Patents

Literature

1510results about How to "High modulus of elasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-compaction filling paste body and preparation process thereof

The invention discloses a self-compaction filling paste body and a preparation process thereof, relates to a filling material with self-compaction performance for coal mine cut and fill mining and a corresponding proportion stirring process, and belongs to the field of construction materials. The self-compaction filling paste body is characterized by being prepared by uniformly mixing coal gangue, coal ash, cements, high-efficiency water reducing agent and water according to proper proportion, wherein the slurry concentration of the paste body is 75-85 percent; and in terms of mass percentage, the proportion of the coal gangue to the coal ash to the cements to the water reducing agent to the water is 45-55 percent to 15-20 percent to 10-15 percent to 3-5 percent to 15-25 percent. The paste body is high in flowability, stability and filling performance, low in bleeding rate and uniform and consistent in quality, and fully fills every corner of a worked-out section; the bleeding and the segregation of the aggregates are avoided; the convenience in transportation and control is achieved; a pipeline is not blocked during transportation; and original mine wastes are adopted for the paste body for realizing the filling so as to protect the environment.

Owner:TAIYUAN UNIV OF TECH

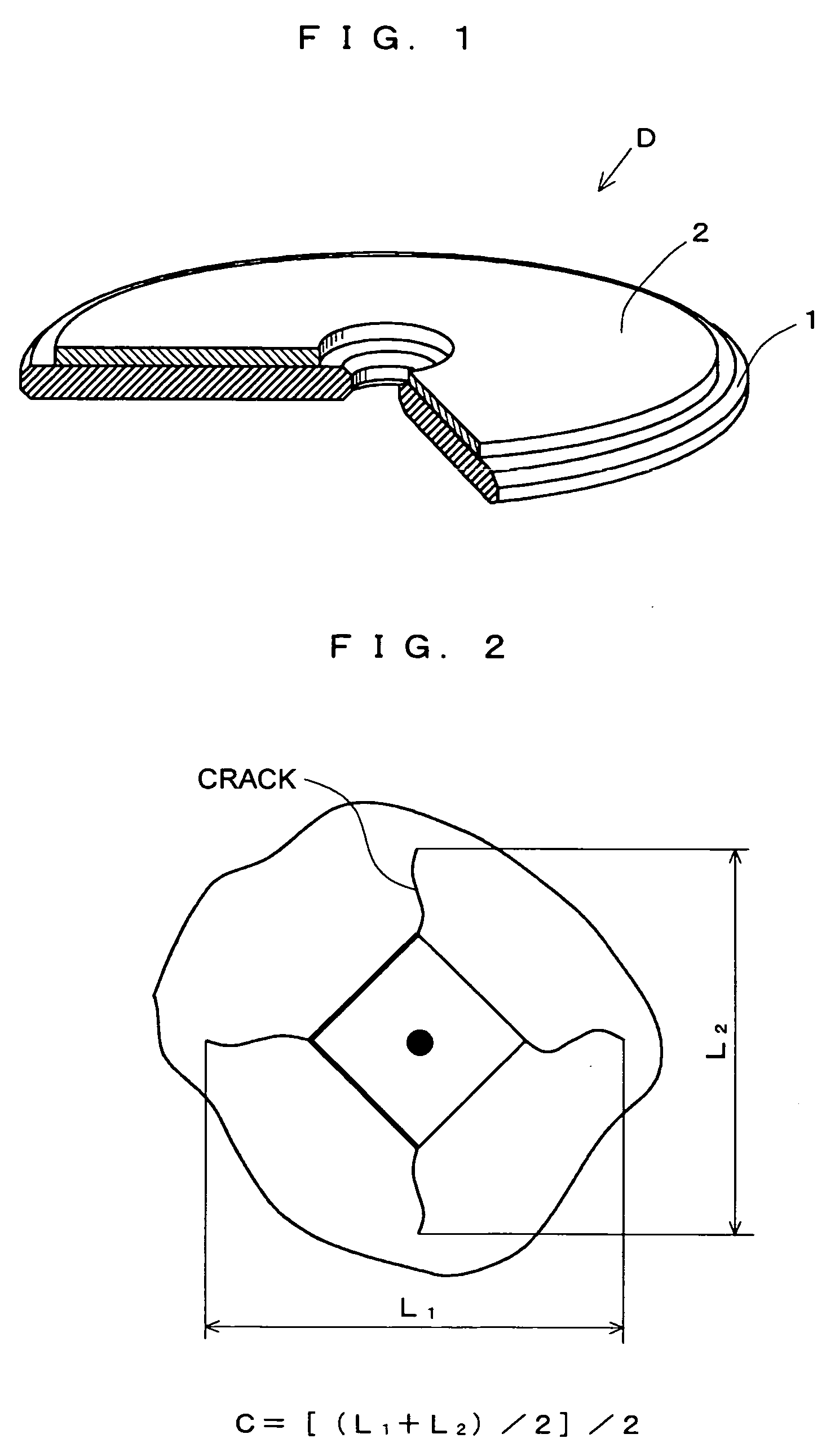

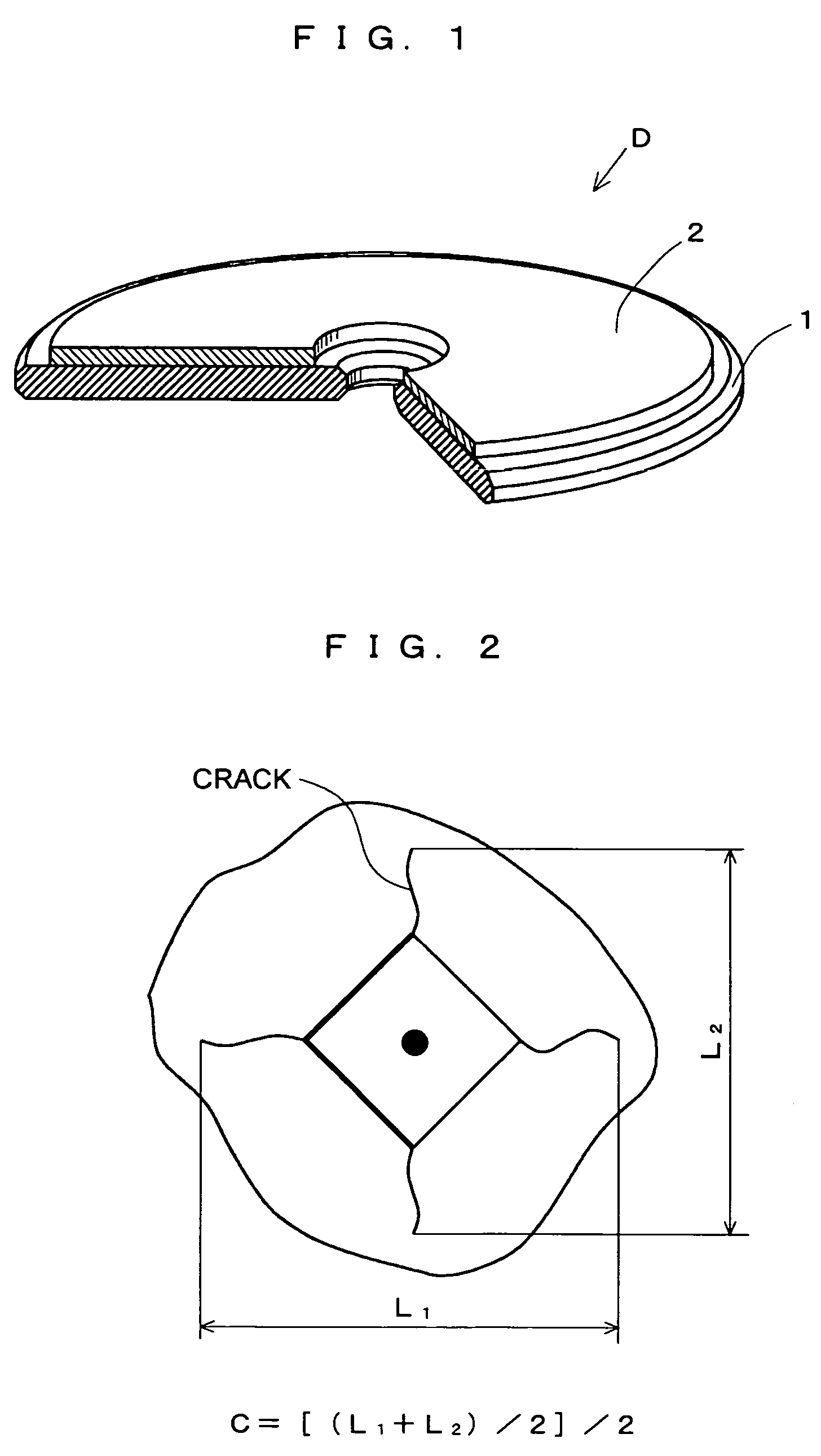

Glass composition, glass substrate employing it for an information recording medium, and information recording medium employing it

ActiveUS20050215414A1Excellent specific elastic modulusLow alkali elutionBase layers for recording layersRecord information storageRecording mediaChemistry

A glass substrate used as a substrate of an information recording medium such as a magnetic disk, magneto-optical disk, DVD, or MD, and a glass composition used to make such a glass substrate, contains the following glass ingredients: 40 to 70% by weight of SiO2; 1 to 20% by weight of Al2O3; 0 to 10% by weight, zero inclusive, of B2O3; SiO2+Al2O3+B2O3 accounting for 60 to 90% by weight; a total of 3.0 to 15% by weight of R2O compounds, where R═Li, Na, and K; a total of 2.0 to 15% by weight of R′O compounds, where R═Mg, and Zn; and a total of 1.0 to 20% by weight of MOx (TiO2+ZrO2+LnxOy), where LnxOy represents at least one compound selected from the group consisting of lanthanoid metal oxides, Y2O3, Nb2O5, and Ta2O5. Here, the following condition is fulfilled: 0.070<(total content of R′O compounds) / (SiO2+Al2O3+B2O3)<0.200.

Owner:HOYA CORP

Glass composition, glass susbstrate employing it for an information recording medium, and information recording medium employing it

ActiveUS7687419B2Excellent specific elastic modulusLow alkali elutionMagnetic materials for record carriersBase layers for recording layersRecording mediaChemistry

A glass substrate used as a substrate of an information recording medium such as a magnetic disk, magneto-optical disk, DVD, or MD, and a glass composition used to make such a glass substrate, contains the following glass ingredients: 40 to 70% by weight of SiO2; 1 to 20% by weight of Al2O3; 0 to 10% by weight, zero inclusive, of B2O3; SiO2+Al2O3+B2O3 accounting for 60 to 90% by weight; a total of 3.0 to 15% by weight of R2O compounds, where R=Li, Na, and K; a total of 2.0 to 15% by weight of R′O compounds, where R=Mg, and Zn; and a total of 1.0 to 20% by weight of MOx (TiO2+ZrO2+LnxOy), where LnxOy represents at least one compound selected from the group consisting of lanthanoid metal oxides, Y2O3, Nb2O5, and Ta2O5. Here, the following condition is fulfilled:0.070<(total content of R′O compounds) / (SiO2+Al2O3+B2O3)<0.200.

Owner:HOYA CORP

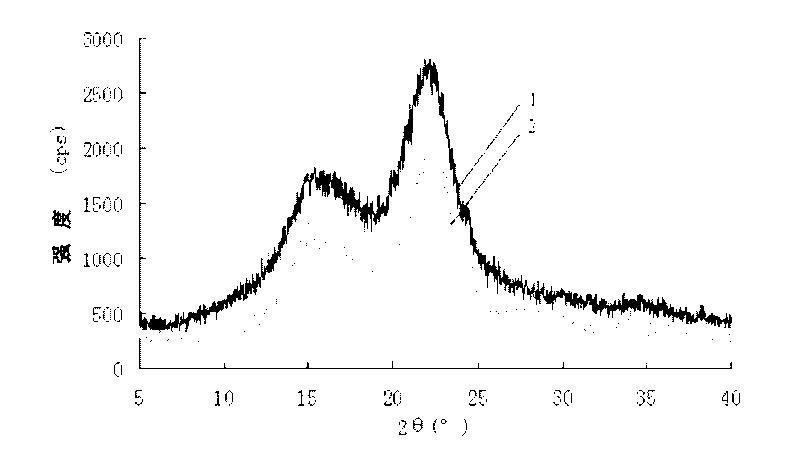

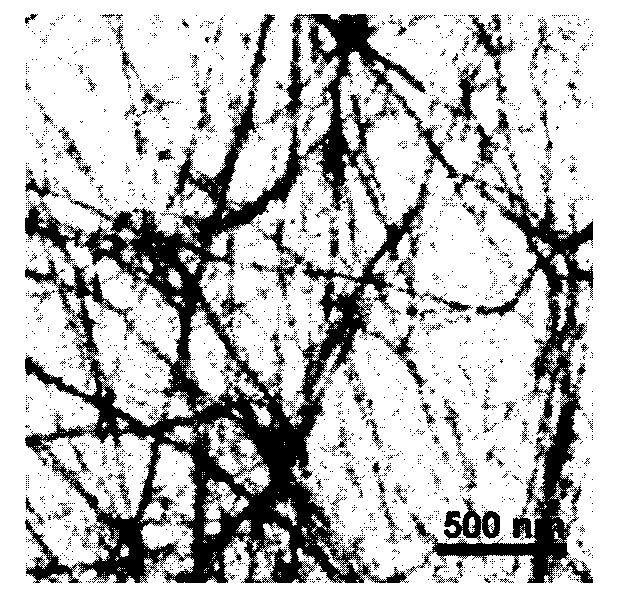

Preparation method of polyacrylonitrile/graphene composite-based carbon fiber

ActiveCN102560746AImprove thermal conductivityUniform deliveryElectroconductive/antistatic filament manufactureSynthetic polymer filament chemical after-treatmentCarbon fibersIn situ polymerization

The invention discloses a preparation method of polyacrylonitrile / graphene composite-based carbon fiber, which comprises the following steps: firstly preparing a polyacrylonitrile mixed solution uniformly dispersed with graphene through an in-situ polymerization method, and then employing the mixed solution as a spinning solution and obtaining a polyacrylonitrile / graphene composite protofilament by a wet spinning or dry-jet wet spinning process, and finally making the protofilament subject to a pre-oxidation treatment and a carbonization treatment to obtain the polyacrylonitrile / graphene composite-based carbon fiber. Compared with the existing polyacrylonitrile-based carbon fiber, the carbon fiber prepared by the method of the invention has a significantly increased mechanical property, and the carbonation yield in the preparation process is improved, therefore, the preparation method is an efficient and reliable preparation method with good application prospects.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

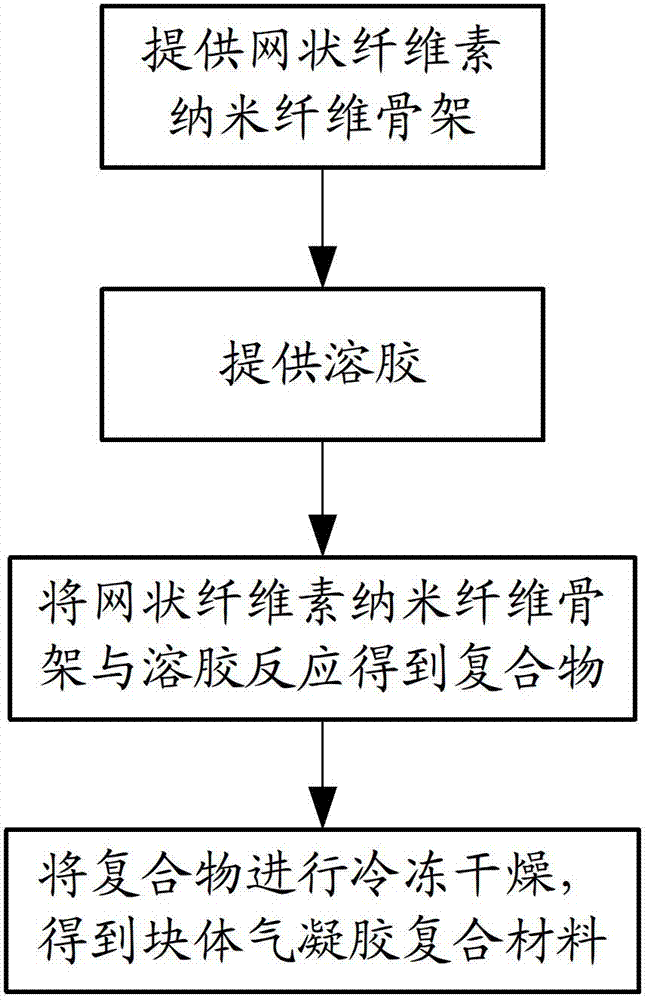

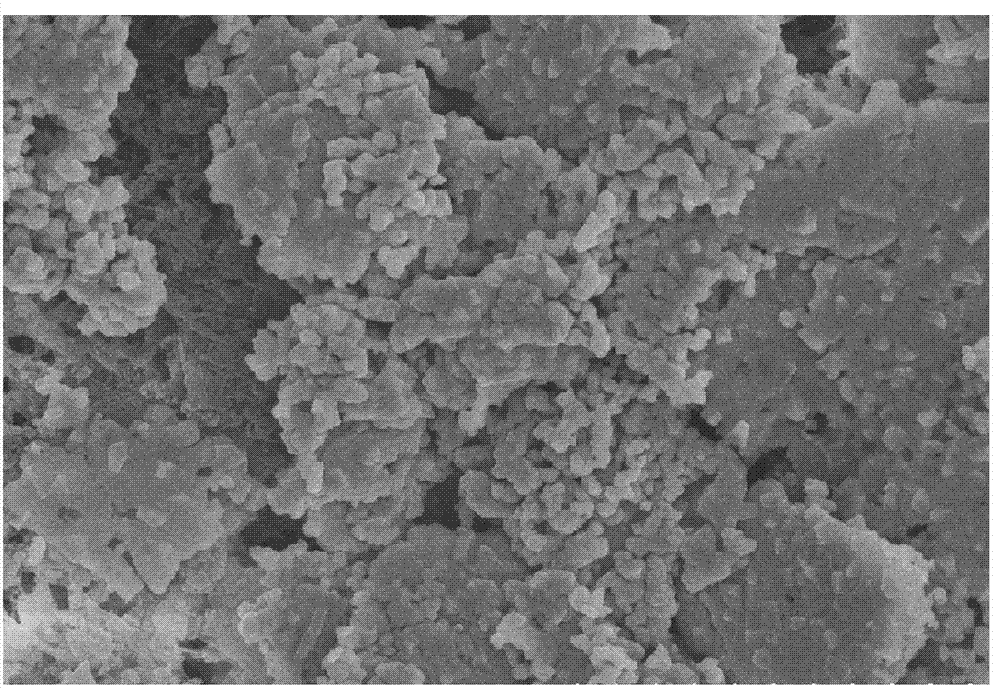

Block aerogel composite material and preparation method thereof

InactiveCN102807357AImprove mechanical propertiesLow thermal conductivitySupercritical dryingElastic modulus

The invention discloses a block aerogel composite material and a preparation method thereof. The block aerogel composite material consists of reticular cellulose nano fiber skeletons and sol in a combining way, wherein the porosity of the aerogel composite material is 80-99.5 percent, the density is 0.015-0.680g / cm<3>, the BET specific surface area is 150-1200m<2> / g, the coefficient of heat conductivity is 0.015-0.045Wm<-1>k<-1> and the modulus of elasticity is 0.5-150MPa. The block aerogel composite material provided by the embodiment of the invention has the advantages that since the material consists of the reticular cellulose nano fiber skeletons and the sol in the combining way, the mechanical property of the block aerogel composite material can be obviously improved, the heat conductivity is low, the density is small and the specific surface area is large; and besides, the equipment cost can be decreased by adopting a relatively low and safe freeze-drying method to replace the traditional supercritical drying method.

