Patents

Literature

1103 results about "Tachometer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tachometer (revolution-counter, tach, rev-counter, RPM gauge) is an instrument measuring the rotation speed of a shaft or disk, as in a motor or other machine. The device usually displays the revolutions per minute (RPM) on a calibrated analogue dial, but digital displays are increasingly common. The word comes from Greek ταχος (tachos "speed") and metron ("measure"). Essentially the words tachometer and speedometer have identical meaning: a device that measures speed. It is by arbitrary convention that in the automotive world one is used for engine and the other for vehicle speed. In formal engineering nomenclature, more precise terms are used to distinguish the two.

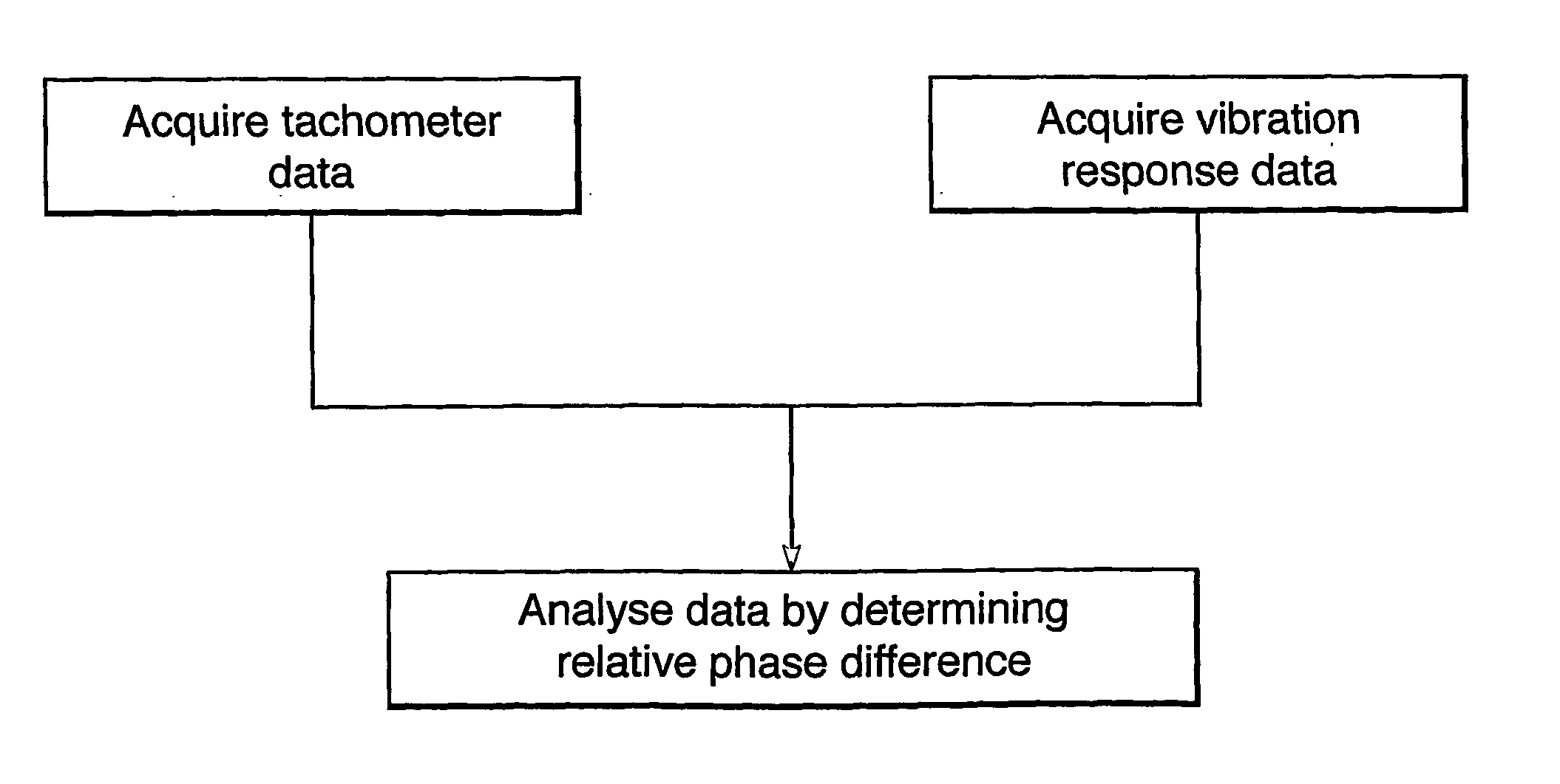

Vehicle data recorder

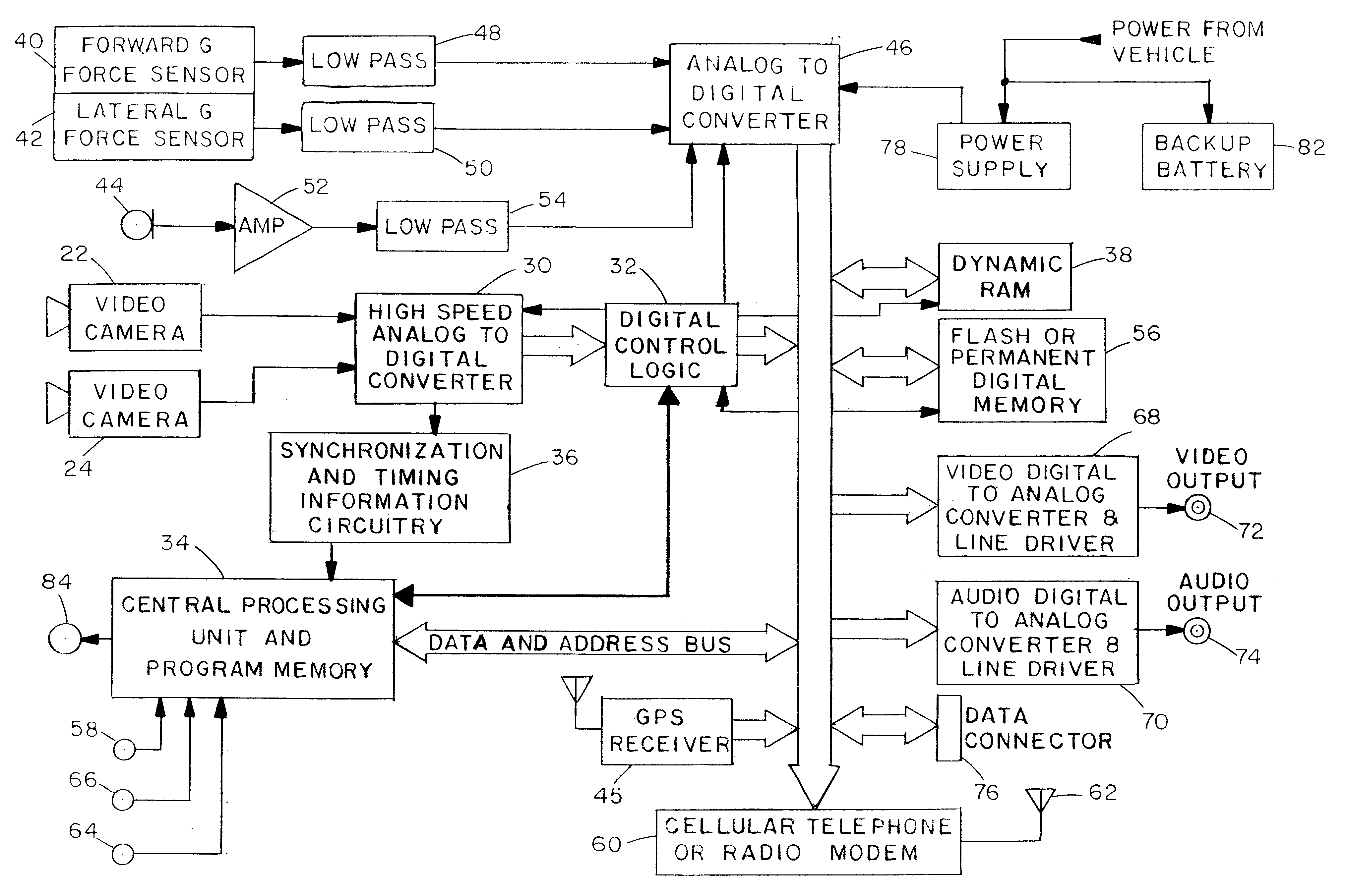

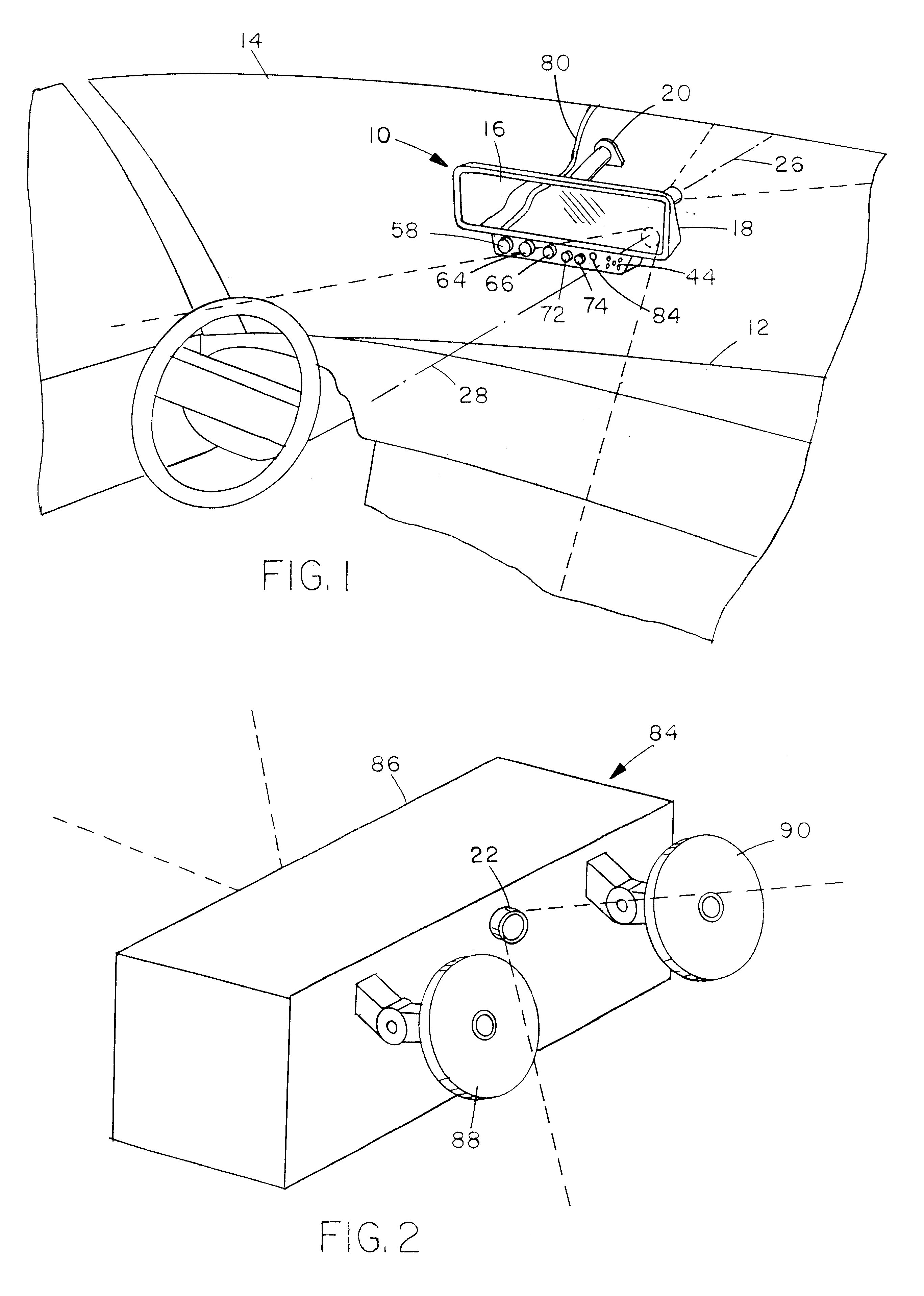

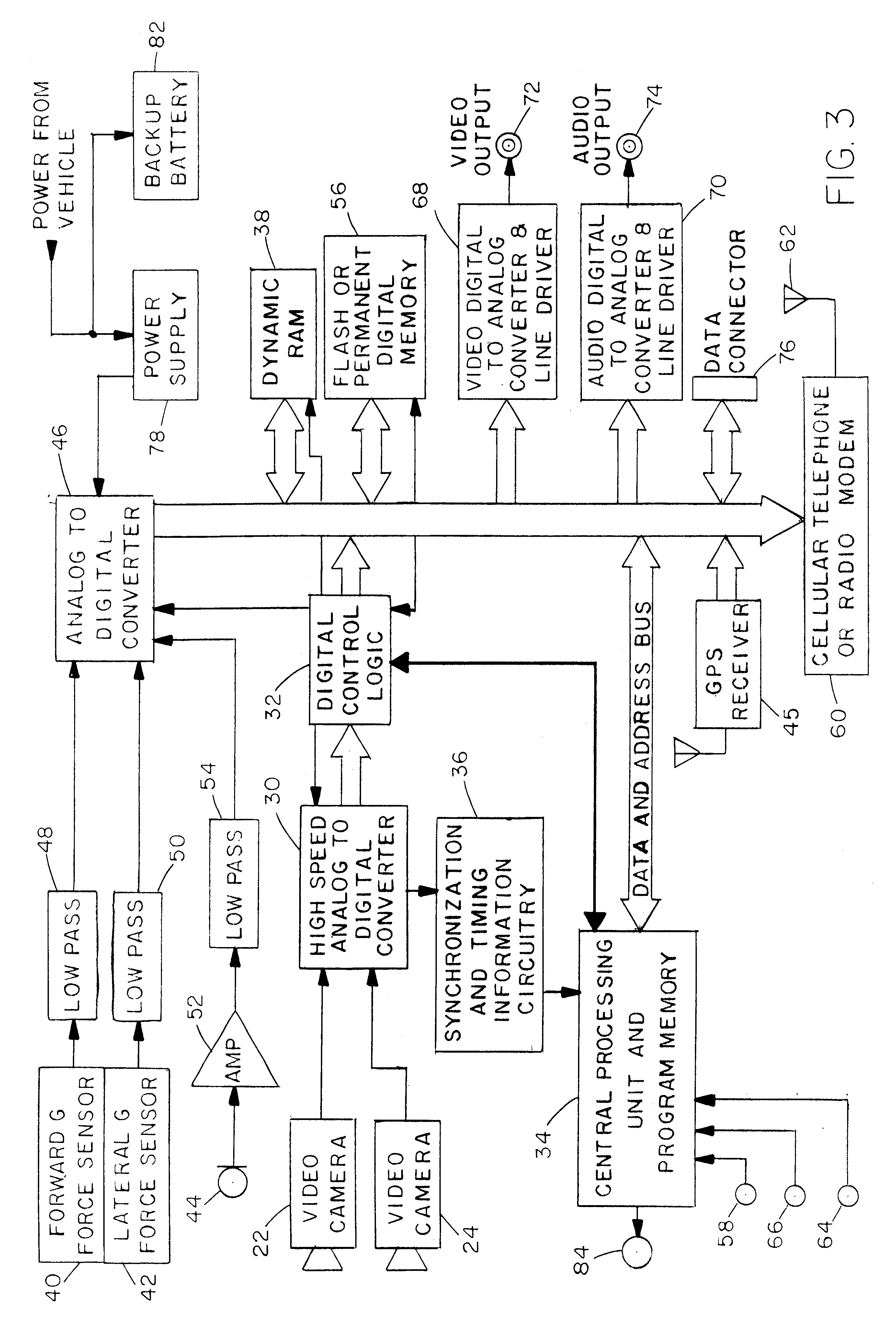

InactiveUS6389340B1Vehicle testingRegistering/indicating working of vehiclesAccelerometerDigital storage

A self-contained device for capturing video imagery in response to a triggering event may include a mirror and be mounted to a vehicle windshield in place of a conventional rear-view mirror. The device includes a housing in which the electronics and related elements of the invention are contained. These elements include one or more data sensors, at least one of which is an image sensor,. Also included are a data sensor circuit and a capture circuit. The data sensor circuit responds to the triggering event, and may include data sensors coupled to vehicle systems such as a speedometer, tachometer, brake, turn signals or the like, or other data sensors such as an accelerometer or a vehicle position sensor. The triggering event may be, for example, a sudden change in acceleration indicative of an impending collision, or it may be a change in the signal provided by any such data sensor, including the image sensor. The capture circuit is coupled to the image sensor and captures a signal representing the video imagery by recording it in a digital memory, by transmitting it to a remote location, or by other suitable means. The capture circuit terminates capture of the signal in response to the data sensor circuit sensing a triggering event. The captured data thus describe circumstances leading up to the time of the triggering event. The data can be analyzed to help police, insurance or other investigative personnel understand those circumstances.

Owner:DRIVECAM

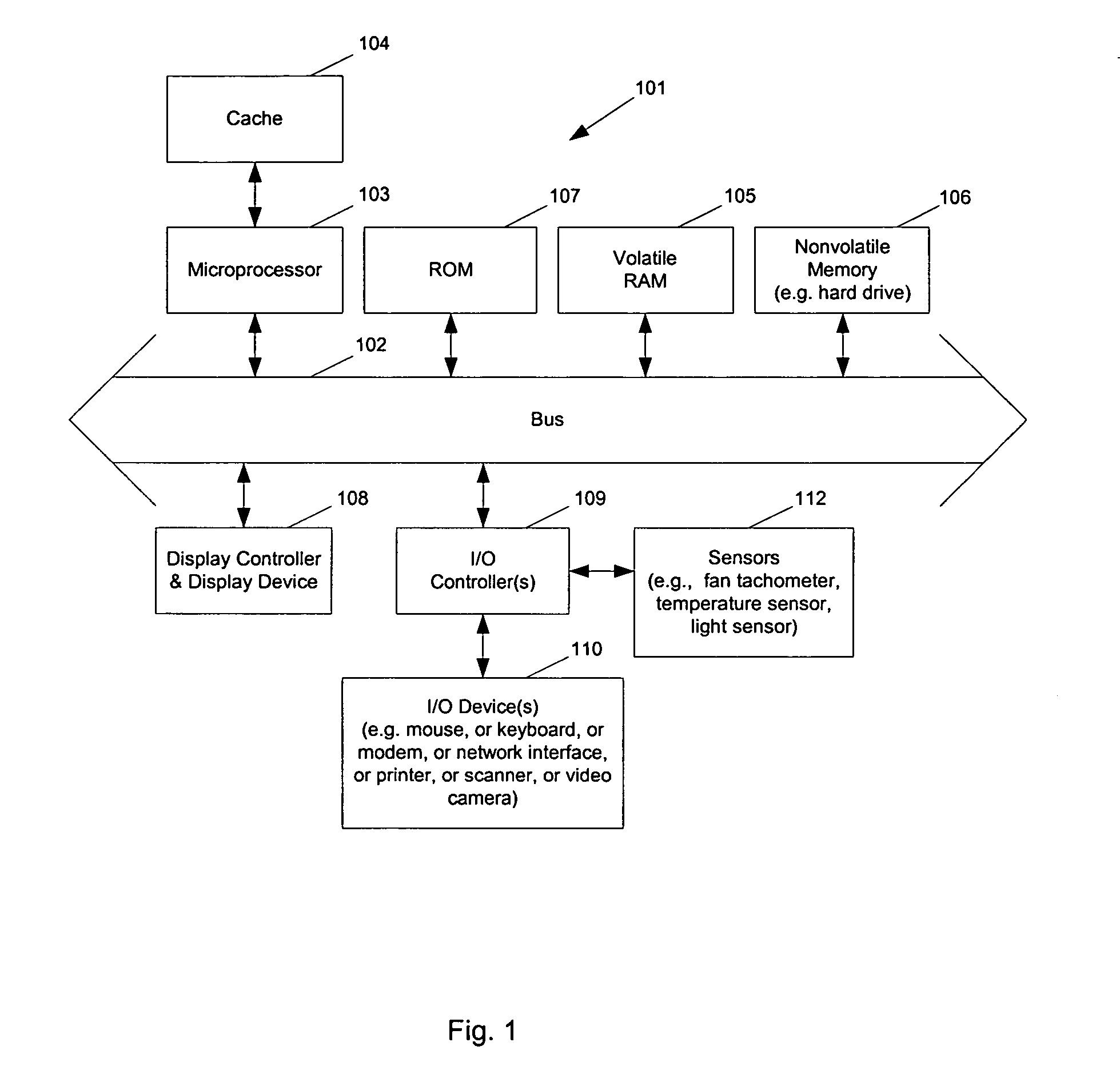

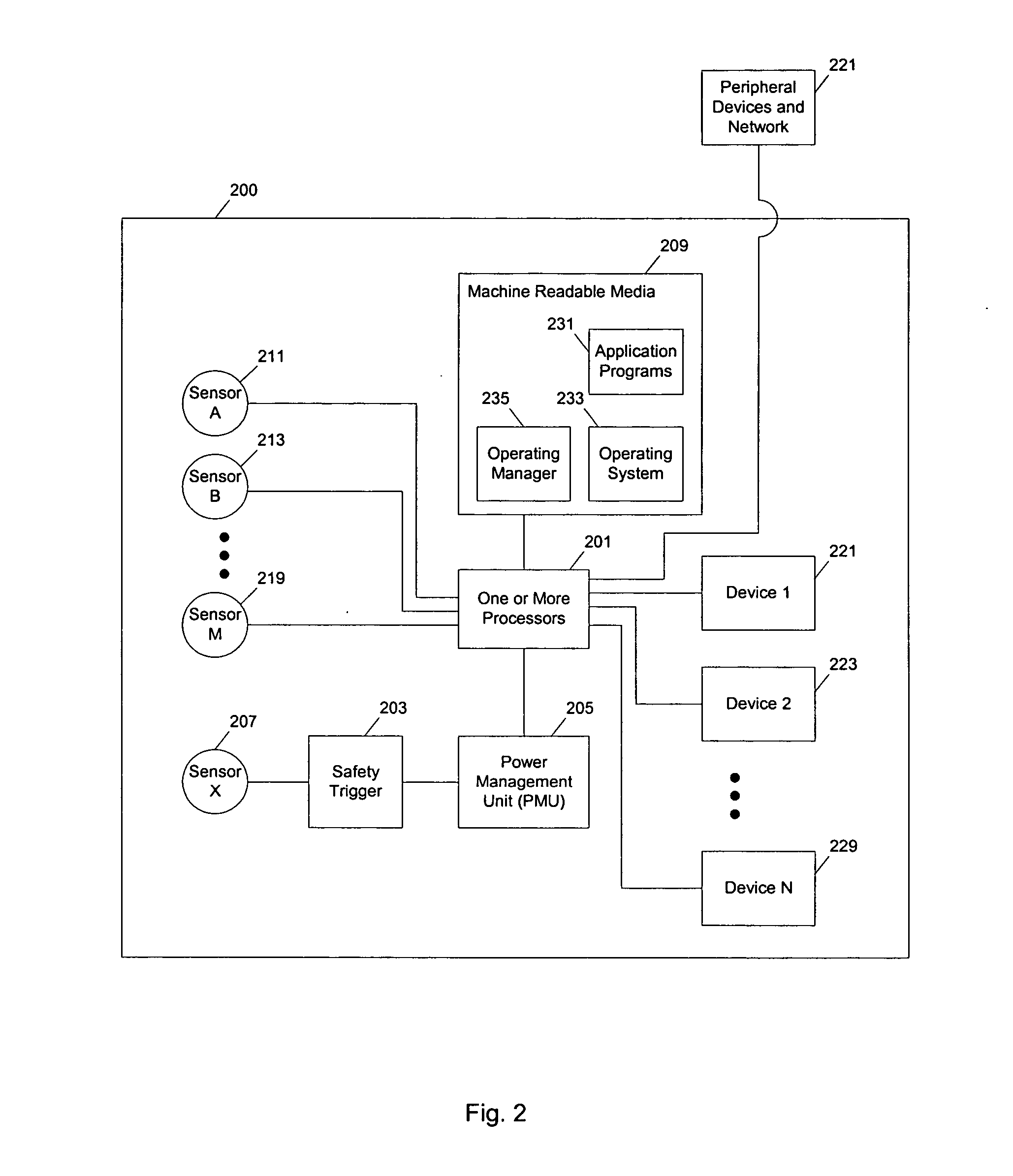

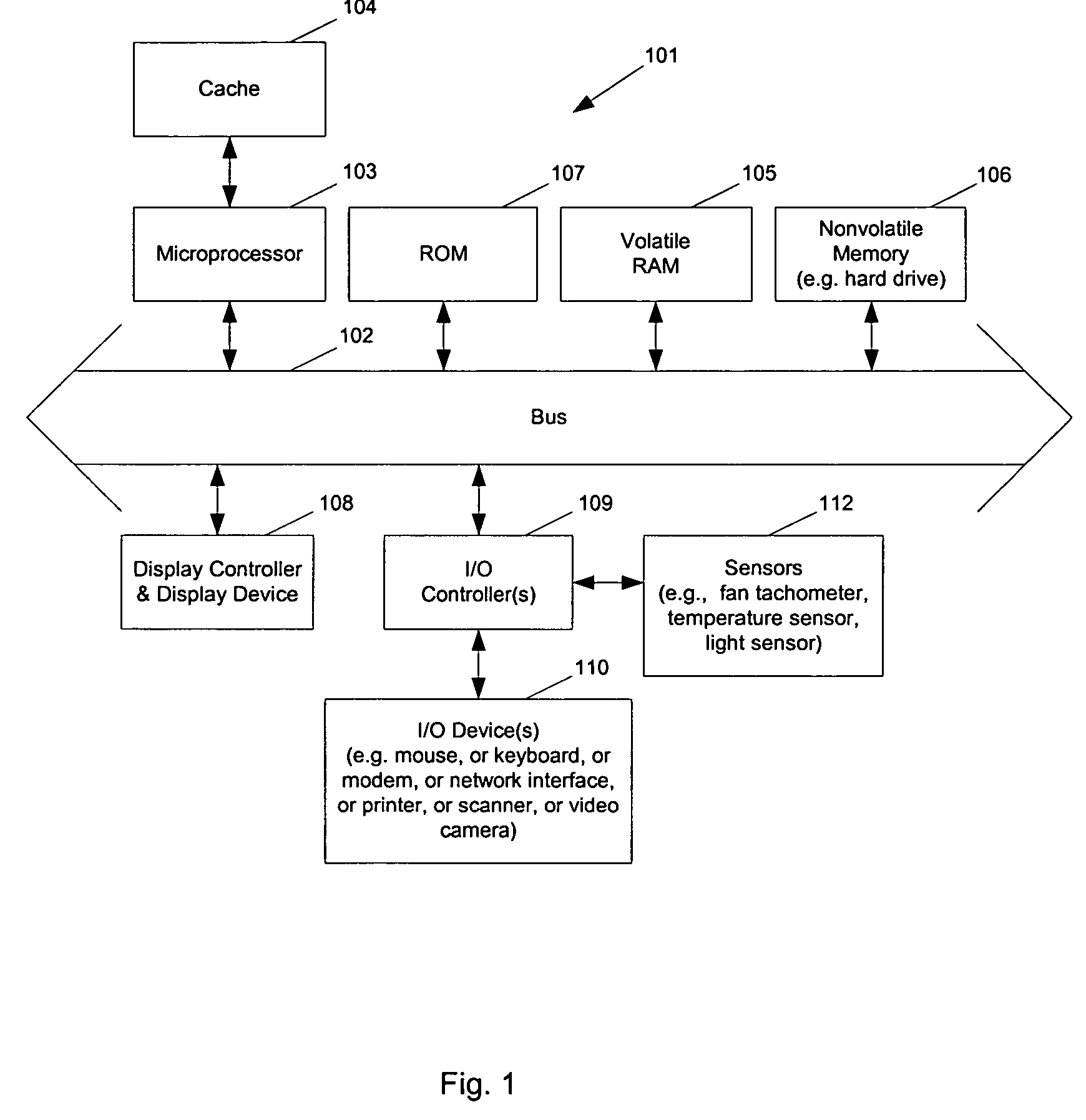

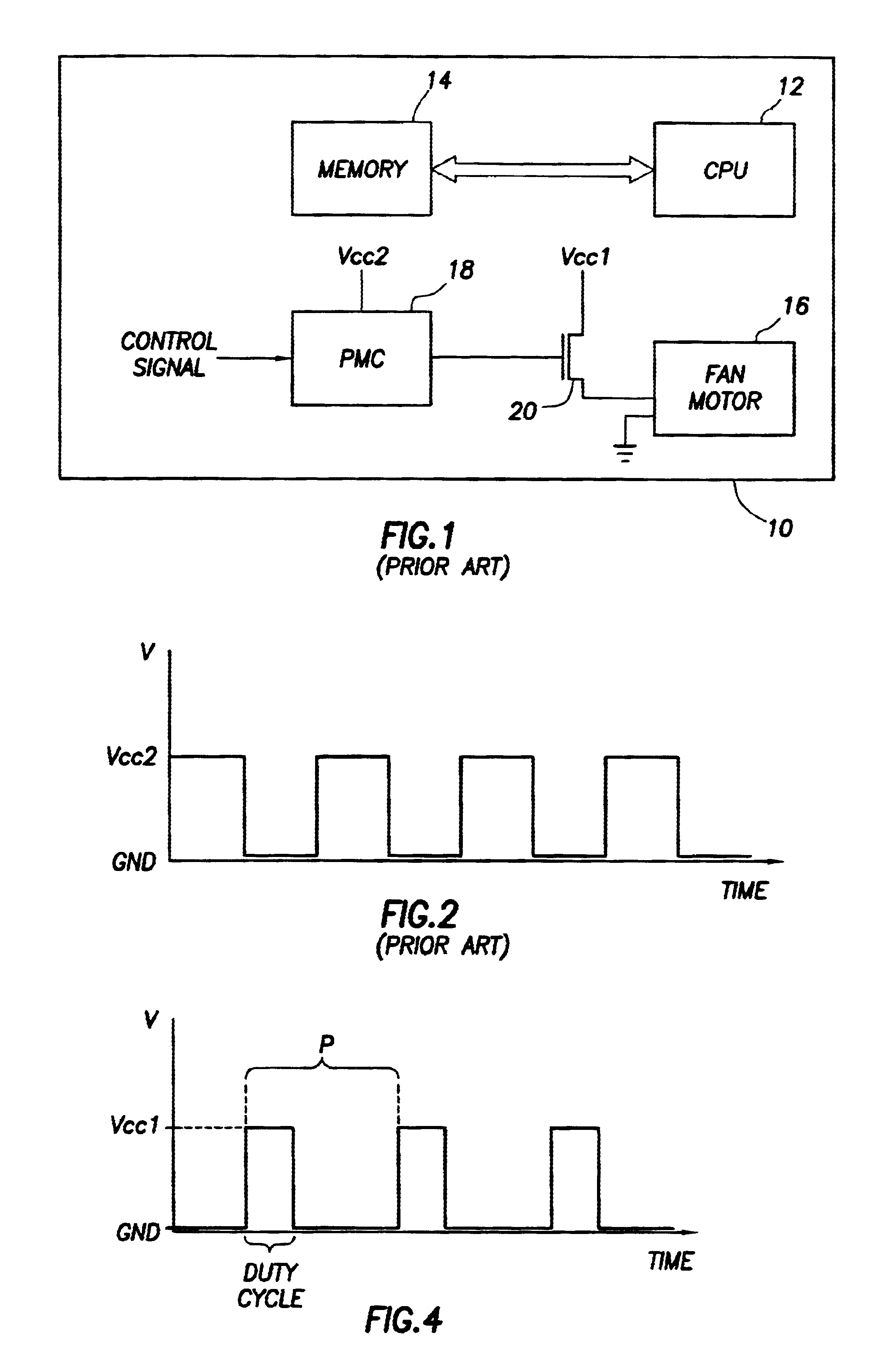

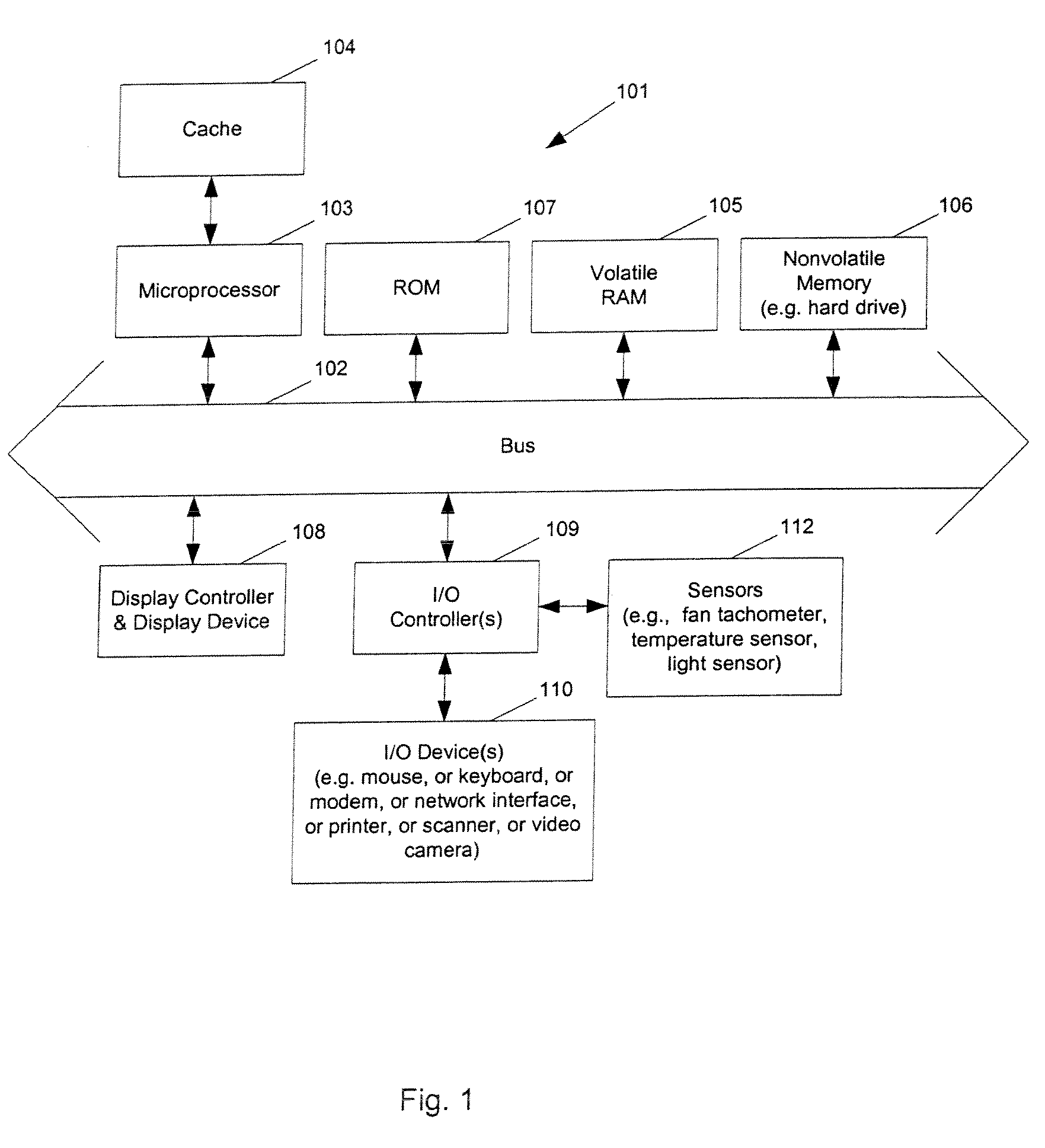

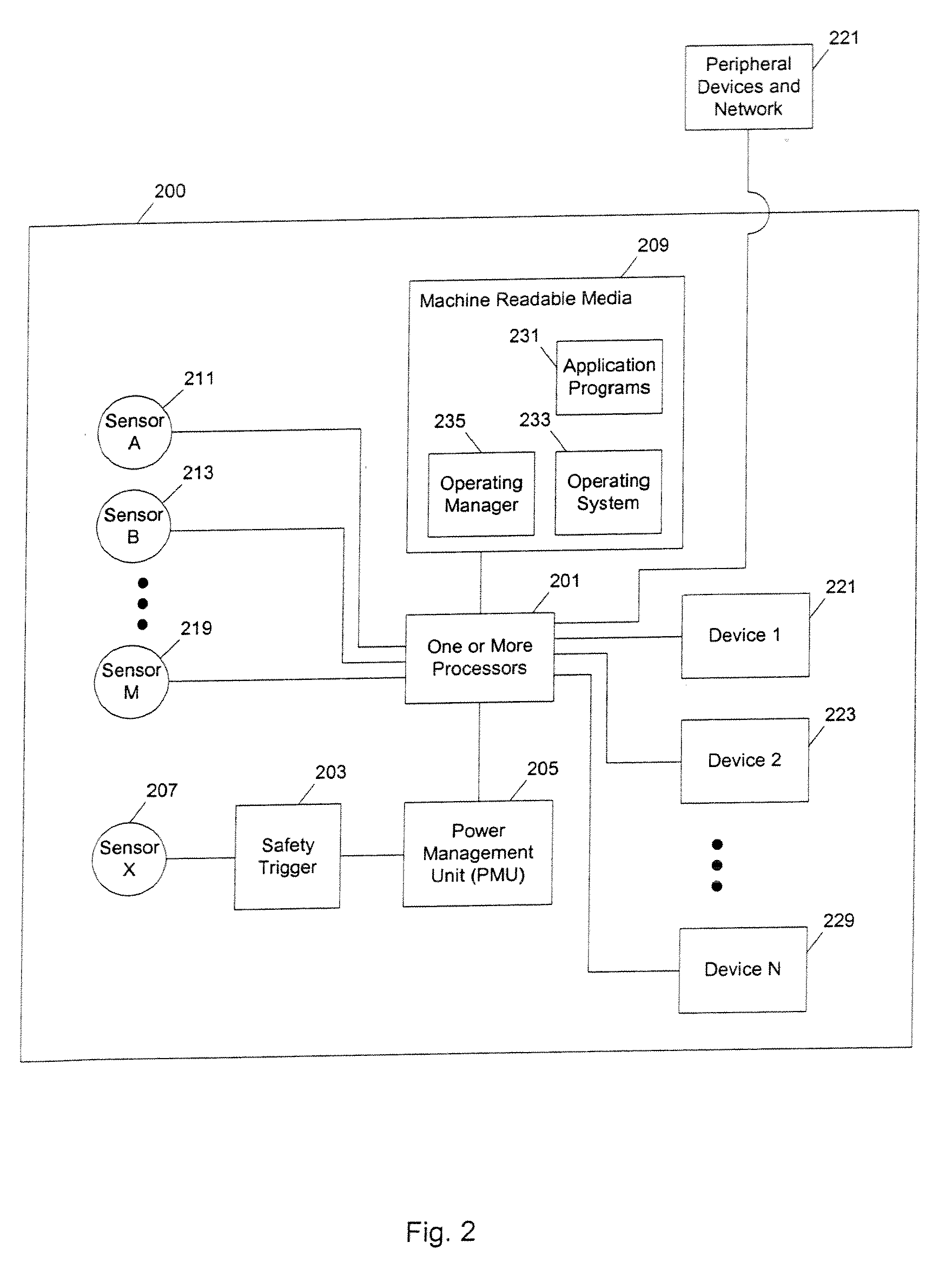

Methods and apparatuses for operating a data processing system

ActiveUS20050049729A1Balance performanceShorten speedMultiplex communicationVolume/mass flow measurementHeat sensitiveThermistor

