Patents

Literature

404 results about "Rubber technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rubber Technology is the subject dealing with the transformation of rubbers or elastomers into useful products, such as automobile tires, rubber mats and, exercise rubber stretching bands. The materials includes latex, natural rubber, synthetic rubber and other polymeric materials, such as thermoplastic elastomers. Rubber processed through such methods are components of a wide range of items.

Polyethylene rubber and processing method thereof

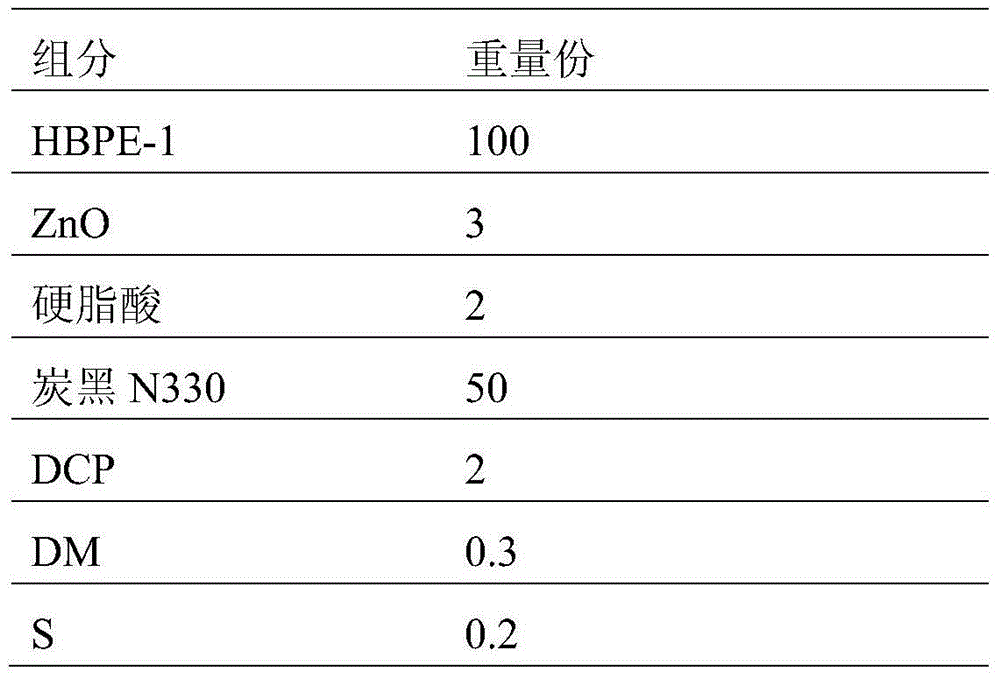

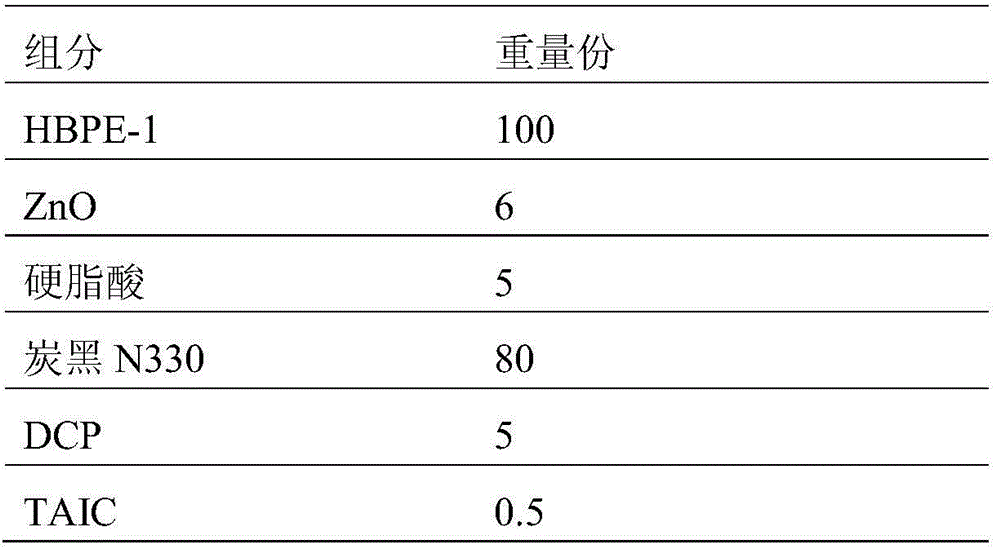

The invention belongs to the technical field of rubber, and particularly relates to polyethylene rubber and a processing method thereof. The polyethylene rubber comprises following raw materials by weight: 100 parts of hyper branched polyethylene, 50-80 parts of carbon black, 2-5 parts of a peroxide crosslinking agent, 0-6 parts of zinc oxide, 0-5 parts of a lubricant, 0.3-0.5 part of an accelerant, and 0-0.2 part of sulfur. Beneficial effects of the polyethylene rubber and the processing method thereof are that: the hyper branched polyethylene (HBPE) is sulfurized by utilization of a peroxide sulfurization system, has good mechanical performances through stress-strain performance tests, and has a characteristic of high elasticity of rubber. The processing method of the polyethylene rubber is totally different from preparation methods of chlorinated polyethylene rubber and chlorosulfonated polyethylene rubber at present. The polyethylene rubber and the processing method thereof break the limit that polyethylene can be only used for making plastic products, expand the application scope of the polyethylene, and largely increase the additional value of polyethylene homopolymers.

Owner:ZHEJIANG UNIV

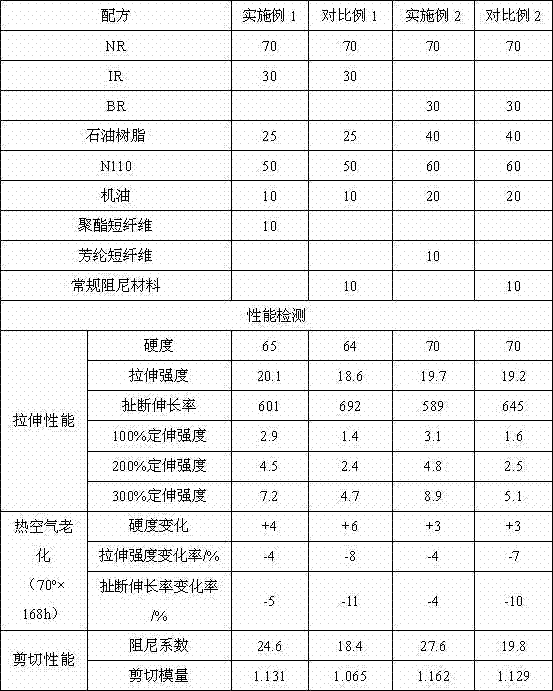

Ultra-high damping rubber composite material and preparation process of rubber composite material

The invention belongs to the technical field of rubber and discloses an ultra-high damping rubber composite material and a preparation process of the rubber composite material. The preparation process disclosed by the invention is mainly technically characterized by comprising the following steps of: adding short fibers, carbon black, petroleum resin, a plasticizer, a vulcanizing agent, an active agent, an accelerant and an anti-aging agent in rubber; and mixing the components in an internal mixer and then vulcanizing in a flat vulcanizing machine. According to the ultra-high damping rubber composite material disclosed by the invention, a predetermined amount of short fibers, carbon black and petroleum resin are uniformly dispersed in a rubber matrix; compared with the common high-damping material, the damping coefficient of the ultra-high damping rubber composite material disclosed by the invention is increased by more than 20%; and the ultra-high damping rubber composite material disclosed by the invention has the advantages of being strong in energy consumption property and ductility and obvious in damping and shock insulating effects, effectively controlling the earthquake response of shock insulating structures, and being environment-friendly and stable in property. The stretching strength is greater under the condition with the same hardness, so that a rubber bearing prepared by the ultra-high damping rubber composite material disclosed by the invention is greater in bearing force; the whole size of the bearing is smaller than the size of the traditional high-damping rubber bearing; and the rubber bearing has the advantages of saving the use space, being convenient to construct and more excellent in resistance to fatigue performance.

Owner:HENGSHUI ZHONGTIEJIAN ENG RUBBER +1

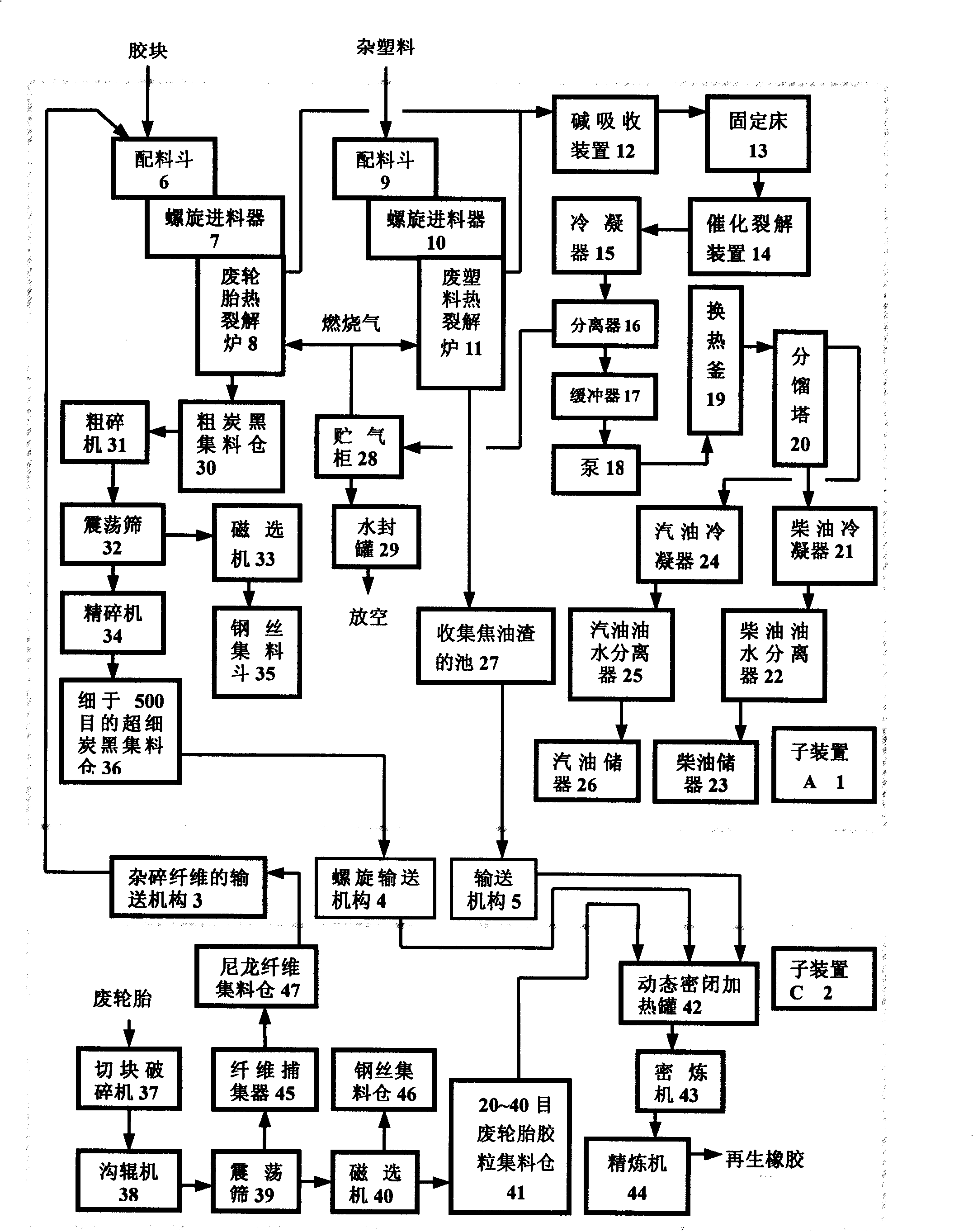

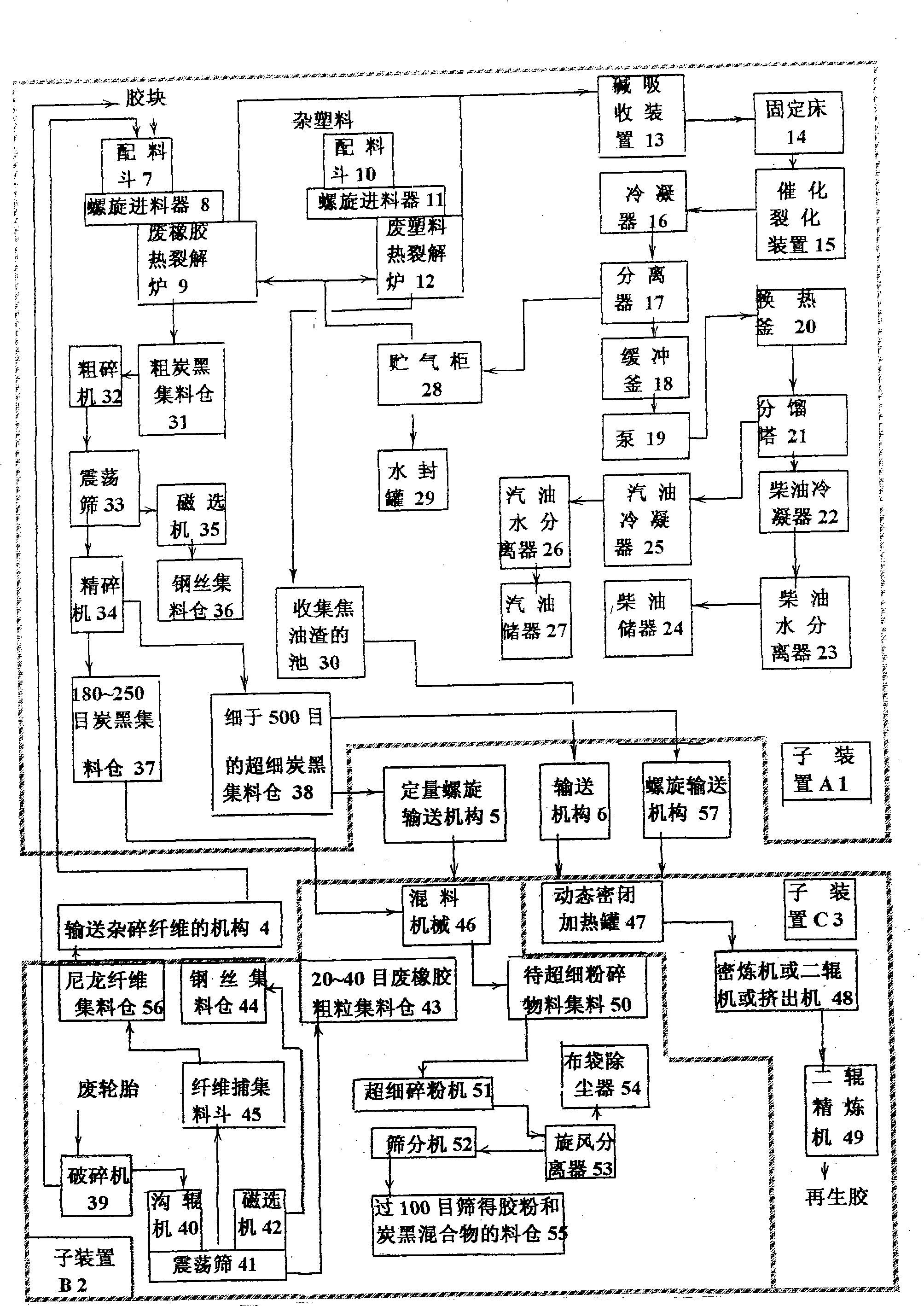

Method and apparatus for combination regeneration, or coproduction with hydrocarbon black of waste and old macromolecule material

