Patents

Literature

137 results about "Loss on ignition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

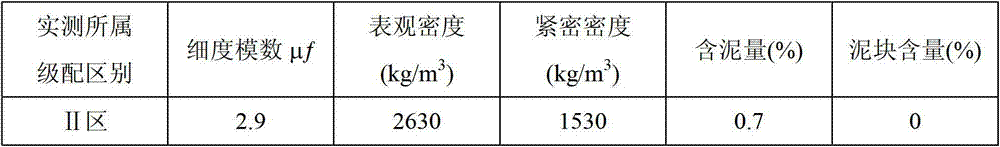

Loss on ignition is a test used in inorganic analytical chemistry, particularly in the analysis of minerals. It consists of strongly heating ("igniting") a sample of the material at a specified temperature, allowing volatile substances to escape, until its mass ceases to change. This may be done in air, or in some other reactive or inert atmosphere. The simple test typically consists of placing a few grams of the material in a tared, pre-ignited crucible and determining its mass, placing it in a temperature-controlled furnace for a set time, cooling it in a controlled (e.g. water-free, CO₂-free) atmosphere, and redetermining the mass. The process may be repeated to show that mass-change is complete. A variant of the test in which mass-change is continually monitored as the temperature is changed, is thermogravimetry.

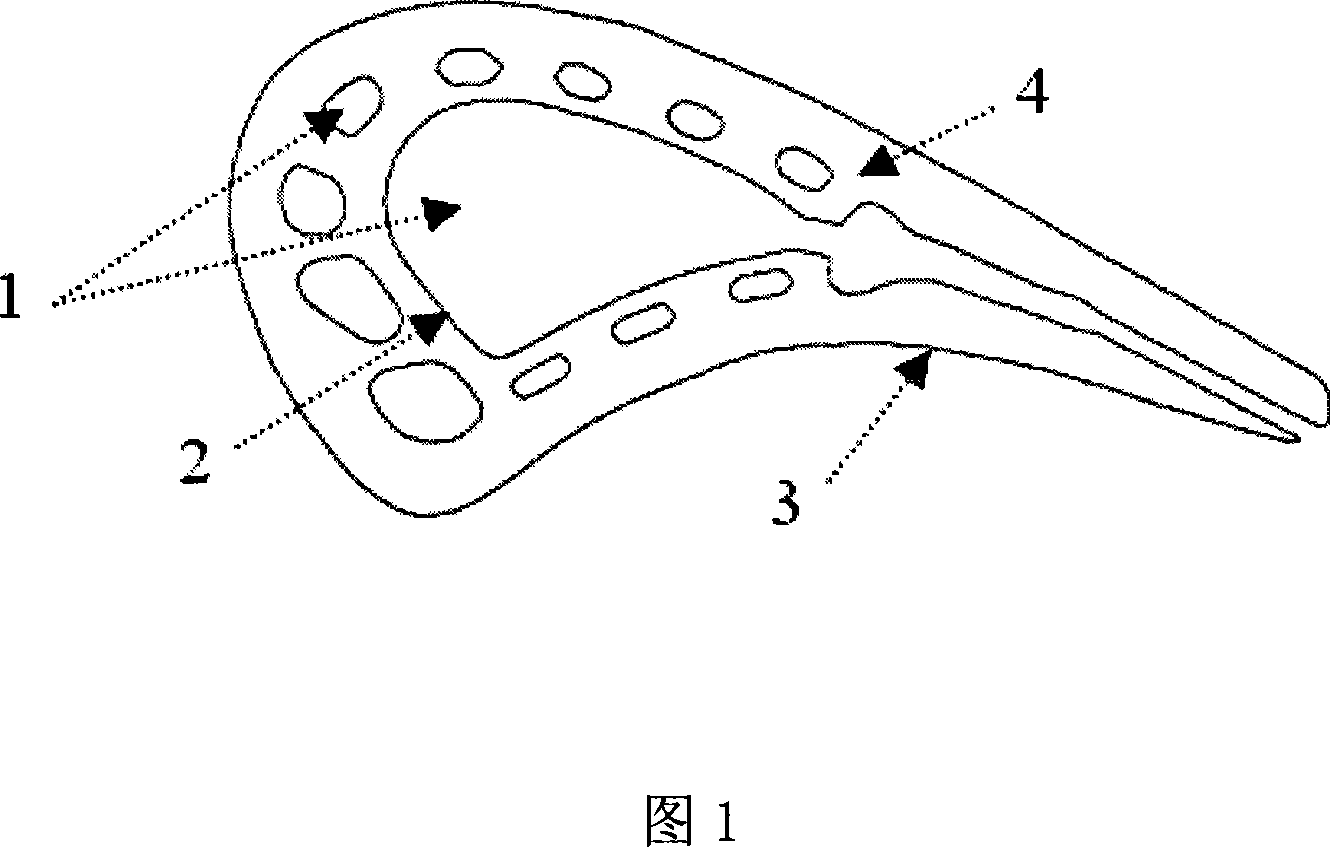

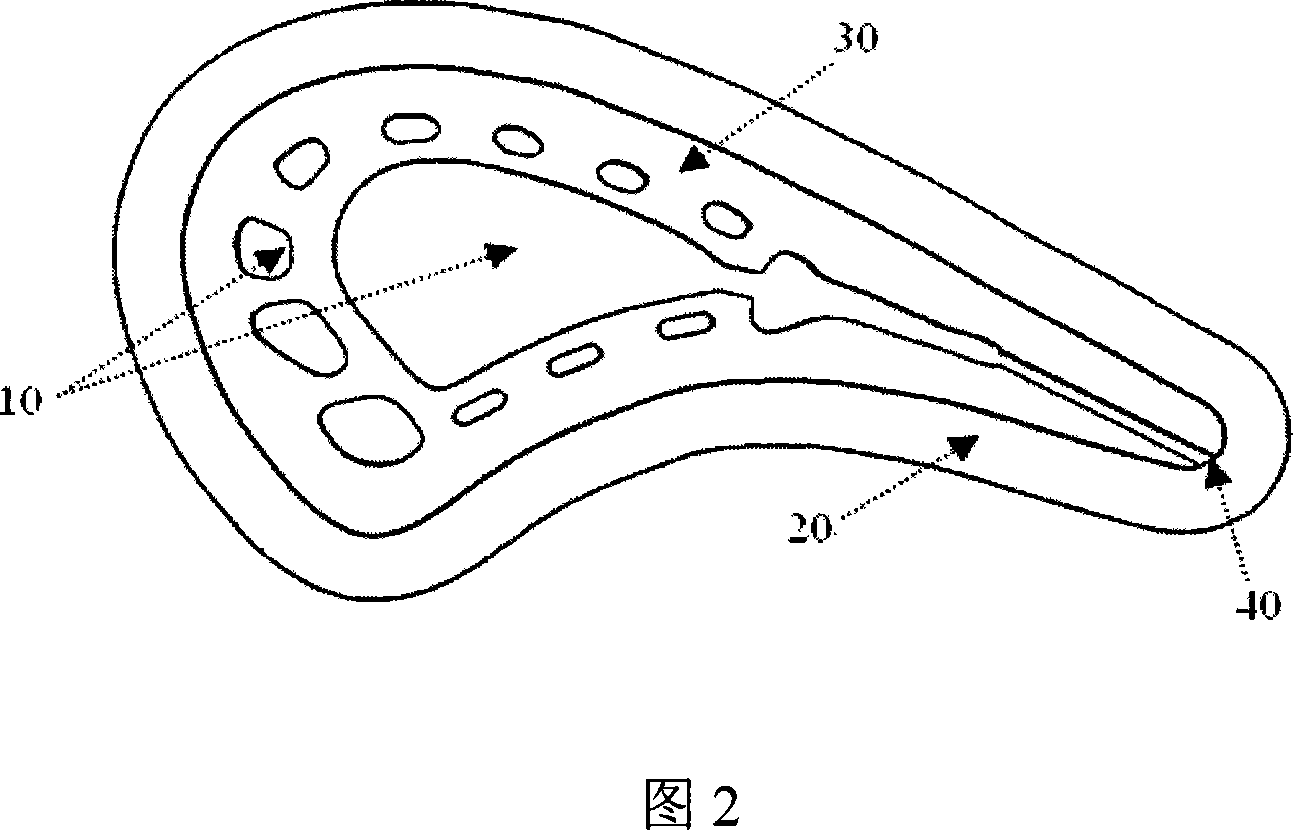

Method for casting mould core and shell integrated ceramic

ActiveCN101073821AHigh mutual position accuracyShort core making timeFoundry mouldsFoundry coresSlurryLoss on ignition

The invention is concerned with a kind of ceramic mould method with integrated mould core and mould shell. At first, produce the resin mould with loss-on-ignition character with laser quick shaped technology and the resin mould has complex inner cavity and figure structure to form integrated cooling channel. Mix ceramic grain, organic substance and deionwater into ceramic slurry and keep the ceramic slurry filling the whole resin mould by controlling the pressure of ceramic slurry. Pour the slurry with vibration to get close-grained ceramic mould core and mould shell, after solidify, the mould core and mould shell will connect with through ceramic slurry and it gets the integrated ceramic mould by drying, heating to degrease and sintering. The ceramic mould core and mould shell connects as a whole and formed in once without assembly and this keep the precision of position between ceramic mould core and mould shell. This ceramic mould is fit to produce the mould with thin wall and complex cavity structure, such as gas turbine engine vane and enhances the percent of pass to mould greatly.

Owner:XI AN JIAOTONG UNIV

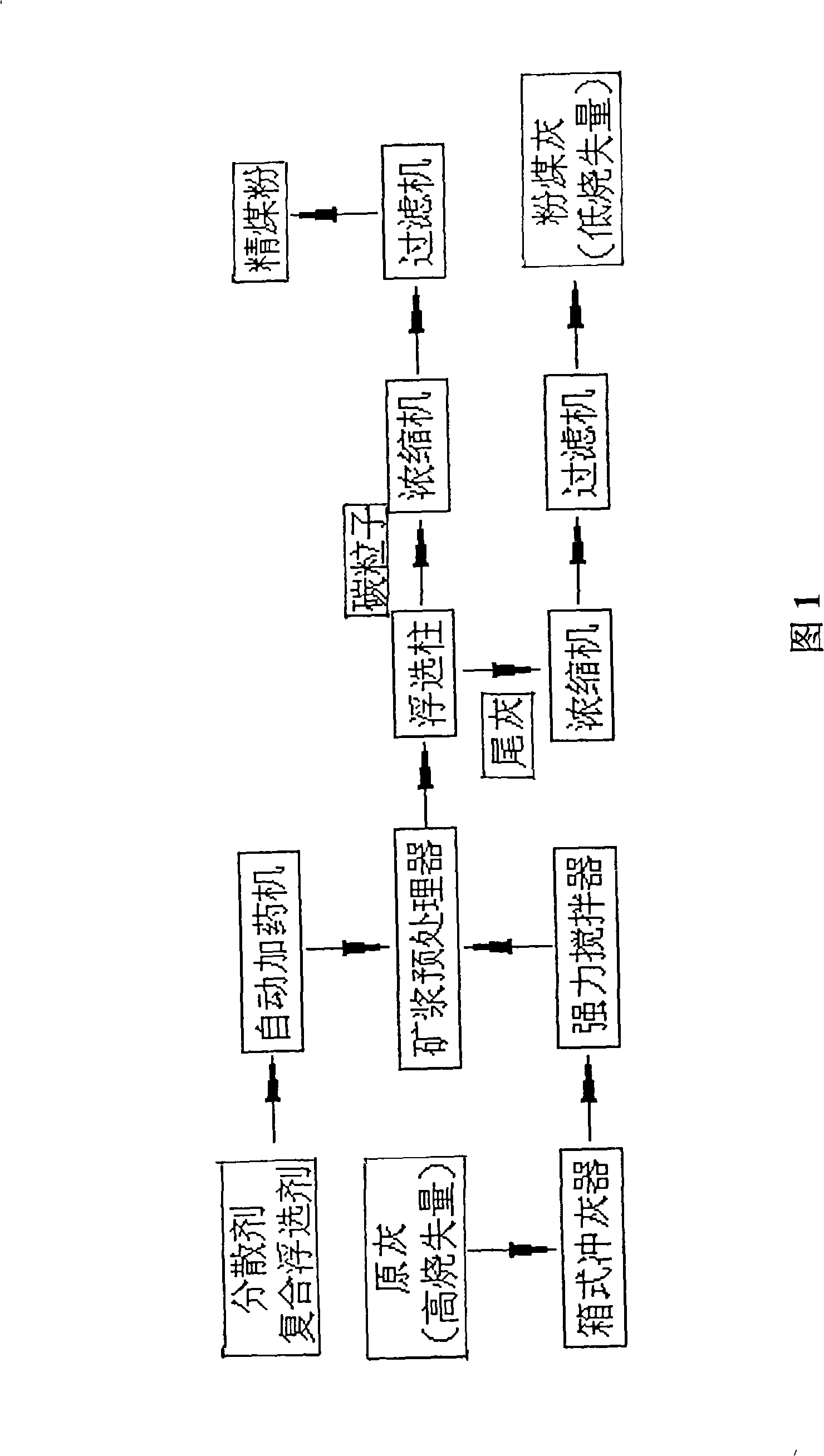

Technique for decarbonizing fly ash with high ignition loss

InactiveCN101284256ASolve the problem of pipe blockageGuaranteed uptimeFlotationEconomic benefitsPulverized fuel ash

The invention relates to a decarbonization technology of coal fly ash with over-standard loss on ignition, original ash of the coal fly ash is sent to an ash storage tank of a treatment plant by a bulk tank car and sent to an ore pulp pre-processor after the measurement, an automatic dosing machine also adds a dispersant and a compound flotation agent into the ore pulp pre-processor for carrying out mixing and stirring, the output of the ore pulp pre-processor after the treatment enters a coal ash special flotation column, carbon particles are separated from the fly ash by the floatation, the carbon particles and the fly ash which are respectively collected are respectively concentrated by a concentrator, filtered by a filter and dehydrated, thus becoming fine coal powder and the coal flay ash with the low loss on ignition. The decarbonization technology can fully utilize the coal fly ash stacked by a power plant, thus generating substantial economic benefits; the coal fly ash during the operation can achieve the zero emission, which can protect environment, increase efficiency and save investment.

Owner:贵州安顺惠海粉煤灰开发有限公司

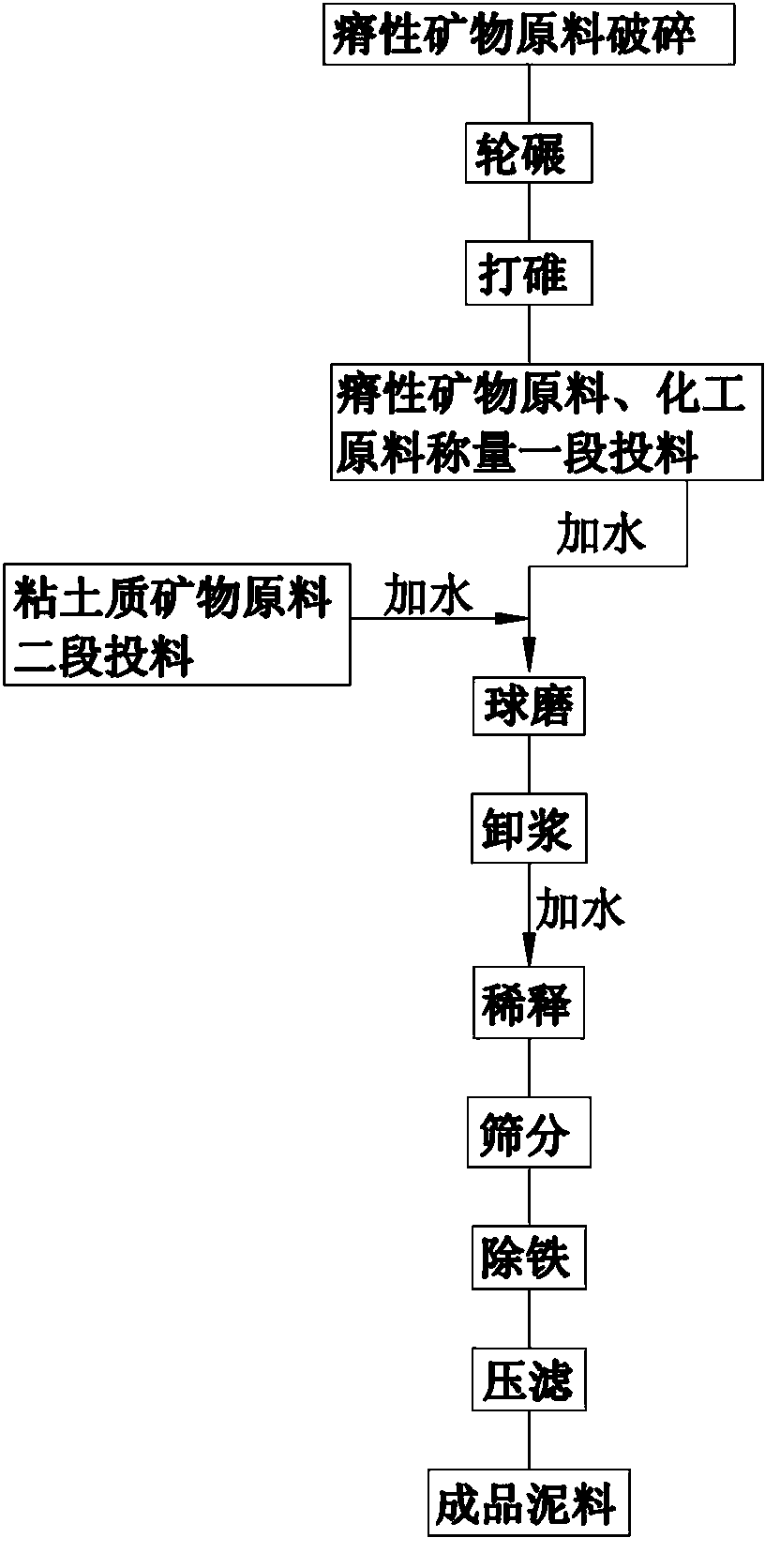

Formula of body mud of high-glass-phase stoneware and preparation process of body mud

The invention relates to a formula of body mud of high-glass-phase stoneware and a preparation process of the body mud. The formula comprises the following chemical components by mass percent: 60.0-67.0% of SiO2, 10.0-14.0% of Al2O3, 8.0-12.0% of MgO, 0.5-2.0% of CaO, 1.0-2.5% of K2O, 0.5-2.0% of Na2O, 3.0-5.0% of BaO and 4-6.5% of loss on ignition. The body mud is prepared according to the formula and the high-glass-phase stoneware is prepared through the processes of body preparing, glazing, firing and the like. By constructing phase equilibrium between polycrystalline phases and material phases in the stoneware body material, the stoneware body material is endowed with the process properties of low firing temperature, short firing time, wide range, low shrinkage, high glass phase and light weight and the economic and technical indexes of energy conservation, consumption reduction and efficiency increase. The body mud has application prospects in the production fields such as top-grade household porcelains, art porcelains, heat insulation porcelains and the like.

