Patents

Literature

63results about How to "Low loss factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

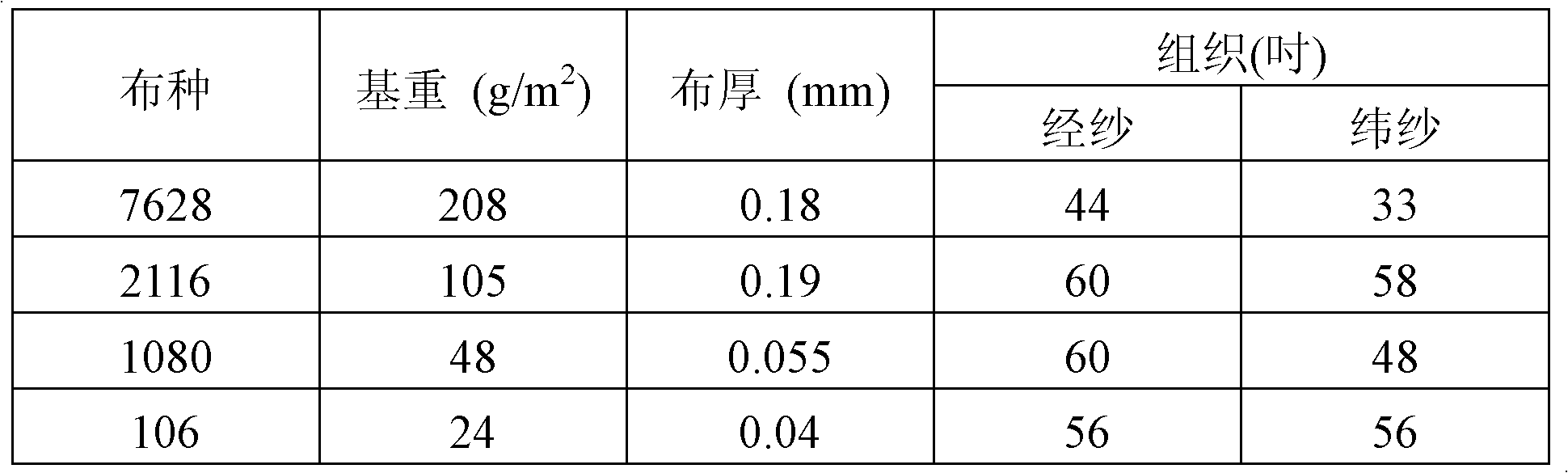

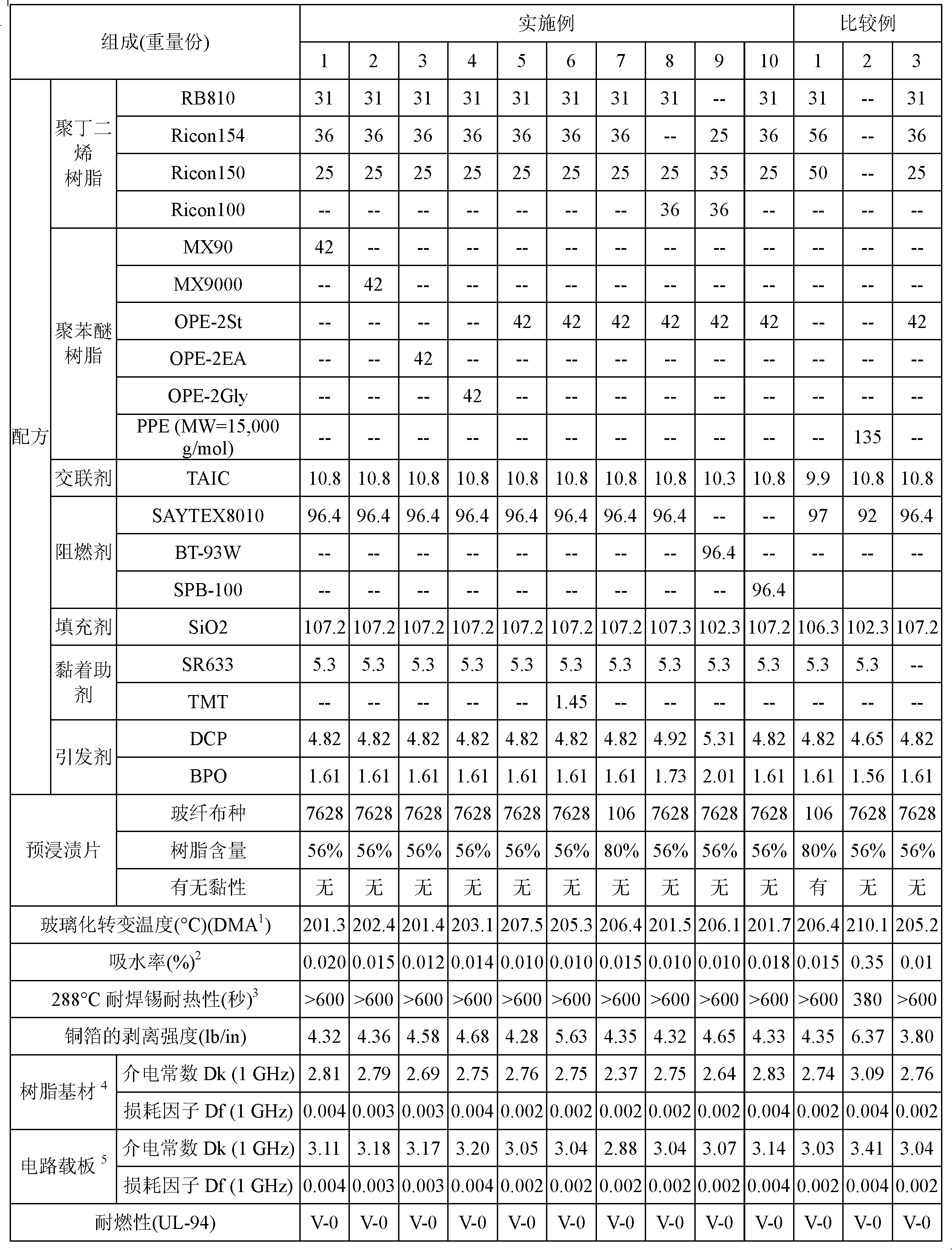

High-frequency copper foil substrate and composite material used thereby

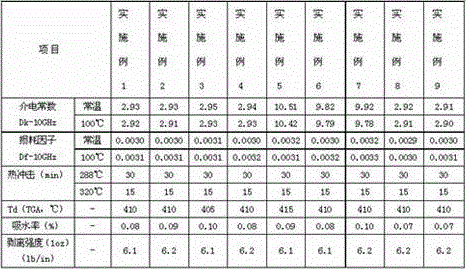

ActiveCN102304264ALow costHigh frequencySynthetic resin layered productsCircuit susbtrate materialsCross-linkSolubility

The invention discloses a high-frequency copper foil substrate with an operating frequency of more than 1GHz, which has a dielectric constant Dk of less than 3.2 and a loss factor Df of less than 0.005 as well as high glass transition temperature, high thermostability and low moisture-absorption characteristic. The high-frequency copper foil substrate contains a special composite material and is prepared by impregnating a reinforcing material with blended resin mixture. The resin mixture of the composite material is prepared by blending the following materials: (a) high molecular weight polybutadiene resin; (b) low molecular weight polybutadiene resin; (c) modified polyphenyl ether thermosetting resin; (d) inorganic powder; (e) flame retardant; (f) cross-linking agent; (g) binding aid; and (h) hardening initiator. In the invention, the drawback of low processability of pure polybutadiene with low viscosity and the drawback of need of adding plasticizer of polyphenyl ether resin (PPE) with low solubility; particularly, the non-viscous pre-impregnated sheets made by the composite material can be processed into copper foil substrates automatically.

Owner:NANYA PLASTICS CORP

A Fabry-Perot interference sensor based on solid-core photonic crystal fiber and its manufacturing method

InactiveCN102261924ASimple structureSmall sizeCoupling light guidesConverting sensor output opticallyThermal dilatationInterferometric sensor

The invention provides a Fabry-Perot interferometric sensor based on a photonic crystal fiber and a manufacturing method thereof. The sensor is composed of a conventional communication single-mode fiber and a solid photonic crystal fiber, wherein the conventional communication single-mode fiber and the solid photonic crystal fiber are welded by using a certain welding method. Because air holes ona cladding of the photonic crystal fiber collapse, an air cavity (namely, an F-P cavity) is formed between the two fibers, and the two end faces (namely, the front and rear surfaces of the air cavity) of the photonic crystal fiber and the single-mode fiber are two reflecting surfaces of the F-P cavity. The solid photonic crystal fiber is made of a single material, and does not cause the mismatching of thermal expansion coefficients of materials in the process of temperature variation, thereby ensuring that the influence of temperature variation on the interferometric sensor is small; in the manufacturing process, only a fiber cutting and welding process is used, therefore, the preparation process is simple; by using the sensor, high-fineness and high-contrast interference fringes can be obtained, therefore, the sensor has a great application potential in large-capacity and quasi-distributed sensing systems; and the sensor is in an all-fiber structure, and has the advantages of small volume, good robustness and low cost.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

