Patents

Literature

66results about How to "Inhibition of lysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for preparing propylene by propane dehydrogenation and its prepn.

InactiveCN101015802AHigh selectivityImprove reaction stabilityCatalyst carriersHydrocarbonsAdhesiveDehydrogenation

The invention relates to a catalyst for dehydrogenating propane to prepare propone, which uses thermal-resistant oxide as carrier, uses palladium-group metal as main catalyst, uses IV A group metal and rare-earth metal as agents, uses halogen as modifier, and uses inorganic oxide with high temperature resistance as adhesive. The inventive catalyst under high temperature and low pressure has higher propane transfer rate, propone selectivity and reaction stability. And the preparation comprises that at 60-100Deg. C, immerging thermal-resistant oxide with rare-earth metal water solution for 2-10h, at 60-180Deg. C baking for 2-10h, at 400-600Deg. C baking for 3-10h, immerging said carrier and the water solution which contains palladium metal and IVA metal at 60-100Deg. C for 2-10h, and baking for 2-10h at 60-180Deg. C, adding adhesive, protruding agent and acid gel solvent, protruding and shaping, baking for 2-10h at 60-180Deg. C, activating for 3-10h at 400-600Deg. C, and reducing for 2-10h in hydrogen flow at 400-600Deg. C.

Owner:SOUTHEAST UNIV

Propane dehydrogenation catalyst with hetero atom molecule sieve as carrier and preparation method thereof

InactiveCN101513613AEnhanced interactionPromote migrationMolecular sieve catalystsCatalyst activation/preparationMolecular sievePtru catalyst

The invention relates to a propane dehydrogenation catalyst with a hetero atom molecule sieve as a carrier. The hetero atom molecule sieve carrier for preparing the catalyst is a ZSM-5 molecule sieve with the skeleton containing metallic elements of the fourth A group and rare earth elements. The catalyst is shaped by taking metallic elements of platinum group as a main catalyst, taking metallic elements of the fourth A group or the metallic elements of the forth A group or the second A group as an assistant, taking halogen elements as a modifying agent, and taking inorganic oxides as a bonder. The preparation of the catalyst adopts a step impregnation method, that is, the method comprises the steps of firstly impregnating the alkaline metal assistant so as to effectively adjust the acidity and alkaline of the catalyst and the variety of positive ions in the pore path of the molecule sieve by cation interchange technology; and then impregnating the metallic elements of platinum group. The catalyst has excellent anti-carbon performance, and higher propane utilization rate, propane selectivity and reaction reliability at the reaction conditions of high temperature and low pressure.

Owner:NANJING JINLIAN TECH +1

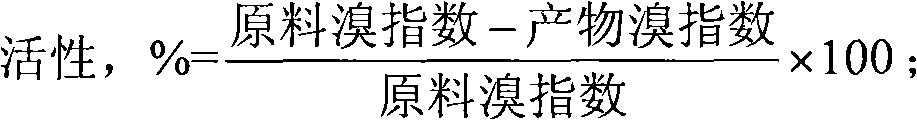

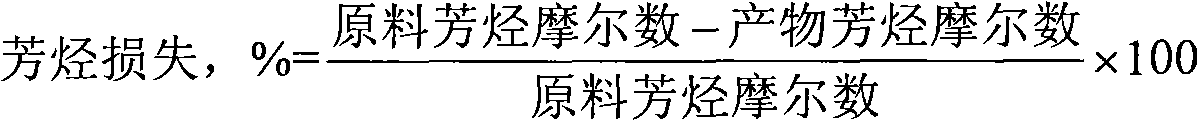

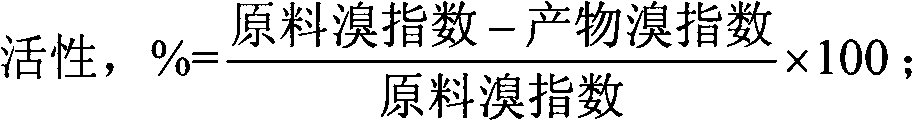

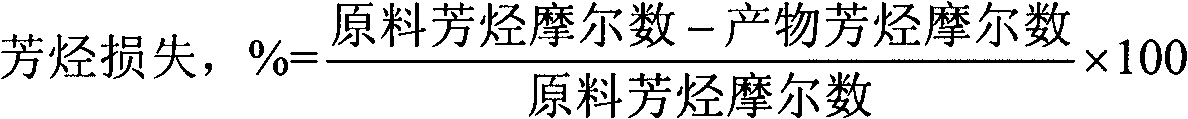

Reformate deolefination method without hydrogen

ActiveCN102041035AHigh catalytic activityImprove catalytic stabilityMolecular sieve catalystsRefining with metal oxidesMolecular sieveAlkyl transfer

The invention relates to a reformate deolefination method without hydrogen, which is mainly used for solving the problems in the prior art that deolefination refining agent is low in activity, short in service life and great in aromatic hydrocarbon loss. The technical scheme adopted by the invention is as follows: olefins in reformate are removed because of polymerization or alkylation reaction carried out on a catalyst for 0.3-20h<-1> at the temperature of 120-240 DEG C and under the pressure of 0.5-3.0 MPa, wherein the catalyst contains 0.1-10 parts by weight of at least one metal or oxide thereof selected from Ni, MO, Zr, and Nb, 0.01-2.00 parts by weight of at least one element or oxide thereof selected from Cl, Br and S, 0.05-5 parts by weight of at least one element or oxide thereofselected from F and P, 20-90 parts by weight of molecular sieve and 10-80 parts by weight of at least one selected from SiO2 and Al2O3 or a mixture thereof, thus the problems in the prior art are solved. The method can be used for industrial production of olefin reduction in reformate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Propane dehydrogenation catalyst containing V and preparation method thereof

ActiveCN103785388AGood dispersionHigh selectivityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsActive componentDehydrogenation

The invention discloses a propane dehydrogenation catalyst, which employs silica as a carrier, Pt as a dehydrogenation active component, and Sn and V as auxiliary agents. The catalyst comprises, by weight, 0.1-2% preferably 0.2-0.8%, of dehydrogenation active component, and comprises, calculated by the weight of the carrier, 0.1-10% preferably 1-5%, of the auxiliary agent Sn, and 0.1-10% preferably 1-5% of the auxiliary agent V. A preparation method of the propane dehydrogenation catalyst is by loading auxiliary agents Sn and V and the active component Pt by using silica gel as a carrier through an impregnation method. The method can substantially increase the activity stability and olefin selectivity of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

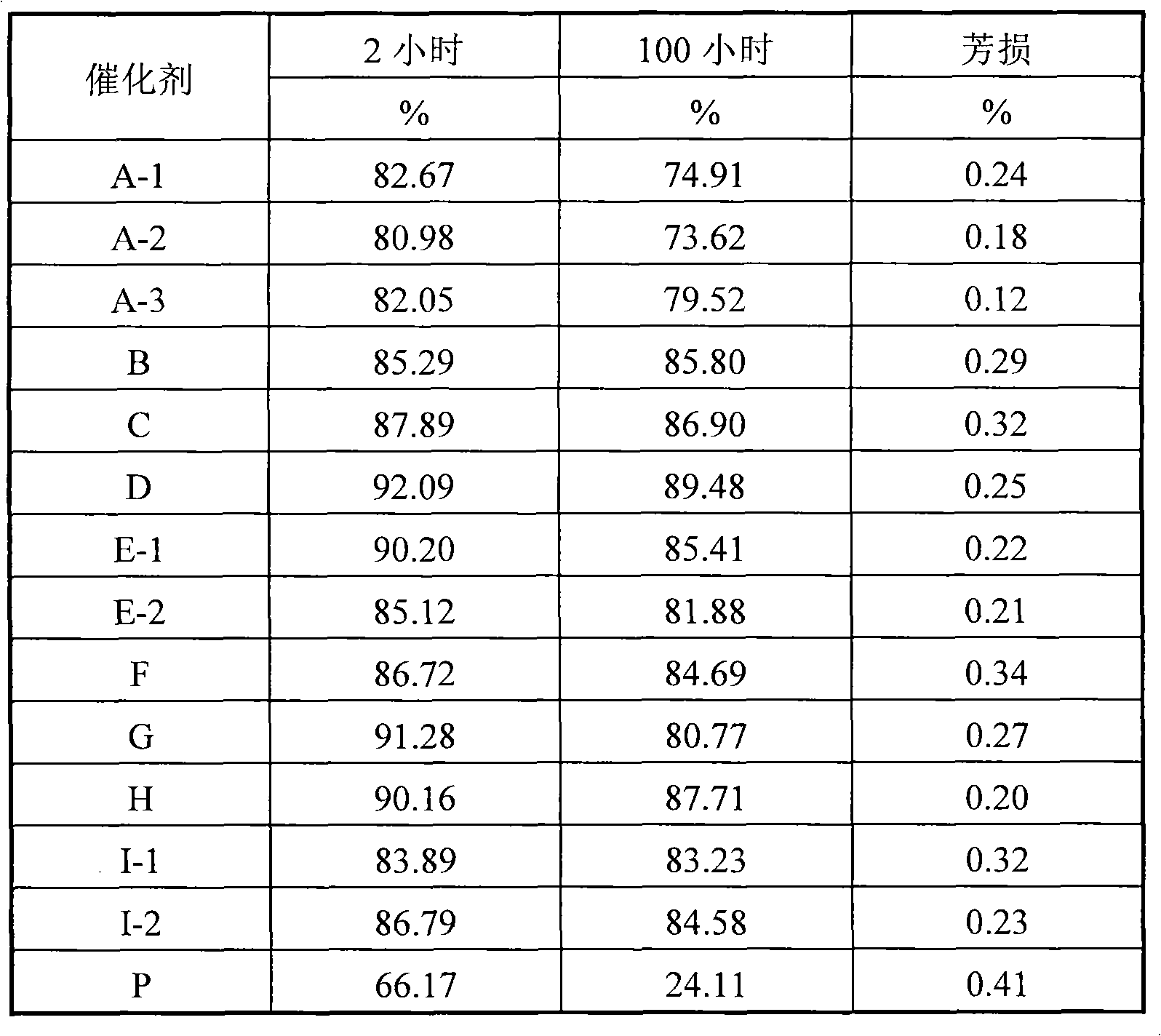

Rapid fuel gas condensation system with double-tower direct spray

ActiveCN101532785AImprove condensation efficiencyHigh condensation efficiencyLiquid hydrocarbon mixture productionDirect contact heat exchangersSpray nozzlePulp and paper industry

The invention discloses a rapid fuel gas condensation system with double-tower direct spray, comprising a first stage spray tower, a second stage spray tower, a connecting pipeline communicated with the first stage spray tower and the second stage spray tower, at least one bio-oil storage tank connected with condensed bio-oil outlets of the first stage spray tower and the second stage spray tower, and at least one atomized spray sub-system. The atomized spray sub-system comprises a first atomized spray unit and a second atomized spray unit respectively arranged inside the first stage spray tower and the second stage spray tower partially and extensively. The first atomized spray unit and the second atomized spray unit respectively comprise two layers or more than two layers of spraying nozzles that are used for the atomized spray of condensed media and arranged at intervals in the height direction of the inner space of the first stage spray tower and the second stage spray tower. The system can fully inhibit the further schizolysis of condensable components and avoid the complicated process of subsequent separation caused by additional condensed media.

Owner:GUANGZHOU DEVOTION THERMAL TECH

Reformate non-hydroisomerization olefin-reducing catalyst

ActiveCN101992117AExtend your lifeIncrease acidityMolecular sieve catalystsRefining with metal oxidesLow activityMolecular sieve

The invention relates to a reformate non-hydroisomerization olefin-reducing catalyst mainly solving the problems of low activity, short service life and big aromatic hydrocarbon loss of a olefin-reducing refining agent in the prior art. The invention well solves the problem through the technical scheme of adopting a novel catalyst comprising the following components in parts by weight: 10-90 parts of molecular sieve and 0.01-2.00 parts of at least one element selected from Cl, Br or S or an oxide thereof, 0.05-5 parts of at least one element selected from F and P or an oxide thereof and 10-90parts of aluminum oxide or silicon oxide binder by elements. The invention can be used for the reformate non-hydroisomerization olefin-reducing industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

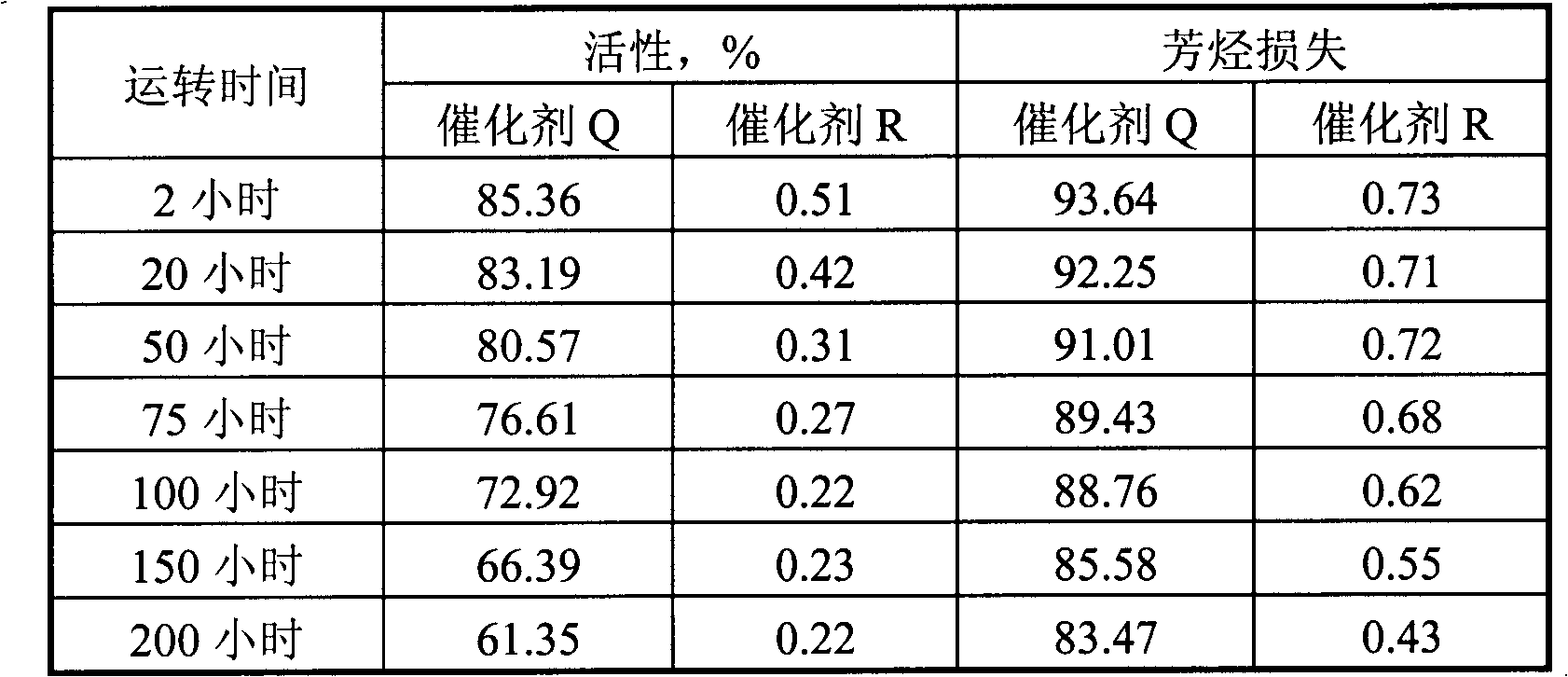

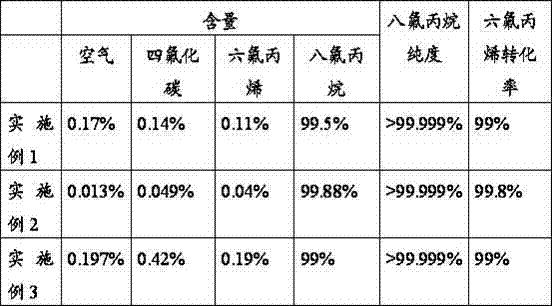

Preparation method of perfluoropropane

InactiveCN103497086AReduce corrosionExtend your lifePreparation by halogen additionElectrolysisHexafluoropropylene

