Rotating arc narrow gap MAG (metal active gas) welding seam offset identification device and method based on visual sensing

A technology of rotary arc welding and weld seam deviation, applied in the direction of arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of not extracting the edge of the groove, not obtaining a complete image during welding, and unfavorable real-time monitoring of welding seam tracking Research and other issues to achieve the effect of overcoming the variation of the groove bottom and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to deepen the understanding of the present invention, the specific implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings. This embodiment is only used to explain the present invention and does not constitute a limitation to the protection scope of the present invention.

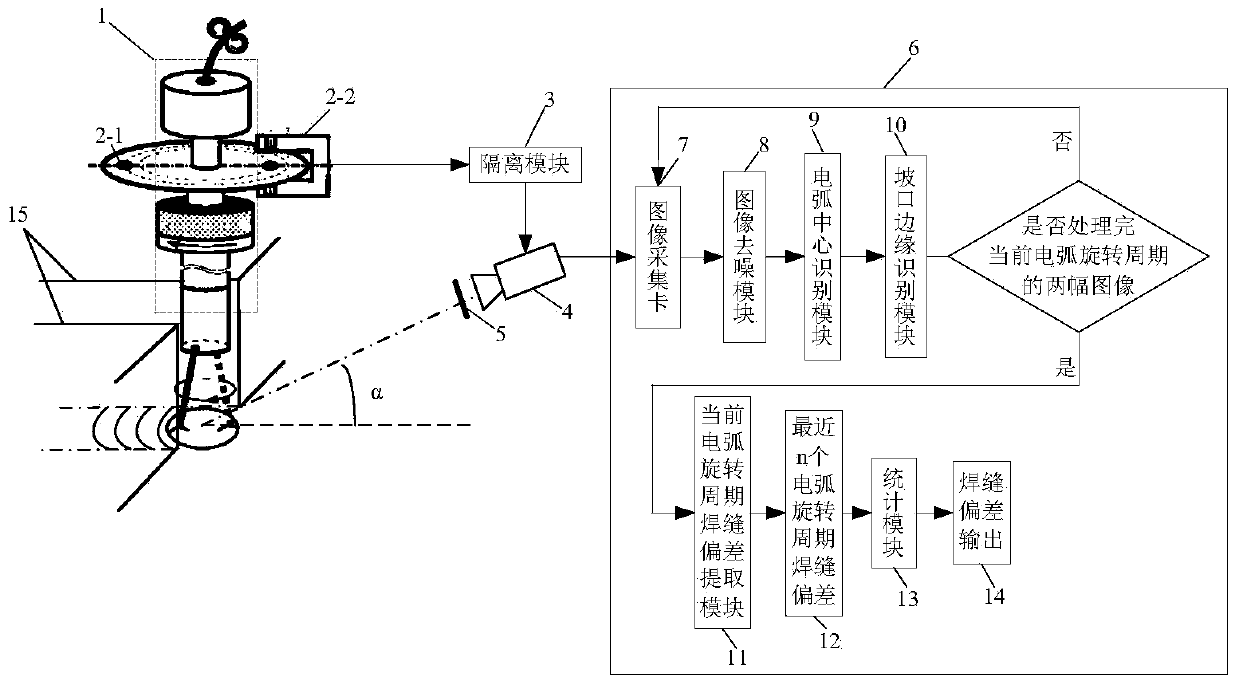

[0046] Such as figure 1 Shown is a visual sensor-based rotary arc narrow gap gas shielded welding seam deviation recognition device of the present invention, including a rotary arc torch 1, an arc rotary position sensor 2, an isolation module 3, a CCD camera 4 and a PC 6, wherein the PC 6 includes an image acquisition card 7, an image denoising module 8, an arc center identification module 9, a groove edge identification module 10, a welding seam deviation extraction module 11 for the current arc rotation cycle, a statistics module 13, a CCD camera 4, Light reduction and filter system5.

[0047] After the lens of the CC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com