Patents

Literature

91results about How to "Reduced shrinkage performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

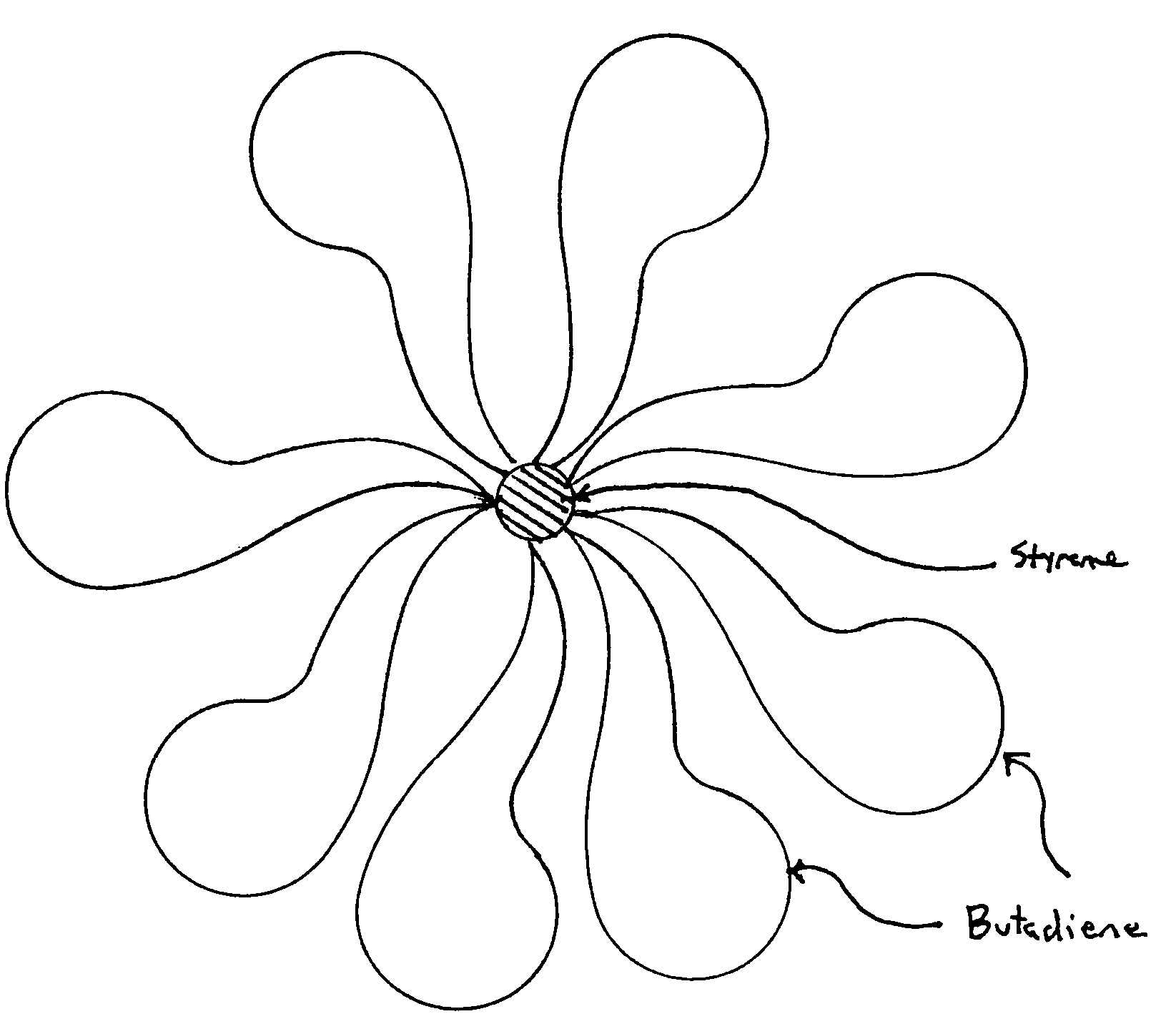

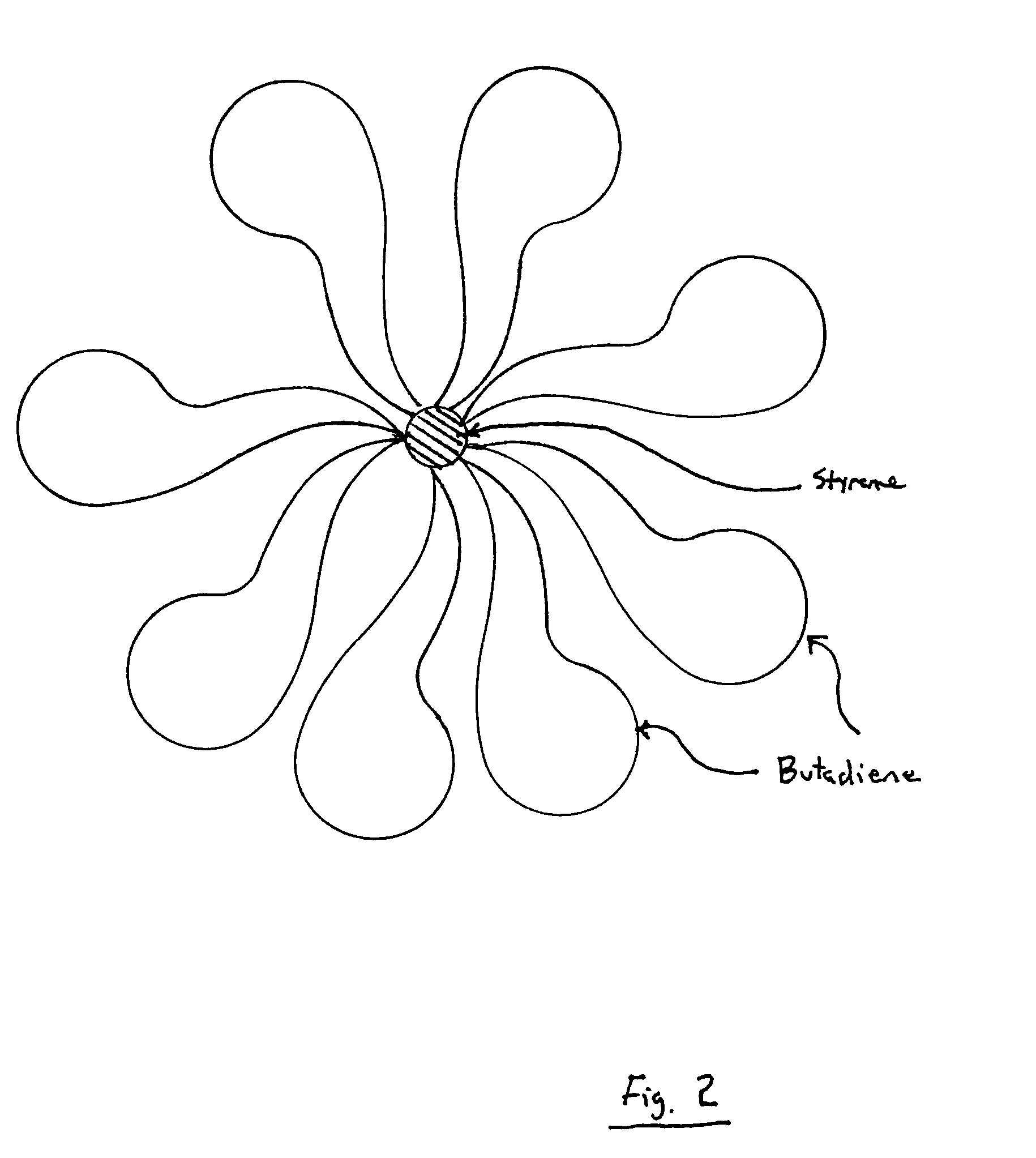

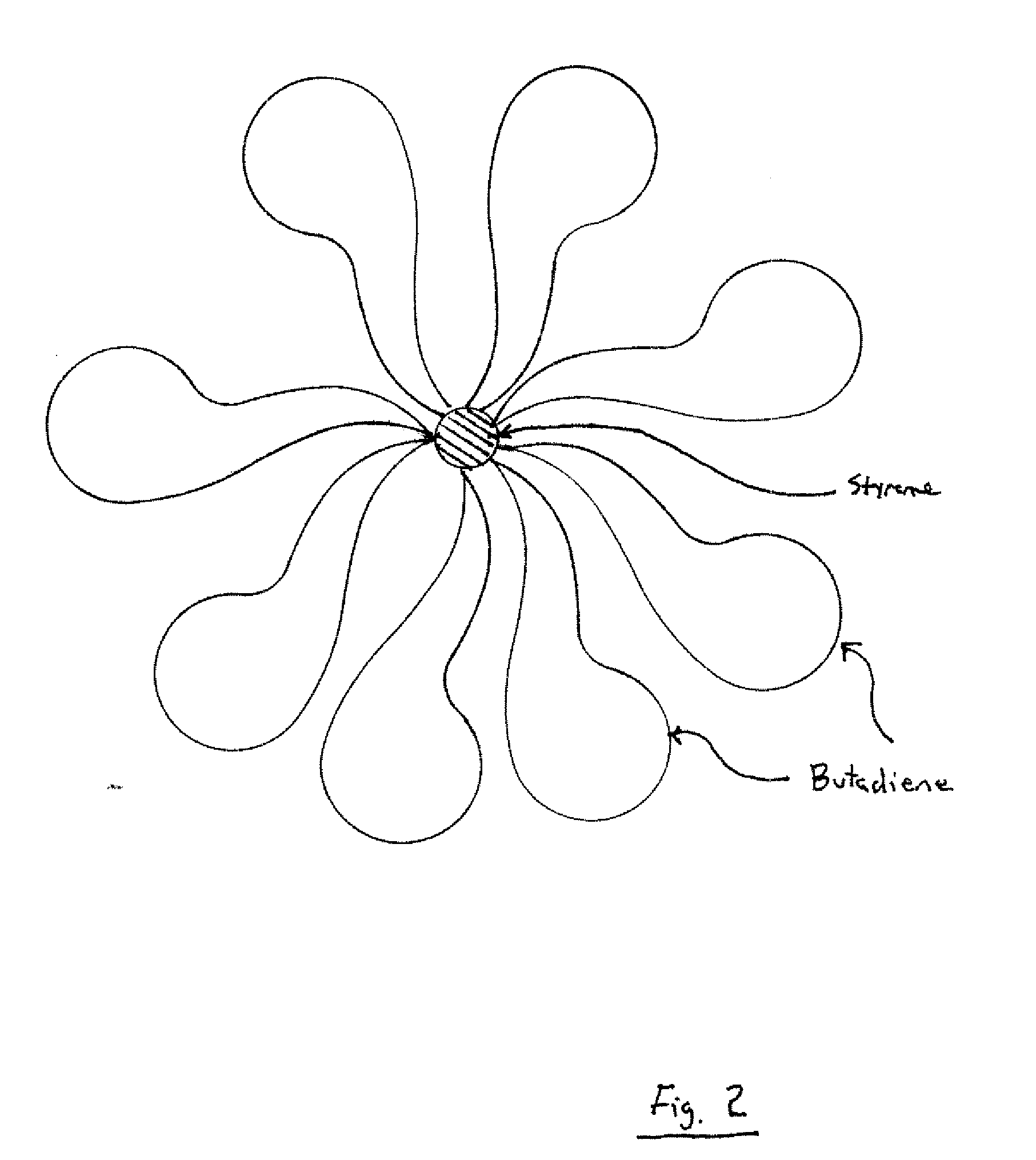

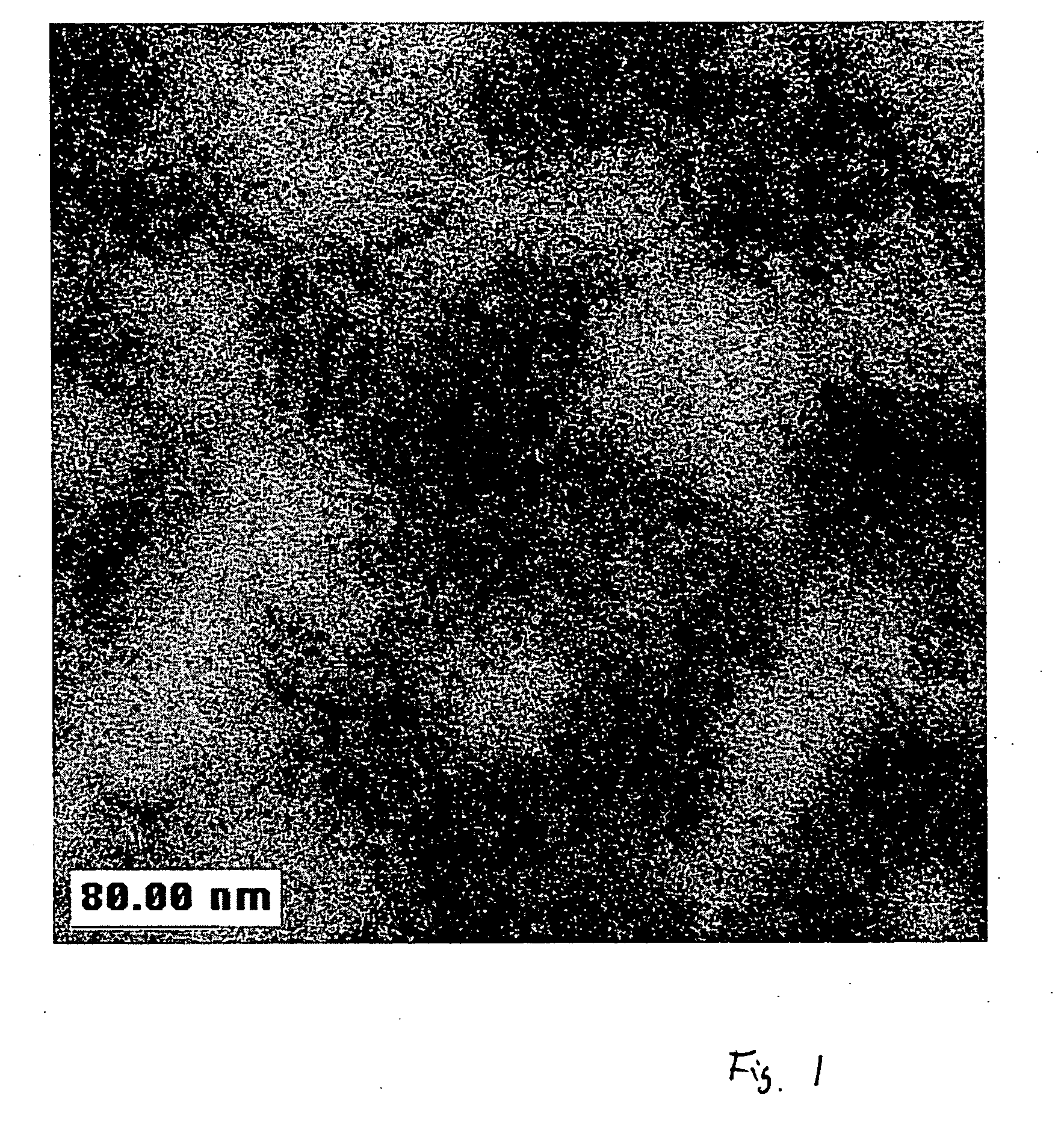

Polymeric nano-particles of flower-like structure and applications

InactiveUS7205370B2Super soft propertyHeat resistantPlastic/resin/waxes insulatorsThermoplasticElastomer