Owner:FUJIAN WILL CERAMIC CO LTD

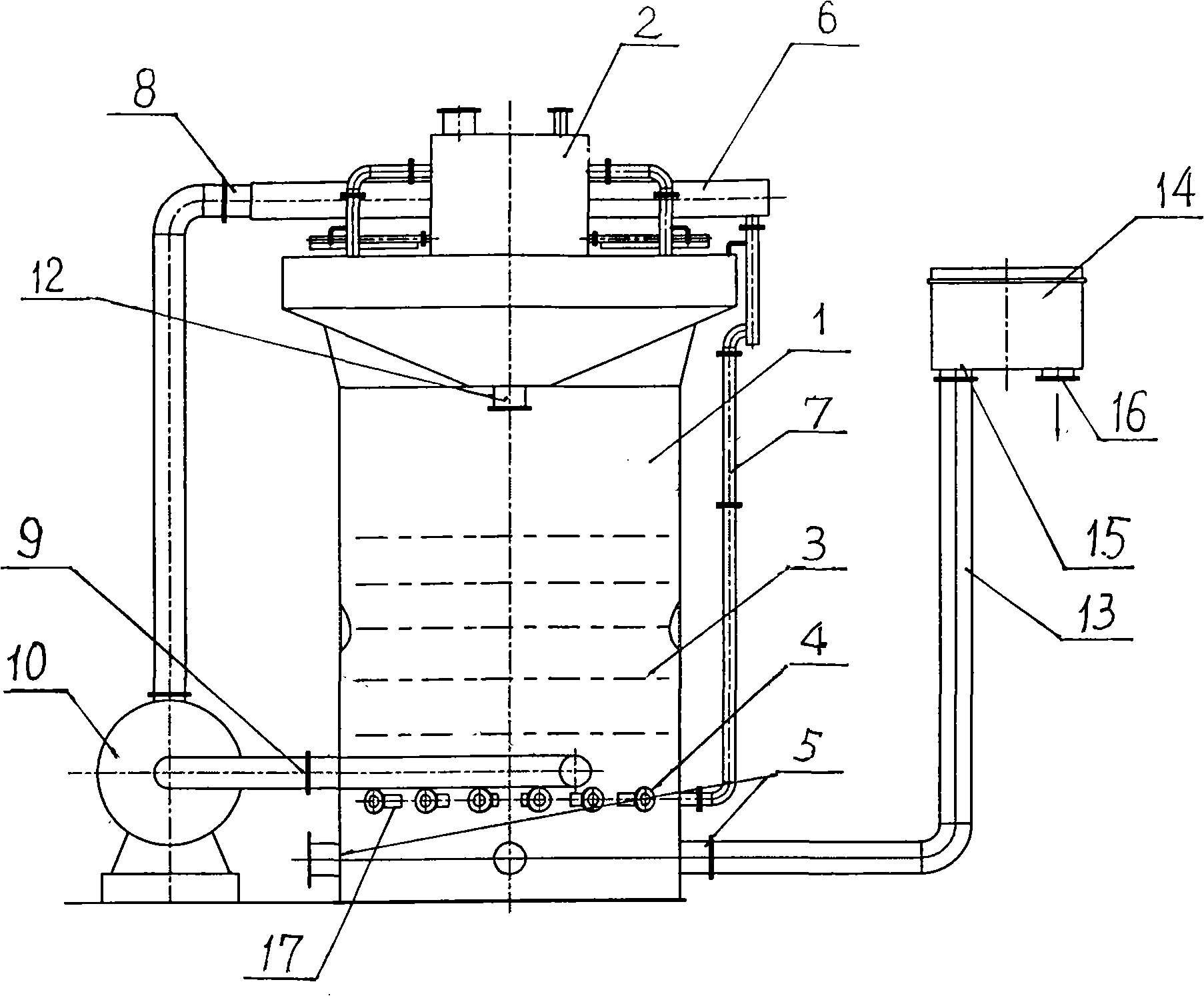

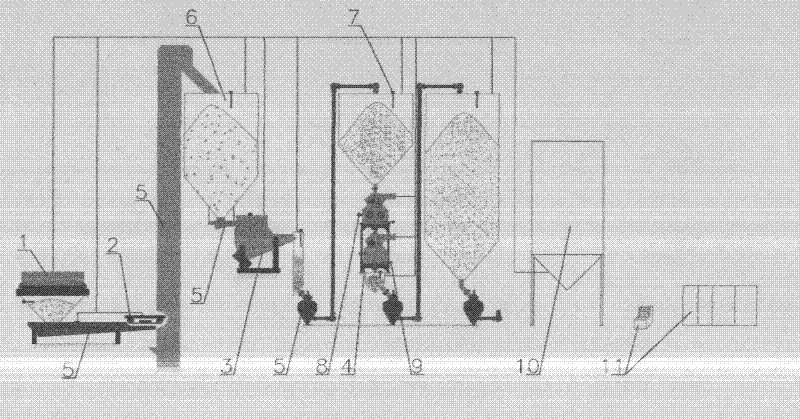

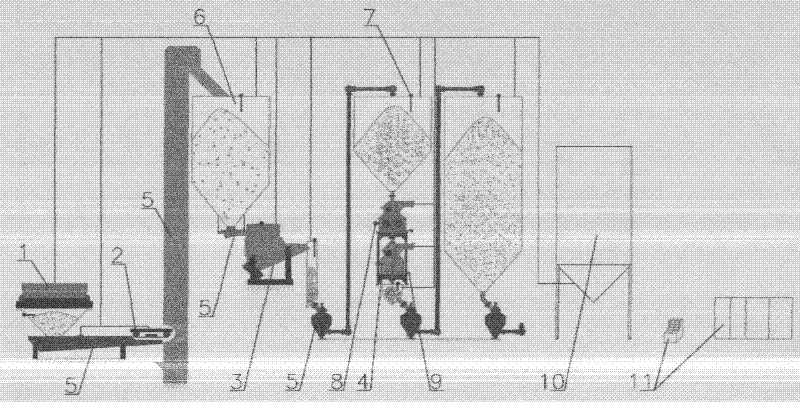

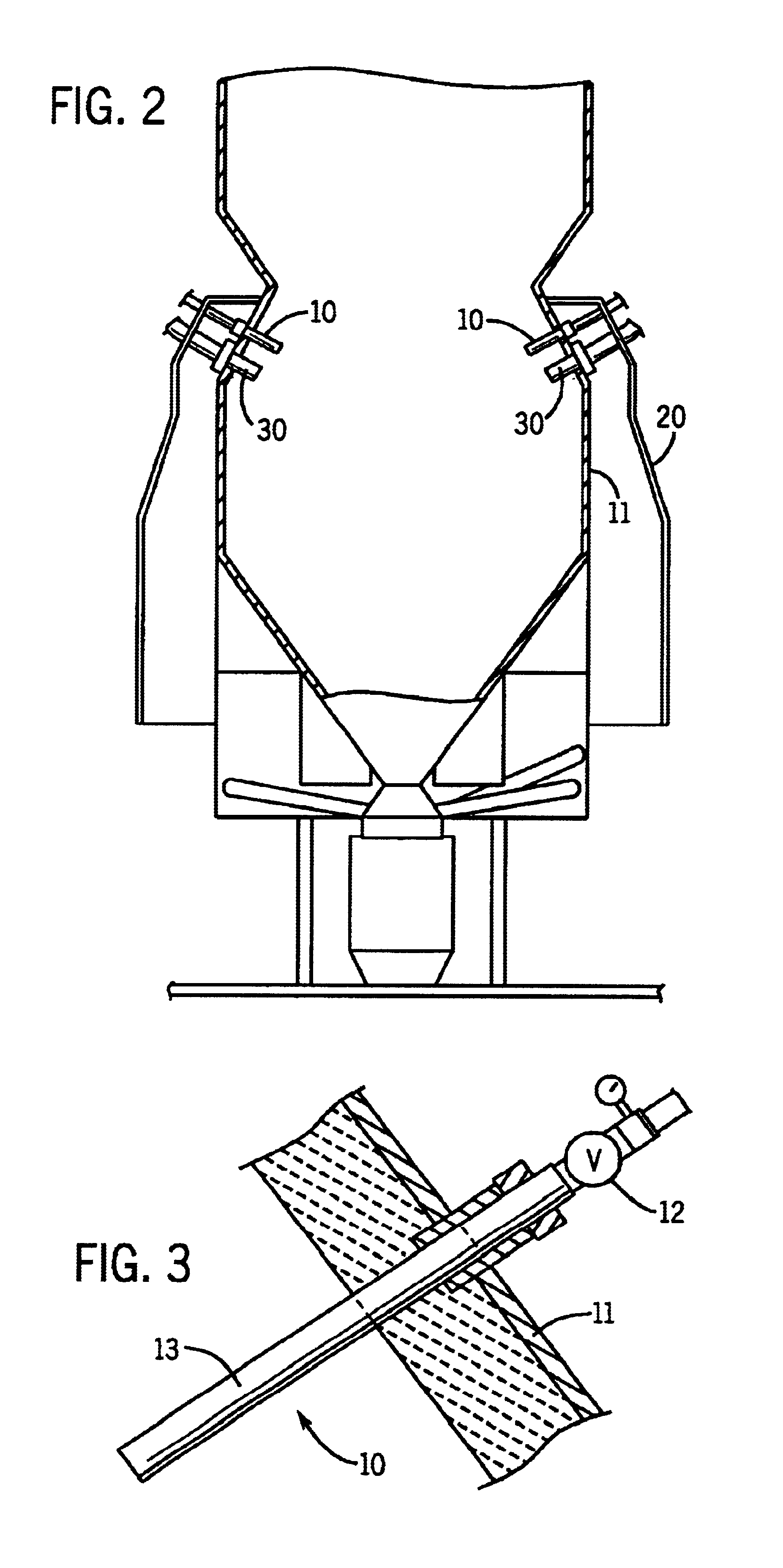

Digital resin sand regeneration system

InactiveCN102233405AMeet the needs of productionAutomatic production controlMould handling/dressing devicesEngineeringElectric control

A digital resin sand regeneration system comprises a vibrating knockout device, a magnetic separation device, a vibrating crushing device, an intermittent grinding regeneration unit, a conveying device, a sand storehouse, a dedusting device, a computer control system, etc. The main working principle is as follows: waste sand blocks are vibrated and crushed into smaller blocks and scattered sand by the knockout device; magnetic separation is performed to remove iron beans and flash; crushing is performed by the crushing device to obtain granular scattered sand; stripping, grading and temperature adjustment are performed by the intermittent grinding regeneration unit to remove micro powder included in the sand, and the sand temperature is adjusted to a temperature required by the process; and the sand is conveyed to the sand storehouse to keep in reserve. Through the additionally installed computer control system which comprises a material level sensor, a temperature sensor, a pressure sensor, and a corresponding electric control component, the whole production line can realize the target control of technological parameters and stock sand amounts; mainly-controlled technological parameters are: stripping rate (loss on ignition, LOI), micro powder content, sand temperature and sand amount; and technical guarantee is provided for the digital production management of the whole factory. Digital control of molding resin amount, hardening stripping time, and sand using amount is basic guarantee for solving energy saving and consumption reduction, improving productivity, and increasing yield.

Owner:于彦奇

High performance jetting treating compound for twistless roving

This invention discloses a formula for high-performance glass roving wetting agent for spraying. The wetting agent comprises: coupling agent, lubricating agent, antistatic agent A, antistatic agent B, film-forming agent A, film-forming agent B, pH regulator and water. The content of water is 85-95 wt. % of the wetting agent. The effective components are 5-15 wt. % of the wetting agent. The loss on ignition is 0.5-1.5%. The wetting agent comprises: coupling agent 1-10 wt.%, lubricating agent 1-10 wt.%, antistatic agent A 1-5 wt.%, antistatic agent B 1-5 wt.%, film-forming agent A 10-85 wt.%, film-forming agent B 85-10 wt.%, and pH regulator 0.1-5 wt.%. Film-forming agent A and film-forming agent B are combined, and their total amount is fixed. Film-forming agent A and film-forming agent B are epoxy resin / polyester. The wetting agent has such advantages as high permeation speed, high spraying performance, and high antistatic performance. The product has such advantages as high glass fiber content, high production efficiency and low production cost.

Owner:JUSHI GRP CO

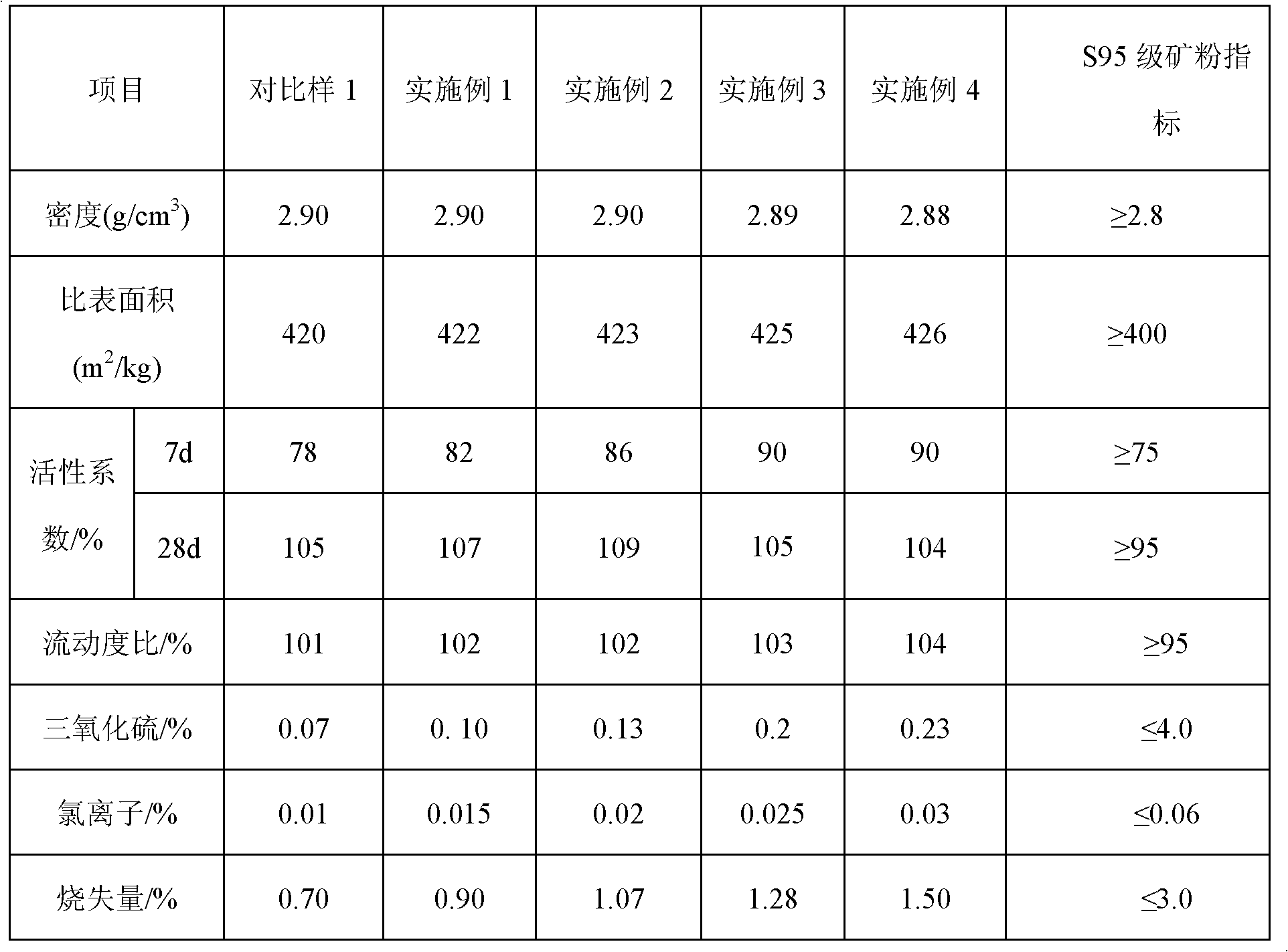

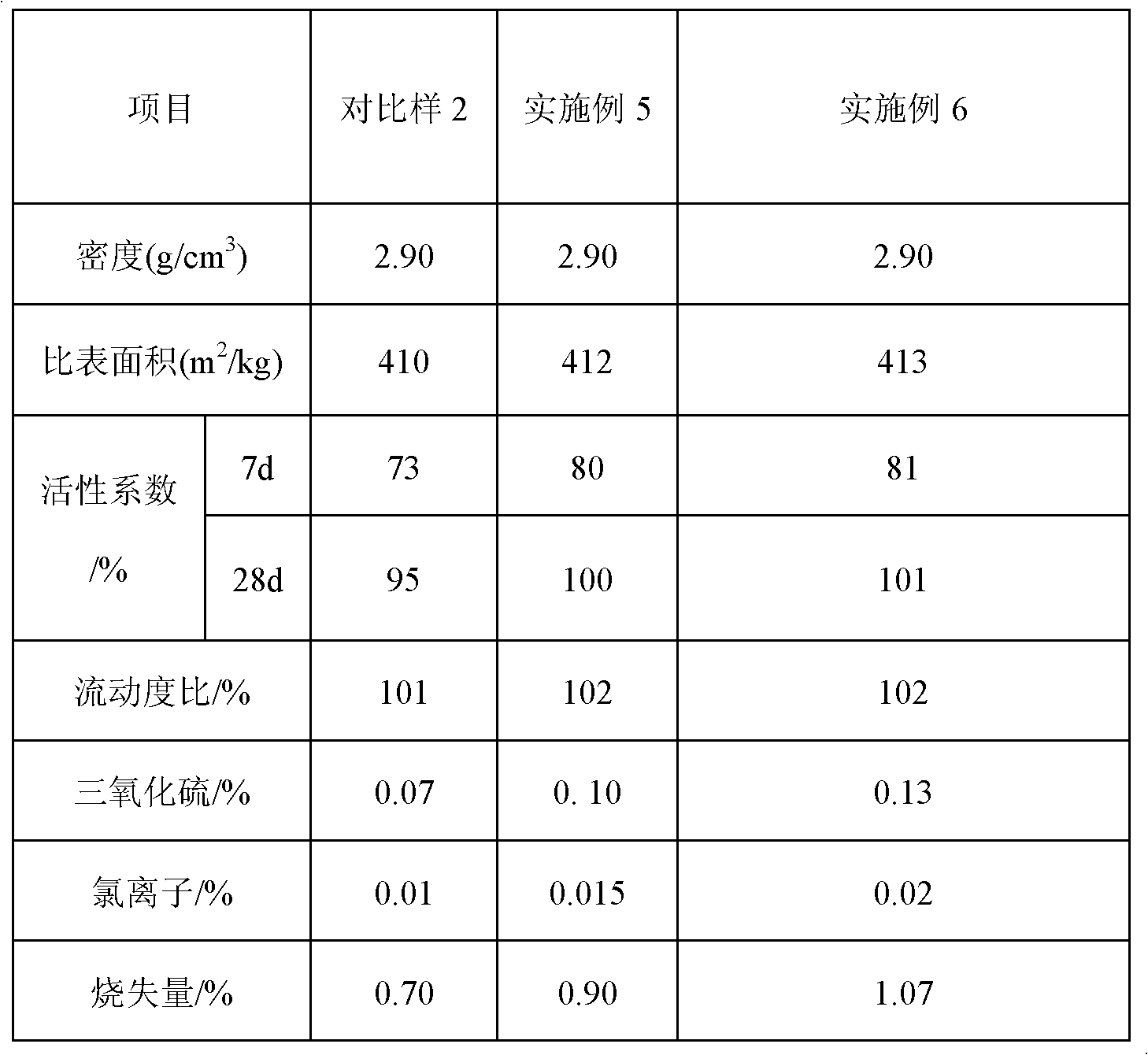

Mineral powder modified by sintering dry desulphurization ash and preparation method thereof

