Patents

Literature

511 results about "Rotation cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rotate Cycle Motor defines rotating motion between 2 user defined angles. The motor is useful for any sort of animation that requires repeating motion of the angular nature. It can also be used as a base entity to drive Bend Physics Motors.

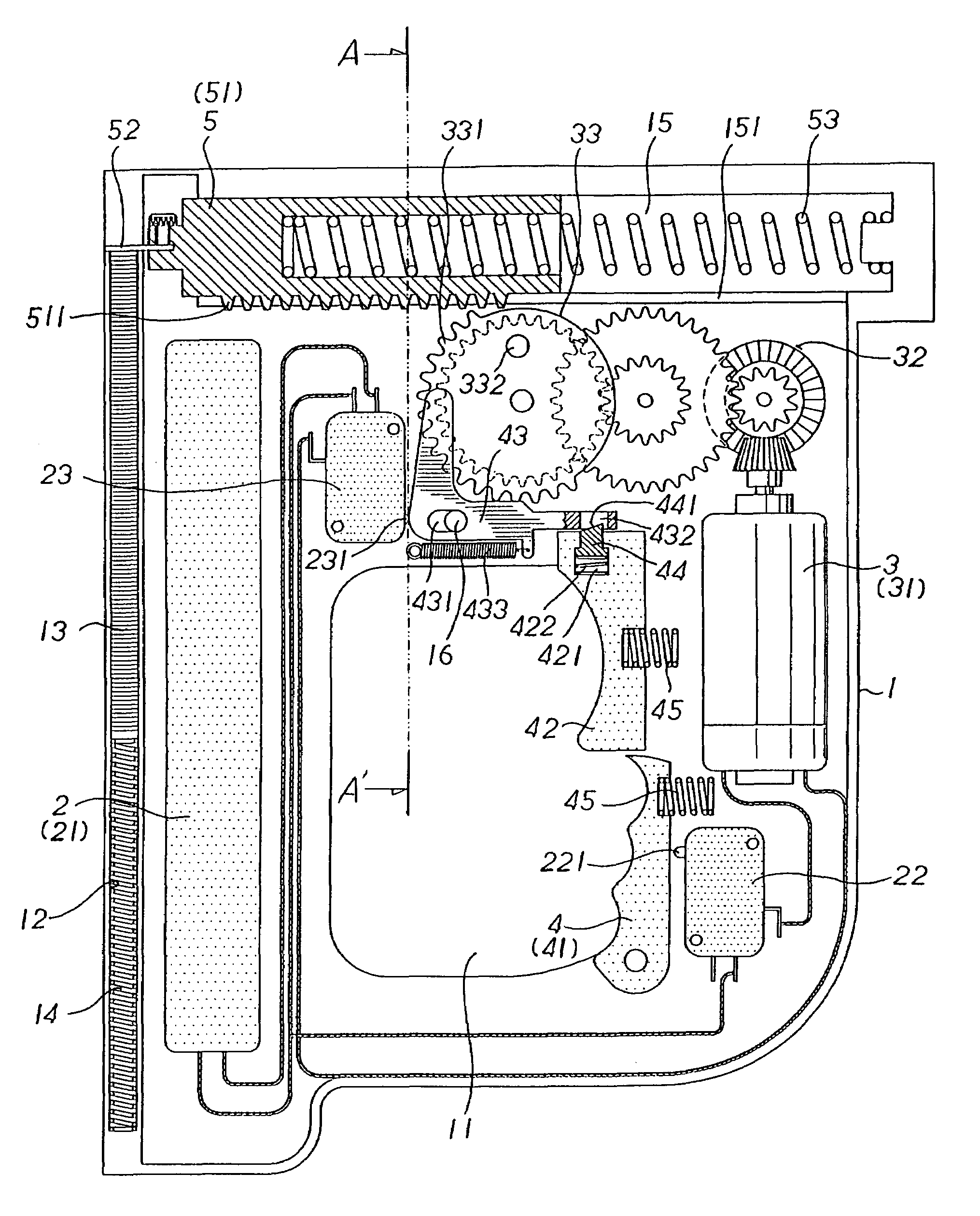

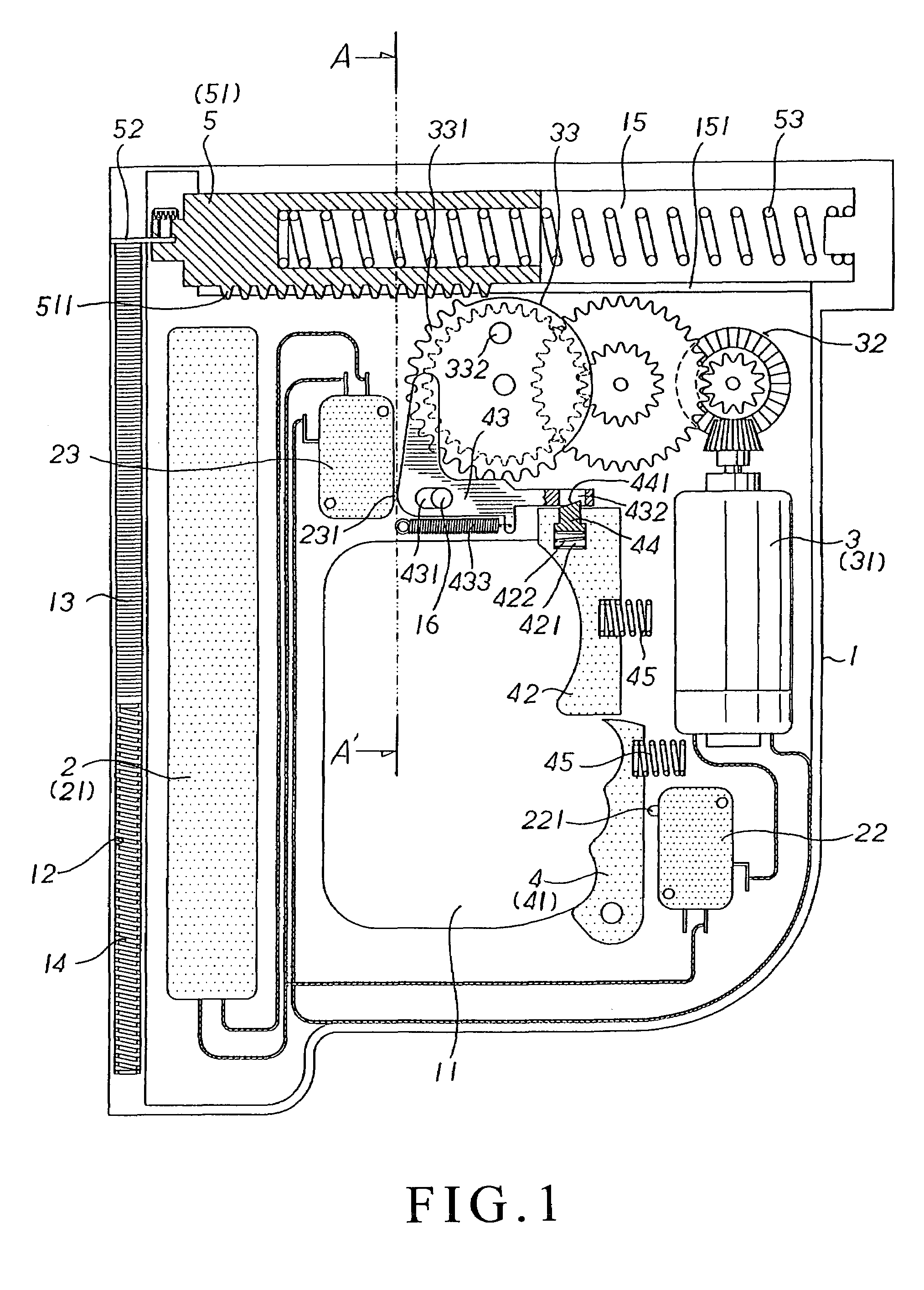

Hand-held nailing tool

A handy electric nailing gun includes a firing pin, a firing spring for pushing the firing pin to drive nails into workpiece, an output gear rotatable by a motor through a transmission gear set to retract the firing pin during the first half run of each rotation cycle and to release the firing pin during the second half run of each rotation cycle, and three power switches electrically connected in series between the motor and the power source (AC adapter / rechargeable battery) for operation by the user to control the operation of the motor.

Owner:YIH KAI ENTERPRISE

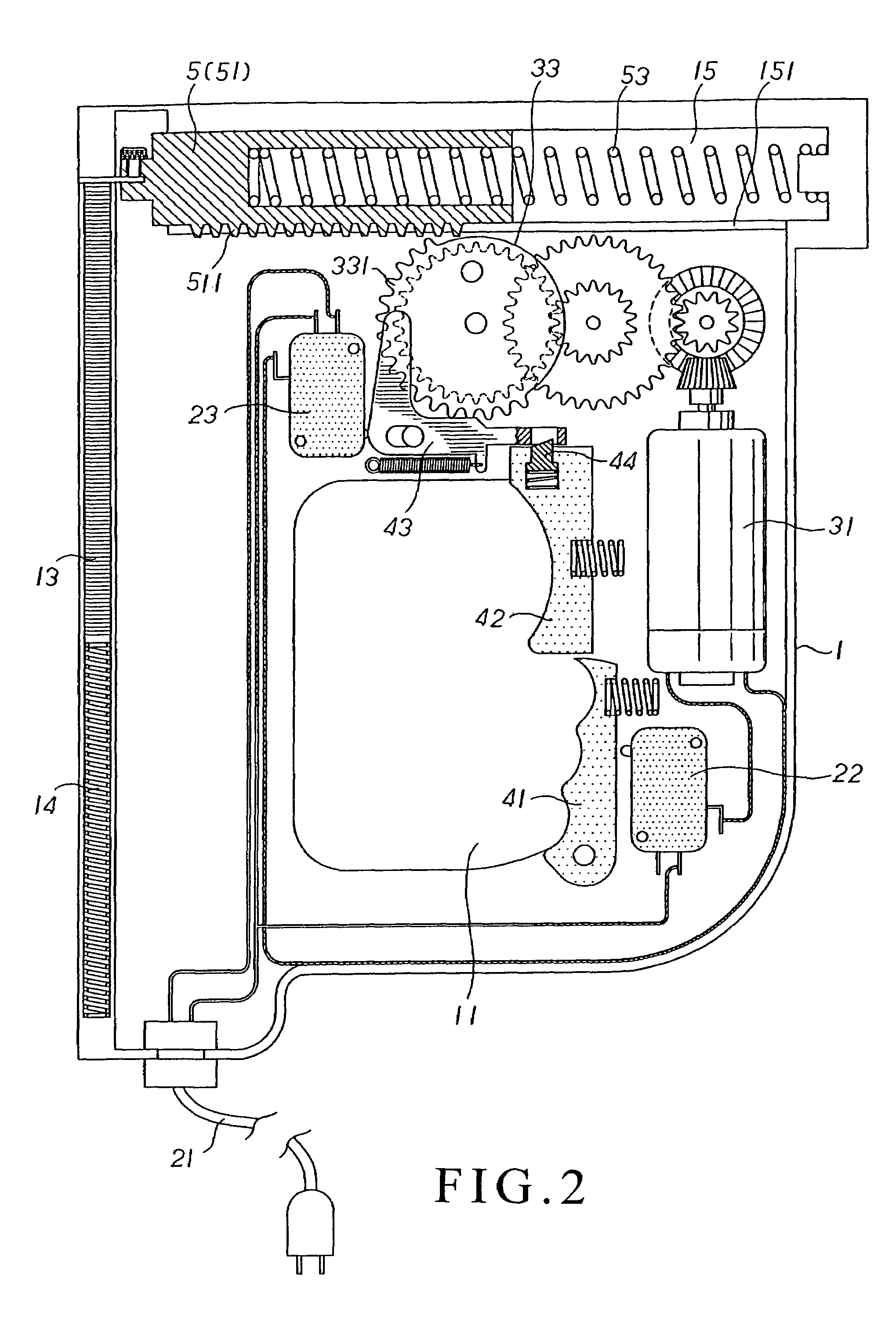

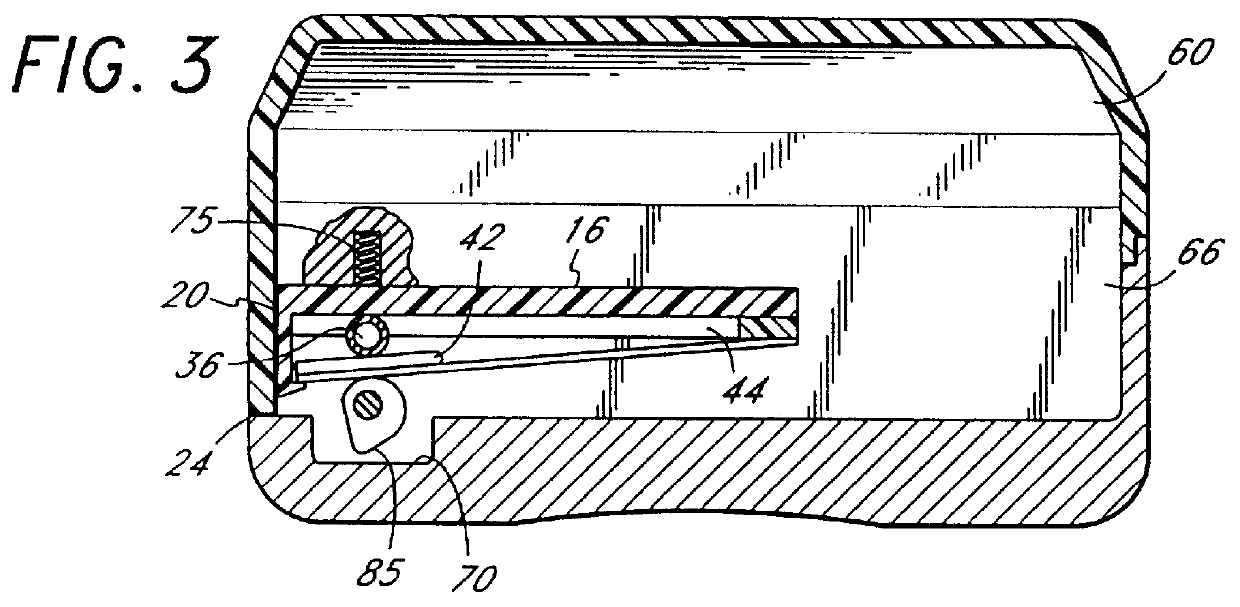

Infusion device with disposable elements

InactiveUS6146109AIncreasing the thicknessWithout sacrificing accuracyFlexible member pumpsMedical devicesDriving currentInfusion set

An infusion device with a disposable administration set which is inexpensive to manufacture. In the preferred embodiment of the present invention the disposable administration set has a plurality of elongated cam followers connected to a plate assembly, wherein the cam followers are displaced in a predetermined sequence and forced against a delivery tube by cam means driven by rotary drive means. The disposable administration set is injection molded as a single integral piece. The disposable administration set includes adjustment spacers disposed between the plate assembly and the cam followers which adjust the distance between them to keep the device accurate. In the preferred embodiment of the present invention the cam assembly is configured to provide fluid delivery at a consistent and uniform rate. The device may also incude a pressure sensing pin positioned on the cam assembly which contacts the tubing during the pumping cycle. The drive current is sampled and processed at predetermined phases during the cam rotation cycle to detect the presence of an occlusion in the tubing.

Owner:CARDINAL HEALTH INC

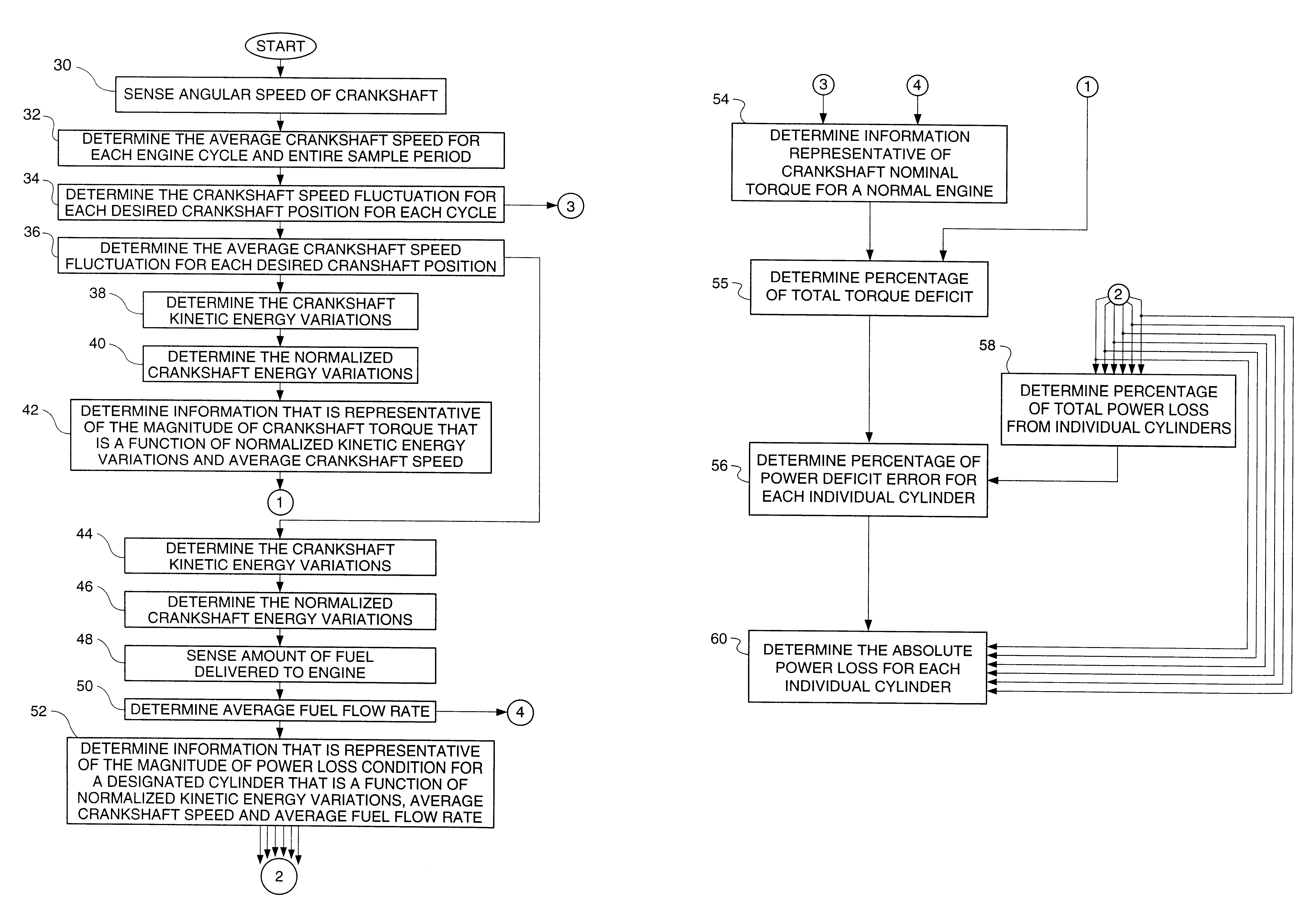

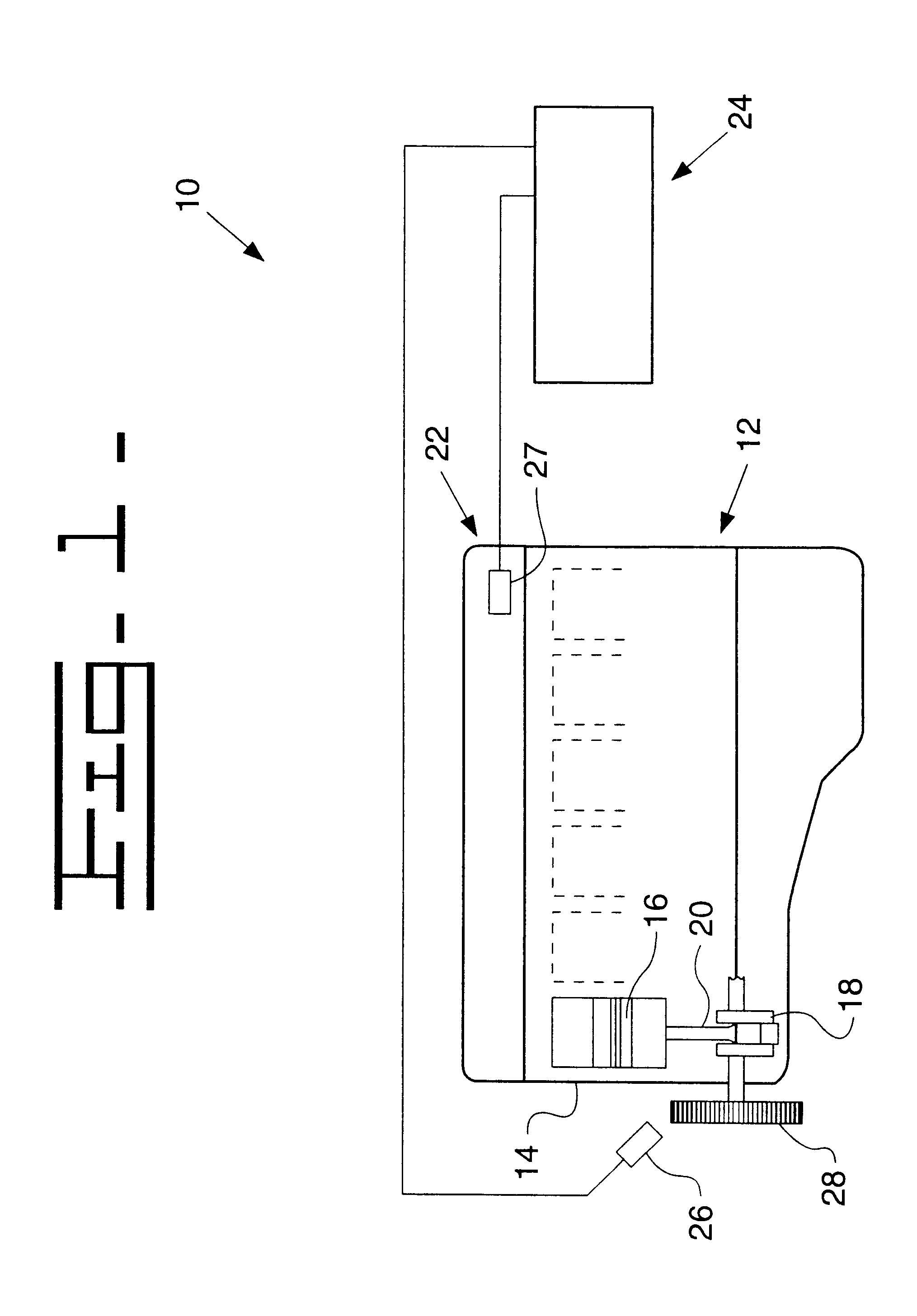

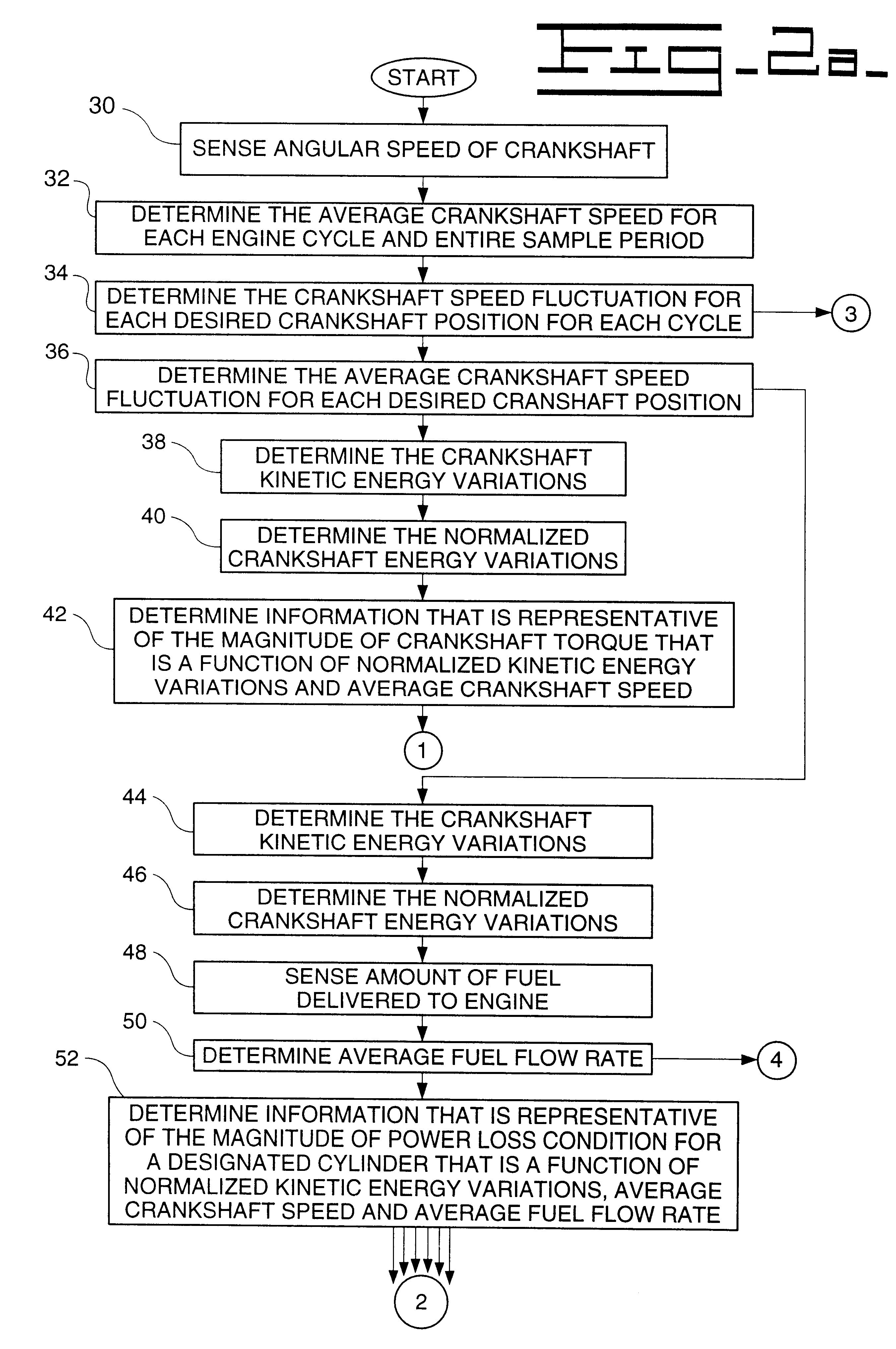

Method and system for determining an absolute power loss condition in an internal combustion engine

InactiveUS6199007B1Internal-combustion engine testingAnalogue computers for vehiclesInternal combustion engineRotation cycle

A method and system for detecting absolute power loss in a cylinder for a reciprocating internal combustion engine, the internal combustion engine having at least one cylinder and a rotatable crankshaft. This method and system includes sensing rotational crankshaft speed for a number of designated crankshaft rotational positions over a predetermined number of cycles of rotation for each of the crankshaft positions and determining an average crankshaft speed fluctuation for each of the crankshaft positions and determining information representative of crankshaft kinetic energy variations due to each firing event or each firing event and compression event in said cylinder and determining information representative of an average fuel flow rate and determining information representative of power loss for the cylinder as a function of the crankshaft kinetic energy variations due to each firing event, the average crankshaft speed and the average fuel flow rate and responsively producing a representative power loss signal and determining information representative of crankshaft torque as a function of the crankshaft kinetic energy variations due to each firing event and compression event and the average crankshaft speed and responsively producing a representative crankshaft torque signal and determining information representative of absolute power loss for each cylinder.

Owner:CATERPILLAR INC

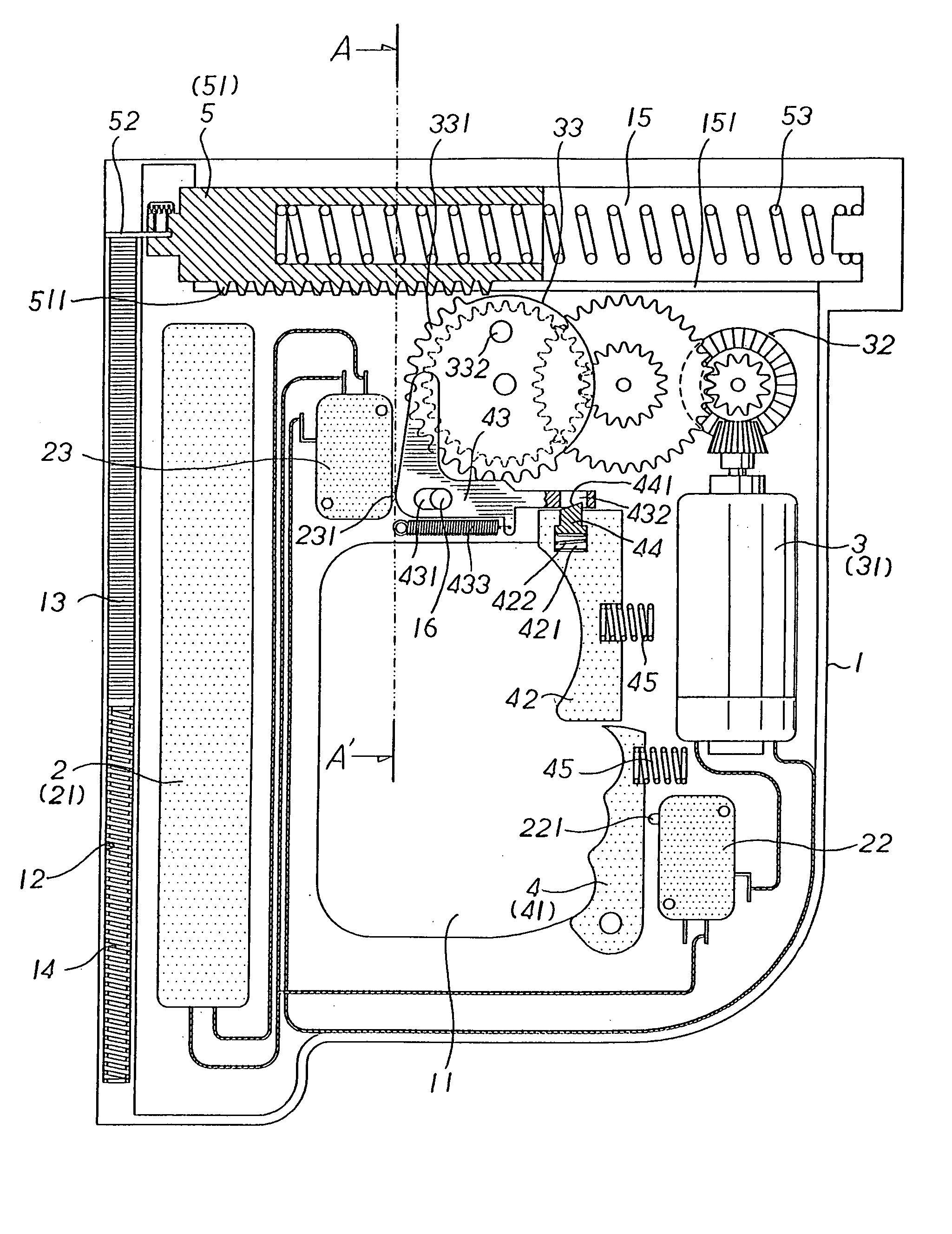

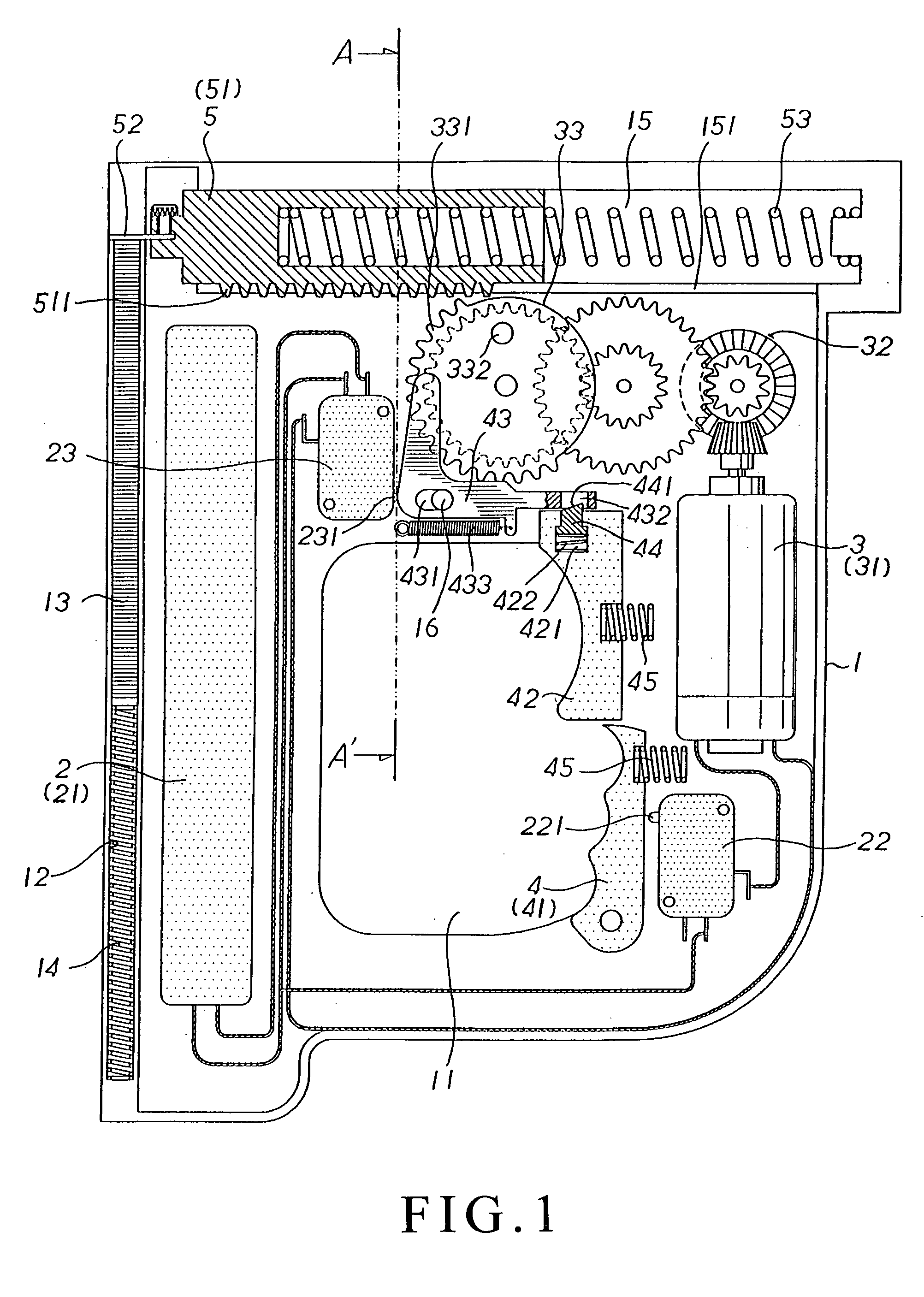

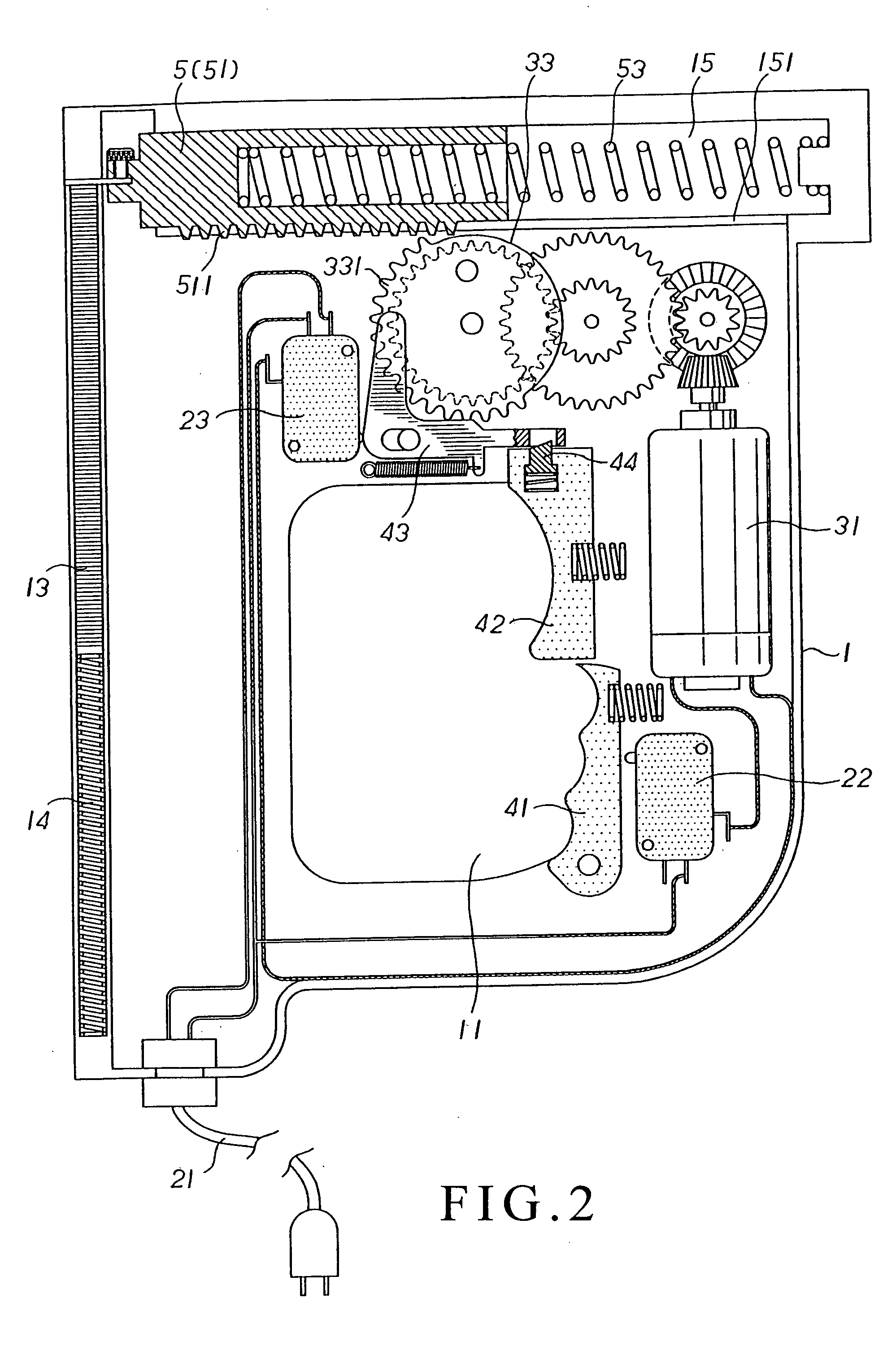

Hand-held nailing tool

InactiveUS20050082334A1Handy and convenient for home useStapling toolsReciprocating drilling machinesAC adapterPower switching

A handy electric nailing gun includes a firing pin, a firing spring for pushing the firing pin to drive nails into workpiece, an output gear rotatable by a motor through a transmission gear set to retract the firing pin during the first half run of each rotation cycle and to release the firing pin during the second half run of each rotation cycle, and three power switches electrically connected in series between the motor and the power source (AC adapter / rechargeable battery) for operation by the user to control the operation of the motor.