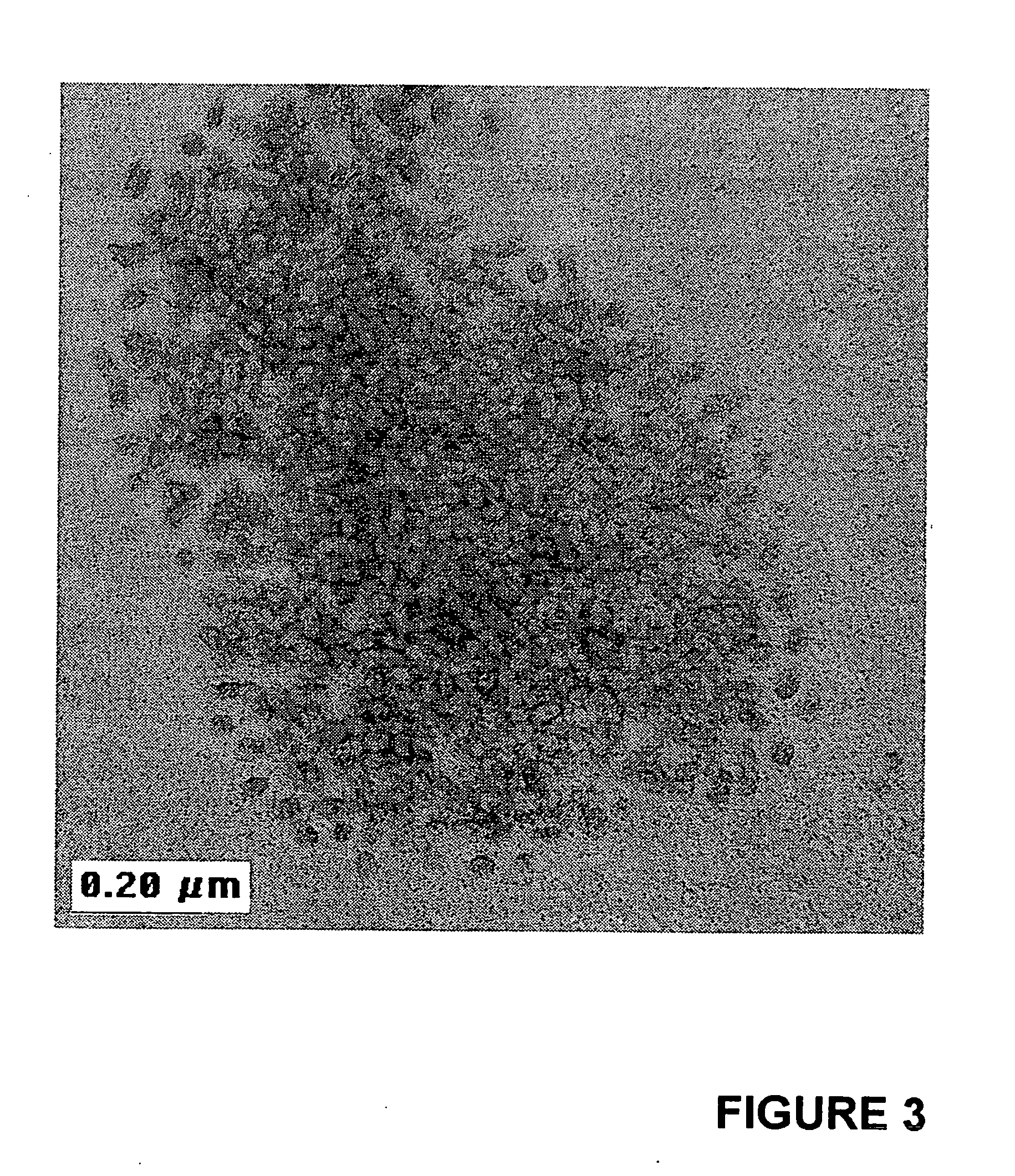

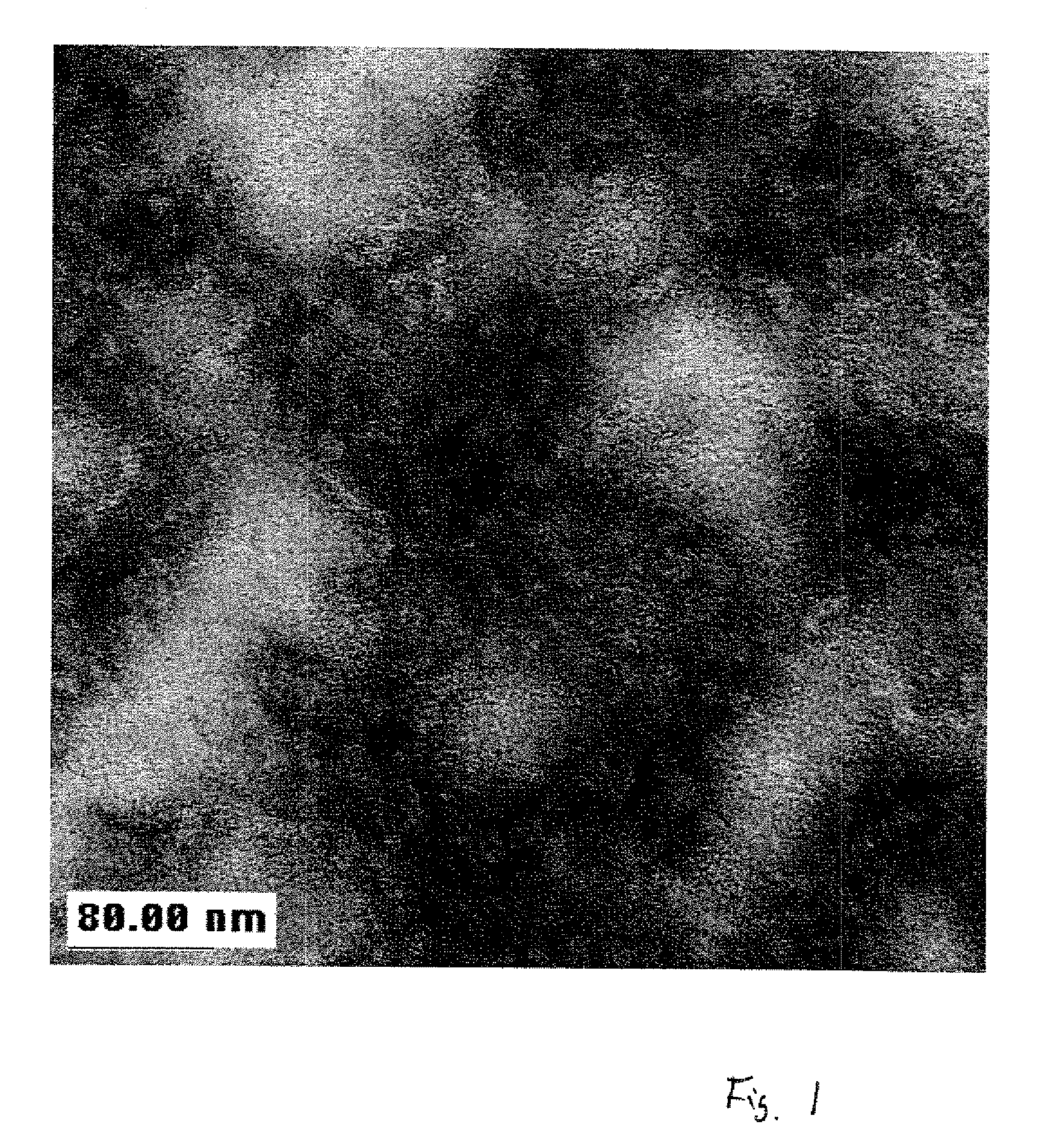

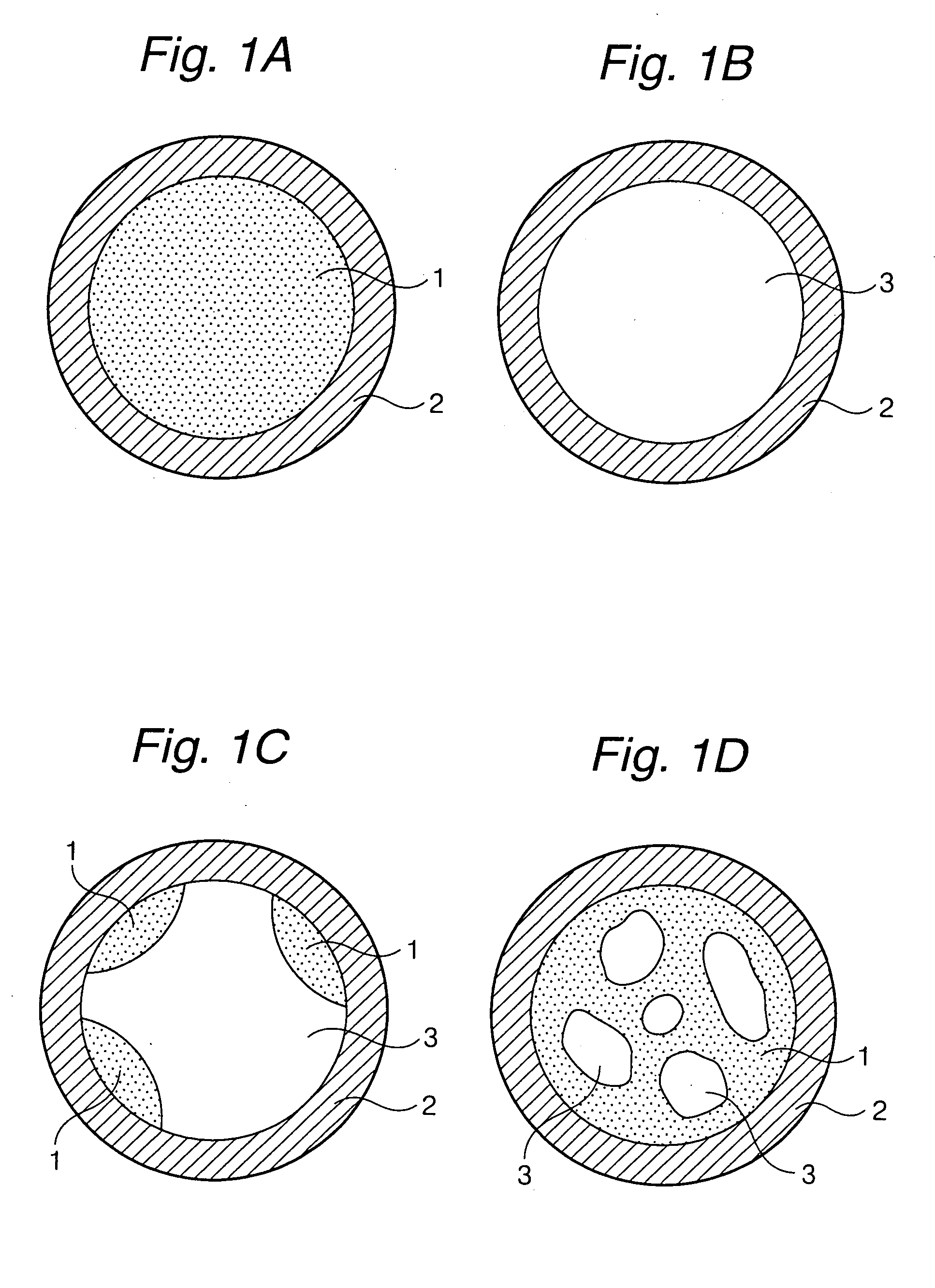

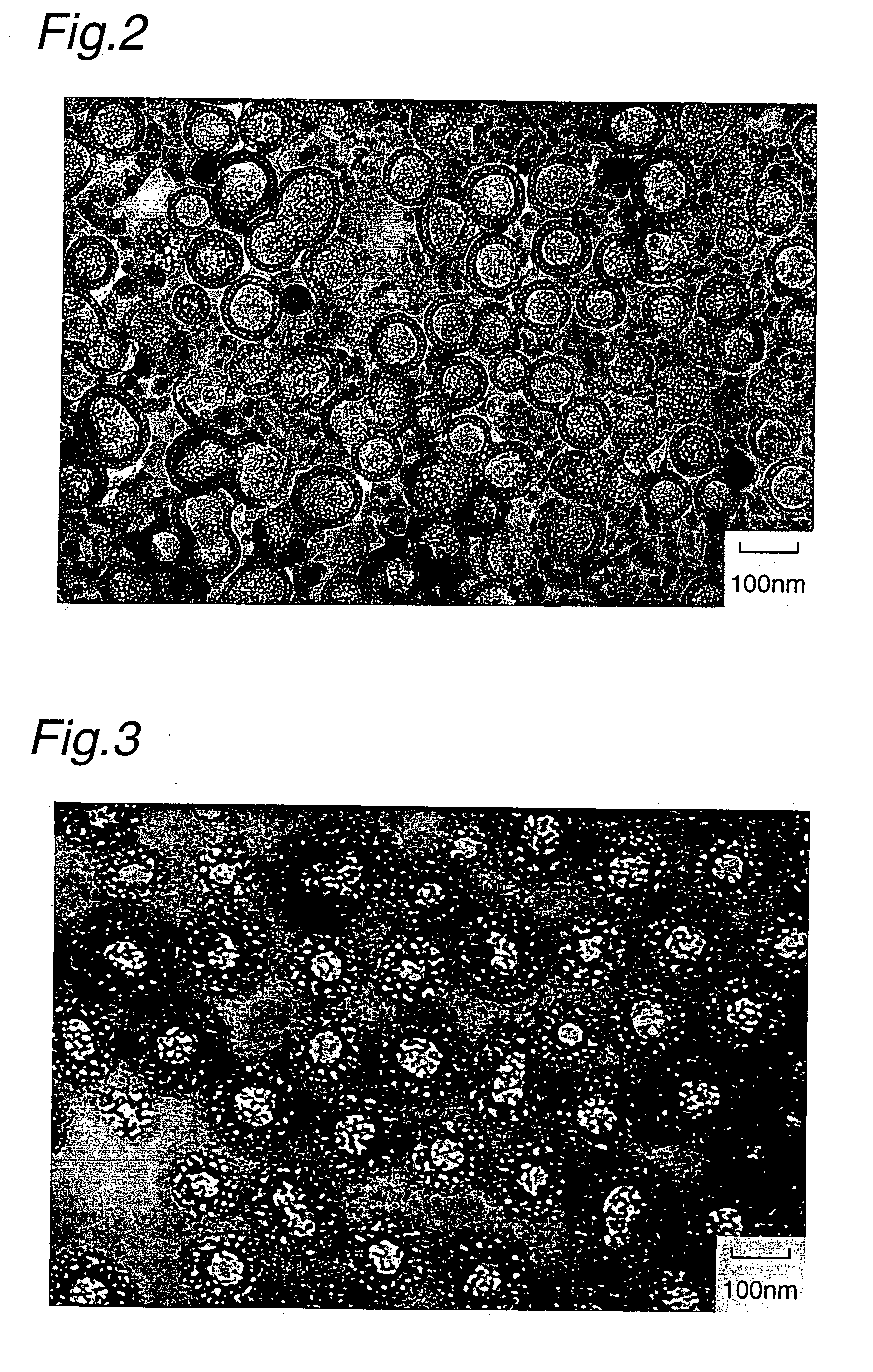

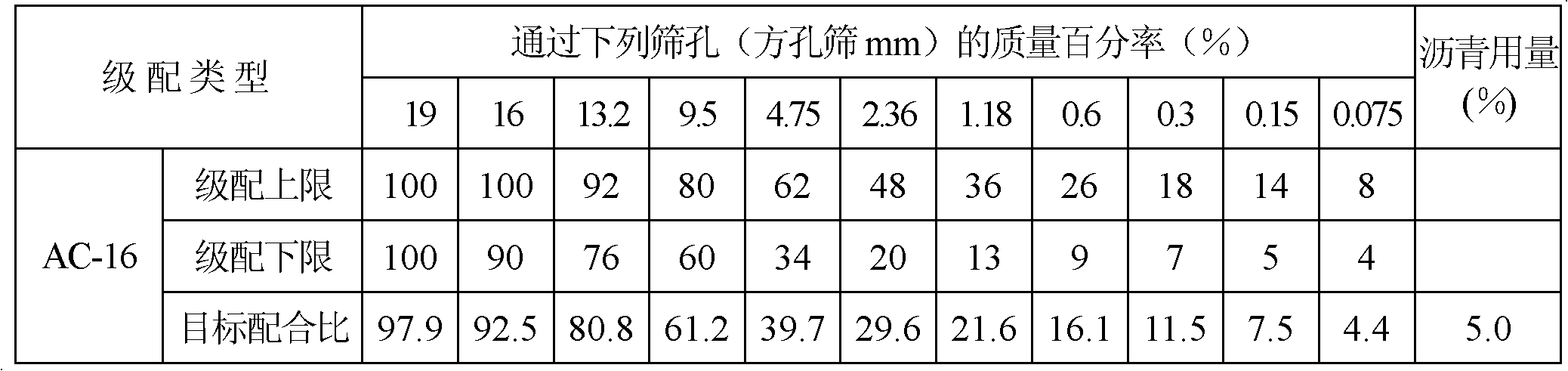

A flower-like nano-particle composition including a poly (alkenylbenzene) core and a poly (conjugated diene) or a poly(alkylene) surface layer is provided. The nano-particles have a mean average diameter less than about 100 nm and are substantially free of chain ends. The nano-particles can be modified via, for example, hydrogenation. The nano-particles can advantageously be incorporated into rubbers, elastomers, and thermoplastics.

Owner:BRIDGESTONE AMERICAS HLDG

Thermoplastic light-duty composite plate and preparing method thereof

The invention discloses a thermoplastic light compound plate and the manufacturing method, characterized in that it comprises acupuncture fiber carpet dipped in double faced foam of thermoplastic glue liquid and thermoplastic glue liquid layer coated on the surface, the density of compound plate is 0.35-0.90g / cm3, the weight of fiber scattered in bunchiness is 15-45% of acupuncture fiber carpet. The merit of invention is very remarkable. Special super long fiber and bunchiness fiber with certain proportion are maintained in the material so that the mechanical performance of material can be improved. In addition, the material is provided with foam structure, very good effect of heat and sound insulation. The invention is also provided with environmental protection and recovery.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

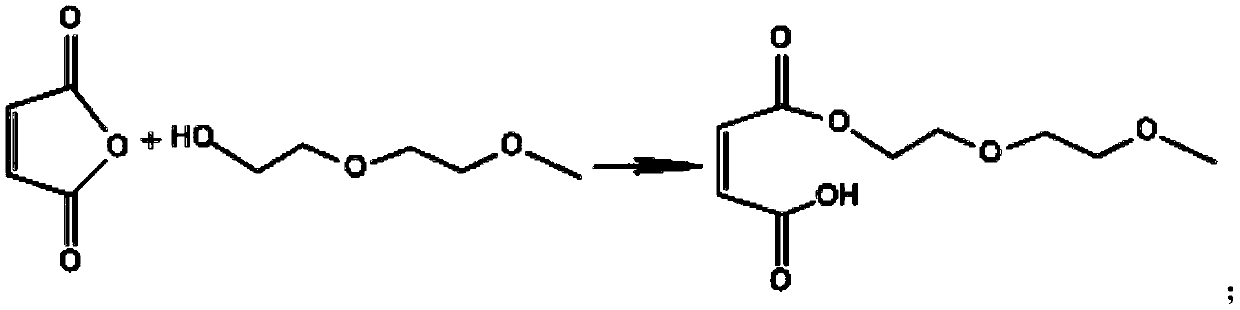

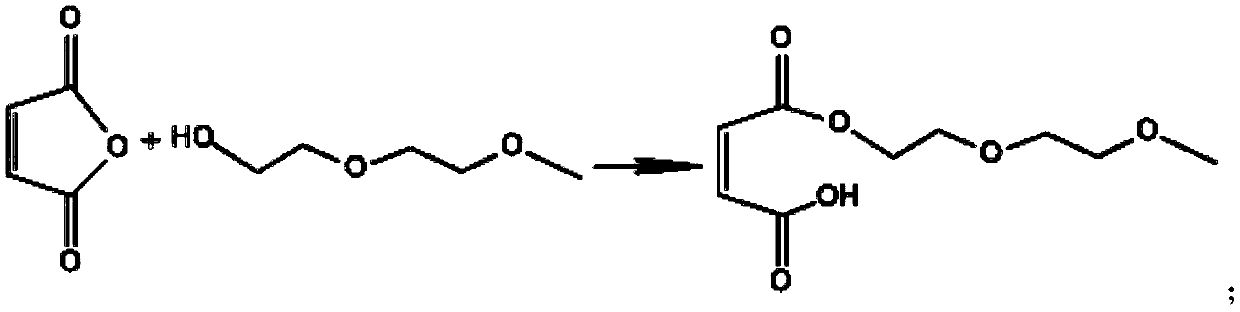

Mud-proof slump-retaining type polycarboxylate superplasticizer with low shrinkage and high adaptability and low-temperature preparation method thereof

InactiveCN110003402AImprove adaptabilityImprove mud slump performanceSuperplasticizerCarboxylic acid

The invention discloses a mud-proof slump-retaining type polycarboxylate superplasticizer with low shrinkage and high adaptability and a low-temperature preparation method thereof. The polycarboxylatesuperplasticizer is mainly prepared by the following steps: carrying out free radical polymerization on 4-hydroxybutylvinyl polyoxyethylene ether, unsaturated carboxylic acid, an unsaturated amide-type monomer, dipolyethylene glycol maleate, an unsaturated quaternary ammonium cationic monomer, an oxidizing agent, a catalyst, a reducing agent, a chain transfer agent and deionized water at 5-15 DEGC through an aqueous solution, regulating pH value by adding a sodium hydroxide solution, and supplementing water. The preparation method of the invention has advantages of low-temperature production, no heat source, simple equipment, no pollution, short reaction time and high production efficiency. The prepared mud-proof slump-retaining type polycarboxylate superplasticizer endows concrete withgood workability, good adaptability, low shrinkage and high strength, has excellent mud-proof slump-retaining property, and greatly reduces construction difficulty.

Owner:SICHUAN TONGZHOU CHEM TECH

Nano-particle preparation and applications

InactiveUS20050192408A1Super soft propertyHeat resistantMaterial nanotechnologyGlass/slag layered productsElastomerThermoplastic

A nano-particle composition including a poly(alkenylbenzene) core and a poly (conjugated diene) or a poly(alkylene) surface layer is provided. The nano-particles have a mean average diameter less than about 100 nm. The nano-particles can be modified via, for example, hydrogenation or functionalization. The nano-particles can advantageously be incorporated into rubbers, elastomers, and thermoplastics.

