Winding device for textile

A technology of winding device and winding drum, which is applied in the direction of winding strips, transportation and packaging, and conveying filamentous materials, etc., which can solve the problems of inability to adjust the use of winding rollers, increase the working intensity of personnel, and reduce the scope of use. , to achieve simple structure, reduce work intensity and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

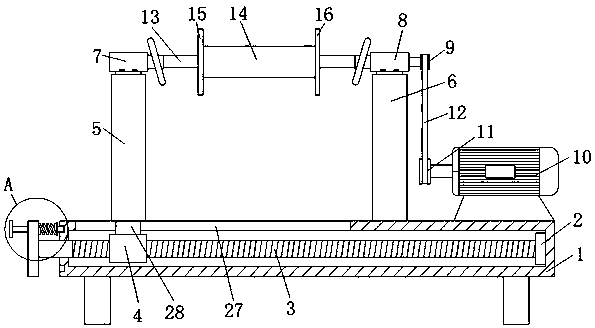

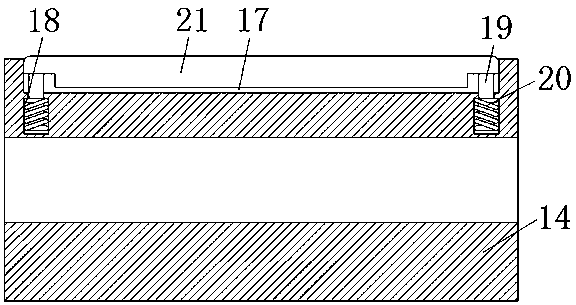

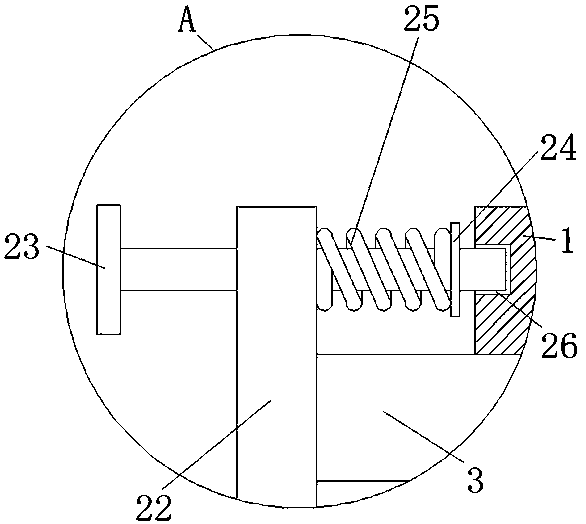

[0028] see Figure 1-4 , this embodiment provides a textile winding device, including a base 1, a rotating base 2 is fixedly connected to the inner side of the base 1, a screw rod 3 is connected to the rotating base 2 in rotation, and the screw rod 3 runs through the base in a transverse direction 1 and extends to the outside of the base 1, the outer wall of the screw rod 3 is threadedly connected with a sliding seat 4, the top of the outer wall of the sliding seat 4 is fixedly connected with a connecting block 28, and the position corresponding to the connecting block 28 on the base 1 is provided with a connection The sliding groove 27 where the blocks 28 slide mutually, the top of the connecting block 28 corresponds to the upper surface of the base 1 and is fixedly connected to the support column 5, the top of the support column 5 is fixedly connected to the first safety chuck 7, and the upper surface of the base 1 corresponds to the support column 5 One side of one side is ...

Embodiment 2

[0031] see Figure 1-4 , a further improvement has been made on the basis of Embodiment 1: a number of draw-in slots 26 are distributed in a ring shape, and the distance between two adjacent draw-in slots 26 is equal, and by setting a number of draw-in slots 26, it is convenient for the rotating disk 22 to fixed, improved stability, the diameter of the air expansion shaft 13 is 30mm smaller than the inner diameter of the reel 14, which is convenient for the operation and use of the reel 14, and the upper surface of the base 1 corresponds to the front and rear sides of the sliding groove 27. Position chute 29, the position corresponding to the position of the limit chute 29 at the bottom of the support column 5 is all fixedly connected with the slide block 30 that slides mutually with the limit chute 29, by the cooperation of the limit chute 29 and the slide block 30, can Effectively improve the sliding stability of the support column 5, avoiding the situation of tilting or jam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com