The invention discloses a preparation method of perfluoropropane. The preparation method sequentially comprises the following steps: (1) electrolyzing potassium bifluoride to obtain a mixed fluorine gas, and sequentially carrying out dust extraction, condensation and adsorption treatments on the mixed fluorine gas to purify the mixed fluorine gas to raw material fluoride; (2) pressurizing the raw material fluoride and uniformly mixing the raw material fluoride with an inert gas to obtain a mixed gas; (3) introducing the mixed gas into a reactor filled with cobaltous fluoride to react to obtain cobaltic oxide; (4) carrying out purging and vacuumizing replacement treatments on the reactor and related pipelines and pipe fittings after the reaction; (5) introducing hexafluoropropylene into the reactor to react with the cobaltic oxide to obtain perfluoropropane containing impurities; (6) cooling and adsorbing the perfluoropropane; and (7) introducing the perfluoropropane into a rectifying column through a compressor to be rectified. By adopting the preparation method disclosed by the invention, the corrosion of impurities on the reactor can be reduced, such unfavorable side reactions as hexafluoropropylene pyrolysis, self polymerization, addition, and the like, are inhibited, and perfluoropropane with high purity is prepared.

Owner:FOSHAN HUATE GASES +1

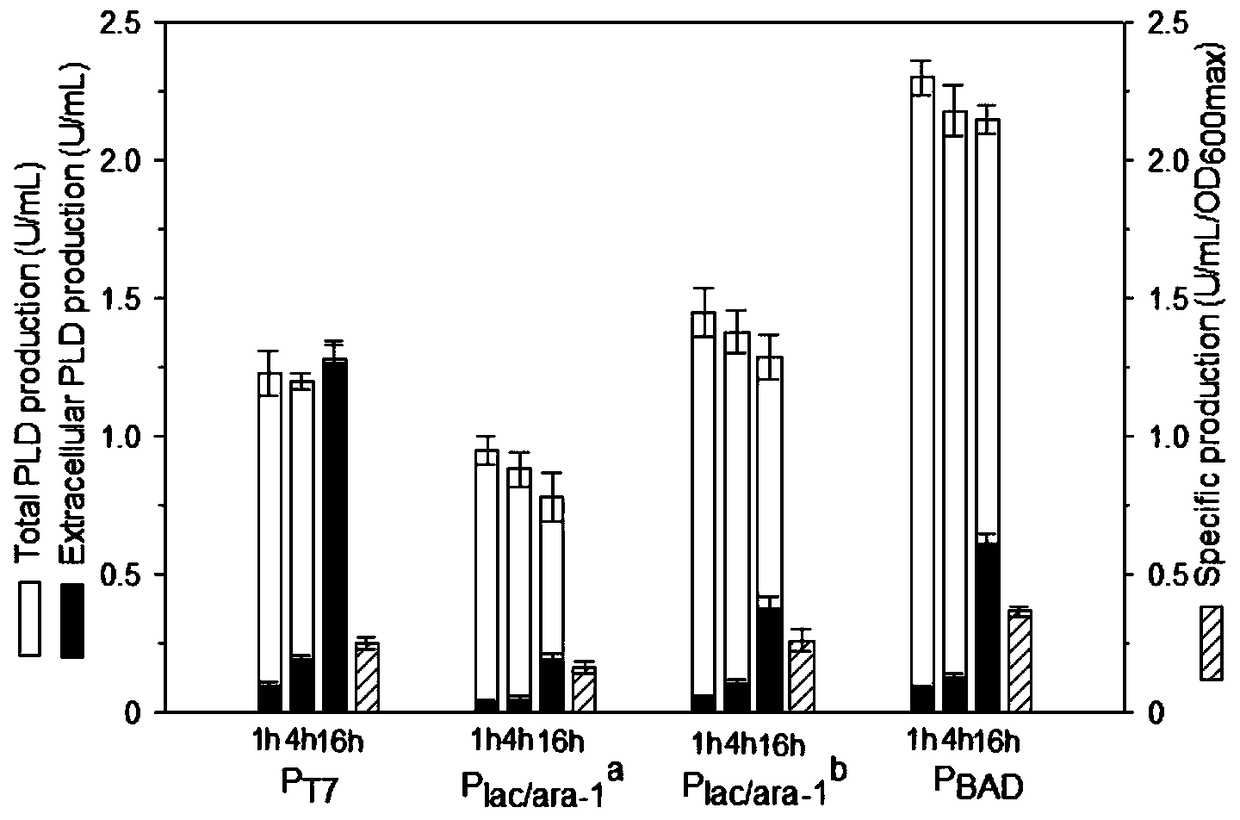

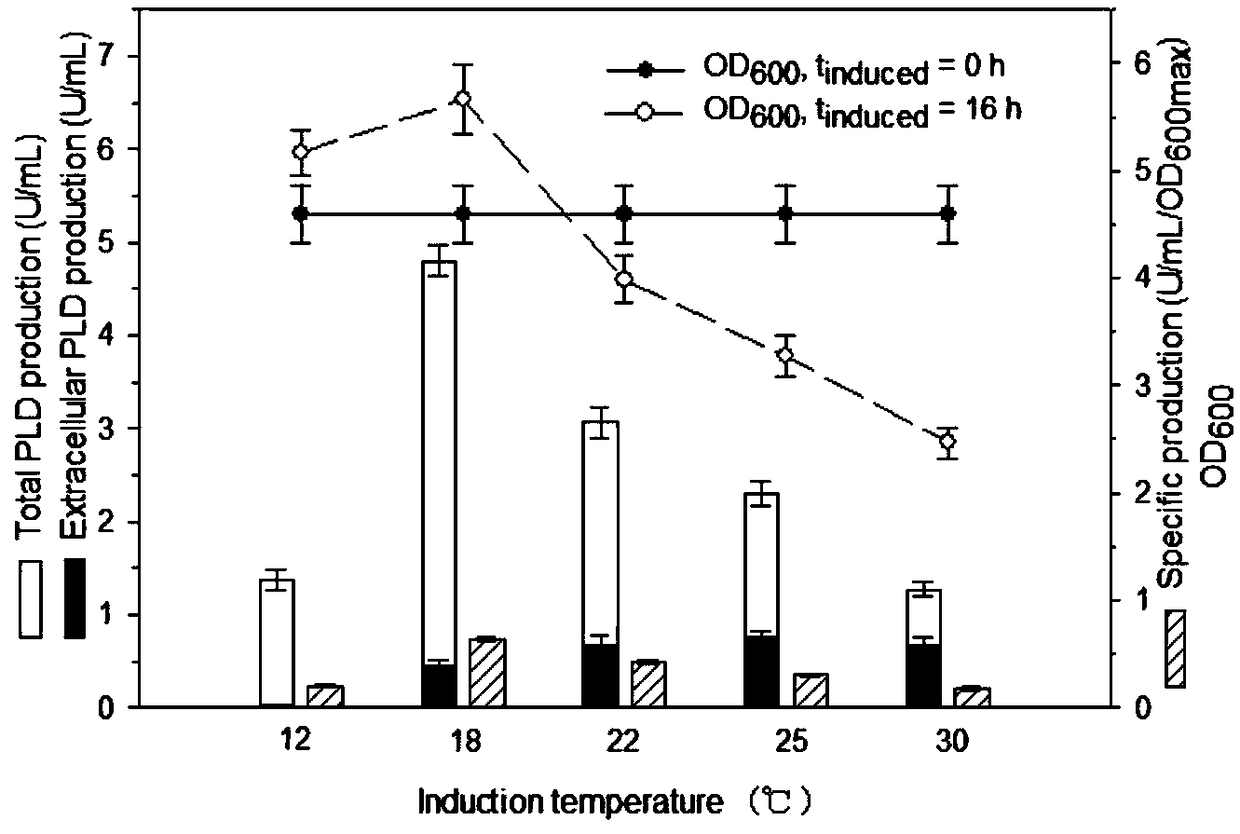

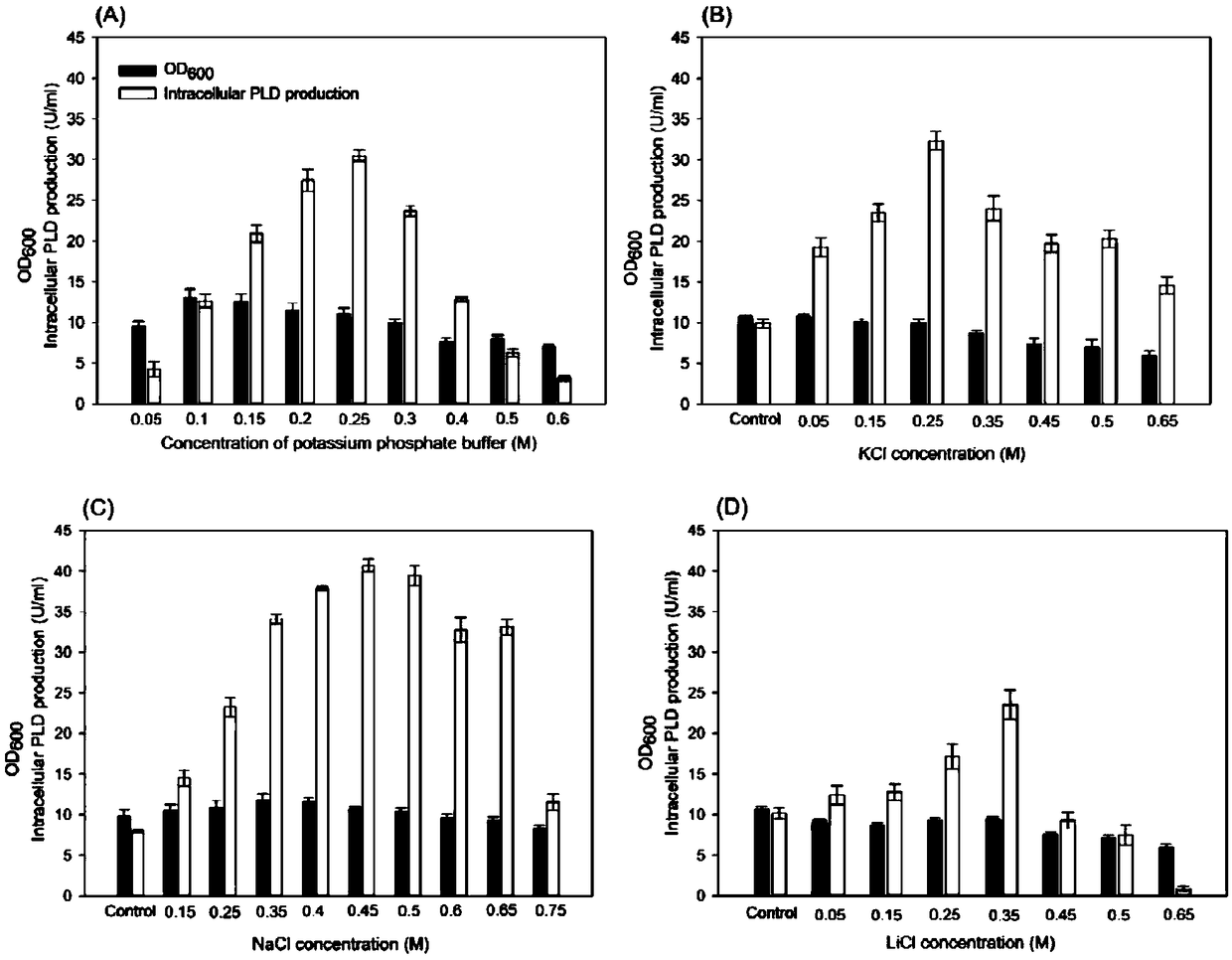

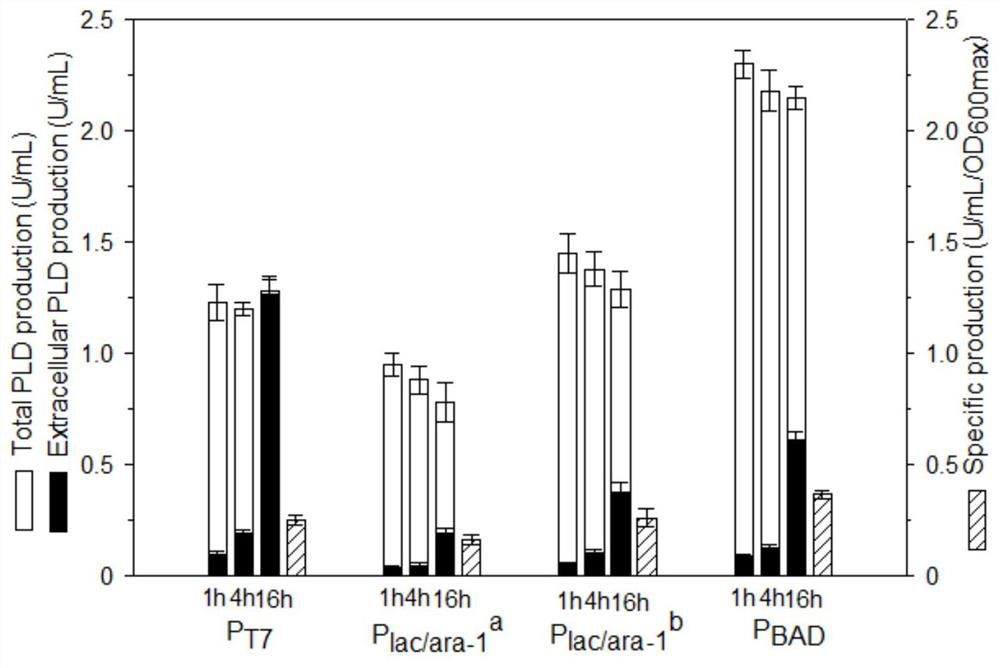

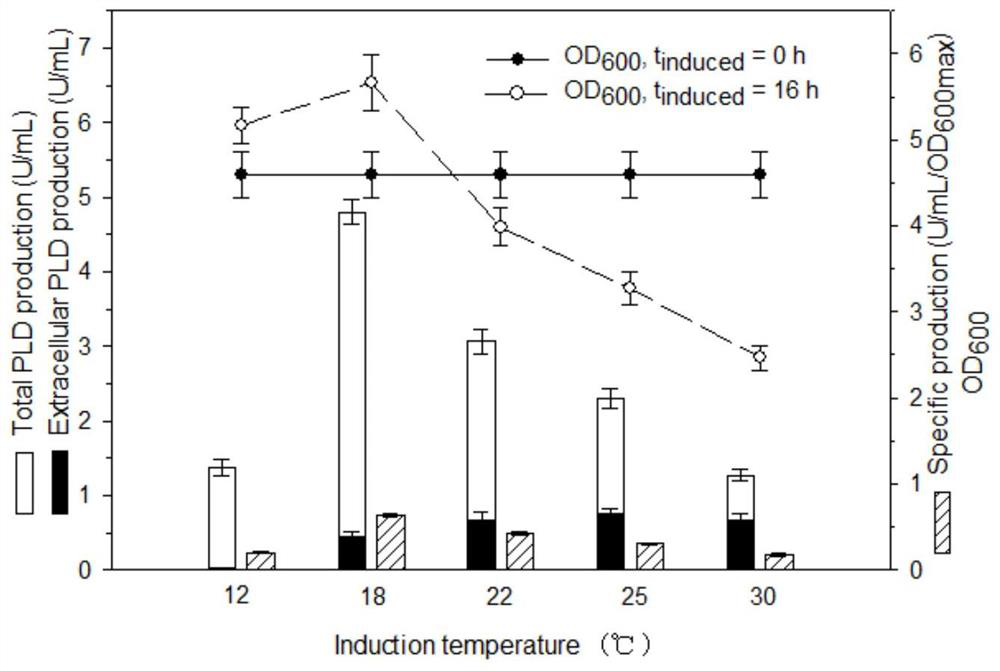

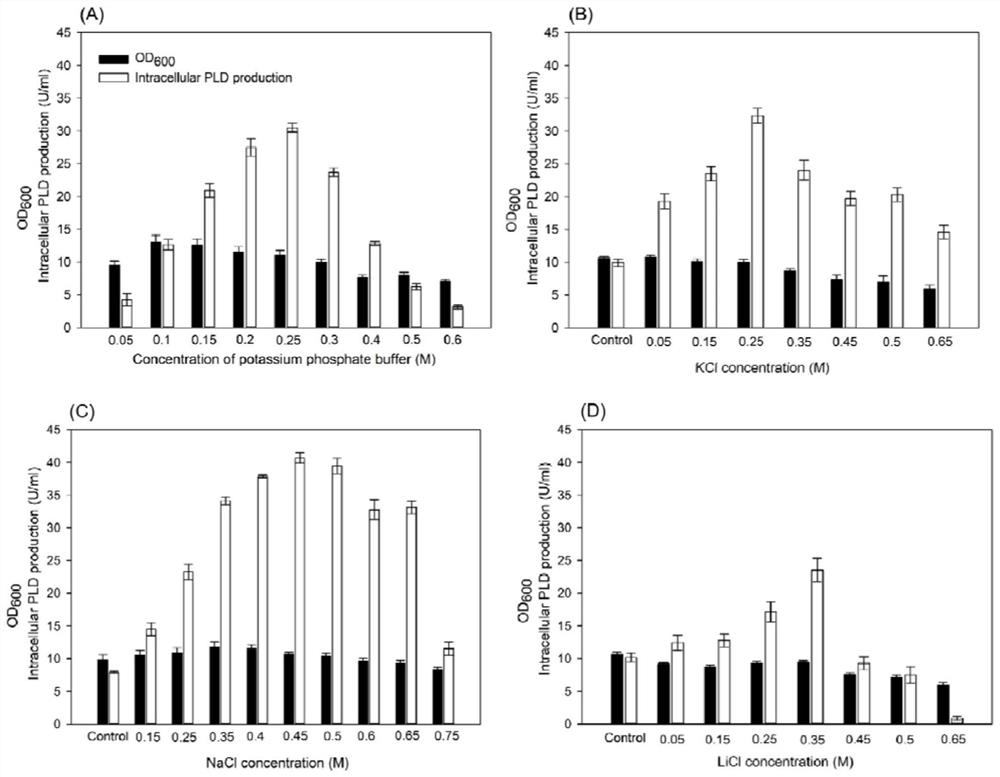

Method for producing phospholipase D through recombinant escherichia coli

ActiveCN109136207AInhibition of lysisOptimal physiological stateBacteriaHydrolasesEscherichia coliHigh density

The invention discloses a method for producing phospholipase D through recombinant escherichia coli. According to the method, a phospholipase D gene is in preciseness-type starting sub control, a pararea of pSC101 is inserted in an expression plasmid, an escherichia coli mutant strain recA is used for keeping the genetic stability of the plasmid, cells containing the plasmid at the growth periodare cultured to high density, and saturation induction is conducted at the induction period; meanwhile, the temperature is decreased, alkali metal salt stress is applied, the cytotoxicity of PLD to ahost is reduced, cell lysis is inhibited, the synthesis time of PLD is prolonged, and accordingly PLD expression is improved.

Owner:XIAMEN UNIV

High temperature-resistant and UV (Ultraviolet)-resistant protective film and preparation method thereof

InactiveCN108707432AReduced shrinkage performancePrevent high temperature deformationNon-macromolecular adhesive additivesEster polymer adhesivesTectorial membraneDisplay device

The invention discloses a high temperature-resistant and UV (Ultraviolet)-resistant protective film and a preparation method thereof. The high temperature-resistant and UV-resistant protective film comprises a PE (Polyethylene)-based film layer and an adhesive layer, wherein the adhesive layer is formed by coating the surface of the PE-based film layer with a heat-resistant and UV-resistant pressure-sensitive adhesive and drying; the pressure-sensitive adhesive is prepared from the following raw materials in parts by weight: 25 to 35 parts of acrylate resin, 55 to 70 parts of ethyl acetate, 1to 2 parts of isocyanate curing agent, 0.1 to 0.5 part of UV absorbent and 0.4 to 0.7 part of free radial collecting agent. Compared with the prior art, the preparation method disclosed by the invention is reasonable in raw material proportioning and simple in preparation technology, and a release force of the high temperature-resistant and UV-resistant protective film provided by the invention ranges from 7N / m to 9N / m; after long-time irradiation under high temperature and UV, the release force of the high temperature-resistant and UV-resistant protective film changes within + / -35 percent, and the high temperature-resistant and UV-resistant protective film has no wrinkling, no degumming, no adhesive residue and no chromatic aberration after long-time irradiation under the UV; the high temperature-resistant and UV-resistant protective film can be used for protecting the surfaces of backlight displays in electronic products such as a computer, a television and a mobile phone and can beused for protecting an overlaid shipment transportation process of the backlight displays.

Owner:芜湖夏鑫新型材料科技有限公司

Method for activating platinum-containing light alkane dehydrogenation catalyst

ActiveCN106607105AAvoid gatheringHigh activityCatalystsHydrocarbon preparation catalystsPlatinumAir atmosphere

The invention relates to a method for activating a light alkane dehydrogenation catalyst. The method mainly solves the problem that the conversion rate and selectivity of the existing platinum-containing light alkane dehydrogenation catalyst are low. The method comprises a) carrying out grading treatment on the catalyst in an air atmosphere, b) treating the catalyst containing 1 to 10mol% of O2 and 1 to 10mol% water vapor flows to promote redispersion of an active metal component Pt and a halogen Cl, and c) reducing the active metal component at 450 to 650 DEG C in a trace hydrogen sulfide / H2 reduction atmosphere so that the deactivated catalyst is completely activated. The method solves the problem and can be used in industrial production of light alkane dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

