Patents

Literature

196 results about "Regenerative process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In applied probability, a regenerative process is a class of stochastic process with the property that certain portions of the process can be treated as being statistically independent of each other. This property can be used in the derivation of theoretical properties of such processes.

Compositions for regenerating defective or absent myocardium

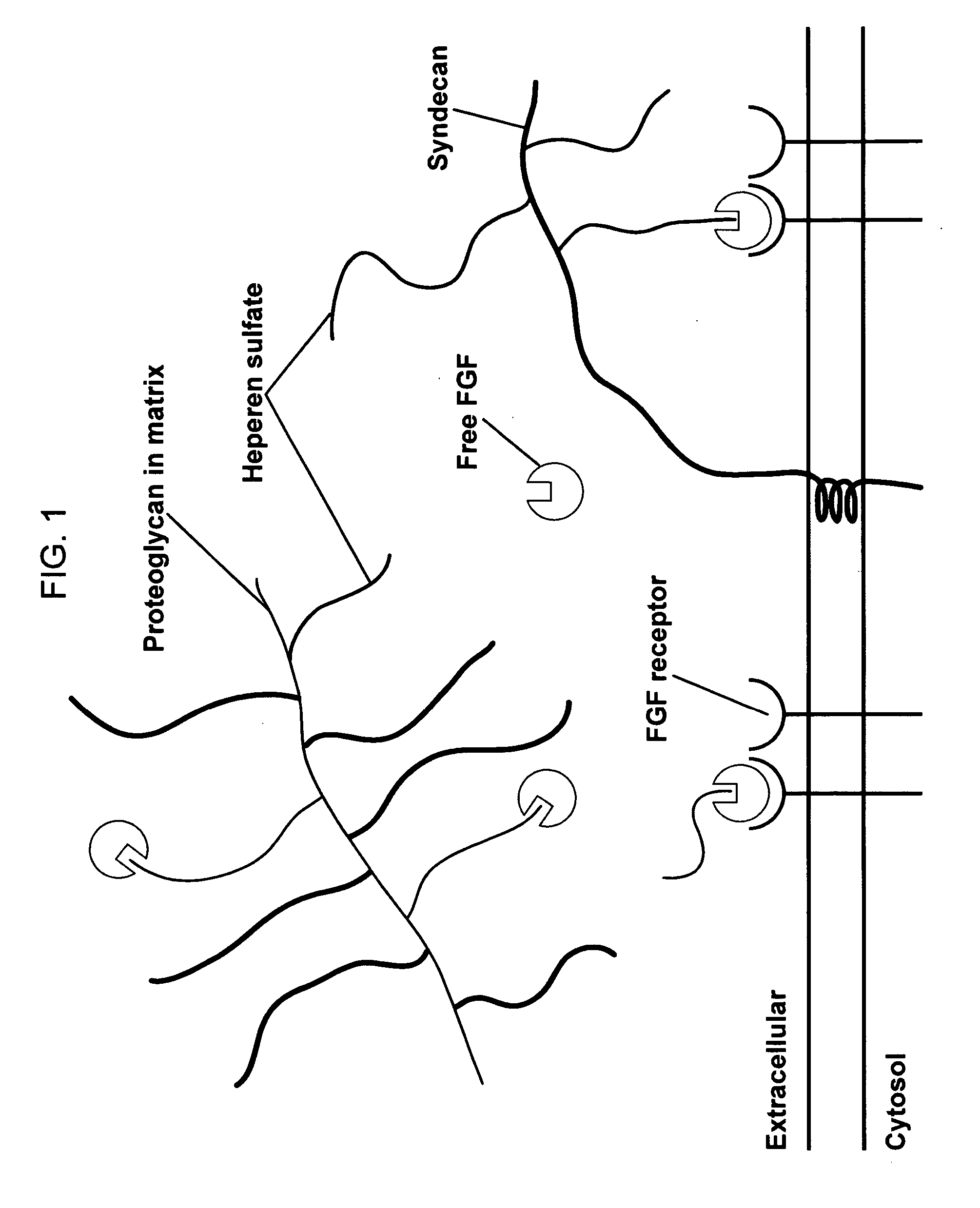

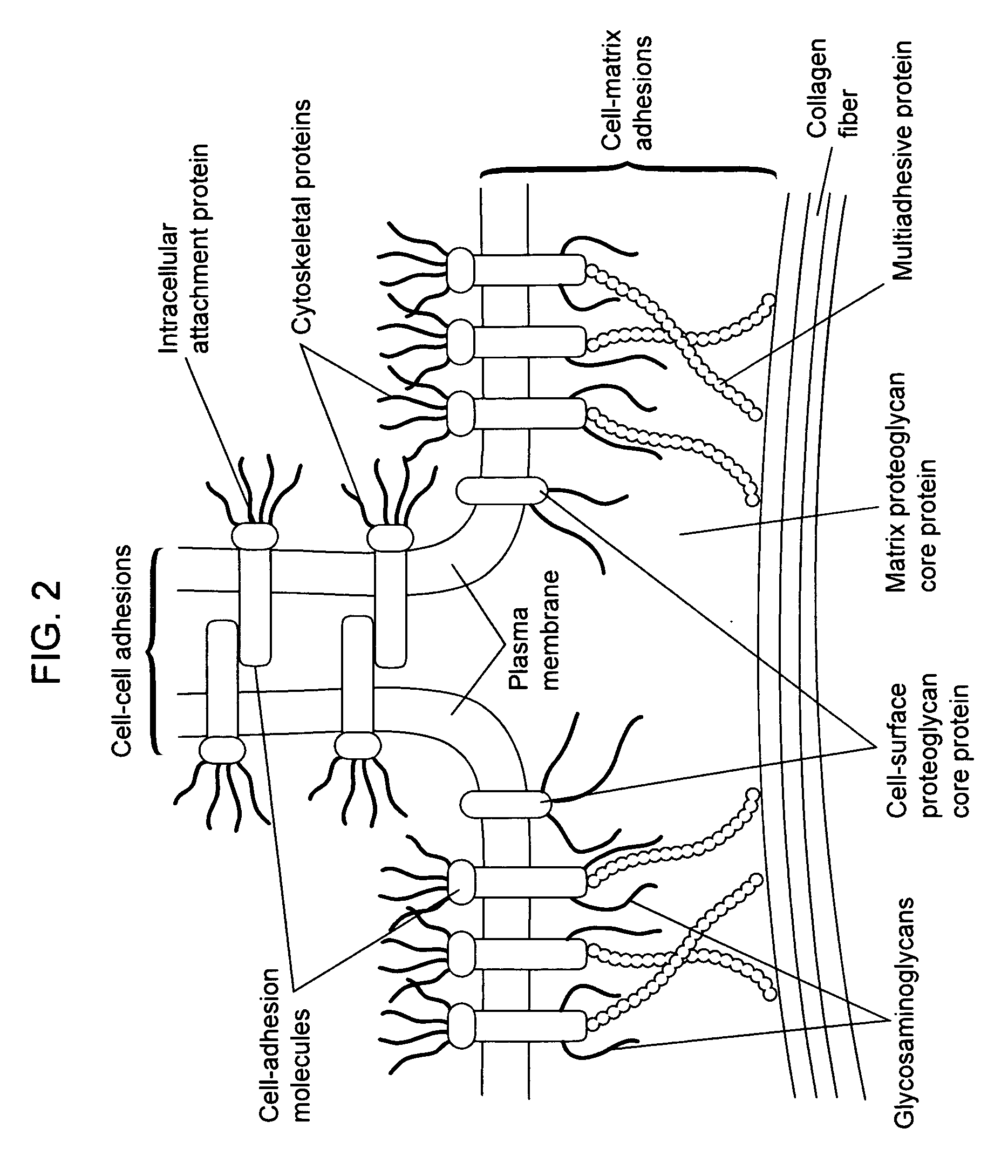

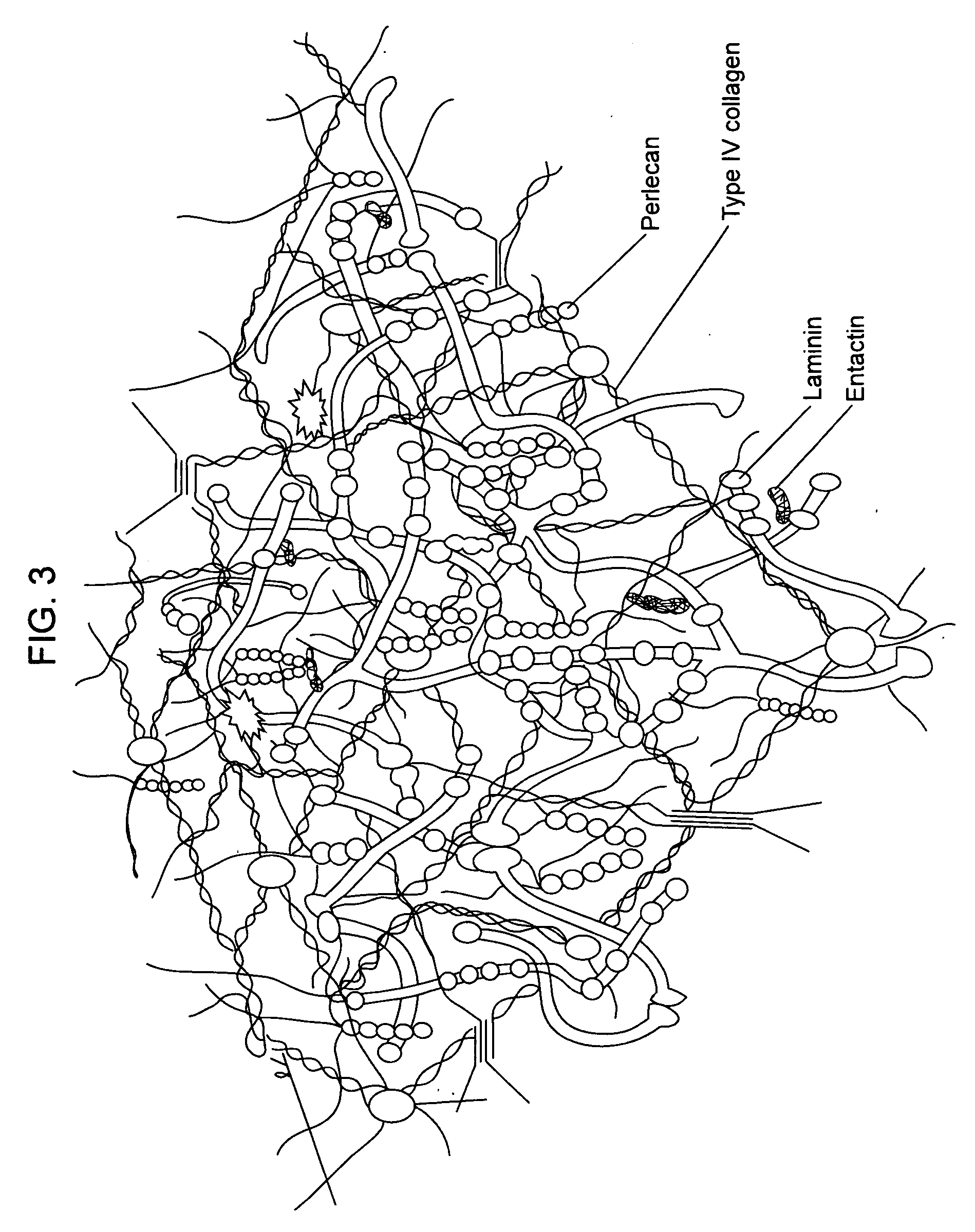

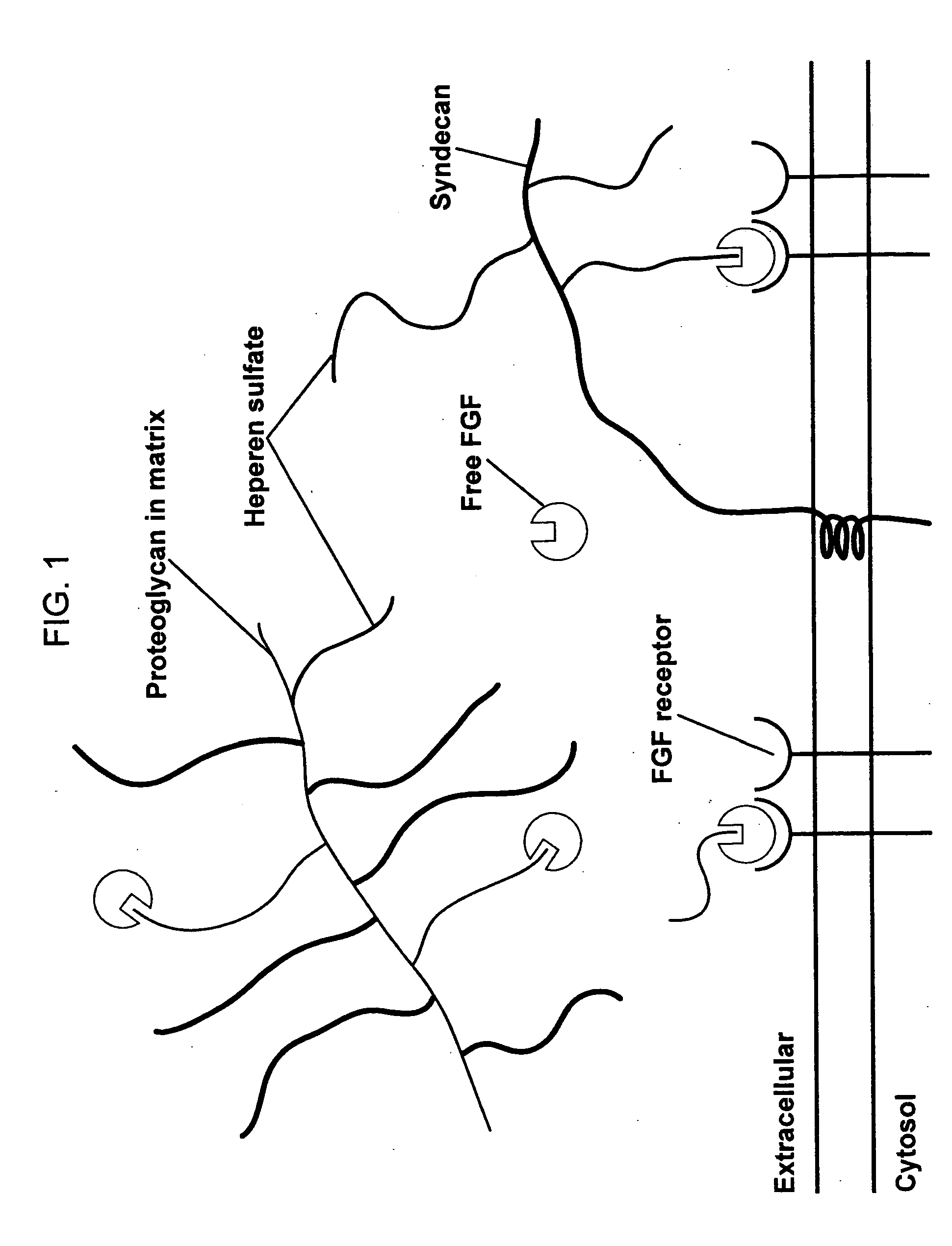

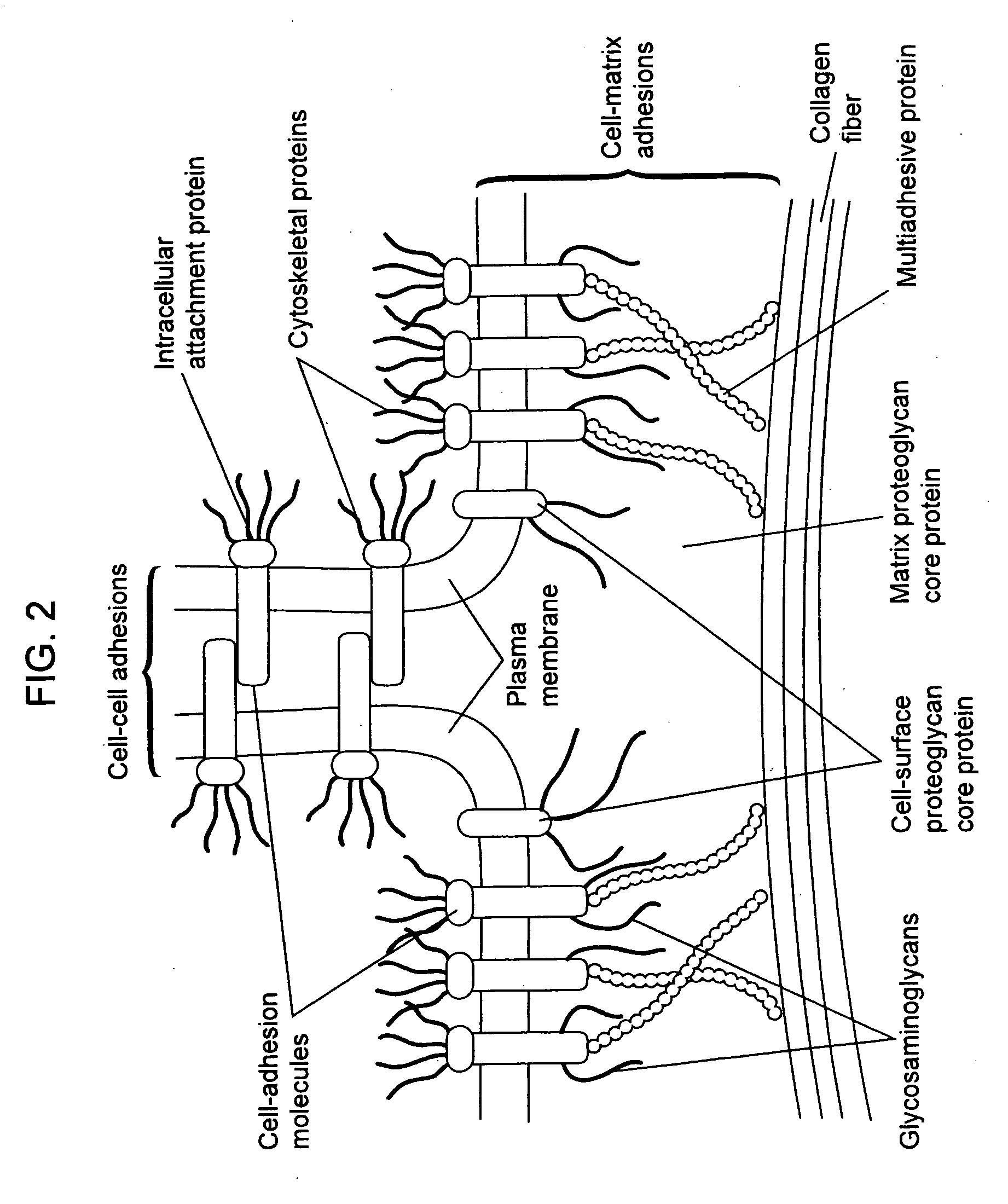

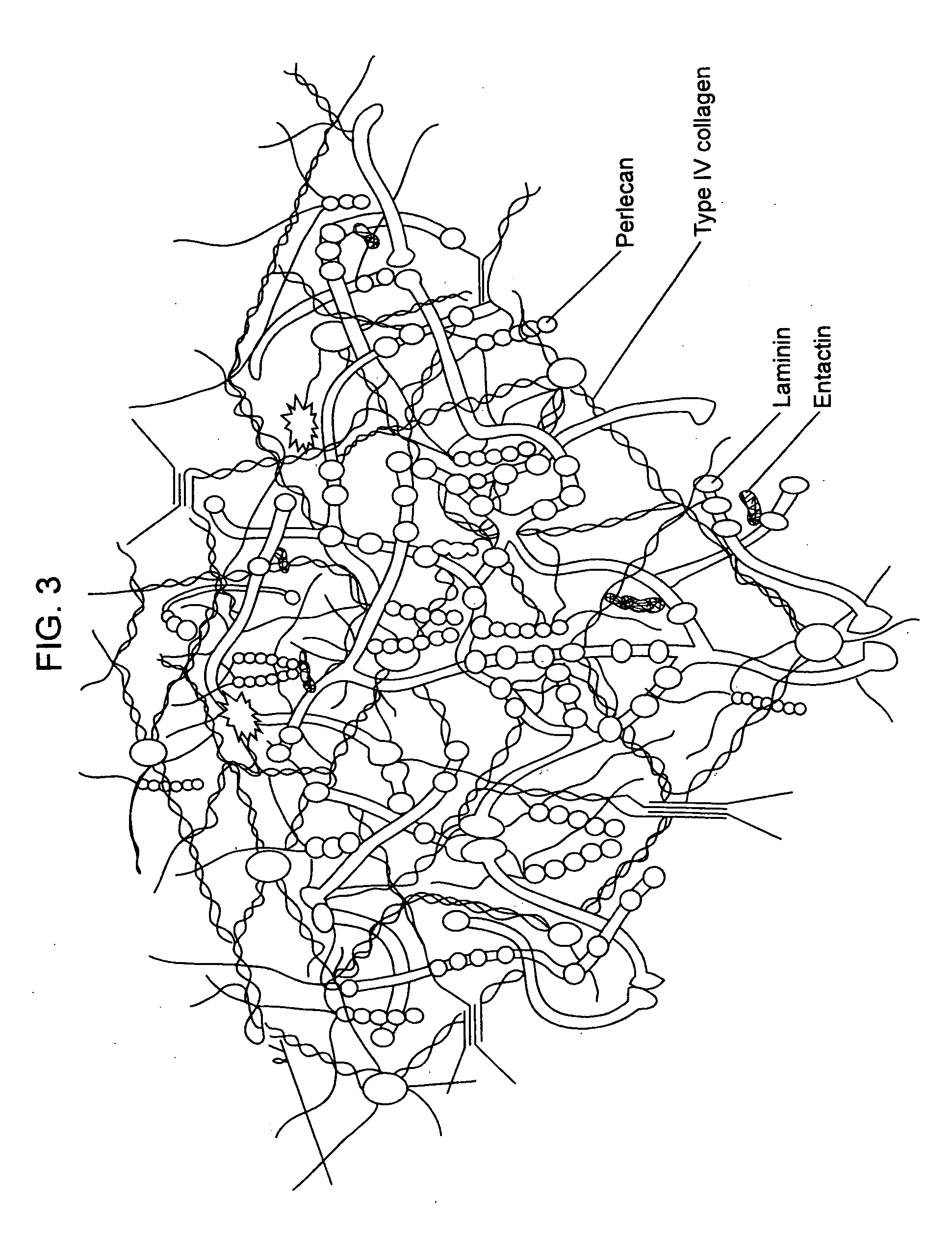

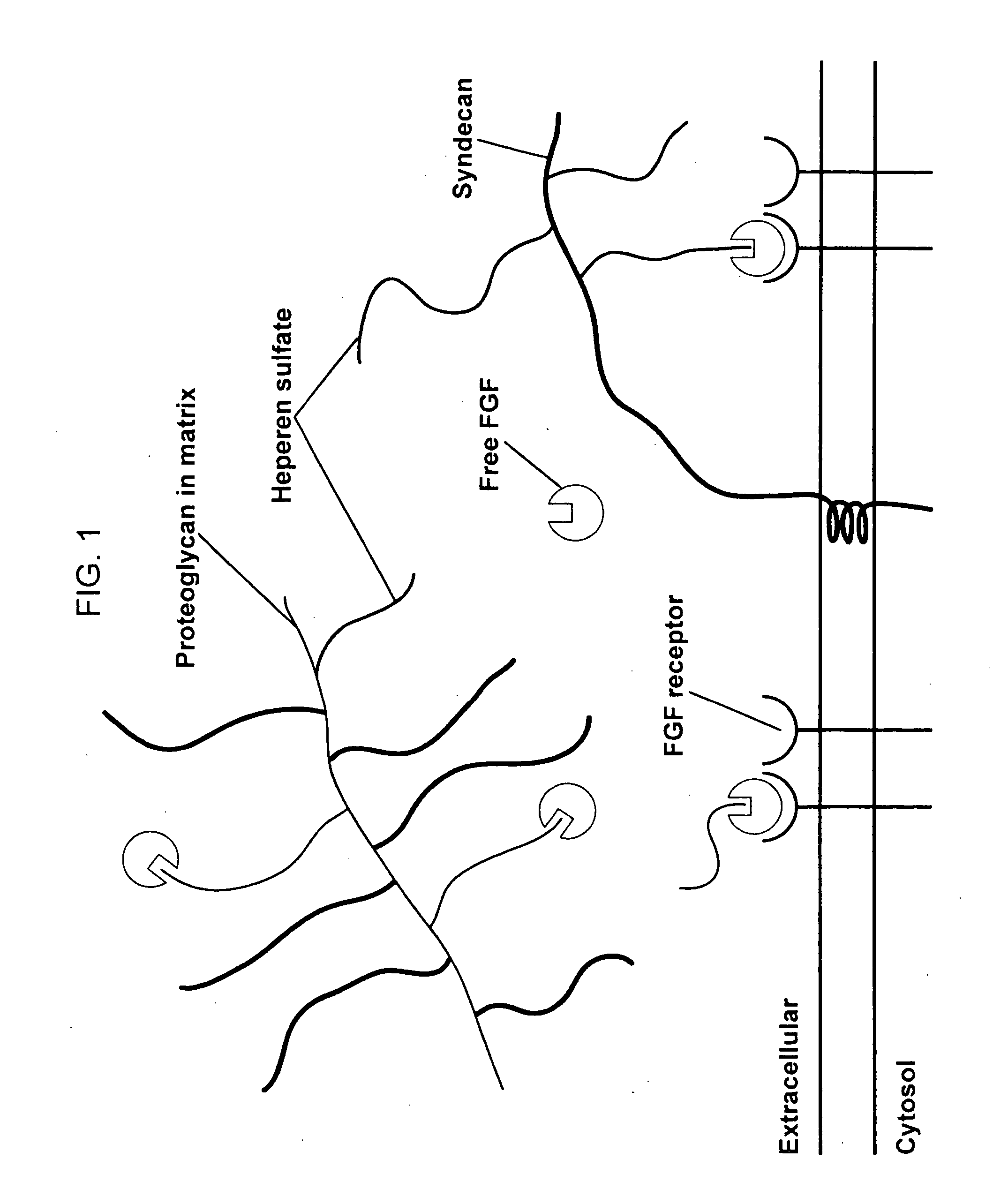

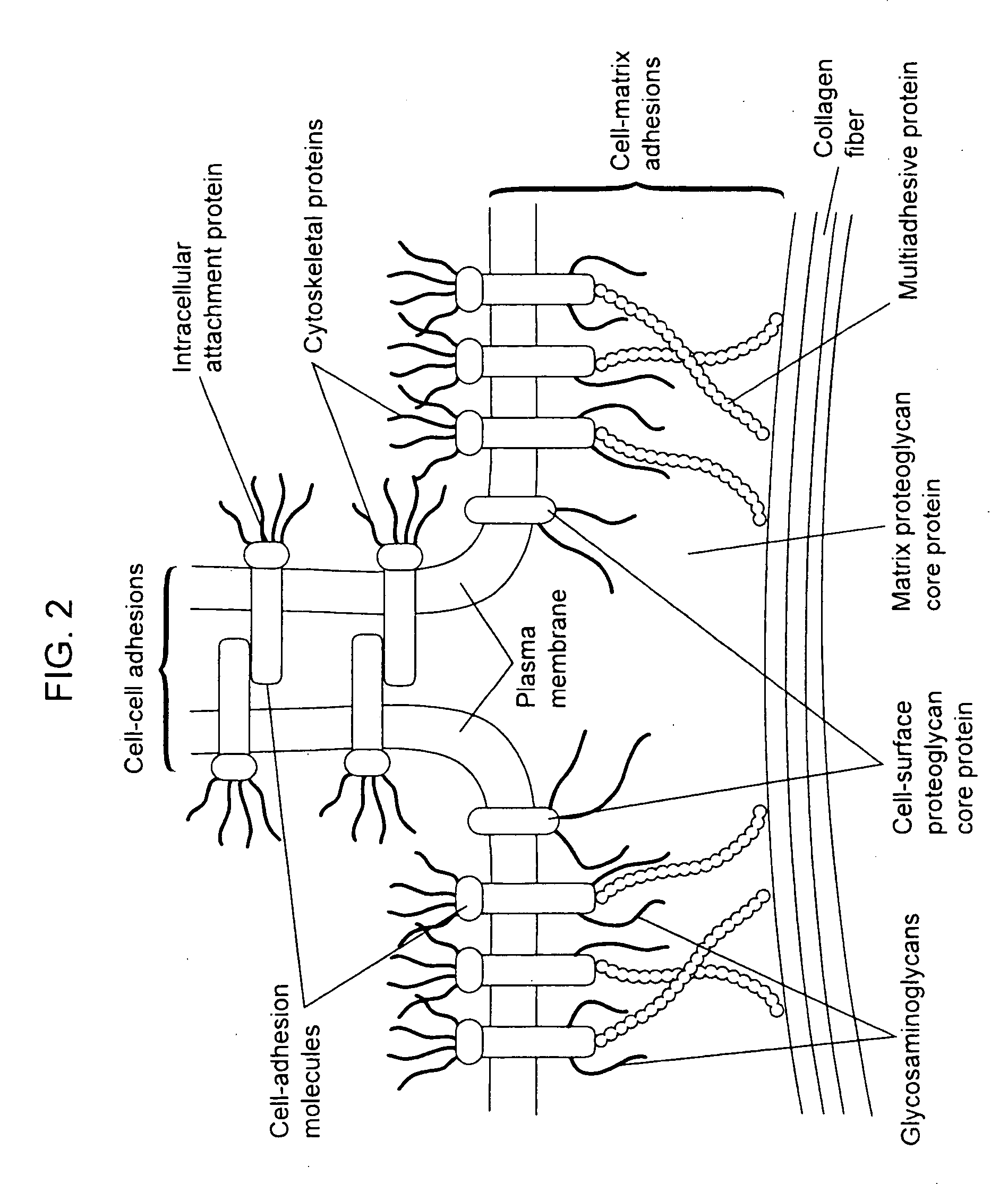

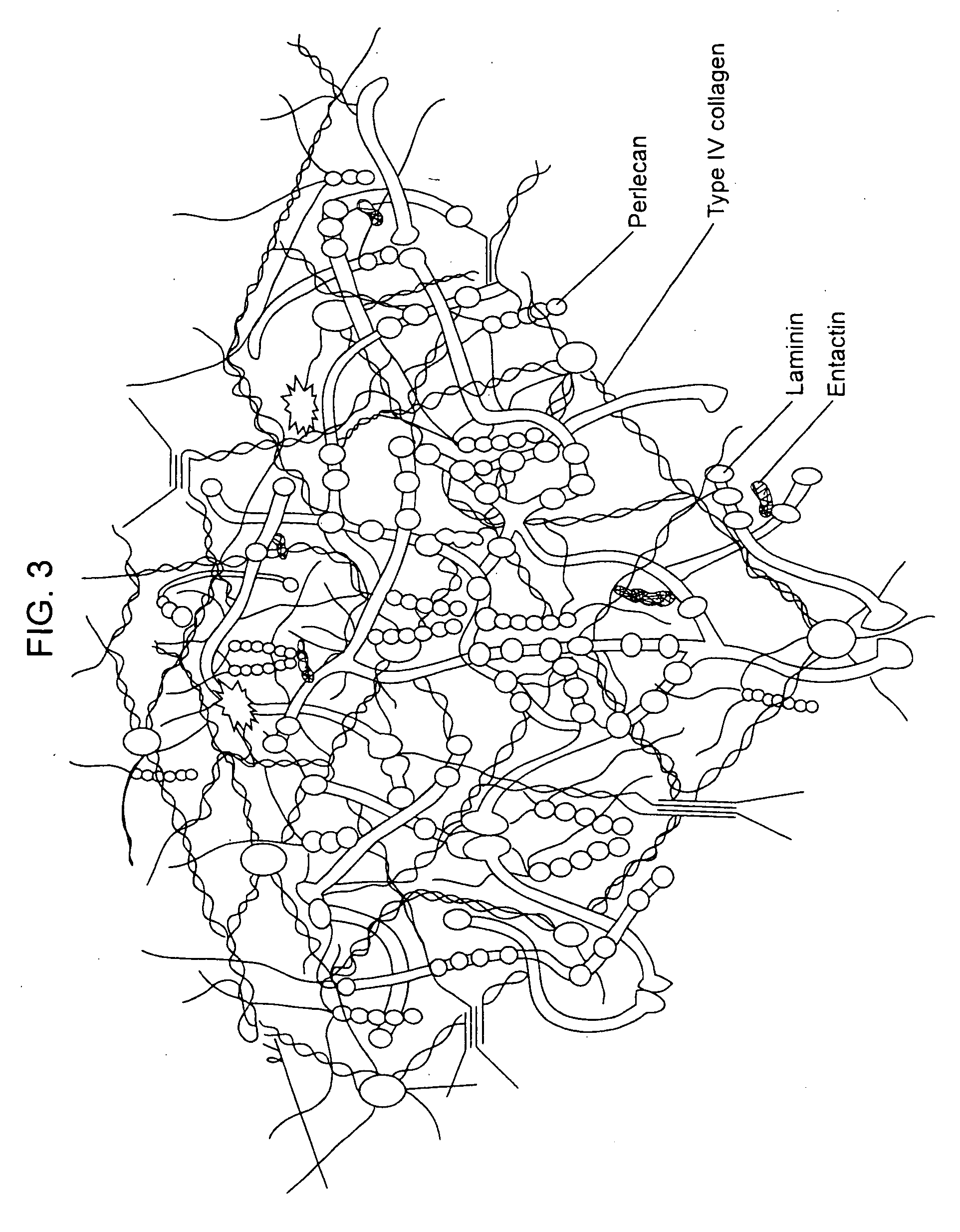

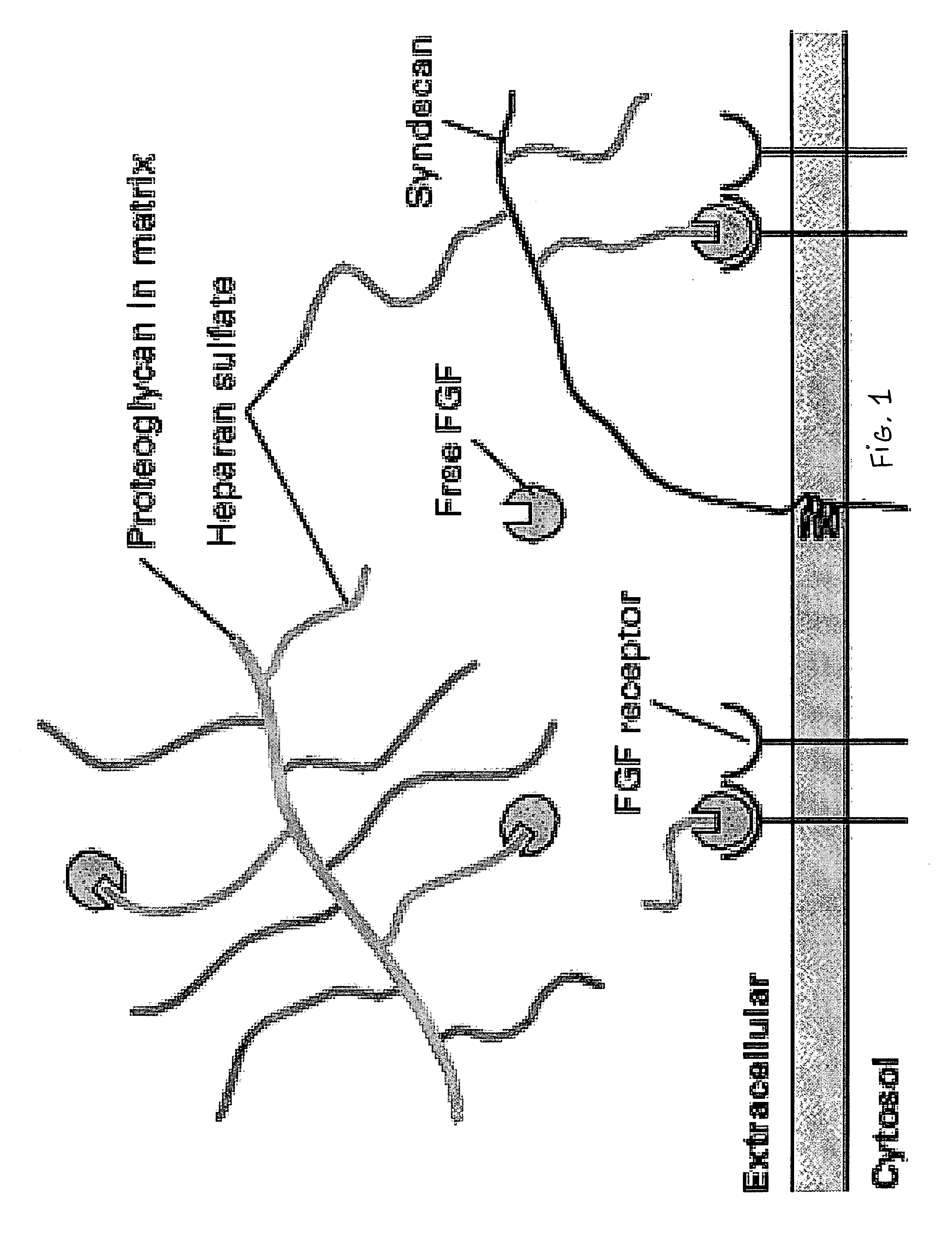

