Silicone rubber foaming material and preparation method thereof

A silicone foaming and liquid silicone technology, applied in the field of silicone rubber, can solve the problems of electronic equipment not working normally, increasing maintenance costs, large compression deformation, etc., and achieve the effects of avoiding fire hazards, reducing maintenance costs, and small compression deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

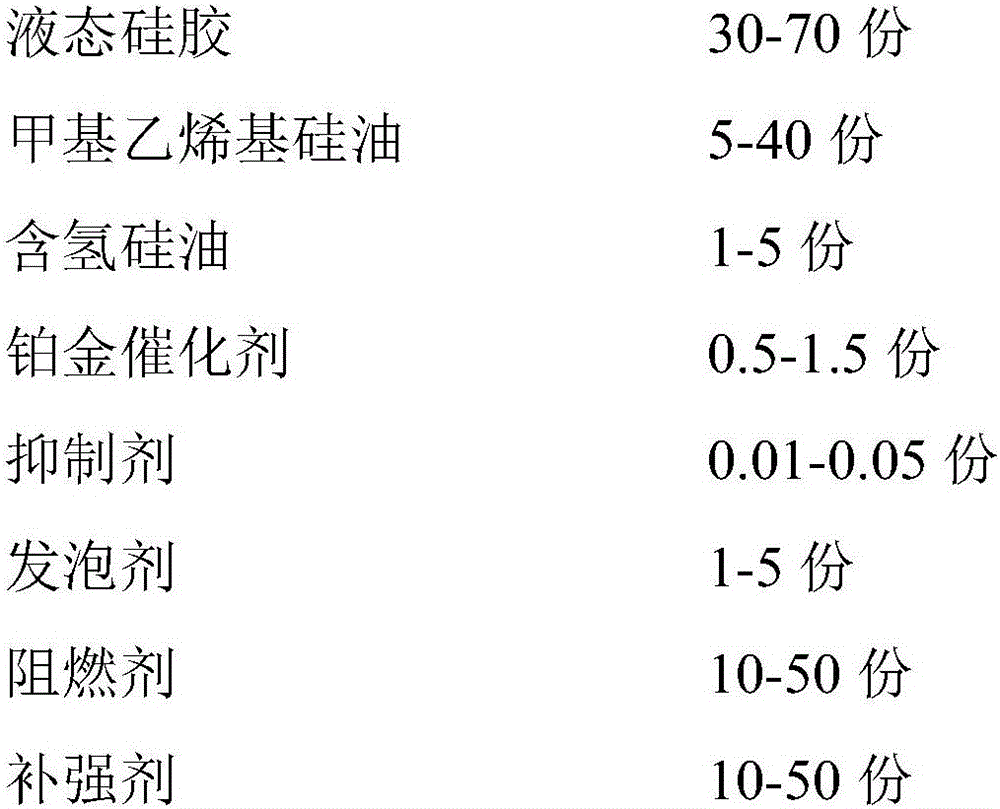

[0055] A kind of silica gel foaming material, it comprises the following components in parts by mass:

[0056]

[0057] In this embodiment, the liquid silica gel is polydimethylsiloxane, the hydrogen content in the hydrogen-containing silicone oil is 0.4wt / %, the viscosity of the liquid silica gel is 10000mPa·s at 25°C, and the viscosity of the methyl vinyl silicone oil The viscosity was 10000 mPa·s at 25°C.

Embodiment 2

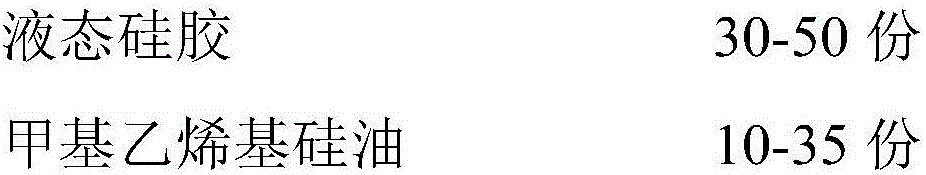

[0059] A kind of silica gel foaming material, it comprises the following components in parts by mass:

[0060]

[0061] In this embodiment, the liquid silica gel is polydimethylsiloxane, the hydrogen content in the hydrogen-containing silicone oil is 0.8wt / %, the viscosity of the liquid silica gel is 100000mPa·s at 25°C, and the viscosity of the methyl vinyl silicone oil The viscosity was 100000 mPa·s at 25°C.

Embodiment 3

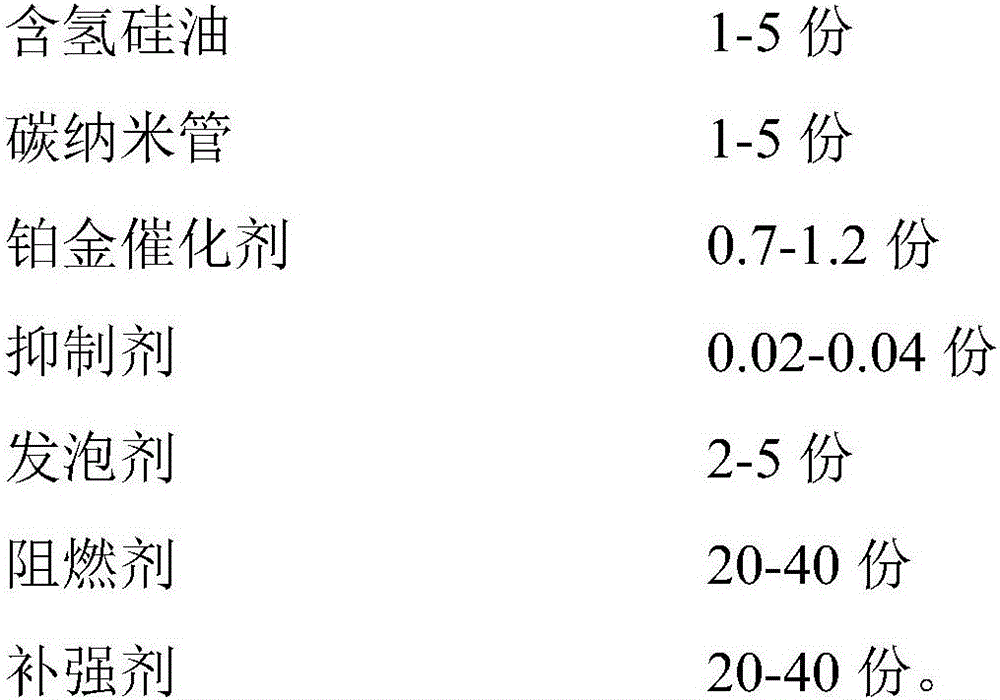

[0063] A kind of silica gel foaming material, it comprises the following components in parts by mass:

[0064]

[0065] In this embodiment, the liquid silica gel is polydimethylsiloxane, the hydrogen content in the hydrogen-containing silicone oil is 0.6wt / %, the viscosity of the liquid silica gel is 30000mPa·s at 25°C, and the viscosity of the methyl vinyl silicone oil is The viscosity was 20000 mPa·s at 25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com