Tunnel maintainable type pressure reducing and water draining method and device for water rich stratum

A technology for water-rich strata and tunnels, which can be used in drainage, safety devices, earth-moving drilling, etc., to solve problems such as water leakage and blockage of tunnel drainage systems, and achieve the effect of not easy to block and good drainage effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0028] A tunnel maintainable decompression and drainage method for water-rich formations, the steps of which are:

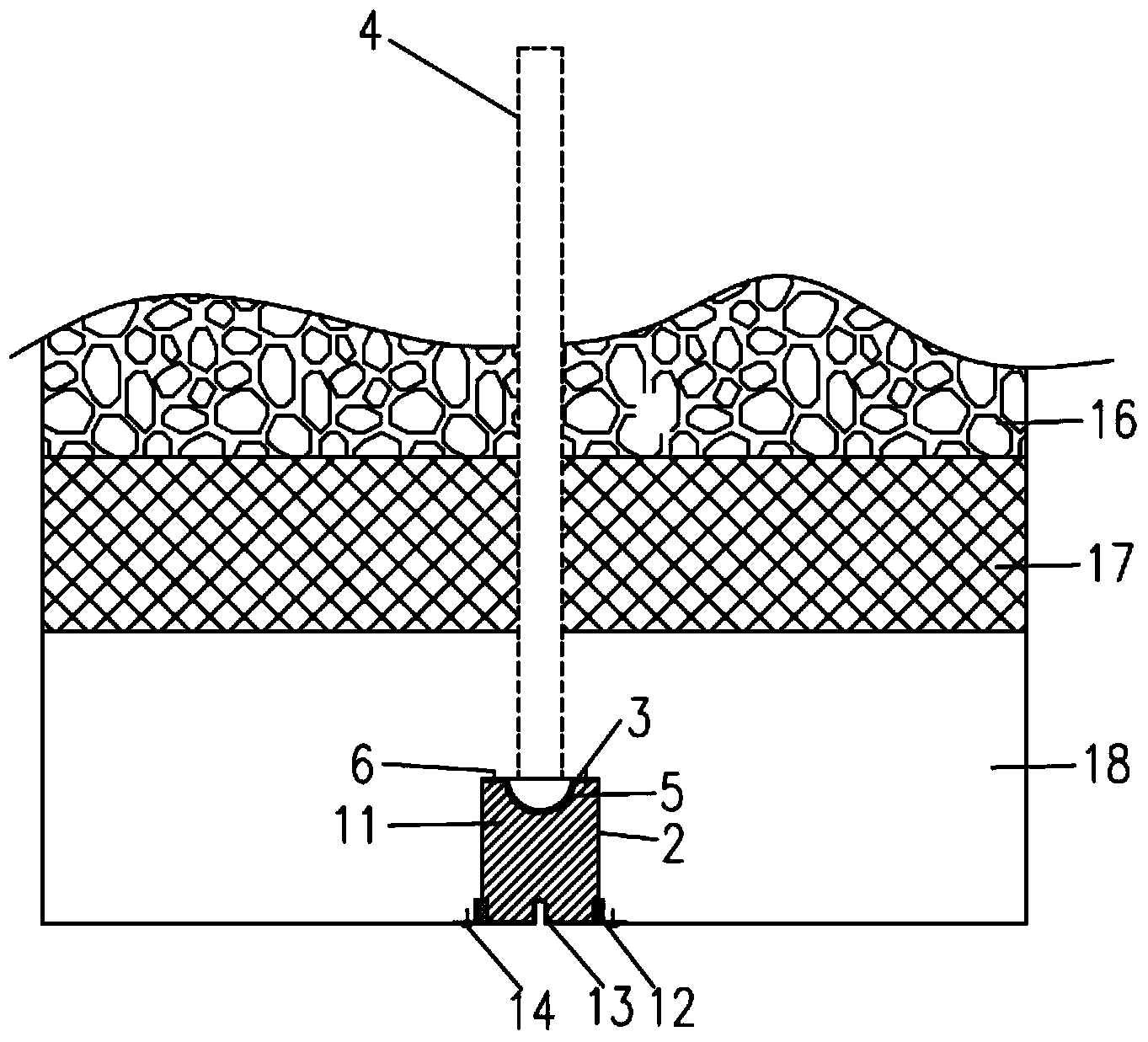

[0029] Step 1. Set drainage groove 2 along the tunnel deformation joint (construction joint) 1 within the lining