ActiveCN101402745AReduce wasteExcellent energy qualityPlastic recyclingLiquid hydrocarbon mixture productionFiberRubber material

The invention discloses a method of combination and regeneration of waste high molecular materials or co-production of the waste high molecular materials and carbon black, and a device thereof, relating to two technologies of existing thermal cracking and non-thermal cracking of the waste high molecular materials and improvement and combination among various technological branches and also relating to the regeneration process of the waste high molecular materials and the combination of the regeneration process of the waste high molecular materials and the production process of general carbon black and an integration device used in the embodiment thereof; and comminution at normal temperature or the combination of the comminution at normal temperature and various branches of renovated rubber technology and an integration device adopted by the embodiment thereof are also included. The method also provides a treatment proposal for applying mixed fiber to recycling and products thereof, which are characterized in that the mixed fiber and plasticized rubber materials or / and oil materials are matched by the weight percentage of 100:5 to 100:100 to obtain a mixture taking the shape of a felt or a rubber felt or a treated felt. The proposal of the integration device also provides a combination device with fractional efficiency higher than that of the existing fractional process for the granularity of rubber powder only by means of a power screen.

Owner:上海橡源驰晨环保科技发展有限公司

Double-component addition-type liquid silicone rubber as well as preparation method of same

The invention belongs to the technical field of silicone rubber and particularly relates to double-component addition-type liquid silicone rubber as well as a preparation method of same. The liquid silicone rubber is prepared by mixing, curing and shaping a component A and a component B, wherein the component A includes 100 parts of basic rubber, 8-18 parts of vinyl-terminated silicone oil, 1-2 parts of a tackifier, and 0.5 parts of a platinum catalyst; the component B includes: 20-70 parts of vinyl-terminated silicone oil, 30-80 parts of hydrogen-containing silicone oil, and 0.3-0.5 parts ofan inhibitor; the basic rubber includes 100 parts of vinyl-terminated silicone oil, 5-10 parts of vinyl-terminated silicone oil having side-chain vinyl group, 40 parts of fumed silica, 10-15 parts ofa silazane processing agent, and 0-5 parts of a siloxane processing agent. In the liquid silicone rubber, the components are cooperated and are matched in reasonable ratio, so that firmness of the liquid silicone rubber on surfaces of fabrics is improved, and tensile strength and tearing strength of the silicone rubber are increased; the silicone rubber is high in vulcanization speed and high in production efficiency. The invention also provides a preparation method of the double-component addition-type liquid silicone rubber. The method is optimized in process and has simple operations.

Owner:佛山市天宝利硅工程科技有限公司

Silicone rubber insulation material applied to high voltage cable accessories in European series and preparation method for material

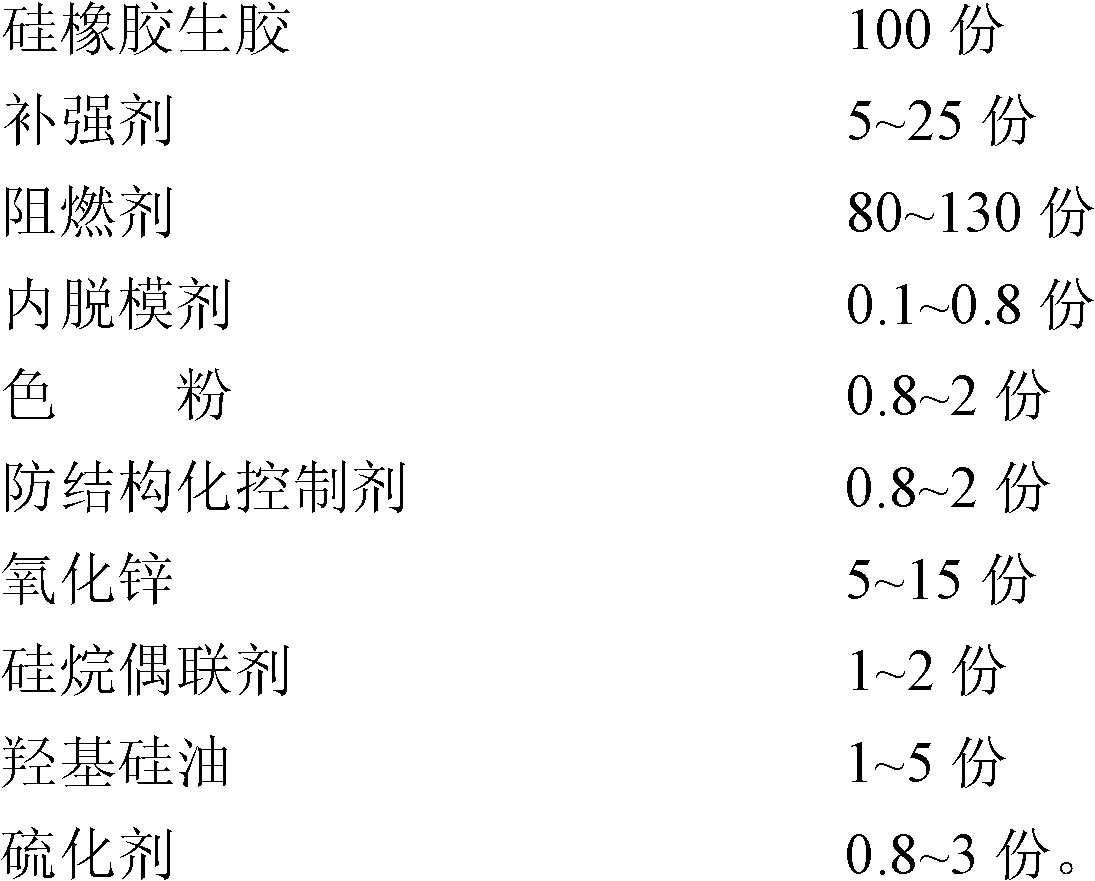

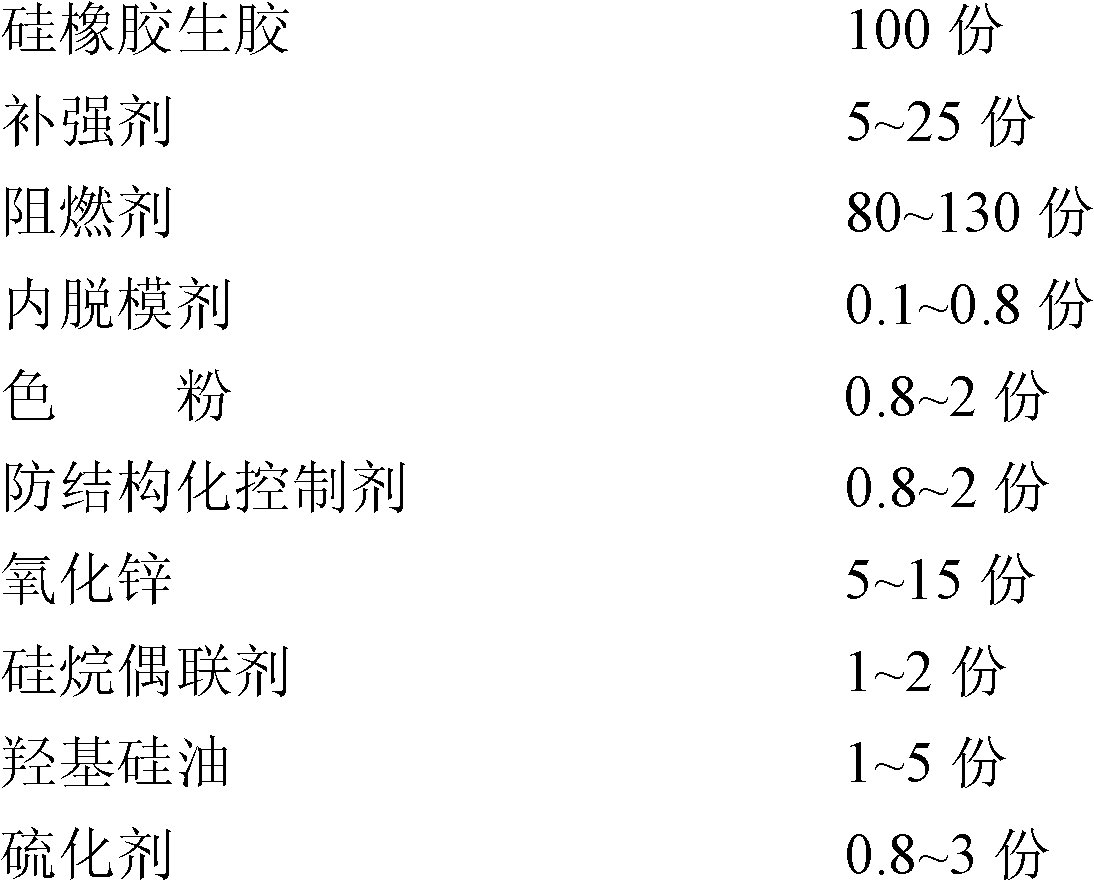

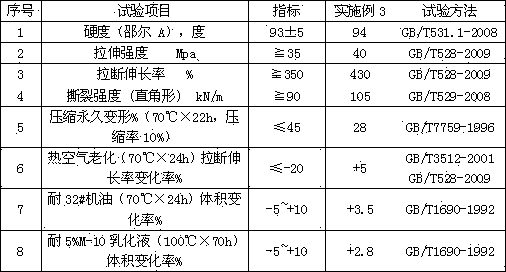

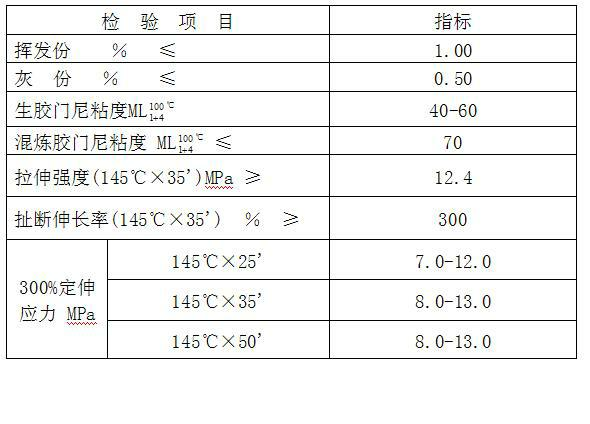

The invention belongs to the fields of special rubber technologies and medium and high voltage electrical equipment, is thorough improvement on the prior art, and in particular relates to a silicone rubber insulation material applied to high voltage cable accessories in European series and a preparation method for the material. The material comprises the following components in part by mass: 100 parts of crude silicone rubber, 5 to 25 parts of reinforcing agent, 80 to 130 parts of flame retardant, 0.1 to 0.8 part of internal release agent, 0.8 to 2 parts of masterbatch, 0.8 to 2 parts of anti-structuring control agent, 5 to 15 parts of zinc oxide, 1 to 2 parts of silane coupling agent, 1 to 5 parts of hydroxy silicone oil and 0.8 to 3 parts of vulcanizing agent. Compared with the conventional ethylene propylene diene monomer (EPDM) rubber, the material has the advantages that tracking resistance and electric corrosion loss can reach TMA4.5, and the material has lasting hydrophobicity and high dielectric constant, joint strength and wet electrical property, can be subjected to injection molding, avoids the phenomenon that an electric field is easily concentrated because EPDM is non-uniformly distributed, and is high in vulcanizing speed and efficiency, and cost is saved.

Owner:深圳市罗庚电气有限公司

High hardness nitrile rubber and preparation method thereof

The invention belongs to the technical field of rubber and provides high hardness nitrile rubber and a preparation method of the nitrile rubber in order to solve the problem that the existing nitrilerubber sealing material cannot integrate high hardness and wear resistance. The rubber is prepared from nitrile rubber, zinc oxide, stearic acid, an antiager, octyl-phenolic tackifying resin, carbon black, a softener, a valcanizer and an accelerator according to certain proportions. The rubber is reasonable in compounding, gets a comprehensive balance among product serviceability, appropriate processability and cost reduction, fully exerts potentials of the raw materials and assistants, and achieves unification of high-efficiency, low-consumption and high-performance economic and social benefits. The obtained material has the high hardness, good wear resistance, better tensile strength, better tearing strength and a better permanent compression set value. At the same time, processing operability of the rubber is high, a post-treatment procedure of a product is easy, and physical and mechanical properties are best.