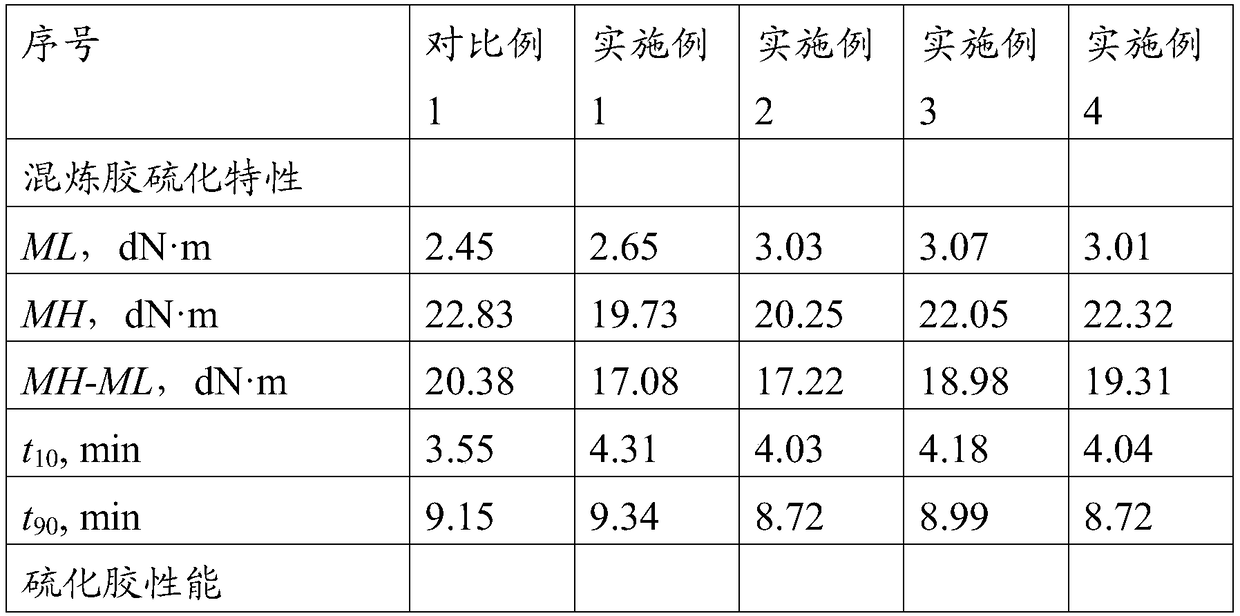

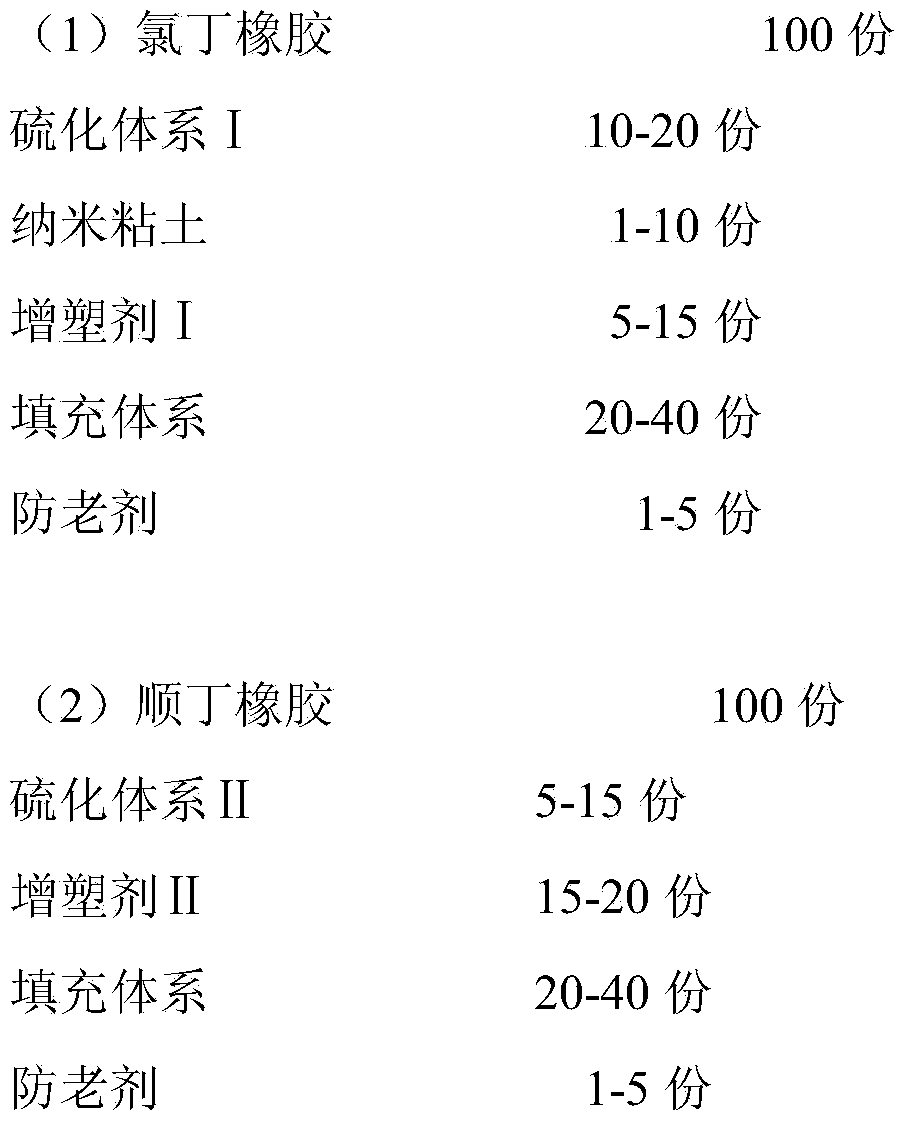

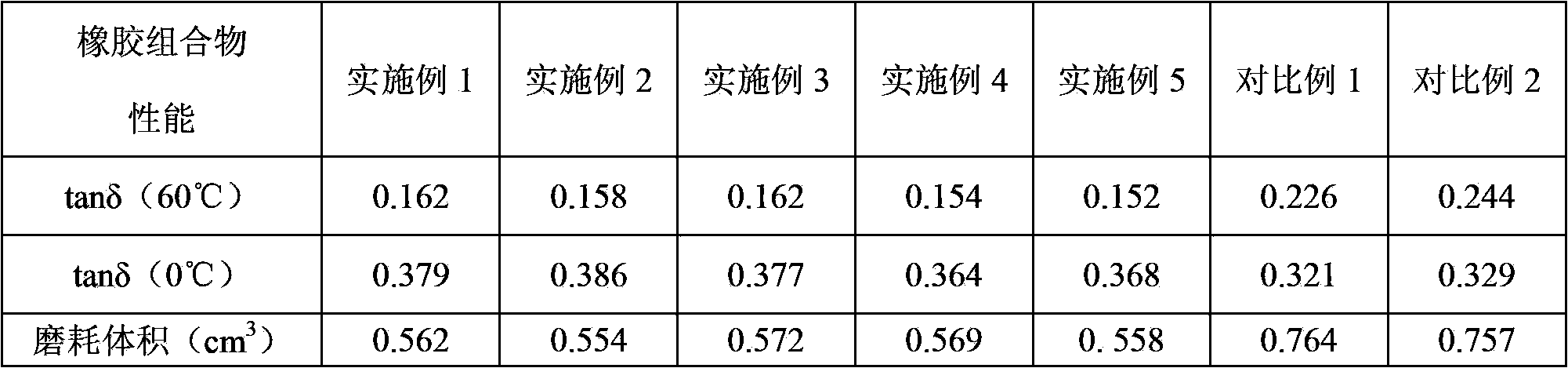

High-performance tire tread rubber and preparation method thereof

ActiveCN109181027AIncreased tensile strengthHigh tensile strengthSpecial tyresRubber materialPolymer science

The invention relates to a high-performance tire tread rubber and a preparation method thereof, wherein the high-performance tire tread rubber comprises, by mass, 60-90 parts of natural rubber, 0-20 parts of cis-1,4-polybutadiene rubber, 9-20 parts of a low molecular weight trans butadiene-isoprene copolymerization rubber, 40-60 parts of carbon black, 0-20 parts of white carbon black, 0-2 parts ofa silane coupling agent, 1-5 parts of zinc oxide, 1-5 parts of stearic acid, 0.3-3 parts of sulfur, 0.5-5 parts of an accelerator, 1-3 parts of an anti-aging agent, and 1-10 parts of other auxiliaryagents. According to the present invention, the tire tread rubber is modified with the low molecular weight trans butadiene-isoprene copolymerization rubber, such that the tensile strength of the vulcanized rubber is increased by 15-20%, the tear strength is increased by 1%-20%, the 60 DEG C loss factor is reduced by 4-20%, and the wear is reduced by 10-25%; and various performances of the tire tread rubber material of the present invention meet the performances of the tire tread rubber.

Owner:SHANDONG HUAJU POLYMER MATERIALS CO LTD

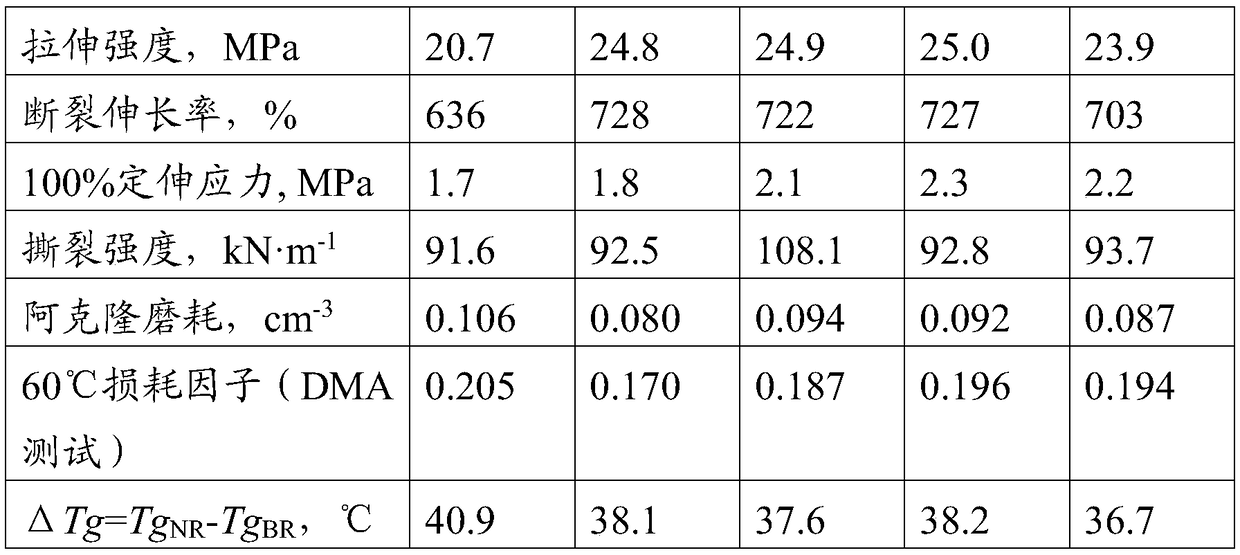

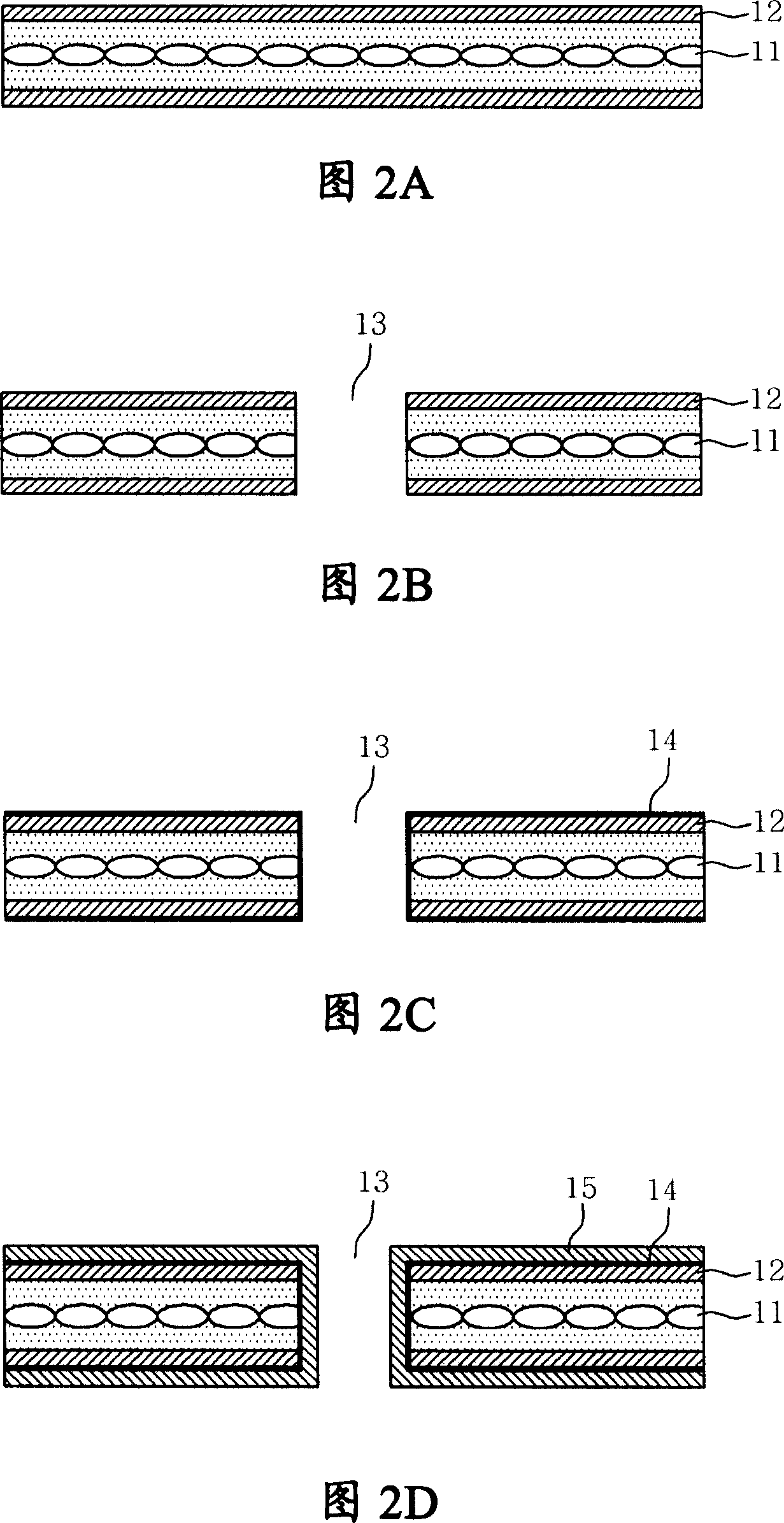

Printed circuit board and method of manufacturing the same

InactiveCN1988768AIncreased durabilityImprove interface adhesionInsulating substrate metal adhesion improvementPrinted circuit aspectsCopper platingInterfacial adhesion

Disclosed are a printed circuit board and a method of manufacturing the same, in which a fluorine resin coating layer is formed on a resin substrate, and then a copper layer is formed using a dry process including ion beam surface treatment and vacuum deposition instead of a conventional wet process including surface roughening and electroless copper plating. According to this invention, the interfacial adhesion of the substrate material may be increased without changing the surface roughness thereof, thus realizing a highly reliable fine circuit. As well, a low dielectric constant and a low loss coefficient may be obtained thanks to the formation of the fluorine resin layer. Further, a wet process is replaced with a dry process, whereby the copper plating layer may be formed in an environmentally friendly manner.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Modified carcass ply compound of all-steel radial tire

InactiveCN103012870AGood viscosity increasing effectImprove adhesionSpecial tyresCopper platingMooney viscosity

The invention provides a modified carcass ply compound of an all-steel radial tire. According to the modified carcass ply compound, resorcin is replaced with phenolic resin. The resorcin is replaced with modified phenolic resin Penacolite B-20-S, modified phenolic resin Elaztobond A250 and phenolic resin TYC-0219, the Mooney viscosity of a sizing material is increased, and the scorch time is prolonged; except for the condition that the resin TYC-0219 enables the vulcanizing time to be prolonged obviously, and little difference of other resin exists; the tensile strength and the stretching stress of vulcanized rubber are reduced slightly, and other physical and mechanical properties are not changed much; and storage moduli and loss factors are all reduced; and the drawing force between the sizing material and a coppered steel wire is increased obviously.

