Patents

Literature

60results about How to "Small amplification effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

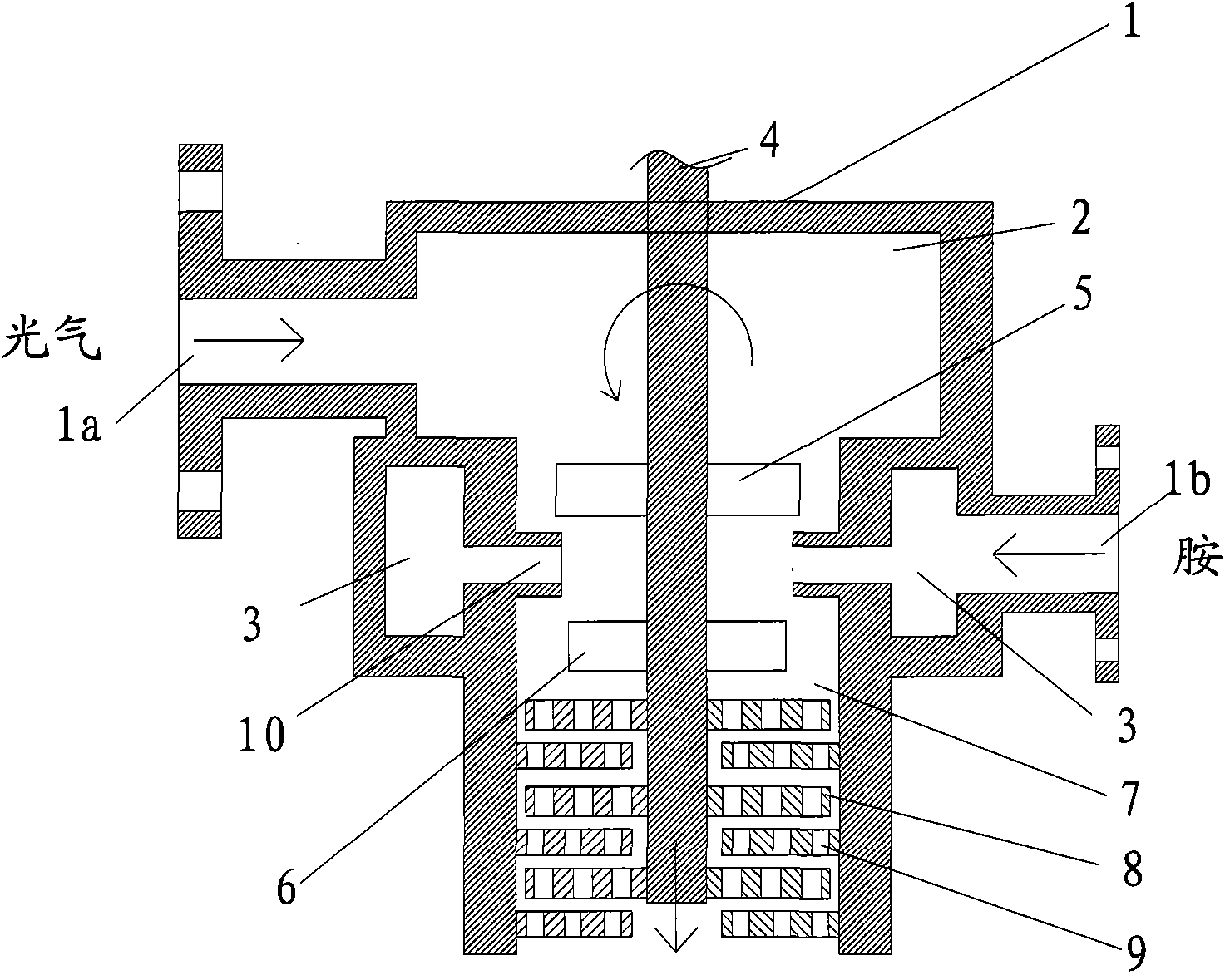

Stirring and grinding reactor and method for preparing isocyanate with same

ActiveCN101811017AIncreased initial mixingRapid responseIsocyanic acid derivatives preparationOrganic compound preparationSolid reactionEngineering

The invention relates to a stirring and grinding integrated reactor and a method for preparing isocyanate by using the reactor. The reactor comprises a reactor shell, a first reactant feeding hole, a first reactant distributing tray, a second reactant main feeding hole, an annular second reactant distributing tray, a stirring shaft, an axial stirring paddle, a radial stirring paddle, a dynamic grinding sheet, a static grinding sheet and at least one second reactant sub feeding hole, wherein the dynamic and static grinding sheets are provided with a plurality of passage holes. Quick mixing and quick reaction between the raw materials are realized by axial and radial strong stirring and a feeding method of a strongest mixing area, and the solid reaction product is further pulverized by hole passage type quick grinding combined through multilayer dynamic and static grinding trays so as to enhance the reaction effect, improve the yield and quality of the isocyanate, reduce the using amount of a solvent and the excess ratio of phosgene, improve the yield of the device, improve the quality of the product and reduce the energy consumption.

Owner:WANHUA CHEM GRP CO LTD +1

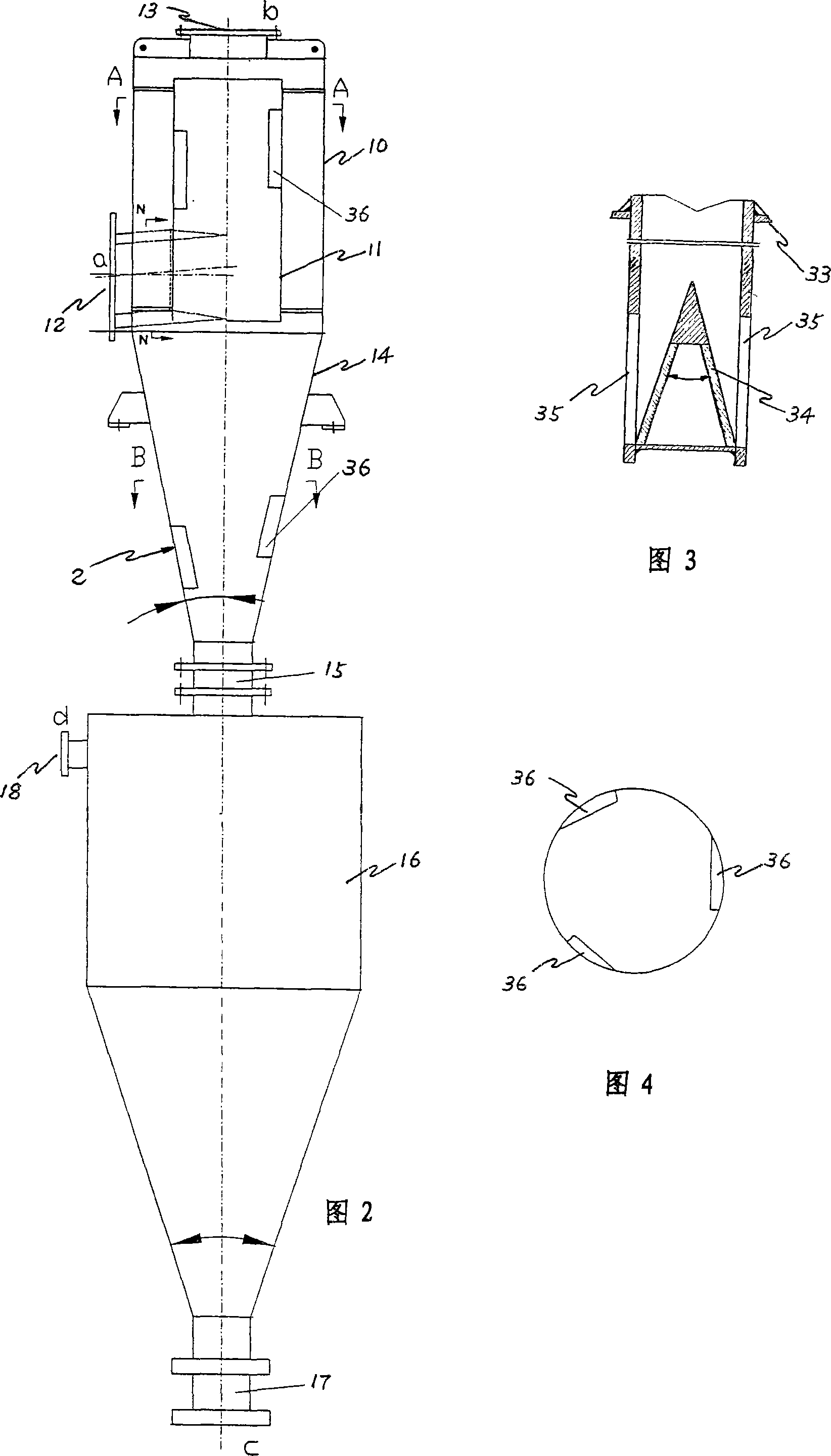

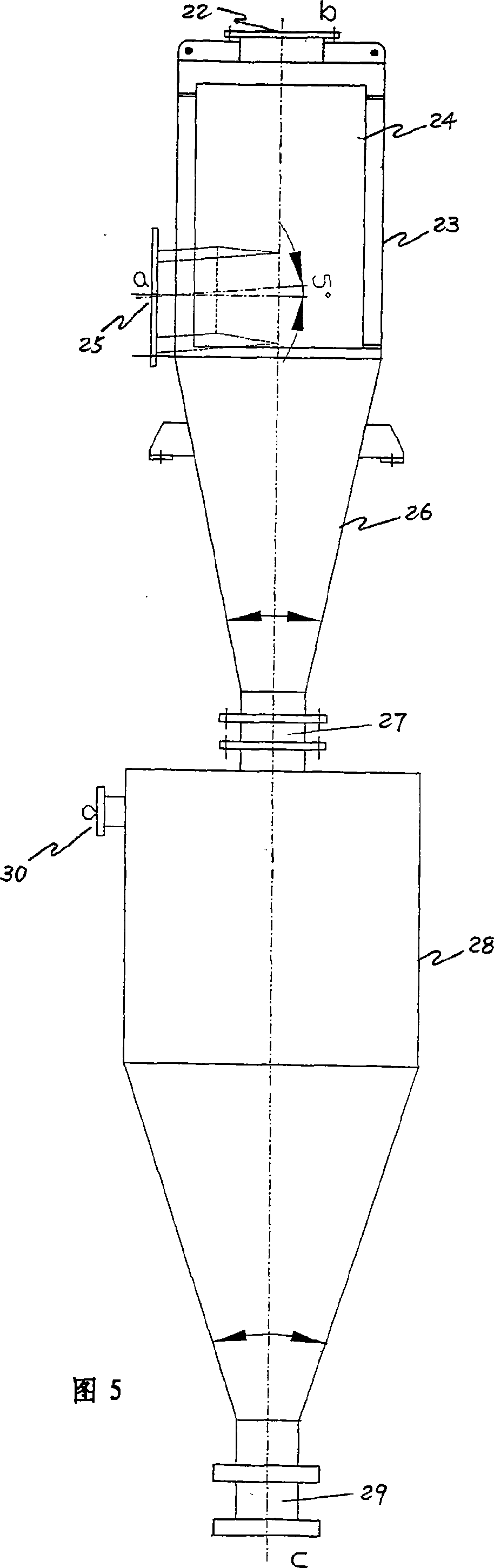

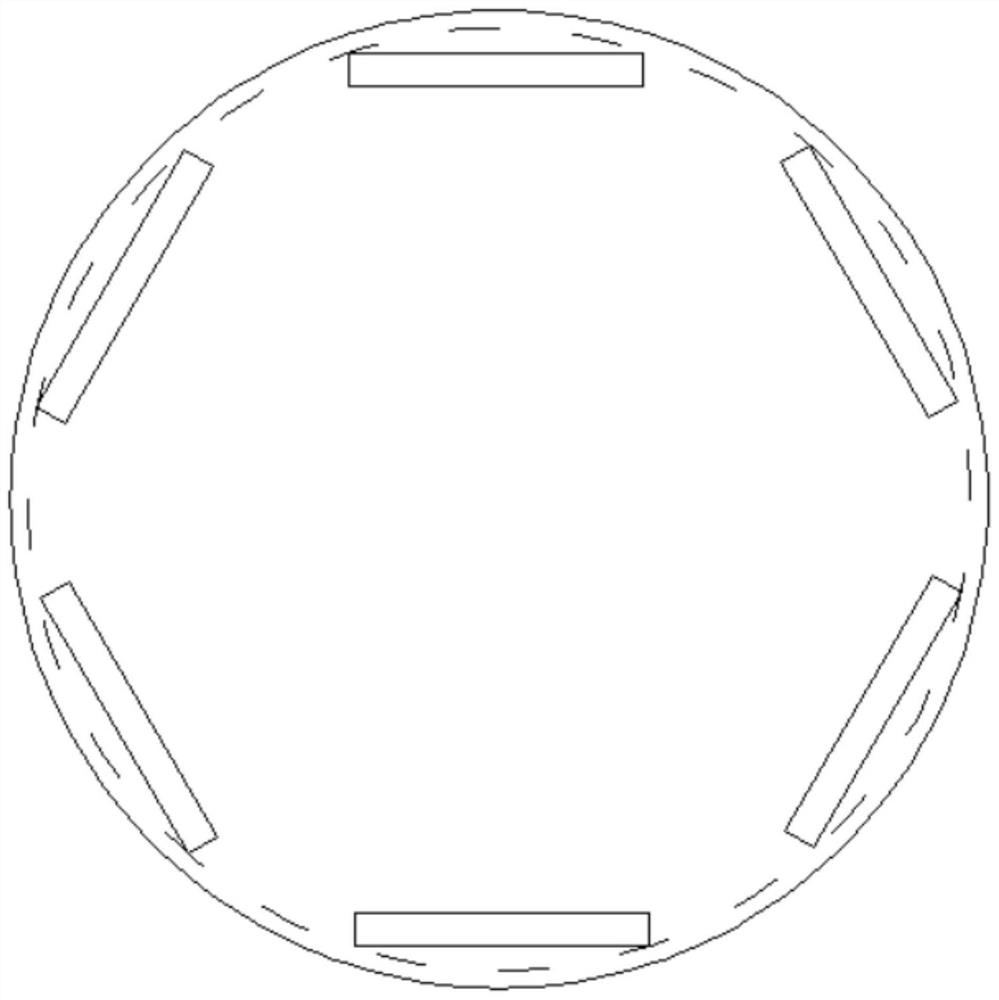

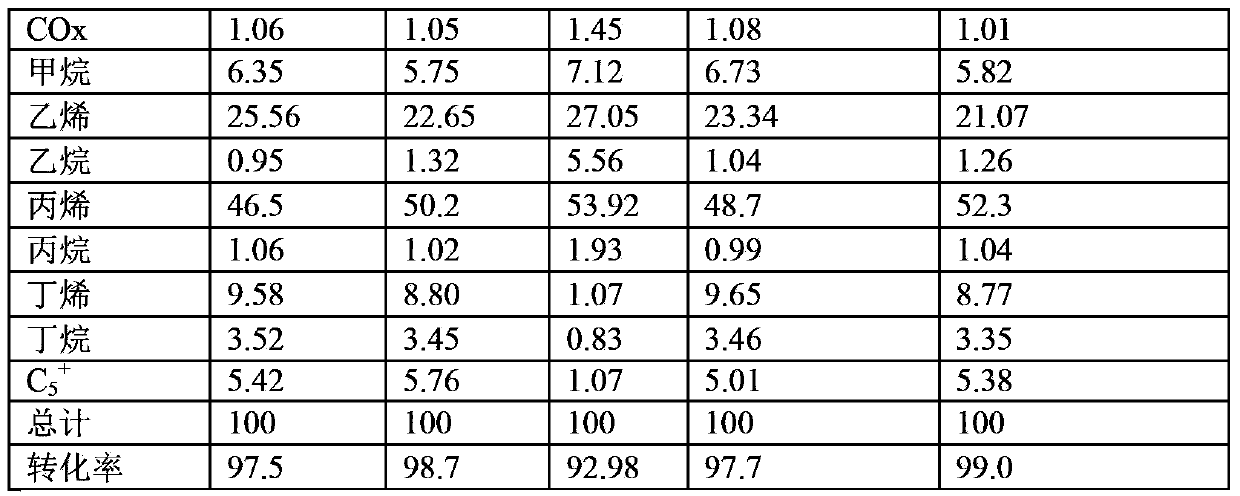

Alpha type cyclone separator

InactiveCN101116844AAvoid double hoistingGood drainageReversed direction vortexHigh concentrationCyclone

An alpha type cyclone separator which belongs to the isolation technique comprises a straight bowl body, a conical bowl body, an ash exhausting pipe, a coping, a liquid inlet, and a liquid outlet. The utility model is of small conical angle and long conical body structure, and the angle between the axes of the liquid inlet and the horizontal direction is of alpha. The coping is a spiral lamina with an obliquity of alpha, and an air inlet and the straight bowl boy, as well as the coping are tangent according to the obliquity alpha of the coping. The alpha is from 5 DEG C to 25 DEG C, and a second class or a second and third circumfluent cyclone separator also can be connected in series. The separating efficiency of the alpha type cyclone separator is obviously superior to a traditional hydrocyclones, and the alpha type cyclone separator is of low pressure drop, small amplification effect, high separation definition, and obvious energy saving effect. The pressure drop is about 70 percent that of traditional hydrocyclones, therefore, the utility model can satisfy the separating demand of high concentration, widely distributed granularity of solid particles, highly required technical process, and great difficulty for classification. The cyclone separator can be widely popularized and applied in chemical engineering, petroleum, metallurgy, medicine, and environmental protection field.

