High dispersion nanometer oxide/polyvinyl alcohol composite material preparation method

A nano-oxide and polyvinyl alcohol technology, which is applied in the field of preparation of nano-oxide/polyvinyl alcohol composite materials, can solve problems such as being unsuitable for large-scale application and restricting the range of polymers, and achieve enhanced elastic modulus and loss factor. The effect of reducing and increasing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

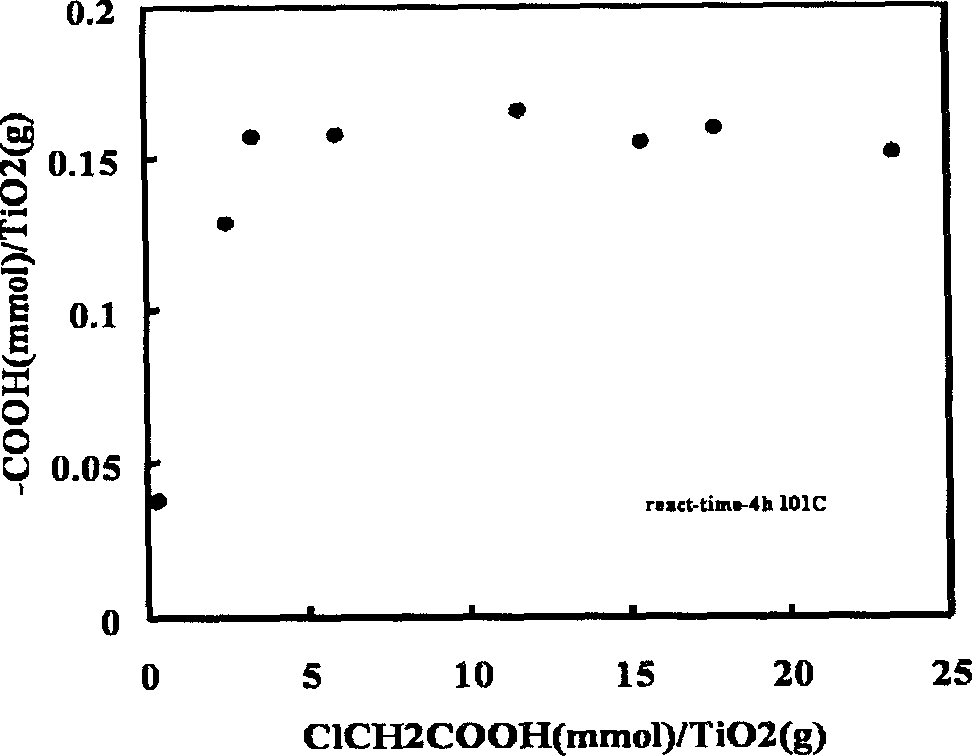

[0026] Embodiment 1. Weigh 6g of activated nano-TiO 2 , add 100ml of distilled water. Shake in an ultrasonic generator for 30 min to form a uniform suspension. Then add a certain amount of ClCH 2 COOH is taken out after the reaction at a certain temperature. By repeated centrifugation, washed with distilled water until AgNO 3 Check that there is no white precipitate AgCl in the clear liquid in the upper layer of the centrifuge tube, and it is neutral. Carboxylated nano-TiO 2 The surface carboxyl group content was obtained by adding a standard amount of NaOH first, and then using the HCl standard solution to drop back.

