Patents

Literature

254results about How to "Uniform and stable temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional graphene electrothermal paste, multifunctional electrothermal film prepared by same, preparation method and application

ActiveCN107682943AImprove machinabilityFast heat conductionChemical industryHeating element materialsCross-linkAviation

The present invention discloses multifunctional graphene electrothermal paste, a multifunctional electrothermal film prepared by the same, a preparation method and application. The preparation methodcomprises the following steps that: (1) graphene nanoplatelets are modified by introducing inducible lipidation and cross-linking reaction groups; (2) the modified graphene, a lipidizable and cross-linking reaction emulsion and various kinds of additives are subjected to liquid phase mixing, the above dispersion liquid is induced to undergo in-situ esterification and cross-linking reaction, so that graphene-based homogeneous electrothermal paste can be formed; (3) an electrothermal paste loading matrix is modified, so that the interfacial property of the electrothermal paste and the matrix material can be enhanced; and (4) the graphene electrothermal paste can be combined with different base materials, so that electrothermal products can be prepared. The graphene electrothermal material ofthe invention has the advantages of adjustable resistivity, adjustable use voltage, adjustable heating efficiency, far infrared heating function, flame retardancy, wide application range, high safety, energy-saving performance and the like, and can be applied to home building material manufacturing, human body care, aviation equipment, medical equipment, transportation pipelines, automobiles andother fields.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

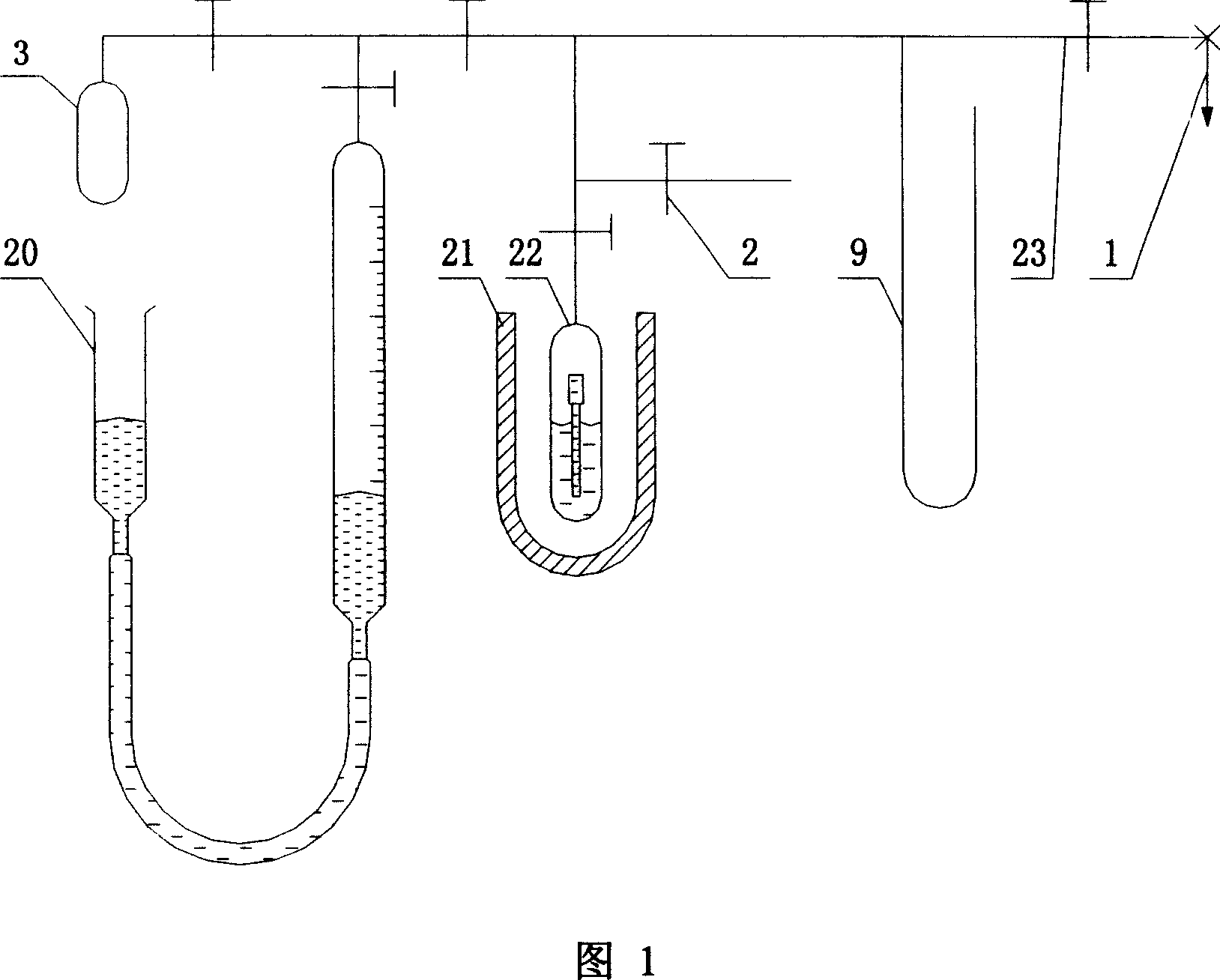

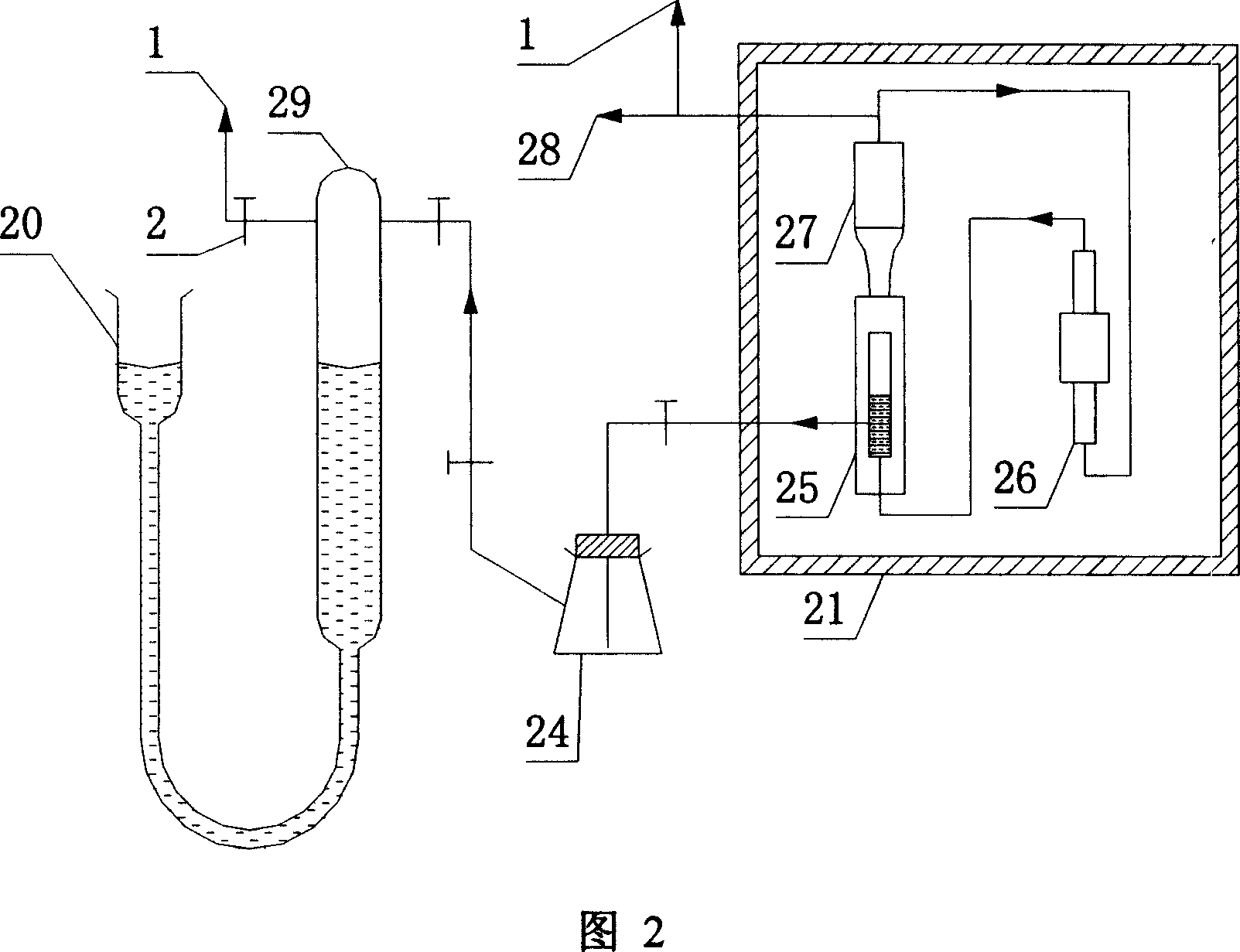

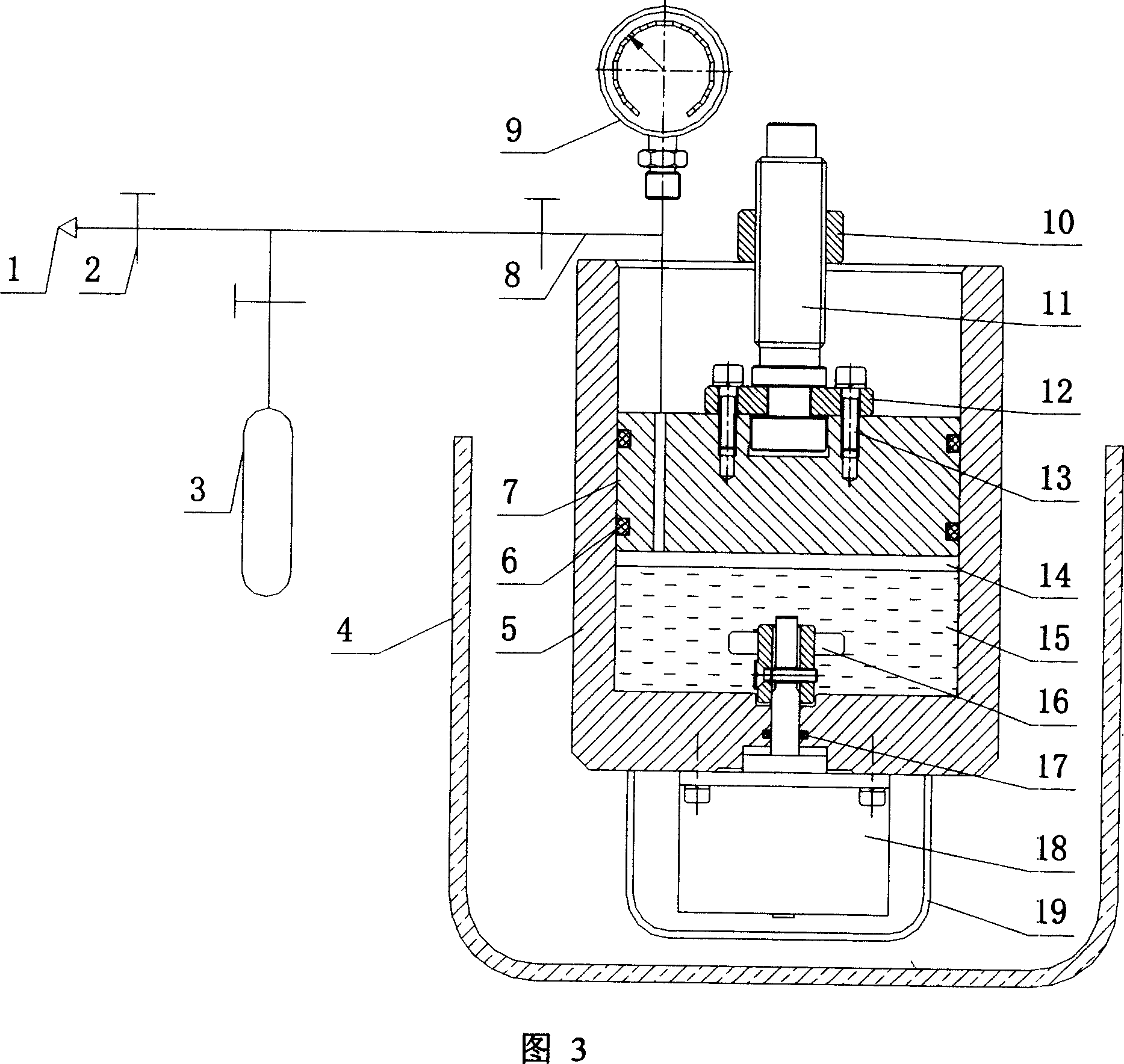

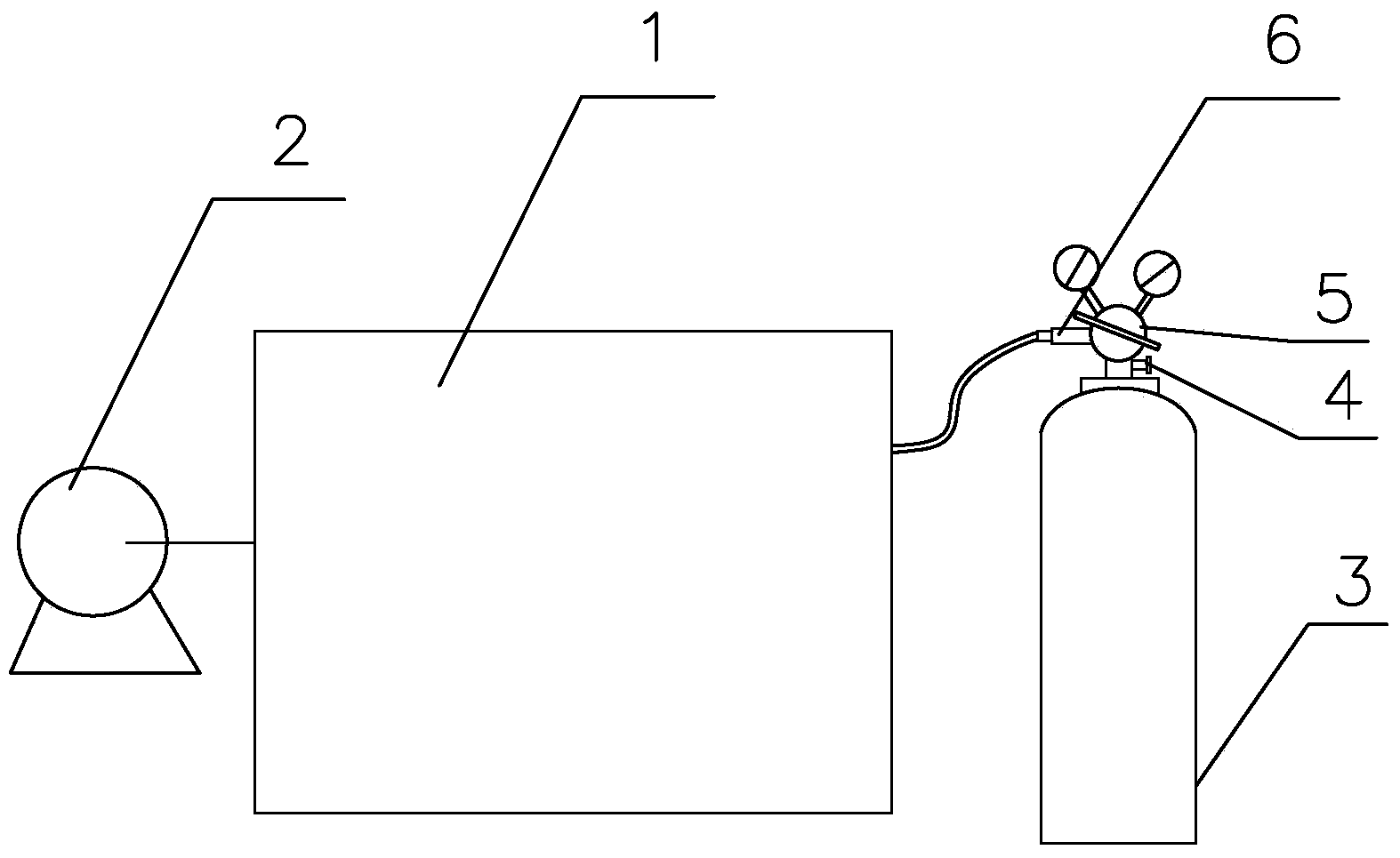

Detector for gas solubility in liquid

The present invention is instrument for gas solubility in liquid. The instrument has stirring blades soaked in test liquid and connected to the shaft of torque motor, one cylinder with piston connected to a lead screw, one precise constant temperature water bath with temperature display for the cylinder to be set in, and one gas source connected to gas pipe and precise manometer, with the precise manometer being connected to the inner cavity of the cylinder through the axial hole in the piston. The present invention converts the rotation of the lead screw into the axial motion of the piston inside the cylinder to control the gas pressure in the liquid inside the cylinder cavity, and has precise measurement of temperature, piston displacement and in-cavity gas pressure. The gas amount over the liquid may be calculated based on the gas state equation and the dissolved gas amount may be obtained. The present invention is used in measuring gas content and solubility in liquid.

Owner:ZHEJIANG UNIV

Technique for producing ultra high-strength terylene industry filament yarn

InactiveCN101144195AGuaranteed purityGuaranteed viscosity uniformityArtificial filament heat treatmentMelt spinning methodsSetting timeFilament yarn

The present invention discloses a production process for an ultra high tenacity polyester industrial filament. The production process adopts a one-step method of spinning and stretching, and the method comprises the solid state tackifying, the melt spinning, the high temperature stretching, the heat setting, and the winding forming. The present invention adopts the innovative five-pair hot roll stretching heat setting process, compared with the traditional four-pair hot roll stretching heat setting, the the present invention adopts two-stage heat stretching, the processing method of the two-stage heat setting effectively reduces the stretching speed of fiber, and prolongs the heat setting time of the fiber, so that the fiber has an even stable orientation structure while the physical performance of products is ensured, the spinning condition is optimized. The ultra high tenacity polyester industrial filament prepared by utilizing the method of the present invention has the advantages that the intensity is high, the stretching and the dry heat shrinkage are reasonable, the heat resistant performance is good, and the impact resistant performance and the fatigue resistant performance are good.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

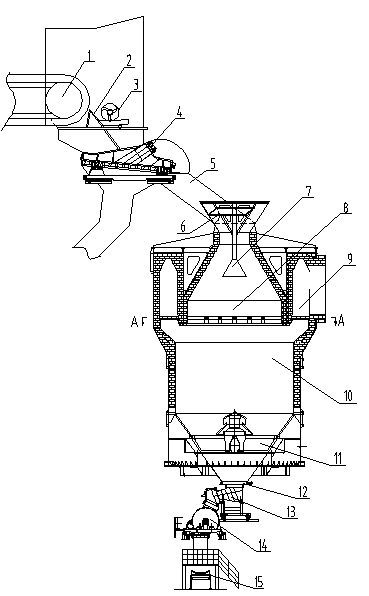

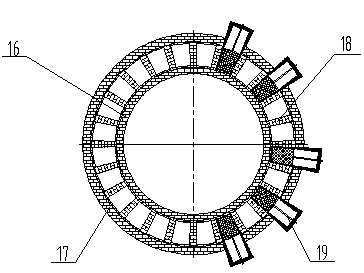

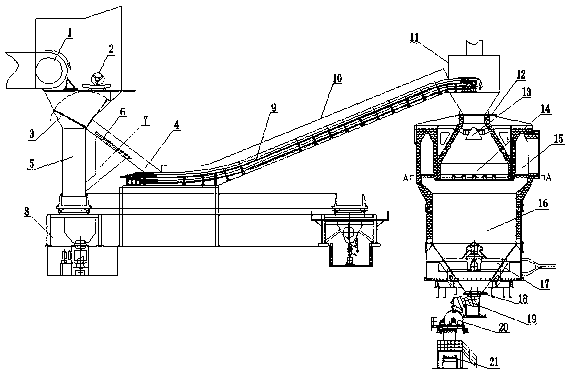

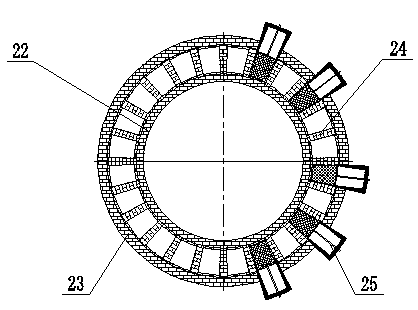

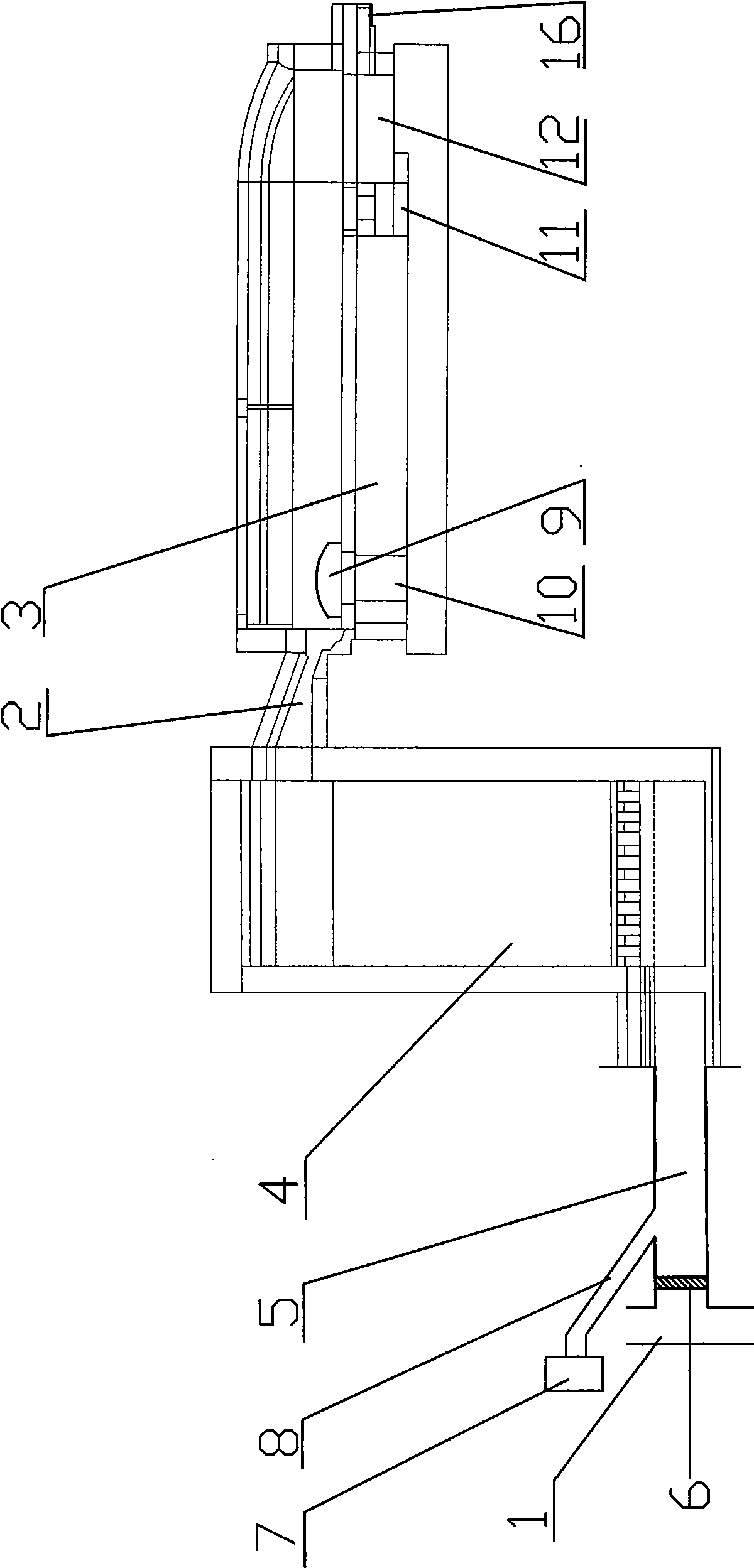

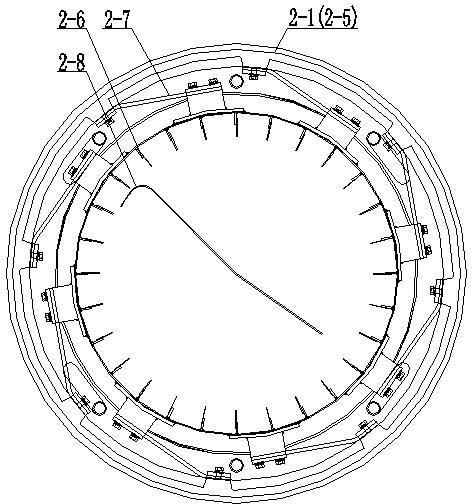

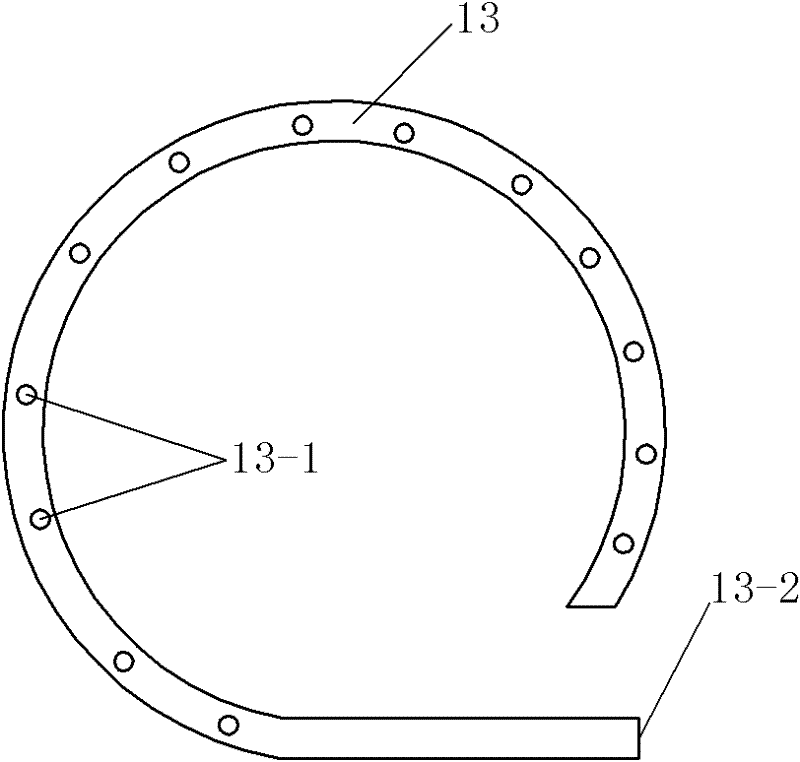

Sintering furnace type cooling device

ActiveCN103234359AReduce height differenceImprove qualityHandling discharged materialThermal energyFlue gas

