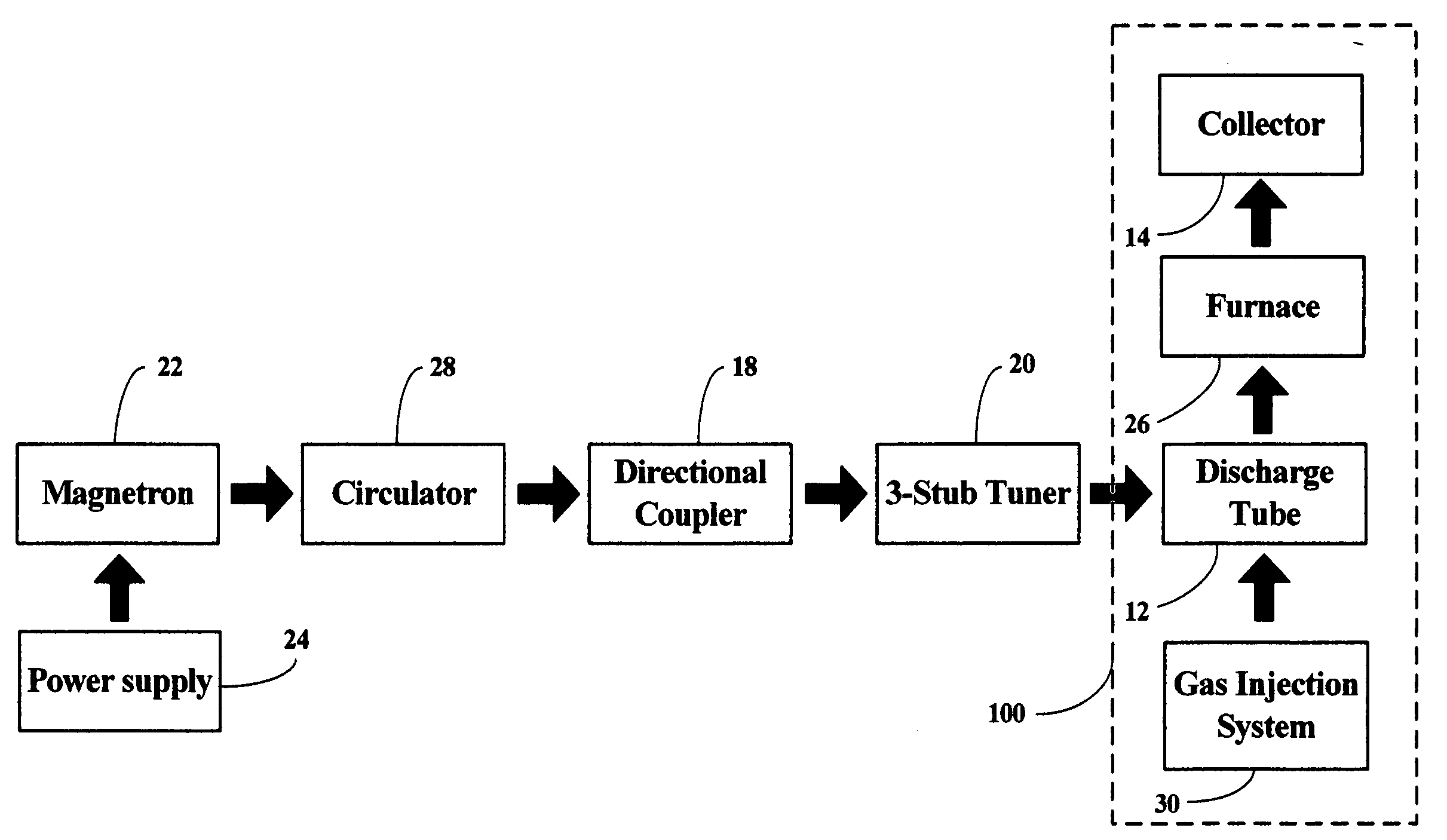

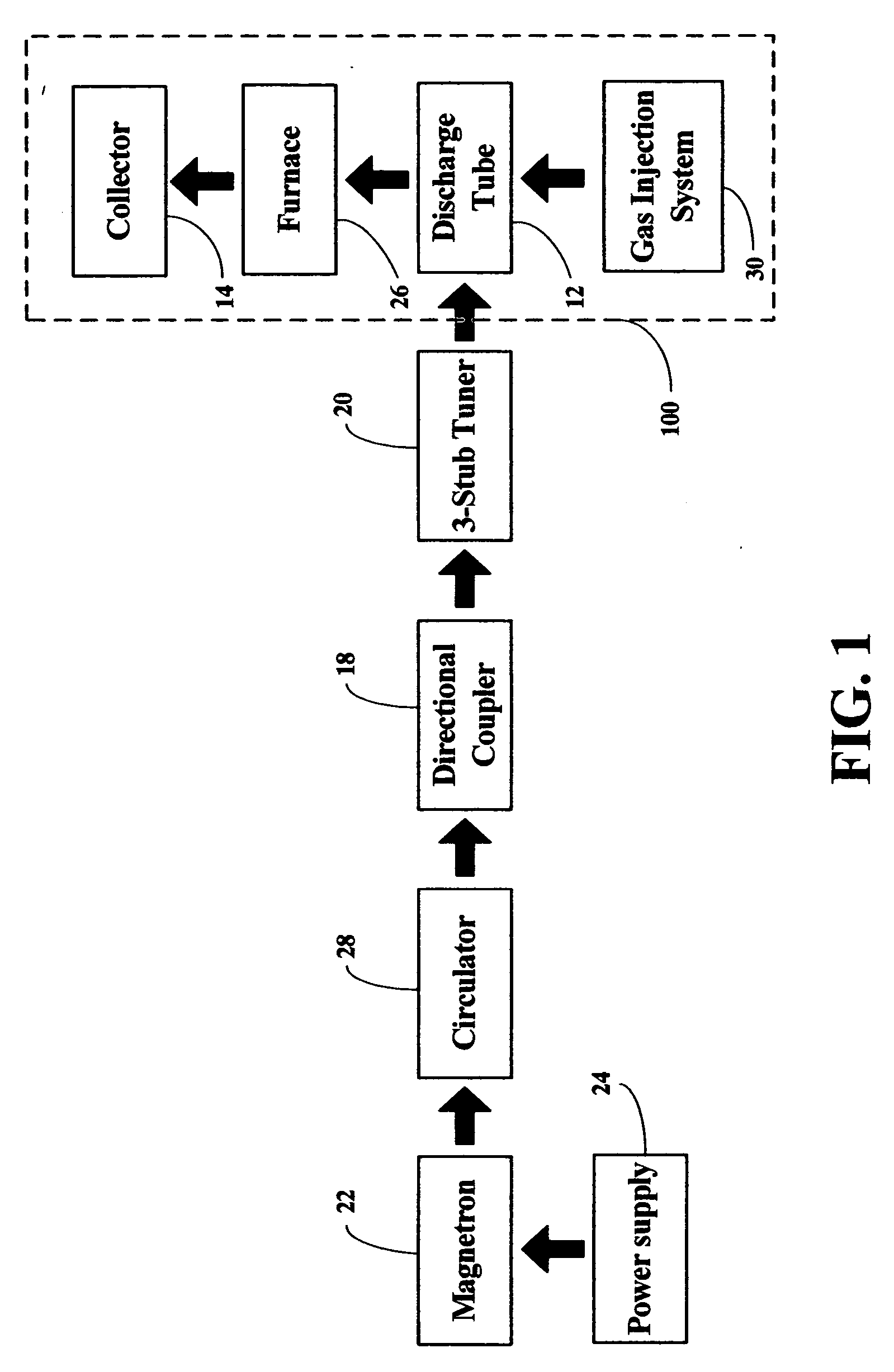

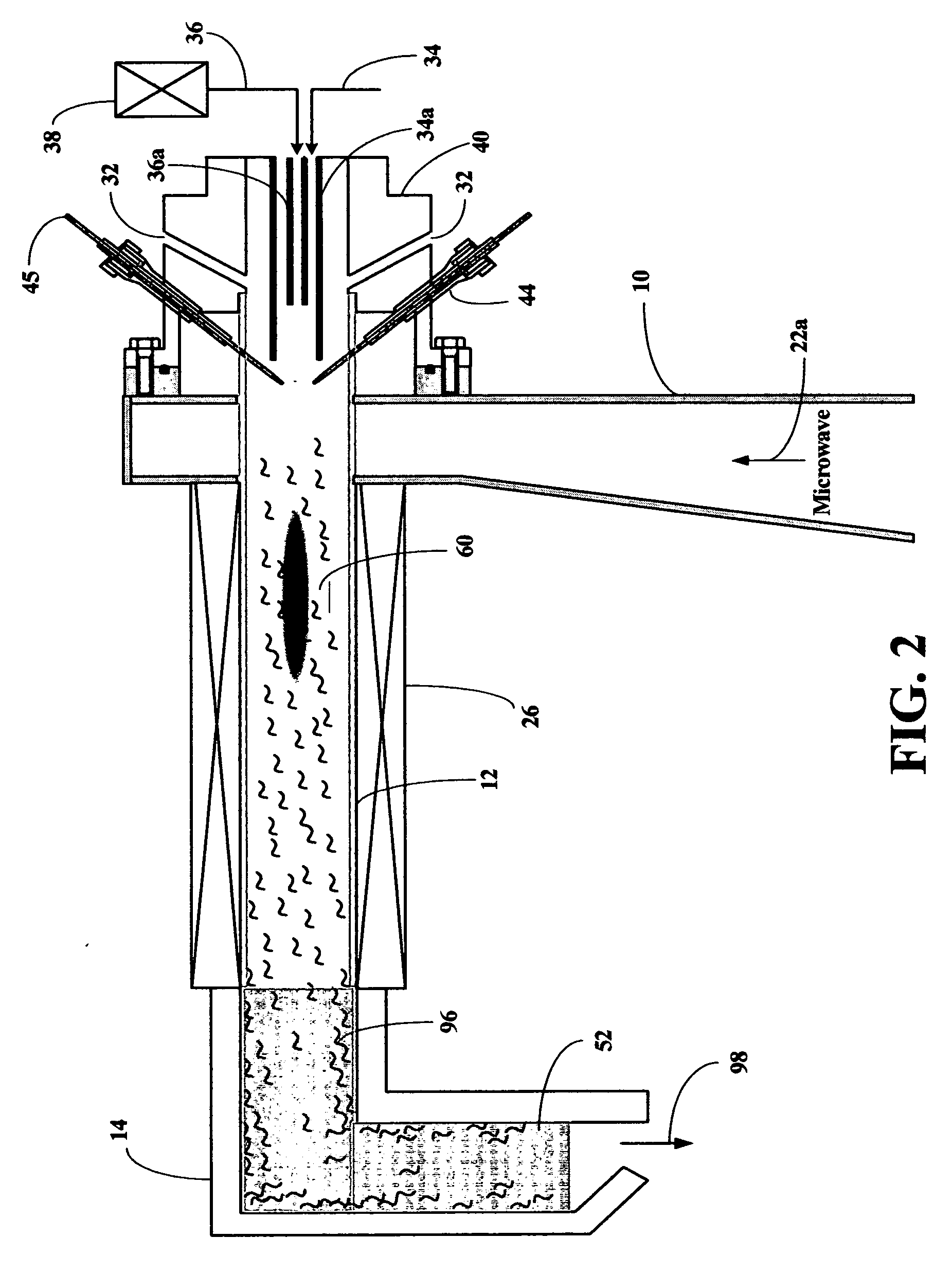

Synthesis of carbon nanotubes by making use of microwave plasma torch

InactiveUS20050163696A1Increase the electric field strengthInexpensive, commercially available and compactMaterial nanotechnologyNanoinformaticsGas phaseSynthesis methods

The present invention relates to a synthesis method of carbon nanotubes, and more particularly to an apparatus for a mass synthesis of carbon nanotubes in gas phase using an atmospheric-pressure microwave plasma torch. The method and apparatus is described for the continuous production of carbon nanotubes by making use of a microwave plasma torch operated at a frequency of 2.45 GHz, by introducing a transition metal catalyst precursor and a carbon containing gas into the microwave plasma torch to produce atomized catalyst metal and to decompose the carbon containing gas, by passing the resulting gaseous mixtures through a furnace, and by quenching rapidly and collecting the products so formed at the exit of the furnace. The resultant products are the carbon nanotubes.