Owner:党亮才

Ceramic fire-resistant and flame-retardant silicone rubber and preparation method thereof

InactiveCN106398231AImprove fire and flame retardant performanceImprove performancePolymer scienceSilanes

The invention relates to the technical field of silicone rubber, and particularly relates to a ceramic fire-resistant and flame-retardant silicone rubber and a preparation method thereof. The ceramic fire-resistant and flame-retardant silicone rubber is composed of a component A and a component B in a weight ratio of 0.8-1.2: 1. The component A comprises the following raw materials in weight part: 60-140 parts of silicone rubber A, 35-45 parts of reinforcing agent, 60-100 parts of filler A, 11.4-17.2 parts of silane auxiliary agent A, 0.15-0.25 part of lubricant A, 0.1-0.3 part of flame retardant, and 0.5-1.5 parts of vulcanizing agent. The component B comprises the following raw materials in weight part: 60-140 parts of silicone rubber B, 230-290 parts of filler B, 3-6 parts of silane auxiliary agent B, and 0.2-0.4 part of lubricant B. According to the technical scheme of the invention, the ceramic fire-resistant and flame-retardant silicone rubber is good in fire-resistant and flame-retardant property, and excellent in comprehensive performance.

Owner:东莞市朗晟材料科技有限公司

Tread rubber composition for semisteel meridian snow tire used in extremely cold area

The invention relates to the technical field of rubber, and in particular relates to a tread rubber composition for a semisteel meridian snow tire used in an extremely cold area. By taking 100 parts by weight of rubber component as a reference, the tread rubber composition comprises the following components in parts by weight: 30-110 parts of high-dispersibility silicon dioxide, 5-70 parts of carbon black, 10-65 parts of rubber processing softener, 5-25 parts of silane coupling agent, 0-14 parts of anti-ageing agent, 0-10 parts of sulphur and 0-8.5 parts of promoter, wherein the rubber component comprises modified styrene-butadiene rubber, natural rubber and polybutadiene rubber, the modified styrene-butadiene rubber is solution-polymerized styrene-butadiene rubber containing 15-30wt% of combined styrene and 10-50wt% of vinyl; and the polybutadiene rubber is nickel polybutadiene rubber or a blended system of the nickel polybutadiene rubber and neodymium butadiene rubber, wherein percent by weight of cis-butadiene structure (cis) is more than 95%.

Owner:TRIANGLE TIRE

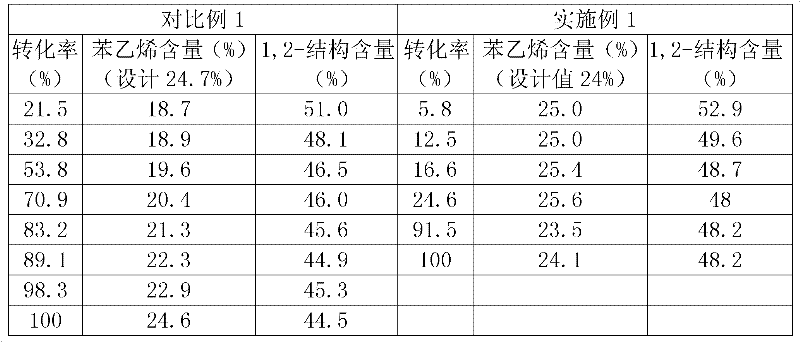

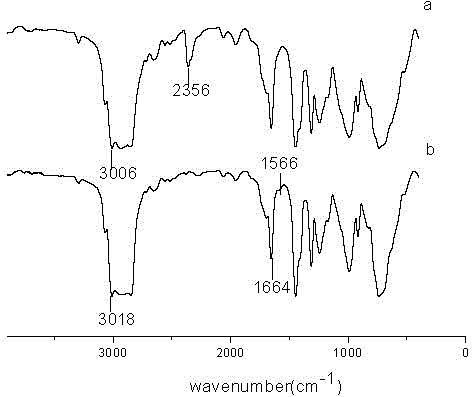

Method for synthesis of solution-polymerized styrene butadiene rubber through two-component regulator

ActiveCN102344530APerfectly uniform random distributionSimple processPolymer scienceMature technology

The present invention discloses a method for synthesis of solution-polymerized styrene butadiene rubber through a two-component regulator, and belongs to the technical field of rubber. The method comprises the following steps: in the protection of nitrogen and in a hydrocarbon solvent, adopting organic lithium as an initiator, adopting butadiene and styrene as monomers, adopting tetrahydrofuran as a structure regulator, adopting tetrahydrofuran and potassium alkoxide as randomizing agents, carrying out an anionic random copolymerization reaction for the butadiene and the styrene; after completing the polymerization, carrying out flocculation and drying to obtain the solution-polymerized styrene butadiene rubber. The method provided by the present invention has characteristics of simple process and mature technology; with precise control of the use amounts of the regulator and the initiator, the 1,2- structure content can be controlled in the medium vinyl range, complete and uniform random distribution of the styrene units on the macromolecular chain can be realized.

Owner:BEIJING UNIV OF CHEM TECH

High-strength and high-hardness fluorinated silicone rubber composition and preparation method thereof

InactiveCN106280495ASolve the disadvantage of lower vinyl contentIncrease the degree of cross-linkingVulcanizationPolymer science

The invention relates to a high-strength and high-hardness fluorinated silicone rubber composition and a preparation method thereof, and belongs to the technical field of rubber. The high-strength and high-hardness fluorinated silicone rubber composition comprises the following raw materials in parts by mass: 100 parts of raw fluorinated silicone rubber, 35 to 65 parts of fumed silica, 3 to 7 parts of a heat-resistant additive, 0.5 to 2.0 parts of vulcanizing agents and 5 to 8 parts of a structure controlling agent. In the mixing process, a vinylsiloxane rubber vulcanizing agent and a universal silicone rubber vulcanizing agent are used simultaneously, and the vulcanization reaction degree of the fluorinated silicone rubber is increased under the synergistic effect of the vinylsiloxane rubber vulcanizing agent and the universal silicone rubber vulcanizing agent; heat treatment and segmental vulcanization methods are adopted in the processing process, so that the micromolecule content of the fluorinated silicone rubber composition is reduced, the cross-linking degree of the whole system is increased, and the high-strength and high-hardness fluorinated silicone rubber composition is obtained.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

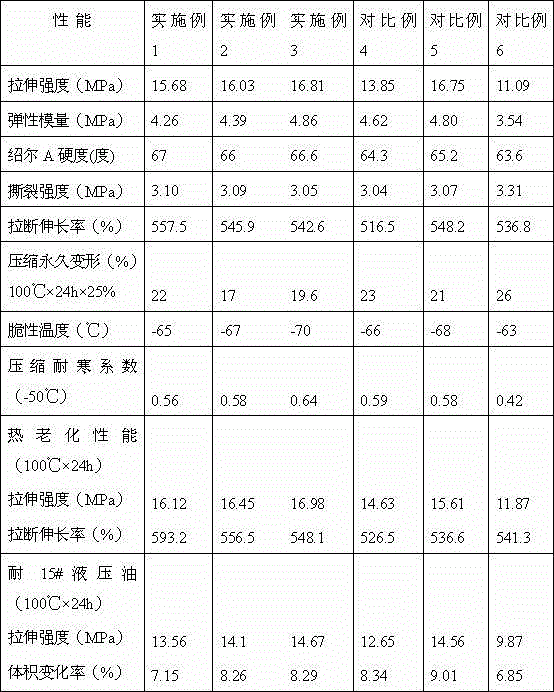

Low temperature resistant and oil proof nitrile butadiene rubber-modified butadiene rubber (BR) blend material and preparation method thereof

InactiveCN104893028AGood oil resistance and low temperature resistanceExtended service lifePolymer scienceVulcanization

Belonging to the technical field of rubber, the invention provides a low temperature resistant and oil proof rubber seal material and a preparation method thereof. The rubber seal material includes nitrile butadiene rubber, modified butadiene rubber, zinc oxide, stearic acid, an antioxidant, carbon black, sulfur, an accelerator, and a plasticizer, wherein the sum of nitrile butadiene rubber and modified butadiene rubber is 100 parts. The preparation method of the material consists of: subjecting nitrile butadiene rubber to plastication on an open mill, then adding modified butadiene rubber to conduct mixing, then adding 1 / 2 carbon black, zinc oxide, stearic acid, the antioxidant, 1 / 2 carbon black, the plasticizer and a curing agent in order, carrying out tight milling and sheet extrusion, conducting standing for 24h, and vulcanizing the rubber sheet. While guaranteeing oil proofness and ageing resistance, the rubber seal material provided by the invention also significantly improves the low temperature resistance of the seal material and can be used as the seal material for field equipment in cold regions.

Owner:JILIN ELECTRIC POWER RES INST LTD +3

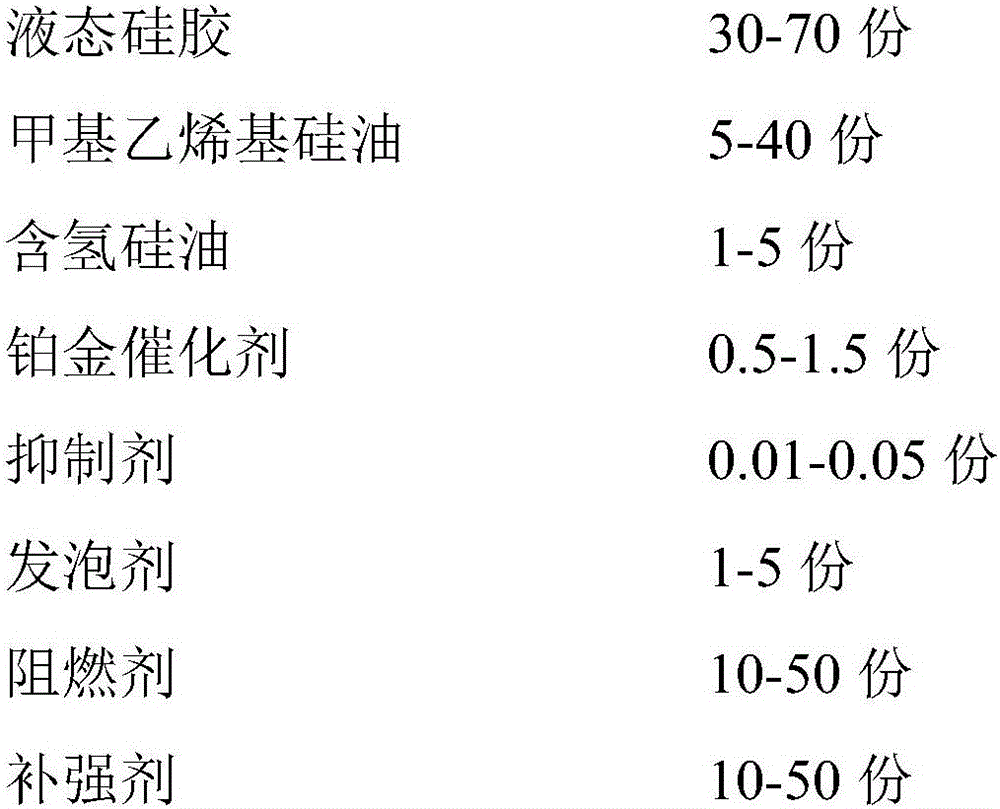

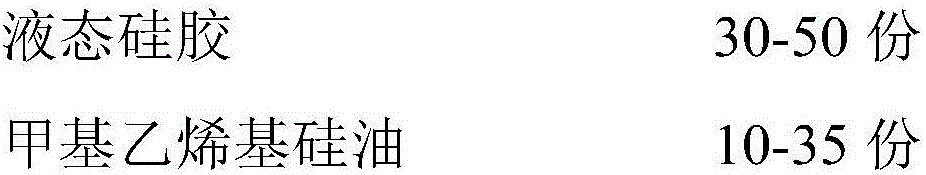

Silicone rubber foaming material and preparation method thereof

The invention relates to the technical field of silicone rubber, in particular to a silicone rubber foaming material and a preparation method thereof. The silicone rubber foaming material is prepared from the following components in parts by mass: 30 to 70 parts of liquid silicone rubber, 5 to 40 parts of methyl vinyl silicone oil, 1 to 5 parts of hydrogen-containing silicone oil, 0.5 to 1.5 parts of platinum catalyst, 0.01 to 0.05 part of inhibitor, 1 to 5 parts of foaming agent, 10 to 50 parts of flame retardant and 10 to 50 parts of reinforcing agent. The silicone rubber foaming material provided by the invention is characterized in that an Si-H bond of the hydrogen-containing silicone oil is activated by the platinum catalyst to generate a silicon hydrogenation addition reaction, so as to form an elastomer with a three-dimensional net structure, so that the silicone rubber foaming material provided by the invention has good flexibility; by adding the foaming agent, dense and uniform pores are formed inside the silicone rubber foaming material, the silicone rubber foaming material has better elasticity and smaller stress relaxation property, a sealing effect of communication equipment is guaranteed, and the maintenance cost is reduced.

Owner:昆山市硕鸿电子科技有限公司

Wear-resistant rubber

The invention discloses wear-resistant rubber, belonging to the technical field of rubber. The wear-resistant rubber is prepared from the following ingredients in parts by weight: 40-65 parts of polyurethane rubber, 20-30 parts of acrylate rubber, 20-30 parts of nitrile-butadiene rubber, 180-420 parts of styrene-butadiene rubber, 20-30 parts of brominated bivinyl rubber, 1-2 parts of tris (2,4-di-t-butylphenyl) phosphite, 5-10 parts of polypropadiene siloxane, 20-30 parts of magnesia, 10-20 parts of carbon black and 5-10 parts of ethyl urethane. The wear-resistant rubber disclosed by the invention has relatively high wear resistance.