Owner:BRIDGESTONE FIRESTONE NORTH AMERICAN TIRE

Polymeric Nano-Particles Of Flower-Like Structure And Applications

InactiveUS20070185273A1Super soft propertyHeat resistantPlastic/resin/waxes insulatorsCrystallographyElastomer

Owner:BRIDGESTONE CORP

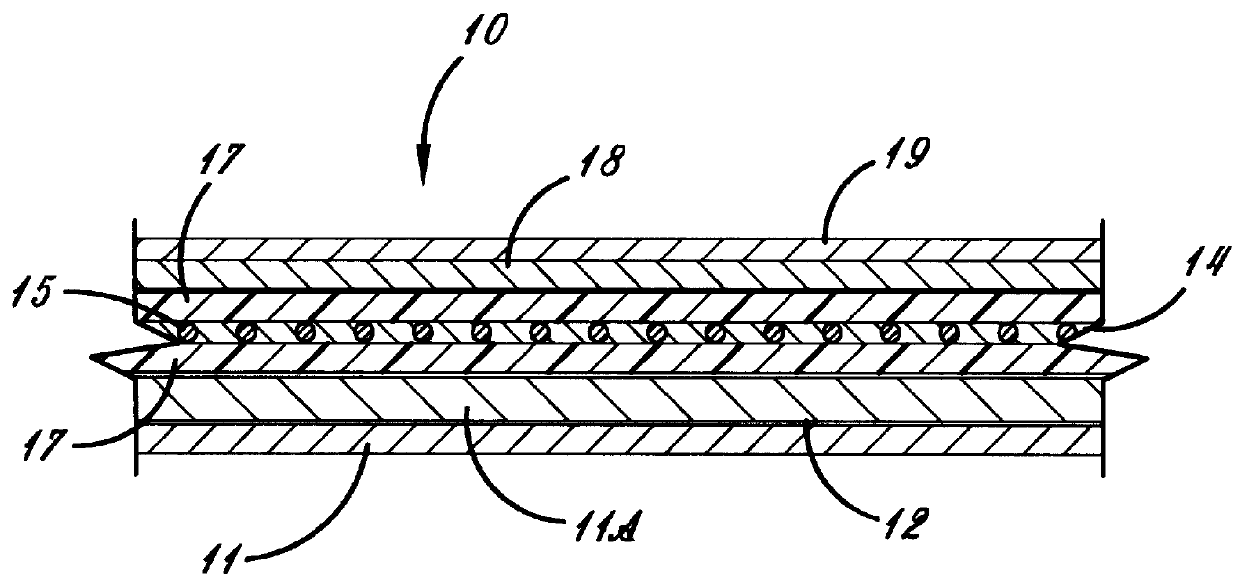

Composite polymer electrolytes for alkali metal electrochemical devices which contain a glass fiber net

InactiveUS6080511ALow costImprove adhesionSolid electrolyte cellsSecondary cellsSolid state electrolyteGlass fiber

Polymer electrolyte composites for alkali metal electrochemical devices which are formed by coating an inert, lightweight, electrically insulating, woven or non-woven glass fiber net with a liquid, ion-conductive polymer, and curing the polymer to form a solid state or semi-solid state electrolyte composite.

Owner:LITHIUM TECH CORP

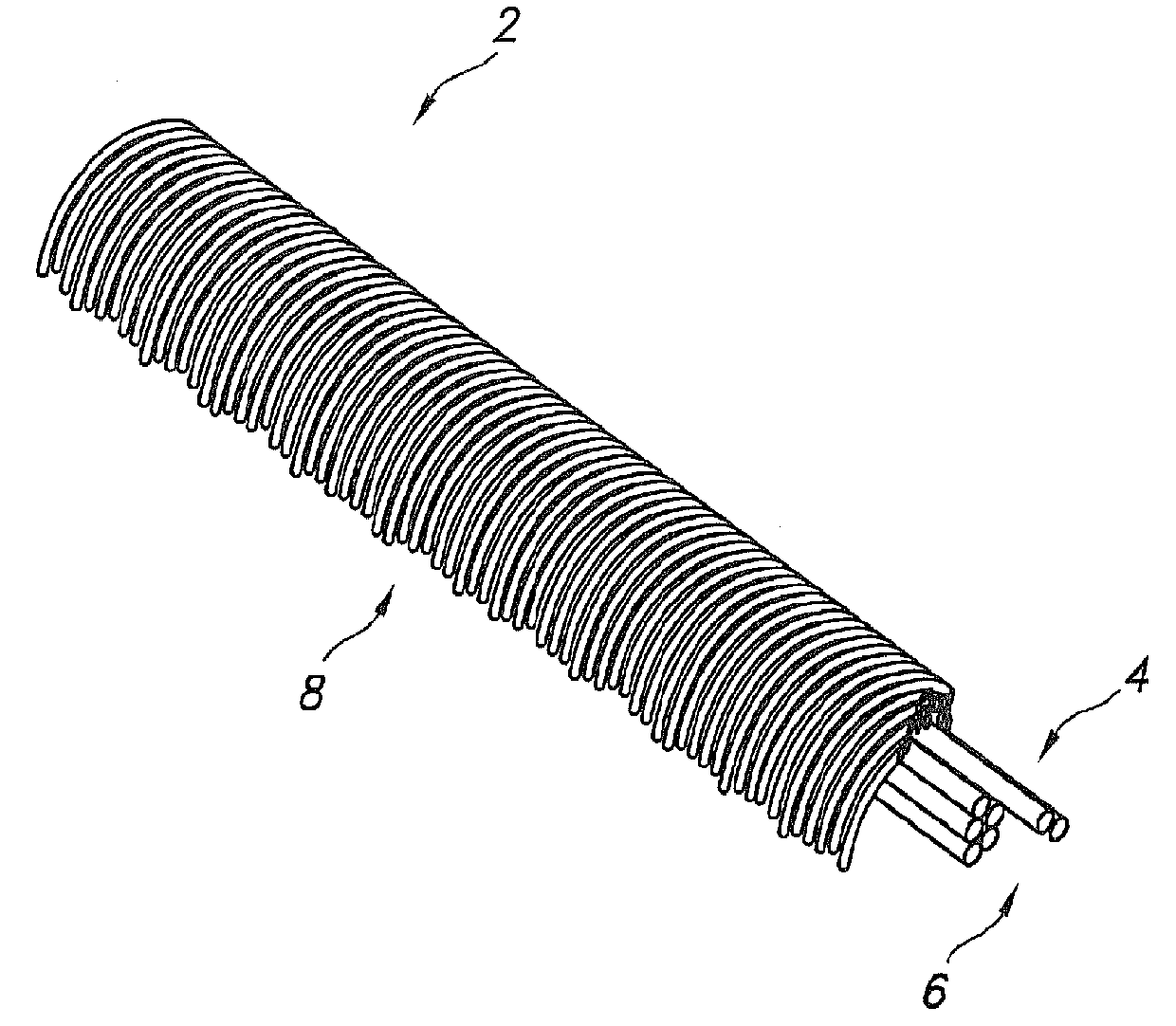

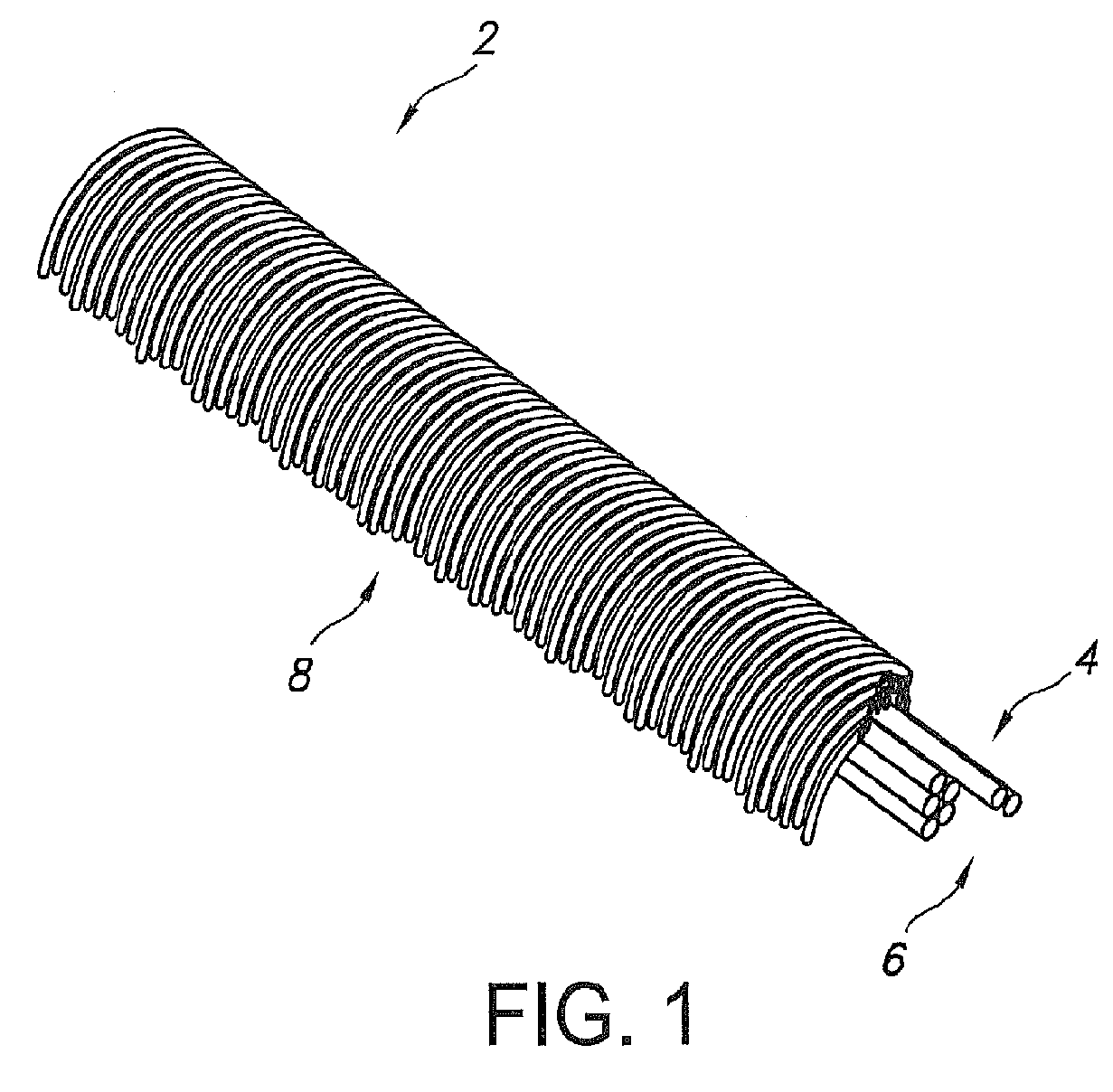

Stretch yarns and fabrics with multiple elastic yarns

Included herein is an articles and methods including a core spun yarn. The core spun yarn includes a sheath of hard fibers and two sets of elastic fibers wherein the sets of elastic fibers have different properties. The properties may differ in one or more ways such as having a different denier, composition or draft. One or both of the sets of elastic fibers can be precovered.