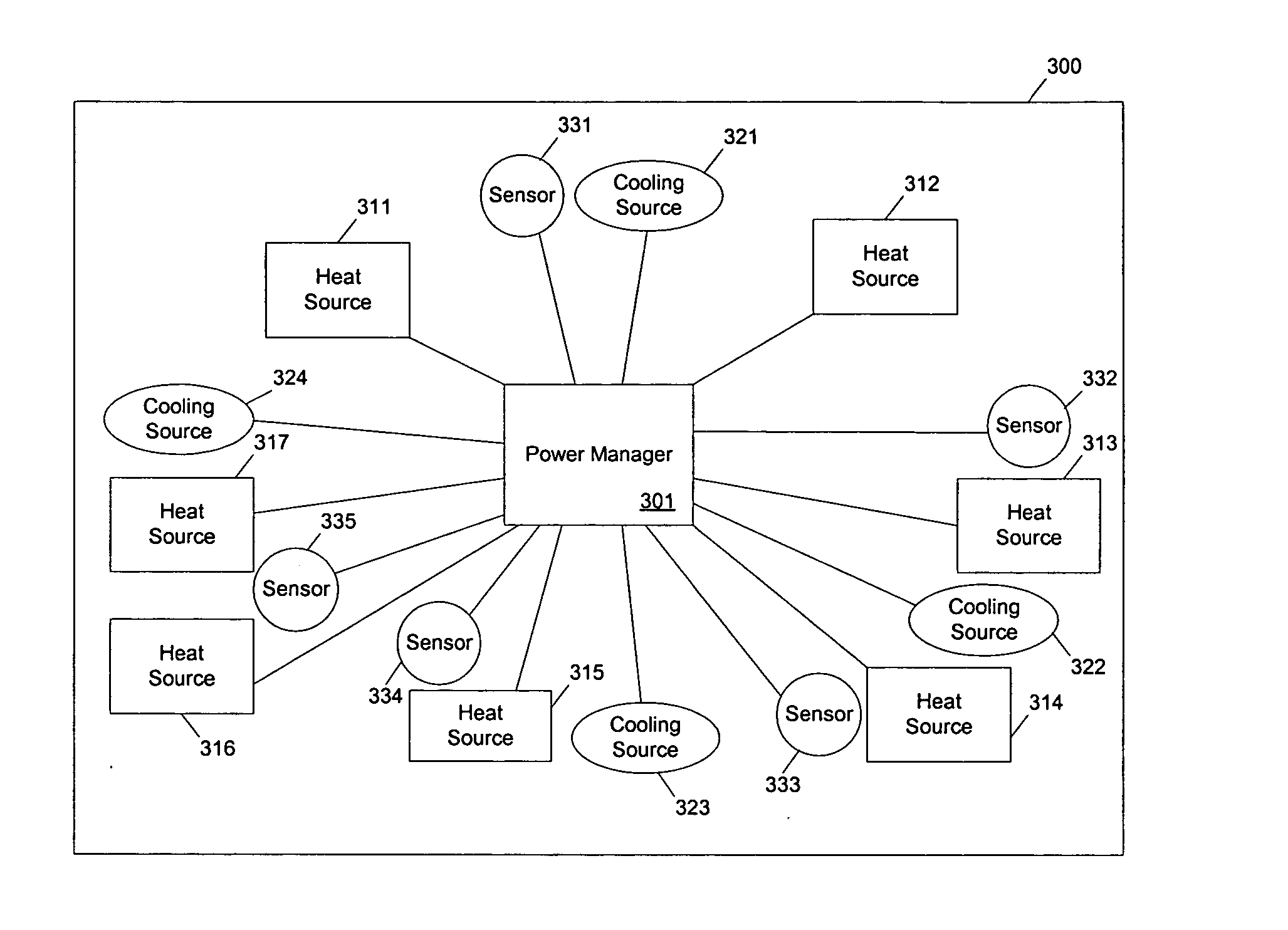

Methods and apparatuses to manage working states of a data processing system. At least one embodiment of the present invention includes a data processing system with one or more sensors (e.g., physical sensors such as tachometer and thermistors, and logical sensors such as CPU load) for fine grain control of one or more components (e.g., processor, fan, hard drive, optical drive) of the system for working conditions that balance various goals (e.g., user preferences, performance, power consumption, thermal constraints, acoustic noise). In one example, the clock frequency and core voltage for a processor are actively managed to balance performance and power consumption (heat generation) without a significant latency. In one example, the speed of a cooling fan is actively managed to balance cooling effort and noise (and / or power consumption).

Owner:APPLE INC

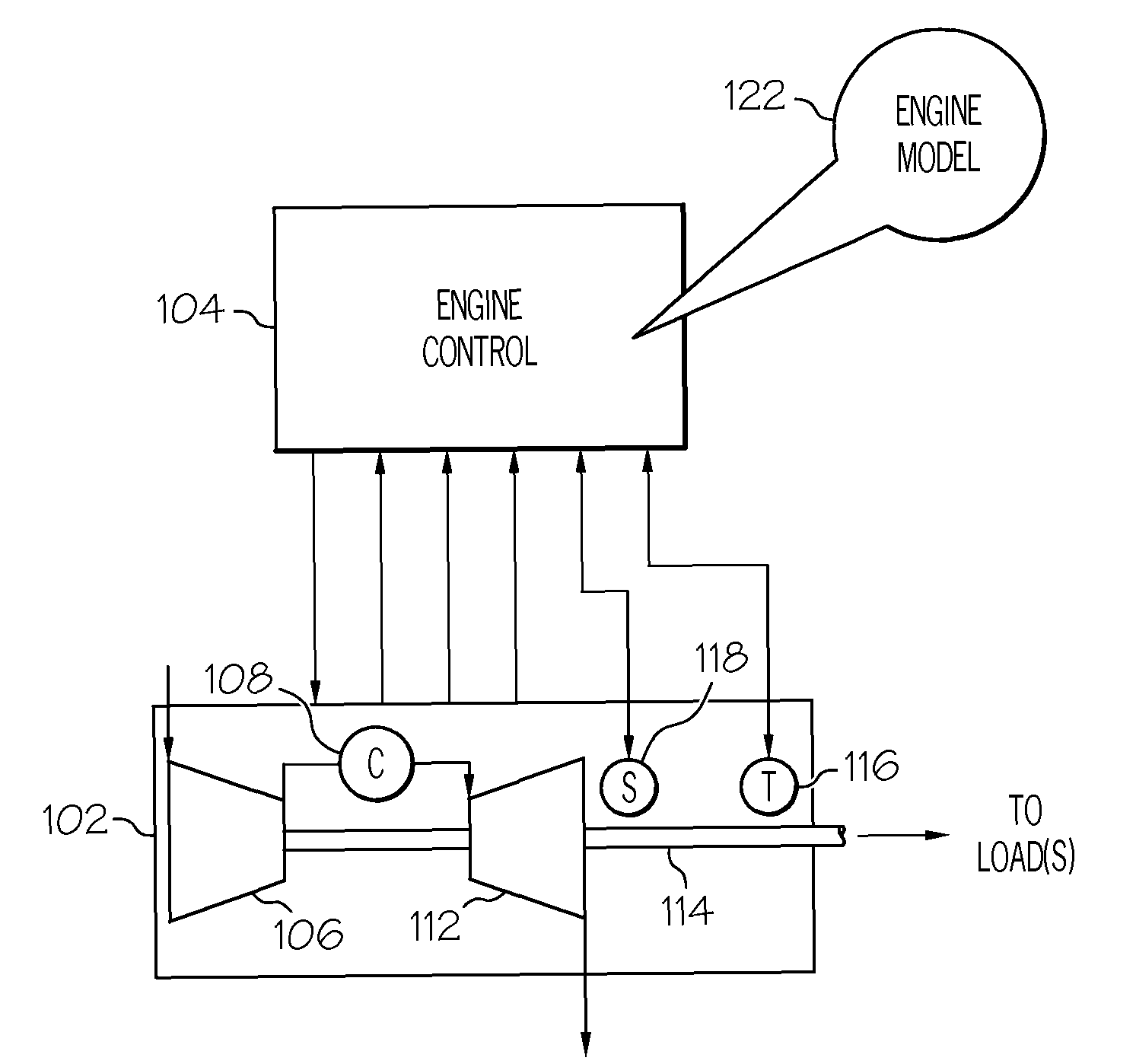

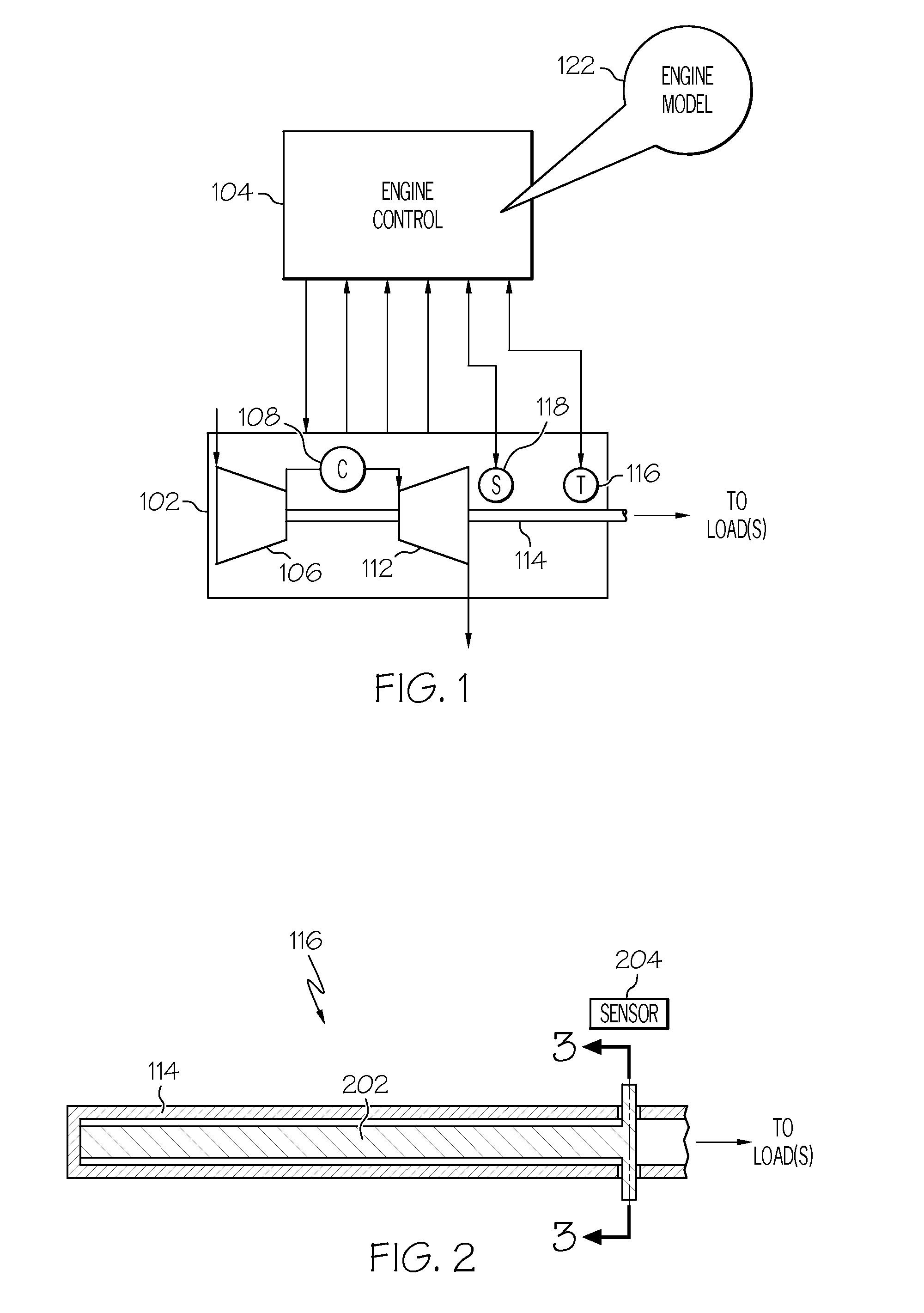

System and method for providing gas turbine engine output torque sensor validation and sensor backup using a speed sensor

Methods and apparatus are provided for verifying proper operation of a gas turbine engine output torque sensor using a speed sensor, and using the speed sensor as a backup torque sensor. Gas turbine engine output torque is sensed using a reference torque sensor, and gas turbine engine output shaft rotational speed is sensed. Gas turbine engine output torque is calculated from the sensed gas turbine engine output shaft rotational speed. The sensed gas turbine engine output torque is compared to the calculated gas turbine engine output torque to determine if the reference torque sensor is operating properly. The gas turbine engine is controlled at least partially based on the sensed gas turbine engine output torque if the reference torque sensor is determined to be operating properly, and is controlled at least partially based on the calculated output torque if the reference torque sensor is determined to be not operating properly.