Owner:QINGDAO UNIV OF SCI & TECH

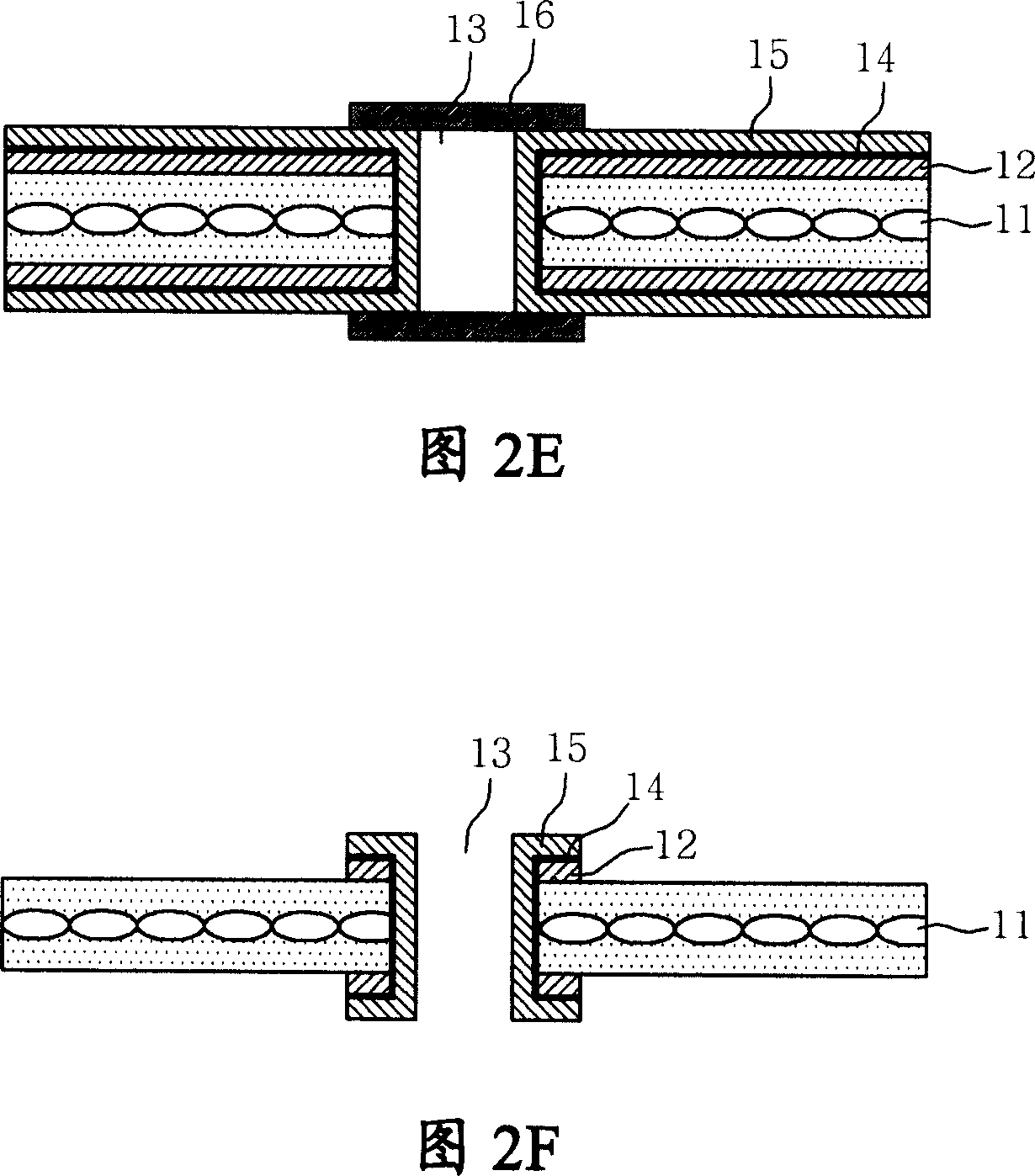

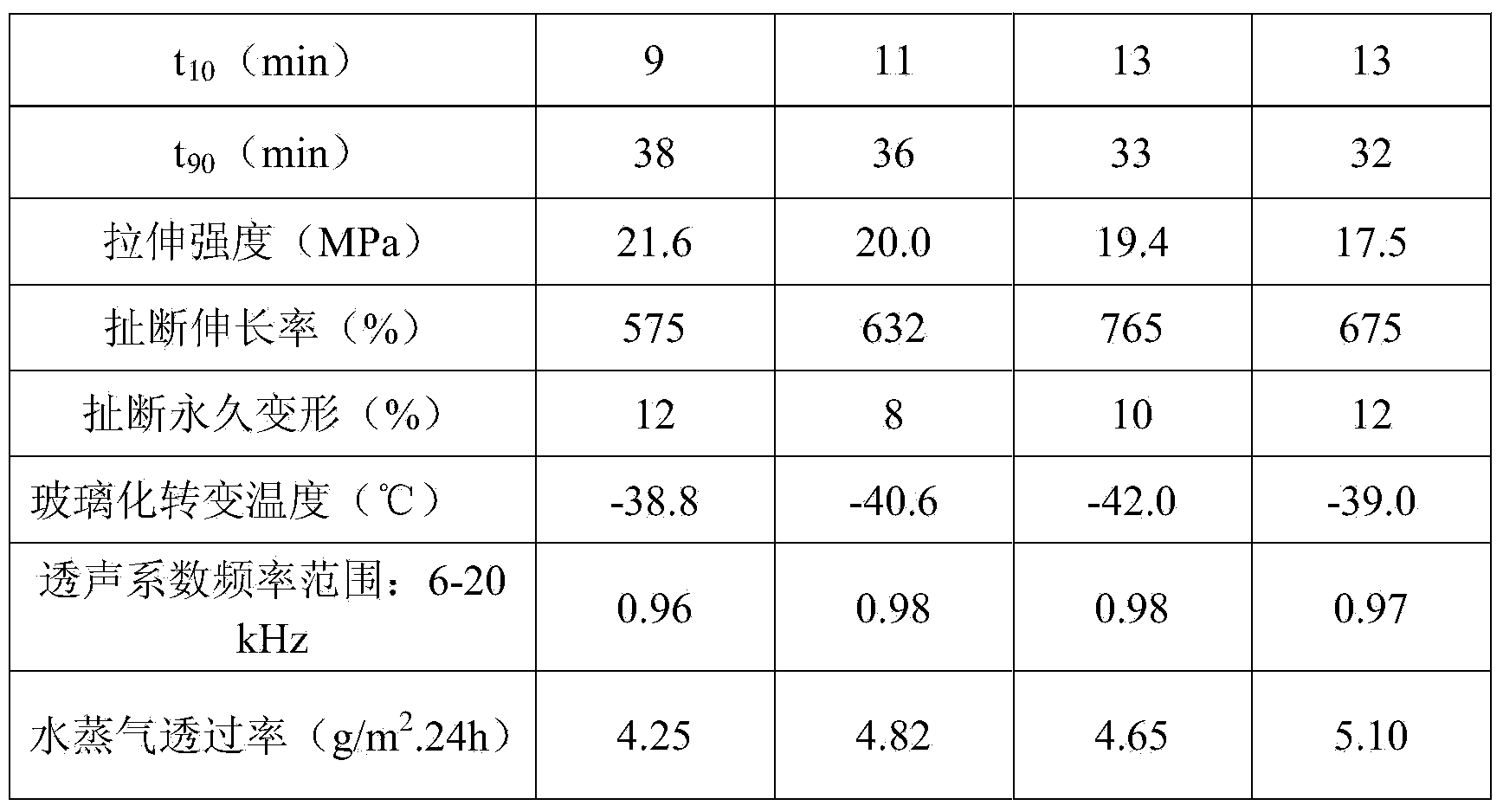

High-temperature underwater sound transmission rubber material and preparation method thereof

ActiveCN103589025AImprove sound transmission performanceImprove stabilityRubber materialVulcanization

The invention relates to a high-temperature underwater sound transmission rubber material and a preparation method thereof. The crystallization of chloroprene rubbers is restrained through selecting the chloroprene rubbers with slow crystallization speed and using butadiene rubbers (BR) with a certain ratio, so that the sound transmission performance and the temperature stability of the rubber material are improved; a certain parts of nanometer clay are added in a formula system to improve the water tightness of the sound transmission material; quick low-temperature and low-pressure vulcanization (100-120 DEG C, 30-40 minutes) of the rubber material is realized through optimizing the rubber material formula and the processing technique design. The underwater sound transmission rubber material with high sound transmission performance, high temperature stability, high water tightness and excellent physical and mechanical properties can be prepared through the method. The material can satisfy the requirements of a coating material of ship underwater sound equipment, and is an excellent underwater sound transmission material.

Owner:BEIJING UNIV OF CHEM TECH

Bookbinding machine motor installation base PBT engineering plastic and motor installation base

The invention relates to the technical field of engineering plastic, in particular to bookbinding machine motor installation base PBT engineering plastic and a motor installation base. The motor installation base PBT engineering plastic is prepared from the following raw materials in parts by weight: 50 to 70 parts of PBT, 5 to 60 parts of glass fiber, 6 to 12 parts of composite toughening agent, 0.5 to 1 part of lubricant, 20 to 30 parts of composite flame retardant, 1 to 2 parts of weather-proof agent, 1 to 2 parts of antioxidant and 4 to 8 parts of inorganic filler. The bookbinding machine motor installation base PBT engineering plastic prepared in the invention has excellent comprehensive mechanical property and processing property, further has lower dielectric constant and good fire resistance and insulation, can reduce the weight of the motor base when being applied to manufacturing the bookbinding machine motor installation base, improves safety performance, shortens a production and manufacturing period, improves product yield, reduces abrasion and has long service life and excellent comprehensive performance.

Owner:东莞市票友机电科技有限公司 +1

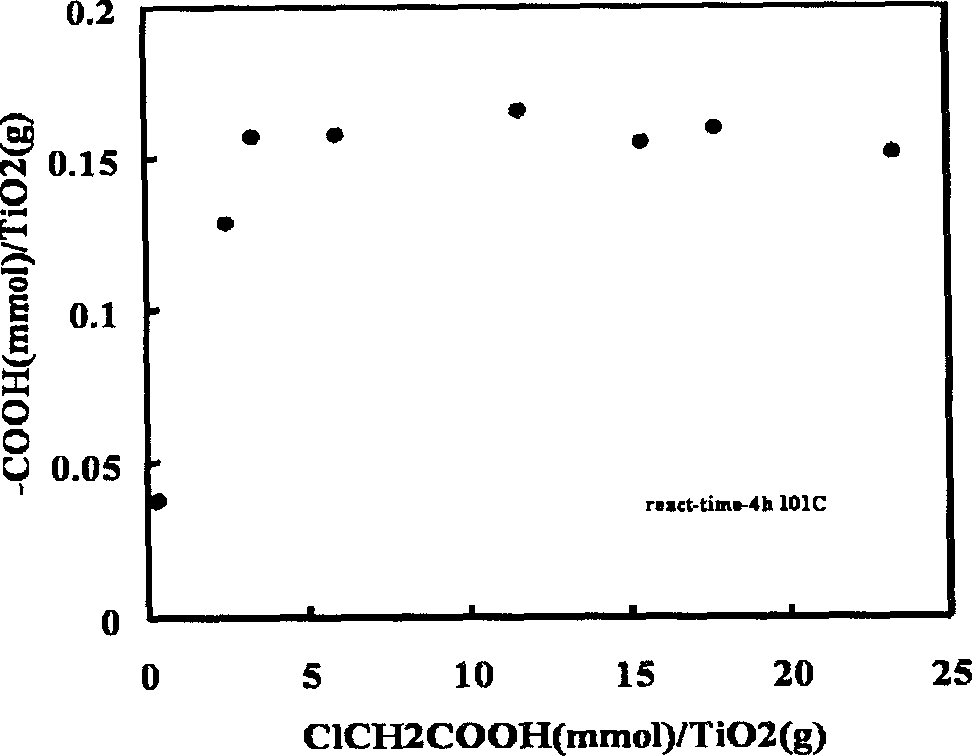

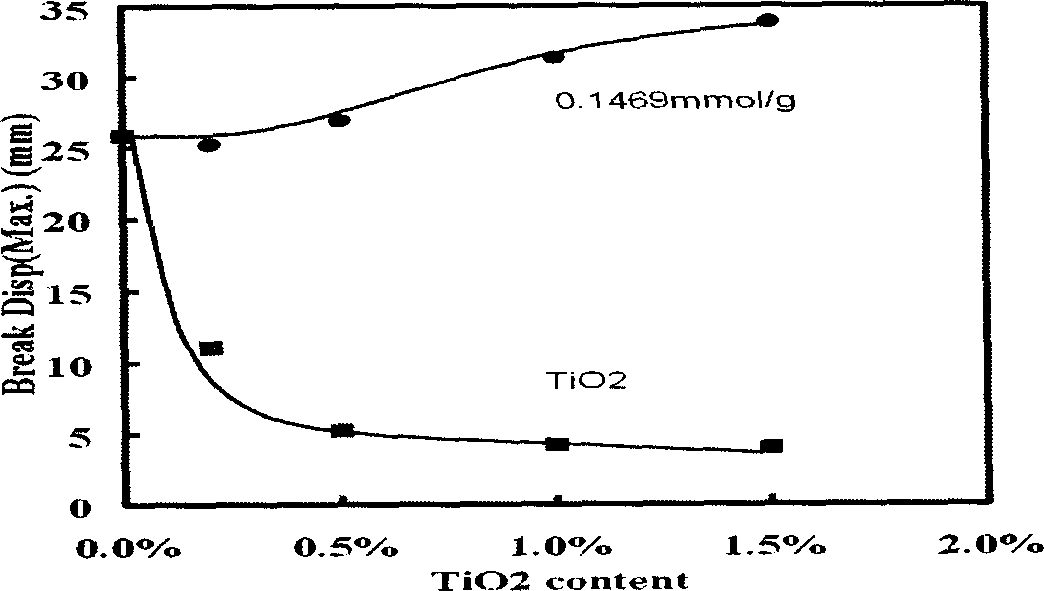

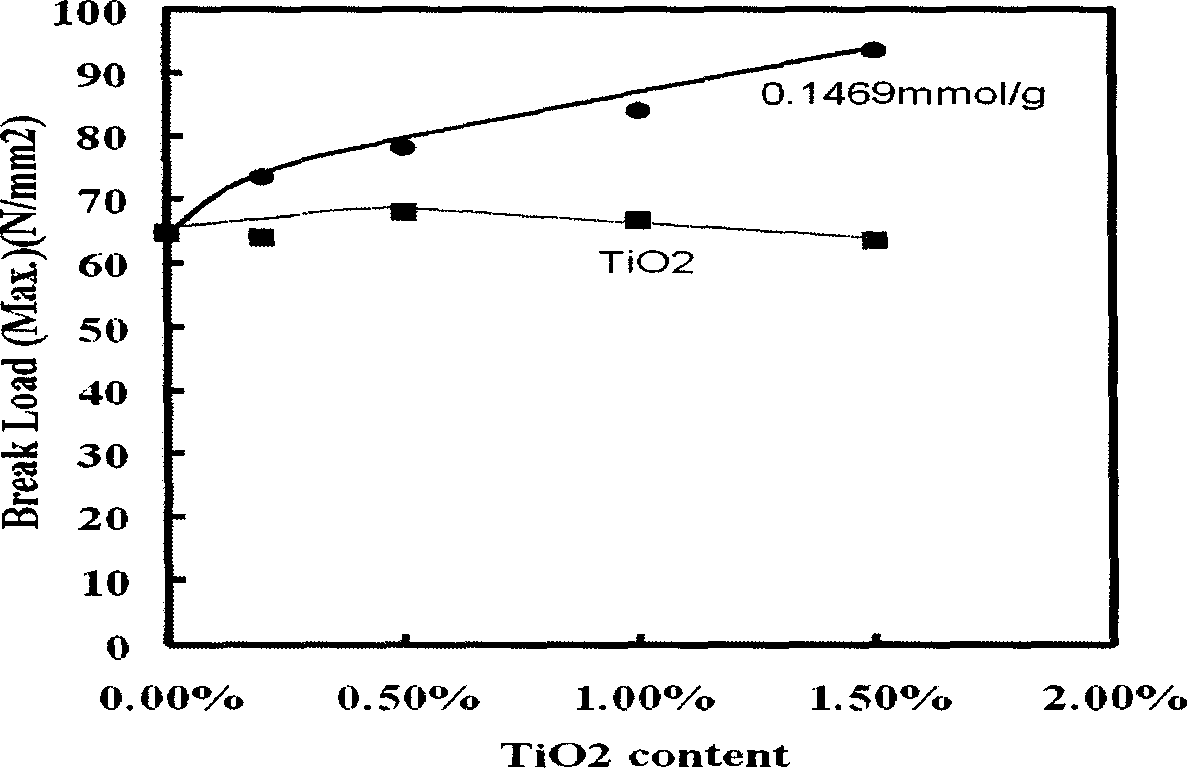

High dispersion nanometer oxide/polyvinyl alcohol composite material preparation method

The invention provides a process for preparing nano oxide / polyvinyl alcohol composite material, which comprises carboxylating the surface of the nano oxide, making the surface of the nano oxide have -COOH radicals, interacting the radicals with -OH on the polyvinyl alcohol polymer, thus achieving nano level dispersion of the nano oxide in polyvinyl alcohol.

