Self-heat-insulating fly ash autoclaved aerated concrete block and preparation method thereof

A technology of concrete blocks and autoclaved air filling, which is applied in the field of building wall materials, can solve the problems of poor thermal insulation performance, rare self-insulating blocks, and high dry density of blocks, and achieves small heat transfer resistance and high raw material Sufficient sources and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

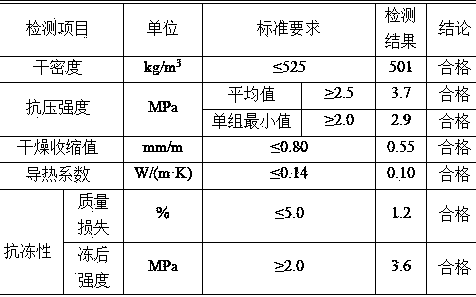

Embodiment 1

[0030] A self-insulating fly ash autoclaved aerated concrete block, the concrete block includes the following components by weight ratio: 1400 kg of fly ash, 330 kg of cement, 390 kg of quicklime, 100 kg of slaked lime, and 50 kg of desulfurized gypsum kg, block waste 255 kg, aluminum powder paste 2.90 kg, acacia powder 0.50 kg. The loss on ignition of the fly ash is not more than 8%, and the sieve residue of the square hole sieve with a fineness (45 μm) is less than 20%. The block waste is leftovers produced during the cutting of autoclaved aerated concrete blocks. The aluminum powder paste is a water-based aluminum powder paste.

[0031] The preparation method of the above-mentioned self-insulating fly ash autoclaved aerated concrete block comprises the following steps:

[0032] 1) After the quicklime is crushed with a jaw crusher, it is ground with a ball mill until the fineness is 0.08 mm and the sieve with a square hole does not exceed 10% of the powder;

[0033] 2) Mi...

Embodiment 2

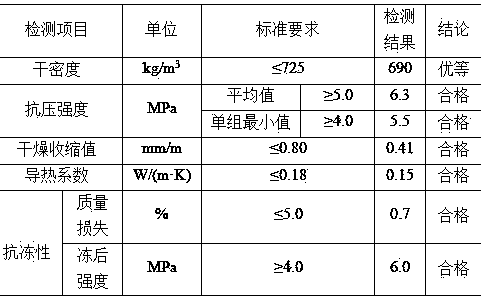

[0040] A self-insulating fly ash autoclaved aerated concrete block, the concrete block includes the following weight ratio components: 1710 kg of fly ash, 370 kg of cement, 405 kg of quicklime, 150 kg of slaked lime, and 50 kg of desulfurized gypsum , block waste 270 kg, aluminum powder paste 2.75 kg, tea saponin 0.45 kg. The loss on ignition of the fly ash is not more than 8%, and the sieve residue of the square hole sieve with a fineness (45 μm) is less than 20%. The block waste is leftovers produced during the cutting of autoclaved aerated concrete blocks. The aluminum powder paste is a water-based aluminum powder paste.

[0041] The preparation method of the above-mentioned self-insulating fly ash autoclaved aerated concrete block comprises the following steps:

[0042] 1) After the quicklime is crushed with a jaw crusher, it is ground with a ball mill until the fineness is 0.08 mm and the sieve with a square hole does not exceed 10% of the powder;

[0043] 2) Mix fly a...

Embodiment 3

[0050] A self-insulating fly ash autoclaved aerated concrete block, the concrete block includes the following weight ratio components: 1890 kg of fly ash, 380 kg of cement, 455 kg of quicklime, 175 kg of slaked lime, and 65 kg of desulfurized gypsum , block waste 310 kg, aluminum powder paste 2.40 kg, pull apart powder 0.35 kg. The loss on ignition of the fly ash is not more than 8%, and the sieve residue of the square hole sieve with a fineness (45 μm) is less than 20%. The block waste is leftovers produced during the cutting of autoclaved aerated concrete blocks. The aluminum powder paste is a water-based aluminum powder paste.

[0051] The preparation method of the above-mentioned self-insulating fly ash autoclaved aerated concrete block comprises the following steps:

[0052] 1) After the quicklime is crushed with a jaw crusher, it is ground with a ball mill until the fineness is 0.08 mm and the sieve with a square hole does not exceed 10% of the powder;

[0053] 2) Mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com