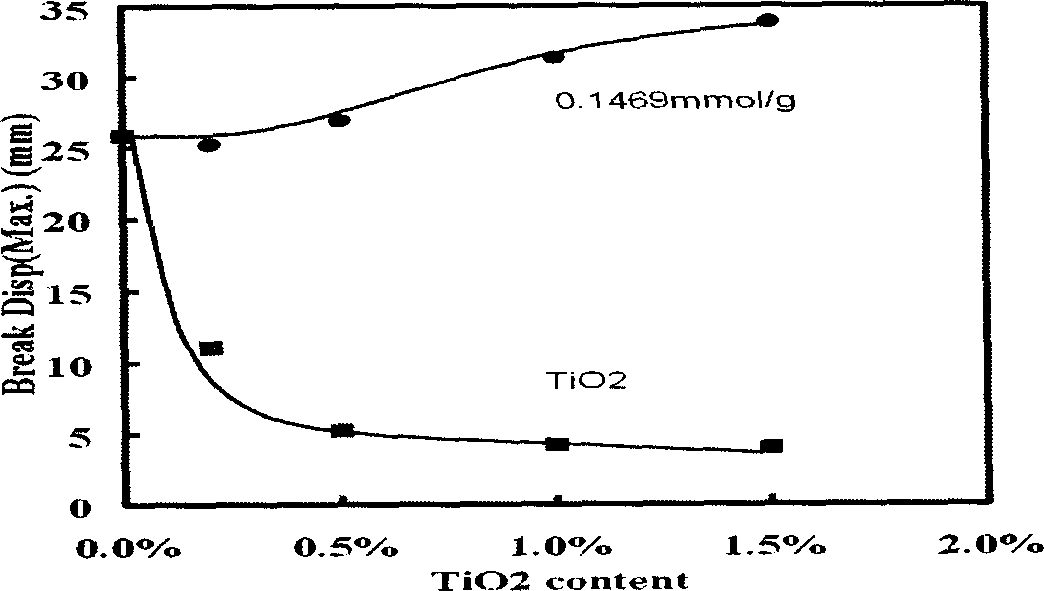

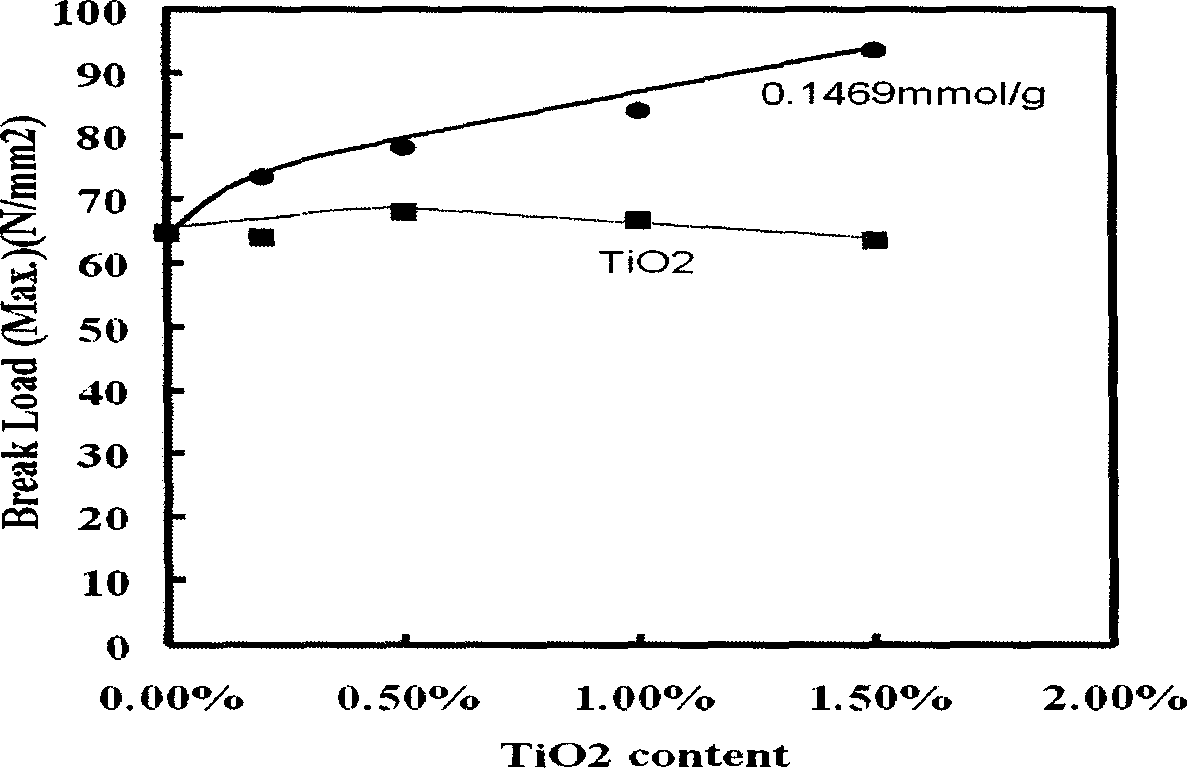

[0027] Take 1 gram of polyvinyl alcohol, dissolve it in 50 ml of water, and under stirring, prepare a polyvinyl alcohol solution, and then add a certain amount of nano-TiO into the solution dropwise 2 suspension. It was then treated in a sonicator for 30 min. Pour it into a petri dish and dry it at 45°C, and then place it in a vacuum drying oven for 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com