Patents

Literature

1151results about How to "Reduce rotation speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

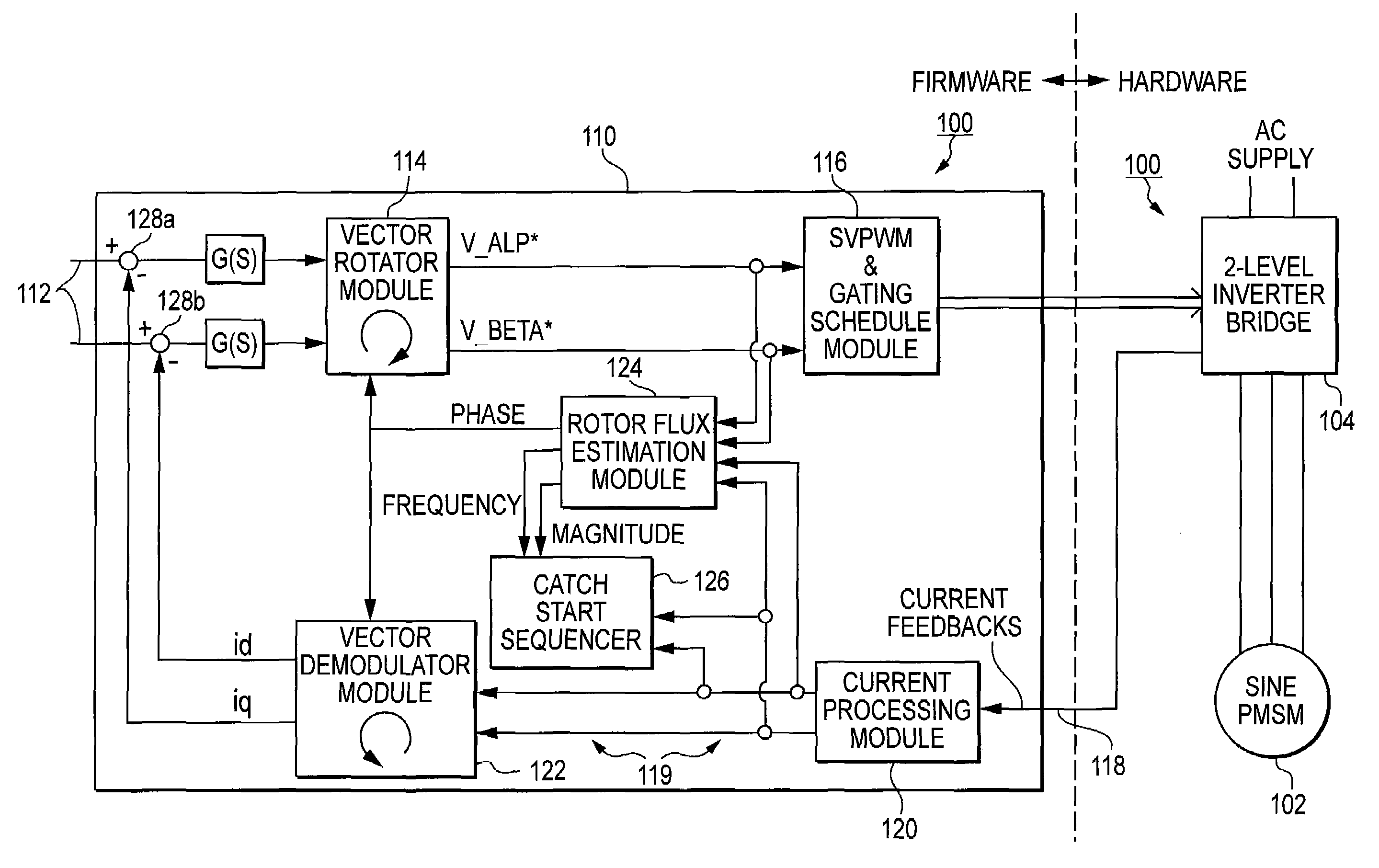

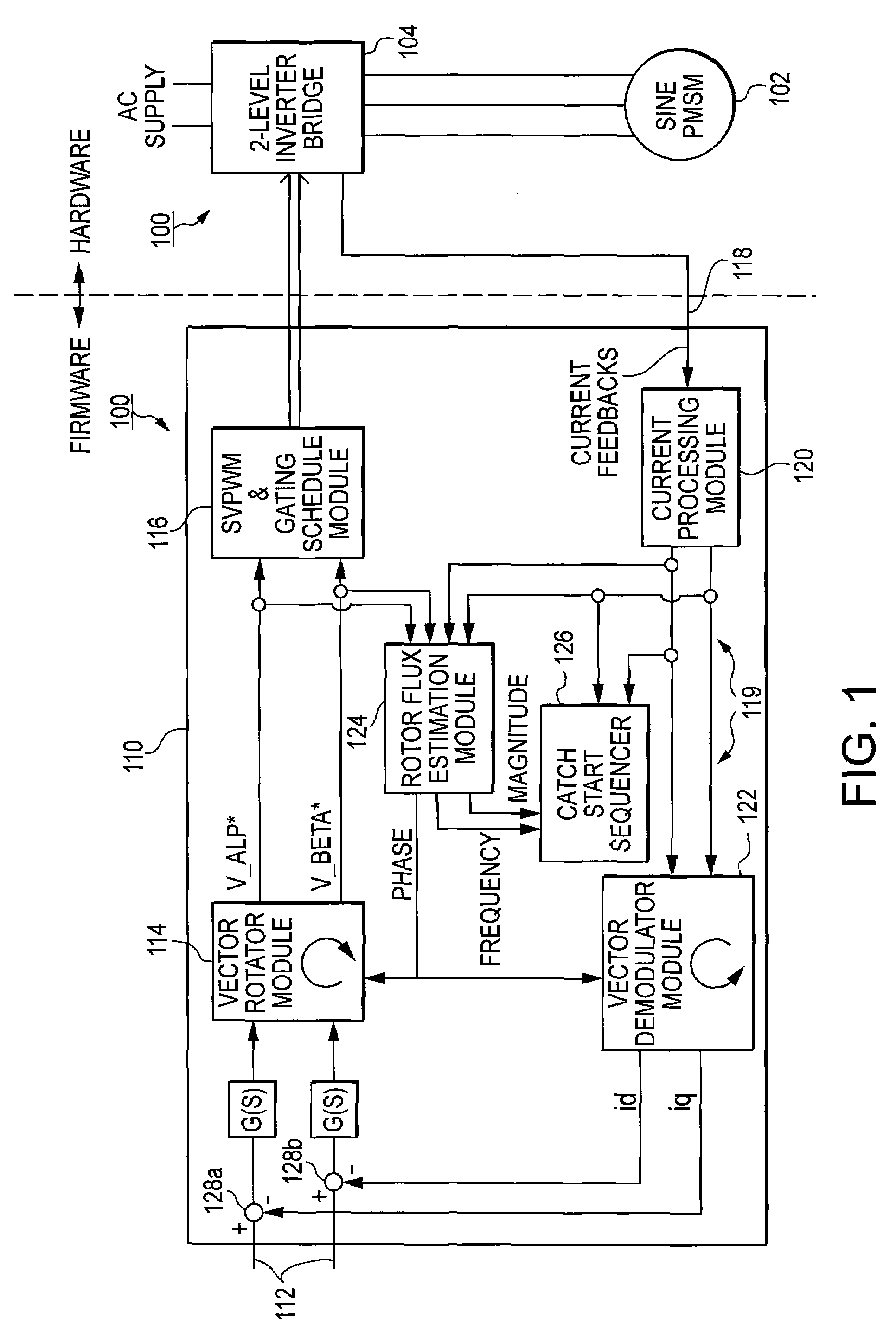

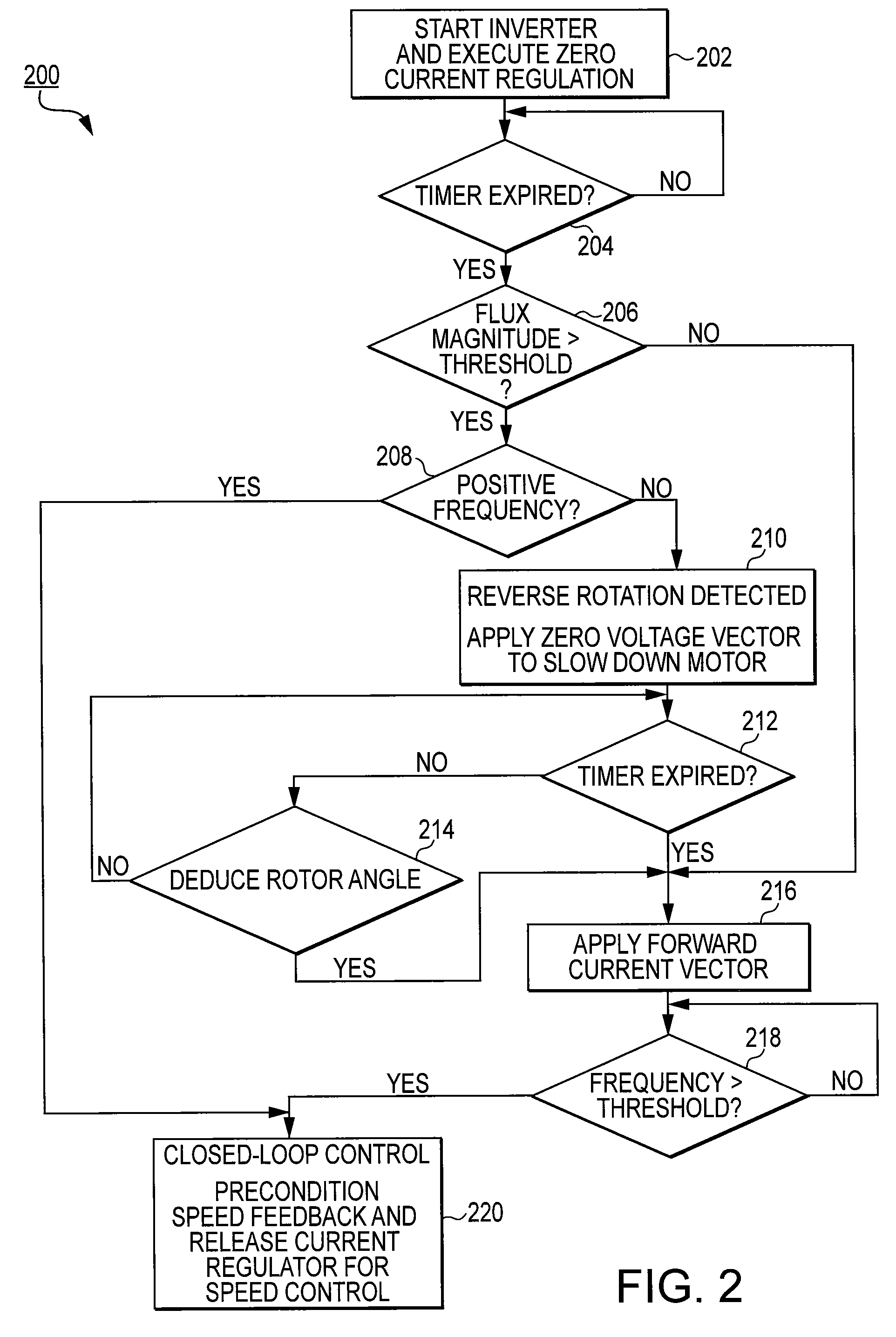

Method and system for starting a sensorless motor

ActiveUS20070001635A1Preventing over current shutdownHigh currentAC motor controlSynchronous motors startersMotor driveEngineering

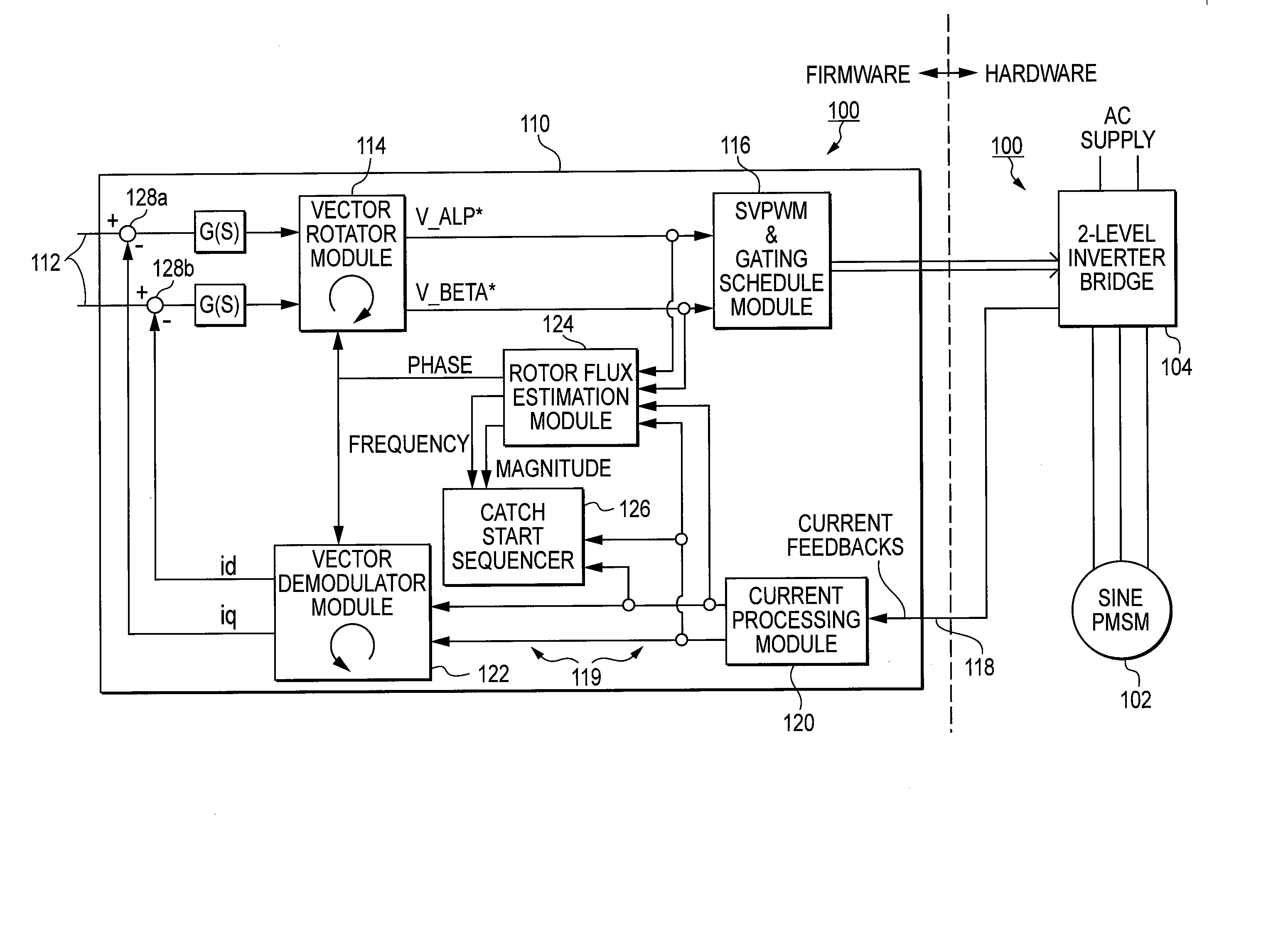

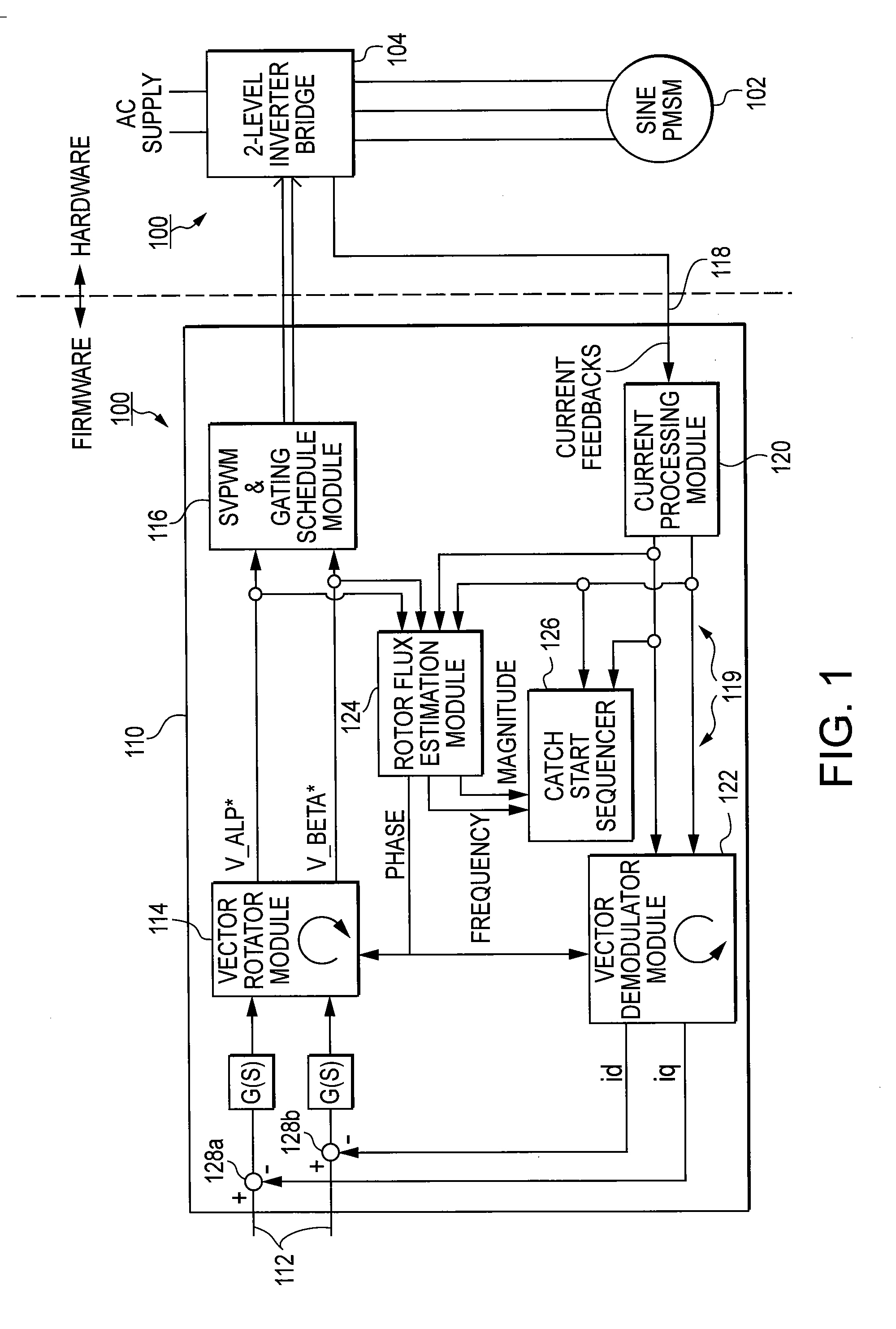

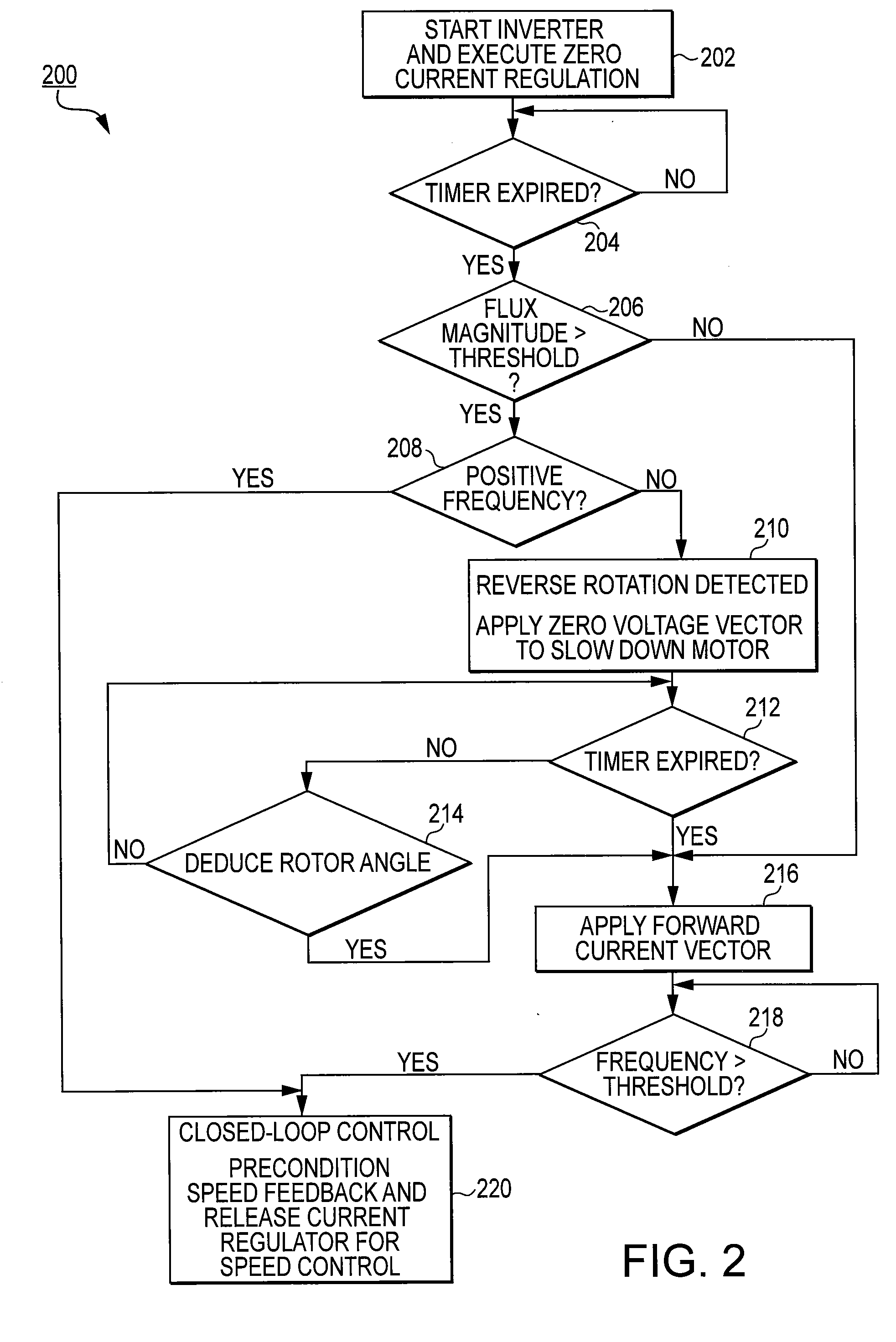

A motor drive system for a sensorless motor includes a catch start sequencer that controls the motor drive system to robustly start the motor in the event the motor rotor is rotating in forward or reverse direction prior to activating the motor drive system. In particular, the catch start sequencer causes the motor drive system to initially find and track the rotor position, and then determines the speed and possibly the direction of rotation of the rotor. If the rotor is rotating in the reverse direction, the catch start sequencer controls the motor drive system to slow the speed of rotation and to then start the rotor rotating in the forward direction.

Owner:INFINEON TECH AMERICAS CORP

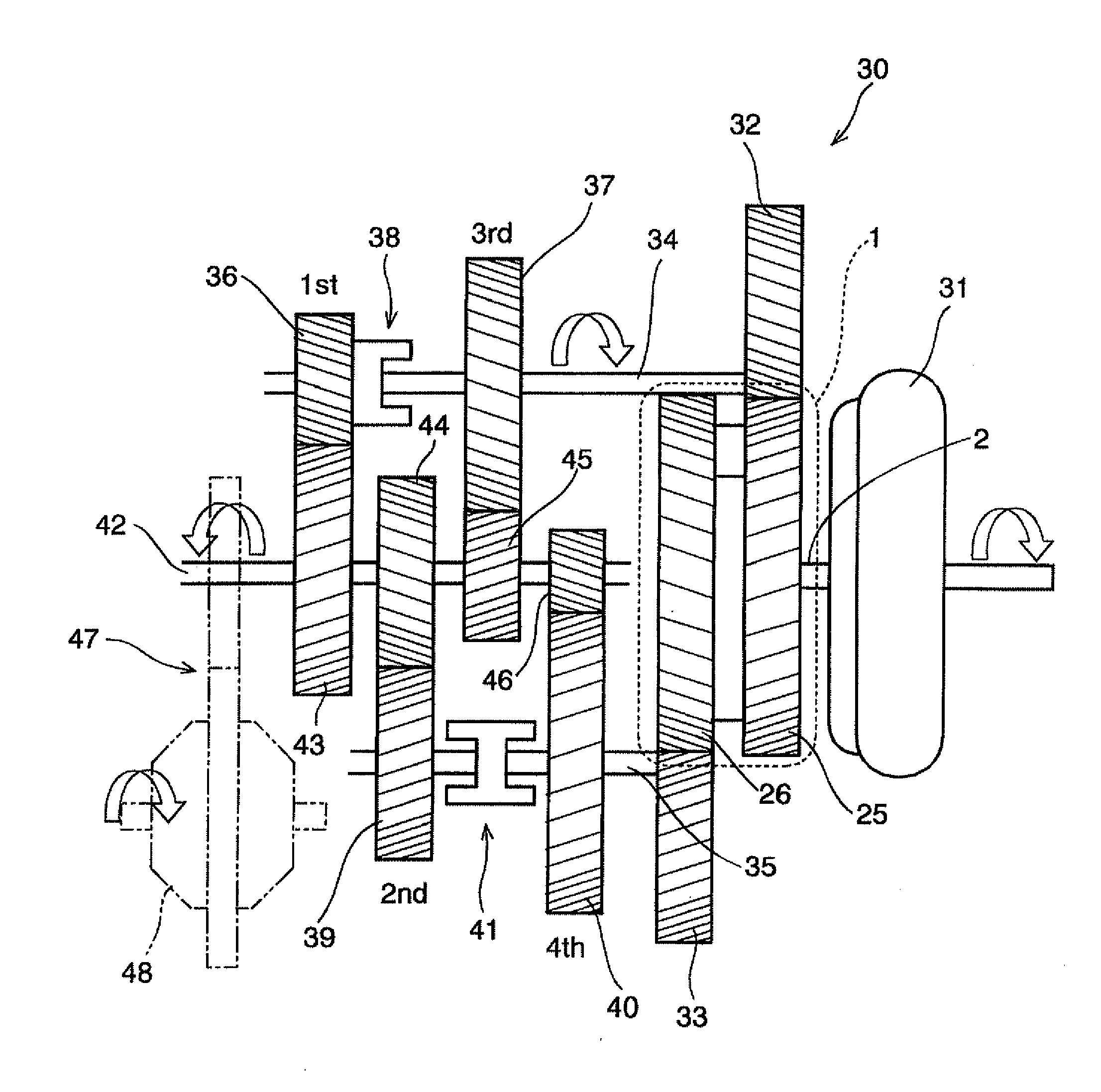

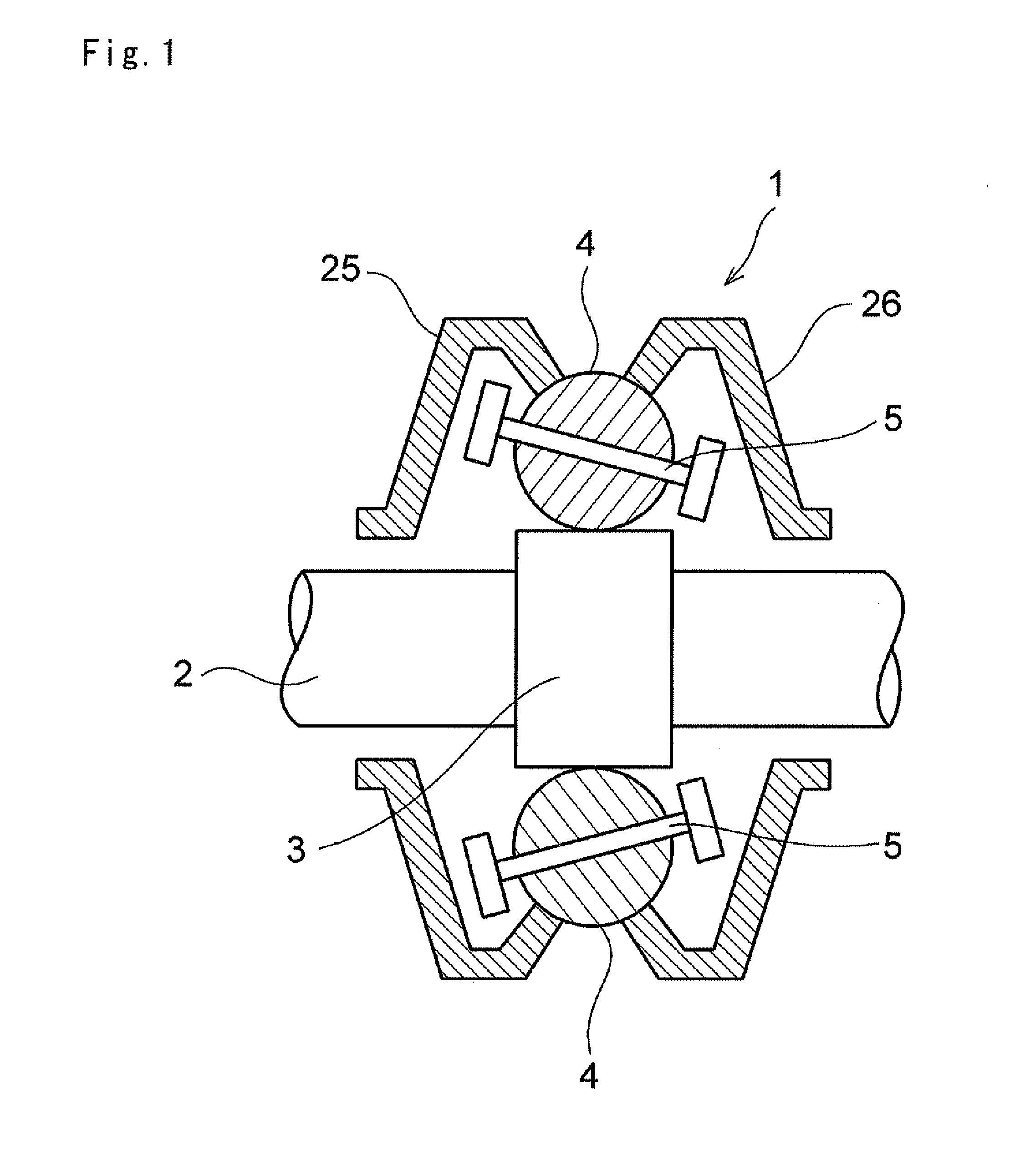

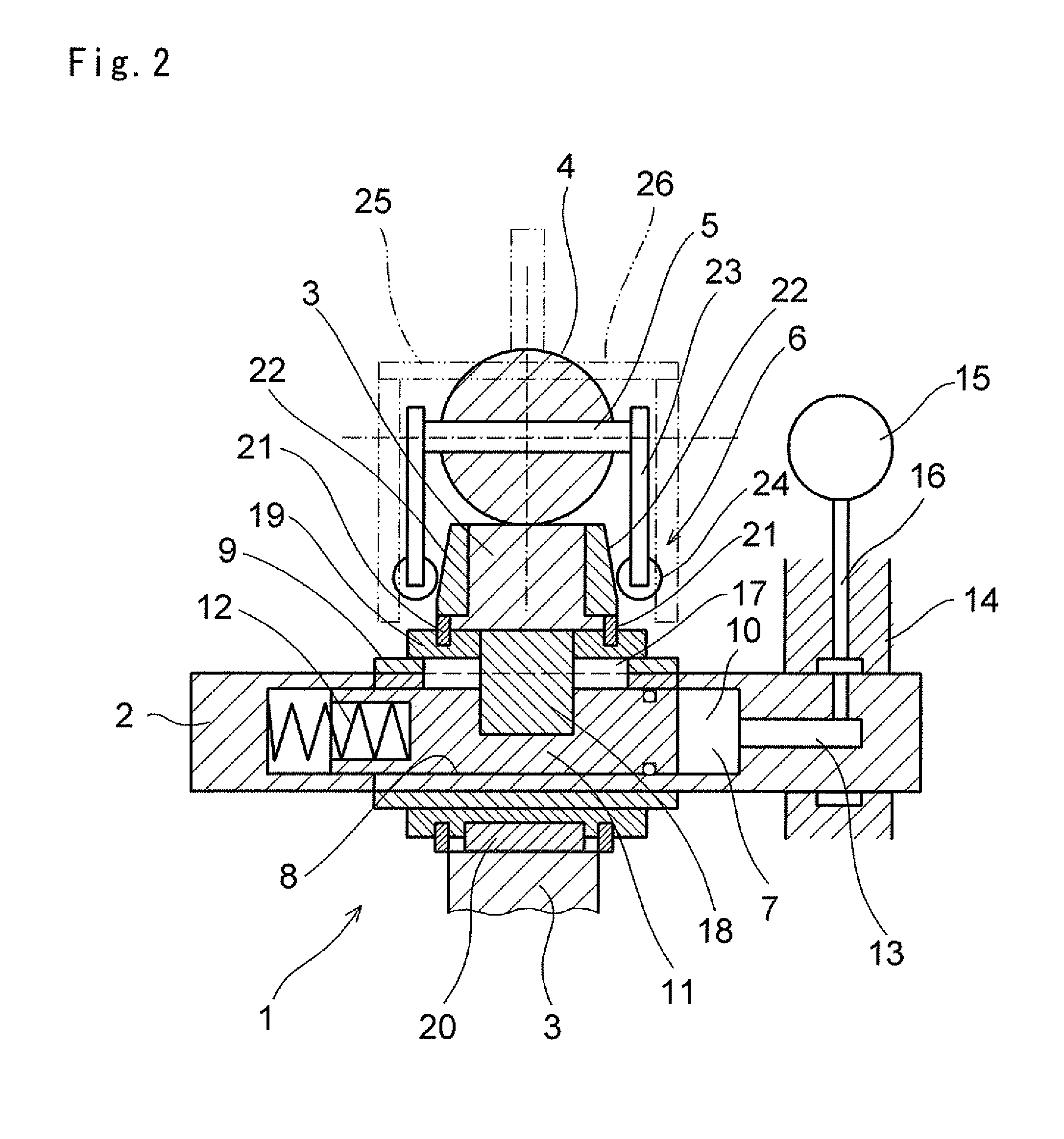

Continuously variable transmission mechanism and transmission using the same

InactiveUS20110319222A1Increase rotation speedRotational radiusFriction gearingsRotation velocityControl theory

A continuously variable transmission adapted to set a speed change ratio in accordance with a tilt angle of a rolling member mediating a torque being transmitted, and to transmit a torque among three elements. The transmission mechanism is provided with a rolling member having a smooth outer face and capable of tilting a rotational center axis thereof, and a rotary member arranged to be contacted with a predetermined portion of the outer face of the rolling member in a torque transmittable manner. Specifically, the continuously variable transmission mechanism is configured to vary a rotational speed of the rotary member by changing a rotation radius of a contact point between the rolling member and the rotary member by tilting the rotational center axis of the rolling member.

