Patents

Literature

607results about How to "Effective rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

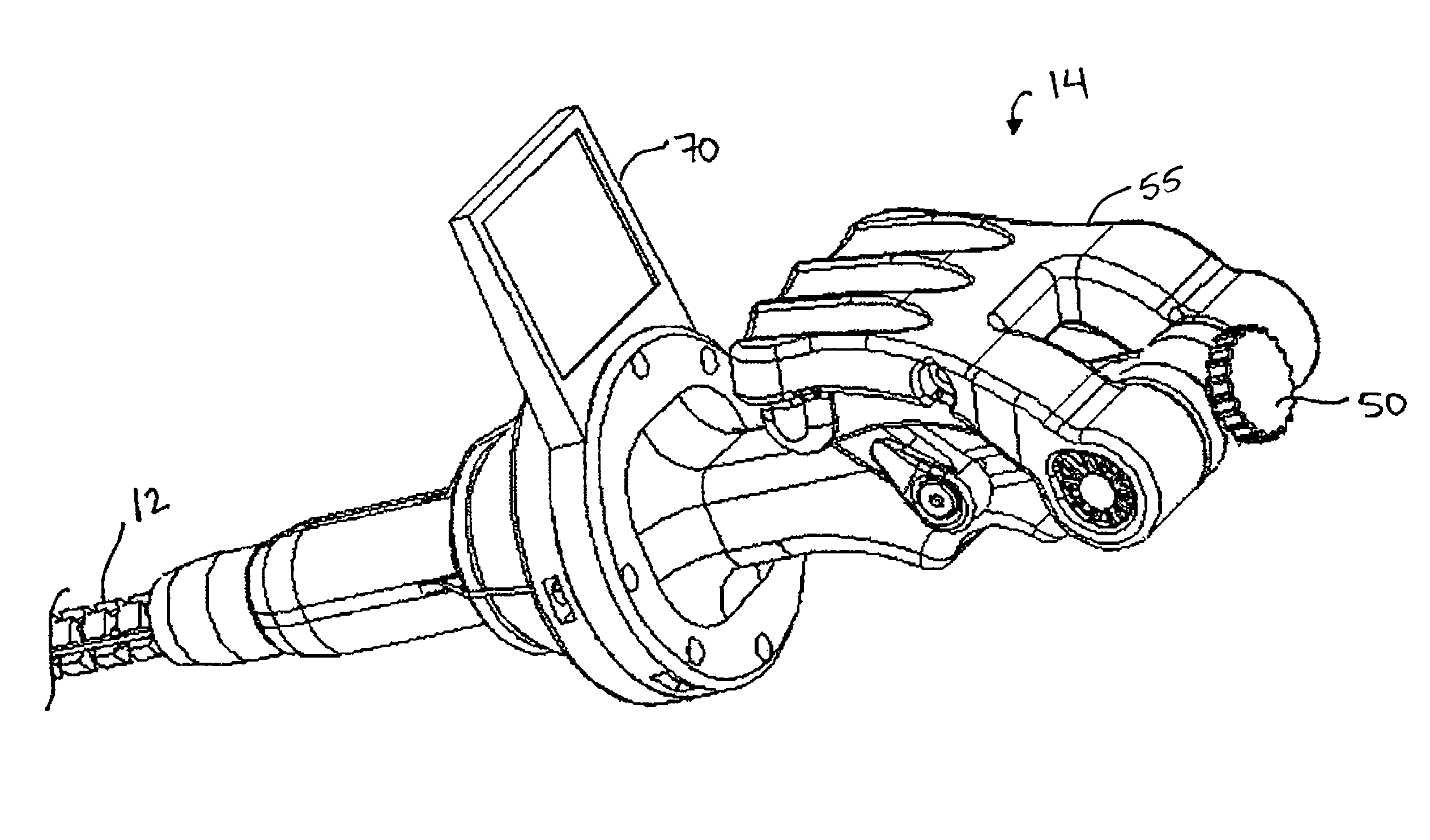

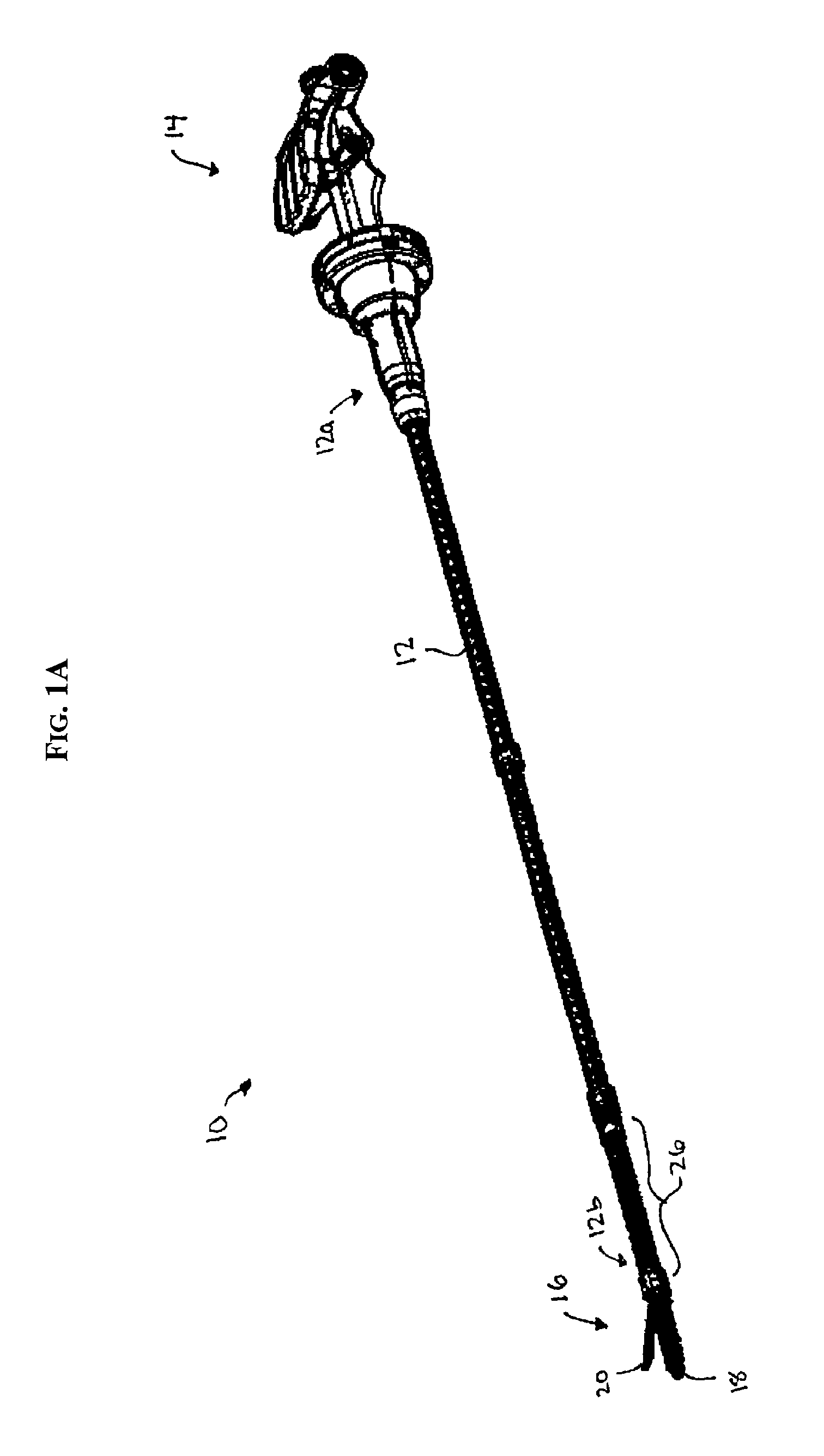

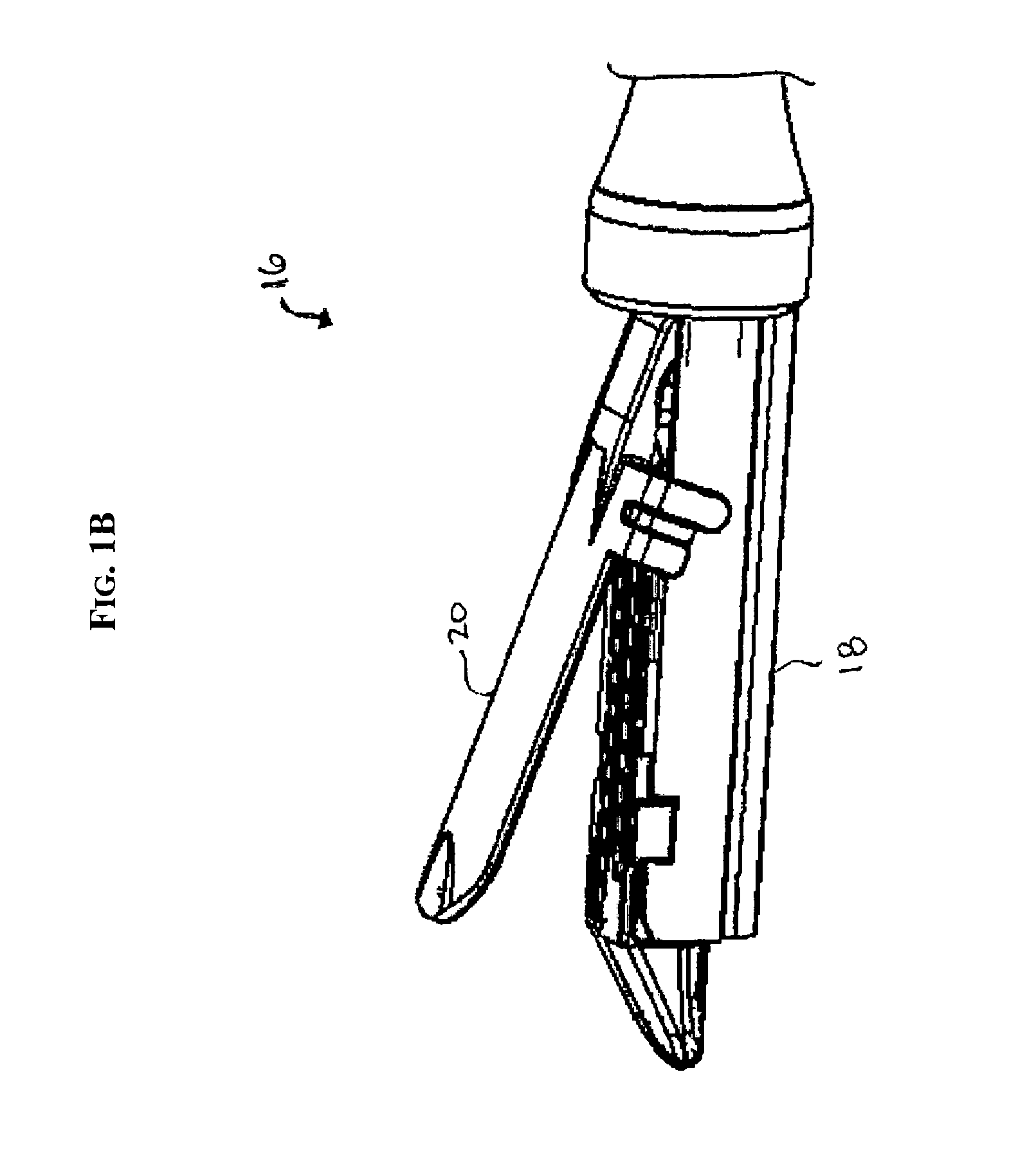

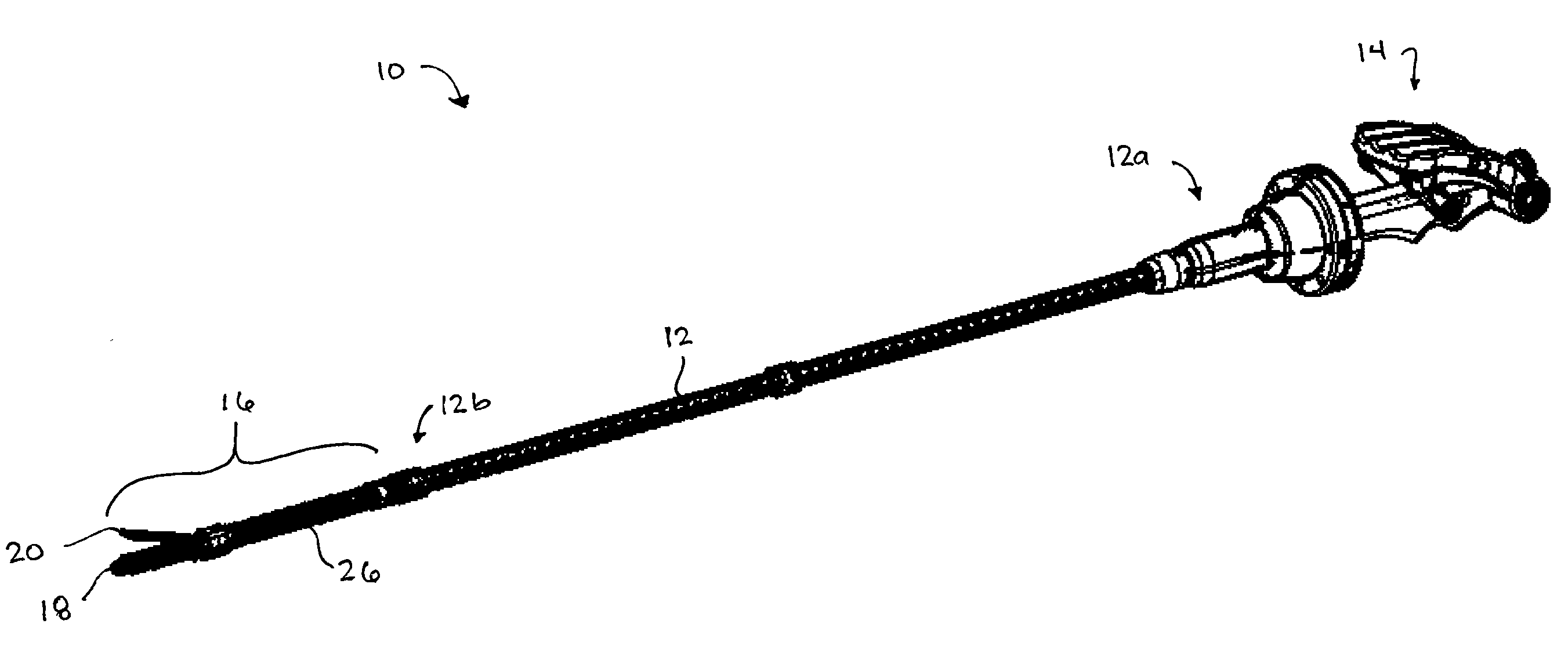

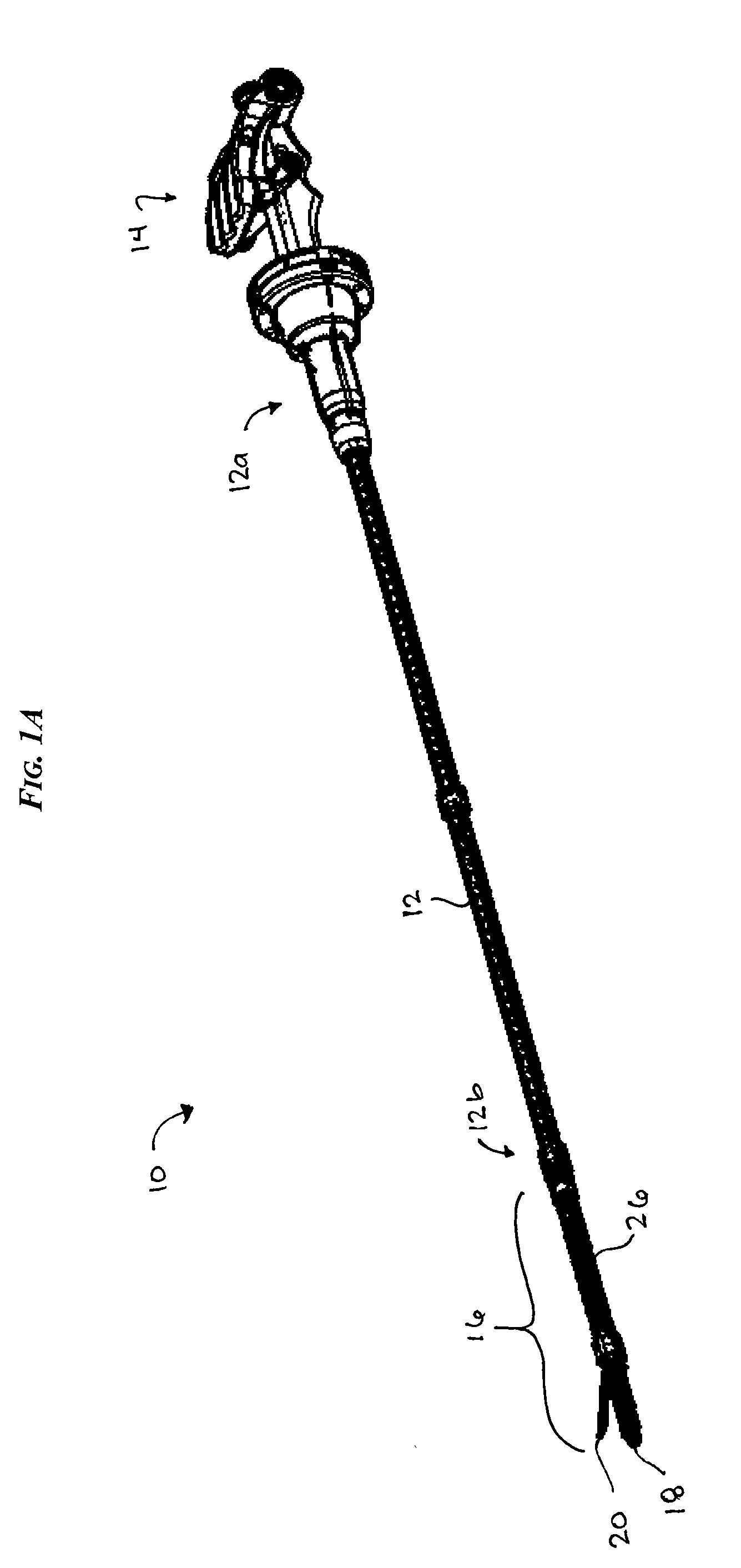

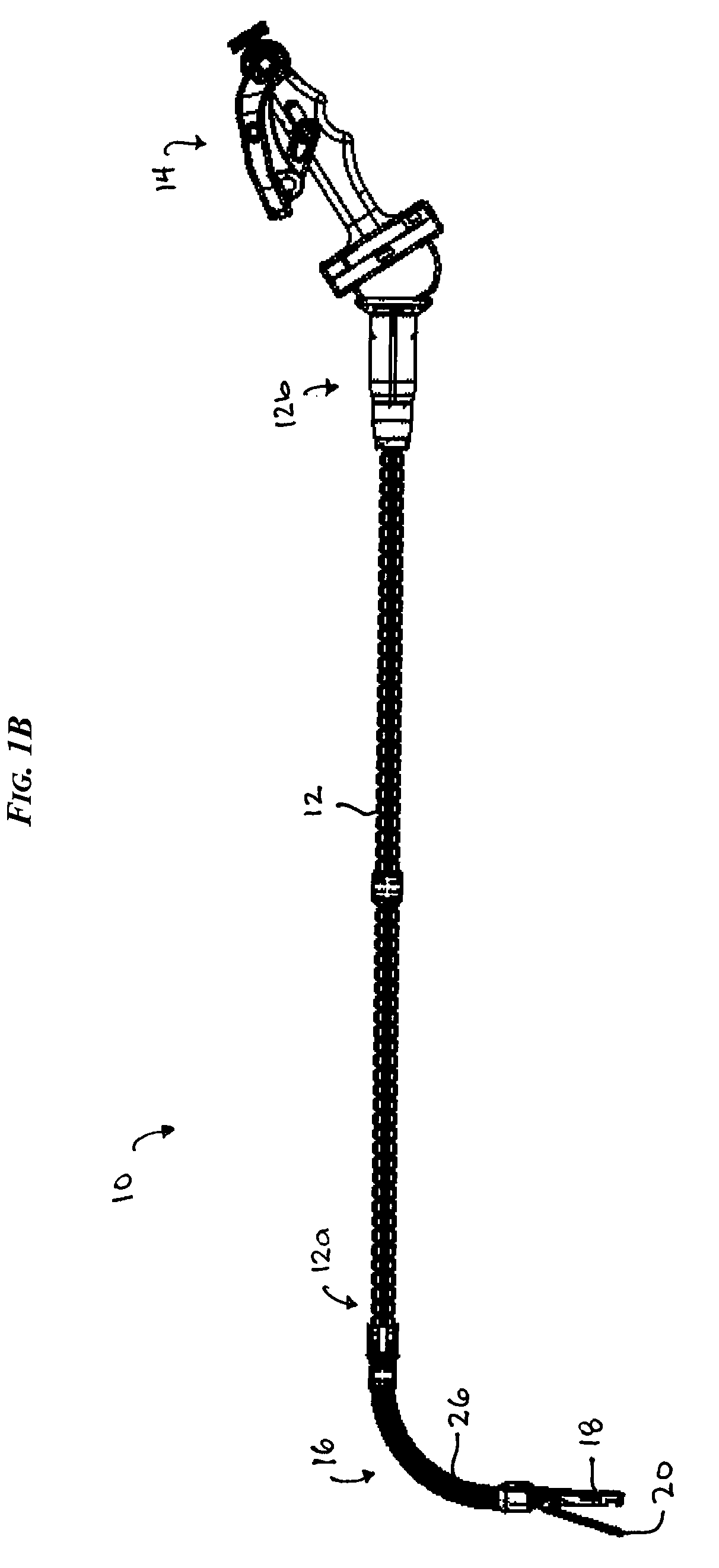

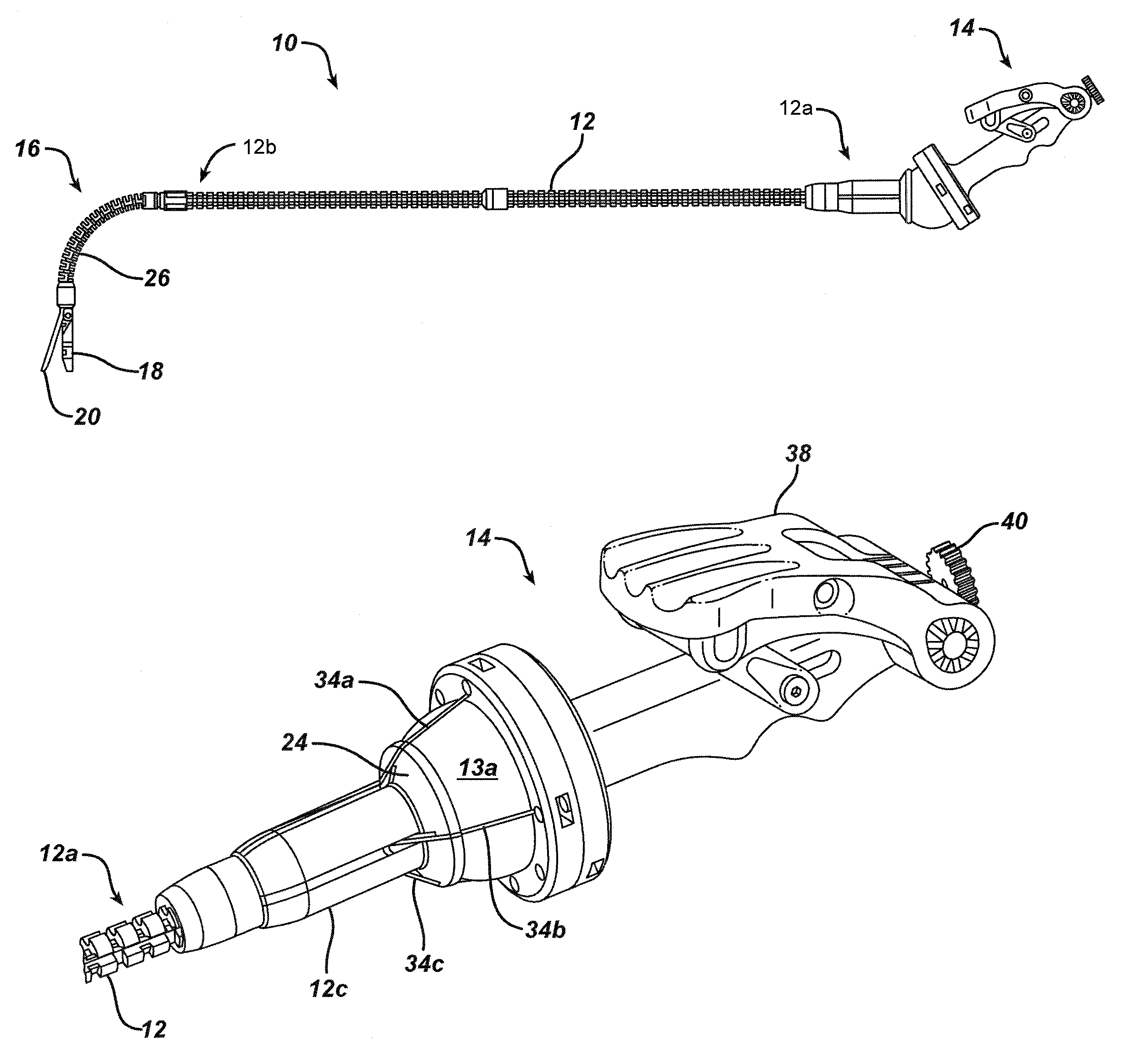

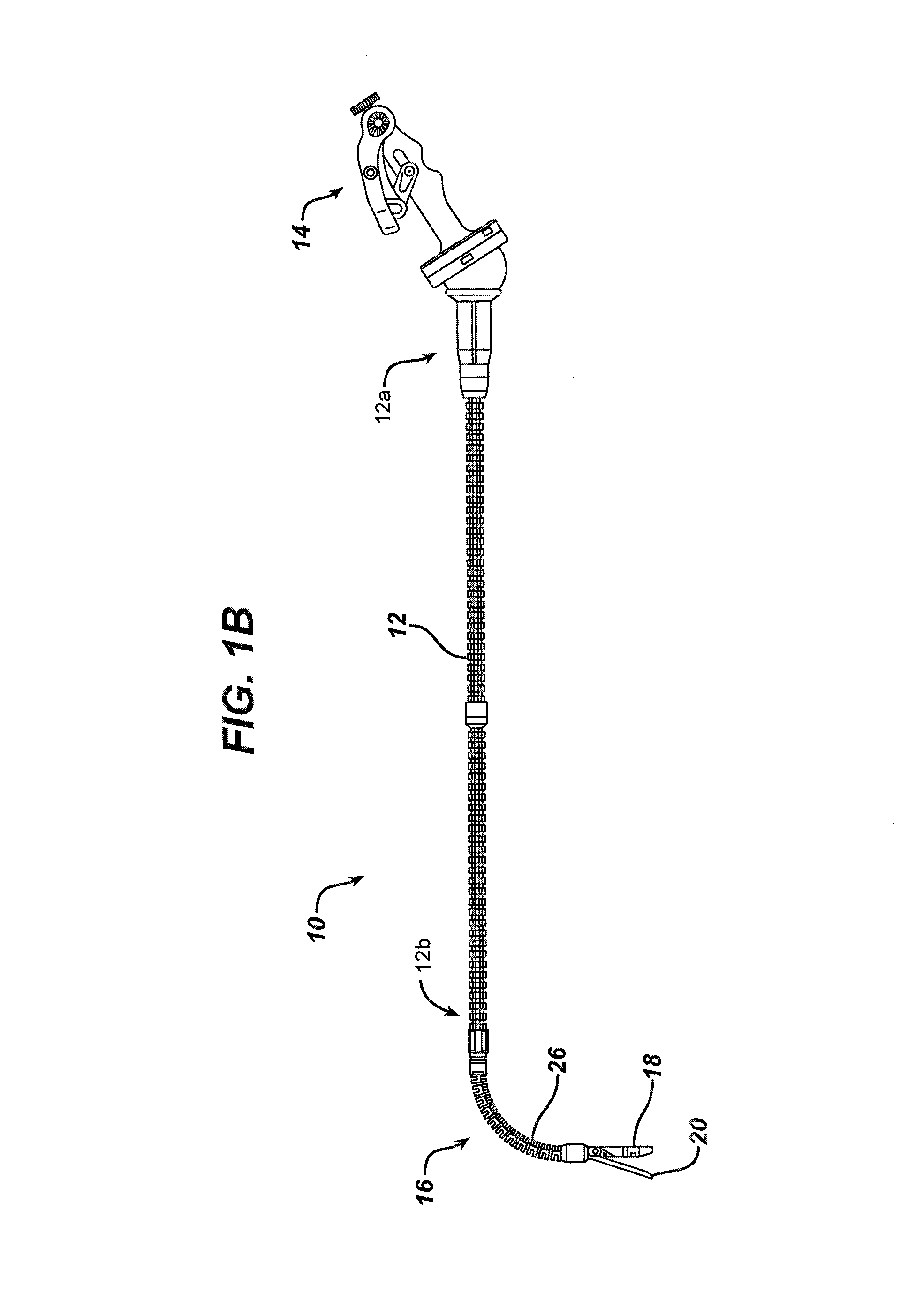

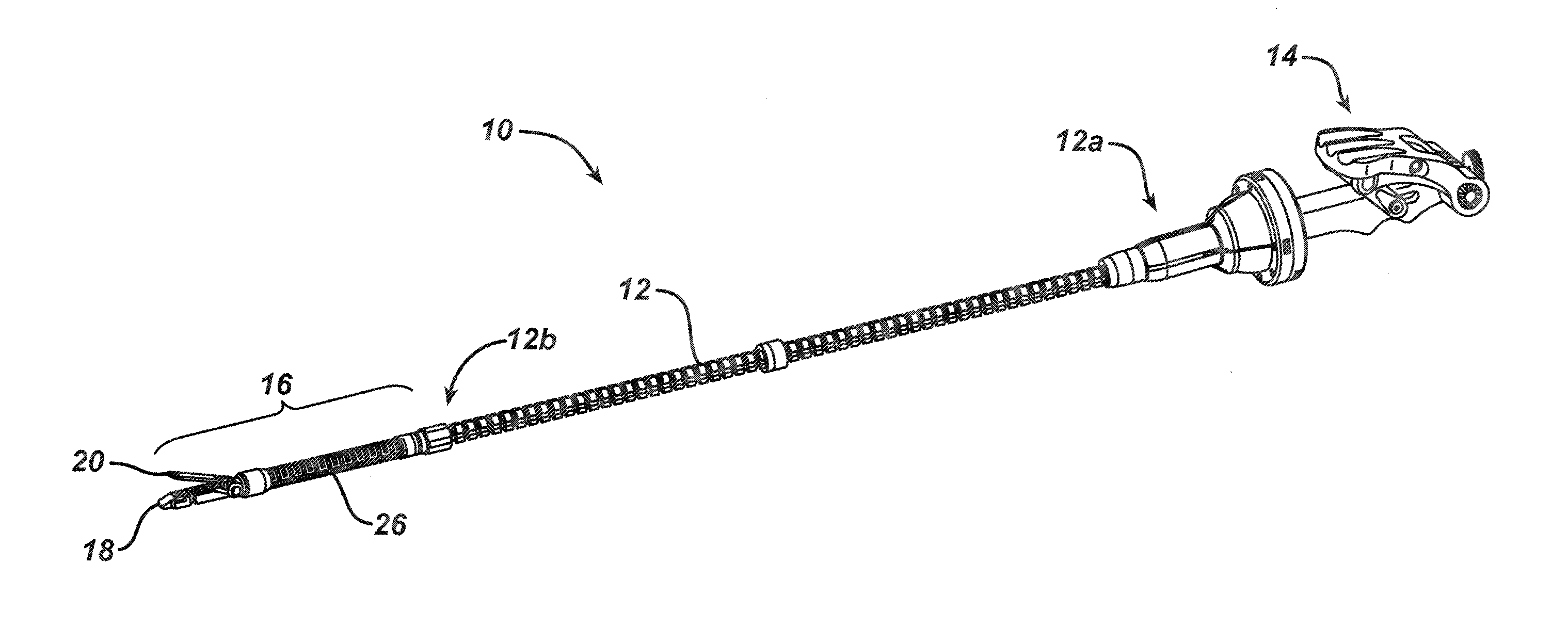

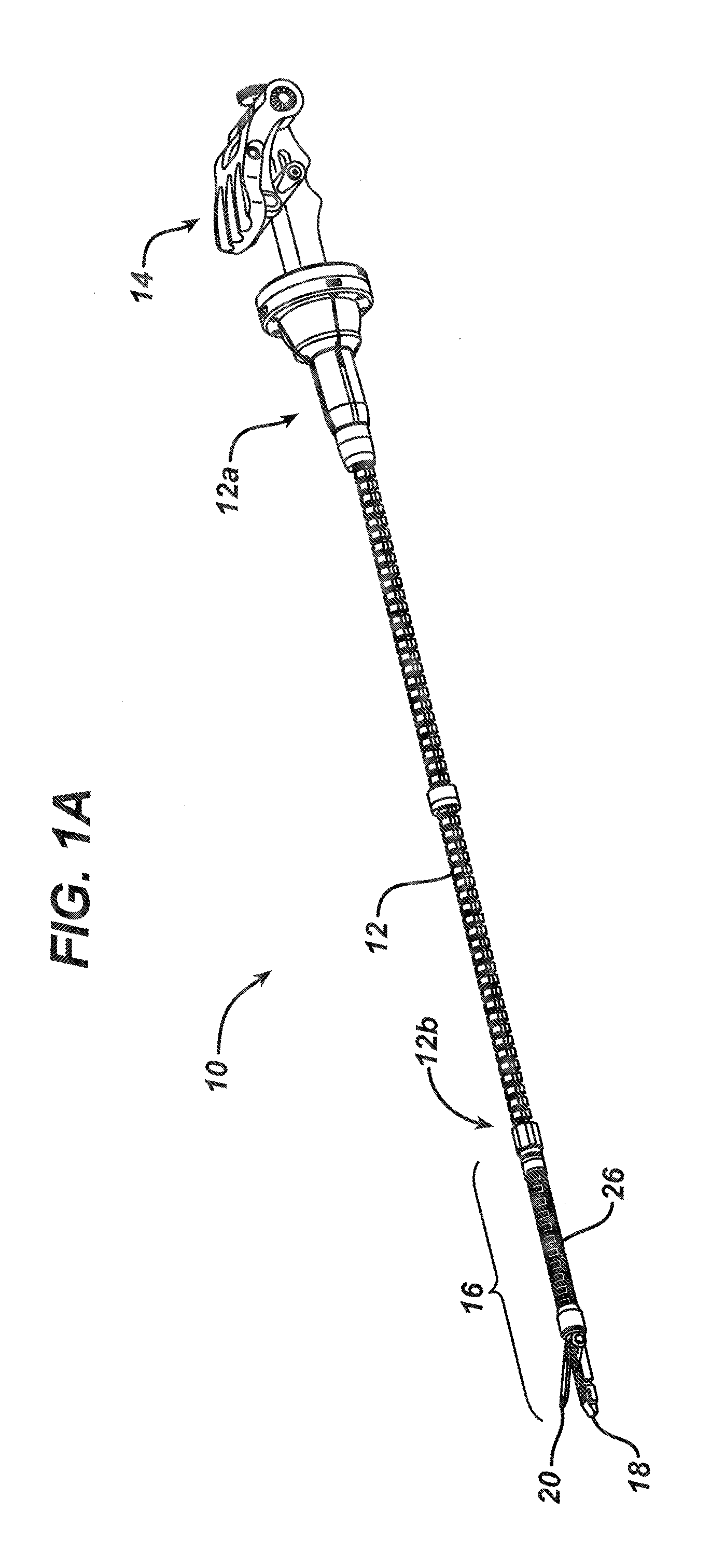

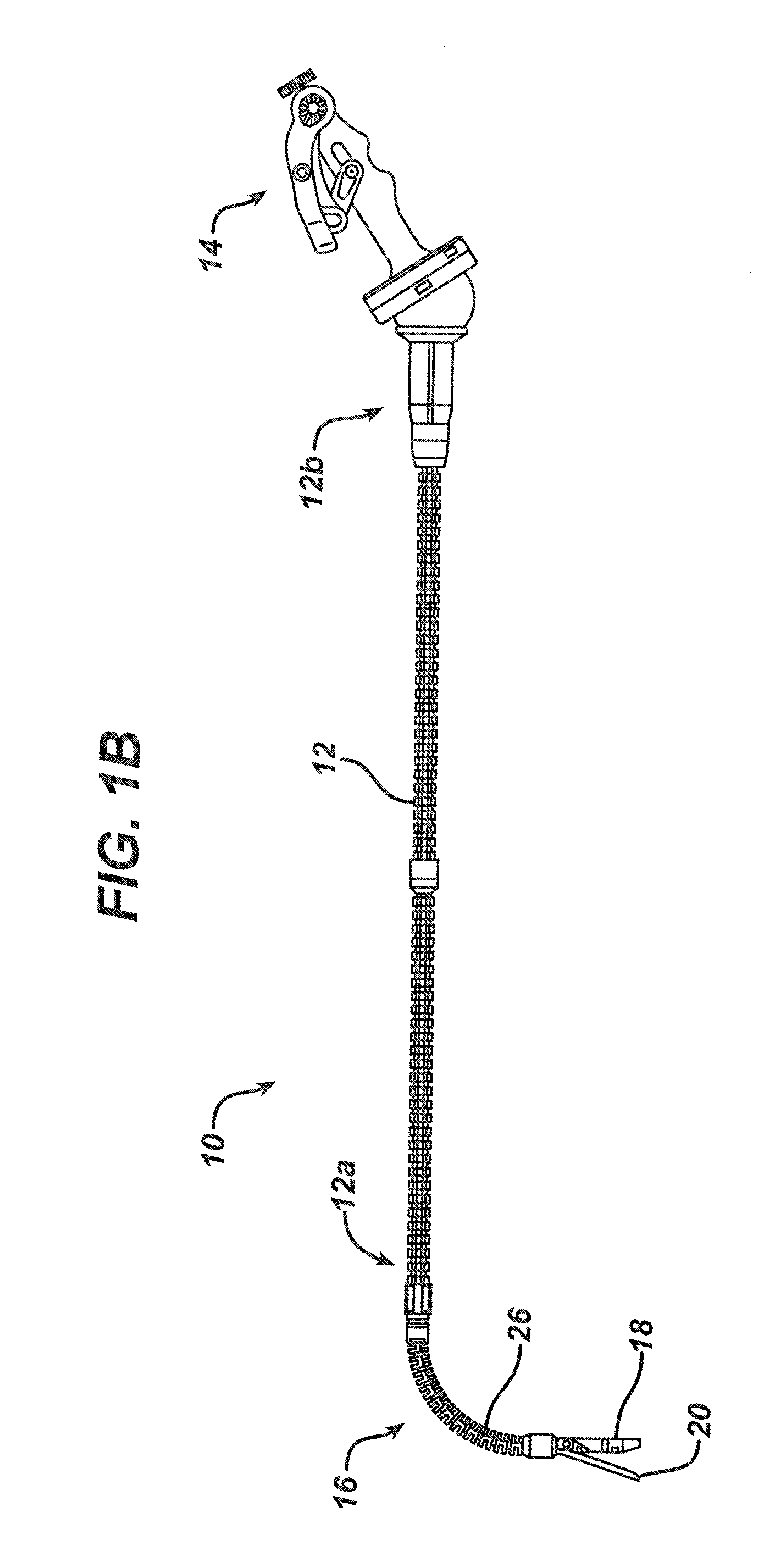

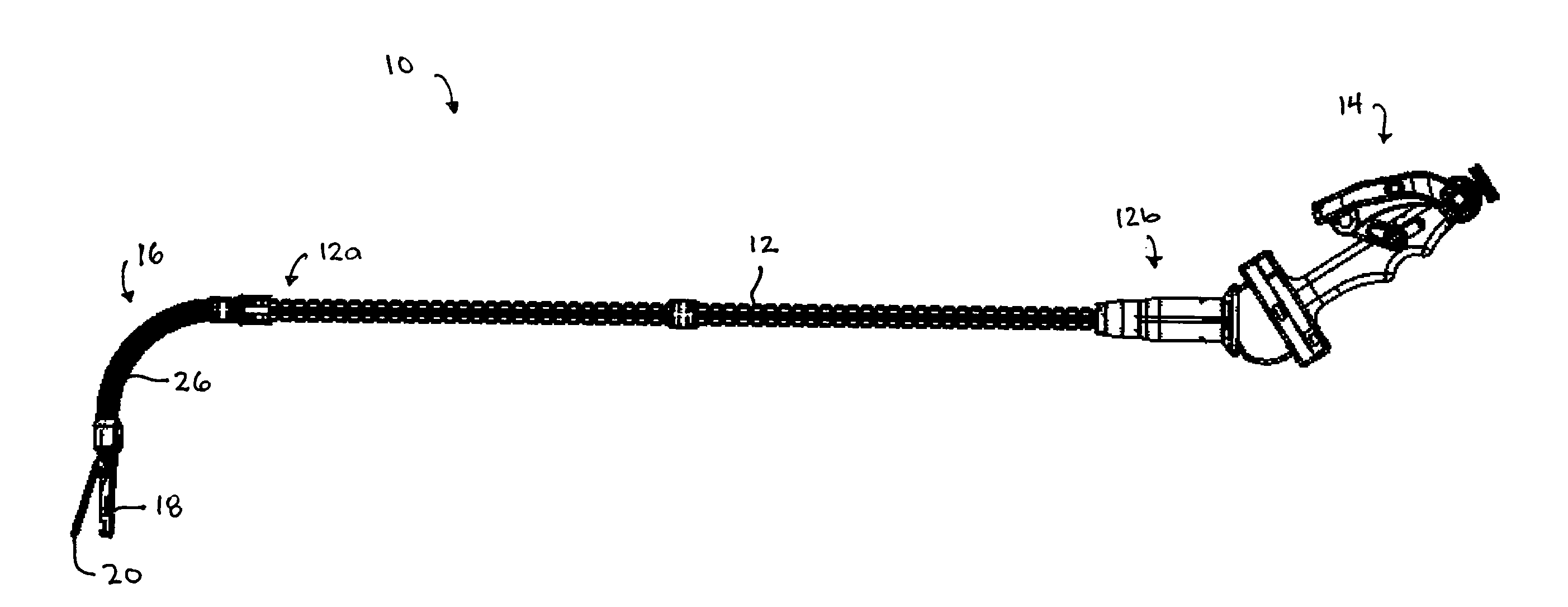

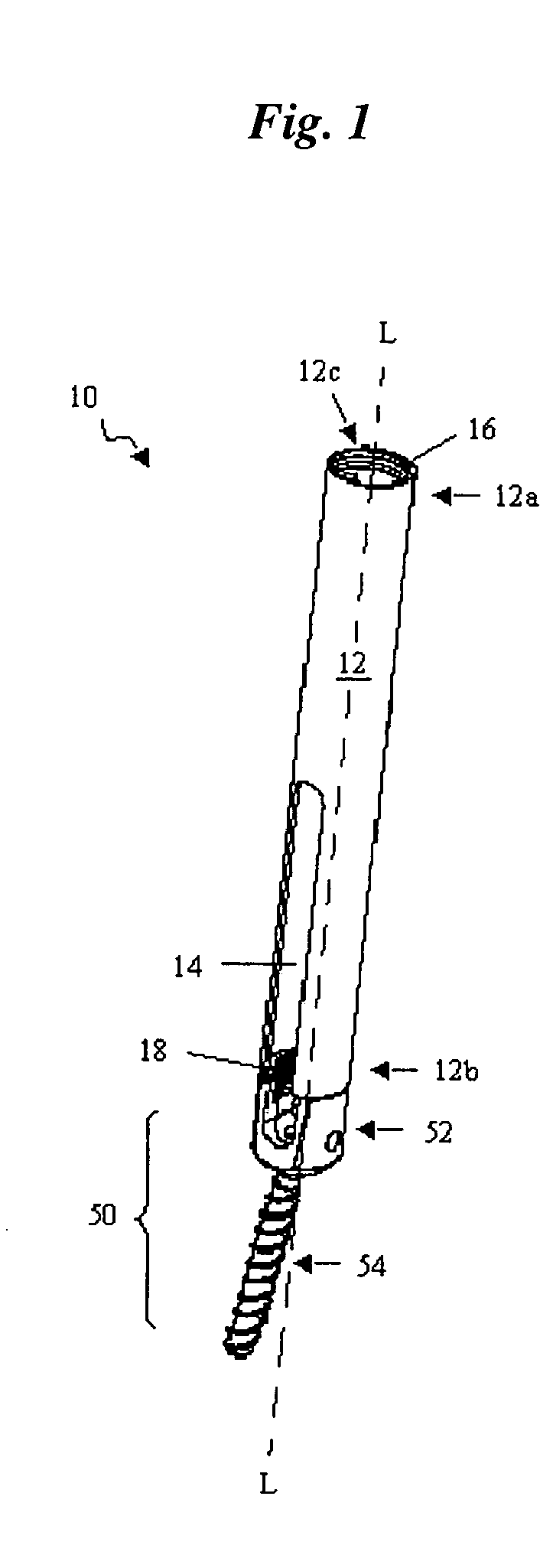

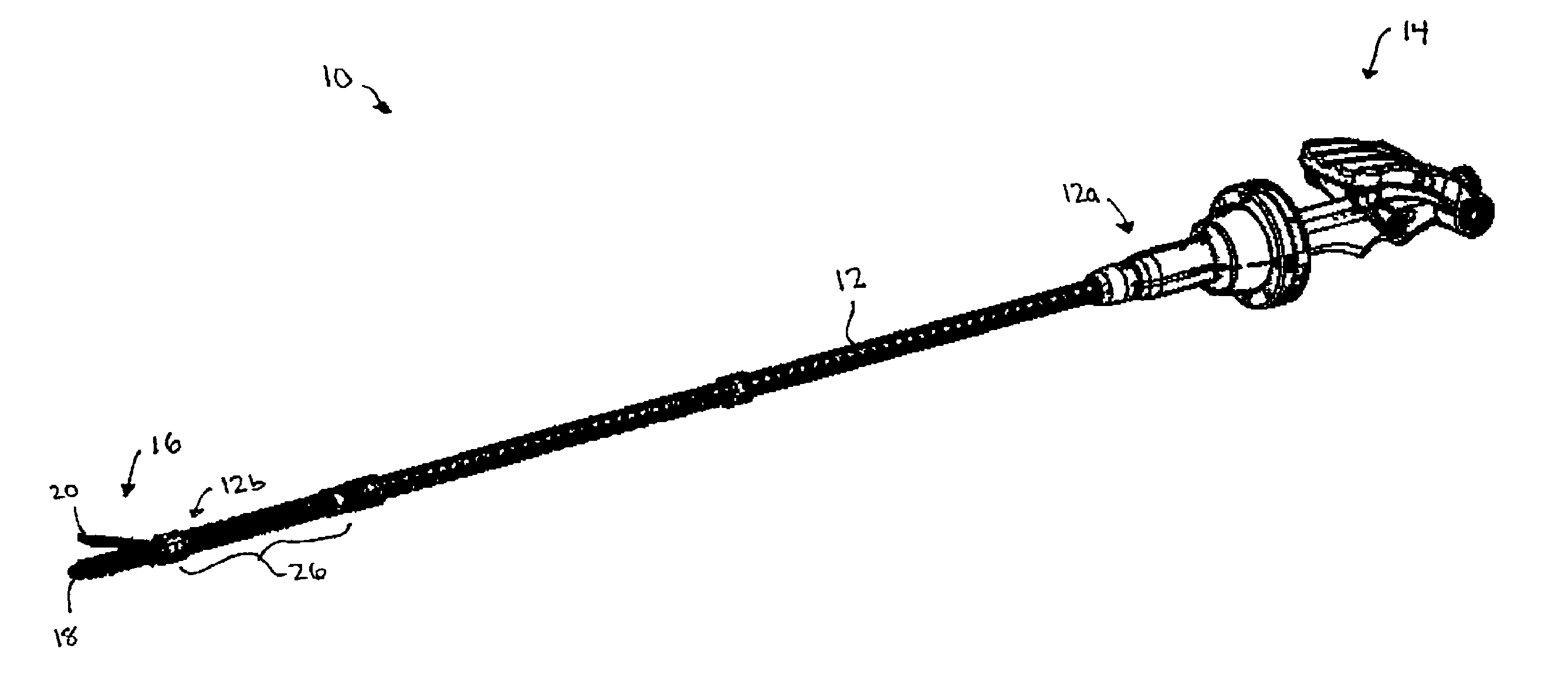

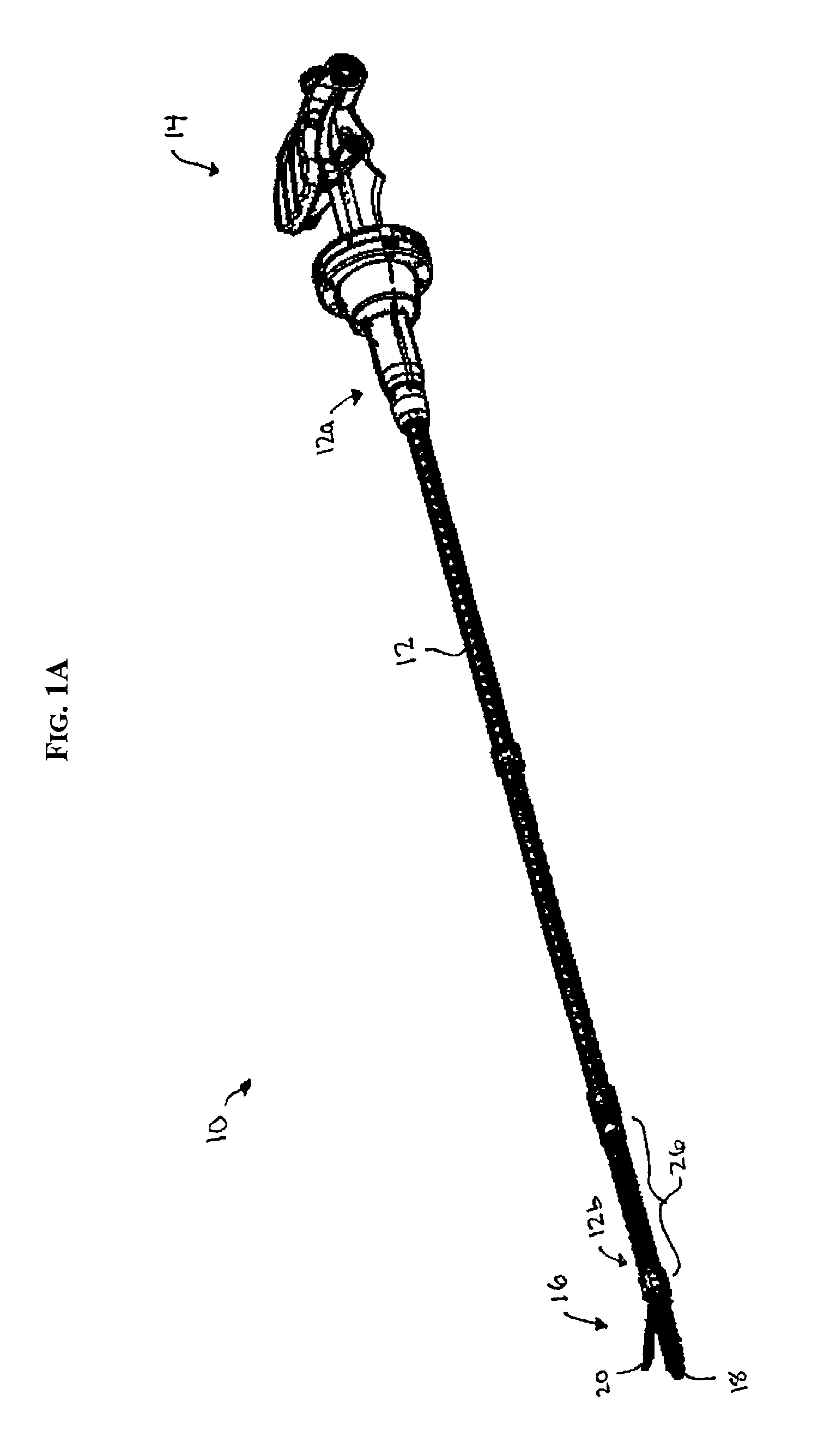

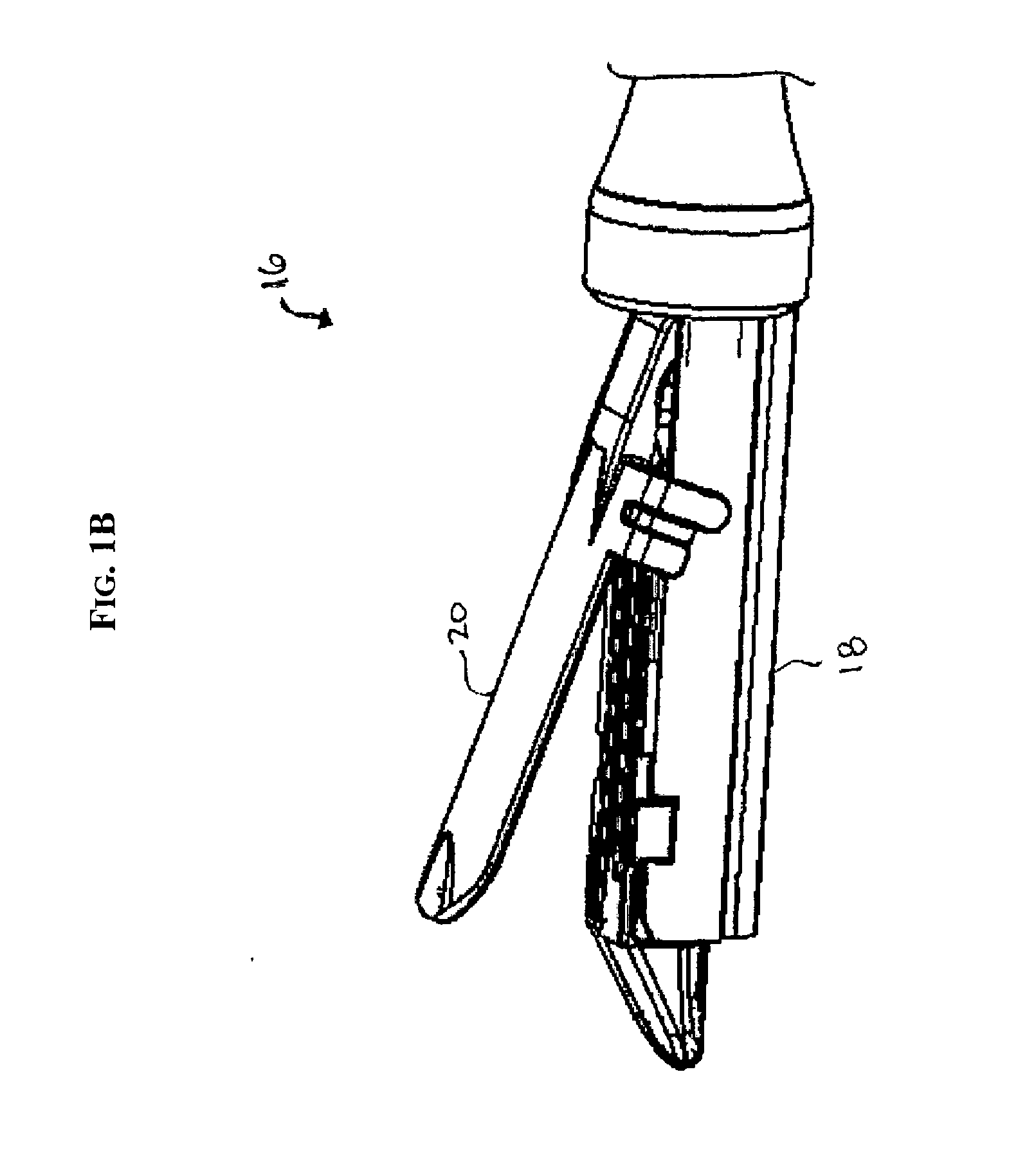

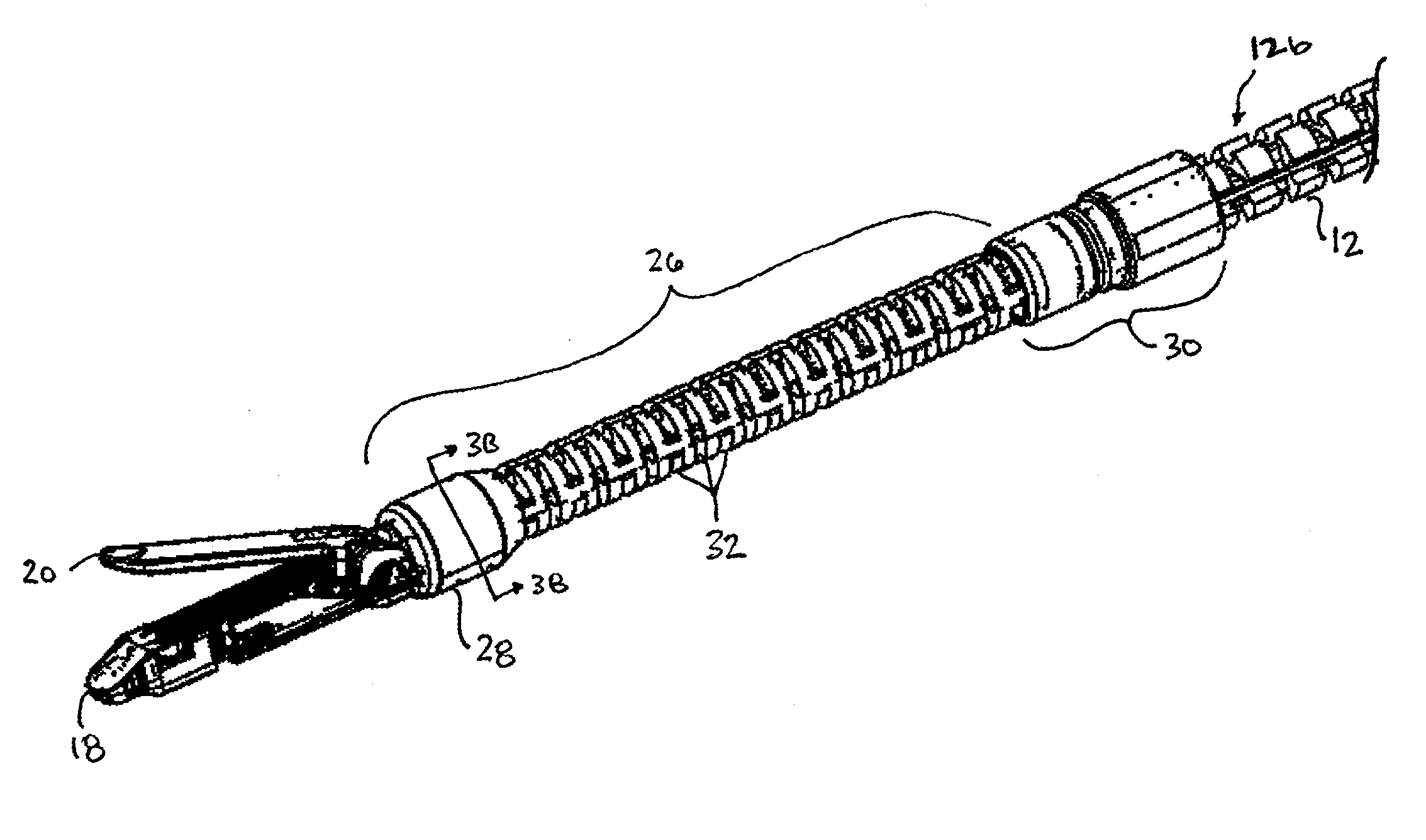

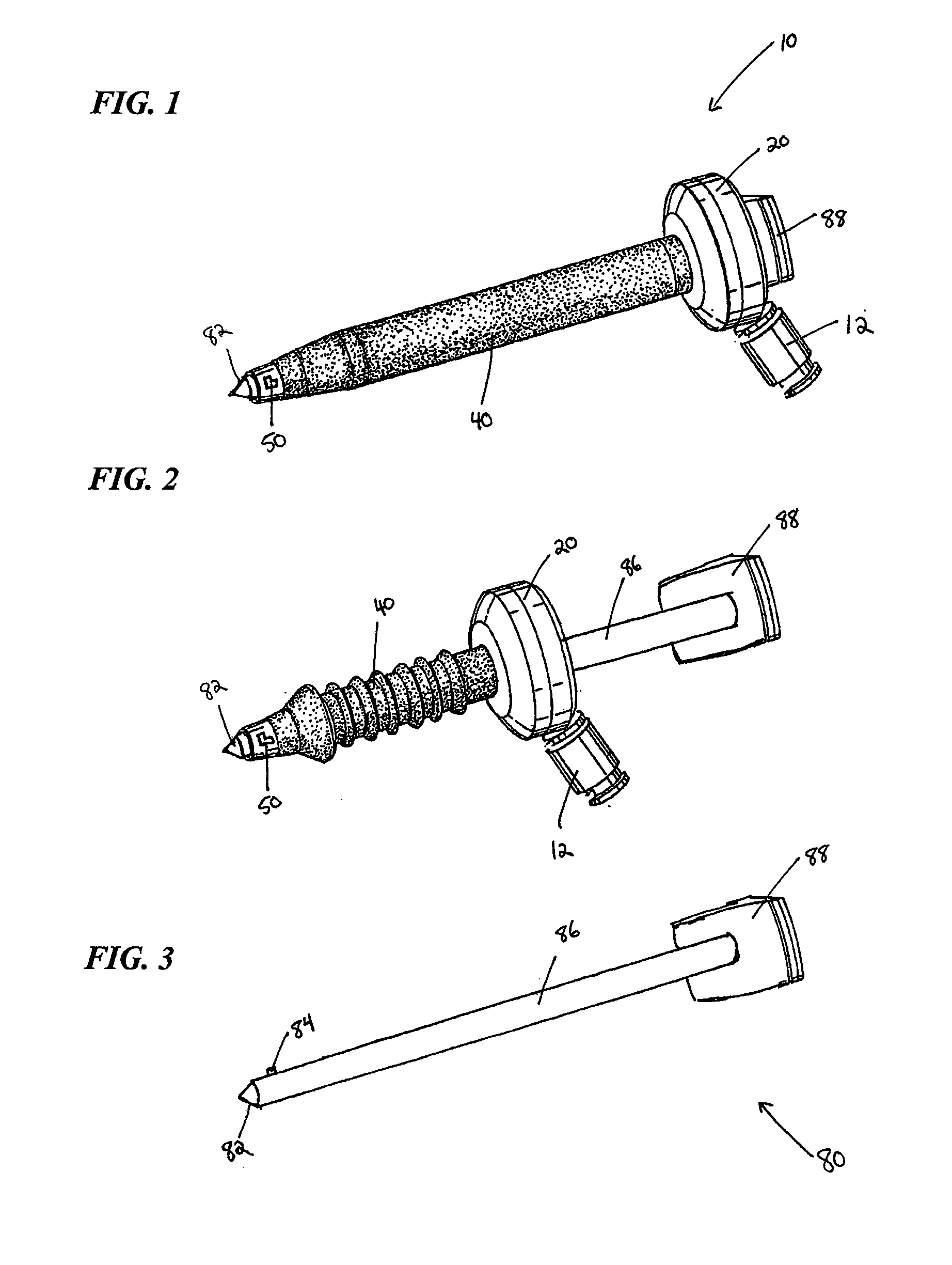

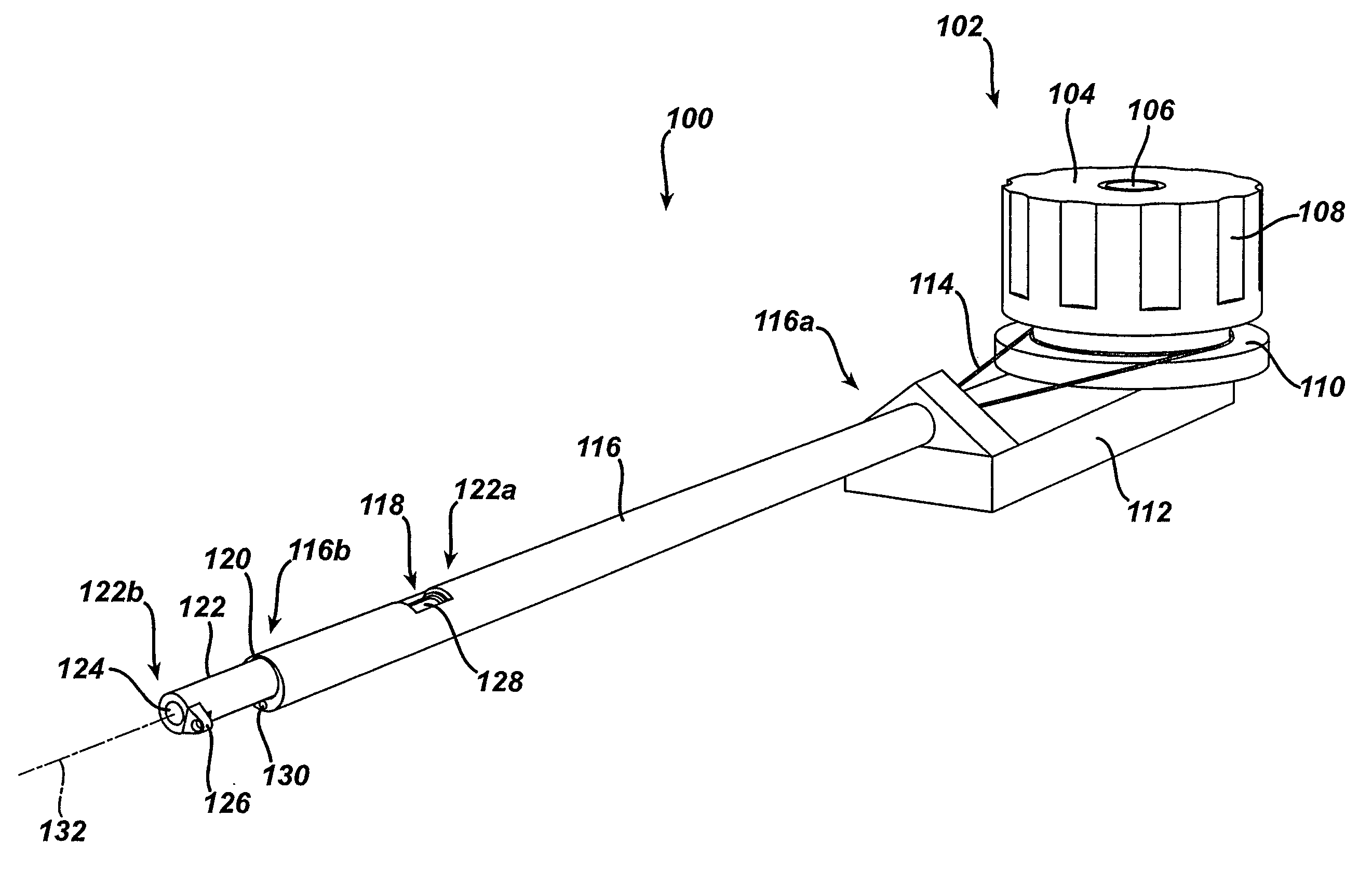

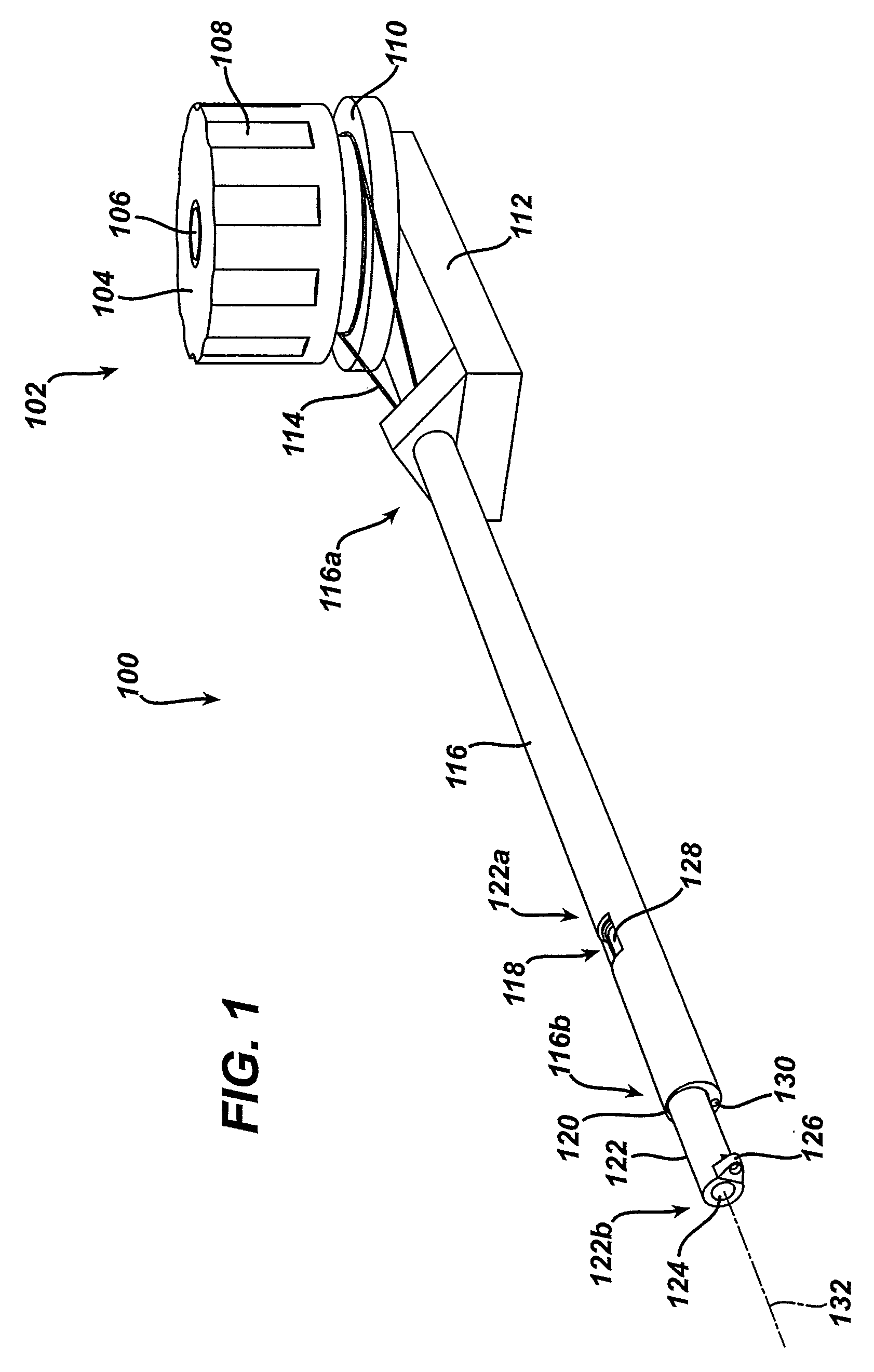

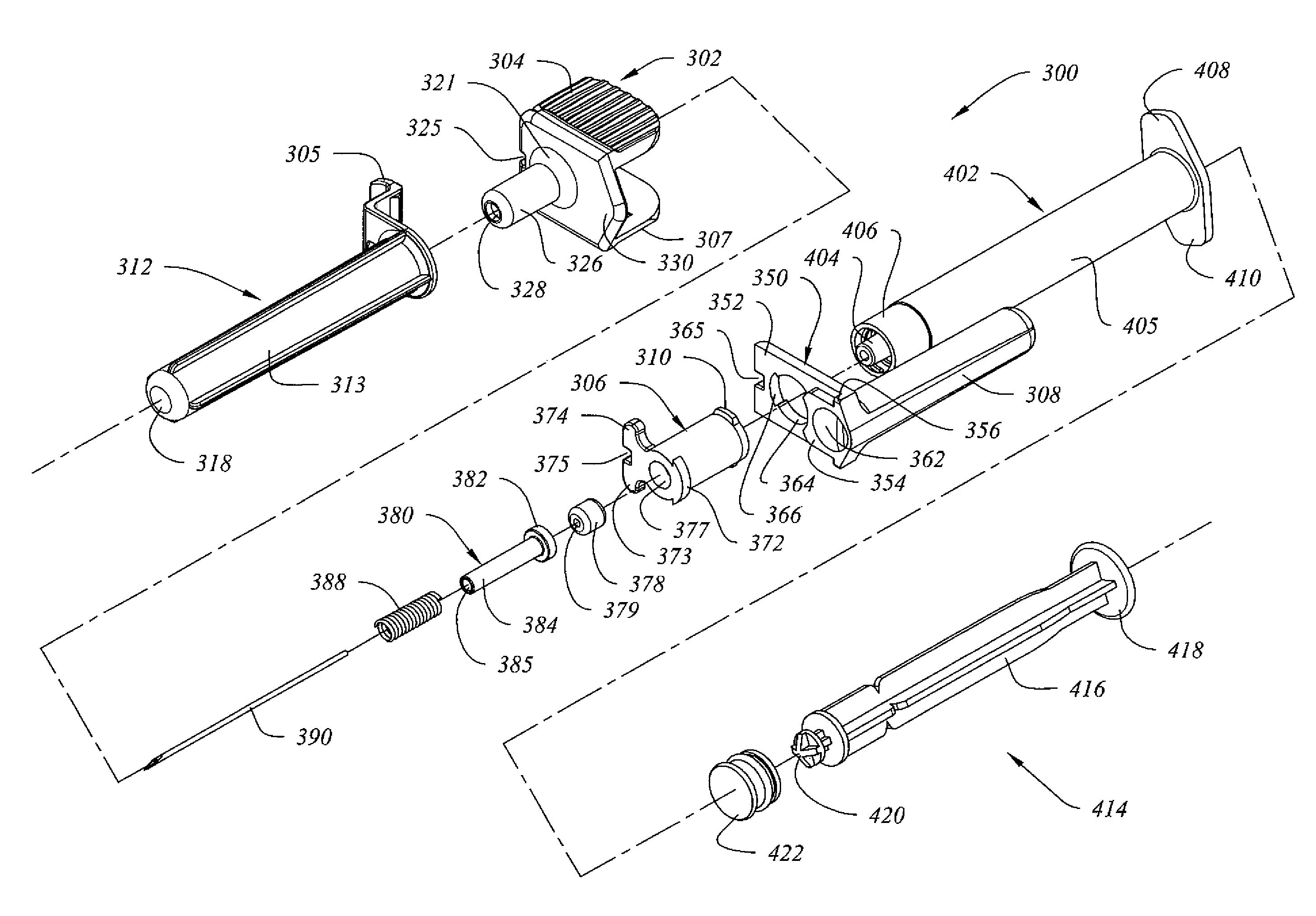

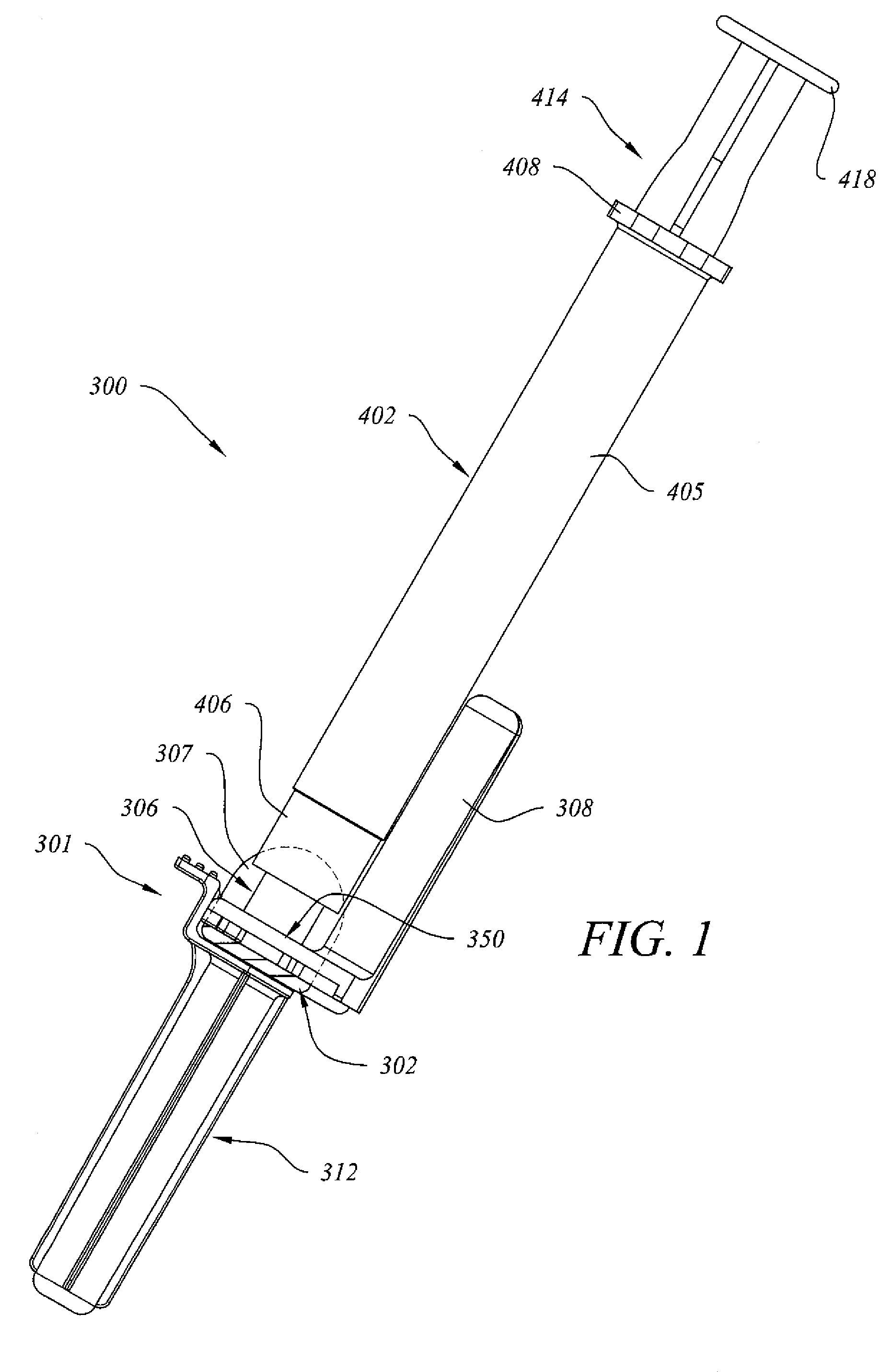

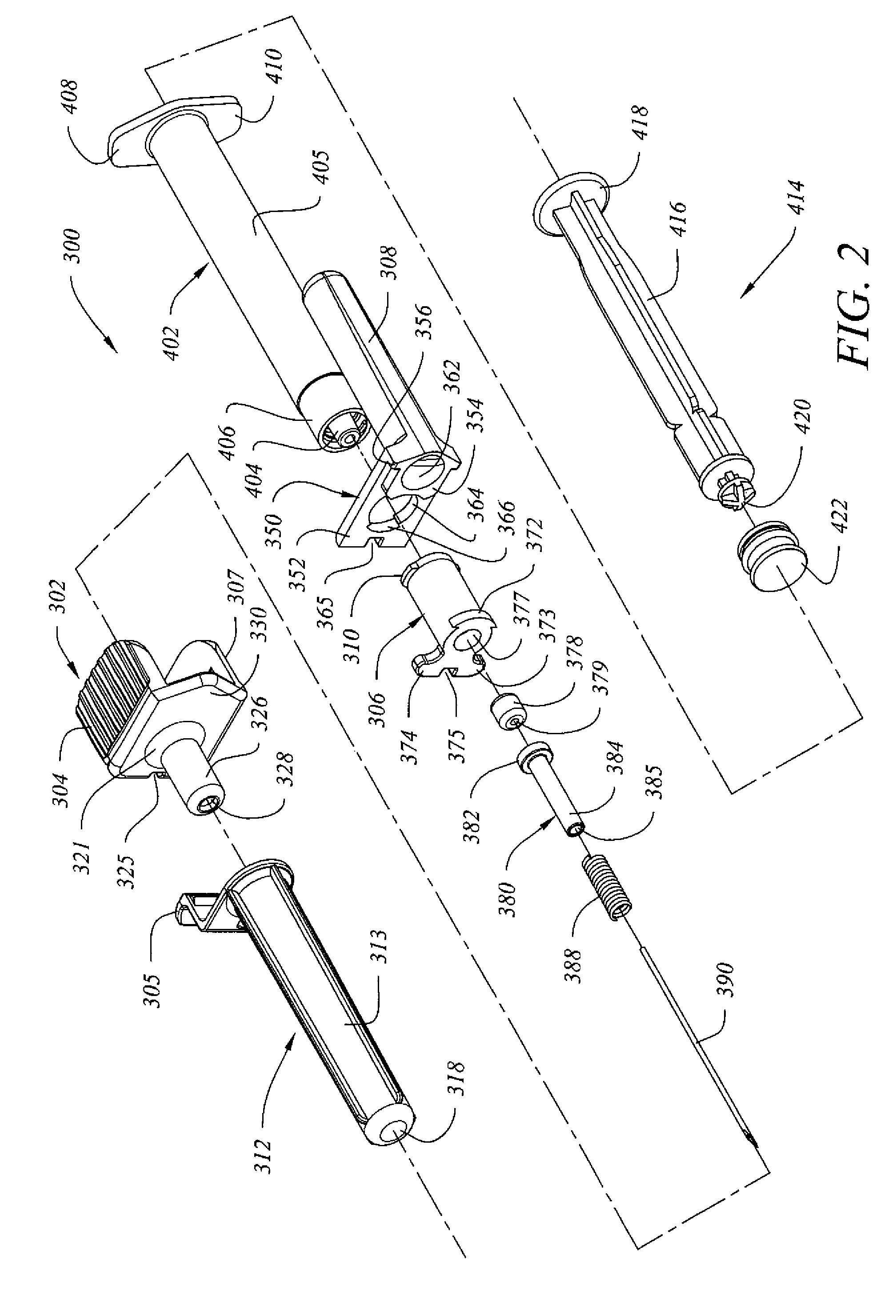

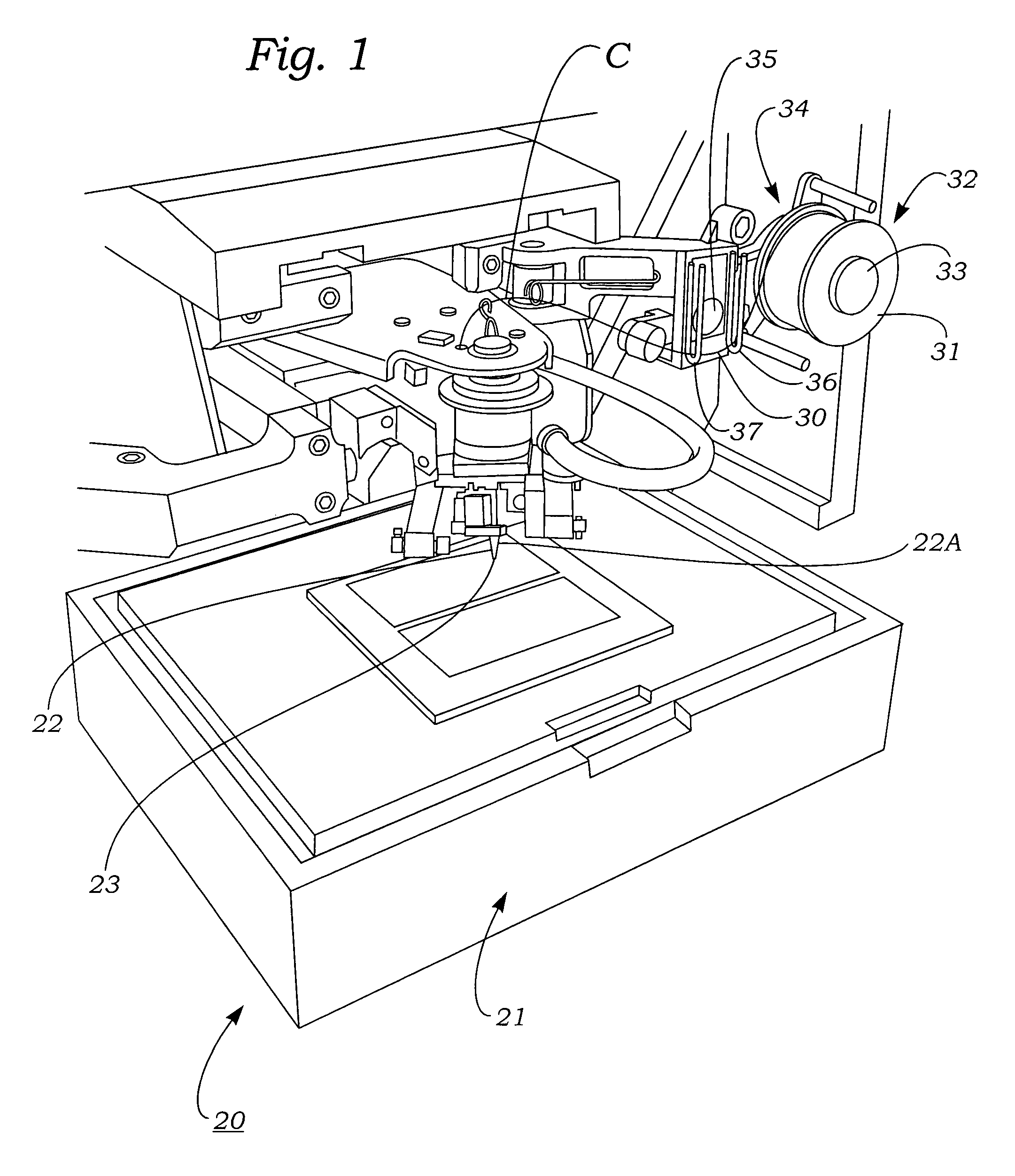

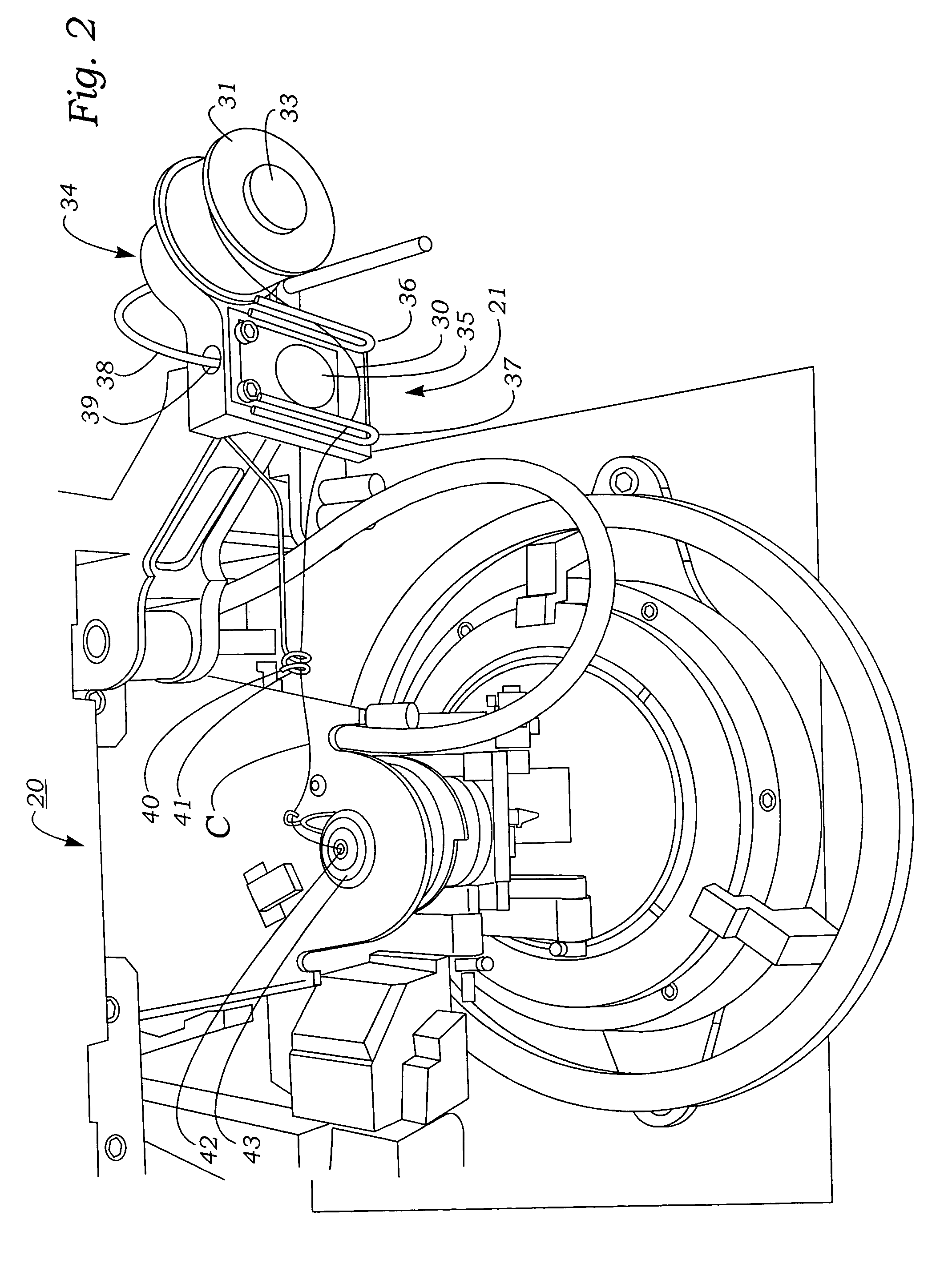

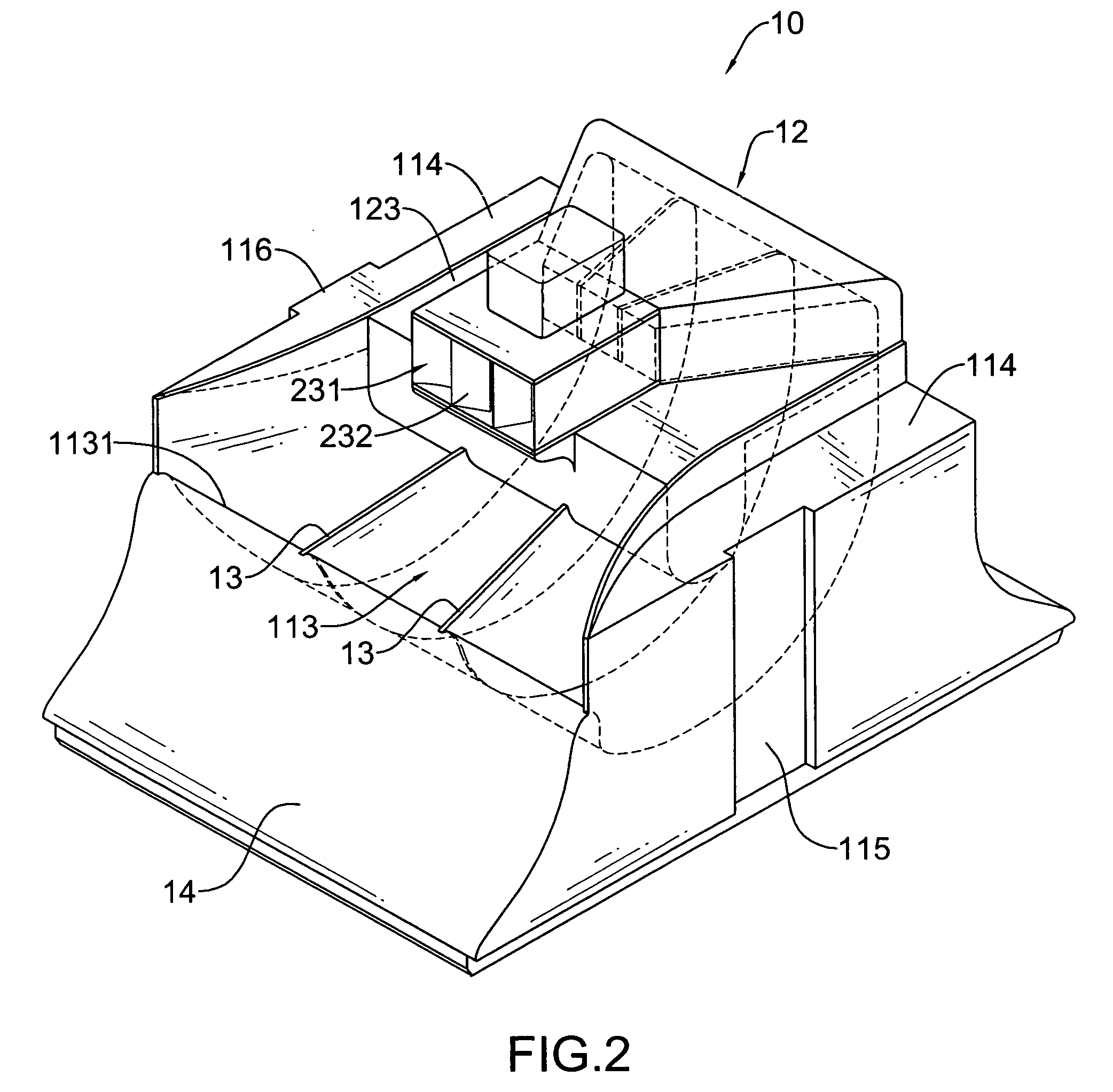

Surgical fastener and cutter with single cable actuator

ActiveUS7575144B2Effective rotationEnergy efficiencySuture equipmentsStapling toolsEngineeringActuator

Methods and devices are provided for controlling rotation and actuation of an end effector on a surgical fastening device. In an exemplary embodiment, a single cable actuator is provided and is movable between a first position, in which it is effective to rotate an end effector without actuating (i.e., closing and firing) the end effector, and a second position, in which it is effective to actuate the end effector without rotating the end effector. The single cable can also be effective to close opposed jaws of the end effector.

Owner:ETHICON ENDO SURGERY INC

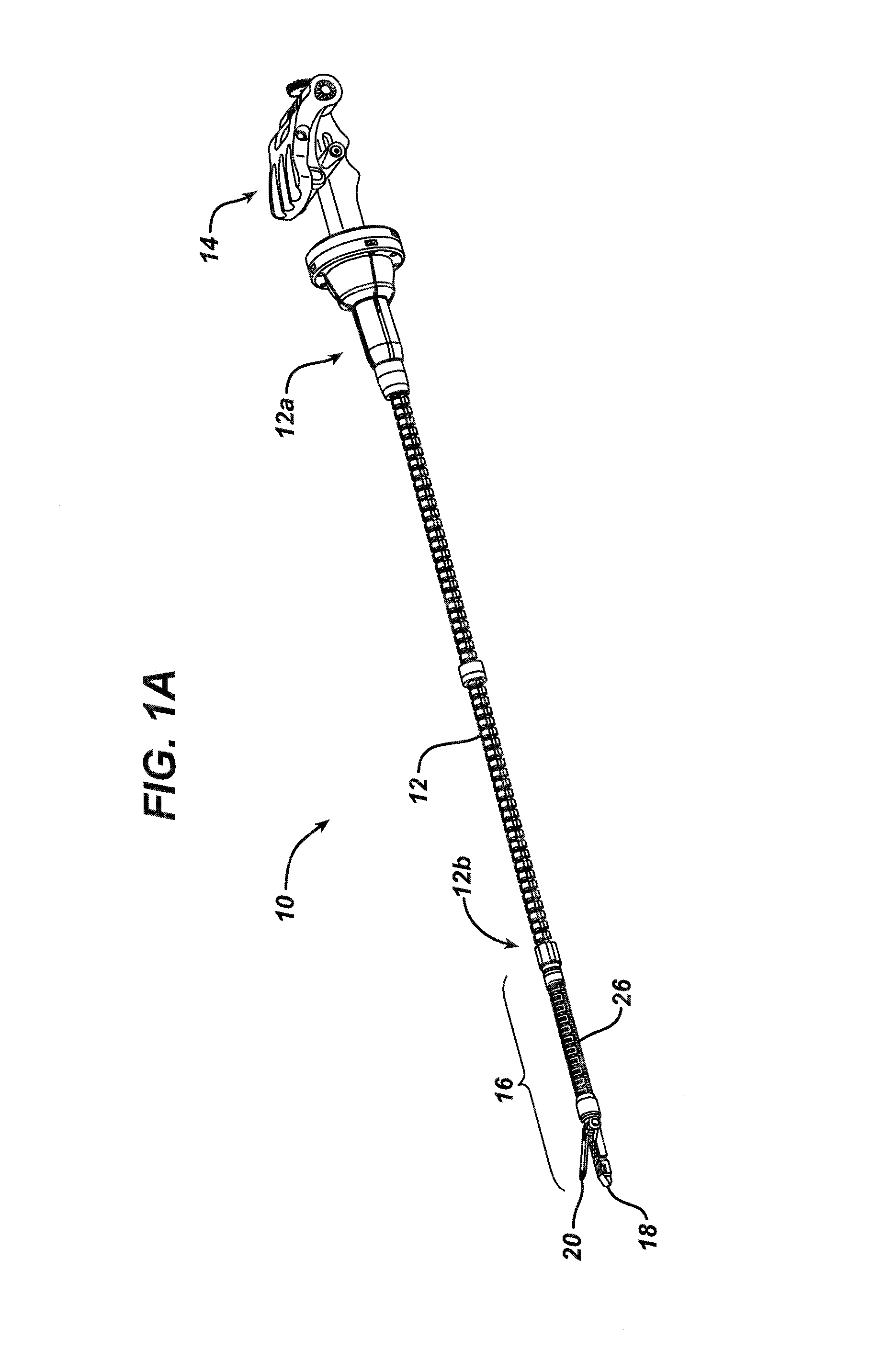

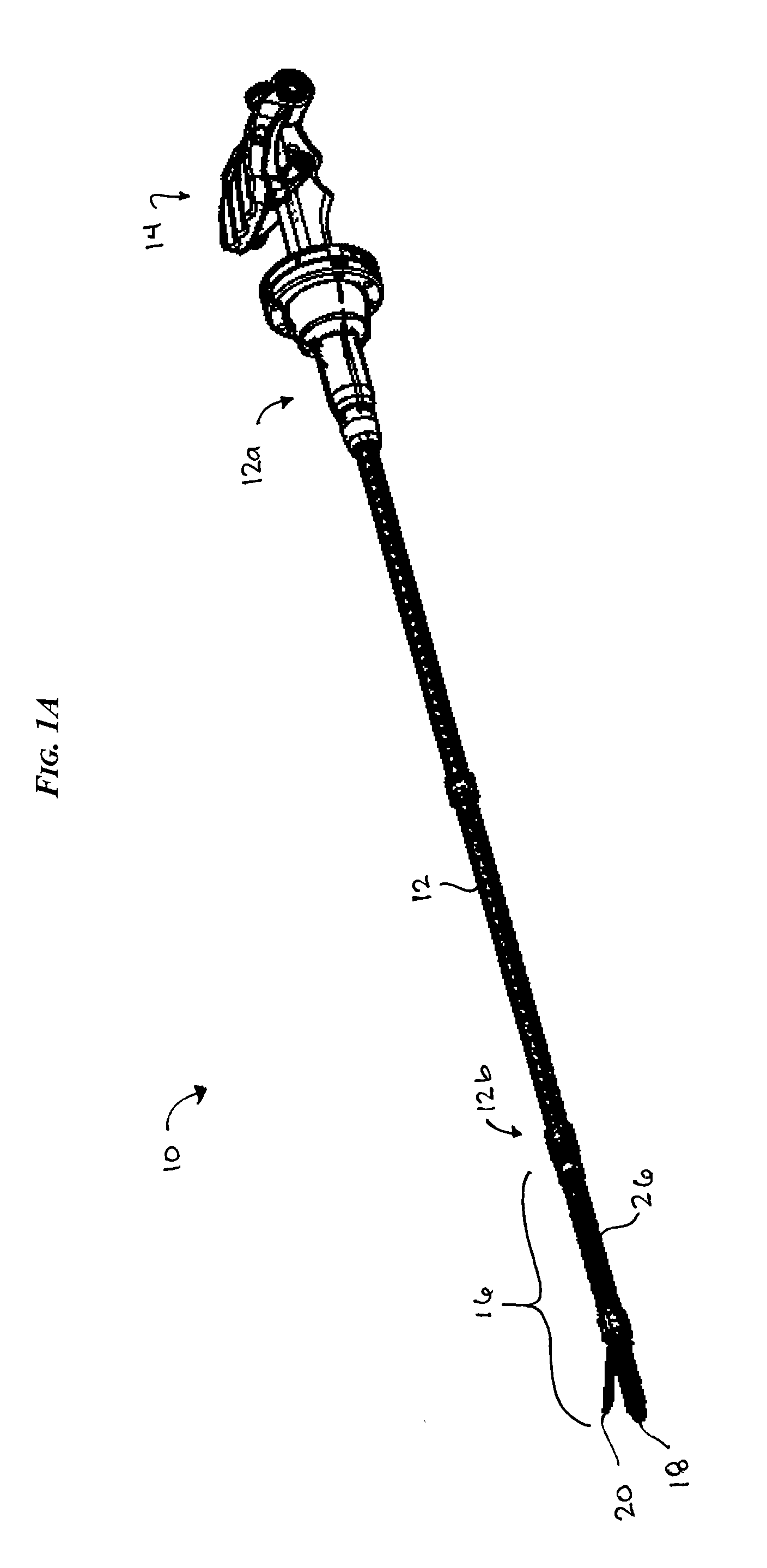

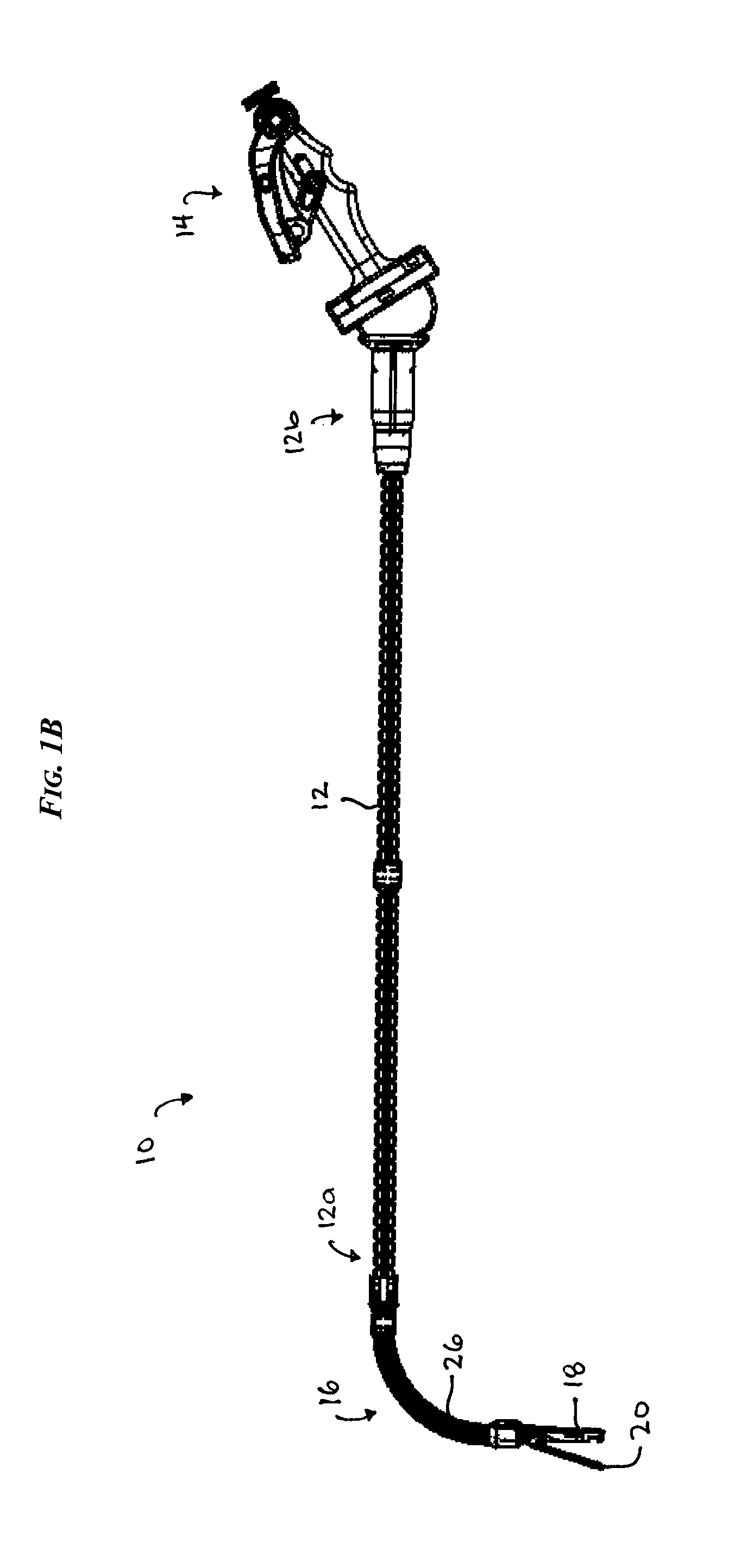

