Purification method of isoquinoline

A purification method, the technology of isoquinoline, applied in the chemical field, can solve the problems of low product purity, inability to meet the needs of pharmaceutical production, and no significant reduction in impurity content, and achieve the effects of simple process, reduced production cost, and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

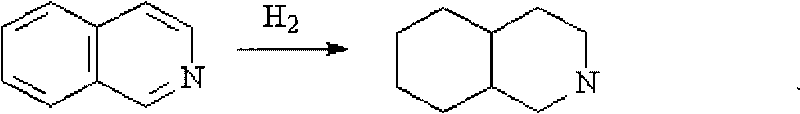

Image

Examples

Embodiment Construction

[0019] The method for purifying isoquinoline of the present invention will be further described below in conjunction with specific data and examples.

[0020] The invention discloses a purification method capable of preparing isoquinoline with high purity and low impurity content. The content of the purified isoquinoline is more than 99%, and the impurity content is low at the same time, which can meet the needs of pharmaceutical production.

[0021] The preparation method (purification method) of the said high-purity and low-impurity isoquinoline of the present invention comprises the steps:

[0022] 1) The washing oil (a fraction of coal tar) is acid-washed and alkali-washed to obtain a crude quinoline fraction, and then rectified to obtain a fraction containing 85-90% of isoquinoline, which contains 0.18-2% of methylnaphthalene , 2-methylquinoline 5-8%, 8-methylquinoline 2-5% and other impurities around 1%.

[0023] 2) The above-mentioned cut containing 85-90% of isoquinol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com