range of 4 or 5m above the cable trench cover plate 10, and measure the length of the drainage groove 2, which is about 4.2 or 4.5 or 4.8 or 5.0 or 5.2m, select a semicircular pipe 3 whose length is 20 or 25 or 30 or 35 or 40cm longer than the drainage tank;

[0030] Step 2, constructing five diversion holes 4 equidistantly toward one side of the surrounding rock in the drainage channel 2, and introducing water from the surrounding rock 16 into the drainage channel 2 through the diversion holes 4;

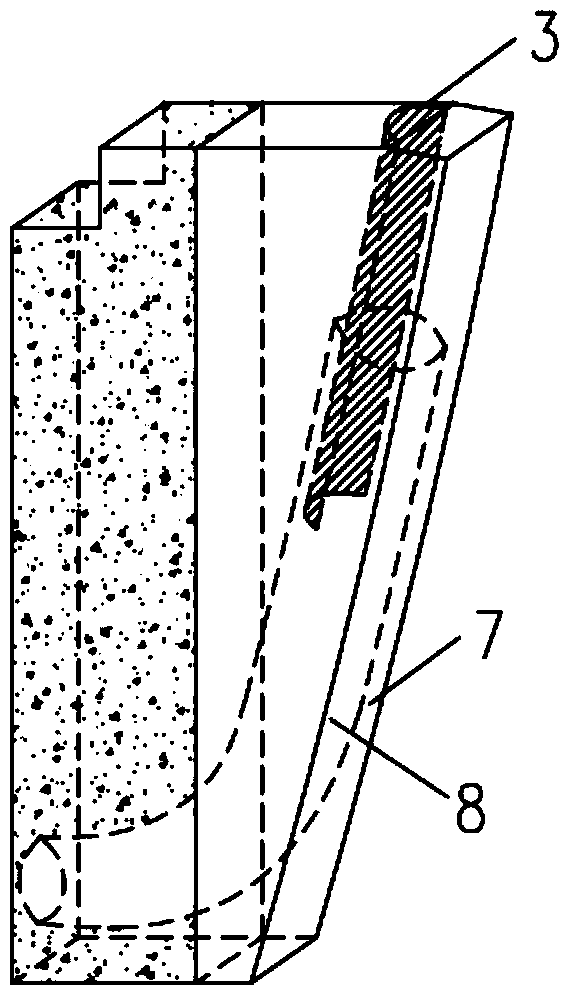

[0031] Step 3, wrapping the semicircular pipe 3 with a waterproof board 5 of non-woven fabric, and fixing the semicircular pipe 3 on the wall 2 o...