Owner:THE LYCRA CO LLC

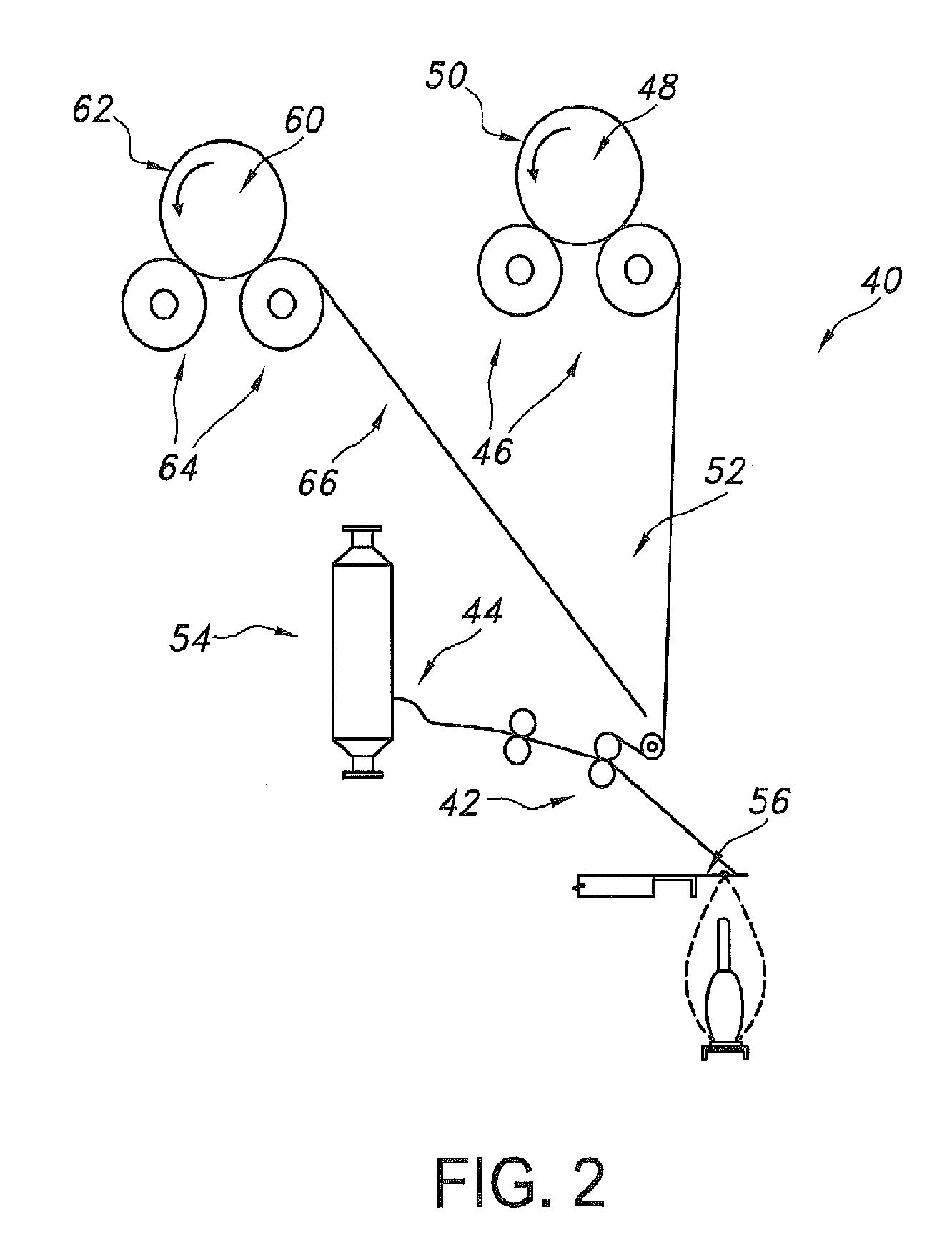

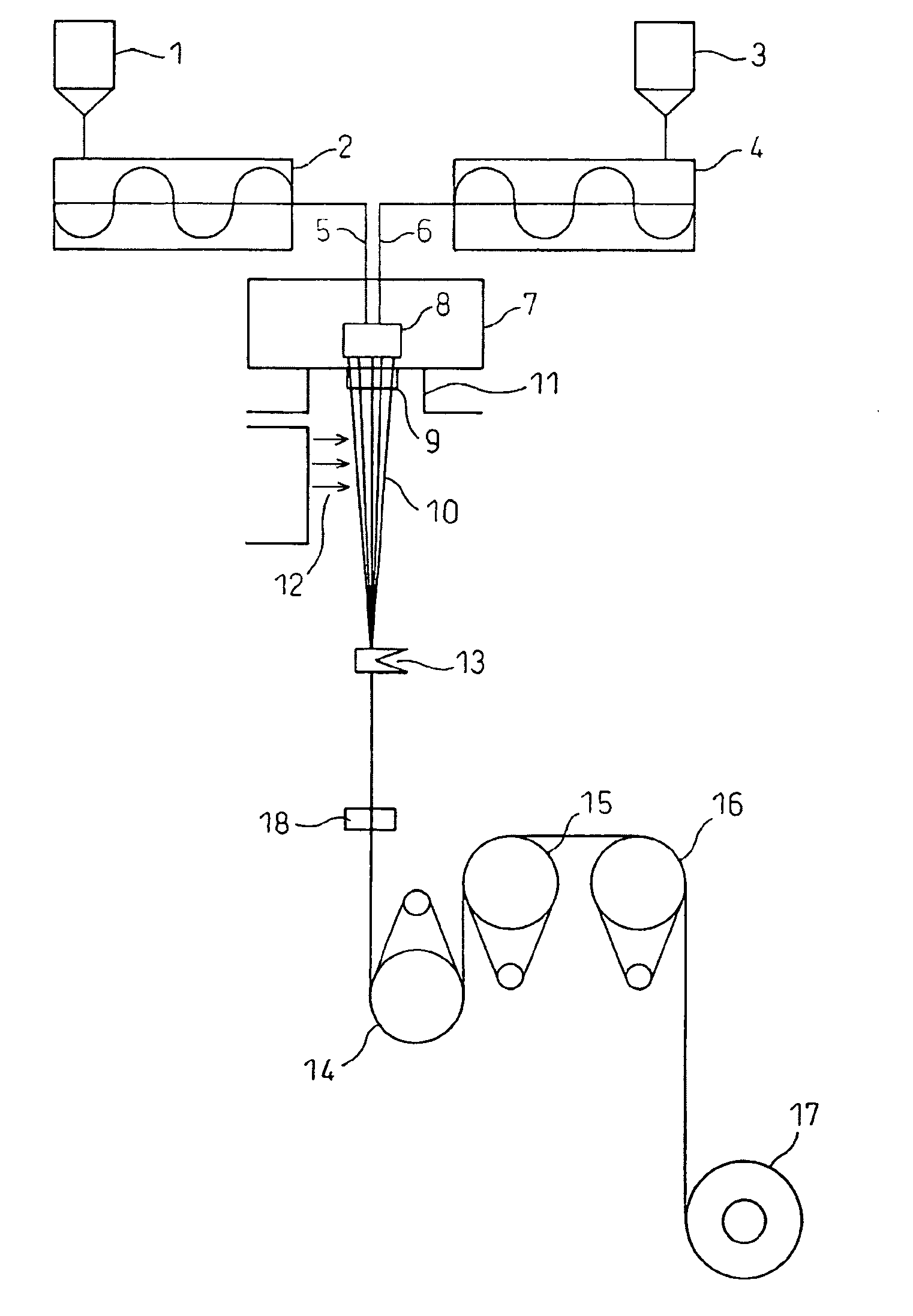

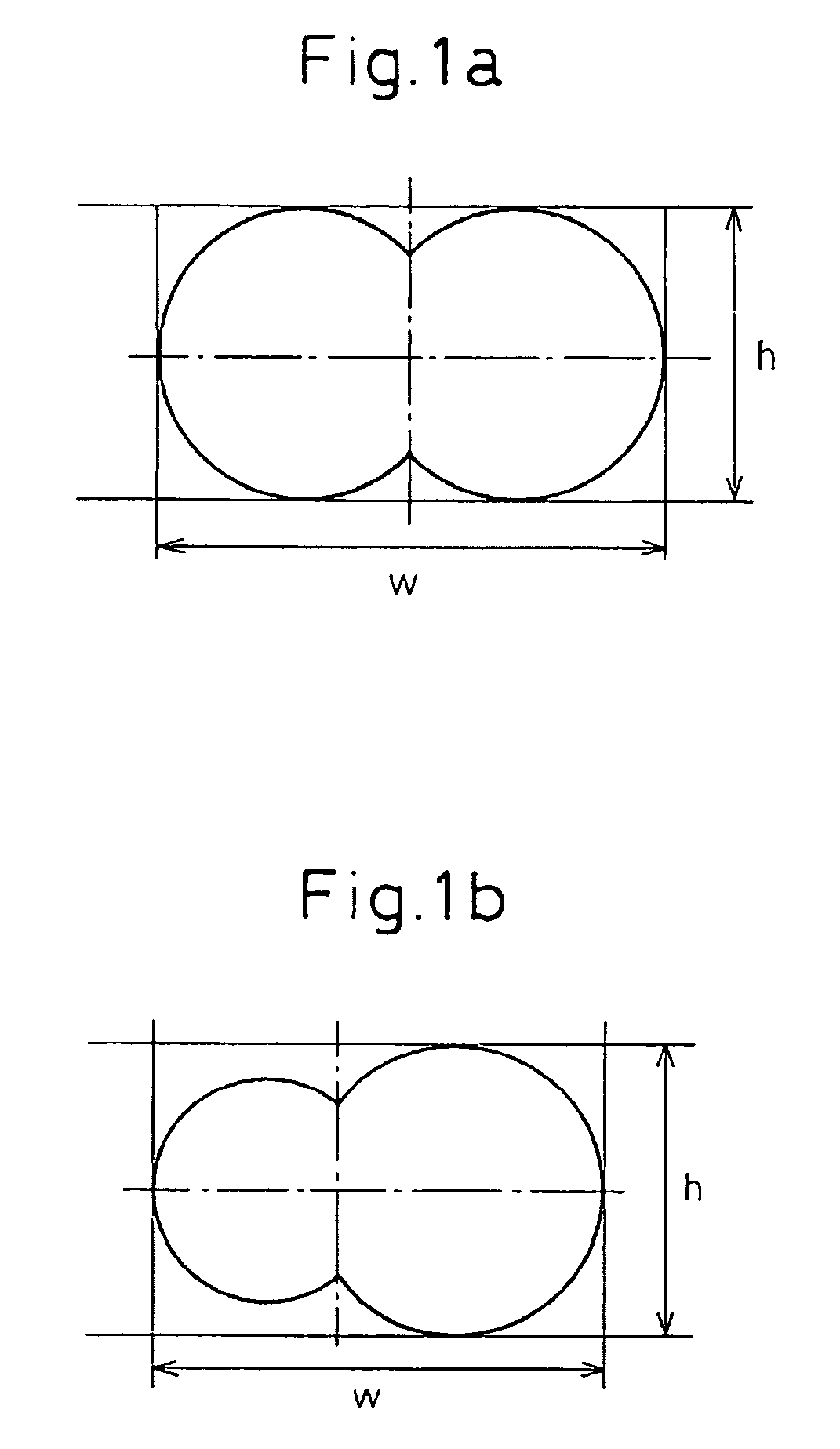

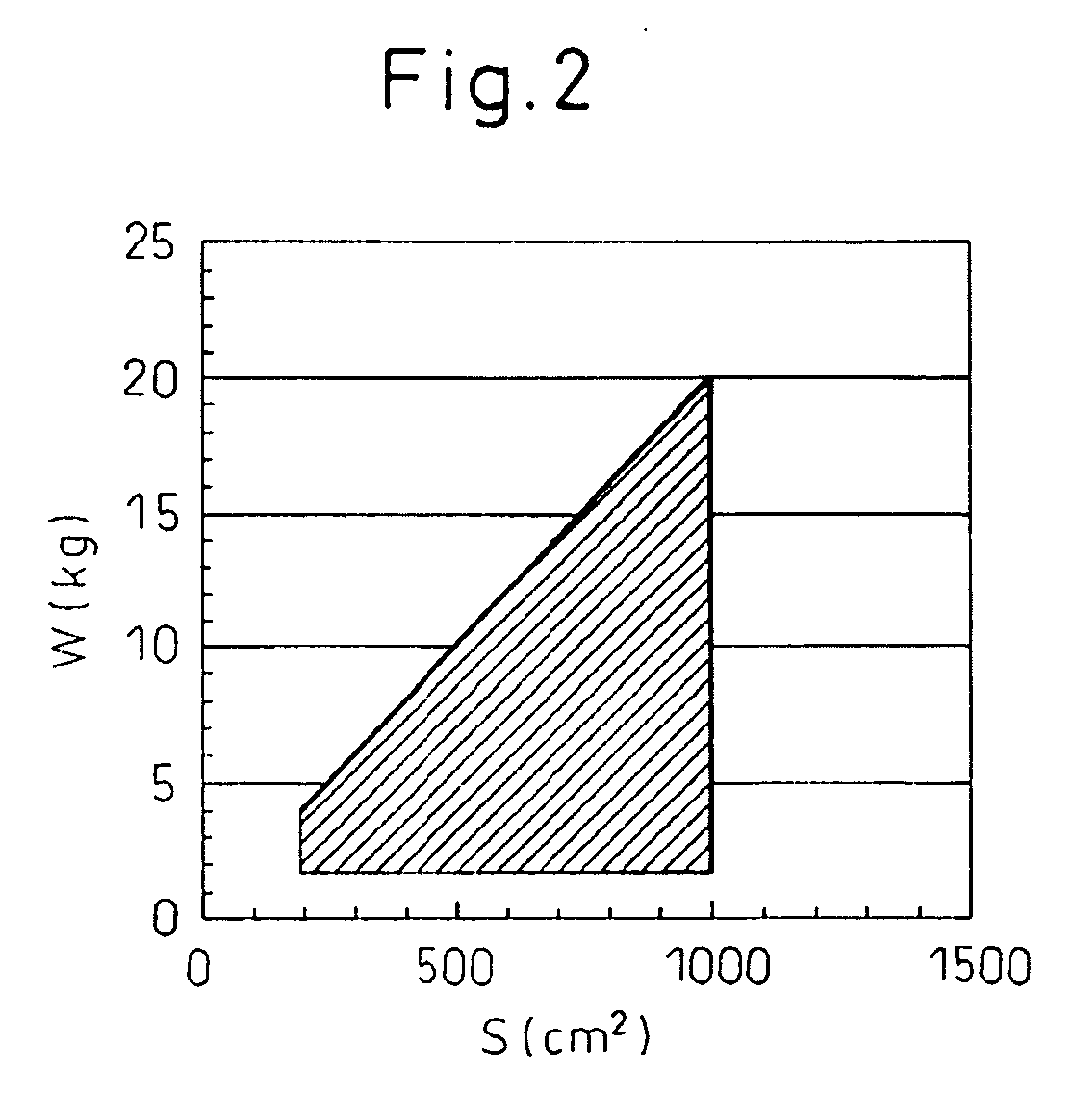

Highly Crimped Conjugated Fiber Cheese Package and Process for Its Production

InactiveUS20080317984A1Easy alignmentImprove shrinkageNew-spun product collectionHollow filament manufacturePolymer sciencePolytrimethylene terephthalate

A highly crimped conjugate fiber cheese package which is obtained by layering on a paper bobbin a conjugate fiber consisting of a plurality of single filament composed of polytrimethylene terephthalate components having different intrinsic viscosities and consisting of at least 90 mol % of a trimethylene terephthalate unit and no more than 10 mol % of another ester repeating unit and laminated to each other in a side-by-side type, the cheese package being characterized by satisfying the following conditions (1)-(4).(1) The single filament composing the conjugate fiber has cross-sectional shape which is flat cross-section with a flatness of 1.1-3 as the ratio between the long axis and short axis.(2) The developed crimp elongation of the conjugate fiber is 30-200%.(3) The relationship between the contact area (compressed net area) S (cm2) between the paper bobbin and conjugate fiber and the wound weight W (kg) satisfies the following formula (1):2≦W≦0.02S (Formula 1)where 240≦S≦1000(4) The package density of the conjugate fiber cheese package is 0.92-1.05 g / cm3.

Owner:SOLOTEX CORP

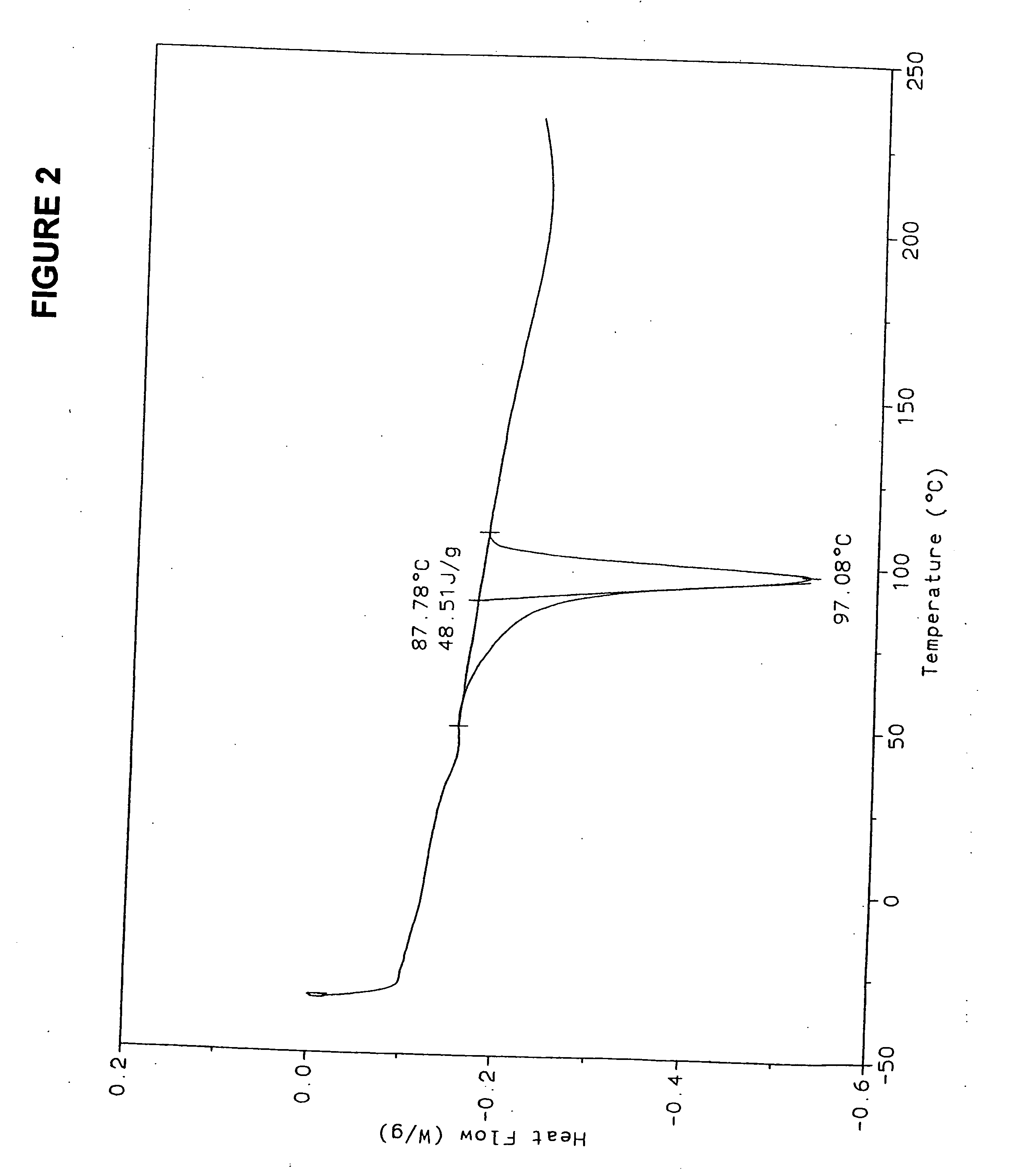

Microporous Polyolefin Multilayer Film Possessing Good Mechanical Properties and Thermal Stability

InactiveUS20120070644A1Good effectHigh propertySemi-permeable membranesMembranesPolyolefinCrystallinity

Provided is a microporous polyolefin multilayer film which may be used as a separator for a battery, and a method for preparing the same. At least one layer of the microporous polyolefin multilayer film contains 90˜100 wt % of polyethylene having a melting temperature of 130˜140° C. and at least the other layer has 20 wt % or more of a heat resistant resin and 80 wt % or less of a filler selected from the group consisting of an organic filler, an inorganic filler and a mixture thereof. The heat resistant resin is preferably a semi crystalline polymer or an amorphous polymer. Preferably, the semi crystalline polymer has a degree of crystallinity of 10-45% or a heat of fusion for melting of 20˜90 J / g and has a melting temperature of 145˜250° C. and a glass transition temperature of −100˜90° C. Also, preferably, the amorphous polymer has no crystal and has a glass transition temperature of 90˜120° C.

Owner:SK INNOVATION CO LTD

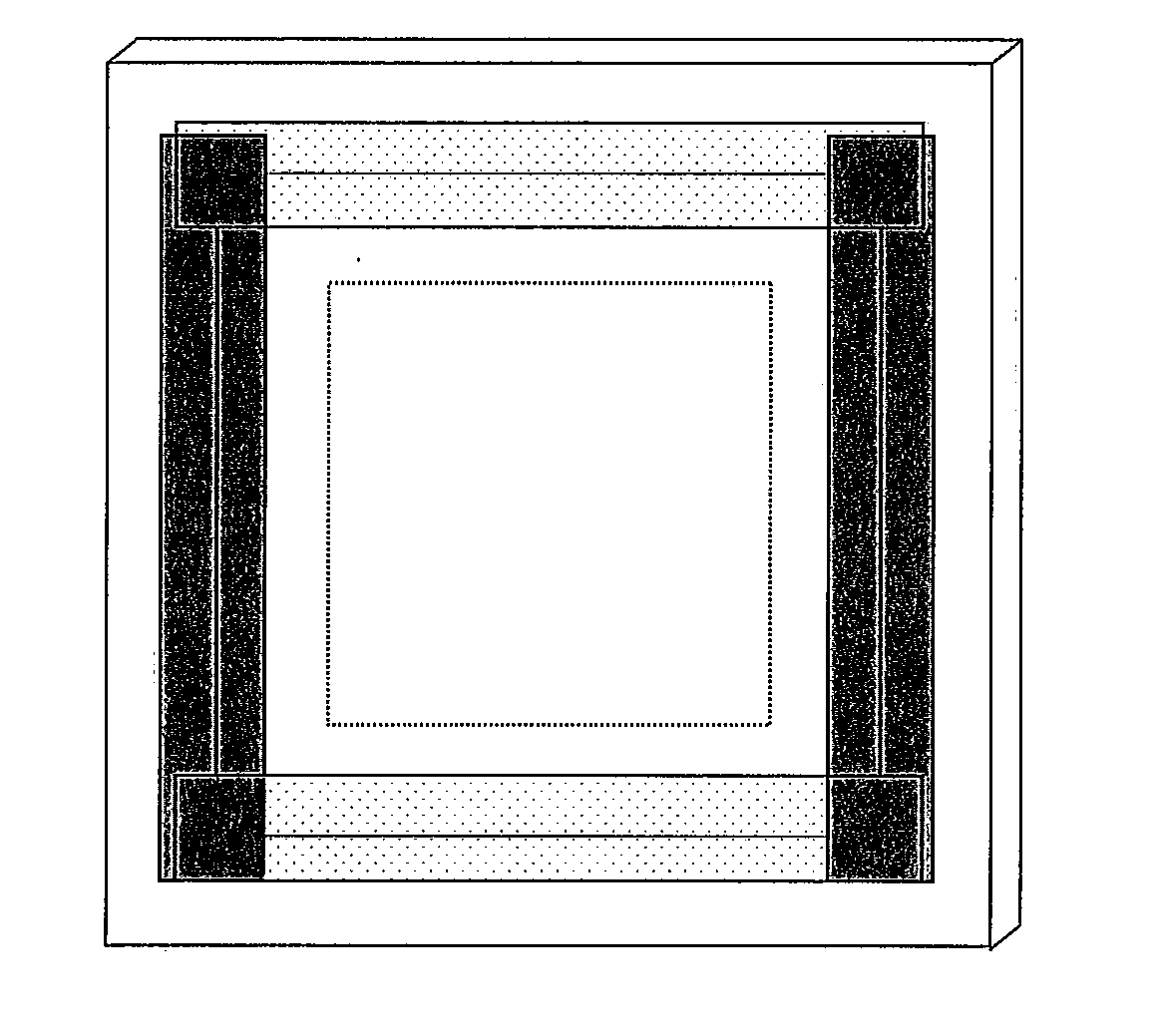

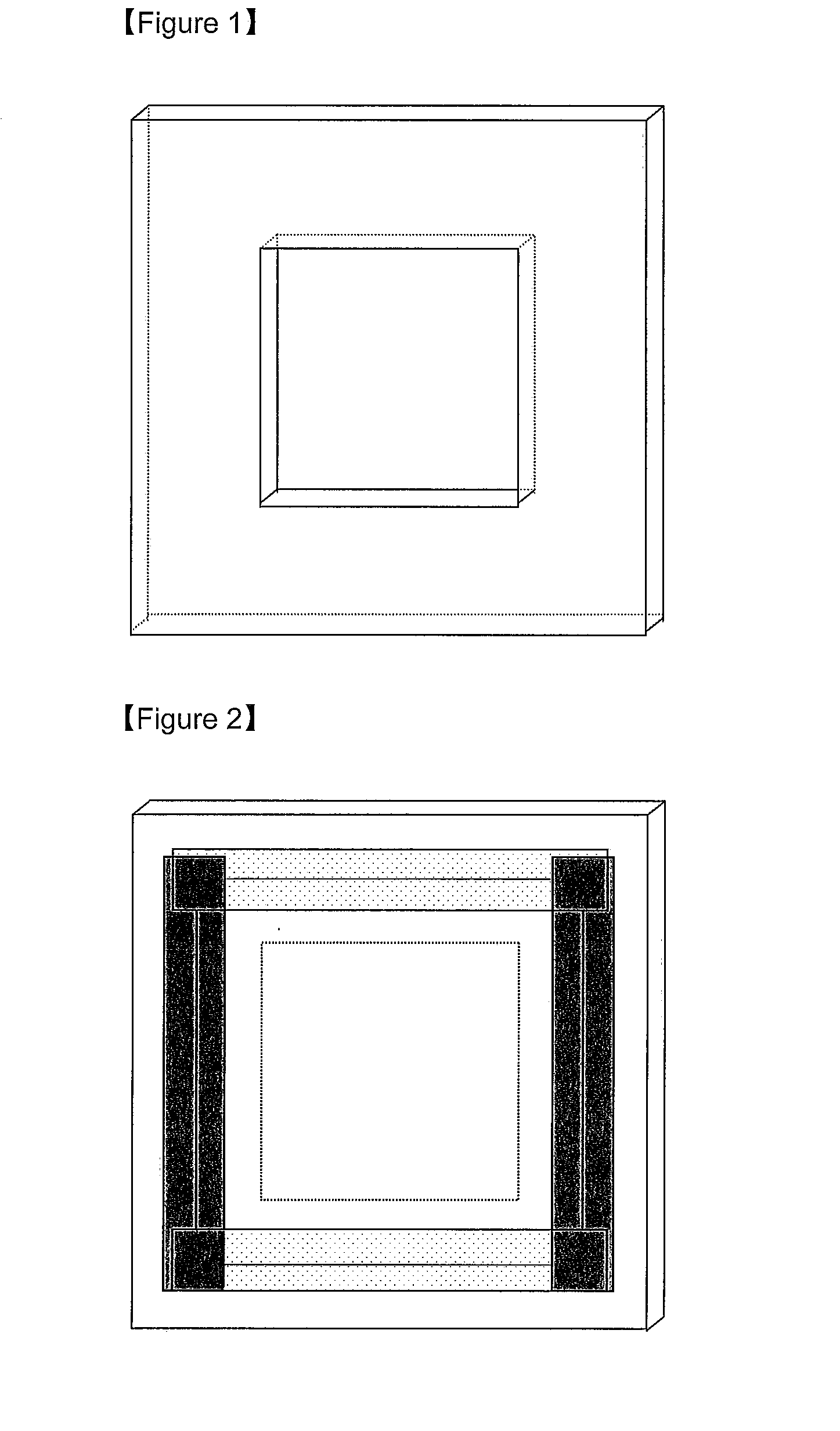

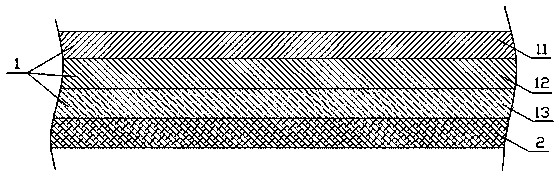

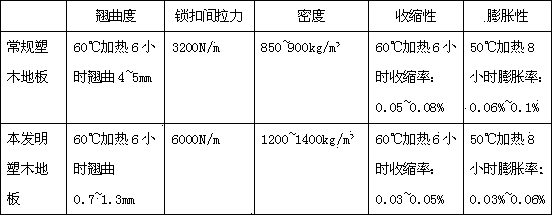

Plastic-wood floor and manufacturing method thereof

The invention relates to a plastic-wood floor and a manufacturing method thereof. The plastic-wood floor is composed of a plastic layer located on an upper layer and a plastic-wood layer located on a lower layer. The plastic layer is composed of an abrasion-resistant layer, a printing color film layer and a medium material layer. The abrasion-resistant layer comprises, by weight, 80-100 parts of pvc resin powder, 2-5 parts of stabilizers and 25-30 parts of plasticizers; the medium material layer comprises, by weight, 80-100 parts of pvc resin powder, 40-45 parts of plasticizers, 2-5 parts of stabilizers and 360 parts of calcium carbonate; and the plastic-wood layer comprises, by weight, 40-50 parts of wood powder, 25-35 parts of polyvinyl chloride, 1-3 parts of coupling agents, 8-10 parts of stabilizers, 3-5 parts of flexibilizer, 1-3 parts of foaming agents and 25-35 parts of calcium carbonate. The floor is good in stability and low in processing cost, and the warping degree, contractility and the expansion rate are obviously reduced.

