Patents

Literature

8538results about "Electronic commutators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

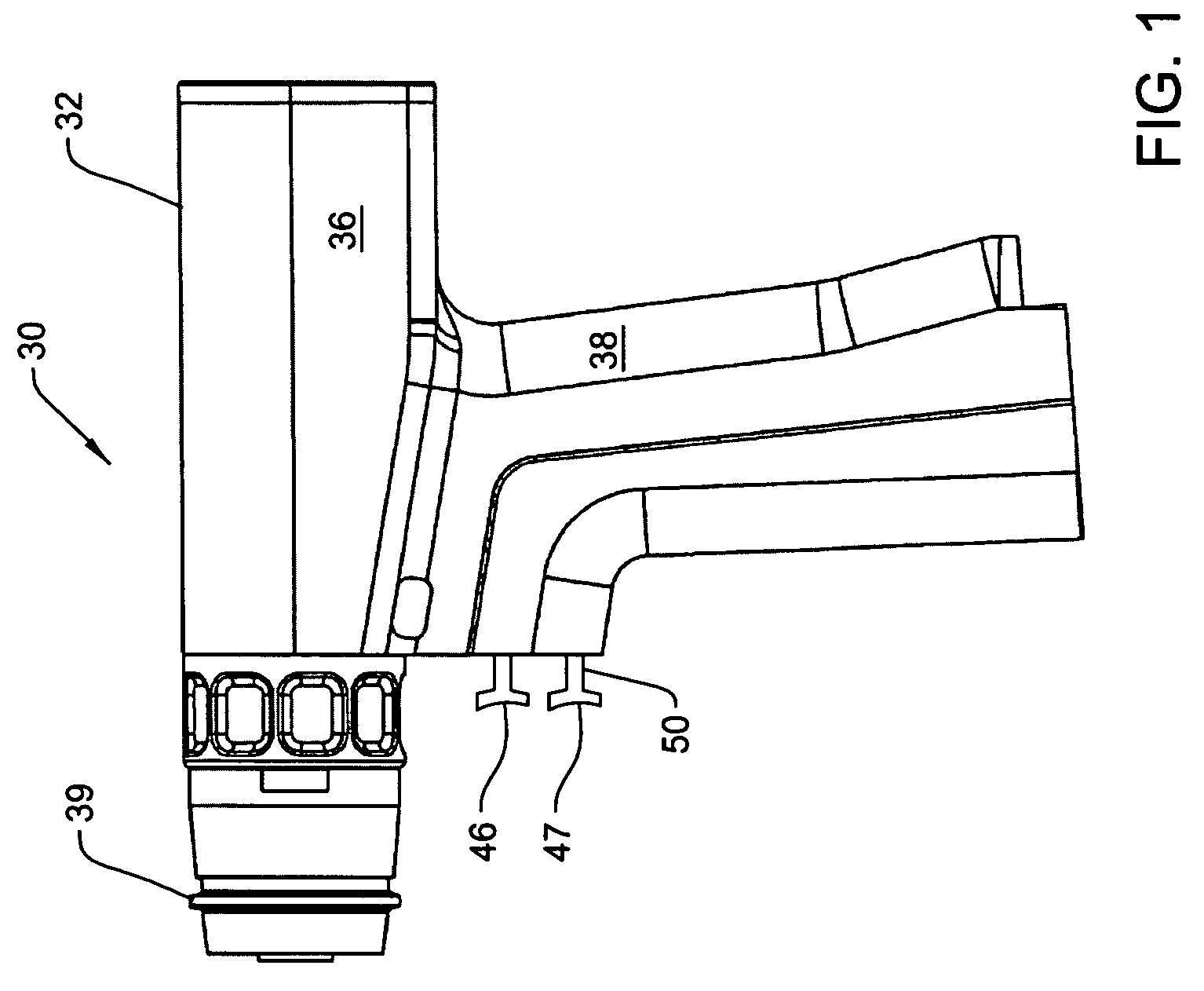

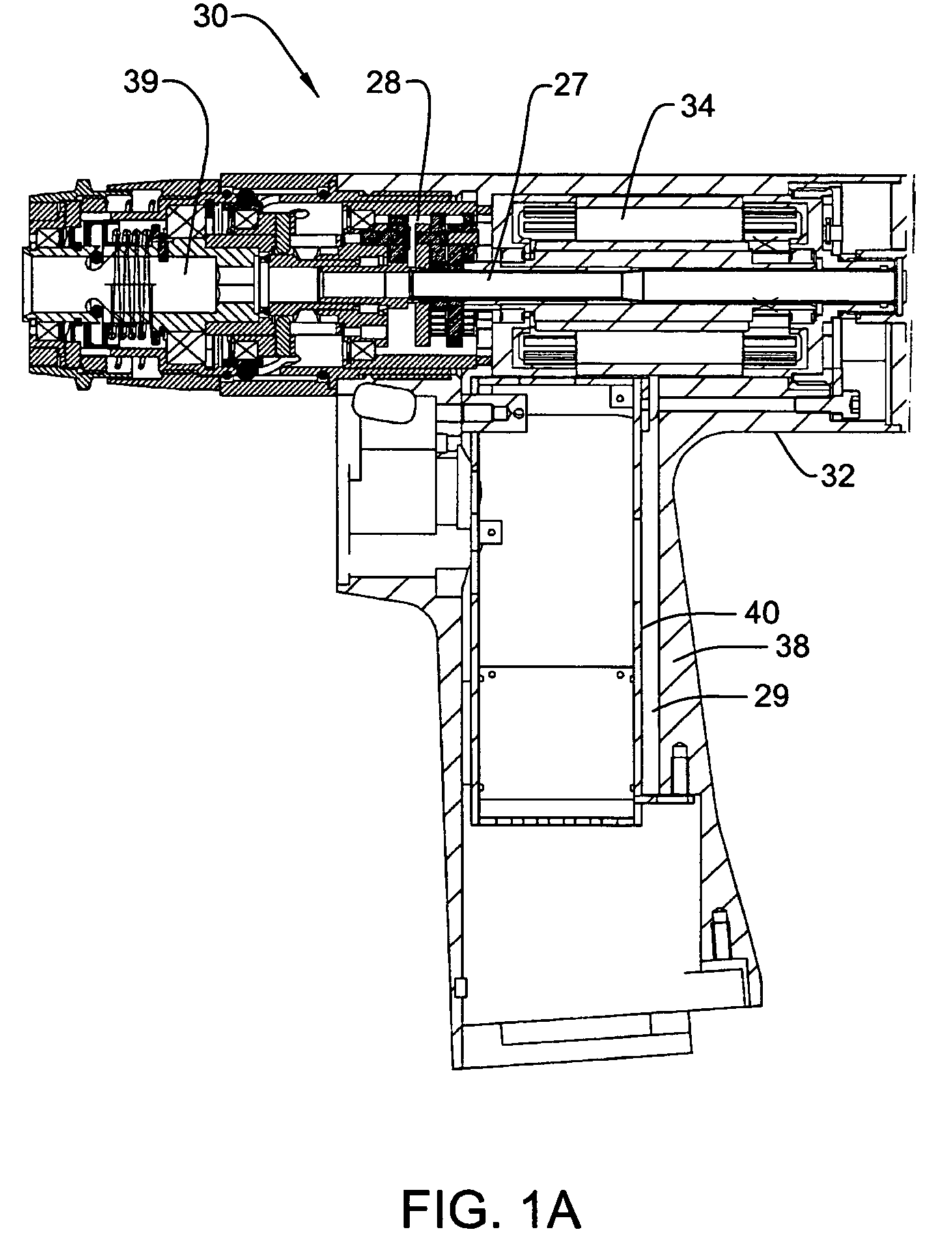

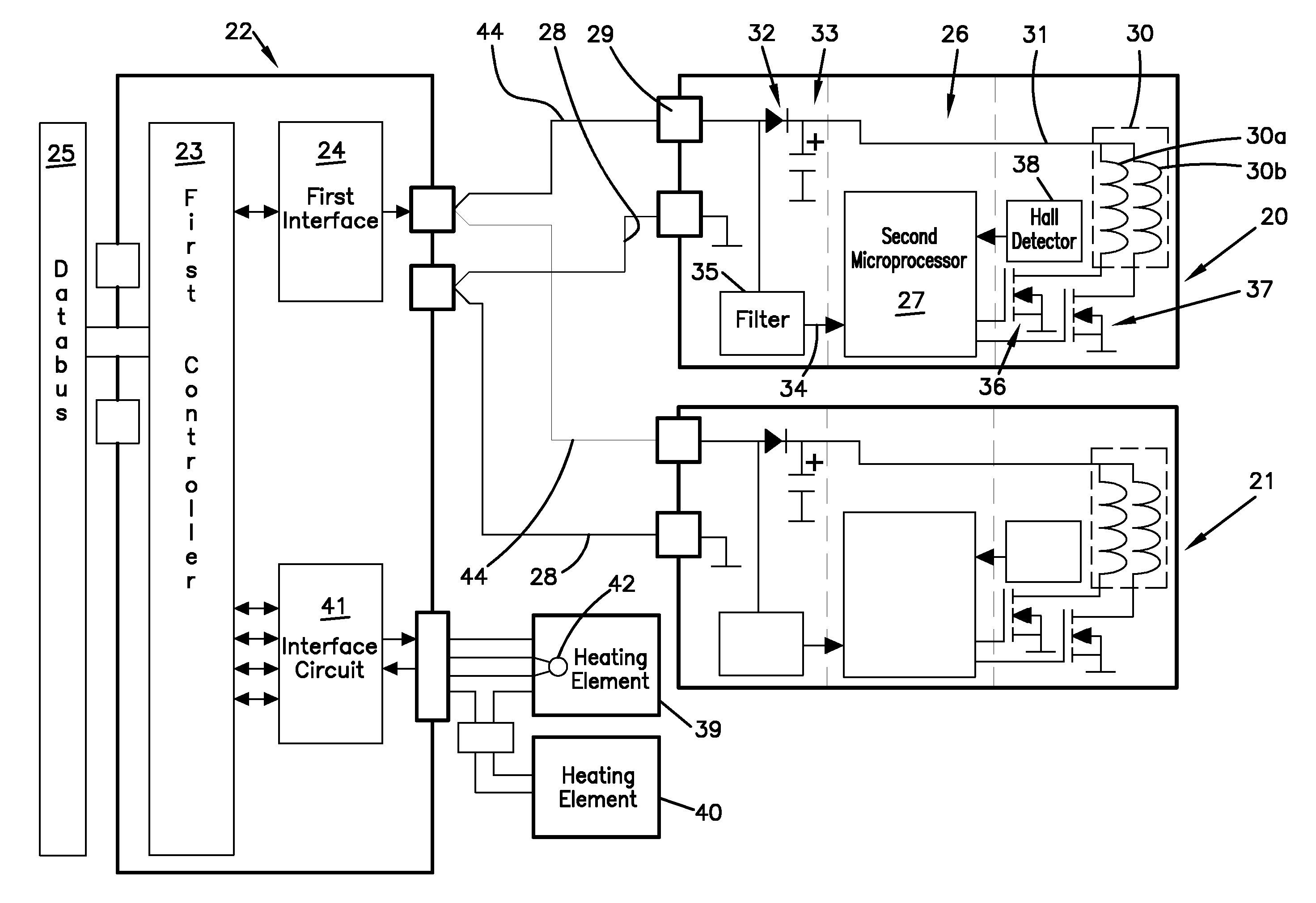

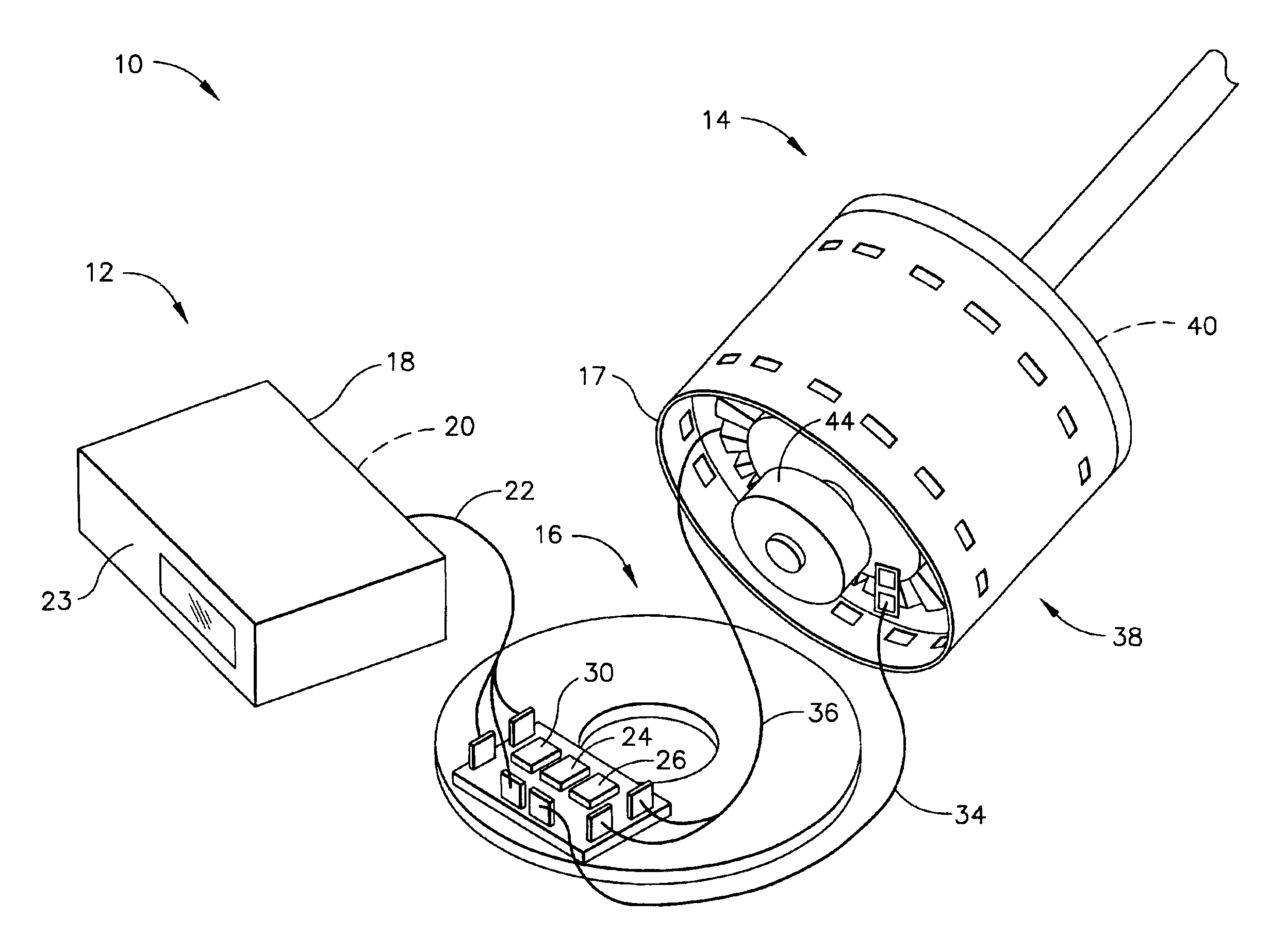

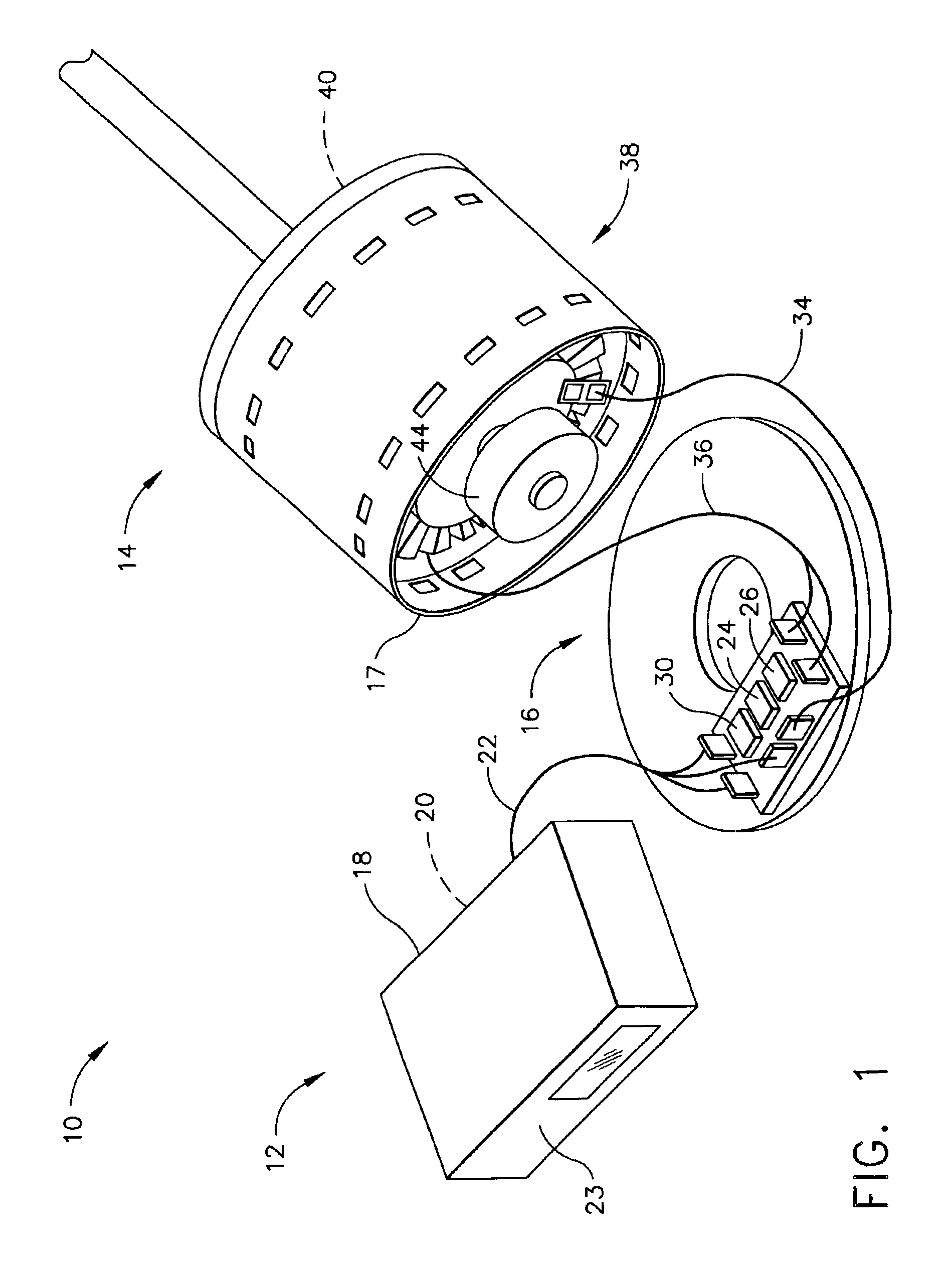

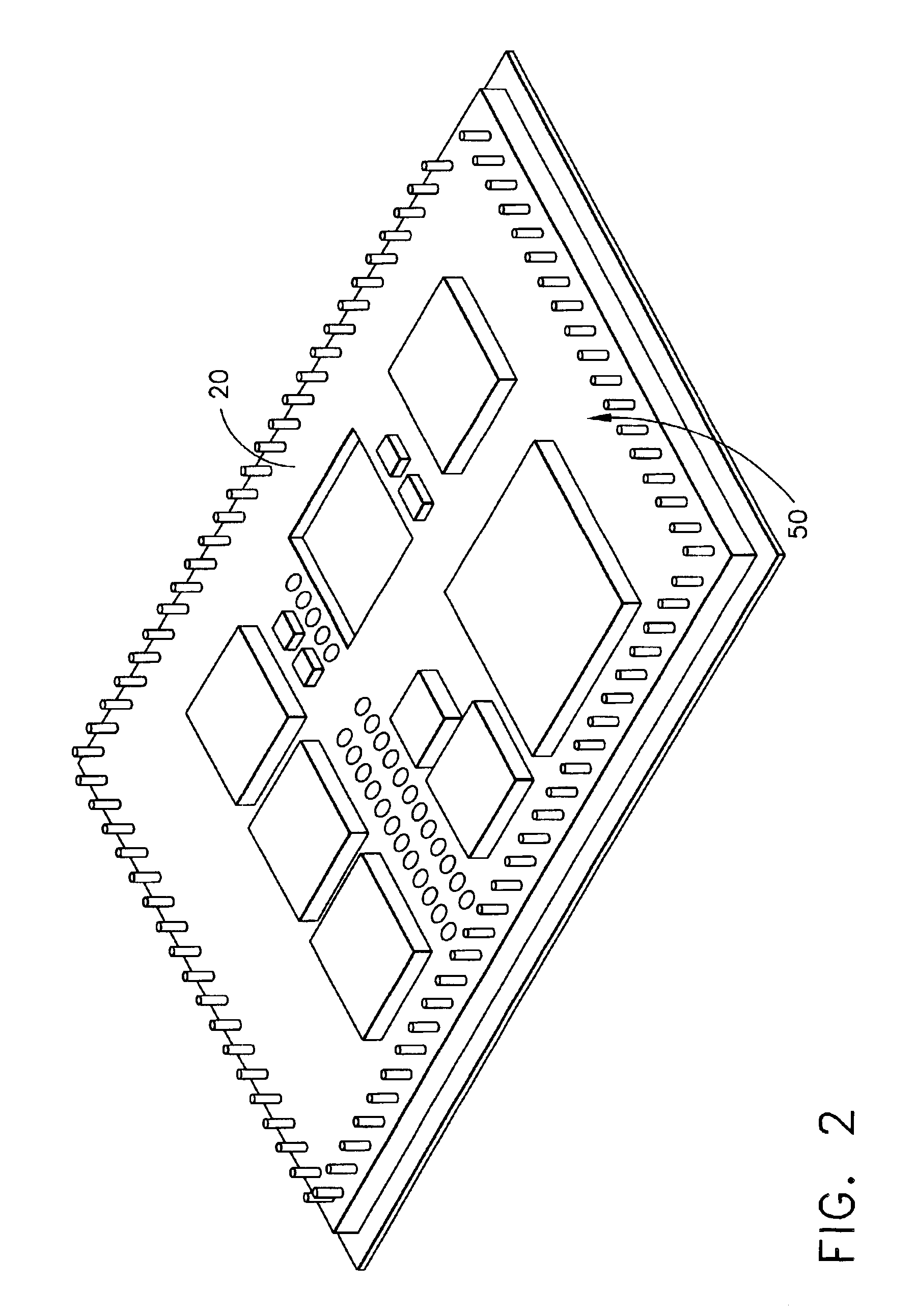

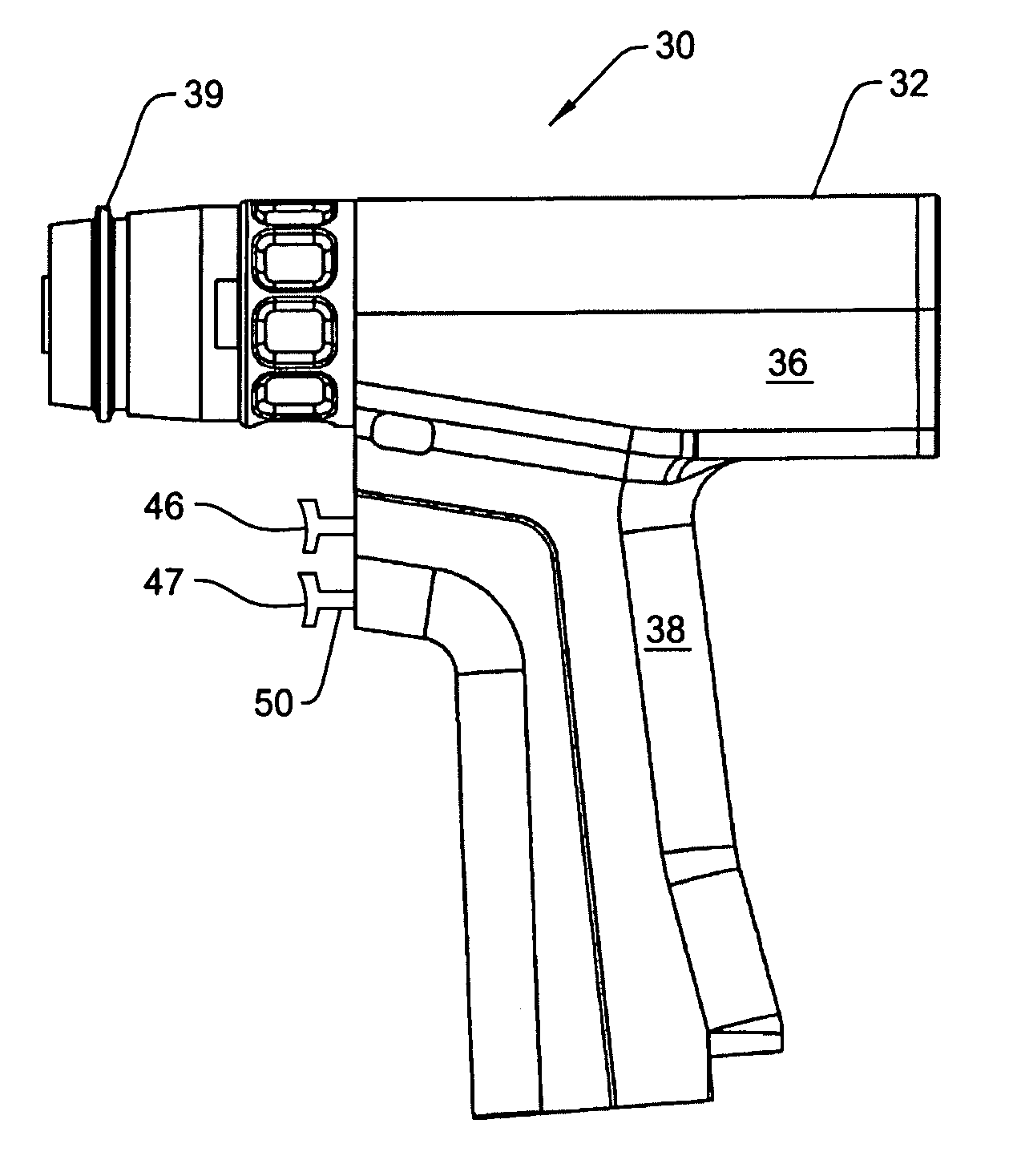

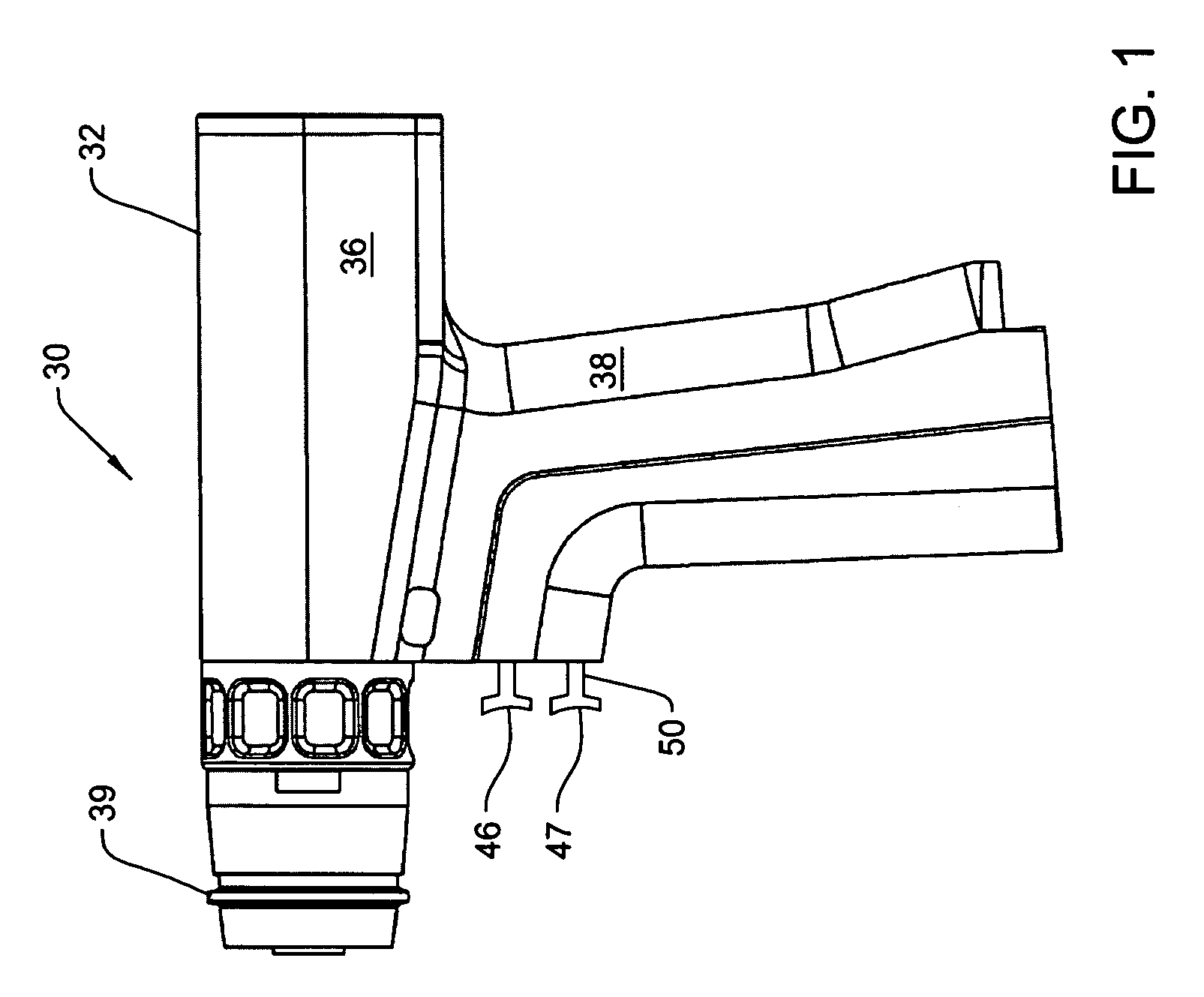

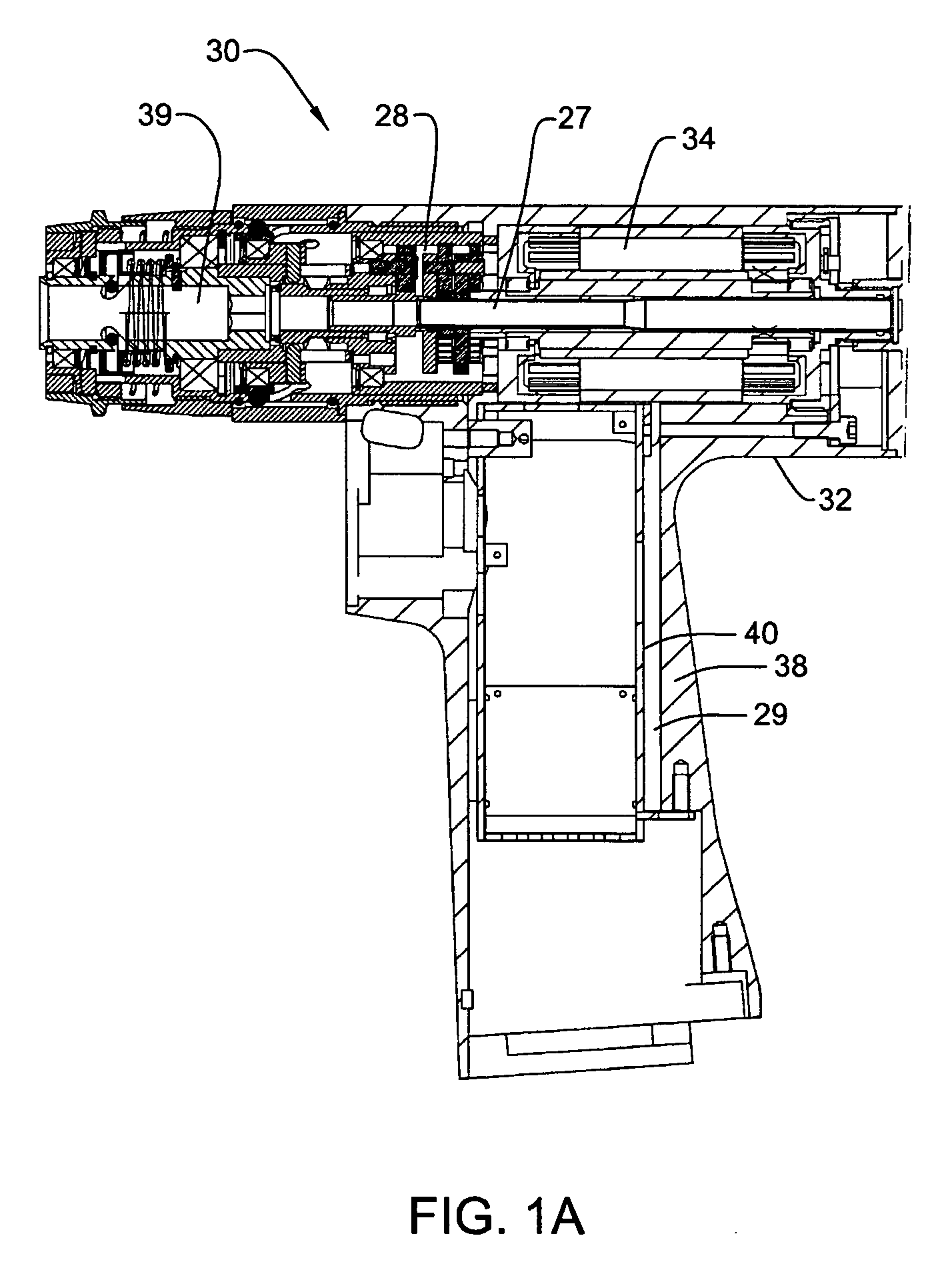

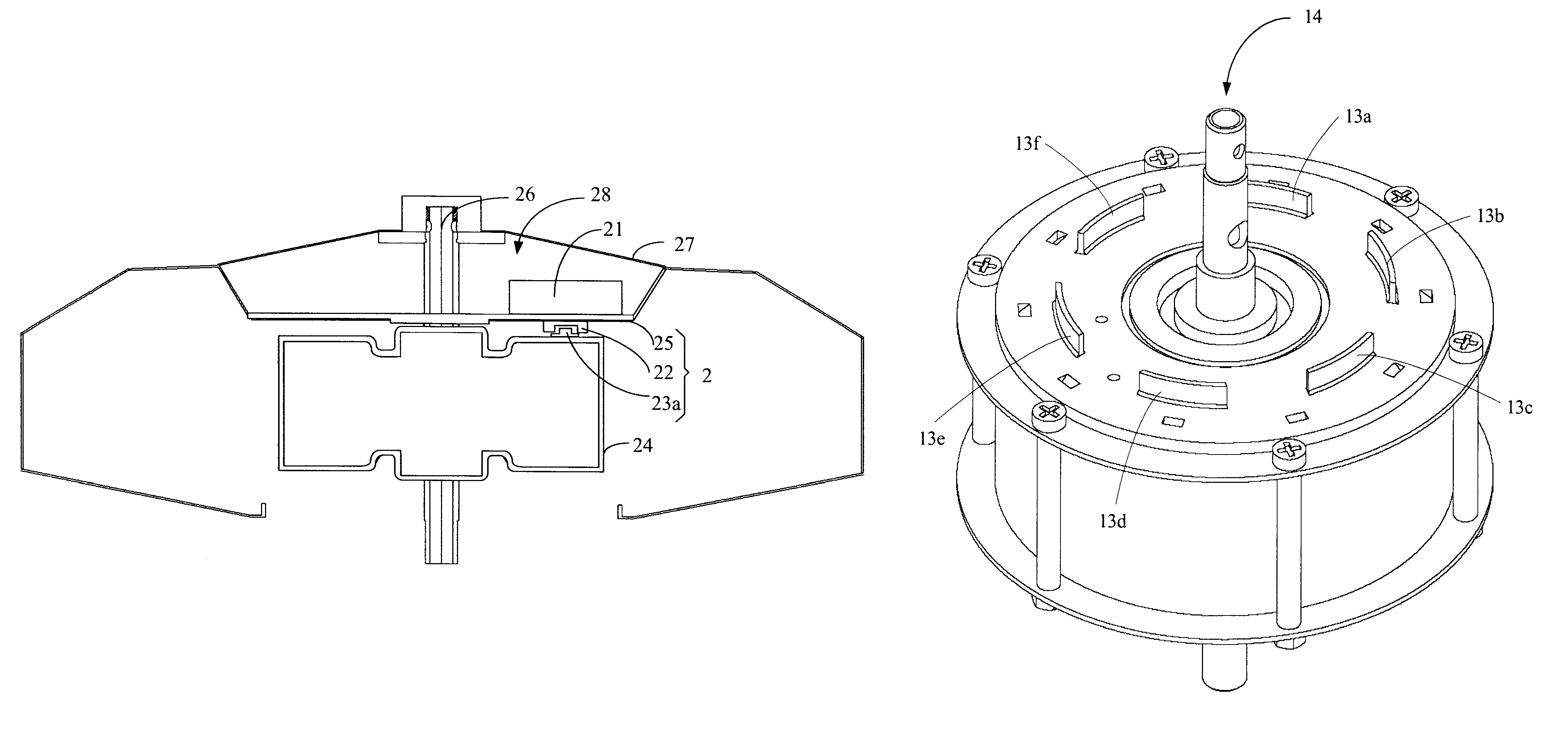

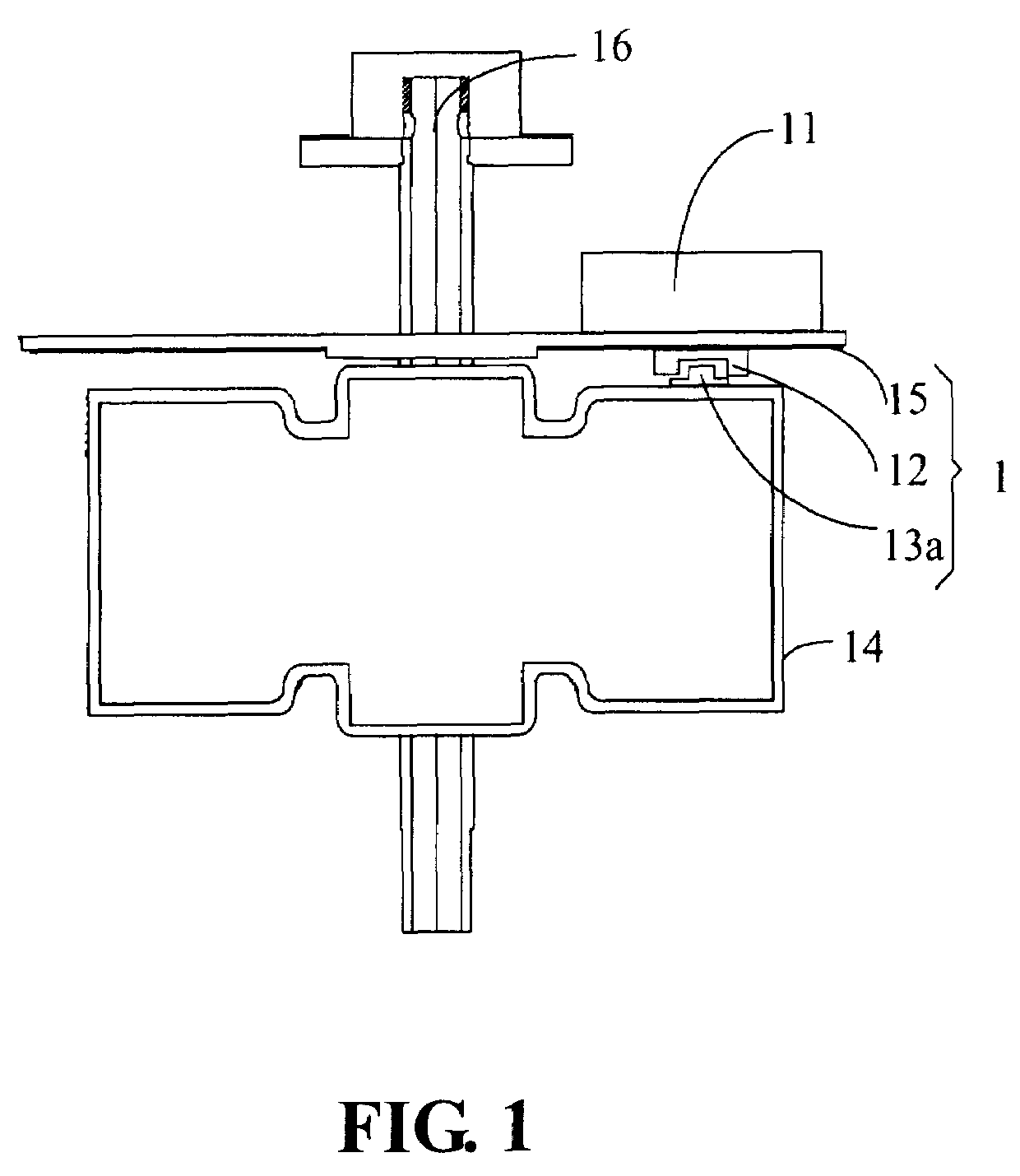

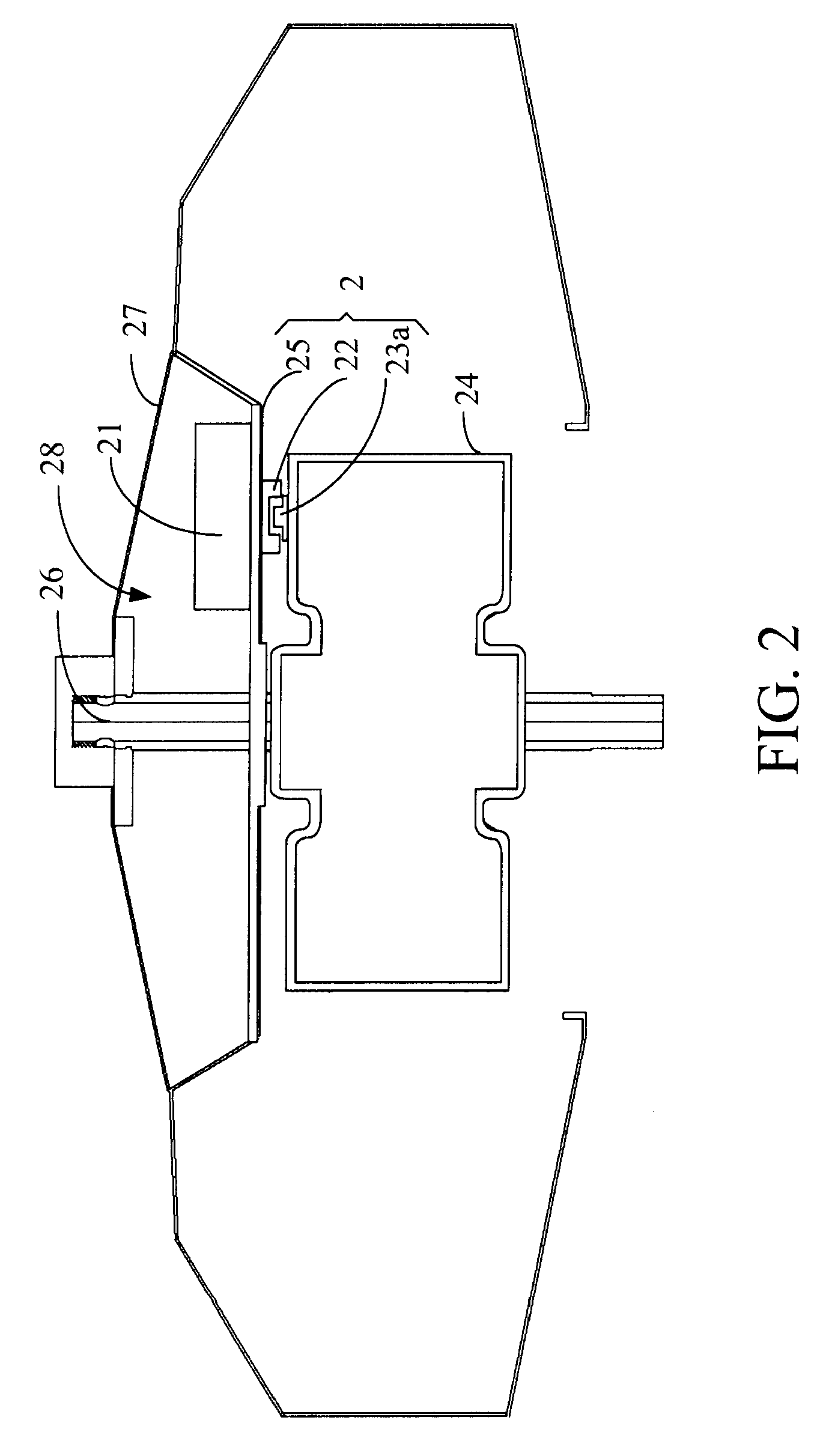

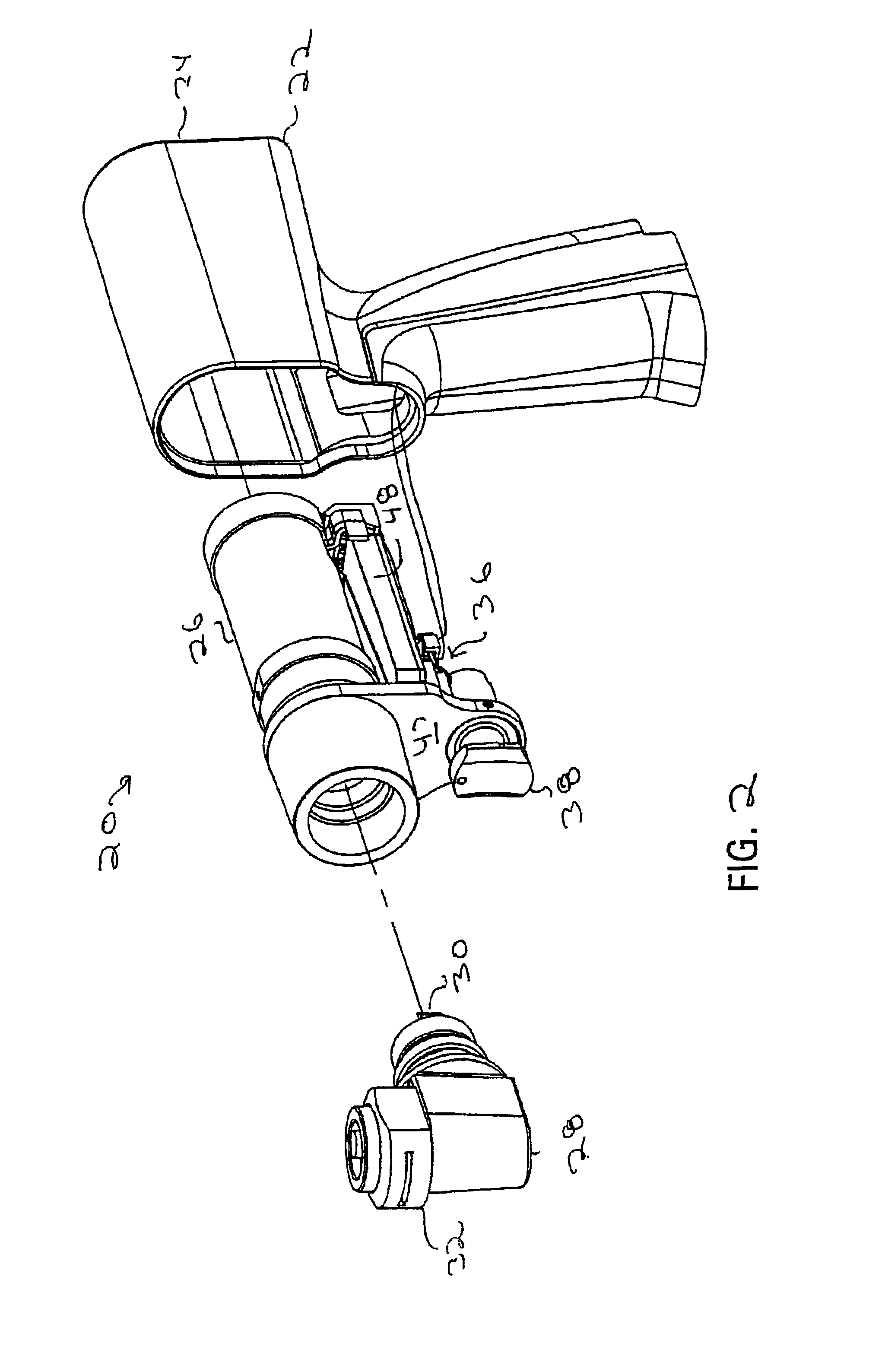

Powered surgical tool with control module that contains a sensor for remotely monitoring the tool power generating unit