A sintering furnace type cooling device relates to the technology field of sintering cooling devices. An outlet of a sintering machine is provided with a single roll crusher; an outlet of the single roll crusher is provided with a hot sinter screen; the hot sinter screen is connected with an inlet of a chute; an outlet of the chute is connected with a furnace opening of a cooling furnace; a distributing device is arranged inside the furnace opening of the cooling furnace; a ventilation device is arranged at the bottom of the cooling furnace; a discharging device is connected under the ventilation device; a belt conveyer is arranged under the discharging device; the cooling furnace comprises a pre-store area which is arranged on the upper portion, a cooling area which is arranged on the lower portion and an annular flue area which is arranged on the periphery of the pre-store area; radial supporting columns which are integrally and radially distributed are arranged at the bottom of the annular flue area; a high-temperature flue gas adjustment plate is coated on two adjacent radial supporting columns; and the high-temperature flue gas adjustment plate is capable of sliding along a diametrical direction of the annular flue. The sintering furnace type cooling device has the advantages of effectively overcoming the defects that an existing sintering cooling system is serious in air infiltration and low in waste heat utilization rate, achieving efficient heat replacement, improving the temperature of the flue gas and reducing energy consumption in cooling.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Preparation technology of ultralow contraction terylene industry long filament

ActiveCN1904153AAvoid RelaysGuaranteed viscosity uniformityMelt spinning methodsMonocomponent polyesters artificial filamentTextile fiberPolyester

This invention relates to the process of a kind of ultra-low contraction polyester fiber industry filament, which introduces the spinning and stretch one-stage process, including: solid phase increases sticks, melting spinning, high temperature stretches, heat setting, coiling formation. This invention adopts the innovative 5 pairs of hot rollers stretch heat setting technique, in comparison with the tradition 4 pairs, which adopts the 2-step heat stretch and 2-step heat setting. The new level heat setting processing method can reduce the textile fiber stretch speed effectively, lengthen the textile fiber heat setting time, and enables the textile fiber possessing evenly stable orientation structure, which guarantees product physics performance, optimizes the spinning condition. This ultra-low contraction polyester fiber industry filament preparation method provided with polyester fiber industry having high density, big module, small elongate, good heat-resisting performance, resisting impingement, and bearing the fagged performance.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

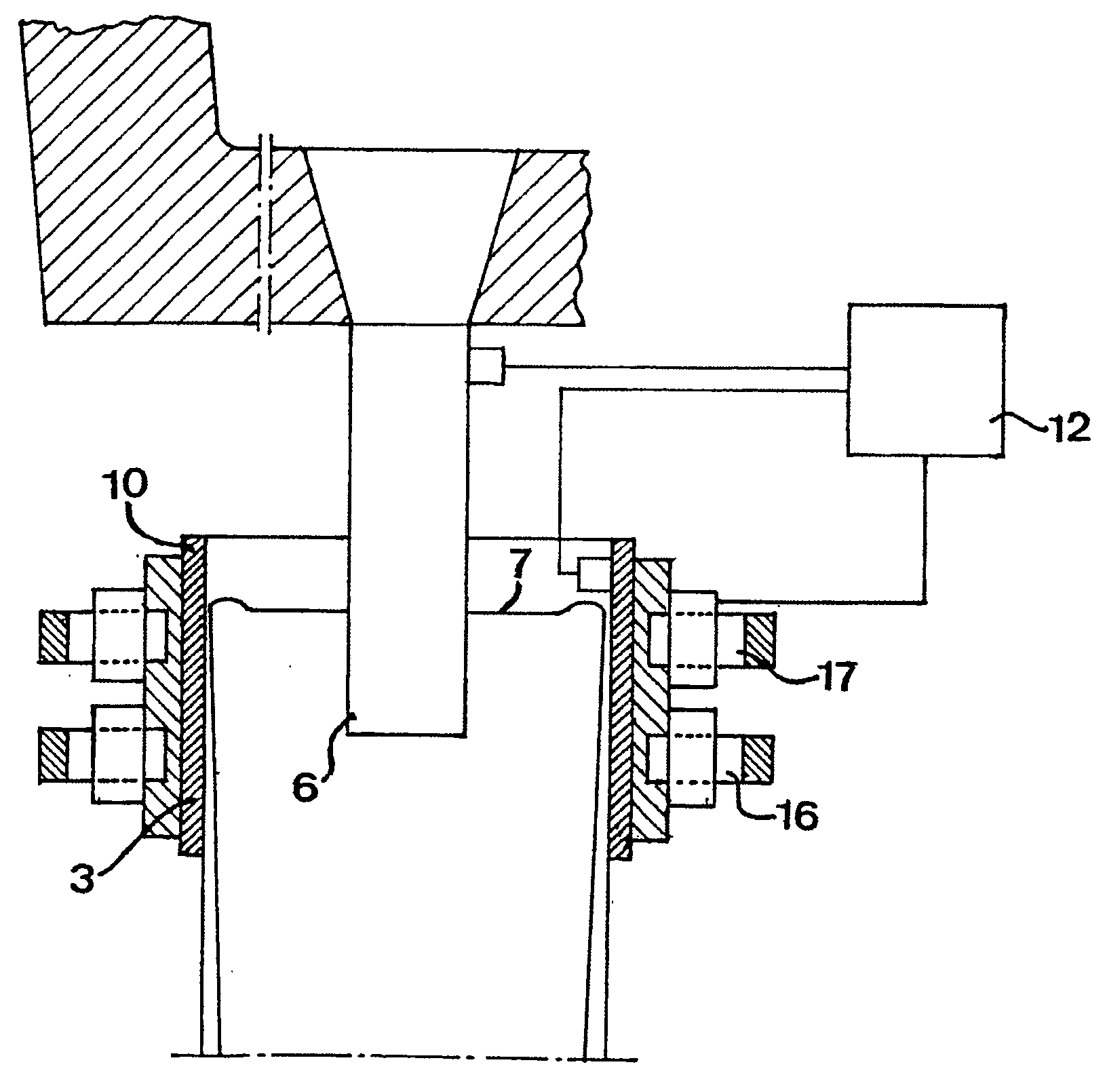

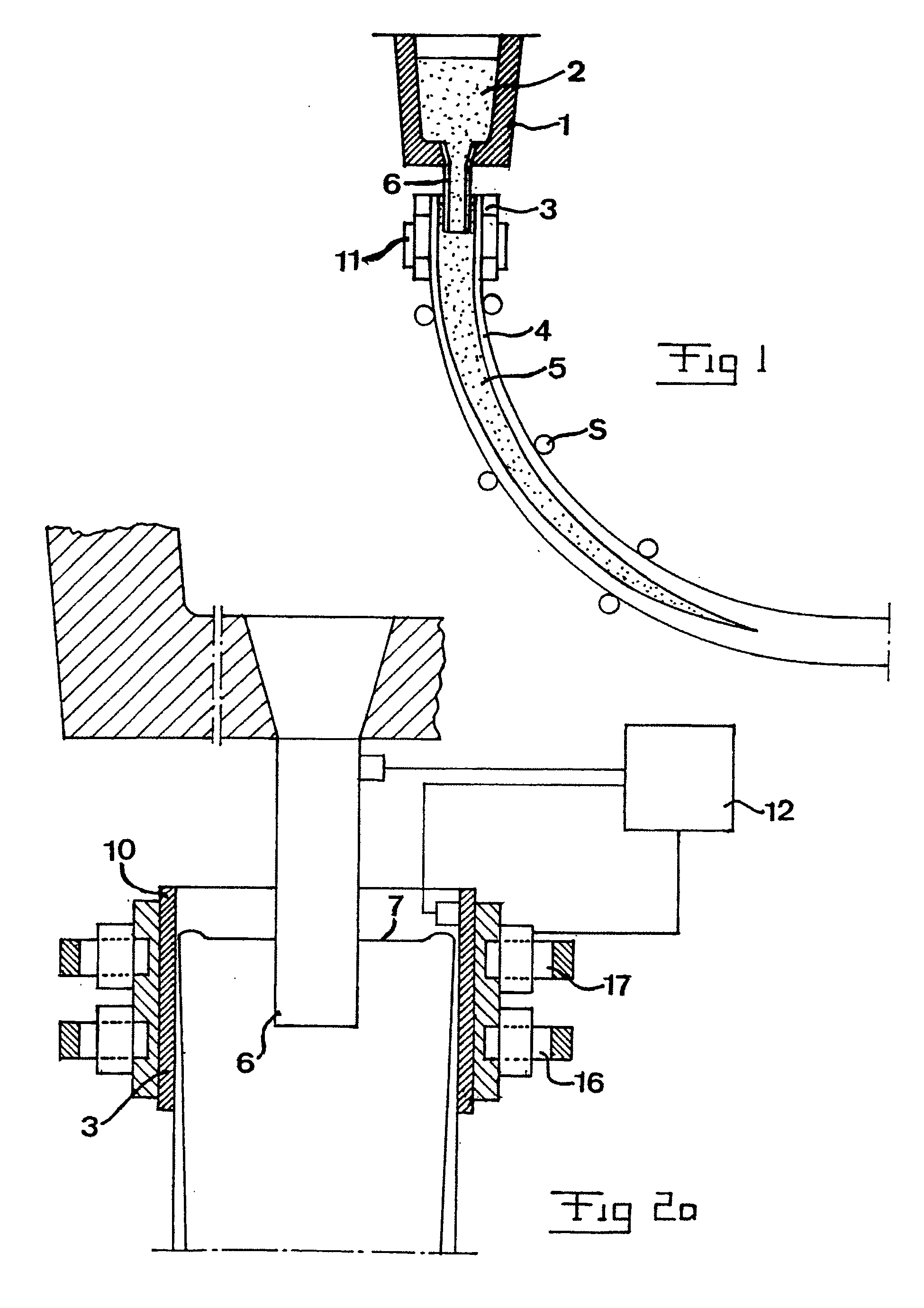

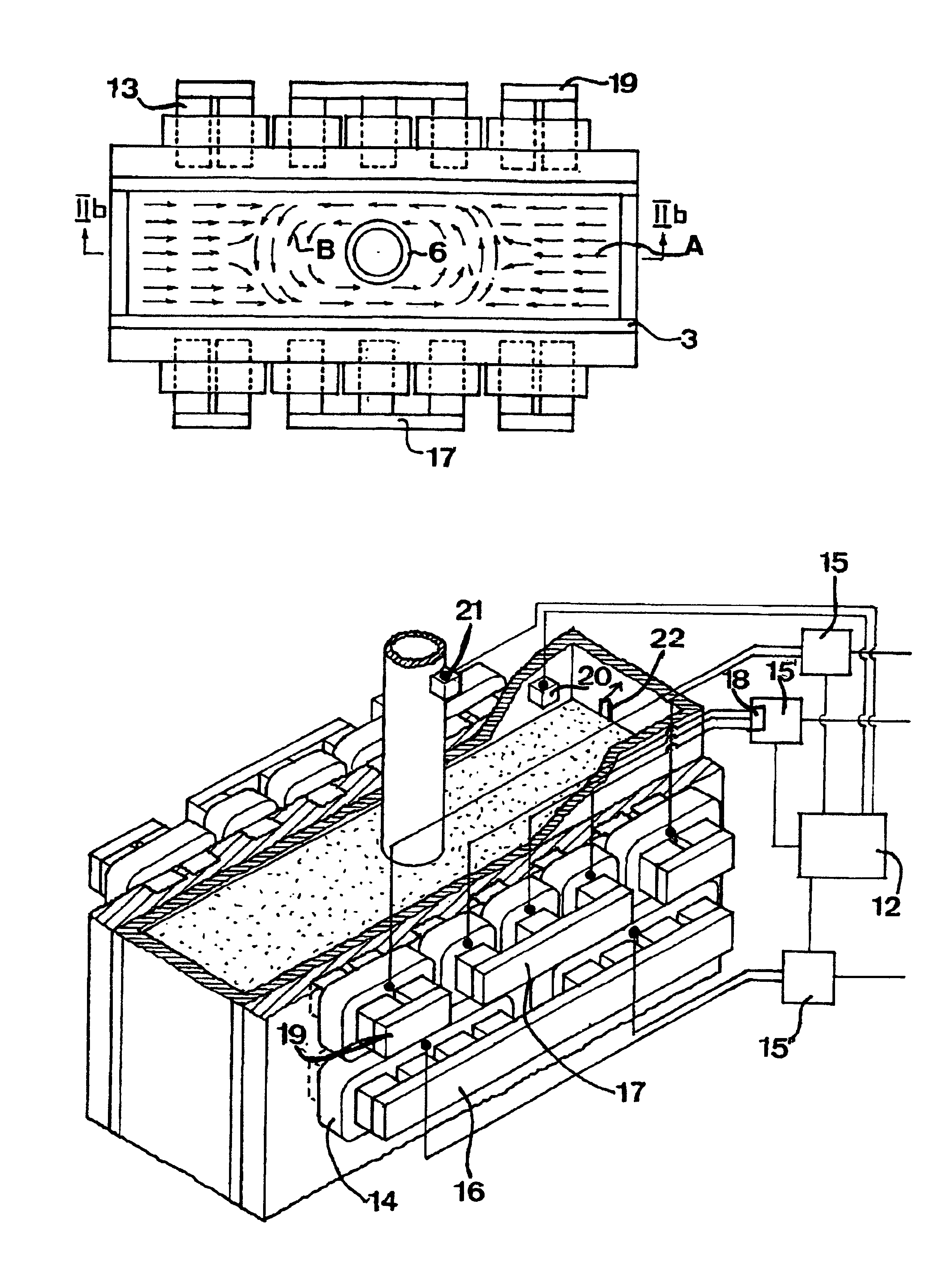

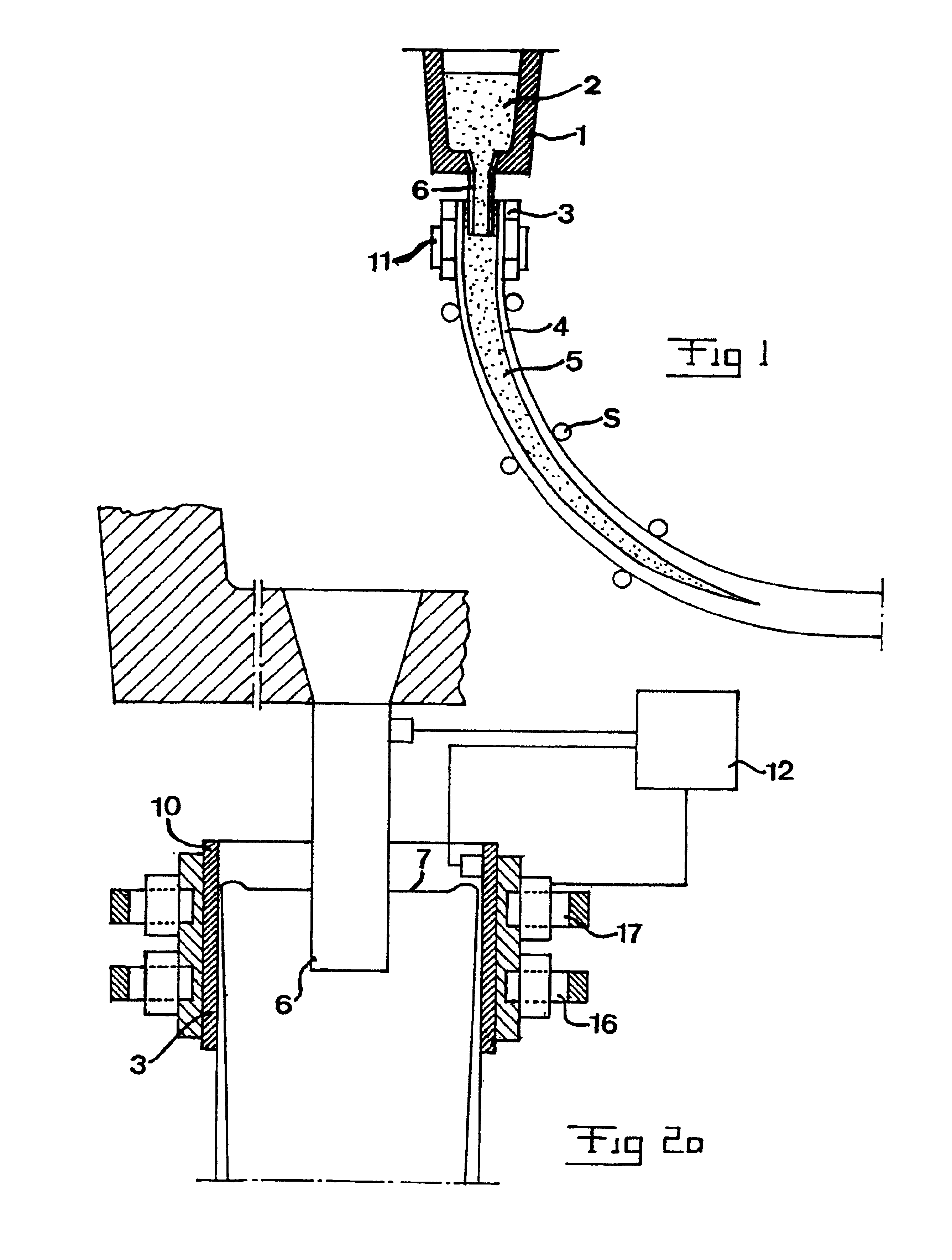

Device and a method for continuous casting

InactiveUS20050039876A1Promote resultsUniform and stable temperatureCasting safety devicesMetallurgyMolten metal

An apparatus for continuous casting of metals has members (16) adapted to generate a stationary magnetic field of a variable strength over substantially the entire horizontal cross section of the mould from one long side to the other long side close to, or below, the region for supply of molten metal at a distance below the upper surface of the molten metal. There are also members (17) adapted to generate a variable magnetic field in the area of the upper surface in a region that is centrally located with respect to said cross section and close to a region for supply of molten metal. A unit (12) is adapted to control said magnetic members (16, 17) to generate, independently of each other, magnetic fields with an appearance that is dependent on the value prevailing of one or more predetermined casting parameters.