Owner:HONEYWELL INT INC

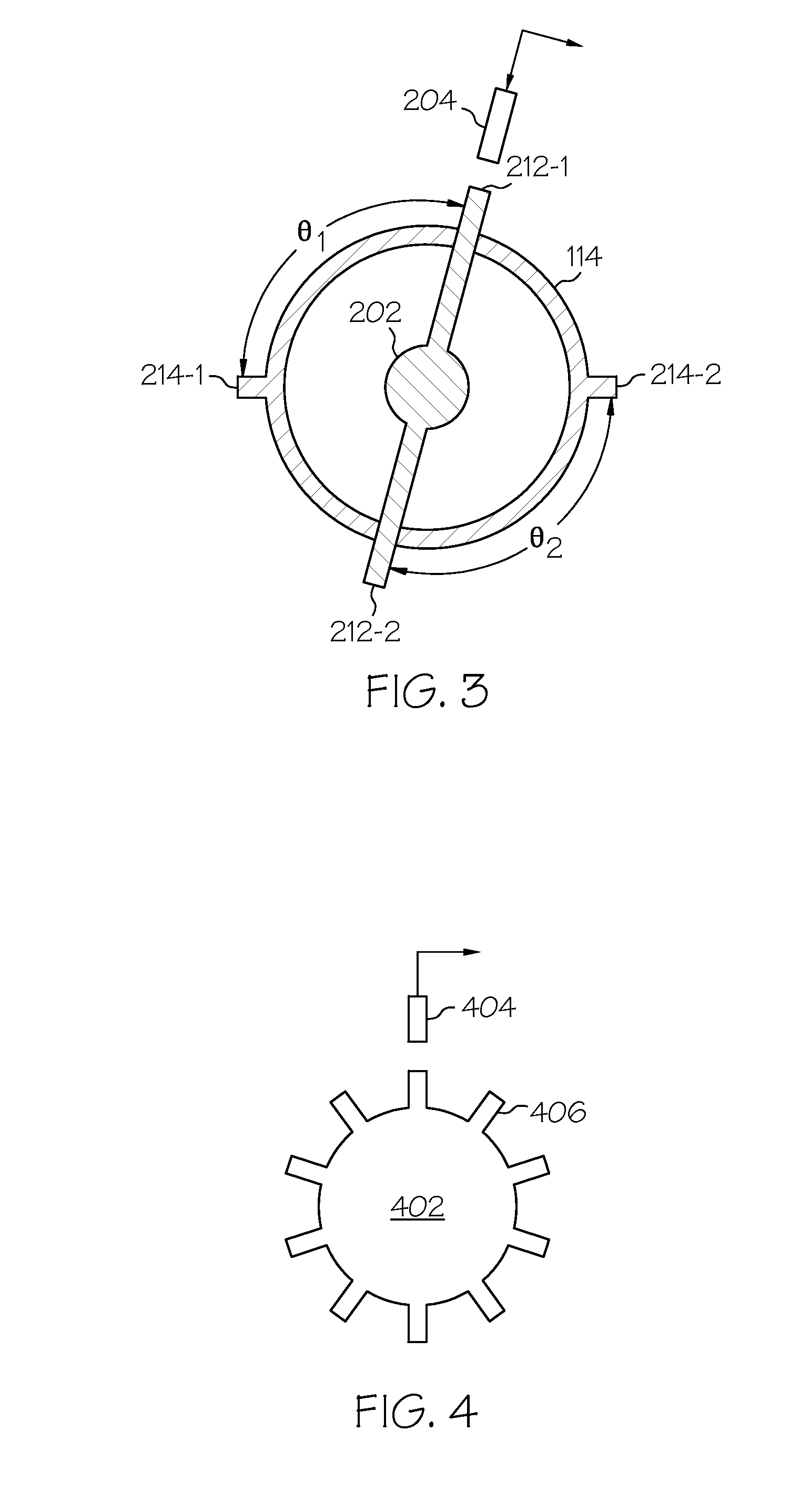

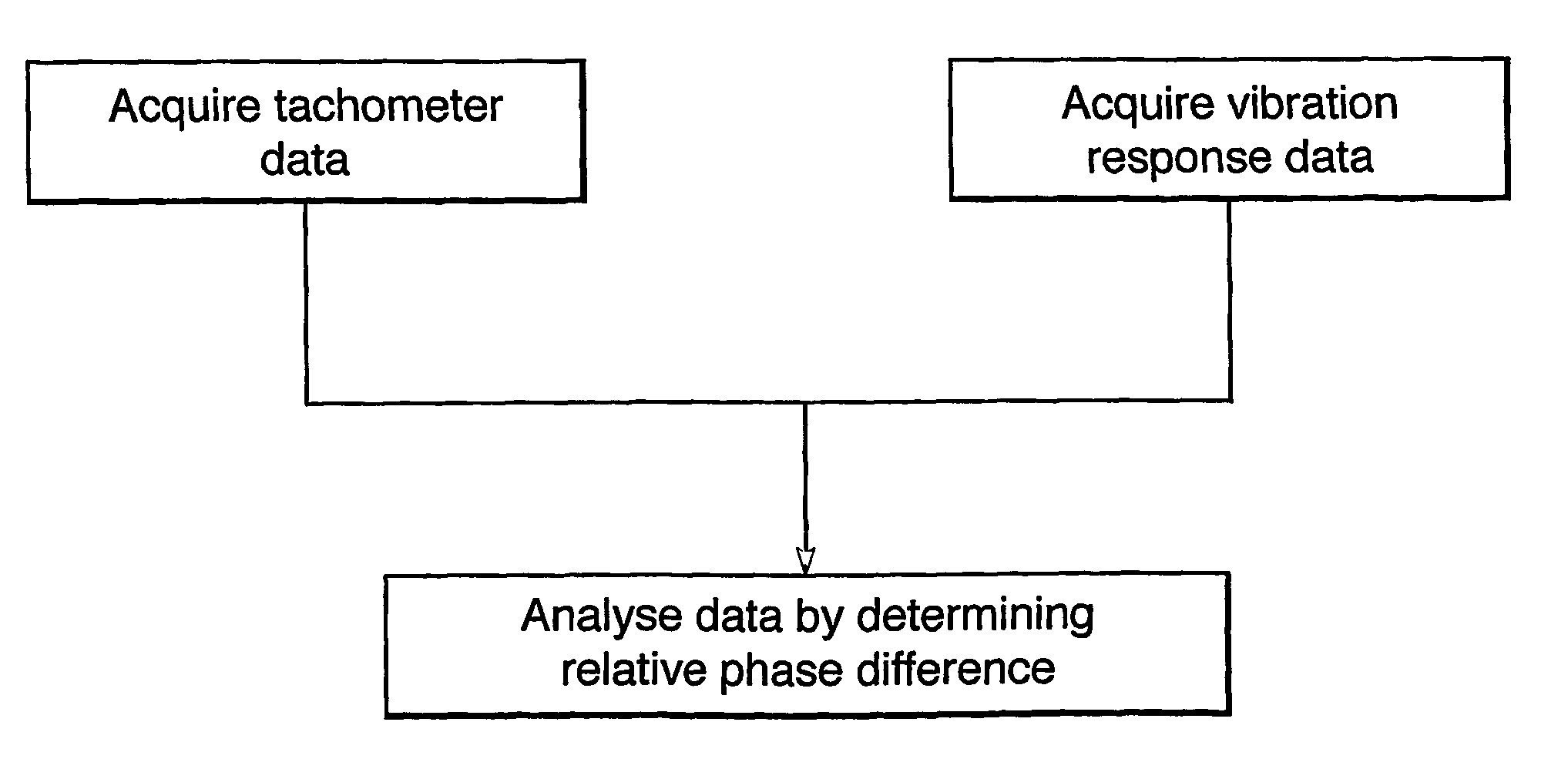

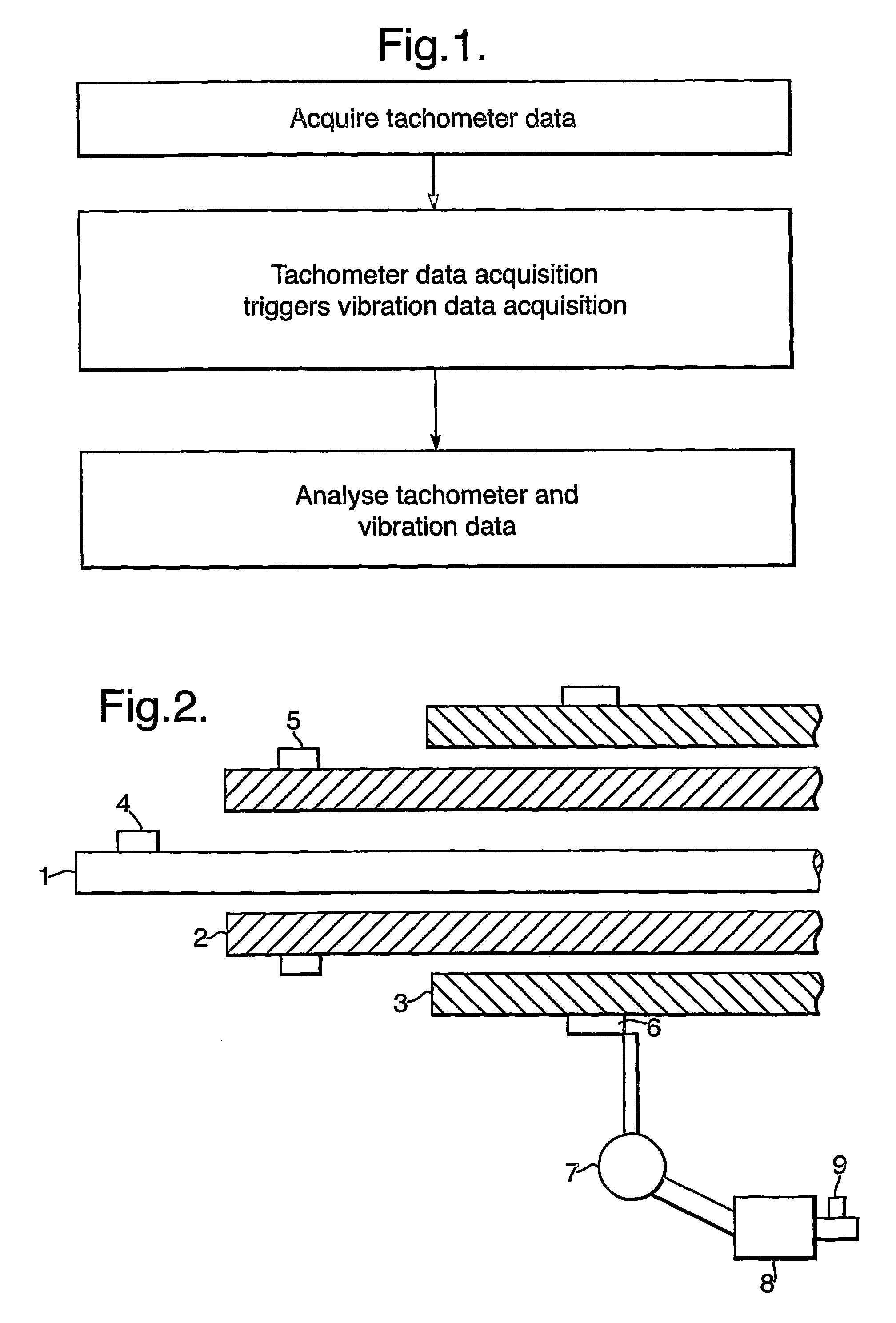

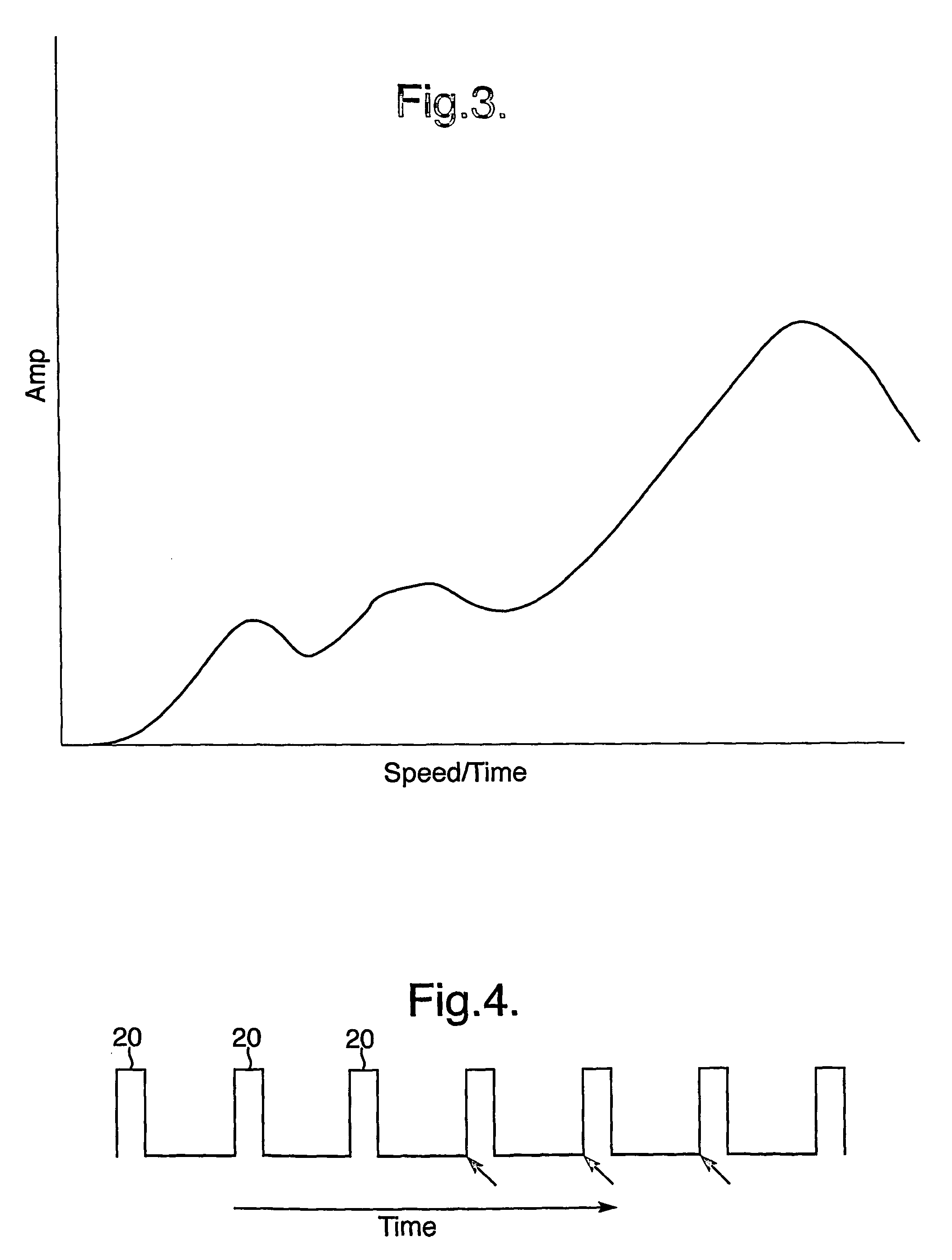

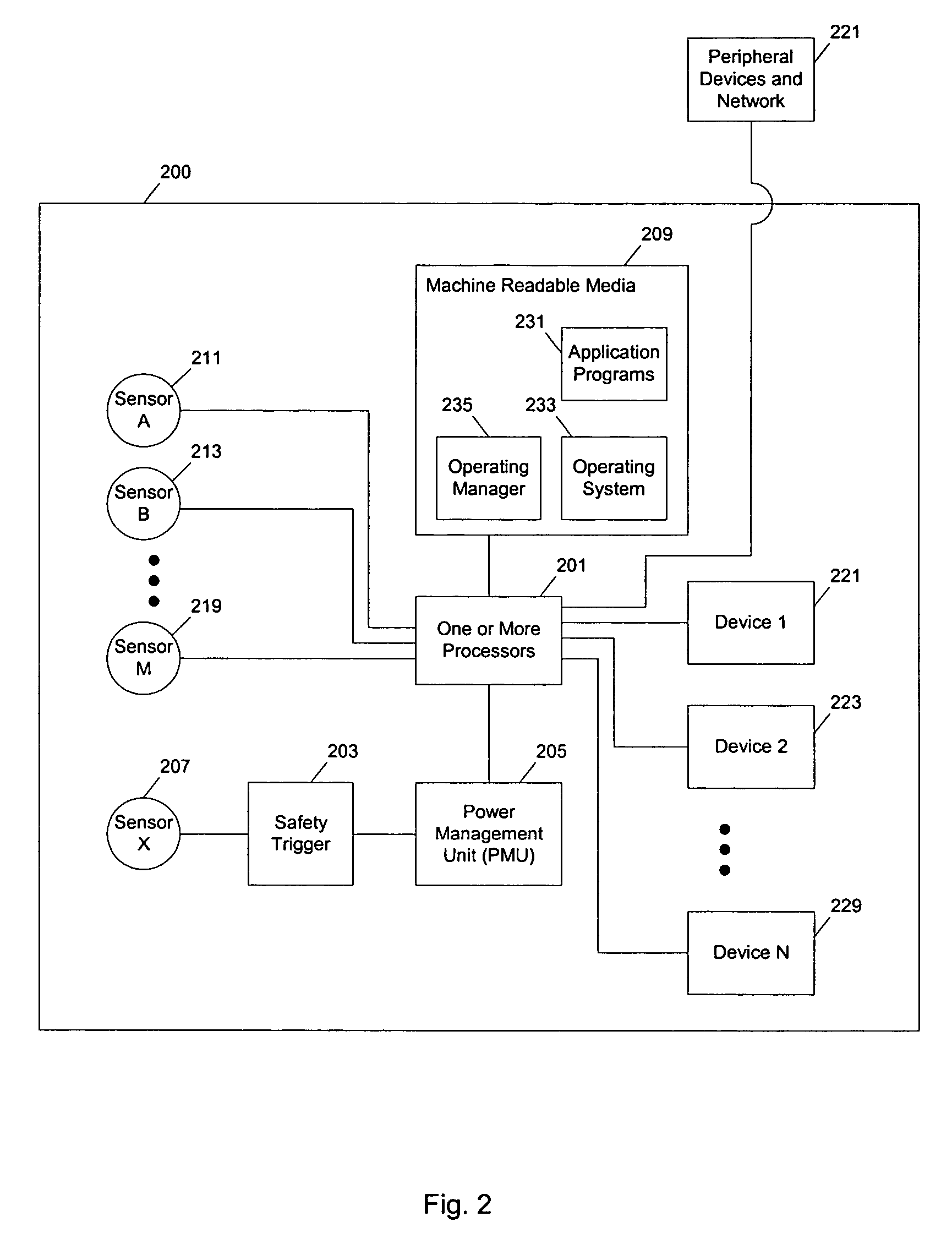

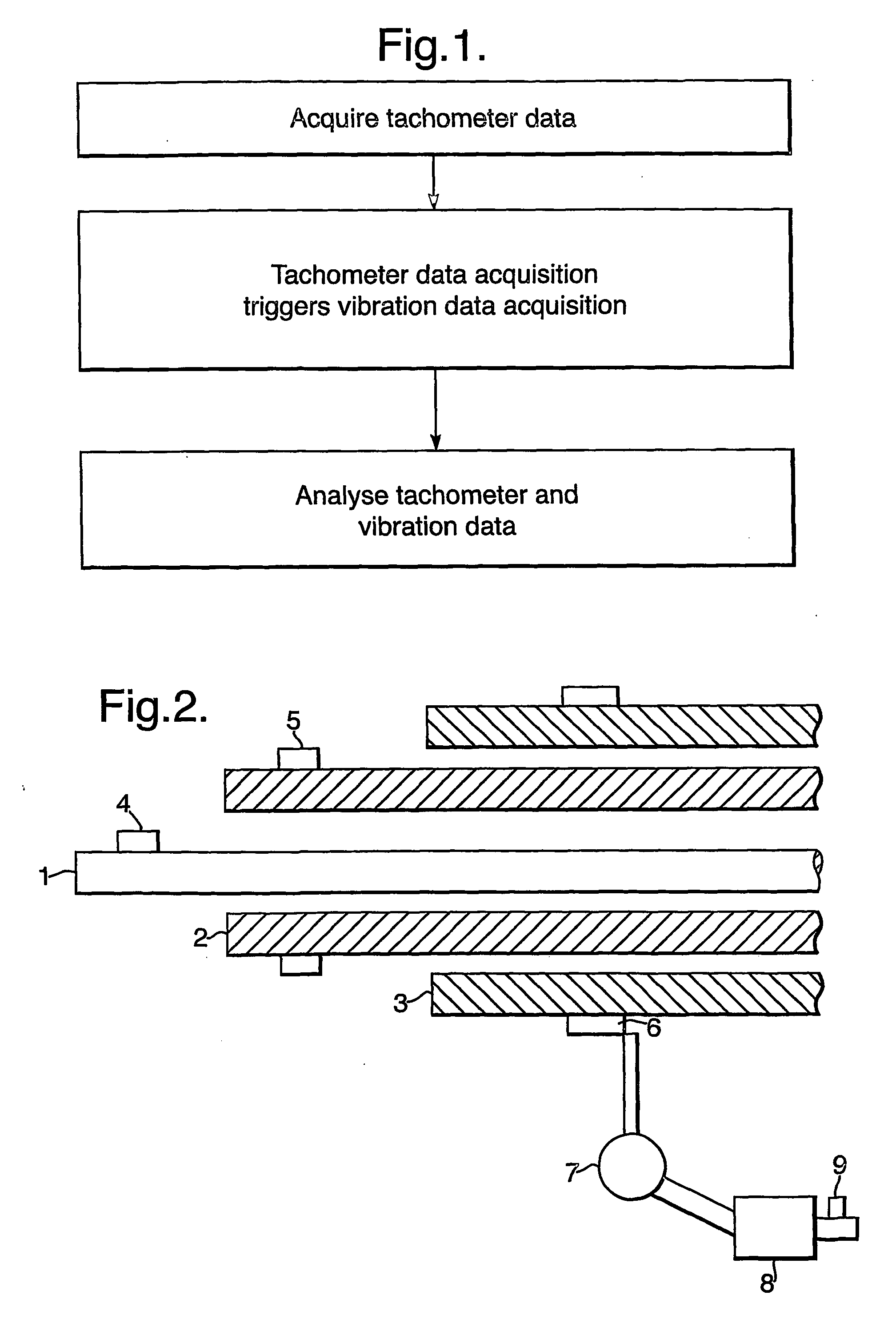

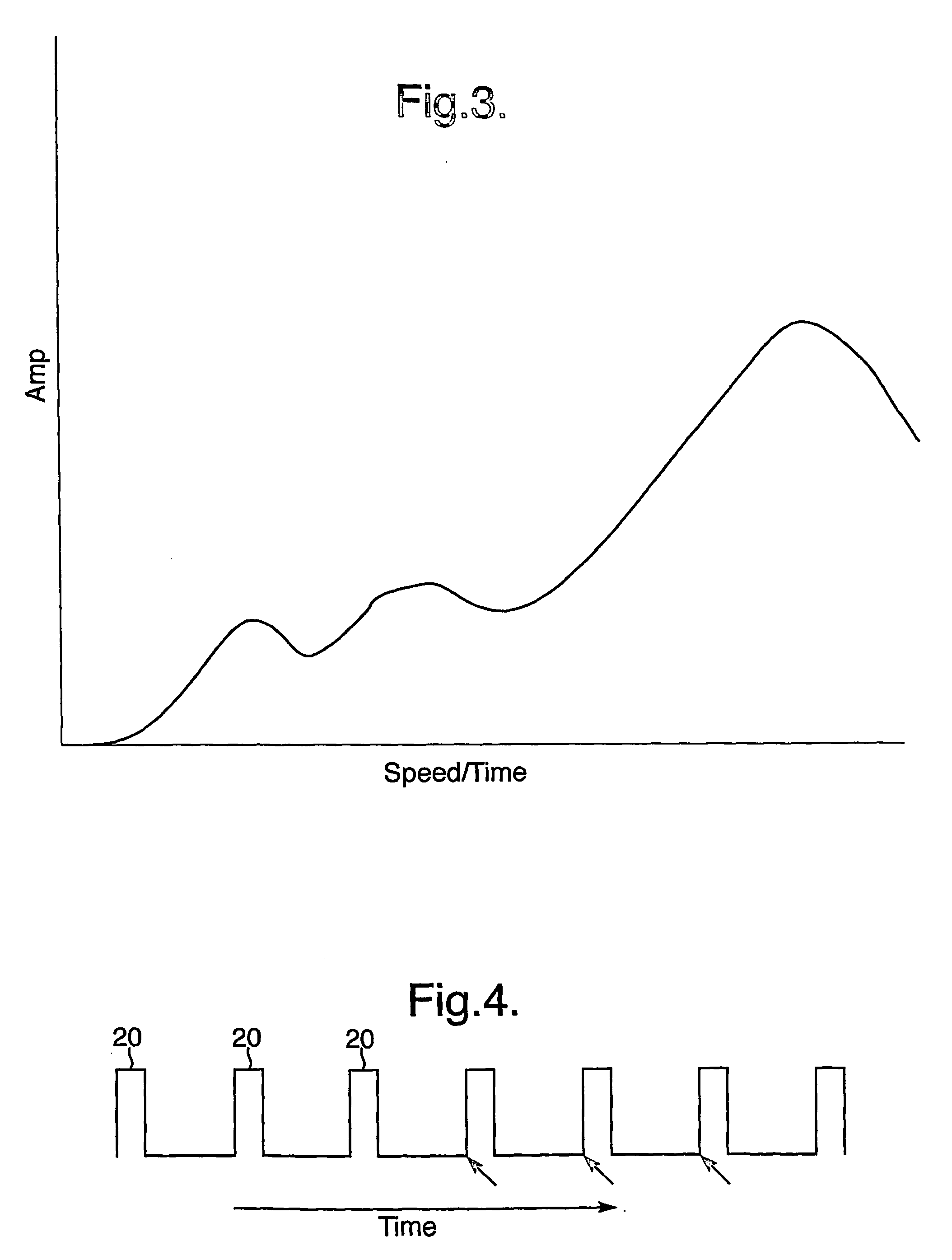

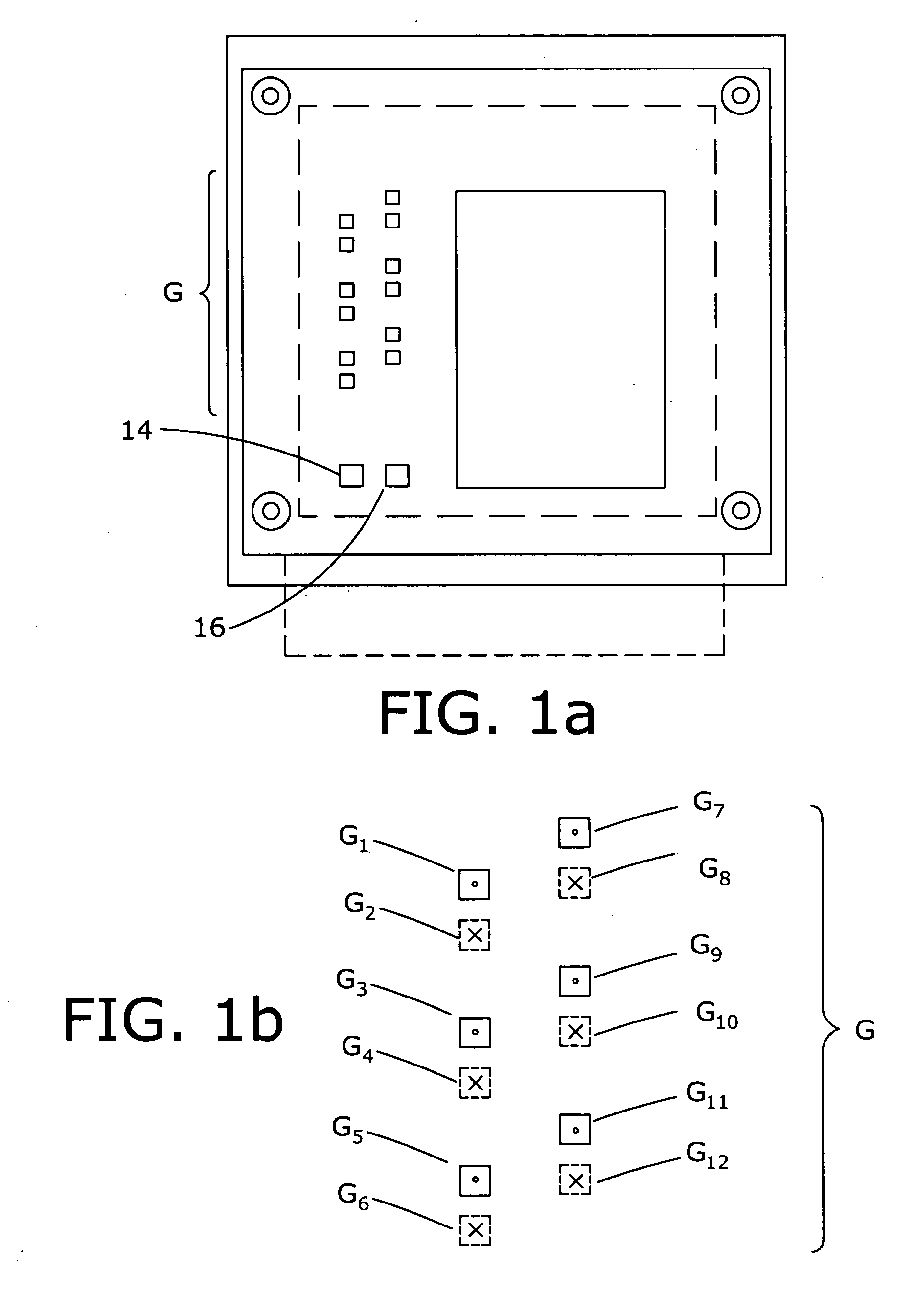

Method and system for analysing tachometer and vibration data from an apparatus having one or more rotary components

ActiveUS7640802B2Avoid problemsEasy to getVibration measurement in solidsVehicle testingForce frequencyVibration amplitude

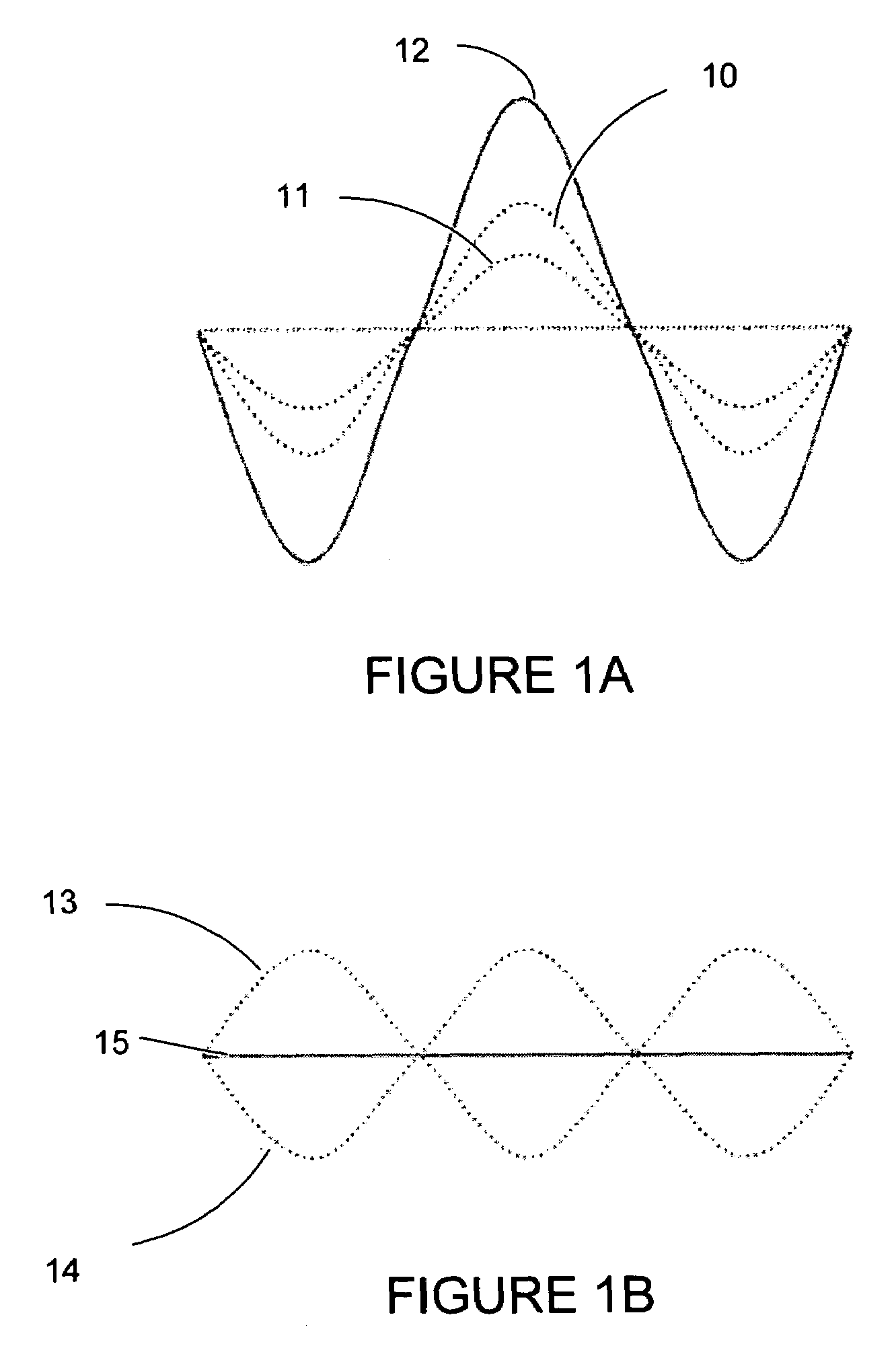

A method of analysing tachometer and vibration response data from an apparatus having one or more rotary components is provided. The method comprises the steps of: providing vibration response data and corresponding tachometer data from the apparatus for a period over which a rotary component of the apparatus varies in rotational speed, the tachometer data being for that component; repeatedly performing at intervals throughout the period the sub-steps of: determining a forcing frequency of the component from the tachometer data and a corresponding vibration response frequency of the apparatus from the vibration response data, comparing the forcing and vibration response frequencies to determine the relative phase difference between the frequencies, and determining the corresponding amplitude of the vibration response from the vibration response data; and plotting the relative phase differences and vibration amplitudes on a polar diagram. The plot trajectory is characteristic of the behavior of the apparatus over the period.

Owner:ROLLS ROYCE PLC +1

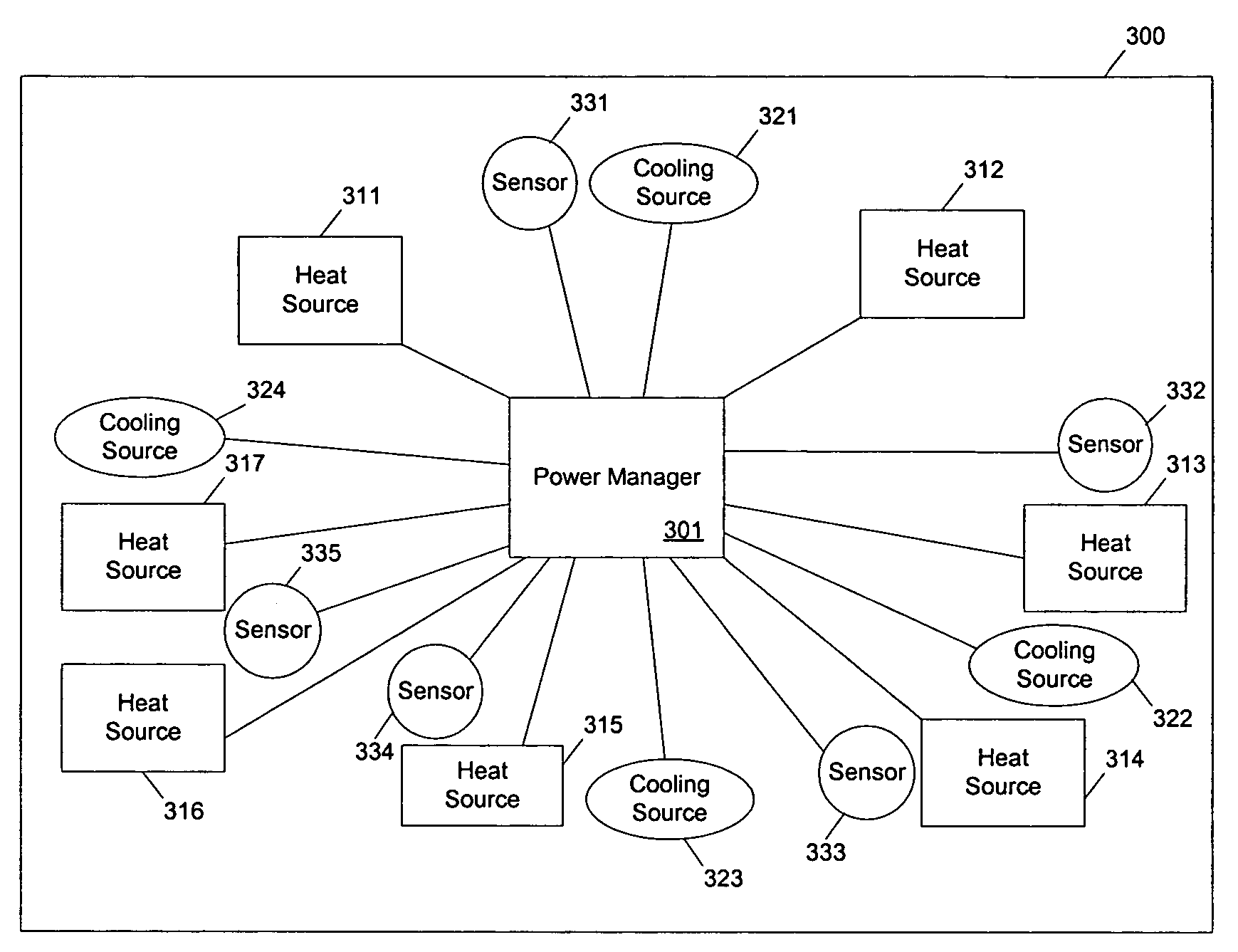

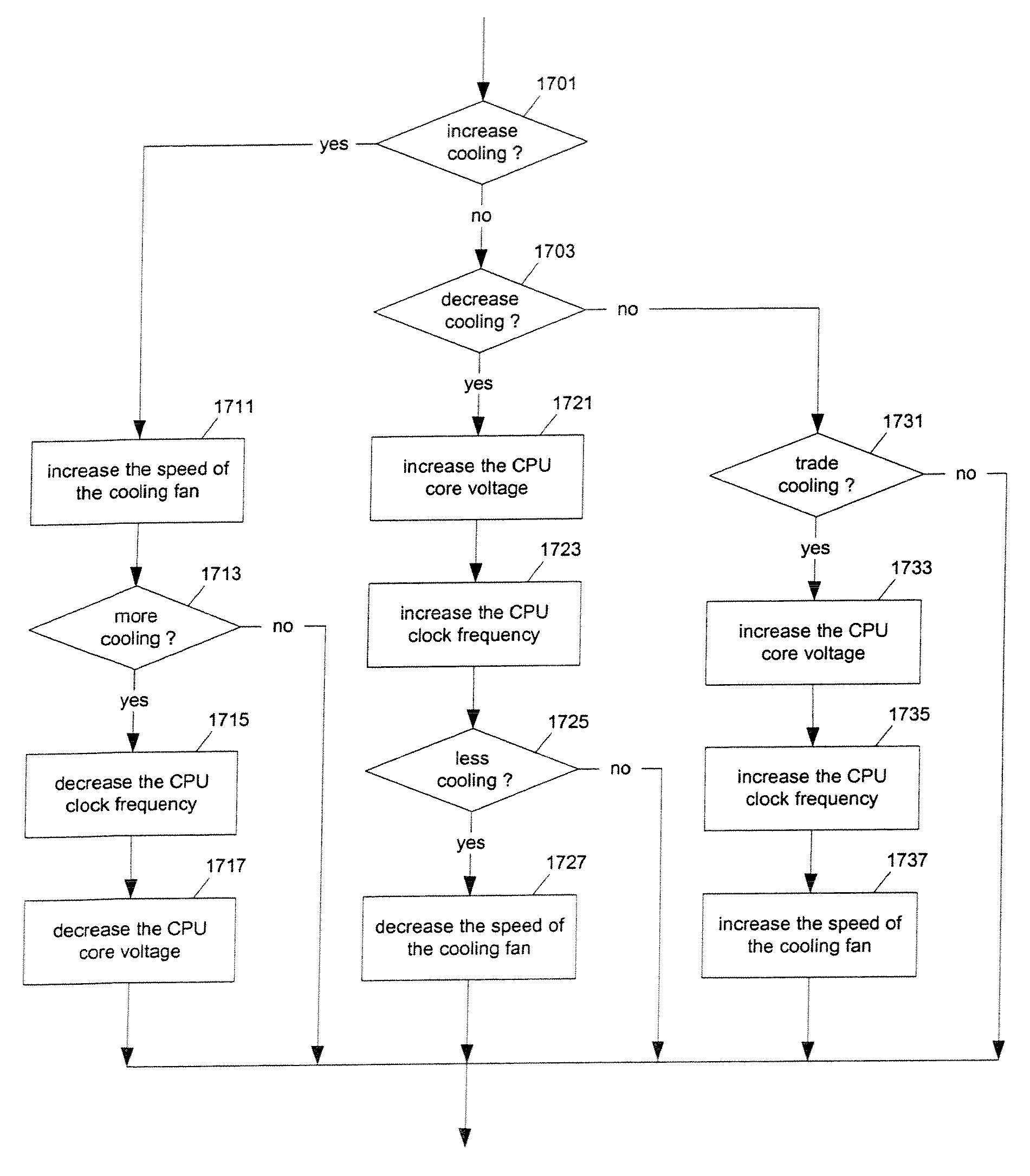

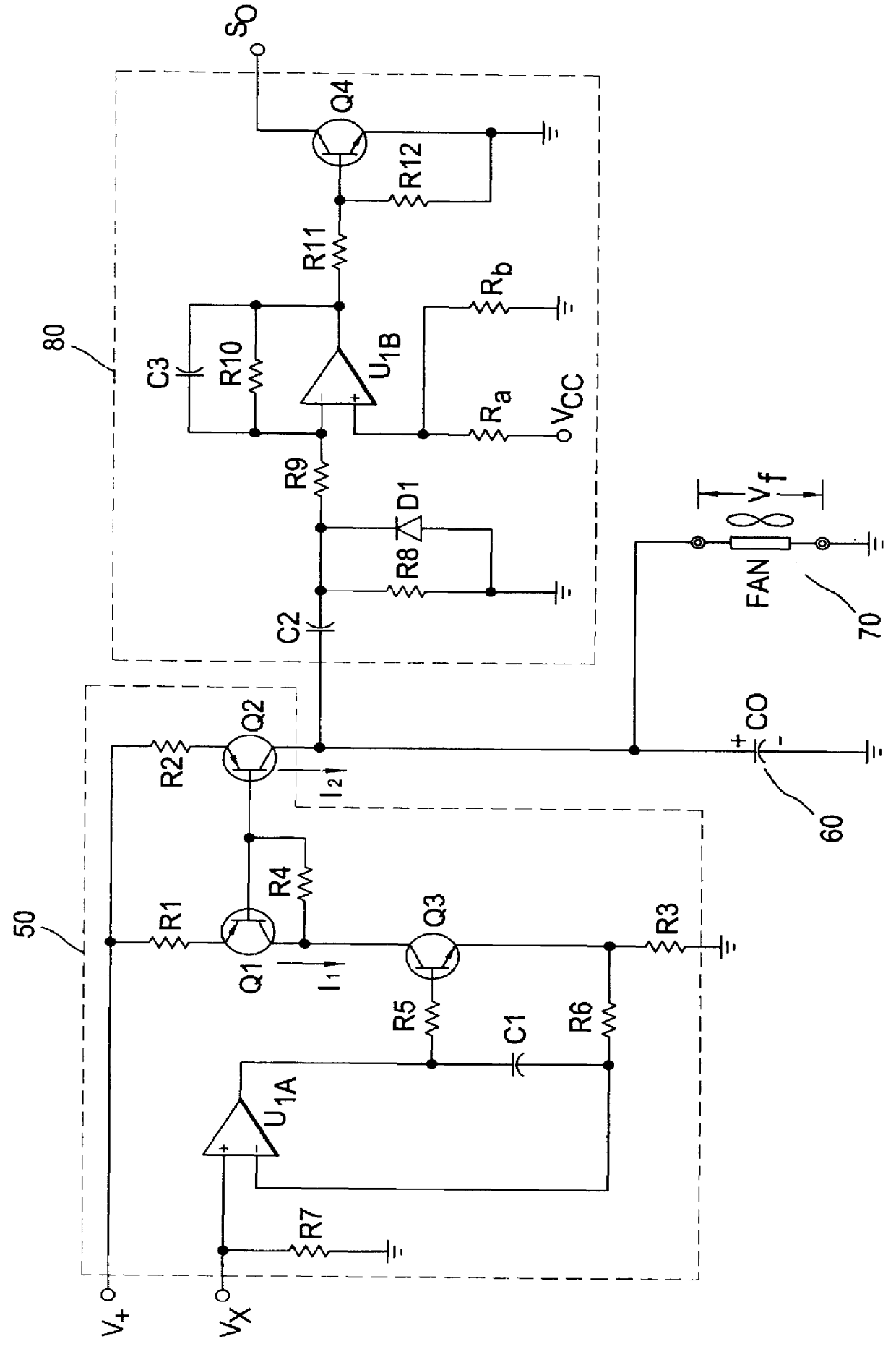

Methods and apparatuses for controlling the temperature of a data processing system

ActiveUS7451332B2Low heat generationImprove performanceEnergy efficient ICTVolume/mass flow measurementHard disc driveHeat sensitive

Methods and apparatuses to manage working states of a data processing system. At least one embodiment of the present invention includes a data processing system with one or more sensors (e.g., physical sensors such as tachometer and thermistors, and logical sensors such as CPU load) for fine grain control of one or more components (e.g., processor, fan, hard drive, optical drive) of the system for working conditions that balance various goals (e.g., user preferences, performance, power consumption, thermal constraints, acoustic noise). In one example, the clock frequency and core voltage for a processor are actively managed to balance performance and power consumption (heat generation) without a significant latency. In one example, the speed of a cooling fan is actively managed to balance cooling effort and noise (and / or power consumption).

Owner:APPLE INC

Method and system for analysing tachometer and vibration data from an apparatus having one or more rotary components

ActiveUS20070006636A1Avoid problemsEasy to getVehicle testingVibration measurement in solidsForce frequencyVibration amplitude

A method of analysing tachometer and vibration response data from an apparatus having one or more rotary components is provided. The method comprises the steps of: providing vibration response data and corresponding tachometer data from the apparatus for a period over which a rotary component of the apparatus varies in rotational speed, the tachometer data being for that component; repeatedly performing at intervals throughout the period the sub-steps of: determining a forcing frequency of the component from the tachometer data and a corresponding vibration response frequency of the apparatus from the vibration response data, comparing the forcing and vibration response frequencies to determine the relative phase difference between the frequencies, and determining the corresponding amplitude of the vibration response from the vibration response data; and plotting the relative phase differences and vibration amplitudes on a polar diagram. The plot trajectory is characteristic of the behaviour of the apparatus over the period.

Owner:ROLLS ROYCE PLC +1

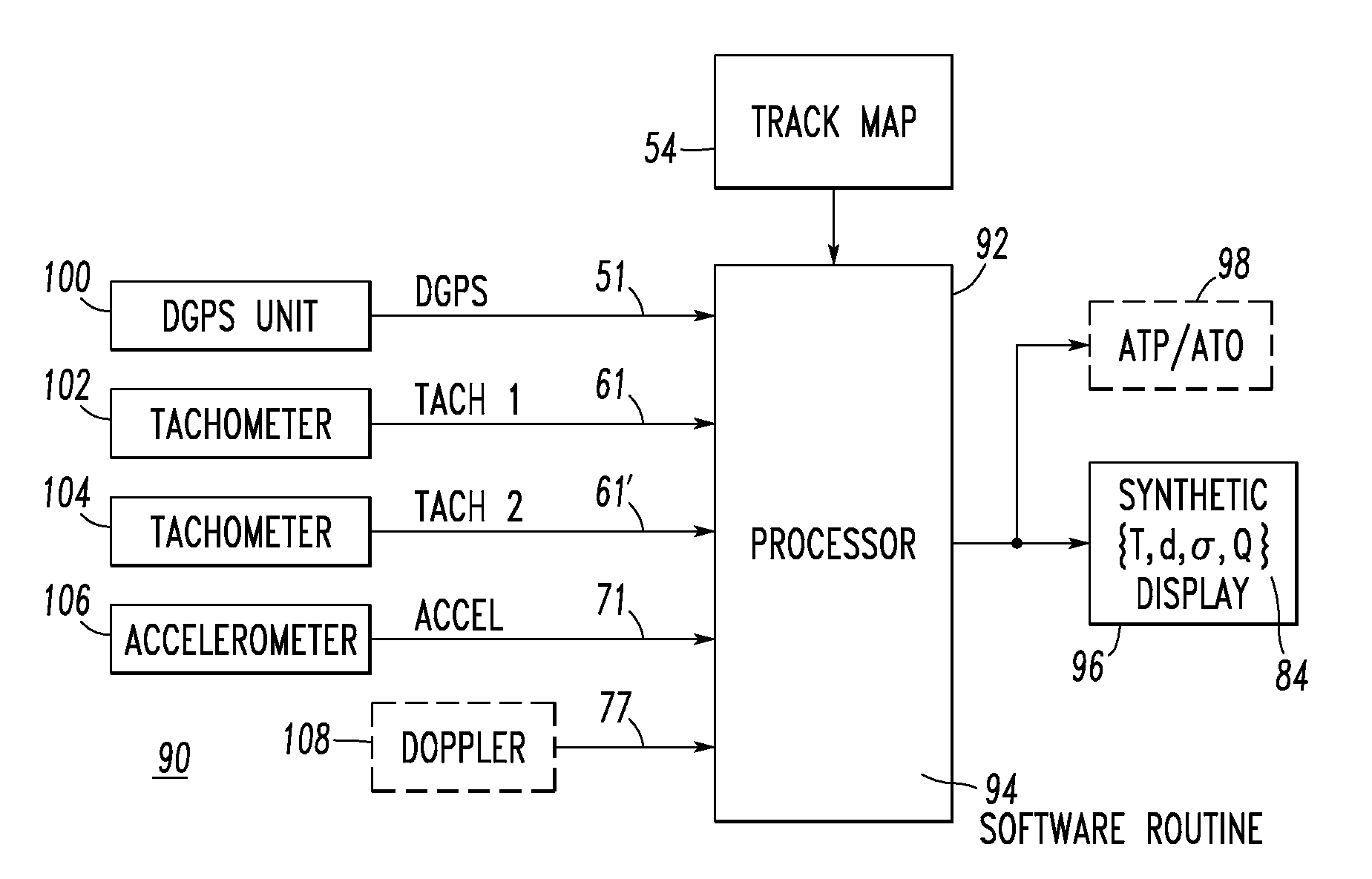

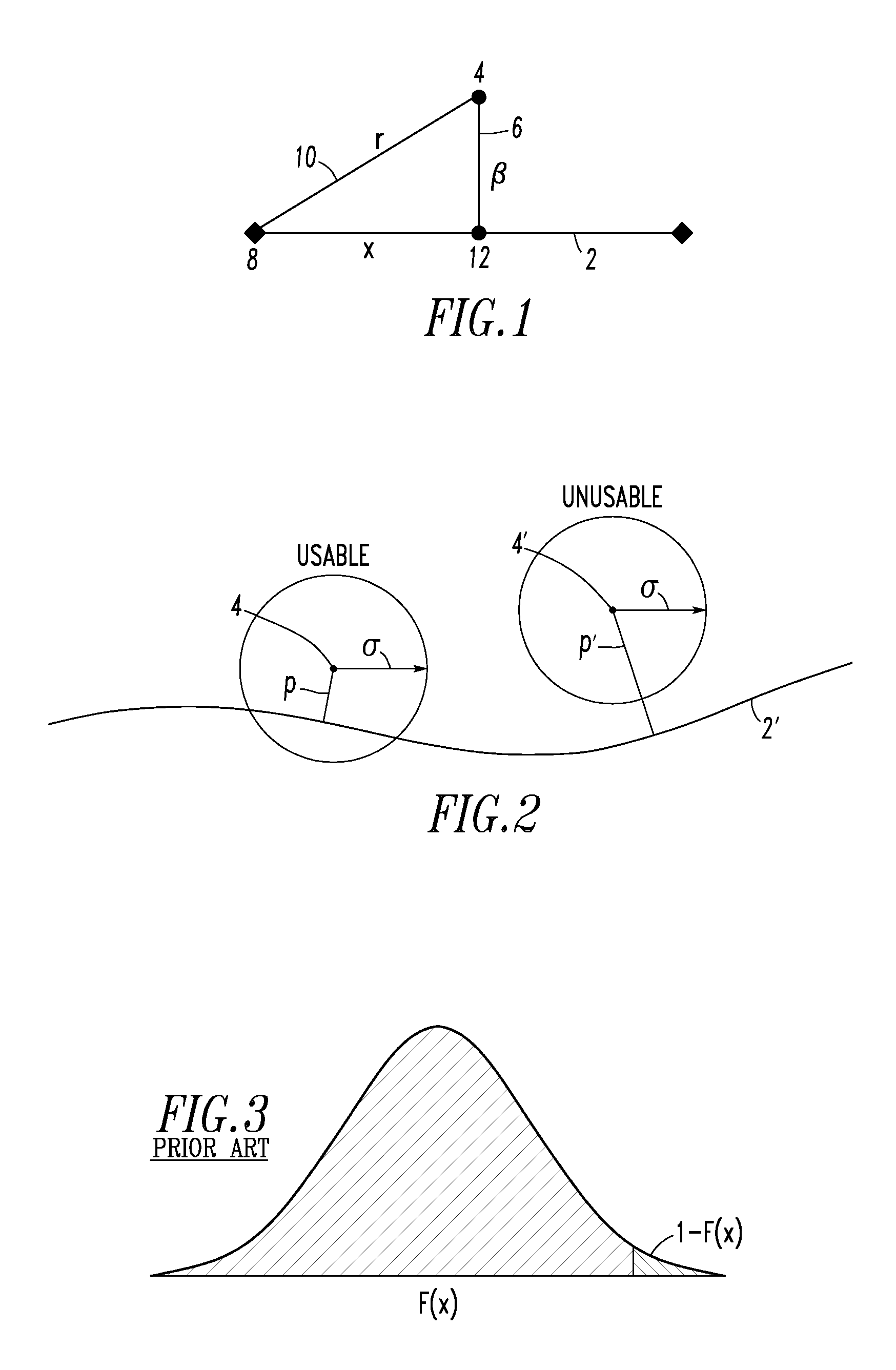

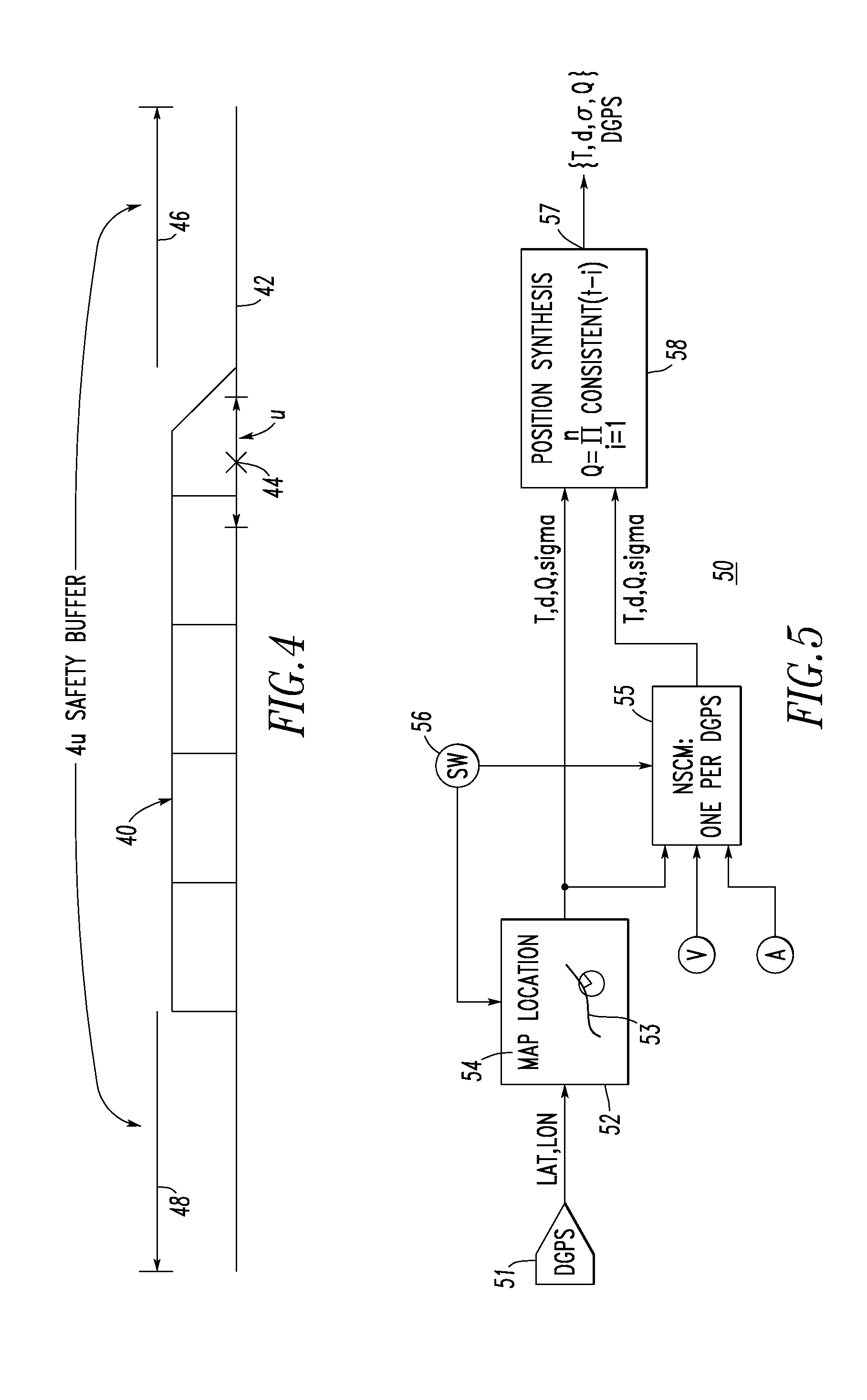

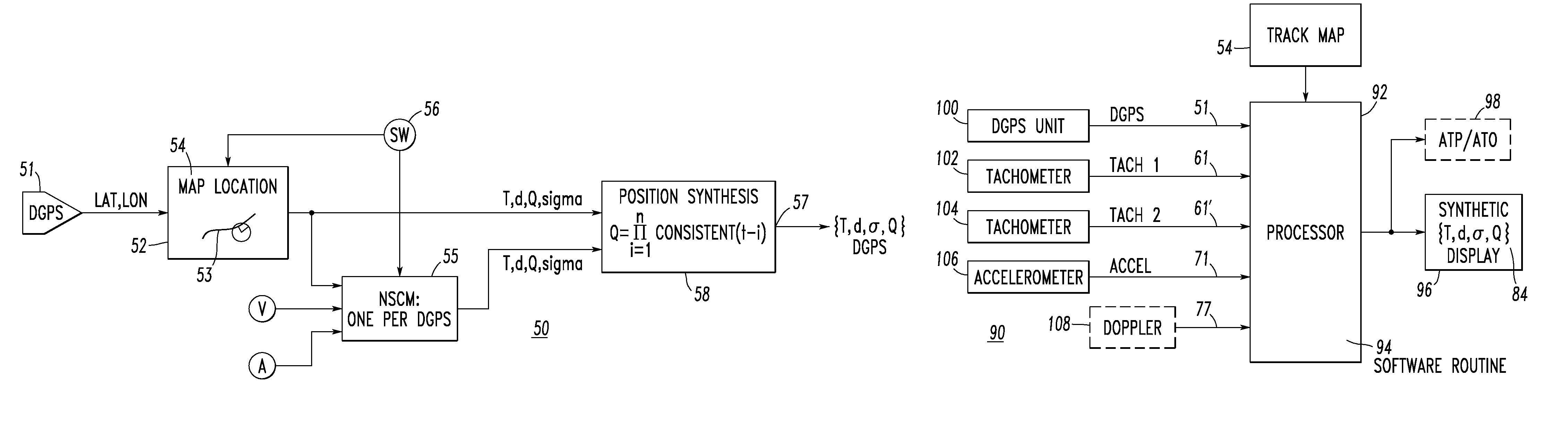

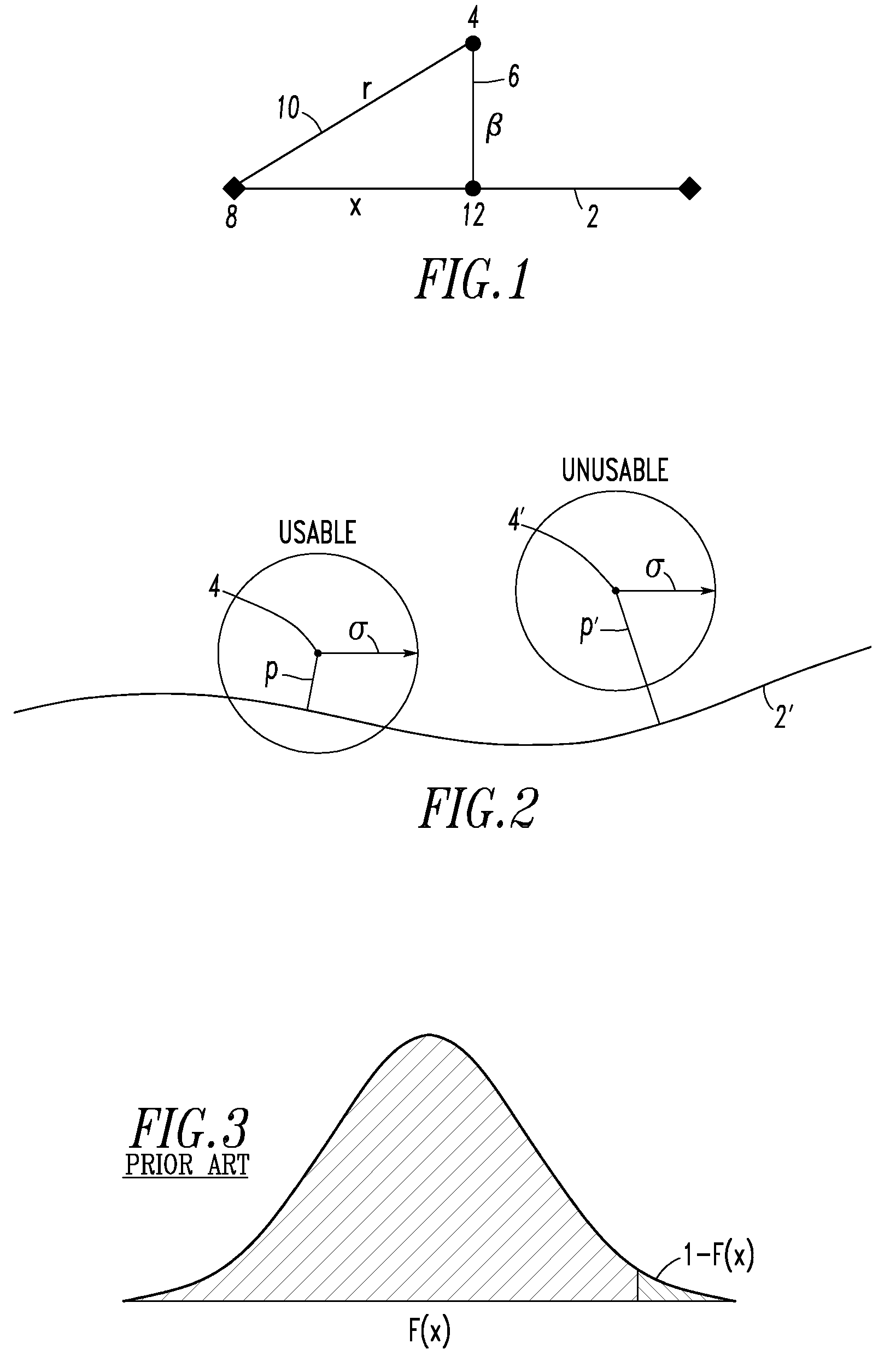

System and method for vitally determining position and position uncertainty of a railroad vehicle employing diverse sensors including a global positioning system sensor

ActiveUS20100312461A1Analogue computers for vehiclesAnalogue computers for trafficAccelerometerEngineering

A system vitally determines a position of a train. The system includes a plurality of diverse sensors, such as tachometers and accelerometers, structured to repetitively sense at least change in position and acceleration of the train, a global positioning system sensor, which is diverse from each of the diverse sensors, structured to repetitively sense position of the train, and a track map including a plurality of track segments which may be occupied by the train. A processor cooperates with the diverse sensors, the global positioning system sensor and the track map. The processor includes a routine structured to provide measurement uncertainty for each of the diverse sensors and the global positioning system sensor. The routine cross-checks measurements for the diverse sensors, and cross-checks the global positioning system sensor against the track map. The routine provides the vitally determined position of the train and the uncertainty of the vitally determined position.