Owner:TOYOTA JIDOSHA KK

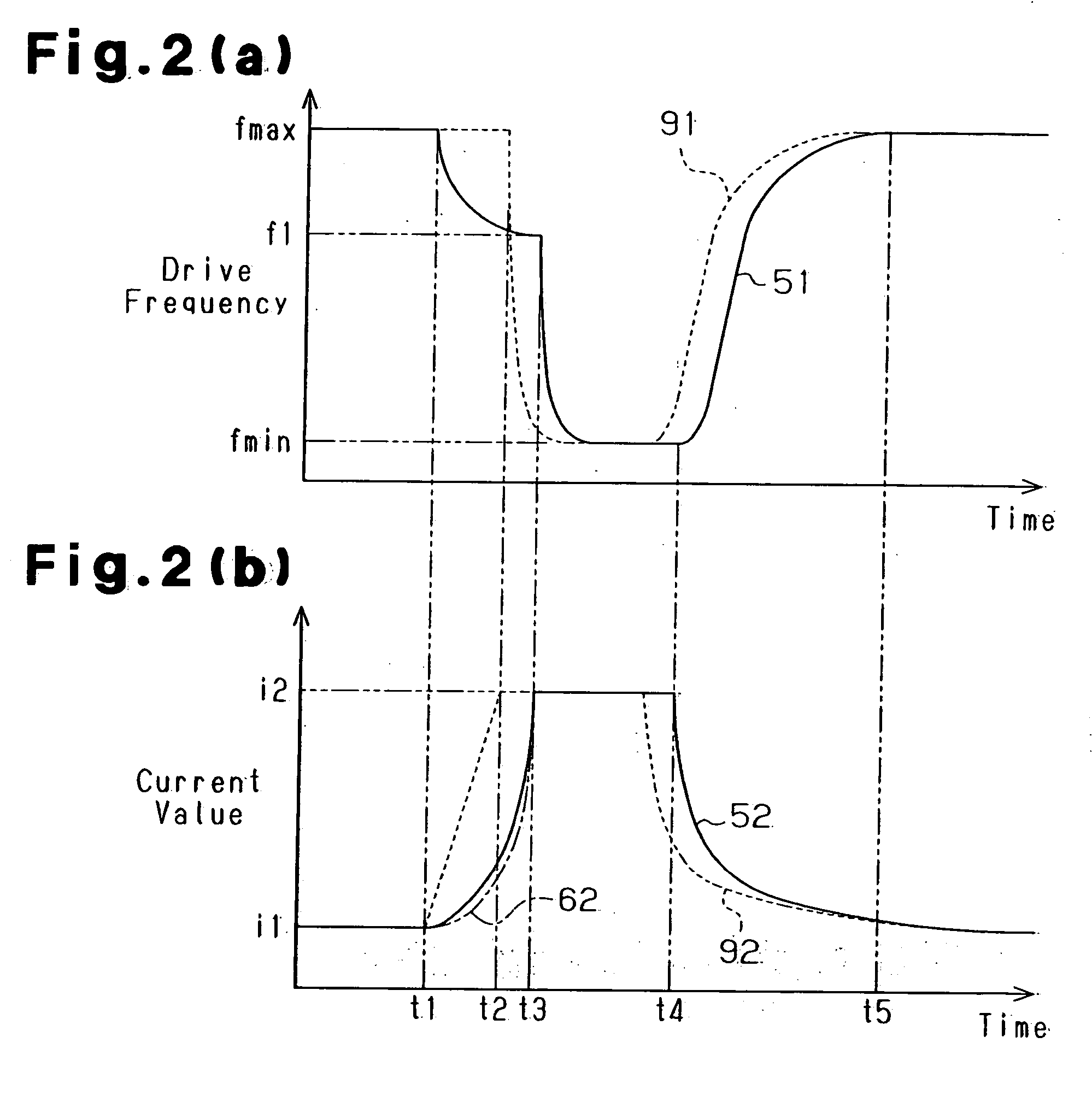

Method and system for starting a sensorless motor

ActiveUS7652441B2Preventing over current shutdownHigh currentAC motor controlSynchronous motors startersMotor driveControl theory

A motor drive system for a sensorless motor includes a catch start sequencer that controls the motor drive system to robustly start the motor in the event the motor rotor is rotating in forward or reverse direction prior to activating the motor drive system. In particular, the catch start sequencer causes the motor drive system to initially find and track the rotor position, and then determines the speed and possibly the direction of rotation of the rotor. If the rotor is rotating in the reverse direction, the catch start sequencer controls the motor drive system to slow the speed of rotation and to then start the rotor rotating in the forward direction.

Owner:INFINEON TECH AMERICAS CORP

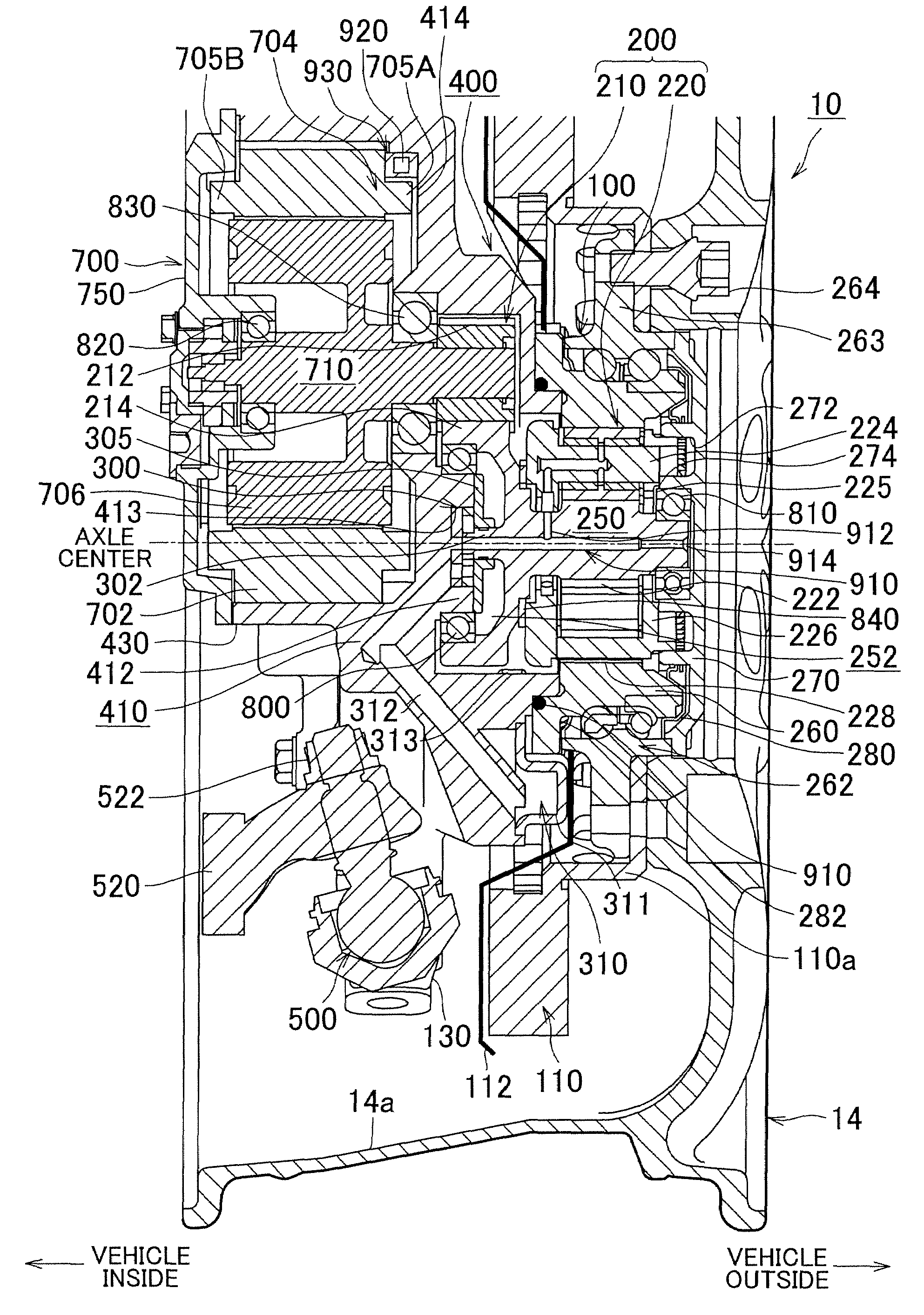

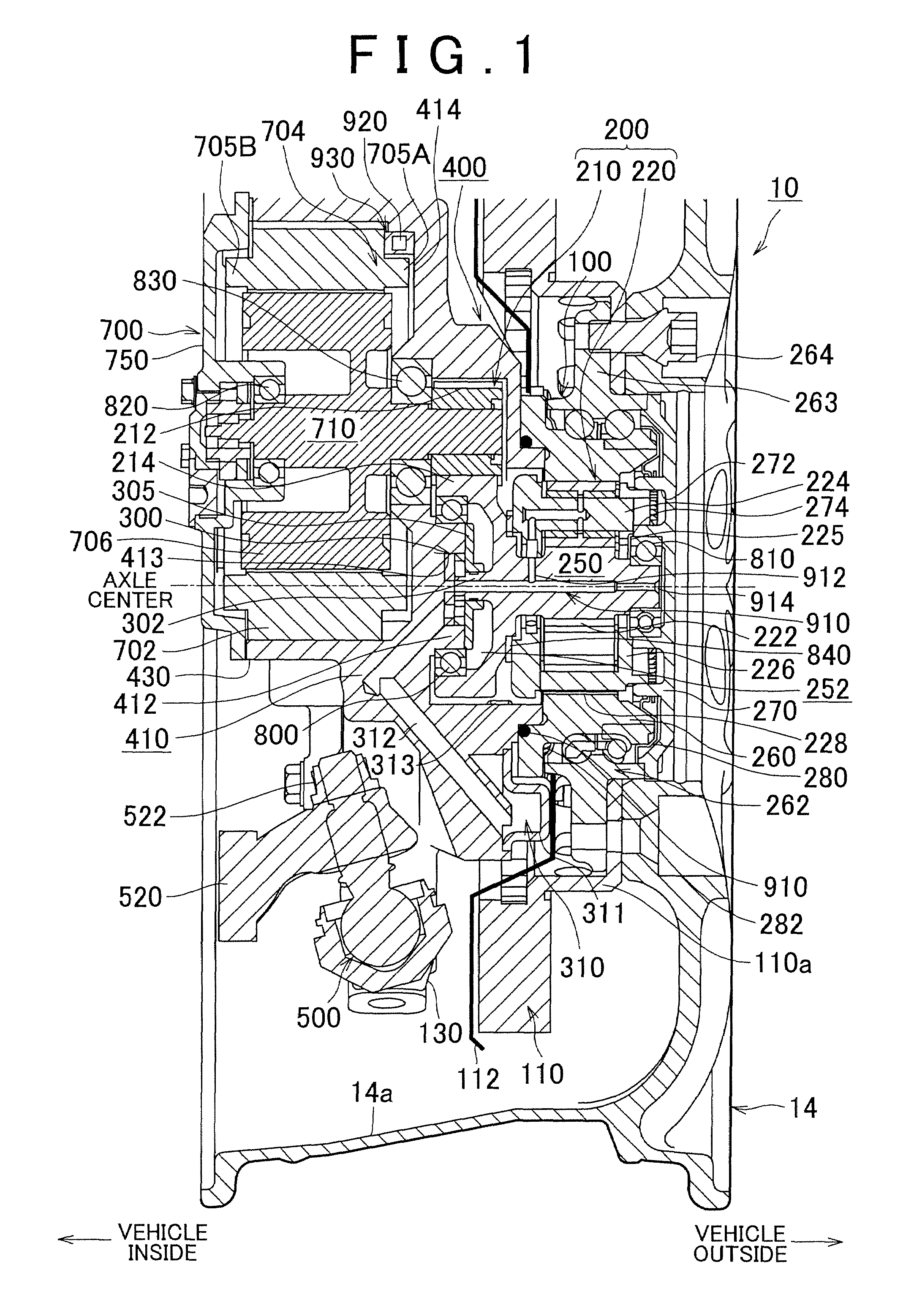

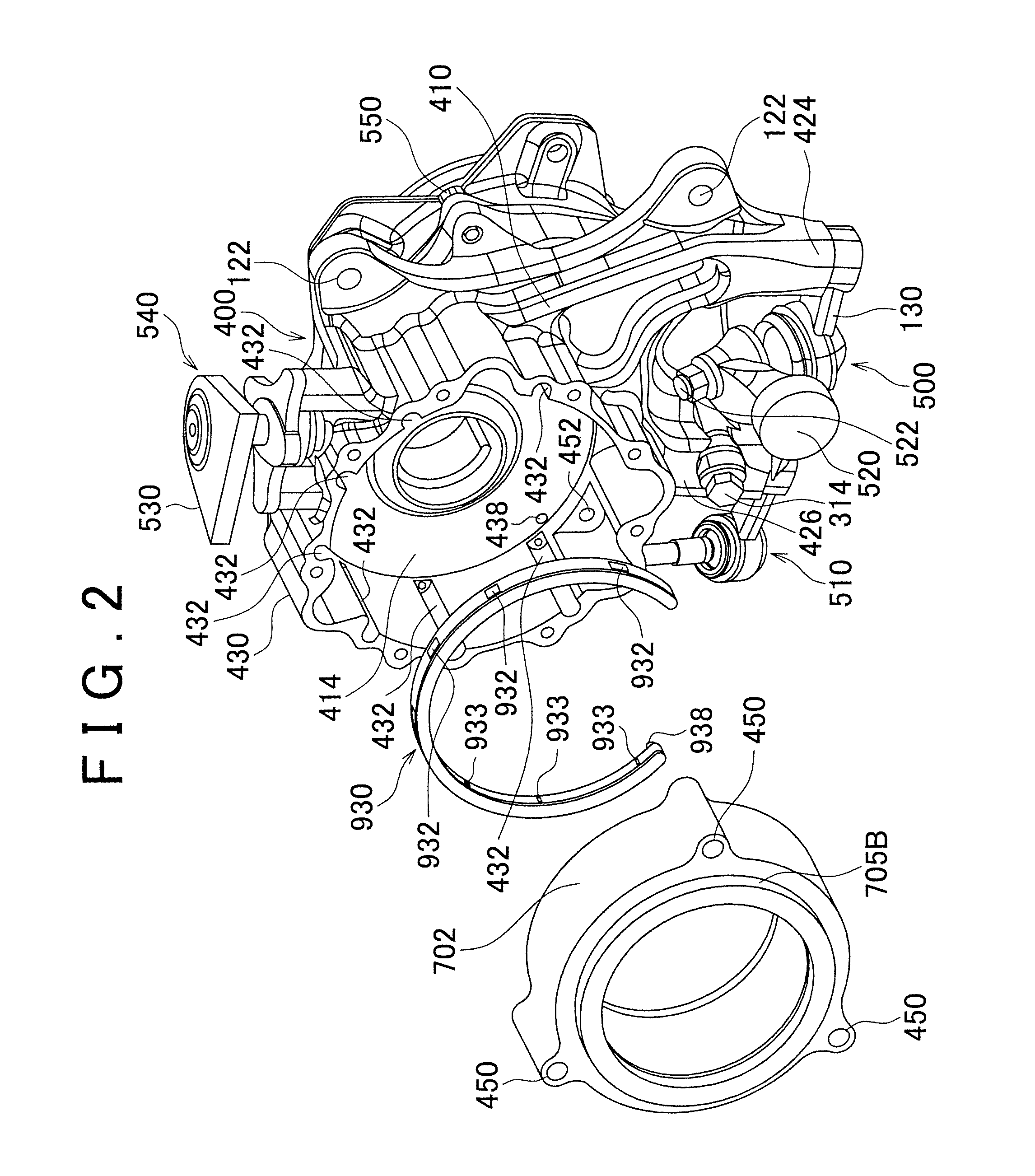

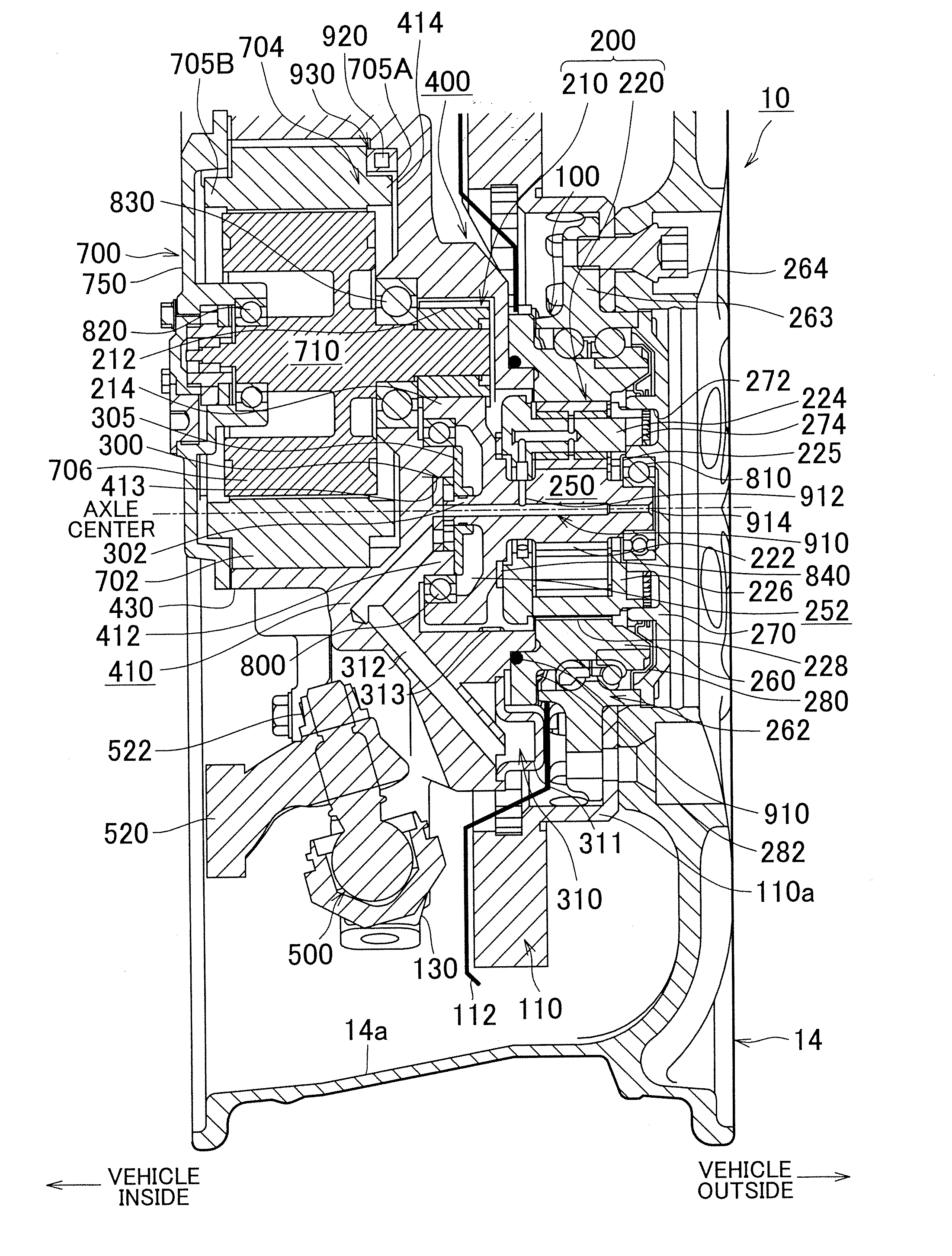

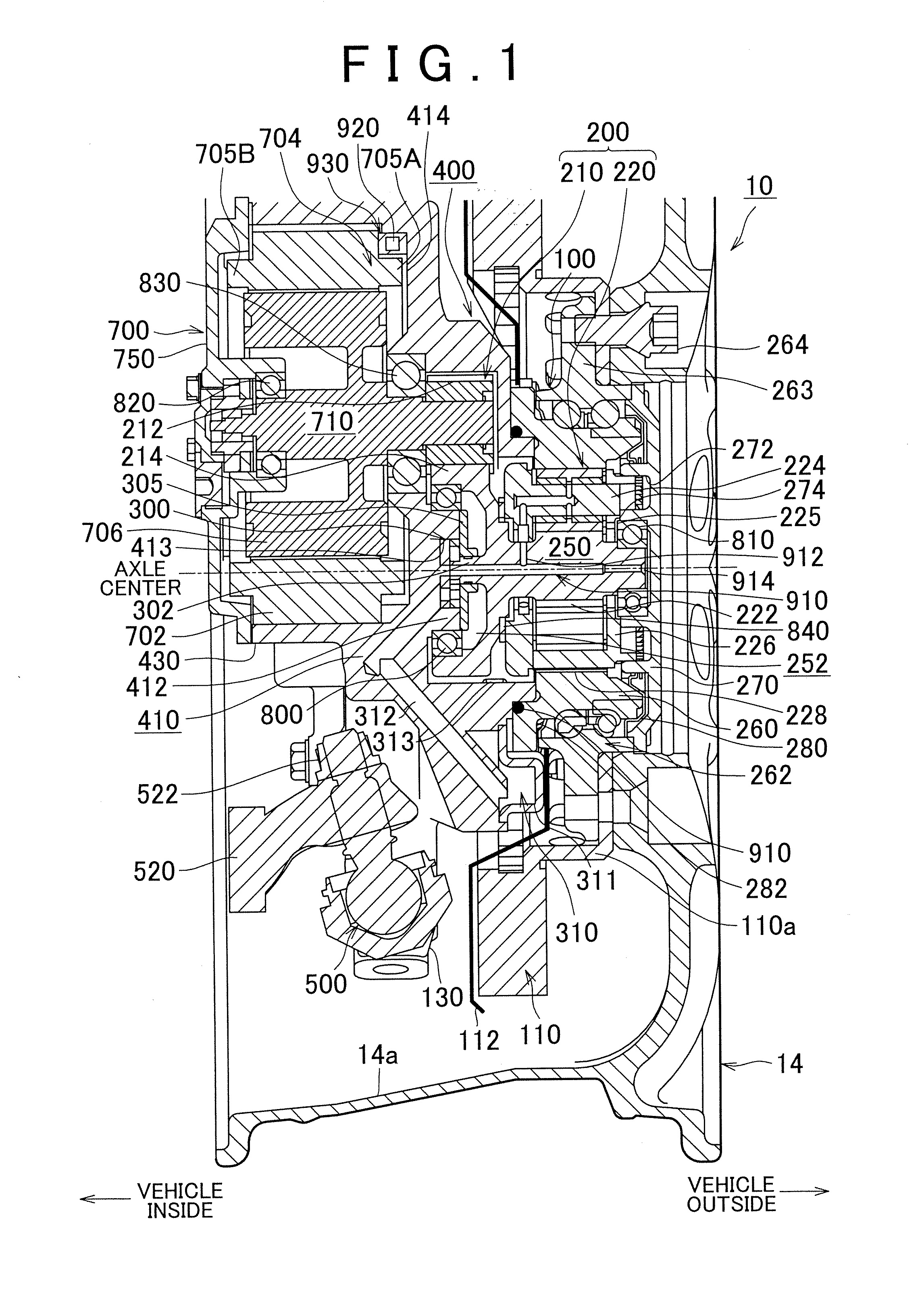

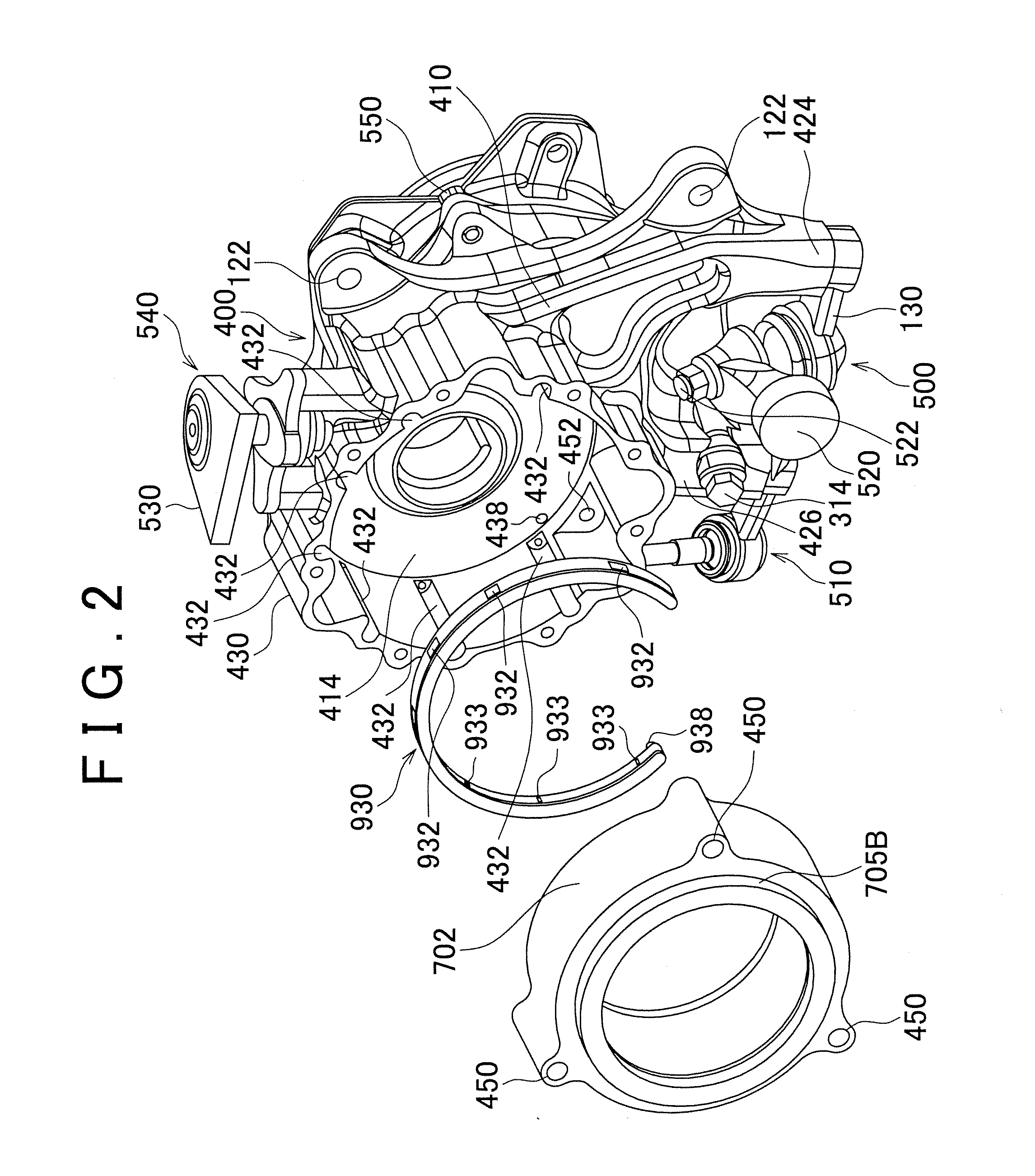

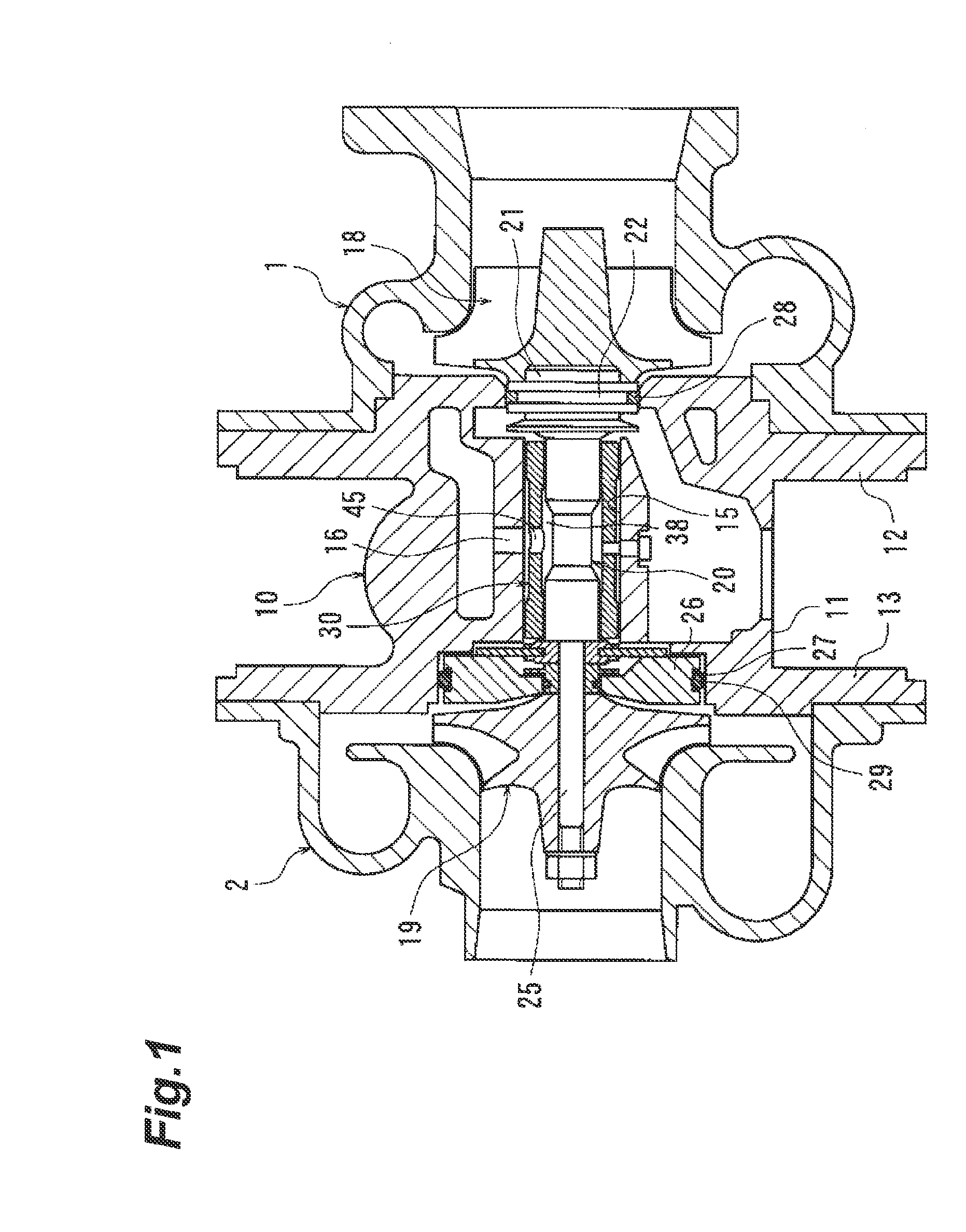

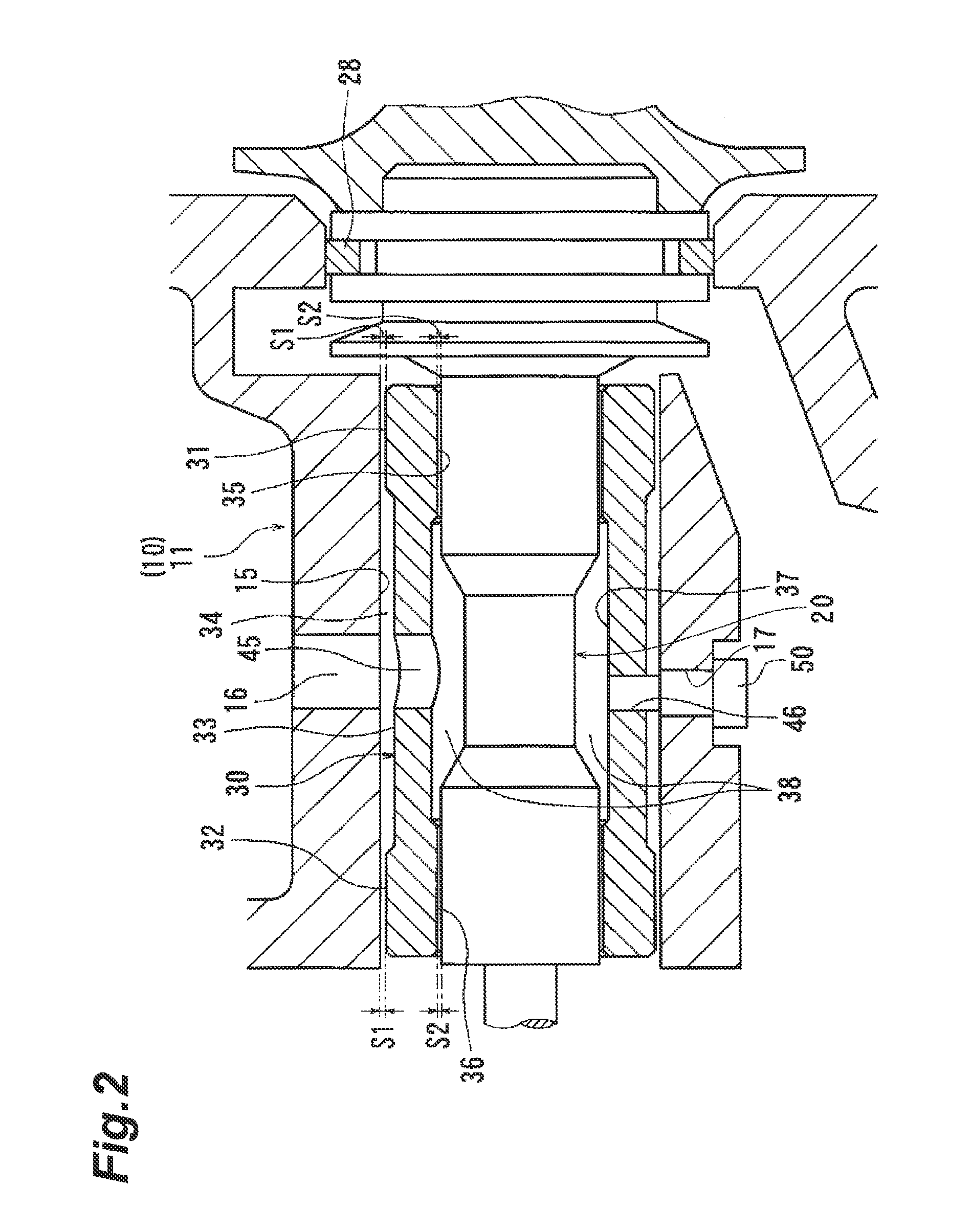

In-wheel motor and wheel assembly with this in-wheel motor

ActiveUS7828095B2Simple processReduce probabilityElectric devicesElectric propulsion mountingFluid supplyElectric motor

A motor has a stator core, a coil, a rotor, and a motor case in which the stator core, the coil, and the rotor are housed. The motor is also provided with a fluid carrying member that is arranged around a coil end of the coil in the motor case and has an inlet hole that is communicated with a fluid supply source and a distribution hole that is communicated with a space inside the motor case.

Owner:TOYOTA JIDOSHA KK

In-wheel motor and wheel assembly with this in-wheel motor

ActiveUS20080035399A1Simple processReduce probabilityElectric devicesElectric propulsion mountingFluid supplyElectric motor

A motor has a stator core, a coil, a rotor, and a motor case in which the stator core, the coil, and the rotor are housed. The motor is also provided with a fluid carrying member that is arranged around a coil end of the coil in the motor case and has an inlet hole that is communicated with a fluid supply source and a distribution hole that is communicated with a space inside the motor case.

Owner:TOYOTA JIDOSHA KK

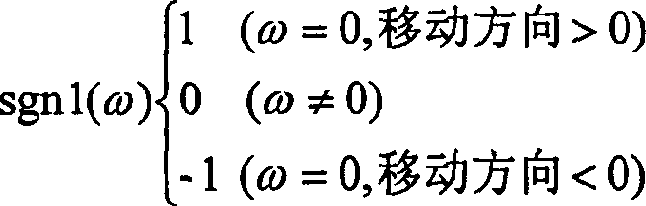

Robot arm control method and control device

By appropriately selecting a command value or an actually measured value as the angular velocity used for friction torque calculation, friction compensation can be effective in both cases when actively operating according to the angular velocity command and passively operating, that is, when being pushed by an external force . Also, after a collision is detected, when the motor rotation direction is opposite to the collision direction, the position control is switched to current control so that the motor generates torque in the opposite direction to the motor rotation direction, thereby reducing the motor rotation speed and weakening the collision energy. Thereafter, when the motor rotation speed becomes the set value or lower, the mode is set to flexible control, thereby eliminating deformation of the speed reduction device or the like caused by the collision. On the other hand, when the motor rotation direction and the collision direction are the same, the position control is directly transferred to the flexibility control without going through the current control. By performing operations according to the collision force, it is possible to weaken the collision torque.