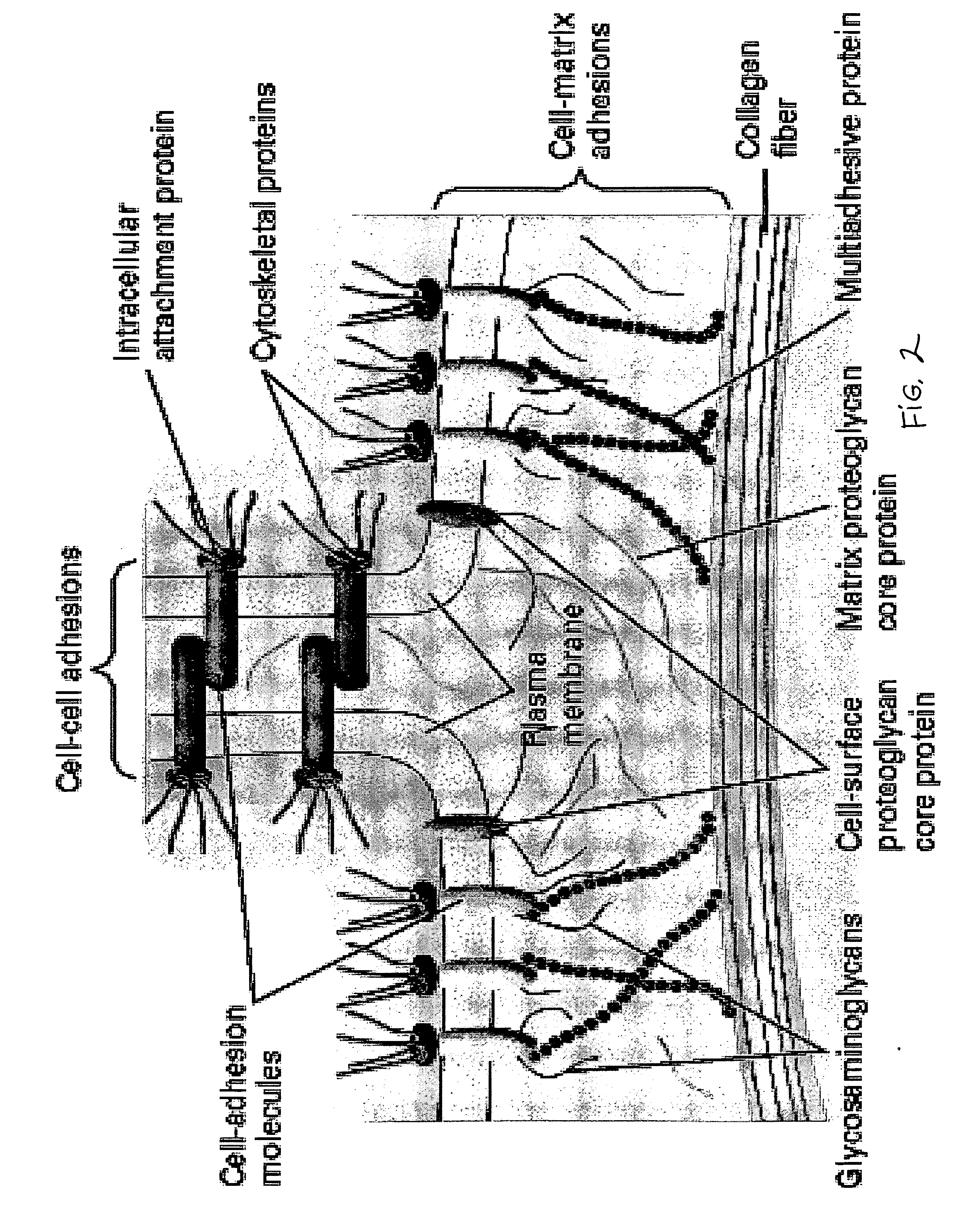

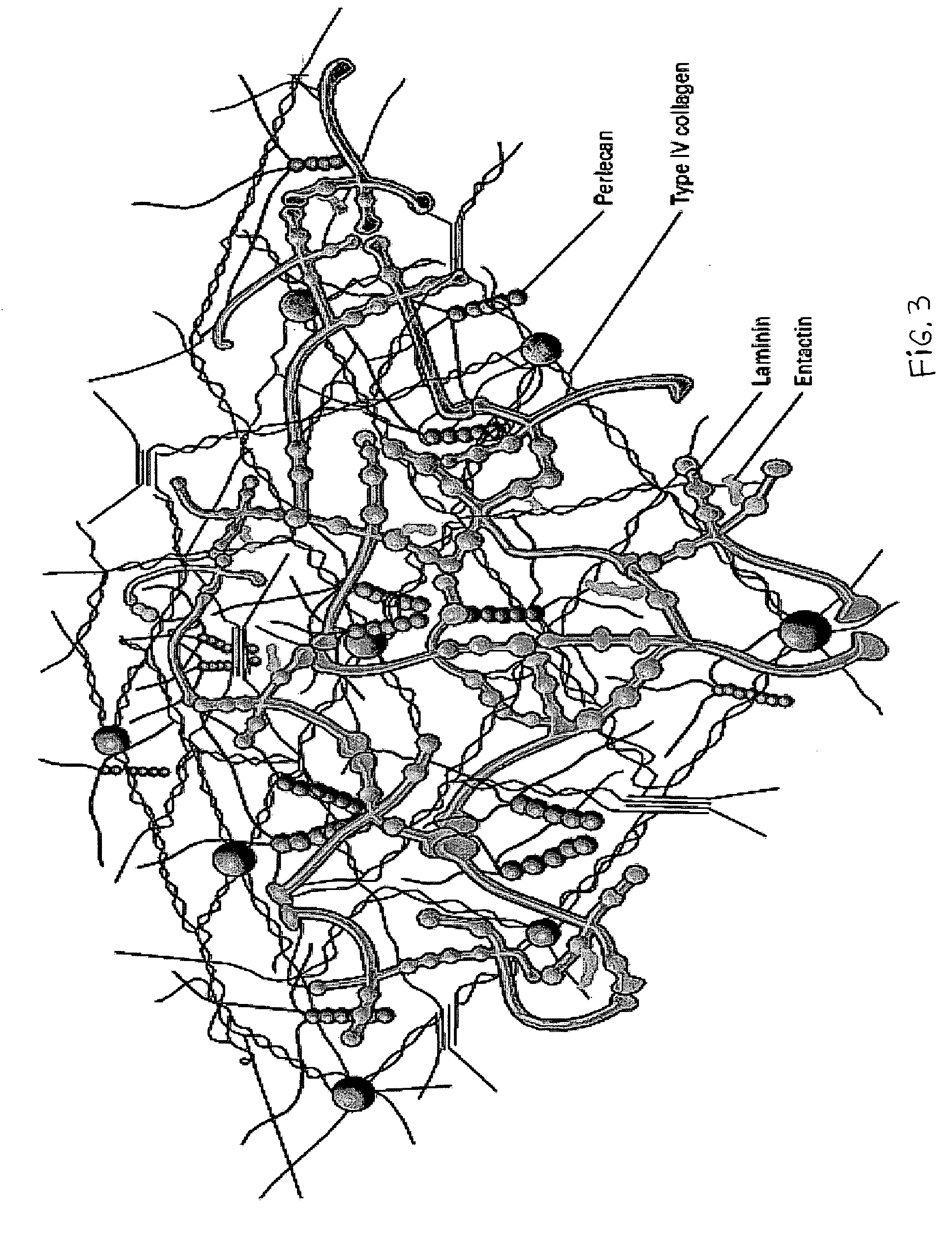

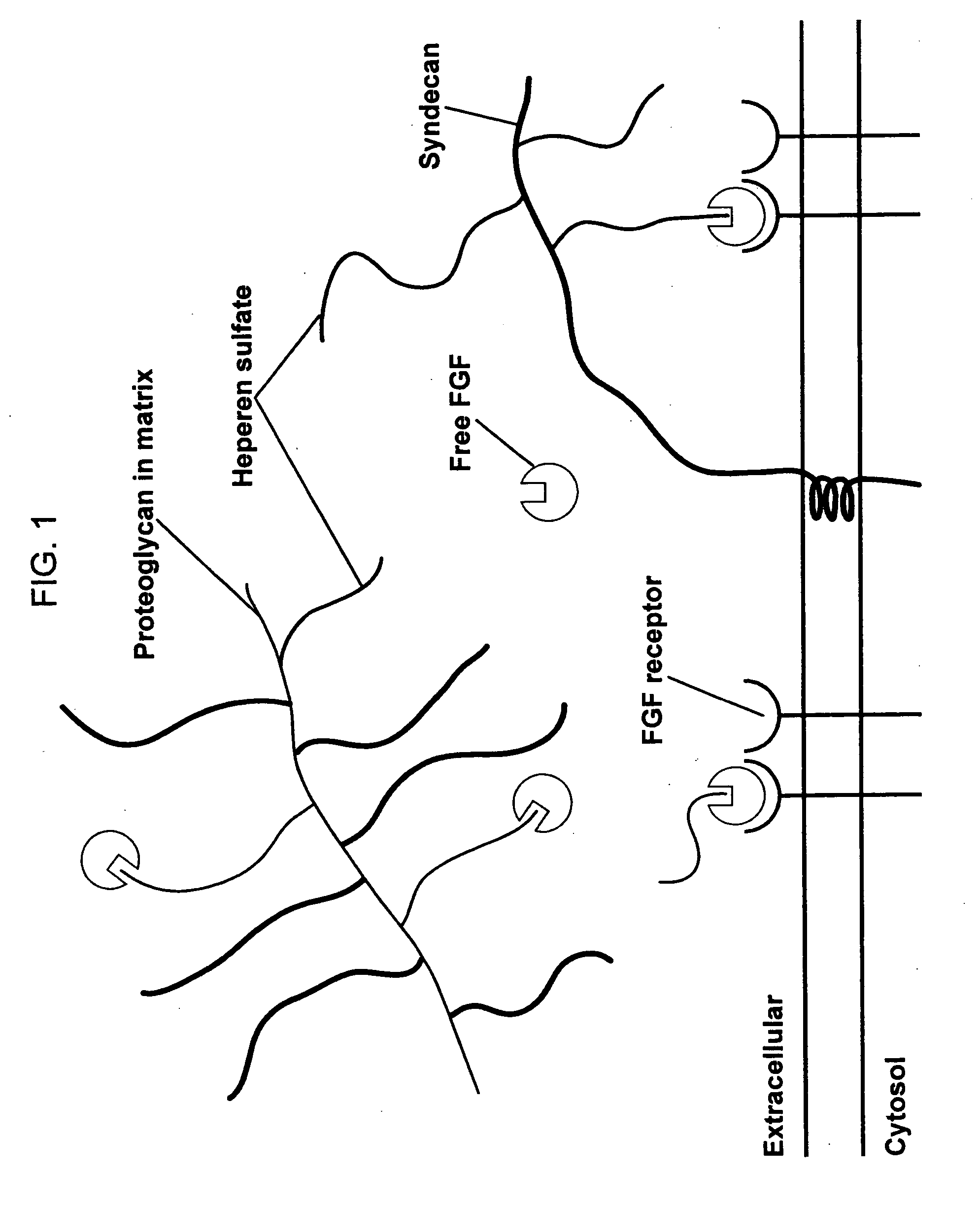

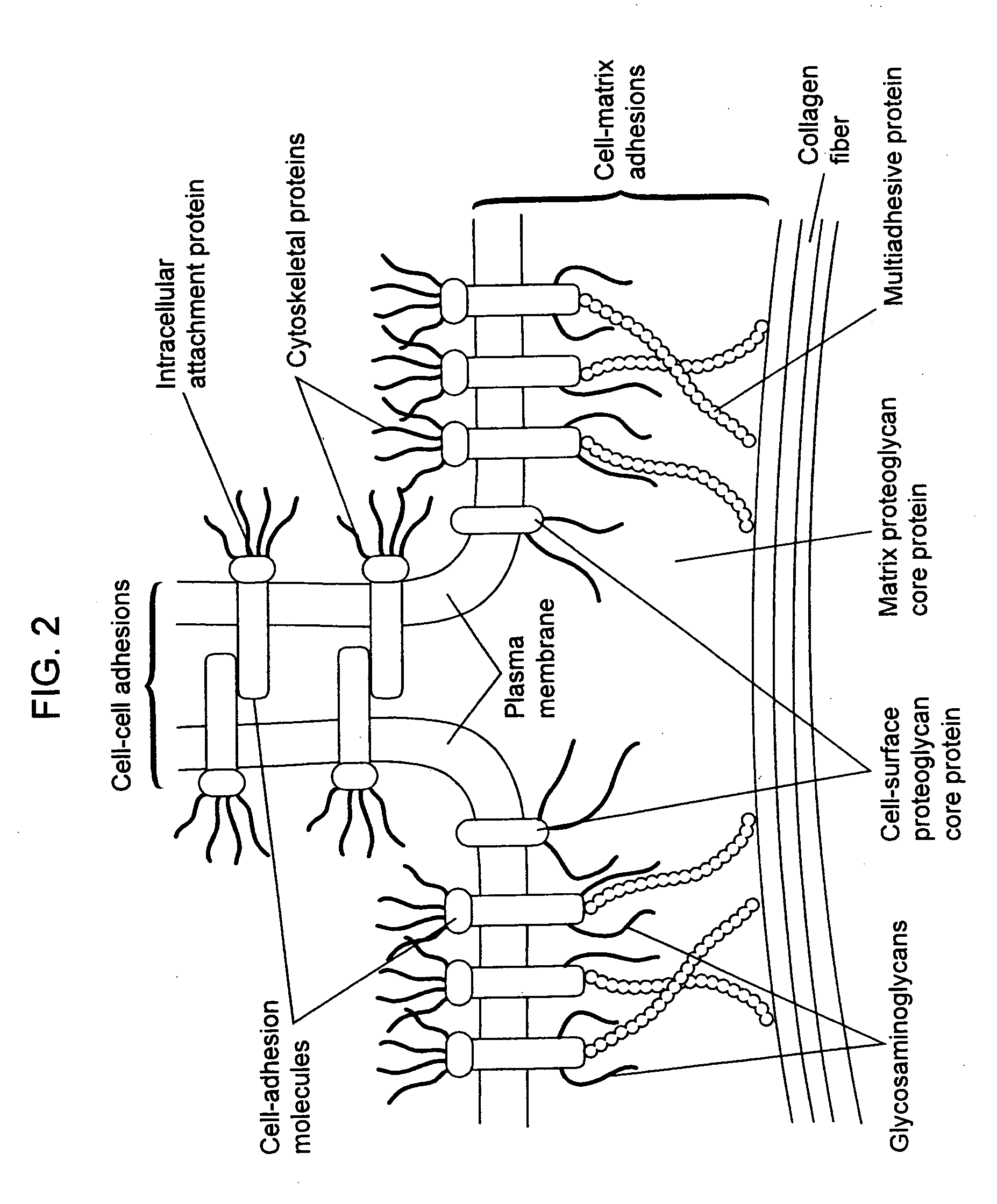

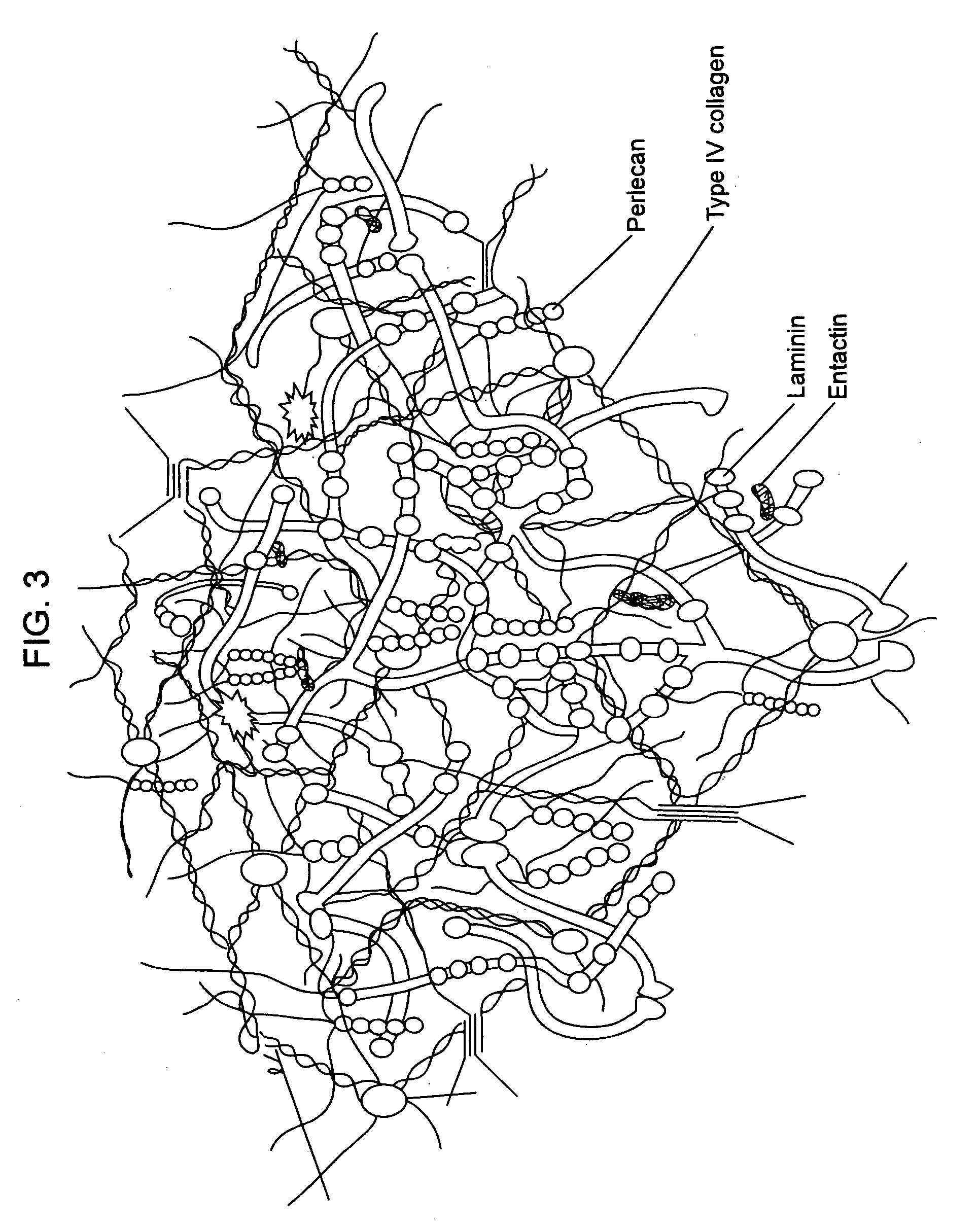

ActiveUS20070014773A1Restoring cardiac functionEffective amountBiocideOrganic active ingredientsCell-Extracellular MatrixRegenerative process

Compositions of the invention for regenerating defective or absent myocardium comprise an emulsified or injectable extracellular matrix composition. The composition may also include an extracellular matrix scaffold component of any formulation, and further include added cells, proteins, or other components to optimize the regenerative process and restore cardiac function. Methods for regenerating defective or absent myocardium apply a composition to a site of myocardium in need of regeneration using a delivery mode appropriate for the particular formulation.