Owner:GRADUATE SCHOOL OF THE CHINESE ACAD OF SCI GSCAS

Internal rib reinforcing outer ripple type plastic twining structured wall pipe and manufacturing method thereof

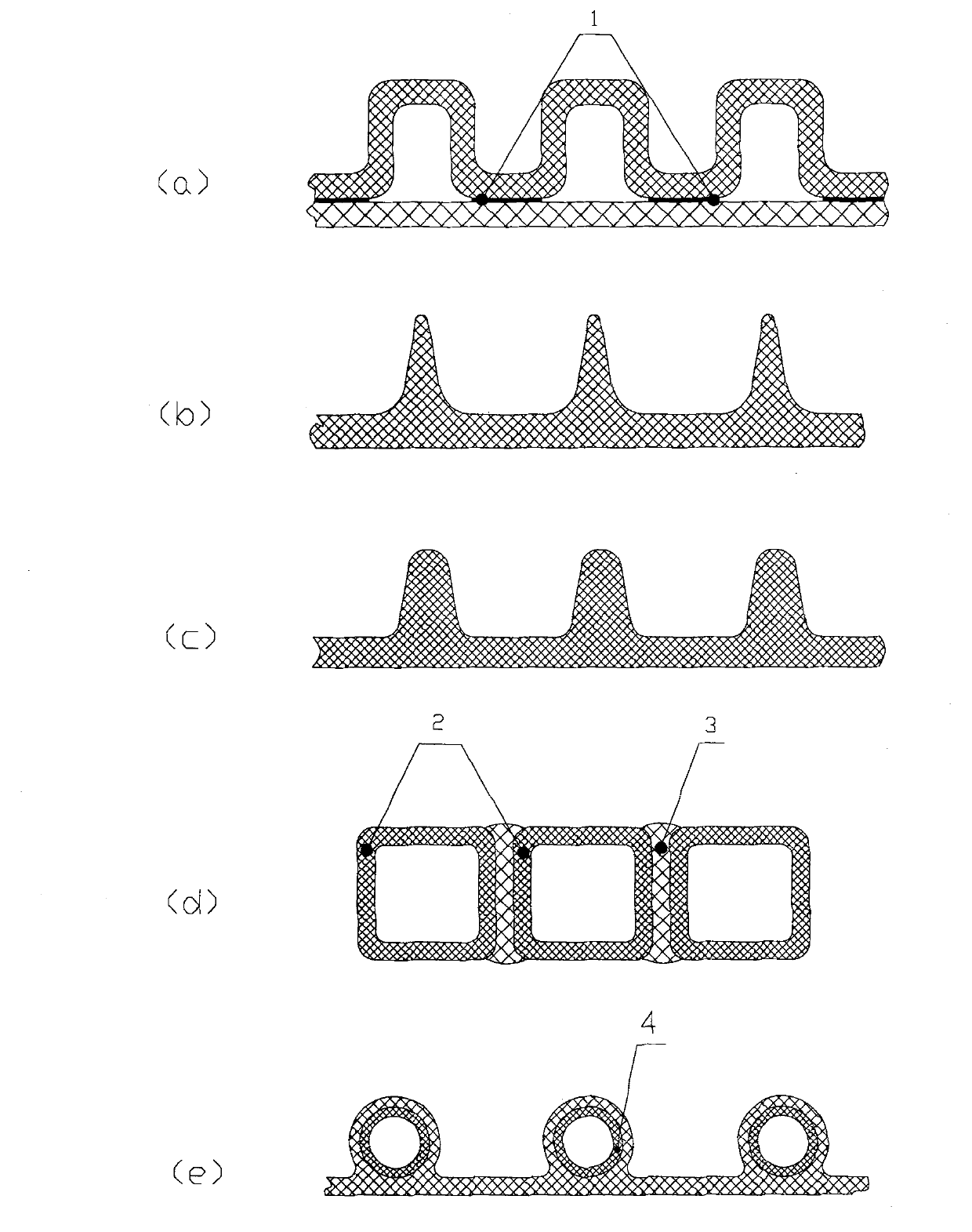

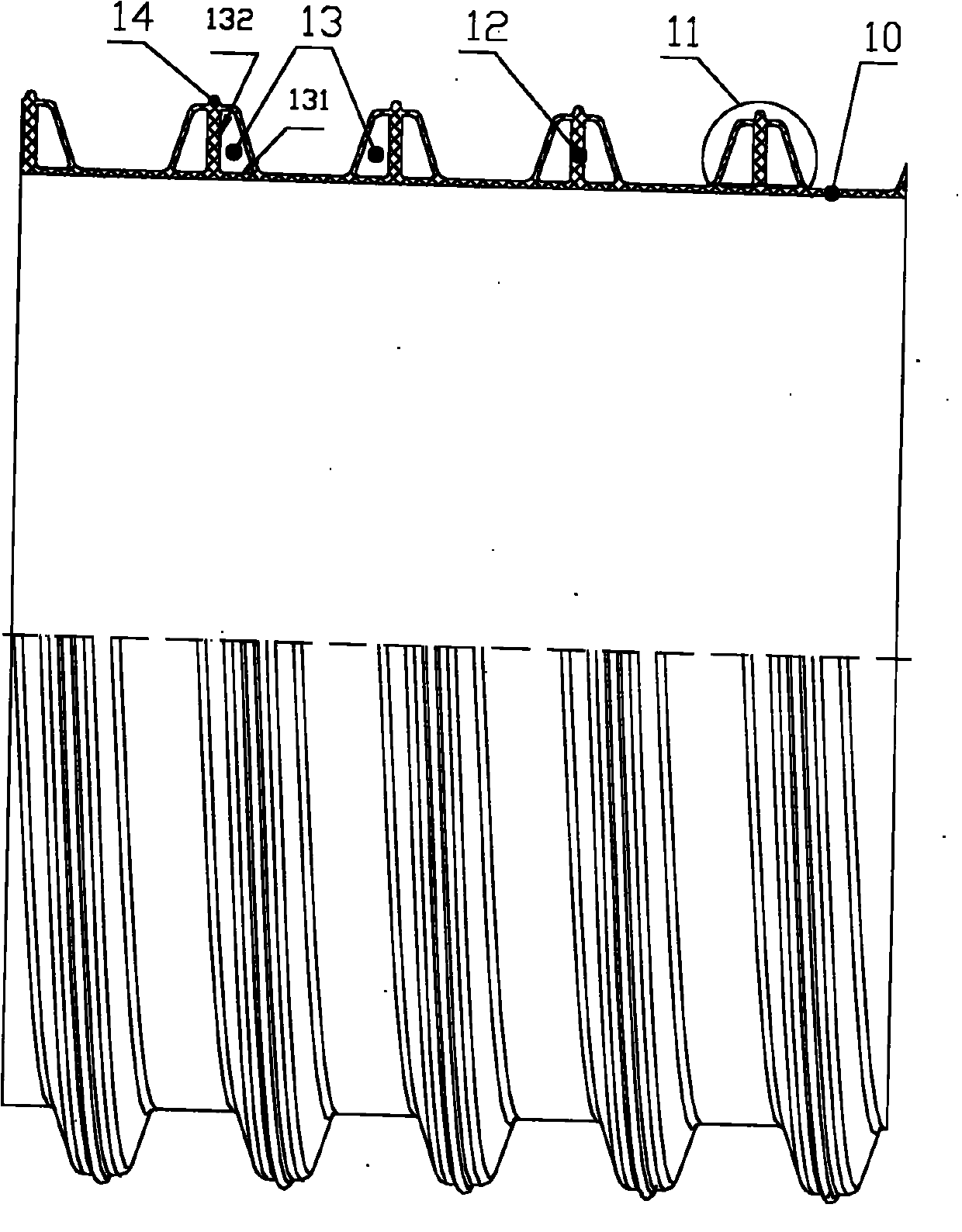

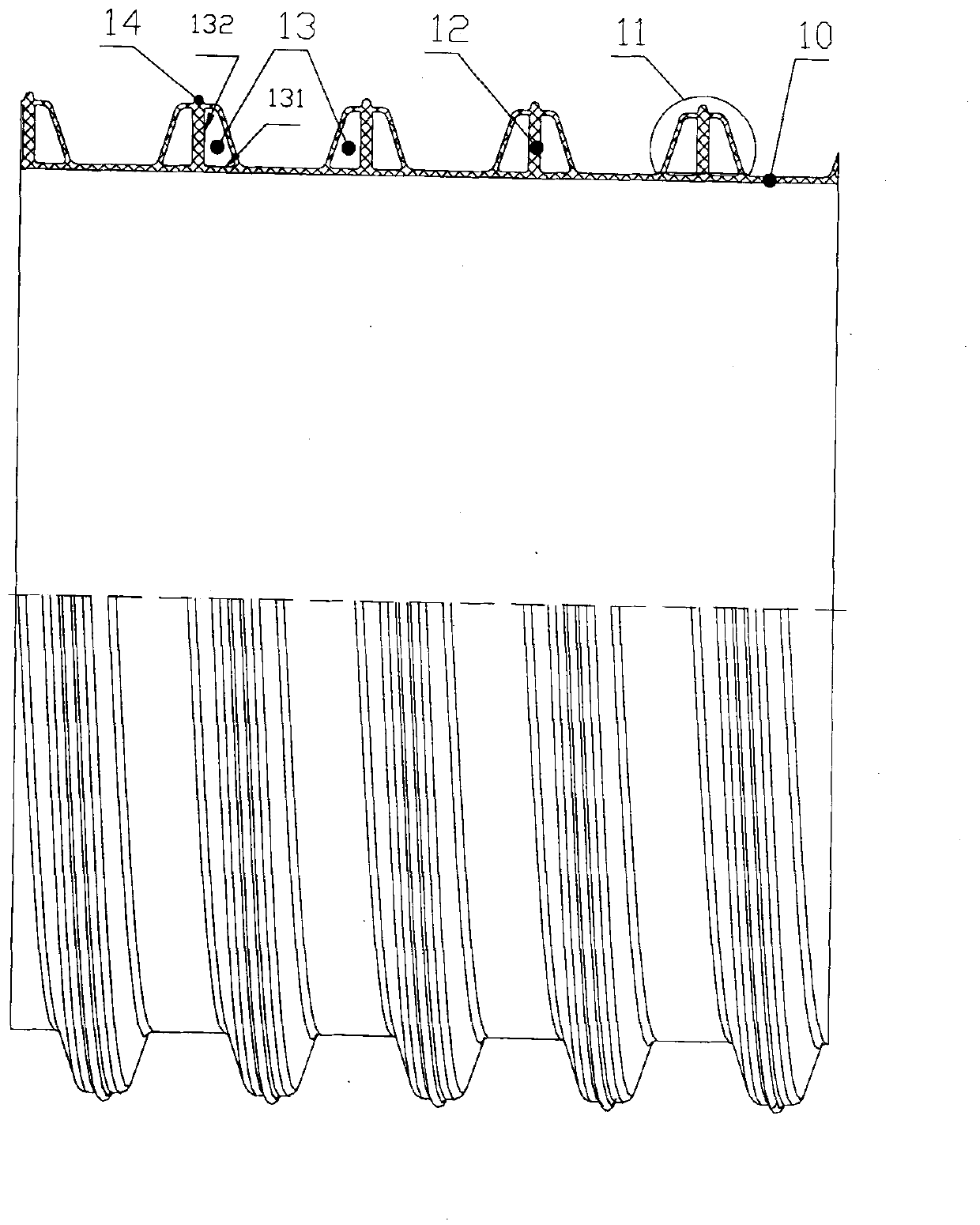

InactiveCN101907207AIncrease the outer surface areaGood synergyRigid pipesTubular articlesMechanical engineeringHot-melt adhesive

The invention relates to an internal rib reinforcing outer ripple type plastic spirally twining structured wall pipe, which comprises a cylindrical surfaced pipe main body and a reinforcing rib wound outside of the pipe main body. The reinforcing rib contains an inner reinforcing rib vertical to the pipe wall, wherein the inner rib divides the reinforcing rib into two parallel hollow cavities. The upper part of the reinforcing rib and the top of the inner rib are both provided with a solid bulge. A method for manufacturing the plastic reinforcing pipe of the invention comprises the steps of: continuously extruding a plastic abnormal strip with two tubular bulges and containing a hollow cavity inside through a first plastic extruder, continuously, regularly, spirally twining the plastic abnormal strip on a formed roller in parallel, at the same time, extruding fused plastic gel in a clearance between adjacent side walls of the spirally wound plastic abnormal strip through a second plastic extruder, rolling two projected tubular cavities corresponding to two sides of the clearances connected by fusing the adjacent plastic abnormal pipe through a rolling wheel which is arranged at the corresponding part on the periphery of the formed roller with a slot structure, forming an outer projected reinforcing rib of the pipe outer wall by fusing the two tubular bulges, and extruding the residual fused gel in the clearance by the rolling wheel so as to form the solid bulge.

Owner:戴爱清

Carbon nanotube reinforced aluminum based composite material and its vacuum hot pressing prepn. method

InactiveCN1834280AImprove wear resistanceImprove anti-friction performanceDistilled waterCarbon nanotube

This invention discloses a method for preparing carbon nanotube-reinforced aluminum-based composite by vacuum hot pressing. The composite, comprising carbon nanotubes 0.1-5 wt.% and aluminum alloy powders 95-99.9 wt.%, is prepared by: (1) immersing carbon nanotubes in mixed acids, and adding surfactant; (2) dispersing; (3) filtrating, and washing carbon nanotubes with distilled water to neutrality; (4) performing two-step ball milling; (5) vacuum drying; (6) hot pressing in vacuum; and (7) hot extruding to obtain carbon nanotube-reinforced aluminum-based composite. This invention improves the capacity of aluminum alloy matrix in resisting abrasion, reducing friction, self-lubricating, surface wettability and mechanical properties.