Owner:QINGDAO UNIV OF SCI & TECH

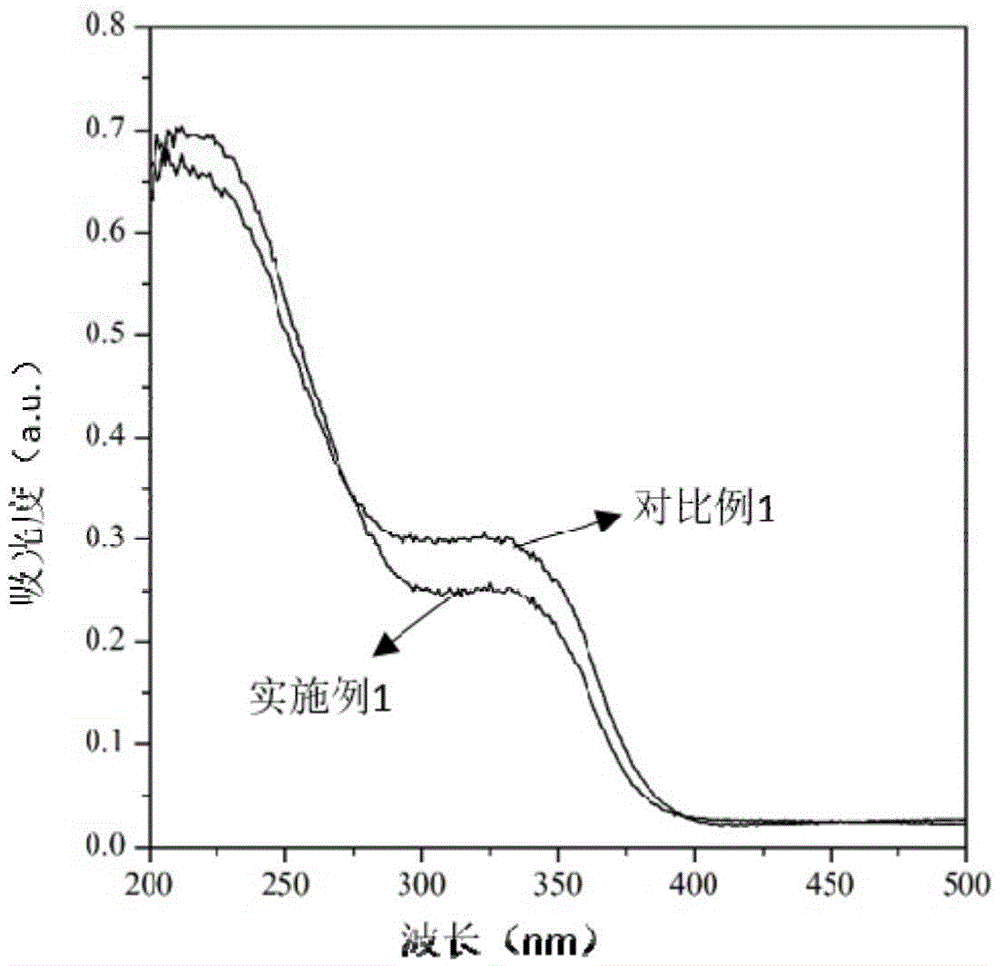

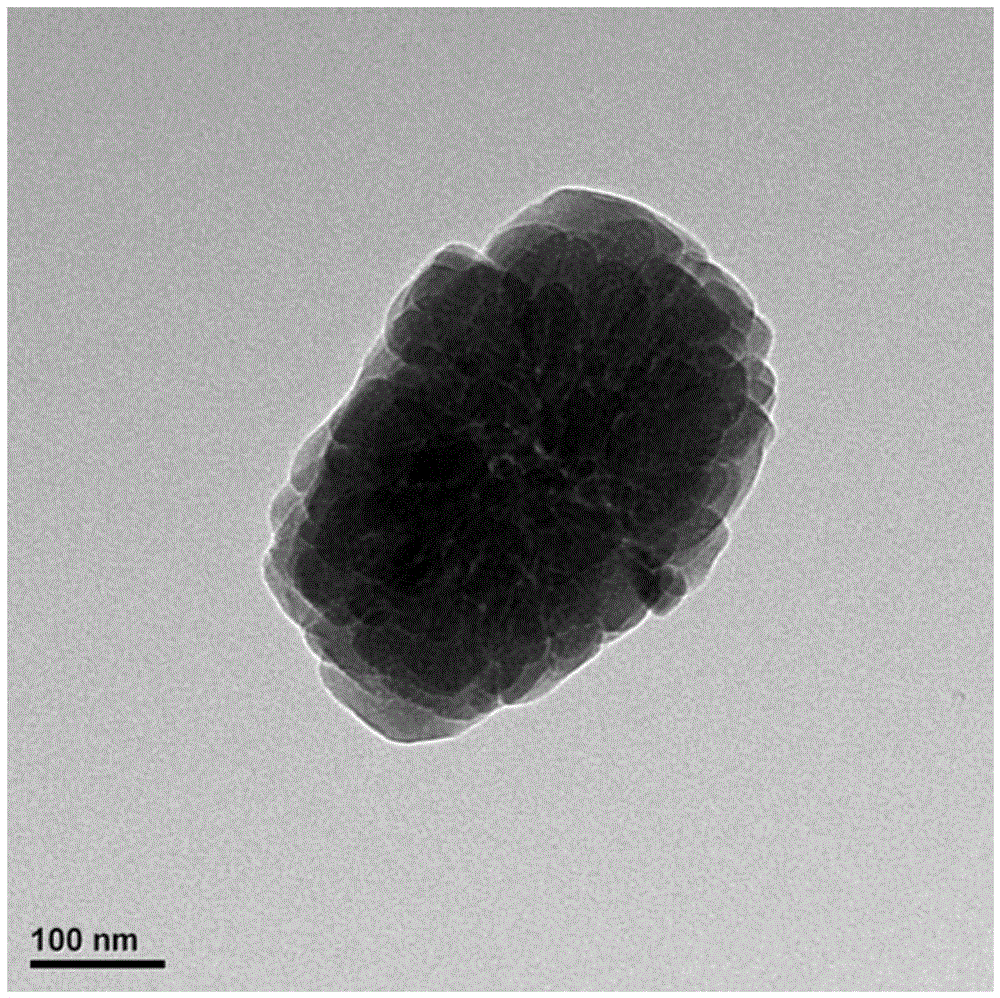

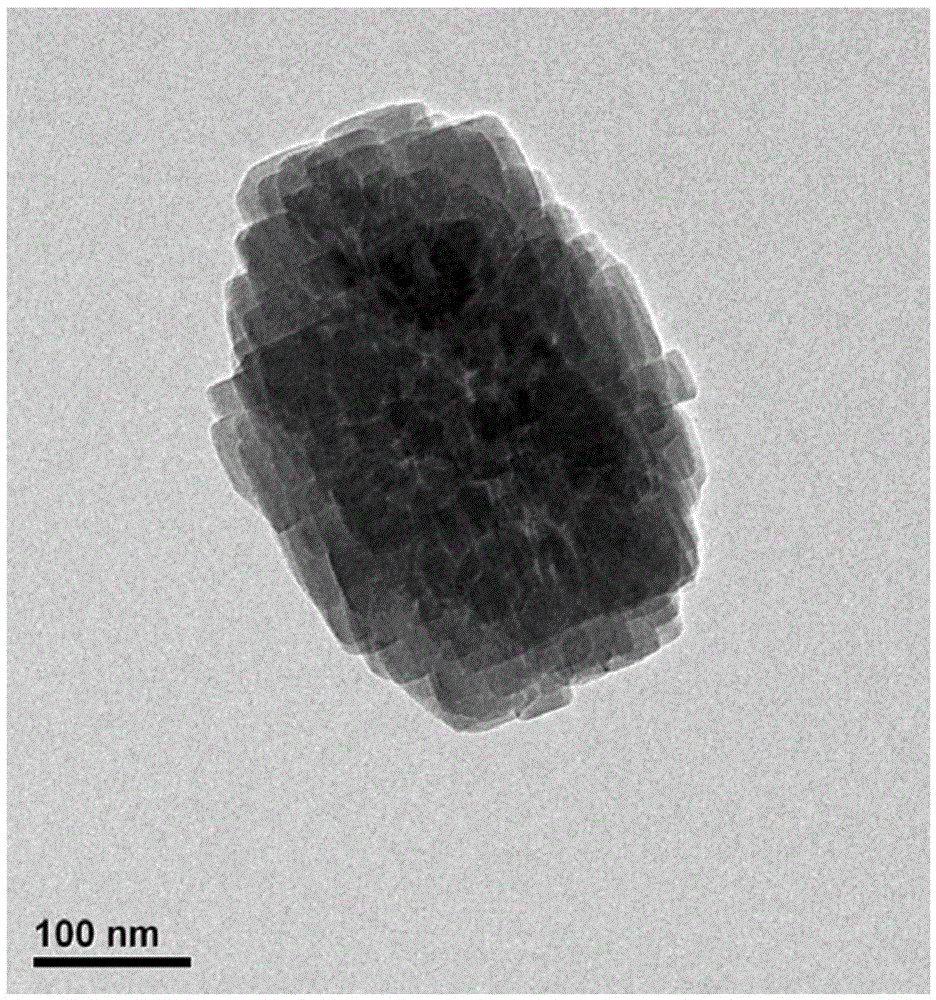

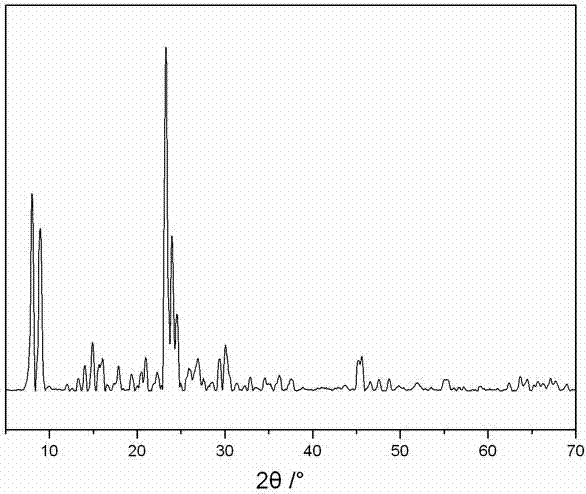

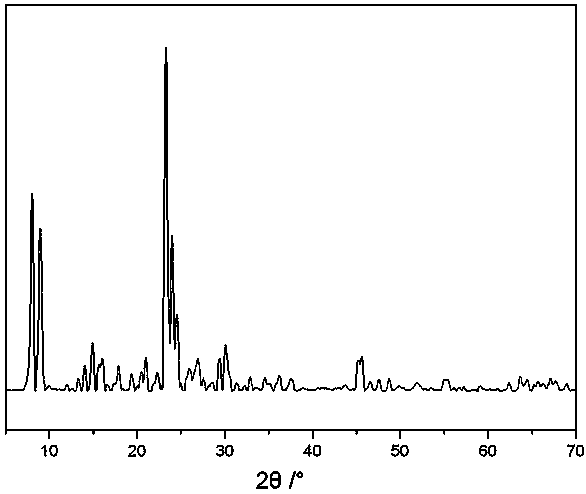

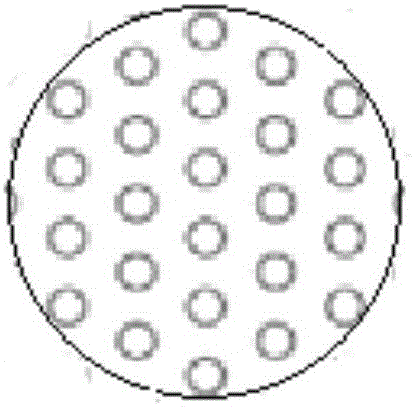

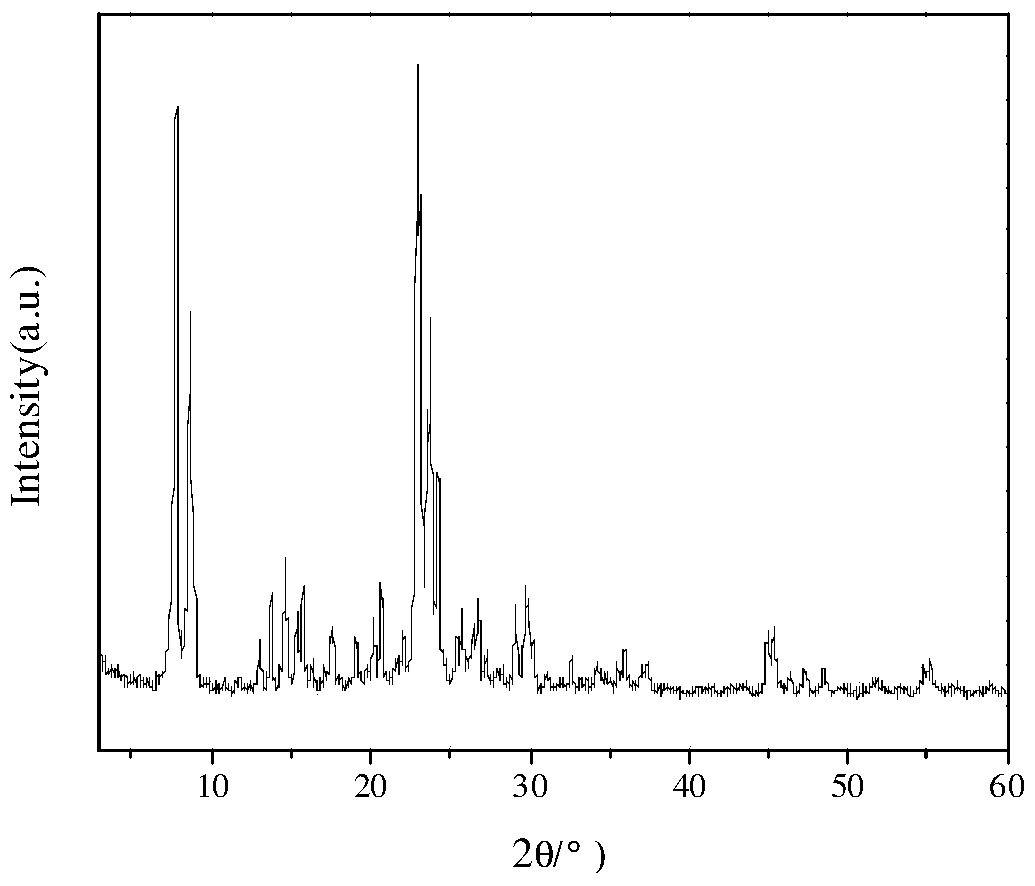

Hydro-thermal synthesis method for TS-1 molecular sieve and obtained product

InactiveCN105597818AReduce formationHigh titanium contentMolecular sieve catalystsCatalyst activation/preparationMolecular sieveLevel structure

The invention provides a hydro-thermal synthesis method for a TS-1 molecular sieve. The hydro-thermal synthesis method includes the steps that 1, a silicon source and a template agent are mixed to obtain silicon source hydrolysate, a titanium source and polyhydric alcohol are mixed to be added into the silicon source hydrolysate, and then water is added; 2, a product obtained through step1 is subjected to pre-crystallization for 5-24 hours; 3, a silicon source is added again and heated to 60 DEG C-90 DEG C, and then polyhydric alcohol is removed; 4, a product obtained through step3 is crystallized, after the crystallization reaction, a reaction mixture is subjected to solid-liquid separation, and a solid is taken to be dried and calcined. In the hydro-thermal synthesis method, after the silicon source and the titanium source are gelatinized, alcohol is not removed, namely, crystallization is performed for 5-24 hours at 90 DEG C-100 DEG C under the presence of alcohol, in this way, forming of non-framework titanium can be effectively reduced, and the content of framework titanium can be increased. In the process of constructing a multi-level structure in the TS-1 molecular sieve, no mesporous template agent, organosilane and other organic additives are needed, in the whole synthesis process, operation is easy, the cost is low, an expected amplification effect is small, and large-scale industrial production and popularization are easy.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

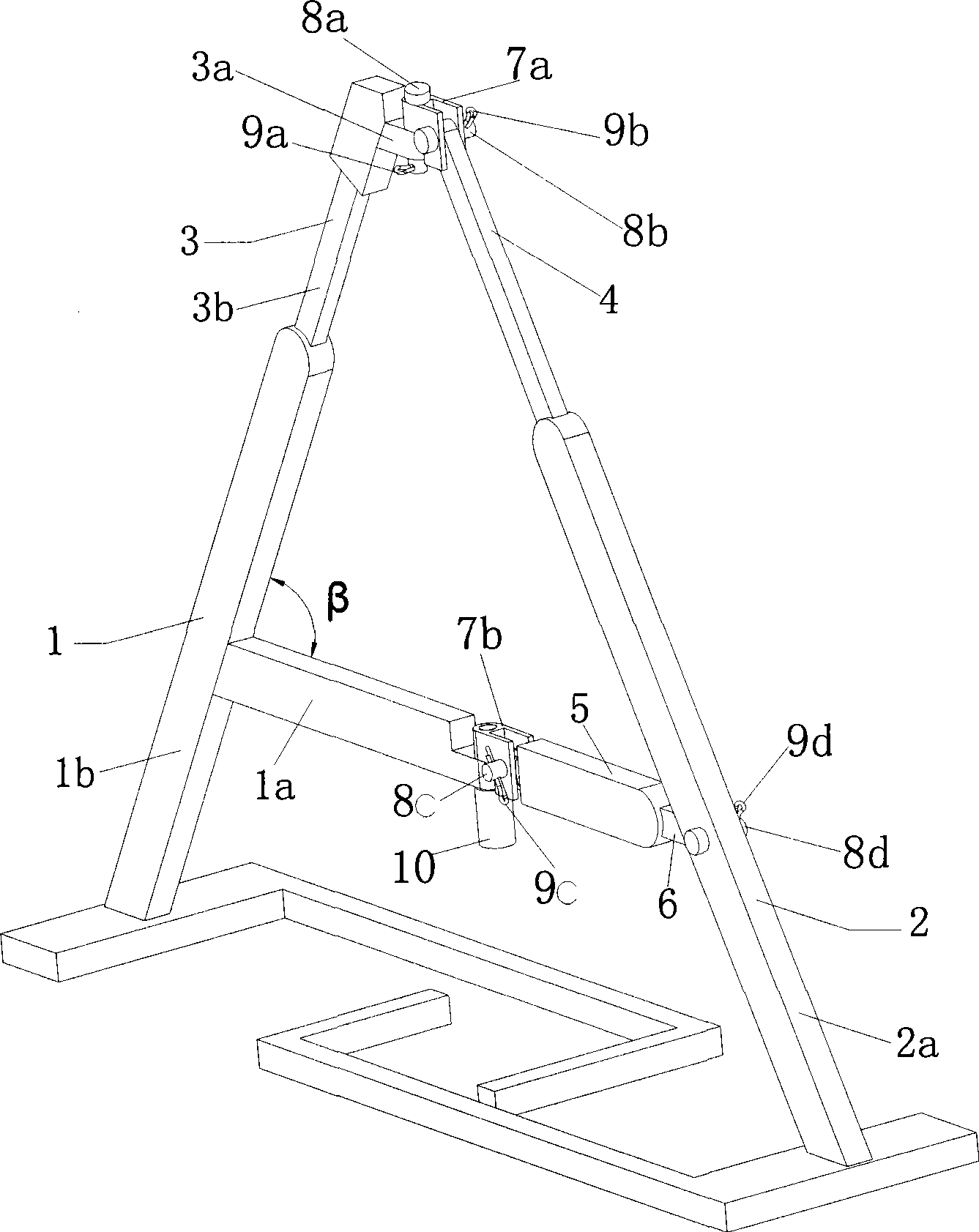

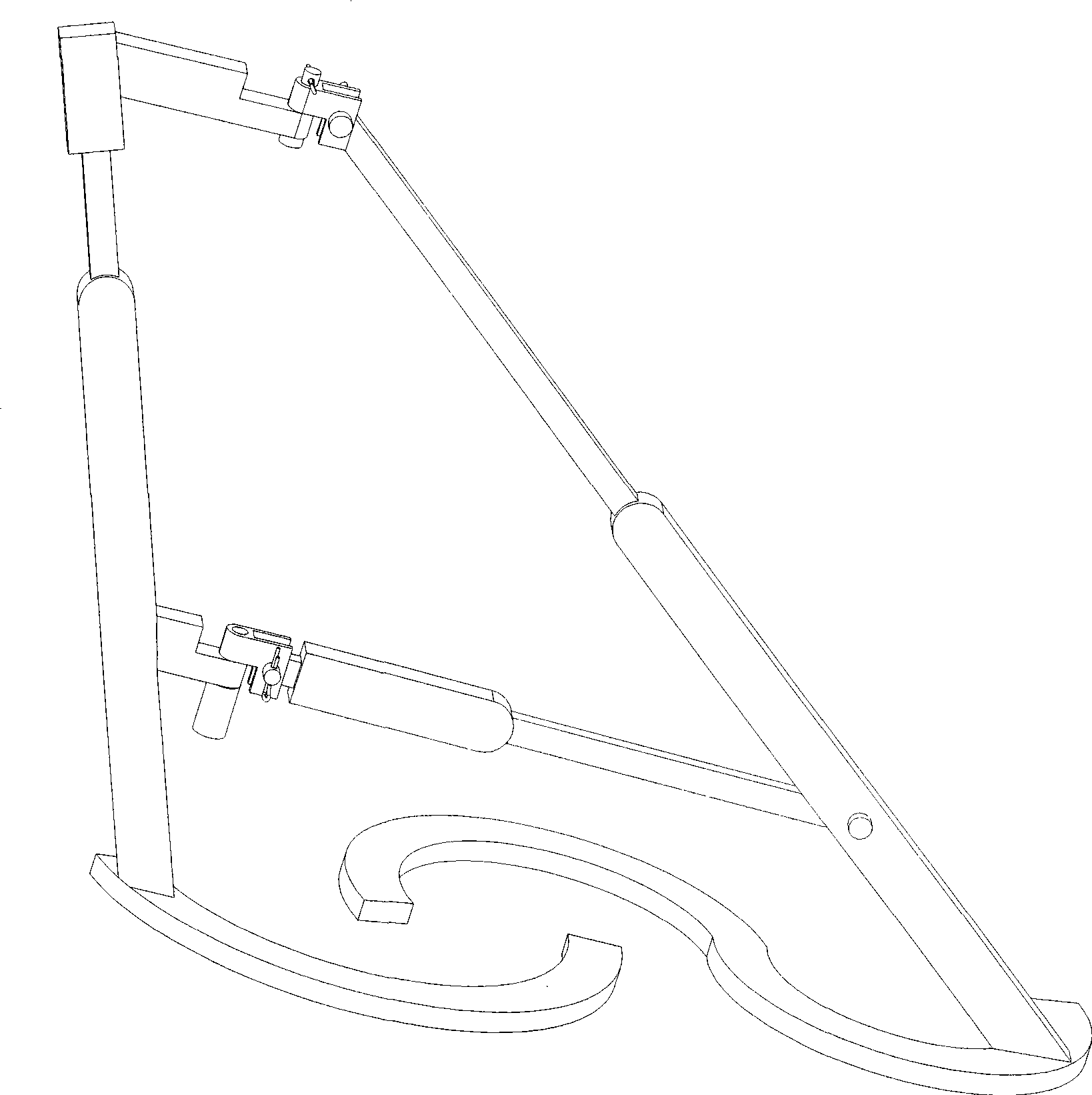

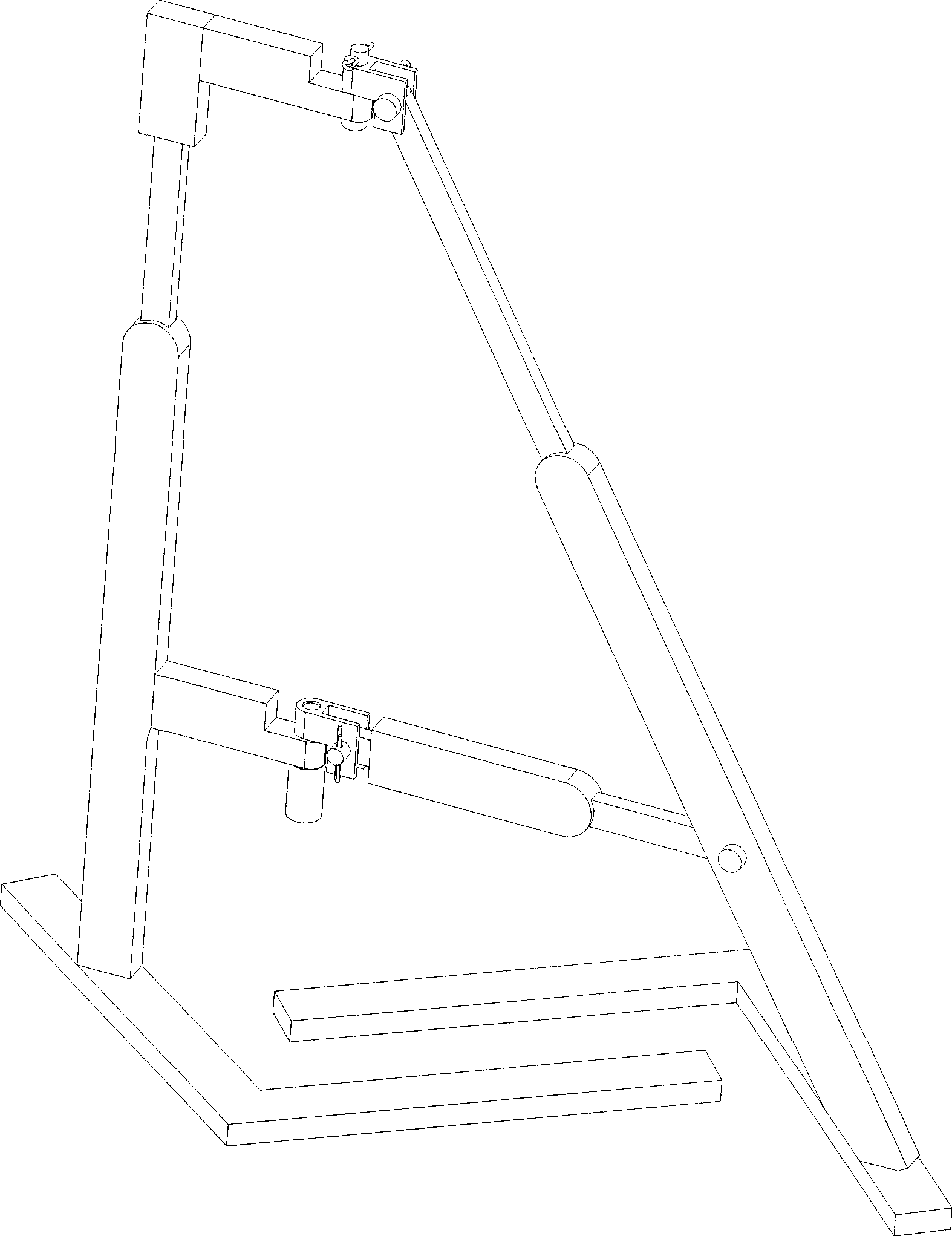

Two-foot walk triangle robot

A biped walking triangular robot comprises connections of the six member bars forming the three edges of the triangular robot, wherein, a moving pair which serves as one side edge of the triangular robot comprises a left foot outer rod (1) and a left foot inner rod (3); a moving pair which serves as the other side edge of the triangular robot comprises a right foot outer rod (2) and a tight foot inner rod (4); and a moving pair which serves as the bottom edge of the triangular robot comprises the rod (1a) of the left foot outer rod (1), cross rod outer rod (5) and cross rod inner rod (6). The triangular robot works as follows: regulating the lengths of the three edges to lift, protract or land the left foot outer rod (1) and the right foot outer rod (2) so as to realize the straight movement; stopping regulating the lengths of the three edges and starting the motor (10) when the vertical hole on the left foot outer rod (1) and the vertical hole on the left foot inner rod (3) are coaxial so as to realize the turning. The triangular robot has the advantages that the closed chain structure is adopted to increase the rigidity of the robot and improve the load capacity; the linear driving is adopted to avoid the amplification effect of the lengths of the member bars to the angle turning driving error; the elements are fewer; and the structure and the control are simple.