Owner:南京中配橡塑制品有限公司

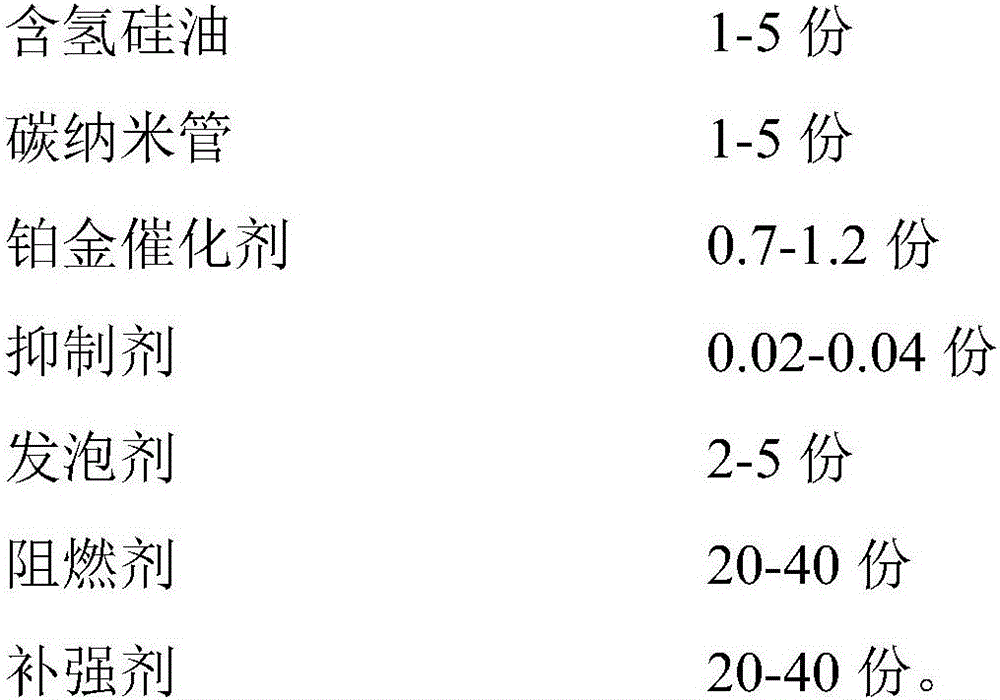

Ethylene propylene rubber material for sealing part of automobile heat dissipation system and production method of ethylene propylene rubber material

InactiveCN107090133AImprove high temperature resistanceLow temperature resistanceCross-linkRubber material

The invention discloses an ethylene propylene rubber material for a sealing part of an automobile heat dissipation system and a production method of the ethylene propylene rubber material and belongs to the technical field of rubber. The rubber material is prepared from the following components in parts by weight: 100 parts of raw ethylene propylene rubber, 5 parts of zinc oxide, 0.5 to 1.5 parts of stearic acid, 3 to 6 parts of an anti-ageing agent, 20 to 30 parts of fast extruding carbon black N550, 10 to 20 parts of semi-reinforced carbon black N774, 3.5 to 7 parts of a cross-linking auxiliary agent Ricon 153D and 5 to 8.5 parts of a vulcanizing agent Perkadox 14-40B-GR. The rubber material disclosed by the invention has excellent high-temperature-resisting performance and can be used for a long time under the condition that the temperature is -50 DEG C to 150 DEG C; meanwhile, the rubber material has remarkable advantages of low temperature resistance and low-compression permanent deformation.

Owner:南京金三力高分子科技有限公司

Flame-retardant chloroprene rubber

The invention relates to a flame-retardant chloroprene rubber and belongs to the technical field of rubber. The chloroprene rubber disclosed by the invention is prepared from the following raw material constituents in parts by weight: 100 parts of chloroprene rubber, 10-15 parts of natural rubber, 1-5 parts of anti-aging agent RD, 0.2-0.35 parts of thiuram accelerants, 0.4-1 parts of zinc oxide, 5-8 parts of magnesium chloride, 3-6 parts of stearic acid, 45-52 parts of carbon black, 2-4 parts of softening agent, 5-10 parts of antimonous oxide and 3-7 parts of zinc borate. The flame-retardant chloroprene rubber disclosed by the invention has the excellent performances of chloroprene rubber and natural rubber due to a small amount of added natural rubber, thus improving the defects of single rubber; the flame-retardant chloroprene rubber disclosed by the invention is good in comprehensive performances, heat-resistant and flame-retardant due to antimonous oxide and zinc borate which are used as flame retardants.

Owner:ANHUI JIAMU RUBBLE & PLASTIC IND

Heat-conducting silicone rubber with high electric dielectric strength and preparation method of heat-conducting silicone rubber

InactiveCN105542476AIncrease the degree of cross-linkingImprove insulation performancePolymer sciencePtru catalyst

The invention discloses heat-conducting silicone rubber with high electric dielectric strength, belonging to the technical field of silicone rubber. The heat-conducting silicone rubber comprises a component A and a component B in a mass ratio of (1 to 0.1)-(1 to 15), wherein the component A comprises the following components in parts by weight: 100 parts of alpha-omega-terminal hydroxyl hydrogen-containing polydimethylsiloxane, 5-15 parts of a silane coupling agent, 0.05-5 parts of a catalyst I, 100-200 parts of a heat-conducting insulating filling and 5-15 parts of an anti-sedimentation agent; and the component B comprises the following components in parts by weight: 100 parts of low-molecular-weight alpha-omega-vinyl polydimethylsiloxane and 0.5-5 parts of a catalyst II. The invention further provides a preparation method of the heat-conducting silicone rubber with high electric dielectric strength. The preparation method comprises the following steps: (1) preparing the component A; (2) preparing the component B; and (C) preparing the silicone rubber. The silicone rubber has good heat-conducting property and high electric dielectric strength, and the degrading of the electric dielectric performance caused by the introduction of the heat-conducting filling is avoided.

