Digital resin sand regeneration system

A regeneration system, resin sand technology, applied in foundry molding equipment, machinery for cleaning/processing of casting materials, metal processing equipment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

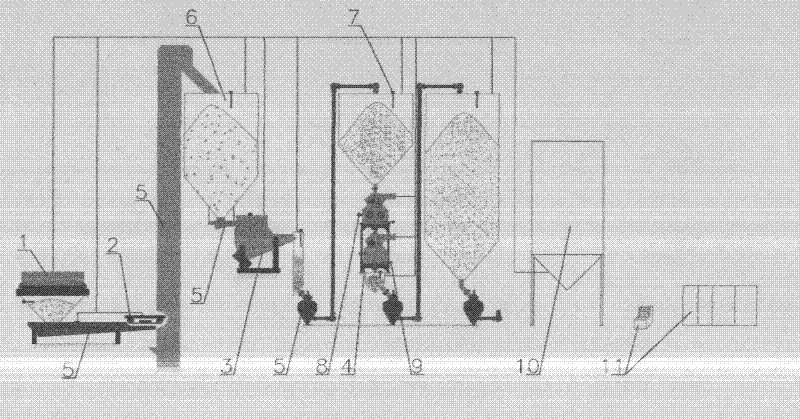

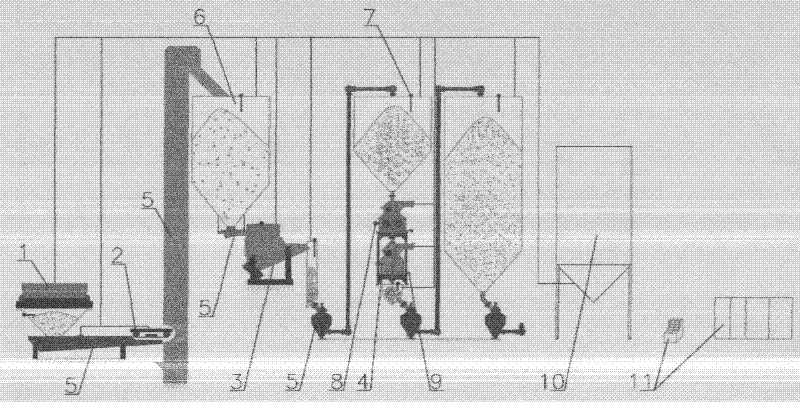

[0015] As shown in Figure 1, a digital resin sand regeneration system includes: vibration shakeout equipment 1, magnetic separation equipment 2, vibration crushing equipment 3, intermittent friction regeneration unit 4, conveying equipment 5, sand storage 6, special material Potometer 7, pressure sensor 8, temperature sensor 9, dust removal equipment 10, electric control system 11, etc., the vibration shakeout equipment 1 transports the resin sand to the magnetic separation equipment 2 through the conveying equipment 5, and then the conveying equipment 5 enters the In the first sand warehouse 6, the bottom of the sand warehouse 6 is connected with the conveying equipment 5, and the resin sand is transported to the vibrating crushing equipment 3 for vibration crushing, and then transported into the second sand warehouse 6 by the conveying equipment 5 , the bottom of the second sand warehouse 6 is connected with the conveying equipment 5, and transported to the third sand warehou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com