Owner:ANSALDO STS USA INC

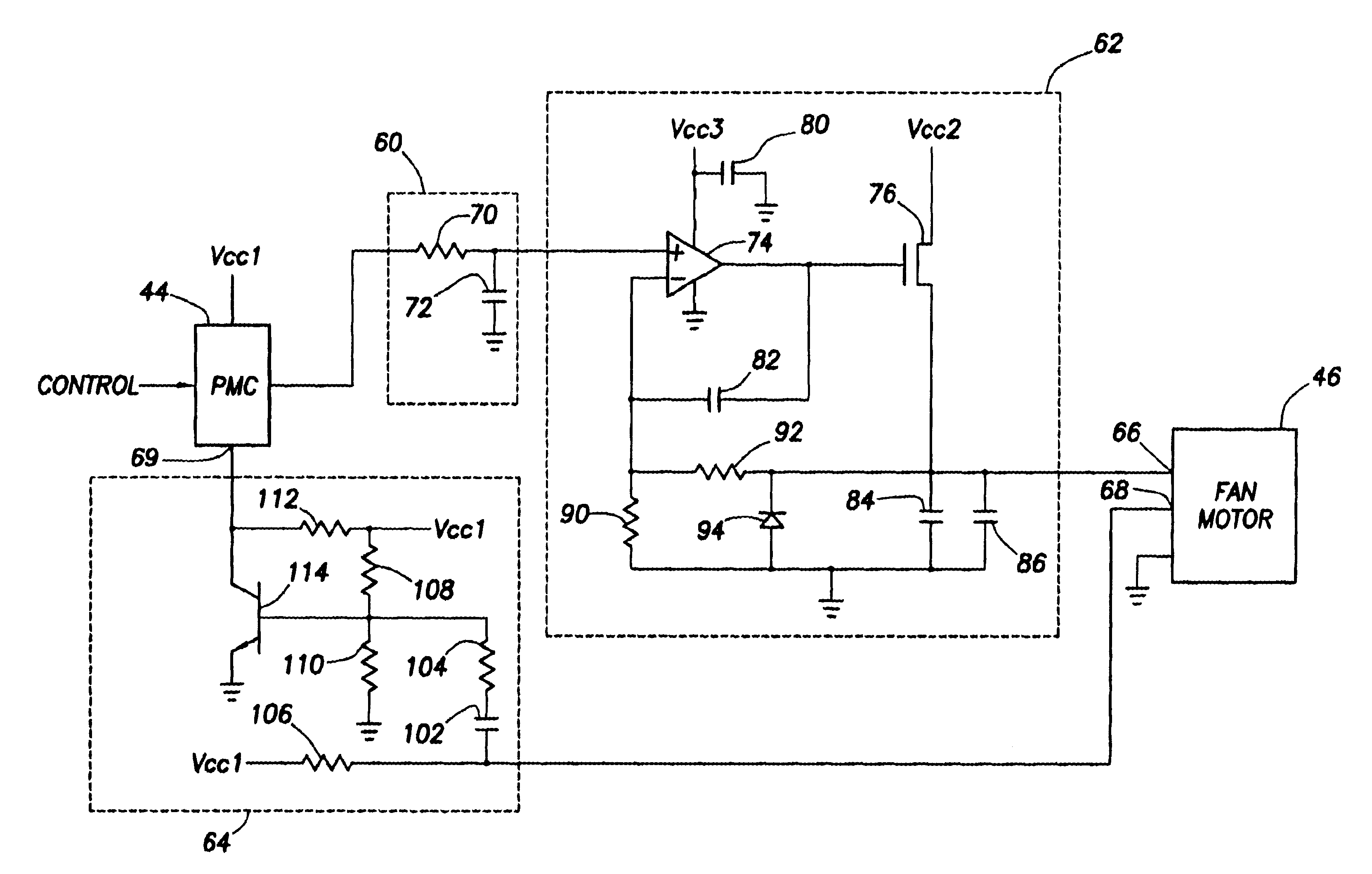

Fan speed controller with conditioned tachometer signal

The speed of a fan motor is controlled by varying a DC voltage to the fan motor. A series pass transistor is used to vary the DC voltage to the fan motor. A power management controller sets the fan motor speed by outputting pulses to a pulse-to-DC voltage converter that changes the pulses to a proportional DC control voltage for controlling the series pass transistor. A tachometer output amplifier circuit is used to remove DC components and amplify to useful logic levels a low level tachometer output signal from the fan motor. The amplified tachometer signal is used by the power management controller in controlling the rotational speed of the fan motor.

Owner:DELL PROD LP

Methods and apparatuses for operating a data processing system

ActiveUS20100117579A1Balance performanceShorten speedDigital data processing detailsTemperatue controlHard disc driveThermistor

Methods and apparatuses to manage working states of a data processing system. At least one embodiment of the present invention includes a data processing system with one or more sensors (e.g., physical sensors such as tachometer and thermistors, and logical sensors such as CPU load) for fine grain control of one or more components (e.g., processor, fan, hard drive, optical drive) of the system for working conditions that balance various goals (e.g., user preferences, performance, power consumption, thermal constraints, acoustic noise). In one example, the clock frequency and core voltage for a processor are actively managed to balance performance and power consumption (heat generation) without a significant latency. In one example, the speed of a cooling fan is actively managed to balance cooling effort and noise (and / or power consumption).

Owner:APPLE INC

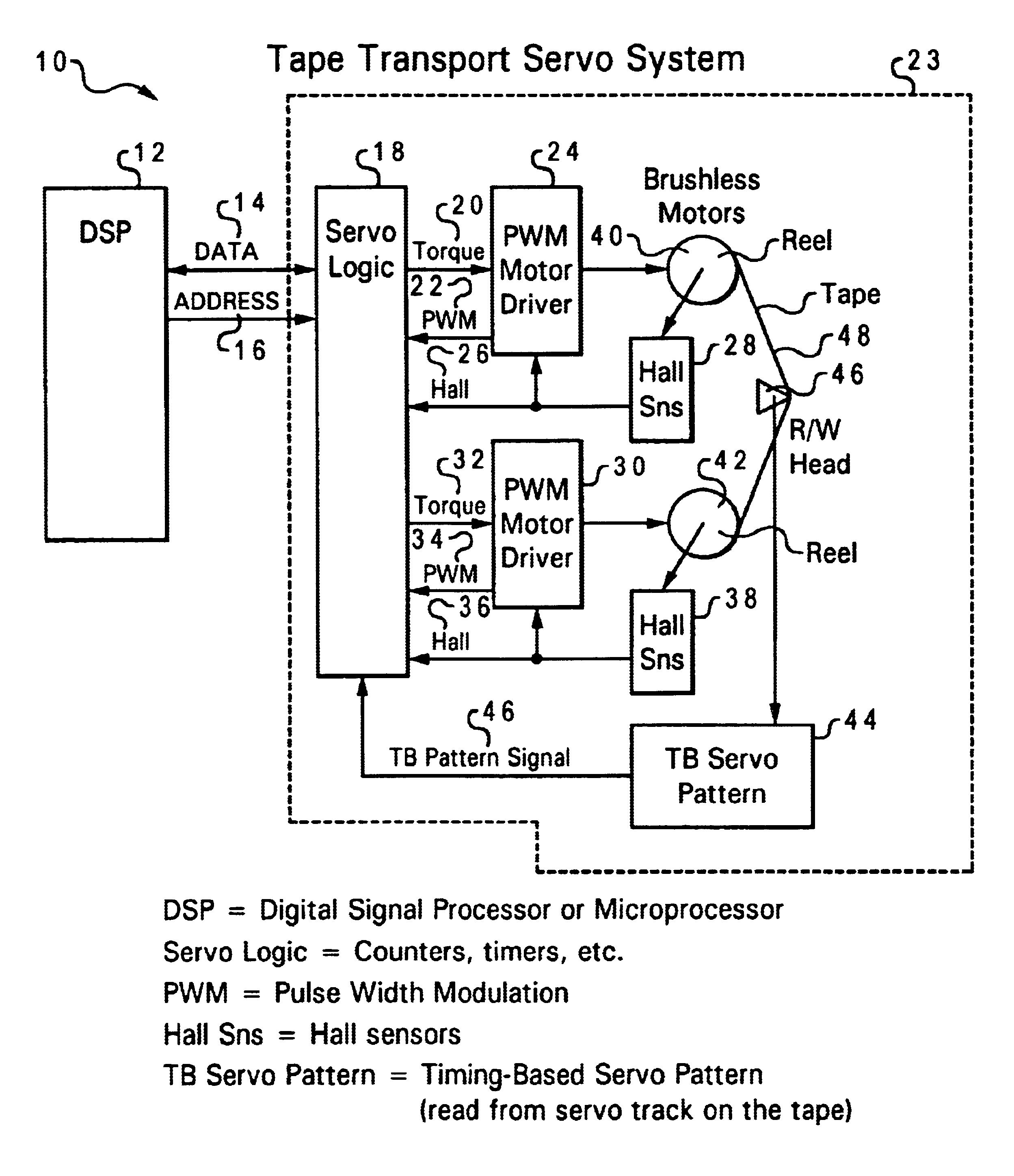

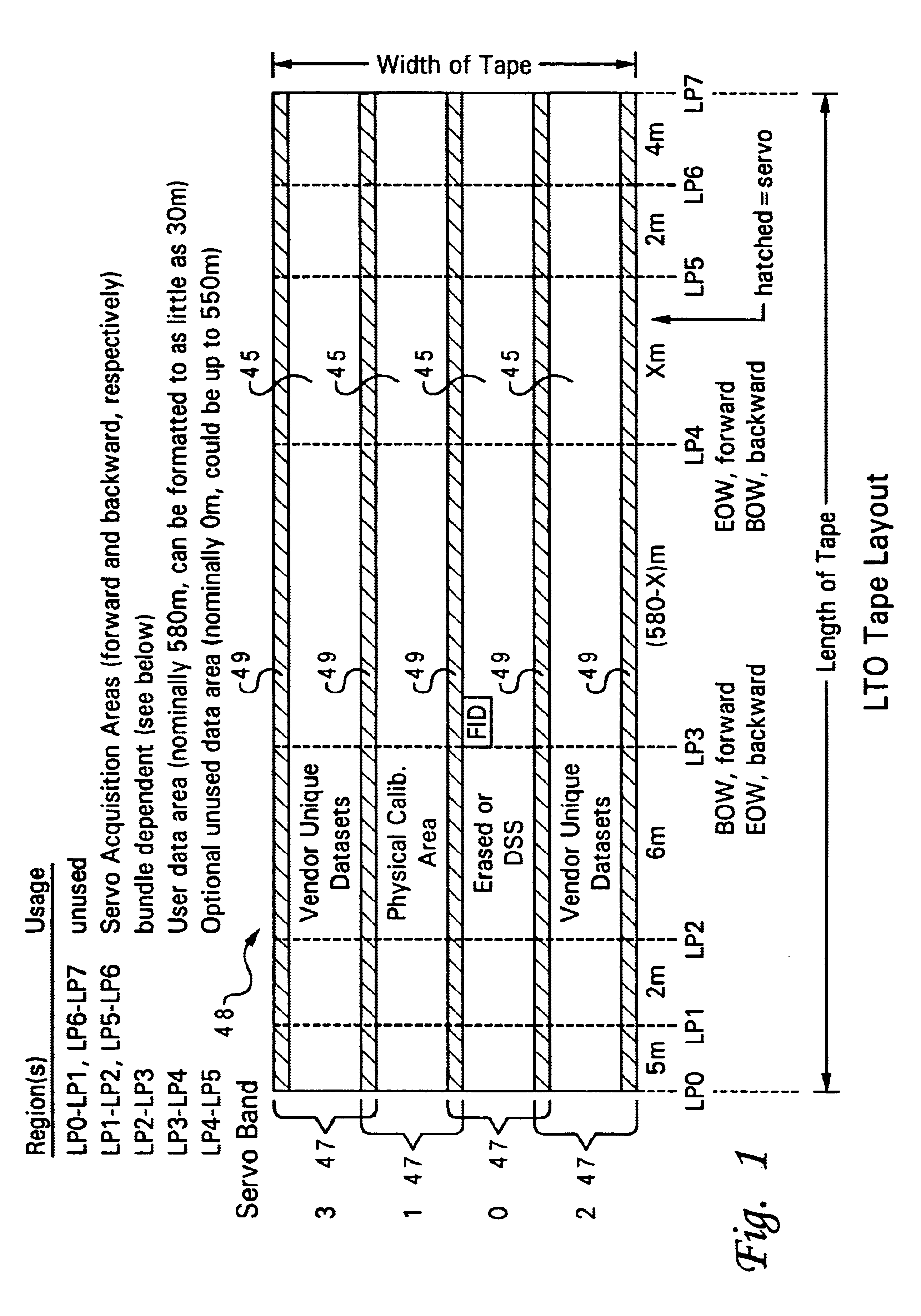

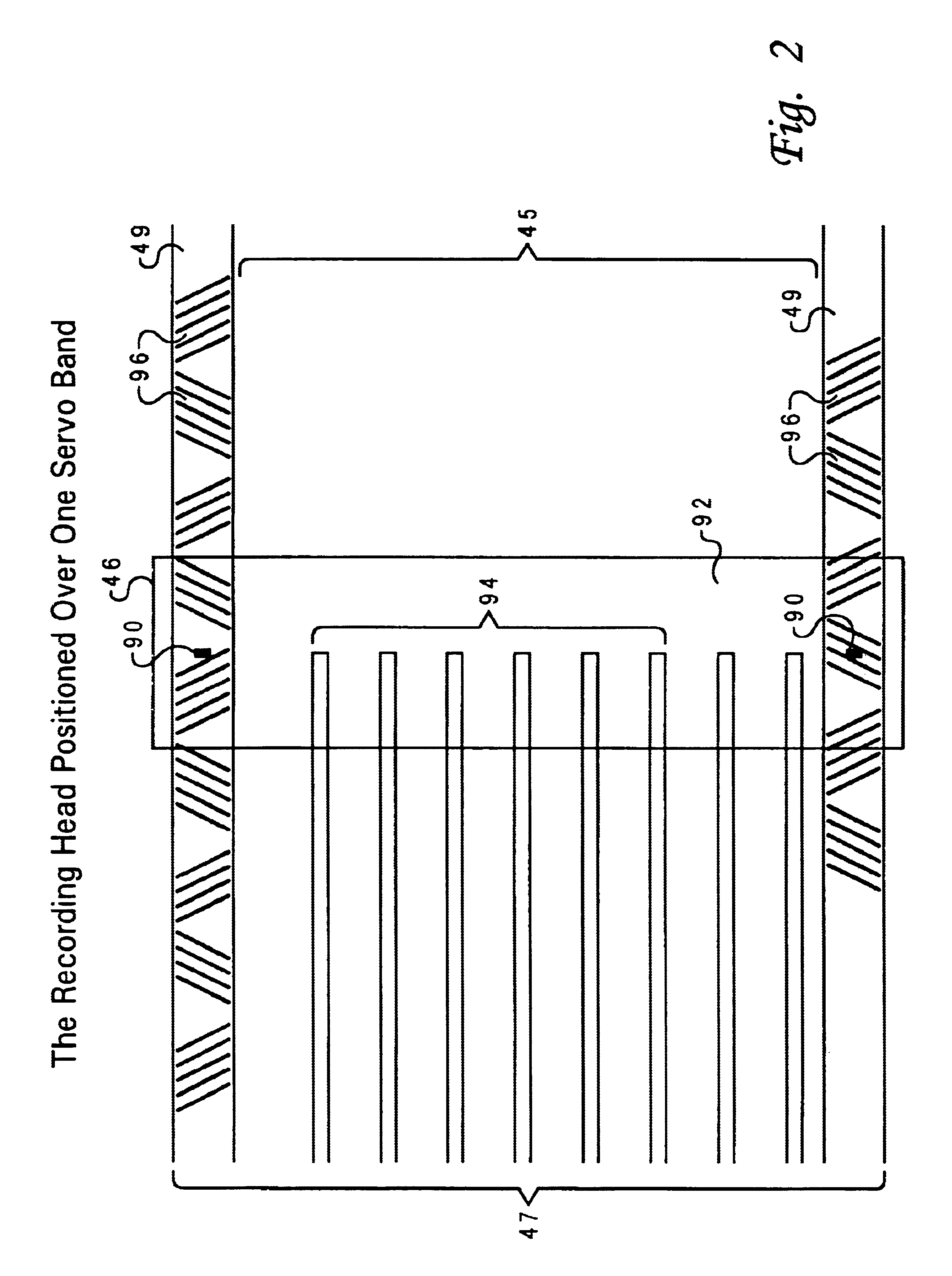

Tape transport servo system and method for a computer tape drive

InactiveUS6754026B1Alignment for track following on tapesRecord information storageTape speedTape drive

A tape transport servo system and method that do not make use of tachometers and / or encoders to derive tape velocity and position are provided. The tape transport servo system and method derive velocity and position of the tape from a primary and direct manner and also a secondary or alternative manner, especially when the primary or direct manner cannot be used. The tape transport servo system and method control a tape drive and moves a tape between one reel driven by one motor to another reel driven by another motor. The tape is read by a recording head composed of data readers, data writers and a dedicated set of servo read elements. A position and a velocity of the tape are determined from a primary velocity source when the tape is being read by the head. The position and the velocity of the tape are determined from a secondary velocity source when the tape is not being read by the head. The velocity of the tape is compared to a desired programmed reference velocity for the tape. The velocity of the tape is driven to the desired programmed reference velocity if the velocity is not equal to the desired velocity. The velocity of the tape is controlled by regulating the velocity and the driving currents of the motors. The tape transport servo system comprises a digital signal processor and a servo motor control system. The servo motor control system comprises a servo logic system, sensors, PWM motor drivers, power amplifiers, DACs, counters, computation systems, and a timing-based servo pattern monitoring system.

Owner:IBM CORP

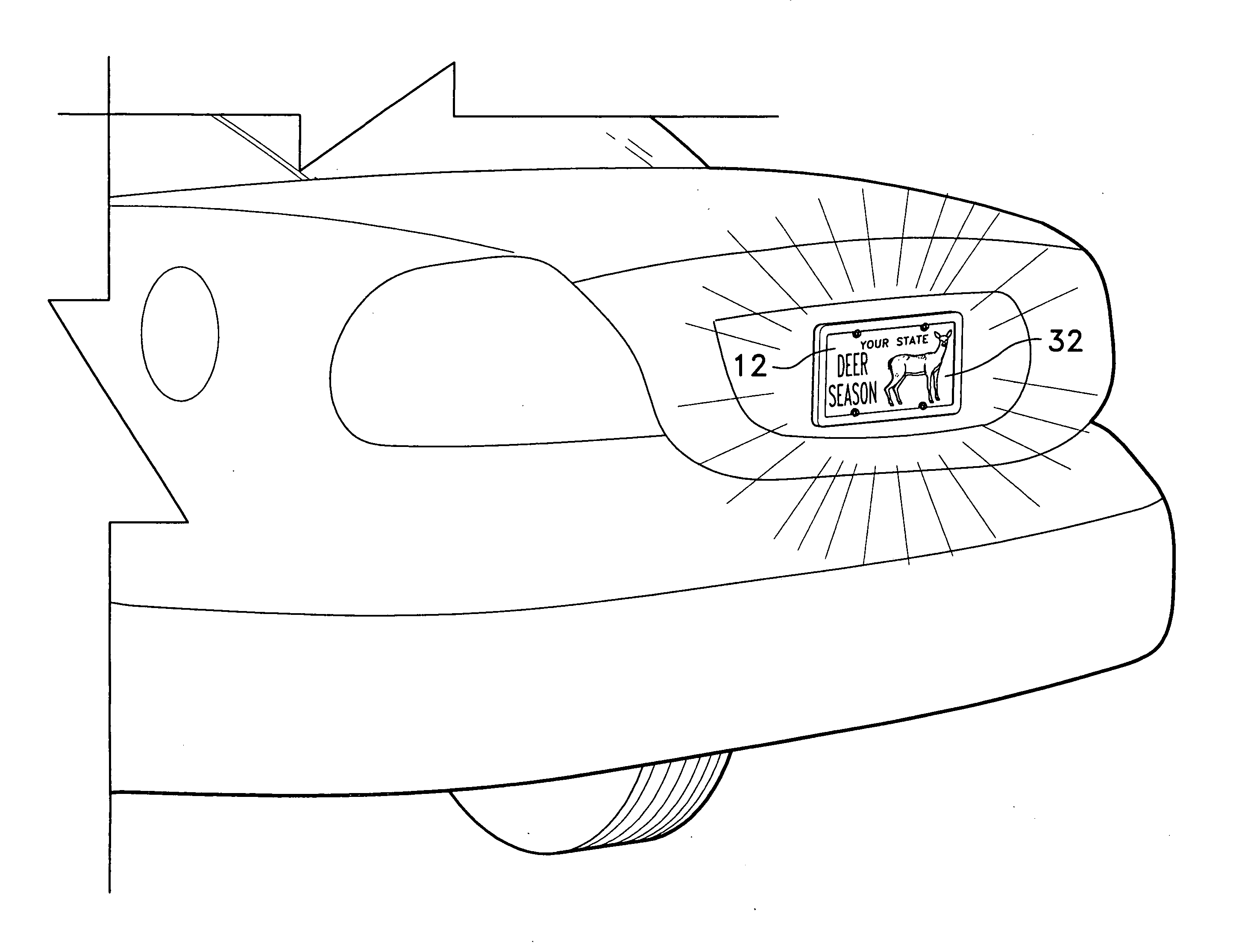

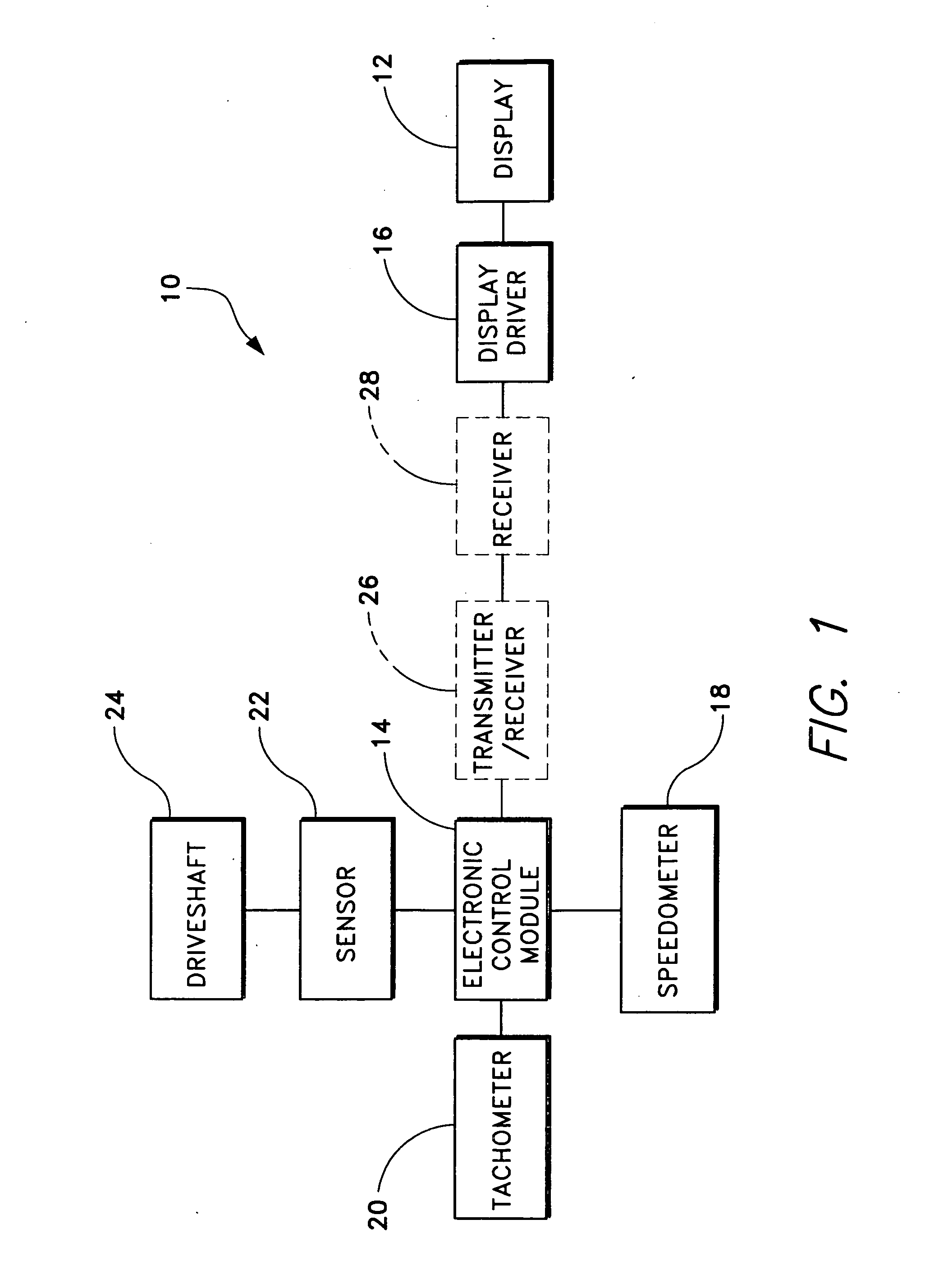

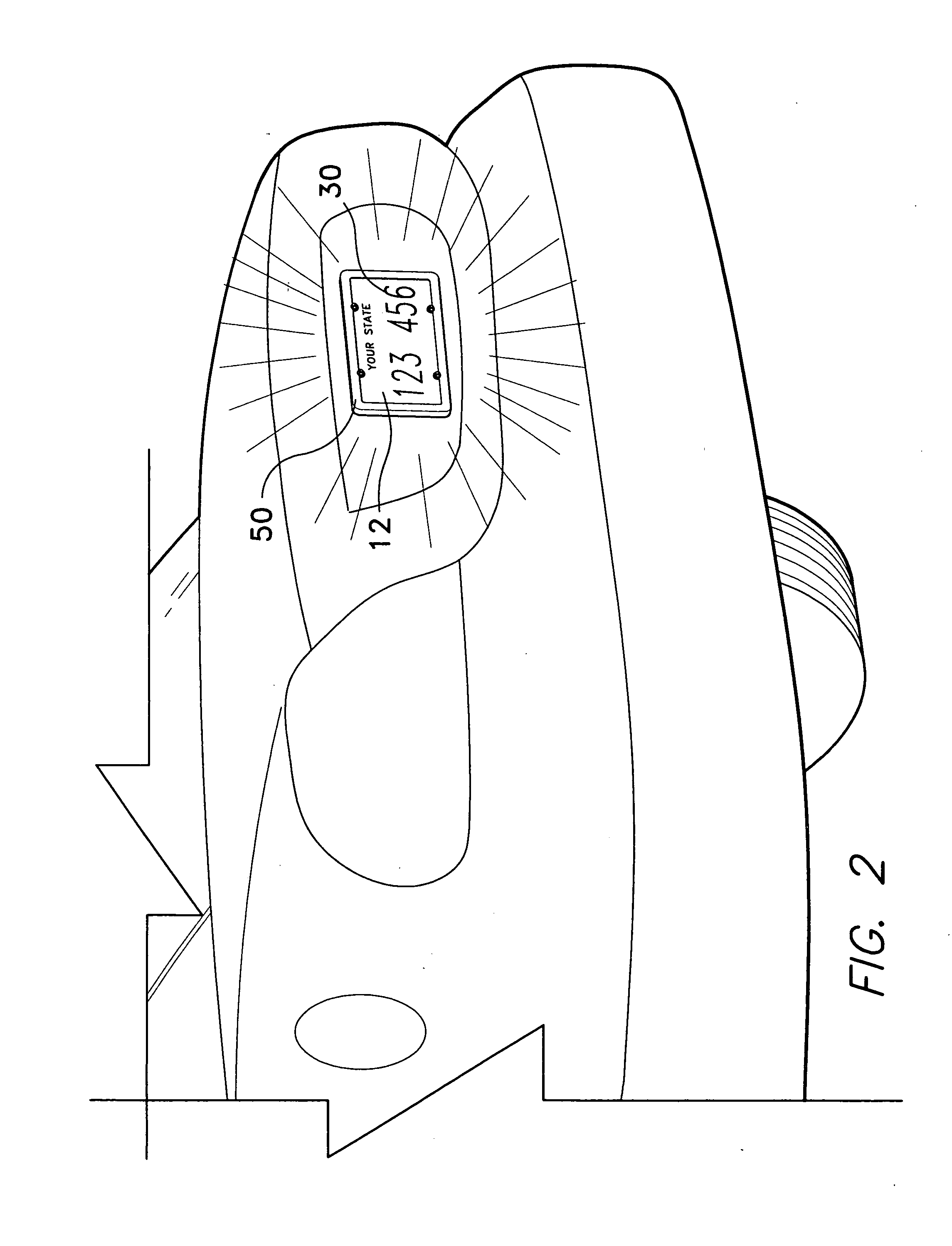

Electronic display system

The electronic display system displays advertisements, traffic and weather information on a display panel mounted to the license plate support of an automobile or any vehicle when the vehicle is moving beneath a predetermined threshold speed. The display can be mounted elsewhere, for example, anywhere on the rear or sides of a larger vehicle such as a van, bus or truck, where it will be readily seen. Once the vehicle exceeds the predetermined threshold speed, the display changes, showing vehicle license plate information, such as the license plate number, State of registration, etc. The electronic display system includes a programmable electronic display, driven by a display driver, and an electronic control module that allows information to be sent to and shown on the electronic display. The electronic control module is coupled to a speedometer, a tachometer, or a sensor that determines the rate at which the drive shaft rotates, which allows the control module to determine whether the threshold speed has been reached.

