Asphalt material, asphalt mixture comprising same and preparation methods of asphalt material and asphalt mixture

A technology of asphalt mixture and asphalt materials, which is applied in the direction of building insulation materials, building components, buildings, etc., can solve the problems of large inherent shrinkage of asphalt and asphalt mixture, and achieve the effect of alleviating road surface cracking and reducing shrinkage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] Specific Embodiment 1: In this embodiment, a kind of asphalt material is composed of pitch, zirconium tungstate and silane coupling agent, wherein the mass ratio of pitch to zirconium tungstate is 1: (0.1~1), zirconium tungstate and silane coupling The mass ratio of the agent is 100:(0.5~2).

[0017] In this embodiment, by adding a certain proportion of zirconium tungstate anti-expansion material to the asphalt, the shrinkage of the asphalt material is reduced, and its linear expansion coefficient is reduced to 3.5×10 -4 ~2.8×10 -4 ( / °C), using the asphalt material of the present invention for road construction can reduce the shrinkage performance of the asphalt pavement and alleviate the cracking of the pavement.

specific Embodiment approach 2

[0018] Specific embodiment two: a kind of preparation method of asphalt material in this embodiment is characterized in that the preparation method of described asphalt material is carried out according to the following steps:

[0019] 1. Weigh pitch, zirconium tungstate and silane coupling agent, wherein the mass ratio of pitch to zirconium tungstate is 1:(0.1~1), and the mass ratio of zirconium tungstate to silane coupling agent is 100:(0.5~ 2);

[0020] 2. Heat the pitch weighed in step 1 to 100-200°C, add the zirconium tungstate weighed in step 1 to it, and stir for 0.5-600rpm at a temperature of 100-200°C and a stirring speed of 30-600rpm. After 2 hours, add the silane coupling agent weighed in step 1, stir for 0.5-6 hours at a temperature of 100-200° C. and a stirring speed of 30-600 rpm, and cool to room temperature to obtain an asphalt material.

[0021] In this embodiment, asphalt mixing equipment is used for stirring. The asphalt of this embodiment is a commerciall...

specific Embodiment approach 3

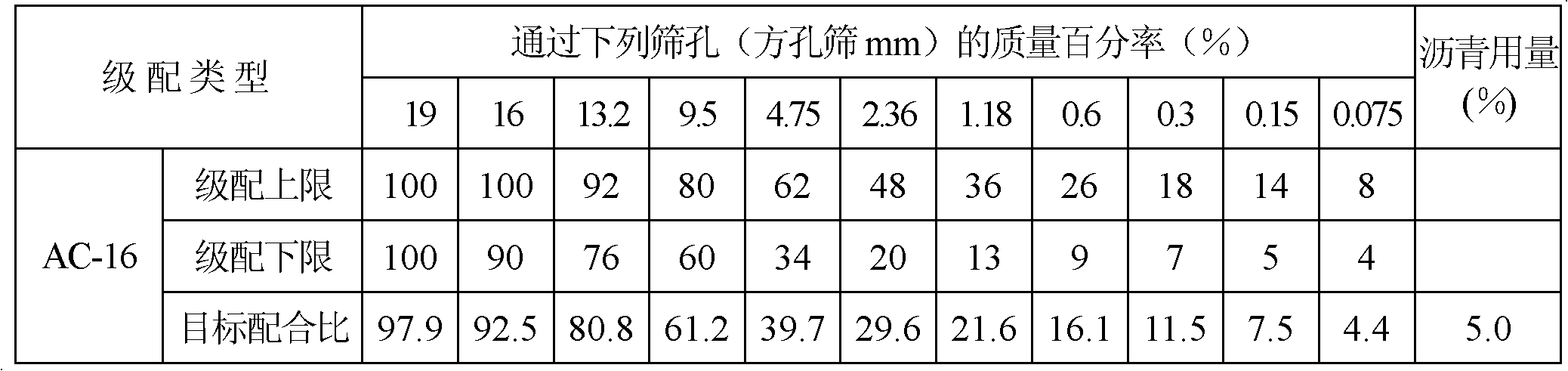

[0023] Embodiment 3: In this embodiment, an asphalt mixture containing the asphalt material described in Embodiment 1 is composed of 4%-6% asphalt material and 94%-96% aggregate by mass percentage.

[0024] The shrinkage of the asphalt mixture in this embodiment is reduced, and its coefficient of linear expansion is reduced to 3.0×10 -5 ( / °C), using the asphalt material of the present invention for road construction can reduce the shrinkage performance of the asphalt pavement and alleviate the cracking of the pavement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com