Owner:ABB (SCHWEIZ) AG

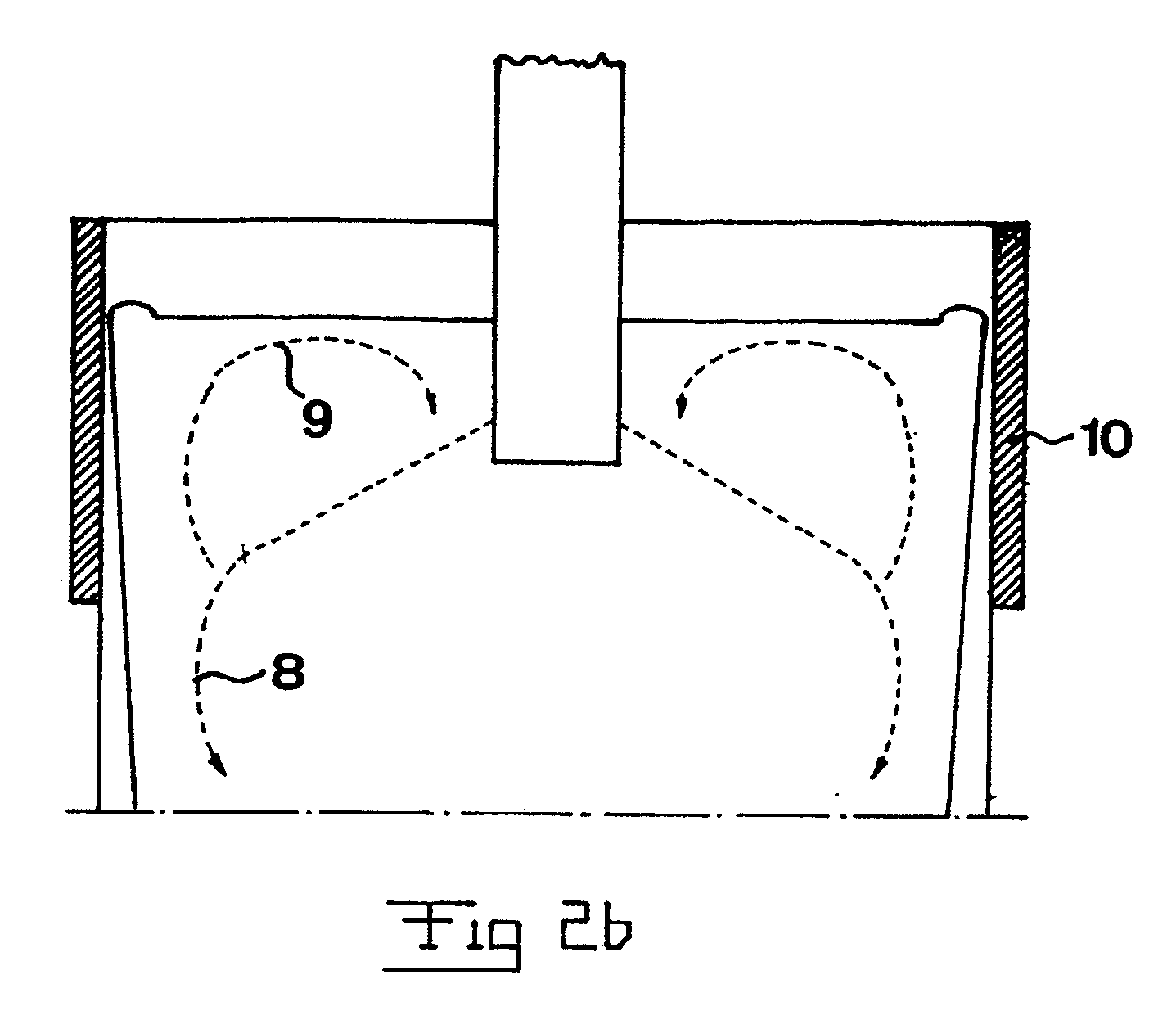

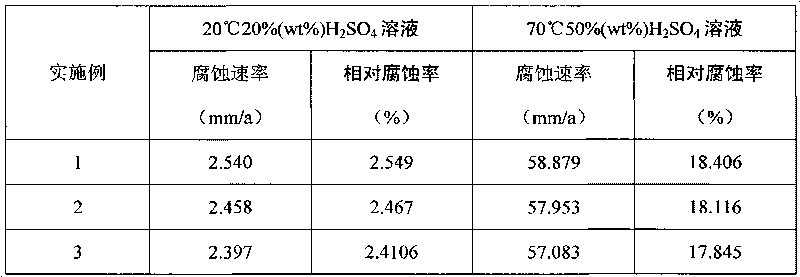

Sulphuric acid dew point corrosion resisting steel and method for producing same

InactiveCN101736202AShort Cooling IntensityStable temperatureProcess efficiency improvementElectric furnaceChemical compositionMolten steel

The invention discloses sulphuric acid dew point corrosion resisting steel and a method for producing the same by continuously casting and rolling a thin steel billet with an electric furnace. The molten steel comprises the following chemical components by weight percent: 0.03-0.08 percent of C, 0.10-0.45 percent of Si, 0.40-1.0 percent of Mn, 0.025 percent of P or less, 0.035 percent of S or less, 0.15-0.50 percent of Cu, 0.40-1.0 percent of Cr, 0.02-0.15 percent of Sb, 0.04-0.30 percent of Ni and 0.01-0.05 percent of Ti and also comprises 100ppm of N or less. The thin steel billet is continuously cast at the speed of 3.5-5.5m / min, and the cast thin steel billet is placed in the electric furnace of 900-1050 DEG C, soaked at 1100-1200 DEG C, rolled at 1040-1120 DEG C, finally rolled at 850-920 DEG C and winded at 550-650 DEG C. The Cu-Cr-Sb composite micro-alloyed sulphuric acid dew point corrosion resisting steel having good mechanical performance, welding performance and corrosion resisting performance can be produced by continuously casting and rolling the thin steel billet with the electric furnace.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

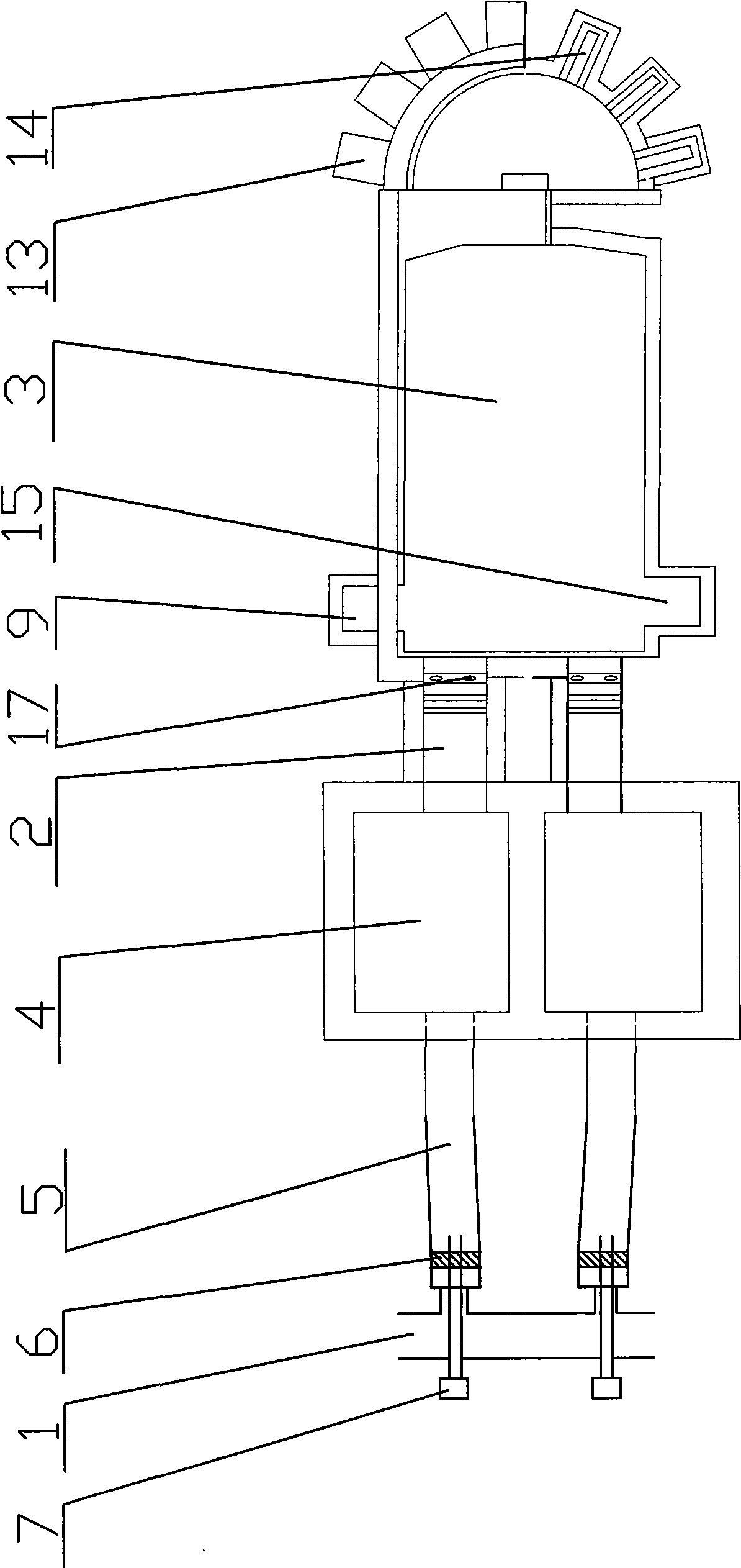

Furnace type cooling and heat exchange device for sintered ores

ActiveCN103234349AGuaranteed operating rateImprove qualityCharge manipulationIncreasing energy efficiencyCooling effectFlap valve

The invention discloses a furnace type cooling and heat exchange device for sintered ores and relates to the technical field of cooling devices of sintered ores. A single-roll crusher is arranged at an outlet of a sintering machine, a flap valve is arranged under the single-roll crusher, the bottom of the flap valve is arranged at the connection position of a furnace cooling system chute and an annular cooling system chute / a belt cooling system chute, the flap valve can be switched between the furnace cooling system chute and the annular cooling system chute / the belt cooling system chute, a hot vibration screen also serves as the bottom wall of the furnace cooling system chute, a hot return mine chute is connected under the hot vibration screen and is connected with the annular cooling system chute / the belt cooling system chute, an outlet of the furnace cooling system chute is connected with one end of a chain-scraper conveyor, the other end of the chain-scraper conveyor is connected with a fire door of a cooling furnace, and a heat-insulating cover is arranged above the chain-scraper conveyor. By the aid of the device, the cooling effect and the waste heat utilization ratio of sintered ores are effectively improved, and the furnace cooling system device can be arranged in a remote distance without being limited by fields.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

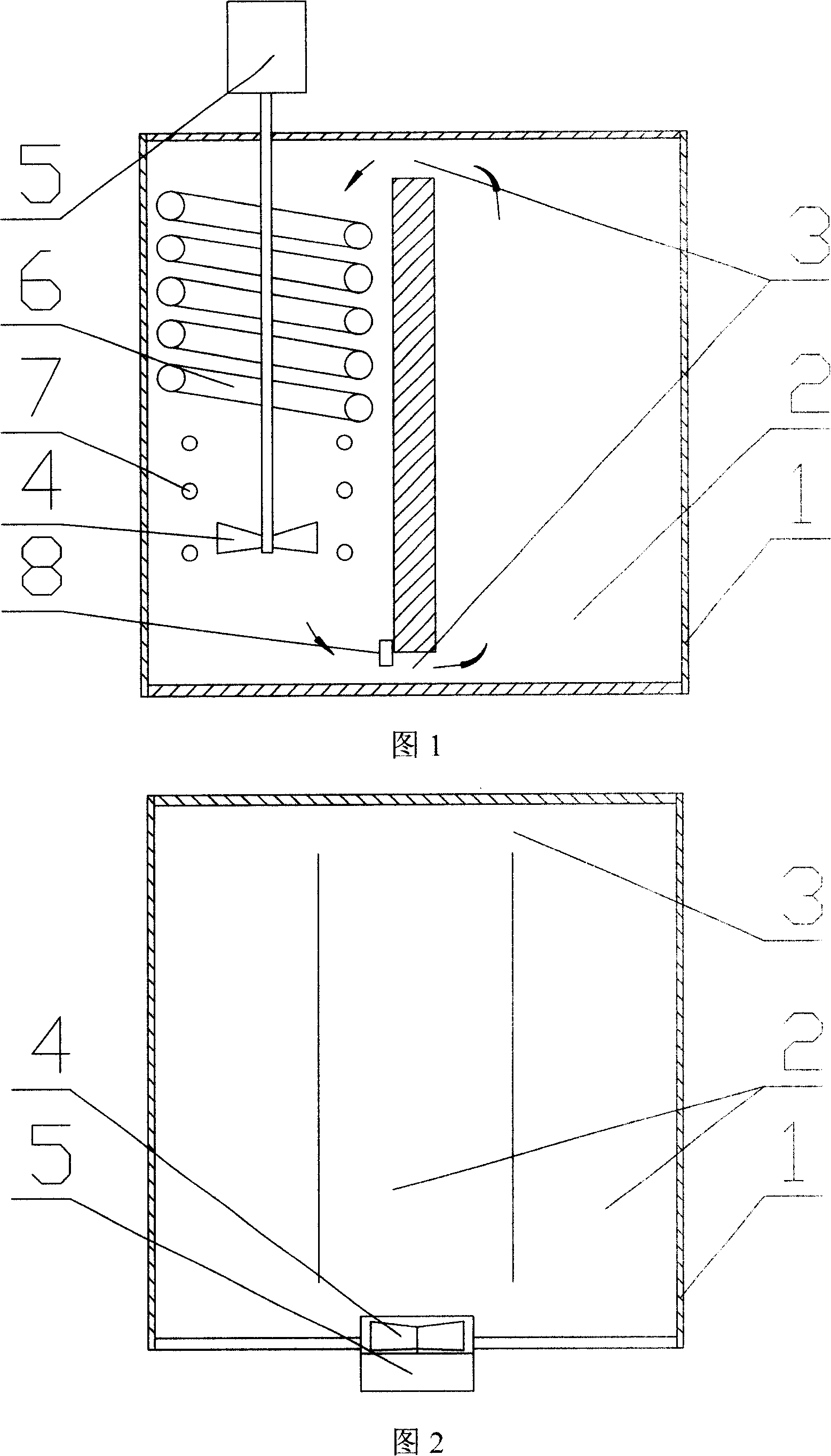

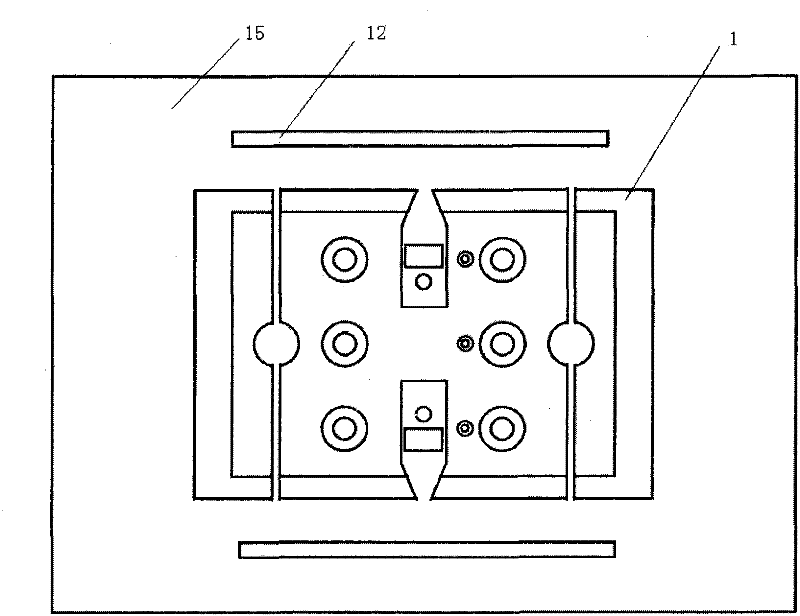

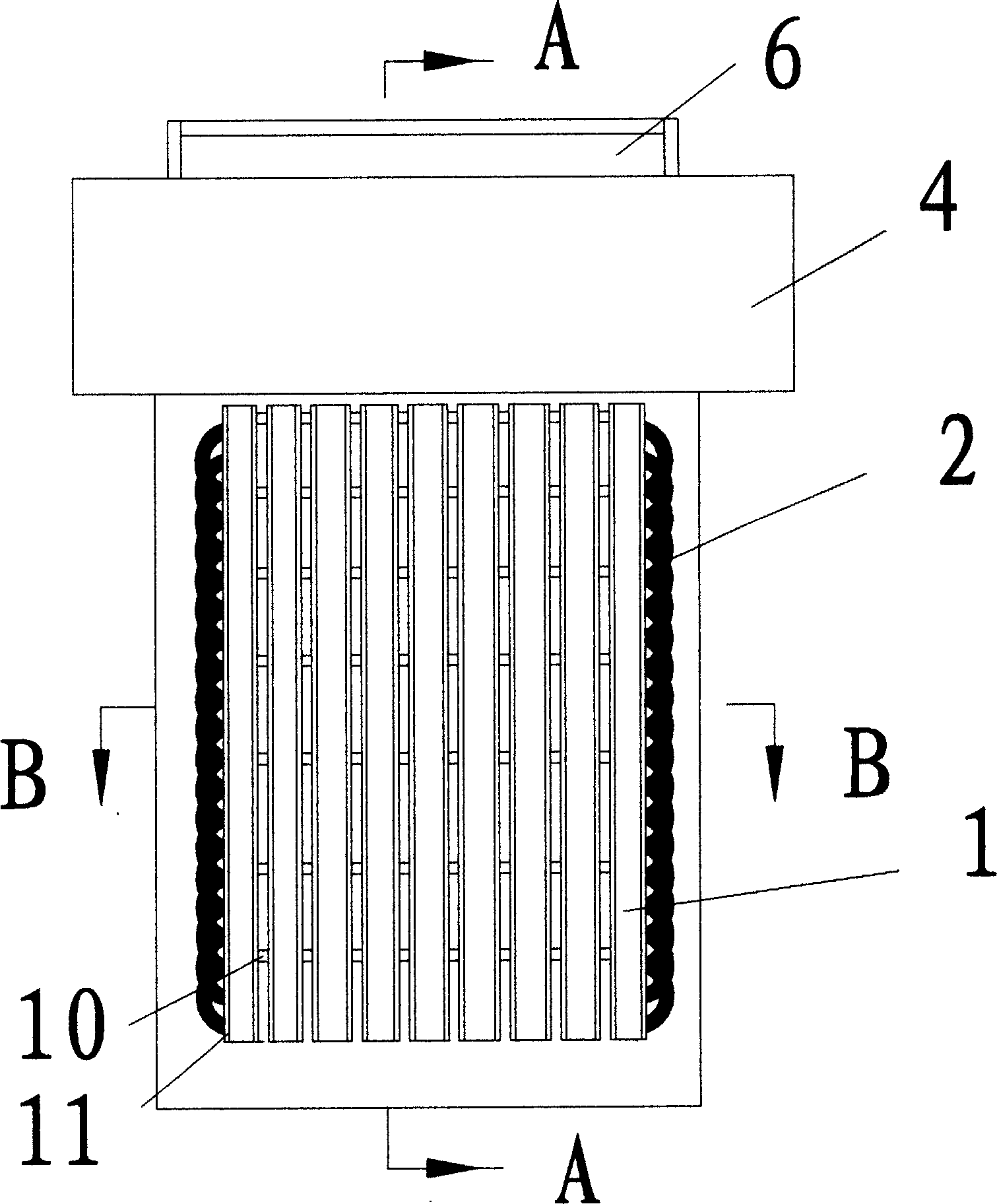

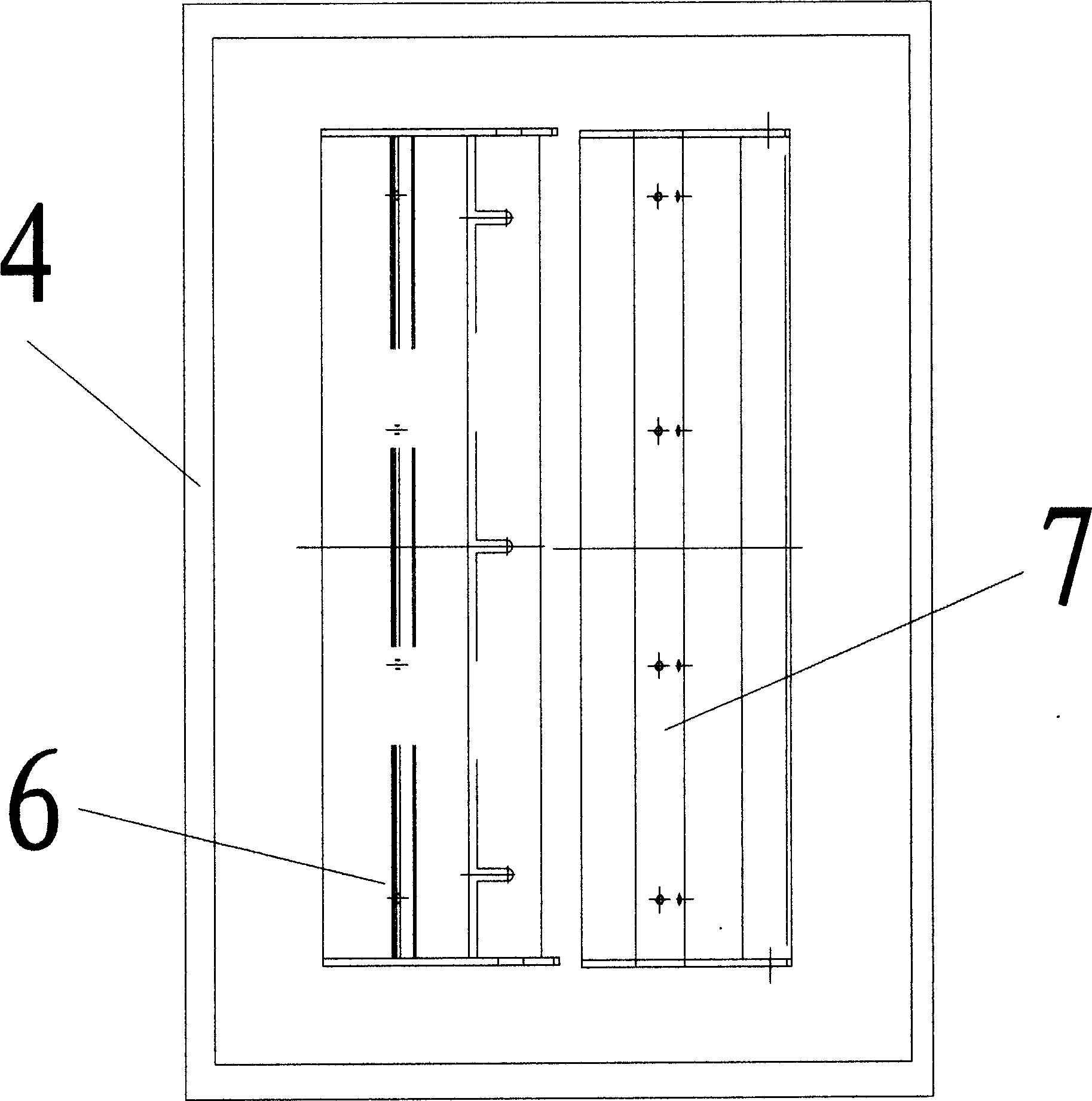

Constant temperature oven

InactiveCN101116835ASimple structureImprove technical indicatorsWater/sand/air bathsMetrologyElectric machinery

The present invention discloses a constant-temperature groove, which comprises a groove body (1) and is characterized in that the groove body (1) is divided into 2 cavities (2) including a left one and a right one, wherein circulation channels (3) are arranged on the upper end and the lower end between the cavities (2), a stirring oar (4) is arranged inside one of the cavities (2) and connected with an electrical machine (5). The groove body provided by the present invention is divided into 2 cavities, one of which is adopted as the working area, and the other is provided with the stirring oar inside to form a single circulation of the medium, thereby having simple structure, higher technical standard, and the temperature which is much more stable and even. As proved by the test carried out by National institute of metrology, the technical index of the present invention is superior to or meet the national standard, meanwhile the present invention adopts the stirring on the lateral of the working area, thereby preventing the stirring oar of the constant-temperature groove from being damaged by the fallen thermometer used to measure the temperature. The present invention has the advantages of a simple structure, small fluctuation of both the temperature and the maximum temperature difference, and the technical index superior to the national standard, etc.