Owner:MCCANN KEITH H

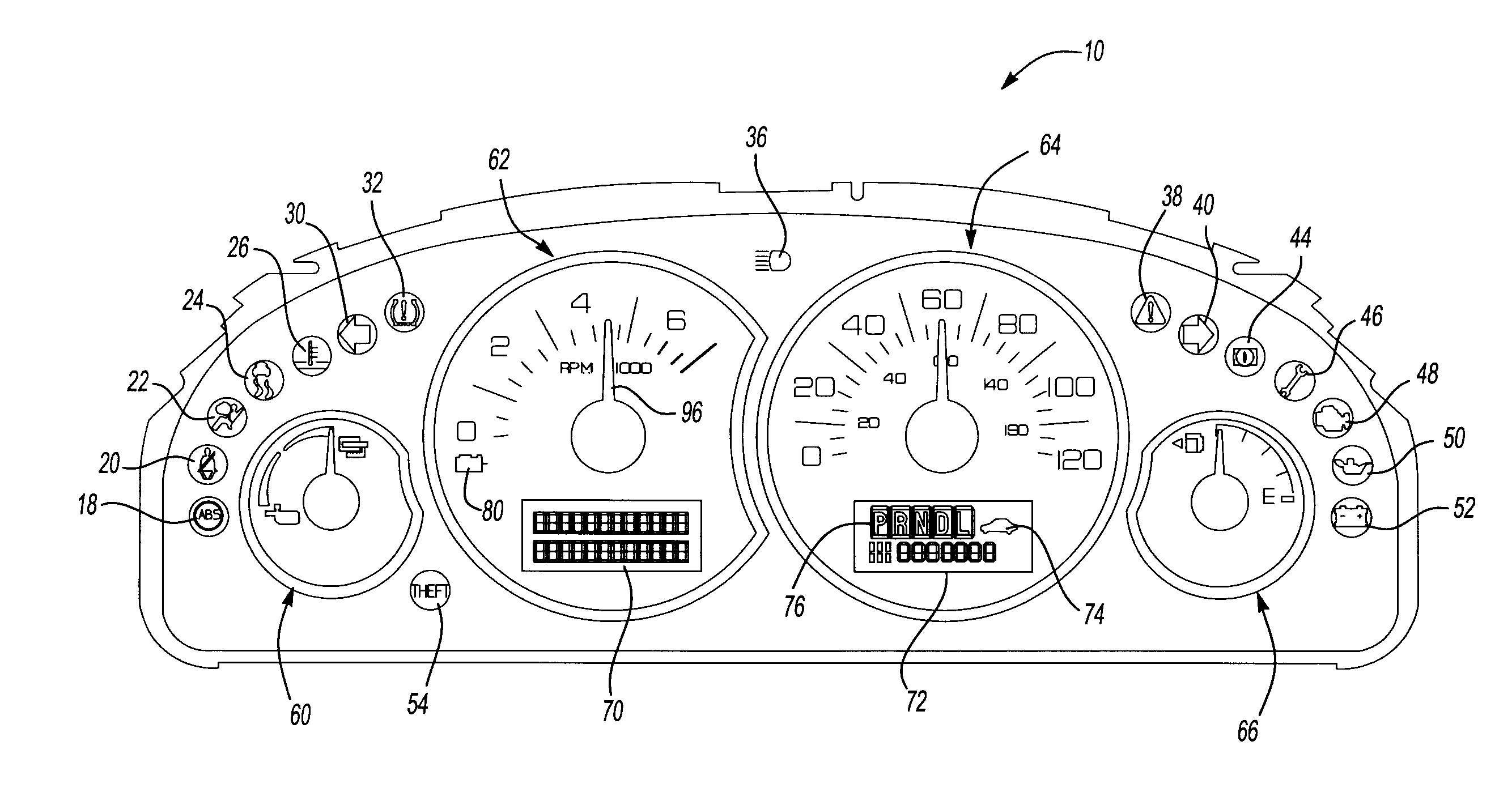

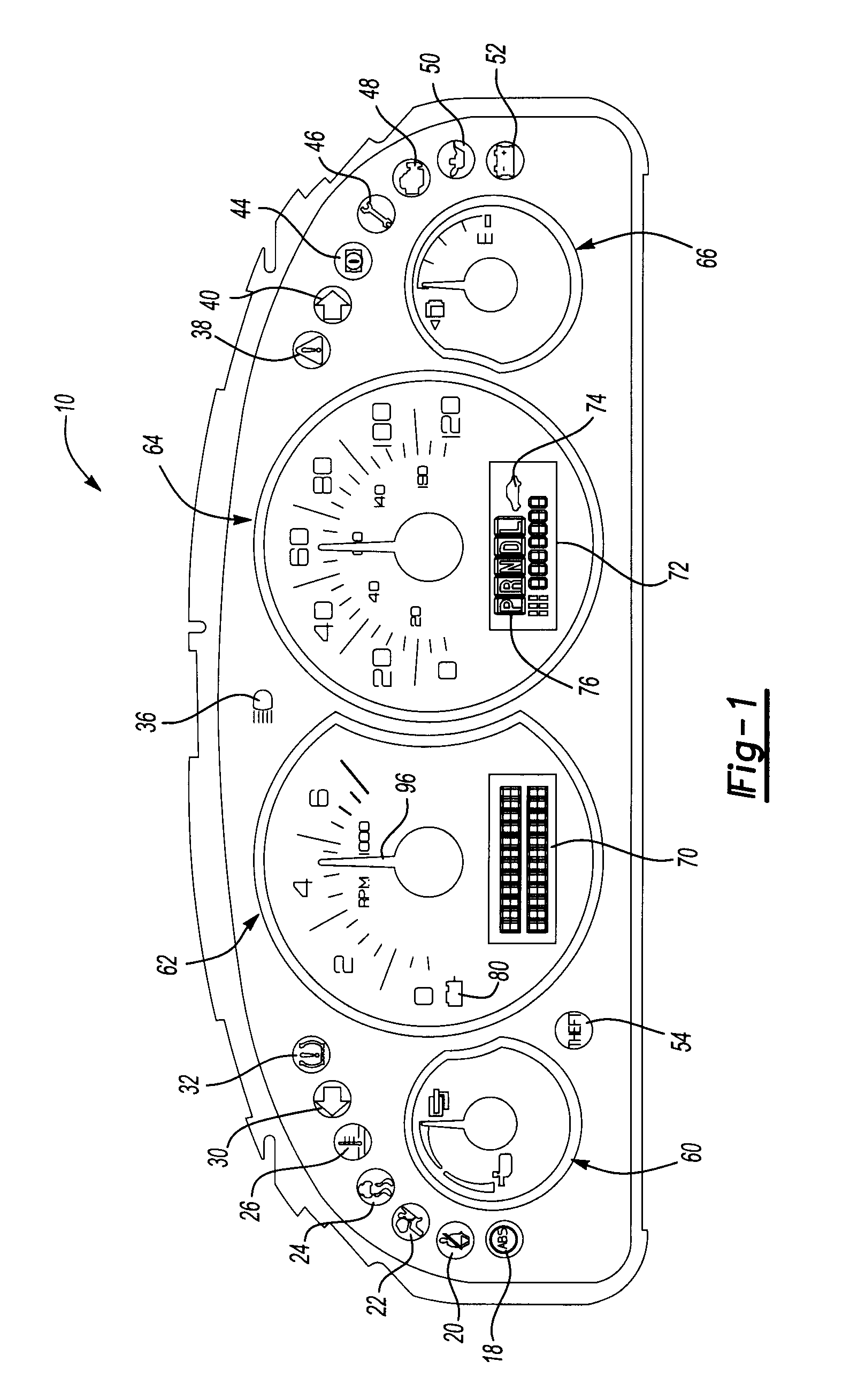

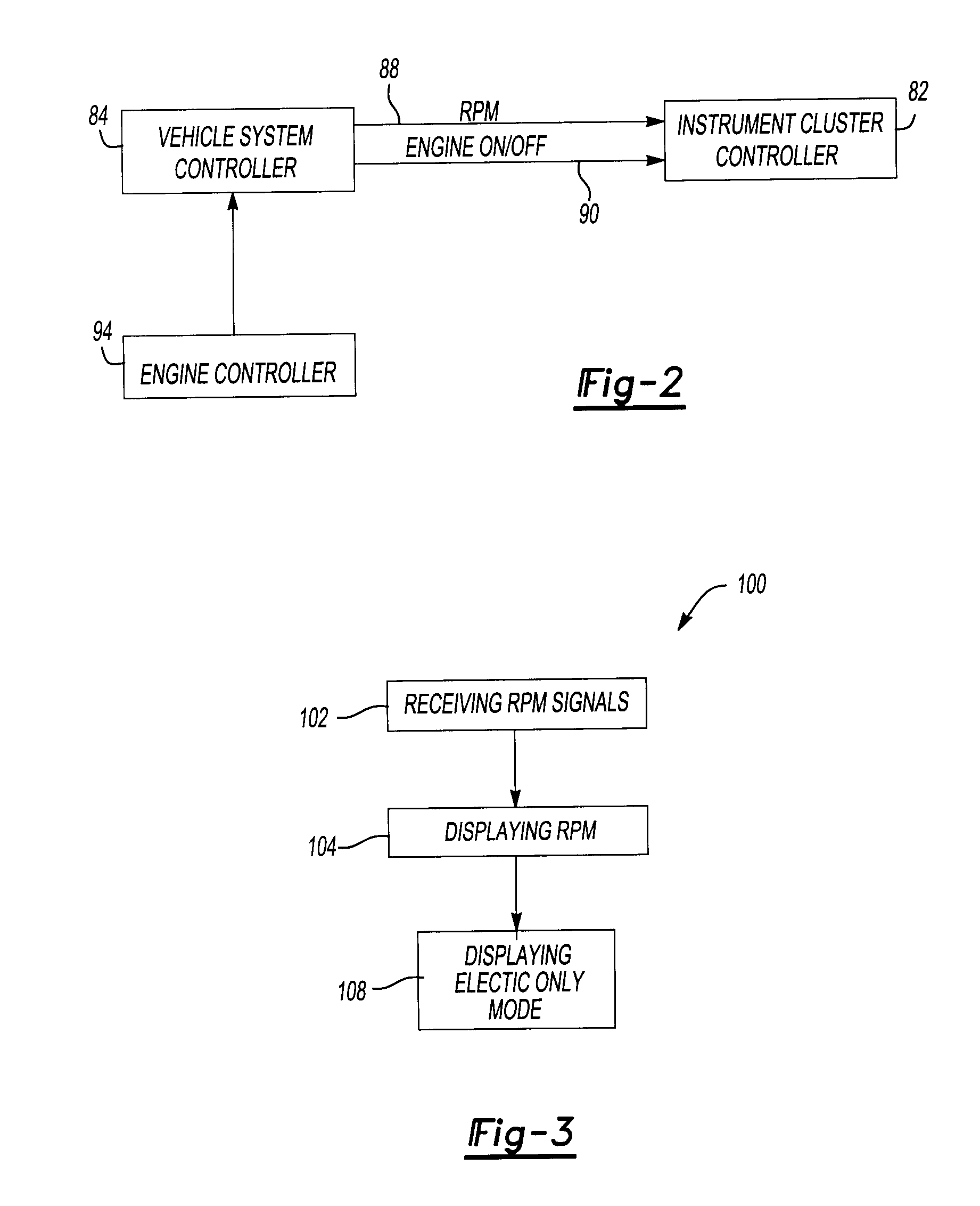

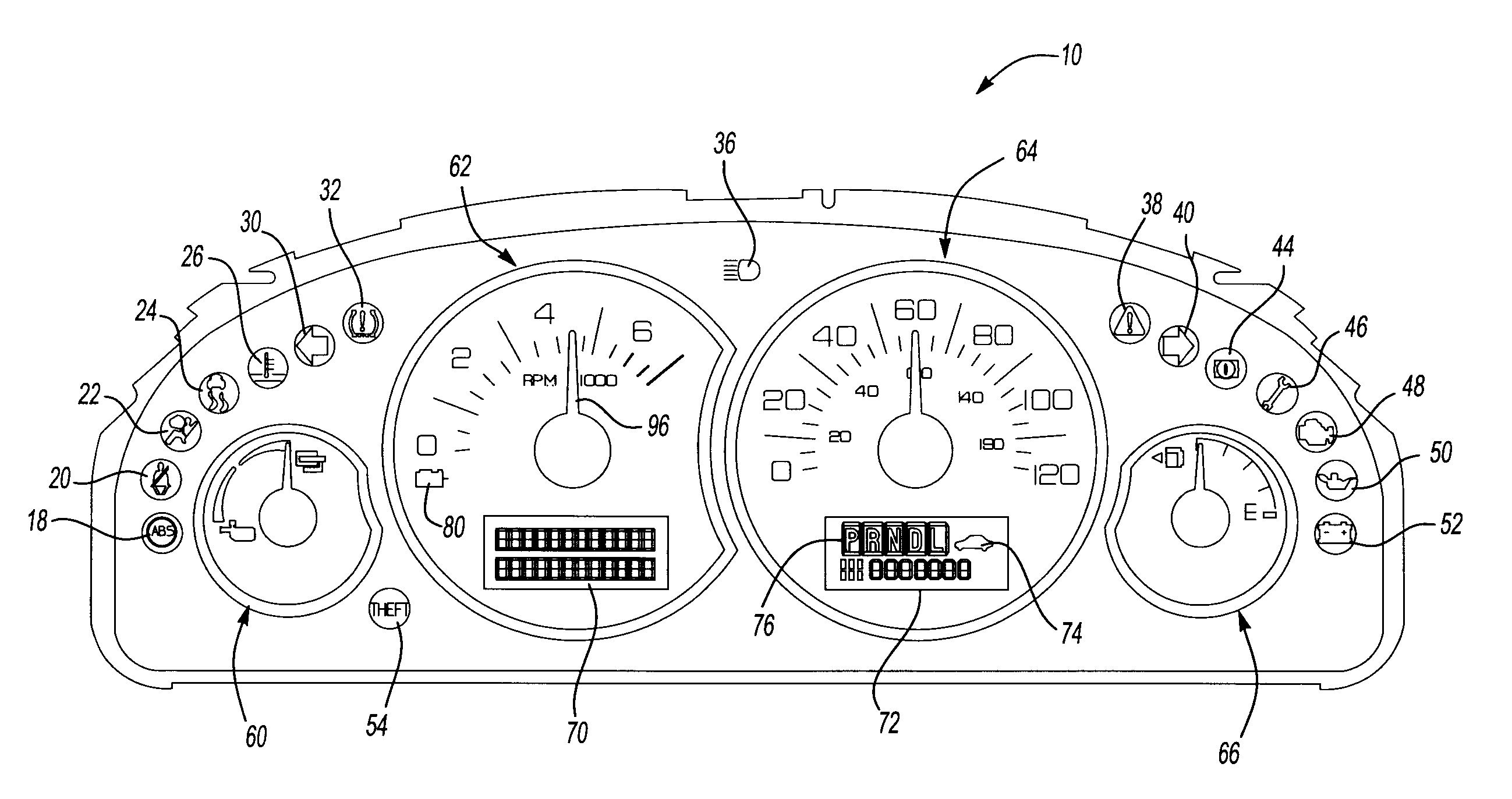

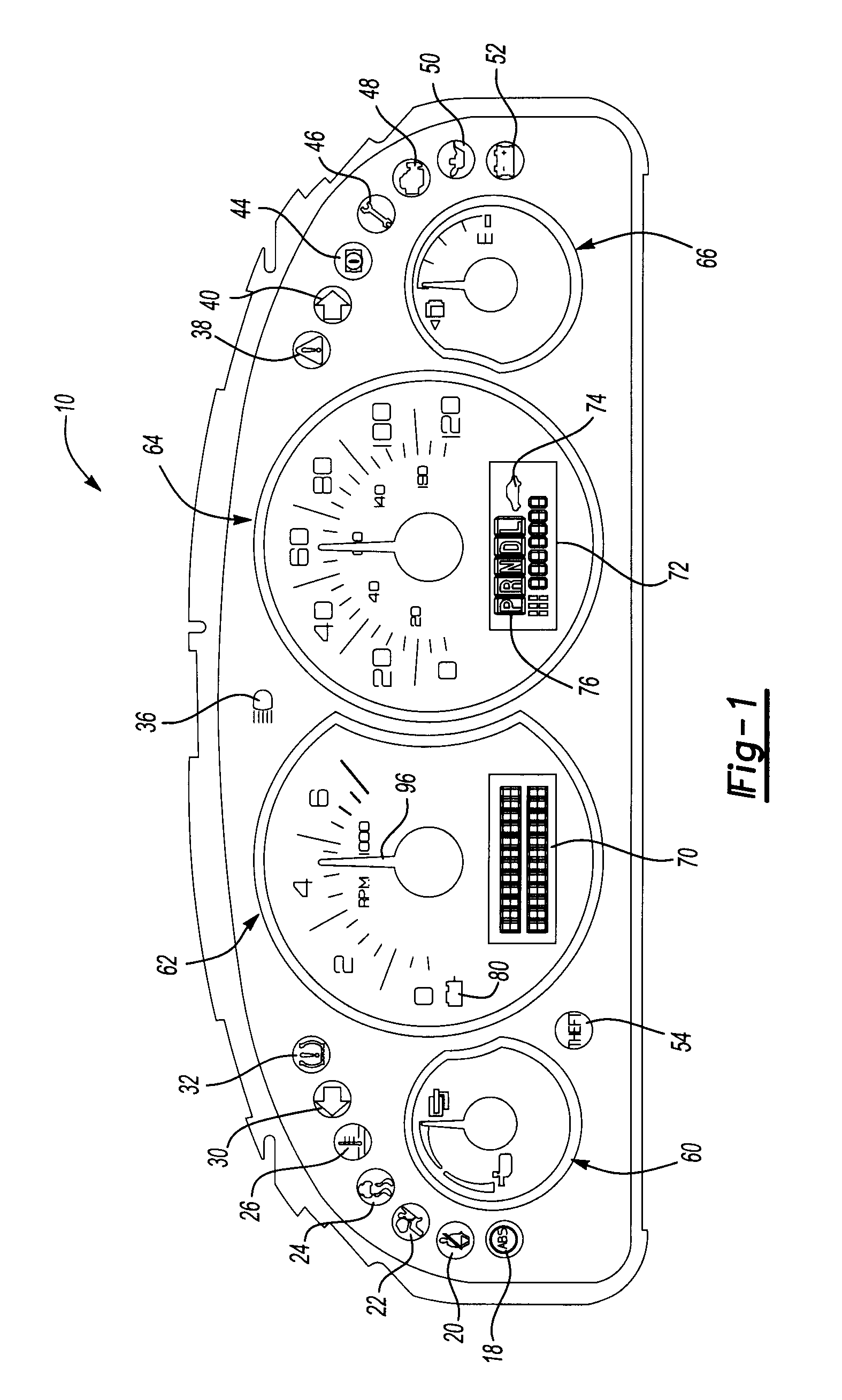

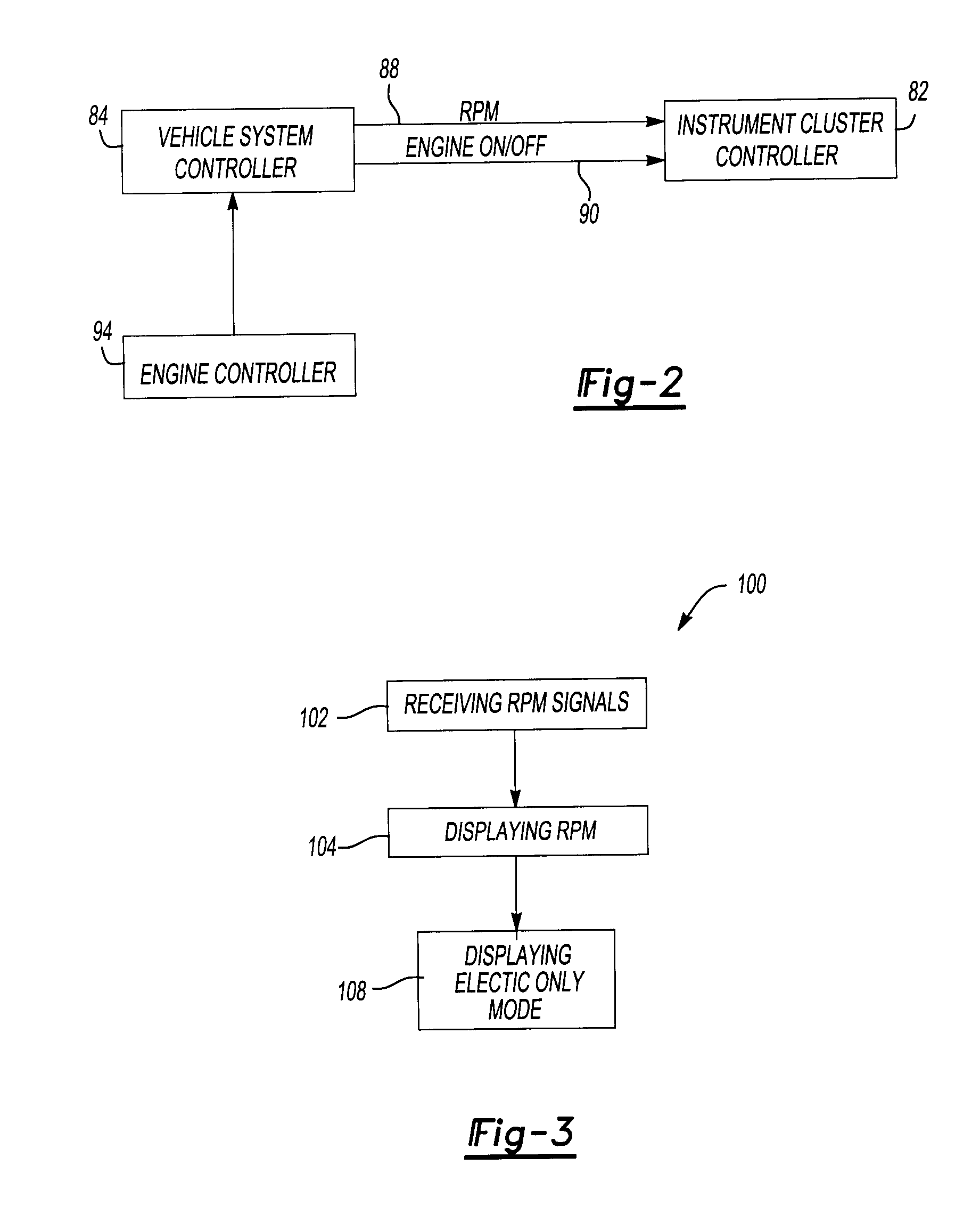

Indicator for a hybrid electric vehicle

ActiveUS7091839B2Hybrid vehiclesInstrument arrangements/adaptationsEngineeringBattery electric vehicle

An indicator for use with an electric vehicle having an engine and an electric traction motor. The indicator includes a tachometer gauge for displaying engine revolution speed. The indicator further includes an electric only indicator for displaying whether the vehicle is operating in an electric only mode.

Owner:FORD GLOBAL TECH LLC

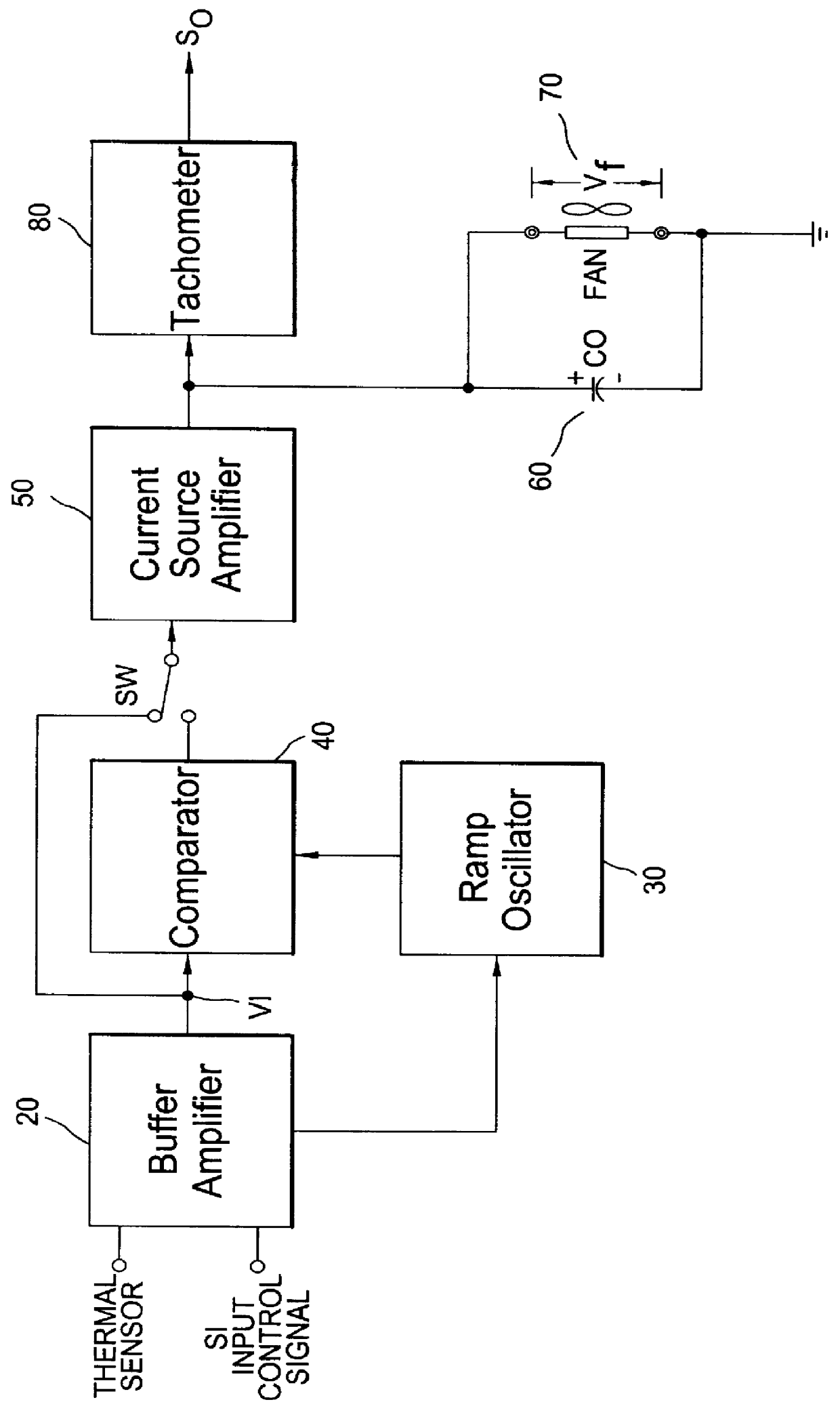

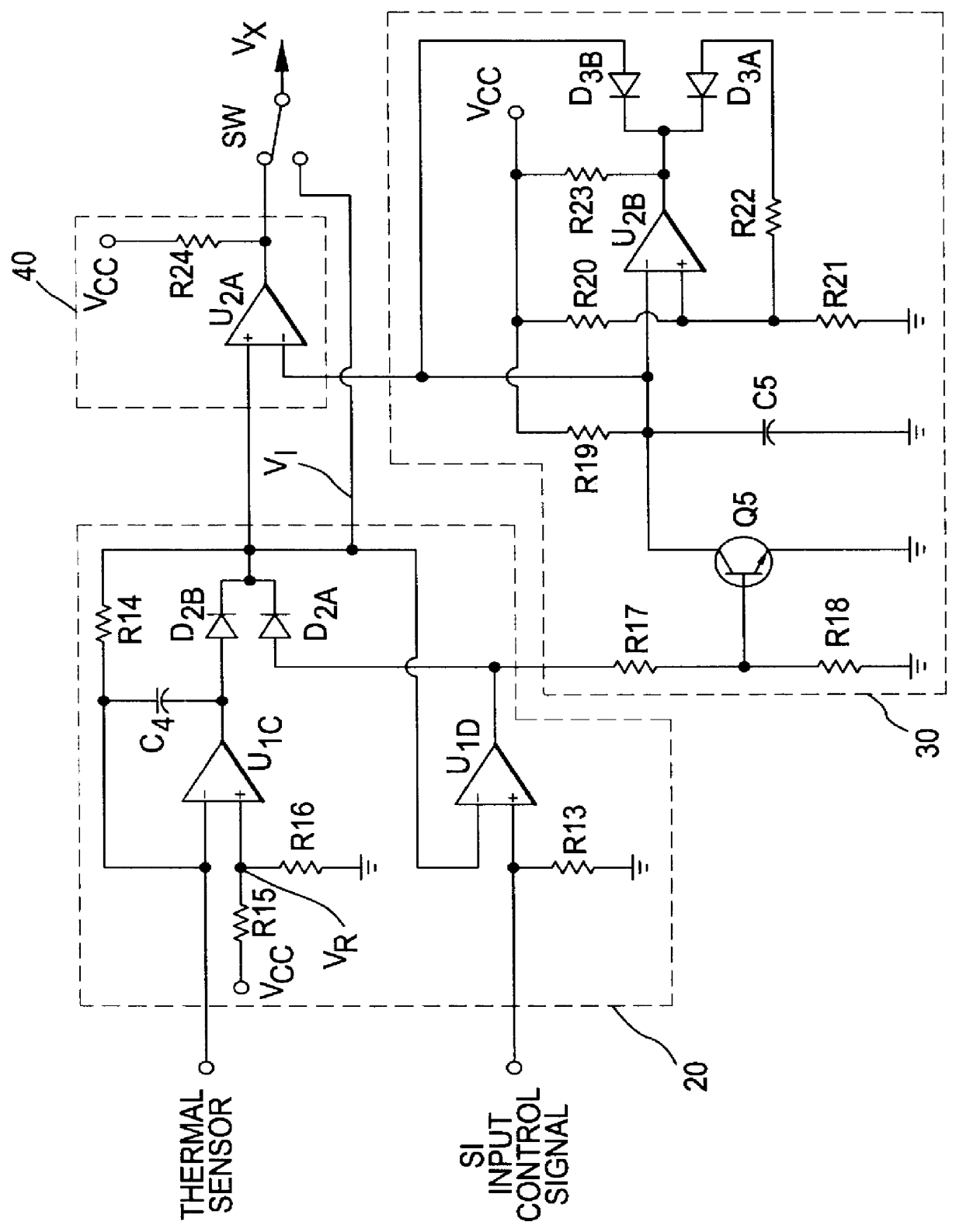

Interface apparatus for fan monitoring and control

InactiveUS6135718ADifficult to filterIncrease output impedancePump componentsTemperatue controlCapacitanceAudio power amplifier

An interface apparatus for fan monitoring and control includes a current source amplifier that generates a programmable current in response to its input voltages. Associated with an output capacitor, which is able to reduce noise, the programmable current drives the fan at a desired speed. The rotating fan induces a ripple signal in the output capacitor, which is fed to a band-pass amplifier to produce a tachometer pulse. Through a buffer amplifier, an input control signal combined with a thermal sensor signal has direct control over the current source amplifier. Alternatively, a PWM circuit having a comparator, a ramp oscillator and the output of the buffer amplifier drives the current source amplifier in switching mode. Since the ramp oscillator can be synchronized by the input, both analog and pulse signals can function as the input control signals.

Owner:SEMICON COMPONENTS IND LLC

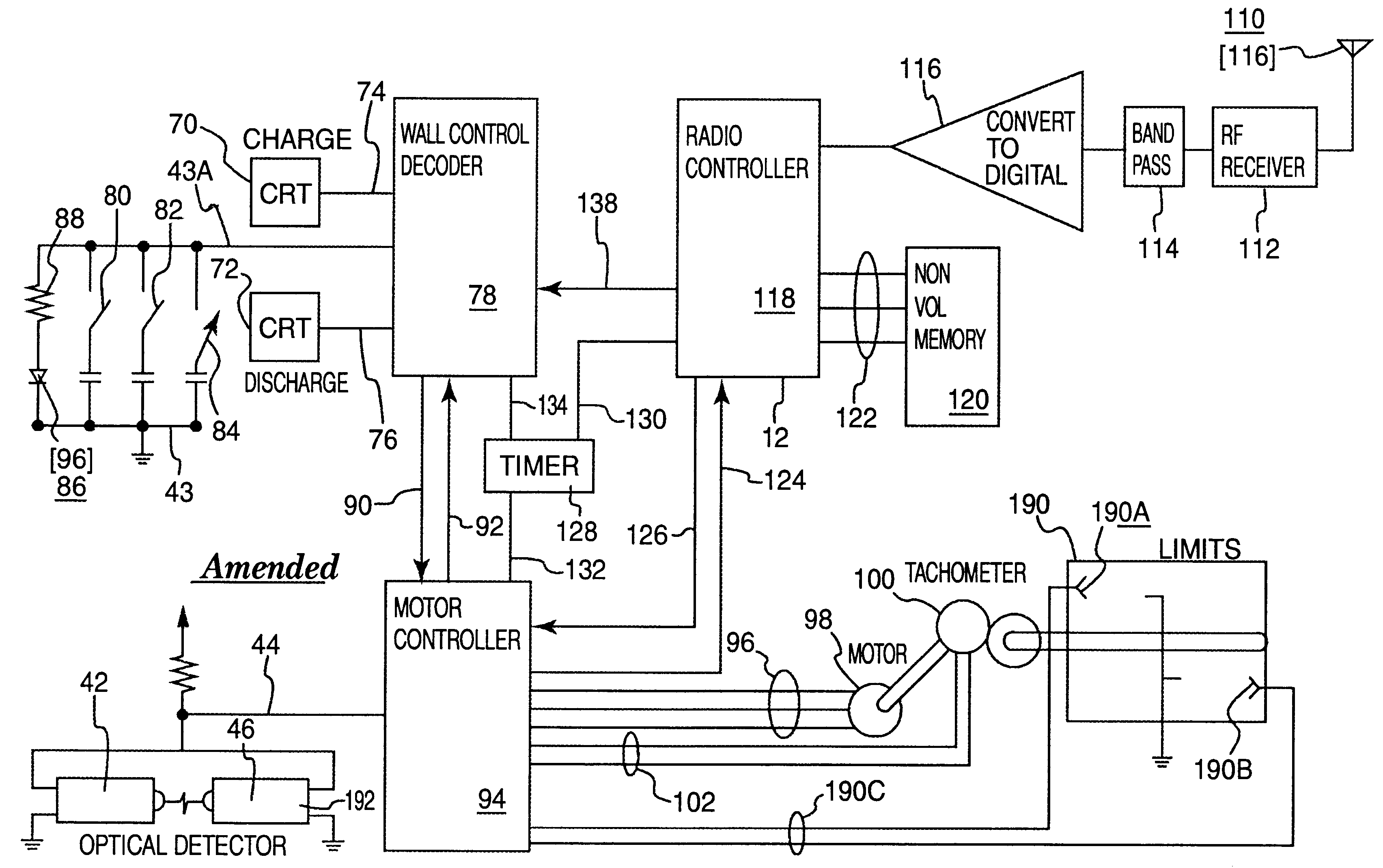

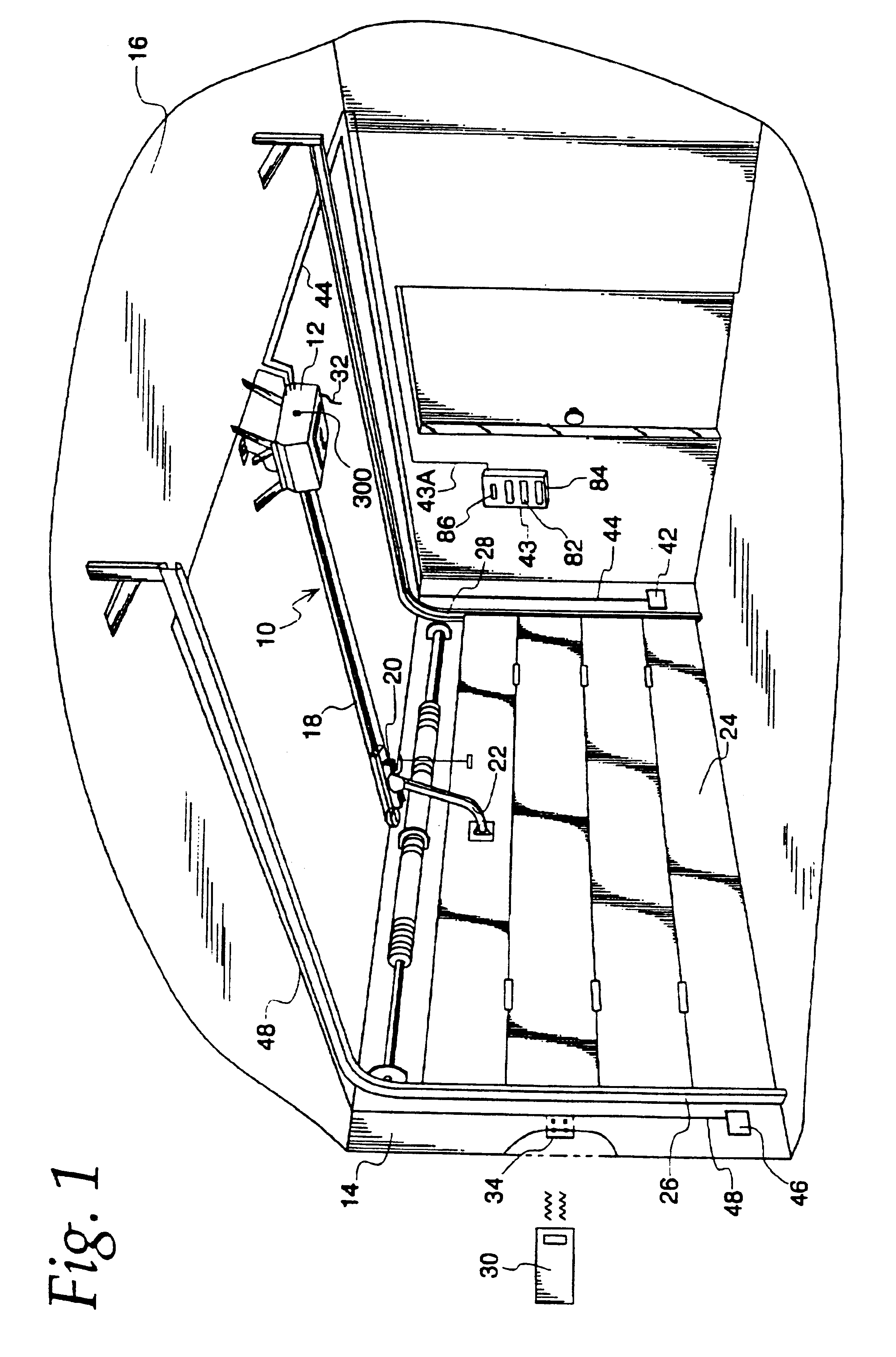

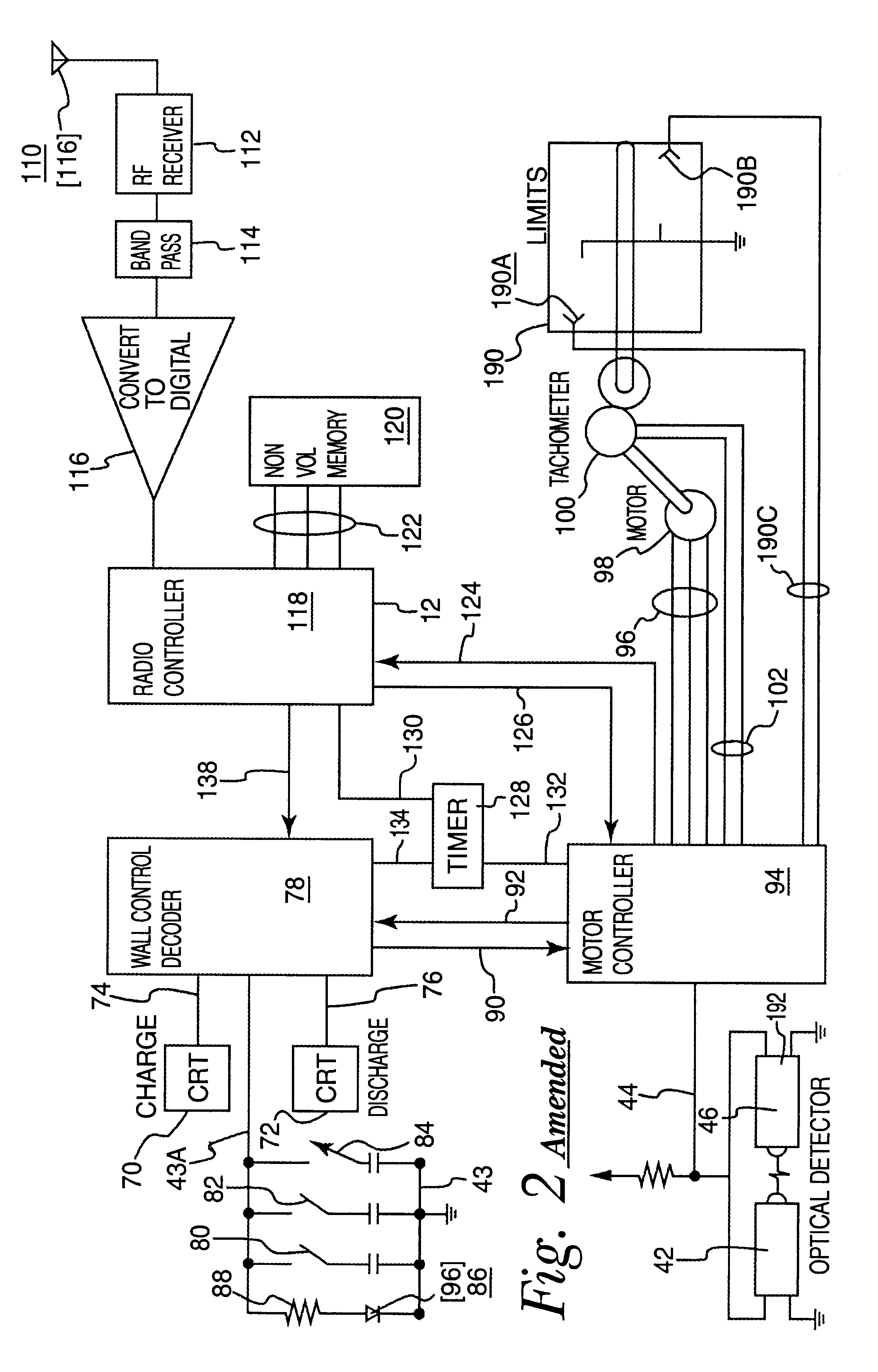

Barrier operator having system for detecting attempted forced entry

InactiveUSRE37784E1Prevent openingDC motor speed/torque controlEmergency protective circuit arrangementsPreventing injuryEngineering

A movable barrier or garage door operator has a barrier drive for moving the movable barrier or garage door between open and closed positions. Motion of the barrier is detected by a tachometer connected to the barrier drive or by upper and lower barrier travel limit switches. A test is made to determine if the barrier has been commanded to be in a closed state and to determine if a preselected time interval has elapsed following closure of the barrier. When both of those conditions are present and the door is moved upward without authorization an alarm signal is generated and can signal the barrier drive to apply a closing force. The timer prevents the barrier from being closed on a person or obstacle during normal operation and prevents injury. An obstacle detector also prevents unwanted closure on an obstacle.