InactiveCN102584062ASmall specific surface areaImprove early shrinkage crack resistanceSolid waste managementCrack resistanceWork performance

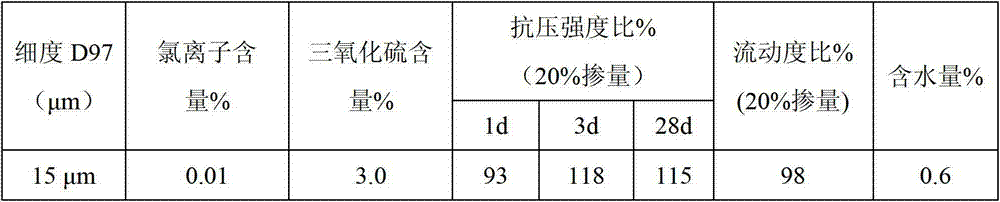

The invention discloses a mineral powder modified by sintering dry desulphurization ash and a preparation method thereof. The 7-day activity index of the mineral powder modified by sintering dry desulphurization ash is more than 80%, the 28-day activity index is more than 100%, the specific surface area is more than or equal to 400 m2 / kg, the sulfur trioxide content is less than or equal to 4.0%, the chloride ion content is less than or equal to 0.06%, the loss on ignition is less than or equal to 3.0% and the motility ratio is more than or equal to 100%. The mineral powder is made from the following raw materials in percentage by weight: 95 to 99% of blast-furnace slag powders and 1 to 5% of sintering dry desulphurization ash. The 7-day activity index and 28-day activity index of the modified mineral powder are greatly increased as compared with the common mineral powders, the requirement for specific surface area is reduced, and the energy consumption for milling slag powders can be reduced effectively. When applied to premixed concrete, the modified mineral powder is excellent in durability indices such as carbonization resistance, freeze resistance and chloride ion infiltration resistance, can effectively improve the working performance of concrete and improve the early-stage shrinkage crack resistance of hardened concrete.

Owner:BAOSHAN IRON & STEEL CO LTD +1

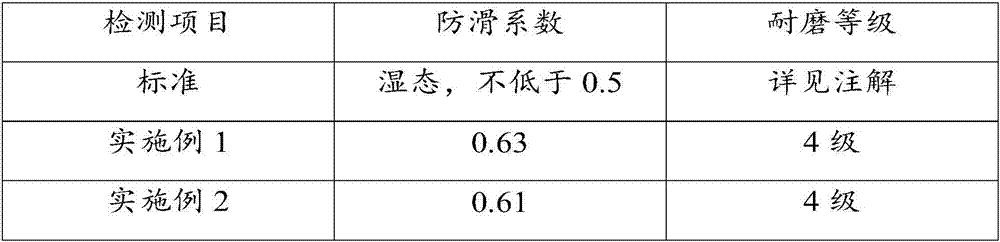

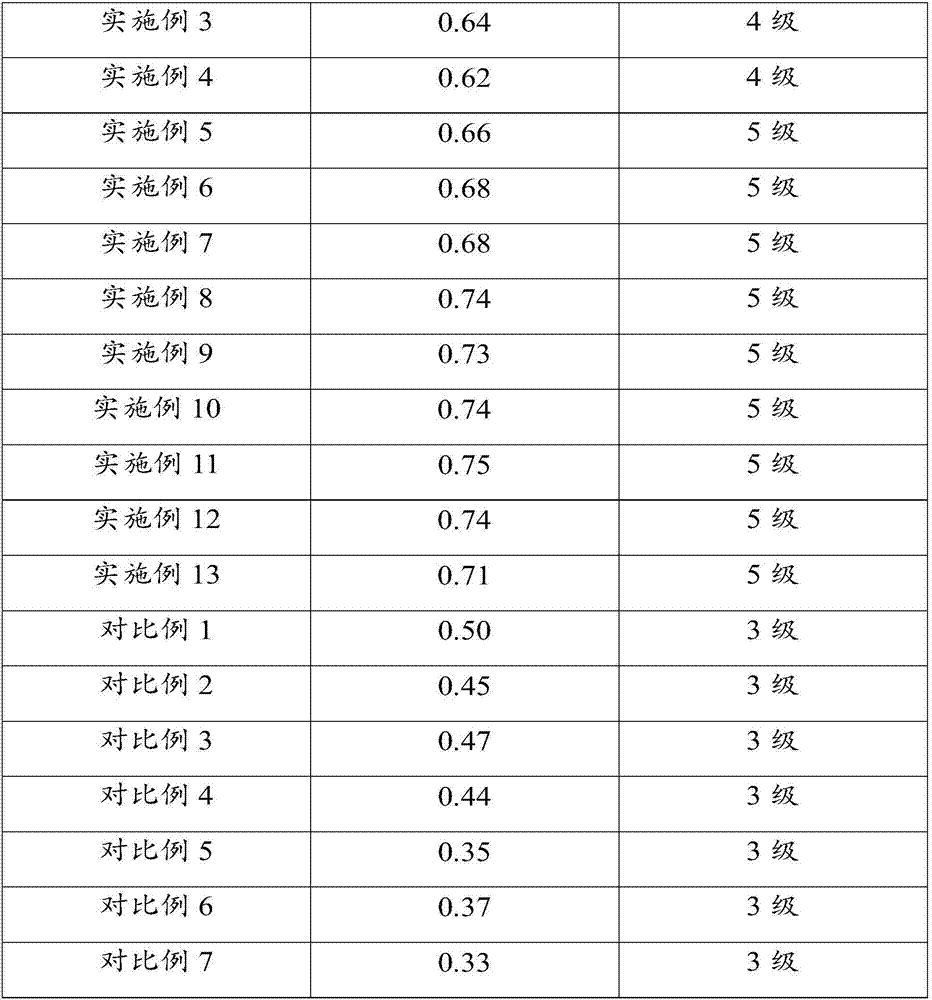

Anti-slip wear-resistant ceramic tile

The invention relates to the field of ceramic tiles, and particularly provides an anti-slip wear-resistant ceramic tile. The anti-slip wear-resistant ceramic tile comprises a green body layer and an anti-slip wear-resistant layer formed after the surface of the green body layer is coated with anti-slip wear-resistant glaze, wherein the anti-slip wear-resistant glaze is mainly prepared from the following raw materials in parts by mass: 90 to 110 parts of anti-slip wear-resistant particles, 90 to 110 parts of printing paste and 0.2 to 0.4 part of sodium tripolyphosphate; the anti-slip wear-resistant particles are mainly prepared from the following components in parts by mass: 60 to 70 parts of SiO2, 20 to 30 parts of Al2O3, 0.01 to 1 part of Fe2O3, 0.1 to 2 parts of TiO2, 1 to 5 parts of Na2O, 1 to 10 parts of K2O, 0.01 to 1 part of MgO, 0.1 to 5 parts of CaO and 0.1 to 2 parts of loss on ignition. The anti-slip wear-resistant ceramic tile has an excellent anti-slip effect and an excellent wear-resistant effect, has high product quality, and is durable, safe and reliable.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

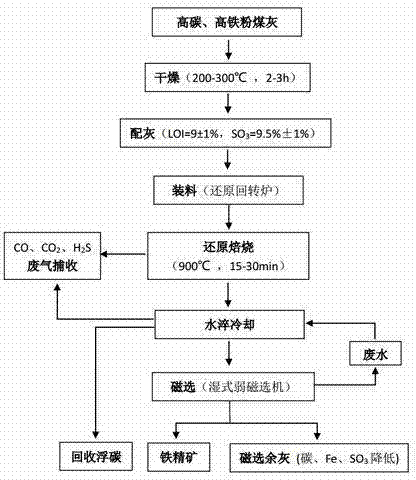

Carbon reducing, sulfur reducing, iron removing and iron ore concentrate recovering method for coal ash

InactiveCN103572040AFe content decreasedProcess efficiency improvementMagnetic separationMagnetiteOxygen

The invention discloses a carbon reducing, sulfur reducing, iron removing and iron ore concentrate recovering method for coal ash with unburned carbons and higher SO3 and Fe (hematite) contents. With the unburned carbons in the coal ash as reducing agent, dry coal ash raw materials (9%+ / -1% of loss on ignition and 9.5%+ / -1% of SO3 content) mixed beforehand are reduced and roasted for 15-30 minutes at 900 DEG C, then are quickly separated from oxygen for water quenching and cooling; the iron ore concentrate is magnetically separated by a wet low-intensity magnetic separator. Gypsum (CaSO4) in the coal ash is converted to CaS after reducing and roasting, so that the SO3 content is reduced; the hematite with weak magnetism is converted to a magnetite with strong magnetism; weak magnetic separator is adopted to separate. The carbon, Fe and SO3 contents of the treated coal ash are respectively reduced below 5.3%, 5% and 1.32%; the coal ash can be directly used in the fields such as production of cement and concrete; at the same time, the iron ore concentrate with 48-53% of TFe level is obtained, and can be used as iron smelting raw materials or dense medium powder in industries such as coal dressing. The method has the advantages of prominent overall economic efficiency, no need of adding reducing agent, fewer auxiliary facilities, short process flow and easy realization of industrialization.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

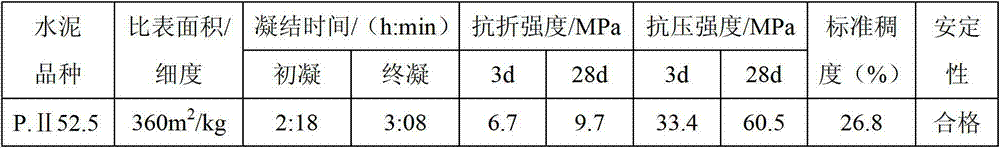

Inorganic high performance fiber composite material and preparation method thereof

The invention discloses an inorganic high performance fiber composite material, prepared from the following raw materials in parts by weight: 450-900 parts of cement with the mean grain size of 30-60 mu. m and strength grade not less than 42.5, 180-360 parts of active mineral admixture with the mean grain size of 0.1-60 mu. m, loss on ignition being less than or equal to 3.0 percent, and a 28-day activity index not lower than 90 percent, 70-120 parts of inert admixture with the mean grain size of 0.1-60 mu. m, 850-1250 parts of sand with the continuous grading grain size of 0.16-4.75mm, 25-32 parts of water reducer with a water reducing rate greater than 30 percent, 130-150 parts of water, and 50-120 parts of copper plating end hook-shape steel fiber with the diameter less than 0.20mm and length of 12-14mm. The composite material is relatively low in overall price, uniform in fiber distribution, high in compressive strength and flexural strength, good in tenacity and suitable for being popularized and used in the constructional engineering industry.

Owner:黄贺明

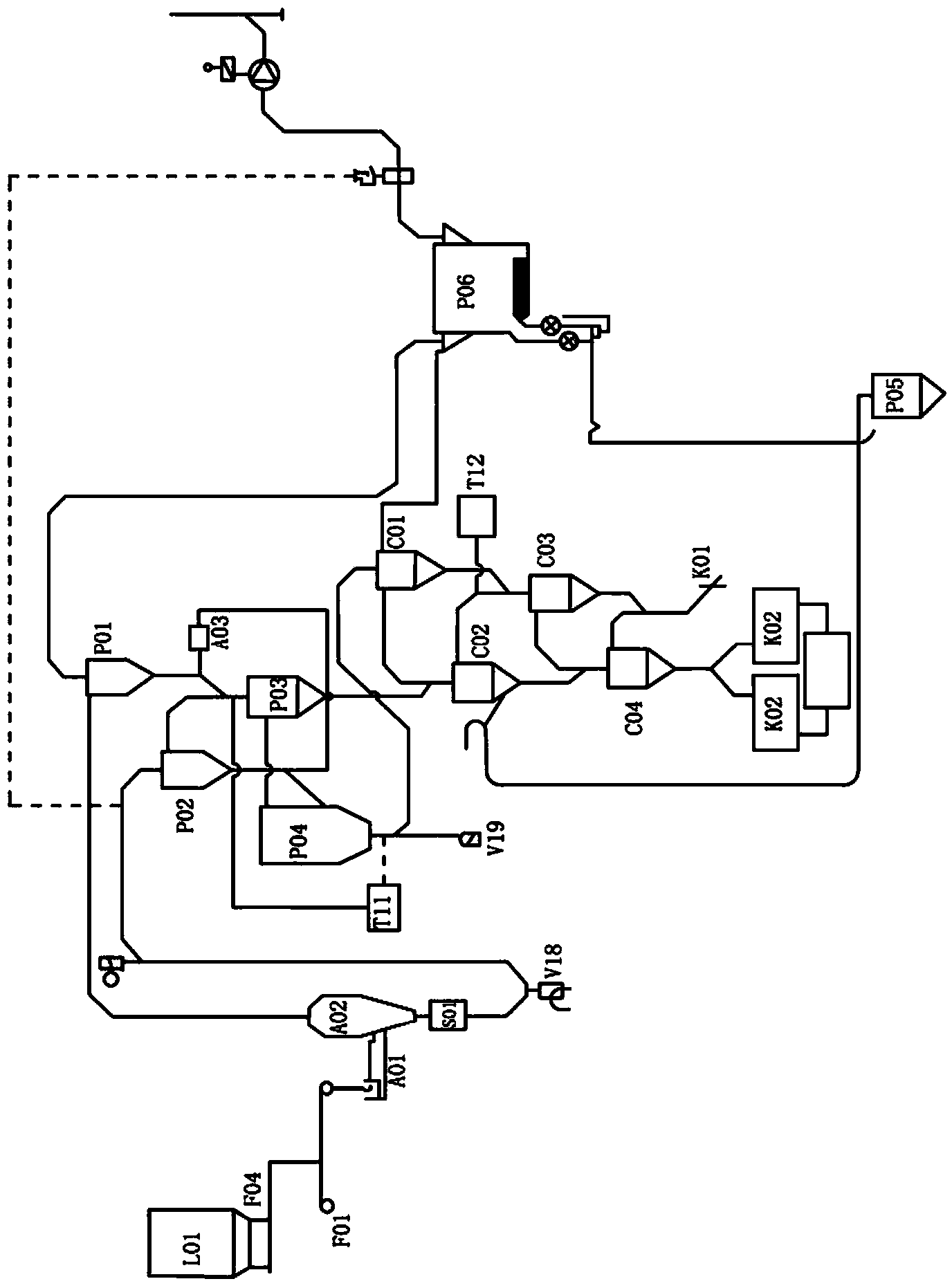

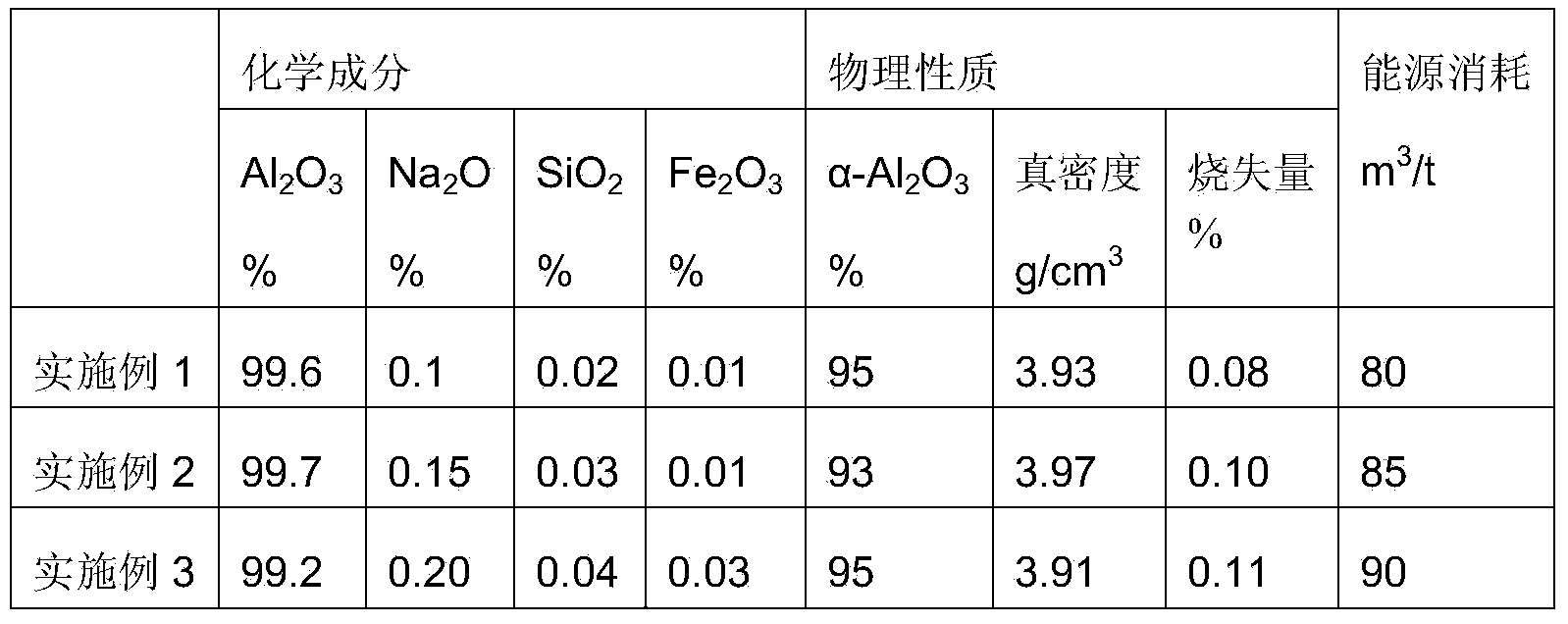

Method for producing alpha-aluminum oxide by utilizing gas-suspension roasting furnace

InactiveCN103771476AWell mixedSevere dehydrationAluminium oxide/hydroxide preparationCycloneChemical composition

The invention relates to a method for producing alpha-aluminum oxide by utilizing a gas-suspension roasting furnace. A quantitative mineralizing-agent discharging device is added between a cyclone preheater and a thermal-separation cyclone drum of the gas-suspension roasting furnace; and an electric dust collector is provided with a collecting device of dust and enriched particles. The production method comprises the following steps of: (1) feeding of aluminum hydroxide; (2) drying; (3) preheating; (4) roasting and separation; (5) primary cooling; (6) secondary cooling; (7) dust removal and ash return. The produced alpha-aluminum oxide comprises the following chemical components in percentage by weight: 99.2%-99.7% of Al2O3, 0.1-0.35% of Na2O, 0.02-0.05% of SiO2 and 0.01-0.03% of Fe2O3; and the physical properties are as follows: alpha-Al2O3 is 89-95%, the true density is 3.89-3.97g / cm<3> and the loss on ignition is 0.08-0.13%.