Owner:BEIJING JIAOTONG UNIV

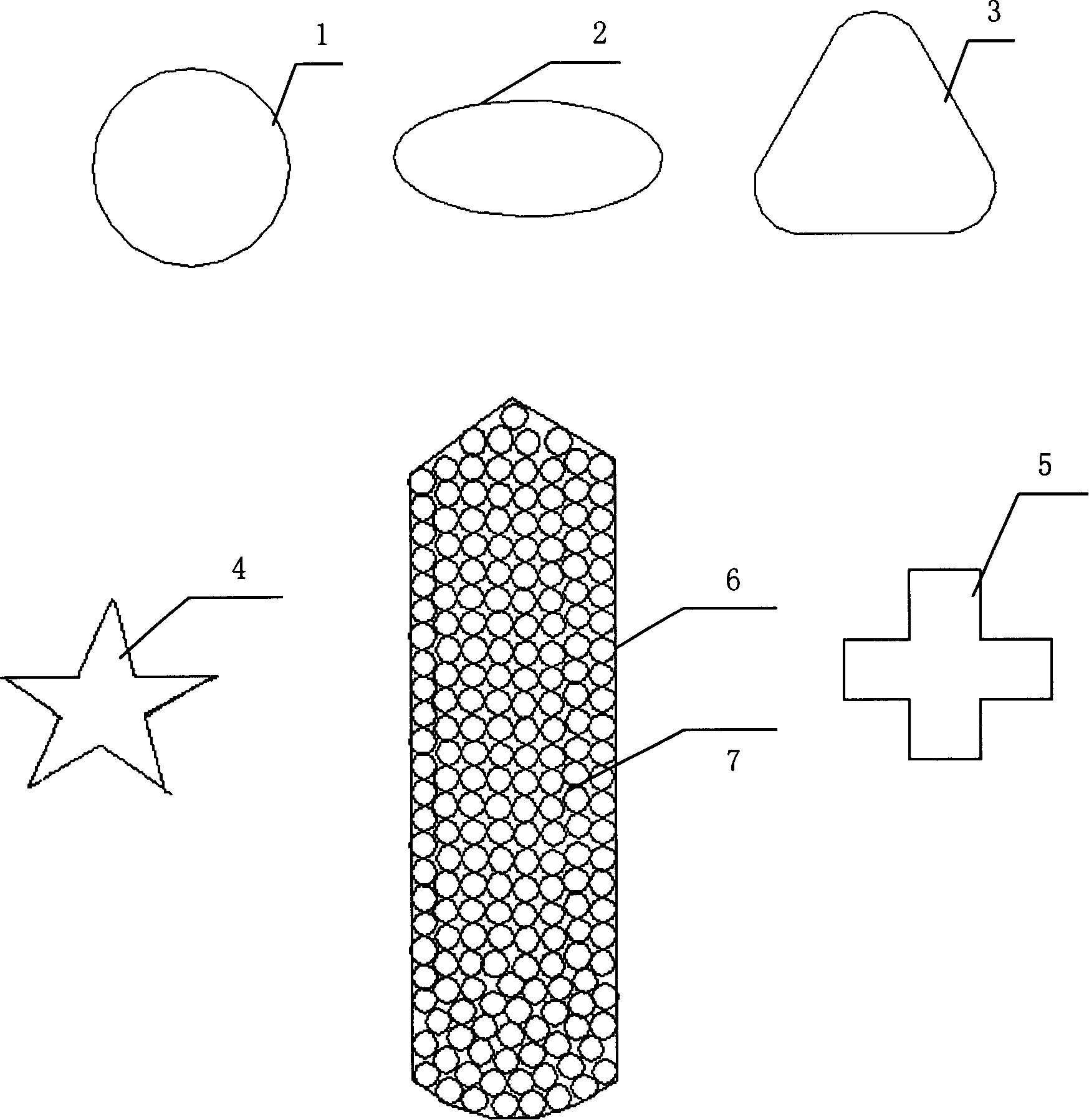

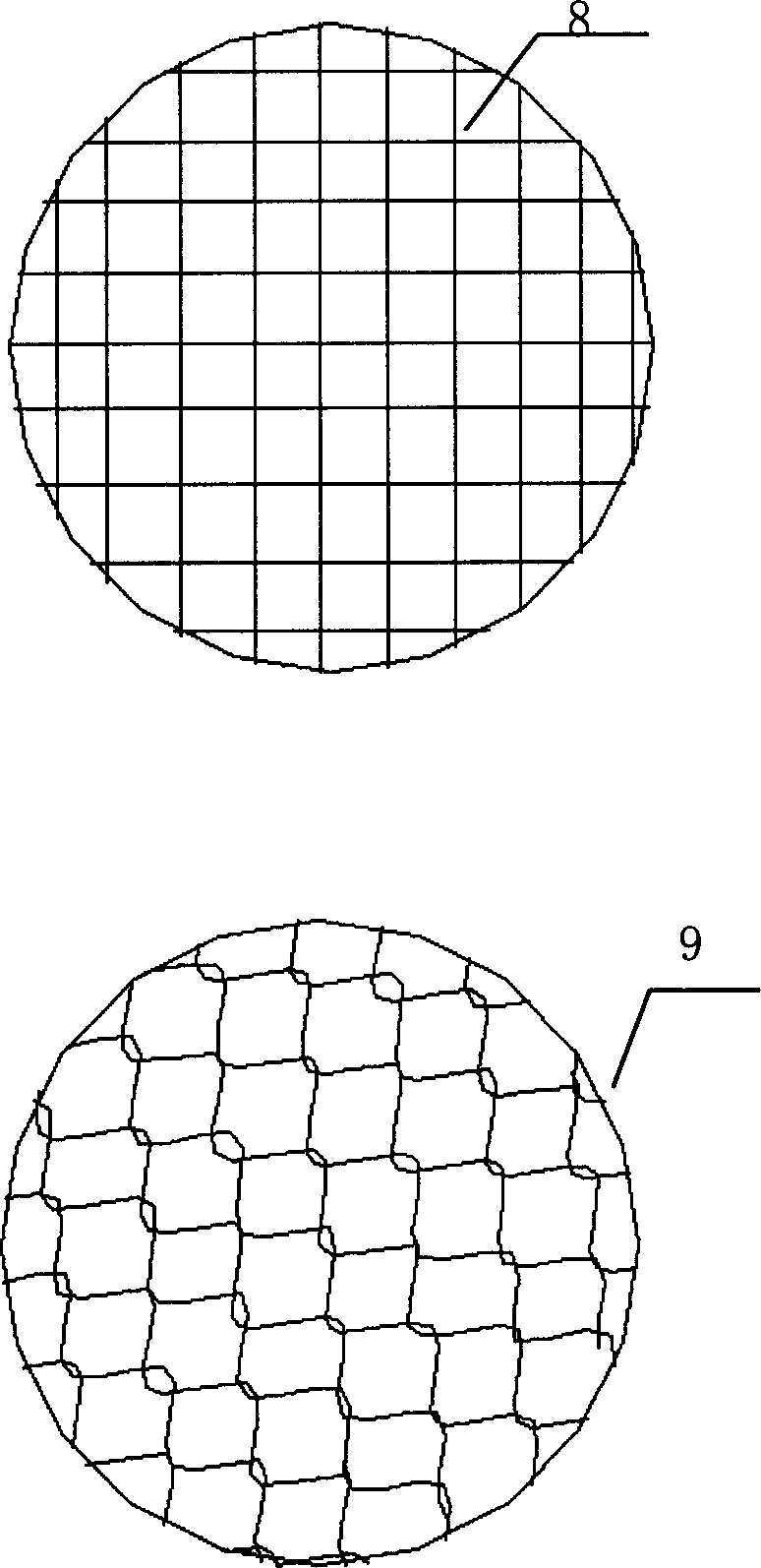

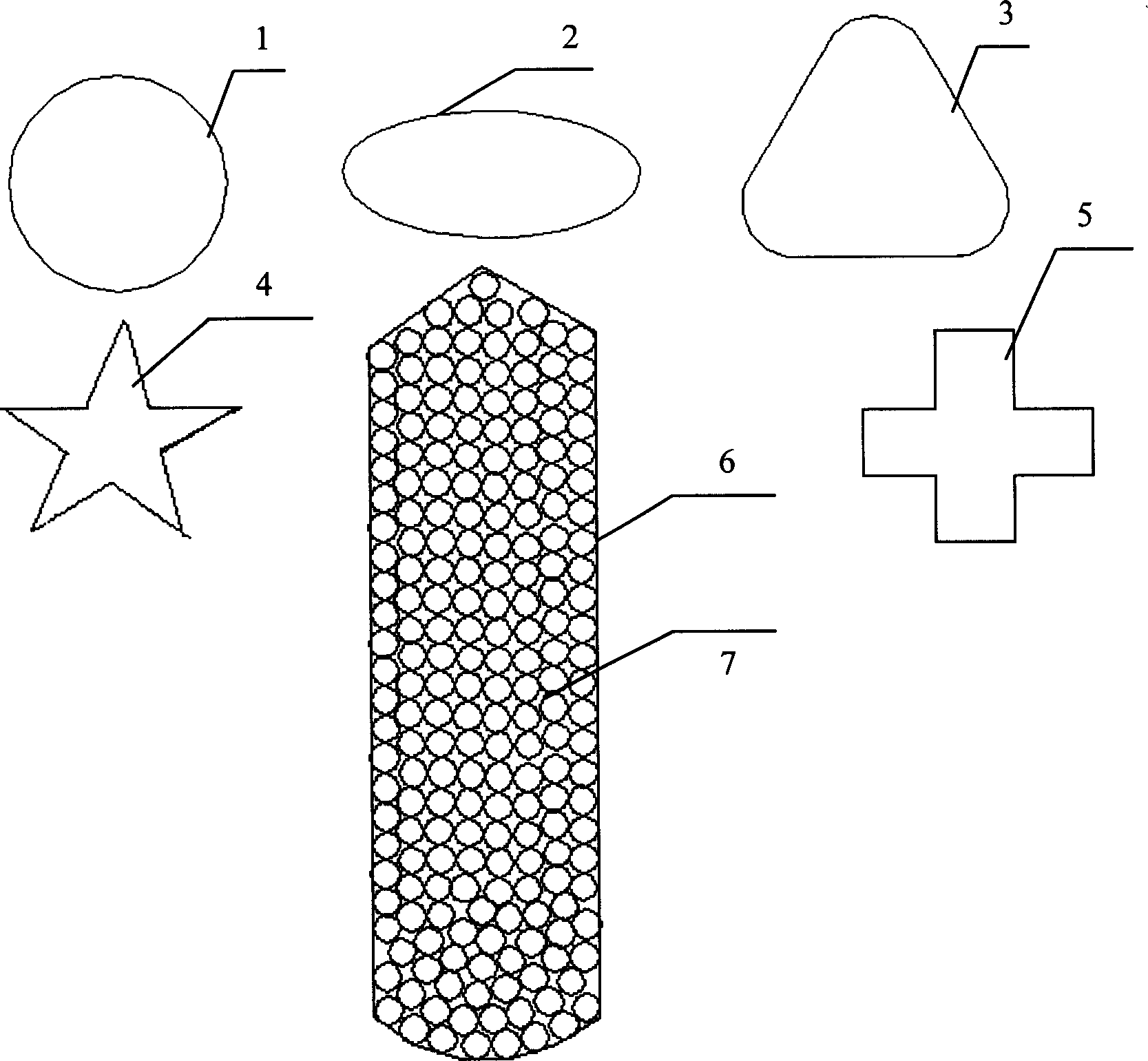

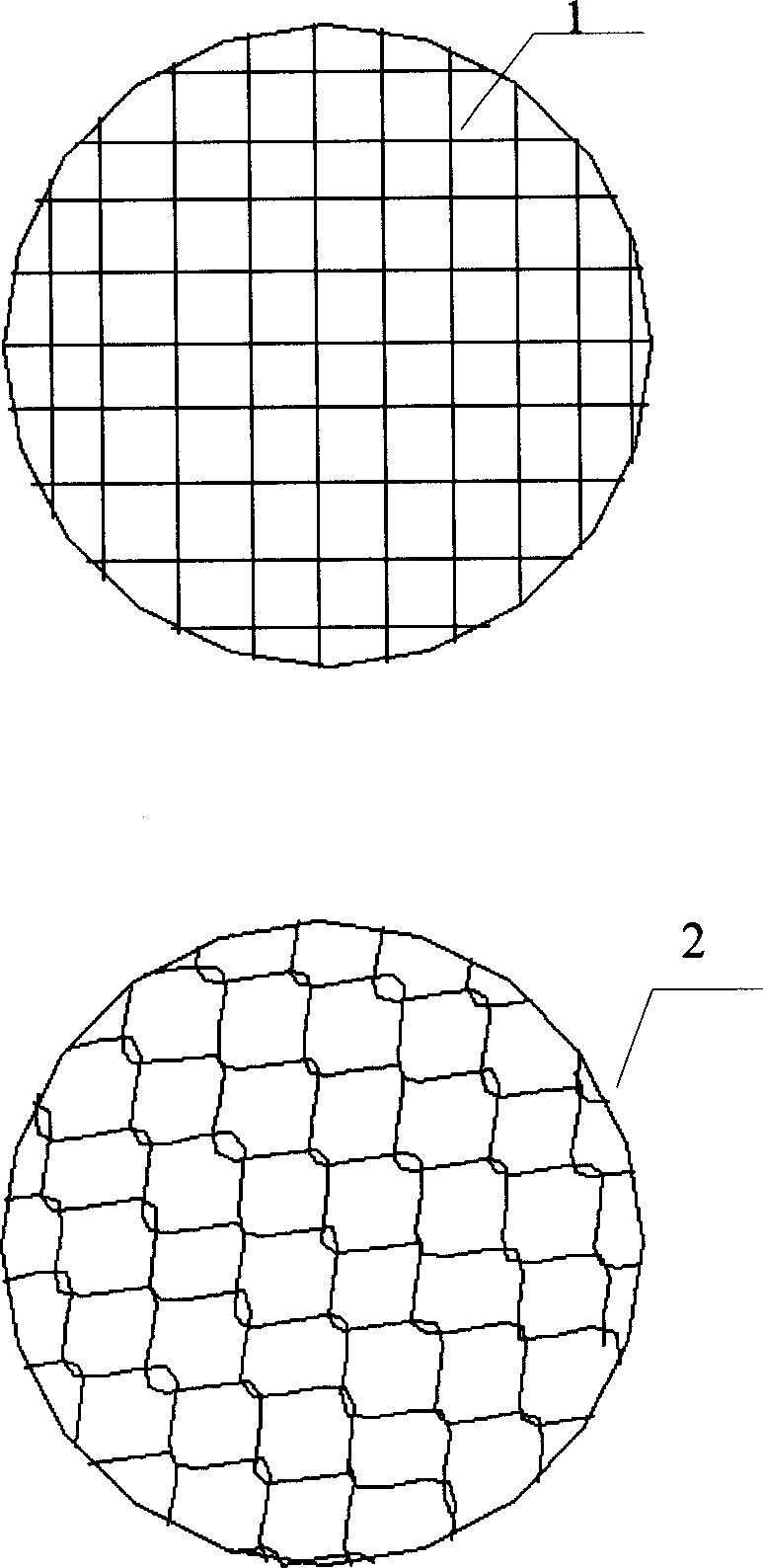

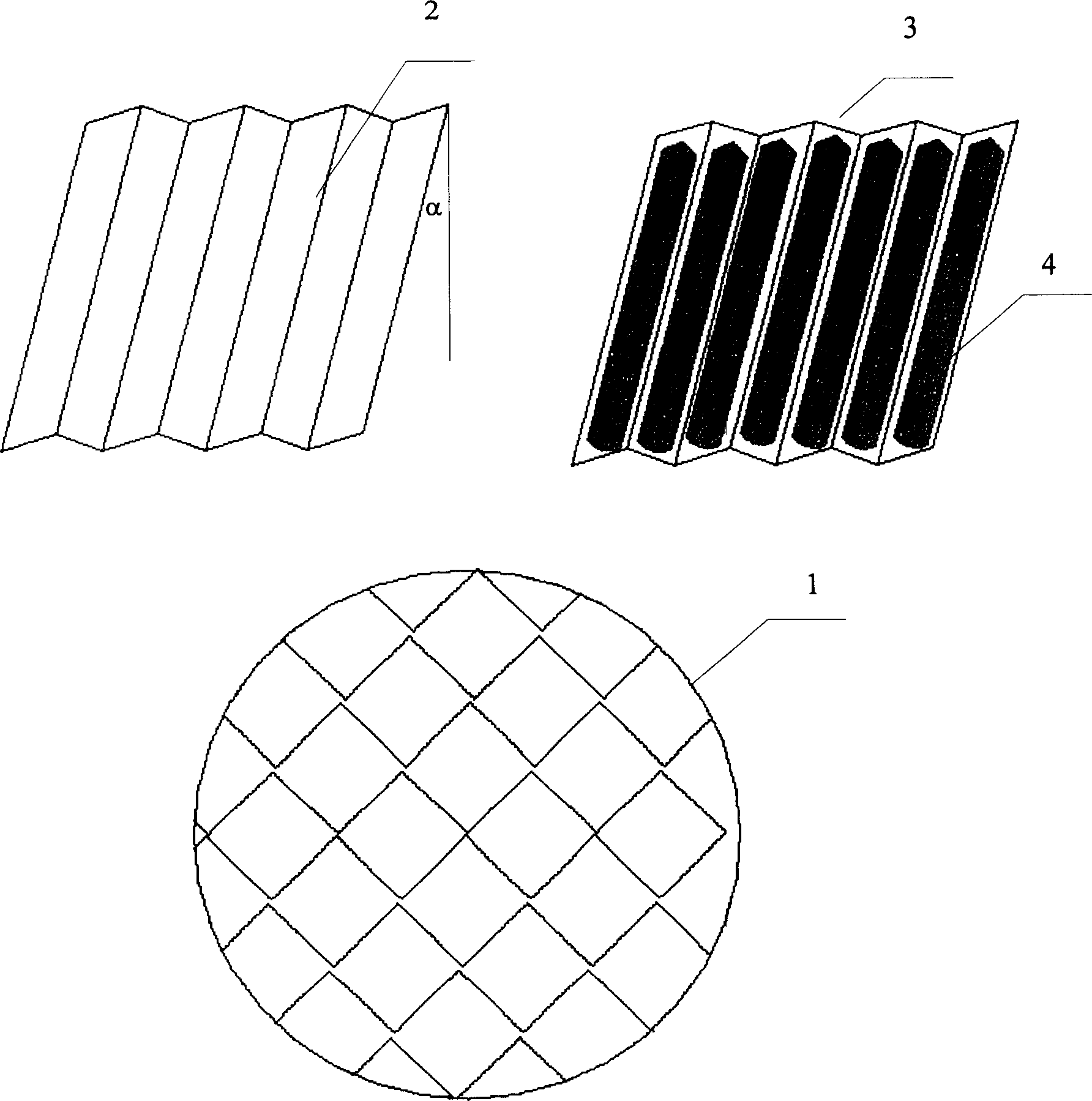

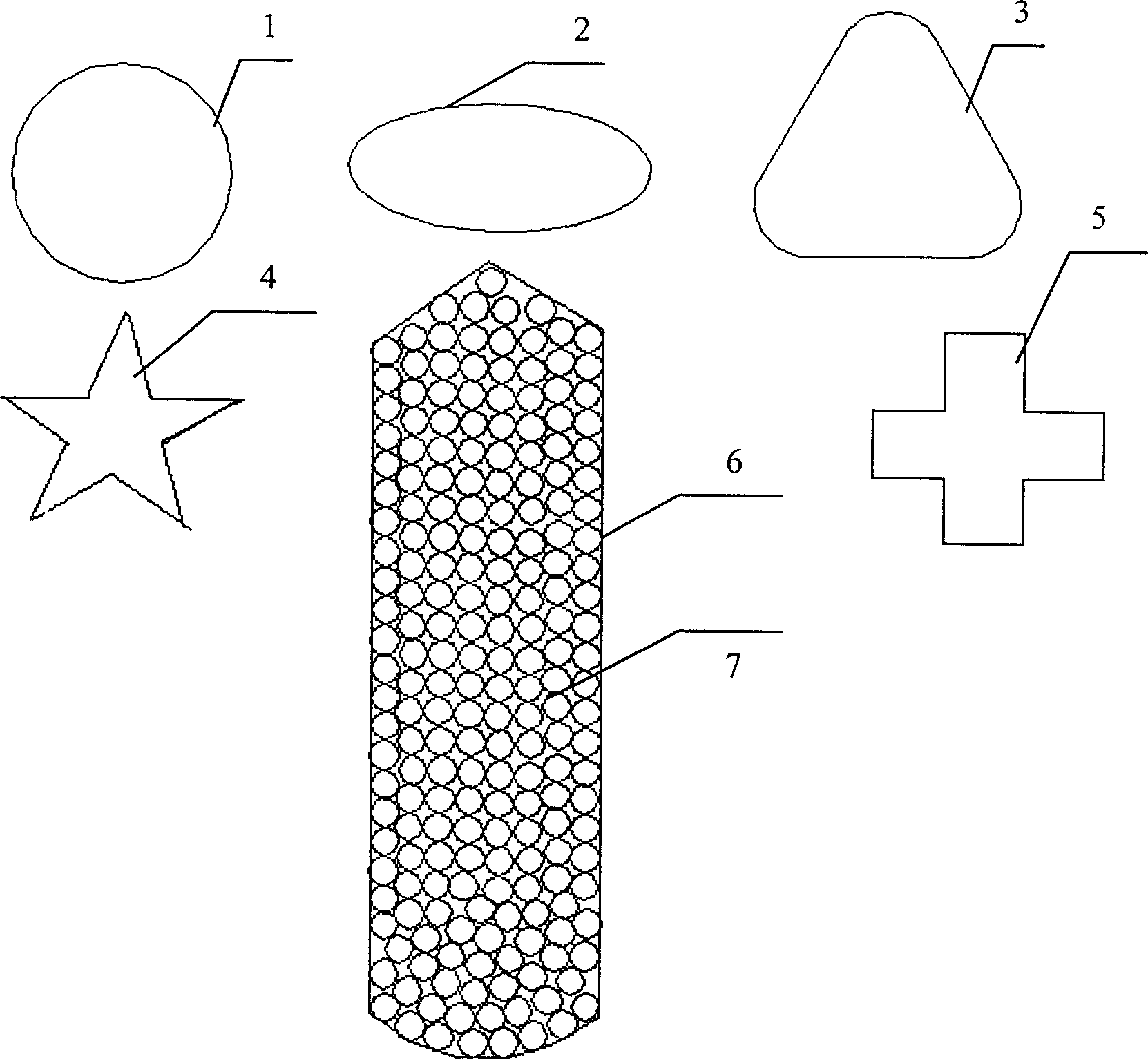

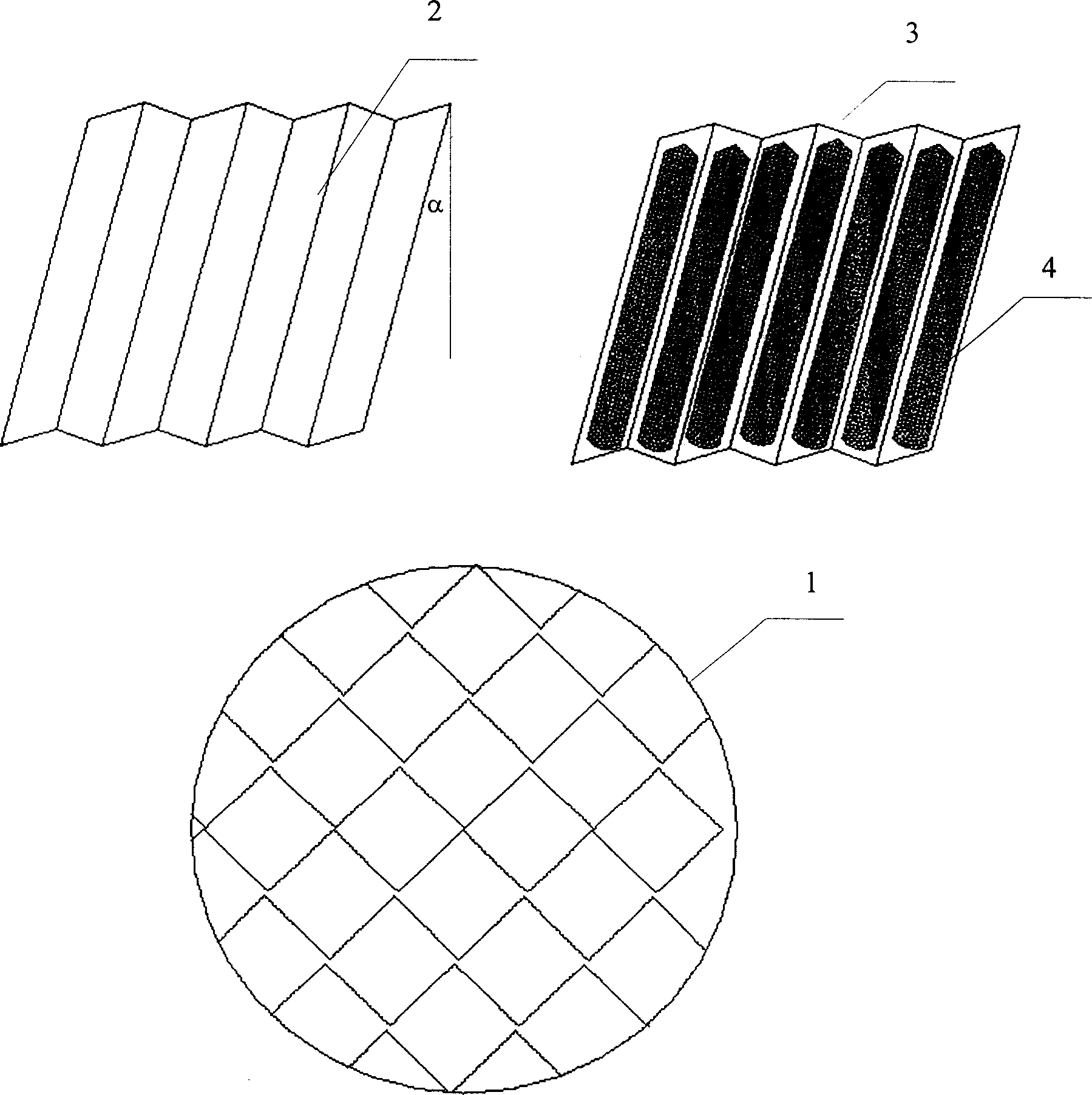

Catalyst distillation component and catalyst distillation method used said component

InactiveCN1602988AGood liquid redistribution abilityOvercome the defect of mass transfer effect declineChemical/physical processesFractional distillationCatalytic distillationReaction zone

The invention discloses a kind of catalyst distillation module and uses this module the catalyst distillation method.The invention catalyst distillation module includes the granules of catalyst, the silk screen vessel and the filler plate, its characteristic lies in, in the stated silk screen vessel which is used to load and fill granules of catalyst one by one or interval lays to the stated free channel which is formed by fold put the filler plate;Among them the stated filler plate is the corrugated sheet padding,open arbitrary shape holes on the corrugated sheet trough,remove the open hole part on the stated corrugated sheet, or divides the hole opened part into two parts along the ripple direction, then move upward or downward the formed two teeth pieces.The invention module has the force fluid redistribute ability, overcame the flaw that channel and so on cause the mass transfer effect droppes ; Lengthenes the fluid mobile way, increases the hold liquid volume of the reaction zone liquid.