Owner:THE CHAMBERLAIN GRP INC

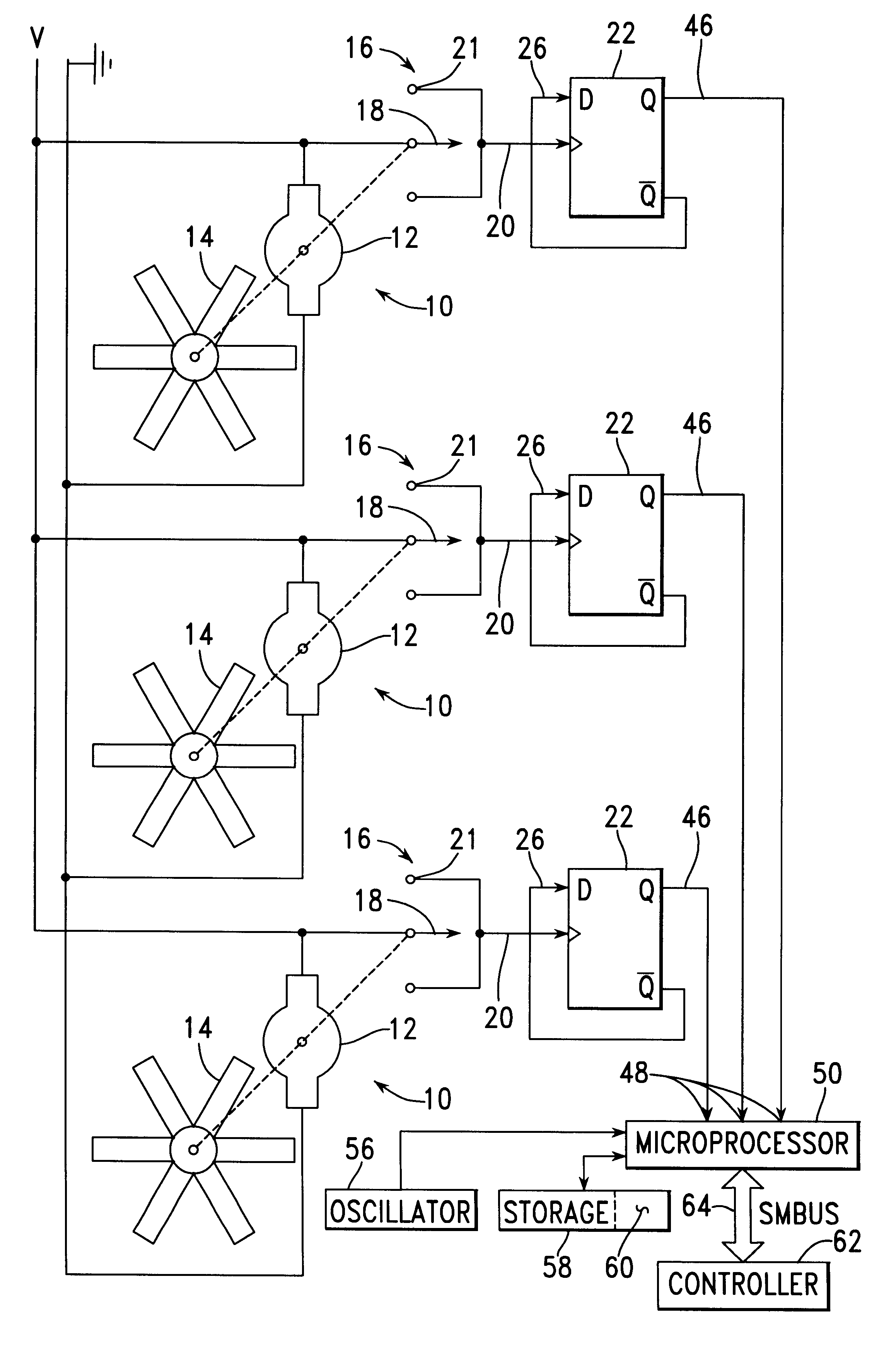

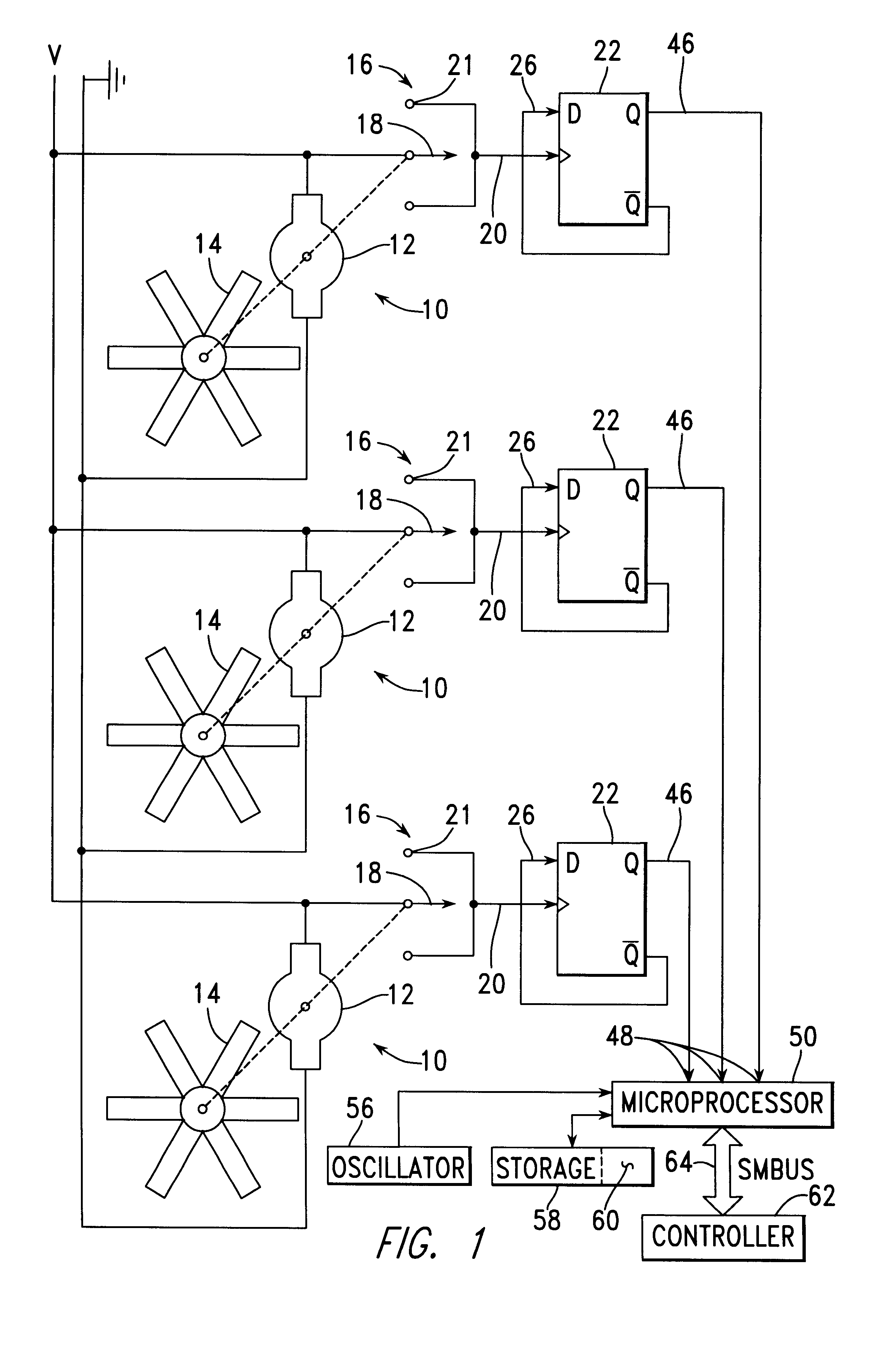

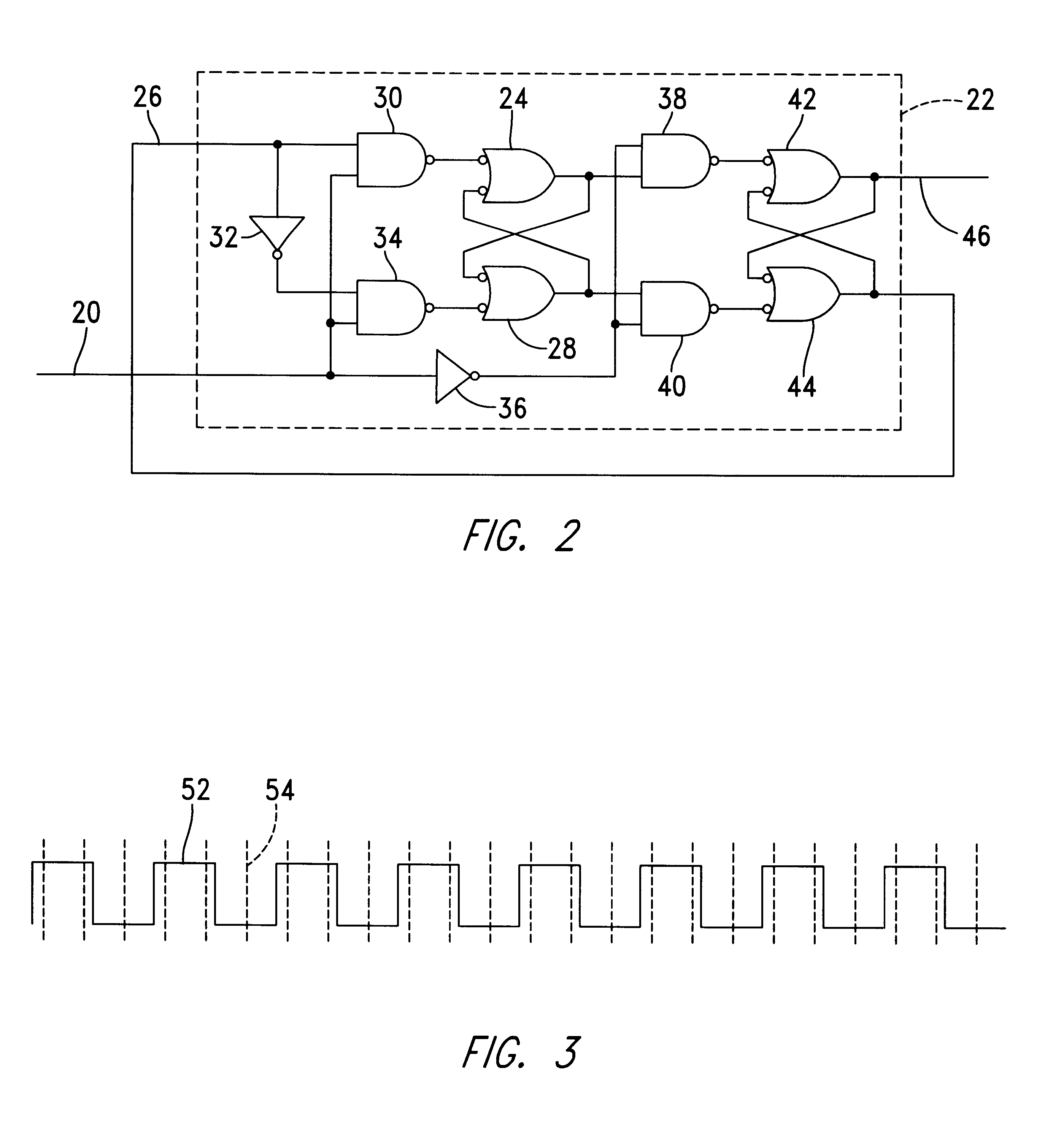

Apparatus and method for monitoring fan speeds within a computing system

InactiveUS6400113B1DC motor speed/torque controlElectric motor controlSignal generatorComputing systems

Apparatus for monitoring fan speeds within a computing system includes a tachometer turning with the fan, providing a tachometer signal including a number of pulses during each revolution of the fan. This tachometer signal is provided as an input to a signal generator in the form of a flip-flop, which generates a square-wave signal having transitions between high and low levels corresponding to tachometer signal pulses. The square-wave signals are provided as inputs to separate input ports of a microprocessor. These input ports are sequentially sampled at a rate providing at least two samples per period of the fastest square-wave signal, so that transitions of each square wave signal during a predetermined time interval can be detected and counted. For each input port, the number of counted transitions is compared to a stored acceptable value to establish whether the fan is operating in an acceptable speed range.

Owner:IBM CORP

Indicator for a hybrid electric vehicle

ActiveUS20050200463A1Hybrid vehiclesInstrument arrangements/adaptationsElectric vehicleElectric traction

An indicator for use with an electric vehicle having an engine and an electric traction motor. The indicator includes a tachometer gauge for displaying engine revolution speed. The indicator further includes an electric only indicator for displaying whether the vehicle is operating in an electric only mode.

Owner:FORD GLOBAL TECH LLC

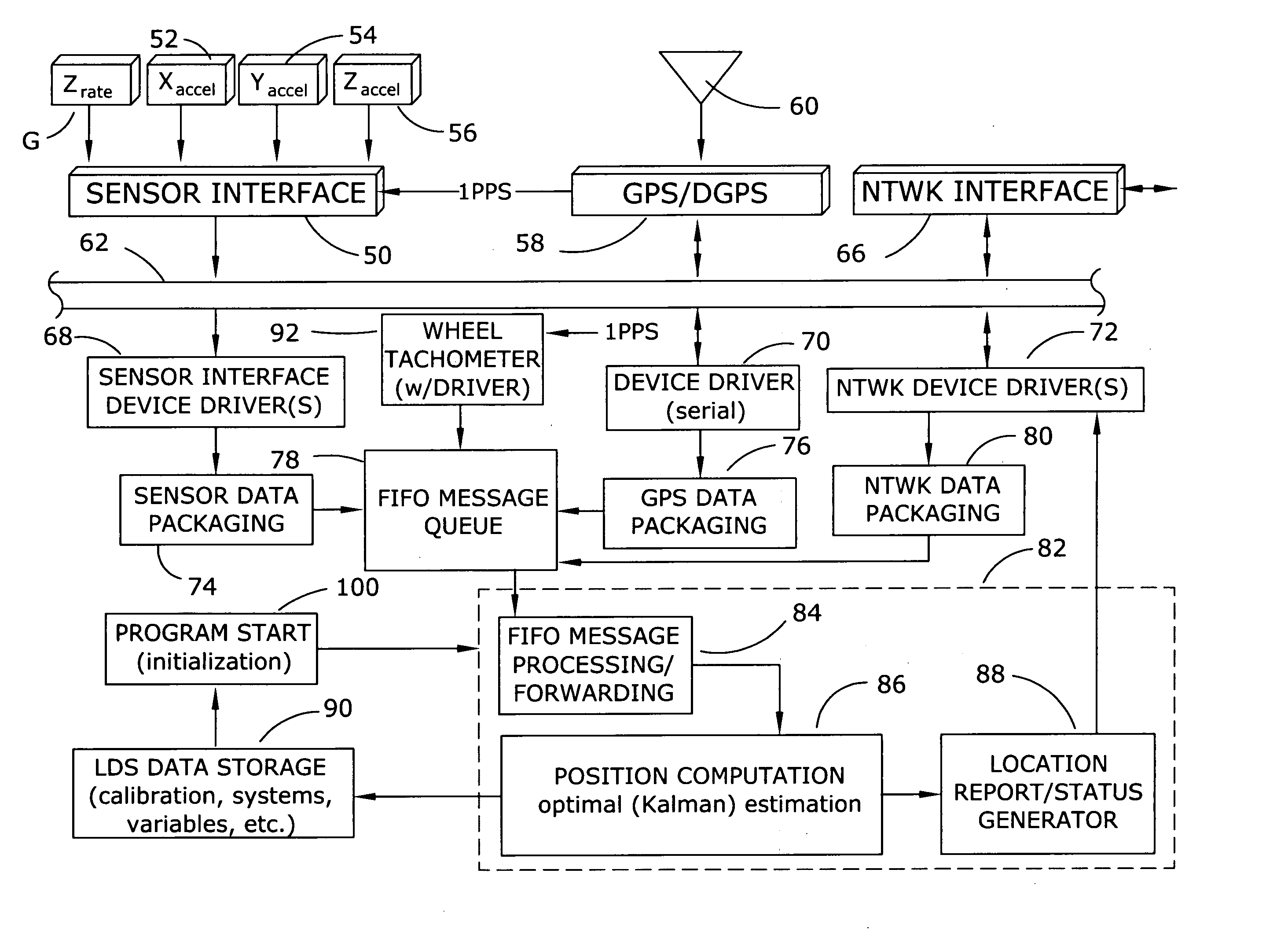

Locomotive location system and method

InactiveUS20050065726A1Improve accuracyInstruments for road network navigationDigital data processing detailsEngineeringMOTION LIMITATION

A locomotive location system and method utilizes inertial measurement inputs, including orthogonal acceleration inputs and turn rate information, in combination with wheel-mounted tachometer information and GPS / DGPS position fixes to provide processed outputs indicative of track occupancy, position, direction of travel, velocity, etc. Various navigation solutions are combined together to provide the desired information outputs using an optimal estimator designed specifically for rail applications and subjected to motion constraints reflecting the physical motion limitations of a locomotive. The system utilizes geo-reconciliation to minimize errors and solutions that identify track occupancy when traveling through a turnout.

Owner:AUSTRALIAN RAIL TRACK CORP

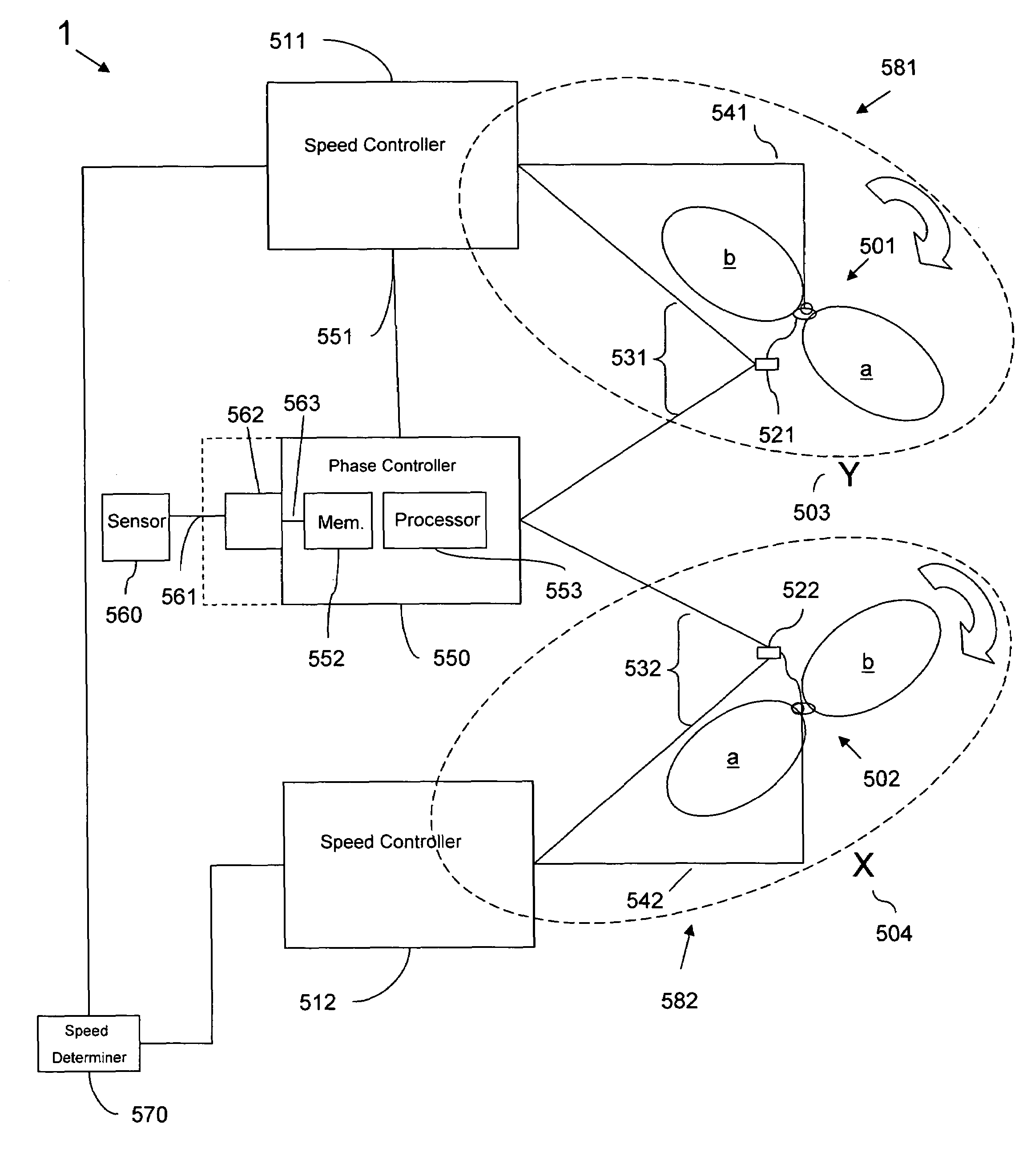

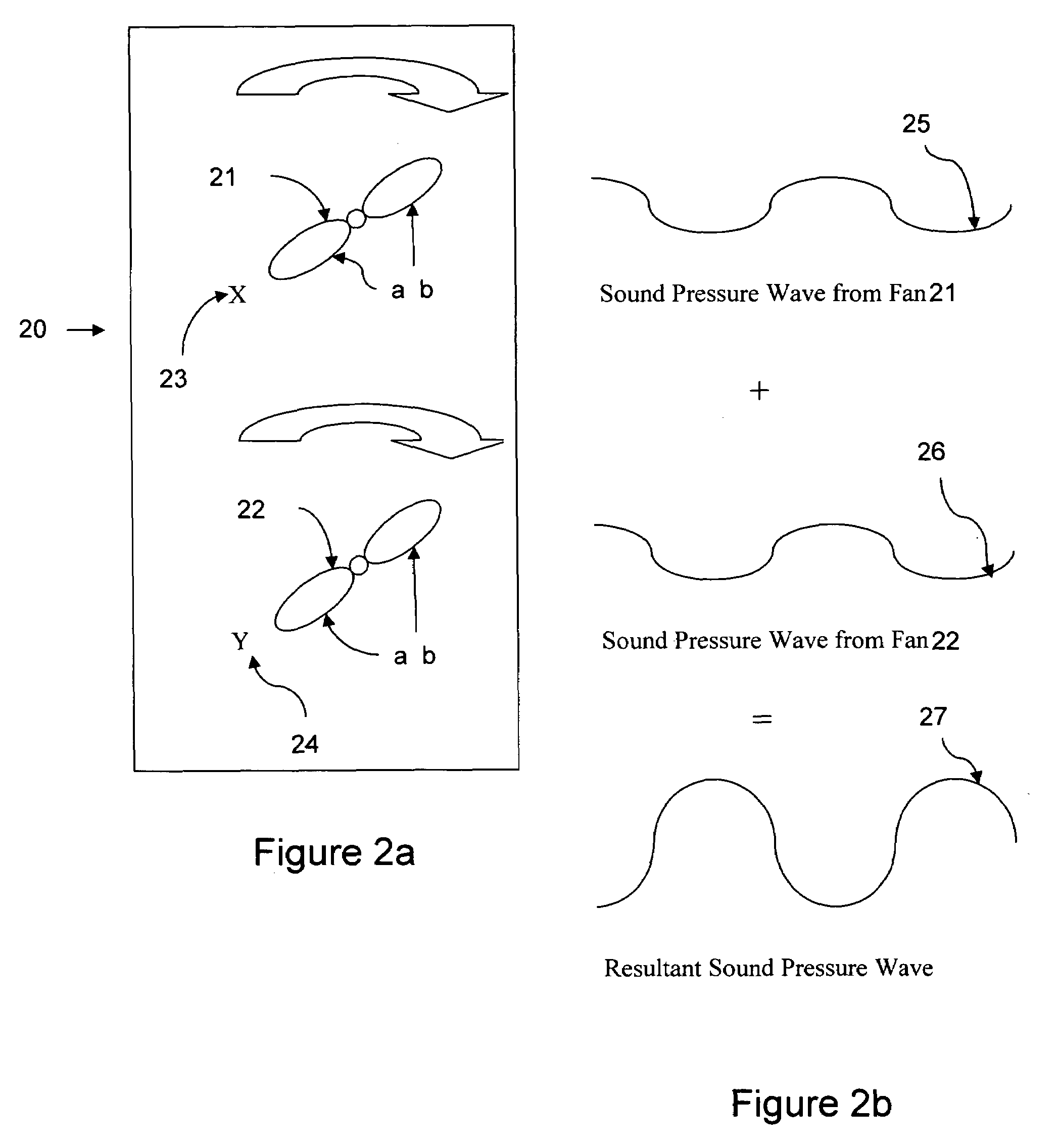

Mutual active cancellation of fan noise and vibration

ActiveUS7282873B2Reduce vibration and noiseReduce noiseDC motor speed/torque controlMultiple dynamo-motor startersPhase differenceEngineering

A multi-fan apparatus and method incorporates mutual active cancellation of fan noise and / or vibrations. The multi-fan apparatus includes two or more fans circuits, each comprising a fan, a fan speed controller and a separate tachometer, and a fan phase controller. The phase controller is connected to at least one fan speed controller and to each tachometer. Each fan's speed is independently and dynamically maintained at the same set speed by the fan speed controllers using an independent control loops. A noise and / or vibration cancellation phase difference between fans is determined in order to achieve destructive interference of pressure waves and, thus, noise and / or vibration reduction, in pre-determined region of a system incorporating the multi-fan apparatus. The phase controller establishes and maintains this cancellation phase difference between the fans based upon feedback from the tachometers.

Owner:LENOVO PC INT

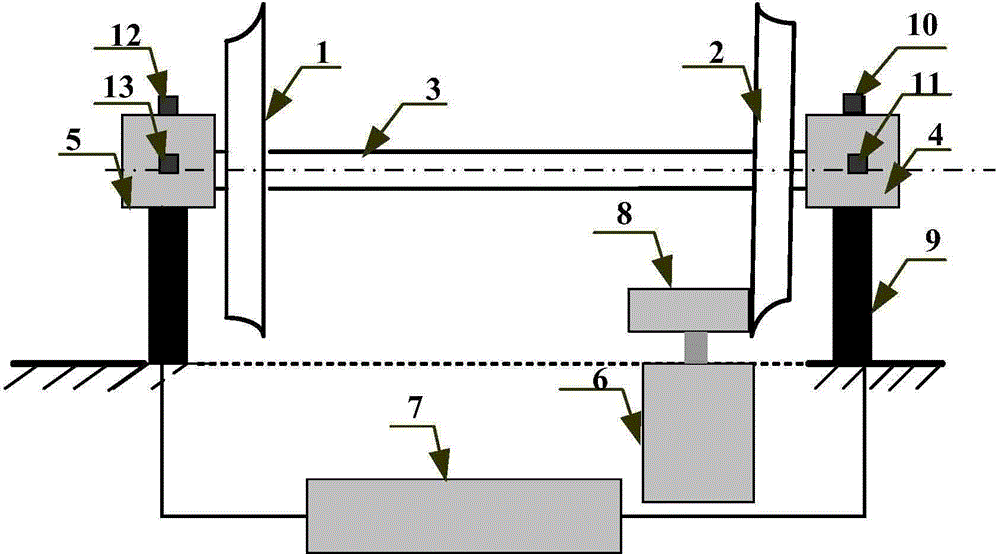

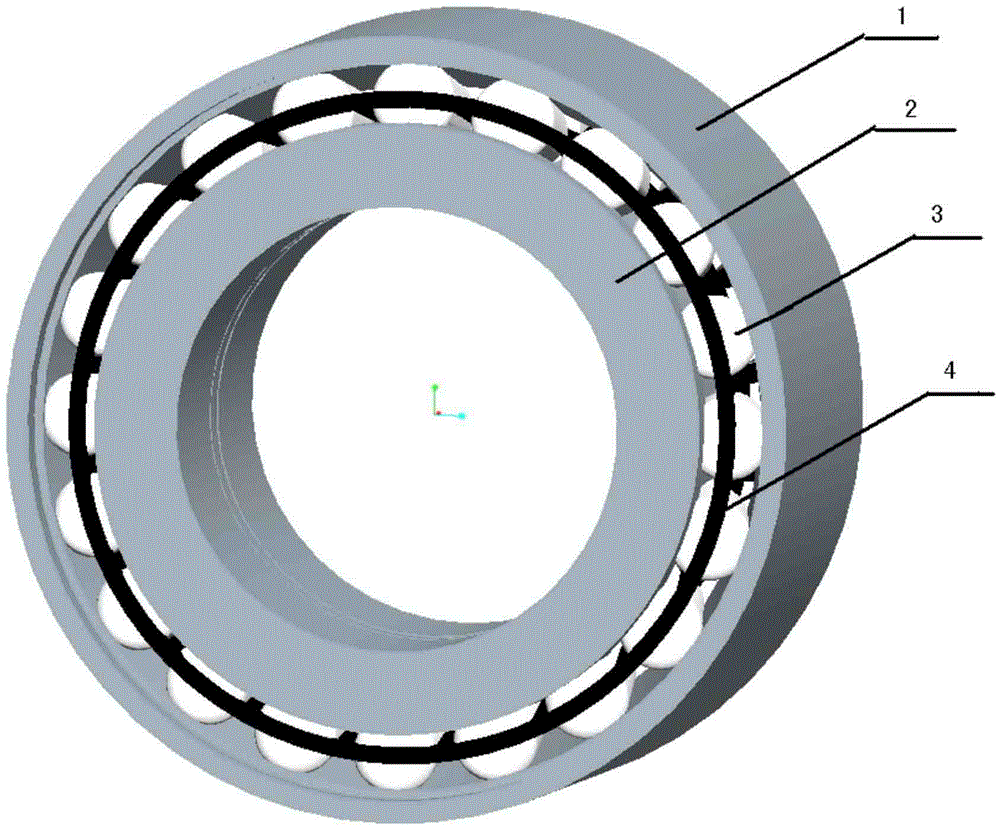

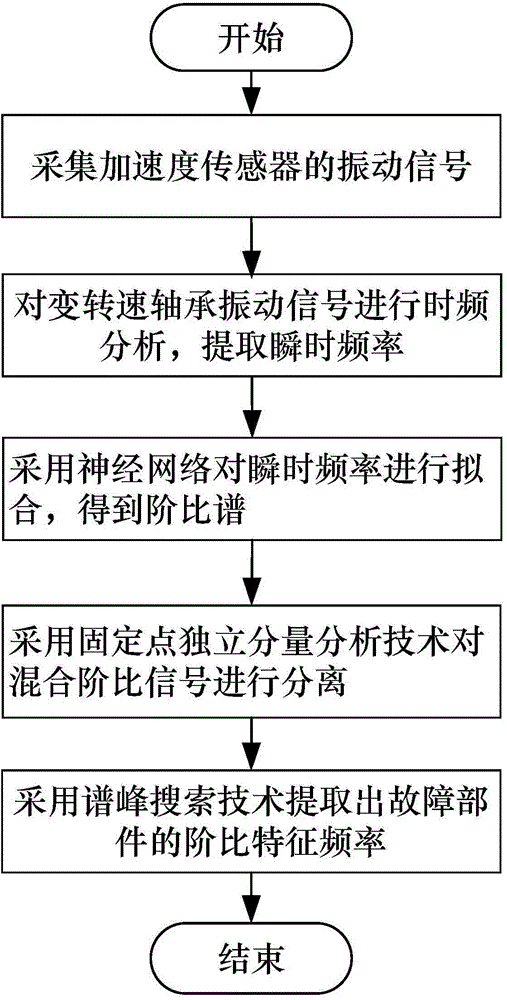

Method for extracting fault characteristic frequencies of train rolling bearings with variable rotational speeds

ActiveCN104568444AIncrease flexibilityCancel noiseMachine bearings testingRolling-element bearingSignal on

The invention discloses a method for extracting fault characteristic frequencies of train rolling bearings with variable rotational speeds, and belongs to the field of technologies for diagnosing faults and processing signals. The method includes steps of analyzing vibration signals of the bearings with the variable rotational speeds in time and frequency domains, searching local peak values of the vibration signals and extracting instantaneous frequency values corresponding to the rotational speeds at different moments; fitting instantaneous frequencies by the aid of neural networks, acquiring rotational speed curves of reference spindles, re-sampling original signals at uniform angles on the basis of the rotational speed curves and analyzing order ratios of the original signals on the basis of the rotational speed curves; separating signals with mixed order ratio signals by the aid of fixed-point independent component analysis and spectrum peak search technologies to acquire order ratio component characteristics of fault components of the bearings. The method has the advantages that the method is used for estimating the rotational speeds of the train bearings without tachometers in real time, the instable fault bearing signals can be converted into the stable signals in uniform-angle domains, independent order ratio components can be effectively separated from the signals, and the method is favorable for extracting the fault characteristic frequencies of the train bearings and detecting the fault characteristic frequencies of the train bearings in an online manner.