Owner:ZHENGZHOU JINYANGGUAN CERAMICS CO LTD

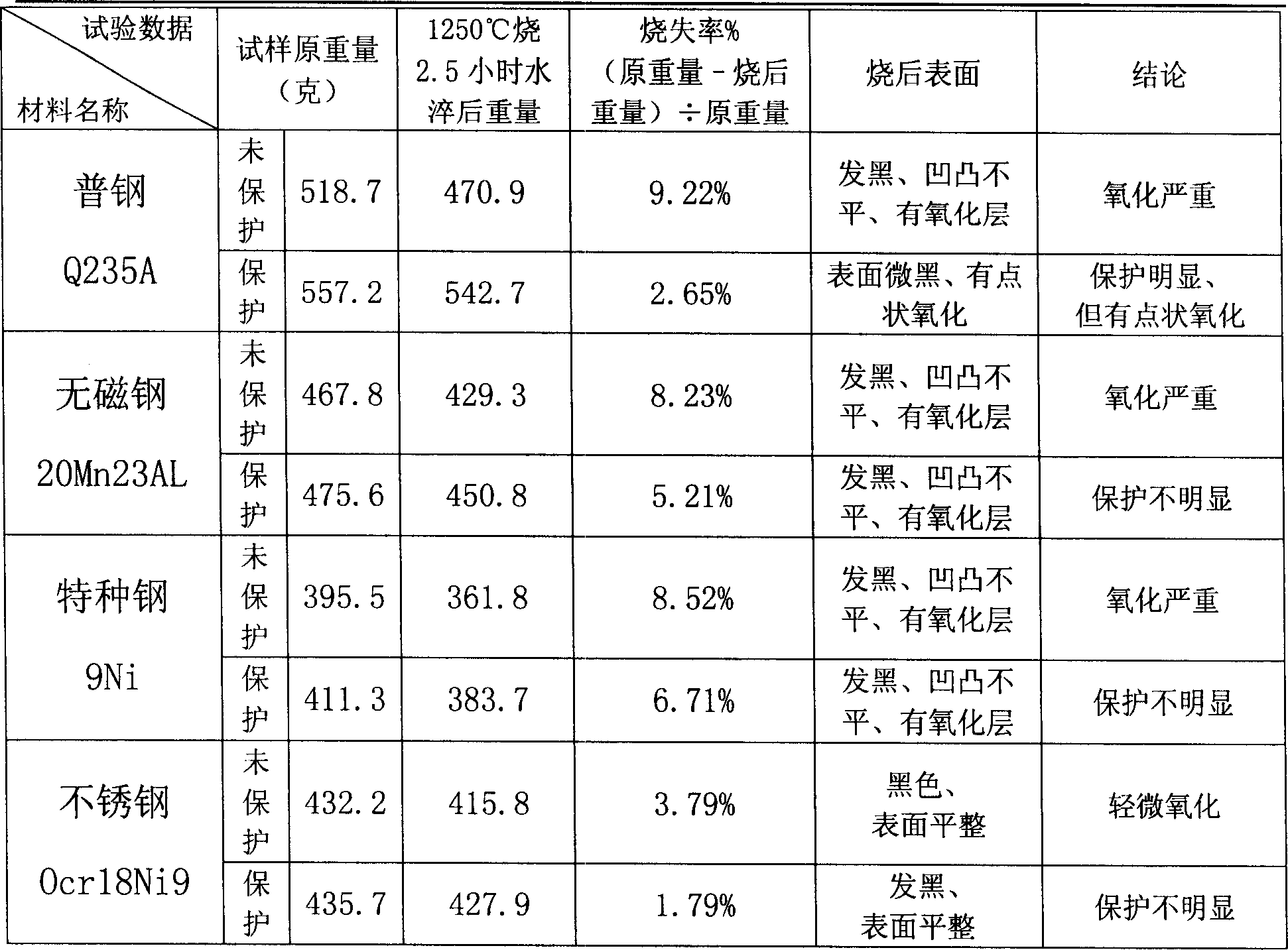

Antioxidation coating material of Nano silicate in use for annealing billet in series

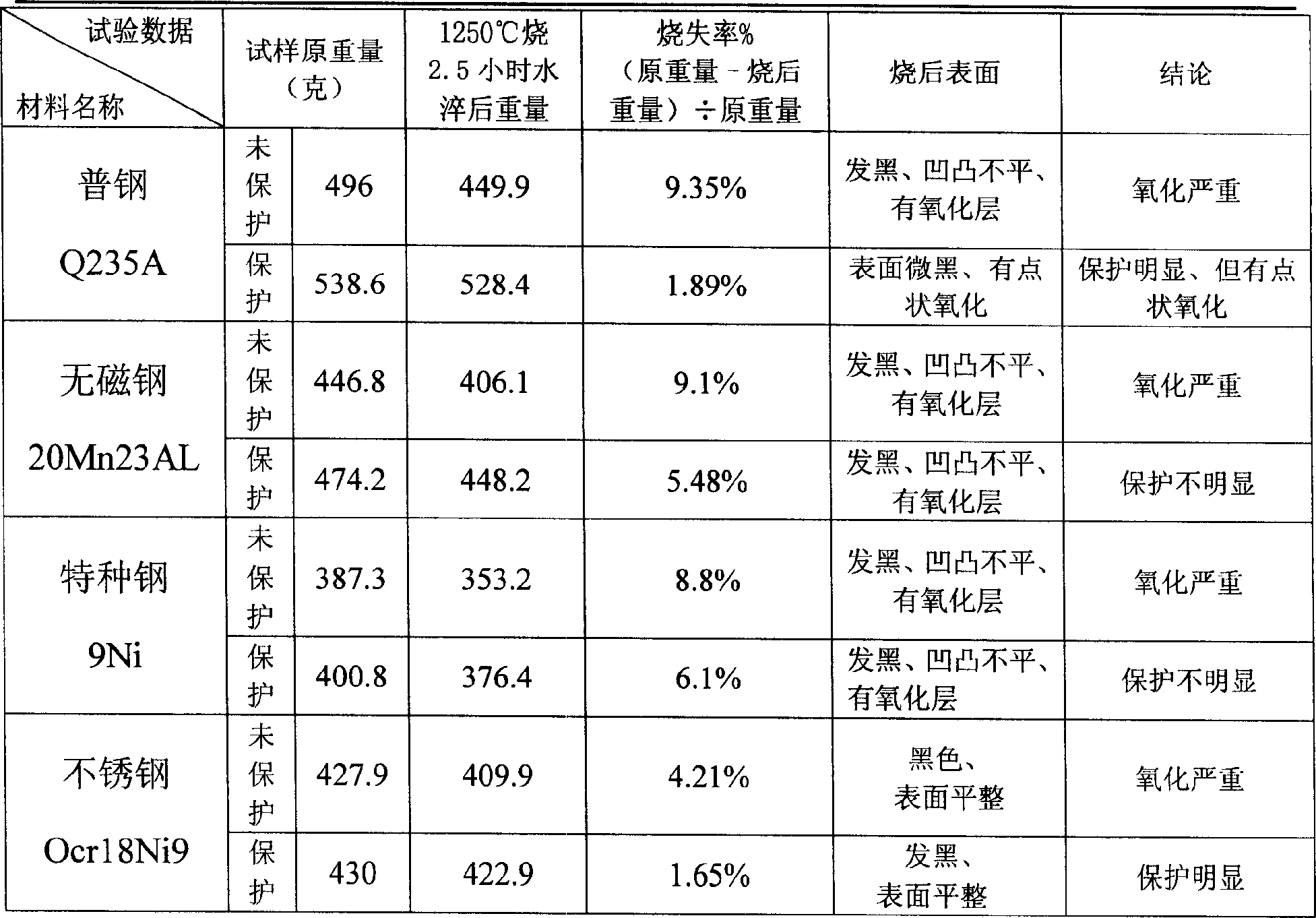

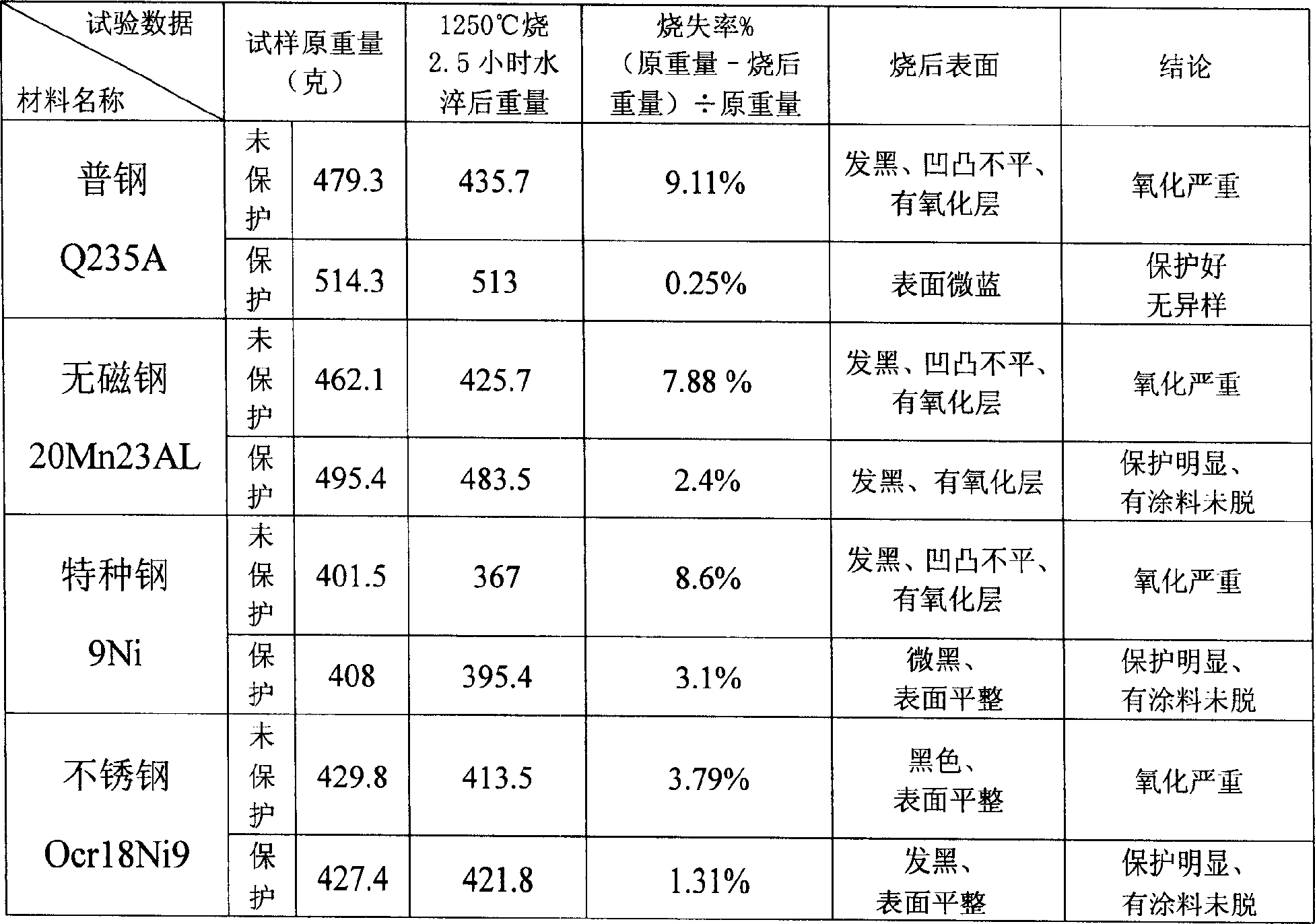

This invention relates to nanoscale silicate anti-oxidation coating for steel billet annealing. The coating is composed of: composite binder 20-30 wt.%, composite phosphate curing agent 8-12 wt.%, and composite aluminosilicate filler 58-72 wt.%. The coating can resist 1500 deg.C high temperature. The coating does not need any surface treatment, and can be directly sprayed onto the surface of steel billet, and cured at normal temperature for 10 min. Before annealed and hot-rolled, the coated steel billet is water-quenched for several seconds so that the coating layer is removed without any trace, and the surface quality is improved. The coating can reduce the loss-on-ignition of various steels, thus can be used for surface protection of refractory materials used as furnace kiln lining. Besides, the coating can also be used as inner and outer wall coating, and metal surface (bridge, bridge pier and dam) coating with water, corrosion and oxidation resistance.

Owner:沁阳市皇甫喷射防腐技术有限公司

Mineral blending material for producing PHC (Pyrolysis Hydrocarbon) tubular pipe free from high pressure steaming process as well as application

The invention discloses a mineral blending material for producing a PHC (Pyrolysis Hydrocarbon) tubular pipe free from a high pressure steaming process. The mineral blending material comprises the components in percentage by weight as follows: 60-80% of superfine blast furnace slag micropowder and 20-40% of desulfurization gypsum. According to the mineral blending material, the loss on ignition is less than or equal to 3%, the chlorine ion content is less than or equal to 0.02% and the water content is less than or equal to 1.0%. The mineral blending material provided by the invention is in particular suitable for preparing concrete for producing the PHC tubular pipe free from the high pressure steaming process and can replace 15-25% of cement equivalently. The prepared concrete has the advantages of high strength in early stage, continuous development of strength in later stage, good durability and the like. In the production process of the PHC tubular pipe, the high pressure steam maintenance link is omitted, so that the demand on the production device and the production energy consumption are reduced. According to the invention, industrial wastes such as flue gas desulfurization gypsum in a power plant are used as main materials, so that the materials are wide in source and low in cost. Meanwhile, the environmental pollution caused by industrial residue is reduced, and good economic and environment-friendly benefits are obtained.

Owner:TONGJI UNIV +1

Rutile titania catalyst carrier

InactiveUS20060286026A1High pore volumeIncrease surface areaAmmonium nitratesWood working apparatusPolymer sciencePartial oxidation

A method of forming a shaped article includes forming a mixture which includes a titania hydrate pulp having a loss on ignition of from about 10 to 45 wt. %, a seed material comprising a titanium oxide, at least a portion of the titanium oxide being in a rutile form, and optionally a dispersion aid. The method includes forming the mixture into a shaped article and firing the shaped article. A shaped article suitable for use as a catalyst carrier is at least 90% titanium oxide, greater than 80% of the titanium oxide being in the rutile phase. The article has a surface area of at least 2.5 m2 / g and a mercury pore volume of greater than 0.15 cc / g.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

Method of catalyst making for superior attrition performance

InactiveUS20130098804A1Increase line speedIncrease severityCatalytic crackingMolecular sieve catalystsGasolineLiquid fuel

A catalyst composition that has superior attrition performance and a method that produces said catalyst composition to be used for fluid catalytic cracking processes to convert a heavy hydrocarbon fraction into mainly liquid fuels, particularly gasoline and light olefins. The catalyst composition has a moisture level or loss on ignition below 12 wt % and attrition rate below 3 wt. % / hr.