Owner:ZHEJIANG SCI-TECH UNIV

Formula of tread rubber of low-rolling-resistance semi-steel radial tire

InactiveCN105801942AImprove environmental safetyLow heat generationRolling resistance optimizationEnvironmental resistancePolymer science

The invention relates to a formula of tread rubber of a low-rolling-resistance semi-steel radial tire. The formula is prepared from the following components: 20 to 30 parts of emulsion polymerized butadiene styrene rubber, 80 to 130 parts of solution polymerized butadiene styrene rubber, 5 to 20 parts of new-process carbon black, 50 to 125 parts of white carbon black, 2 to 15 parts of a super silane coupling agent Si747, 3 to 10 parts of environment-friendly oil, 2 to 6 parts of zinc oxide, 1.2 to 5.6 parts of stearic acid, 0.8 to 3.2 parts of sulfur and 1.2 to 4.2 parts of an accelerant NS. The tire produced by the formula provided by the invention has good environment-friendly property, low rolling resistance, high wear resistance and less generated heat, the oil consumption of vehicles can be reduced and the service life of the vehicle tire is prolonged.

Owner:JIANGSU HUAAN RUBBER TECH CO LTD

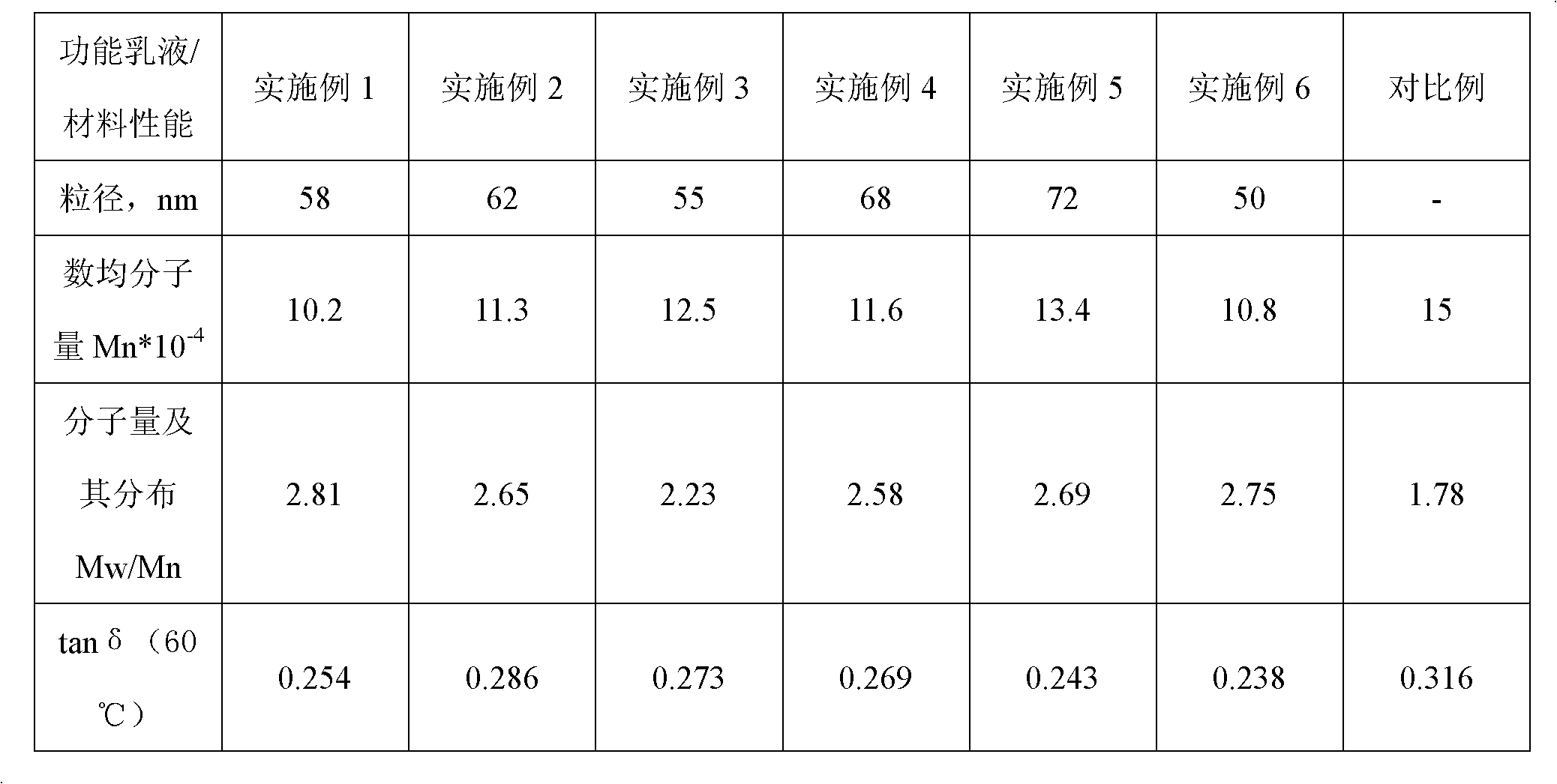

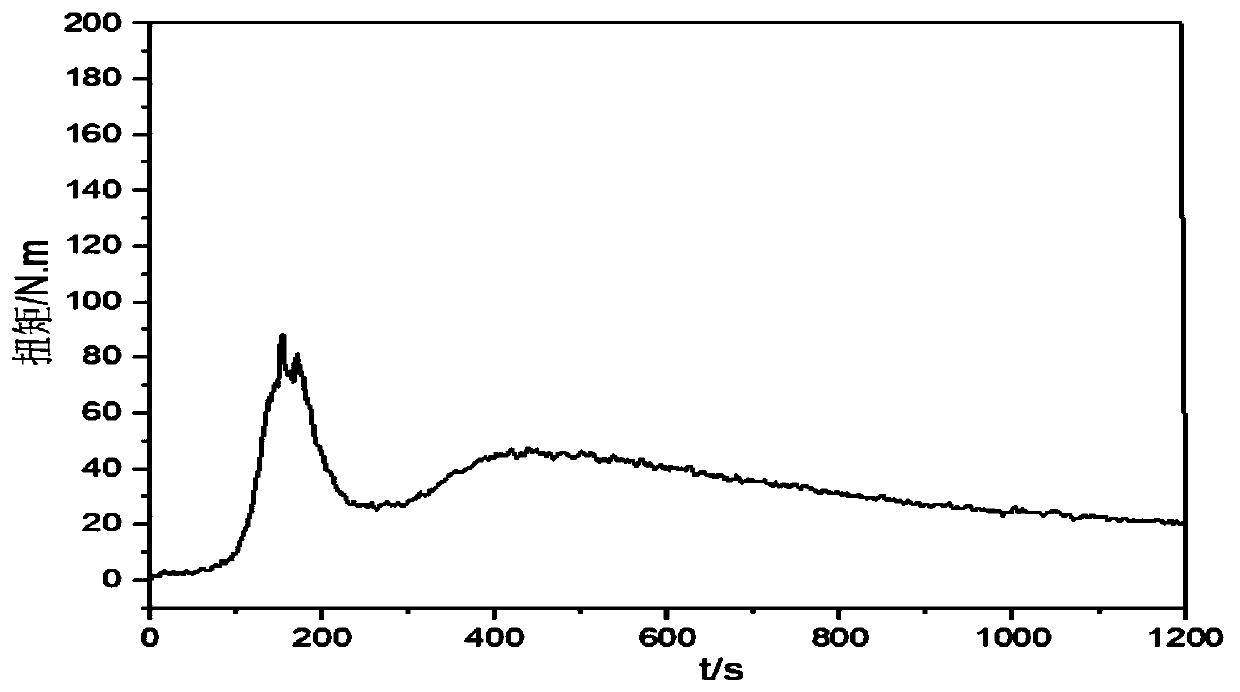

Nano-silica/poly(conjugated diene) composite emulsion and preparation method thereof

The invention discloses a nano-silica / poly(conjugated diene) composite emulsion and a preparation method thereof. Based on emulsion dry basis, the nano-silica / poly(conjugated diene) composite emulsion comprises 0.1 to 5 parts of surface functionalization-modified nano-silica. The nano-silica / poly(conjugated diene) composite emulsion has granularity of 50 to 80nm, number-average molecular weight of 100000 to 120000, and molecular weight distribution of 2 to 3. The invention also discloses the preparation method of the nano-silica / poly(conjugated diene) composite emulsion.

Owner:PETROCHINA CO LTD

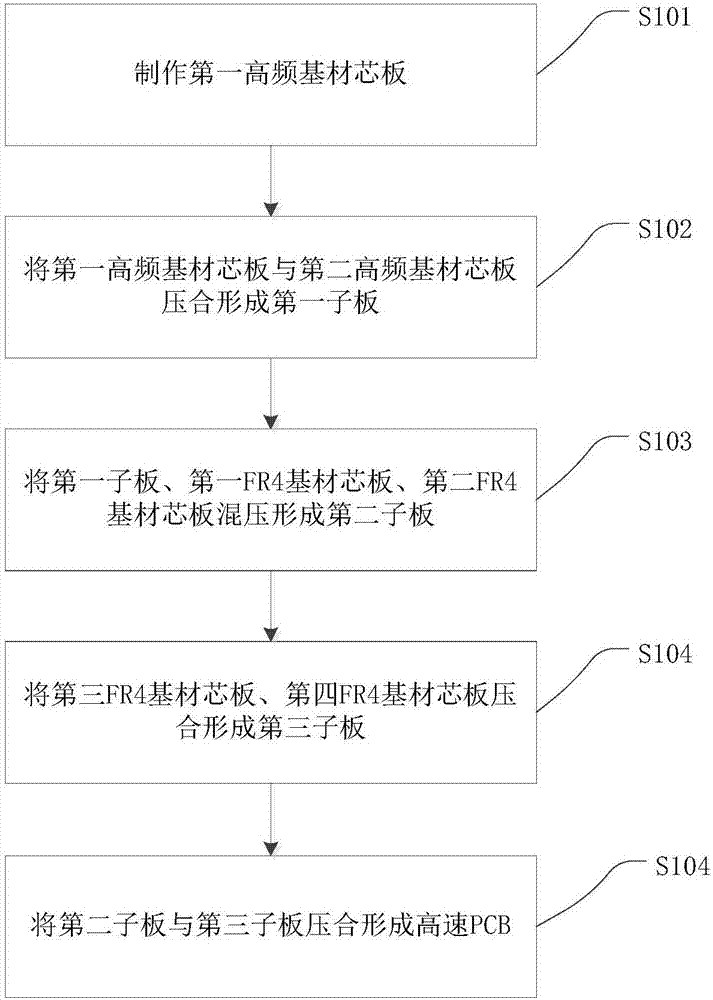

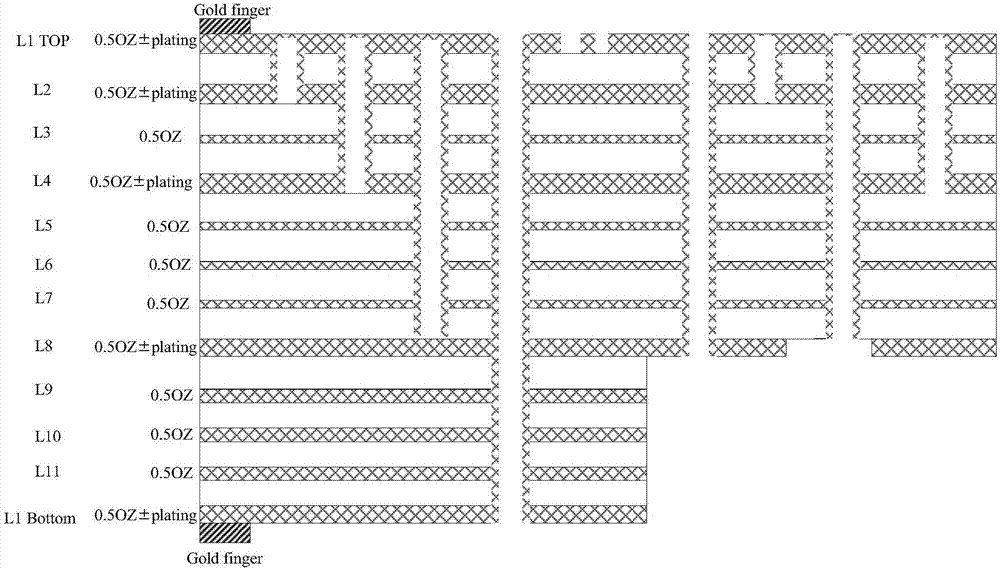

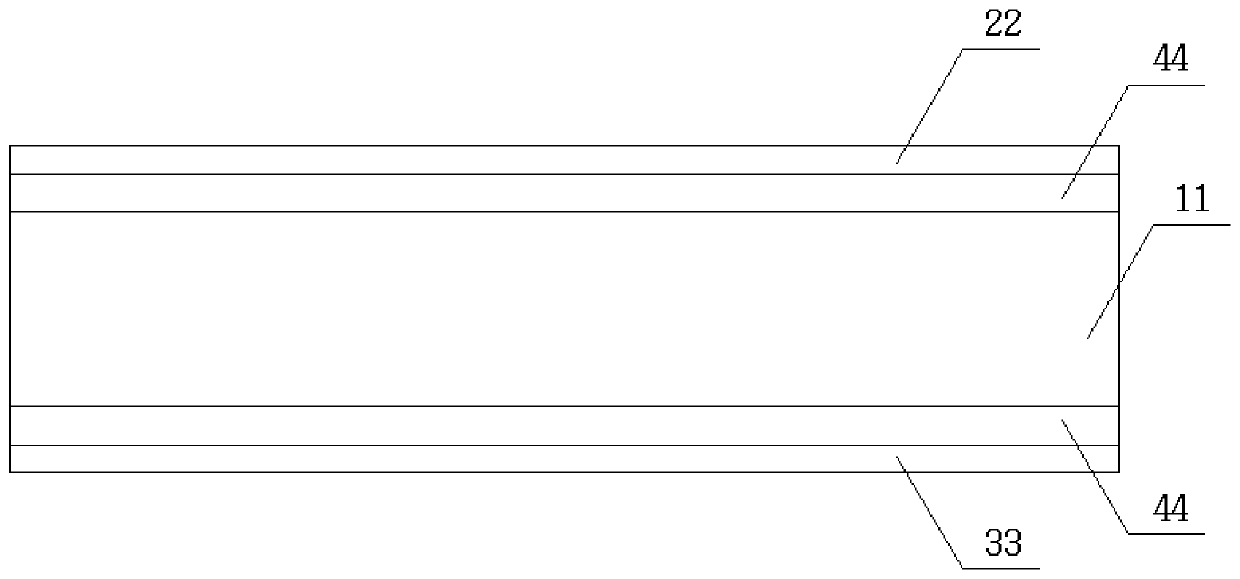

Manufacturing method for high-speed PCB, and high-speed PCB

InactiveCN107484361ALow loss factorLow Conductor Surface RoughnessPrinted circuit aspectsHigh frequency circuit adaptationsMicrowaveCopper

The invention discloses a manufacturing method for a high-speed PCB and the high-speed PCB, and the method comprises the steps: carrying out the stitching of at least two high-frequency base material core boards to form a first subboard; Carrying out the mixed pressing of the first subboard and at least one FR4 base material core board to form the high-speed PCB, wherein the outer core boards on two surfaces are respectively a high-frequency base material core board and an FR4 base material core board. The high-speed PCB is formed by the high-frequency base material core board and the FR4 base material core board in a mode of multiple mixed pressing, and the high-frequency base material core board serves as the outer core board. Because a high-frequency base material is low in dielectric constant and is low in loss factor, the transmission of high-frequency microwaves and other function signals can be achieved through manufacturing a radio frequency circuit on the first high-frequency base material core board, and the production cost is reduced at the same time. In addition, the second high-frequency base material core board is employed as the secondary outer core board, and a copper layer based on the second high-frequency base material core board is good in uniformity, thereby achieving the signal transmission through the combination of two sides, and greatly improving the signal transmission quality.

