Electromagnetic pump single/double wave crest generator

An electromagnetic pump and generator technology, used in high-frequency current welding equipment, electrical components to assemble printed circuits, manufacturing tools, etc. and other problems to achieve the effect of ensuring interchangeability and flexibility, improving work efficiency and practicability, and improving the quality of welded plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

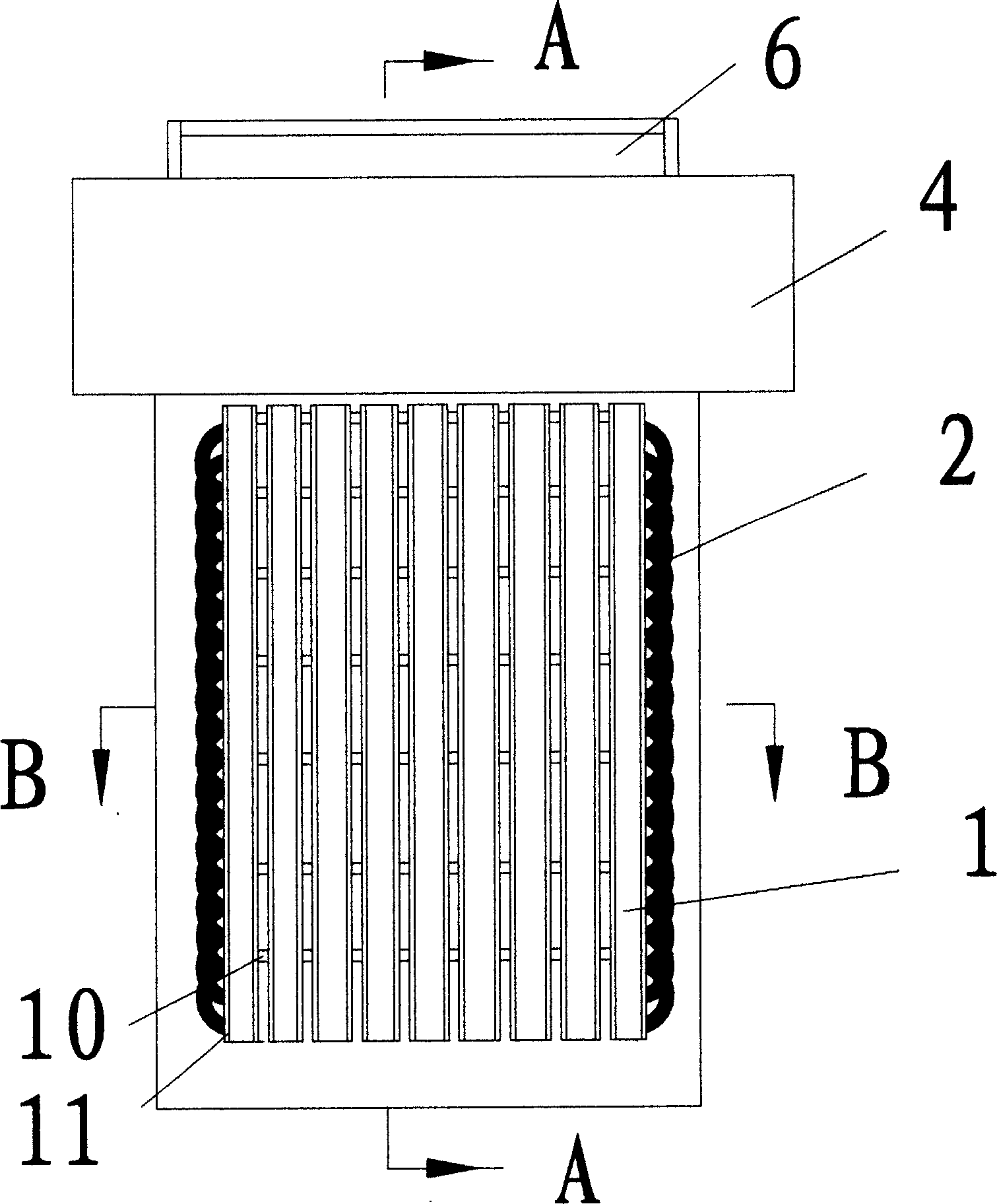

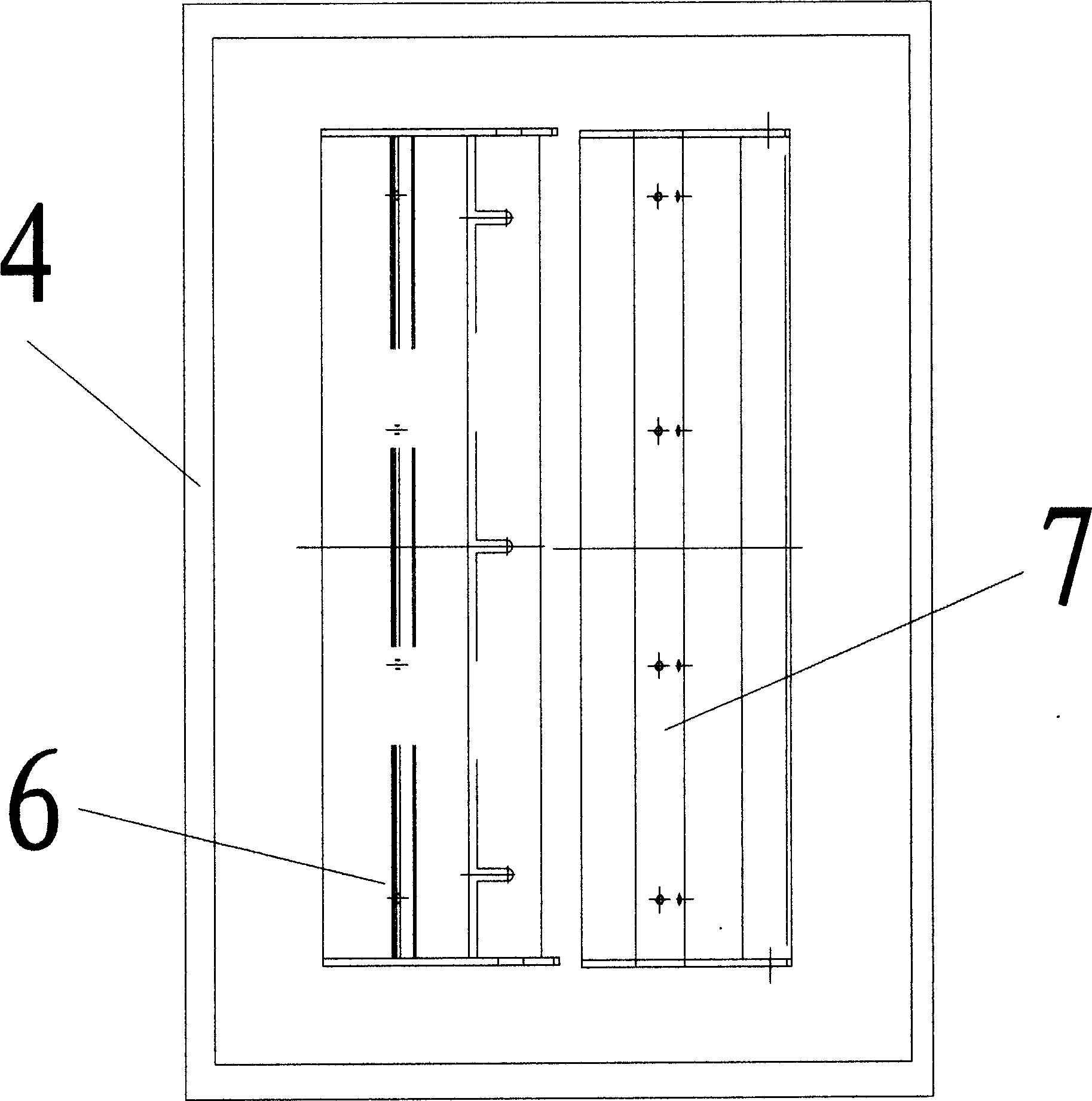