Owner:CHANG YUN FENG +1

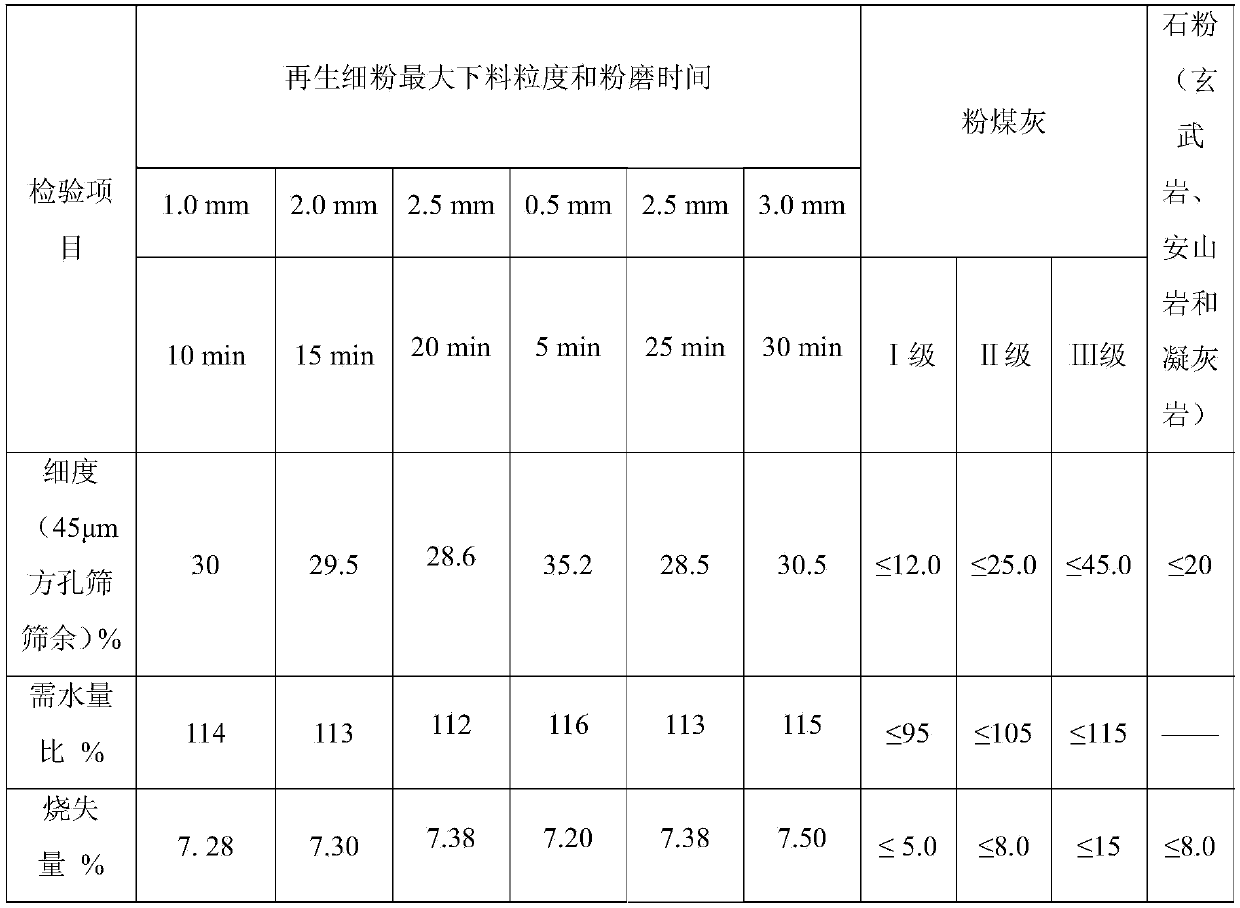

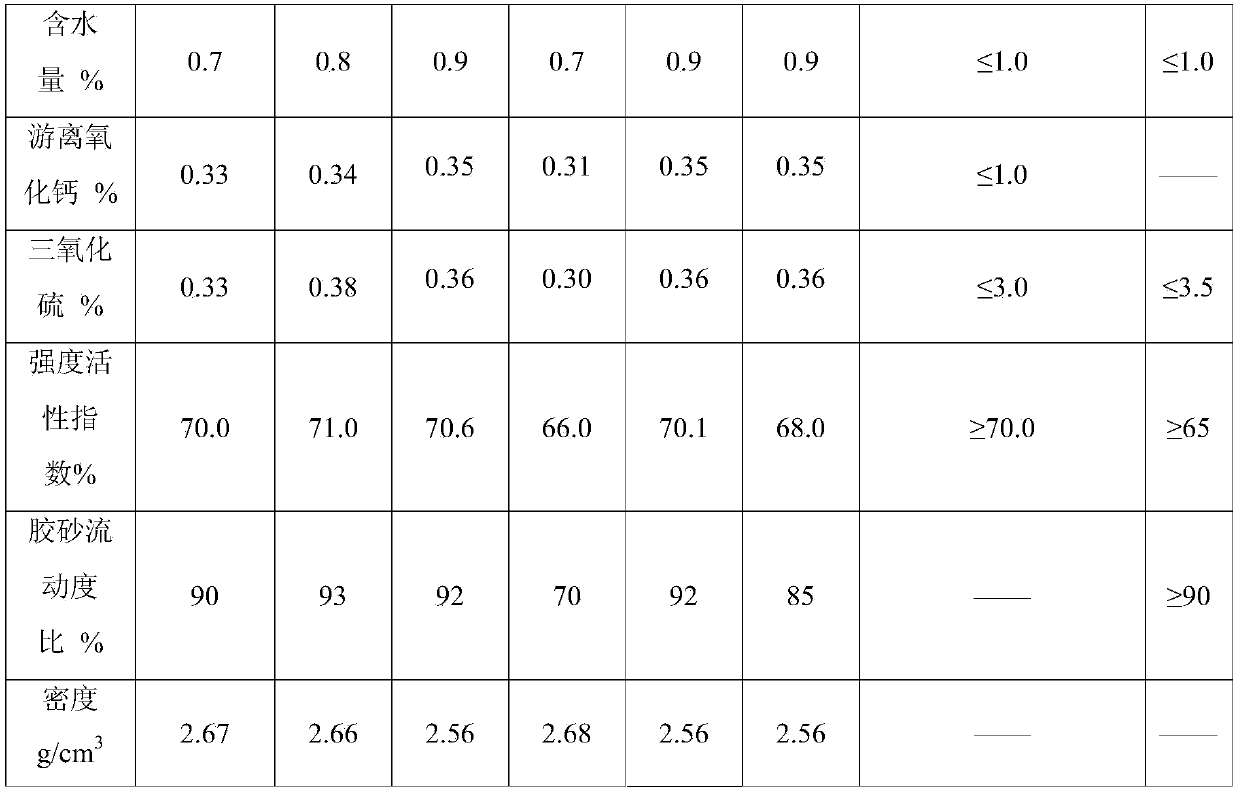

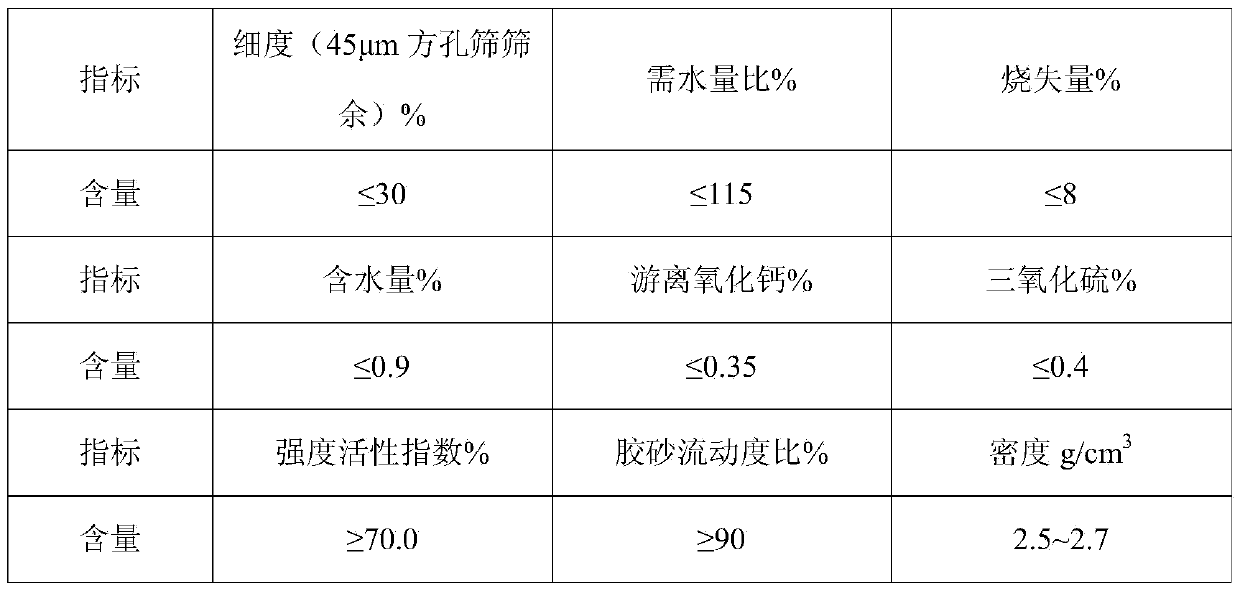

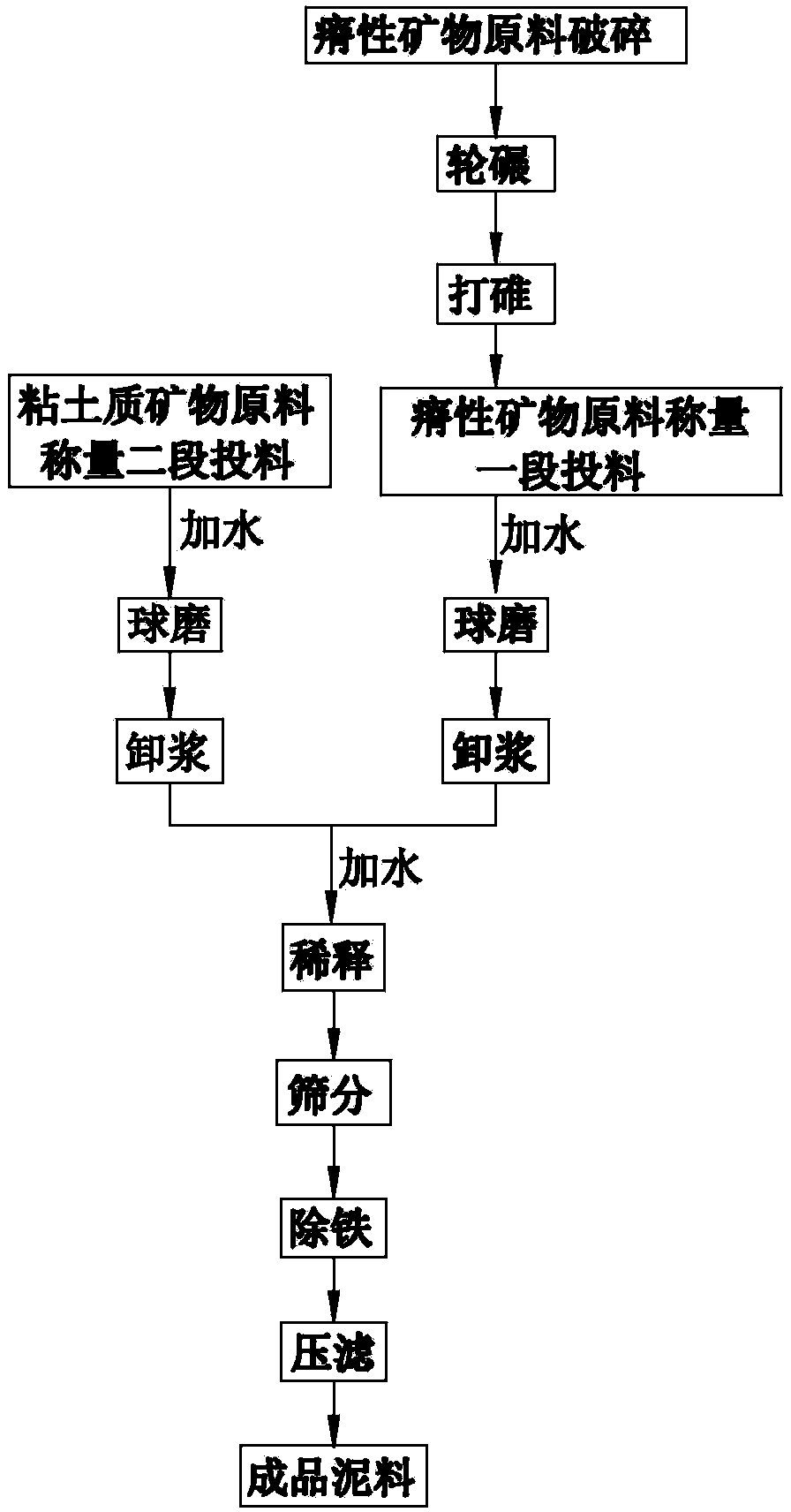

Method for preparation of regenerated fine powder from concrete mixing station waste residue, prepared regenerated fine powder and use thereof

ActiveCN105366974AReduce energy consumptionShort grinding timeSolid waste managementActivity indexMicrometer

The invention discloses a method for preparation of regenerated fine powder from concrete mixing station waste residue, prepared regenerated fine powder and use thereof. The method for preparation of regenerated fine powder comprises the steps of: S1. breaking concrete waste residue, sorting out residue powder with a particle size of less than or equal to 2.5mm, and conducting air drying; and S2. grinding the residue powder of S1 for 10-20min to obtain regenerated fine powder. The regenerated fine powder has the following main component and technical index range: 45 micrometer square hole sieve residue of less than or equal to 30%, a water demand ratio of less than or equal to 115%, a loss on ignition of less than or equal to 8%, a water content of less than or equal to 0.9%, a free calcium oxide content of less than or equal to 0.35%, a sulfur trioxide content of less than or equal to 0.4%, a density of 2.5-2.7g / cm<3>, mortar fluidity of larger than or equal to 90%, and a strength activity index of greater than or equal to 70%. The regenerated fine powder can be used for preparation of mortar and concrete.

Owner:GUANGZHOU UNIVERSITY

Strengthened dolomite pottery blank mud

ActiveCN103626474AReach the technological goal of low temperature glaze formationCouple fitClaywaresDolomiteLoss on ignition

The invention relates to strengthened dolomite pottery blank mud and particularly relates to a formula of the strengthened dolomite pottery blank mud, which can form a coupling and self-adapting blank glaze intermediate layer through blank glaze mass transfer interaction, and a preparation process thereof. The blank mud contains the following chemical ingredients in percentage by weight: 60-70% of SiO2, 11-15% of Al2O3, 6-10% of MgO, 2-8% of CaO, 0.5-3.0% of K2O, 0.5-3.0% of Na2O and 3.5-7.0% of loss on ignition, wherein the total ingredient content of MgO and CaO is higher than 12%, and the total ingredient content of Na2O and K2O is lower than 3%. According to strengthened dolomite pottery prepared from the blank glaze coupled and self-adapted strengthened dolomite pottery blank mud disclosed by the invention through firing, when the strengthened dolomite pottery is autoclaved for 30 minutes in an autoclave at the temperature of 170 DEG C while maintaining the pressure of 500KPa, the phenomena of glaze peeling and glaze cracking do not occur, so that the blank glaze binding performance reaches the standards of export products.

Owner:FUJIAN WILL CERAMIC CO LTD

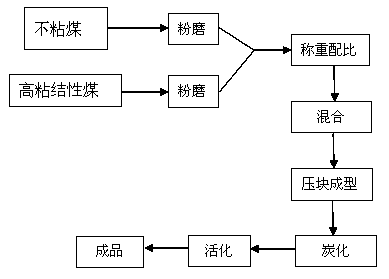

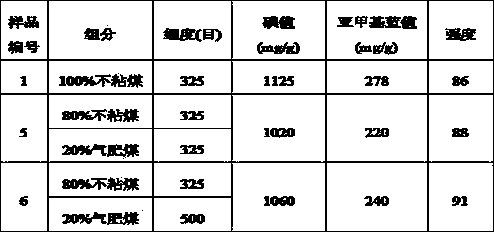

Particle size gradation coal blending method capable of improving strength of briquetted activated carbon

InactiveCN103738960AGive full play to the bonding effectReduce dosageOther chemical processesCarbon compoundsCoal briquetteActivated carbon

The invention discloses a particle size gradation coal blending method capable of improving the strength of briquetted activated carbon. The particle size gradation coal blending method comprises the following steps: (1) grinding: respectively grinding non-caking coal and highly caking coal, wherein the particle size of the non-caking coal after grinding is 300-400 meshes, and the particle size of the highly caking coal is 300-800 meshes; (2) weighing and proportioning: adding 5%-30% by weight fraction of the highly caking coal after grinding into the non-caking coal after grinding, and stirring till uniform mixing; (3) briquetting and forming: sending coal powder after mixing into a forming device for briquetting; (4) carbonizing: putting coal briquettes after briquetting and forming into a rotary furnace for carbonization; (5) activating: activating the coal briquettes after carbonization in an activating furnace till the loss on ignition achieves 45%-55% to obtain a briquetted activated carbon finished product. According to the particle size gradation coal blending method disclosed by the invention, by controlling the particle size gradation of the non-caking coal and the highly caking coal, the strength of the briquetted activated carbon finished product can be significantly improved. The particle size gradation coal blending method has the advantages of low cost and easiness in implementation.

