Patents

Literature

489 results about "Loss factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A building's loss factor is the percentage of the building's area shared by tenants or space that are dedicated to the common areas of a building used to calculate the difference between the net and gross areas. That portion of the space is considered "lost" because it cannot be directly leased and the maintenance and operation costs must be covered by the other rentable areas. The loss factor is often confused with load factor, but the formulas for each term vary. The loss factor is calculated as follows: Loss Factor = / Rentable Area The Building Owners and Managers Association has established a standard with American National Standards Institute, ANSI/BOMA Z65.1-2010 for measuring floor area and calculating gross leasable area and loss factor.

Resin composition for production of optical element, the optical element, and projection screen

InactiveUS6650471B2Increase crosslink densityHigh refractive indexProjectorsOptical articlesTemperature curveProjection screen

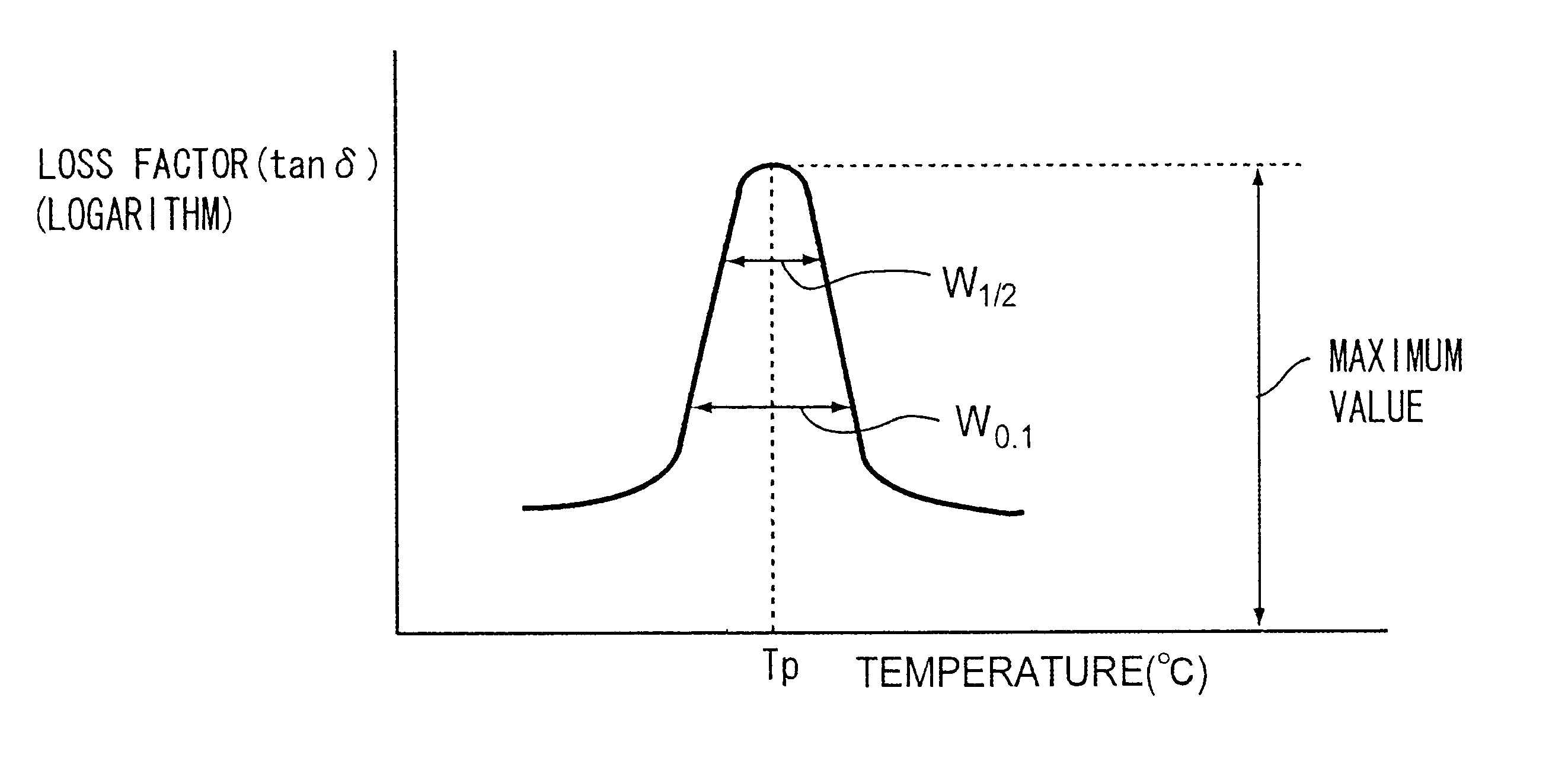

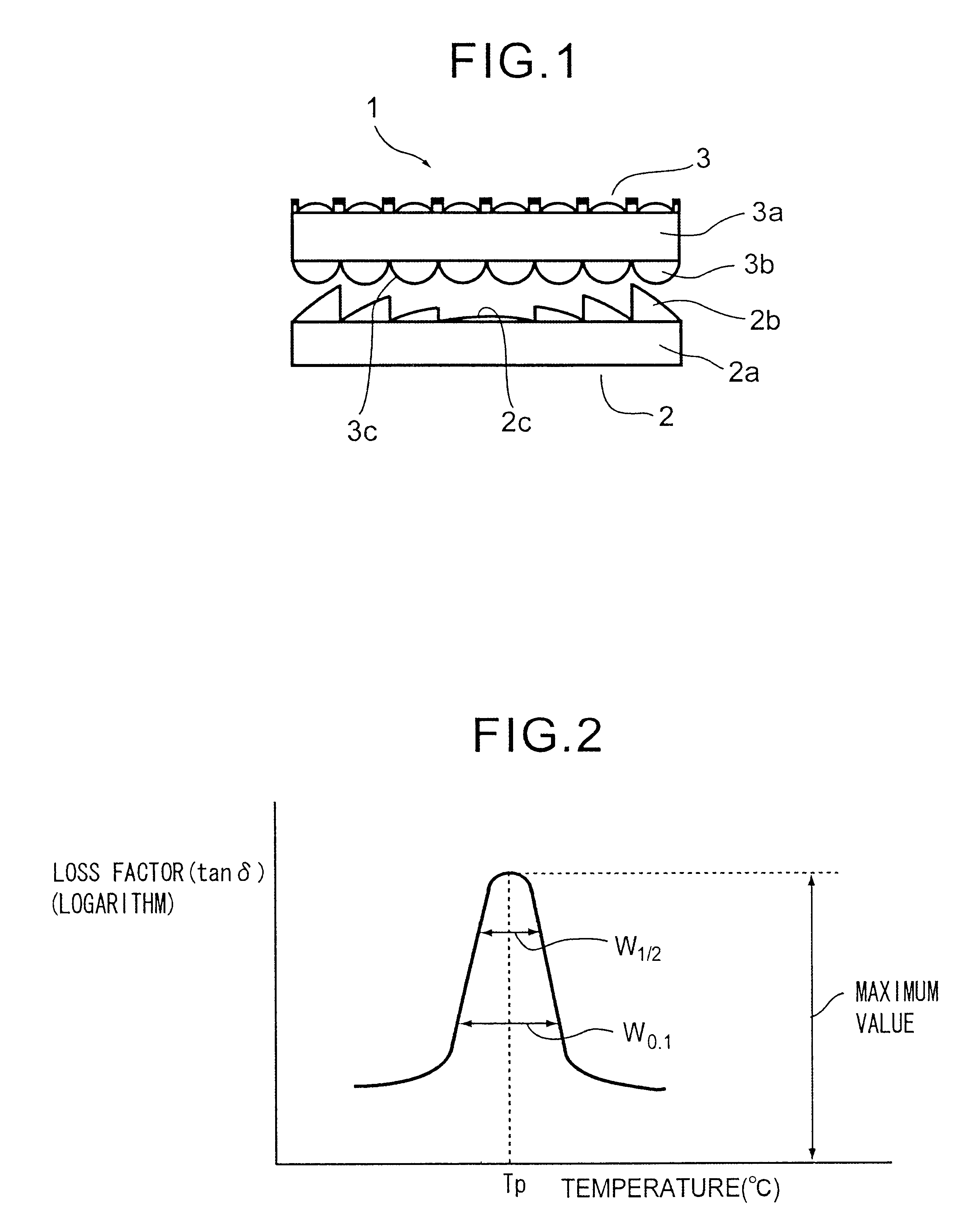

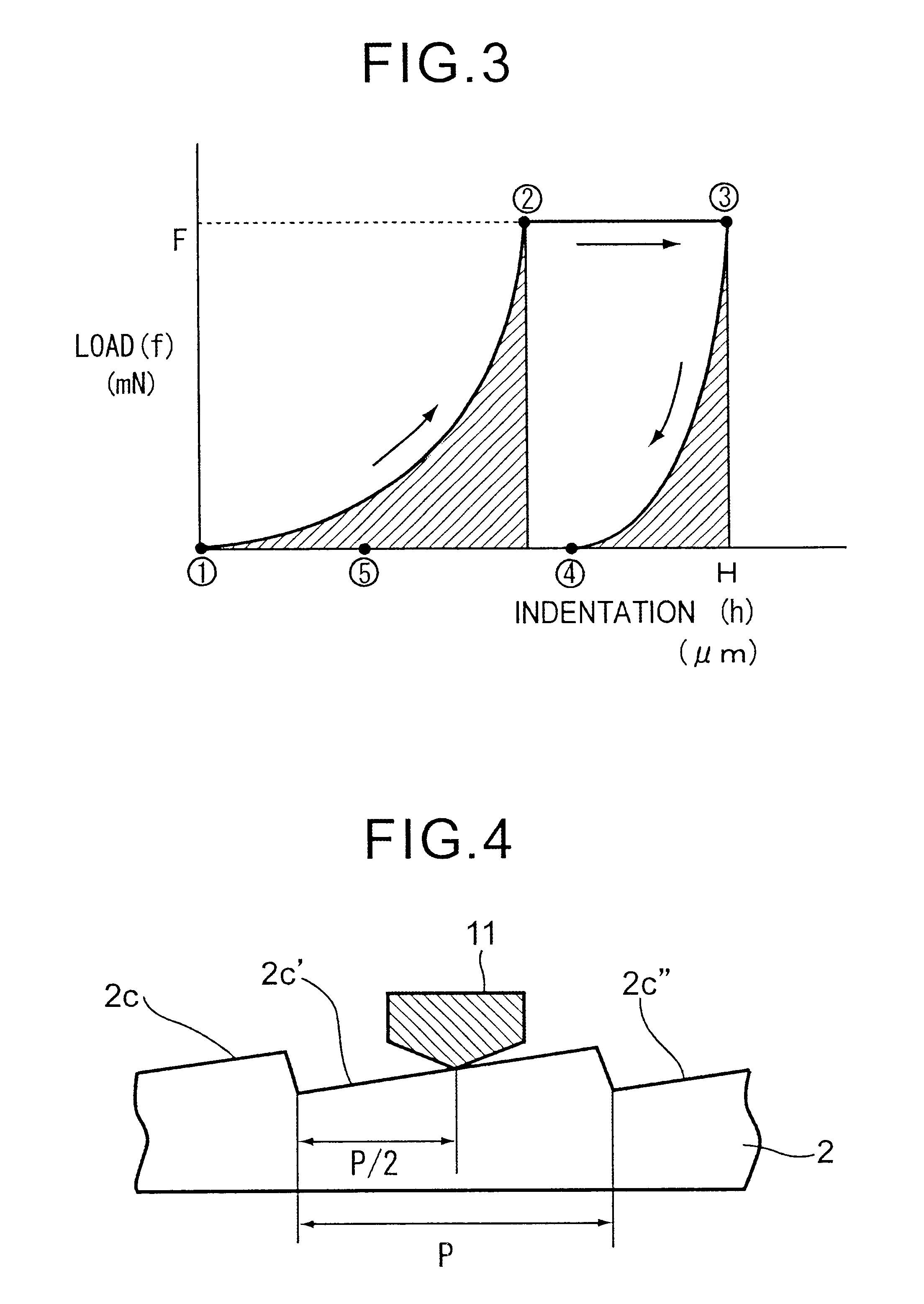

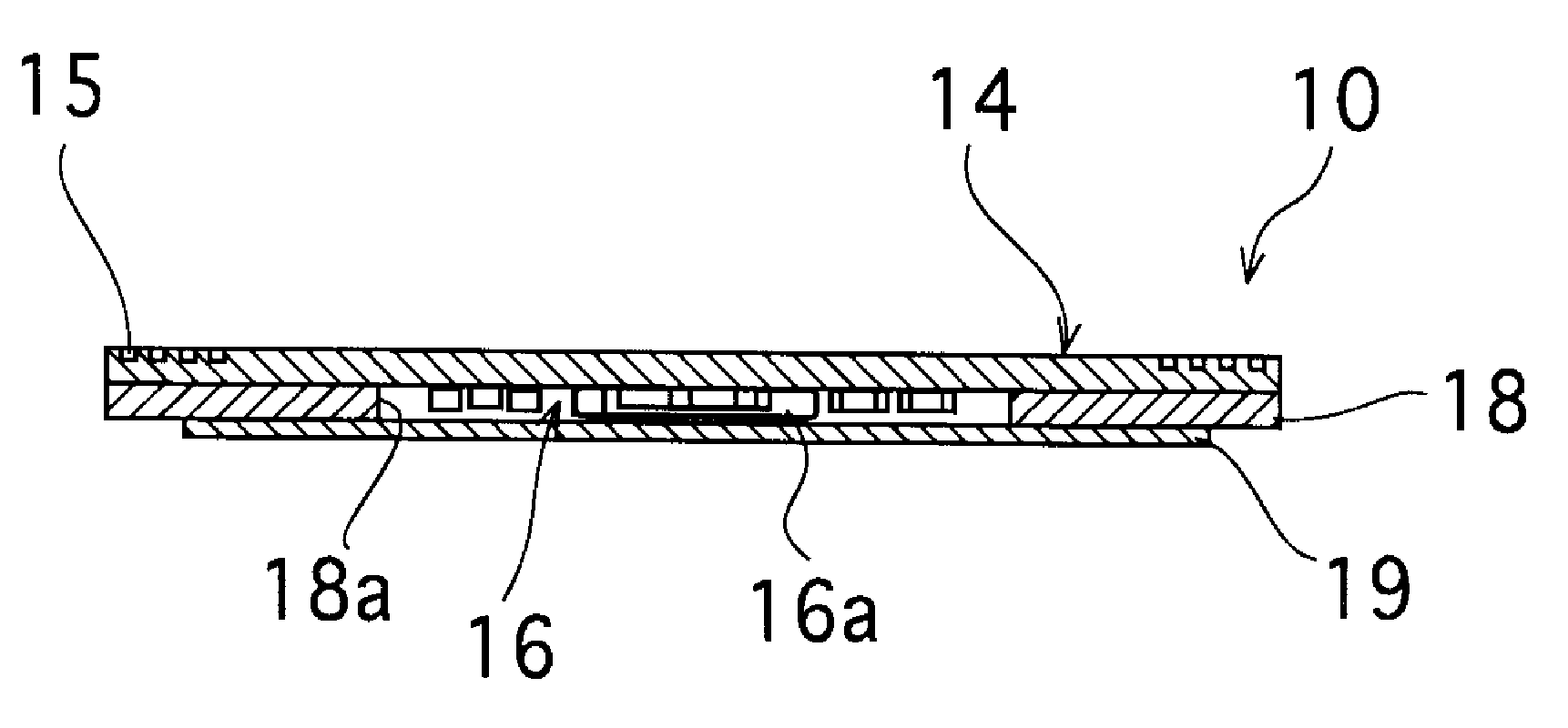

A resin composition for production of an optical element being adapted to form the optical element has a characteristics of which, when W1 / 2 (° C.) represents, regarding a crest portion in a loss factor / temperature curve obtained by measuring the loss factor of the resin composition relative to a change in the temperature, the width of the crest portion at the position of ½ of the maximum value of the loss factor in the crest portion temperature range; W0.1 (° C.) represents, regarding the crest portion, the width of the crest portion at the position of 0.1 of the maximum value of the loss factor; and DeltaW (° C.), the difference between the widths of the two crest portions, is set to be DeltaW=W0.1-W1 / 2, the DeltaW is in the range of from 16° C. to 31° C.

Owner:DAI NIPPON PRINTING CO LTD

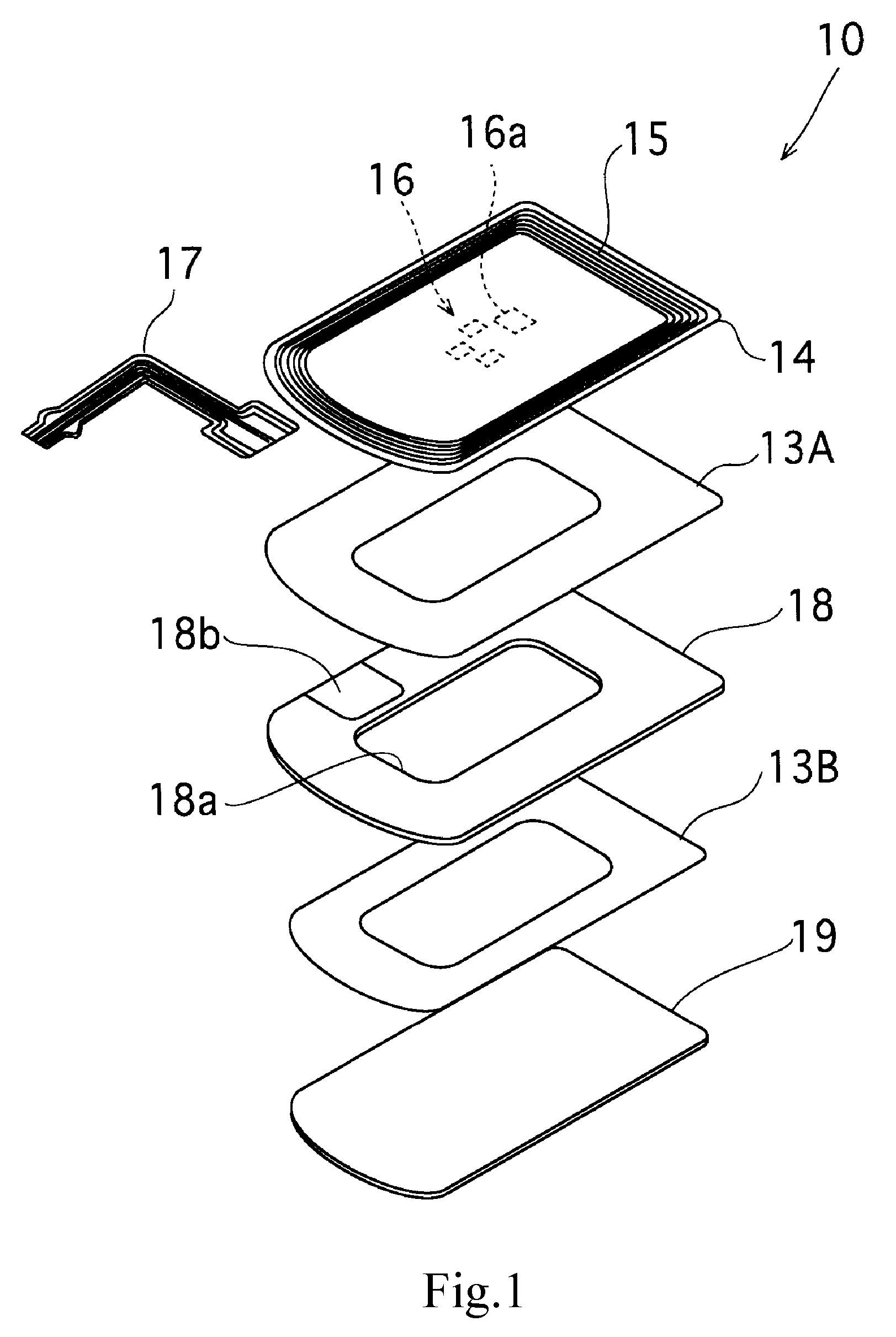

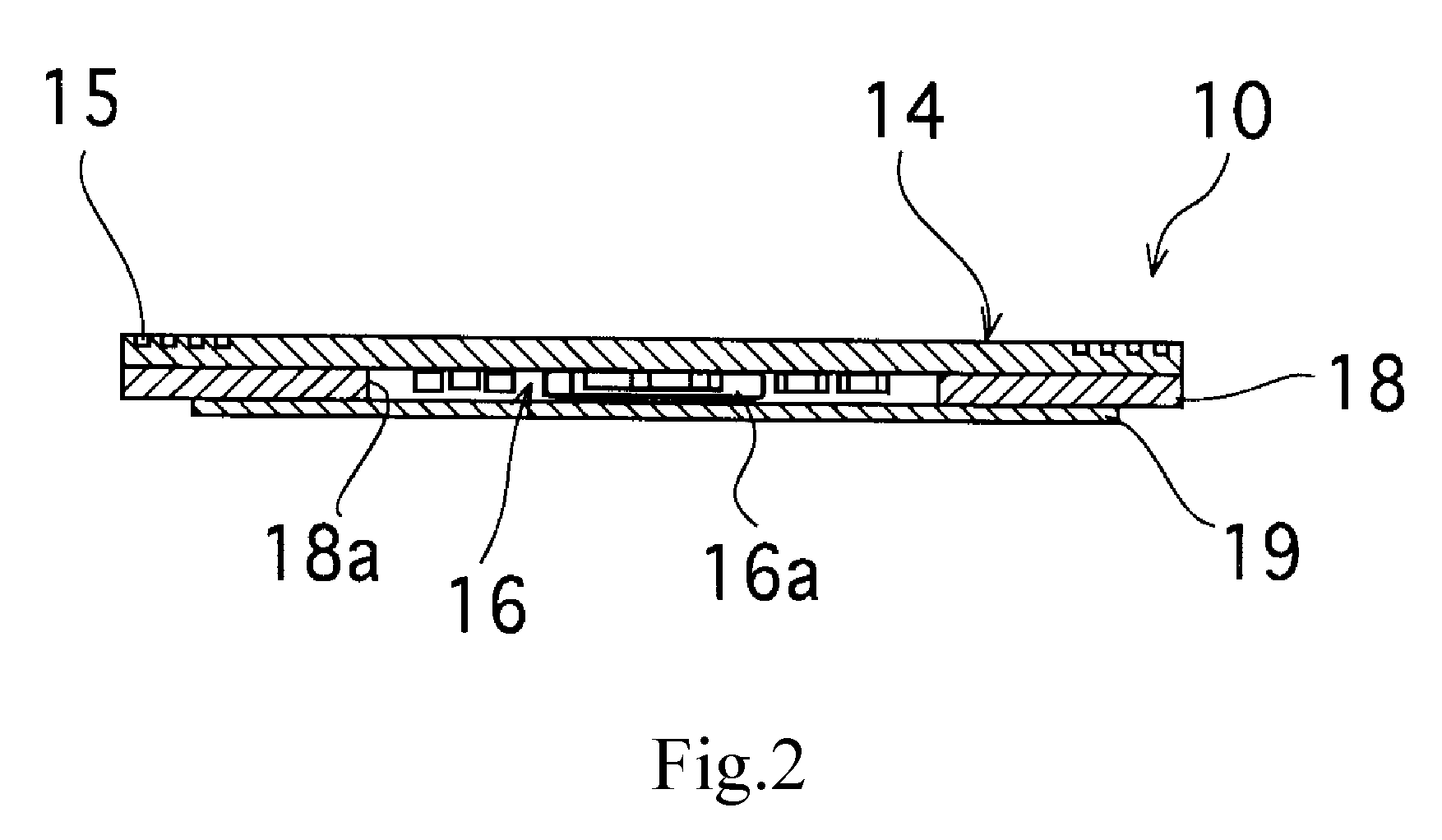

Antenna Module-Use Magnetic Core Member, Antenna Module, and Portable Information Terminal Having the Same

InactiveUS20090146898A1Improve permeabilityTotal current dropLoop antennas with ferromagnetic coreAntenna supports/mountingsComputer moduleComputer terminal

There are provided an antenna module-use magnetic core member, an antenna module and a portable information terminal provided with the same, capable of improving a communication distance without increasing a module thickness. In an antenna module (1) in which a sheet-formed magnetic core member (4) is stacked on an antenna substrate (2) on which a looped antenna is formed, one having a performance index, expressed by μ′×Q, of 300 or higher when Q is a reciprocal of a loss factor (tan δ=μ″ / μ′) expressed by a real part μ′ and an imaginary part μ″ of a complex permeability at an applied frequency is used as the magnetic core member (4).