Owner:YIH KAI ENTERPRISE

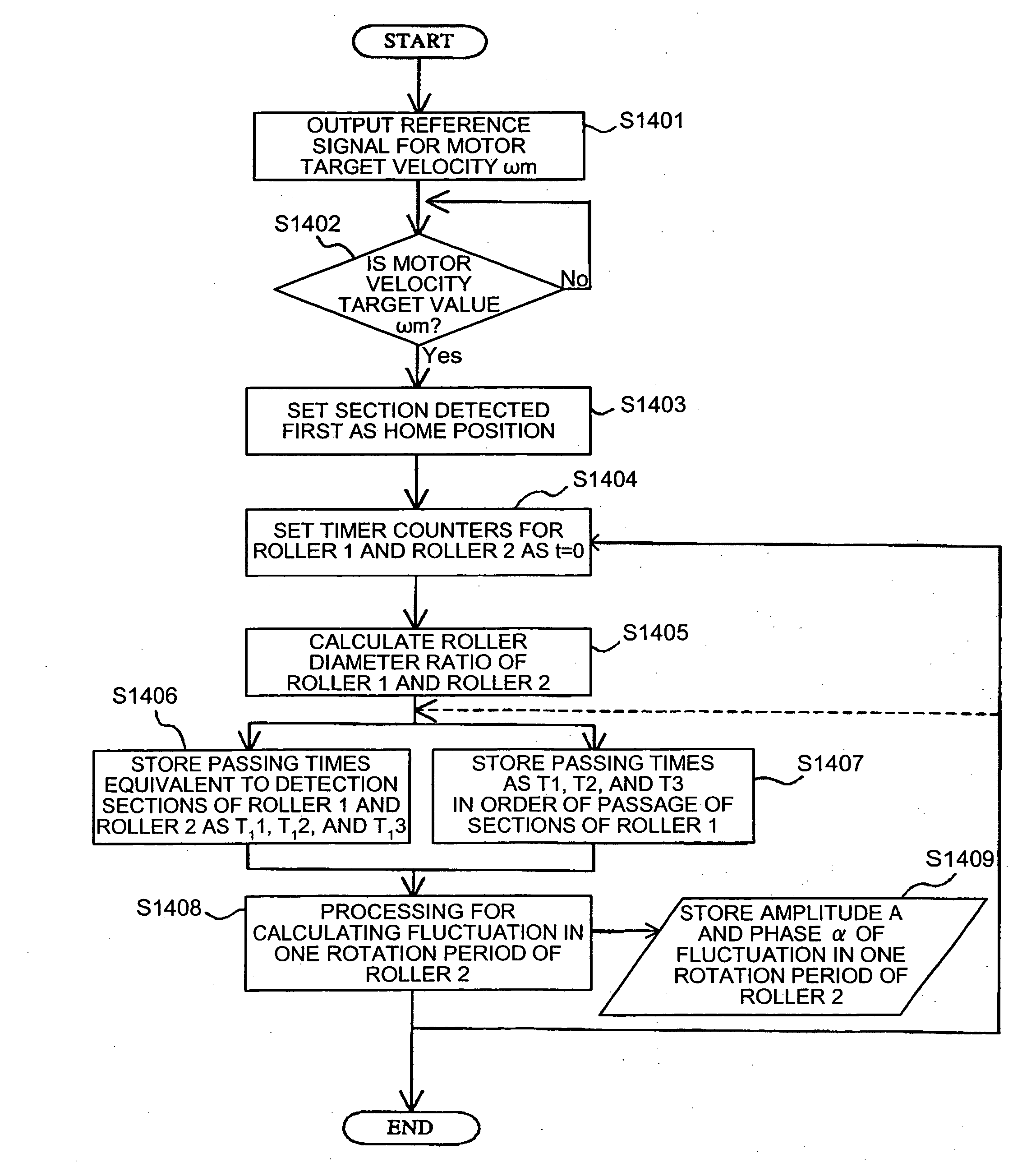

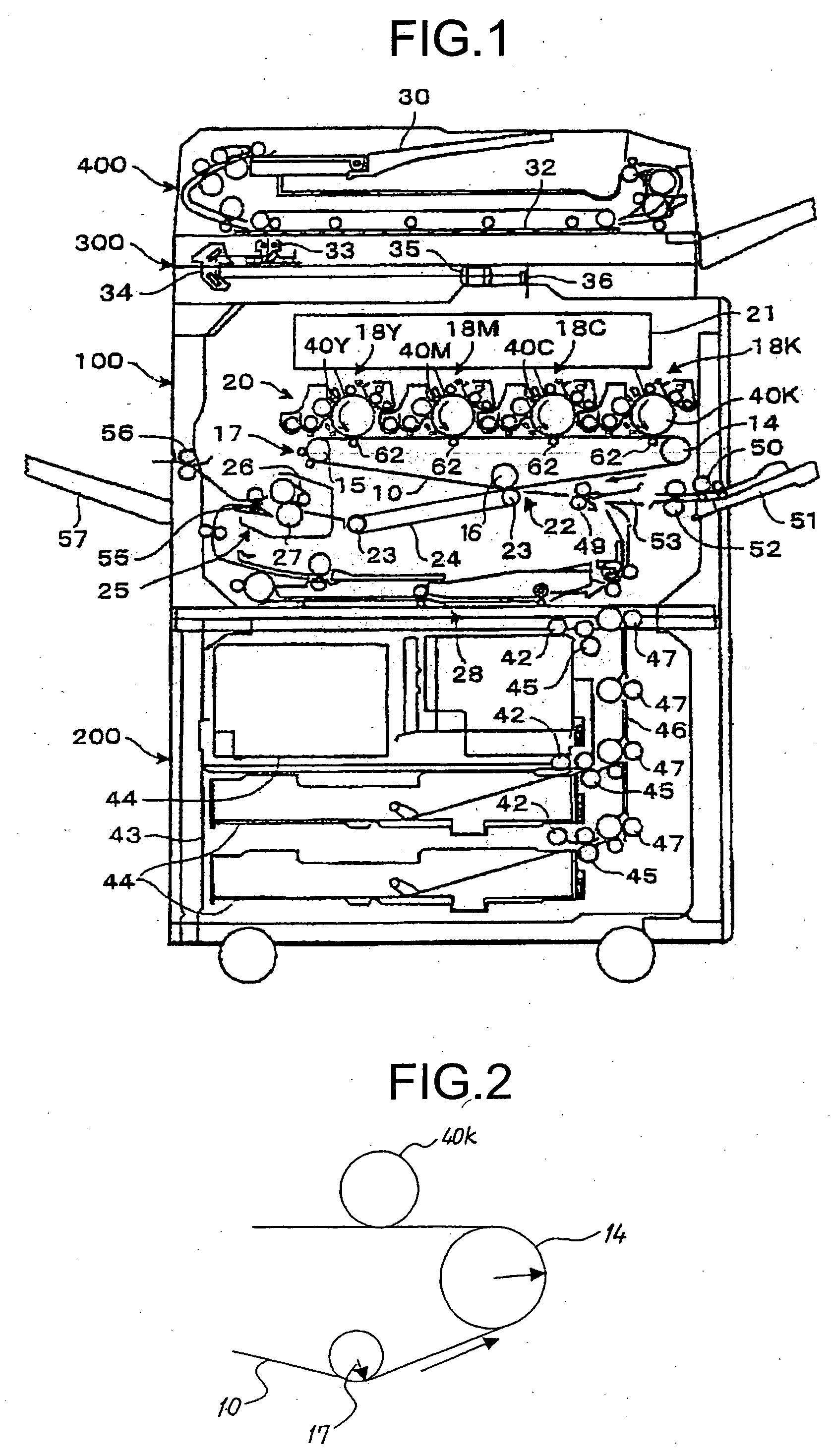

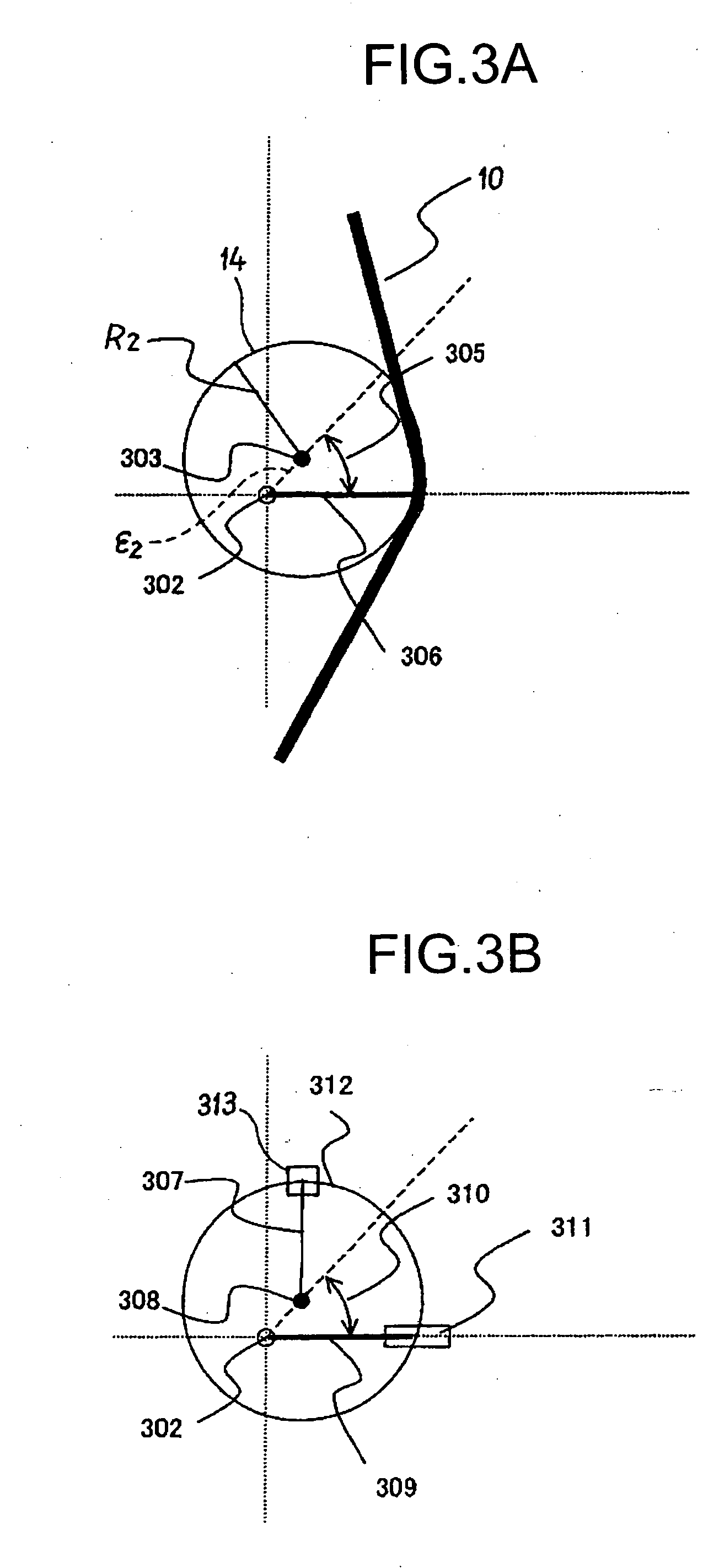

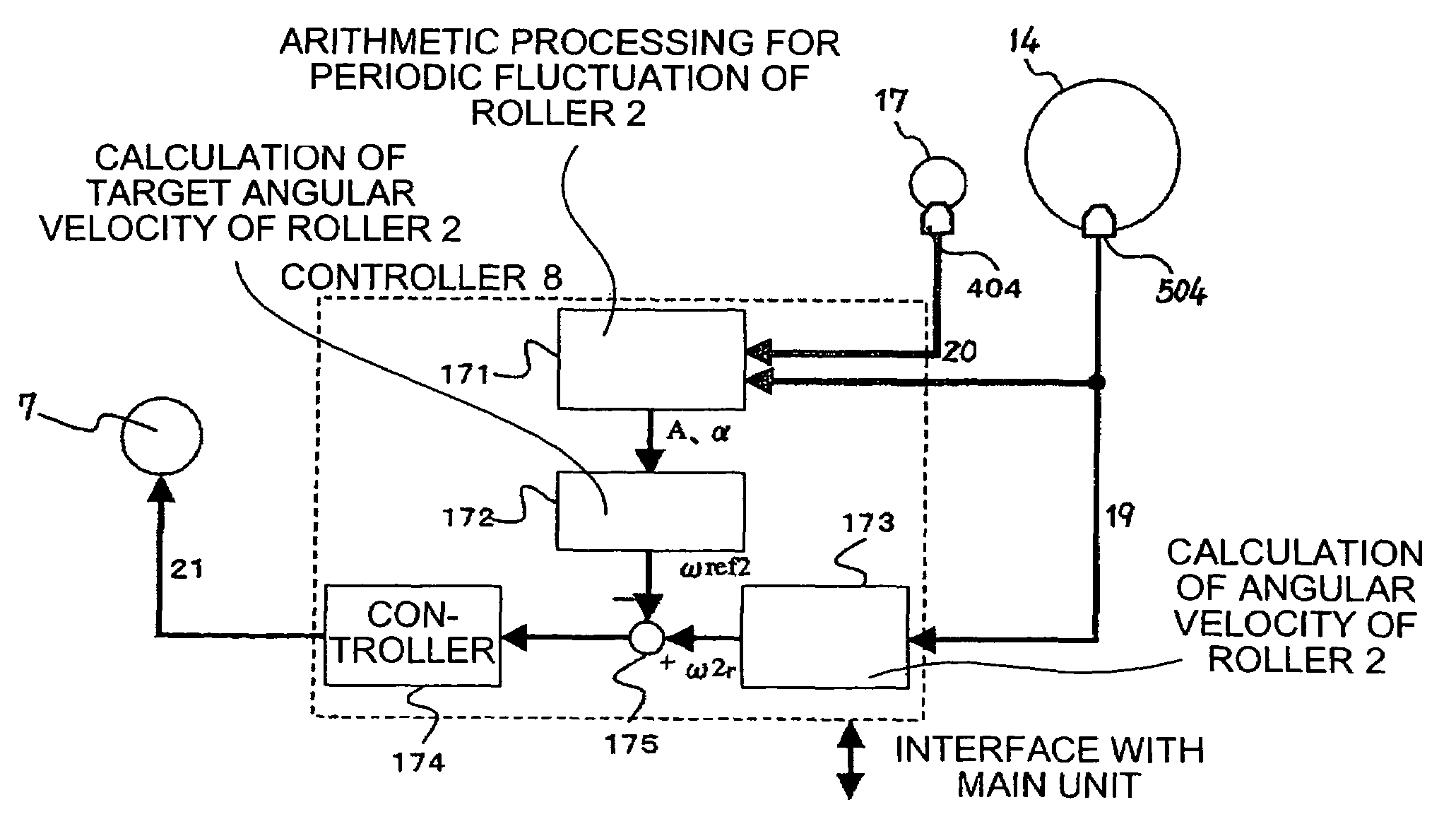

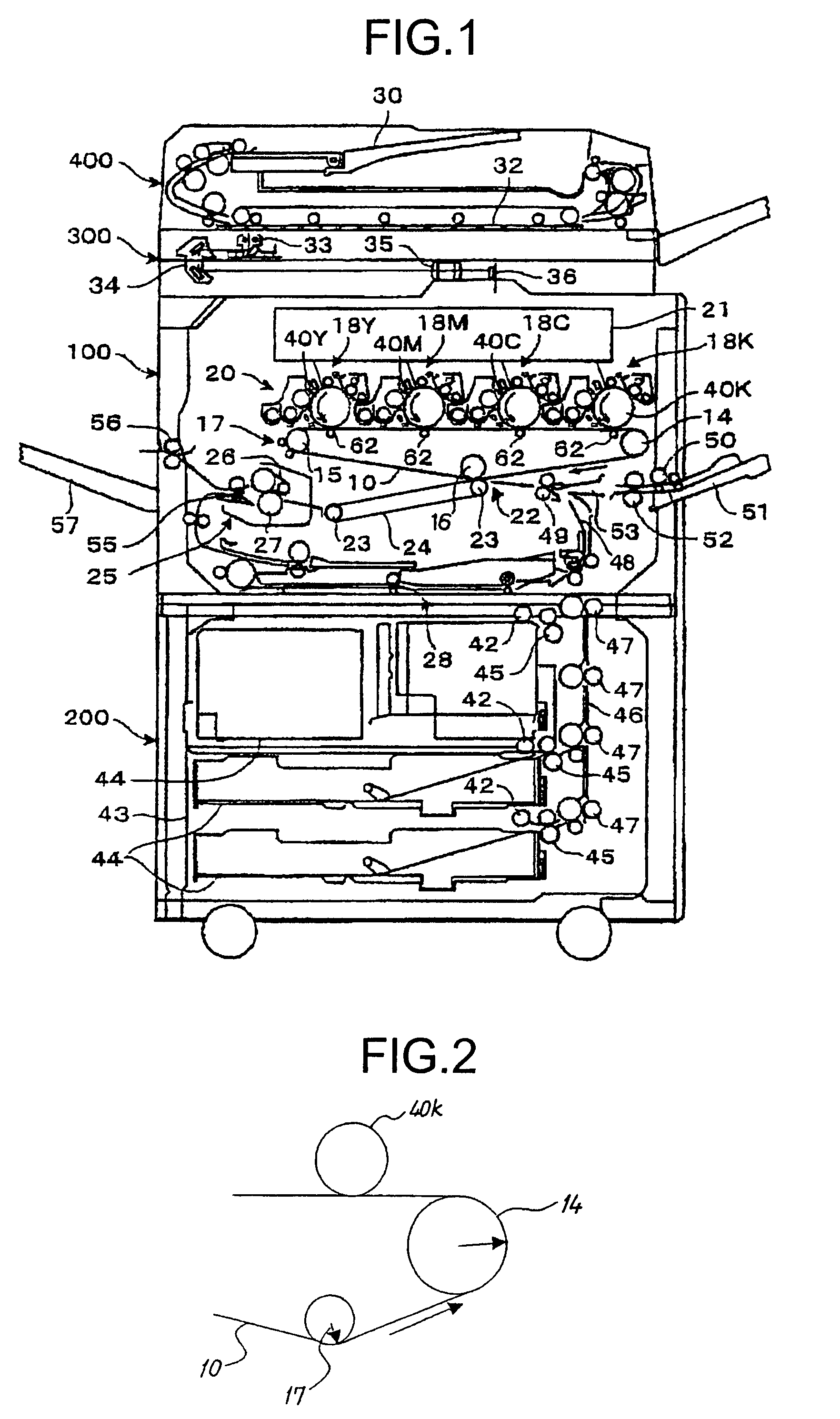

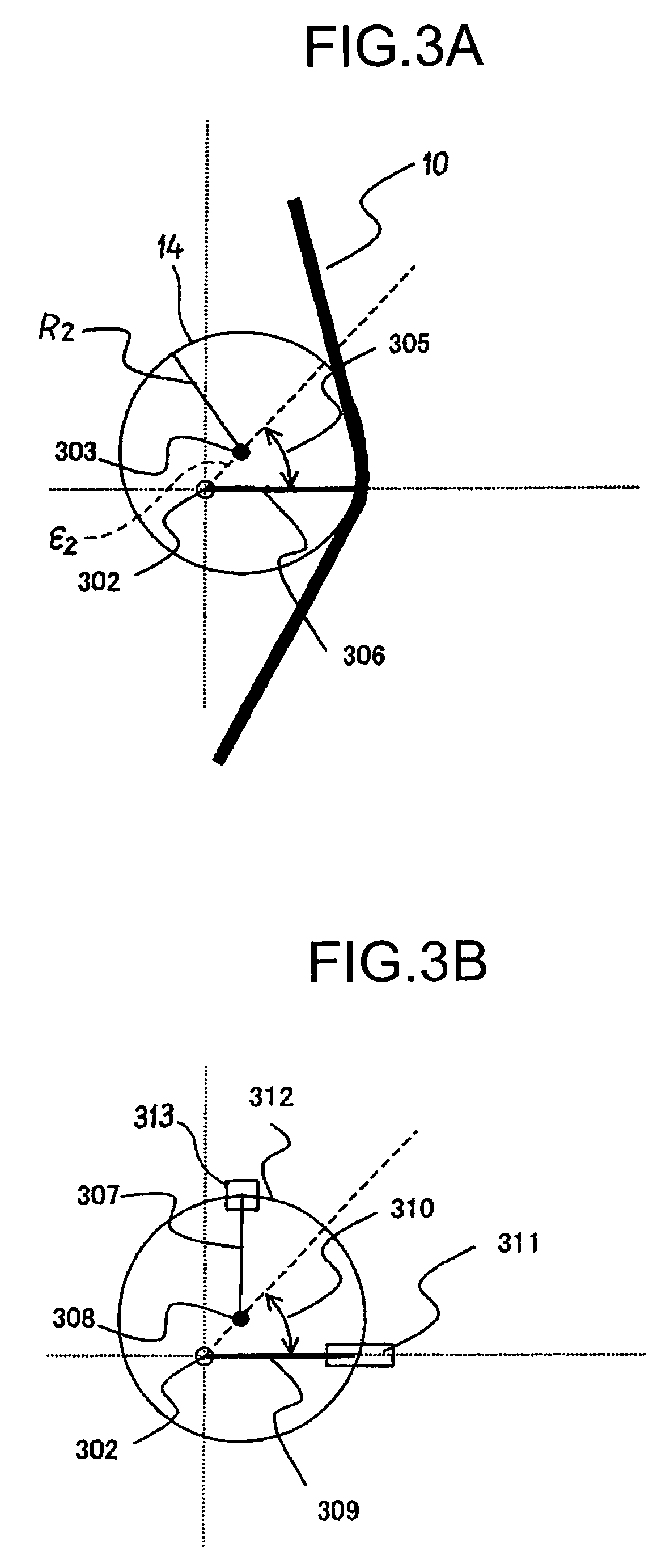

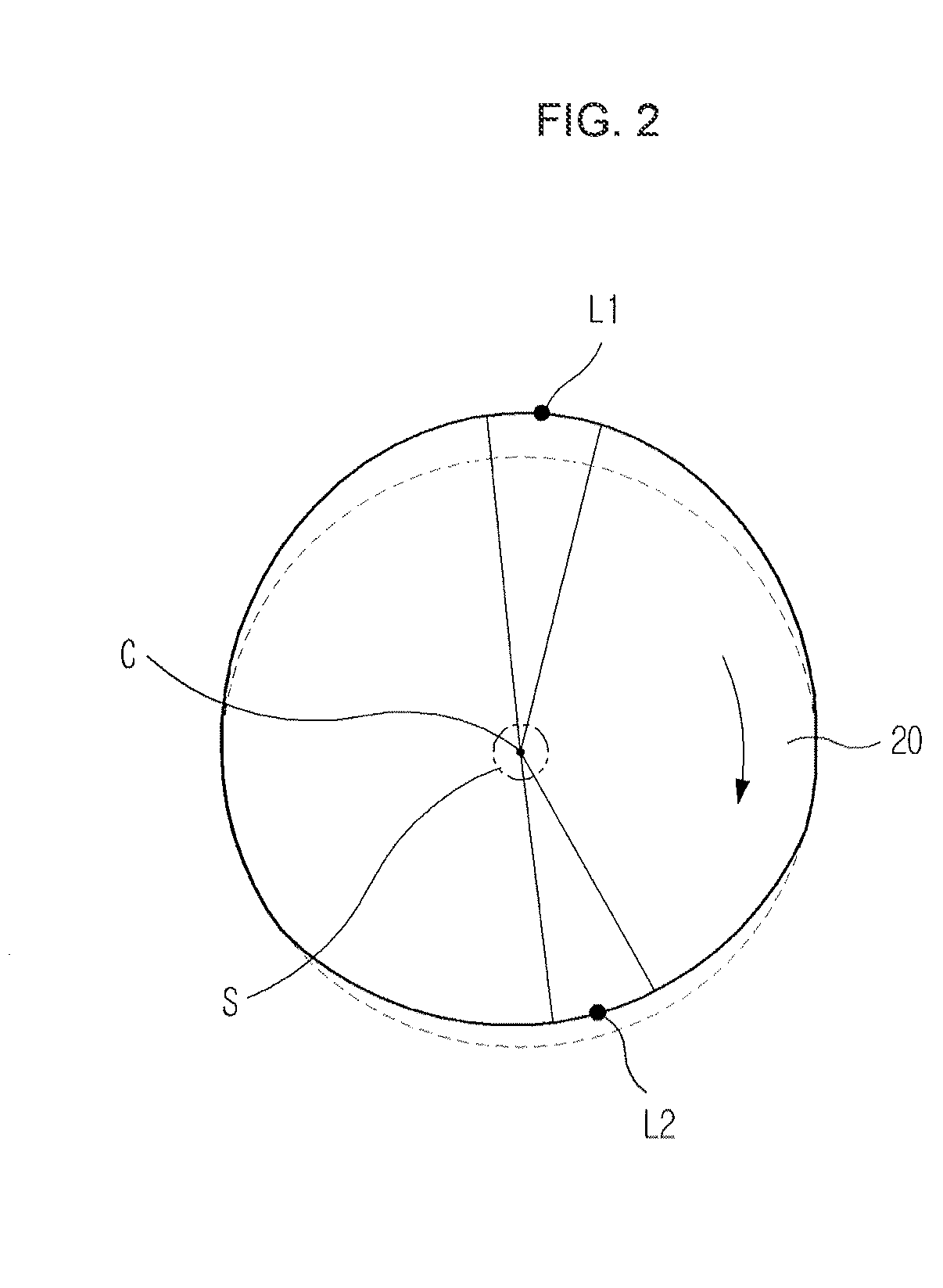

Belt drive control method, belt-drive control device, and image forming apparatus

A rotational speed of a first roller and a time required for a second roller to make one rotation are measured. A controller calculates an amplitude and a phase of fluctuation in a rotational speed in one rotation period of the first roller while the first roller is rotated by a predefined angle based on the speed and the time. The controller corrects measured speed of the first roller based on the amplitude and the phase, and controls a driving roller based on corrected speed.

Owner:RICOH KK

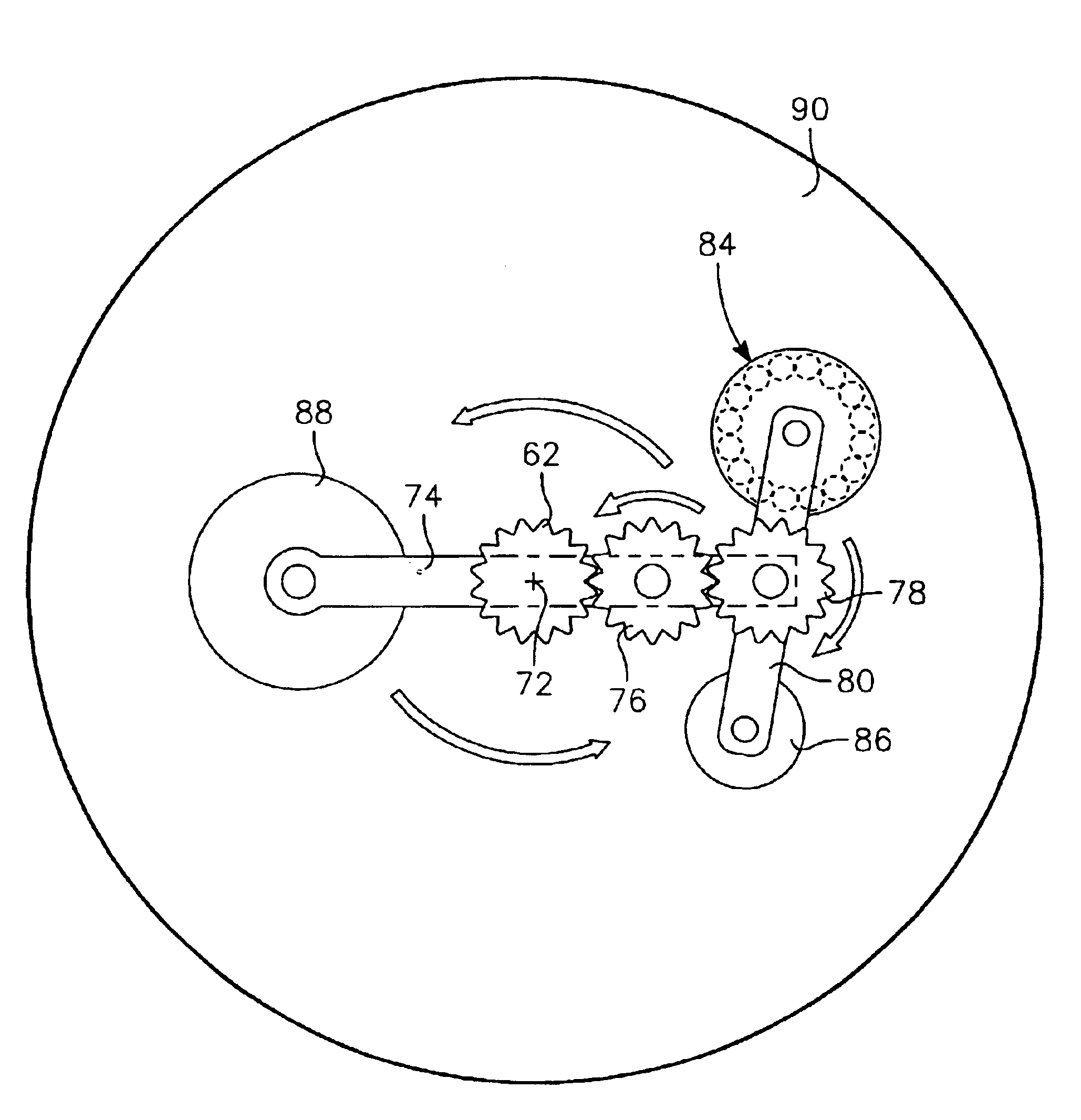

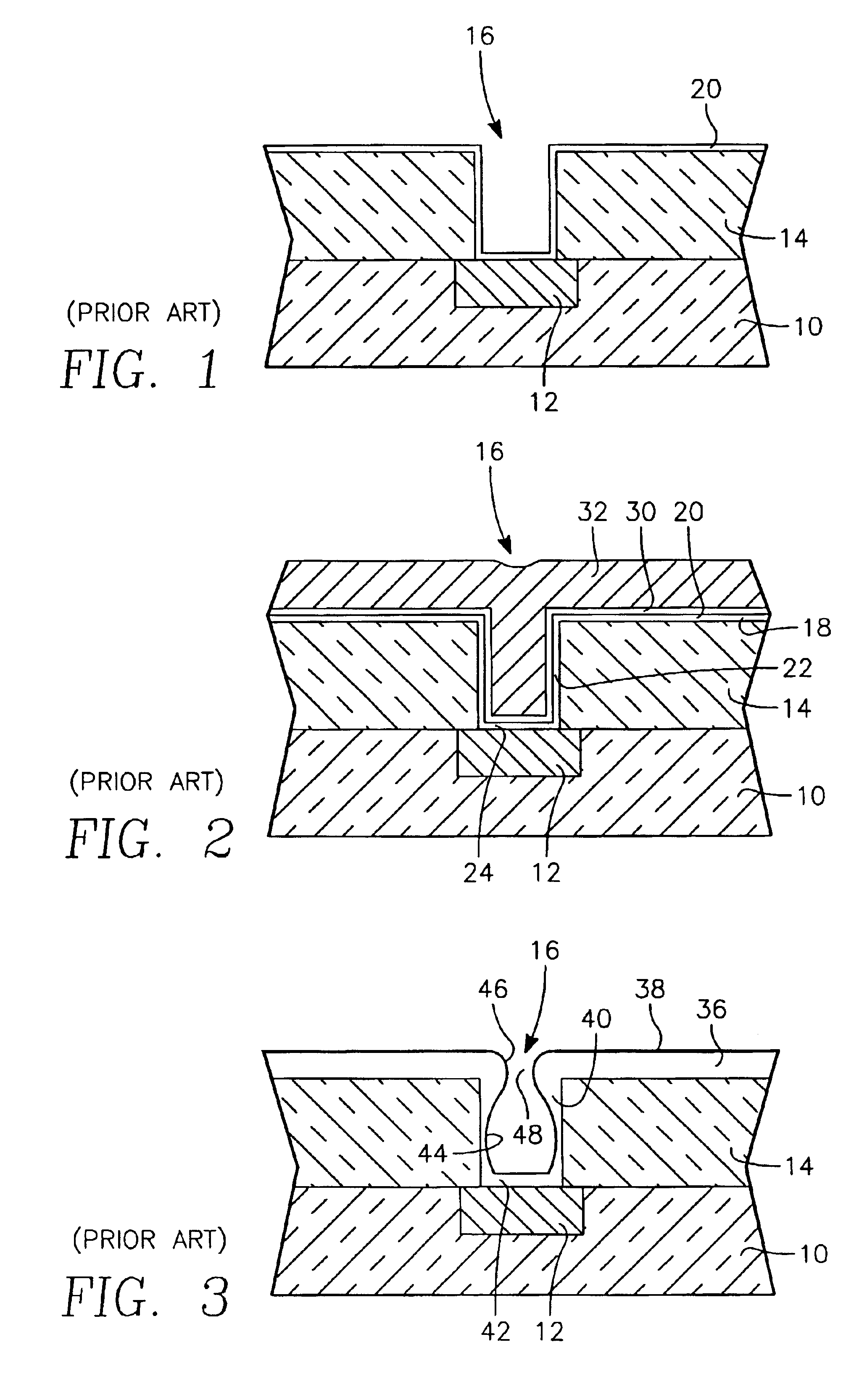

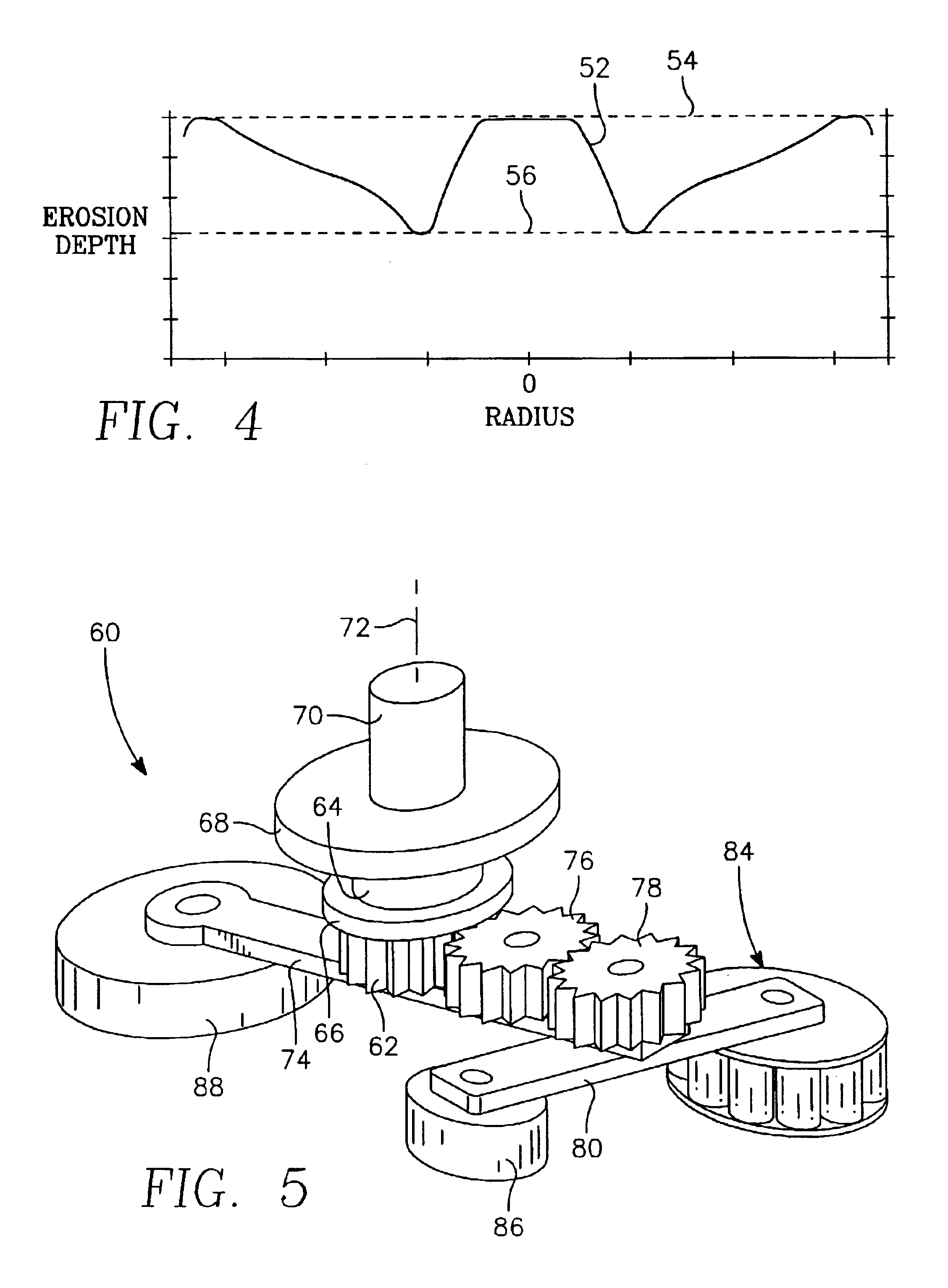

Small epicyclic magnetron with controlled radial sputtering profile

InactiveUS6852202B2Improve uniformityMore target utilizationCellsElectric discharge tubesSputteringSection plane

A small unbalanced magnet assembly is scanned in a retrograde planetary or epicyclic path about the back of a target being plasma sputtered including an orbital rotation about the center axis of the target and a planetary rotation about another axis rotating about the target center axis. The magnet assembly may pass through the target center, thus allowing full target coverage. A geared planetary mechanism may include a rotating drive plate, a fixed center gear, and an idler and a follower gear rotatably supported in the drive plate supporting a cantilevered magnet assembly on the side of the drive plate facing the target. The erosion profile may be controlled by varying the rotation rate through the rotation cycle or by modulating the target power. A second planetary stage may be added or non-circular gears be used. Auxiliary electromagnetic coils may create a focusing magnetic field.