Owner:CHINA UNIV OF MINING & TECH +1

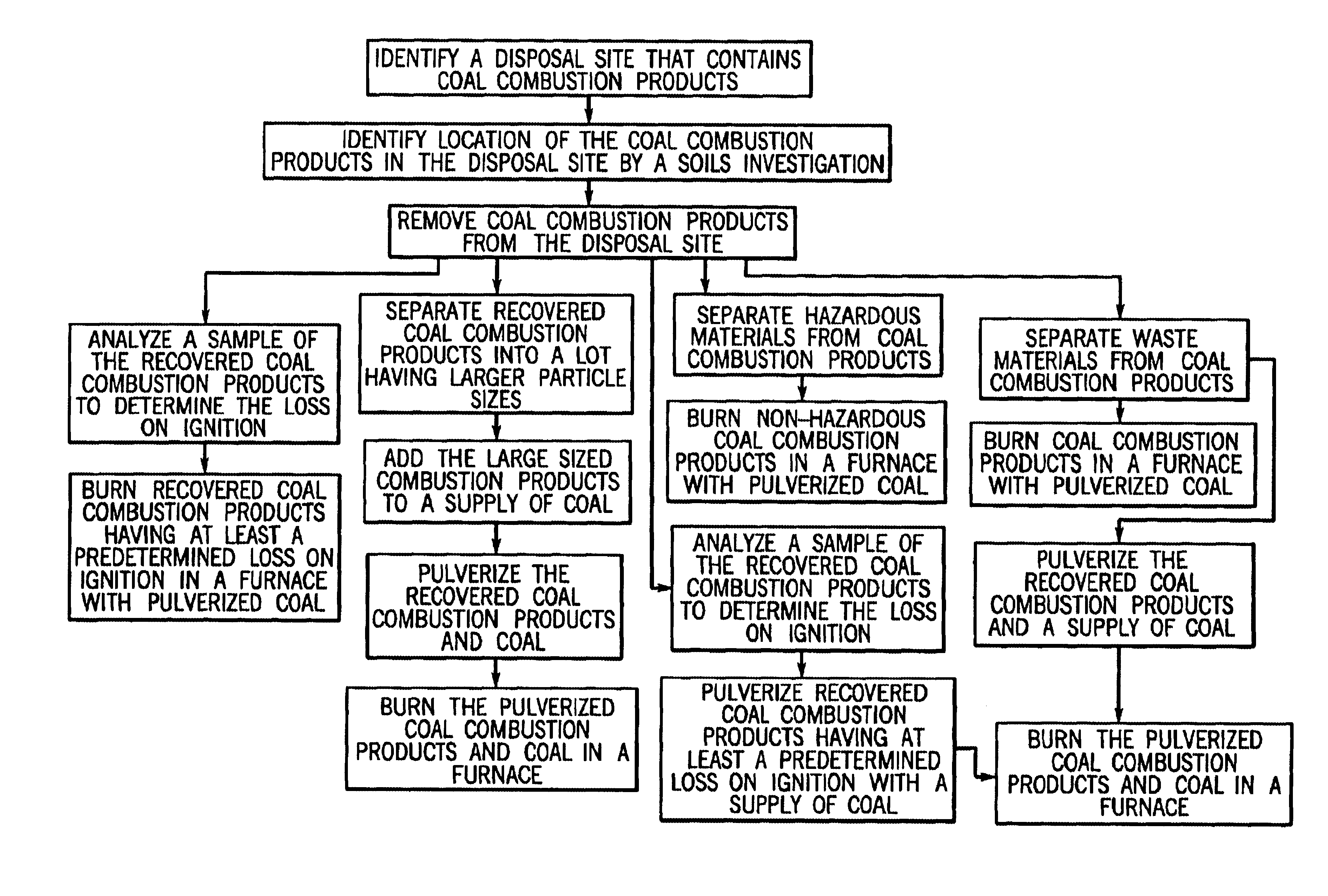

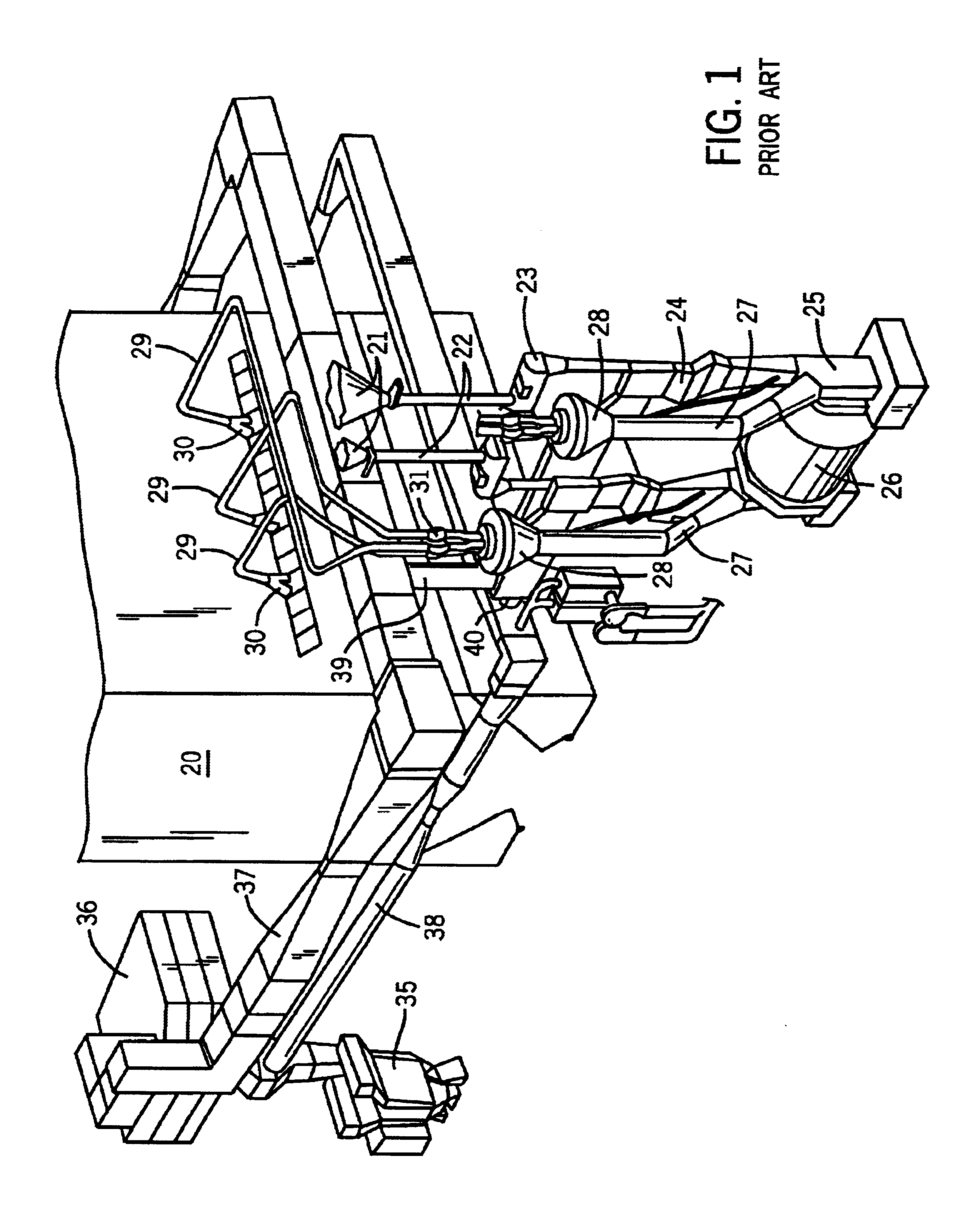

Coal combustion products recovery process

InactiveUS6637354B2Low ignitionReduce lossSolid fuel pretreatmentCombustion using multiple fuelsBottom ashEnvironmental engineering

A process for recovering the byproducts of a process that burns coal and for reusing the byproducts is disclosed. The process includes the steps of identifying a disposal site that contains the byproducts (typically flyash and bottom ash), removing at least a portion of the byproducts from the disposal site, analyzing a sample of the portion of the byproducts to determine the loss on ignition of the portion of the byproducts, introducing the portion of the byproducts along with pulverized coal into a pulverized coal furnace if the portion of byproducts have a loss on ignition greater than or equal to a predetermined loss on ignition value (typically greater than or equal to 1 to 5%), and burning the portion of the byproducts in the furnace with the pulverized coal to render the byproducts into a commercially valuable fly ash and bottom ash having very low loss on ignition, typically lower than 3%.

Owner:WISCONSIN ELECTRIC POWER

Method for purifying aedelforsite by pure physical process

The invention provides a method for purifying aedelforsite by a pure physical process. The method comprises the following steps of: firstly crushing aedelforsite raw material, and then adding water to get ore slurry A; removing iron impurities in the ore slurry A by adopting a magnetic separation process to get ore slurry B; then performing gravity classification on the ore slurry B through a shaking table, and getting a front-section material, a middle-section material and a back-section material after classification; performing wet type screening on the front-section material and the middle-section material by adopting a spin-vibrating screen, wherein a screen A of the spin-vibrating screen, which is used for the front-section material is of 300 meshes, a screen B of the spin-vibrating screen, which is used for the middle-section material is of 180 meshes, and residues on the screen A and the screen B are screened matters after the screening is completed; and finally performing dehydration and drying on the screened matters to get a high-purity aedelforsite product. In the product prepared by the method disclosed by the invention, the content of CaSiO3 is more than 96%, the content of Fe2O3 is less than 0.2% and the loss on ignition is less than 1.5%; and the production method disclosed by the invention has the advantages of simple operation process, high production efficiency and no environmental pollution.

Owner:HUBEI FENGJIASHAN WOLLASTONITE FIBER

Method to produce durable non-vitrified fly ash bricks and blocks

A method of making durable, non-vitrified masonry units comprising fly ash, the method comprising mixing fly ash comprising a minimum of 15% CaO by weight and no more than about 10% loss on ignition, water, and an air entrainment agent to form a fly ash mixture; compacting the fly ash mixture in a shaping device by applying pressure of at least 1000 psi to the fly ash mixture; and curing the compacted fly ash mixture to cause the mixture to harden and gain strength.

Owner:ECOLOGIC TECH

Nonluminous glaze

The invention relates to nonluminous glaze. The nonluminous glaze is prepared by adding a proper amount of aluminum powder into slaked talc, quartz and feldspar to generate metal aluminum oxide without glossiness, so that the production cost of the nonluminous glaze can be effectively reduced; the added slaked talc is subjected to high-temperature calcination, so the impurity content is low, the loss on ignition is small and new grain which people do not like is avoided; a proper amount of silicon micropowder is added into the nonluminous glaze, the temperature resistance and the acid and alkali resistance of the glaze layer can be improved and the effect of improving the mechanical strength of the glaze layer is achieved; and the nonluminous glaze is obtained by performing wet ball milling by a wet ball mill, the raw materials for forming the nonluminous glaze are stirred and mixed uniformly, slurry with the physical and chemical properties tending to be uniform and consistent can beobtained, and glazing is fertilized.

Owner:GUANGXI NANSHAN PORCELAIN

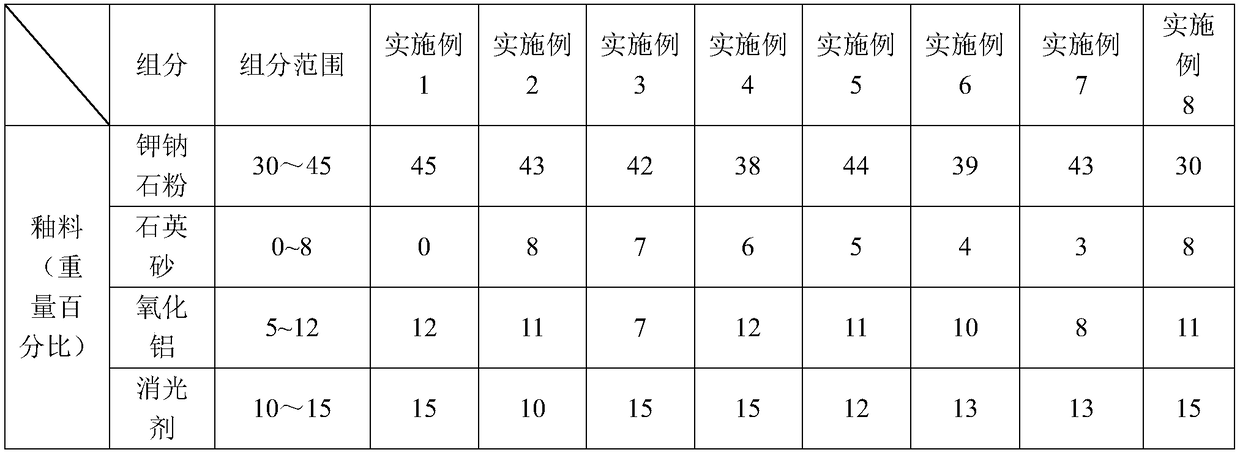

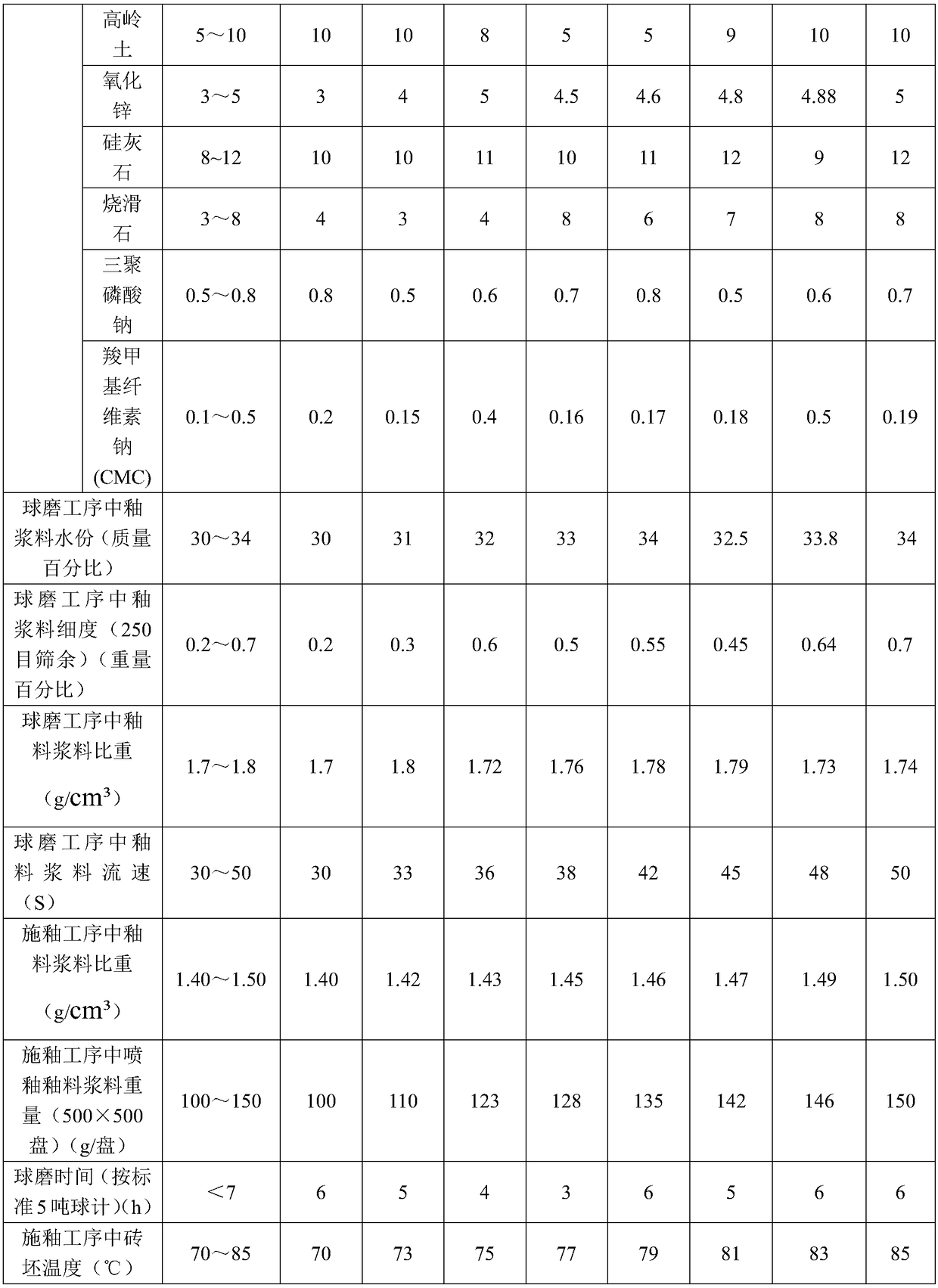

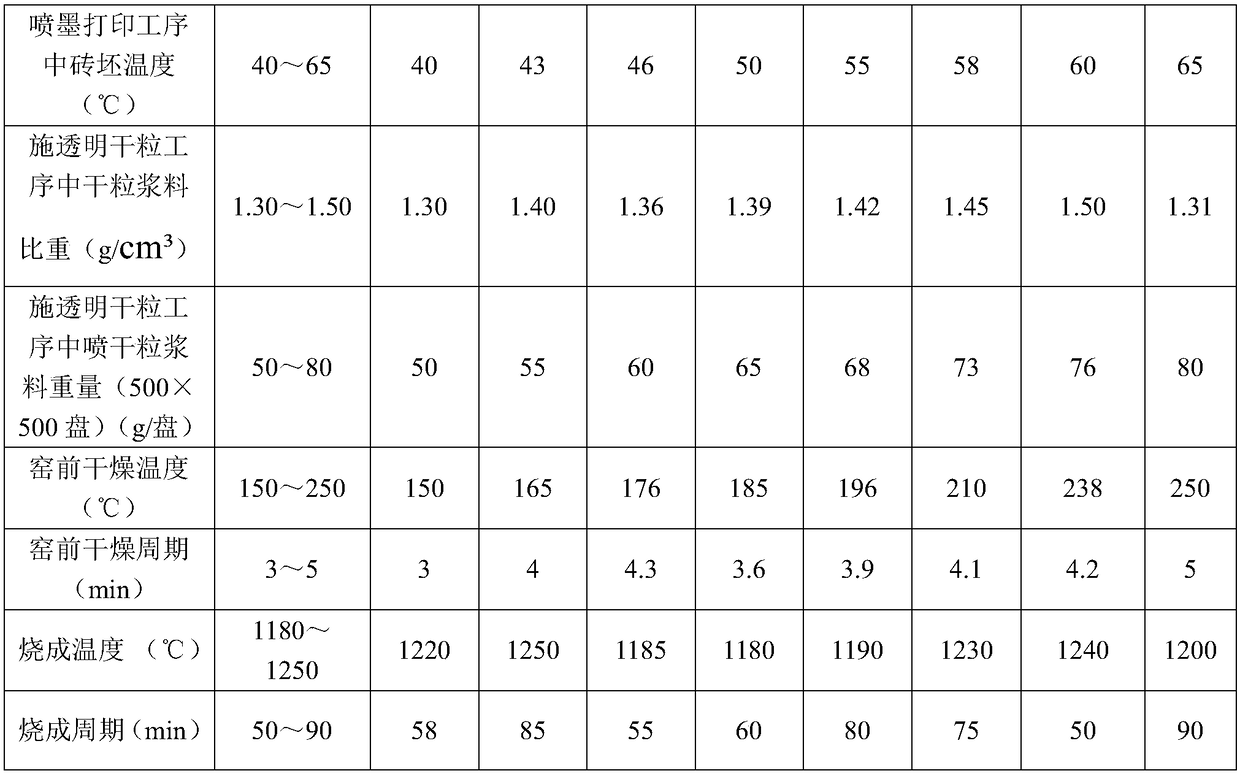

Manufacturing method of archaized brick transparent glaze

The invention discloses a manufacturing method of archaized brick transparent glaze. The manufacturing method of archaized brick transparent glaze comprises following steps: material selection; formula adjusting; material preparation; ball milling; iron removing; sieving and impurity removing; glaze slurry aging; glazing; glaze slurry technological parameter adjusting; glaze cabinet transparent glaze applying; ink-jet printing; glaze cabinet transparent (or dry particle) applying; pre-kiln drying; high temperature sintering; semi-finished product technology processing; sorting; packaging; andwarehousing. The raw materials comprise, by weight, 30 to 45% of potassium sodium stone powder, 0 to 8% of quartz sand, 5 to 12% of alumina, 10 to 15% of a delustering agent, 5 to 10% of kaolin, 3 to5% of zinc oxide, 8 to 12% of silica fume, 3 to 8% of sintered talcum, 0.5 to 0.8% of sodium tripolyphosphate, and 0.1 to 0.5% of carboxymethyl cellulose sodium (CMC); and the chemical composition comprises loss on ignition (LOSS) 10 to 15%, alumina Al2O3 15 to 18%, silica SiO2 40 to 50%, ferric oxide Fe2O3 <0.45%, calcium oxide CaO 1 to 6%, magnesium oxide MgO 1 to 6%, potassium oxide K2O 1 to 4%, sodium oxide Na2O 1 to 5%, titanium dioxide TiO2 <0.35%, zirconium dioxide ZrO2<0.015%, barium oxide BaO 10 to 20%, zinc oxide ZnO 0 to 6%, strontium oxide SrO 0 to 2.5%, and phosphoric pentoxide P2O5 0 to 2.5%. According to the manufacturing method, glaze material and a blank body are combined naturally, the texture is transparent, mild, and soft.