Owner:陈坚

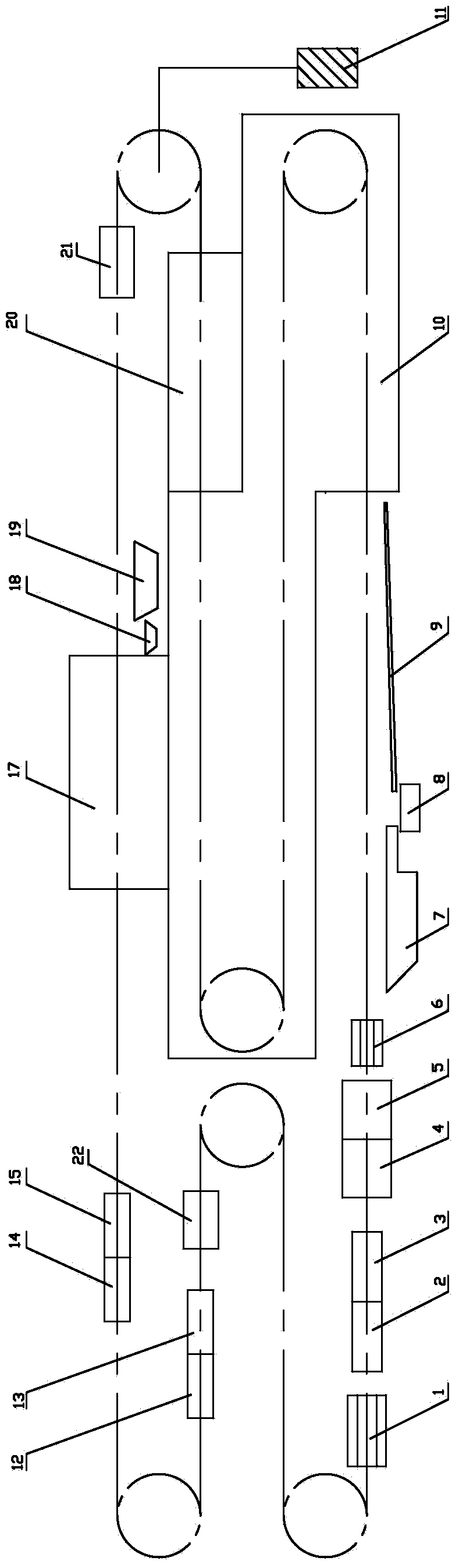

Two-hand mould PVC (polyvinyl chloride) glove production equipment

The invention discloses two-hand mould PVC (polyvinyl chloride) glove production equipment. The two-hand mould PVC glove production equipment comprises a hand mould railway line and a glove production line, wherein the hand mould railway line is arranged above the glove production line, and the hand mould railway line is a two-hand mould railway line and is composed of a two-hand mould main railway and a two-hand mould subsidiary railway; the two-hand mould main railway is an open type U-shaped railway, the two-hand mould subsidiary railway is a single-side double-layer rail, the glove production line is successively provided with a pre-dropping device, demoulding devices of No.1 and No.2 lines, counting machines of No.1 and No.2 lines, a mould-cleaning device, a PVC material groove, a PVC recovering groove, a PVC drip-drooping section, a PVC main oven, a smoke collecting section, a PU material groove, a PU drip-drooping recovering groove, a PU oven, a hemming of No.2 line, an edge-shaping machine, a hemming of No.1 line and an edge-shaping machine, wherein the smoke collecting section is respectively communicated with the PVC main oven and the PU oven, and a production line balance-weight system is arranged between the smoke collecting section and the PU material groove. Compared with the traditional single-hand mould PVC production line, the two-hand mould PVC glove production equipment provided by the invention has the advantages that the production efficiency is improved, and the energy consumption is effectively reduced.

Owner:安徽英科医疗用品有限公司

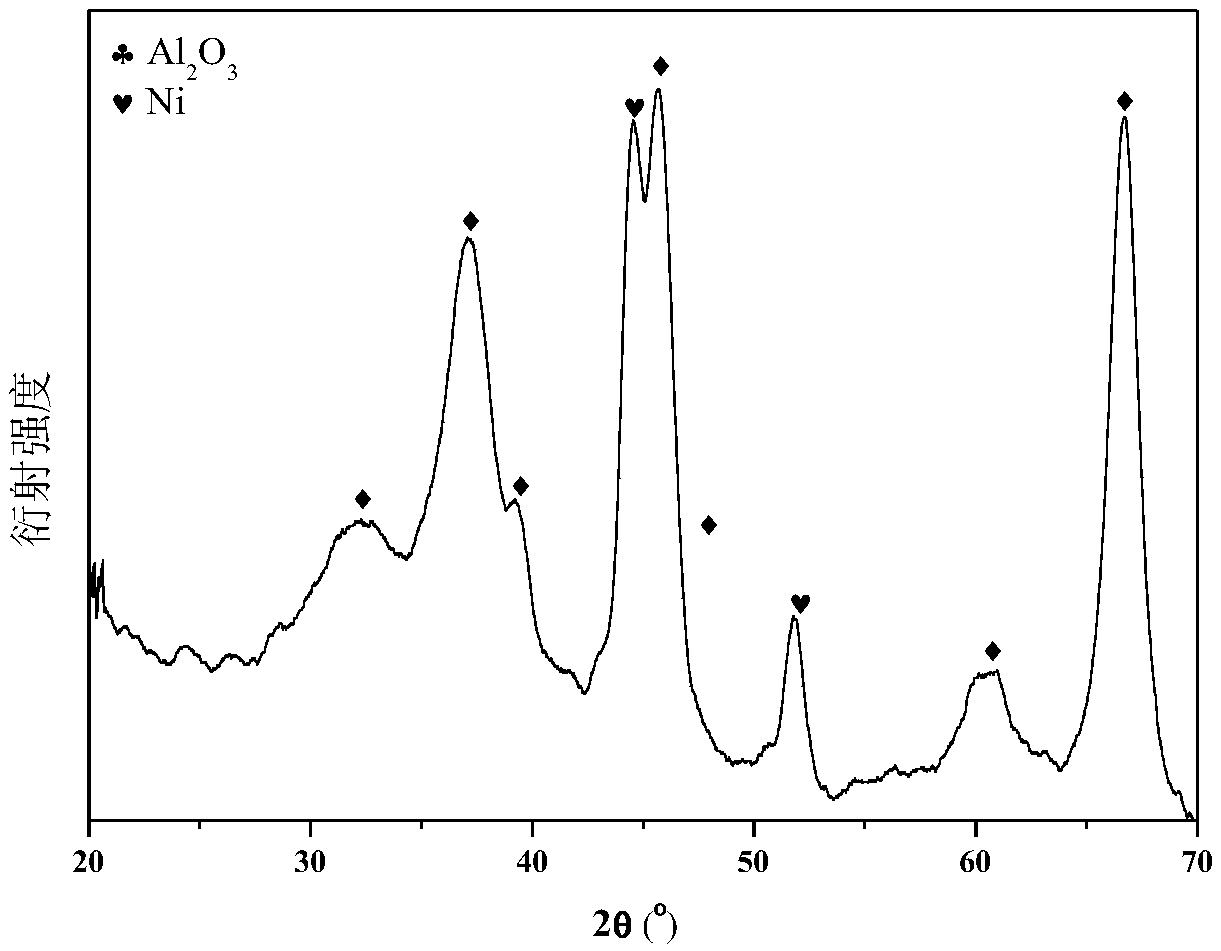

Methanation catalyst as well as preparation method and application thereof

ActiveCN108355668AEvenly dispersedSmall grain sizeHeterogenous catalyst chemical elementsGaseous fuelsAlkaline earth metalPtru catalyst

The invention discloses a methanation catalyst as well as a preparation method and application thereof. The preparation method comprises the following steps: taking aluminum isopropoxide as a raw material to prepare aluminum sol through adopting a solvent-gel method; meanwhile, directly dissolving alkali metal auxiliary agent soluble salt and alkaline earth metal or rare earth metal modified auxiliary agent soluble salt into the aluminum sol; then concentrating, spraying and molding to obtain a micro-sphere carrier precursor; after drying and roasting, screening micro-sphere powder with a certain granularity range as a catalyst carrier; taking the micro-sphere powder as a carrier and loading active metal Ni and an auxiliary agent La2O3 by adopting a isovolumetric immersion method, so as toprepare the complete methanation catalyst applicable to a micro-channel reactor. The catalyst prepared by the method has relatively high activity, hydrothermal stability and carbon deposition resisting performance.

Owner:壹碳环投(北京)科技有限公司

Device and a method for continuous casting

InactiveUS6938674B2Uniform and stable temperatureUniform speedCasting safety devicesUltimate tensile strengthMolten metal

An apparatus for continuous casting of metals has members (16) adapted to generate a stationary magnetic field of a variable strength over substantially the entire horizontal cross section of the mould from one long side to the other long side close to, or below, the region for supply of molten metal at a distance below the upper surface of the molten metal. There are also members (17) adapted to generate a variable magnetic field in the area of the upper surface in a region that is centrally located with respect to said cross section and close to a region for supply of molten metal. A unit (12) is adapted to control said magnetic members (16, 17) to generate, independently of each other, magnetic fields with an appearance that is dependent on the value prevailing of one or more predetermined casting parameters.

Owner:ABB (SCHWEIZ) AG

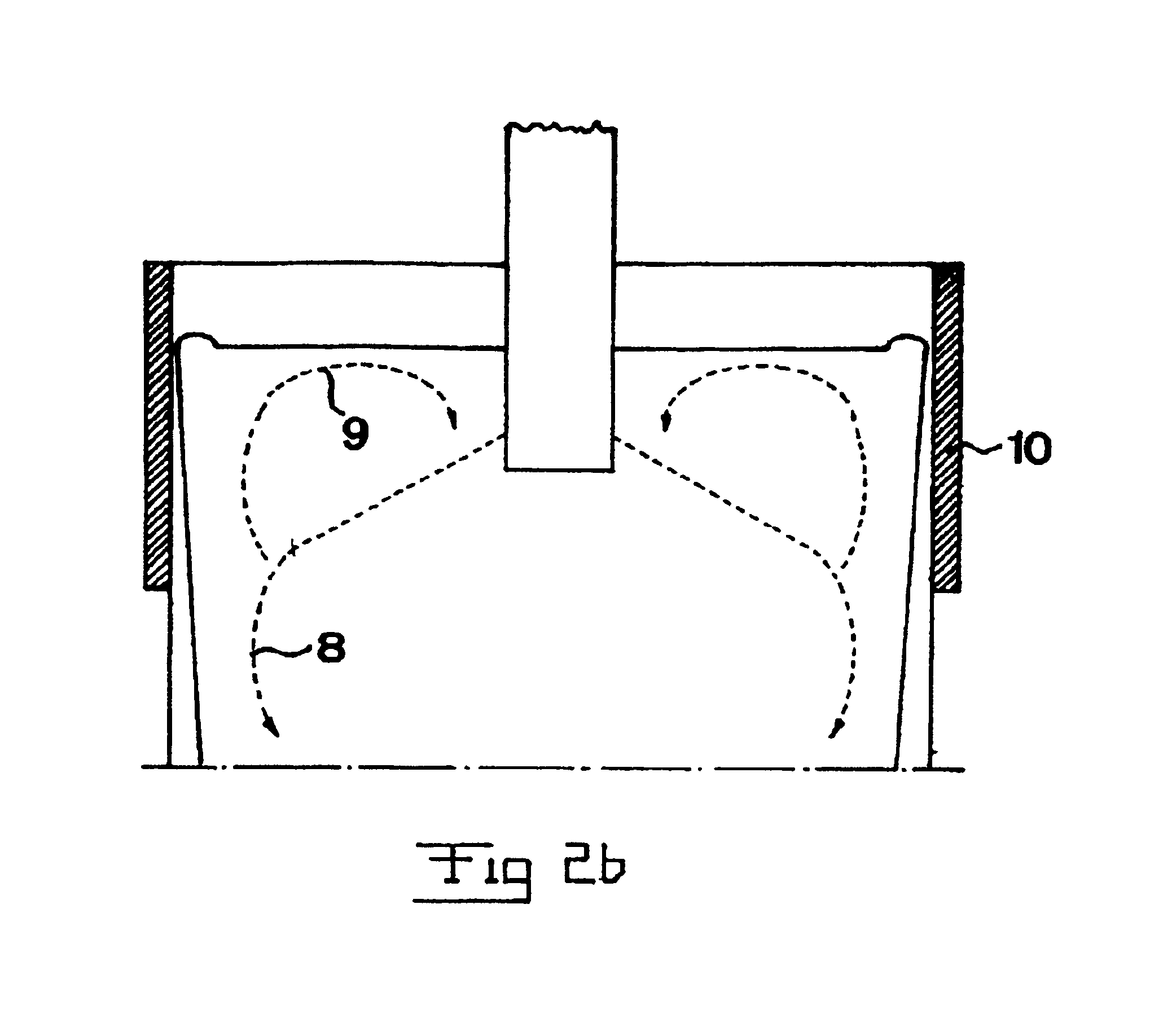

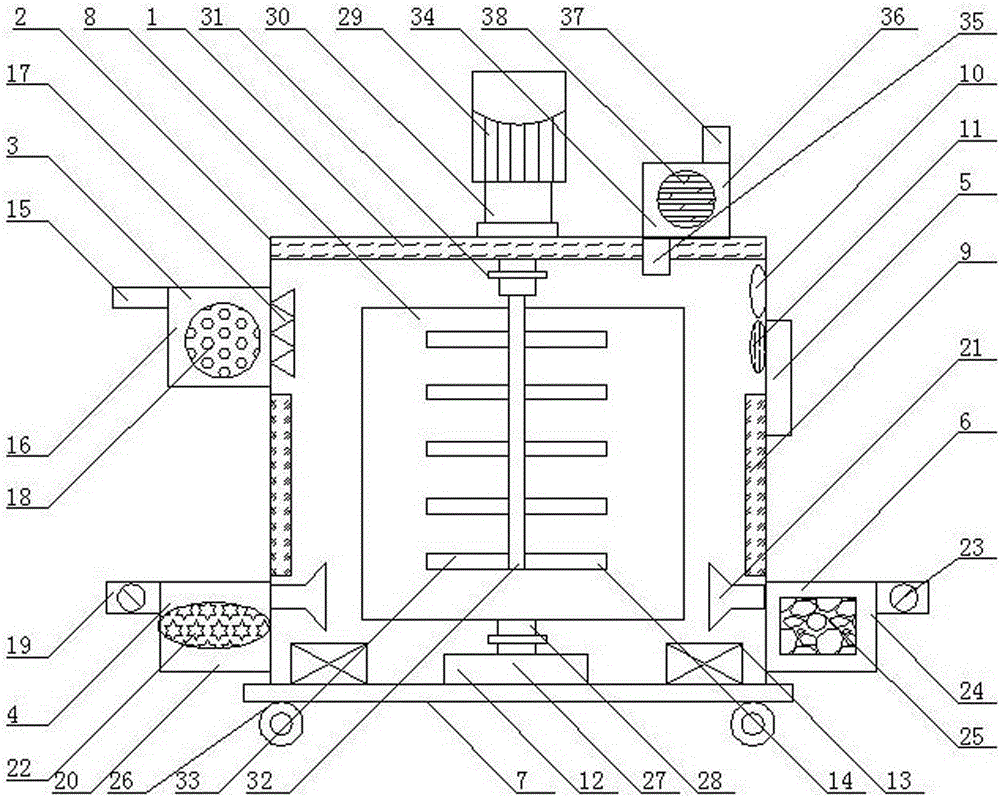

Multifunctional seed storage device

InactiveCN106171315AUniform and stable temperatureAvoid Bacterial Contamination of SeedsAgriculture tools and machinesHarvested fruit hanging devicesEngineeringMultiple function

The invention discloses a multifunctional seed storage device which comprises a box body. A top cover is arranged at the top end of the box body. An air exhaust box is arranged on the right side of the top end of the box body. The upper end of the left side of the box body is provided with a humidifying box. The lower end of the left side of the box body is provided with a refrigeration box. The upper end of the right side of the box body is provided with a controller. The lower end of the right side of the box body is provided with a heating box. The bottom end of the box body is provided with a base. The middle end inside the box body is provided with a storage screen. The middles of the left and right sides inside the box body are each provided with an ultraviolet light sterilization modulator tube, the upper end of the right side inside the box body is provided with a temperature sensor, the lower end of the temperature sensor is provided with a humidity sensor, the middle of the bottom end inside the box body is provided with a rotating device, the left side and the right side of the rotating device are each provided with an air blower, and a stirring device is arranged inside the storage screen. The multifunctional seed storage device is good in ventilation performance and capable of effectively preventing seeds from being moldy, has heating, refrigeration, humidifying and stirring functions, and is multifunctional and convenient to use.

Owner:哈尔滨尼亚农业有限公司

Production formula for alkali-resistant glass marble, production method and production kiln thereof

ActiveCN101531457AMix well and evenlyControl moisture contentGlass furnace apparatusGlass shaping apparatusProduction rateCLARITY

The invention relates to a production formula for alkali-resistant glass marble in building material industry, a production method and a production kiln thereof. The invention is reasonable in selecting weight proportions of ingredients, which is favorable for the control of quality system, and the produced finished product of the glass marble has high clarity and good quality; the entire technological process consists of screening, weighting and mixing raw materials, founding and discharging, the technology is simple and the operation is convenient; using a horseshoe-fired furnace for producing the alkali-resistant glass marble solves the technical prejudice in a long term that the horseshoe-fired furnace is unsuitable for the production of the alkali-resistant glass marble; a general glass marble kiln is utilized to realize the production of the alkali-resistant glass marble without improving kiln refractory, which has the advantages of large production scale, easy control and regulation for the production process, good scale effect and prominent energy-saving effect; the cost is dramatically reduced while the production rate is greatly improved in contrast to a full-electric melting kiln.

Owner:ZIGONG DENGGUAN GLASS FIBER

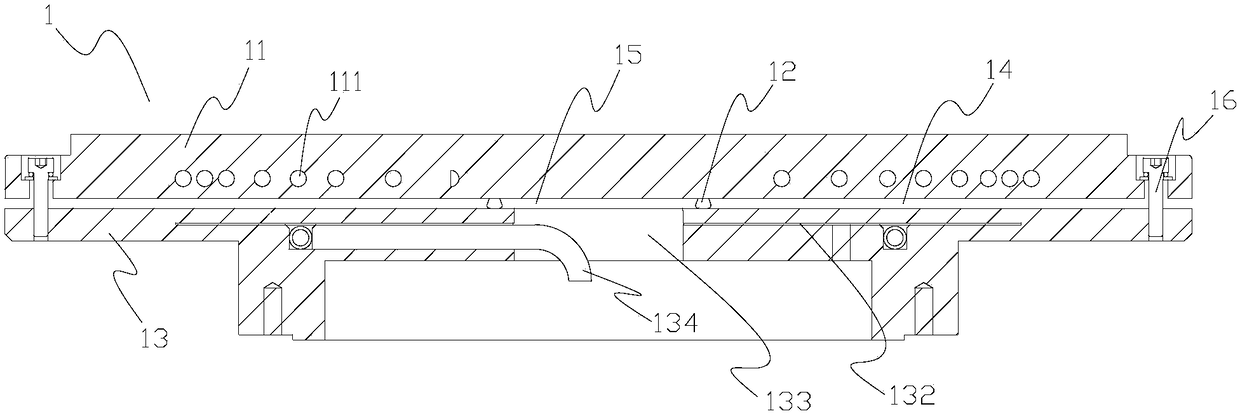

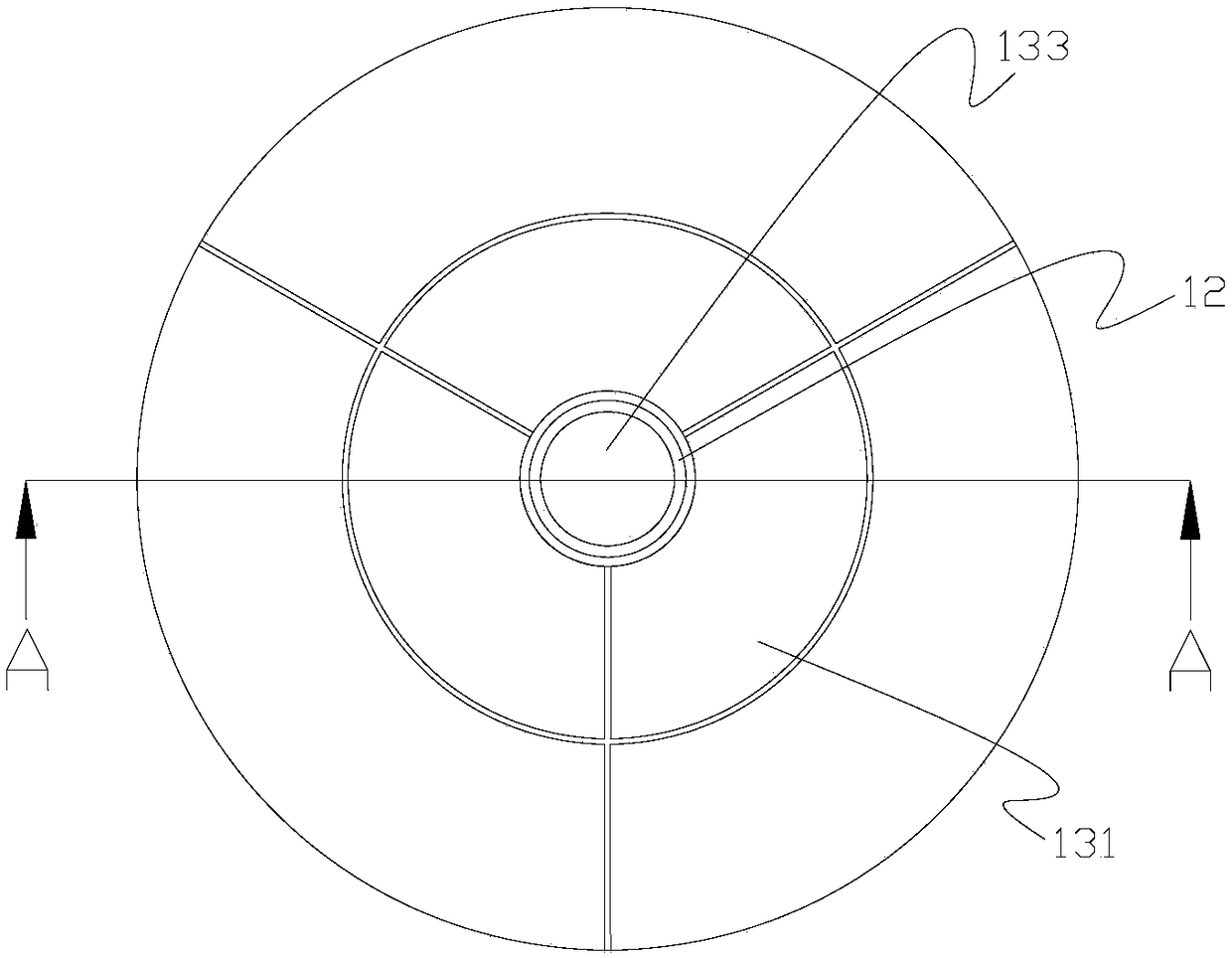

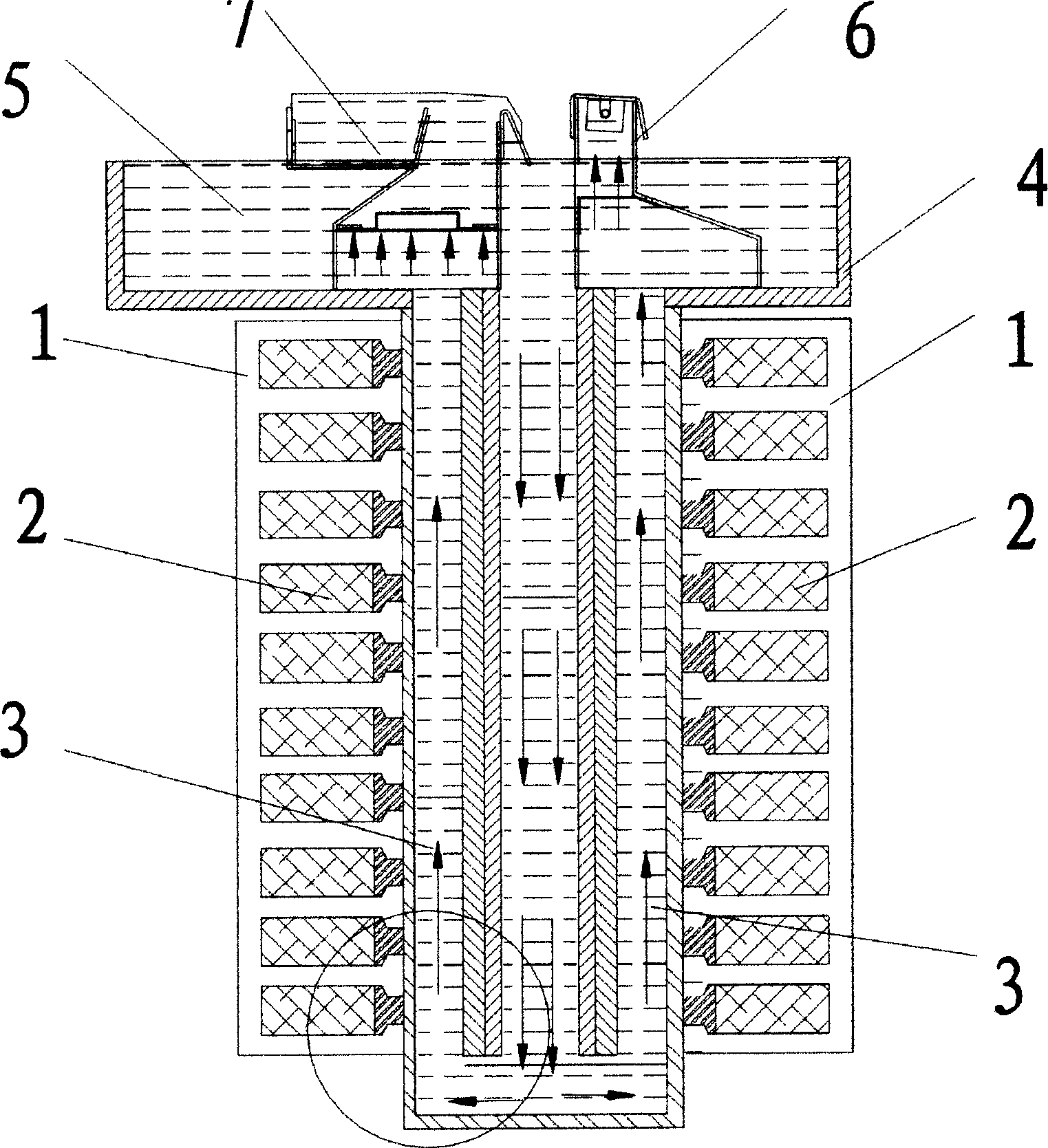

A bearing device and a semiconductor processing apparatus

ActiveCN108987323ALimit deliveryUniform and stable temperatureElectric discharge tubesVacuum evaporation coatingEngineeringSemiconductor

