Patents

Literature

184results about How to "Small compression deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

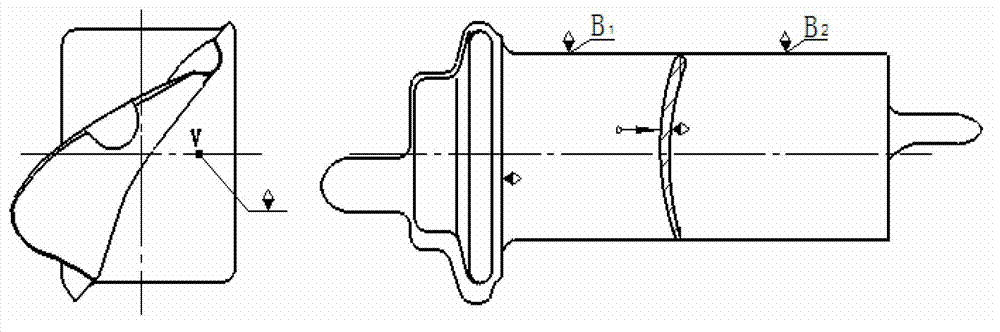

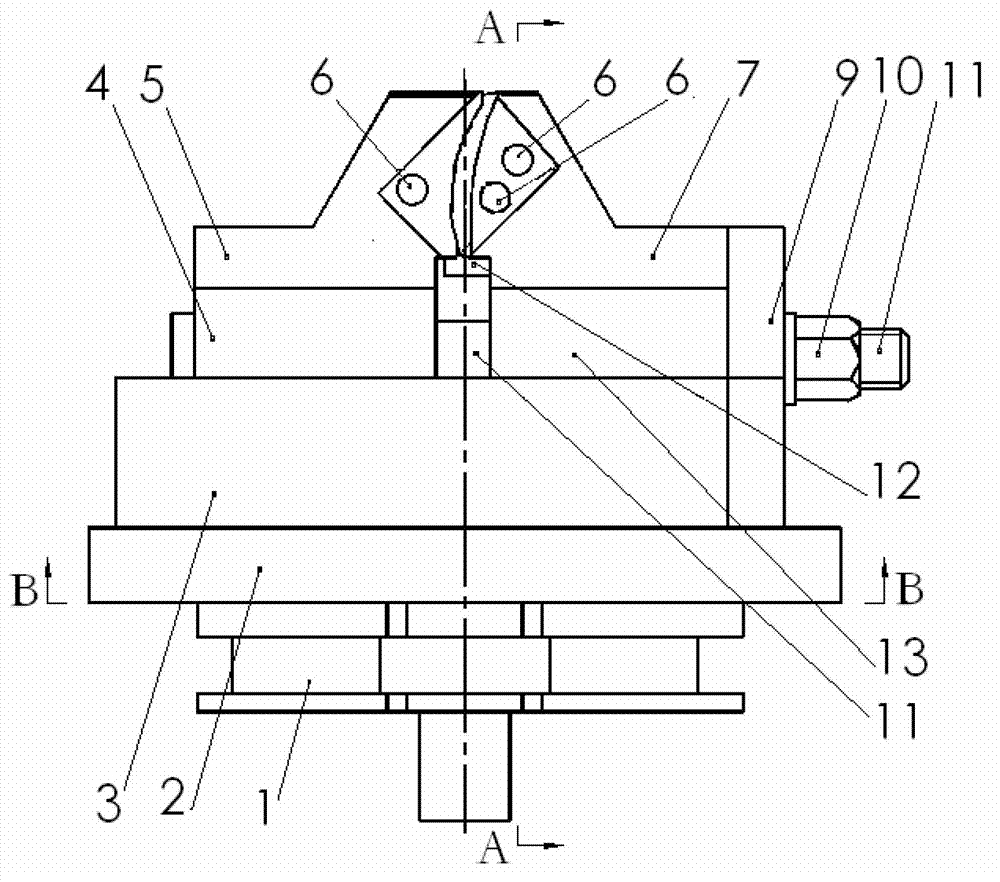

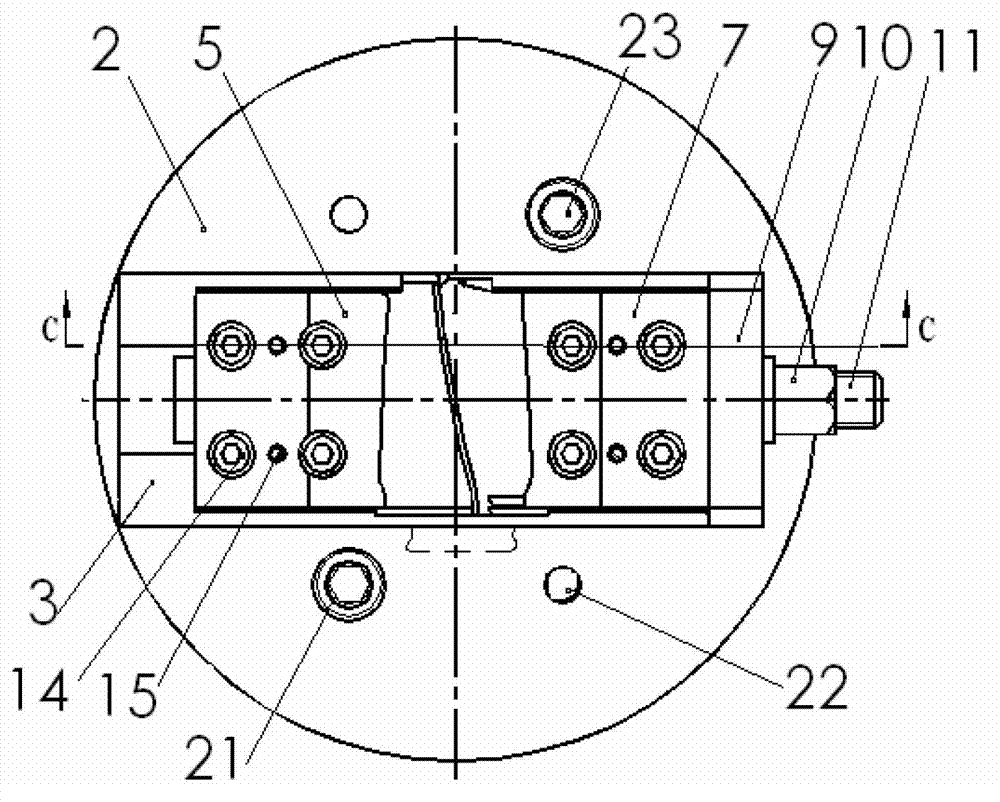

Method and clamp for moulding surface positioning clamping of finish forge blade

ActiveCN102773733AImprove rigidityImprove quality and efficiencyPositioning apparatusMetal-working holdersAdhesiveEngineering

The invention relates to a method and a clamp for moulding surface positioning clamping of a finish forge blade. According to the method, a vane is subjected to positioning clamping through a basin mounding surface of the blade, an inner side moulding surface of a blade root marginal plate, and a V point on the inner side mounting surface of the blade root marginal plate, by the positioning of an air inlet edge, and the clamping of a back mounding surface of the blade, as well as by using a high-accuracy positioning adhesive, and an adhesive coating method, and through a positioning block of the basin moulding surface of the blade and a clamping block of the back moulding surface of the blade. According to the method and the clamp, a satisfying contact area can be obtained by adoption of the high-accuracy adhesive, and the positioning rigidity of the blade is enhanced by adoption of the basin moulding surface of the blade, the inner side moulding surface of the blade root marginal plate and the V point on the inner side moulding surface of the blade root marginal plate for the positioning. According to the method and the device, the problems that the accurate positioning is difficult to realize and the moulding surface of the blade deforms or is damaged because the blade is thin, the blade body is small and the moulding surface is complex are solved. By the method and the device, the positioning accuracy of the mechanical processing of the blade is improved, and the technological process is optimized, so that the processing quality and the production efficiency of the blade are improved, the process is simple, the number of fixtures is reduced, the processing cycle is shortened, and the production cost is reduced.

Owner:AECC AVIATION POWER CO LTD

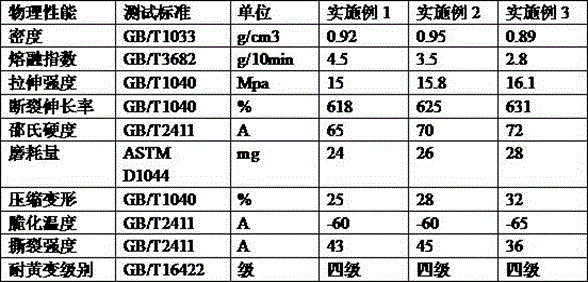

Highly wear-resistant elastomer sole material and preparation method thereof

The present invention discloses a highly wear-resistant elastomer sole material, which comprises the following raw materials: a SBS rubber elastomer, a softening plasticizer, a thermoplastic polyurethane elastomer, a polyolefin elastomer, ethylene propylene diene monomer, a polystyrene resin, a styrene-butadiene rubber, a filler, an antioxidant, a light stabilizer and a processing aid. The invention further discloses a preparation method of the highly wear-resistant elastomer sole material. According to the present invention, the formula of the highly wear-resistant elastomer sole material is reasonable, the thermoplastic elastomer SBS is adopted as the substrate, and the highly wear-resistant elastomer sole material has advantages of high elasticity, high wear resistance, low compression deformation, weather resistance, low temperature resistance, excellent mechanical property, extremely easy extrusion processing molding, and the like; and the preparation method has characteristics of simple process, easy achieving and high production efficiency, and can quickly produce the highly wear-resistant elastomer sole material product, and the product can be widely used in the fields of sports shoes and casual shoes.

Owner:DONGGUAN JISU PLASTIC TECH

Single-core cable insulating rubber for low-smoke and zero-halogen flame-resistant rail vehicle with rated voltage of 3000V

ActiveCN101914244ASmall compression deformationImprove mechanical propertiesRubber insulatorsInsulated cablesHalogenFlame resistance

The invention discloses single-core cable insulating rubber for a low-smoke and zero-halogen flame-resistant rail vehicle with rated voltage of 3000V and temperature resistance of a 125 DEG C level. The single-core cable insulating rubber comprises the following components in parts by weight: 100 parts of crude rubber, 2-6 parts of organic peroxide curing agent, 1-5 parts of auxiliary curing agent, 1-4 parts of coupling agent, 3-8 parts of anti-aging agent, 10-25 parts of strengthening agent and 5-10 parts of plasticizing agent. The single-core cable insulating rubber has excellent insulating property and is very soft. A cable produced by the rubber is soft and is easy to bend, install and lay. The single-core cable insulating rubber has excellent insulating property, can continuously and normally work at voltage of 1000V and high temperature of 125 DEG C, can resist climates, ozone, heat, ageing, acid, alkali and fuel oil well and has low-smoke and zero-halogen flame resistance, environmental protection, safety and long service life.

Owner:JIANGSU JUYE CABLE

Preparation method of EVA/plant fiber foamed composite material for shoes

The invention discloses a preparing method of EVS plant fiber foaming composite shoe material, which is characterized by the following: setting EVA as main material, plant fiber powder and inorganic powder material as auxiliary; matching cross linker, auxiliary cross linker, foaming agent AC, organic silicon wool sanforizing agent CS, plasticizer and surface additive. The preparing course comprises the following steps: grinding the plant fiber; drying; putting the fiber in the high-speed stirrer to knead; removing water; proceeding surface active disposal; adding the prepared material with EVA, surface additive A and other materials in the closed-smelting machine; squeezing the grain to produce high foaming composite shoe material of EVA plant fiber.

Owner:FUZHOU UNIV

Process for preparing EVA/PE/starch composite foam material

The invention discloses a making method of EVA / PE / starch composite foaming material, which comprises the following steps: adopting EVA and PE as main raw material and starch and inorganic flour as auxiliary material; allocating glycerin, crosslinking agent, foamer AC and surface modifier; kneading starch and glycerin in the high-speed stirrer to form gelatinized starch; fusing in the open-fusing machine with EVA, PE surface modifier and other raw materials; grafting surface modifier and EVA and PE in the fusing course; modifying the binding property of two-phase interface of EVA and PE; forming piece after fusing and plasticizing; cutting; weighing; placing in the flat vulcanizer to do vulcanization foaming; obtaining the product.

Owner:FUZHOU UNIV

High-wear-resistance elastic polymer rubber material and preparation method thereof

The invention discloses a high-wear-resistance elastic polymer rubber material and a preparation method thereof. The high-wear-resistance elastic polymer rubber material is characterized by being composed of a rubber composition and rubber auxiliaries. The rubber composition comprises an ethylene-vinyl acetate copolymer, ethylene-propylene-diene monomer rubber, SEBS, a POE elastomer and an ethylene-octylene segmented copolymer. The rubber auxiliaries comprise a wear resisting agent, a foaming agent, a vulcanizing agent, a softener, an accelerant, a reinforcing agent and other auxiliaries. According to the preparation method, the finished product is obtained through the steps of batching, banburying, mixing, open milling and pelleting. The compatible and complementary factors existing between all types of synthetic rubber are utilized, so that the obtained high-wear-resistance elastomer sole material has high elasticity, high flexibility, high wear resistance and good mechanical performance, is low in cost and can be widely applied to the fields of soles, insoles and the like.