Owner:SONY CORP

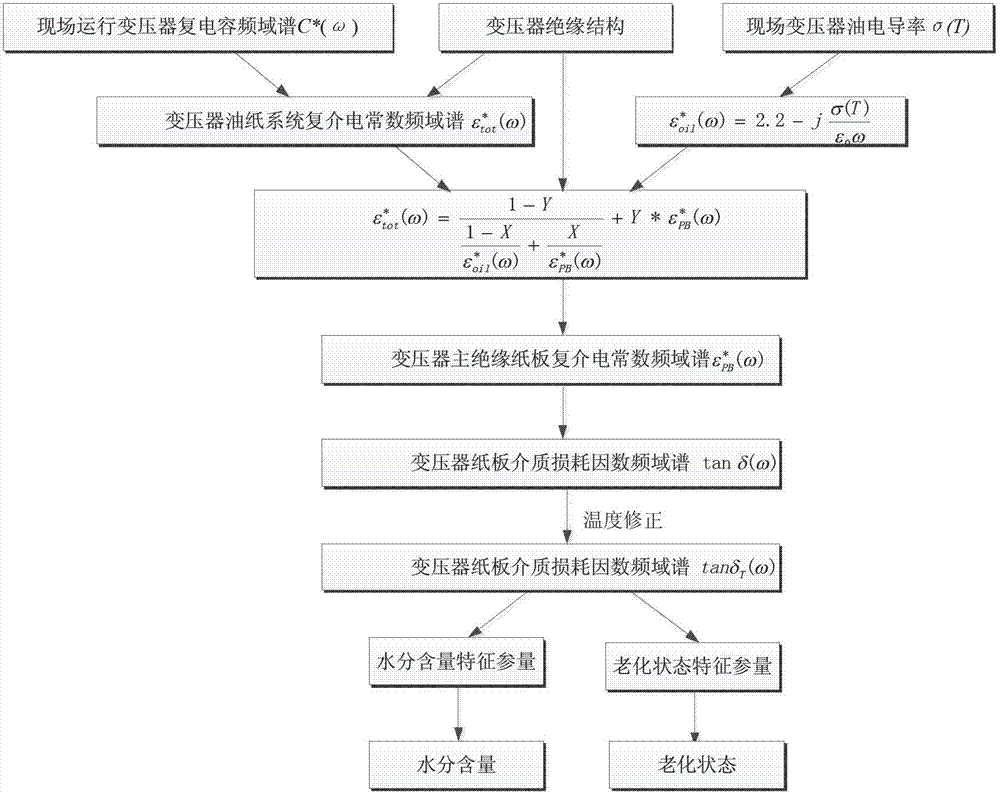

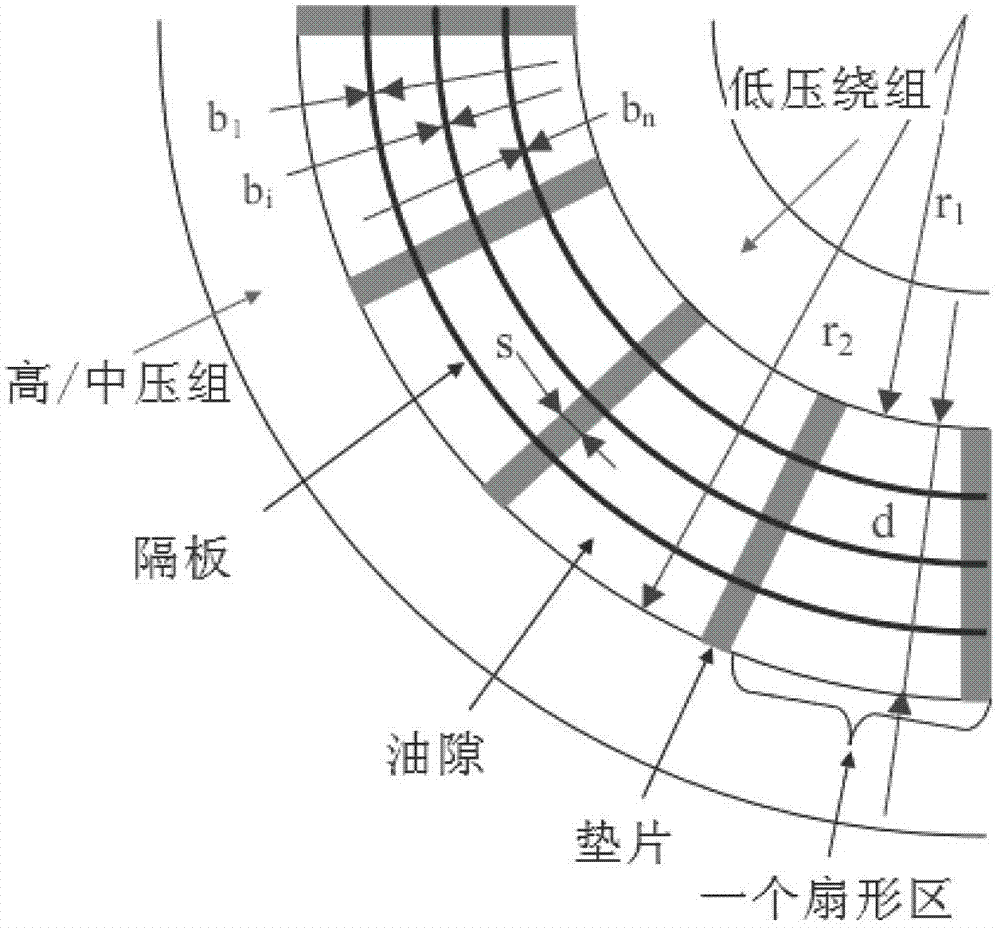

Method for evaluating aging degree of main insulation of transformer

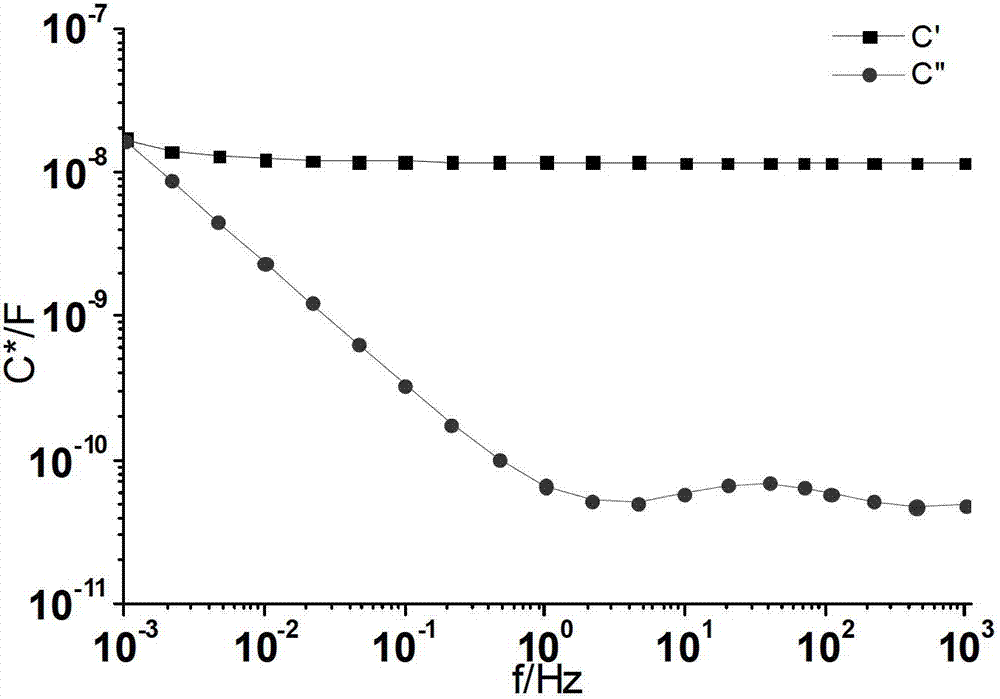

ActiveCN102818974AWide applicabilityEasy to moveTesting dielectric strengthResistance/reactance/impedenceCapacitanceElectricity

The invention discloses a method for evaluating the aging degree of main insulation of a transformer. The method comprises the following steps of: firstly measuring a complex capacitance frequency domain spectrum C*(ohm) and an oil conductivity sigma of the main insulation of the transformer on the scene, collecting structure parameters of the main insulation of the transformer and transmitting the structure parameters to a data processing device; subsequently calculating the complex capacitance frequency domain spectrum so as to obtain a medium loss factor frequency domain spectrum of a main insulation paper board of the transformer; and finally evaluating the state of the main insulation of the transformer by adopting frequency domain-based dielectric characteristic parameters. The method considers the influence of multiple factors such as measuring temperature, a main insulation structure, and oil conductivity, and has wide applicability to an oil-immersed transformer; the defects in a traditional chemical and electric method are compensated; the moisture content of the main insulation of the transformer can be diagnosed, and meanwhile the aging state of the insulation can be evaluated; and moreover the method can be used for on-site diagnosis directly, and has the advantages of lossless, convenience, transplantation and the like.

Owner:云南电力试验研究院(集团)有限公司

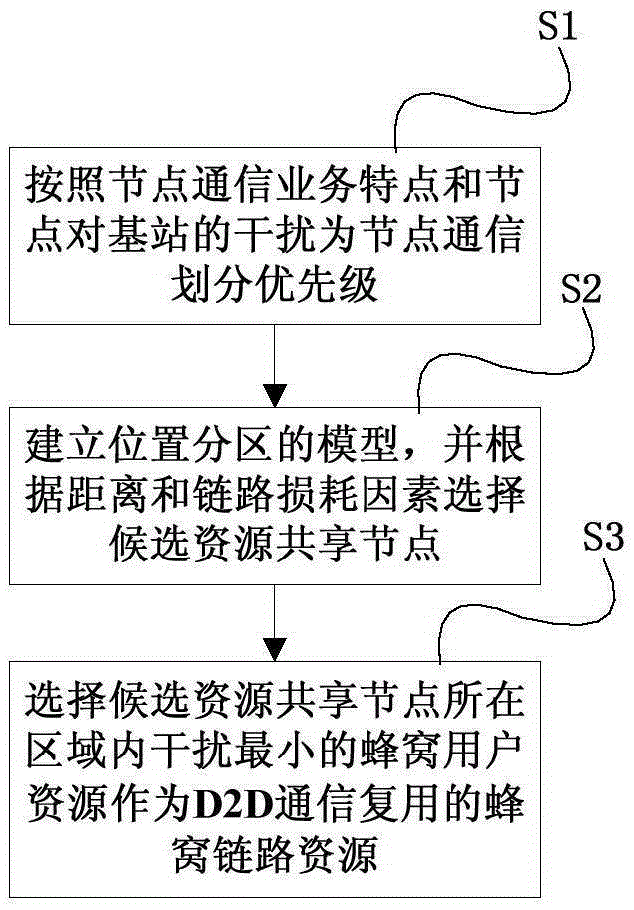

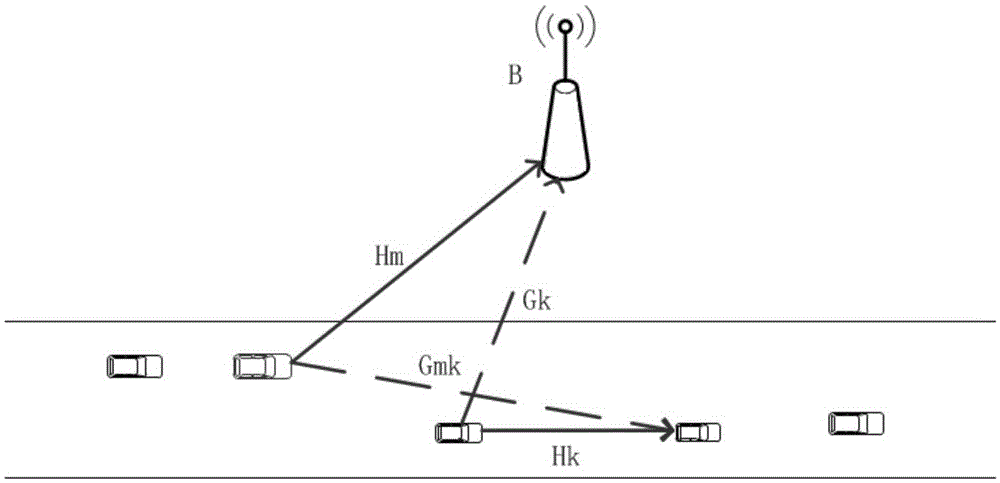

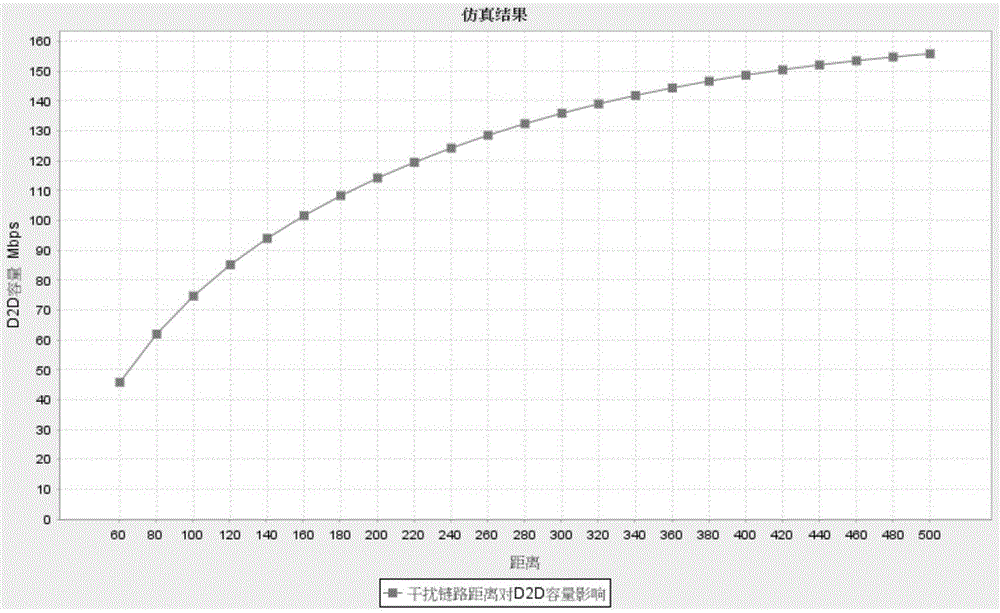

LTE-based radio resource allocation method of Internet of vehicles

ActiveCN105307216AReduce loadReduce running timeNetwork traffic/resource managementWireless commuication servicesThe InternetWireless resource allocation

The invention provides an LTE-based radio resource allocation method of Internet of vehicles. The method comprises the following steps: step S1, dividing priority for node communications according to node communication service characteristics and interference of node to a base station; step S2, building a position division model, wherein the base station dispatches D2D users in sequence according to the priority and selects candidate resource share nodes according to distance and link loss factors; and step S3, selecting cellular user resources with smallest interference in a region where the candidate resource share nodes are located as cellular link resources for D2D communication multiplex. the number of nodes needed to be fed back to the base station in the invention is obviously smaller than that in optimal algorithm, thereby largely reducing the load of the base station; in addition, the operating time of the algorithm used in the invention is obviously shorter than that of the optimal algorithm, thereby effectively reducing processing delay.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

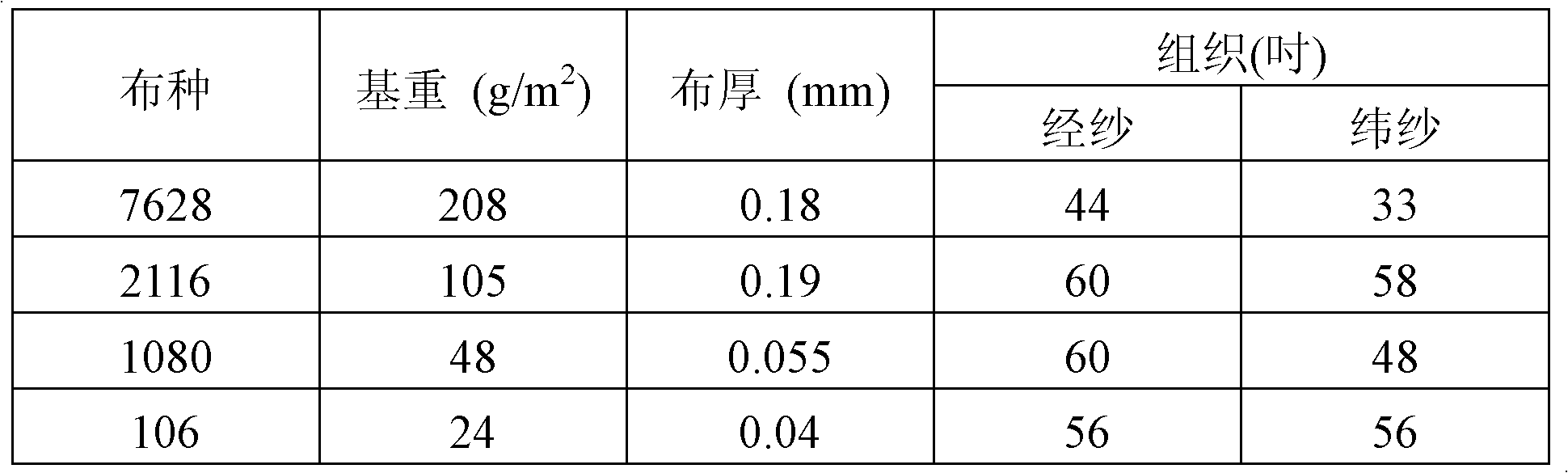

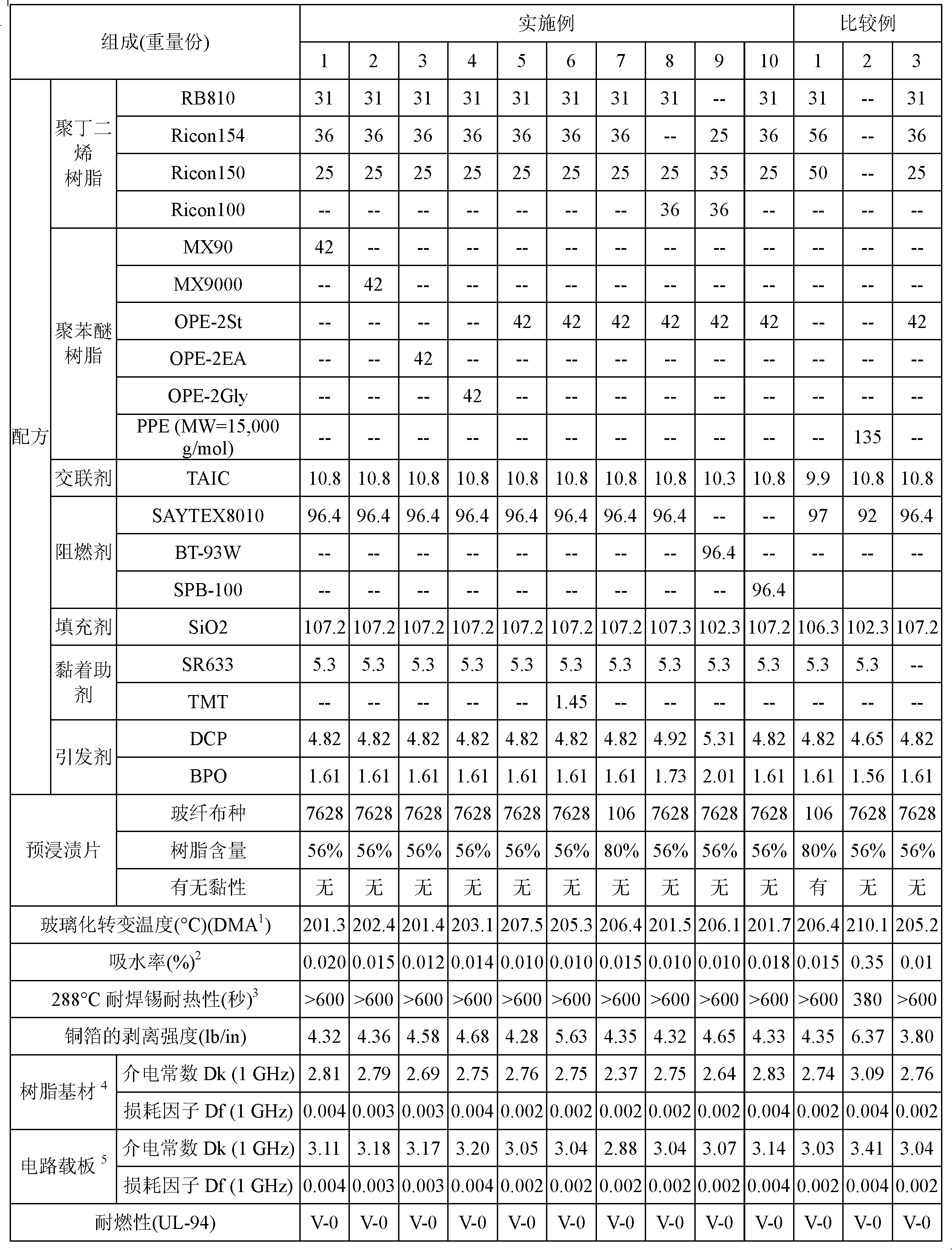

High-frequency copper foil substrate and composite material used thereby

ActiveCN102304264ALow costHigh frequencySynthetic resin layered productsCircuit susbtrate materialsCross-linkSolubility

The invention discloses a high-frequency copper foil substrate with an operating frequency of more than 1GHz, which has a dielectric constant Dk of less than 3.2 and a loss factor Df of less than 0.005 as well as high glass transition temperature, high thermostability and low moisture-absorption characteristic. The high-frequency copper foil substrate contains a special composite material and is prepared by impregnating a reinforcing material with blended resin mixture. The resin mixture of the composite material is prepared by blending the following materials: (a) high molecular weight polybutadiene resin; (b) low molecular weight polybutadiene resin; (c) modified polyphenyl ether thermosetting resin; (d) inorganic powder; (e) flame retardant; (f) cross-linking agent; (g) binding aid; and (h) hardening initiator. In the invention, the drawback of low processability of pure polybutadiene with low viscosity and the drawback of need of adding plasticizer of polyphenyl ether resin (PPE) with low solubility; particularly, the non-viscous pre-impregnated sheets made by the composite material can be processed into copper foil substrates automatically.