Owner:CORMATRIX CARDIOVASCULAR INC

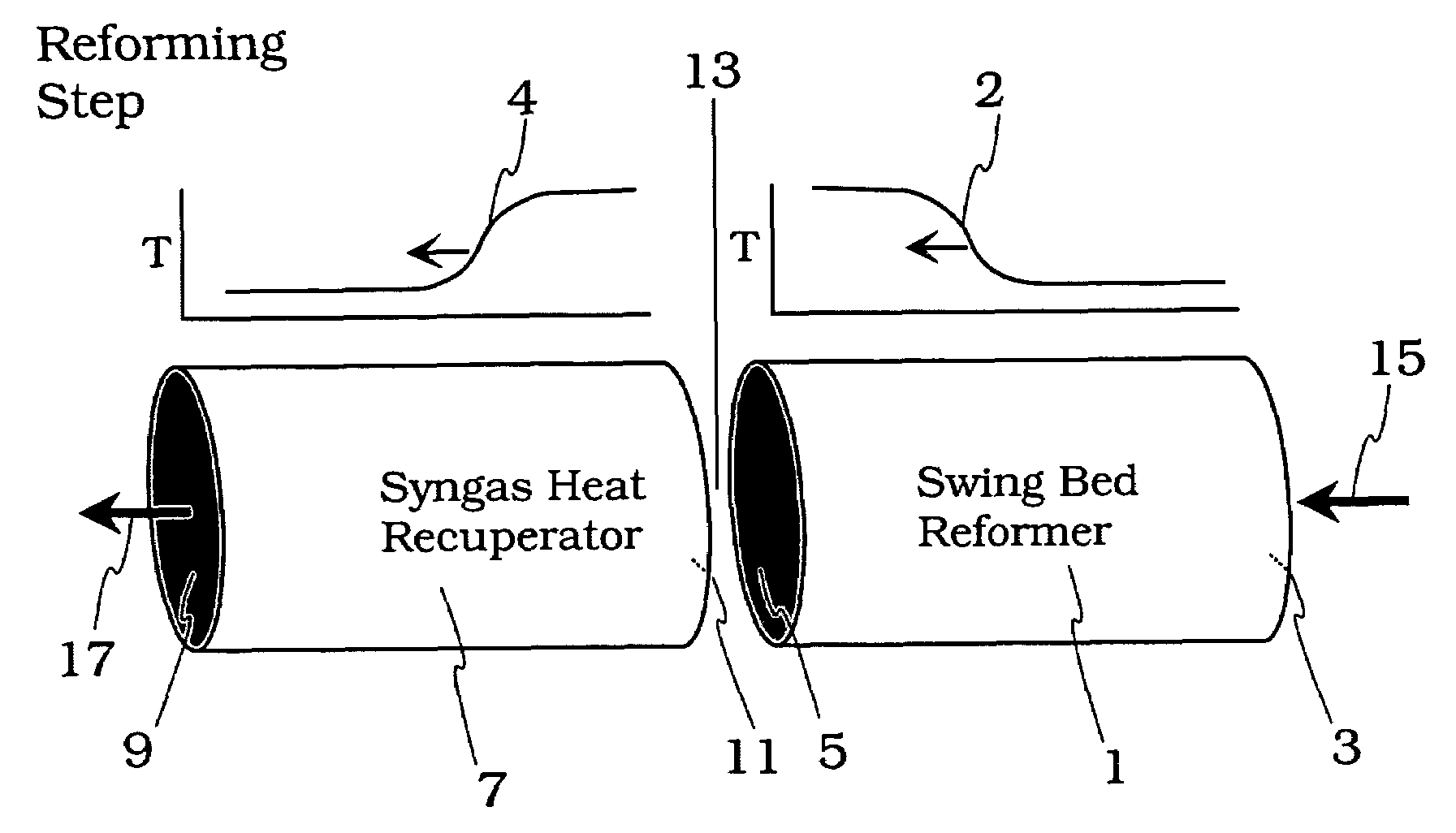

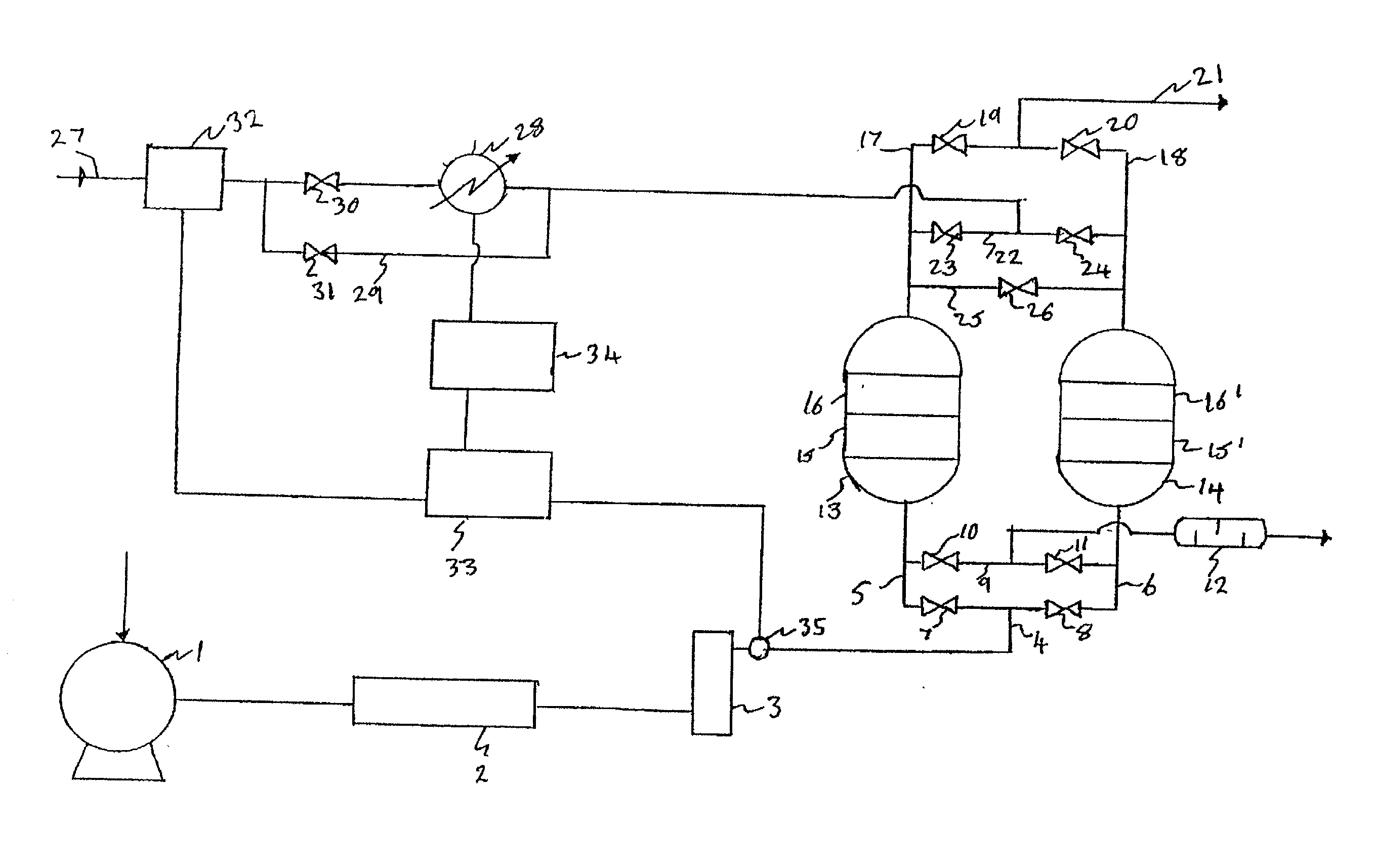

Controlled combustion for regenerative reactors

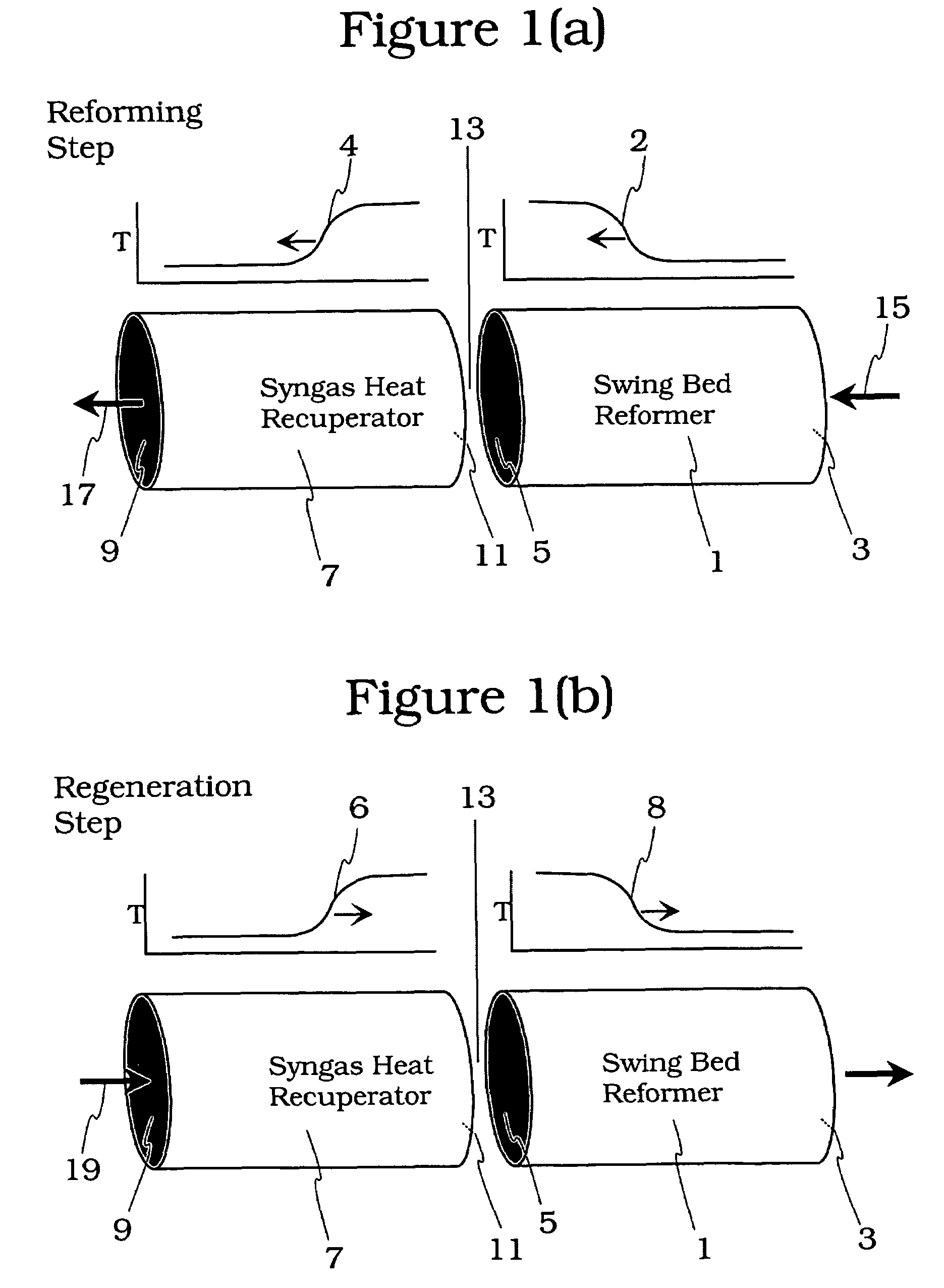

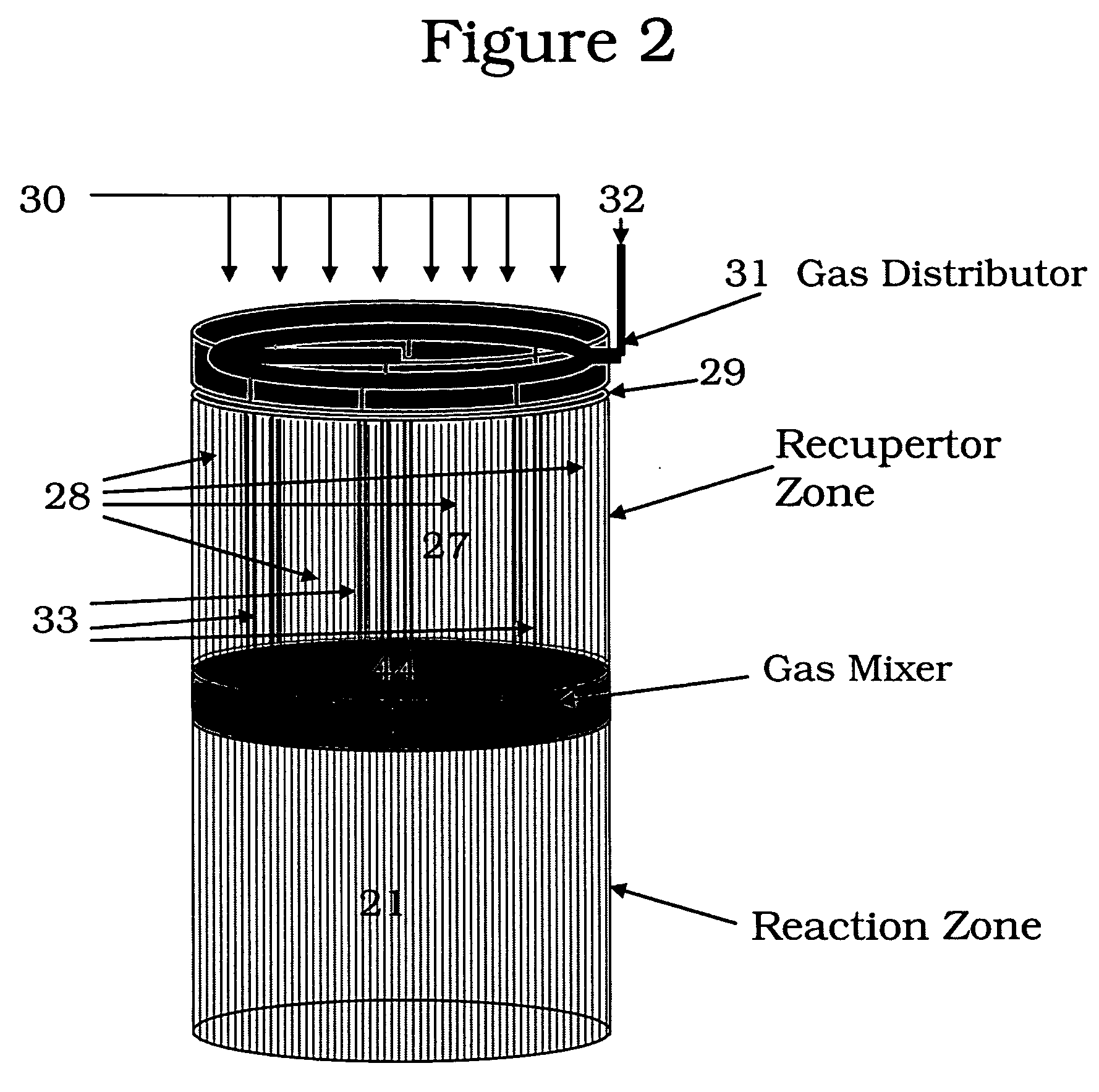

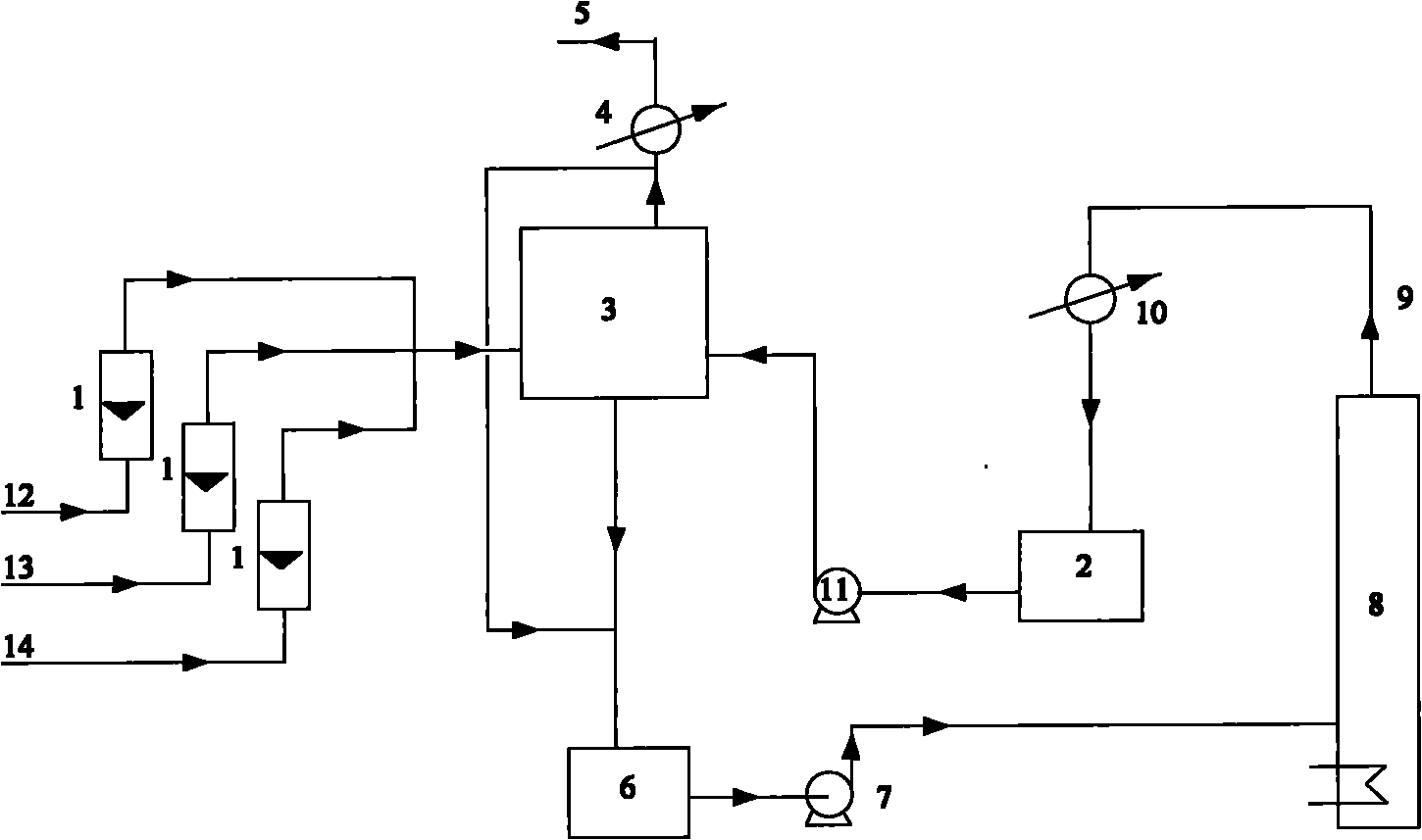

The overall efficiency of a regenerative bed reverse flow reactor system is increased where the location of the exothermic reaction used for regeneration is suitably controlled. The present invention provides a method and apparatus for controlling the combustion to improve the thermal efficiency of bed regeneration in a cyclic reaction / regeneration processes. The process for thermal regeneration of a regenerative reactor bed entails(a) supplying the first reactant through a first channel means in a first regenerative bed and supplying at least a second reactant through a second channel means in the first regenerative bed,(b) combining said first and second reactants by a gas mixing means situated at an exit of the first regenerative bed and reacting the combined gas to produce a heated reaction product,(c) passing the heated reaction product through a second regenerative bed thereby transferring heat from the reaction product to the second regenerative bed.