Owner:DONGGUAN SHENGYI ELECTRONICS

High-toughness flame-retardant amorphous copolyester foam and preparation method thereof

The invention relates to high-toughness flame-retardant amorphous copolyester foam and a preparation method thereof. The amorphous copolyester foam is obtained by blending, foaming and molding amorphous copolyester and a multifunctional master batch, wherein the multifunctional master batch is prepared from 25-50 parts by weight of a toughening and compatibilizing low-melting-point carrier resin,40-60 parts by weight of a halogen-free flame retardant, 5-10 parts by weight of a tackifier and 2-5 parts by weight of an antioxidant by adopting internal mixer-single screw combination equipment. The obtained amorphous copolyester foam material has the excellent characteristics of high toughness, excellent elongation, oxygen index (LOI) being greater than or equal to 27%, combustion grade of B2or above, high compression strength, high shear strength and the like, and can be applied to the high-end fields of aerospace, wind power, rail transit and the like.

Owner:CHINA RESOURCES PACKAGING MATERIALS CO LTD

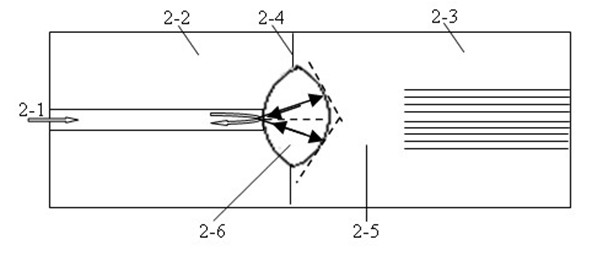

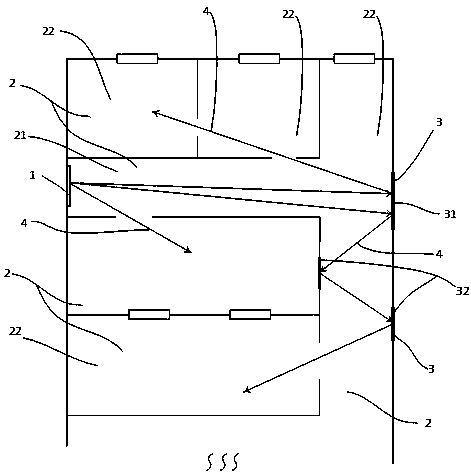

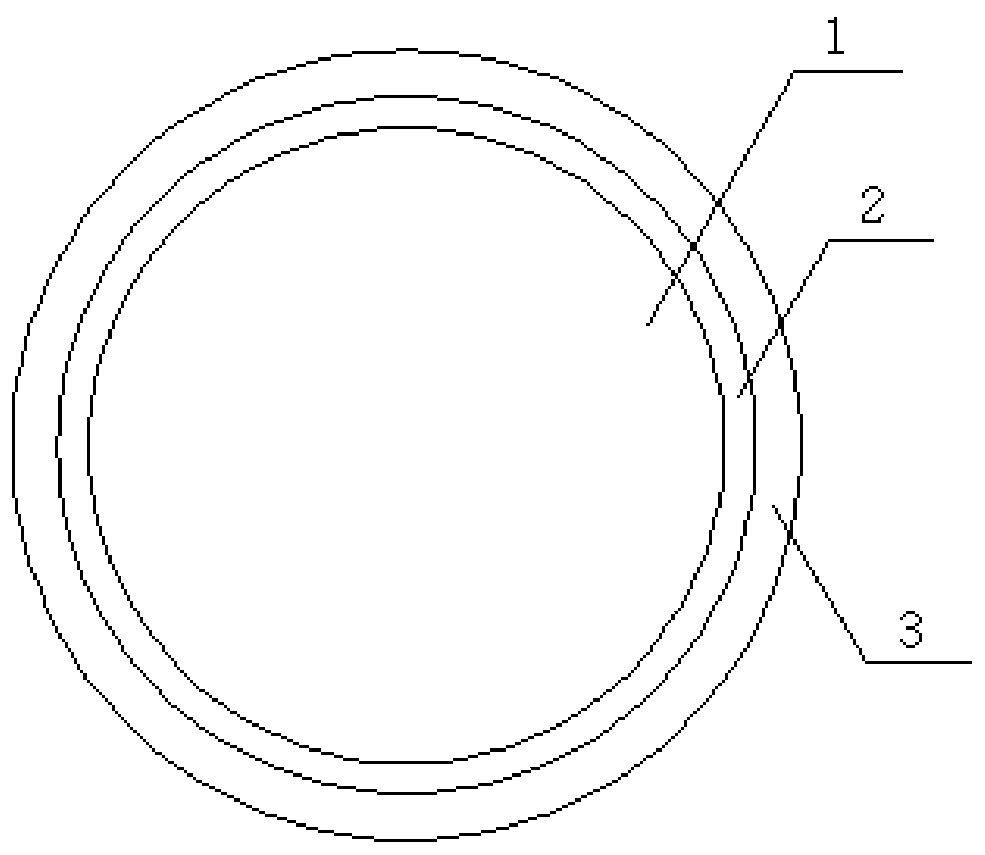

Millimeter wave indoor passive coverage method

ActiveCN108055668AImprove path lossImprove channel correlationRadio transmissionHigh level techniquesEngineeringMillimetre wave

The invention provides a millimeter wave indoor passive coverage method. A direct irradiation coverage method is adopted in a direct irradiation area (21), and an irradiation coverage method of a passive reflector (3) is adopted in a shadow area (22); the signal of a base station (1) passes through indoor doors and windows and parts where the millimeter wave is easy to penetrate through to arriveat the shadow area after being reflected by the passive reflector (3); due to the position of the passive reflector (3), the total number of reflections of the signal of the base station (1) on a path(4) of arriving at the shadow area (22) through the passive reflector (3) is reduced as much as possible, and the total distance is as short as possible. By adoption of the method, the path loss of millimeter wave propagation can be reduced, the number of independent channels can also be increased, and the independence of an MIMO channel is improved; and no power supply is used, so that the millimeter wave indoor passive coverage method has the characteristics of energy saving, wide working frequency bandwidth and low cost, and can be easily integrated with the existing indoor environment.

Owner:南京海得逻捷信息科技有限公司

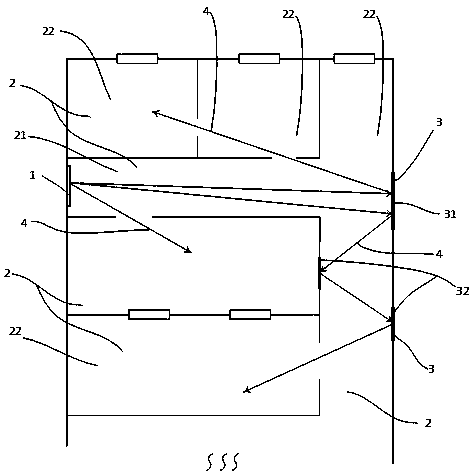

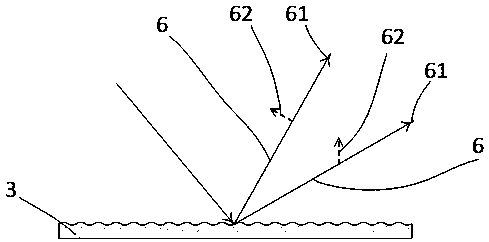

Millimeter-wave indoor intelligent passive coverage method

ActiveCN107708134AReduce path lossPath loss improvementRadio transmissionNetwork planningBeam directionEngineering

The invention discloses a millimeter-wave indoor intelligent passive coverage method. Direct irradiation coverage is employed in a perpendicular incidence region (21), and a passive reflector (3) is employed for irradiation coverage in a shadow region (22). A signal from a base station (1) is reflected by the passive reflector (3), and then passes through an indoor window and other parts which allow millimeter waves to penetrate easily to arrive at the shadow region (22). The position of the passive reflector (3) enables the number of total reflections of the signal of the base station (1) from the passive reflector (3) to the shadow region (22) to be small as much as possible and enables the path (5) from the passive reflector (3) to the shadow region (22) to be short as much as possible.The wave beam direction (61) of a reflection wave (6) of the passive reflector (3), the number of wave beams and the polarization direction (62) can be adjusted and changed in real time according tothe business demands. The method can reduce the path loss of the millimeter waves, improves the independence of an MIMO channel, and can adjust the number of wave beams and characteristics of the shadow region (22) in real time according to the business demands. The method is characterized in energy saving performance, wide working band and low cost, and is liable to be integrated with a conventional indoor environment.

Owner:南京海得威尔通信科技有限公司

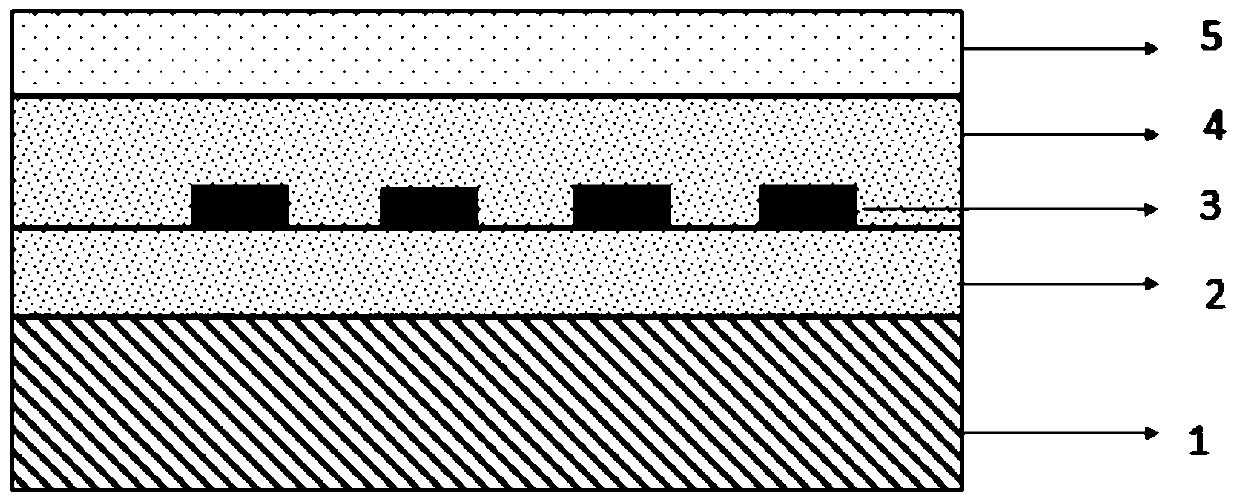

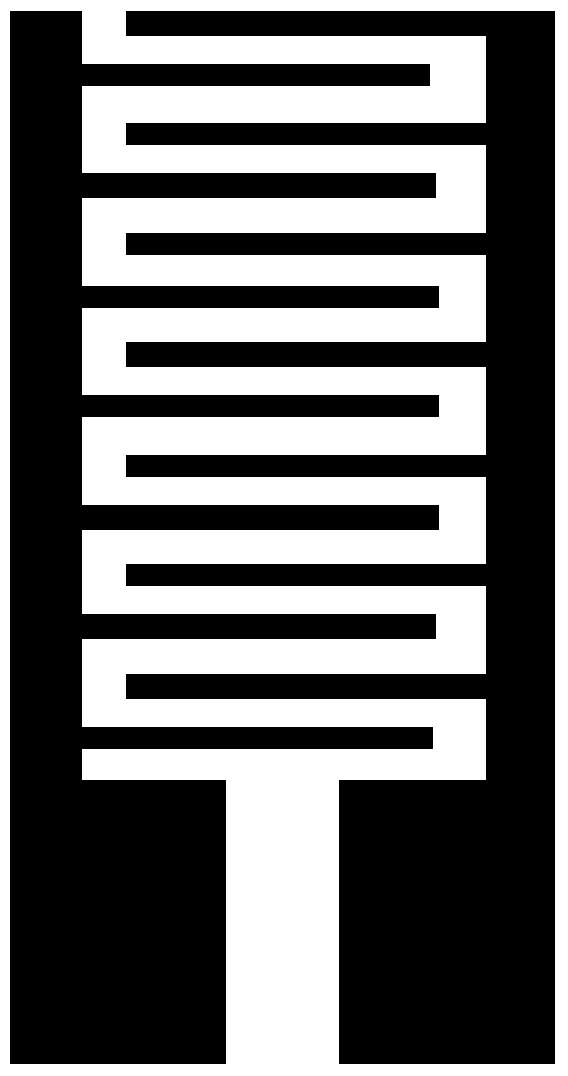

A kind of capacitive strain sensor and preparation method thereof

ActiveCN105021120BIncreased strain sensitivityLarge GF factorElectrical/magnetic solid deformation measurementDielectricCapacitance

The invention provides a capacitive strain sensor and a preparation method thereof, which belong to the technical field of sensor design and production. The capacitive strain sensor consists of a substrate, a first barium strontium titanate dielectric film layer, a PdCr electrode layer, a second barium strontium titanate dielectric film layer, and an Al strontium barium titanate dielectric film layer from bottom to top. 2 o 3 The protective layer, wherein the PdCr electrode layer is an interdigitated electrode structure. The present invention adopts the planar structure of interdigitated capacitance, and barium strontium titanate (Ba 0.5 Sr 0.5 TiO 3 ) as the dielectric material, PdCr as the electrode material, and the preparation technology of magnetron sputtering coating and photolithography technology are used to realize the higher temperature (500℃) of the capacitive strain sensor under the larger strain (2500με). The purpose of stabilizing work.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Modified rubber and preparation method thereof

Owner:PETROCHINA CO LTD

Thermosetting polymer

InactiveCN105733240ALow loss factorLow dielectric constantLamination ancillary operationsLaminationPolymer scienceBarium titanate

The invention relates to a thermosetting polymer, which is used to make laminates, prepregs and pure films in high-frequency and high-speed applications. It is composed of polyarylether, olefin polymer, olefin block copolymer and filler. In parts by weight of solids, 5-40 parts of polyarylether, 5-30 parts of olefinic polymer, 5-30 parts of olefinic block copolymer, and 10-70 parts of inorganic filler are added to every 100 parts of thermosetting polymer. The filler is silica, fumed silica, titanium dioxide, strontium titanate, barium titanate, magnesium hydroxide, aluminum hydroxide, boron nitride, aluminum nitride, aluminum oxide, mica, kaolin, talc, One or more than one mixture of clay, Teflon and other substances. The laminate made of this thermosetting polymer has excellent comprehensive properties, including excellent thermal reliability, extremely superior electrical properties and extremely low water absorption. The glue solution of the present invention is suitable for substrates and prepregs used in high-frequency and high-speed applications and pure film.