The invention provides a bearing device and a semiconductor processing device. The bearing device includes a heating pan, a spacer and a cooling pan, wherein the spacer is positioned between the heating pan and the cooling pan to partition an area between the heating pan and the cooling pan into at least one insulating area and at least one heat transfer area. At least one heat insulation region and at least one heat transfer region can be separate from each other by a separator, and that excess heat caused by the metal ion deposited on the workpiece to be processed can be carried away by thearrangement of the heat transfer region; At the same time, a large amount of heat transfer between the heating plate and the cooling plate can be limited by the setting of the heat insulation zone, sothat the temperature of the bearing device can be kept uniform and stable in the whole process, so that the qualified and stable process temperature can be provided for the workpiece to be processed,and the better process result can be obtained finally.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

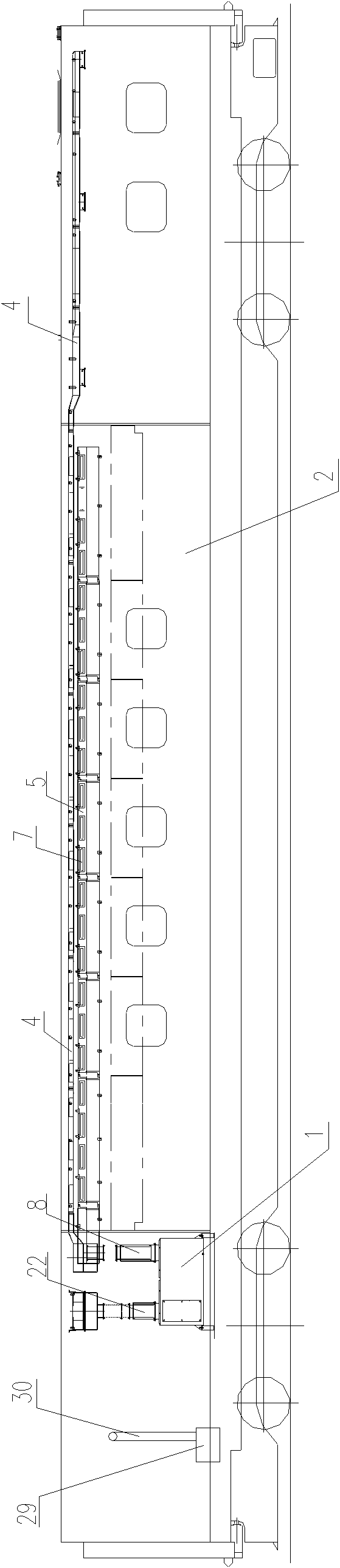

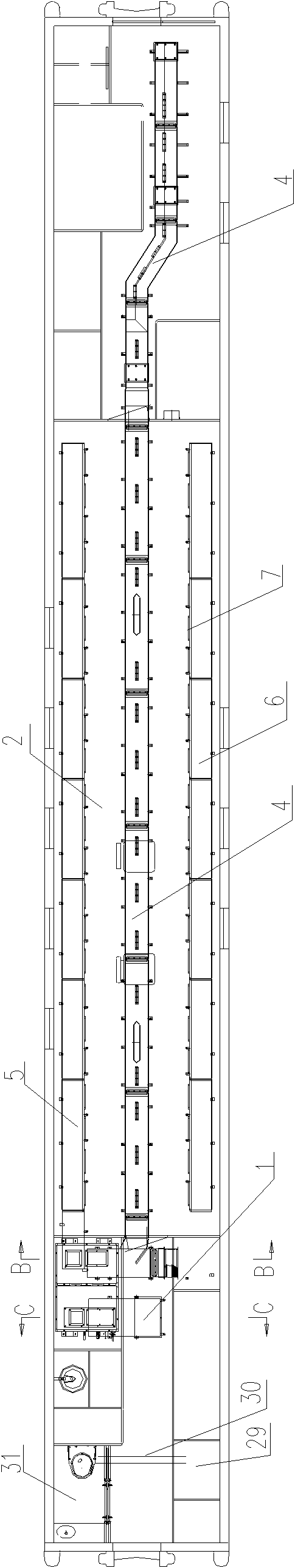

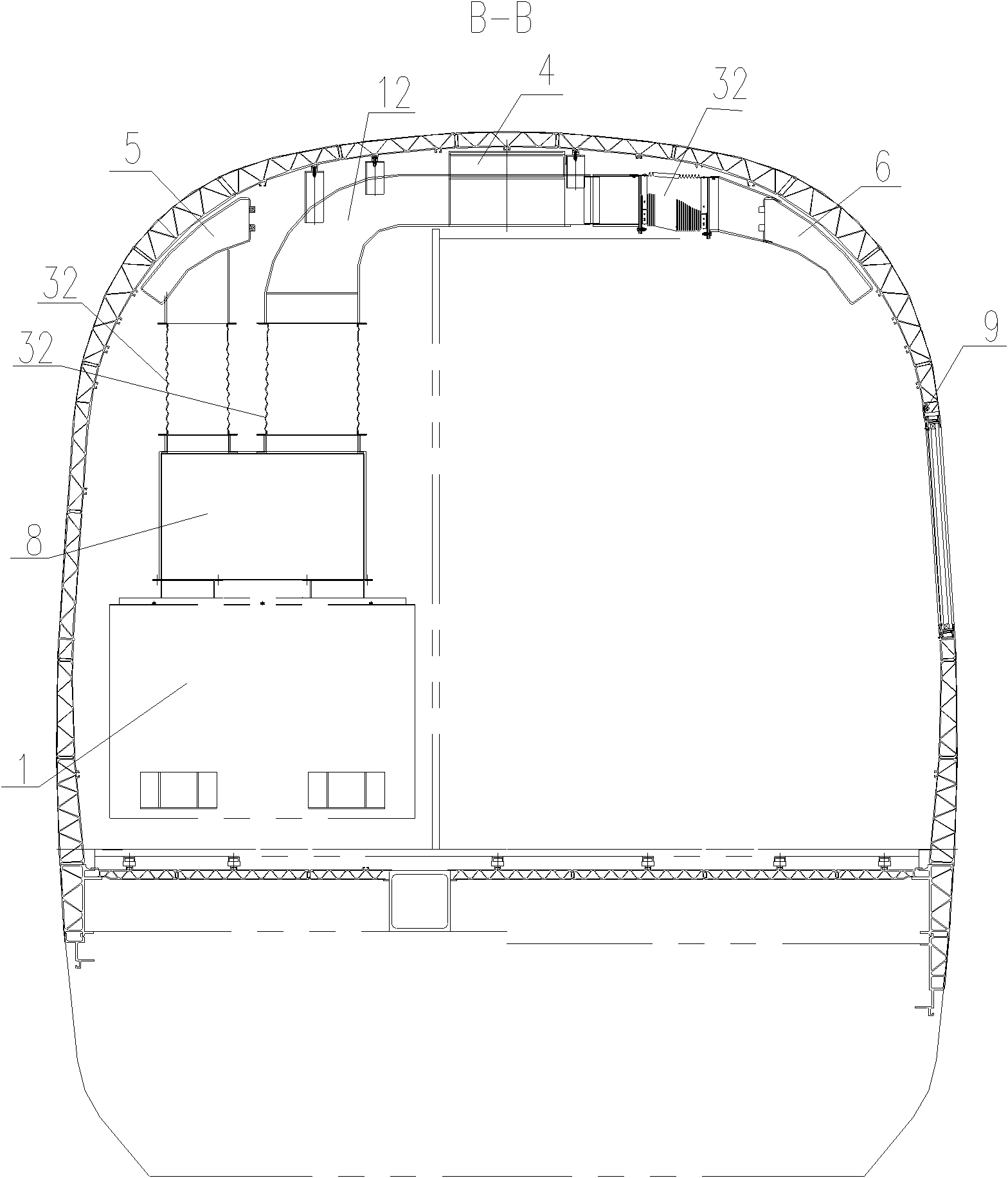

Air conditioning air duct system of high-speed motor train unit

ActiveCN103158732AEven air distributionReduce return wind resistanceRailway heating/coolingAutomotive engineeringAirflow

The invention relates to an air conditioning air duct system of a high-speed motor train unit. The air conditioning air duct system of the high-speed motor train unit comprises an air conditioning unit, wherein the air conditioning unit is communicated with an air-supply outlet and an air-return inlet which are arranged in a train through an air-supply duct and an air-return duct, and the air conditioning unit is communicated with a fresh air port through a fresh air duct. The air-supply duct comprises a middle-top air-supply duct arranged in the central area on the top of a train body and / or side-top air-supply ducts arranged in the side-top areas on two sides of train body, and a plurality of air-supply outlets are evenly formed in the middle-top air-supply duct and the side-top air-supply ducts. According to the air conditioning air duct system of the high-speed motor train unit, air is supplied from the center and two sides of a coach of the train and returns from one end of the coach of the train, air motion and air distribution in the whole train are benefited, therefore air distribution in the train is uniform, the uniformity and stability of temperature, humidity, air speed and cleanliness in the train are guaranteed, and the requirement of comfort of passengers is met. Besides, an indoor machine is arranged at one end of the coach of the train, the air-return inlet is arranged on the position near the indoor machine, thus air return resistance is reduced, noise inside the train is reduced, and comfort in riding the train is improved.

Owner:CRRC QINGDAO SIFANG CO LTD

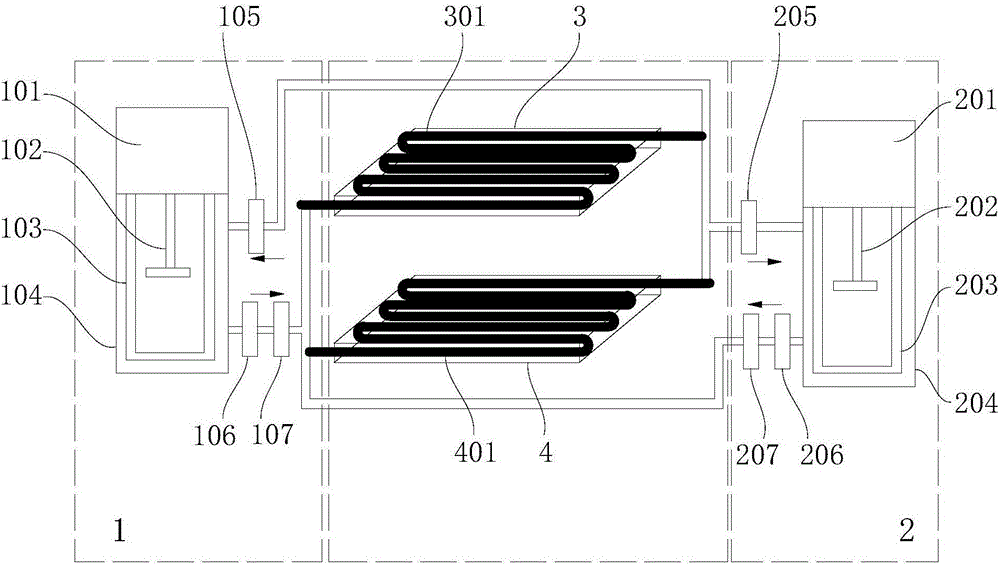

Mold system with high/low-temperature rapid conversion function

The invention discloses a mold system with a high / low-temperature fast conversion function. An upper mold plate and a lower mold plate of a mold are each internally provided with a snake-shaped pipe. The upper mold snake-shaped pipe and a high-temperature circulating system form an independent loop. The lower mold snake-shaped pipe and a cooling circulating system form an independent loop. A circulating fluid medium is adopted for the high-temperature circulating system for heating, a circulating fluid medium is adopted for the cooling circulating system for cooling, and the loop of the high-temperature circulating system and the loop of the low-temperature circulating system are each provided with a switching valve. According to the mold system with the high / low-temperature fast conversion function, the mold can be heated or cooled rapidly through high-temperature fluid or low-temperature fluid, high / low temperature rapid conversion of the mold is achieved, it is guaranteed that a material (or a component) is shaped under a uniform temperature field, internal stress distribution is uniform, and it is guaranteed that the performance of products is stable and deformation is prevented; and besides, rapid and safe demolding can be achieved.

Owner:CENT SOUTH UNIV

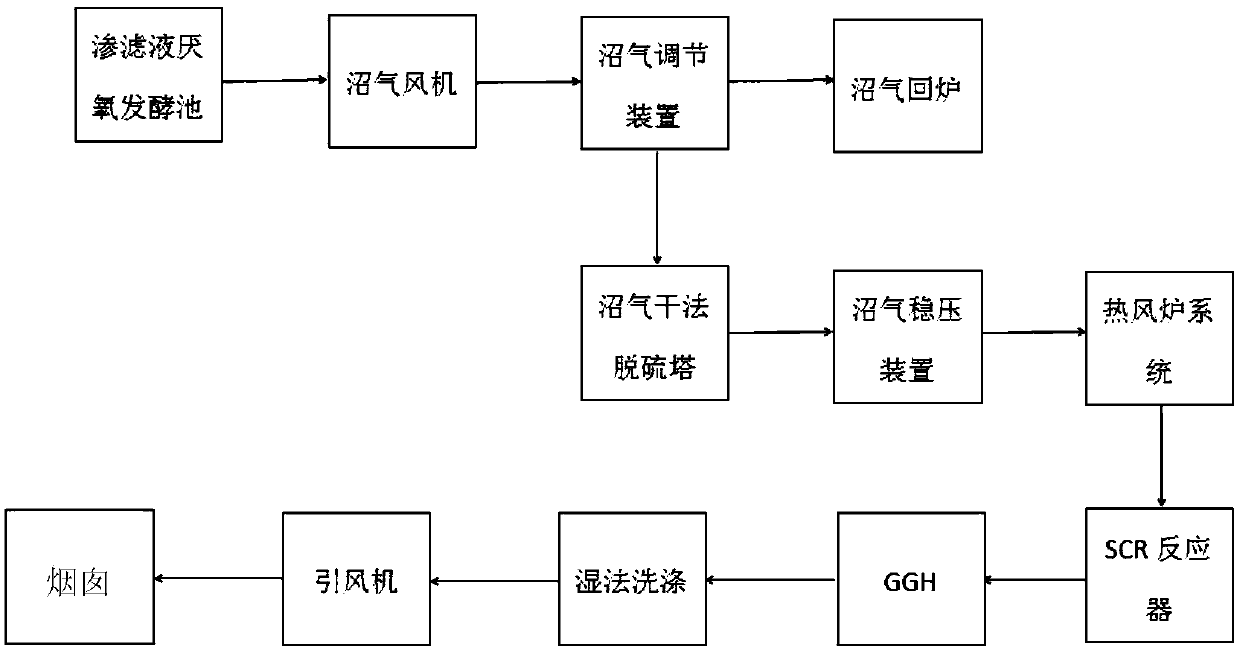

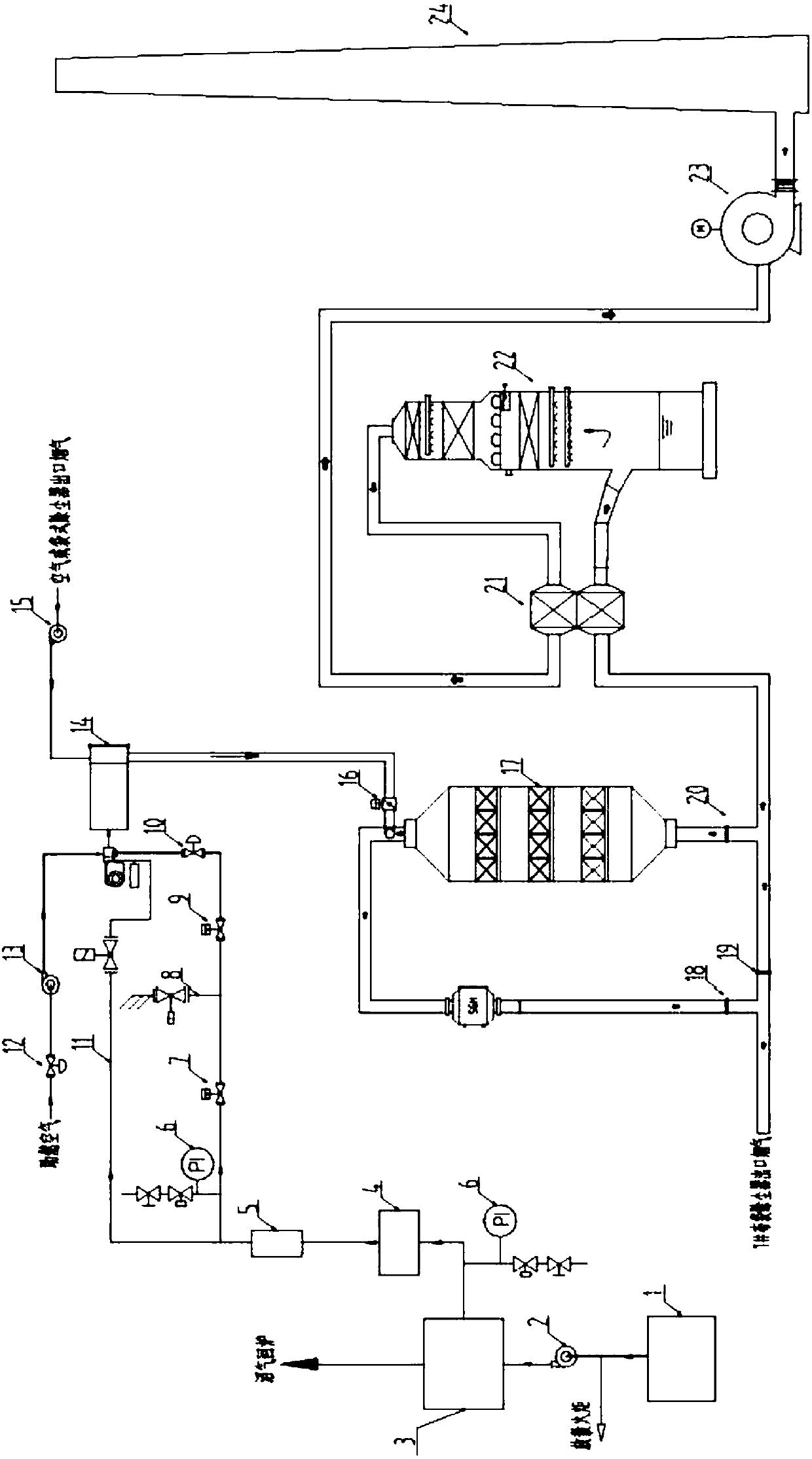

In-situ regeneration device of SCR catalyst for household garbage burning

PendingCN107890884AReduce recycling costsTo achieve the purpose of energy savingDispersed particle separationCatalyst regeneration/reactivationCombustionFlue gas

An in-situ regeneration device of an SCR catalyst for household garbage burning comprises an anaerobic fermentation tank, a biogas blower fan, a biogas adjusting device, a biogas desulfurization tower, a combustion fan, a hot wind furnace, a secondary air fan, a regeneration flue baffle door, an SCR reactor, an SCR catalyst, a flue collector baffle door, GGH, a wet process washing tower, an induced draught fan, and a chimney. The anaerobic fermentation tank, the biogas blower fan, the biogas adjusting device, the biogas desulfurization tower, the combustion fan, the hot wind furnace, the secondary air fan, the regeneration flue baffle door, the SCR reactor, and the SCR catalyst form a catalyst regeneration system. A wet type acid removing tower removes SOx and NH3 in regenerated flue gas,and the discharged flue gas can meet the discharge standards during the regeneration period.