Owner:APPLIED MATERIALS INC

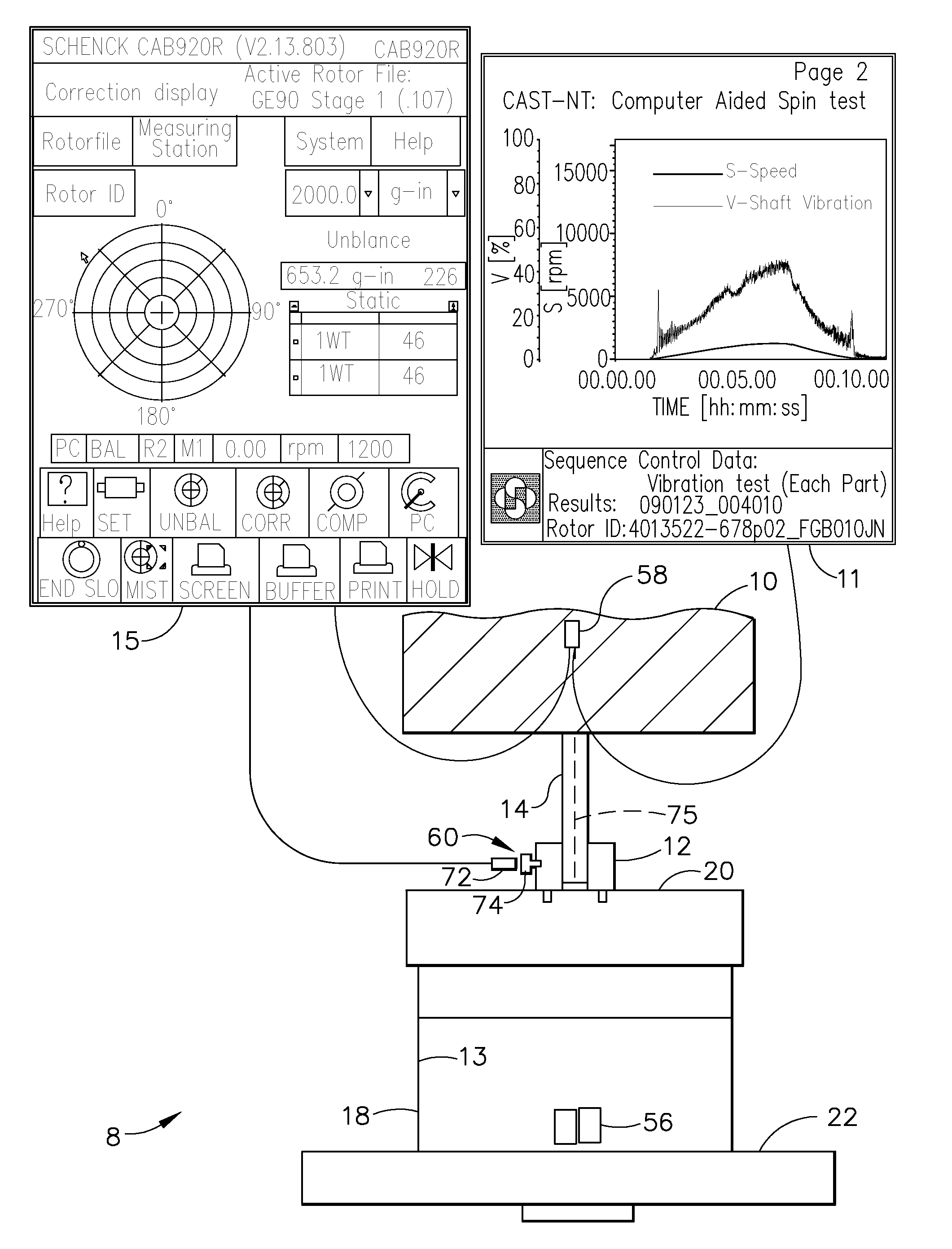

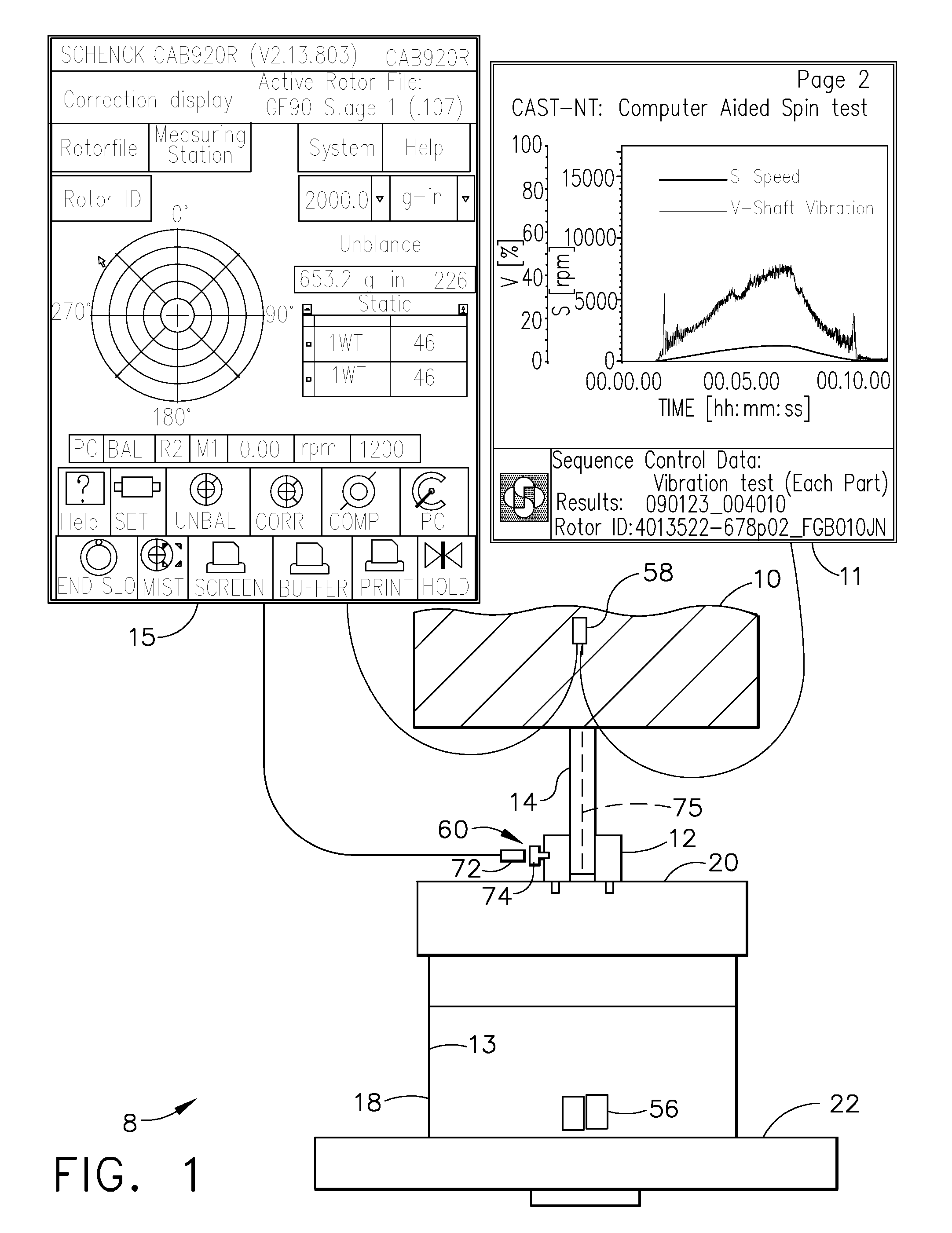

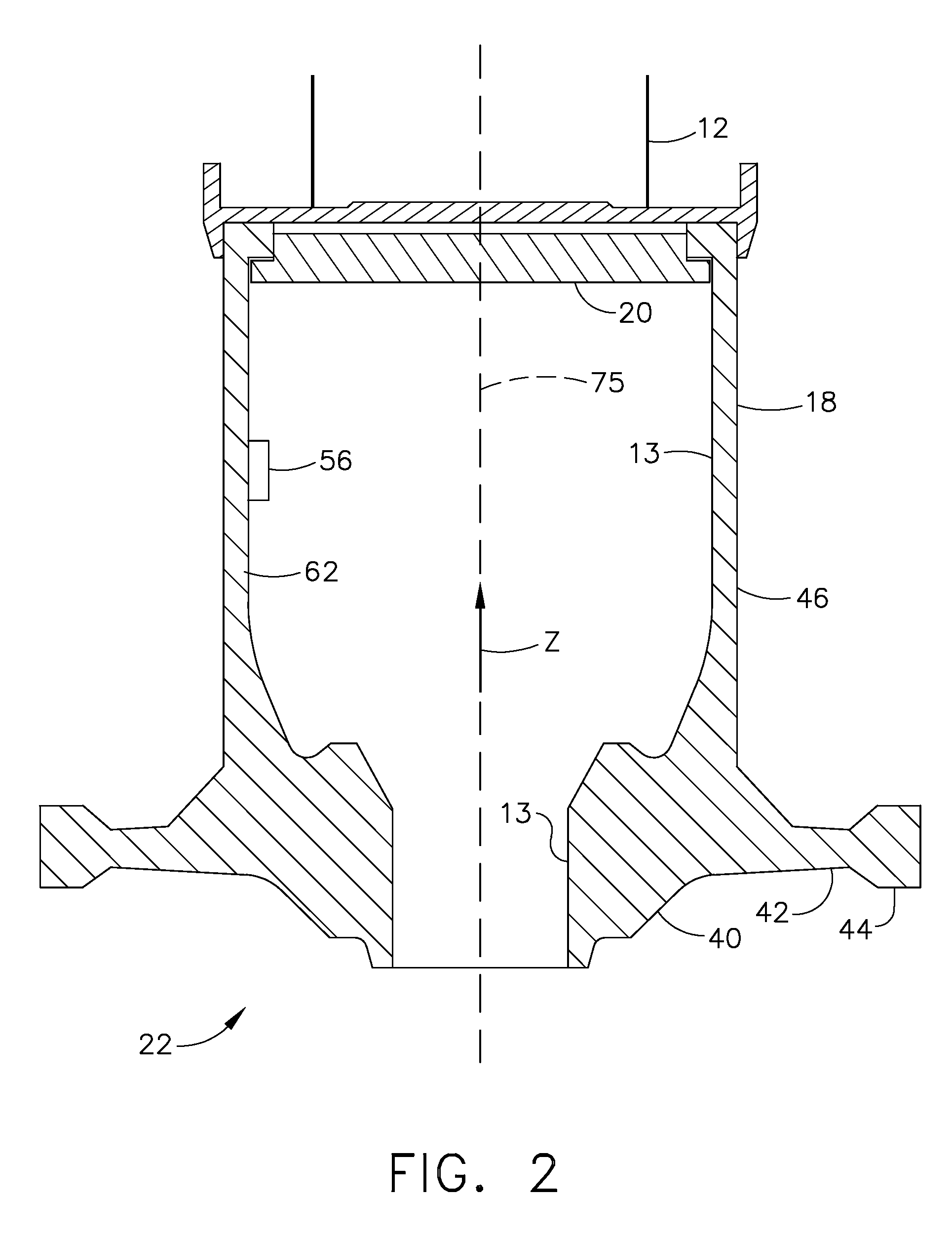

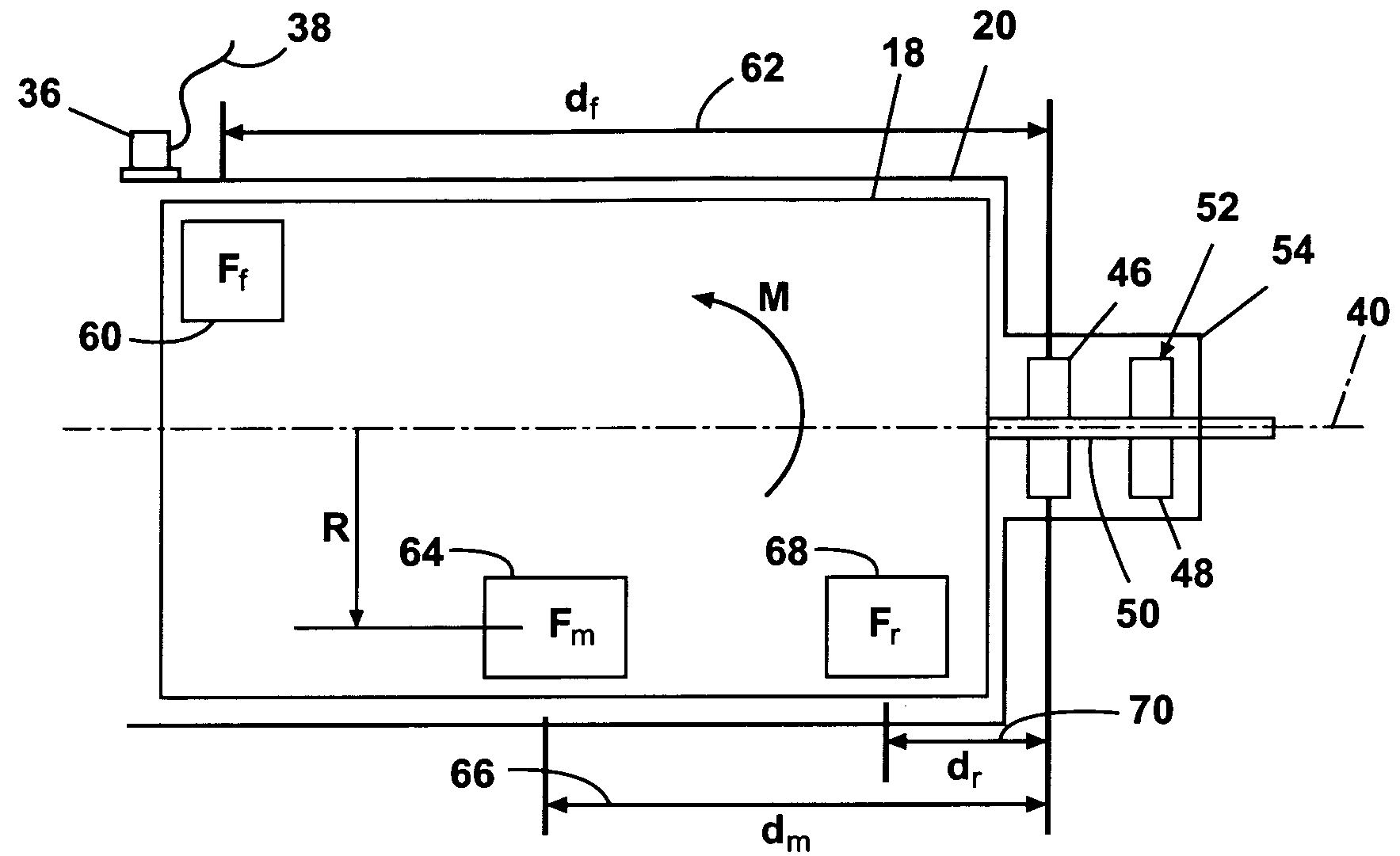

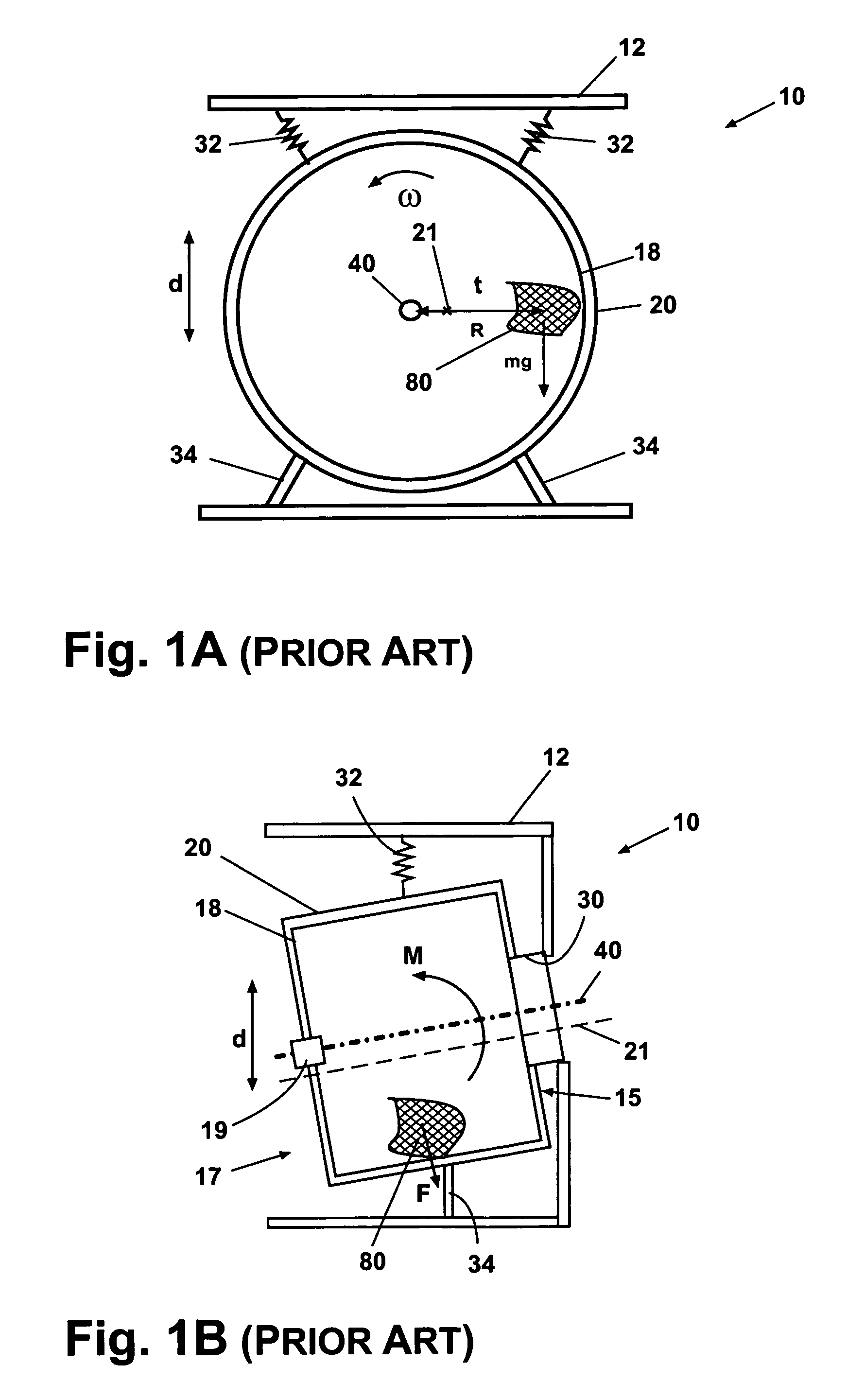

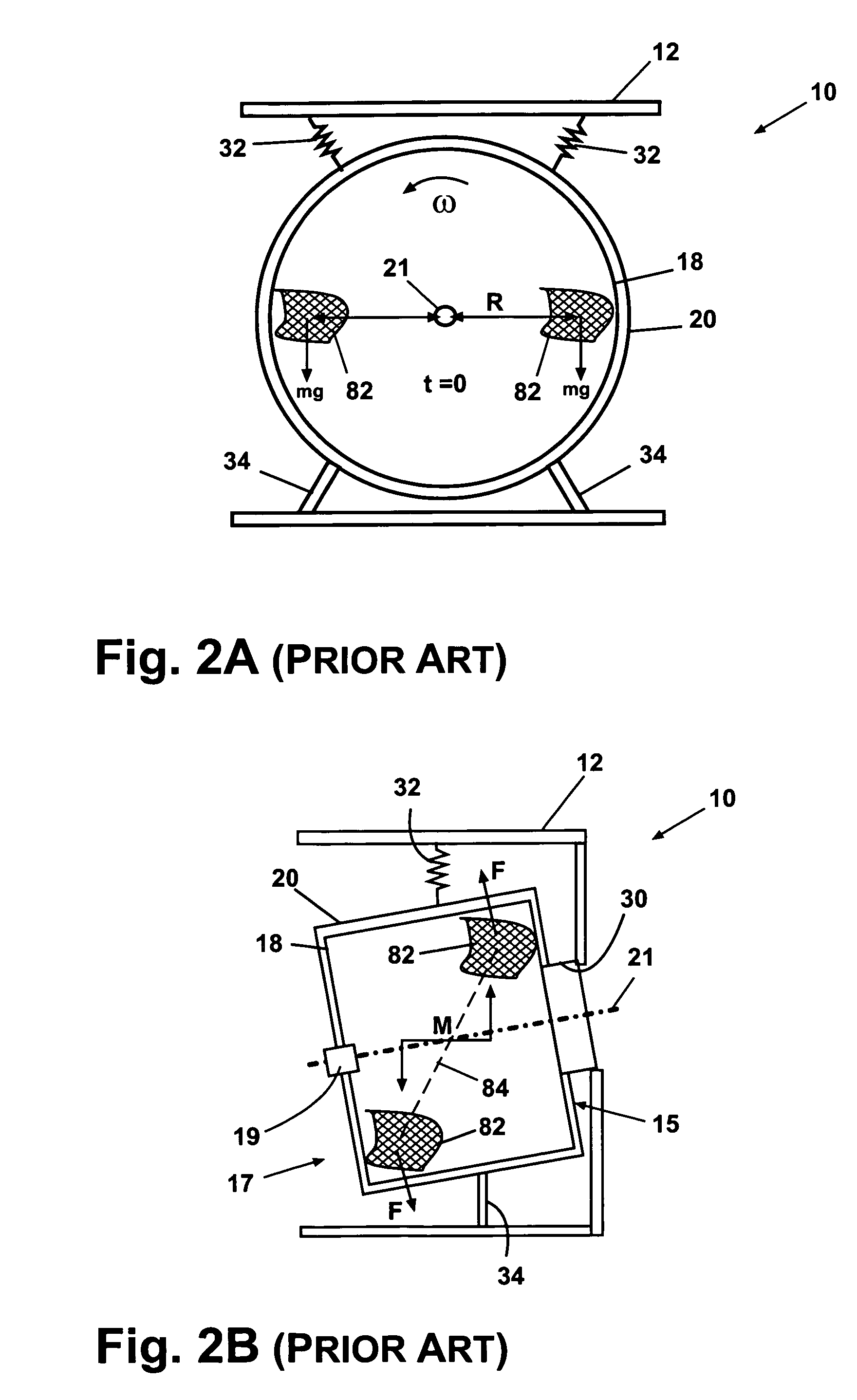

Method and apparatus for pre-spinning rotor forgings

ActiveUS20100212422A1Relieve forging induced residual stressAvoid excessive rotationForce measurementStatic/dynamic balance measurementHigh densityRotation velocity

A method and system for relieving forging induced residual stresses in a rotor forging balances a pre-spin machine with the forging mounted thereon at a first rotational speed and then pre-spins the forging with it mounted on the machine at a substantially greater second rotational speed. A one per rev sensor is used for determining a weight placement angle and a vibration sensor is used for determining an amount of weight to add to a spinning assembly including the forging during the balancing. High-density non-metallic balance weights adhesively attached on an inside surface of the forging or spinning assembly may be used. The rotational inertia of the spinning assembly may be checked during a spin up period by determining a rate of rotational acceleration vs. torque applied to the spinning assembly and used to stop the pre-spinning if it is to great.

Owner:GENERAL ELECTRIC CO

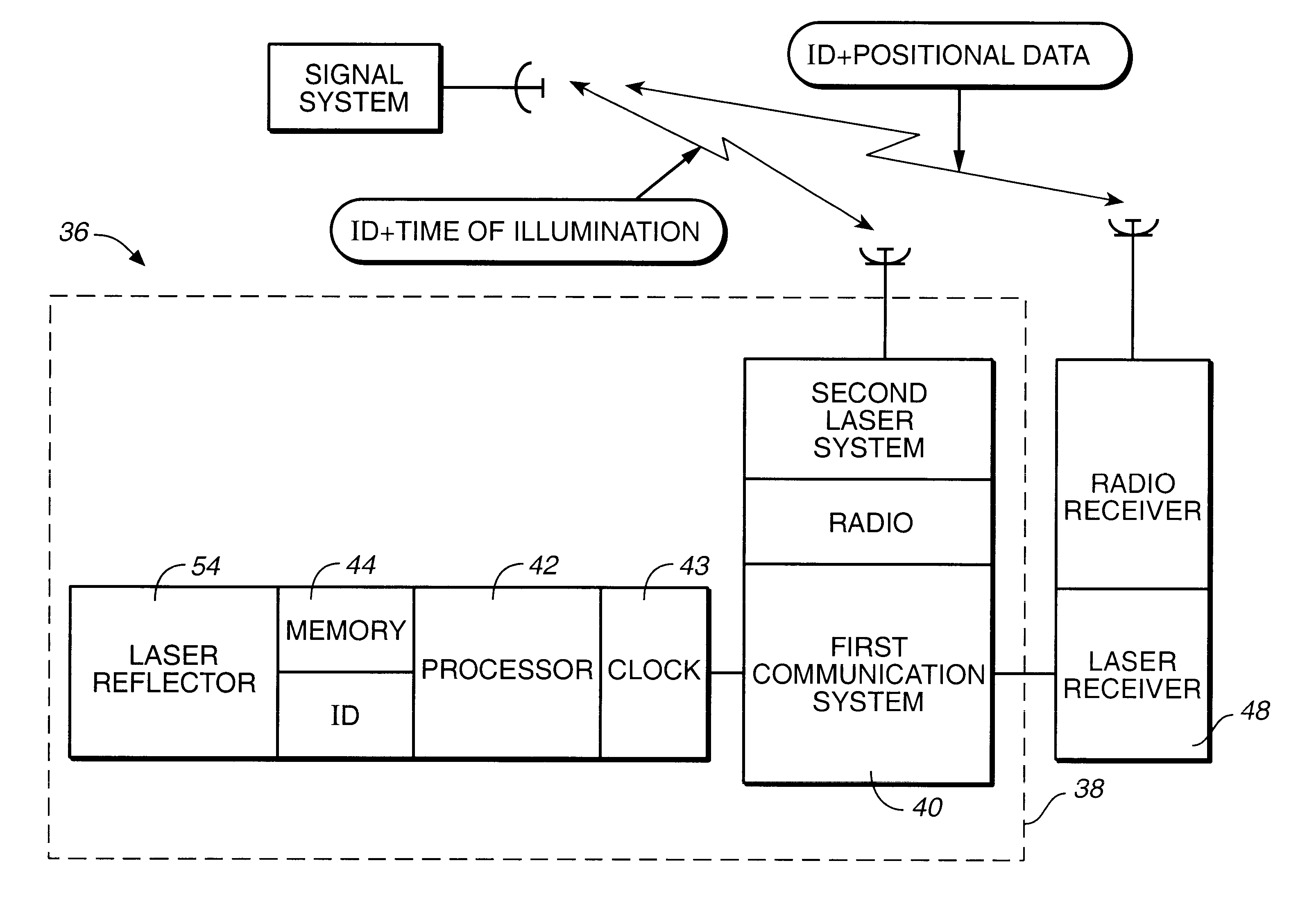

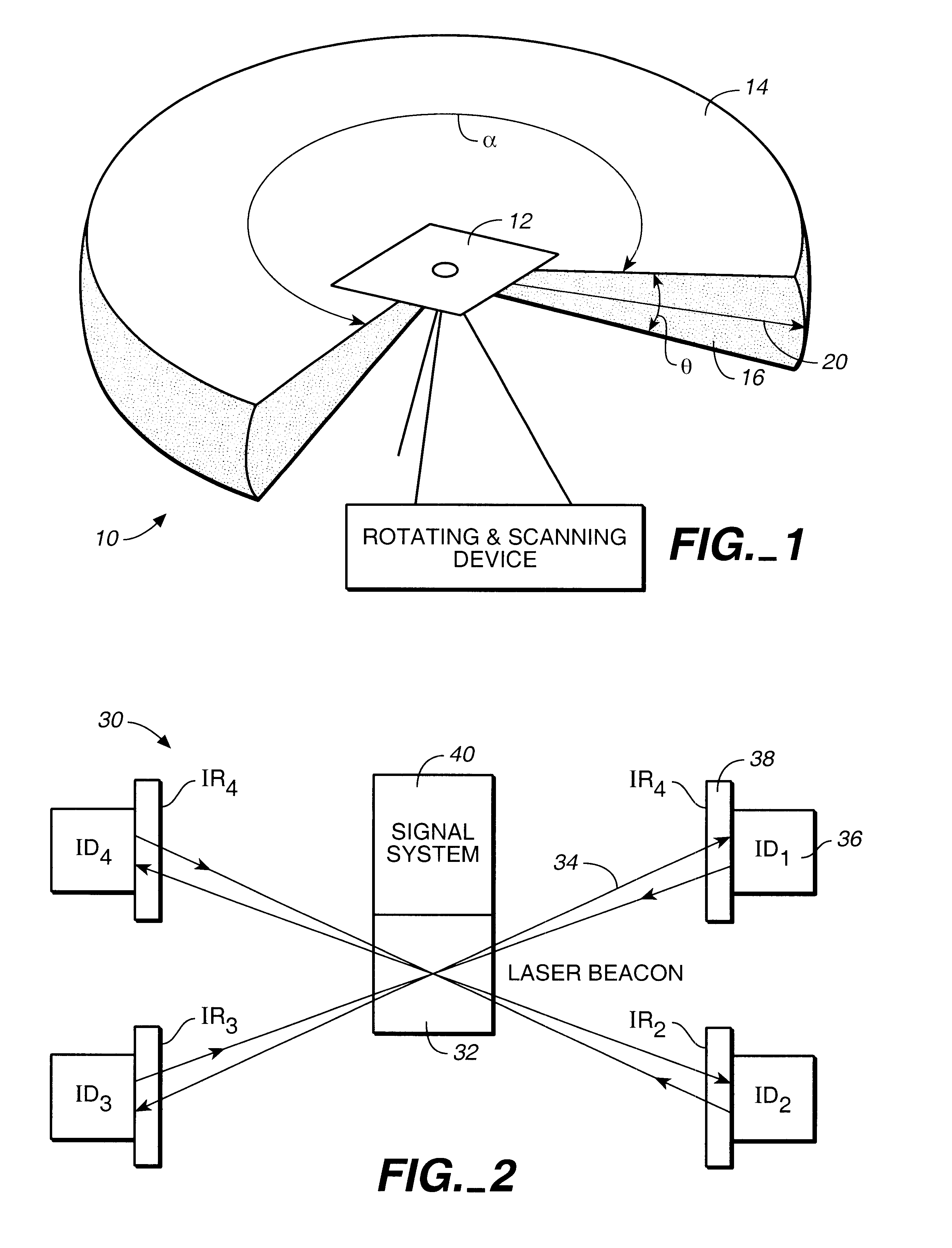

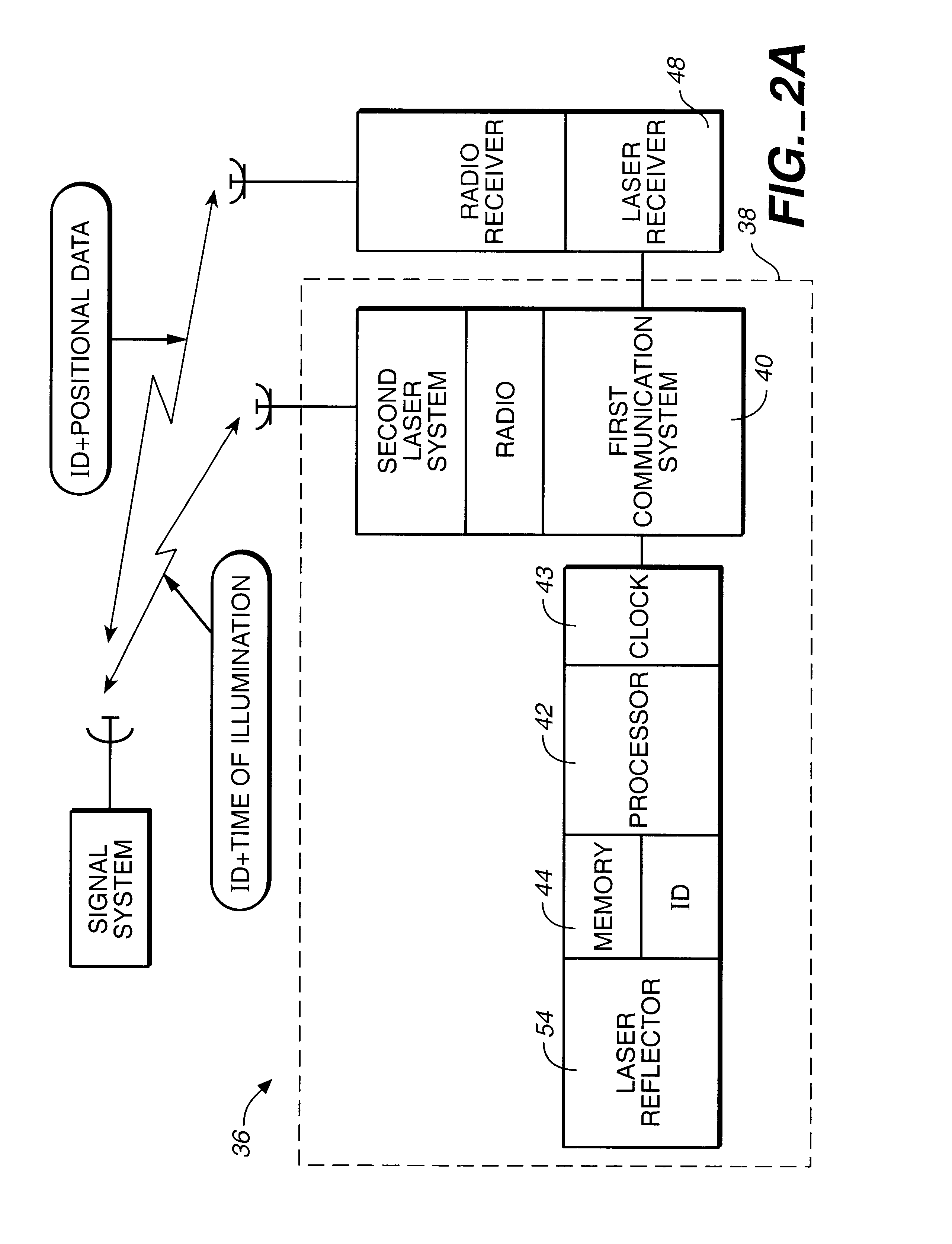

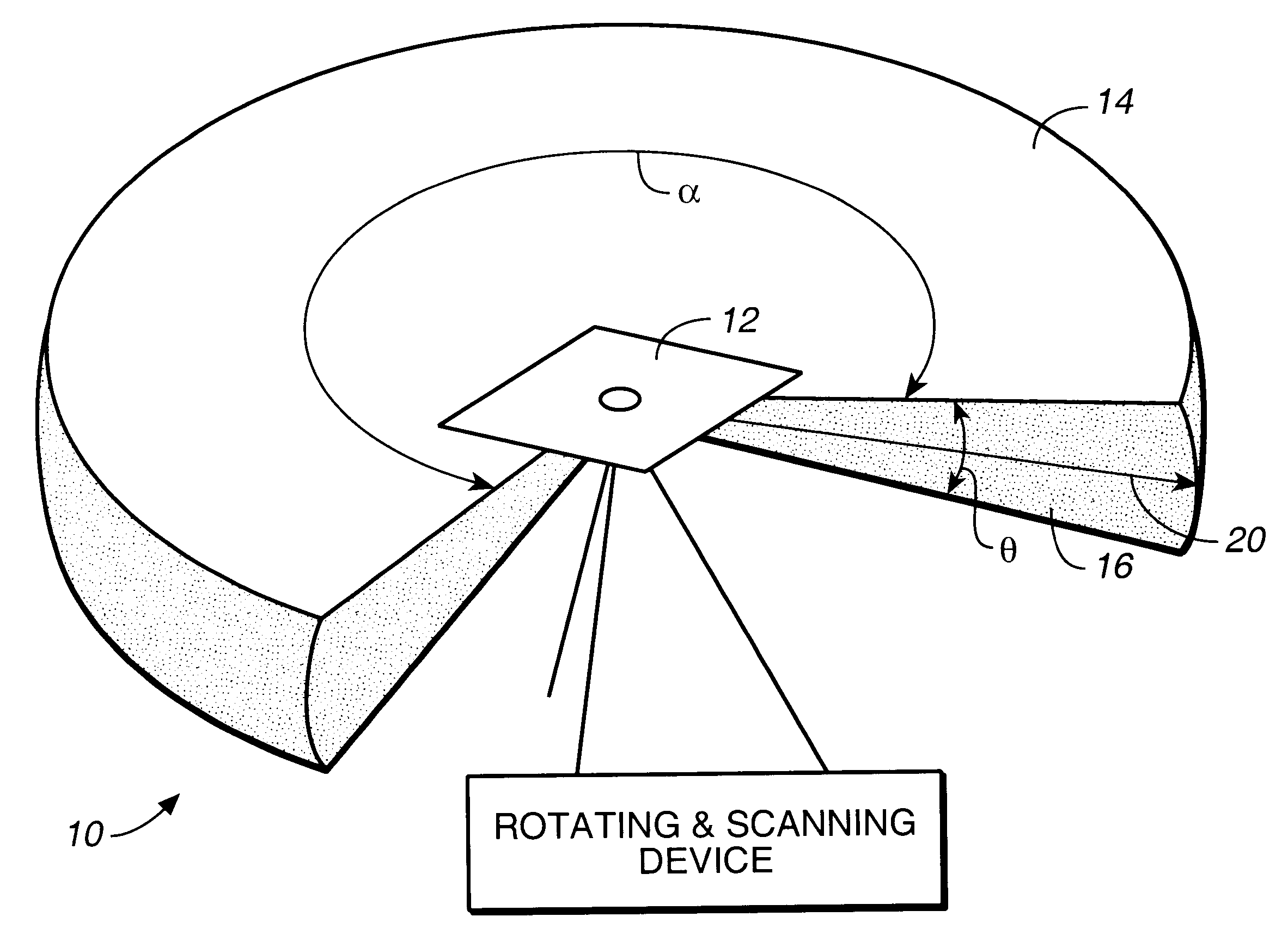

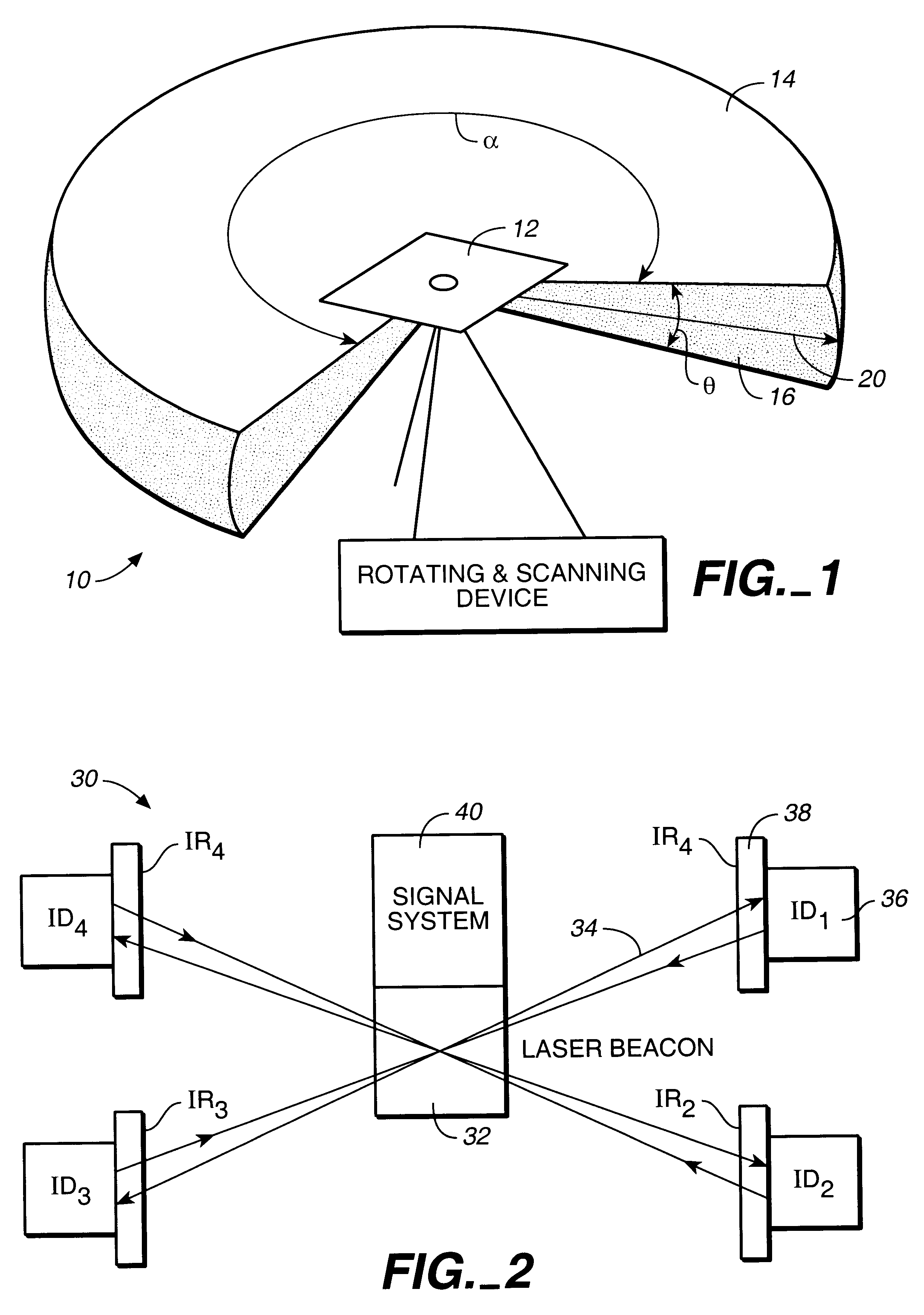

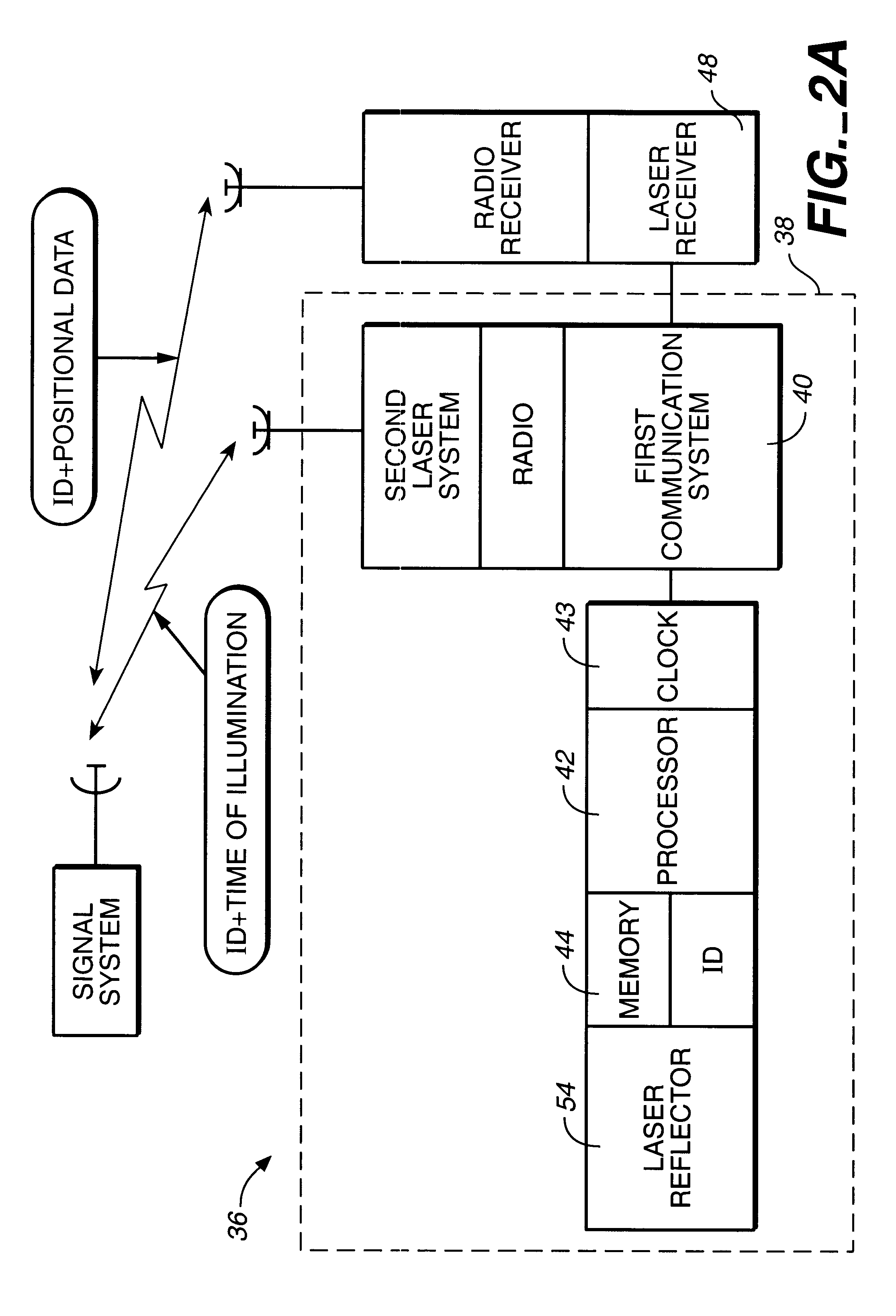

Three dimensional laser control and tracking system

InactiveUS6400452B1Angle measurementDirection finders using radio wavesControl systemOptoelectronics

A three dimensional laser tracking and control system is disclosed. The system includes a laser beacon generating a three dimensional rotating and scanning laser beam that covers a three-dimensional area. Each mobile unit has identification number (ID) and is equipped with a intelligent reflector (IR). Each mobile unit uses its intelligent reflector (IR) to communicate to the signal system its ID and the time of illumination by the laser beam. The signal system calculates the three dimensional coordinates for each mobile unit and communicates the positional data back to each mobile unit using the same laser beam during the subsequent rotation cycles.

Owner:TRIMBLE NAVIGATION LTD

Laser-based three dimensional tracking system

InactiveUS6198528B1Angle measurementDirection finders using radio wavesControl systemOptoelectronics

A three dimensional laser tracking and control system is disclosed. The system includes a laser beacon generating a three dimensional rotating and scanning laser beam that covers a three-dimensional area. Each mobile unit has identification number (ID) and is equipped with a intelligent reflector (IR). Each mobile unit uses its intelligent reflector (IR) to communicate to the signal system its ID and the time of illumination by the laser beam. The signal system calculates the three dimensional coordinates for each mobile unit and communicates the positional data back to each mobile unit using the same laser beam during the subsequent rotation cycles.