Owner:HEFEI UNIV OF TECH

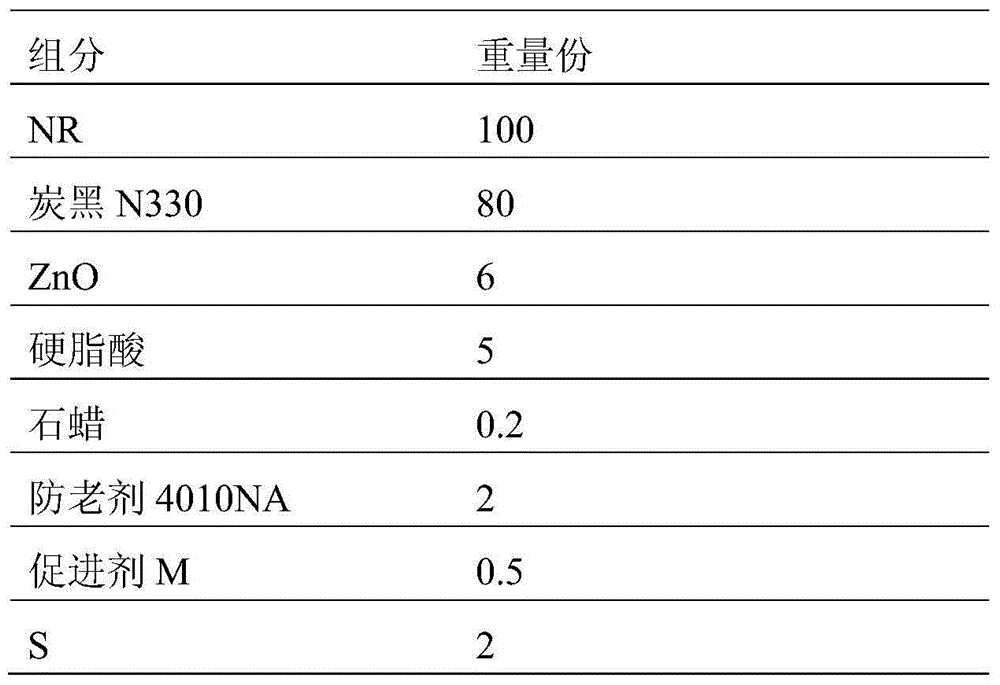

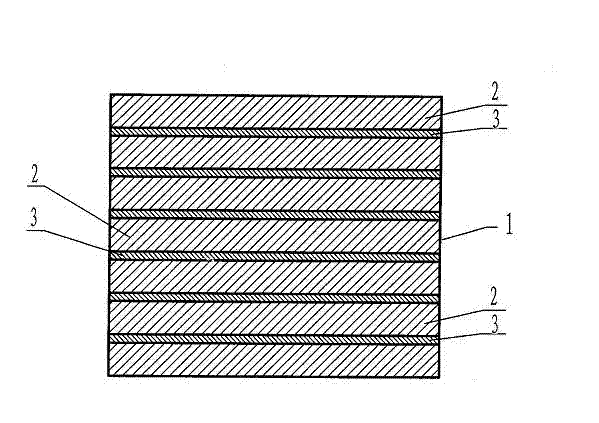

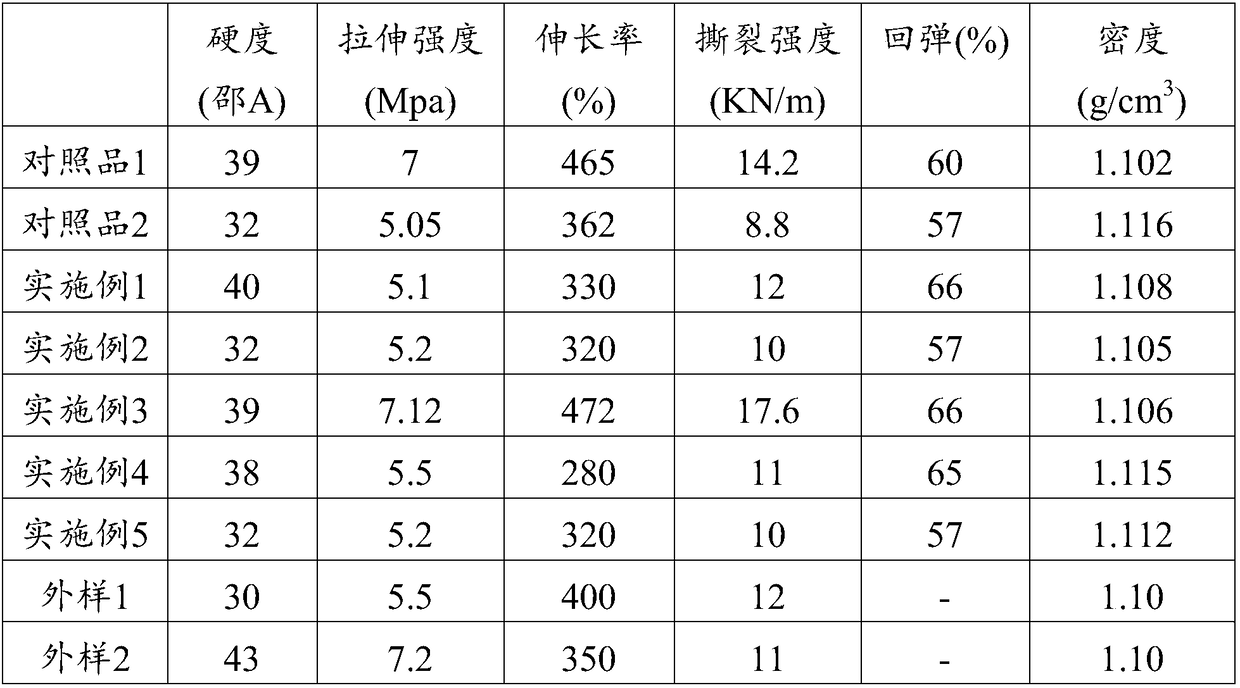

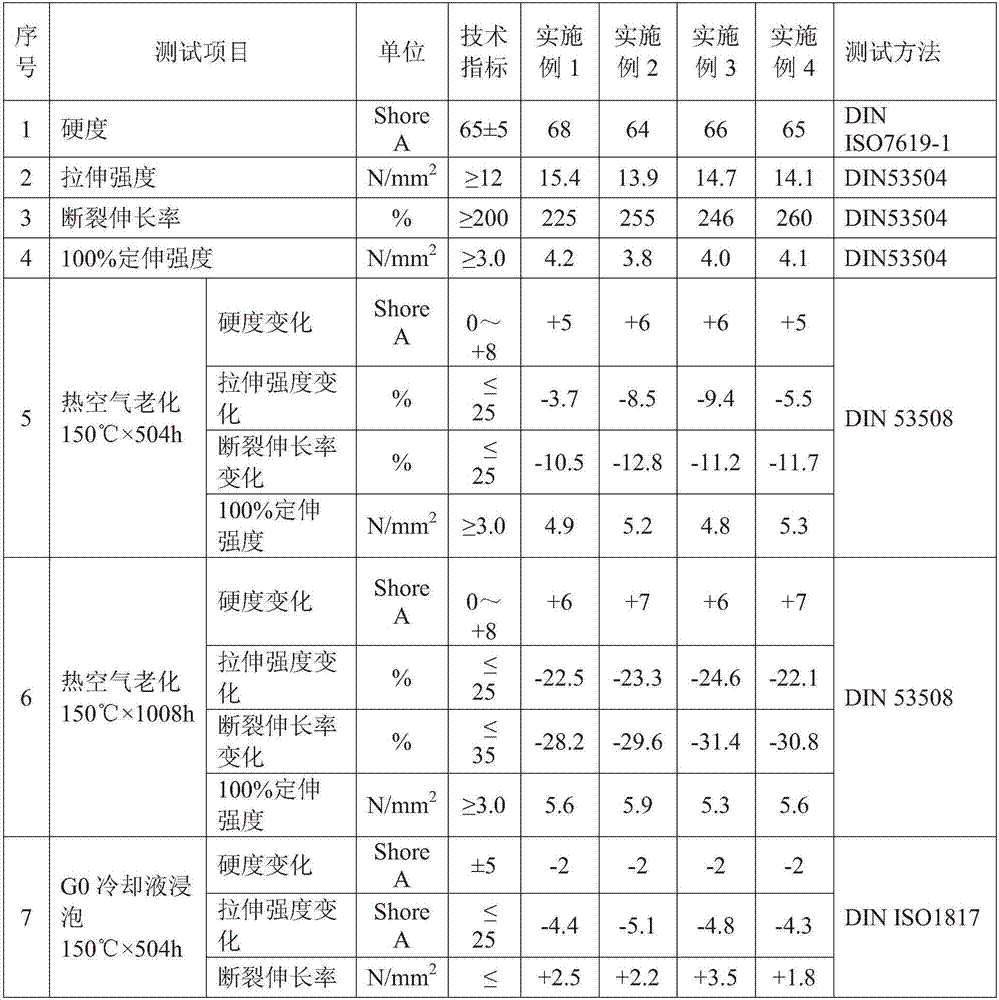

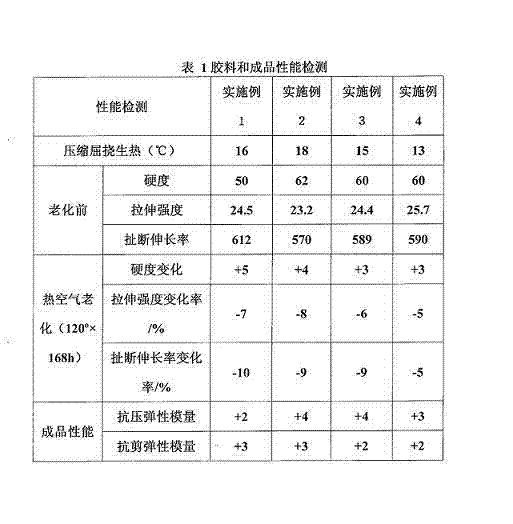

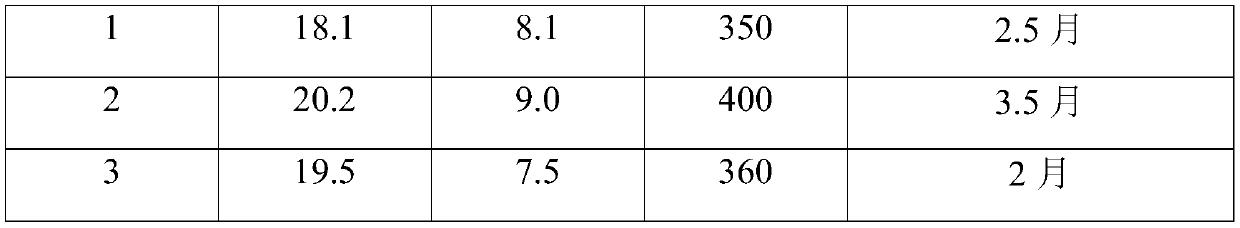

Organic clay rubber composite material for laminated rubber supporting seat and preparation process thereof

The invention belongs to the technical field of rubber, and discloses an organic clay rubber composite material for a laminated rubber supporting seat and a preparation process thereof. The organic clay rubber composite material is mainly characterized by adding organic clay, carbon black, a vulcanizing agent, an activating agent, an accelerating agent and an anti-aging agent to rubber.The organic clay rubber composite material for the laminated rubber supporting seat, which is provided by the invention, is prepared by adopting a mechanical blending intercalation method and substitutes reinforced carbon black or wholly substitutes low-cost reinforced materials, such as calcium powder and the like, by adopting an organic clay part; the laminated rubber supporting seat manufactured by using the organic clay rubber composite material can not only fundamentally solves the problems of potential quality safety hazards, namely incapable aging resistance, poor fatigue-resistant property, and the like, but also lowers the production cost, enhances the heat-resistant property, compression-resistant property and fatigue-resistant property of a rubber base body and keeps the higher breaking and tensile strength and breaking elongation of the rubber material.

Owner:HENGSHUI ZHONGTIEJIAN ENG RUBBER

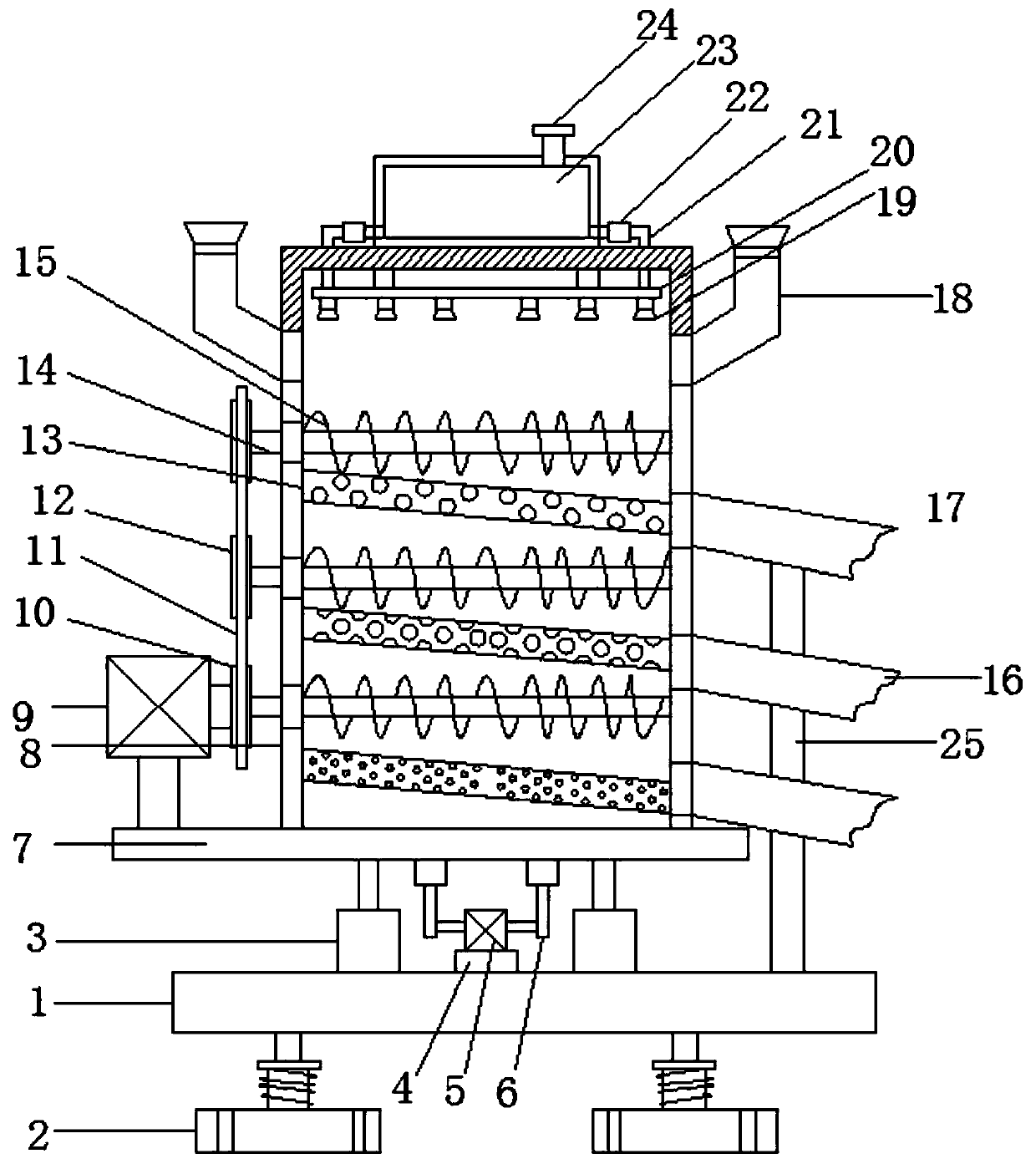

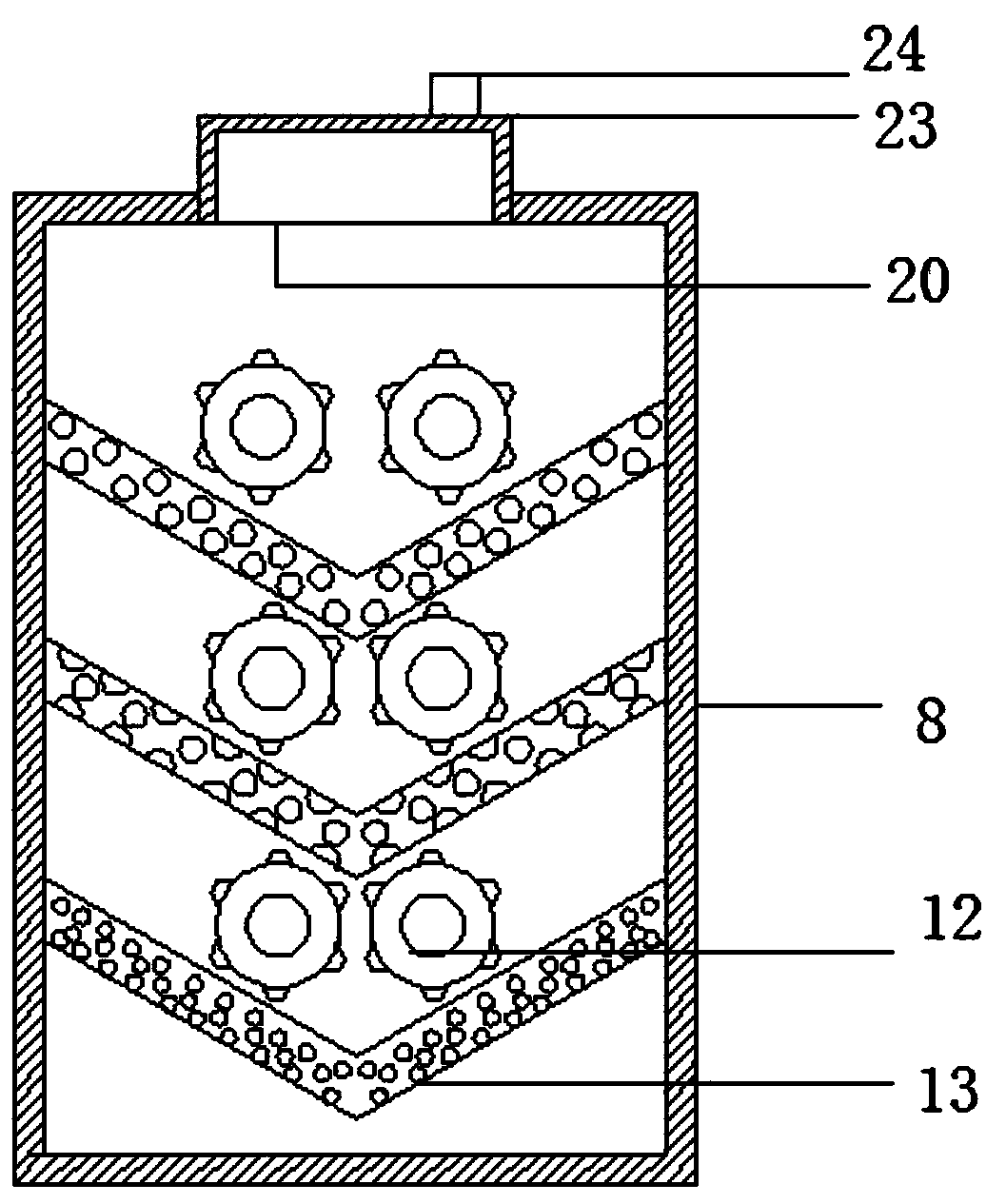

Rubber pulverizing device for rubber producing machining

PendingCN110815638AImprove screening efficiencyExtended service lifeSievingScreeningReciprocating motionSprayer

The invention discloses a rubber pulverizing device for rubber producing machining in the technical field of rubber. A first supporting plate is included. Supporting legs are fixed to the axis symmetric positions of the two sides of the bottom of the first supporting plate through welding. Telescopic rods are in threaded connection to the axis symmetric positions of the two sides of the upper portion of the first supporting plate. A feeding port is arranged so that rubber can be conveyed into a box, and crushing rollers are used for crushing the rubber; a plurality of screens are arranged to conduct multi-level screening on the rubber; through the arrangement of a cam structure, the device can reciprocate up and down, and the rubber screening efficiency is improved; and through the arrangement of a damping assembly, the amplitude generated during crusher work is effectively reduced, the damping effect is achieved for the device, and the service life of the machine is prolonged; and through the arrangement of water box sprayers, dust generated during crushing is isolated in a water curtain, the surrounding raise dust situation can be effectively reduced, and the surrounding construction environment is improved.

Owner:绨亚希西纺织橡胶(连云港)有限公司

Oxygen Compounds as Plasticizers for Rubbers

The invention relates to the use of fatty acid esters, either unsaturated or saturated, as plasticizers for rubbers, especially for NBR and CR rubbers. The plasticizers used according to the invention are safe, in contrast to the conventionally used toxic phthalates such as DEHP and DBP, and can be obtained from renewable raw materials, especially from vegetable oils such as palm oil. For rubbers comprising these plasticizers, there is a multitude of possible uses in the rubber technology sector, especially as a material for cable sheathing, hoses, seals, membranes, shoe soles, floor coverings, damping devices and the like.