Owner:EXXON RES & ENG CO

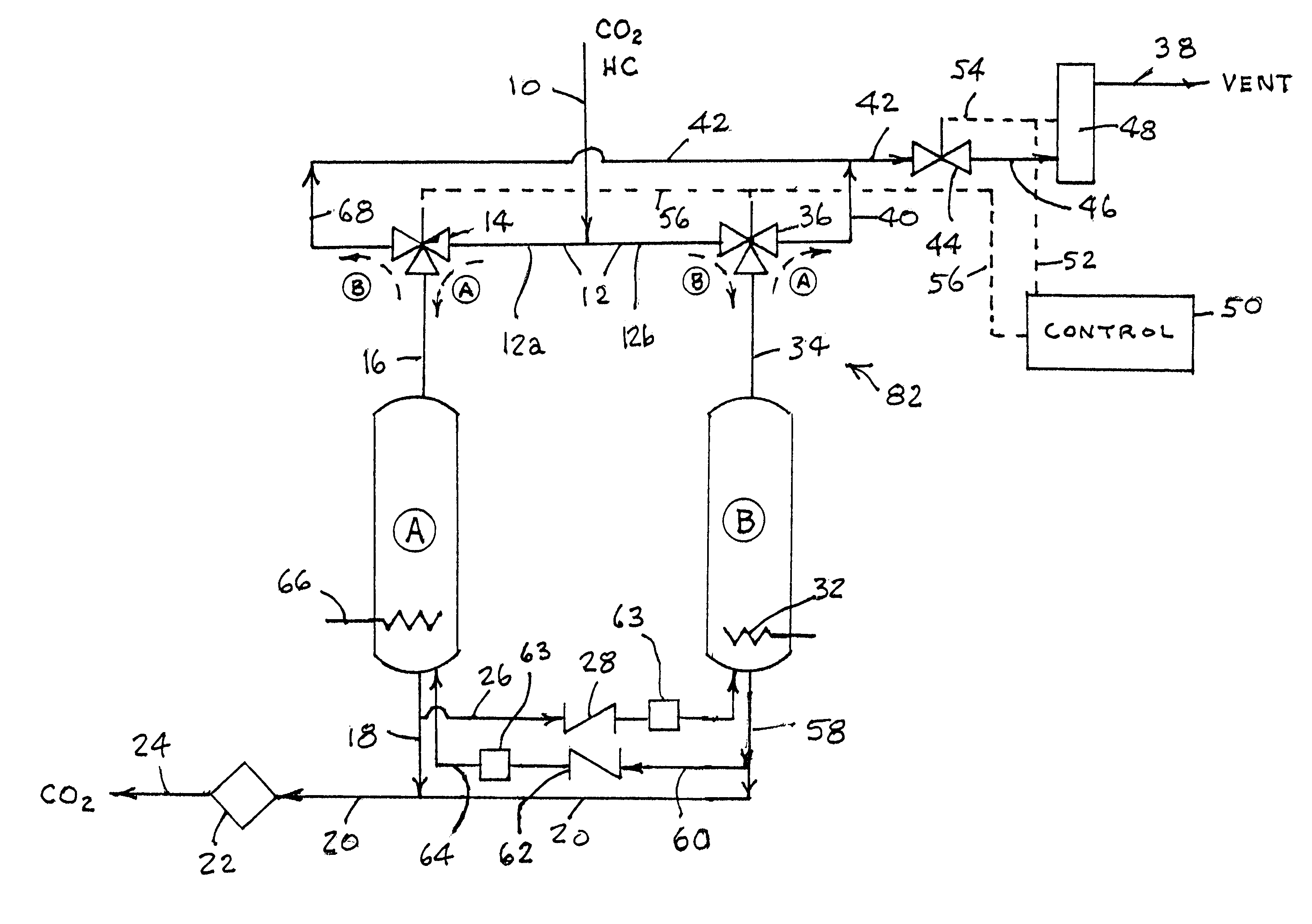

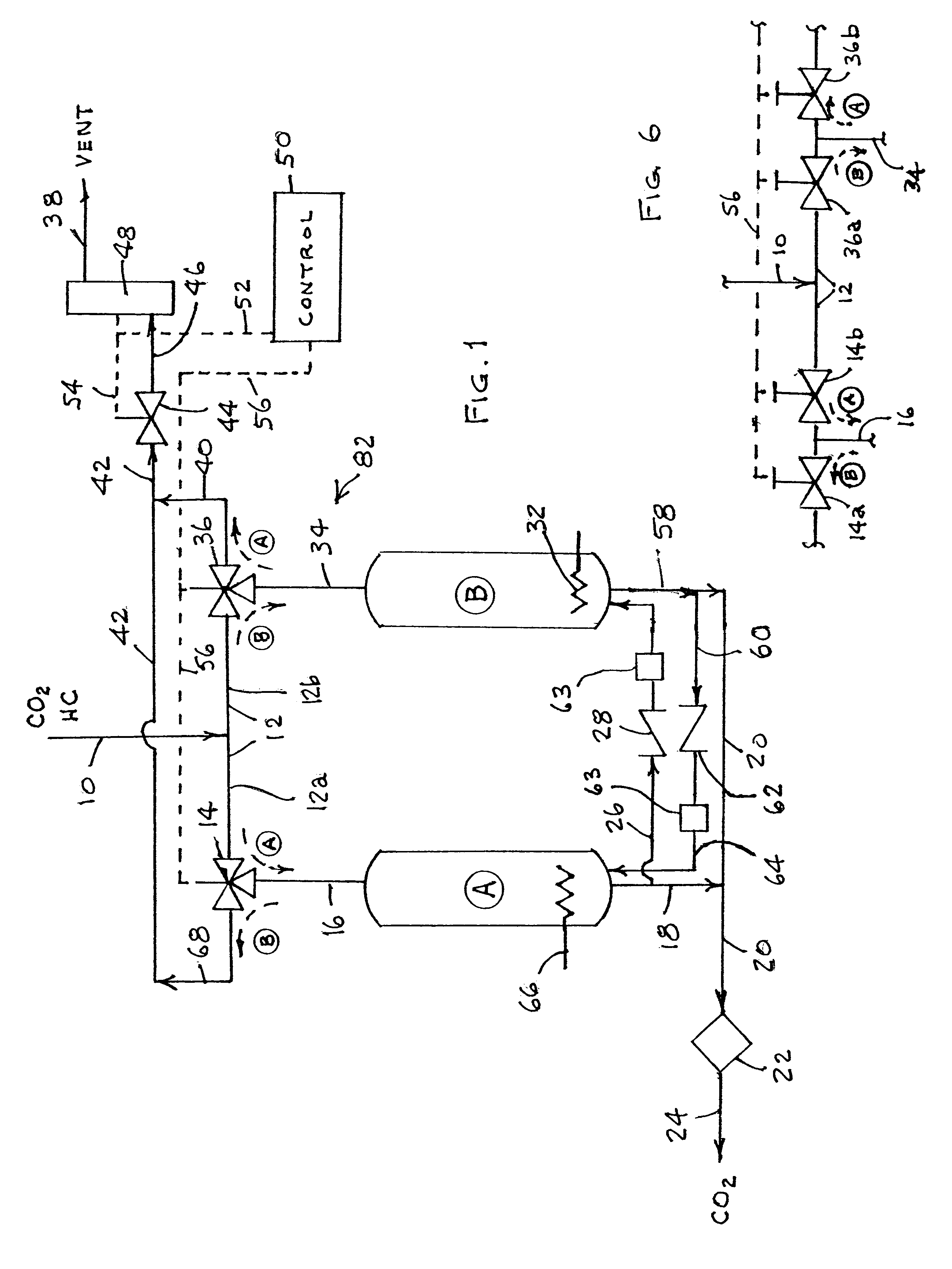

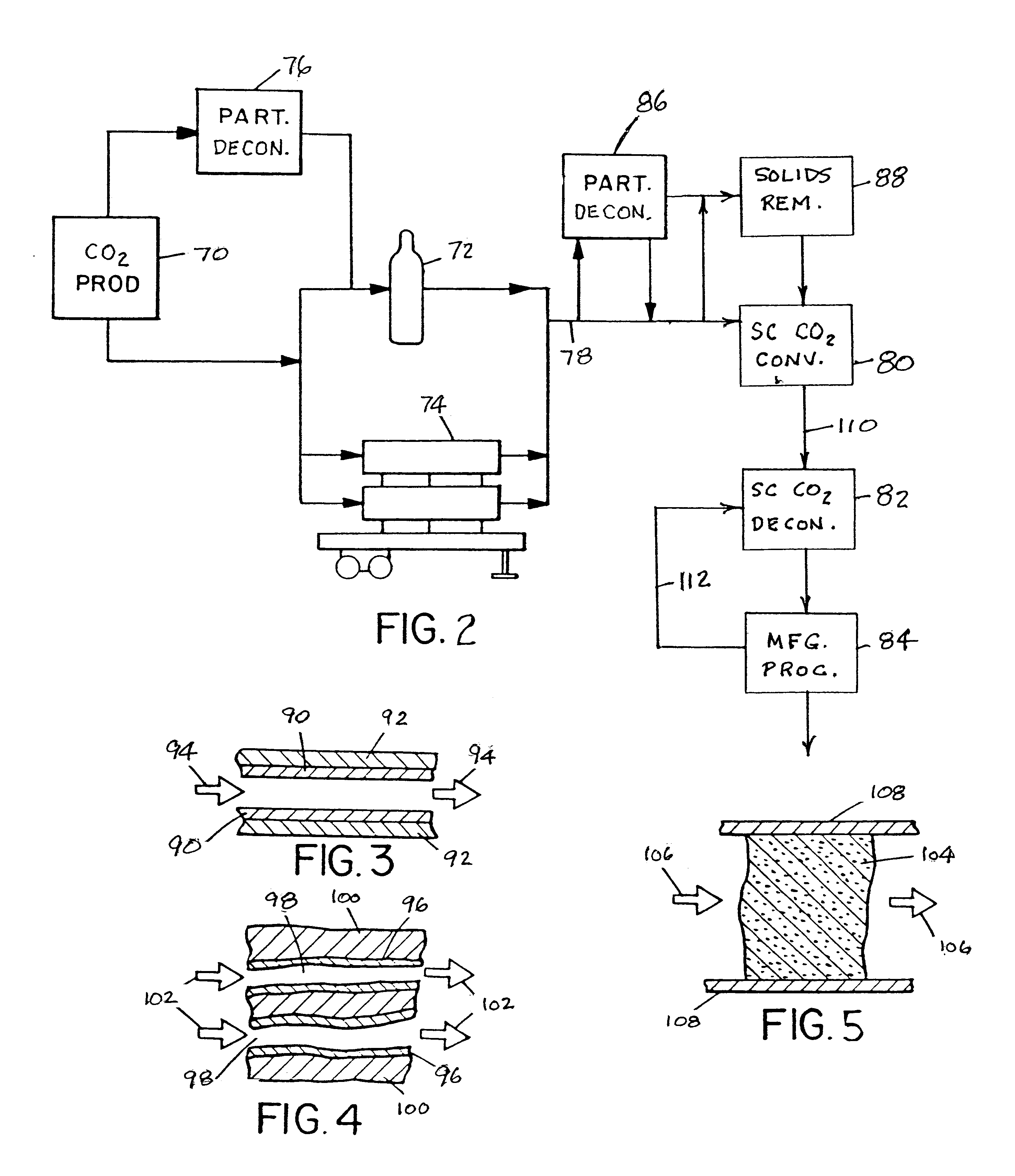

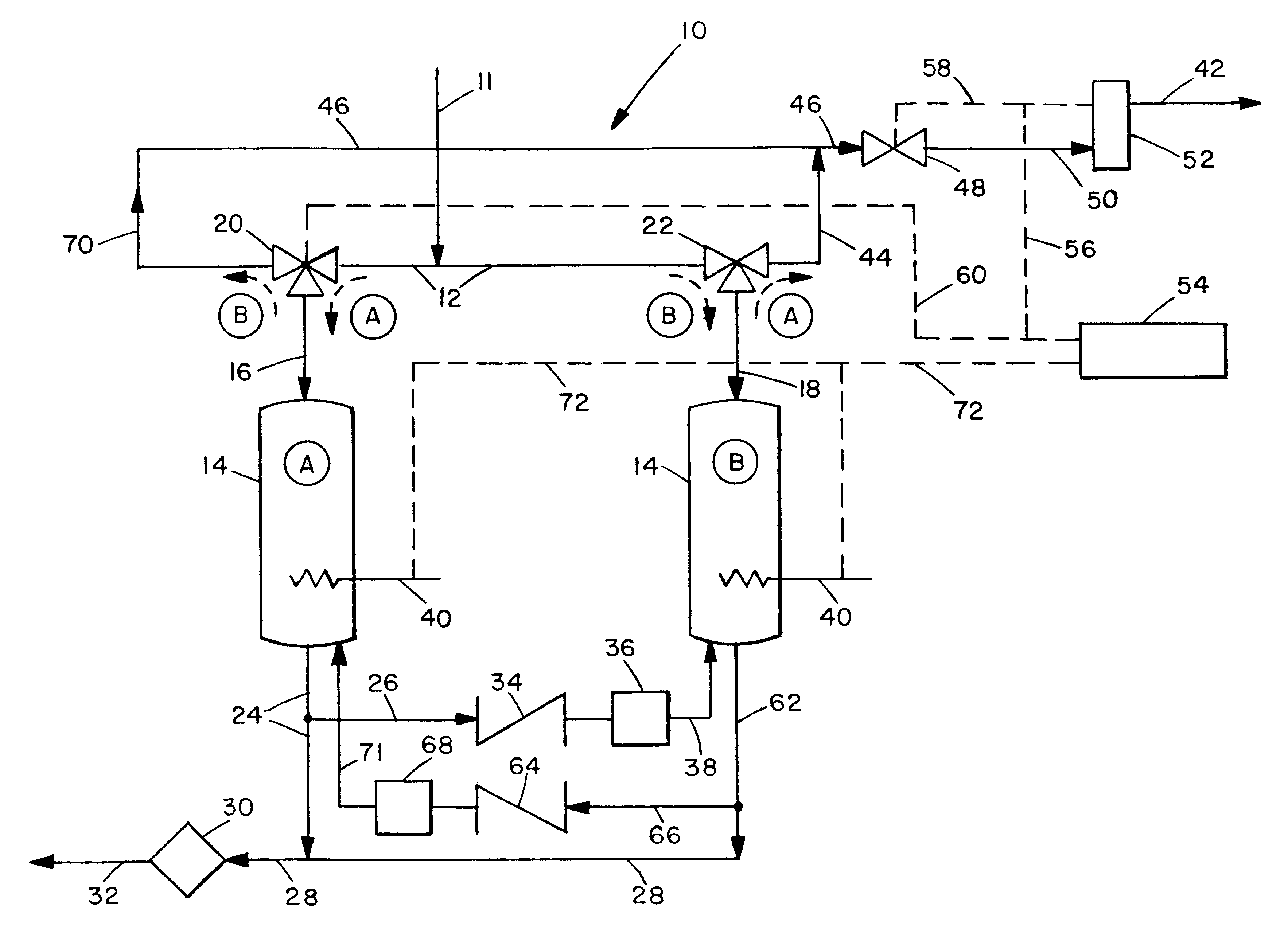

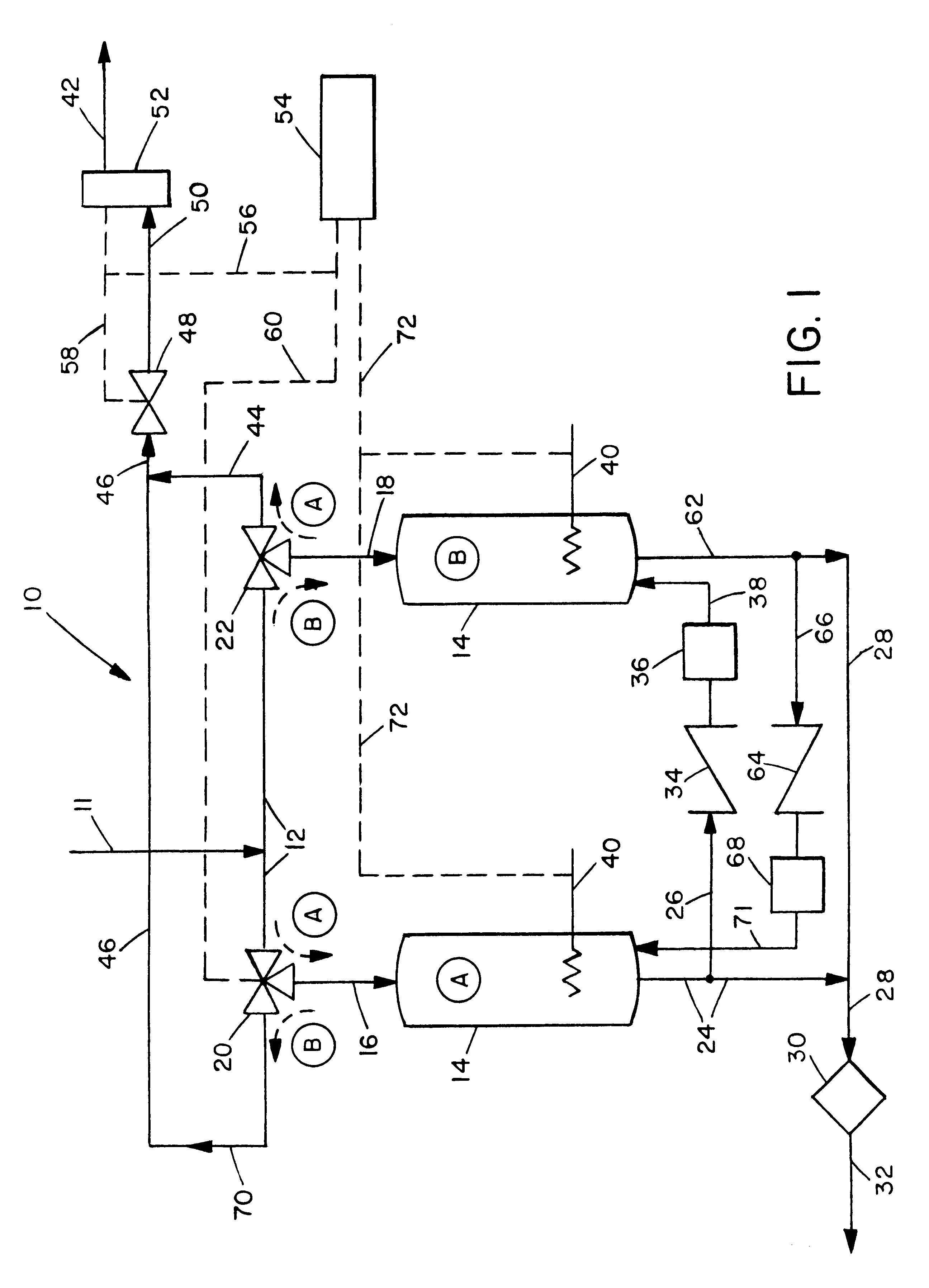

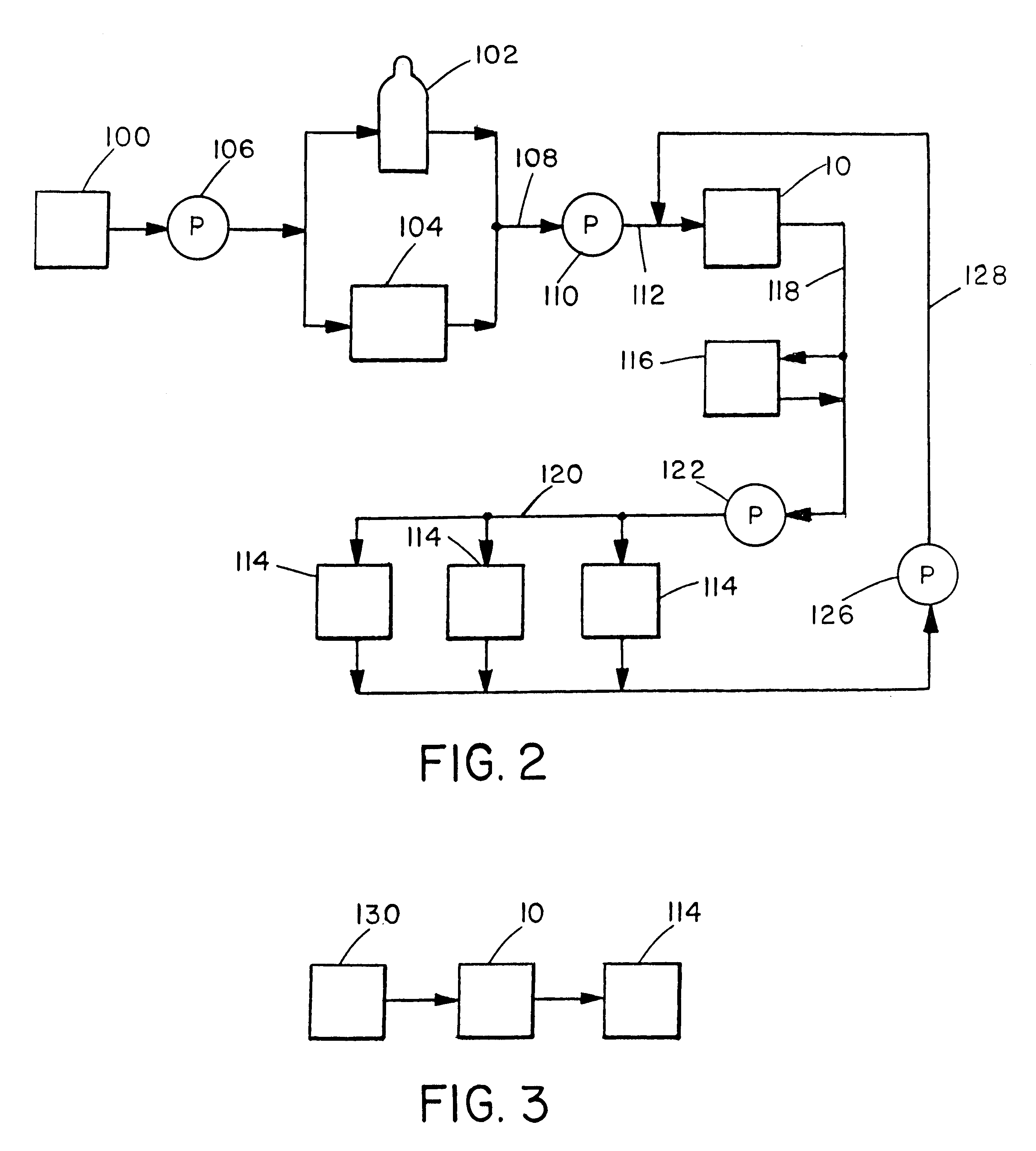

Self-regenerative process for contaminant removal from liquid and supercritical CO2 fluid streams

A method for the decontamination of fluid (liquid or supercritical) carbon dioxide fluid, especially of hydrocarbon contaminants, down to <=100 ppb concentration are described. The critical component is a high silica zeolite, preferably a high silica Y-type zeolite, ZSM-5 or a high silica mordenite, which in a variety of physical forms is capable of decontaminating such fluid CO2 to <=100 ppb, <=10-50 ppb, or ~1 ppb, without being detrimentally affected by the supercritical operating environment. The high silica zeolite may be produced by the removal of alumina from a natural or synthetic zeolite while retaining the desirable zeolite structure, to a silica:alumina ratio of from 20-2000:1. Preferably the zeolite is disposed in separate quantities in at least two vessels, which operate alternately. A portion of the purified product from the operating vessel is directed to the other vessel and there used to remove accumulated contaminants from that vessel's zeolite. The process thus provides self-regeneration, in that regeneration of one vessel occurs while the other vessel decontaminates contaminated fluid carbon dioxide, so that use of the two can be alternated for substantially continual production of purified fluid carbon dioxide. The invention provides purified fluid carbon dioxide used in manufacture of such products as high purity electronic, optical, prosthetic or similar products or polymers or pharmaceuticals or in beverages.

Owner:ENTEGRIS INC

Dietary regimen of nutritional supplements for relief of symptoms of arthritis

InactiveUS6136795AReduce inflammationPermits healingBiocideAcidic food ingredientsDocosahexaenoic acidRegimen

This invention is directed to a dietary regimen and a unique combination of nutritional supplements and a method. More specifically, this invention is directed to a unique combination of nutritional supplements which provides symptomatic relief from arthritis. The unique combination of nutritional supplements of this invention is believed to function by both increasing the available (effective blood level) of anti-inflammatory agents and promotion of the healing / regenerative process in the effected joints, thus, producing unexpected and lasting symptomatic relief from the debilitating effects of both osteoarthritis and rheumatoid arthritis. The essential nutritional supplements of the dietary regimen of this invention are as follows: (a) gamma linolenic acid (unrefined), hereinafter "GLA"(b) a mixture of eicosapentaenoic acid and docosahexaneoic acid, hereinafter collectively "EPA"(c) a mixture of chondroitin sulfate, N-acetyl glucosamine sulfate, glucosamine sulfate and manganese aspartate, hereinafter collectively "CHONDROX"The regimen is adjusted based upon the weight of the individual, and once symptomatic relief is achieved, the individual remains essentially free from the debilitating effects of arthritis so as long the daily regimen is faithfully followed.

Owner:IRWIN NATURALS 4HEALTH INC +1

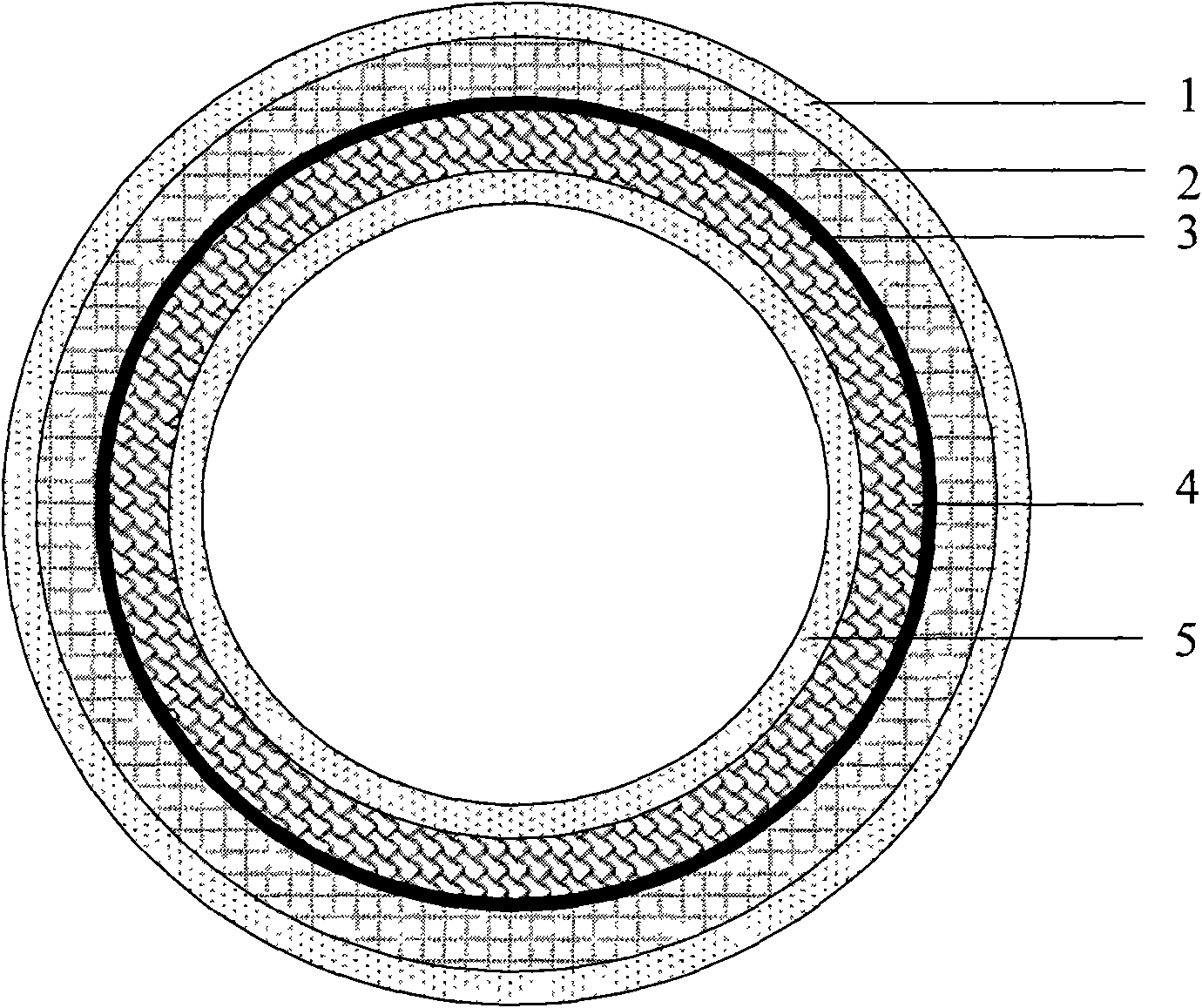

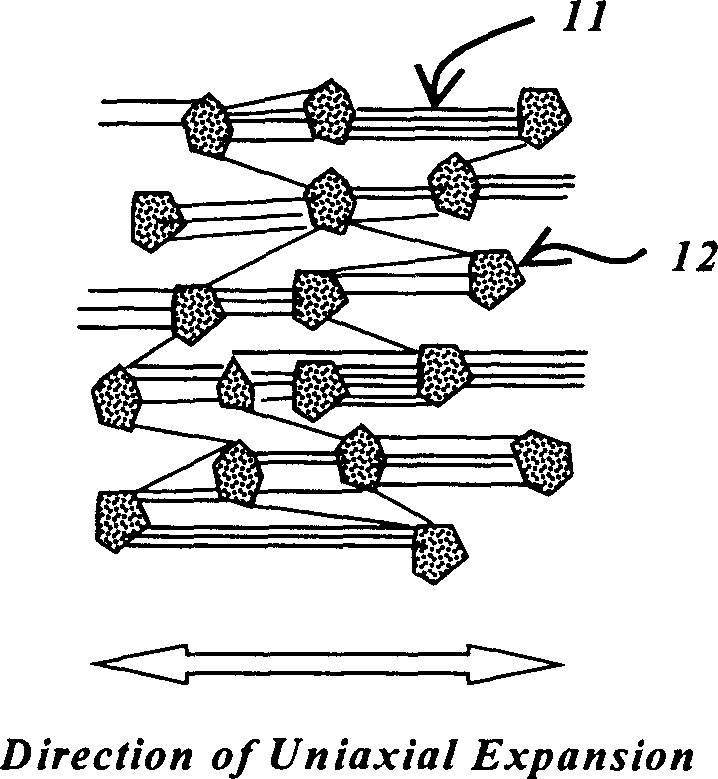

Regeneration type artificial blood vessel based on in-situ self stem cell technology and preparation method thereof

The present invention discloses a regeneration type artificial blood vessel based on an in-situ self stem cell technology and a preparation method thereof. The artificial blood vessel is a structure composed of at least three connected bionic support layers, wherein the bionic support layer is prepared by nanometer bionic supports and hydrosol attached to the nanometer bionic supports; the structure is a concentric circle loop and has an inner layer, an insulating layer and an outer layer outwards; the hydrosol of the inner layer and the outer layer are packaged with one or more specificity antibodies and / or cytokines and / or adhered short peptides and / or medicaments. The preparation method includes preparing the inner layer by an electrostatic spinning; preparing the insulating layer on an external surface of the inner layer; preparing the outer layer on an external surface of the insulating layer. The artificial blood vessel of the invention may be degraded safely and automatically during a wound surface repair process, and defect blood vessel is repaired completely during the degradation process, thus a regenerative process and a normal differentiation process are identical, and a good repairing effect will be obtained.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

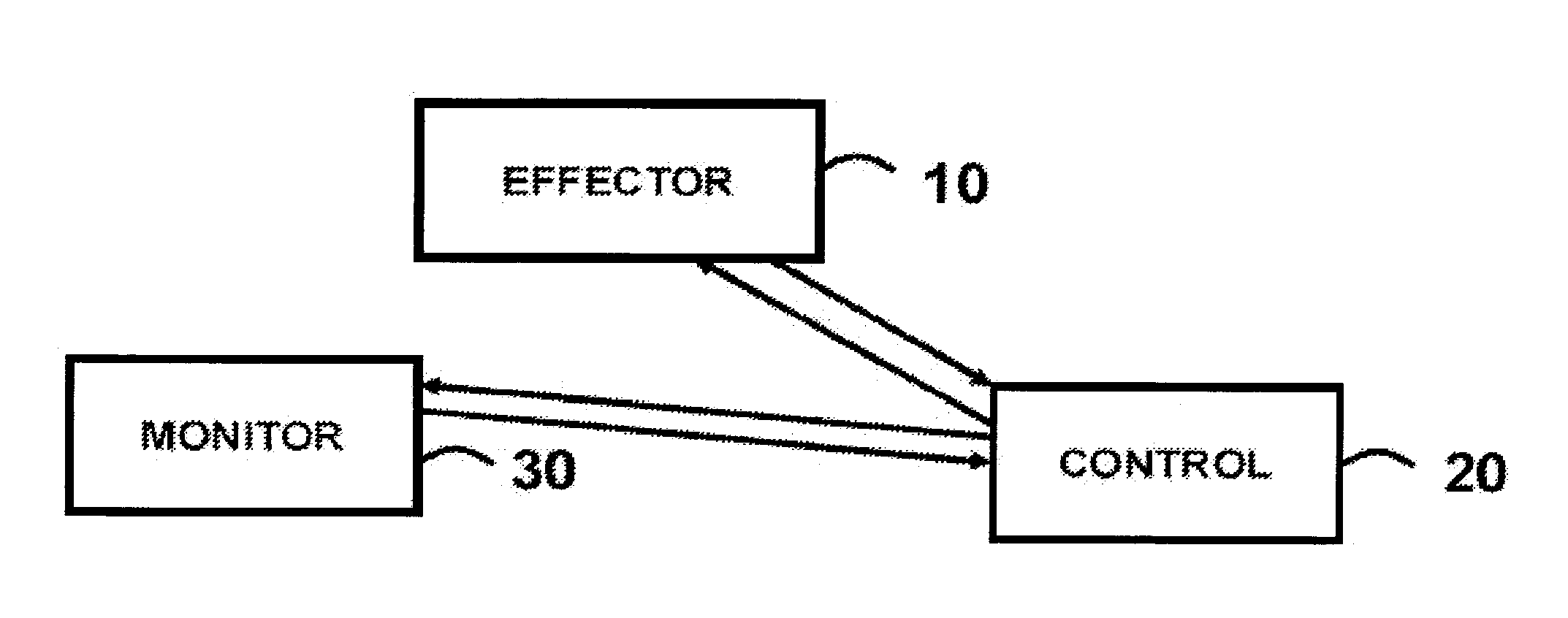

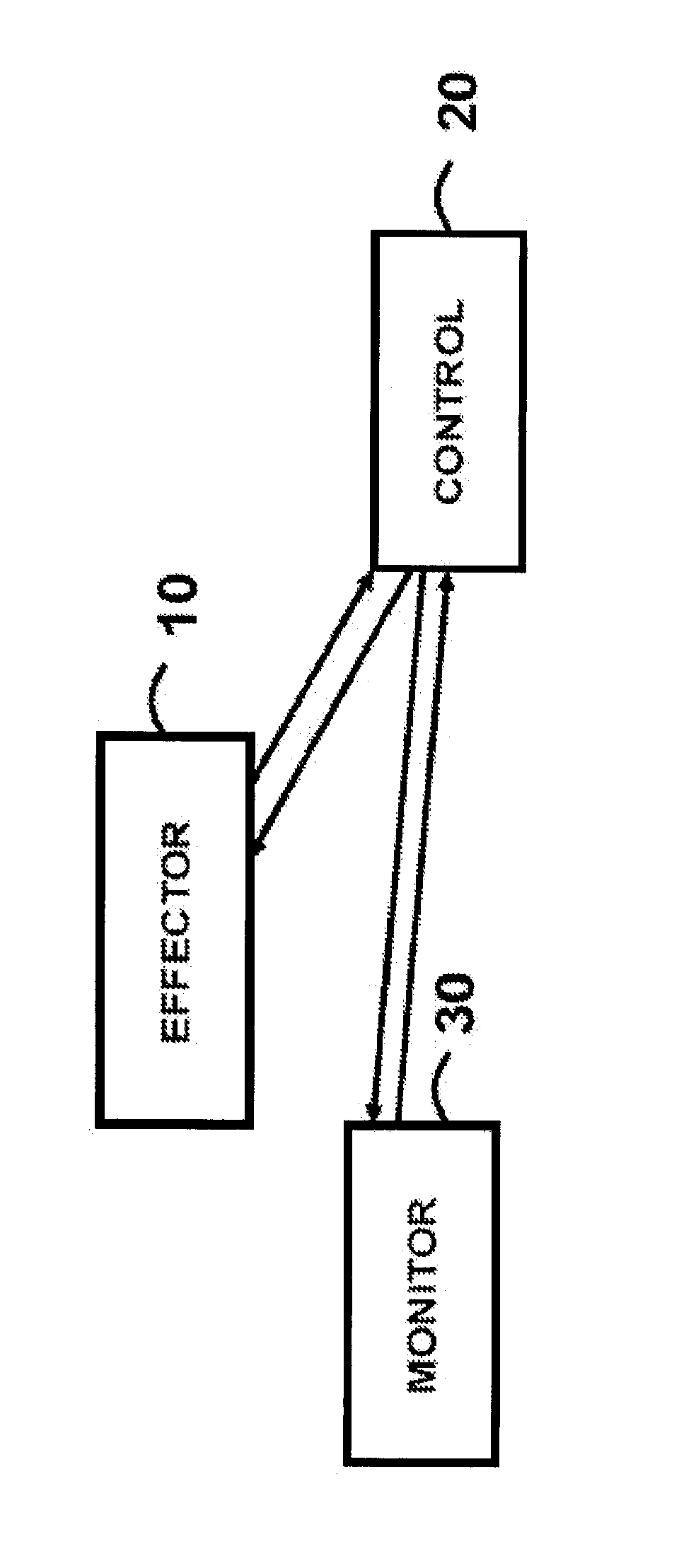

Methods, compositions and apparatuses for facilitating regeneration

ActiveUS20120183534A1Function increaseReduce the ratioElectrotherapyChiropractic devicesRegenerative processBiology

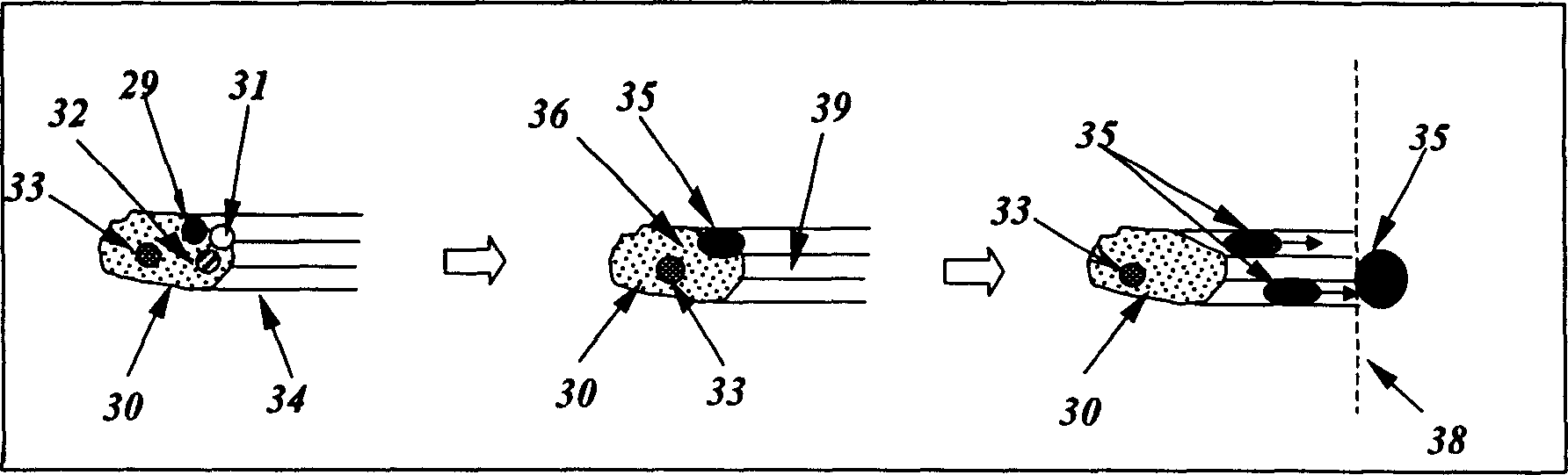

Apparatuses, compositions and methods for removing cells which interfere with regenerative processes. The apparatuses, compositions and methods selectively kill partially functional and / or non-functional cells versus functional cells while protecting functional proliferative cells to the extent that, upon removal of the killed cells by disintegration or scavenging, functional cells replace the partially- or non-functional cells.

Owner:SIWA CORP (US)

Devices and methods for the regeneration of bony defects

This invention relates to methods for producing a composite bone graft material that can regenerate bony defects in the body. The invention further relates to methods that allow for the production of bioactive glass particles used in the composite that have been surface treated to allow for the production of a highly porous composite that can hold significant amounts of body fluid or other molecules that will aid in the regenerative process. The method of surface treatment allows for the manufacture of a suitable implantable composite while retaining the unique osteostimulative properties that are associated with bioactive glass particles.

Owner:NOVABONE PRODS

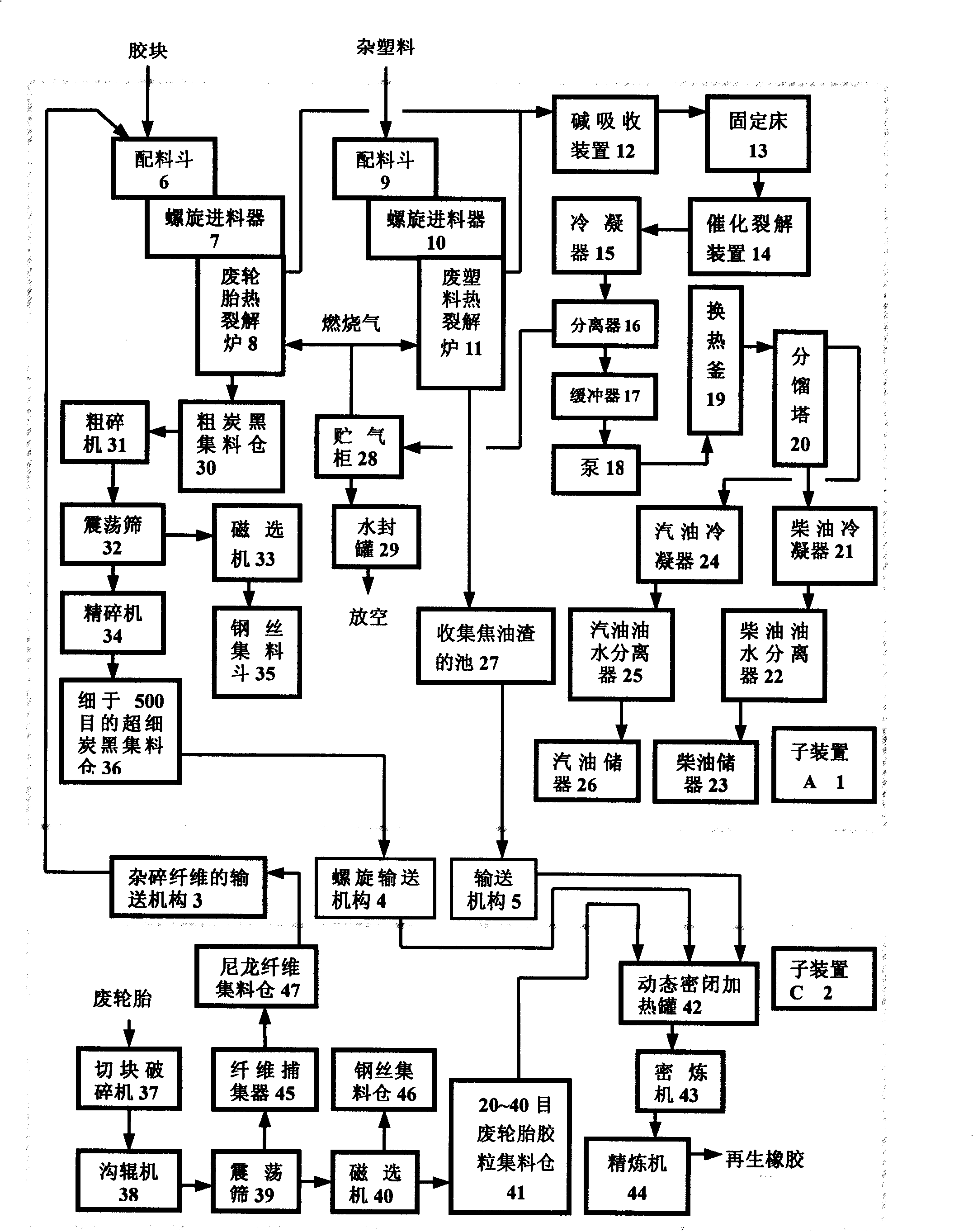

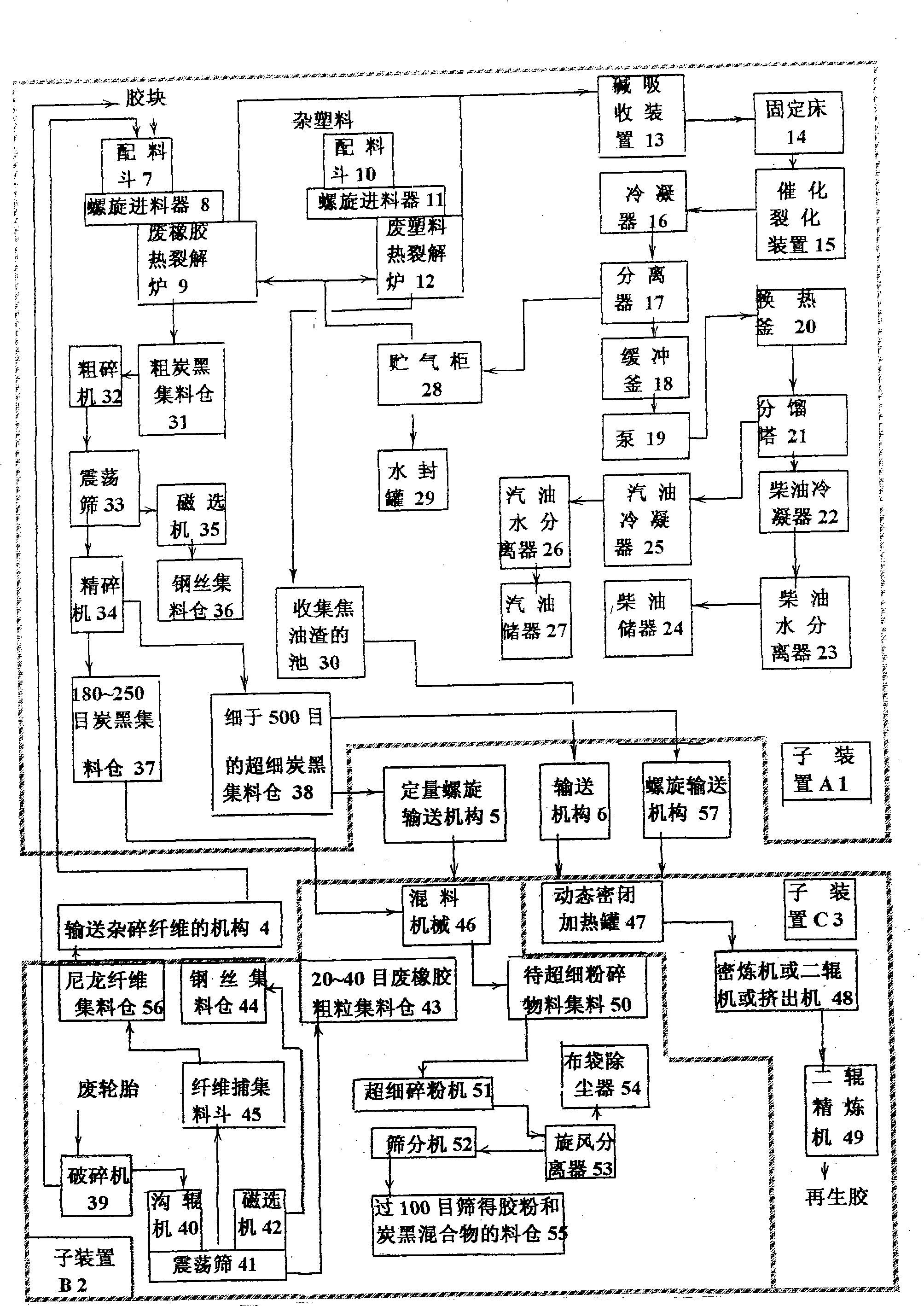

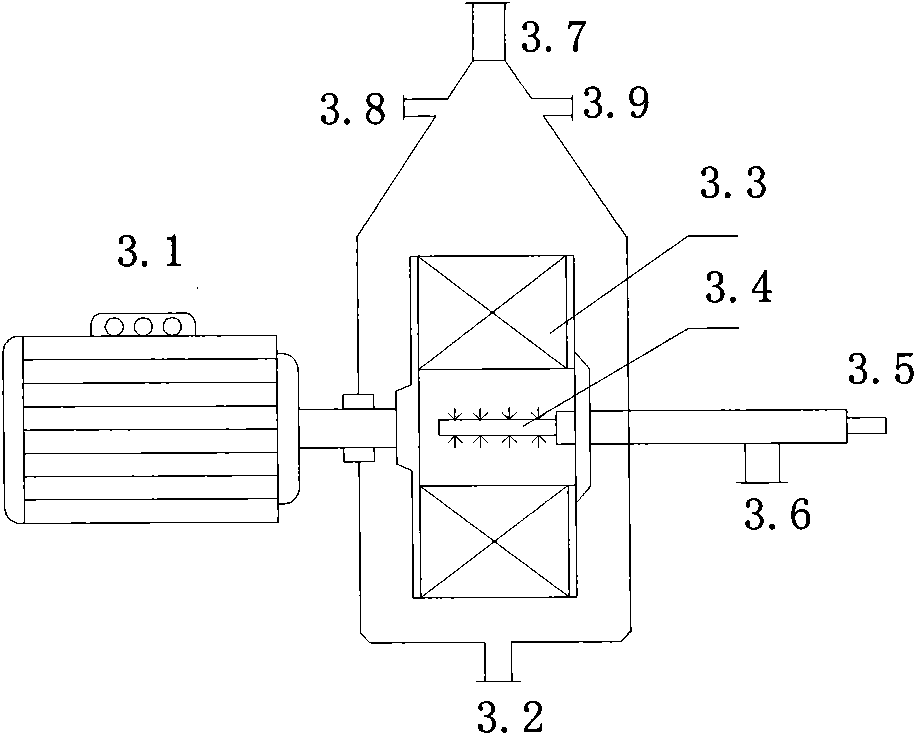

Method and apparatus for combination regeneration, or coproduction with hydrocarbon black of waste and old macromolecule material

ActiveCN101402745AReduce wasteExcellent energy qualityPlastic recyclingLiquid hydrocarbon mixture productionFiberRubber material

The invention discloses a method of combination and regeneration of waste high molecular materials or co-production of the waste high molecular materials and carbon black, and a device thereof, relating to two technologies of existing thermal cracking and non-thermal cracking of the waste high molecular materials and improvement and combination among various technological branches and also relating to the regeneration process of the waste high molecular materials and the combination of the regeneration process of the waste high molecular materials and the production process of general carbon black and an integration device used in the embodiment thereof; and comminution at normal temperature or the combination of the comminution at normal temperature and various branches of renovated rubber technology and an integration device adopted by the embodiment thereof are also included. The method also provides a treatment proposal for applying mixed fiber to recycling and products thereof, which are characterized in that the mixed fiber and plasticized rubber materials or / and oil materials are matched by the weight percentage of 100:5 to 100:100 to obtain a mixture taking the shape of a felt or a rubber felt or a treated felt. The proposal of the integration device also provides a combination device with fractional efficiency higher than that of the existing fractional process for the granularity of rubber powder only by means of a power screen.