Owner:TRIMBLE NAVIGATION LTD

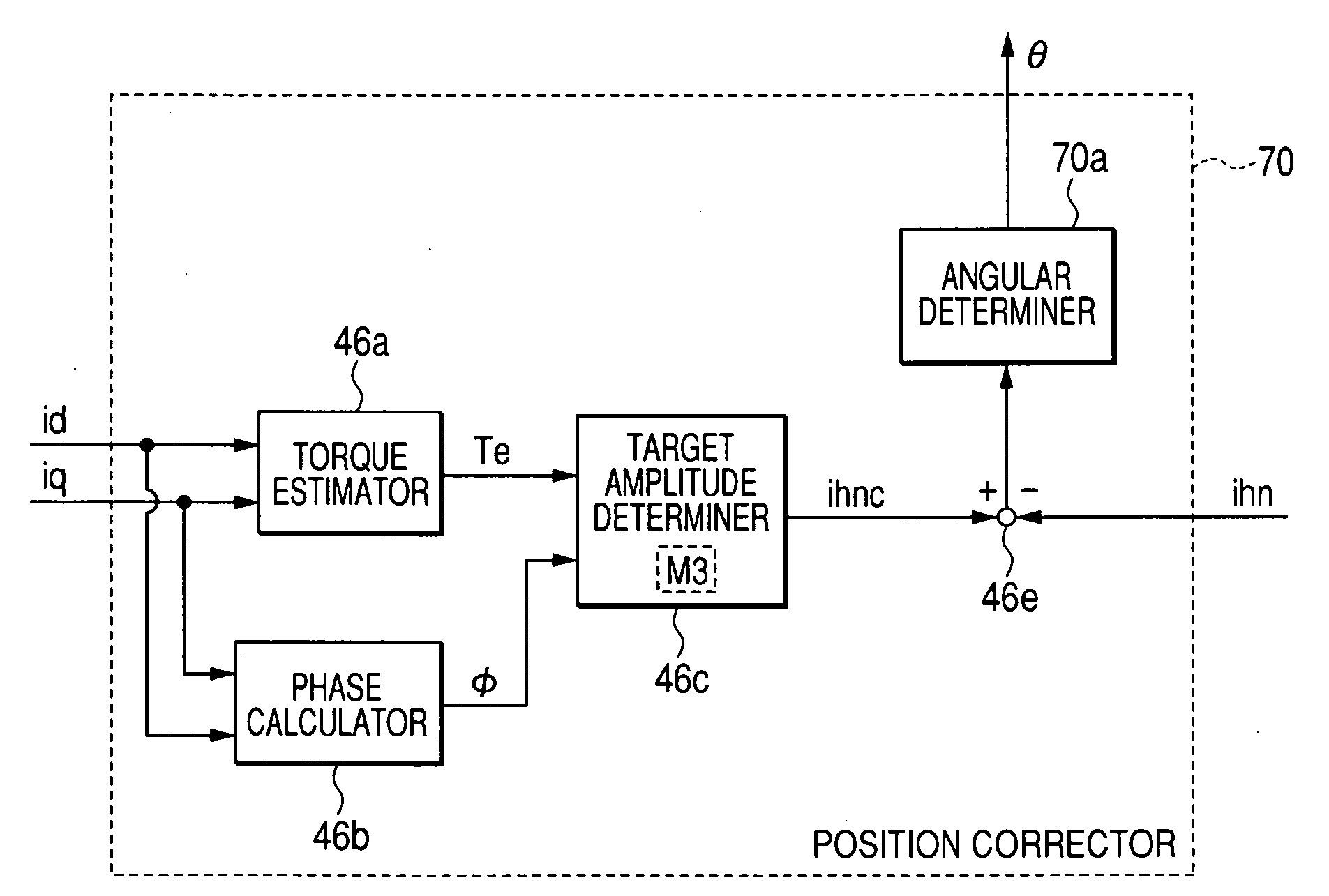

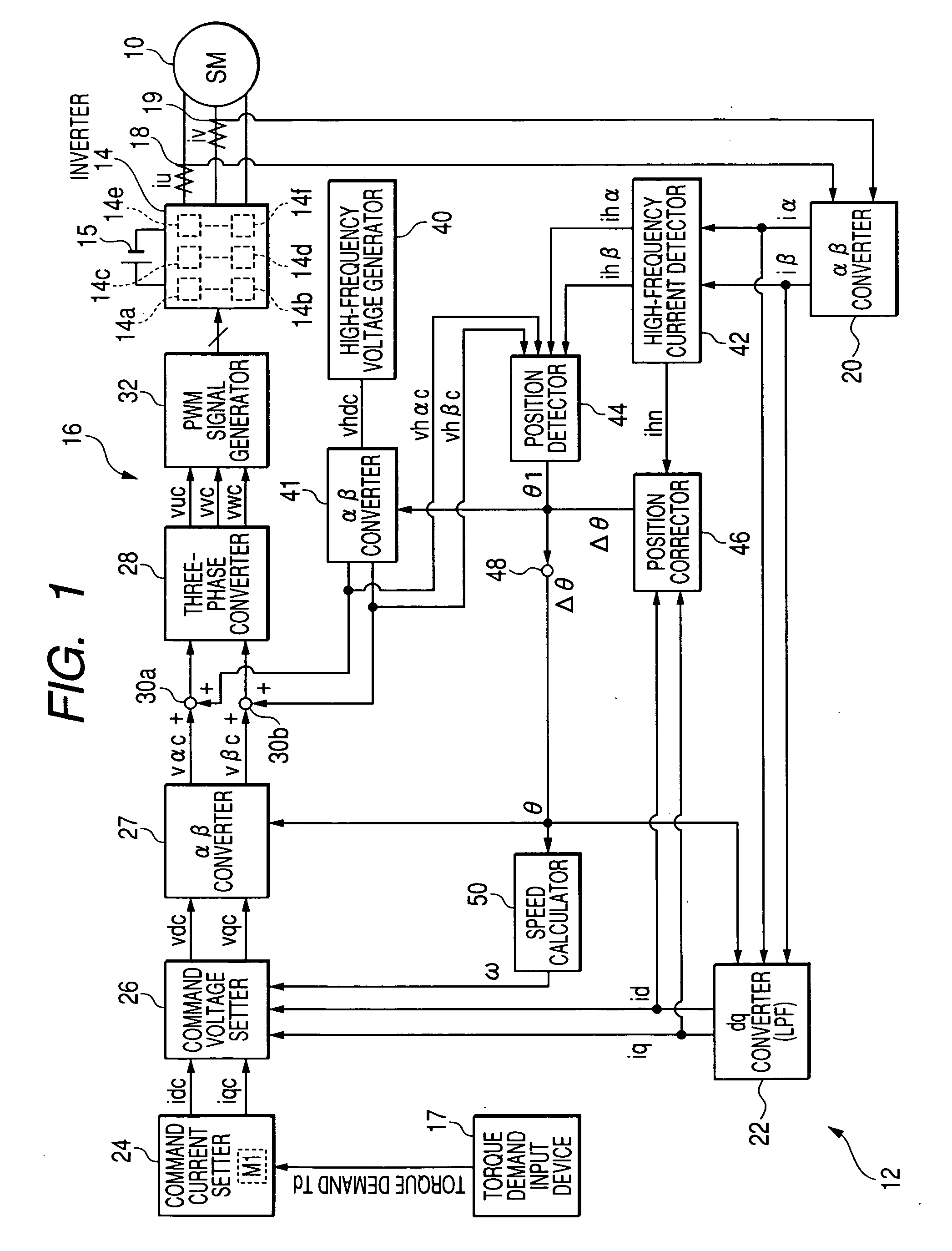

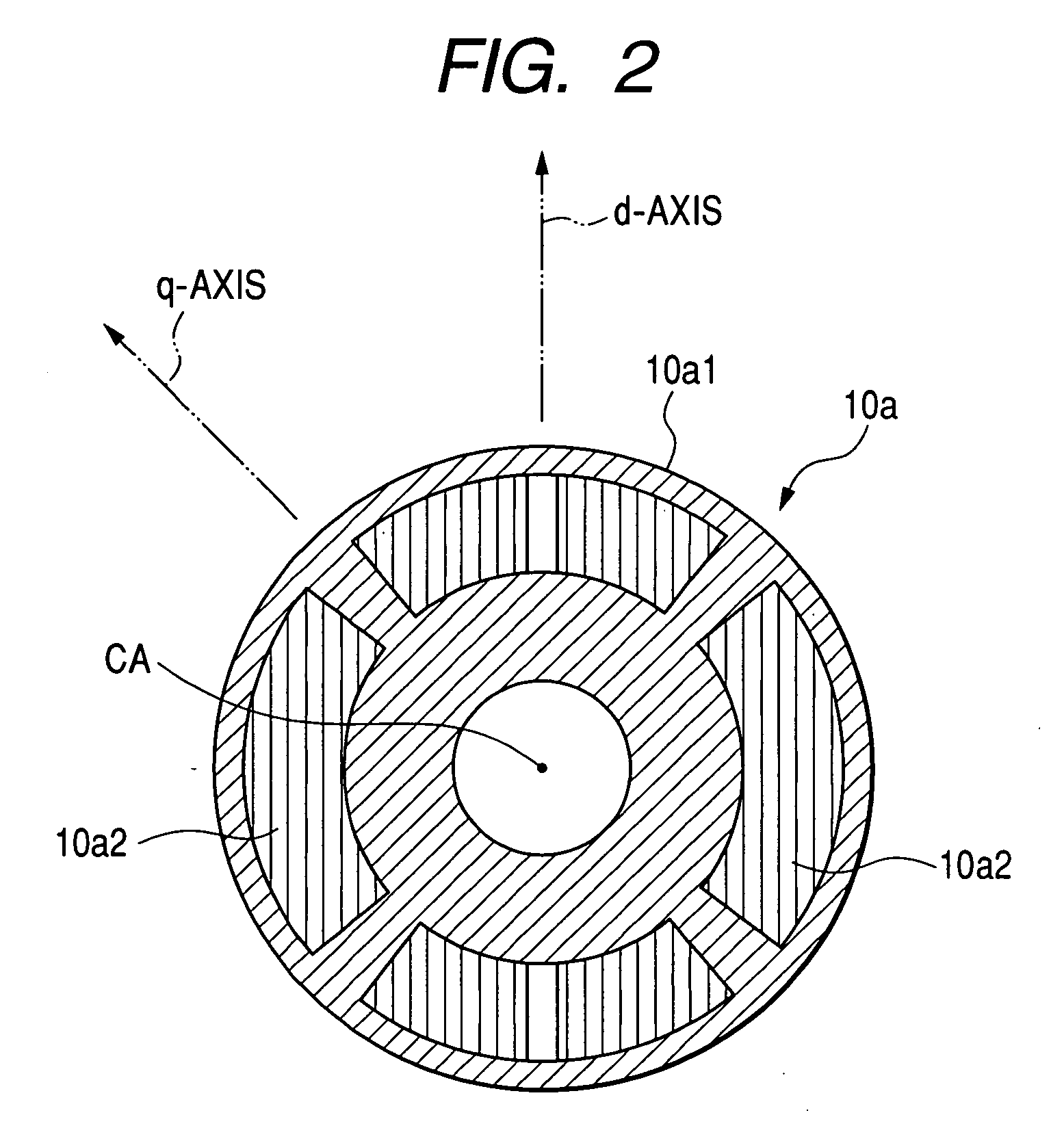

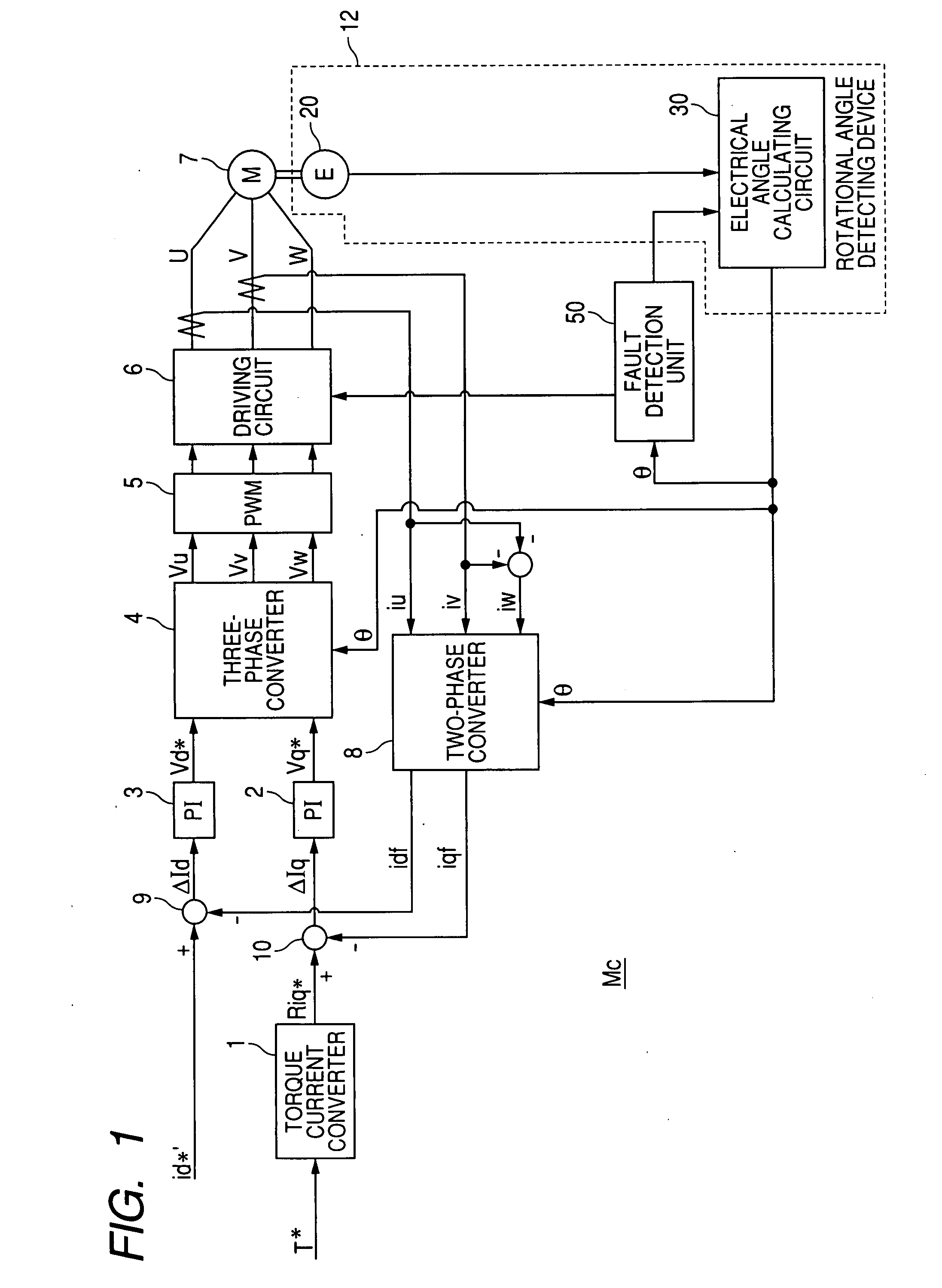

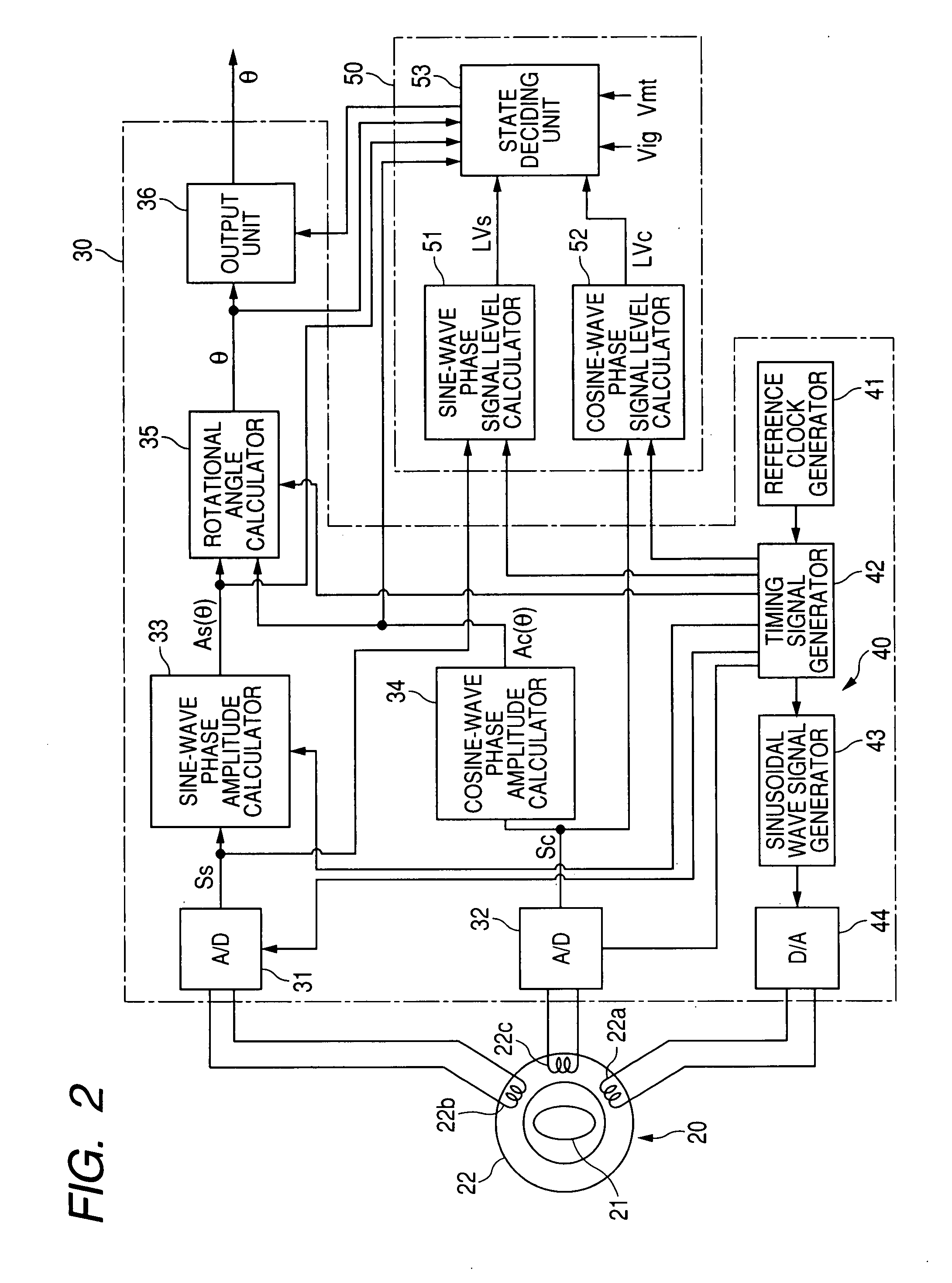

Control system for rotary electric machine with salient structure

ActiveUS20080111516A1Eliminate differencesSingle-phase induction motor startersMotor/generator/converter stoppersSignal onElectric machine

In a system for controlling rotation of a rotor of a multiphase rotary electric machine in relation to a stator thereof, a superimposing unit superimposes a first frequency signal on the input signal to the multiphase rotary electric machine. The first frequency signal has a first phase and a first period, and the first period is different from a period of rotation of the rotor. An amplitude detector detects an amplitude of a second frequency signal. The second frequency signal is actually propagated in the multiphase rotary electric machine with a second phase based on the superimposed first frequency signal. A rotation angle determiner determines a rotation angle of the rotor so as to eliminate a difference between the detected amplitude of the second frequency signal and a predetermined target amplitude thereof.

Owner:DENSO CORP

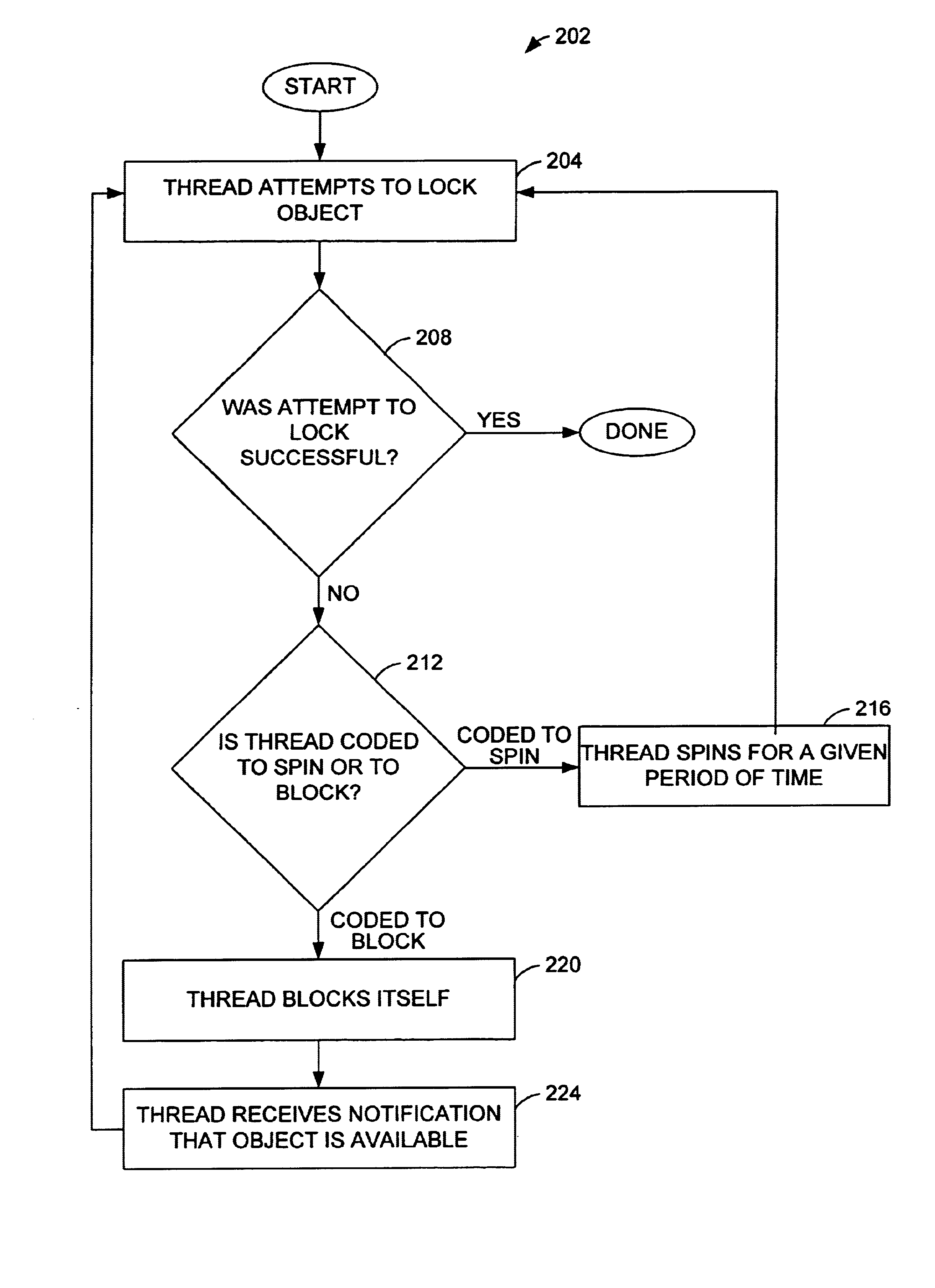

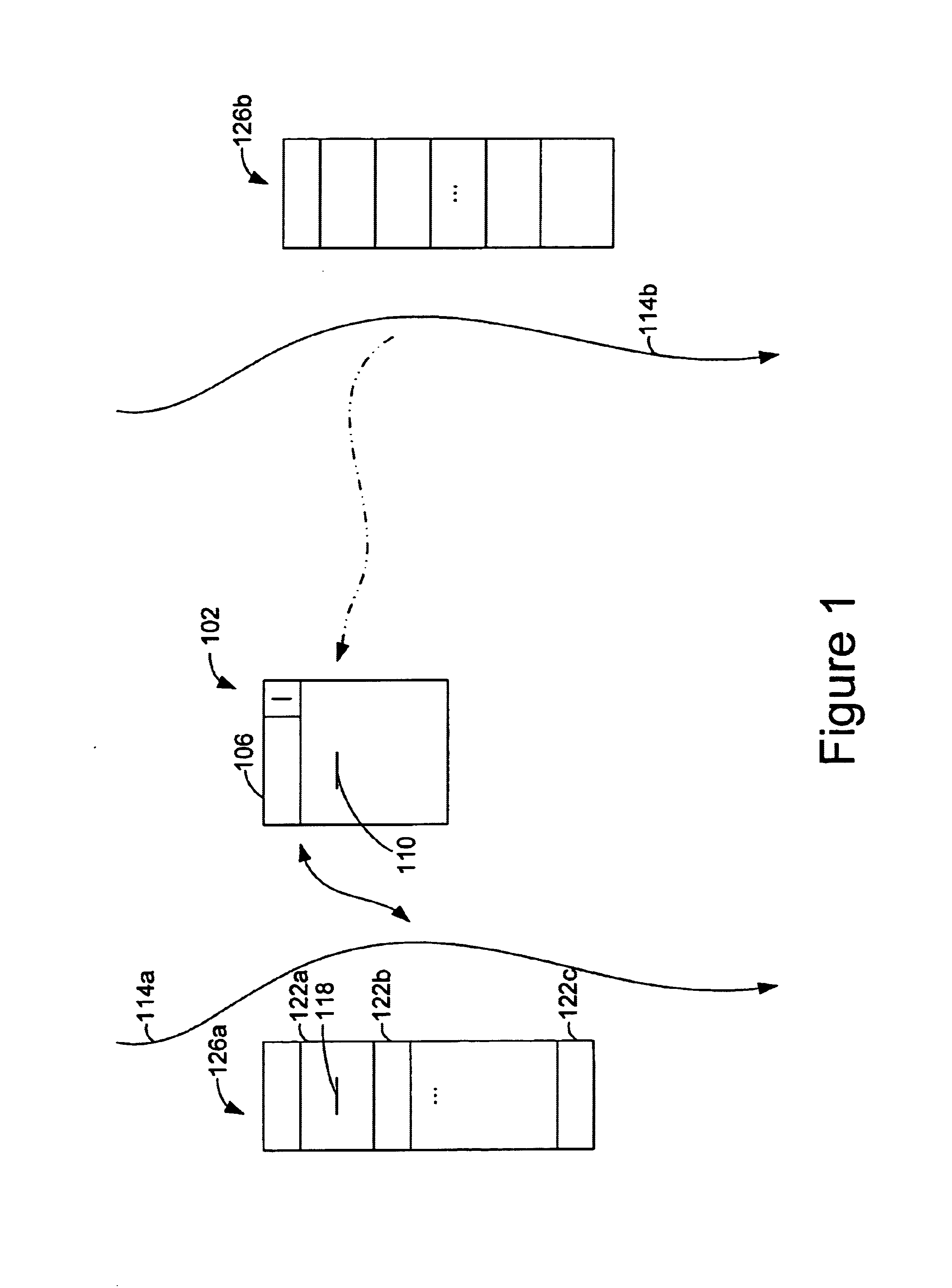

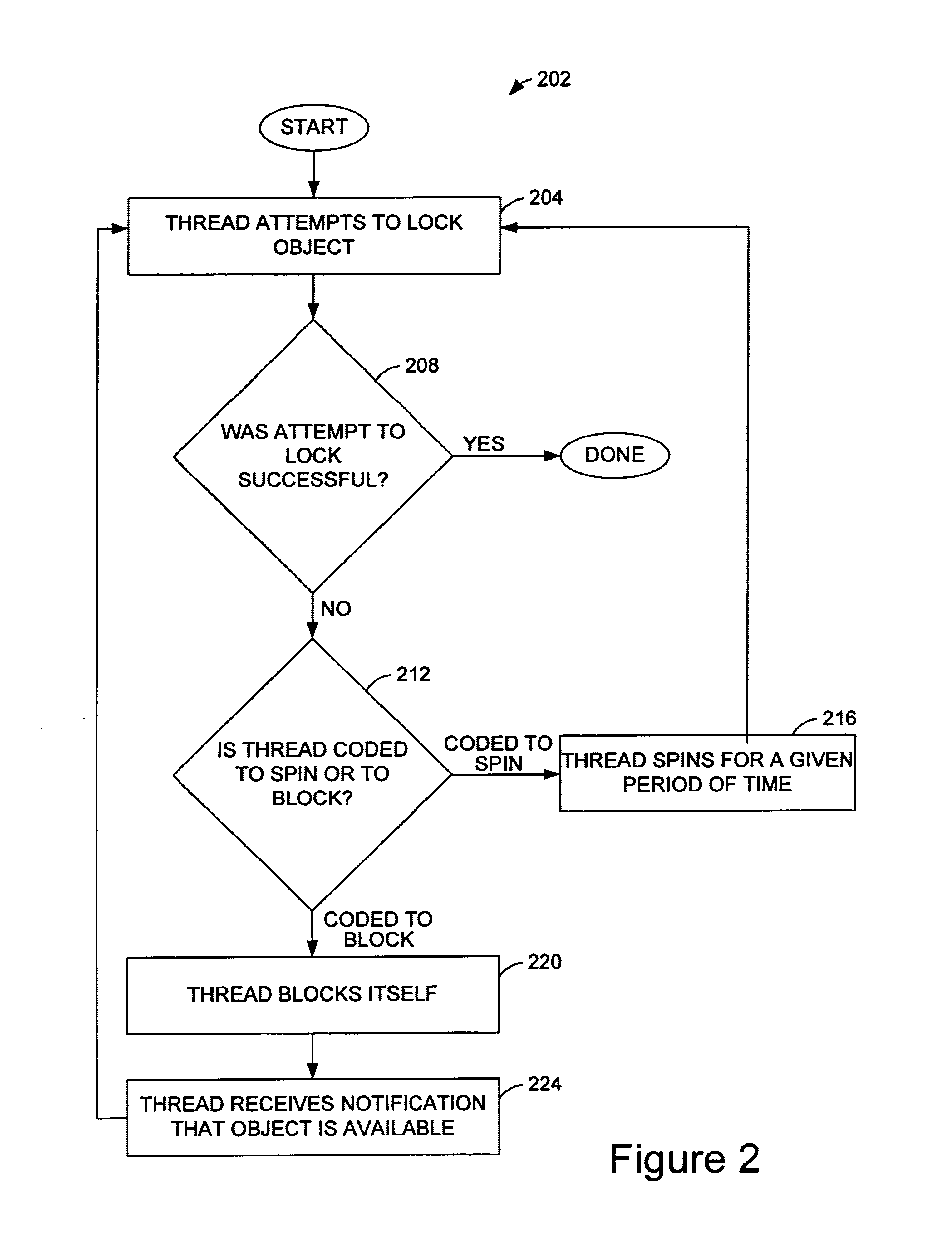

Method and apparatus for selecting a locking policy based on a per-object locking history

Methods and apparatus for locking an object using an efficient combination spinning and blocking process are disclosed. According to one aspect of the present invention, a method for acquiring ownership of an object in an object-based environment using a current thread includes determining when the object is owned by another thread, and locking the object when it is determined that the object is not owned by the another thread. A first spinning process, which is implemented when it is determined that the object is owned by the another thread, is arranged such that the current thread spins for up to a predetermined number of spin cycles associated with the current thread and the object. The predetermined number of spin cycles is determined using historical information, and is not based upon an overall system specification. When it is determined that the object has not been locked by the current thread during the first spinning process, a first blocking process is implemented.

Owner:ORACLE INT CORP

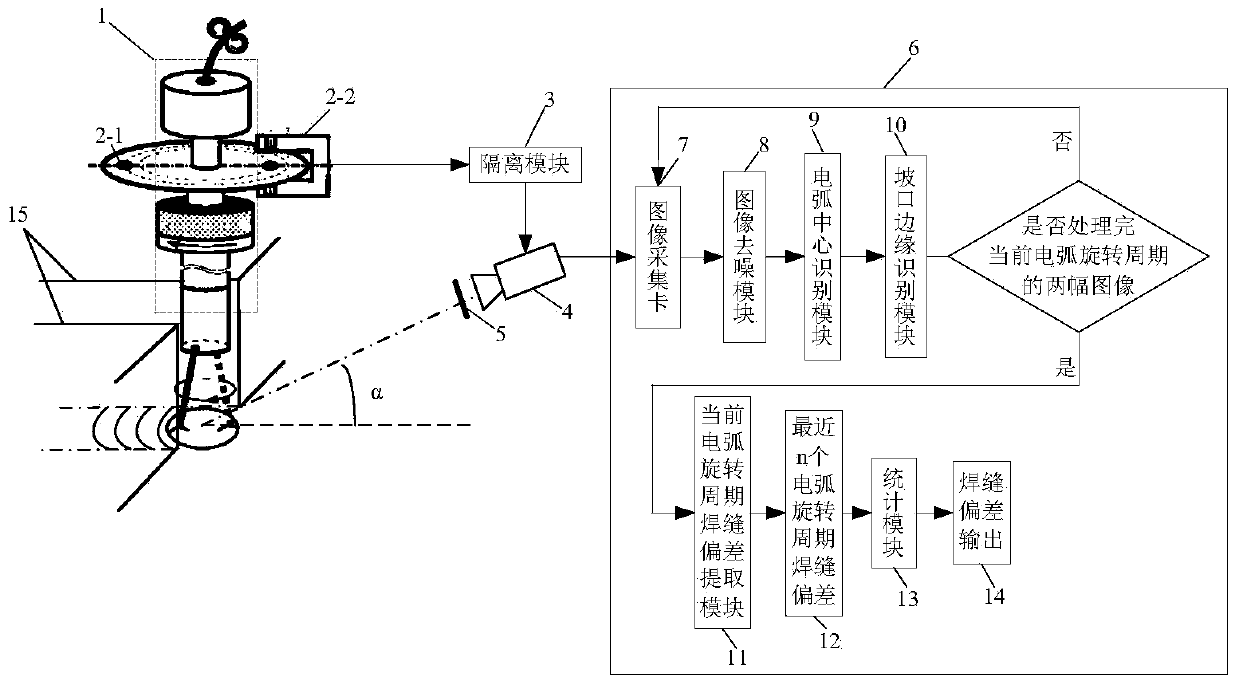

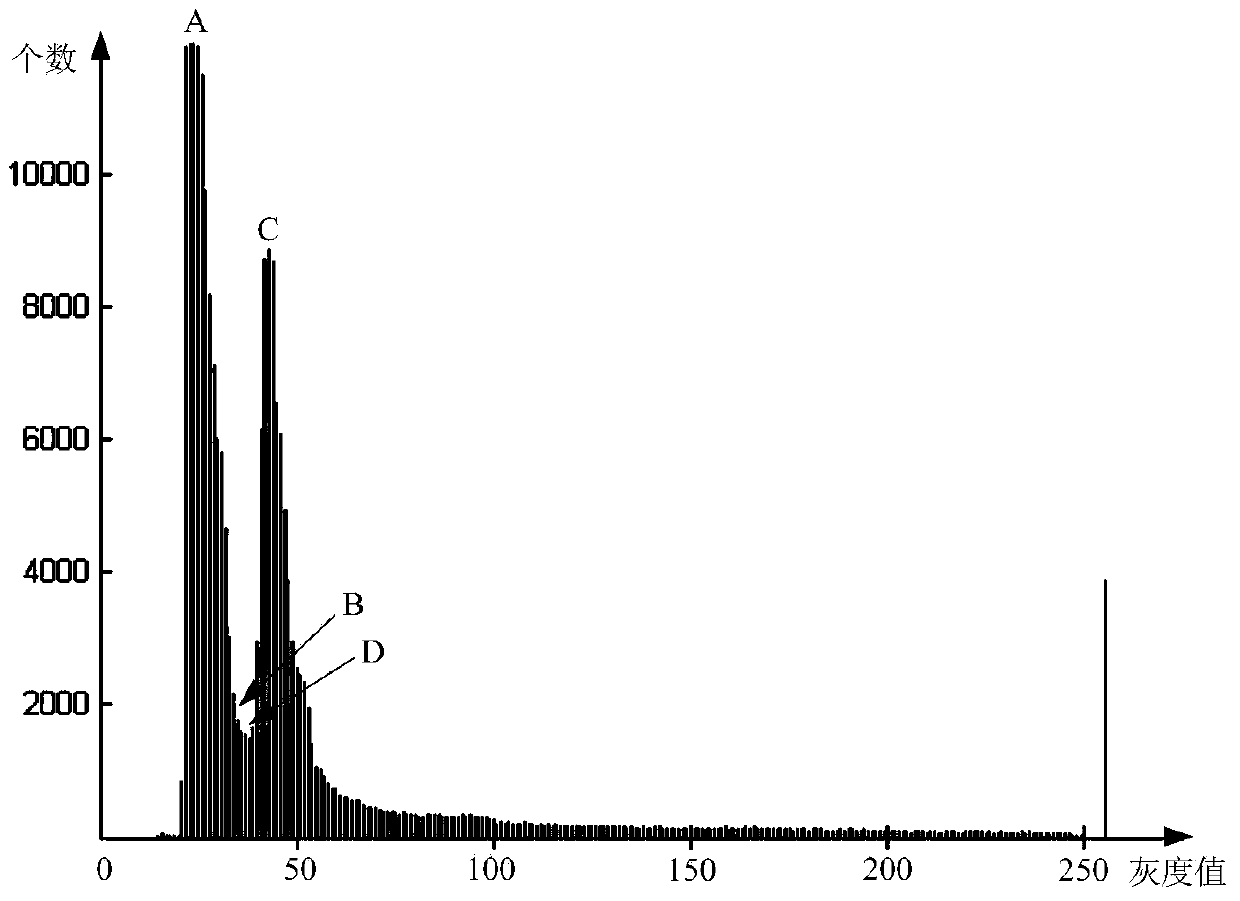

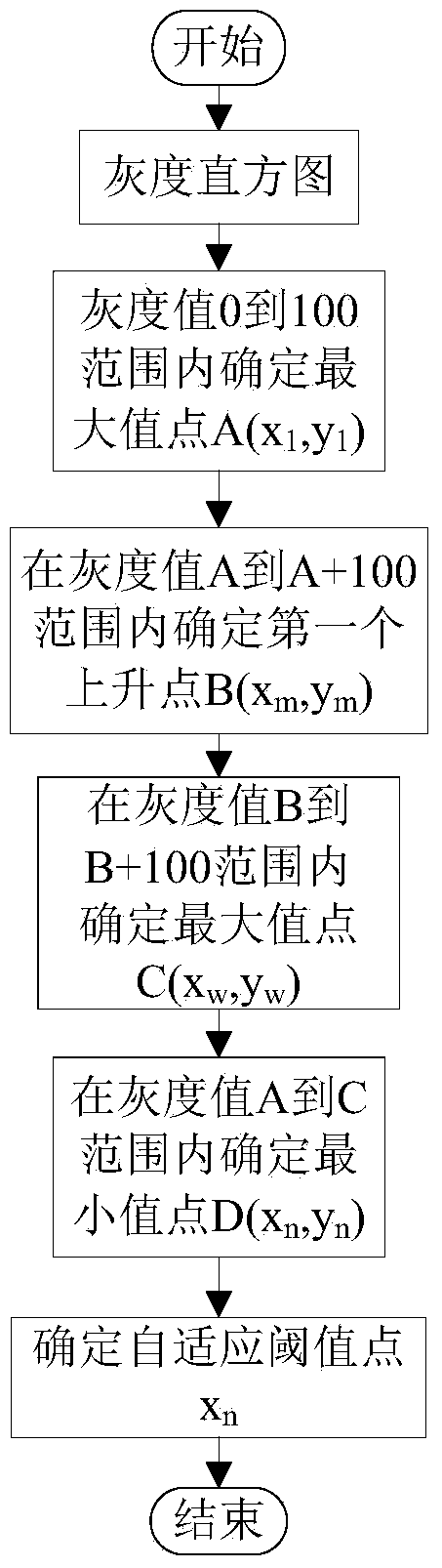

Rotating arc narrow gap MAG (metal active gas) welding seam offset identification device and method based on visual sensing

ActiveCN103464869AOvercoming Susceptibility to InterferenceHigh seam deviation efficiencyArc welding apparatusTorchWeld seam

The invention discloses a rotating arc narrow gap MAG (metal active gas) welding seam offset identification device and method based on visual sensing. The device comprises a rotating arc welding torch, an arc rotational position sensor, an insulation module, a CCD (charge coupled device) camera and a PC (personal computer). The PC comprises an image capture card, an image denoising module, an arc center recognizing module, a bevel edge recognizing module, a current arc rotating period welding seam offset extracting module, and a counting module. The front of the CCD camera is provided with dimmer glass, an optical filter and a UV lens. The method includes adopting the CCD camera and triggering a sampling manner to accurately acquire welding images that an arc rotates to the left and right of a bevel in each arc rotating period, and rapidly detecting the left and right bevel positions of the arc in the two images to acquire welding seam offset. According to the device and the method, efficiency of acquiring the welding seam offset is high, calculating method is accurate and reliable, and bevel bottom changes and arc electrical signals are affected rarely, and the method and the device are adaptable to high-frequency rotating arc welding.