Owner:PANASONIC CORP

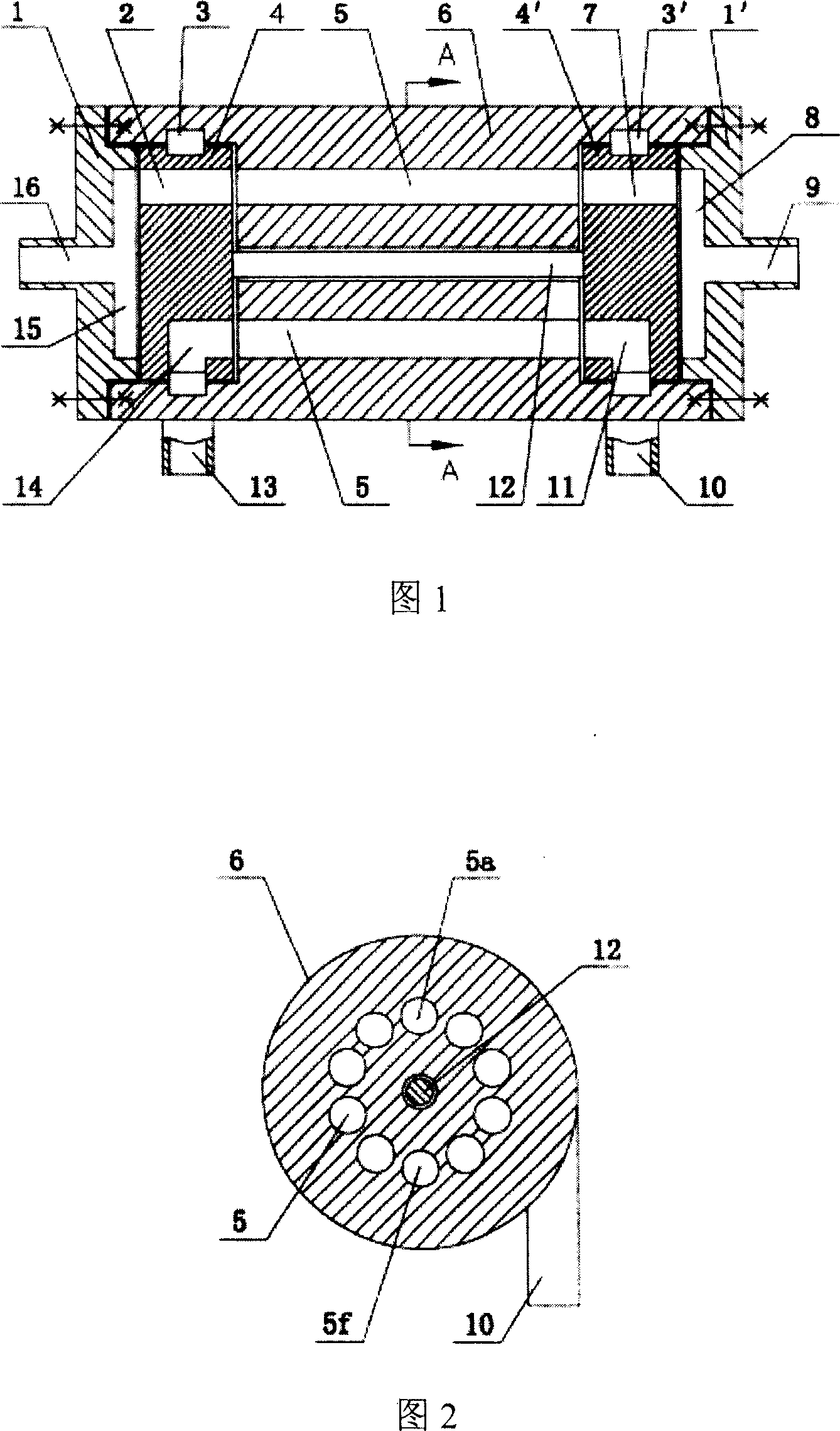

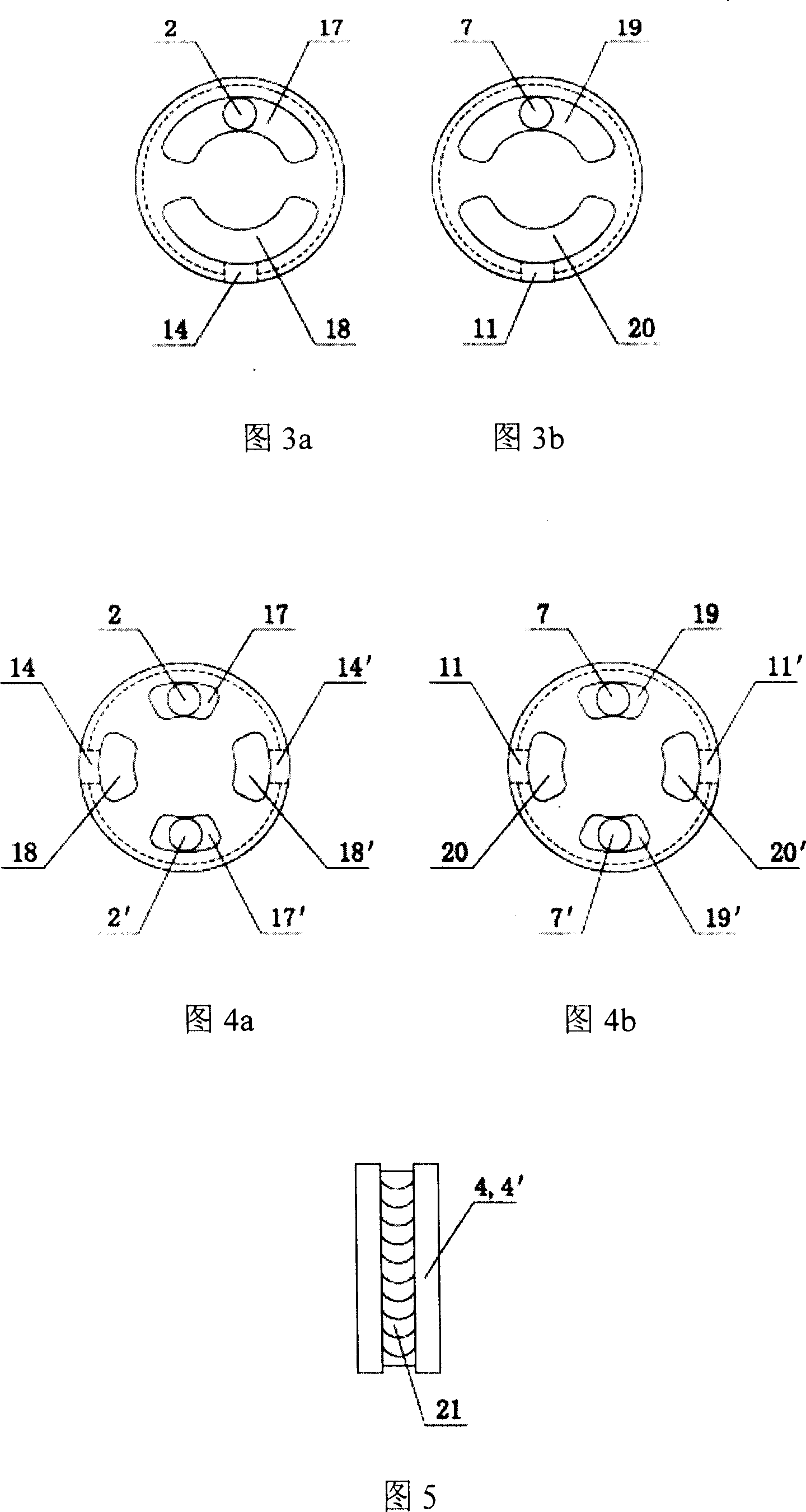

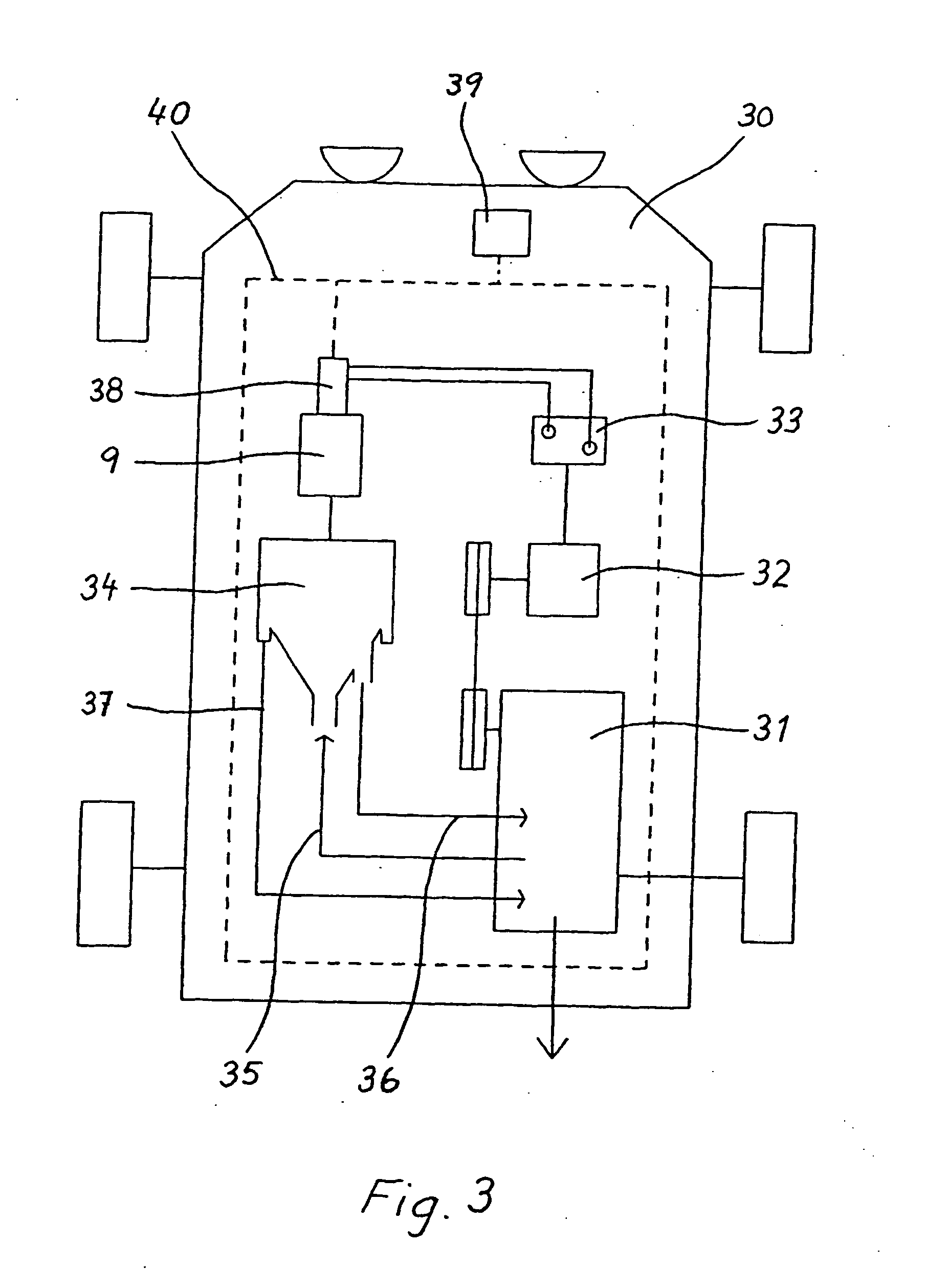

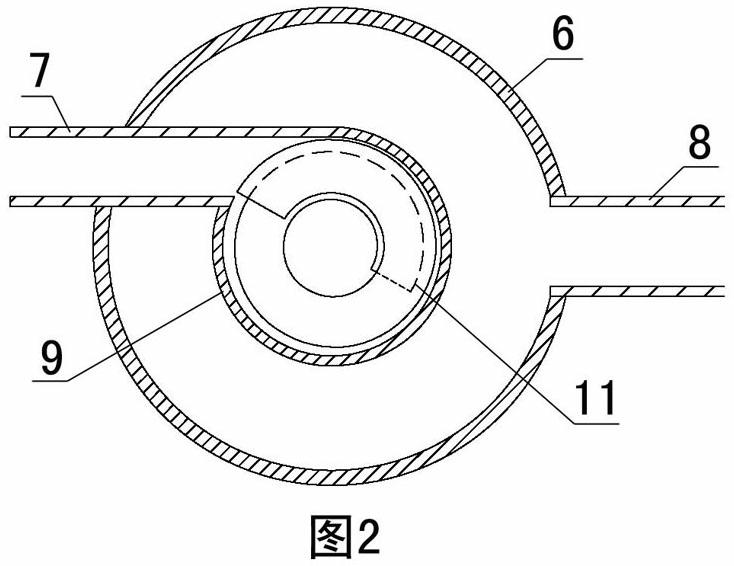

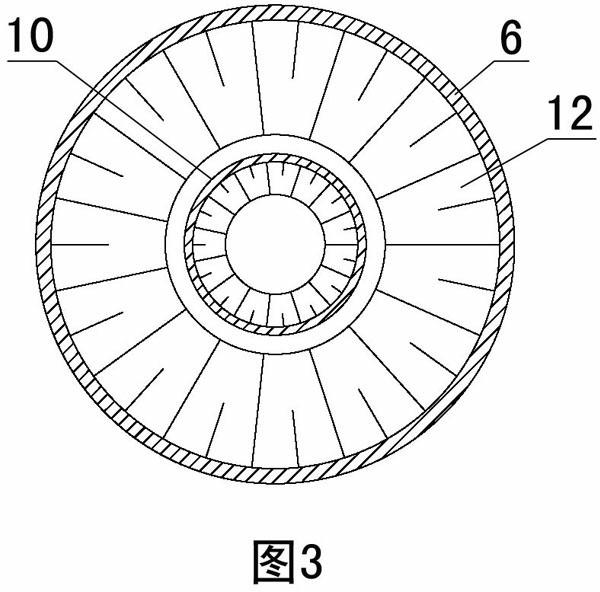

Double-dial coupled type pressure exchanger for sea water or brine reverse osmosis desalination system

InactiveCN1994905AReduce rotation speedIncrease the processing load of a single machineGeneral water supply conservationSeawater treatmentSaline waterCoupling

The invention discloses a double-rotary disc coupling typed pressure exchanger of seawater or bitter saline water reverse osmosis desalination system, which comprises the following parts: cylinder, left rotary disc, right rotary disc, left end lid, right end lid and middle axle. The invention increases single set disposing load of pressure exchanger, which reduces rotary speed to flow working liquid continuity and stability.