ActiveUS7638958B2Shaking/oscillating/vibrating mixersTransportation and packagingEngineeringControl circuit

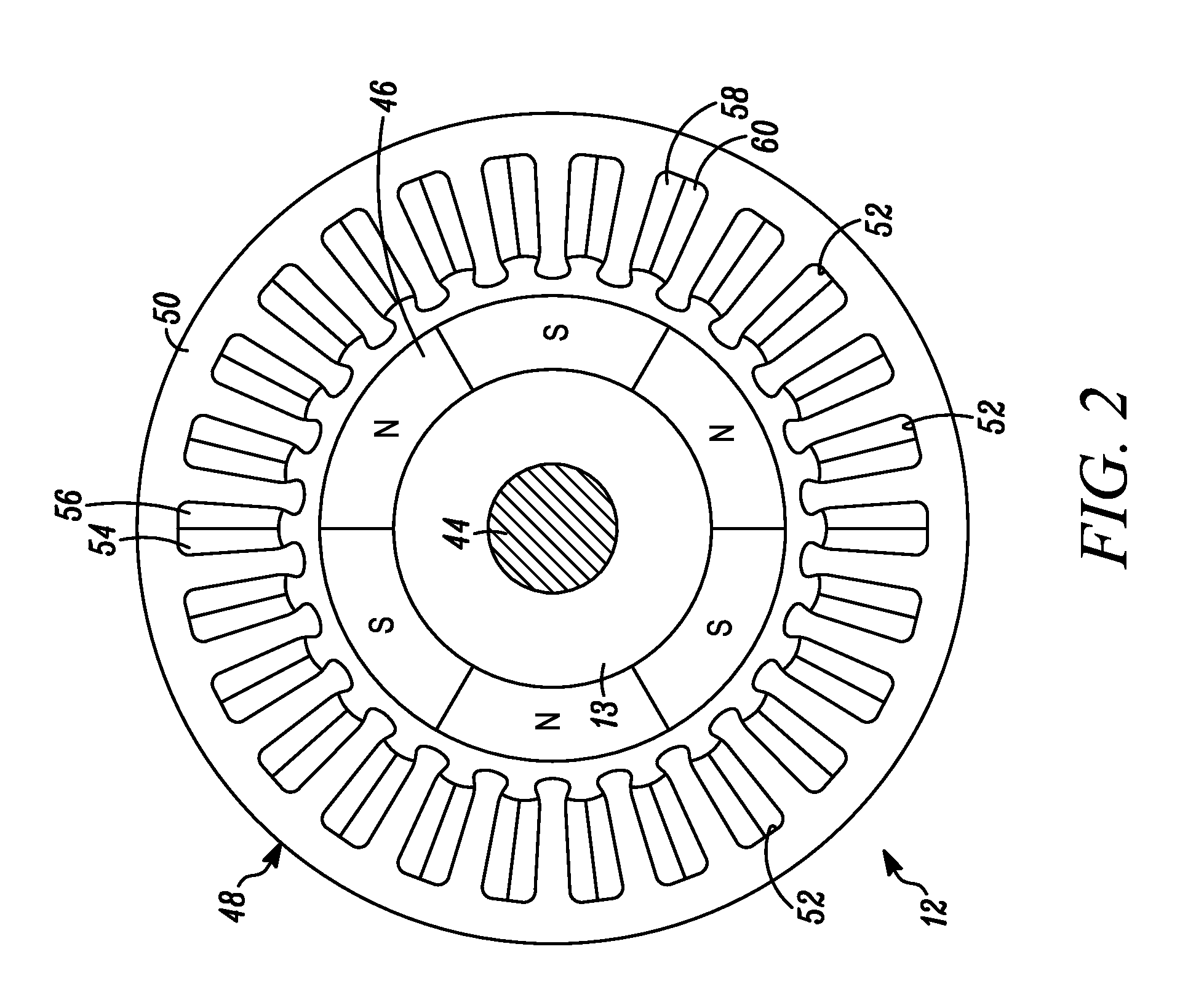

A powered surgical tool with a housing that contains a power generating unit such as a motor. A control module is disposed in a shell that is mounted in the housing. The control module contains a control circuit for regulating the actuation of the power generating unit. The power generating unit emits a signal representative of the operating state of the unit that is transmitted through the structural material forming the shell. Also internal to the control module shell is a sensor that monitors the signal emitted by the power generating unit. This signal output by the sensor is applied to the control circuit. The control circuit, based on the sensor signal regulates actuation of the power generating unit. Wherein the power generating unit is a motor, the signal emitted is the magnetic field that varies with rotor position. The sensor monitors the strength of this field.

Owner:STRYKER CORP

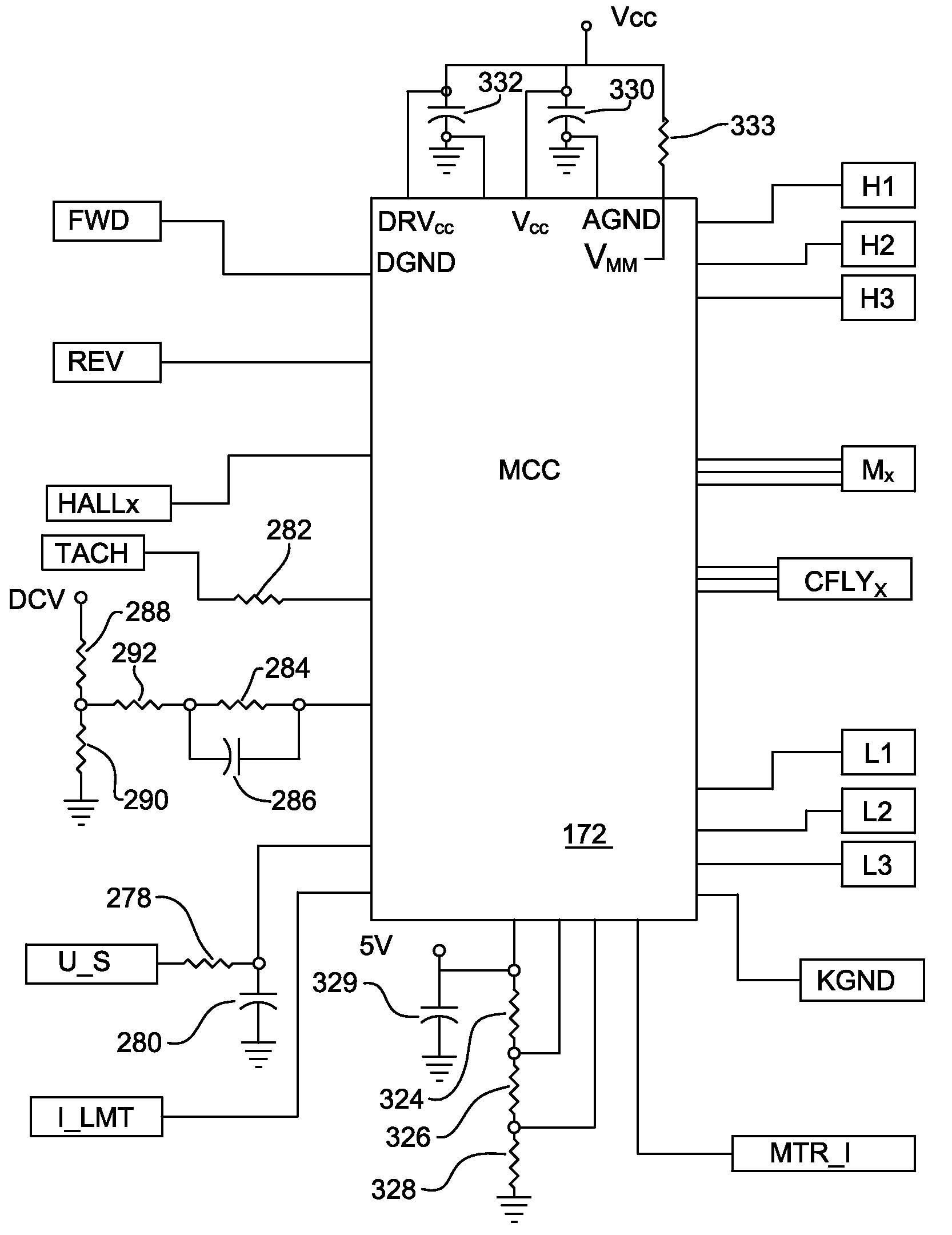

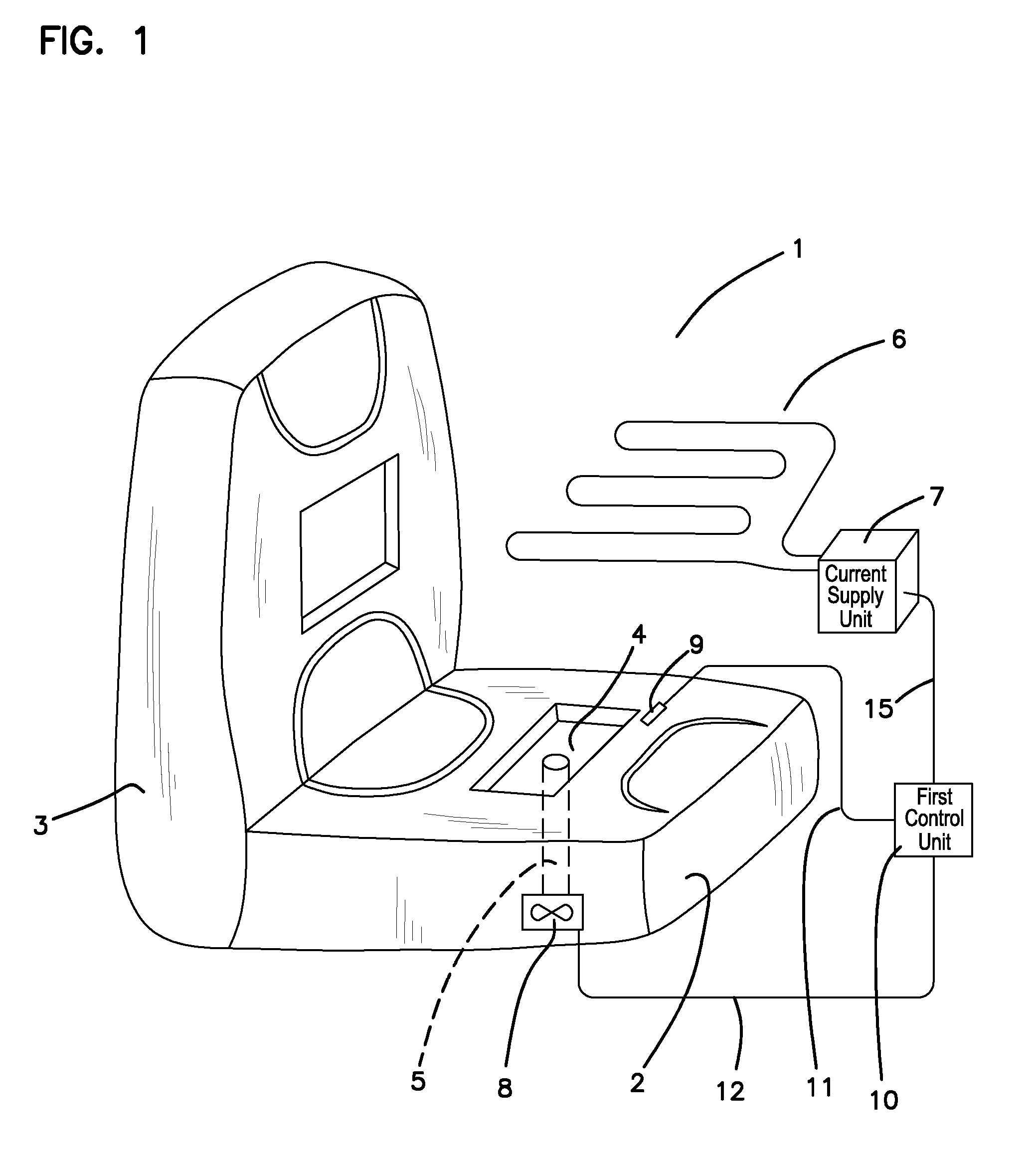

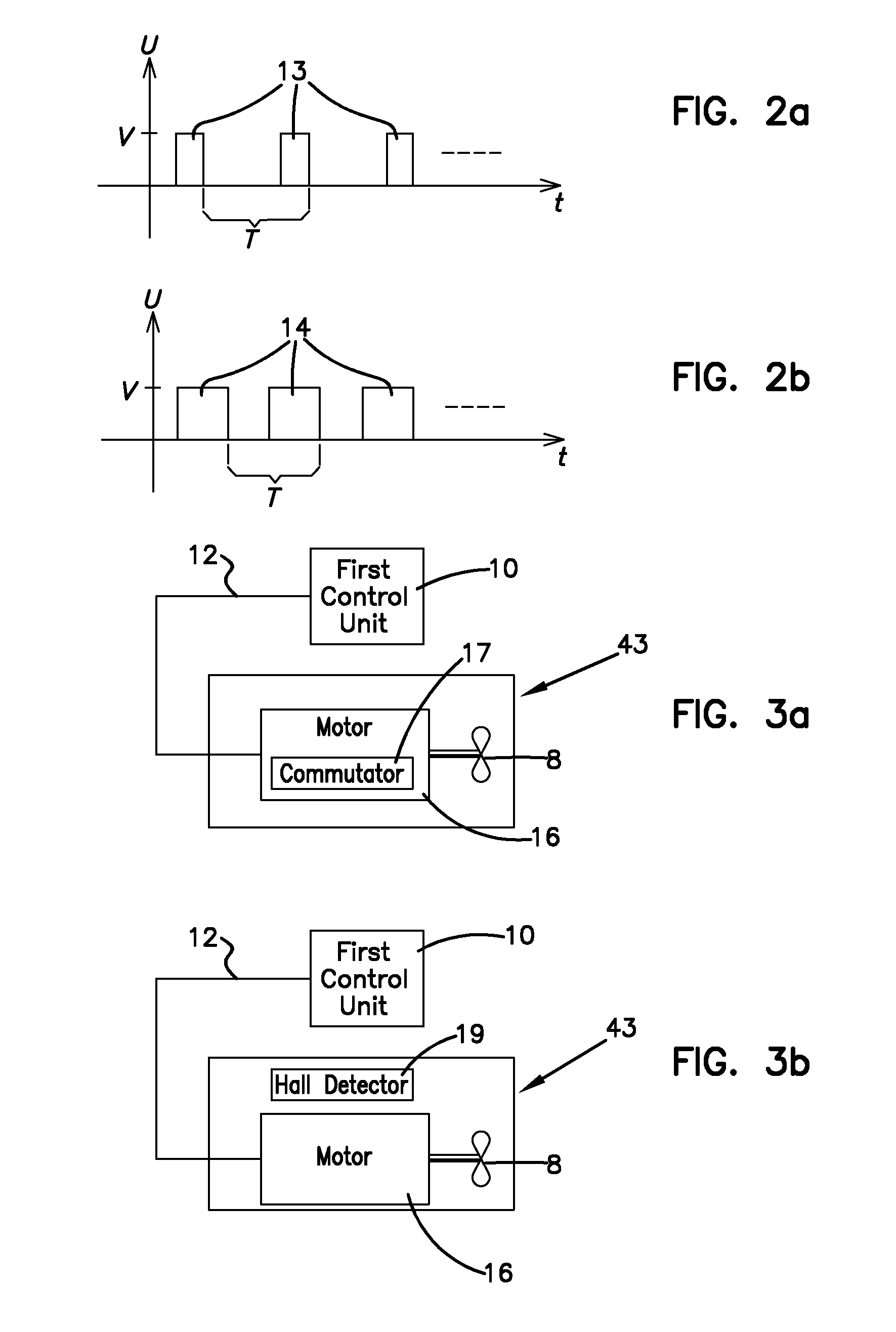

Method and arrangement for control of direct current motor

InactiveUS7567045B2Efficient coordinationLow costVehicle seatsMultiple motor speed/torque controlTelecommunications linkControl signal

Owner:KONGSBERG AUTOMOTIVE AB (SE)

Motor having controllable torque

InactiveUS8125168B2Single-phase induction motor startersCommutation monitoringMotor controlElectric motor

A controllable motor includes a rotor. A first stator winding set is operable, upon being energized, to generate and apply a first torque to the rotor. A second stator winding set independent of the first stator winding set is operable, upon being energized, to generate and apply a second torque to the rotor. A motor control is coupled to the first and second stator winding sets. The motor control is operable to selectively energize one of the first or second stator winding sets to thereby generate and apply one of the first or second torques to the rotor, and simultaneously energize both the first and second stator winding sets to thereby generate and apply a third torque greater than the first or the second torque.

Owner:HONEYWELL INT INC

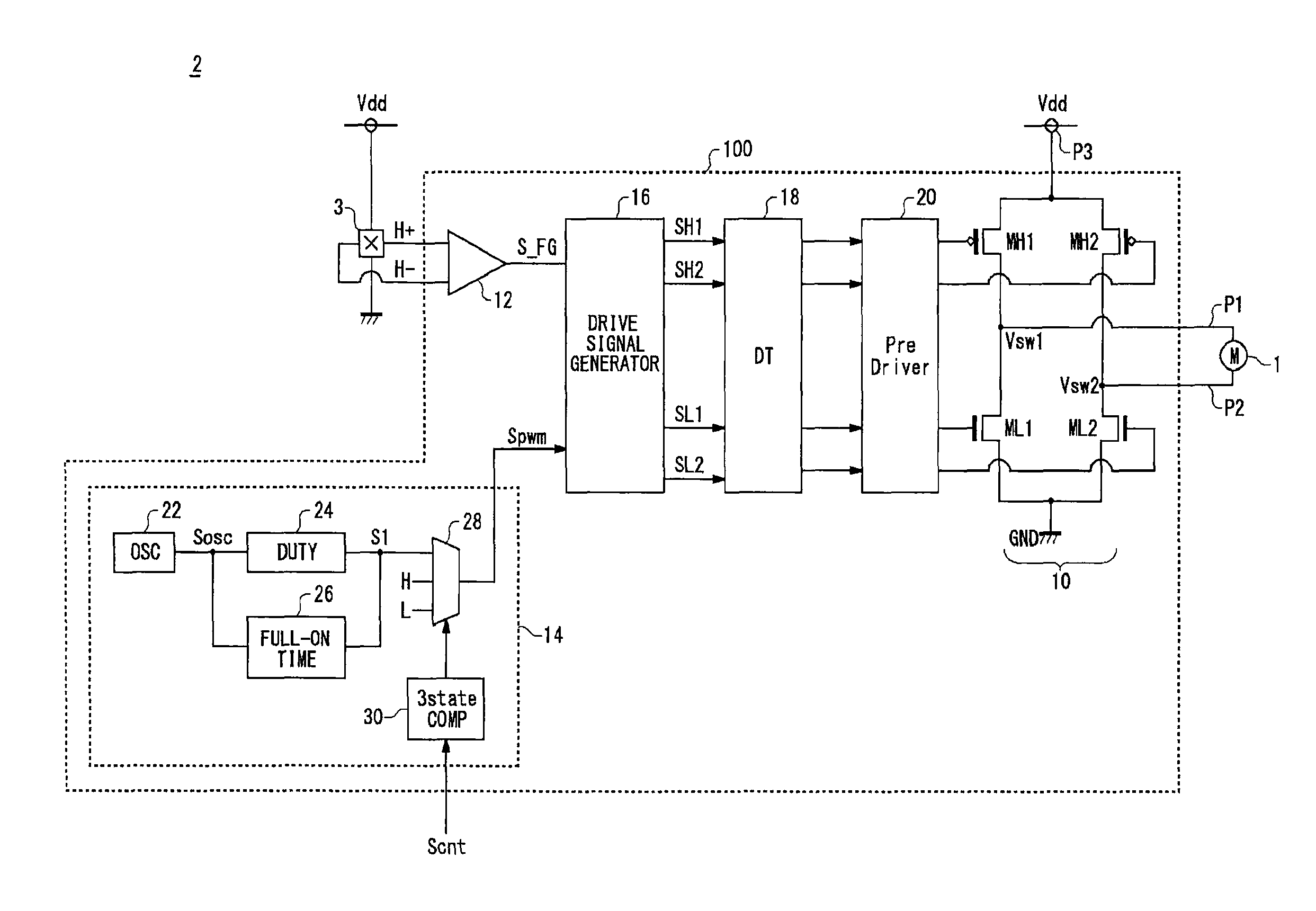

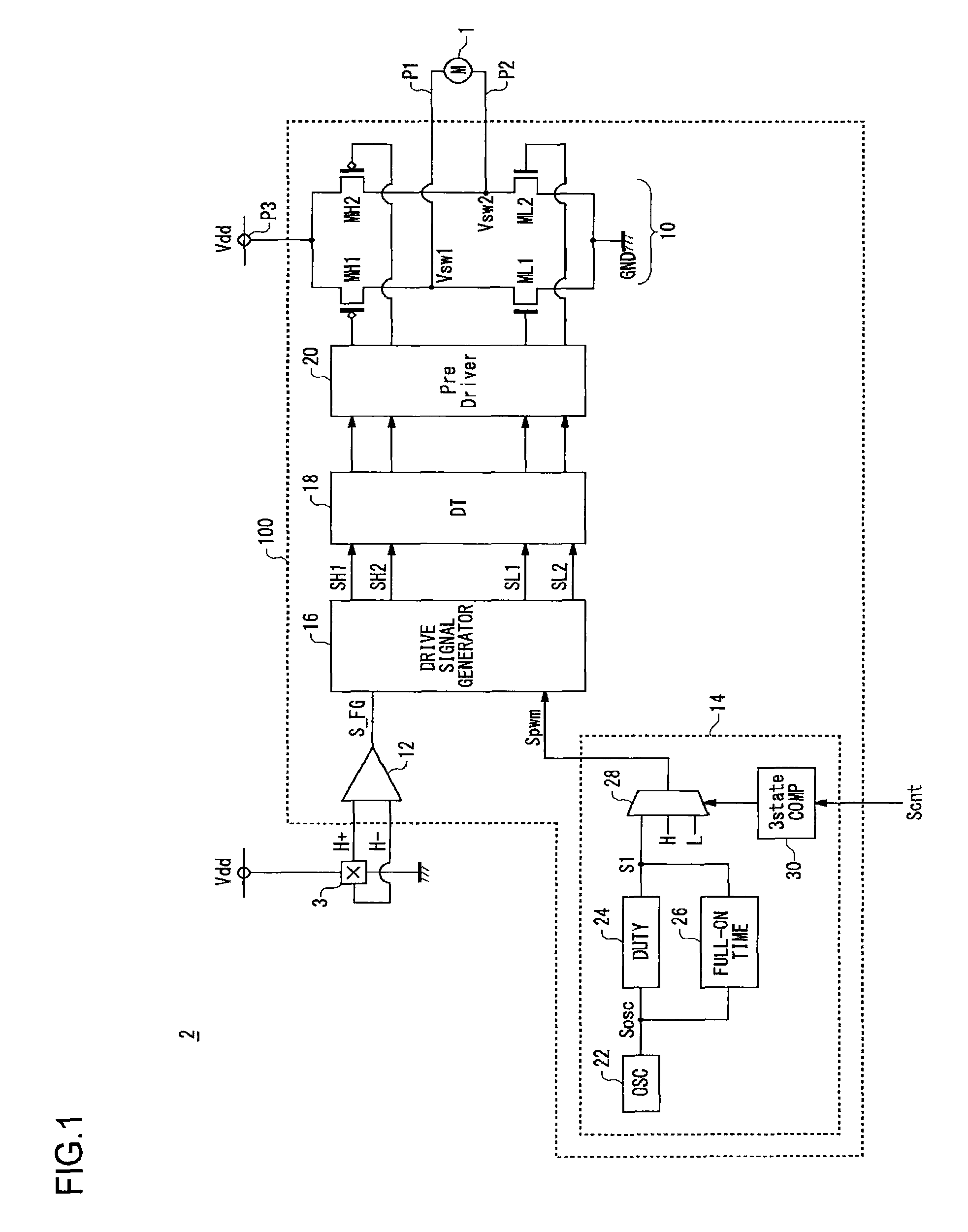

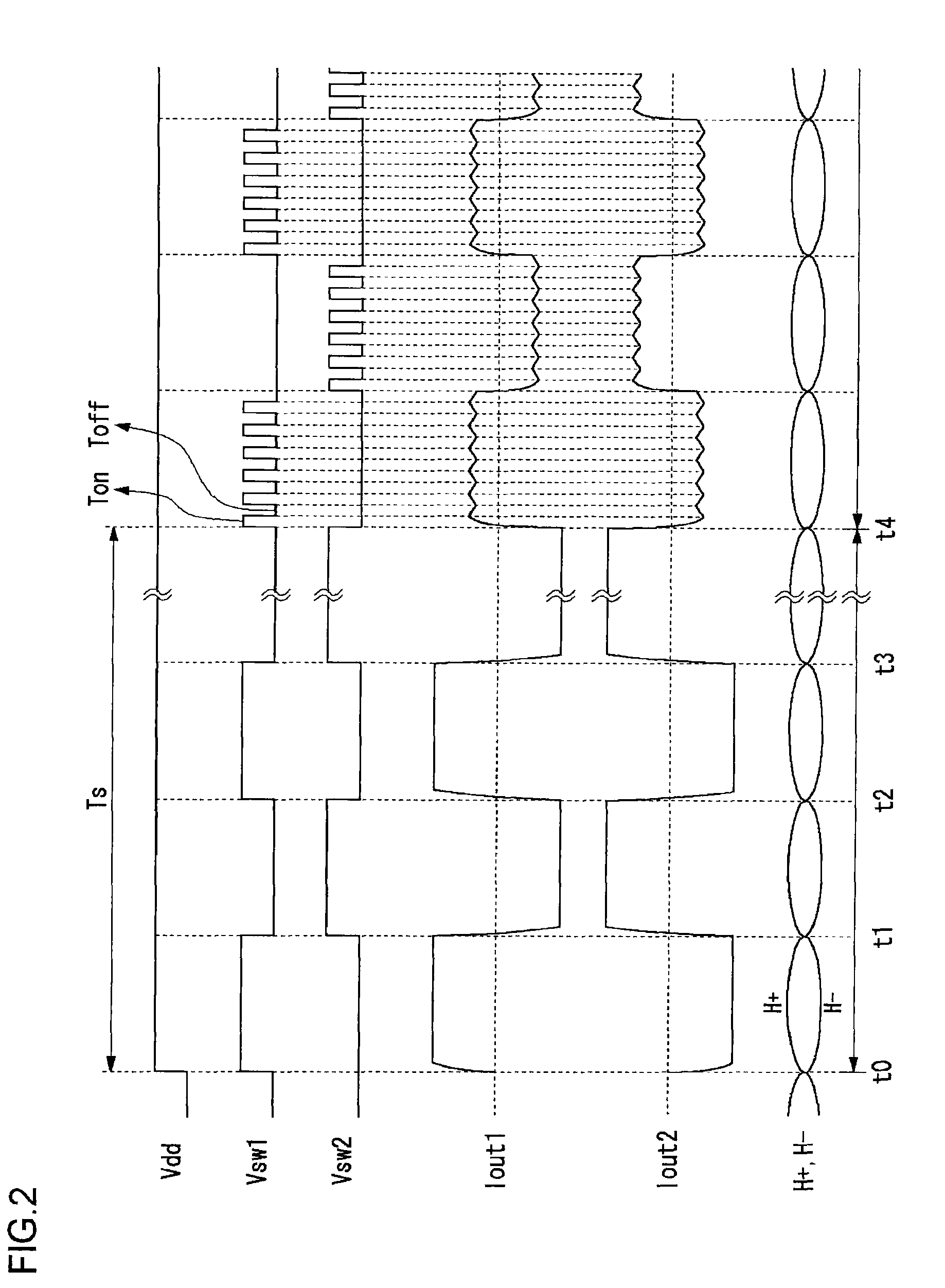

Motor drive circuit with short startup time

An H-bridge circuit is connected to a coil of the vibration motor that is to be driven. A comparator receives Hall signals indicating position information of a rotor of the vibration motor, and converts to an FG signal. A pulse width modulator generates a pulse-modulated pulse signal specifying energization time of the coil of the vibration motor. The pulse width modulator, in a first mode, after commencing start-up of the vibration motor, sets a duty ratio of the pulse signal to 100%, and after that, switches the duty ratio to a predetermined value in accordance with rotational frequency of the motor. In a second mode, the duty ratio of the pulse signal continues to be set to 100%. In a third mode, frequency and the duty ratio of the pulse signal are set based on a control signal of a pulse form inputted from outside. The control signal is used also in switching mode.

Owner:ROHM CO LTD

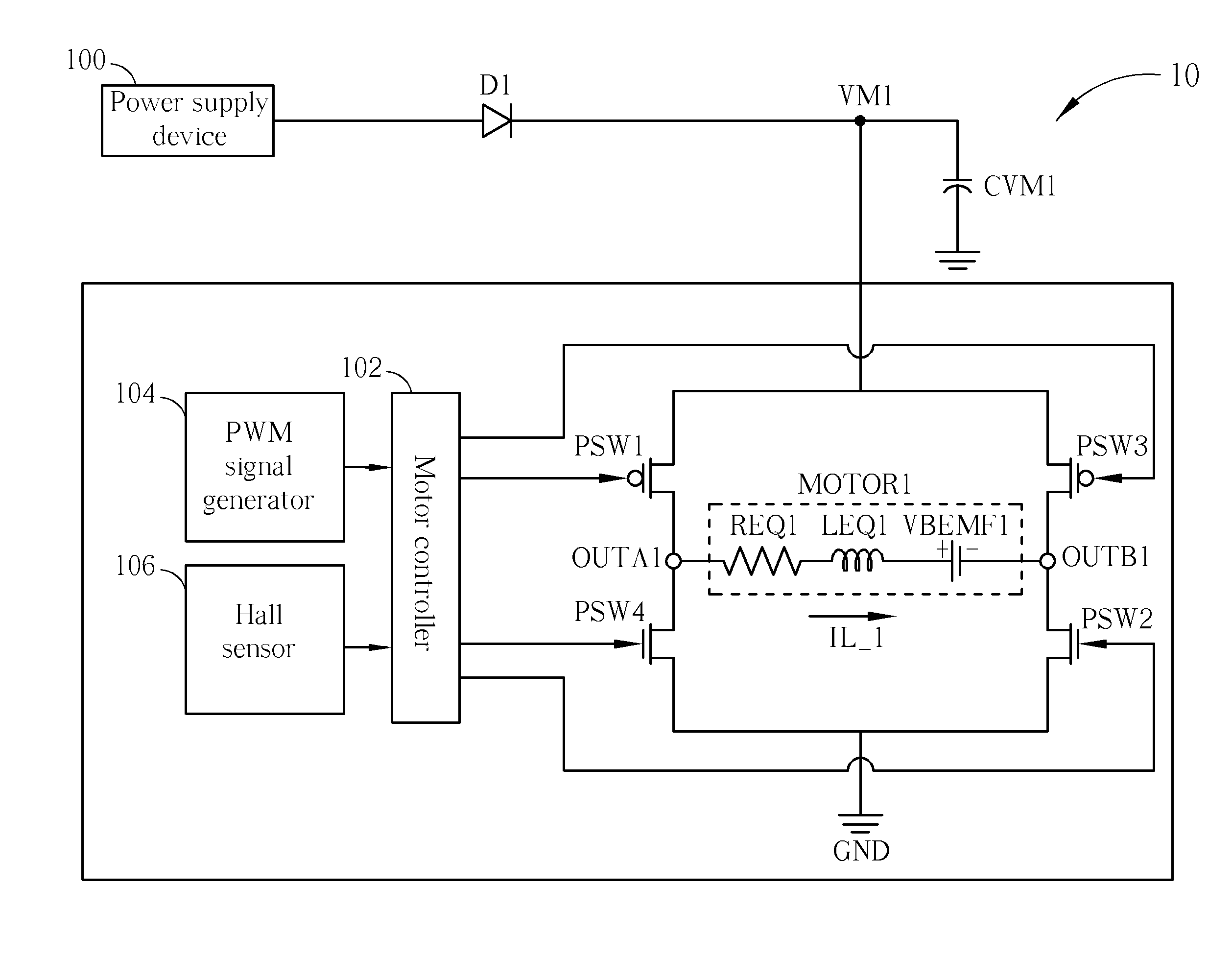

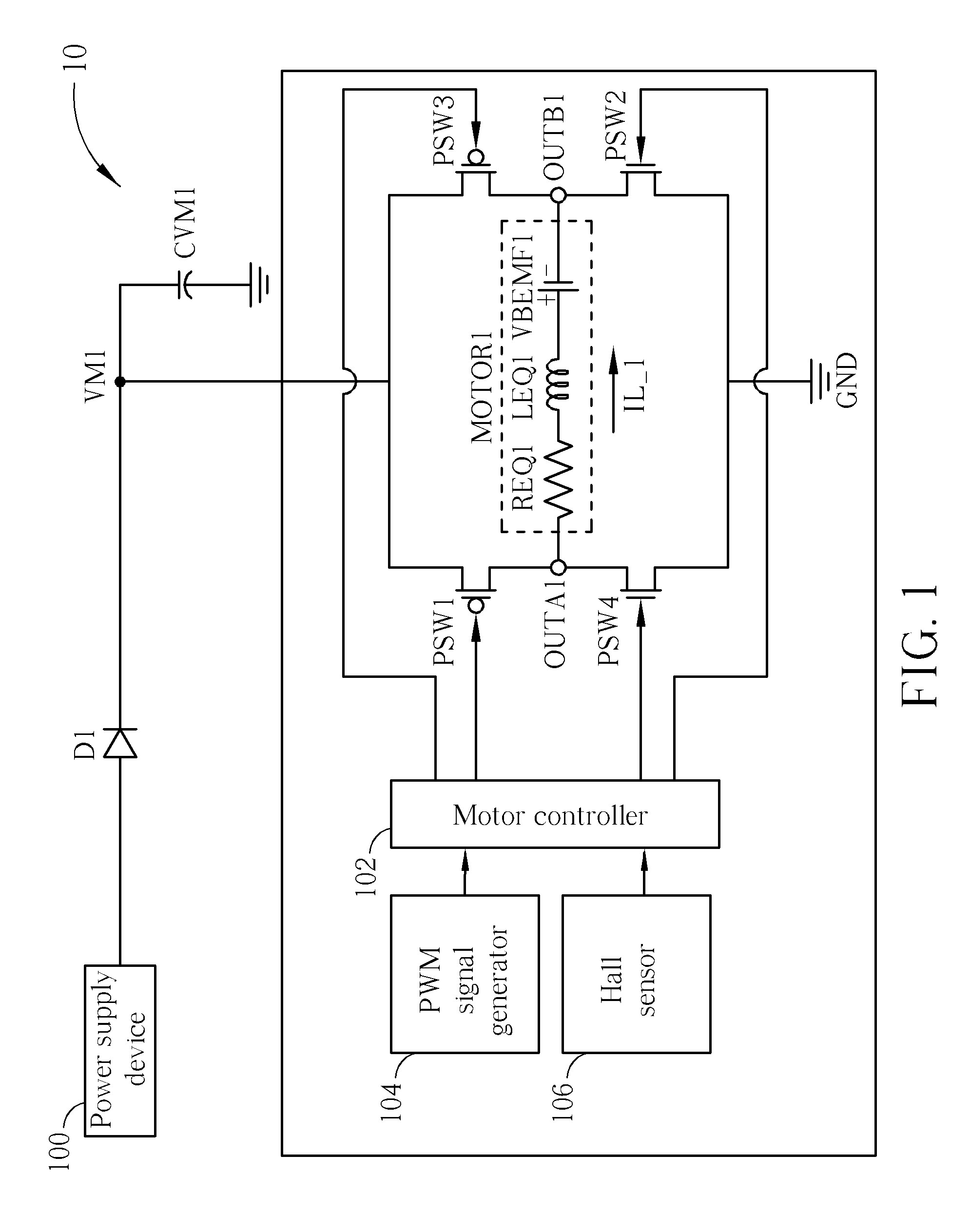

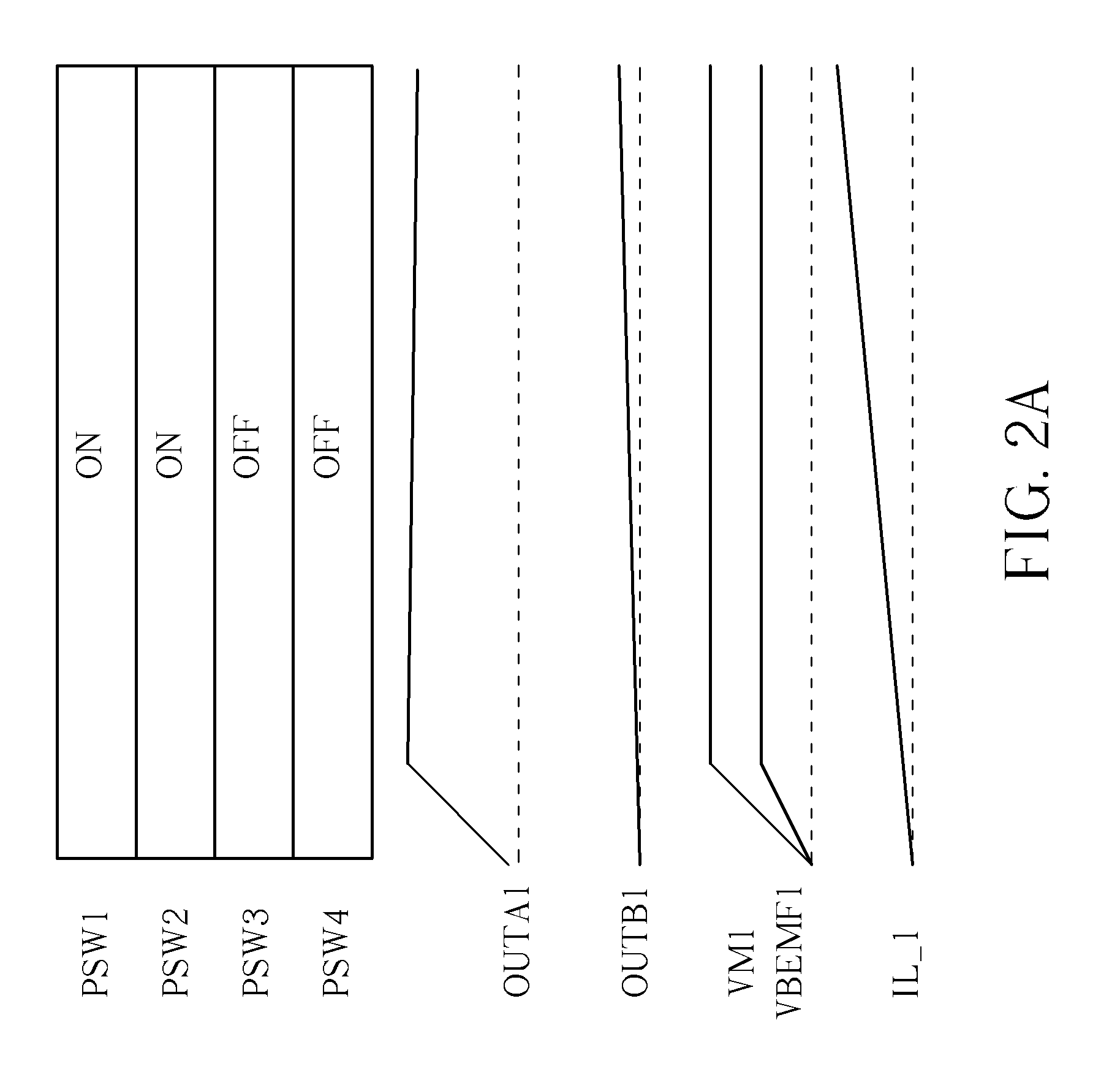

Method of driving DC motor and related circuit for avoiding reverse current

ActiveUS8183807B2Avoid it happening againMotor/generator/converter stoppersAC motor controlDriver circuitPower flow