Owner:SHANGHAI SUS ENVIRONMENT

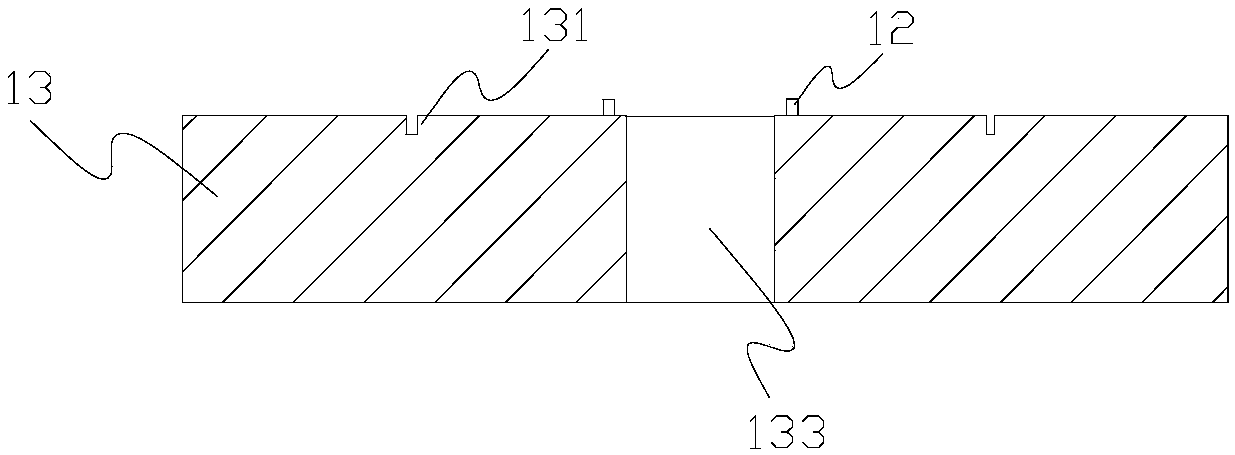

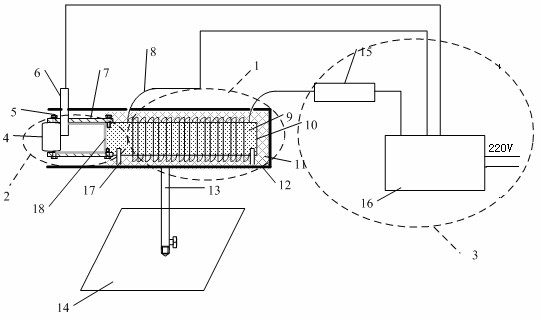

Tobacco material redrying equipment and method

ActiveCN102423109AUniform and stable temperatureReduce lossesTobacco preparationProcess engineeringSlide plate

The invention provides redrying equipment and a redrying process method for realizing simple, high-efficiency and low-processing-intensity tobacco sheets or tobacco stems which are dried uniformly. The redrying equipment comprises a baking rotary drum which is arranged on a stander, and a hot air system, wherein a plurality of heat conduction oil heat exchange pipes which are equally arranged in parallel along the outer wall surface are arranged on the outer wall surface of the baking rotary drum; the heat conduction oil heat exchange pipes are communicated with a heat conduction oil cyclic heating system; a section from the feeding end of the baking rotary drum to the position of which the length is about 1 / 3 of the total length of the baking rotary drum is a preheating section, and the residual 2 / 3 section is a drying section; the feeding end of the baking rotary drum is higher than the discharging end of the baking rotary drum; and a shovelling plate and a material-receiving sliding plate are arranged in the drum. By using the equipment, tobacco materials can be directly redried only by heating and drying processes until the moisture content and the temperature of the tobacco materials meet the requirements of the next process; and furthermore, the process is simple, efficient, energy-saving and environmentally-friendly.

Owner:ZHISI HLDG GRP

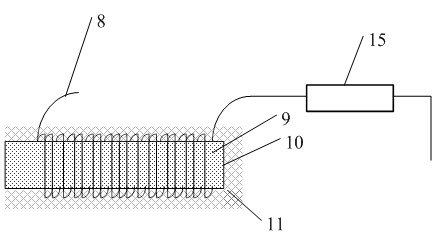

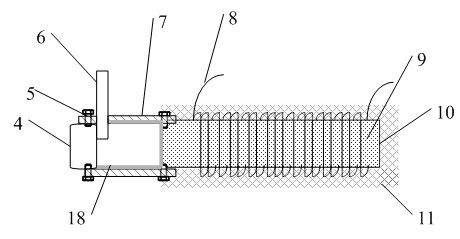

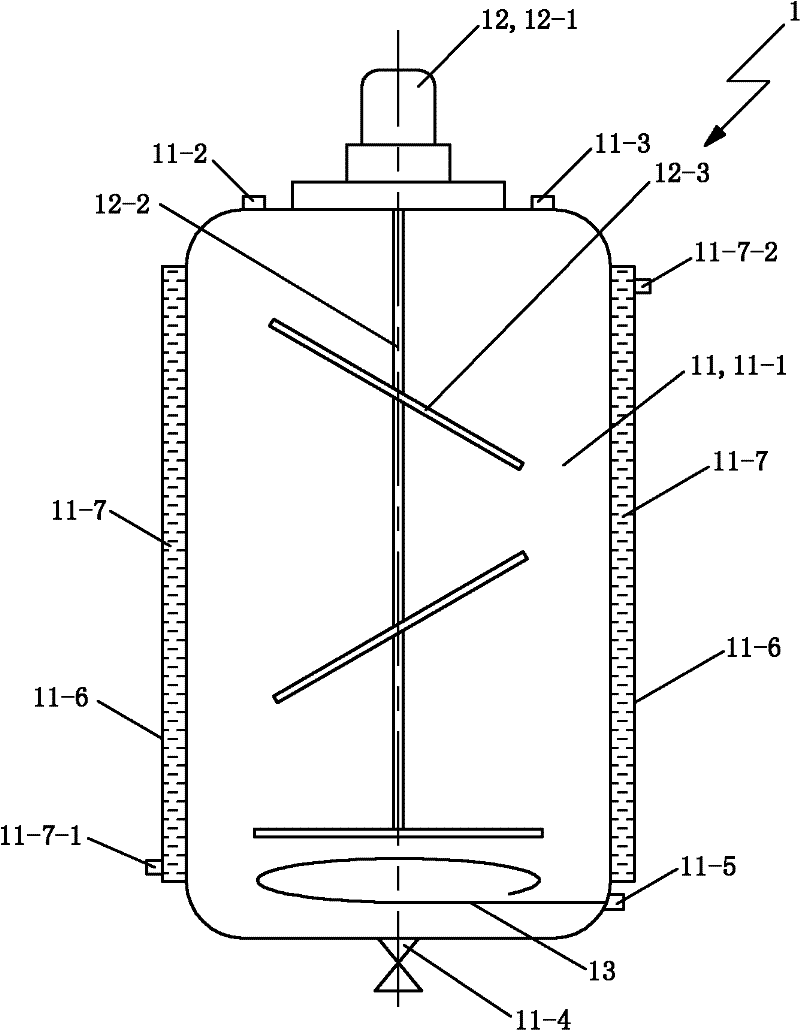

Evaporation source and evaporation coating device

ActiveCN102312198AStable temperatureStable and uniform temperature controlVacuum evaporation coatingSputtering coatingTemperature controlEvaporation

The invention relates to a coating device applied to the field of semiconductors, LEDs and solar cells, in particular to an evaporation source and an evaporation coating device. The evaporation source comprises a temperature control module, a carrier gas inlet module, a feeding module, an exhaust module and a thermal insulating module, wherein the temperature control module, the carrier gas inletmodule, the feeding module and the exhaust module are all arranged in the evaporation source body, and the thermal insulating module encloses the external surface of the evaporation source body. The evaporation coating device comprises the evaporation source and a vacuum cavity surrounding the evaporation source. In this invention, various functional modules that constitute coating equipments areintegrated in a single structure, that is, the evaporation source body, so that the temperature can be controlled stably and uniformly, and the evaporation source and the evaporation coating device achieve simple and compact structure, high integral heat conductivity, high melting point, stable temperature, high raw material utilization rate and uniform coating.

Owner:ZHEJIANG SHANGFANG ELECTRONICS EQUIP

Sample heating device used in integrating-sphere reflectivity measurement

InactiveCN102426129AImprove protectionMeasure temperature in real timePreparing sample for investigationElectrical resistance and conductanceBlackbody cavity

The invention discloses a sample heating device used in integrating-sphere reflectivity measurement. The sample heating device comprises a copper bar, a heat-insulating ceramic shell, a resistance wire, a temperature controller and a K-type thermocouple, wherein, the copper bar is wrapped with an insulating material and then wound with the resistance wire, and the resistance wire is connected with a resistance regulator in series and then is connected with the temperature controller; one side of the copper bar is used for fixing a ceramic tube sleeve, high-emissivity coating is coated on one side of the copper bar and all over the ceramic tube sleeve to obtain a blackbody cavity, and a test sample is heated by radiation of the blackbody cavity; the test sample is fixed at the other side of the ceramic tube sleeve; the K-type thermocouple is fixed on a vertical side surface of the test sample and is taken as a temperature sensor to be connected with the temperature controller so as to regulate and control the heating time of the resistance wire; and the heat-insulating ceramic shell is fixed outside the whole heating device. The sample heating device has the beneficial effects thatthe sample can be stably heated in reflectivity measurement, the problem that the existing integrating-sphere reflectivity test device can only test the sample at room temperature is solved, and the heat-insulating ceramic shell plays a role in protecting the integrating-sphere reflectivity test device.

Owner:CHINA JILIANG UNIV

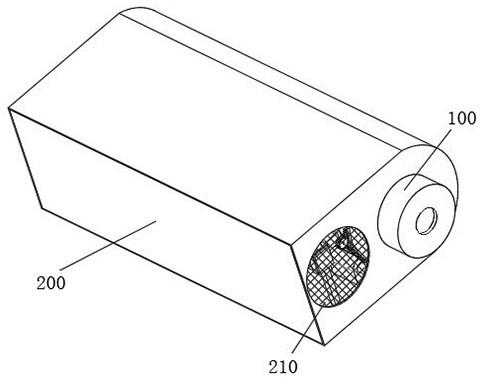

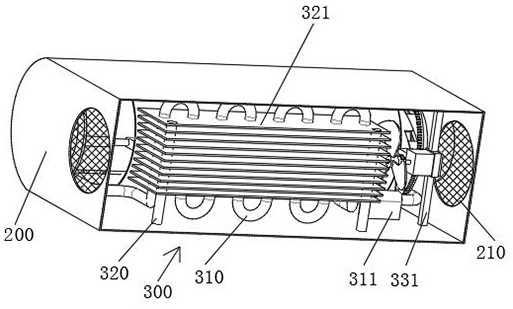

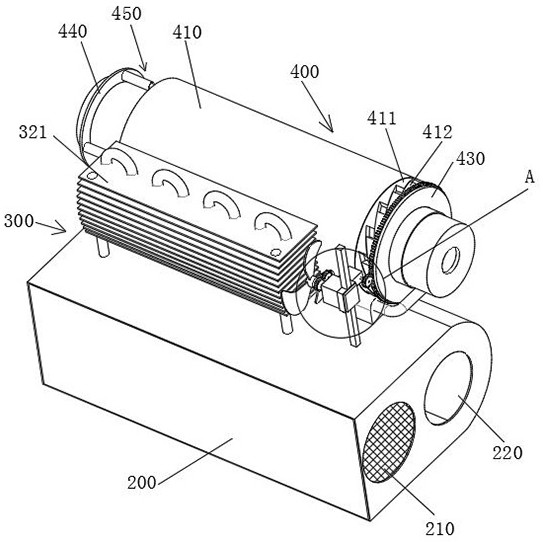

Laser with rapid heat dissipation function

ActiveCN112397976AIncrease heat exchange speedRapid cooling and heat dissipationLaser cooling arrangementsCold airThermodynamics

The invention relates to the technical field of rapid heat dissipation lasers, in particular to a laser with a rapid heat dissipation function. The laser comprises a shell, a heat dissipation mechanism is fixedly connected to the interior of the shell, the heat dissipation mechanism comprises a heat conduction cylinder, and one end of the heat conduction cylinder is fixedly connected with the inner side wall of one end of the shell, and the inner side wall of the heat conduction cylinder is fixedly sleeved with a laser generator. According to the laser with the rapid heat dissipation function,through the arrangement of an annular cavity, cooling liquid makes direct contact with the outer side wall of the heat conduction cylinder, the heat exchange speed between the cooling liquid and theheat conduction cylinder is increased, and the laser generator can achieve rapid cooling and heat dissipation, the high-lower temperature stratification phenomenon can be broken through the arrangement of a flow guide plate, so that the temperature in the annular cavity is uniform and stable, the use stability of the laser generator is improved, a straight air duct is formed in the shell through two vent holes in the shell, hot air is conveniently and quickly exhausted, cold air is conveniently sucked in, and rapid heat dissipation of the laser generator is achieved.

Owner:SOUTHWEST PETROLEUM UNIV

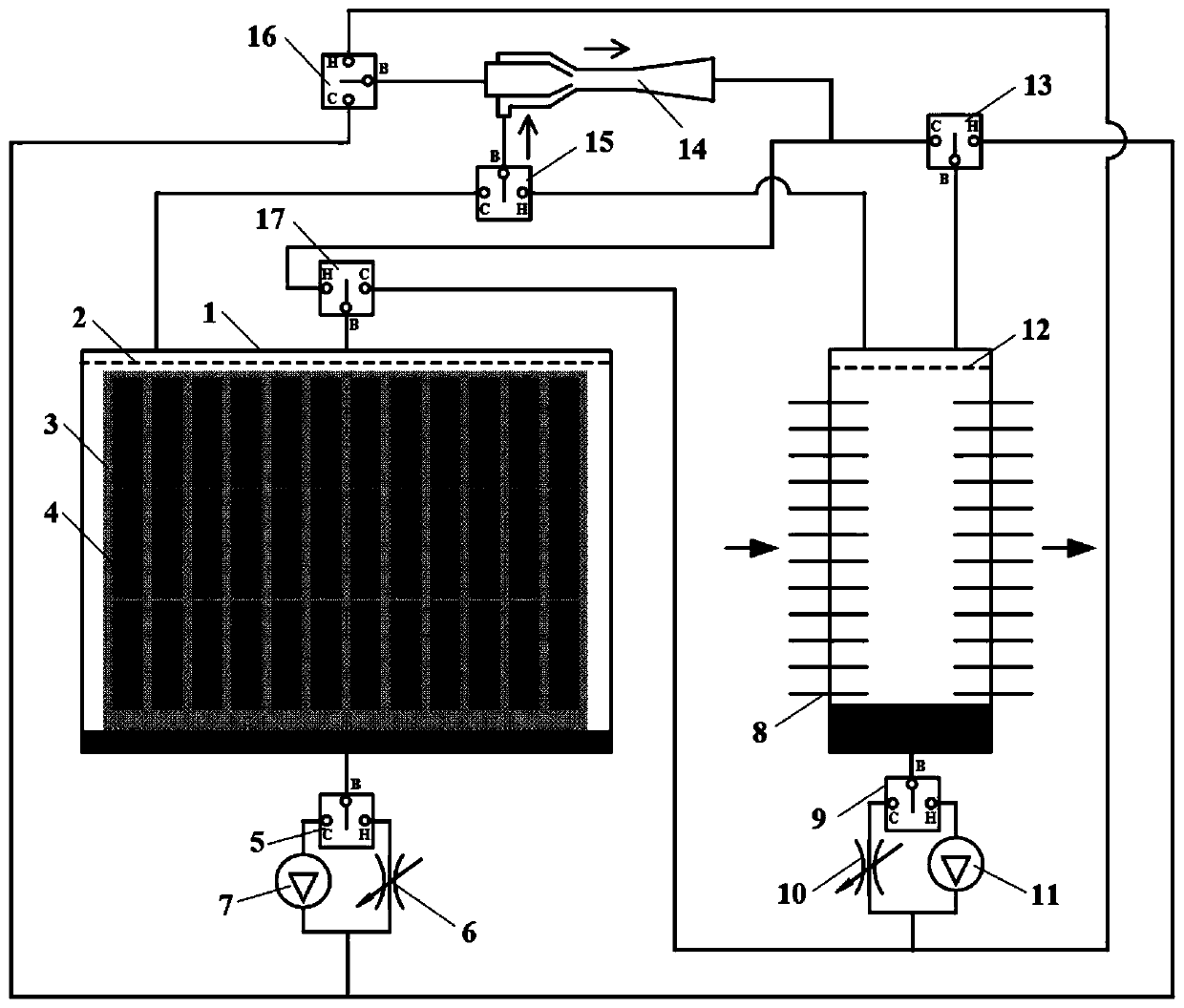

Thermal management system for jet-absorption thermodynamic cycle battery and working method of thermal management system

ActiveCN110165102AImprove heat transfer efficiencyGood temperature control effectBattery isolationSecondary cellsThermodynamic cycleBoiling point

The invention discloses a thermal management system for a jet-absorption thermodynamic cycle battery and a working method of the thermal management system. The system comprises a heat exchanger, a battery packaging box, a first reversing valve, a second reversing valve, a third reversing valve, a fourth reversing valve, a fifth reversing valve, a sixth reversing valve, an ejector, a first circulating pump, a second circulating pump, a first throttling valve and a second throttling valve. The system and the working method can enable the temperature of the battery to be stably and evenly kept near the boiling point of a working medium.

Owner:XI AN JIAOTONG UNIV

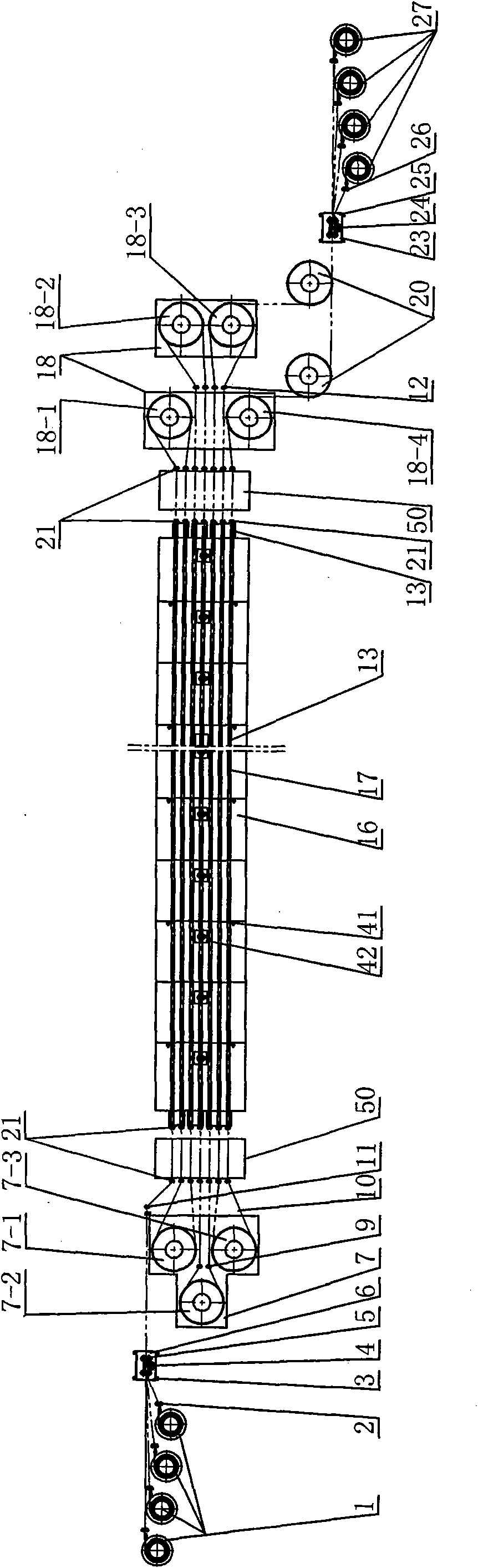

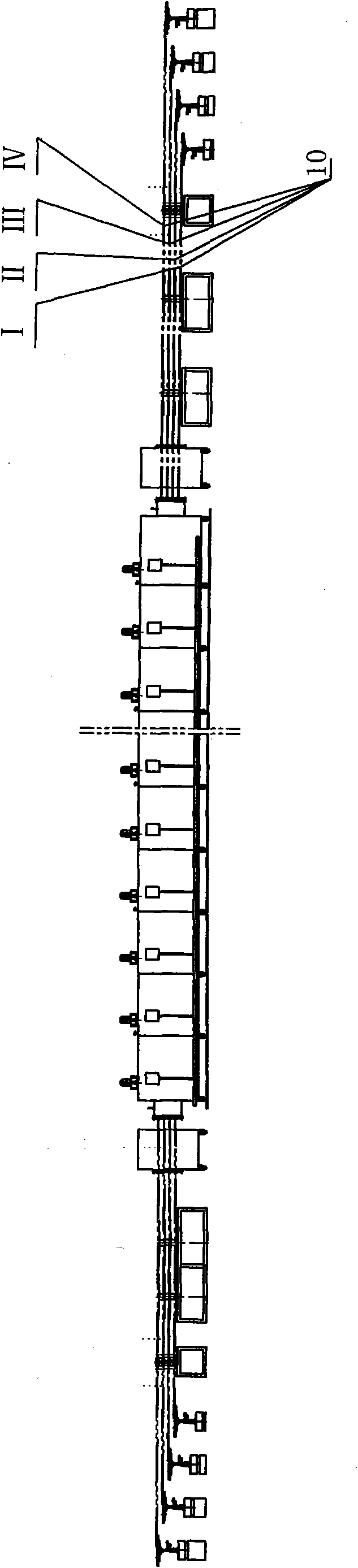

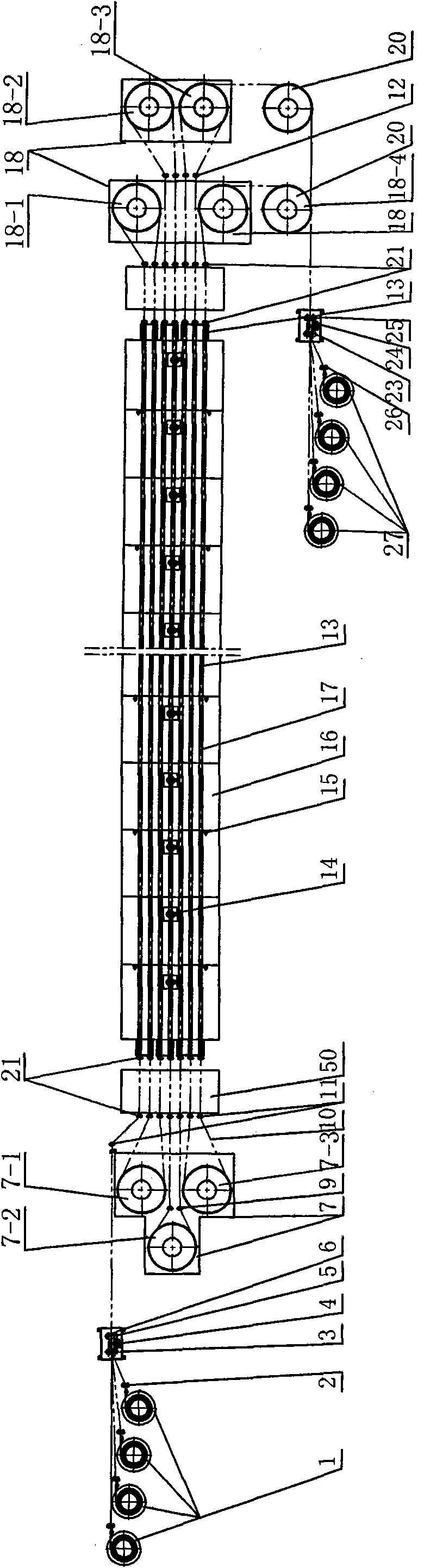

Online full-automatic tempering equipment and technology for same-furnace multi-strip bimetal strip saw

ActiveCN102002574ASolve the accuracy problemIncrease heating speedFurnace typesHeat treatment furnacesProduction lineHigh energy

The invention discloses online full-automatic tempering equipment and technology for a same-furnace multi-strip bimetal strip saw, and relates to tempering equipment and tempering technology. The invention solves the problems that the conventional tempering equipment and technology for the bimetal strip saw cannot finish the tempering technology on one production line at one time, the tempering technology has low production efficiency and high energy consumption and the like. The tempering equipment comprises a front rotating device, a box-type tempering furnace and a rear rotating device. The production efficiency of the saw is improved by 5 to 8 times, the energy consumption is greatly reduced, a great amount of energy is saved, the energy consumption of the box-type tempering furnace is reduced by over 60 percent compared with that of a bell-type tempering furnace or a well-type tempering furnace due to calculation, the occupancy area is reduced by over 90 percent, the problems that the bell-type tempering furnace or the well-type tempering furnace has non-uniform inner and outer temperature field and upper and lower temperature field, the bending stress of the saw is non-uniform, and the saw is easily upwarped are solved, repeated rewinding processes needed by the box-type tempering furnace or the well-type tempering furnace are canceled, and the problem of difficulty in controlling the saw tempering technology and quality and the problem of difficulty in maintaining the equipment are solved.