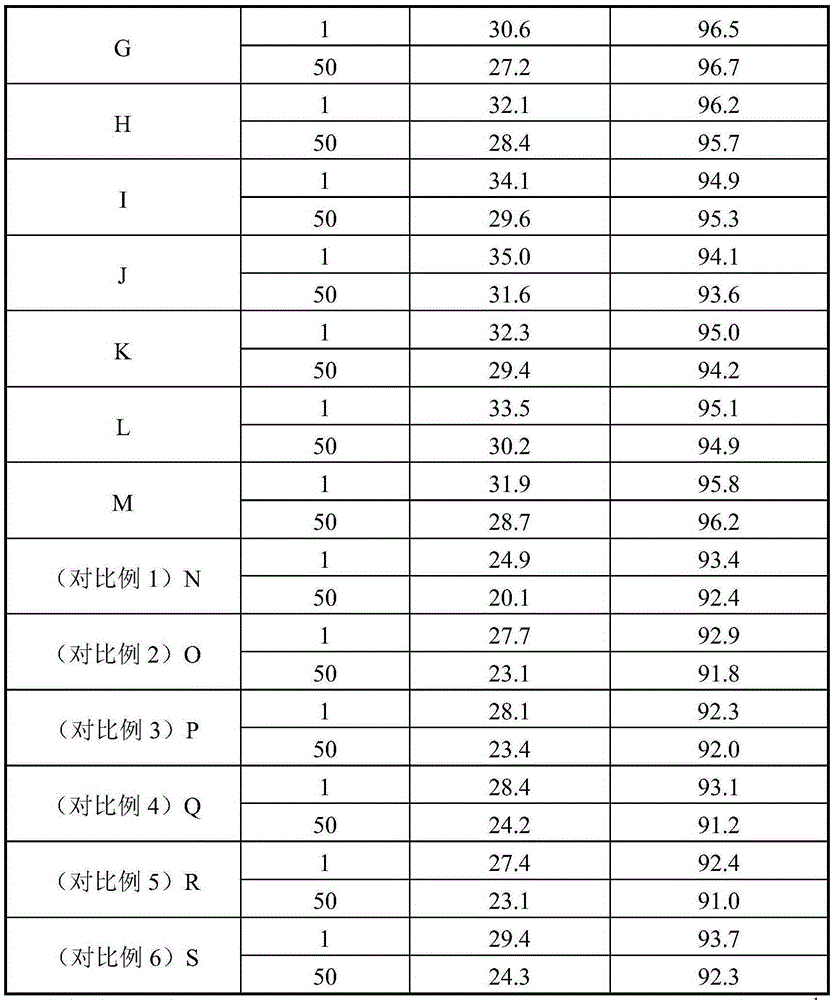

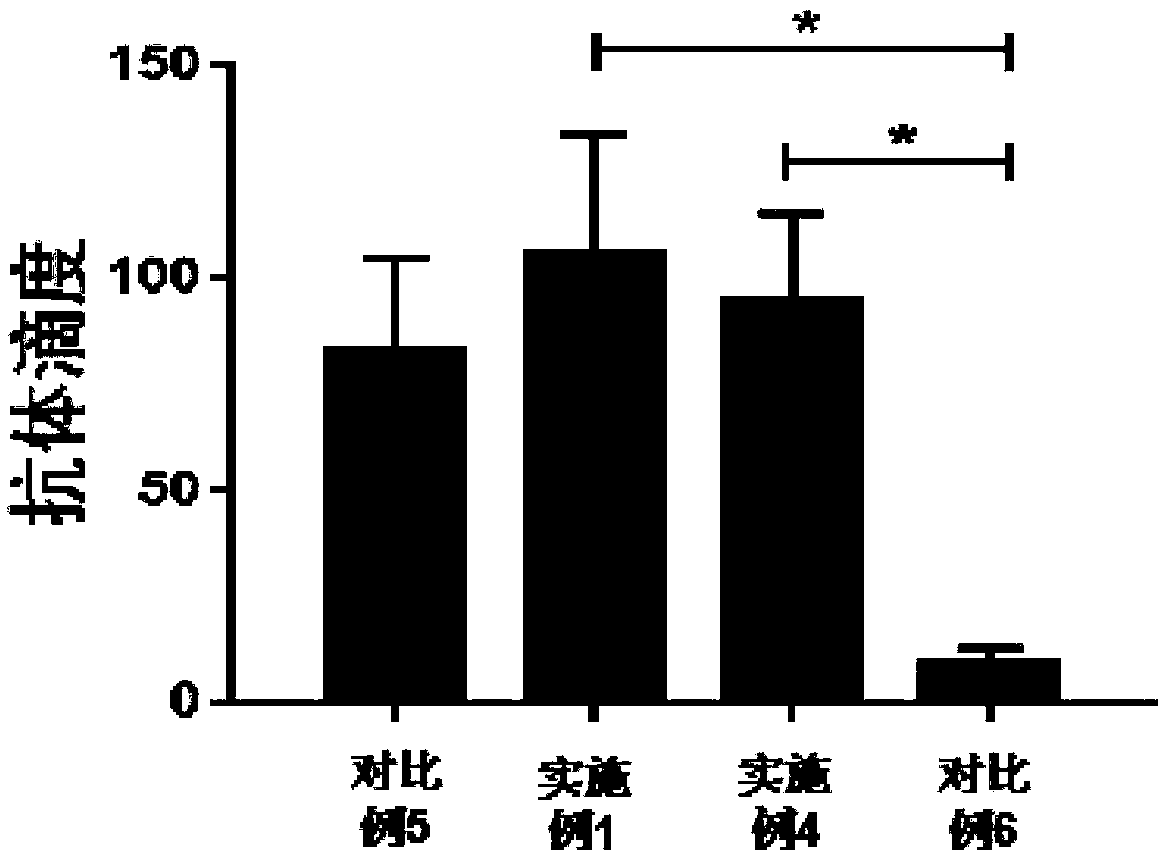

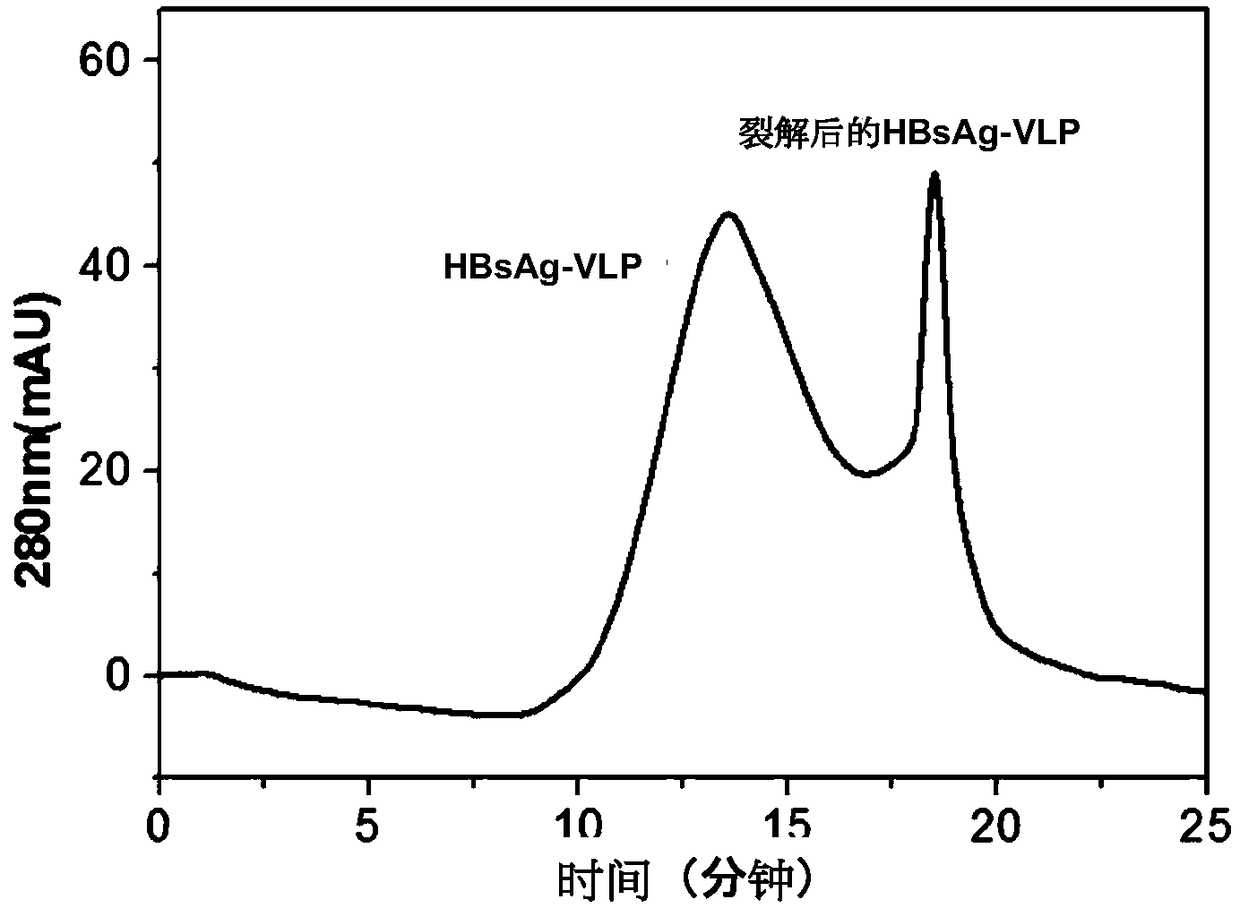

Vaccine antigen composition and preparation method thereof

ActiveCN109464661AImprove thermal stabilityImprove stabilityViral antigen ingredientsPharmaceutical delivery mechanismFreeze thawingAdjuvant

The invention provides a vaccine antigen composition. The vaccine antigen composition comprises a vaccine antigen and choline-type ionic liquid. According to the vaccine antigen composition, through addition of the choline-type ionic liquid with good biocompatibility as an additive, the heat stability, the repeated freeze-thaw stability, the accelerated stability and the long-term storage stability of the vaccine antigen are significantly improved, the stability of the antigen in a solution and in an adjuvant environment is significantly improved and the antigen activity is not affected.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Chlorinated polyethylene cable sheath for coal mine

InactiveCN104788834AInhibition of lysisImprove liquidityPlastic/resin/waxes insulatorsInsulated cablesMethacrylatePolymer science

The invention discloses a chlorinated polyethylene cable sheath for a coal mine. The chlorinated polyethylene cable sheath comprises the following raw materials by weight: 100 parts of chlorinated polyethylene 135B, 3 to 5 parts of a vulcanizing agent 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, 1 to 1.5 parts of a co-vulcanizing agent trimethylol trimethacrylate, 3 to 5 parts of a calcium-zinc stabilizing agent, 10 to 15 parts of precipitated white carbon black, 20 to 30 parts of potter's clay, 3 to 4 parts of oxidized polyethlene wax, 8 to 12 parts of magnesium oxide, 2 to 5 parts of chlorinated paraffin, 15 to 20 parts of magnesium hydroxide, 1 to 3 parts of tritolyl phosphate, 1.2 to 1.3 parts of an auxiliary crosslinking agent TAIC, 2 to 5 parts of paraffin, 20 to 30 parts of powdered steatile and 50 to 60 parts of nanometer kaolin. The chlorinated polyethylene cable sheath provided by the invention has excellent heat resistance and flame retardation performance, high hardness, good resilience and small permanent compression set.

Owner:ANHUI TIANCAI CABLE GRP

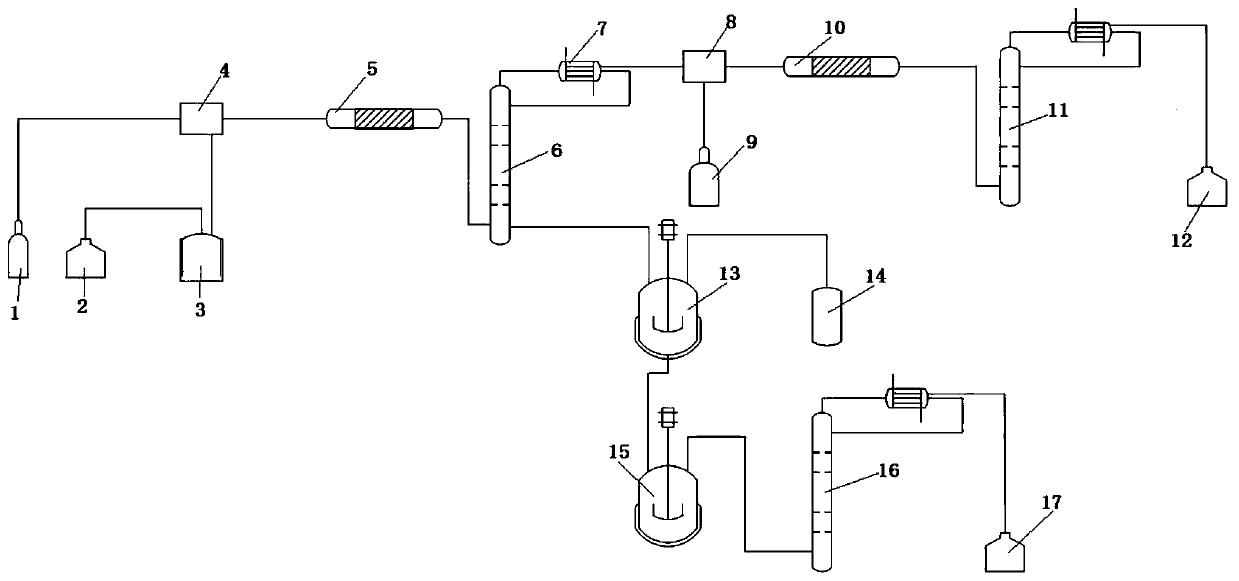

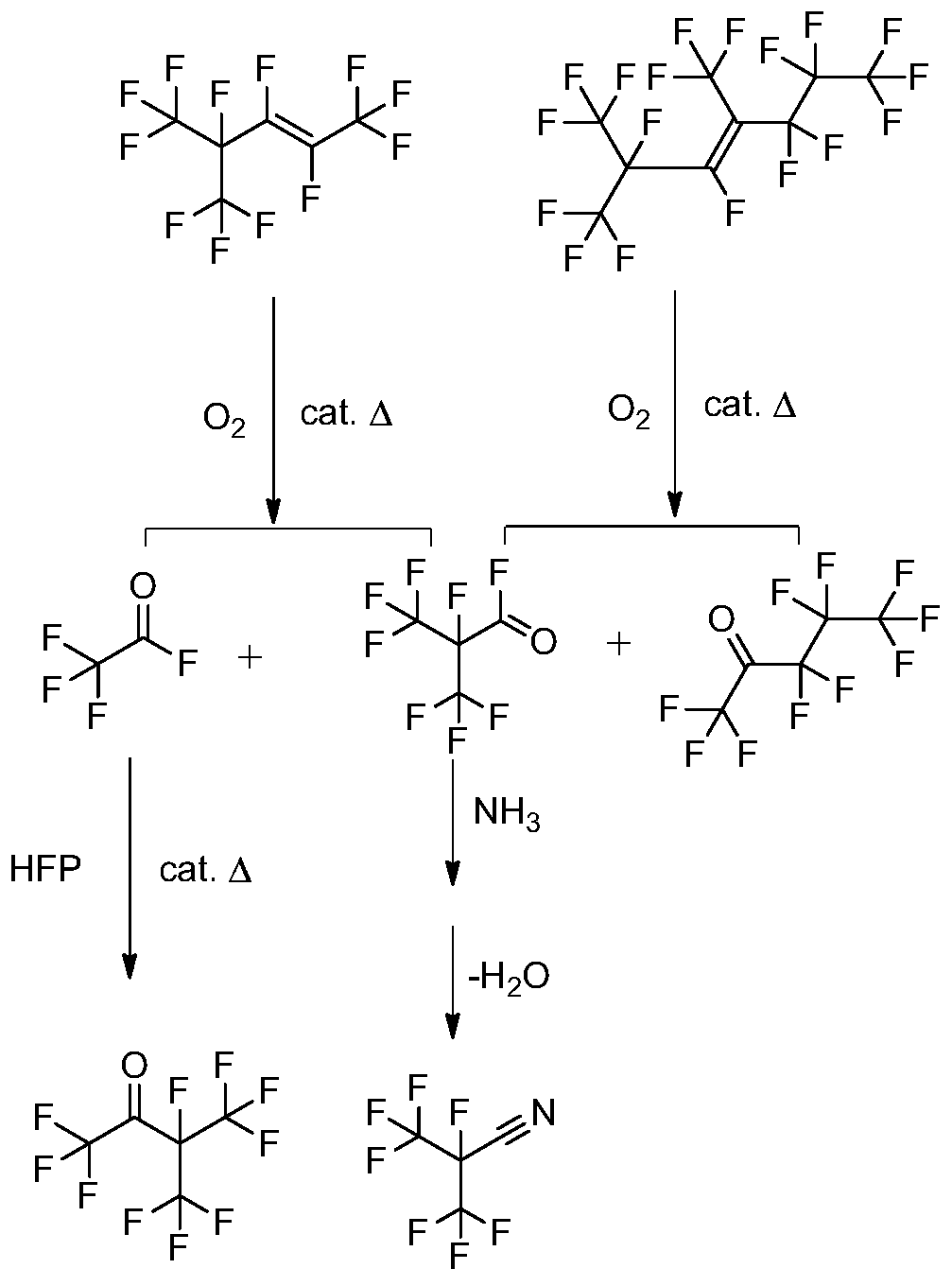

Economical and efficient perfluoronitrile and perfluoroketone co-production process and device

InactiveCN111233653ABig difference in boiling pointEmission reductionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHexafluoropropylenePhysical chemistry

The invention discloses an economical and efficient perfluoronitrile and perfluoroketone co-production process and a device. The economicaland efficient perfluoronitrile and perfluoroketone co-production process comprises the following steps: reacting oxygen with an asymmetric perfluoroolefin to generate two acyl fluoride gases or generate a perfluoroketone gas and an acyl fluoride gas; when the two kinds of acyl fluoride gas are generated, and the boiling point of the first acyl fluoride gas is higher than that of the second acyl fluoride gas, subjectingthe first acyl fluoride gas and ammoniagascontact reaction for conversion into a perfluoroamide, and dehydrating and convertingthe perfluoroamide is into a perfluoronitrile; mixing and reacting the second acyl fluoride gas with hexafluoropropylene to generate a perfluoroketone compound; when perfluoroketone gas and an acyl fluoride gas are generated, separating the perfluoroketone gas and the acyl fluoride gas, condensing and collecting the perfluoroketone gas, and subjecting the acyl fluoride gas and ammonia gastocontact reaction for conversion into perfluoroamide, anddehydrating and converting the perfluoroamideinto the perfluoronitrile. According to the method, the perfluoronitrileand the perfluoroketone can be prepared at the same time, the preparation conditions are simple, and the atom economy of the reaction route is high.

Owner:STATE GRID SHAANXI ELECTRIC POWER RES INST +1

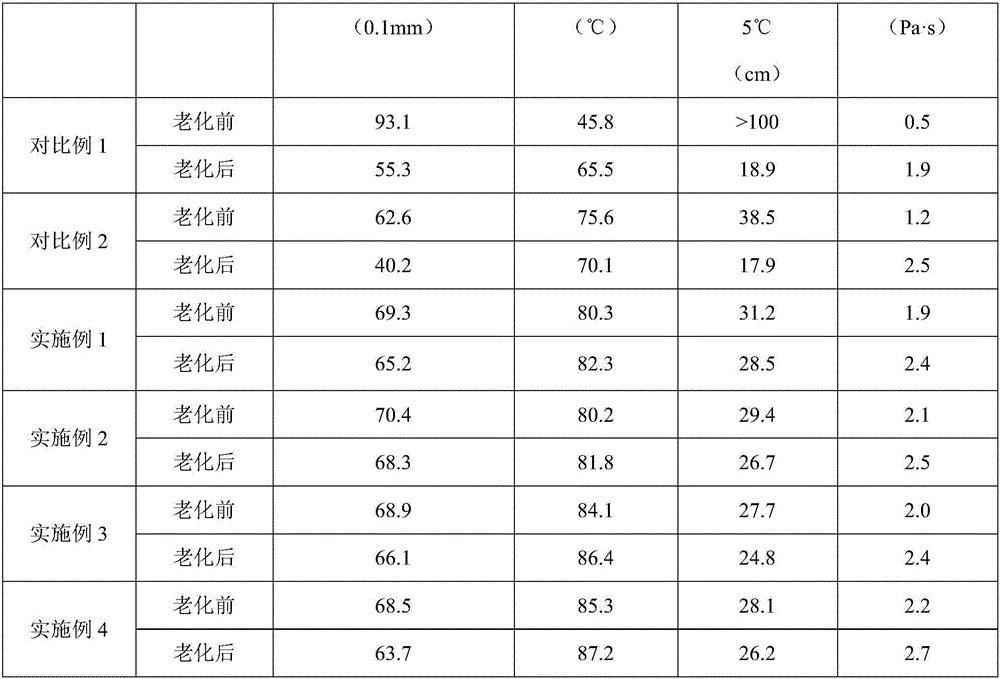

High-aging-resistance modified asphalt and preparation method thereof

InactiveCN106433164AImprove thermal stabilityImprove photostabilityBuilding insulationsMethyl isobutyl ketoneAging resistance

The invention discloses a high-aging-resistance modified asphalt and a preparation method thereof. The high-aging-resistance modified asphalt comprises the following components in percentage by mass: 72-80% of substrate asphalt, 1.3-2.7% of hindered amine light stabilizer, 0.5-1.2% of trilauryl phosphite, 0.5-2% of barium stearate, 6-8% of diatomite, 5-10% of epoxy soybean oil and 5-8% of methyl isobutyl ketone. The preparation method comprises the following steps: adding the hindered amine light stabilizer, trilauryl phosphite and barium stearate into the substrate asphalt at appropriate temperature, uniformly mixing with the asphalt, and adding the diatomite, epoxy soybean oil and methyl isobutyl ketone to obtain the high-aging-resistance modified asphalt. The asphalt has very high heat stability and light stability, is capable of greatly enhancing the pavement performance and durability and prolonging the maintenance period and service life of the high-grade asphalt pavement when being applied to the asphalt pavement, and thus, has very high cost performance and wide application prospects.

