Controller of vacuum pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

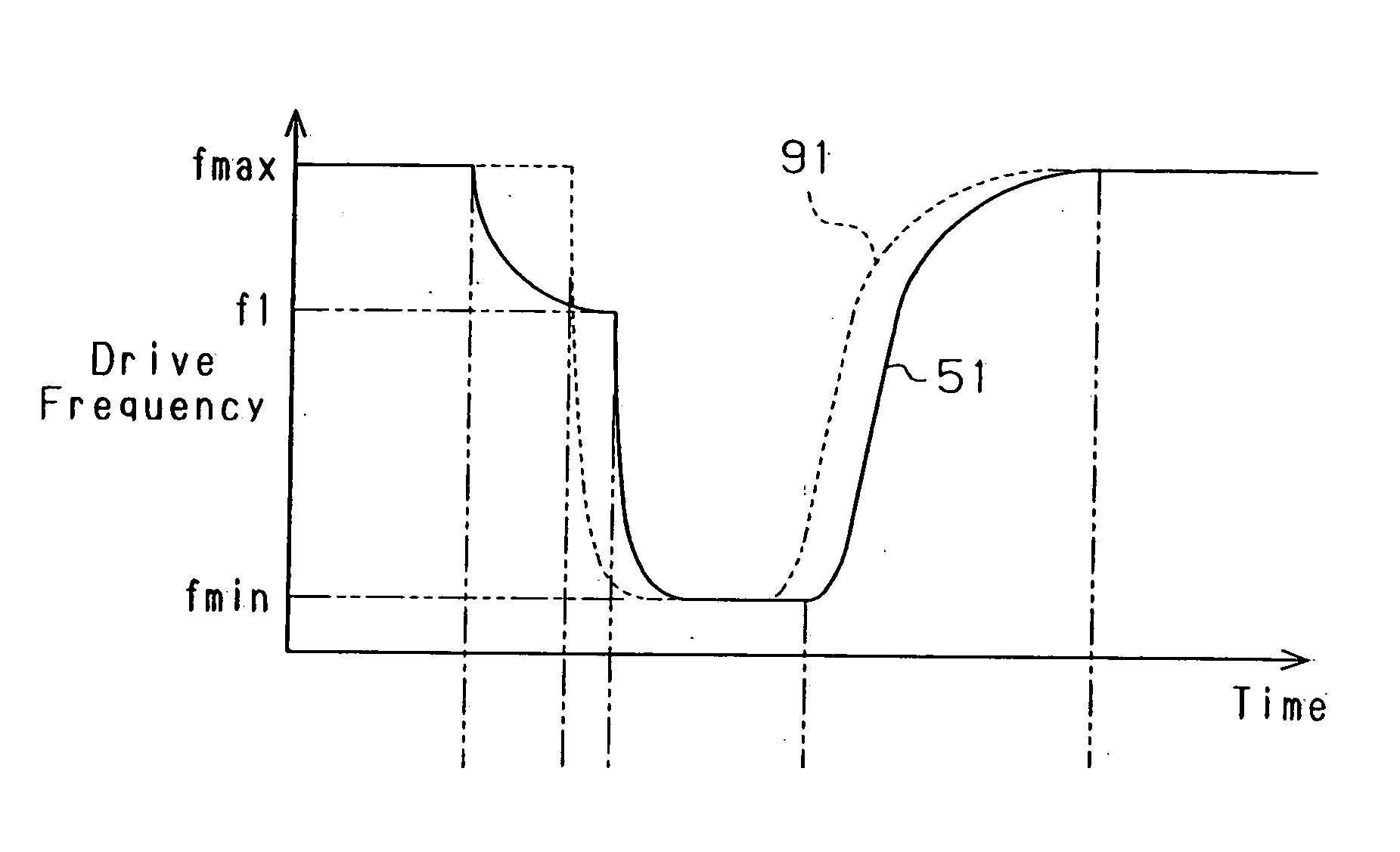

[0021] One embodiment of the invention as embodied in a vacuum pump for evacuating a load-lock chamber in a semiconductor production apparatus is described below with reference to the accompanying drawings.

[0022] As shown in FIG. 1, a process chamber 12 is provided side-by-side with respect to a load-lock chamber 13 in a semiconductor production apparatus 11. Deposition processes, such as vacuum deposition or sputtering on a wafer, are carried out in the process chamber 12. Those processes are executed after the process chamber 12 is set to a predetermined degree of vacuum by using an unillustrated evacuation system.

[0023] Wafer exchange between the exterior (atmospheric pressure space) of the semiconductor production apparatus 11 and the process chamber 12 is carried out via the load-lock chamber 13. That is, a passage for exchanging a wafer at the time of wafer exchange is provided between both chambers 12 and 13 and a gate valve 14 that connects and disconnects both chambers 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com