Owner:BEIJING UNIV OF POSTS & TELECOMM

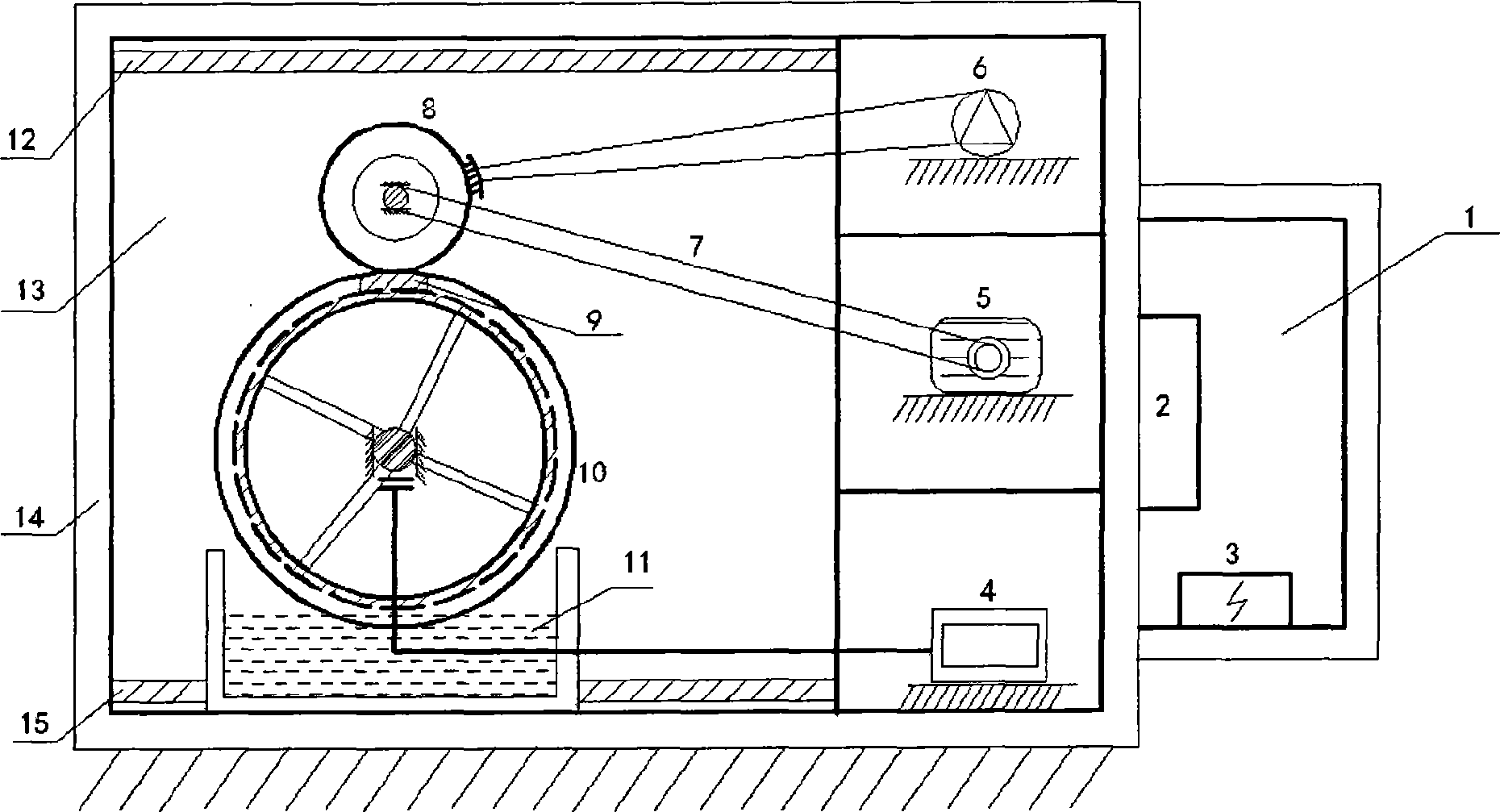

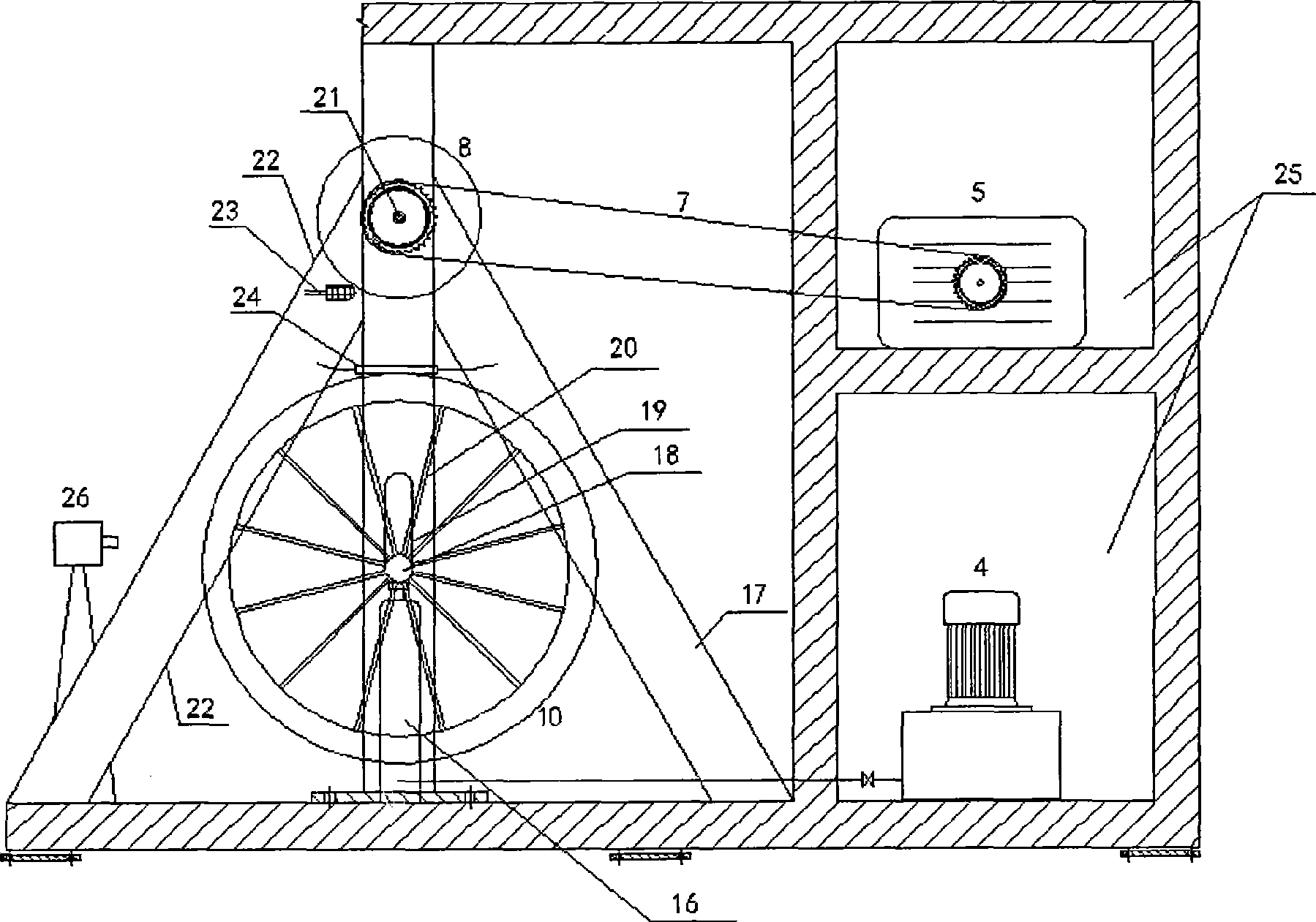

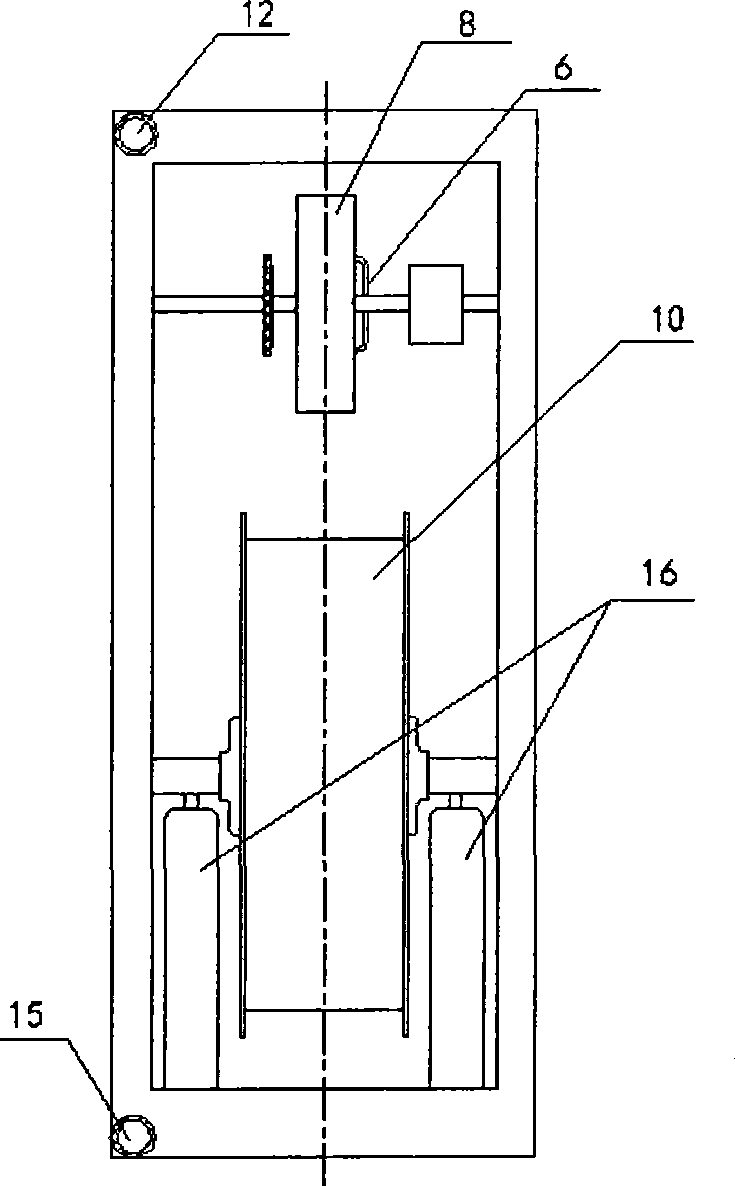

Method for testing accelerating and loading of main drive wheel type pavement materials and device

InactiveCN101532934AImprove guidanceImprove applicabilityMaterial strength using tensile/compressive forcesUsing mechanical meansWater bathsDrive wheel

The invention discloses a method for testing accelerating and loading of main drive wheel type pavement materials and a device thereof. The device comprises a control console, a PLC control box, an electronic box, a hydraulic device, a motor, a brake, a driving chain and chain wheel, a drive wheel, a driven wheel, a water bath tank, a circulated air inlet duct, a thermostatic chamber, a test cabinet and a circulated air outlet duct; the control console is positioned on the outside of the test cabinet; the hydraulic device is connected with the driven wheel; the motor is connected with the drive wheel via the driving chain and chain wheel; the drive wheel is fixed on a bracket; the driven wheel is positioned in a guide slot; the water bath tank is arranged right below the driven wheel; a ranging laser is positioned on one side of the driven wheel; one end of the drive wheel is provided with a microphone and the bottom thereof is provided with a torque sensor; the contact surface of the drive wheel and a test piece is provided with a pressure sensor; two tachometers are fixed on the bracket and are respectively positioned on the outsides of the drive wheel and the driven wheel. The device has simple structure, low prices, flexible use and good reliability.

Owner:SOUTH CHINA UNIV OF TECH

System and method for vitally determining position and position uncertainty of a railroad vehicle employing diverse sensors including a global positioning system sensor

A system vitally determines a position of a train. The system includes a plurality of diverse sensors, such as tachometers and accelerometers, structured to repetitively sense at least change in position and acceleration of the train, a global positioning system sensor, which is diverse from each of the diverse sensors, structured to repetitively sense position of the train, and a track map including a plurality of track segments which may be occupied by the train. A processor cooperates with the diverse sensors, the global positioning system sensor and the track map. The processor includes a routine structured to provide measurement uncertainty for each of the diverse sensors and the global positioning system sensor. The routine cross-checks measurements for the diverse sensors, and cross-checks the global positioning system sensor against the track map. The routine provides the vitally determined position of the train and the uncertainty of the vitally determined position.

Owner:ANSALDO STS USA INC

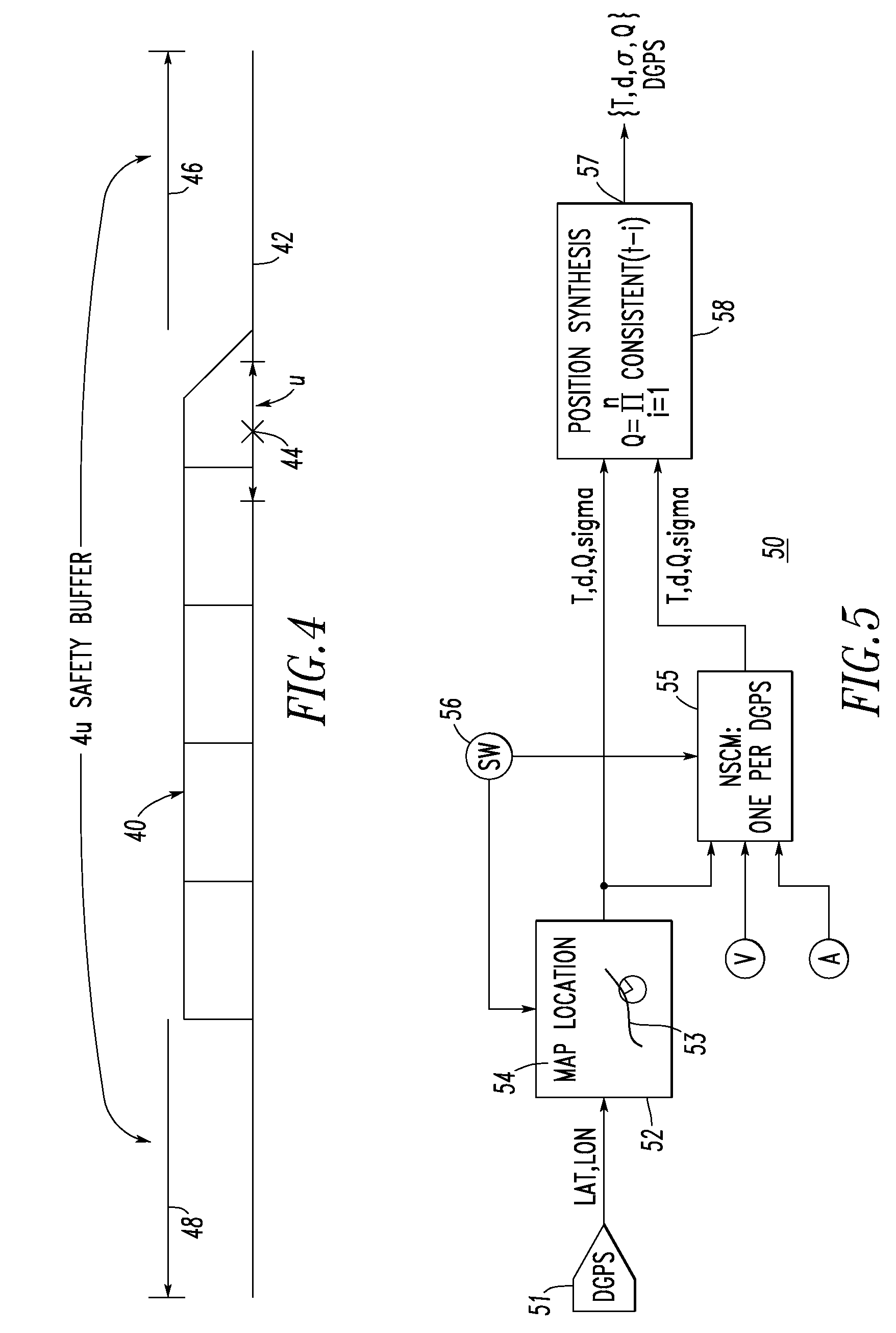

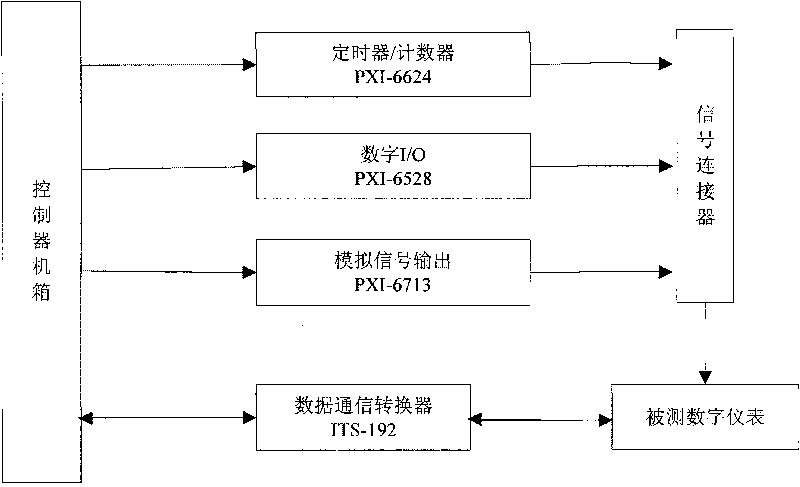

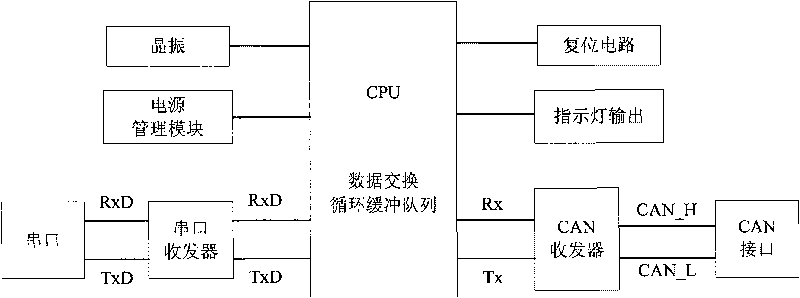

LabVIEW and PXI based automobile digital instrument testing system

InactiveCN101699224ASecure data communicationMeet the test requirementsSpecific program execution arrangementsIntegration testingEngineering

The invention discloses a LabVIEW and PXI based automobile digital instrument testing system, which comprises a LabVIEW graphical program compiling platform and a PXI hardware platform which are in charge of testing the automobile digital instrument to be tested, a speedometer, a tachometer of an engine, a fuel gauge, a water-temperature gauge, a switching value testing module, a user-customized CAN communication testing module which is used for testing and calibrating a digital instrument with a CAN interface to test a communication protocol and a calibration protocol, and a data communication switching card for calibrating parameters of the instrument to be tested and implementing data exchange between an interface of a controller serial port and the CAN interface of the automobile digital instrument to be tested, wherein a related board card is connected with a controller mainboard and is connected with the automobile digital instrument to be tested through a signal connector; the data communication switching card adopts a circulating queue-based buffering mechanism. The system can perform module testing on the speedometer, the tachometer, the water-temperature gauge, the fuel gauge and a switching value signal by modules, and also can perform integration testing on the digital instrument.

Owner:CHINA AUTOMOTIVE TECH & RES CENT

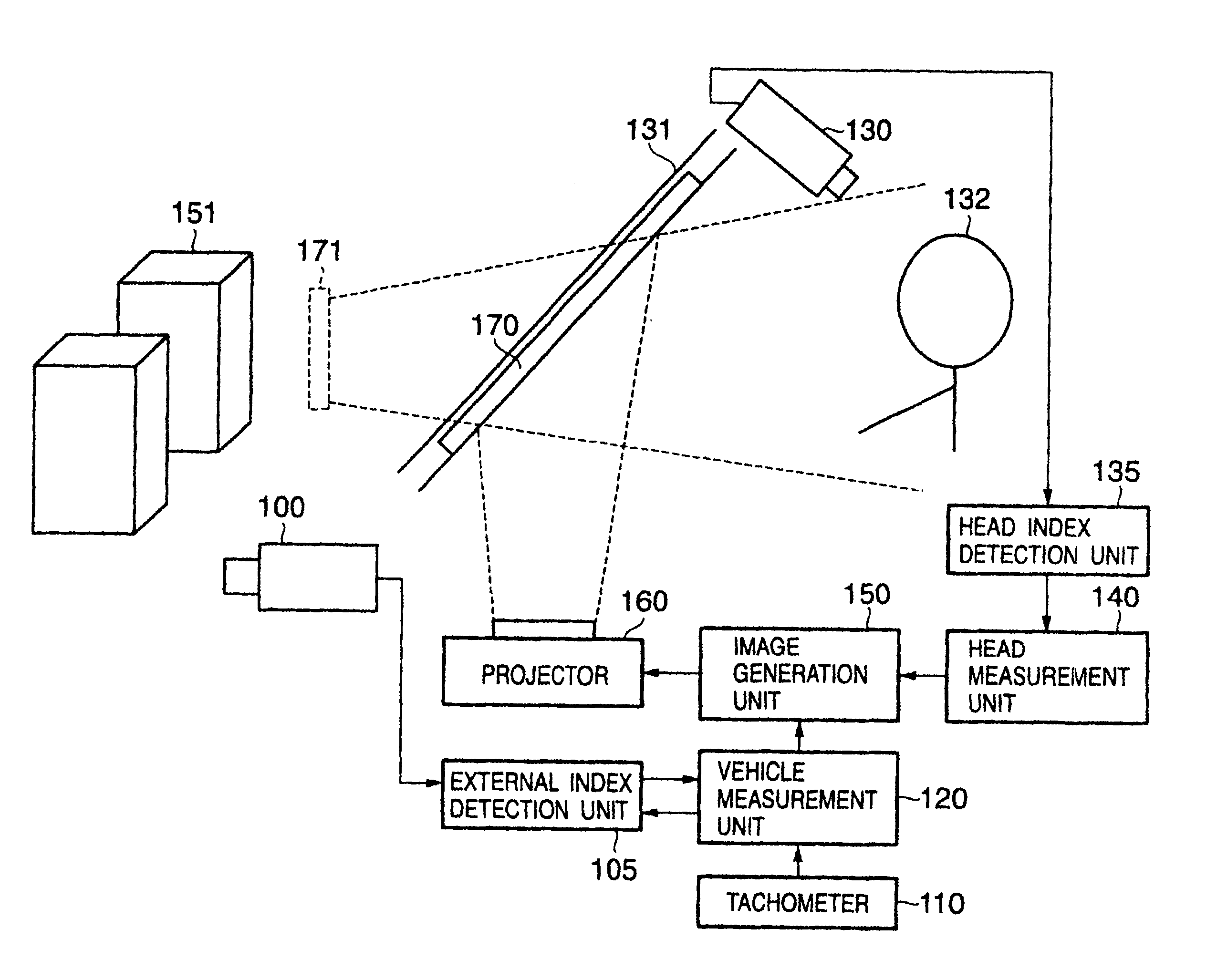

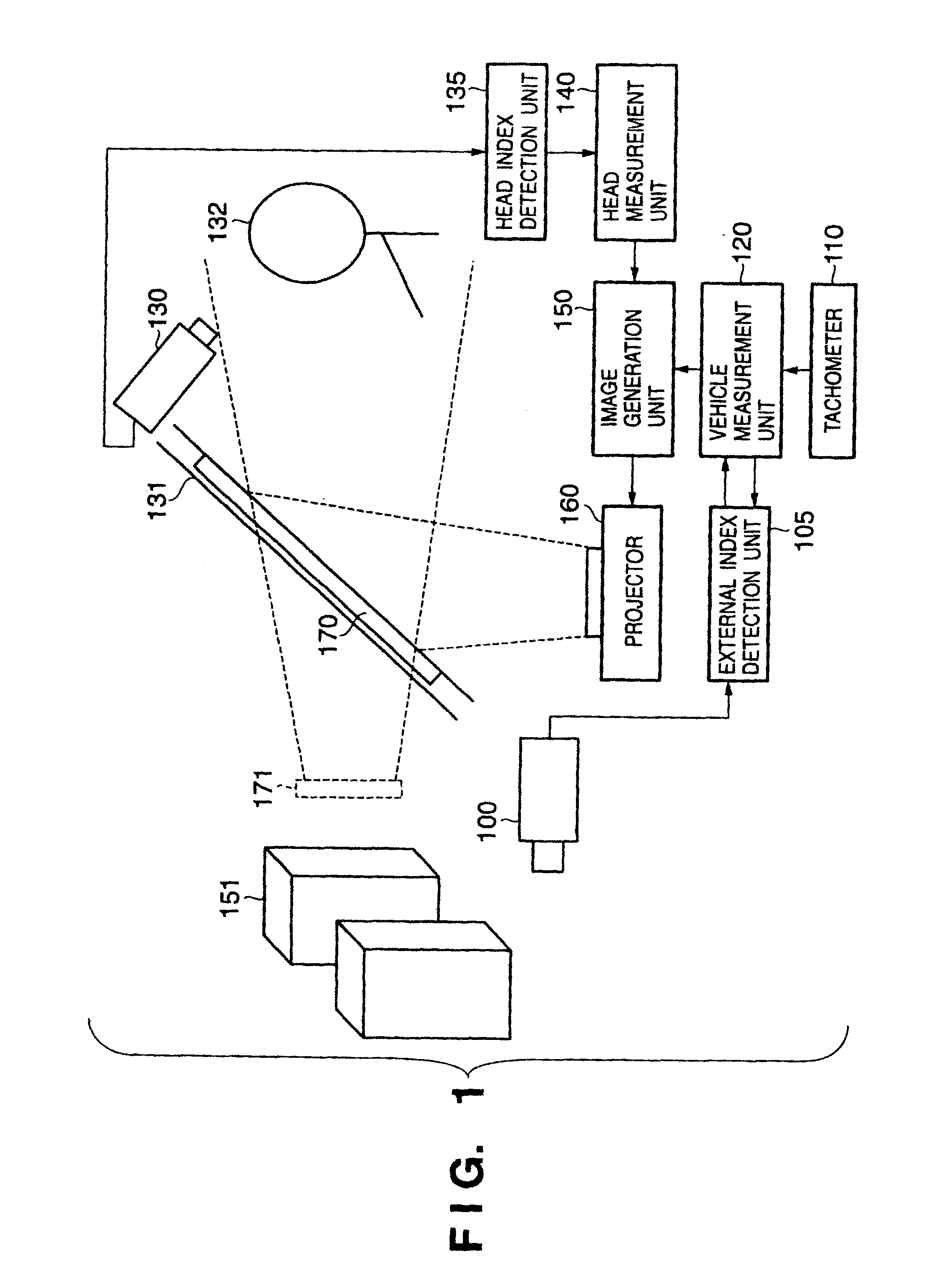

Image display apparatus, image display method, measurement apparatus, measurement method, information processing method, information processing apparatus, and identification method

ActiveUS6956503B2Image enhancementInstruments for road network navigationInformation processingHead measurements

Owner:CANON KK

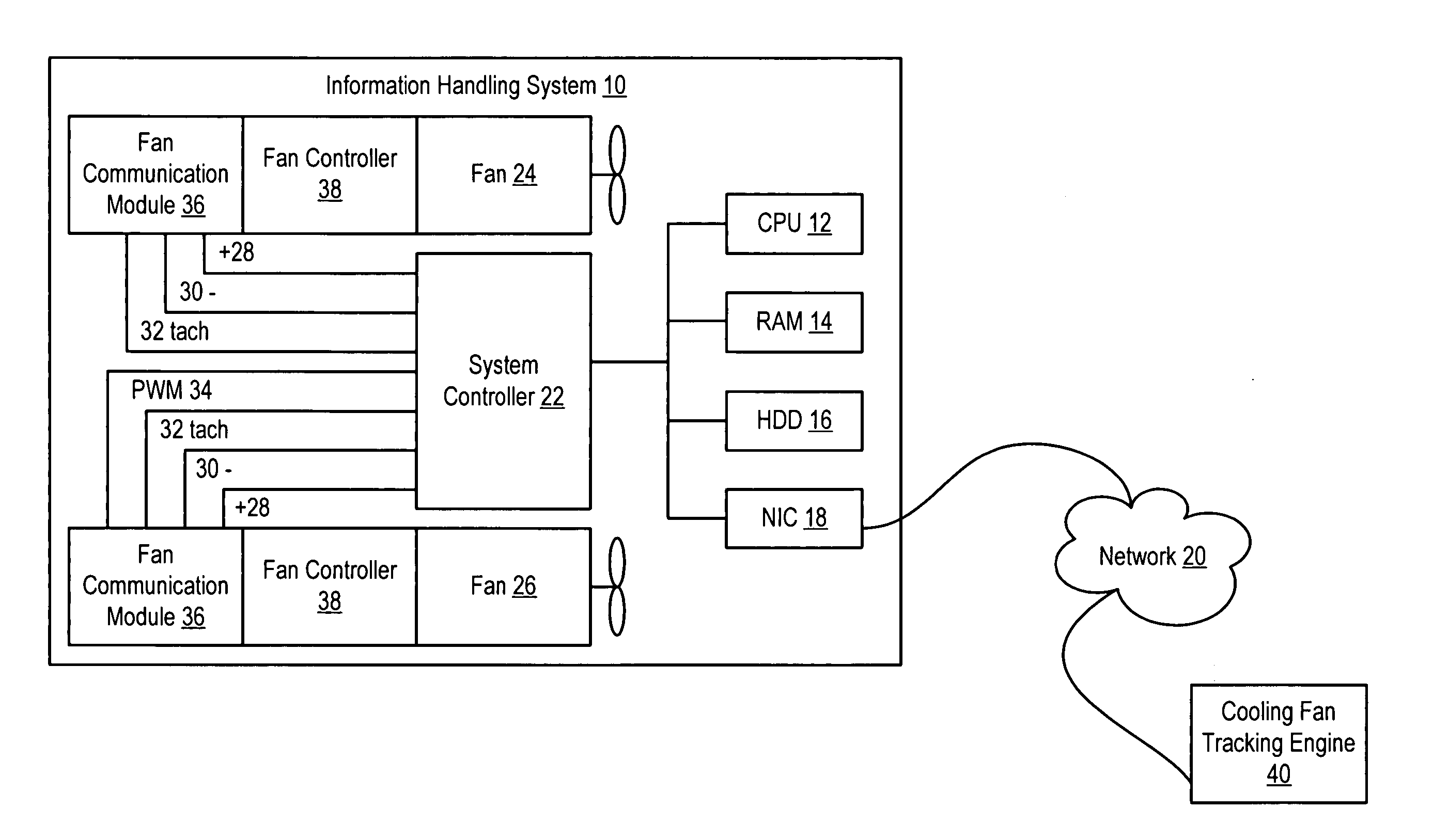

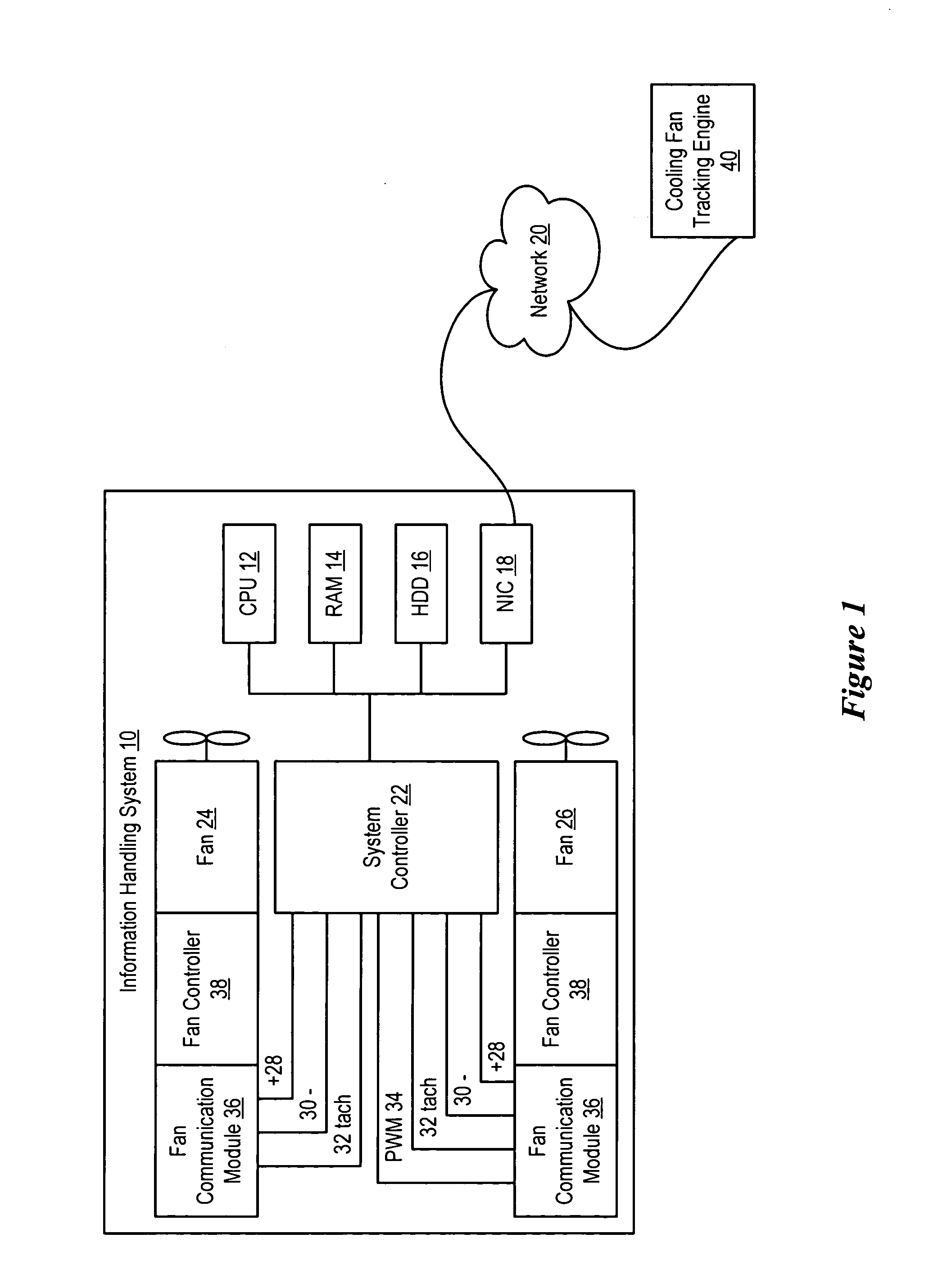

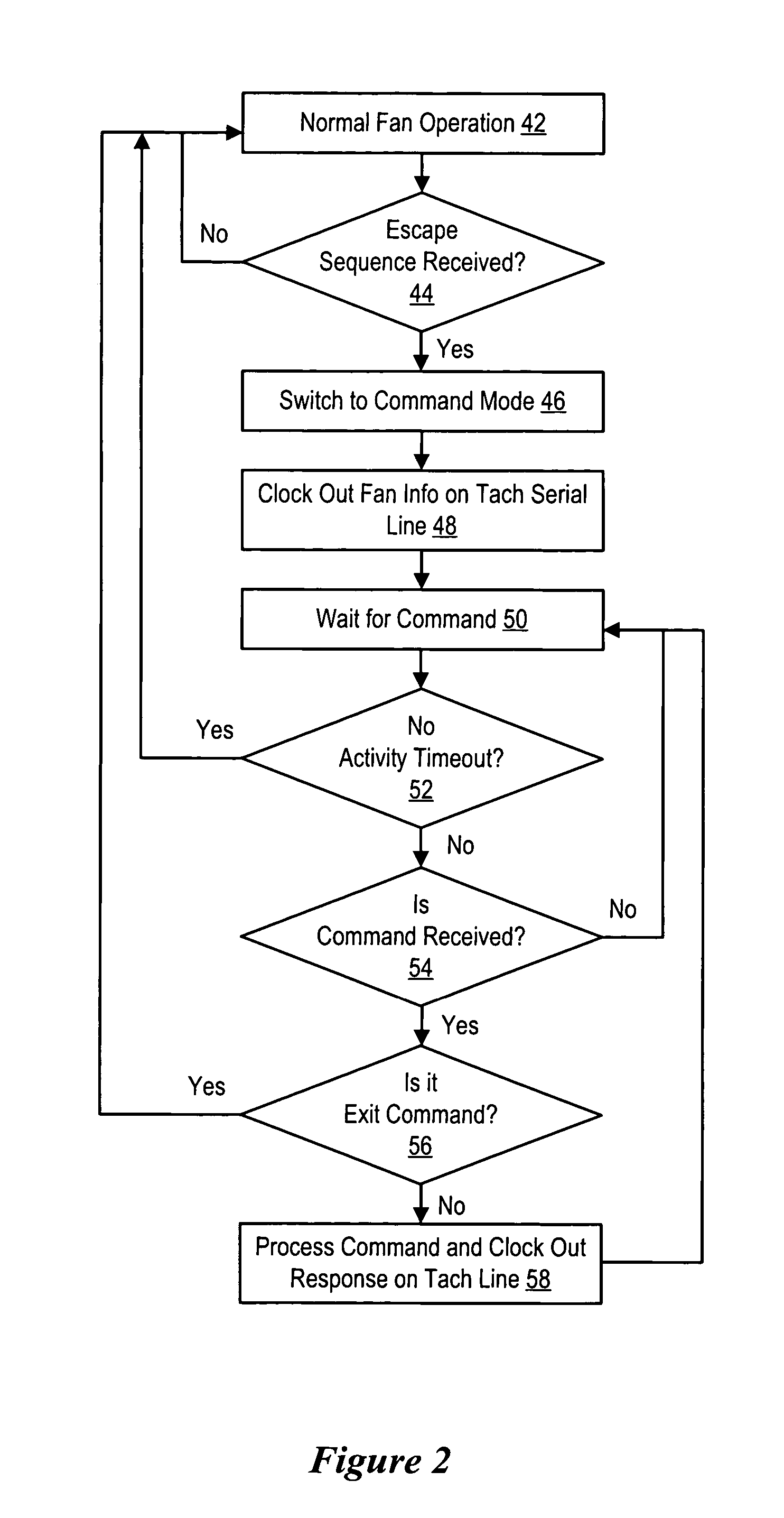

System and method for communication with an information handling system cooling fan

ActiveUS20060152891A1Reduce disadvantagesReduce problemsSynchronous motors startersAC motor controlInformation processingTelecommunications link

An escape sequence coded in power commands from a system controller, such as a BMC, to a cooling fan controller directs the cooling fan to send identification information coded in tachometer readings to the system controller for use by an information handling system. Electronic confirmation of the cooling fan identification ensures compatibility of the information handling system and cooling fan at initial manufacture or subsequent repair. Communication of information over existing power and tachometer wires supports the electronic confirmation without adding additional communication lines. Further, once a communication link is established between an information handling system controller and a cooling fan, other functions are enabled, such as a reflash of the cooling fan controller firmware.