Owner:CHINA PETROLEUM & CHEM CORP +1

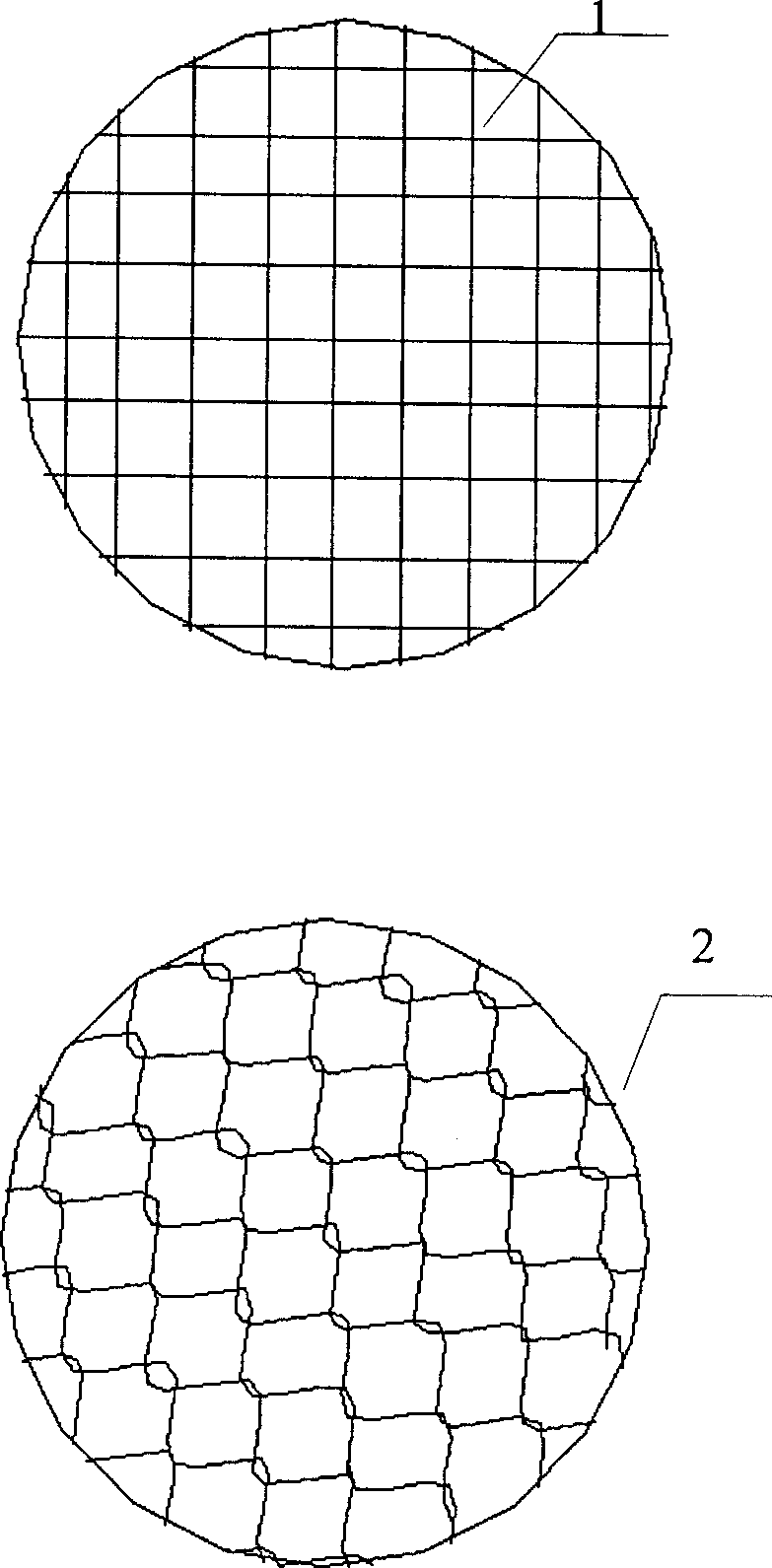

Catalytic distillation assembly and catalytic distillation method using the same

InactiveCN1569301AImproved hydrodynamic propertiesSmall pressure dropChemical/physical processesFractional distillationVoid ratioGas phase

The invention relates to a catalyzing distillation component and a method. The component includes catalyst particles, silk network container and regulated fillers, its character lies in: the catalyst particles and other inertial particles are blended together and filled into the container, and the mentioned silk network containers are arranged in the regulated fillers one by one. The invention favors the transition of media to liquid phase in the gas phase reaction. It can make the reacting bed with large gap rate, and the catalyst is distributed in the whole reaction segment evenly.

Owner:CHINA PETROLEUM & CHEM CORP +1

Monolithic catalyst for synthesizing dimethyl carbonate as well as preparation method and application method of the catalyst

InactiveCN110479287AImprove catalytic performanceImprove stabilityProductsReagentsNanoparticleActive component

The invention discloses a monolithic catalyst for synthesizing dimethyl carbonate. The catalyst is composed of active components Cu and Ni nanoparticles, a carrier that is a triphenylphosphine porouspolymer and a honeycomb ceramic matrix. The Cu and Ni nanoparticles are loaded on the triphenylphosphine porous polymer POP-PPh3, and the honeycomb ceramic matrix is coated with the triphenylphosphineporous polymer POP-PPh3 loaded with the CuNi nanoparticles to form the CuNi / POP-PPh3 monolithic catalyst. The application method comprises the following steps: putting the CuNi / POP-PPh3 monolithic catalyst into a steel pipe of a fixed bed reactor, and introducing CO2 for 5 minutes to remove other gases in a reaction system; heating to 120-180 DEG C, transporting the liquid methanol to a preheaterthrough a high-pressure constant-flow pump for gasification treatment, and reacting the mixture for 2-6 hours with the molar ratio of CH3OH to CO2 in the reaction gas being 1-3 to obtain the dimethylcarbonate. The monolithic catalyst provided by the invention is used for one-step synthesis of DMC from CO2 and methanol, and the yield of DMC exceeds 8%.

Owner:SOUTHWEST PETROLEUM UNIV

Production method and production system for continuously producing 107 glue with double screws

The invention provides a production system for continuously producing 107 glue with double screws. A dehydration kettle, a preheater, an on-line mixer, a polymerization cylinder, a degradation device, a low molecule remover and a twin-screw extruder are sequentially connected, wherein the low molecule remover is further connected with a steam-water separator; the steam-water separator is in valve pipeline connection with the dehydration kettle; and the dehydration kettle, the on-line mixer and the degradation device are provided with feed ports. The invention further provides a production method for continuously producing the 107 glue with the double screws. According to the method and the system, technological equipment is simple, the investment, the power consumption and the production cost are low, the production capacity and the product quality are high, the 107 glue can be continuously produced by the double screws via improvement, relatively thorough automation is realized, the operation is simple, and the production is stable.

Owner:矽时代材料科技股份有限公司

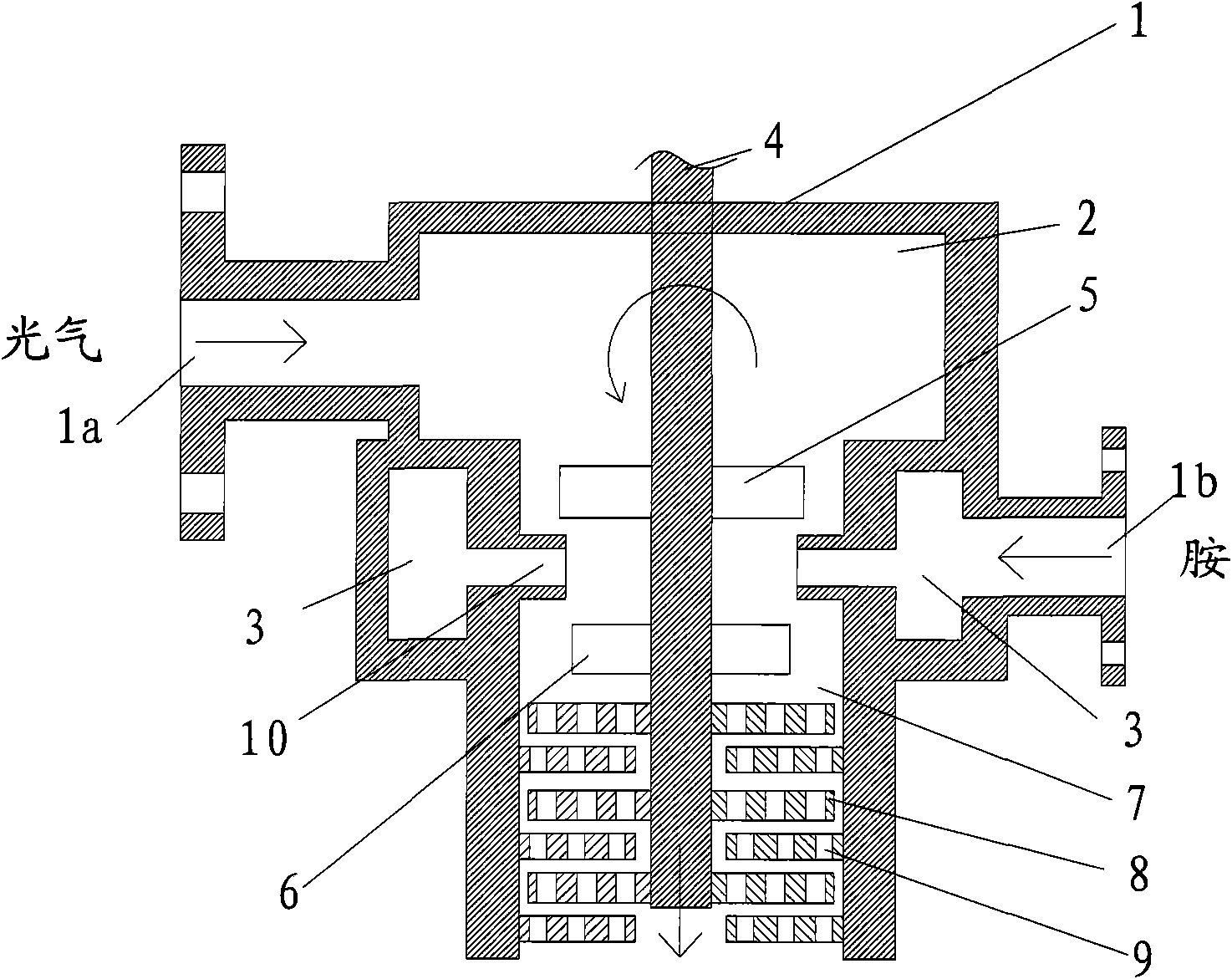

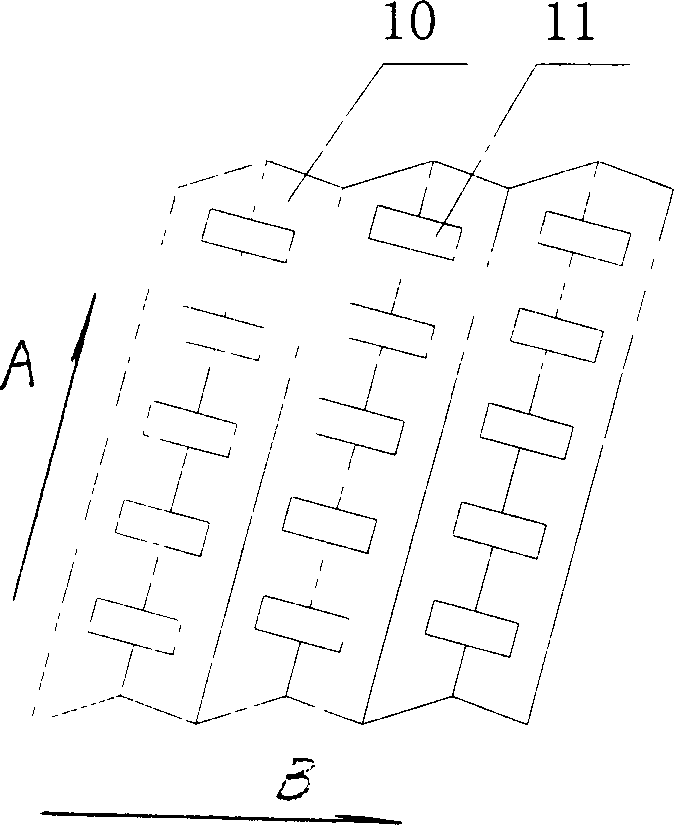

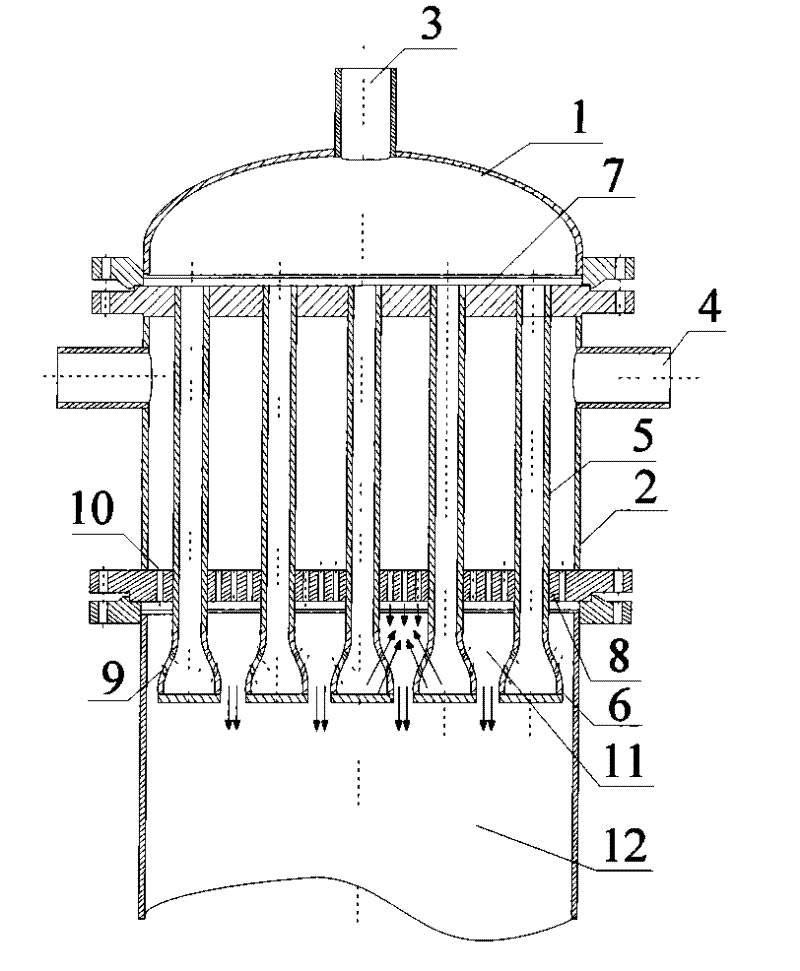

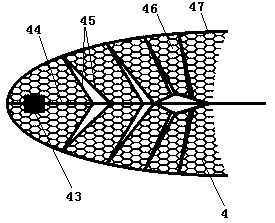

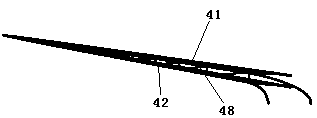

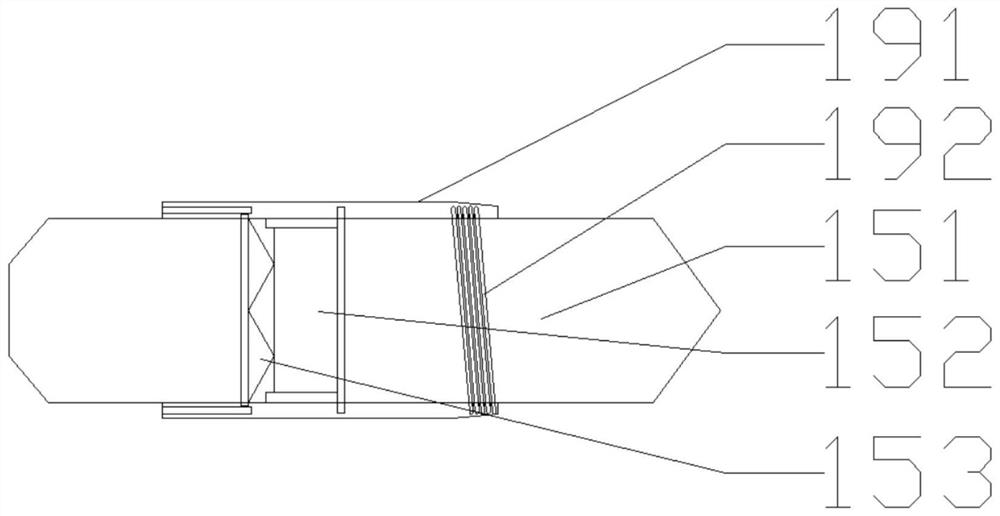

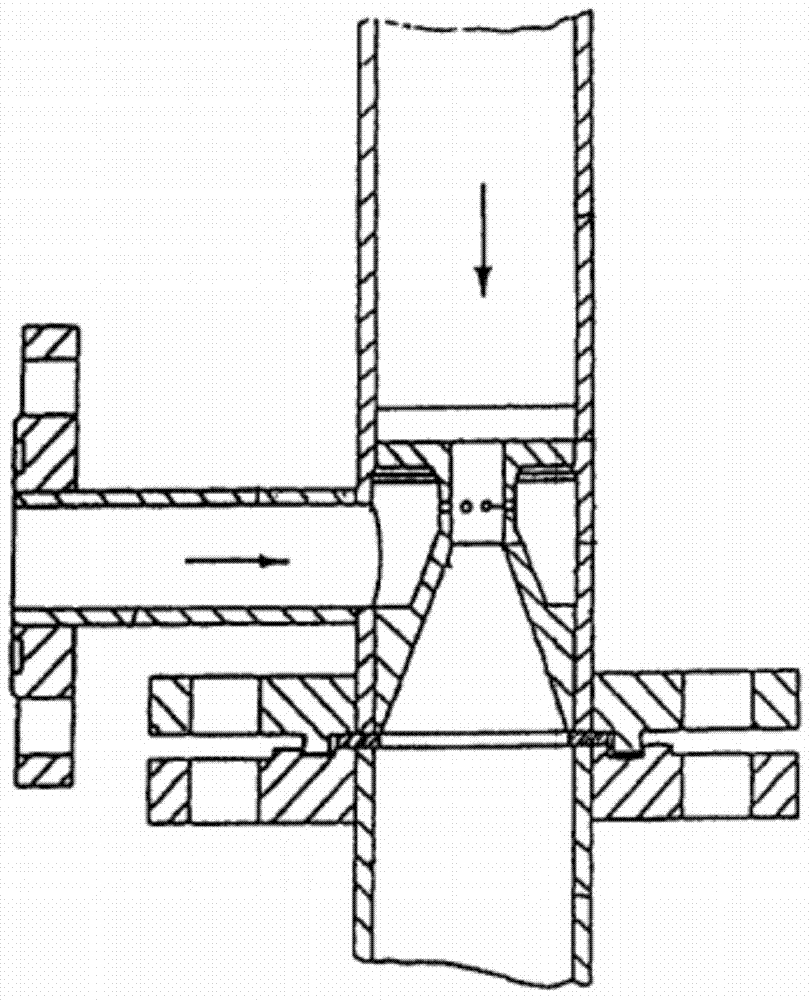

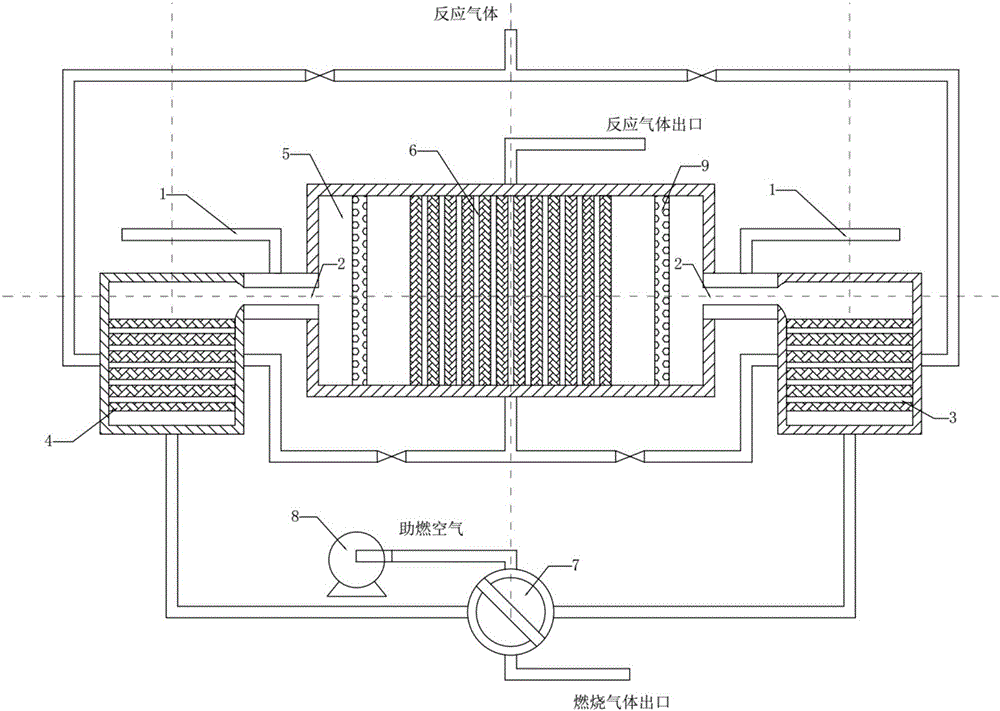

Column tube type impinging stream reactor and operating system for producing toluene diisocynate

ActiveCN101612547BSmall amplification effectReduce generationIsocyanic acid derivatives preparationOrganic compound preparationToluene diisocyanateEngineering

The invention relates to a column tube type impinging stream reactor and an operating system for producing toluene diisocynate. The upper head of the column tube type impinging stream reactor is connected with a barrel body on which a barrel body feeding hole (4) is arranged, the column tubes pass through the barrel body and are evenly distributed on the upper tube-plate and the lower tube-plate in the barrel body, jet orifices (10) of the lower tube-plate are evenly distributed on the lower tube-plate; the lower end of the column tube is connected with an expanding section of the column tube; and the jet orifices (9) of the column tubes are arranged on the lower ends of the column tubes and the expanding sections of the column tubes. A stream of material is injected by the jet orifices (10) of the lower tube-plate in a jet current mode; around the jet orifices of the lower tube-plate, the column tubes and column tube expanding sections are arranged in parallel and are vertical to thelower tube-plate; the other stream of fluid is injected into an impinging mixed zone with a certain angle in a jet current mode by the jet orifices (9) of the column tubes arranged on the column tubes and the column tube expanding sections and is impacted with the first stream of material and then is quickly mixed; and the reaction material enters into a second reaction zone (12) for further reaction. The size of the impinging mixed zone can be flexibly changed by adjusting the structure parameters of the mixed zone, therefore, the reactor has strong adaptability.