Owner:JIANGSU UNIV OF SCI & TECH

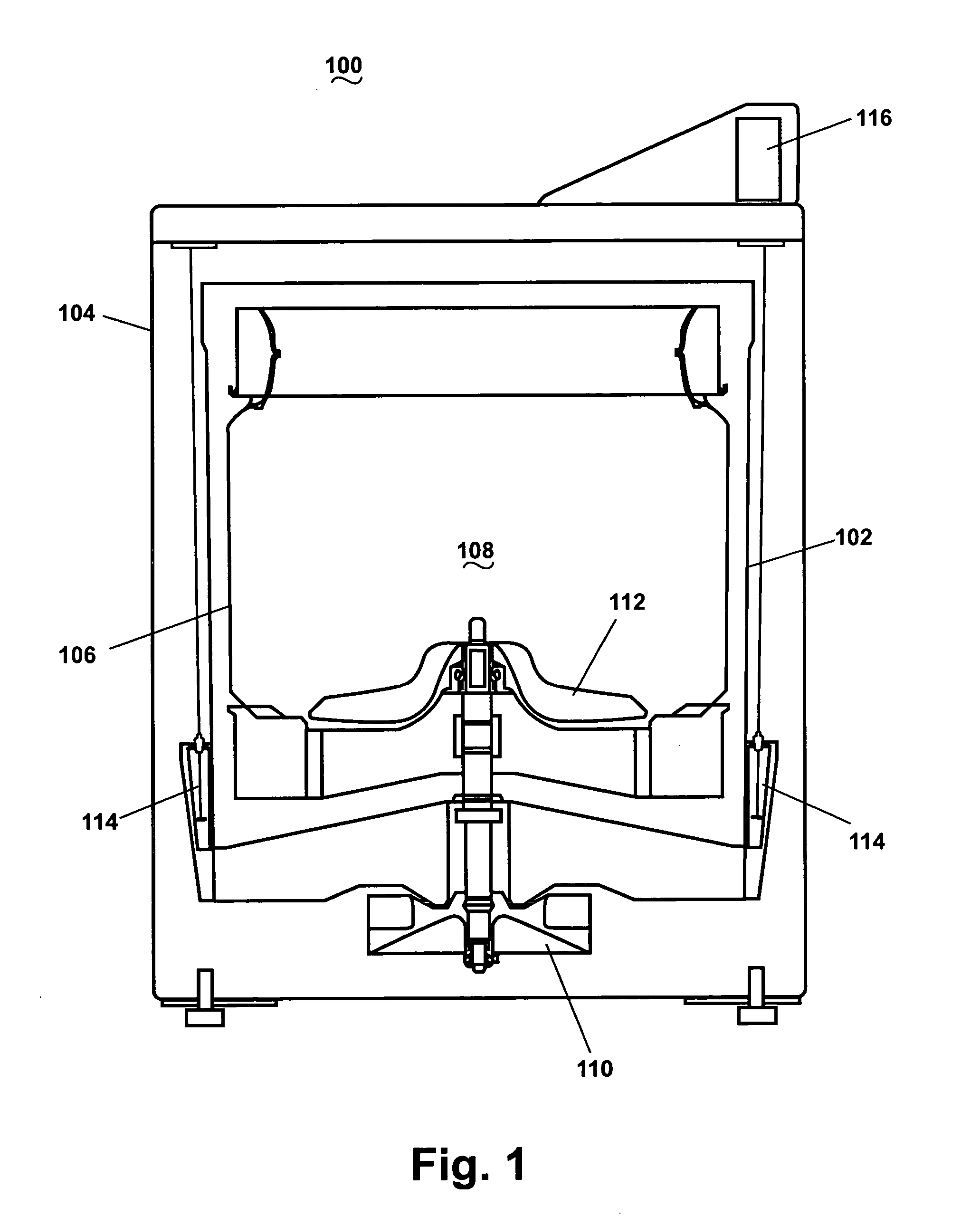

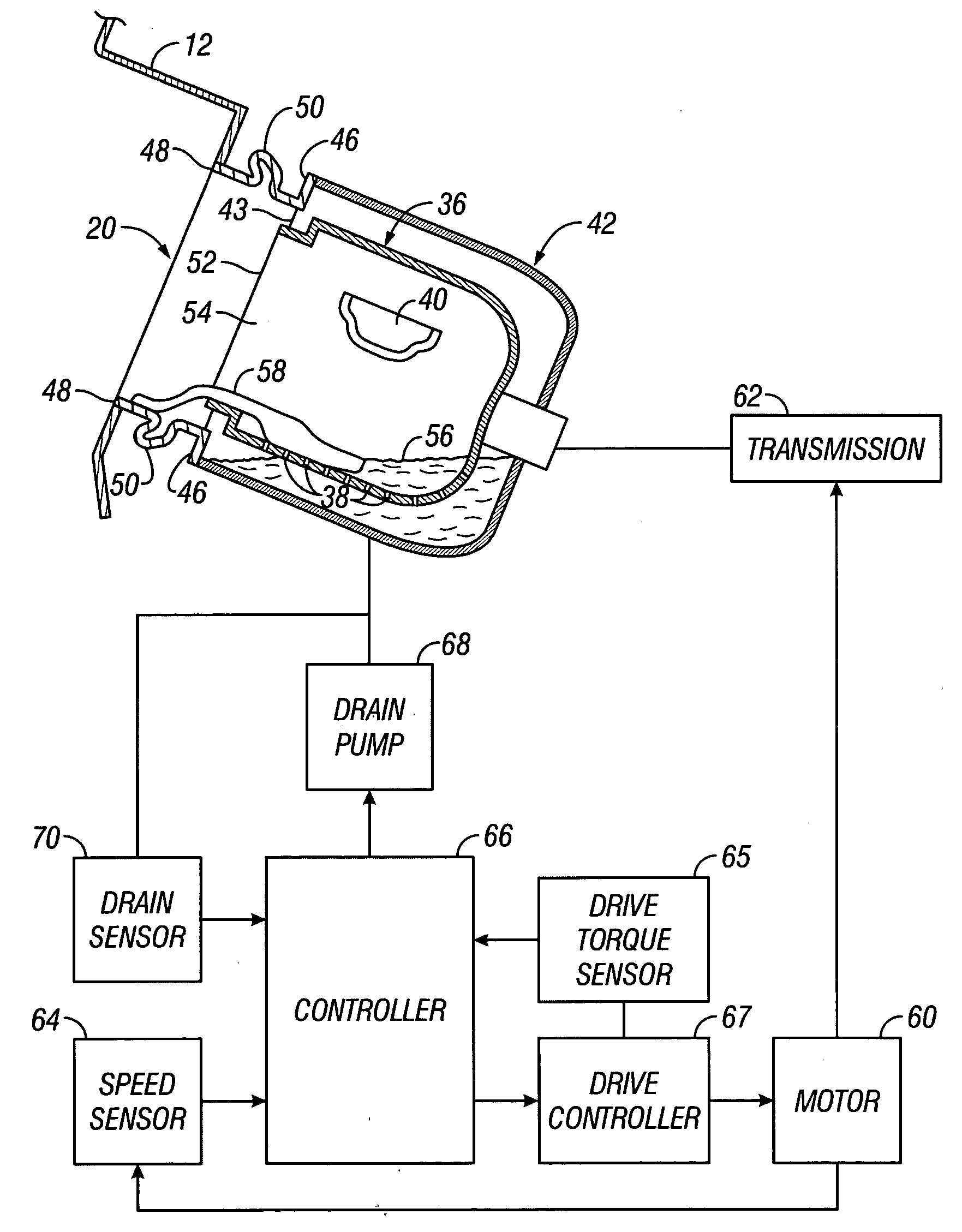

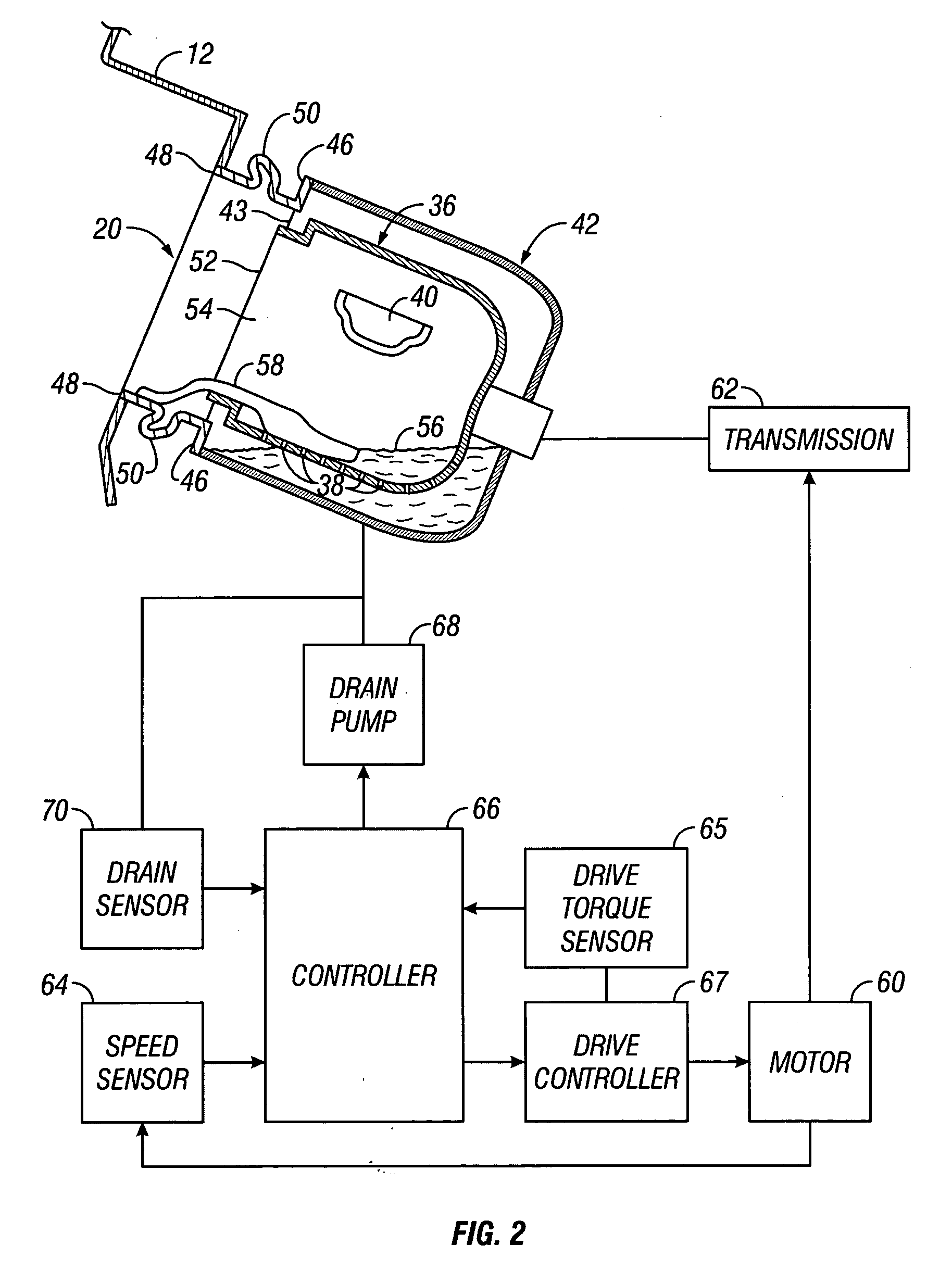

Method of detecting an off-balance condition of a clothes load in a washing machine

An off-balance detection method comprises a plurality of off-balance detection schemes that utilize wash basket speed to detect an off-balance load condition at speed ranges that span the entire spin cycle and include speeds corresponding to natural frequencies of a mass comprising a wash tub and a wash basket. The schemes can be used alone or in combination with one or more of the other schemes. The off-balance detection method can further comprise a power limiting method to prevent motor overload when an off-balance condition is present.

Owner:WHIRLPOOL CORP +1

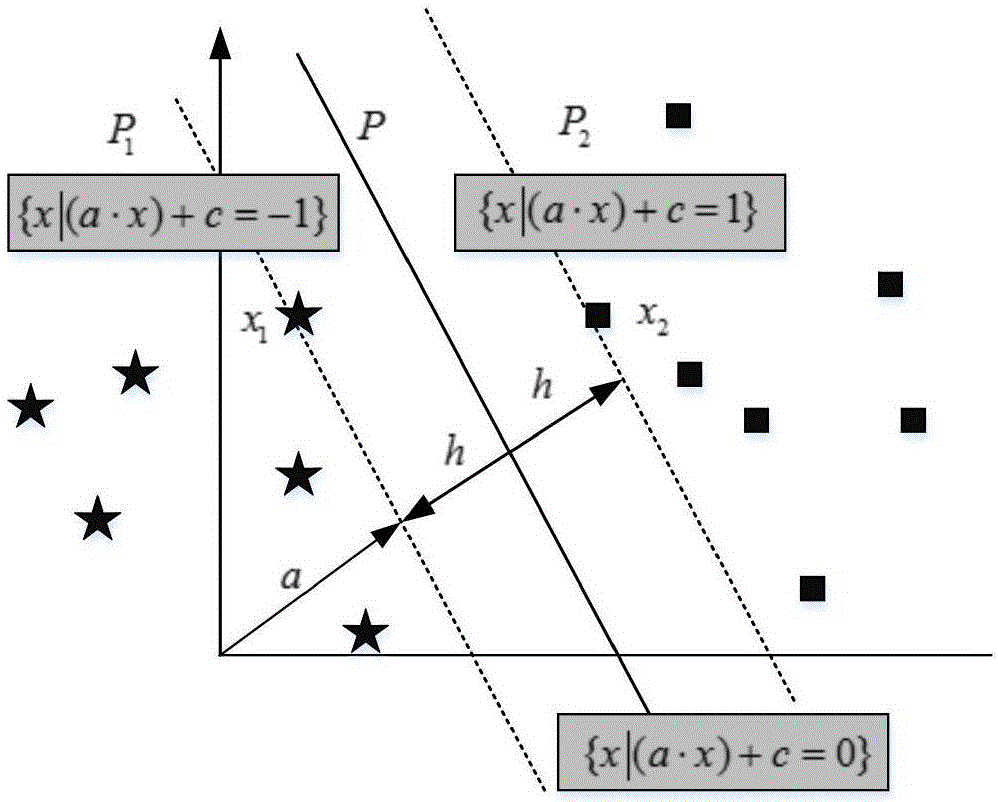

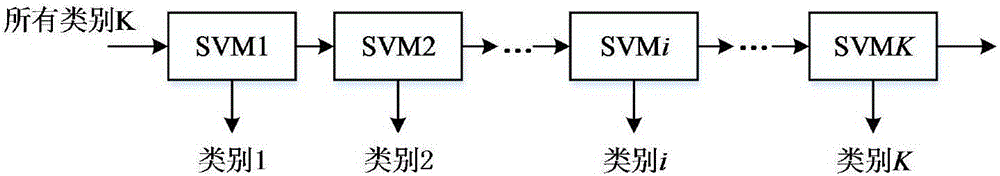

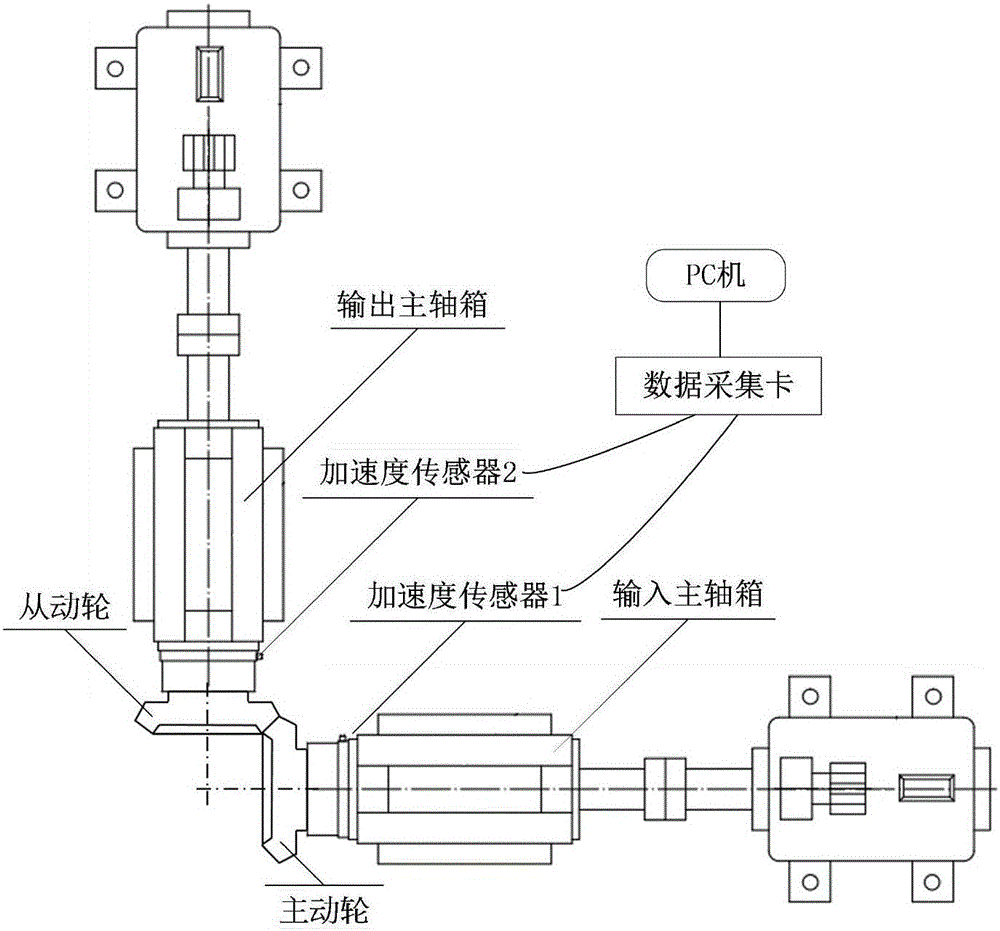

Analysis method of gear train noise based on ensemble empirical mode decomposition and support vector machine

InactiveCN106778694AEfficient extractionHigh recognition accuracy and fastMachine gearing/transmission testingCharacter and pattern recognitionSupport vector machineFeature vector

The invention provides an analysis method of gear train noise based on ensemble empirical mode decomposition and support vector machine. Firstly, the method of ensemble empirical mode decomposition stepwise decomposes the different time scale wave or trend of gear train noise signals and a set of intrinsic mode functions IMF. Gear train noise useful signals are extracted and the signals including mesh frequency are found from the result of ensemble empirical mode decomposition and conducted reconsitution. time synchronous averaging is operated according to gear rotation period and the signal irrelevant to gear rotation frequency is weaken through time expansion treatment. The characteristic parameter of treated gear train noise signals is calculated and a set of characteristic parameters with large differences is selected as characteristic vector. The characteristic vector as sample is divided into two groups, wherein the two groups have the same numbers and are used as a training sample and a testing sample. The method has little man-made operation and ensures the accuracy of analysis. The intelligent analysis method is based on support vector machine and has high and fast recognition accuracy of gear train prosperity.

Owner:BEIJING UNIV OF TECH

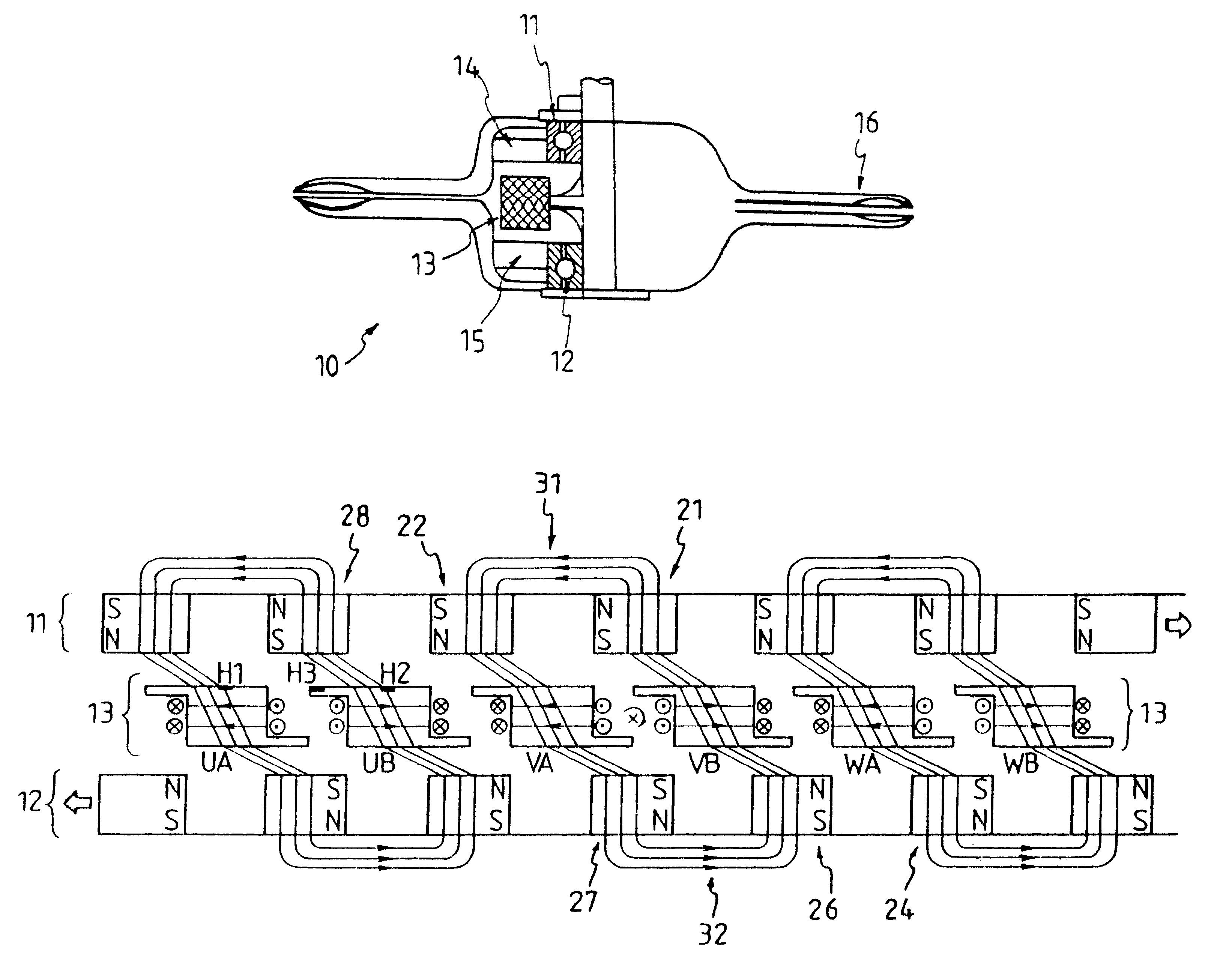

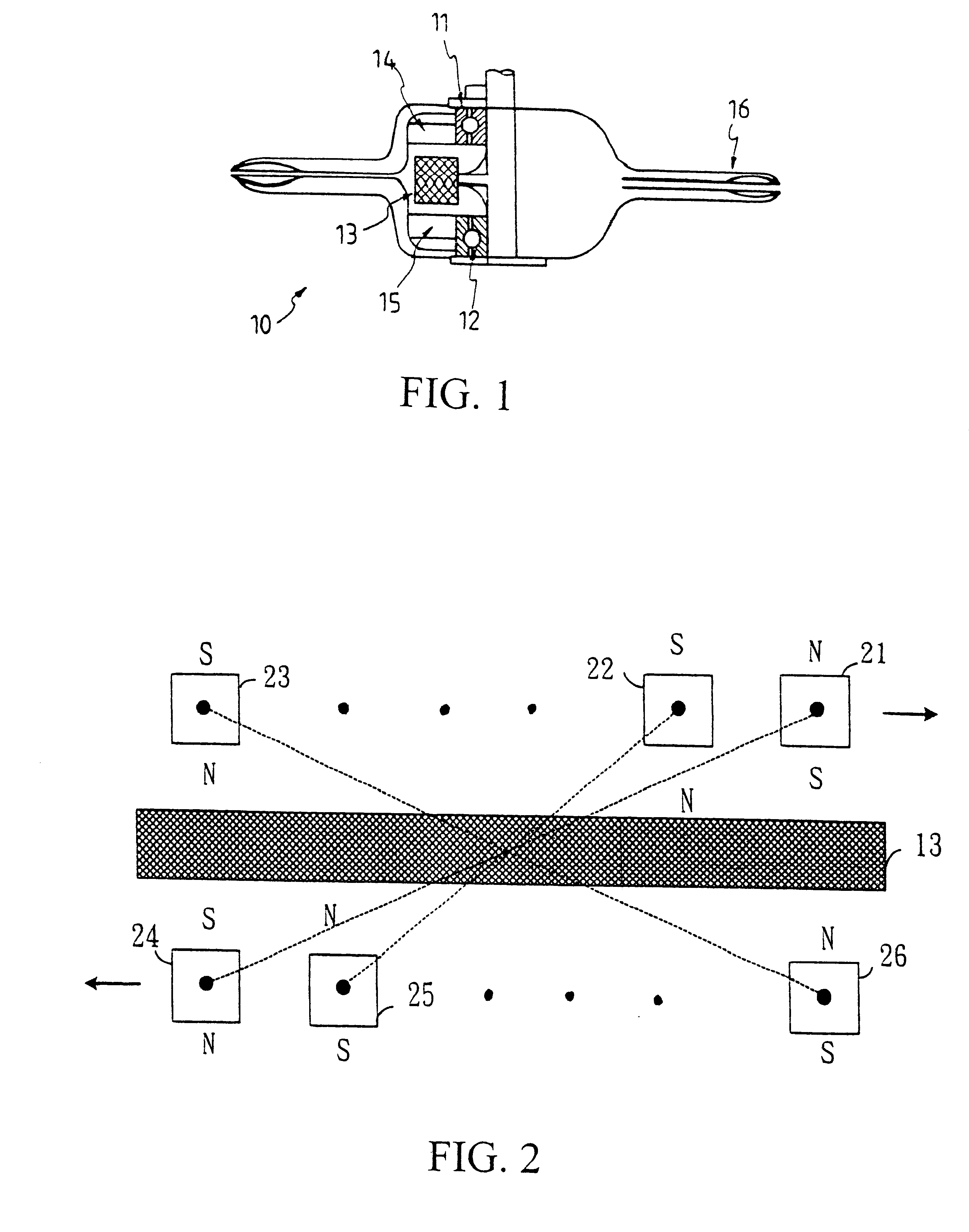

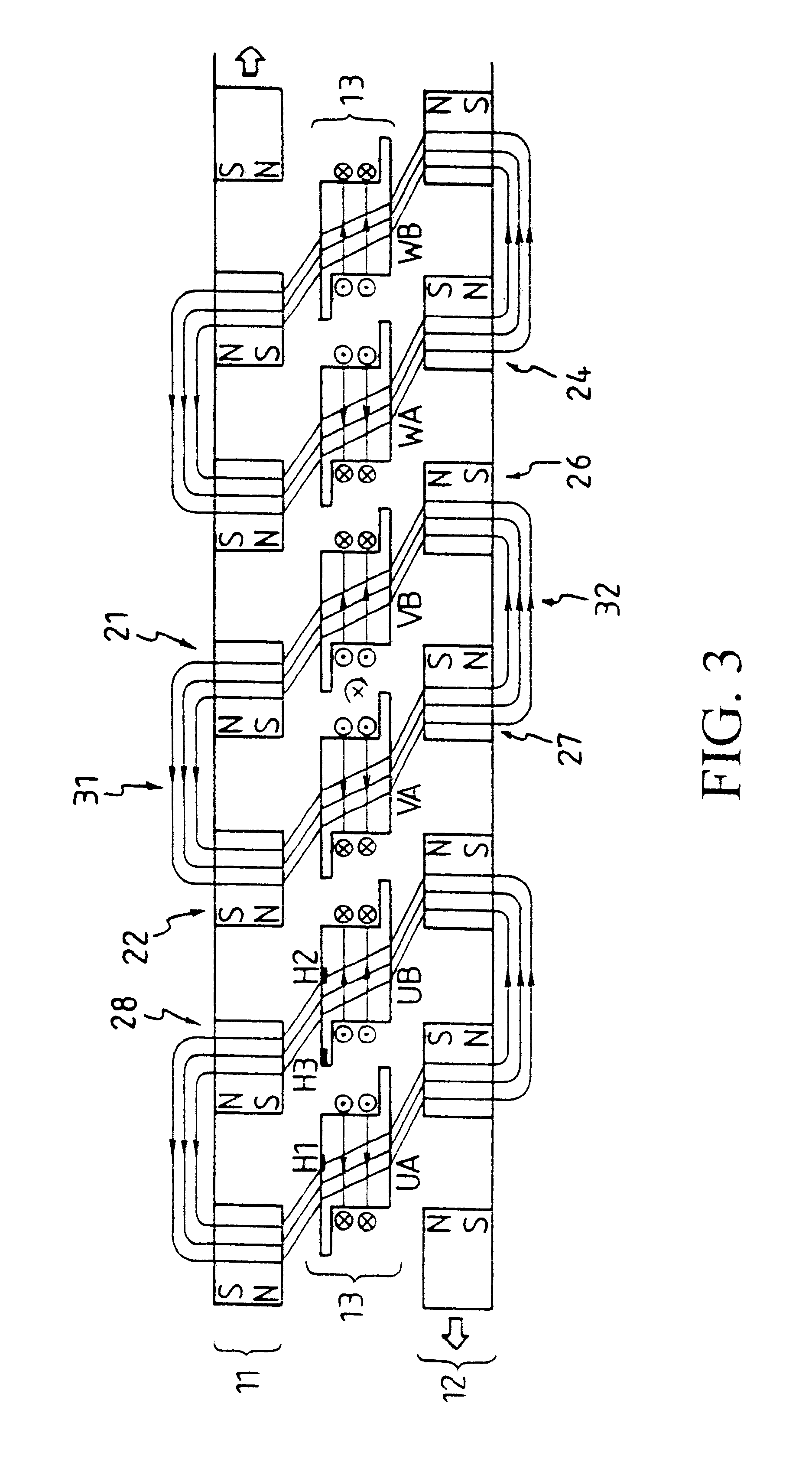

Multiple layer double rotor single stator skew symmetry permanent magnet rotating motor

InactiveUS6455969B1Simple structureHigh-efficient powerMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsMagnetic polesRotation cycle

A single-stator-double-rotor rotating motor has one upper-layer rotor, one intermediate-layer armature and one lower-layer rotor. The upper-layer rotor and lower-layer rotor are embedded with the same number of magnets to form a magneto type magnetic pole, stator electrodes of the same number as the number of magnets are disposed on the intermediate-layer armature to form an electro type magnetic pole. A skew symmetry exists between an upper-layer rotor and a corresponding lower-layer rotor, and the upper-layer rotor and the lower-layer rotor are rotated in opposite directions by commutation of the current flowing through exciting coils of the stator electrodes every T / N of time, wherein T is a rotation period of the upper-layer rotor, and N is the number of the magnets.

Owner:NAT CHUNG SHAN INST SCI & TECH

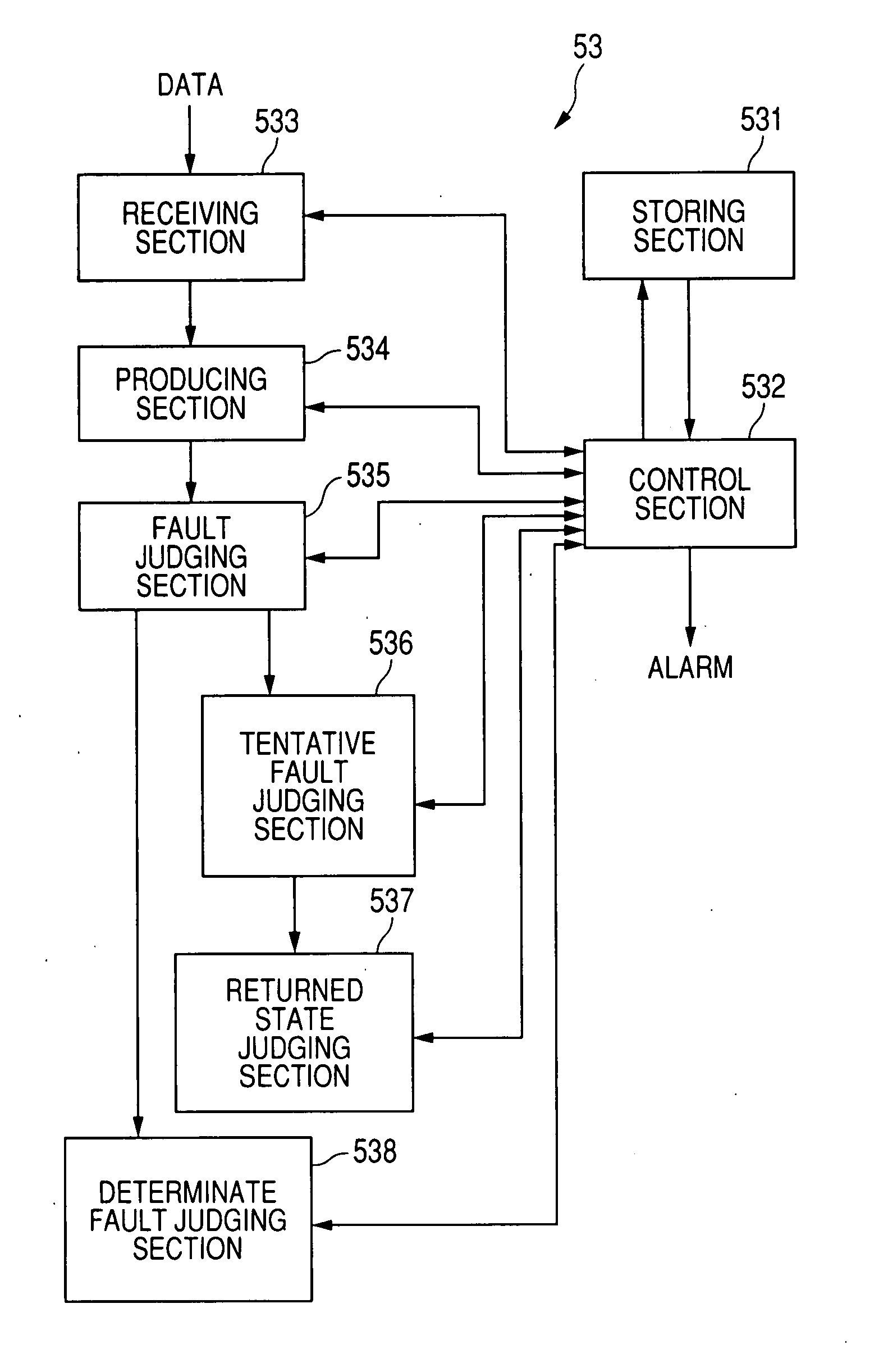

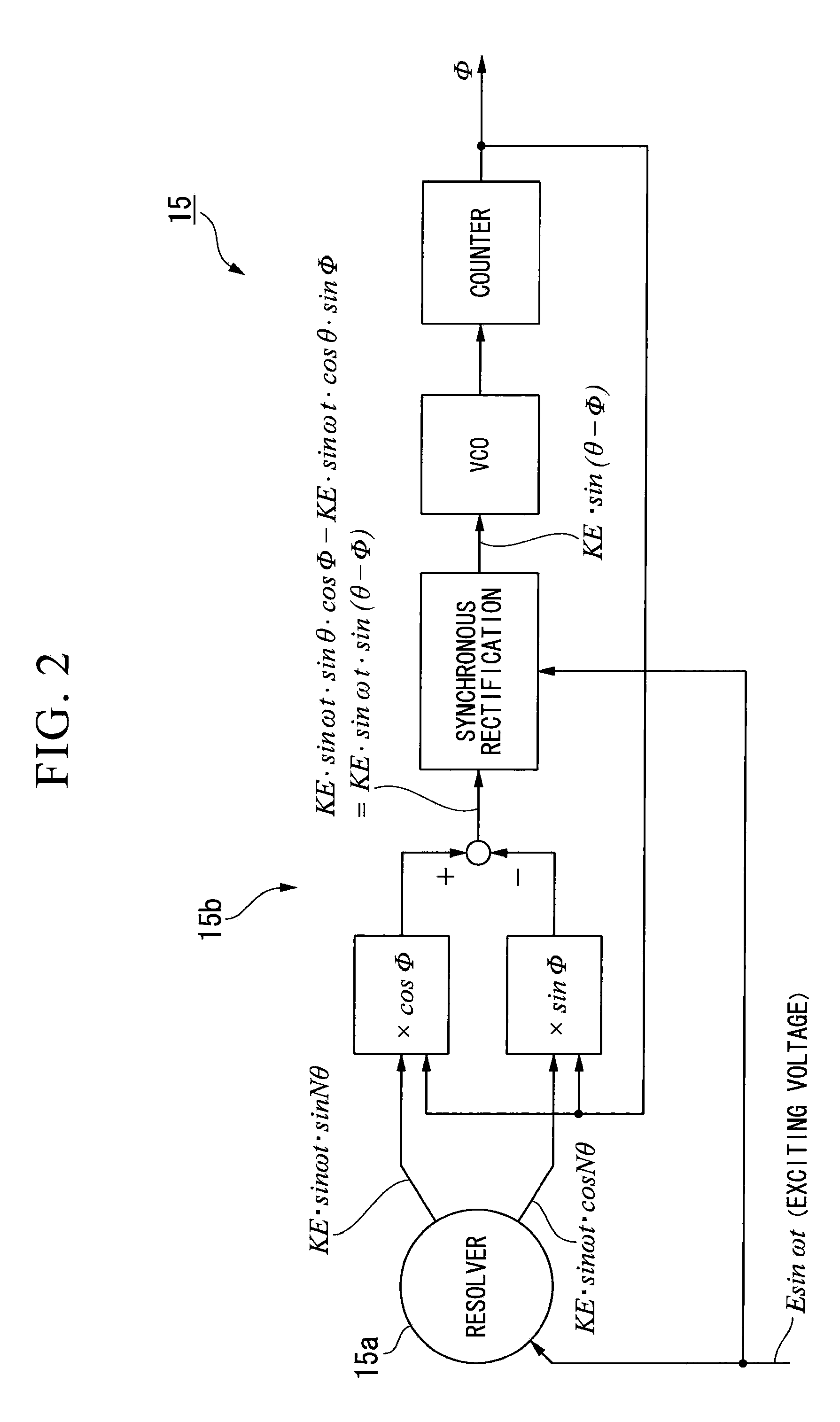

Fault detection unit for rotation angle detecting device

InactiveUS20080052562A1Accurately detect occurrenceDigital computer detailsNuclear monitoringWave shapeRotation cycle

A fault detection unit detects a fault occurred in a detecting device which detects a rotational angle of a rotor with respect to a stator from sine and cosine wave signals having amplitudes modulated in a sinusoidal wave shape in a cycle of rotation of the rotor. The unit produces a judging value from the signals, judges occurrence of a fault from the value placed out of a normal range, and judges the device to be in a tentative fault state when the judgment is continued. After this judgment, when the rotational angle is changed over its entire range while the value is placed within the normal range, the unit judges the device to have returned to a normal state. In contrast, when the judgment is still continued, the unit judges the device to be in a determinate fault state and decides the occurrence of the fault.