Owner:HARBIN INST OF TECH

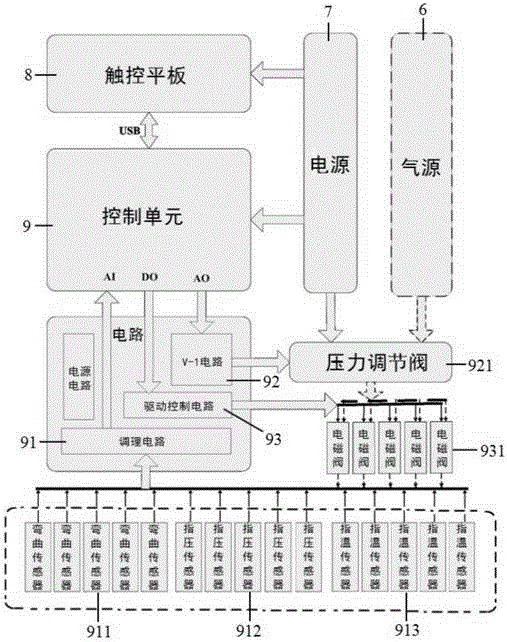

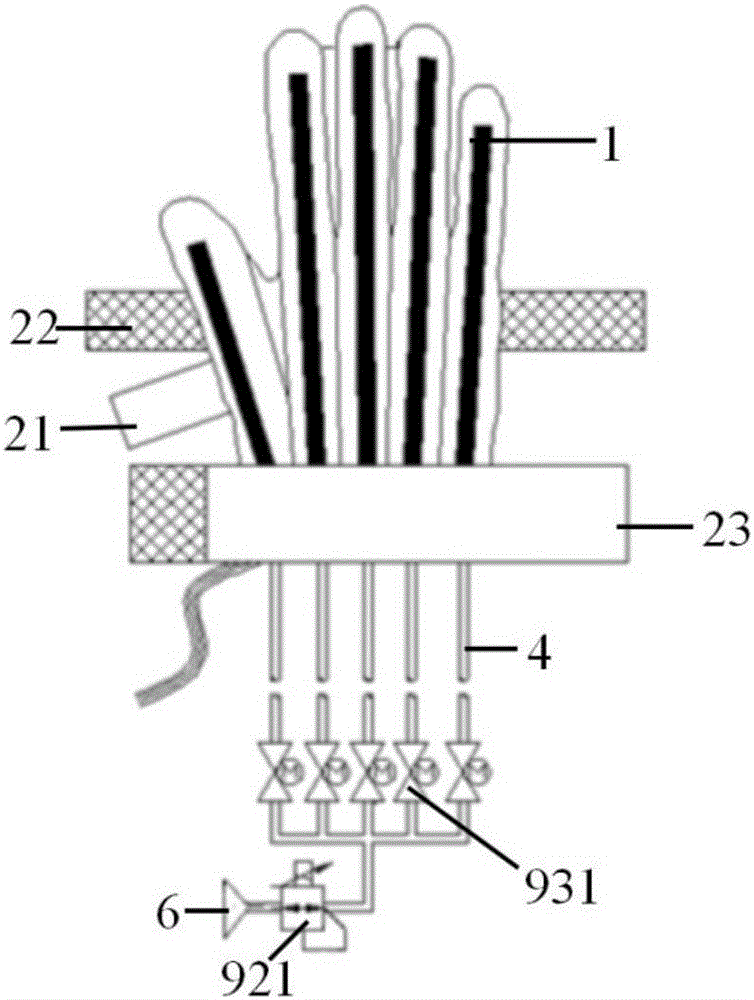

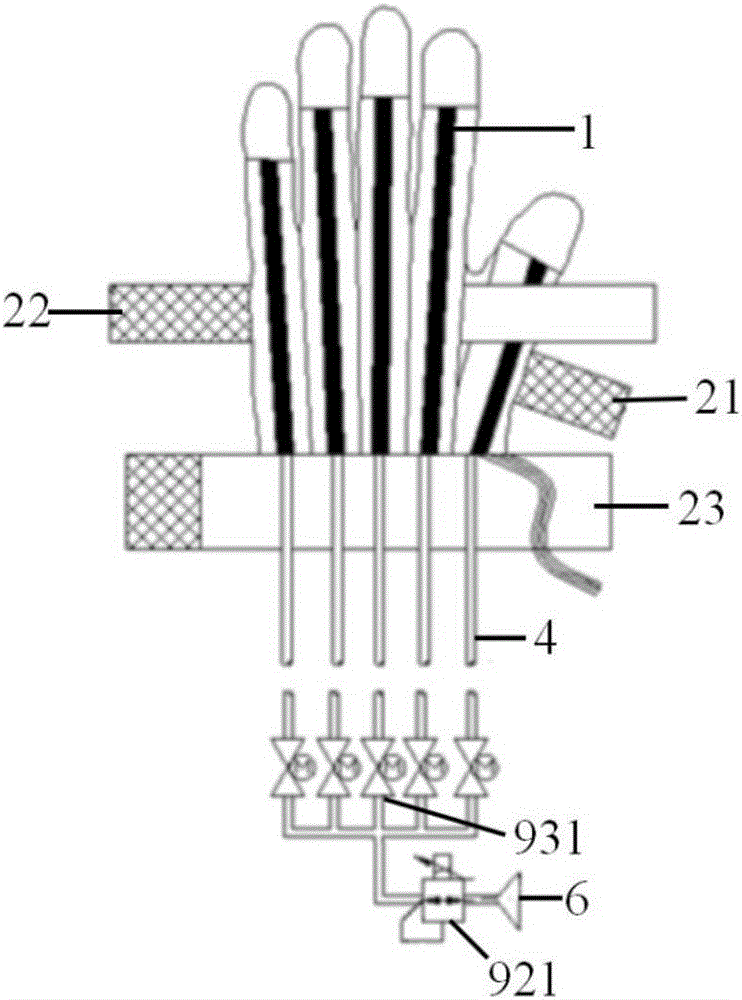

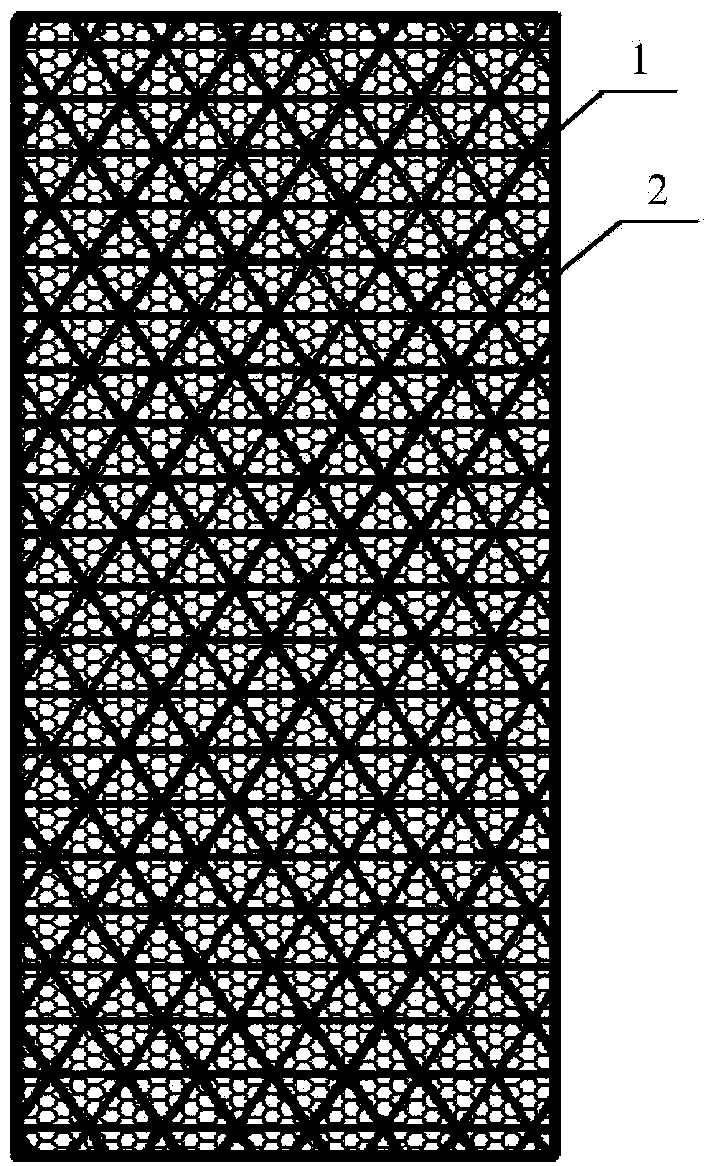

Wearable hand rehabilitation training device

The invention discloses a wearable hand rehabilitation training device which can achieve rehabilitation training of human body hands. The wearable hand rehabilitation training device includes: a glove body; the glove body includes a set of bionic muscle strips; each of the bionic muscle strips is internally provided with a plurality of inflatable airbags which are mutually independent; the bionic muscle strips can drive a human body hand to achieved multi-freedom motion such as bending, stretching, retracting inward, expanding outward, and rotating. The wearable hand rehabilitation training device is convenient and comfortable in wearing, can achieve all-round training of fingers, meet disease demands of different patients, and can allow hand functional rehabilitation training of stroked patients.

Owner:海门奥勃纳机电科技有限公司

Macroscopic-microcosmic-nanometer hierarchical mechanical compatible bone restoration and preparation thereof

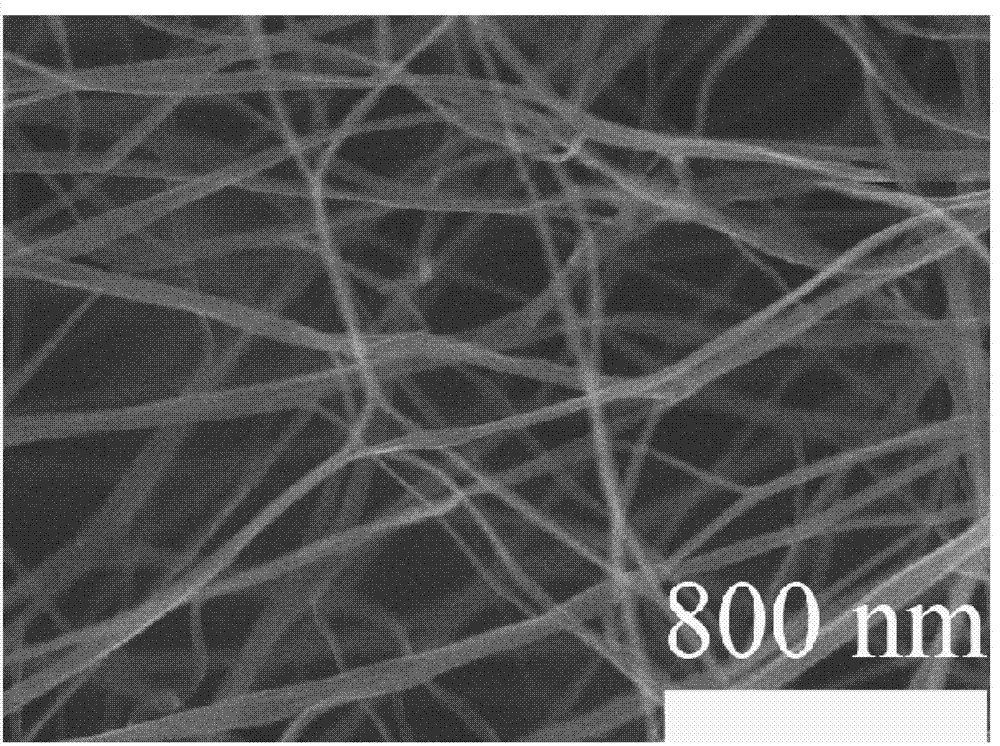

InactiveCN104107097AGood biological propertiesAchieving perfect integrationBone implantMicrometerNanofiber

Disclosed are a macroscopic-microcosmic-nanometer hierarchical mechanical compatible bone restoration and preparation thereof. The bone restoration comprises a macroscopic pore metal structural body, a microscopic pore structural body and nanofibers. The appearance of the macroscopic pore metal structural body is consistent with an anatomic form of defect part bone tissues, the size of internal macroscopic pores is 300-1500 micrometers, porosity ranges from 50% to 90%, microscopic roughness Ra of pore walls is 5-30 micrometers, all the macroscopic pores are communicated with one another completely, mechanical property of the macroscopic pore metal structural body is compatible with that of the defect part bone tissues, compressive strength is 60-300MPa, and elasticity modulus is 0.5-30GPa. The microscopic pore structural body is positioned in the macroscopic pore metal structural body, internal microscopic pores are uniform in structure and are communicated with one another completely, the pore size is 50-250 micrometers, and pore walls of the microscopic pores consist of the nanofibers which are made of biodegradable polymer materials. The bone restoration perfectly integrates the anatomic form, the mechanical property and biological property and can be applied to treatment of large segmental bone defects of bearing parts clinically.

Owner:SHANGHAI JIAO TONG UNIV

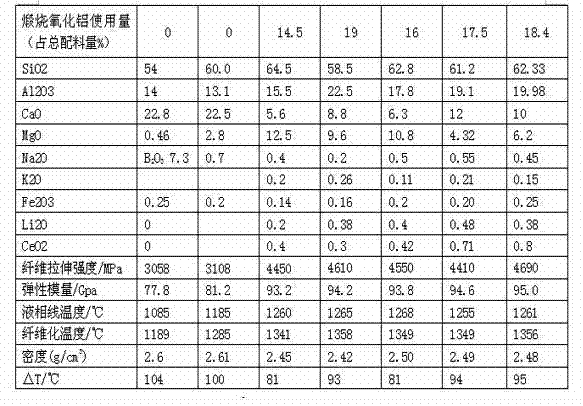

High-strength glass fiber composition

InactiveCN102786223ARelieve pressureLower fiberization temperatureGlass making apparatusFiberMechanical property

The invention relates to a high-strength glass fiber which has an excellent mechanical property and a product of the glass fiber. The high-strength glass fiber can serve as an ideal enhancing base material of a high-performance composite material and is applied widely in the fields of windmill blades, space shuttles and the like, which have high requirements for the specific strength and the specific elasticity modulus. The system is characterized in that calcinated aluminum oxide serves as on of the raw materials, impurities in glass compositions are reduced, the diathermancy of molten glass is improved, the energy consumption is reduced, and the stability of glass fiber drawing operation is improved greatly. The glass fiber with the compositions is required to be produced by direct drawing on a specific tank furnace, the electric boosting input energy of the tank furnace accounts for more than 20% of the total energy input, and more than 60% of the electric boosting energy is applied to raw material melting areas. The fiber mainly comprises 56-65 wt.% of SiO2, 18.5-25.8 wt.% of Al2O3, 11.5-23.0 wt.% of RO (RO is sum of CaO, MgO, SrO and BaO), 0.1-1.0 wt.% of CeO2 and 0.1-0.8 wt.% of Li2O.

Owner:TAISHAN FIBERGLASS INC

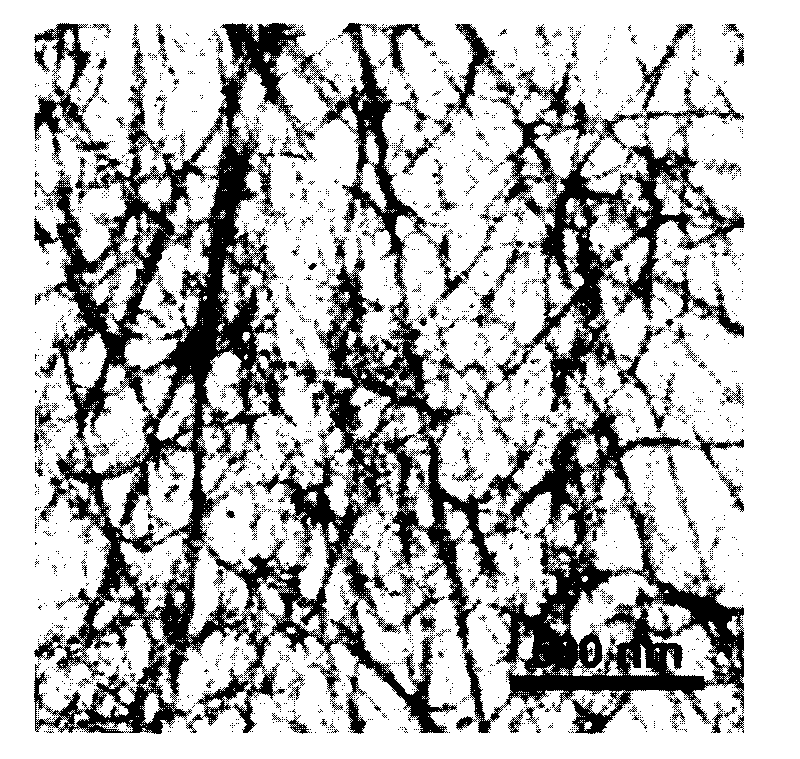

Method for preparing lignocellulosic nanofibrils

ActiveCN101691698AHigh yieldReduce forcePulping with acid salts/anhydridesPulping with inorganic basesAcetic acidFibril

The invention discloses a method for preparing lignocellulosic nanofibrils, which relates to a method for preparing nanofibrils. The method solves the problems that the traditional cellulose fiber manufactured by taking timber as a raw material has poor strengthening and toughening effects and cellulose fibrils obtained through the preparation have low yield. The method comprises the steps of: 1, extracting wood meal; 2, mixing raw materials and performing heating treatment on the mixture; 3, then adding glacial acetic acid and sodium chlorite into the mixture, and performing heating treatment after the mixing; 4, removing lignin; 5, removing hemicellulose; 6, re-removing the lignin; 7 re-removing the hemicellulose; and 8, performing ultrasonic crushing treatment to obtain the lignocellulosic nanofibrils. The yield of the manufacturing method is between 80 and 90 percent and is high; and the lignocellulosic nanofibrils prepared by the method have good strengthening and toughening effects.