Owner:TIANJIN UNIV

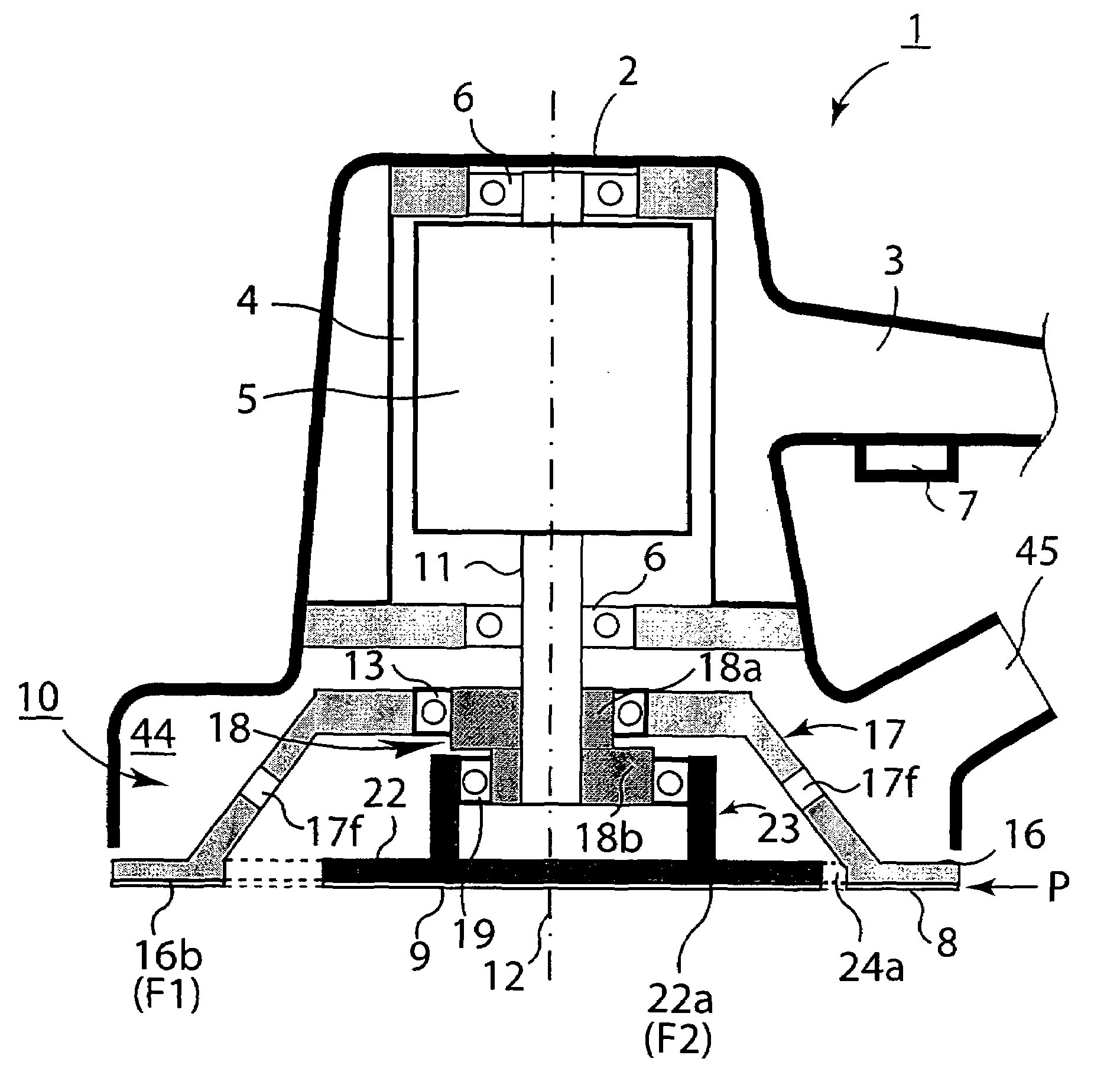

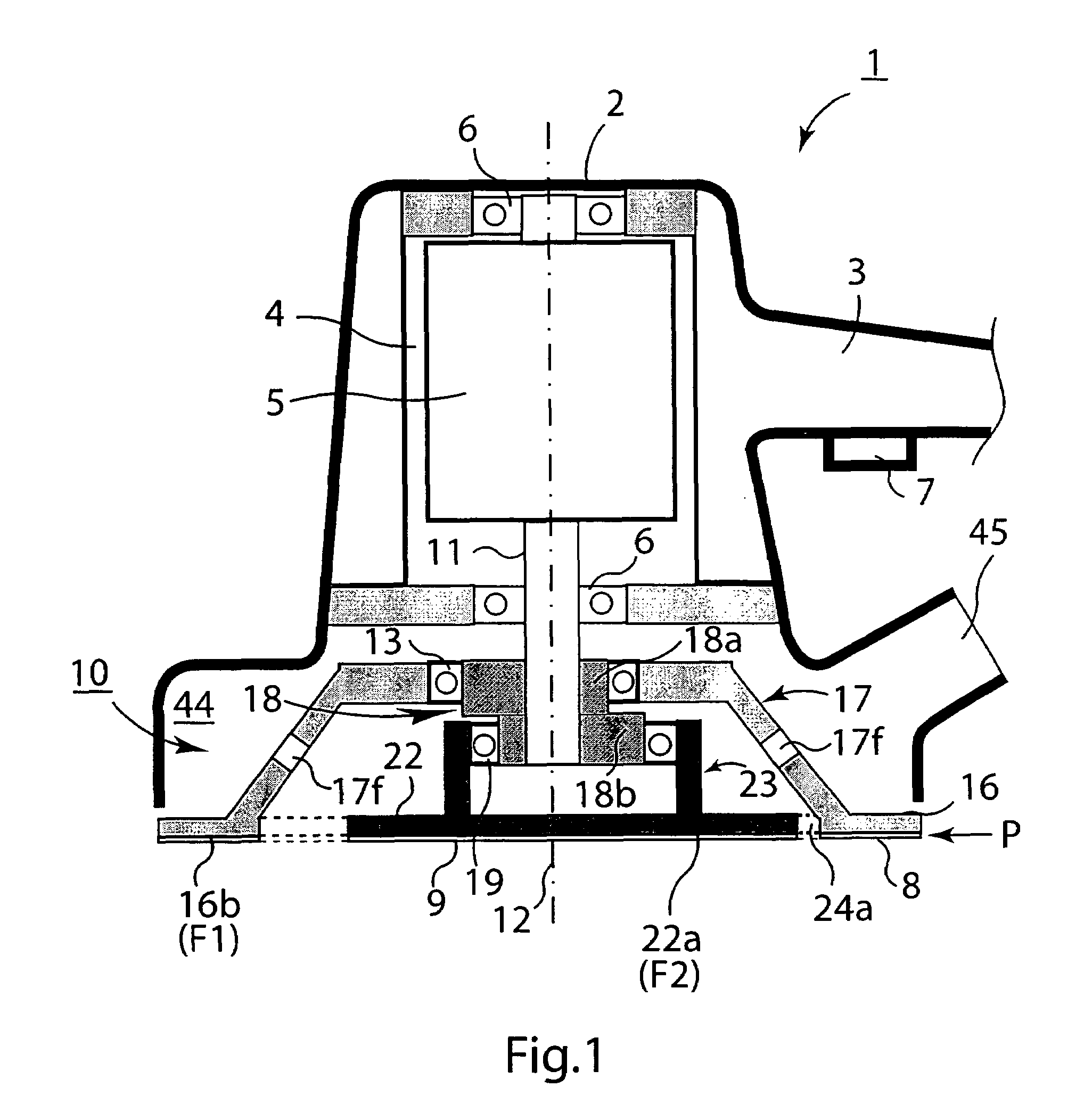

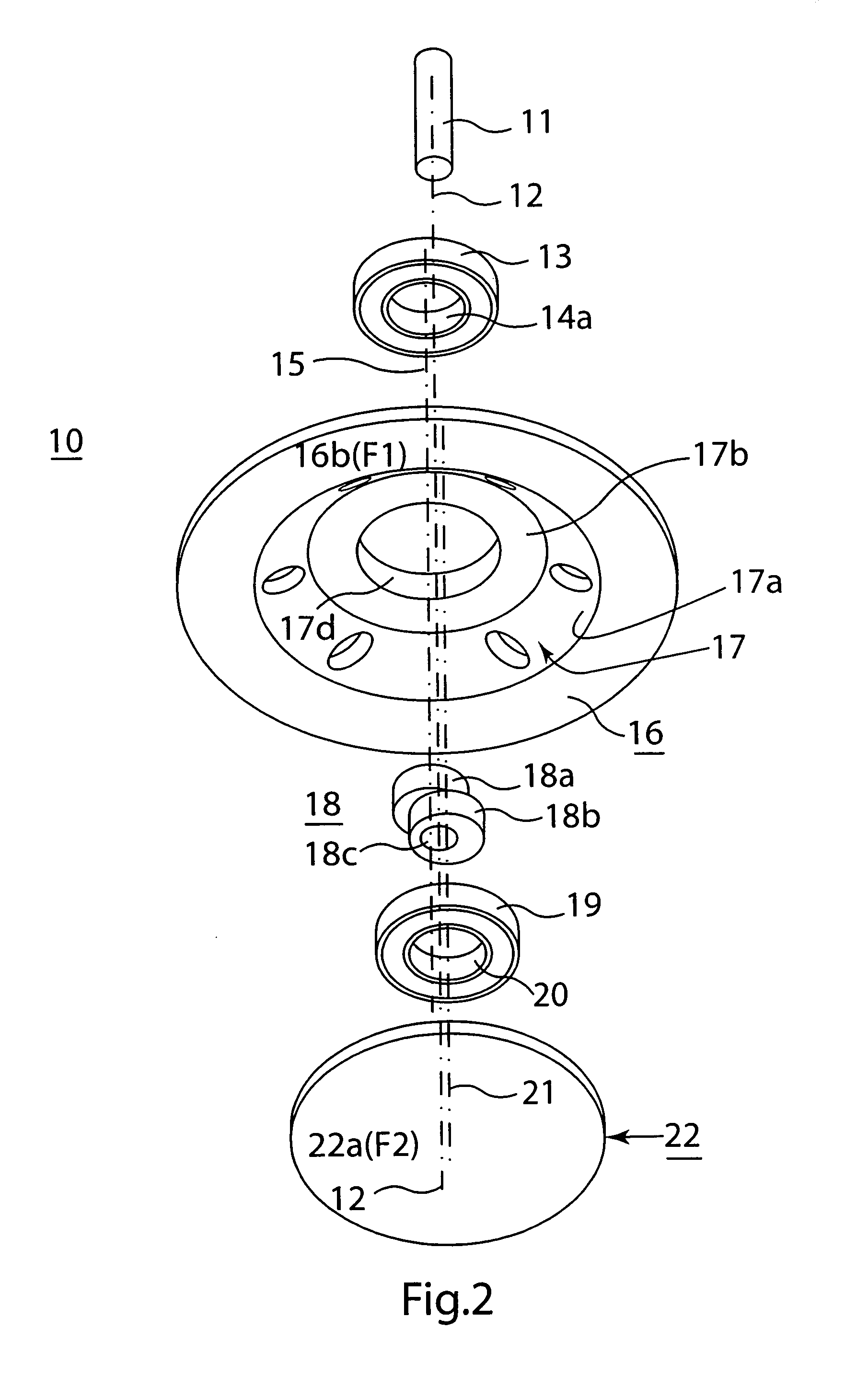

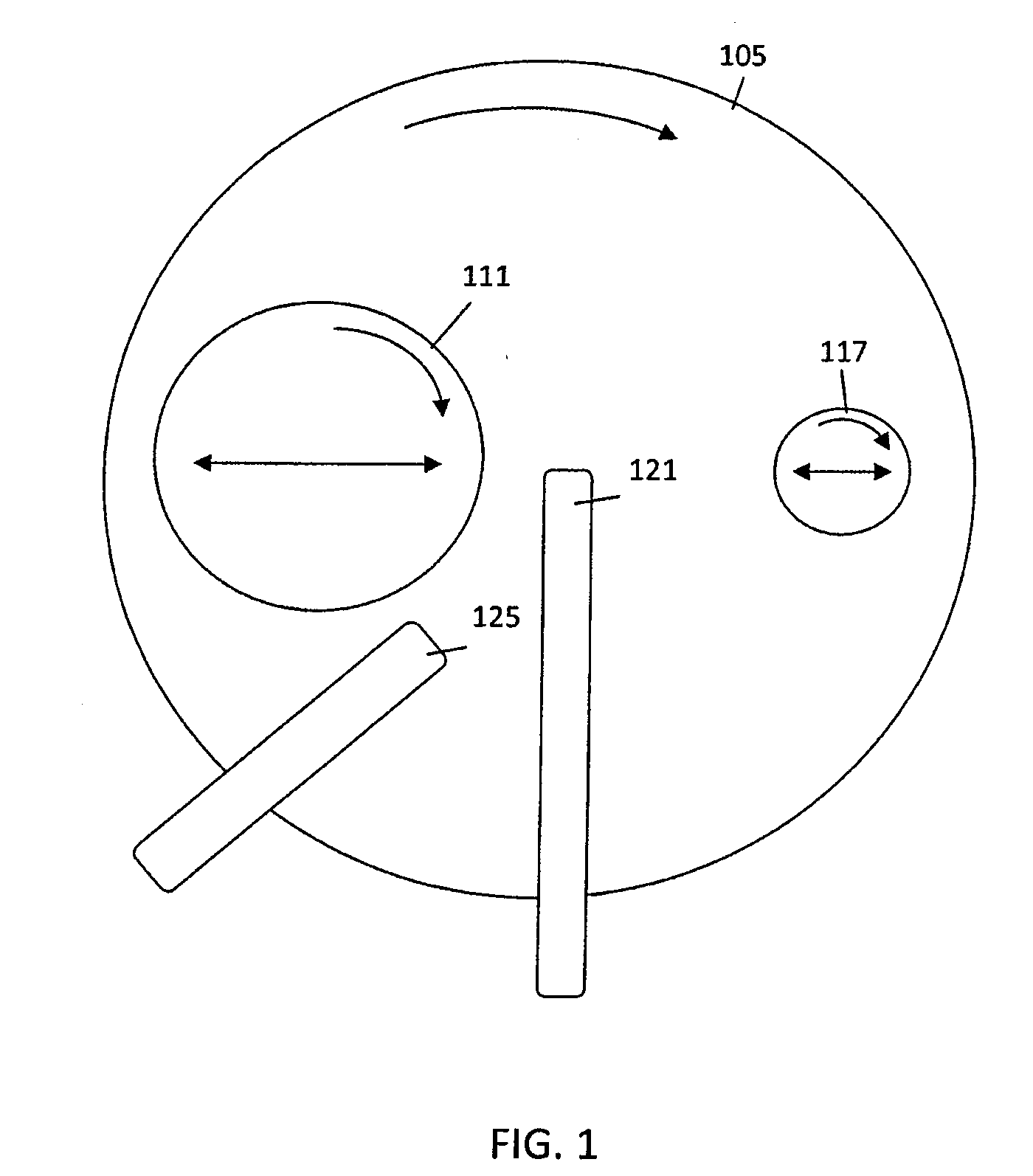

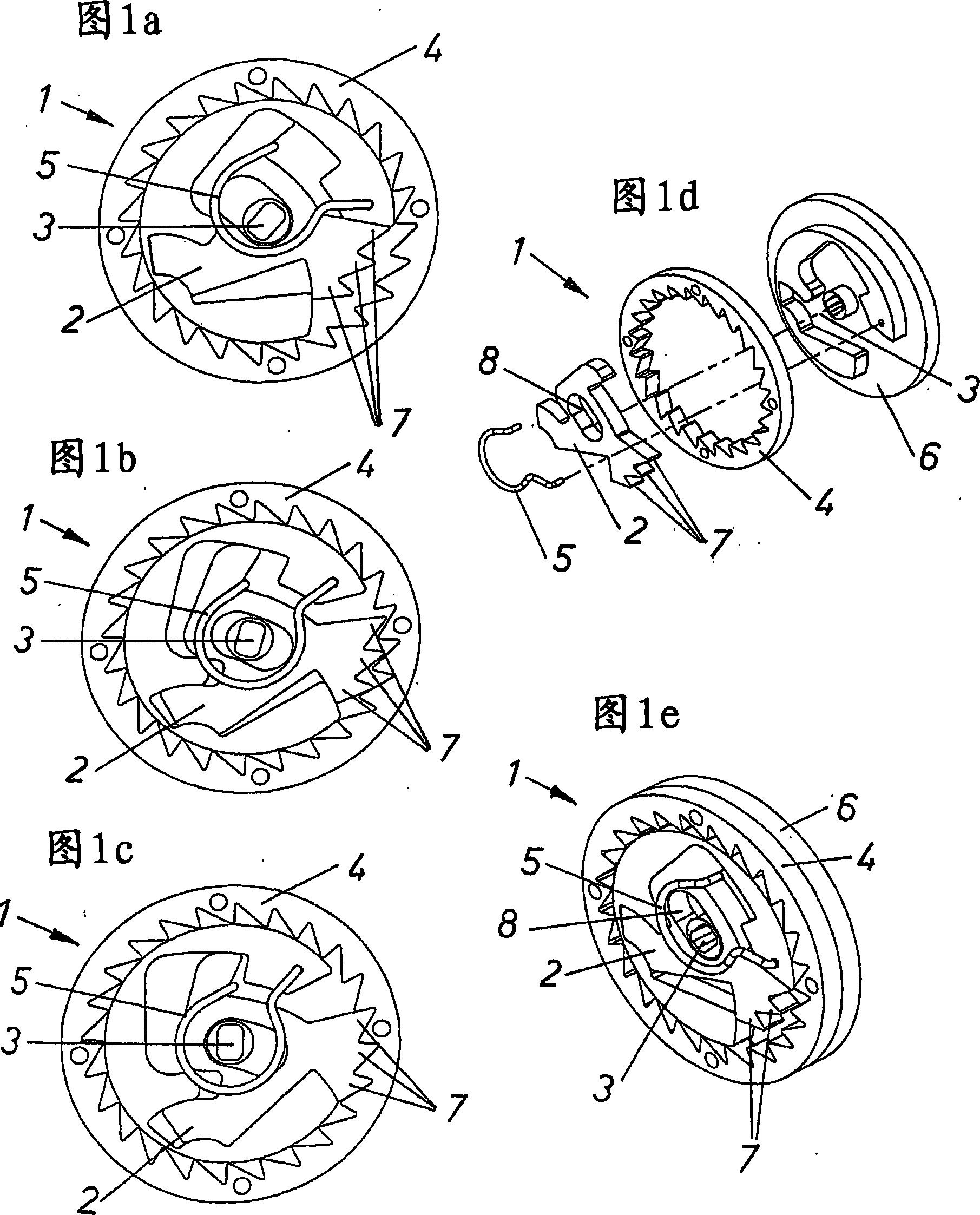

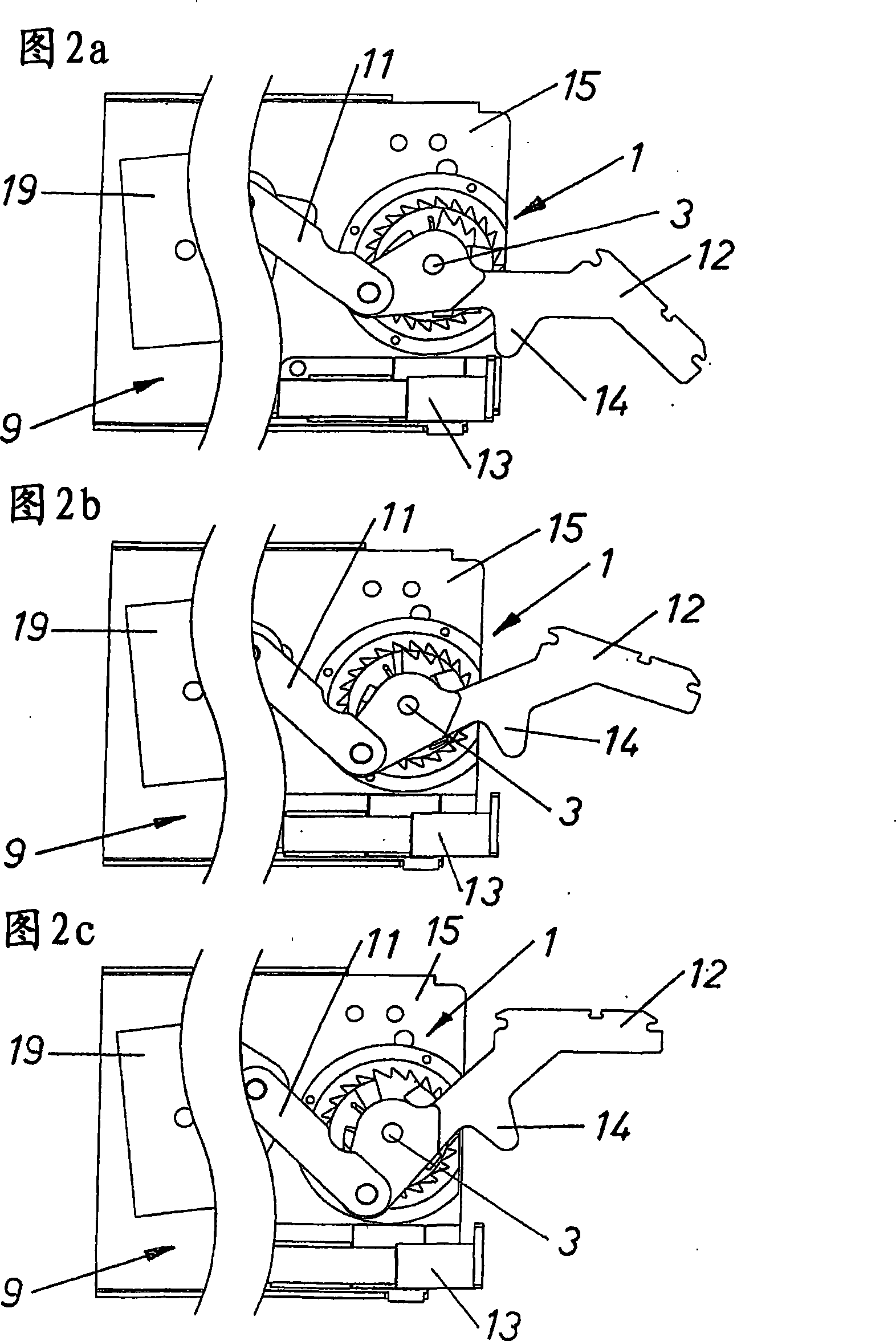

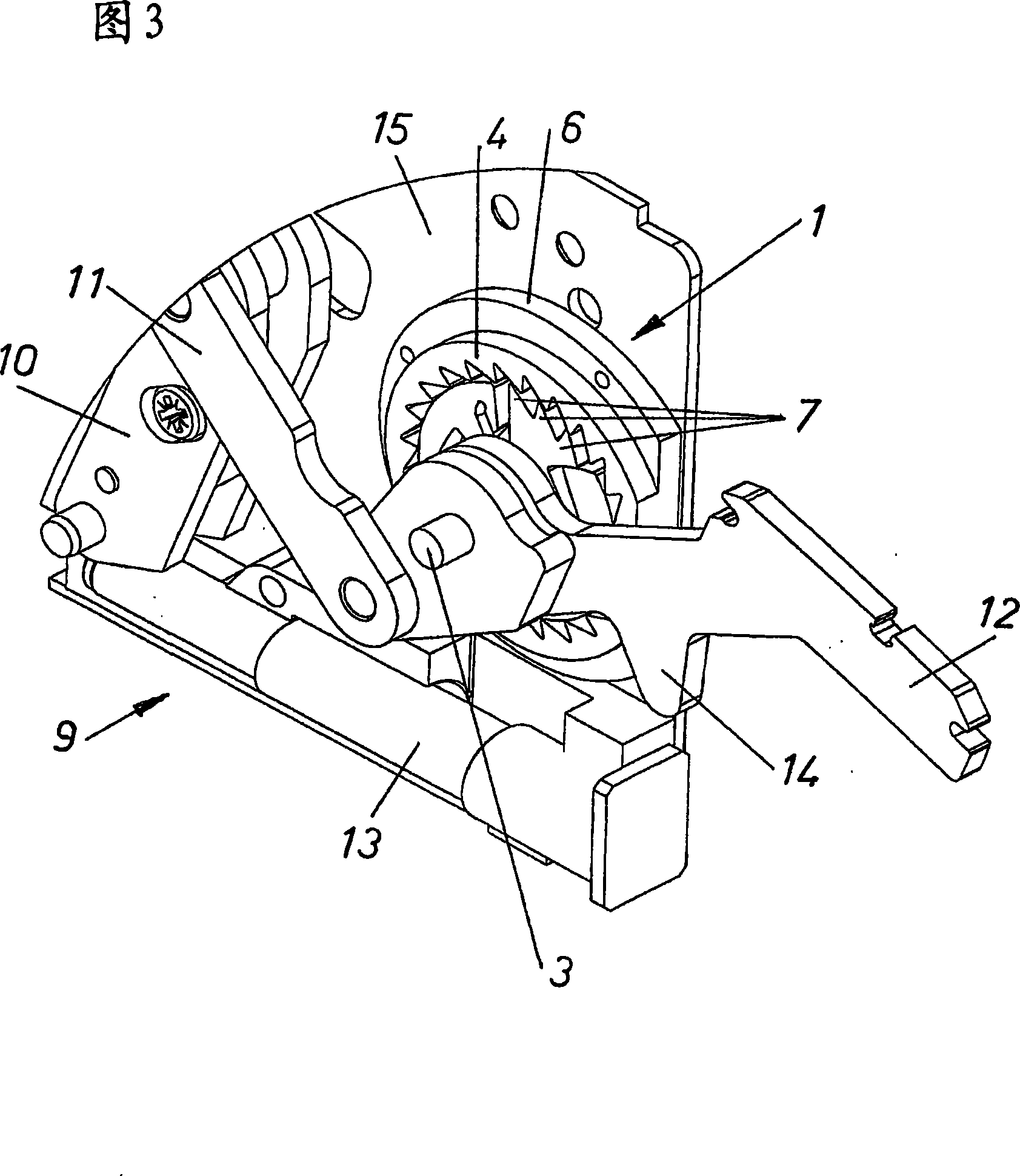

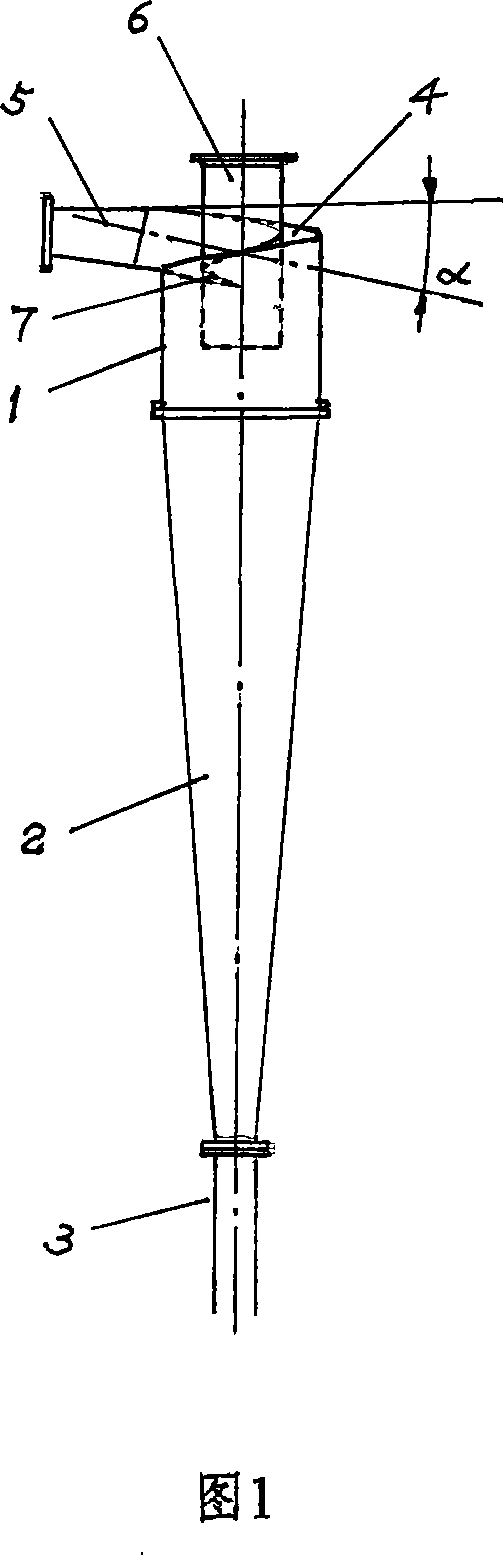

Anti-vibration arrangement

ActiveUS7104873B1Reduce speedReduce rotation speedEdge grinding machinesPortable grinding machinesOut of phaseEngineering

The present invention relates to an anti-vibration arrangement (10) for a power sander (1) which comprises a housing (2), a motor (4) arranged in the housing (2), a rotary drive shaft (11), a first outer or ring-shaped pad surface (16) for attaching a first sanding paper (8) and a second inner or circular pad surface (22) for attaching a second sanding paper (9). The anti-vibration arrangement (10) serves to transfer energy from the motor (4) to the pads (16, 22) with out-of-phase motions to dynamically compensate for inertial and friction forces. For this purpose, twin cams (18a, 18b) are fixed on the rotary drive shaft (11). The cams (18a, 18b) rotate the central axes (15, 21) of the pads (16, 22) about the rotary drive shaft axis (12) with a phase differential of typically 180°. Vibration which would otherwise be transmitted to the rotary drive shaft (11) and from there to the operator of the machine (1) are drastically reduced irrespective of whether or not the operator increases the applied force (1) in order to increase the sanding depth or to speed up the sanding operation.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

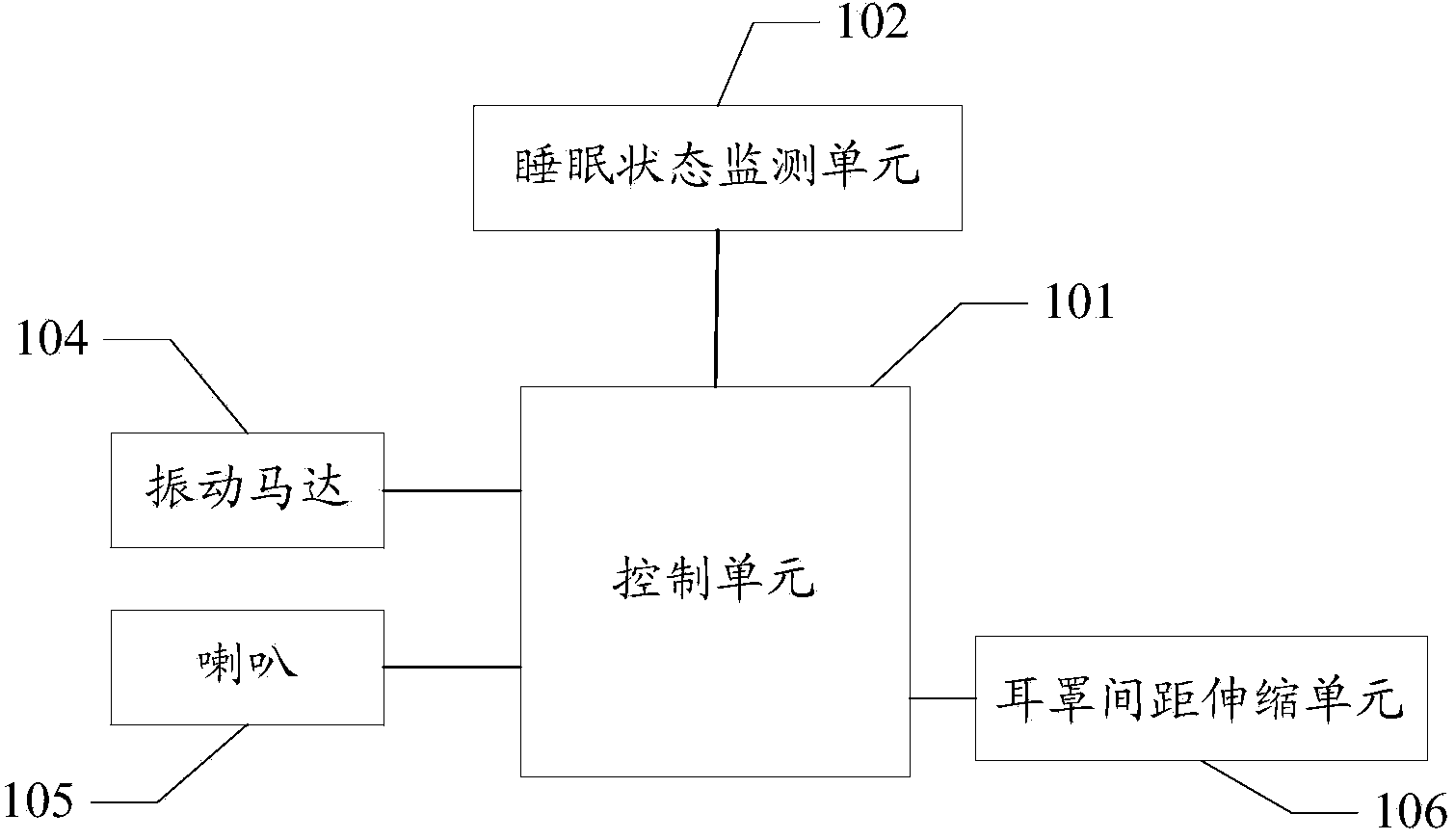

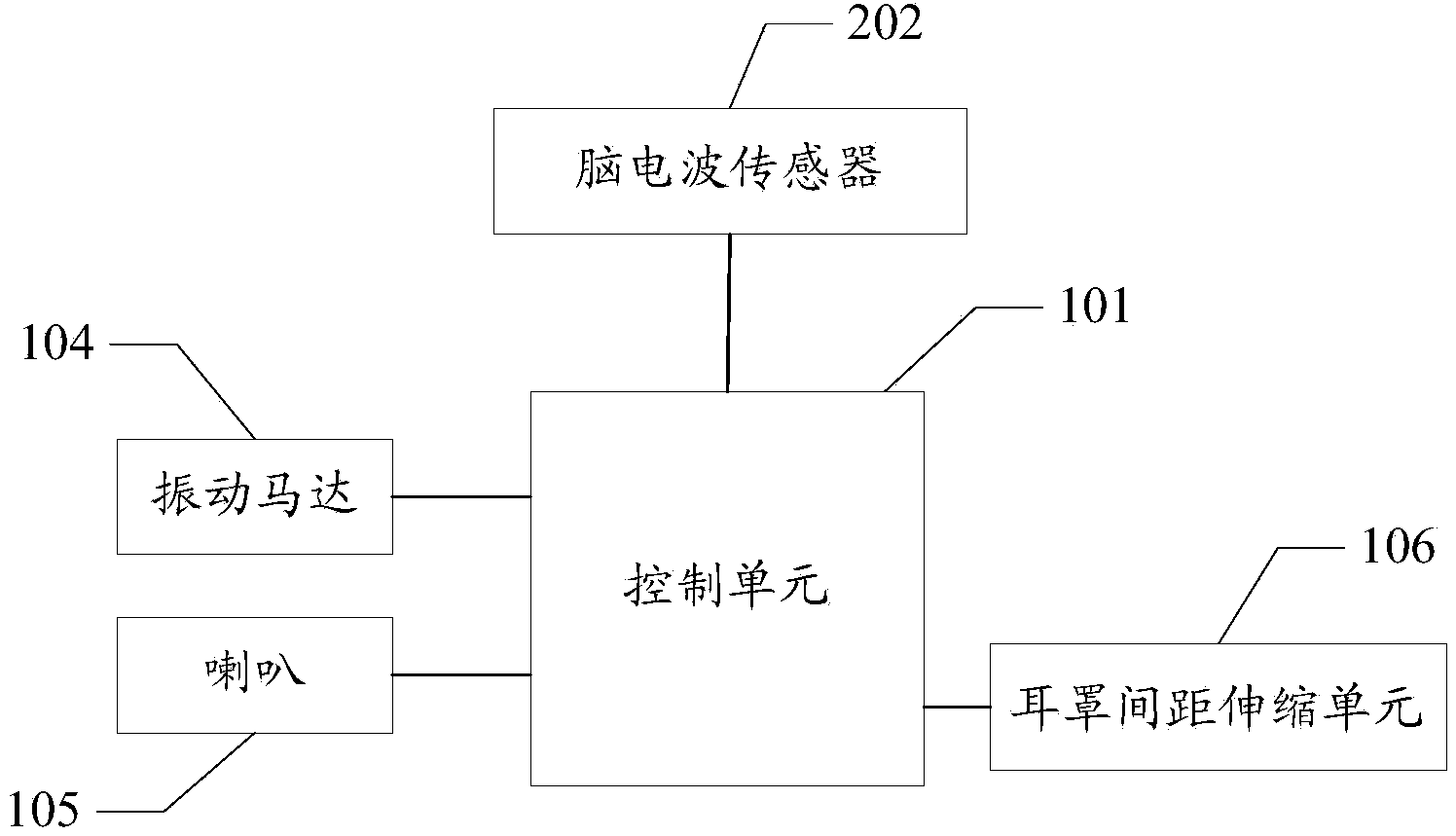

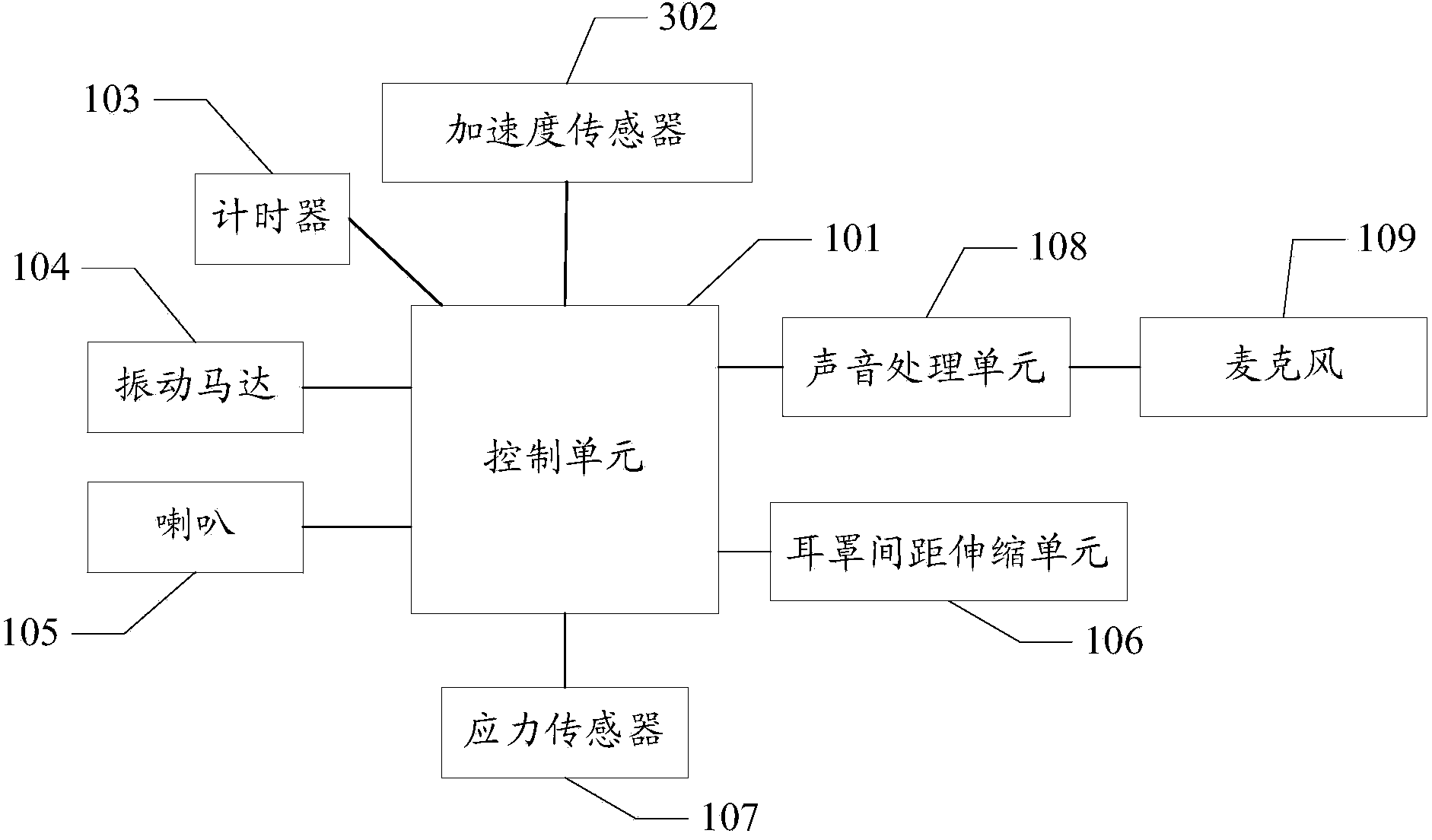

Headset

ActiveCN103475971AControls the output volume of the speaker by reducing the rotation speedOutput volume downEarpiece/earphone attachmentsSleep stateLight sleep

The invention discloses a headset. The headset comprises a left earmuff, a right earmuff, a head band portion, two horns, a vibration motor, a sleep state monitoring unit, a control unit and an earmuff distance telescopic unit. The sleep state monitoring unit is used for monitoring different sleep states of a user of the headset and sending a monitoring result to the control unit. The control unit is used for controlling the output volume of the horns to be lowered when the monitoring result of the sleep state monitoring unit is light sleep; the control unit is used for sending a distance increasing signal to the earmuff distance telescopic unit when the monitoring result of the sleep state monitoring unit is deep sleep. The earmuff distance telescopic unit is used for increasing the distance between the left earmuff and the right earmuff when the distance increasing signal sent by the control unit is received. The headset can solve the problems that an existing headset can work after the user falls asleep so that hearing impairment can be caused easily.

Owner:QINGDAO GOERTEK

Method and a device for cleaning of crankcase gas

InactiveUS20060048761A1Satisfy cleanlinessReduce rotation speedNon-fuel substance addition to fuelDispersed particle separationCombustionUnit of time

Upon cleaning of crankcase gas generated during operation of an internal combustion engine in its crankcase, a centrifugal separator is used, which includes a rotor arranged for rotation by means of a driving motor and arranged by its rotation suck crankcase gas from the crankcase through a conduit to the centrifugal separator. During operation of the combustion engine a parameter, e.g. a measurement of the load on the combustion engine is sensed, the magnitude of said parameter being related to the amount of crankcase gas generated per unit of time in the crankcase. Depending upon a sensed change of the sensed parameter the rotational speed of the rotor of the centrifugal separator is changed in a way such that the gas pressure in the crankcase is maintained at a predetermined value, or within a predetermined pressure interval, during the operation of the combustion engine.

Owner:ALFA LAVAL CORP AB

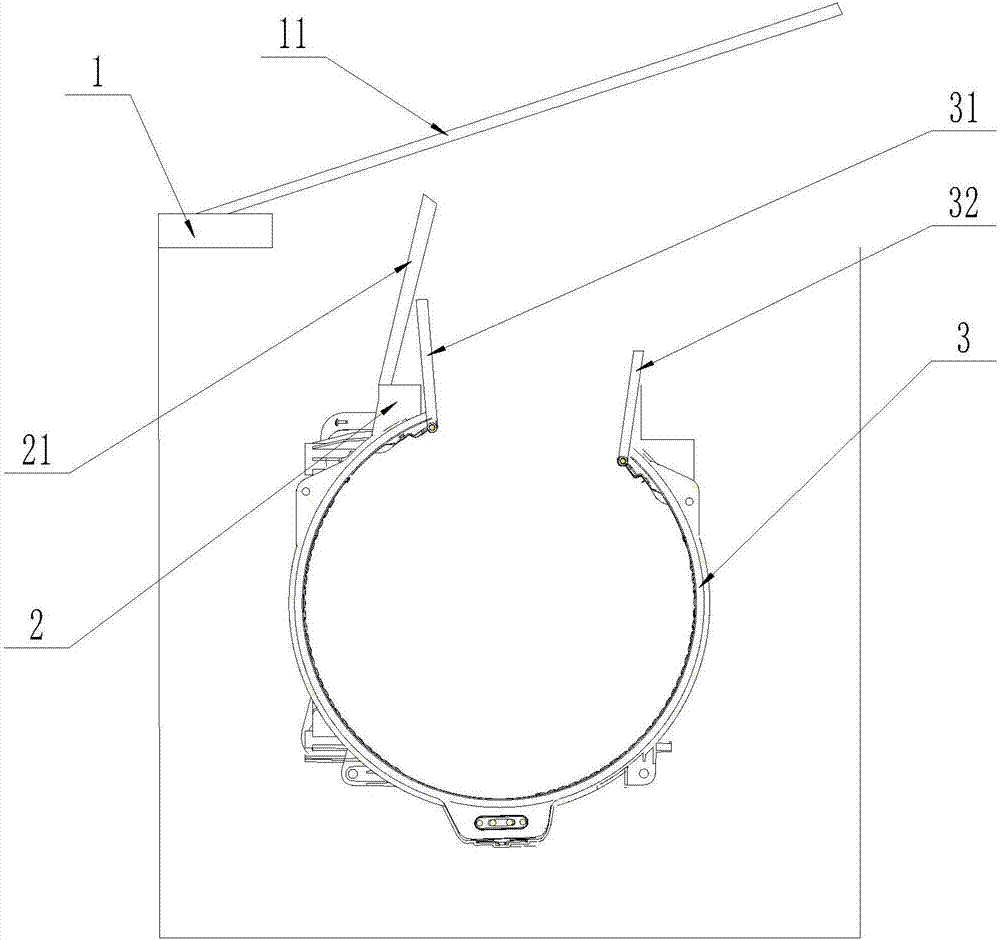

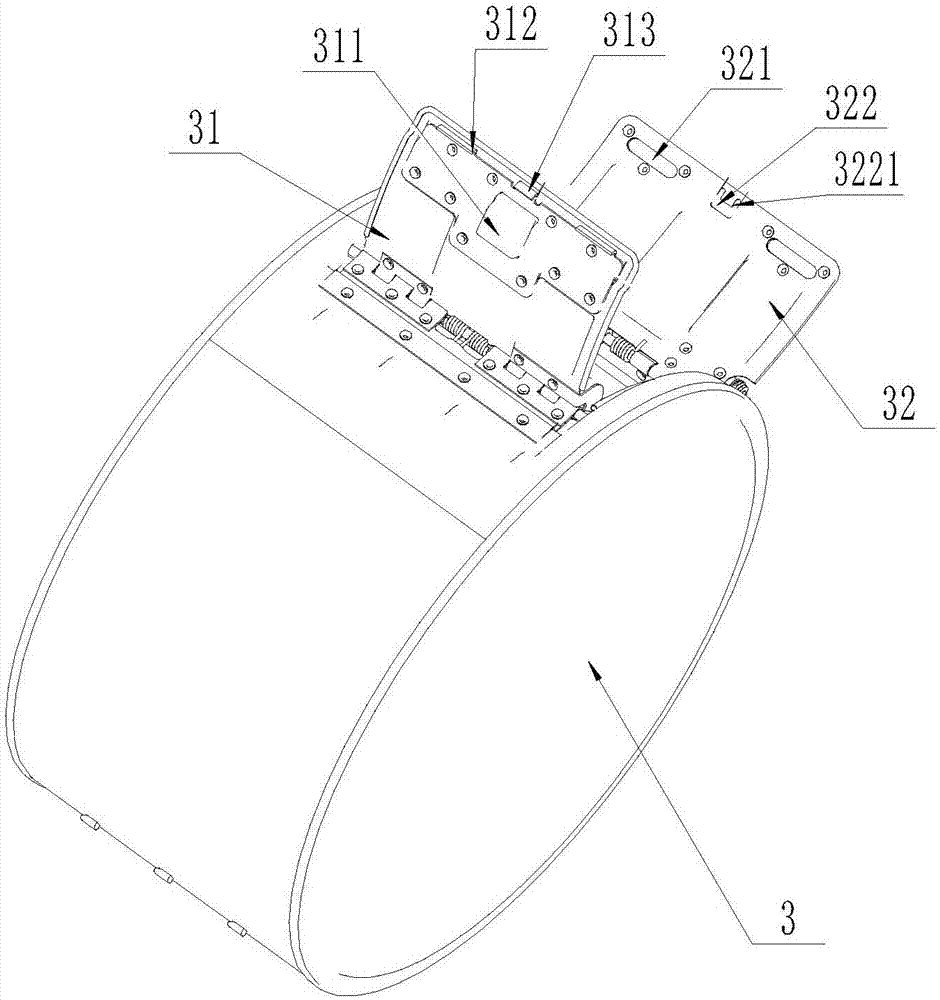

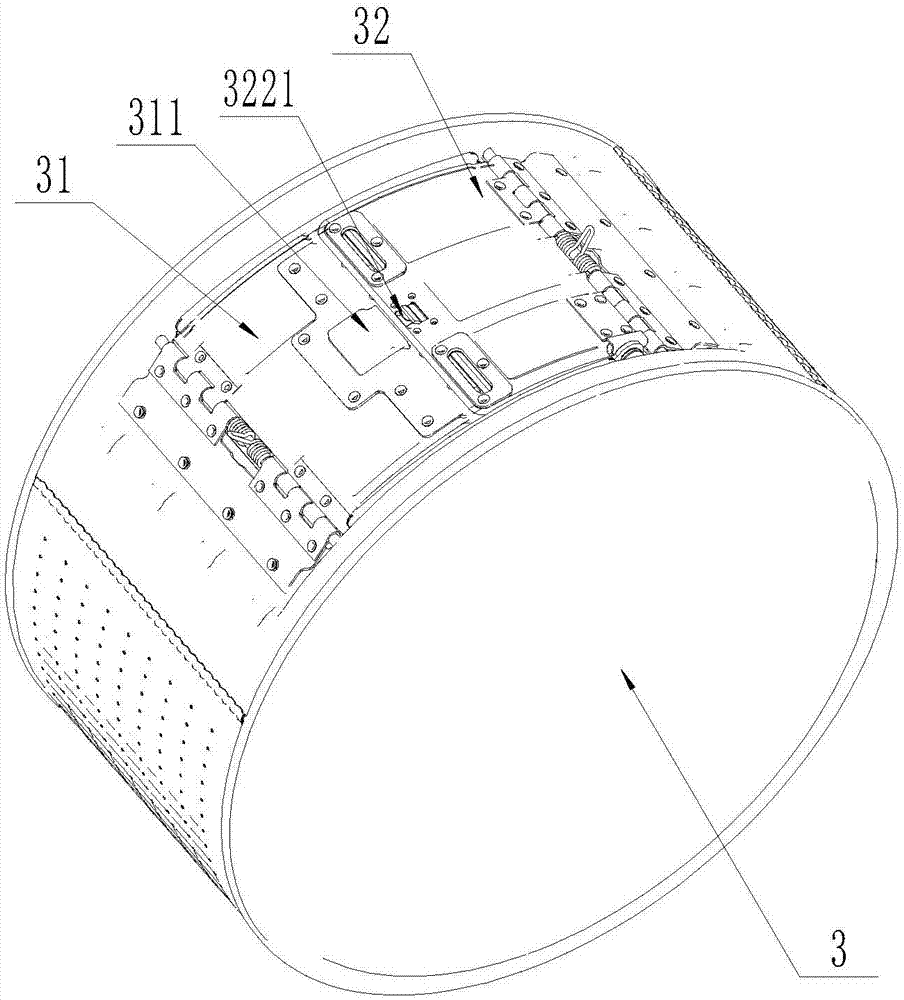

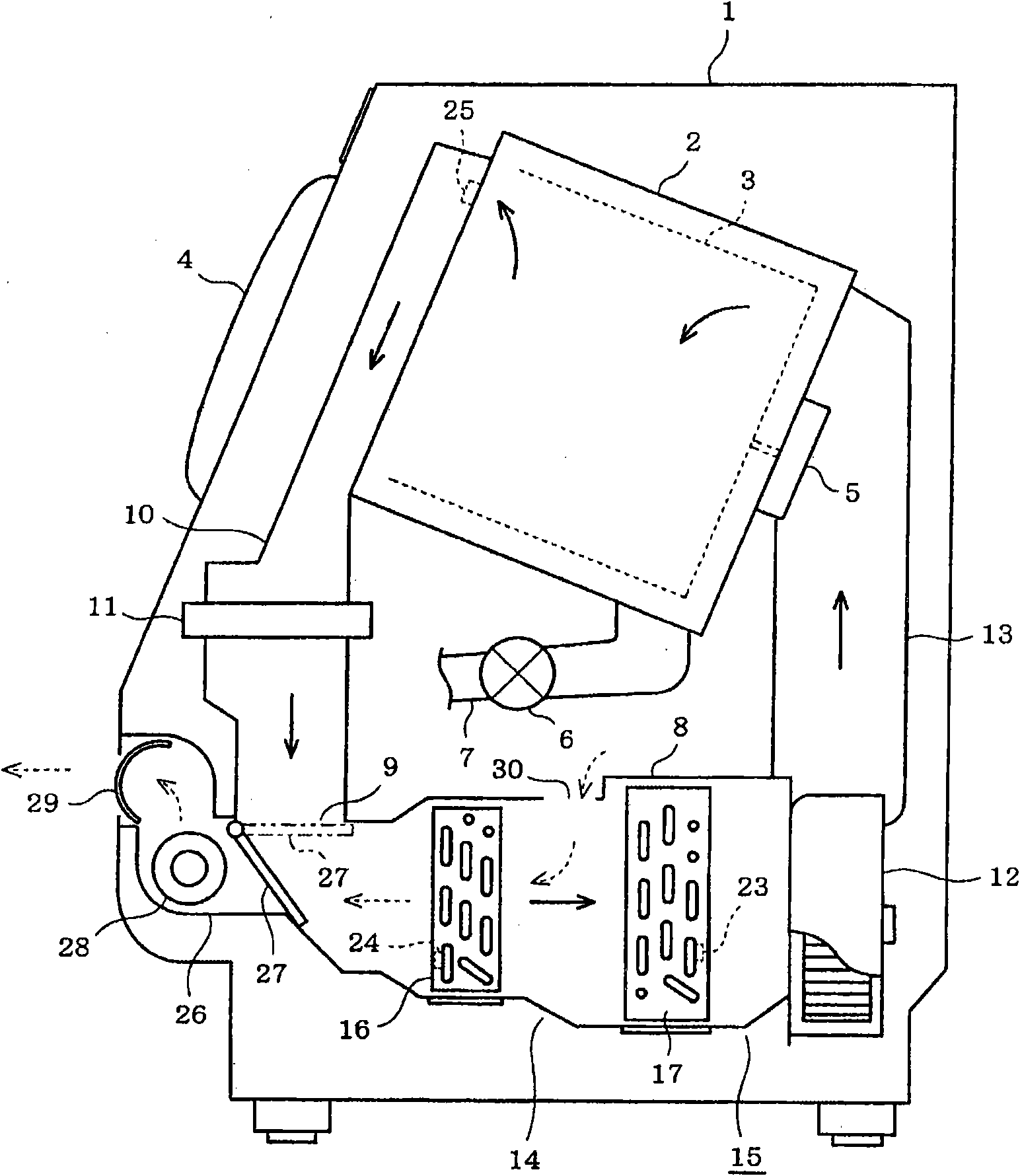

Linkage cover assembly, top-open type roller washing machine and inner barrel of top-open type roller washing machine

PendingCN107164917AAvoid noiseAvoiding problems that bruise usersOther washing machinesTextiles and paperPulp and paper industryOpen type

The invention belongs to the field of household appliances, and specifically provides a linkage cover assembly, a top-loading drum washing machine and an inner cylinder thereof. The invention aims to solve the problem of complex structure and high cost of the linkage mechanism of two inner cylinder covers on the inner cylinder of the existing top-opening drum washing machine. For this purpose, the interlocking cover assembly of the present invention comprises a first cover body and a second cover body arranged in the circumferential direction of the inner drum of the top-loading drum washing machine, and a linkage mechanism arranged between the first cover body and the second cover body . The linkage mechanism includes a first connecting rod and a second connecting rod, one end of the first connecting rod is fixedly connected to the first cover, the other end of the first connecting rod is pivotally connected to one end of the second connecting rod, and the second connecting rod The other end of the second cover is pivotally connected to the second cover, and the first cover and the second cover can rotate synchronously in opposite directions through the above-mentioned connection relationship between the first link and the second link. Compared with the electric linkage mechanism in the prior art, the linkage mechanism of the present invention is simpler in structure and lower in cost.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