Owner:CHANGAN UNIV

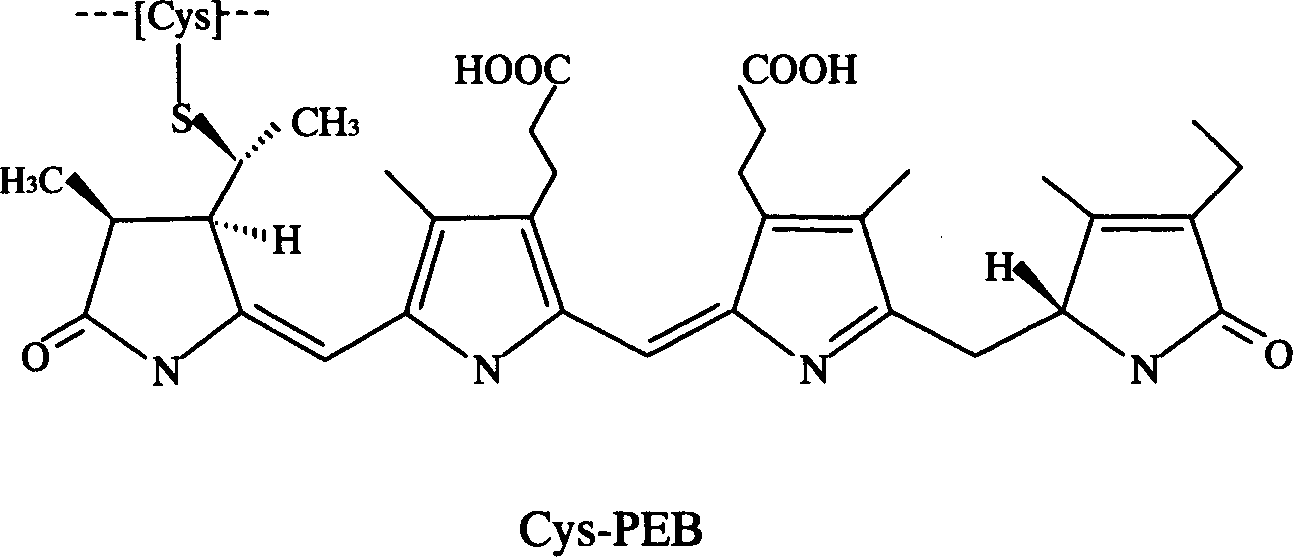

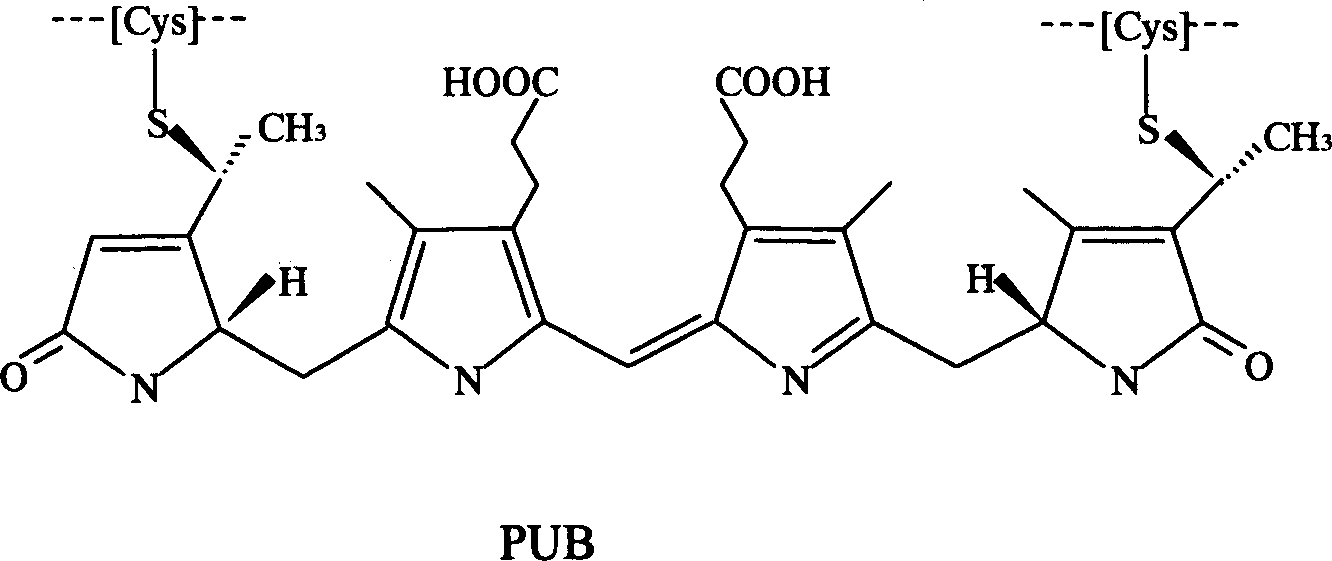

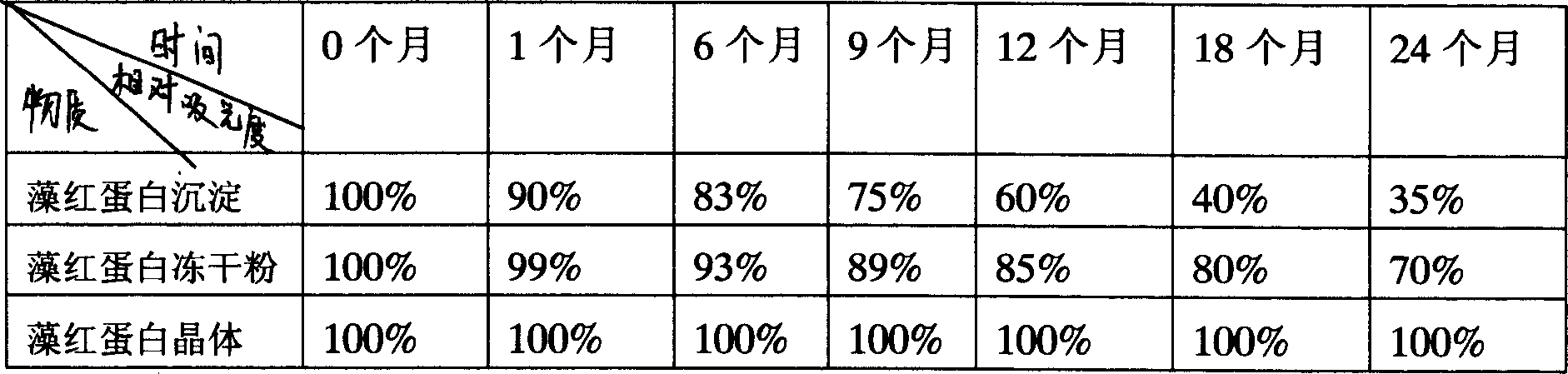

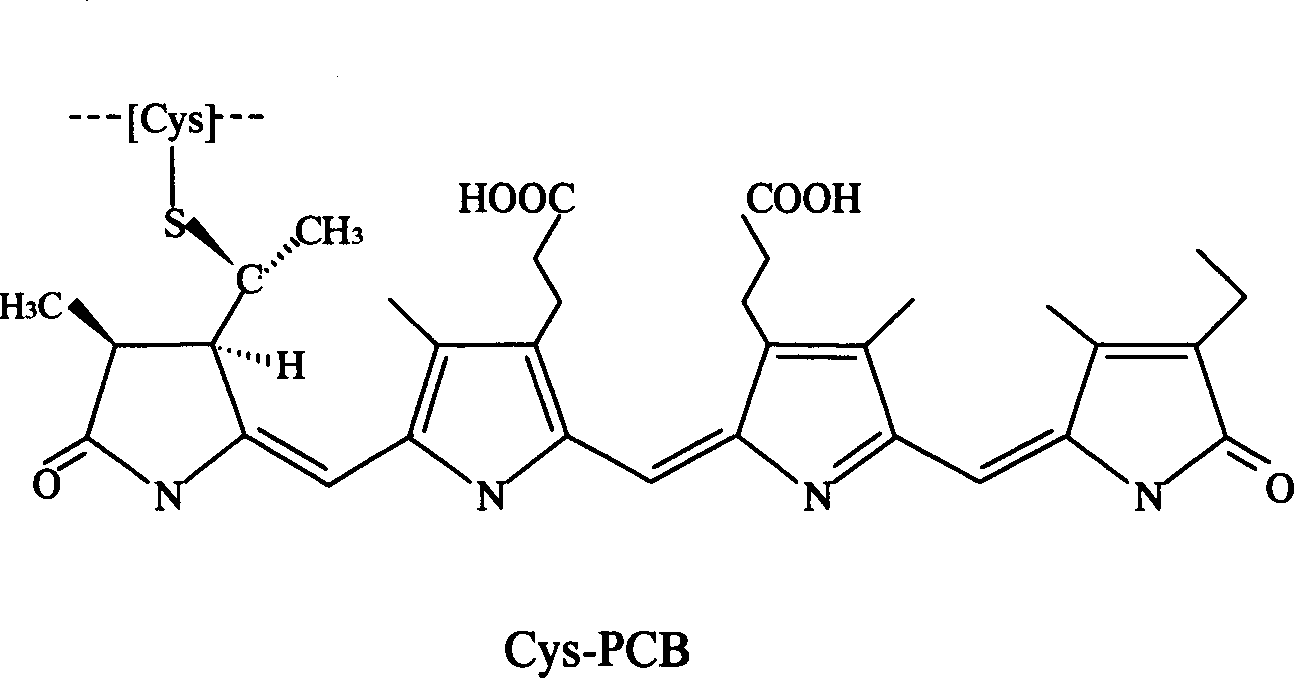

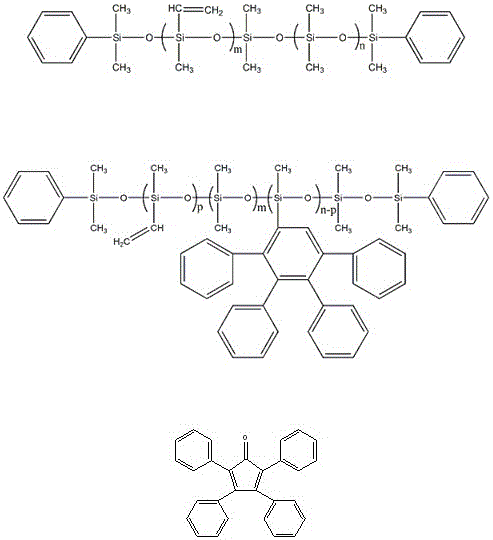

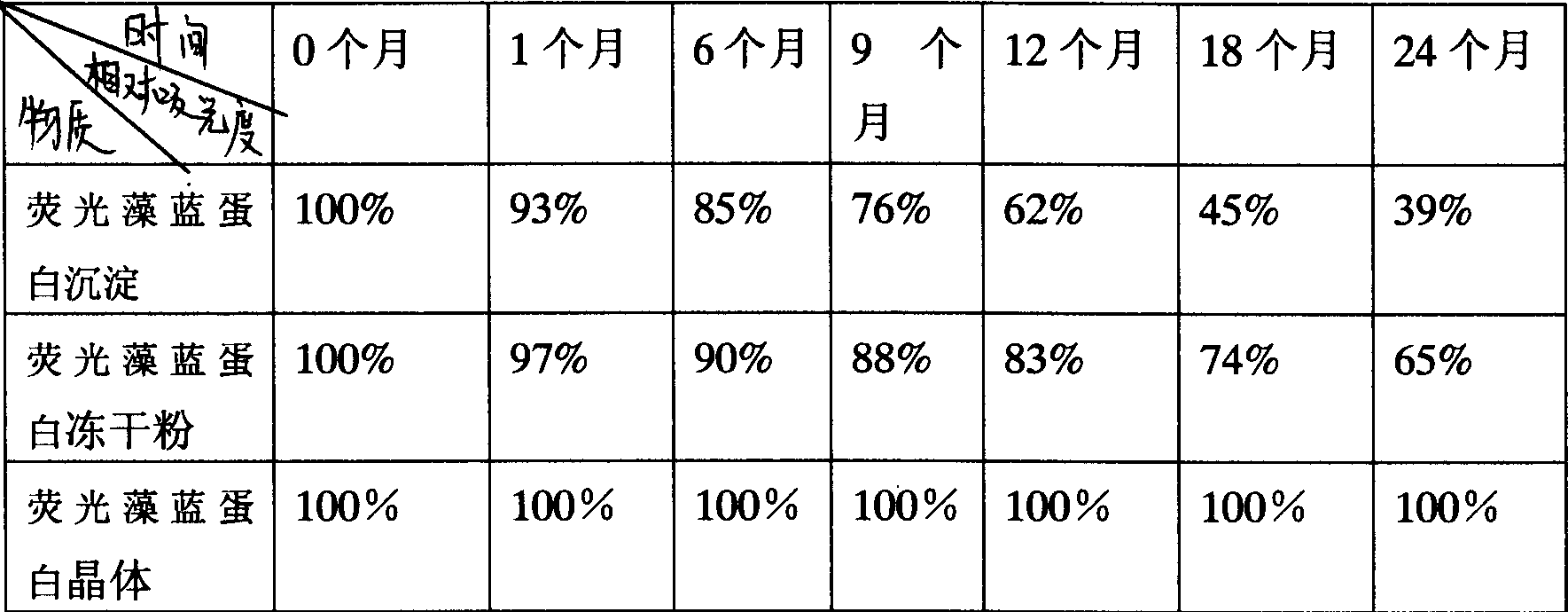

Production technology of phycoerythrin and crystal and product thereof

InactiveCN1786024AFor long-term storagePreservation conditions require littlePeptide preparation methodsAlgae/lichens peptidesFluorescencePhycoerythrin

The present invention relates to a protein, crystal preparation process and its product. In particular, it relates to a phycoerythrin which is extracted from algae under the general condition and can emit strong fluorescence, and can convert it into crystal form, It can be extensively used in the fields of scientific research, medicine detection and telecommunication, etc.