Owner:DENSO CORP

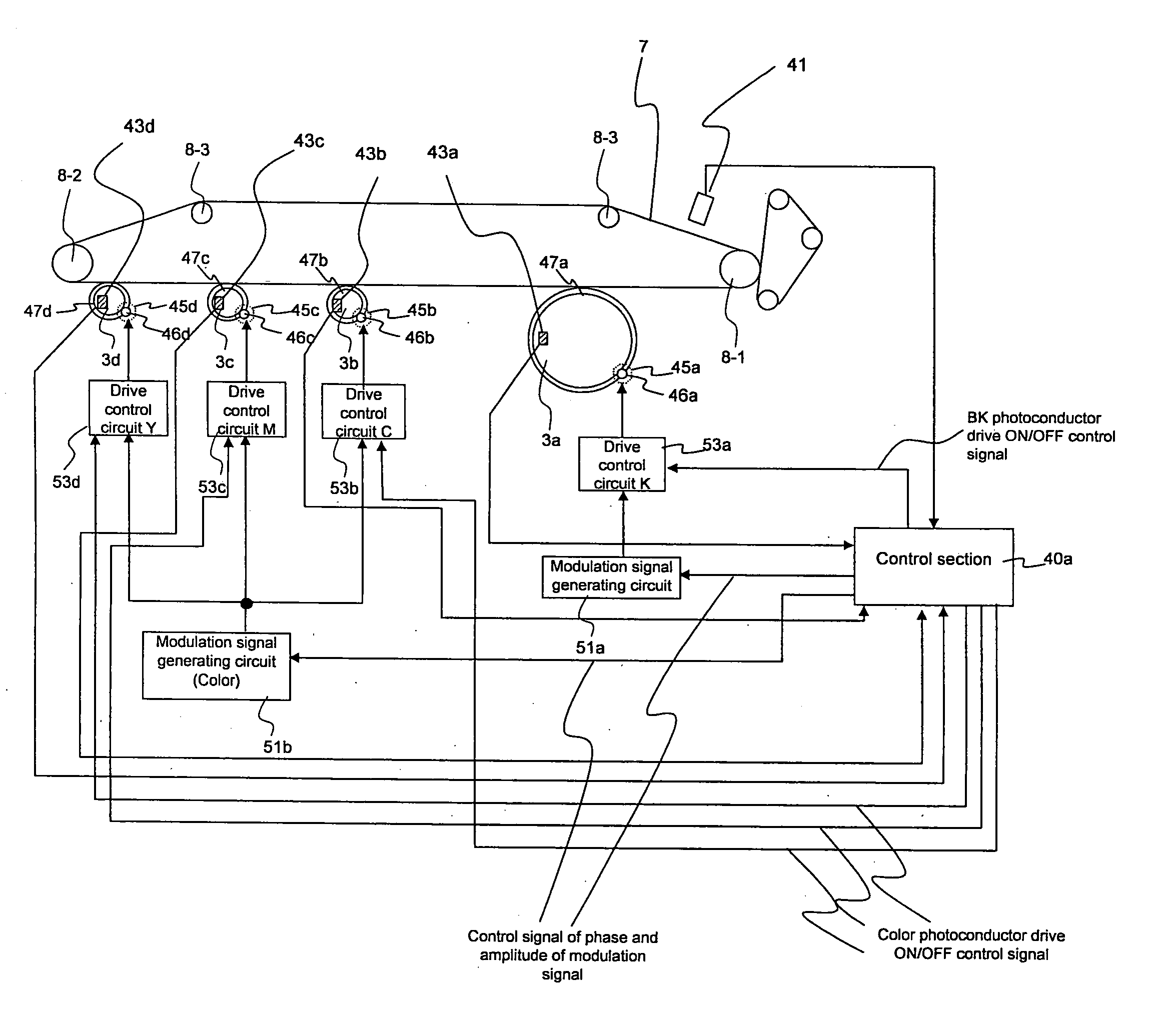

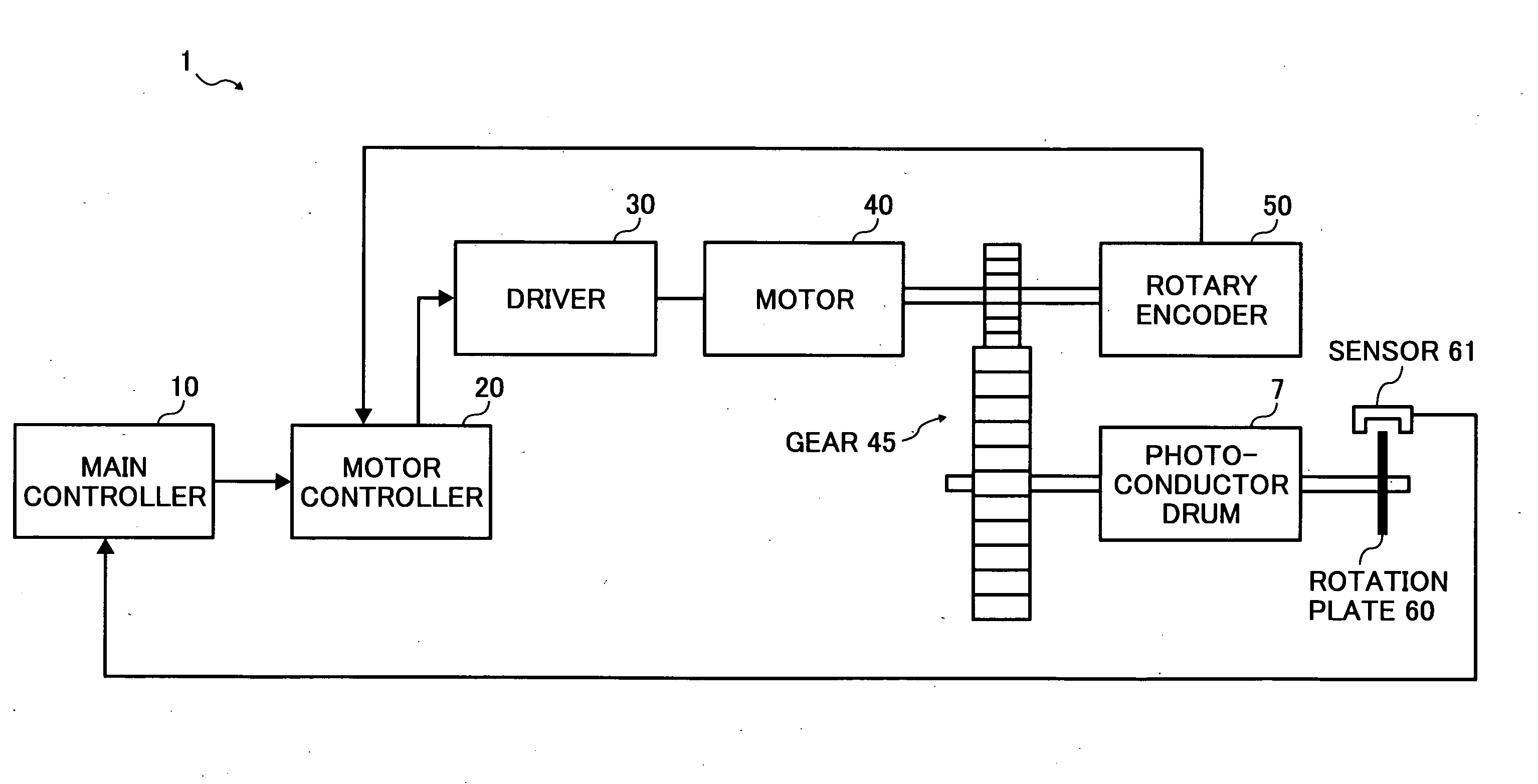

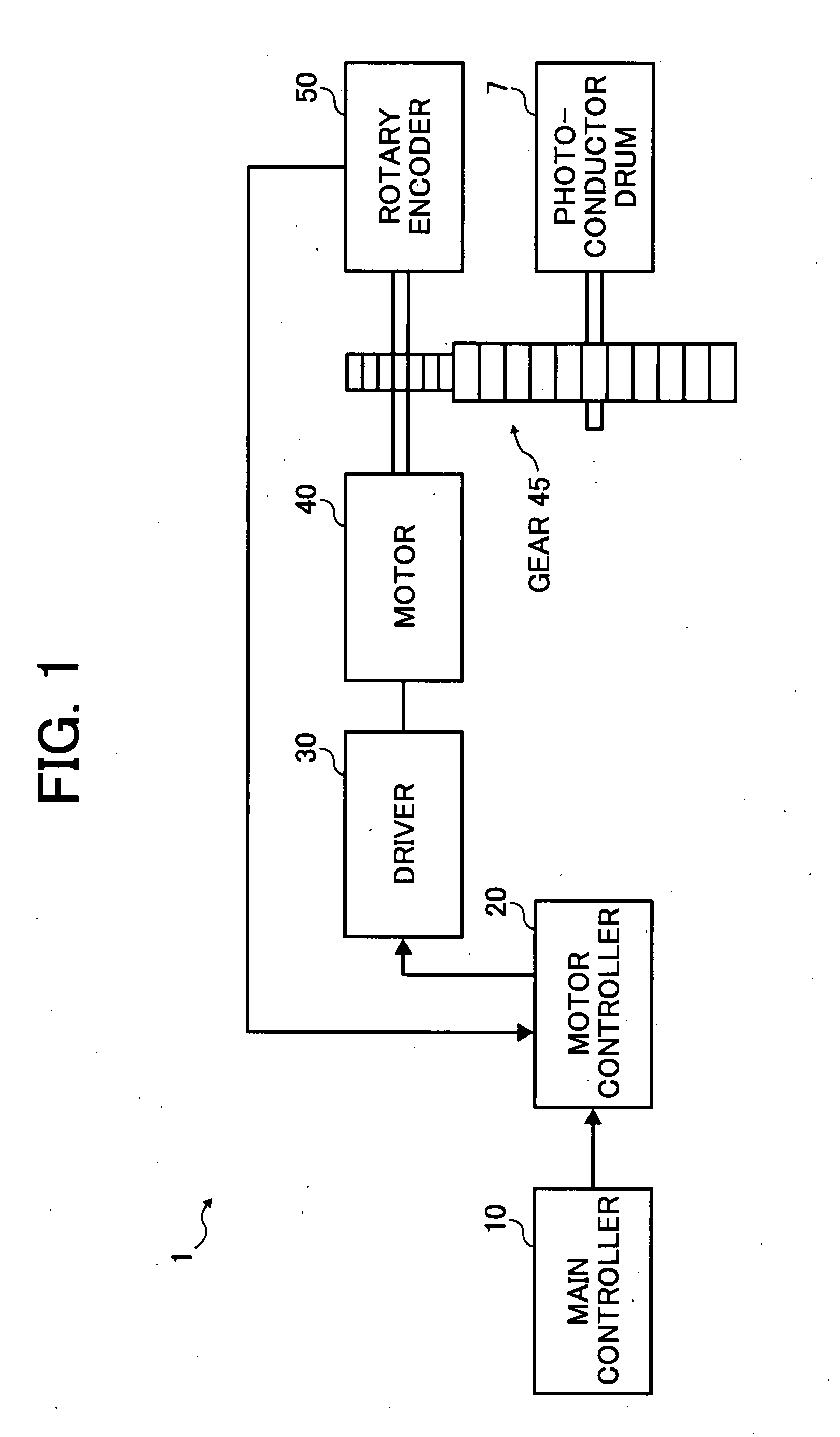

Belt drive control method, belt-drive control device, and image forming apparatus

A rotational speed of a first roller and a time required for a second roller to make one rotation are measured. A controller calculates an amplitude and a phase of fluctuation in a rotational speed in one rotation period of the first roller while the first roller is rotated by a predefined angle based on the speed and the time. The controller corrects measured speed of the first roller based on the amplitude and the phase, and controls a driving roller based on corrected speed.

Owner:RICOH KK

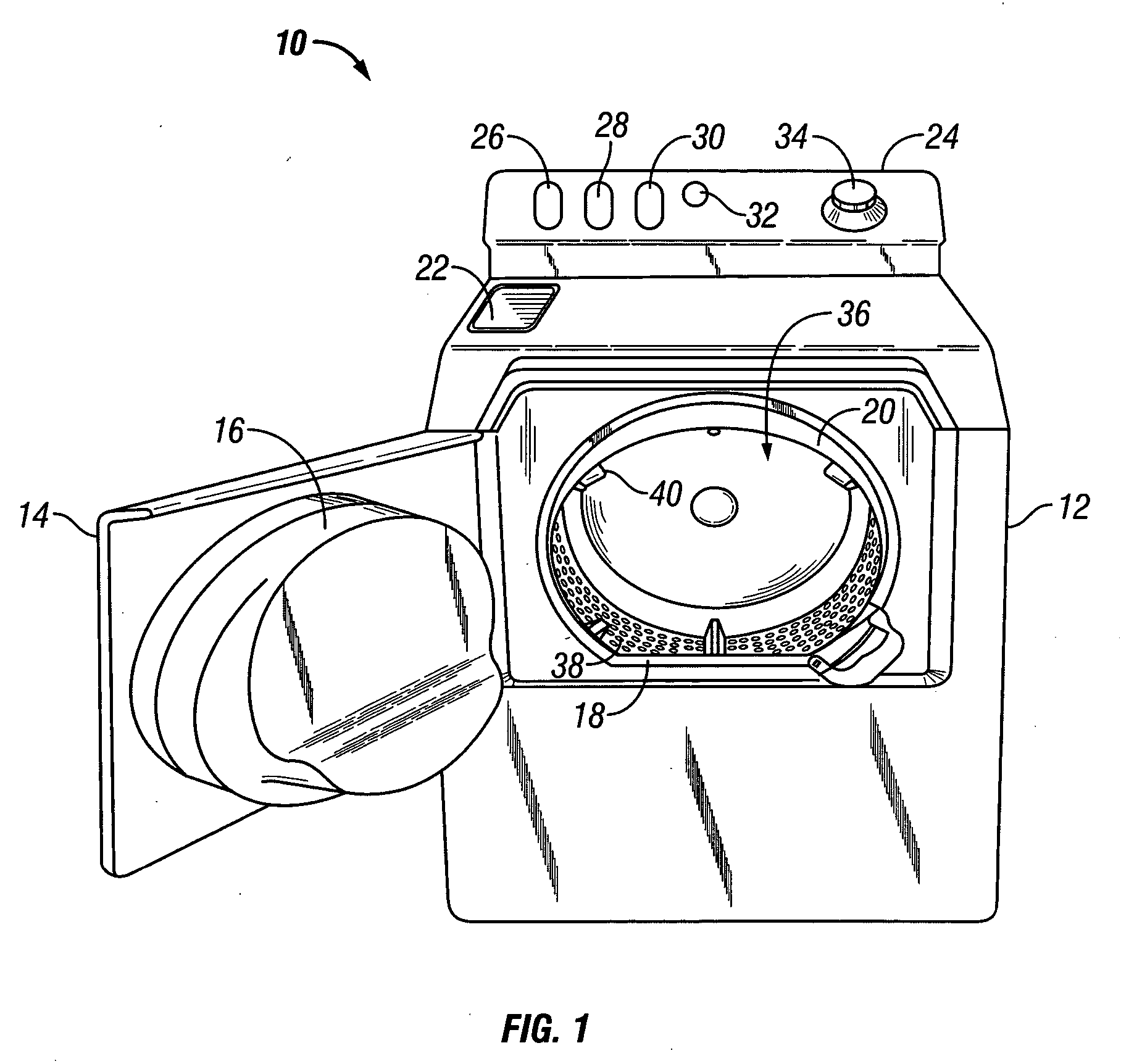

Method and apparatus for spinning fabrics

InactiveUS20050102766A1Reduce rotation speedOther washing machinesControl devices for washing apparatusControl theorySpin speed

The method of the present invention includes rotating the washing basket at a tumble speed insufficient to plaster the fabrics against the basket wall. The rotational speed is increased to a first plaster speed which causes the fabrics to be plastered against the basket wall. The plaster speed is increased to a second plaster speed higher than the first. Then the rotational speed of the washing basket is returned to the first plaster speed and the washing fluid is drained from the washing basket. The spin cycle is then begun. During the spin cycle a torque or speed sensor senses increased torque or reduced rotational speed of the washing basket caused by fabrics frictionally engaging the flexible boot during rotation of the washing basket at the spin speed. If such conditions are sensed, the spin cycle is terminated.

Owner:MAYTAG

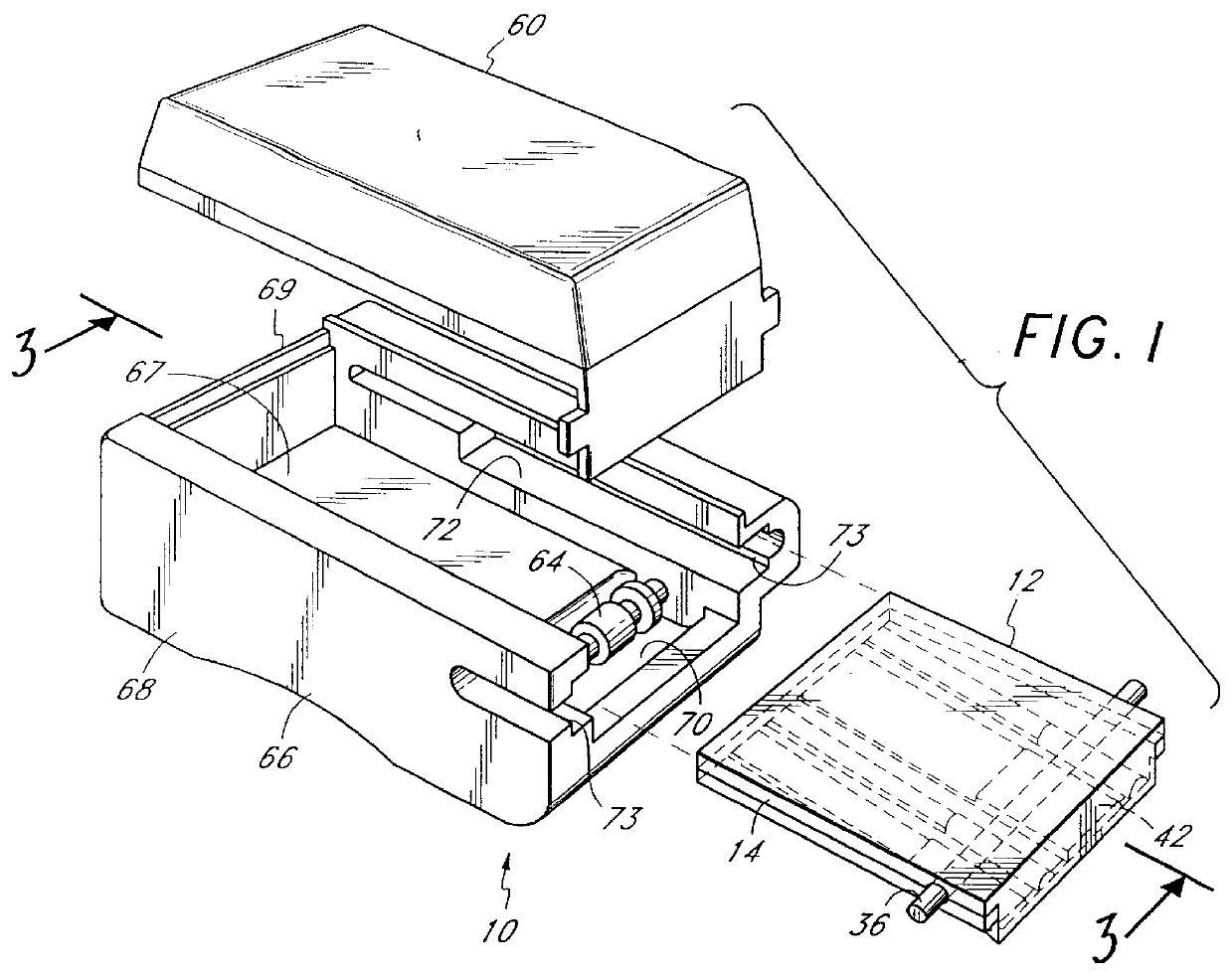

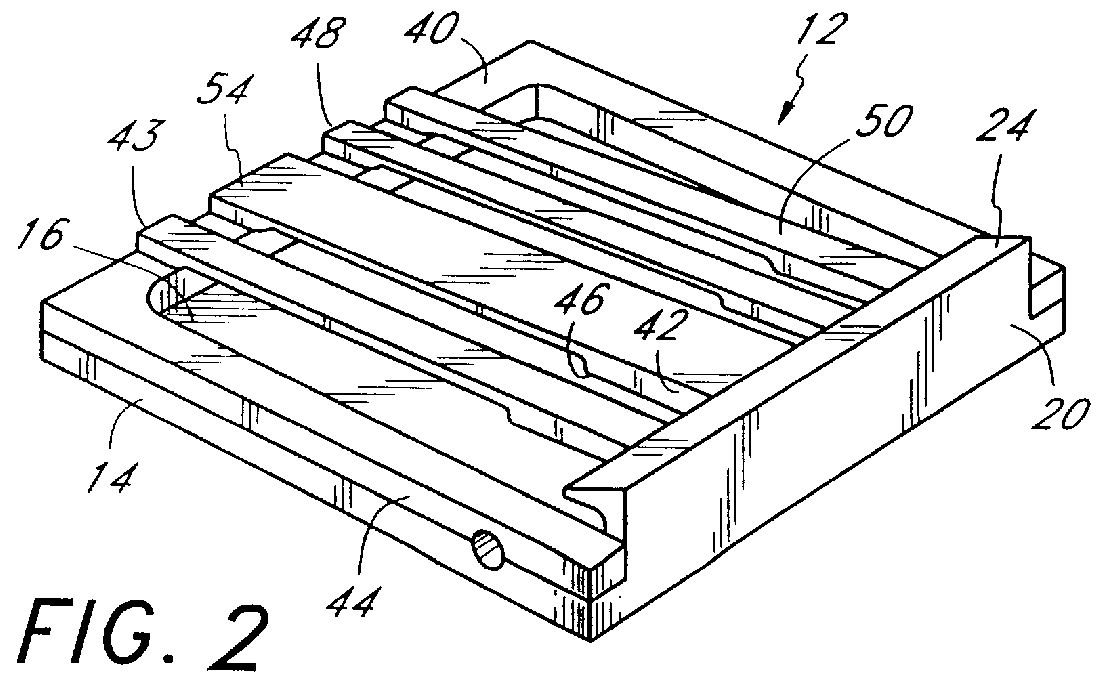

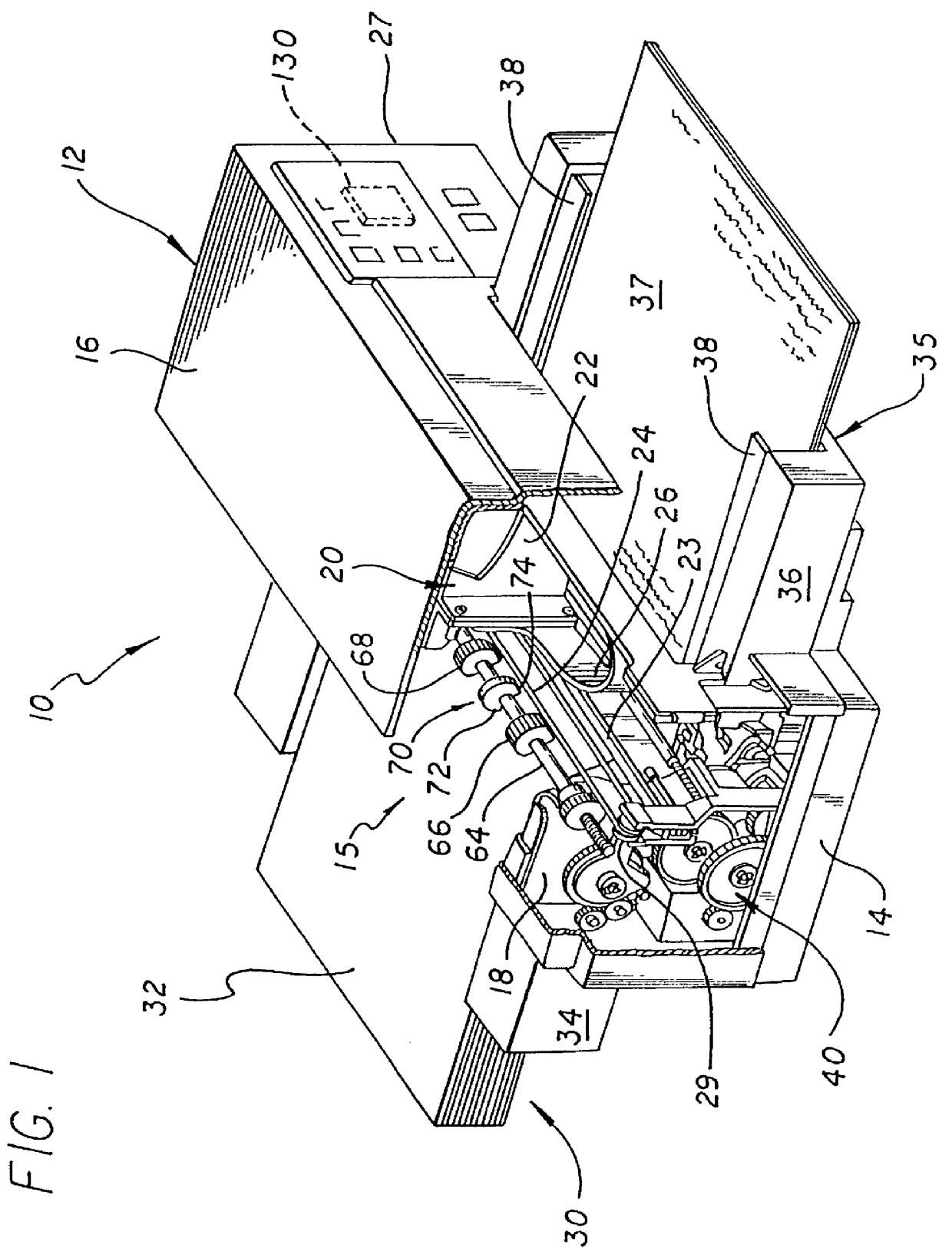

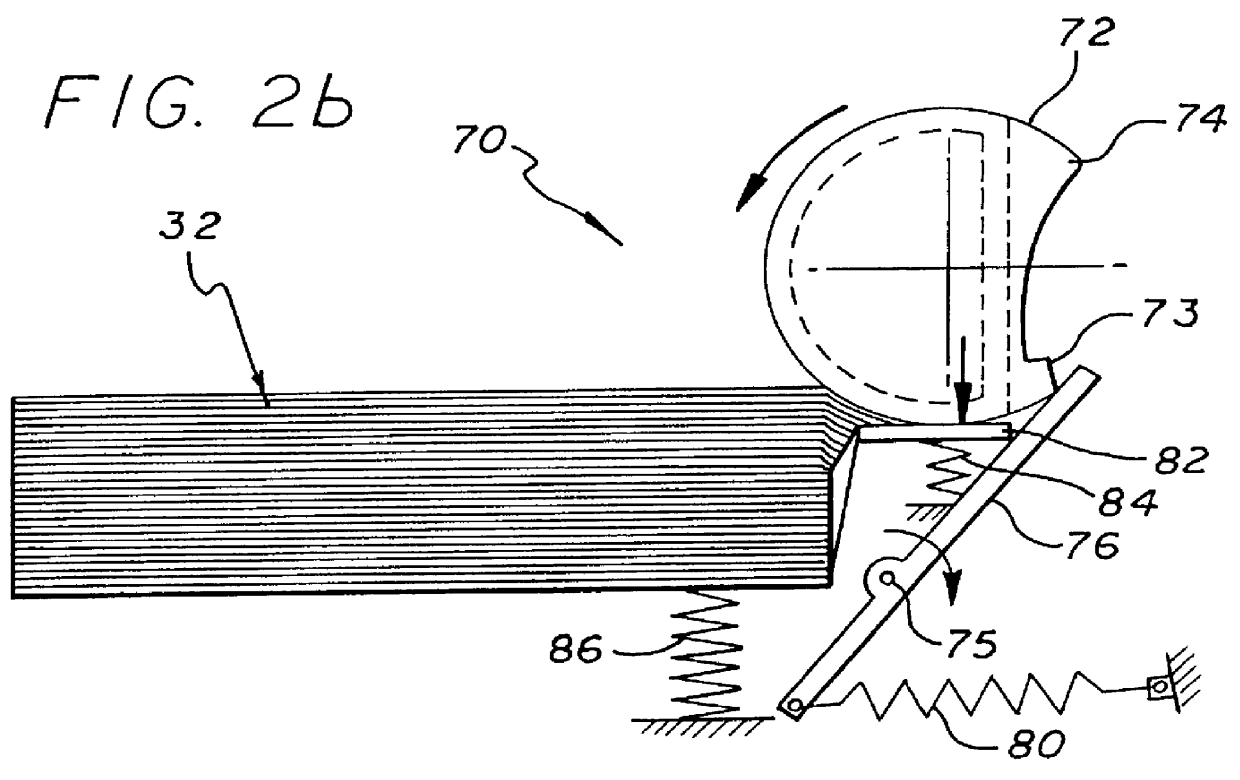

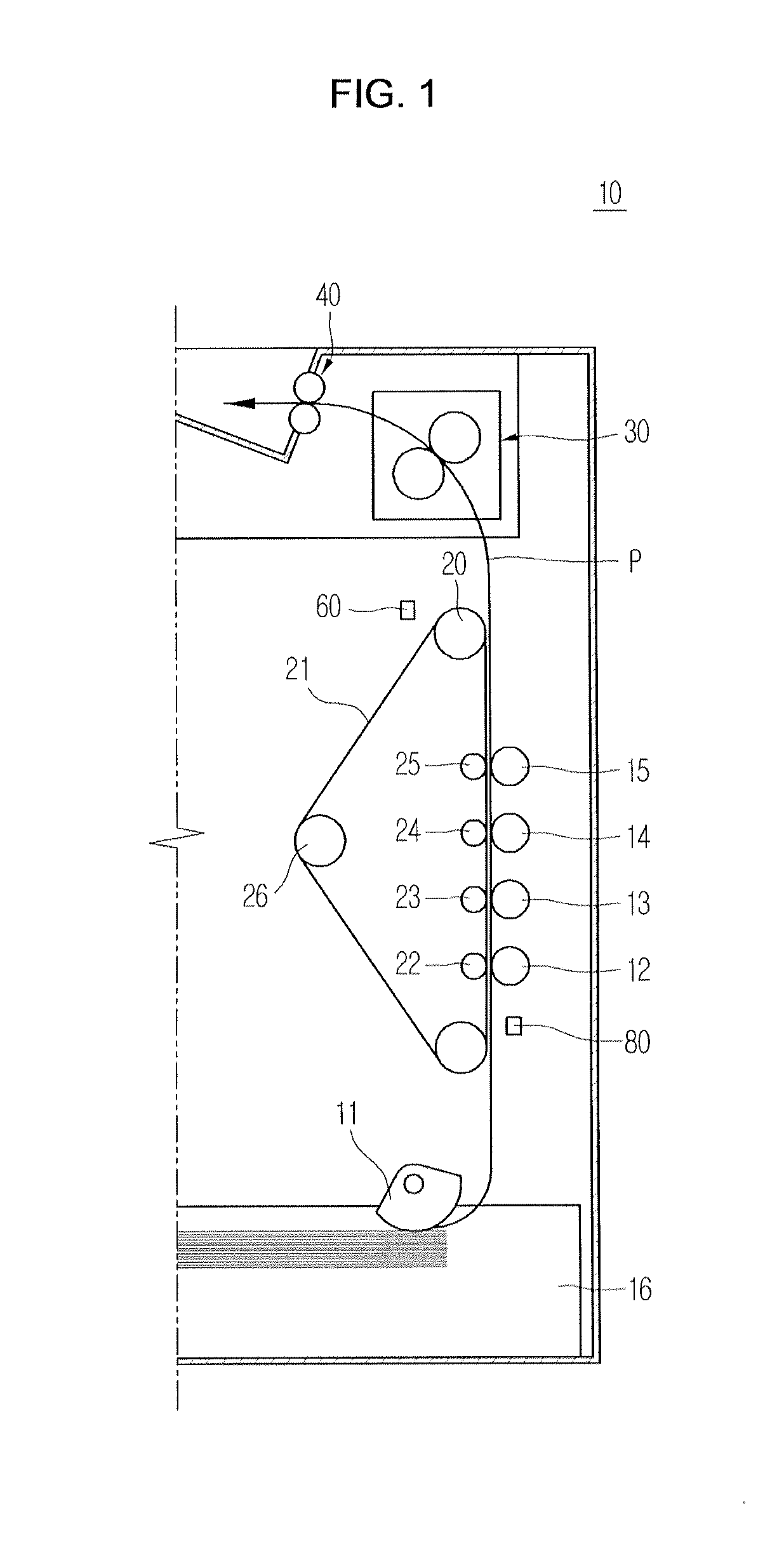

Automatic sheet feeding mechanism

A sheet feeding mechanism including a pick apparatus for selectively moving a sheet of media from a stack. A kicker is disclosed in several embodiments and serves to retain media on the stack. In a first embodiment, a cam is coupled to the pick apparatus for deflecting the kicker from the first position at which it retains media on the stack to a second position at which paper is allowed to move through the mechanism. In a particular implementation of the first illustrative embodiment, the mechanism includes a frame and a shaft mounted on the frame for rotational movement relative thereto. The pick apparatus includes a pick tire mounted on the shaft and adapted to rotate therewith. The kicker is mounted on the frame for retaining media on the stack in a first position. The cam is adapted to deflect the kicker during a first portion of a rotational cycle and to release the kicker when the cam is in a second rotational position. In a second embodiment, the cam is contoured to provide a protruded edge which engages the kicker when the cam is counter-rotated. This forces the kicker to push media remaining on a separation roll back onto the stack and is particularly well suited for printers utilizing inclined media trays. In a third embodiment, the kicker is mounted on a shaft along with a separation roll. In a specific implementation of this embodiment, the kicker is a flexible strip of plastic that flexes as it engages the stack when the shaft is rotated and after it has rotated around, pushes media remaining on the separation roll back onto the stack. Finally, a fourth embodiment is disclosed by which the kickers are implemented with a plurality of small gravity actuated kickers mounted between two pick tires. The kickers are adapted to fall out of the way when the pick tires are rotating in a first direction and to fall into position to push media back onto the stack when the pick tires are counter-rotated.

Owner:HEWLETT PACKARD DEV CO LP

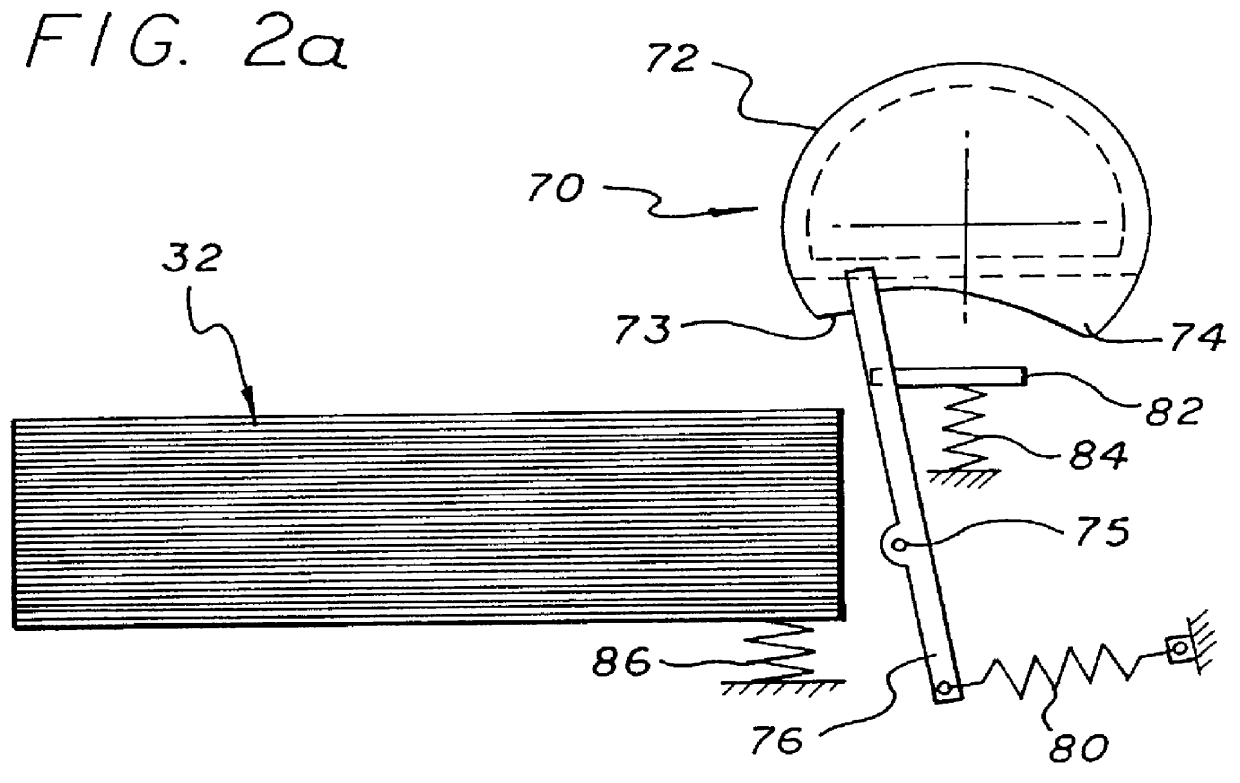

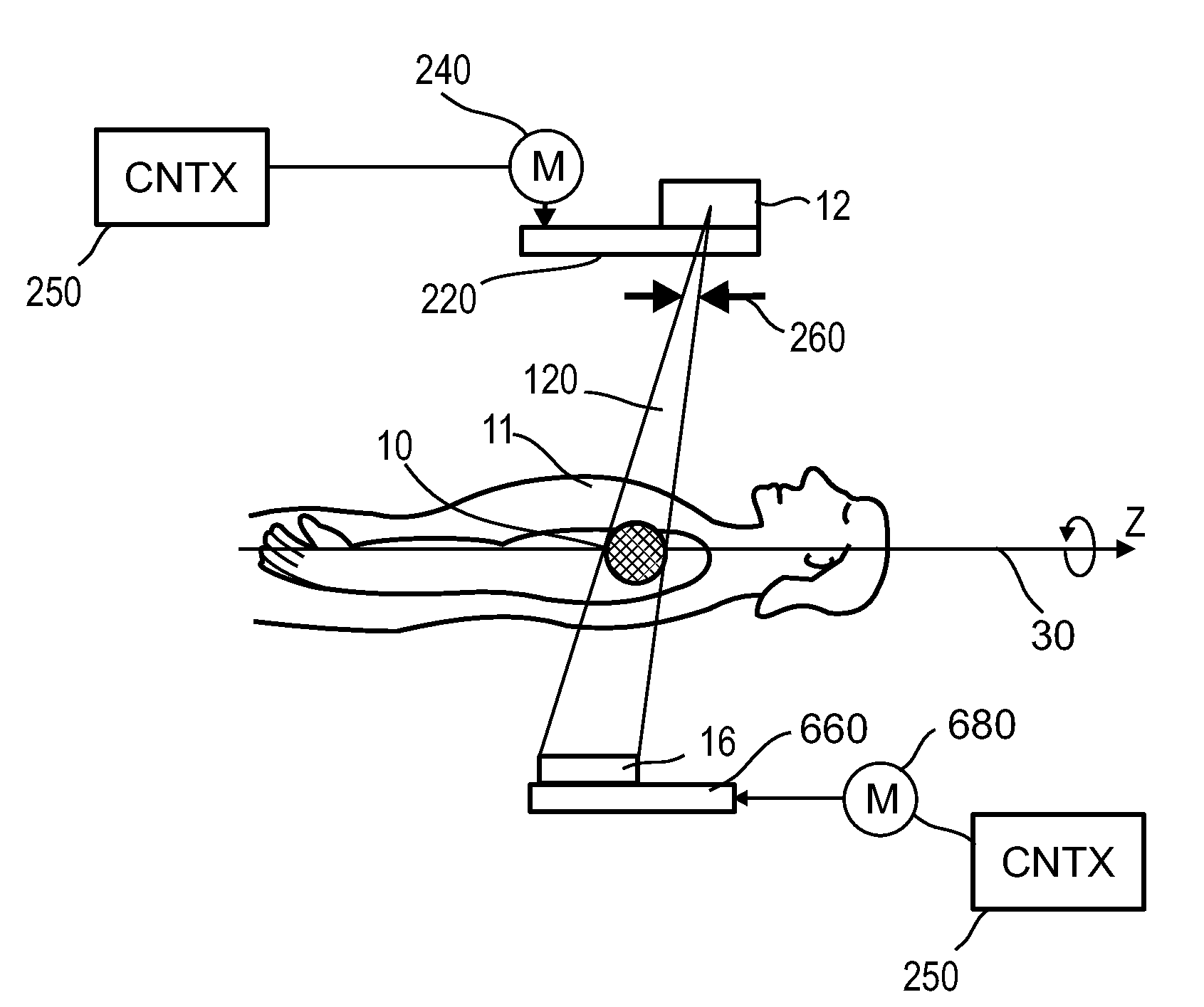

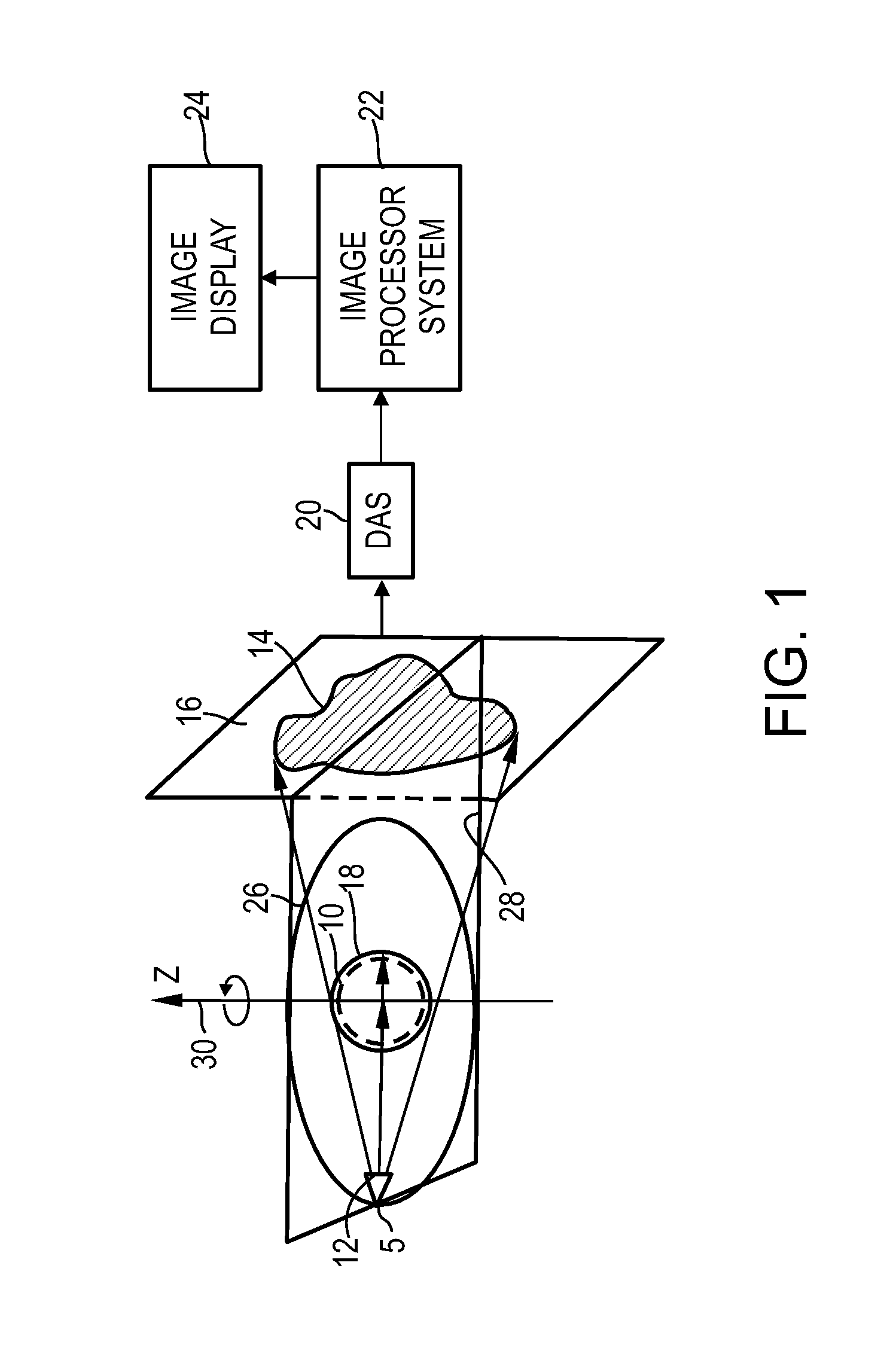

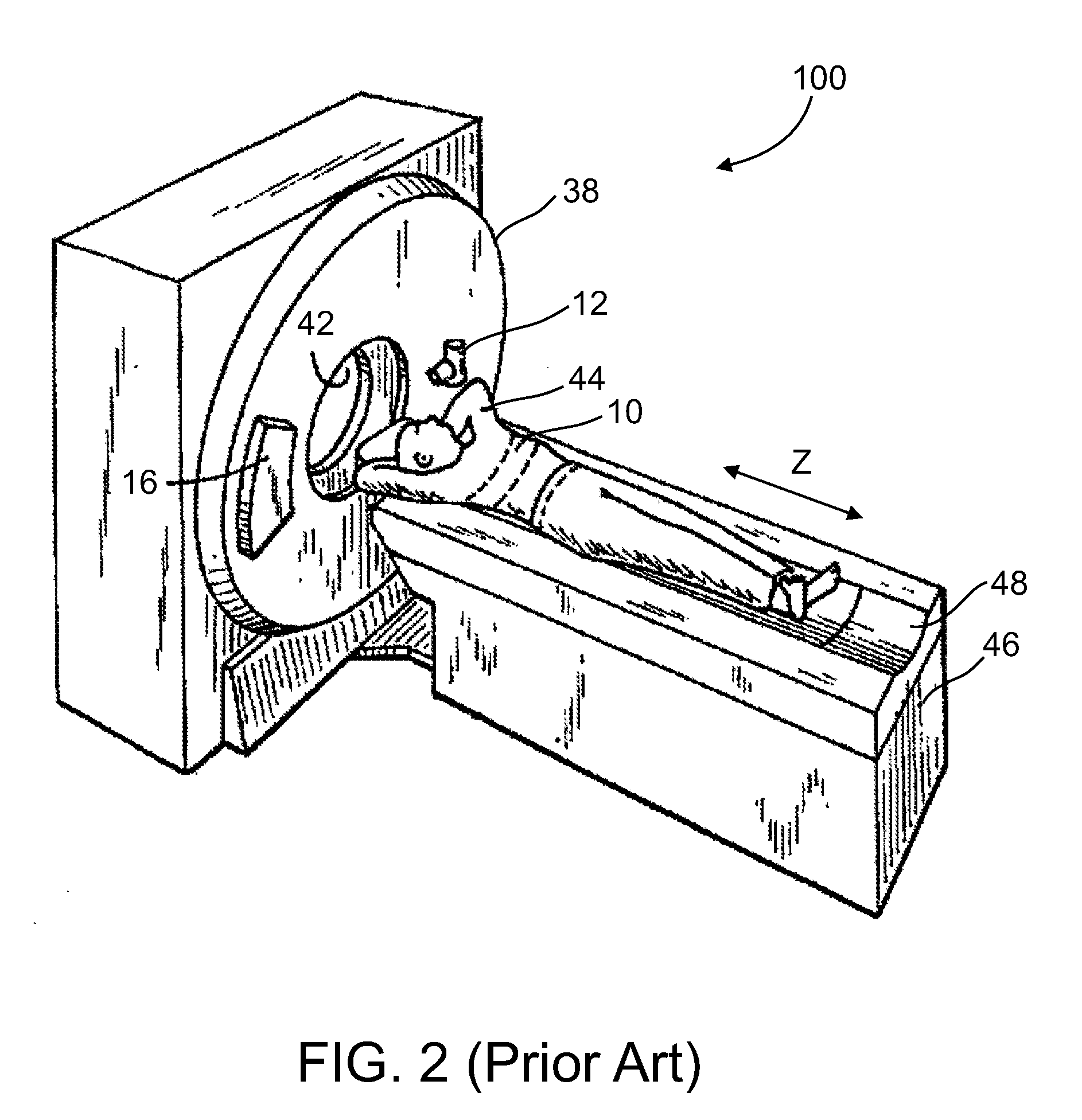

Ct cone beam scanner

ActiveUS20110033024A1Improve time resolutionMaterial analysis using wave/particle radiationRadiation/particle handlingCt scannersX-ray

A CT scanner comprises at least one cone beam x-ray source assembly mounted on a gantry frame, the gantry frame rotatable about a rotation axis, the x-ray source assembly operable to emit a cone beam at an orientation with respect to the rotation axis, and a controller operable to adjust an orientation of the cone beam during a rotation cycle of the gantry, wherein the controller adjusts the orientation to radiate a substantially same volume of interest over the rotation cycle.