Owner:GUANGDONG XINRUNCHENG CERAMICS

Method for preparing secondary coal ash of goods by using high-calcium coal ash

InactiveCN102584060AReduce the requirement of grinding finenessTake advantage ofSolid waste managementSocial benefitsActivity index

The invention discloses a method for preparing secondary coal ash of goods by using high-calcium coal ash, which comprises the following steps of: (1) milling the high-calcium coal ash into 45 microns and sieving and remaining 4%-14%, milling the hearth ash into 45 microns and sieving and remaining 15%-33%, wherein the indexes of the high-calcium coal ash and the hearth ash are as follows: 28d activity index is more than 70%, the loss on ignition is not more than 8%, sulfur trioxide is not more than 3% and water content is not more than 1%; and (2) calculating the mixing ratio of the high-calcium coal ash to the hearth ash, causing the sieved residue of the 45-micron mixed ash to be not more than 20%, and according to the calculated mixing ratio, uniformly mixing the high-calcium coal ash with the hearth ash. According to the method provided by the invention, the demand on the fineness of the high-calcium coal ash is reduced, the problem of high cost caused by high power consumption during the process of milling the high-calcium coal ash is solved, the economic benefit is higher, the high-calcium coal ash and the solid wastes, namely, the hearth ash, are fully utilized, the environmental protection is facilitated and the social benefit is higher.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

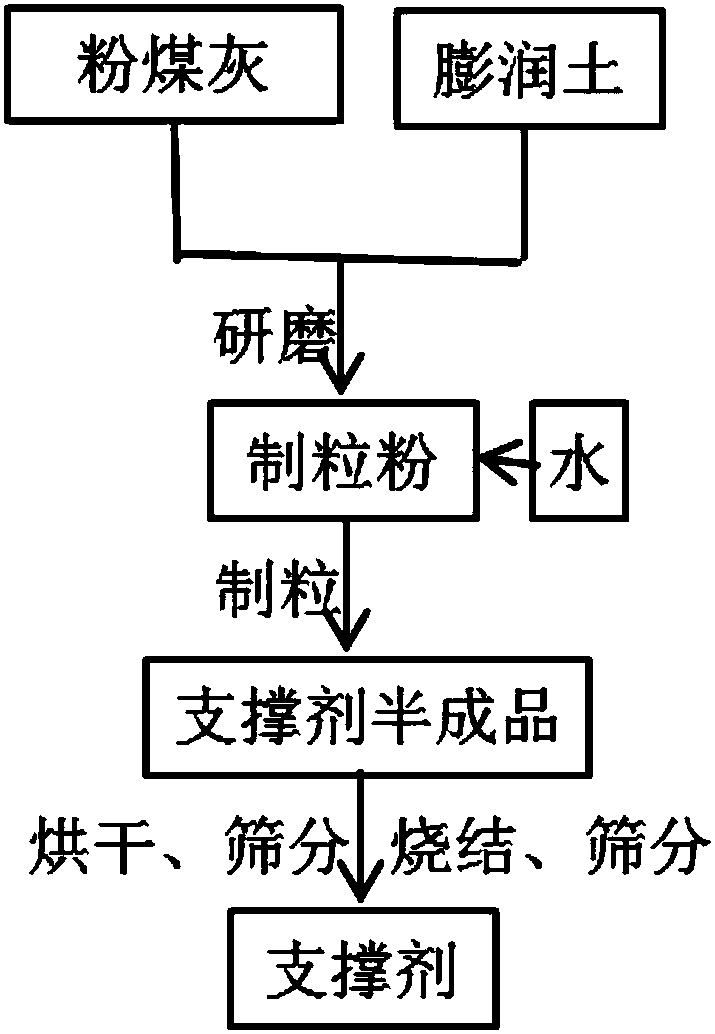

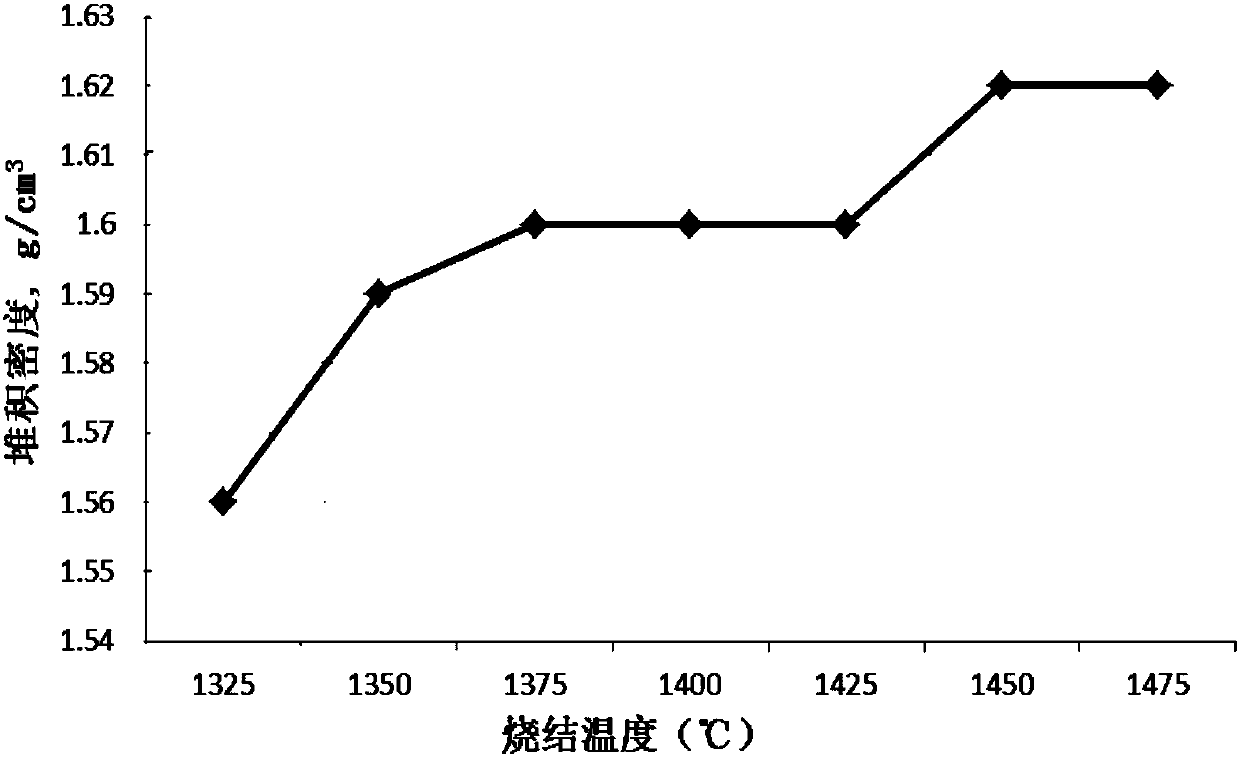

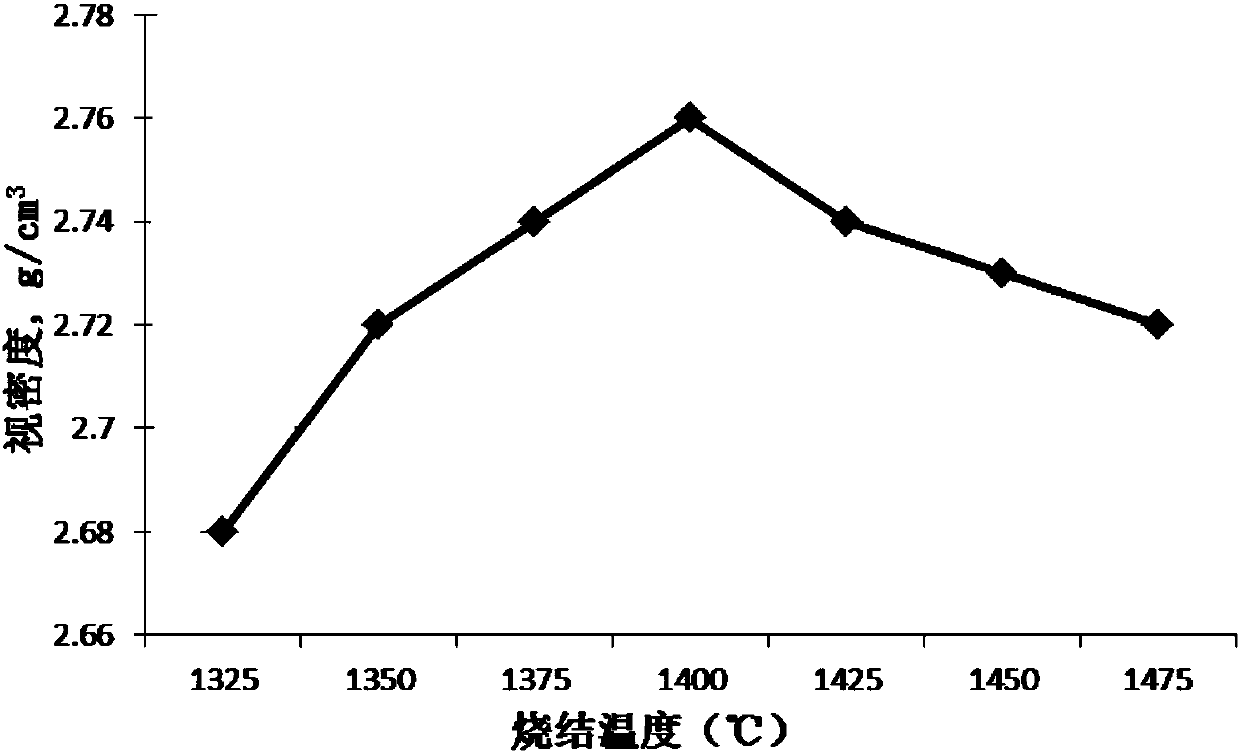

Fracturing propping agent composition, fracturing propping agent, and preparation method thereof

InactiveCN107721392ALow densityHigh strengthFluid removalDrilling compositionLoss on ignitionPetroleum

The invention belongs to the field of petroleum fracturing propping agent, and discloses a fracturing propping agent composition, a fracturing propping agent, and a preparation method thereof. The fracturing propping agent composition comprises, by weight, 60 to 99.5% of fly ash, and 0.5 to 40% of bentonite; the fly ash contains, by weight, more than 35% of Al2O3, and more than 30% of SiO2, and the loss on ignition is smaller than 5wt%; the bentonite contains, by weight, more than 70% of Al2O3 and SiO2, and the loss on ignition is 10 to 20wt%. The formula of the fracturing propping agent composition is simple, cost is low, and low density fracturing propping agents can be prepared taking the fracturing propping agent composition as a raw material; in the fracturing propping agent composition, industrial solid waste fly ash is taken as a raw material, so that environmental pollution caused by direct discharge of fly ash is avoided; the preparation method is simple; and the preparation method is convenient for large scale industrialized production.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Product containing magnesium pyrophosphate and use thereof as a raising acid for the production of bakery products

ActiveUS20110111110A1Dough treatmentProtein composition from eggsMagnesium phosphateMagnesium pyrophosphate

A product which contains acid magnesium pyrophosphate (magnesium dihydrogen diphosphate) and at least magnesium orthophosphate, producible by removal of water from an aqueous solution or suspension of a magnesium phosphate compound which has a molar ratio of Mg:P of 0.4-0.6:I, wherein the product has a loss on ignition of 7.5 to 13.5% and its method of preparation and its use in a leavening agent for bakery products.

Owner:CHEM FAB BUDENHEIM AG

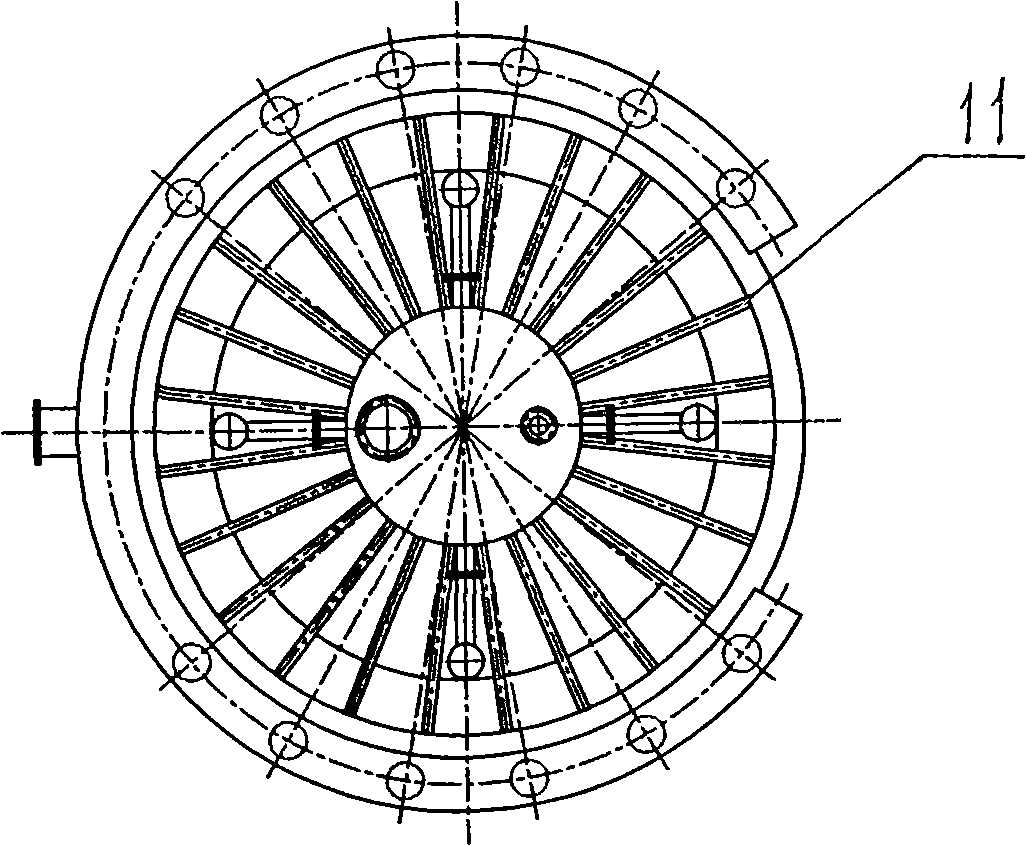

Siliceous clay slurry

A clay slurry with a solids content of at least about 60 weight percent and a casting rate of at least 60 grams per hour, wherein said slurry contains from about 61.5 to about 71.5 weight percent of silica, from about 18.8 to about 26.8 weight percent of alumina, and less than about 0.6 percent of carbon, wherein said slurry has a loss on ignition of from about 7.4 to about 8.6, wherein from about at least about 9 weight percent of the particles in said slurry are larger than about 45 microns, wherein at least about 5 weight percent of the particles in said slurry are larger than about 75 microns, wherein from about 29 to about 36 weight percent of the particles in such slurry are smaller than 0.5 microns, wherein the ratio of such particles larger than 75 microns to such particles larger than 45 microns is from about 0.5 to about 0.7, and wherein at least 90 weight percent of such silica contains less than about 1017 Si and Si—O silicon-based radicals per gram.

Owner:THOMAS RONALD J

Hollowed-out Jun procelian and preparation technology thereof

InactiveCN107188540AClear and pure glaze colorMoist and delicateCeramic materials productionCeramicwareMicrowaveHardness

The invention relates to hollowed-out Jun procelian, comprising two parts, i.e., base procelian and glazed porcelain, wherein a plurality of through holes are formed in the outer surface of the base procelian; the pre-separation between pore-making granules and a green body is realized by means of microwave treatment on the pore-making granules evenly doped in the base procelian green body through the through holes; then, the green body is subjected to high-temperature sintering, so that the pore-making granules are melted, and the hollowed-out Jun procelian is obtained. After the hollowed-out Jun procelian and a preparation technology thereof, provided by the invention, are adopted, the preparation of the hollowed-out Jun procelian which is good in finished product hardness, high in molding rate and low in loss on ignition can be realized by means of a base procelian raw material formula, a base procelian firing method and improvement for a glaze formula and a glaze firing technology.

Owner:任合超

High-hardness abrasion-proof ceramic brick and preparation method thereof

The invention discloses a high-hardness abrasion-proof ceramic brick. The high-hardness abrasion-proof ceramic brick comprises a blank body, a ground coat layer, a decorative layer and a high-hardnessabrasion-proof glazed layer from bottom to top, wherein the high-hardness abrasion-proof glazed layer comprises the following chemical components in percentage by weight: 68-75% of SiO2, 10-13% of Al2O3, 0.05-0.1% of Fe2O3, 0.01-0.03% of TiO2, 1-3% of CaO, 2-4% of MgO, 2-5% of K2O, 1.5-3% of Na2O, 0.1-0.3% of Li2O, and 1-2.5% of BaO, wherein loss on ignition is 2.5-4%. According to the high-hardness abrasion-proof ceramic brick disclosed by the invention, through controlling chemical constituents in glaze, high-silicon glaze is obtained, so that formation of the high-hardness abrasion-proof glazed layer at the later stage is guaranteed. The invention further discloses a preparation method of the ceramic brick. Through the nanocrystallization technology of raw materials and thickness matching of particle diameters of the high-silicon glaze, the defects of a glaze surface, for example, the glaze layer is easy to subject to cut glaze when the glaze layer is formed at the later stage areovercome, and the hardness and the abrasion resistance of the glaze surface of the ceramic brick are greatly improved.