Owner:ANPEC ELECTRONICS CORPORATION

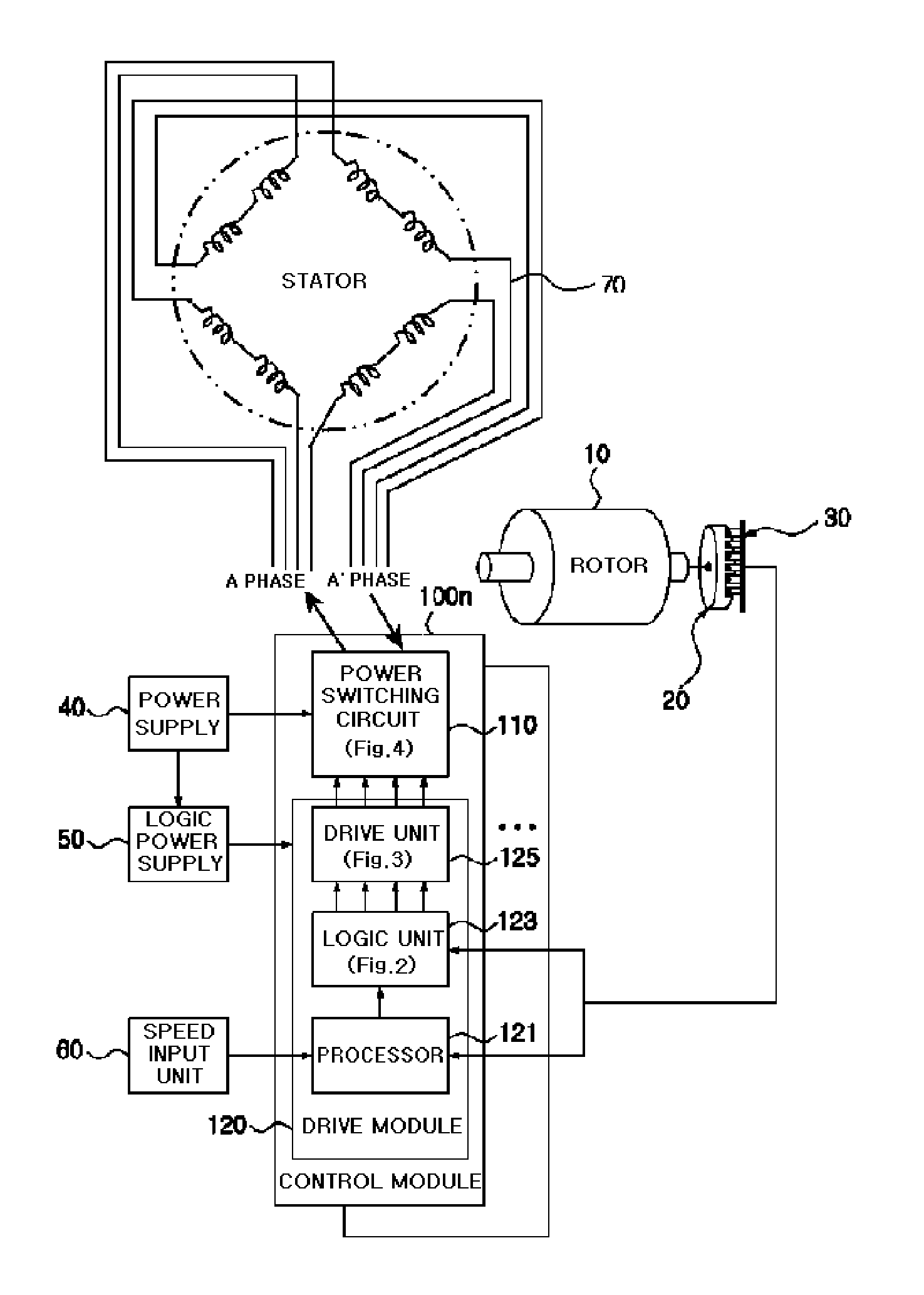

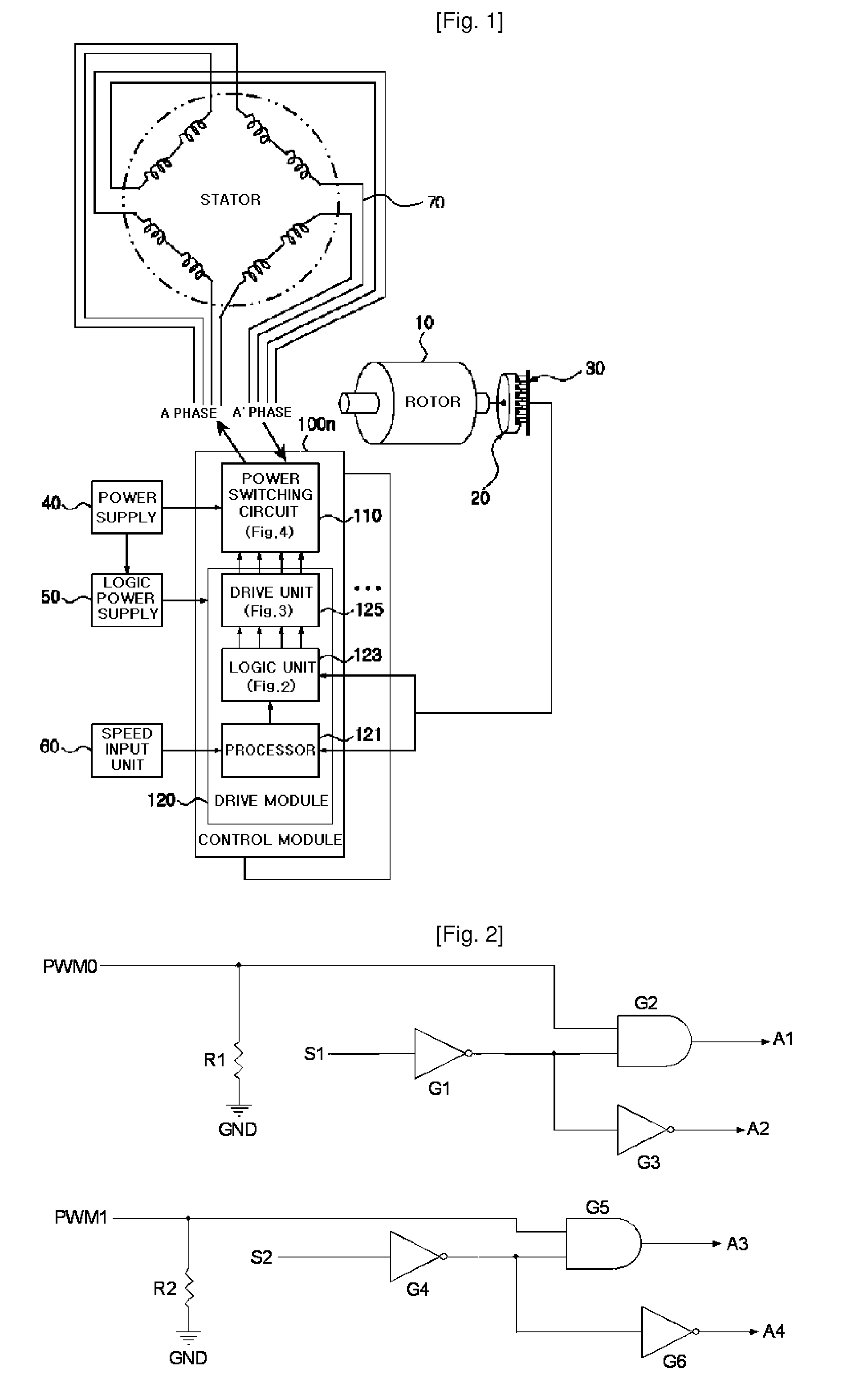

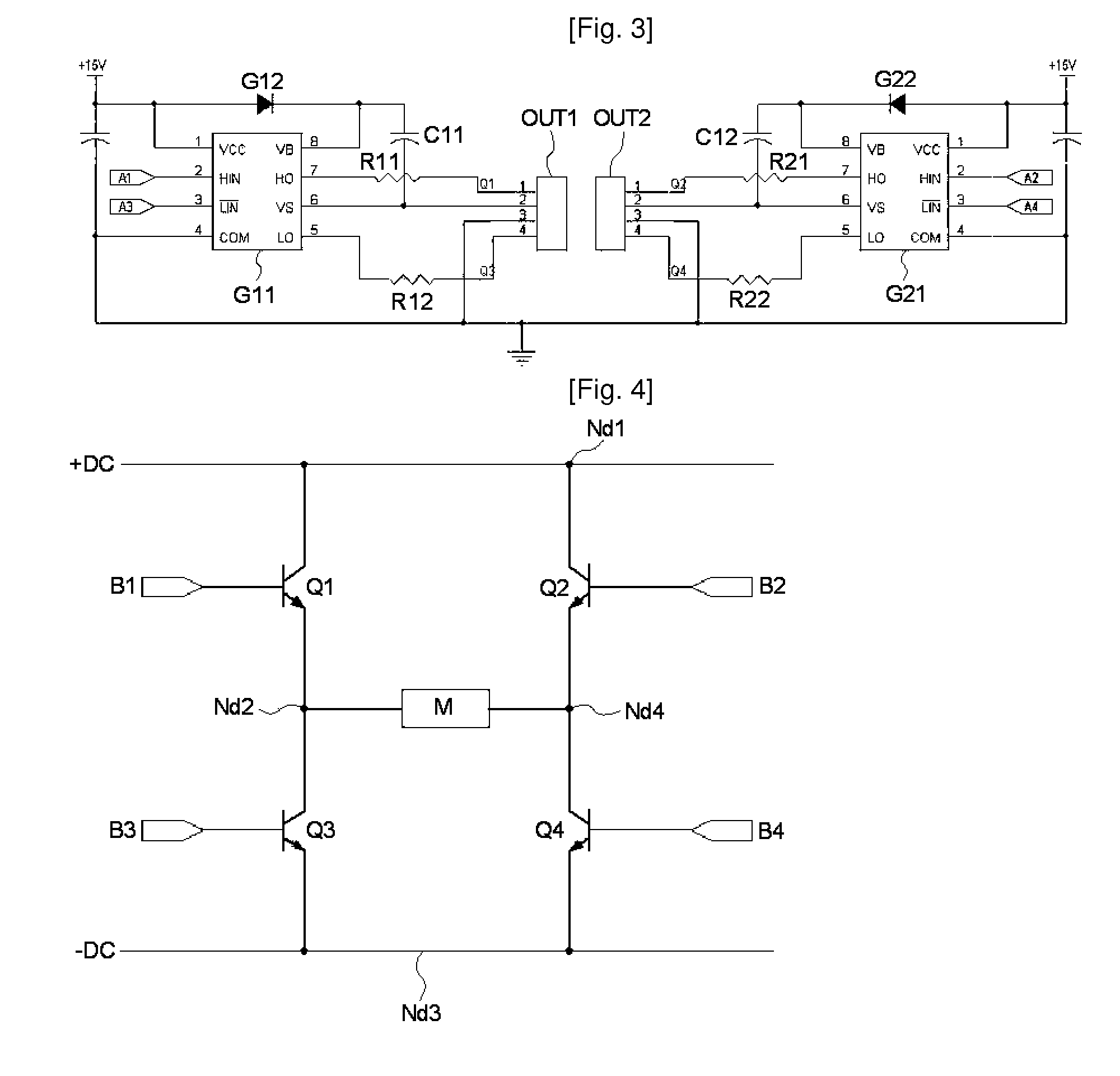

Apparatus and method for controlling hybrid motor

ActiveUS8228020B2Reduce capacityReduce electricity loadSingle-phase induction motor startersWindingsDriver circuitPower switching

An apparatus and method for controlling a hybrid motor, The hybrid motor, uses a permanent magnet instead of a field coil for a rotor, winds a coil round a stator in a multi-phase independent parallel manner, fixes a rectifying type encoder to the rotor and connects a sensor to a driving circuit. The apparatus comprises: an encoder attached to a rotor in cooperation with a pole sensor a speed input unit for generating a speed instruction signal a power switching circuit to generate motor driving signals; a drive module receiving the speed instruction signal and the sensor signal and outputting the speed instruction signal synchronized with the sensor signal as a driving motor signal; a power supply for applying a DC voltage to the power switching circuit; A logic power supply for converting the DC voltage into a logic voltage, and applying logic voltage to the drive module. The motor has n phases, n power switching circuits and n drive modules.

Owner:NAMYANG NEXMO CO LTD

Method and apparatus for controlling electronically commutated motor operating characteristics

InactiveUS6895176B2Operation controlSingle-phase induction motor startersAC motor controlBrushless motorsControl electronics

A permanent magnet DC brushless motor control assembly permits a user to select the permanent magnet DC brushless motor operating characteristics by selecting appropriate control circuits to interface with the motor. The assembly includes a permanent magnet DC brushless motor, a commutator electrically coupled to the motor, and at least one control module electrically coupled to the commutator, to control operating characteristics of the permanent magnet DC brushless motor.

Owner:REGAL BELOIT AMERICA

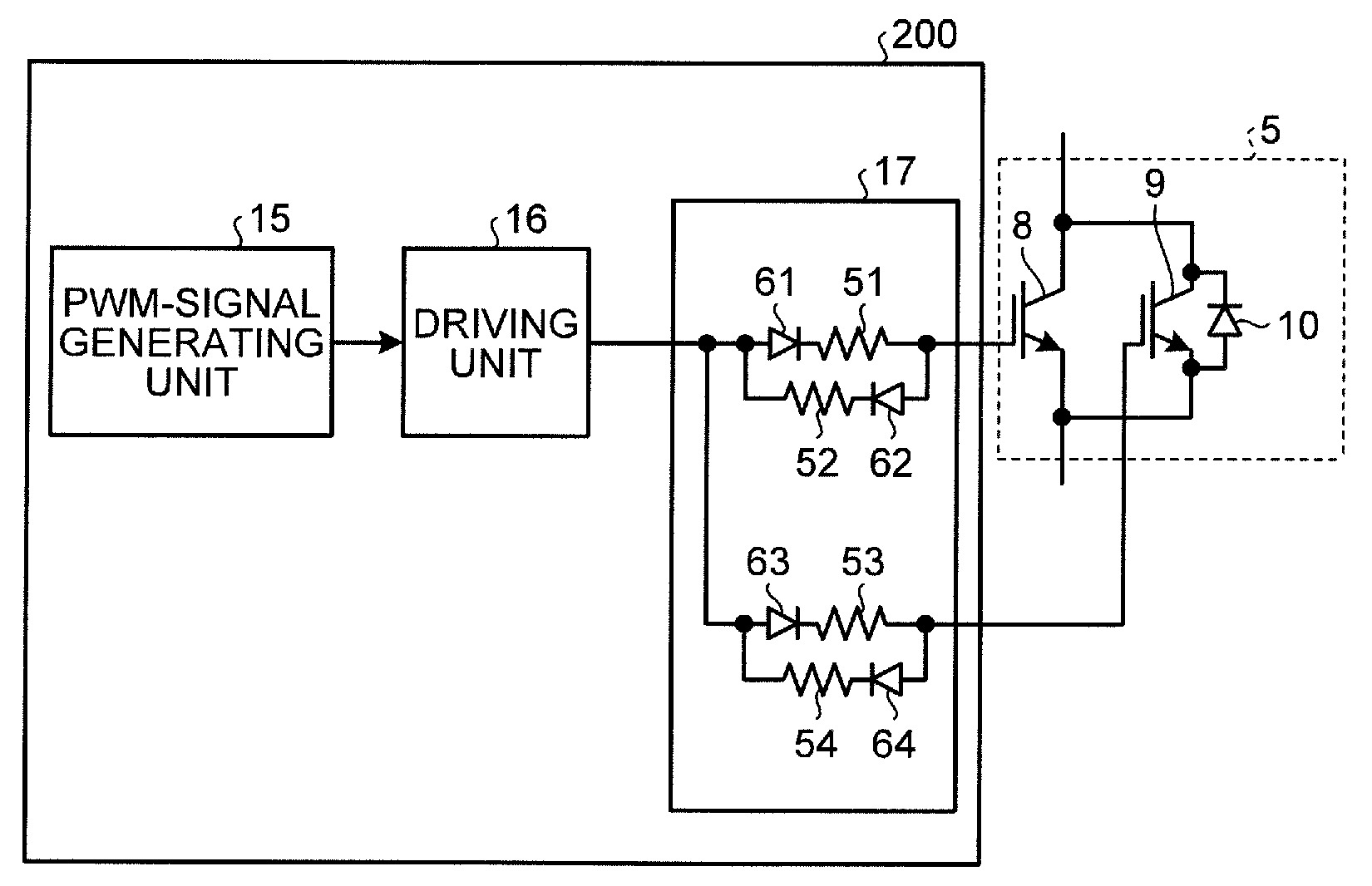

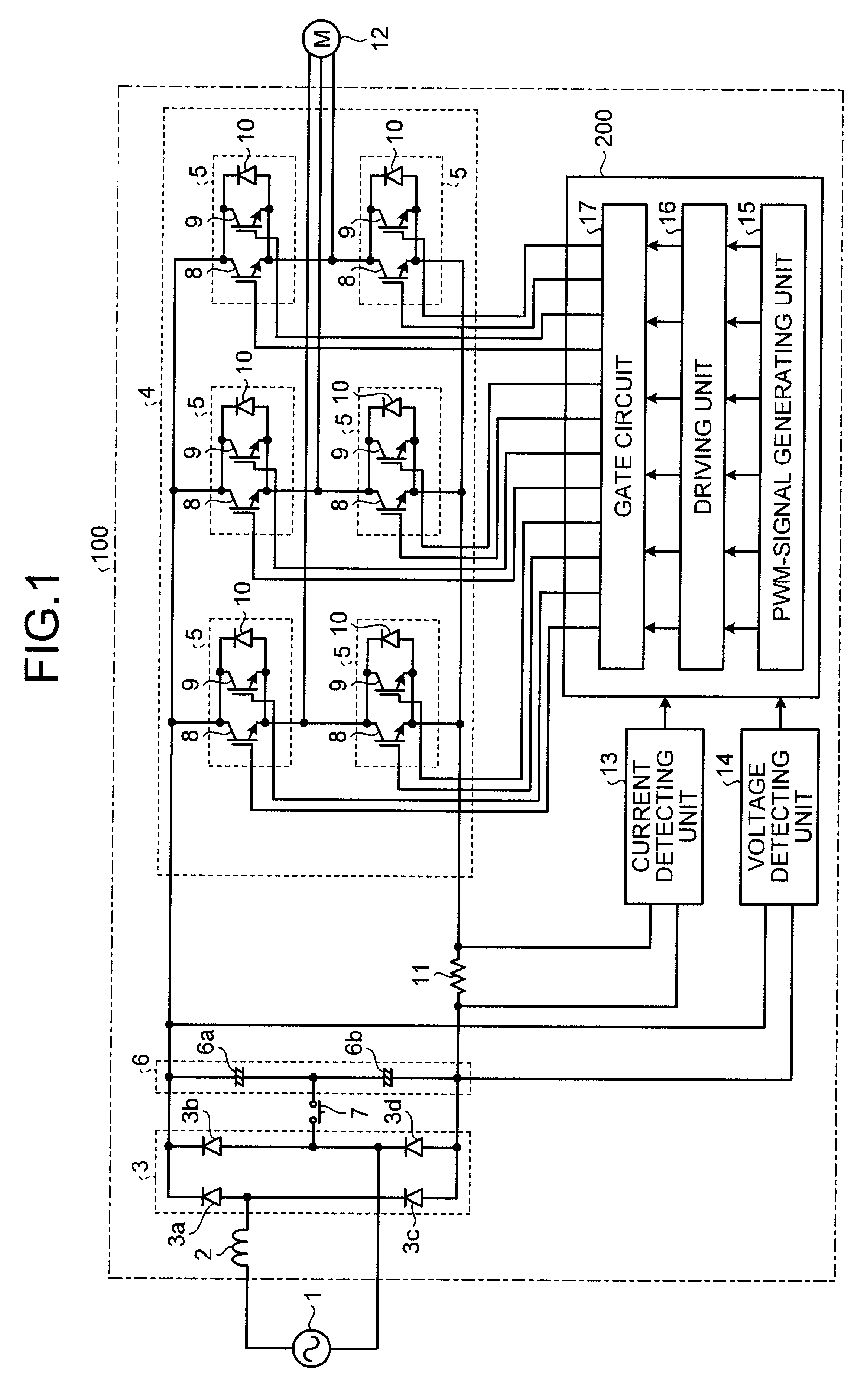

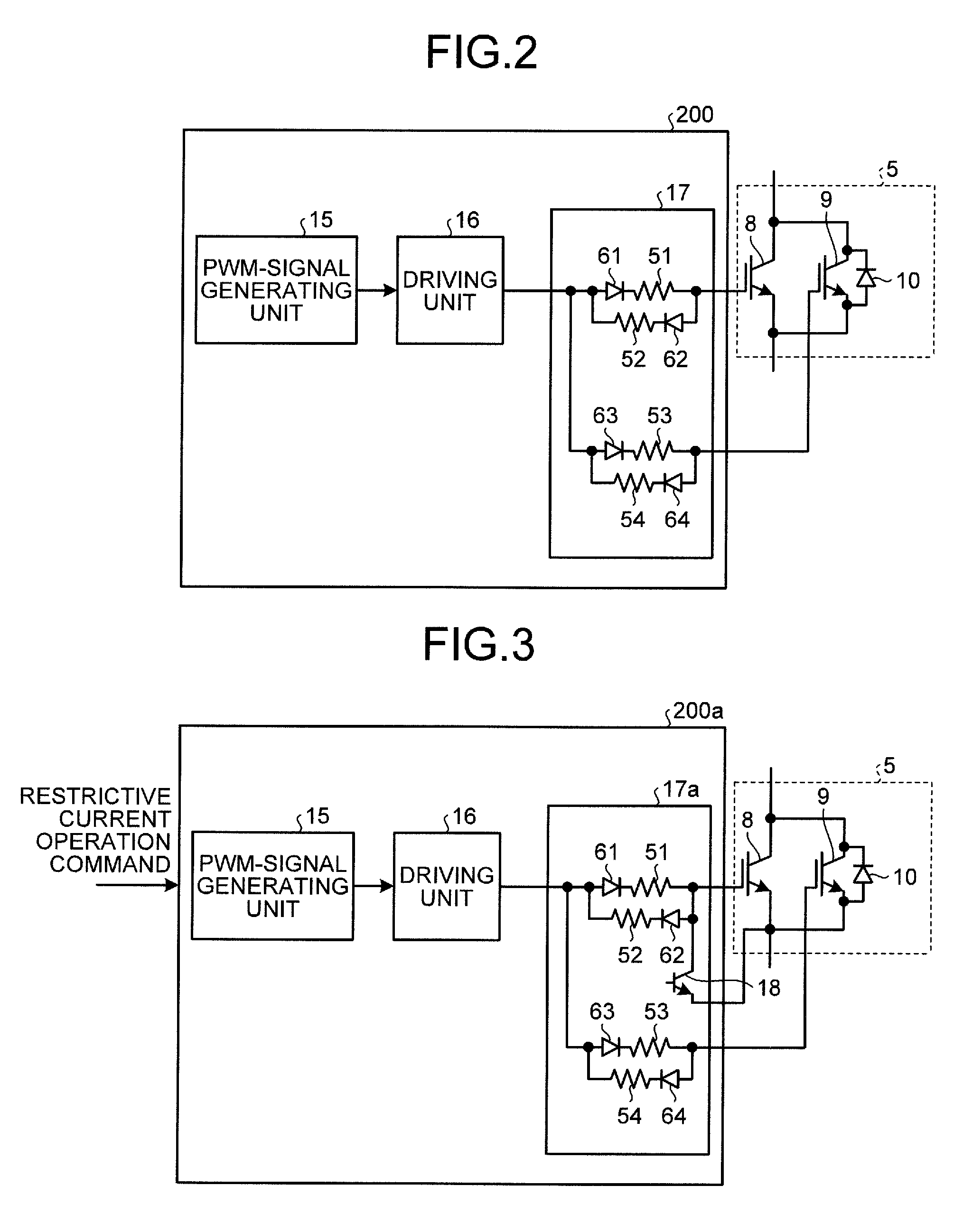

Inverter device and air conditioner including the same

Owner:MITSUBISHI ELECTRIC CORP

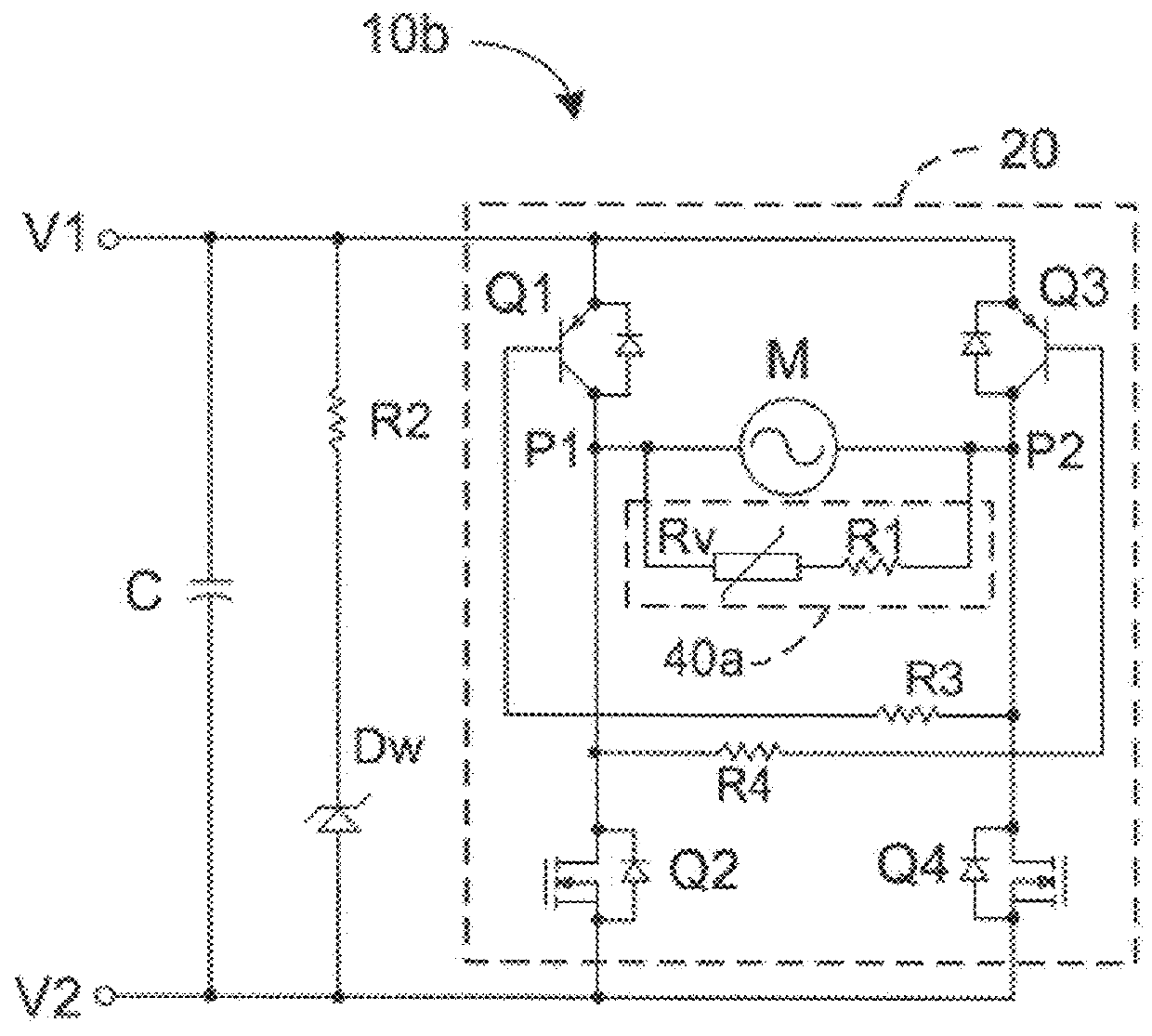

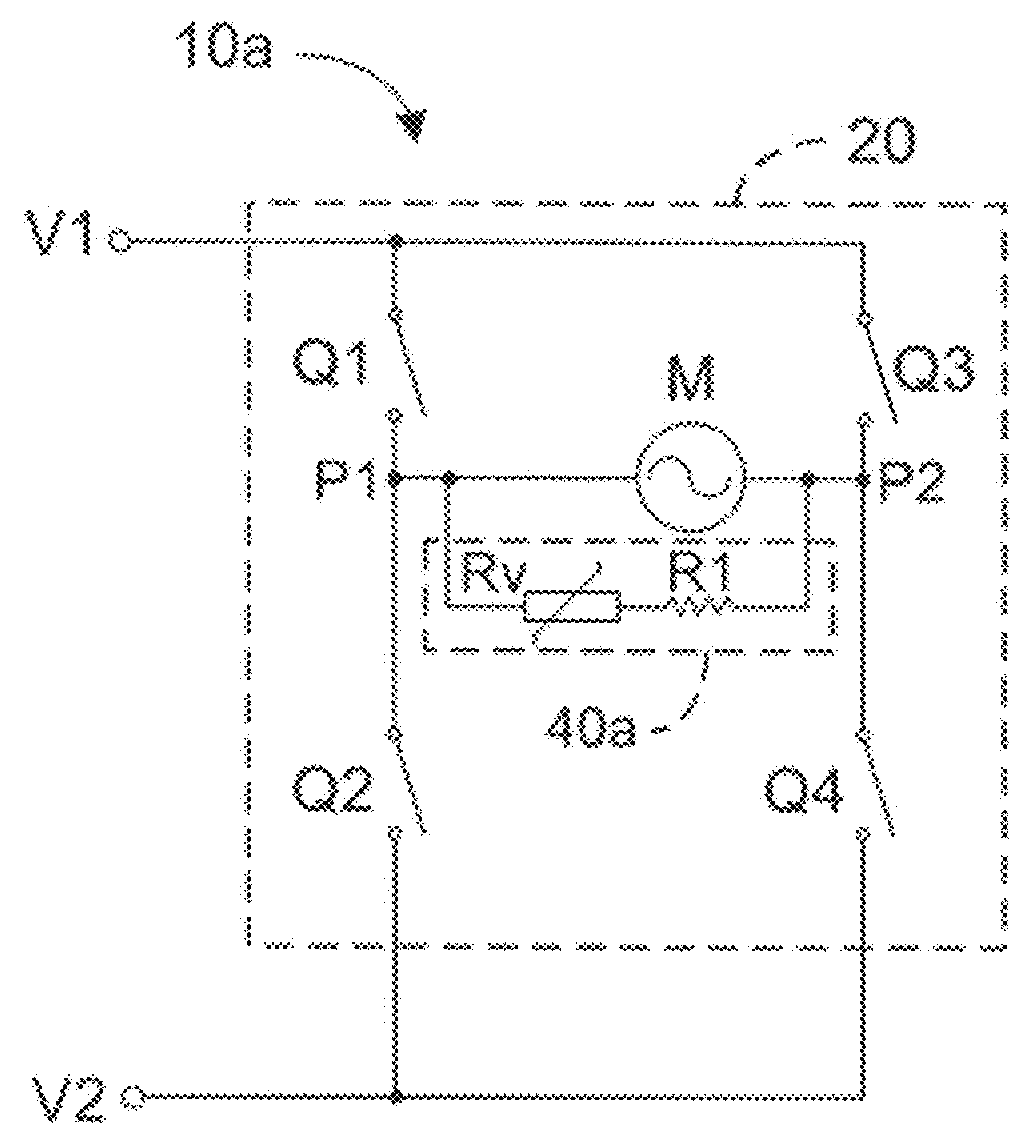

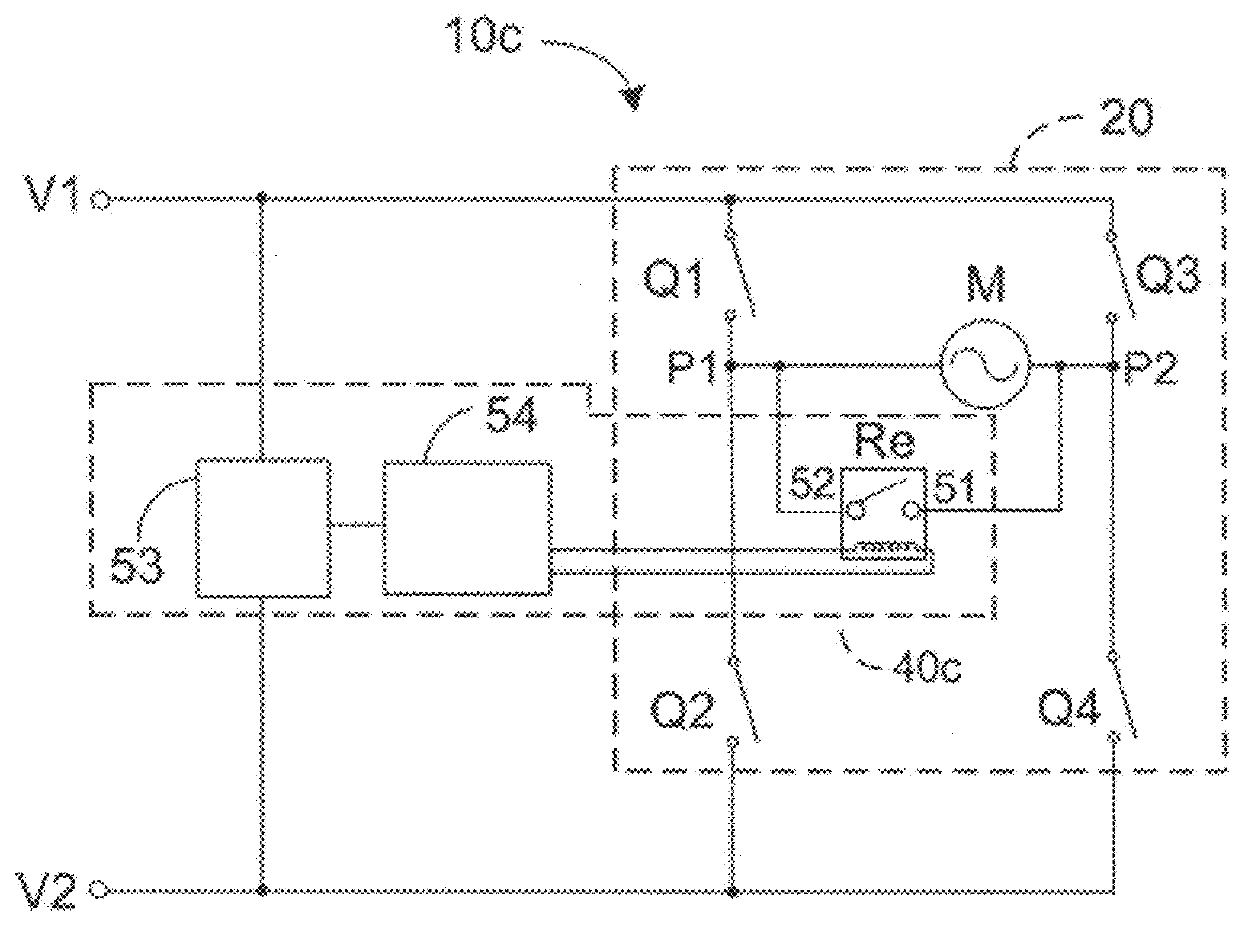

Control circuit for a DC motor

ActiveUS9385640B2Inhibit currentSingle motor speed/torque controlField or armature current controlControl circuitDC motor

A control circuit for a DC motor, has: a first and second input ports for connection to a DC source; a H-bridge driving circuit, having first and second switches connected in series between the input ports, and third and fourth switches connected in series between the input ports, a first output port between the first and second switches and a second output port between the third and fourth switches, and a shunt circuit and / or a blocking circuit. The motor is connected between the first and second output ports. The shunt circuit is connected between the first second output ports and has a resistance that will decrease in response to BEMF generated by the motor. The blocking circuit is connected in series with the motor between the output ports and has a resistance that increases in response to BEMF generated by the motor.

Owner:JOHNSON ELECTRIC SA

Powered surgical tool with control module that contains a sensor for remotely monitoring the tool power generating unit

A powered surgical tool with a housing that contains a power generating unit such as a motor. A control module is disposed in a shell that is mounted in the housing. The control module contains a control circuit for regulating the actuation of the power generating unit. The power generating unit emits a signal representative of the operating state of the unit that is transmitted through the structural material forming the shell. Also internal to the control module shell is a sensor that monitors the signal emitted by the power generating unit. This signal output by the sensor is applied to the control circuit. The control circuit, based on the sensor signal regulates actuation of the power generating unit. Wherein the power generating unit is a motor, the signal emitted is the magnetic field that varies with rotor position. The sensor monitors the strength of this field.