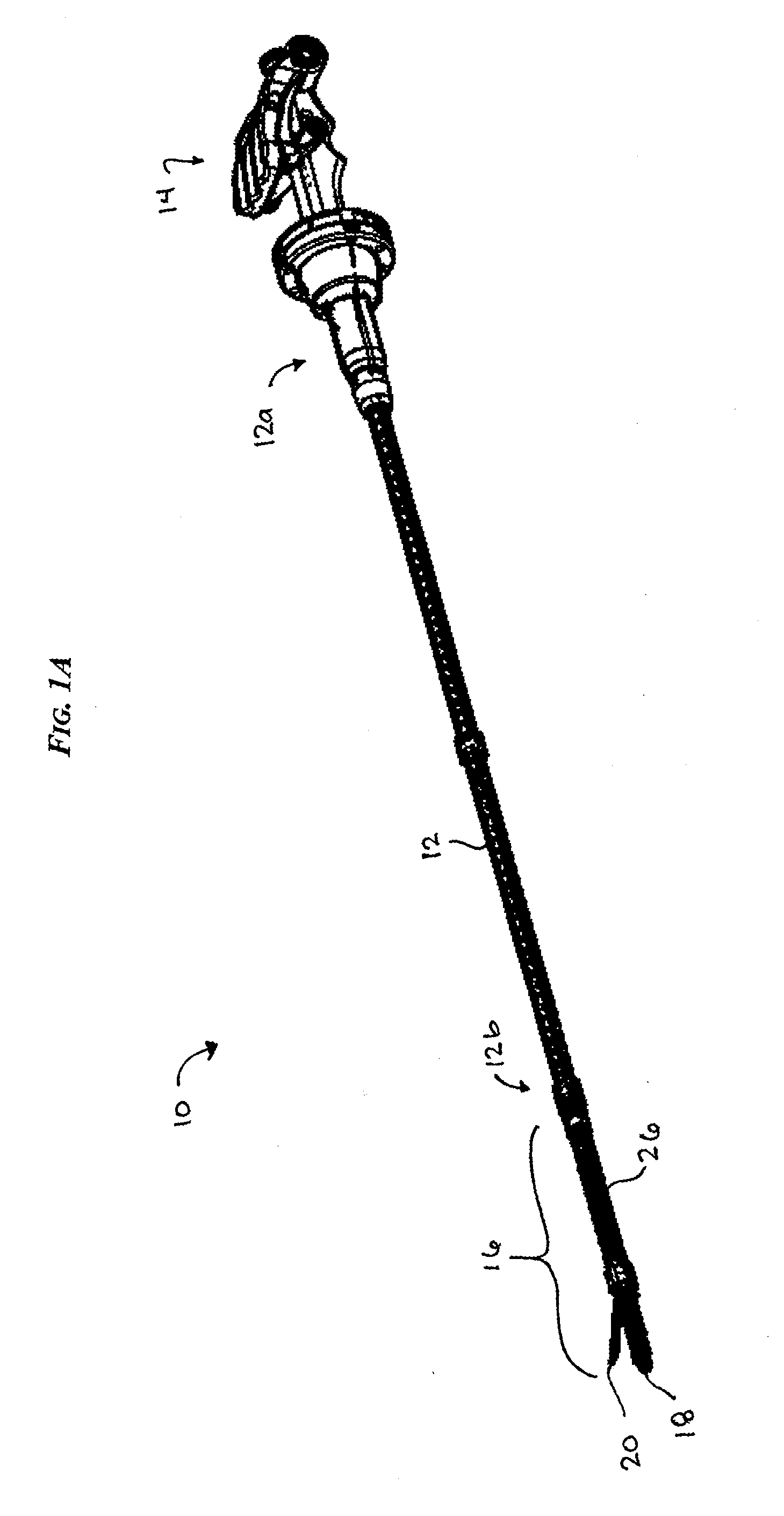

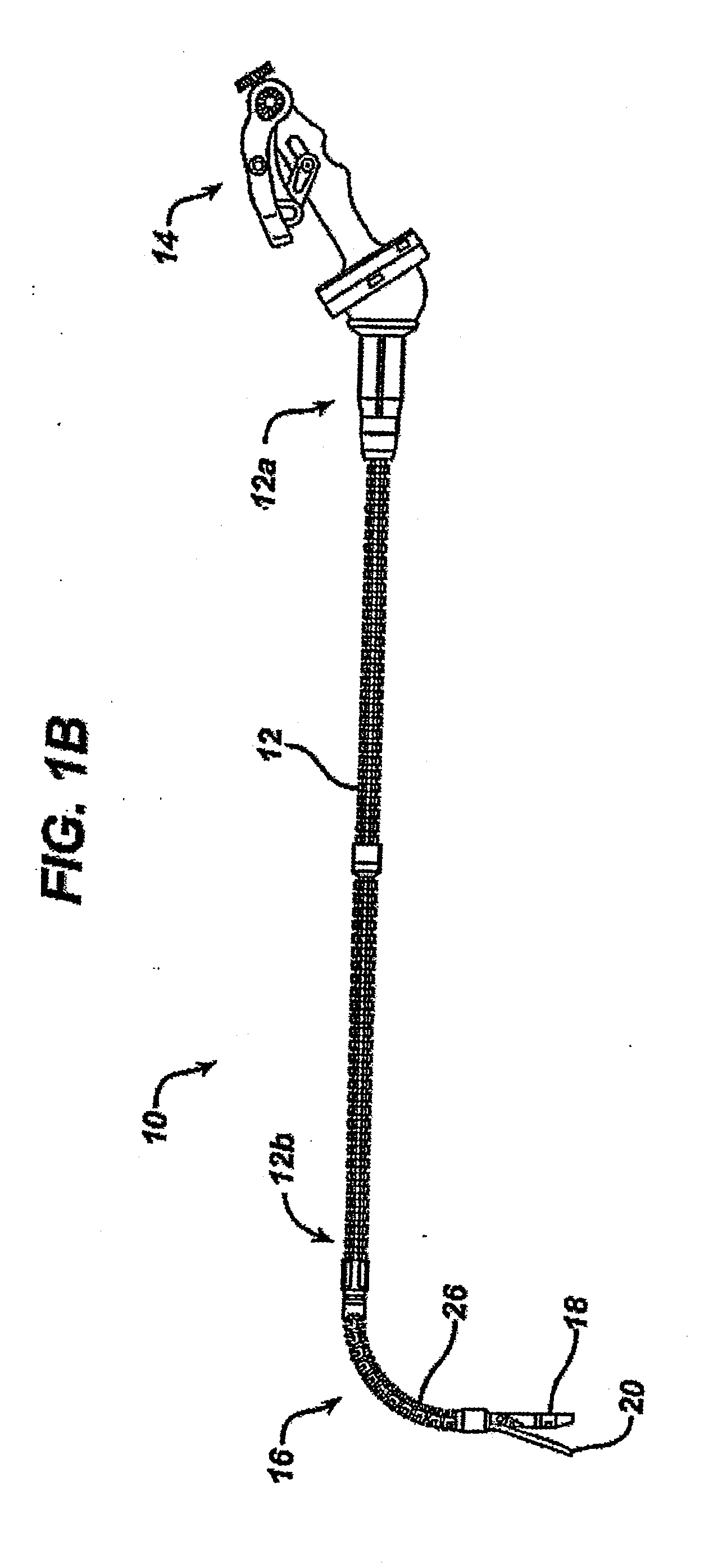

Articulating endoscopic accessory channel

InactiveUS20070225562A1Effective rotationEndoscopesEndoscopic cutting instrumentsEngineeringActuator

Methods and devices are provided for controlling movement of a working end of a surgical device. In one embodiment, methods and devices are provided for moving an end effector on a distal end of a surgical fastening device. Movement can include rotational movement of the end effector about an axis of the shaft, articulation of the end effector relative to the shaft, and actuation of an end effector, e.g., closing, firing, and / or cutting. In other embodiments, a single cable actuator is provided and is movable between a first position, in which it is effective to rotate an end effector without actuating (i.e., closing and firing) the end effector, and a second position, in which it is effective to actuate the end effector without rotating the end effector. In other aspects, methods and devices are provided for moving a flexible neck formed on a distal end of an accessory channel for use with an endoscope. Movement of the flexible neck can be used to control positioning of a tool extending through the flexible neck.

Owner:CILAG GMBH INT +1

Methods and devices for controlling articulation

Methods and devices are provided for controlling movement of a working end of a surgical device. In one embodiment, methods and devices are provided for moving an end effector on a distal end of a surgical fastening device. Movement can include rotational movement of the end effector about an axis of the shaft, articulation of the end effector relative to the shaft, and actuation of an end effector, e.g., closing, firing, and / or cutting. In other embodiments, a single cable actuator is provided and is movable between a first position, in which it is effective to rotate an end effector without actuating (i.e., closing and firing) the end effector, and a second position, in