Owner:VENTEC ELECTRONICS SUZHOU

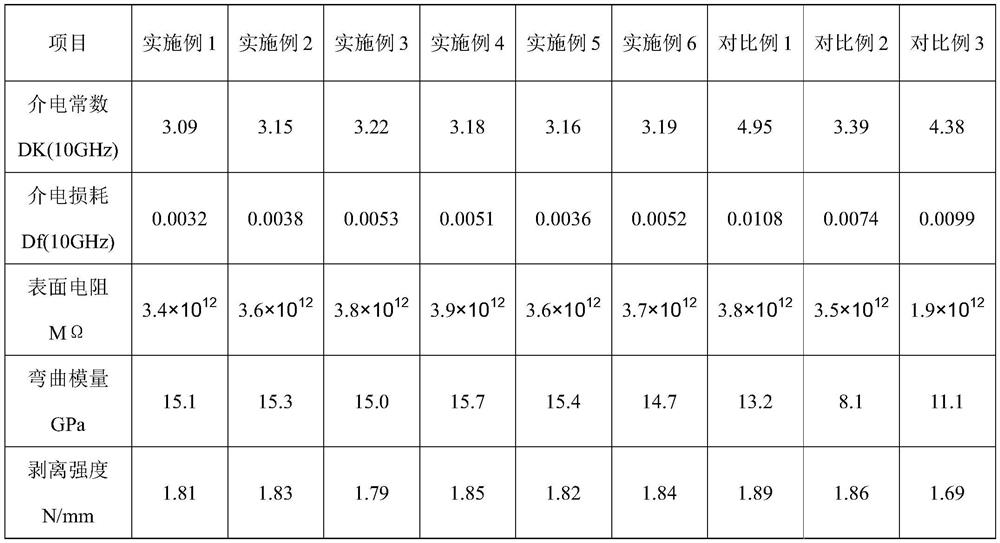

Manufacturing method of glass fiber cloth reinforced copper-clad plate

ActiveCN113597121AReduce the total volumeDoes not affect impregnationLamination ancillary operationsLaminationEpoxyGlass fiber

The invention belongs to the technical field of copper-clad plates, and particularly relates to a manufacturing method of a glass fiber cloth reinforced copper-clad plate. The manufacturing method comprises the following steps: preparing a reinforcing material, preparing modified resin, mixing the reinforcing material and the modified resin, impregnating, and semi-curing to obtain a prepreg, and finally, copper foil laminating, combining and pressing the prepreg into the copper-clad plate according to the product specification. By controlling the total integral number of the glass fiber cloth accounting for the copper-clad plate, adopting two times of preimpregnation treatment, reasonably controlling the proportion of the prepreg, performing surface treatment on the glass fiber cloth by utilizing the silane coupling agent, and impregnating the glass fiber cloth with the modified epoxy resin, the rigidity, the dielectric property and the insulation reliability of the copper-clad plate can be effectively improved, the process is reliable and simple to operate.

Owner:江西倍韬新材料科技有限公司

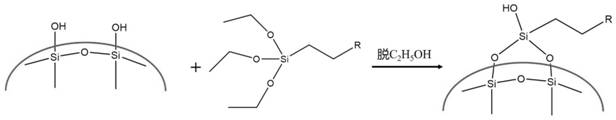

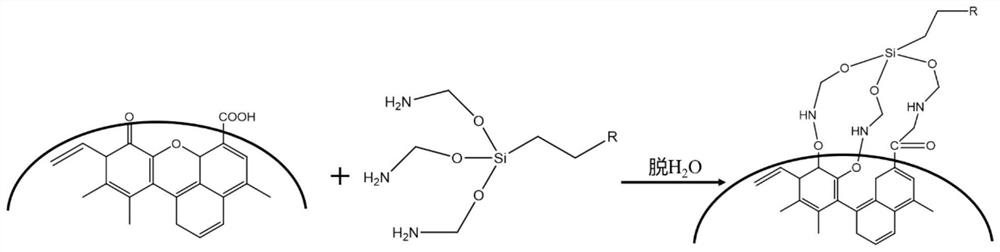

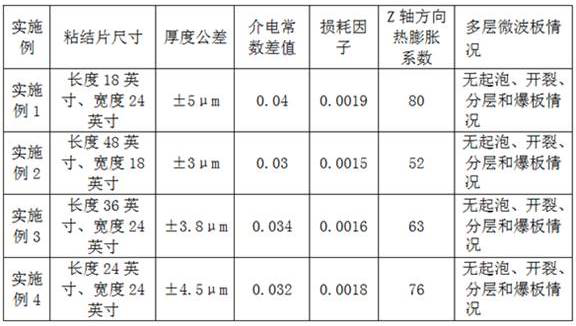

Coupling agent for carbon black, and preparation method and application thereof

ActiveCN113337010AGood dispersionInhibition of agglomerationGroup 4/14 element organic compoundsRolling resistance optimizationPolymer sciencePolymer chemistry

The invention relates to a coupling agent for carbon black. The coupling agent for carbon black is an amphiphilic coupling agent containing sulfydryl and amino at the same time, can effectively improve the dispersion degree of carbon black in a rubber / carbon black nano composite material, can construct chemical bonding between carbon black / rubber molecular chains, does not generate VOC emission in the use process, improves the dynamic performance of the carbon black / rubber nano composite material, reduces the friction among carbon black particles and the friction between the carbon black particles and a rubber molecular chain, effectively reduces the loss of the material, and reduces the rolling resistance.

Owner:BEIJING UNIV OF CHEM TECH

Energy-saving textile whole core flame-retardant conveyor belt and method for manufacturing same

ActiveCN107177115AReduce weightReduce energy consumptionConveyorsVegetal fibresPolyesterVulcanization

The invention discloses an energy-saving textile whole core flame-retardant conveyor belt and a method for manufacturing the same. The energy-saving textile whole core flame-retardant conveyor belt comprises covering layers, textile whole belt cores and belt core impregnating adhesive. The covering layers are made of powdered butadiene rubber / chlorinated polyethylene / thermoplastic polyurethane elastomers which are used as main materials, and auxiliaries for reducing loss factors are added into the main materials. The energy-saving textile whole core flame-retardant conveyor belt and the method have the advantages that formulas and processes are optimized, accordingly, the loss factors (tan delta values at the temperatures of 60 DEG C) of the covering layers can be reduced to the greatest extent, and running resistance of the energy-saving textile whole core flame-retardant conveyor belt can be reduced; radial stress lines of the textile whole belt cores are made of aramid fibers and polyester fibers, accordingly, the energy-saving textile whole core flame-retardant conveyor belt is high in strength, has thin belt bodies and is light after being impregnated and plasticized, and energy consumption of the energy-saving textile whole core flame-retardant conveyor belt in running procedures can be reduced to a great extent; the energy-saving textile whole core flame-retardant conveyor belt is produced by facing forming and dynamic vulcanization processes by the aid of extruders, and the processes are simple and are low in energy consumption and high in production efficiency.

Owner:ANHUI ZHONGYI RUBBER BELTS

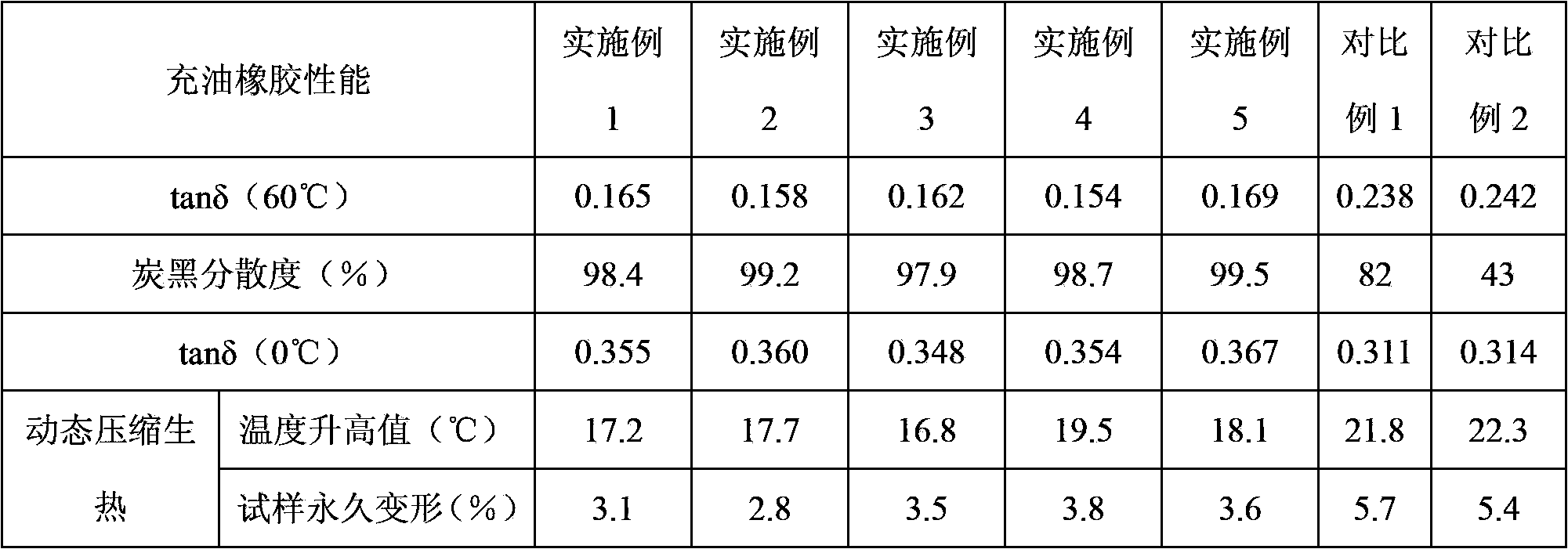

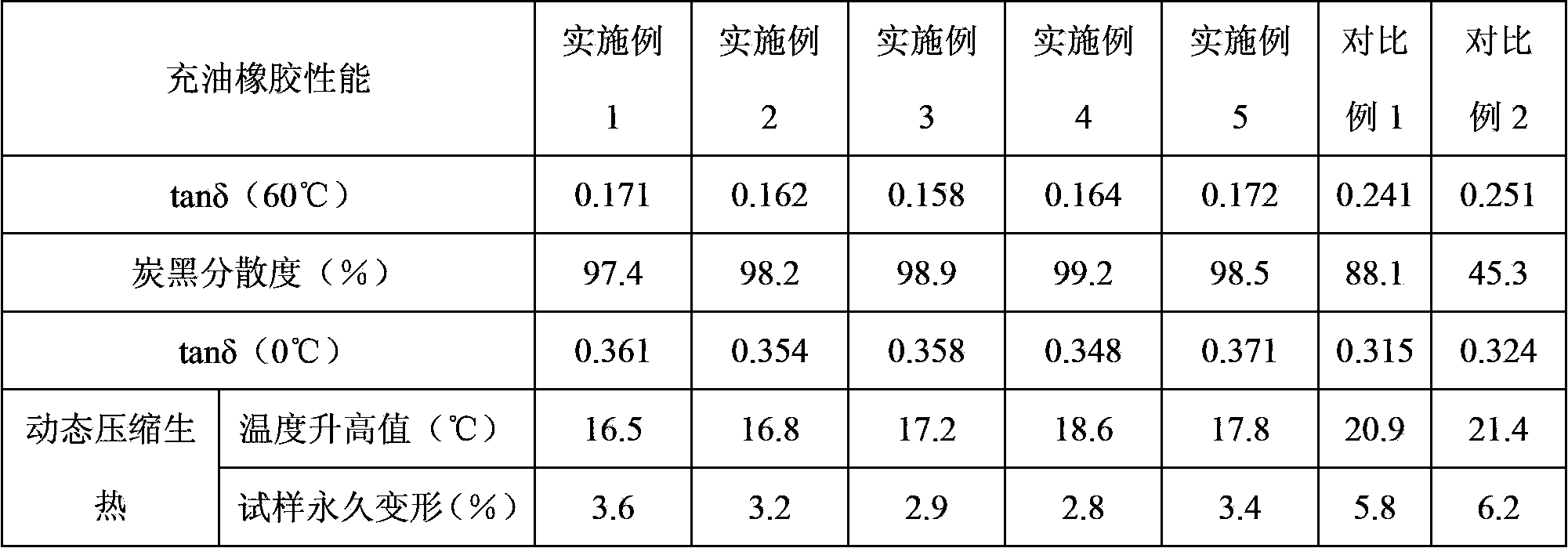

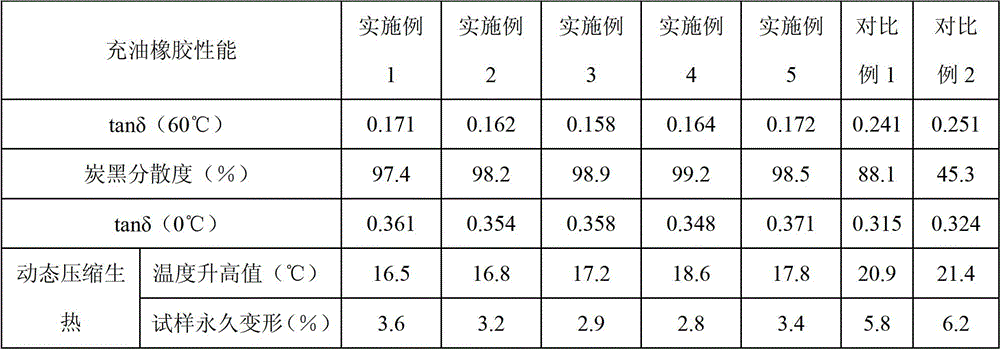

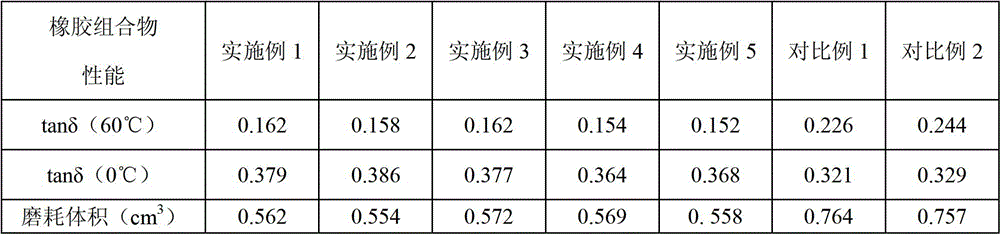

Oil-extended carbon-black-extended styrene-butadiene rubber master batch, and rubber composition and preparation method thereof