Owner:NANYA PLASTICS CORP

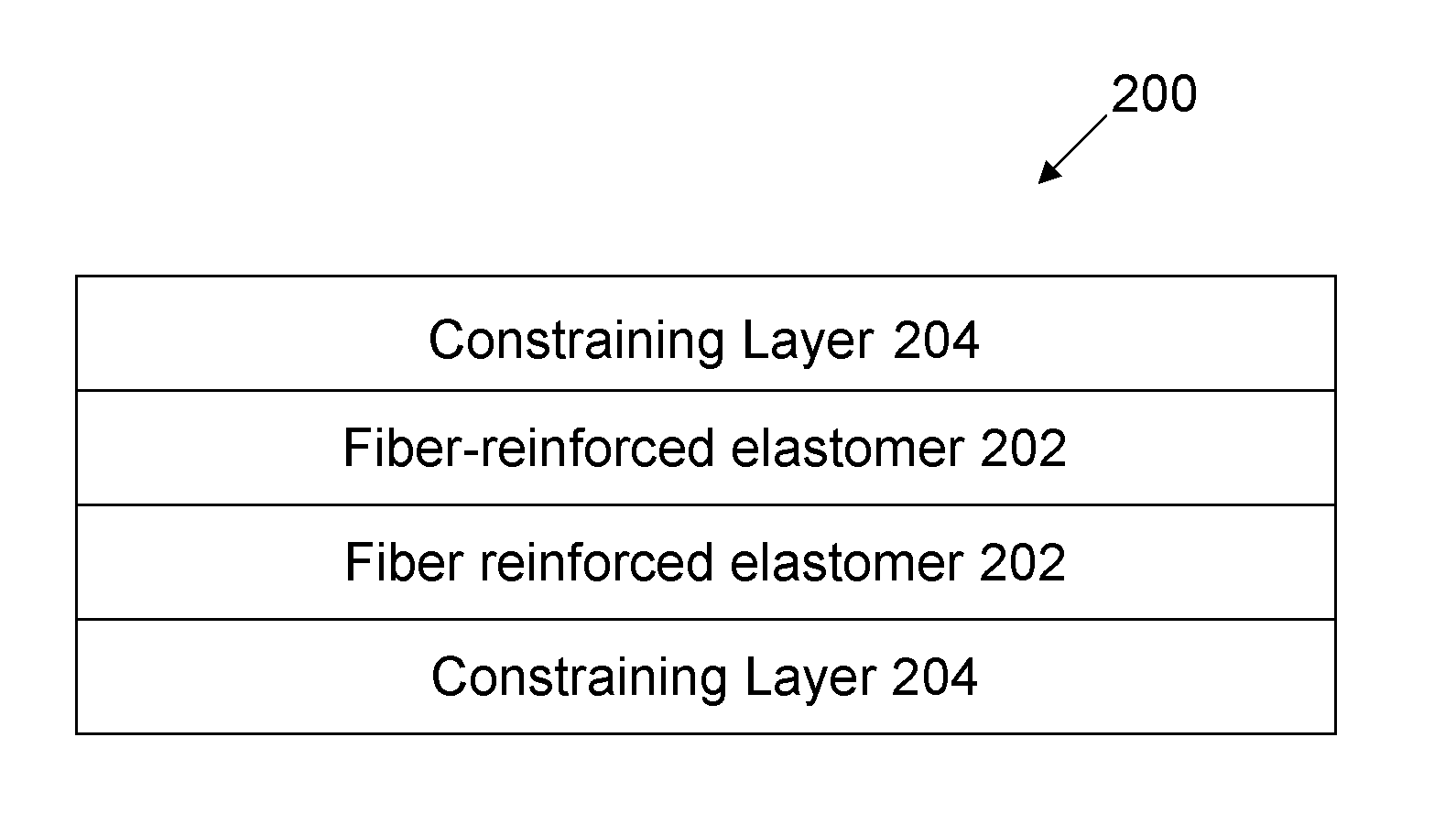

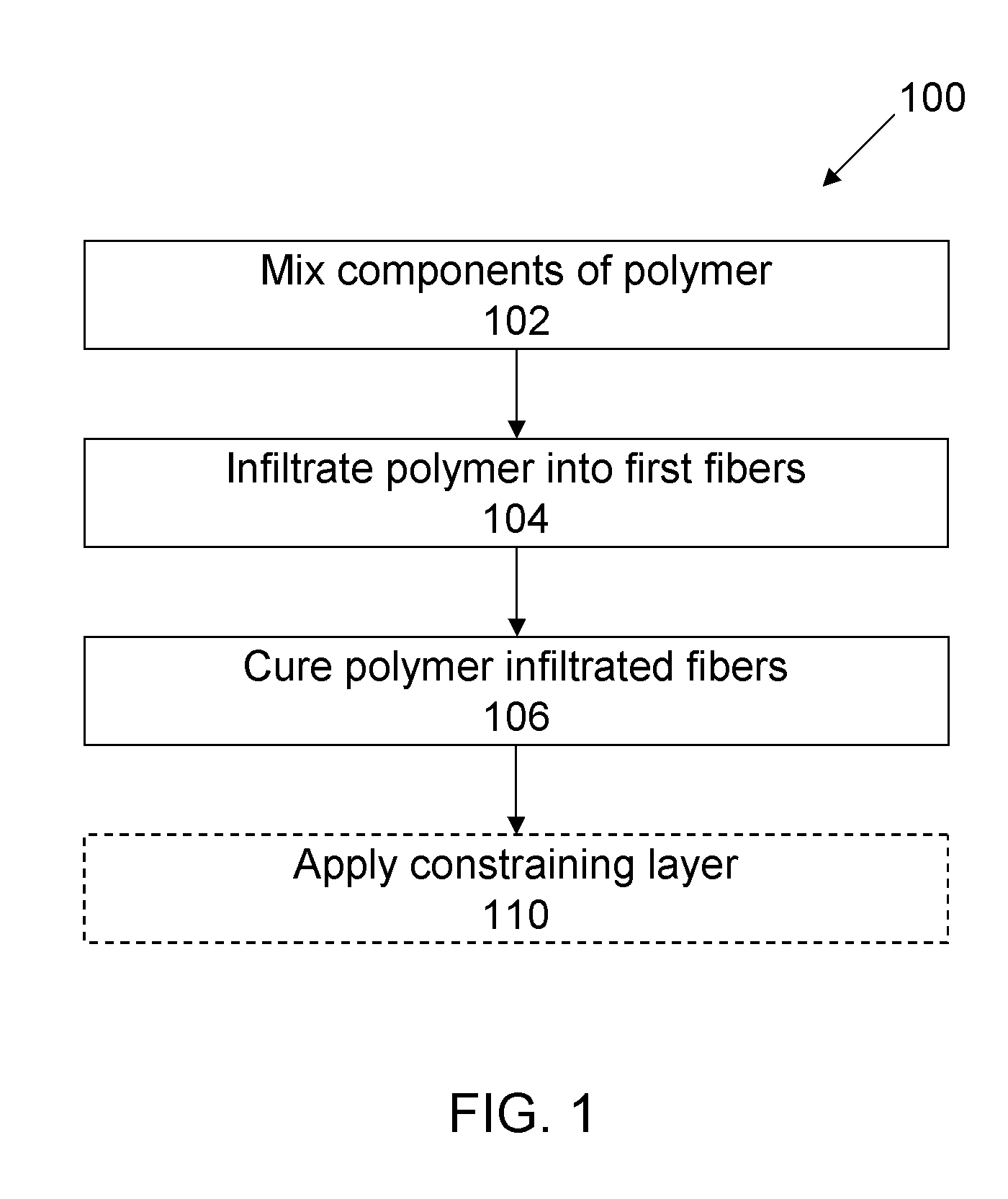

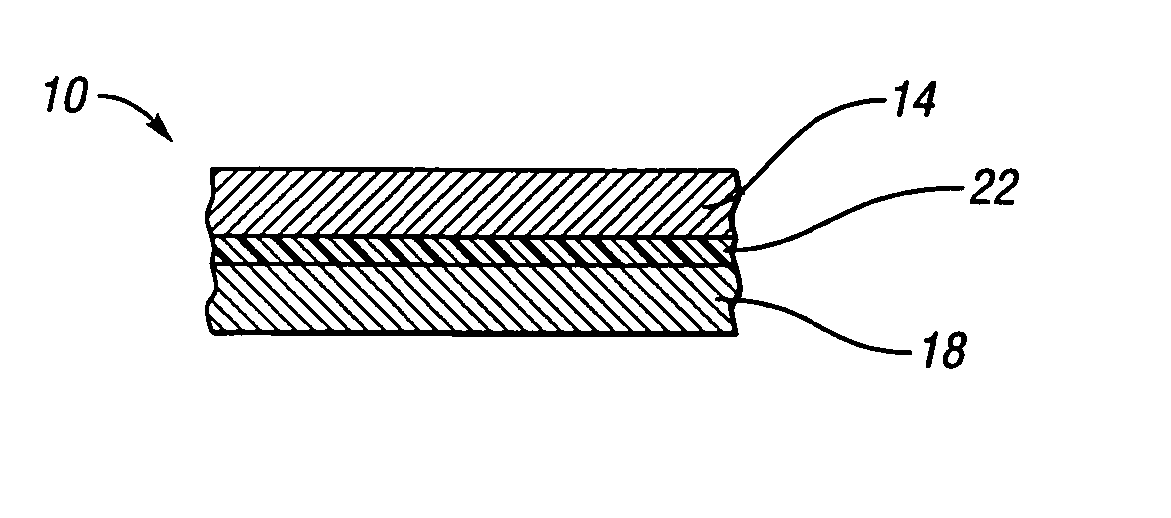

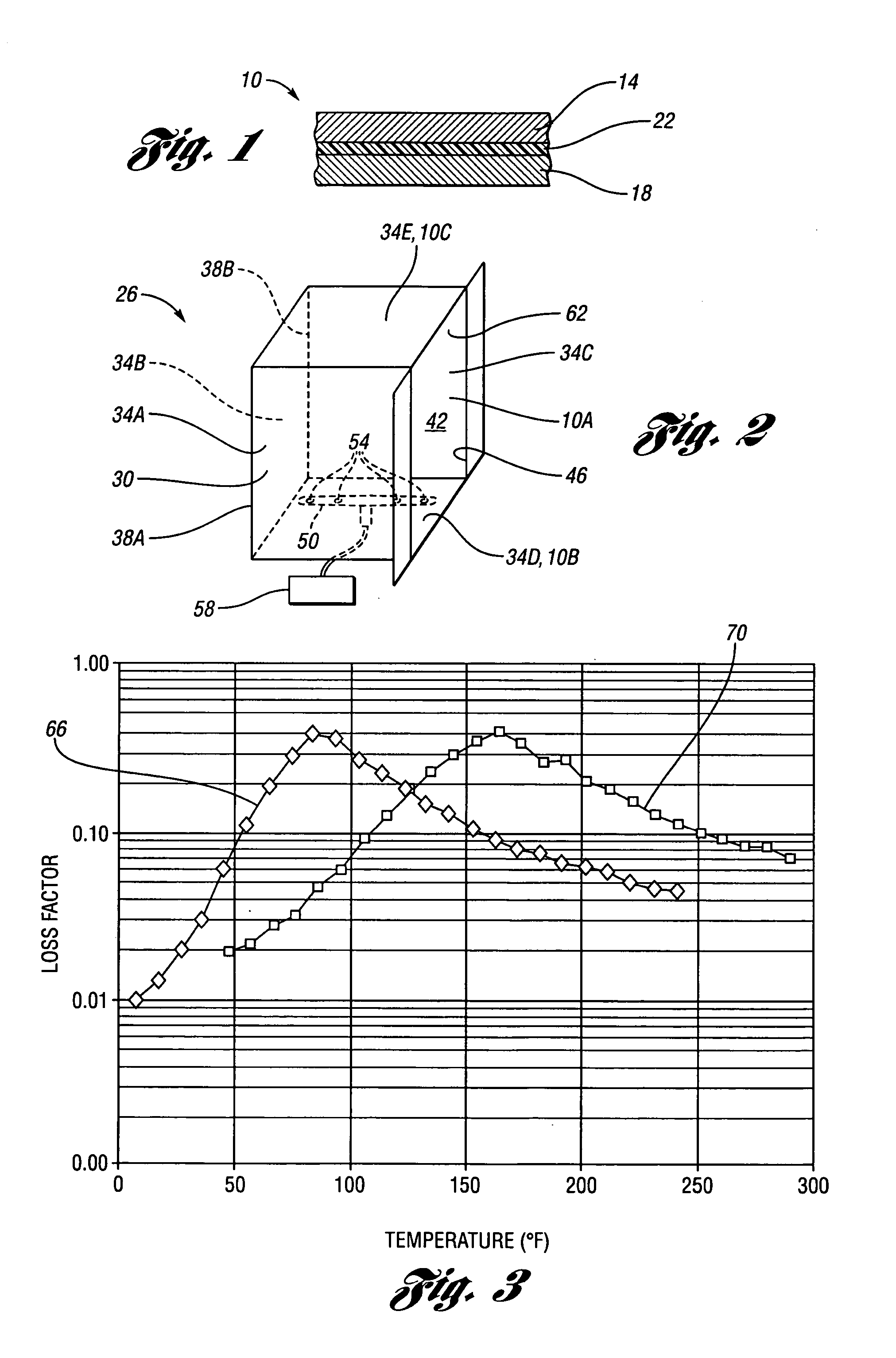

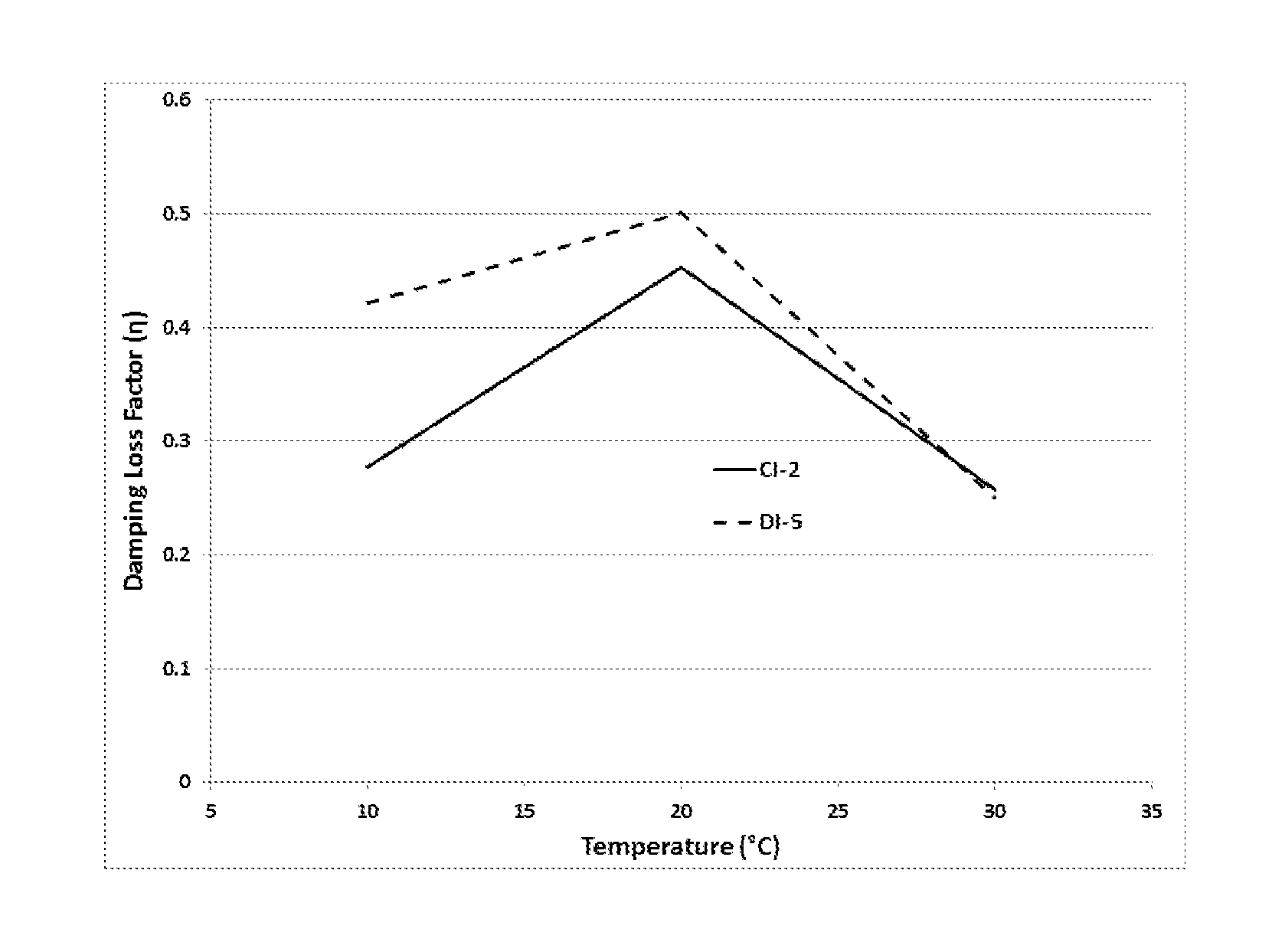

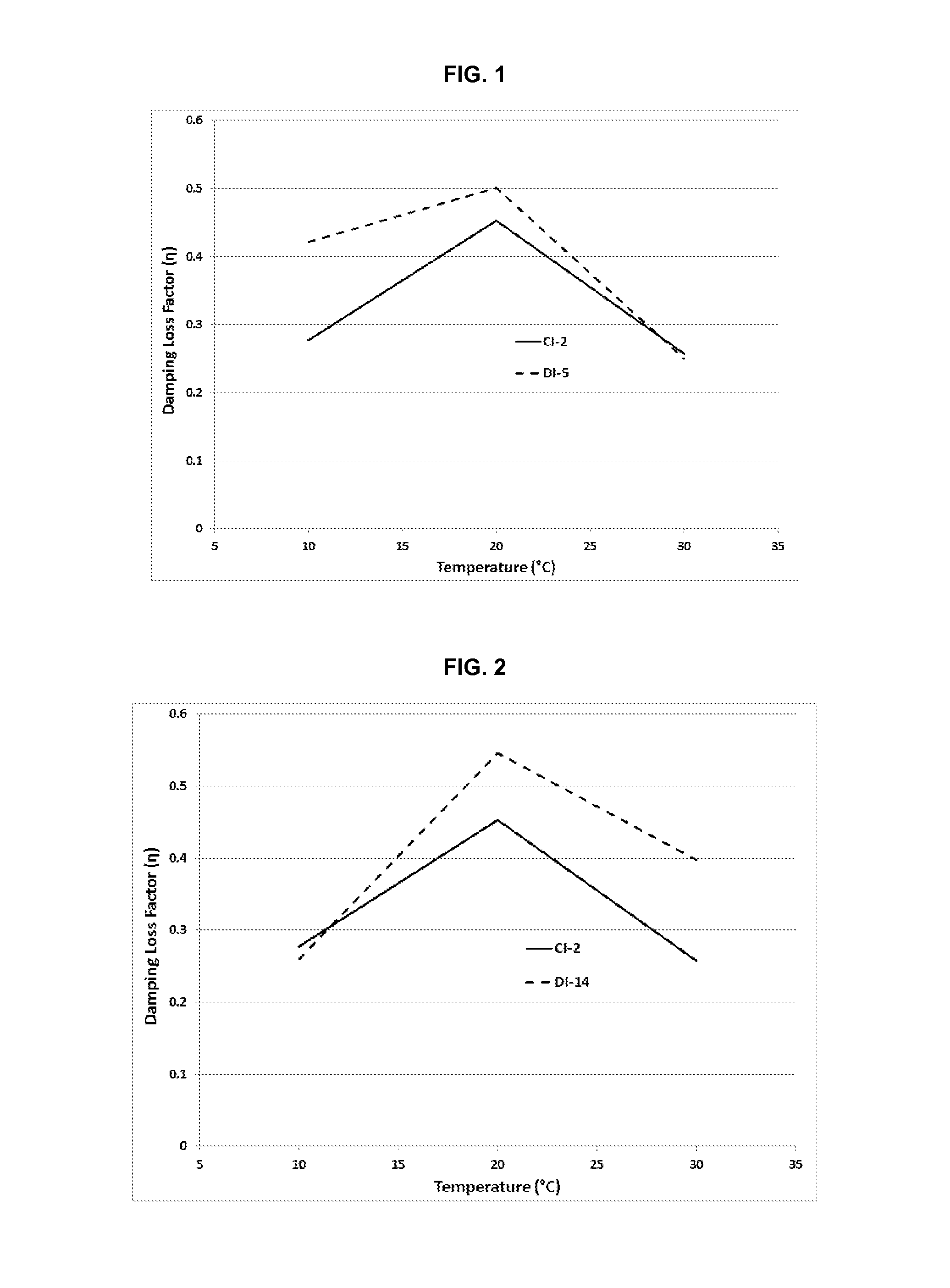

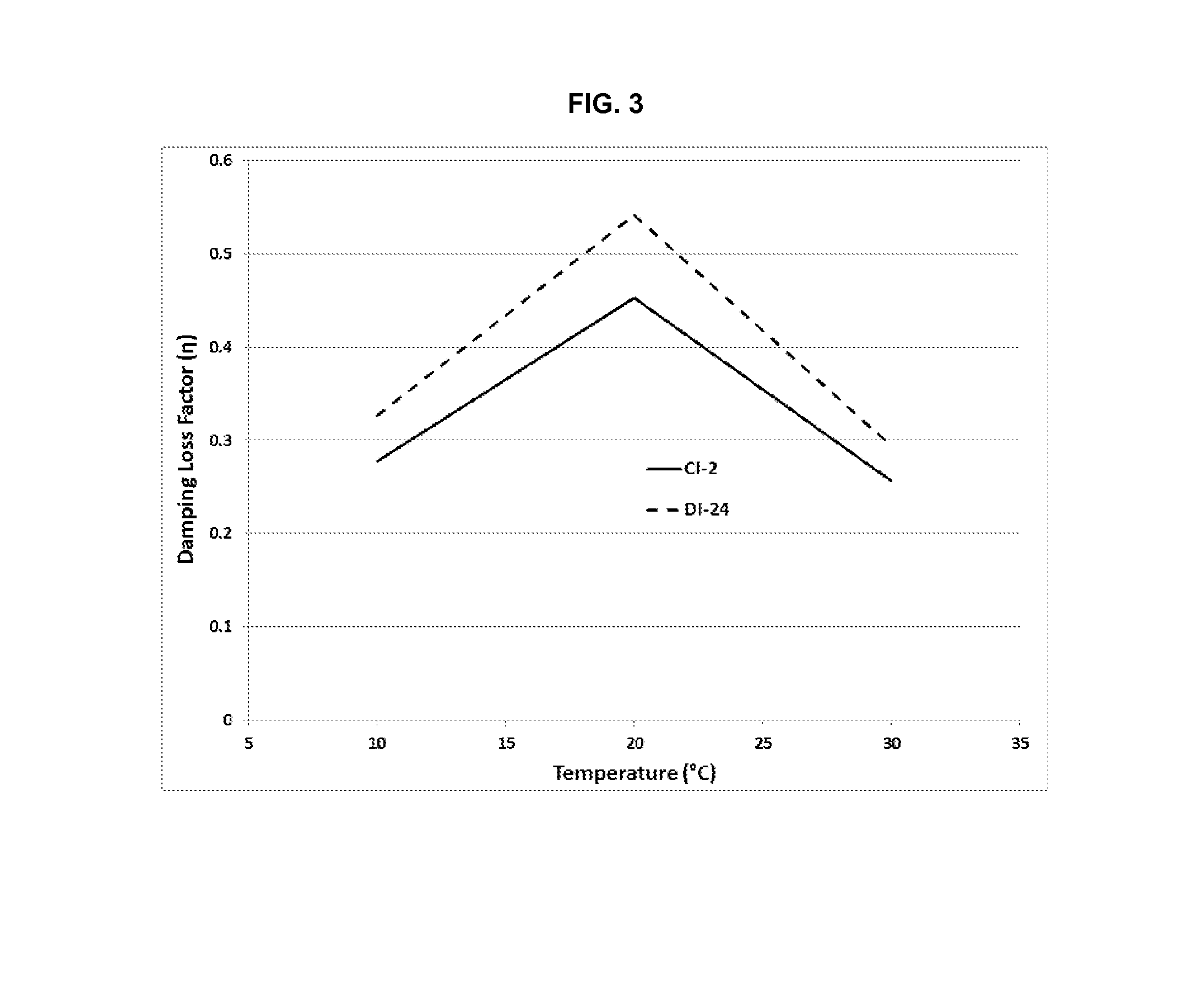

Polymer composites possessing improved vibration damping

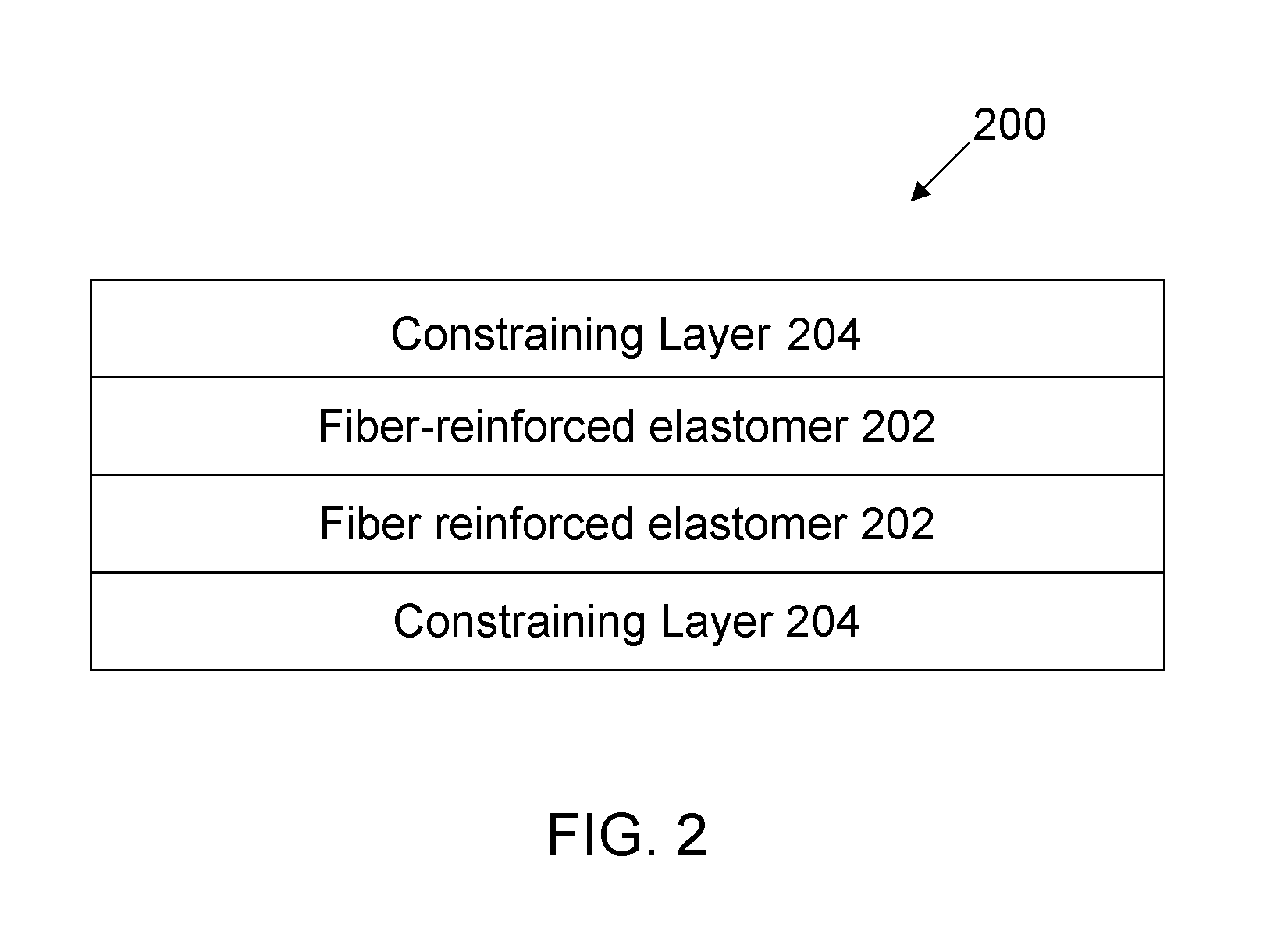

ActiveUS20120313307A1Increase dampingIncrease system loss factorLaminationWood working apparatusPolymer compositesCenter frequency

Fiber-reinforced polymer composites possessing improved damping ability are provided. In one aspect, the fibers provide the composite with a relatively high dynamic modulus over a broad range of frequencies for a given temperature. In another aspect, the polymer may comprise a viscoelastic polymer possessing a relatively high loss factor for a given frequency and temperature. The polymer may be further tailored to control the center frequency at which the maximum loss factor of the polymer is achieved. The composite so formed exhibits a relatively small reduction in loss factor with significant increase in dynamic modulus over a broad range of frequencies for a given temperature. As a result, a structure damped by the composite exhibits a relatively high, constant loss factor as compared to conventional damping materials. Thus, embodiments of the disclosed composites dissipate significantly more energy during each vibration cycle than conventional damping materials.

Owner:THE BF GOODRICH CO

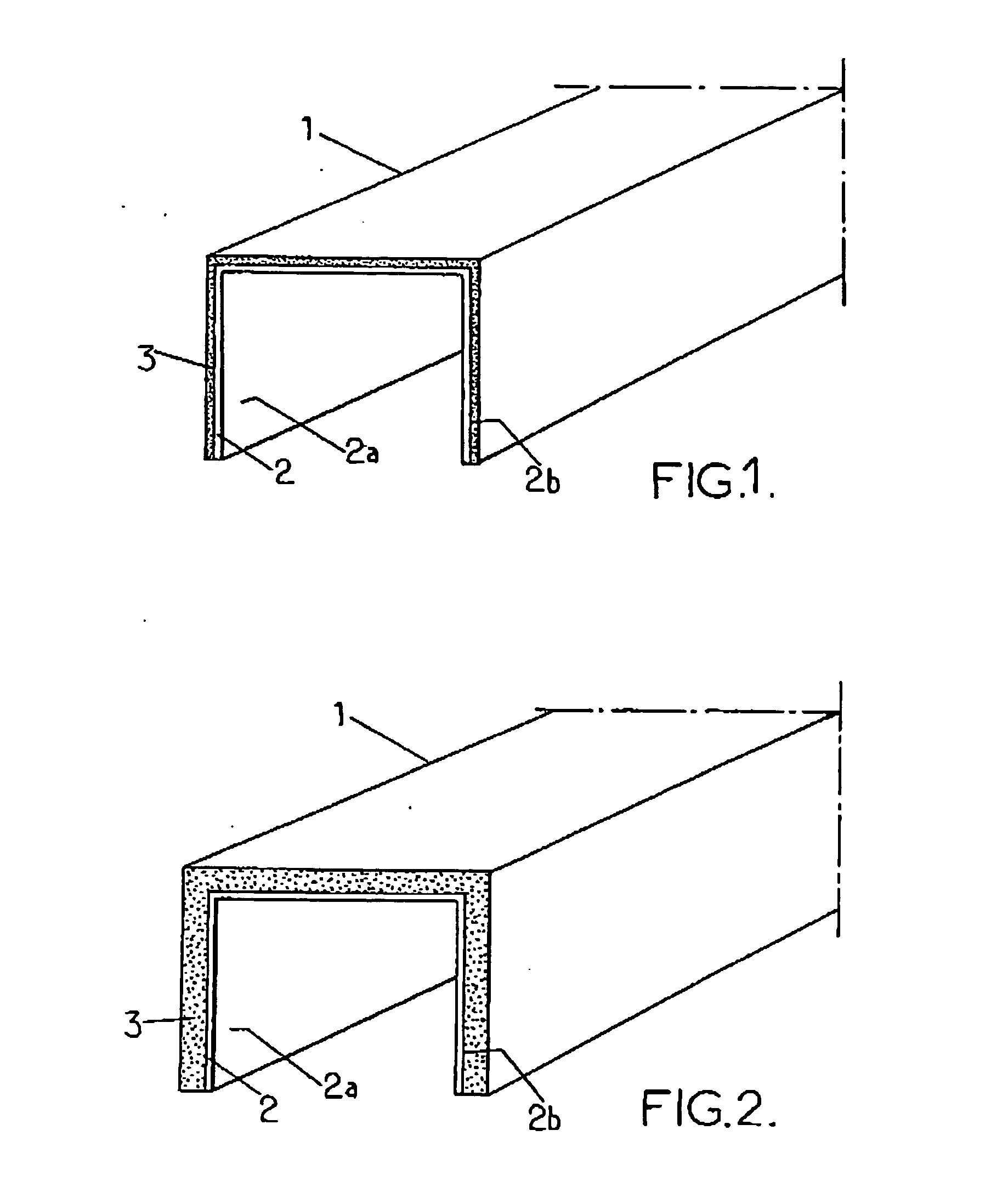

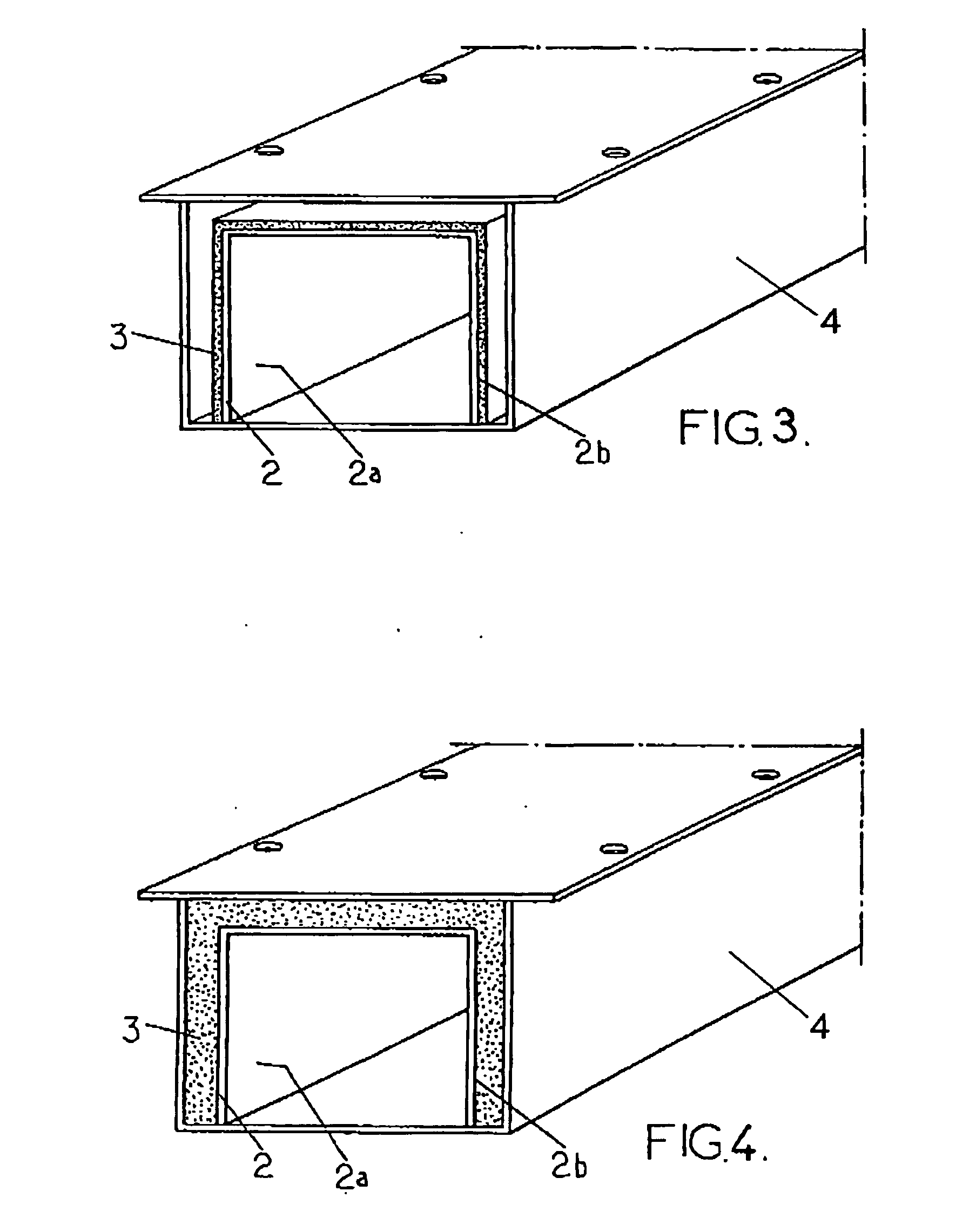

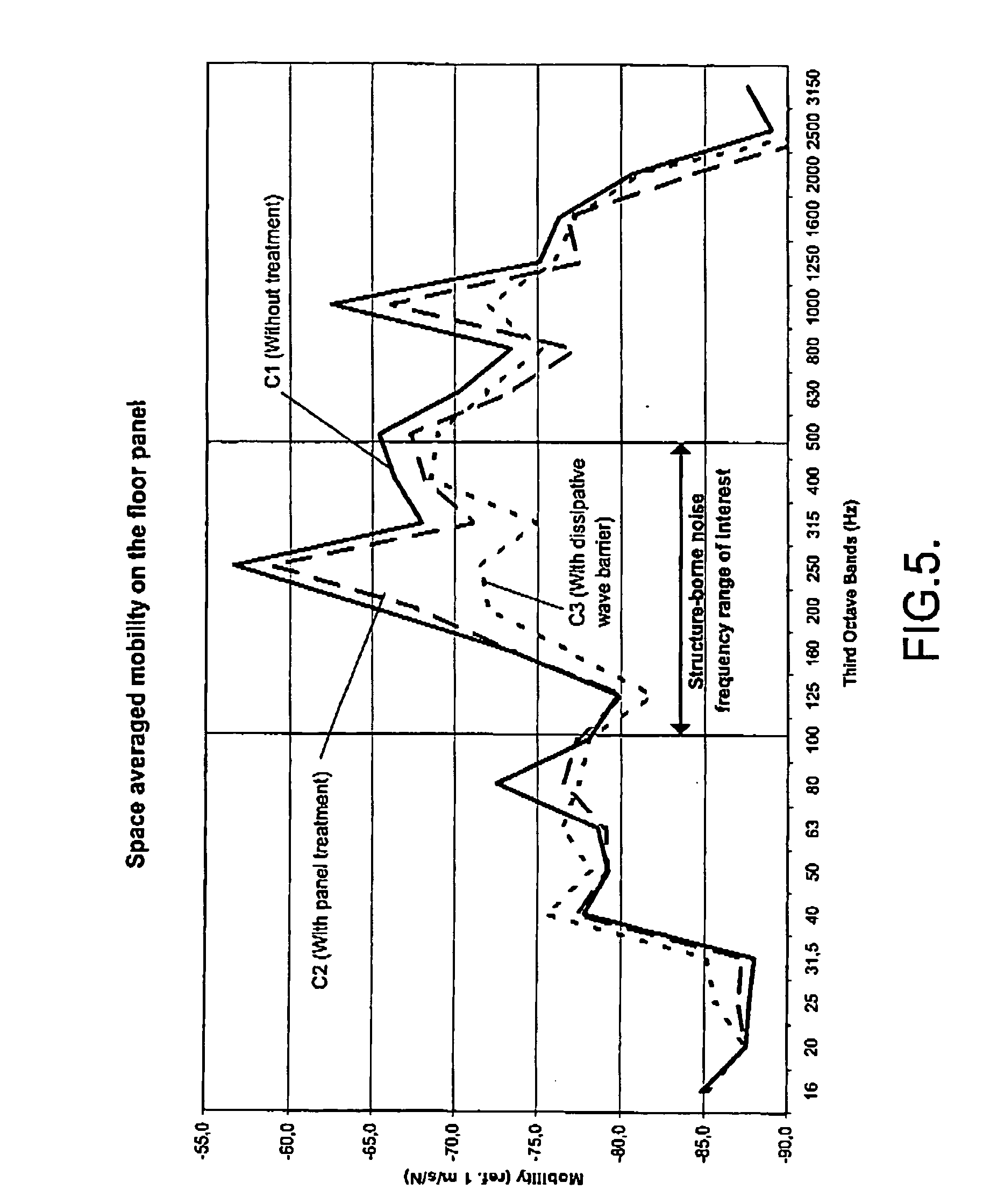

Reduction of vibration transfer

A thermally expandable material is provided that, once expanded, has a Young's storage modulus E′ between 0.1 MPa and 1000 MPa, a loss factor of at least 0.3 (preferably, at least 1) and preferably a shear storage modulus G′ between 0.1 MPa and 500 MPa at a temperature between −10 and +40 degrees C. in the frequency range 0 to 500 Hz. Such materials are useful in combination with a carrier to form a dissipative vibratory wave barrier that effectively reduces the transfer of vibrations from a vibration generator, as may be present in a vehicle.