Owner:NORTHEAST FORESTRY UNIVERSITY

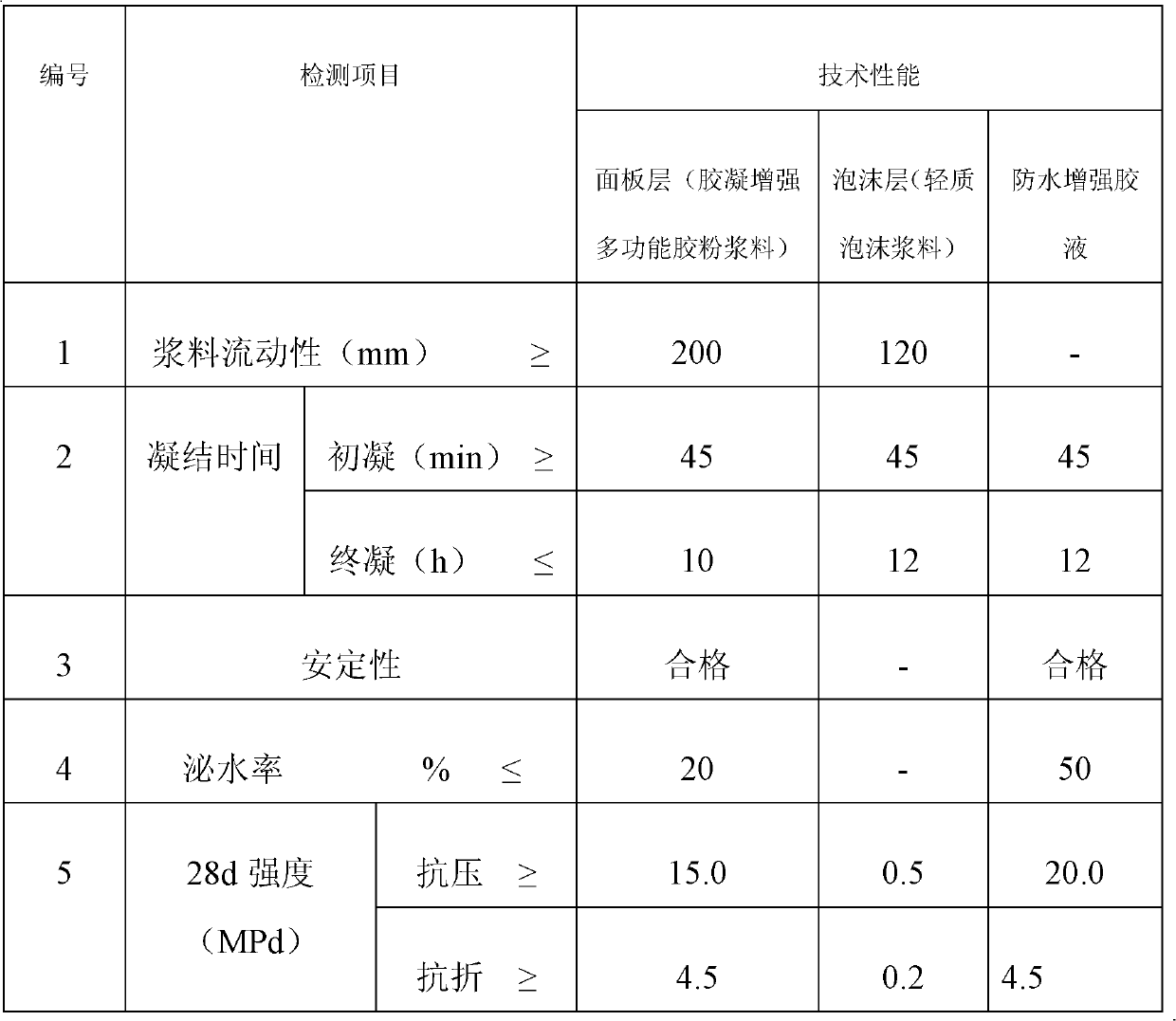

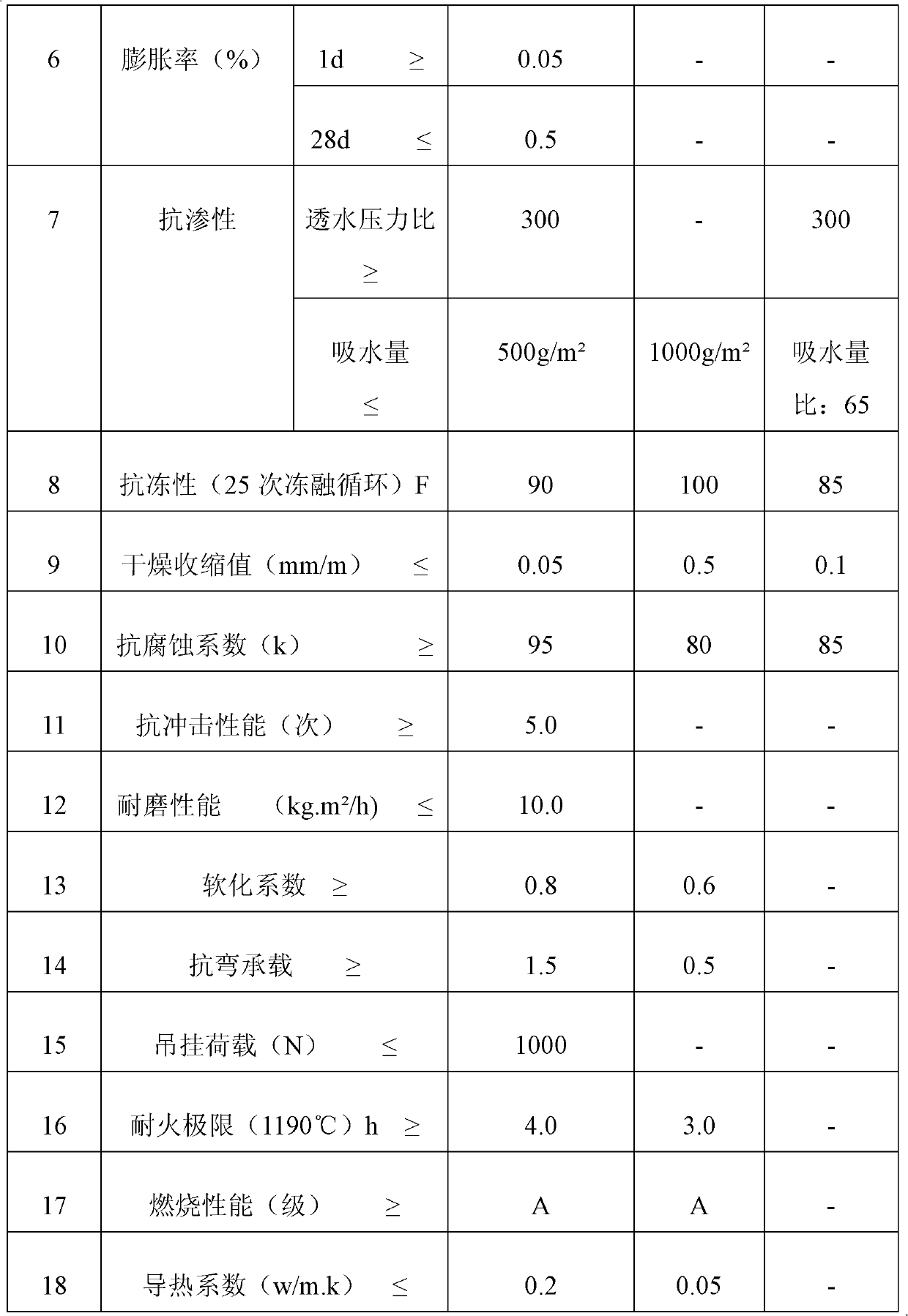

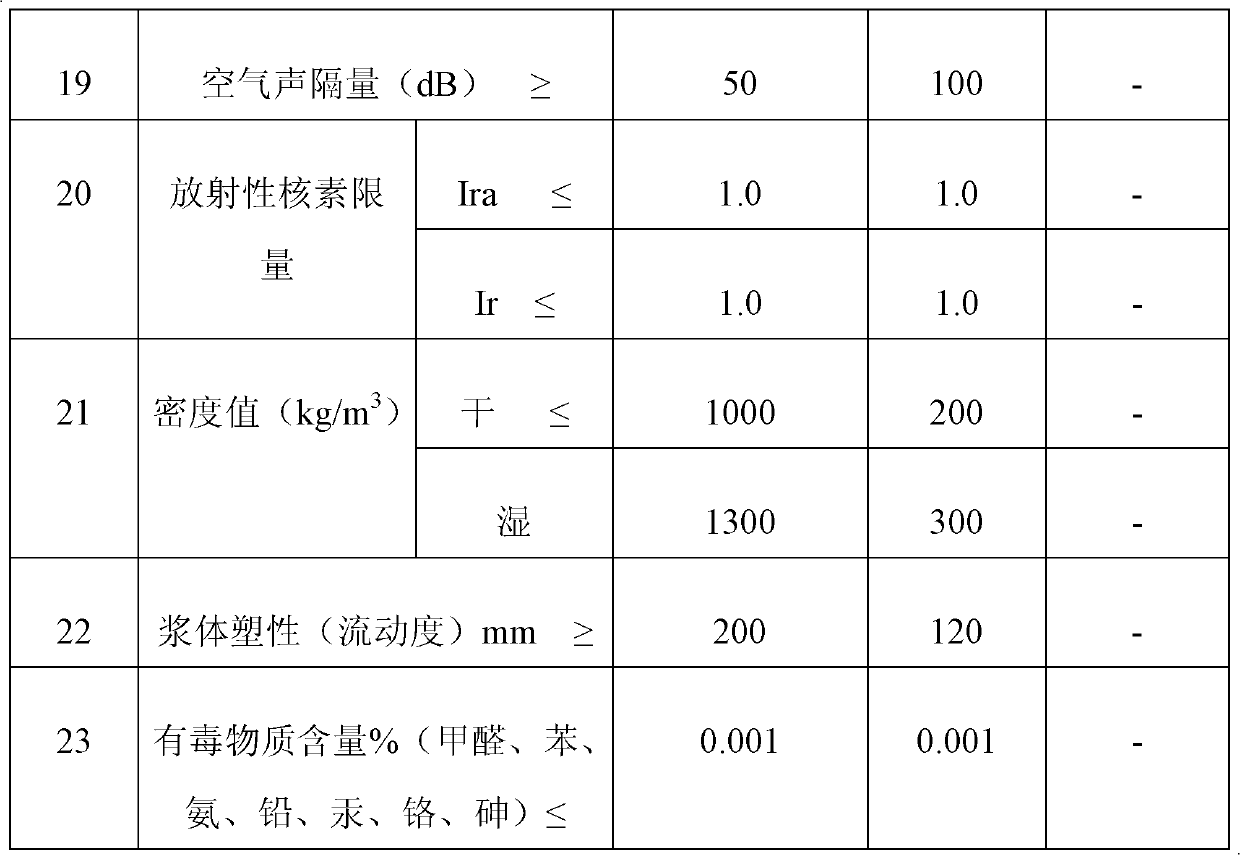

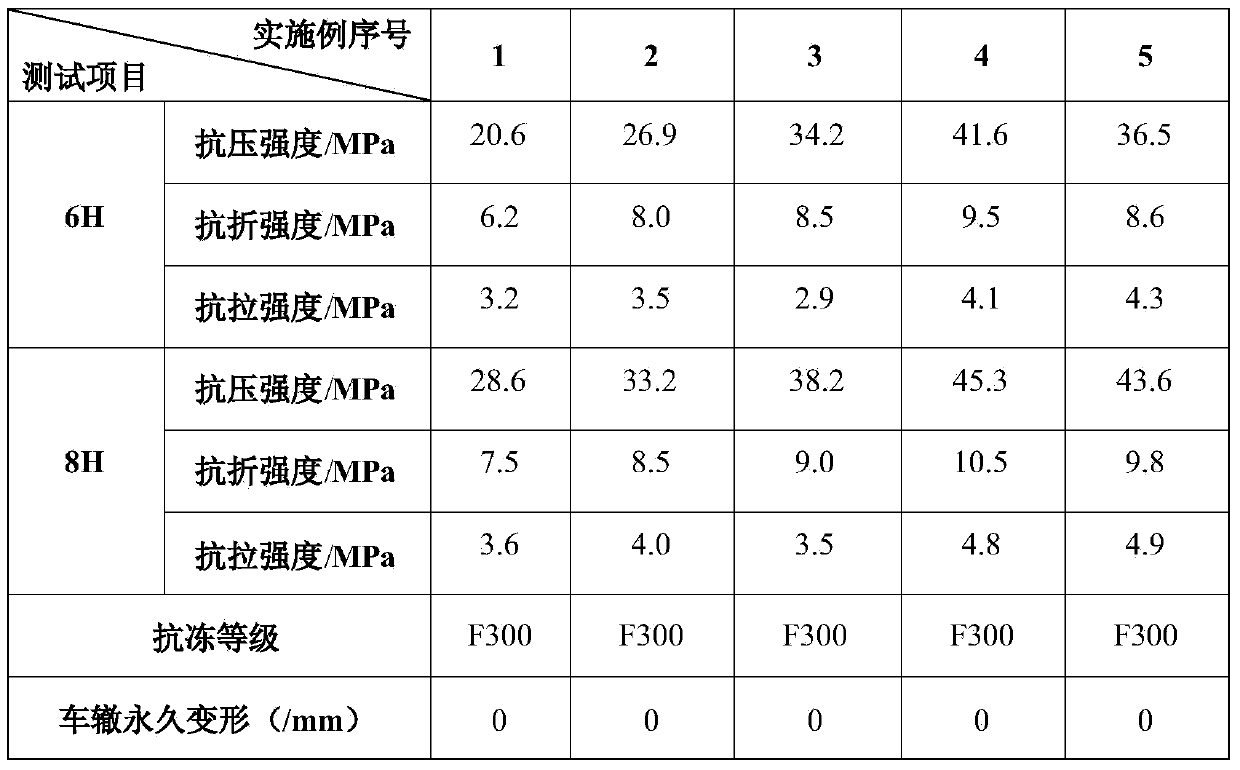

Multifunctional inorganic thermal insulation material composition, product comprising same and preparation method of product

The invention provides a multifunctional inorganic thermal insulation material composition, a multifunctional inorganic thermal insulation material product prepared from the multifunctional inorganic thermal insulation material composition and a preparation method of the multifunctional inorganic thermal insulation material product. By substantially utilizing industrial and construction wastes as a gel enhancement and inorganic thermal insulation system and adding a little amount of cement as well as a proper amount of regulator, the multifunctional inorganic thermal insulation material composition is molded in a casing mode by one step, thereby forming a wall plate, a block material (wall materials decorated by wall floor tiles) and a roof. Therefore, the wall body, the block material and the roof have the multifunction and the characteristics of thermal insulation, fire prevention, water resistance, freezing resistance, crack resistance, sound insulation, light weight, corrosion resistance, weather resistance, decoration, energy conservation, environmental friendliness, safety, sanitation, work saving, time saving, cost saving and the like.

Owner:苏琳

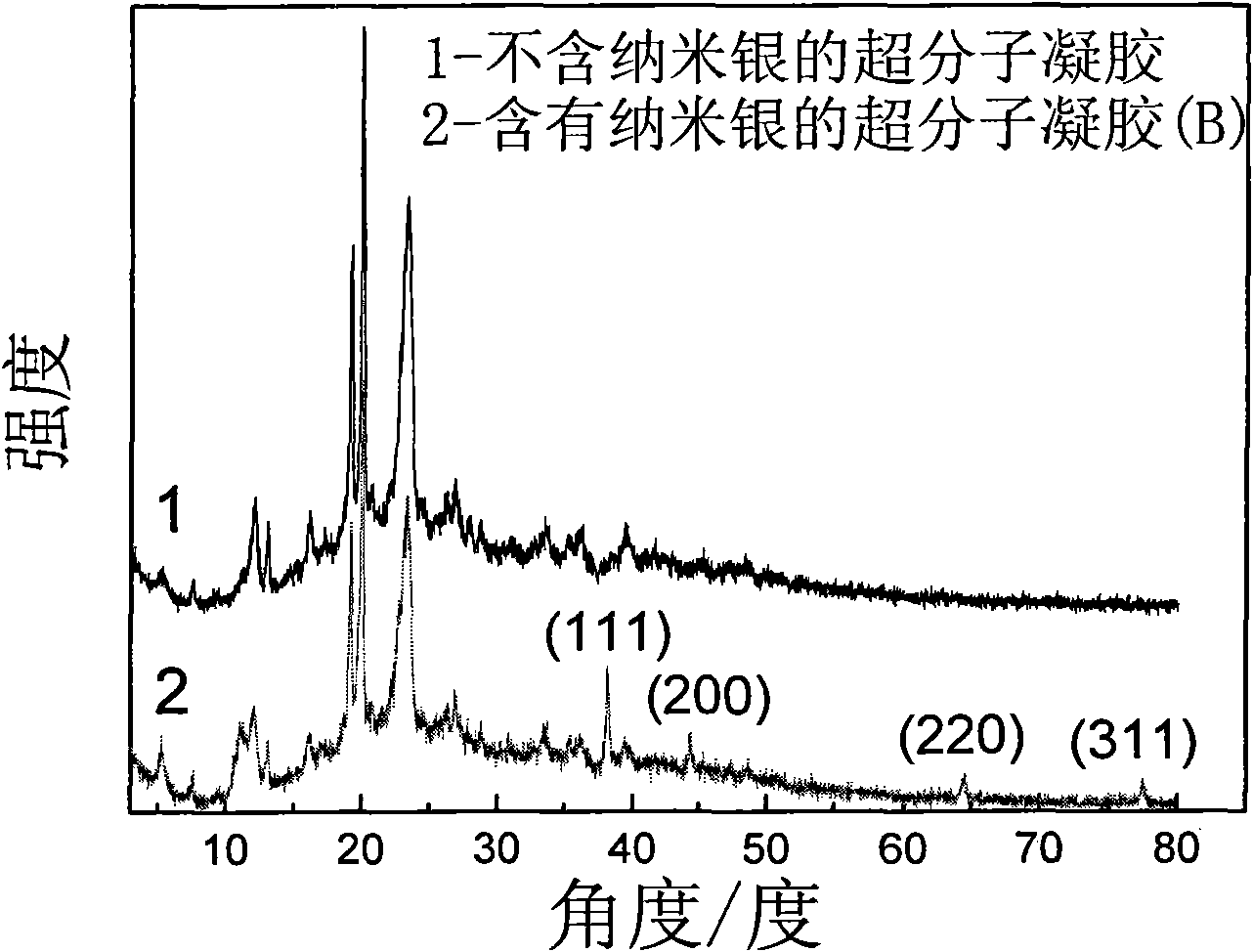

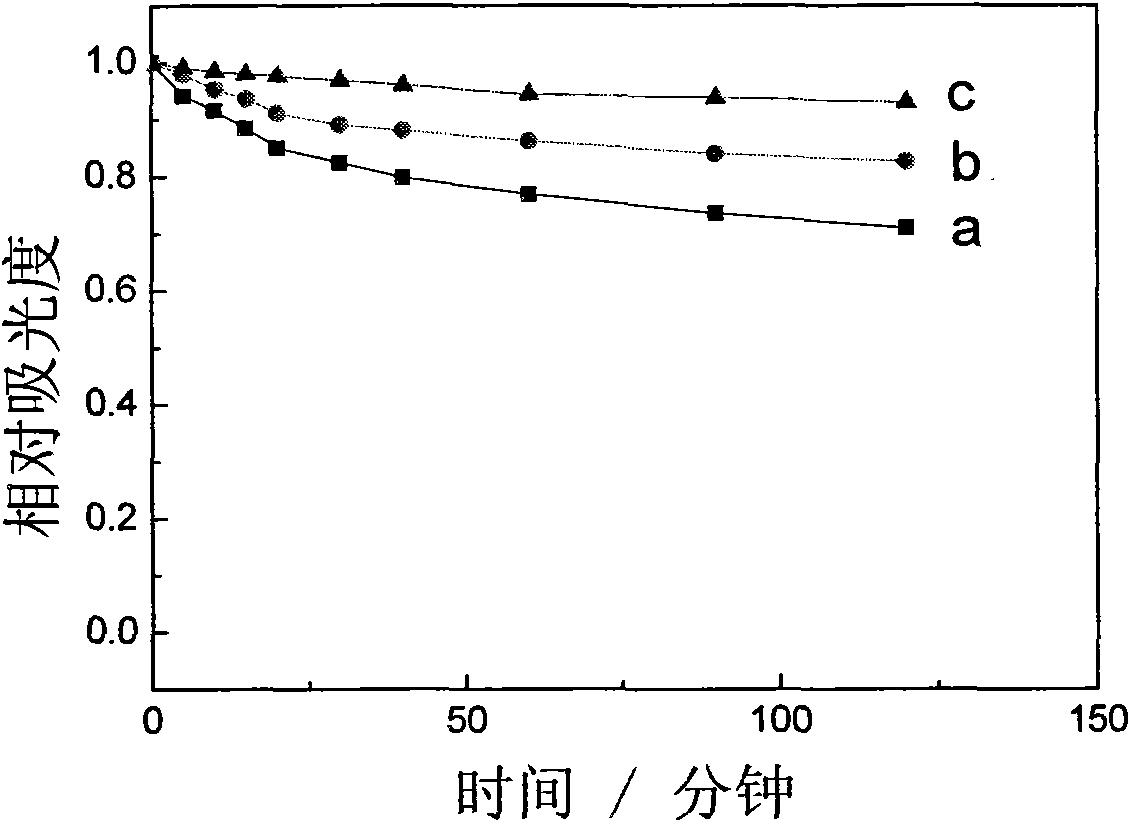

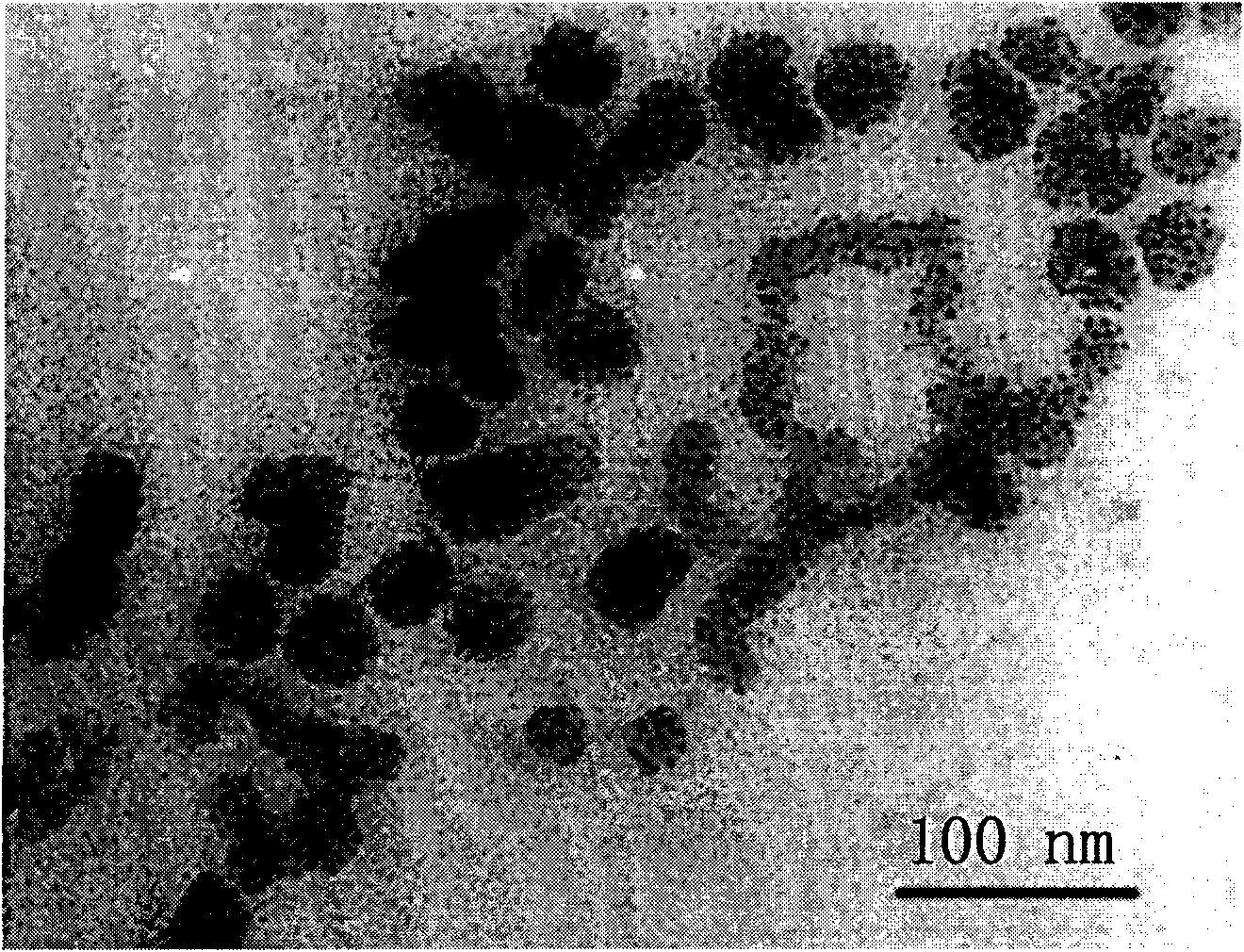

Antibacterial supermolecule aquogel and preparation method and application thereof