ActiveCN103665491AGood processing performanceWell balanced physical propertiesEmulsionFunctional composite

The invention relates to an oil-extended carbon-black-extended styrene-butadiene rubber master batch, and a rubber composition and a preparation method thereof. The oil-extended carbon-black-extended styrene-butadiene rubber master batch is prepared by mixing and condensing an extender oil, carbon black slurry and a silicon dioxide / poly-conjugated diene modified styrene-butadiene rubber latex, wherein the silicon dioxide / poly-conjugated diene modified styrene-butadiene rubber latex is prepared by blending a nano silicon dioxide / poly-conjugated diene functional composite emulsion and a styrene-butadiene rubber latex; and the functional composite emulsion introduces the nano silicon dioxide onto the molecular chain of the poly-conjugated diene. The rubber master batch and rubber composition disclosed by the invention greatly lower the generated heat when being used in tire treads, and have the comprehensive properties of excellent wet-road holding capacity and excellent abrasion resistance.

Owner:PETROCHINA CO LTD

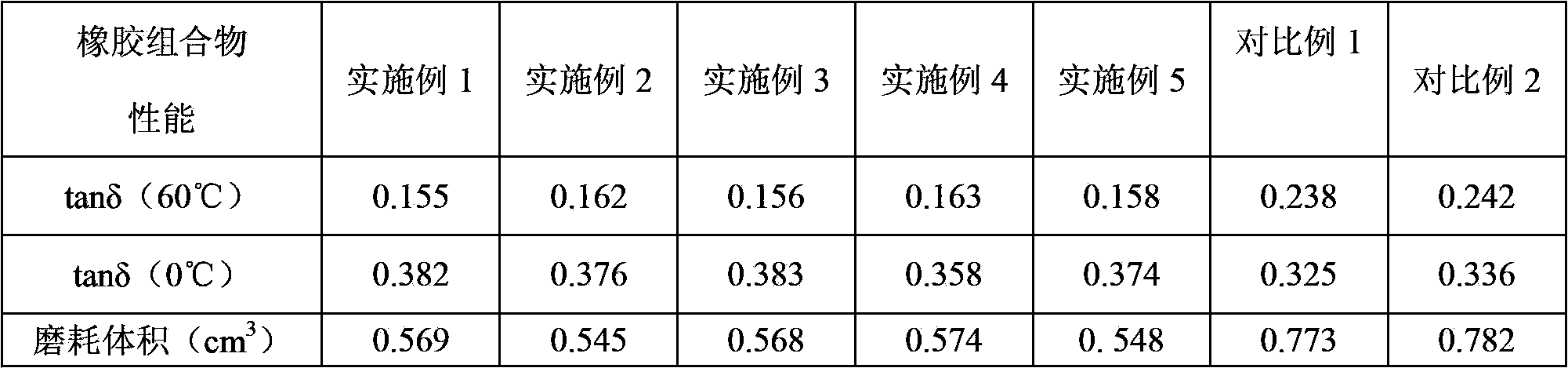

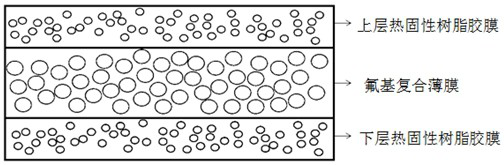

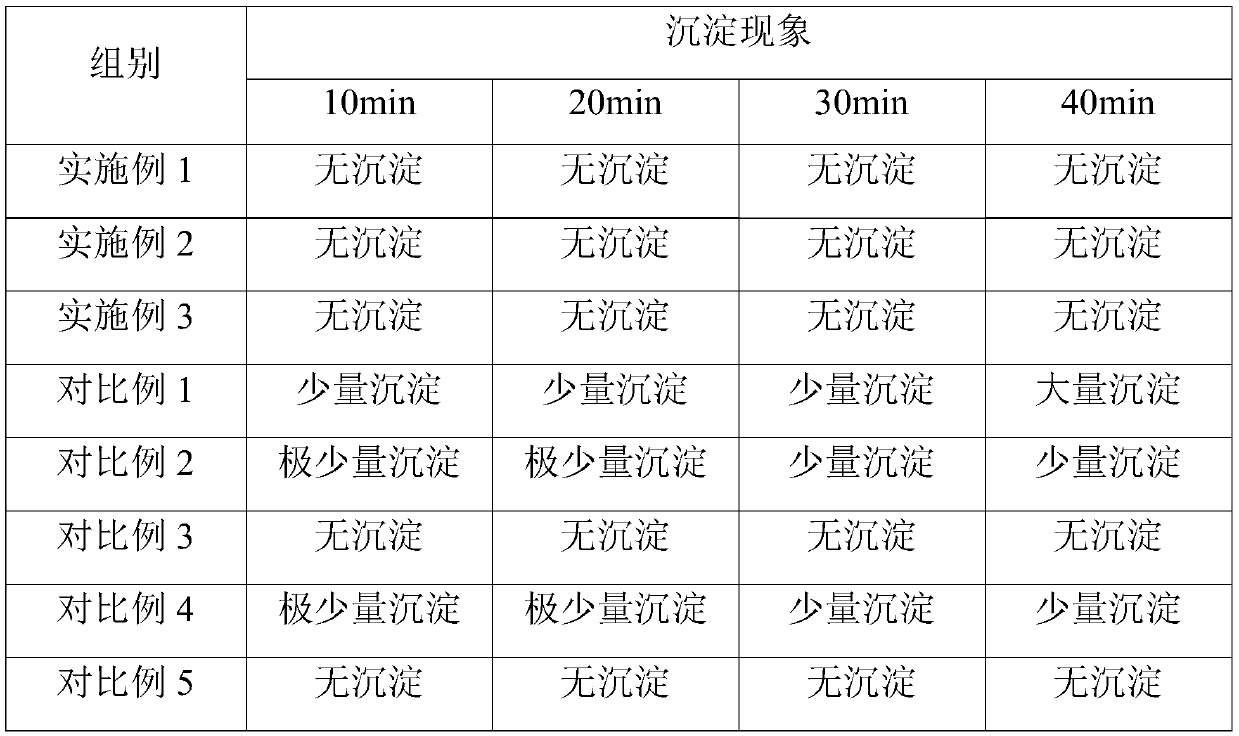

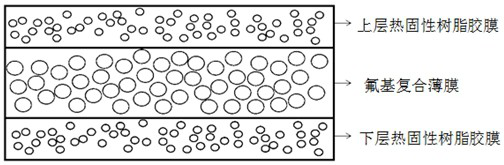

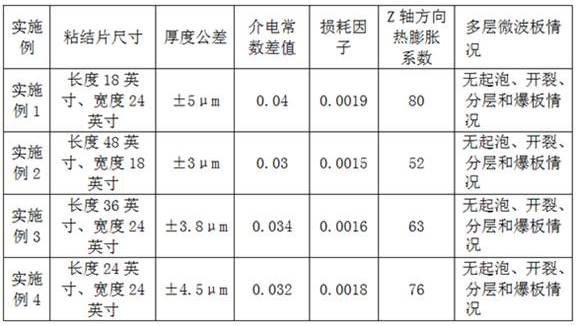

A method for preparing a low-loss and high-uniform adhesive sheet and a multi-layer microwave board

ActiveCN113861864BSmall coefficient of thermal expansionLow loss factorNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerPolymer science

The invention relates to a low loss and high uniformity adhesive sheet and a method for preparing a multilayer microwave board. The adhesive sheet is composed of an upper thermosetting resin film and a lower thermosetting resin film of a fluorine-based composite film; the upper thermosetting resin film and The components of the lower thermosetting resin film are thermosetting resin, initiator and filler. In order to achieve specific functions, thermoplastic elastomers, flame retardants, antioxidants and plasticizers can be added to it; among them, thermosetting resin and thermoplastic elastic The body is the matrix, the cross-linking agent, flame retardant, antioxidant and plasticizer are the additives, and the filler is the reinforcing material; the additives and reinforcing materials are randomly distributed in the matrix; the thermosetting resin film is semi-cured or uncured. In the cured state, it has certain fluidity and is prepared on the upper and lower surfaces of the fluorine-based composite film through a coating process. The components of the invention exhibit high uniformity and do not contain fiberglass cloth, thus avoiding the impact of the "glass fiber effect" on high-frequency signal transmission.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

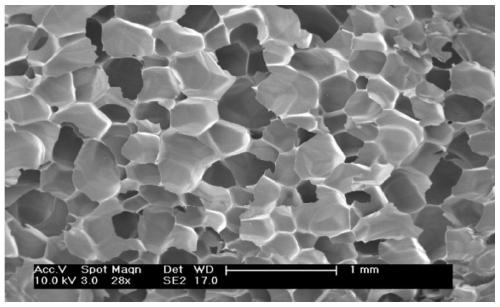

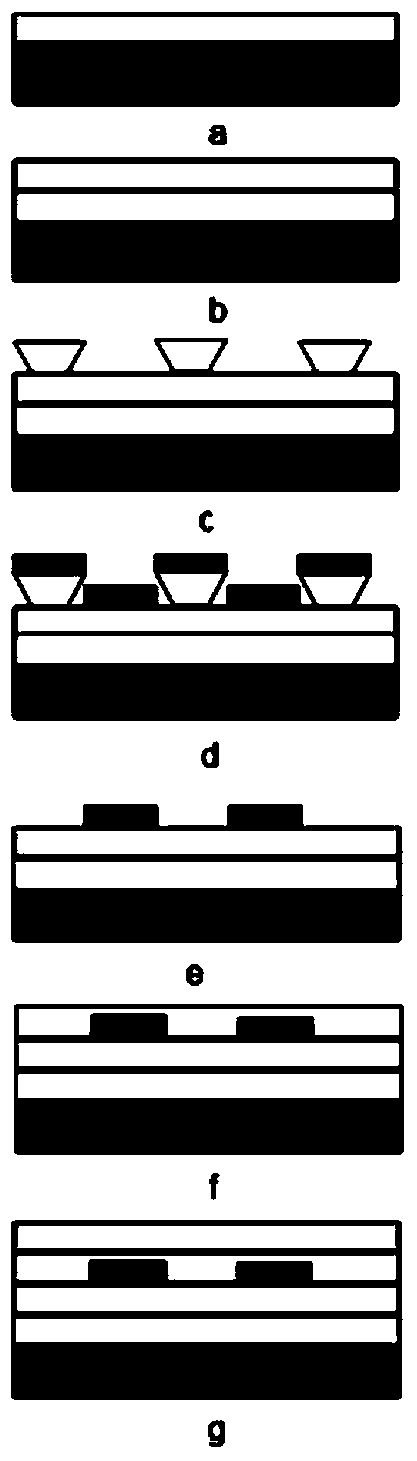

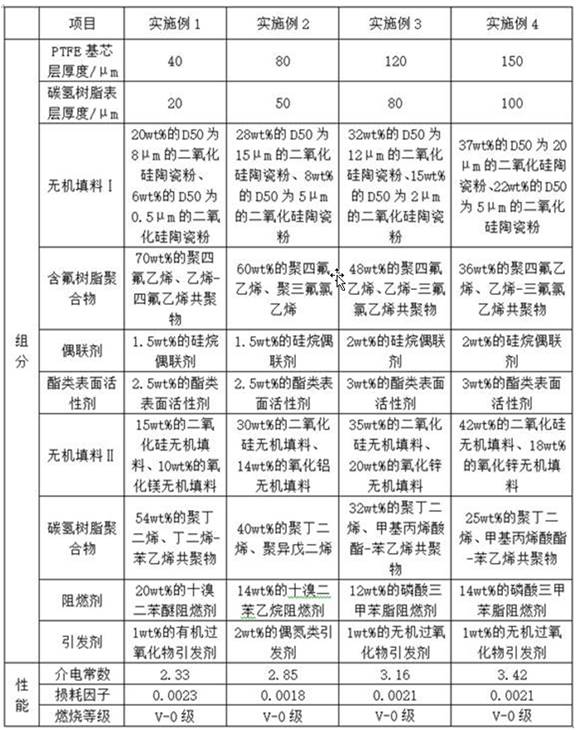

Preparation method of ceramic filled PTFE copper-clad plate

ActiveCN111216427ALow dielectric constantLow loss factorElectrical equipmentGlass/slag layered productsAdhesive glueCopper foil

The invention belongs to the technical field of electronic circuits, and particularly relates to a preparation method of a ceramic filled PTFE copper-clad plate. The preparation method of impregnatedglass fiber cloth comprises the following steps: stirring a composite ceramic filler, polytetrafluoroethylene emulsion, a thickening agent and water in a stirrer for 30-60 minutes, standing, and removing bubbles to obtain glue; and soaking the glass fiber cloth in the glue, controlling the glue attaching amount of the glass fiber cloth to be 350 g / m<2> through a metering roller, and carrying out baking to obtain the impregnated glass fiber cloth. According to the invention, the composite ceramic filler with a three-layer structure (the ceramic filler, the coupling agent layer and the fluororesin layer) is blended with the polytetrafluoroethylene emulsion, the thickening agent and the water, so that the glue with good stability can be obtained to impregnate the glass fiber cloth, and the copper-clad plate obtained by laminating the impregnated glass fiber cloth, a first copper foil and a second copper foil meets the requirements of a high-frequency technology.