Owner:HENKEL KGAA

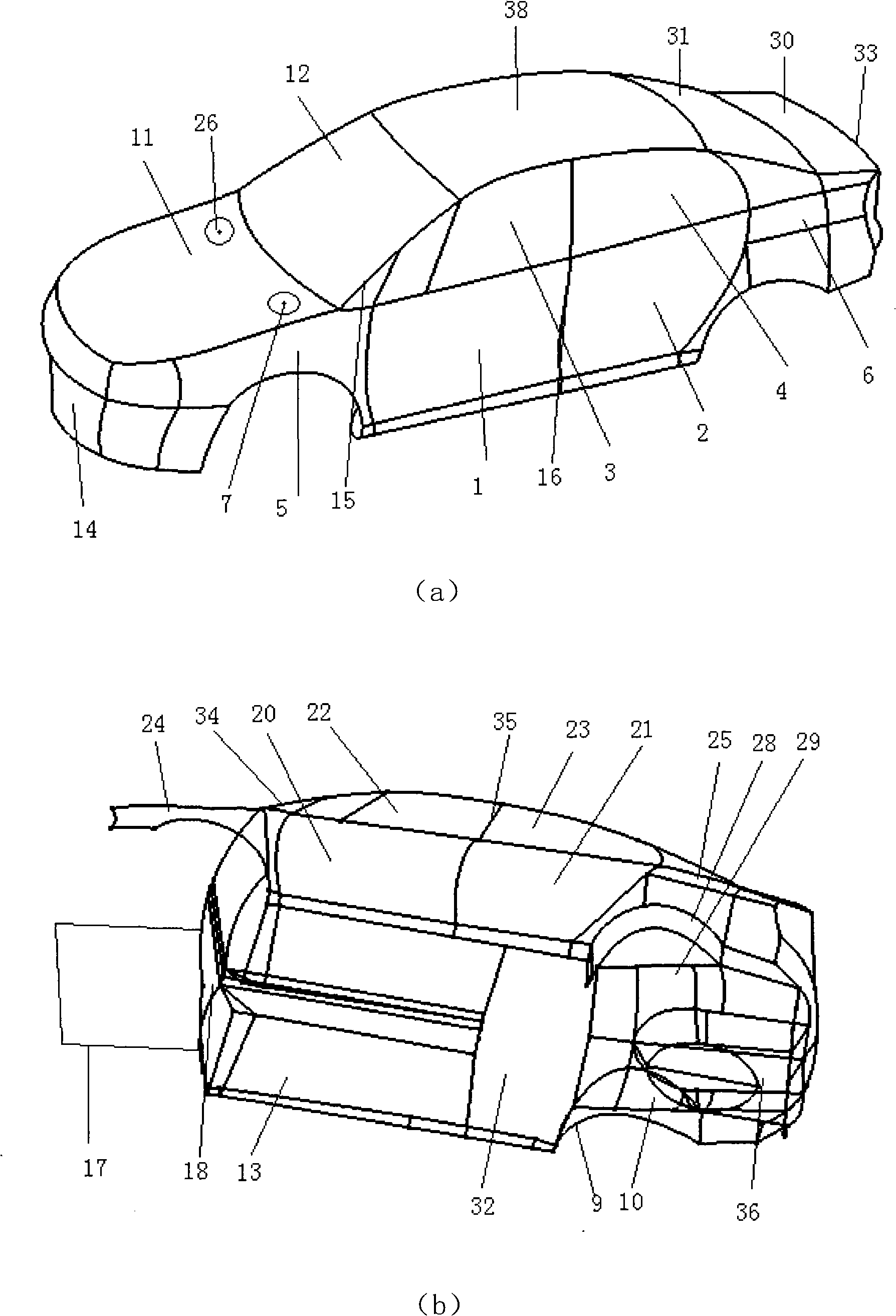

Method for analyzing and predicting noise outside car

InactiveCN101661522AShorten the development cycleReduce development costsSpecial data processing applicationsCoupling lossPredictive methods

The invention discloses a method for analyzing and predicting noise outside a car, which aims at overcoming the problem that the noise outside the car is difficult to be predicted in the developing and designing stage of the car product. The method comprises the steps of: 1) establishing an SEA model of the car body structure: dividing the car body into a plurality of structural sub-systems, and connecting all structural sub-systems according to the correlations; 2) establishing an SEA model for an external acoustic cavity of the car: establishing SEA models for the external acoustic cavitiesof the car at two sides and on the external surface of the car body in the SEA model of the car body; 3) determining the SEA parameter of the car body and the external acoustic cavity sub-system of the car: determining the mode density of each sub-system, determining the internal loss factor of each sub-system, and determining the coupling loss factor of all sub-systems; 4) determining the external excitation energy of the car body: determining the acoustic excitation energy of an engine cabin, determining the excitation energy of suspended engine, determining the excitation energy of unevenness of the road surface on the car body, and determining the excitation energy of the wind pressure on the external surface of the car body; and 5) analyzing and predicting the noise outside the car.

Owner:JILIN UNIV

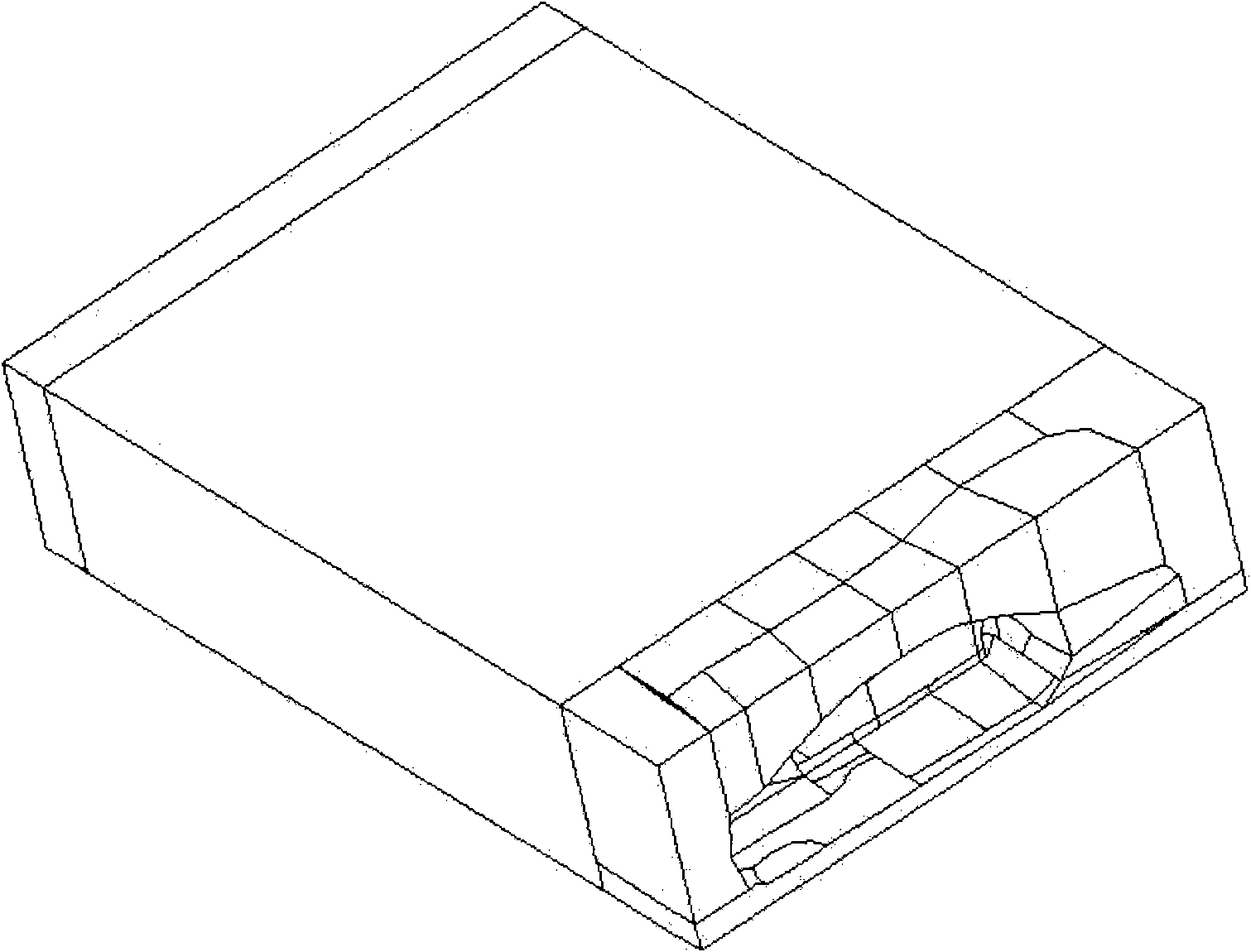

Medium-temperature high-performance water-based damping coating material and preparation method of same

The invention relates to medium-temperature high-performance water-based damping coating material and a preparation method of the medium-temperature high-performance water-based damping coating material. The coating material is made from binding base material, functional filling material, auxiliary agent and the like. The preparation method adopts a low-speed mixing, dispersion and three-roll grinding technology, thereby effectively avoiding cross linked deterioration of ternary polymer emulsion in the binding base material under high temperature because of high-speed mixing and dispersion. The coating material is added with the ternary polymer emulsion, addition agent and the functional filling material, wherein the ternary polymer emulsion belongs to rubber emulsion that is beneficial to improve the damping capacity and the drying of coating films, and the functional filling material has the functions of damping vibration, reducing noises, retarding flame and the like. The coating material can form a network structure through cross linked solidification under low-temperature baking of about 60 degrees, thereby obviously increasing the damping recombination loss factor, the flame-retardant heat-insulation performance and the sound-absorbing noise-reducing property. The water-based damping coating material is widely applied to railway vehicles, has the advantages of high damping recombination loss factor, small specific weight, strong adhesive force, good flame-retardant performance, low toxicity level and easy construction, and is not easy to crack in thick coatings.

Owner:ZHUZHOU HUALIAN HI TECH

Diaphragm for sounding device, sounding device and assembling method thereof

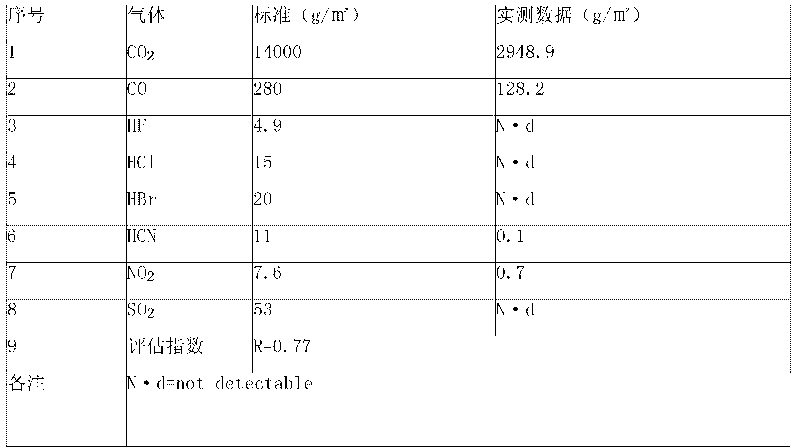

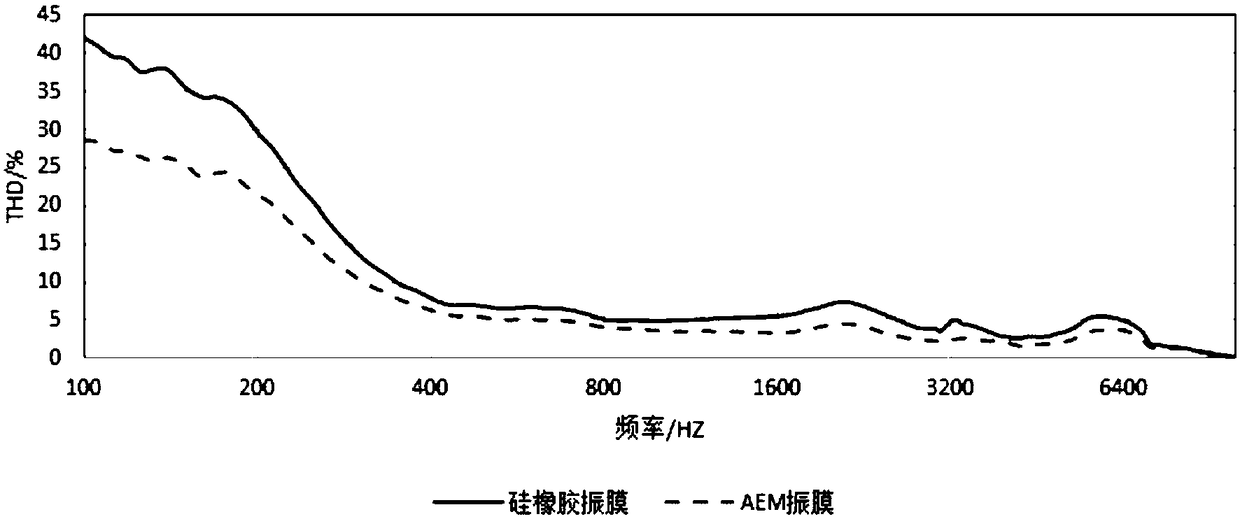

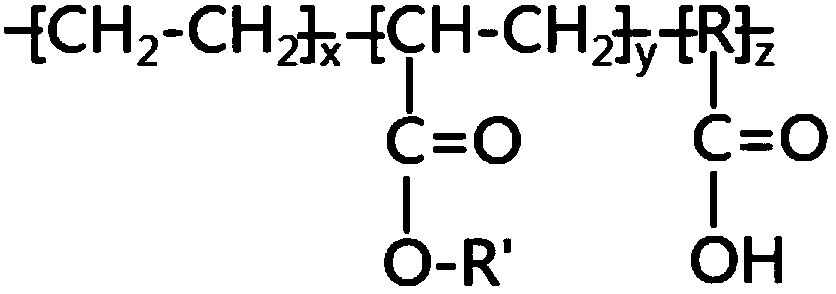

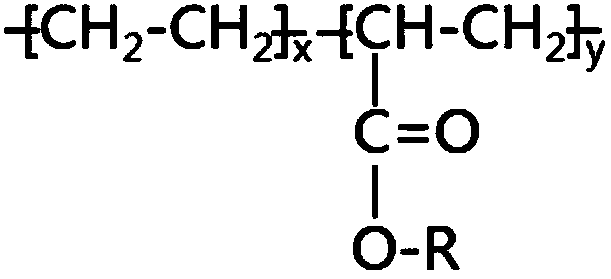

PendingCN109218924AImprove loss factorReduced chemical structure symmetryDiaphragm extensionsPlane diaphragmsChemical structureCarboxylic acid

The invention discloses a diaphragm for a sounding device, a sounding device and an assembling method thereof. The diaphragm includes a diaphragm layer prepared by subjecting at least one of an ethylene-acrylate copolymer and an ethylene-acrylic ester-carboxylic acid copolymer to crosslinking reaction. The molecular structure of the diaphragm includes a vinyl-acrylic group. The group reduces the chemical structure symmetry of a material, reduces tacticity, and increase steric hindrance, so that the diaphragm has a high loss factor and the sounding device has a good damping effect.

Owner:GOERTEK INC

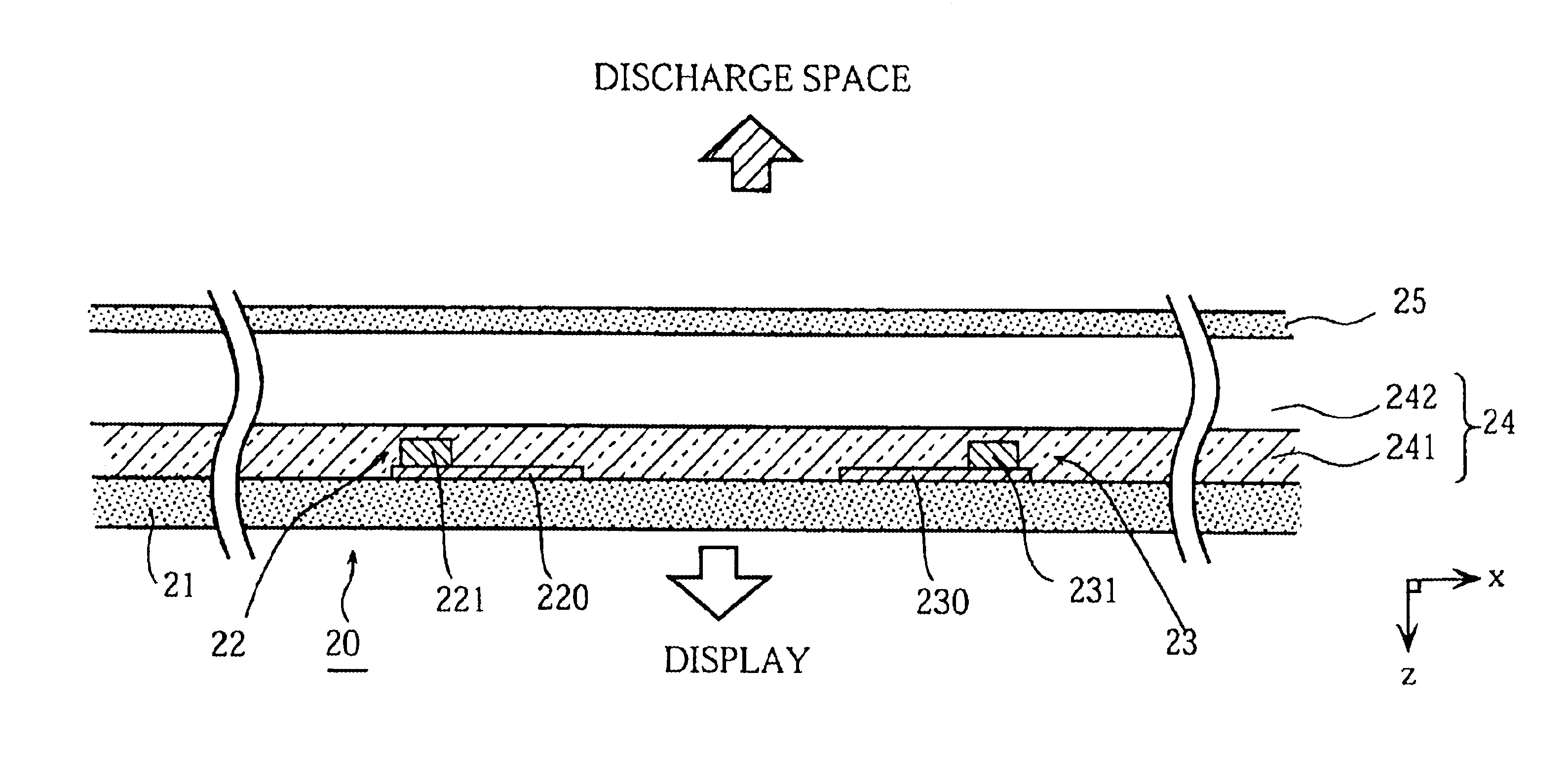

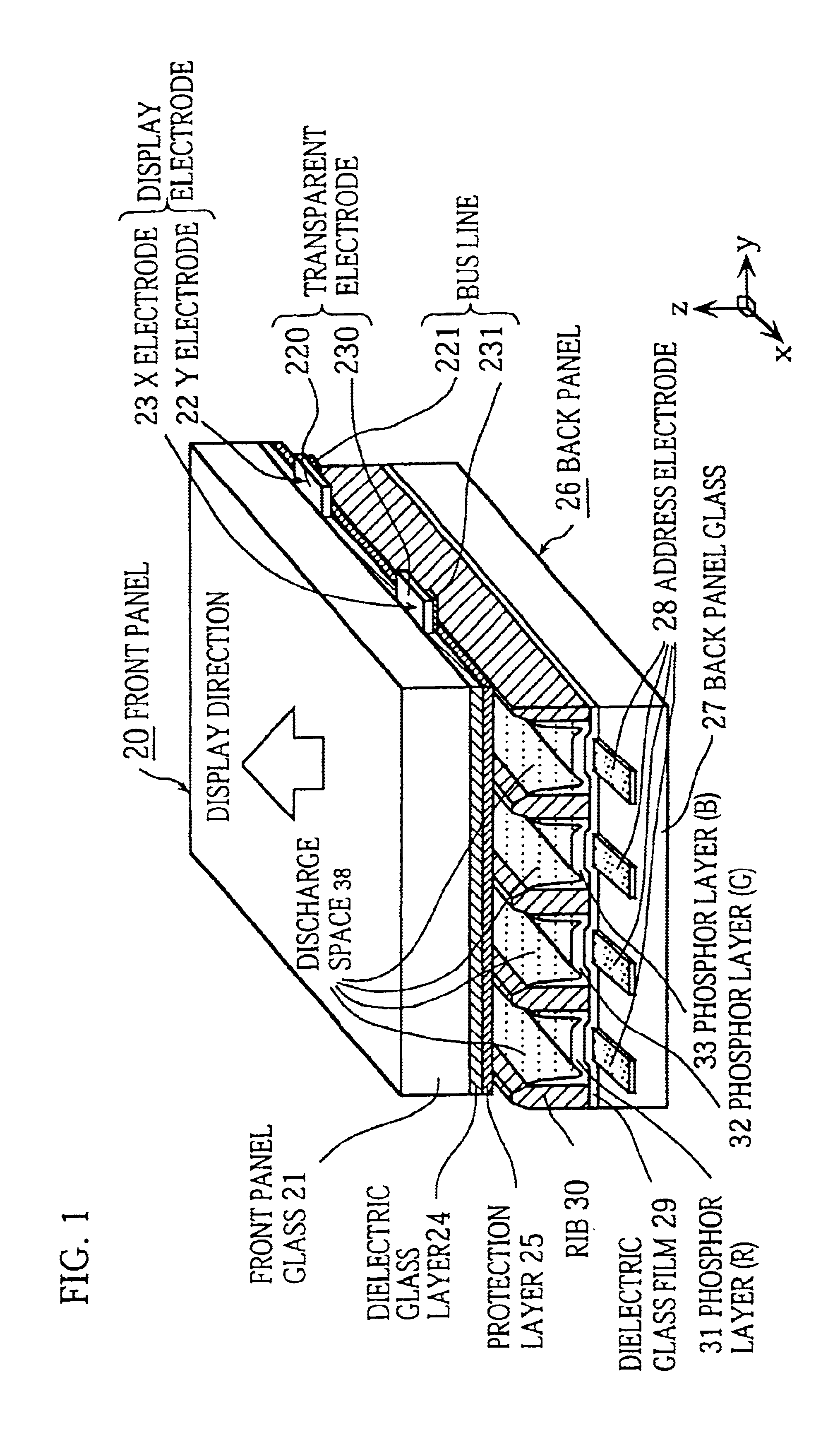

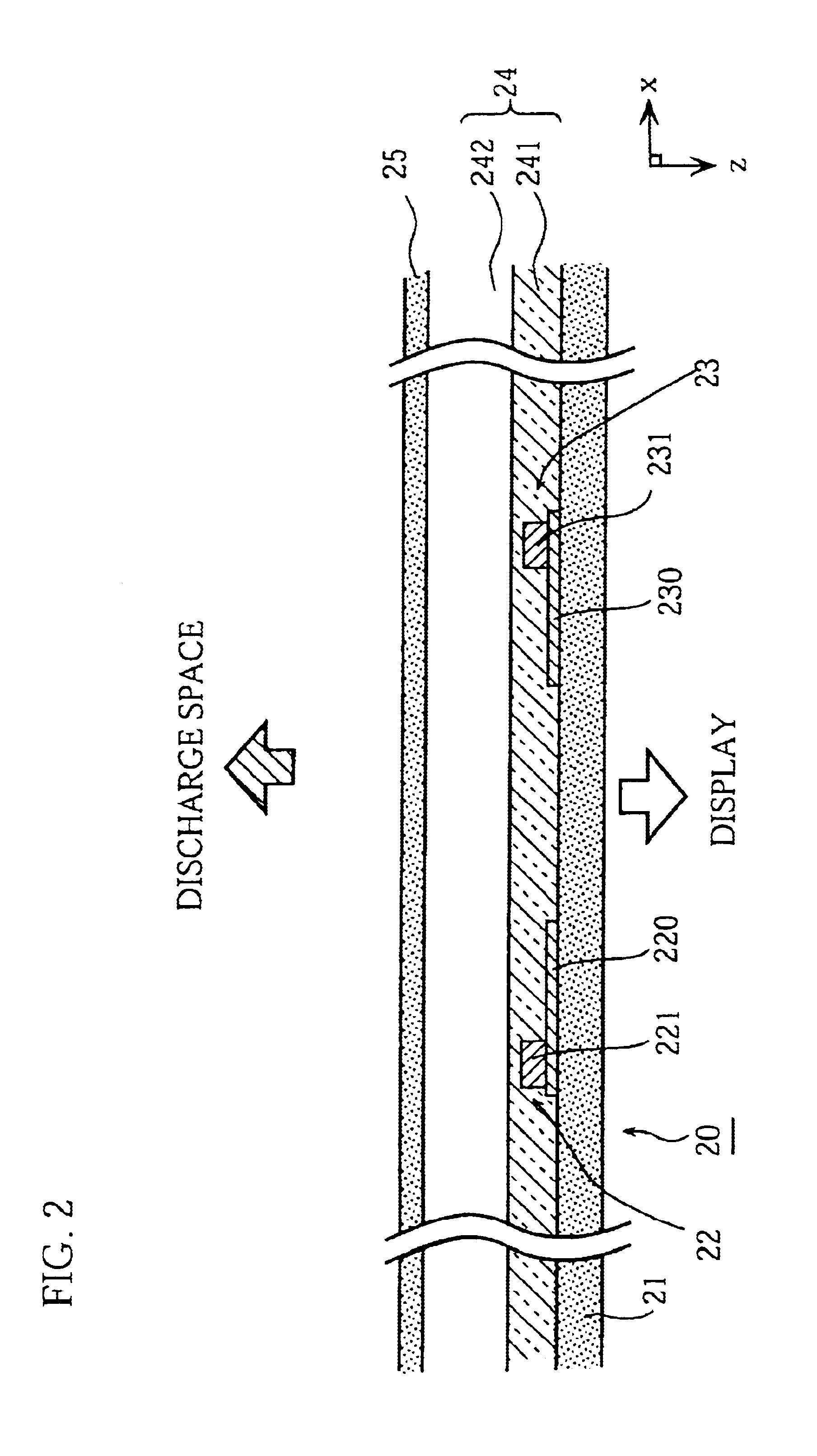

Plasma display panel

InactiveUS6897610B1Improve the display effectReduce power consumptionAlternating current plasma display panelsCold-cathode tubesEngineeringPermittivity

The present invention provides a plasma display panel in which a space between a first plate and a second plate facing each other is filled with a discharge gas, a plurality of pairs of display electrodes made of Ag or Cu are formed on a surface of the first plate facing the second plate, and the surface of the first plate is covered with a dielectric layer covering the plurality of pairs of display electrodes, where the dielectric layer is made of a glass that contains at least ZnO and 10 wt % or less of R2O and does not substantially contain PbO and Bi2O3, and a product of permittivity ε and loss factor tan δ of the dielectric layer is 0.12 or less, wherein R is selected from a group consisting of K, Rb, Cs, Cu, and Ag.