which it is effective to actuate the end effector without rotating the end effector. In other aspects, methods and devices are provided for moving a flexible neck formed on a distal end of an accessory channel for use with an endoscope. Movement of the flexible neck can be used to control positioning of a tool extending through the flexible neck.

Owner:CILAG GMBH INT

Robotically-controlled surgical instrument with selectively articulatable end effector

Devices and systems are provided for controlling movement of a working end of a surgical device by means of a robotic system. In one embodiment, systems and devices are provided for moving an end effector on a distal end of a surgical fastening device. Movement can include rotational movement of the end effector about an axis of the shaft, articulation of the end effector relative to the shaft, and actuation of an end effector, e.g., closing, firing, and / or cutting.

Owner:CILAG GMBH INT

Methods and devices for controlling articulation

Methods and devices are provided for controlling movement of a working end of a surgical device. In one embodiment, methods and devices are provided for moving an end effector on a distal end of a surgical fastening device. Movement can include rotational movement of the end effector about an axis of the shaft, articulation of the end effector relative to the shaft, and actuation of an end effector, e.g., closing, firing, and / or cutting. In other embodiments, a single cable actuator is provided and is movable between a first position, in which it is effective to rotate an end effector without actuating (i.e., closing and firing) the end effector, and a second position, in which it is effective to actuate the end effector without rotating the end effector. In other aspects, methods and devices are provided for moving a flexible neck formed on a distal end of an accessory channel for use with an endoscope. Movement of the flexible neck can be used to control positioning of a tool extending through the flexible neck.