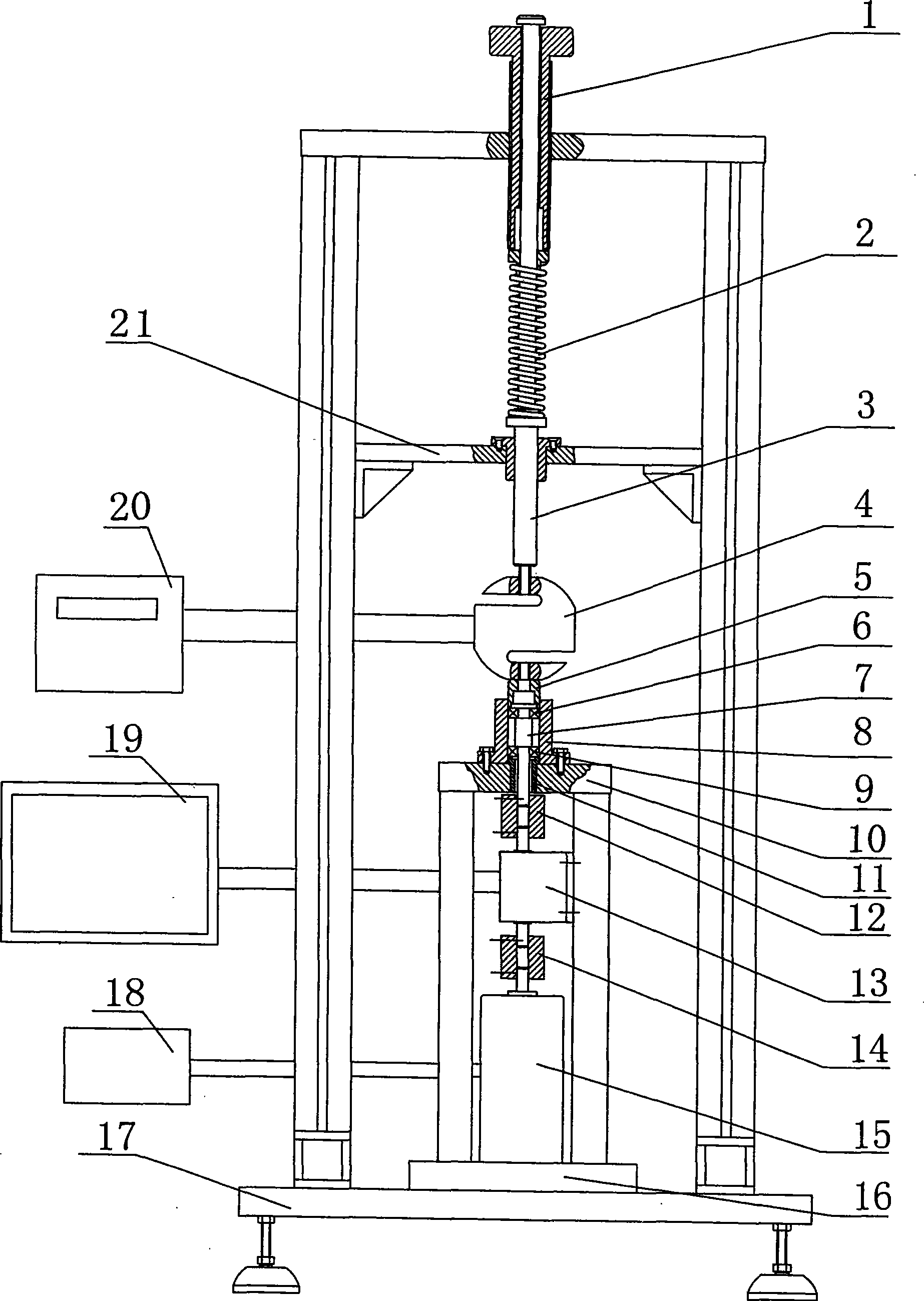

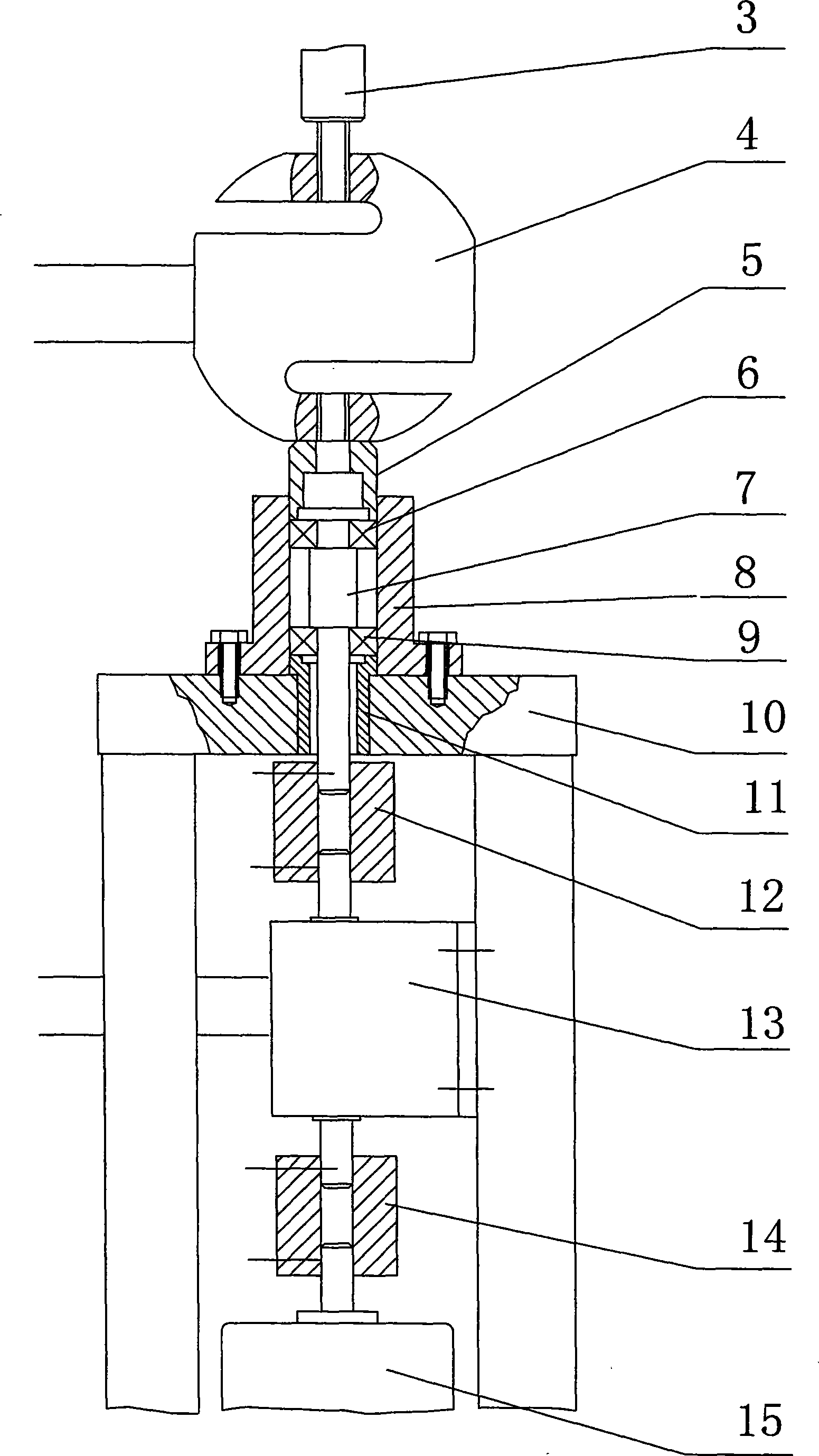

Measuring apparatus for frictional moment of bearing under different axial loads and rotation speeds

ActiveCN101487751AReduce rotation speedUnable to measure frictional torqueWork measurementTorque measurementHead pressingFriction torque

The invention relates to a device for measuring friction torque of a bearing under different axial load and revolution speed, comprising a fixing component, an axial loading component, a display component and a measurement component arranged on a stander base, wherein, the measurement component is arranged in a bearing support by an upper bearing and a lower bearing which are the same and fixed on a stander workbench, a bushing on the workbench supports the end face of the bearing outer ring of the lower bearing, so as not to contact the end face of the inner ring, and a loading head presses the end face of the bearing outer ring of the upper bearing. The two same bearings are used for measurement so that the axial load is not directly applied to a transmission shaft and a driving device to influence and damage the operation of the driving device. The voltage of a direct current motor is adjusted by a voltage regulator, so as to adjust the rotate speed of the motor. The axial load is adjusted by rotating a screw. The device can measure larger and different load and bearings with higher and different rotate speed, has wide measurement range which can be adjusted, can meet different requirements of users, and has the advantages of simple structure, easy fabrication, convenient, accurate and intuitive operation and use, wide universality and strong practicability.

Owner:NINGBO CIXING BEARING

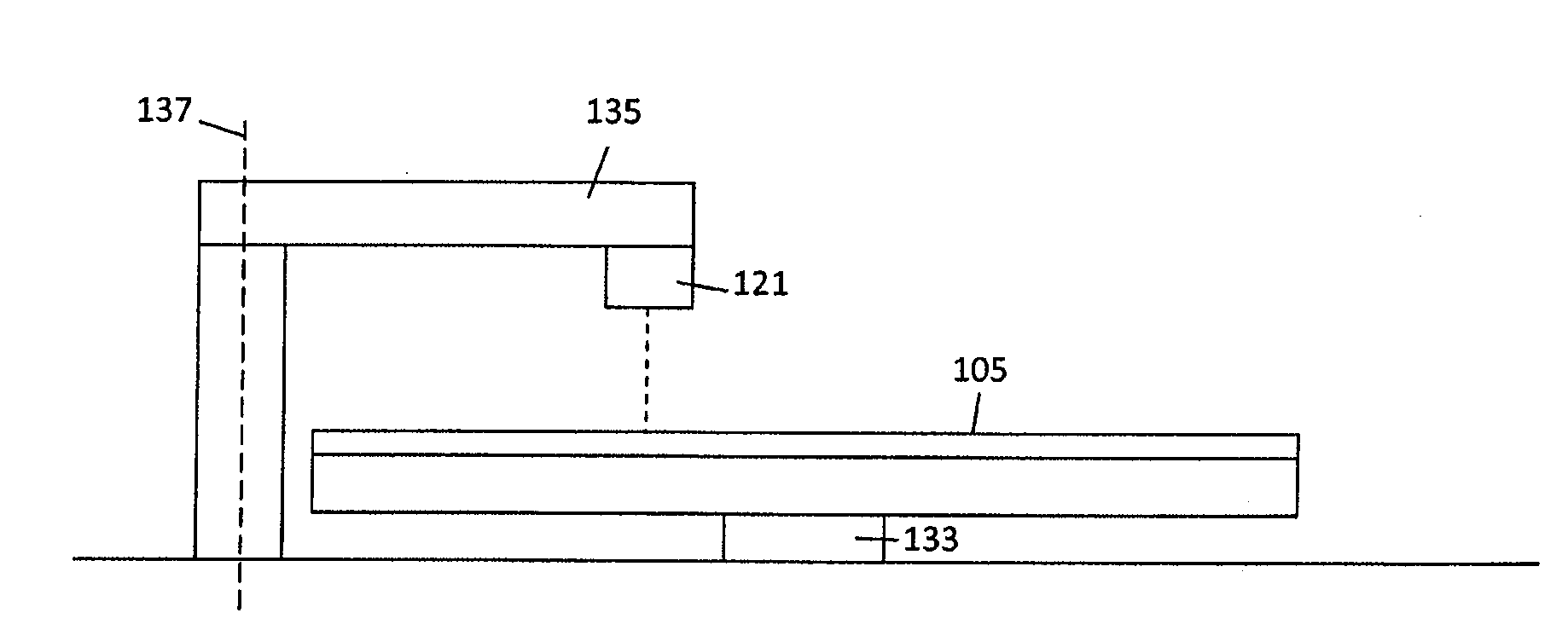

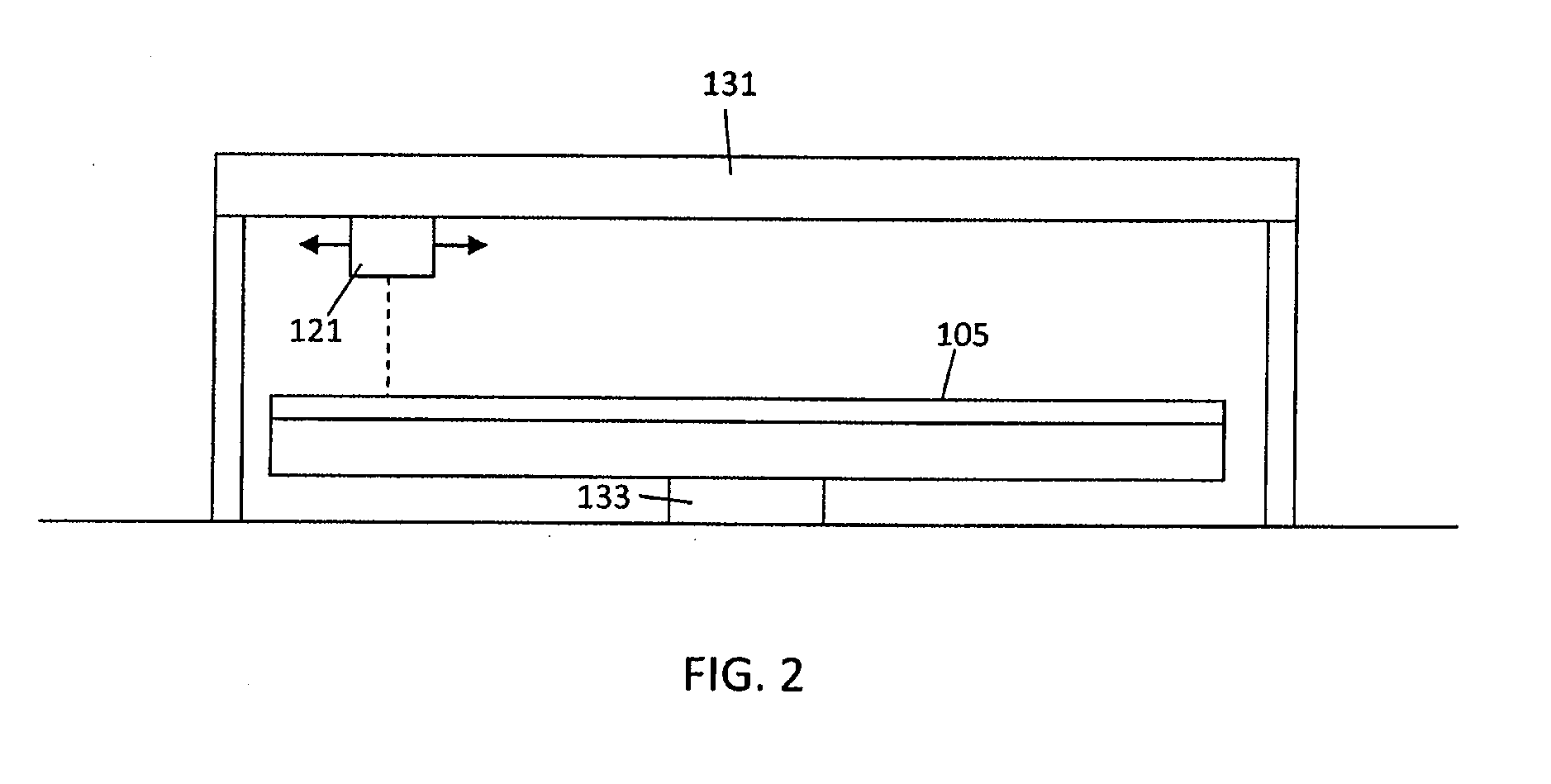

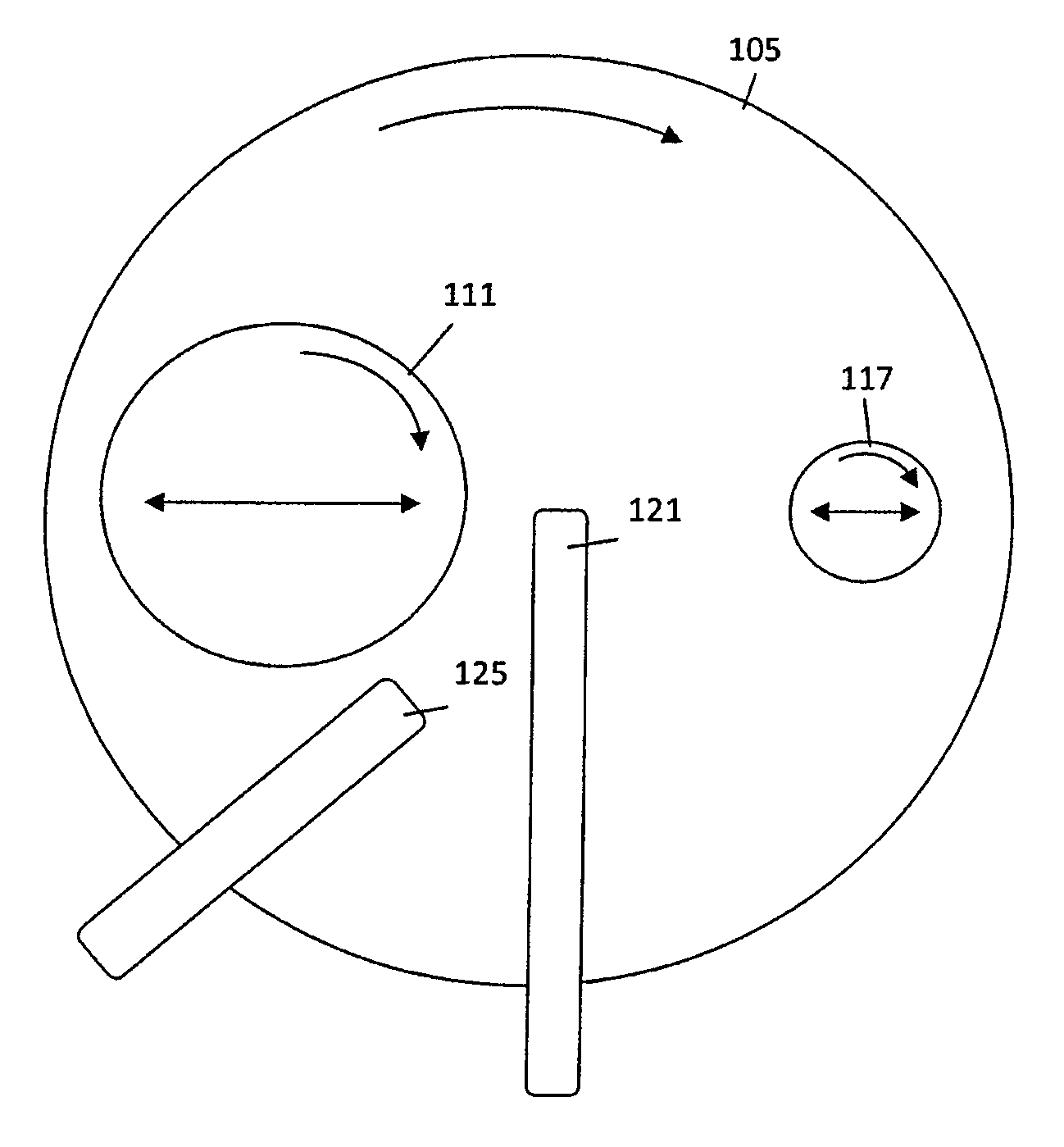

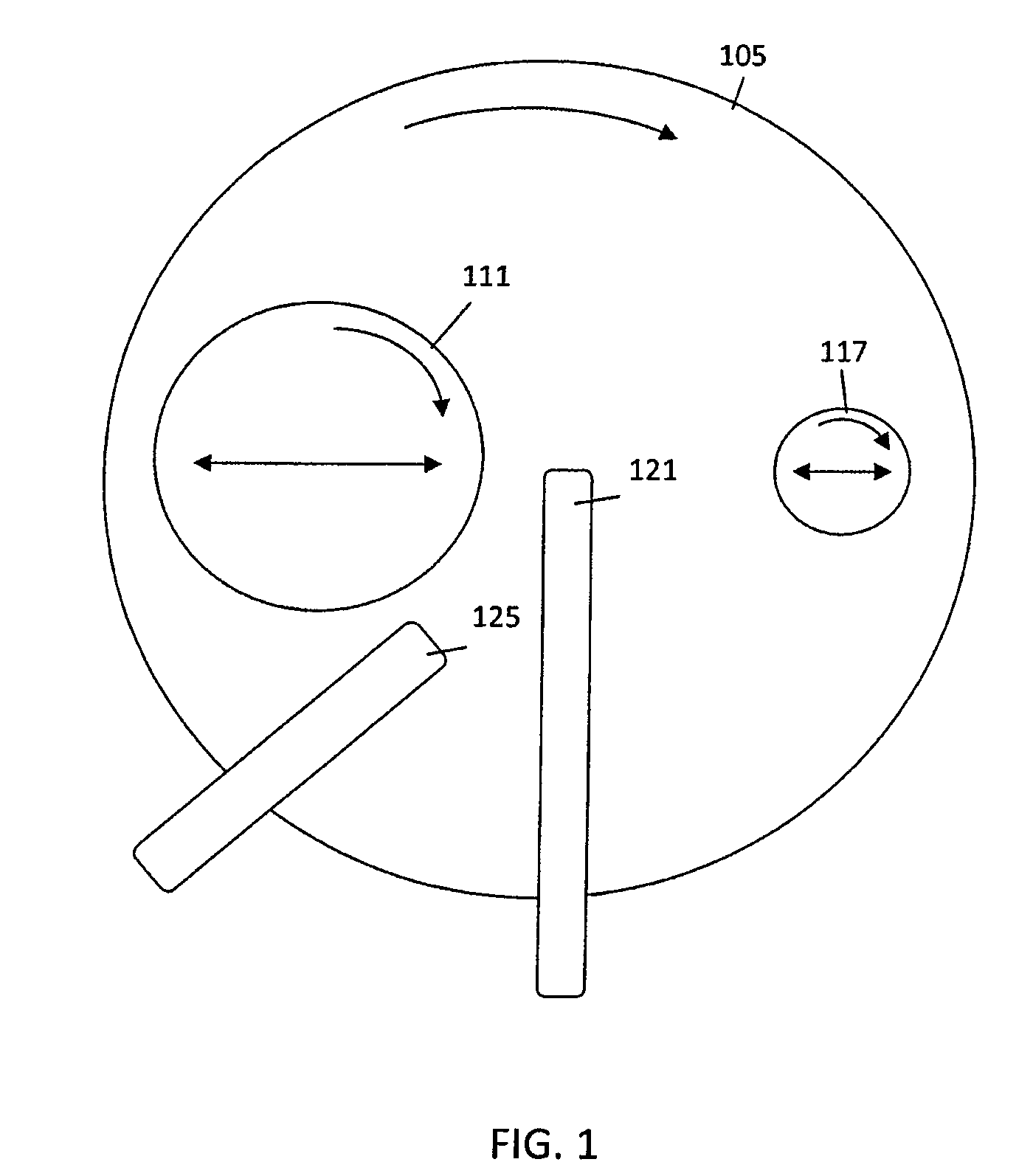

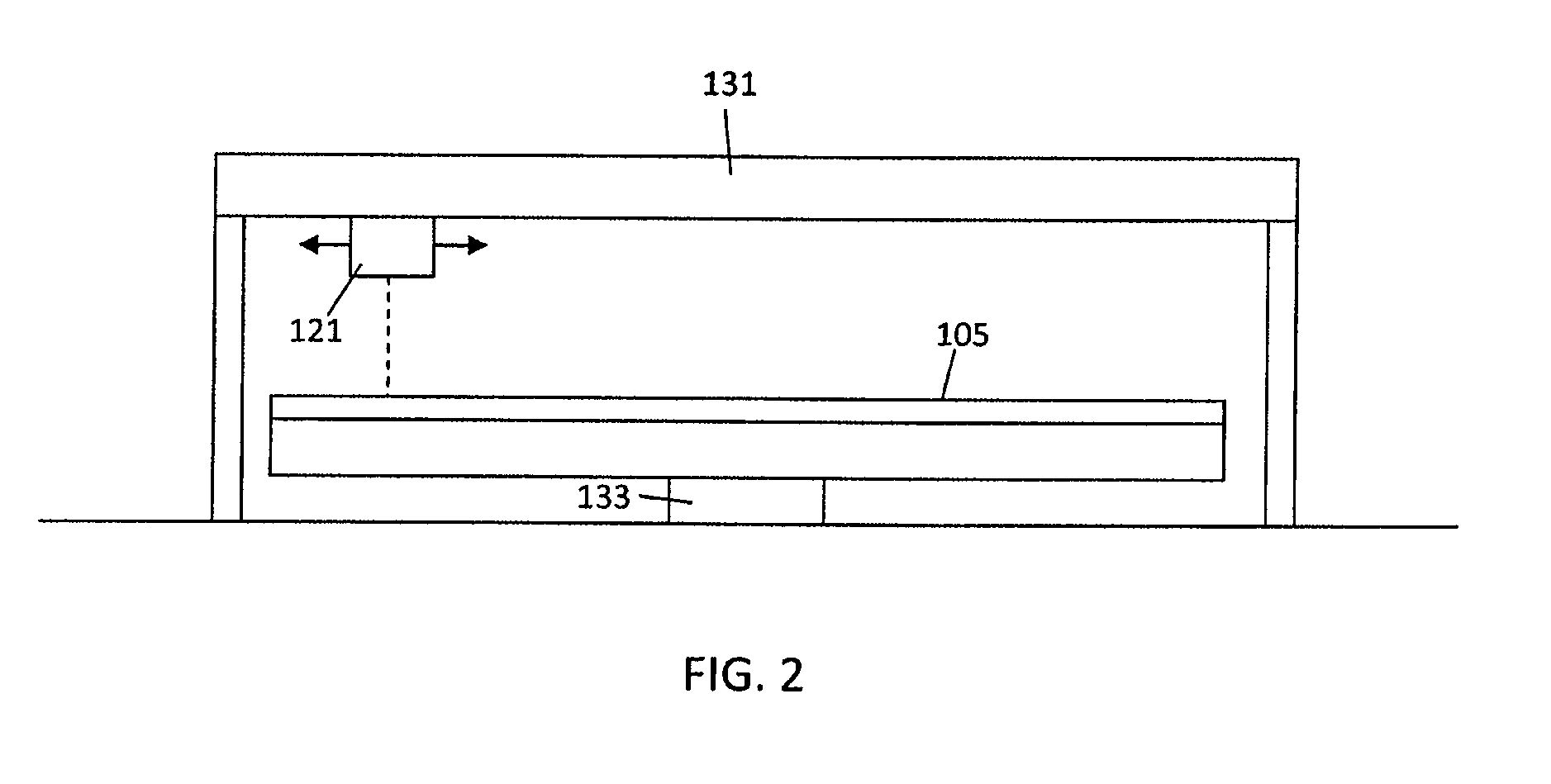

Closed loop control of pad profile based on metrology feedback

ActiveUS20100035518A1Prolong lifePrecise processingEdge grinding machinesSemiconductor/solid-state device manufacturingMetrologyLoop control

A chemical mechanical polishing apparatus includes a metrology system that detects the thickness of the polishing pad as semiconductor wafers are processed and the thickness of the polishing pad is reduced. The chemical mechanical polishing apparatus includes a controller that adjusts the rate of material removal of a conditioning disk when areas of the polishing surface are detected that are higher or lower than the adjacent areas of the polishing pad.

Owner:APPLIED MATERIALS INC

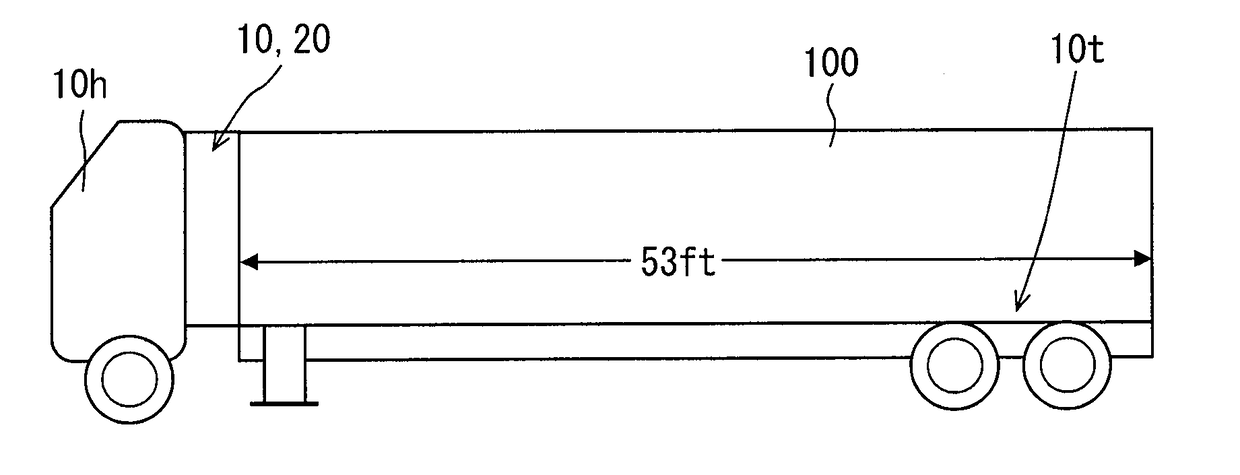

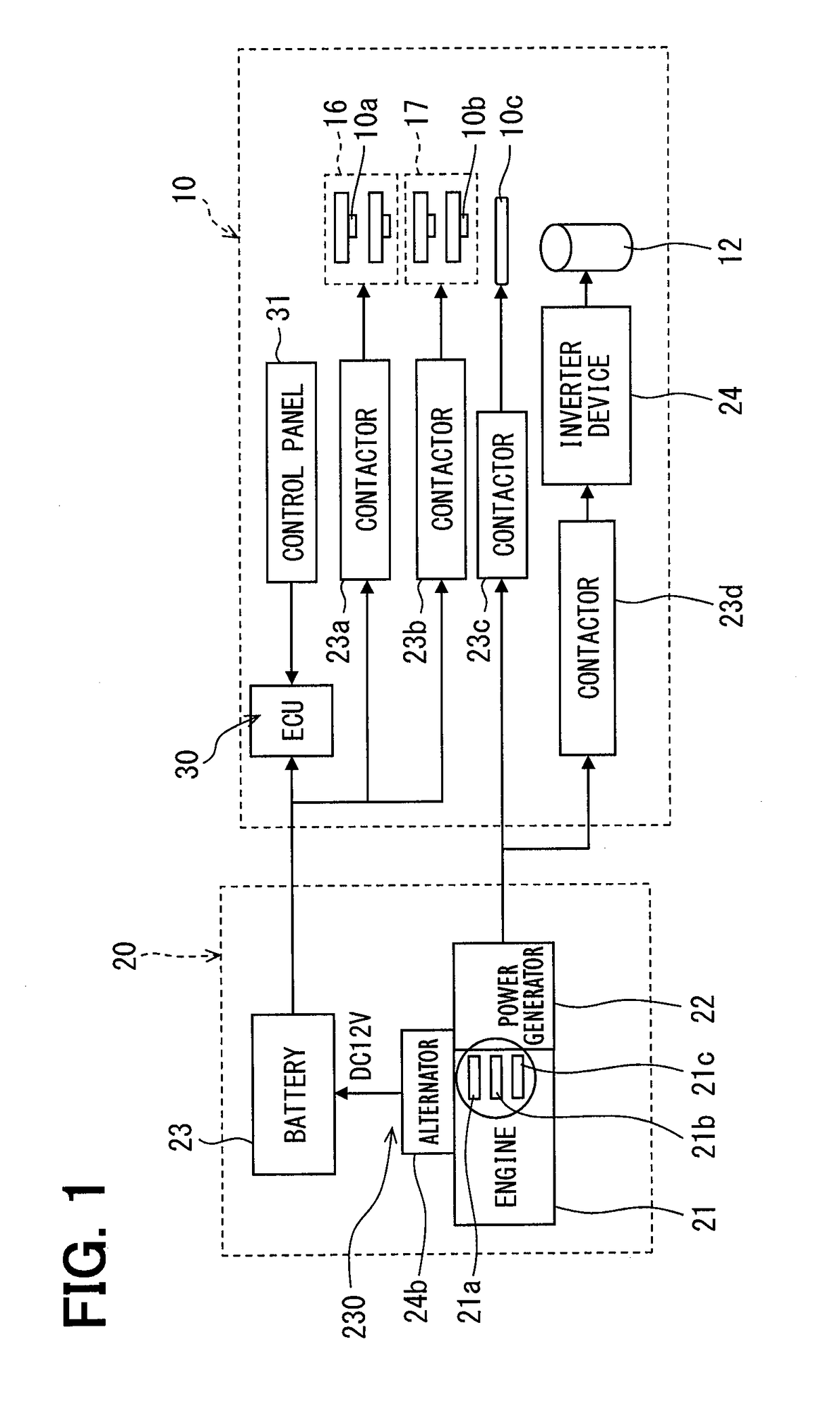

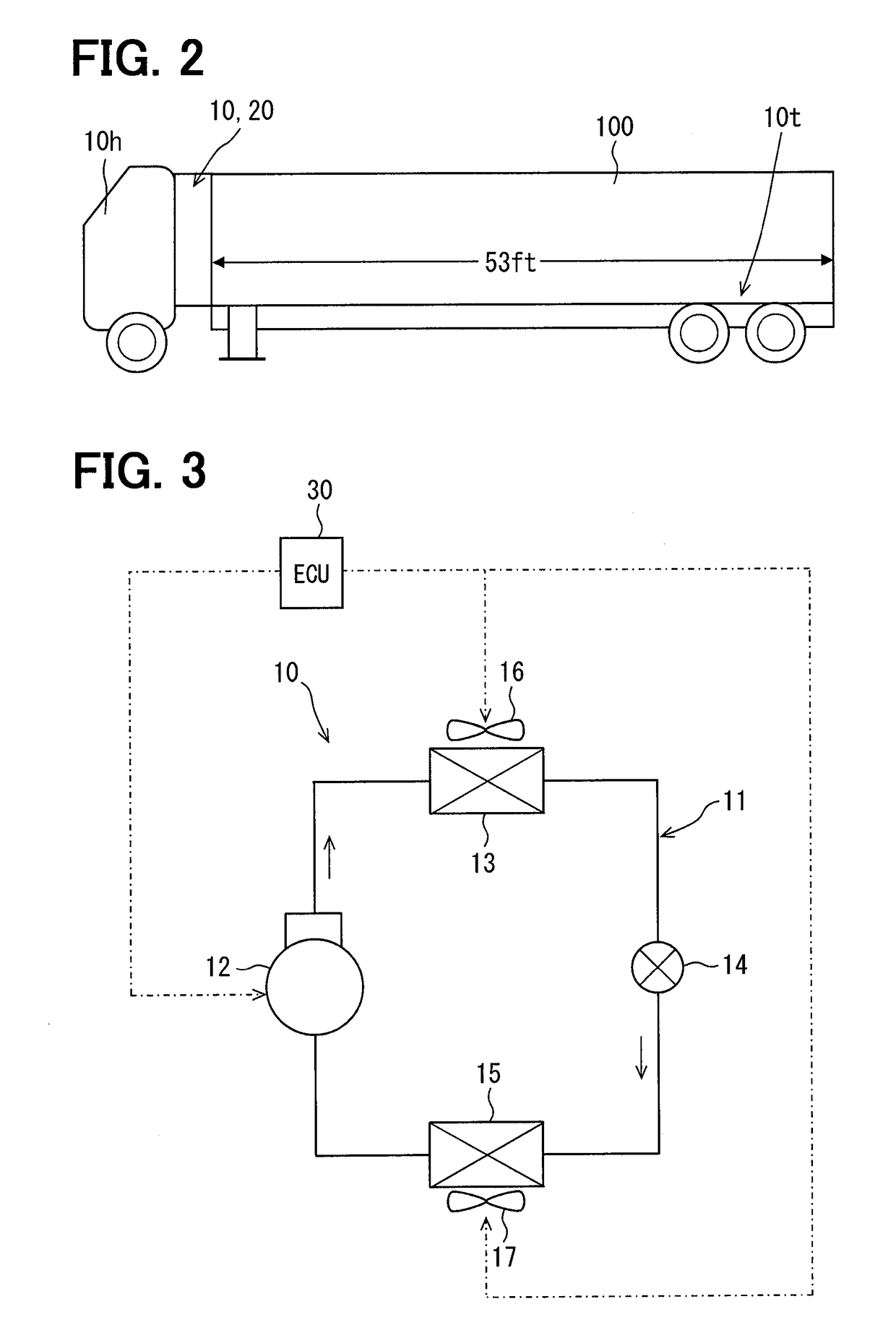

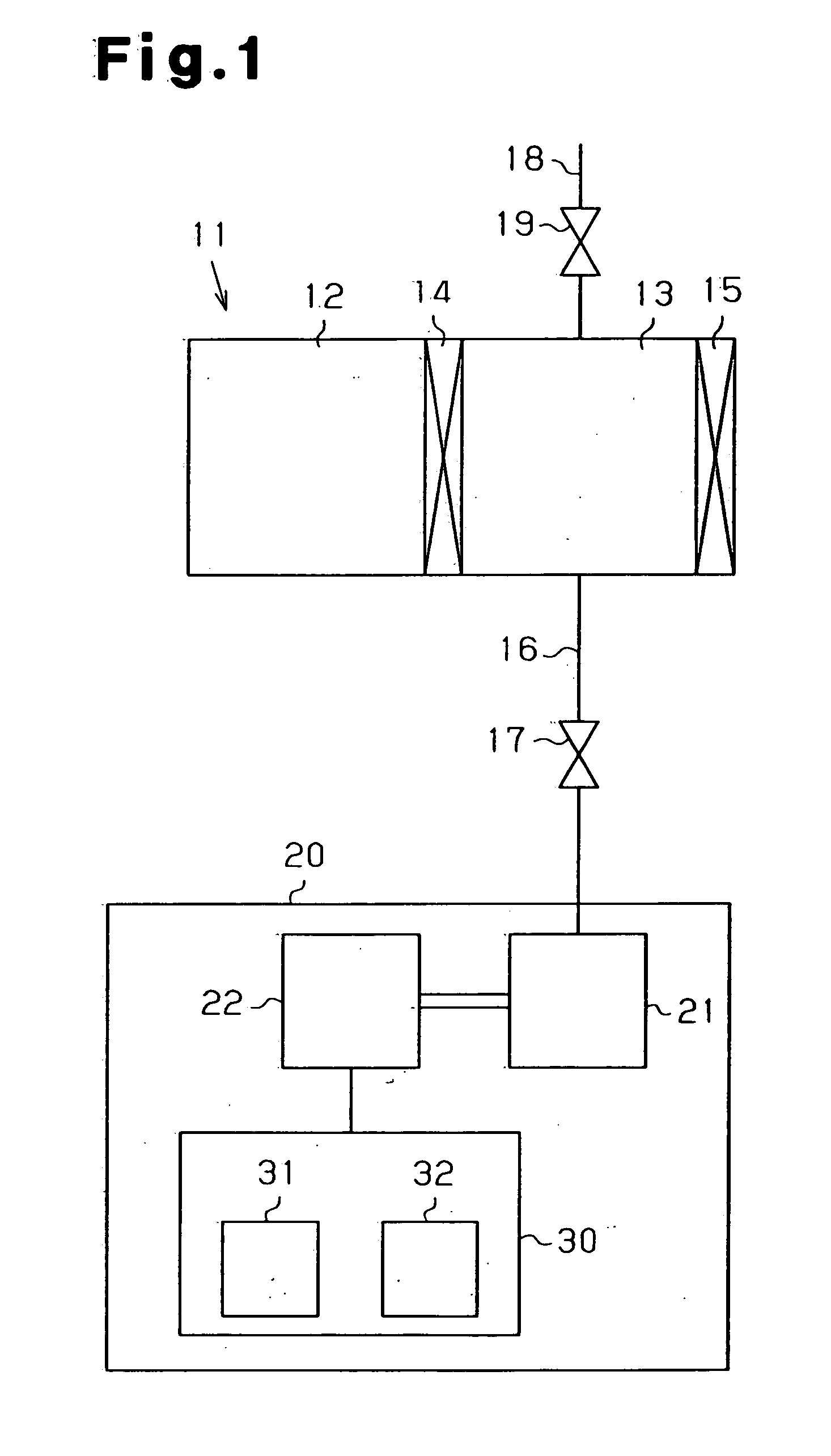

Refrigeration device and container refrigeration system

InactiveUS20180222278A1Reduce rotation speedChange rotation speedAir-treating devicesAC motor controlRefrigerantEvaporator

The refrigeration device has an inverter device, an electric compressor, a condenser, an evaporator, a condenser fan, an evaporator fan, and a controller. An AC output from a power generator is supplied to the inverter device. A refrigerant discharge amount of the electric compressor is controlled by the inverter device. The refrigerant from the electric compressor flows in the condenser, and the condenser causes the refrigerant to radiate heat to outside air outside a container. The refrigerant from the condenser flows in the evaporator, and the evaporator cools an interior of the container. The condenser fan is driven by a DC output from a DC power supply device and blows air to the condenser. The evaporator fan is driven by the DC output from the DC power supply device and blows air to the evaporator. The controller controls at least the electric compressor, the inverter device, and the engine.