Owner:REBECCA LIMS INT CO LTD

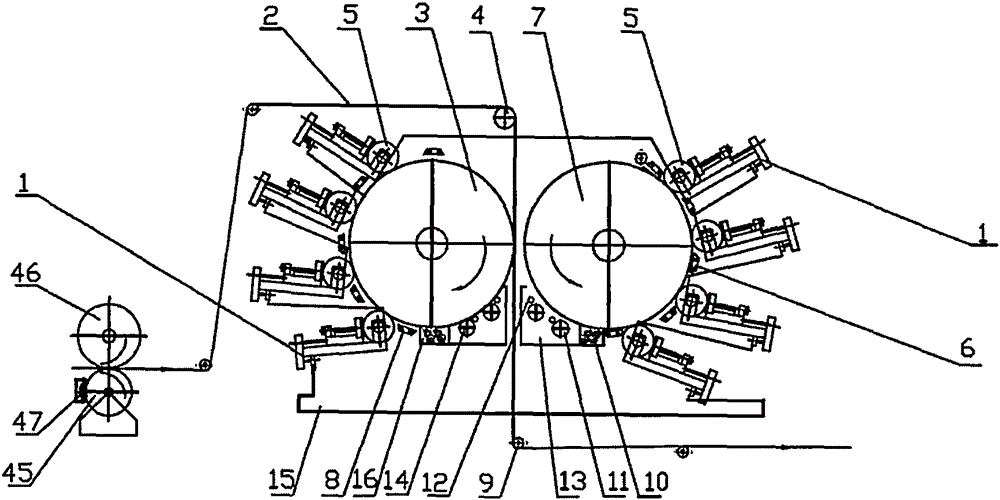

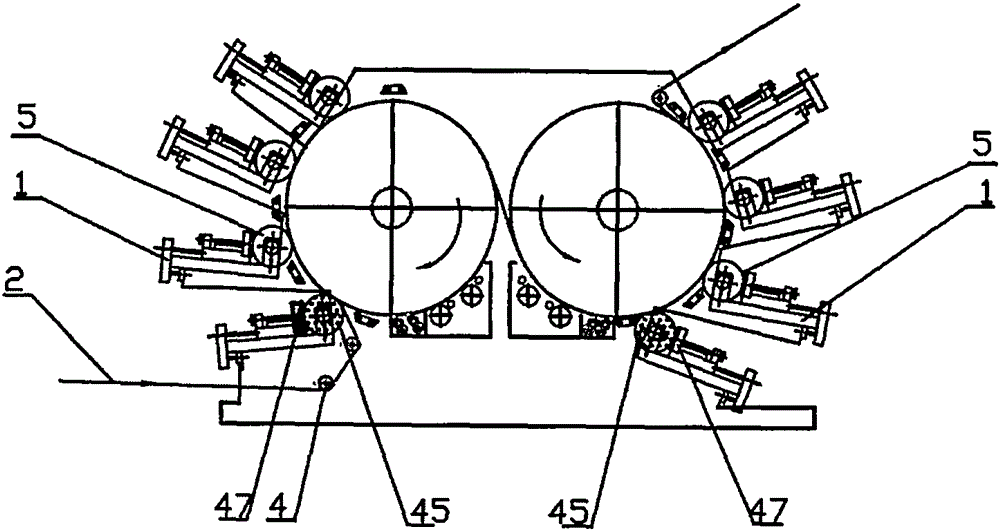

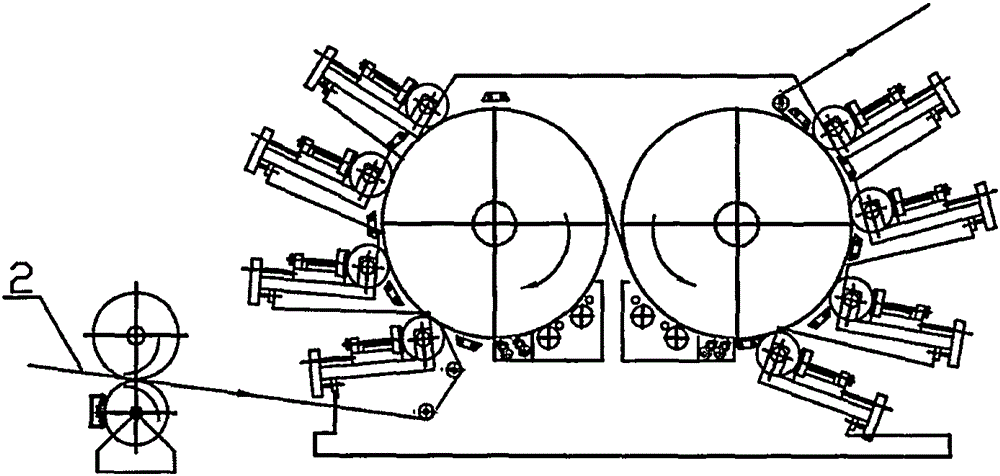

Dual-purpose printing equipment with functions of transfer printing and direct printing

InactiveCN105058968AModerate hardnessSmall compression deformationTransfer printingScreen printersEngineeringDirect printing

The invention discloses dual-purpose printing equipment with the functions of transfer printing and direct printing. The equipment consists of a preprocessing device and a printing device, wherein the preprocessing device consists of a reticulate pattern roller (45) and a bearing roller (46); the printing device consists of a front main roller and a rear main roller, and each main roller is matched with printing plate rollers, roller barrel washing devices and roller barrel drying devices. The dual-purpose printing equipment disclosed by the invention adopts integrated dual-purpose design with the functions of the transfer printing and the direct printing and can meet requirements for low cost and high speed of the direct printing, and the dual-purpose printing equipment can also meet requirements for high fineness of the transfer printing.

Owner:NEWTECH TEXTILE TECH DEV SHANGHAI

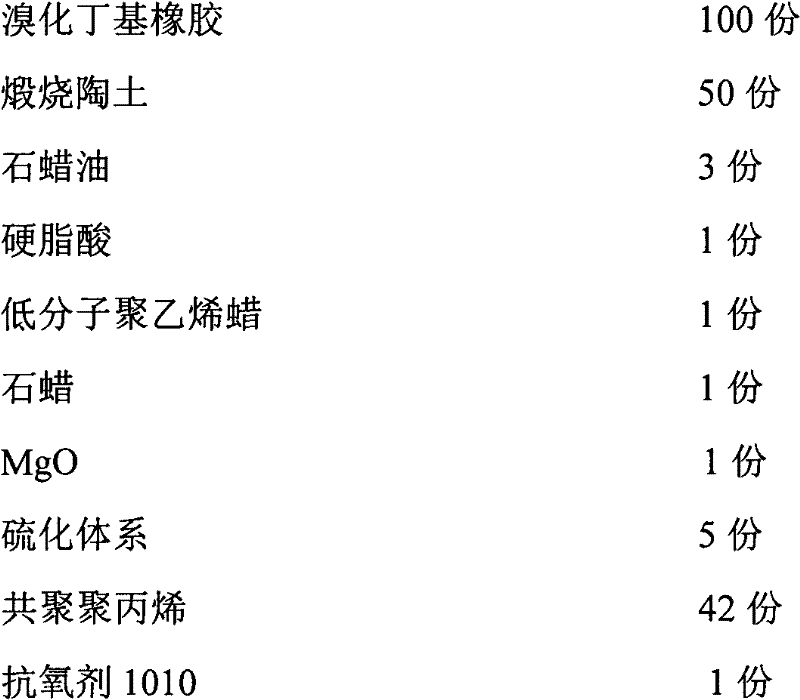

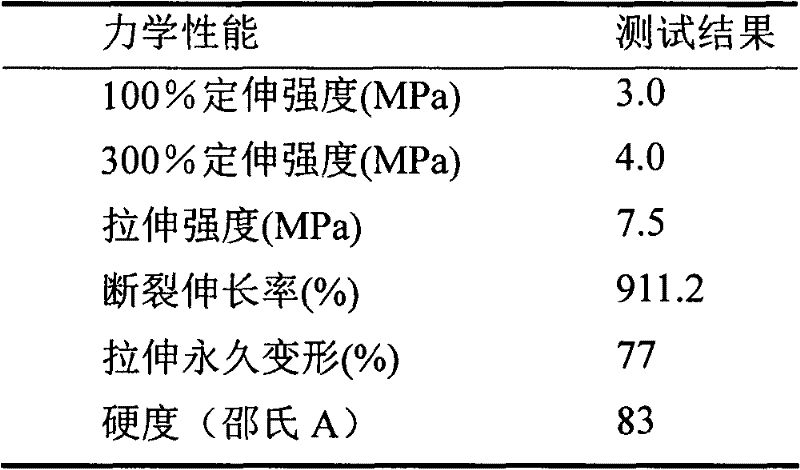

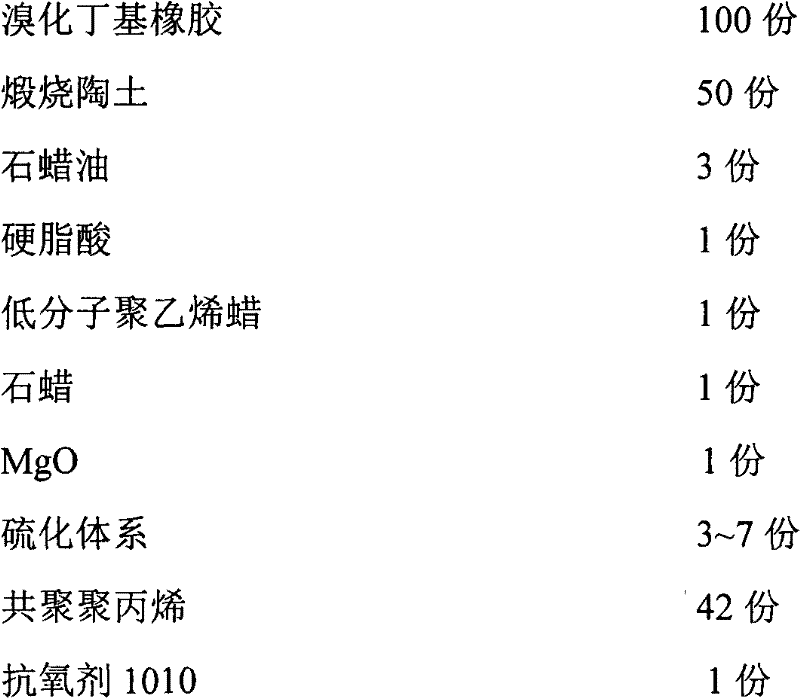

Vulcanizing system of brominated butyl rubber/ polypropylene thermoplastic elastomer sealing material and preparation method for sealing material

InactiveCN102585319APlay a role in vulcanizationHigh elongation at breakOther chemical processesCross-linkPolymer science

The invention provides a vulcanizing system of a brominated butyl rubber / polypropylene thermoplastic elastomer sealing material and a preparation method for the sealing material. The vulcanizing system comprises a vulcanizing agent, a catalyst and an active agent. The vulcanizing agent is a sulfur-free vulcanizing system, is granular and dustless, and is easy to weigh, calculate and disperse and safe in operation. The preparation method is a dynamic vulcanizing blending method, and can comprise injection and extrusion molding; the cross-linked rubber phase is dispersed uniformly in a plastic phase; and the preparation method has the advantages of simple process, a small amount of waste, high production efficiency and the like. The performance of the prepared sealing material meets the requirement of national standard YBB00232004. The vulcanizing system can substitute brominated butyl vulcanized rubber and can be applied in various fields.