Owner:CILAG GMBH INT

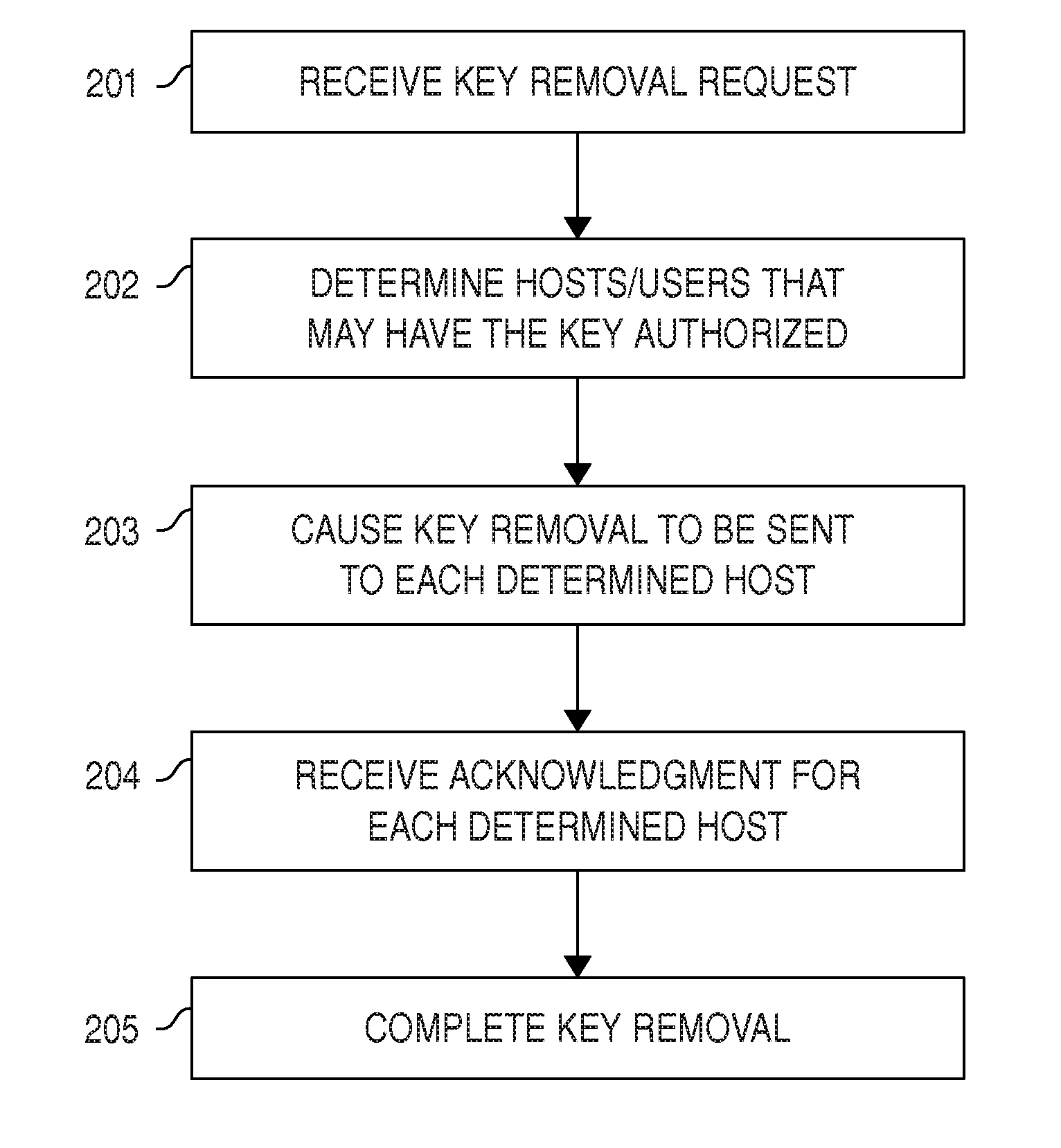

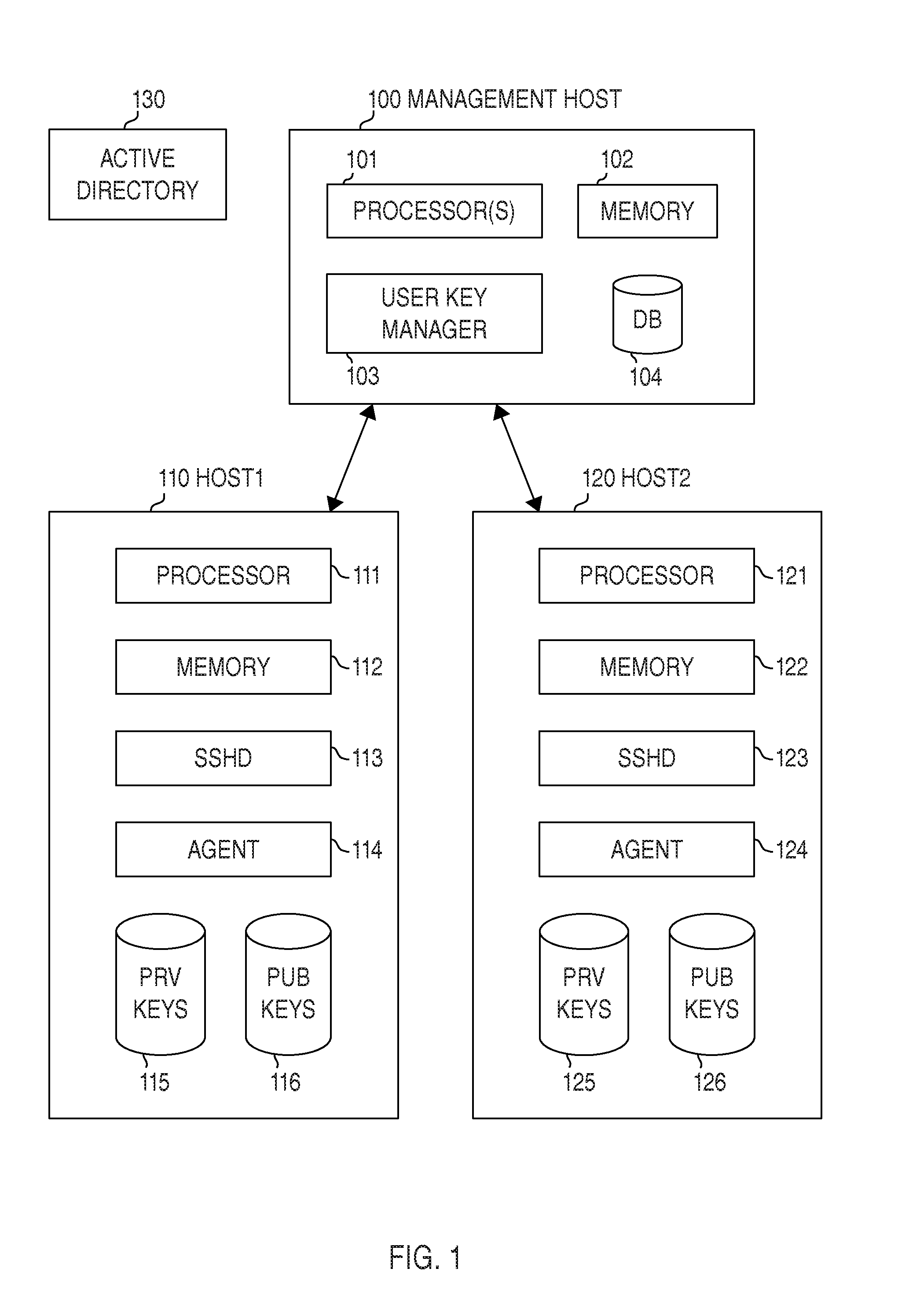

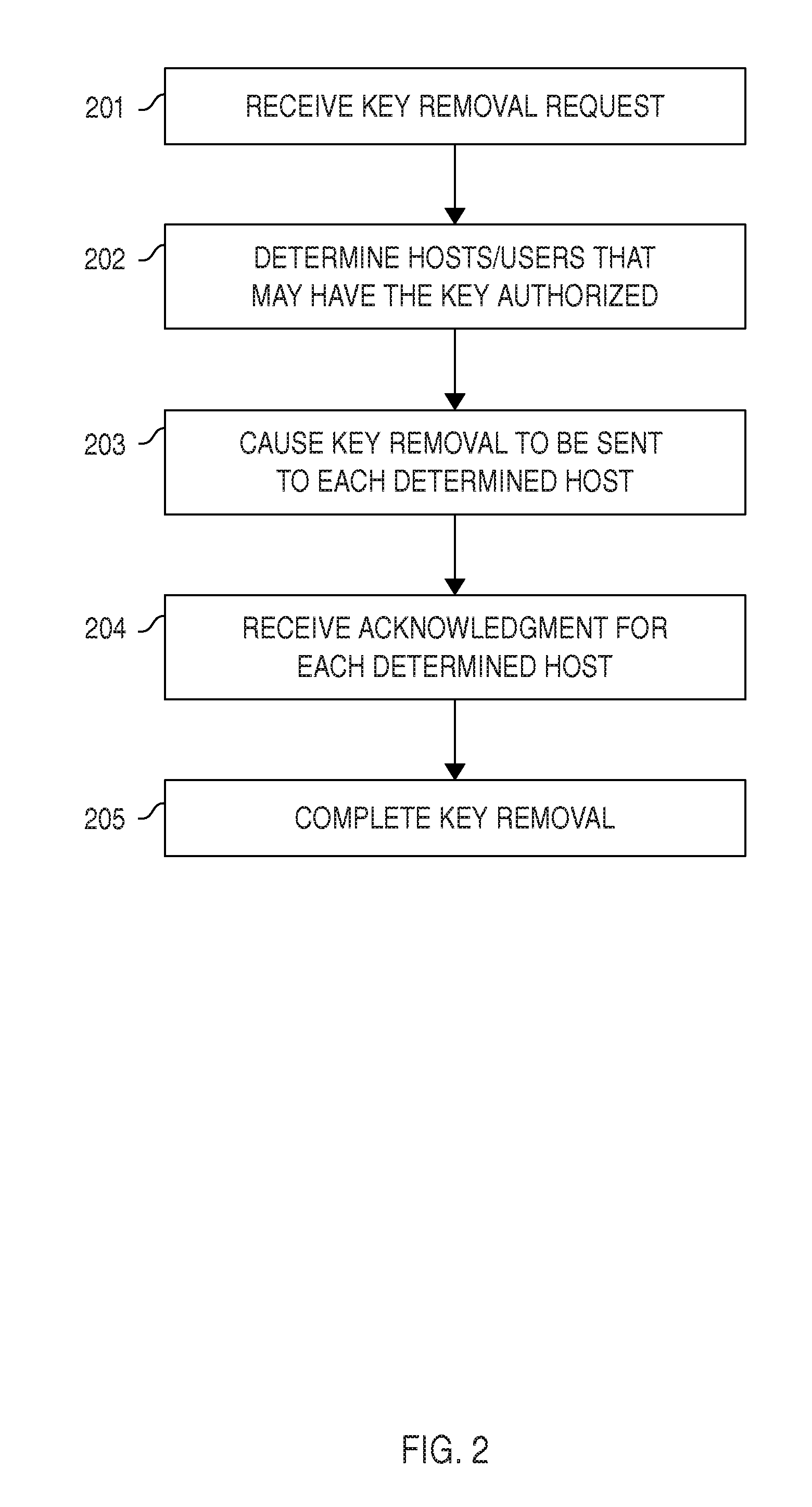

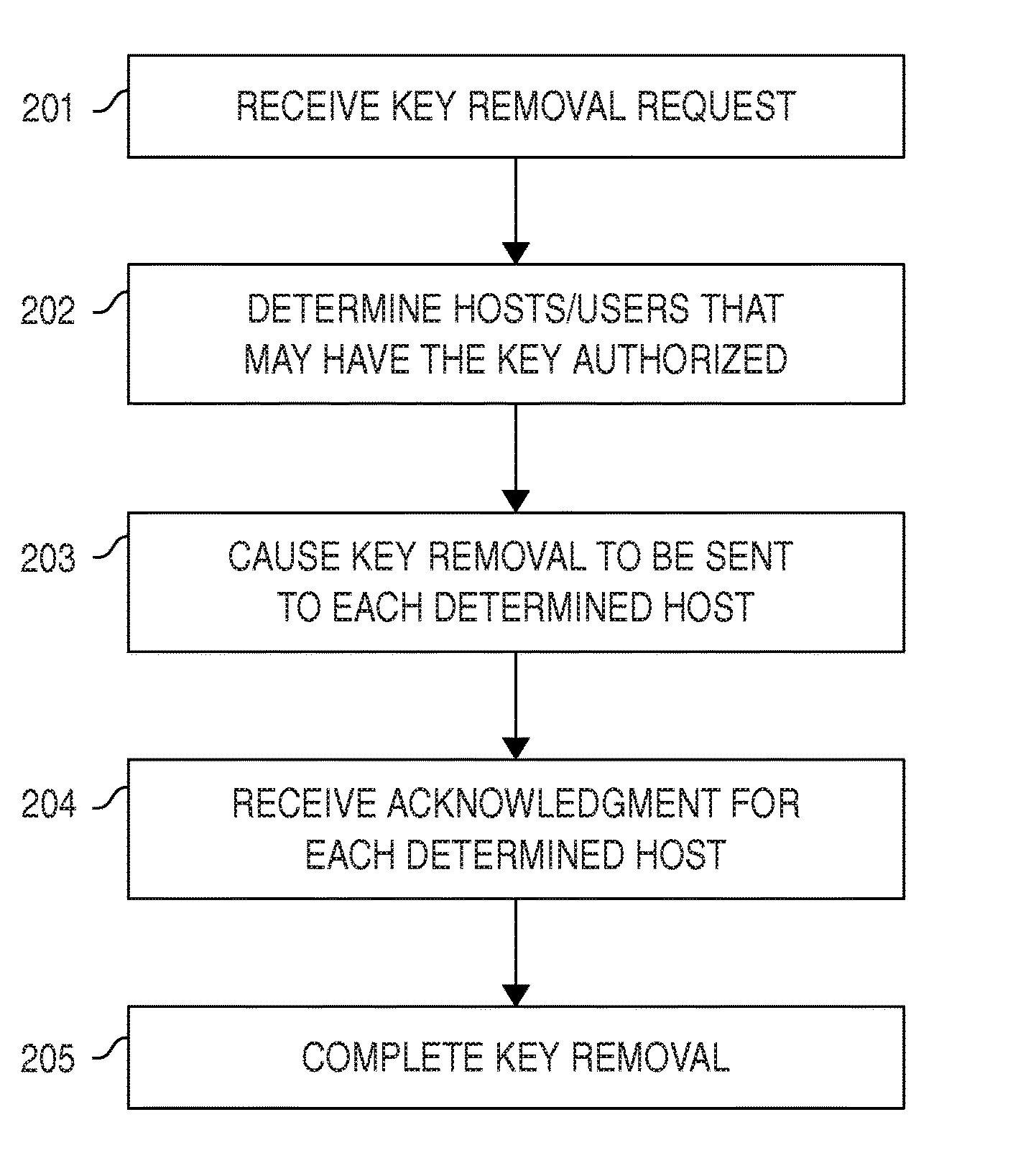

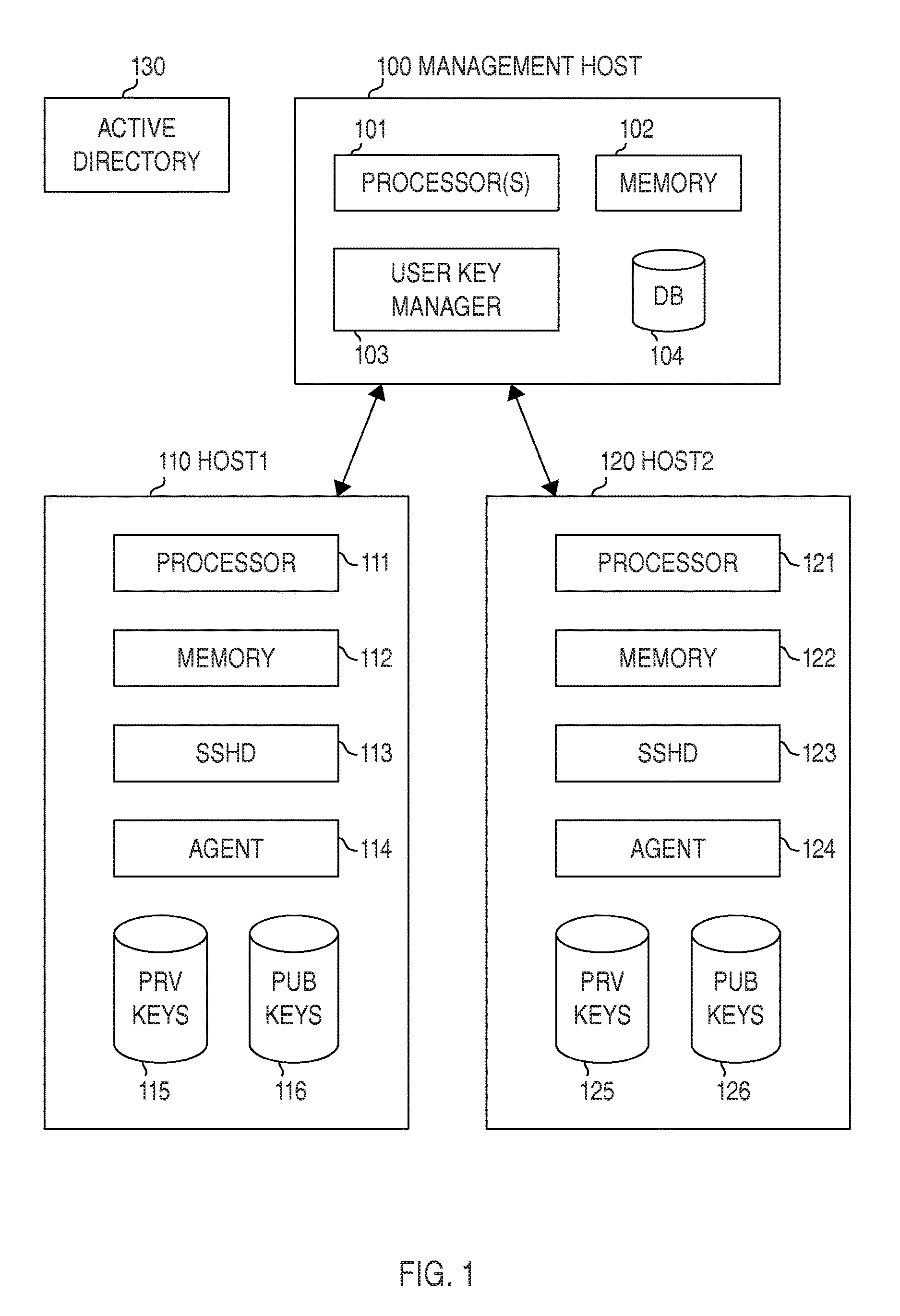

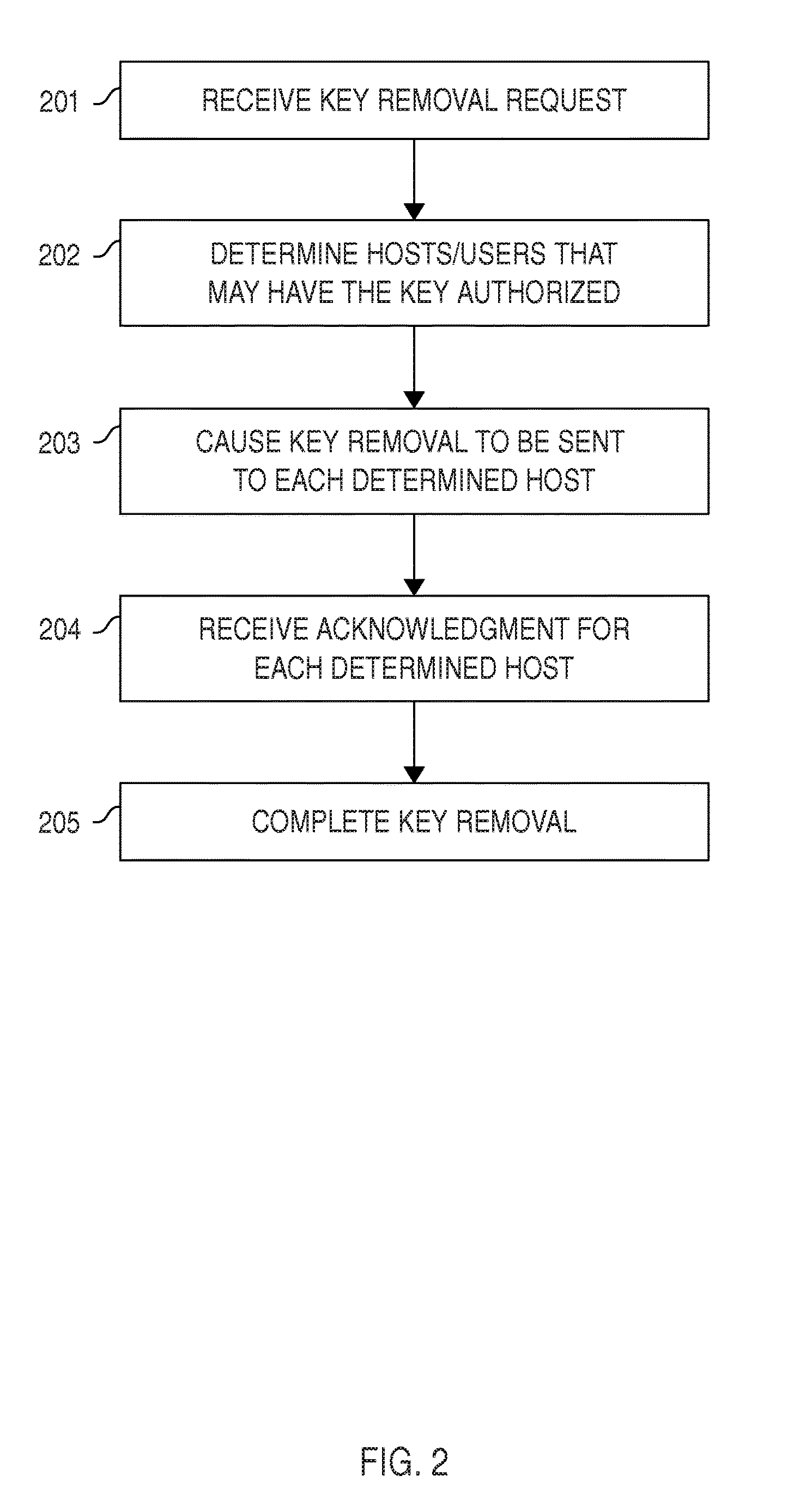

Automated Access, Key, Certificate, and Credential Management

ActiveUS20150222604A1Effective rotationLow costMultiple keys/algorithms usagePublic key for secure communicationCredential managementTrust relationship

Certain embodiments provide means for managing automated access to computers, e.g., using SSH user keys and other kinds of trust relationships. Certain embodiments also provide for managing certificates, Kerberos credentials, and cryptographic keys. Certain embodiments provide for remediating legacy SSH key problems and for automating configuration of SSH keys, as well as for continuous monitoring.

Owner:SSH COMMUNICATIONS SECURITY

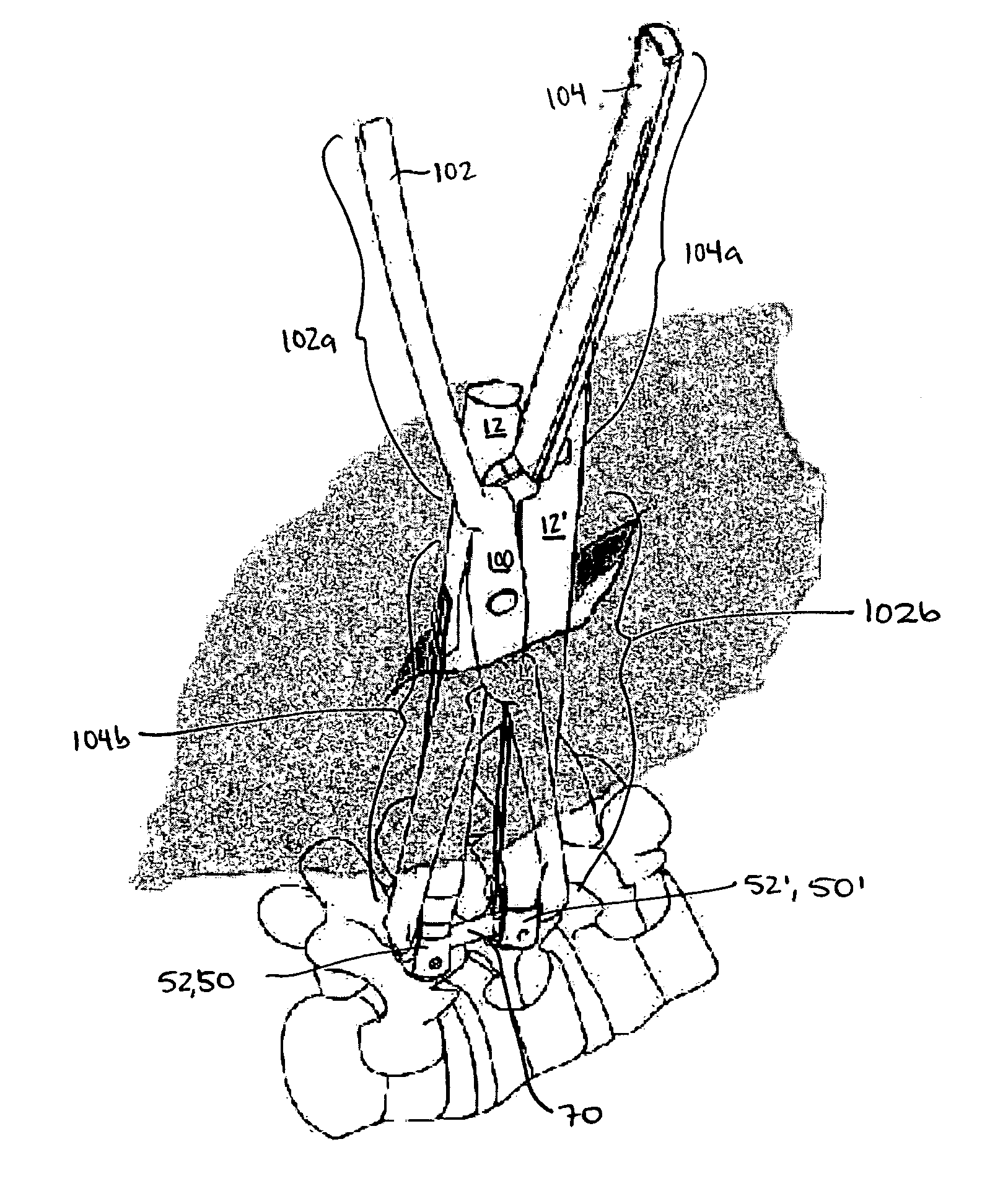

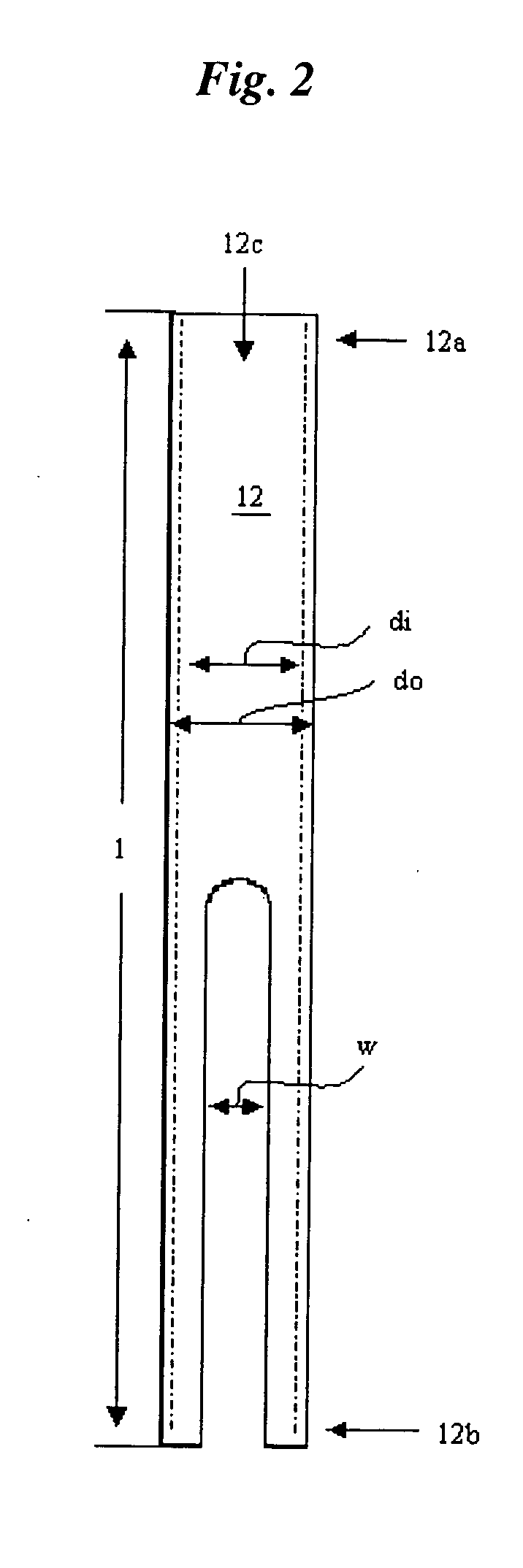

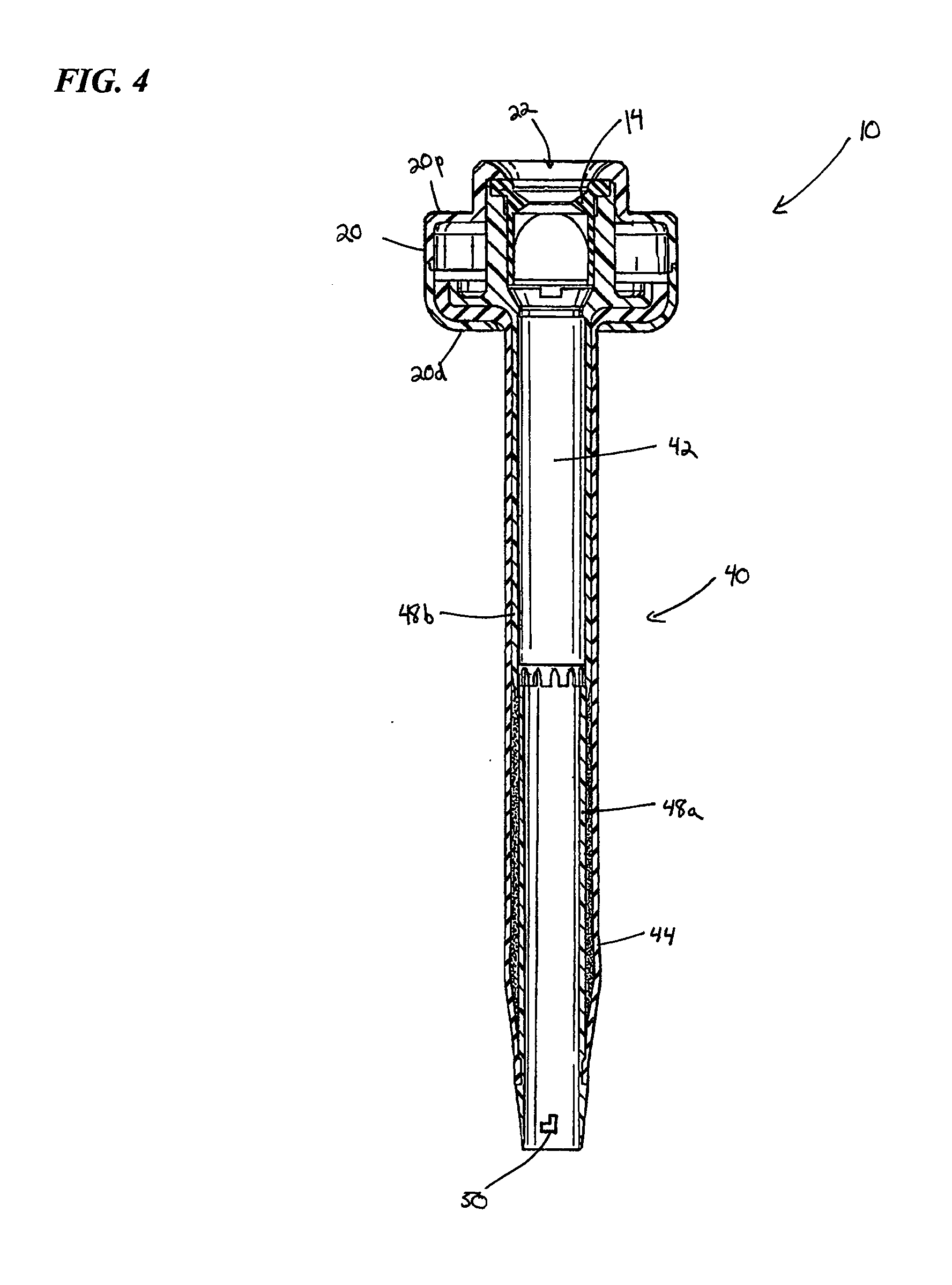

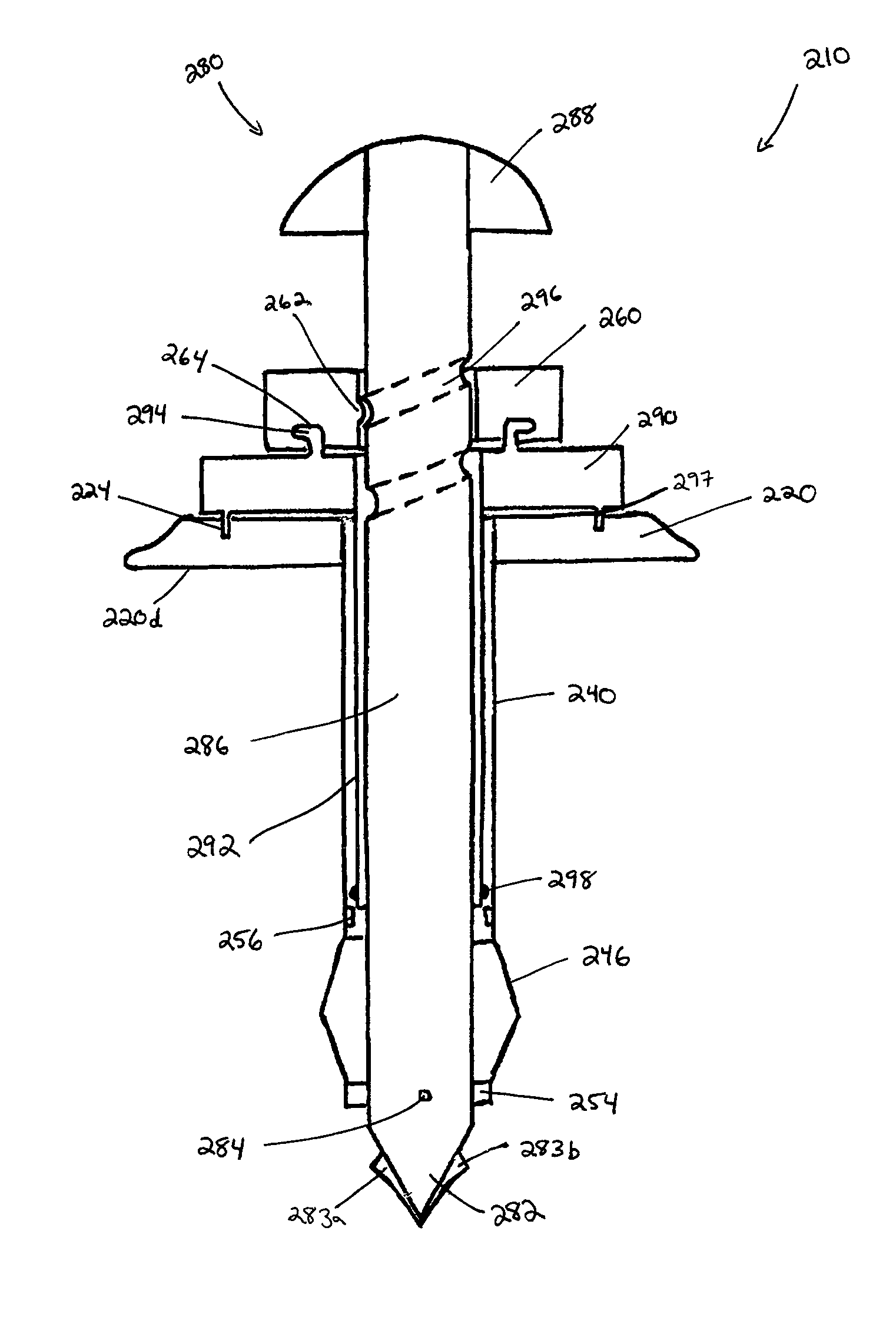

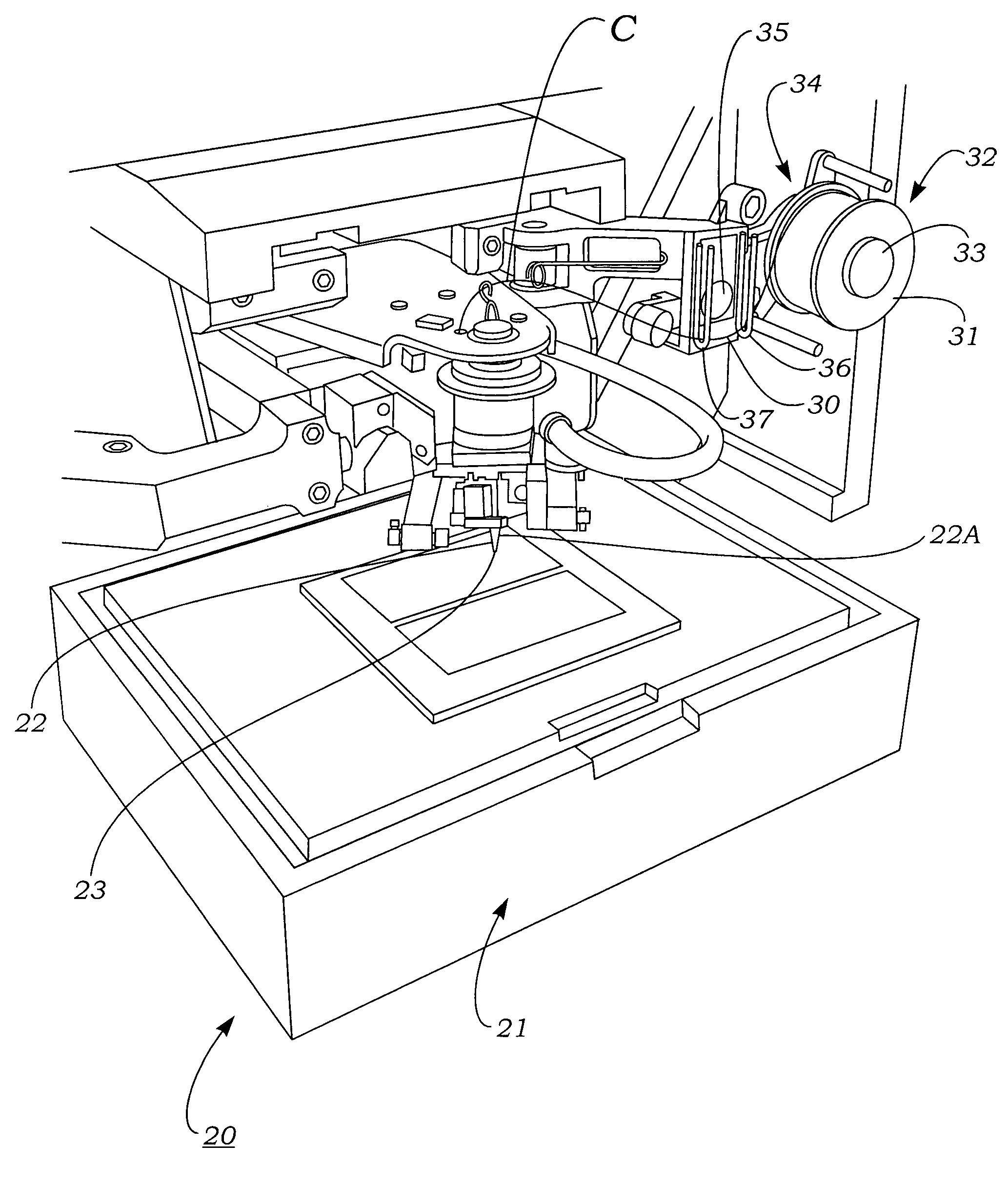

Methods and devices for spinal fixation element placement

ActiveUS20050131422A1Effective rotationInternal osteosythesisSpinal implantsSpinal columnBiomedical engineering

Minimally invasive methods and devices are provided for positioning a spinal fixation element in relation to adjacent spinal anchors. In an exemplary embodiment, the device is a percutaneous access device that can be coupled to a spinal anchor, and the method includes the step of positioning a spinal fixation element through at least one sidewall opening of at least two percutaneous access devices such that the spinal fixation element extends in a lengthwise orientation that is substantially transverse to the longitudinal axis of each percutaneous access device. The spinal fixation element can then be advanced in the lengthwise orientation to seat the spinal fixation element in or adjacent to the receiver heads of at least two adjacent spinal anchors. A fastening element or other closure mechanism can then be applied to each spinal anchor to engage the spinal fixation element within the receiver heads of the adjacent anchors.

Owner:DEPUY SYNTHES PROD INC

Surgical fastener and cutter with single cable actuator

ActiveUS20070175947A1Effective rotationEnergy efficiencySuture equipmentsStapling toolsEngineeringActuator

Methods and devices are provided for controlling rotation and actuation of an end effector on a surgical fastening device. In an exemplary embodiment, a single cable actuator is provided and is movable between a first position, in which it is effective to rotate an end effector without actuating (i.e., closing and firing) the end effector, and a second position, in which it is effective to actuate the end effector without rotating the end effector. The single cable can also be effective to close opposed jaws of the end effector.

Owner:ETHICON ENDO SURGERY INC

Articulating endoscopic accessory channel

Methods and devices are provided for controlling movement of a working end of a surgical device. In one embodiment, methods and devices are provided for moving an end effector on a distal end of a surgical fastening device. Movement can include rotational movement of the end effector about an axis of the shaft, articulation of the end effector relative to the shaft, and actuation of an end effector, e.g., closing, firing, and / or cutting. In other embodiments, a single cable actuator is provided and is movable between a first position, in which it is effective to rotate an end effector without actuating (i.e., closing and firing) the end effector, and a second position, in which it is effective to actuate the end effector without rotating the end effector. In other aspects, methods and devices are provided for moving a flexible neck formed on a distal end of an accessory channel for use with an endoscope. Movement of the flexible neck can be used to control positioning of a tool extending through the flexible neck.

Owner:CILAG GMBH INT

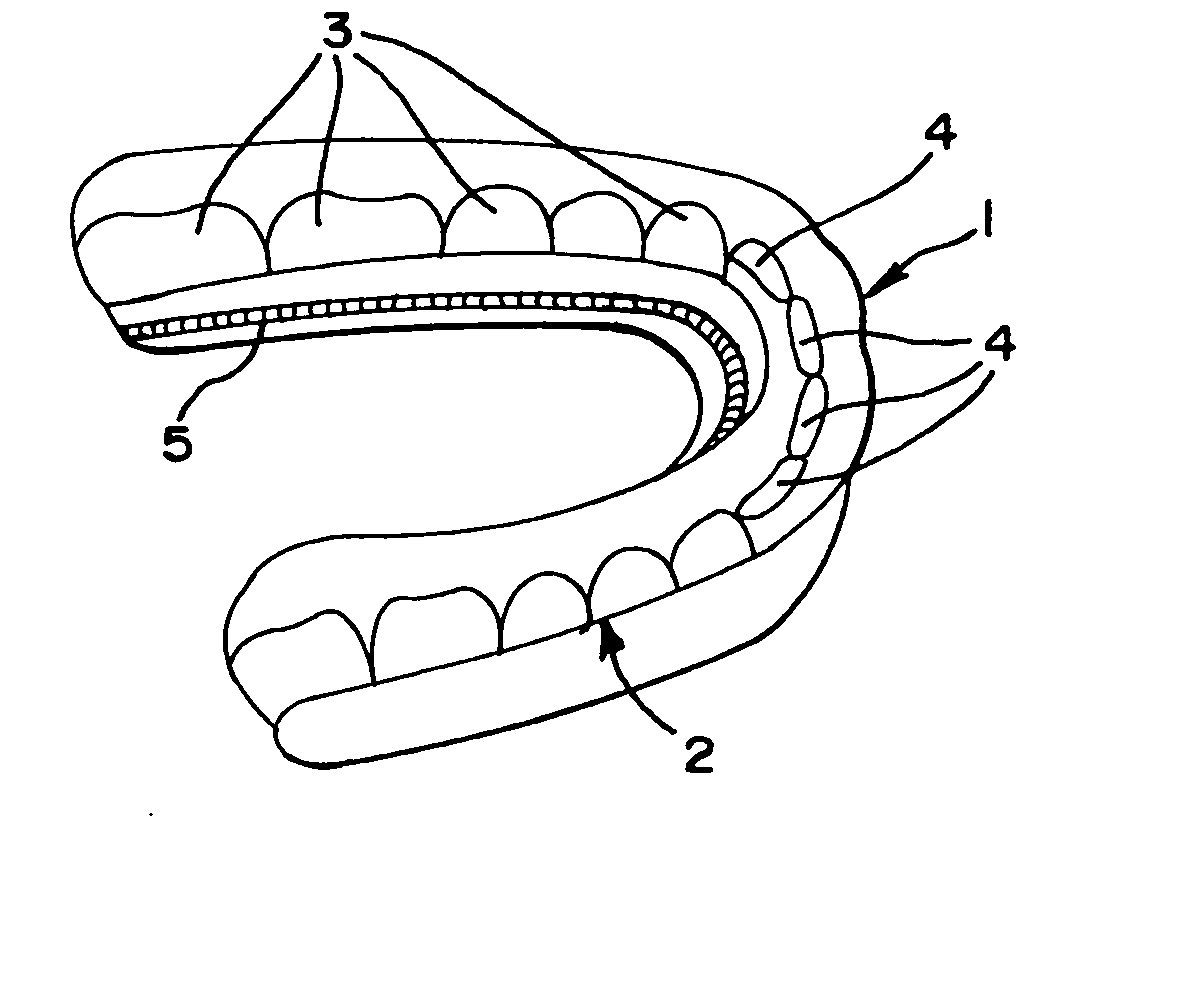

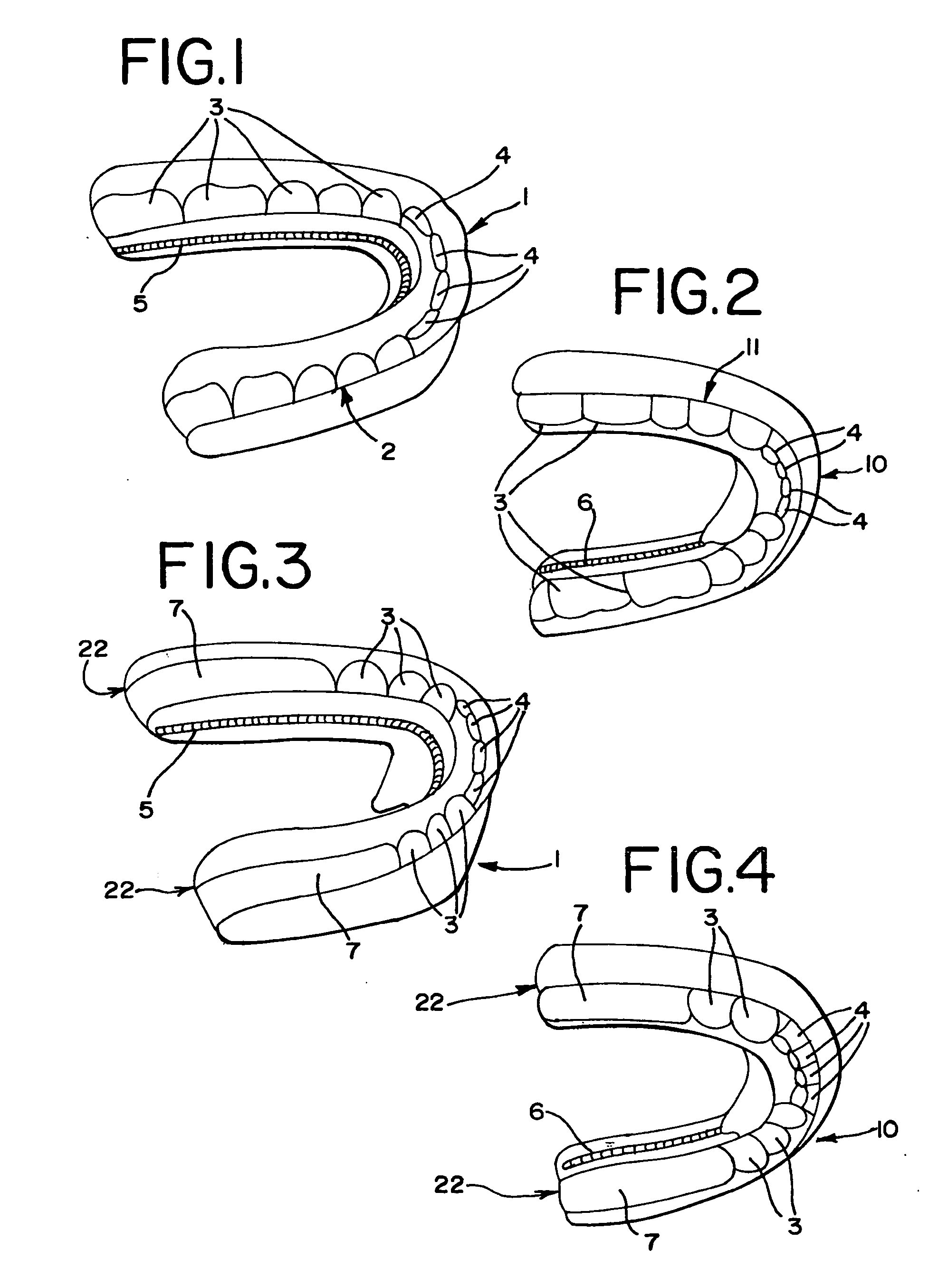

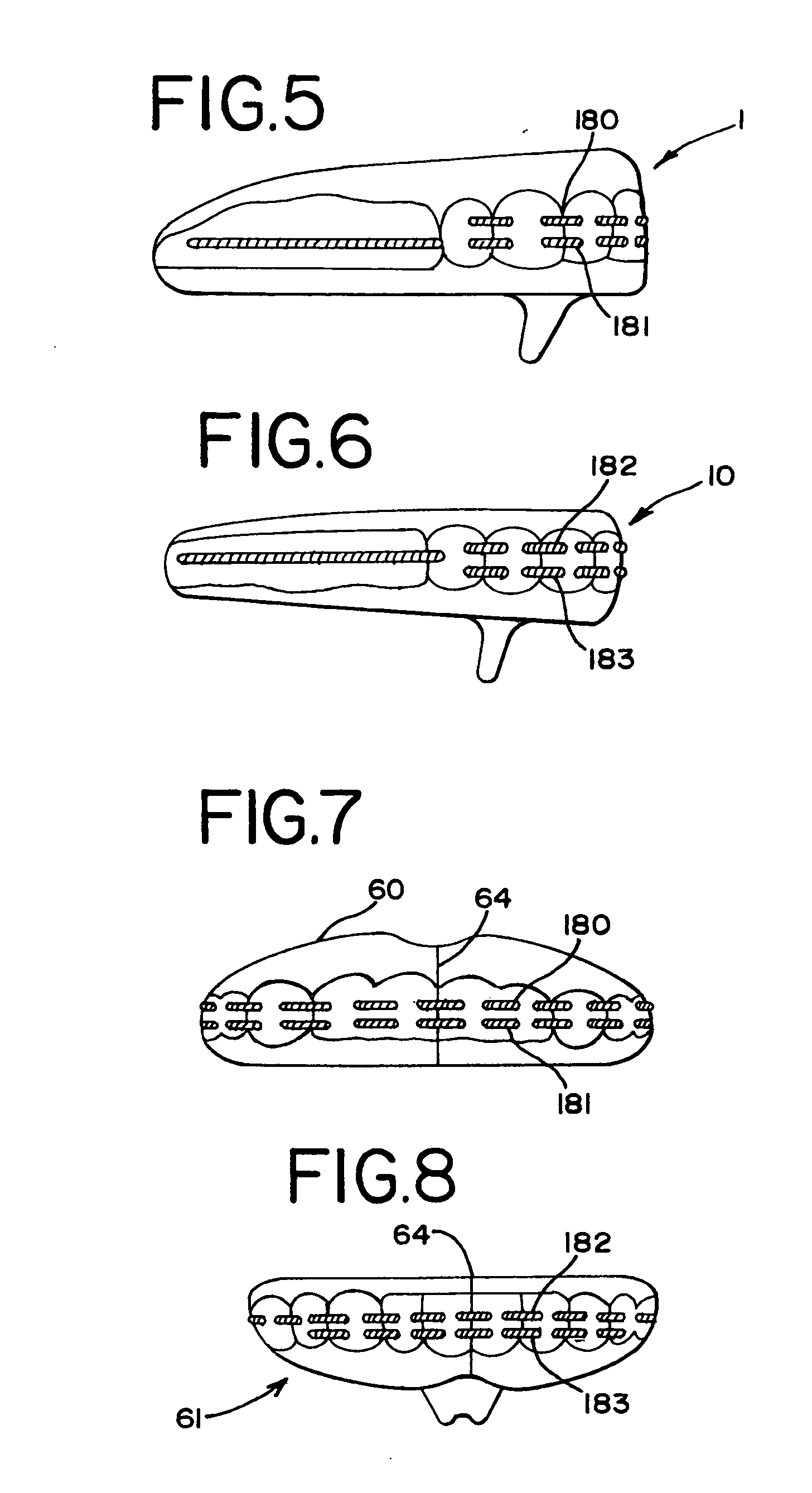

Upper and a lower single preformed and/or customized appliance and a method for attaching the appliance to a first area of a dentition and moving teeth at a second area of the dentition

InactiveUS20060099546A1Rotate the teeth more effectivelyEffective rotationOthrodonticsDental toolsDentitionOral cavity

An upper orthodontic appliance and / or a lower orthodontic appliance are provided for attaching to teeth in a mouth of a patient and / or straightening the teeth of the patient. The upper appliance and / or the lower appliance have a first area and / or a second area. The first area attaches to a first area of a dentition of the patient. The second area moves the teeth at a second area of the dentition of the patient. The upper appliance and / or the lower appliance have a single slot, sockets or a combination of both the slot and the sockets therein. The upper appliance and / or the lower appliance may be preformed, customized to receive the teeth of the patient or preformed and customized to receive the teeth of the patient. The upper appliance and / or the lower appliance move one or more teeth of the patient to correct an orthodontic condition of the patient. A wire is insertable into the upper appliance and / or the lower appliance. The wire bends to expand or to constrict the upper appliance and / or the lower appliance. As a result, the upper appliance and / or the lower appliance may abut an arch of the upper jaw and / or an arch of the lower jaw in a mouth of the patient to correct jaw misalignment in the mouth of the patient.