Owner:DENSO CORP

Hydraulic loop device used for coordinating machine body rotation and movable arm swinging of digging machine

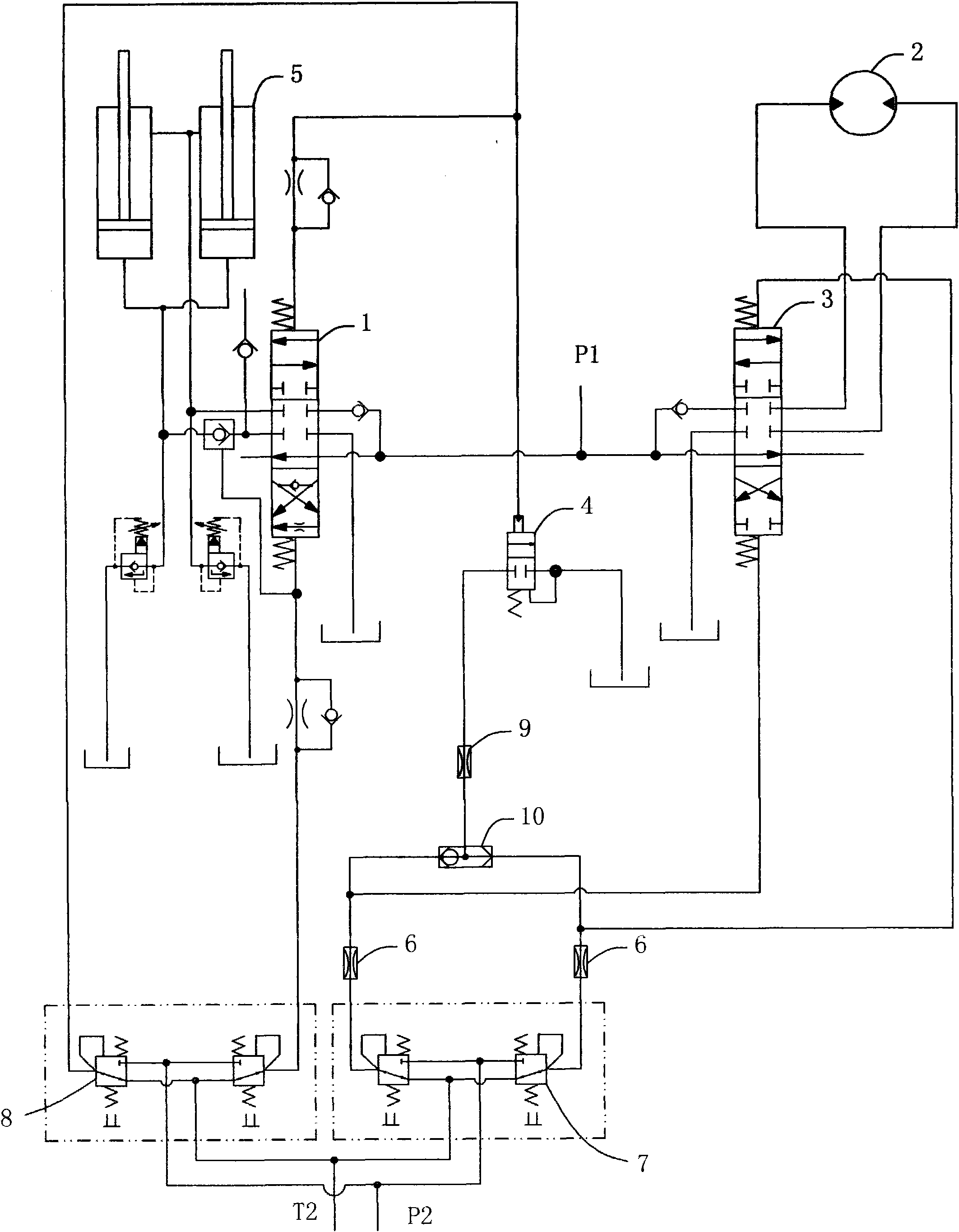

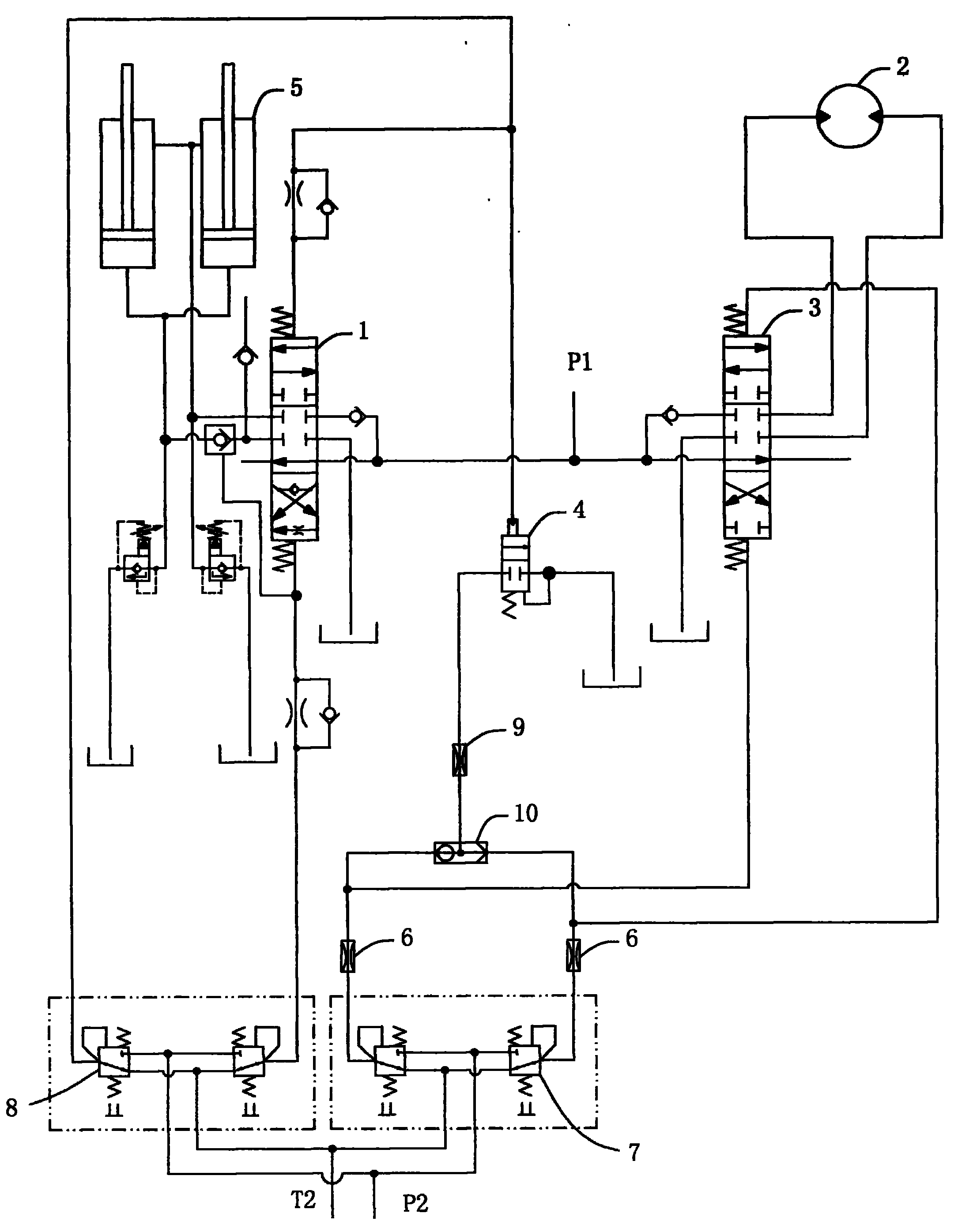

ActiveCN101793042ARelieve pressureReduce rotation speedServomotor componentsSoil-shifting machines/dredgersHydraulic pumpEngineering

The invention discloses a hydraulic loop device used for coordinating machine body rotation and movable arm swinging of a digging machine, which belongs to a hydraulic loop device of the digging machine. The hydraulic loop device mainly comprises a hydraulic pump, a rotation motor, a movable arm oil cylinder, a rotation two-way hydraulic control reversing valve, a movable arm two-way hydraulic control reversing valve and a pilot control branch circuit, wherein a rotation manual pilot valve, a movable arm manual pilot valve, a shuttle valve and a one-way hydraulic control stop valve are arranged on the pilot control branch circuit, a first throttle valve is arranged between an oil inlet opening of the shuttle valve and an oil outlet opening of the rotation manual pilot valve, and a second throttle valve is arranged between an oil outlet opening of the shuttle valve and a work oil opening of the one-way hydraulic control stop valve. The invention solves the technical problems of low movable arm swinging speed and inconsistent movable arm swinging and machine body rotation action in the machine body rotation process of the digging machine. The invention has a reasonable structure, and can be widely applied to production and manufacture industry of the digging machine.

Owner:QINGDAO LOVOL EXCAVATOR

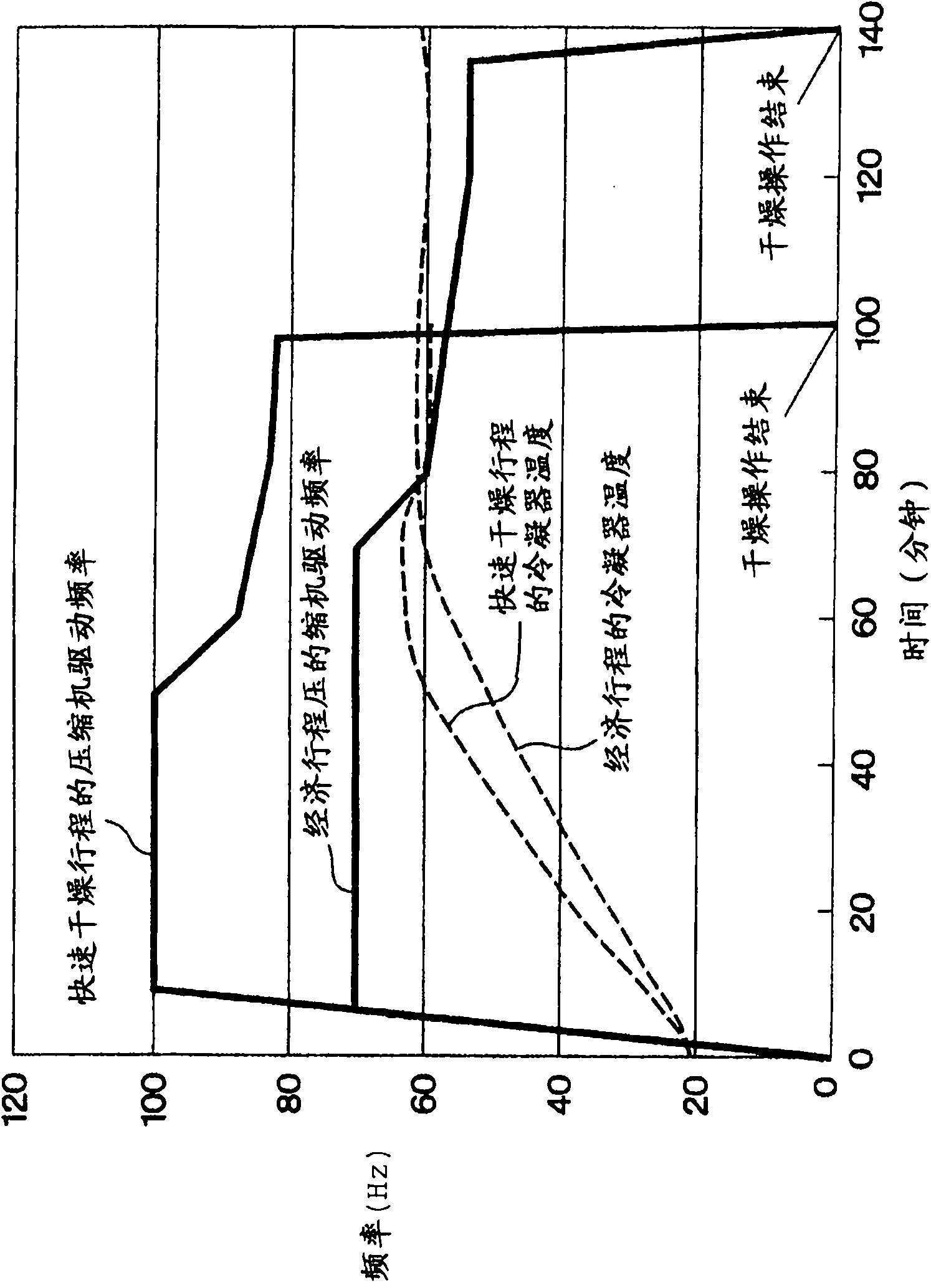

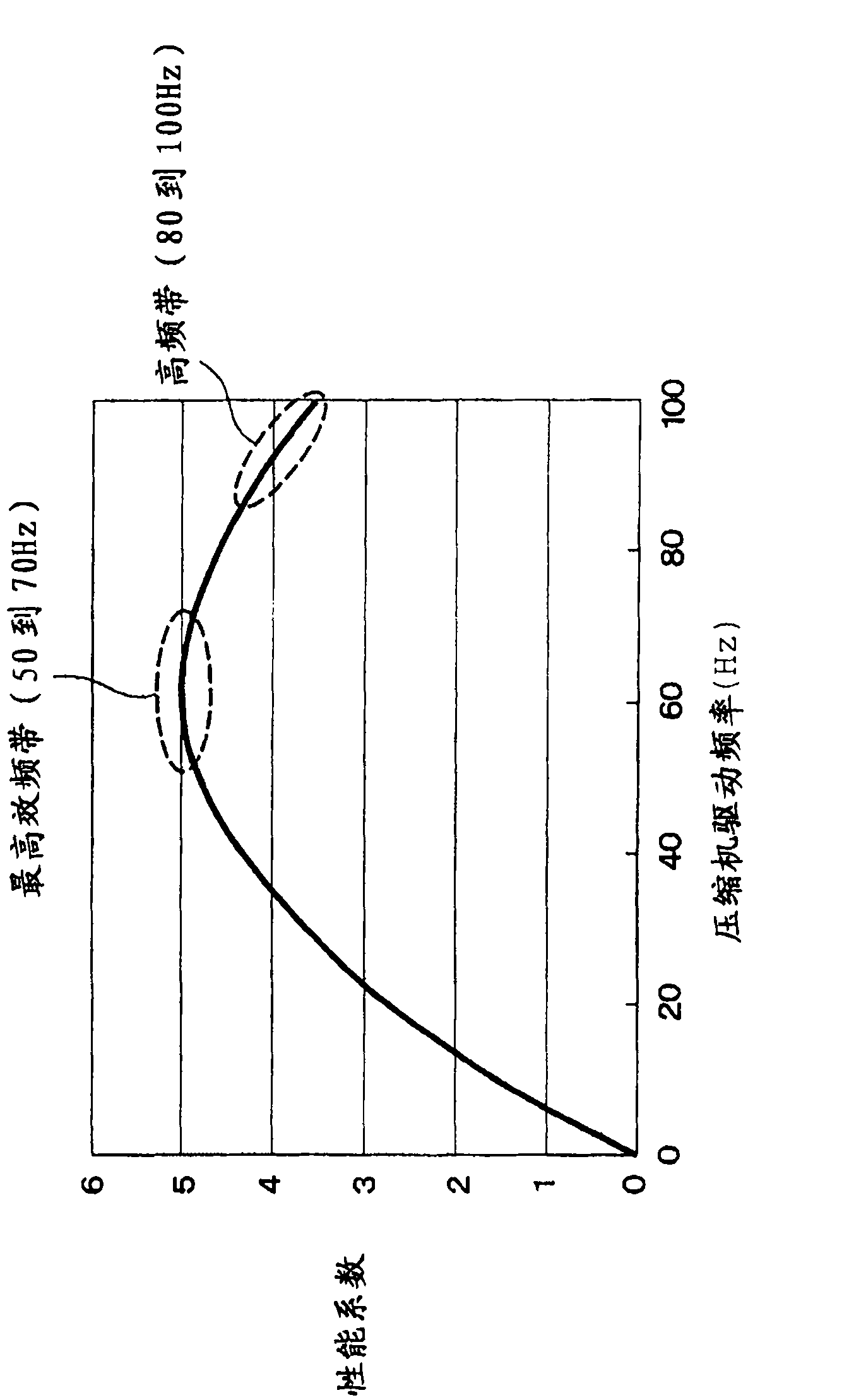

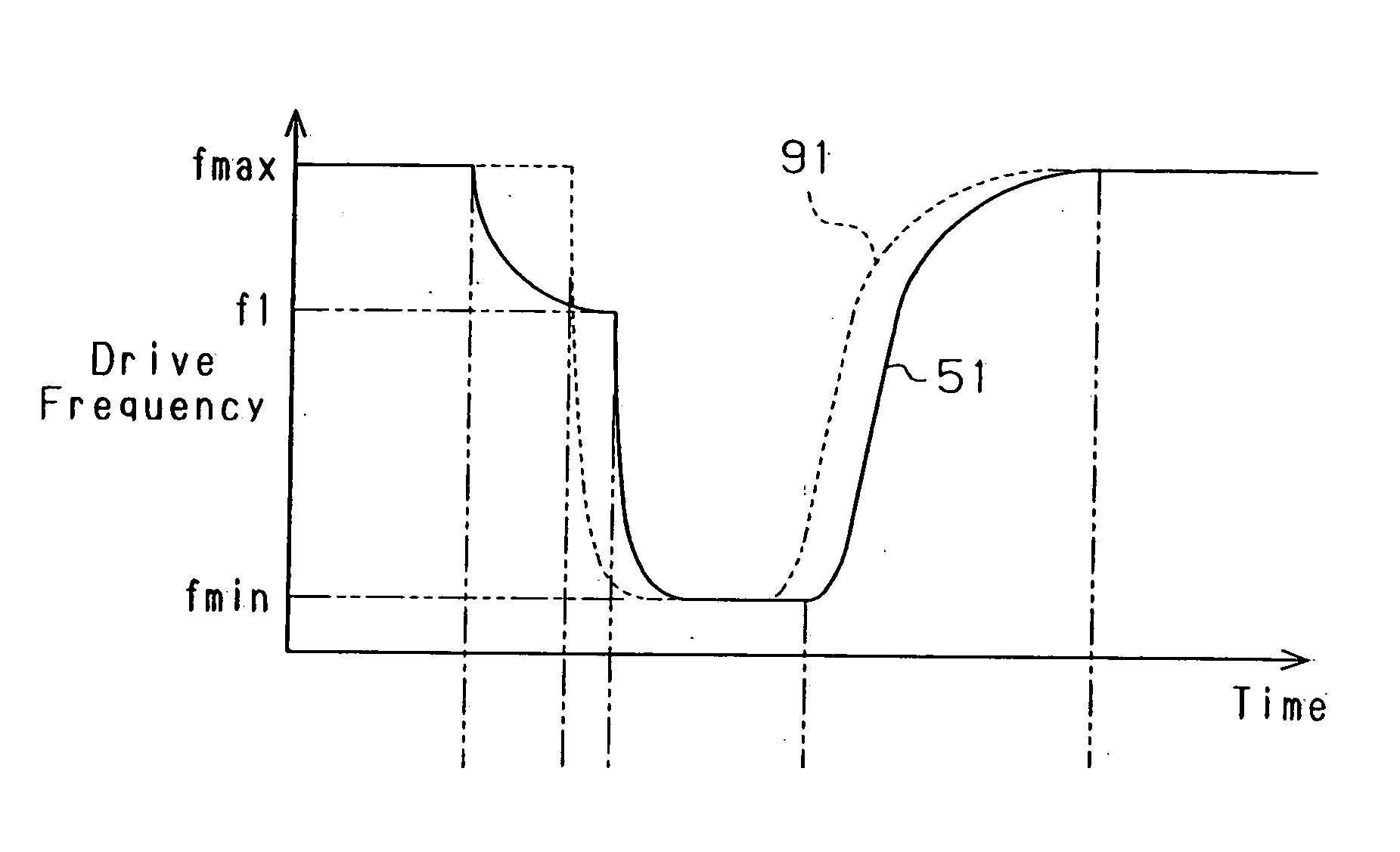

Clothes dryer

ActiveCN102105631AIncrease rotation speedReduce electrical power consumptionLaundry dryer apparatusWashing machine with receptaclesAir cycleProcess engineering

A clothes dryer provided with a washing tub, an air circulator, and a heat pump and drying laundry by operation of the air circulator and the heat pump. The rotational speed of a compressor is changed by controlling frequency, and the clothes dryer can be operated by selection of either a quick-drying mode for drying the laundry in a relatively short time by changing a drive frequency of the compressor or a saving mode for drying the laundry in a time longer than the time of the quick-drying mode. In the saving mode, the compressor is driven in a frequency band providing a high coefficient of performance.

Owner:TOSHIBA LIFESTYLE PROD & SERVICES CORP

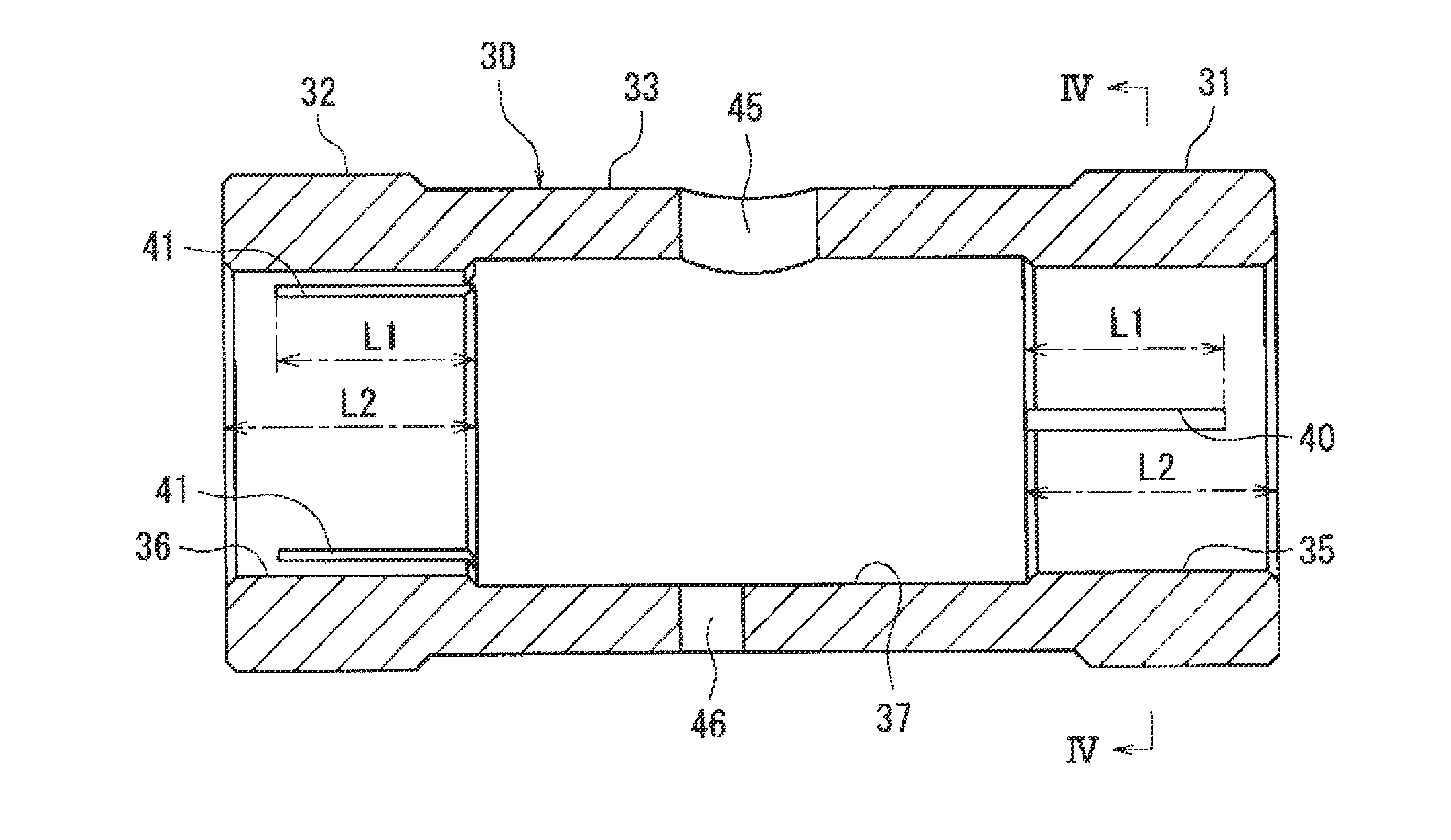

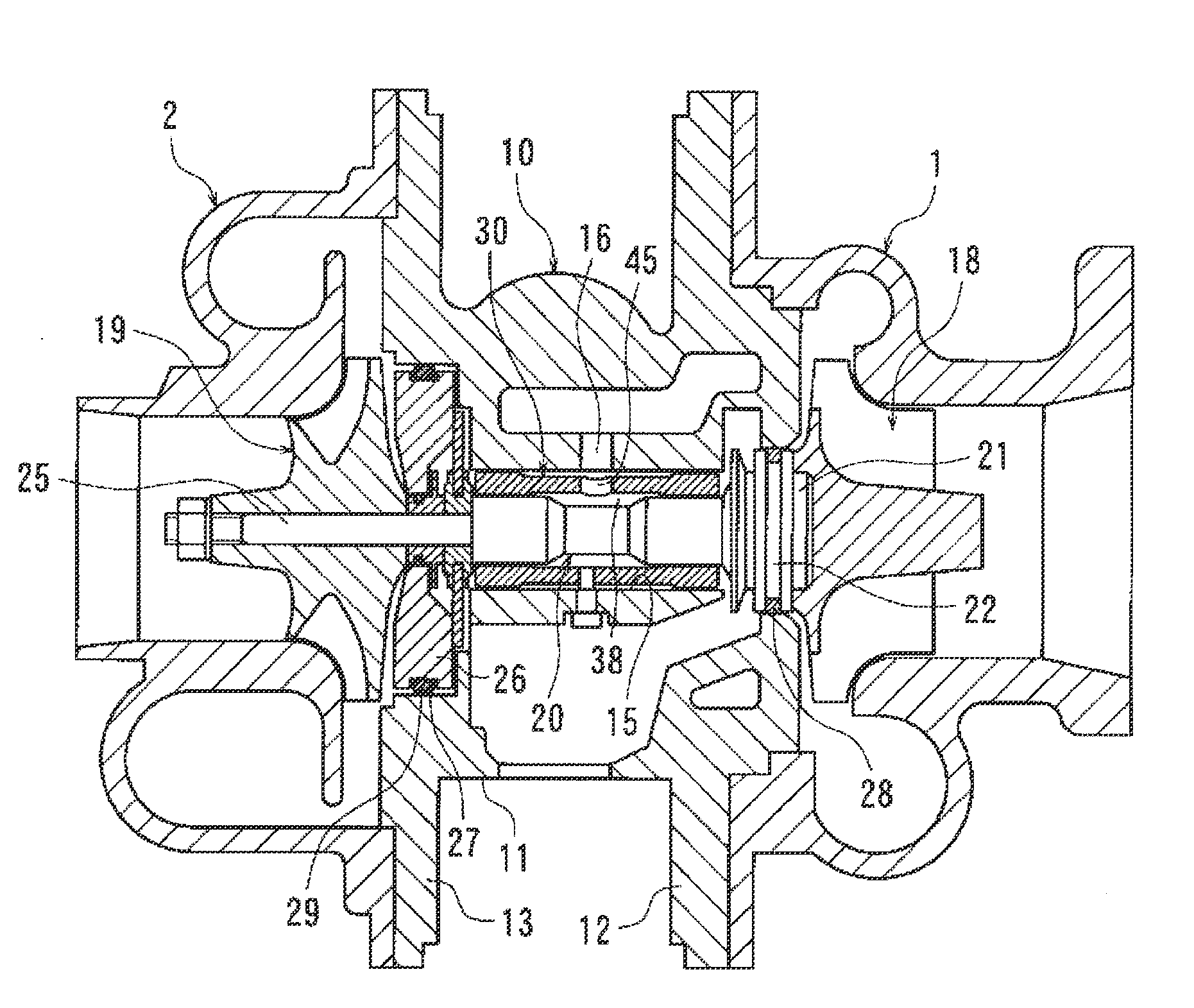

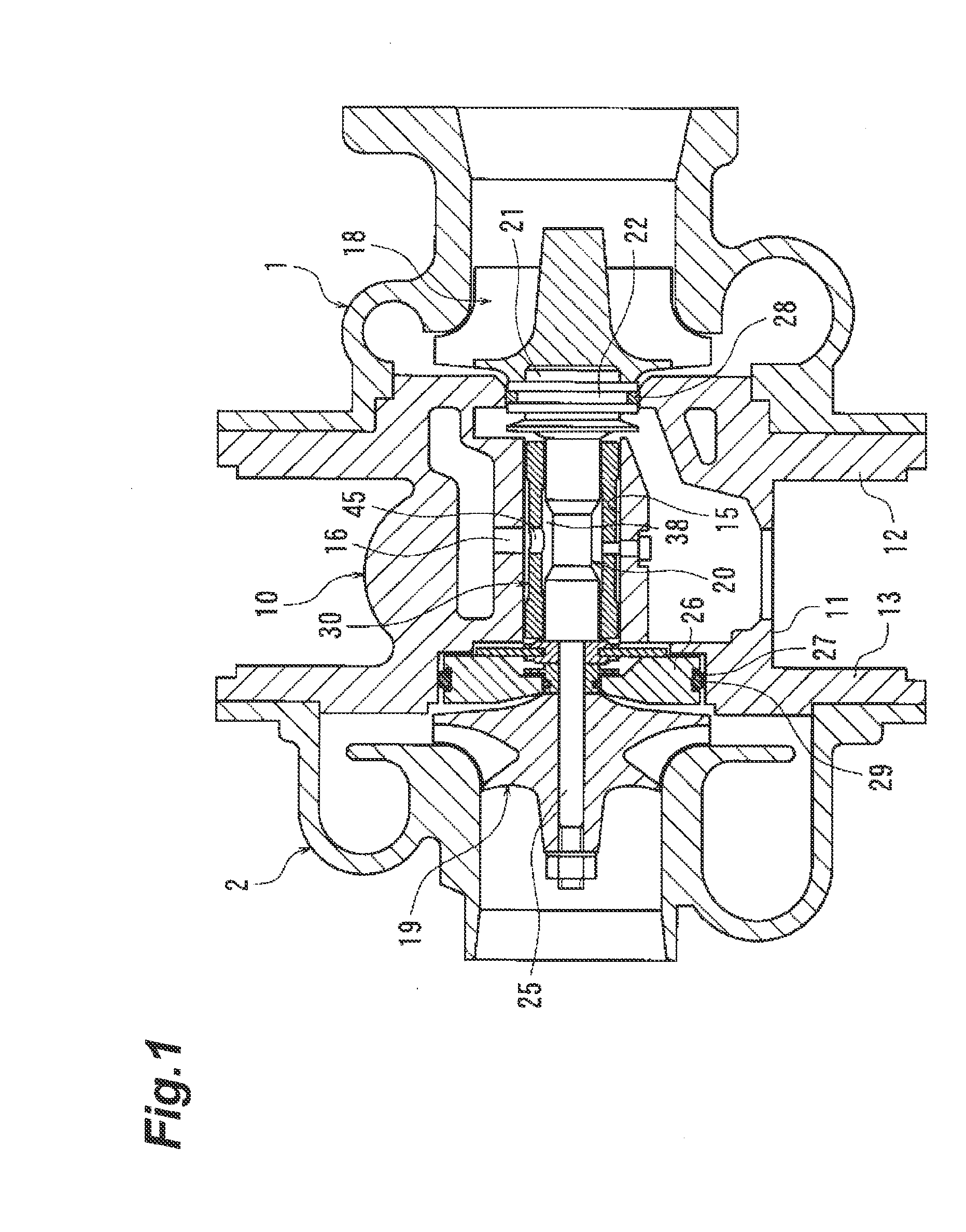

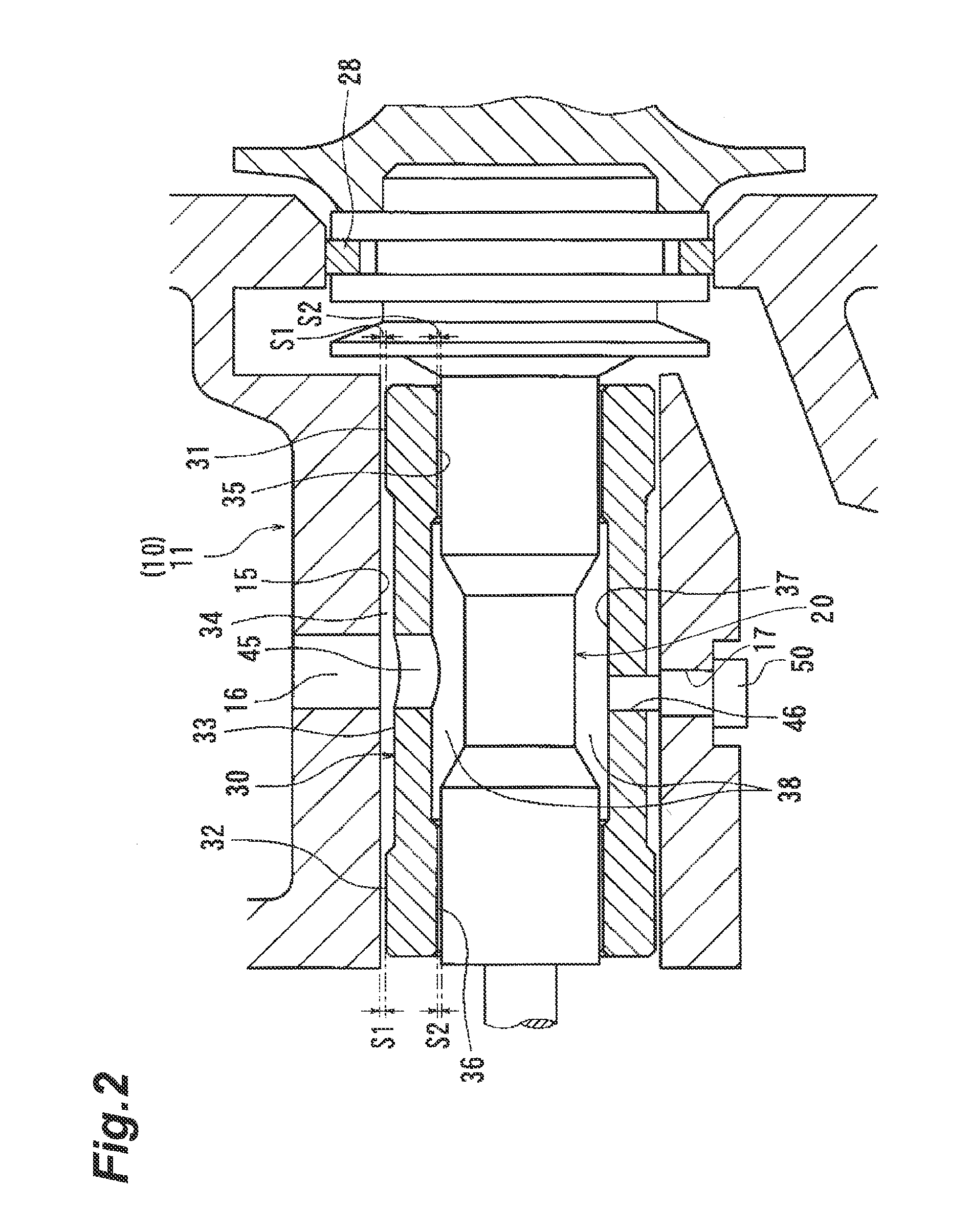

Bearing structure of turbocharger

InactiveUS8628247B2Reduce rotation speedReduce vibrationCrankshaftsBearing assemblyTurbochargerMechanical engineering