InactiveCN101564400AEasy to prepareEasy to operateAntibacterial agentsInorganic active ingredientsBiocompatibility TestingSILVER NITRATE CRYSTALS

The invention discloses a method for in-situ preparing antibacterial supermolecule aquogel. The method comprises the following operation steps: silver nitrate crystal and polyethyleneglycol-polypropylene glycol-polyethyleneglycol triblock copolymer solution are mixed and stirred to obtain mixed solution; the steps of stirring the mixed solution for 15 minutes and ultrasonically dispersing the mixed solution for 5 minutes are alternatively carried out for 2-4 hours to obtain nano silver sol; and the nano silver sol and Alpha-cyclodextrin solution are mixed, stirred and stands at the room temperature to obtain hydrogel. The hydrogel can be used for preparing injectable drug carriers. The invention has the advantages of simple operation, adjustable gel strength and the gelation time, room temperature forming, no involvement of chemical cross linking reaction and the usage of organic solvent, favorable biocompatibility and antibacterial property of obtained gel, and the like and is prospective to be widely applied in the field of biomedical engineering materials.

Owner:SUN YAT SEN UNIV

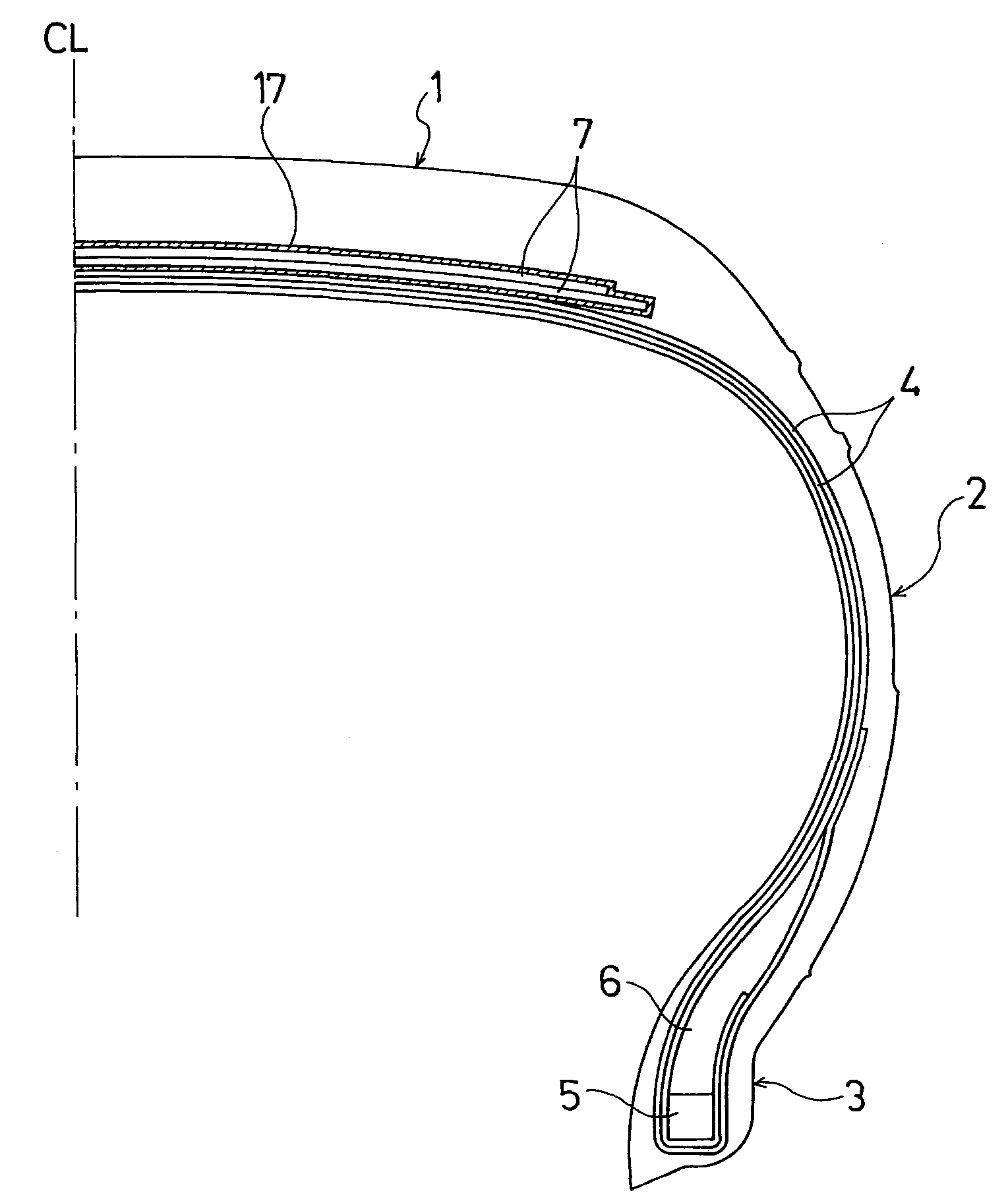

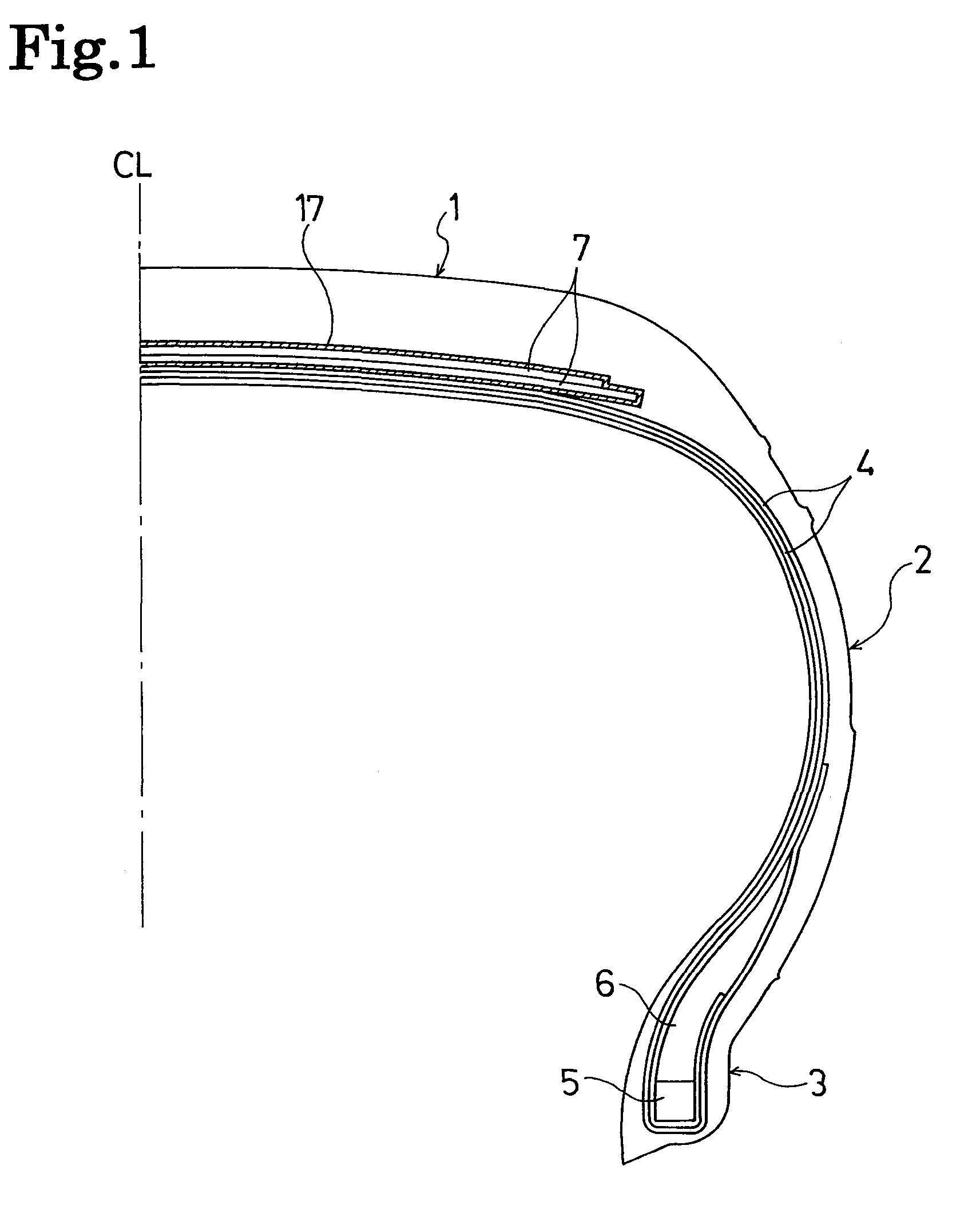

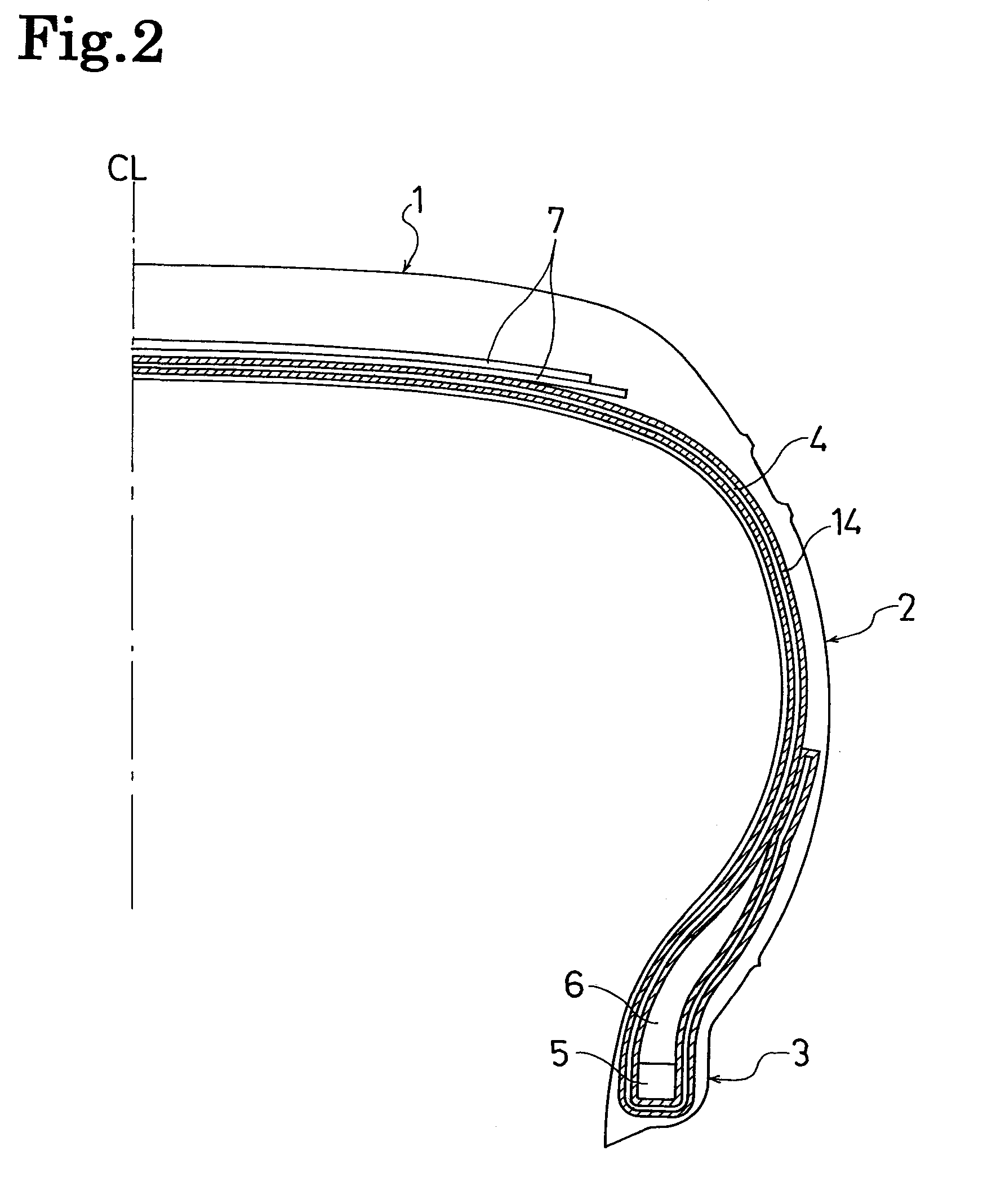

Pneumatic tire and method of manufacturing the same

InactiveUS20090283194A1Increased durabilityPreventing oxygen deteriorationTyresSpecial tyresElastomerThermoplastic elastomer

Provided are a pneumatic tire with a durability which is improved by preventing oxygen deterioration of coating rubber of a reinforcement layer, and a method of manufacturing the pneumatic tire. The pneumatic tire according to the present invention is a pneumatic tire including a reinforcement layer having reinforcement cords. In the pneumatic tire, the reinforcement layer is covered with thin films each made of a thermoplastic resin or a thermoplastic elastomer composition obtained by blending a thermoplastic resin with an elastomer in a way that the reinforcement is wrapped with the thin films. A method of manufacturing the pneumatic tire includes: arranging a thin film made of a thermoplastic resin or a thermoplastic elastomer composition on an outer periphery of a making drum, the thermoplastic elastomer composition being obtained by blending a thermoplastic resin with an elastomer; arranging a reinforcement layer including reinforcement cords on an outer periphery of the thin film; arranging another thin film on an outer periphery of the reinforcement layer; covering the reinforcement layer with these thin films in a way that the reinforcement layer is wrapped with the thin films; making an uncured tire including the reinforcement layer; and curing the uncured tire.

Owner:THE YOKOHAMA RUBBER CO LTD

Concrete pavement material for heavy traffic roads and preparation method thereof

ActiveCN104193221AElastic modulus controllableHigh modulus of elasticitySolid waste managementMass ratioWaste rubber

The invention relates to a concrete pavement material for heavy traffic roads and a preparation method thereof. The material is composed of a component A, a component B and a component C in a mass ratio of 1:(0.2-0.6):(4-8). The component A comprises the following components in parts by mass: 40-80 parts of epoxy resin, 0-20 parts of epoxy reactive diluent, 10-50 parts of elastic modifier, 0.2 part of defoaming agent and 0.2 part of dispersing agent. The component B comprises the following components in parts by mass: 100 parts of curing agent, 0-10 parts of curing accelerator and 1 part of coupling agent. The component C comprises the following components in parts by volume: 100 parts of fine stone, 30-300 parts of fine sand, 130-800 parts of waste rubber particle, 50-100 parts of waste rubber powder and 10-20 parts of crystal whisker. Compared with the prior art, the concrete pavement material for heavy traffic roads has the advantages of high strength, favorable durability, favorable roadability, energy saving, environment friendliness and the like, and is convenient for construction.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

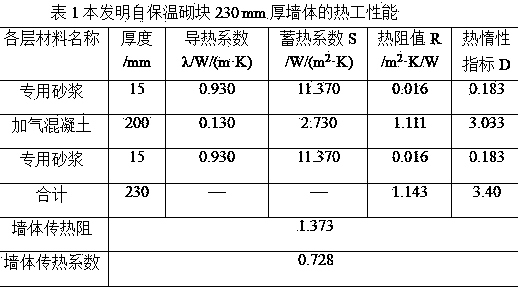

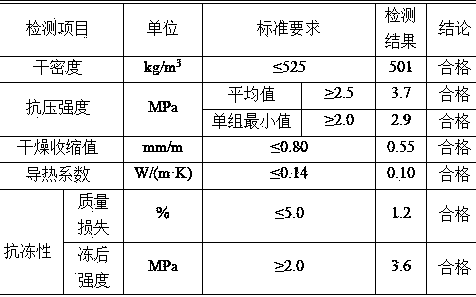

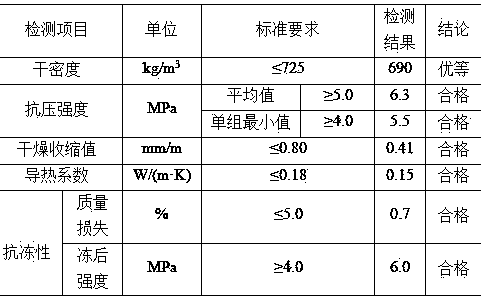

Self-heat-insulating fly ash autoclaved aerated concrete block and preparation method thereof

The invention relates to a self-heat-insulating fly ash autoclaved aerated concrete block which comprises the following components in parts by weight: 1400-2200kg of fly ash, 330-400kg of cement, 390-550kg of quicklime, 100-200kg of white lime, 50-100kg of desulfurized gypsum, 255-420kg of block waste, 2.15-2.90kg of aluminum powder paste and 0.20-0.50kg of foam stabilizer. According to the invention, the fly ash, desulfurized gypsum and excessive cut waste from a power plant are fully utilized, and meanwhile, the Level B04, Level B05, Level B06 and Level B07 self-heat-insulating fly ash aerated concrete blocks can be prepared. The block products contain a large amount of micro and macro pores, and are uniform in pore size, low in heat conductivity coefficient and favorable in self-heat-insulating property.