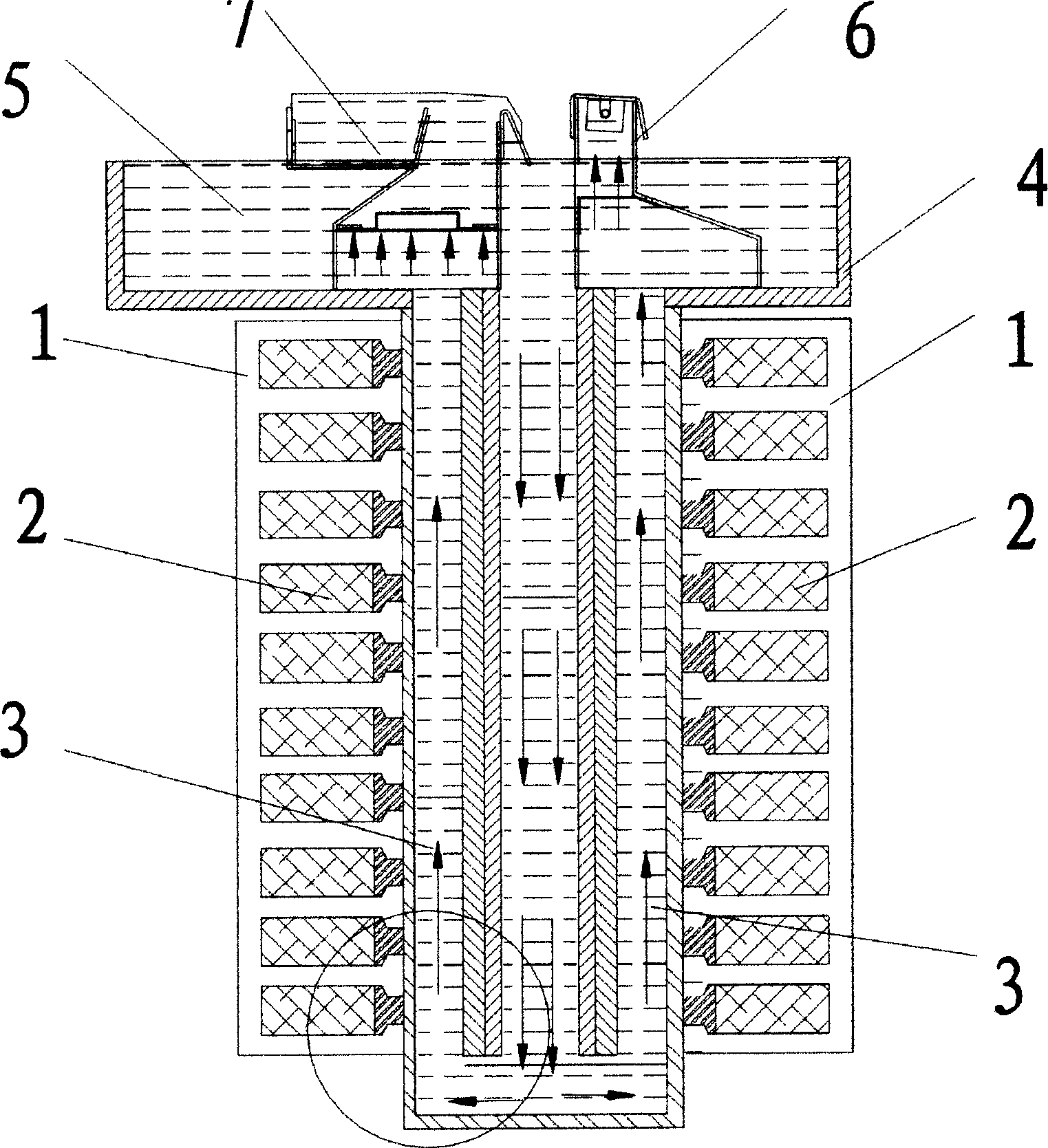

[0016] Below in conjunction with accompanying drawing, the present invention is further described:

[0017] In the above views, 1-three-phase stator core, 2-three-phase stator winding, 3-channel, 4-liquid metal container, 5-liquid metal, 6-turbulent wave pump nozzle, two-way wide plane pump nozzle, 7 -two-way wide flat pump nozzle, 8-magnetic isolation plate, 9-magnetic slot wedge, 10-sleeve, 11-ventilation slot plate, 12-screw,

[0018] The electromagnetic pump consists of a unilateral linear motor primary stator core (1) and its winding (2), a magnetic isolation plate (8), a liquid metal container (4), a pump groove (3) and a pump nozzle system (6, 7) composition. The liquid metal container (4) has a T-shaped structure, and a plurality of symmetrical longitudinal grooves (3) are arranged in the longitudinal part of the T shape. The other end communicates with the container (4), two linear motor stator cores (1) with windings (2) are placed on both sides of the liquid metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com