Owner:TOYOTA IND CORP

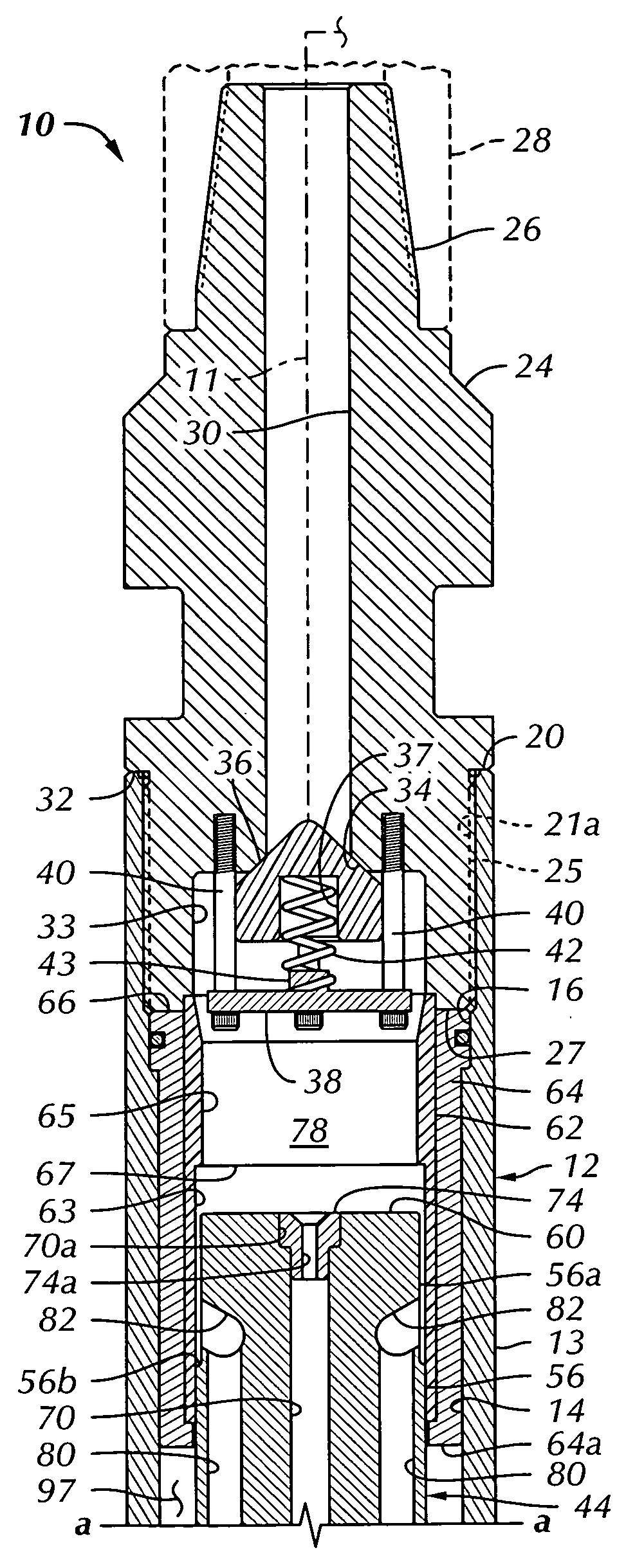

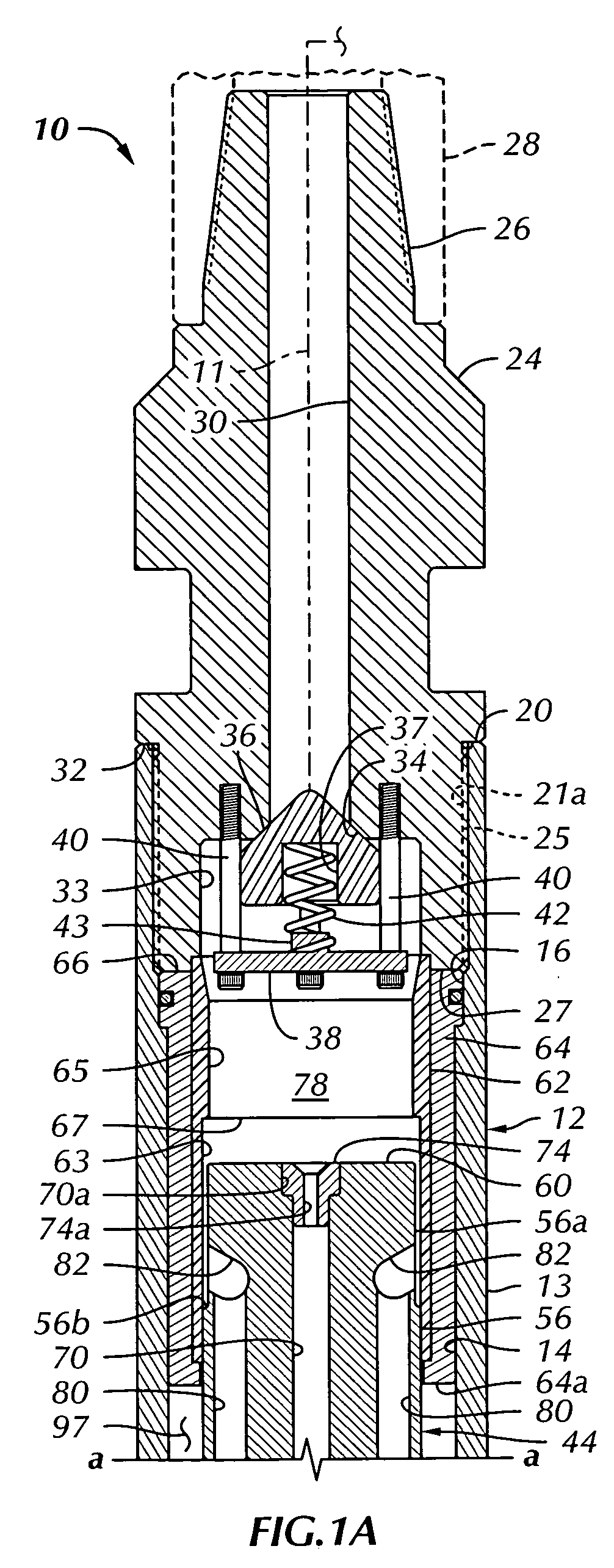

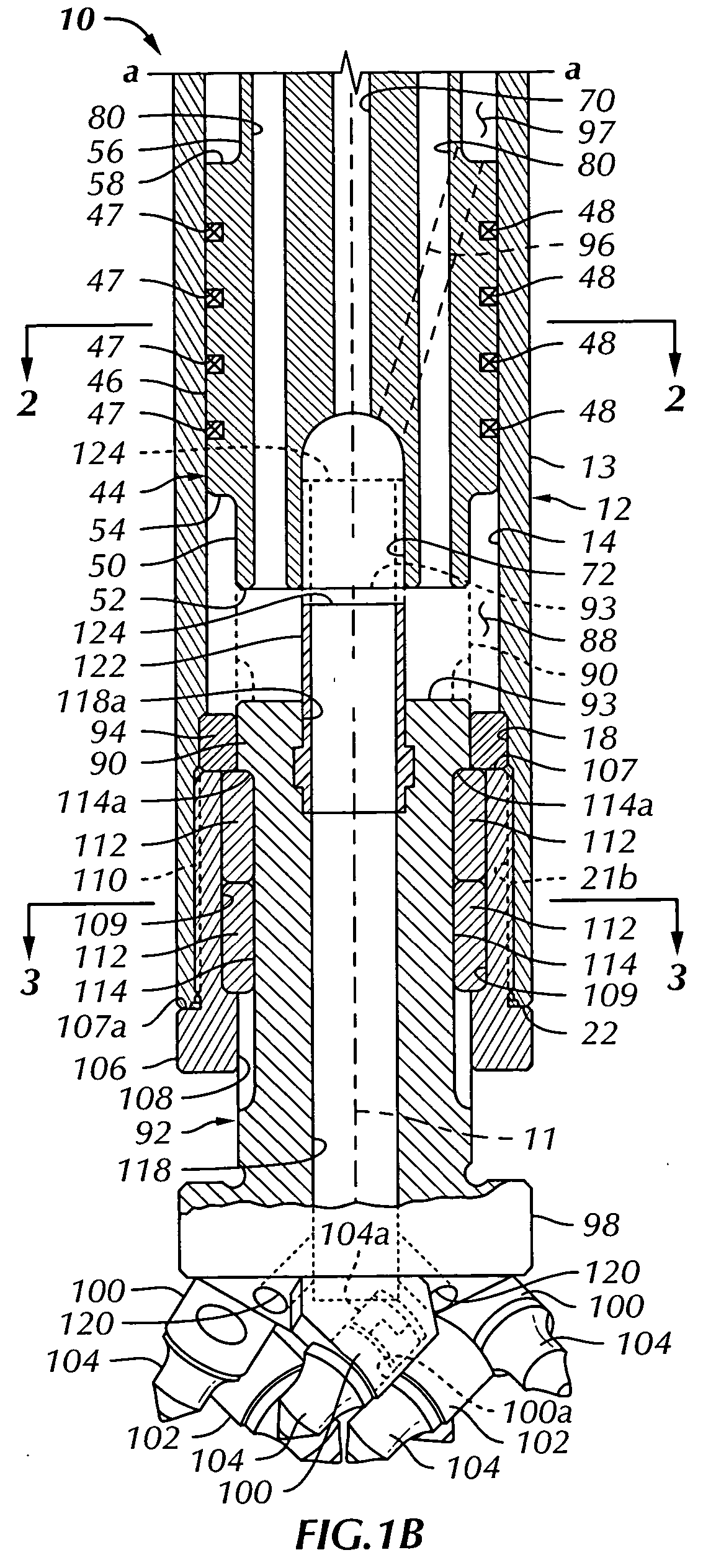

Downhole percussion tool

ActiveUS20070102196A1Increase ratingsSmooth rotationDrill bitsBorehole drivesTransverse pressureEngineering

A pressure fluid actuated downhole percussion tool includes a reciprocating piston hammer with differential transverse pressure surfaces cooperable with a cylinder housing, a guide sleeve and a bit carried exhaust tube to form opposed pressure fluid chambers to which pressure fluid may be conducted to deliver repeated impact blows to a bit having circumferentially spaced bosses and replaceable cutting inserts. The bit is drivenly connected to the tool by plural drive pins supported in circumferentially spaced grooves in the bit shank and in a removable sub supported by the tool housing. Improved earth penetration performance is realized utilizing a claw bit with a pressure fluid actuated percussion tool providing rotation as well as selective deliverance of impact blows through the bit.

Owner:VAREL MINING & IND LLC

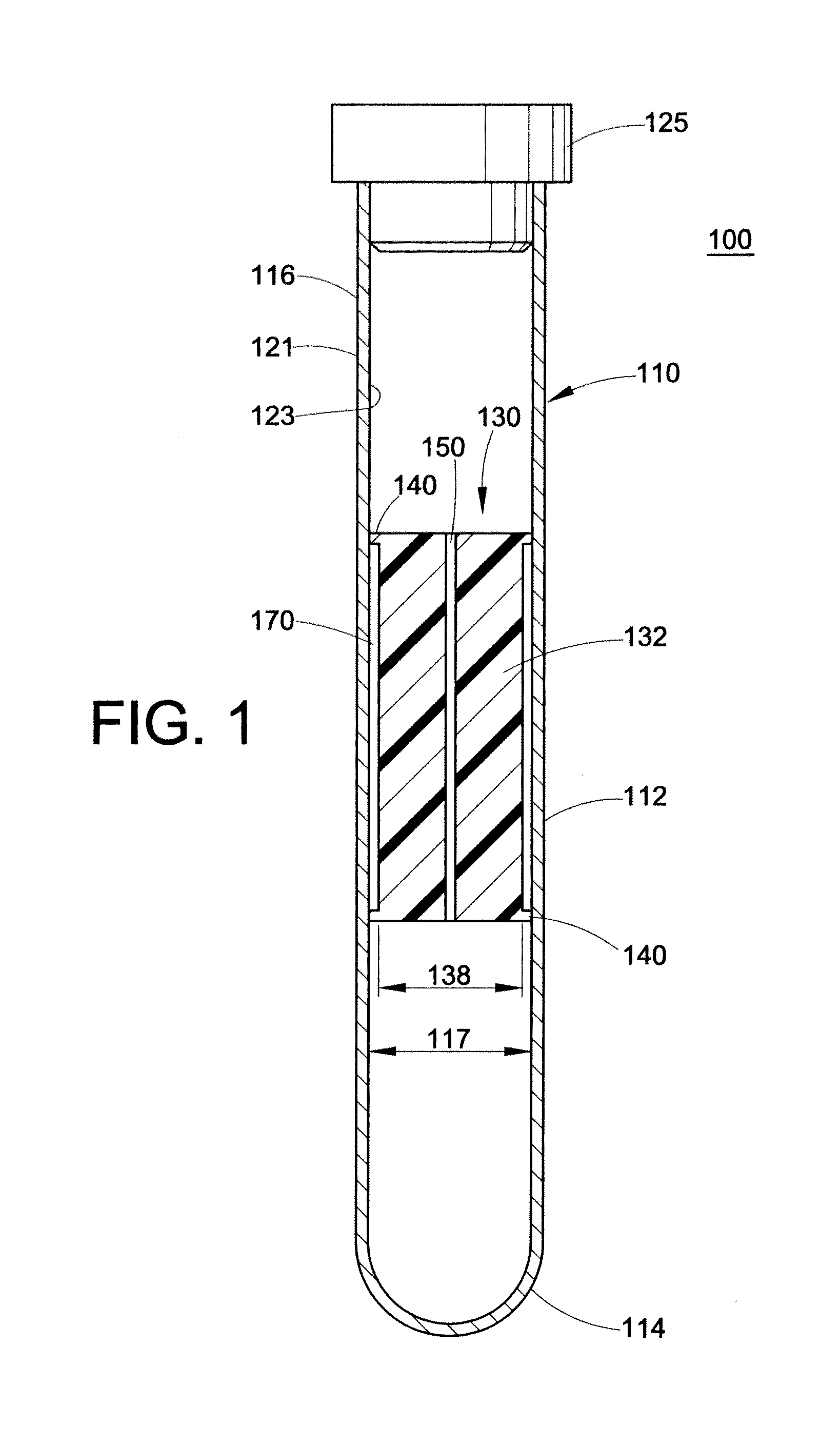

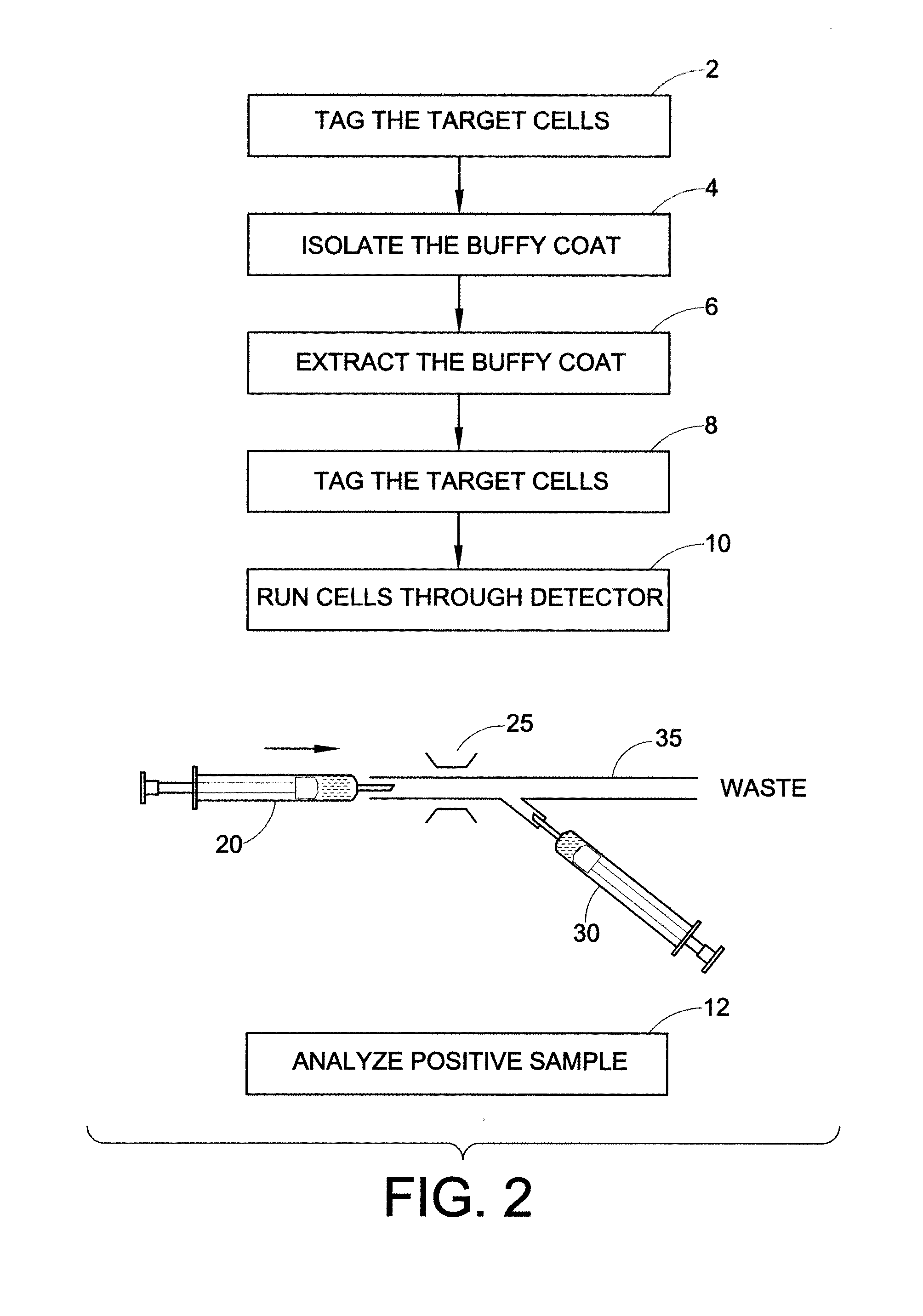

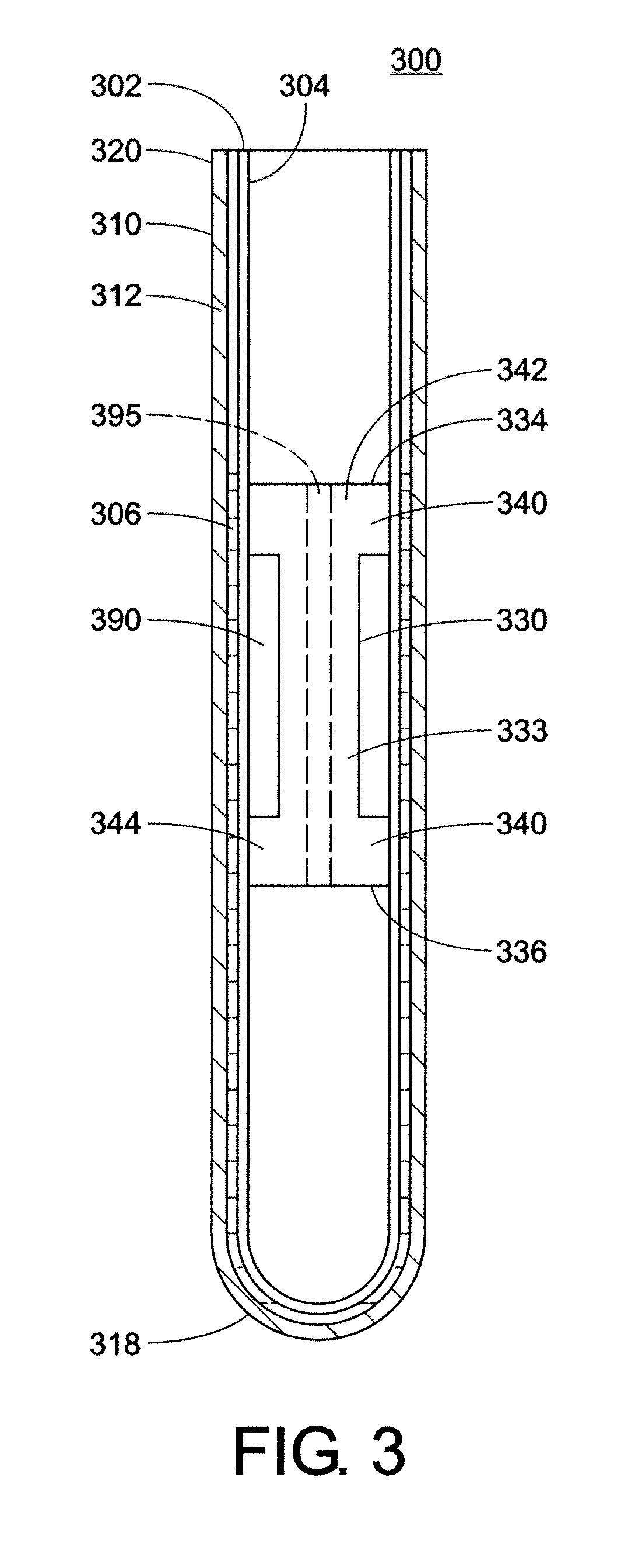

Buffy coat separator float systems and methods

InactiveUS20130017130A1Reduce speedReduce pressurePreparing sample for investigationDispersed particle separationCentrifugationBuffy coat

Tube and float systems for separation and axial expansion of the buffy coat are provided. Generally, the systems include a flexible sample tube and a rigid separator float having a specific gravity intermediate that of red blood cells and plasma. The sample tube has an elongated sidewall having a first cross-sectional inner diameter. The float has a main body portion and one or more support members protruding from the main body portion to engage and support the sidewall of the sample tube. During centrifugation, the centrifugal force enlarges the diameter of the tube to permit density-based axial movement of the float in the tube. After centrifugation is ended, the tube sidewall returns to its first diameter, thereby capturing the float and trapping the buffy coat constituents in an annular volume. Several different systems for capturing and retrieving the buffy coat constituents are described.

Owner:BATTELLE MEMORIAL INST

Method for the separation of blood plasma particles from a blood plasma suspension

InactiveUS7081082B2Reduce speedSimple designWater/sewage treatment by centrifugal separationDispersed particle separationEngineeringBlood plasma

Method for separating blood plasma particles from a blood plasma suspension in a self-discharging centrifuge having two or more discharge slits and axially stacked baffle plates, in which the blood plasma particles are separated from the liquid phase by centrifuging and removal of the liquid phase, suctioning off liquid remaining in the drum after separation of the blood plasma particles and discharging the sediment of solid blood plasma particles from the drum by centrifugal force into a collecting container underneath the drum, the drum and the blood plasma sediment being cooled during one or more of the process steps.