Owner:BERGERSEN EARL O

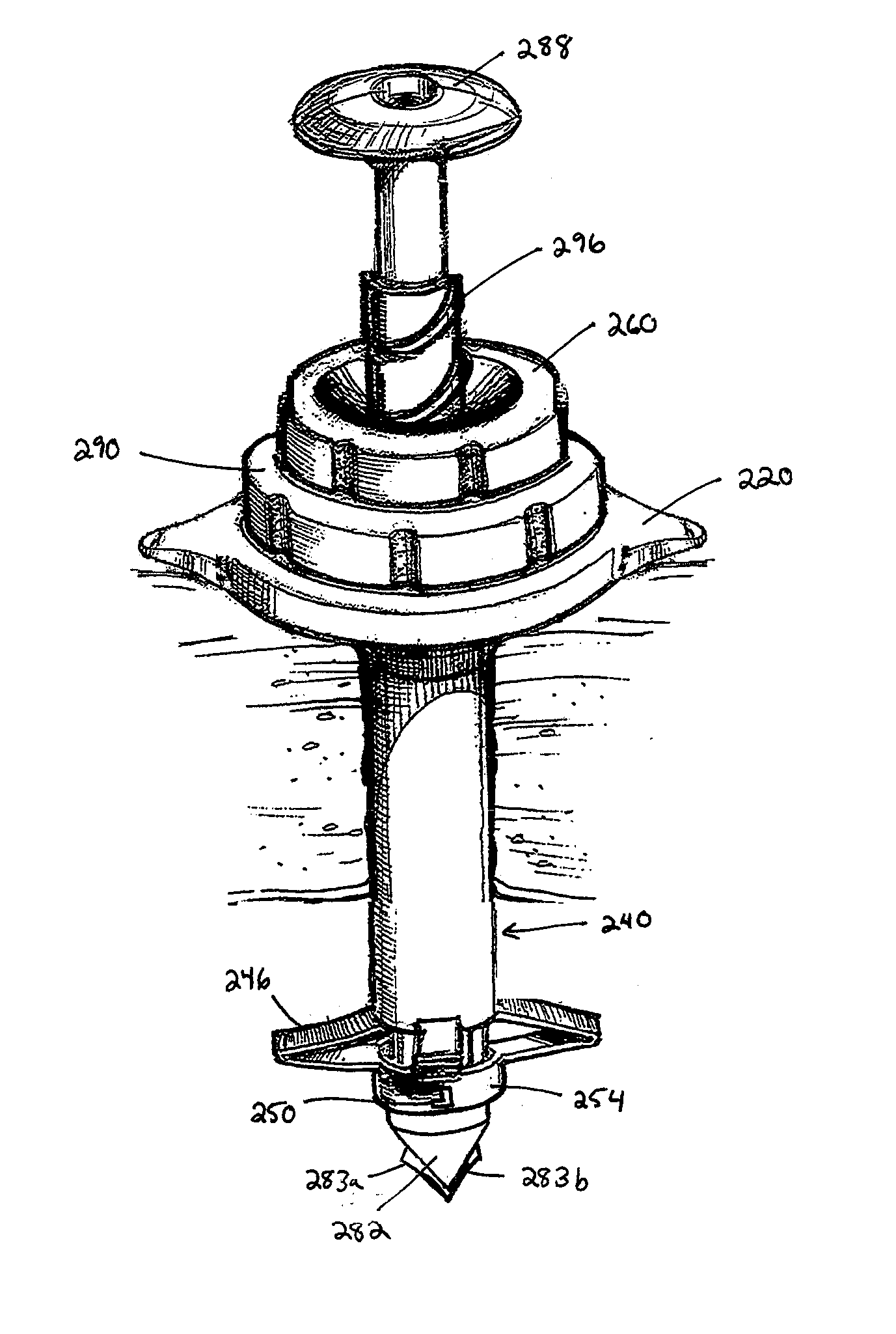

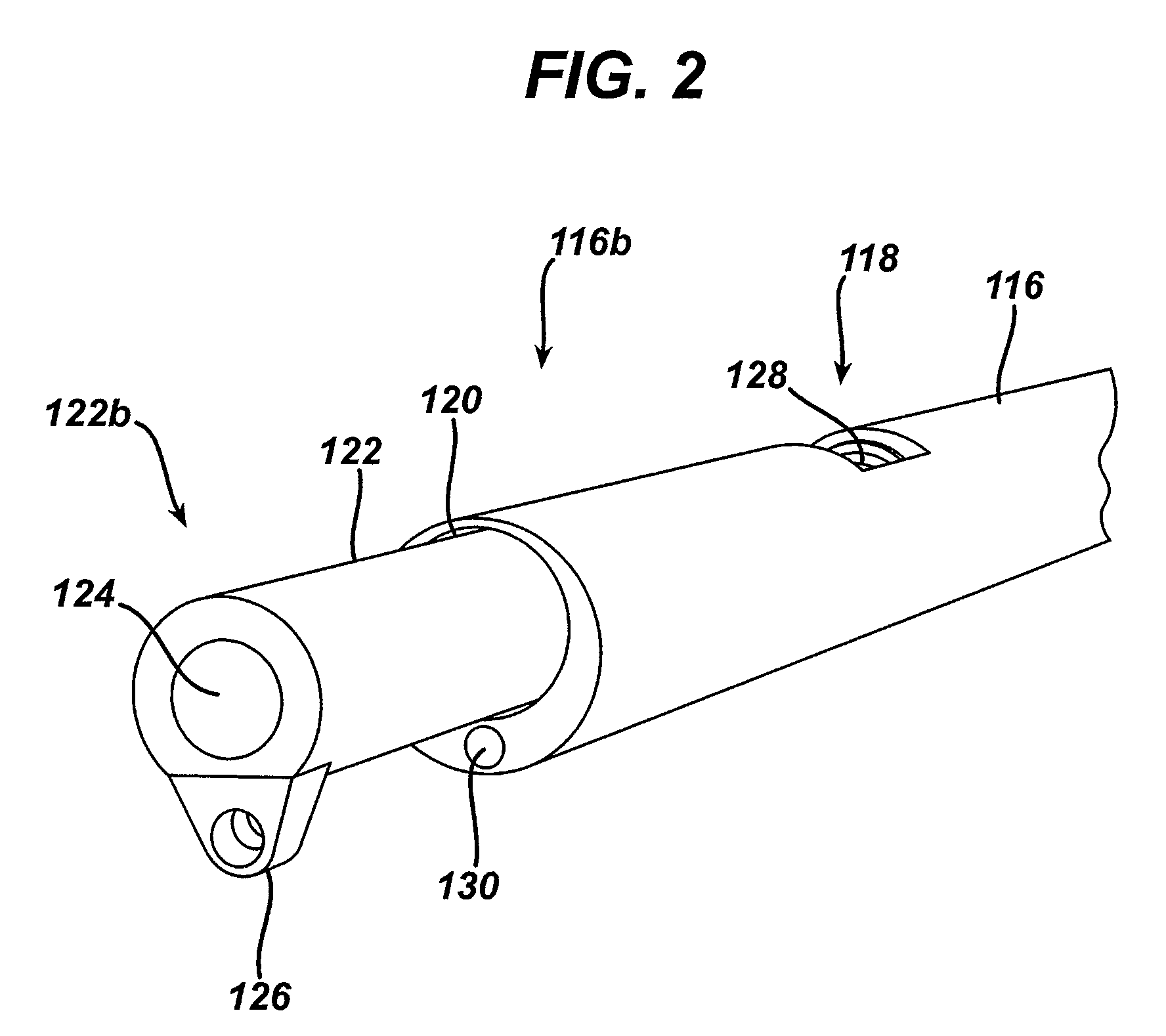

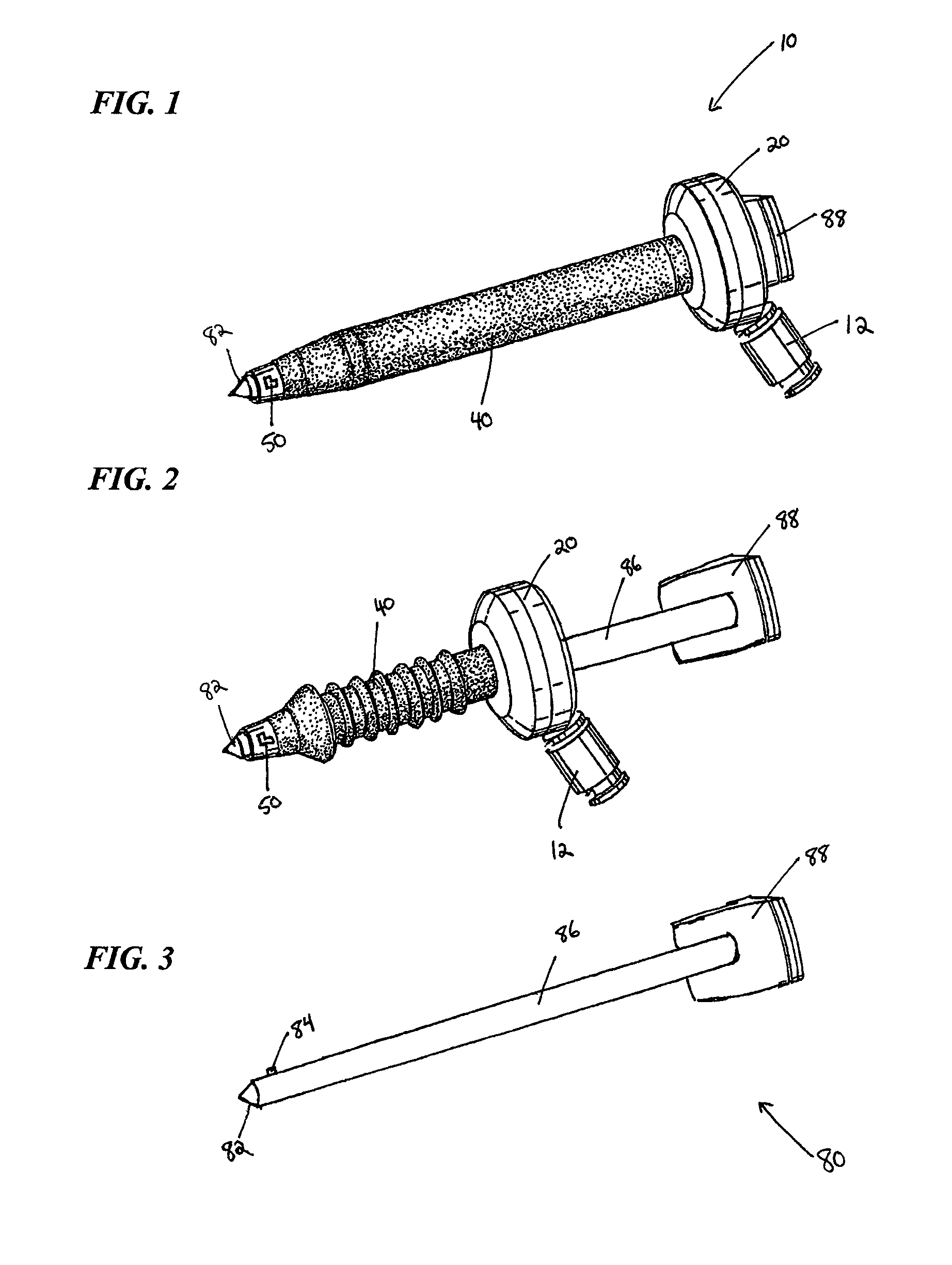

Methods and devices for accessing a body cavity

InactiveUS20110144440A1Efficiently rotatedEfficient changeCannulasSurgical needlesSurgical siteGeneral surgery

Methods and devices are provided for accessing a surgical site. In one embodiment, an access device is provided having a housing and a cannula extending distally therefrom. The cannula and the housing can define a working channel extending longitudinally therethrough. The cannula can be movable between an insertion configuration and a deployed configuration. The access device can also include an obturator insertable through the working channel. In one embodiment, the obturator can be configured to selectively mate with the cannula such that rotation of the obturator is effective to cause corresponding rotation of the cannula. In another embodiment, the obturator can be configured to move the cannula from the insertion configuration to the deployed configuration when the obturator is fully disposed within the cannula.

Owner:CILAG GMBH INTERNATIONAL

Automated access, key, certificate, and credential management

ActiveUS9515999B2Low costImprove securityKey distribution for secure communicationMultiple keys/algorithms usageCredential managementTrust relationship

Certain embodiments provide means for managing automated access to computers, e.g., using SSH user keys and other kinds of trust relationships. Certain embodiments also provide for managing certificates, Kerberos credentials, and cryptographic keys. Certain embodiments provide for remediating legacy SSH key problems and for automating configuration of SSH keys, as well as for continuous monitoring.

Owner:SSH COMMUNICATIONS SECURITY

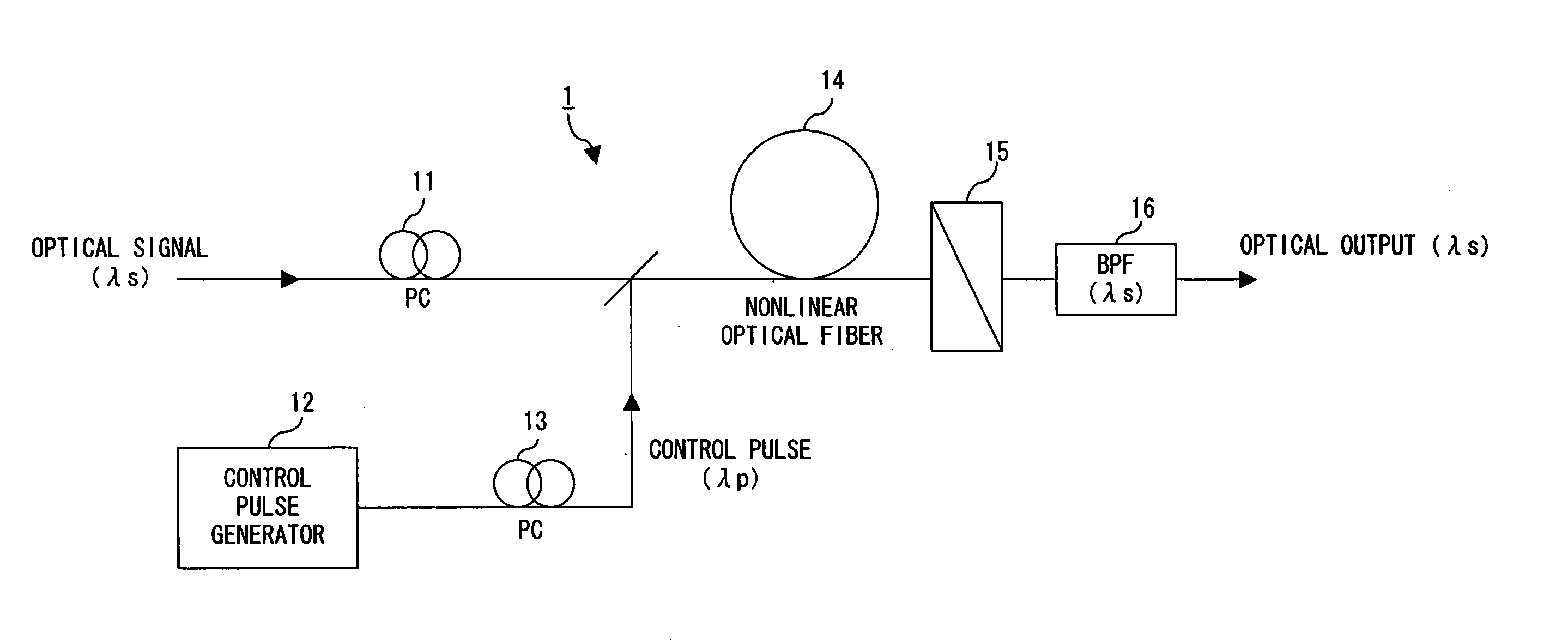

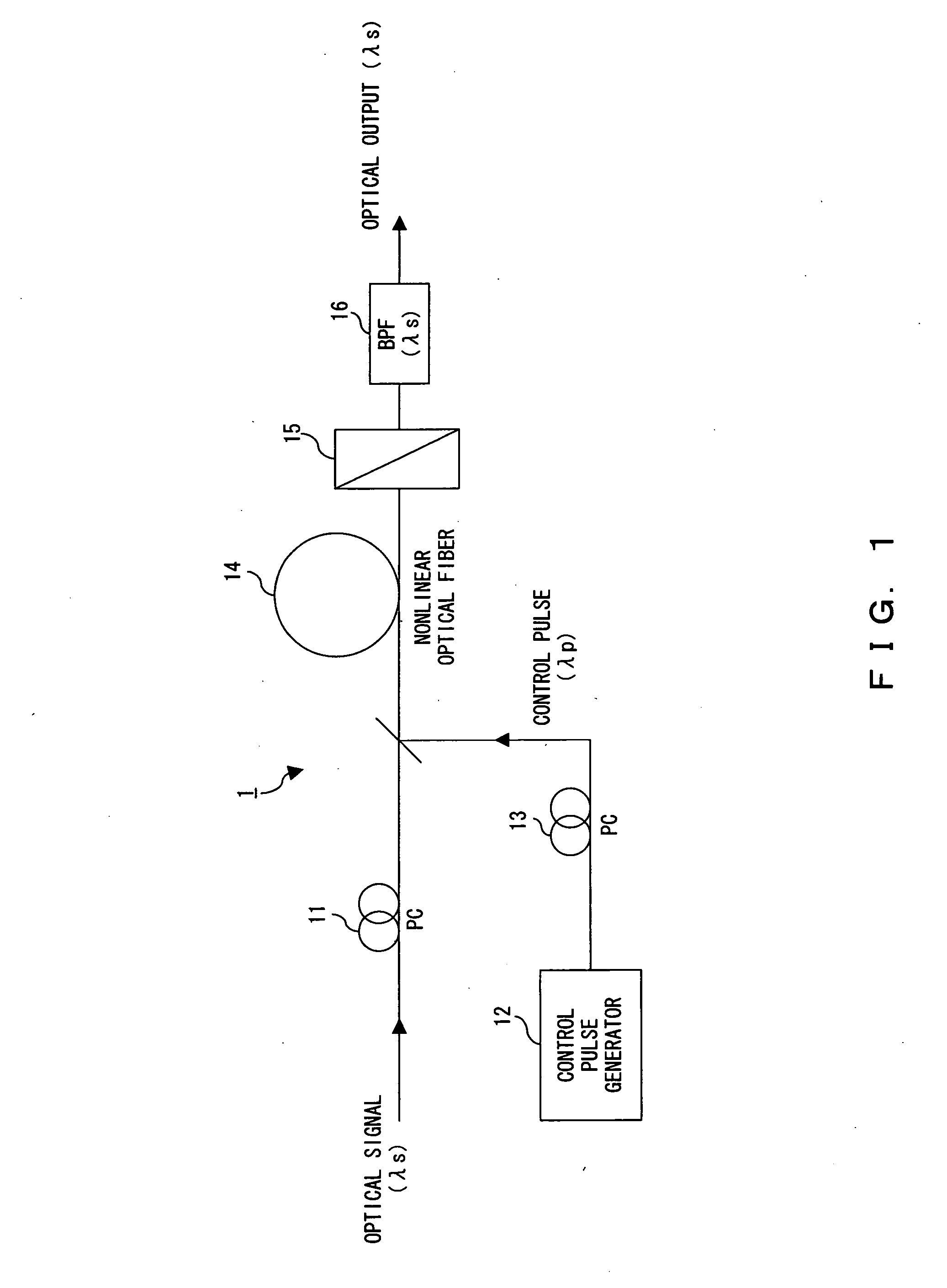

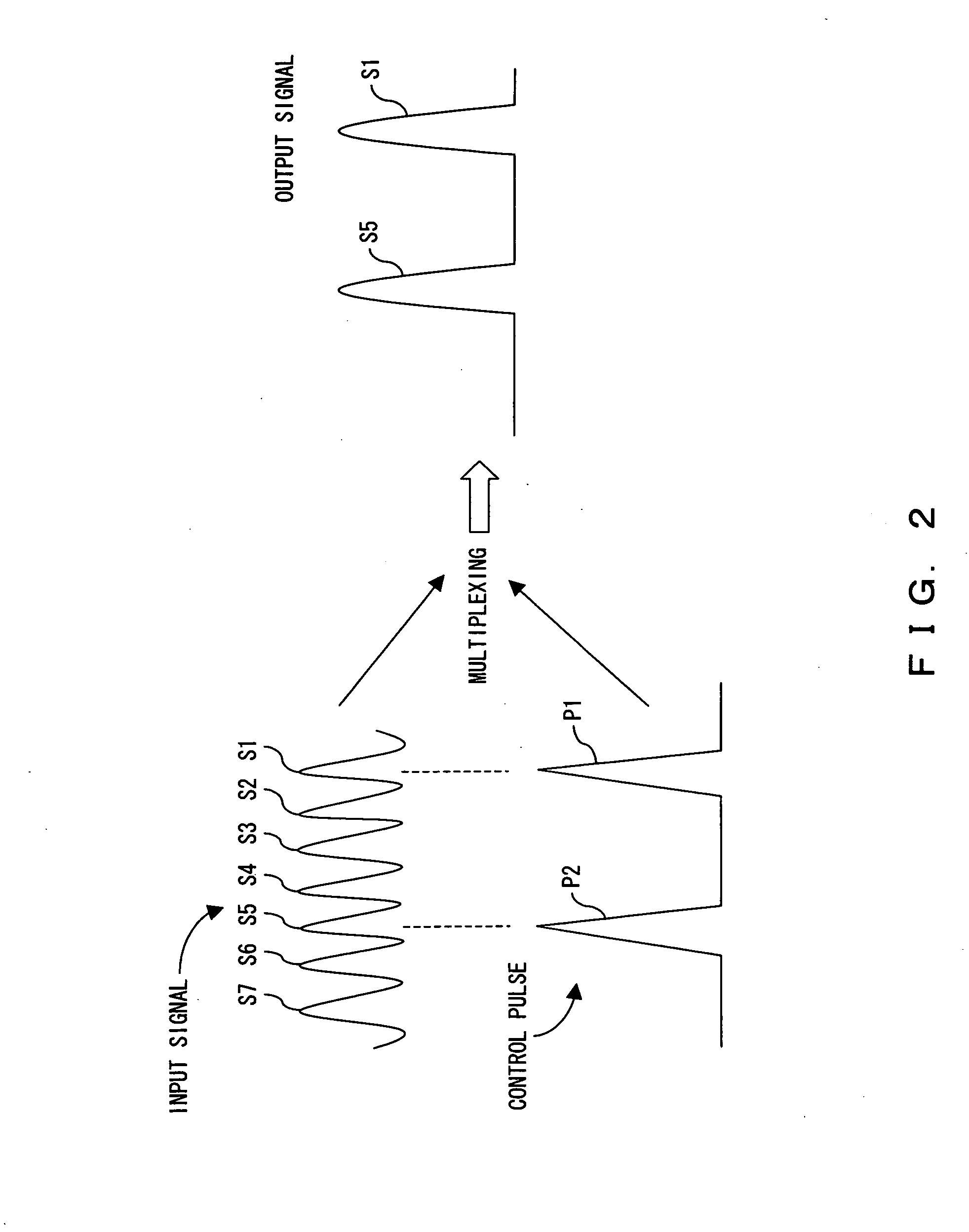

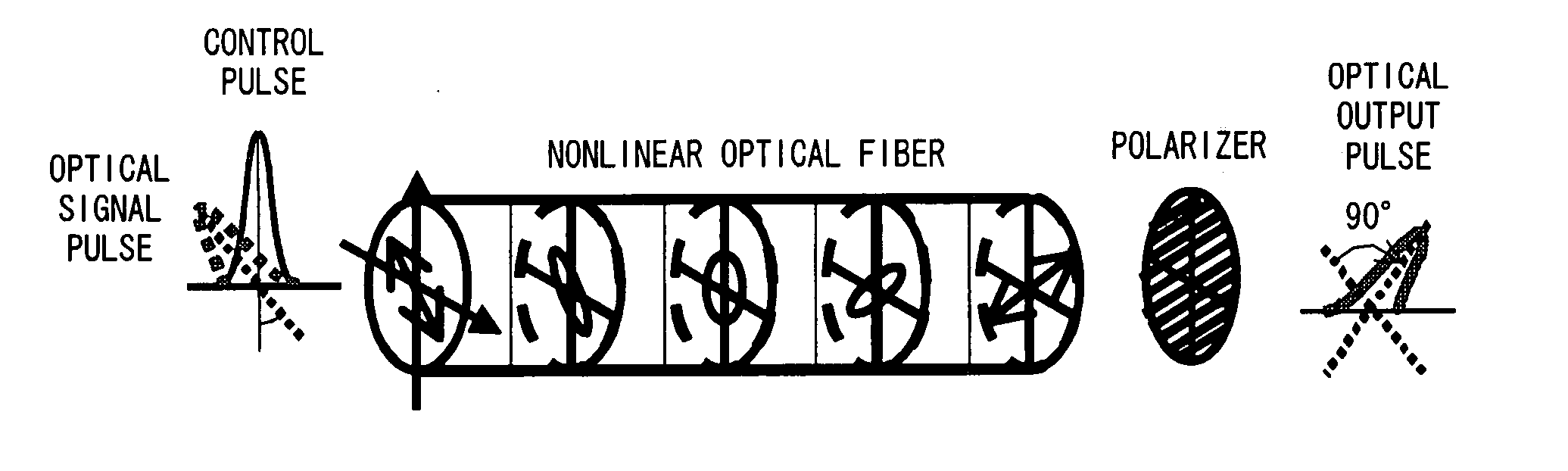

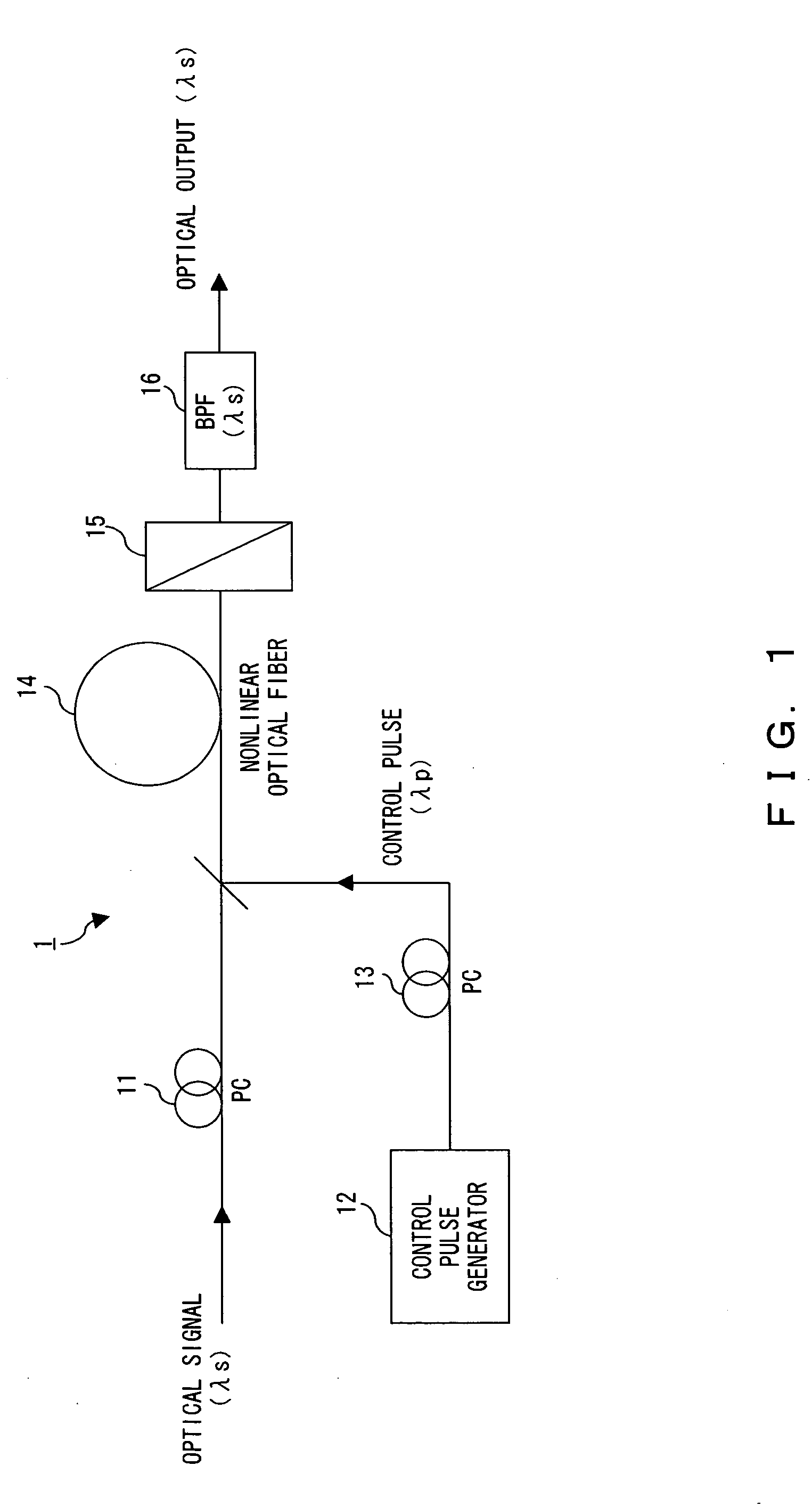

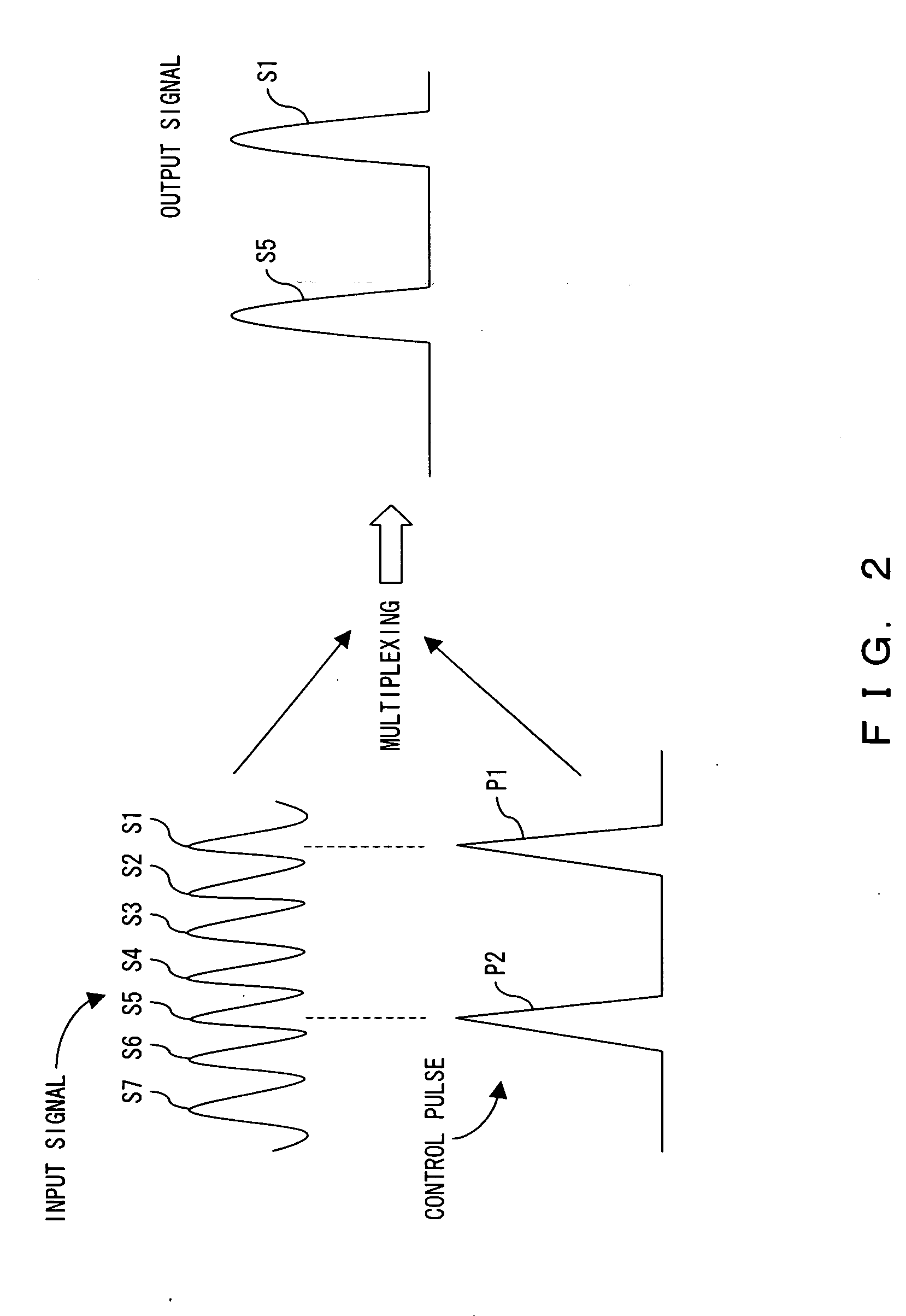

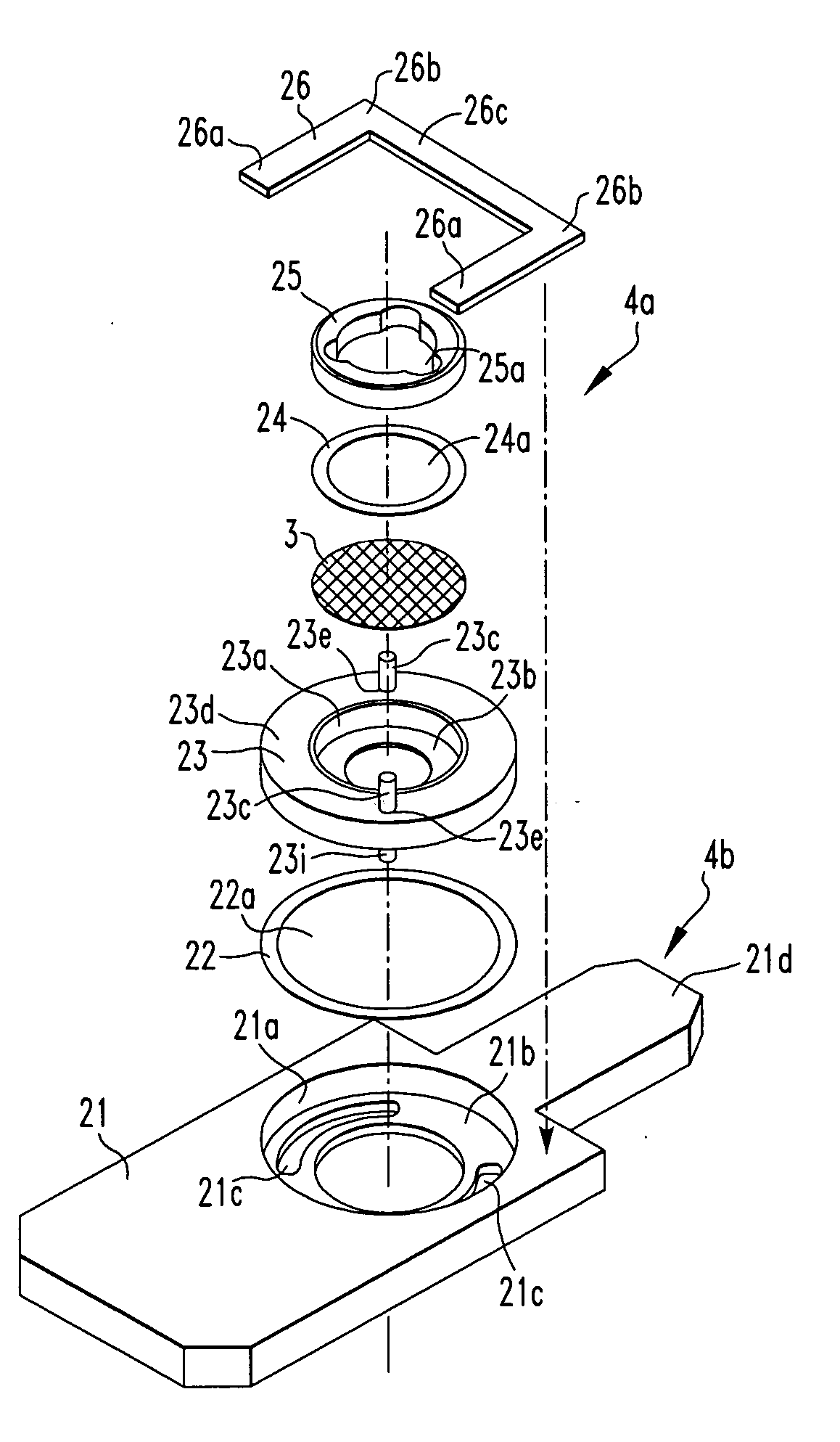

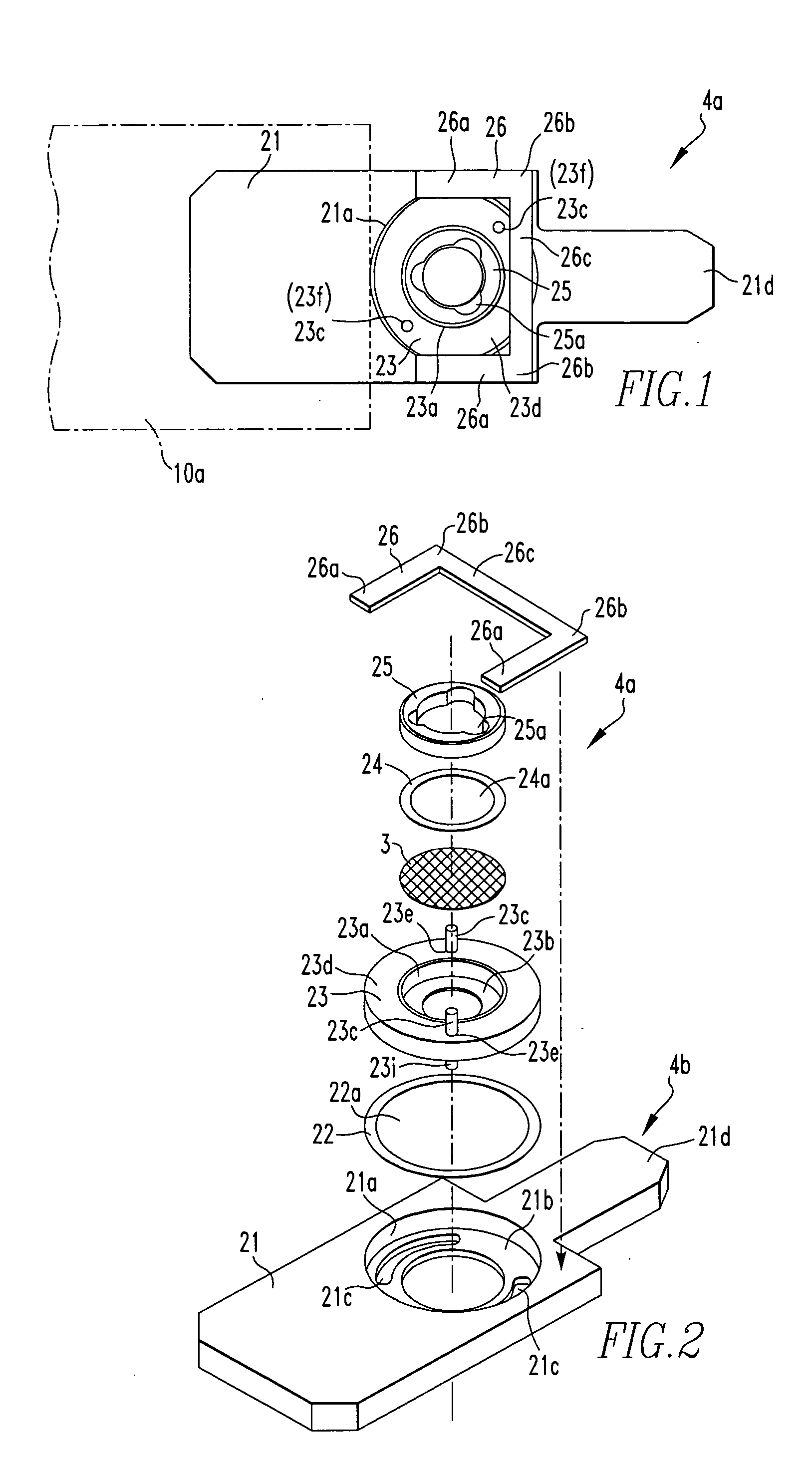

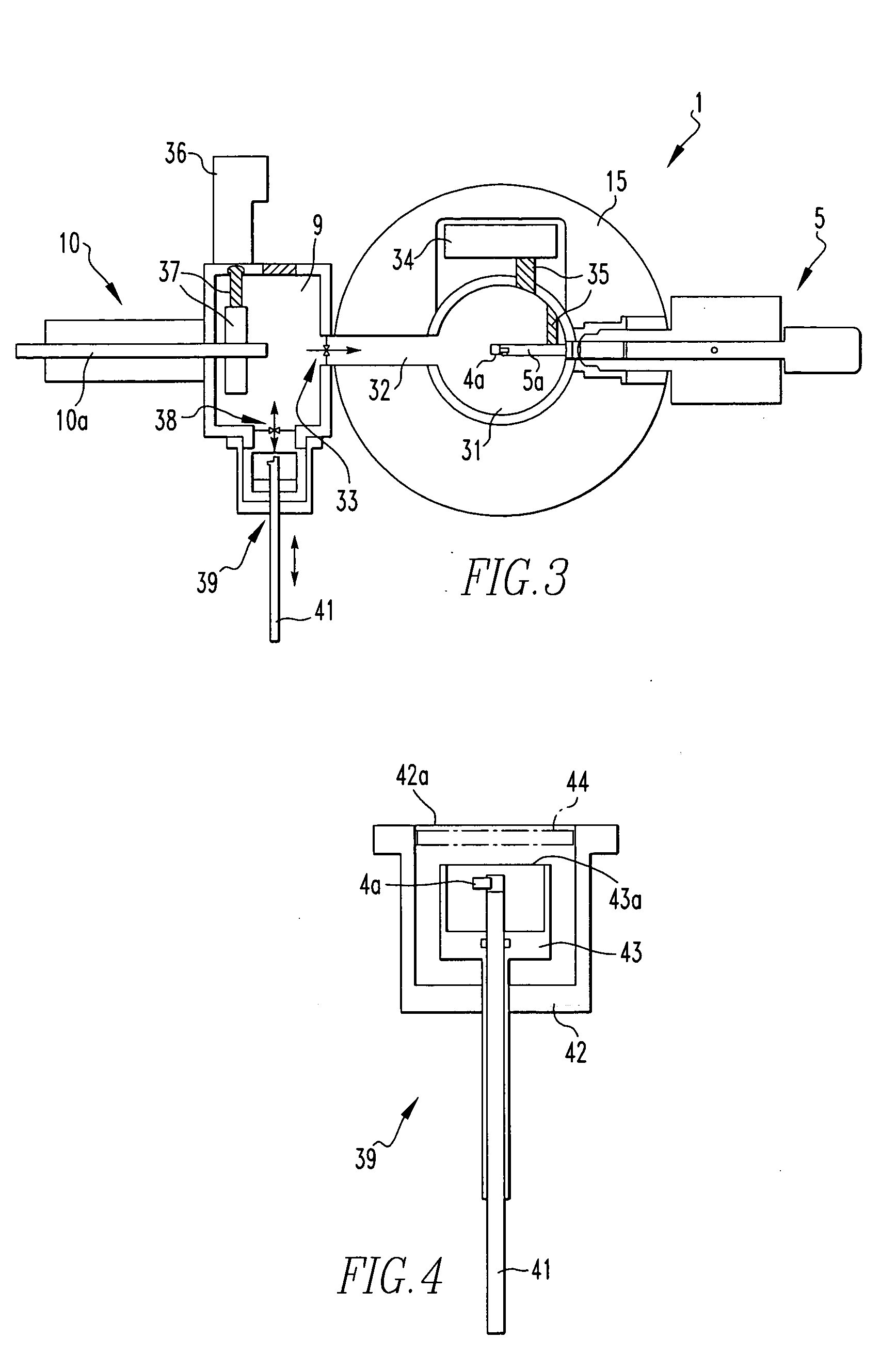

Optical switch and optical waveform monitoring device utilizing optical switch

ActiveUS20060051100A1Improve switching efficiencyExcellent optical S/N ratioLaser detailsPolarisation multiplex systemsPolarizerLength wave

The polarization direction of an optical signal is changed by a polarization controller so as to be orthogonal to a main axis of a polarizer. A control pulse generator generates control pulses from control beam with a wavelength which is different from the wavelength of the optical signal. The optical signal and the control pulse are input to a nonlinear optical fiber. In the nonlinear optical fiber, the optical signal, during a time period in which the optical signal and the control pulse coincide, is amplified with optical parametric amplification around a polarization direction of the control pulse. The optical signal, during the time period in which the optical signal and the control pulse coincide, passes through the polarizer.