Owner:ZHEJIANG KINGDOM NEW MATERIAL GRP CO LTD

(METH)acrylamide based urethane oligomer and active energy ray curable resin composition containing same

ActiveUS20180244831A1Improve compatibilityImprove curing effectCosmetic preparationsAdditive manufacturing apparatusGeneral purposeOligomer

An object is to provide a (meth)acrylamide based urethane oligomer which has excellent compatibility with organic solvents and general purpose acrylic monomers and oligomers, a high curing property with an active energy ray, and a low curing shrinkage property, and to provide an active energy ray curable resin composition containing the same which has an excellent adhesion property, moisture resistance, surface curing property, and also a low curing shrinkage property, and a molded article of the same. By using a (meth)acrylamide based urethane oligomer characterized by having a (meth)acrylamide group at the end or in side chain thereof and a cure shrinkage rate of 5% or less, it is possible to prepare a urethane oligomer having high curing property and excellent compatibility with organic solvents and general purpose acrylic monomers and oligomers, and an active energy ray curable resin composition containing the same and having excellent adhesion property can be prepared.

Owner:KJ CHEM

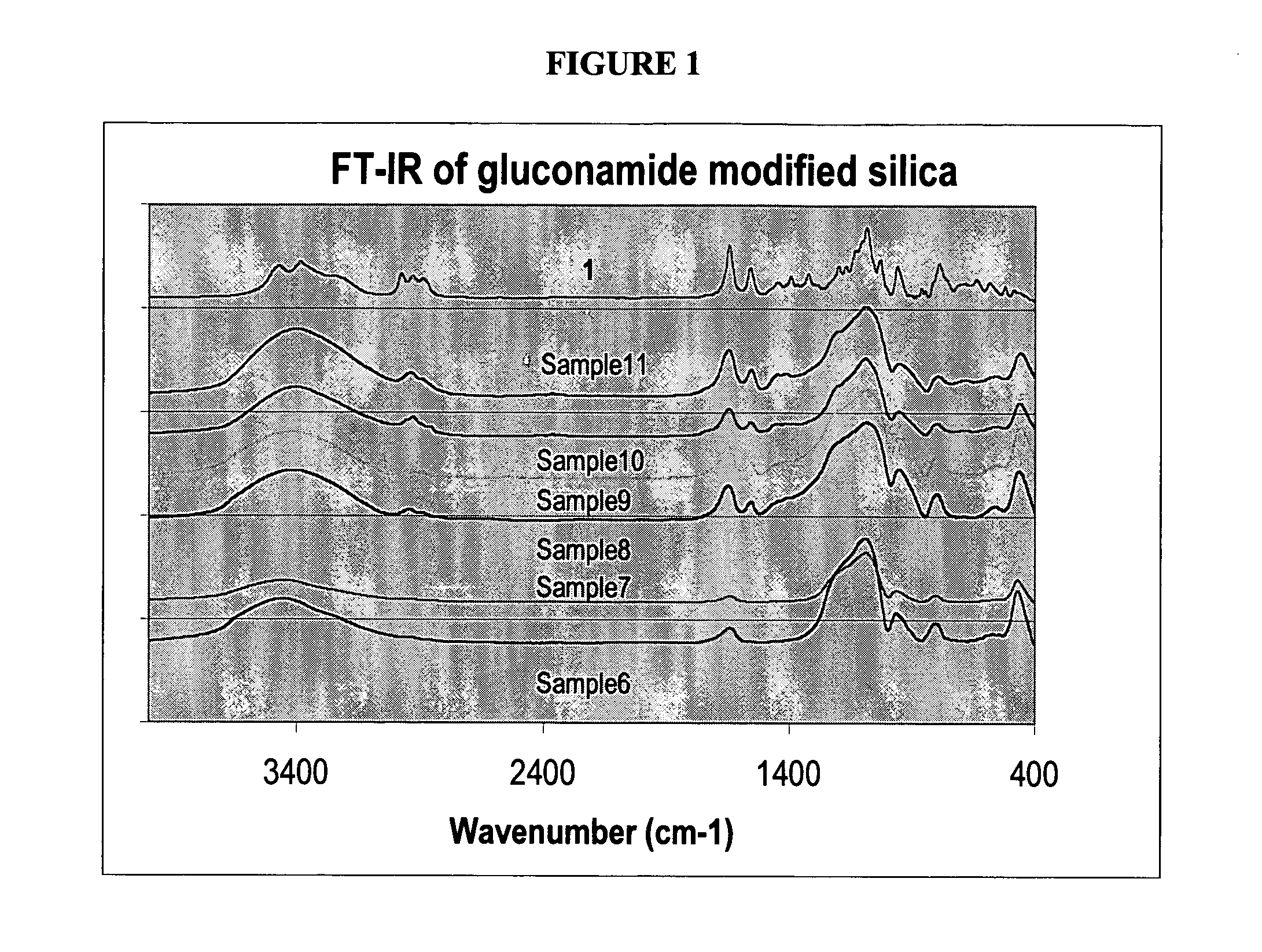

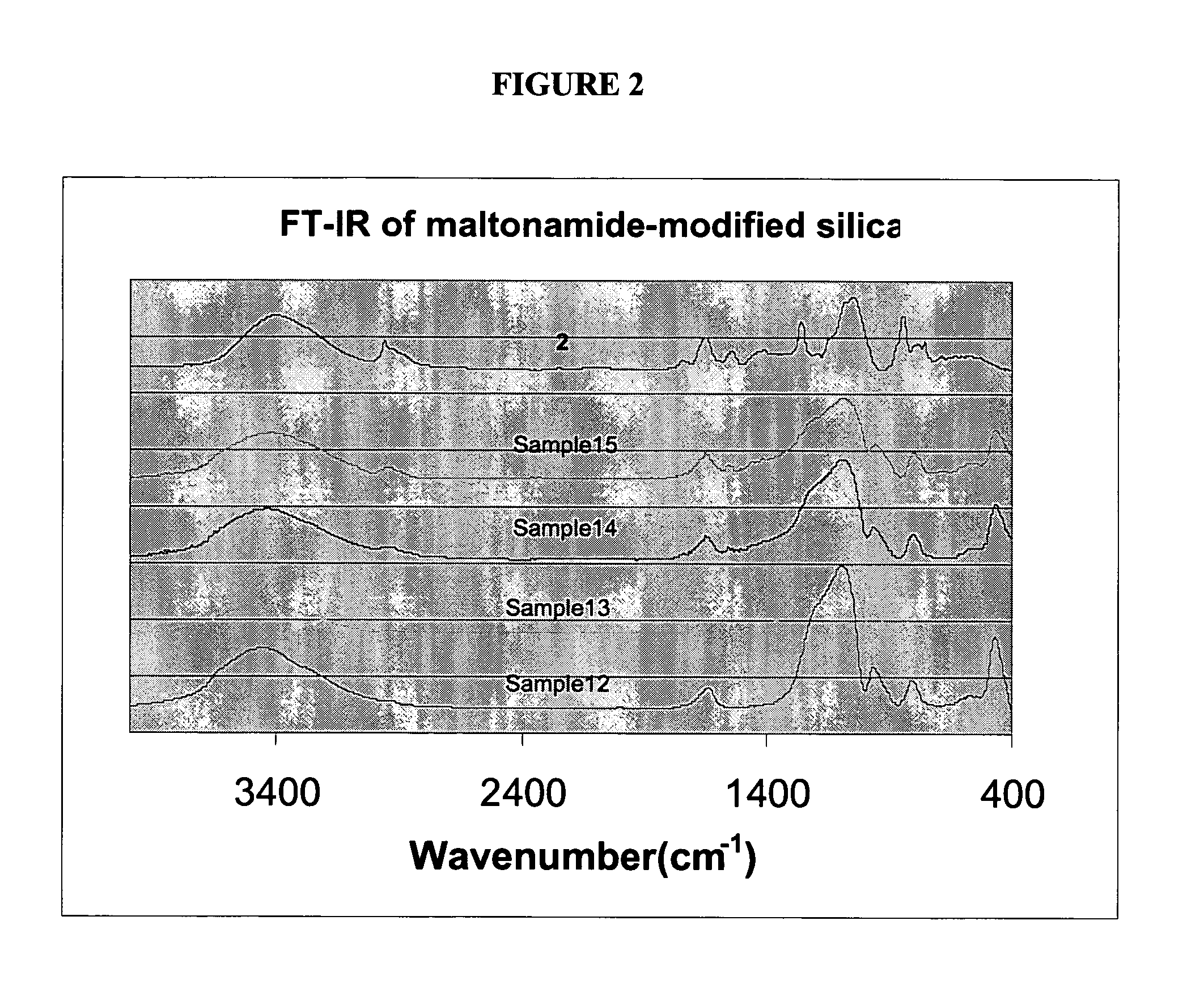

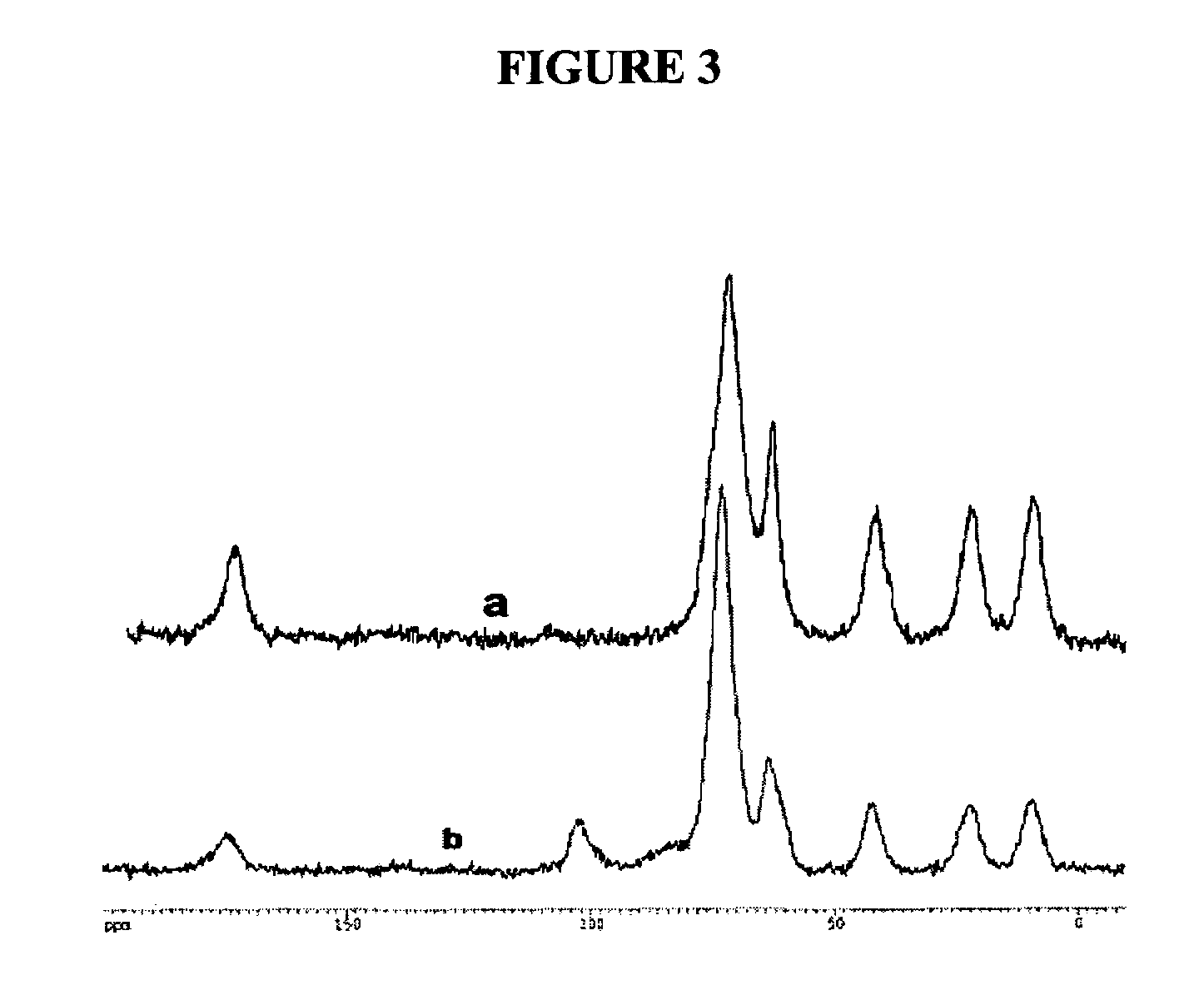

Protein compatible methods and compounds for controlling the morphology and shrinkage of silica derived from polyol-modified silanes

InactiveUS7375168B2Reduce shrinkageReduce Shrinkage ProblemsSilicaComponent separationWater soluble polymersChemistry

Siliceous materials were prepared by adding one or more additives, including one or more water soluble polymers, and derivatives thereof, as well as trifunctional silanes, to sols containing tetraalkoxysilanes derived from polyols. The polymers facilitate phase separation of the growing silica gel matrix, leading to high surface area self-supporting silica gels with cure occurring at ambient temperatures. The materials also show a significant reduction in shrinkage properties and significant protein stabilization abilities.

Owner:MCMASTER UNIV

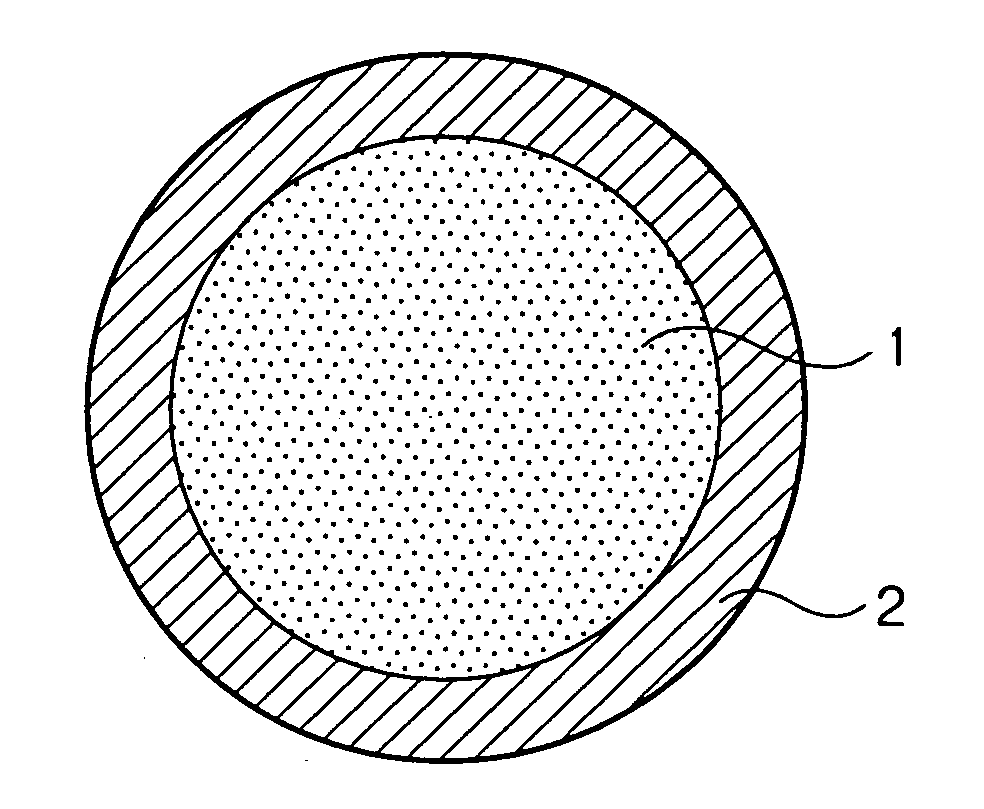

Inorganic compound particle and process for preparation thereof

InactiveUS20050037201A1Reduce reflectivityImprove hydrophobicityLiquid surface applicatorsSilicaInorganic compoundMaterials science

Inorganic compound particles constituted of a shell, a porous matter or a cavity enclosed therein, and the porous matter or the cavity being kept unchanged in a subsequently formed transparent coating film.

Owner:JGC CATALYSTS & CHEM LTD

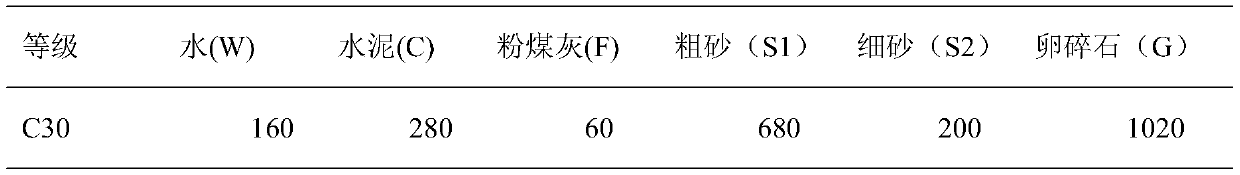

Lightweight ceramsite concrete and preparation method thereof

InactiveCN105523737AReduced shrinkage performanceOvercome the defect of easy segregationExpanded clay aggregateSuperplasticizer

The invention provides a lightweight ceramsite concrete and a preparation method thereof. The lightweight ceramsite concrete comprises, by weight, 200-219 parts of medium sand, 462-470 parts of cement, 280-316 parts of cobblestones, 110-116 parts of fly ash, 230-240 parts of super light ceramsite, 230-240 parts of pottery sand, 150-155 parts of water, 8-12 parts of a calcium aluminum sulfate expanding agent and 7.0-9.6 parts of a polycarboxylate superplasticizer. The feeding sequence in the preparation process is changed, sandstones are first added, then cement, fly ash and ceramsite are added, and water and additives are added after the ceramsite and other raw materials are fully and uniformly stirred in order to obtain concrete with good workability; and gravity type mixing of a mixer truck is adopted in the transportation process to prevent the segregation and bleeding phenomena in the transportation process, so the defect of easy segregation of the ceramsite and cement grout is effectively solved. A ratio of all raw materials is optimized to reduce the slump, so the ceramsite difficultly floats up to the surface of concrete, and the defect of the easy segregation of the ceramsite and slurry is avoided.