Owner:骆建华

Dehydrogenation catalyst with silicon oxide as carrier and preparation method thereof

ActiveCN103785411ARestore fastInhibition decreasedHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsActive componentDehydrogenation

The invention discloses a dehydrogenation catalyst, which uses silica as a carrier, Pt as a dehydrogenation active component, Sn as a first aid, one or more metal of Cu, Fe, Co and Ni other as a second aid; and the catalyst comprises 0.1%-2% of the dehydrogenation active component, and calculated by the weight of the carrier 0.1-10 wt% of the first aid and 0.1-10 wt% of the second aid. A preparation method of the dehydrogenation catalyst is as below: loading the first aid Sn and the second aid, which is one or more selected from Cu, Fe, Co and Ni, and the active component Pt, by using silica gel as the carrier through an immersion method. This method can substantially increase the activity and stability of the catalyst and selectivity of alkene.

Owner:CHINA PETROLEUM & CHEM CORP +1

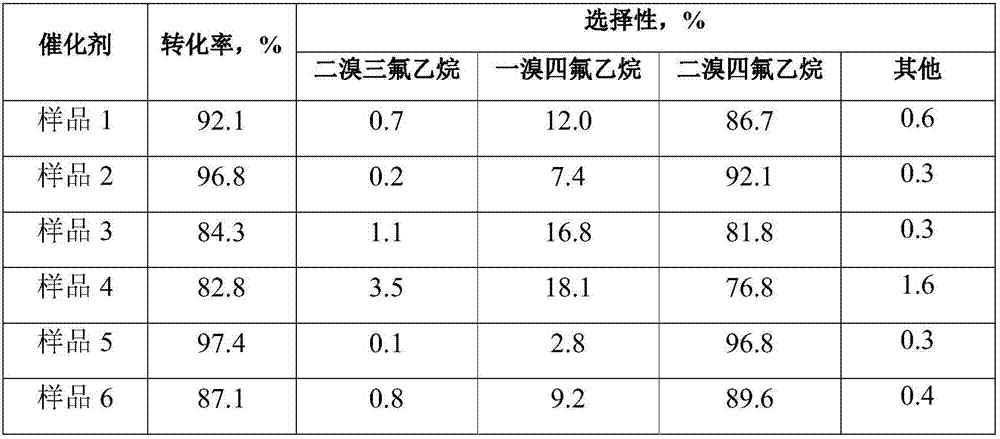

Catalyst as well as preparation method and application thereof

ActiveCN106902851ASimple preparation processEasy to operatePhysical/chemical process catalystsHalogenated hydrocarbon preparationActivated carbonGas phase

The invention discloses a catalyst as well as a preparation method and an application thereof and aims to solve the problems that high reaction temperature and lower target product selectivity during bromination synthesis of 1,1-dibromo-1,2,2,2-tetrafluoroethane from 1,1,1,2-tetrafluoroethane. The catalyst takes one or more of Fe, Al, Cu, Sn, Zn and P halides as active components, is loaded on activated carbon, porous metal fluoride or oxyfluoride with an impregnation method, is used for gaseous-phase synthesis of 1,1-dibromo-1,2,2,2-tetrafluoroethane after being dried and has the advantages of low reaction temperature, high target product selectivity and the like.

Owner:泉州宇极新材料科技有限公司

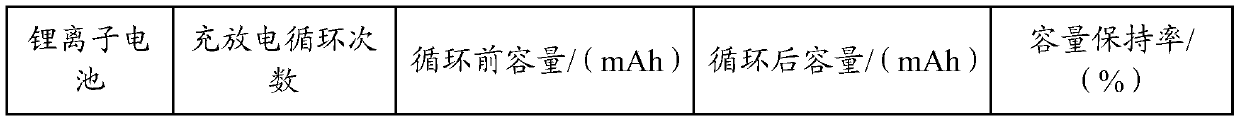

Electrolyte and lithium ion battery

ActiveCN111162315ALow melting pointImprove high temperature stabilitySecondary cellsComposite electrolytesPropanoic acidHigh energy

The invention relates to the field of lithium ion batteries, and discloses an electrolyte which comprises a high-temperature organic solvent, a positive and negative electrode protection additive andan electrolyte lithium salt, wherein the high-temperature organic solvent comprises the following components in parts by weight of 5-30 parts of ethylene carbonate, 5-30 parts of propylene carbonate,5-30 parts of diethyl carbonate, 5-50 parts of propyl propionate and 1-10 parts of fluorobenzene; the positive and negative electrode protection additive comprises the following components in parts byweight of 0.2 to 5 parts of ethylene sulfate, 0.2 to 5 parts of fluoroethylene carbonate, 0.2 to 5 parts of difluoroethylene carbonate, 0.2 to 5 parts of a dinitrile organic matter, 0.2 to 3 parts oflithium difluorophosphate, 0.2 to 5 parts of diethylene glycol dipropionitrile ether, 0.2 to 3 parts of lithium fluorosulfonyl imide, 0.1 to 2 parts of 1-propyl phosphoric anhydride, 0.5 to 20 partsof 1, 1, 2, 2-tetrafluoroethyl-2, 2, 3, 3-tetrafluoropropyl ether, 0.1 to 2 parts of lithium oxalyldifluoroborate and 0.1 to 1 part of methylene methanedisulfonate. The electrolyte is excellent in high-temperature resistance, enables the lithium ion battery with high energy density to normally work at the temperature of 70 DEG C or above, and can keep the relatively better endurance.

Owner:EVE ENERGY CO LTD

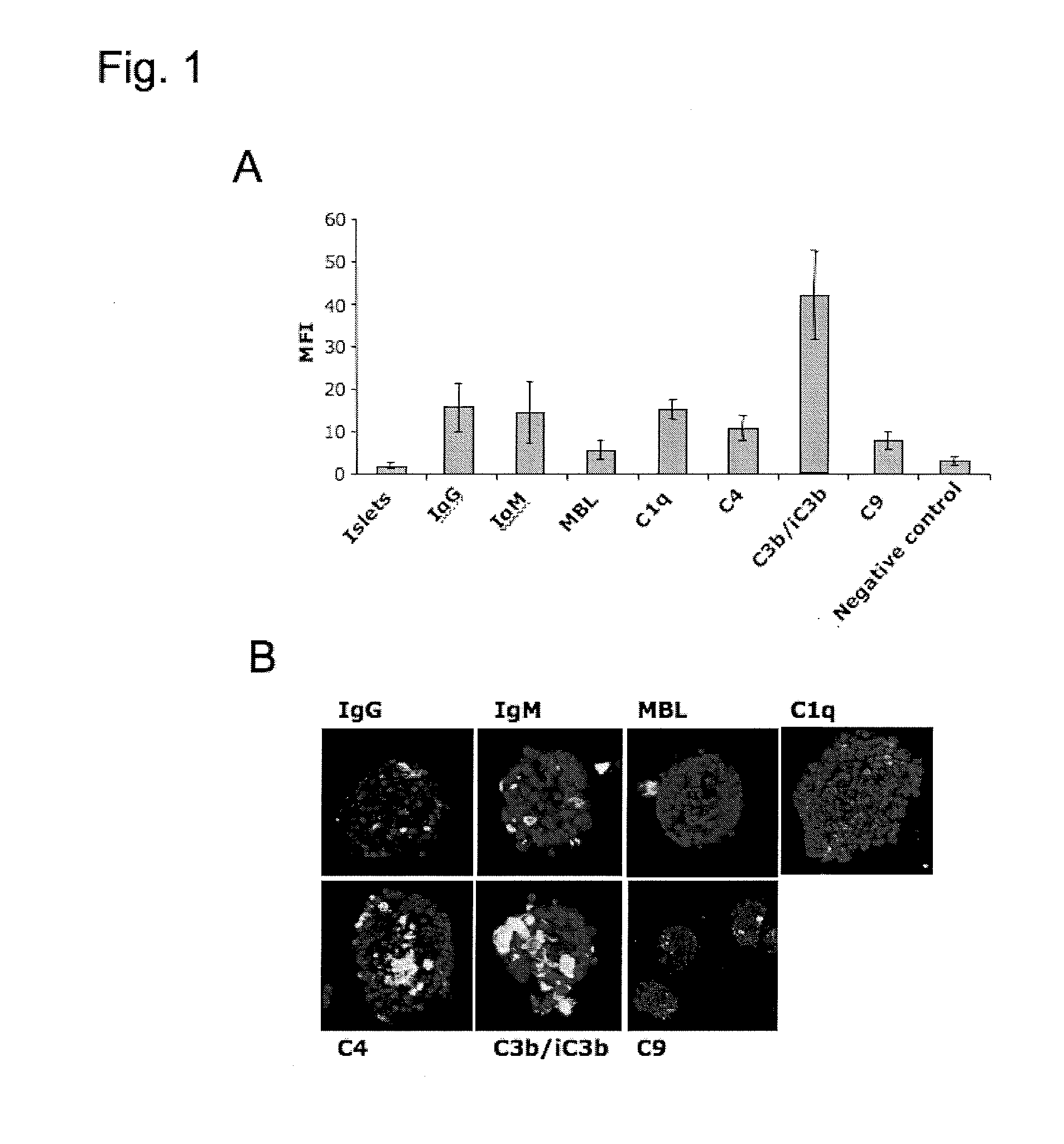

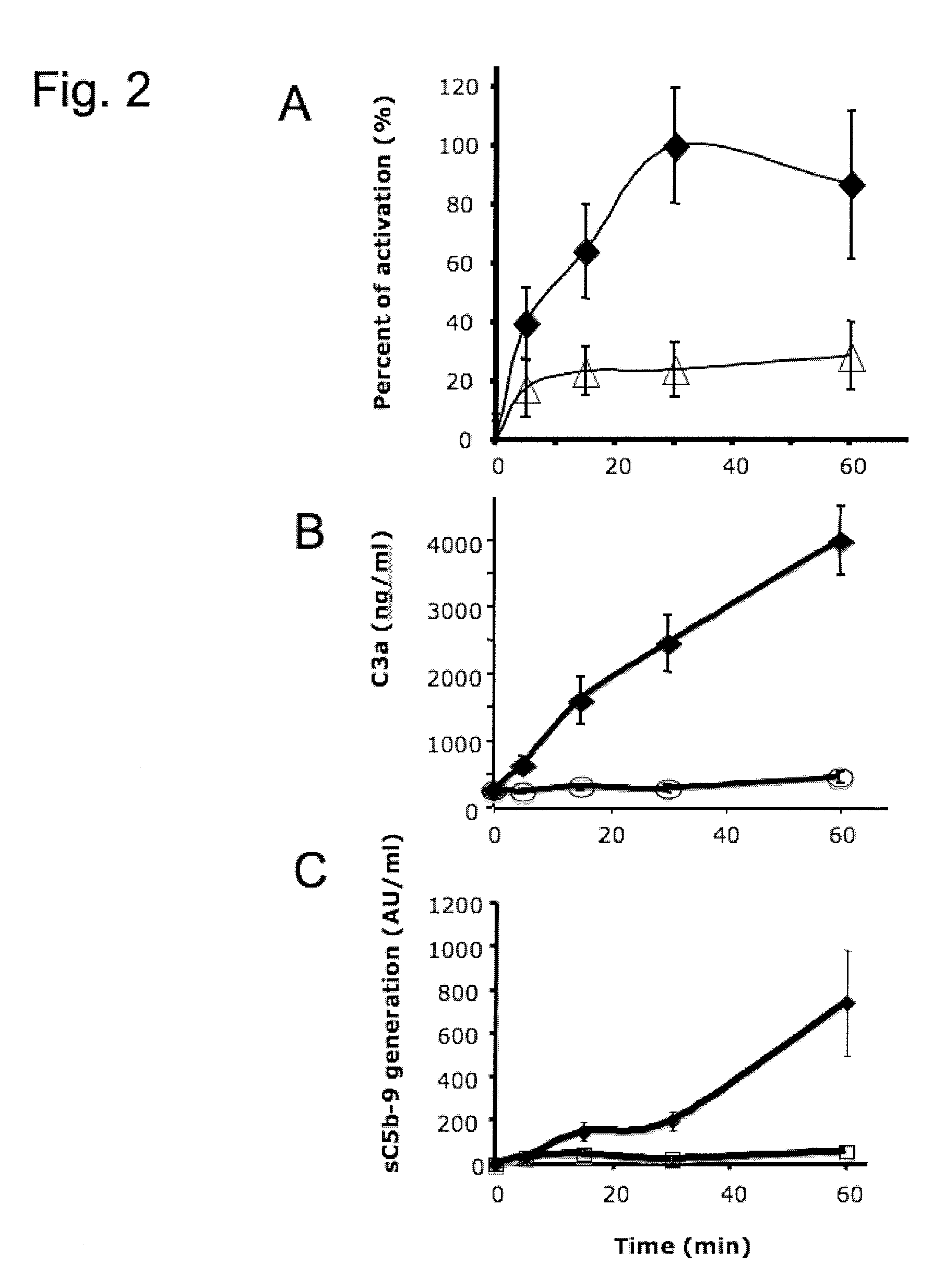

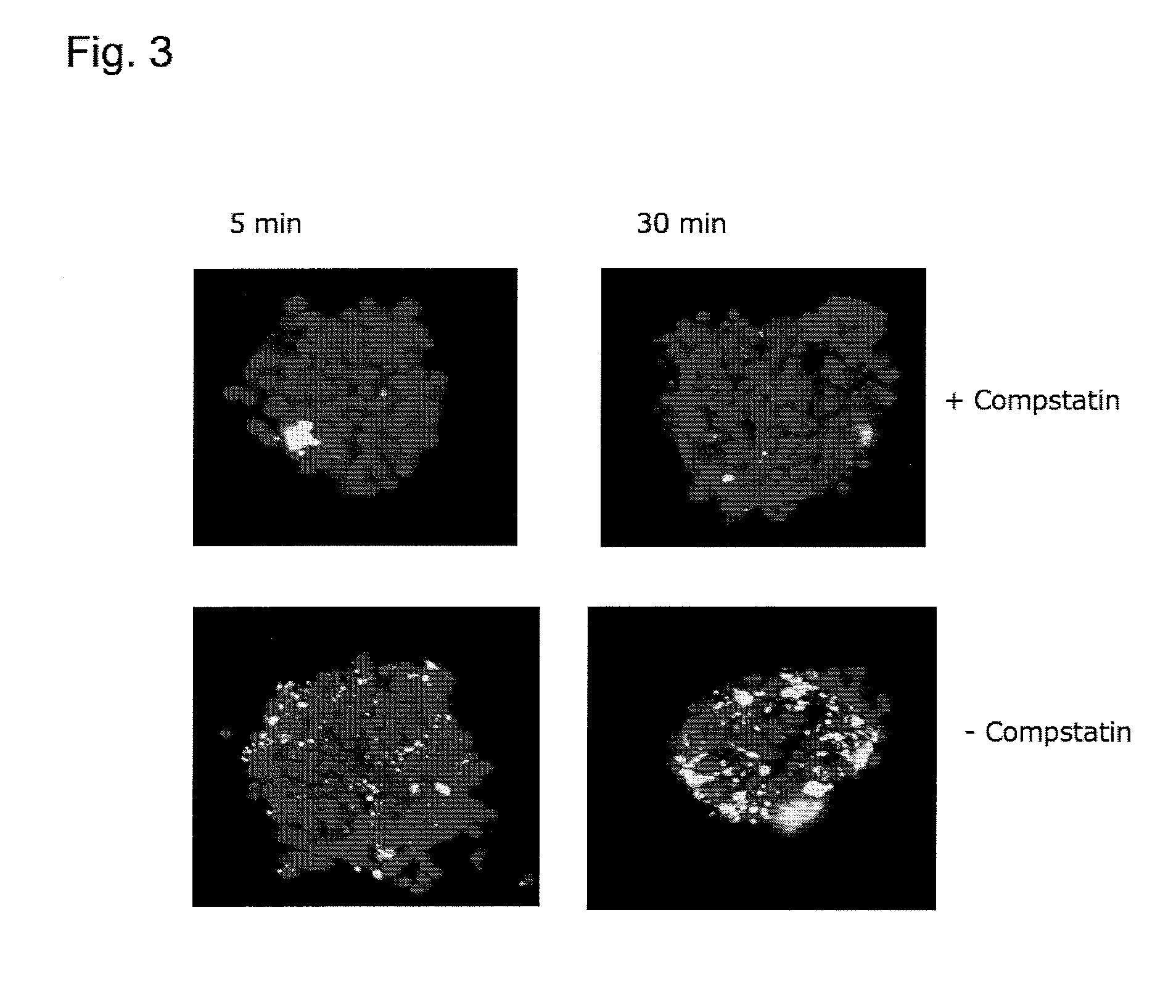

Method Of Reducing Tissue Loss In Pancreatic Islet Cell Transplantation

InactiveUS20110008343A1Inhibition releaseEasy to implantPeptide/protein ingredientsUnknown materialsComplement InhibitorsPancreatic islets