Owner:STRYKER CORP

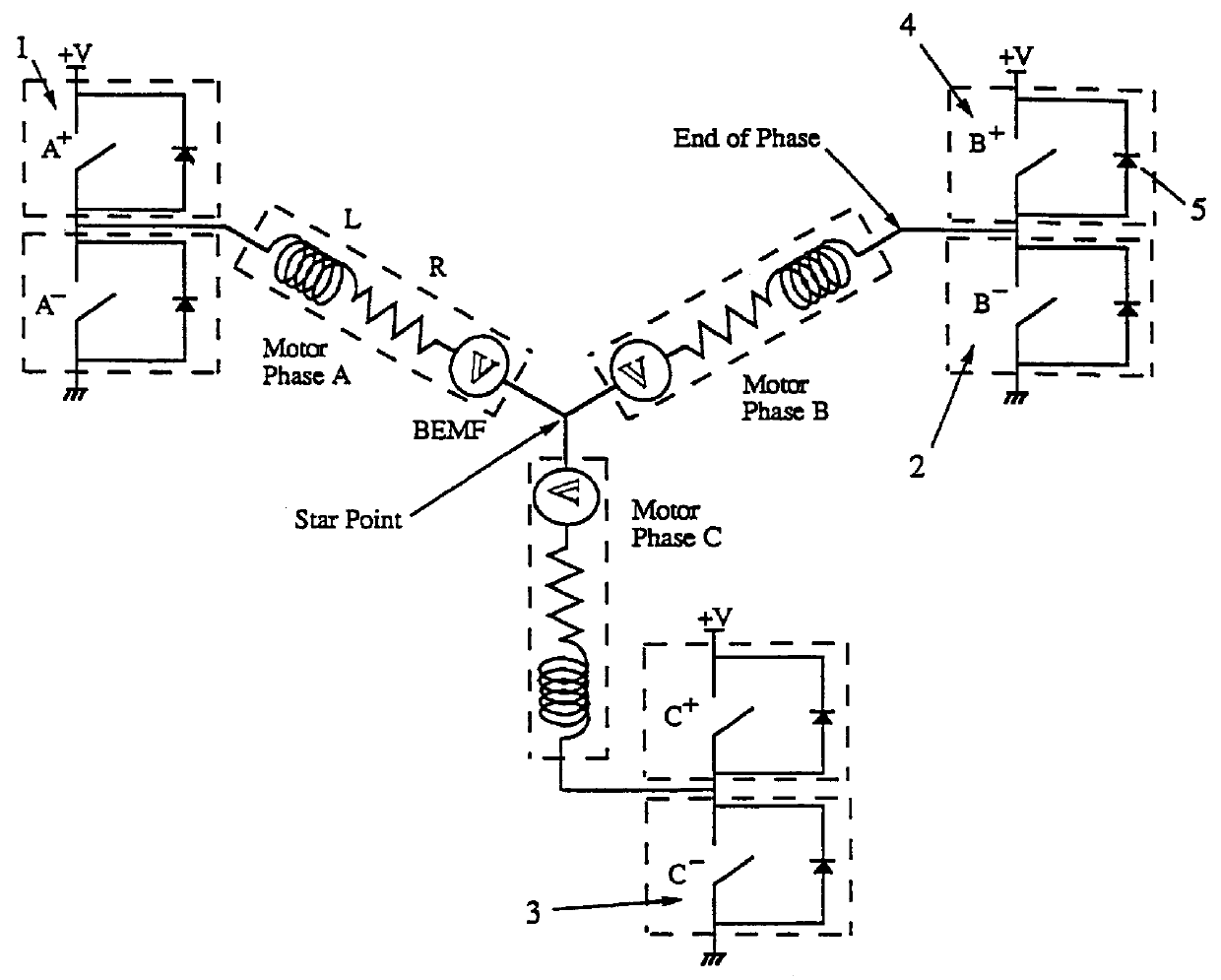

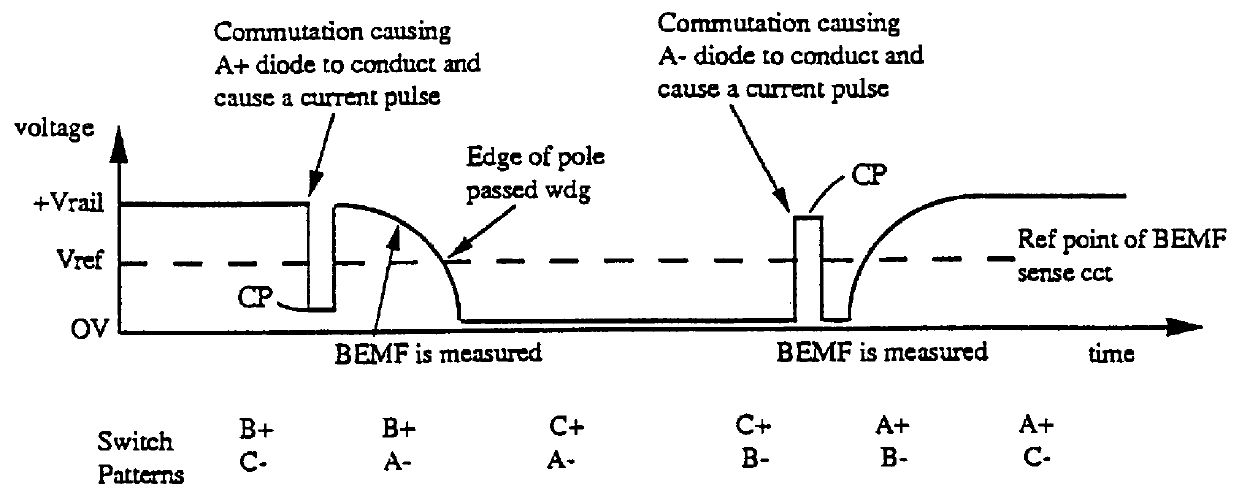

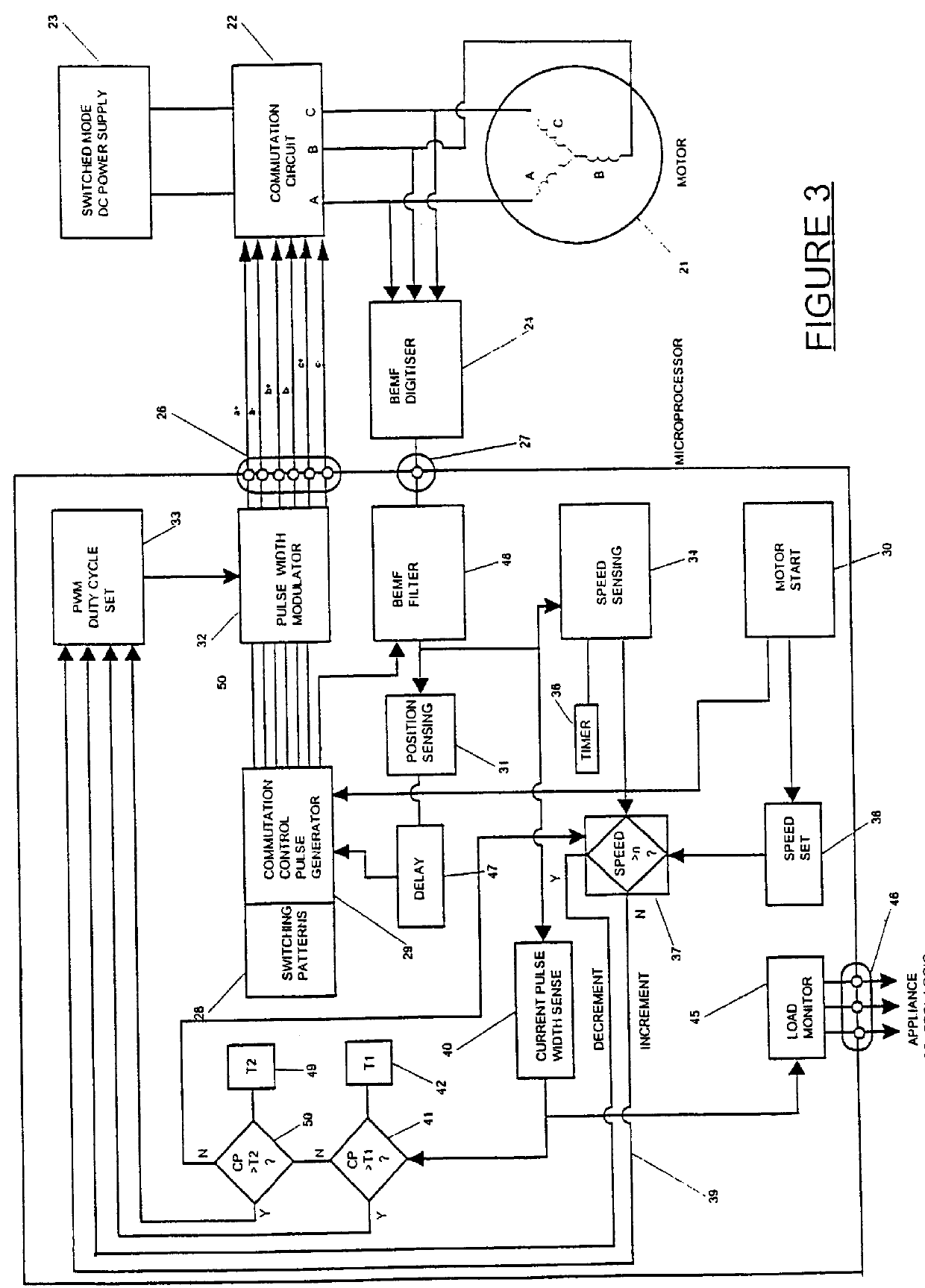

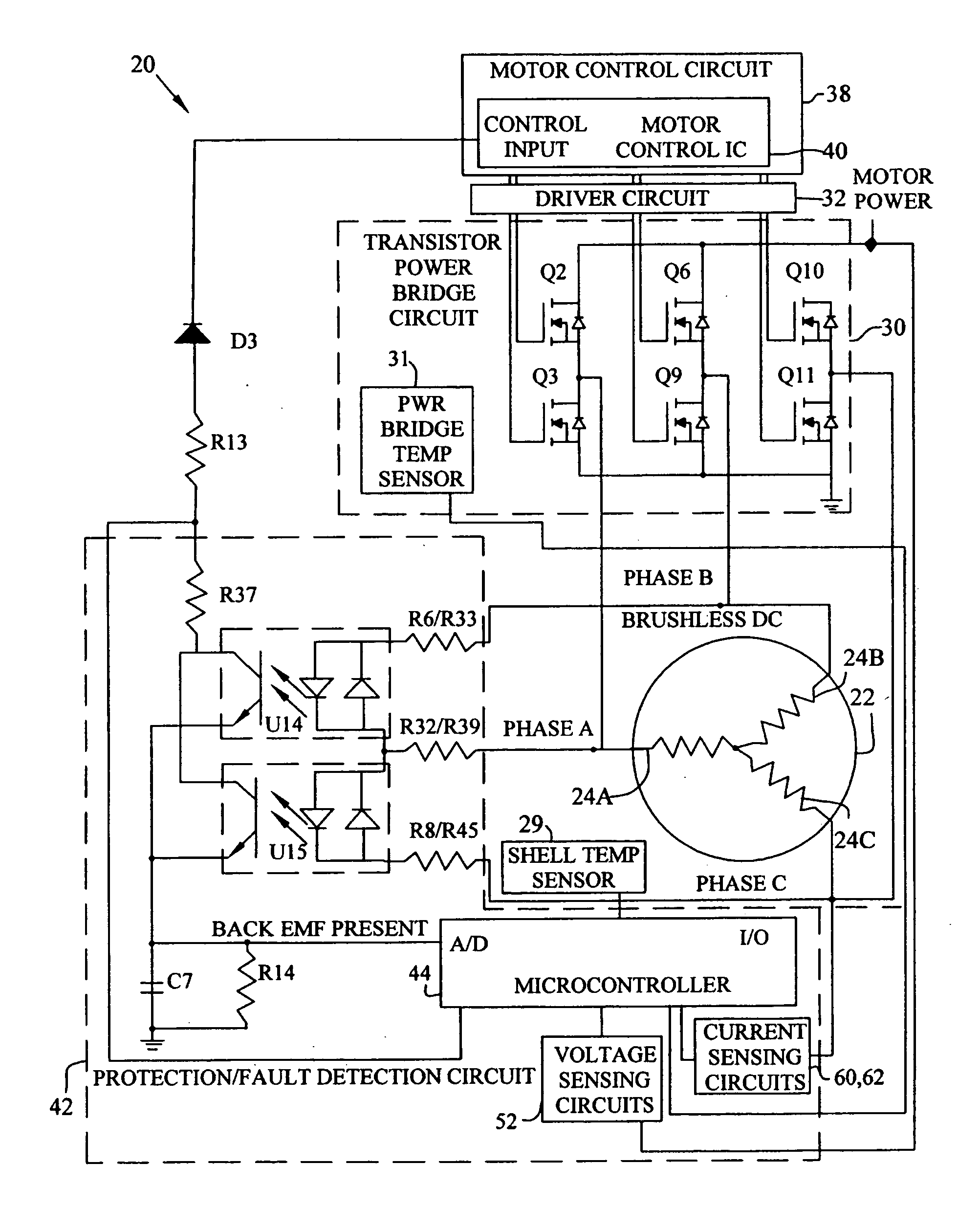

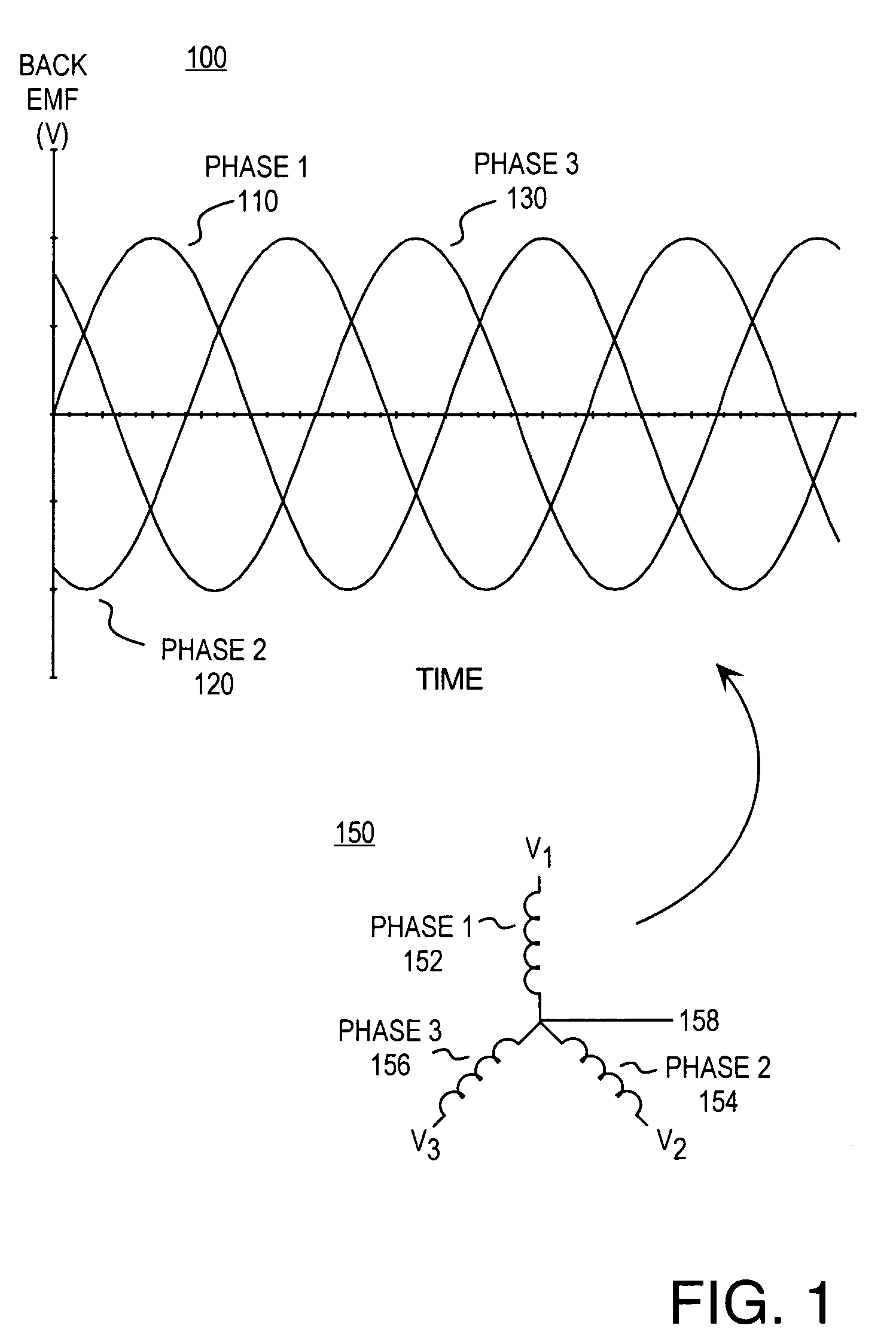

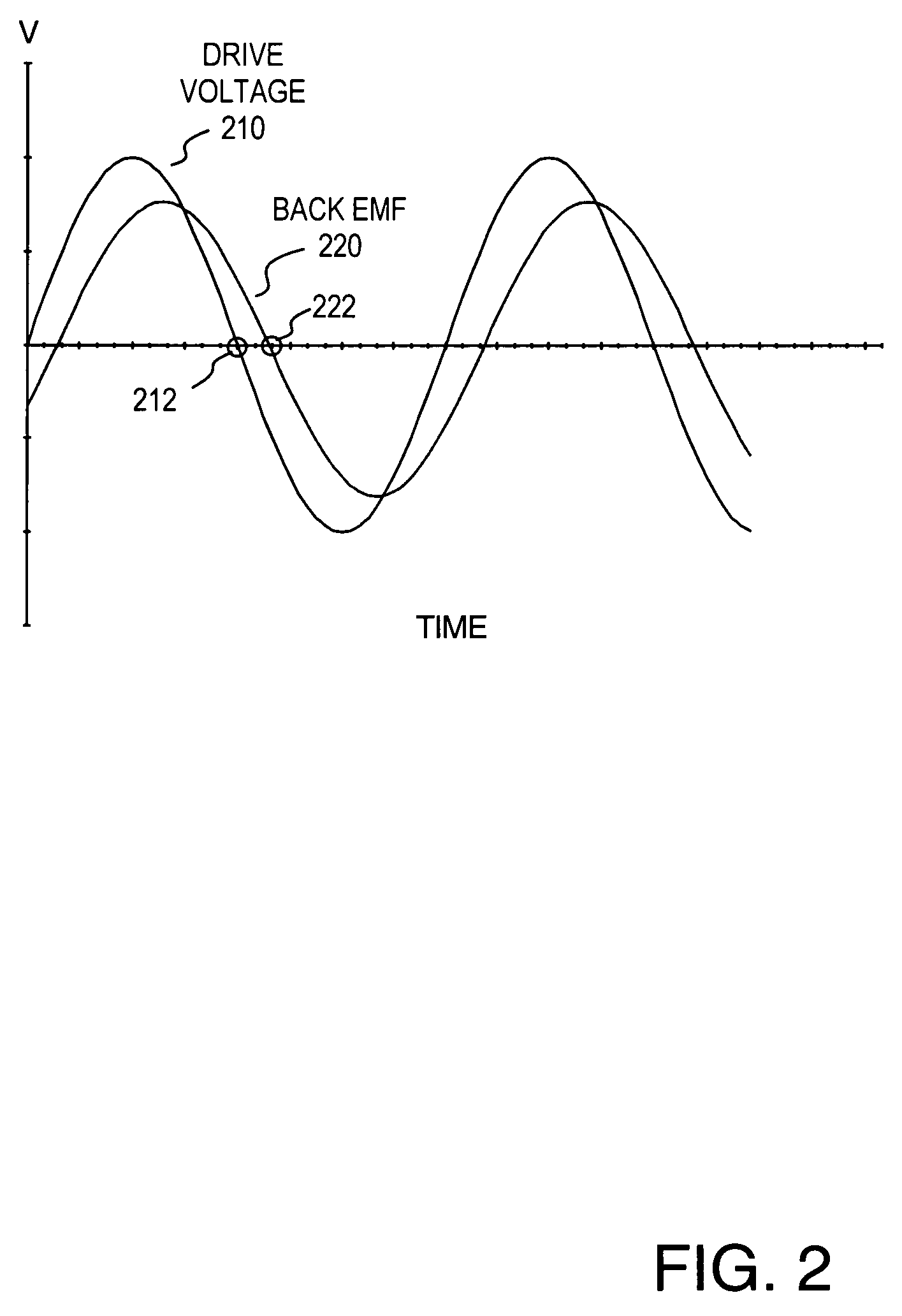

Brushless DC motor control

An electronically commutated brushless DC motor primarily for fractional horsepower applications of the type where at any instant one motor winding is unpowered and used to detect back EMF zero-crossings which information is used to initiate winding commutations. The duration of the pulse produced in this winding due to dissipation of stored energy by free-wheel diodes in parallel with the commutation devices after supply of current has been removed from this winding is used to provide a measure of motor current. This allows for simplified commutation device current limiting circuits and is available for control purposes which are a function of motor torque. There is also disclosed a method for maximizing useful power output by reducing the phase angle between the motor current and the back EMF. This is accomplished by introducing a delay in commutating the motor windings beyond the occurrence of each back EMF zero-crossing, with the delay being a function of the time between commutations.

Owner:FISHER & PAYKEL APPLIANCES LTD

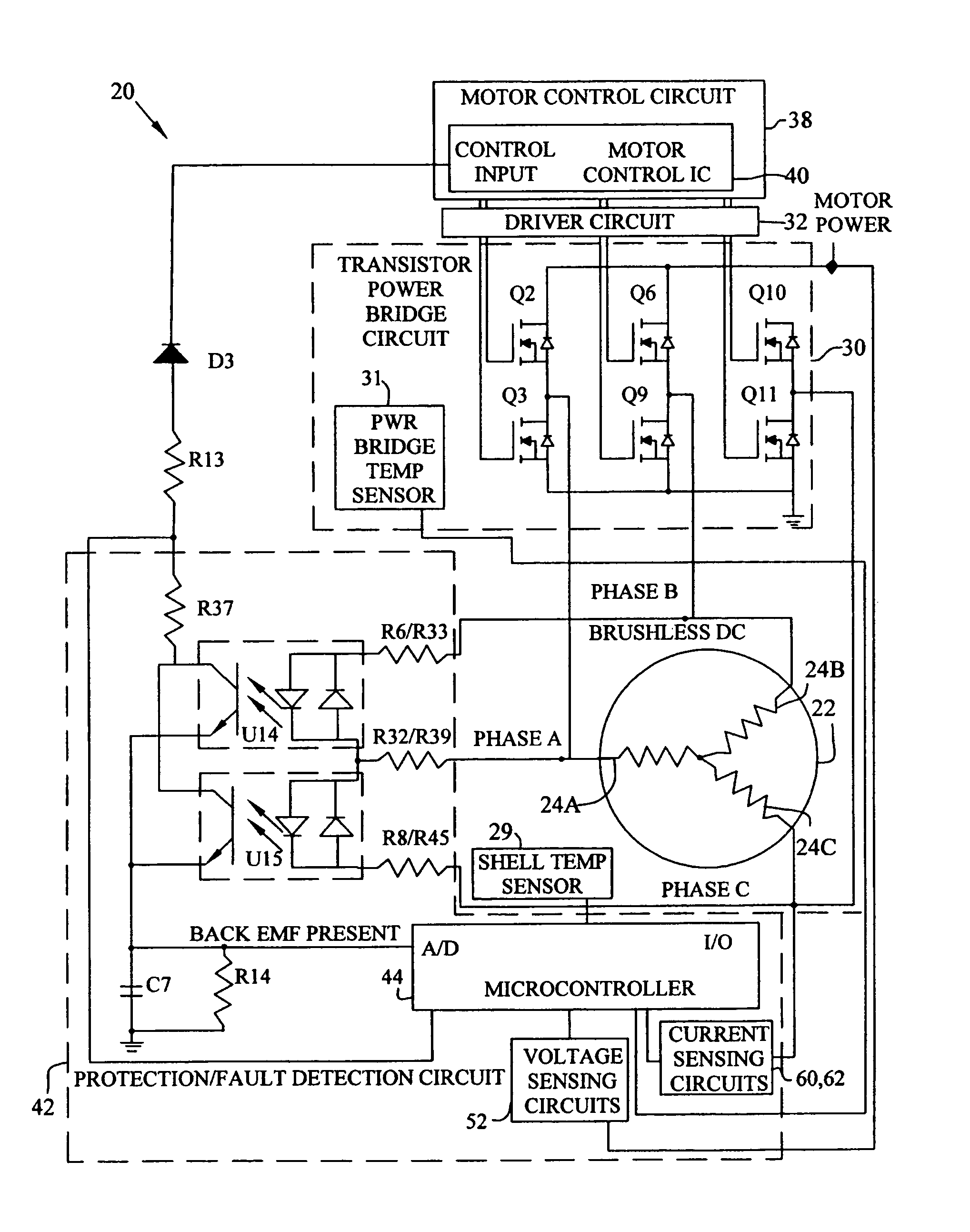

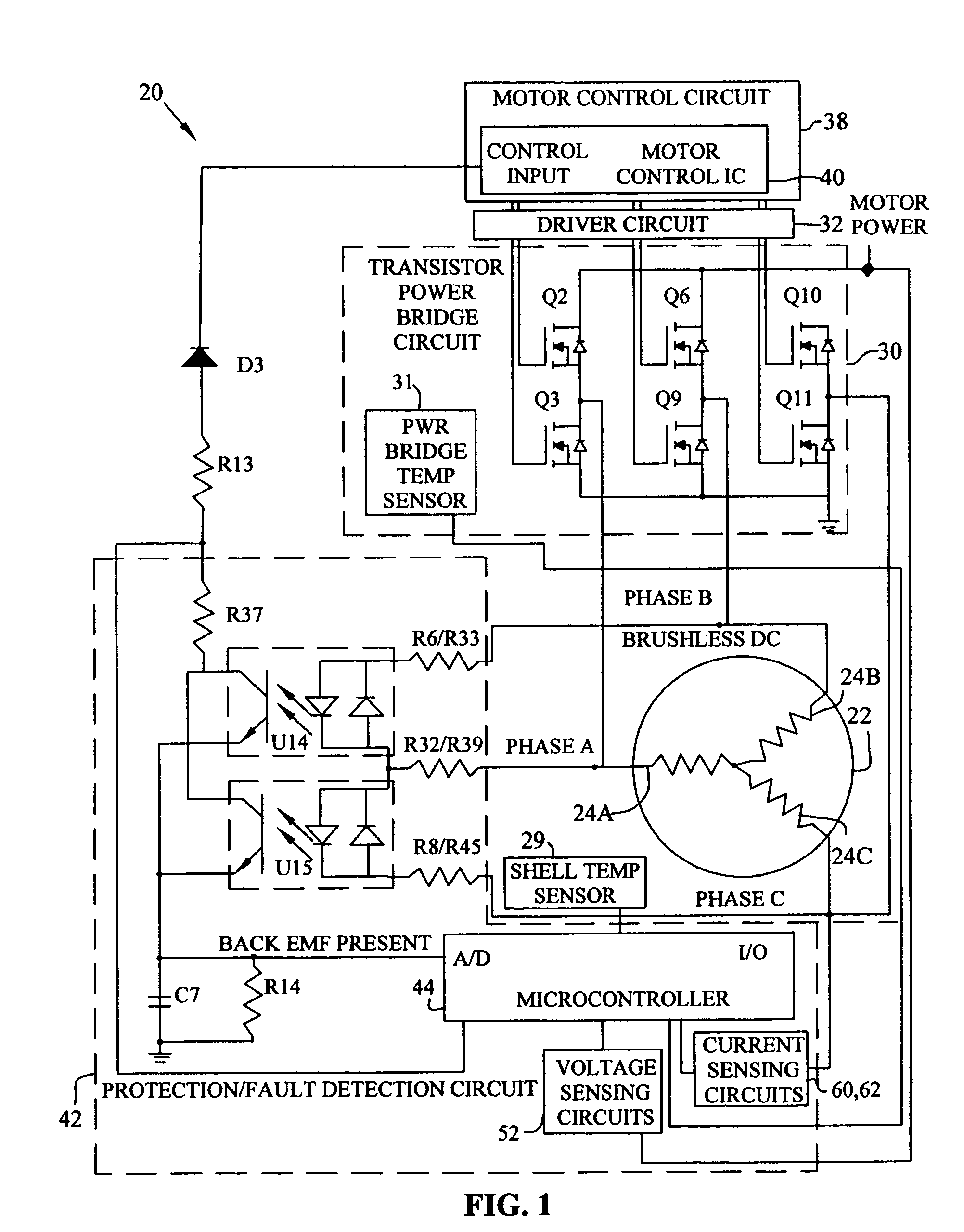

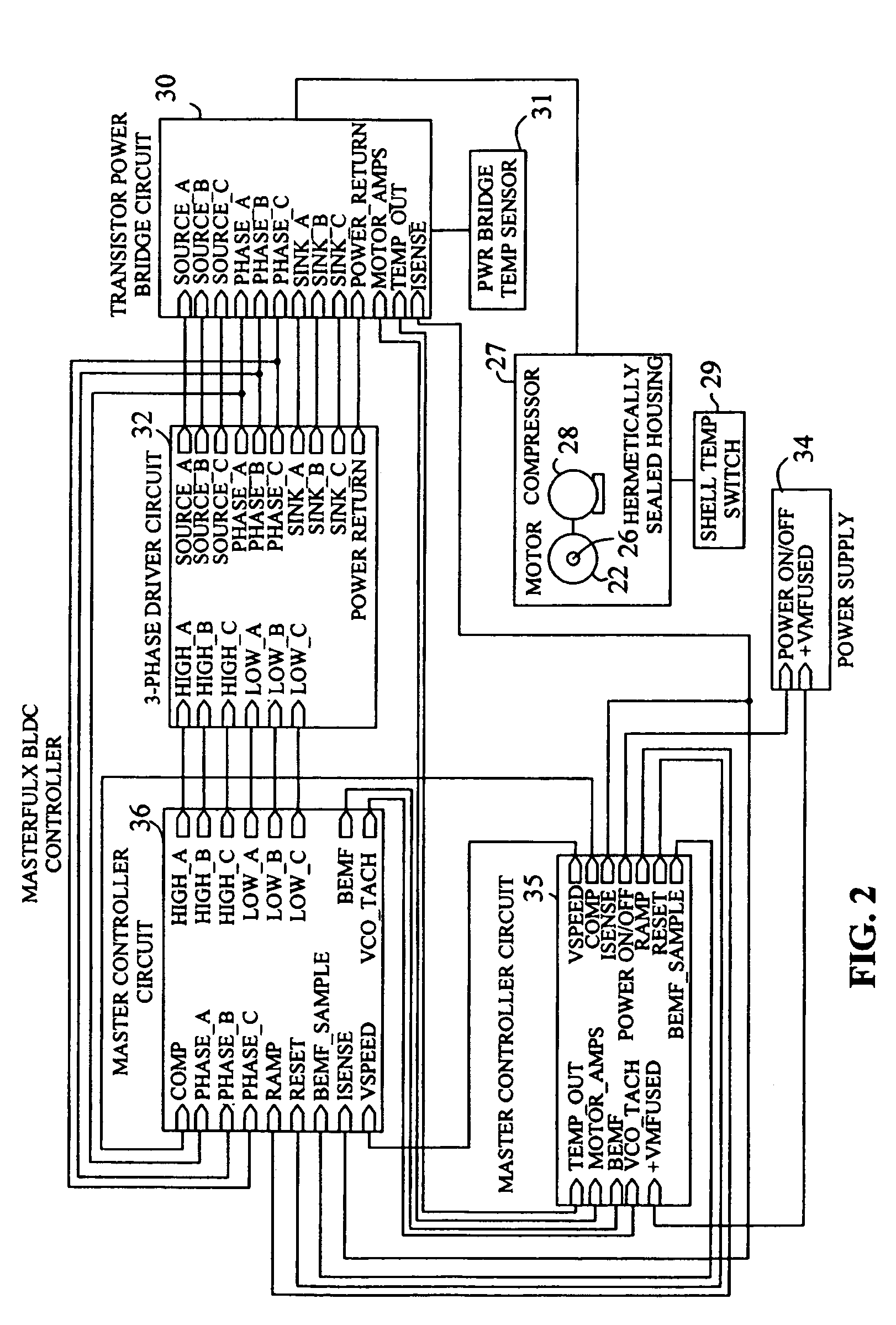

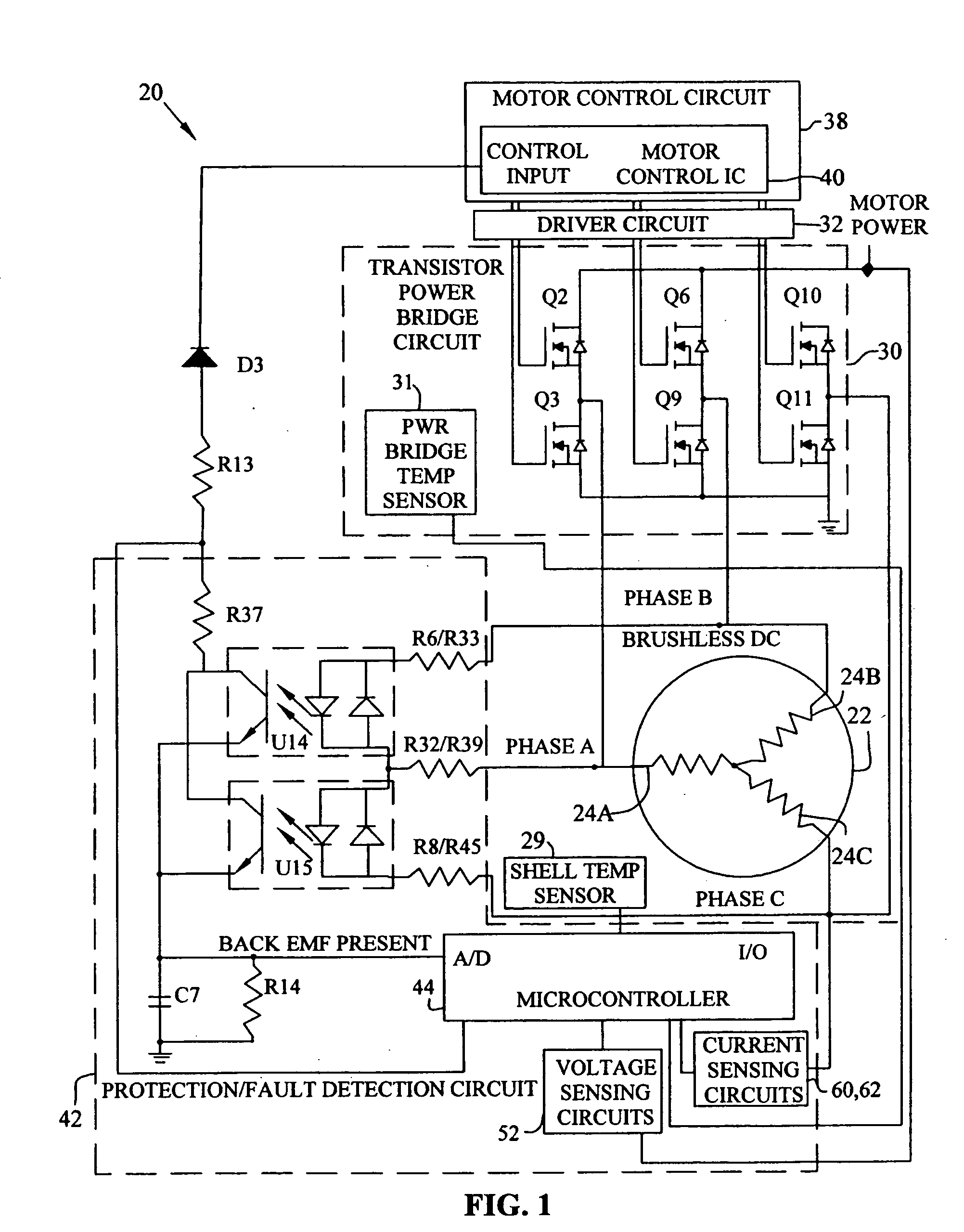

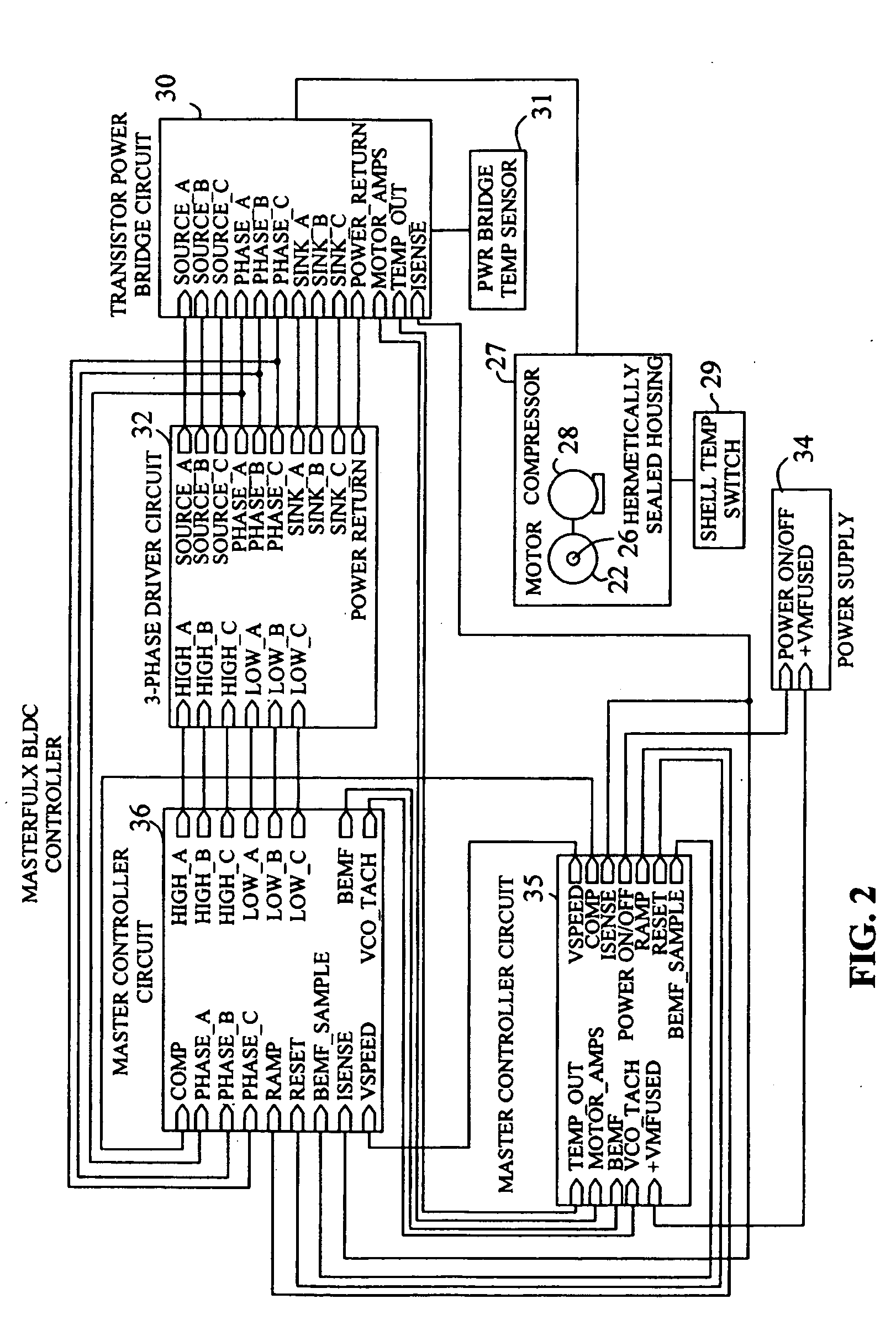

Brushless and sensorless DC motor control system with locked and stopped rotor detection

ActiveUS7042180B2Simple control methodEasily interfaceCommutation monitoringAC motor controlMotor speedDc motor control

A motor control system for a brushless and sensorless DC motor for driving a compressor, pump or other application, includes a protection and fault detection circuit for detecting a locked rotor and a rotor which has stopped because of lost rotor phase lock. The motor control system also includes an off-the-shelf motor control integrated circuit having an input for disabling power outputs to the motor phase coils. The protection and fault detection circuit uses a back EMF sampling circuit coupled to the motor phase coils and momentarily disables power to the motor phase coils, via the motor control integrated circuit input, to determine if the motor rotor is rotating. The system also monitors supply voltage, supply current, temperature, and motor speed limits to detect faults and protect system components.