Owner:上海橡源驰晨环保科技发展有限公司

Compositions for regenerating defective or absent myocardium

InactiveUS20070014871A1Organic active ingredientsPeptide/protein ingredientsCell-Extracellular MatrixRegenerative process

Compositions of the invention for regenerating defective or absent myocardium comprise an emulsified or injectable extracellular matrix composition. The composition can also have an extracellular matrix scaffold component of any formulation, then including also added cells, proteins, or other components to optimize the regenerative process and restore cardiac function. Methods for regenerating defective or absent myocardium apply a composition to a site of myocardium in need of regeneration using a delivery mode appropriate for the particular formulation.

Owner:CORMATRIX CARDIOVASCULAR INC

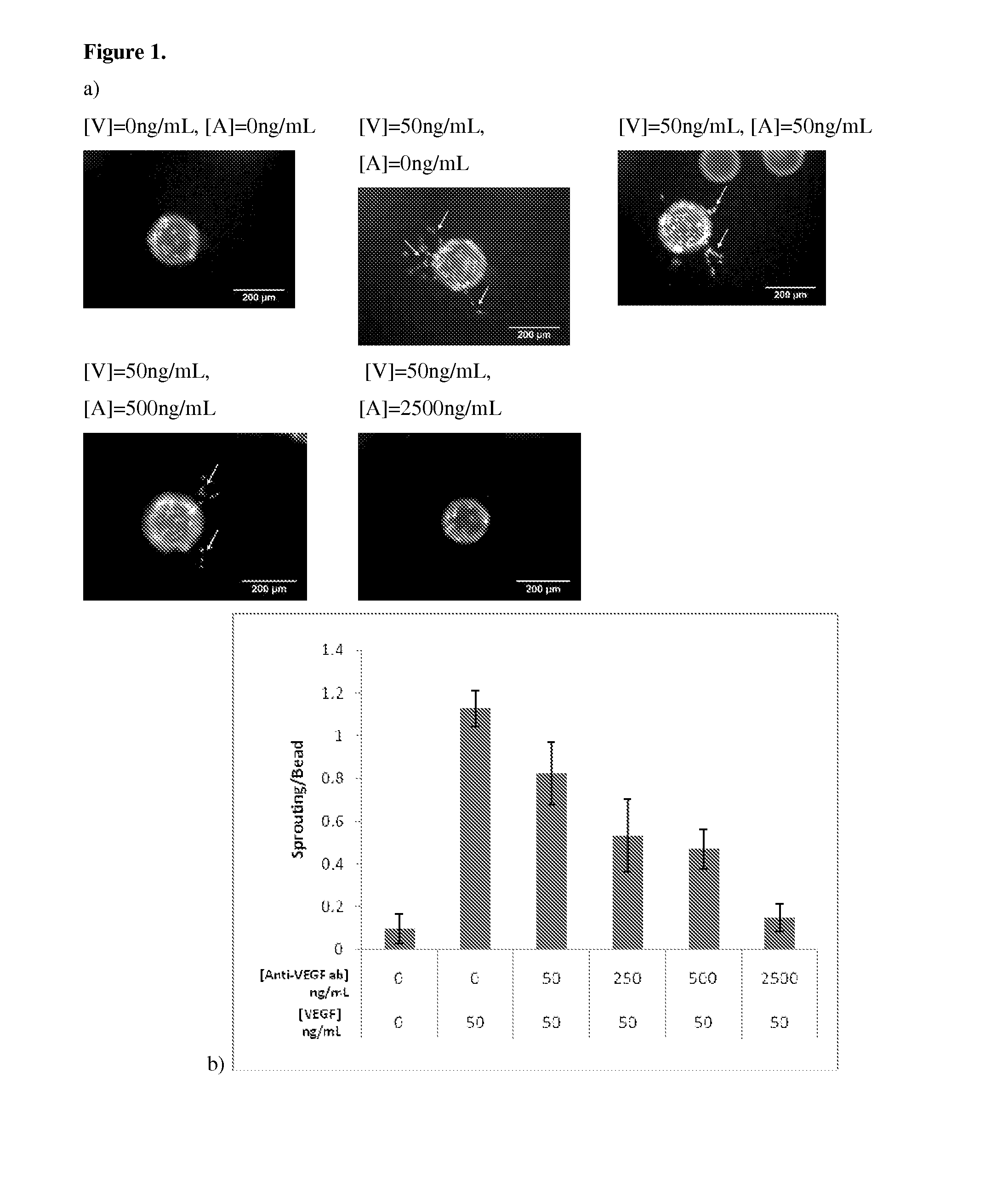

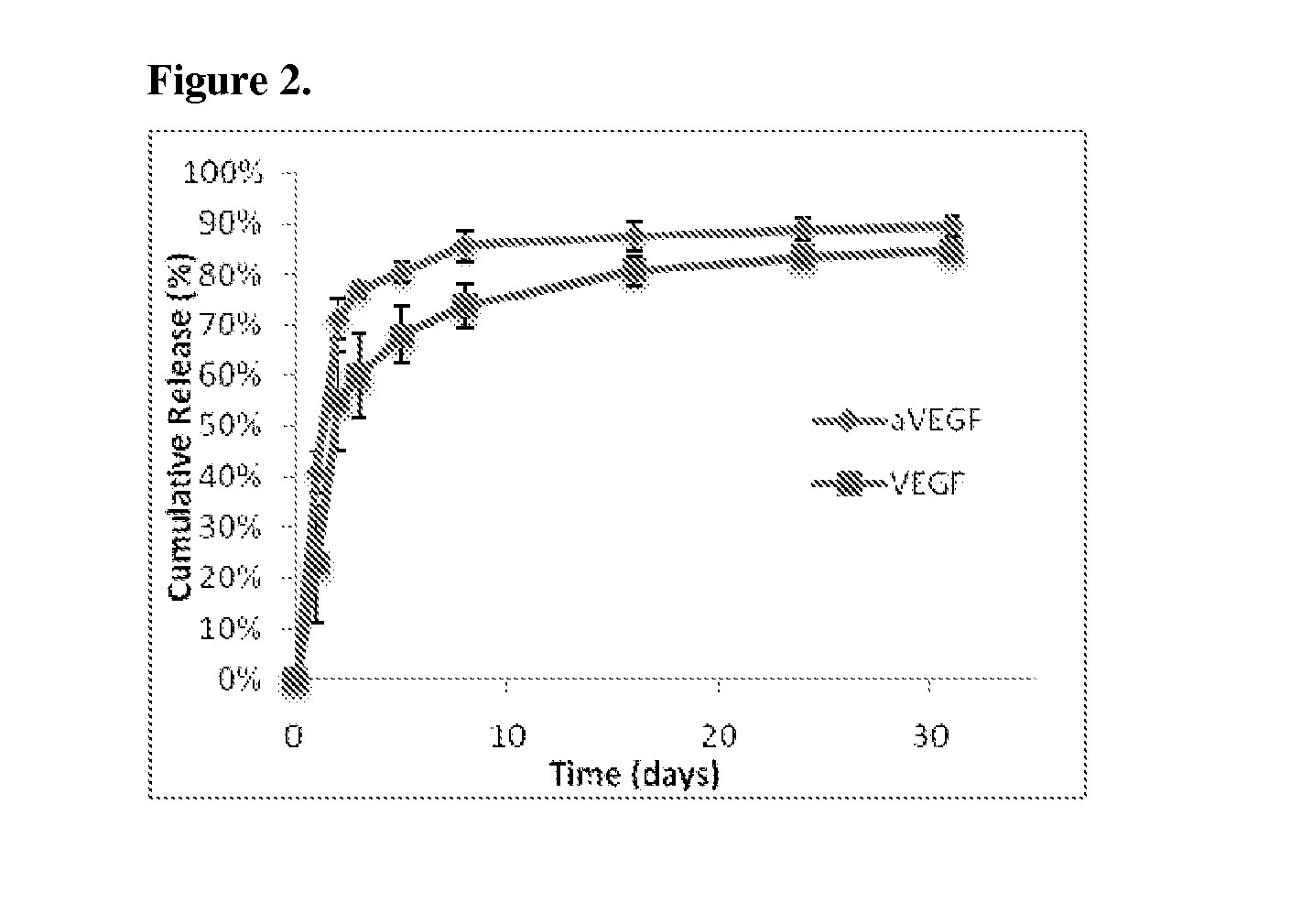

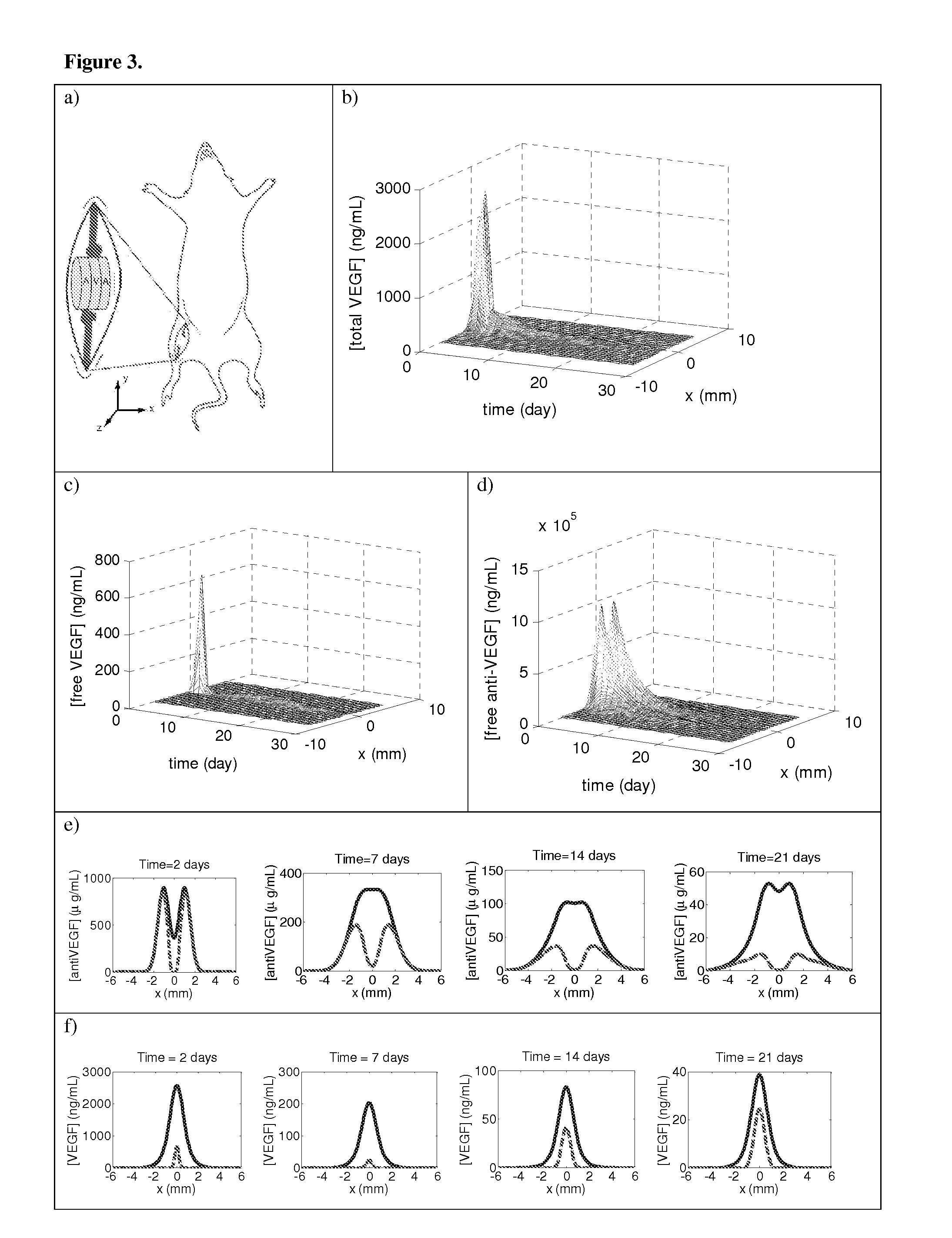

Co-Delivery Of Stimulatory And Inhibitory Factors To Create Temporally Stable And Spatially Restricted Zones

ActiveUS20130302396A1Reduce negative impactStop and retard disease progressionBiocidePeptide/protein ingredientsRegenerative processMedicine

The invention provides methods and compositions for local manipulation of regenerative processes via exogenous factor delivery.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Method for preparing hydrofining catalyst by waste catalyst

ActiveCN1552521AHigh activitySave resourcesCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsRegenerative processCatalyst regeneration

A process for preparing the hydrorefining catalyst from the used one includes such steps as adding less active metal component to the used hydrorefining catalyst powder and activating (regenerating). It features that in said regeneration procedure, the metallic salt is decomposed to absorb heat and generate gas to improve the artery structure of catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

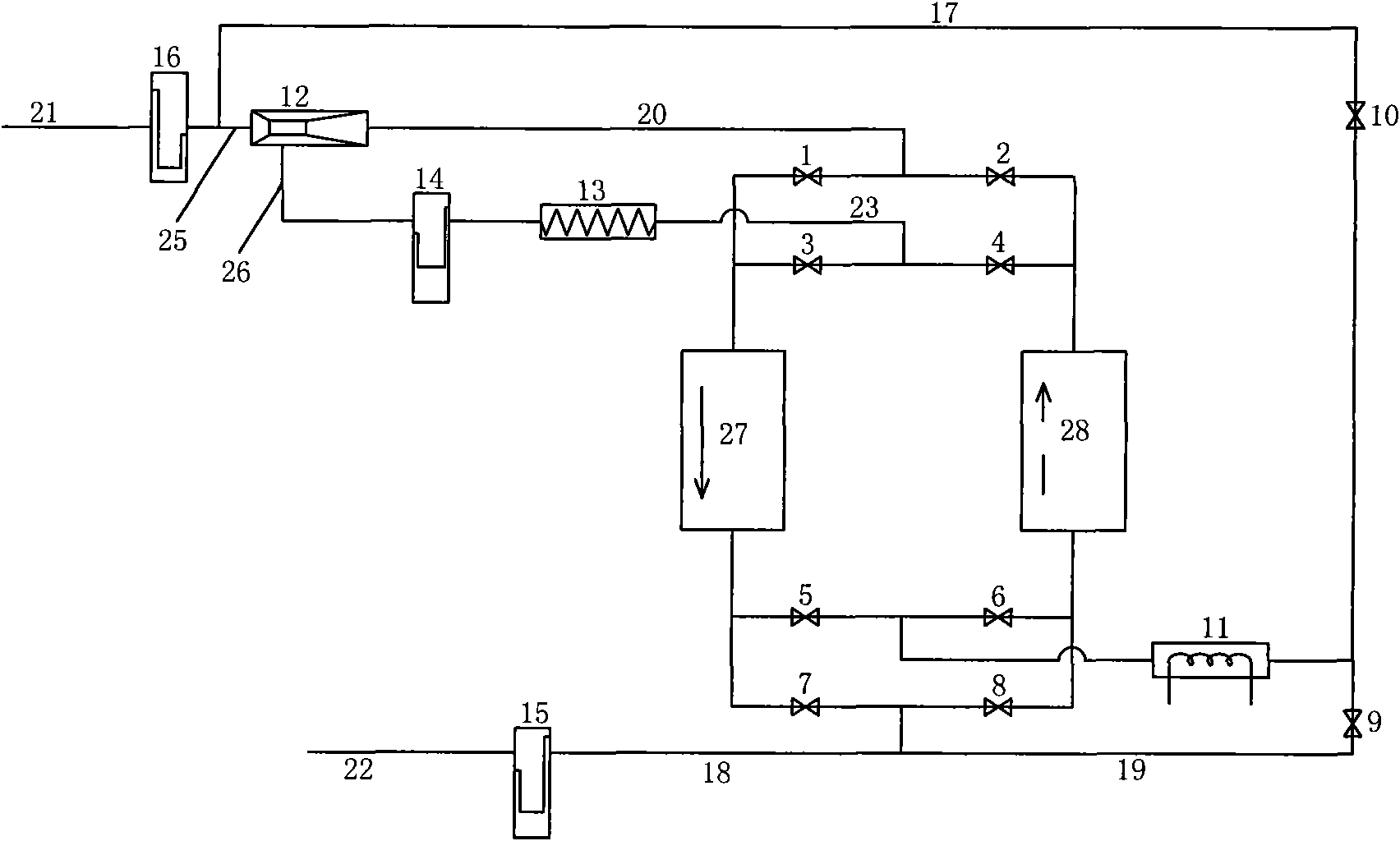

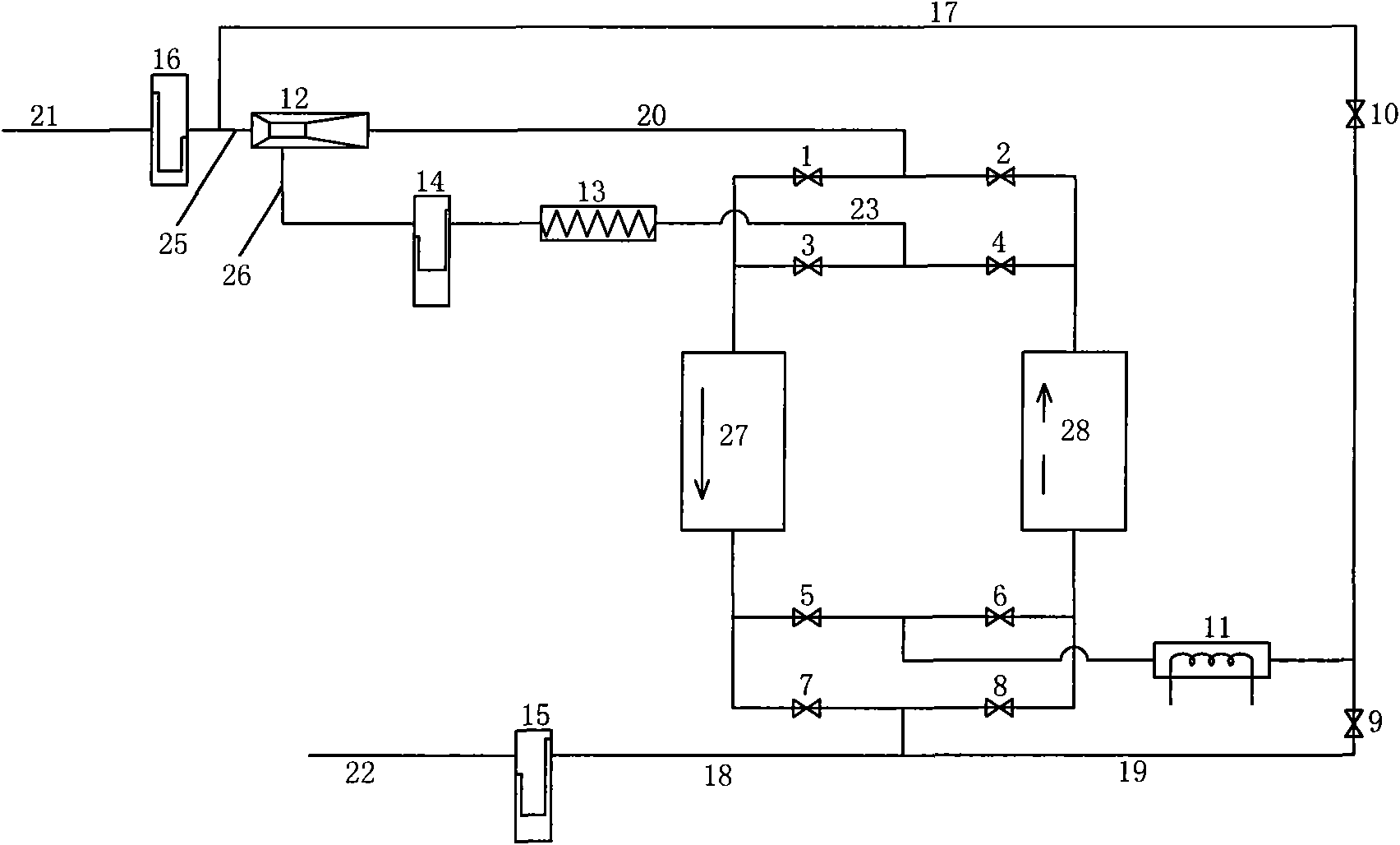

Self-regenerative process for contaminant removal from ammonia

A method and apparatus for the decontamination of fluid ammonia are described. Liquid or gaseous ammonia is purified of contaminants by passage through an adsorbent bed, the contaminants accumulating in the bed. A portion of the purified ammonia discharged from the bed is decomposed to hydrogen and nitrogen. The hydrogen is used to regenerate an adsorbent bed which has accumulated sufficient contaminants to reduce its ability to further decontaminate incoming ammonia satisfactorily. Preferably there are a plurality of interconnected adsorbent beds, with some being operated for ammonia decontamination while others are being regenerated, with their operations being reversed as needed to maintain a continual production of decontaminated ammonia from the plurality of beds. Computers or other controllers can be used to control such bed operations and interchanges. Internal production of hydrogen makes the system self-contained and no addition of hydrogen is needed.