Owner:SEDIN ENG +1

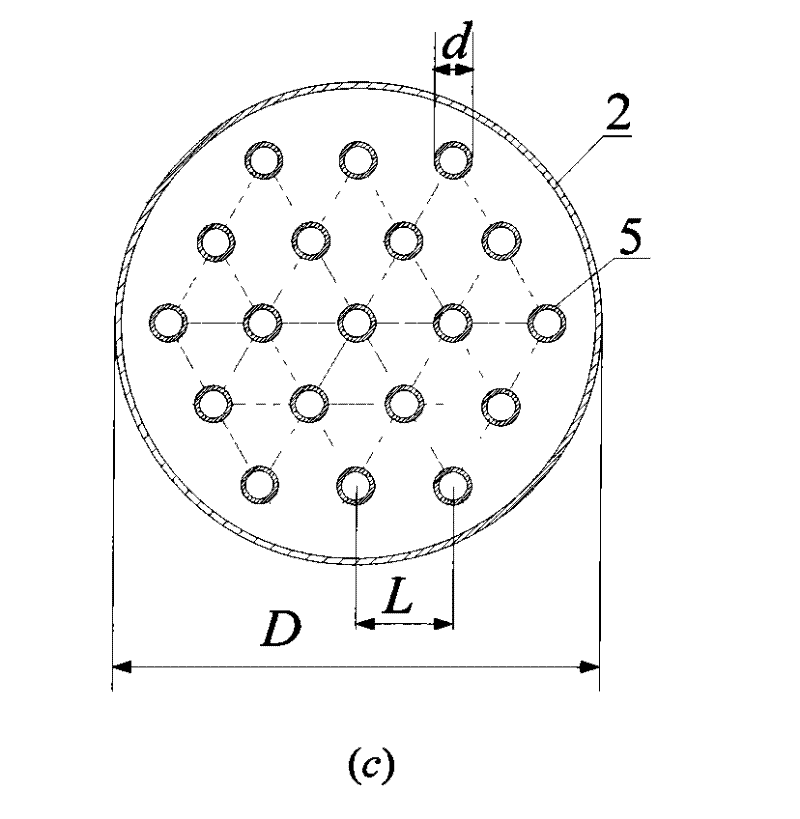

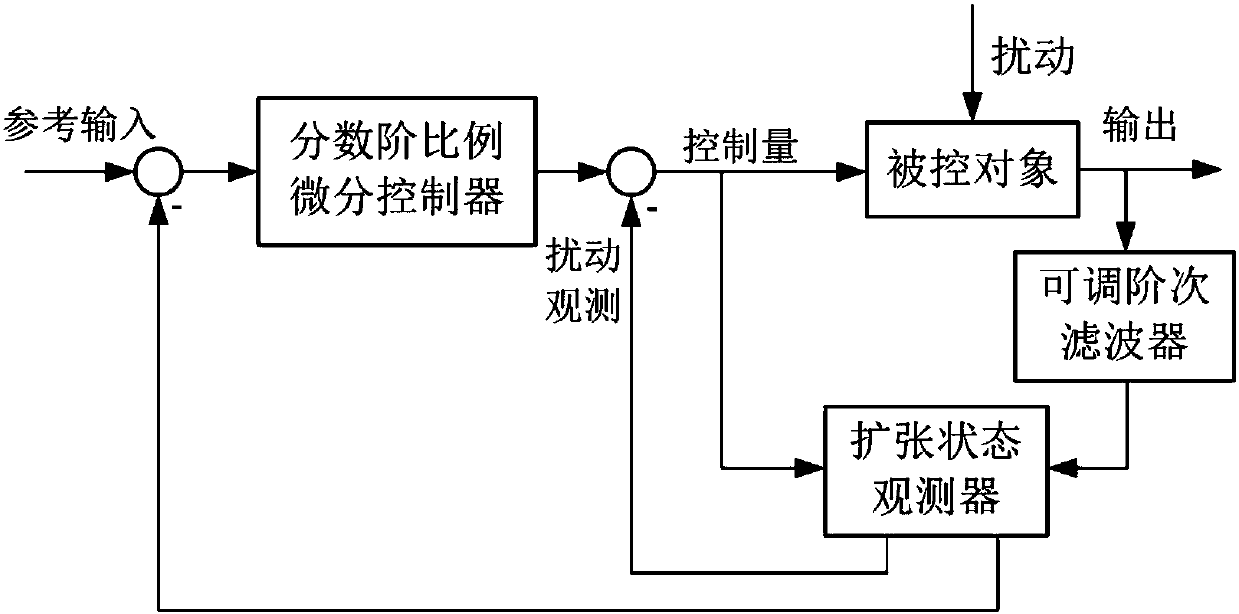

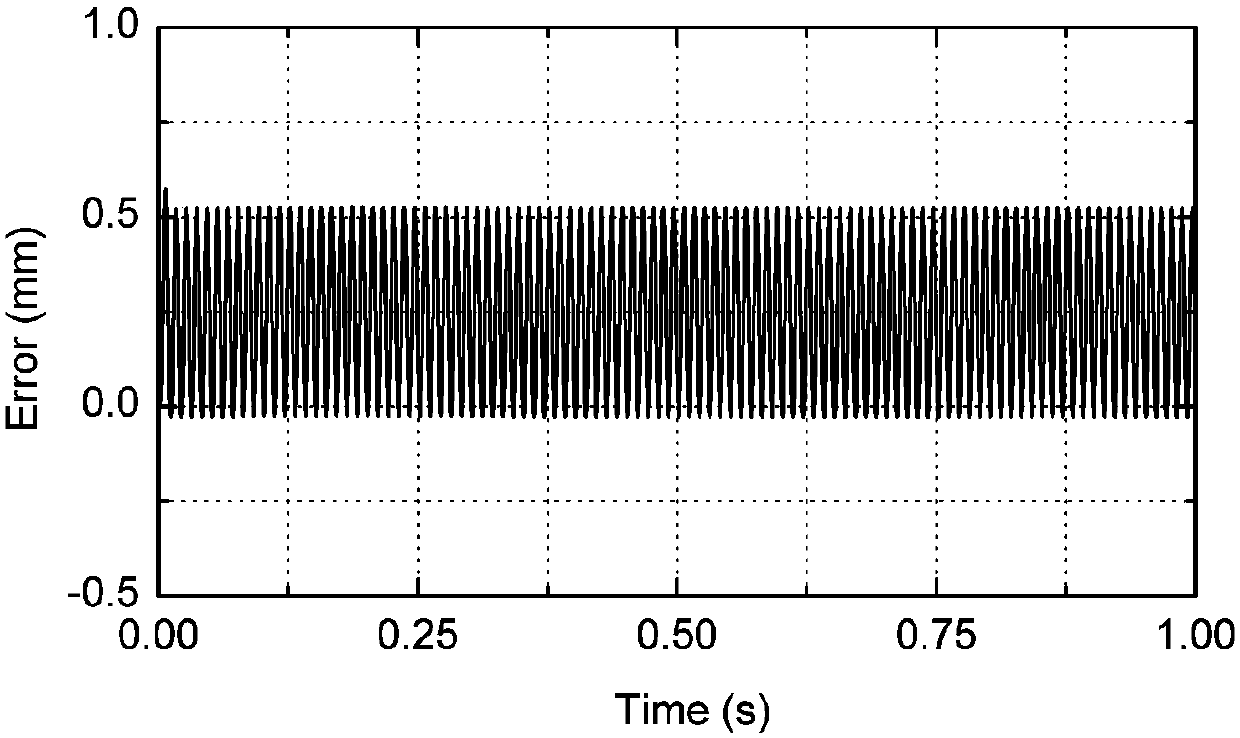

Fractional order auto-disturbance motion control method based on adjustable-order filter

ActiveCN108459507AImprove filtering effectSmall amplification effectAdaptive controlNewton's laws of motionEngineering

The invention discloses a fractional order auto-disturbance motion control method based on an adjustable-order filter. The method comprises steps that according to the Newton's law of motion, a nonlinear dynamic model of a motion control system is established; measurement noise is filtered through utilizing the adjustable-order filter; the order of the filter is adjusted to achieve the better filtering result; an extended state observer is utilized to improve the disturbance suppression effect of the system; a motion controller is designed through utilizing the fractional proportional differential algorithm, and the tracking reference input is made to output. The method is advantaged in that parameter adjustment is flexible, engineering realization is easy, and the suppressing ability of the motion control system for measurement noise and interference is effectively improved.

Owner:NANJING INST OF TECH

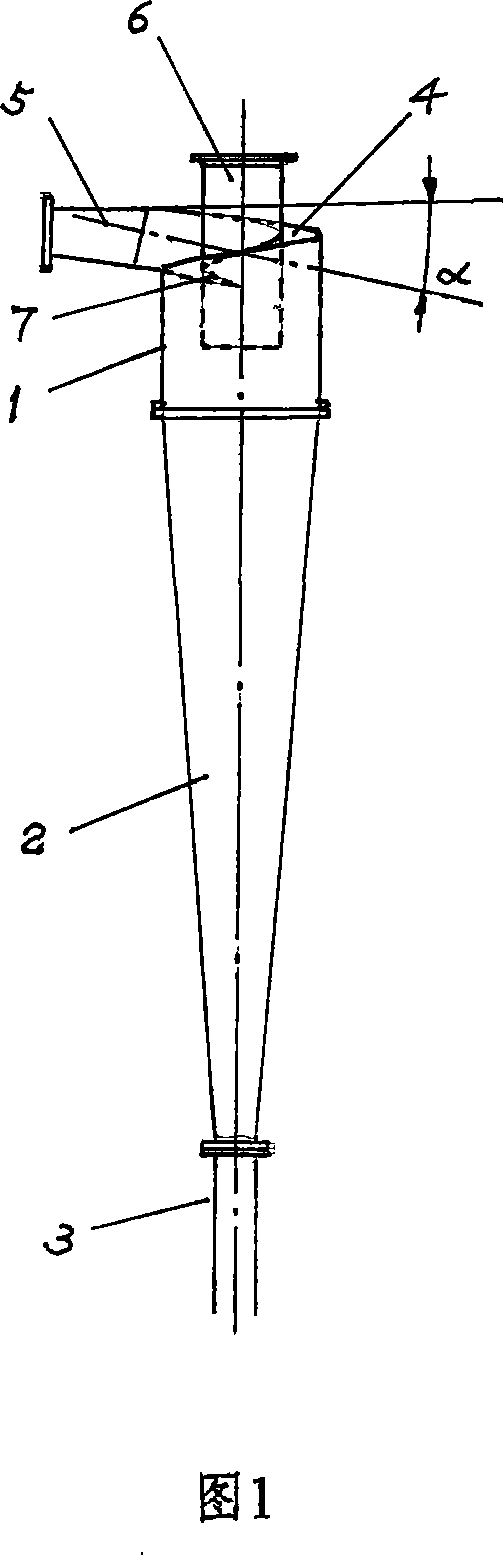

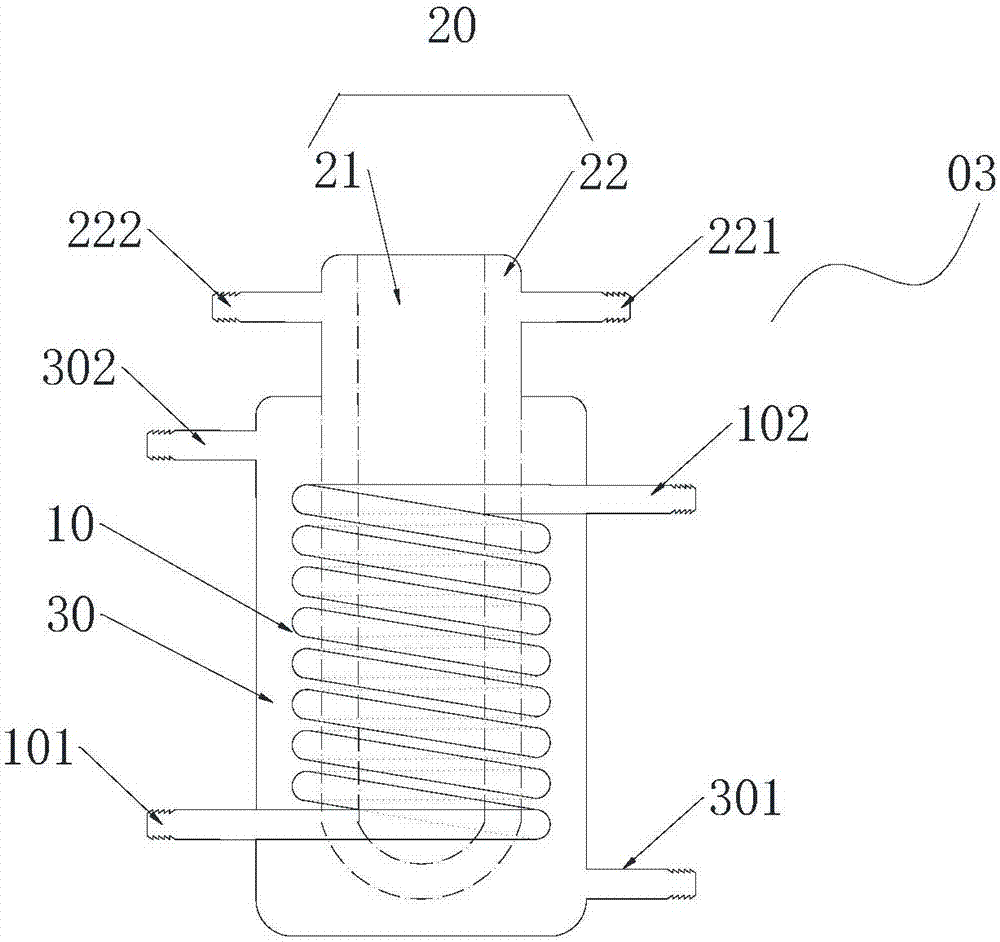

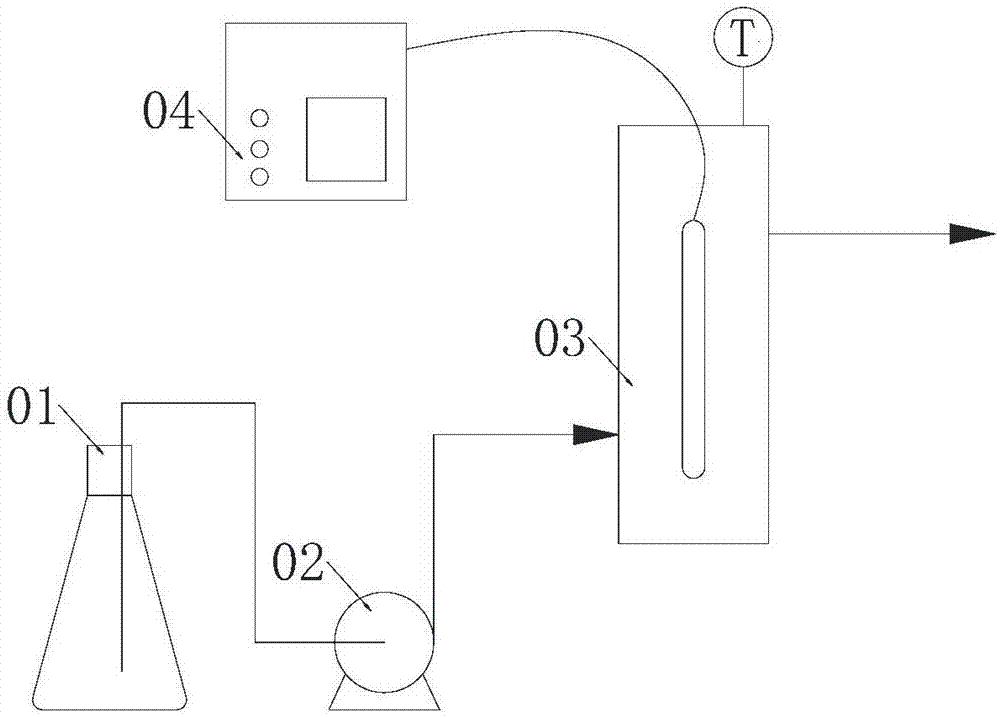

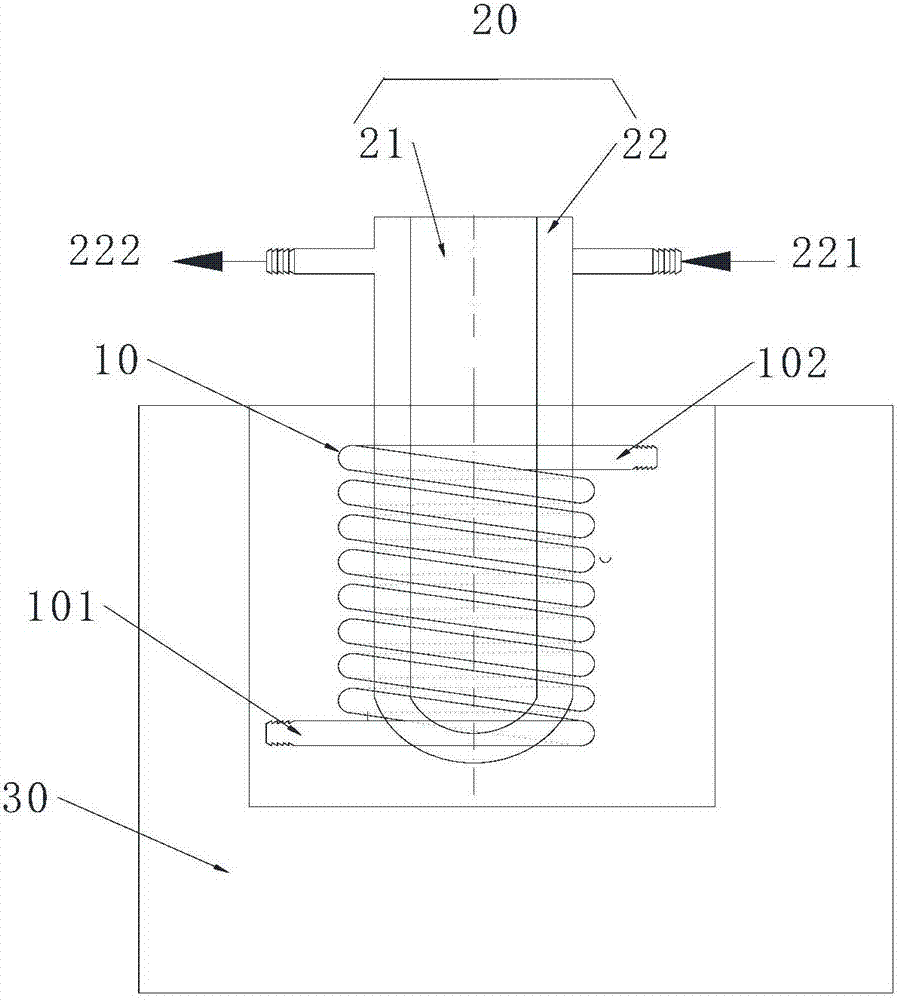

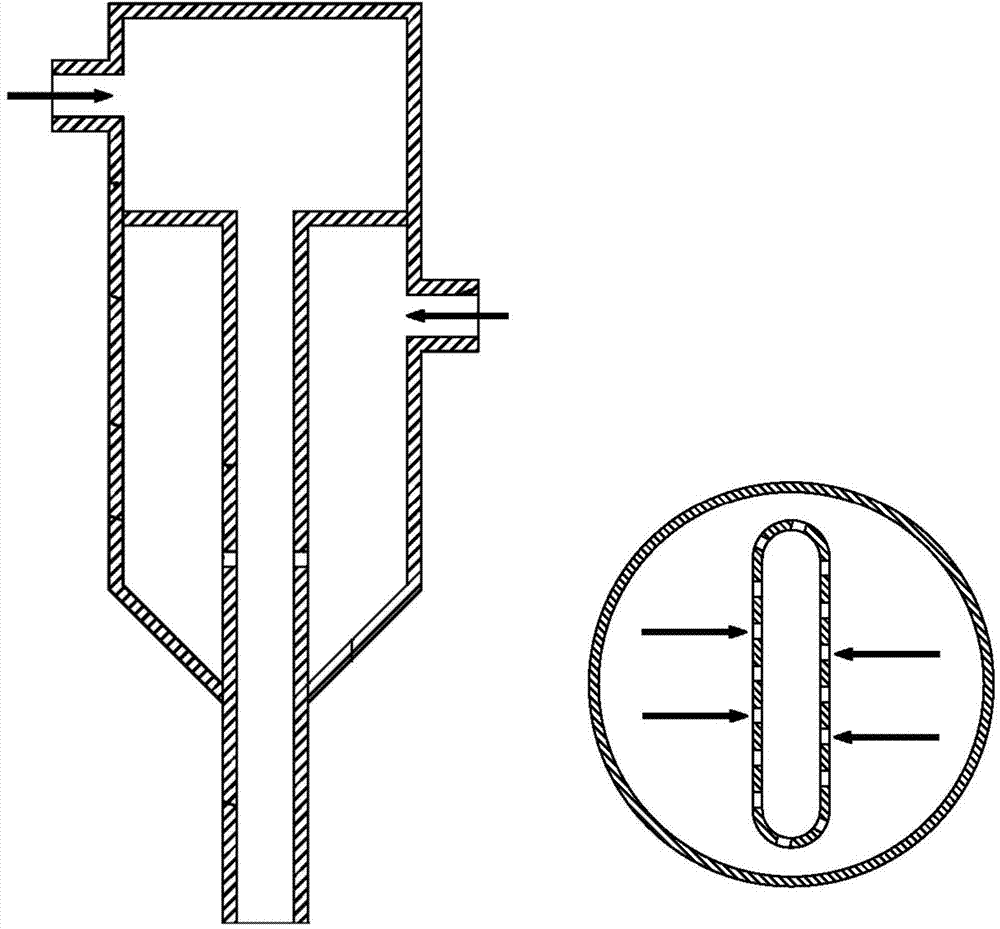

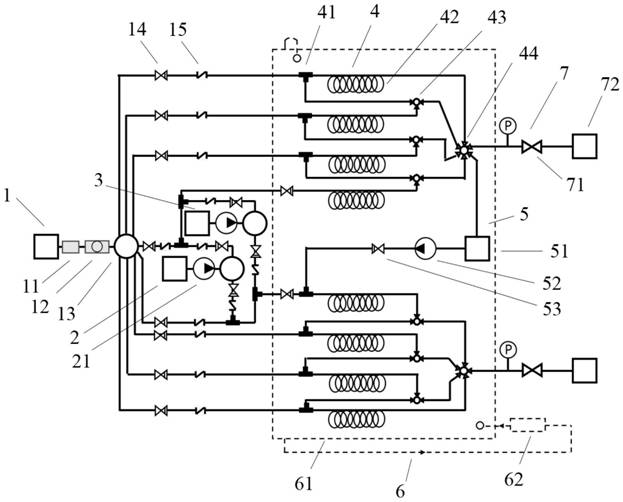

Continuous light chemical reaction apparatus, system and continuous preparation method of propellane carbonylation reaction

PendingCN107486115AImprove transfer efficiencyShort reaction timeOrganic compound preparationCarbonyl compound preparationContinuous lightOptical radiation

The invention provides a continuous light chemical reaction apparatus, a system and a continuous preparation method of a propellane carbonylation reaction. The continuous light chemical reaction apparatus comprises a continuous reactor, an irradiation light source used for providing illumination to a continuous reactor for performing the continuous light chemical reaction, and a temperature control apparatus, the continuous reactor of the temperature control apparatus and the irradiation light source are positioned in the temperature control apparatus, by arranging the continuous reactor, the light chemical reaction can be continuously generated, the reaction raw materials are continuously introduced into the reactor, the reaction products are continuously discharged from the reactor, the continuous reaction can effectively improve the transmission efficiency of optical radiation in a reaction mixture, so that the reaction time is shortened, the reaction efficiency is increased, and side reaction is reduced. The batch reaction is stable, the temperature control operation is convenient, the continuous light chemical reaction apparatus is benefit for amplification of the light chemical reactions from a laboratory scale to a factory grade, and the amplification effect is smaller.