Owner:ARINETA

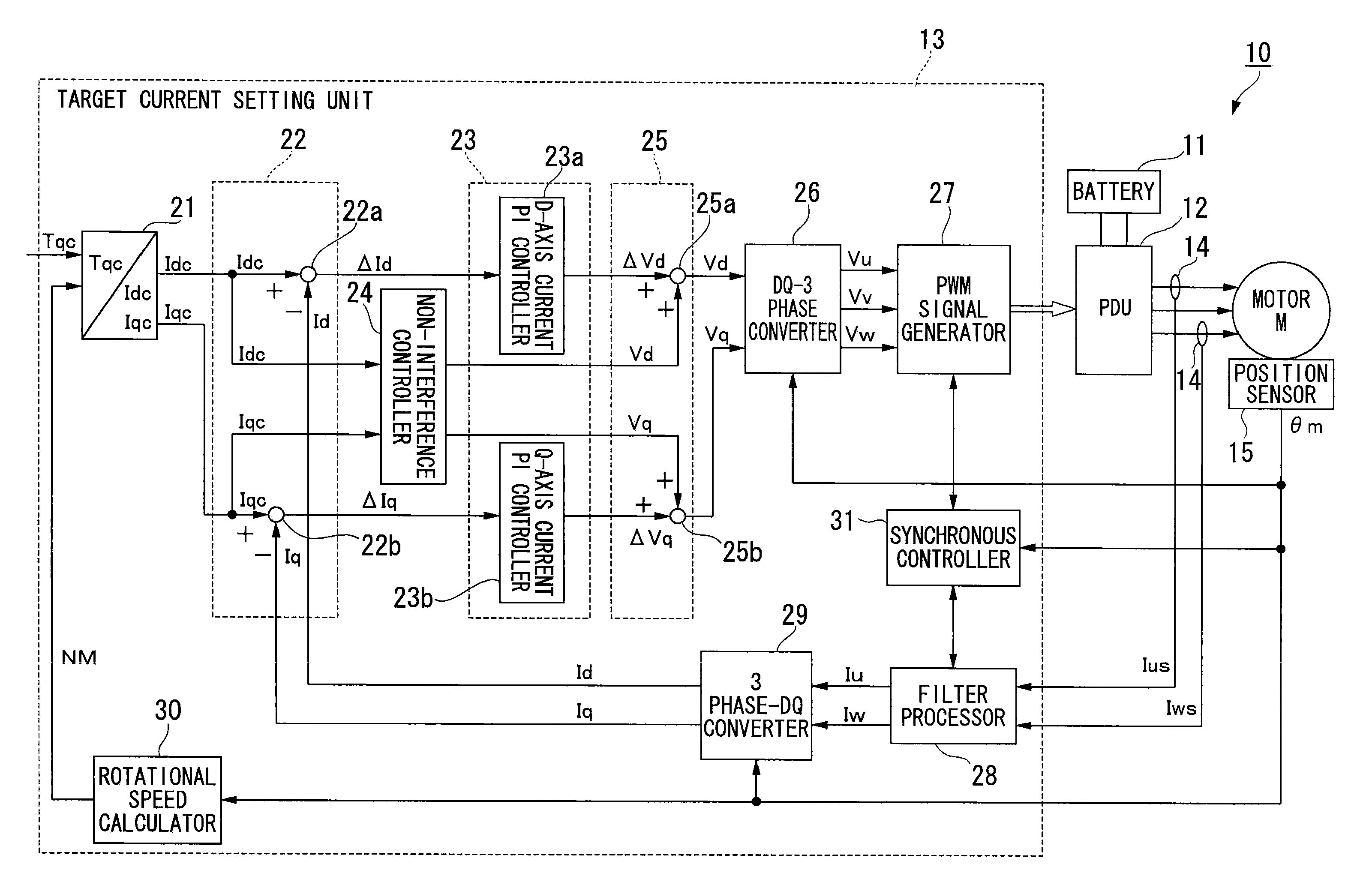

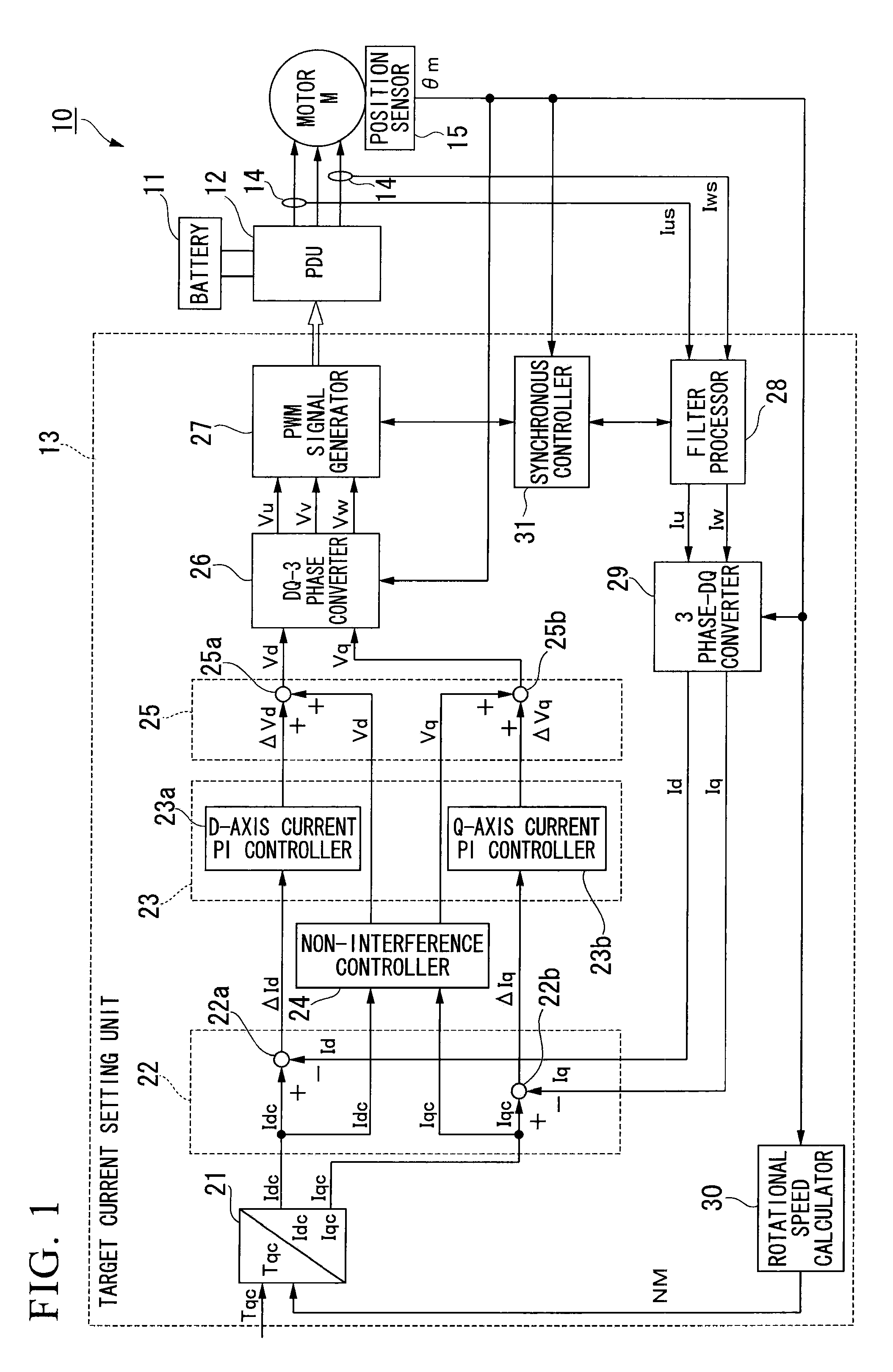

Motor control apparatus

InactiveUS20080265831A1Excessive execution of processingAvoid oscillationAC motor controlVector control systemsPhase differenceCarrier signal

A motor control apparatus provided with an inverter for successively commutating the current to a motor using a PWM signal; a PWM signal generating device for generating the PWM signal using a carrier signal; a rotational state quantity sensor for detecting a rotational state quantity; a phase difference detecting device for detecting the phase difference between the carrier signal and the rotational period based on the rotational state quantity; a frequency setting device for setting a frequency of the carrier signal to a value in accordance with a multiplier for one period in terms of electrical angle of the rotational period of the motor, when the rotational frequency is equal to or greater than a specified frequency and the phase difference is equal to or less than a specified value; and a synchronizing device for synchronizing a control period of the carrier signal to the rotational period.

Owner:HONDA MOTOR CO LTD

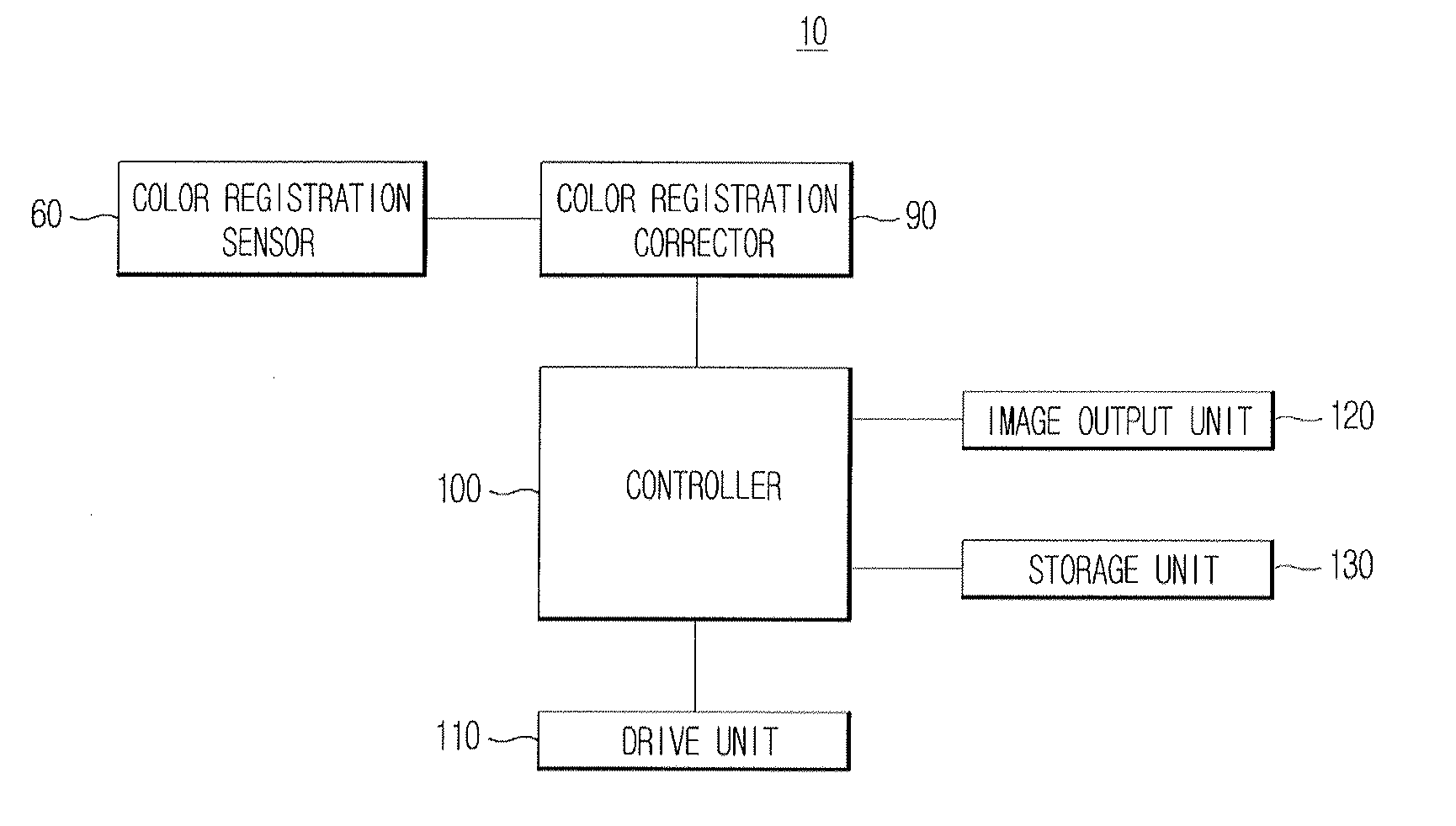

Image forming apparatus and auto color registration method thereof

ActiveUS20100178084A1Accurate correctionImprove image qualityDigitally marking record carriersDigital computer detailsImage formationRotation cycle

An image forming apparatus and an auto color registration method thereof. The image forming apparatus performs an auto color registration (ACR) operation by excluding or minimizing the influence caused by variation in speed of a drive unit driving a transfer member. The image forming apparatus includes a controller, which prints a test pattern of each color according to a rotation period of the drive unit, and controls an operation for outputting an image in which each color registration error is corrected on the basis of the test pattern, such that a reliability of the ACR operation is increased and a quality of an image output from the image forming apparatus is also increased.

Owner:HEWLETT PACKARD DEV CO LP

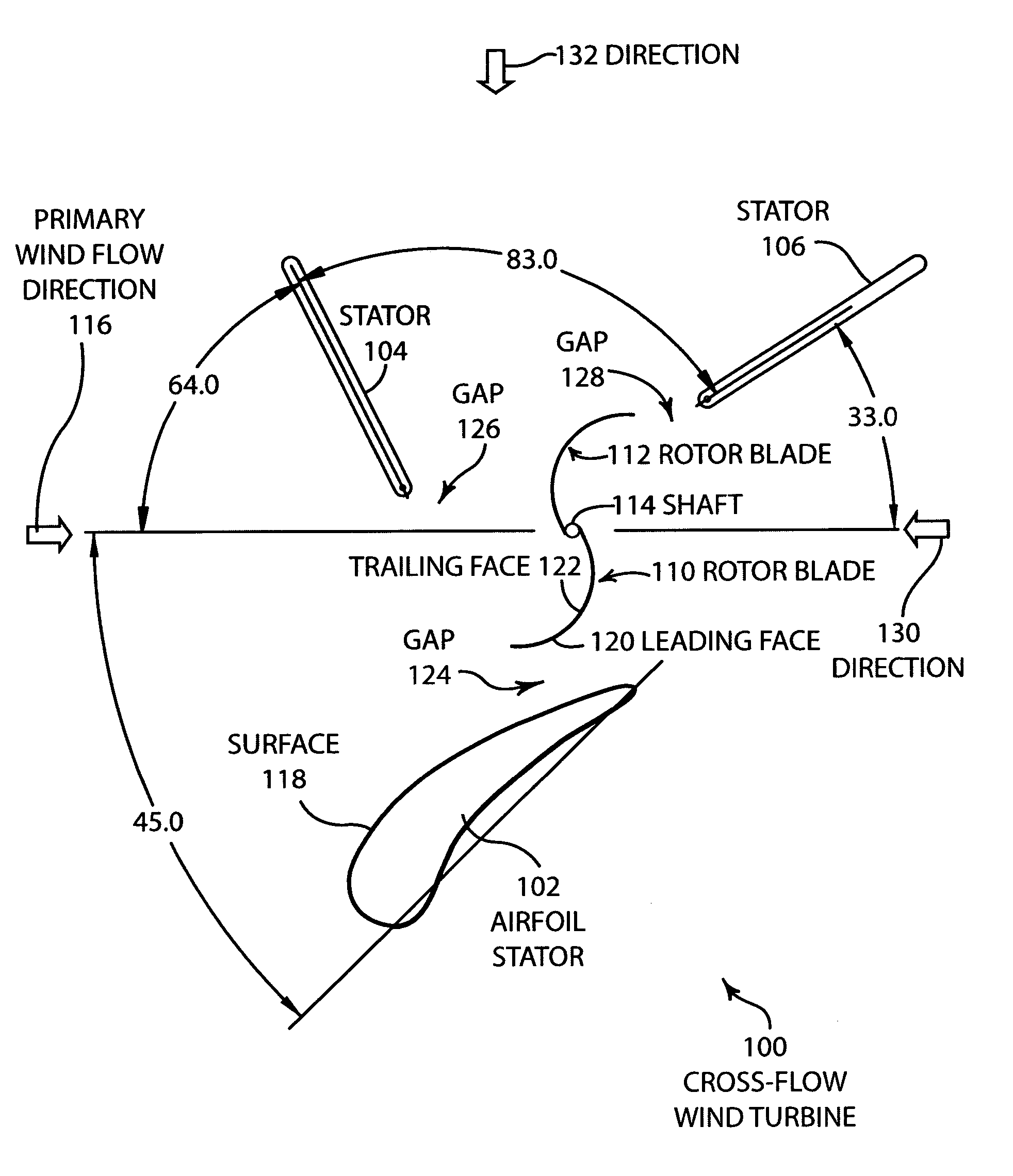

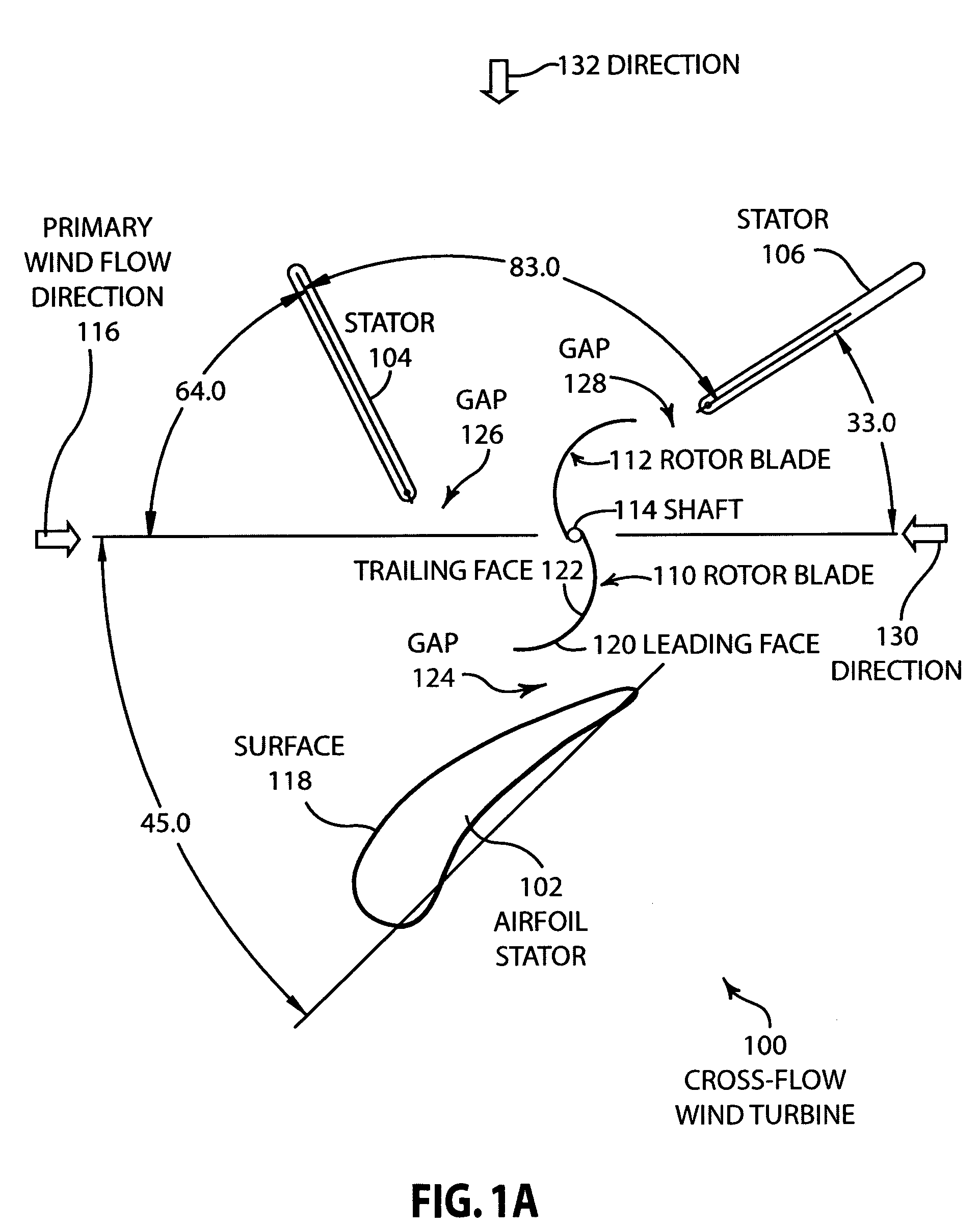

Cross-flow wind turbine

InactiveUS7189050B2Improve efficiencyEffective rotationCircumferential flow pumpsPump componentsPower cycleLow-pressure area

Disclosed are various embodiments of cross-wind turbines that are capable of providing high efficiencies over a wide range of wind velocities. An airfoil stator causes wind to accelerate along its surface and creates a low pressure area on the leading face of the rotor blade during the power stroke. A blocking stator blocks wind from impeding the movement of the rotor blades during the return cycle and directs wind onto the trailing face of the rotor blades during the power cycle. A large pressure differential is created between the leading face of the rotor blade and the trailing face of the rotor blade during the power cycle which creates a large amount of force that rotates the rotor blade about the central shaft. In some embodiments, gaps are provided between the inside edge of the rotor blade and a stationary shaft which vents wind collected by the rotor blade during certain portions of the rotation cycle. The vented wind increases the pressure on the trailing face of the rotor blades during the return cycle to further assist in the efficiency of this system.

Owner:TERRA MOYA AQUA

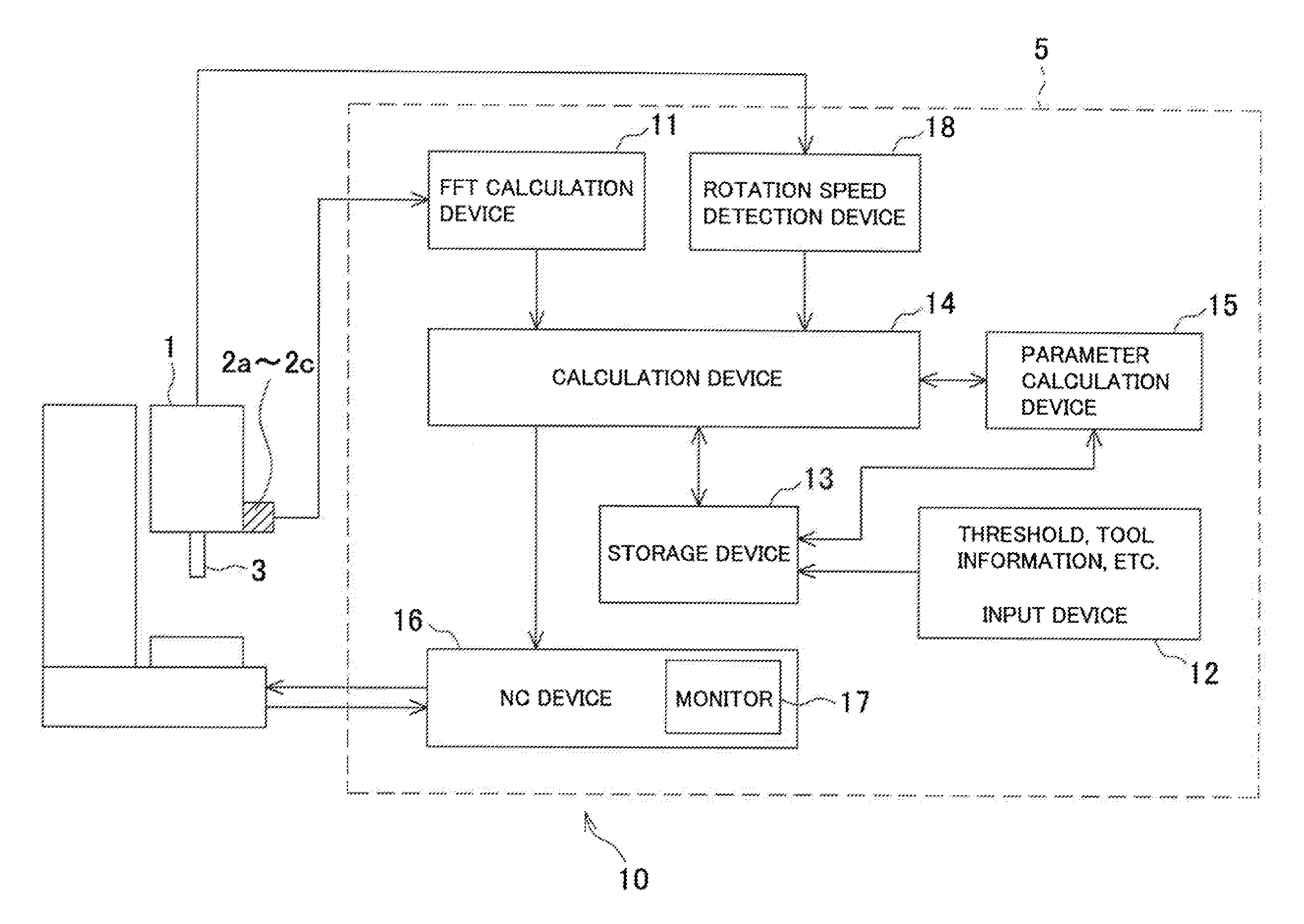

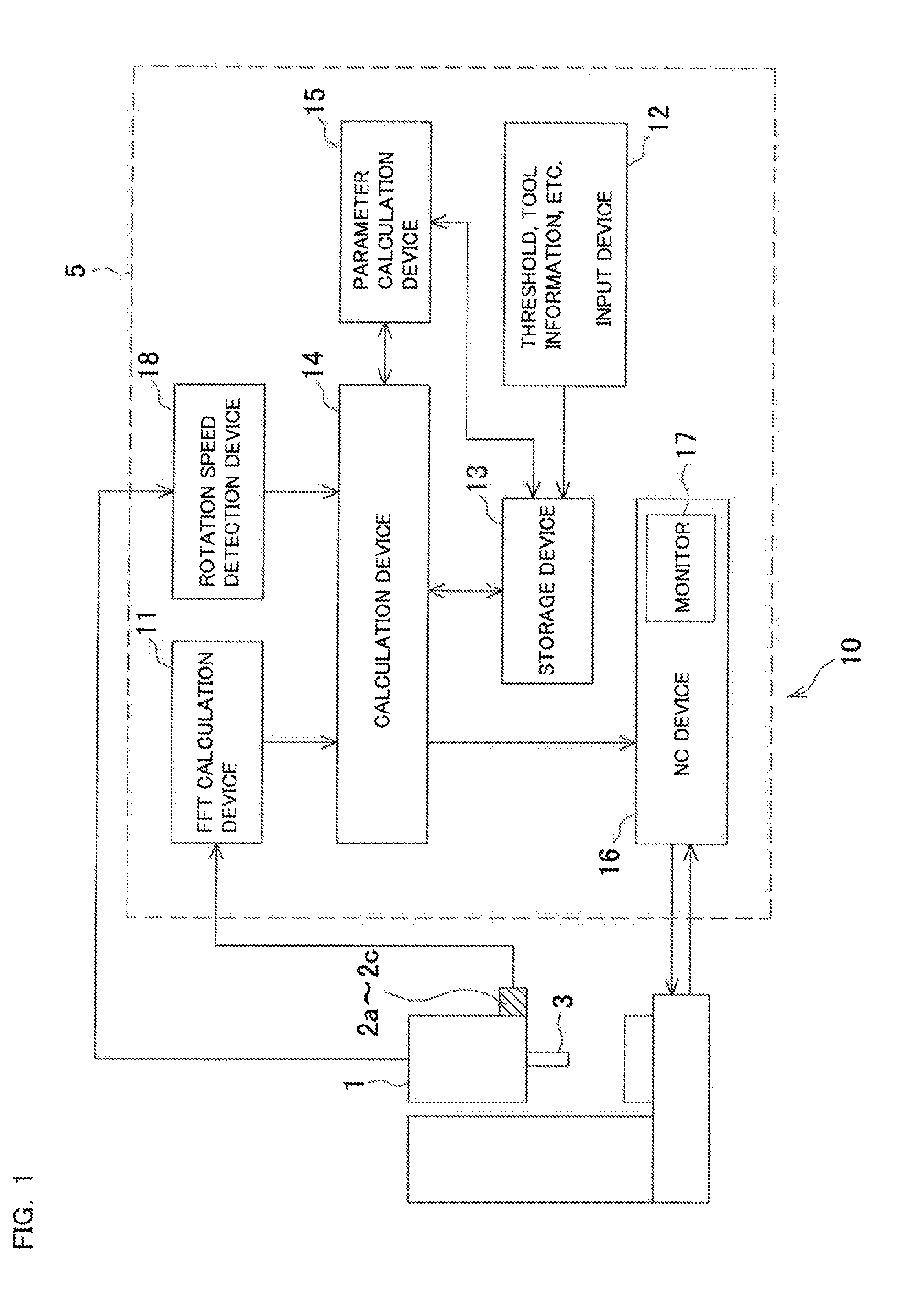

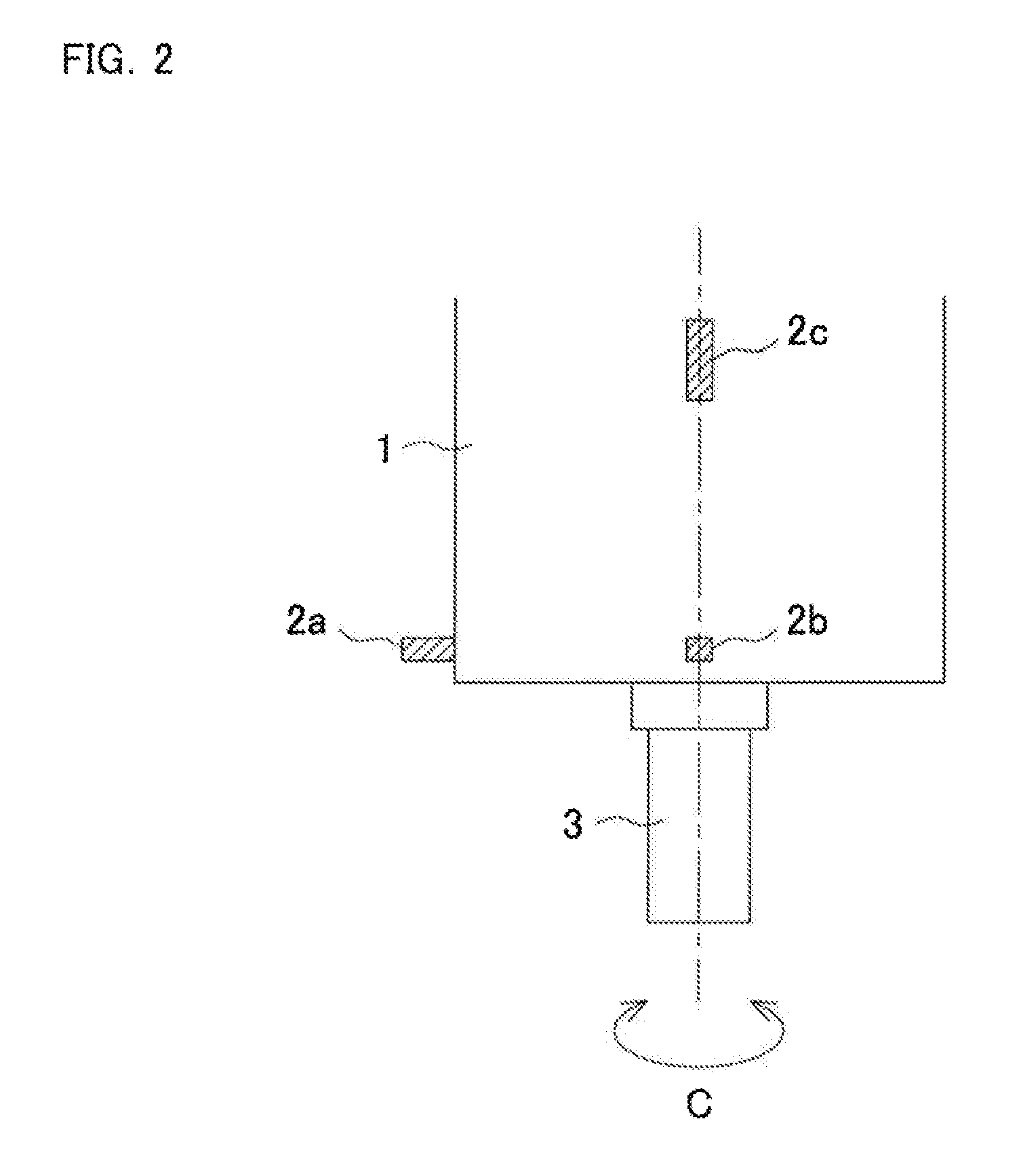

Vibration determination method and vibration determination device

ActiveUS20120253708A1Chatter vibration can be more suppressedAccurately determineProgramme controlFlow propertiesChatter vibrationFlute

When generation of a chatter vibration is detected, a parameter calculation device calculates a first frequency range and a second frequency range. A determination validity is calculated in consideration of a rotation speed detection resolution and a frequency resolution, and based on a ratio of a frequency range of rotational-period forced chatter vibration to a frequency range of regenerative chatter vibration. It is determined based on the determination validity whether the generated chatter vibration is regenerative chatter vibration, rotational-period forced chatter vibration, or flute-passage-period forced chatter vibration.