Owner:曹玉贵

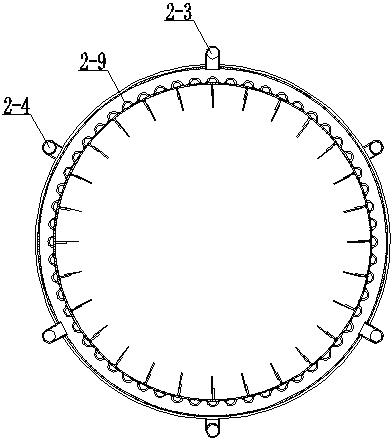

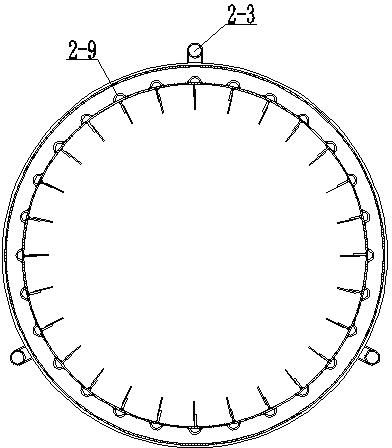

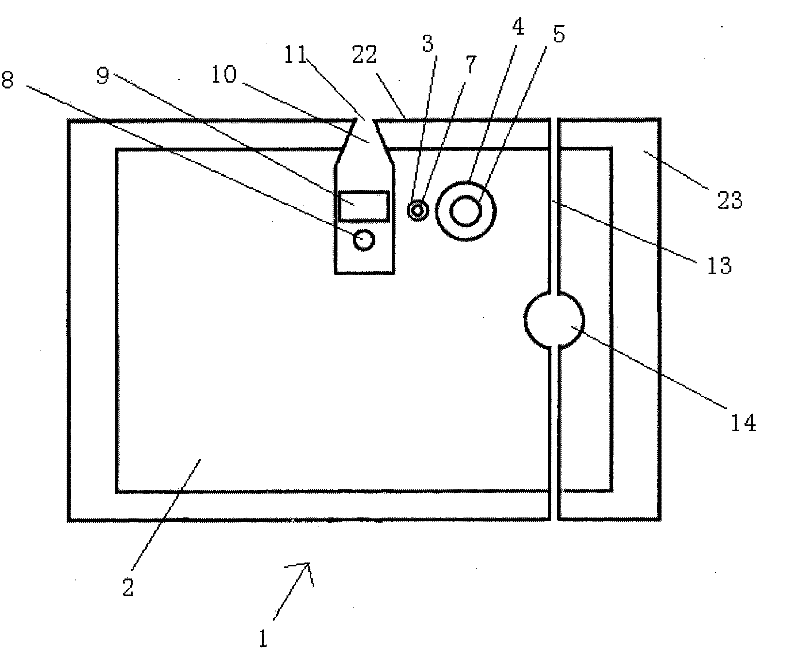

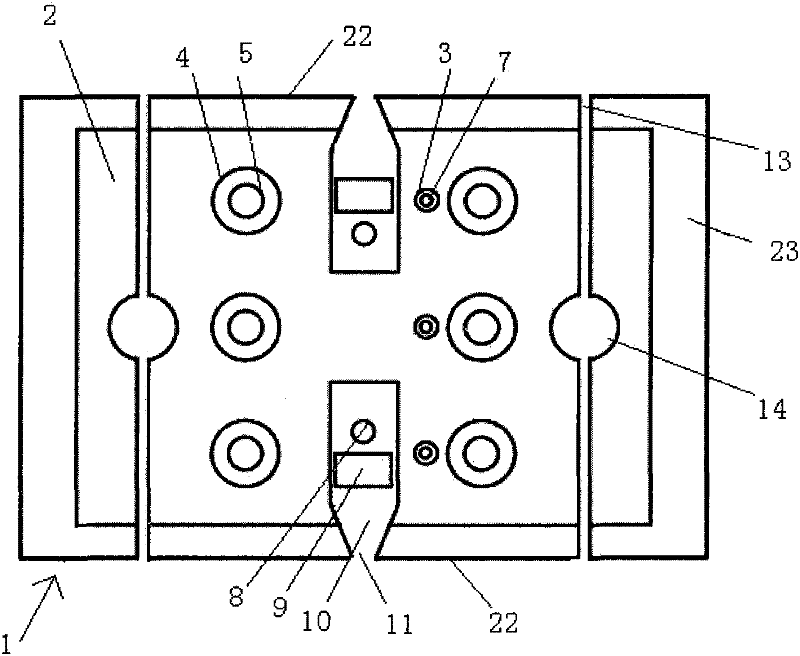

Electromagnetic pump single/double wave crest generator

InactiveCN1802073AReduce eddy current lossImprove motor efficiencyPrinted circuit assemblingHigh frequency current welding apparatusWave crestStator

Said invention belongs to welding equipment, especially automatization welding equipment suitable for PWB printed wiring board in surface mounting technology (SMT). It contains an electromagnetic pump type single / double wave crest generator consisting of single side type linear motor primary stator core and winding, magnetism shielding plate, liquid metal container, pump mouth etc, wherein said liquid metal container is T-type structure, longitudinal part of T-type structure having plurality of symmetric longitudinal channel whose one end communicated with pump mouth, another end communicated with container, both sides of liquid metal longitudinal part having two linear motor stator core with winding, electromagnetic pump having two pump mouth, respectively connected with two symmetric pump channels, channel mouth size is less than size of channel body and adopting magnetic wedge fixing winding. Said technology forms electromagnetic pump type single / double wave crest generator with smoothness reliable wave crest.

Owner:日东电子发展(深圳)有限公司

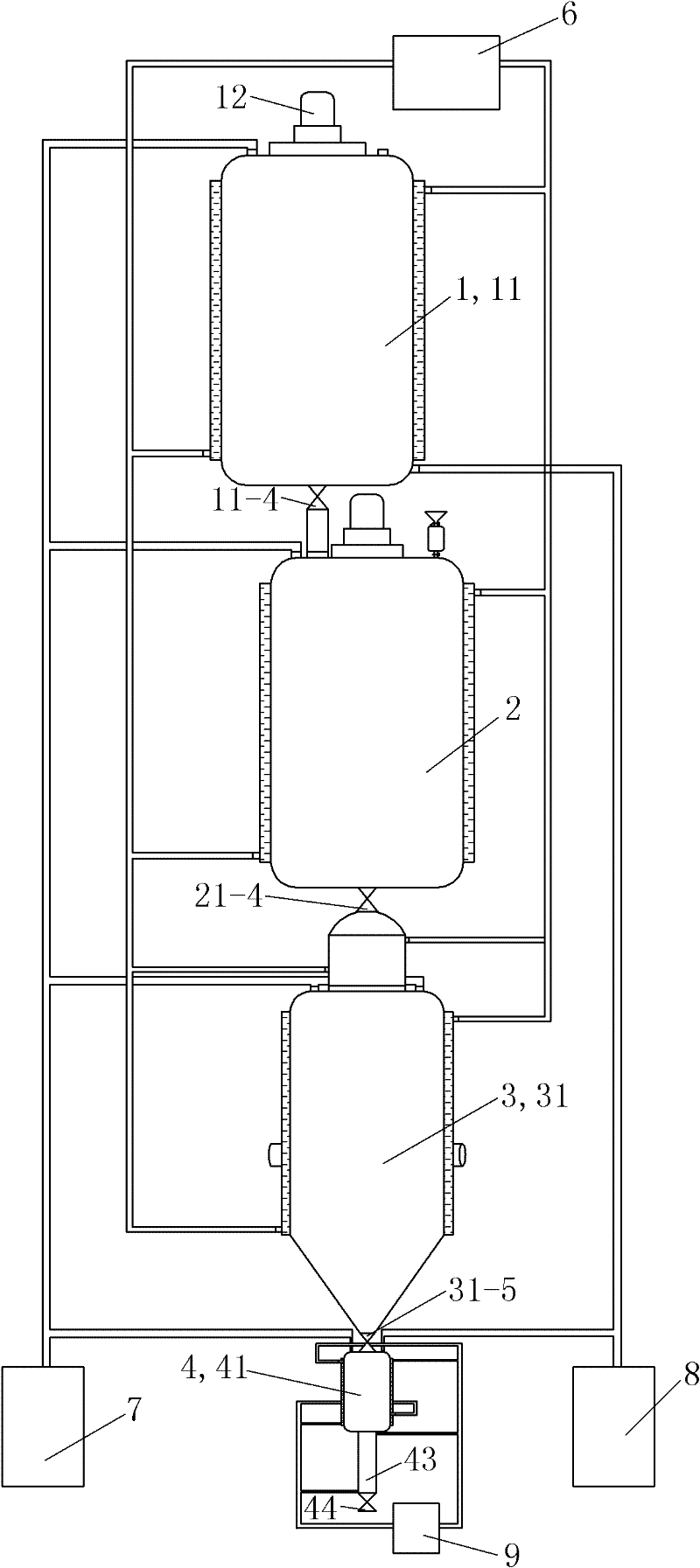

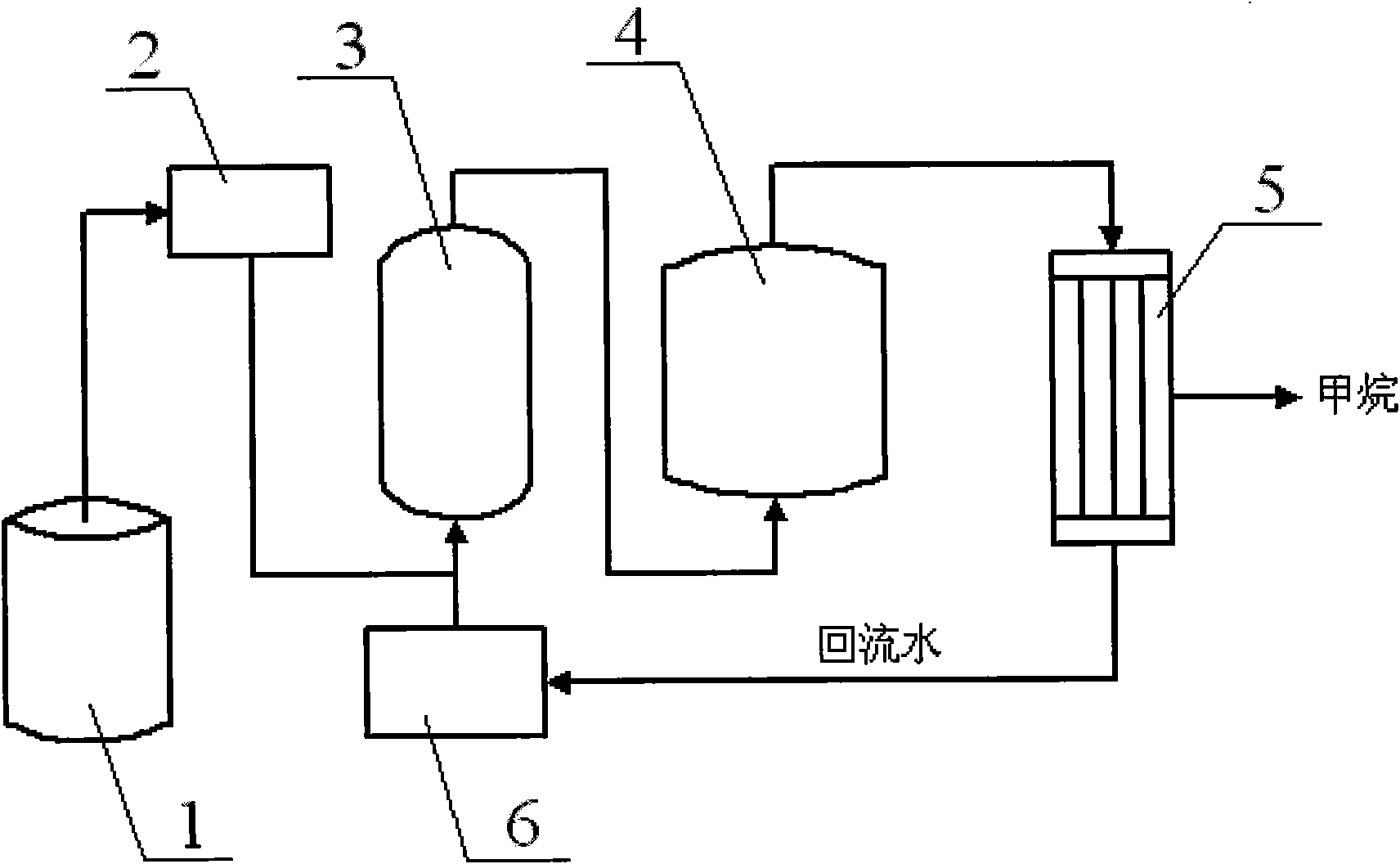

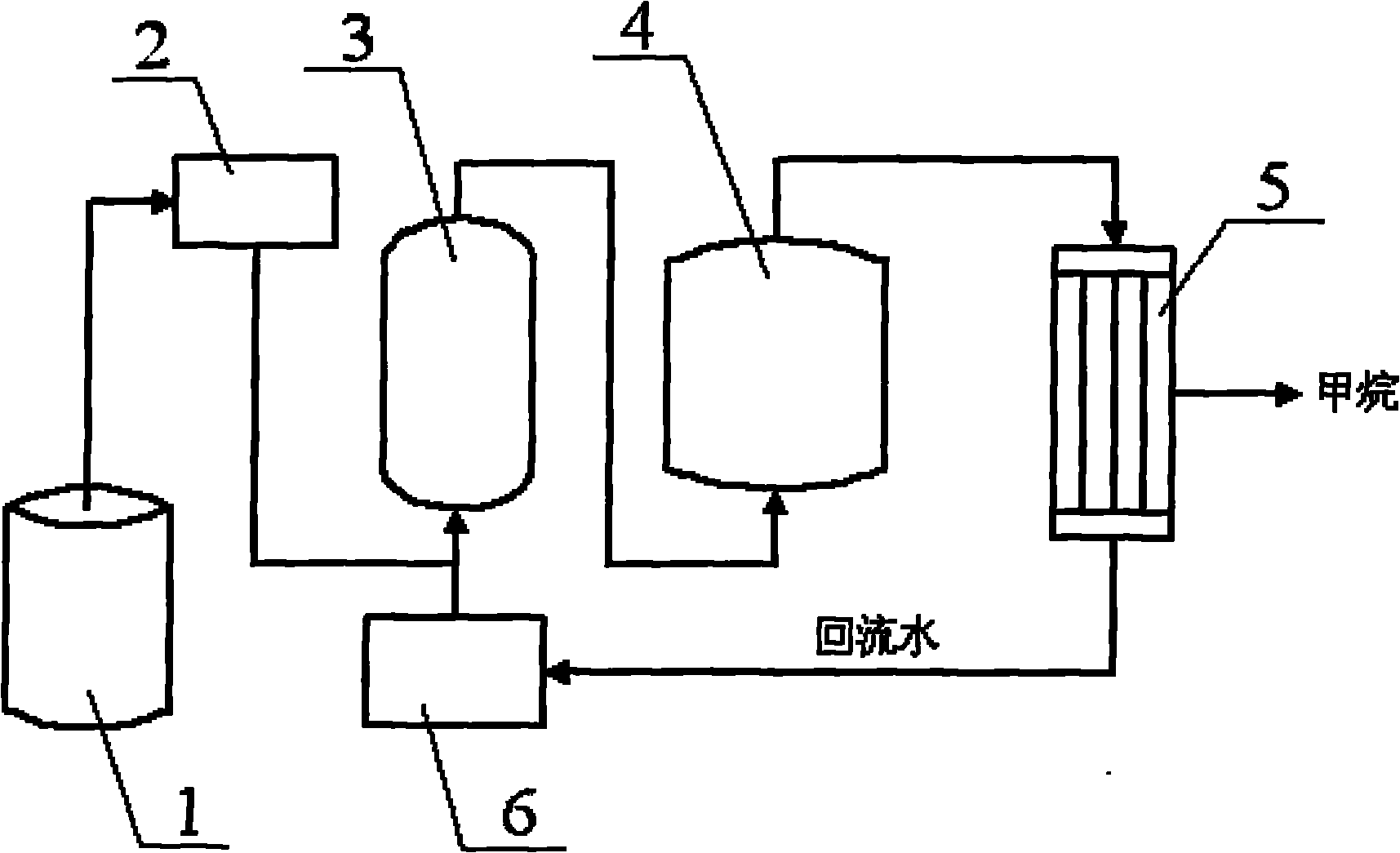

Crude rubber production system

The invention relates to a crude rubber production system which comprises a crude rubber dehydration device, a crude rubber polymerization reaction device, a crude rubber low-molecular removal device, a crude rubber receiver, a rubber discharge device, a hot oil circulation heating device, a vacuuming device, a nitrogen feeding device and a cooling water circulation cooling device, wherein the hot oil circulation heating device is communicated with the clamp sleeve of the dehydration kettle of the crude rubber dehydration device, the clamp sleeve of the reaction kettle of the crude rubber polymerization reaction device, the clamp sleeve of the devolatiligation kettle of the crude rubber low-molecular removal device and the tubulation preheater of the crude rubber low-molecular removal device; the vacuuming device is communicated with the dehydration kettle of the crude rubber dehydration device, the reaction kettle of the crude rubber polymerization reaction device, the devolatiligation kettle of the crude rubber low-molecular removal device and the tank bodies of the crude rubber receiver and the rubber discharge device; the nitrogen feeding device is communicated with a nitrogen transportation connector piece in the dehydration kettle and the tank bodies of the crude rubber receiver and the rubber discharge device; and the water inlet and water outlet of the cooling water circulation cooling device are communicated with the cooling disks of the crude rubber receiver and the rubber discharge device and a tabulation cooler.

Owner:LIYANG LIDA SILICONE TECH

Modified tempering furnace and tempering method

InactiveCN104313257AWon't breakPrevent oxidationFurnace typesHeat treatment furnacesVacuum extractorOxygen

The invention discloses a tempering method. The tempering method comprises the following steps: additionally mounting a vacuum extractor and an inert gas charging device on a common tempering furnace, and tempering and cooling a workpiece under a protective atmosphere, so as to prevent that the workpiece is oxidized by the oxygen in the air at high temperature, further obviously prolong the service life of the workpiece, and lower the production cost.