Owner:EAST CHINA UNIV OF SCI & TECH

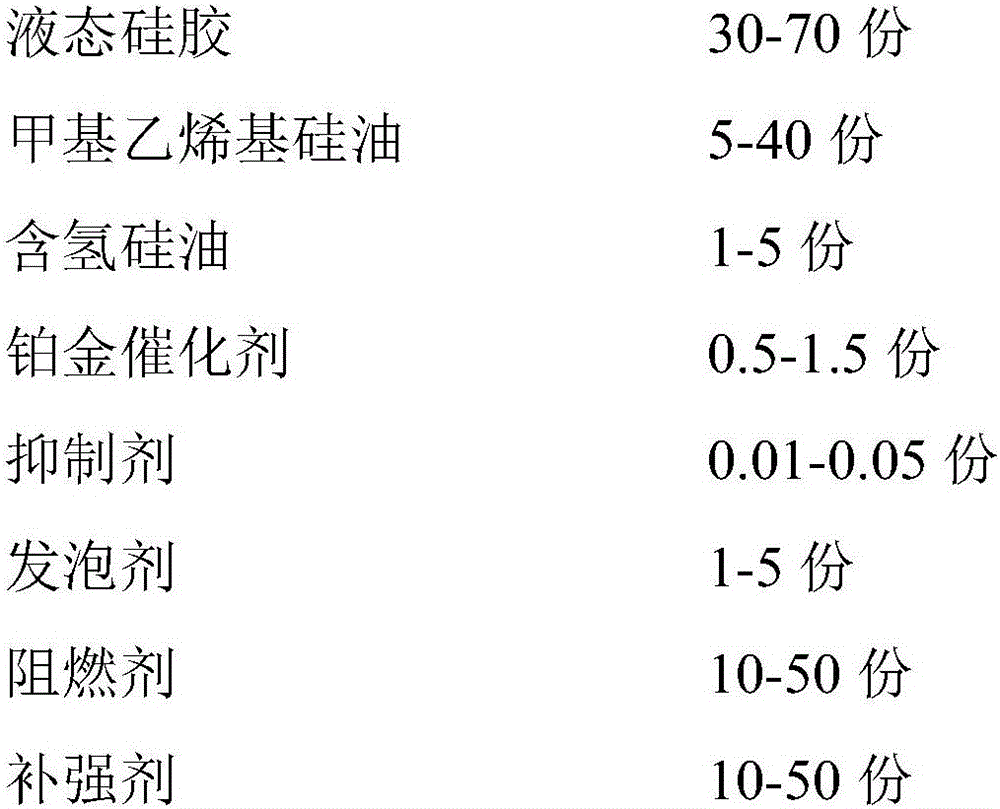

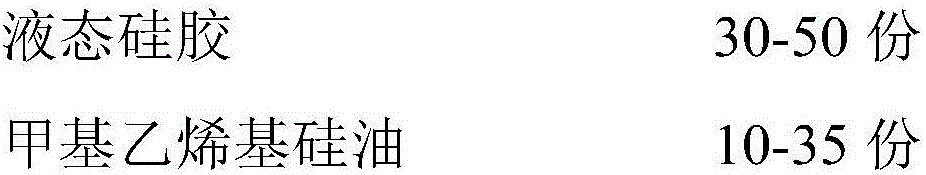

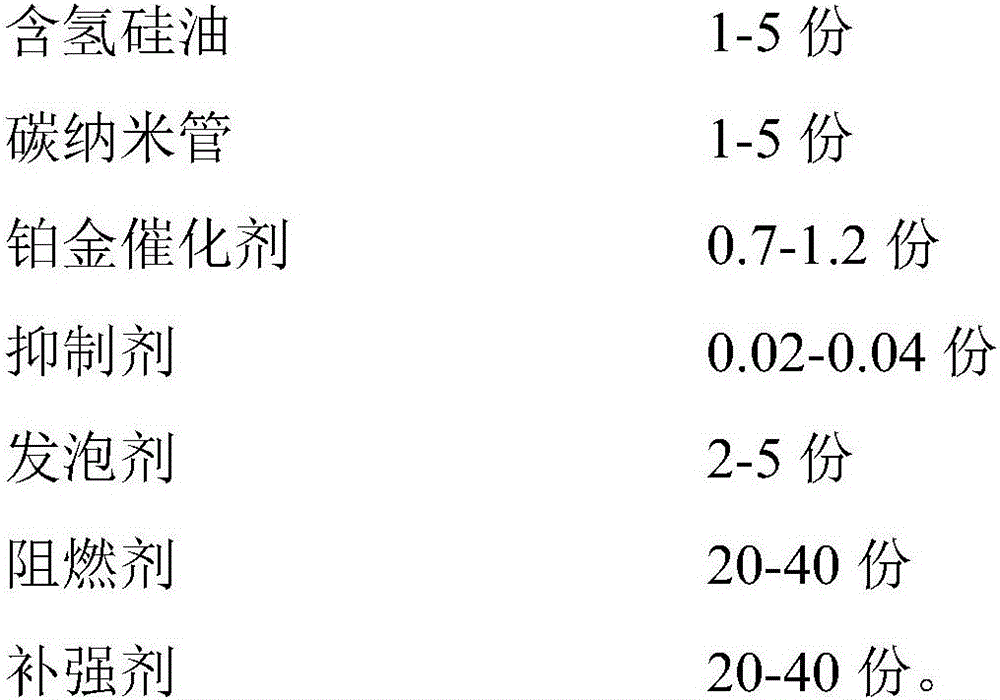

Silicone rubber foaming material and preparation method thereof

The invention relates to the technical field of silicone rubber, in particular to a silicone rubber foaming material and a preparation method thereof. The silicone rubber foaming material is prepared from the following components in parts by mass: 30 to 70 parts of liquid silicone rubber, 5 to 40 parts of methyl vinyl silicone oil, 1 to 5 parts of hydrogen-containing silicone oil, 0.5 to 1.5 parts of platinum catalyst, 0.01 to 0.05 part of inhibitor, 1 to 5 parts of foaming agent, 10 to 50 parts of flame retardant and 10 to 50 parts of reinforcing agent. The silicone rubber foaming material provided by the invention is characterized in that an Si-H bond of the hydrogen-containing silicone oil is activated by the platinum catalyst to generate a silicon hydrogenation addition reaction, so as to form an elastomer with a three-dimensional net structure, so that the silicone rubber foaming material provided by the invention has good flexibility; by adding the foaming agent, dense and uniform pores are formed inside the silicone rubber foaming material, the silicone rubber foaming material has better elasticity and smaller stress relaxation property, a sealing effect of communication equipment is guaranteed, and the maintenance cost is reduced.

Owner:昆山市硕鸿电子科技有限公司

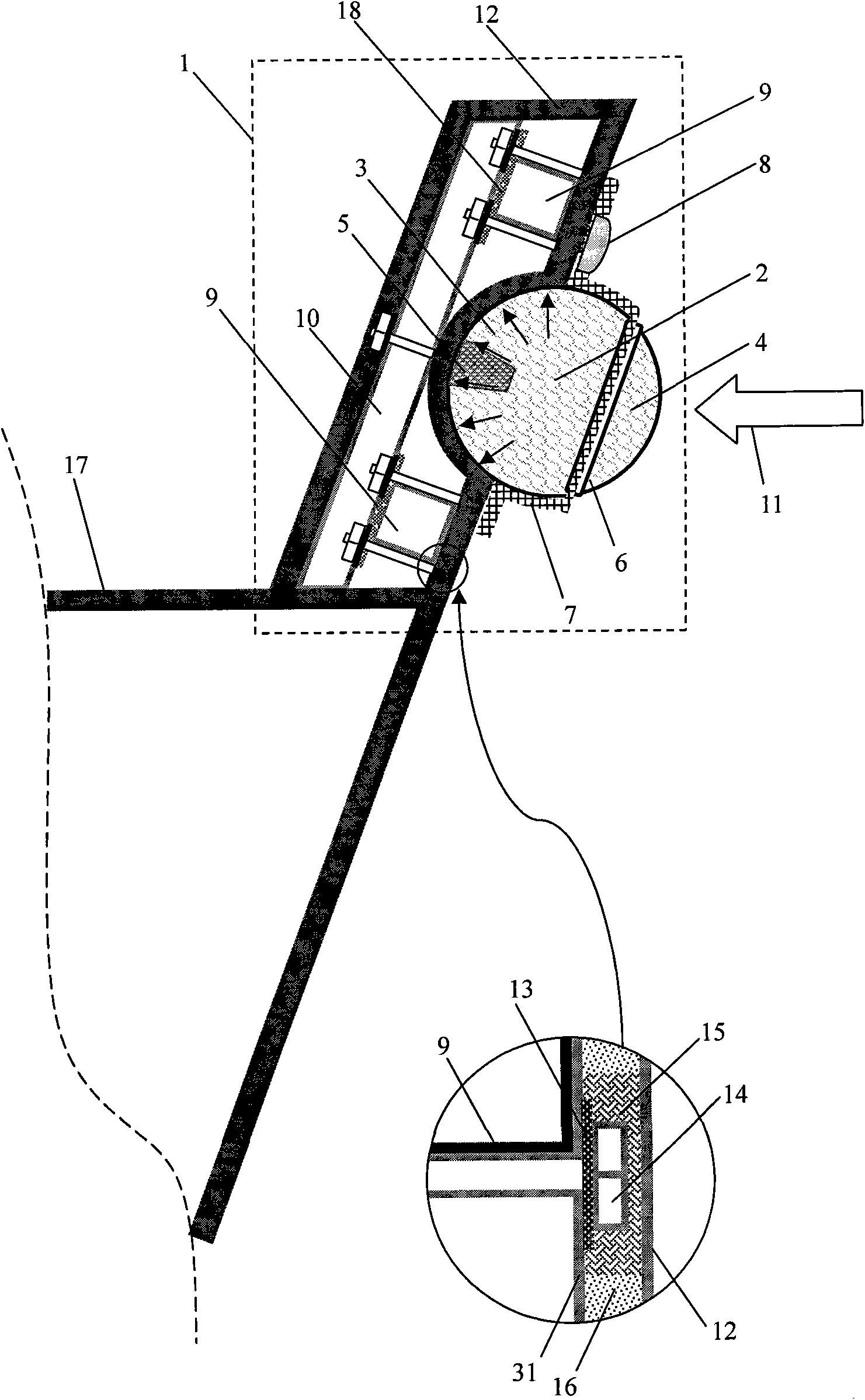

Anti-collision method of ship made of composite materials and hull structure

ActiveCN101898621AImprove protectionImprove rigidityVessel cleaningHull partsHull structureMarine engineering

The invention discloses an anti-collision method of a ship made of composite materials and a hull structure. The invention is mainly characterized in that sandwich plates (12) made of the composite materials are used as the outer walls of the hull, an integrated anti-collision bulwark (1) is adopted, the hull is in a 'cage type' structure, annular reinforced ribs are arranged on the side surfaces of the hull, and an energy-absorbing bow is adopted. The hull structure has the characteristics of light weight and high strength, and simultaneously, the overall anti-collision performance of the ship made of the composite materials is effectively improved through the comprehensive anti-collision structure design. When the ship has a collision on a front surface or a side surface, the comprehensive passive safety protection hull structure provided by the invention can effectively buffer an impact force caused by the collision of the ship, has good energy-absorbing effect and strong anti-deformation capacity, and is favorable for preventing or reducing casualties and property loss caused by the collision of the ship. The invention is especially suitable for the anti-collision design of the ship made of composite materials and has better application and popularization prospects.

Owner:SHENZHEN HISPEED BOATS TECH

Thermoplastic elastomer and its production process

InactiveCN1441003ASmall compression deformationStrong bending resistancePlasticizerThermoplastic elastomer

The thermoplastic elastomer is used in environment-protecting cable sheath. It consists of at least thermoplastic polyurethane elastomer, styrene-butadidne-methyl methacrylate copolymer, modifier, plasticizer and stuffing. It is acid resistant, alkali resistant, low temperature resistant and light and the cable and wire produced with the said elastomer has less compression deformation, high flex resistance, high oil resistance and high resilience. The elastomer may be also used in sealing stripe for automobile, tractor, door and window, various hose and other mechanical parts.

Owner:阎俊龙

Wear-resistant heat-resistant anti-aging rubber material

The invention discloses a wear-resistant heat-resistant anti-aging rubber material. The raw materials comprises the following components in parts by weight: 30-40 parts of styrene butadiene rubber, 10-18 parts of butyl rubber, 10-20 parts of chloroprene rubber, 1-3 parts of a silane coupling agent, 1.5-3 parts of LH-C96 vulcanizing agent, 0.5-1.5 parts of CZ accelerator, 2-4 parts of magnesium oxide, 5-8 parts of phenolic resin, 4.0-4.4 parts of trioctyl trimellitate, 0.3-0.5 part of paraffin, 2-4 parts of environment-friendly flame retardant FR-T801, 0.5-1.5 parts of antimony trioxide, 18-23 parts of nanometer carbon black, 15-20 parts of white carbon black, 20-30 parts of carbon black N375, 15-20 parts of modified kaolin, 2-5 parts of anti-aging agent RD and 2-4 parts of anti-aging agent 4010NA. The rubber material disclosed by the invention has the advantages of excellent abrasion resistance, heat resistance and aging resistance.

Owner:宁国日格美橡塑股份有限公司

Raw material formula of type-A automobile tire

InactiveCN103012869AImprove mechanical propertiesImprove performanceSpecial tyresStearic acidAromatic hydrocarbon

The invention relates to a raw material formula of a type-A automobile tire, and solves the problem that the physical mechanical properties of the traditional type-A automobile tire are not stable due to the raw materials. The raw material formula comprises the following raw materials by weight: 30-70 parts of NR (natural rubber), 30-70 parts of SBR (styrene butadiene rubber), 15-30 parts of N330 carbon black, 10-20 parts of N660 carbon black, 5-20 parts of sericite powder, 2-8 parts of zinc oxide, 1-5 parts of stearic acid, 0.5-2 parts of antioxidant 6PPD, 0.5-2 parts of antioxidant TMQ , 0.5-2 parts of modified wax, 1-3 parts of physical peptizer WP-1, 3-9 parts of aromatic hydrocarbon oil, 3-8 parts of hydrocarbon resin, 0.5-3 parts of sulfur, 0.5-1 part of accelerant CZ, and 0.1-0.5 part of accelerant TMTD. The formula is scientific; the proportioning is reasonable; and the raw materials are easily obtained. The type-A automobile inner tire produced by the raw material formula is stable in the physical mechanical properties; and the comprehensive performances can meet the national standards.