Owner:ENTEGRIS INC

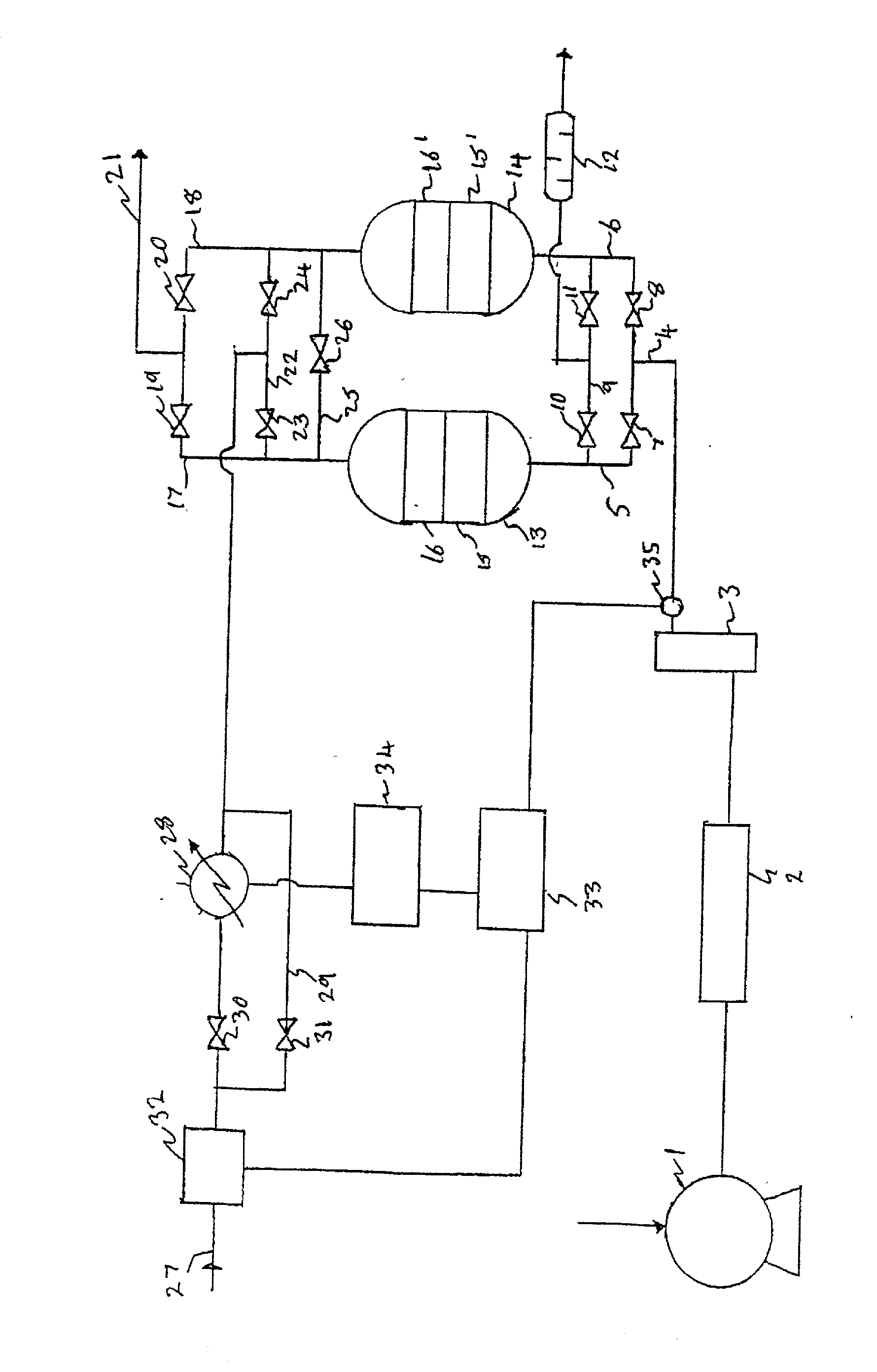

Process for treating a feed gas

Owner:AIR PROD & CHEM INC

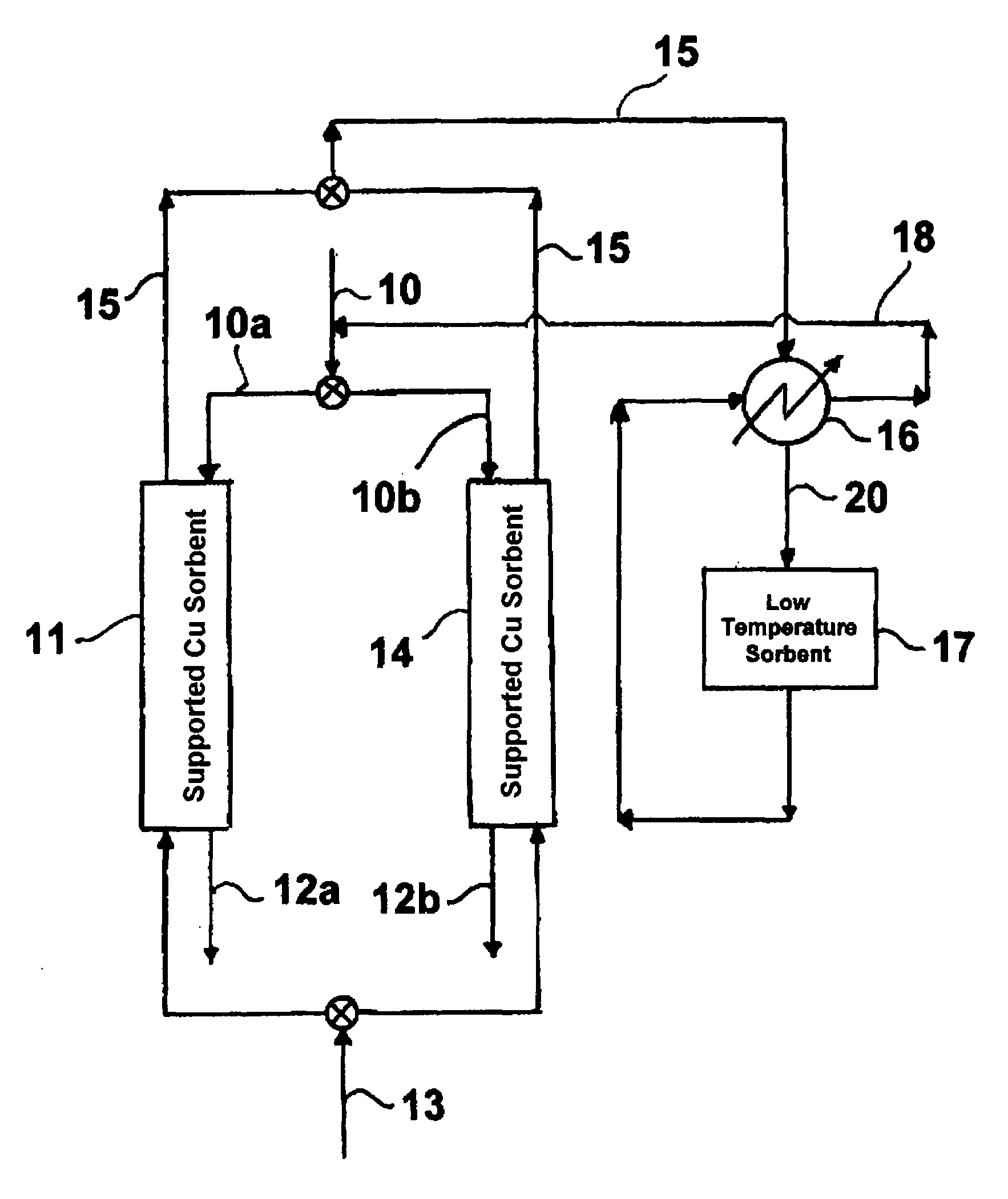

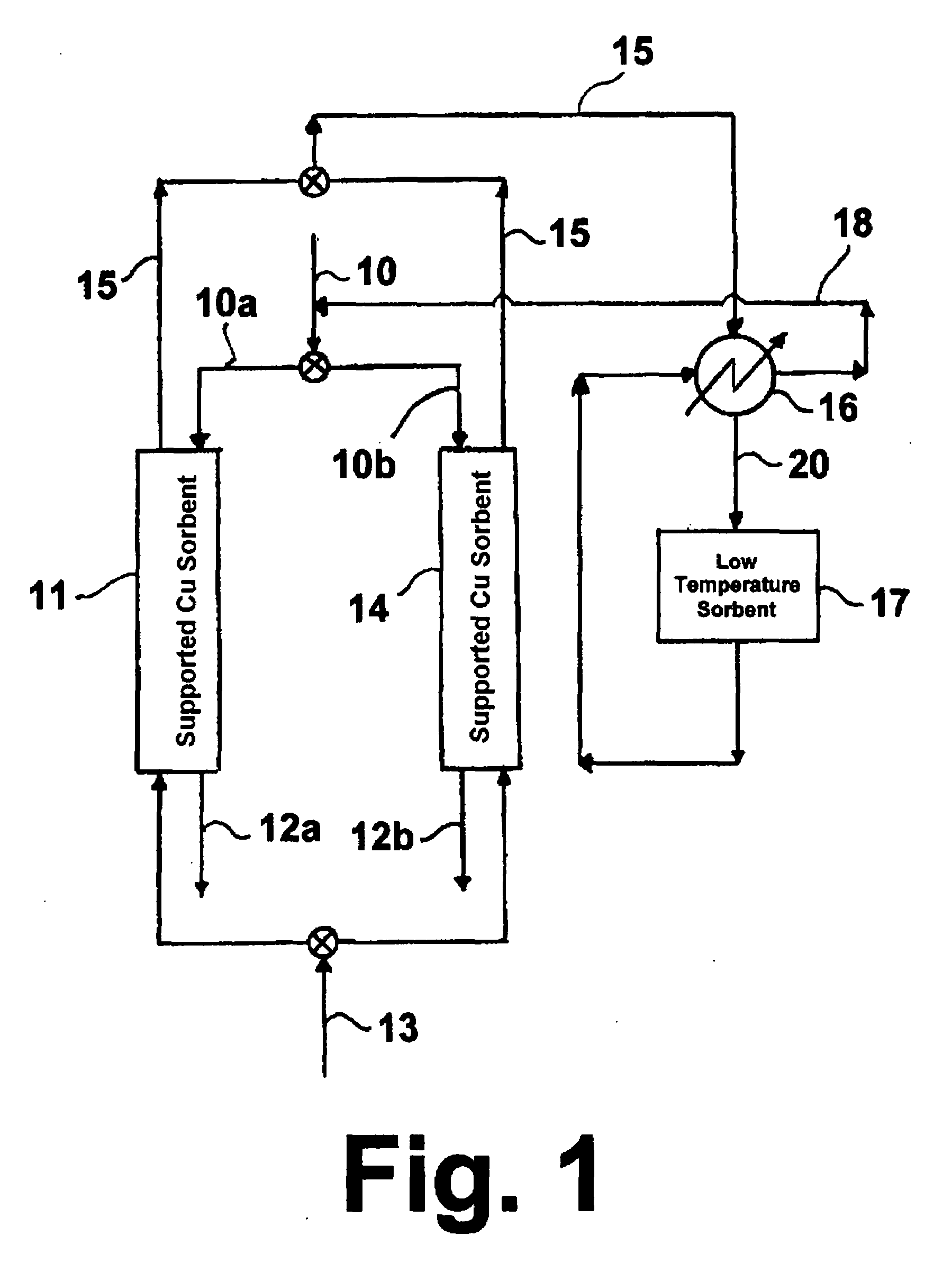

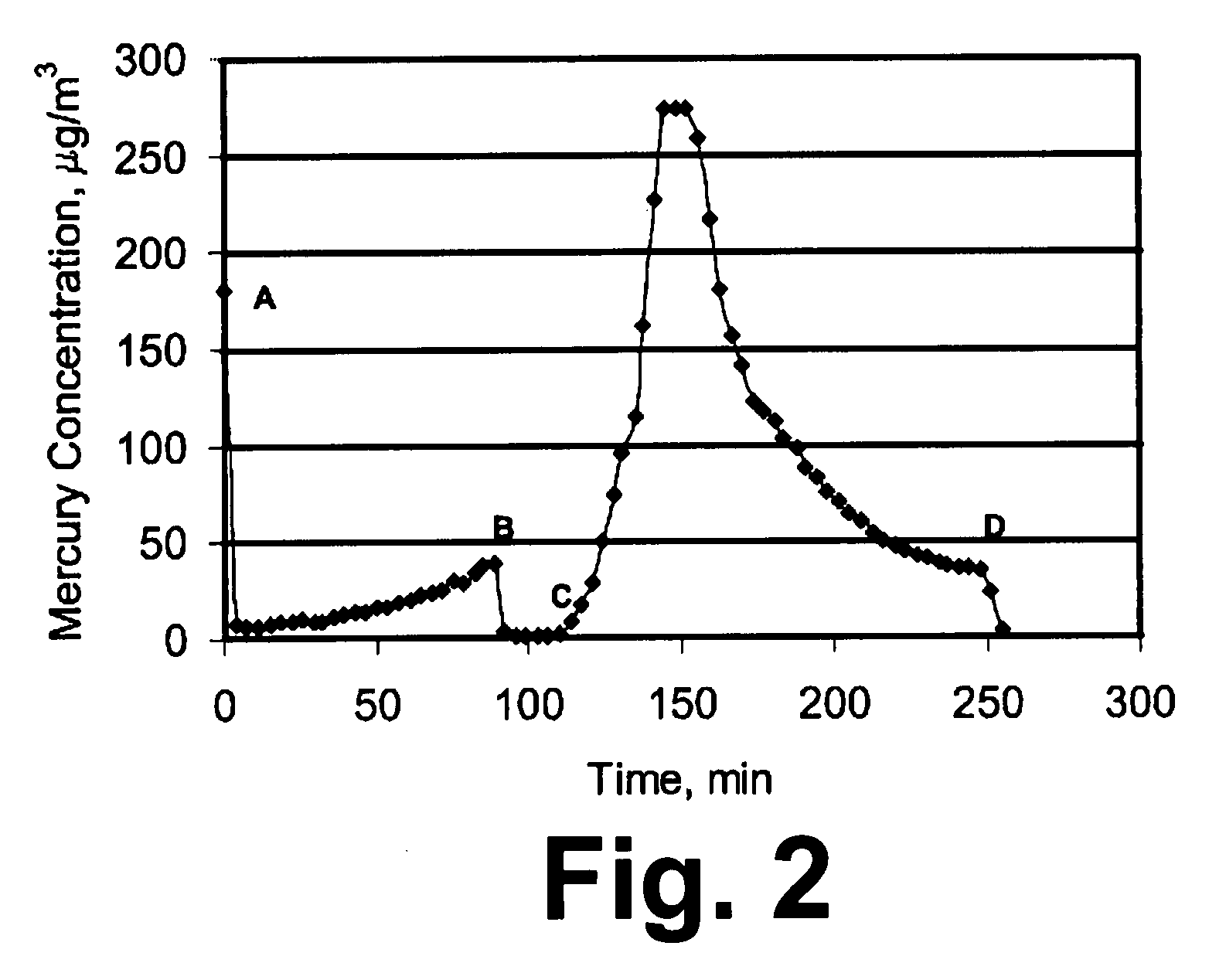

Regenerative process for removal of mercury and other heavy metals from gases containing H2 and/or CO

ActiveUS20080184884A1Increase release rateRaise regeneration temperatureGas treatmentIsotope separationSorbentCarbonyl sulfide

A method for removal of mercury from a gaseous stream containing the mercury, hydrogen and / or CO, and hydrogen sulfide and / or carbonyl sulfide in which a dispersed Cu-containing sorbent is contacted with the gaseous stream at a temperature in the range of about 25° C. to about 300° C. until the mercury concentration in the gaseous stream after contacting the sorbent exceeds a predetermined breakthrough level, signaling a spent sorbent. Arsenic, cadmium and selenium present in the gaseous stream may also be captured along with the mercury. The spent sorbent is then contacted with a desorbing gaseous stream at a temperature equal to or slightly higher than the temperature at which the mercury adsorption is carried out, producing a regenerated sorbent and an exhaust gas comprising released mercury. The released mercury in the exhaust gas is then captured using a high-capacity sorbent, such as sulfur-impregnated activated carbon, at a temperature less than about 100° C. The regenerated sorbent may then be used to capture additional mercury from the mercury-containing gaseous stream. The process may be carried out at pressures in the range of about 1 bar to about 200 bar.

Owner:GAS TECH INST

Compositions for regenerating defective or absent myocardium

InactiveUS20070014874A1Organic active ingredientsPeptide/protein ingredientsCell-Extracellular MatrixRegenerative process

Compositions of the invention for regenerating defective or absent myocardium comprise an emulsified or injectable extracellular matrix composition. The composition can also have an extracellular matrix scaffold component of any formulation, then including also added cells, proteins, or other components to optimize the regenerative process and restore cardiac function. Methods for regenerating defective or absent myocardium apply a composition to a site of myocardium in need of regeneration using a delivery mode appropriate for the particular formulation.

Owner:CORMATRIX CARDIOVASCULAR INC

Compositions for regenerating defective or absent myocardium

InactiveUS20070014870A1Restoring cardiac functionOrganic active ingredientsPeptide/protein ingredientsCell-Extracellular MatrixRegenerative process

Compositions of the invention for regenerating defective or absent myocardium comprise an emulsified or injectable extracellular matrix composition. The composition can also have an extracellular matrix scaffold component of any formulation, then including also added cells, proteins, or other components to optimize the regenerative process and restore cardiac function. Methods for regenerating defective or absent myocardium apply a composition to a site of myocardium in need of regeneration using a delivery mode appropriate for the particular formulation.

Owner:CORMATRIX CARDIOVASCULAR INC

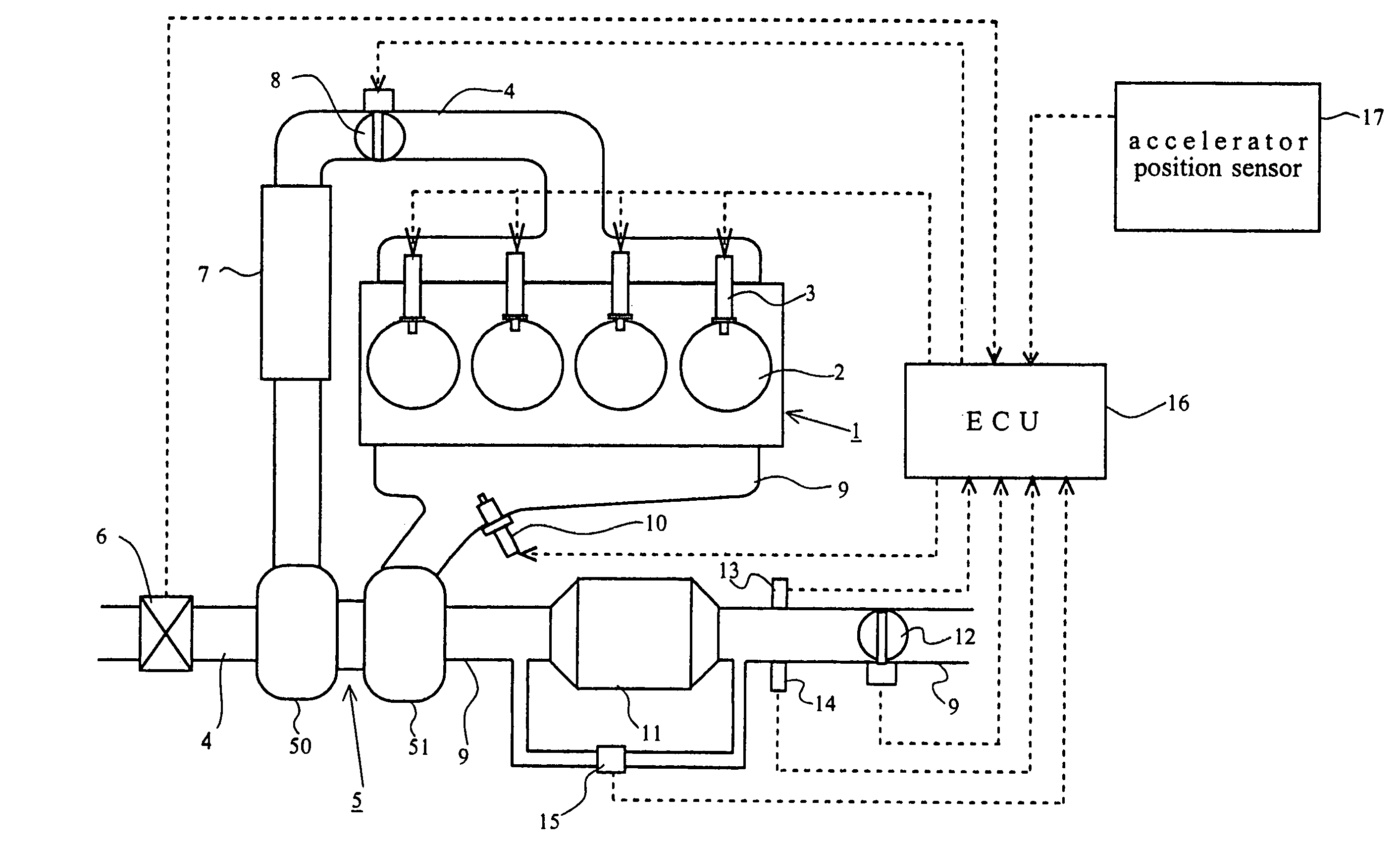

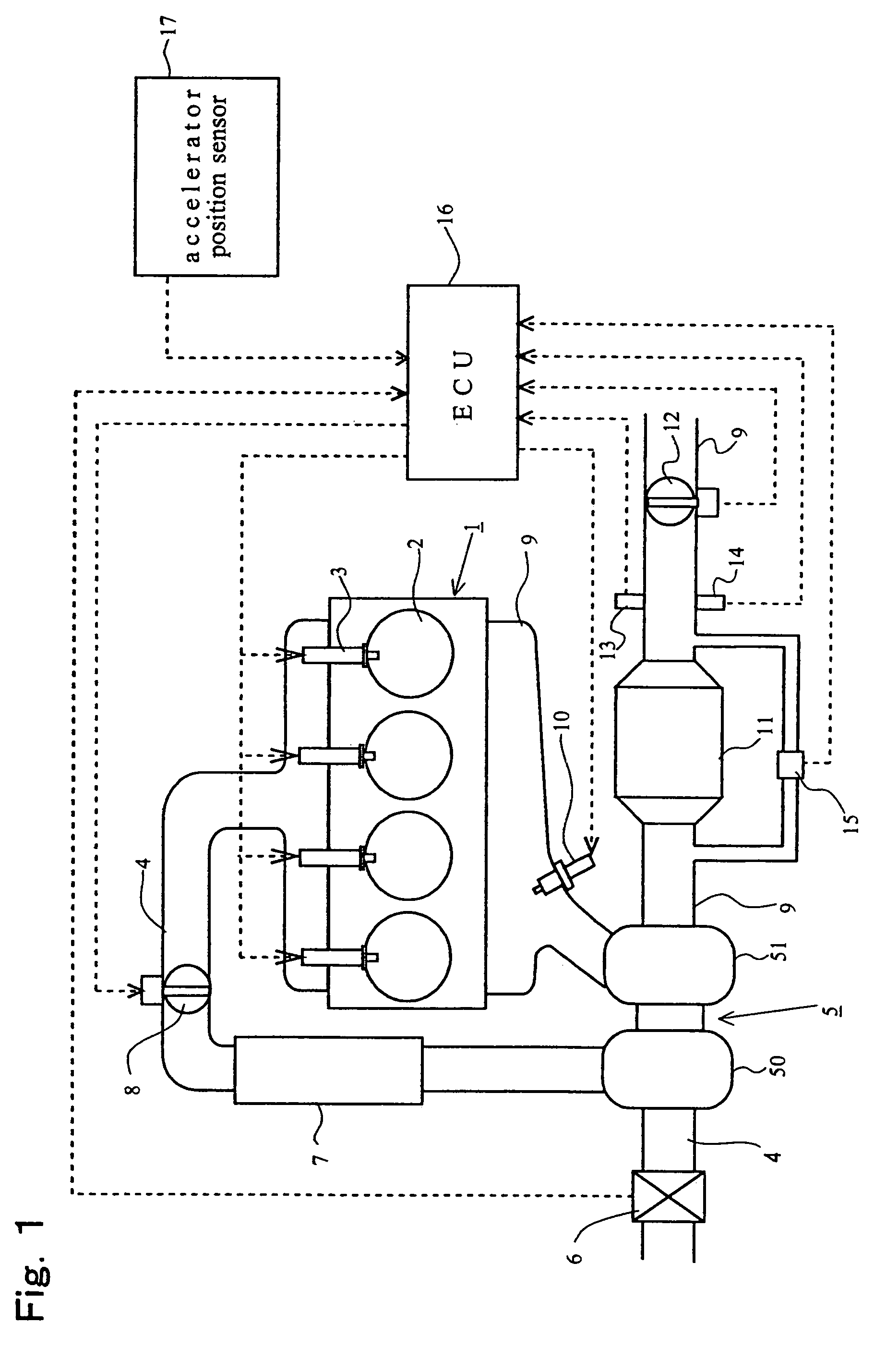

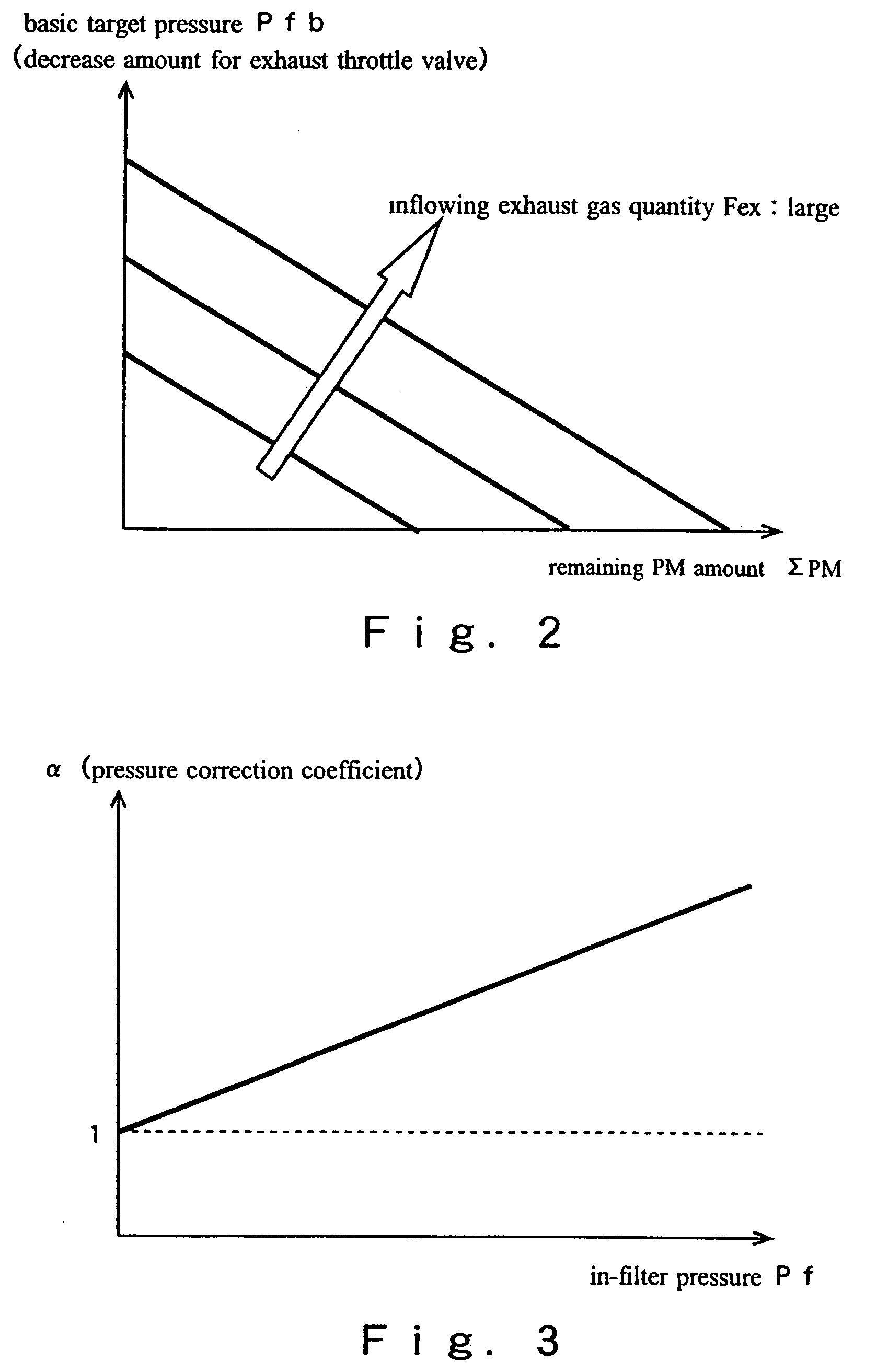

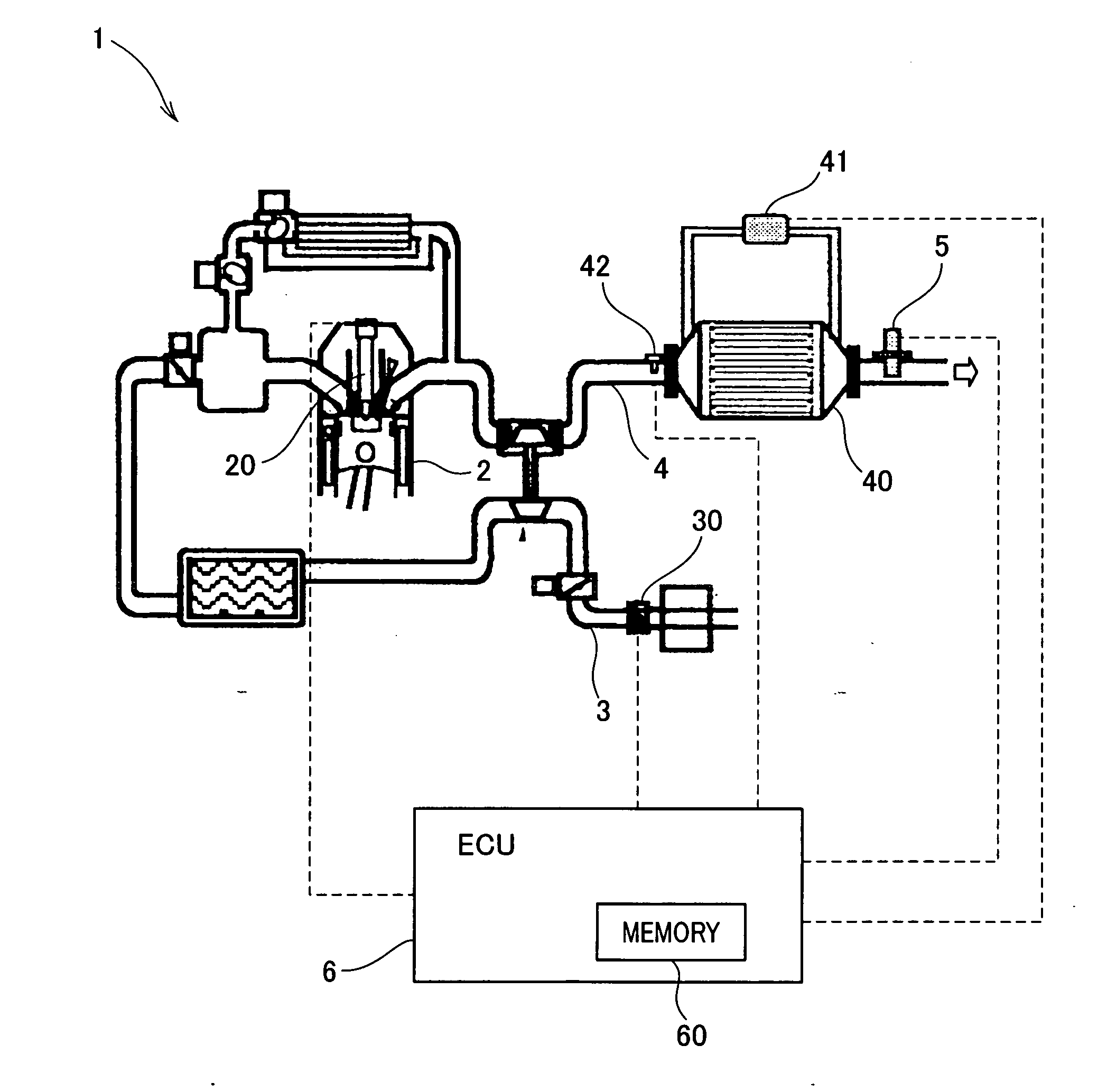

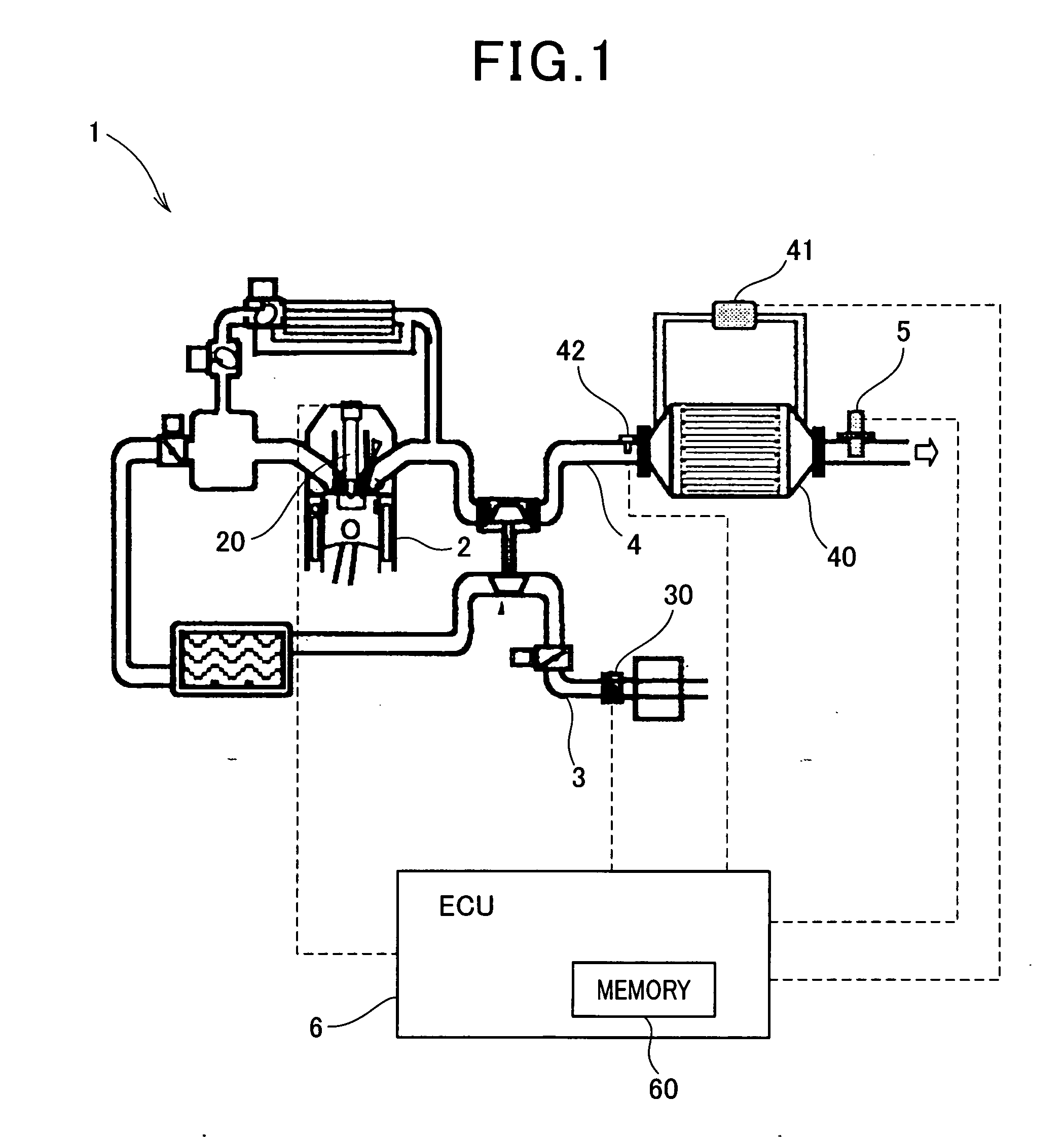

Exhaust Gas Purification System For Internal Combustion Engine

InactiveUS20080196395A1Easy to changeIncrease internal pressureElectrical controlInternal combustion piston enginesRegenerative processExhaust fumes

The present invention is directed to an exhaust gas purification system for an internal combustion engine that performs high pressure PM filter regeneration process by decreasing the degree of opening of an exhaust throttle valve in regenerating the particulate matter trapping capacity of a particulate filter and has as an object to provide a technology that enables to perform the high pressure PM filter regeneration process while suppressing excessive temperature rise of the particulate filter even while the vehicle is moving. According to the invention, a prediction is made, when the high pressure PM filter regeneration process is performed, as to whether there is a possibility that the temperature of the particulate filter will reach a predetermined upper limit temperature, and the pressure inside the particulate filter is controlled in accordance with the prediction.