Owner:HENAN XIAN NEW BUILDING MATERIALS

A water tree-resistant polyolefin cable material and a preparation method thereof

ActiveCN103289162AShorten the lengthExcellent water tree resistancePlastic/resin/waxes insulatorsLow-density polyethylenePolymer science

The invention discloses a water tree-resistant polyolefin cable material and a preparation method thereof. The water tree-resistant polyolefin cable material comprises, by mass, 70 to 95 parts of low density polyethylene, 5 to 30 parts of water tree resistant masterbatch, 1 to 2 parts of a crosslinking agent, 0.3 to 0.5 parts of a crosslinking coagent, 1 to 2 parts of an antioxidant, and 0.1 to 0.5 parts of a rheology modifier. Porous particles in the prepared water tree-resistant polyolefin cable material have adsorption characteristics, so that a more uniform distribution of water is obtained, water will not gather to be droplets, the probability of water tree growth is reduced by 50% or more than that of a conventional cross-linked polyethylene cable material, and the water tree-resistant polyolefin cable material of the invention has excellent water tree resistance; an elastic modulus ratio increases by 30% than that of a conventional cross-linked polyethylene cable material, so the water tree-resistant polyolefin cable material of the invention has excellent mechanical strength and toughness; and the water tree-resistant polyolefin cable material of the invention meet electrical performance standards of chemically cross-linked polyethylene insulation materials used for medium / low-voltage cable, etc., and has good processability.

Owner:XI AN JIAOTONG UNIV

Preparation method of PTFE (polytetrafluoroethylene) copper-clad plate with high elastic modulus

InactiveCN102166852ALow dielectric constantLow elastic modulusGlass/slag layered productsMetal layered productsGlass fiberPolymer science

The invention provides a preparation method of a PTFE (polytetrafluoroethylene) copper-clad plate with a high elastic modulus, which comprises the following steps of: preparing copper foil and glass fiber cloth with a low dielectric constant, and preparing a fluororesin mixture; soaking the glass fiber cloth with the prepared fluororesin mixture, transferring the soaked glass fiber cloth into a baking oven for baking and drying, and repeating the steps to enable the glass fiber cloth to be soaked, baked and dried many times, thereby obtaining soaking pieces the resin content of which is about 60-70%; and superposing the soaking pieces, coating the copper foil on two sides, and laminating to obtain the PTFE copper-clad plate. The baking and drying process comprises three stages, wherein the temperature of the baking oven in the first stage is 50-100 DEG C, the temperature of the baking oven in the second stage is 200-320 DEG C, and the temperature of the baking oven in the third stage is 380-400 DEG C. The plate prepared by the method provided by the invention not only has a lower dielectric constant but also has a higher elastic modulus, and the plate has the advantages of consistent internal structure and good dimensional stability.

Owner:GUANGDONG SHENGYI SCI TECH

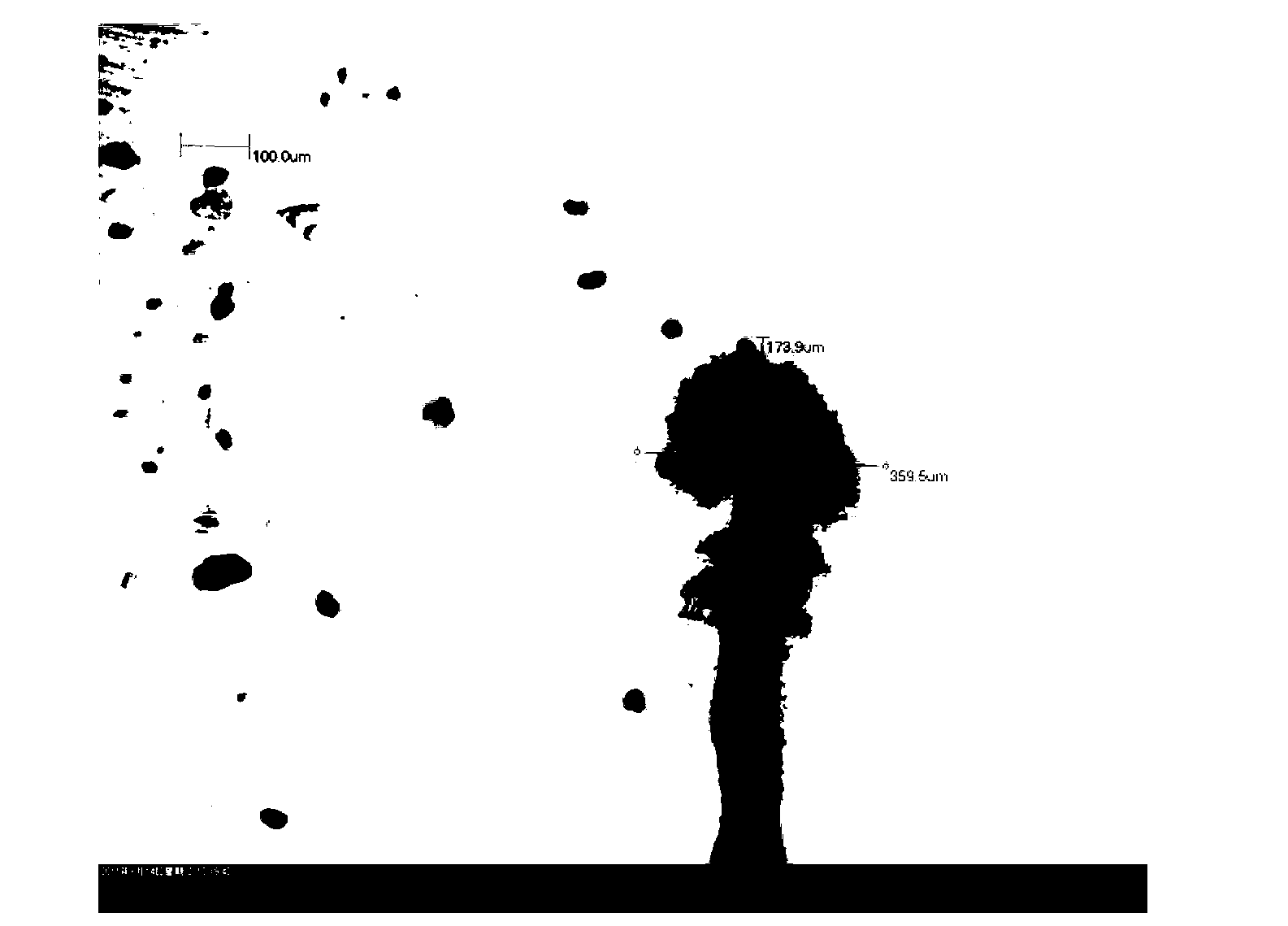

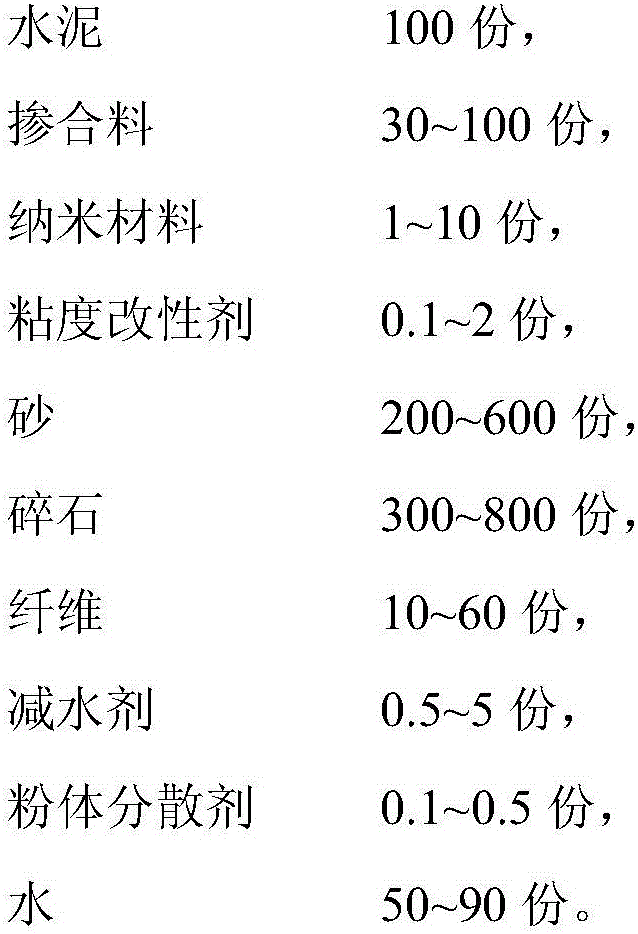

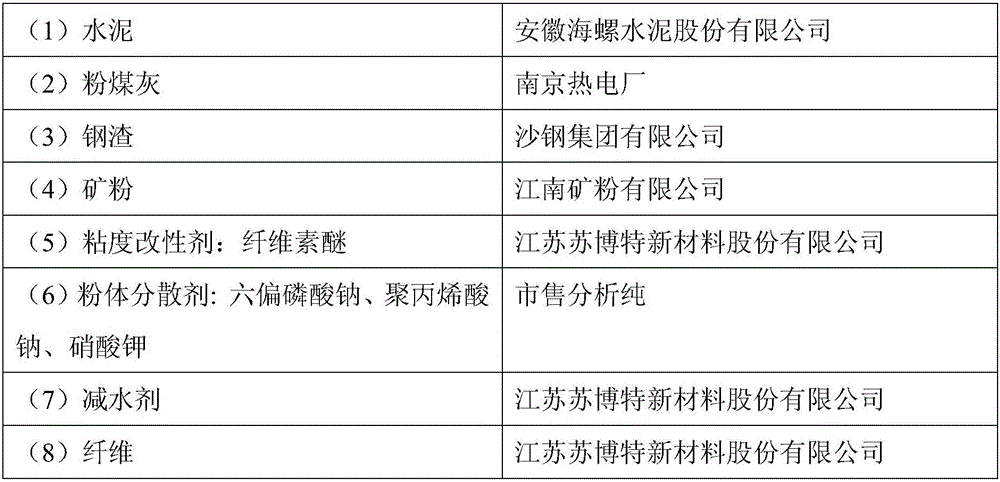

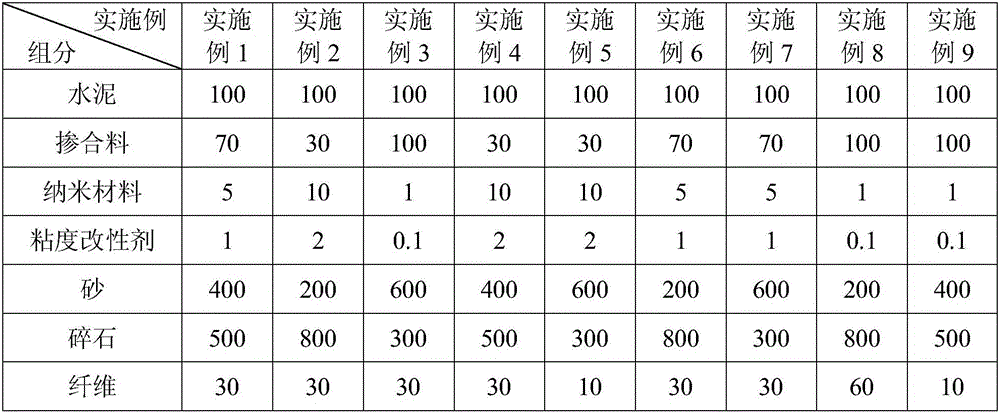

Concrete with common strength and high elastic modulus and preparation method thereof

The invention discloses concrete with common strength and high elastic modulus and a preparation method thereof. The concrete with common strength and high elastic modulus, disclosed by the invention, is prepared from the following components in parts by mass: 100 parts of cement, 30-100 parts of an admixture, 1-10 parts of a nano material, 0.1-2 parts of a viscosity modifier, 200-600 parts of sand, 300-800 parts of crushed stones, 10-60 parts of fibers, 0.5-5 parts of a water reducing agent, 0.1-0.5 part of a powder dispersant and 50-90 parts of water. After the concrete with common strength and high elastic modulus, disclosed by the invention, is subjected to standard curing or natural curing for 28d, the strength grade of the concrete is C40-C50, and the elastic modulus can reach 50GPa or more; and the concrete has excellent working performance and endurance performance.

Owner:JIANGSU SOBUTE NEW MATERIALS

Sand texture type polyester/epoxy powder coating and preparation method thereof

InactiveCN103160192AImprove thermal stabilityImprove scratch resistance and anti-agingPowdery paintsEpoxy resin coatingsEpoxyPollution

The invention discloses a sand texture type polyester / epoxy powder coating and a preparation method thereof. The sand texture type polyester / epoxy powder coating comprises the following raw materials, by weight, 350-400 parts of polyester resin (P5040), 240-280 parts of epoxy resin (E-12), 100-150 parts of extinction barium sulfate, 40-60 parts of spherical silica powder, 8-12 parts of modified polyethylene wax powder, 10-15 parts of organic coated titanium dioxide, 5-10 parts of sand texture agent (SWMBX-30), 4-6 parts of benzoin, 5-8 parts of 2-phenyl imidazoline, 4-6 parts of 2-methylimidazole, 5-10 parts of ferrite yellow, 5-10 parts of iron oxide red and 10-15 parts of carbon black. The prepared powder coating has the advantages of being high in hardness, high in intensity, high in abrasion resistance, good in heat resistance, good in ageing resistance, short in solidifying time, environment-friendly, free of pollution and the like. The solidified coating produces a texture effect of the sand texture, the sand texture is meticulous and clear, distribution is even, visual comfort is provided for people, and combination properties of the coating are good.

Owner:ANHUI HUAHUI SUYE TECH SHARE CO LTD

Dispersion liquid of chemical for rubbers, method for producing same, rubber wet master batch containing chemical for rubbers, rubber composition, and tire

Owner:BRIDGESTONE CORP

High-dielectric elastomer composite material with low content of carbon nanometer tubes and preparation method of composite material