Methods for reducing rejection of pancreatic islet cells transplanted into a subject are disclosed. The methods involve transplanting pancreatic islet cells into a subject in the presence of a complement inhibitor, alone or combined with dextran sulfate.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

A method for producing phospholipase D by recombinant Escherichia coli

ActiveCN109136207BInhibition of lysisOptimal physiological stateBacteriaHydrolasesEscherichia coliPhospholipase

Owner:XIAMEN UNIV

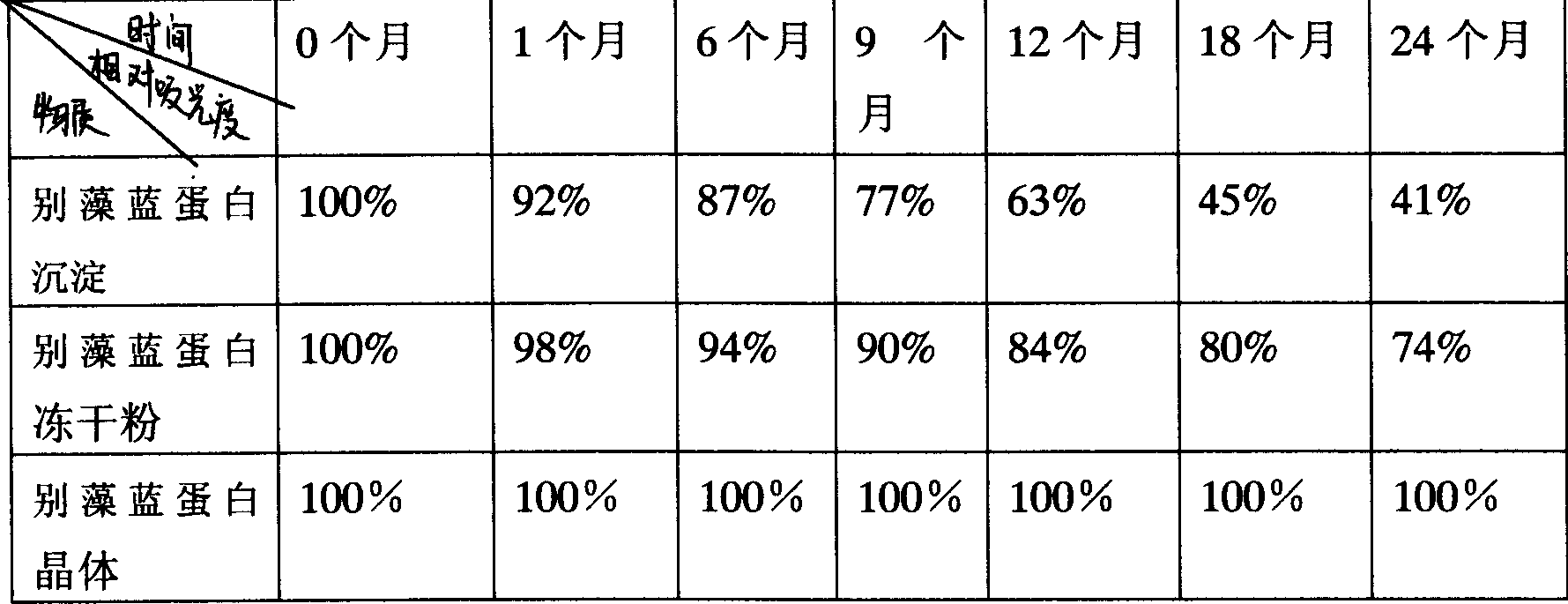

Production technology of allophycocyanin and crystal and product thereof

ActiveCN1786025AFor long-term storagePreservation conditions require littlePeptide preparation methodsAlgae/lichens peptidesFluorescenceAllophycocyanin

The present invention relates to a protein, crystal preparation process and its product, in particular, it relates to an allophycocyanin which is extracted from algae under the general condition and can emit strong fluorescence, and can convert it into crystal form. It can be extensively used in the fields of scientific research, medicine, detection and telecommunication, etc.

Owner:福建省神六保健食品有限公司

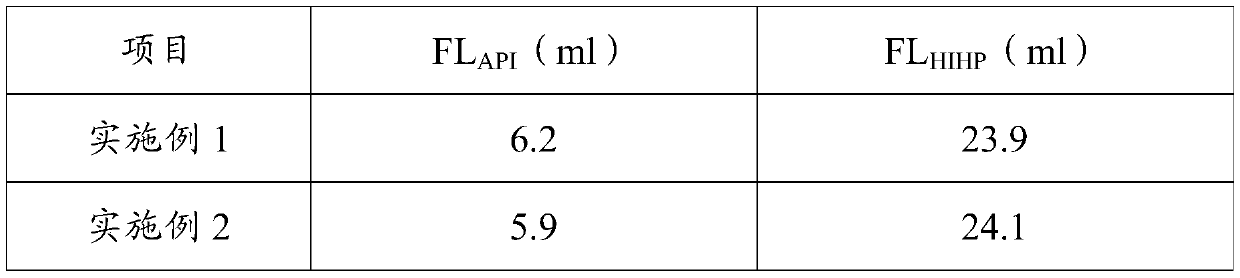

Petroleum drilling auxiliary and preparation method thereof

ActiveCN109913186AImproved heat and salt resistanceGood heat and salt resistanceDrilling compositionPotassiumPetroleum

The invention discloses a petroleum drilling auxiliary, the petroleum drilling auxiliary comprises the following components by mass: 80-100 parts of modified humic acid, 20-30 parts of 4-hydroxyl-6-acetamido-2-naphthalene sulfonic acid, 10-15 parts of maleic anhydride acylated chitosan, 5-10 parts of modified potassium hexatitanate whisker, 1-2 parts of a surfactant, and 400-500 parts of water. The invention further provides a preparation method of the petroleum drilling auxiliary. The modified humic acid and the 4-hydroxyl-6-acetamido-2-naphthalene sulfonic acid in the formula are matched inuse and produce a synergistic interaction, the effects of high temperature resistance and salt resistance of a filtrate reducer are improved, and the particularly excellent high temperature resistanceof the modified potassium hexatitanate whisker reduces the use level of the filtrate reducer in a drilling fluid. The petroleum drilling auxiliary has the functions of resisting the high temperatureof 260 DEG C and resisting saturated salt water, further effectively reduces the filter loss of the drilling fluid, and has a broad application prospect.

Owner:SHAANXI YANCHANG PETROLEUM GRP

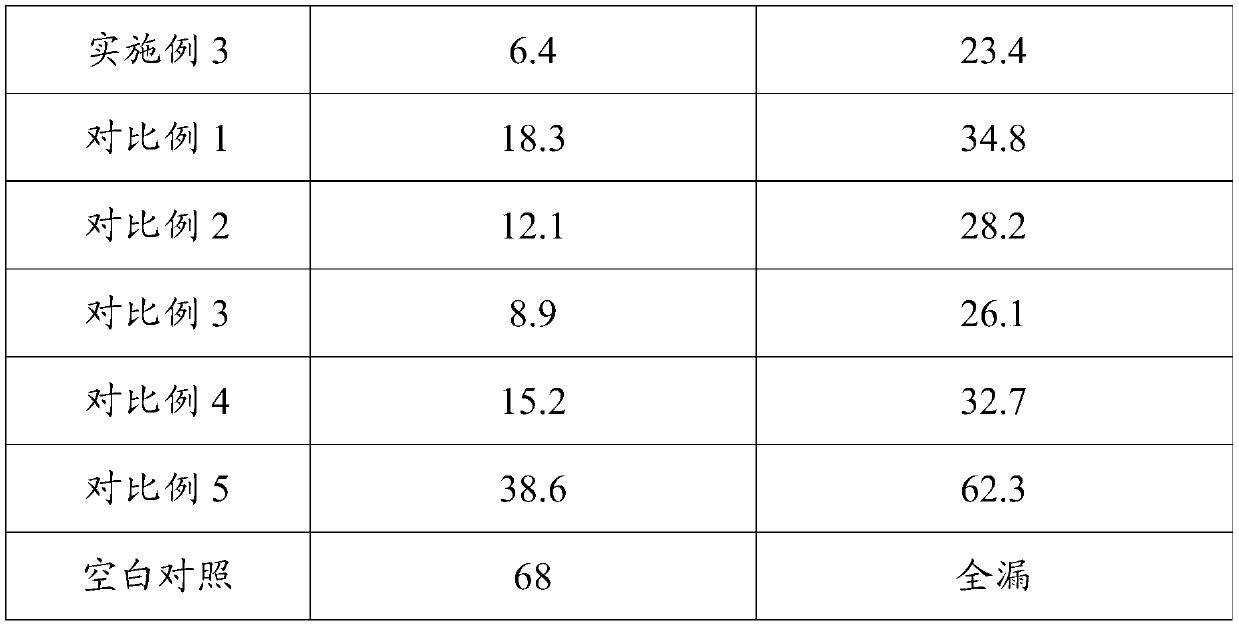

Novel silicone rubber containing phenyl-terminated methylvinyl(tetraphenyl)phenyl

Novel silicone rubber containing phenyl-terminated methylvinyl(tetraphenyl)phenyl relates to silicone rubber; the invention relates to novel silicone rubber containing phenyl-terminated methylvinyl(tetraphenyl)phenyl, made from, by weight, 100 parts of 107 silicone rubber of specific viscosity, 10 parts of a reinforcing agent, 10 parts of a heat resistant additive, 10 parts of a cross-linking agent, 5 parts of a catalyst, and 10 parts of an aid. The novel silicone rubber can be kept elastic in a wide temperature range, has good adhesion with various base materials, and has good tolerance to high temperature; by adding the rubber containing phenyl-terminated methylvinyl(tetraphenyl)phenyl to the silicone rubber, heat resistance of the silicone rubber is improved and the applicable range of the silicone rubber is widened.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Production technology of fluorescent phycocyanin and crystal and product thereof

ActiveCN1786026AFor long-term storagePreservation conditions require littlePeptide preparation methodsAlgae/lichens peptidesFluorescencePhycocyanin

The present invention relates to a protein, crystal preparation process and its product, in particular, it relates to a fluorophycocyanin which is extracted from algae under the general condition and can emit strong fluorescence, and can convert it into crystal form. It can be extensively used in the fields of scientific research, medicine, detection and telecommunication, etc.

Owner:福建省神六保健食品有限公司

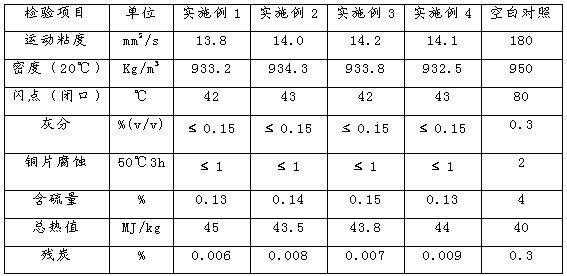

Environment-friendly composite fuel oil additive and preparation method thereof

ActiveCN103627456AInhibition of lysisThe catalytic effect of combustion is remarkableLiquid carbonaceous fuelsEnvironmental chemistryCarbon black

The invention provides an environment-friendly composite fuel oil additive and a preparation method thereof. The environment-friendly composite fuel oil additive comprises 120# solvent oil, calcium sulfonate, isooctyl nitrate, barium naphthanate, ferrocene / manganese complex and sodium diisooctyl sulfosuccinate. The additive solves the problems of high pollutant content and harm to the human body after combustion of heavy oil; and the heavy fuel oil catalytic combustion additive added into the heavy oil can greatly lower the concentration of carbon black in fume, thereby alleviating the environmental problem caused by combustion of heavy oil.

Owner:SHANDONG TAIDE NEW ENERGY

A kind of dehydrogenation catalyst with silica as carrier and preparation method thereof

ActiveCN103785411BRestore fastInhibition decreasedHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsActive componentDehydrogenation

The invention discloses a dehydrogenation catalyst, which uses silica as a carrier, Pt as a dehydrogenation active component, Sn as a first aid, one or more metal of Cu, Fe, Co and Ni other as a second aid; and the catalyst comprises 0.1%-2% of the dehydrogenation active component, and calculated by the weight of the carrier 0.1-10 wt% of the first aid and 0.1-10 wt% of the second aid. A preparation method of the dehydrogenation catalyst is as below: loading the first aid Sn and the second aid, which is one or more selected from Cu, Fe, Co and Ni, and the active component Pt, by using silica gel as the carrier through an immersion method. This method can substantially increase the activity and stability of the catalyst and selectivity of alkene.