Owner:PANASONIC CORP

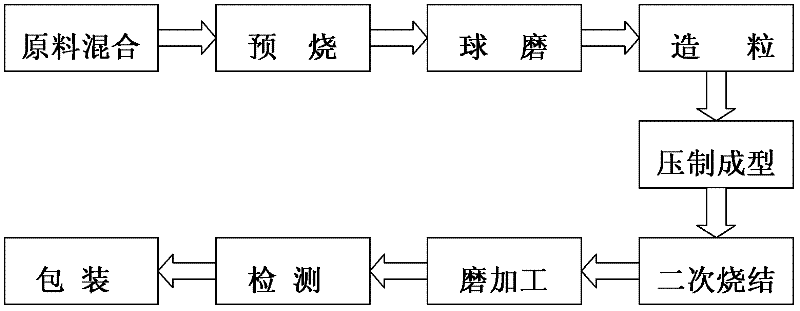

High magnetic conductivity and low loss factor manganese-zinc ferrite material and manufacture process thereof

InactiveCN101905970AImprove permeabilityLow Permeability Temperature FactorLoss factorManganese-zinc ferrite

The invention discloses a high magnetic conductivity and low loss factor manganese-zinc ferrite material and a manufacture process thereof. The high magnetic conductivity and low loss factor manganese-zinc ferrite material mainly comprises the main components in percent by mole (calculated by oxide) of 51-56 mol percent of Fe2O3, 22-29 percent of MnO and 20-25 mol percent of ZnO and the auxiliarymaterials including P2O5, CaO, SiO2, Bi2O3 and the like. The manganese-zinc ferrite material with high magnetic conductivity, low magnetic conductivity temperature factor and low relevant loss factoris prepared by the steps of mixing, pre-roasting, sanding, pelleting, forming and sintering. The invention has the advantages of simple and proper formulation and advanced and reasonable manufacture process. The prepared manganese-zinc ferrite material has property exceeding CL11F-brand property and superior to the H5C2-brand material property of a TDK company in Japan.

Owner:TIANCHANG CITY ZHAOTIAN MAGNETOELECTRICITY TECH

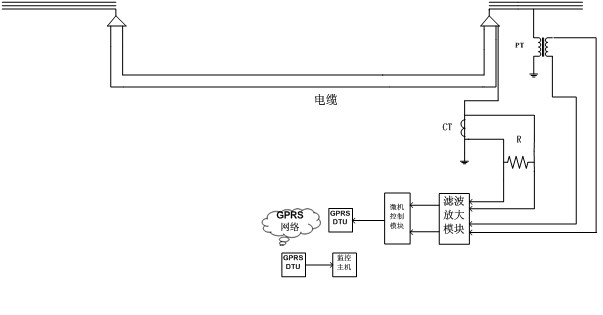

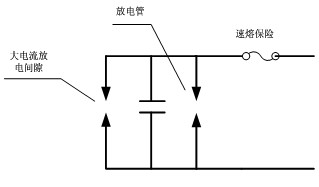

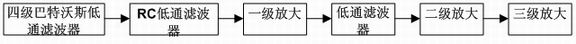

On-line monitoring method and device for insulating state of power cable

InactiveCN101975914AAffect operational safetyTesting dielectric strengthPower cablePhase angle difference

The invention discloses on-line monitoring method and device for the insulating state of a power cable. Two factors are mainly considered for the monitoring of the insulating state of the cable, wherein one factor is a low-frequency current value generated by low-frequency oscillation of a power system; and the other factor is a cable medium loss factor value acquired by calculating the phase angle difference between a low-frequency voltage signal and the current signal, which is generated by the oscillation of the power system and seeking an arctangent value. If any one of the two factors is greater than the corresponding insulated safety threshold, the cable has the insulated ageing hidden trouble. By using the low-frequency signal to monitor, the invention has high detection precision and can remarkably reflect the ageing state of the cable; and in addition, the extra superposition power supply is avoided, so that the invention avoids the damage to the safety of a power grid.

Owner:HUAZHONG UNIV OF SCI & TECH

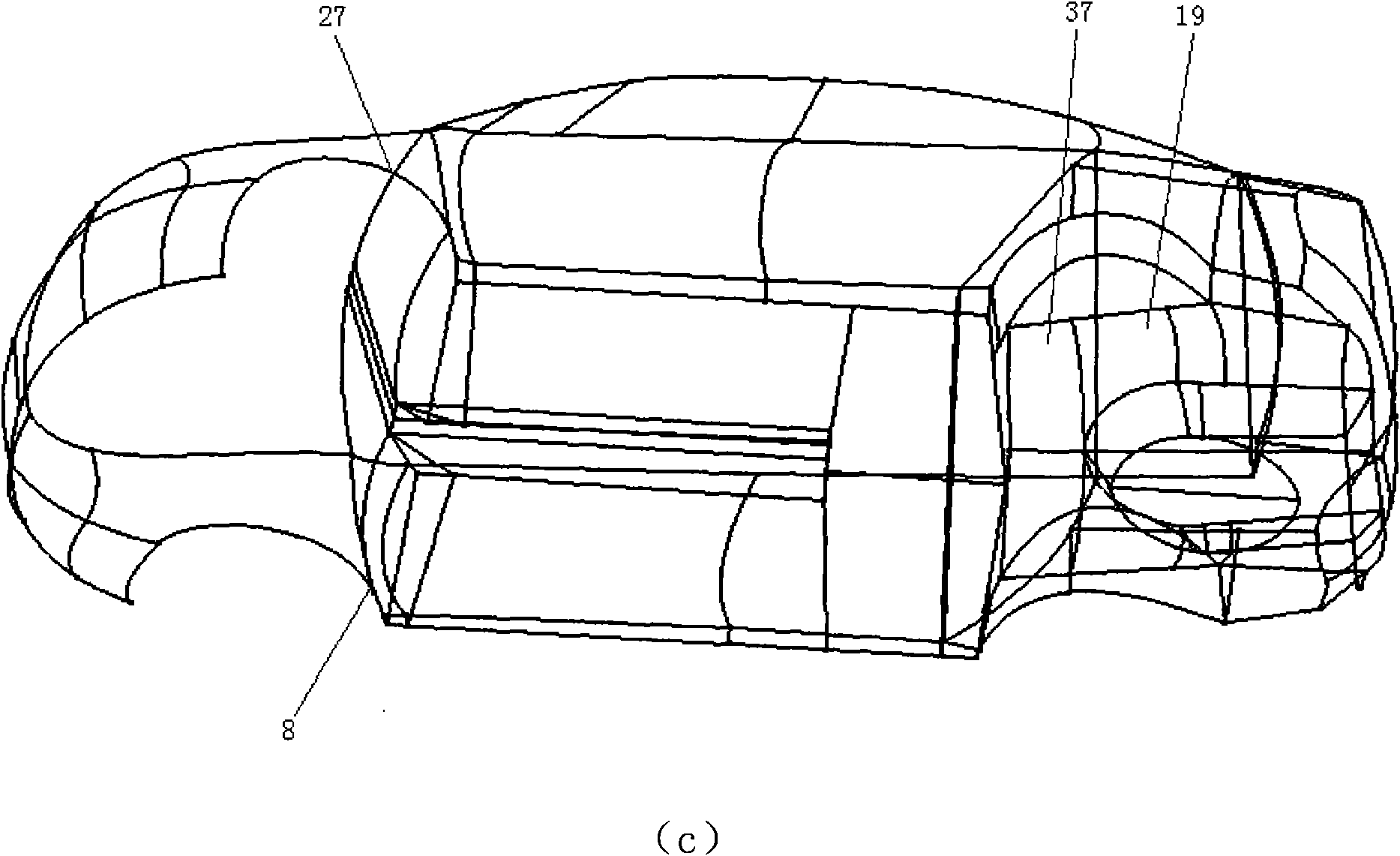

Modified asphalt hot-melt damping material for vehicles and preparation method and construction method thereof

ActiveCN101654561AHigh dampingWide temperature rangeVehicle componentsBuilding insulationsEngineeringHot melt

The invention relates to a modified asphalt hot-melt damping material for vehicles. Modified asphalt and rubber are blended; tackifying resin is added for strengthening the adhesive property of the damping material; the damping material comprises the following components in portion by weight: 100 to 200 portions of the modified asphalt, 5 to 60 portions of the rubber, 50 to 200 portions of the resin, and 250 to 800 portions of filler; and the materials are subjected to modification, rubber refining, kneading, extrusion and tabletting molding to produce the modified asphalt hot-melt damping material for the vehicles. When the modified asphalt hot-melt damping material is used on a vehicle, the modified asphalt hot-melt damping material for the vehicles is paved on a vehicle body to achievethermal lamination by only directly using the enamel paint heating process of the vehicle body. The damping material is an excellent vibration-damping noise-reduction material and has the characteristics of wide temperature range and high damping, and the damping loss factor can reach 0.8 at a temperature of between 20 and 40 DEG C.

Owner:BOGE RUBBER&PLASTICS ZHUZHOU CO LTD

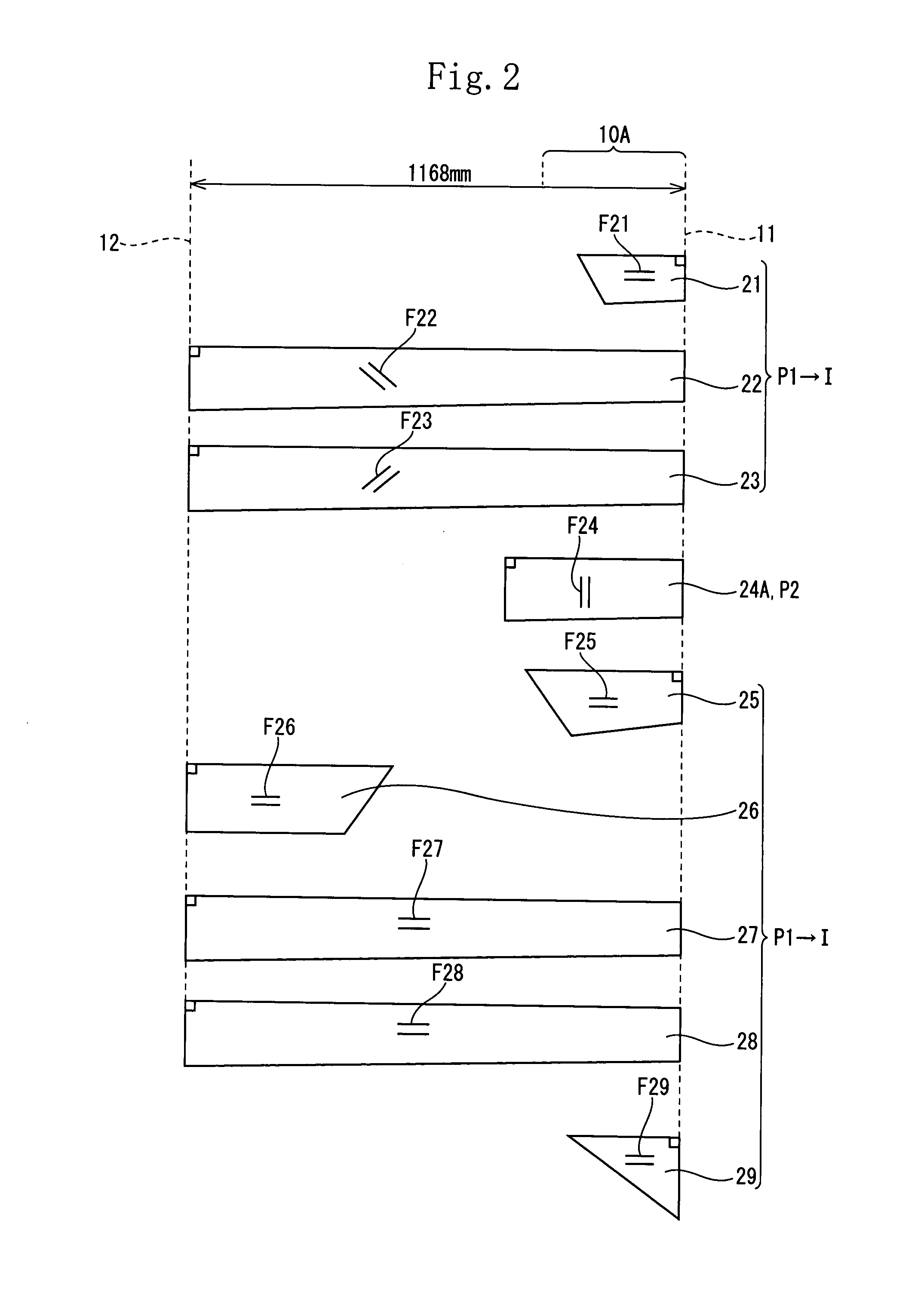

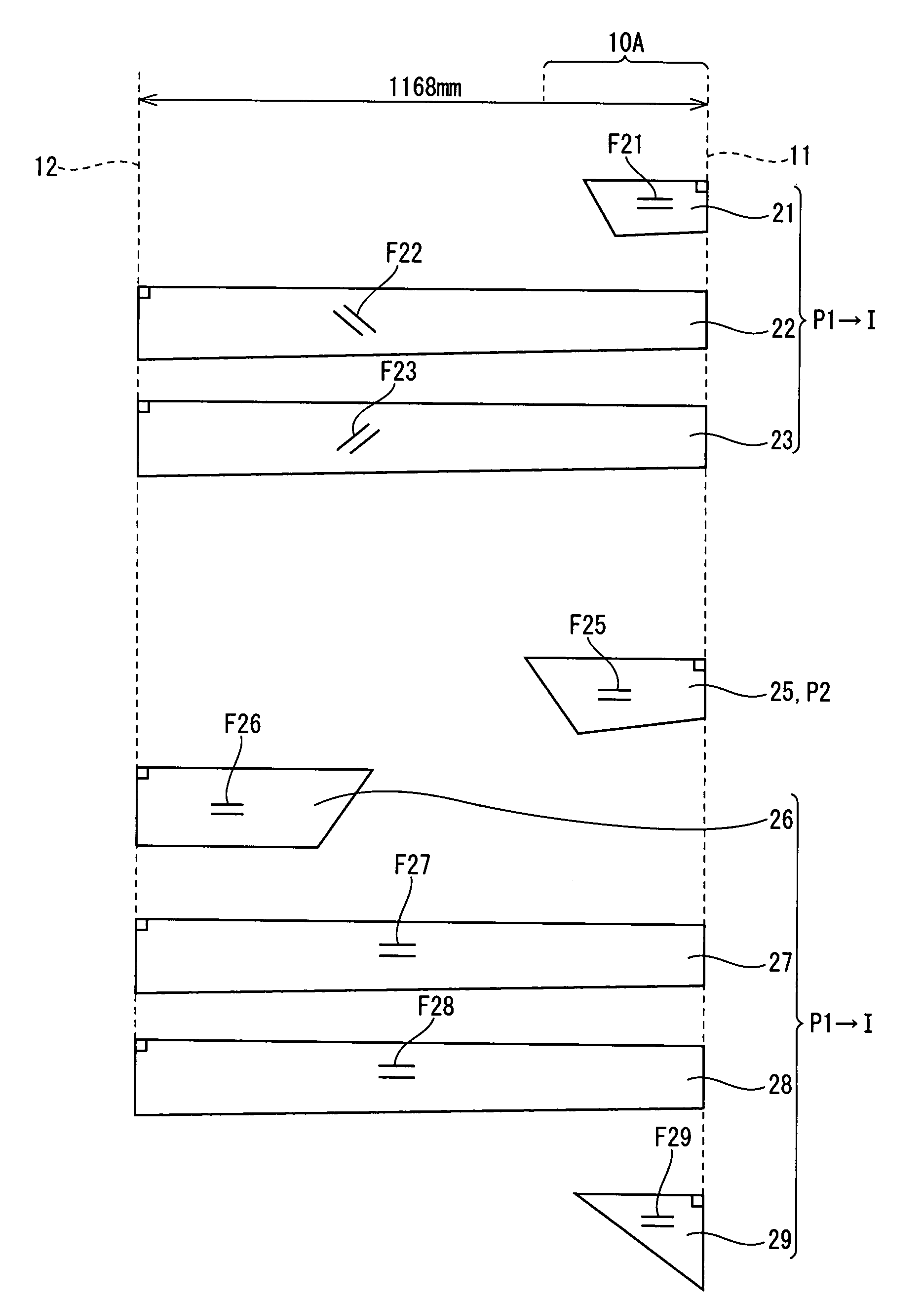

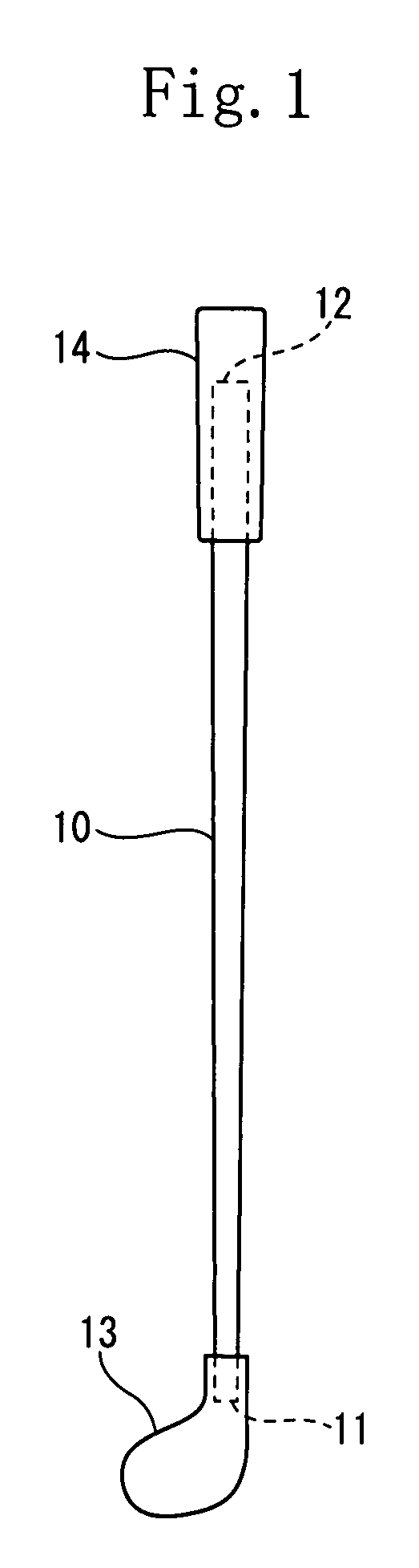

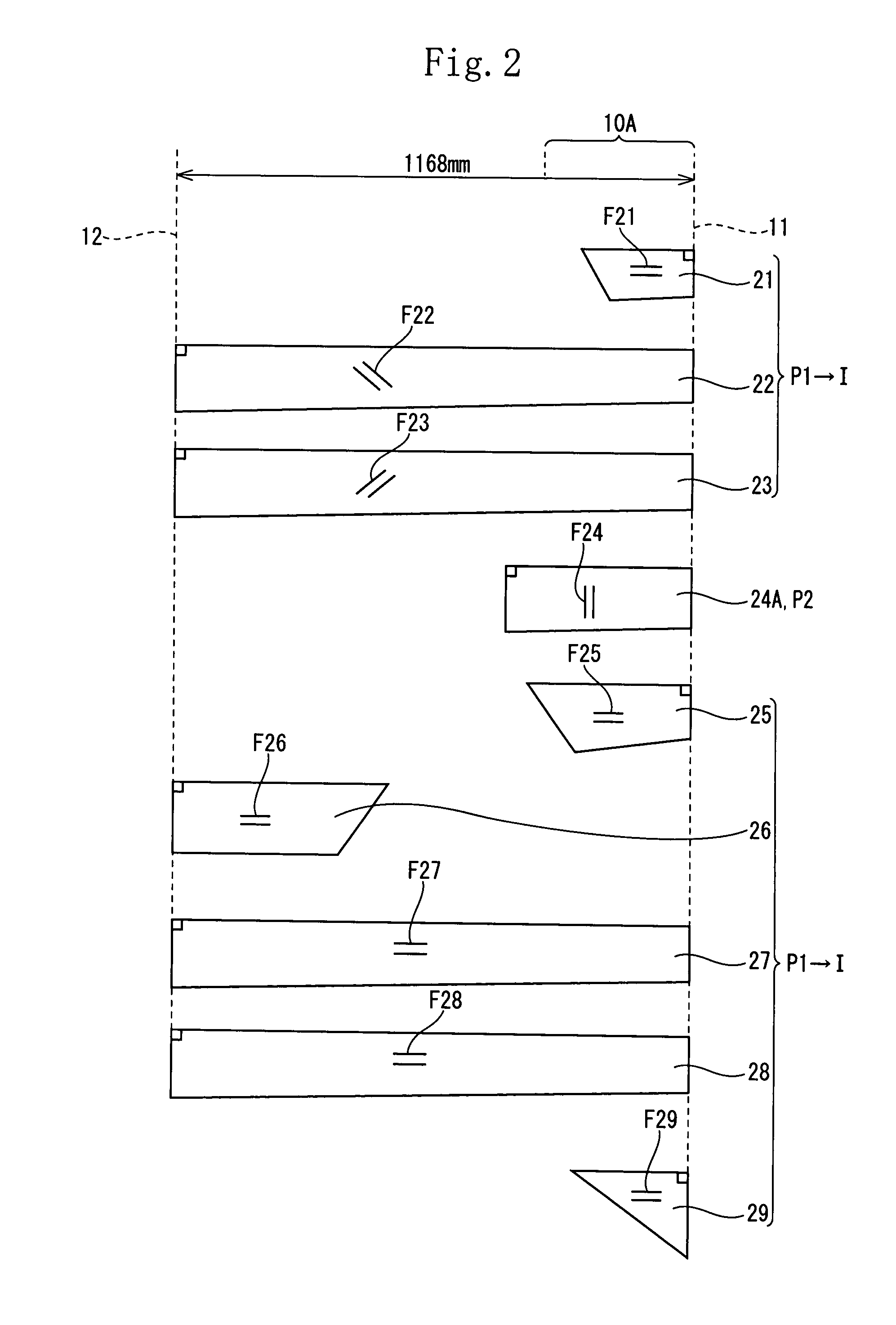

Golf club shaft

A golf club shaft (10), tubular and having a hollow portion, which includes a laminate of fiber reinforced prepregs (21 through 23, 24A, 25 through 29). The laminate has a first part (I) composed of a plurality of first prepregs (P1) and a second part (P2). A loss factor (tan δ) of the first part (I) is set to not less than 0.005 nor more than 0.02, when the loss factor is measured at a frequency of 10 Hz under a condition of 10° C. A loss factor (tan δ) of the second part (P2) is set to not less than 0.10 nor more than 0.50, when the loss factor is measured at a frequency of 10 Hz under the condition of 10° C.