Owner:珠海国能新材料股份有限公司

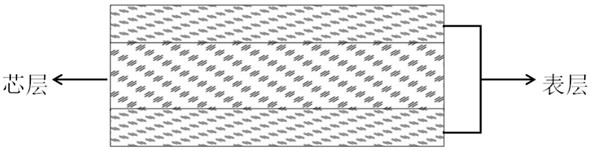

Flame-retardant low-dielectric-constant bonding sheet and preparation method thereof

ActiveCN113861863AConvenient sourceSimple preparation processNon-macromolecular adhesive additivesFilm/foil adhesivesRaw materialLow-k dielectric

The invention discloses a flame-retardant low-dielectric-constant bonding sheet and a preparation method thereof. The bonding sheet comprises a PTFE-based core layer in the middle and hydrocarbon resin surface layers on the upper surface and the lower surface; the PTFE-based core layer is reinforced by adopting two kinds of ceramic powder with different particle sizes, and the core layer film is obtained through an extrusion stretching forming process, so that the density and the elongation at break of the core layer can be obviously improved, and support is provided for the upper surface layer and the lower surface layer; the film is formed on the surface layer by adopting a multi-time blade coating process, so that defects are reduced, density is improved, and flame retardance is improved. The bonding sheet abandons the traditional glass fiber cloth reinforcing material, has the advantages of isotropy, high density, flame retardance, adjustable dielectric constant, lower loss, good bonding strength and mechanical property, can meet the interlayer bonding of a multi-layer circuit board, and is stable and reliable in signal transmission. The bonding sheet is wide in raw material source, simple in operation process, environment-friendly, easy for large-scale batch production, wide in application field and good in market prospect.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

Oil-extended carbon-black-extended styrene-butadiene rubber master batch for tire treads, and rubber composition and preparation method thereof.

ActiveCN103665485ASolve the problem of fragmentationEvenly dispersedSpecial tyresPolymer scienceEmulsion

The invention relates to an oil-extended carbon-black-extended styrene-butadiene rubber master batch, and a rubber composition and a preparation method thereof. The oil-extended carbon-black-extended styrene-butadiene rubber master batch is prepared by mixing and condensing an extender oil, carbon black slurry and a silicon dioxide / poly-conjugated diene modified styrene-butadiene rubber latex, wherein the silicon dioxide / poly-conjugated diene modified styrene-butadiene rubber latex is prepared by carrying out graft polymerization on a nano silicon dioxide / poly-conjugated diene functional composite emulsion and a styrene-butadiene rubber latex; and the functional composite emulsion introduces the nano silicon dioxide onto the molecular chain of the poly-conjugated diene. The rubber master batch and rubber composition disclosed by the invention greatly lower the generated heat when being used in tire treads, and have the comprehensive properties of excellent wet-road holding capacity and excellent abrasion resistance.

Owner:PETROCHINA CO LTD

Antibacterial anti-aging polypropylene composite material for water meter casing

An antibacterial anti-aging polypropylene composite material for a water meter casing is disclosed. Raw materials of the composite material include, by weight, 100 parts of polypropylene, 10-20 partsof POE, 2-4 parts of ultra high molecular weight polyethylene, 3-5 parts of polycarbonate, 1-5 parts of nanometer titanium dioxide, 3-8 parts of nanometer zinc oxide, 2-5 parts of glass fibers, 2-5 parts of quartz sand, 3-8.5 parts of ultrafine bamboo charcoal, 1-5 parts of talc powder, 2-7 parts of wollastonite, 0.05-0.15 part of an anti-ultraviolet agent, 0.1-0.2 part of an antioxidant, 0.5-1.2parts of itaconic acid, 0.1-0.38 part of dicumyl peroxide and 0.1-0.38 part of cinnamyl aldehyde. The composite material has high strength, good impact resistance, and excellent antibacterial performance and aging resistance.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

Low-loss high-uniformity bonding sheet and preparation method of multilayer microwave plate

ActiveCN113861864ASmall coefficient of thermal expansionLow loss factorNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerGlass fiber

The invention relates to a low-loss high-uniformity bonding sheet and a preparation method of a multilayer microwave plate. The bonding sheet is composed of an upper thermosetting resin adhesive film and a lower thermosetting resin adhesive film of a fluorine-based composite film. The components of the upper thermosetting resin adhesive film and the lower thermosetting resin adhesive film are both thermosetting resin, an initiator and a filler, and a thermoplastic elastomer, a flame retardant, an antioxidant and a plasticizer can be added to the thermosetting resin, the initiator and the filler to achieve a specific function, wherein the thermosetting resin and the thermoplastic elastomer are matrixes, the cross-linking agent, the flame retardant, the antioxidant and the plasticizer are additives, and the filler is a reinforcing material; the additive and the reinforcing material are randomly distributed in the matrix; the thermosetting resin adhesive film is in a semi-cured or uncured state, has certain fluidity and is prepared on the upper surface and the lower surface of the fluorine-based composite film through a coating process. The components have the characteristic of high uniformity and do not contain glass fiber cloth, so that the influence of a glass fiber effect on high-frequency signal transmission is avoided.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

Method for preparing novel sound absorption composite material

PendingCN110183769ASignificant elastic hysteresisLow loss factorSound producing devicesDicumyl peroxidePolystyrene

The invention discloses a method for preparing a novel sound absorption composite material. According to the method, ethylene vinyl acetate (EVA), dimethicone and dicumyl peroxide are taken as main raw materials, meanwhile, a polystyrene / ZnO nano composite material is introduced, and a porous sound absorption material which is good in sound absorption capability and high in sound absorption coefficient is prepared under the action of a polymer and an additive. Compared with a conventional sound absorption material, the porous sound absorption material prepared by using the method has pores ofa high porosity in three-dimensional uniform distribution, is high in sound absorption coefficient, is applicable to a wide audio frequency band range, and is excellent in sound absorption.

Owner:邳州易萨新型材料有限公司

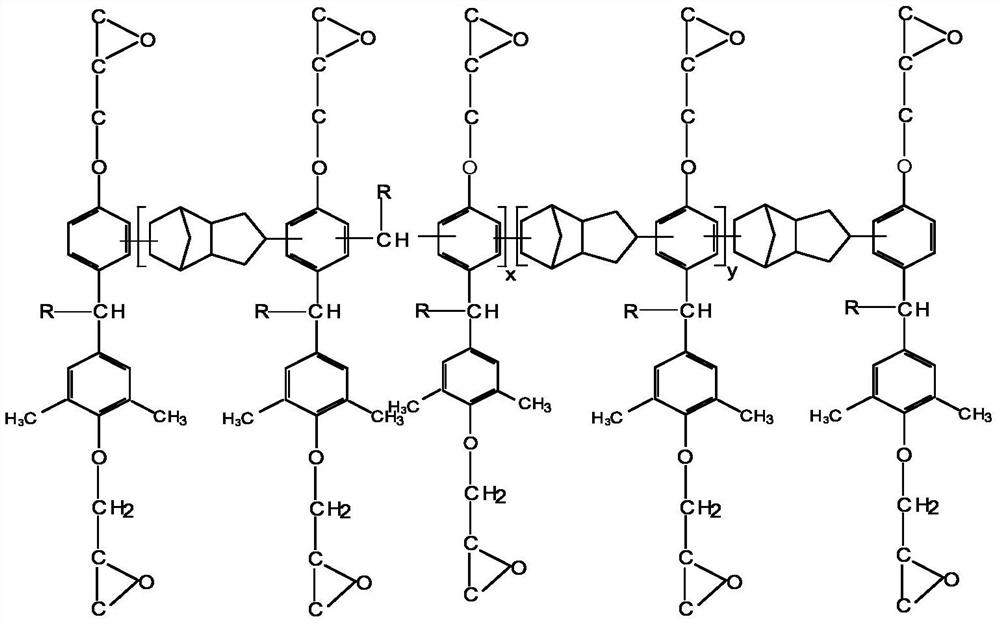

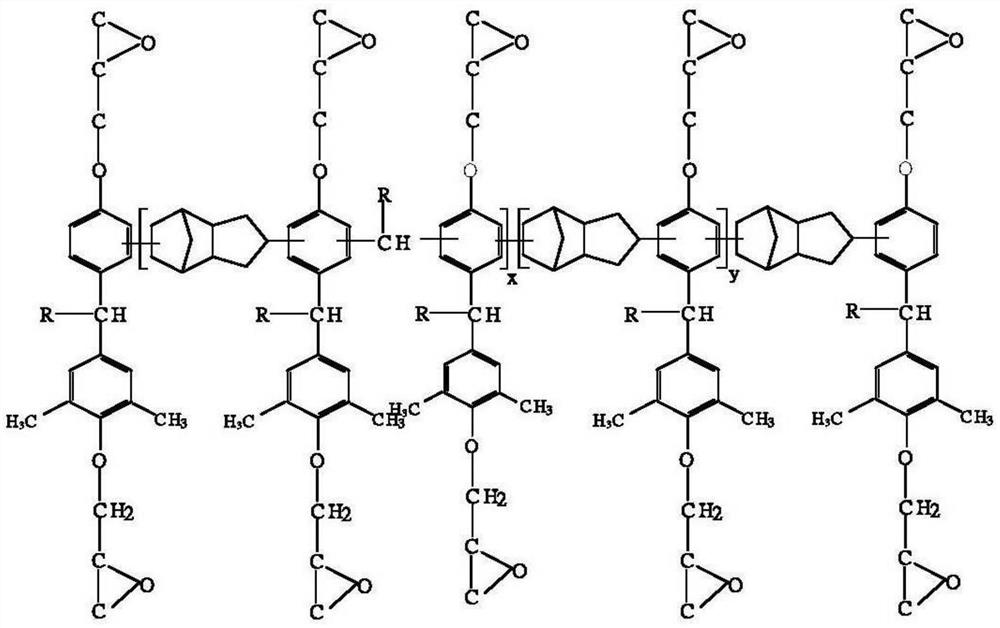

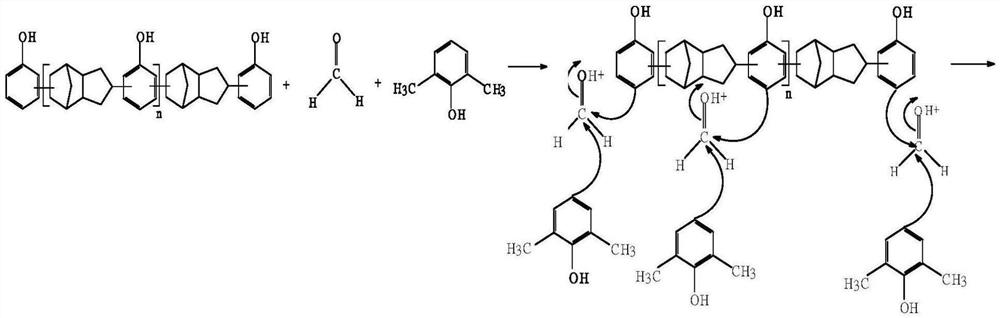

Preparation and Application of Copolymer Epoxy Resin of Dicyclopentadiene-Phenol and 2,6-Dimethylphenol

ActiveCN107540816BExcellent electrical propertiesImprove heat resistanceSynthetic resin layered productsGlass/slag layered productsEpoxyPolymer science

The present invention provides a novel dicyclopentadiene-phenol and 2,6-dimethylphenol copolymer epoxy resin (molecular structure represented by a formula 1) with characteristics of excellent heat resistance, low dielectric constant Dk and low loss factor Df. The preparation of the novel dicyclopentadiene-phenol and 2,6-dimethylphenol copolymer epoxy resin comprises two steps: (1) carrying out a reaction on a (a1) dicyclopentadiene-phenol resin (formula 2) and (a2) 2,6-dimethylphenol in the presence of an acidic catalyst through a (a3) aldehyde-based compound to form a dicyclopentadiene-phenoland 2,6-dimethylphenol copolymer phenol formaldehyde resin; and (2) preparing the dicyclopentadiene-phenol and 2,6-dimethylphenol copolymer epoxy resin from the dicyclopentadiene-phenol and 2,6-dimethylphenol copolymer phenol formaldehyde resin and excess epichlorohydrin under a NaOH condition. According to the present invention, with the substitution of the copolymer epoxy resin into the glass fiber laminating plate formula composition, the popcorn cannot be generated after the pressure pot PCT for 2 h (water absorption test) and 288 DEG C tin welding heat resistance test for 10 min; and inthe formula, x is an integer of 0-5, y is an integer of 0-5, and R represents hydrogen, C1-C10 alkyl, phenyl, hydroxyphenyl and the like. The formulas are defined in the specification.

Owner:NANYA PLASTICS CORP

Oil-extended carbon black styrene-butadiene masterbatch for tire tread, rubber composition and preparation method thereof

ActiveCN103665485BSolve the problem of fragmentationEvenly dispersedSpecial tyresMasterbatchPolymer science

The invention relates to an oil-extended carbon-black-extended styrene-butadiene rubber master batch, and a rubber composition and a preparation method thereof. The oil-extended carbon-black-extended styrene-butadiene rubber master batch is prepared by mixing and condensing an extender oil, carbon black slurry and a silicon dioxide / poly-conjugated diene modified styrene-butadiene rubber latex, wherein the silicon dioxide / poly-conjugated diene modified styrene-butadiene rubber latex is prepared by carrying out graft polymerization on a nano silicon dioxide / poly-conjugated diene functional composite emulsion and a styrene-butadiene rubber latex; and the functional composite emulsion introduces the nano silicon dioxide onto the molecular chain of the poly-conjugated diene. The rubber master batch and rubber composition disclosed by the invention greatly lower the generated heat when being used in tire treads, and have the comprehensive properties of excellent wet-road holding capacity and excellent abrasion resistance.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com