Owner:TUDAGASOLINE MINERALOLERZEUGNISSE NILS HANSEN +1

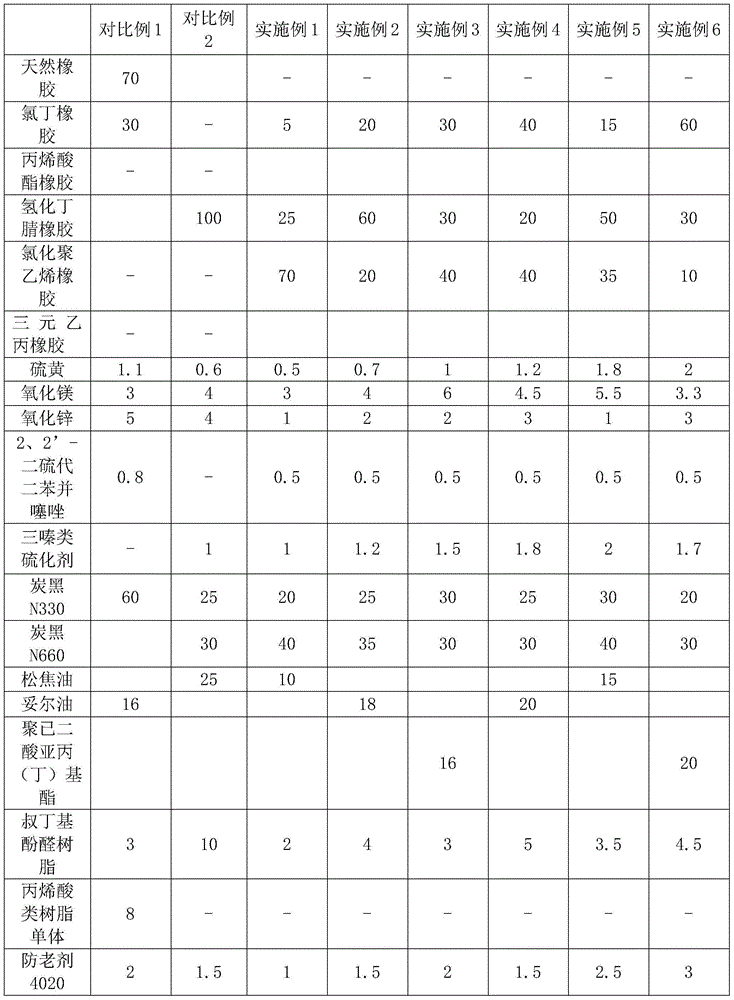

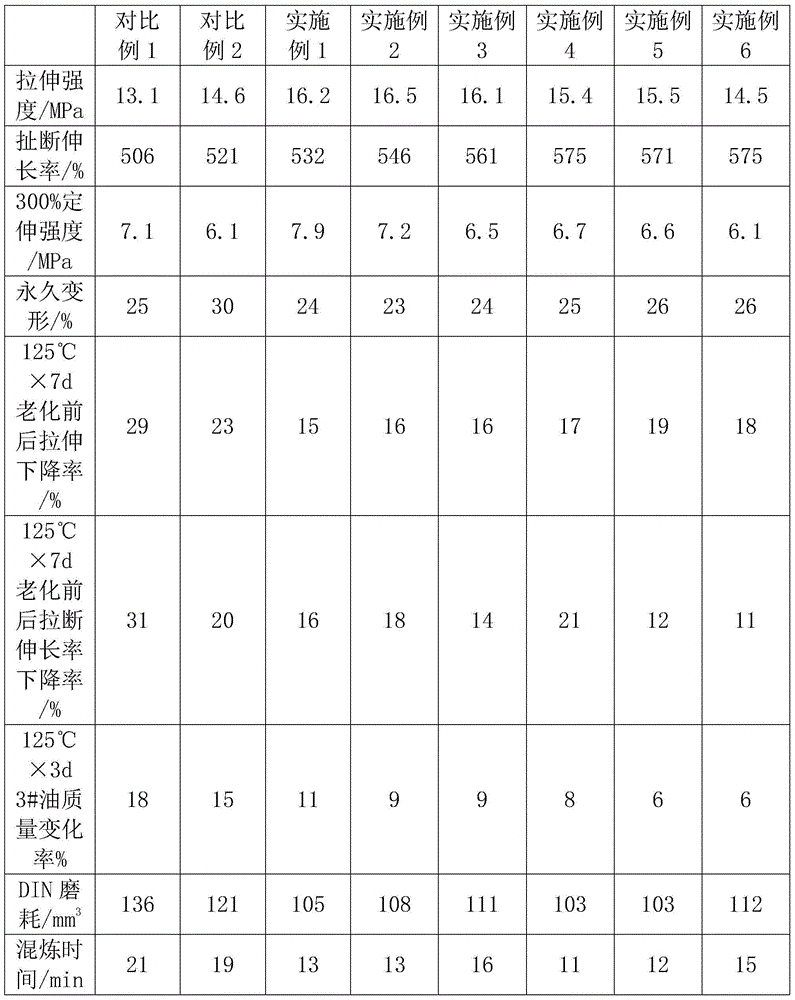

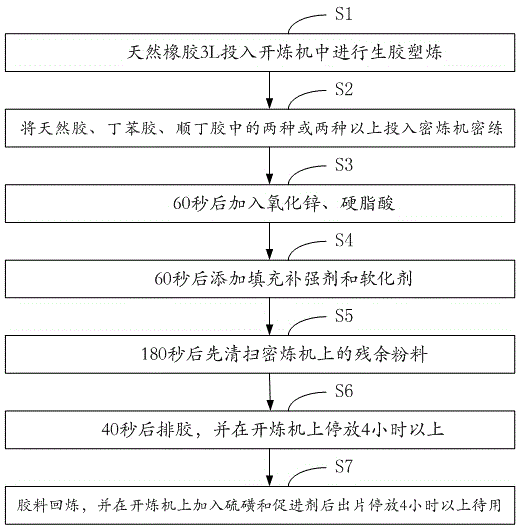

Rubber composition, V belt wrapper glue with adoption of rubber composition and preparation method of V belt wrapper glue

The invention belongs to the field of rubber for transmission belts and in particular relates to a rubber composition for V belt wrapper glue, the V belt wrapper glue and a preparation method of the V belt wrapper glue. The V belt wrapper glue is prepared from the following components in parts by weight: 5-30 parts of acrylate rubber, 40 parts of ethylene propylene diene monomer, 0.5-2 parts of sulfur, 1.5-2.5 parts of an accelerator, 3-6 parts of magnesium oxide, 1-3 parts of zinc oxide, 50-70 parts of a reinforcing agent, 10-20 parts of a softener, 2-5 parts of tackifying resin and 1-3 parts of an antioxidant. The V belt wrapper glue has he characteristics of good oil resistance, high thermal oxidative aging resistance and good processability.

Owner:TAIZHOU BAIHUA RUBBER BELT +1

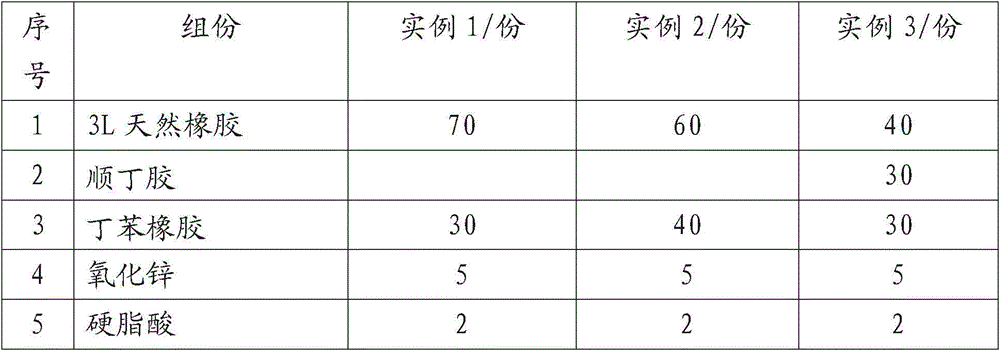

Nylon rubber for bushing and preparation method of nylon rubber

The invention is suitable for the technical field of rubber, and provides nylon rubber for a bushing. The nylon rubber comprises or contains the following components in parts by weight: 100-170 parts of rubber, 4-8 parts of an active agent, 1-3 parts of stearic acid, 2-6 parts of an anti deteriorant, 80-12 parts of a stuffing strengthening agent, 4-10 parts of a softener, 1-2.5 parts of a vulcanizing agent and 1-4 parts of an accelerant. The rubber and the nylon have favorable adhesivity; the fatigue life of products is prolonged. The nylon rubber disclosed by the invention is simple in formula, the hardness of the generated rubber is high, the weariness resistance is high, the deformation rate is reduced, and the density is high.