Owner:DUNLOP SPORTS CO LTD

Reduction of vibration transfer

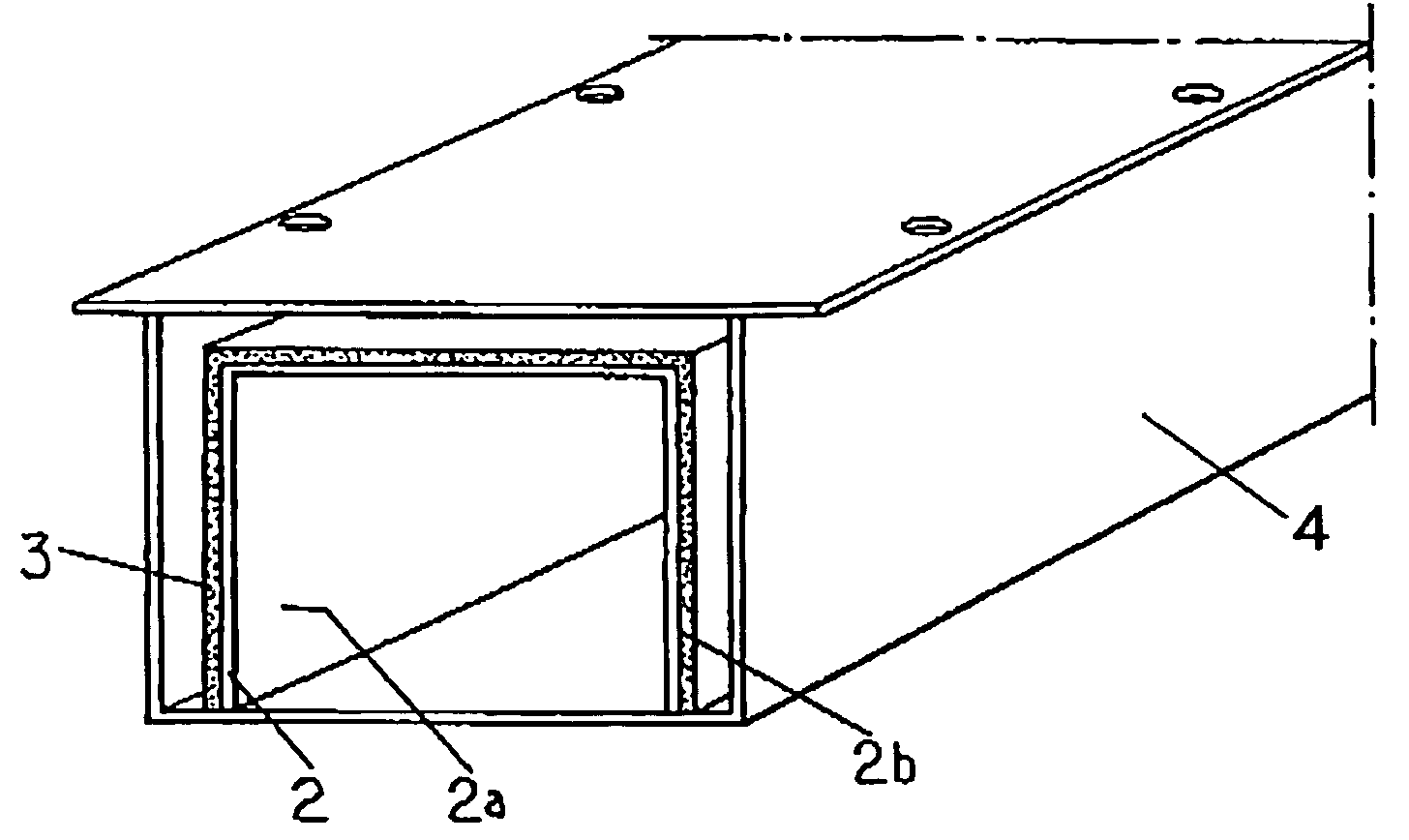

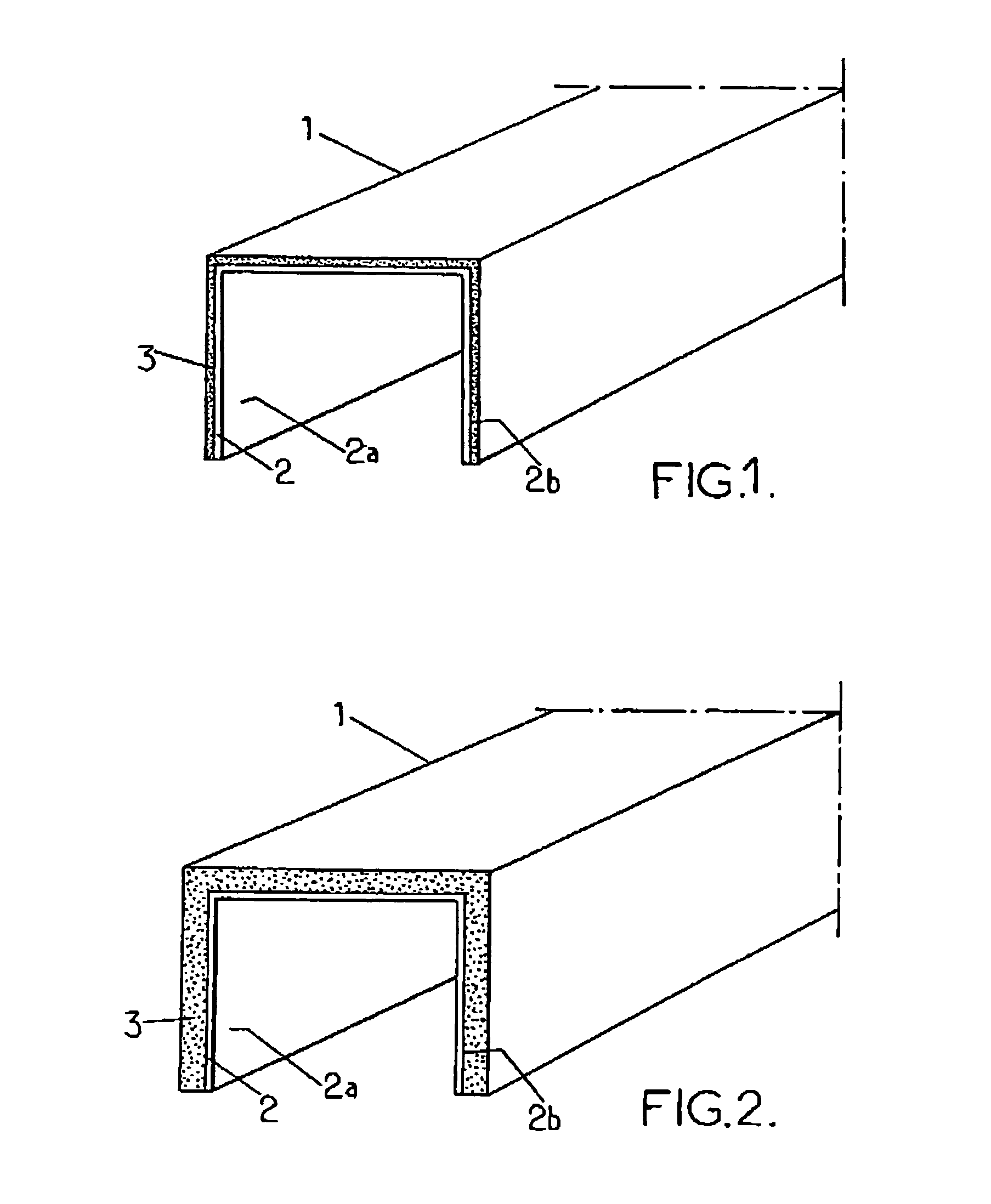

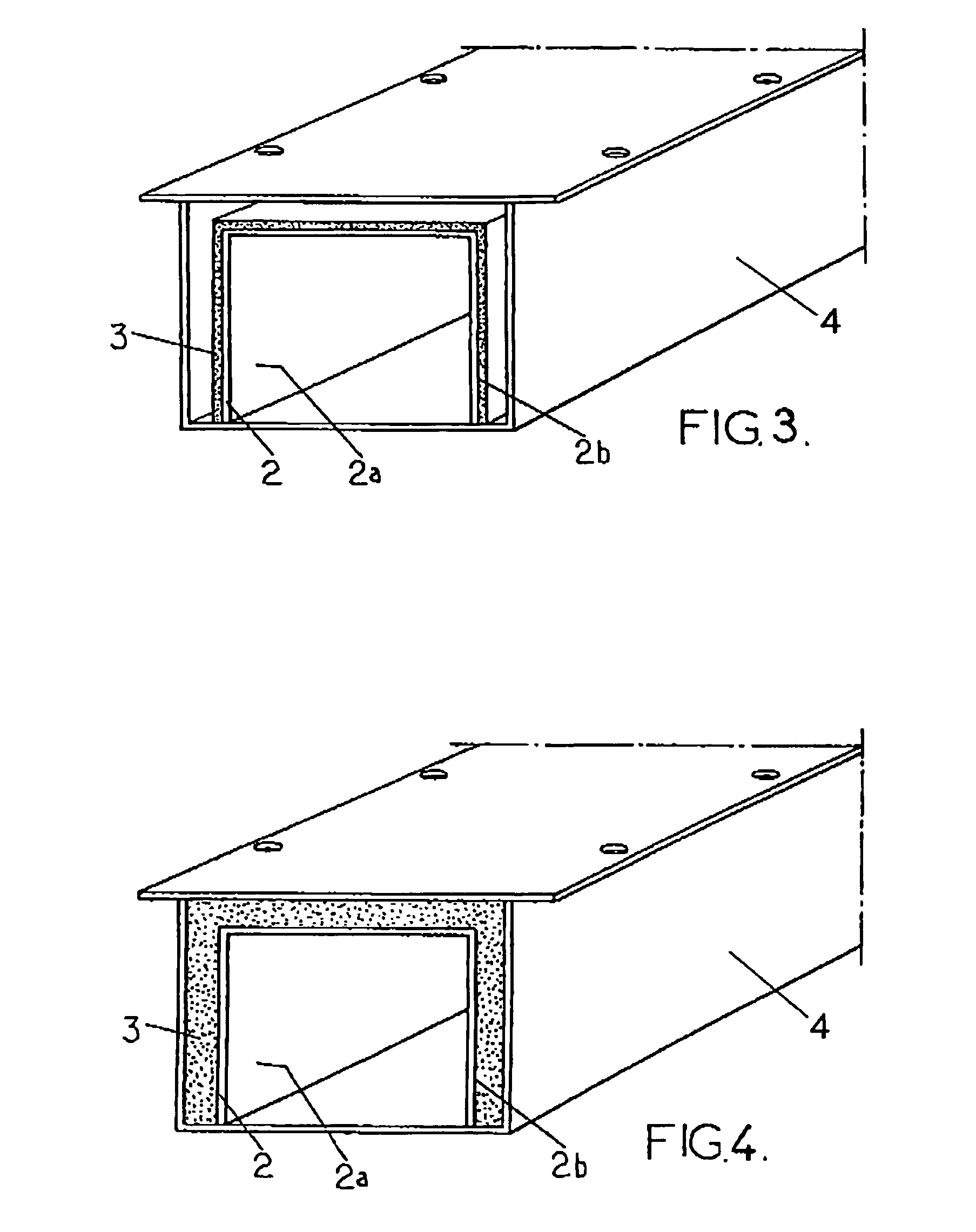

ActiveUS20070100060A1Simple structureRailway wheel guards/bumpersArticle transferringCombined useMaterials science

A thermally expandable material is provided that, once expanded, has a Young's storage modulus E′ between 0.1 MPa and 1000 MPa, a loss factor of at least 0.3 (preferably, at least 1) and preferably a shear storage modulus G′ between 0.1 MPa and 500 MPa at a temperature between −10 and +40 degrees C in the frequency range 0 to 500 Hz. Such materials are useful in combination with a carrier to form a dissipative vibratory wave barrier that effectively reduces the transfer of vibrations from a vibration generator, as may be present in a vehicle.

Owner:HENKEL KGAA

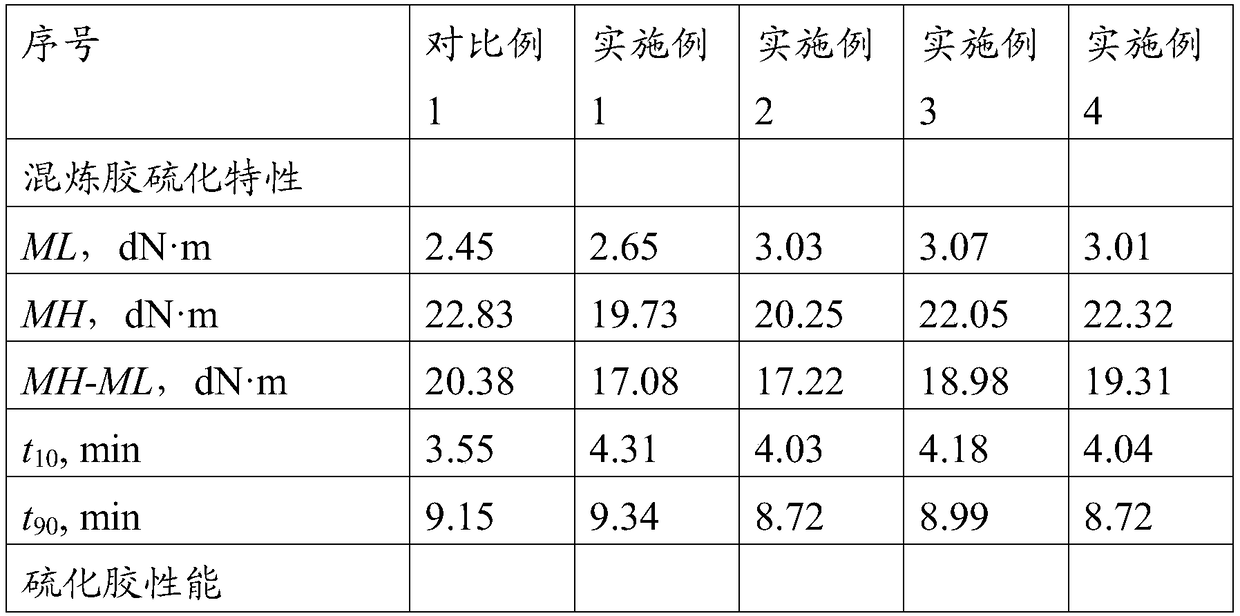

High-performance tire tread rubber and preparation method thereof

ActiveCN109181027AIncreased tensile strengthHigh tensile strengthSpecial tyresRubber materialPolymer science

The invention relates to a high-performance tire tread rubber and a preparation method thereof, wherein the high-performance tire tread rubber comprises, by mass, 60-90 parts of natural rubber, 0-20 parts of cis-1,4-polybutadiene rubber, 9-20 parts of a low molecular weight trans butadiene-isoprene copolymerization rubber, 40-60 parts of carbon black, 0-20 parts of white carbon black, 0-2 parts ofa silane coupling agent, 1-5 parts of zinc oxide, 1-5 parts of stearic acid, 0.3-3 parts of sulfur, 0.5-5 parts of an accelerator, 1-3 parts of an anti-aging agent, and 1-10 parts of other auxiliaryagents. According to the present invention, the tire tread rubber is modified with the low molecular weight trans butadiene-isoprene copolymerization rubber, such that the tensile strength of the vulcanized rubber is increased by 15-20%, the tear strength is increased by 1%-20%, the 60 DEG C loss factor is reduced by 4-20%, and the wear is reduced by 10-25%; and various performances of the tire tread rubber material of the present invention meet the performances of the tire tread rubber.

Owner:SHANDONG HUAJU POLYMER MATERIALS CO LTD

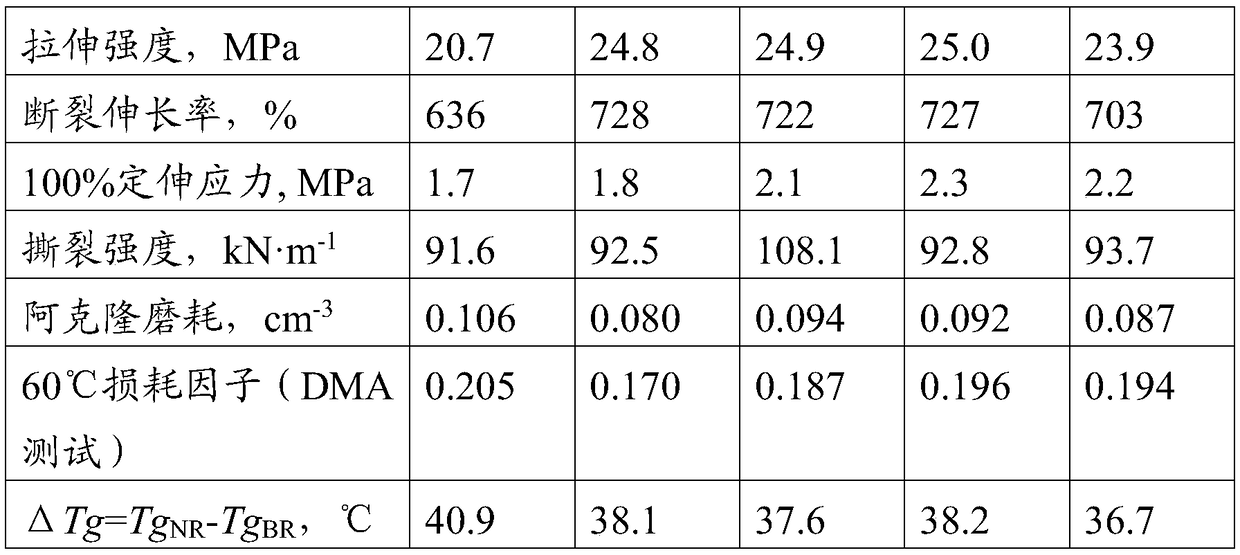

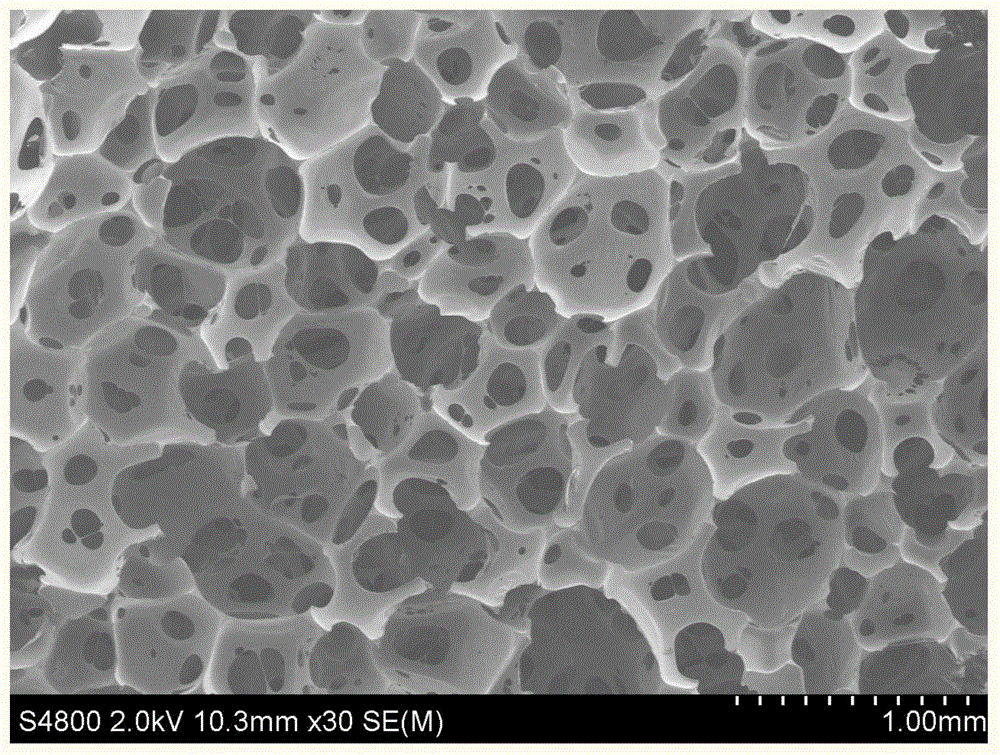

Vehicle-used slowly-springback polyurethane foam composite material

ActiveCN104149455AHigh reactivityGood physical propertiesSynthetic resin layered productsEnvironmental resistanceSilicone oil

The invention discloses a vehicle-used slowly-springback polyurethane foam composite material which is compounded from slowly-springback polyurethane foam and an ethylene-vinyl acetate copolymer. The slowly-springback polyurethane foam is prepared from following components including, by weight, an A material: 40-80 parts of a polyether polyol 1421, 5-40 parts of a polyether polyol 2000D, 5-40 parts of a polyether polyol POP-36 / 28, 0.5-5 parts of diethanolamine, 1-6 parts of water, 0.1-1.5 parts of a catalyst EF-600, 0.1-0.5 parts of a catalyst ZF-10 and 1-6 parts of a silicone oil L-580; a B material: 40-80 parts of a modified MDI. During preparation of the slowly-springback polyurethane foam, a weight usage amount ratio of the A material to the B material is 100:40-80. The vehicle-used slowly-springback polyurethane foam is high in reaction activity, is low in toxicity, is environmental-protective, is high in damp loss factor, is high in sound-insulation performance and is free of addition of a foam-forming agent.

Owner:NINGBO TUOPU GROUP CO LTD

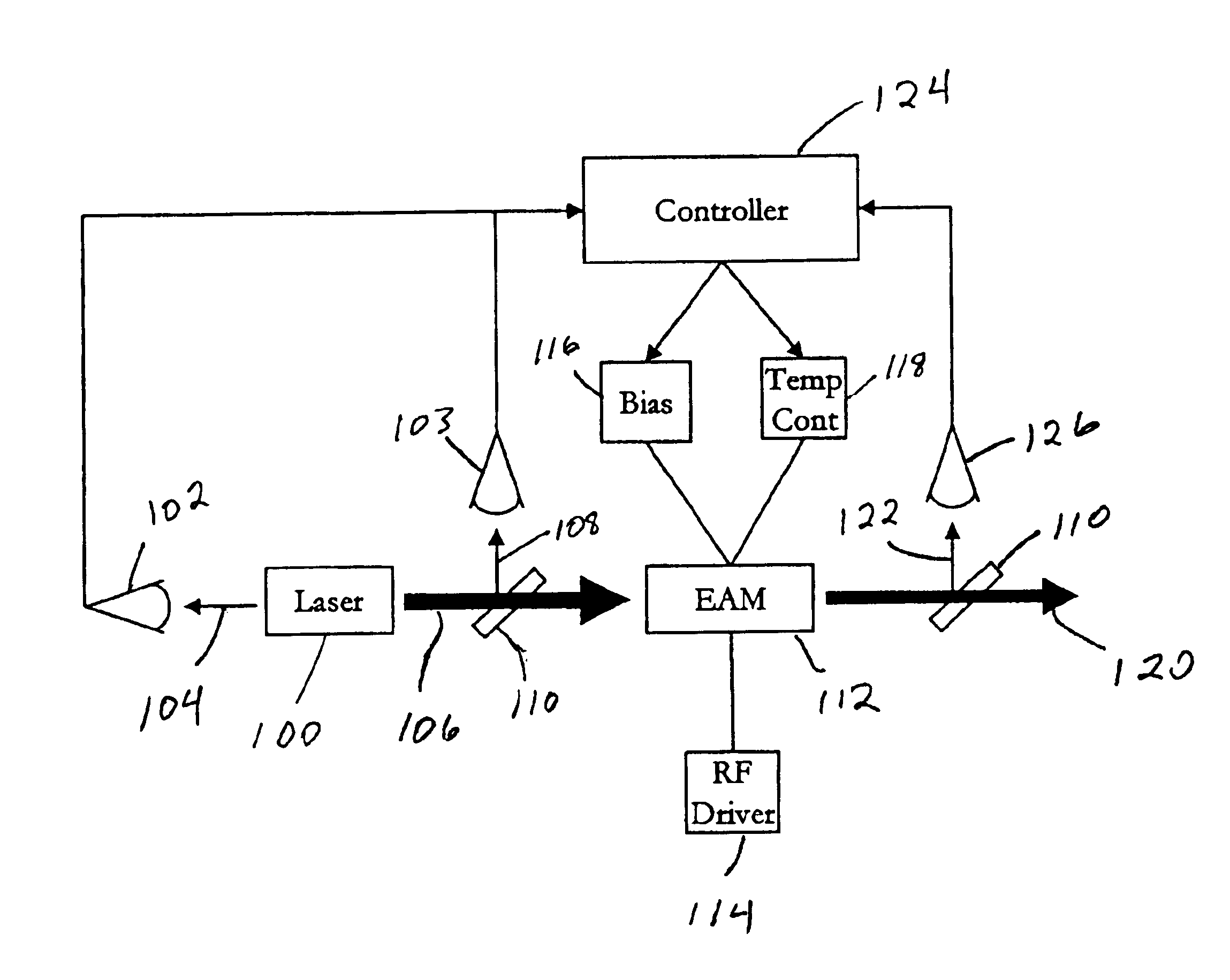

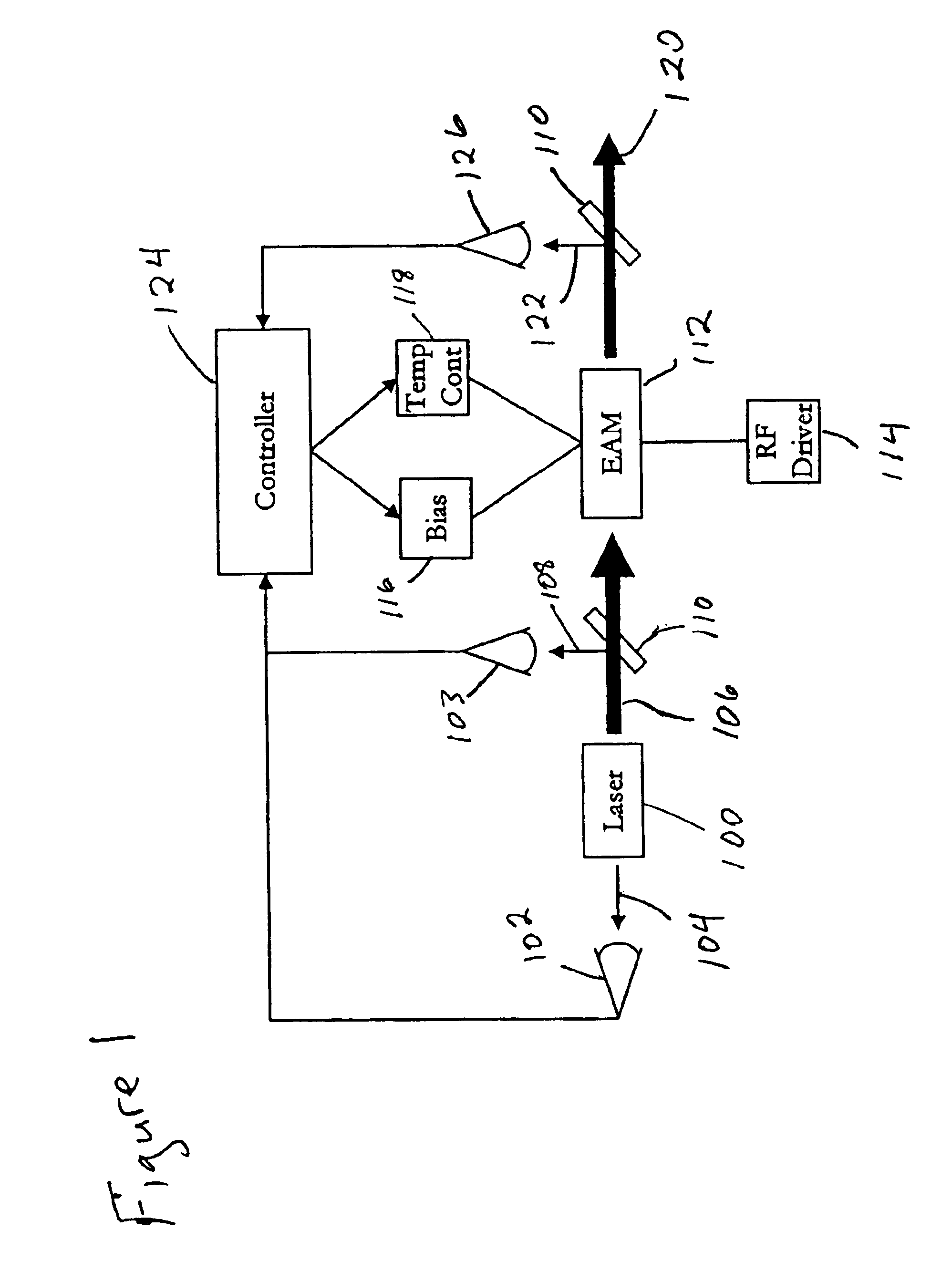

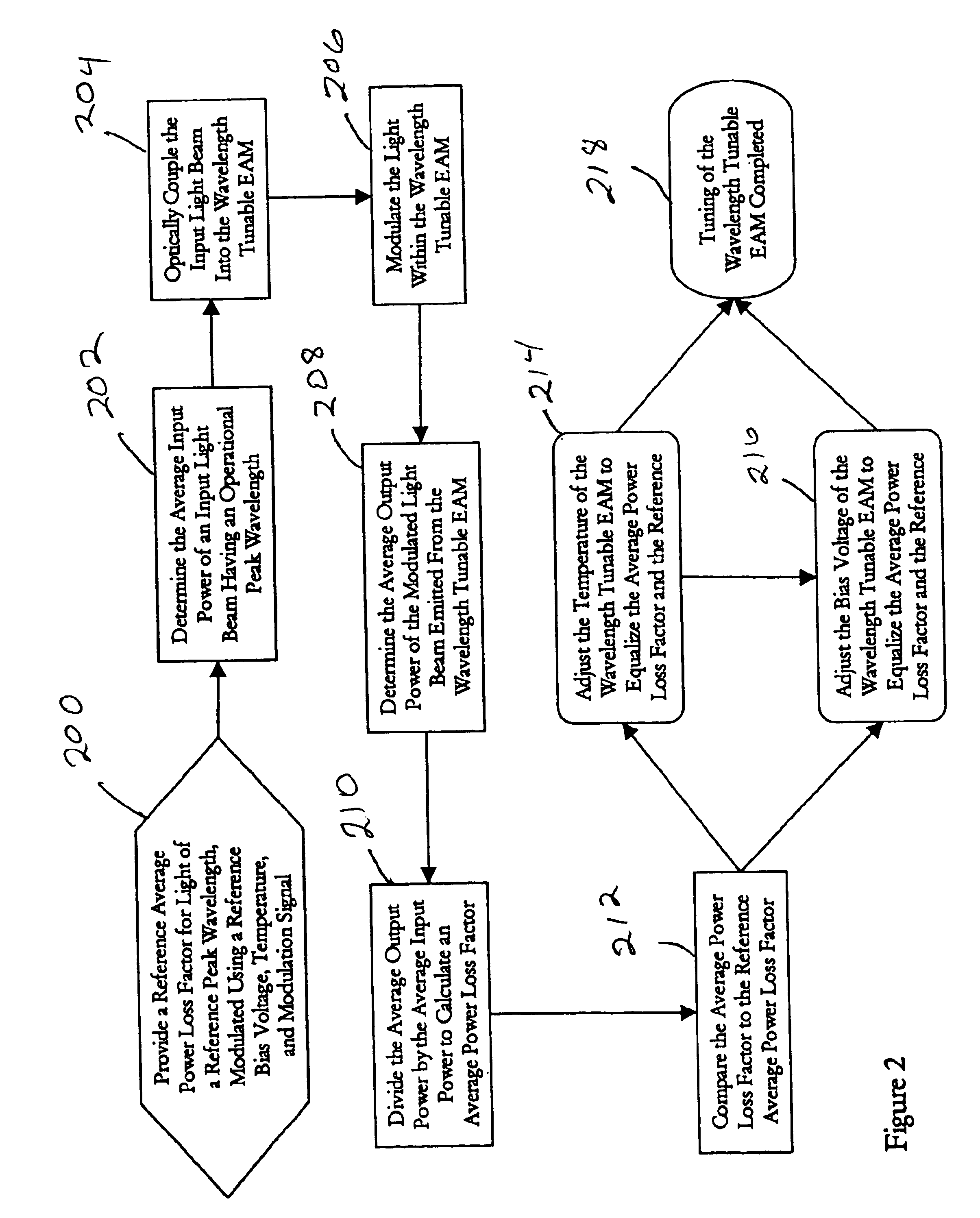

Method of tuning wavelength tunable electro-absorption modulators

A method of tuning an electroabsorption modulator (EAM). A reference average power loss factor for light having a reference peak wavelength that is modulated by the EAM is provided. This loss factor is based on operation of the EAM using a reference bias voltage, a reference temperature, and a reference modulation signal which has a predetermined duty cycle. Input light is coupled into the EAM and modulated using a modulation signal which has the same duty cycle as the reference modulation signal. The input power of the input light and the average output power of light emitted from the EAM are measured. These input and average output powers are used to generate an average power loss factor. The average power loss factor is compared to the reference average power loss factor and the bias voltage and / or the temperature of the EAM are adjusted to reduce differences between these loss factors.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

Damp embedding glue of epoxy resin

InactiveCN1958707AIncrease dampingImprove loss factorOther chemical processesEpoxy resin adhesivesVitrificationEpoxy

This invention relates to a damping sealant, especially an epoxy resin damping sealant, which is composed of component A and component B (15-100 wt. % of component A). Component A is prepared from: rigid epoxy resin 100 parts, flexible epoxy 5-100 parts, active diluent 5-40 parts, and liquid nitrile butadiene rubber 5-25 parts. Component B is amino curing agent. The glass transition temperature of the epoxy resin damping sealant can be adjusted between -20-120 deg.C according to different requirements. The epoxy resin damping sealant has such advantages as wide damping temperature range, high loss factor (tanmax greater than 0.5), and easy operation.