Owner:PRINX CHENGSHAN (SHANDONG) TIRE COMPANY LTD

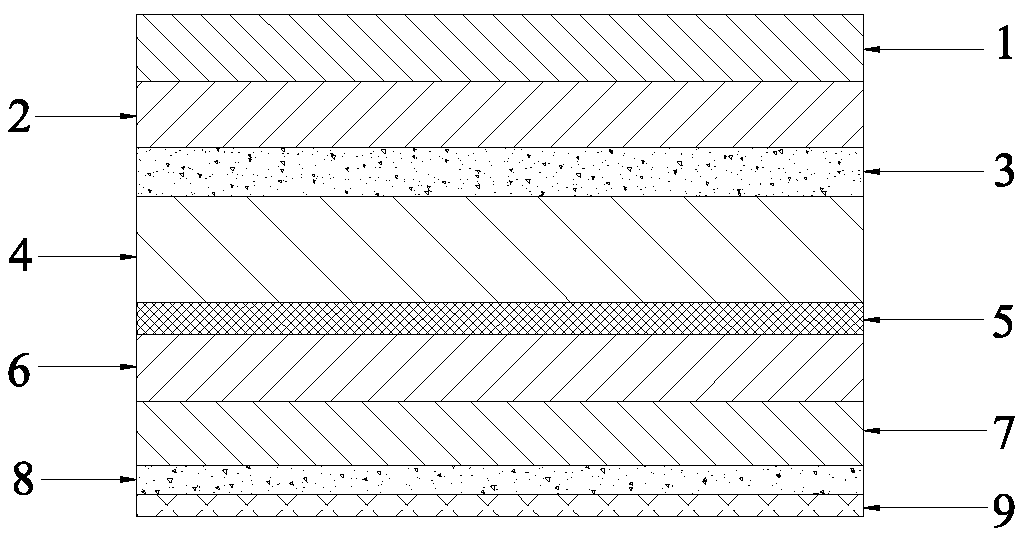

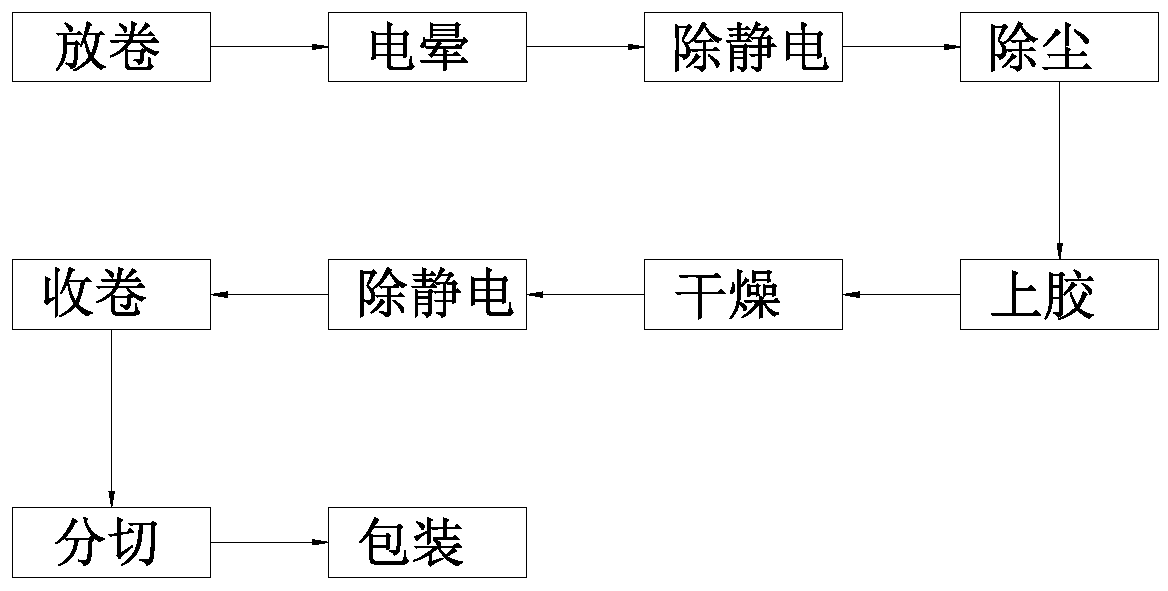

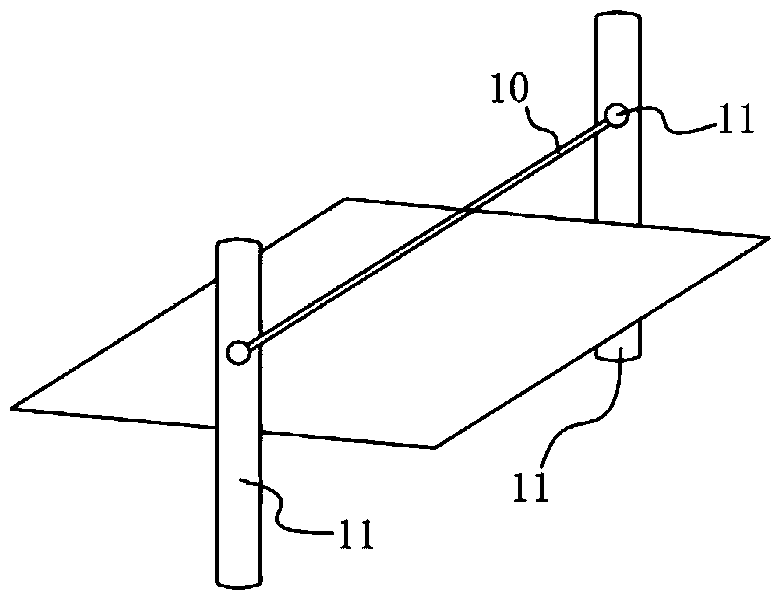

3D curved display TPU protective film and preparation method thereof

PendingCN108116020AImprove performanceImprove protectionLamination ancillary operationsSynthetic resin layered productsEngineering3d surfaces

The invention discloses a 3D curved display TPU protective film and a preparation method thereof. The 3D curved display TPU protective film comprises a matte film layer, a first OCA adhesive layer, aself-repairing layer, a TPU film layer, a prime coat layer, a second OCA adhesive layer, a transparent PET layer, a high-viscosity low-stripping silica gel layer and a fluorine film layer which are sequentially laminated from up to down. The 3D curved display TPU protective film disclosed by the invention is smart in structural design, the TPU film layer is reasonably taken as a base material, flexibility is good, and the 3D curved display TPU protective film can fit on the surface of the 3D curved display; the self-repairing layer is laminated on the TPU film layer, repairing effect is good,and service life of the 3D curved display TPU protective film is prolonged; and the overall closely fits on a 3D surface screen required to be protected, and a high-strength protective effect is achieved for the 3D surface screen. The preparation method provided by the invention is simple and brief and is easy to realize, production efficiency is high, and the 3D curved display TPU protective filmproduct with good protective effect and excellent overall performance can be rapidly produced, so that the preparation method provided by the invention is beneficial to being widely popularized and applied.

Owner:东莞市亮雅塑料制品有限公司

High-strength smoke-inhibiting high-temperature-resisting cable sheath material

ActiveCN103804808AImprove physical and mechanical propertiesGood mechanical properties and high insulation resistanceRubber insulatorsPlastic/resin/waxes insulatorsCarbon blackMagnesium

The invention discloses a high-strength smoke-inhibiting high-temperature-resisting cable sheath material. The high-strength smoke-inhibiting high-temperature-resisting cable sheath material comprises following raw materials in parts by weight: 20-35 parts of chlorosulfonated polyethylene, 20-35 parts of EVA (Ethylene Vinyl Acetate) resin, 10-15 parts of modified methyl vinyl silicone rubber, 1.5-3 parts of stearic acid, 2-5 parts of calcium carbonate, 0.3-0.8 parts of 2,4,6-tritertiary butyl phenol, 0.8-1.3 parts of an accelerant TMTD (Tetramethylthiuram Disulfide), 1.5-2.5 parts of an accelerant DM (2,2'-dibenzothiazoledisulfide), 3-13 parts of microencapsulated covered red phosphorus, 15-20 parts of cetyl trimethyl ammonium bromide modified montmorillonoid, 20-25 parts of magnesium hydroxide, 15-20 parts of aluminum hydroxide, 3.5-8.3 parts of tricresyl phosphate, 35-45 parts of high-wear-resisting carbon black and 25-32 parts of modified kaolin; the content of vinyl acetate in the EVA resin is 18-23%. The high-strength smoke-inhibiting high-temperature-resisting cable sheath material has good smoke-inhibiting and inflaming retarding effects and excellent environmental stress cracking resistance.

Owner:ANHUI HUAYUAN CABLE GROUP

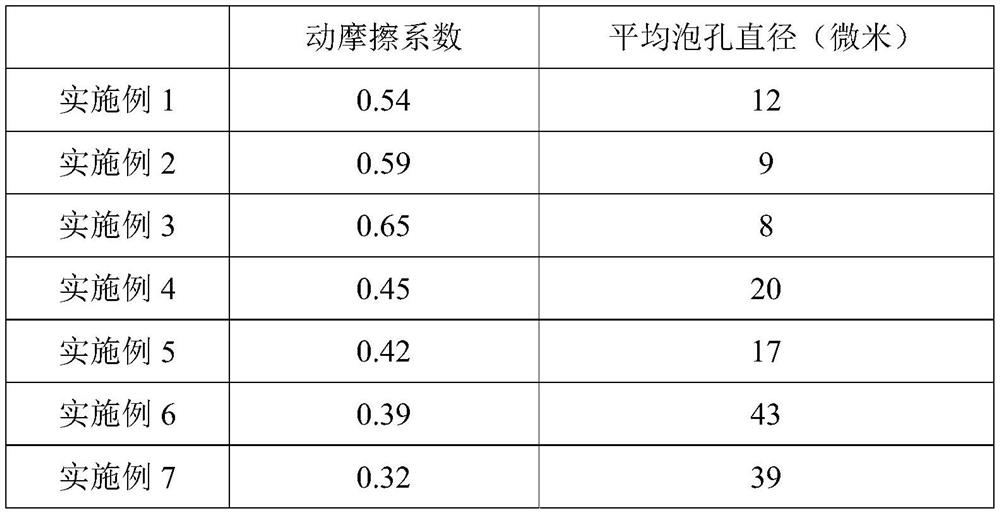

EVA/POE supercritical foaming composite shoe material and preparation method thereof

The invention belongs to the technical field of footwear products, and particularly relates to an EVA / POE supercritical foaming composite material for shoes and a preparation method thereof. The EVA / POE supercritical foaming composite shoe material in the invention at least comprises the following preparation raw materials in parts by weight: 30-40 parts of an ethylene-vinyl acetate copolymer, 20-30 parts of an ethylene-octene copolymer, 10-20 parts of a styrene-butadiene segmented copolymer, 1-3 parts of peroxide and 1.2-1.6 parts of a nucleating agent. Through a supercritical N2 foaming technology, a foaming temperature range is wide, foam holes are uniformly distributed, pore sizes are controllable, and the material has excellent mechanical properties and use performance such as light weight and high strength, and is high in tensile strength, large in elongation at break, good in tear resistance, low in density, extremely low in compression deformation and extremely good in wear resistance. The foaming process is environmentally friendly, a produced product has no odor of a foaming agent and a cross-linking agent, the same mechanical properties as the mechanical properties of achemical foaming material can be obtained, and the material has profound application prospects.

Owner:GUANGDONG GUOLI SCI & TECH CO LTD

Composite foamed shoe material formed by polyolefin and polyolefin elastomers grafted with starch in dry process

The invention provides a composite foamed shoe material formed by polyolefin and polyolefin elastomers grafted with starch in a dry process and a preparation method thereof. According to the invention, widely available and fully degradable starch is used for dry graft copolymerization with EVA resin and elastomers in an internal mixer, additives like an inorganic filler, a cross-linking agent and a foaming agent are added, and then specific process flow is employed so as to prepare the composite foamed shoe material formed by polyolefin and polyolefin elastomers grafted with starch in a dry process. The method provided by the invention can well overcome the problem of compatibility of starch with EVA resin, a solvent is not needed in the process of grafting, an obtained grafted copolymer does not need to be separated, and the method has the advantages of simple operation, convenient processing and high practicability.