Owner:邢台建工商品混凝土有限公司

High temperature-resistant and UV (Ultraviolet)-resistant protective film and preparation method thereof

InactiveCN108707432AReduced shrinkage performancePrevent high temperature deformationNon-macromolecular adhesive additivesEster polymer adhesivesTectorial membraneDisplay device

The invention discloses a high temperature-resistant and UV (Ultraviolet)-resistant protective film and a preparation method thereof. The high temperature-resistant and UV-resistant protective film comprises a PE (Polyethylene)-based film layer and an adhesive layer, wherein the adhesive layer is formed by coating the surface of the PE-based film layer with a heat-resistant and UV-resistant pressure-sensitive adhesive and drying; the pressure-sensitive adhesive is prepared from the following raw materials in parts by weight: 25 to 35 parts of acrylate resin, 55 to 70 parts of ethyl acetate, 1to 2 parts of isocyanate curing agent, 0.1 to 0.5 part of UV absorbent and 0.4 to 0.7 part of free radial collecting agent. Compared with the prior art, the preparation method disclosed by the invention is reasonable in raw material proportioning and simple in preparation technology, and a release force of the high temperature-resistant and UV-resistant protective film provided by the invention ranges from 7N / m to 9N / m; after long-time irradiation under high temperature and UV, the release force of the high temperature-resistant and UV-resistant protective film changes within + / -35 percent, and the high temperature-resistant and UV-resistant protective film has no wrinkling, no degumming, no adhesive residue and no chromatic aberration after long-time irradiation under the UV; the high temperature-resistant and UV-resistant protective film can be used for protecting the surfaces of backlight displays in electronic products such as a computer, a television and a mobile phone and can beused for protecting an overlaid shipment transportation process of the backlight displays.

Owner:芜湖夏鑫新型材料科技有限公司

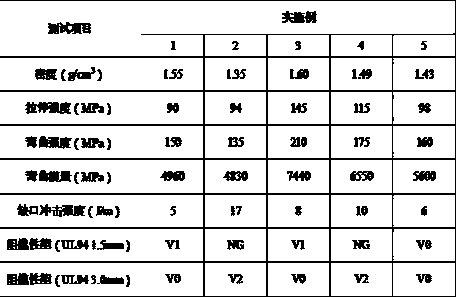

Asphalt material, asphalt mixture comprising same and preparation methods of asphalt material and asphalt mixture

InactiveCN102604399AReduced shrinkage performanceAlleviate pavement crackingBuilding insulationsSilane couplingBituminous materials

The invention discloses an asphalt material, an asphalt mixture comprising the asphalt material and preparation methods of the asphalt material and the asphalt mixture, relating to asphalt materials, asphalt mixtures and preparation methods of asphalt materials and asphalt mixtures. The invention is used to solve the problem that the existing asphalt and asphalt mixtures have large natural shrinkage. The asphalt material provided by the invention consists of asphalt, zirconium tungstate and a silane coupling agent. The preparation method of the asphalt material comprises the following steps: weighing asphalt, zirconium tungstate and the silane coupling agent; adding zirconium tungstate into hot asphalt; stirring and then adding the silane coupling agent; stirring and cooling to obtain the asphalt material. The asphalt mixture consists of the asphalt material and aggregate. The preparation method of the asphalt mixture comprises the following steps: drying the aggregate; adding the dried aggregate into the asphalt material; and stirring to finally obtain the asphalt mixture. The asphalt material and asphalt mixture provided by the invention have the advantages that the linear expansion coefficient is reduced to 3.5*10<-4>-3.0*10<-5> and the shrinkage degree is reduced; if the materials provided by the invention are used for building a road, road cracking can be relieved. The methods disclosed by the invention are used for preparing asphalt materials and asphalt mixtures.

Owner:HARBIN INST OF TECH

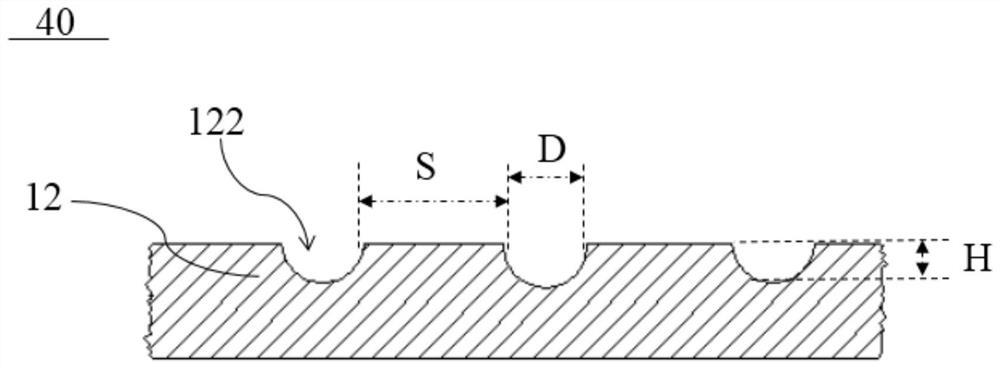

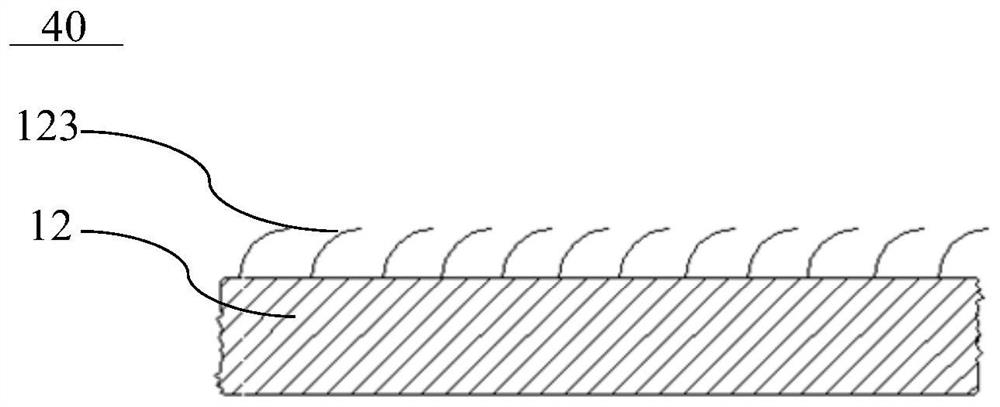

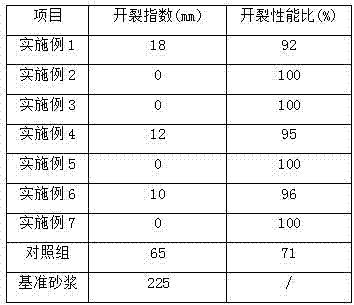

Alkaline-free anti-crack concrete shrinkage reducing agent

The invention discloses an alkaline-free anti-crack concrete shrinkage reducing agent comprising the following components in percentage by weight: 35-66% of I-grade coal ash, 8-18% of polypropylene staple fiber, 2-18% of polyethylene glycol, 3-17% of methacrylic acid, 2-15% of calcium formate, 3-16% of neopentyl glycol and 0.2-0.8% of sodium dodecyl benzene sulfonate. The invention provides possibility for realizing the comprehensive improvement of an additive technology, reducing concrete shrinkage, inhibiting non-loaded cracks and improving the durability of concrete through the research on and application as a shrinkage reducing additive and creates the environment-friendly alkaline-free anti-crack concrete shrinkage reducing agent. The technology is simple in feeding way, easily-controlled in production condition, simple in process and capable of producing the alkaline-free anti-crack concrete shrinkage reducing agent which is low in alkaline content and mixing amount and capable of effectively controlling the shrinkage of concrete. The alkaline-free anti-crack concrete shrinkage reducing agent has a relatively good social benefit and a relatively high economic benefit.

Owner:HUNAN CONSTR ENG GRP COR +1

Halogen-free flame-retardant fiberglass-reinforced PA (Polyamide)/ASA (Acrylonitrile Styrene Acrylate Copolymer) composite material and preparation method thereof

The invention provides a halogen-free flame-retardant fiberglass-reinforced PA (Polyamide) / ASA (Acrylonitrile Styrene Acrylate Copolymer) composite material. The halogen-free flame-retardant fiberglass-reinforced PA / ASA composite material is prepared from the following components in parts by weight: 20 to 65 parts of PA, 10 to 30 parts of an acrylonitile-styrene grafted acrylate rubber copolymer,10 to 25 parts of a flame retardant, 2 to 5 parts of a compatilizer, 10 to 30 parts of fiberglass, 3 to 8 parts of a toughening agent, 0.1 to 1 part of a nucleating agent, 0.1 to 1 part of a lubricating agent and 0.1 to 1 part of an antioxidant. According to the halogen-free flame-retardant fiberglass-reinforced PA / ASA composite material provided by the invention, compounding of the ASA and the PAis adopted, so that the water absorption performance of the PA is effectively improved, the material shrinkage performance is reduced, the size stability is remarkably improved, and meanwhile, good weather resistance and good aging resistance are given to the halogen-free flame-retardant fiberglass-reinforced PA / ASA composite material.

Owner:GUANGDONG JUHANG INST FOR ADVANCED MATERIALS CO LTD +2

Self-compacting micro-expansion concrete and preparation method thereof

The invention discloses self-compacting micro-expansion concrete. The concrete comprises a first group of raw materials including water and ester, and a second group of raw materials including cement, mixed sand, crushed stones, an expanding agent, an admixture, water reducer and dipropyl amine. The admixture comprises active mineral admixture. A preparation method of the self-compacting micro-expansion concrete includes the steps that firstly, ester is dispersed in water to be evenly dispersed, the expanding agent and the water reducer are added into a mixture of the ester and water at a certain flow speed, and the mixture is still standing for 12 h or longer; secondly, the mixed sand and the crushed stones are mixed evenly and smashed into particles, then evenly mixed with cement, the admixture and dipropyl amine and still standing for 3 h or longer; thirdly, the mixture obtained in the second step is added into the mixture obtained in the first step at the flow speed of 20-50 kg / h, and stirring is conducted in the addition process at the speed of 10-20 rpm so as to prepare the self-compacting micro-expansion concrete. Flowability of the concrete can be improved, and the construction requirements for delayed coagulation and plasticity maintenance are met.

Owner:中交三公局工程技术有限公司

Alkaline-free anti-crack concrete shrinkage reducing agent

The invention discloses an alkaline-free anti-crack concrete shrinkage reducing agent comprising the following components in percentage by weight: 35-66% of I-grade coal ash, 8-18% of polypropylene staple fiber, 2-18% of polyethylene glycol, 3-17% of methacrylic acid, 2-15% of calcium formate, 3-16% of neopentyl glycol and 0.2-0.8% of sodium dodecyl benzene sulfonate. The invention provides possibility for realizing the comprehensive improvement of an additive technology, reducing concrete shrinkage, inhibiting non-loaded cracks and improving the durability of concrete through the research on and application as a shrinkage reducing additive and creates the environment-friendly alkaline-free anti-crack concrete shrinkage reducing agent. The technology is simple in feeding way, easily-controlled in production condition, simple in process and capable of producing the alkaline-free anti-crack concrete shrinkage reducing agent which is low in alkaline content and mixing amount and capable of effectively controlling the shrinkage of concrete. The alkaline-free anti-crack concrete shrinkage reducing agent has a relatively good social benefit and a relatively high economic benefit.

Owner:HUNAN CONSTR ENG GRP COR +1

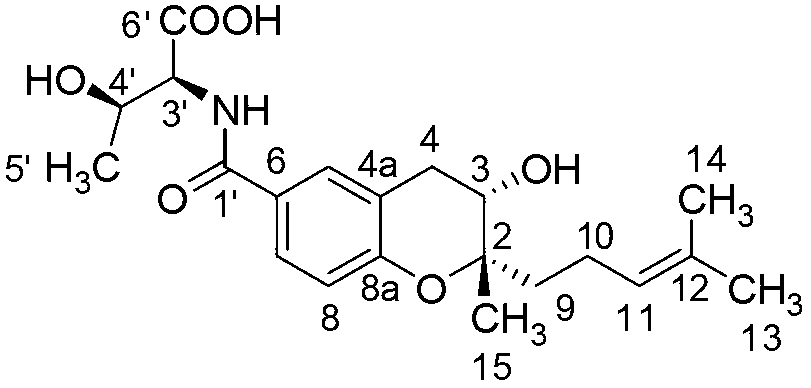

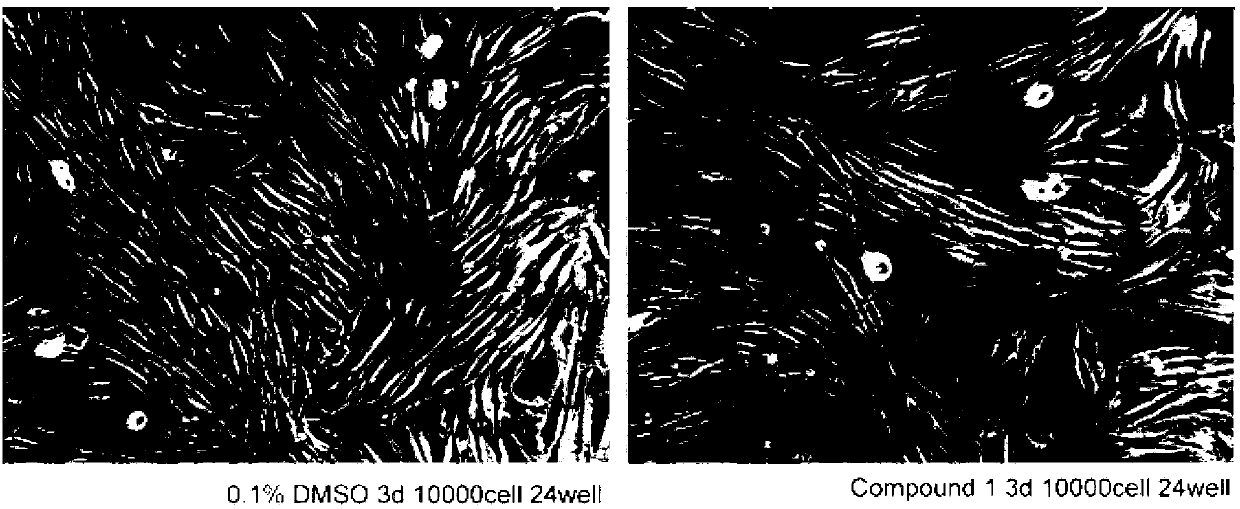

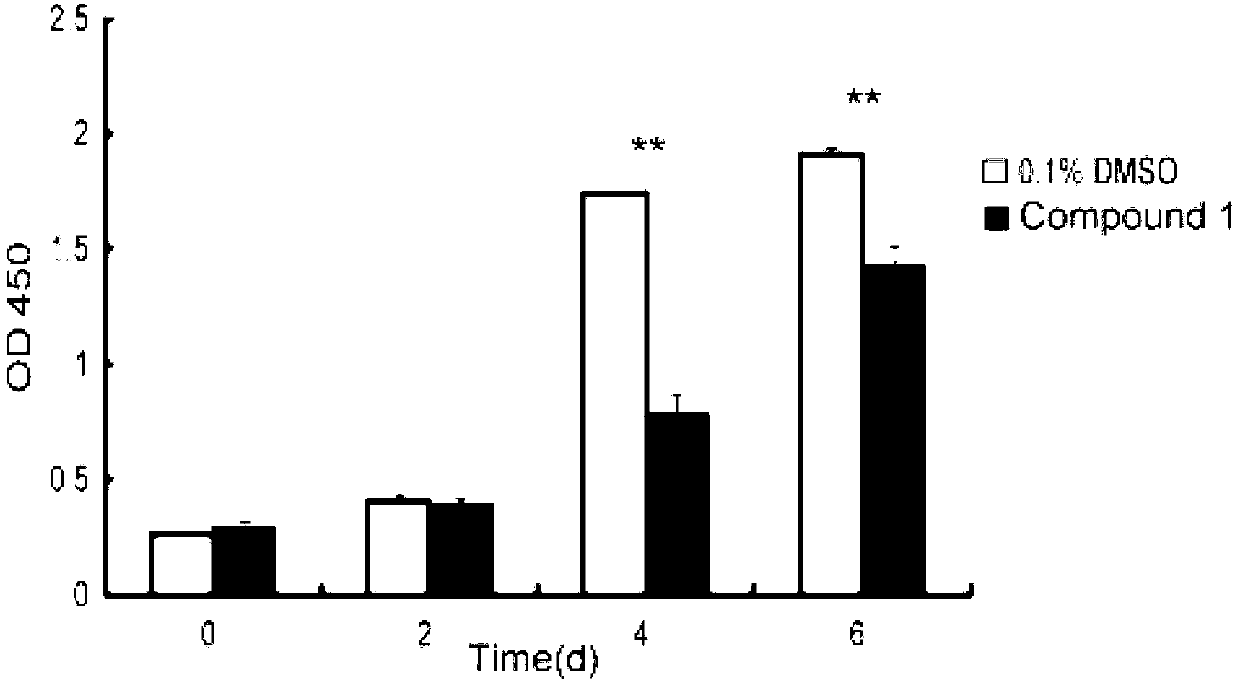

Application of benzopyran alkaloid

ActiveCN102764253AReduced shrinkage performanceBlocking adhesionOrganic active ingredientsDermatological disorderBenzopyranMedicine

The invention relates to the technical field of medicines, in particular to application of a benzopyran alkaloid. The application of the benzopyran alkaloid to the preparation of medicines for restraining formation of hypertrophic scars is involved; the benzopyran alkaloid has the structural formula which is shown in specifications; and the benzopyran alkaloid can restrain proliferation and viability of normal human skin fibroblast, block the adhesion of normal human skin fibroblast (NHSF) and human mononuclear / macrophage (THP-1), and weaken contractility of the normal human skin fibroblast (NHSF).

Owner:上海盛通康维药业有限公司

Dental curing composition

ActiveUS20160030299A1Good shaping effectLow polymerization shrinkage propertyImpression capsDentistry preparationsDental CuringViscosity

The present invention relates to a dental curing composition to restore a lost portion of a tooth generated due to dental caries, tooth fracturing, etc.PROBLEMTo provide a dental curing composition that has packability suitable for restoring a posterior tooth, that has a paste character of avoiding stickiness to a filling instrument, that is excellent in the form shaping property, whose paste character varies little over time, and that has a low polymerization shrinkage property.SOLUTIONThe problem is solved by a dental curing composition that includes components (a) to (d): (a) a matrix resin whose viscosity at 25° C. is 10,000 to 17,000 mPa·s, (b) an organic-inorganic composite filler, (c) an inorganic filler, and (d) a polymeric initiator.