Owner:FUJITSU LTD

Endoscopic tissue resection device

Devices and methods useful for manipulating tools at a surgical site are disclosed. The disclosed devices and methods can be useful, for example, for orbiting the distal end of one tool around the distal end of another tool, such as in an endoscopic resection procedure, and / or for rotating a tool or an end effector. In one exemplary embodiment, an endoscopic device is provided and can include an elongate shaft having a first lumen and a second lumen formed therein, each of the first and the second lumens adapted to receive a tool therethrough. A rotatable element can be disposed at a distal end of the elongate shaft, the rotatable element having a lumen formed therein that is associated with the first lumen of the elongate shaft and also having a tool guide that is adapted to receive a tool and that is associated with the second lumen of the elongate shaft. The rotatable element can be configured to rotate on a longitudinal axis thereof such that the tool guide orbits the longitudinal axis of the rotatable element.

Owner:ETHICON ENDO SURGERY INC

Methods and devices for accessing a body cavity

InactiveUS8435174B2Efficient changeEffective movementCannulasSurgical needlesSurgical siteBody cavity

Methods and devices are provided for accessing a surgical site. In one embodiment, an access device is provided having a housing and a cannula extending distally therefrom. The cannula and the housing can define a working channel extending longitudinally therethrough. The cannula can be movable between an insertion configuration and a deployed configuration. The access device can also include an obturator insertable through the working channel. In one embodiment, the obturator can be configured to selectively mate with the cannula such that rotation of the obturator is effective to cause corresponding rotation of the cannula. In another embodiment, the obturator can be configured to move the cannula from the insertion configuration to the deployed configuration when the obturator is fully disposed within the cannula.

Owner:CILAG GMBH INT

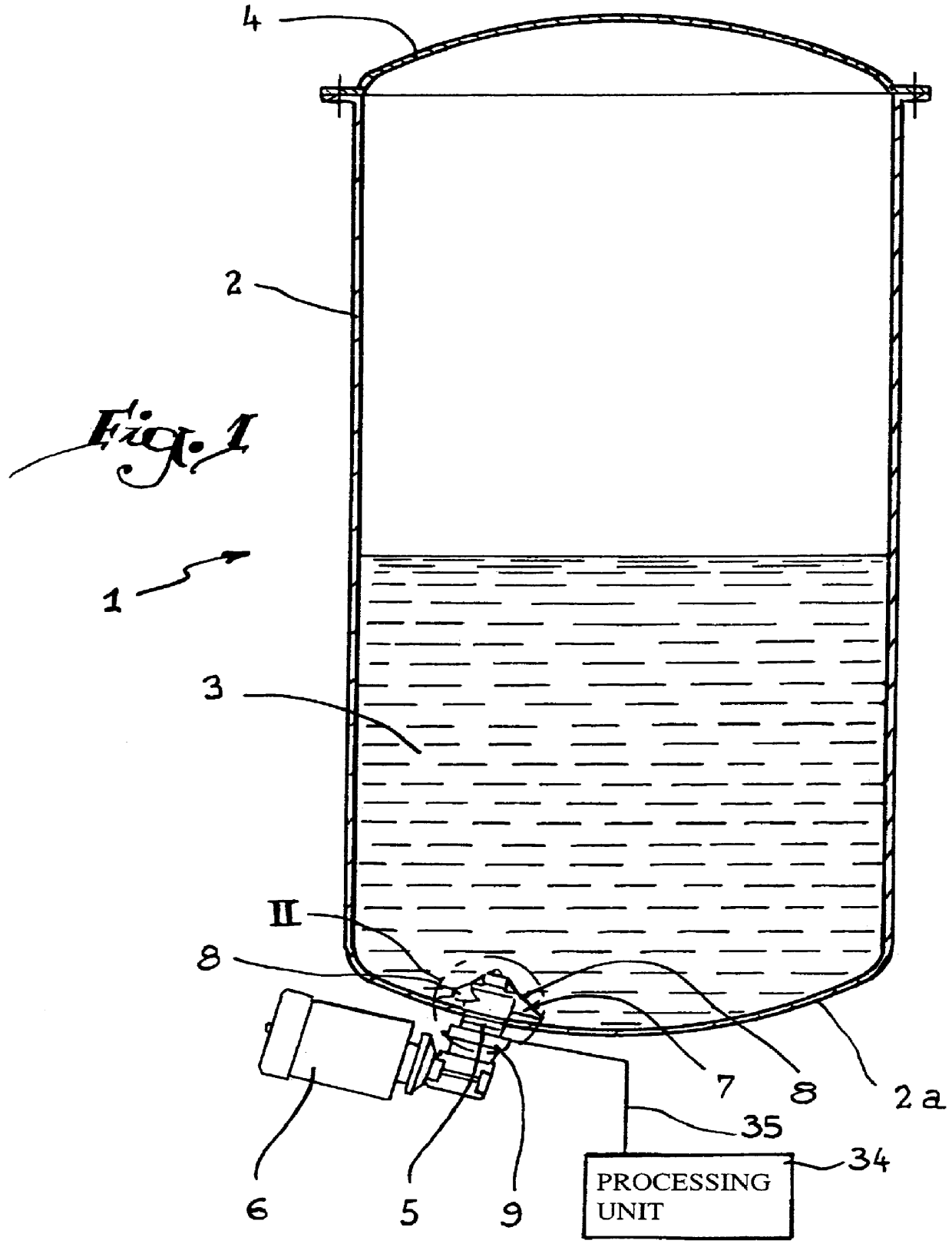

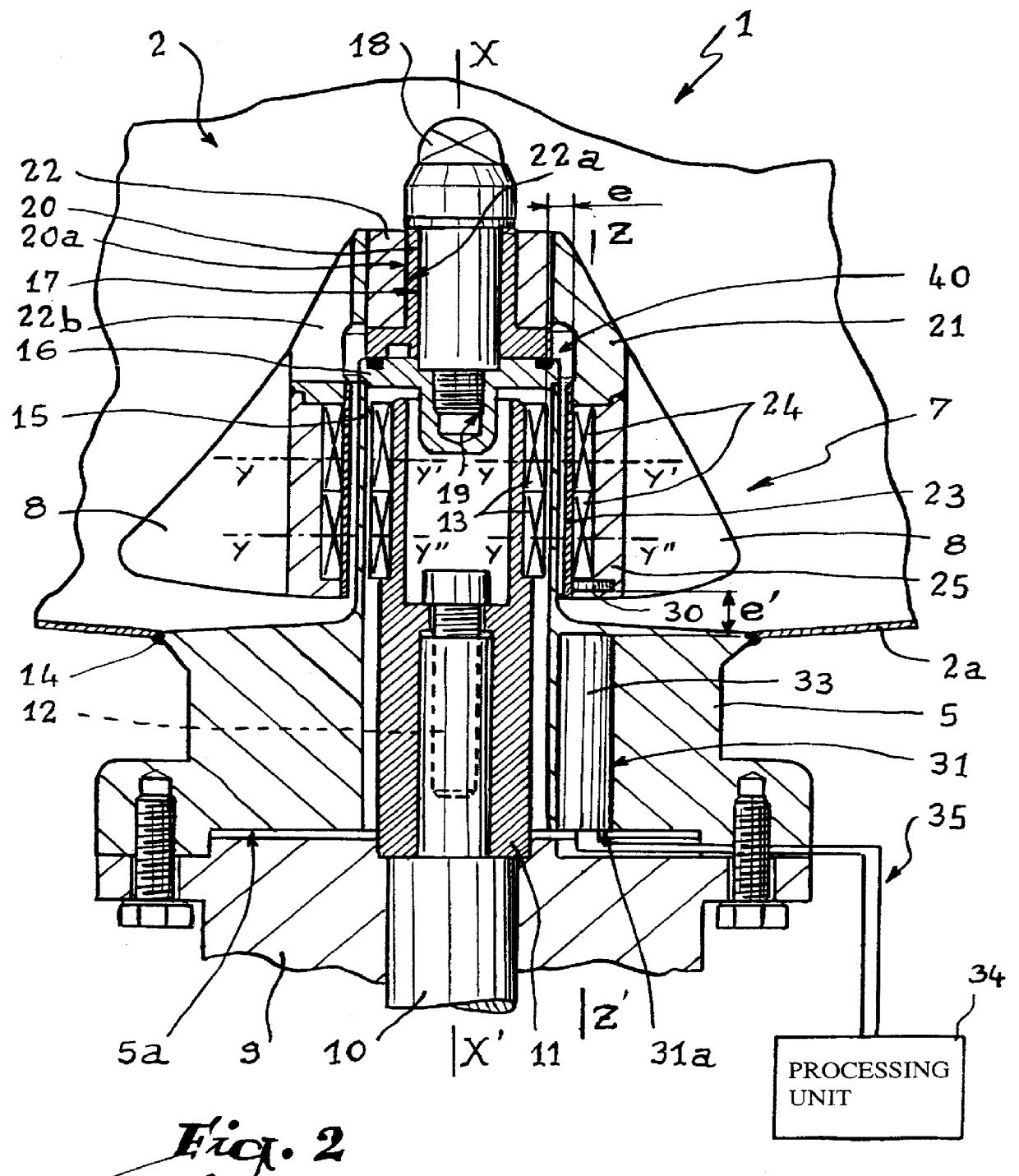

Magnetically driven agitator with magnetic rotation detector

InactiveUS6065865AEffective rotationPrecise positioningTransportation and packagingRotary stirring mixersMagnetic tension forceMagnetic rotation

A magnetically driven agitator for a mixture contained in a recipient which agitator is supported by a collar hermetically mounted in a wall of the recipient and which collar is provided with a blind sleeve inside which is housed a drive shaft provided with a first magnetic coupling. A propelling screw is disposed around the blind sleeve and is provided with a second magnetic coupling adapted to cooperative with the first magnetic coupling for driving the propelling screw about an axis of rotation. A third magnetic element carried by the propelling screw is disposed opposite a cell for detecting the movement of the third coupling element during rotation of the propelling screw about the axis of rotation.

Owner:MIXEL

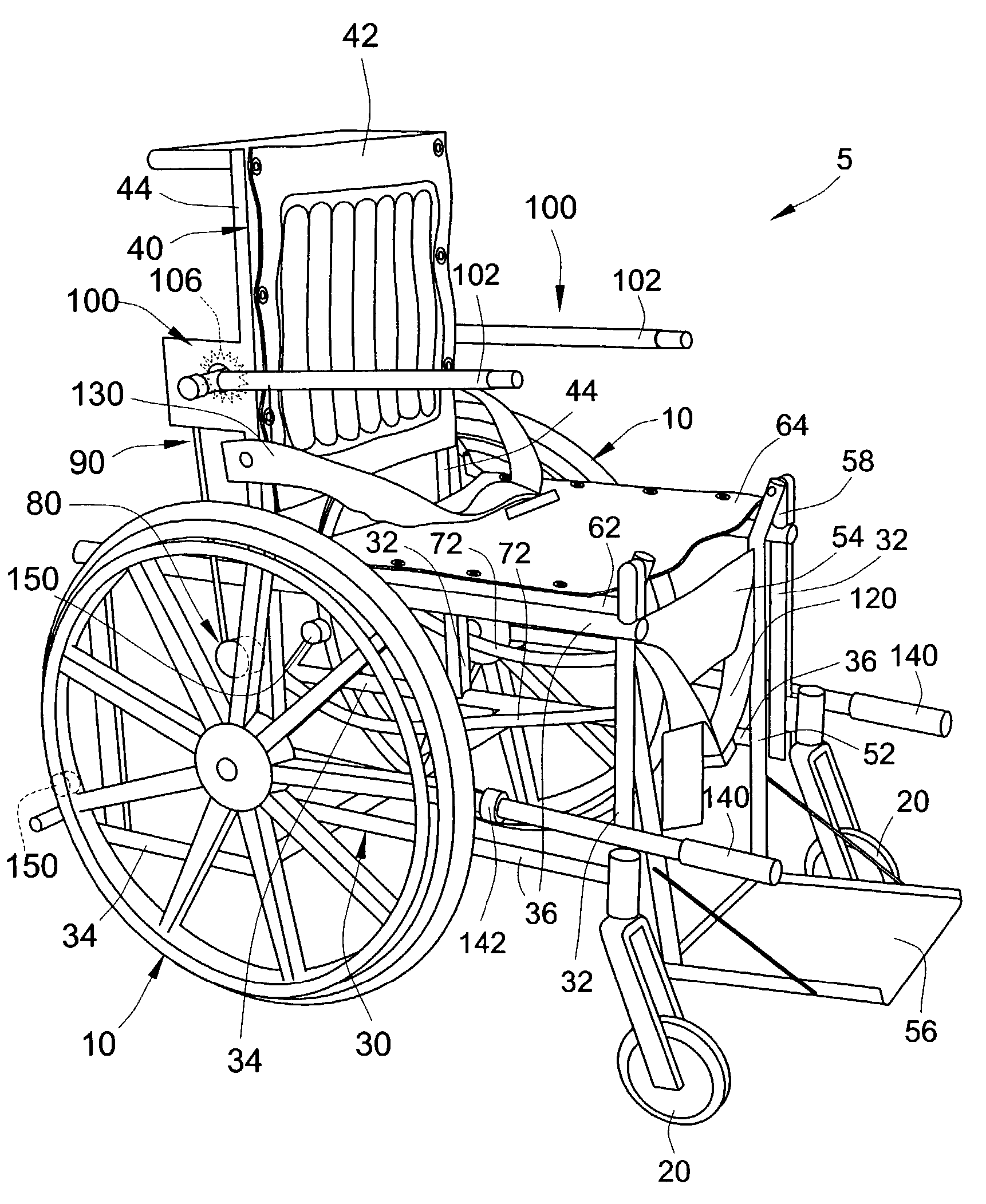

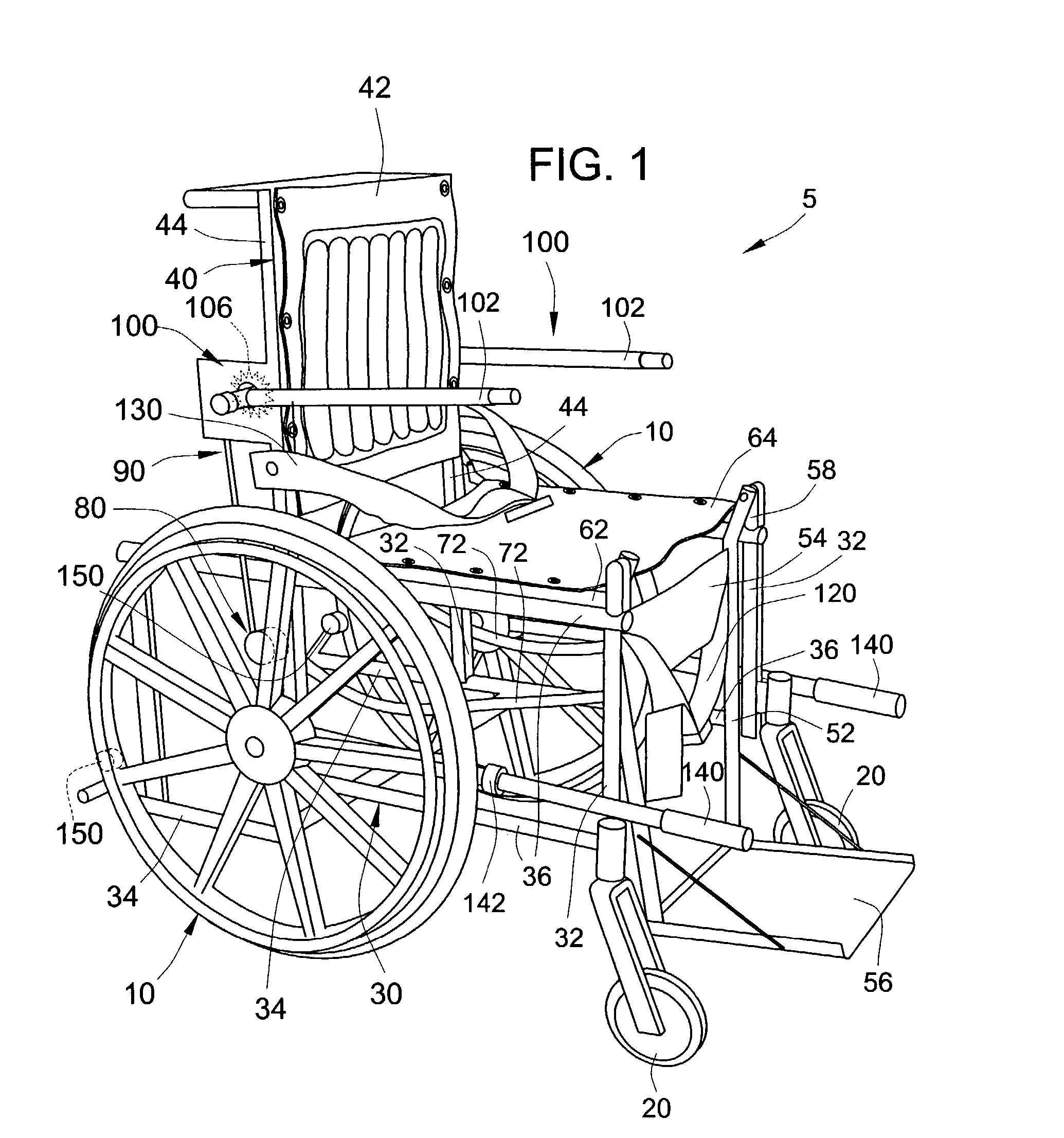

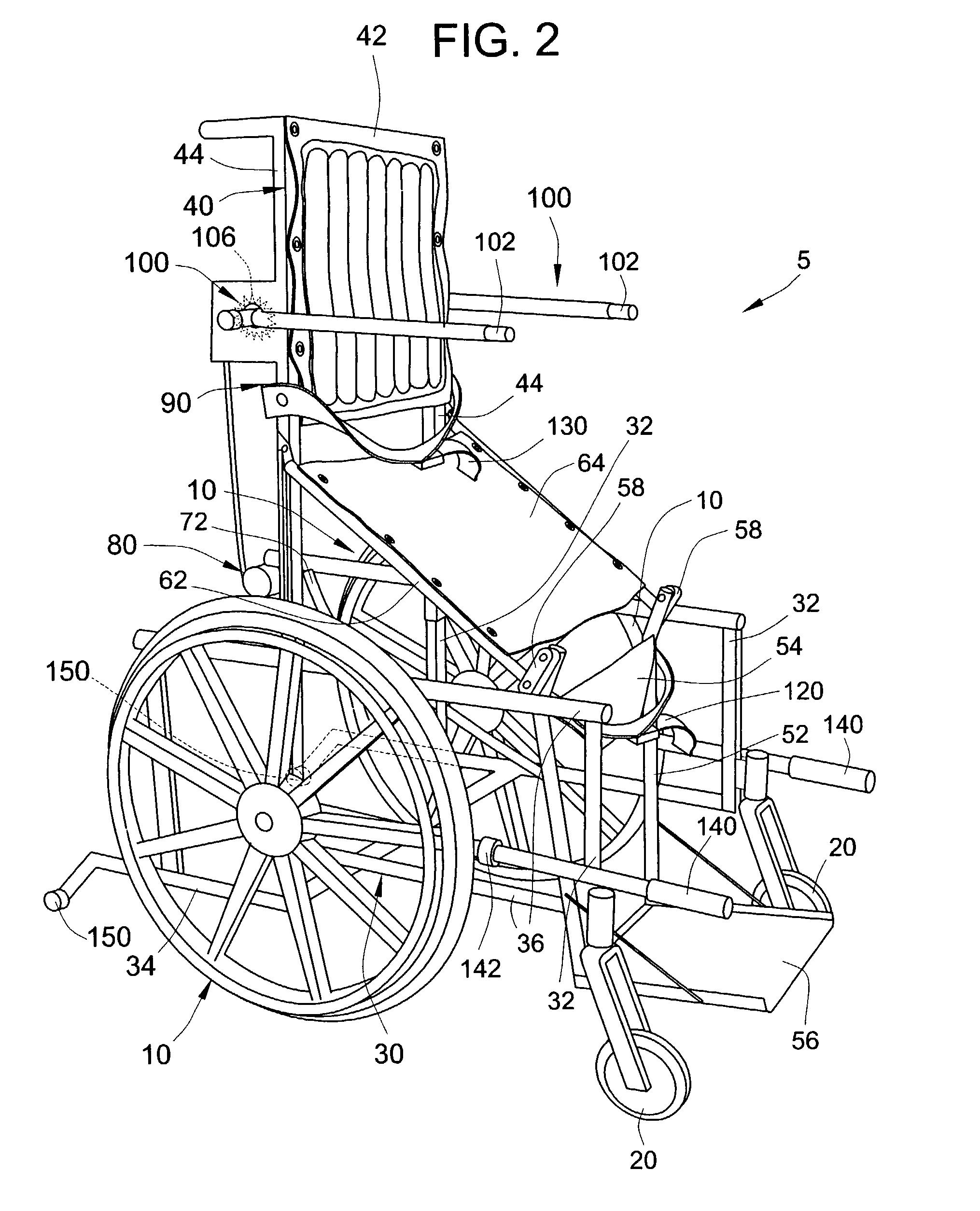

Manually operable standing wheelchair

InactiveUS6976698B2Safe and stable operationOperational securityCarriage/perambulator accessoriesWheelchairs/patient conveyanceStanding PositionsManual wheelchair

A manually operable standing wheelchair includes an actuator for moving an occupant from a sitting position to a standing position. The manually operable standing wheelchair has a lifting mechanism, including, for example, a ratchet, cable, pulley, and telescopic tubes, which the occupant may manually operate to shift from the sitting position to the standing position. There is also a drive system to enable the occupant to manually move himself or herself in and the wheelchair from the sitting position to the standing position, or in any position in between. For example, the drive system may include adjustable lever drive arms with friction pads adapted for allowing the occupant to move in any position. In an embodiment, the wheelchair is equipped with a set of spring loaded anti-tip wheels that automatically deploy when the manual wheelchair begins to lift from the sitting position to the standing position.

Owner:REHABILITATION INST OF CHICAGO

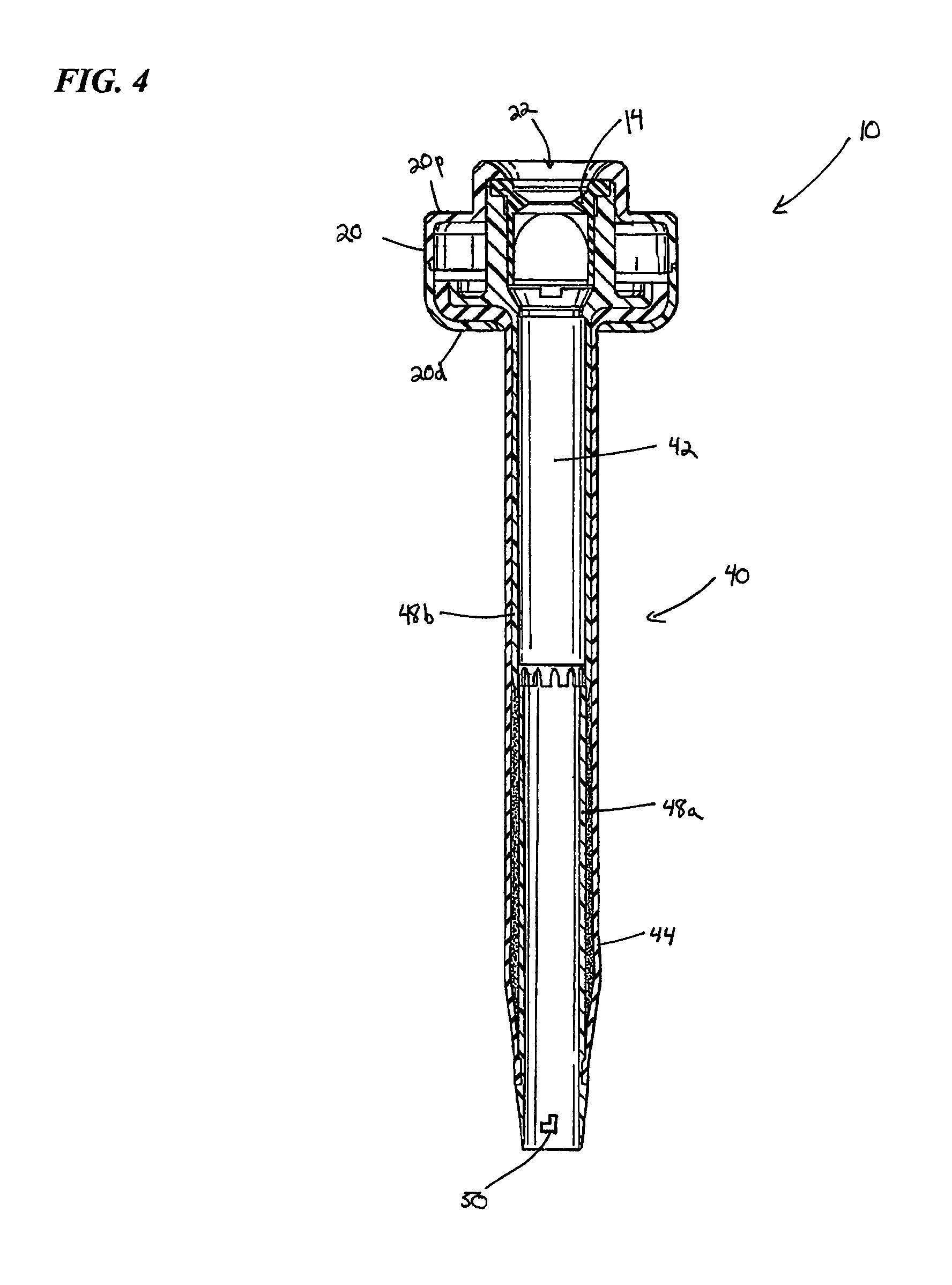

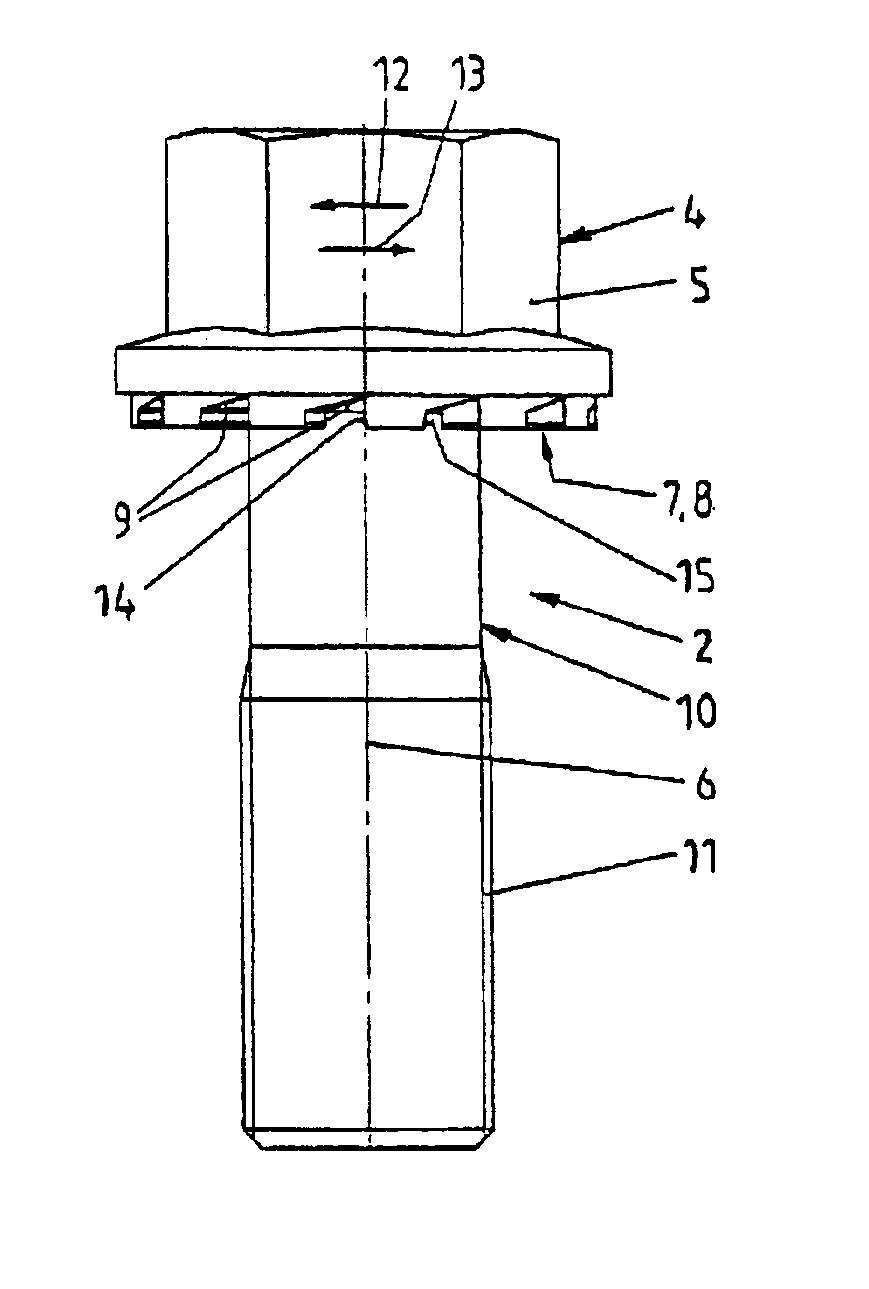

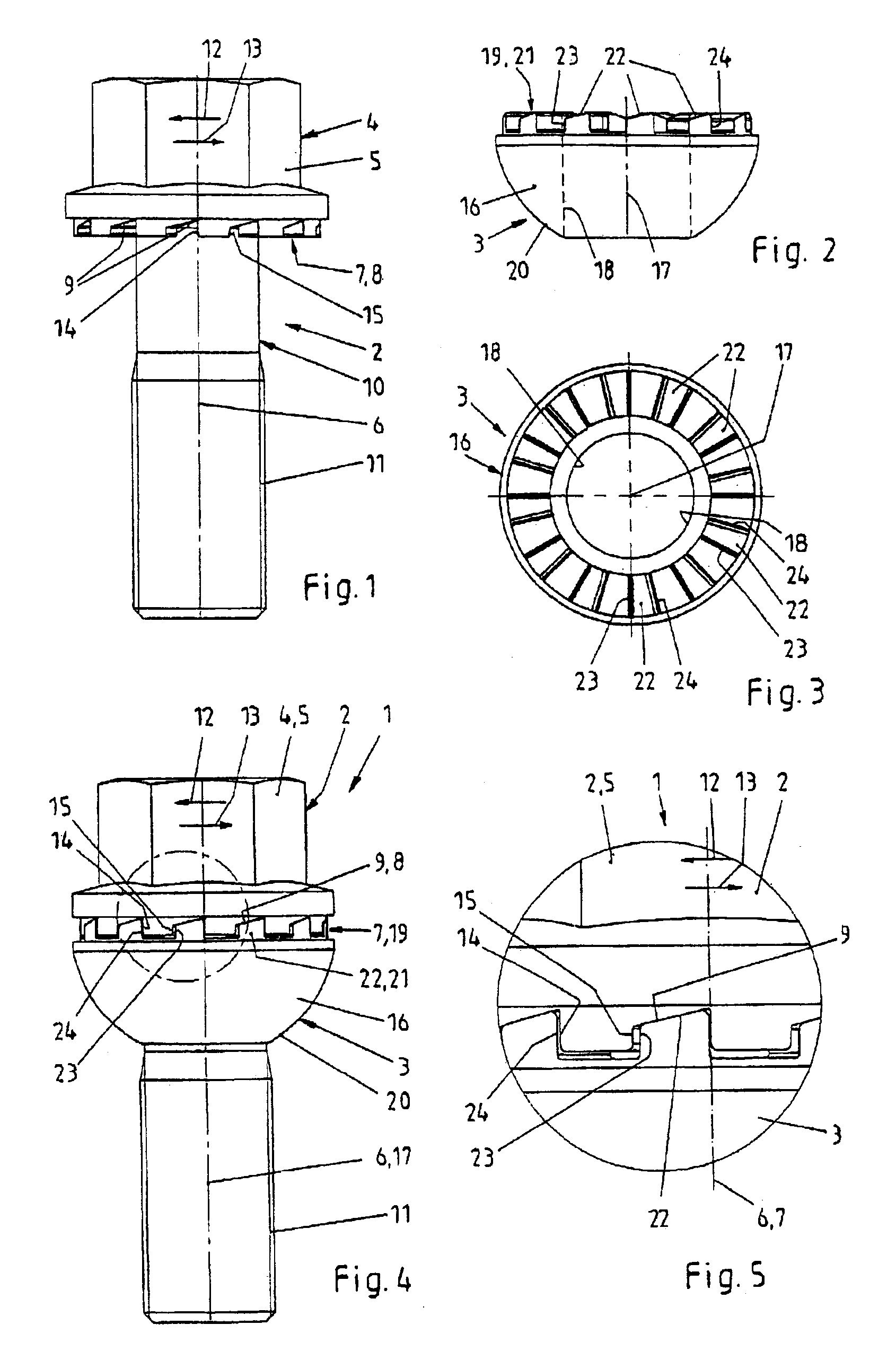

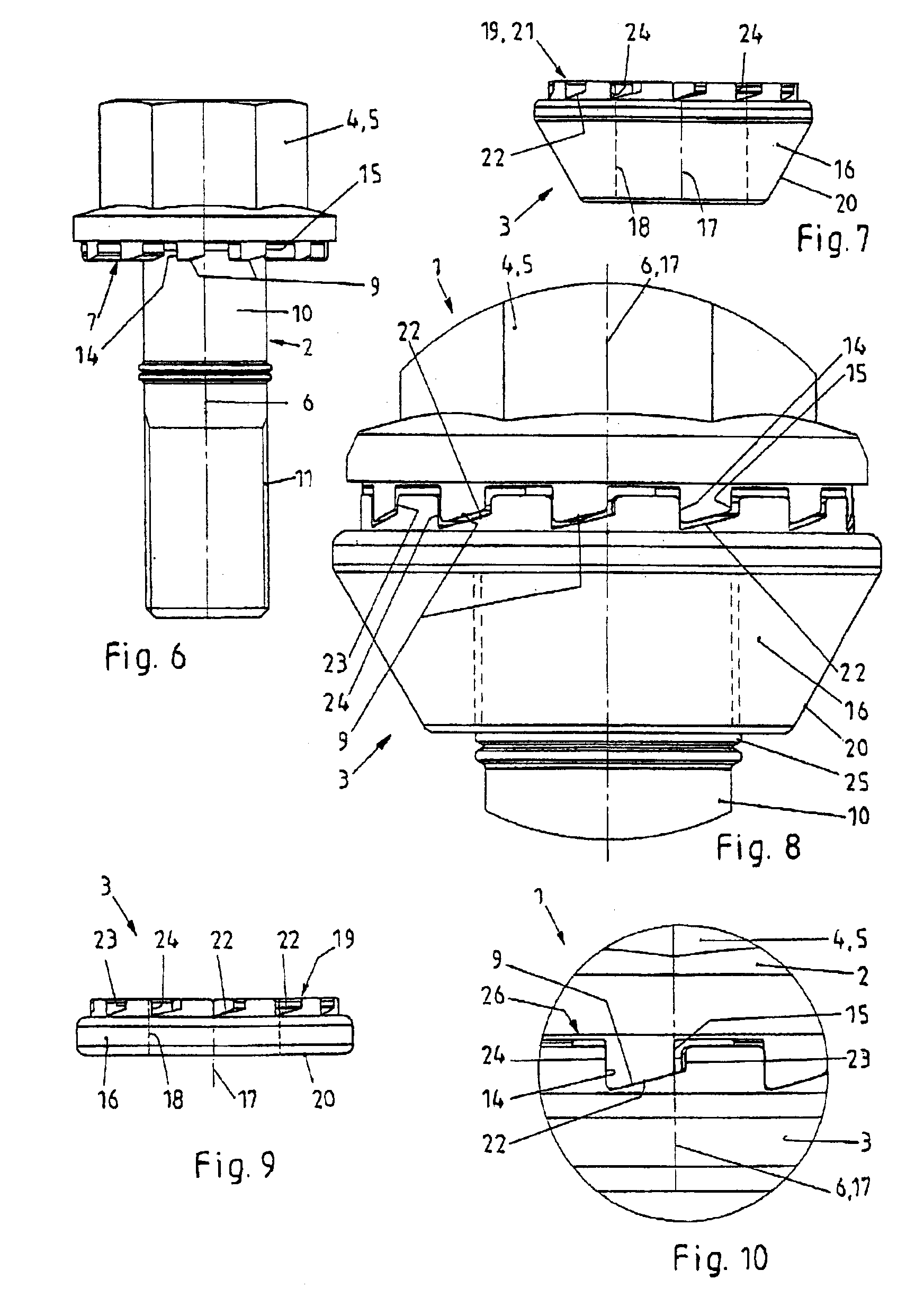

Needle retraction apparatus

ActiveUS9138545B2Effectively preventing reuse“safe” against accidental needle sticksCatheterSensorsActuatorMedical device

A needle retraction apparatus for a medical device such as a liquid infusion or collection device, the apparatus having a body, a needle retraction mechanism seated inside the body, a transverse slide member with an external needle retraction chamber, and a retraction actuator that is rotatable relative to the slide member, the retraction actuator being attachable to or made as part of the liquid infusion or collection device, whereby rotation of the device causes the slide member to move in a linear translational direction to reposition the retraction chamber in alignment with the needle retraction mechanism and allow retraction.

Owner:RETRACTABLE TECH INC

Optical switch and optical waveform monitoring device utilizing optical switch

InactiveUS20060045445A1Improve switching efficiencyReduce lossesTime-division optical multiplex systemsCoupling light guidesOptical parametric amplifierPolarizer

The polarization direction of a signal is rotated by a polarization controller so as to be orthogonal to the main axis of a polarizer. A control pulse generator generates control pulses from control source with a wavelength which is different from the wavelength of the signal. The signal and the control pulse are input to a nonlinear optical fiber. In the nonlinear optical fiber, the signal, during the time period in which the signal and the control pulse coincide, has its polarization direction rotated by cross phase modulation, and is amplified by optical parametric amplification. The signal, during the time period in which the signal and the control pulse coincide, passes through the polarizer.

Owner:FUJITSU LTD

Table

InactiveUS20020062791A1Improve simplicityGuaranteed effective rotationVacuum evaporation coatingSputtering coatingAcute angleClassical mechanics

Structure for disposing a material to be treated at an acute angle relative to the axis of rotation so as to permit the substrate to rotate relative to said structure.