Owner:福建省卓睿新材料科技有限公司

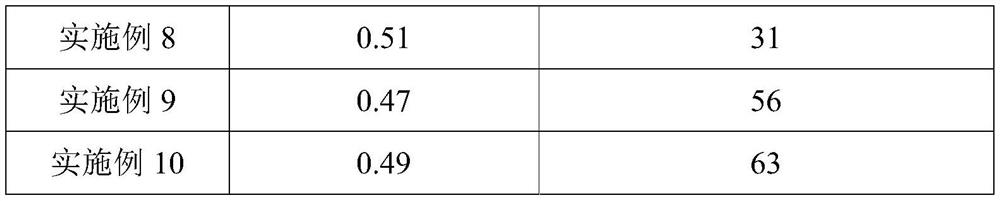

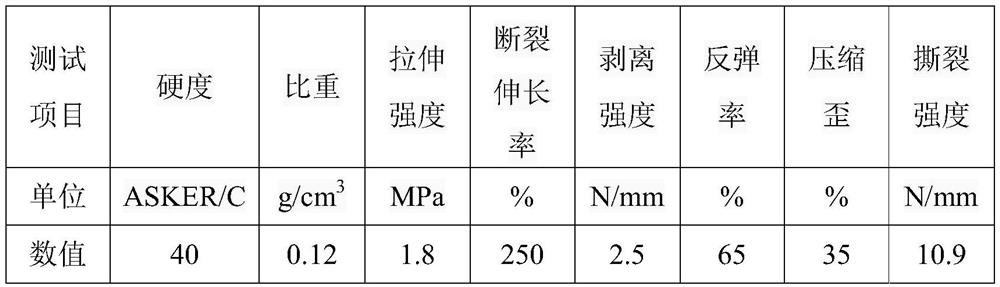

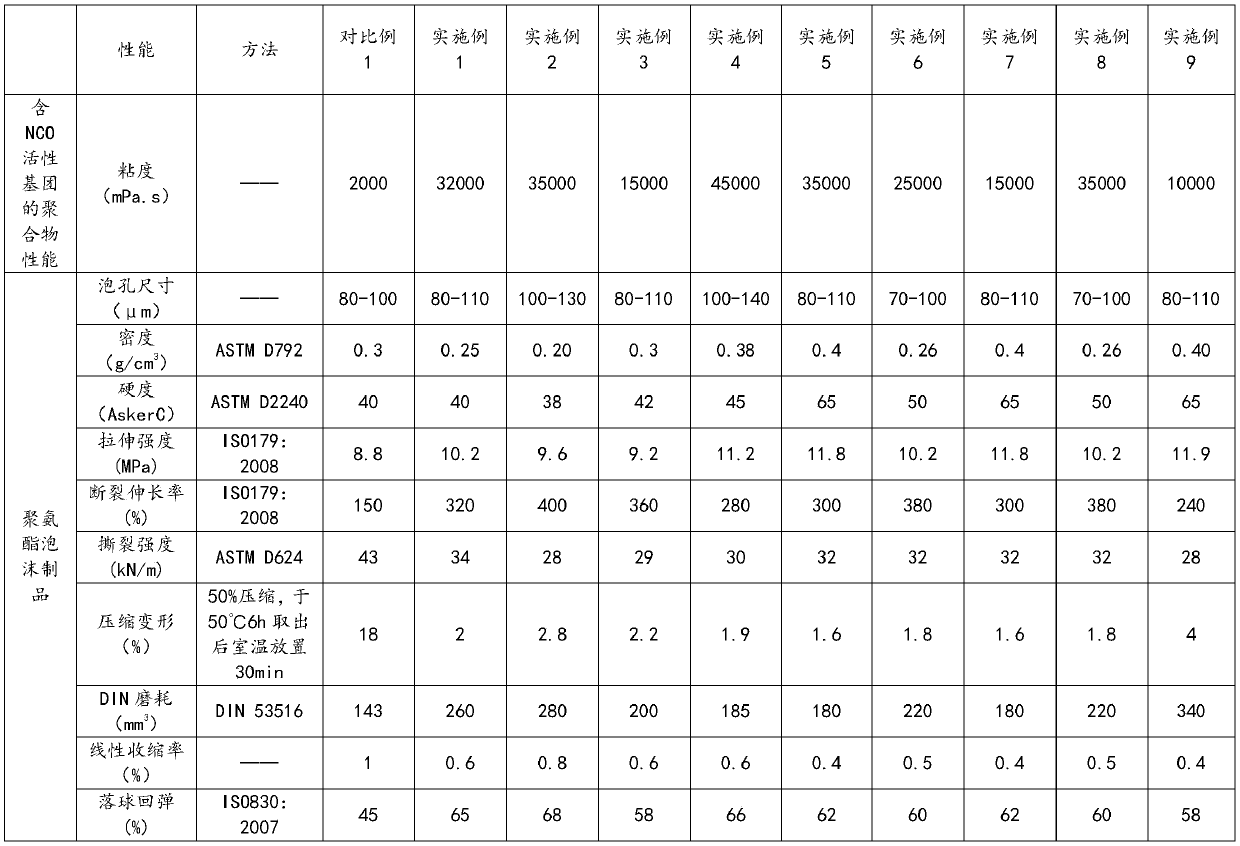

Polyurethane foam product and preparation method and application thereof

The invention relates to a polyurethane foam product and a preparation method and application thereof, and belongs to the field of polymer foam materials. The polyurethane foam product is prepared from an NCO-active-group-containing polymer and water, and the polyurethane foam product has a density of 0.08-0.8 g / cm<3> and a resiliency of 55-75%. The NCO-active-group-containing polymer is directlyreacted and foamed with the water, so that the content of allophanate groups in the prepared polyurethane foam product is high, and compared with carbamate groups formed by reacting NCO groups of a traditional polyurethane foam product with polymer polyol, the allophanate groups in the polyurethane foam product have higher polarity. Therefore, the prepared polyurethane foam product has the characteristics of low compression deformation, high resilience, excellent mechanical strength and the like.

Owner:MIRACLL CHEM

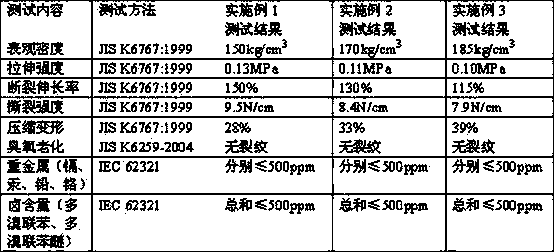

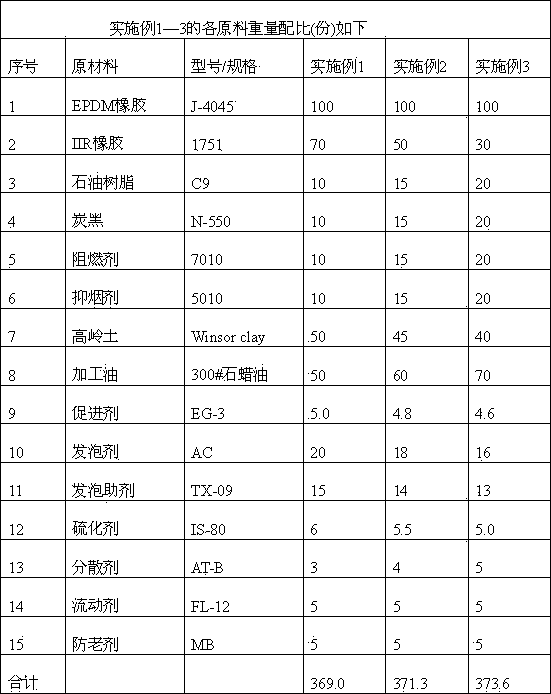

Flame-retardant and slow-rebounded ethylene-propylene-diene-terpolymer rubber porous foaming material and preparation method thereof

The invention relates to a foaming material, and in particular relates to a flame-retardant and slow-rebounded ethylene-propylene-diene-terpolymer rubber porous foaming material and a preparation method thereof. The flame-retardant and slow-rebounded ethylene-propylene-diene-terpolymer rubber porous foaming material with the characteristics of light weight, low smoke, flame retardance, strong shock absorption, small compression deformation, ageing resistance and the like is prepared in a crosslinking and foaming manner according to a proper formula and a proper process. The foaming material is widely applied to various filed of national economy such as engine sealing and shock absorption in automobile industry; leakproof sealing and wall sound absorption in construction industry; rail padding in rail transit; fin sealing in shipping industry, and the like.

Owner:YIBAO FUJIAN POLYMER MATERIALS

Silicon-free heat-conducting gasket and preparation method thereof

InactiveCN103319829AImprove heat resistanceImprove aging resistanceHeat-exchange elementsAcrylic resinPlasticizer

The invention relates to a silicon-free heat-conducting gasket and a preparation method thereof. The silicon-free heat-conducting gasket comprises the following raw materials in parts by weight: 100 parts of acrylics resin, 100-1000 parts of heat conduction powder, 10-40 parts of a plasticizer,1-10 parts of a vulcanizing agent, 0-3 parts of a scorch retarder, and 0-3 parts of pigment, the prepared silicon-free heat-conducting gasket provided by the invention has good insulativity, excellent ageing resistance property, high flexibility and good autohension, is not undergoing oil leakage even though being used for a long time, and is particularly suitable for heat conduction filling gap of a silicone oil sensitive occasion.