Owner:REGAL BELOIT AMERICA

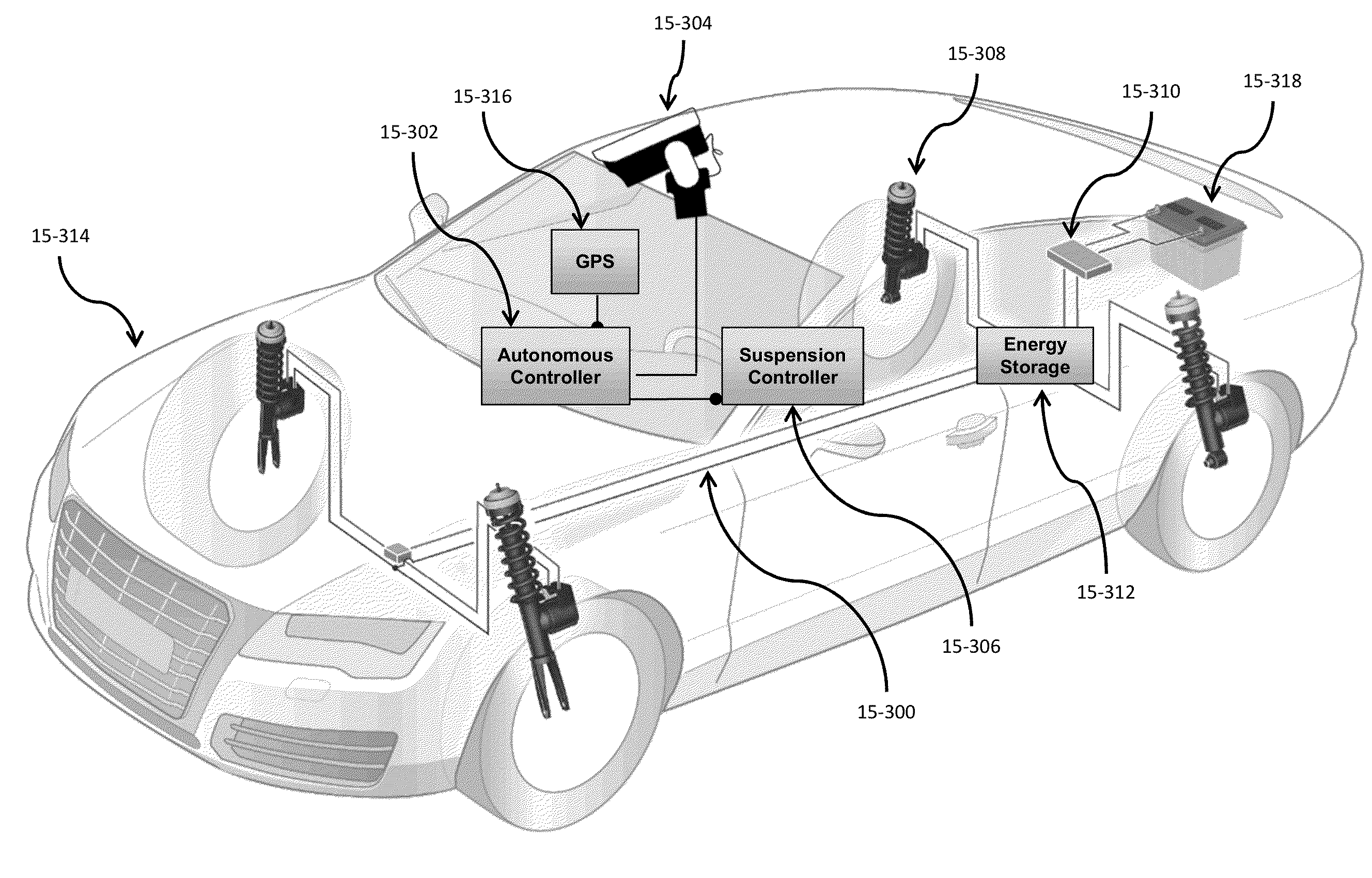

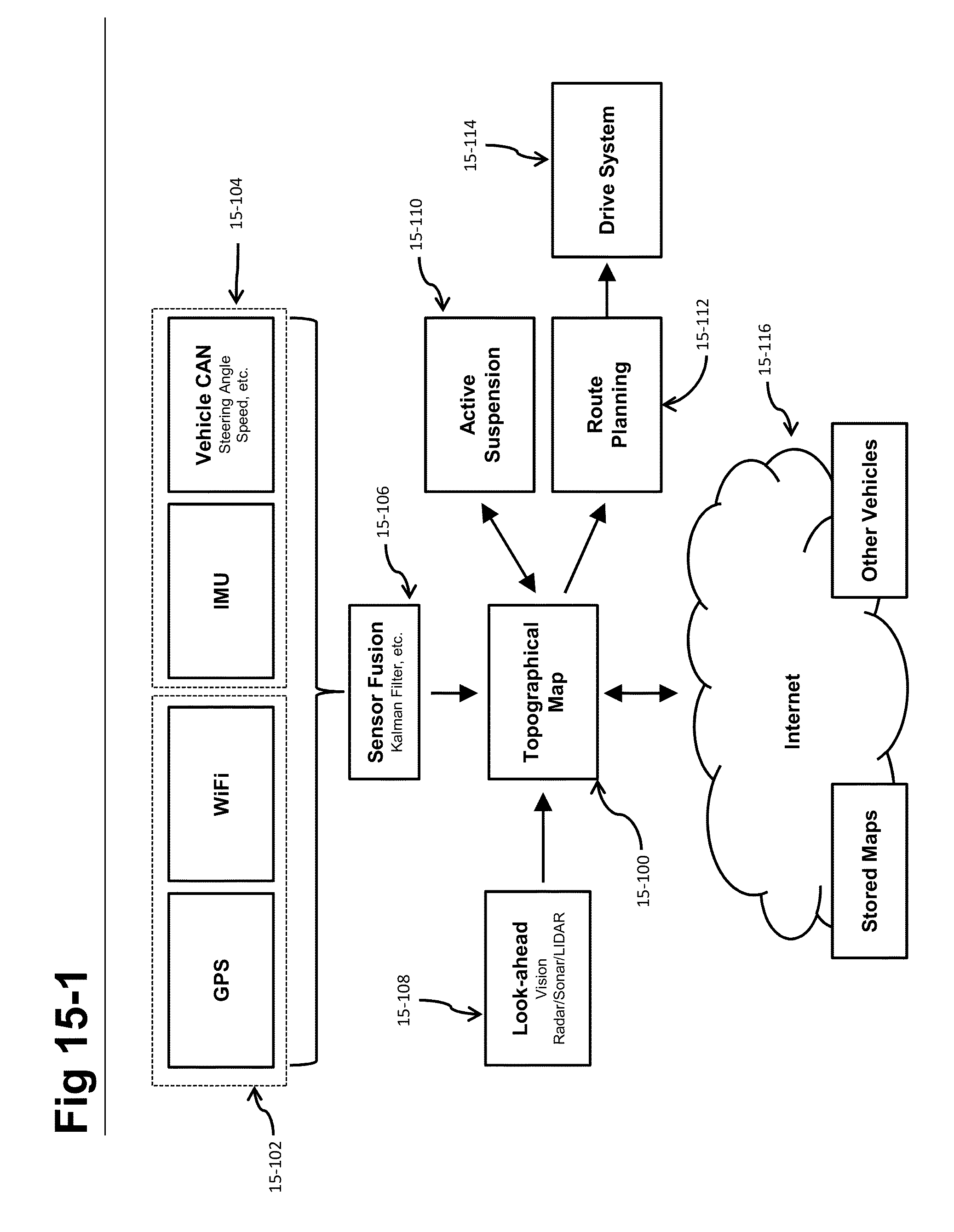

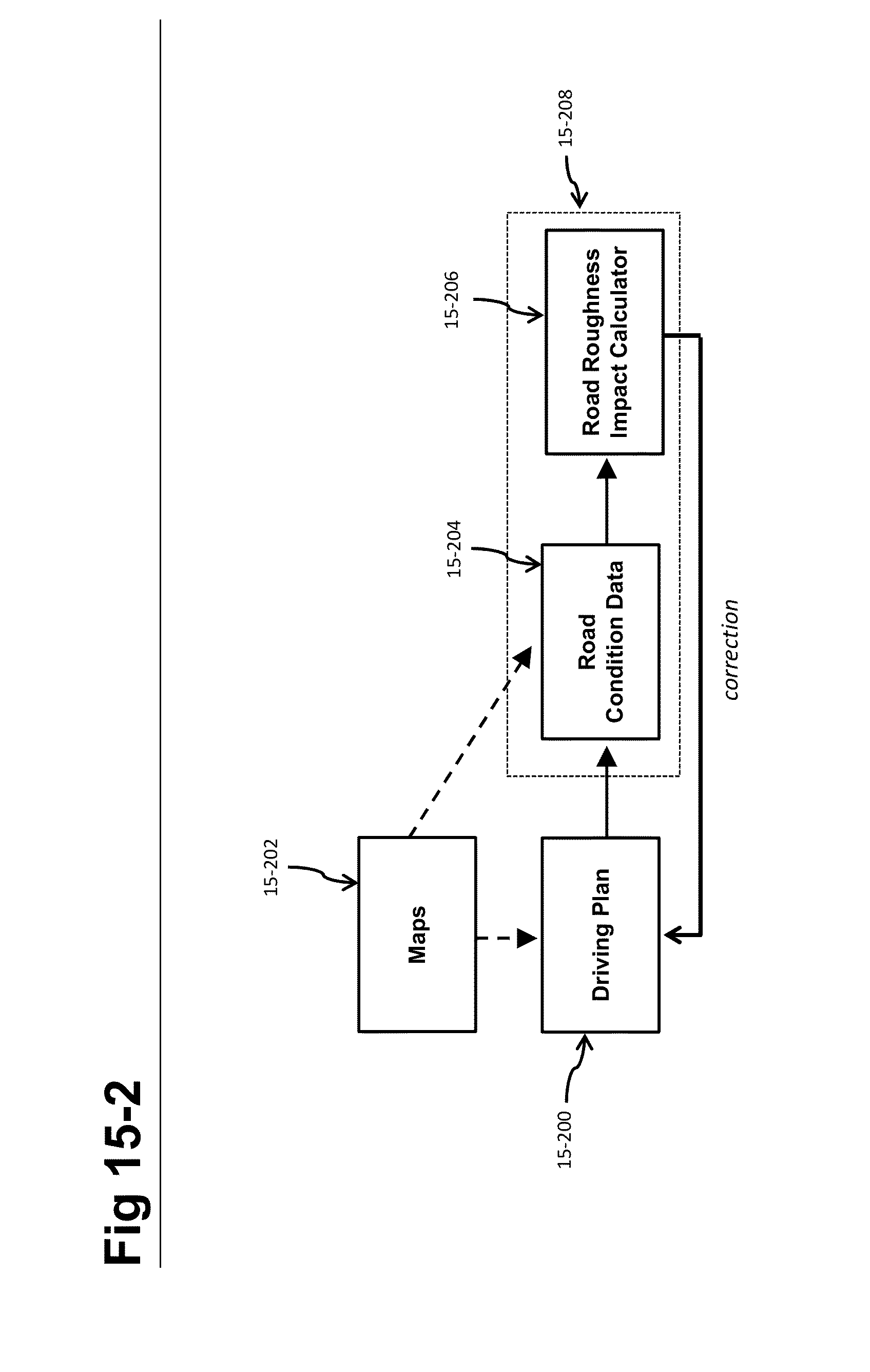

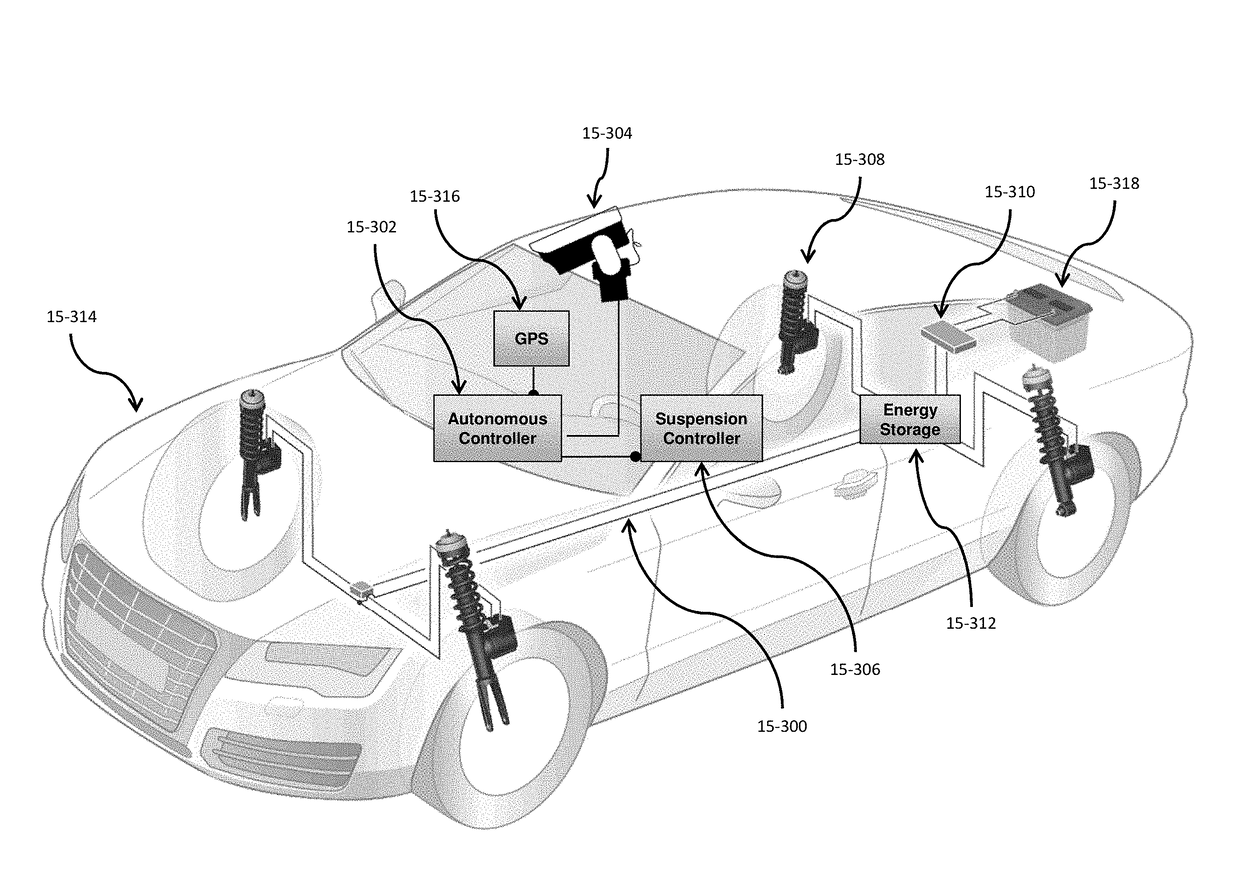

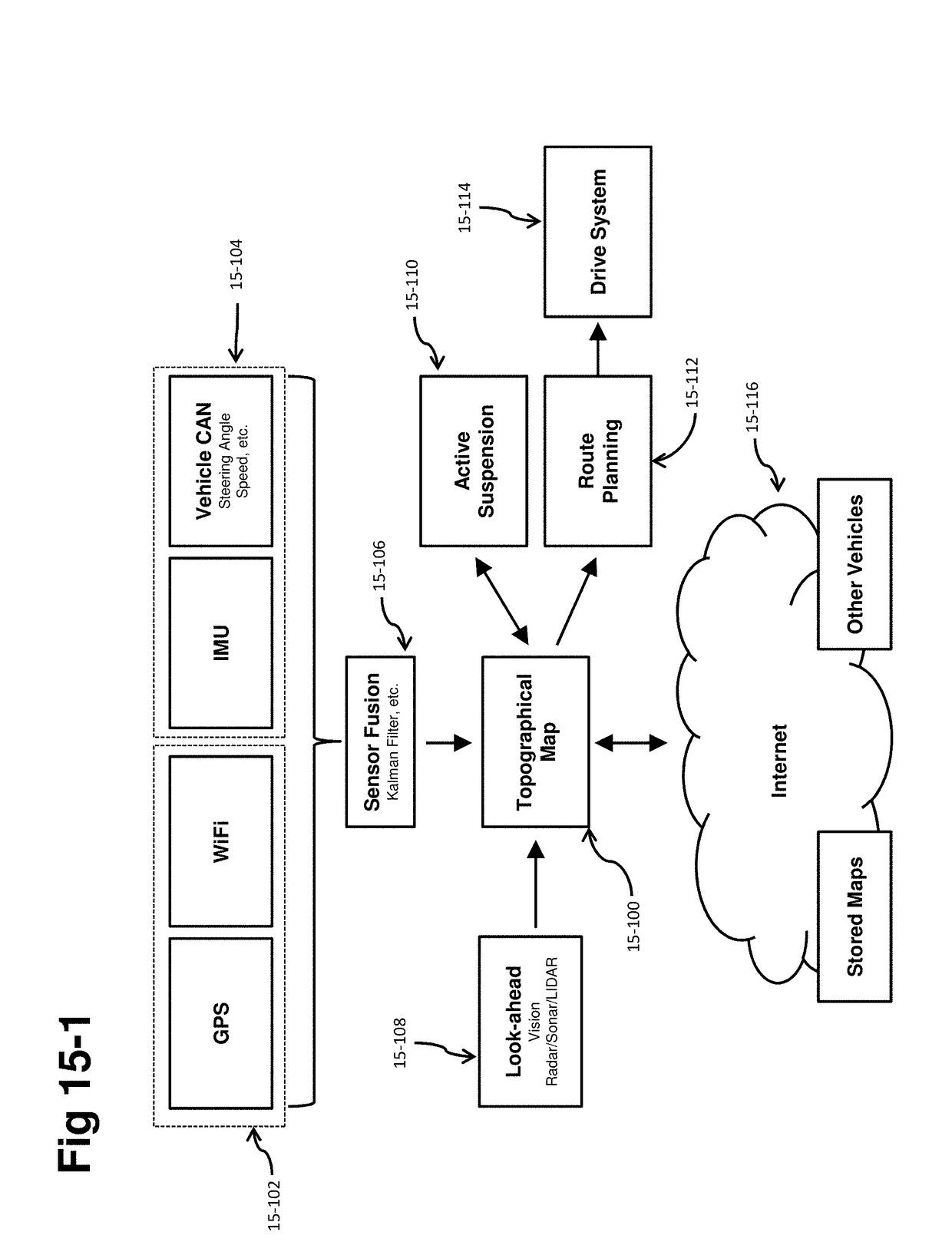

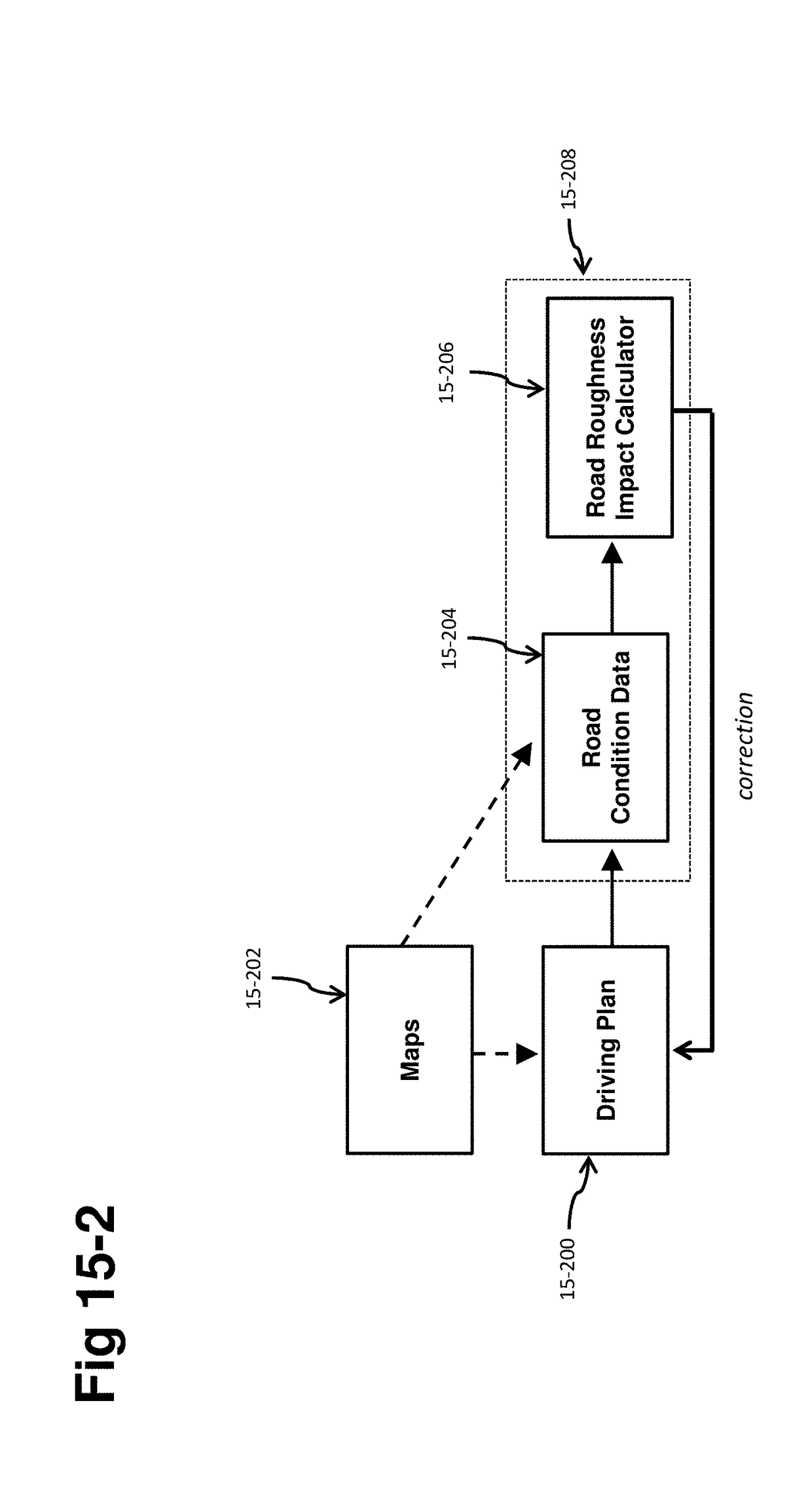

Self-driving vehicle with integrated active suspension

InactiveUS20140297116A1Improve ride comfort performanceActive suspension technologiesDigital data processing detailsAnimal undercarriagesRoad surfaceEngineering

A self-driving vehicle with an integrated fully-active suspension system. The fully-active suspension utilizes data from one or more sensors used for autonomous driving (e.g. vision, LIDAR, GPS) in order to anticipate road conditions in advance. The system builds a topographical map of the road surface. Suspension and road data is delivered back to the vehicle in order to change autonomous driving behavior including route planning. Energy storage is regulated based on a planned route. Forward and lateral acceleration feel is mitigated through active pitch and tilt compensation. The fully-active suspension pushes and pulls the suspension in three or more operational quadrants in order to deliver superior ride comfort, handling, and / safety of the vehicle.

Owner:CLEARMOTION INC

Brushless and sensorless DC motor control system with locked and stopped rotor detection

ActiveUS20050029976A1Easy to modifyEasily interfaceCommutation monitoringDC motor speed/torque controlMotor speedDc motor control

A motor control system for a brushless and sensorless DC motor for driving a compressor, pump or other application, includes a protection and fault detection circuit for detecting a locked rotor and a rotor which has stopped because of lost rotor phase lock. The motor control system also includes an off-the-shelf motor control integrated circuit having an input for disabling power outputs to the motor phase coils. The protection and fault detection circuit uses a back EMF sampling circuit coupled to the motor phase coils and momentarily disables power to the motor phase coils, via the motor control integrated circuit input, to determine if the motor rotor is rotating. The system also monitors supply voltage, supply current, temperature, and motor speed limits to detect faults and protect system components.

Owner:REGAL BELOIT AMERICA

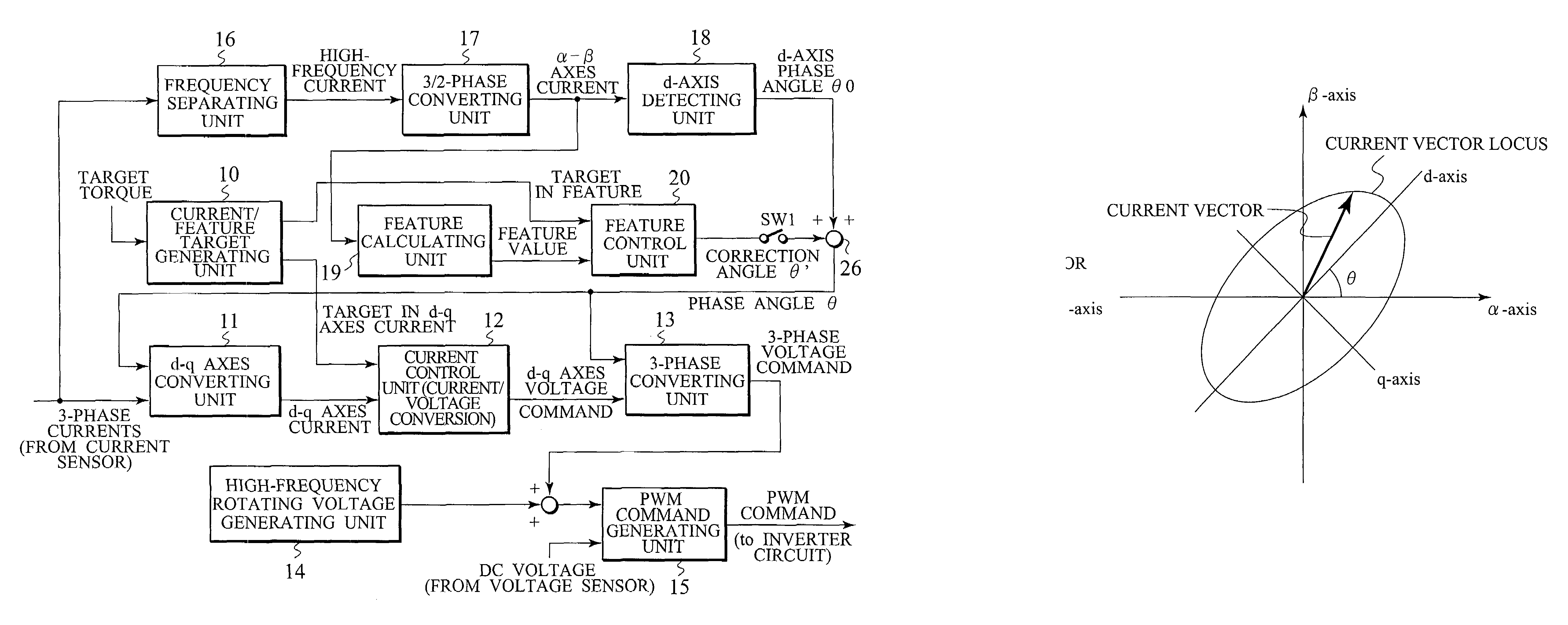

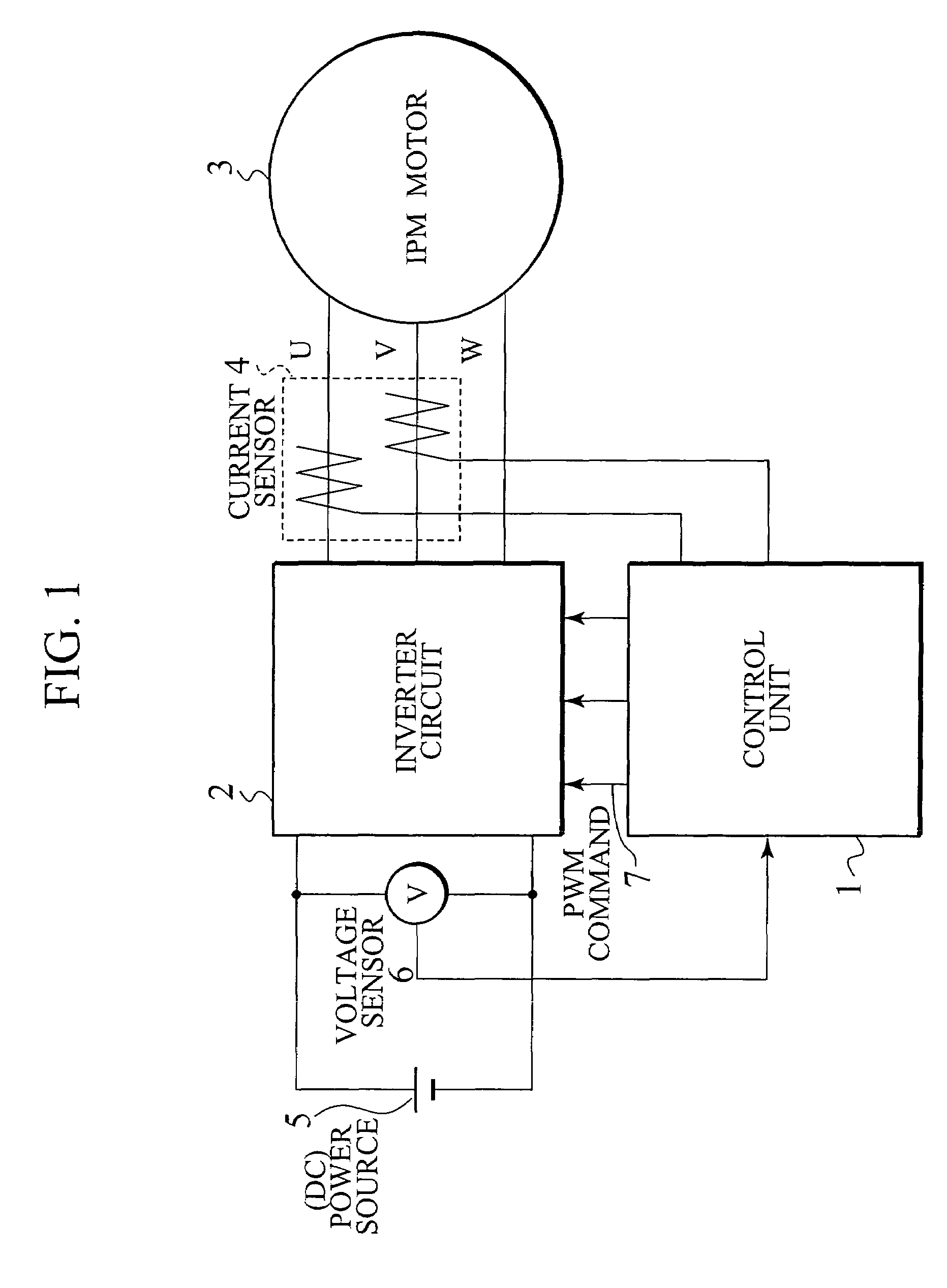

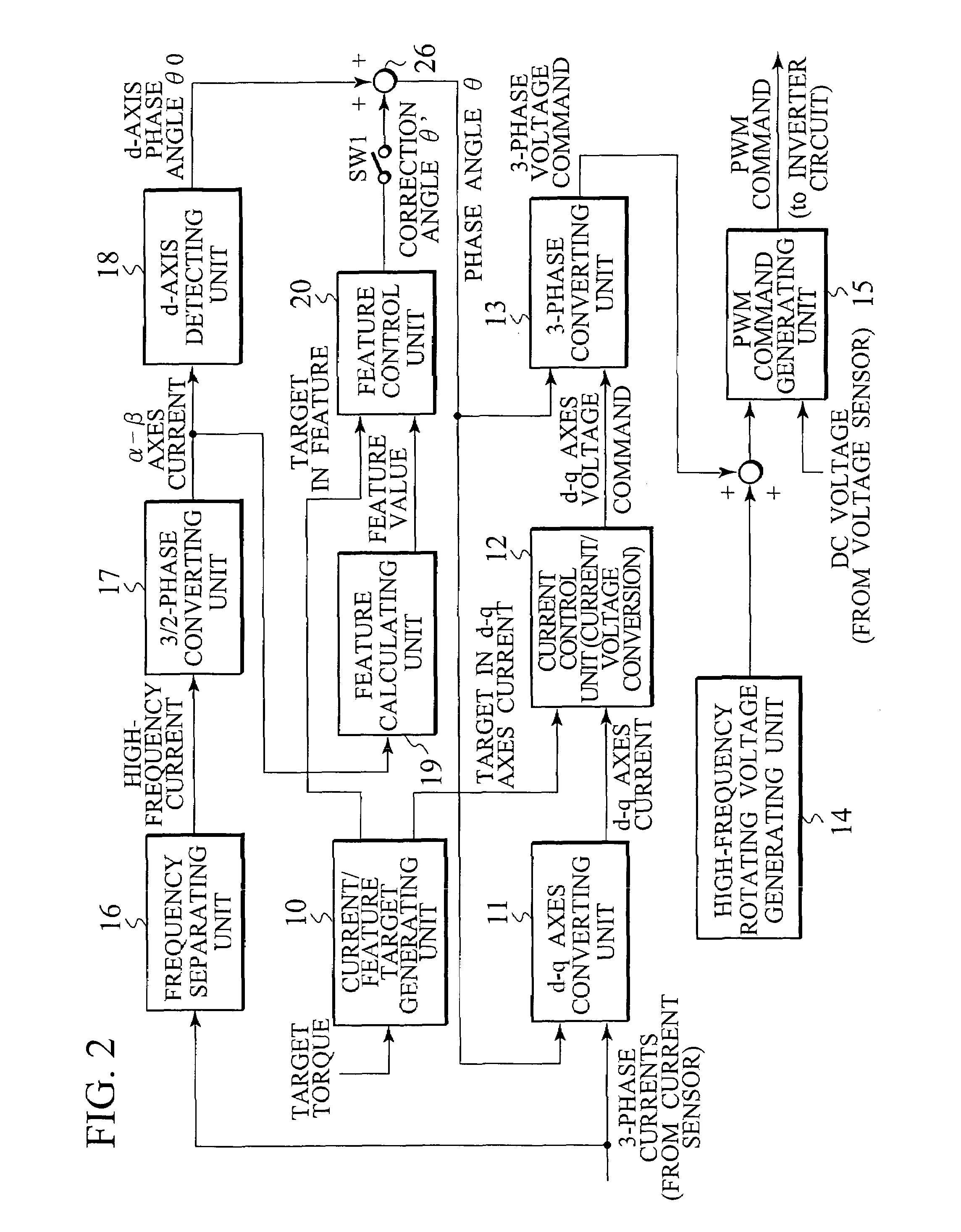

Control device for electric motor

ActiveUS7005828B2Improve artSingle-phase induction motor startersAC motor controlDriving currentAcquired characteristic

Corresponding to a target torque, the control device calculates a target value of a feature based on at least one of the length of a long axis of a current vector locus and the length of the short axis and further superimposes a superimposed current on a drive current for the motor, the superimposed current having a frequency different from the frequency of the drive current. Further, the control device detects an actual value of the feature based on at least one of the length of a long axis of a current vector locus of the superimposed current and the length of the short axis of the same and finally detects a phase angle of the motor based on the target value and the actual value for the feature. The manipulation of a detecting phase is performed by feedback of a feature obtained by the magnitude of the superimposed current. That is, when the actual feature is more than the target value, the detecting phase is advanced. Conversely, when the actual feature is less than the target value, the detecting phase is delayed.

Owner:NISSAN MOTOR CO LTD

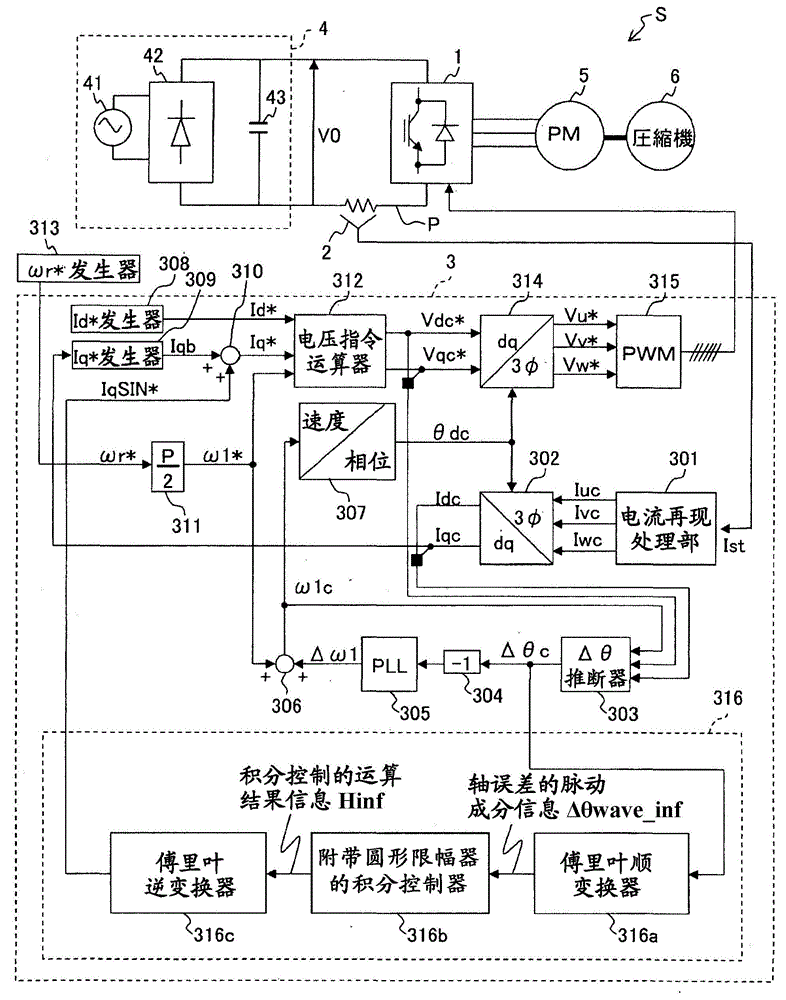

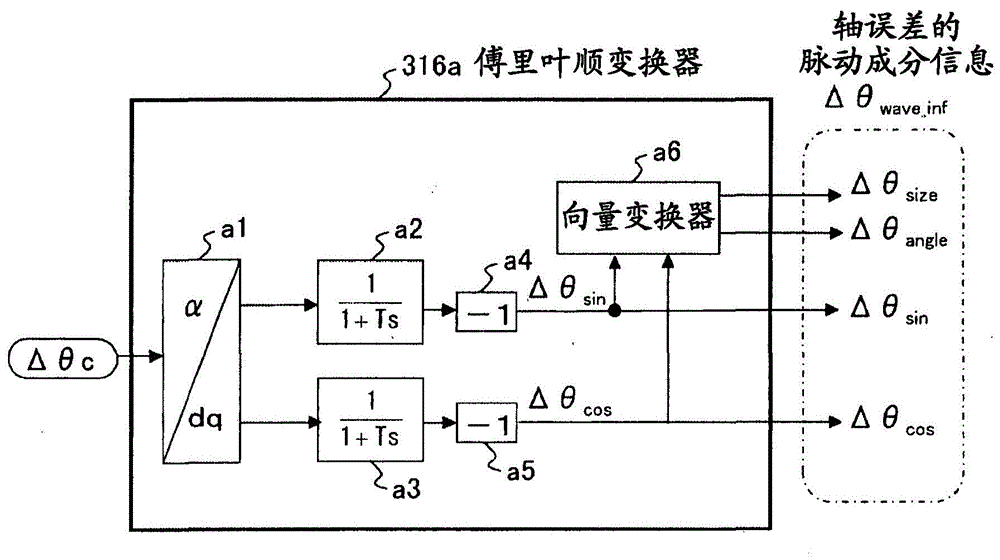

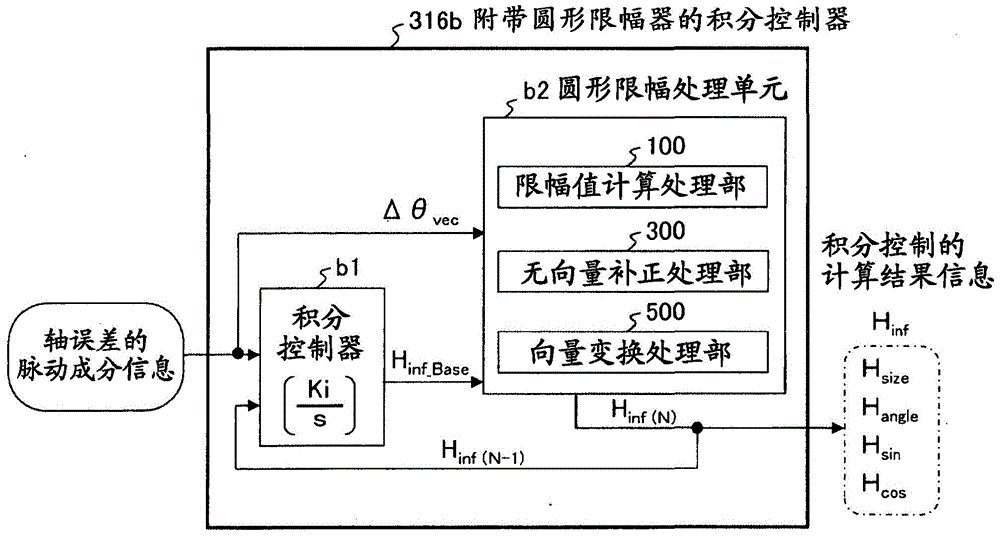

Motor control device

ActiveCN104038127ASuppression of pulsating torqueVector control systemsDynamo-electric converter controlCurrent sensorIntegral controller

A motor control device capable of suitably inhibiting the pulsating torque of an alternating-current motor is provided. The motor control device comprises an axis error inference machine (30) which infers an axis error based on a current value of an inverter, detected by a current sensor (2); a Fourier rectification machine (316a) which extracts an axis error vector from the time-base changes of the axis error; an integral control machine (316b) additionally provided with a circular amplitude limiter, which is used to calculate a correction current vector for offsetting the pulsating torque, wherein a circle with a set amplitude limiting value serving as the radius is used as the base for limiting the movement of the correction current vector, and the integral control machine (316b) additionally provided with the circular amplitude limiter performs the circular amplitude limiting for limiting the movement of the correction current vector so as to enable the deflection angle of the correction current vector to be close to the deflection angle of the axis error vector.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