Embodiment 2

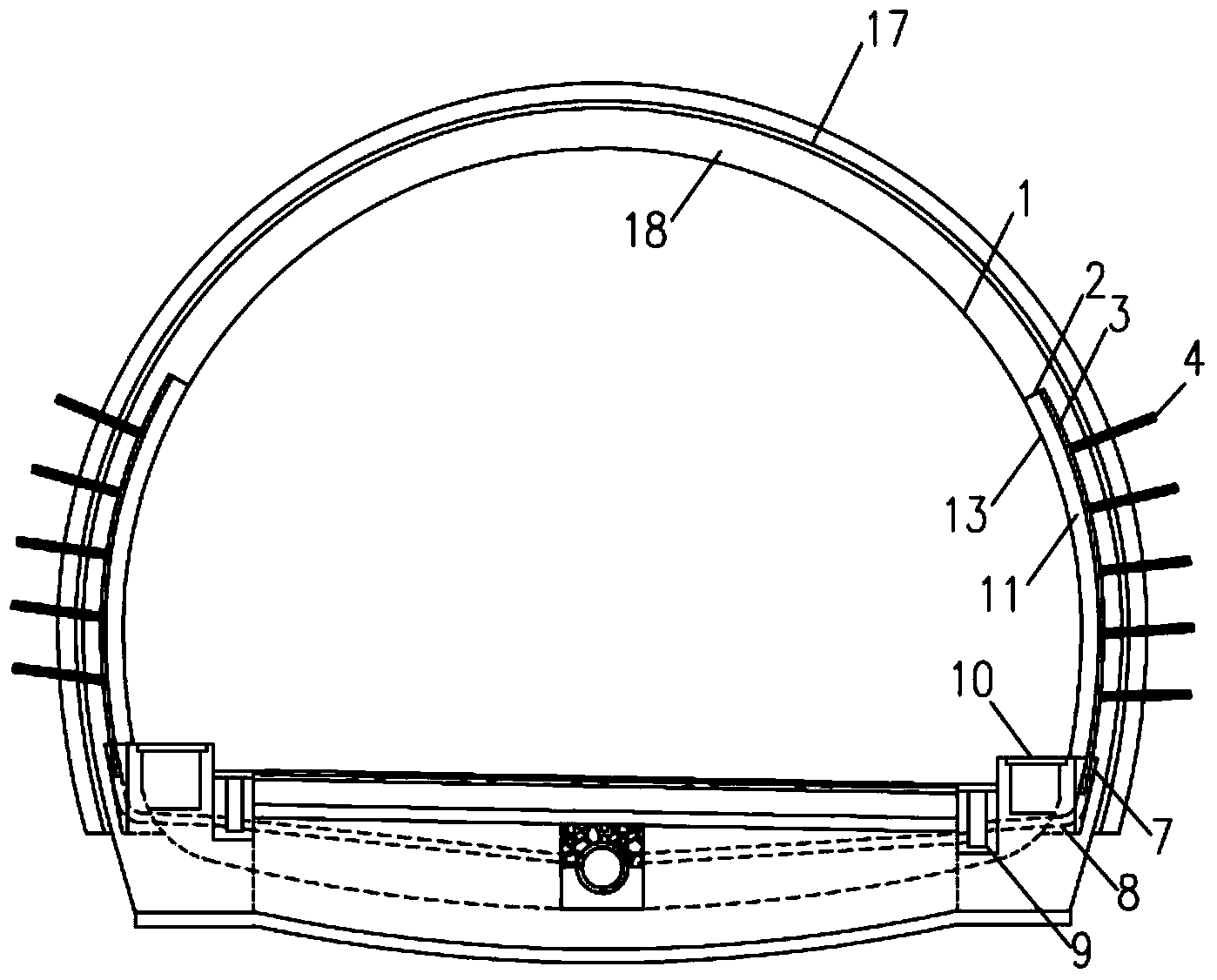

[0035] according to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 It can be seen that a maintainable decompression and drainage device for tunnels includes deformation joints (construction joints) 1, drainage grooves 2, semicircular pipes 3, water diversion holes 4 (10), waterproof boards 5, nails 6, and water collection tanks. 7. Bellows 8, drainage ditch 9, cable trench cover 10, rigid polyurethane foam 11 (purchased from the market), two-component polysulfide sealant 12 (purchased from the market), galvanized steel plate 13, self-tapping screws 14, Screw hole 15, surrounding rock 16, primary lining 17, secondary lining 18. The connection relationship is: within 4 or 5m of the lining of the cable trench cover plate 10, a drainage groove 2 is arranged along the ring direction of the tunnel deformation joint (construction joint) 1, and the length of the drainage groove 2 is measured. The drainage groove 2 is about 4.2 or 4.5 Or 4.8 or 5.0 or 5.2m, choose a semic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com