Owner:SHENZHEN DARBOND INTERFACE MATERIALS

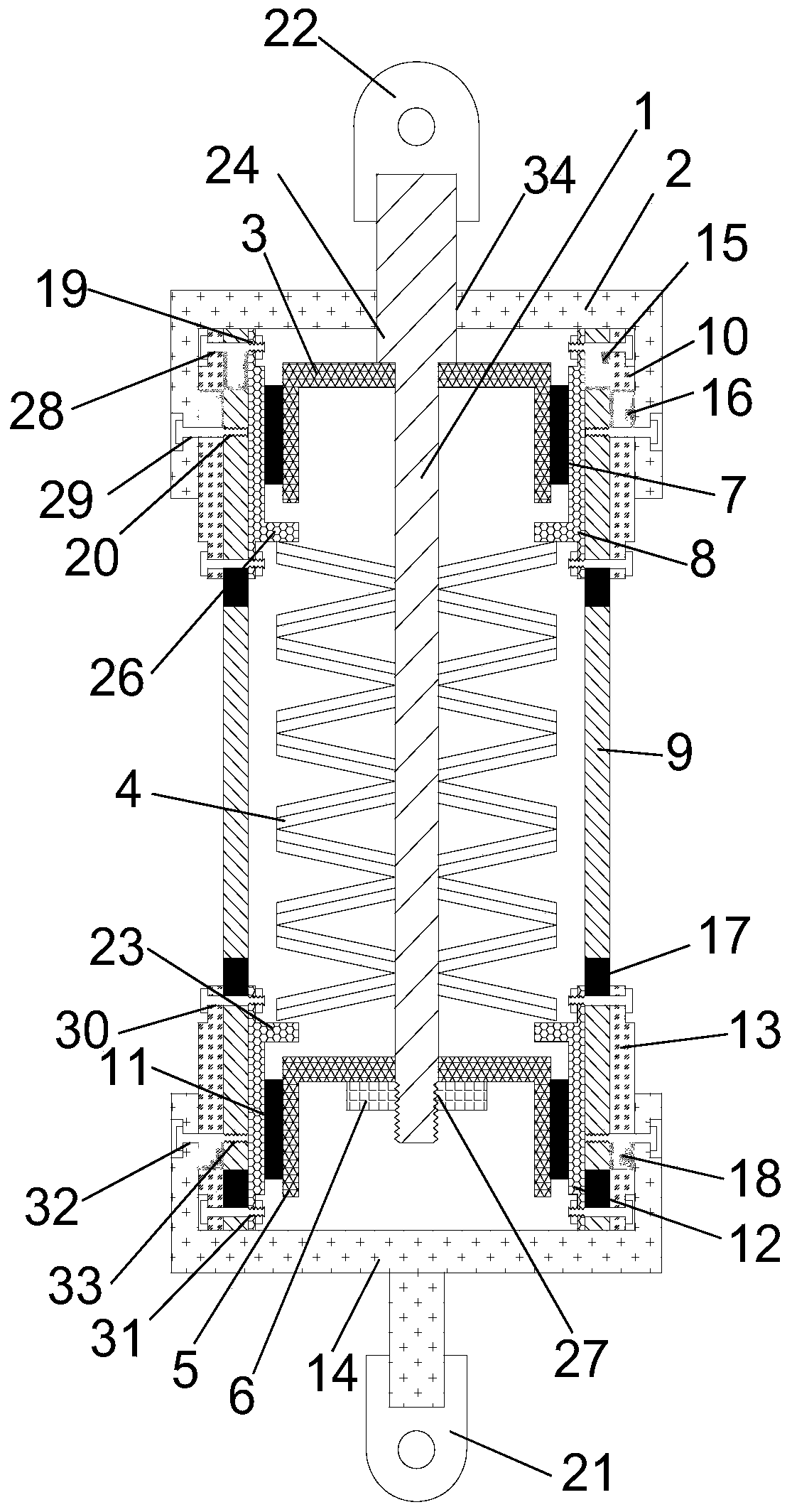

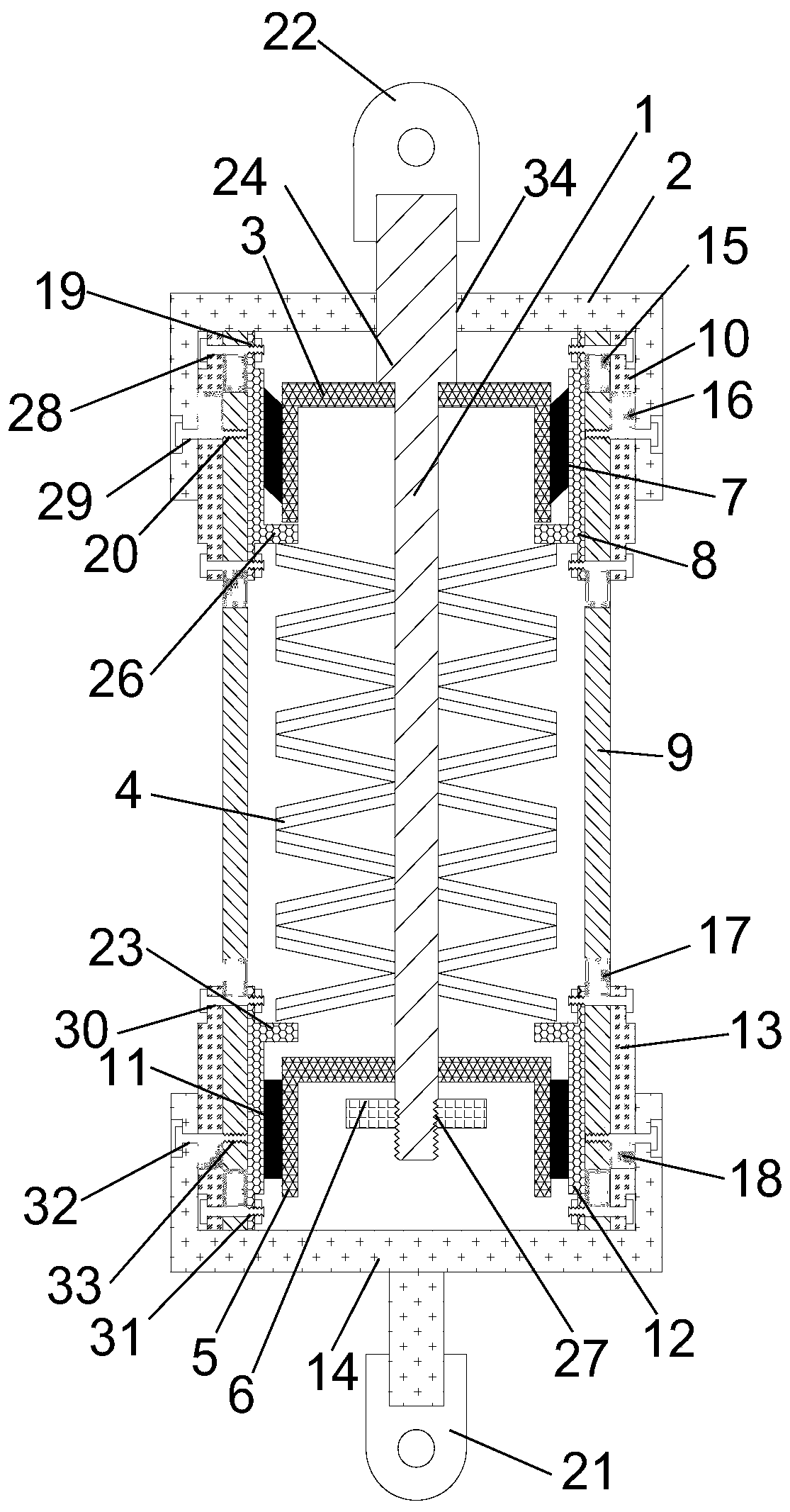

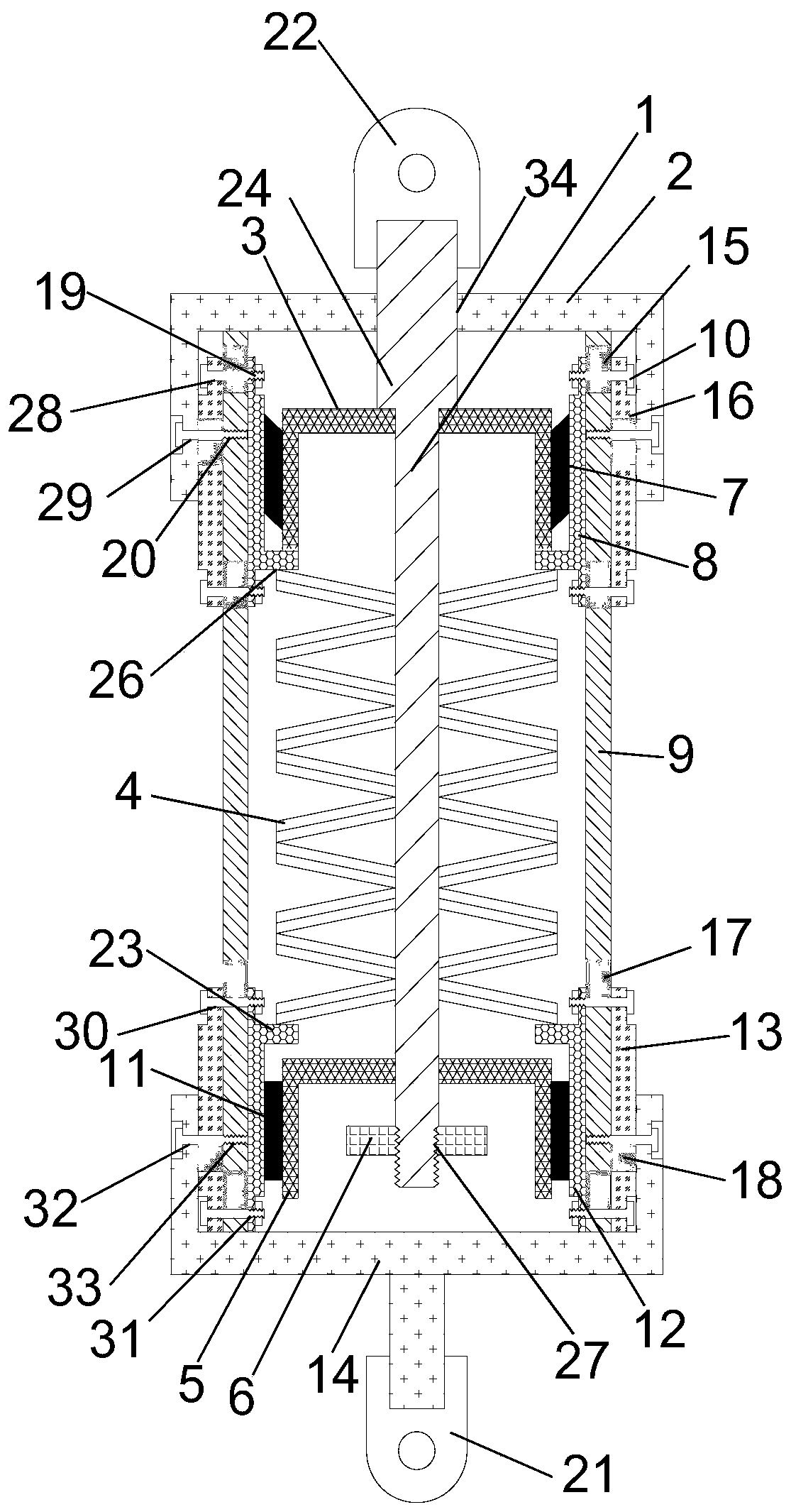

Viscoelastic friction type energy dissipation self-resetting buckling-restrained brace

PendingCN111005613AEnsure movement coordinationGuaranteed deformation coordinationProtective buildings/sheltersShock proofingEngineeringMechanical engineering

The invention provides a viscoelastic friction type energy dissipation self-resetting buckling-restrained brace. The viscoelastic friction type energy dissipation self-resetting buckling-restrained brace comprises an upper fixing cylinder, a lower fixing cylinder, fixing guide plates, a piston rod, a fixing end plate, springs, a first viscoelastic energy dissipation assembly, a second viscoelasticenergy dissipation assembly, first friction structures and second friction structures. Both ends of the fixing guide plates are separately inserted and fixed into the upper fixing cylinder and the lower fixing cylinder. The piston rod is arranged between the interior of the upper fixing cylinder and the interior of the lower fixing cylinder. The first viscoelastic energy dissipation assembly andthe second viscoelastic energy dissipation assembly separately sleeve both ends of the piston rod. The springs are arranged between the first viscoelastic energy dissipation assembly and the second viscoelastic energy dissipation assembly. The first end of the piston rod limits the first viscoelastic energy dissipation assembly, and the fixing end plate limits the second viscoelastic energy dissipation assembly. The viscoelastic friction type energy dissipation self-resetting buckling-restrained brace has self-resetting capability, can be automatically adjusted according to the brace force deformation characteristics to prevent damage to the internal components of the brace, and has stable and efficient energy dissipation capability.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

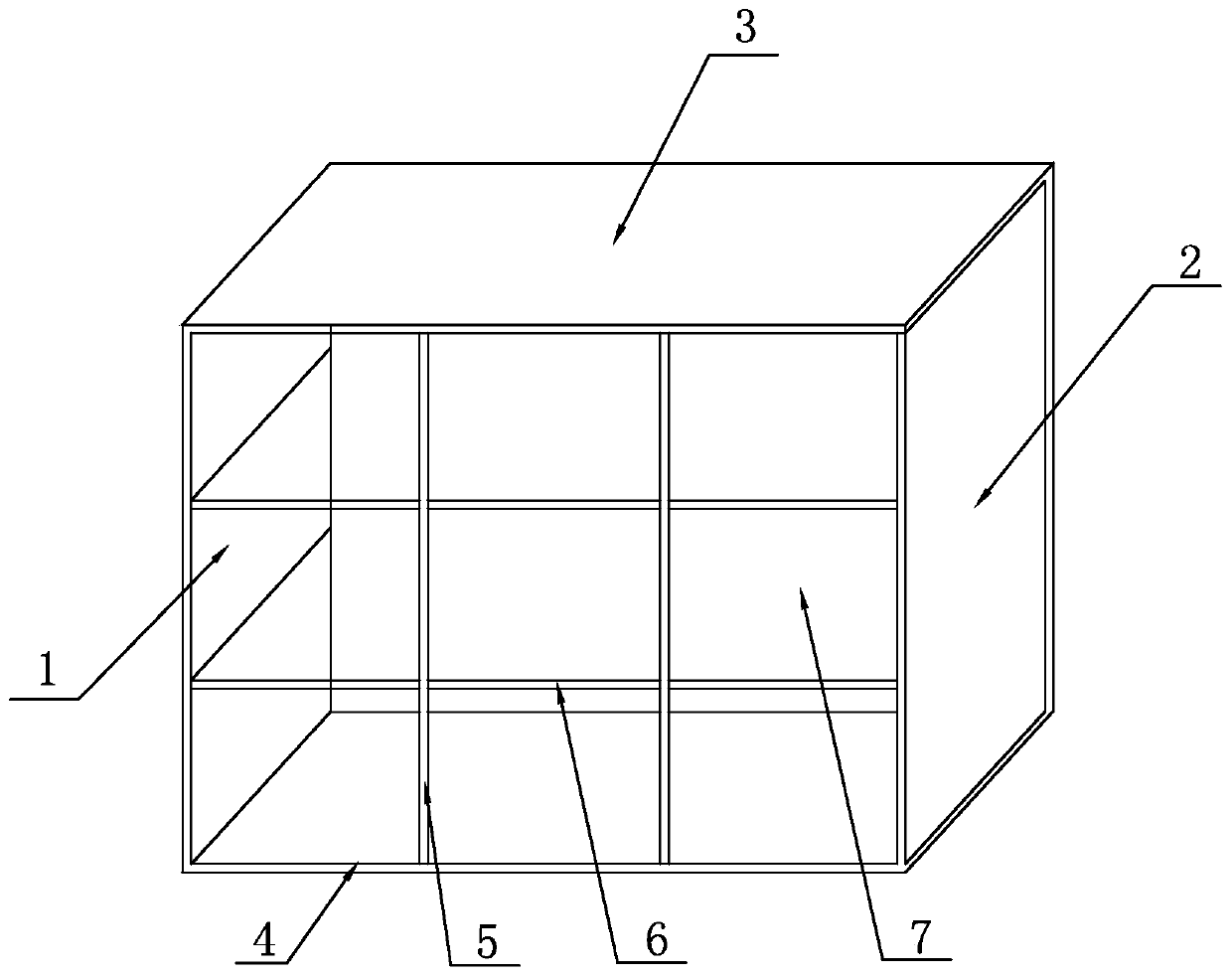

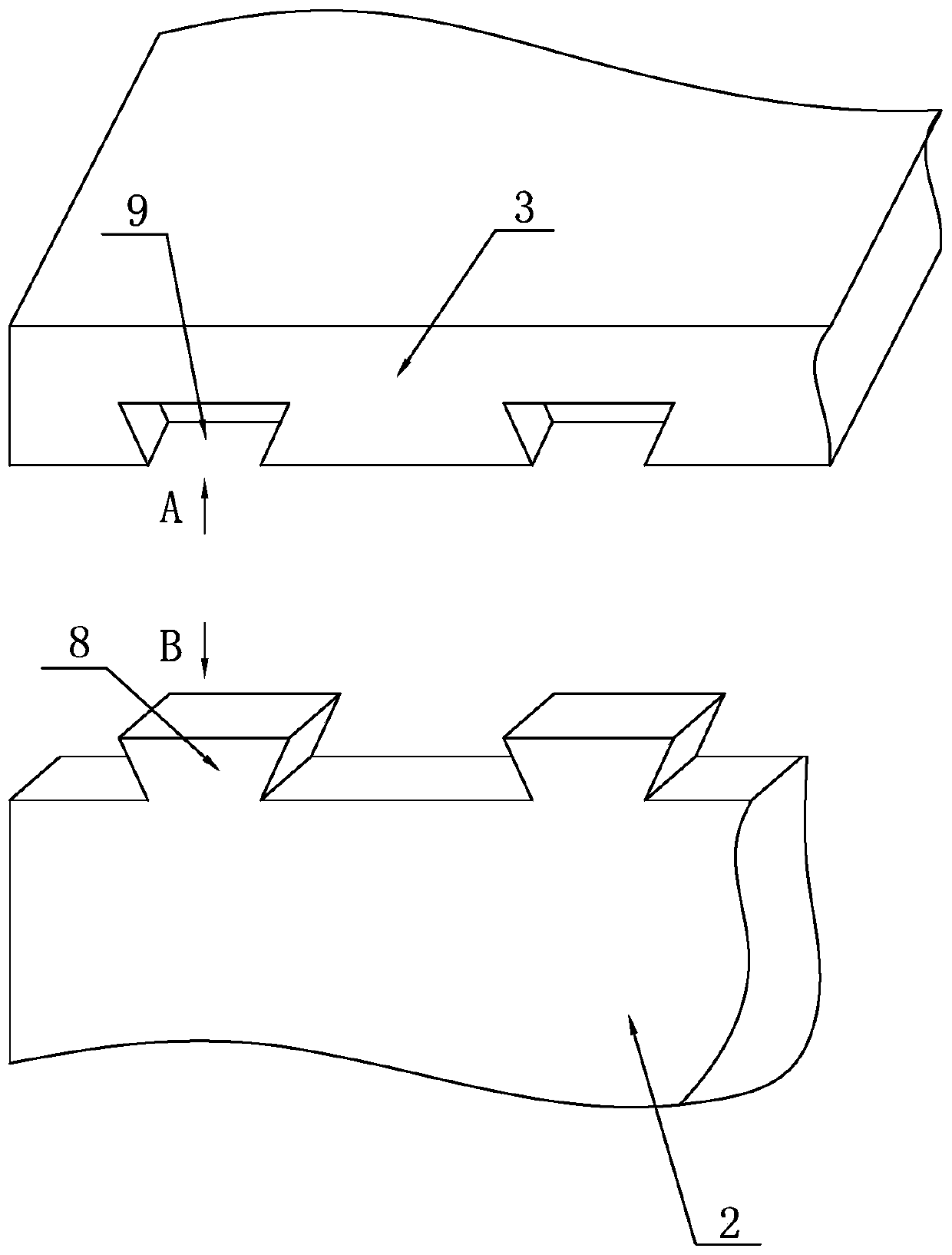

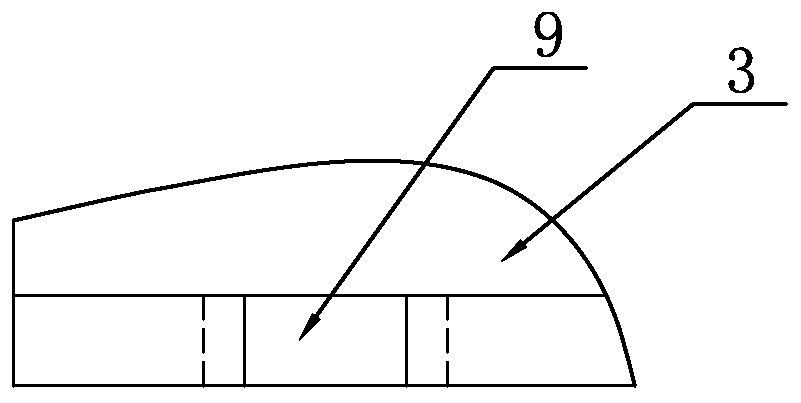

Cabinet body of plate-type mortise-tenon assembly locking structure

PendingCN109764032ASmall compression deformationEliminate gapsSheet joiningFurniture partsClamp connectionMortise and tenon

The invention provides a cabinet body of a plate-type mortise-tenon assembly locking structure. F type fixed connection among a left side plate, a right side plate, a top plate and a baseplate is achieved through mortise-tenon meshing structures, and T type fixed connection between vertical separating plates or horizontal separating plates and a frame is achieved through a seating tapering and inserting meshing structure formed by large and small head section dovetail mortises, seating grooves and tapering dovetail grooves; H type fixed connection between the horizontal separating plates and the vertical separating plates or the right and left side plates is achieved through a guide rail inserting structure; and backplane slots are formed in the same plane of the back sides of the left side plate, the right side plate and the baseplate of the frame, and a backplane is inserted into the backplane slots. A dovetail tenon is designed as a bidirectional trapezoidal cube structure; not onlycan the mortise-tenon joint is achieved, but also the installation and removal resistance can be reduced; the installation and removal are convenient, and a clearance of clamping connection between two plates can be removed; shaking is eliminated, and the stability is high; and the accuracy after repeated installation and removal is improved.