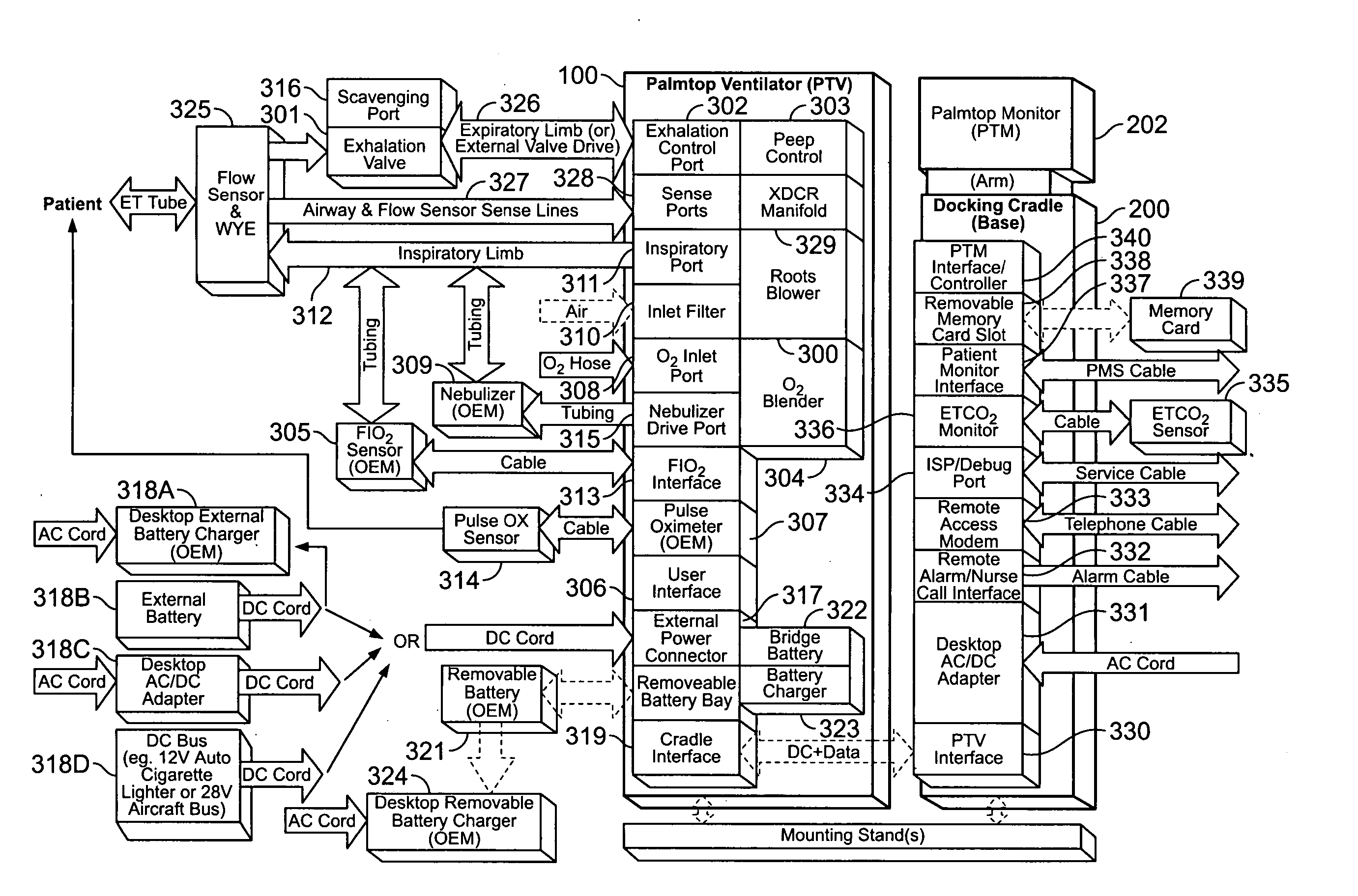

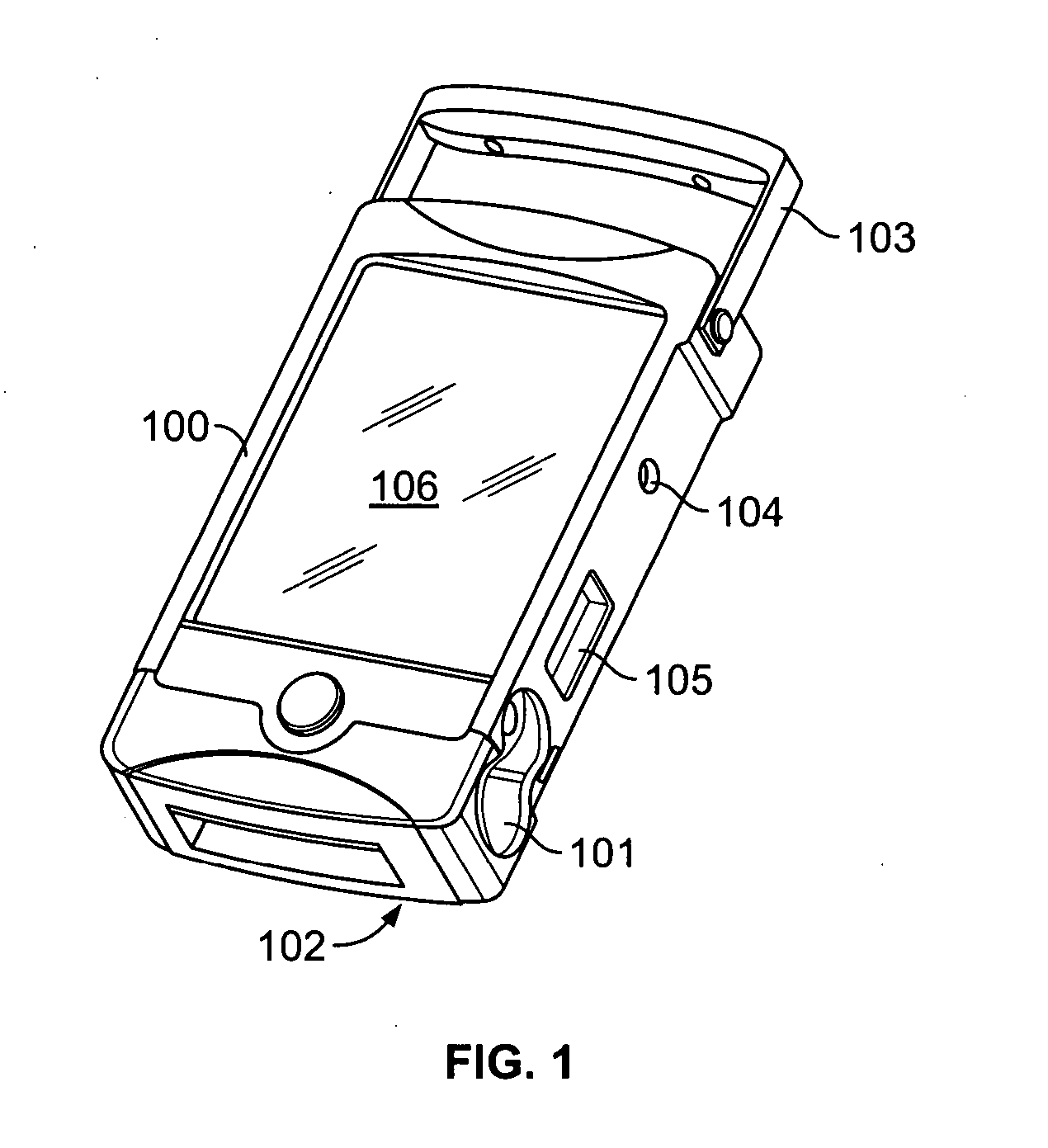

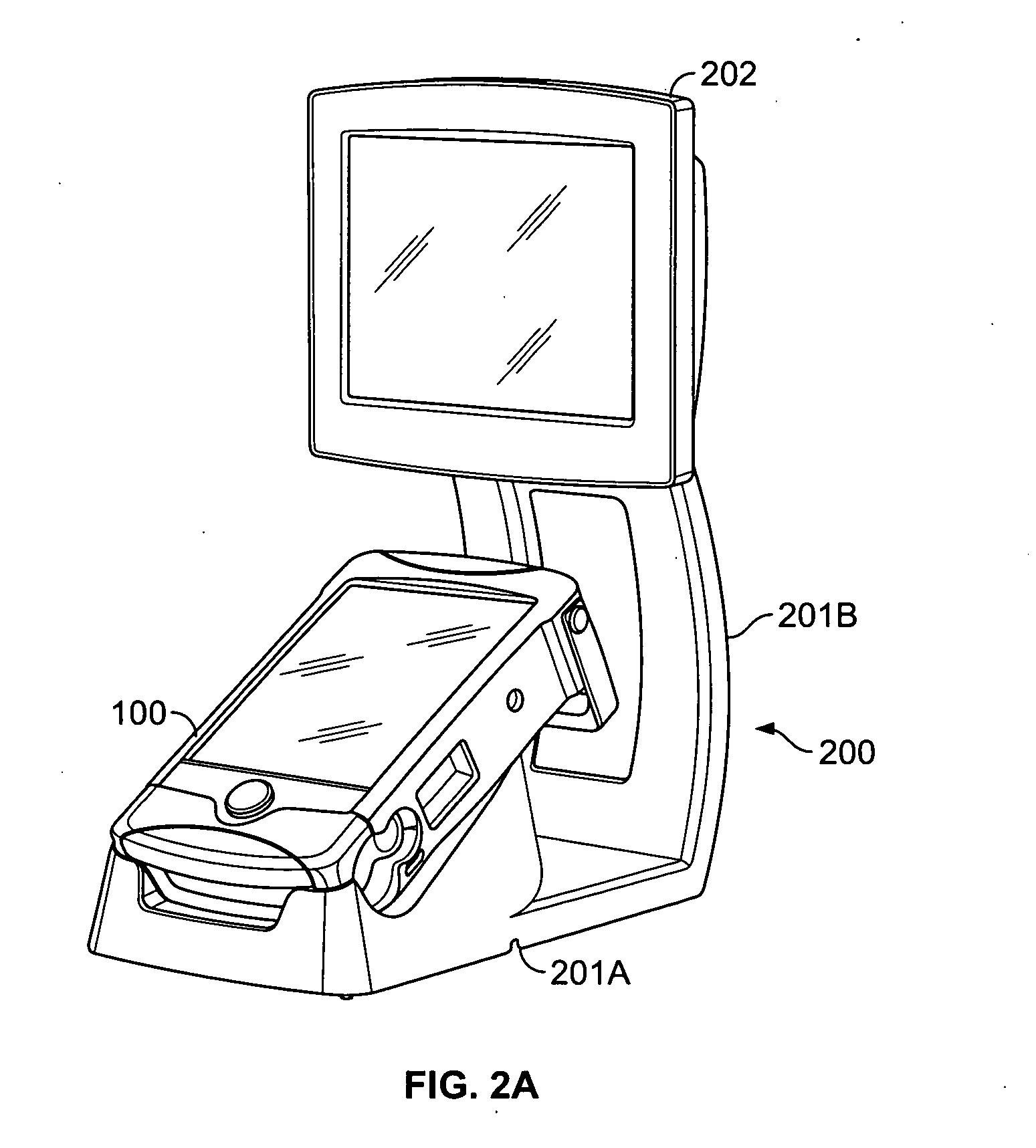

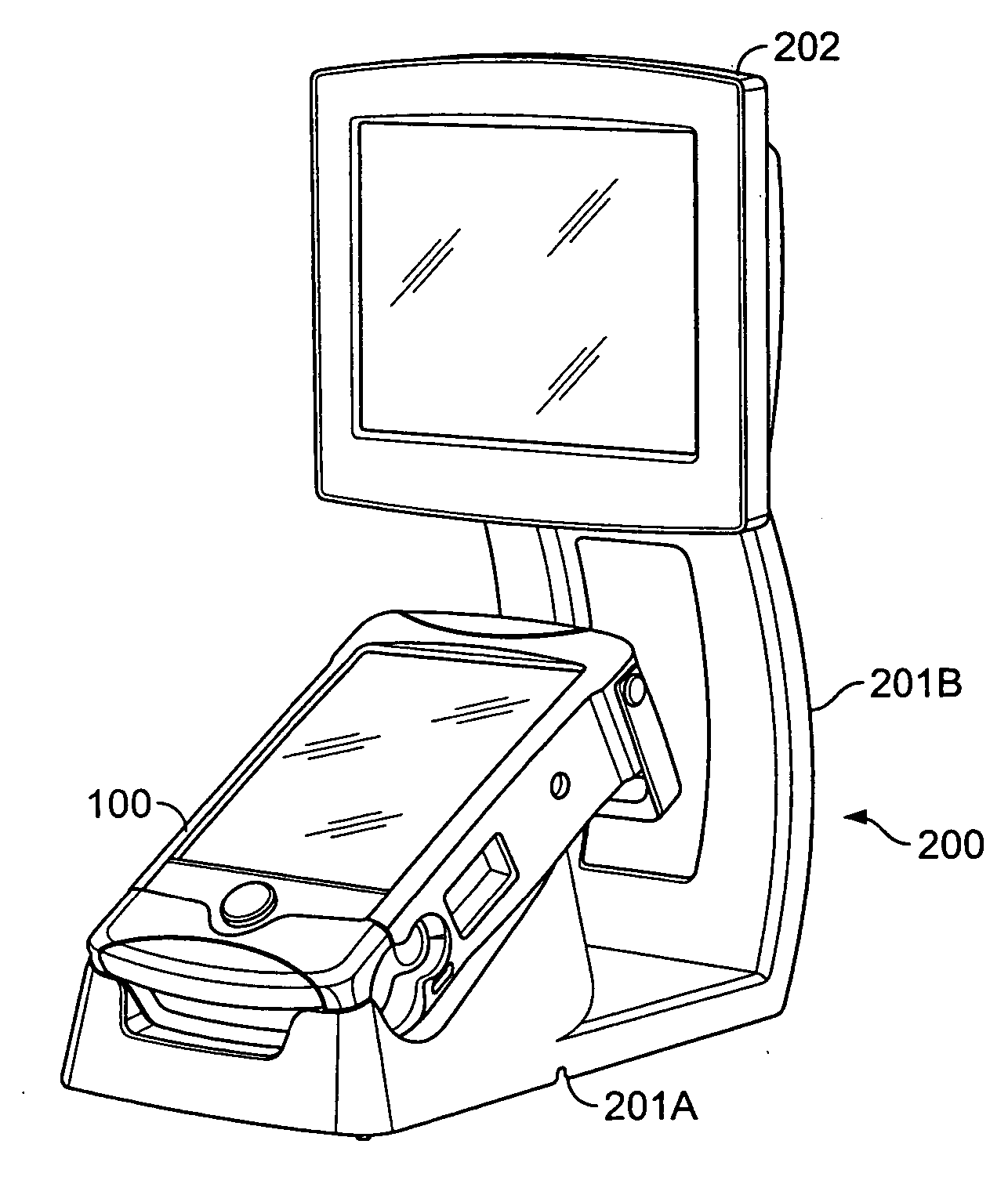

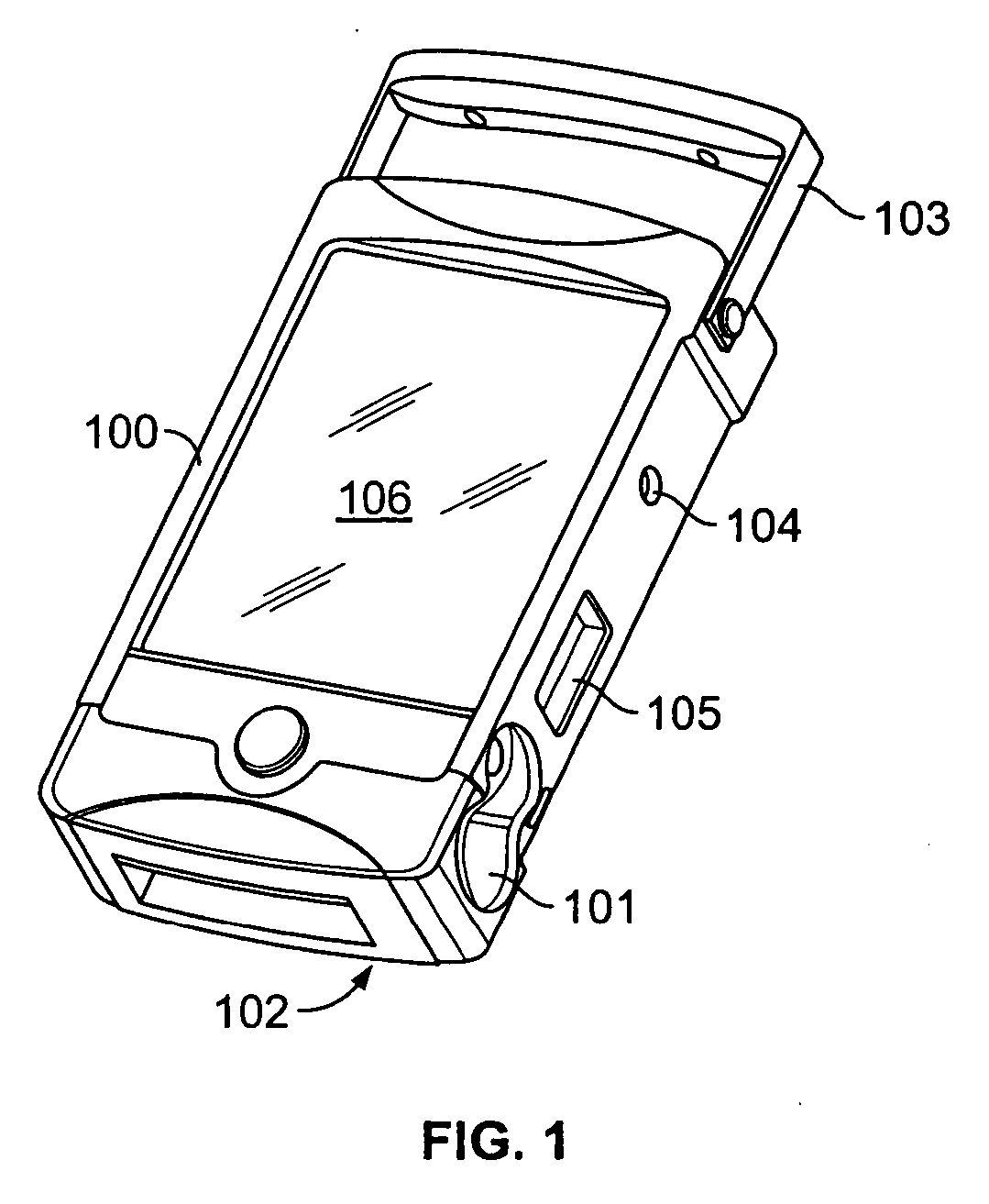

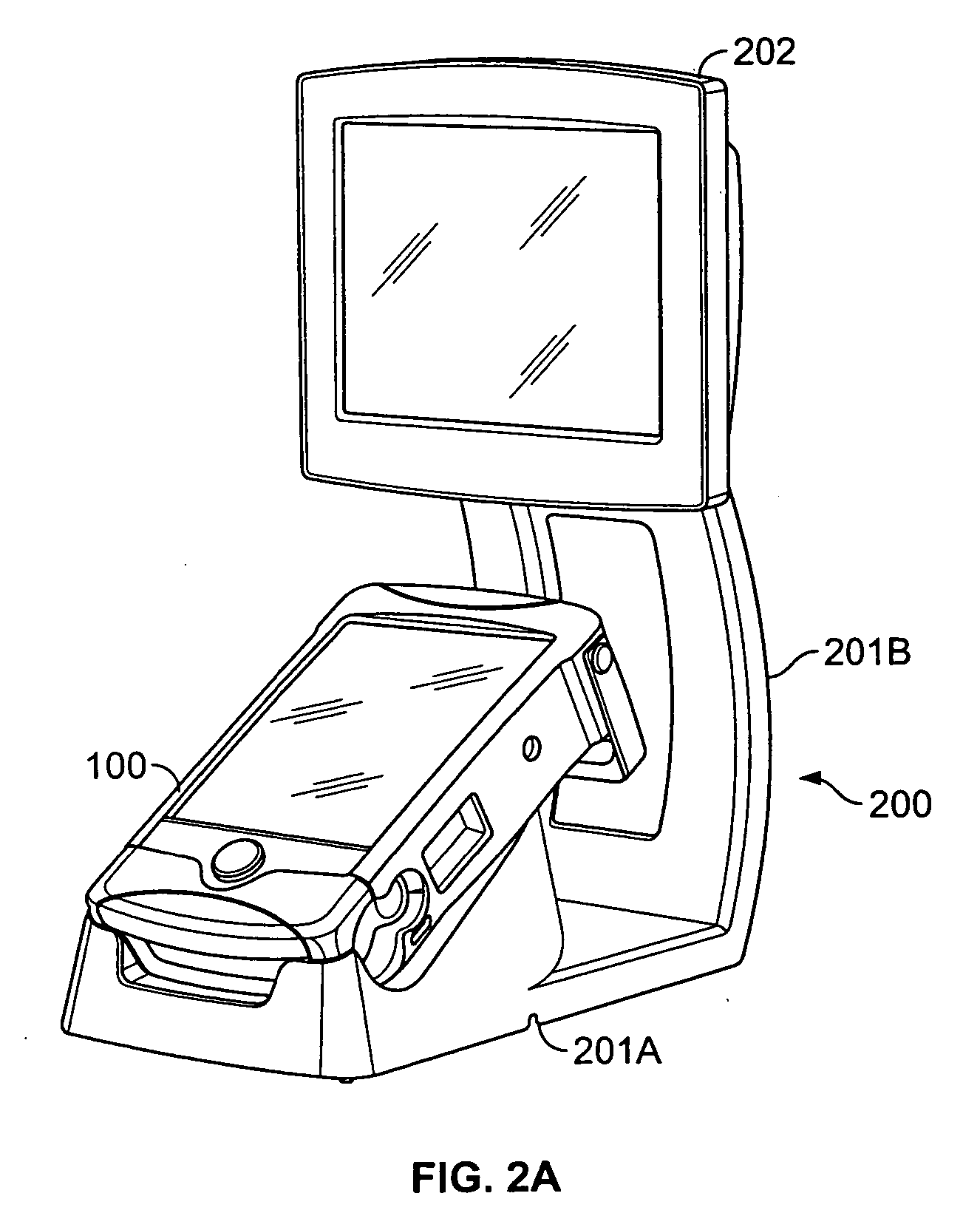

Portable ventilator system

ActiveUS20050051168A1Reduce power consumptionSmall sizeMechanical/radiation/invasive therapiesPhysical therapyPortable ventilatorsEngineering

A portable ventilator uses a Roots-type blower as a compressor to reduce both the size and power consumption of the ventilator. Various functional aspects of the ventilator are delegated to multiple subassemblies having dedicated controllers and software that interact with a ventilator processor to provide user interface functions, exhalation control and flow control servos, and monitoring of patient status. The ventilator overcomes noise problems through the use of noise reducing pressure compensating orifices on the Roots blower housing and multiple baffling chambers. The ventilator is configured with a highly portable form factor, and may be used as a stand-alone device or as a docked device having a docking cradle with enhanced interface and monitoring capabilities.

Owner:VYAIRE MEDICAL 203 INC

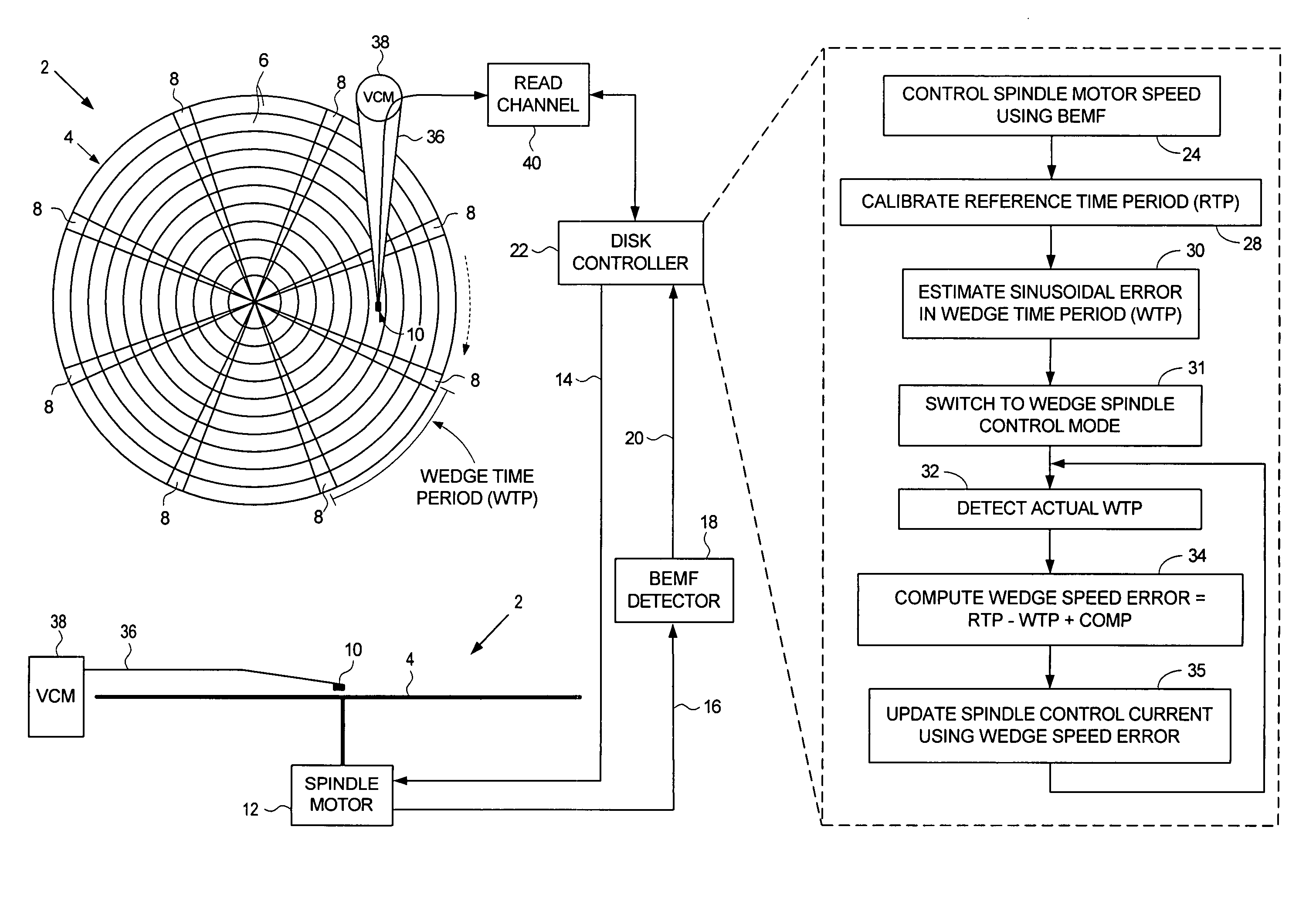

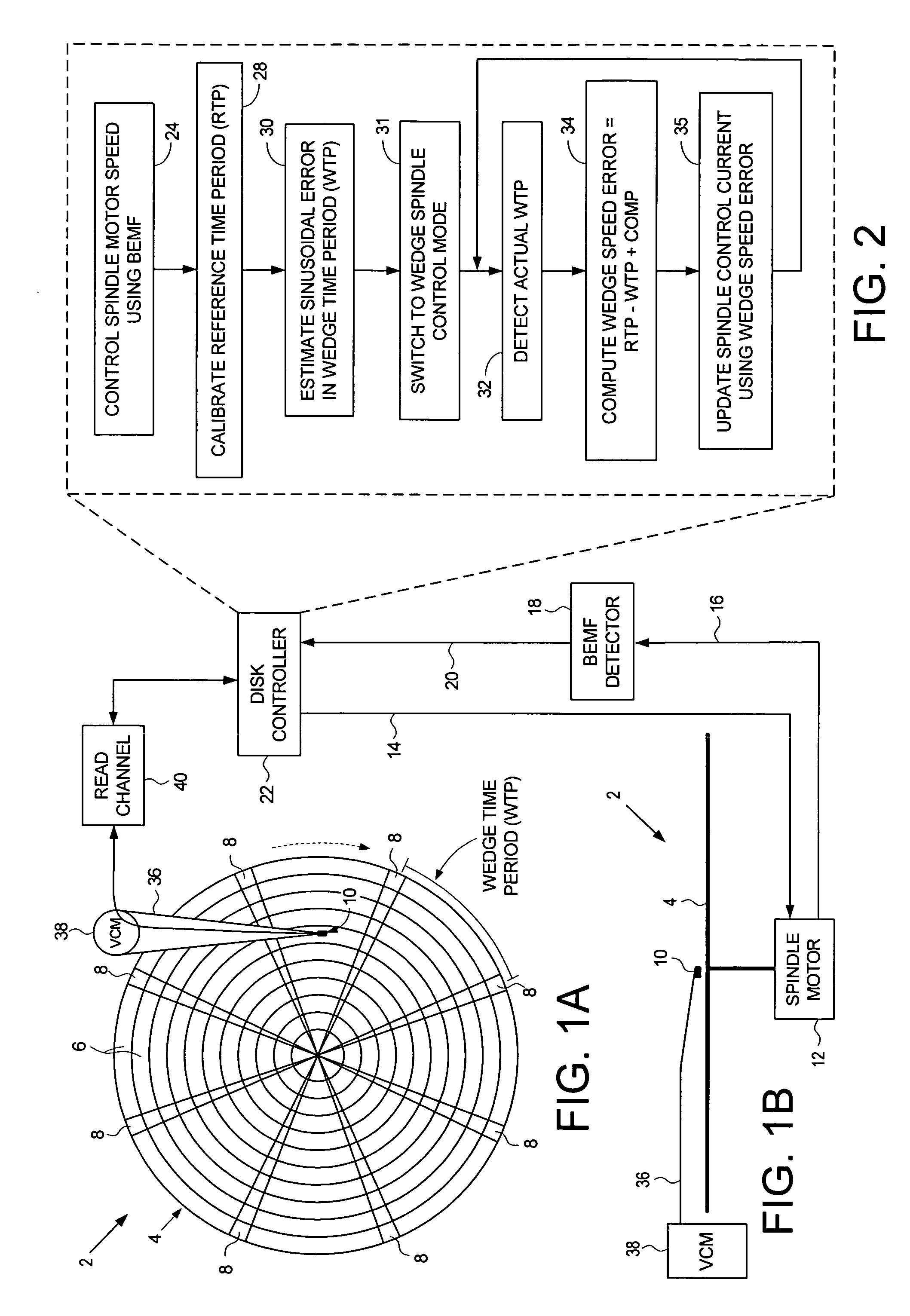

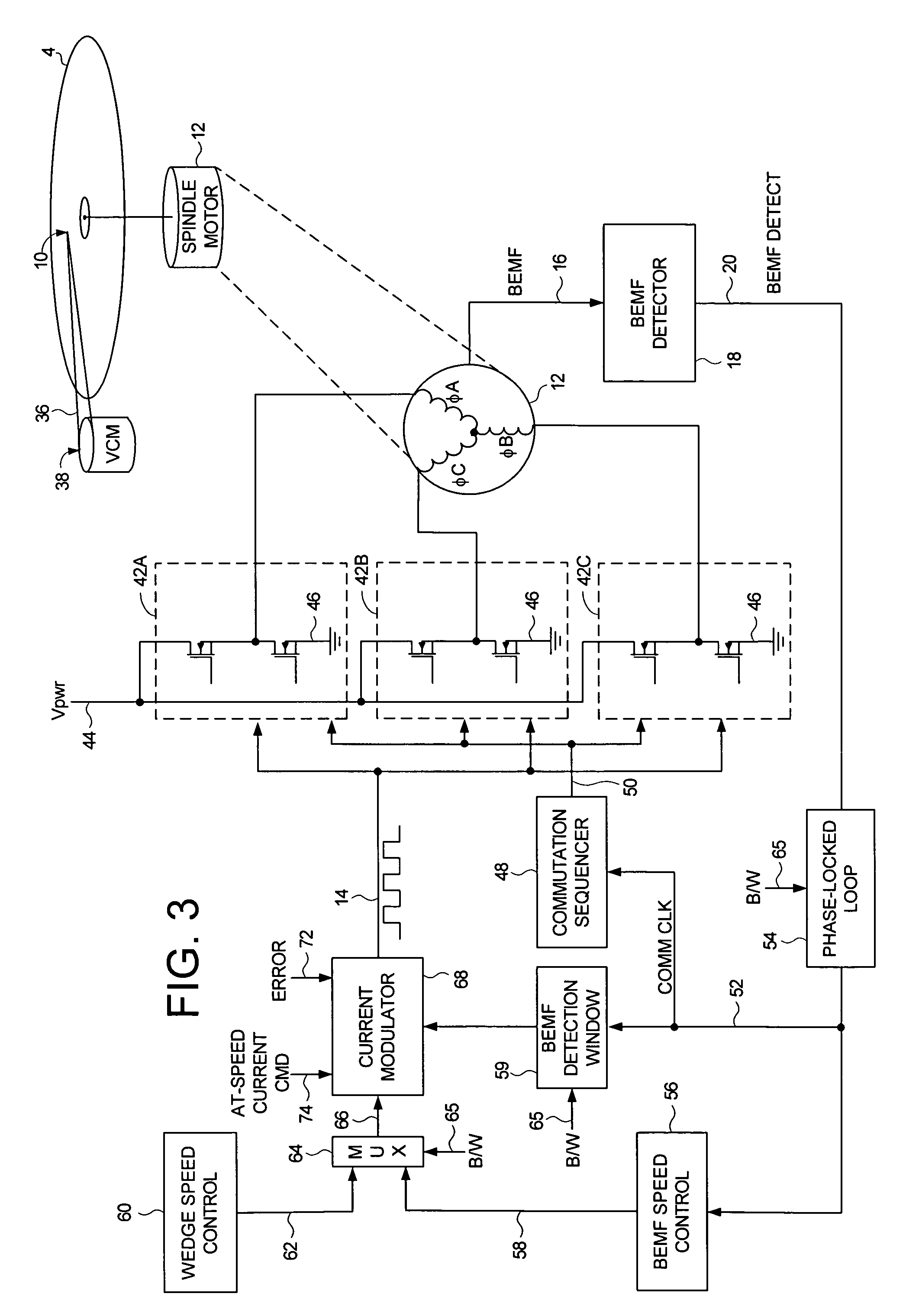

Disk drive employing wedge spindle speed control with eccentricity compensation

A disk drive is disclosed wherein a BEMF speed error is measured during a BEMF spindle speed control mode, and a spindle control current is updated in response to the BEMF speed error to drive the disk at an operating speed. A reference time period (RTP) is calibrated, and a sinusoidal error in a wedge time period (WTP) due to eccentricity in the disk rotating is estimated to generate an eccentricity compensation value. After switching to a wedge spindle speed control mode, an actual WTP is detected and a wedge speed error is generated in response to the RTP, the detected actual WTP, and the eccentricity compensation value. The disk is then maintained at the operating speed by updating the spindle control current in response to the wedge speed error.

Owner:WESTERN DIGITAL TECH INC

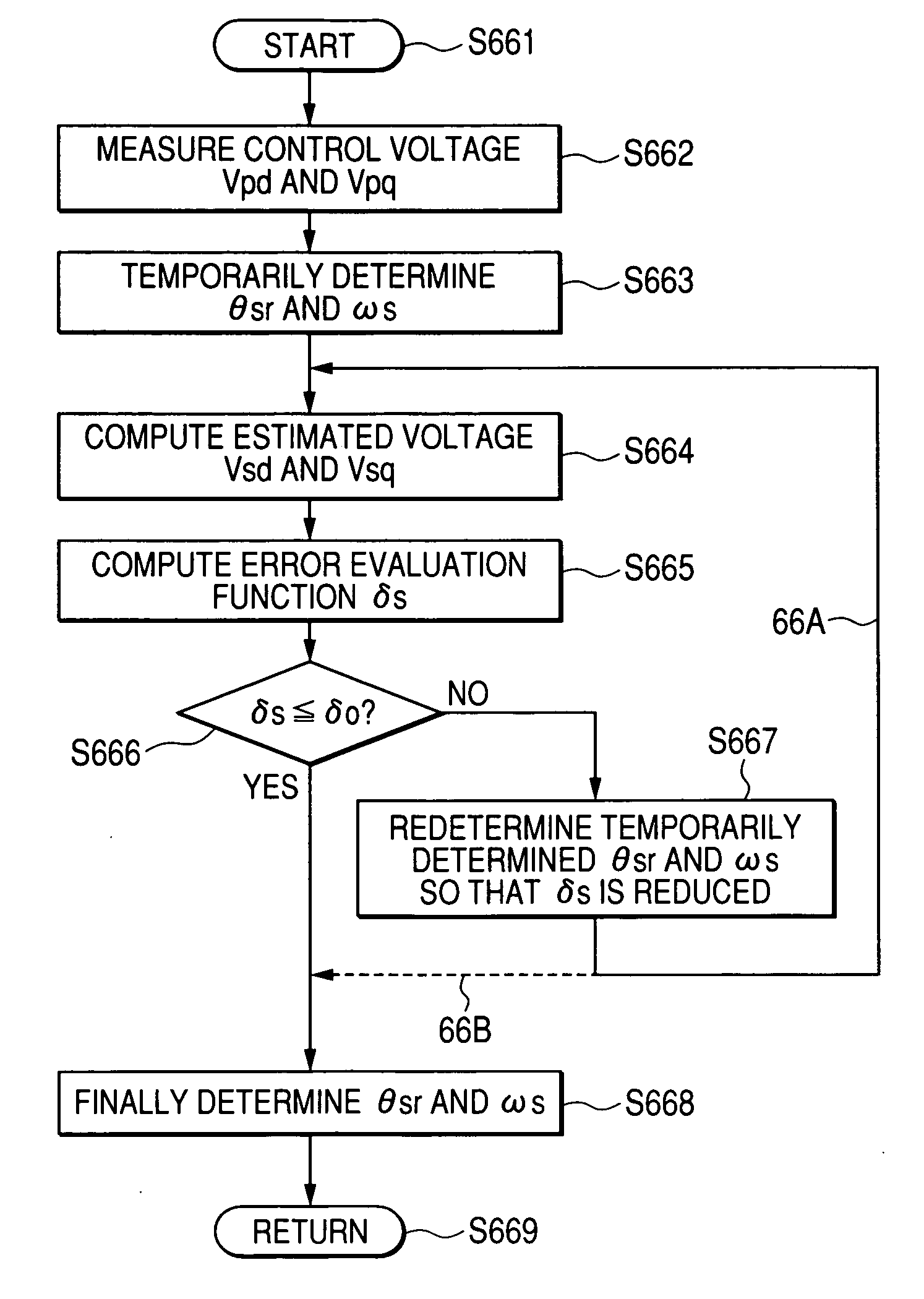

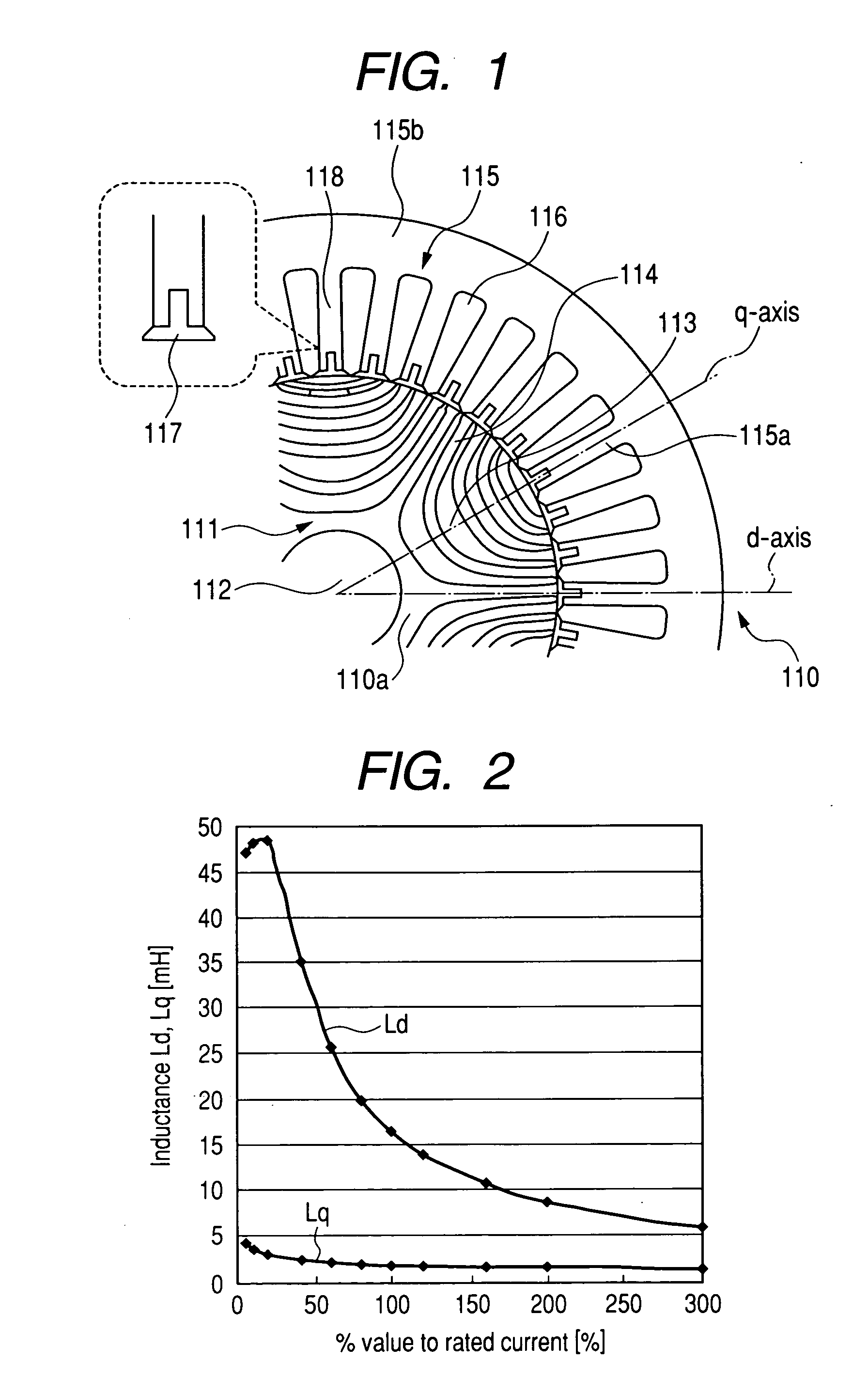

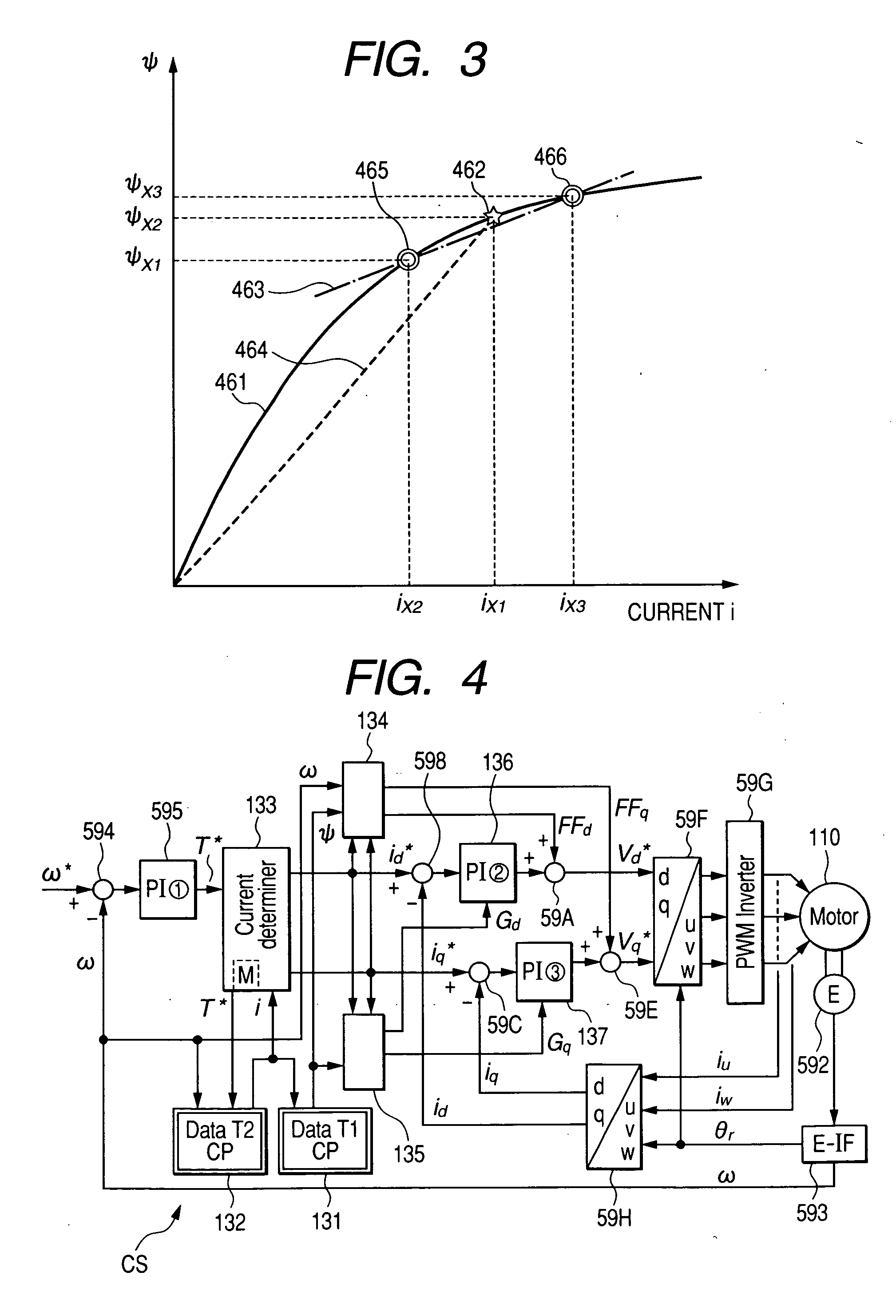

System and method for controlling motor using parameter associated with magnetic flux

InactiveUS20080129243A1Reliably graspTorque ripple controlSynchronous motors startersDriving currentOperating point

A control method for a motor that rotates based on flux linkages to a winding member of the motor when the winding member is energized by a drive current is provided. The method includes storing magnetic-state information indicative of a relationship between each of a plurality of predetermined operating points of the drive current and a magnetic-state parameter associated with the flux linkages. The method includes obtaining at least one of command information associated with an operating state of the motor and detection information associated with the operating state of the motor. The method includes referencing the magnetic-state information with the use of the obtained at least one of the command information and detection information to obtain a value of the magnetic-state parameter based on a result of the reference. The method includes controlling an output of the motor based on the obtained value of the magnetic-state parameter.

Owner:DENSO CORP

Portable ventilator system

ActiveUS20060144396A1Reduce power consumptionSmall sizeLiquid surface applicatorsPowdered material dispensingPortable ventilatorsEngineering

A portable ventilator uses a Roots-type blower as a compressor to reduce both the size and power consumption of the ventilator. Various functional aspects of the ventilator are delegated to multiple subassemblies having dedicated controllers and software that interact with a ventilator processor to provide user interface functions, exhalation control and flow control servos, and monitoring of patient status. The ventilator overcomes noise problems through the use of a noise attenuating system comprising noise reducing pressure compensating orifices on the Roots blower housing and multiple noise reducing chambers. The ventilator is configured with a highly portable form factor, and may be used as a stand-alone device or as a docked device having a docking cradle with enhanced interface and monitoring capabilities.