Owner:TOYOTA JIDOSHA KK

Compositions for regenerating defective or absent myocardium

InactiveUS20070014872A1Induce angiogenesisOrganic active ingredientsPeptide/protein ingredientsCell-Extracellular MatrixRegenerative process

Compositions of the invention for regenerating defective or absent myocardium comprise an emulsified or injectable extracellular matrix composition. The composition can also have an extracellular matrix scaffold component of any formulation, then including also added cells, proteins, or other components to optimize the regenerative process and restore cardiac function. Methods for regenerating defective or absent myocardium apply a composition to a site of myocardium in need of regeneration using a delivery mode appropriate for the particular formulation.

Owner:CORMATRIX CARDIOVASCULAR INC

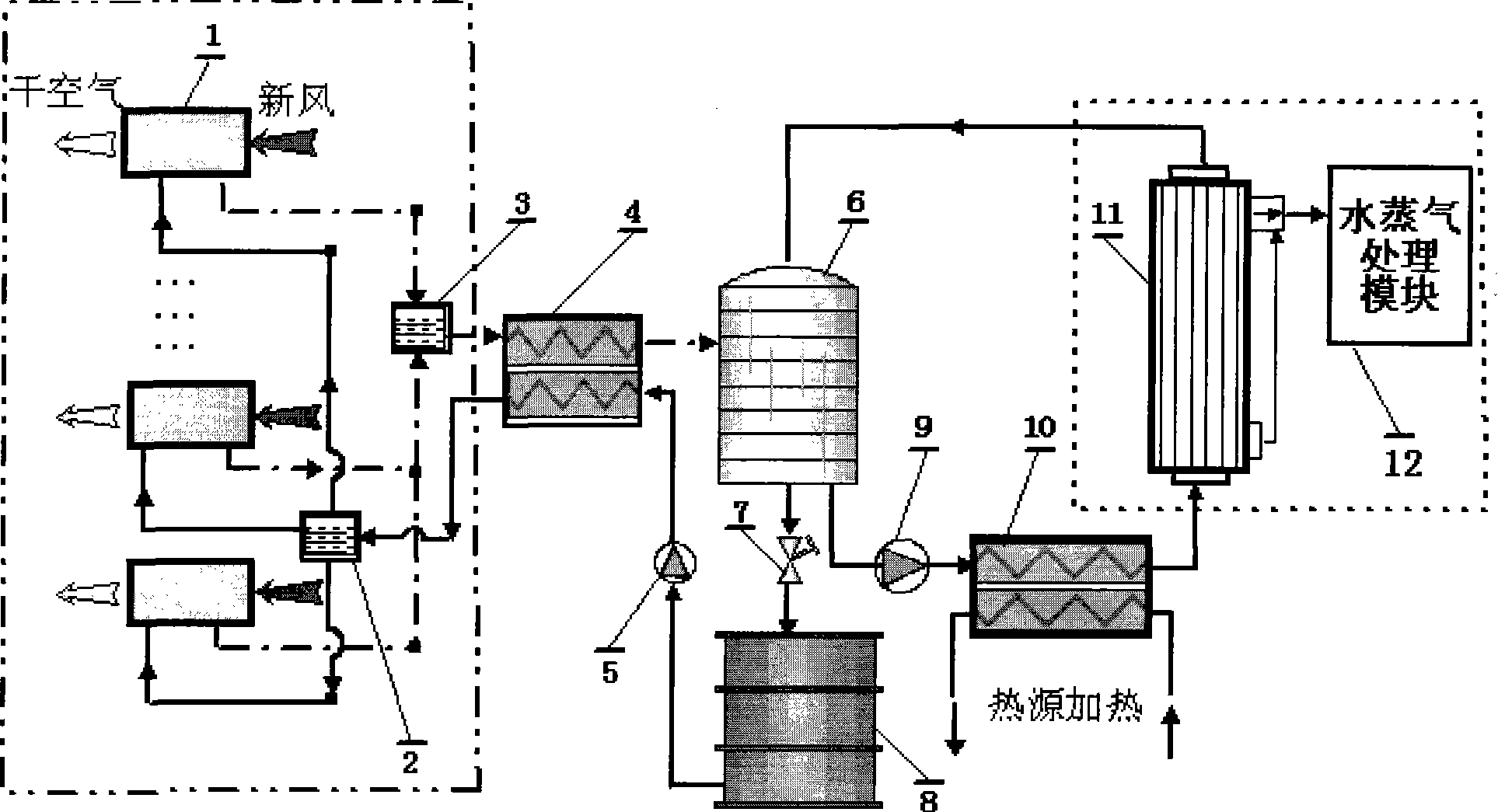

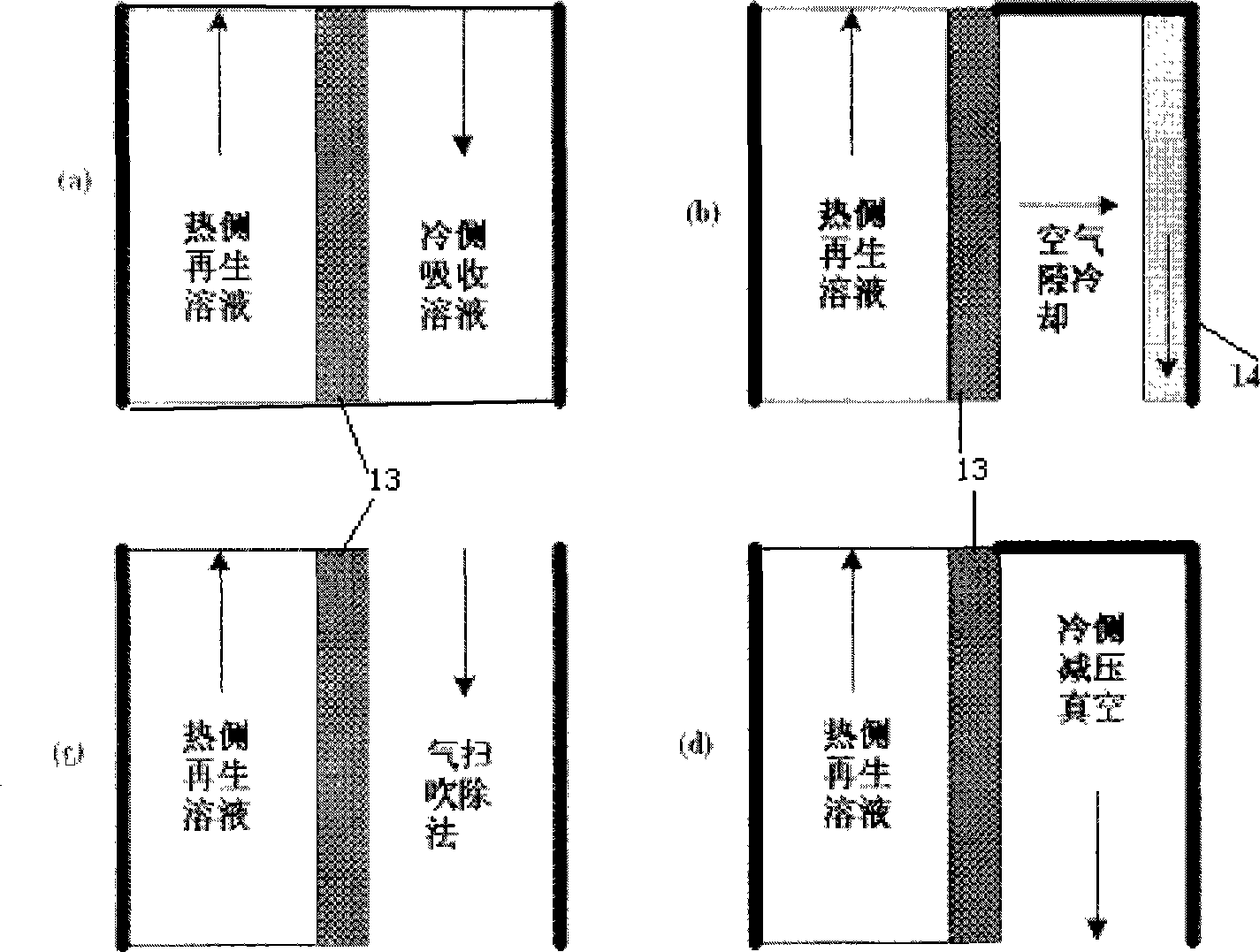

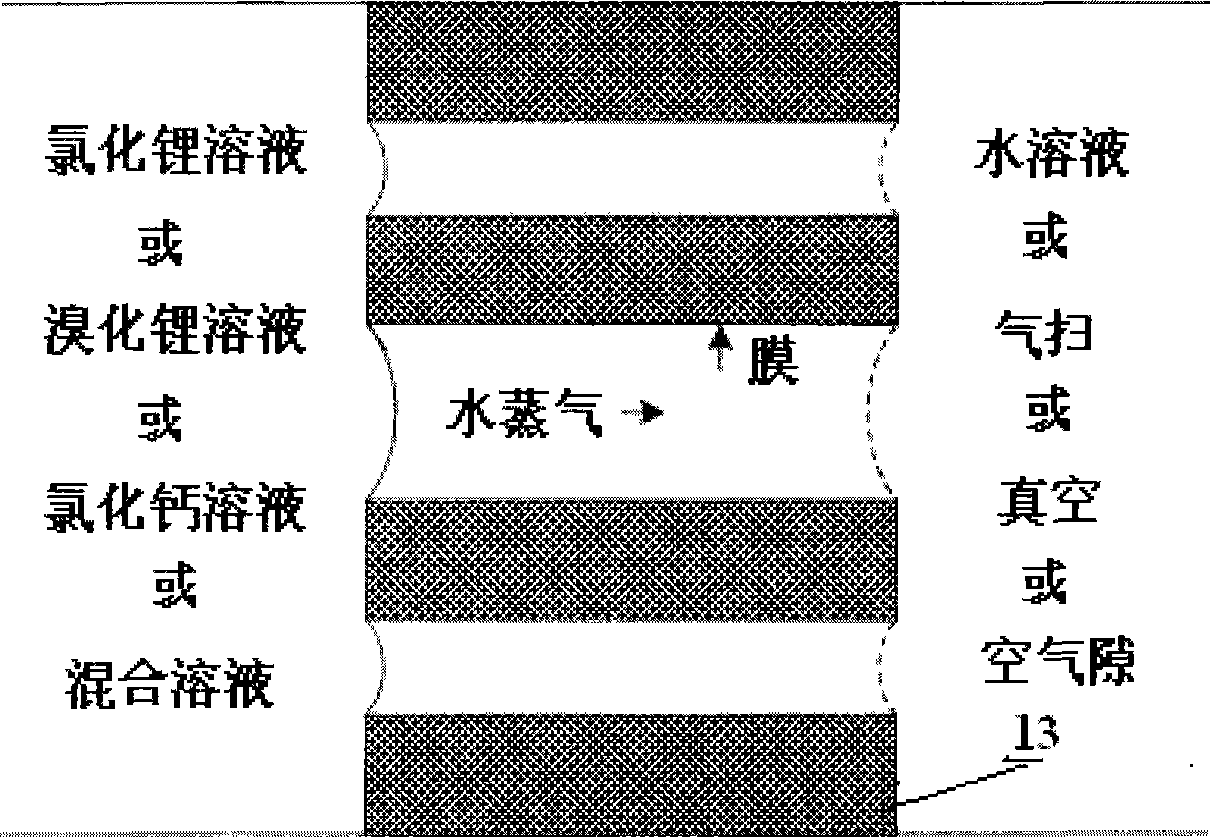

Solution regenerative device of solution dehumidifying air-conditioning system

InactiveCN101435608AWide choiceEasy to combineLighting and heating apparatusDispersed particle separationThermal energyWater vapor

The invention relates to a solution regeneration unit for a solution dehumidification air-conditioning system based on the membrane distillation technology, which mainly comprises a diluted solution reservoir, a concentrated solution reservoir, a solution heating device, a regenerative circulating pump, a water vapor treatment module and a membrane distillation component. By utilization of the characteristic in the membrane distillation technology that the temperature of driving heat source is low, the heat source temperature required by the solution regeneration process is greatly reduced, and the available temperature difference range of heat energy is increased; meanwhile, by utilization of the large contact area provided by a membrane component under unit volume and the expandability of the membrane component, the volume and the weight of a solution regeneration system are greatly reduced. Compared with the prior packed tower solution regeneration unit, the solution regeneration unit has low operating temperature and the heat energy during the operating process is only used for transmembrane latent heat transfer of water vapor, so that the energy consumption is small.

Owner:XI AN JIAOTONG UNIV

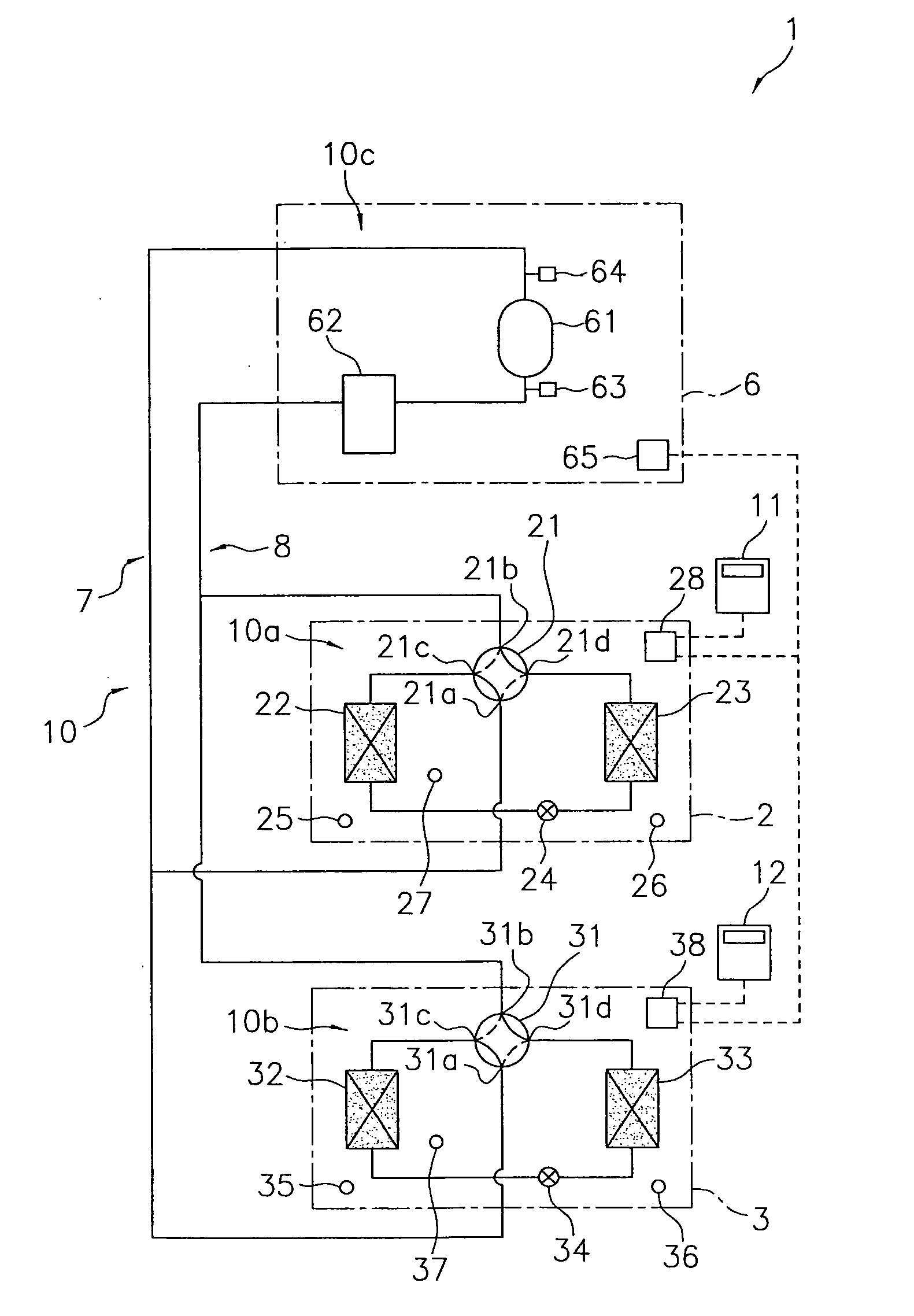

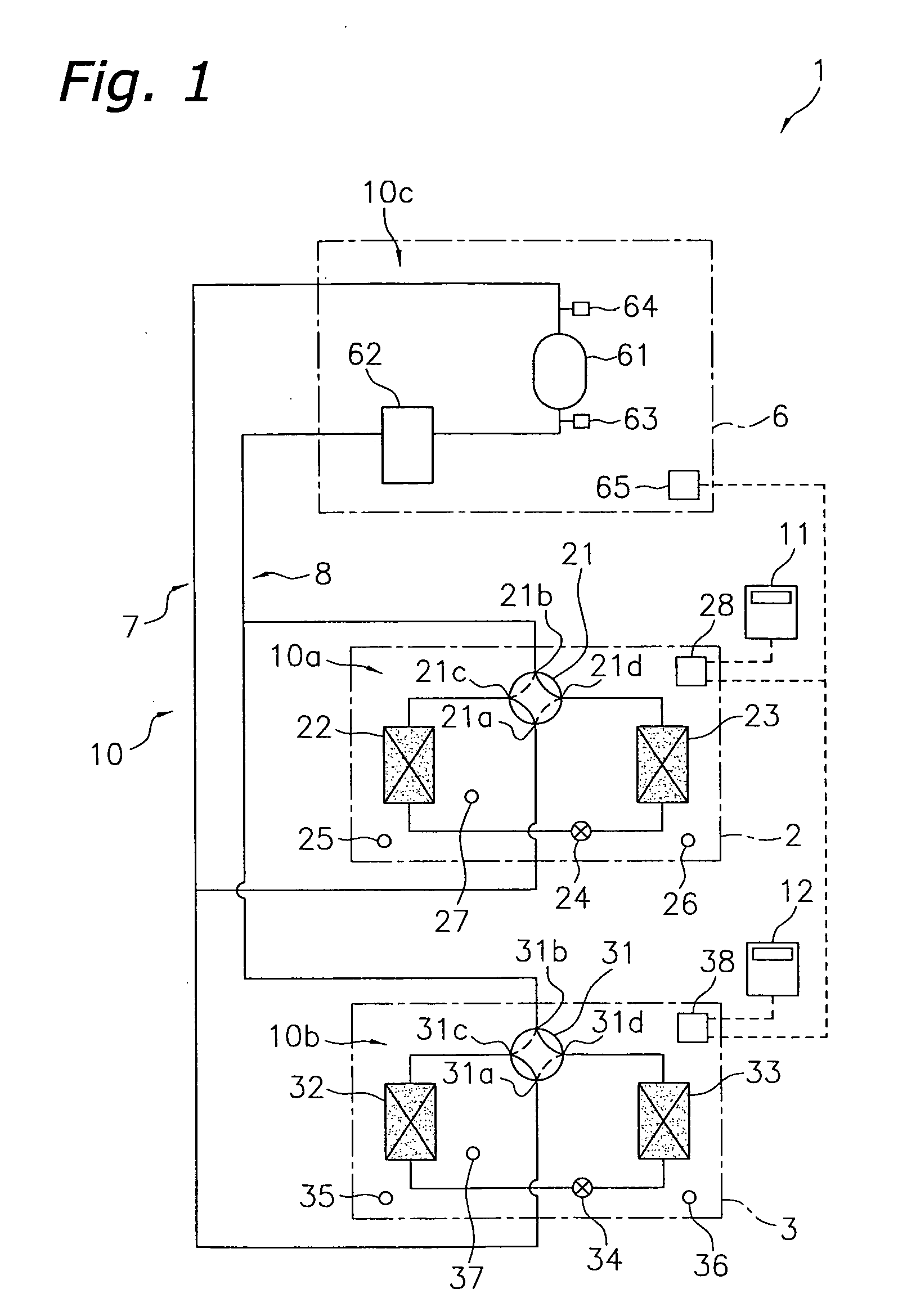

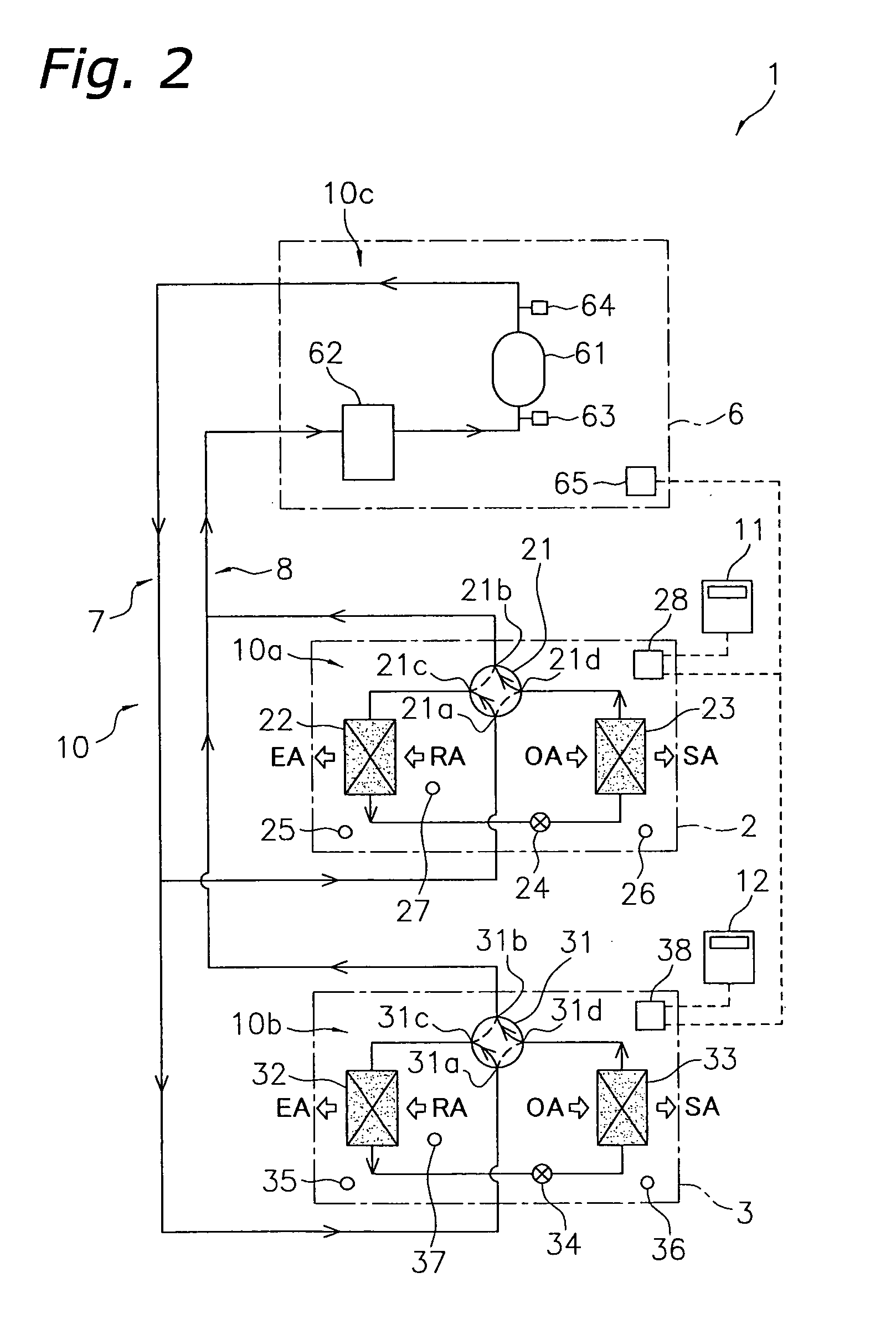

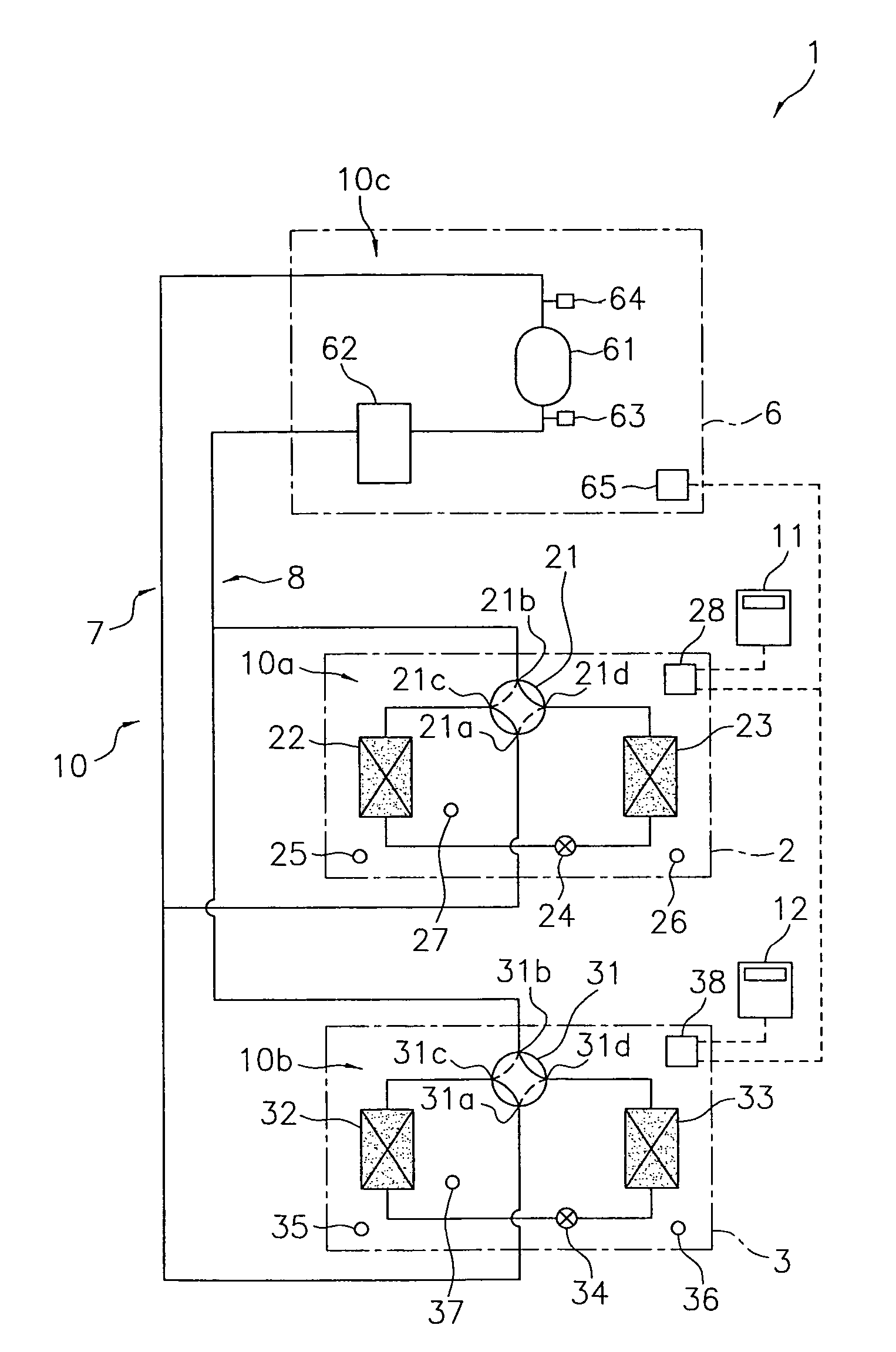

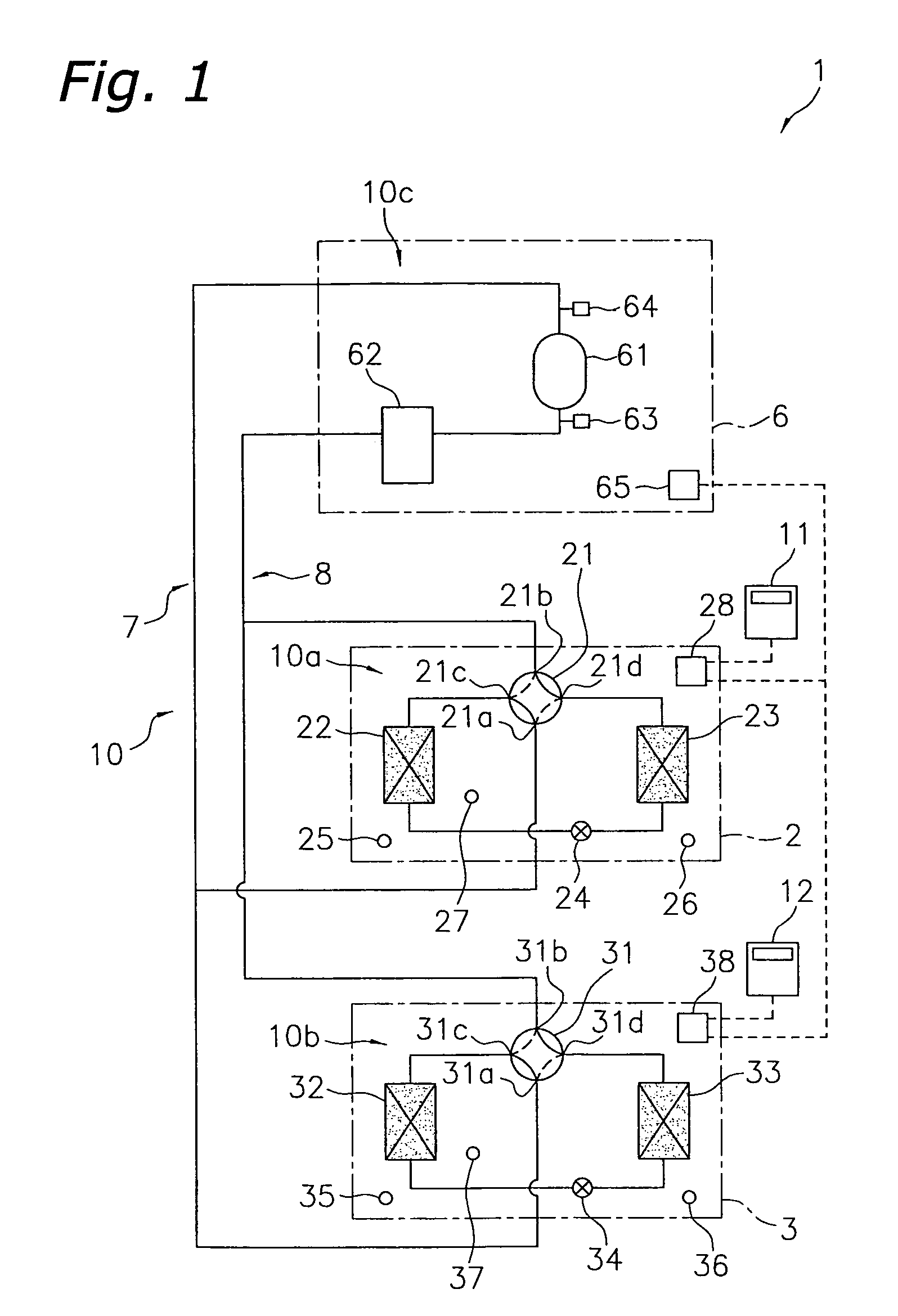

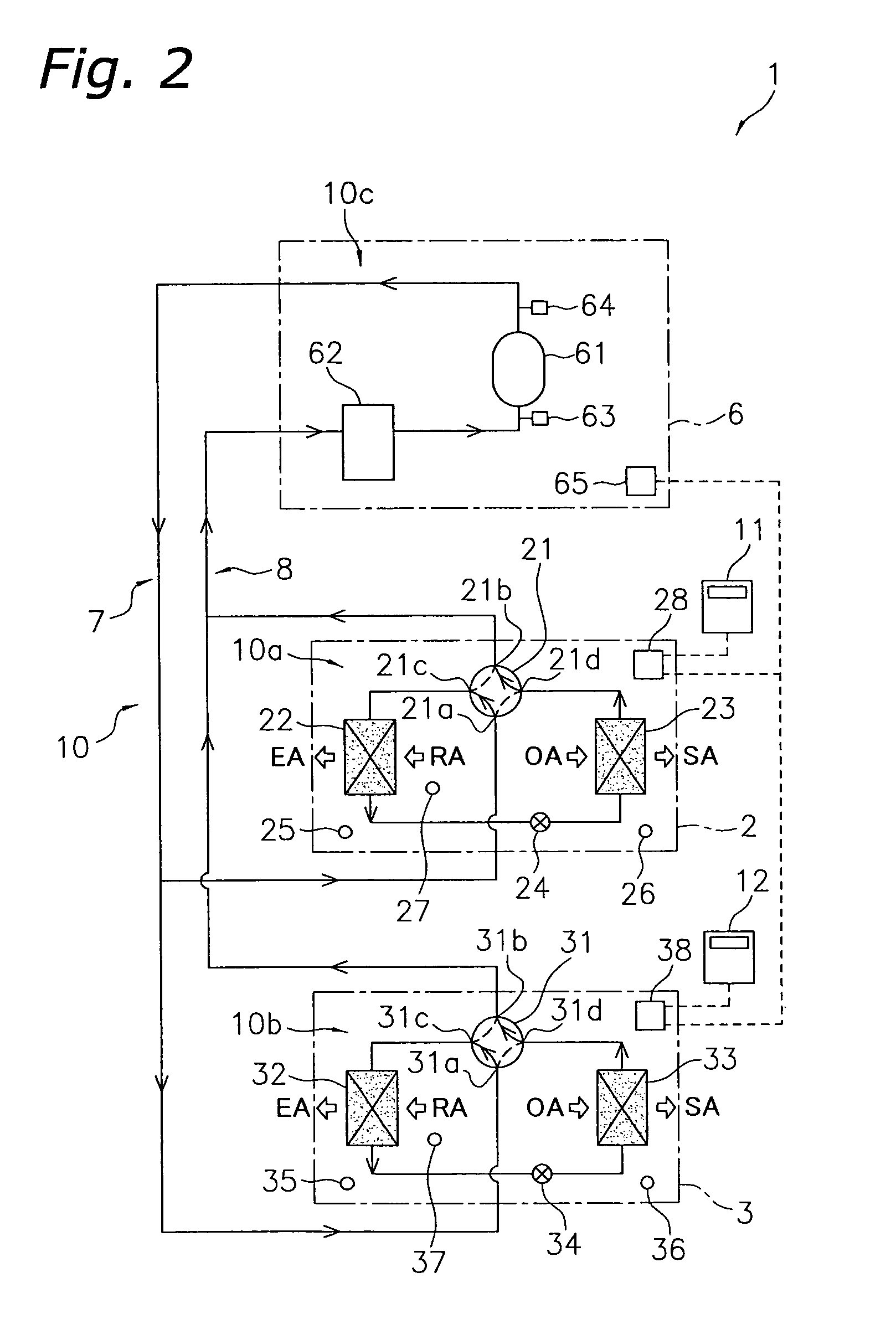

Air conditioning system

InactiveUS20070180844A1Guaranteed uptimeHeat loadMechanical apparatusSpace heating and ventilation safety systemsRegenerative processEngineering