Owner:FOSHAN OCEANO CERAMICS +1

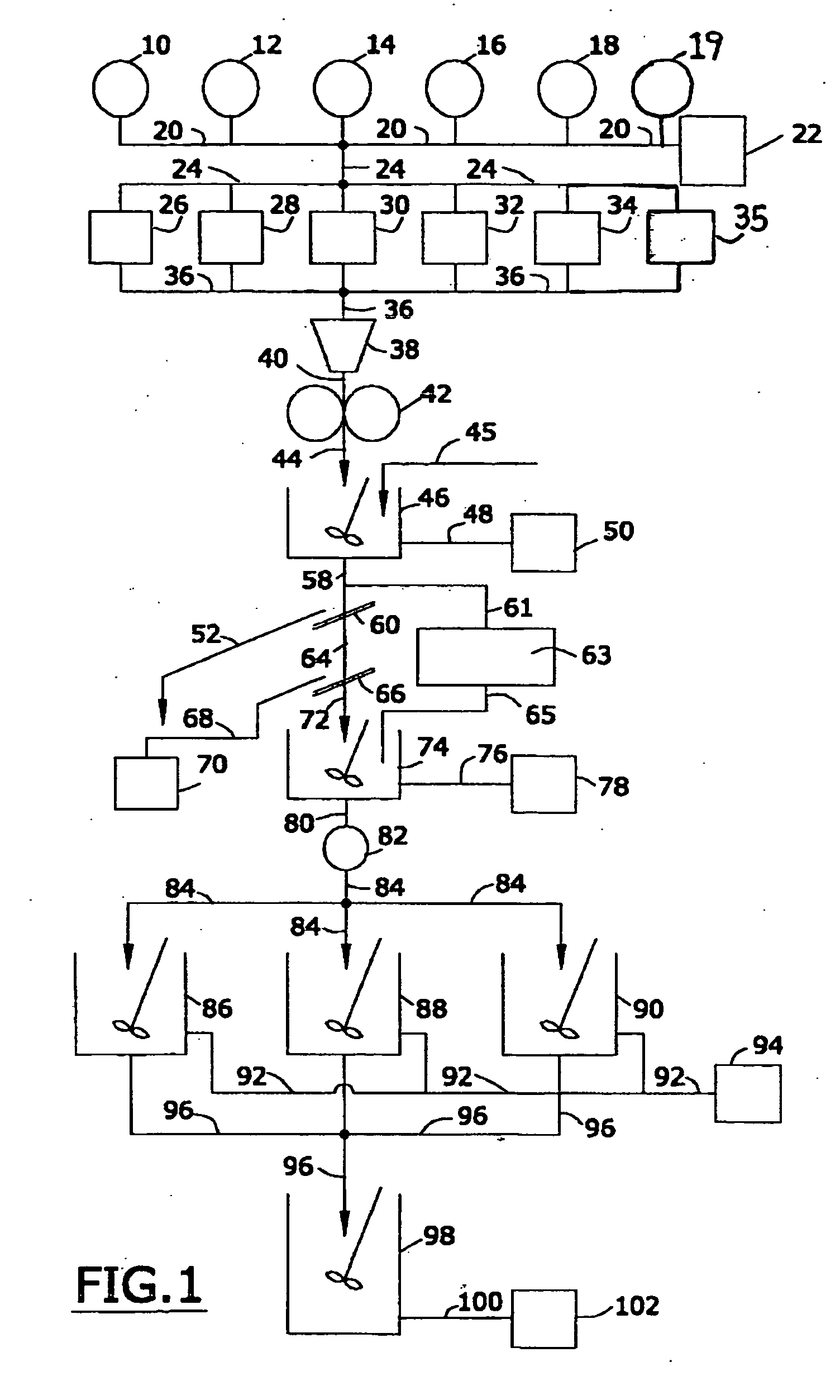

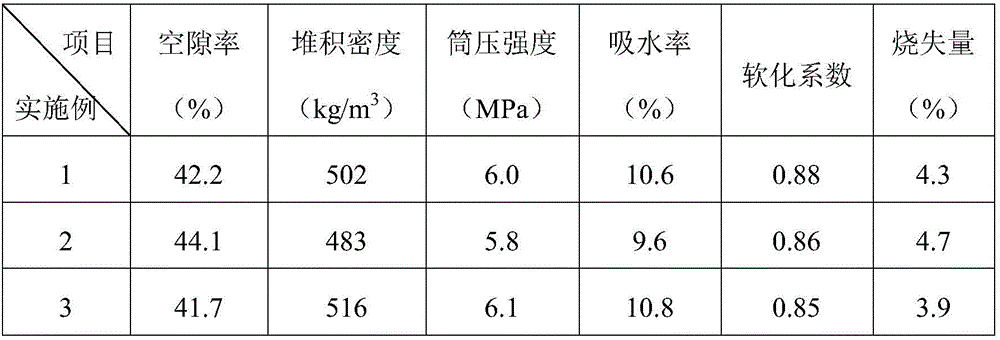

Light and porous sludge ceramisite and preparation method thereof

InactiveCN105948811AGuaranteed lightweightHigh porosityCeramic materials productionCeramicwarePorosityExpanded clay aggregate

The invention discloses light and porous sludge ceramisite and a preparation method thereof. The sludge ceramisite is prepared from raw materials in parts by weight as follows; 10-25 parts of saw dust, 20-30 parts of fly ash, 5-10 parts of silica fume, 30-40 parts of sludge, 10-15 parts of quick lime, 20-30 parts of red mudstone, 1-5 parts of gypsum and 5-10 parts of magnesite. The sludge ceramisite is prepared with sludge produced in a municipal sewage plant as a main raw material, fly ash, red mudstone and gypsum as main addition raw materials and quick lime, saw dust, silica fume and magnesite as additives, and good porosity, high cylindrical compress strength, a high softening coefficient, a high water absorption rate and low loss on ignition of the sludge ceramisite can be further guaranteed on the basis that the light-weight property is guaranteed. The preparation method of the sludge ceramisite is simple, raw materials are widely sourced, waste can be turned into wealth, environmental protection is realized, reutilization of sludge resources in the sewage treatment plant is realized, and the sludge ceramisite has good social and economic benefits.

Owner:郑州德赛尔陶粒有限公司

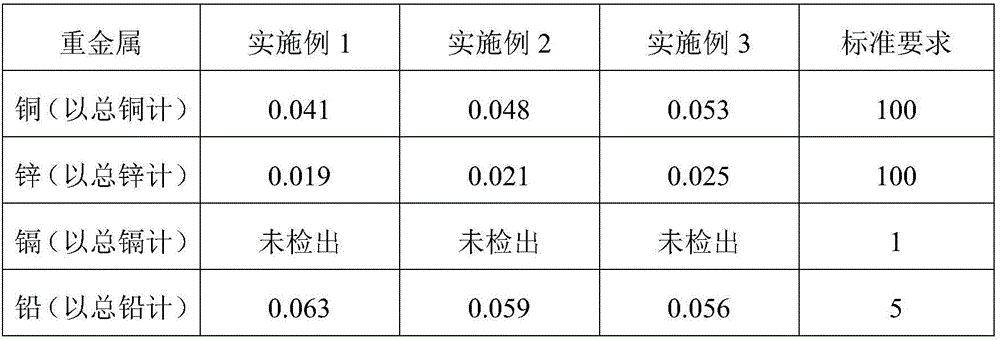

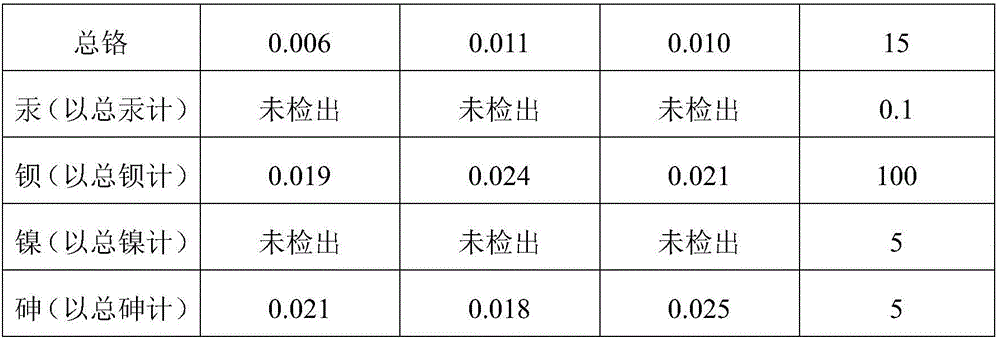

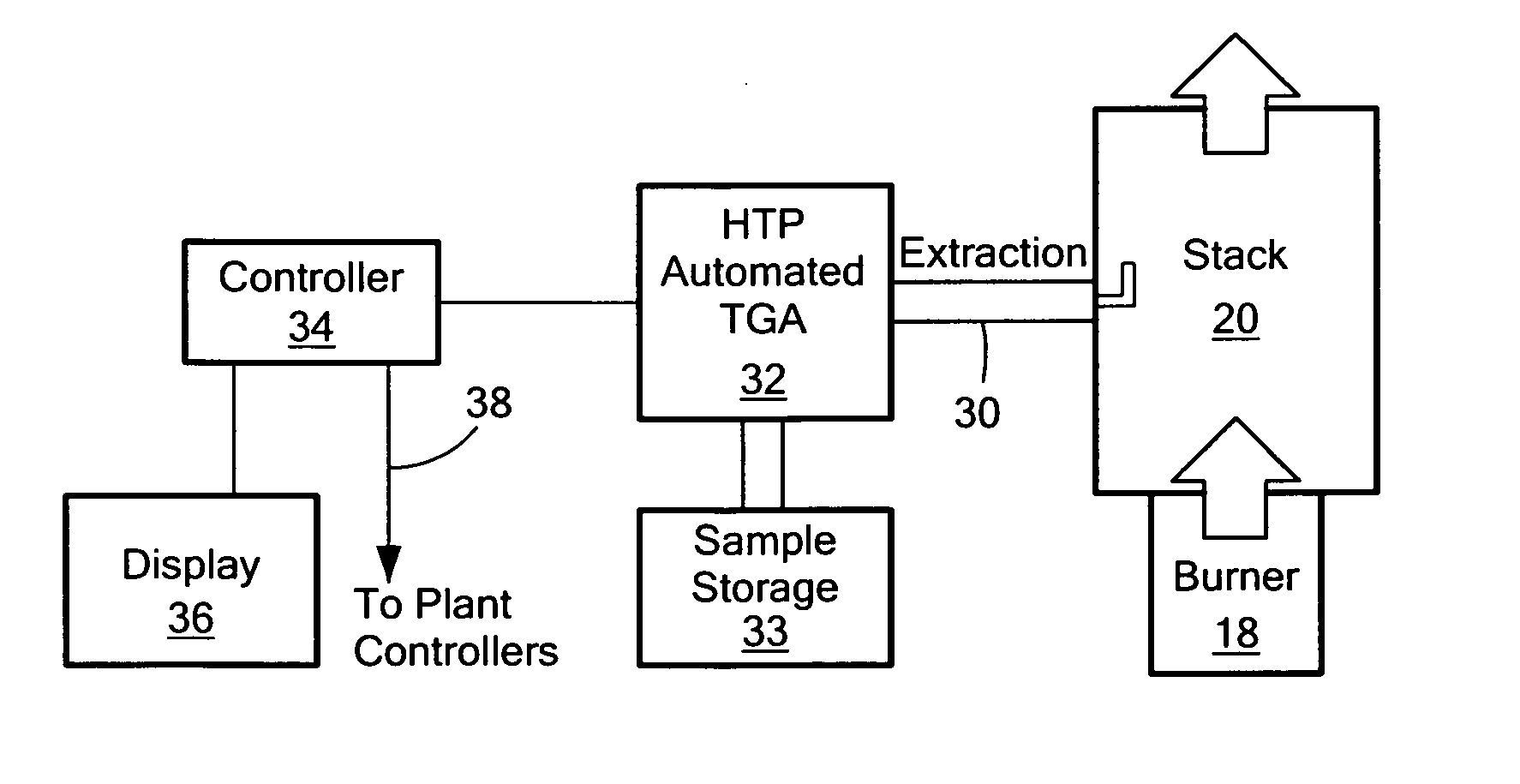

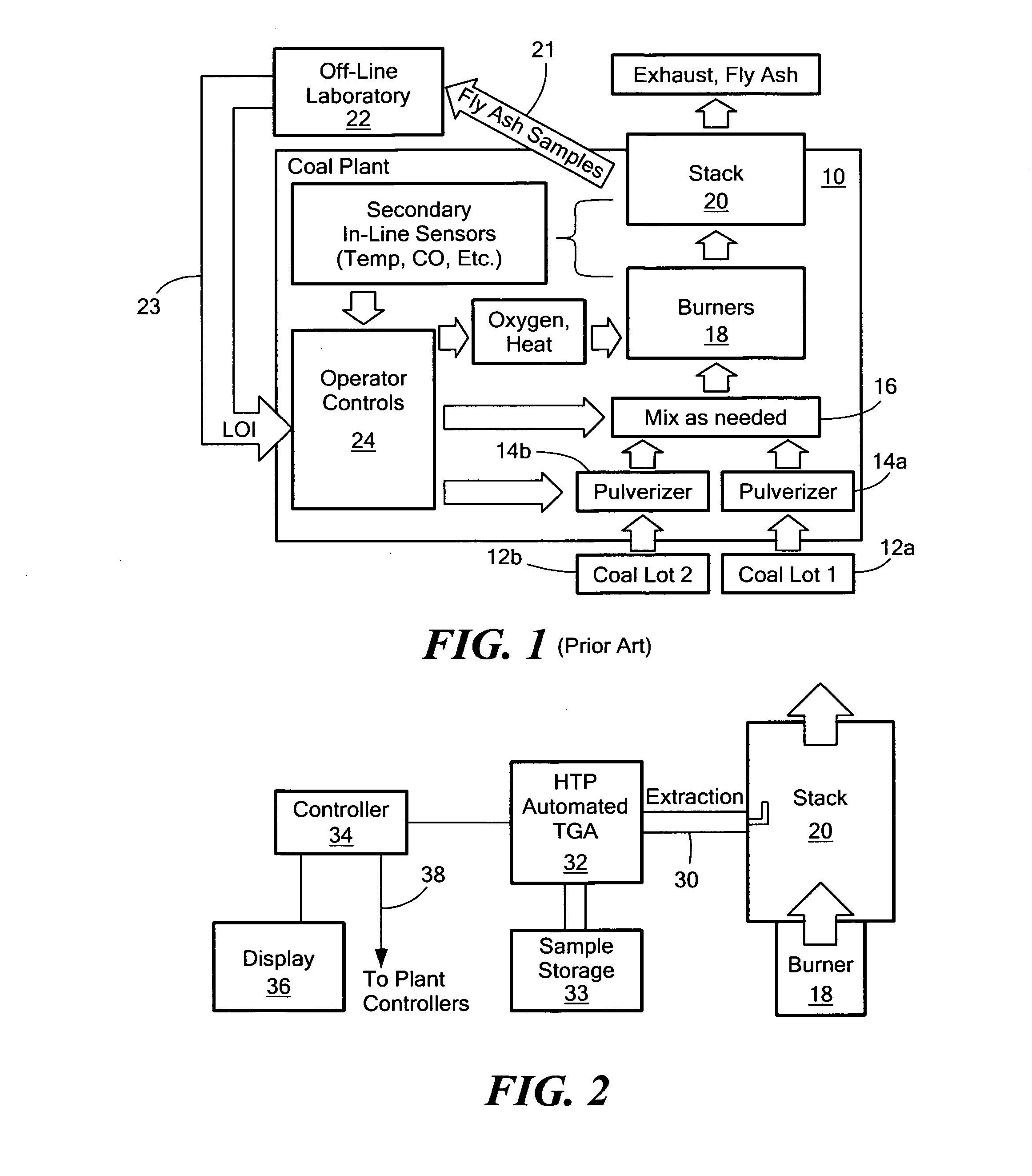

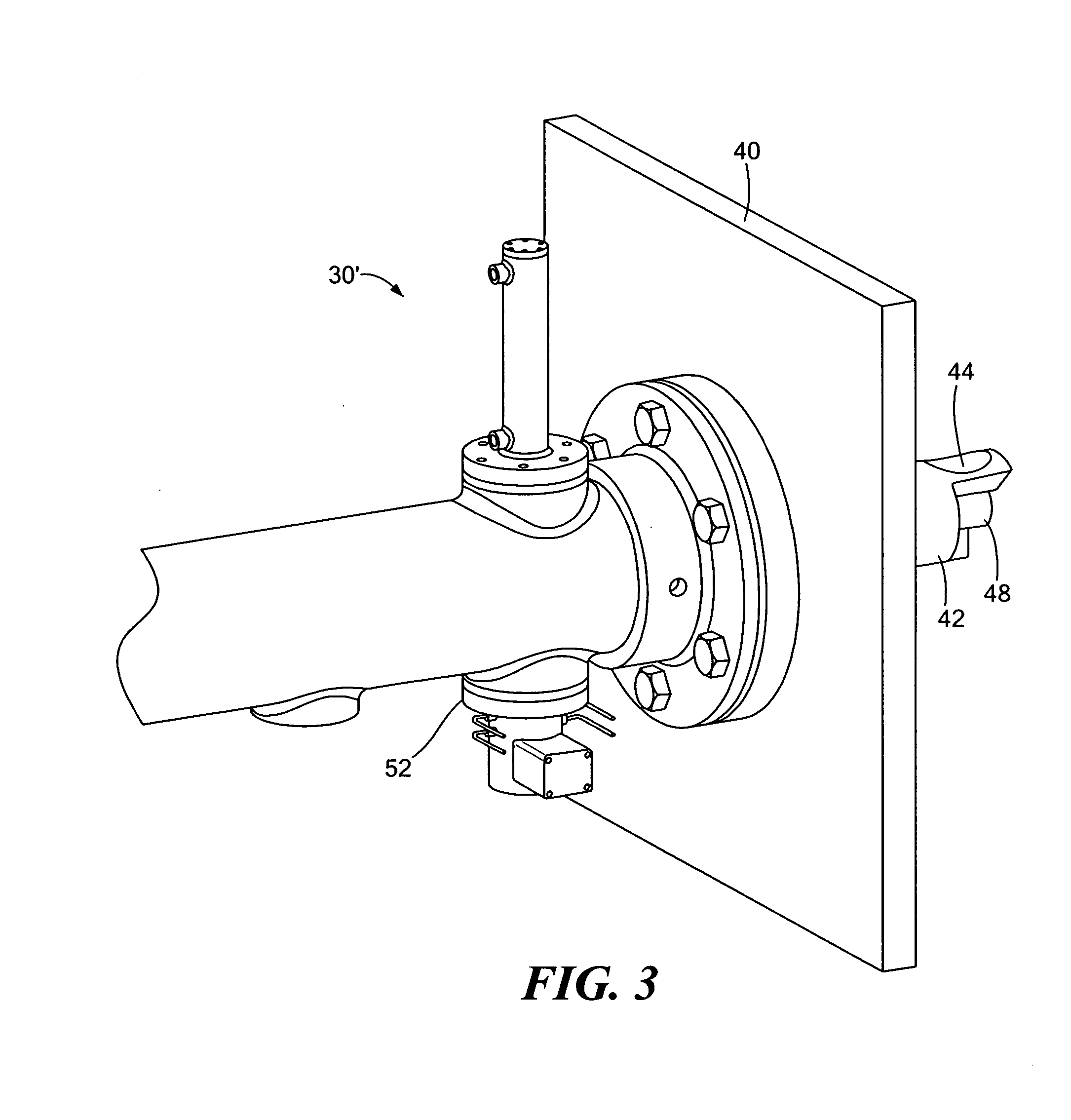

In-line loss-on-ignition measurement system and method

InactiveUS20100198408A1Measure directlySampled-variable control systemsWeighing by removing componentCombustionMarine engineering

An in-line loss-on-ignition measurement system featuring an extractor configured to collect fuel or a combustion by-product from a hydrocarbon fuel burning plant, an on-site analyzer configured to receive the collected matter and determine loss-on-ignition data for the plant, a transfer mechanism configured to transfer the collected matter from the extractor to the analyzer, and a controller for displaying the loss-on-ignition data and / or for automatically adjusting one or more parameters associated with the plant.

Owner:CHARLES STARK DRAPER LABORATORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com