Owner:VYAIRE MEDICAL 203 INC

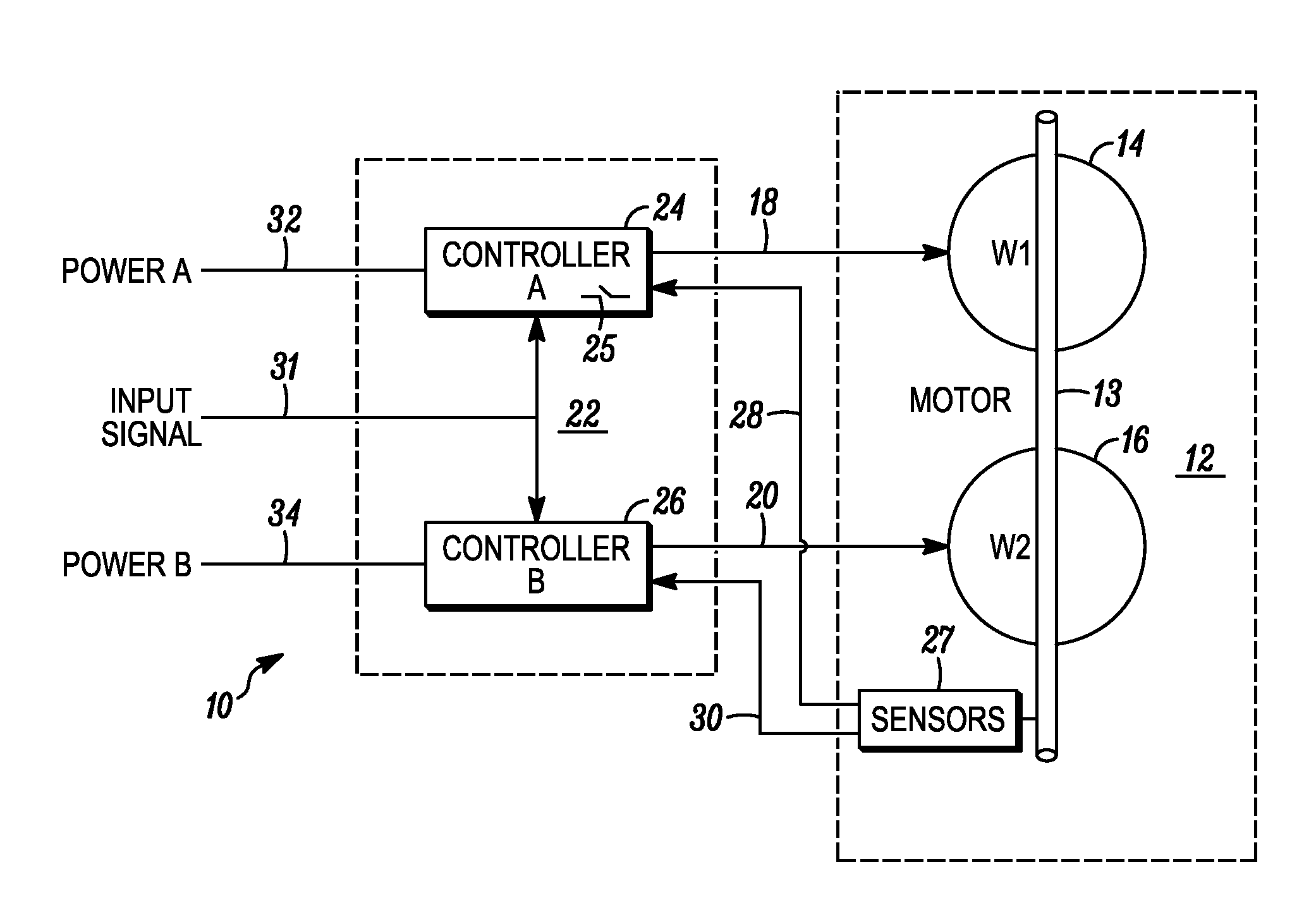

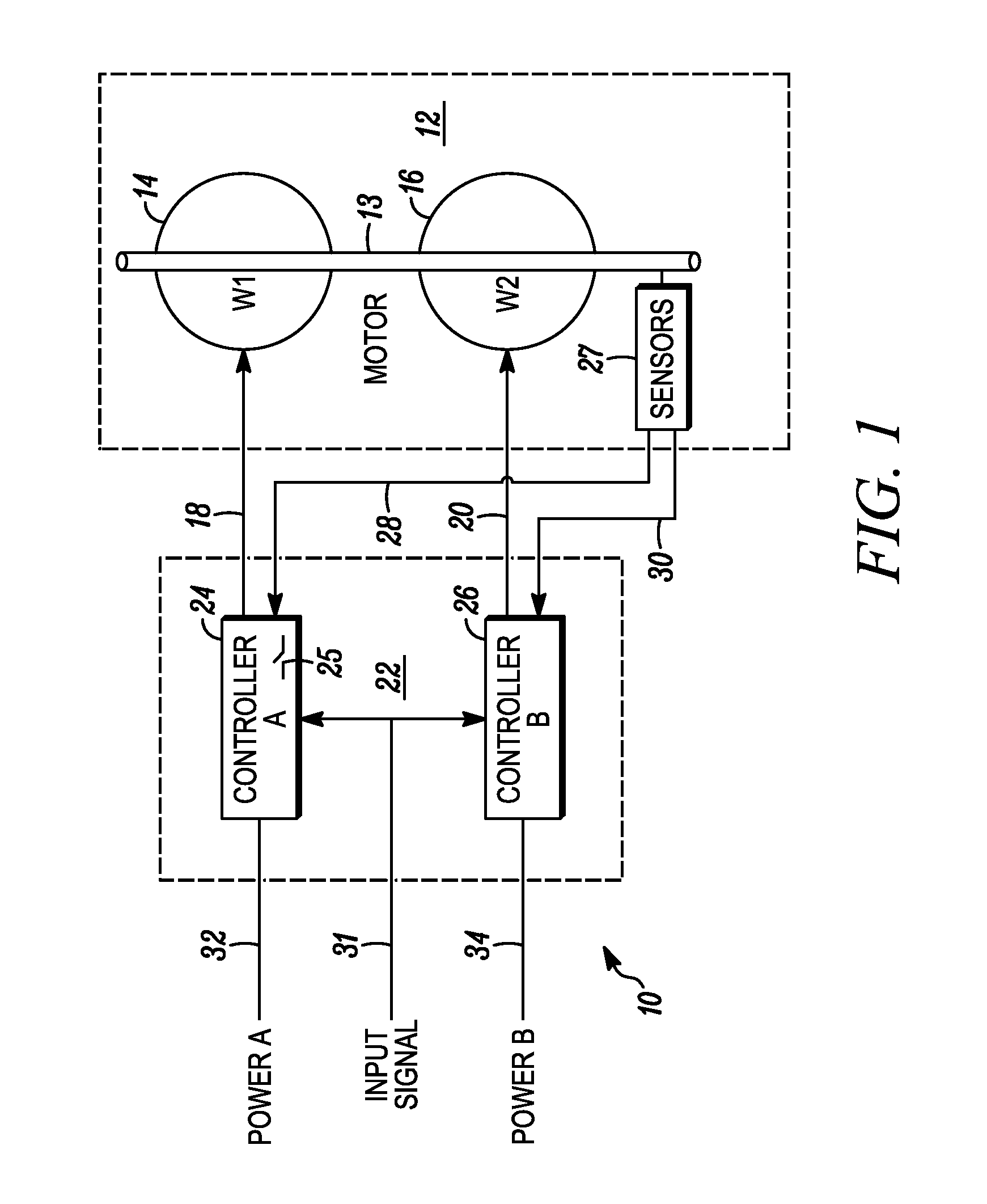

Electric motor and motor control

InactiveUS8575873B2Reduce noiseHigh complexitySingle-phase induction motor startersTorque ripple controlElectric machinePermanent magnet motor

Various embodiments of an electric motor and electronic control for an electric motor are disclosed. An exemplary electric motor comprises a single-phase brushless permanent magnet electric motor. In exemplary embodiments, the electronic motor control is configured to commutate an electric motor at a frequency other than line frequency, perform pulse width modulation, and drive the electric motor with a drive waveform that approximates the counter-electromotive force of the motor.

Owner:NIDEC MOTOR CORP

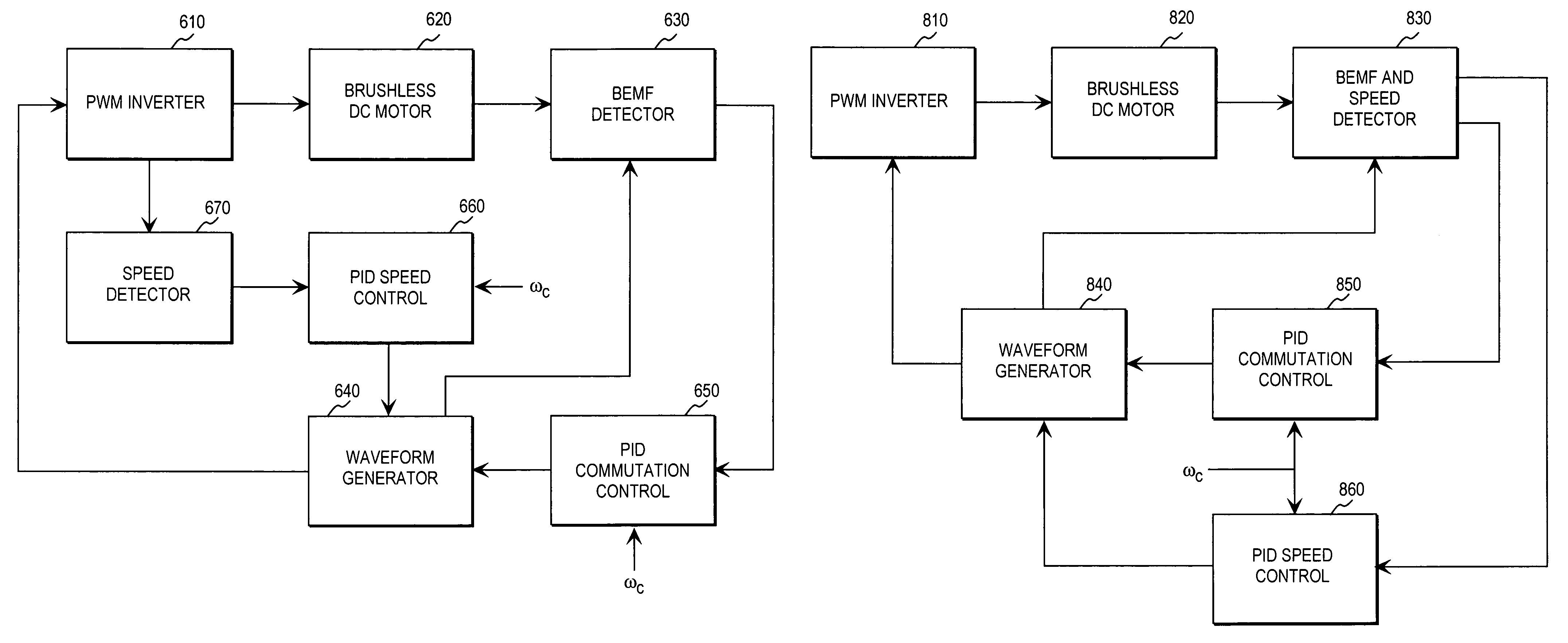

Method and apparatus for controlling brushless DC motors in implantable medical devices

Methods and apparatus for controlling a polyphase motor in implantable medical device applications are provided. In one embodiment, the polyphase motor is a brushless DC motor. The back emf of a selected phase of the motor is sampled while a drive voltage of the selected phase is substantially zero. Various embodiments utilize sinusoidal or trapezoidal drive voltages. The sampled back emf provides an error signal indicative of the positional error of the rotor. In one embodiment, the sampled back emf is normalized with respect to a commanded angular velocity of the rotor to provide an error signal proportional only to the positional error of the motor rotor. The error signal is provided as feedback to control a frequency of the drive voltage. A speed control generates a speed control signal corresponding to a difference between a commanded angular velocity and an angular velocity inferred from the frequency of the drive voltage. The speed control signal is provided as feedback to control an amplitude of the drive voltage. In one embodiment, an apparatus includes a brushless DC motor and a commutation control. The commutation control provides a commutation control signal for a selected phase of the motor in accordance with a sampled back electromotive force (emf) of that phase. The back emf of the phase is sampled only while the corresponding drive voltage for the selected phase is substantially zero, wherein a frequency of a drive voltage of the motor is varied in accordance with the commutation control signal.

Owner:HEARTWARE INC

Self-driving vehicle with integrated active suspension

ActiveUS20180154723A1Improve ride comfort performanceActive suspension technologiesAssociation with control/drive circuitsSpringsEngineeringRoad surface

A self-driving vehicle with an integrated fully-active suspension system. The fully-active suspension utilizes data from one or more sensors used for autonomous driving (e.g. vision, LIDAR, GPS) in order to anticipate road conditions in advance. The system builds a topographical map of the road surface. Suspension and road data is delivered back to the vehicle in order to change autonomous driving behavior including route planning. Energy storage is regulated based on a planned route. Forward and lateral acceleration feel is mitigated through active pitch and tilt compensation. The fully-active suspension pushes and pulls the suspension in three or more operational quadrants in order to deliver superior ride comfort, handling, and / safety of the vehicle.

Owner:CLEARMOTION INC

Driving apparatus for a ceiling fan

InactiveUS7664377B2Reduce the amount presentReduce in quantityPiezoelectric/electrostriction/magnetostriction machinesElectric testing/monitoringBrushless motorsCeiling fan

A driving apparatus for a DC brushless motor of a ceiling fan is provided. By setting at least one coder and one sensor outside the DC brushless motor, the driving apparatus can sense the position of magnetic poles of the motor for driving the motor. Meanwhile, a controller set with the motor stores the rotation speed of the motor before being turned off by detecting the turn-off time of a turn-on / off signal.

Owner:RHINE ELECTRONICS

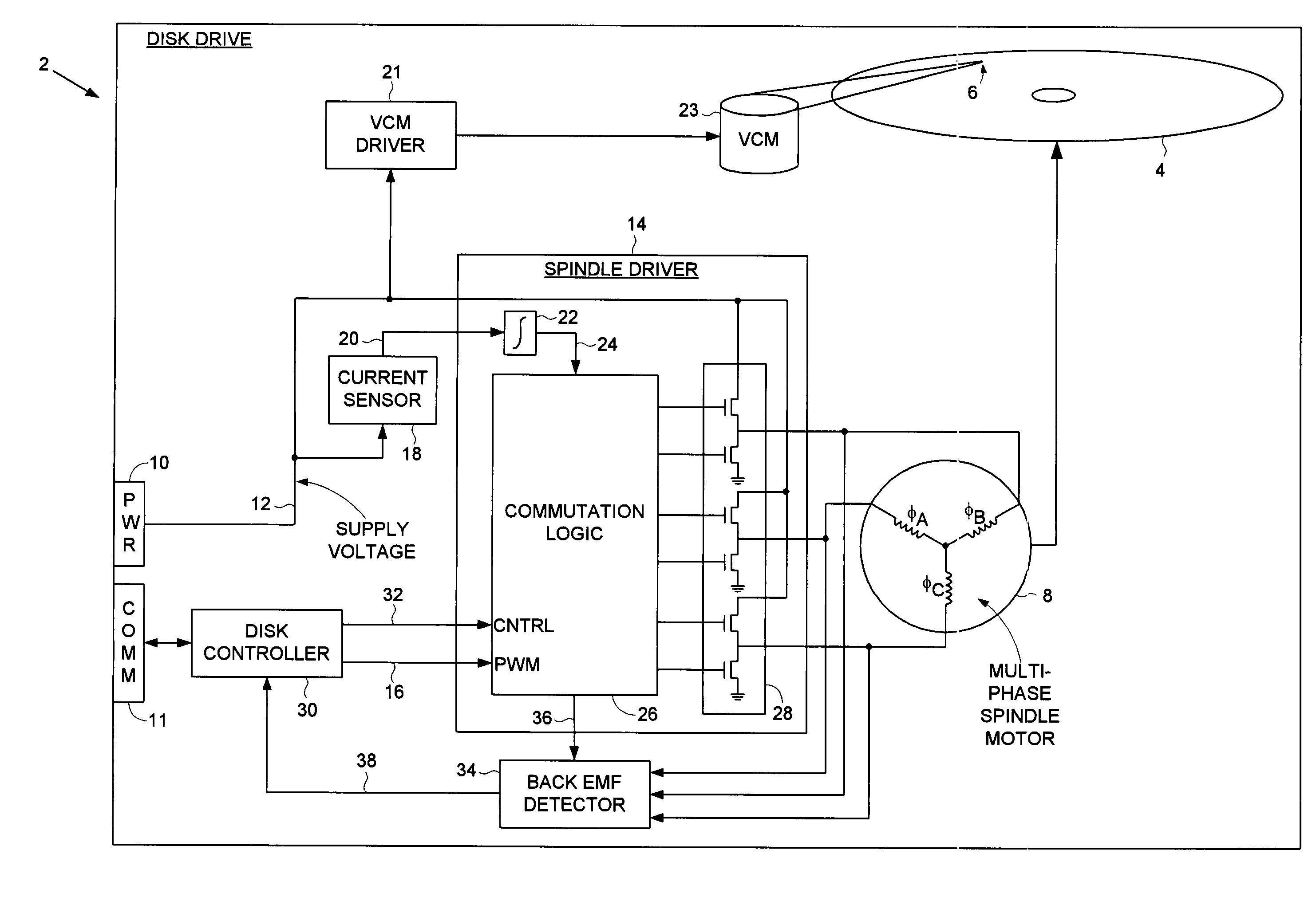

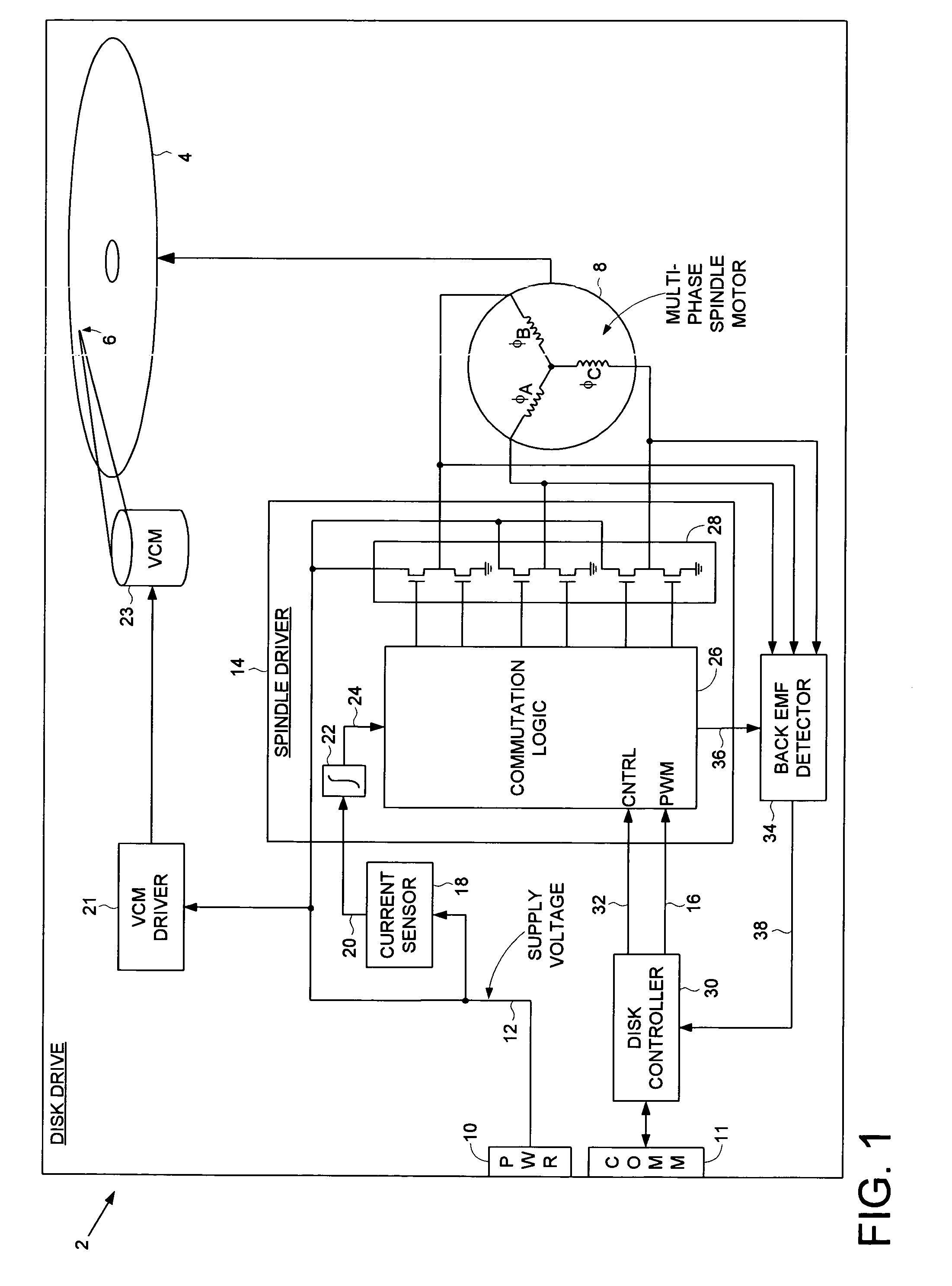

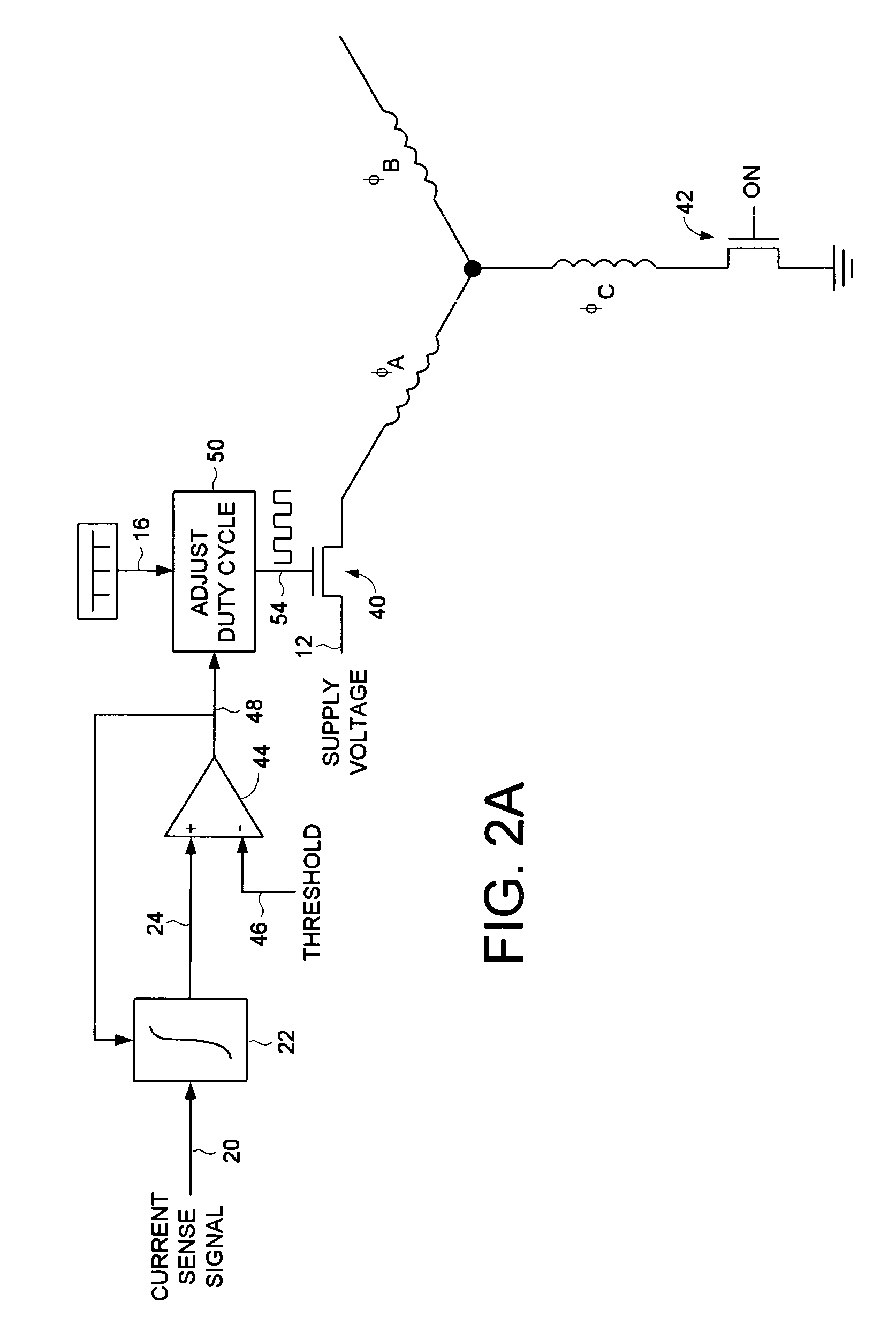

Decreasing spin up time in a disk drive by adjusting a duty cycle of a spindle motor PWM signal to maintain constant average input current

A disk drive is disclosed comprising a spindle motor for rotating a disk, wherein the current applied to the spindle motor is controlled by adjusting a duty cycle of a pulse width modulated (PWM) signal. A current sensor generates a current sense signal representing a current flowing from a supply voltage. The current sense signal is integrated to generate an integration signal. The integration signal is compared to a threshold, and the result of the comparison is used to adjust the duty cycle of the PWM signal. In this manner the disk drive draws essentially constant average input current from the supply voltage which decreases the spin up time of the disk.

Owner:WESTERN DIGITAL TECH INC

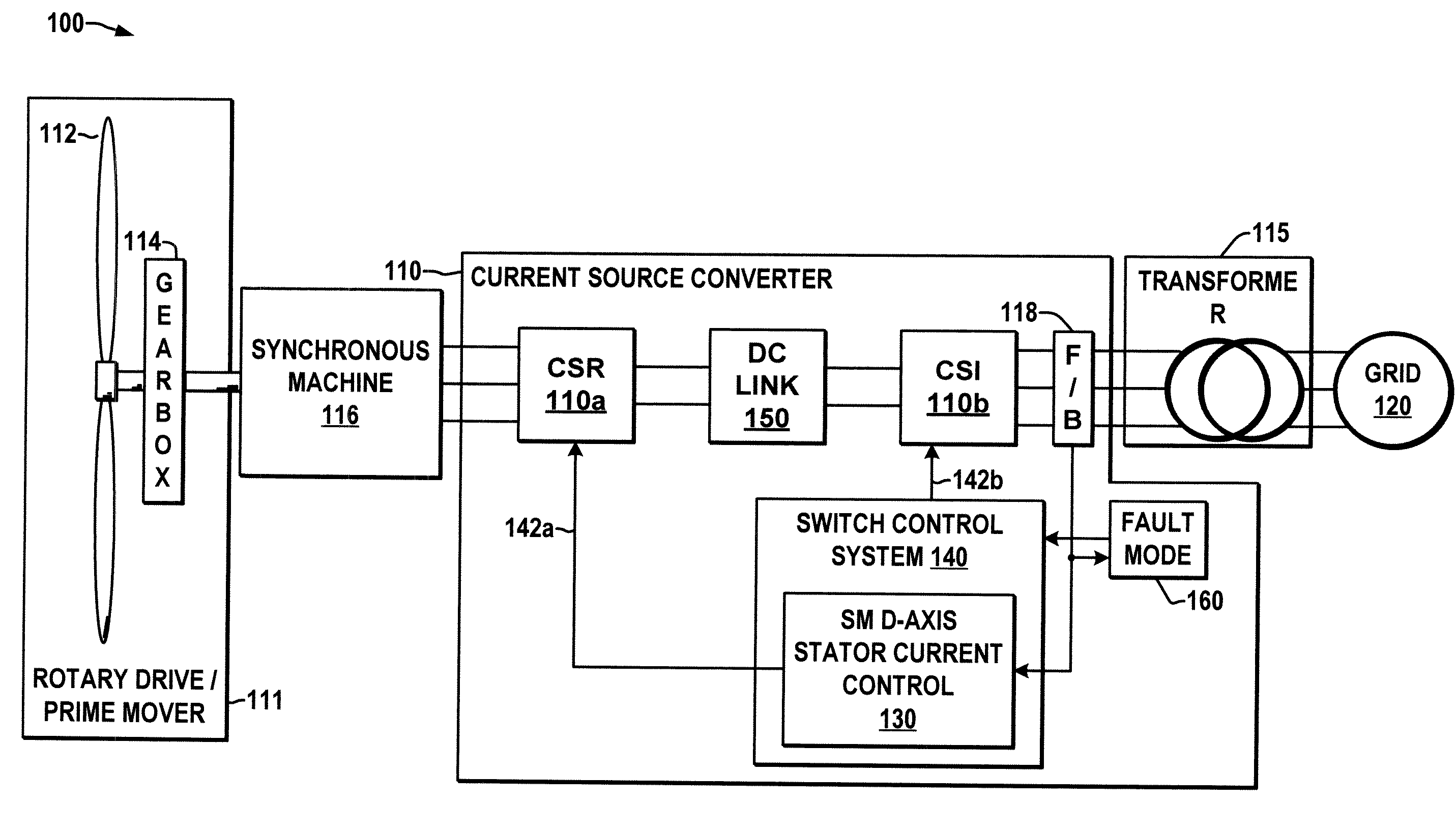

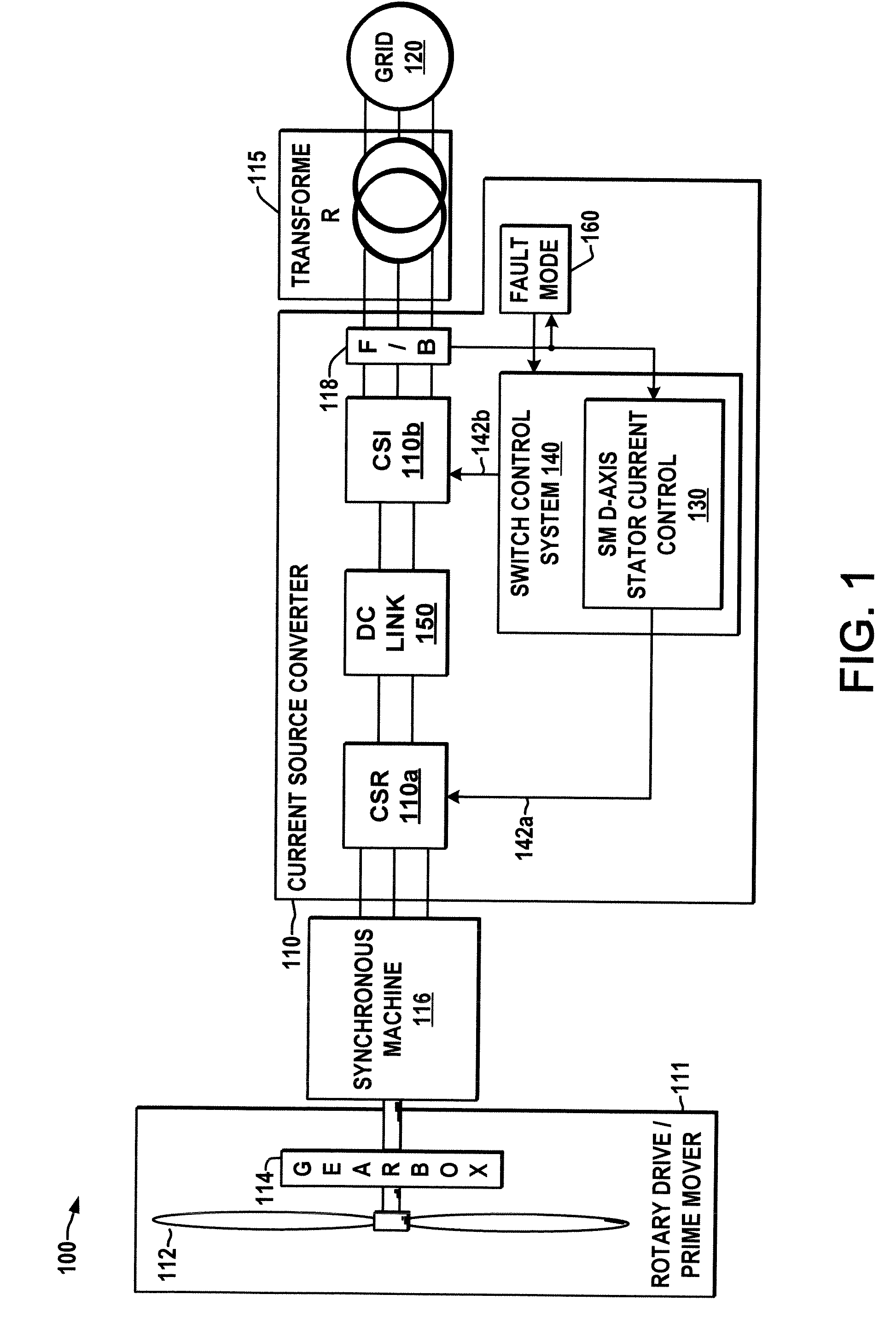

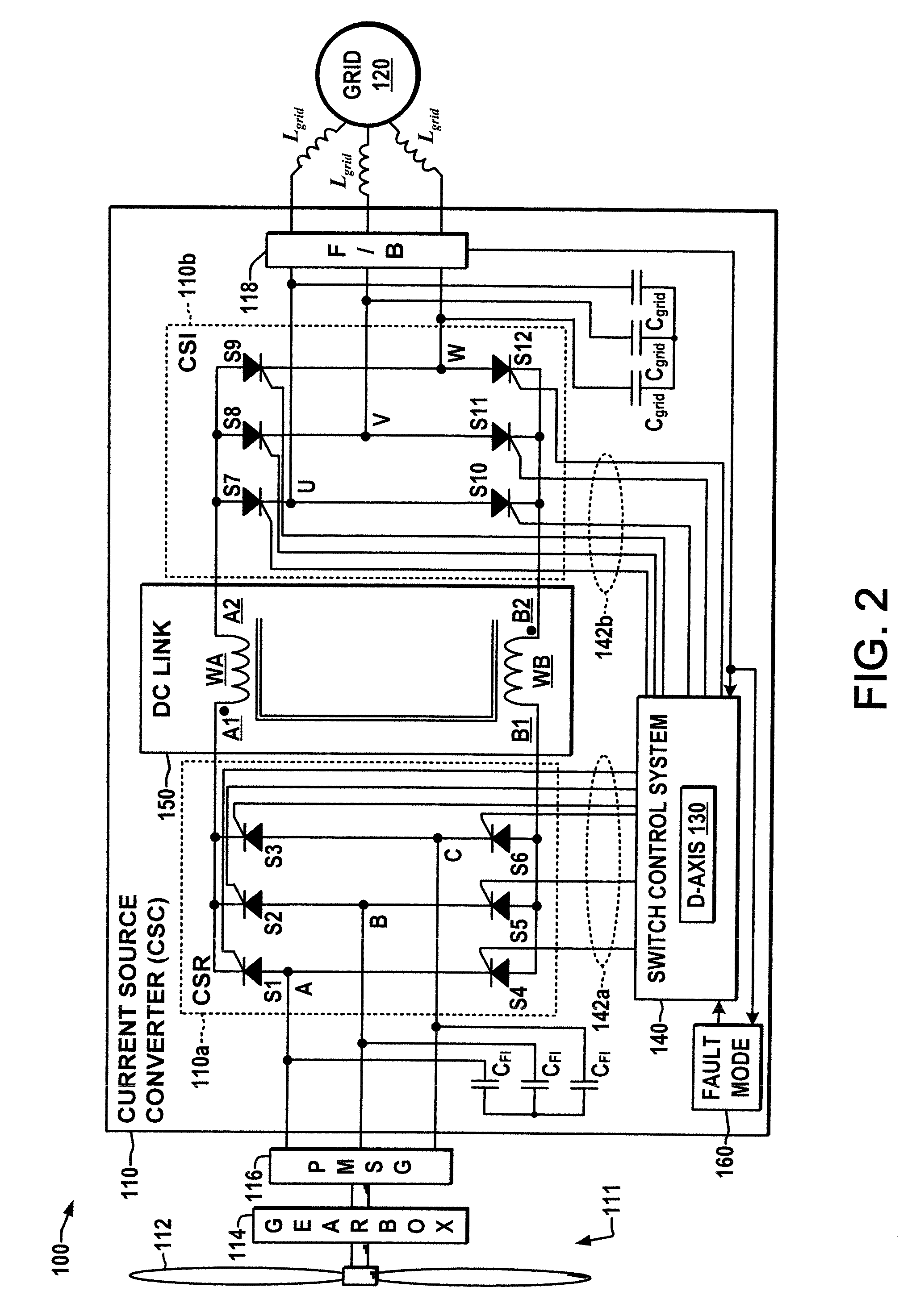

Current source converter-based wind energy system

ActiveUS20100025995A1Excess power being dissipatedAC motor controlSynchronous motors startersResistEngineering

Power conversion apparatus and methods are presented for providing electrical power to a grid or other load in which a synchronous machine is driven by a wind turbine or other prime mover to provide generator power to a switching type current source converter (CSC), with a current source rectifier (CSR) of the CSC being switched to provide d-axis control of the synchronous machine current based on grid power factor feedback, and with a current source inverter (CSI) of the CSC being switched to provide leading firing angle control and selective employment of dumping resists to dissipate excess generator energy in a fault mode when a grid voltage drops below a predetermined level.

Owner:ROCKWELL AUTOMATION TECH

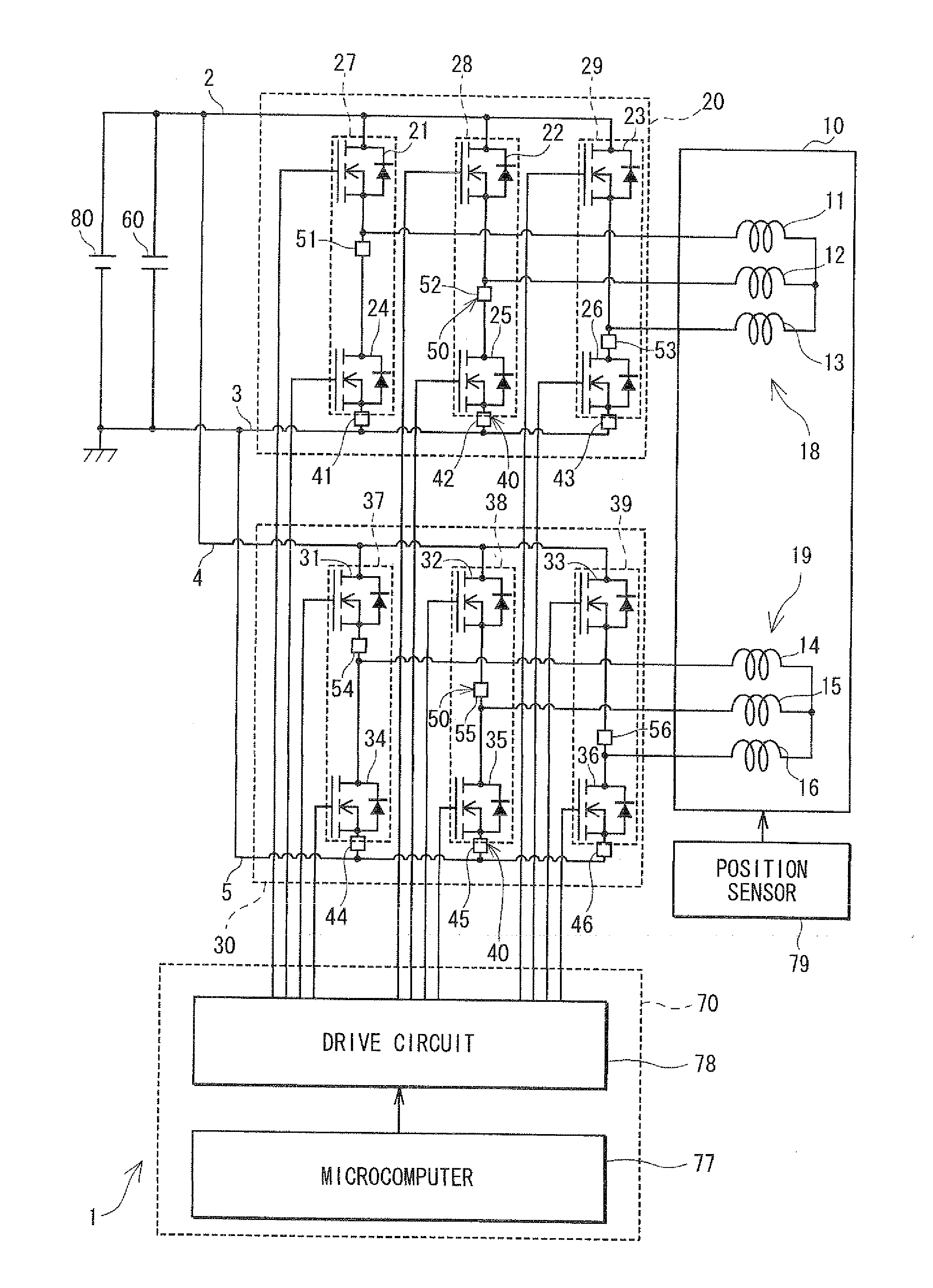

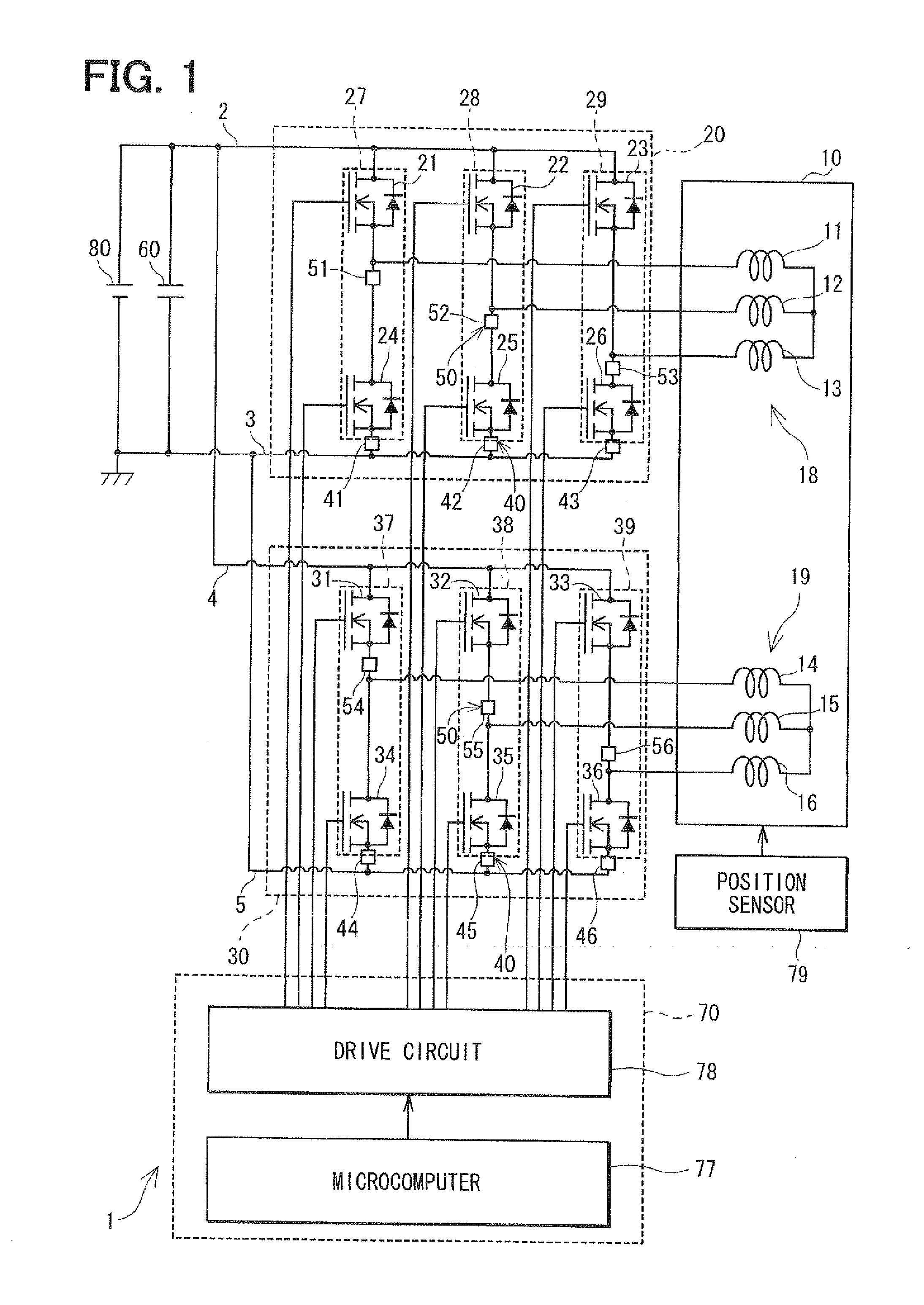

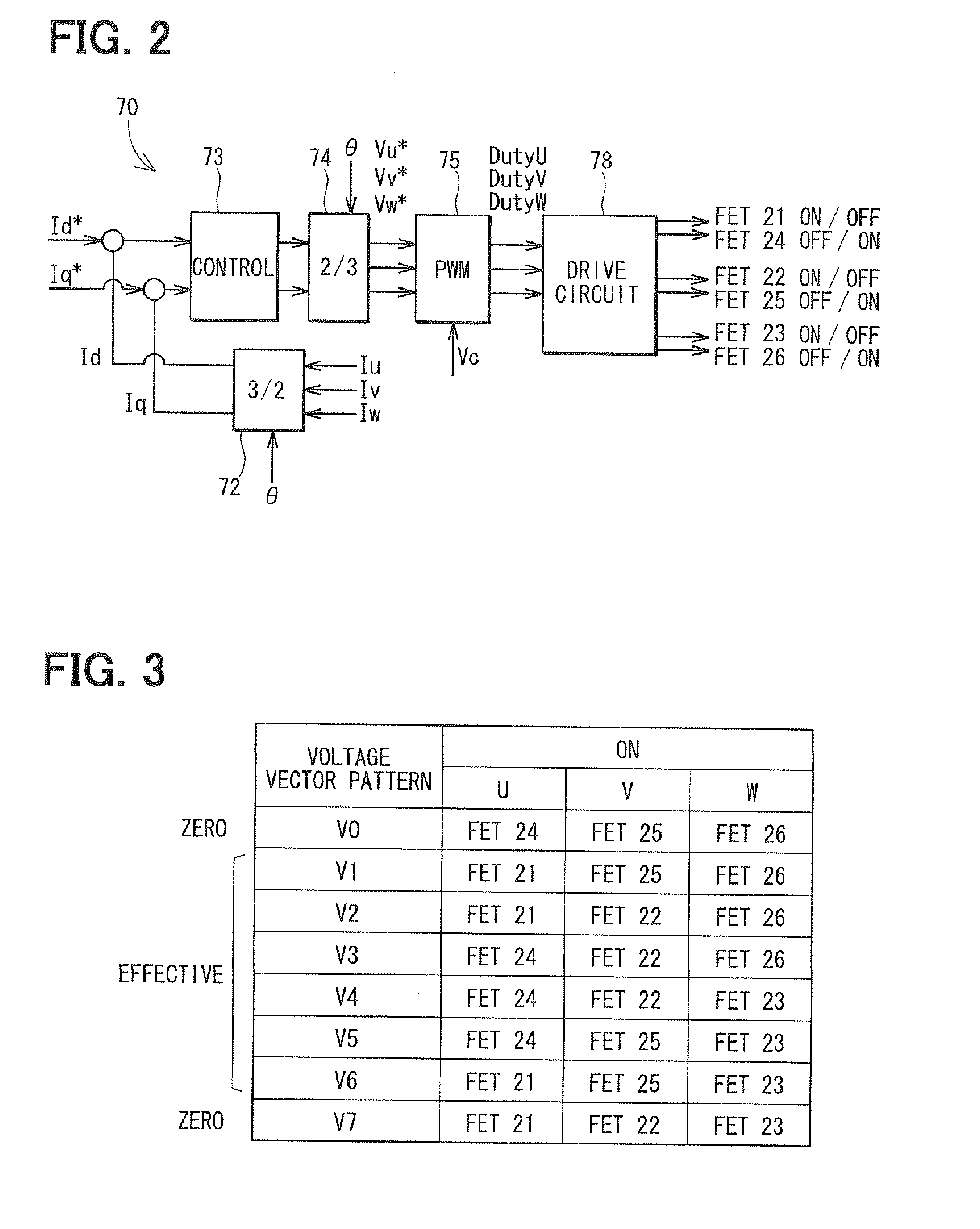

Control apparatus for multi-phase rotary machine and electric power steering system

ActiveUS20110074333A1Smooth rideInhibition effectCommutation monitoringDC motor speed/torque controlBrake torqueElectric power steering

A control apparatus for a multi-phase rotary machine includes a control unit and a plurality of power supply systems including respective inverter units. When a short-circuiting failure occurs in one of the systems due to an ON-failure in any one of FETs in an inverter unit of the failure system, the control unit stops driving of the rotary machine by bringing all the FETs in the failure system into the OFF state. The control unit controls FETs of the non-failure system such that a brake torque generated in the failure system is cancelled or the influence of the brake torque exerted on the driving of the motor is reduced.