Owner:陈国华

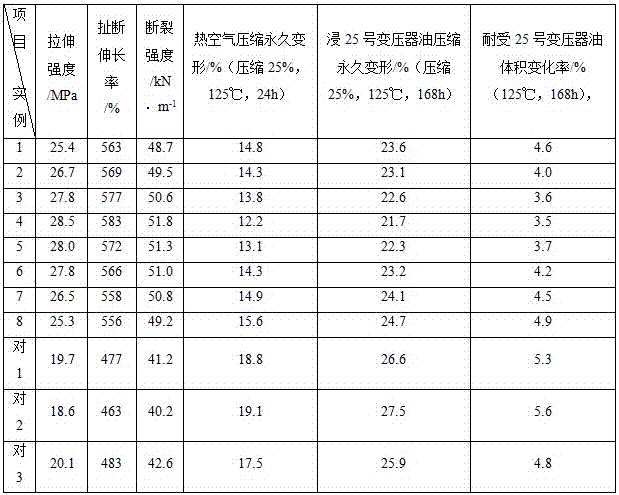

Rubber material for sealing ring of transformer and preparation method of rubber material

ActiveCN106883472AGood oil resistanceImprove wear resistanceBuilding insulationsRubber materialCross-link

The invention belongs to the technical field of sealing materials and particularly relates to a rubber material for a sealing ring of a transformer and a preparation method of the rubber material. The rubber material is prepared from the following raw material in parts by weight: 50-70 parts of nitrile rubber, 20-30 parts of acrylic rubber, 5-10 parts of epichlorohydrin rubber, 3-8 parts of wood fibers, 5-10 parts of nanometer titania, 15-25 parts of a fortifier, 1-5 parts of an anti-aging agent, 1-3 parts of an accelerate, 1-3 parts of sulfur, 3-6 parts of zinc oxide, 4-8 parts of stearic acid, 3-6 parts of asphalt, 1-3 parts of chlorinated paraffin, 10-15 parts of a plasticizer and 5-15 parts of a cross-linking agent. The rubber material for the sealing ring of the transformer is high in strength, small in compressive deformation and excellent in anti-aging performance.

Owner:国网河南省电力公司方城县供电公司

Anti-aging and wear-resistant rubber material for tire

The invention discloses an anti-aging and wear-resistant rubber material for a tire. The anti-aging and wear-resistant rubber material for the tire is prepared from, by weight, 15-35 parts of natural rubber, 25-35 parts of 320 type chloroprene rubber, 25-35 parts of neoprene, 20-50 parts of modified kaolinite, 0.5-1.5 parts of 616 antiager, 0.2-0.8 part of phosphite, 0.5-1.2 parts of tetramethyl thiuram disulfide, 0.5-1.5 parts of zinc oxide, 1-3 parts of magnesium oxide, 5-15 parts of pumice, 10-18 parts of zinc borate, 1-2 parts of aluminum borate whiskers, 12-18 parts of sodium antimonite, 5-15 parts of aluminum phosphate, 10-20 parts of carbon black, 0.2-0.8 part of polyepoxy soybean oil, 0.1-0.9 part of hydroxyl silicone oil, 1-2 parts of white oil, 1-3 parts of pine tar, 0.2-0.8 part of fatty acid, 0.5-1.5 part of stearic acid and 1-2 parts of 3-aminopropyltrimethoxysilane. The anti-aging and wear-resistant rubber material for the tire is good in wear-resistant and anti-tear performance and excellent in anti-aging performance.

Owner:DELUN RUBBER

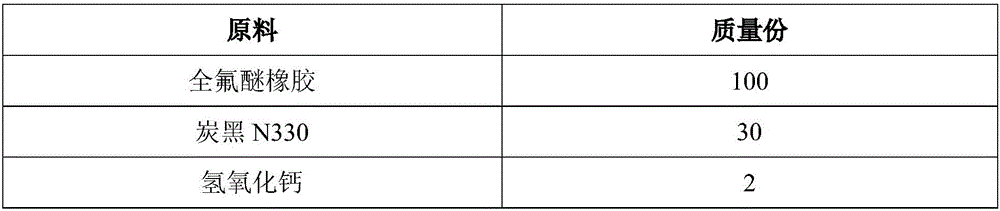

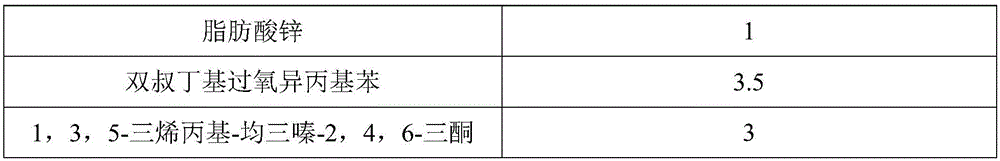

Anti-knock rubber O-ring material and preparation method thereof

The invention discloses an anti-knock rubber O-ring material and a preparation method thereof. The anti-knock rubber O-ring material is composed of the following raw materials in parts by mass: 100 parts of virgin rubber, 15-90 parts of reinforcing agent, 0.5-10 parts of acid acceptor, 0.5-4 parts of processing aid, 0.6-4 parts of vulcanizing agent and 1-6 parts of bridging aid. The preparation method comprises the following steps: adding the virgin rubber into an open mill or Banbury mixer, plasticizing, and adding the premixed reinforcing agent, acid acceptor and processing aid; after the powder is wetted, adding the vulcanizing agent and bridging aid, carrying out compounding and thin passing uniformly, discharging, and cooling to obtain the anti-knock rubber O-ring material. The anti-knock rubber O-ring material has the advantages of high hardness, high strength, high modulus, high tear resistance, excellent dispersity and the like. The O-ring prepared from the material has excellent anti-knock property, and can reach Grade 0000-1111 in NORSOK M-710 in an RGD test; and the compression deformation is small.

Owner:GUANGZHOU JST SEALS TECH

Modified ethylene-propylene-diene monomer rubber material and preparation method thereof

The invention provides a modified ethylene-propylene-diene monomer rubber material and a preparation method thereof. The material is prepared from the following raw materials in parts by weight: 40 to 80 parts of ethylene-propylene-diene monomer rubber, 15 to 30 parts of butyronitrile rubber, 18 to 25 parts of natural rubber, 10 to 20 parts of methyl vinyl silicone rubber, 12 to 18 parts of butadiene rubber, 8 to 15 parts of nano calcium carbonate, 7 to 13 parts of nano silicon dioxide, 5 to 10 parts of nano carbon black, 6 to 18 parts of nano graphene, 5 to 12 parts of nano fibers, and 3 to 8 parts of nano montmorillonite. The preparation method of the modified ethylene-propylene-diene monomer rubber material comprises the following steps: firstly, preparing a rubber compound; then carrying out surface modification on an auxiliary nano-material by adopting an intercalating agent, and then blending the auxiliary nano-material subjected to surface modification with a rubber composite material to enable the auxiliary nano-material to be dispersed into the rubber composite material so as to enhance acting force of auxiliary filler and an interface of a rubber compound. The material prepared by the invention is excellent in performance, and is suitable for a rubber material for a robot vacuum suction cup, so that the working efficiency of a robot under different working environments is improved and the service life of the robot is prolonged.

Owner:苏州世伟恩半导体科技有限公司

Chlorinated polyethylene cable sheath for coal mine

InactiveCN104788834AInhibition of lysisImprove liquidityPlastic/resin/waxes insulatorsInsulated cablesMethacrylatePolymer science

The invention discloses a chlorinated polyethylene cable sheath for a coal mine. The chlorinated polyethylene cable sheath comprises the following raw materials by weight: 100 parts of chlorinated polyethylene 135B, 3 to 5 parts of a vulcanizing agent 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, 1 to 1.5 parts of a co-vulcanizing agent trimethylol trimethacrylate, 3 to 5 parts of a calcium-zinc stabilizing agent, 10 to 15 parts of precipitated white carbon black, 20 to 30 parts of potter's clay, 3 to 4 parts of oxidized polyethlene wax, 8 to 12 parts of magnesium oxide, 2 to 5 parts of chlorinated paraffin, 15 to 20 parts of magnesium hydroxide, 1 to 3 parts of tritolyl phosphate, 1.2 to 1.3 parts of an auxiliary crosslinking agent TAIC, 2 to 5 parts of paraffin, 20 to 30 parts of powdered steatile and 50 to 60 parts of nanometer kaolin. The chlorinated polyethylene cable sheath provided by the invention has excellent heat resistance and flame retardation performance, high hardness, good resilience and small permanent compression set.

Owner:ANHUI TIANCAI CABLE GRP

Horizontal top pipe ground treatment construction method

ActiveCN101280565ASmall compression deformationImprove carrying capacityBulkheads/pilesBasementDeformation modulus

Disclosed is a method for processing horizontal pipe jacking foundation, which adopts the measures of digging well, determining the jacking points of the pipe jacking and the axes of the pipe jacking, installing guide rails, selecting oil cylinders, grouting, detecting, etc. The method has the advantages that: when the construction of the upper structure is finished and the surrounding buildings are too dense to have the conditions of construction sites, the horizontal pipe jacking method can be adopted to avoid the disadvantages. The method implants steel pipes with high deformation modulus on the basis of the existing buildings to form a horizontal enhanced body and ensures that the soil and the reinforcement materials are integrated by making use of the friction force generated between the foundation soil and the tie bars (steel pipes) so as to reduce global deformation and enhance overall stability; meanwhile, cantilever parts at the two ends can extend the foundation area of buildings and reduce basement additional pressure. A composite foundation is formed by pressure grouting towards the surrounding foundation soil by the steel pipes implanted, thereby improving the bearing capacity of the foundation soil, reducing the compression deformation of the foundation soil and fulfilling the purpose of improving the performance of the foundation soil under the basement.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

Environment-friendly high-cushioning polyurethane packaging material

ActiveCN104774304BImprove buffering effectSolve environmental problemsEnvironmental resistanceOzone layer

The invention discloses an environment-friendly high-buffering-property polyurethane packaging material. The packaging material is formed by mixing a combined polyether raw material and polymethylene polyphenyl isocyanate, wherein the combined polyether raw material is composed of, by proportion, 40-45 parts of polyether trihydric alcohol, 30-40 parts of polyether glycol, 3-8 parts of chain extenders, 2-5 parts of foam stabilizers, 20-30 parts of water, 0.3-0.6 part of dimethylamino ethylether and 0.3-0.5 part of triethylene diamine. The proportion of the polymethylene polyphenyl isocyanate to the combined polyether raw material is 0.8-1.0:1. The material has a good buffering property, the buffering property is three times that of a general foaming material, and the material has good elasticity, and can be used repeatedly, and foamed and formed into the packaging material anytime and anywhere within a short time; as the water is used for replacing other foaming agents, intensity is low, the production cost is reduced, substances damaging an ozone layer are avoided, pollution is really reduced, and the environment-friendly effect of the foaming agent is completely achieved.