Owner:ASYMCHEM LAB FUXIN

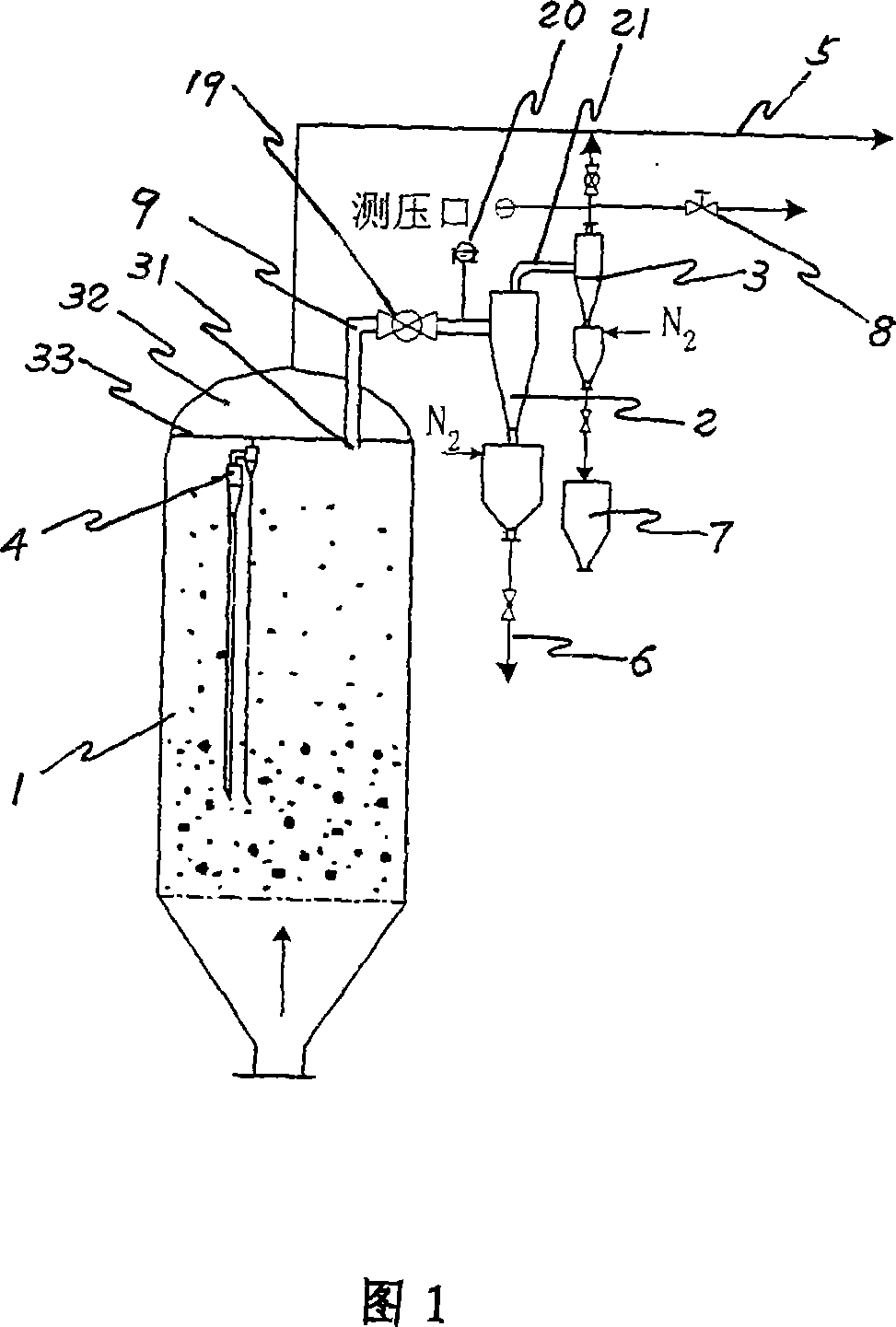

Powder granule circulation whirlwind multi-level grading device and its grading method and use

ActiveCN101143350AImprove separation efficiencyReduce separation efficiencyOrganic chemistryReversed direction vortexCycloneFluidized bed

A circumfluent cyclone multi-grade classification device and a classification method and use of powder particles are provided. The device includes a particle classifier and a cyclone dust remover, which respectively comprises a direct cylinder, an inner part, a gas import, a cone, two ball valves, an ash storehouse, a nitrogen import, etc. the inner lateral of the inner part of the classifier and the inner lateral of the cone are respectively equipped with two to four flat slab-shaped or arc slab-shaped guide slide ways. The method includes that air containing dusts is extracted and is introduced into the particle classifier. The particles lager than 15-20 Mu m are separated and are returned. The extracted air is introduced into the cyclone dust remover. The dust remover is used to remove the fine particles smaller than 15 Mu m. And the air of which the fine particles are returned to a reactor. The catalyst particles which are larger than 20 Mu m are recovered through the classification of the catalyst particles which can be used in an acrylonitrile fluidized bed reactor. Fine catalyst powders can be ensured to be not carried out by airflow, classified and discharged. The equipment can be prevented from being blocked. The efficiency is improved and the cost is lowered. The device can be widely applied to the multi-grade classifications of various powder particles.

Owner:QINGDAO UNIV OF SCI & TECH

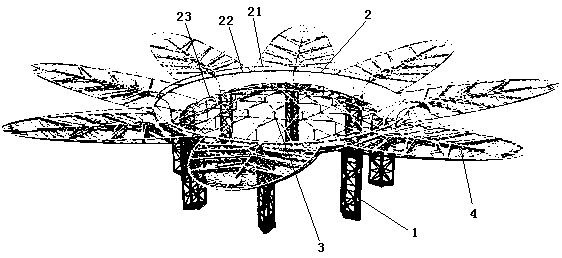

Stable overhanging type double-layer space intelligent cantilever structure system

PendingCN110016972ASmall span of solutionSolve the stiffness problemBuilding roofsArched structuresMaterial consumptionEngineering

The invention discloses a stable overhanging type double-layer space intelligent cantilever structure system, comprising lattice columns, space cantilever structures, a ring beam and a roof. The lattice columns are lattice columns with rhombic sections, the upper end of each lattice column of the bionic double-layer space cantilever structure imitating dragonfly wings. A movable, limiting and locking balance block is arranged at the end of a main vein of an upper layer space structure in each double-layer space cantilever structure. The ring beam comprises a cantilever upper ring beam, a cantilever lower ring beam and a roof ring beam which respectively serve as a double-layer space cantilever structure upper inner edge, a double-layer space cantilever structure lower inner edge and a roofouter edge, the double-layer space cantilever structures and the lattice columns are annularly distributed, the roof is arranged on the inner sides of the double-layer space cantilever structures, and the lattice columns provide support for the double-layer space cantilever structures and the roof through the ring beam. The cantilever structure is large in span, high in structural safety and stability, low in material consumption and light in dead weight, and breaks through the shape of the cantilever structure.

Owner:JIANGNAN UNIV

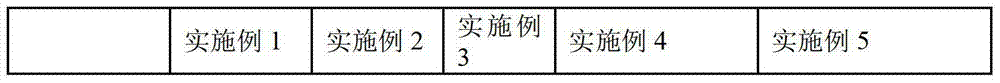

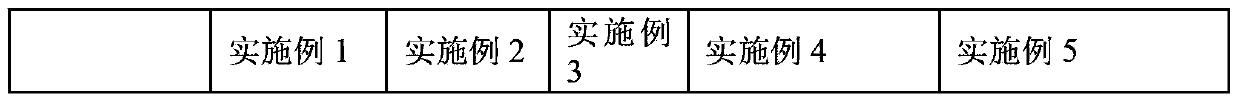

Method for synthesizing propylene by using methanol

ActiveCN103242125ALow selectivityImprove economic efficiencyMolecular sieve catalystsHydrocarbon from oxygen organic compoundsAqueous solutionMethanol

The invention discloses a method for synthesizing propylene by using methanol, for solving the problems that in the existing technique for preparing propylene by using methanol, the selectivity of propylene is low and cannot meet the requirement of industrial application and subsequent separation is very difficult. The method disclosed by the invention comprises the following steps of: preparing an intermediate mixture; synthesizing propylene; and separating propylene. According to the method for synthesizing propylene by using methanol, the raw material is a methanol aqueous solution. By the method disclosed by the invention, the problem that in the existing technique for preparing propylene by using methanol, the selectivity of propylene is low can be solved effectively, and therefore, the subsequent separation difficulty is reduced, the production cost is lowered and the economic efficiency of enterprises is improved.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

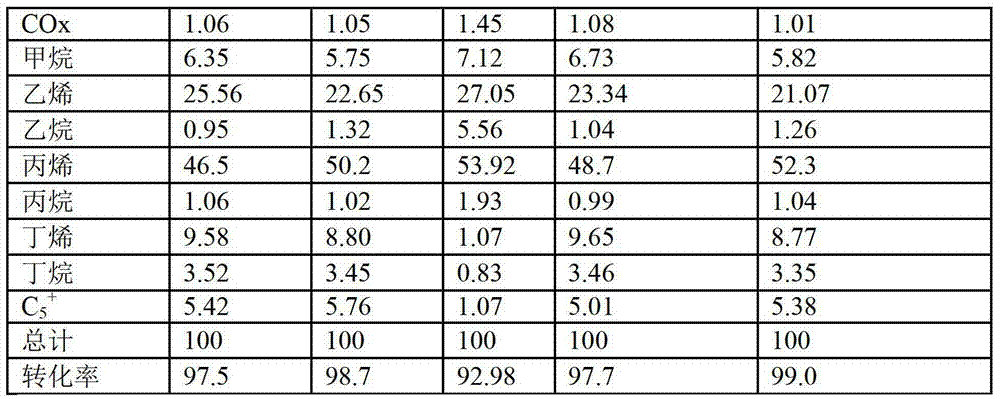

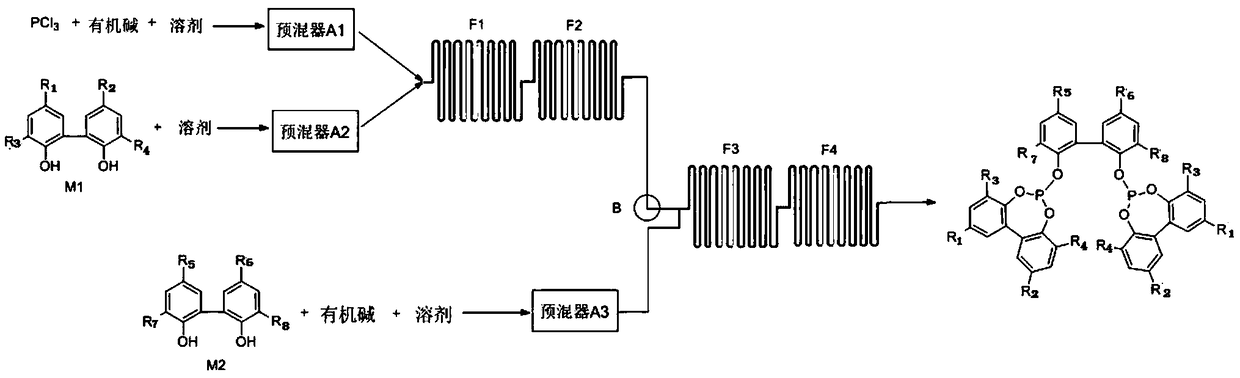

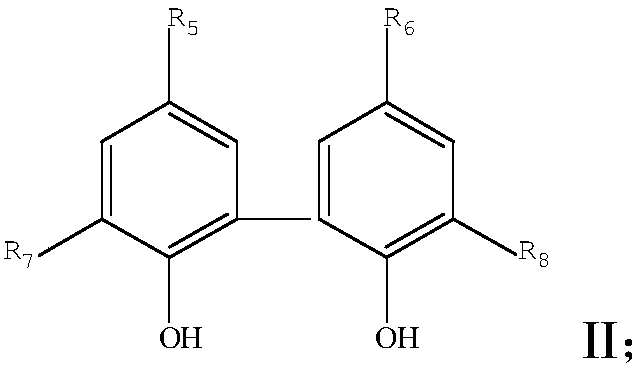

Preparation method of diphosphite

ActiveCN109369722APrecise ratioAccurate timeGroup 5/15 element organic compoundsHazardous substancePhysical chemistry

The invention discloses a preparation method of diphosphate. The method is characterized by mixing reaction raw materials based on agent dosage, and performing continuous flow micro-reaction to obtainthe diphosphate. According to the preparation method, the reaction process can be accurately controlled, and intermediate separation and exposing can be avoided, so that the risk of harmful substances to environmental protection and health safety can be avoided; in addition, the mass transferring and heat transferring are quick in the reaction process; little byproducts are produced; the reactionyield, the reaction purity and the reaction efficiency are extremely increased.

Owner:CHINA NAT OFFSHORE OIL CORP +3

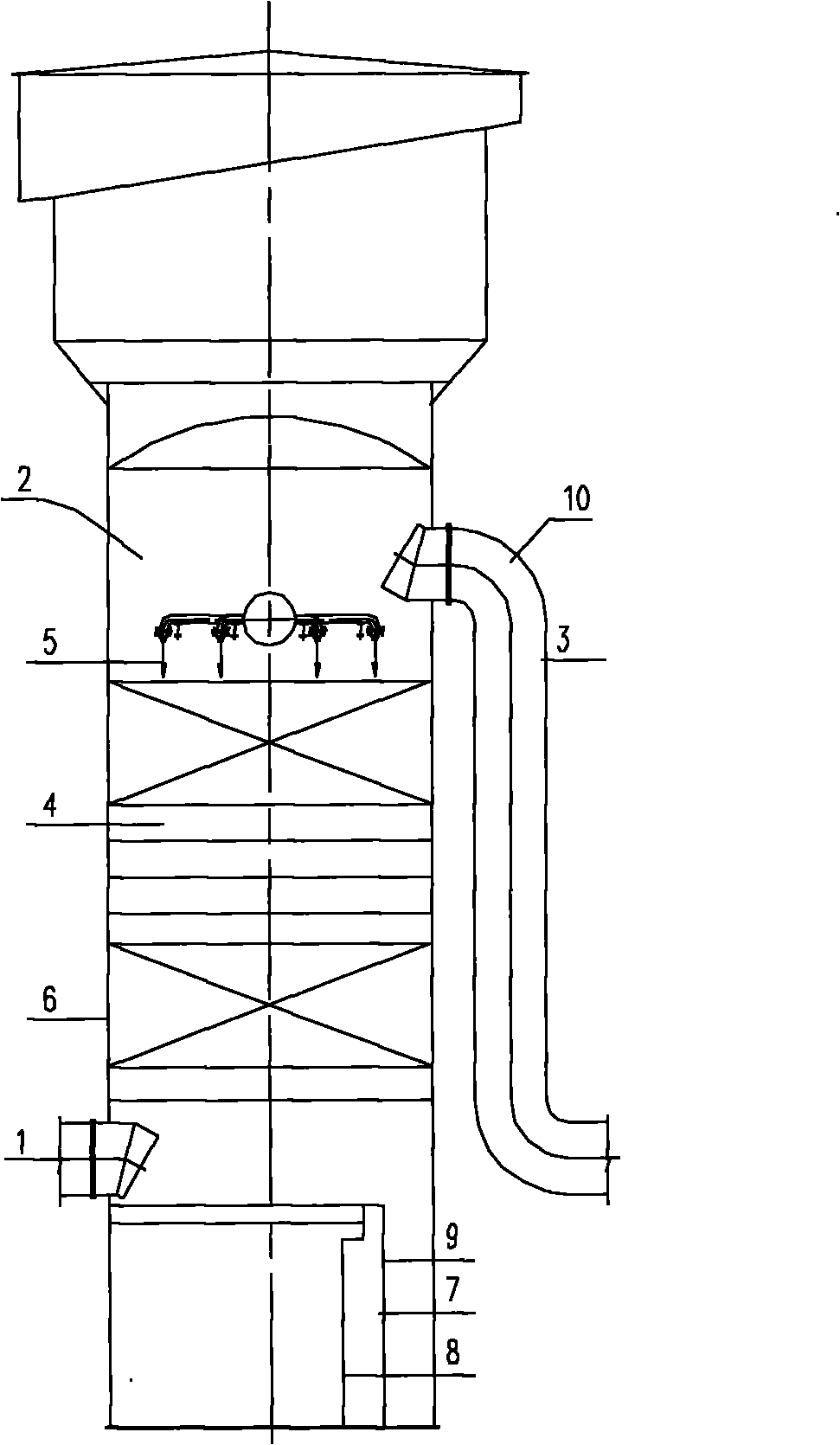

Desulfurizing tower for gas desulfuration by using liquid phase catalytic oxidation

ActiveCN101987976ASimple structureImprove stabilityDispersed particle separationGas purification by liquid washingCatalytic oxidationProduct gas

The invention discloses a desulfurizing tower for gas desulfuration by liquid phase catalytic oxidation. The lower part of the washing segment of a desulfurizing tower is provided with an inlet for gas to be desulfurized, and the upper part of the washing segment of the desulfurizing tower is provided with a doctor solution spraying part. The desulfurizing tower is characterized in that a descending pipeline causing desulfurized gas to pass is arranged along the axis of the washing segment of the desulfurizing tower, and the top of the washing segment of the desulfurizing tower is provided with an entrainment capturing device and is communicated with a horizontal pipeline which can lead the desulfurized gas out of the lower part of the washing segment of the desulfurizing tower. The desulfurizing tower of the invention has simple structure and good stability and is easy to manufacture and install. The structure that sulfurous gas enters or leaves the desulfurizing tower is more reasonable, which is favourable for the even distribution of desulfurized gas which enters or leaves the desulfurizing tower; the entrainment capturing device arranged on the top reduces entrainment, is favourable for lowering tower height and is favourable for reducing the equivalent diameter of the washing segment of the desulfurizing tower so as to bring convenience for reducing amplification effect and improve desulfurizing efficiency; a vertical heavy-calibre gas pipeline which is connected out of the upper part of the washing section is cancelled, namely eccentric load, wind load and the like which are unfavorable for the desulfurizing tower are cancelled.

Owner:鞍钢集团工程技术有限公司

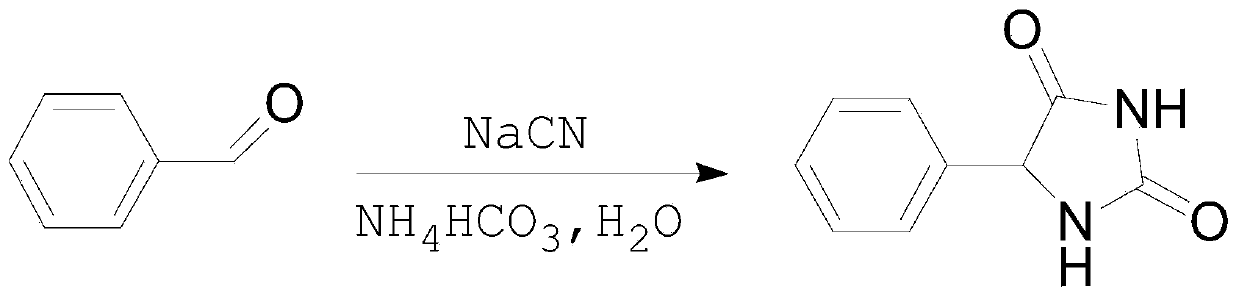

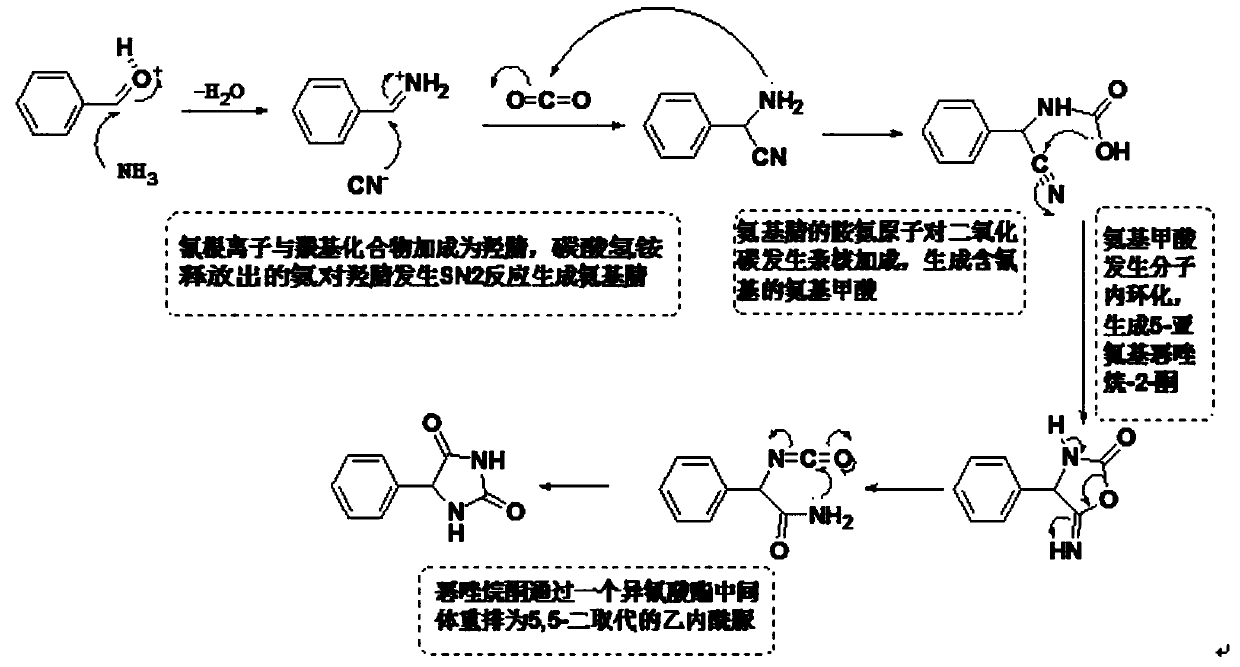

Novel method for L-phenylglycine precursor phenylhydantoin by MIC reactor

The invention relates to a novel method for an L-phenylglycine precursor phenylhydantoin by an MIC reactor. An existing process carries out intermittent production by using a reaction kettle, is morein tissue-free exhaust gas, has the probability that materials on a sealing face in a material transfer process leak and is relatively high in potential safety hazard and environmental protection risks. Ammonium hydrogen carbonate (converted in purity), sodium cyanide (30% aqueous solution) and benzaldehyde are pumped into the MIC reactor preheated to 60 DEG C in a mass ratio of 8.2: 15.8: 10 fora mixed reaction, and a prepared liquid is hydrolyzed to obtain a dl-phenylglycine. The discharge port of the MIC reactor is connected to a gas-liquid separating tank, the gas outlet of the gas-liquidseparating tank is connected to a pressure gauge to display the system pressure, and the gas-liquid separating tank is also connected to a back pressure value to back-press the whole system. By replacing solid ammonium hydrogen carbonate with an ammonium hydrogen carbonate aqueous solution, dust and tissue-free exhaust gas generated in inputting the solid ammonium hydrogen carbonate are avoided successfully. In addition, the dosage of ammonium hydrogen carbonate is reduced from 1.5 equivalent weight to 1.1 equivalent weight, so that the economical benefit is obvious.