Owner:SHOFU INC

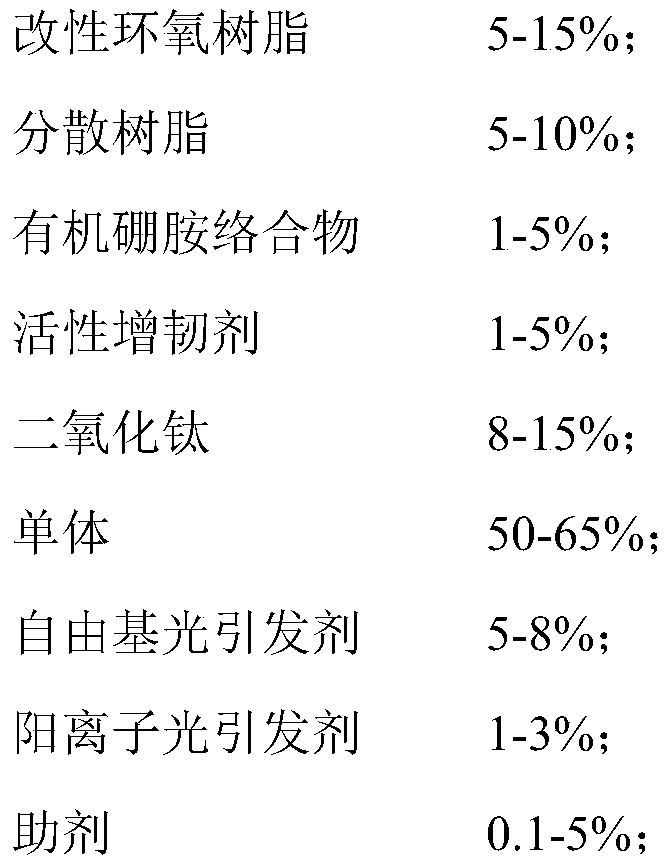

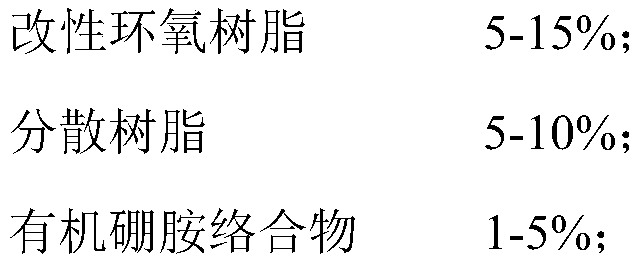

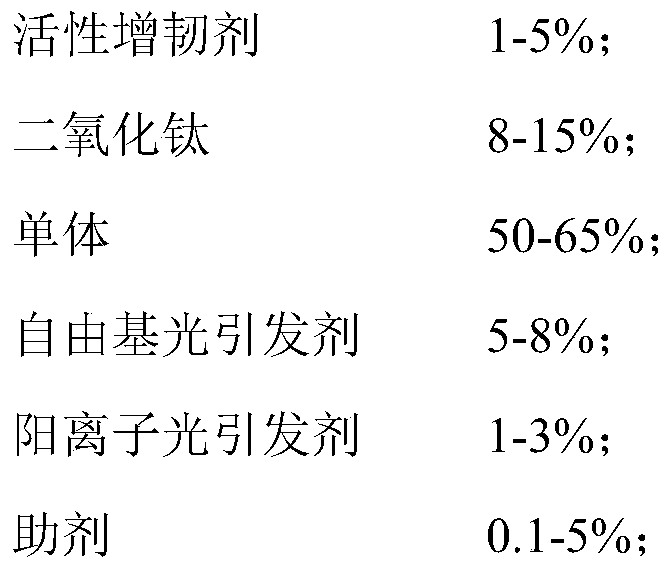

Character printing ink of UV-LED ink-jet printing flexible printed circuit board and preparation method thereof

The invention relates to the technical field of printing ink for circuit boards, in particular to character printing ink of a UV-LED ink-jet printing flexible printed circuit board and a preparation method thereof. The character printing ink of the UV-LED ink-jet printing flexible printed circuit board is prepared from the following components in percent by weight: 5-15% of modified epoxy resin, 5-10% of dispersion resin, 1-5% of an organic boron complex, 1-5% of an active toughener, 8-15% of titanium dioxide, 50-65% of a monomer, 5-8% of a free radical photoinitiator, 1-3% of a cationic photoinitiator and 0.1-5% of an auxiliary agent. The active toughener is a long chain aliphatic compound containing a glycidyl ether group. The monomer is at least one of a monofunctional group monomer, abifunctional group monomer and a trifunctional group monomer. The character printing ink of the UV-LED ink-jet printing flexible printed circuit board is high in curing speed, low in viscosity, excellent in adhesive force, low in shrinkage, good in bending resistance, good in flexibility and good in jet printing performance.

Owner:江门市阪桥电子材料有限公司

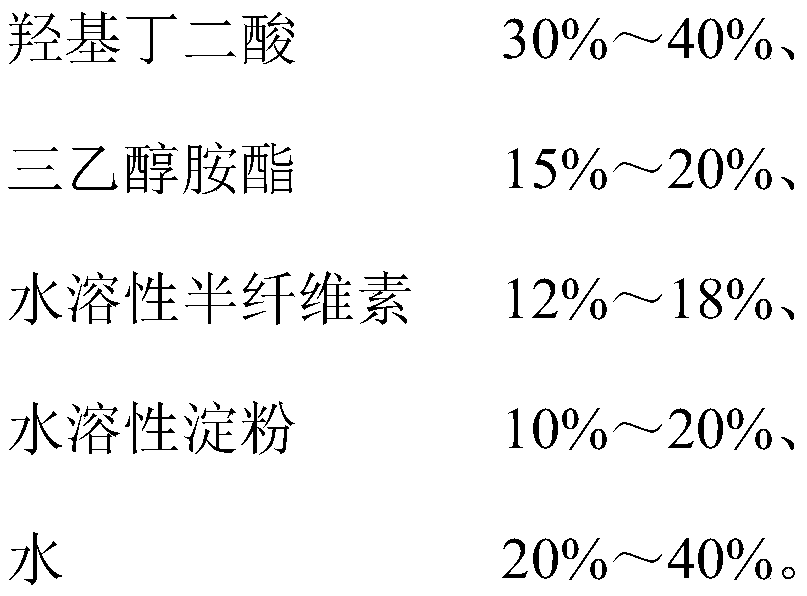

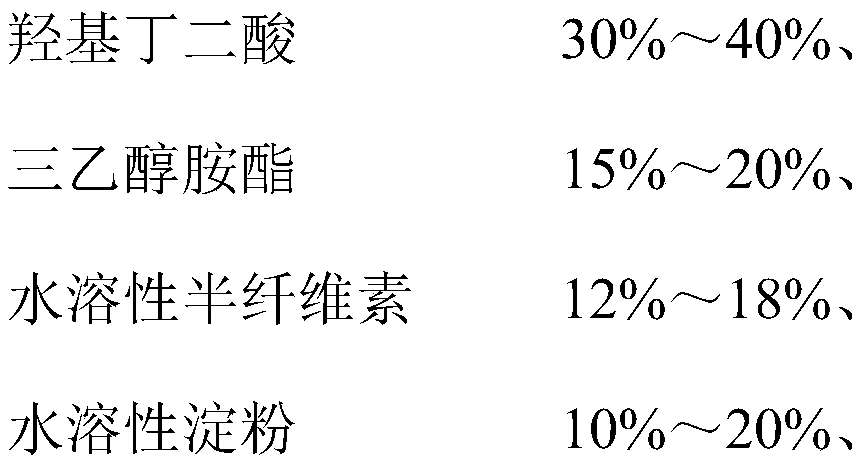

Soil stabilizer capable of improving drying shrinkage performance of compacted soil and preparation method thereof

InactiveCN111575010AEffective consolidationHigh strengthRoadwaysBuilding constructionsButanedioic acidSoil science

The invention discloses a soil stabilizer capable of improving the drying shrinkage performance of compacted soil and a preparation method of the soil stabilizer. The soil stabilizer is prepared fromthe following raw materials (in percentage by mass): 30%-40% of hydroxysuccinic acid, 15%-20% of triethanolamine ester, 12%-18% of water-soluble hemicellulose, 10%-20% of water-soluble starch and 20%-40% of water. The soil stabilizer of the invention have the following beneficial effects that: (1) the formula of the soil stabilizer is reasonable and scientific in collocation, the properties of soil can be changed, so the effects of solidifying and hardening the soil and reducing the shrinkage of the soil in the hardening process are achieved, dry shrinkage resistance is excellent, and the soilstabilizer is an ideal soil stabilizer for projects such as highway subgrades or subbases; and (2) the soil stabilizer provided by the invention is mainly applied to reinforcement soil of highway subgrades or subbases and other projects, can also be used for soil reinforcement of water conservancy projects, airport projects and the like, and has a wide application range.

Owner:SHAANXI COMM CONSTR GRP CO LTD

Polymeric nano-particles of flower-like structure and applications

InactiveUS20050154117A1Super soft propertyHeat resistantPlastic/resin/waxes insulatorsSpecial tyresCrystallographyElastomer

A flower-like nano-particle composition including a poly (alkenylbenzene) core and a poly (conjugated diene) or a poly(alkylene) surface layer is provided. The nano-particles have a mean average diameter less than about 100 nm and are substantially free of chain ends. The nano-particles can be modified via, for example, hydrogenation. The nano-particles can advantageously be incorporated into rubbers, elastomers, and thermoplastics.

Owner:BRIDGESTONE AMERICAS HLDG

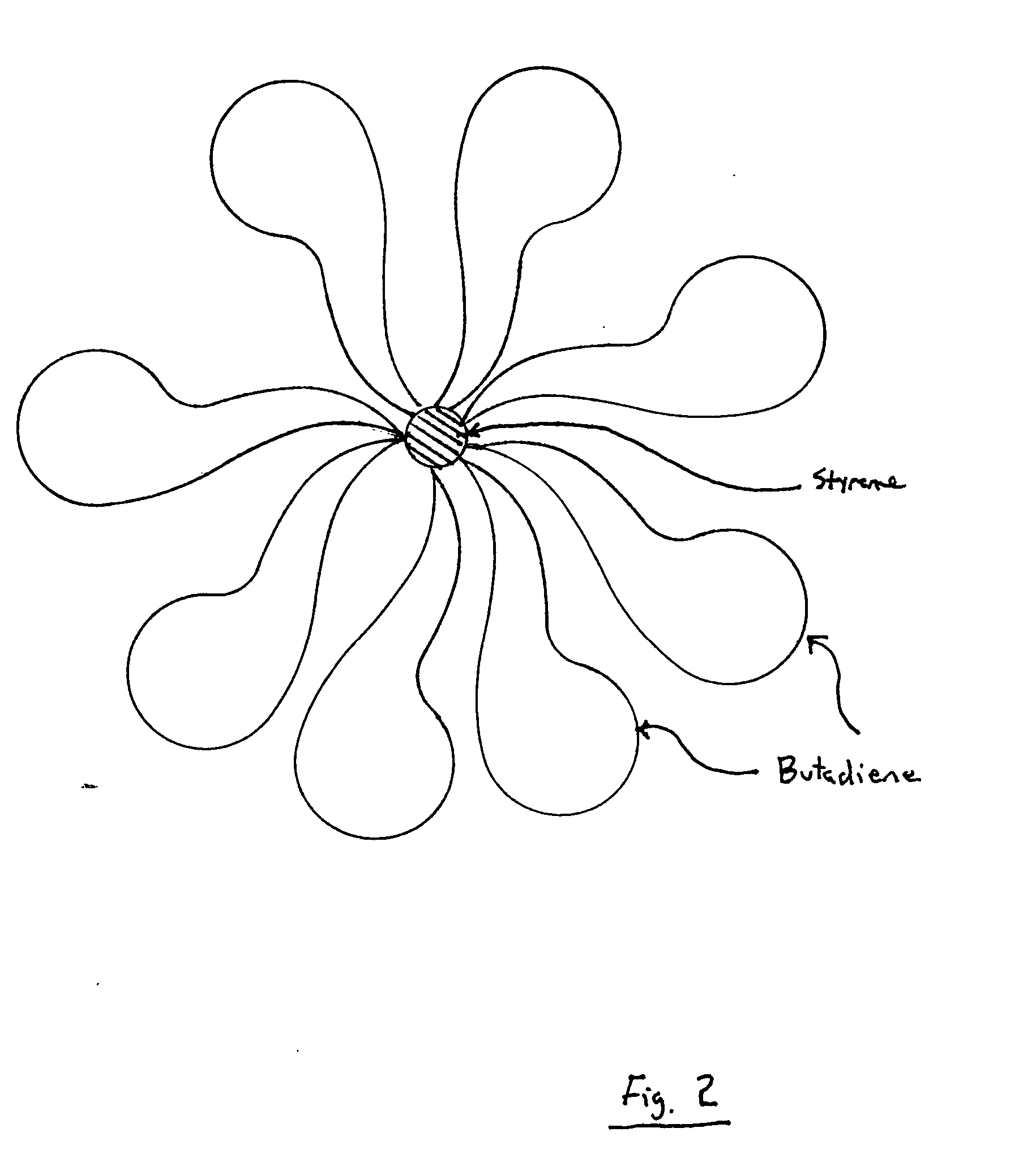

Plugging device

ActiveCN112826561AReduced shrinkage performanceReduce the amplitudeOcculdersAgainst vector-borne diseasesDevice implantPharmacy medicine

The present invention discloses a plugging device which comprises a sealing part relatively located at the near end, a fixing part connected with the sealing part and relatively located at the far end and a medicine supply part, the medicine supply part is at least arranged in the middle or at the far end of the plugging device, and the medicine supply part is at least provided with a first kind of medicine used for promoting platelet aggregation in blood. When the first type of medicine is released into the cavity of the in-vivo tissue from the medicine supply part, platelets in blood in the cavity are promoted to be gathered at least at the position where the fixing part makes contact with the cavity wall of the cavity. The medicine supply part is arranged in the middle or at the far end of the plugging device, and after the plugging device is implanted into a cavity of in-vivo tissue, the first medicine used for promoting platelet aggregation in the medicine supply part is released into a cavity of a left auricle; the platelets in blood in the cavity are gathered at the contact position of the fixing part and the cavity wall of the left auricle, and the fixing part and the cavity wall of the left auricle are fixedly connected together, so that the stability of the plugging device is improved.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

Mortar anti-cracking agent and preparation method thereof

The invention discloses a mortar anti-cracking agent and a preparation method thereof, which belongs to the technical field of building materials. The anti-cracking agent is prepared from the following raw materials by weight percent: 45 to 60 percent of attapulgite, 10 to 15 percent of polyvinyl alcohol, 10 to 20 percent of lauryl sodium sulfate, 0 to 2 percent of sodium gluconate, and 10 to 20 percent of coal ash. The anti-cracking agent disclosed by the invention is mainly used for resisting the crack of premix mortar; by combining the attapulgite and polyvinyl alcohol, good interface combination can be formed by virtue of a hydrogen bond; after the lauryl sodium sulfate, the sodium gluconate and the coal ash are added, when the prepared anti-cracking agent premix mortar resists the cracking, an effect for improving the internal cohensive force of the mortar, reducing the shrinkage of the mortar and improving the anti-cracking performance of the mortar can be realized; by adding the mortar anti-cracking agent disclosed by the invention, no stirring is needed when in use, time and labor are saved; and moreover, the raw material cost for preparing the anti-cracking agent is low, and the mortar anti-cracking agent is suitable for the industrialized mass production.