Owner:KUNSHAN YOUTEWEI HEAT TREATMENT

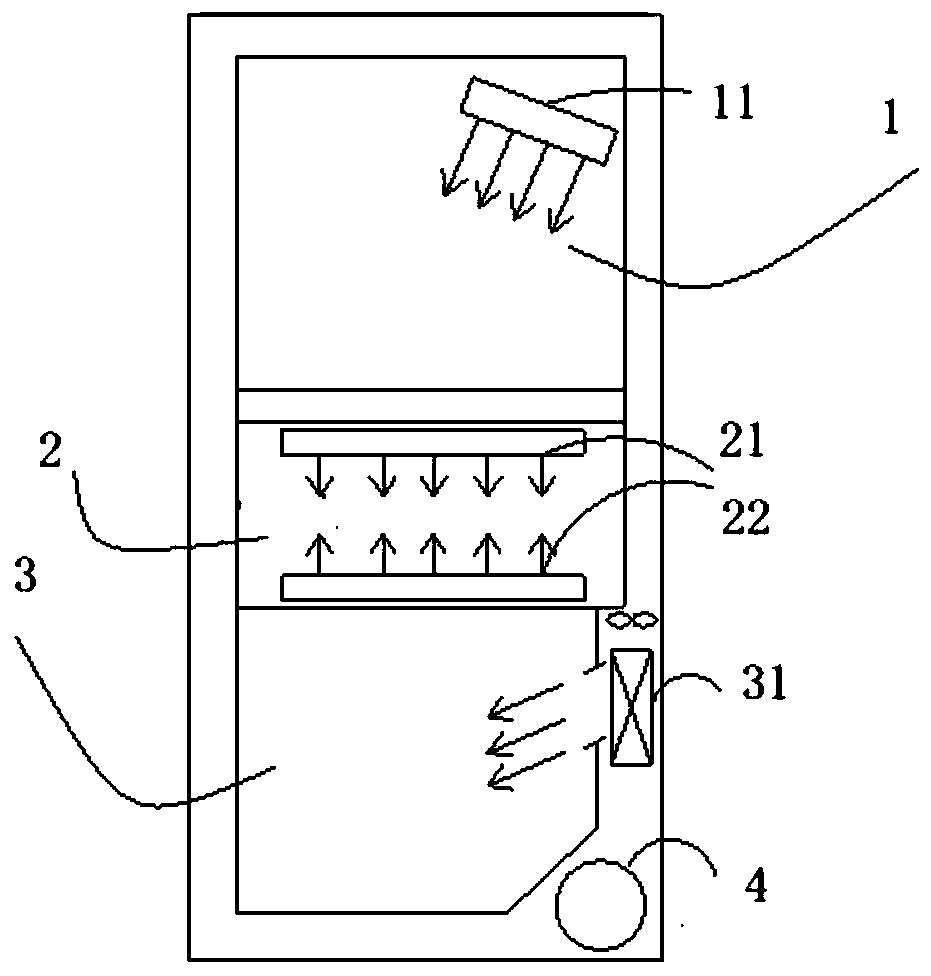

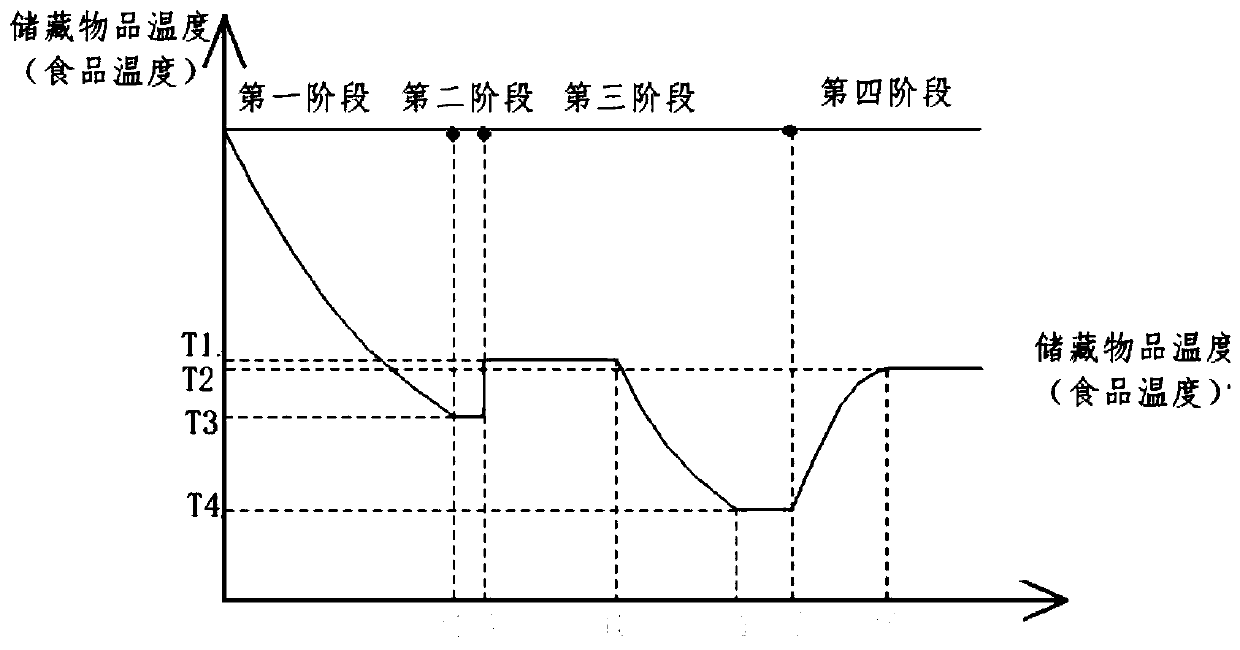

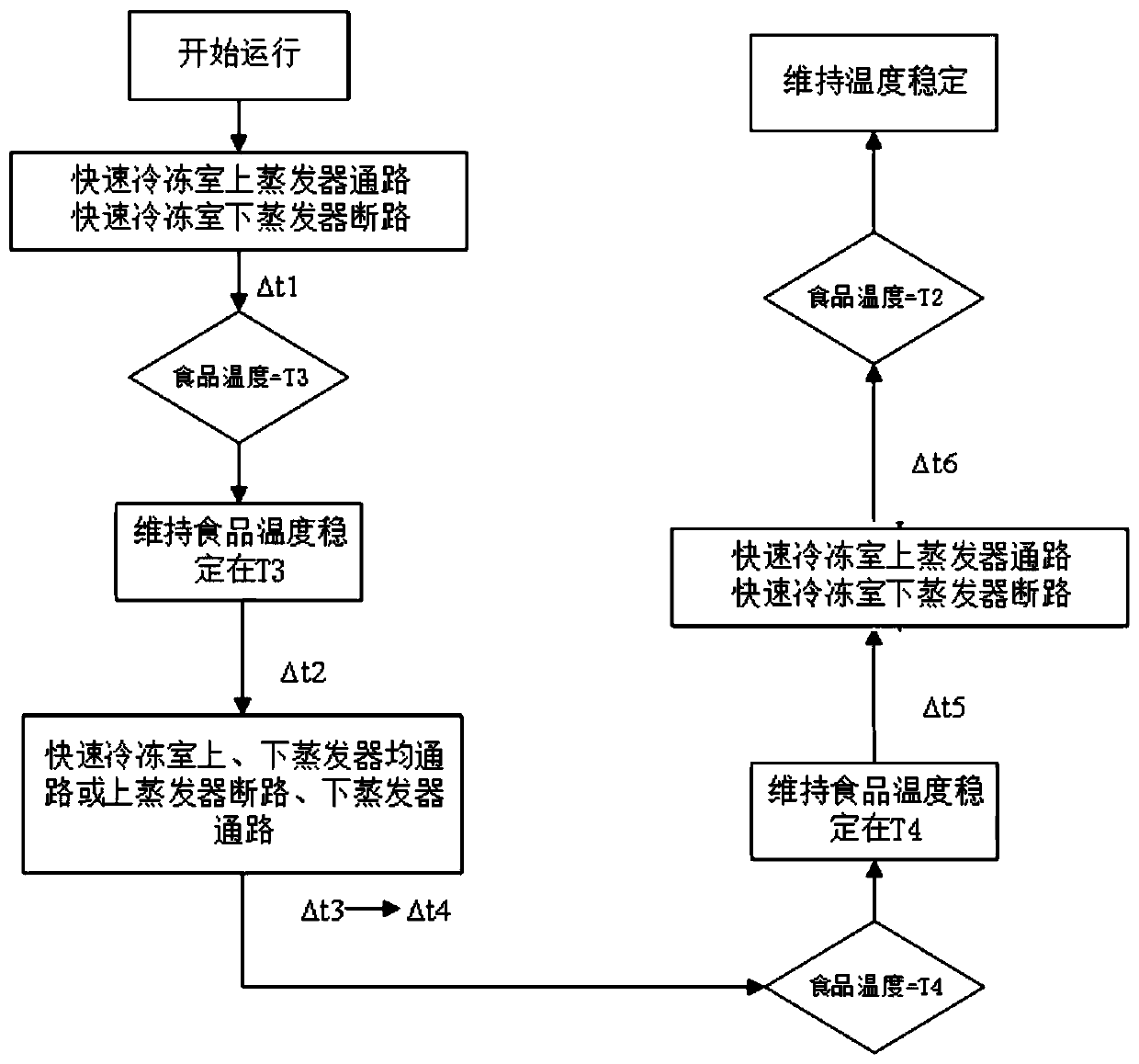

Overcooling freezing method, refrigerator and refrigerator control method

ActiveCN110671877AUniform and stable temperatureAvoid churnLighting and heating apparatusDomestic refrigeratorsFreezing chamberFast freezing

The invention provides an overcooling freezing method, a refrigerator and a refrigerator control method. Direct-cooling-type evaporators are adopted, and the direct-cooling-type evaporators at different positions are controlled to work in different overcooling freezing processes. A top evaporator is used for reducing temperature, so that the temperature reducing conditions of food in a freezing room are as close as possible to natural convection, the situation that the temperature reducing rate is too high due to the fact that the food is in contact thermal conductance with a refrigerated evaporator or the food is too close to the refrigerated evaporator, and keeping the stability of the food overcooling state is facilitated. A bottom evaporator or both the top evaporator and the bottom evaporator are used for reducing temperature at a fast freezing stage of the food to ensure the food to be quickly frozen, ice crystals are smaller and more rounded, the frozen food can be cut with a knife and cooked immediately, the waste of time and loss of food nutritional value caused by the thawing process are avoided.

Owner:GREE ELECTRIC APPLIANCES INC

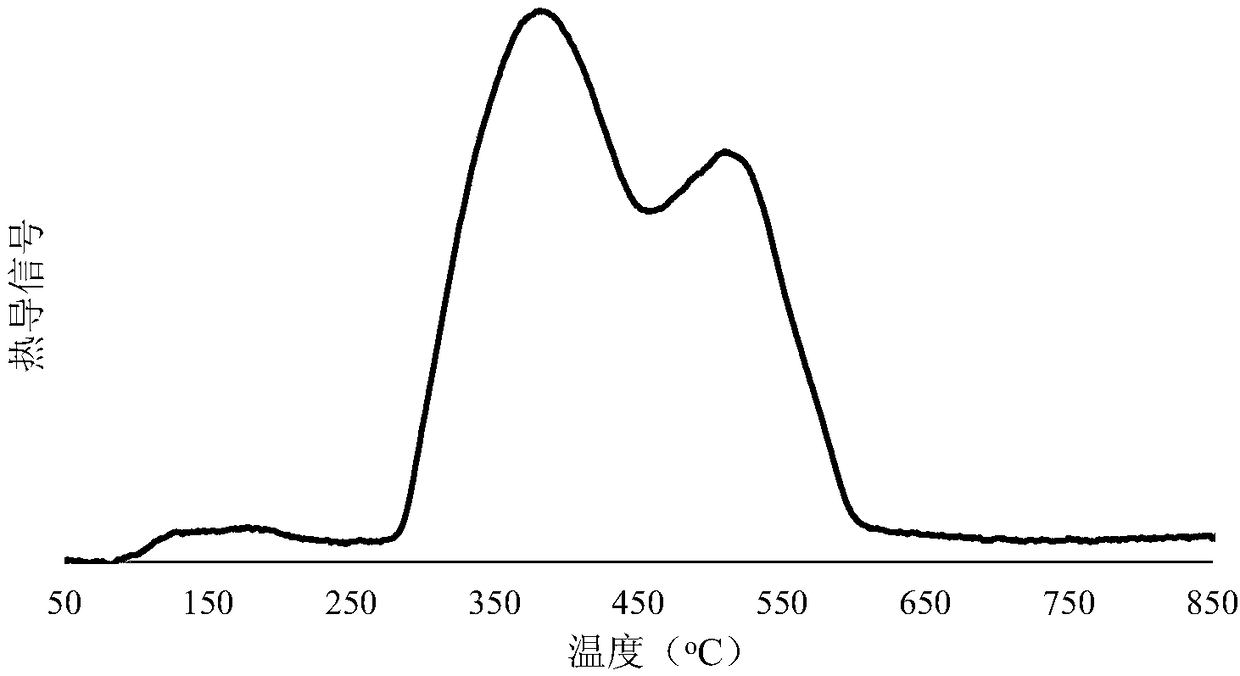

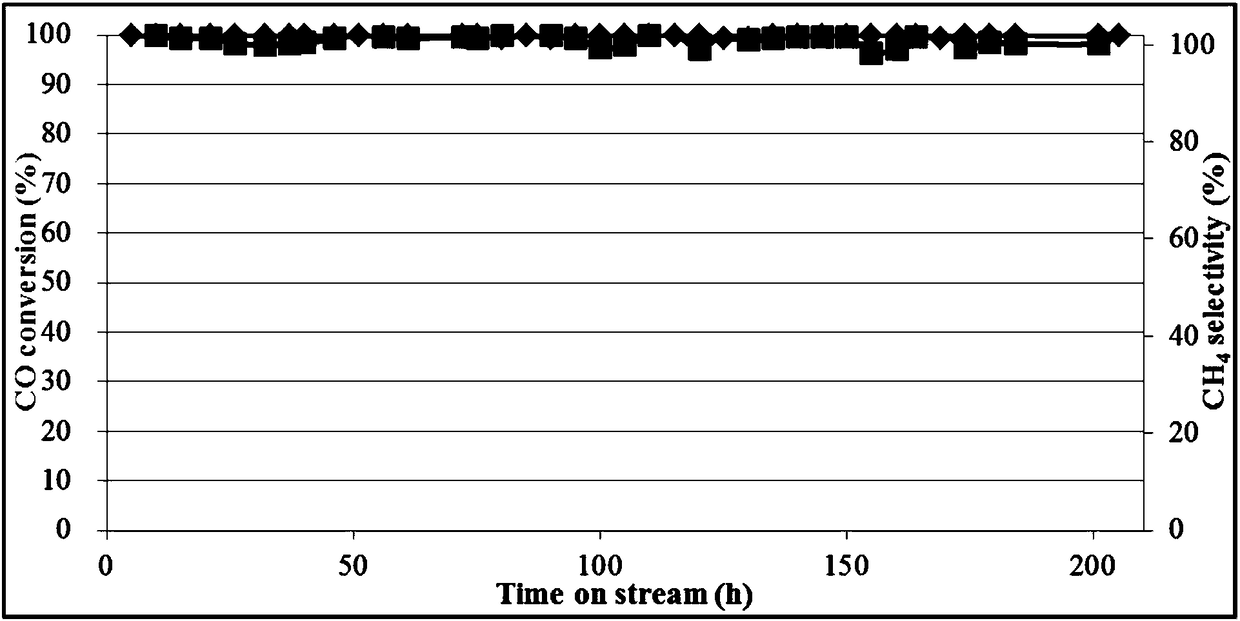

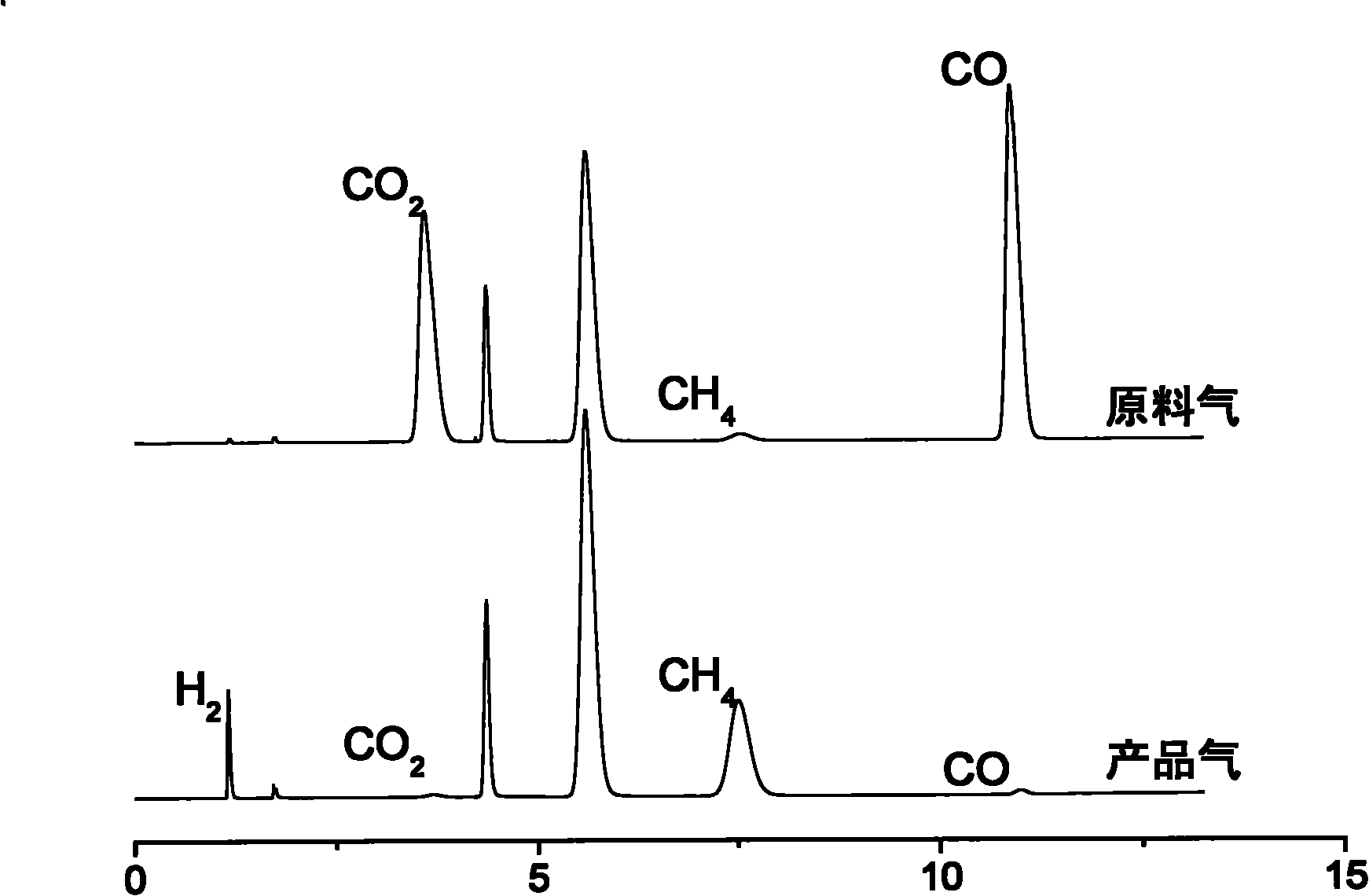

Method for hydrothermally reducing CO2 or CO into methane by using porous nickel catalyst

InactiveCN102464544AOvercoming the problem of temperature instabilitySolve the problem of easy carbon deposition and deactivationHydrocarbon from carbon oxidesDispersed particle separationNickel catalystHydrogen

The invention relates to a method for hydrothermally reducing CO2 or CO into methane by using a porous nickel catalyst. The method comprises the following steps of: placing the porous nickel catalyst into a hydrothermal reactor, mixing hydrogen and CO2 or CO according to the molar ratio of 1:(1-10) in the hydrothermal reactor, controlling the temperature of the reactor to 200 to 400 DEG C, and adjusting the pressure of the reactor to 6 to 20MPa and the reaction time to 5 to 180 minutes to obtain the reaction product, namely methane. When the method is compared with the prior art, the highest conversion rate of CO2 and CO is 99 percent, the whole reaction is performed under a hydrothermal condition, the defect that the catalyst is inactivated because carbon is easy to accumulate on the surface of the catalyst in a gas-phase reduction process is overcome, and the used catalyst has the characteristics of high strength, good activity, good thermal stability, excellent low-temperature activity and the like.

Owner:TONGJI UNIV

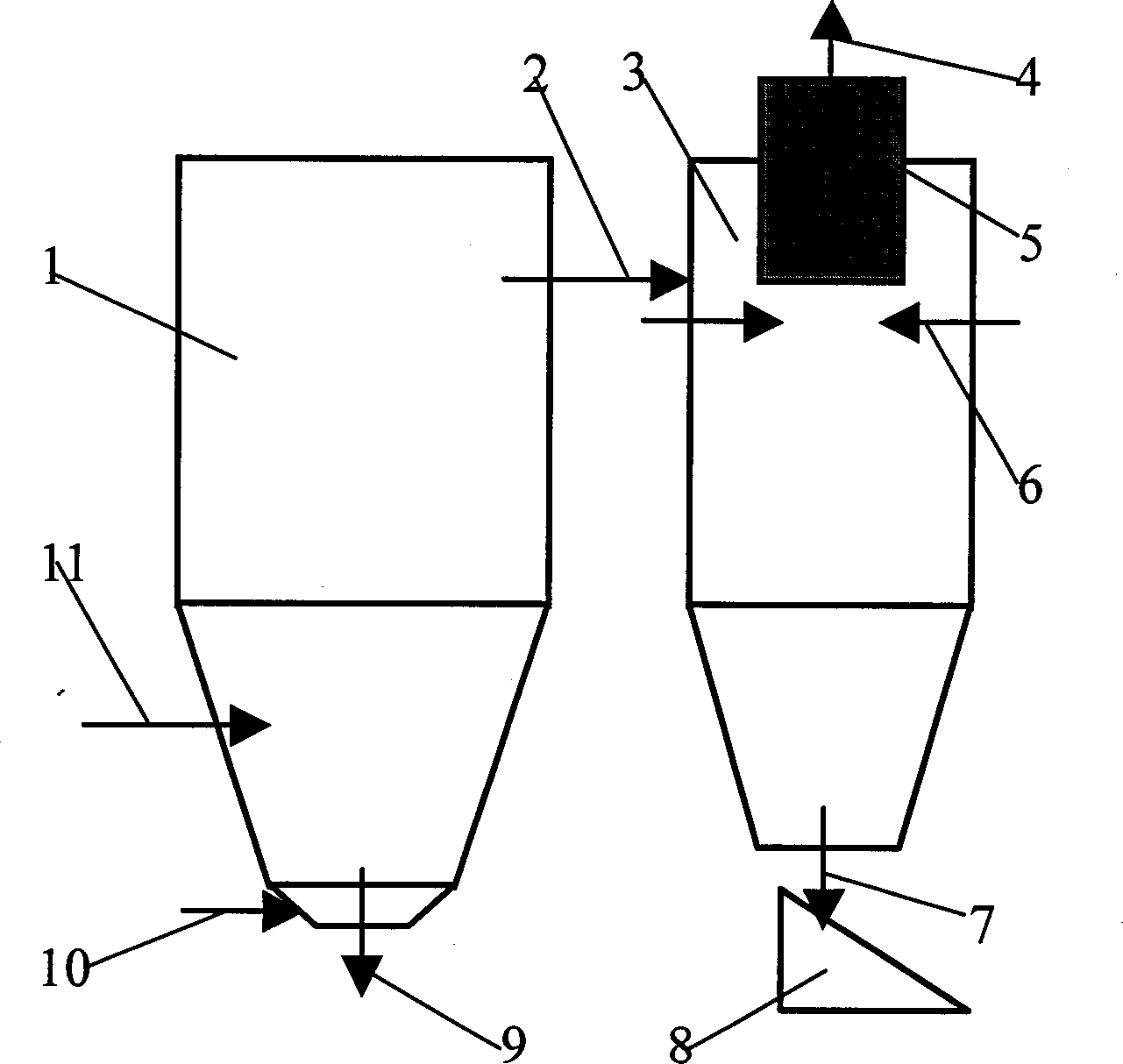

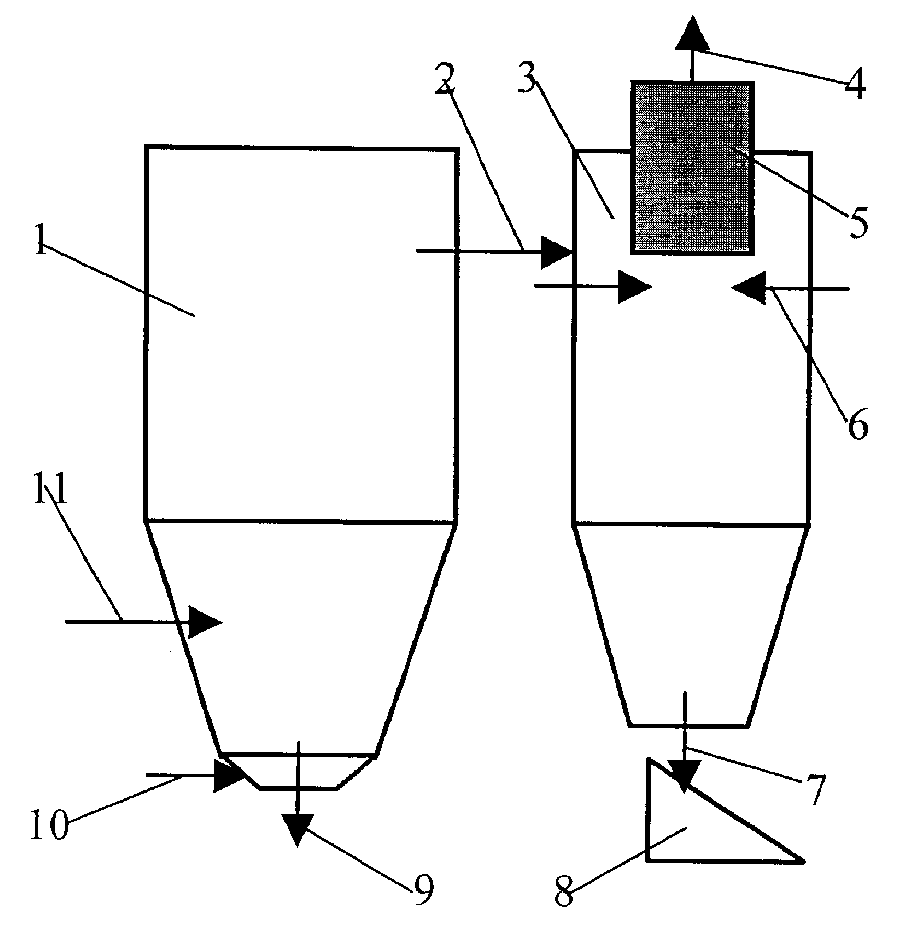

Method for making fluid bed produce high-temp. smoke and its equipment

InactiveCN1341823AGuaranteed uptimeUniform and stable temperatureFluidized bed combustionApparatus for fluidised bed combustionIt equipmentCombustion chamber

The present invention relates to a method for making fluidized bed produce high-temp. smoke and its equipment, belonging to the field of high-temp. smoke production technology by using coal. Said invention adopts the fluidized bed with reducing atmosphere combustion to simultaneously implement pyrolytic gasification and combustion of coal to make produced high-temp. smoke contain a certain quantity of inflammable gas, and make it flow into the heat-insulating secondary combustion chamber, under the action of tangential overfire air makes it continuously combust, and adopts liquid deslagging. The temp. of high-temp. smoke produced by said invention is up to 1350-1600 deg.C, and is uniforml and stable, and its ash content is low, its production cost is low, and the adaptability of the fuel is good, it can effectively prevent coking, and can make fluidized bed normally operate.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com