High-performance tire tread rubber and preparation method thereof

A tire tread, high-performance technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of aromatic oil migration and pollution, and achieve the effects of reduced wear, improved tear strength, and reduced loss factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] A high-performance tire tread rubber compound consists of the following components in parts by weight:

[0082] 80 parts of natural rubber;

[0083] Butadiene rubber 20 parts;

[0084] 10 parts of low molecular weight trans-butadiene-isoprene copolymer rubber;

[0085] Others are the same as Comparative Example 1.

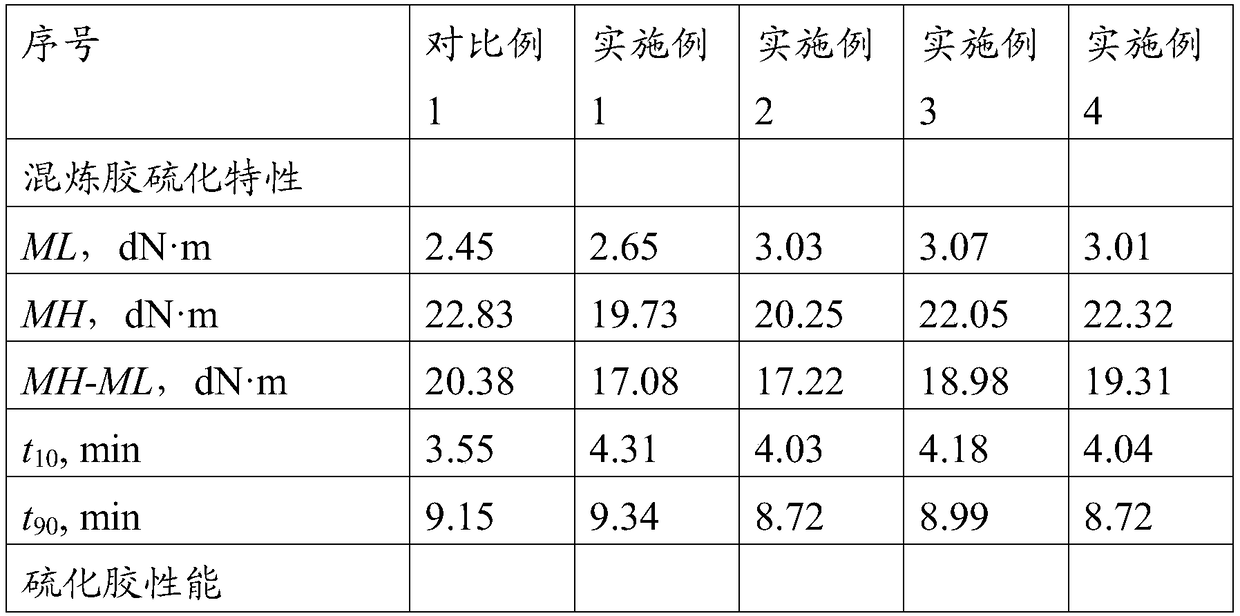

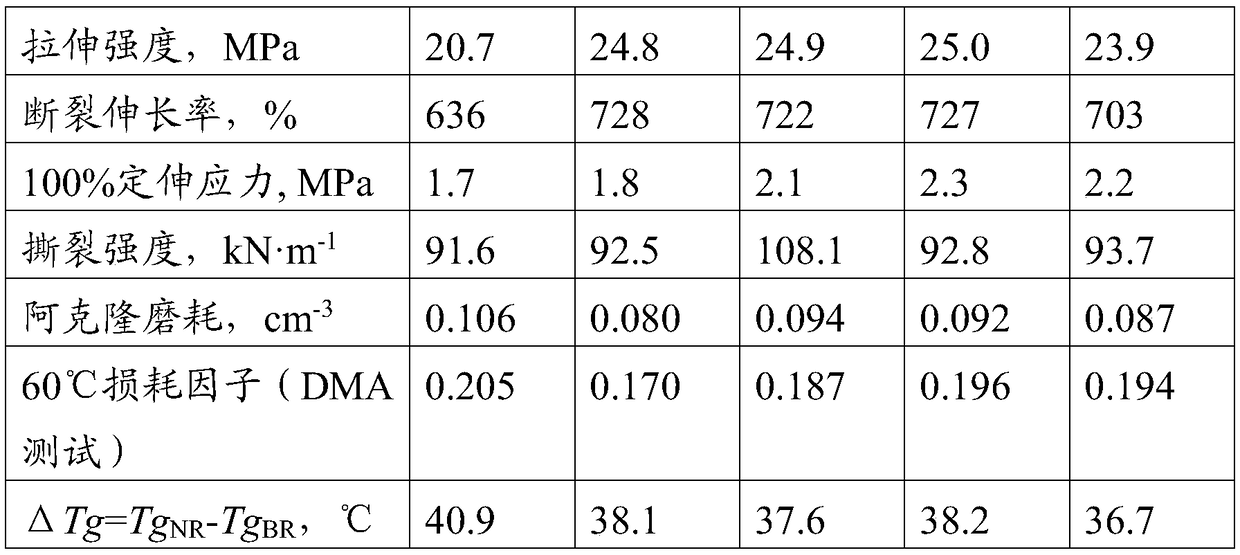

[0086] The molar content of butadiene units in the low molecular weight trans-butadiene-isoprene copolymer rubber is 40.7%, the molar content of isoprene units is 59.3%, and the molar content of trans-1,4-structure is greater than 95% %, Mooney viscosity value (100°C, 3+4) is 21.6. The properties of the vulcanizate are shown in Table 1.

Embodiment 2

[0088] One-stage banburying process is:

[0089] Add natural rubber and butadiene rubber in the internal mixer, banbury for 1min, put in zinc oxide, stearic acid, anti-aging agent and anti-scorch agent, banbury for 1min; put in all carbon black, banbury for 2min; put in white carbon black and Silane coupling agent, banburying for 7min; cleaning the upper bolt; adding low molecular weight trans-butadiene-isoprene copolymer rubber, banburying for 7.5min, 150°C for rubber removal, and standing at room temperature for 1 hour to obtain a section of banbury rubber .

[0090] Others are the same as embodiment 1. The properties of the vulcanizate are shown in Table 1.

Embodiment 3

[0092] 73 parts of natural rubber;

[0093] Butadiene rubber 18 parts;

[0094] 9 parts of low molecular weight trans-butadiene-isoprene copolymer rubber;

[0095] Others are the same as embodiment 1. The properties of the vulcanizate are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com