Owner:柳州日高汽车减振技术有限责任公司

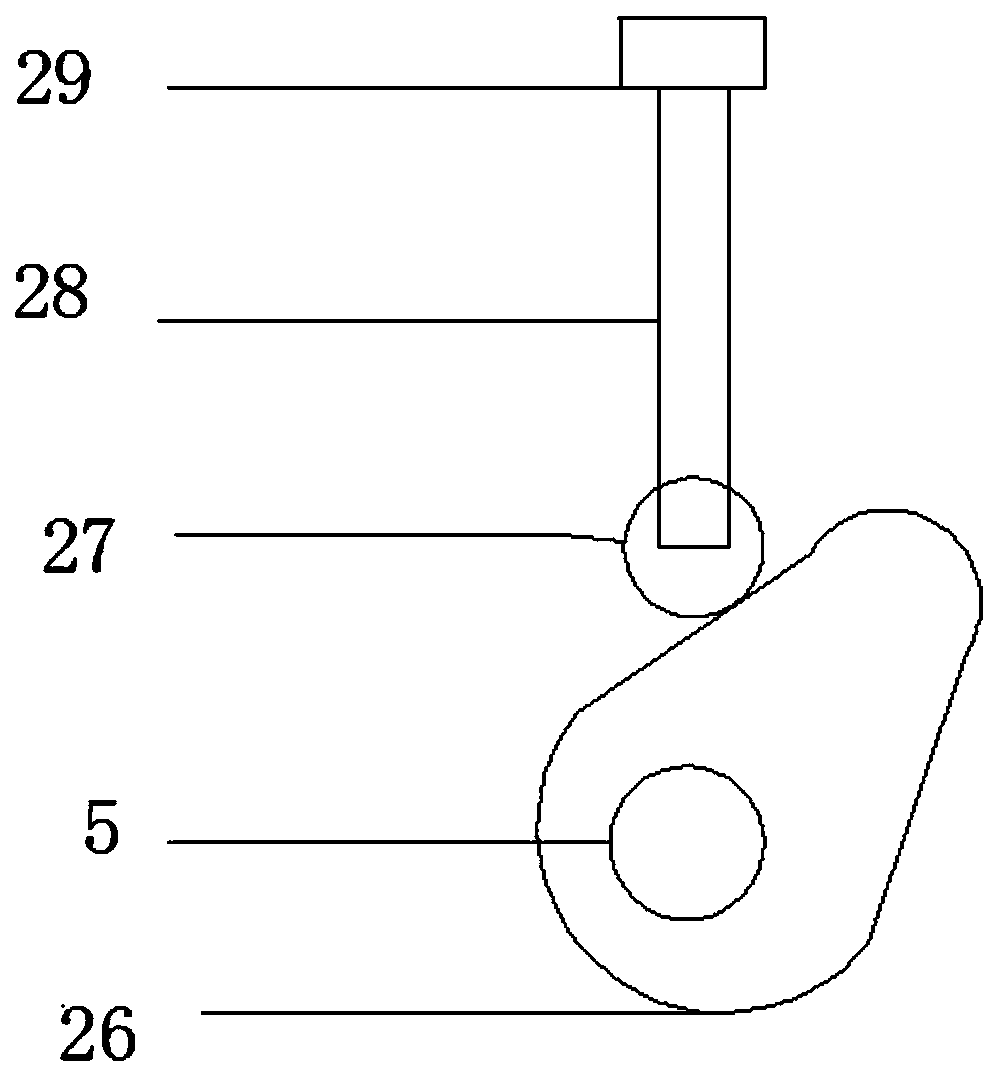

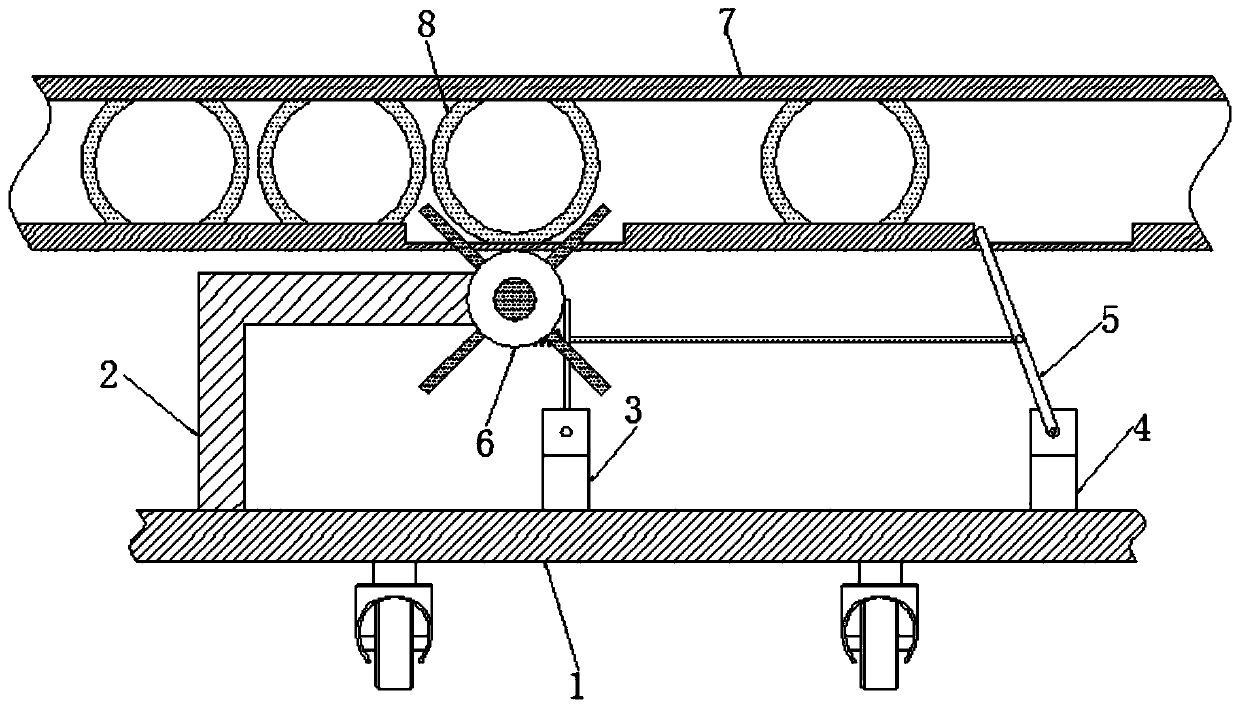

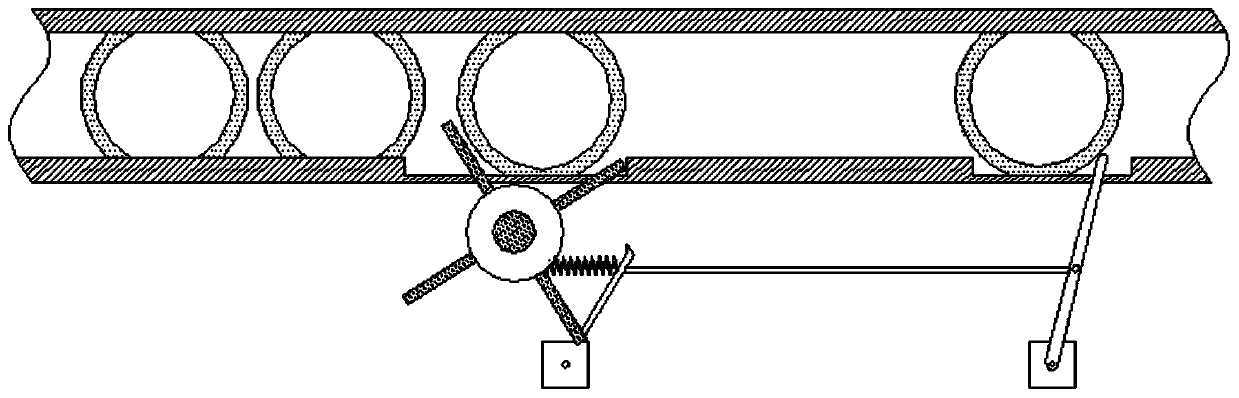

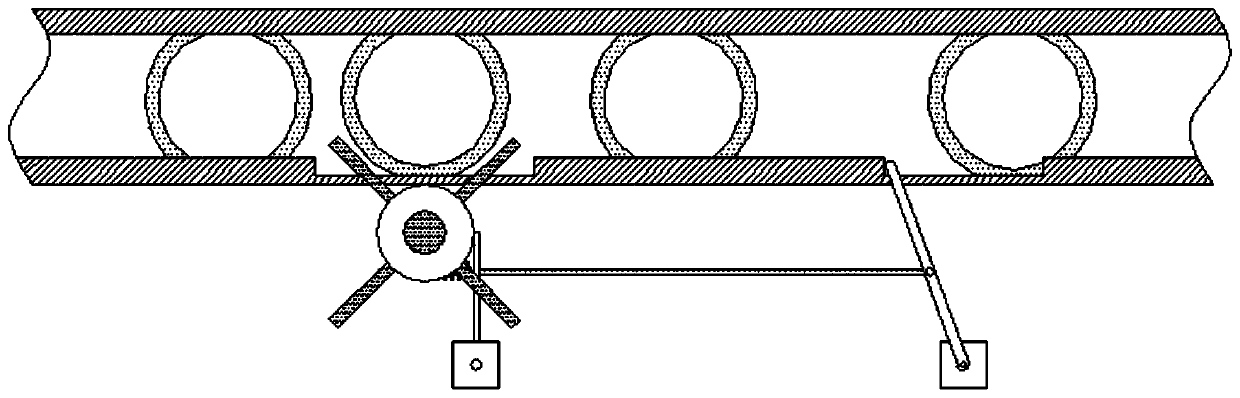

Conveying device for ensuring individual transportation of tires based on self-gravity

InactiveCN110723527ANot easy to accumulateImprove intelligenceConveyorsConveyor partsEngineeringMechanical engineering

The invention relates to the technical field of rubber and discloses a conveying device for ensuring individual transportation of tires based on self-gravity. The conveying device comprises a base. Asupport is fixedly connected above the base. By means of cooperative use of a lower rotating disc, a limiting column, the rubber tires, a swing rod and a conveying plate, along with moving of the rubber tires, the swing rod moves, thus the position of the limiting column and the lower rotating disc is driven, finally, the purpose of transporting the rubber tires individually one by one is completed, the situation that in the transportation process of the rubber tires, due to synchronous transporting, piling is caused easily, and quality of the single tire cannot be detected beneficially is avoided, the self-gravity effect of the rubber tires is utilized for driving the swing rod to move, thus the follow-up reaction is caused, the whole device can complete the process without needing help of the external force effect, the intelligence and the environment friendliness of the whole device are improved, when the swing rod inclines rightwards under the gravity effect, ropes are pulled to move synchronously, thus the limiting column is driven to be away from the lower rotating disc, and the linkage property of the whole device is improved.

Owner:湖州越威家具有限公司

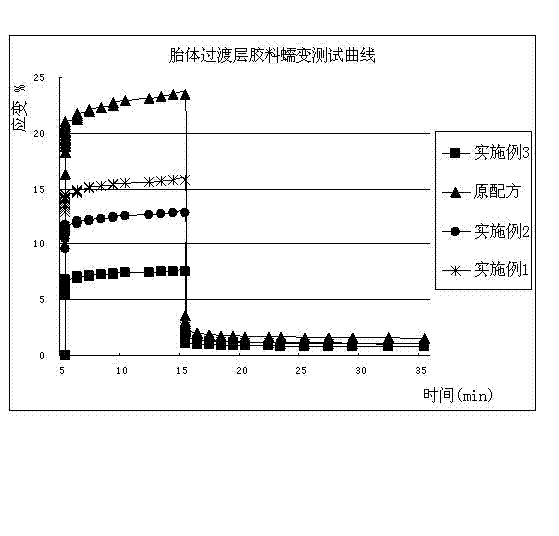

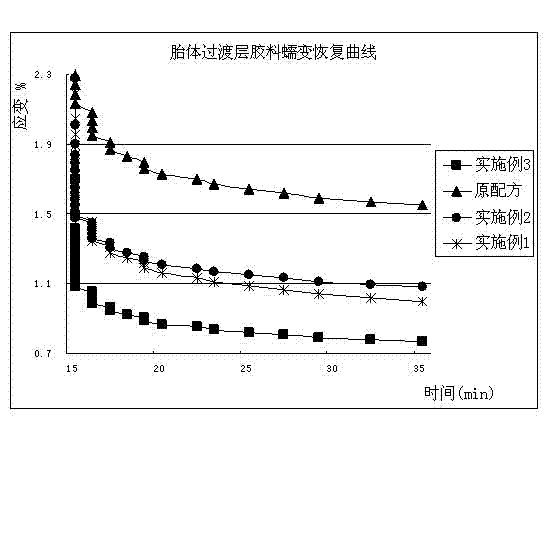

High-modulus low-creep transition layer rubber composition of pneumatic tire body and preparation method of composition

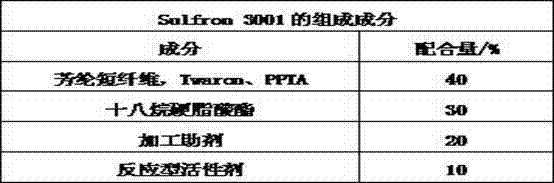

The invention relates to the technical field of rubber, and particularly relates to a high-modulus low-creep transition layer rubber composition of a pneumatic tire body and the preparation method of the composition. By taking 100 parts by weight of natural rubber as reference, the high-modulus low-creep transition layer rubber composition comprises the following components in parts by weight: 50-60 parts of carbon black, 5-10 parts of zinc oxide, 1-2 parts of anti-aging agent, 1.0-1.5 parts of cobalt salt, 0.1-0.4 parts of peptizer, 1.0-1.5 parts of short fibres, 1.0-1.5 parts of resorcinol donor adhesive, 3.0-5.0 parts of adhesive RA, 1.0-1.5 parts of vulcanization accelerant, 4.5-5.0 parts of insoluble sulphur and 0.1-0.3 part of anti-scorching agent. According to the invention, the modulus of the transition layer rubber material of the tire body is increased, the deformation of the rubber material after being stressed is reduced, and the creep of the rubber material is reduced; and an internal wire-exposure shoulder separation ratio in the middle period and later period of the use of a loading radial tire can be decreased, an internal wire-exposure shoulder separation defect ratio can be decreased, the use safety performance of the tire can be improved, and the use life of the tire can be increased.

Owner:TRIANGLE TIRE

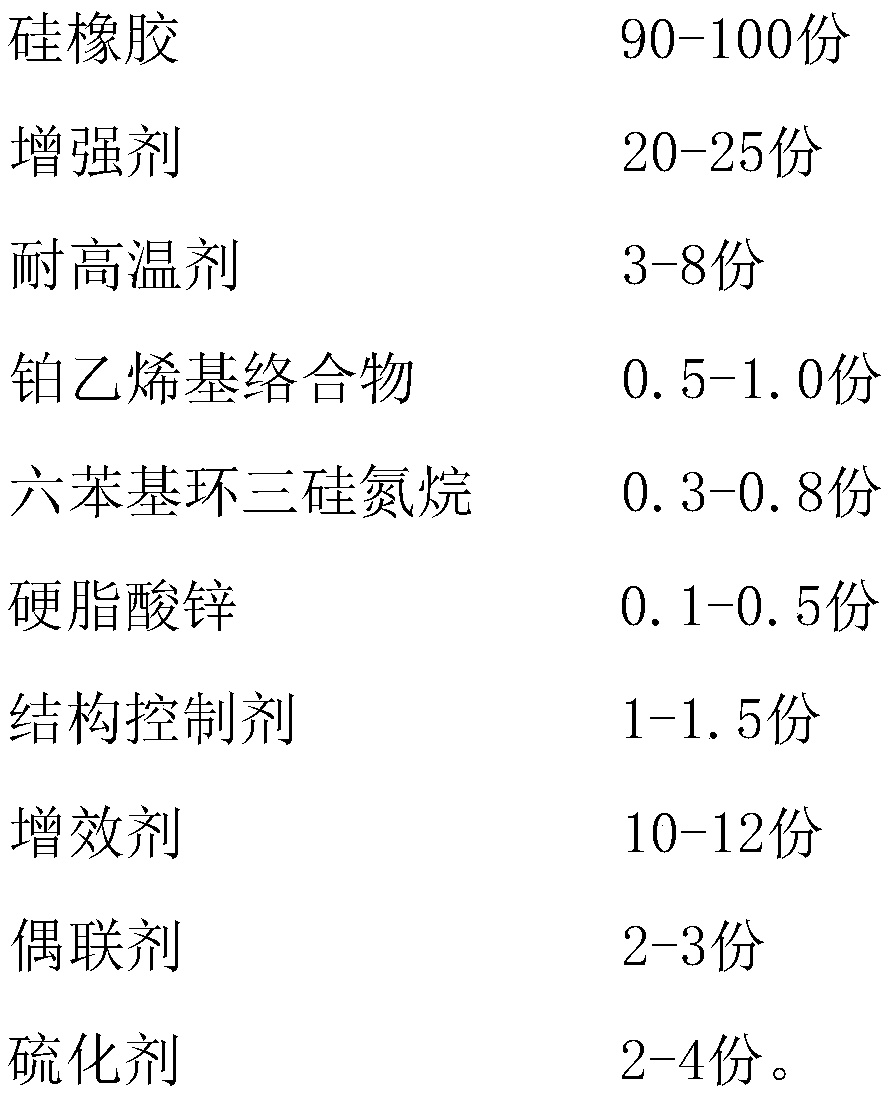

High temperature resistant silicone rubber and preparation method thereof

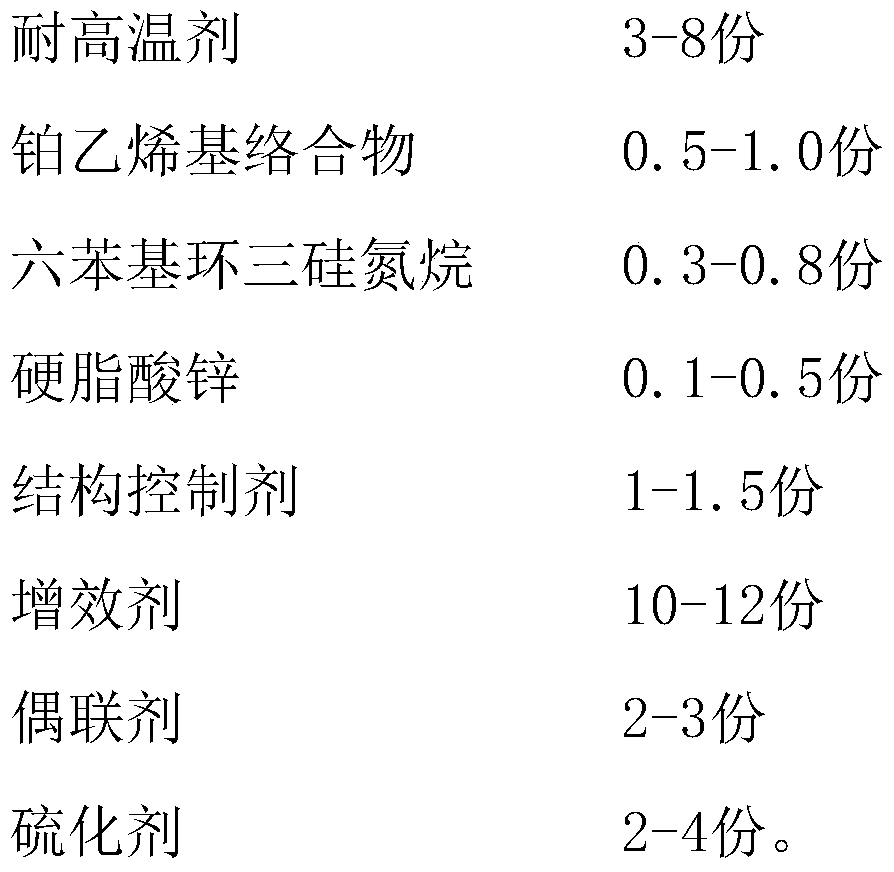

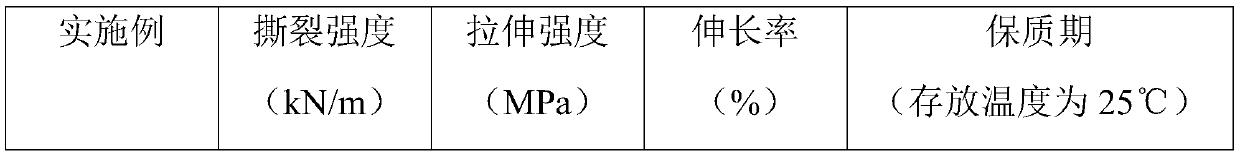

The invention relates to the technical field of silicone rubber, and in particular relates to high-temperature resistant silicone rubber and a preparation method thereof. The high temperature resistant silicone rubber comprises the following raw materials in parts by weight: 90-100 parts of silicone rubber, 20-25 parts of a reinforcing agent, 3-8 parts of a high temperature resistant agent, 0.5-1.0 parts of a platinum vinyl complex, 0.3-0.8 part of hexaphenyl cyclotrisiloxane, 0.1-0.5 part of zinc stearate, 1-1.5 parts of a structure control agent, 10-12 parts of a synergist, 2-3 parts of a coupling agent and 2-4 parts of a vulcanizing agent. The high-temperature resistant silicone rubber prepared by the method is nontoxic and environment-friendly, has excellent high-temperature resistantperformance, has better tensile strength, elongation at break, tear strength and other properties, has high mechanical strength, simultaneously has flame retardant and fireproof properties, and has high stability.