Owner:GINOVKER ANDREY +3

Wire bond fault detection method and apparatus

ActiveUS7004373B1Reduce tensionEffective rotationSolid-state devicesSemiconductor devicesCatenaryDrive motor

A method and apparatus for confirming whether wire bonds are successfully made to sites on a workpiece by an ultrasonic bonding tool using wire supplied to an entrance bore through the tool from a despooling wire supply spool, and for providing a fault detection status signal if bonds are not successfully made, utilizes an automatic wire despooler which includes a spool drive motor for rotating a wire supply spool to thereby pay out wire from the supply spool to form a drooping catenary-shaped length of slack wire, located between the spool and an output wire guide having an aperture through which wire is supplied to a bonding machine head that supports an ultrasonic bonding tool. The apparatus includes a proximity-type feed sensor for detecting when the catenary straightens and shortens a predetermined amount in response to tension caused by moving the tool tip between successive bond sites, thereby drawing wire out through an exit opening of the bonding tool bore. Shortening the slack length a predetermined amount straightens and elevates the center part or vertex of the catenary upwardly towards the proximity sensor; when the slack length is sufficiently short, the catenary vertex is brought into the detection range of the proximity sensor, which then outputs an electrical signal that causes the drive motor to rotate a predetermined amount in a forward sense, paying out wire from the supply spool and increasing the length of the slack length catenary segment to a value which causes the catenary to droop below the detection range of the proximity sensor. After each wire interconnection made between a pair of bond sites of normal or greater length, or a small number of very short interconnections, the proximity sensor is interrogated by a computer logic means to determine that the despooler has been run to advance at least the minimum length of wire. If there has been no run, a bond fault alarm status signal is generated, halting further bonding operations.

Owner:WEST BOND

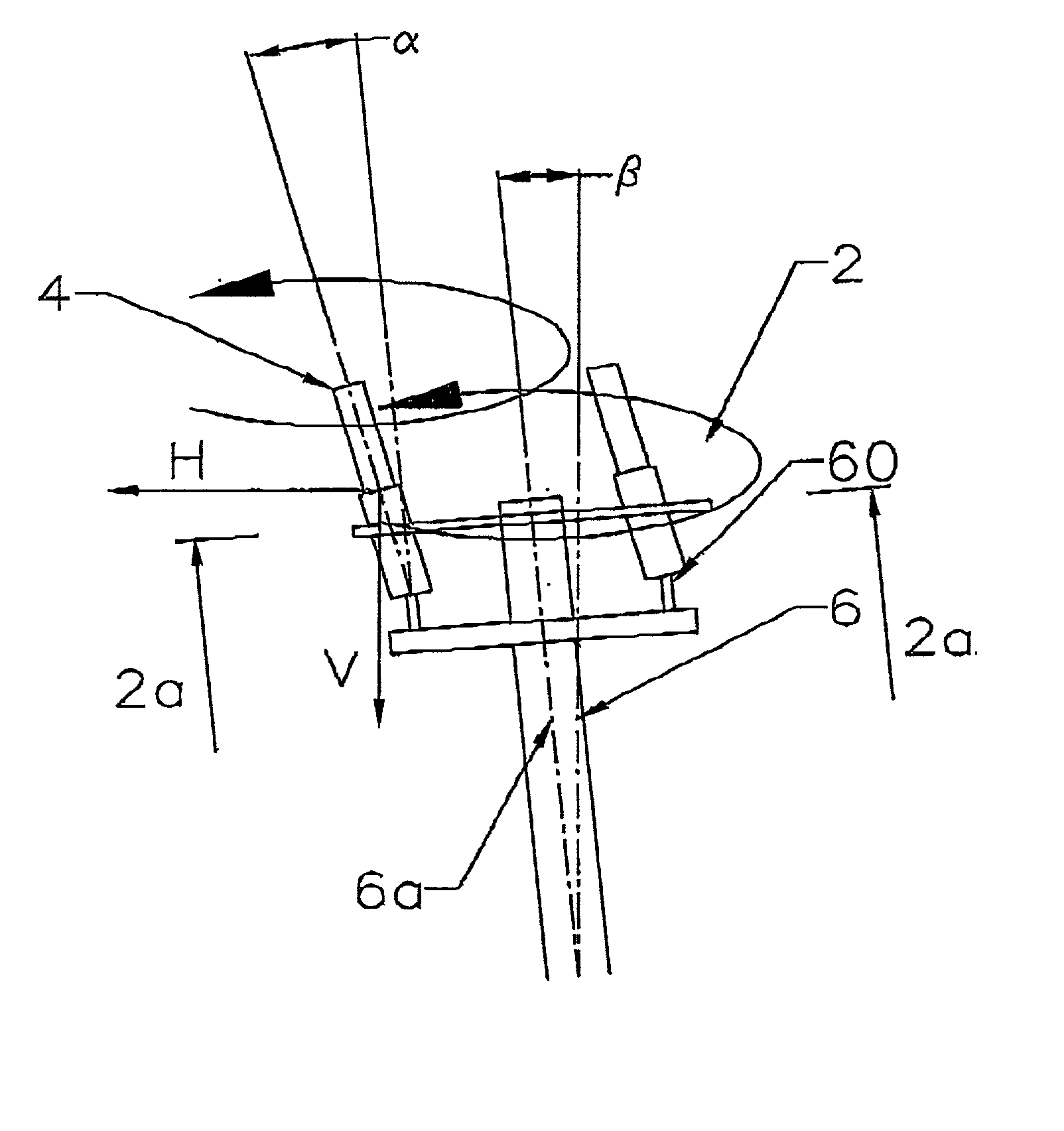

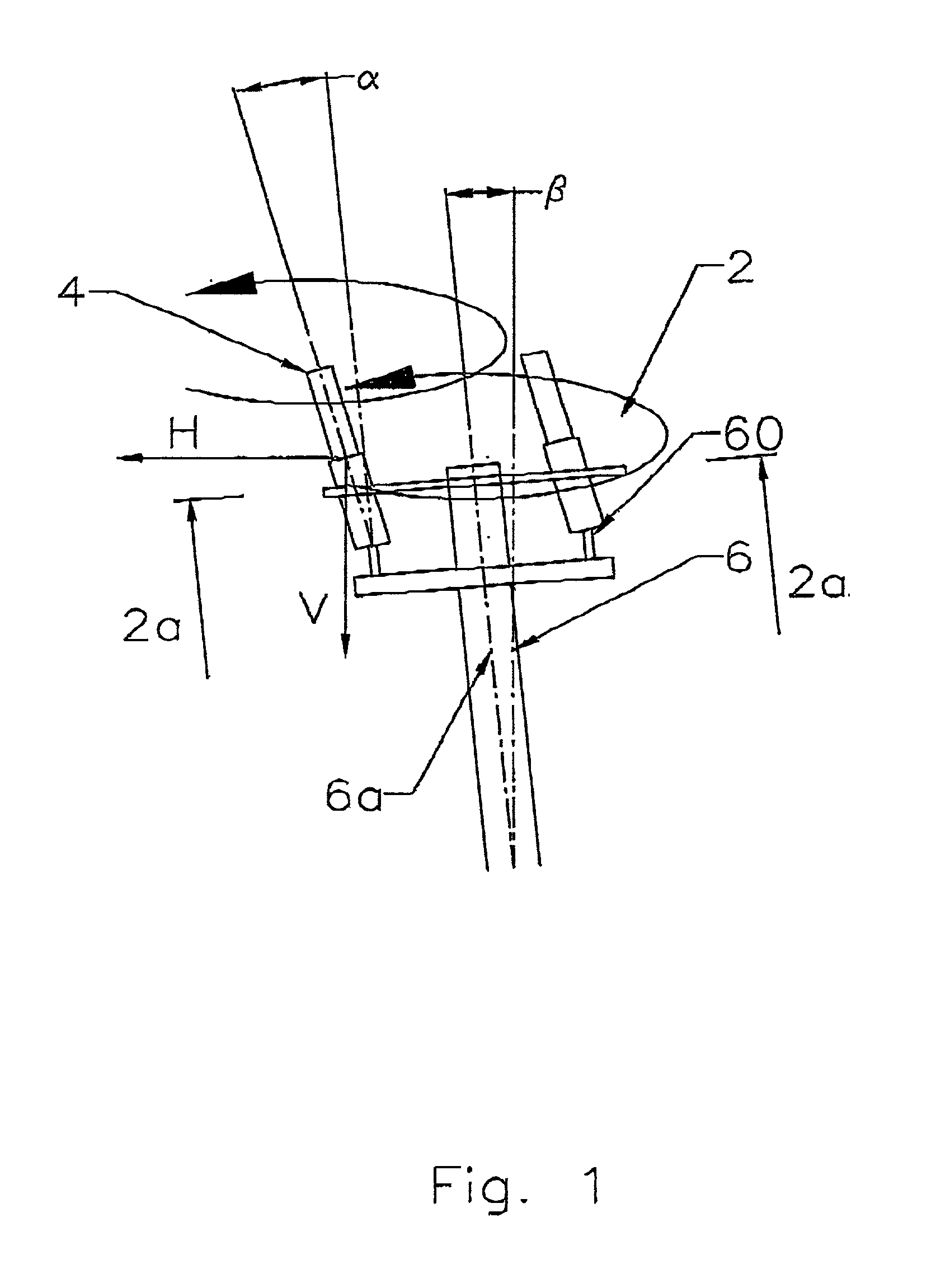

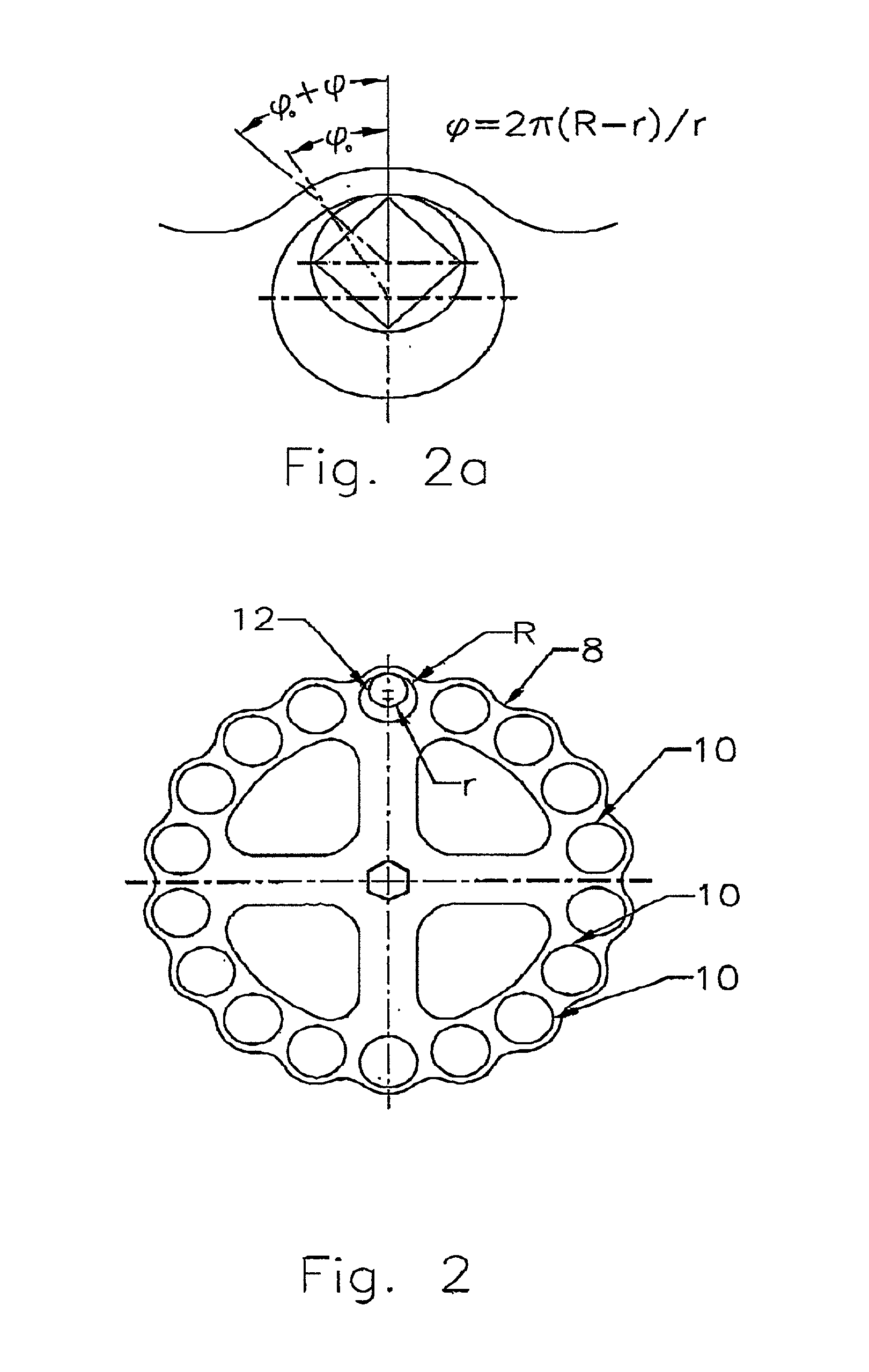

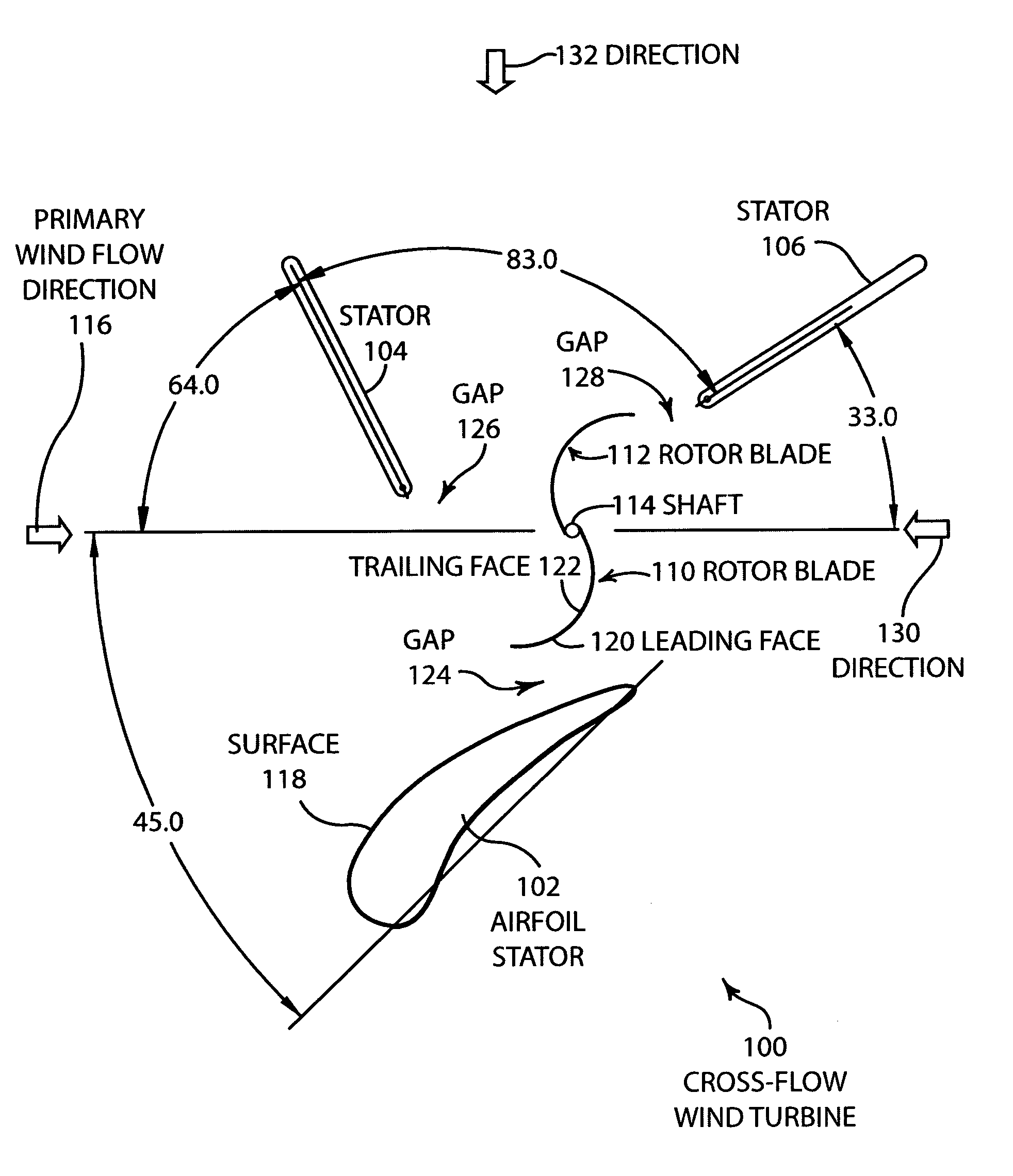

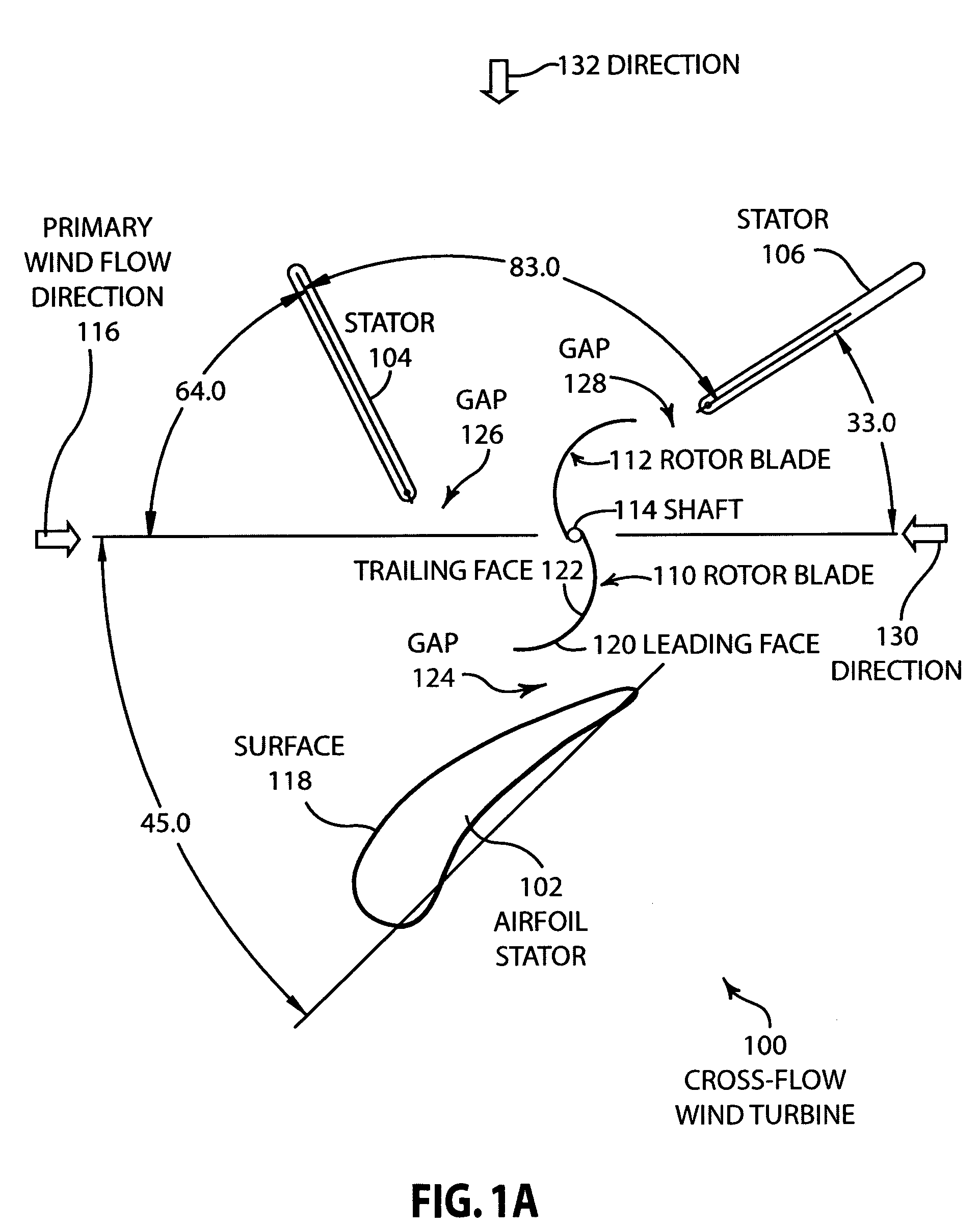

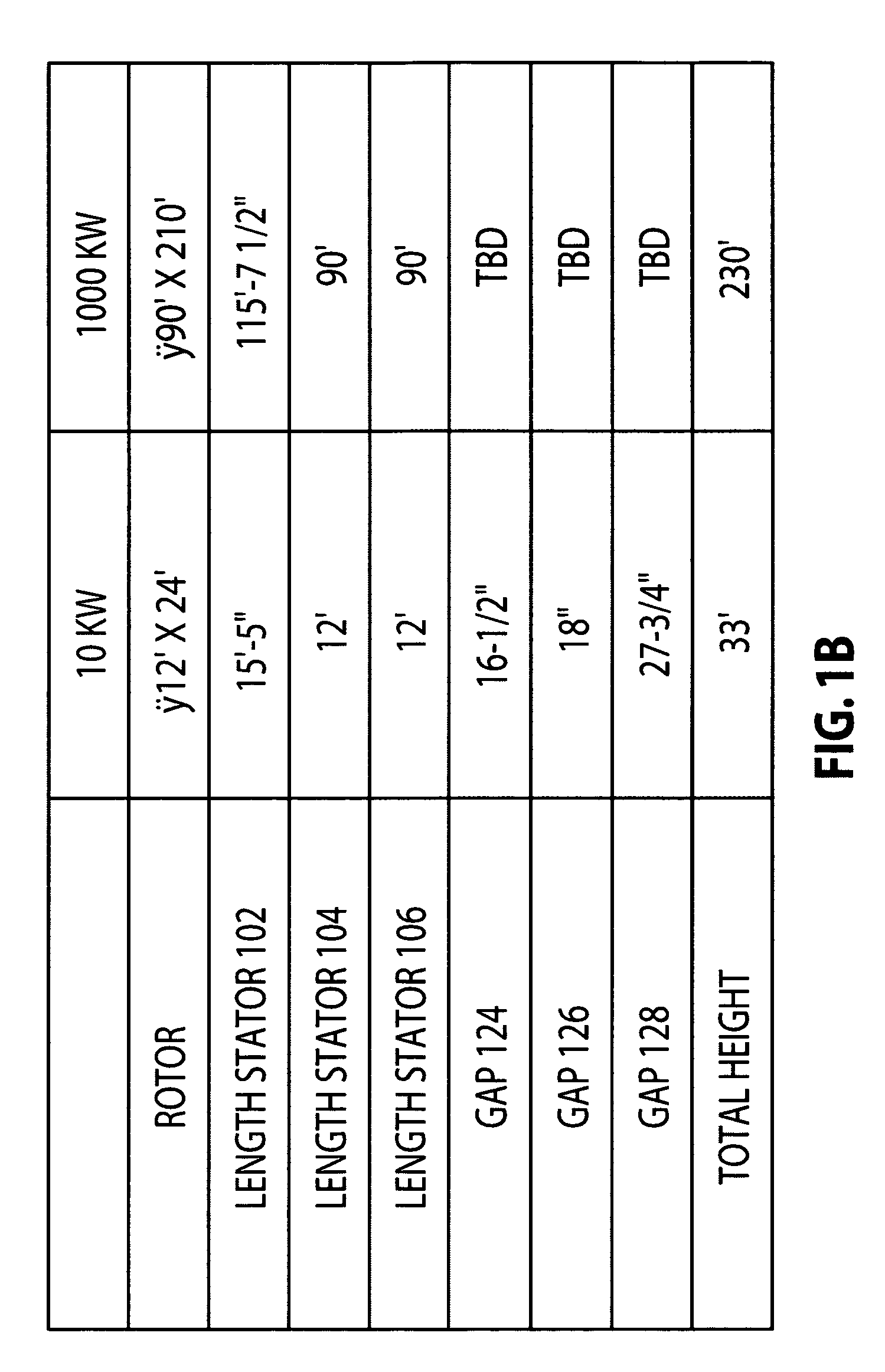

Cross-flow wind turbine

InactiveUS7189050B2Improve efficiencyEffective rotationCircumferential flow pumpsPump componentsPower cycleLow-pressure area

Disclosed are various embodiments of cross-wind turbines that are capable of providing high efficiencies over a wide range of wind velocities. An airfoil stator causes wind to accelerate along its surface and creates a low pressure area on the leading face of the rotor blade during the power stroke. A blocking stator blocks wind from impeding the movement of the rotor blades during the return cycle and directs wind onto the trailing face of the rotor blades during the power cycle. A large pressure differential is created between the leading face of the rotor blade and the trailing face of the rotor blade during the power cycle which creates a large amount of force that rotates the rotor blade about the central shaft. In some embodiments, gaps are provided between the inside edge of the rotor blade and a stationary shaft which vents wind collected by the rotor blade during certain portions of the rotation cycle. The vented wind increases the pressure on the trailing face of the rotor blades during the return cycle to further assist in the efficiency of this system.

Owner:TERRA MOYA AQUA

Specimen holder, observation system, and method of rotating specimen

ActiveUS20050092933A1Rotating a specimen efficientlyAvoid observationElectric discharge tubesPreparing sample for investigationObservation systemBiomedical engineering

Owner:JEOL LTD

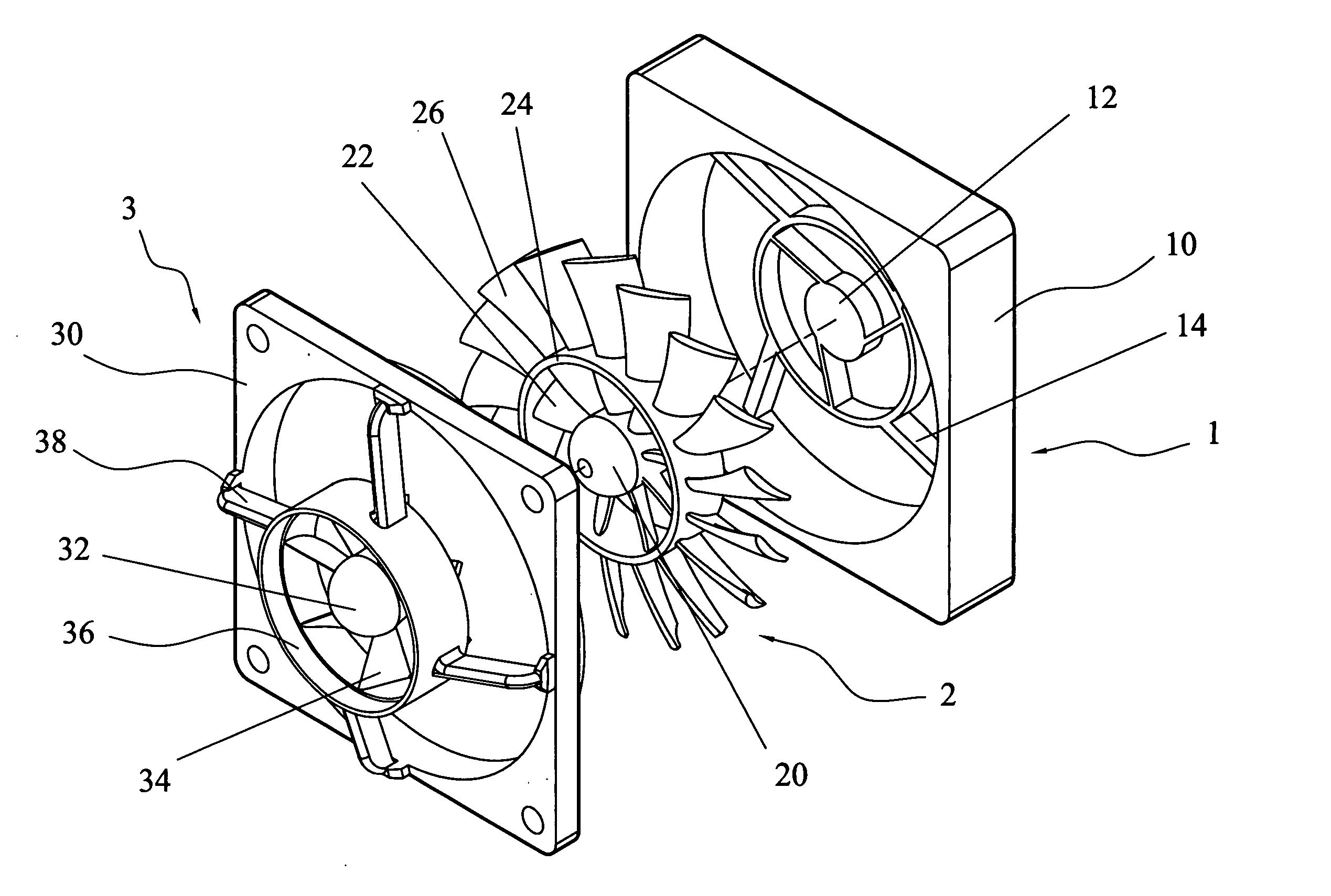

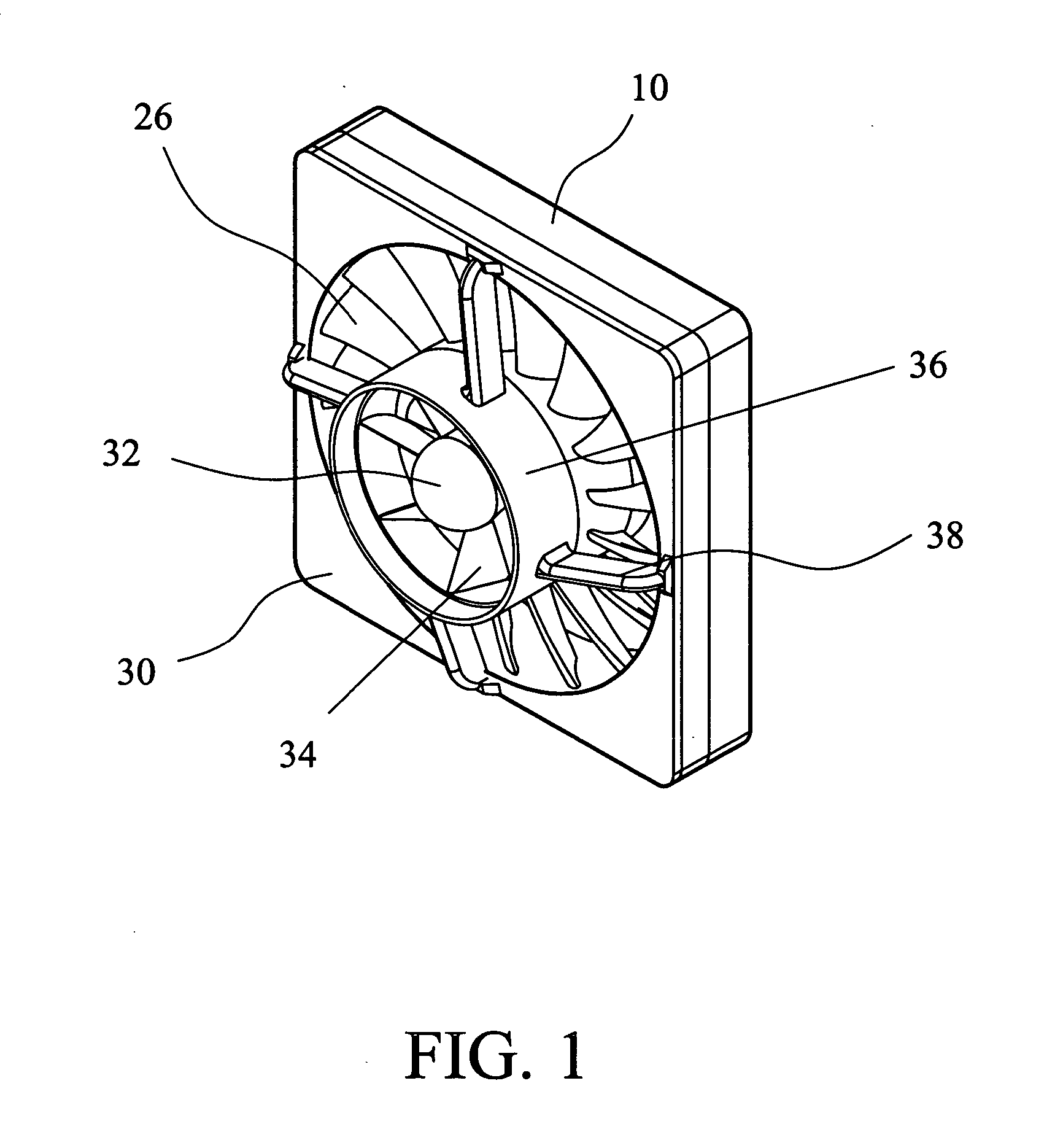

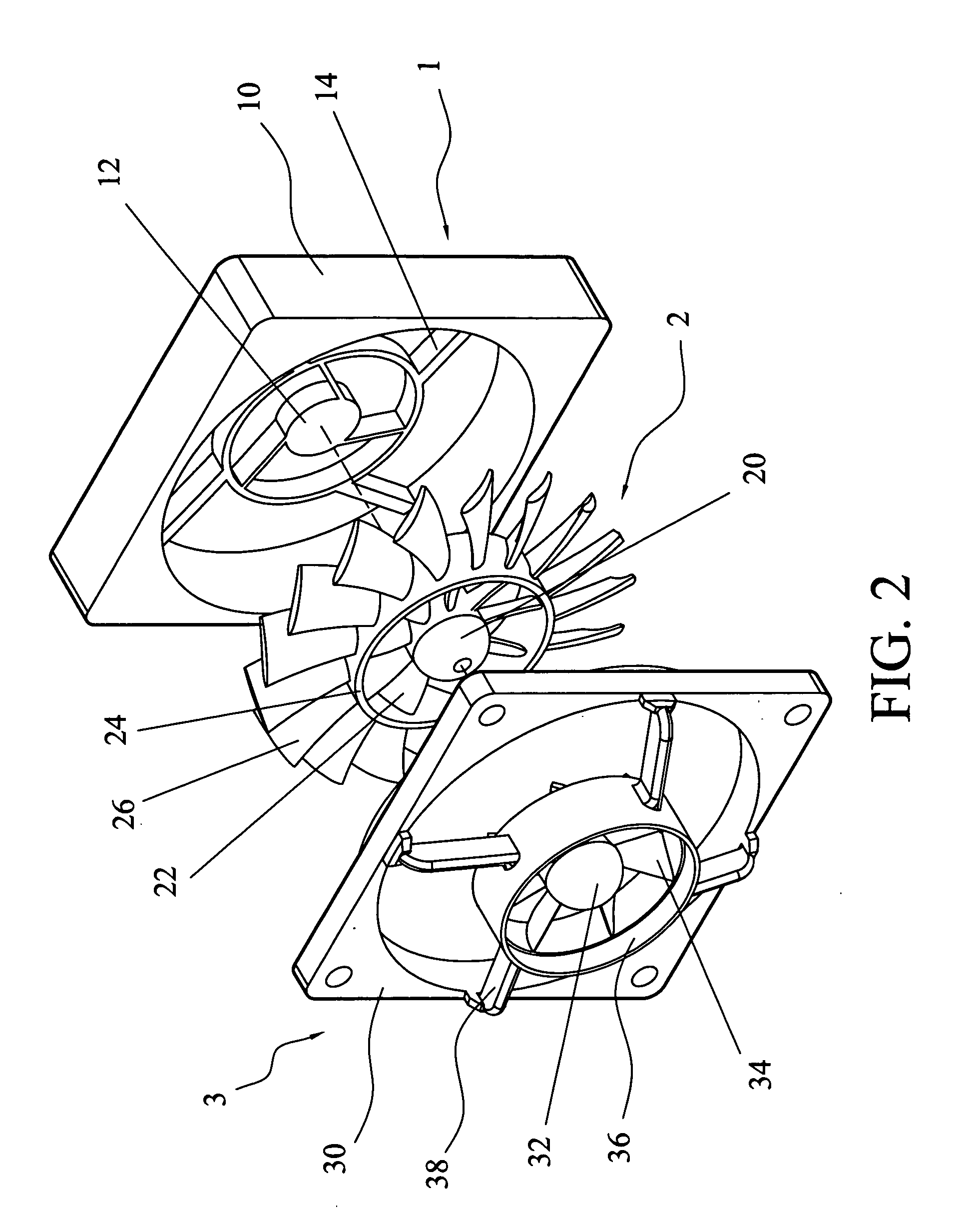

Passive fan assembly

InactiveUS20070031248A1Effectively using airflowImprove cooling efficiencyPump componentsStatorsImpellerAirflow

A passive fan assembly includes an impeller and a plurality of guide blades disposed in front of the impeller. The impeller includes a plurality of blades extending at about 90 degrees relative to the guide blades. Thus, when airflow enters the passive fan assembly, the guide blades guide the airflow to effectively impact on blades of the impeller.