Owner:UHM HAN S

Rapid characterization of polymers for combinatorial, analytical and process control applications

InactiveUS20010027949A1Avoid backlogImprove throughputSequential/parallel process reactionsSamplingFlow injection analysisPolymer

Rapid characterization and screening of polymer samples to determine average molecular weight, molecular weight distribution and other properties is disclosed. Rapid flow characterization systems and methods, including liquid chromatography and flow-injection analysis systems and methods are preferably employed. High throughput, automated sampling systems and methods, high-temperature characterization systems and methods, and rapid, indirect calibration compositions and methods are also disclosed. The described methods, systems, and devices have primary applications in combinatorial polymer research and in industrial process control.

Owner:INTERMOLECULAR

Process utilizing pre-formed cluster catalysts for making single-wall carbon nanotubes

InactiveUS6913789B2Facilitates nucleation phaseFaster and more reproducible and stable clusteringMaterial nanotechnologyFibre chemical featuresGas phaseMetal catalyst

A gas-phase method for producing high yields of single-wall carbon nanotubes with high purity and homogeneity is disclosed. The method involves using preformed metal catalyst clusters to initiate and grow single-wall carbon nanotubes. In one embodiment, multi-metallic catalyst precursors are used to facilitate the metal catalyst cluster formation. The catalyst clusters are grown to the desired size before mixing with a carbon-containing feedstock at a temperature and pressure sufficient to initiate and form single-wall carbon nanotubes. The method also involves using small fullerenes and preformed sections of single-wall carbon nanotubes, either derivatized or underivatized, as seed molecules for expediting the growth and increasing the yield of single-wall carbon nanotubes. The multi-metallic catalyst precursors and the seed molecules may be introduced into the reactor by means of a supercritical fluid. In addition the seed molecules may be introduced into the reactor via an aerosol or smoke.

Owner:RICE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com