Owner:DONGGUAN TIANAN SILICONES TECH

Pulvurent rubber comprising carbon black filler, process for their preparation and application

InactiveUS6825262B2Avoid stickinessPermit treatmentSpecial tyresPolymer scienceSolution polymerization

Owner:PKU PULVERKAUTSCHUK UNION GMBH

TPE (Thermoplastic Elastomer) material for medical supplies

The invention belongs to the field of rubber technology, in particular to a TPE (Thermoplastic Elastomer) material for medical supplies. A formula comprises the following components in parts by weight: 20-50% of styrene segmented copolymer, 15-40% of paroline, 15-25% of polypropylene, 20-40% of thermoplastic dynamic vulcanizate and 0-15% of mineral filler. Compared with the prior art, the TPE material obtained by the formula and the process of the invention has various excellent capacities of high elasticity, high intensity, high rebound resilience, ageing resistance and oil resistance of a traditional cross-linking vulcanized rubber, and has the characteristics of ordinary plastic of being convenient to process and wide in processing way; furthermore, crushed corners can be directly and secondarily used by 100%; in addition, the processing process can be simplified, and the processing cost can be reduced; furthermore, the TPE is environmental-friendly, toxic-free and safe, and is wide in rigidity scope, flexible in feeling, and excellent in weather fastness, fatigue resistance and temperature tolerance and processing performance, and is free from vulcanization is not needed, and the cost can be reduced by recycling.

Owner:DONGGUAN LIHONG PLASTIC CO LTD

Single-component addition type liquid silicone rubber and preparation method thereof

InactiveCN110669344AThere will be no unstable product qualitySolve the problem of reaction at room temperaturePolymer sciencePlatinum complex

The invention belongs to the technical field of liquid silicone rubbers, and particularly relates to a single-component addition type liquid silicone rubber and a preparation method thereof. The single-component addition type liquid silicone rubber comprises, by weight, 20-50 parts of low-viscosity vinyl silicone oil, 20-50 parts of high-viscosity vinyl silicone oil, 20-35 parts of white carbon black, 5-8 parts of hexamethyldisilazane, 1-5 parts of high vinyl silicone oil, 1.5-2 parts of water, 2-4 parts of hydrogen-containing silicone oil, 0.2-0.5 part of a platinum complex and 0.02-0.08 partof 3-methyl-1-dodecyn-3-ol, wherein the total amount of parts by weight of the high-viscosity vinyl silicone oil and the low-viscosity vinyl silicone oil is 70. The invention also discloses the preparation method of the single-component addition type liquid silicone rubber. The single-component addition type liquid silicone rubber can be directly used without metering mixing when used; and the single-component addition type liquid silicone rubber solves the problem of reaction at room temperature, so that protection is not needed during shutdown, and a large amount of cost is saved.

Owner:DONGGUAN TIANAN SILICONES TECH

Pulverulent rubbers comprising carbon black fillers and based on rubbers present in organic solvents, process for their preparation, and applications

The invention relates to a process for preparing fine-particle free-flowing rubber powders, composed of carbon black fillers and a rubber, prepared by solution polymerization. The process operates on the basis of a two-phase system involving transfer of the organic rubber phase in a non-aggressive manner into the inorganic filler suspension, without addition of chemicals. A rubber / carbon black composite is formed. The process comprises measures to avoid clumping of product in the aqueous phase. After mechanical water removal and thermal drying, the product obtained flows freely and is a storage-stable powder or pellet and are markedly superior to the standard both in their processing and in their rubber-technology property profile.

Owner:PKU PULVERKAUTSCHUK UNION GMBH

Nitrile rubber for extra-high voltage large-scale oil-immersed type transformer

The invention belongs to the technical field of rubber, and mainly relates to a nitrile rubber for an extra-high voltage large-scale oil-immersed type transformer. The nitrile rubber comprises the following components in parts by mass: 100 parts of nitrile rubber NBR (nitrile -butadiene rubber), 0.1 to 20 parts of stearic acid, 10 to 80 parts of carbon black, 10 to 80 parts of spraying carbon black, 1 to 30 parts of zinc oxide, 0.1 to 20 parts of a vulcanizing agent DTDM (4,4'-Dithiodimorpholine), 0.1 to 20 parts of a vulcanizing agent TETD (Tetraethylthiuram Disufide), 0.1 to 20 parts of a vulcanizing agent TMTD (Tetramethyl Thiuram Disulfide), 0.1 to 20 parts of an accelerant CZ, 0 to 20 parts of an antioxidant RD, 0.1 to 20 parts of an antioxidant RB, 0.1 to 20 parts of an antioxidant 4010, 1 to 20 parts of paraffin, 1 to 30 parts of coumarone and 5 to 50 parts of decadioctyl. The compatibility of the nitrile rubber with respect to the oil of the transformer is further improved, so that the problem that the gas is generated by the rubber in the transformer can be solved, and the stability and the safety of the extra-high voltage large-scale oil-immersed type transformer in running can be ensured.

Owner:SHENYANG POLYTECHNIC UNIV

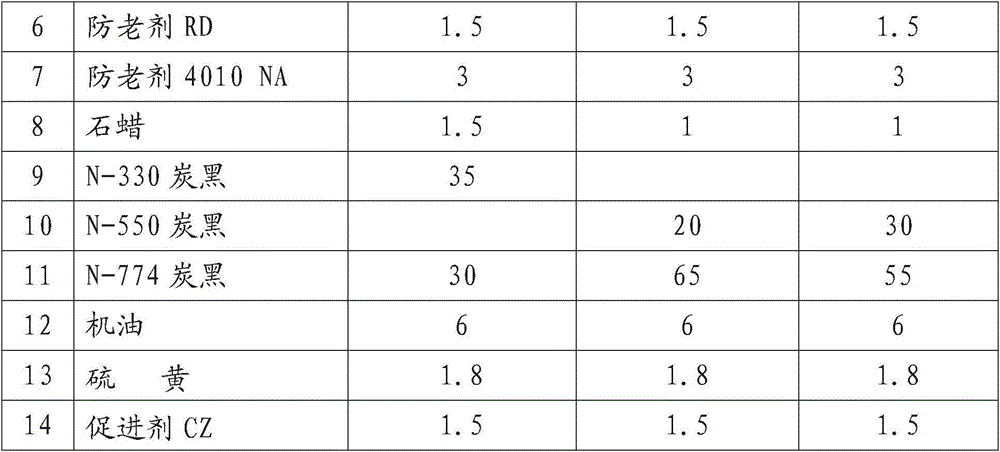

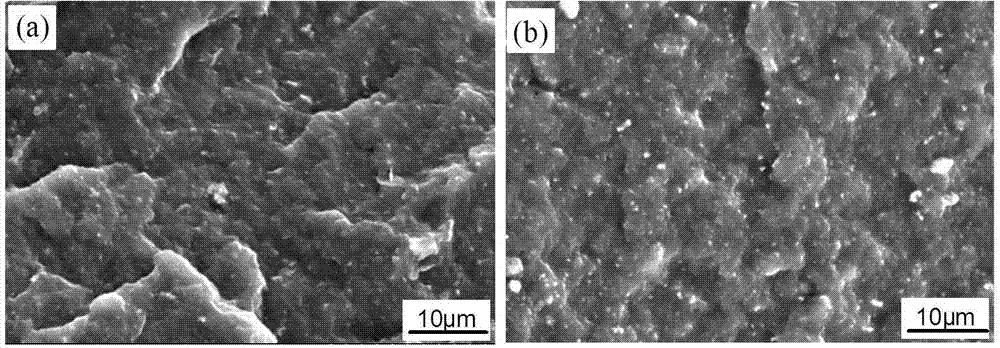

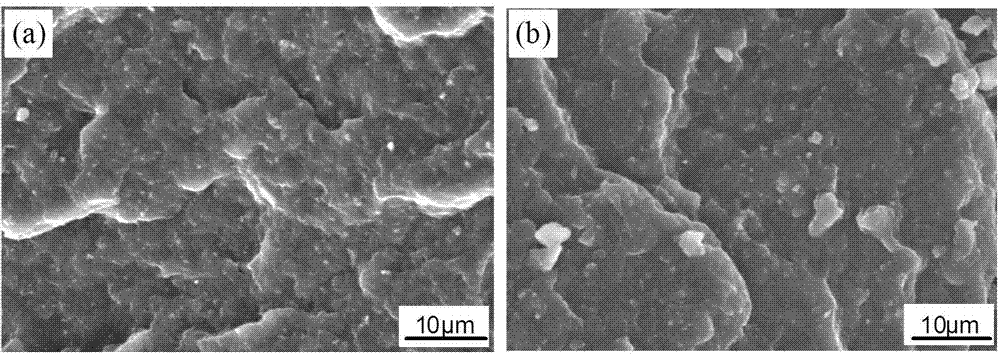

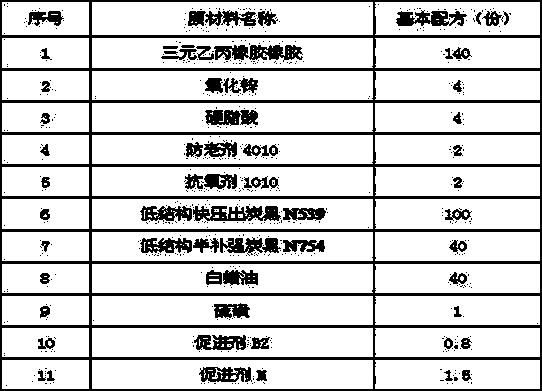

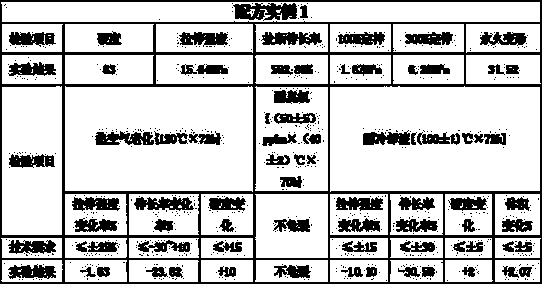

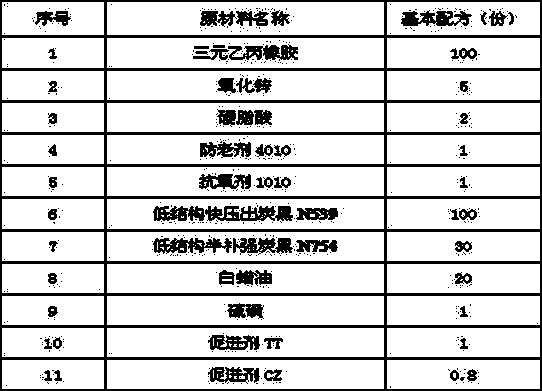

EPDM (Ethylene-Propylene-Diene Monomer) rubber composition and preparation method thereof

InactiveCN103881241AImprove heat and oxygen aging resistanceImprove ozone aging resistancePolymer scienceVulcanization

The invention relates to the technical field of rubber, and particularly relates to an EPDM (Ethylene-Propylene-Diene Monomer) rubber composition and a preparation method thereof. The EPDM rubber composition comprises the following ingredients: EPDM rubber, zinc oxide, stearic acid, antiaging agent, antioxidant, low-structure fast-extruding carbon black N539, low-structure semi-reinforcing carbon black N754, white wax oil, sulfur and accelerant. The preparation method sequentially comprises the steps of: weighing rubber and raw materials; plastifying the rubber; carrying out internal mixing and charging materials; performing one-section open-milling and batching off; stopping and cooling; carrying out two-section open-milling and sulphurating; vulcanizing rubber pieces; cutting patterns according to standard; and carrying out test detection. By use of the EPDM rubber composition, the heat-oxygen aging resistance, ozone aging resistance, weather aging resistance and low temperature resistance of a rubber pipe product can be improved, and the defect that the rubber pipe can resist high temperature, but is hardened and gets fragile under a low-temperature condition can be overcome. Furthermore, the product cost can be greatly saved, and the processing technique is simple and practical.

Owner:柳州日高汽车减振技术有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com