An air conditioning system to treat a latent heat load and a sensible heat load in a room includes a plurality of utilization units, a heat source unit, and connection pipes that connect between the units. The utilization units include adsorbent heat exchangers provided with an adsorbent on the surface of each. The utilization units are configured to alternate between an adsorption process and a regeneration process. The heat source unit includes a compression mechanism and an accumulator.

Owner:DAIKIN IND LTD

Gas drying process and device

ActiveCN101920154AReduce investmentSimple processDispersed particle separationRegenerative processAtmospheric air

The invention provides a gas drying process and a gas drying device and mainly solves the problem of environmental pollution caused by directly exhausting gases in a regeneration tower or waste and high cost caused by burning the gases in the reduced regeneration process of the prior art. The gas drying process comprises three steps of adsorption, regeneration and circulation. The gases are not exhausted to the atmosphere any more during operation so as to prevent environmental pollution and waste caused by burning the exhaust gases; equipment for recycling the exhaust gases is not needed, sothe investment is reduced; and the process is simple and convenient to operate, saves the pressure reduction for exhaust and pressurization after regeneration, and reduces the cost.

Owner:无锡联合超滤净化设备科技有限公司

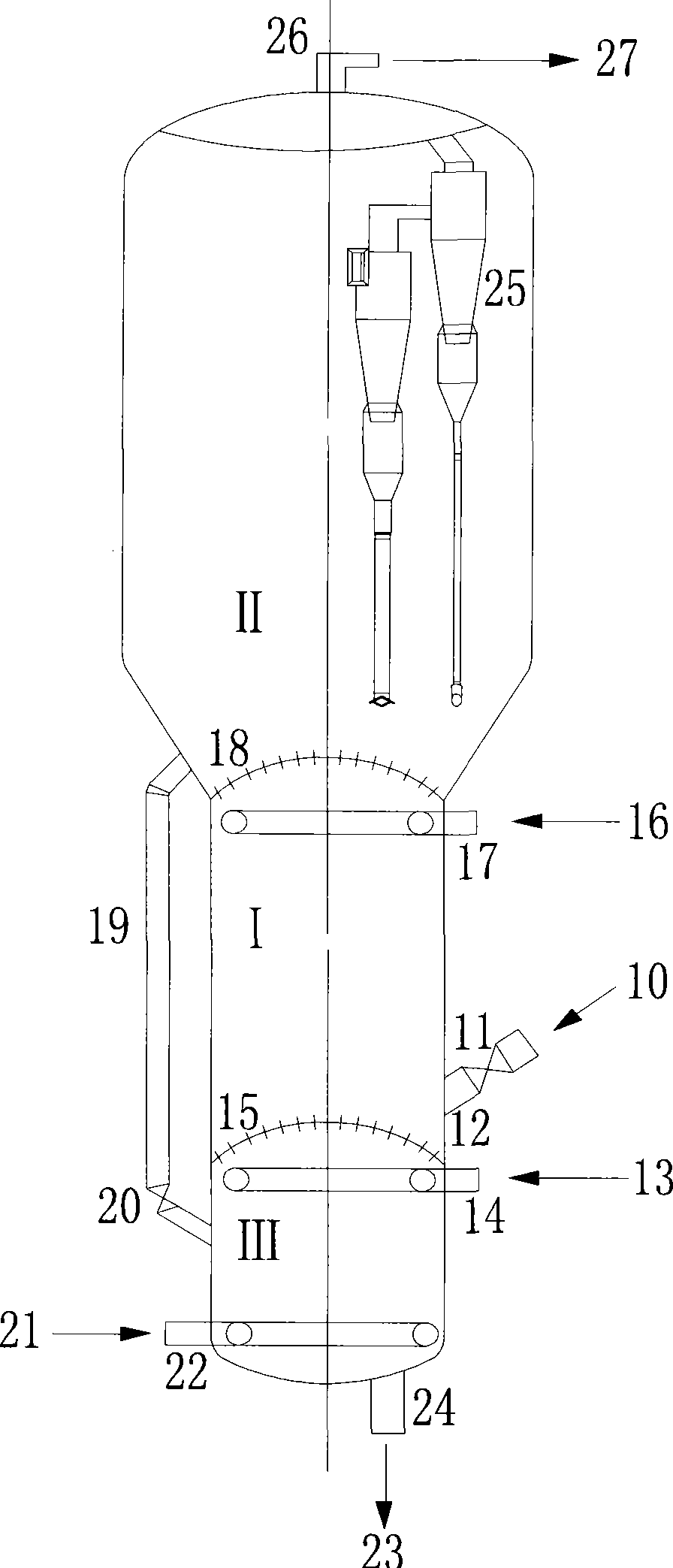

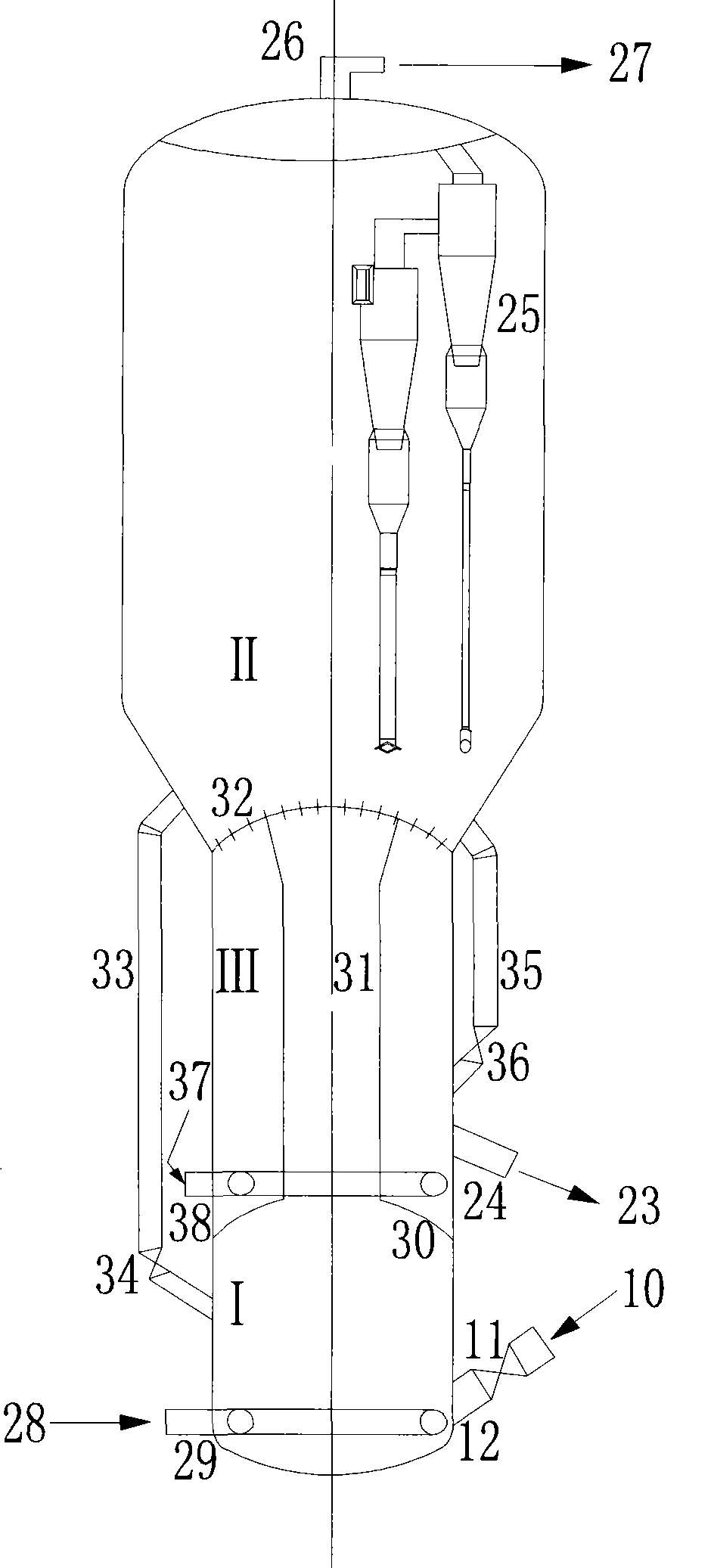

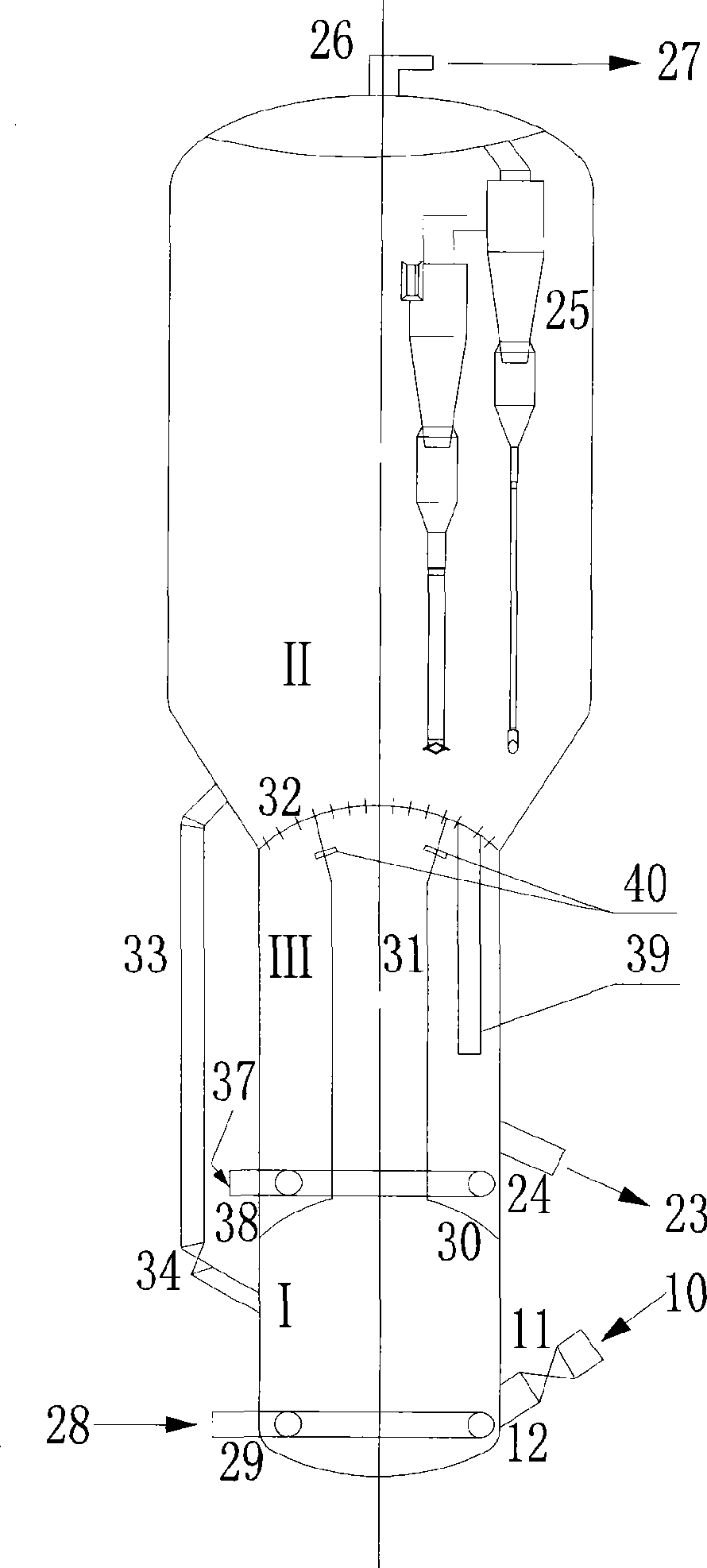

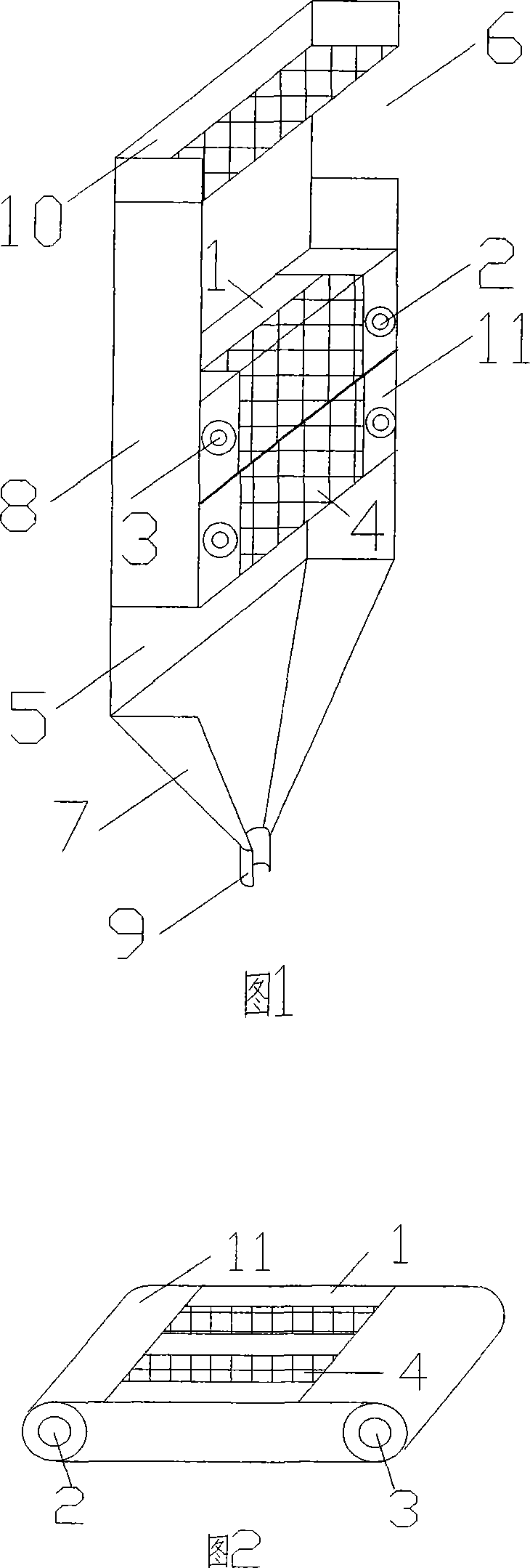

Catalyst multistage regeneration method and device

InactiveCN101391234AIncreased average chemical kinetic speedPromote regenerationCatalyst regeneration/reactivationRegenerative processLine tubing

The invention introduces a catalyst multi-section regeneration method and an apparatus, firstly, a spent catalyst enters a first section regenerator, and is in contact reaction with oxygen-containing gases in the first section regenerator, a second section regenerator and a third section regenerator sequentially, oxygen-containing regeneration flue gas of the first section enters the second section for continuous utilization, and the fresh compressed air is input to the third section for regeneration reaction, so as to complete the whole regenerative process. The fresh compressed air can also be supplemented to the first section regeneration reaction or the second section regeneration reaction, and the catalyst can also reflux to other sections for regeneration. The regeneration apparatus is composed of a first section turbulent bed regenerator, a second section turbulent bed regenerator and a third section turbulent bed regenerator in series connection, a distribution plate or a baffle and a catalyst standpipe are arranged, and all the regenerators are in coaxial arrangement. The invention adopts the multi-section counter-current regeneration, increases the average chemical kinetics speed, strengthens the regenerative process, saves the oxygen-containing gas usage, and reduces the production expense; and realizes the feeding of the spent catalyst from the bottom part or the middle part of each regenerator, lowers the height of the corresponding catalytic conversion device, shortens the oil-gas pipe-line, and reduces the construction investment.

Owner:QINGDAO JINGRUN PETROCHEM ENG

Activated carbon regeneration method

InactiveCN105080521AHigh recovery rateHigh regeneration rateOther chemical processesCombustible gas purificationFiltrationDesorption

The invention discloses an activated carbon regeneration method. Waste activated carbon and a desorption solution are mixed and pulped to obtain slurry, post treatment is conducted on the slurry to obtain regenerated activated carbon, and the desorption solution contains an organic solvent and water. The post treatment is performed in the mode (a) that the slurry performs catalyzed wet oxidation reaction, and the regenerated activated carbon and an oxidation filtrate serving as the desorption solution to be repeatedly used are obtained through filtration; or the mode (b) that the slurry performs desorption regeneration reaction, the regenerated activated carbon and a desorption filtrate are obtained through filtration, and then the desorption filtrate performs catalyzed wet oxidation reaction to obtain a reaction solution serving as the desorption solution to be repeatedly used. The catalyst adopted for the catalyzed wet oxidation reaction is one or more of copper salt, rhodium salt and palladium salt. The waste activated carbon is regenerated by means of the activated carbon regeneration method, the activated carbon regeneration rate is high, the losses of the activated carbon and the desorption solution are small, the reaction conditions in the regeneration process are moderate, and energy consumption is lower.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

Internal cooling, heating type apparatus for dehumidifying and regenerating solution, and dehumidifying and regenerating method

InactiveCN101091866AExpel as soon as possibleReplenish as soon as possibleLighting and heating apparatusDispersed particle separationSurface coolingHeat carrier

The invention relates to a bore surface cooling-internal heat type solution dehumidify-regeneration method, in the interior of dehumidifies / regeneration unit, the cold / heat carrier channel and the caloric exchange bed interaction are arranged. In the solution dehumidifies / regenerative process, the cold / heat carrier incessancy carries the heat exchange with the solution, and takes away the heat which is produced in the dehumidify process to keep the temperature of the solution in the dehumidify / regenerative process in the low / high condition, in the set, the receiving tank (7) is located below the rectangular outer covering and the heat insulating layer (8) and connects, the solution exports (9) is located below the receiving tank (7) and connects, the cloth fluid bath (10) and the dehumidifies regeneration unit (11) separately is located at the upside and middle of rectangular outer covering and heat insulating layer, the deficiency wind exports (6) is located at the rectangular outer covering and one side of the heat insulating layer between the cloth fluid bath (10) and the dehumidify / regeneration unit, the new atmosphere imports (5) is located at the rectangular outer covering and another side of the heat insulating layer between the dehumidifies / regeneration unit and receiving tank.

Owner:SOUTHEAST UNIV

Methods, compositions and apparatuses for facilitating regeneration

InactiveUS20110105961A1Function increaseReduce the ratioUltrasound therapyImmunoglobulins against animals/humansRegenerative processBiology

Apparatuses, compositions and methods for removing cells which interfere with regenerative processes. The apparatuses, compositions and methods selectively kill partially functional and / or non-functional cells versus functional cells while protecting functional proliferative cells to the extent that, upon removal of the killed cells by disintegration or scavenging, functional cells replace the partially- or non-functional cells.

Owner:SIWA CORP (US)

Air conditioning system

InactiveUS7395677B2Heat loadCondensing moisture in the airMechanical apparatusSpace heating and ventilation safety systemsRegenerative processEngineering

An air conditioning system to treat a latent heat load and a sensible heat load in a room includes a plurality of utilization units, a heat source unit, and connection pipes that connect between the units. The utilization units include adsorbent heat exchangers provided with an adsorbent on the surface of each. The utilization units are configured to alternate between an adsorption process and a regeneration process. The heat source unit includes a compression mechanism and an accumulator.

Owner:DAIKIN IND LTD

Flue-gas processing technique based on adsorbent-polymer composite material

ActiveCN1772340ALarge mercury adsorption capacityOther chemical processesDispersed particle separationHigh concentrationSorbent

The present invention provides one process of eliminating air pollutant, such as sulfur oxide, nitrogen oxide, mercury vapor and fine dust, from industrial fume. The process is based on one kind of microporous adsorbent-fluoride polymer composite material, which converts the sulfur oxide into acid solution and excludes the acid solution to its outer surface and needs no complicated regeneration. Inside the adsorbent chamber with the modularized composite material, sulfur oxide is converted into high concentration sulfuric acid and thus eliminated from the fume. The composite material adsorbs the mercury vapor inside it via chemical adsorption and eliminates fine dust via surface filtering. The converted sulfuric acid and the fine dust on the surface of the composite material drops into one acid collector.

Owner:WL GORE & ASSOC INC

Method of regenerating activated charcoal for processing phenolic waste water

InactiveCN1546223AReduce energy consumptionReduce lossesOther chemical processesCombustible gas purificationSorbentGas phase

The invention is a kind of regeneration method of active carbon for processing phenol waste water, which uses metal / active carbon sorption agent which carries some catalyst activity components, when it is absorbed and saturated, dries the sorption agent system under normal temperature, then carries on gas phase constant temperature oxidization, oxides and decomposes the organic contamination material, thus the active carbon can be regenerated, the merits of the invention is that it can be carried on under low temperature, reduces the energy consumption of regeneration process; it uses proper oxidization temperature and time, it can reduces the loss of the active carbon, increase the circular utilization of active carbon.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

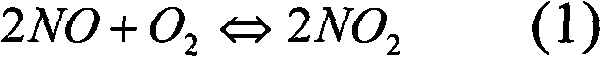

Process method and method for regenerating methyl nitrite in production of dimethyl oxalate

InactiveCN102008922AEfficient use ofEfficient recyclingNitrous acid preparation ester preparationChemical/physical processesGas phaseNitric oxide

The invention belongs to the technical field of the production of dimethyl oxalate, and particularly relates to a process method and a device for regenerating methyl nitrite in the production of the dimethyl oxalate. In the method, the utilization rate of nitric oxide in the regenerative process is improved, and the using amount of methanol is reduced. The device comprises a rotary filler bed, wherein a gas inlet of the rotary filler bed is connected with sources of nitrogen, oxygen and nitric oxide respectively, a liquid inlet is connected with a methanol storage tank, a liquid outlet is connected with an inlet of a methanol-water mixture storage tank, and a gas outlet is connected with a condenser I. The process method comprises the following steps of: opening the rotary filler bed, so that the nitric oxide, the nitrogen and the oxygen are contacted and reacted with absolute methanol in the rotary filler bed to form a gas phase and a liquid phase; and discharging the gas phase, condensing, and allowing the liquid phase to flow into the methanol-water mixture storage tank. The process method has the advantages that: the process reaction efficiency is high; all NO is used efficiently; and the equipment has a compact structure and small volume and requires a small investment. The equipment has the advantages of making operation easy, along with simple structure, small energy consumption, simple flow, convenience for starting and stopping and the like.

Owner:ZHONGBEI UNIV

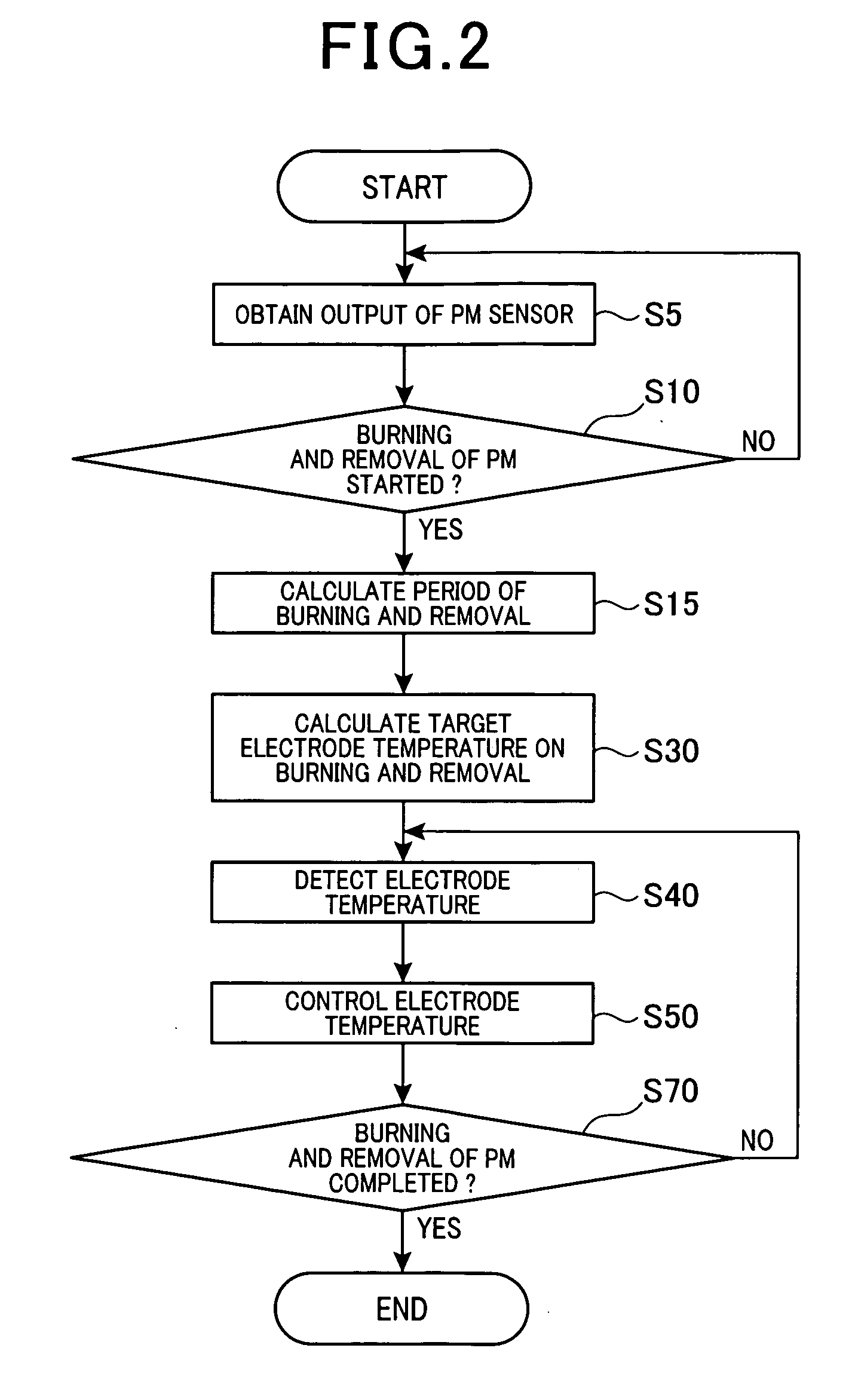

Detection apparatus

ActiveUS20120186230A1Improve accuracyKeep for a long timeElectrical controlExhaust apparatusParticulatesRegenerative process

A detection apparatus includes a detection unit, a control unit, a first setting unit, and a second setting unit. The detection unit is disposed in an exhaust path through which an exhaust gas flows, and detects a correlation value correlated with an amount of particulate matter (PM) attaching to an attachment element. The control unit controls a temperature of the attachment element to follow a target temperature while a regeneration process is performed to heat the attachment element so as to burn PM. The first setting unit sets the target temperature to be lower, as the amount of PM becomes larger. The second setting unit sets a completion timing of the regeneration process so that a period of the regeneration process becomes longer, as the amount of PM becomes larger or a temperature of the attachment element becomes lower while the regeneration process is performed.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com