Owner:WUHAN UNIV OF TECH

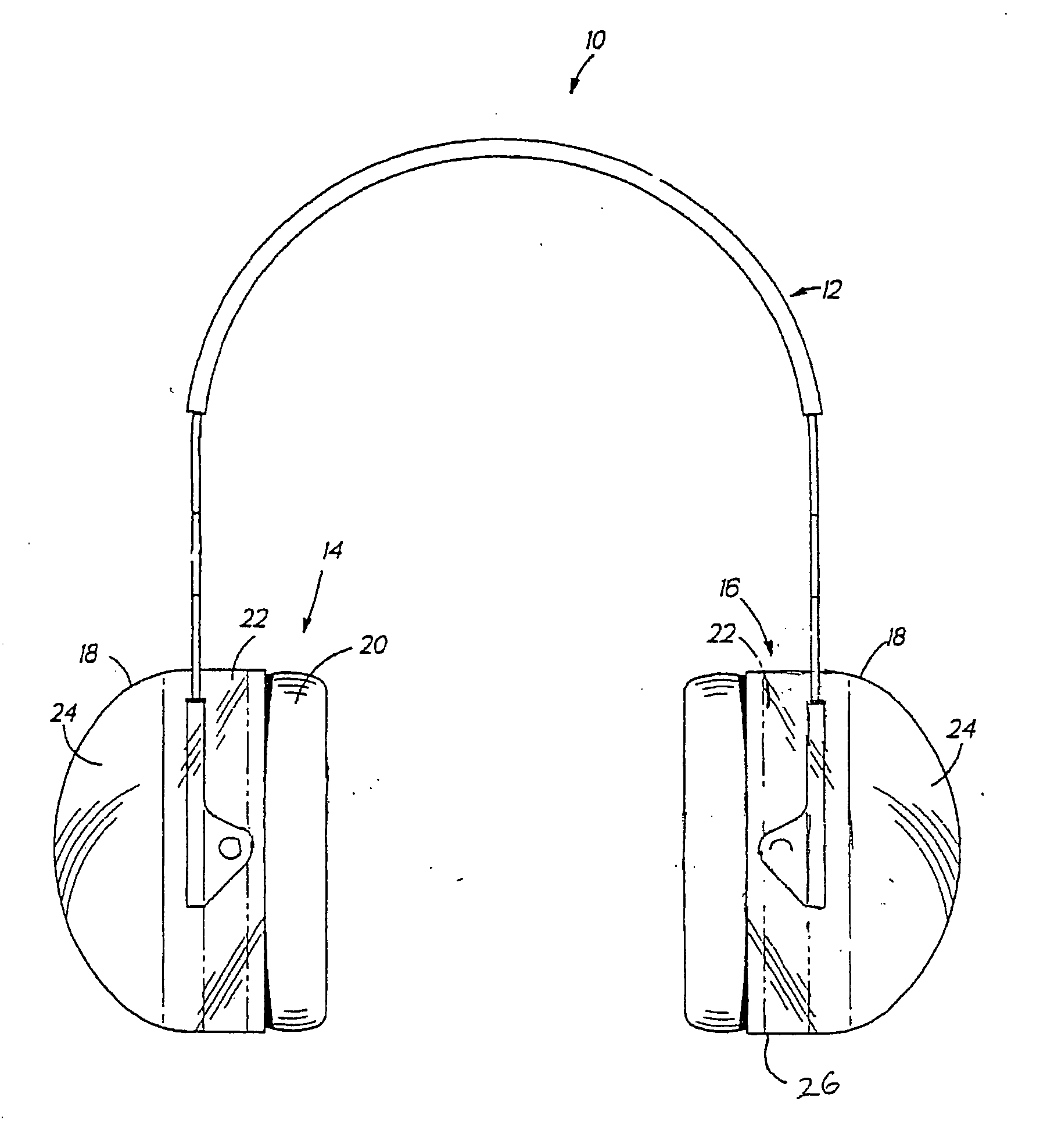

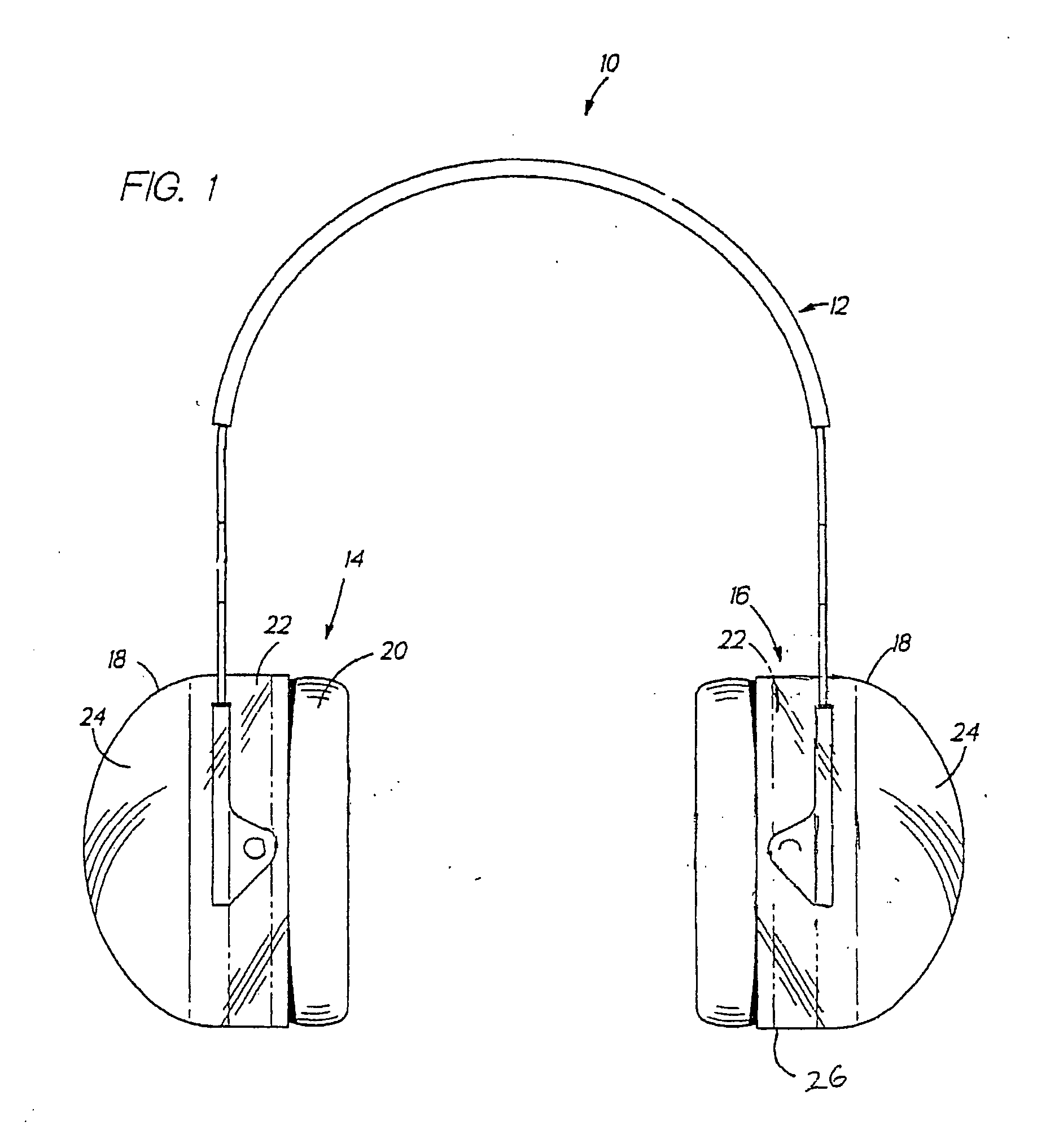

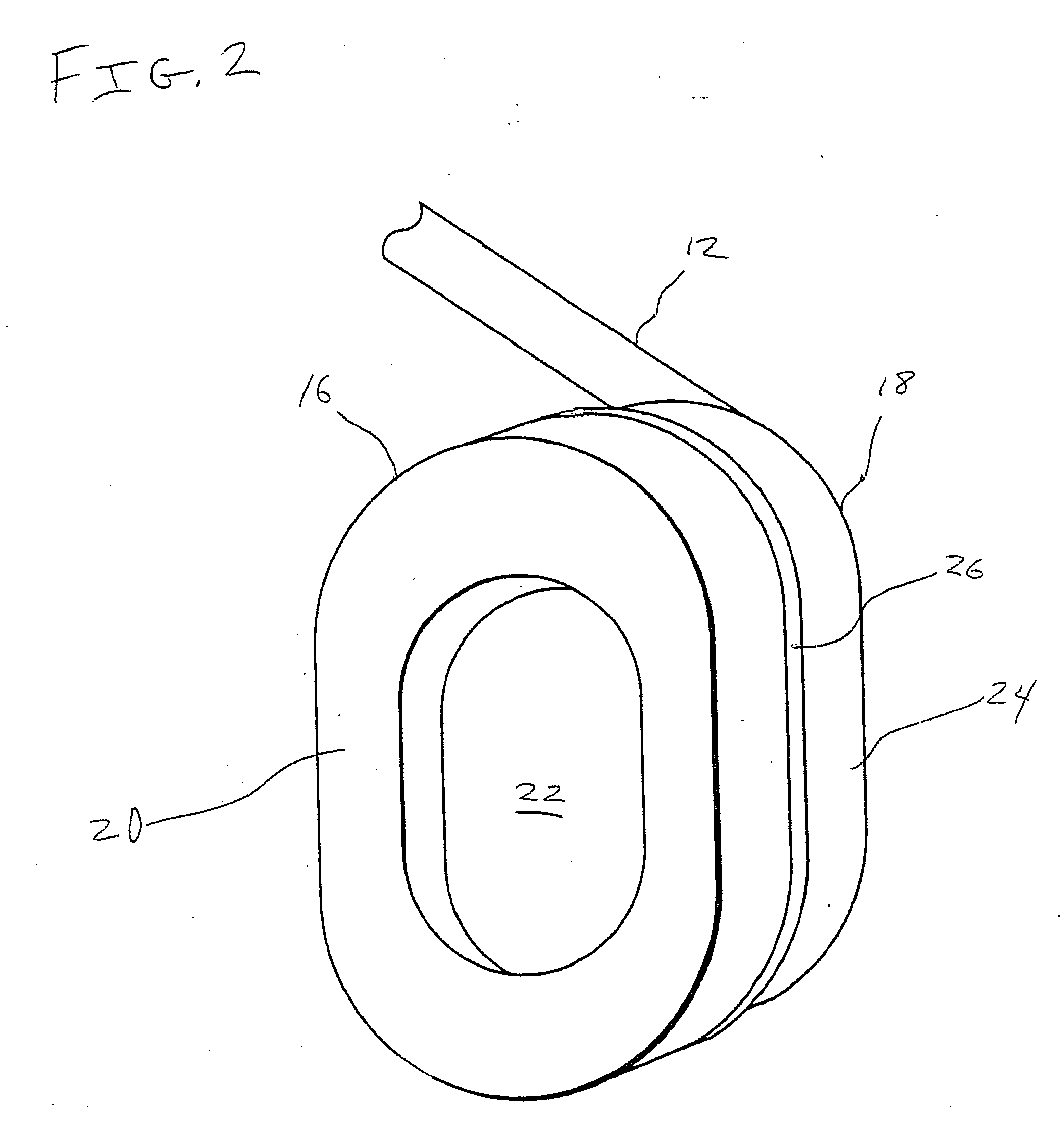

High attenuating earmuff device

InactiveUS20050283882A1Large dampingHighly engineered polymer transition propertyHatsHeadwear capsHigh densityEngineering

An earmuff device is provided, including a connecting band having opposing first and second ends, a pair of earmuff cup assemblies connected to the opposing first and second ends of the connecting band, a first foam disposed at the earmuff cup assemblies, and a second foam disposed at the earmuff cup assemblies, where the first foam comprises a moderately high density foam having highly engineered polymer transition properties with precise loss factor values, modulus values, and polymer transition values and maximum damping at prescribed temperature and frequency conditions, and where the second foam comprises a moderately high density hydrophilic foam particularly employed for optimal property convergence in cell size, air flow, density, and static stiffness. An earmuff cup, an earmuff cushion, and an earmuff liner including the respective first and / or second foams, are also provided.

Owner:CABOT SAFETY INTERMEDIATE CORP

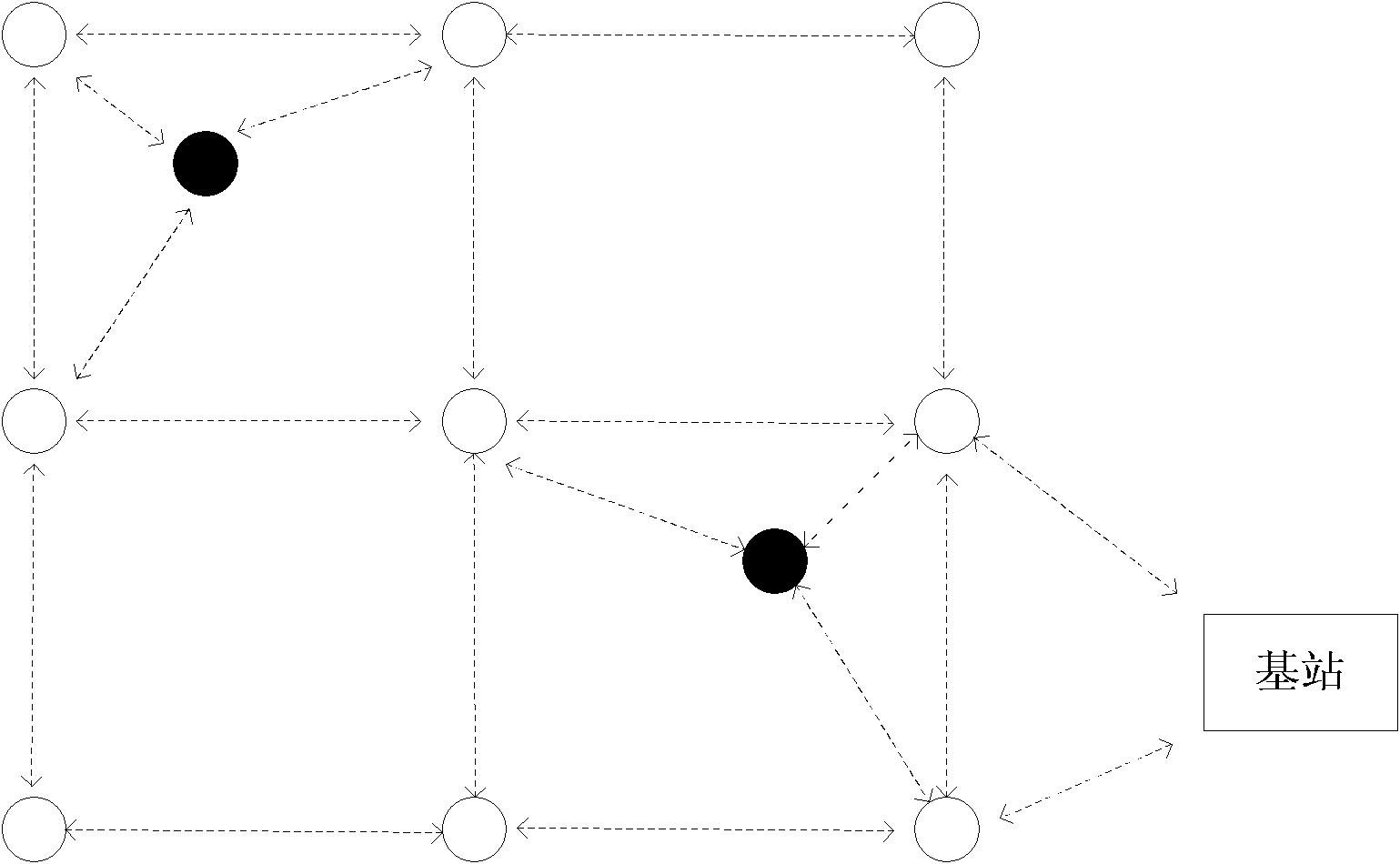

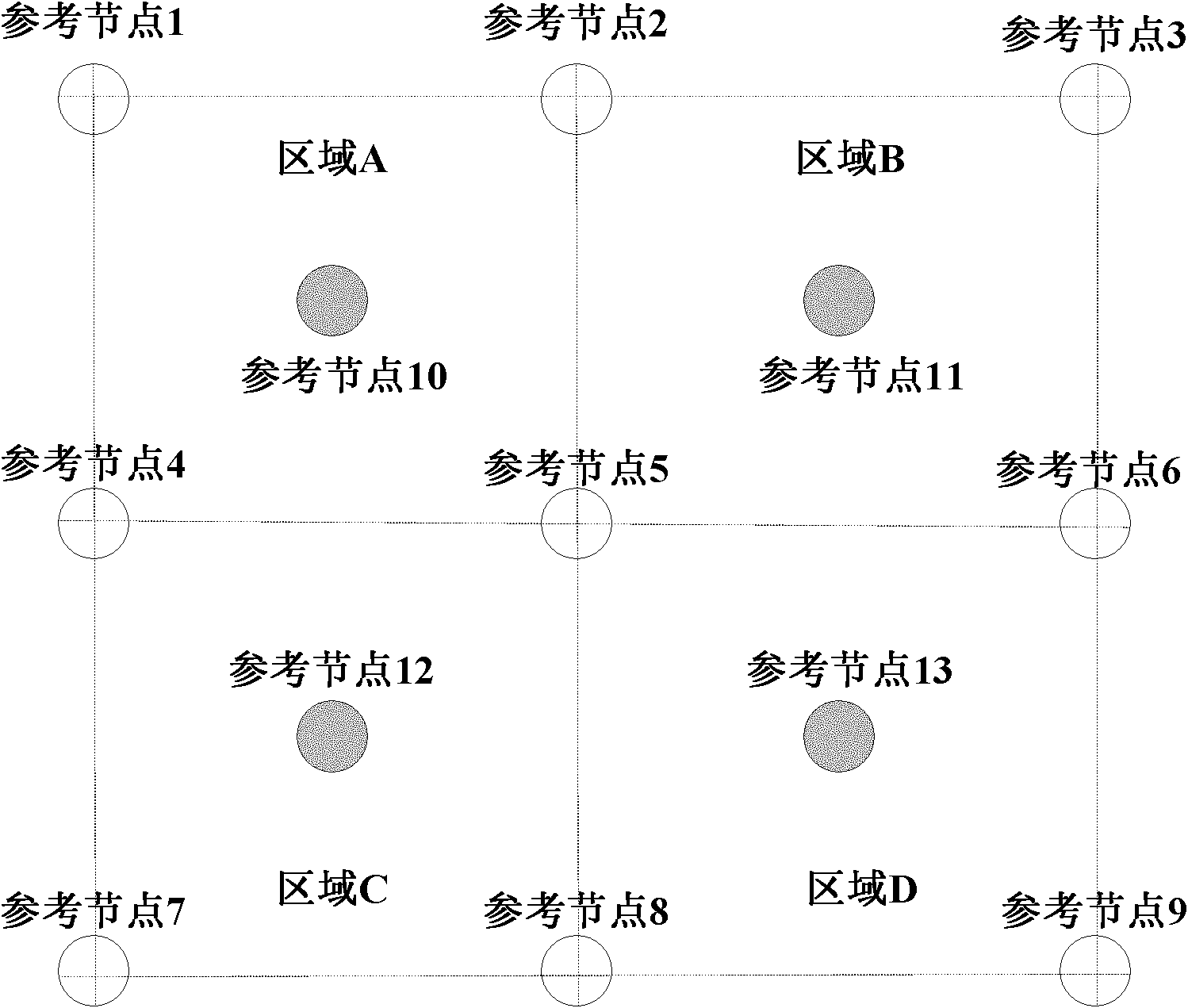

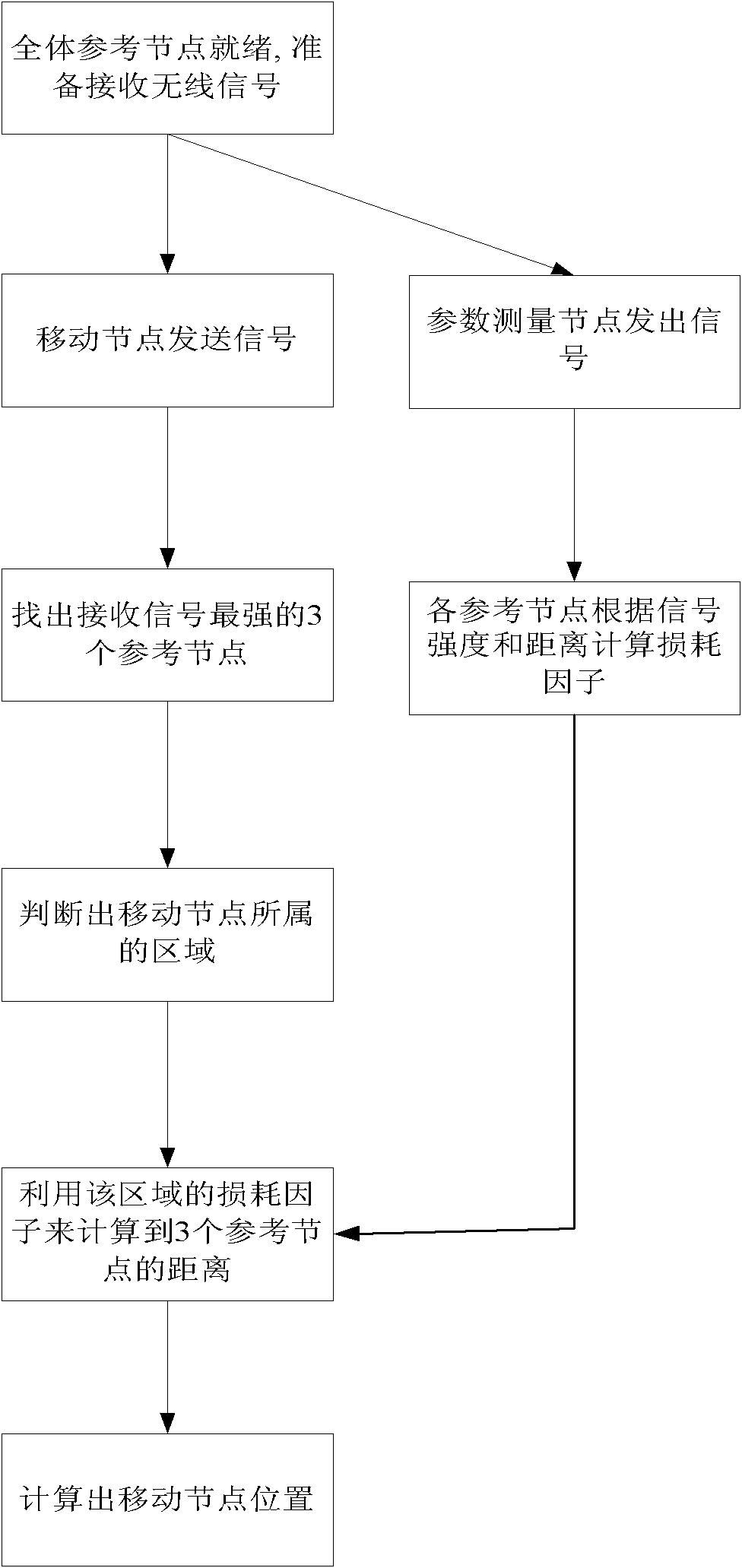

Environment adaptive RSSI local positioning system and method

ActiveCN102014489AEasy to implementHigh precisionTransmission monitoringWireless communicationEngineeringPositioning system

The invention provides an environment adaptive received signal strength indicator (RSSI) local positioning system and an environment adaptive RSSI local positioning method. The system and the method implement positioning based on signal energy strength, wherein the signals can be radio-frequency signals or underwater acoustic signals. The method comprises the following positioning steps of: in the positioning process, measuring reference node path loss factors of each corresponding area in real time by using reference nodes, and updating a database of the loss factors according to the set frequency; when the signal of a movable node is received, determining the area of the movable node by using three nodes with strongest signals; calculating the distance from the movable node to the threereference nodes by using the loss factors of the reference nodes of the corresponding area; and calculating the position of the movable node by using a trilateration method. The positioning technology has the advantage of overcoming the defect of low precision of the conventional RSSI positioning technology due to environmental change in a variable environment, for example, a warehouse where goods are frequently delivered.

Owner:58TH RES INST OF CETC

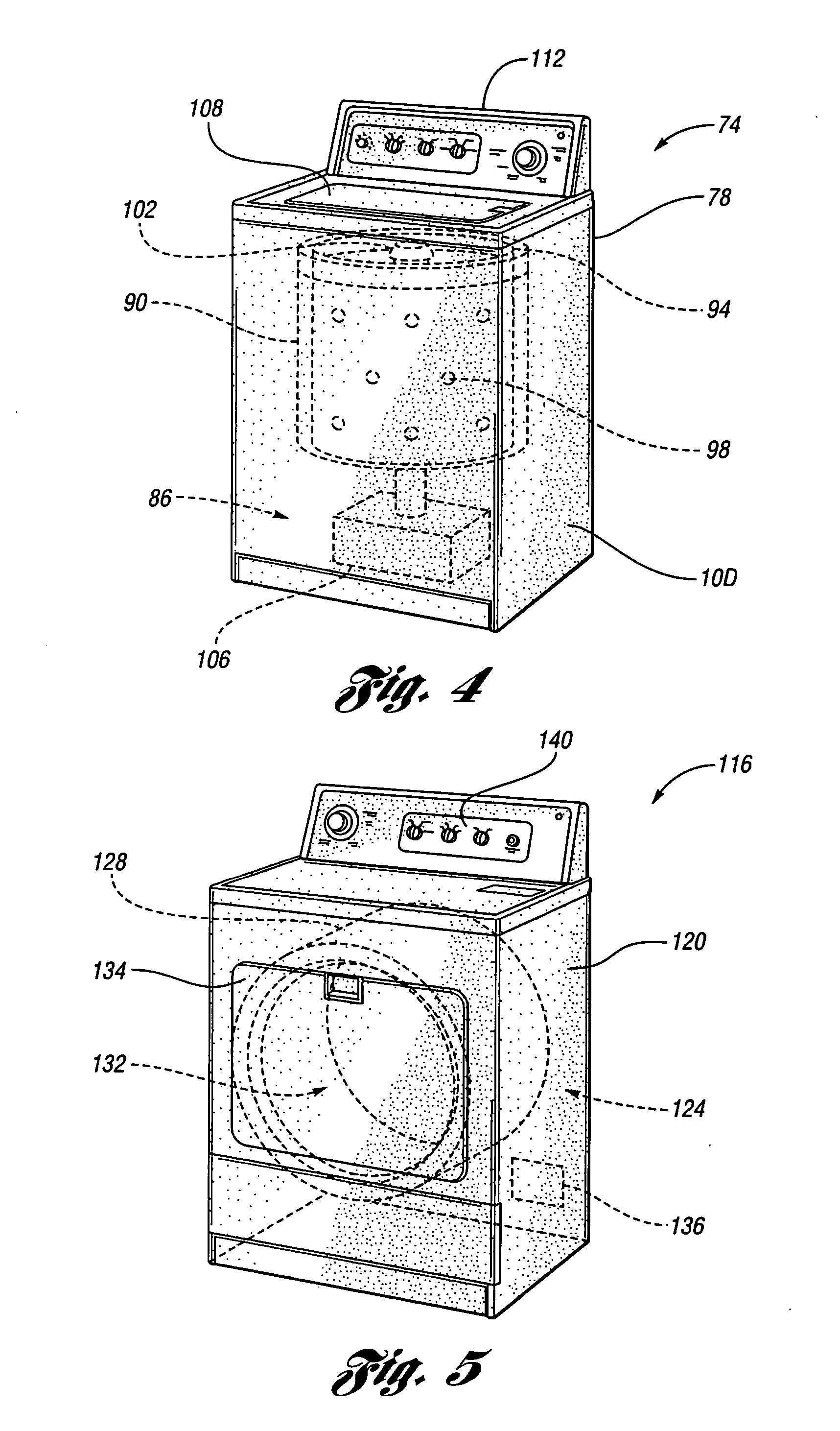

Home appliance structure with integral noise attenuation

InactiveUS20060266385A1Improve aestheticsCost optimizationOther washing machinesElectrostatic cleaningEngineeringHome appliance

A home appliance includes a panel forming one of a tub, drum, and a housing for the appliance. The panel includes a first metal layer, a second metal layer, and a viscoelastic layer between, and spanning the entireties of, the first and second metal layers. The viscoelastic layer is configured such that the panel exhibits a composite loss factor of at least 0.05. The panel therefore forms appliance structure with integral noise attenuation, which improves upon the prior art by reducing the number of parts and manufacturing steps necessary for add-on noise attenuators. Furthermore, since the viscoelastic layer spans the entirety of the metal layers, noise attenuation is continuous across the panel, unlike many prior art noise attenuators which provide only localized noise attenuation.