Owner:DELTA ELECTRONICS INC

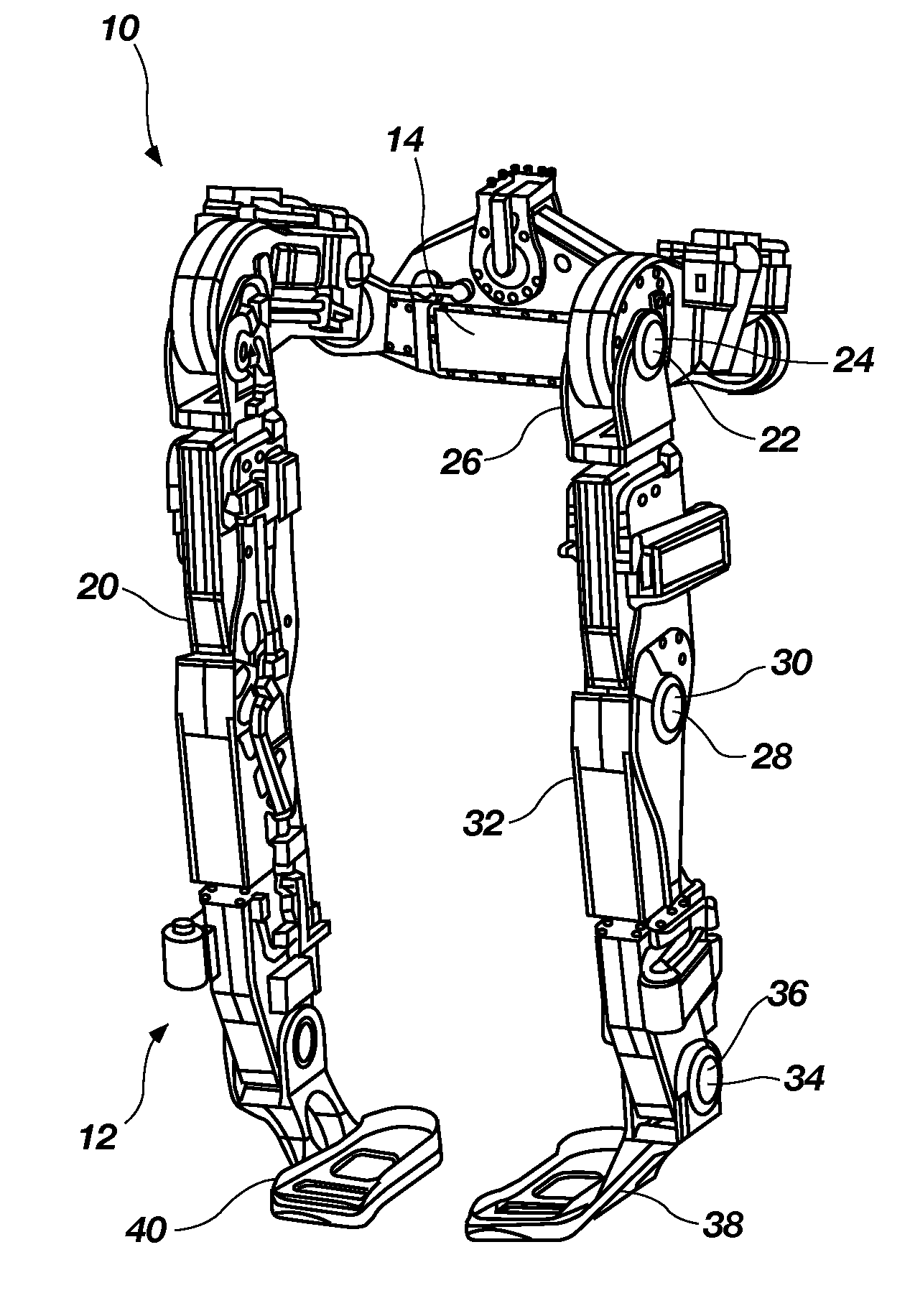

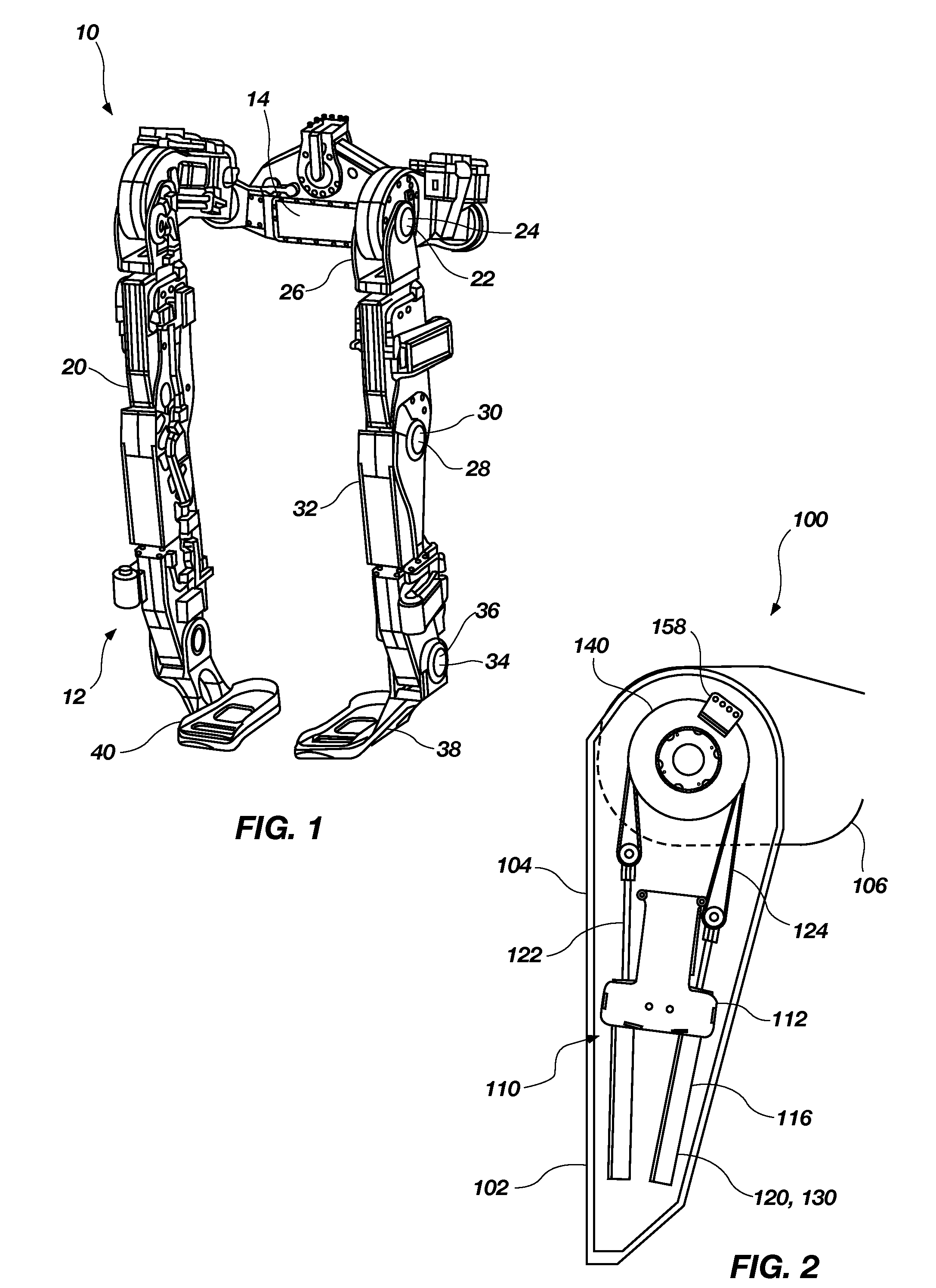

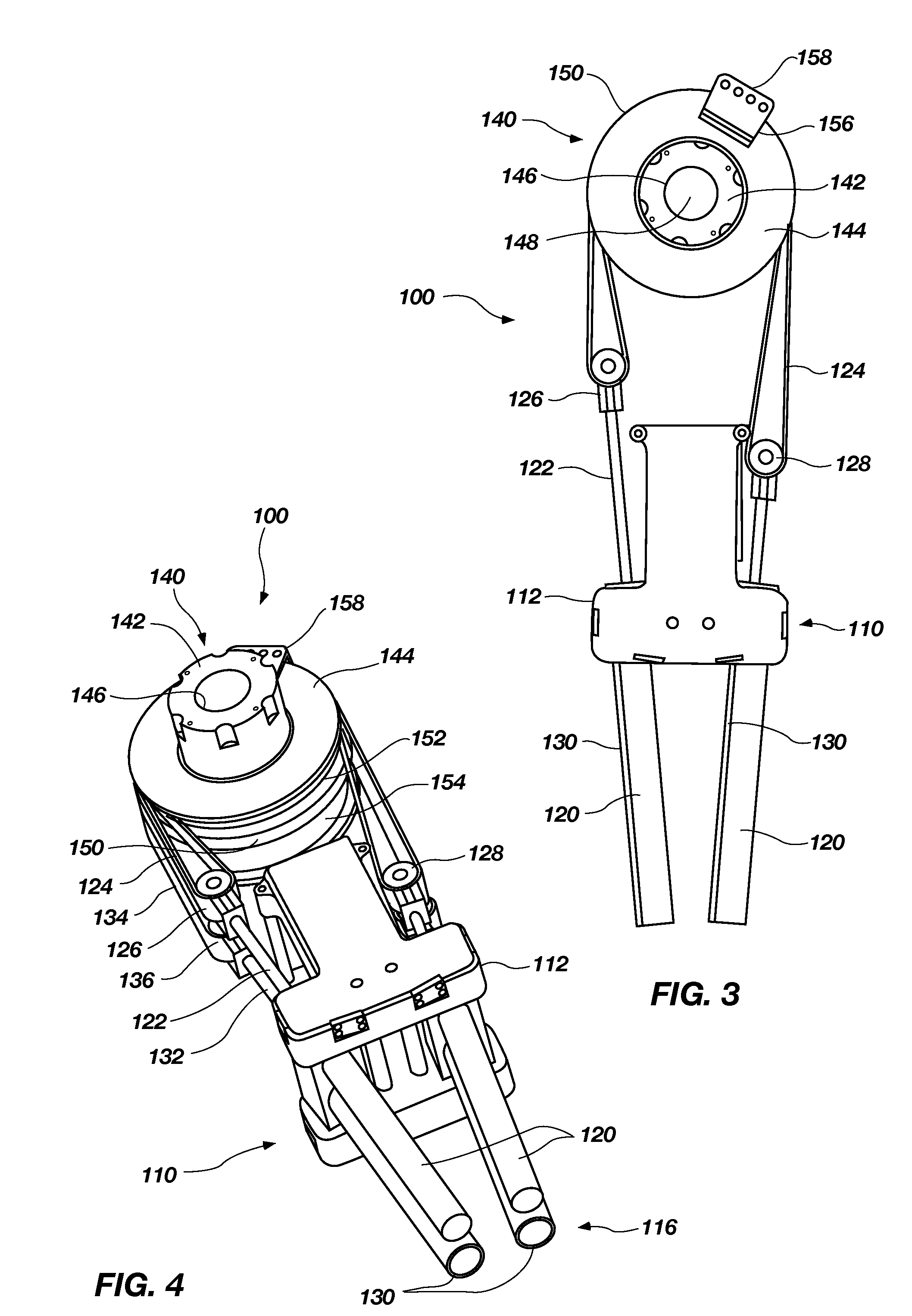

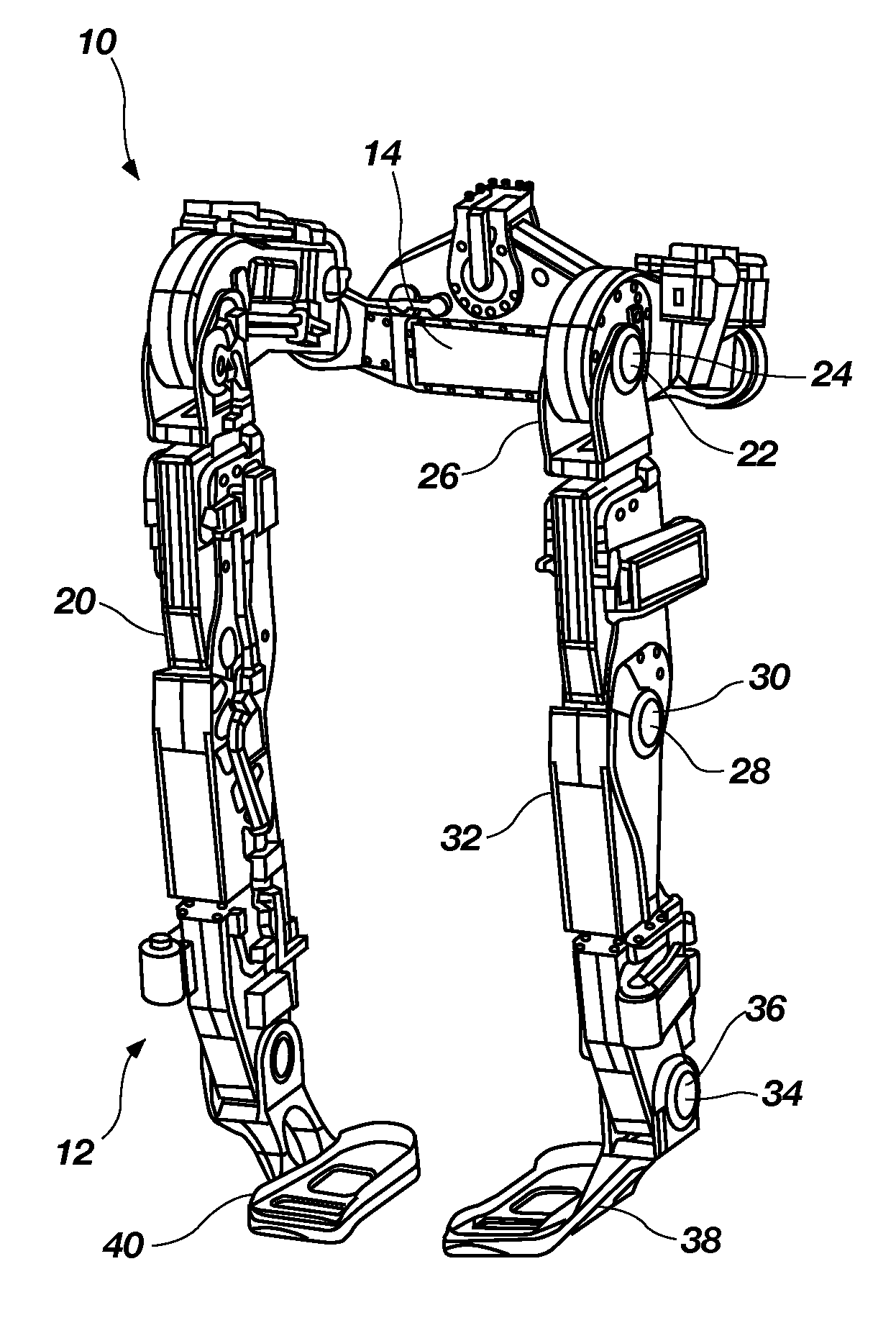

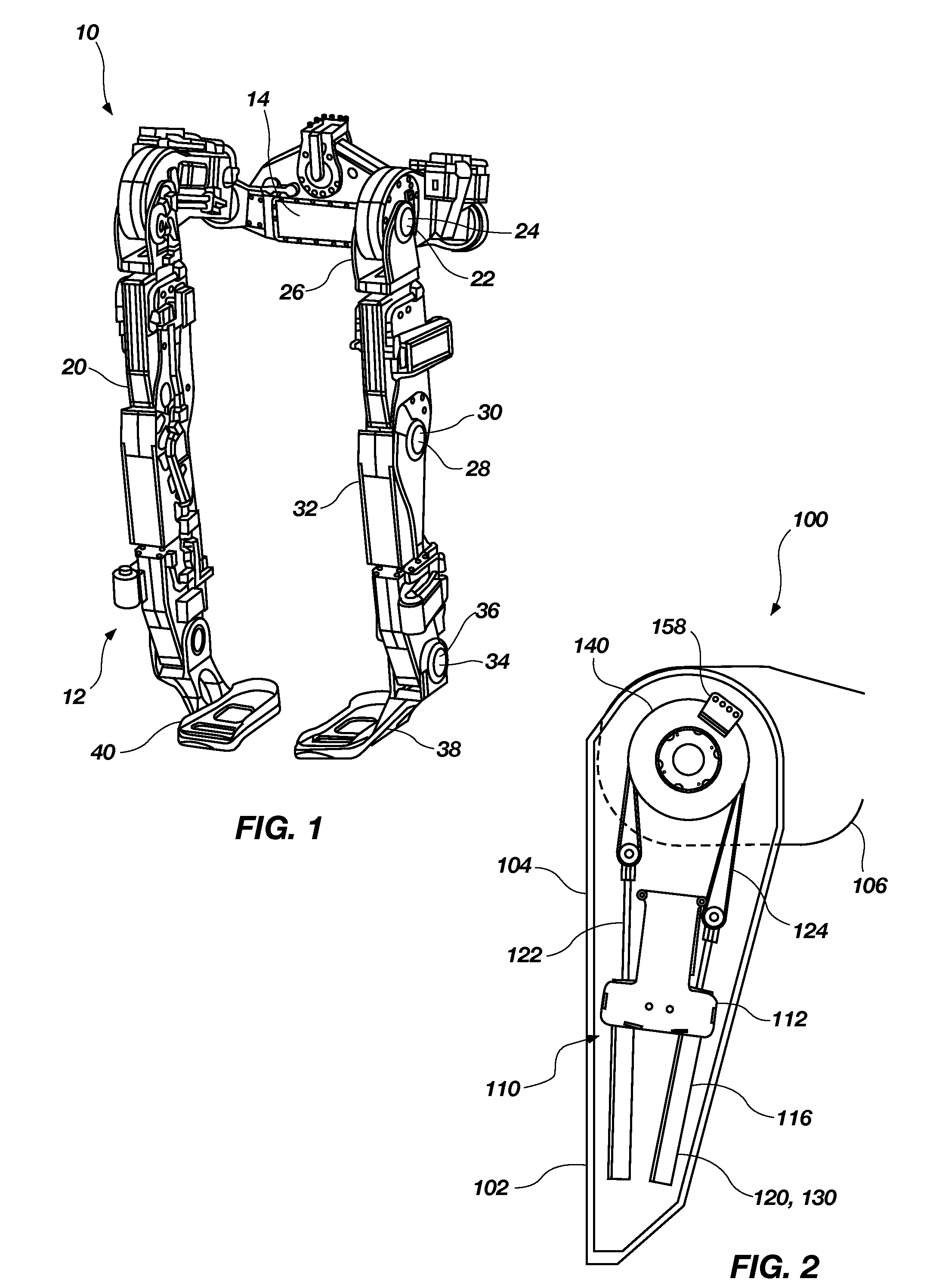

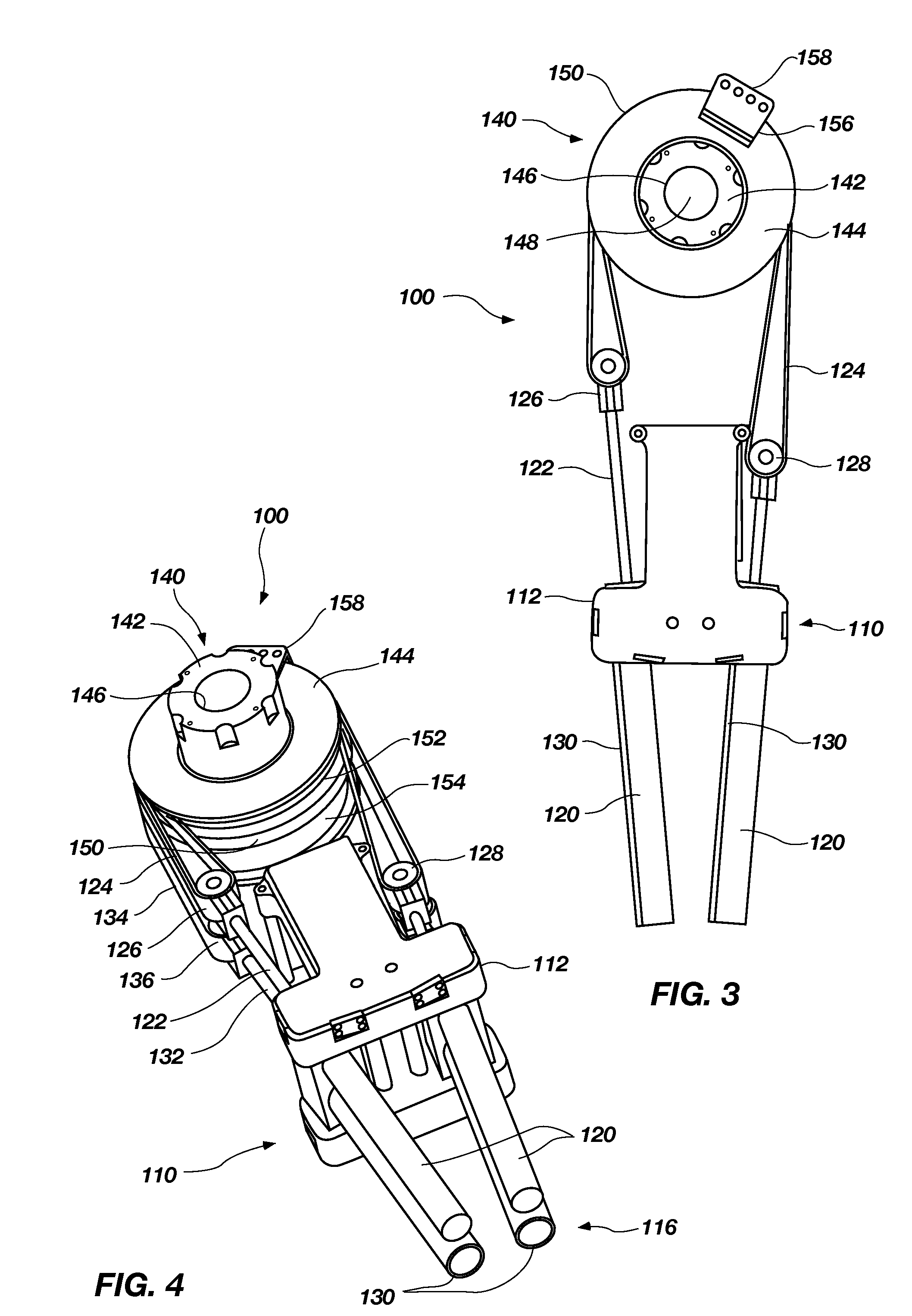

Control logic for biomimetic joint actuators

InactiveUS8731716B2Effective rotationShorten speedProgramme-controlled manipulatorComputer controlGeneral purposeHigh acceleration

A method of operating a biomimetic mechanical joint having a plurality of fractional actuators configured for rotating a support member about a pivot device. The fractional actuators can be selectively recruited during operation, either individually or together, to efficiently rotate the support member about the mechanical joint throughout a range of movements and under a variety of load conditions. Each fractional actuator can be continuously throttled to reduce the speed or torque at which the actuator operates. The capability of selectively recruiting and throttling each fractional actuator results in an actuator system having two degrees of freedom, in which a single operating state of the mechanical joint may be reached with one or more of actuator arrangements and throttling settings. The method of the present invention allows for selection from the available actuator arrangements and throttle settings according to predetermined operating modes such as high-efficiency, high-acceleration or general-purpose, etc.

Owner:SARCOS LC

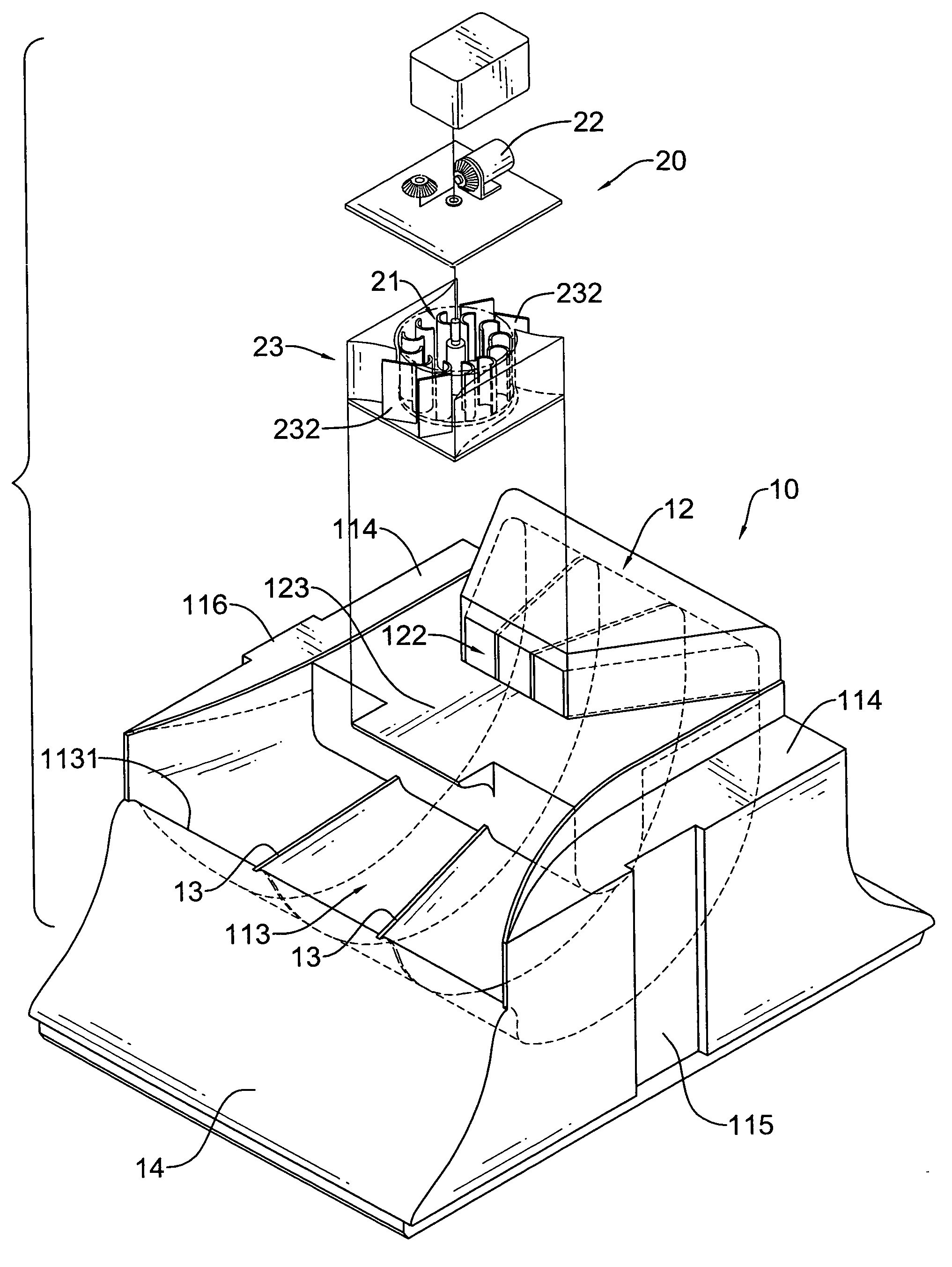

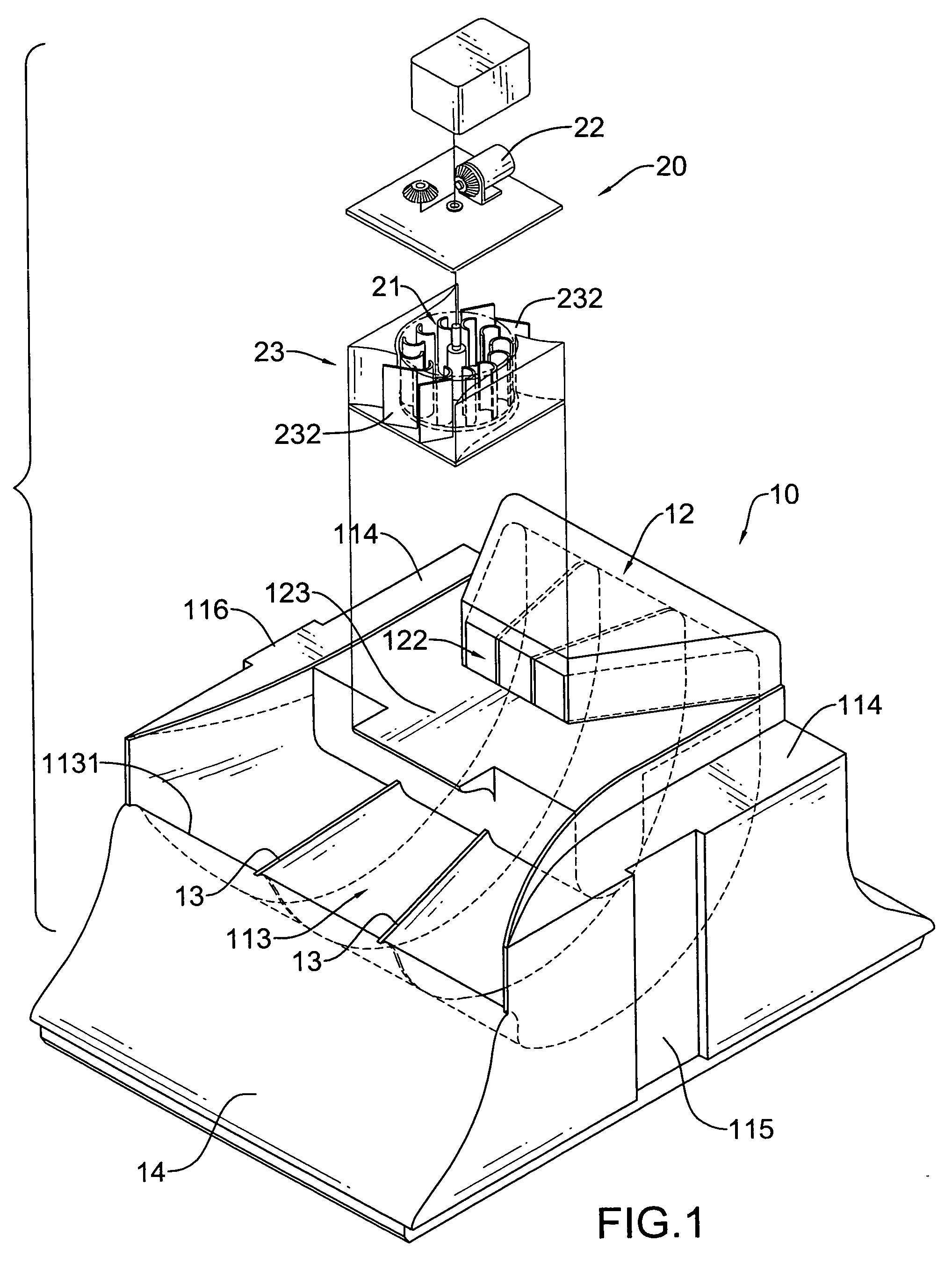

Wave-dissipating block

A wave-dissipating block has a body and a turbine generator assembly. The body has an airway and an overhang. The airway is formed in the body, is substantially J-shape and has an opening communicating with a front of the body and substantially facing upward. The overhang hangs over the airway and has an air window formed in the overhang and communicating with the airway. The turbine generator assembly has a housing mounted on the overhang and has an air channel communicating with the air window, a turbine fan mounted in the air channel and a generator connected to the turbinate fan. Waves can directly pour into the airway with minimized loss of kinetic energy and forms a water column in the airway to effectively suck or push air to passing through the air channel to rotate the turbinate fan to drive the generator to efficiently generate electric power.

Owner:LIOU BAI CHIENG +3

Detachable fastener including a screw element and a securing ring

A detachable fastener includes a screw element and a securing ring. The screw element and the securing ring each include cooperating wedge-shaped surface tooth arrangements and two different pairs of stop surfaces. The wedge-shaped surface tooth arrangements face one another and form sliding surfaces sliding upon one another in a loosening direction of rotation resulting in an increase of the axial force. The first pair of stop surfaces transmits torque in a tightening direction of rotation. The second pair of stop surfaces transmits torque in a loosening direction of rotation. The stop surfaces are arranged with a clearance existing between one another such that the wedge-shaped surface tooth arrangements can slide upon one another without skipping.

Owner:KAMAX HLDG

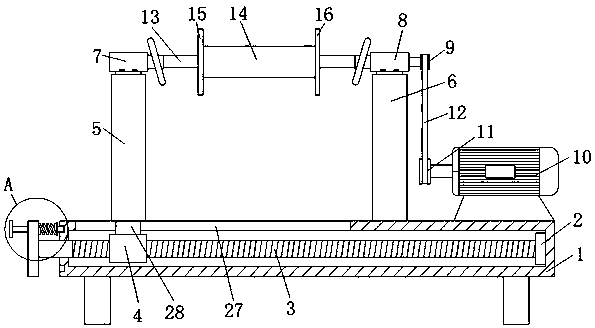

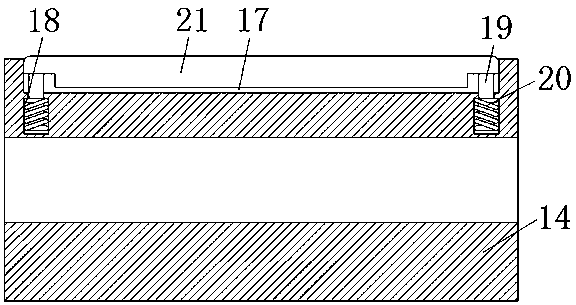

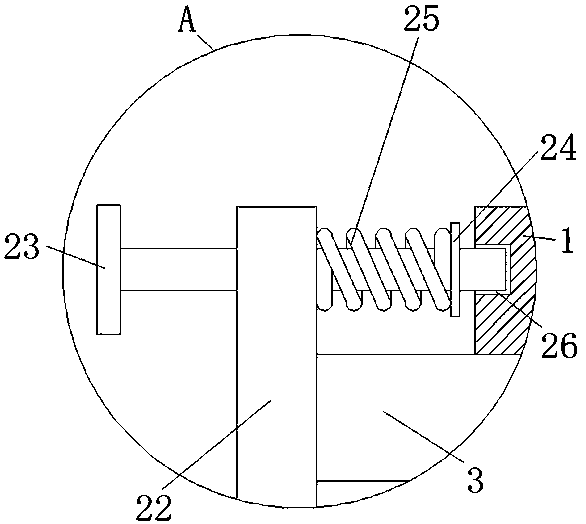

Winding device for textile

The invention discloses a winding device for textile. The winding device comprises a base. A rotating base is fixedly connected with one side in the base and rotationally connected with a lead screw.The lead screw transversely penetrates through the base and extends out of the base. The outer surface wall of the lead screw is in threaded connection with a sliding base. The top end of the outer surface wall of the sliding base is fixedly connected with a connecting block. The position, corresponding to the connecting block, of the base is provided with a sliding groove sliding relative to theconnecting block. The upper surface, corresponding to the base, of the top end of the connecting block is fixedly connected with a supporting column. A first safety chuck is fixedly connected with thetop end of the supporting column. A fixed column is fixedly connected with the side, corresponding to the supporting column, of the upper surface of the base. A second safety chuck is fixedly connected with the top end of the fixed column. The winding device can be adjusted for use according to winding rollers with different sizes, efficiency is improved, the use range is expanded, it is avoidedthat spinning yarn or cloth is manually wound on winding rollers to be wound, the structure is simple, operations are convenient, and the work intensity of personnel is reduced.

Owner:安徽双盈纺织有限公司

Control Logic for Biomimetic Joint Actuators

InactiveUS20110295164A1Effective rotationShorten speedProgramme-controlled manipulatorChiropractic devicesGeneral purposeHigh acceleration

A method of operating a biomimetic mechanical joint having a plurality of fractional actuators configured for rotating a support member about a pivot device. The fractional actuators can be selectively recruited during operation, either individually or together, to efficiently rotate the support member about the mechanical joint throughout a range of movements and under a variety of load conditions. Each fractional actuator can be continuously throttled to reduce the speed or torque at which the actuator operates. The capability of selectively recruiting and throttling each fractional actuator results in an actuator system having two degrees of freedom, in which a single operating state of the mechanical joint may be reached with one or more of actuator arrangements and throttling settings. The method of the present invention allows for selection from the available actuator arrangements and throttle settings according to predetermined operating modes such as high-efficiency, high-acceleration or general-purpose, etc.

Owner:SARCOS LC

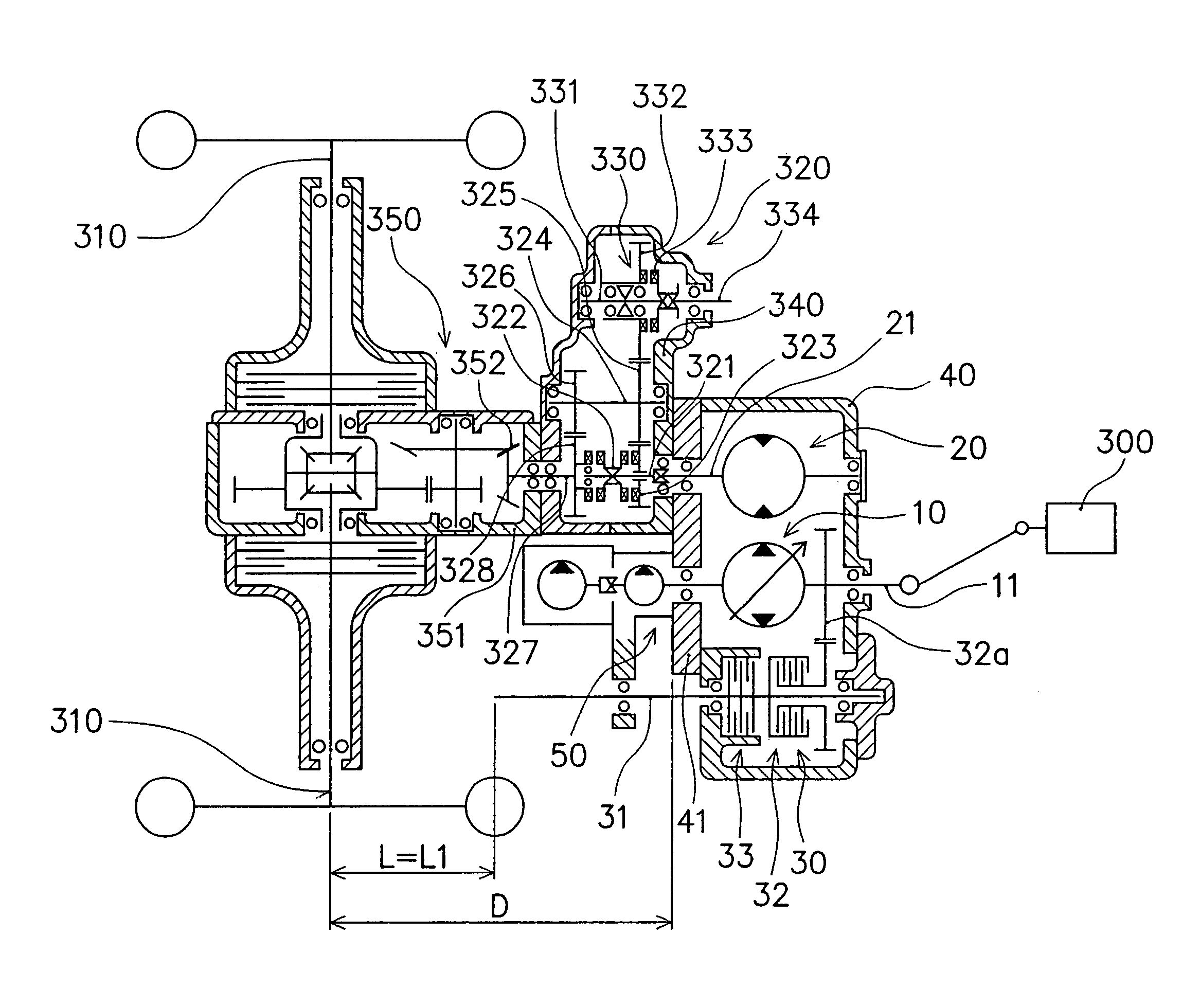

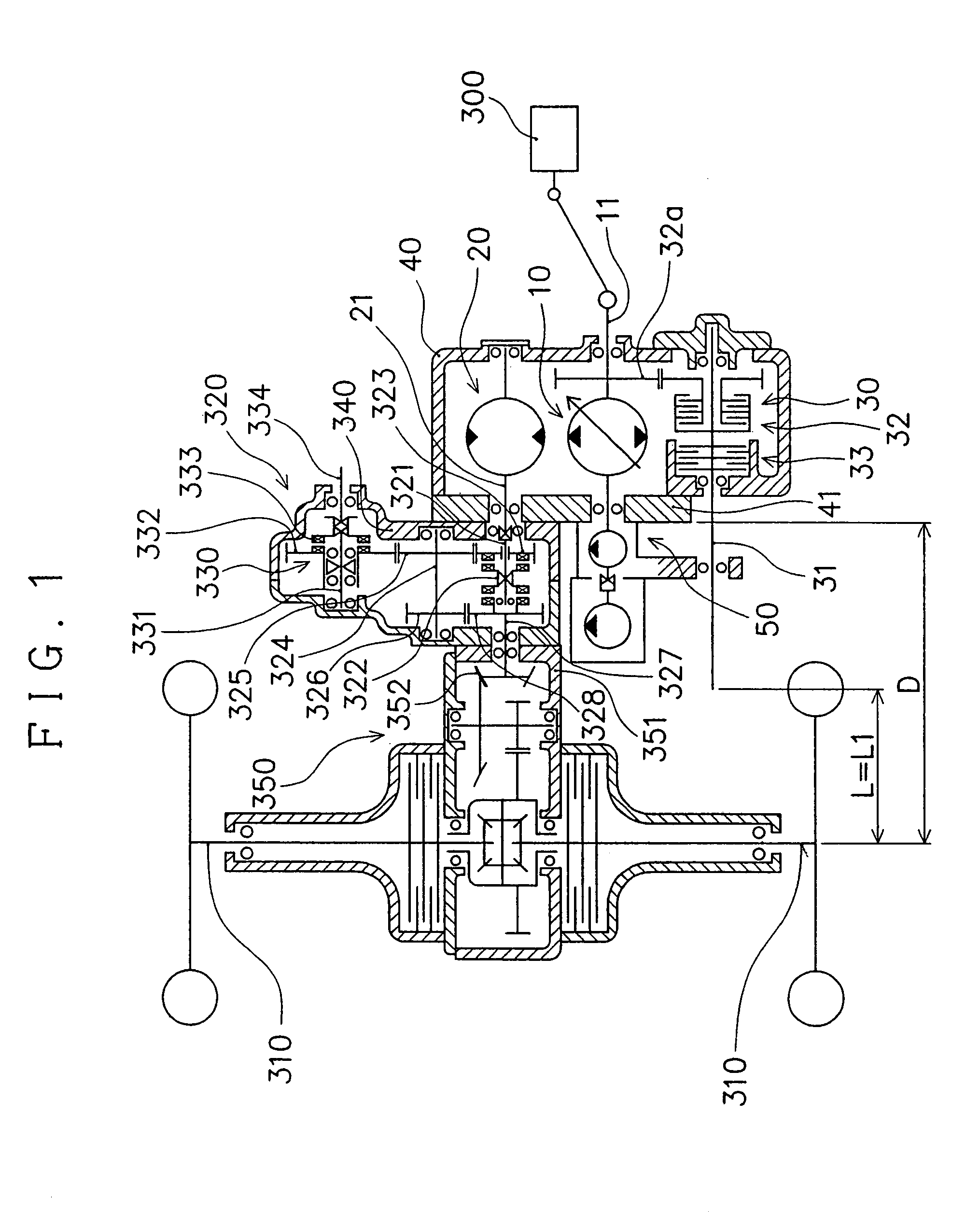

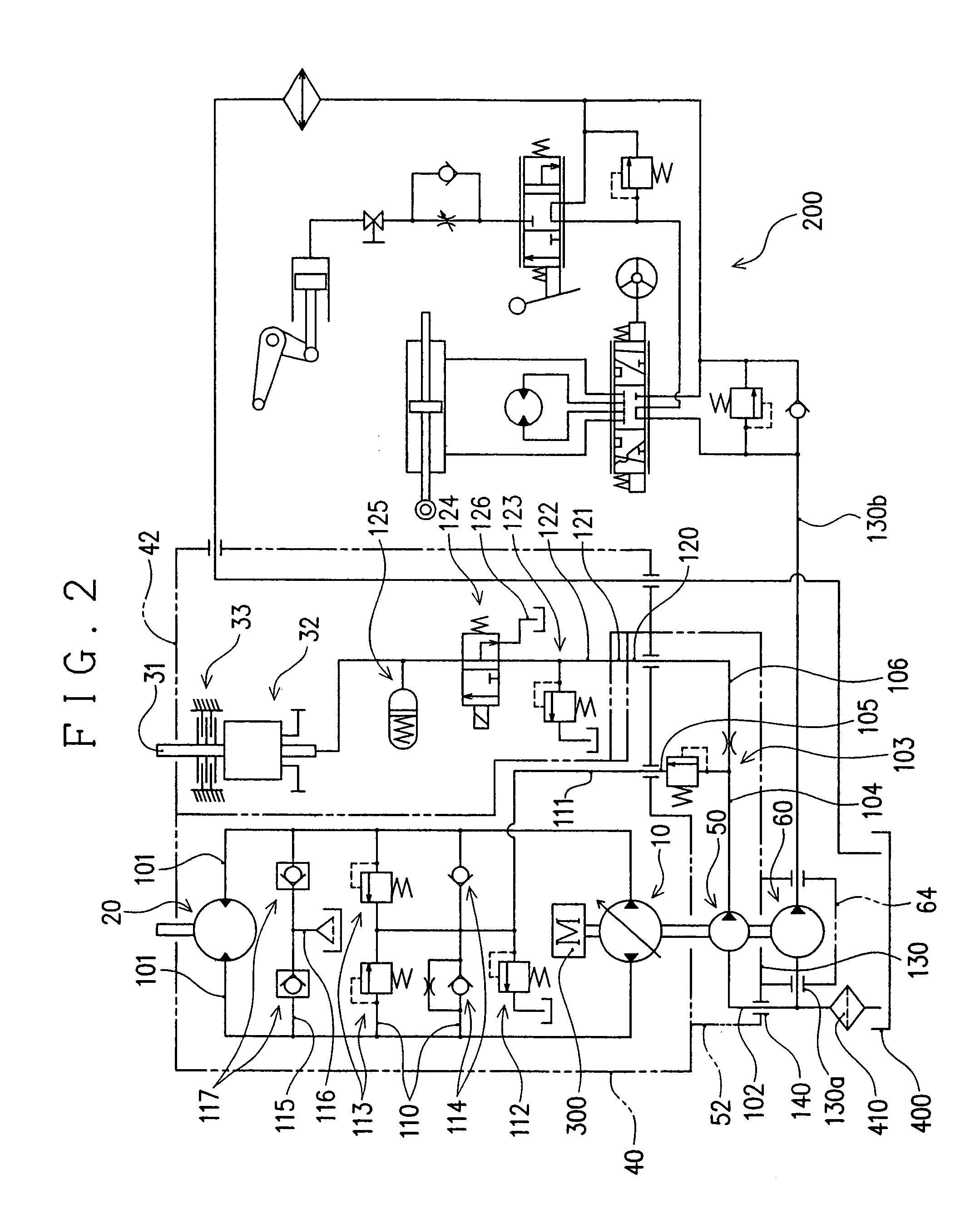

Hydrostatic transmission and power train for vehicle

InactiveUS7150693B2Easy to modifyEffectively prevented from interferingFluid couplingsGearing controlHydraulic circuitHydraulic pump

A hydrostatic transmission for vehicle interposed in a drive-power transmission path between a driving power source and a driving axle for non-stepwisely changing the speed of the vehicle includes an HST housing; a hydraulic pump unit having a pump shaft with first and second ends extending in a fore-aft direction of the vehicle away from each other; a hydraulic motor unit having a motor shaft for outputting the drive power from the motor shaft whose speed is non-stepwisely varied in cooperation with the hydraulic pump unit; a PTO unit having a PTO shaft extending in the fore-aft direction of the vehicle, the PTO shaft being operatively connected to the pump shaft; a charge pump unit for replenishing pressurized hydraulic fluid to a hydraulic circuit, the hydraulic circuit hydraulically connecting the hydraulic pump unit with the hydraulic motor unit, the charge pump unit including a charge pump body, and a charge pump case connected to the HST housing through its wall closer to the driving axle for supporting the charge pump body; the PTO shaft having an one end closer to the driving axle, the one end extending outwardly through the HST housing to have an outer extension positioned outside of the HST housing; and the charge pump case being designed so as to bearing-support the outer extension of the PTO shaft.

Owner:ISHIMARU YOSHITAKA +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com