Method and apparatus for combination regeneration, or coproduction with hydrocarbon black of waste and old macromolecule material

A polymer and sub-device technology, which is used in the field of combined regeneration of waste polymer materials, or co-production with carbon black and its devices, can solve the problems of black dust pollution, inability to use high value, and environmental hazards, and achieve product performance. Excellent quality, eliminating the need for refining treatment, and the effect of large benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

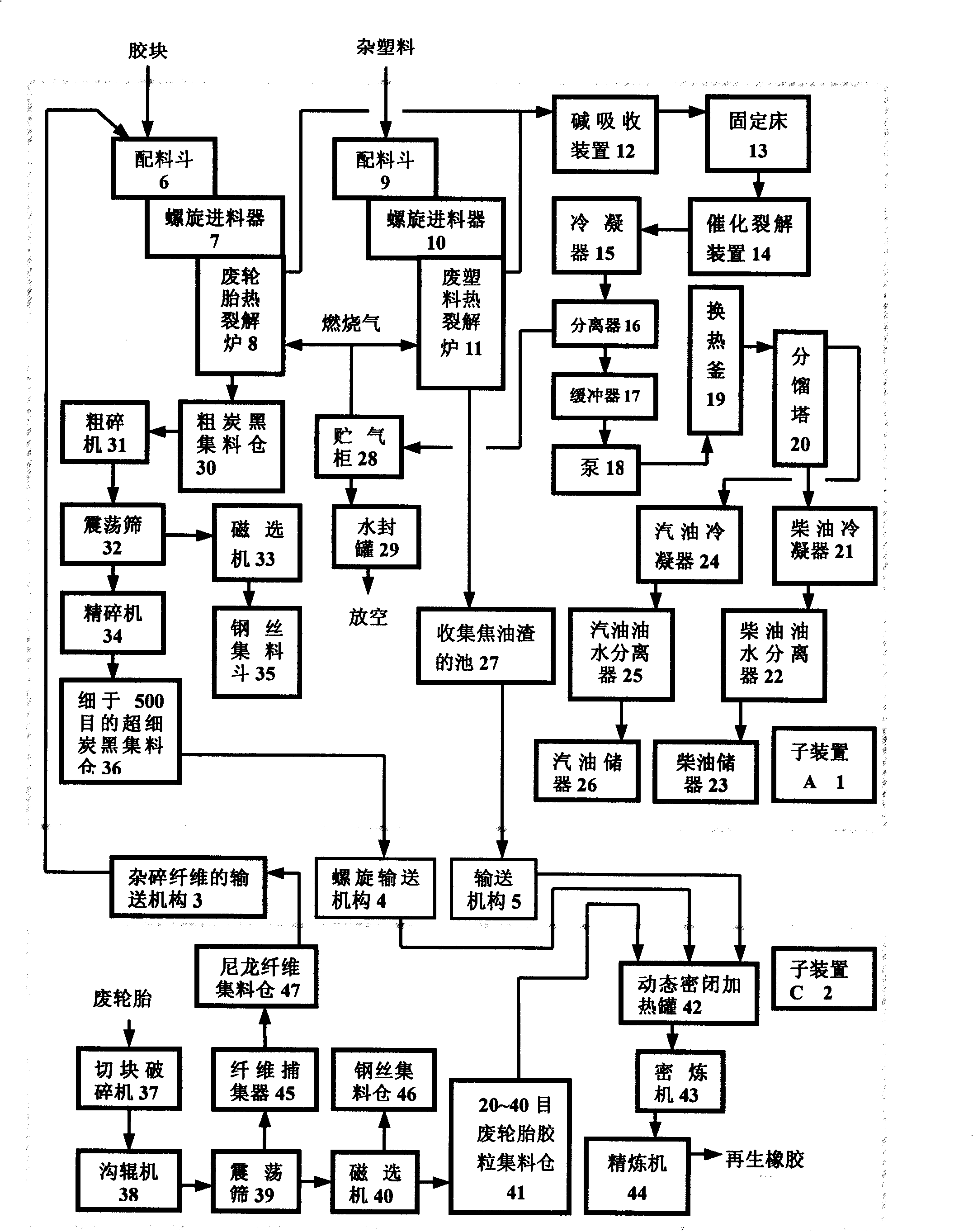

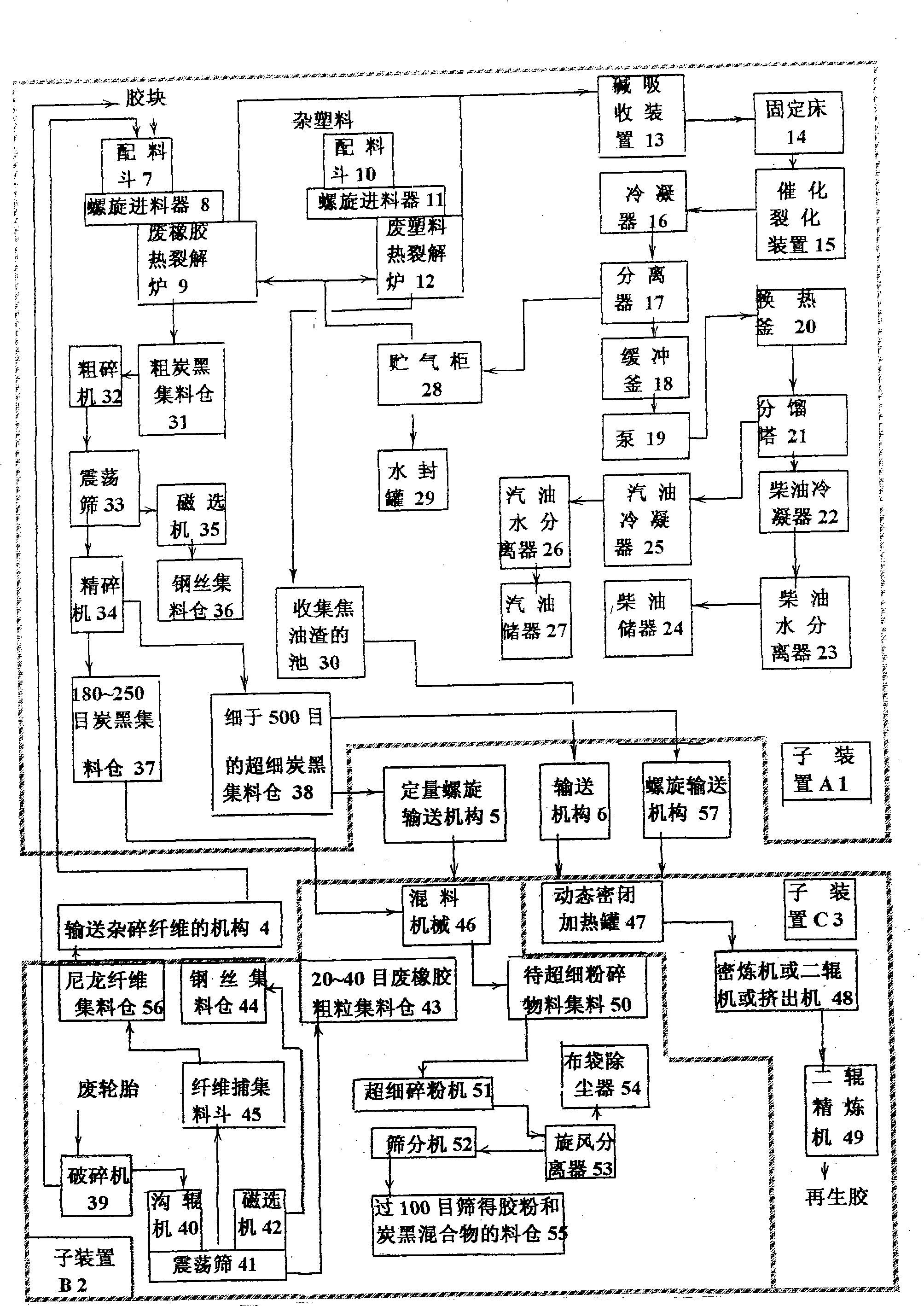

Image

Examples

Embodiment 1

[0187] The method of recycling combined regeneration used in this embodiment involves the combination of thermal cracking and the recycling of ultra-finely pulverized polymer materials, and the integrated device used in its implementation. The process method has the following three steps: The embodiment is specifically:

[0188] Step I, take 175 parts by weight of car waste tires, place it in the batching pretreatment section of sub-device B in the integrated device, and first use the shears crusher in sub-combination device B to crush it into about 5cm × 5cm Then use groove roller machine, vibrating sieve and magnetic separator to further crush, sieve, fiber capture and magnetically separate the 5cm x 5cm rubber block to obtain intermediate product group I, the intermediate product described in this example. Product group I includes: 100 parts by weight of 20-purpose passenger car waste tire rubber particles and 75 parts by weight of a mixture of steel wire, nylon fiber and r...

Embodiment 2