Owner:MATERIAL SCIENCES CORPORATION

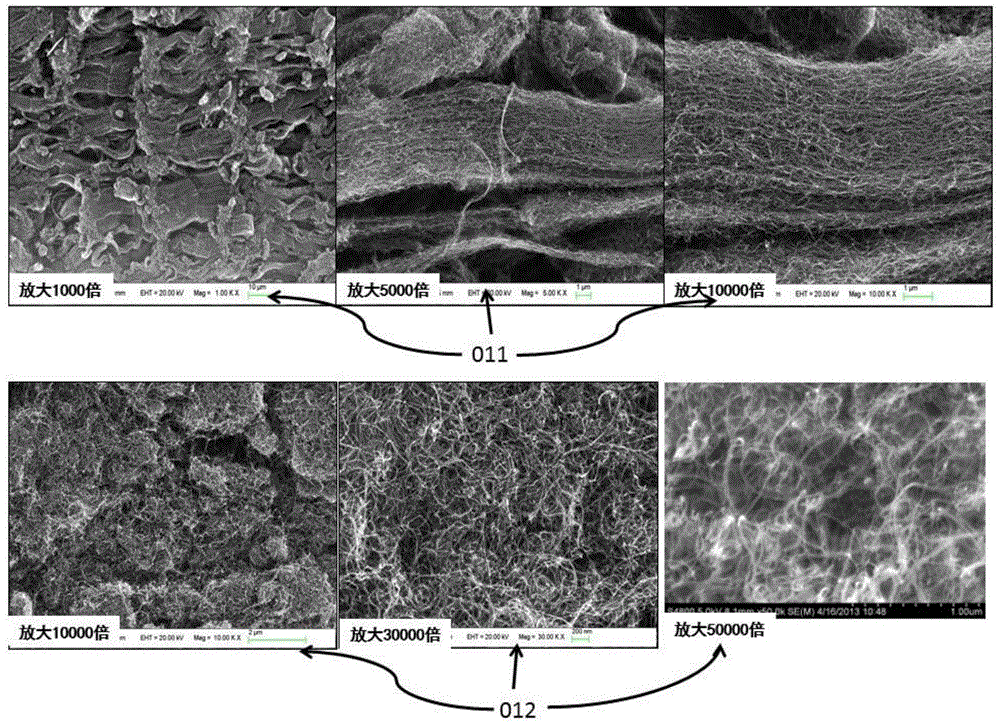

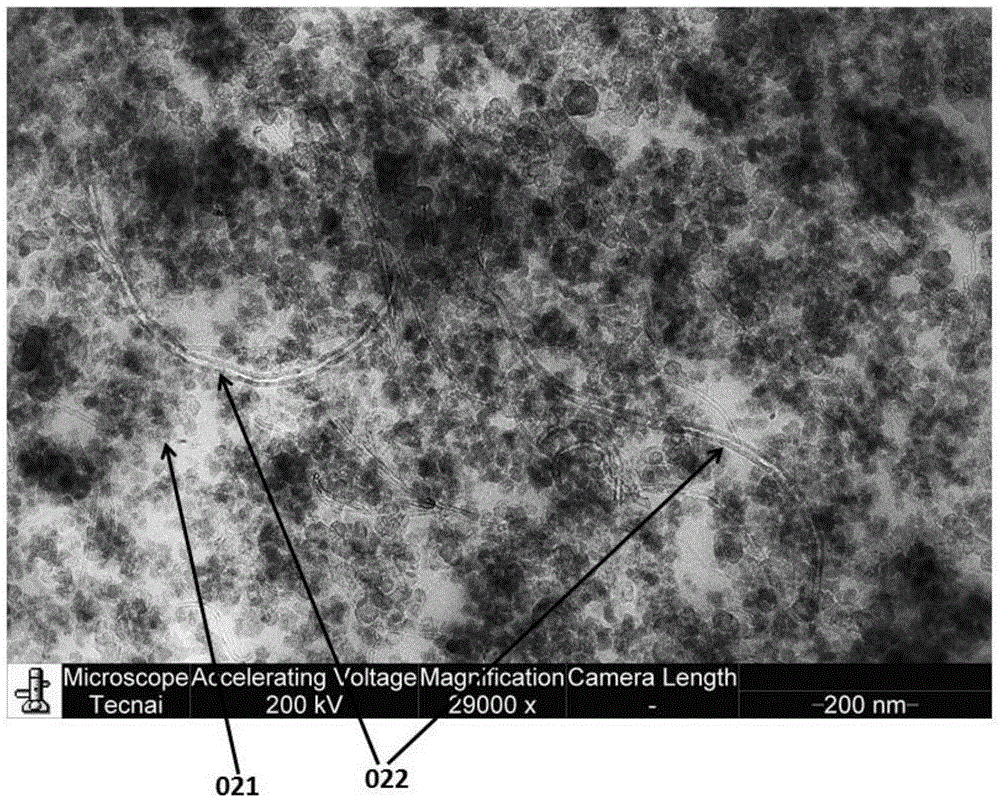

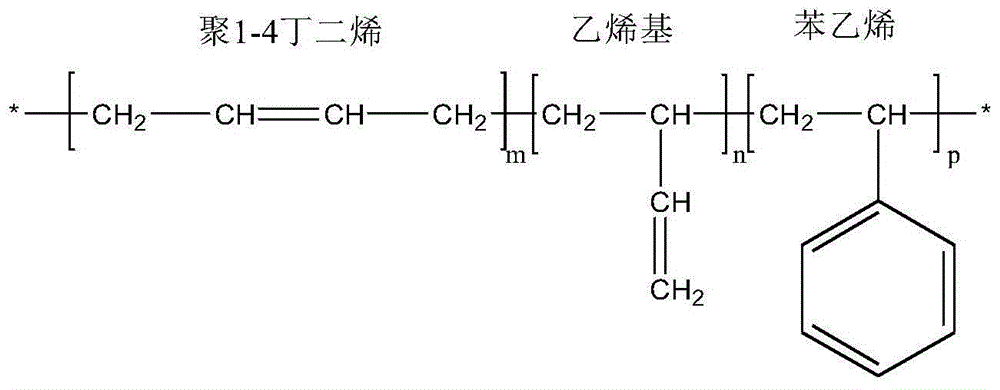

Low-hysteresis antistatic tread rubber material for fuel-efficient tires, and preparation method thereof

ActiveCN104130478AConductiveImprove reliabilitySpecial tyresRolling resistance optimizationRubber materialHysteresis

The invention relates to a low-hysteresis antistatic tread rubber composite material and a preparation method thereof. According to the rubber composite material, mixed rubber formed by solution polymerization of styrene-butadiene rubber and butadiene rubber is adopted as substrate rubber. Carbon nano-tube bundles, white carbon black, and carbon black enhancing filling materials are added. A silane coupling agent, an anti-aging agent, an accelerator, and a cross-linking agent are added. The mixing of the rubber composite material can be carried out with a multi-stage manner in an open mill or an internal mixer. The rubber composite material provided by the invention has low-dynamic-hysteresis and antistatic characteristics. Under a temperature of 60 DEG C and dynamic strain of 7%, dynamic loss factor tandelta is no higher than 0.14. According to GB / T1410-2006 determination, a volume resistivity is lower than 1*10<9>omega.cm. The mechanical strength and wear resistance of the material are better than or equivalent to those of a regular tire tread rubber material. When the rubber composite material provided by the invention is used for preparing a tire tread, tire rolling resistance can be reduced, and a problem of high white carbon black tire material static electricity accumulation can be solved.

Owner:BEIJING UNIV OF CHEM TECH

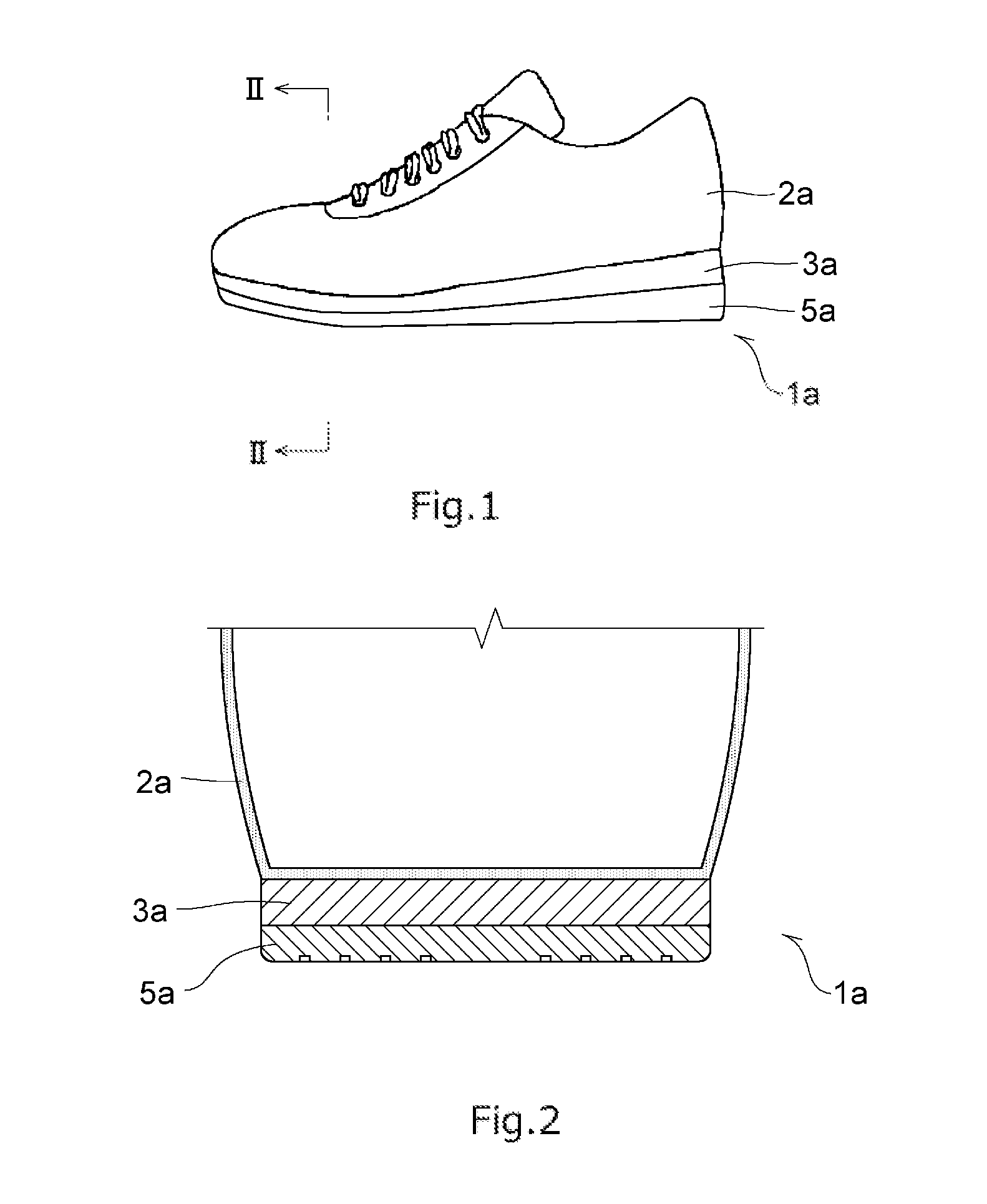

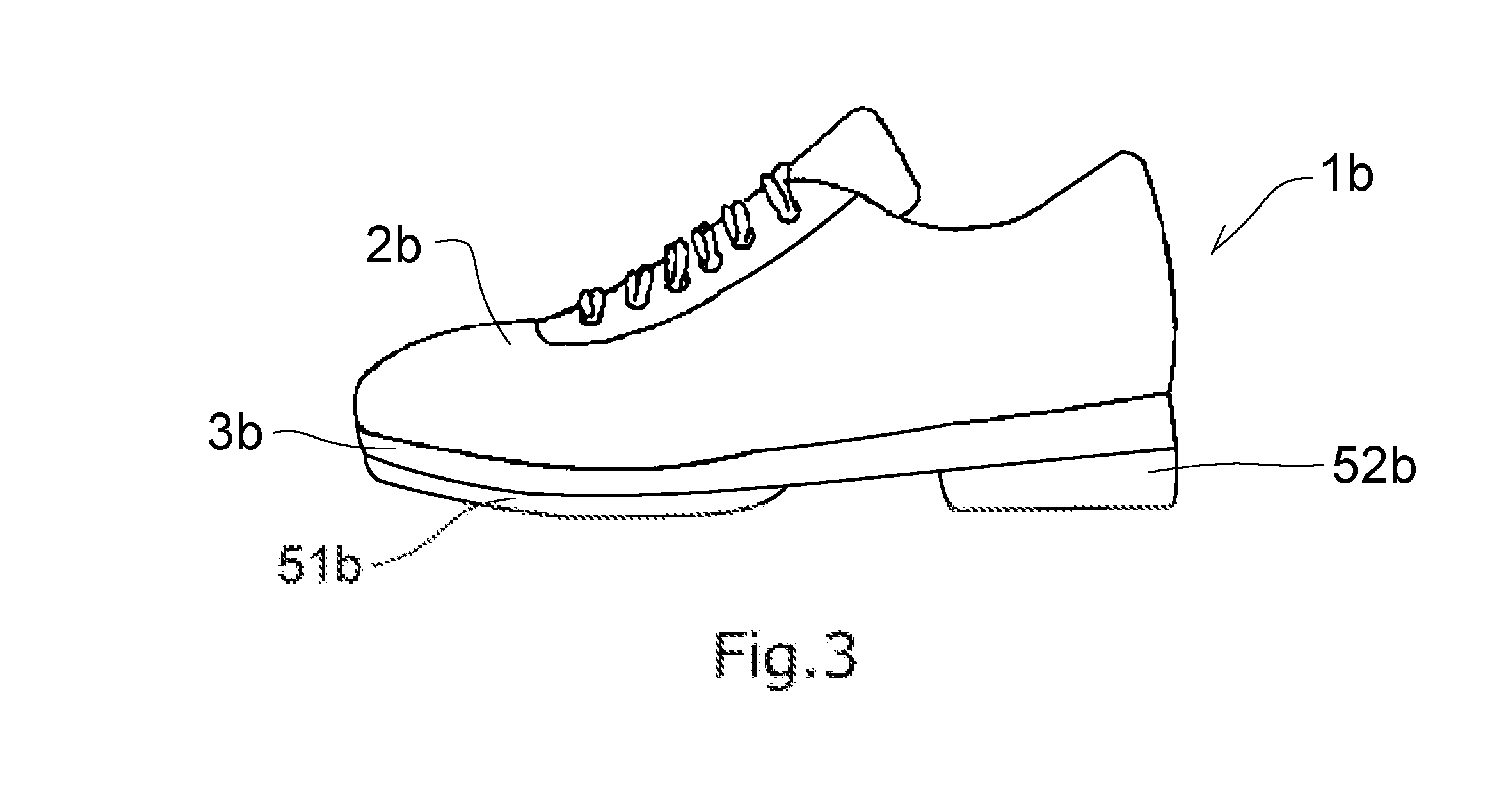

Foamed Sole and Shoe

A foamed sole according to the present invention includes a foam molding containing a rubber component and a resin component, wherein the maximum value of a loss factor [tan δ] at a frequency of 10 Hz and at 30° C. to 80° C. of the foam molding is 0.18 or less, and a peak of a loss factor [tan δ] at a frequency of 10 Hz of the foam molding lies within the range of 100° C. or higher. The foamed sole has a feature that it hardly shrinks when it is heated.

Owner:ASICS CORP

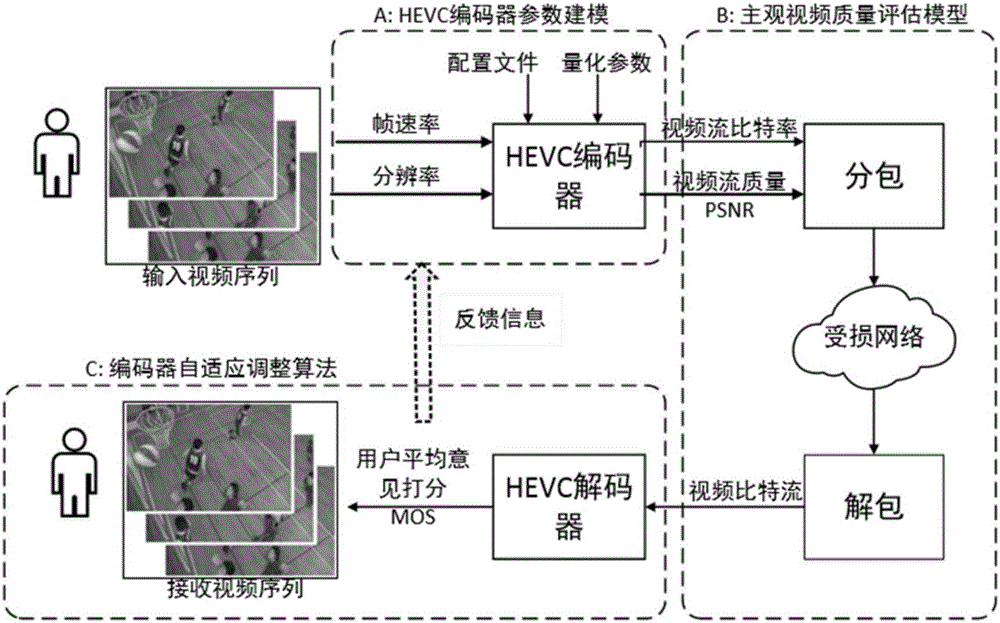

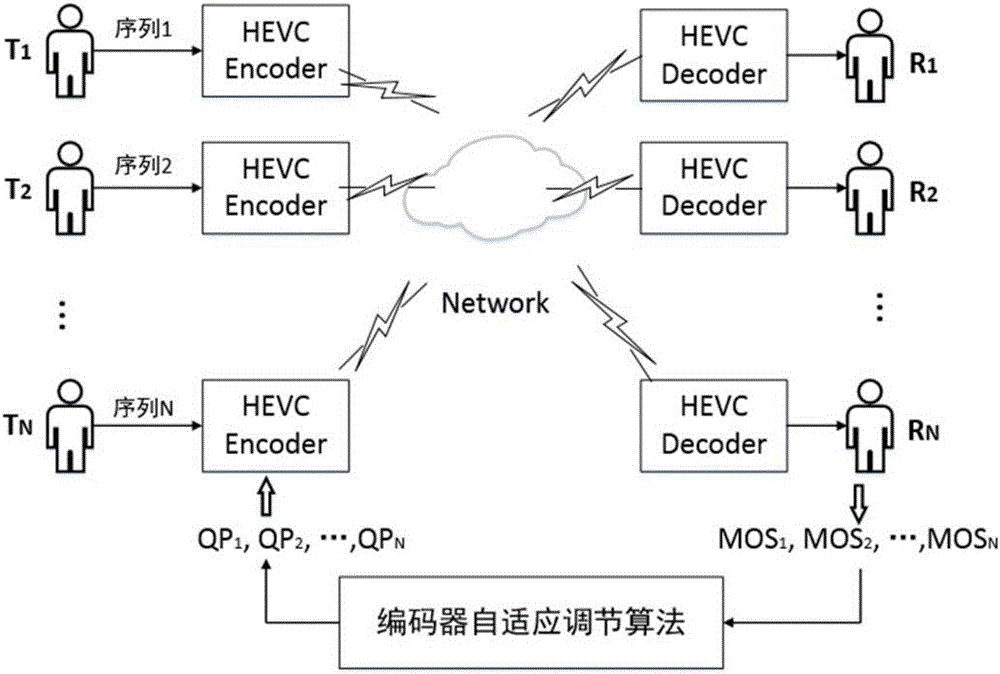

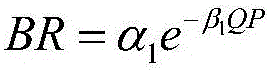

Encoder adaptive adjustment method based on subjective quality evaluation

ActiveCN105828069AOptimize allocationImprove satisfactionDigital video signal modificationTransmissionSubjective perceptionVideo quality

The invention relates to an encoder adaptive adjustment method based on subjective quality evaluation. The method comprises the following steps: step A, through analyzing influences exerted by encoding parameters and configuration conditions on a video stream code rate, establishing an HEVC encoder parameter model; step B, by use of subjective perception of a terminal user for received video quality, establishing a subjective QoE model integrally taking encoder arrangement and network loss factors into consideration; and step C, based on the established subjective QoE model, for video service of multiple users, constructing an adaptive adjustment algorithm maximizing total QoE of all the users under the condition of a limited channel capacity. Compared to the prior art, the method provided by the invention substantially improves user total satisfaction under the condition of multiple users, at the same time, supports resource distribution according to user priorities, and has great significance on improvement of system performance and optimization of network resource distribution.

Owner:SHANGHAI JIAO TONG UNIV

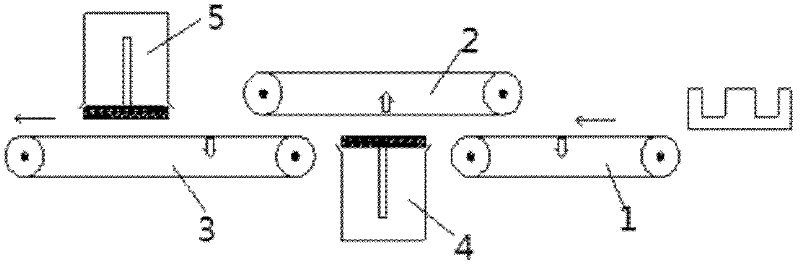

Method for producing soft magnetic ferrite core

InactiveCN102643083AImprove permeabilityLow dissipation factorEdge grinding machinesPolishing machinesInitial permeabilitySoft magnet

The invention discloses a method for producing a soft magnetic ferrite core. The method comprises the following steps of: mixing of raw materials, pre-sintering, ball milling, compression moulding, secondary sintering, grinding and detection, wherein an integral magnetic-attraction double-sided grinding machine is adopted in the grinding process. The magnetic core produced by the method has high magnetic conductivity and low loss factor, and energy sources can be saved; the magnetic core has uniform color, flat end surface and bright and clean surface; the ball milling as well as the uniformity and sphericity of the mixed material are improved; a low-temperature sintering technology is adopted, the heating rate and cooling rate of each stage are adjusted, the ferrite transformation of the material is promoted, and the grain size can be effectively controlled; and the initial permeability and temperature characteristic are improved.

Owner:ANHUI TAIDE ELECTRONICS TECH

Multilayer interlayer having sound damping properties over a broad temperature range

ActiveUS20160111077A1Improve sound insulationWallsSynthetic resin layered productsSoft layerPlasticizer

A polymer interlayer having improved sound insulation is disclosed. The polymer interlayer comprises at least one soft layer wherein the soft layer comprises: a first poly(vinyl butyral) resin having a first residual hydroxyl content and a first glass transition temperature (Tg); a second poly(vinyl butyral) resin having a second residual hydroxyl content and a second glass transition temperature (Tg), wherein the difference between the first residual hydroxyl content and the second residual hydroxyl content is at least 1.0 weight percent; wherein the difference between the first glass transition temperature (Tg) the second glass transition temperature (Tg) is at least 1.5° C.; and a plasticizer; at least one stiffer layer comprising a third poly(vinyl butyral resin) having a third residual hydroxyl content; and a plasticizer, wherein the polymer interlayer has a damping loss factor (q) (as measured by Mechanical Impedance Measurement according to ISO 16940) of at least about 0.16 measured at two or more different temperatures selected from 10° C., 20° C. and 30° C.

Owner:SOLUTIA INC

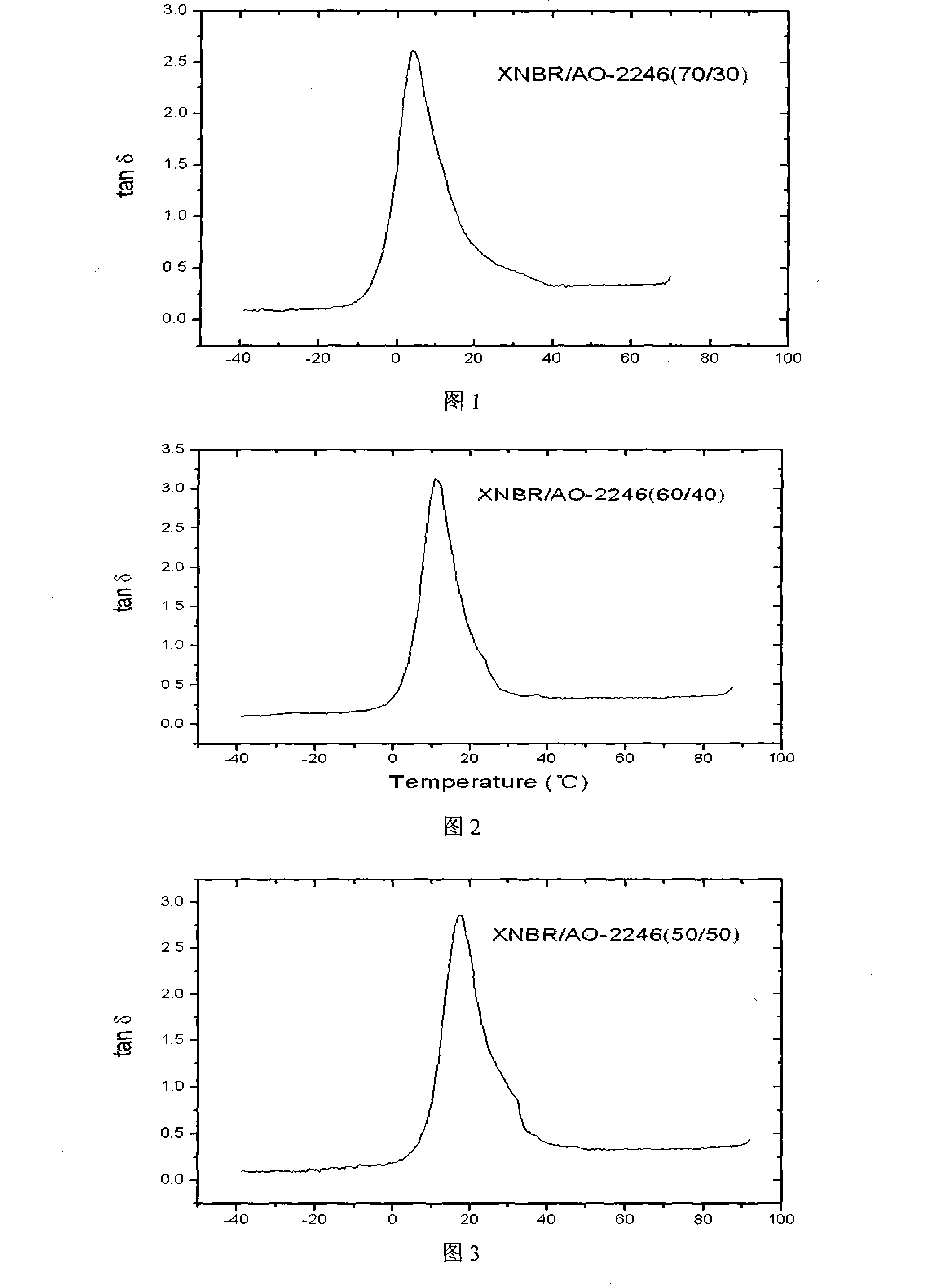

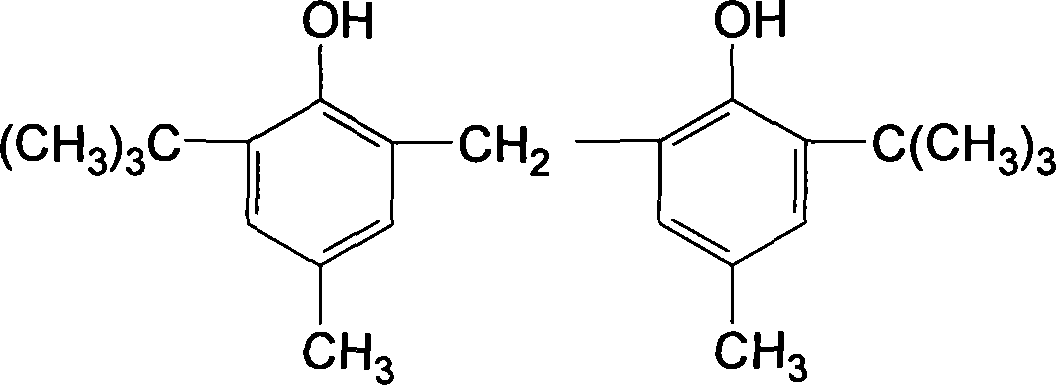

Carboxy nitrile rubber high-performance damping material and method for producing the same

InactiveCN101173066AImprove loss factorWide effective damping temperature rangeNitrile rubberPhenolic antioxidant

The invention relates to a carboxylated nitrile rubber-based high-performance damping material and a preparation method thereof. The material uses carboxylated nitrile rubber (XNBR) as a matrix and a hindered phenolic antioxidant 2,2'-methylene bis( 4-methyl-6-tert-butylphenol) is a damping additive obtained by blending and tableting; preparation: (1) Blending a certain proportion of carboxylated nitrile rubber and damping additives on a double-roller mixer Making a mixed film; (2) hot pressing the mixed film on a flat vulcanizing machine to obtain a thin sheet sample; (3) using a dynamic mechanical analyzer to perform a dynamic mechanical test on the sample to characterize its damping performance. The damping material of the present invention is characterized by a large loss factor, a wide effective damping temperature range, and the position of the damping peak can be regulated by adjusting the content of the damping additive, thereby obtaining a high-performance damping material suitable for use at different temperatures.

Owner:DONGHUA UNIV

Golf club shaft

A golf club shaft (10), tubular and having a hollow portion, which includes a laminate of fiber reinforced prepregs (21 through 23, 24A, 25 through 29). The laminate has a first part (I) composed of a plurality of first prepregs (P1) and a second part (P2). A loss factor (tan δ) of the first part (I) is set to not less than 0.005 nor more than 0.02, when the loss factor is measured at a frequency of 10 Hz under a condition of 10° C. A loss factor (tan δ) of the second part (P2) is set to not less than 0.10 nor more than 0.50, when the loss factor is measured at a frequency of 10 Hz under the condition of 10° C.

Owner:DUNLOP SPORTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com