Owner:WESTFALIA SEPARATOR AG

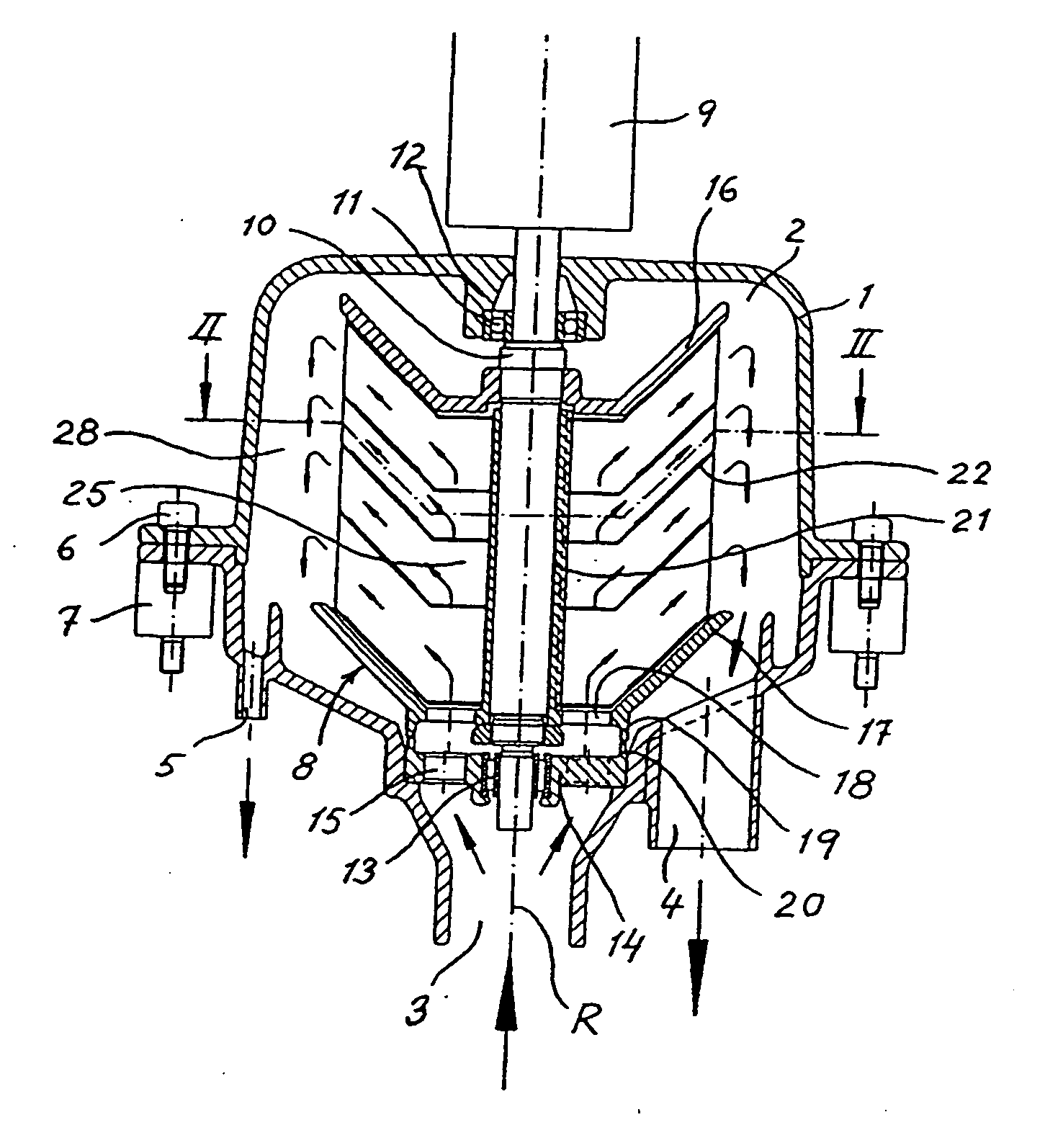

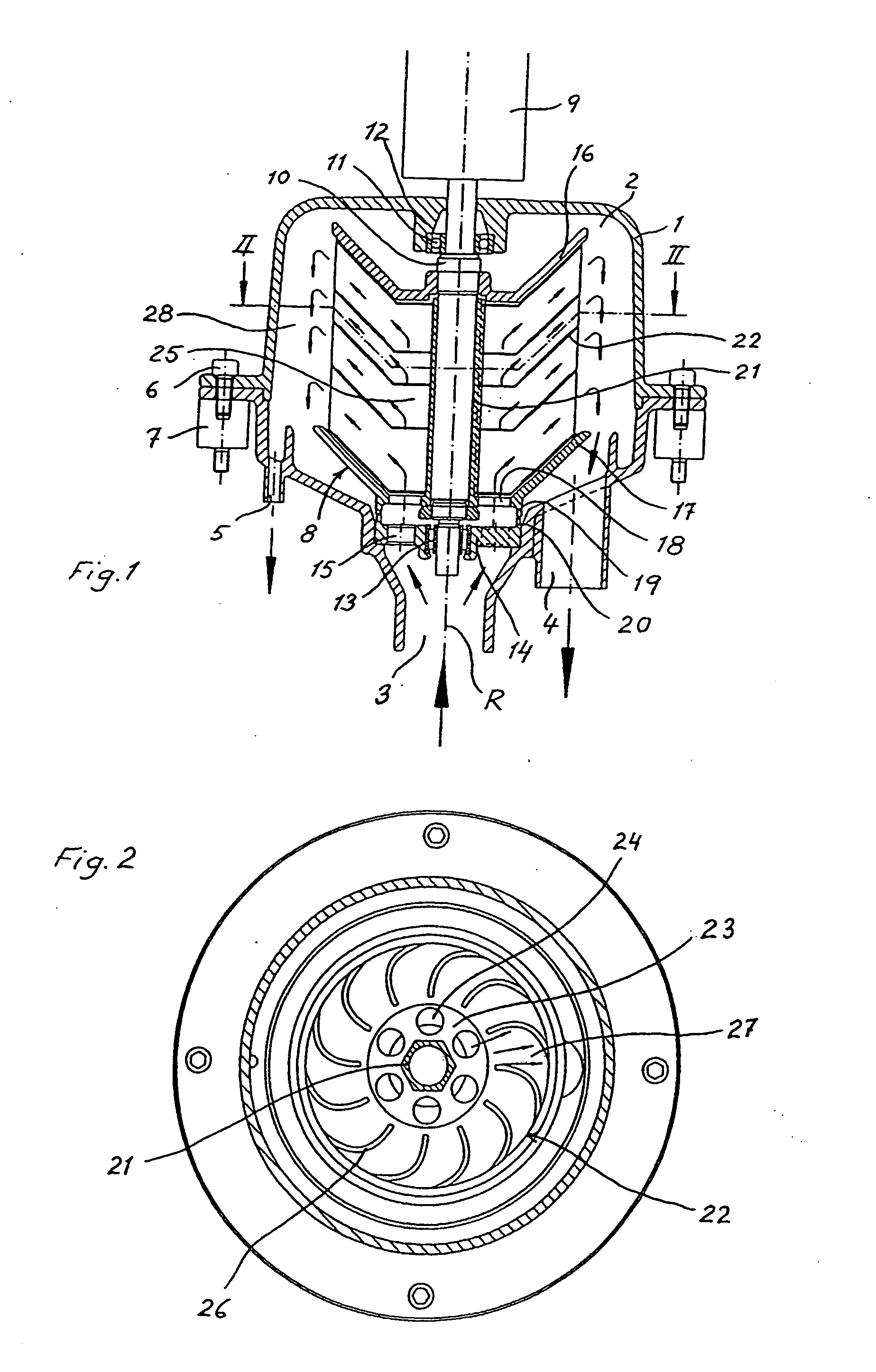

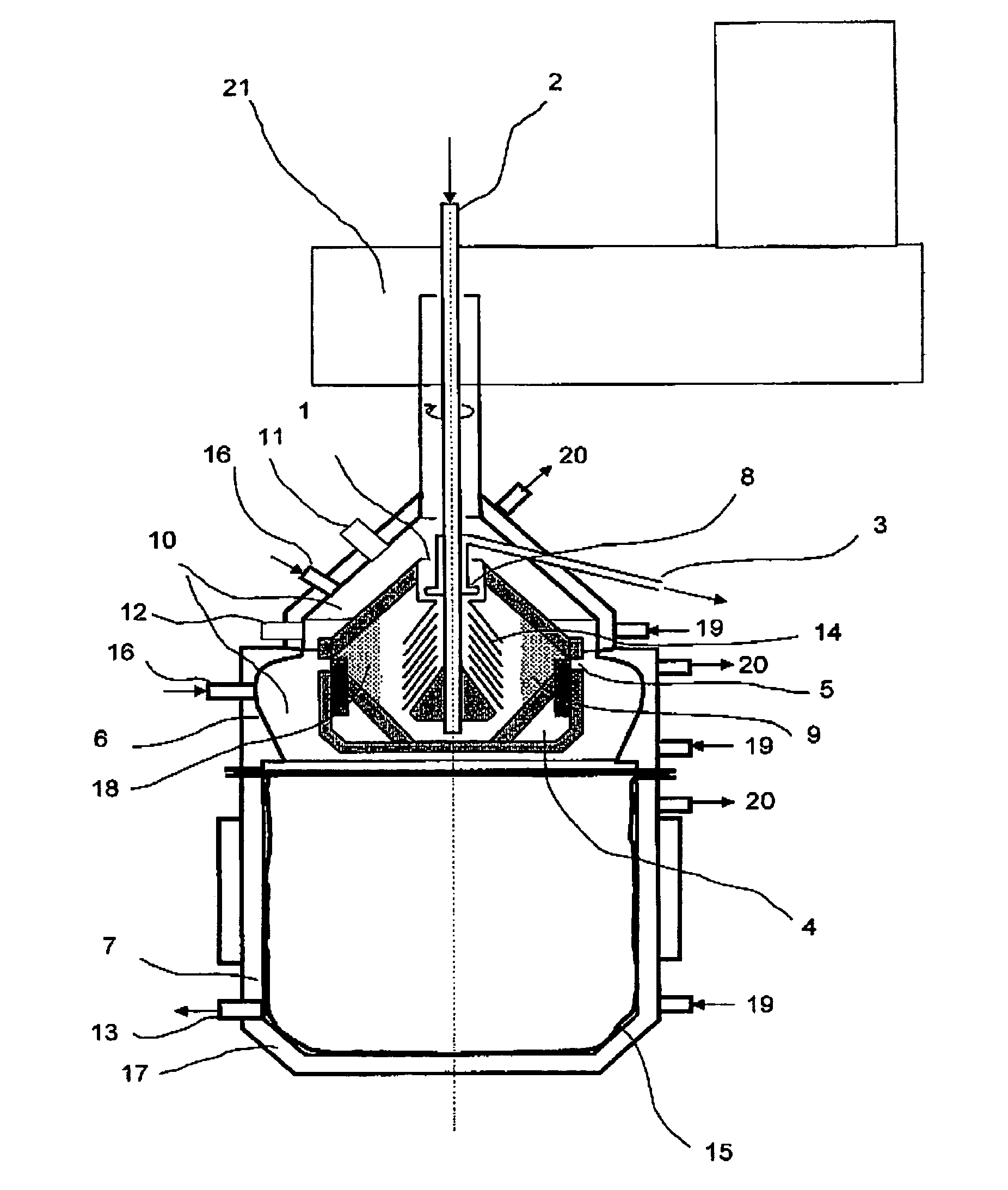

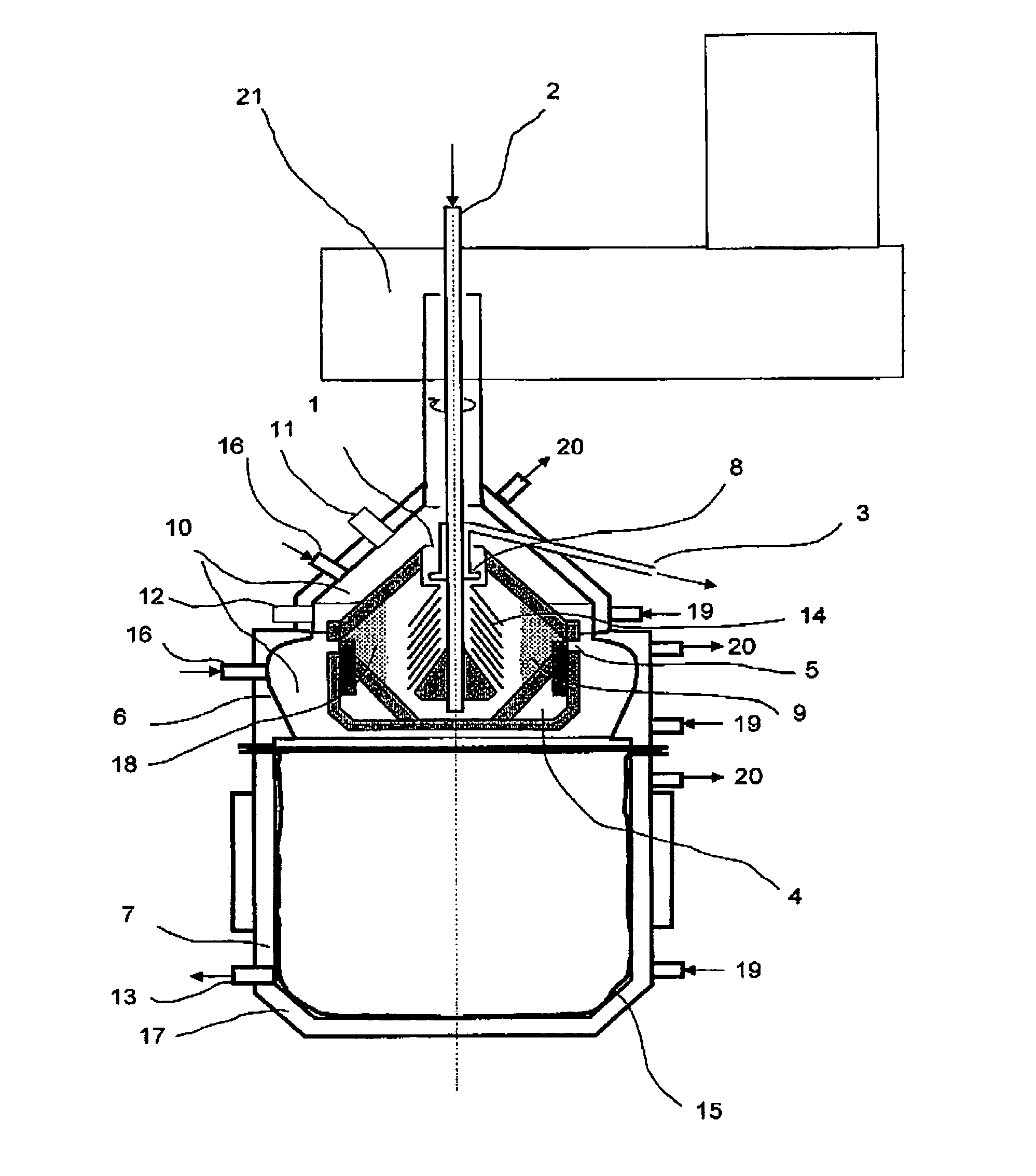

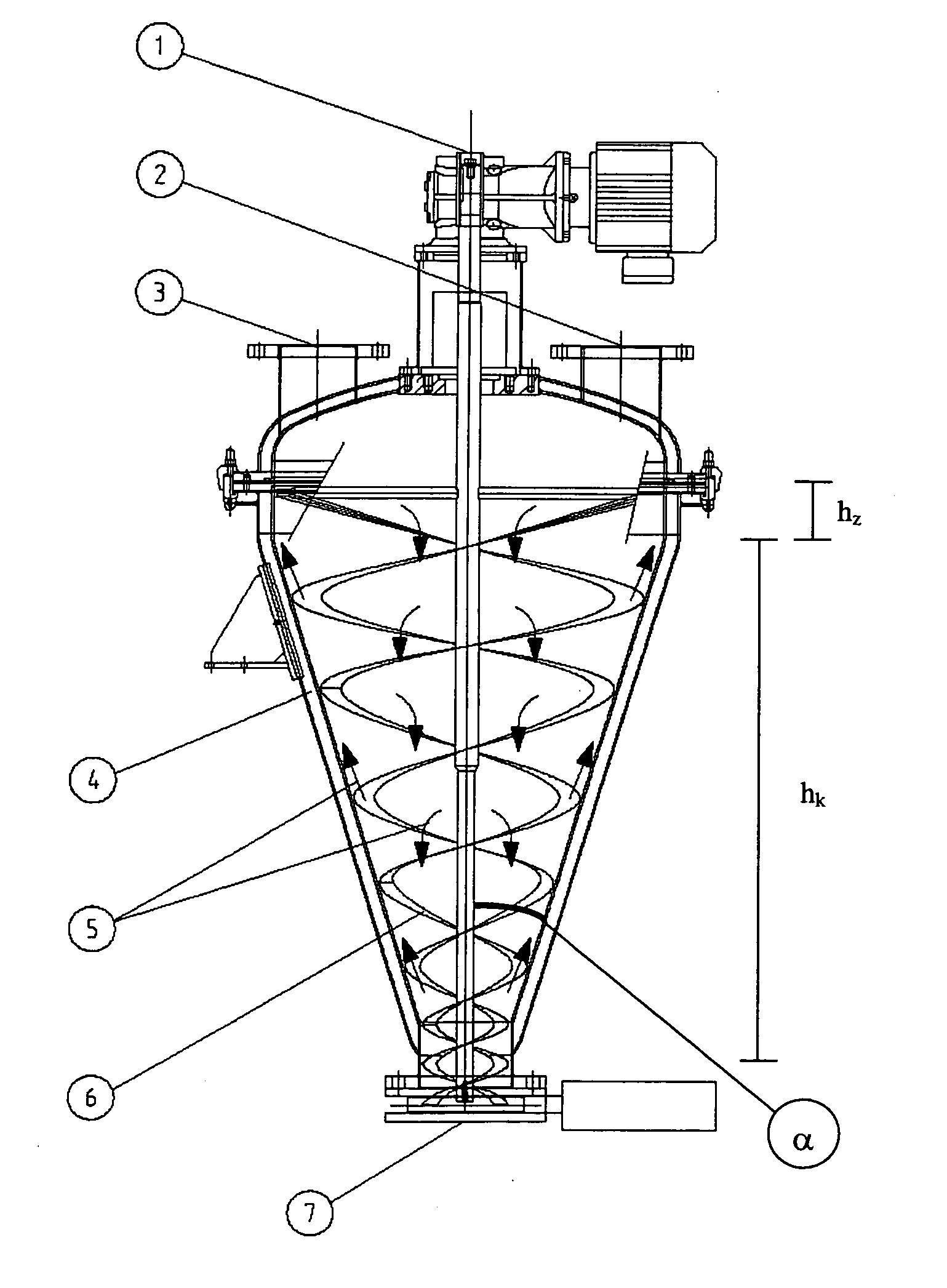

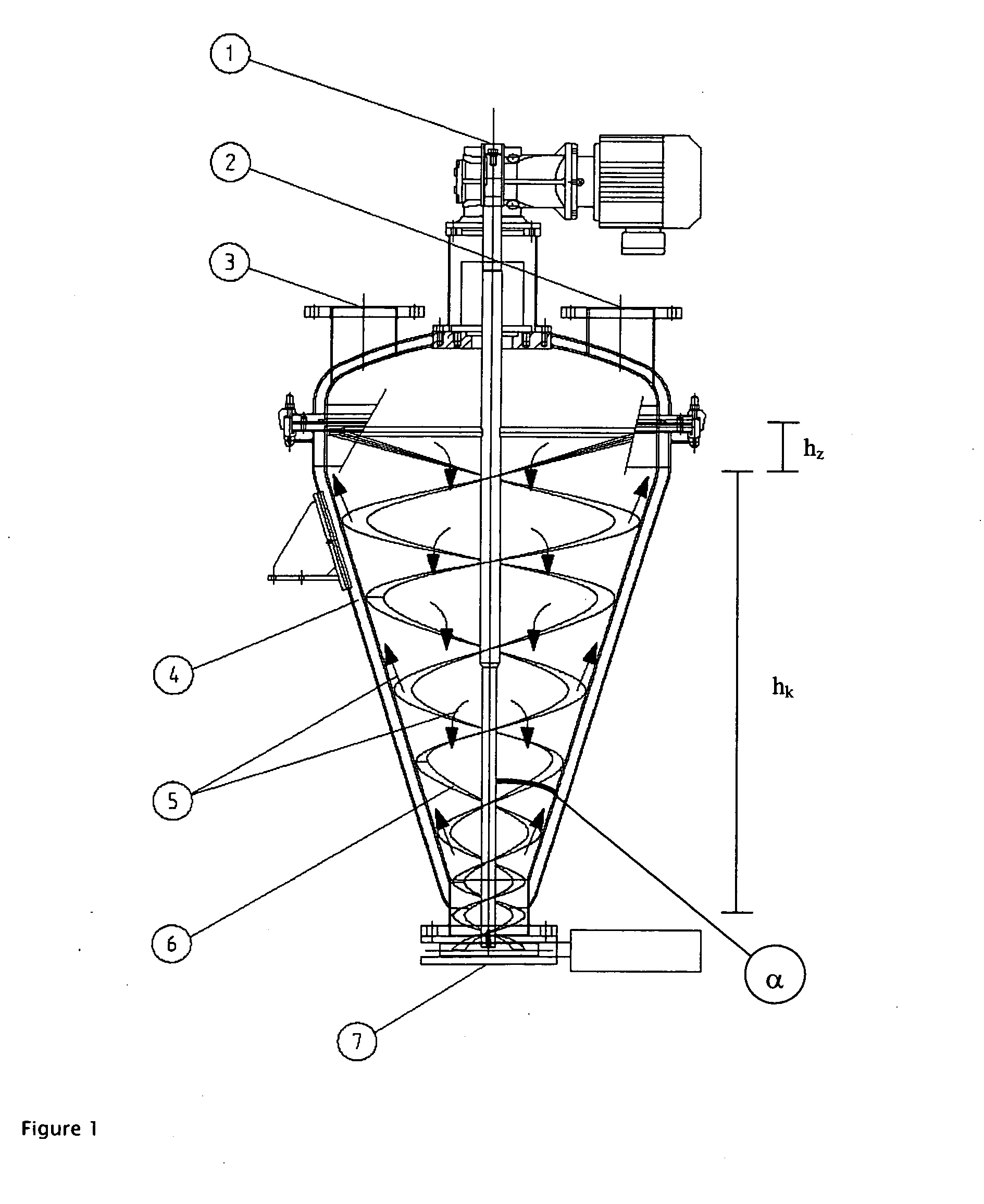

Apparatus and process for batchwise polycondensation

InactiveUS20050014922A1Promote emptyingReduces excessive inputRotary stirring mixersTransportation and packagingIntrinsic viscosity

The invention relates to an apparatus and to a process for batchwise preparation of polycondensation polymers having an intrinsic viscosity of from 50 to 150 cm3 / g at the particular polycondensation temperature.

Owner:DEGUSSA AG

Closed loop control of pad profile based on metrology feedback

ActiveUS8221193B2Increase ratingsReduce thicknessEdge grinding machinesSemiconductor/solid-state device manufacturingLoop controlMetrology

A chemical mechanical polishing apparatus includes a metrology system that detects the thickness of the polishing pad as semiconductor wafers are processed and the thickness of the polishing pad is reduced. The chemical mechanical polishing apparatus includes a controller that adjusts the rate of material removal of a conditioning disk when areas of the polishing surface are detected that are higher or lower than the adjacent areas of the polishing pad.

Owner:APPLIED MATERIALS INC

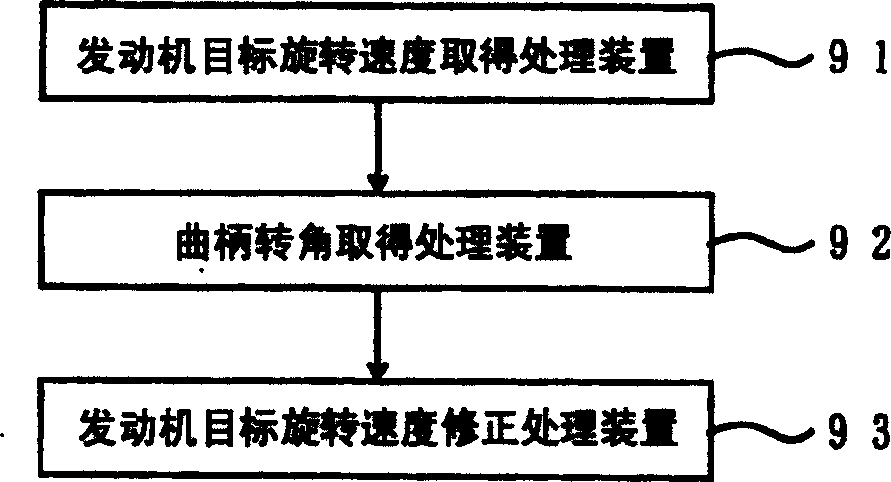

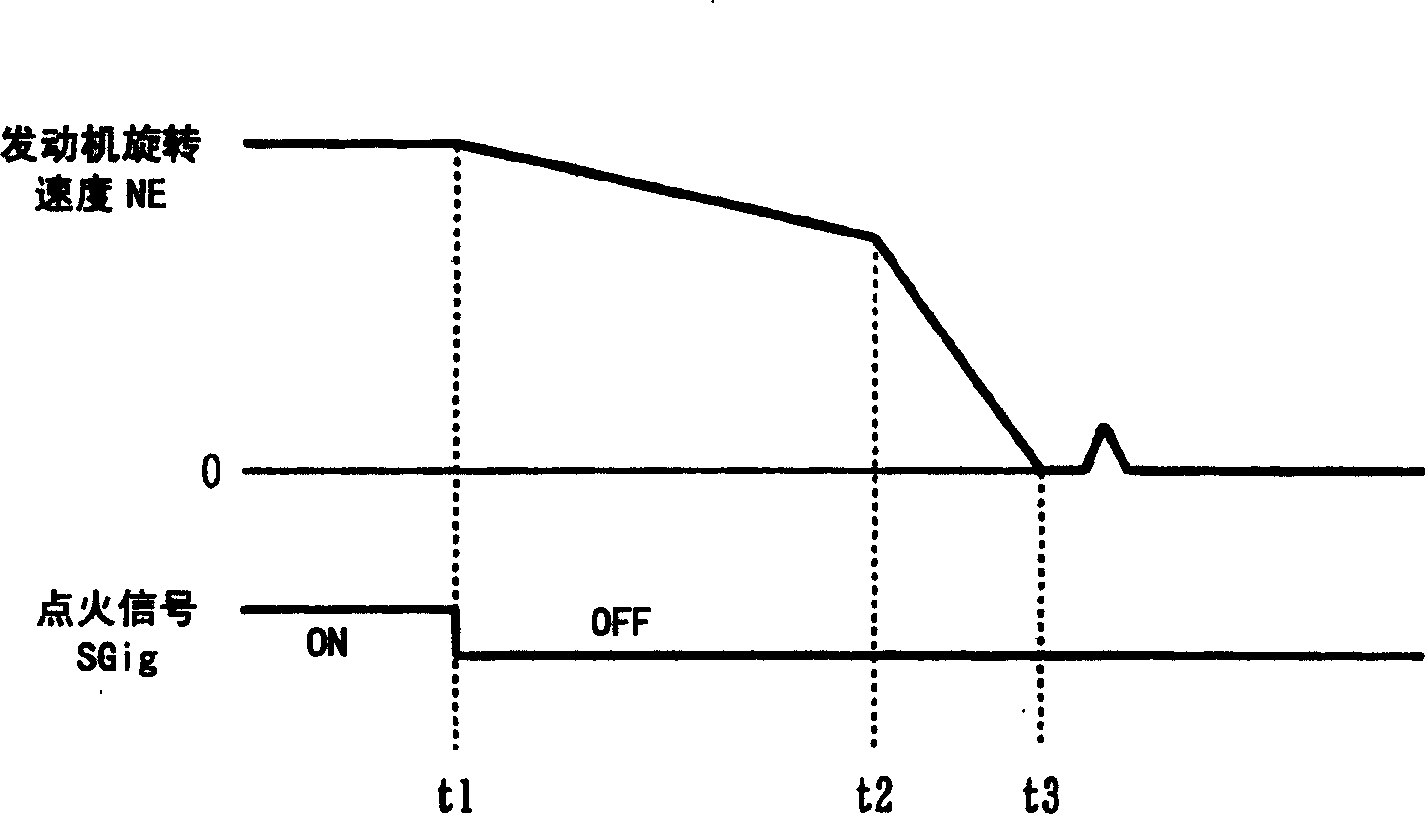

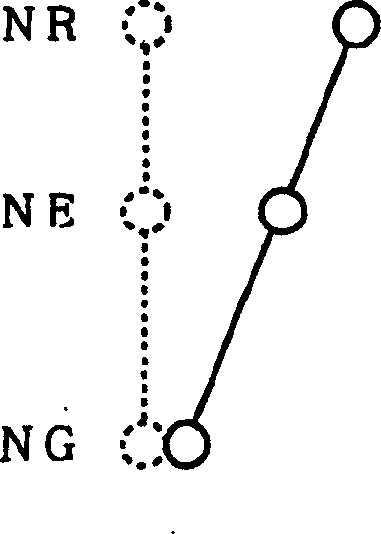

Vehicle-drive control device and method and program therefor

ActiveCN1573087AReduce rotation speedHybrid vehiclesPower operated startersRotation velocityViscosity

The present invention includes a target-engine-speed acquisition means for acquiring a target engine speed necessary to reduce engine speed, thereby stopping the engine at a target stop position; a crank-angle acquisition means for acquiring a crank angle indicative of the position of a crankshaft; and a target-engine-speed correction means for correcting the target engine speed according to the acquired crank angle. Since the target engine speed is corrected according to the crank angle, the engine can be stopped at the target stop position even if the friction in the engine, the electric motor, etc. varies, even if the temperature or viscosity of the lubricating and cooling oils varies, or even if the vehicle is accelerated or decelerated during the reduction of the engine speed.

Owner:AISIN AW CO LTD

Bearing structure of turbocharger

InactiveUS20120237149A1Reduce rotation speedReduce vibrationCrankshaftsBearing assemblyTurbochargerEngineering

A turbocharger is provided with a rotor shaft, a bearing housing in which a bearing hole is formed, and a bearing member of the semi-floating type arranged in the bearing hole and supporting the rotor shaft in a rotatable state. The bearing member has a first bearing portion and a second bearing portion spaced at a predetermined interval in the axial direction of the rotor shaft, in its inner periphery. A region between the first bearing portion and the second bearing portion in the inner periphery of the bearing member, and an outer periphery of the rotor shaft constitute an oil passage for supply of lubricant oil to inside surfaces of the first and second bearing portions. Oil grooves to suppress the whirl vibration are formed in each of the inside surfaces of the first and second bearing portions. The oil grooves are closed in part.

Owner:TOYOTA IND CORP

Multi-line array type LED plane based on rotation and stereo display

InactiveCN101354859AReduce rotation speedEasy to achieve dynamic balanceAdvertisingDisplay meansElectric machineryHigh definition

The invention relates to a rotary multi-linear array high definition LED flat and stereoscopic display which comprises an LED linear array structure and a rotary cylinder display substrate which can rotate at a uniform speed, and a double linear array LED or an LED linear array set in different turning radius is arranged on the rotary cylinder display substrate. A double linear array structure is adopted on the linear array with the same turning radius. LEDs of every two linear arrays are staggered by a unit to display corresponding interlaced information at the same time respectively; LED linear arrays are arranged in different turning radius to realize stereo display; and a rotary encoder is adopted to provide line-scanning signals. The invention has the advantages that the rotary multi-linear array high definition LED flat and stereoscopic display can improve the definition remarkably and realize stereo display; a plurality of channels can be played within 360 degrees; the problem of display asynchronization can not produced under the conditions that the rotary speed of a motor is affected by power frequency or other factors; and the drive proposal is simple and the cost is low.

Owner:DONGHUA UNIV

Controller of vacuum pump

InactiveUS20050031468A1Reduce rotation speedImprove shock resistanceFlexible member pumpsSemiconductor/solid-state device manufacturingFree spaceEngineering

A vacuum pump has a pump mechanism section that performs evacuation to set a space to be evacuated to a predetermined degree of vacuum and an electric motor section for driving the pump mechanism section. A controller of the vacuum pump executes deceleration control to decrease a rotational speed of the electric motor section when an increase in load torque of the vacuum pump per unit time abruptly changes upward.

Owner:KAWAGUCHI MASAHIRO +4

Control mechanism provided with at least one adjusting arm

ActiveCN101091034APrevent openingAvoid deflectionBuilding braking devicesWing openersMechanical engineeringEngineering

The invention relates to an actuating device for moving a flap of a piece of furniture, including at least one actuating arm for moving the flap, a base member on which the actuating arm is pivotally arranged, and a spring device able to act upon the actuating arm. An assembly securing device for the vacant actuating arm, which has not yet been fitted with a flap, includes a braking device which limits the opening speed of the vacant actuating arm.

Owner:JULIUS BLUM GMBH

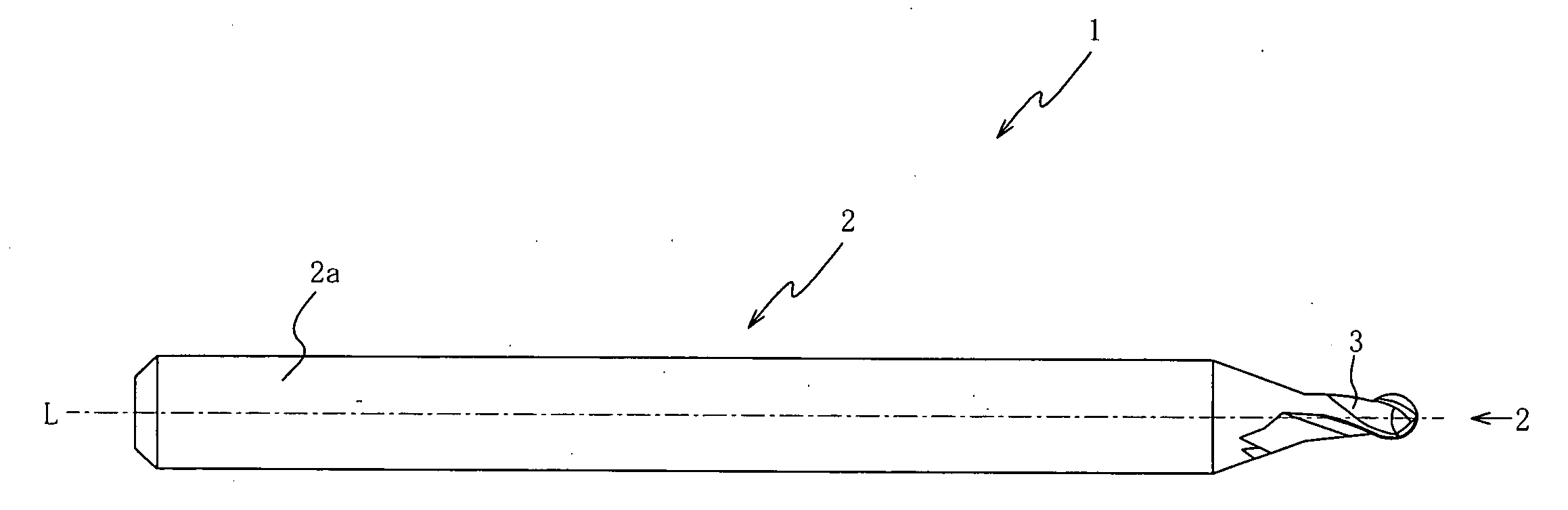

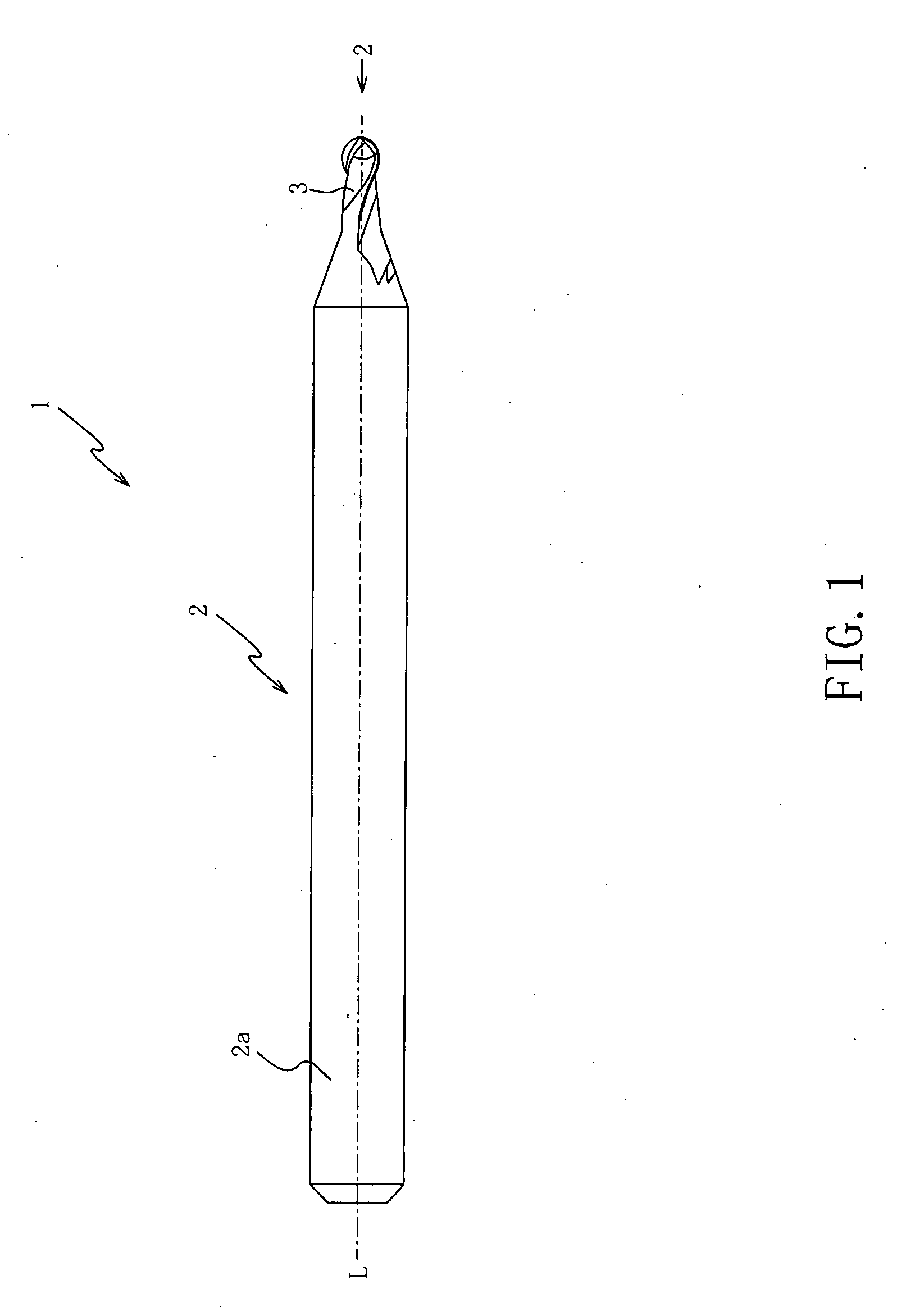

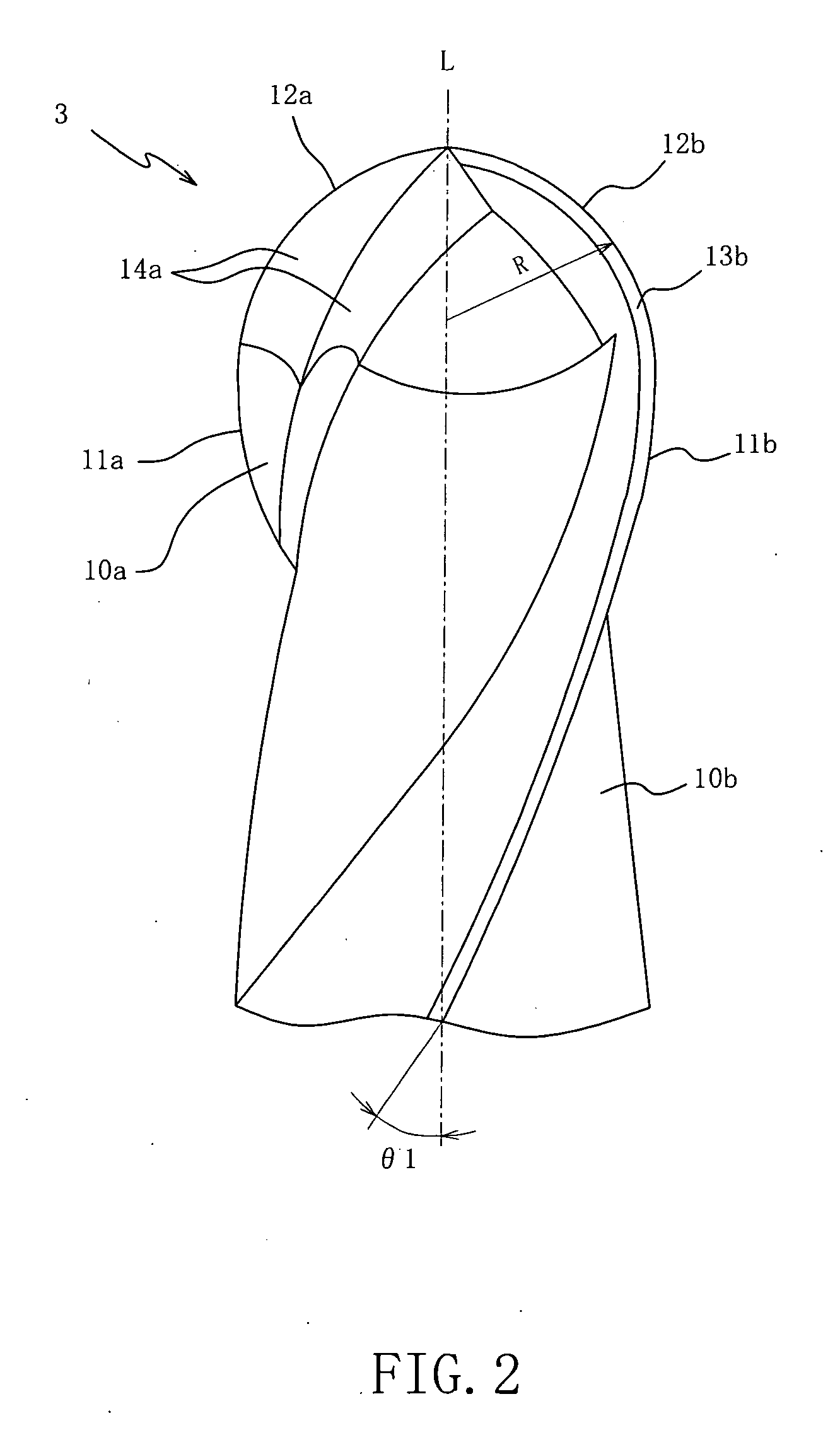

Ball endmill

InactiveUS20070172321A1Increase speedLarge depth of cutMilling cuttersWorkpiecesEngineeringSpherical shaped

A ball endmill includes a cylindrical tool body that is to be rotated about its axis, ball-nosed end cutting edges located in an axially distal end portion of the tool body and describing a semi-spherical-shaped locus during rotation of the tool body, and spiral gashes located in the axially distal end portion of the tool body and defining rake faces of the respective ball-nosed end cutting edges. The tool body is made, at least at its part providing each ball-nosed end cutting edge, of a hard sintered body. Each ball-nosed end cutting edge is inclined with respect to the axis by a helix angle in a range from about 10° to about 30°. The tool body has, in its distal end, a non-gashed central area in which the spiral gashes do not exist. A ratio of a size of the non-gashed central area to a ball nose radius is in a range from about 0.03 to about 0.1.

Owner:OSG +1

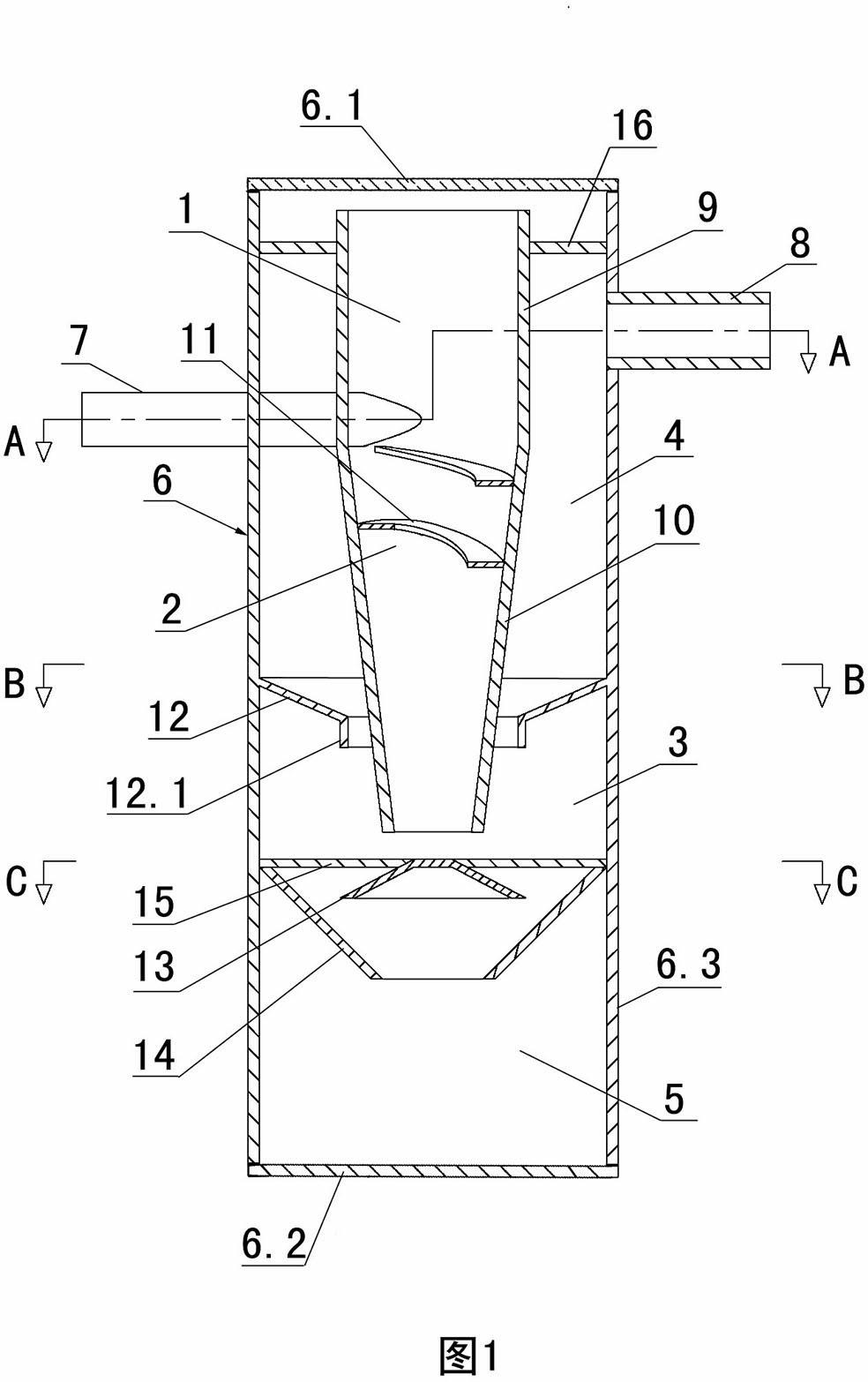

Multistage integrated hydrodynamic cyclone separator

InactiveCN102512857ASmall footprintEasy to install and controlCentrifugal force sediment separationEngineeringCyclone

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE

Alpha type cyclone separator

InactiveCN101116844AAvoid double hoistingGood drainageReversed direction vortexHigh concentrationCyclone

An alpha type cyclone separator which belongs to the isolation technique comprises a straight bowl body, a conical bowl body, an ash exhausting pipe, a coping, a liquid inlet, and a liquid outlet. The utility model is of small conical angle and long conical body structure, and the angle between the axes of the liquid inlet and the horizontal direction is of alpha. The coping is a spiral lamina with an obliquity of alpha, and an air inlet and the straight bowl boy, as well as the coping are tangent according to the obliquity alpha of the coping. The alpha is from 5 DEG C to 25 DEG C, and a second class or a second and third circumfluent cyclone separator also can be connected in series. The separating efficiency of the alpha type cyclone separator is obviously superior to a traditional hydrocyclones, and the alpha type cyclone separator is of low pressure drop, small amplification effect, high separation definition, and obvious energy saving effect. The pressure drop is about 70 percent that of traditional hydrocyclones, therefore, the utility model can satisfy the separating demand of high concentration, widely distributed granularity of solid particles, highly required technical process, and great difficulty for classification. The cyclone separator can be widely popularized and applied in chemical engineering, petroleum, metallurgy, medicine, and environmental protection field.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com