Owner:OKUMA CORP

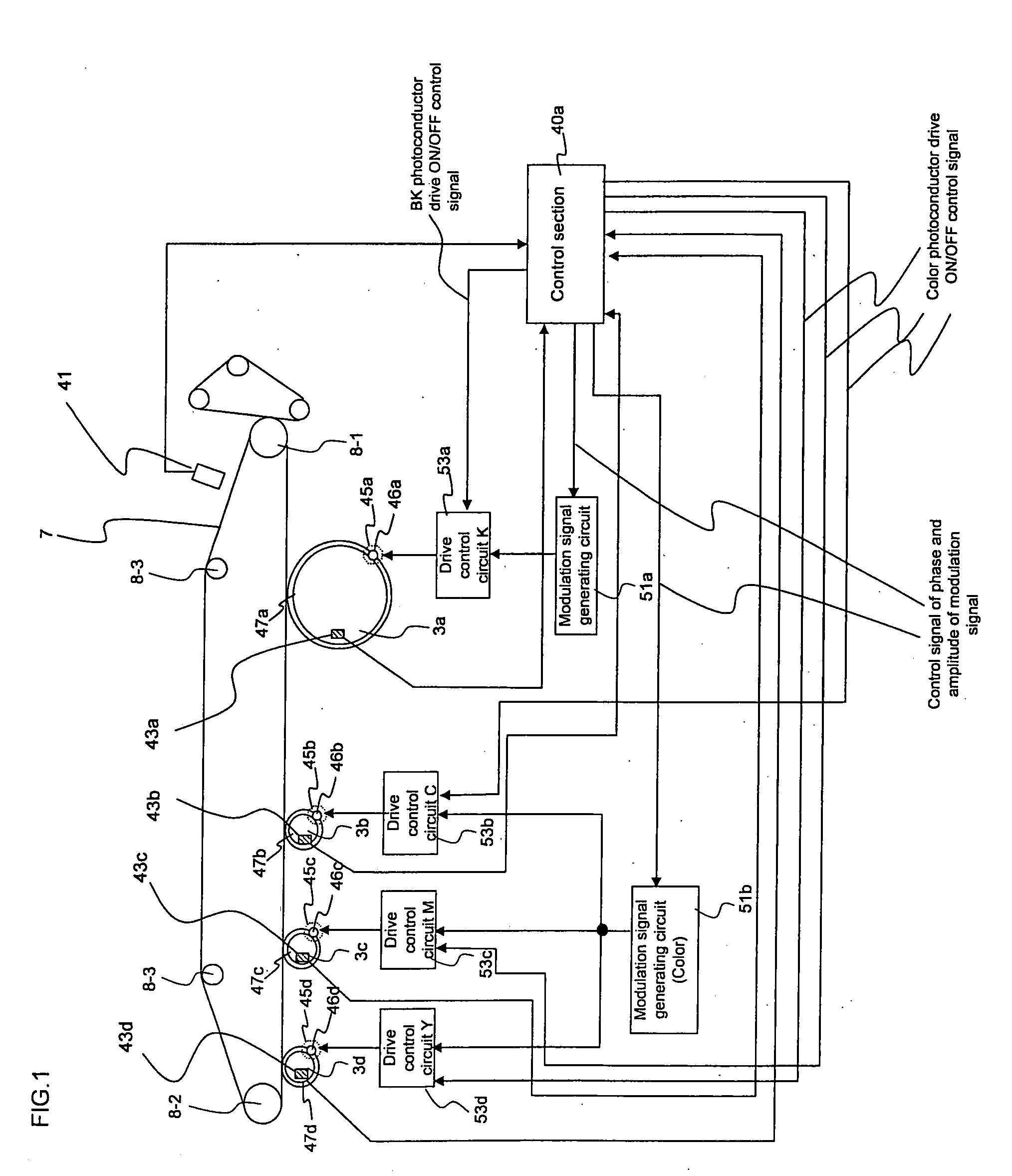

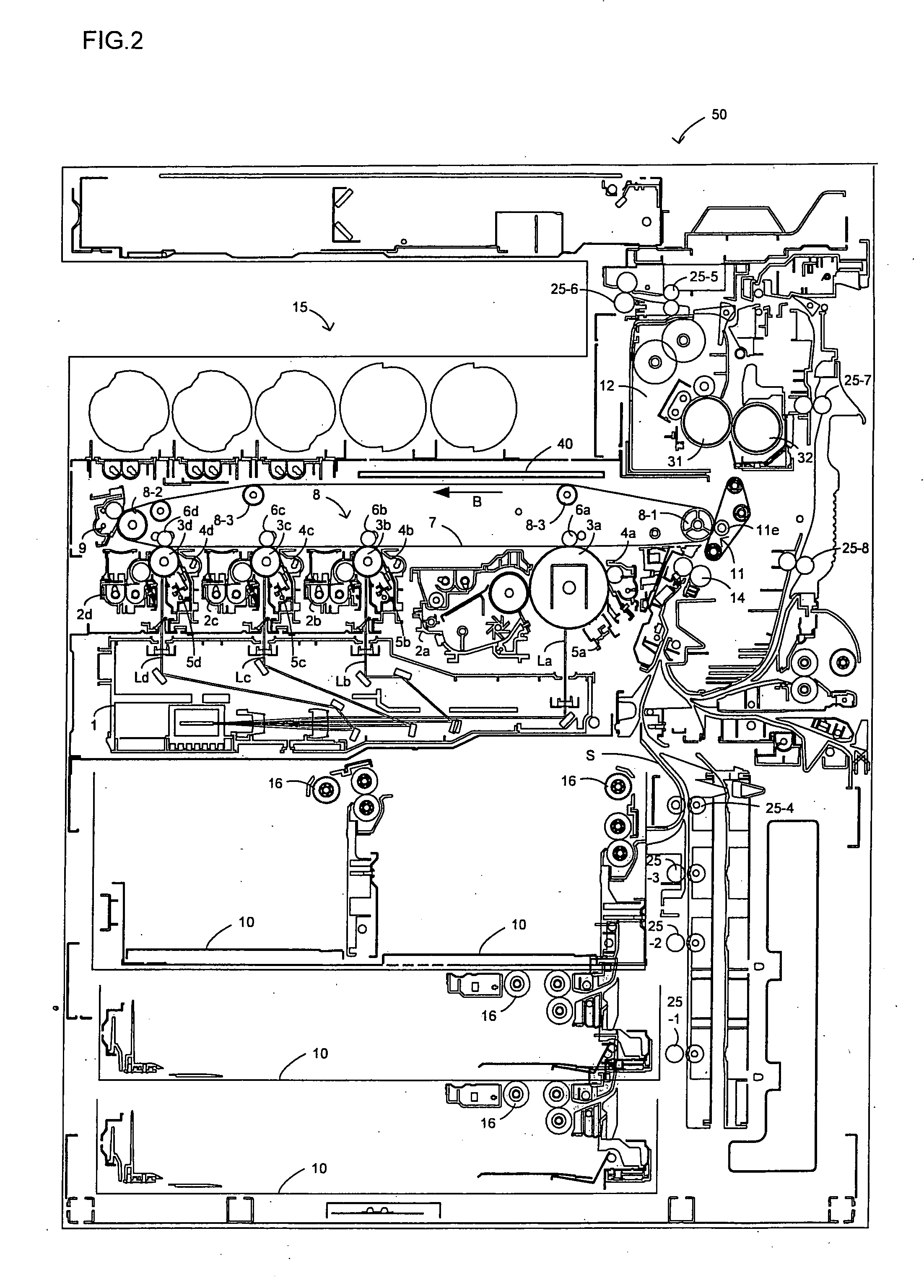

Color image forming apparatus

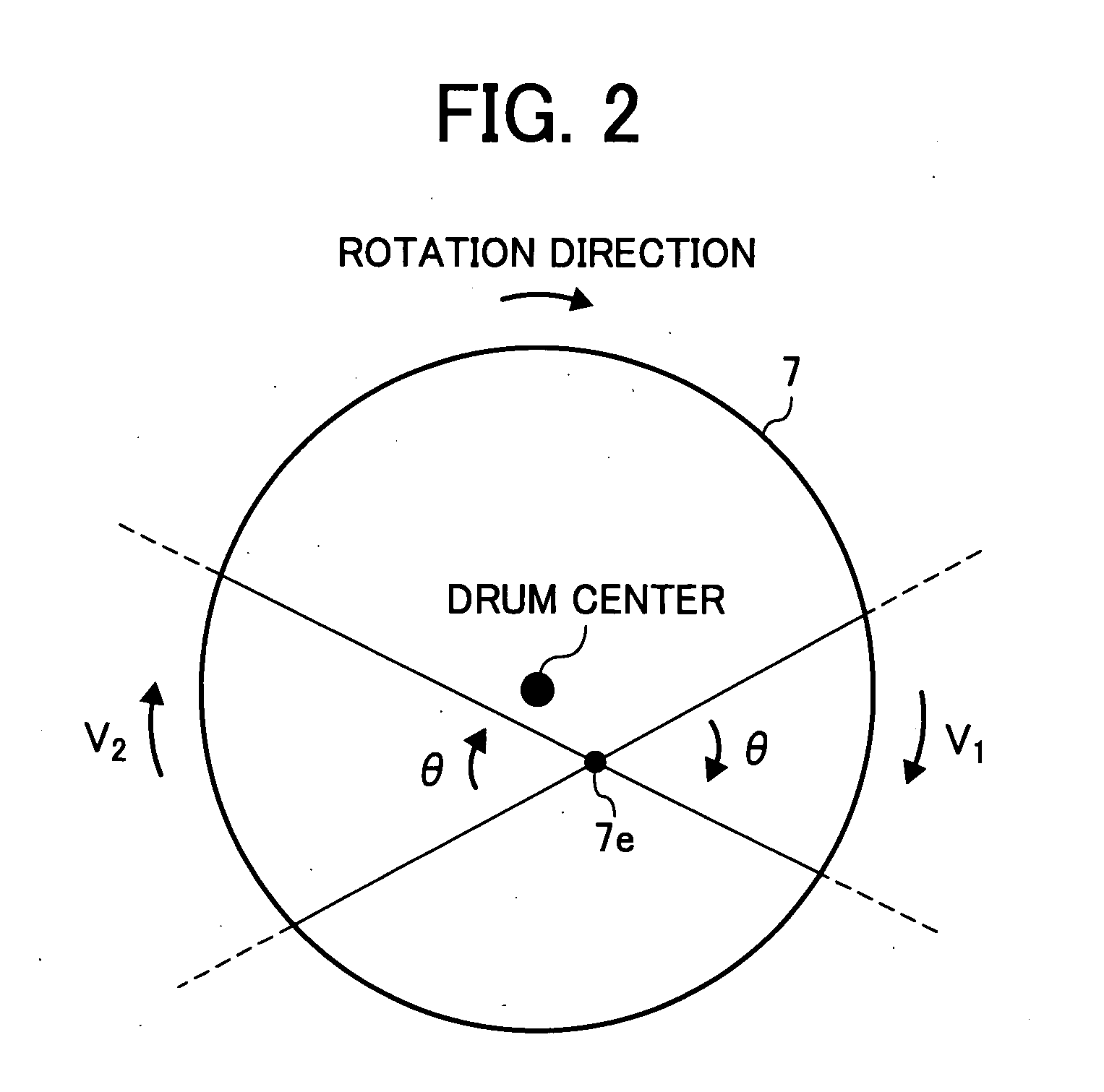

InactiveUS20070242980A1Suppressed pitch fluctuationSimple configurationElectrographic process apparatusColor imageSignal correction

A color image forming apparatus including: a plurality of drum-type photoconductors for forming an image in a different color on each peripheral surface and the photoconductors having at least two different diameters; a plurality of driving sections for driving each photoconductor at a driving speed in accordance with the diameter so that each photoconductor rotates at a predetermined peripheral speed; a correction signal output section for outputting a speed correction signal to correct a periodic pitch fluctuation included in each formed image; and a drive control section for controlling the driving section to correct the driving speed of each photoconductor by the speed correction signal, wherein the speed correction signal is a signal having the same cycle as a rotational cycle of each photoconductor.

Owner:SHARP KK

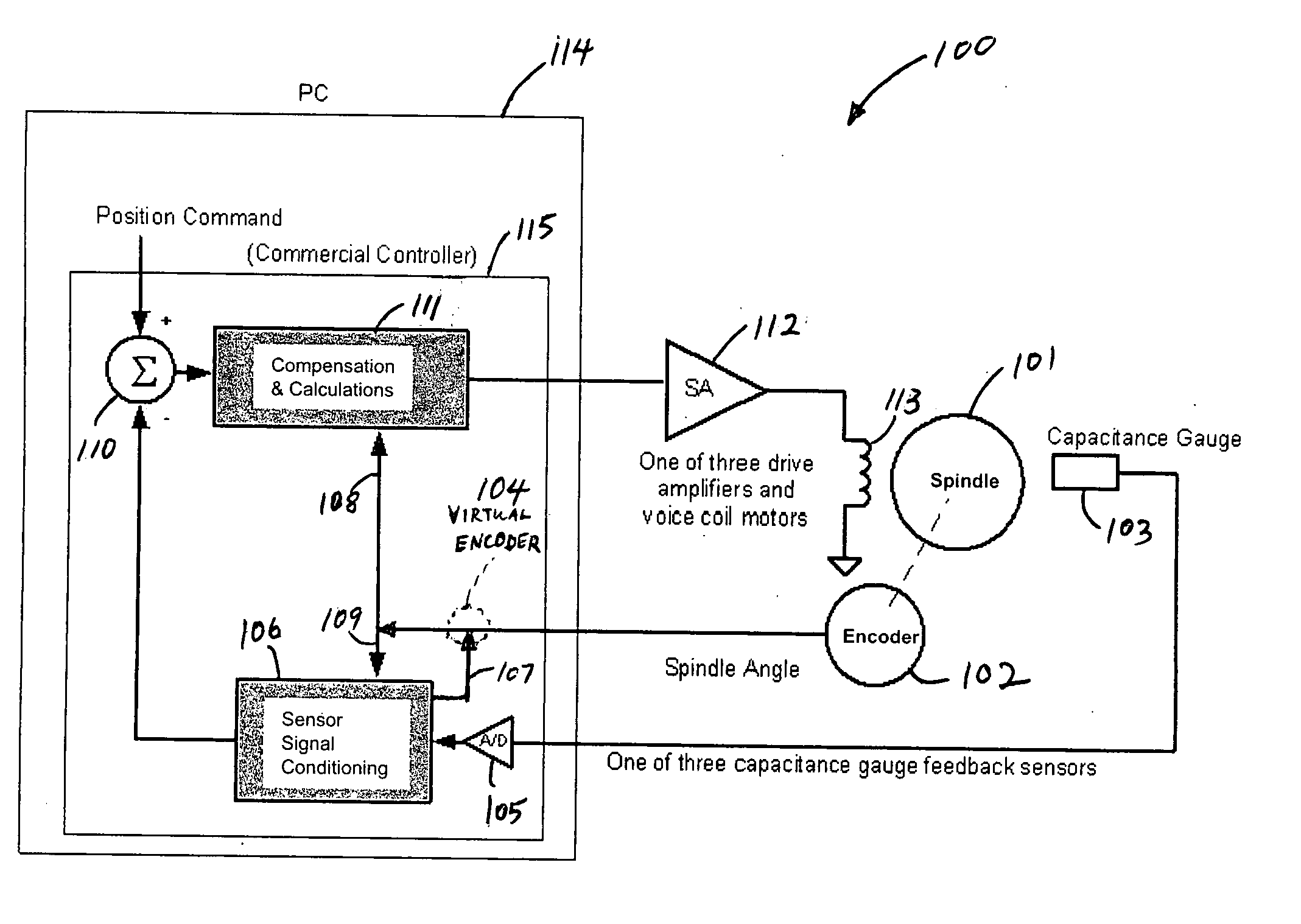

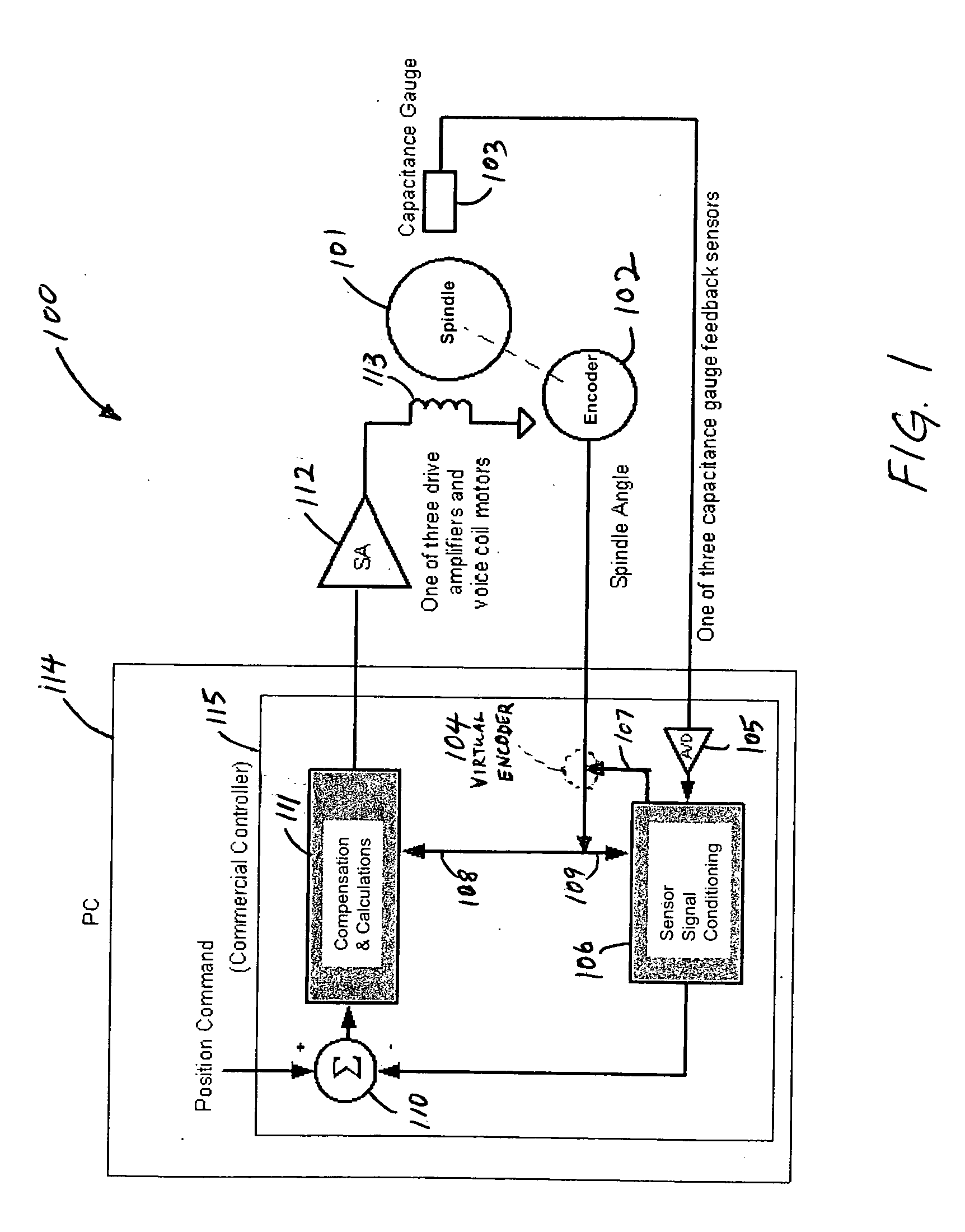

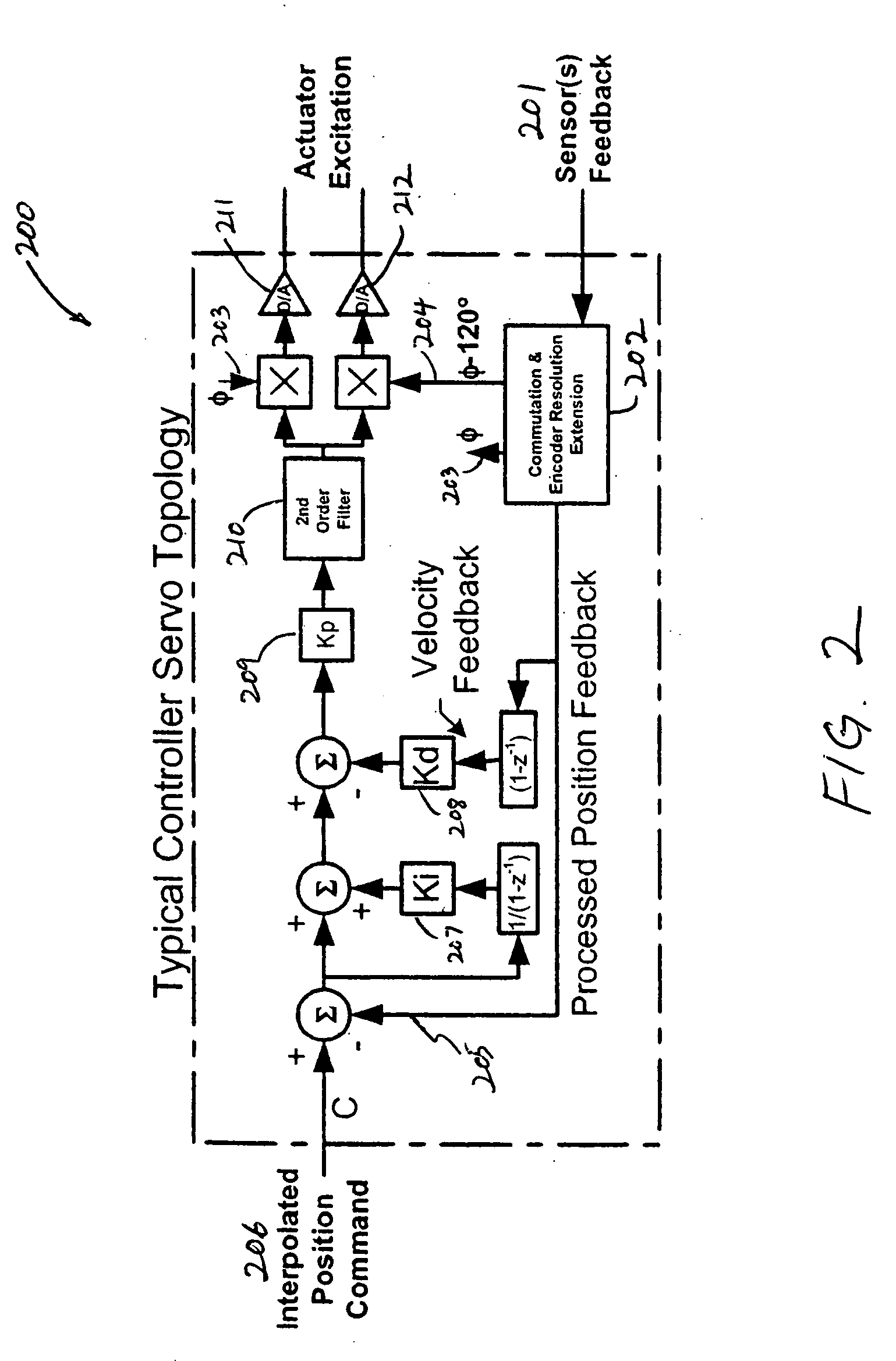

Adaptive vibration control using synchronous demodulation with machine tool controller motor commutation

InactiveUS20060036351A1Actively dampenReduce decreaseSampled-variable control systemsMechanical oscillations controlVibration controlControl system

A control system and method for actively reducing vibration in a spindle housing caused by unbalance forces on a rotating spindle, by measuring the force-induced spindle-housing motion, determining control signals based on synchronous demodulation, and provide compensation for the measured displacement to cancel or otherwise reduce or attenuate the vibration. In particular, the synchronous demodulation technique is performed to recover a measured spindle housing displacement signal related only to the rotation of a machine tool spindle, and consequently rejects measured displacement not related to spindle motion or synchronous to a cycle of revolution. Furthermore, the controller actuates at least one voice-coil (VC) motor, to cancel the original force-induced motion, and adapts the magnitude of voice coil signal until this measured displacement signal is brought to a null. In order to adjust the signal to a null, it must have the correct phase relative to the spindle angle. The feedback phase signal is used to adjust a common (to both outputs) commutation offset register (offset relative to spindle encoder angle) to force the feedback phase signal output to a null. Once both of these feedback signals are null, the system is compensating properly for the spindle-induced motion.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Rotation device, method for controlling rotation of a driving source, computer readible medium and image forming apparatus including the rotation device

ActiveUS20070231009A1Reduce speedRotation speed is limitedElectric motor controlElectrographic process apparatusRotation velocityImage formation

A rotation device includes a rotation member, rotation driving source, transmission mechanism, rotation pulse generation mechanism, target value arrangement mechanism, correction value computation mechanism, and control mechanism. The transmission mechanism decreases the rotation speed at a non-integer gear ratio. The target value arrangement mechanism includes a rotation unevenness provision mechanism to impart a plurality of kinds of sine-wave unevenness to the rotation speed target value. The correction value computation mechanism determines the correction value to adjust rotation fluctuation caused by a rotation axis eccentricity component of the rotation driving source and at least one noise component having a cycle relationship with a rotation cycle of the rotation member based on a time interval of a pulse train generated every rotation of the rotation member by the rotation pulse generation mechanism when the plurality of kinds of the rotation unevenness are imparted to the rotation speed target value.

Owner:RICOH KK

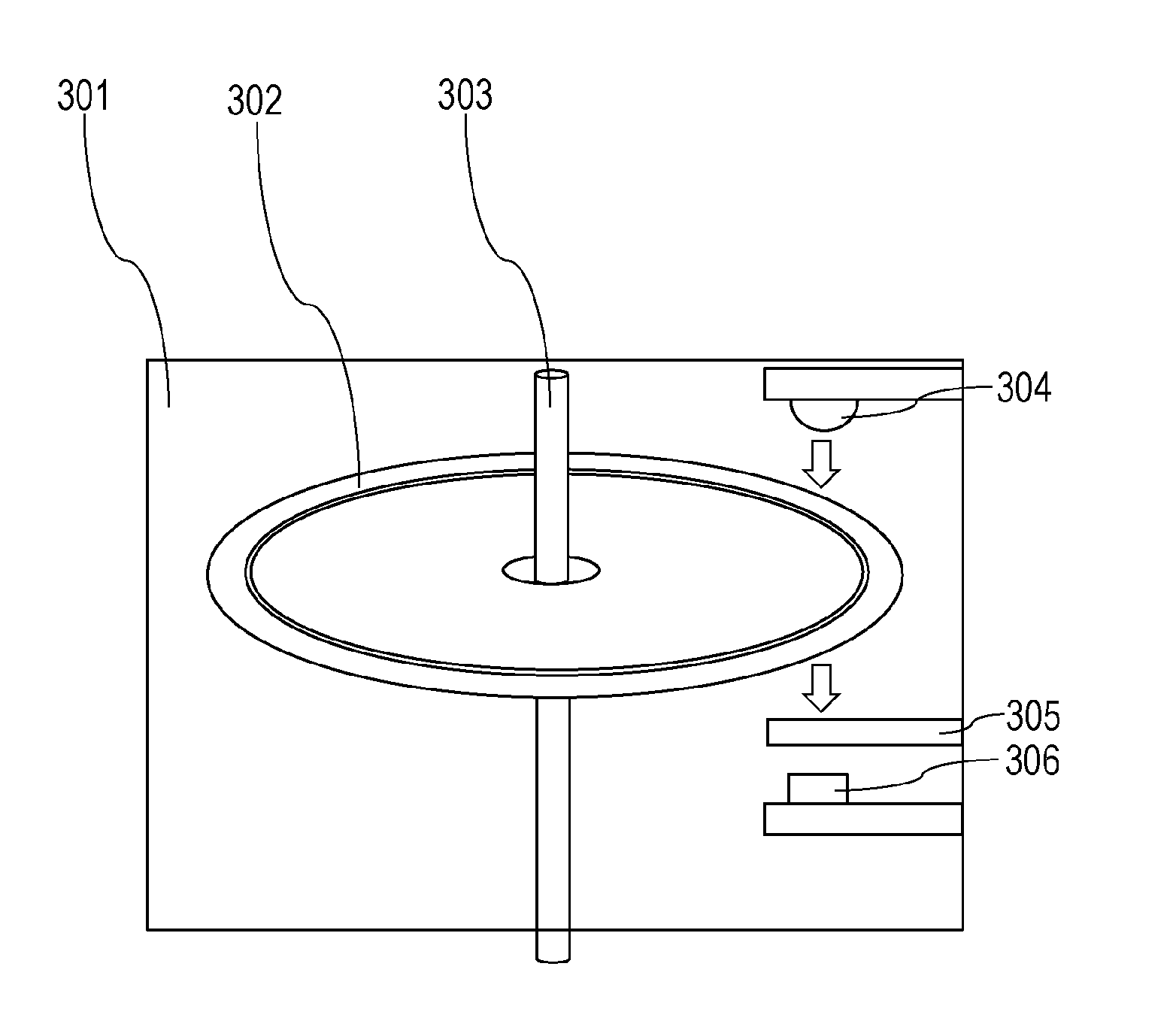

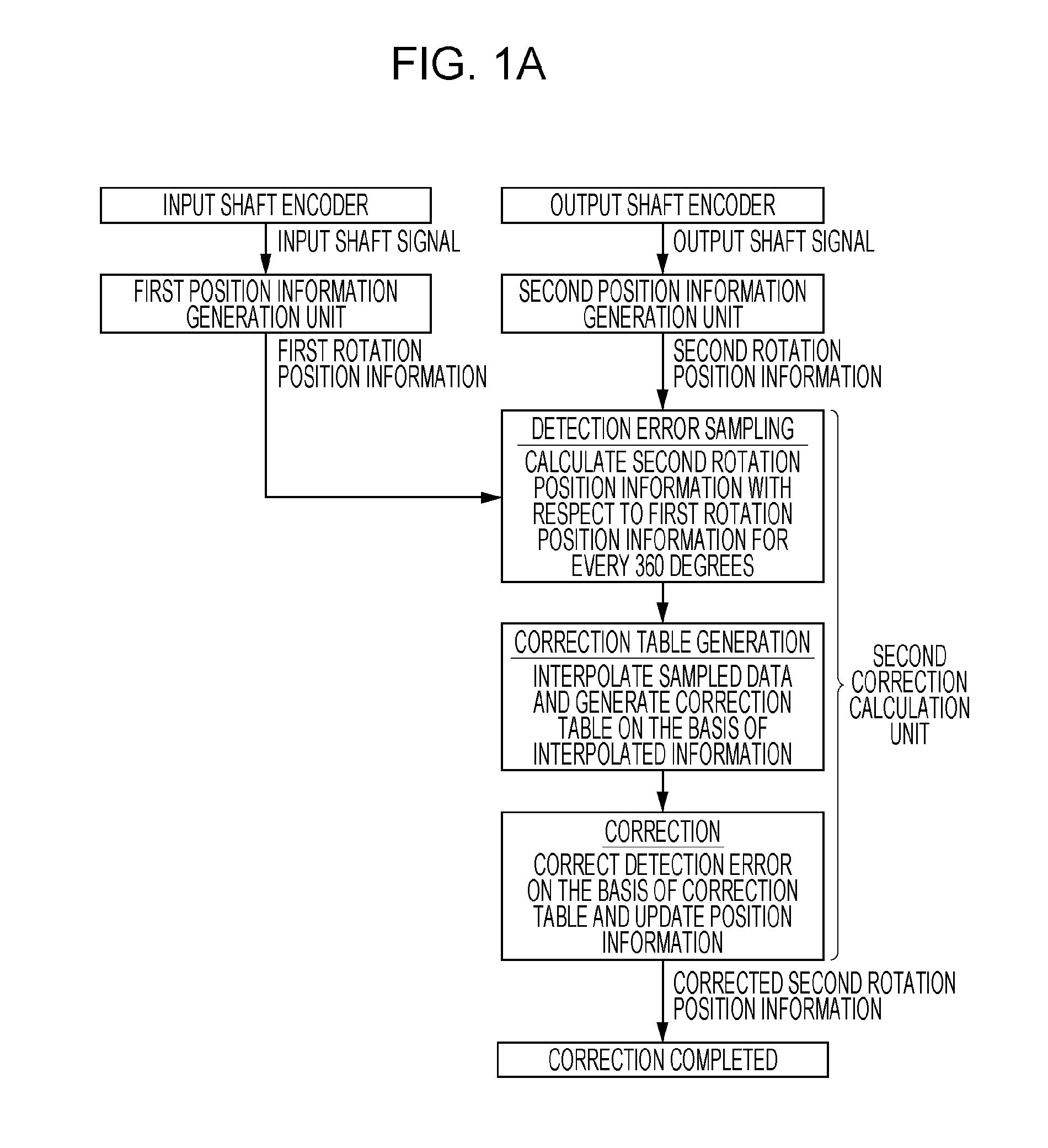

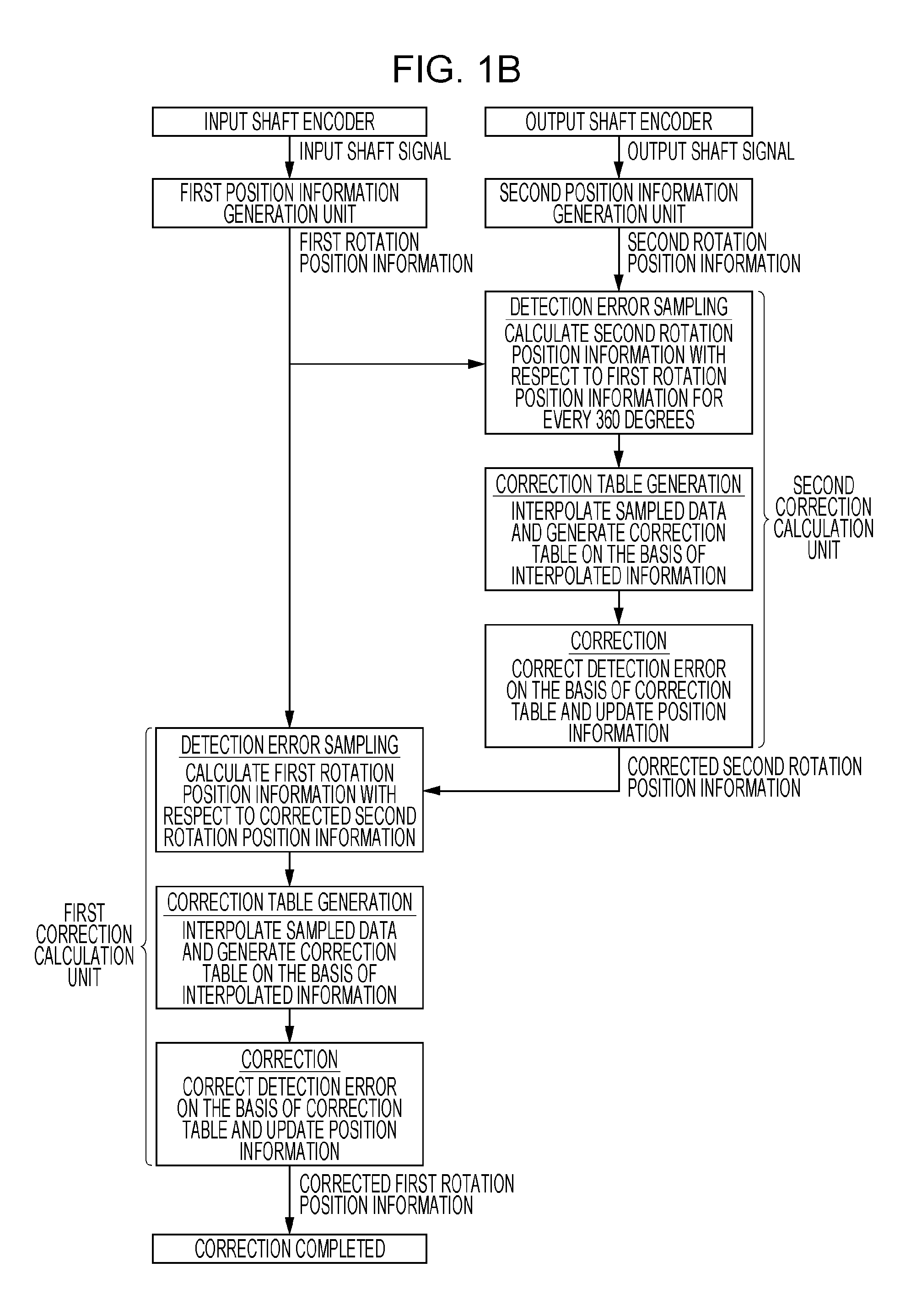

Angle detection method, angle detection apparatus, rotation drive apparatus, robot apparatus, and storage medium

ActiveUS20150276436A1Programme-controlled manipulatorMechanical apparatusRotation cycleFeedback control

To provide an angle detection method with which a control for positioning an output shaft using an input shaft encoder and output shaft encoder at a high accuracy and a torsional feedback control can be realized and an angle detection apparatus that executes the angle detection method. In a robot arm constituted by an input shaft encoder, an output shaft encoder, a motor, a reduction gear, and the like, an output shaft encoder detection error is corrected by setting rotation position information using a periodicity of rotations of the input shaft encoder as a reference. When the input / output shaft encoder detection error is corrected in this manner, the control for positioning the output shaft at a high accuracy and the torsional feedback control can be realized.

Owner:CANON KK

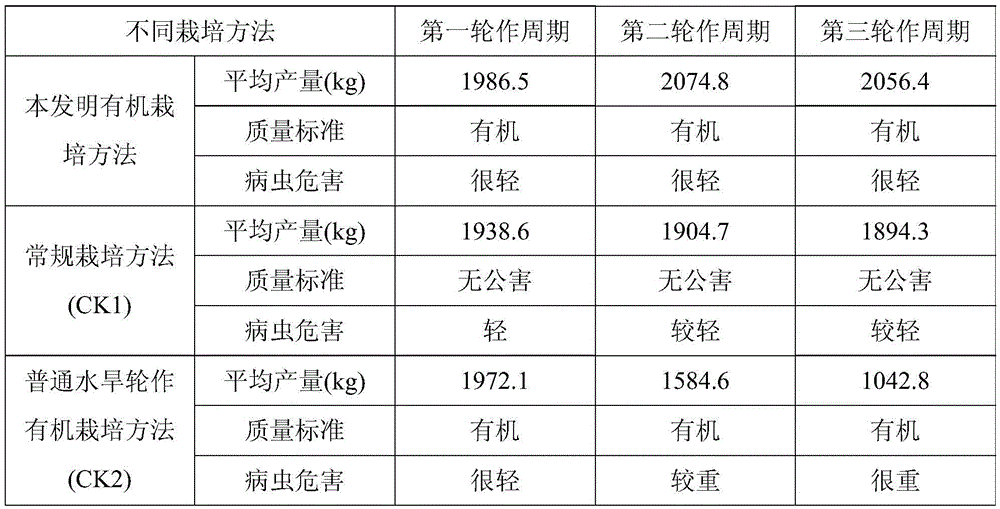

Organic cultivation method based on rotation of autumn melons, vegetable broad beans, rice and water chestnuts

InactiveCN105519347AReduce the degree of occurrenceSimple structureCultivating equipmentsPlant cultivationWater ChestnutsRotation method

The invention discloses an organic cultivation method based on rotation of autumn melons, vegetable broad beans, rice and water chestnuts, and relates to the technical field of rotation cropping. The organic cultivation method includes the following steps: (1), establishing an organic cultivation production base; (2), cultivating according to a rotation method; (3), cultivating organic melons, organic vegetable broad beans, organic rice (planting one batch of early-season rice in the first year and the second year of a rotation cycle) and organic water chestnuts according to quality requirements and production technology standards of organic agricultural products, and fertilizing soil by straw turnover and organic fertilizer preparation. The rotation method includes sequentially cultivating the early-season rice, the autumn melons and the vegetable broad beans at the first year, and sequentially cultivating the early-season rice and the water chestnuts at the second year, wherein every two years serve as a rotation cycle. The organic cultivation method has the advantages that the organic melons, the organic vegetable broad beans, the water chestnuts and the organic rice can be cultivated in the same cultivation production base, a high-efficiency ecological circular agriculture cultivation mode, high practicability and operability and high social, economic and ecological benefits are achieved, and the method has a broad promotion and application prospect in the middle and lower reaches of Yangtze River.

Owner:HUNAN AGRI INFORMATION & ENG RES INST +1

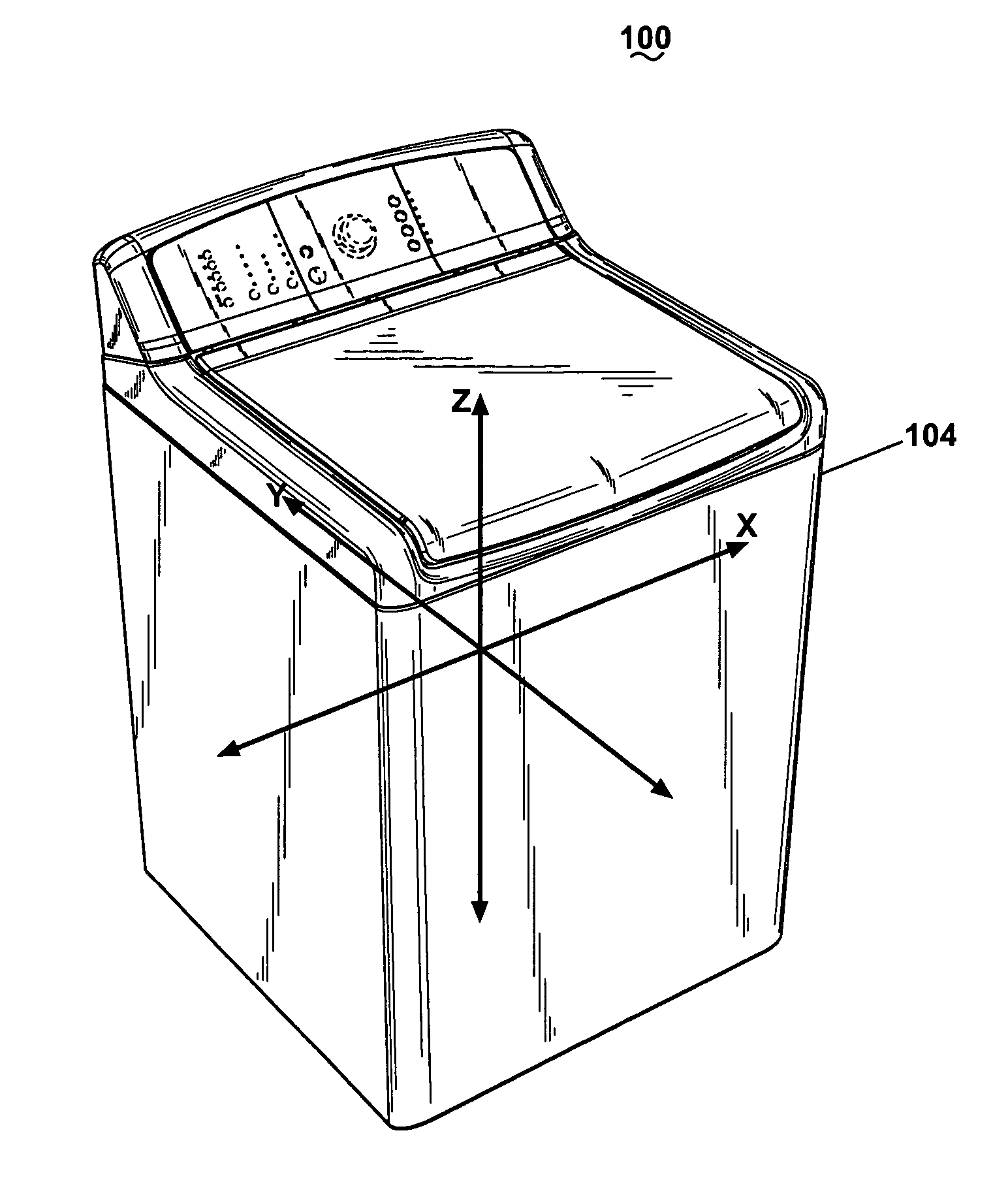

Dynamic load detection for a clothes washer

InactiveUS7581272B2Reduce vibrationSave energyOther washing machinesControl devices for washing apparatusRotational axisDrive shaft

Owner:WHIRLPOOL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com