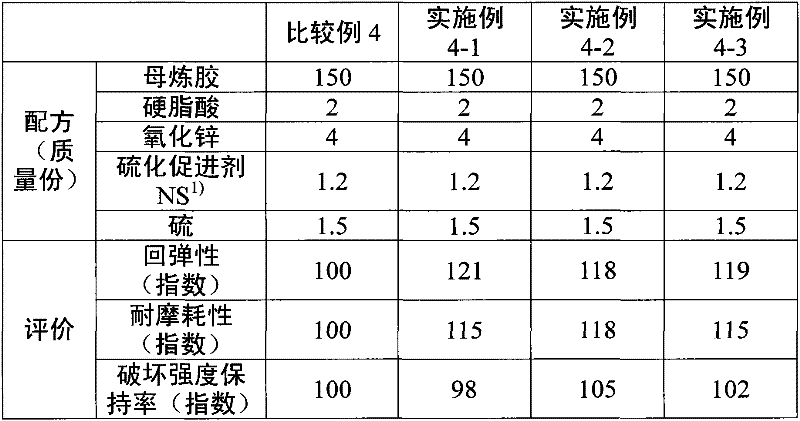

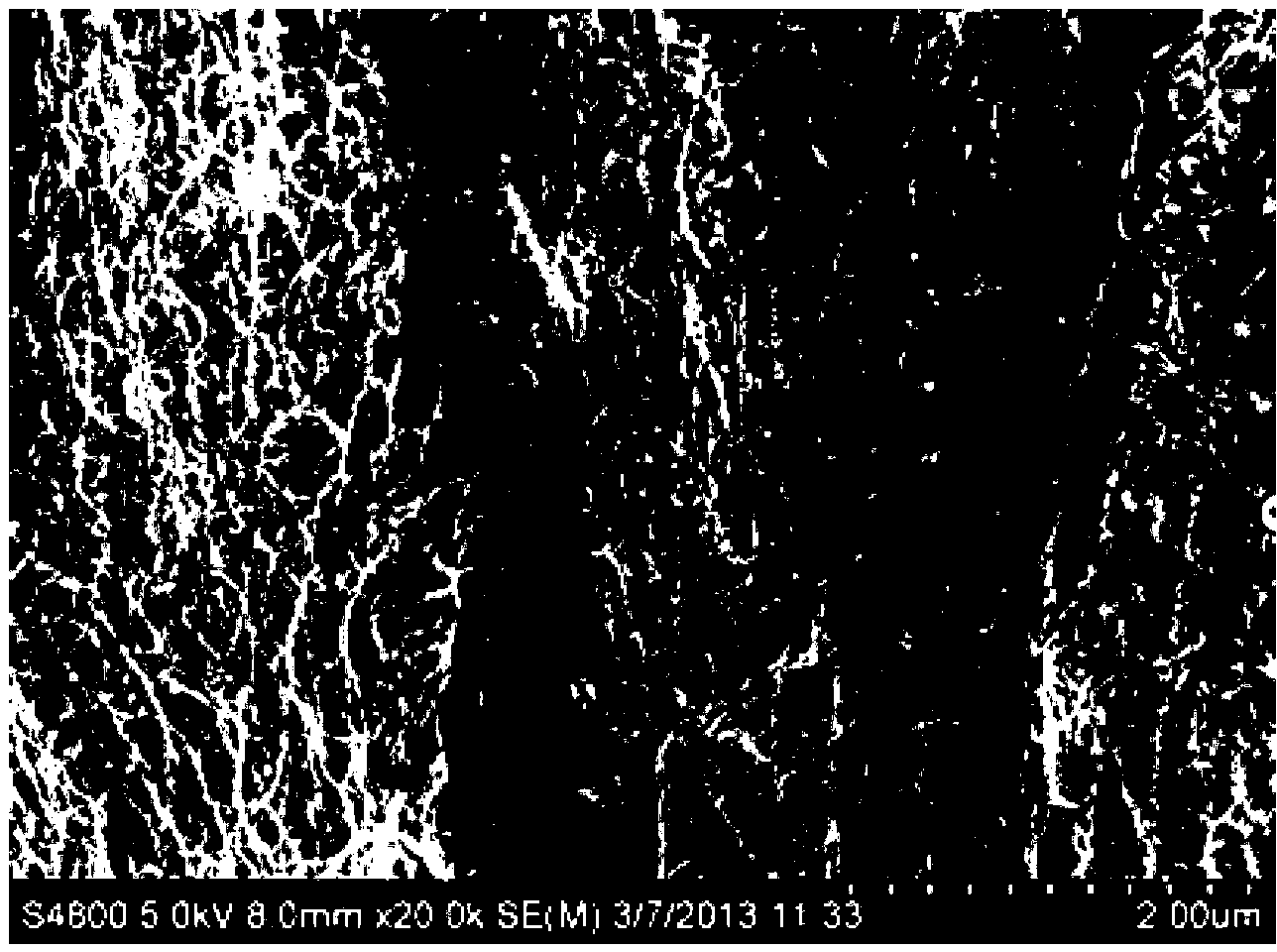

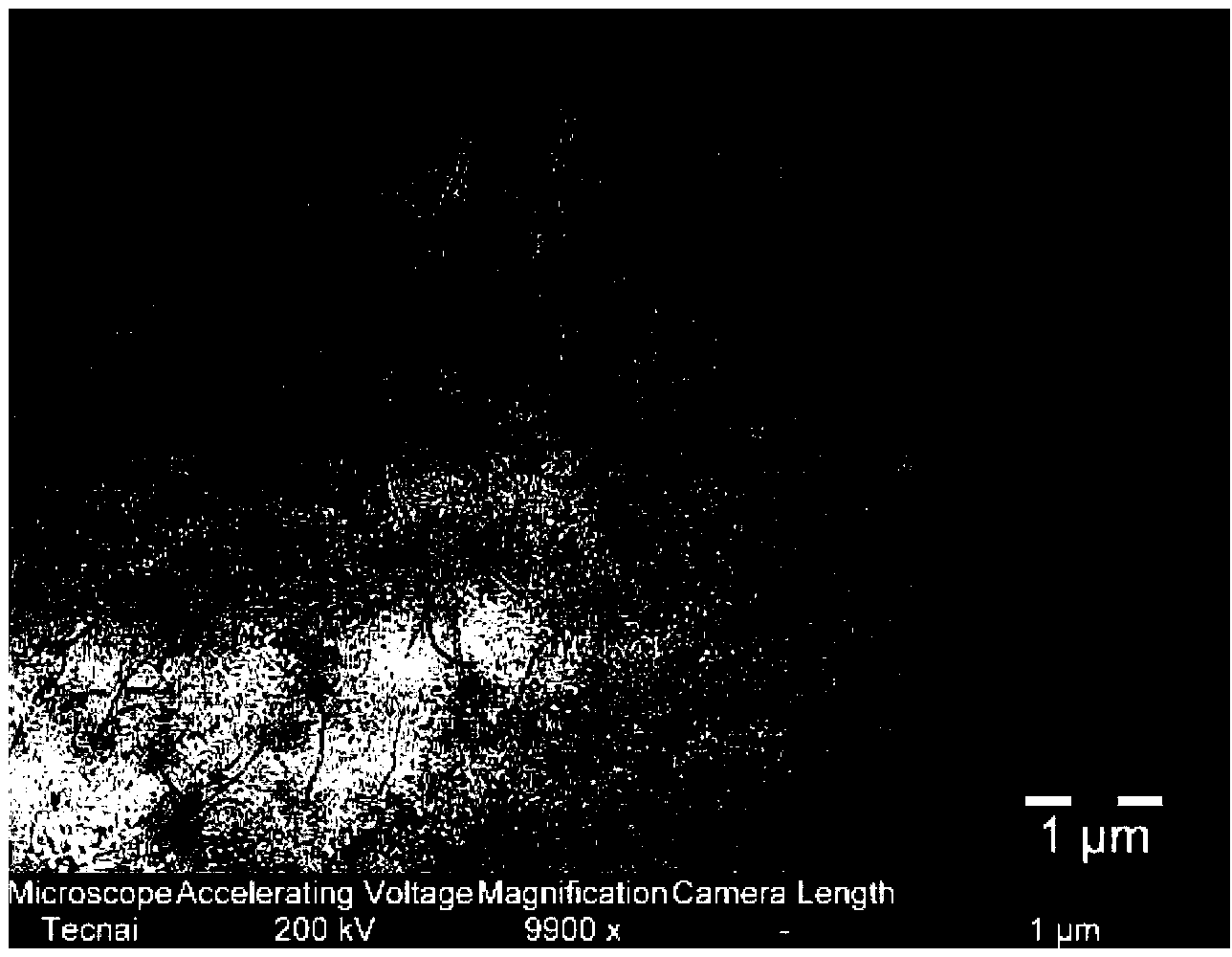

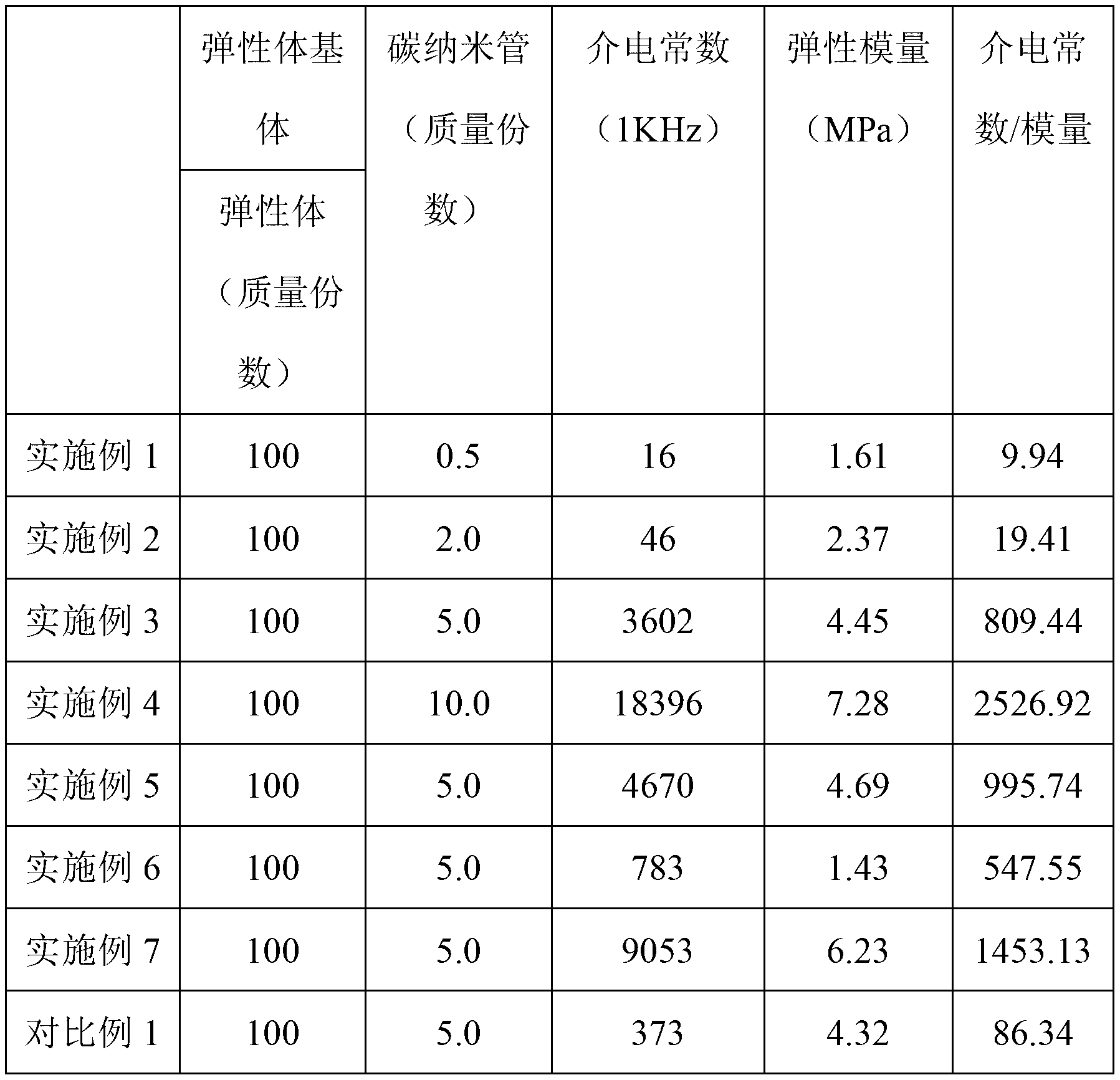

ActiveCN103214707AHigh dielectric constantHigh dielectric constant/modulus ratioDielectricElastomer composites

The invention discloses a high-dielectric elastomer composite material with low content of carbon nanometer tubes and a preparation method of the composite material and belongs to an elastomer composite material. The high-dielectric elastomer composite material contains the following components in parts by weight: 100 parts of elastomers, 0.5-10 parts of array carbon tubes, 0 or 0.5-12 parts of a vulcanizing agent, and 0 or 1-7 parts of a vulcanizing-assisting agent, wherein when the elastomers are rubber matrixes, the vulcanizing agent and the vulcanizing-assisting agent are needed; and when the elastomers are thermoplastic elastomer matrixes, the vulcanizing agent and the vulcanizing-assisting agent are not needed. The composite material is prepared by a mechanical blending method. The composite material with good dispersing performance is obtained by means of adding the array carbon tubes with a one-dimensional orientation arrangement structure, the dielectric constant of the elastomer can be enhanced greatly under the condition of a low stuffing content, simultaneously the modulus of the elastomer is not increased remarkably and a high ratio value of dielectric constant / modulus is obtained.

Owner:BEIJING UNIV OF CHEM TECH

Cr/CrN/(Ti, Al, Si, Cr)N composite hard coating and preparation method thereof

InactiveCN103789723AIncrease ionization rateImprove bindingVacuum evaporation coatingSputtering coatingIntermediate frequencyAlloy

The invention discloses a preparation method of a Cr / CrN / (Ti, Al, Si, Cr)N composite hard coating. The preparation method comprises the steps of pretreatment, heating, plasma cleaning, Cr adhesion layer preparation, CrN transition layer preparation, (Ti, Al, Si, Cr)N anti-wearing layer preparation and the like. As a plasma enhanced intermediate frequency reaction magnetron sputtering technology is adopted in the preparation method provided by the invention, the ionization rate of a target material is substantially increased, so that the surface nano-hardness of the prepared composite hard coating can reach above 34 GPa, and the membrane base bonding force grade of the hard coating is HF1-HF2 of German Standard VDI3198. Therefore, the preparation method is suitable for preparation of the coating for high-speed dry-type cutting stainless steel, iron-based high-temperature alloy, high-strength constructional steel and anti-wearing cast steel cutters. The coating is simple in process and suitable for industrial production.

Owner:SICHUAN UNIV

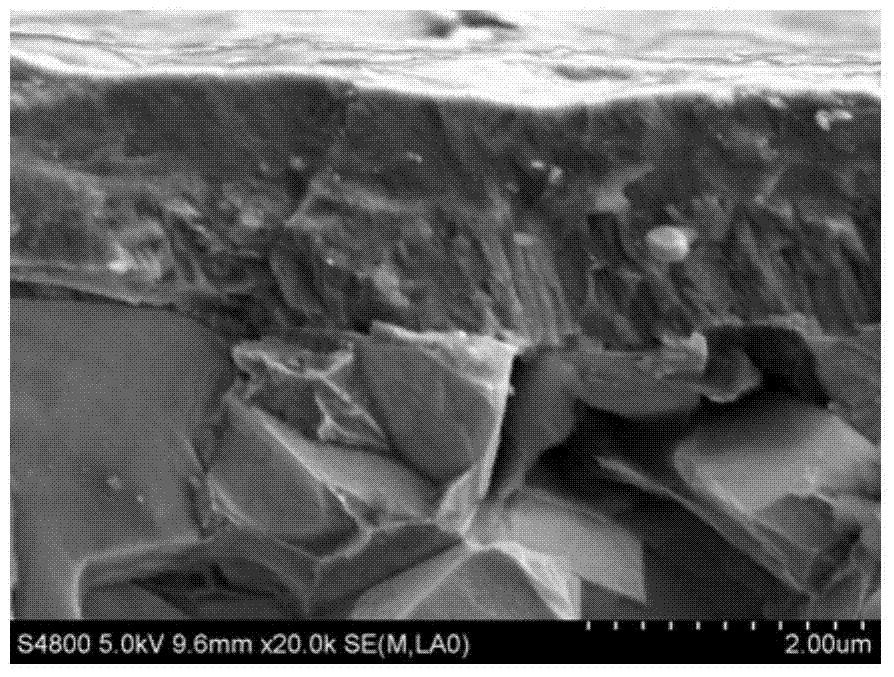

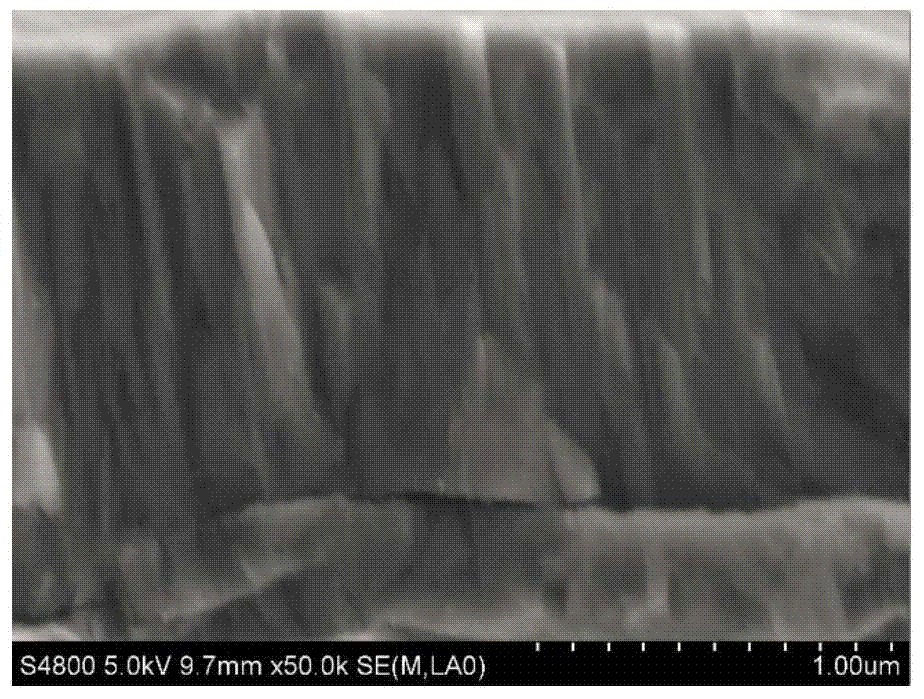

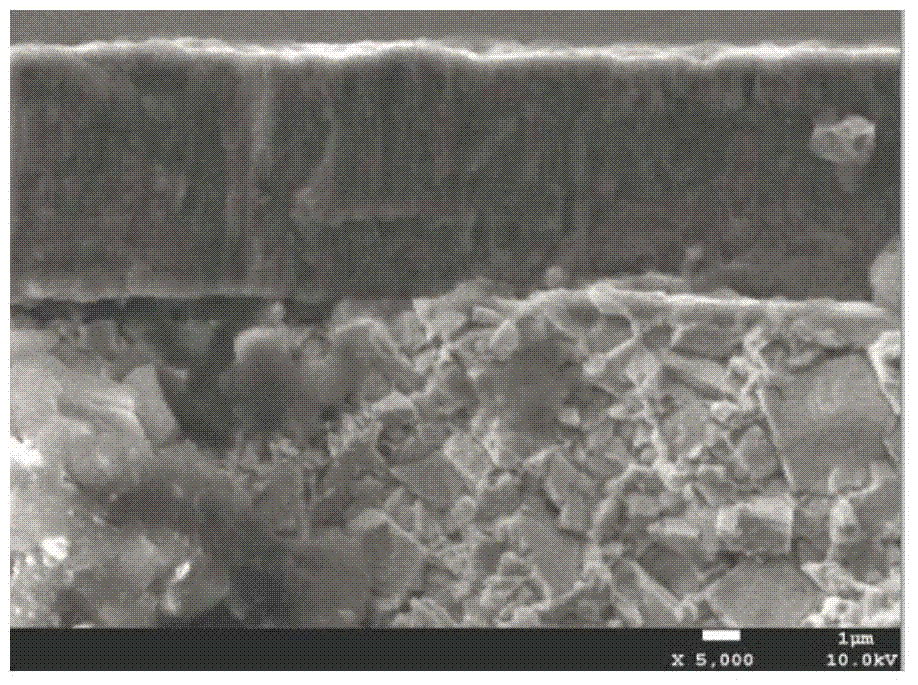

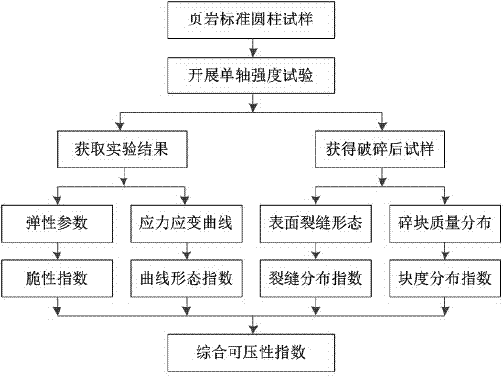

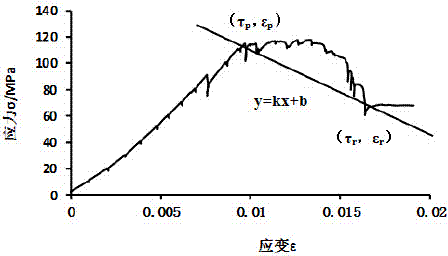

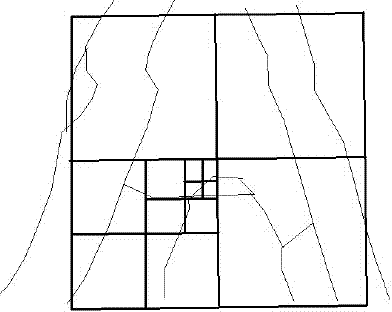

Shale compressibility comprehensive evaluation method based on uniaxial strength experiment

InactiveCN104777035AThe experimental process is simple and easyLow equipment requirementsMaterial strength using tensile/compressive forcesMass distributionElastic modulus

The invention provides a shale compressibility comprehensive evaluation method based on uniaxial strength experiment. The method comprises the steps of (1) taking a shale core sample for executing uniaxial compressive strength test, testing an elasticity parameter, and drawing a stress-strain curve diagram; (2) calculating normalized elasticity modulus and normalized poisson ratio to obtain a brittleness index; (3) obtaining key points on the stress-strain curve, and calculating the shape index of the stress-strain curve; (4) obtaining fracture distribution diagram of the side face of the fixed sample, and calculating a fracture distribution index through box-counting dimension method; (5) measuring spallation fragment mass distribution at different scales through a screen and a balance so as to obtain a block distribution index; and (6) calculating arithmetic mean value of the obtained brittleness index, shape index of the stress-strain curve, fracture distribution index and block distribution index of fragments to get the comprehensive compressibility index. The method provided by the invention is used for evaluating fracture net forming capability of the shale after being compressed, the experiment is simple and easy to carry out, and post treatment is visual and simple, so that the method is suitable for indoor evaluation and oilfield in-site application.