Owner:ZHEJIANG YUNTAO BIOTECH

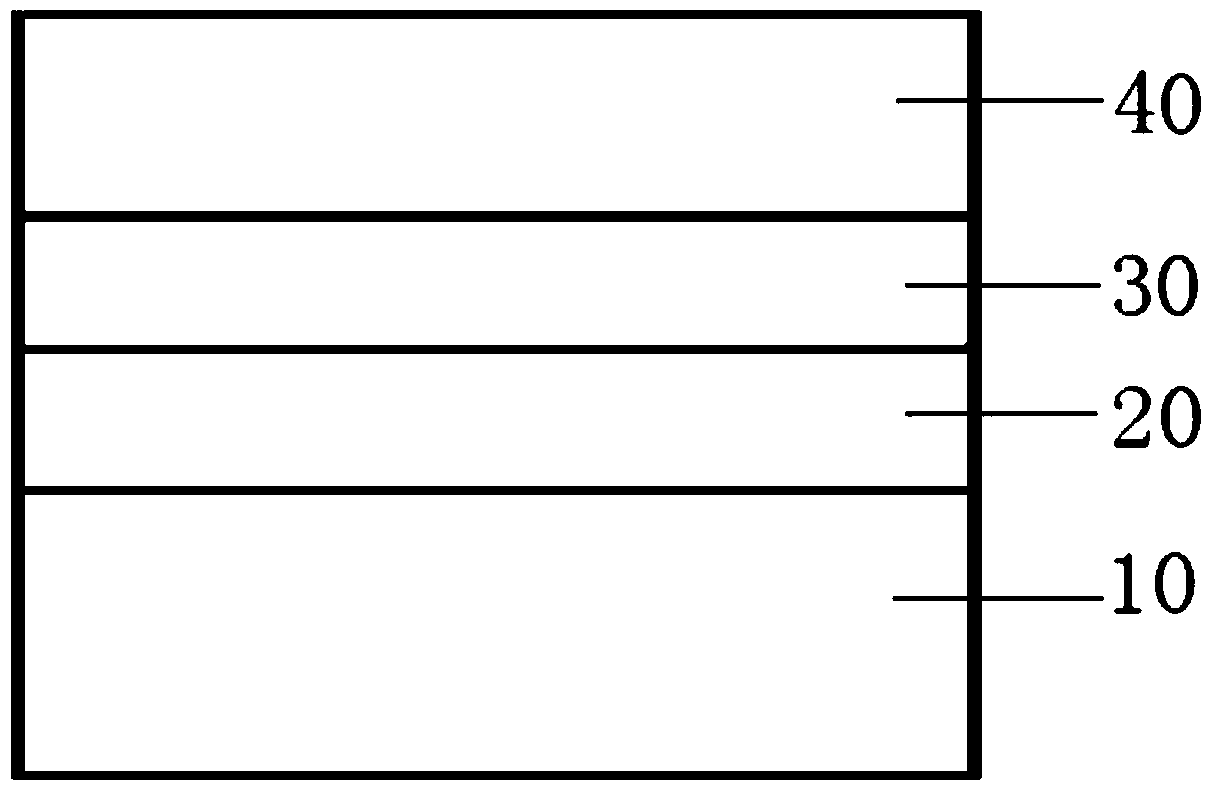

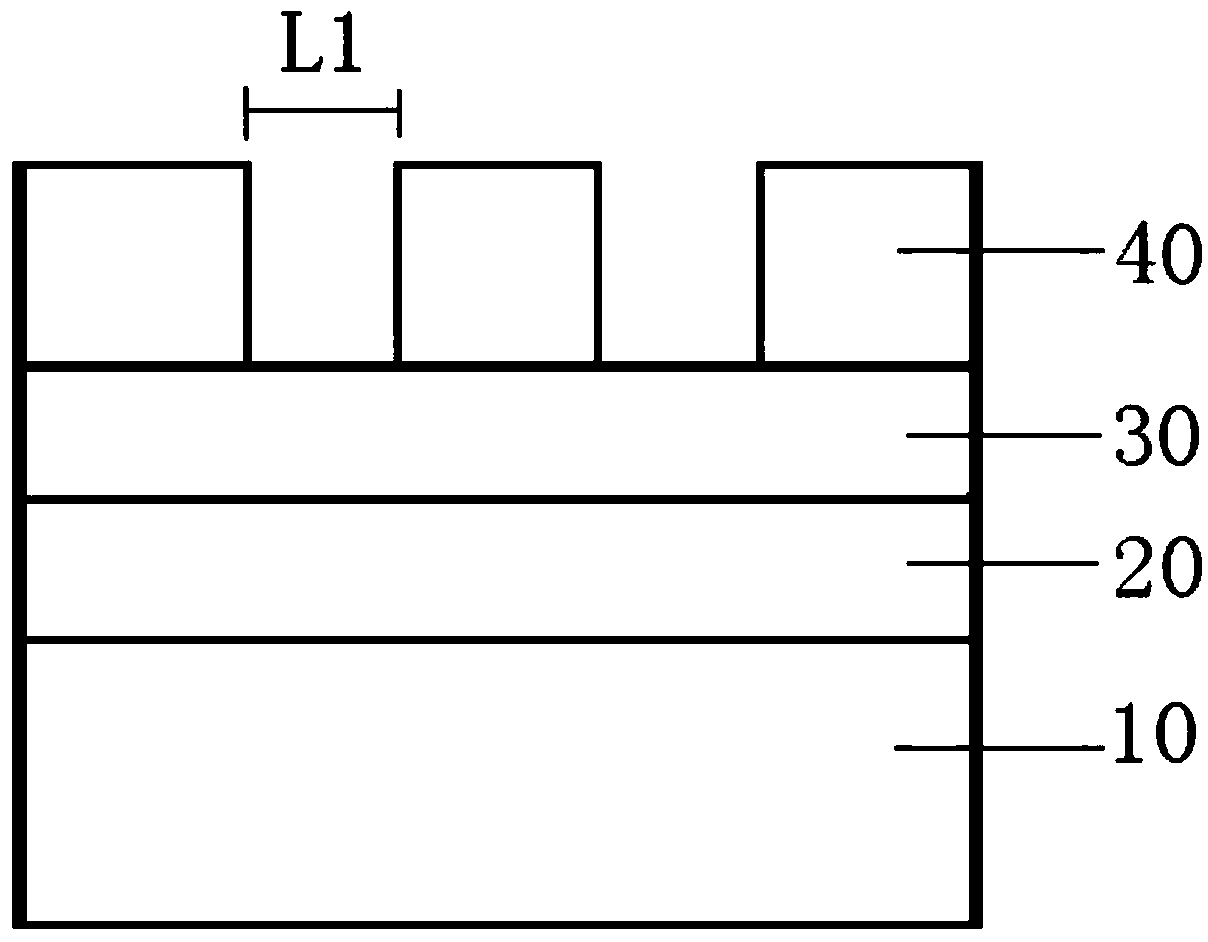

Narrow trench manufacturing method

InactiveCN103972147ASmall amplification effectIncrease etch rateSemiconductor/solid-state device manufacturingPhotoresistSemiconductor

The invention provides a narrow trench manufacturing method. The method includes the steps that (1) a silicon nitride layer and a hard mask are arranged on a semiconductor substrate in sequence; (2) photoresist is arranged on the hard mask; (3) the photoresist is exposed and developed to form a phototresist pattern with a first size; (4) after the phototresist pattern is formed, ion injection is conducted on a wafer so as to conduct non-crystallizing processing on the exposed area of the phototresist pattern; (5) after ion injection is conducted, dry etching processing is conducted by using the phototresist with the phototresist pattern so as to form a trench with a second size in the substrate.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

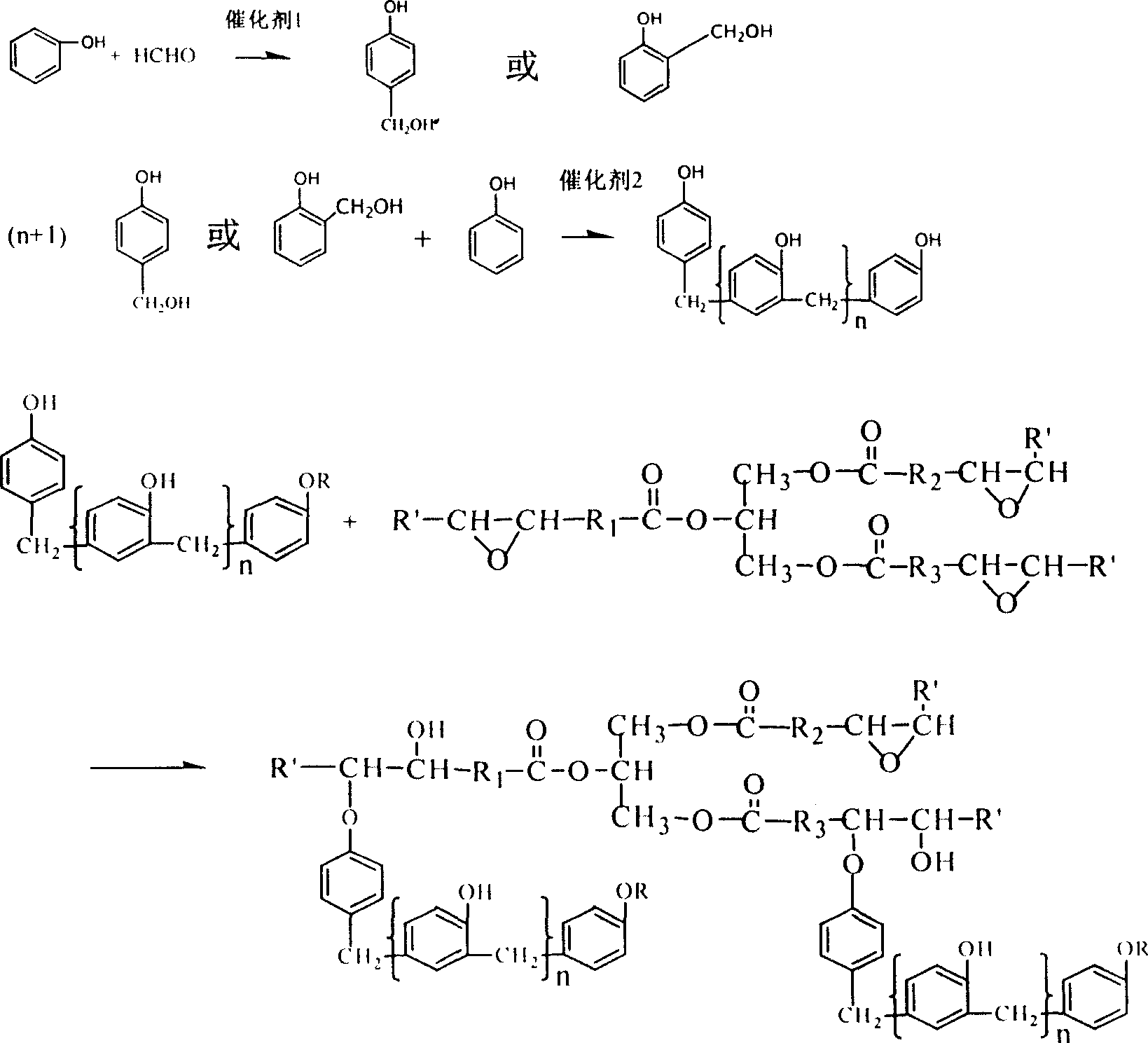

Epoxy plant oil modified phenol-formaldehyde resin, its preparation method and application

InactiveCN100347213CImprove punching effectImprove electrical performanceCircuit susbtrate materialsEpoxyVegetable oil

The preparation method for phenolic resin modified by epoxy vegetable oil comprises: putting thephenol, formaldehyde and nontoxic acid catalyst into a reactor; controlling temperature and holding for 1-8h; cooling to room temperature to obtain the coarse phenolic resin; transferring the coarse product into vacuum distillation kettle to dewater for refine; adding the epoxy vegetable oil, phenolic resin and faintly-alkaline catalyst into the reactor; heating and holding; reacting till the specified range of gelling time; cooling and adding solvent and additive to obtain the target with wide application. This invention has well security and quality with low cost and high efficiency.

Owner:SOUTH CHINA UNIV OF TECH

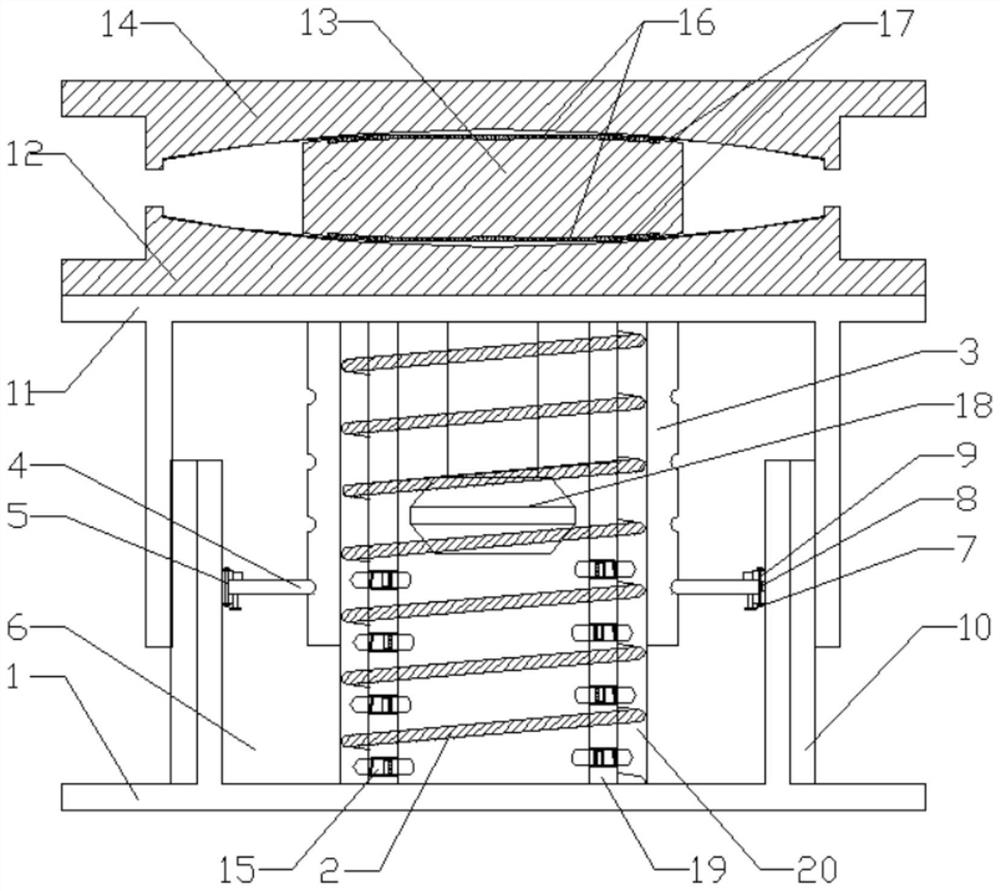

Friction pendulum type three-dimensional multi-stage vibration isolation device with inerter

PendingCN114165092AAchieve isolationGood vibration isolationProtective buildings/sheltersShock proofingVertical vibrationEarthquake resistance

The invention relates to the field of earthquake resistance and shock absorption of buildings, in particular to a friction pendulum type three-dimensional multi-stage vibration isolation device with an inerter, which comprises a decoupling system, a horizontal vibration isolation system and a vertical vibration isolation system, the horizontal vibration isolation system is a friction pendulum support mechanism, and the vertical center line of the vertical vibration isolation system and the vertical center line of the friction pendulum support mechanism are kept consistent; the friction pendulum support mechanism is connected with the upper structure; the vertical vibration isolation system is arranged below the friction pendulum support mechanism and connected with a foundation. The inerter vibration isolation system and the friction pendulum support are connected in a decoupling mode to achieve three-dimensional vibration isolation. Effective vertical vibration isolation can be achieved by connecting the spiral spring and the inerter system in parallel, the friction pendulum support can play a role in horizontal vibration isolation, due to the existence of the decoupling system, horizontal vibration isolation and vertical vibration isolation can play roles respectively, and three-dimensional vibration isolation is achieved.

Owner:NANCHANG UNIV

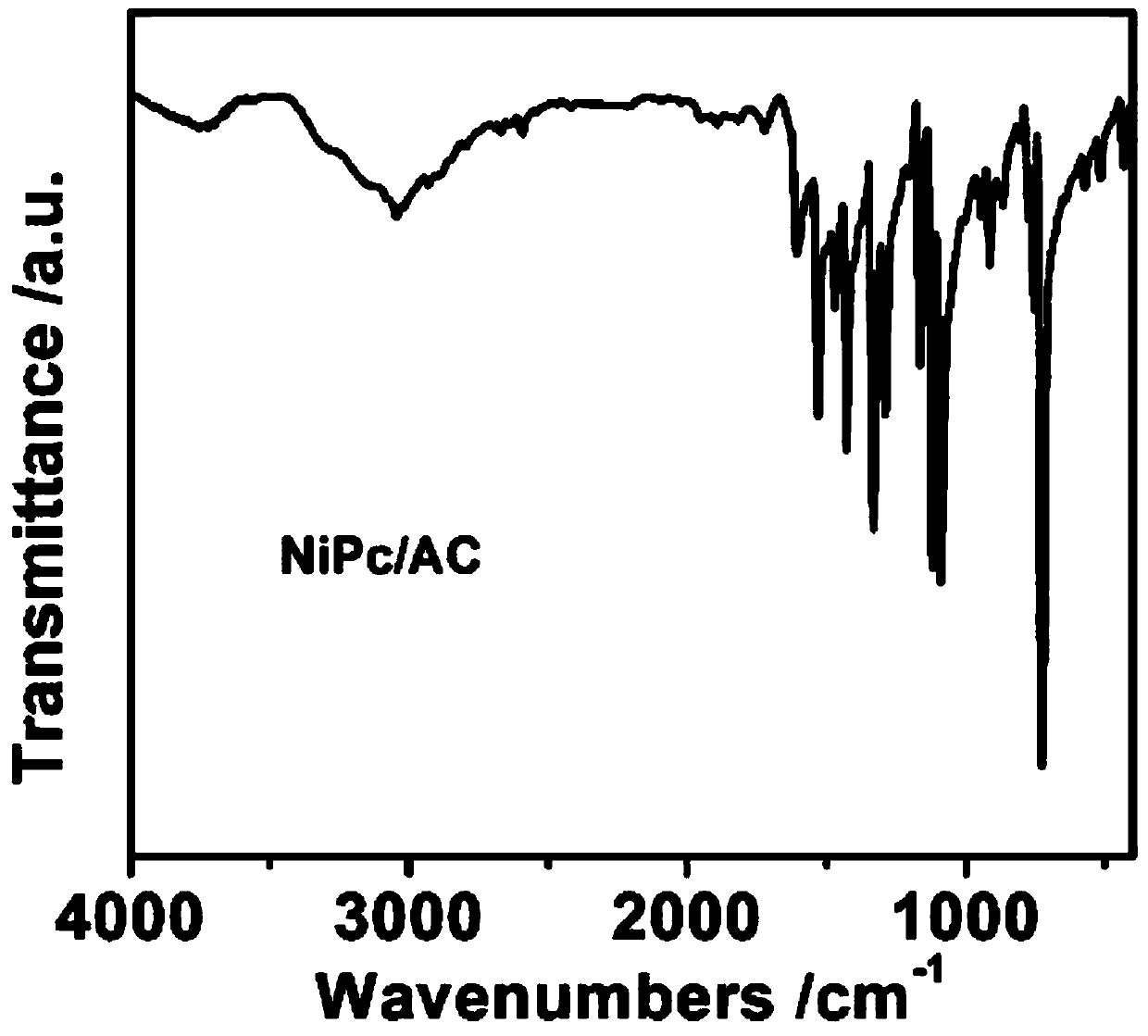

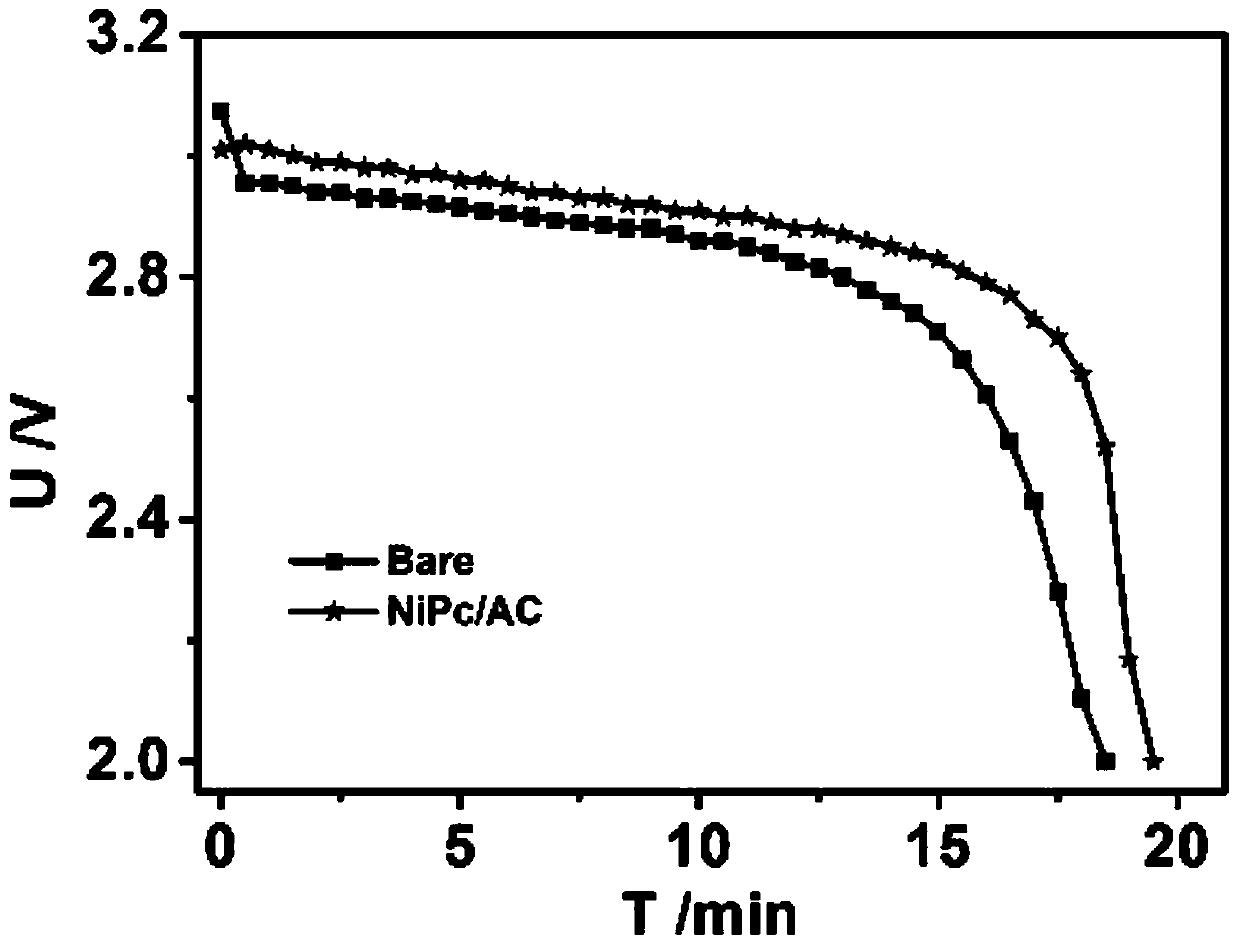

Preparation method of Li/socl2 battery positive electrode catalytic material nipc/AC

InactiveCN110931811AImprove electronic conductivityFully exposedCell electrodesActivated carbonNickel chloride hexahydrate

The invention discloses a preparation method of a Li / SOCl2 battery positive electrode catalytic material NiPc / AC. The method comprises the following steps of respectively grinding and mixing phthalicanhydride, pitch coke activated carbon, urea, nickel chloride hexahydrate and ammonium molybdate tetrahydrate to obtain a mixture; putting the mixture into a crucible for solid-phase sintering, and cooling to room temperature to obtain a crude product; and grinding the crude product, purifying and drying to obtain the Li / SOCl2 battery positive electrode catalytic material NiPc / AC. The prepared positive electrode catalytic material has the excellent catalytic performance for the Li / SOCl2 batteries.

