Flame-retarding electronic composite material base plate

A composite material and substrate technology, applied in electronic equipment, lamination, application, etc., can solve the problem of large signal loss, and achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

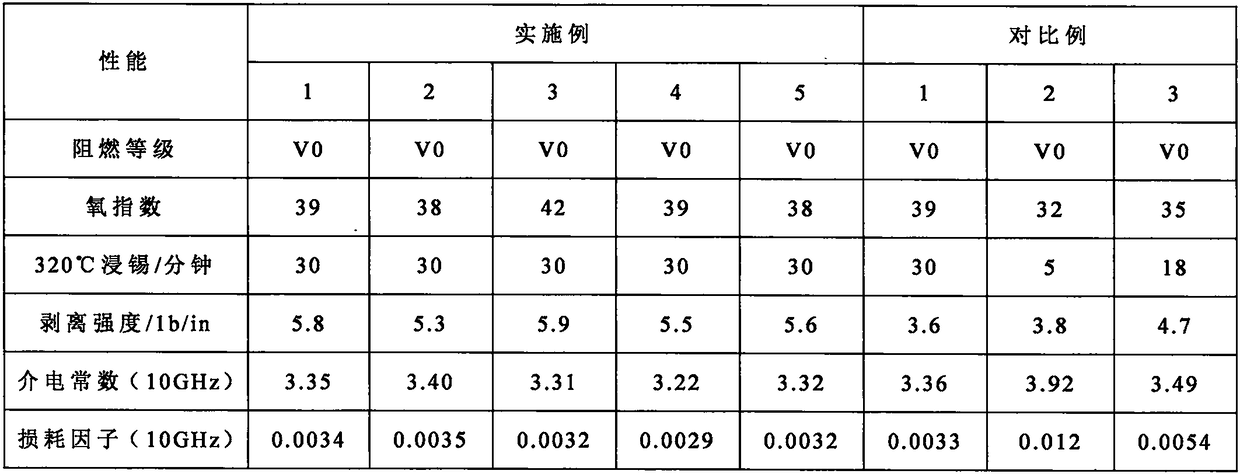

Examples

Embodiment 1

[0032] Dissolve 100 parts by weight of styrene-butadiene block copolymer (D1101) in toluene, add 85 parts by weight of silicon dioxide (525), 6.5 parts by weight of curing agent DCP, 22 parts by weight of The fuel SAYTEX8010 was stirred to obtain a resin solution (80% solid content), and 80 parts by weight of 1080 fiberglass cloth was used to impregnate the above resin solution to obtain a prepreg. Then dry the prepreg to remove the solvent. Laminate 8 prepregs, laminate copper foil on both sides, and heat and press in a press to make a flame-retardant electronic composite substrate.

[0033] In this embodiment, the particle size of the filler is 30-40 microns; the copper foil is 1 ounce copper foil, and the copper nodule height of the copper foil is 9-10 microns; the rough surface of the copper foil is passed through the vinyl coupling agent vinyl trimethyl Silane treatment; copper nodules are prepared on one side of the rolled copper foil or electrolytic copper foil to form...

Embodiment 2

[0036] Dissolve 100 parts by weight of styrene-butadiene block copolymer (D1101) in toluene, add 240 parts by weight of silicon dioxide (525), 7.5 parts by weight of curing agent DCP, 28 parts by weight of Combustion agent SAYTEX8010, stir to obtain resin liquid (solid content is 80%), use 125 parts by weight of 1080 fiber glass cloth to impregnate the above resin liquid and then dry to remove solvent to make prepreg, then stack 8 prepregs, place on both sides Laminated copper foil, after high-temperature hot-press curing in a press, is made into a flame-retardant electronic composite substrate; the drying temperature is 100°C, and the time is 3 minutes; the hot-pressing temperature is 250°C, and the time is 50 minutes. The pressure is 70kg / cm 2 ; Its physical data are shown in Table 1.

[0037] In this embodiment, the particle size of the filler is 40-50 microns; the copper foil is 1 ounce copper foil, and the height of the copper nodules is 10-11 microns; the rough surface ...

Embodiment 3

[0039] 90 parts by weight of styrene-butadiene block copolymer (D1101) was dissolved in toluene, and 45 parts by weight of silicon dioxide (525), 5.6 parts by weight of curing agent (mass ratio of 1:0.2 Lithium thiocyanate, neopentyl glycol diborate), flame retardant 2 of 12 weight parts, 6-dimethylphenylphosphoryl benzene, stir to obtain resin liquid (solid content is 80%), use 78 weight 1080 pieces of fiberglass cloth impregnated with the above resin solution and then dried to remove the solvent to make a prepreg, and then laminated 8 prepregs, laminated copper foil on both sides, and cured by high temperature and hot pressing in a press to make a flame retardant Electronic composite material substrate; the drying temperature is 130°C, the time is 2 minutes, the temperature of hot pressing is 290°C, the time is 42 minutes, and the pressure is 60kg / cm 2 ; Its physical data are shown in Table 1.

[0040] In this embodiment, the particle size of the filler is 30-35 microns; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com