Owner:河南铎润新材料有限公司

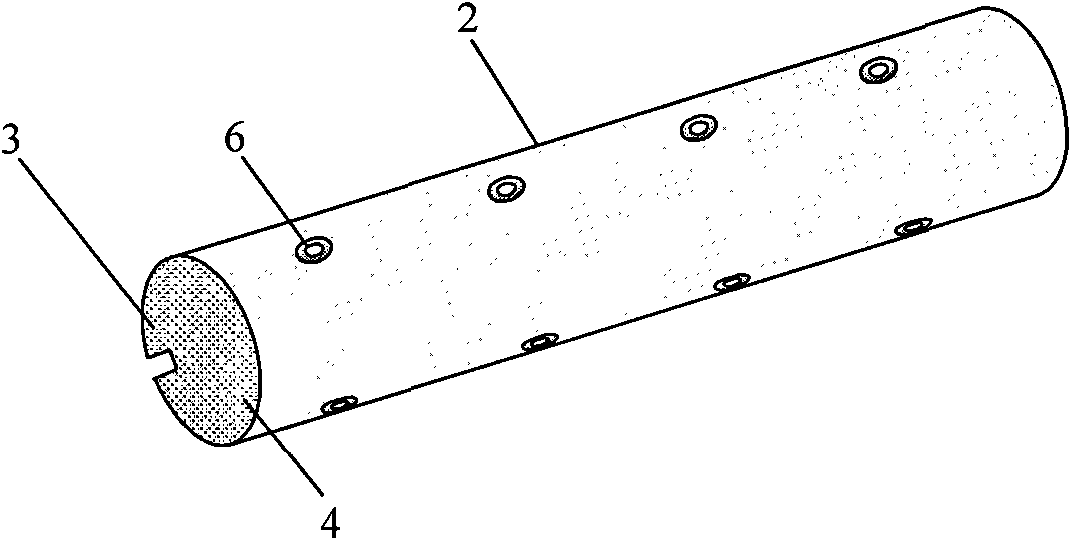

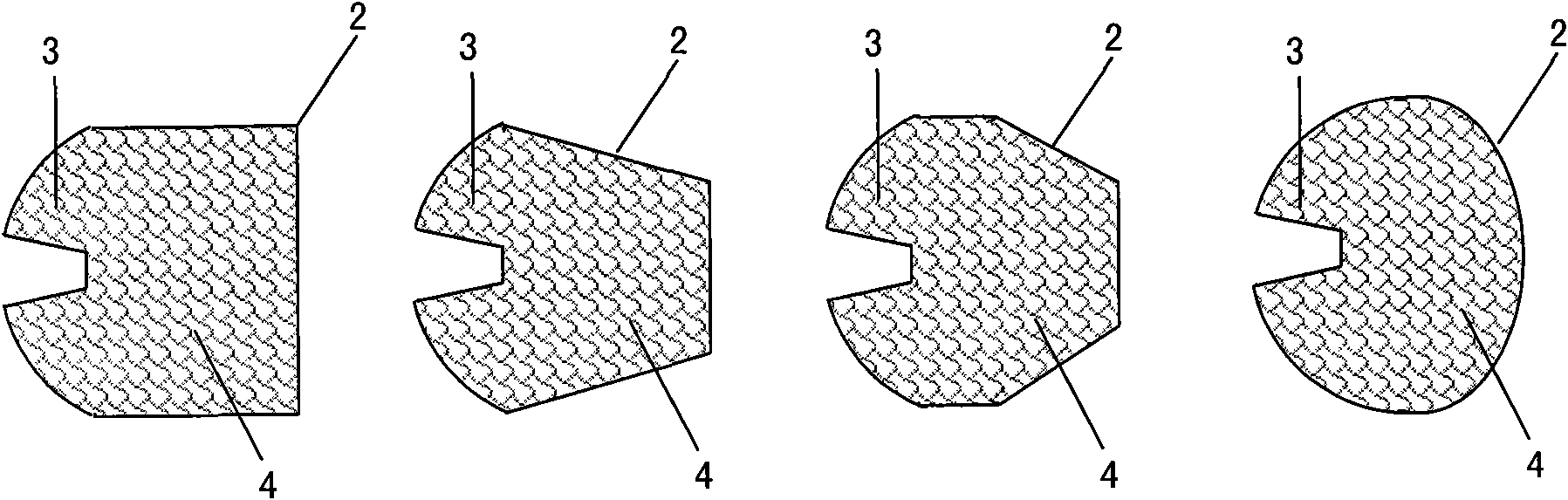

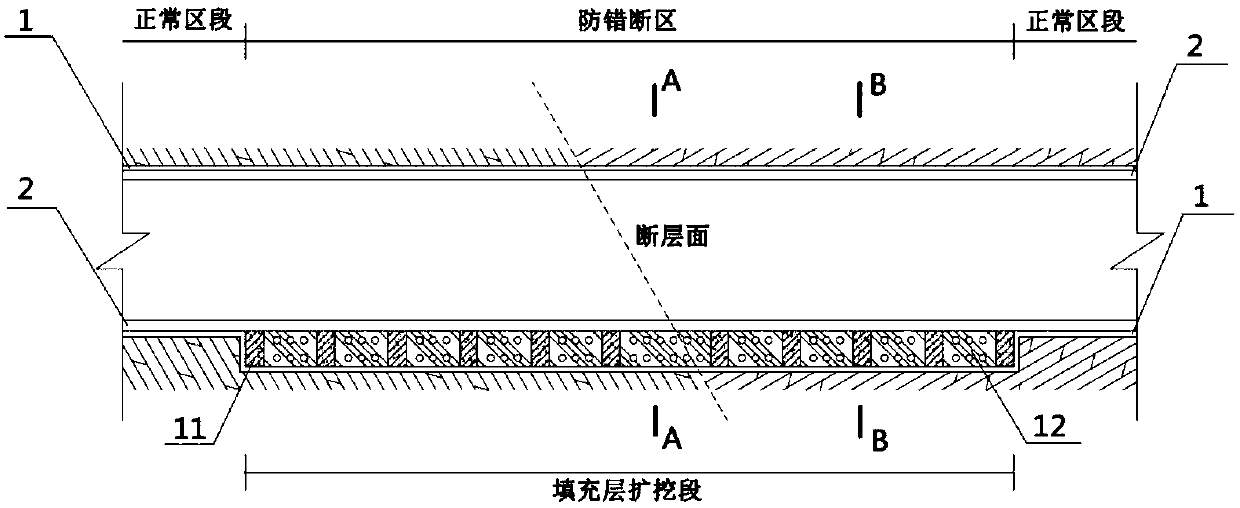

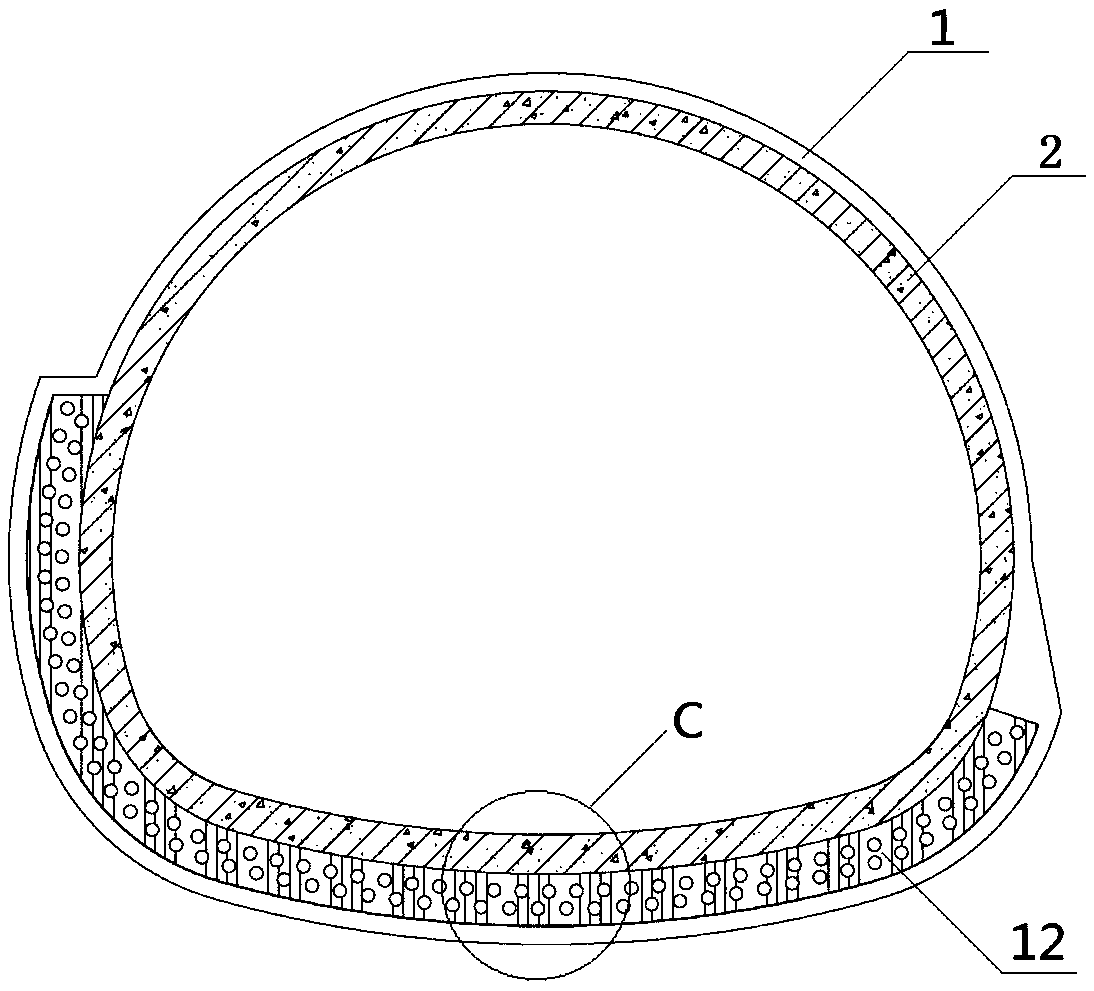

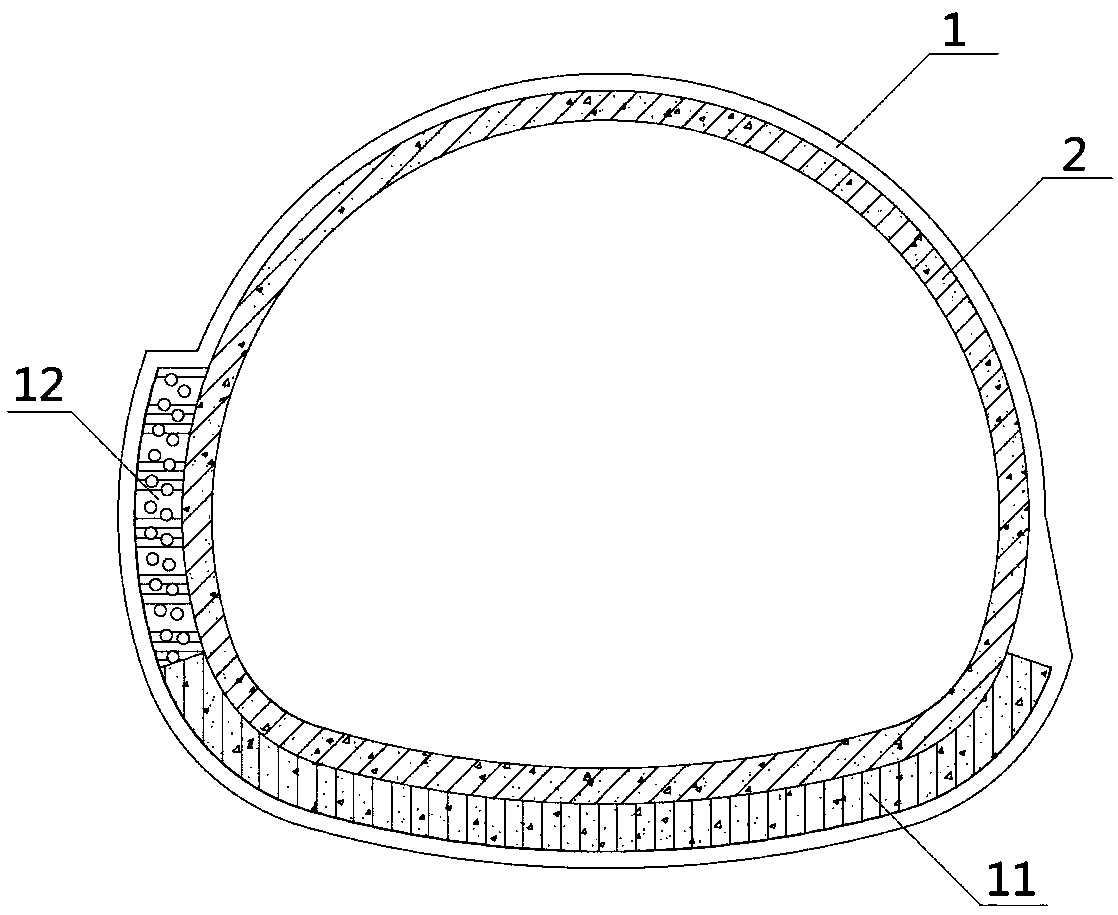

Self-adaptive structure for displacement of tunnel by active fault sectional mining method and installation method

PendingCN109681231AAvoid mistakesReduce the amount of structural misalignmentGeometric CADUnderground chambersActive faultShotcrete

The invention discloses a self-adaptive structure for displacement of a tunnel by an active fault sectional mining method. An anti-offset area is arranged at a section, longitudinally crossing the active fault, of the tunnel, and comprises sprayed concrete (1), secondary lining (2) and a filling layer, wherein the filling layer is arranged between the sprayed concrete (1) and the secondary lining(2) and is of a half-coating structure; the filling layer comprises a bottom filling section and side filling sections, the bottom filling section is arranged at the bottom part of the tunnel, and theside filling sections are arranged at the side edges of the tunnel; porous rubber (12) is filled into each side filling section, a plurality of support piers (11) are arranged in the bottom filling section at intervals, the porous rubber (12) is arranged between the adjacent support piers (11), and the porous rubber (12) is of a pre-compressed structure. The invention also discloses an installation method of the self-adaptive structure for displacement of the tunnel by the active fault sectional mining method. The displacement self-adaptive structure provides by the invention provides supportfor the tunnel structure, and is capable of reducing the offsetting quantity of the structure.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com