Owner:CHINA PETROLEUM & CHEM CORP +1

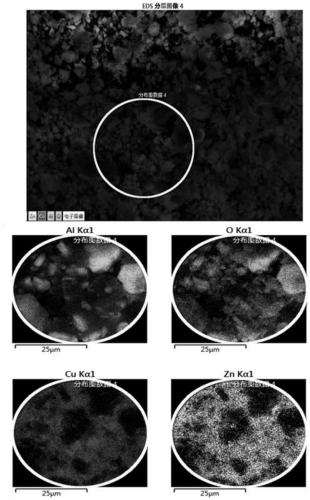

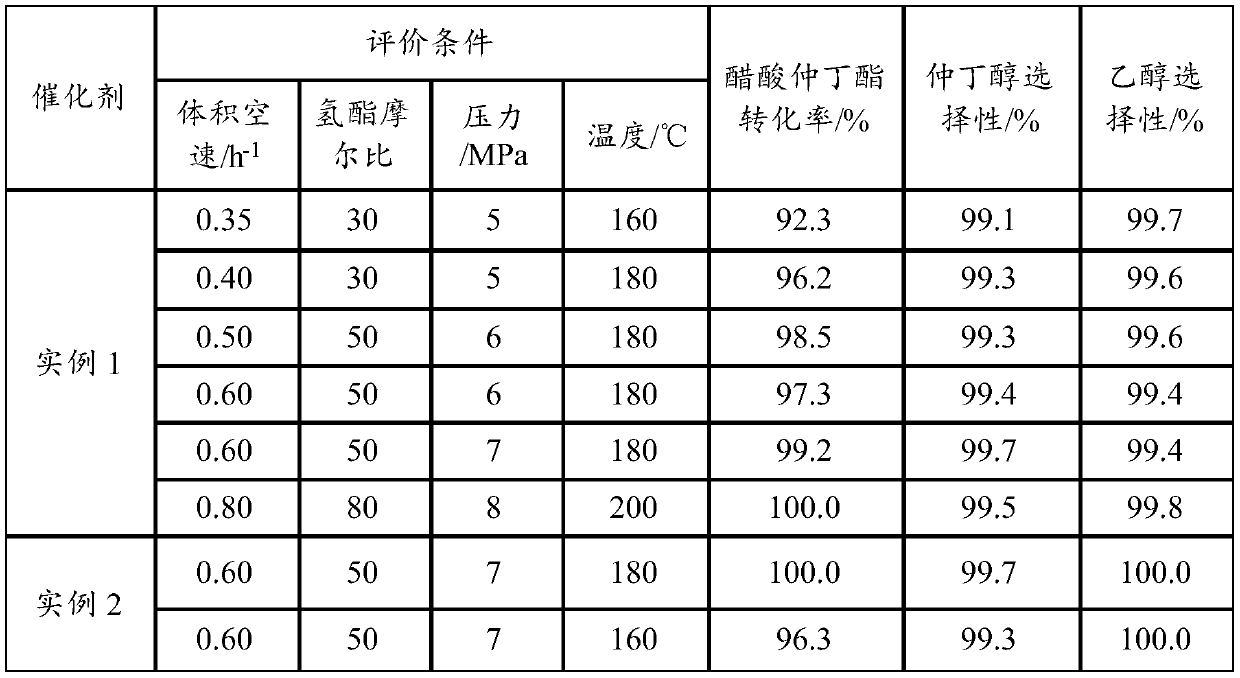

Catalyst for sec-butyl acetate hydrogenation reaction, and preparation method and application thereof

PendingCN111036218AEvenly dispersedImprove thermal stabilityOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystMagnesium salt

The invention provides a catalyst for a sec-butyl acetate hydrogenation reaction, and a preparation method and an application thereof. The preparation method comprises the following steps: adding a metal salt solution and a precipitant solution into a suspension of an Al2O3 precursor, performing a precipitation reaction, and aging to obtain a precipitate, wherein the Al2O3 precursor is selected from one or more of aluminum hydroxide dry glue, pseudo-boehmite and gamma-Al2O3 powder, the metal salt solution comprises a soluble copper salt and a soluble auxiliary agent, the soluble additive is selected from one or more of a soluble zinc salt, a soluble magnesium salt, a soluble calcium salt and a soluble barium salt, and the precipitator solution comprises sodium carbonate, sodium hydroxide and water in a mass ratio of (3.0-8.0):1.0:(3.5-10.0); and filtering, washing, drying and roasting the precipitate to obtain the catalyst. The catalyst comprises 5-60 wt% of Al2O3, 10-30 wt% of CuO and30-70 wt% of auxiliary oxide. The catalyst has high selectivity, good low-temperature reaction performance and sintering resistance.

Owner:SHANDONG JINGBO PETROCHEM

PVC plastic pipe fitting

The invention discloses a PVC plastic pipe fitting prepared from the following raw materials in parts by weight: 30-50 parts of ASA resin, 9-15 parts of a thermoplastic polyurethane elastomer, 7-14 parts of butyl acrylate, 7-14 parts of magnesium hydroxide, 22-42 parts of polyvinyl chloride resin, 11-16 parts of nitrile rubber powder, 10-16 parts of crosslinked starch, 8-16 parts of attapulgite, 9-14 parts of silicon carbide whisker and 6-9 parts of a lubricant. The PVC plastic pipe fitting provided by the invention has the advantages of high toughness, high rate of elongation, good anti-aging effect, high strength, low cost and good corrosion and high-temperature resisting effects.

Owner:QINGDAO JISHUNLONG TRADING

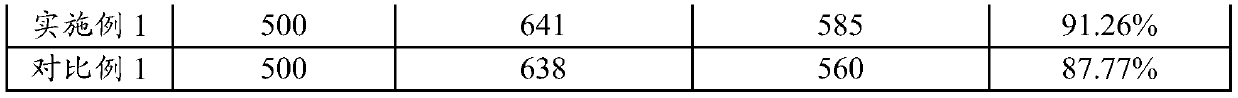

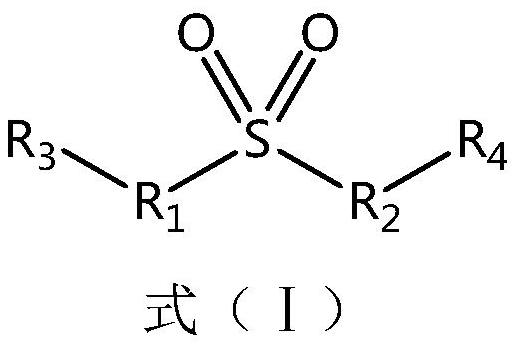

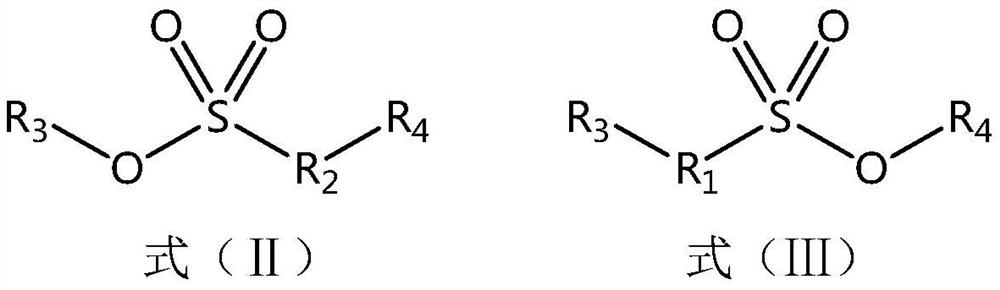

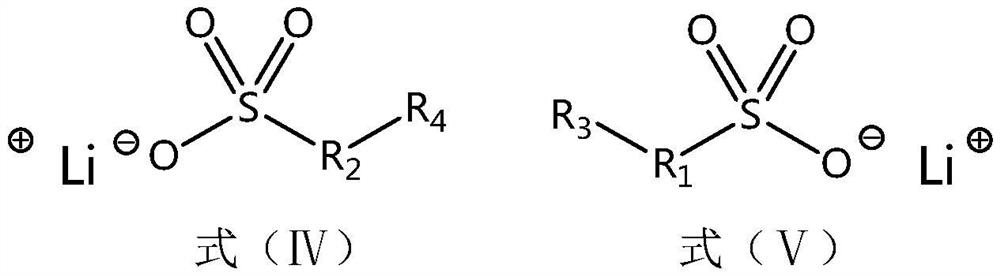

Lithium ion battery non-aqueous electrolyte and lithium ion battery

ActiveCN112310475ALower impedanceElasticSecondary cellsOrganic electrolytesElectrolytic agentAqueous electrolyte

The invention belongs to the technical field of lithium ion batteries, and discloses a lithium ion battery non-aqueous electrolyte and a lithium ion battery. The non-aqueous electrolyte of the lithiumion battery comprises an electrolyte lithium salt, a non-aqueous organic solvent and a film-forming additive, wherein the film-forming additive comprises a compound with a structure shown in a formula (I), and the formula (I) is shown in the description. The chalcogenide additive with the structure shown in the formula (I) can form a passivation film on a negative electrode interface better, so that the cracking of the passivation film caused by the expansion of graphite or a silicon-based material in the charging and discharging process is inhibited. Meanwhile, the increase of alternating-current impedance of the battery in the cycle process can be reduced, and the battery cycle performance is improved. Besides, novel conductive lithium salt lithium difluorophosphate and lithium bis(fluorosulfonyl)imide with good film-forming characteristics are added, and compared with single use of LiPF6, multiple novel film-forming lithium salts are combined for use, so that the high and low temperature performance, the rate capability and the long cycle performance of the power battery are improved.

Owner:SHANSHAN ADVANCED MATERIALS QUZHOU CO LTD

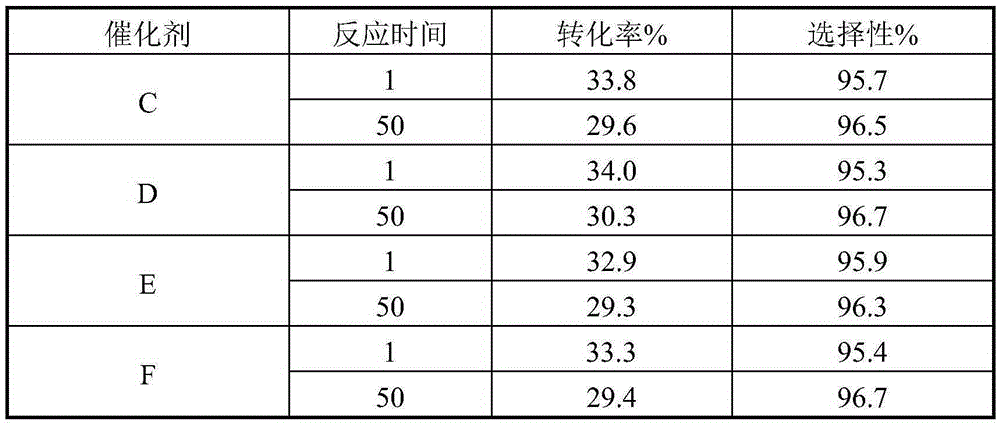

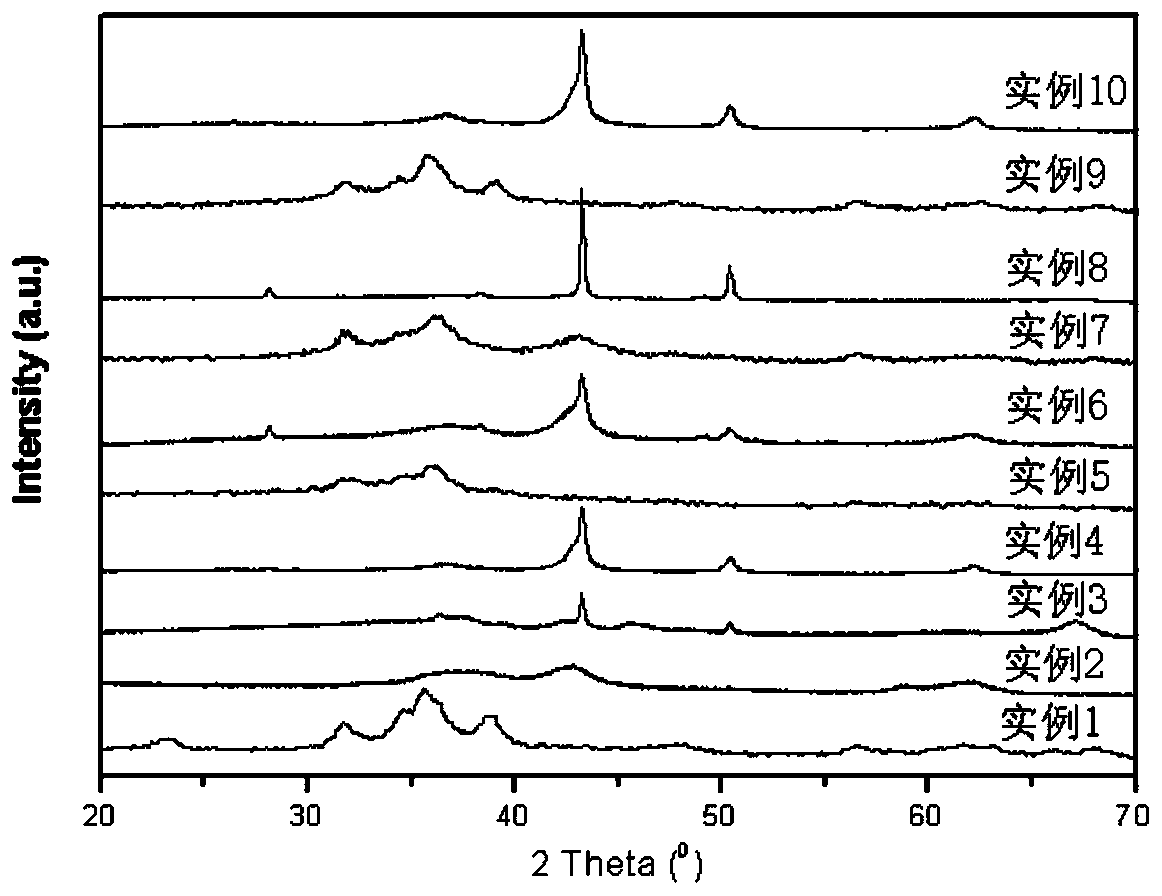

Pt-based multi-component catalyst for dehydrogenation of propane to propylene and preparation method thereof

ActiveCN111790384BGood dispersionInhibition of lysisHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystDehydrogenation

The invention discloses a Pt-based multi-component catalyst for propane dehydrogenation to propylene, as well as its preparation and application. The catalyst is composed of four components A, B, C and D, wherein A is any one of transition metal oxides, alkaline earth metal oxides or rare earth metal oxides, B is the simple substance of Pt, and C is the oxidation of Sn material, D is dehydrated alumina. The present invention utilizes the interaction between metal additives and Pt and Sn to realize high dispersion of active metal Pt and reduce Sn 4+ The reduction can effectively control the composition of multi-component catalysts, so as to accurately prepare Pt-based multi-component catalysts that are stable at high temperatures, low carbon deposition coverage and good durability. The catalyst prepared by the invention has high-efficiency propane dehydrogenation performance and propylene selectivity, provides an efficient catalyst for the propane dehydrogenation technology, and thus can promote the rapid and healthy development of the propane dehydrogenation technology.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com