Heat accumulation tubular reaction system

A tube-and-tube reaction and reaction system technology, which is applied in the field of thermal storage and tube-and-tube reaction systems, can solve problems such as energy waste, uneven reaction gas completion temperature, and uneven temperature field of reaction tubes, so as to reduce the amplification effect and eliminate volume Expansion problems, effects of temperature uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

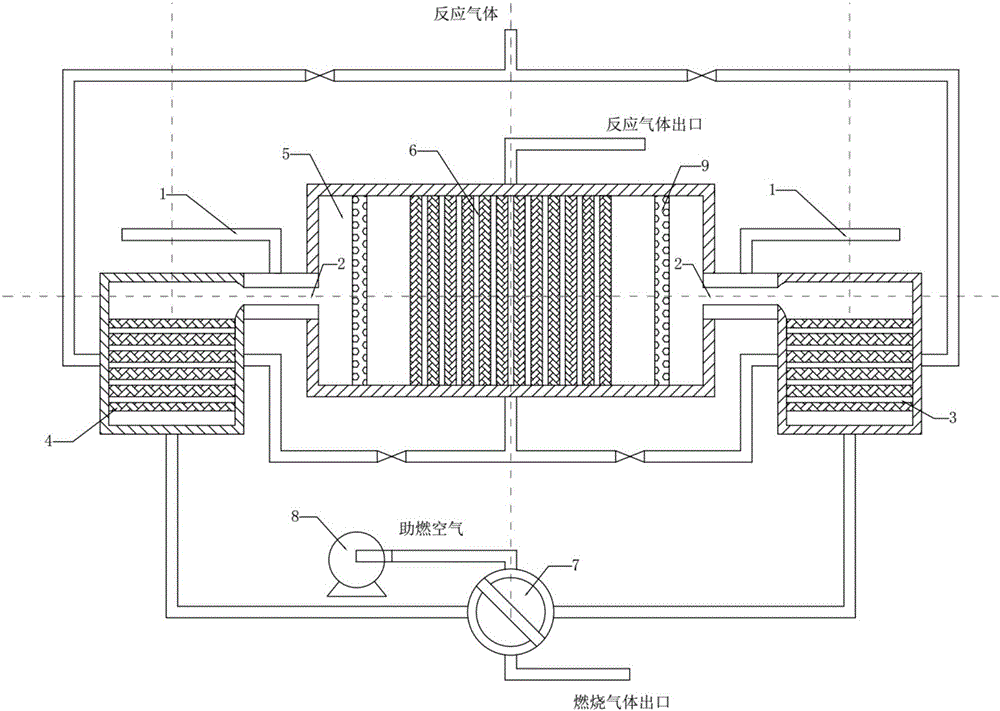

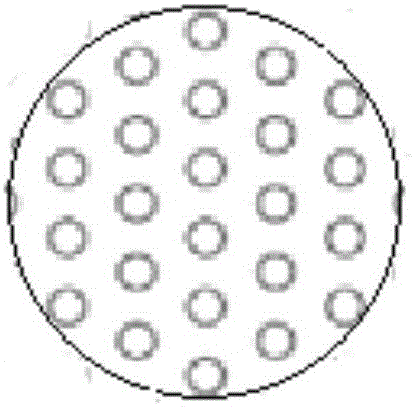

[0051] Such as figure 1 As shown, a heat storage shell and tube reaction system for the production of benzene and ethylene from acetylene, the heat storage shell and tube reactor reaction system includes: oil and gas pipelines, burners, shell and tube heat exchangers, heat storage bodies, A combustion chamber, a tubular reactor, a reversing valve, an induced draft fan and a porous fire-resistant wall; the combustion chamber contains a tubular reactor, two porous fire-resistant walls, and two burners are symmetrically distributed on both sides of the combustion chamber; The material of the tube reactor can be quartz, ceramic or stainless steel; each burner has a separate oil and gas pipeline, which is connected to a separate heat storage chamber; each heat storage chamber is filled with heat storage materials, and the heat storage Tubes are evenly distributed in the material; the regenerator is connected to the reversing valve, and the reversing valve is connected to the induce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com