Owner:DENSO CORP

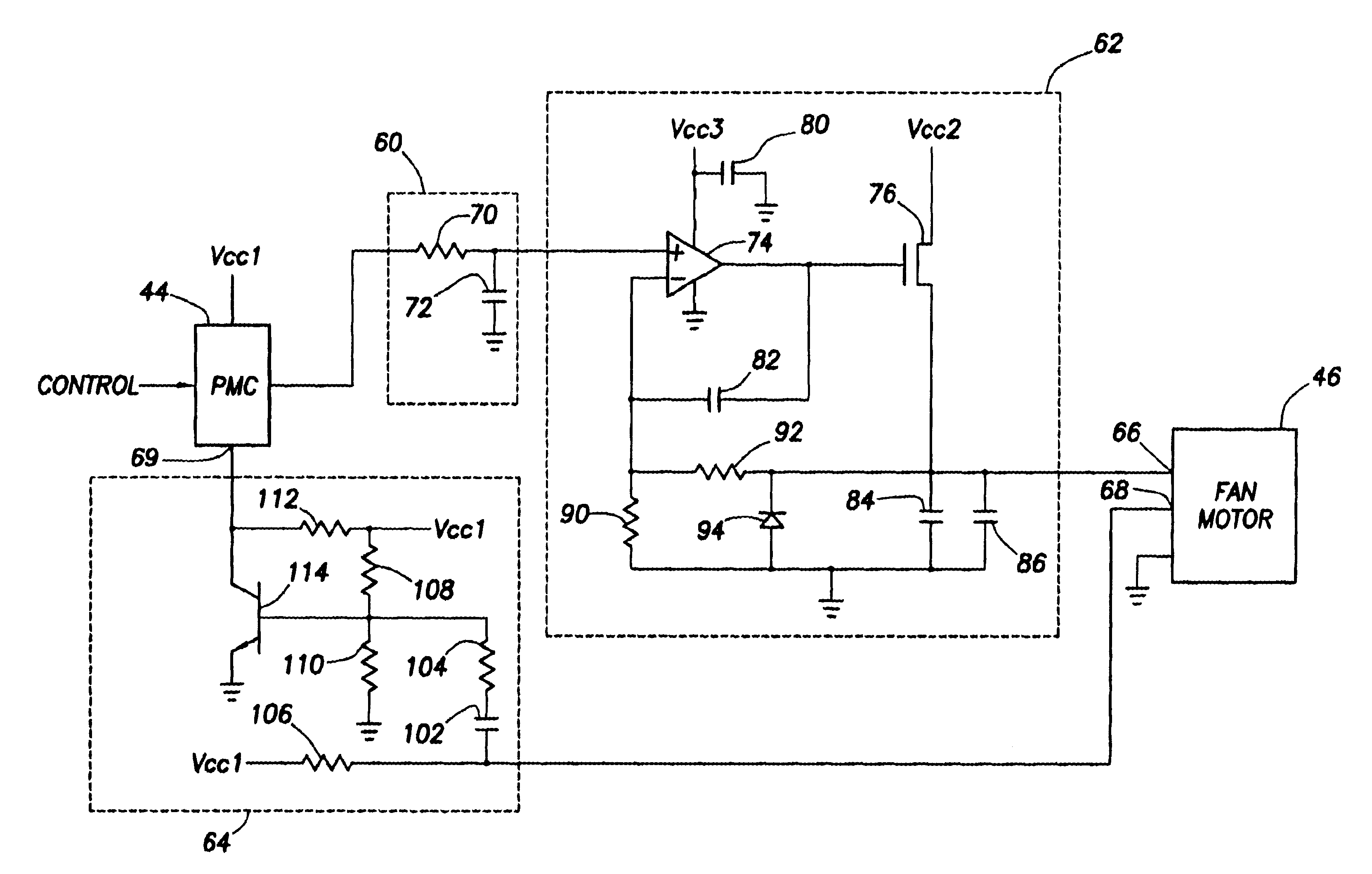

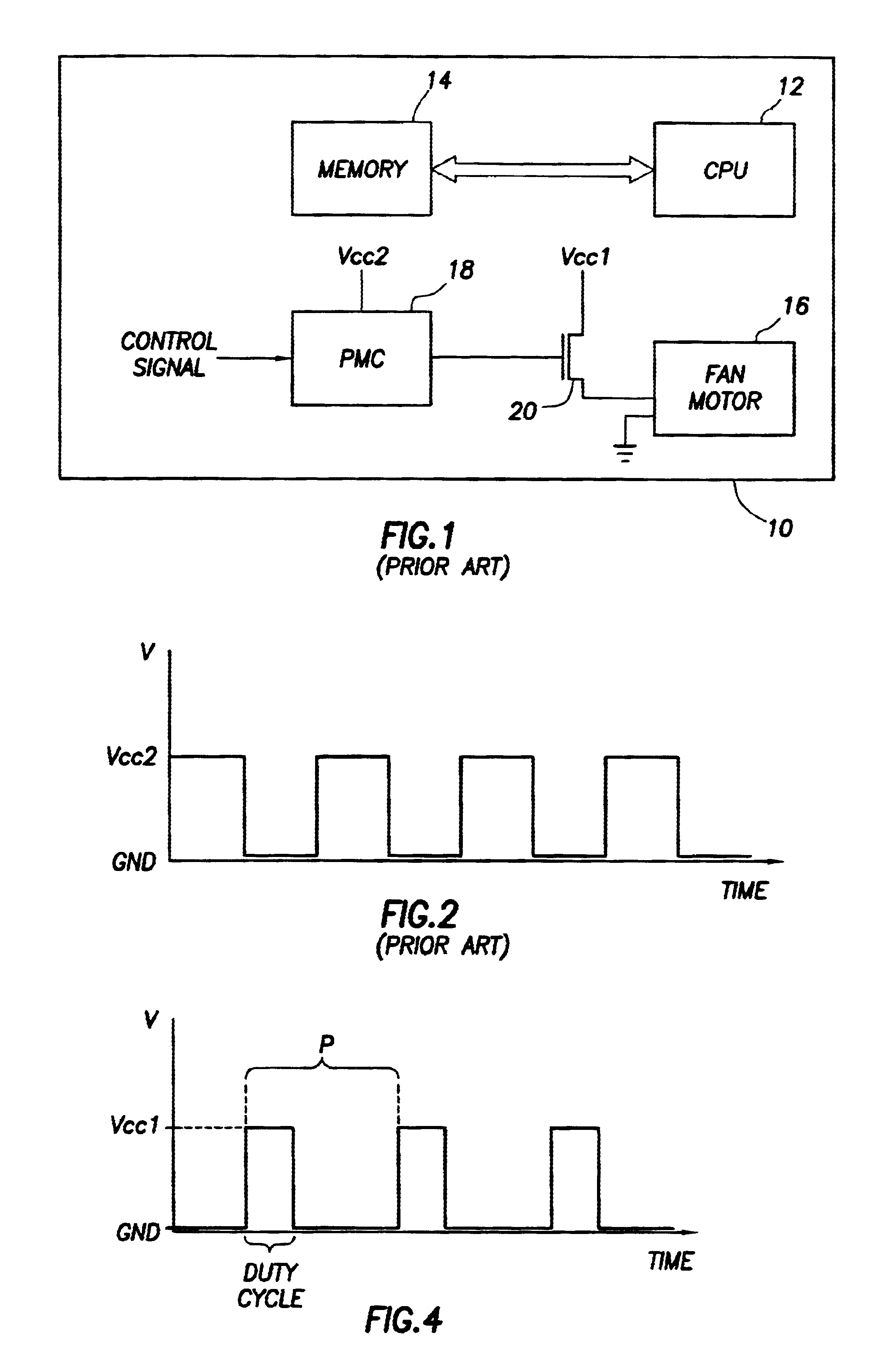

Fan speed controller with conditioned tachometer signal

The speed of a fan motor is controlled by varying a DC voltage to the fan motor. A series pass transistor is used to vary the DC voltage to the fan motor. A power management controller sets the fan motor speed by outputting pulses to a pulse-to-DC voltage converter that changes the pulses to a proportional DC control voltage for controlling the series pass transistor. A tachometer output amplifier circuit is used to remove DC components and amplify to useful logic levels a low level tachometer output signal from the fan motor. The amplified tachometer signal is used by the power management controller in controlling the rotational speed of the fan motor.

Owner:DELL PROD LP

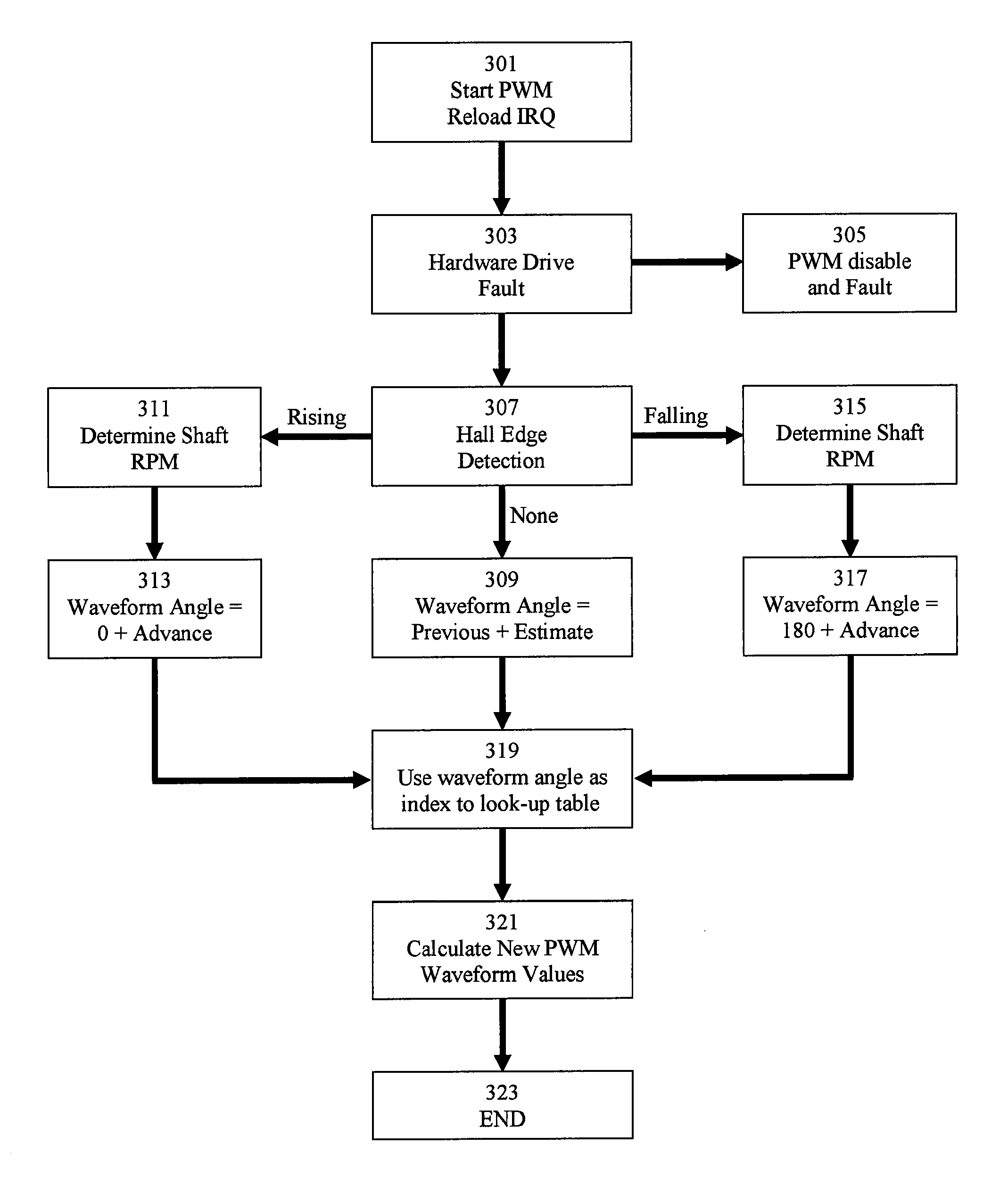

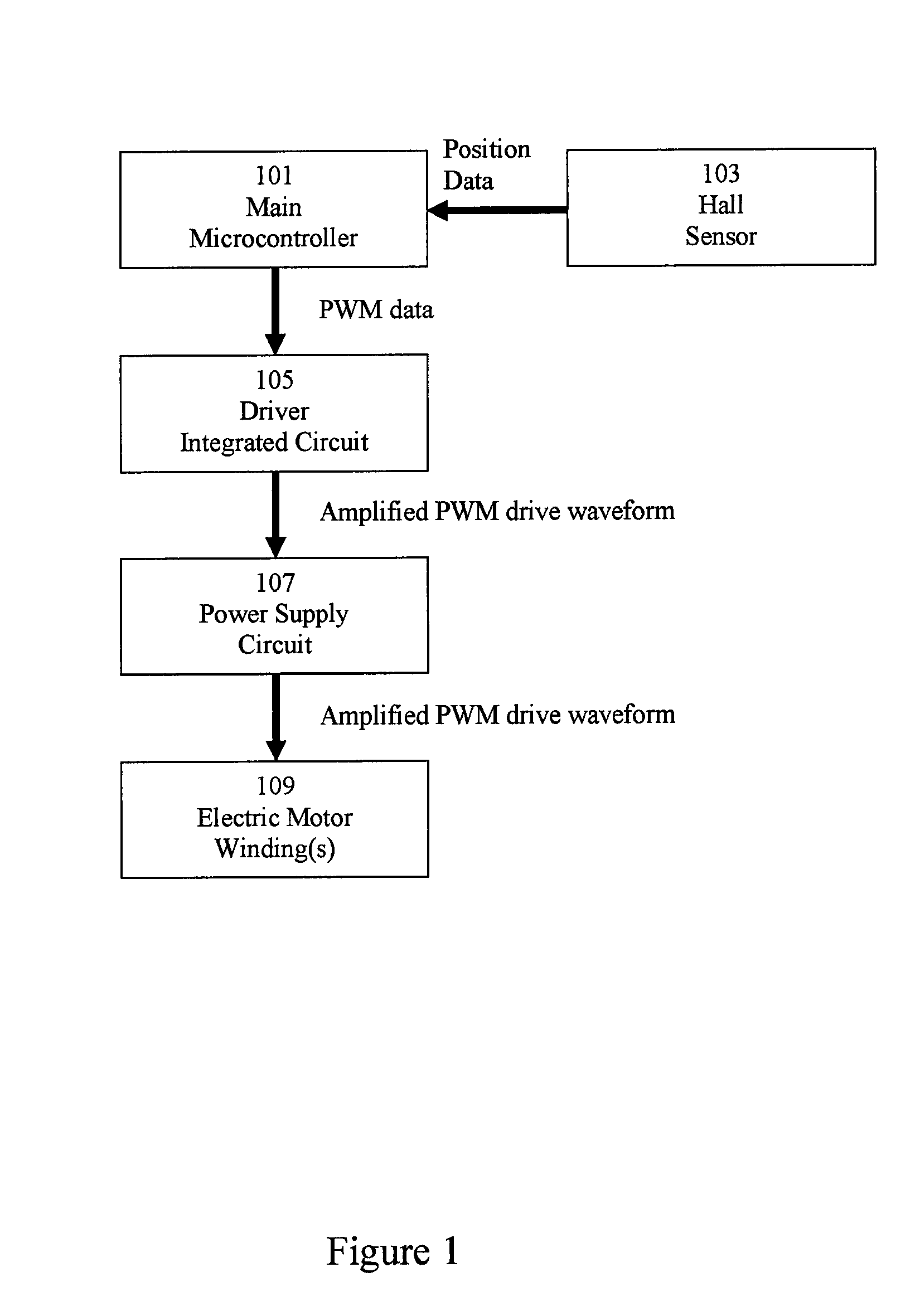

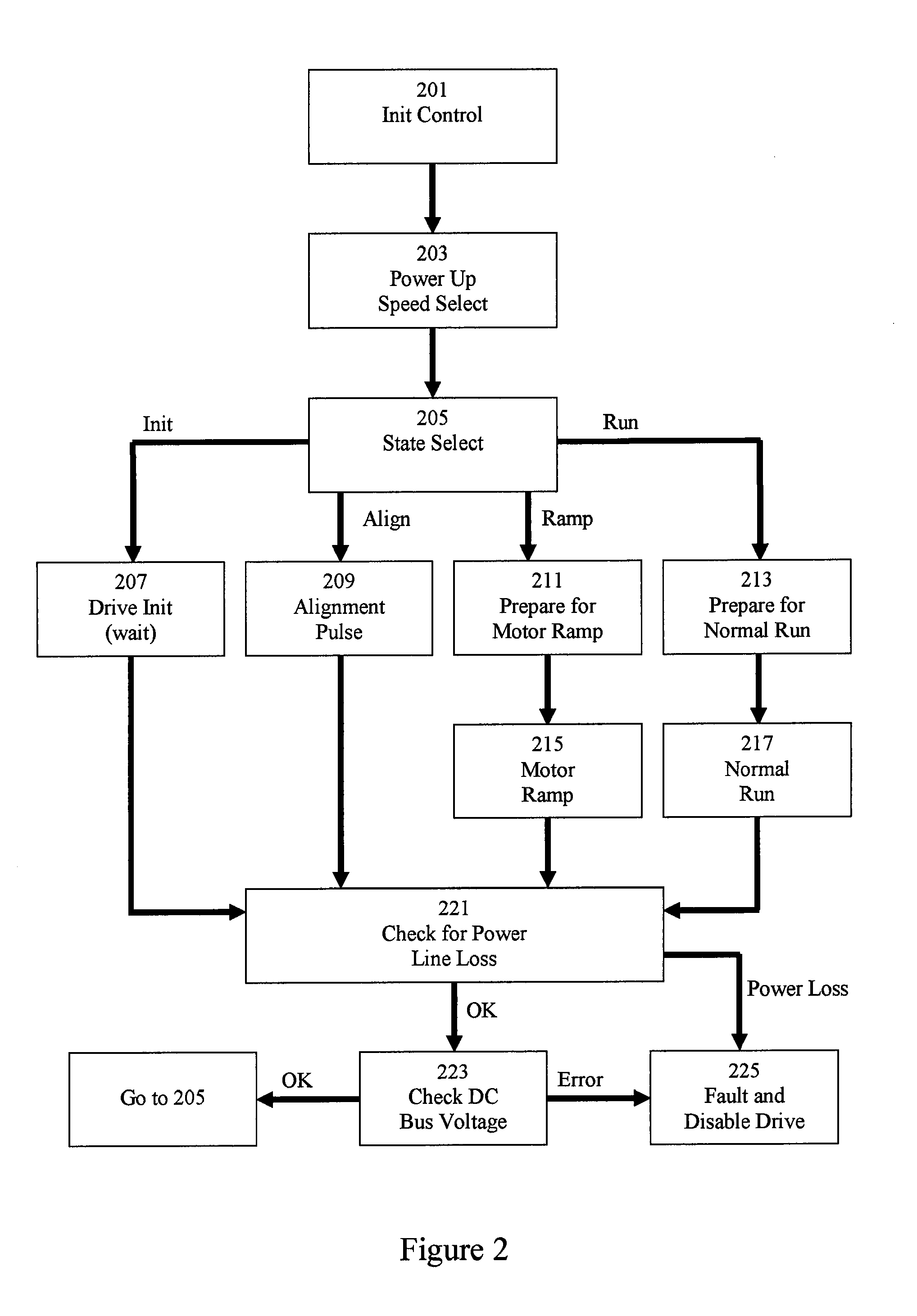

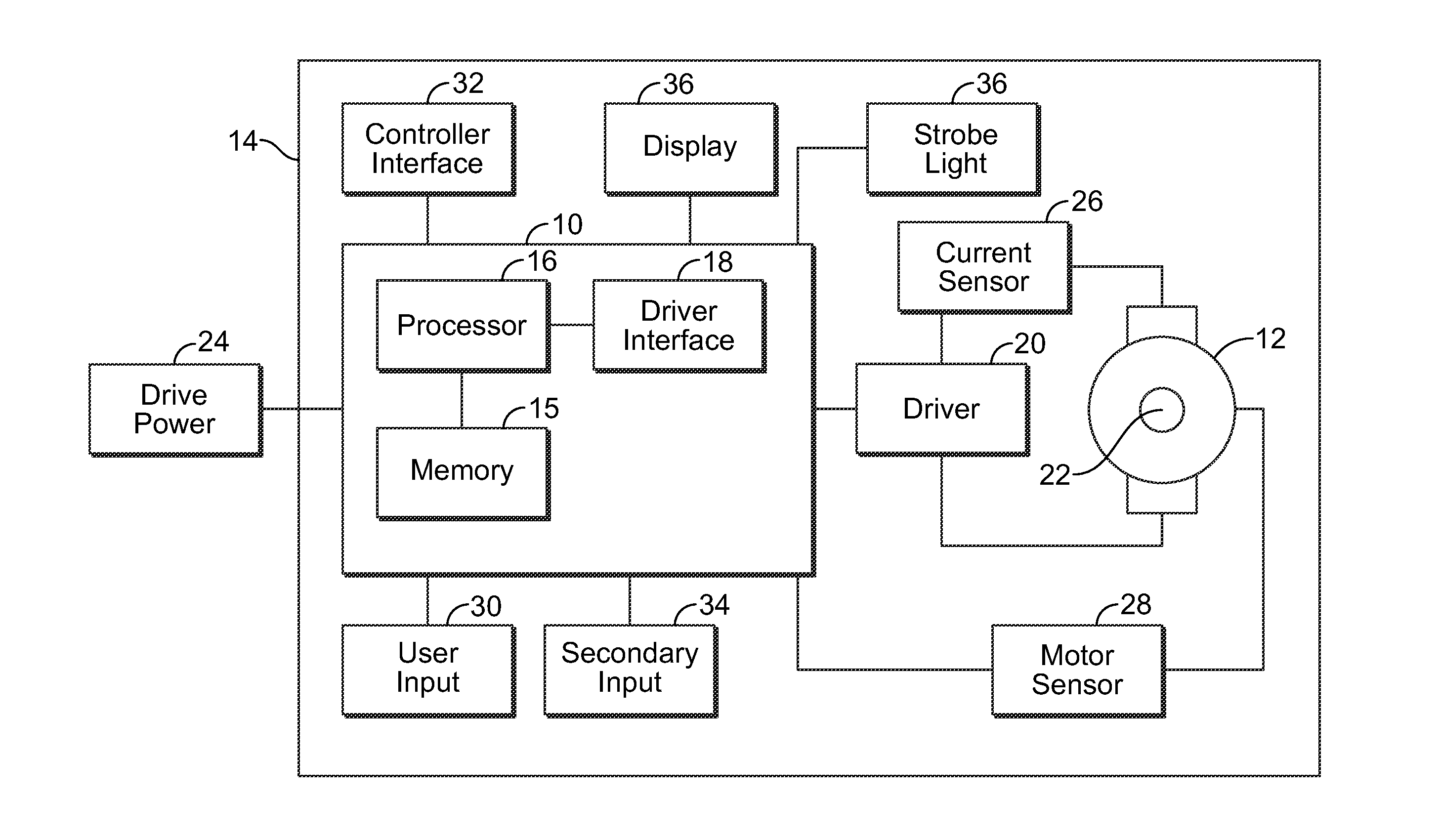

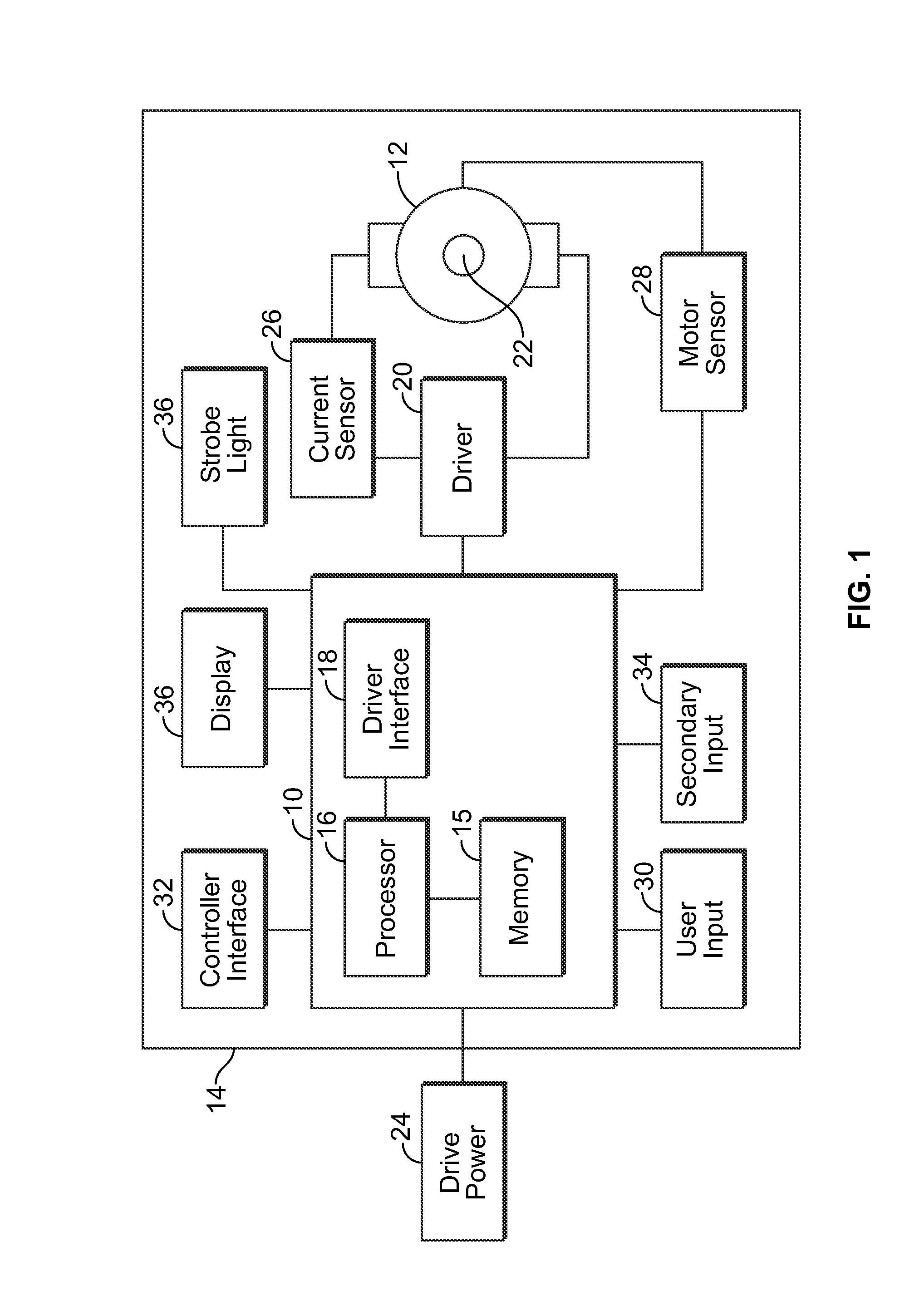

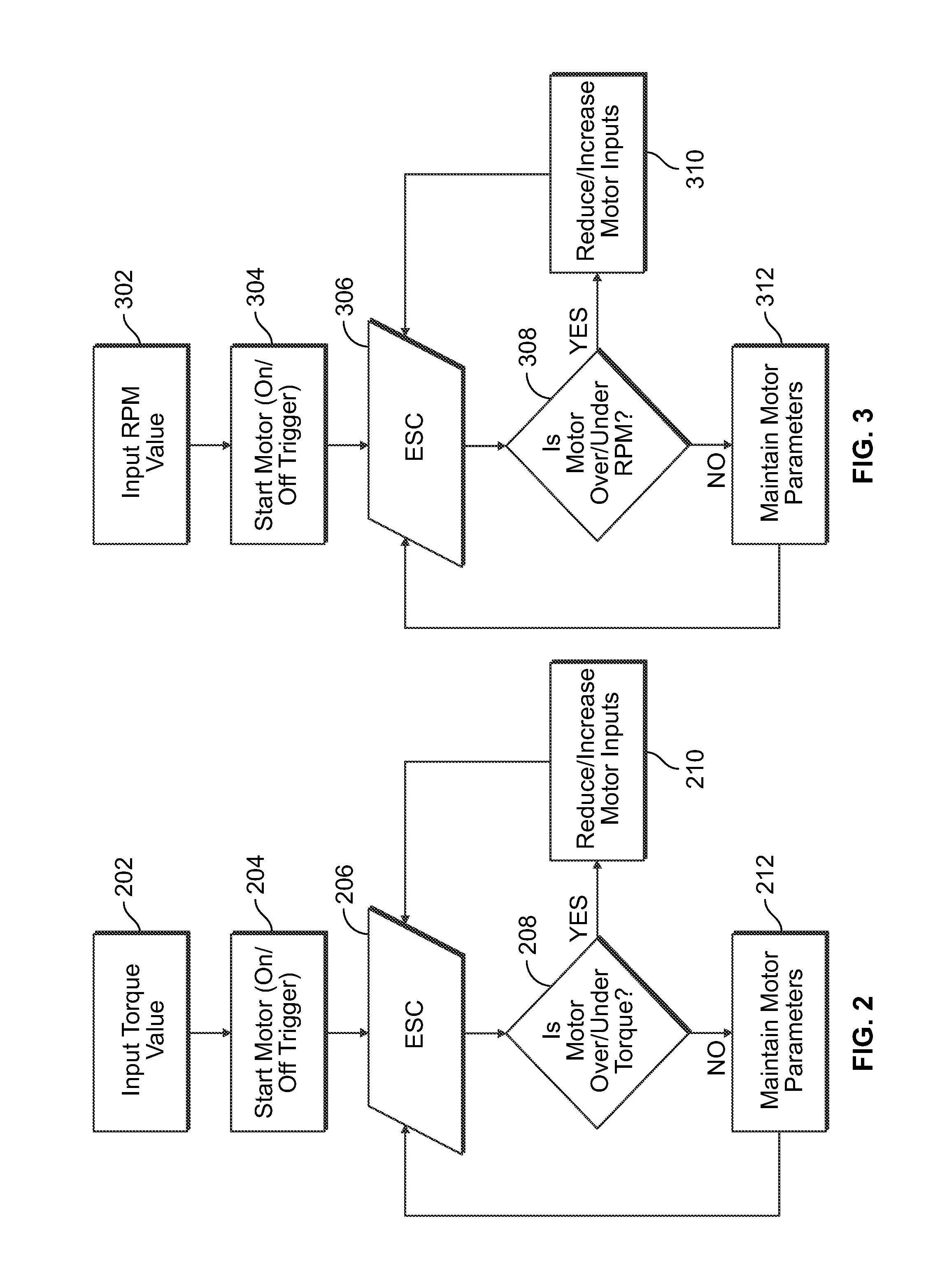

Programmable power tool with brushless DC motor

ActiveUS20130187587A1High performance featuresAccurate stopMotor/generator/converter stoppersSynchronous motors startersEngineeringPower tool

A power tool that includes a brushless DC motor, one or more motor sensors, and a controller, such as, for example, an electronic speed control (ESC) circuit. The controller is adapted to provide instructions to control the operation of one or more parameters of the brushless DC motor. The controller is also adapted to receive feedback from one or more motor sensors that reflect whether the motor is attaining the one or more parameters. The controller may also be adapted to have a learning mode, in which feedback provided during use of the power tool is stored by the controller as a program so that the same operating parameters may be subsequently replicated by using the program to operate the tool. The controller may also use the feedback to adjust the operation of the motor so that the motor maintains one or more selected or programed operating parameters.

Owner:TRANSFORM SR BRANDS LLC

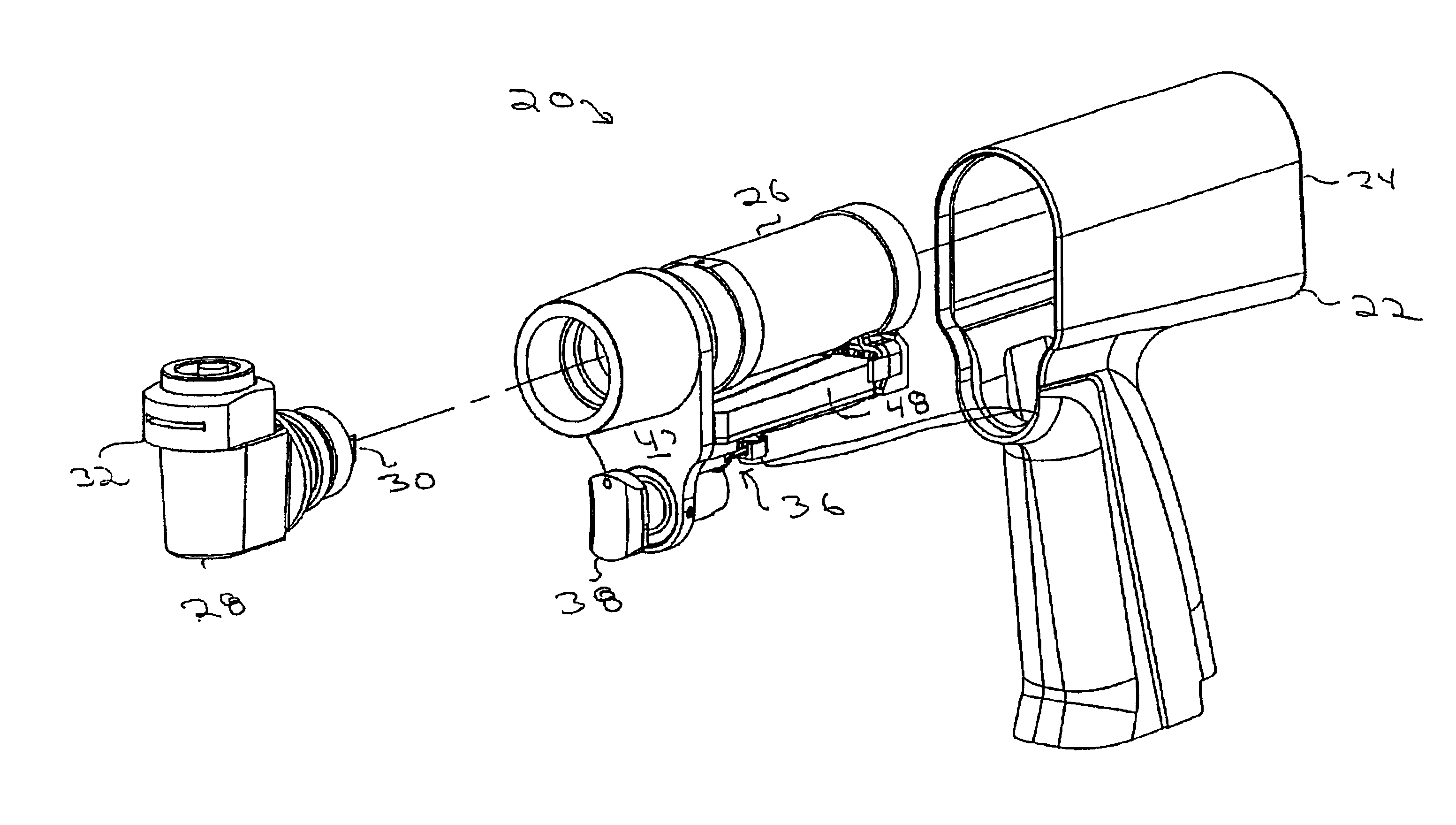

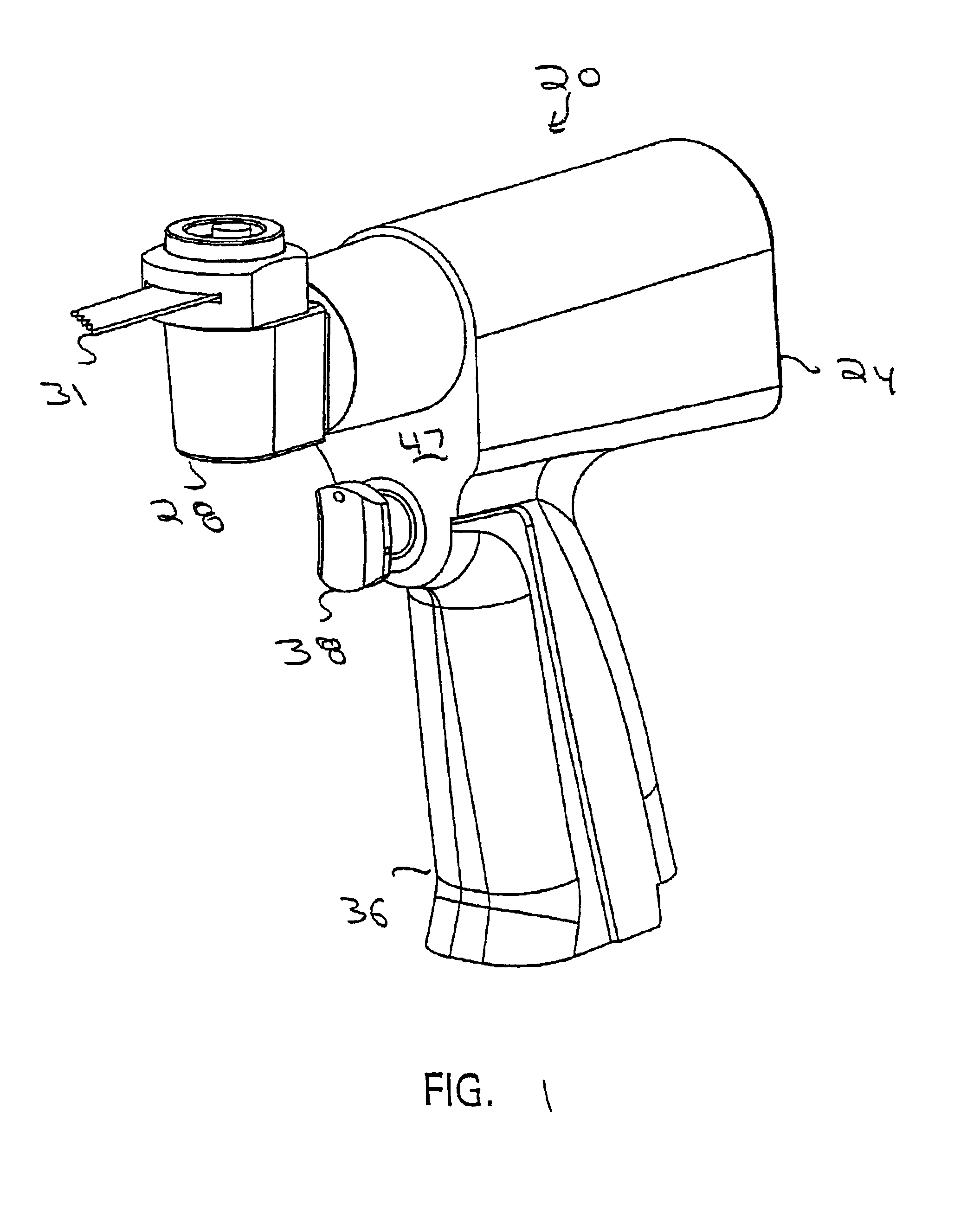

Cordless, powered surgical tool

InactiveUS6960894B2Reduce noiseAvoid difficult choicesSynchronous motors startersAC motor controlComputer moduleControl theory

A powered tool for performing surgical procedures. The tool includes a handpiece in which a power generating unit is housed. A control member is mounted to the handpiece. The control member is mounted to the handpiece so that the orientation of the control member can be selectively set relative to the point to which it is mounted to the handpiece and so it can move relative to a reference point on the handpiece. A control module monitors the orientation of the control member and its position relative to the reference point. Based on the control member orientation and position, the control module generates signals to regulate the operation of the power generating unit. When the power generating unit is a motor, the control module generates signals to ensure that the maximum speed at which the motor can be driven is less than the no load speed.

Owner:STRYKER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com