[0205] The recycling combined regeneration method used in this example involves the combination of pyrolysis, sulfur breakage, plasticization and other recycling branches of waste polymer materials, as well as the integrated device used in the implementation plan. The process methods are as follows The steps are combined, and the embodiment is specifically:

[0206] Step I, take 175 parts by weight of car waste tires, place it in the dynamic closed heating tank pretreatment section of sub-device C in the integrated device, and first use the shear crusher in the sub-combination device C to break it into about 5cm * 5cm fragments, then use the ditch stick machine, vibrating screen, magnetic separator to further crush, sieve, and magnetically separate the 5cm * 5cm glue blocks to obtain intermediate product I, the intermediate product group described in this example I comprises: 100 parts by weight of waste car tire granules of 20 to 40 meshes and 75 parts by weight of a mixture ...

Embodiment 3

[0230] The recycling combined regeneration method used in this example involves the combination of pyrolysis, ultra-fine crushing, sulfur breakage, plasticization and other recycling branches of waste polymer materials, and the integrated device used in the implementation plan. The process method Have the combination of following 3 steps, embodiment is specifically:

[0231] Step I, get 175 parts by weight of waste semi-steel radial tires, put it in the integrated device before the batching of sub-device B to set up a treatment section, first use the shear breaker in the sub-combination device B to break it into about 5cm × 5cm fragments, then use groove roller machine and vibrating screen, magnetic separator to further crush, sieve and magnetically separate the 5cm * 5cm glue pieces to obtain intermediate product I. The intermediate product group I described in this example includes : 100 parts by weight of 20-30 mesh waste semi-steel radial tire rubber particles and 75 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com