Owner:SHAANXI UNIV OF SCI & TECH

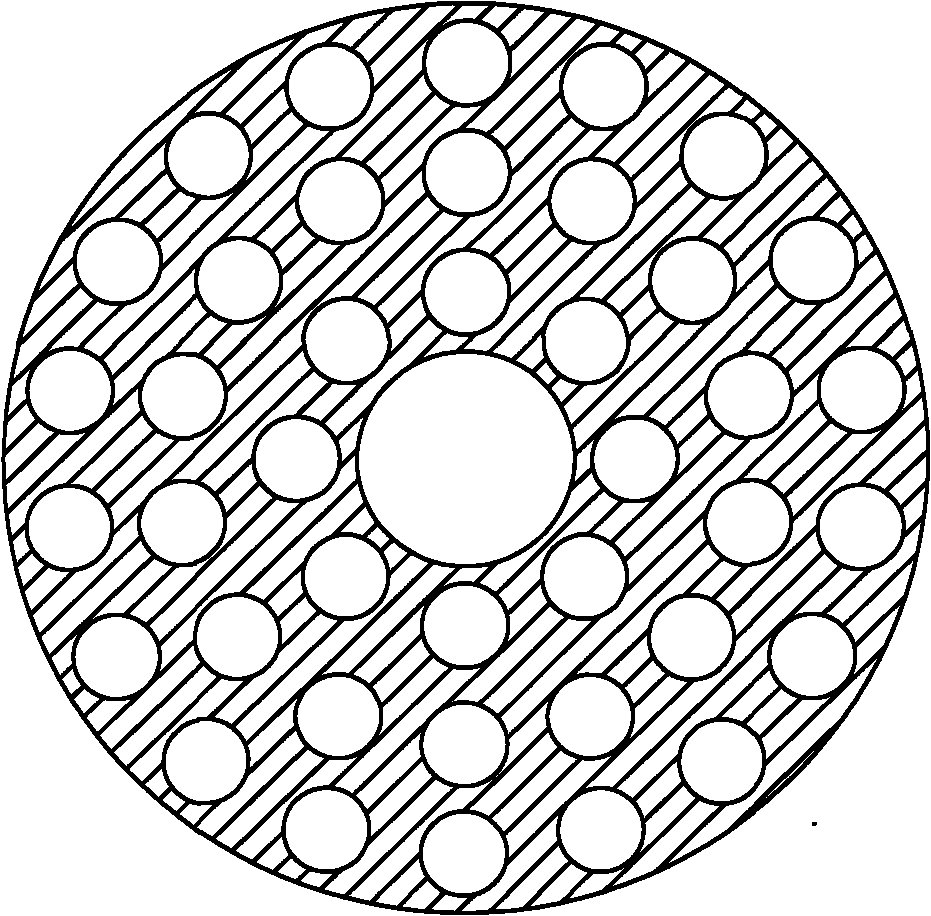

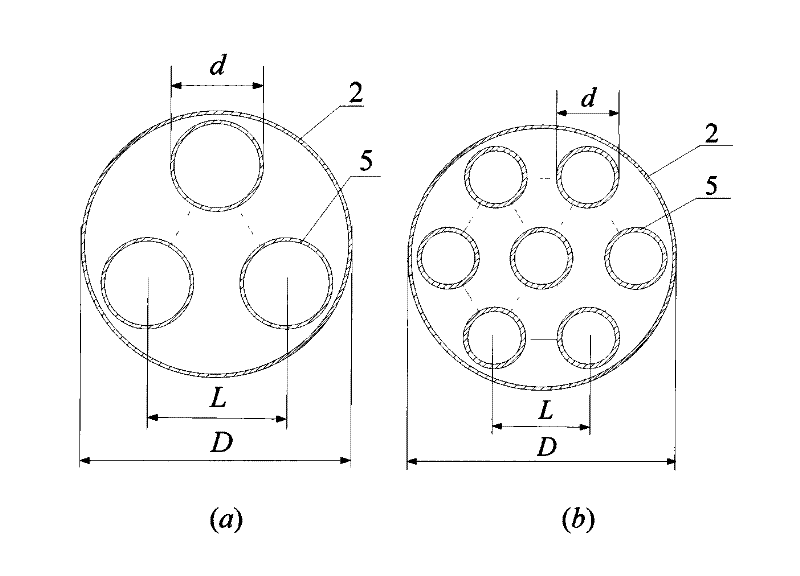

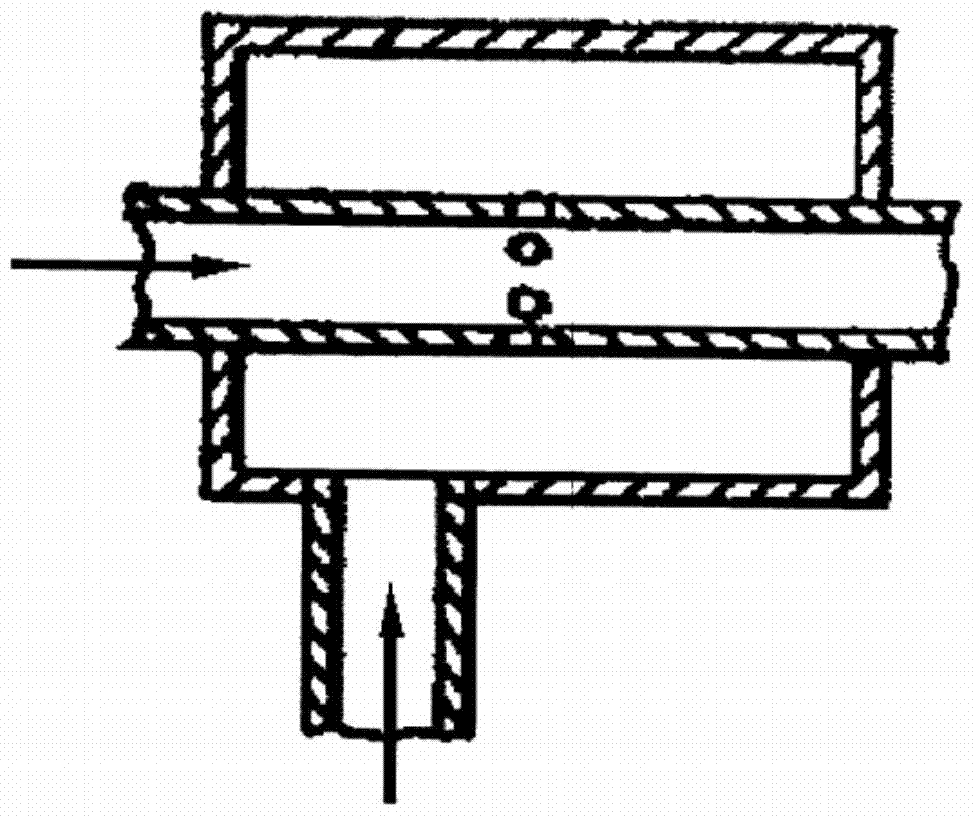

Tube array hole jet flow jet mixer

ActiveCN103521106AShort initial mixing timeImprove the mixing effectFlow mixersChemical/physical/physico-chemical stationary reactorsJet flowMixing zone

The invention provides a tube array hole jet flow jet mixer. The tube array hole jet flow jet mixer comprises a shell (1), fixed plates (2) and inner sleeves (3), wherein a first feed port (8) is arranged on the top of the shell (1), and a second feed port (9) is arranged on the side wall of the shell (1); the fixed plates (2) are arranged on the upper portion of the shell (1), wherein a buffer chamber (5) is formed by the fixed plates (2) and the top of the shell (1) in an enclosed mode, and an annular space is formed by the fixed plates (2) and the side wall and bottom of the shell (1) in an enclosed mode; the inner sleeves (3) are fixed to the fixed plates (2), wherein each inner sleeve (3) is provided with a group of jet flow holes (4), and a mixing zone (7) is arranged under the jet flow holes (4) of each inner sleeve (3). The tube array hole jet flow jet mixer is simple in structure, low in cost, convenient to use, and capable of realizing efficient mixing of two streams of fluid in an extremely short time (at a millisecond level) with mass production capacity, thereby reinforcing main reactions, restraining secondary reactions and improving the selectivity of target products.

Owner:SOUTHEAST UNIV

Method for synthesizing propylene by using methanol

ActiveCN103242125BLow selectivityImprove economic efficiencyMolecular sieve catalystsHydrocarbon from oxygen organic compoundsAqueous solutionMethanol

The invention discloses a method for synthesizing propylene by using methanol, for solving the problems that in the existing technique for preparing propylene by using methanol, the selectivity of propylene is low and cannot meet the requirement of industrial application and subsequent separation is very difficult. The method disclosed by the invention comprises the following steps of: preparing an intermediate mixture; synthesizing propylene; and separating propylene. According to the method for synthesizing propylene by using methanol, the raw material is a methanol aqueous solution. By the method disclosed by the invention, the problem that in the existing technique for preparing propylene by using methanol, the selectivity of propylene is low can be solved effectively, and therefore, the subsequent separation difficulty is reduced, the production cost is lowered and the economic efficiency of enterprises is improved.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

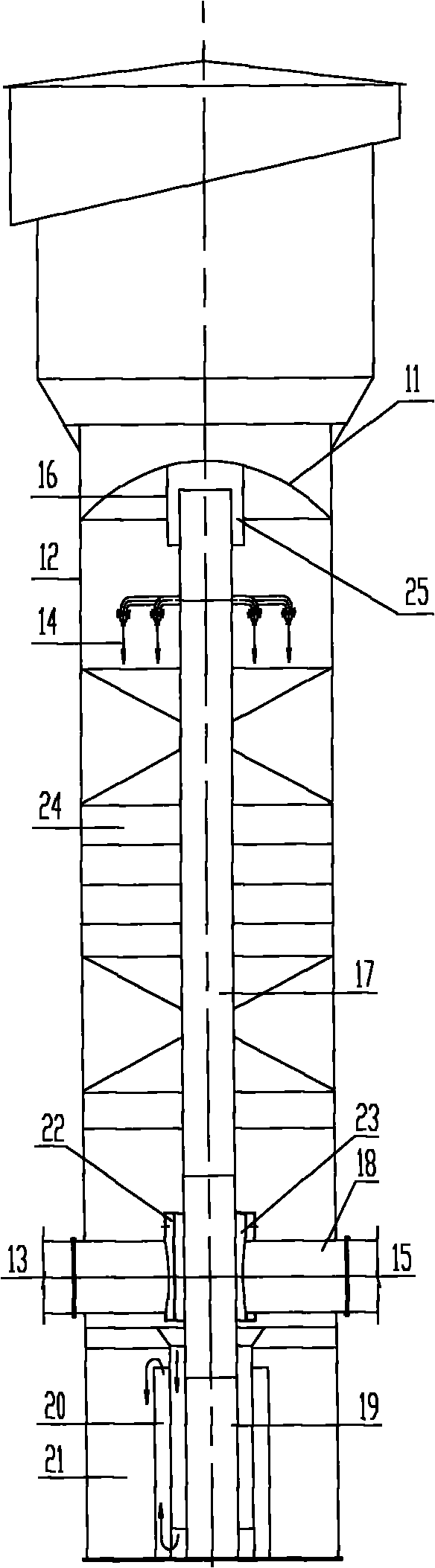

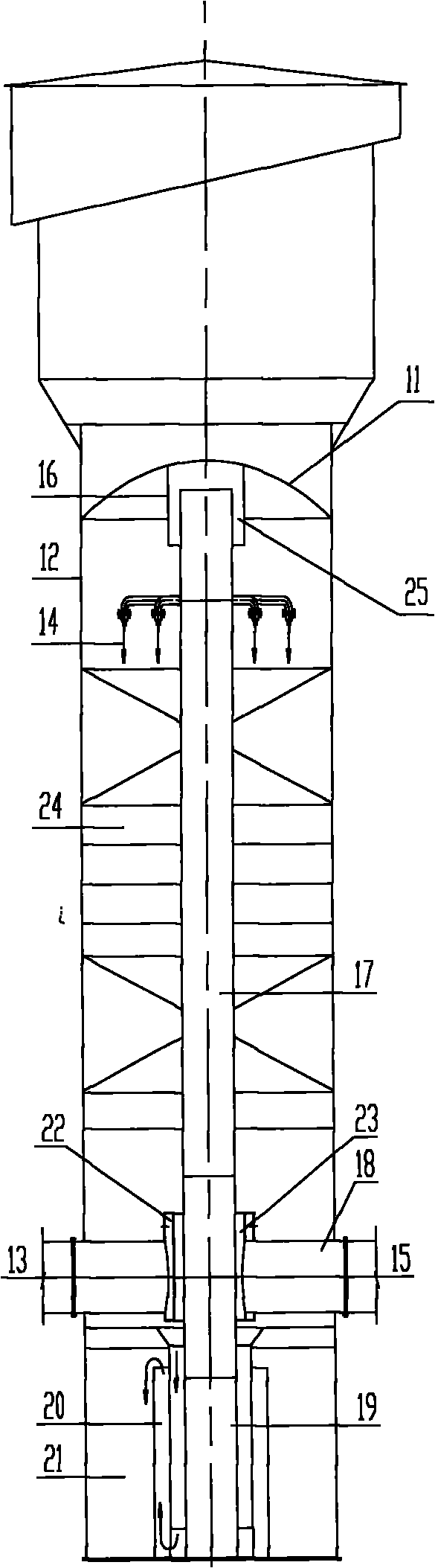

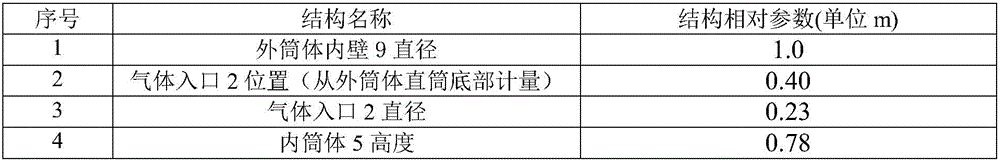

Cyclone separator for crude gas dust removal in crushed coal pressurized gasification and application

InactiveCN106190339AReduce sensible heat lossReduce resistanceGas dust removalThermodynamicsDust control

A cyclone separator for crude gas dust removal in crushed coal pressurized gasification comprises a cyclone dust collector (1) and a dust tank (13). The cyclone dust collector (1) comprises an outer cylinder (11) and an inner cylinder (5). The upper portion of the outer cylinder (11) is vertical, the lower portion of the outer cylinder (11) is conical, and the outer cylinder (11) is composed of an outer cylinder outer wall (8) and an outer cylinder inner wall (9). The inner cylinder (5) is fixed to the outer cylinder inner wall (9) through a stretching part (10). A gas inlet (2) is connected with the lower portion of the inner cylinder (5) through the outer cylinder (11), and a gas outlet (3) is located in the top end of the outer cylinder (11). A cyclone dust collector hot water outlet (7) is formed in the upper portion of the outer cylinder outer wall (8), and a cyclone dust collector hot water inlet (6) is formed in the lower portion of the outer cylinder outer wall (8). A bottom end outlet of the outer cylinder (11) is connected with the top end of the dust tank (13) through an oily dust discharge valve (4). The cyclone separator for crude gas dust removal in crushed coal pressurized gasification has the advantages of being high in oily dust removal efficiency, free of wastewater generation, high in treatment capacity and high in operation flexibility.

Owner:SEDIN ENG

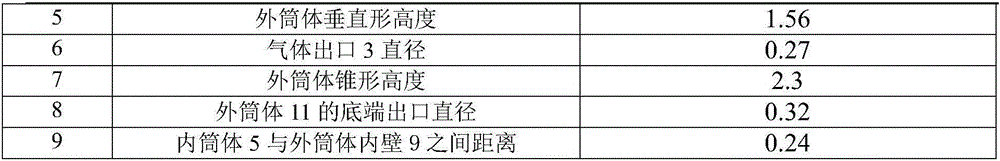

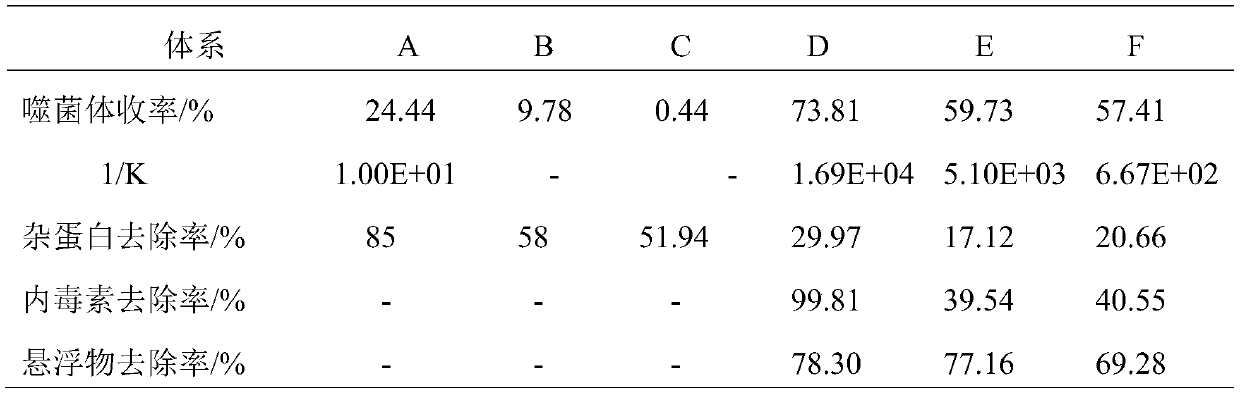

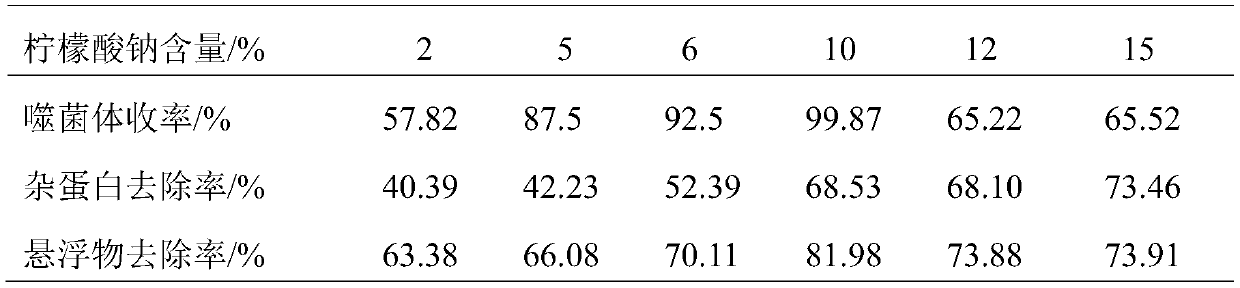

Method for separating and purifying phage in phage lysate by two-step salting-out extraction

ActiveCN110484514AHigh yieldHigh purityRecovery/purificationBacteriophagesDipotassium hydrogen phosphateMetabolite

The invention belongs to the technical field of biological engineering, and provides a method for separating and purifying phage in a phage lysate by two-step salting-out extraction. The method includes the following steps: dissolving sodium citrate or dipotassium hydrogen phosphate in a phage lysate, adding a lipophilic organic solvent such as ethyl acetate, gently carrying out vortex mixing, andseparating phases to form a three-phase system of top, medium and bottom phases to complete the first step of salting-out extraction; and adding a hydrophilic organic solvent such as n-propanol to the bottom-phase solution obtained in the first step of salting-out extraction, carrying out the second step of salting-out extraction to enrich and purify the phage in the medium phase. The problem that the phage and the bacterial metabolite are hard to separate and the cost is high in the current phage separation process is solved. The method has advantages of simple process, short separation time, high recovery rate, low separation cost and high impurity removal rate, and is a separation method with great industrial application prospects.

Owner:DALIAN UNIV OF TECH

Catalytic distillation assembly and catalytic distillation method using the same

InactiveCN1241667CImproved hydrodynamic propertiesSmall pressure dropChemical/physical processesFractional distillationVoid ratioGas phase

The invention relates to a catalyzing distillation component and a method. The component includes catalyst particles, silk network container and regulated fillers, its character lies in: the catalyst particles and other inertial particles are blended together and filled into the container, and the mentioned silk network containers are arranged in the regulated fillers one by one. The invention favors the transition of media to liquid phase in the gas phase reaction. It can make the reacting bed with large gap rate, and the catalyst is distributed in the whole reaction segment evenly.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing polyolefin through coordination polymerization in micro-reactor

ActiveCN111777700AImprove efficiencySolving Polymerization Reaction Residence Time ProblemsMicroreactorPolyolefin

The invention belongs to the technical field of polyolefin, and particularly relates to a method for preparing polyolefin through coordination polymerization in a micro-reactor. The method includes: letting an olefin monomer fluid, a main catalyst fluid and a cocatalyst fluid respectively enter the micro-reactor through shunting runners; arranging a micro-reaction runner of the micro-reactor in aconstant-temperature box and carrying out polymerization reaction; and collecting the polymerization liquid to obtain the polymer. According to the preparation method, the monomer and the catalyst canbe quickly mixed, the uniformity of a local reaction environment is controlled, and the problem of polymerization reaction retention time in the prior art is solved; the prepared polymerization product realizes excellent polymer performance and realizes high flux of polymerization. The olefin monomer concentration of the main reaction runner can be timely and effectively regulated, and the molecular structure and molecular weight of the polymerization product can be controlled. The micro-reactor polymerization technology provided by the invention is low in equipment investment, small in device size and safer and more flexible to operate; and the method is suitable for continuous production, small in amplification effect and suitable for industrial production.

Owner:INST OF CHEM CHINESE ACAD OF SCI

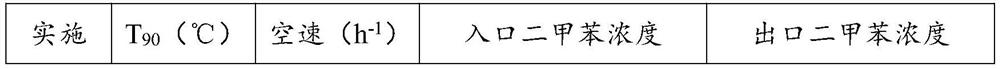

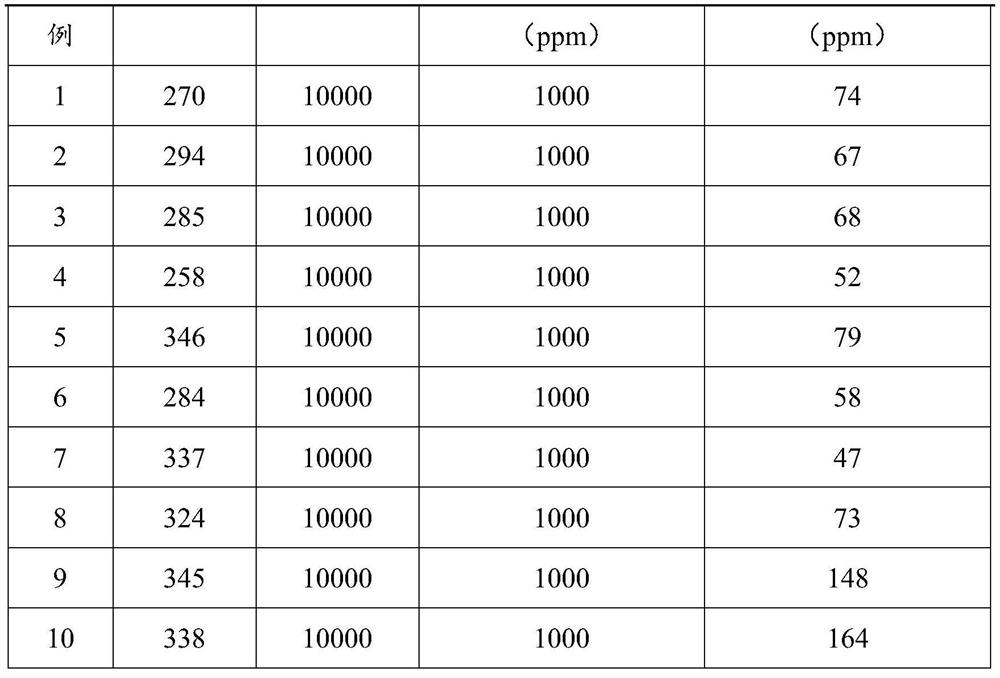

Organic contaminated soil thermal desorption waste gas catalytic oxidation purification catalyst and preparation method and application thereof

ActiveCN113731409AImprove catalytic performanceImprove the ability to resist chlorine poisoningDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCatalytic oxidation

The invention relates to the technical field of catalysts, and provides an organic contaminated soil thermal desorption waste gas catalytic oxidation purification catalyst and a preparation method and application thereof. The catalyst provided by the invention comprises a matrix, a carrier and active components, the matrix is honeycomb cordierite, the carrier is a CeO2-ZrO2 compound or a CeO2-ZrO2-R compound (R is one or more of La2O3, Co3O4, Y2O3 and SiO2), the active components are MnO2 and RuO2, and an auxiliary agent WO3-TiO2 is further loaded on the matrix. The catalyst provided by the invention has high catalytic efficiency in a temperature range of 450-650 DEG C, can completely convert organic contaminated soil thermal desorption waste gas, has good high-temperature stability, strong sintering resistance and carbon deposition resistance, and also has good alkali, alkaline earth and heavy metal resistance, chlorine resistance and sulfur poisoning resistance.

Owner:KUNMING UNIV OF SCI & TECH

Heat accumulation tubular reaction system

PendingCN106732203AEfficient use ofEasy to recycleChemical/physical processesPlate heat exchangerCombustion chamber

The invention relates to a heat accumulation tubular reaction system. The system comprises a tubular reactor and a heat accumulation tubular heating device, wherein the heat accumulation tubular heating device comprises a left heat accumulation chamber, a right heat accumulation chamber, a combustion chamber and an oil gas pipeline; the left heat accumulation chamber and the right heat accumulation chamber are connected with a reversing valve through pipelines respectively; the reversing valve is connected with a combustion-supporting air inlet and a combustion gas outlet respectively; the left heat accumulation chamber and the right heat accumulation chamber are connected with the combustion chamber through burner nozzles respectively; the combustion chamber is internally provided with a left porous fire-proof wall and a right porous fire-proof wall; the tubular reactor is arranged in the combustion chamber and is located between the two porous fire-proof walls; a reaction gas outlet, which penetrates through the top of the combustion chamber, is formed in the upper end of the tubular reactor; a reaction gas inlet, which penetrates through the bottom of the combustion chamber, is formed in the lower end of the tubular reactor; the reaction gas inlet is connected with a gas outlet of a tubular heat exchanger. The heat accumulation tubular reaction system can be used for pre-heating reaction gas and the reaction efficiency is improved; the heat accumulation tubular heating device is adopted so that residual heat of flue gas is extremely recycled; the porous fire-proof walls are arranged so that the distribution of the temperature in the combustion chamber is more uniform.

Owner:SHENWU TECH GRP CO LTD

A method for directly preparing hzsm-5 molecular sieve and forming hzsm-5 molecular sieve

ActiveCN105600804BCraft shortCrystallization method is simplePentasil aluminosilicate zeoliteMolecular sieveSeed crystal

The invention relates to a method for directly preparing an HZSM-5 molecular sieve and molding the HZSM-5 molecular sieve. The method is characterized by comprising the following steps: by taking a silicon source, an aluminum source, HZSM-5 seed crystal and a template agent as raw materials, firstly, grinding the solid raw materials, sufficiently mixing, further adding the liquid raw materials, mixing, putting into a crystallization kettle for crystallization, washing and drying the obtained sample, and roasting, thereby obtaining the HZSM-5 molecular sieve. Mainly aiming to solve the problems that the conventional synthesis process route is relatively long, a relatively large amount of template agent is used, a relatively great amount of waste liquids are discharged, the properties of a molecular sieve can be affected by a molding process, the molding process is relatively long in route, and the like, the invention provides the method for preparing the HZSM-5 molecular sieve and molding the HZSM-5 molecular sieve; the method can be used for directly preparing the HZSM-5 and molding the HZSM-5, and is relatively short in preparation and molding process route, very small in waste liquid discharge, simple in crystallization mode and high in yield.

Owner:NINGXIA UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com