Owner:JIAHUA SPECIAL CEMENT

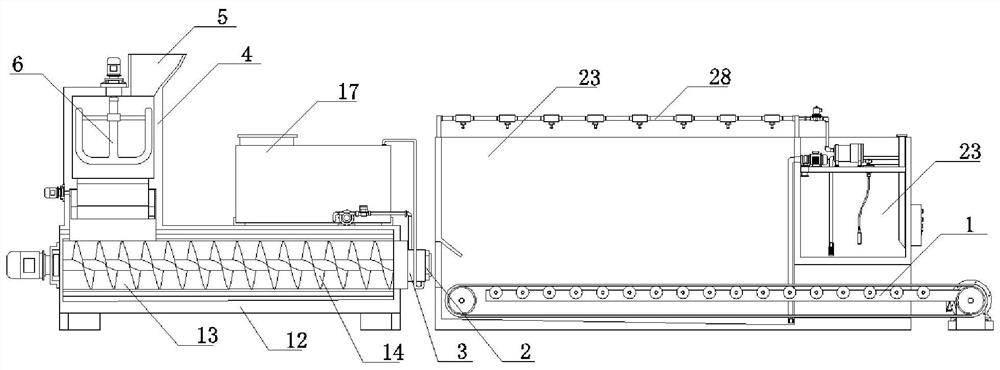

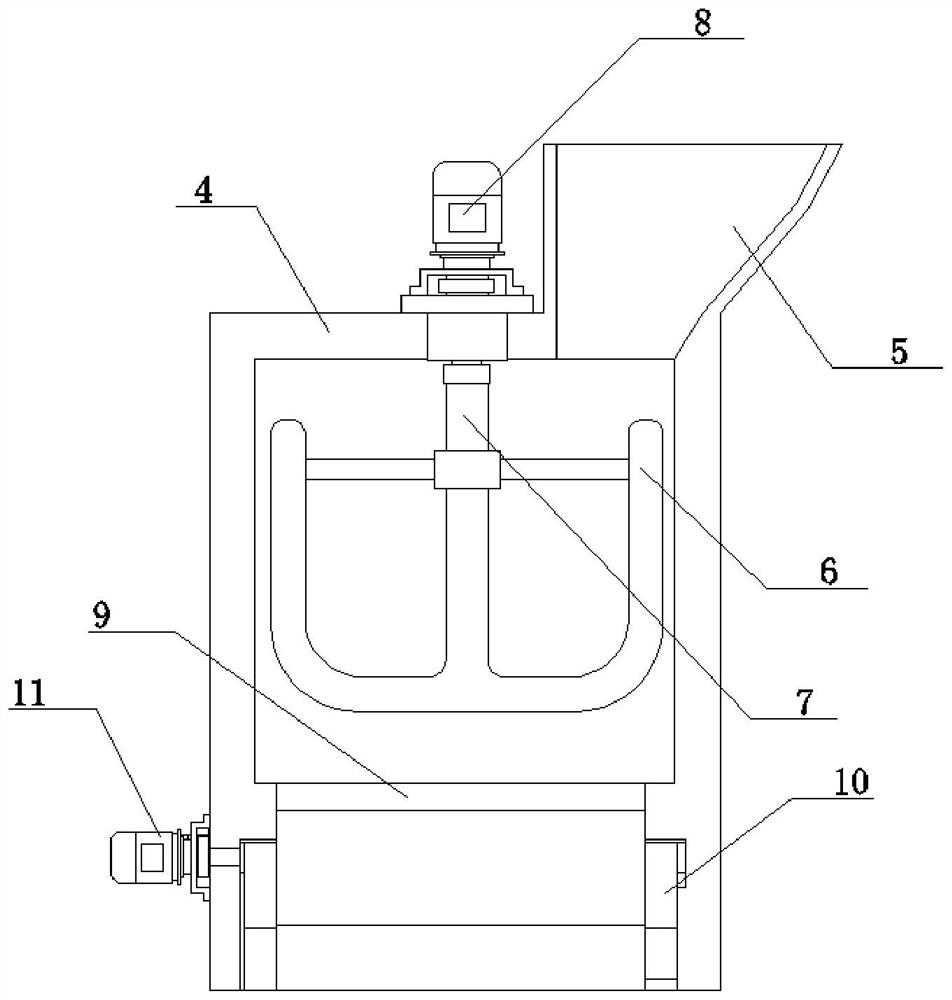

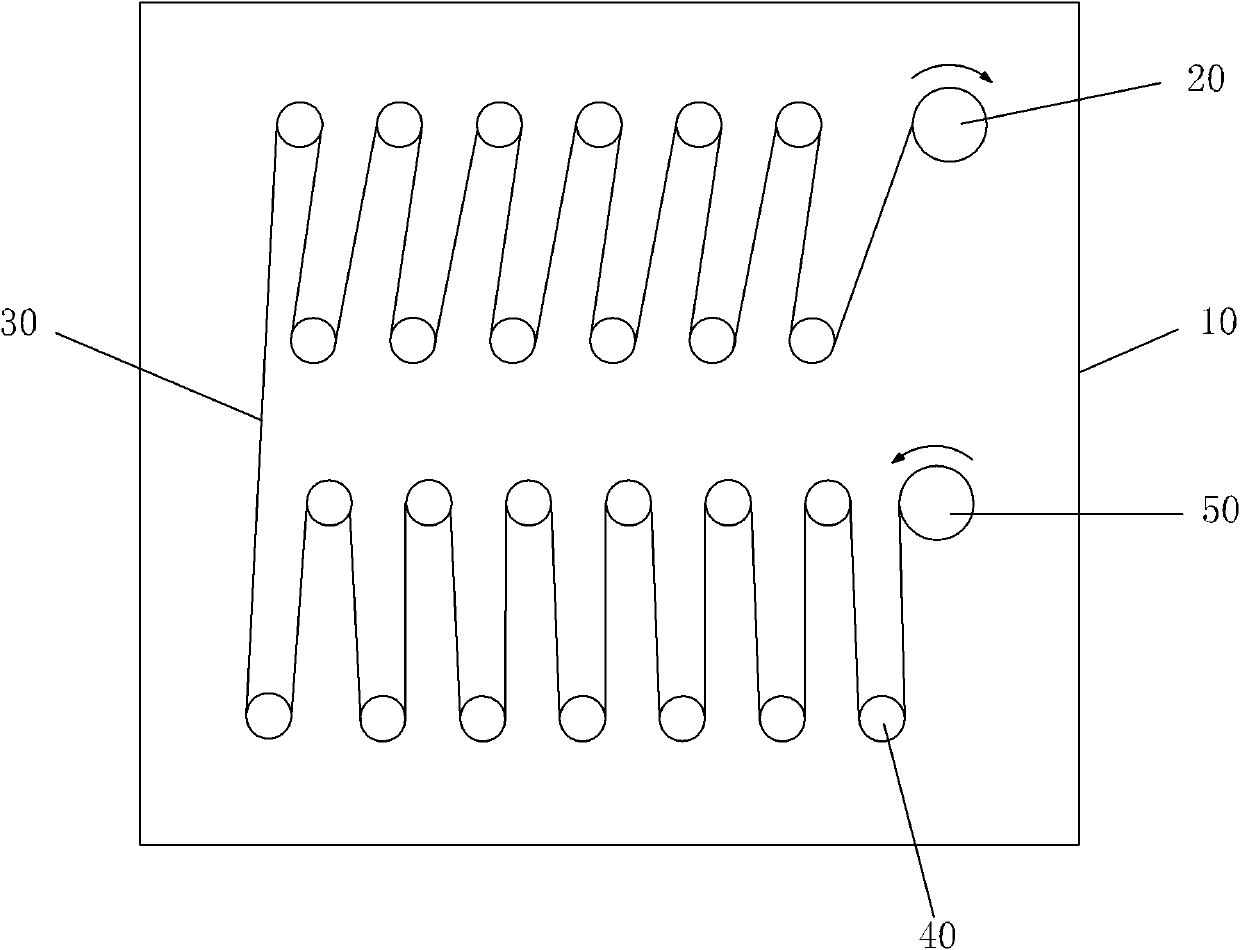

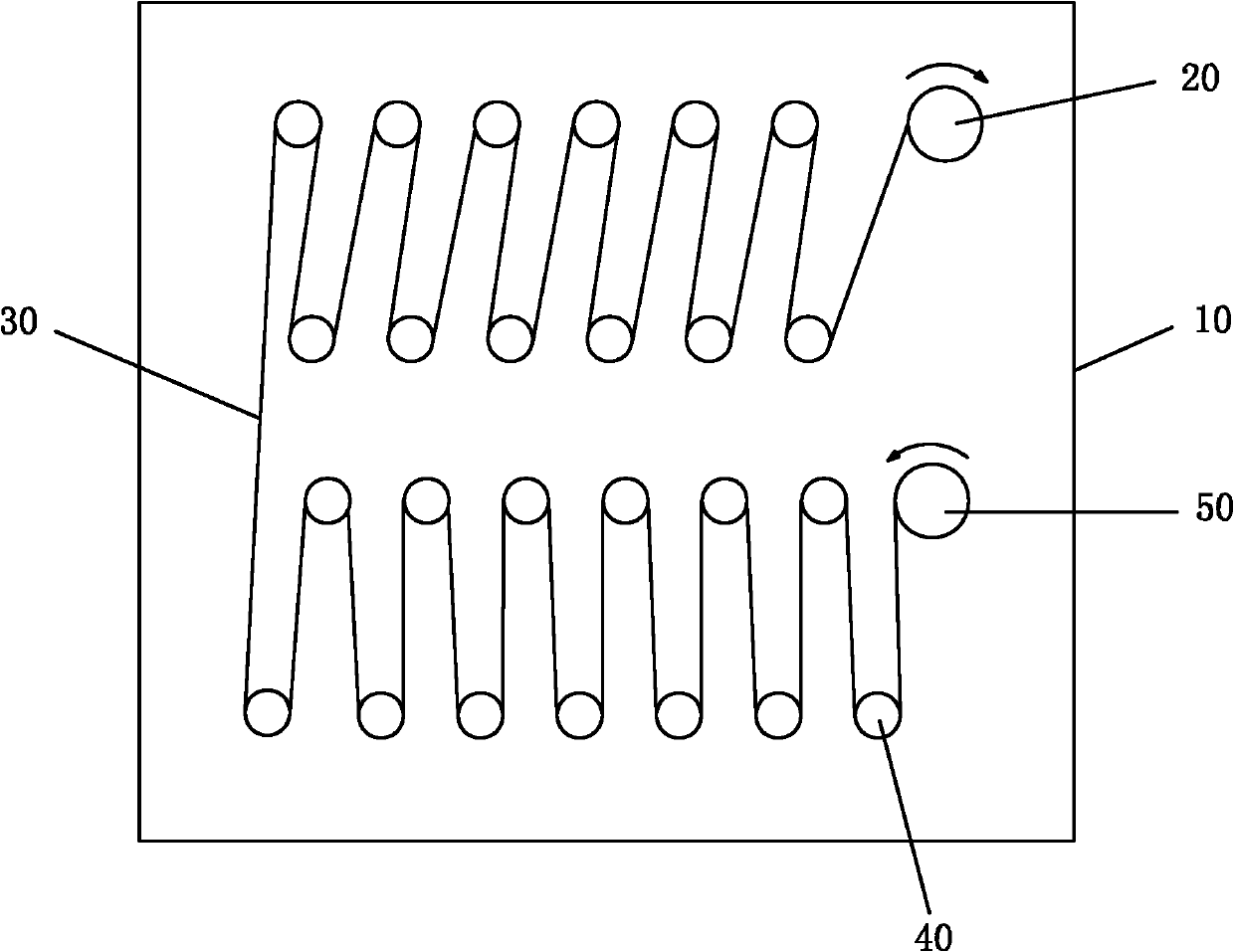

Equipment for reducing internal stress of injection-molded part and injection-molding production method

InactiveCN112606313AAvoid the phenomenon of poor plasticizationMeet the qualityPlasticultureMixed materials

The invention discloses equipment for reducing internal stress of an injection-molded part and an injection molding production method. The equipment comprises a raw material mixing assembly, an injection molding assembly, an injection molding cooling assembly, a finished product cooling assembly and a conveying belt; the raw material mixing assembly is connected with the injection molding assembly; and an injection molding mold is connected to a discharging outlet of the injection molding assembly, a cooling cavity is formed outside the injection molding mold, the cooling cavity is connected with the injection molding cooling assembly, the finished product cooling assembly is located on the side of the injection molding mold, and the conveying belt is arranged in the finished product cooling assembly. By arranging the raw material mixing assembly, material particles for injection molding can be mixed, the material mixing uniformity can be effectively improved, and the mixed material plasticizing capacity is guaranteed; by arranging the injection molding cooling assembly, the injection molding mold can be cooled, and the internal stress existing in an injection molding product can be eliminated advantageously; and by arranging the finished product cooling assembly, the injection-molded part can be continuously cooled through spraying of cooling liquid after being demolded, and the situations that the thick part of the injection-molded part is sunken and the surface bonding line is enlarged due to the fact that internal heat is difficult to release can be prevented.

Owner:NANJING TAOTESI SOFTWARE TECH CO LTD

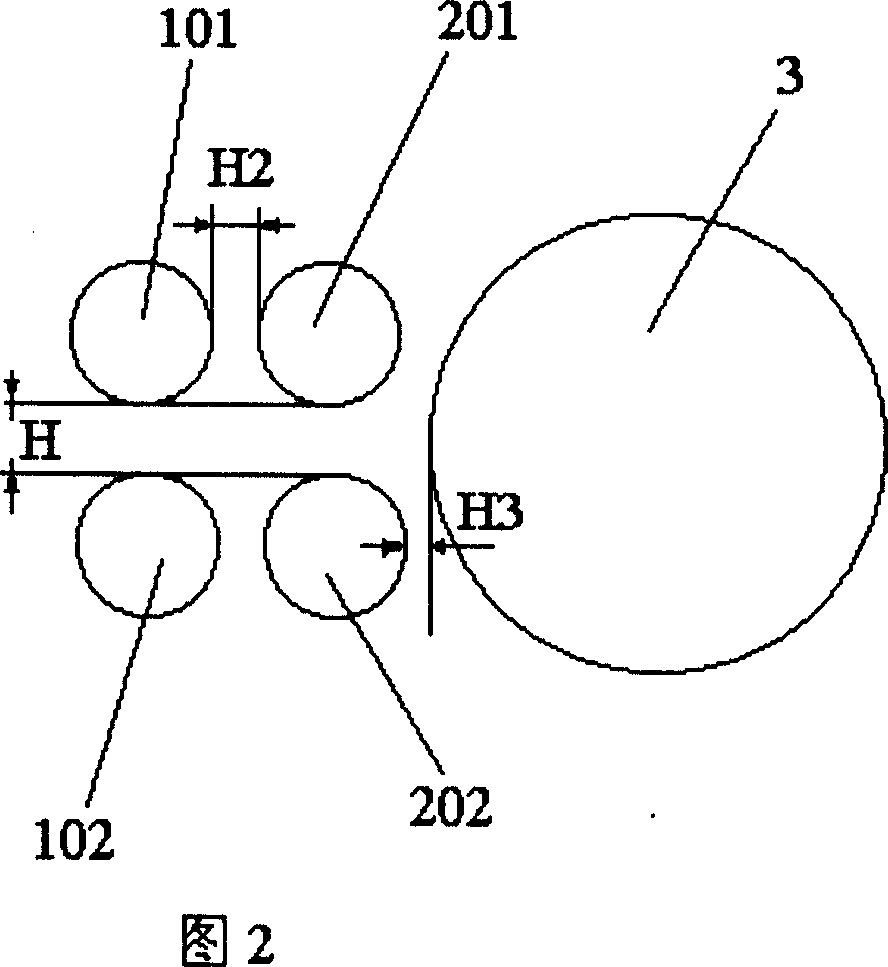

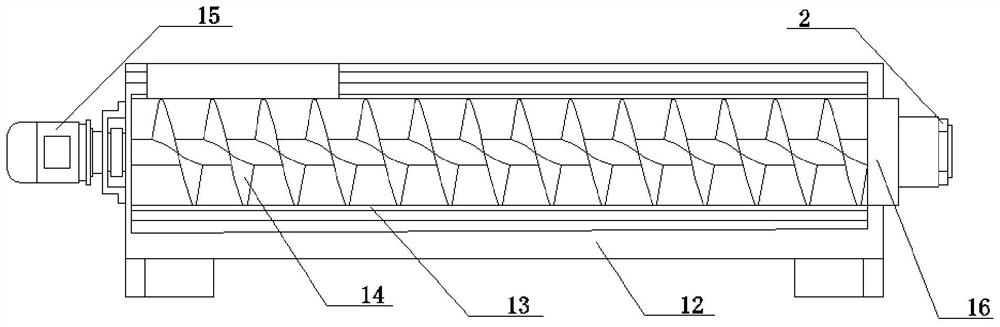

Production facility and process for super-low tensibility poly V-belt cord

InactiveCN102002873AMake up for the lack of elongationLow elongationV-beltsRope making machinesEngineeringTension control

The invention relates to a production facility and process for a super-low tensibility poly V-belt cord. A stretching device is arranged in a drying oven, and the stretching device is characterized in that a stretching wheel group is formed by two groups of stretching wheels in left and right or front and back arrangement; each stretching wheel group is composed of 10-25 stretching wheels left and right or front and back arranged in two rows; a tensioner controlling the tension of the cord among the stretching wheels is arranged between the stretching wheel groups; the front part of one stretching wheel group is provided with a paying off wheel or a winding up wheel; the rear part of the other stretching wheel group is provided with a paying off wheel or a winding up wheel; and the winding up wheels provide power for driving the stretching wheels, the paying off wheels and the winding up wheels to rotate. The process comprises the following concrete steps: 1) preparation; 2) heating; and 3) stretching. In the invention, the measures such as forced stretching, re-stretching and the like are carried out on the cord, so that the stretching ratio is greatly reduced and the cord can be contracted after being heated at a certain temperature; and the elongation at break of the manufactured poly V-belt is controlled to be below 7% and the manufactured poly V-belt can be used for sixty thousand miles.

Owner:浙江沪天胶带有限公司

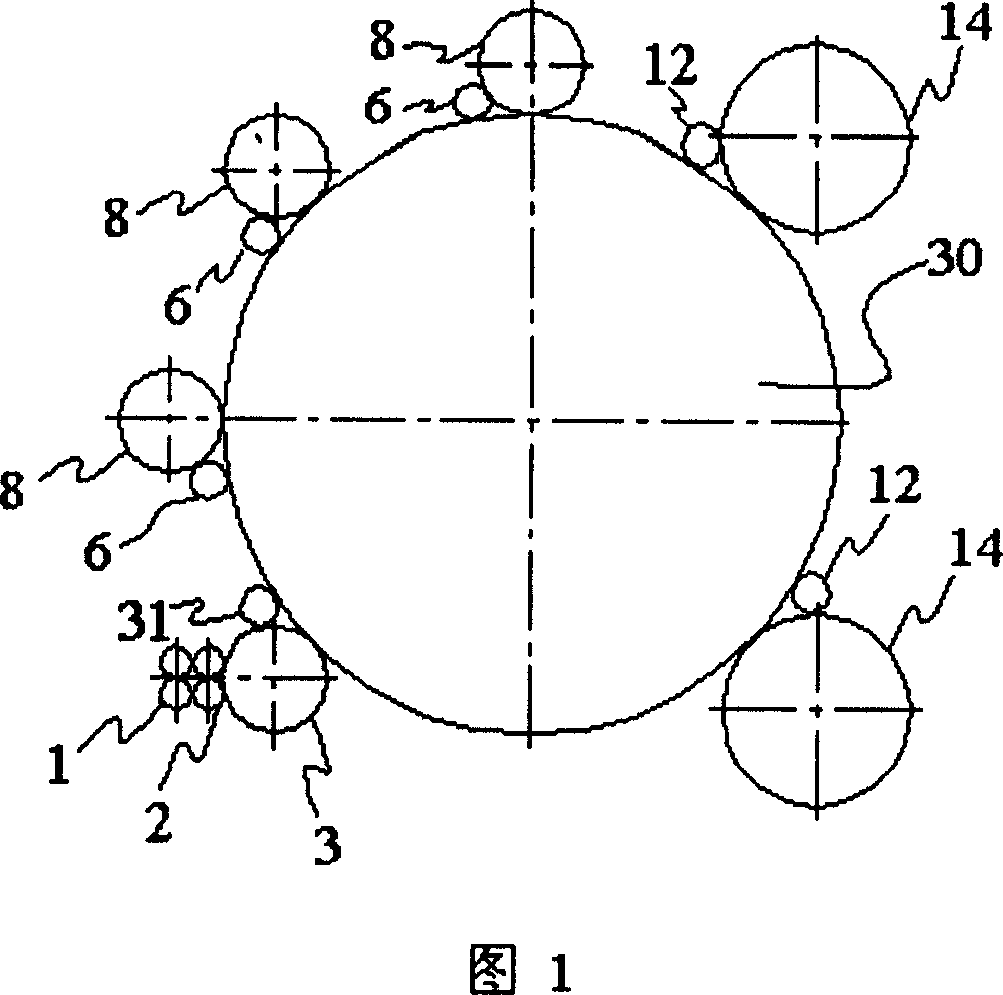

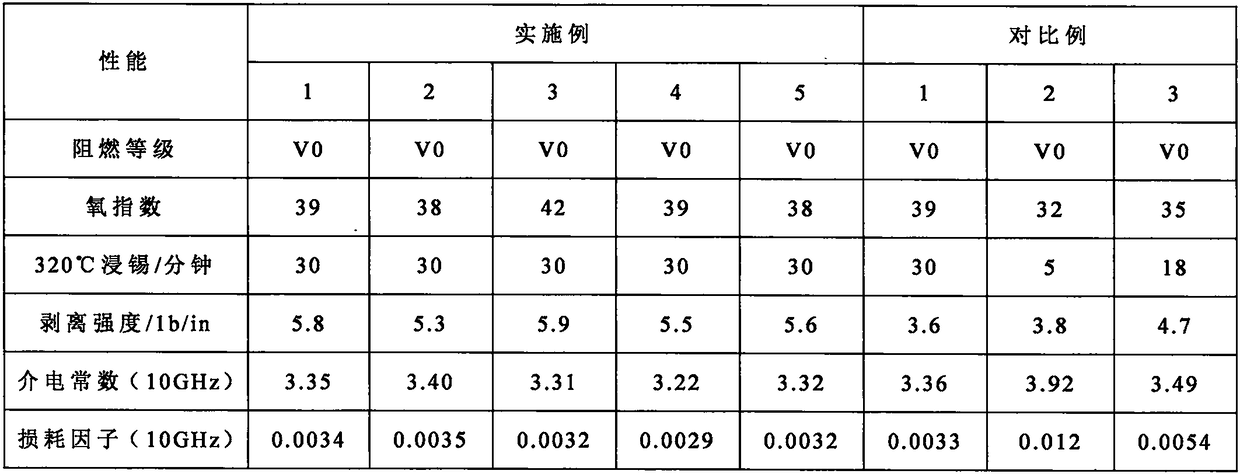

Flame-retarding electronic composite material base plate

InactiveCN109504020AImprove heat resistanceImprove water resistanceLaminationLamination apparatusThermal expansionThermosetting polymer

The invention relates to a flame-retarding electronic composite material base plate. The material has a base body with a low dielectric constant and a low loss factor, and is used for manufacturing alaminated board and a prepreg in the field of high-frequency and high-speed application. The thermosetting electronic composite material comprises butadiene, styrene, a butadiene-styrene copolymer ora styrene-butadiene-styrene copolymer. One important property of the laminated board prepared from a thermosetting polymer is that the laminated board has relatively low content of glass textiles andhas good comprehensive performance relative to a high particle filler range; the laminated board has excellent thermal stability (a CTE (Coefficient of Thermal Expansion) reduced in a Z axis or thickness direction), improved electric performance (loss factor) and extremely low water absorbability and is applied to the base plate for the high-frequency and high-speed application.

Owner:SUZHOU YIKETAI ELECTRONICS MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com