Owner:SOUTHWEST PETROLEUM UNIV

Preparation method of full biodegradation film

The invention discloses a preparation method of a full biodegradation film, which takes poly adipic acid / polybutylene terephthalate (PBAT) and starch as base materials, poly-epsilon carpolaction (PCL), epoxidized soybean oil (ESO), and phosphorous acid dialkyl ester as plasticizers, and montmorillonoid or calcium carbonate, talcum powder and the like as inorganic fillers. The method comprises the steps that modification and pelleting are performed in a twin screw; modified resin is added to a film blowing machine for film blowing; and the full biodegradation film can be obtained finally. The full biodegradation film produced by the method is better in physical characteristic, can be directly prepared into a film bag, and can serve as a daily-used packaging film, a waistcoat bag, a food packaging bag and the like; the preparation method of the full biodegradation film is simple in technology, and easy to control, and is suitable for industrial mass production; the film bag produced by the method is high in strength, can be biodegraded fully after use, and is easy to dispose; and environmental pollution is reduced.

Owner:DONGGUAN XINHAI ENVIRONMENT PROTECTION MATERIAL

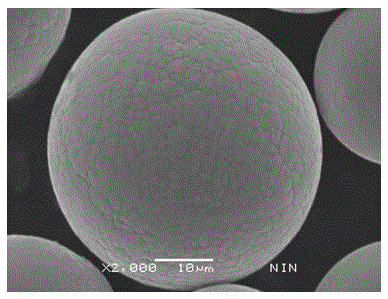

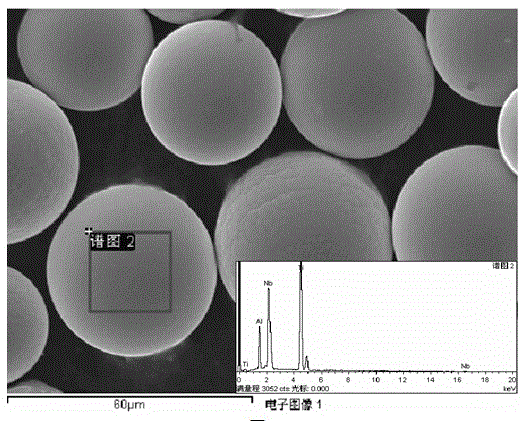

Preparing method for ultra-fine high-purity Ti2AlNb alloy powder

ActiveCN105537603AHigh purityHigh sphericityTransportation and packagingMetal-working apparatusAlloyUltra fine

The invention provides a preparing method for ultra-fine high-purity Ti2AlNb alloy powder. The preparing method comprises the following steps that 1, components of a Ti2AlNb base alloy are used as ingredients and smelted into a Ti2AlNb alloy bar; 2, finish turning is carried out on the smelted Ti2AlNb alloy bar, the diameter of a processed electrode bar ranges from 10 mm to 100 mm, and the length ranges from 100 mm to 1000 mm; 3, the electrode bar is loaded into a reaction chamber, the reaction chamber is vacuumized, and helium or argon or helium and argon mixed gas is introduced into the reaction chamber; 4, plasma gun powder of PREP powder manufacturing equipment ranges from 100 kW to 300 kW, a plasma torch comprises a tungsten cathode and a copper anode, the electrode bar is not used as an electrode, the end of the electrode bar is heated to be melted uniformly, atomized drops are tossed out from the end of the electrode bar, the drops are cooled fast in an inert gas environment to form spherical particles, and the spherical particles drop into a bottom collector of the reaction chamber; 5, prepared Ti2AlNb alloy powder is screened and packaged in the inert gas protection environment; 6, the Ti2AlNb alloy powder prepared through the method has the advantages of being ultra-fine, high in purity, high in spherical degree and low in oxygen content.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

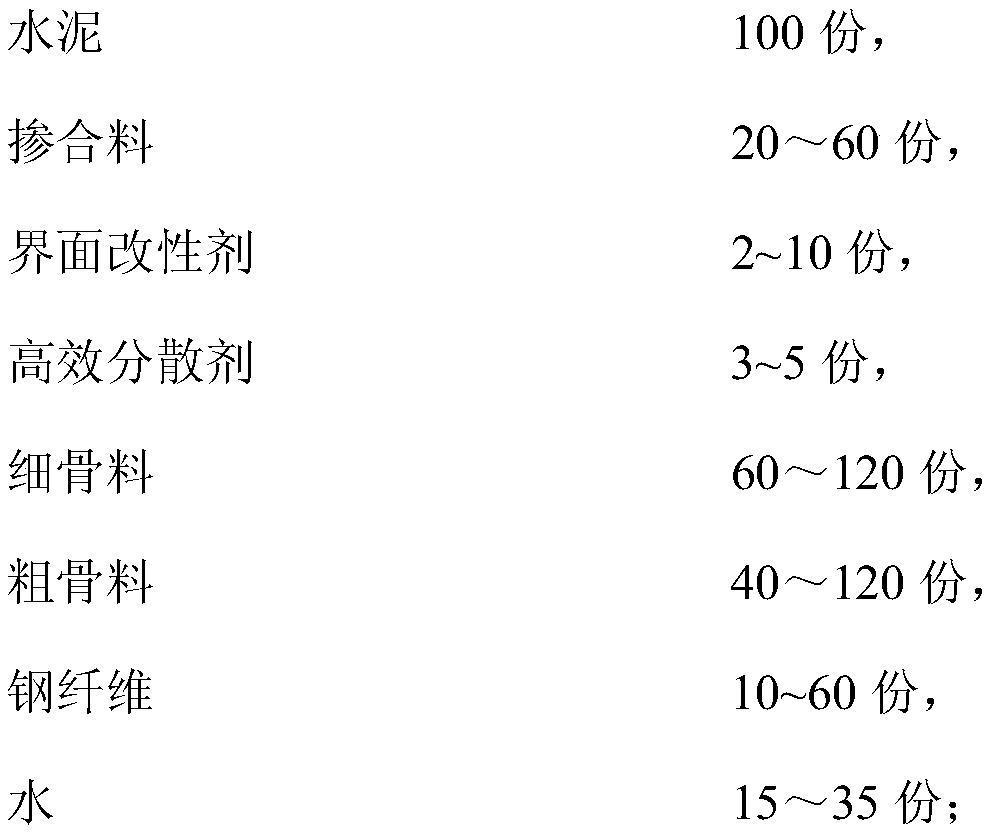

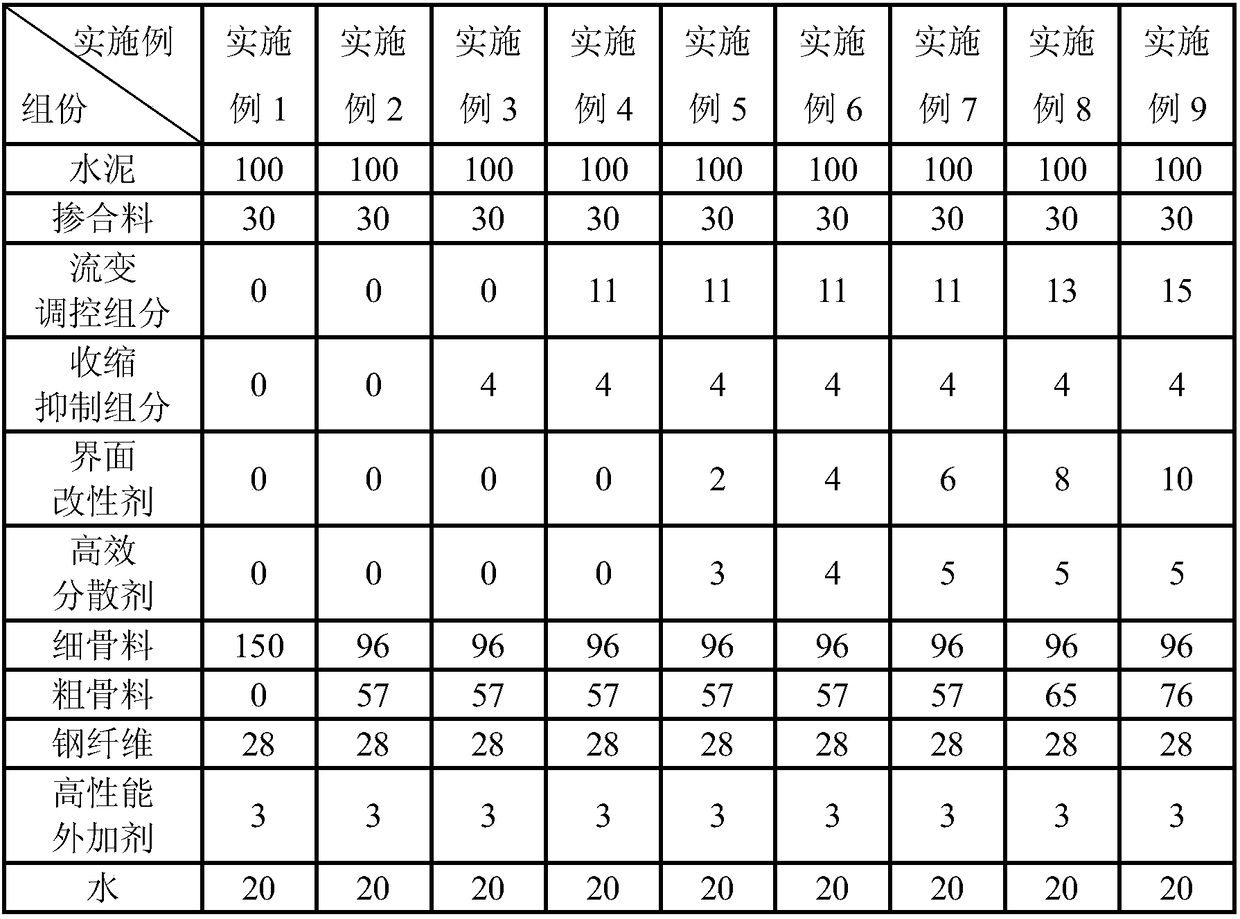

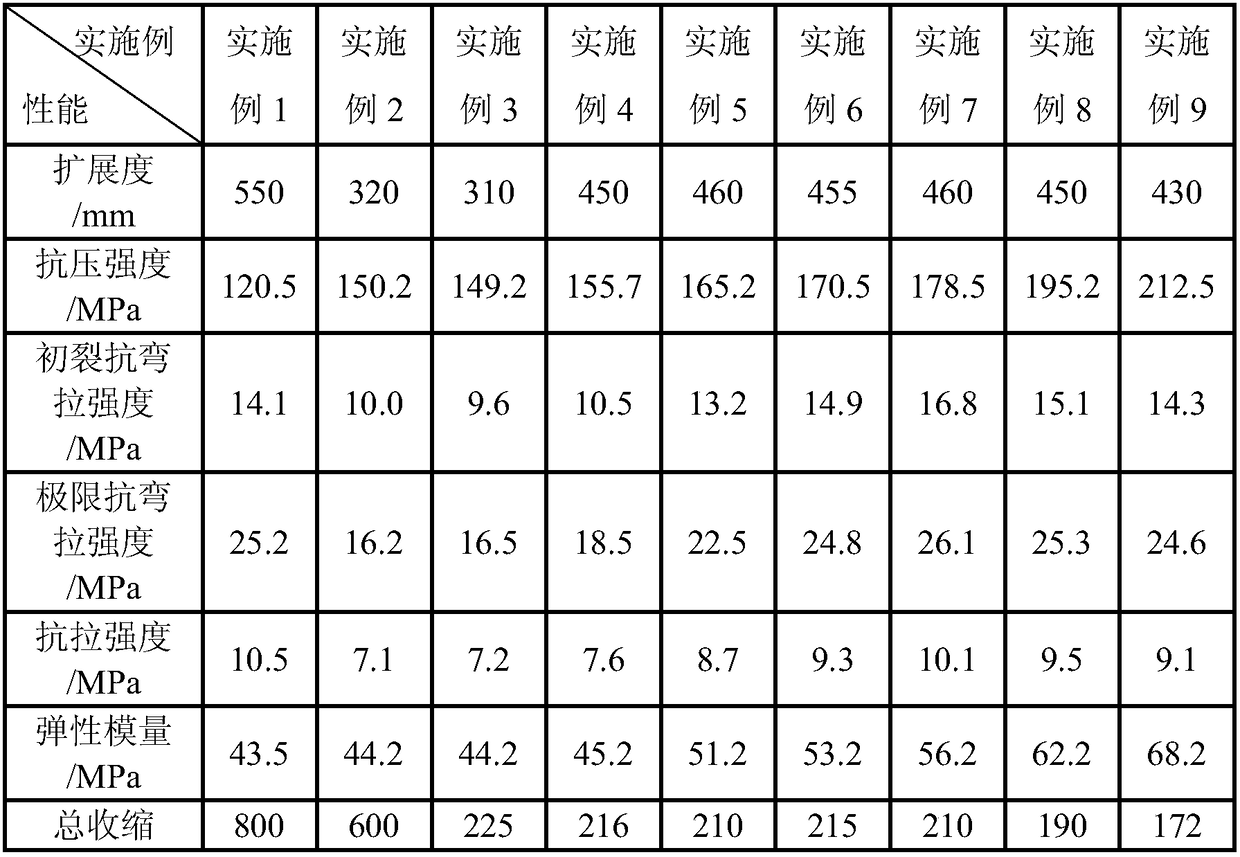

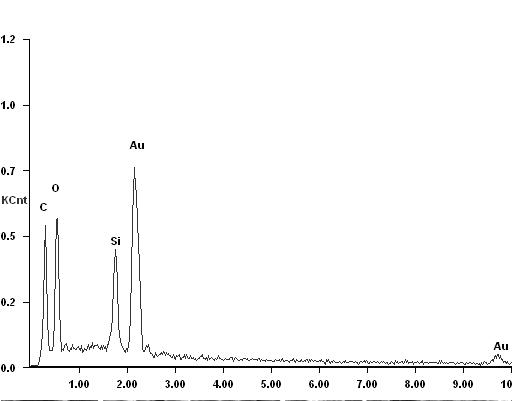

Bridge coarse aggregate active powder concrete and preparation method thereof

The invention discloses bridge coarse aggregate active powder concrete and a preparation method thereof. The coarse aggregate active powder concrete comprises, by weight, 100 parts of cement, 20-60 parts of blending materials, 2-10 parts of interface modifying agents, 60-120 parts of fine aggregates, 40-120 parts of coarse aggregates, 10-60 parts of fibers and 15-30 parts of water. Under conventional curing processes such as natural conditions, the coarse aggregate active powder concrete has super-high compressive strength, bending tensile strength and tensile strength and bonding strength andlow contraction performance and further has high elasticity modulus, anti-fatigue performance and durable performance and excellent construction performance, dead weight and shrinkage and creep influence of a bridge can be reduced, and the span, the structural stiffness and the bearing capacity of the bridge can be remarkably improved, and the service life of the bridge is prolonged.

Owner:南京市公共工程建设中心 +3

Polyoxymethylene fiber and method for production thereof

InactiveCN1555430AIncrease productivityHigh strengthMonocomponent polyethers artificial filamentFilament/thread formingMolten stateFiber

A polyoxymethylene fiber which comprises a polyoxymethylene copolymer which exhibits a half crystallization time of 30 sec or more when it is cooled from the molten state at 200 DEG C to 150 DEG C at a cooling rate of 80 DEG C / min and then is held at 150 DEG C constantly. The polyoxymethylene fiber has a high strength and a high modulus of elasticity.

Owner:POLYPLASTICS CO LTD

Method for preparing coal mine filling paste by utilizing waste concrete

The invention discloses a method for preparing a coal mine filling paste by utilizing waste concrete, and belongs to the technical field of cementation filling materials. The method comprises the steps: crushing the waste concrete and coal gangue, sieving, and allowing to become a powder having the particle size smaller than 1 mm, a fine aggregate with the particle size of 1-5 mm and a coarse aggregate with the particle size of 5-15 mm; then adding an admixture, raw lime and a gypsum solid into the powder with the particle size of less than 1 mm, stirring uniformly, then carrying out ball milling, and thus obtaining an ultrafine powder with the specific surface area of greater than or equal to 300 m<2> / kg; and finally, mixing and stirring cement, the fine aggregate, the coarse aggregate, the ultrafine powder, a conditioning agent and water to obtain the coal mine filling paste. The waste concrete is fully recycled under a condition without calcination, and thus the problems of land occupation and ecological environment destruction are solved, besides, more adequate cheap raw materials are provided for coal mine filling and mining, the filling cost is reduced, and a foundation is laid for full implementation of a filling and mining technology.

Owner:TAIYUAN UNIV OF TECH

Preparation method of organic and inorganic wood composite material

ActiveCN101905471AGood dimensional stabilityImprove anti-corrosion performanceWood impregnation detailsWeather resistanceHardness

The invention discloses a preparation method of an organic and inorganic wood composite material, relating to the preparation method of a composite material and solving the problems that the wood composite material prepared by the traditional method has poor durability and mechanical property. The method comprises the following steps of: firstly, pre-polymerizing a monomer; secondly, preparing dilute sol; thirdly, impregnating the wood with the dilute sol under the vacuum-pressurizing condition; and fourthly, heating the impregnated wet wood to obtain the organic and inorganic wood composite material. The organic and inorganic wood composite material has higher strength-to-weight ratio; and compared with the wood, the hardness, the wearing resistance, the bending strength, the elastic modulus, the parallel-to-grain compressive strength and other mechanical properties of the organic and inorganic wood composite material are improved by 5 times to maximum extent; and the dimensional stability and the antiseptic property of the organic and inorganic wood composite material are improved by over 50-70 percent. In addition, the duality test shows that the thermal stability and the weather resistance of the organic and inorganic wood composite material are remarkably improved.

Owner:NORTHEAST FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com