Alpha type cyclone separator

A technology of cyclone separator and fluid, which is applied in the direction of cyclone devices and devices in which the axial direction of the cyclone can be reversed, etc., can solve the problem of low separation efficiency of cyclone dust collector and hydrocyclone, wide distribution of solid particle size, The technical process requires high problems, and achieves the effect of obvious energy saving effect, small pressure drop and high segmentation definition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

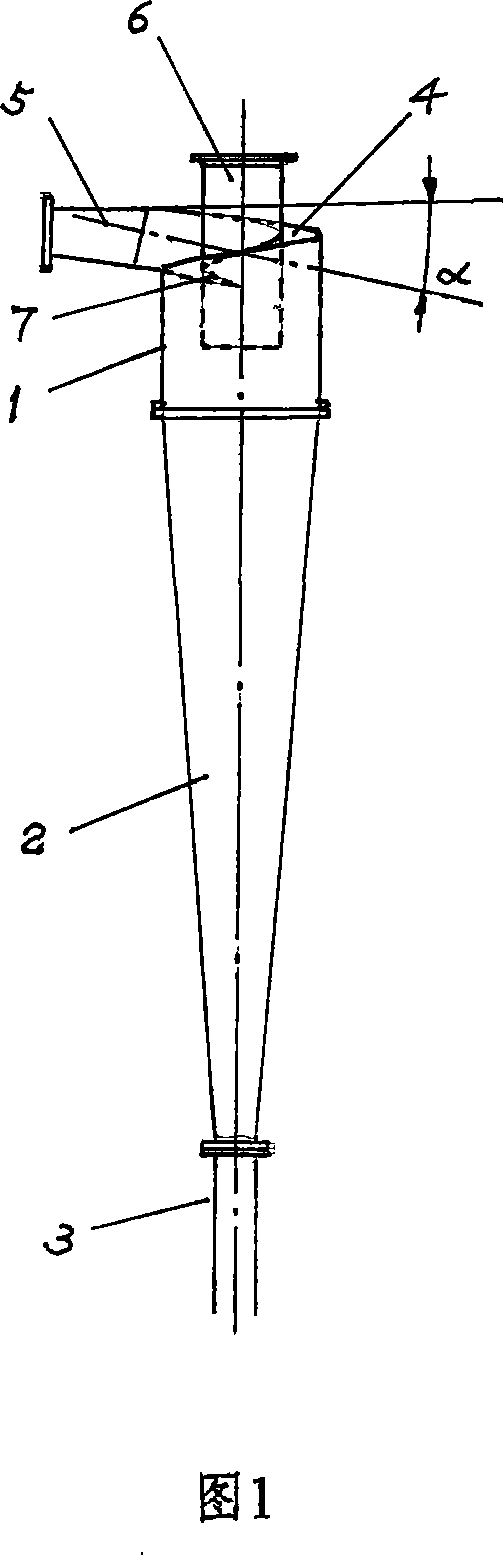

[0017] Example 1. An α-type cyclone separator, as shown in Figure 1. It includes a straight cylinder body 1, a cone cylinder body 2 fixedly connected to the lower end of the straight cylinder body 1, an ash discharge pipe 3 fixedly connected to the lower end of the cone cylinder body 2, a top cover 4 fixedly connected to the upper end of the straight cylinder body 1, 1. The internal deflector rectifier 7, the fluid inlet 5 fixed on the straight cylinder 1 tangentially entering the straight cylinder, and the fluid outlet 6 installed and fixed on the top cover 4 and located in the middle of the straight cylinder 1. It is a long cone structure with a small cone angle, and the axis of the fluid inlet 5 forms an included angle α with the horizontal direction. The top cover 4 is a spiral plate with a certain inclination angle α, and the fluid inlet 5 is tangent to the straight cylinder body 1 and the top cover 4 according to the inclination angle α of the top cover 4 . The inclina...

Embodiment 2

[0022] Example 2. An α-type cyclone dust collector. It is on the α-type cyclone dust collector and is connected in series with a two-stage circulation cyclone dust collector and a three-stage circulation cyclone dust collector in turn. That is, the fluid outlet of the α-type cyclone dust collector is connected to the fluid inlet of the second-stage circulation cyclone dust collector, and the fluid outlet of the second-stage circulation cyclone dust collector is connected to the fluid inlet of the third-stage circulation cyclone dust collector. The fluid outlet of the cyclone dust collector is used to discharge the separated fluid, and the ash discharge pipes of the α-type cyclone dust collector and the secondary and tertiary circulation cyclone dust collectors are all used for ash discharge.

[0023] The characteristics of this α-type cyclone dust collector are: (1) Pressure drop. Because of the diversion and drainage measures, the fluid shear stress is small, so the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com