Owner:DELL PROD LP

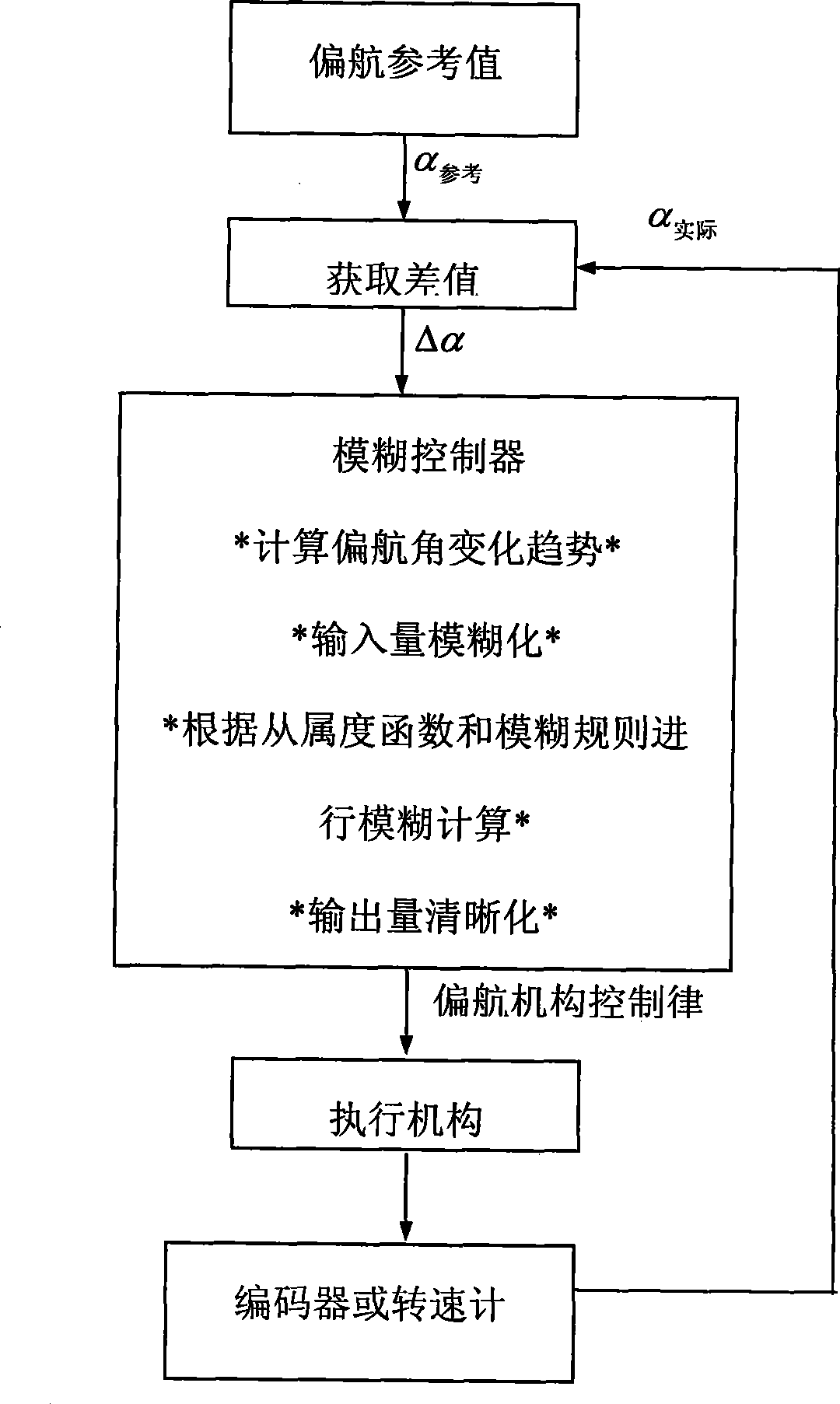

Yaw control method for large-sized wind-driven generator group

InactiveCN101498282AIncrease annual power generationHigh precisionWind motor controlMachines/enginesWind drivenBlade pitch

The invention relates to a yaw control method for a large-sized wind powered generator unit. A current yaw angle reference value alpha reference is obtained according to a current wind direction, a current yaw angle practical value alpha practice is obtained by a encoder or a tachometer, a yaw angular error delta alpha is obtained by subtracting the yaw angle practical value alpha practice by the current yaw angle reference value alpha reference, and a corresponding yaw mechanism control rule is calculated by integrating the yaw angular error delta alpha and the variation tendency thereof by a fuzzy controller. Furthermore, an obtained electrical signal of the yaw mechanism control rule is sent to a yaw actuating mechanism to control a propeller pitch angle, and the yaw angle of the wind powered generator unit traces the yaw angle reference value alpha reference to enable the yaw angle practical value alpha practice and the yaw angle reference value alpha reference of the wind powered generator unit to be kept consistent. The invention obviously enhances the total precision, is favorable to increasing the year total generated energy of the wind powered generator unit, has high adaptability for complex and extreme cases, greatly enhances the operating effectiveness, furthest prolongs the mechanical life of the yaw actuating mechanism, and also has low remodel difficulty and low cost.

Owner:BEIJING NEGO AUTOMATION TECH

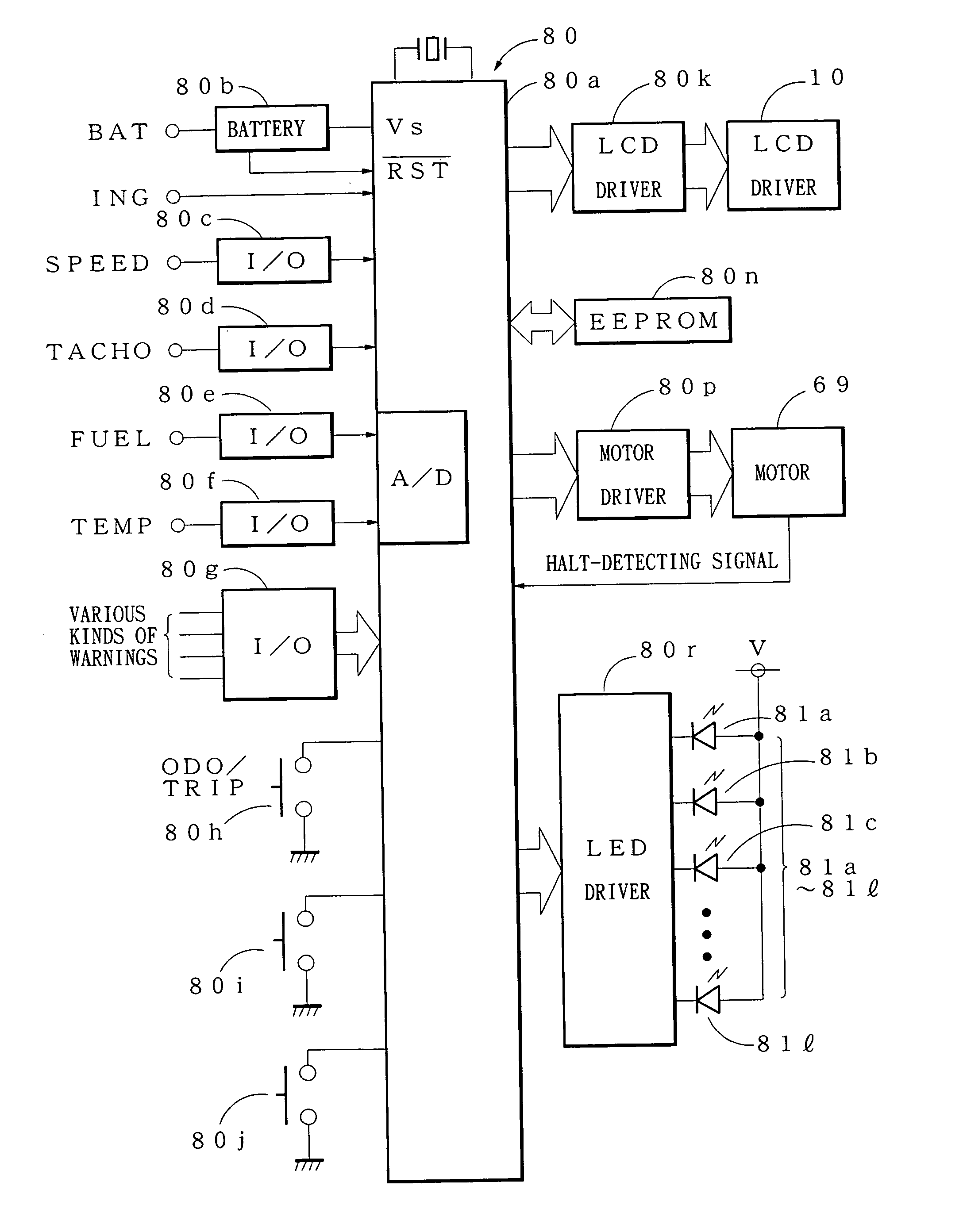

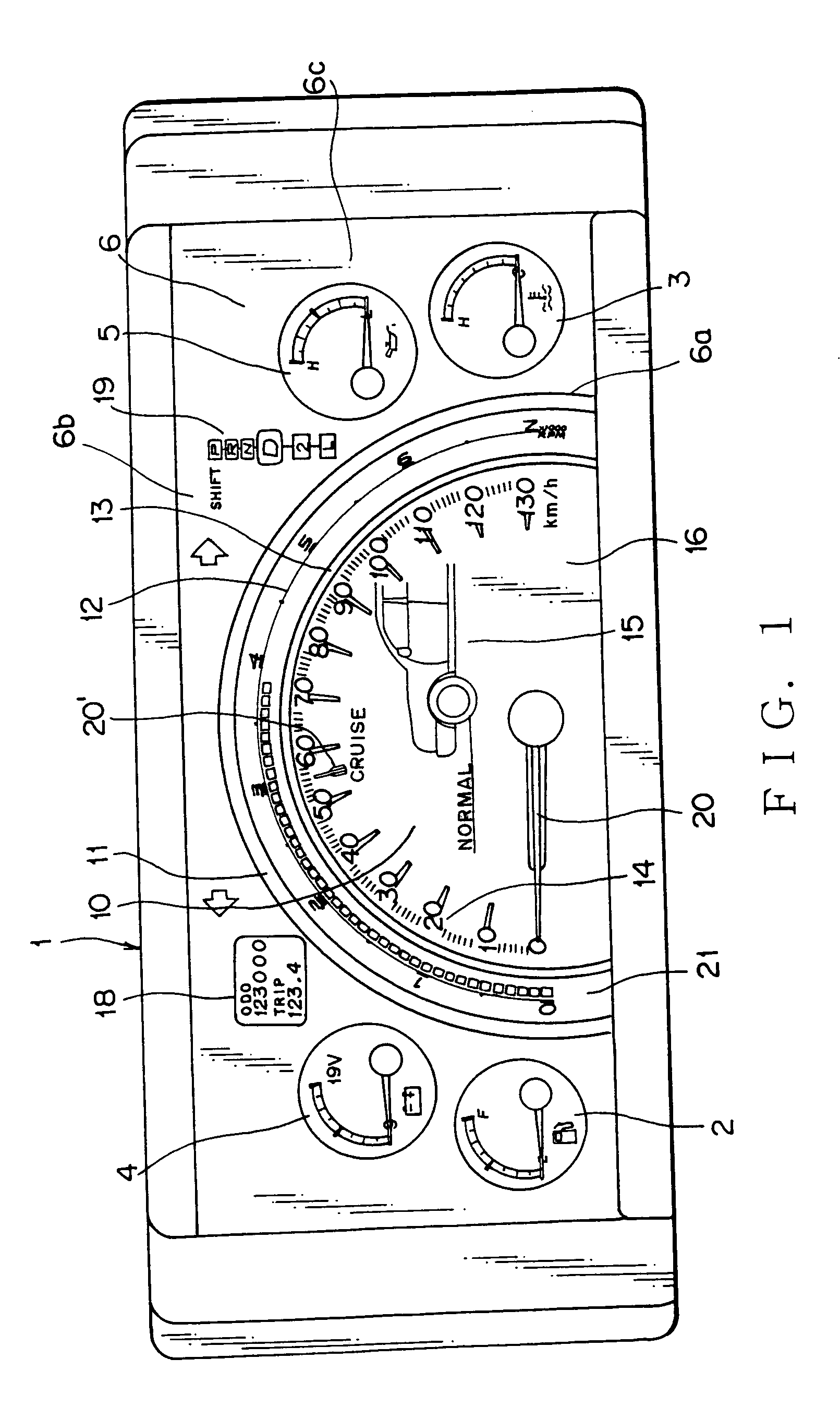

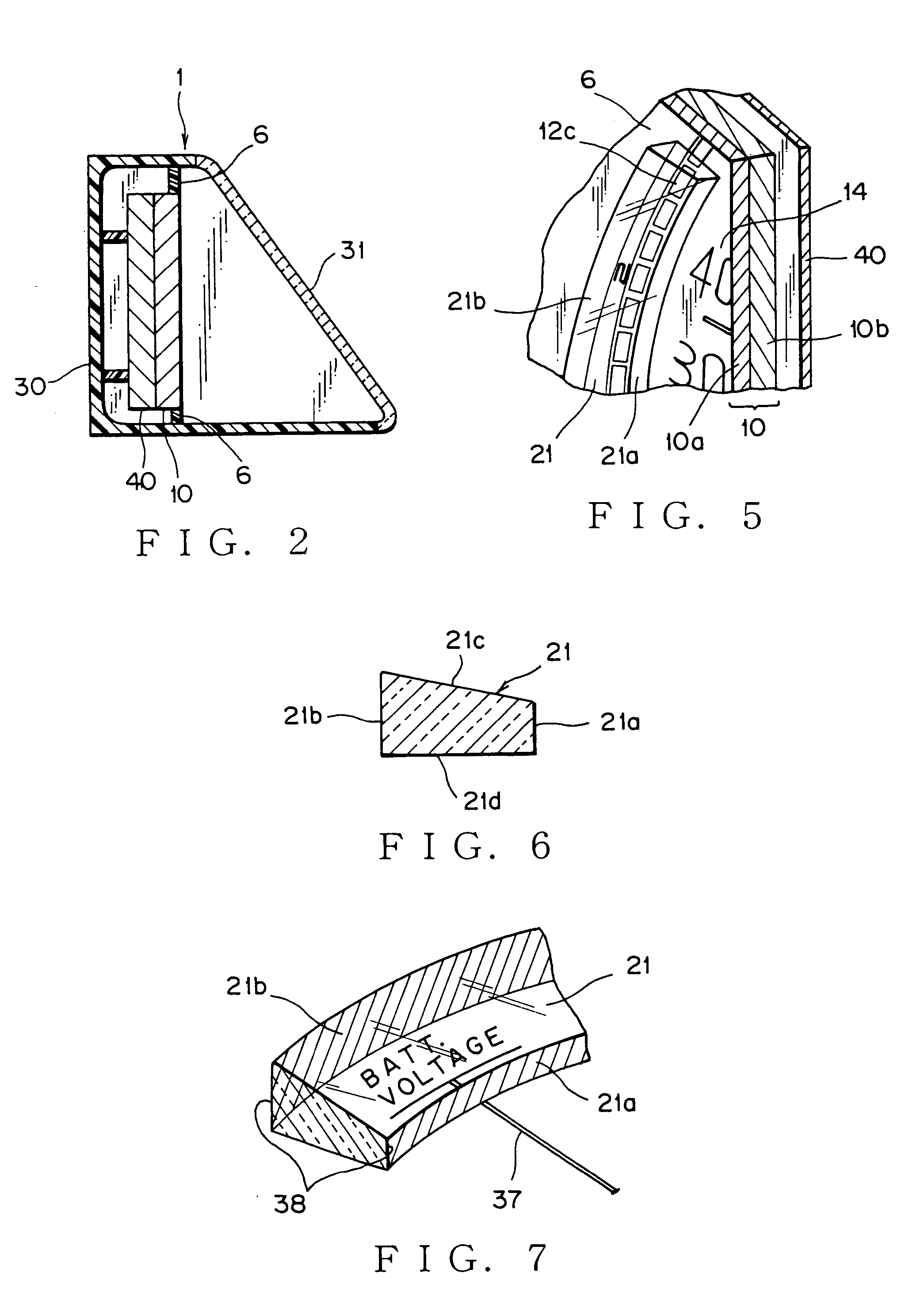

Display apparatus for vehicle

ActiveUS20050212669A1Image degradationInstrument arrangements/adaptationsCathode-ray tube indicatorsSimulationTachometer

A display apparatus for a vehicle includes display screen having a plurality of display areas such as a tachometer display area, a speedometer display area, and an auxiliary display area. The display apparatus for a vehicle further includes a CPU for controlling images displayed on the display screen. A display partition member is mounted on a part of the display screen.

Owner:YAZAKI CORP

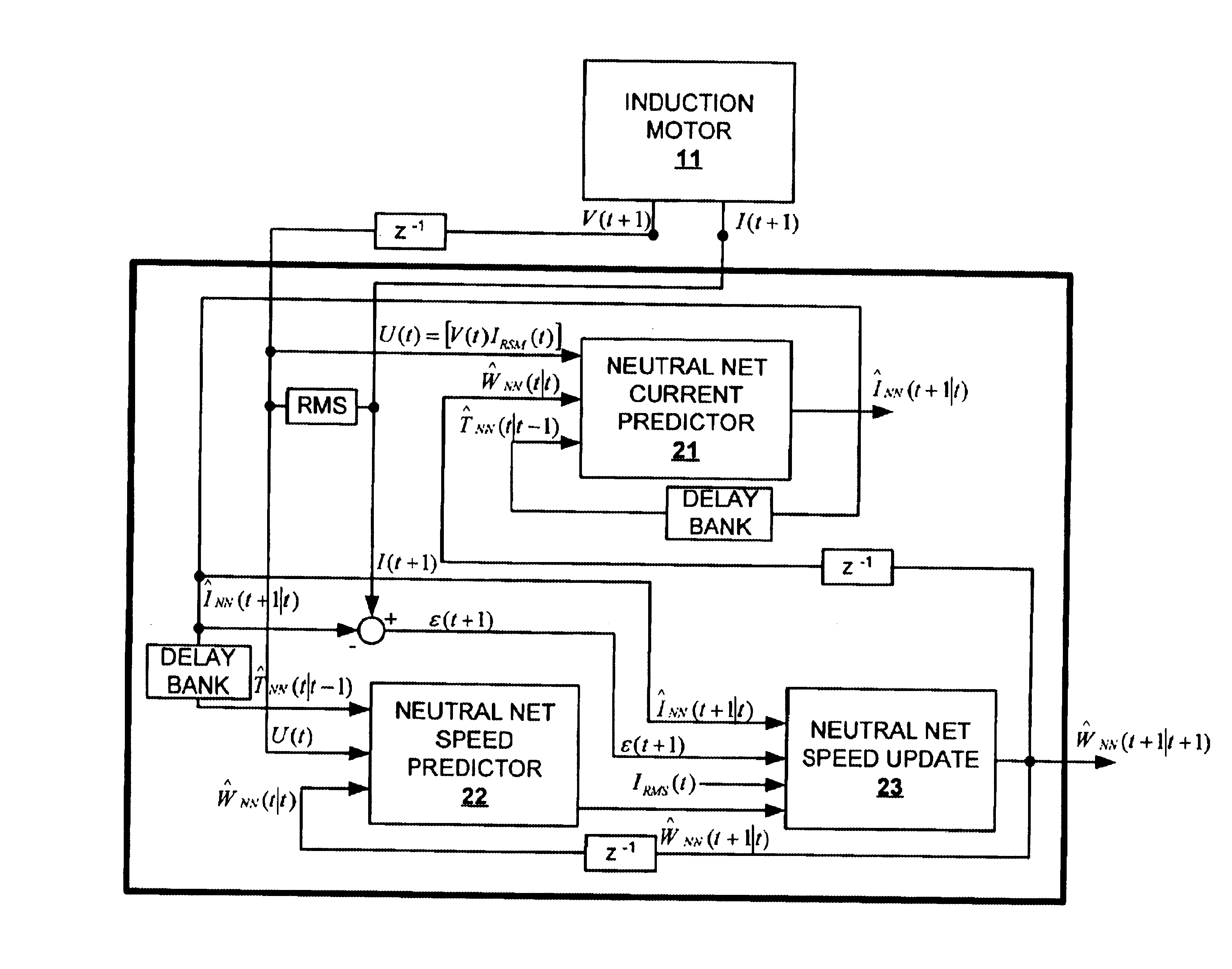

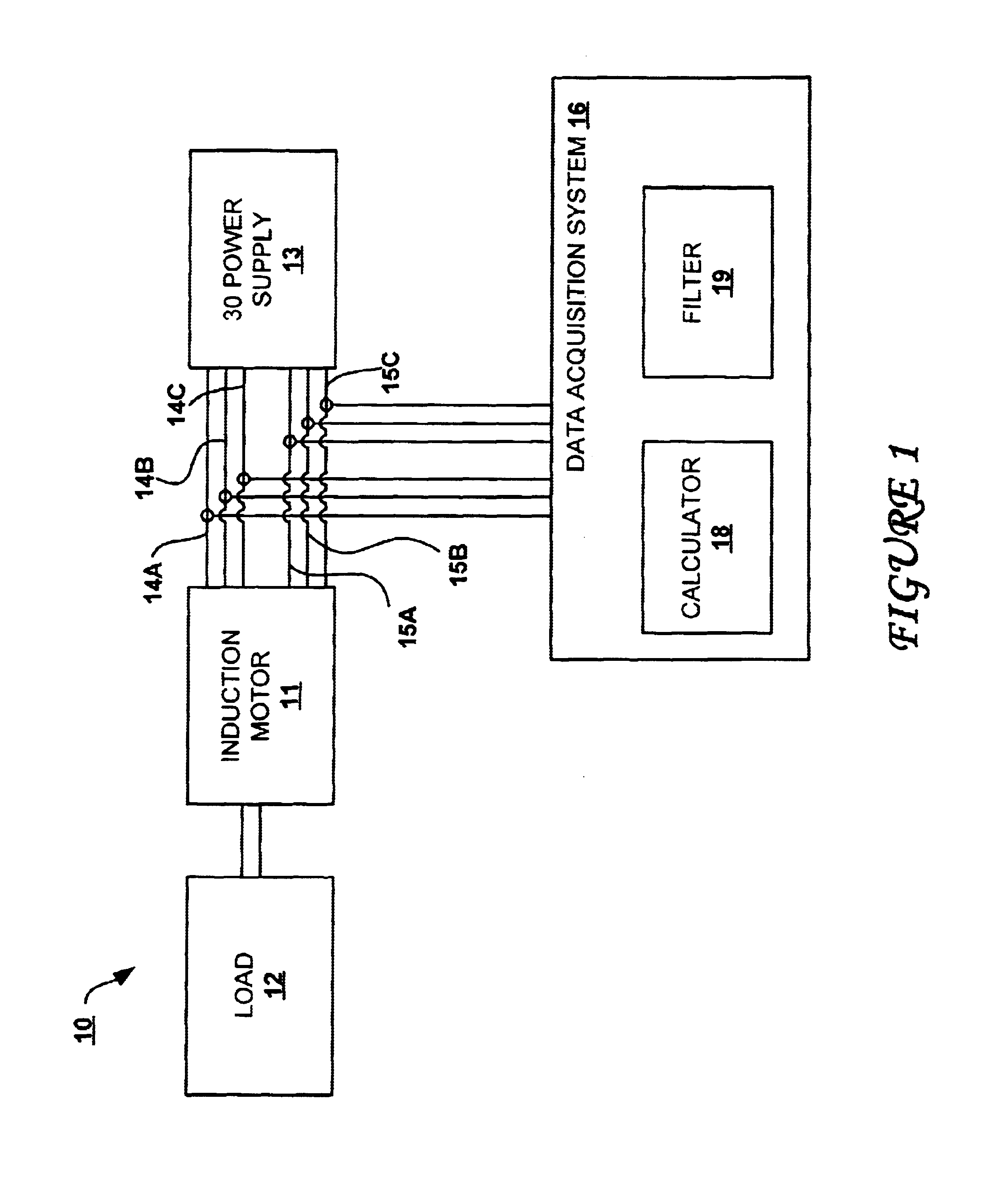

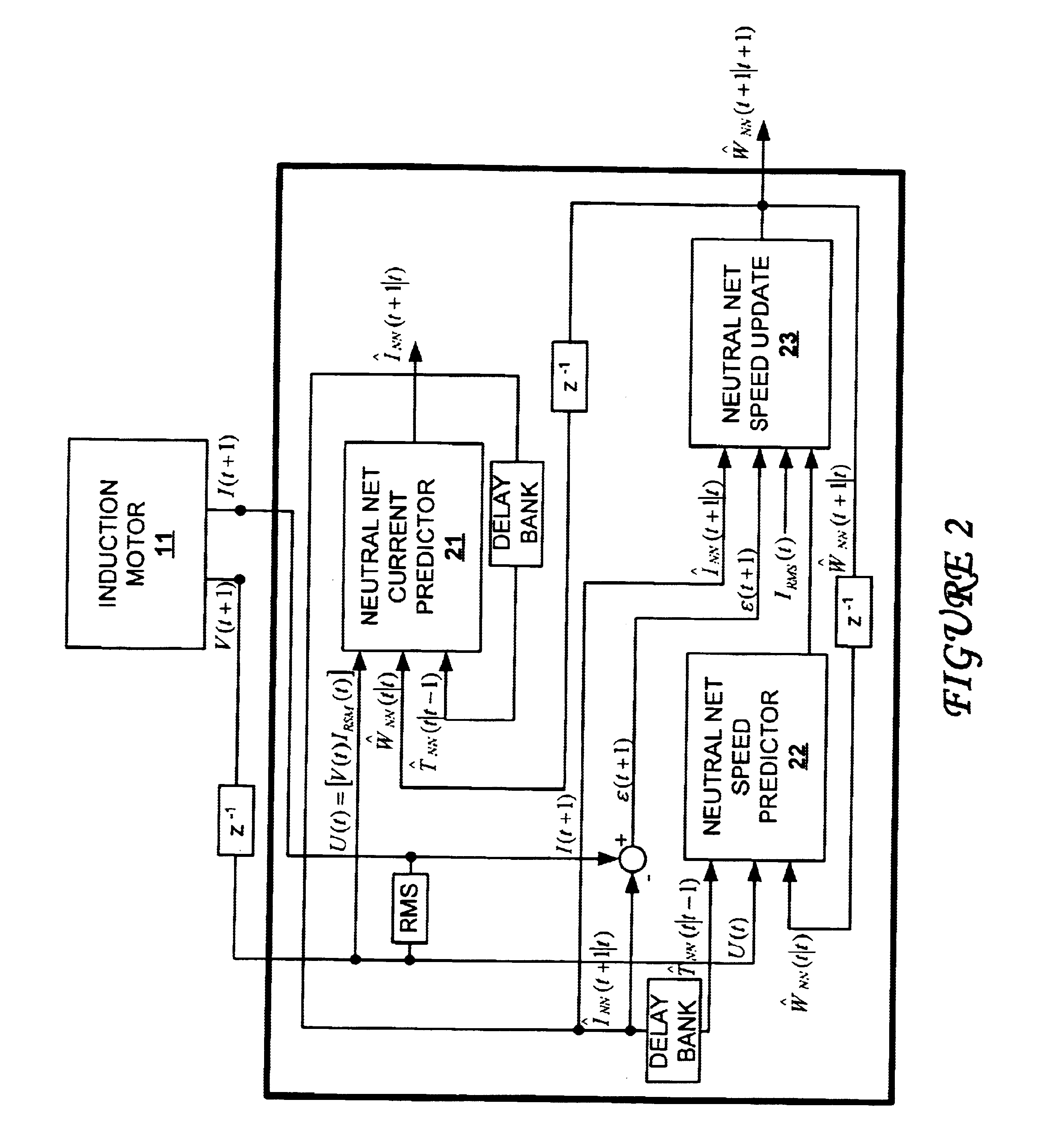

Method and system for determining induction motor speed

A non-linear, semi-parametric neural network-based adaptive filter is utilized to determine the dynamic speed of a rotating rotor within an induction motor, without the explicit use of a speed sensor, such as a tachometer, is disclosed. The neural network-based filter is developed using actual motor current measurements, voltage measurements, and nameplate information. The neural network-based adaptive filter is trained using an estimated speed calculator derived from the actual current and voltage measurements. The neural network-based adaptive filter uses voltage and current measurements to determine the instantaneous speed of a rotating rotor. The neural network-based adaptive filter also includes an on-line adaptation scheme that permits the filter to be readily adapted for new operating conditions during operations.

Owner:TEXAS A&M UNIVERSITY

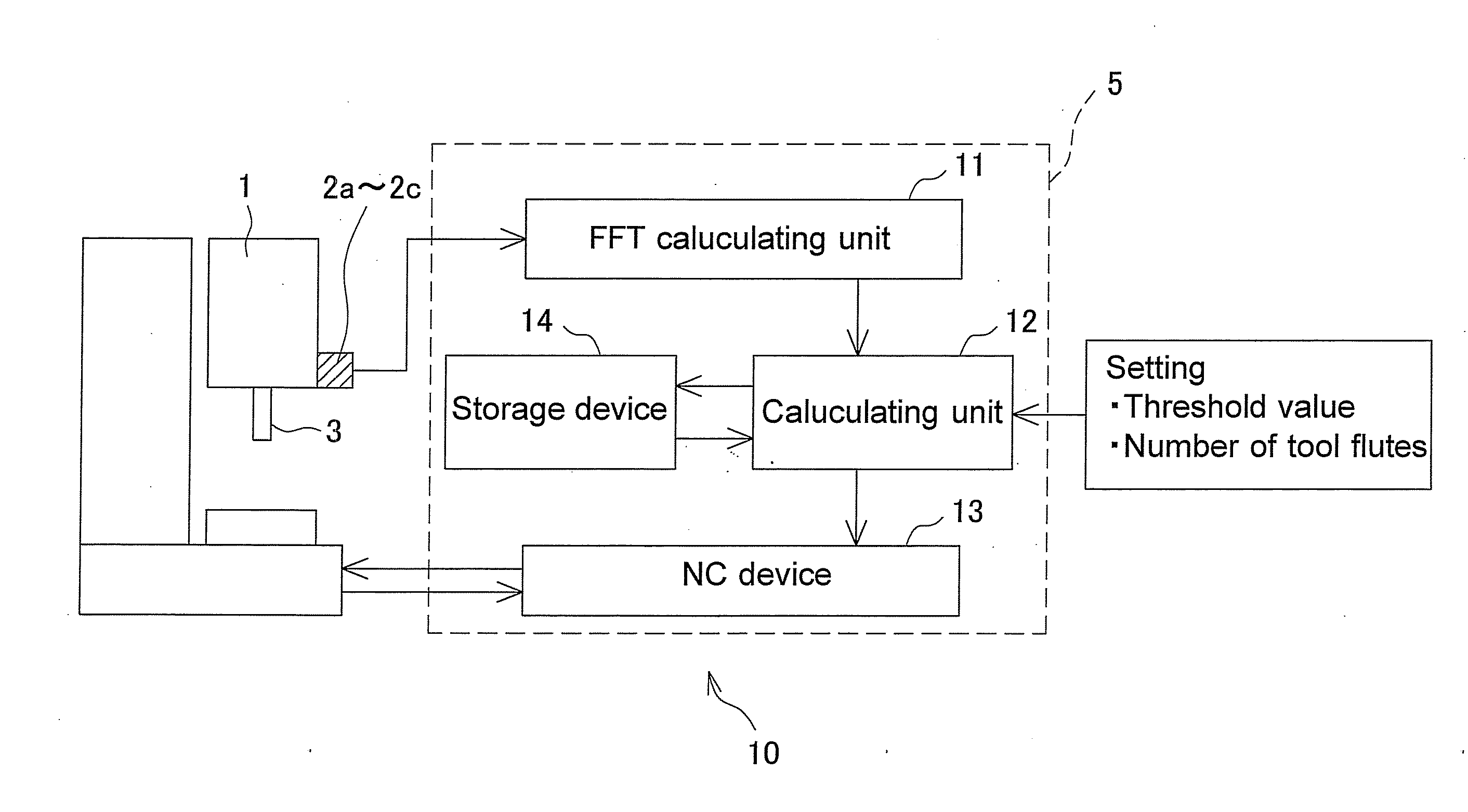

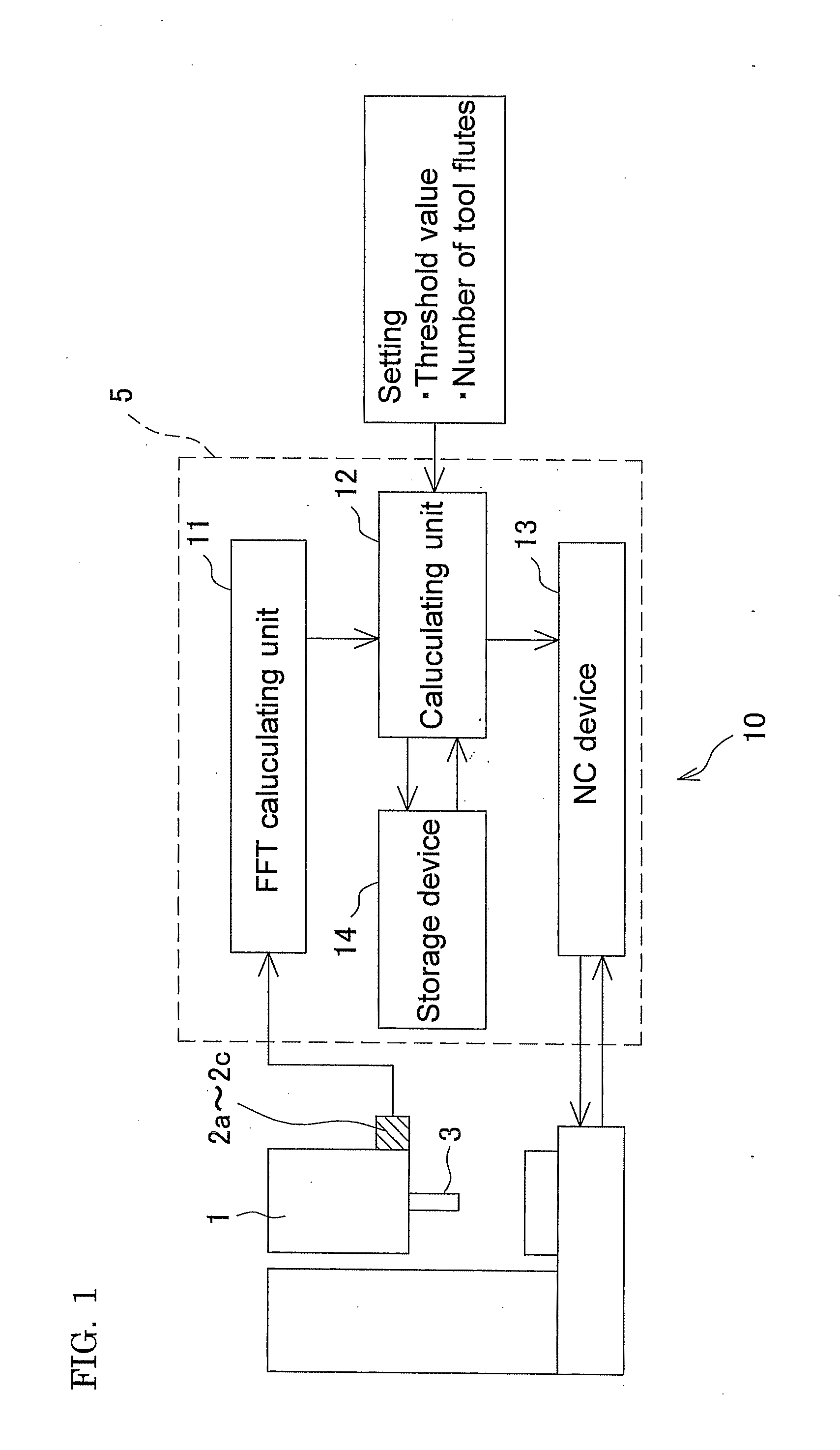

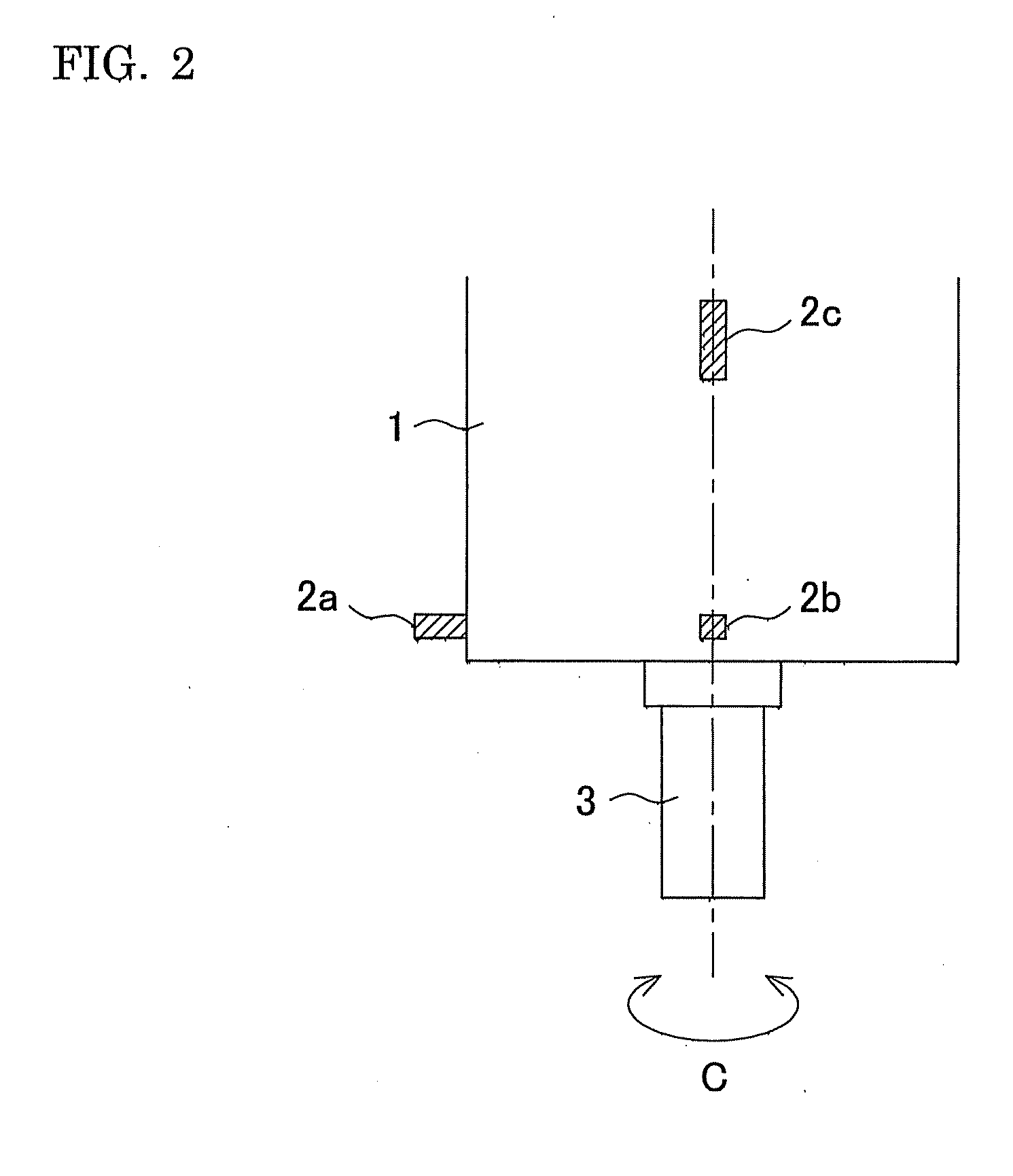

Vibration suppressing method and device

InactiveUS20100010662A1Suppresses tool wearImprove workpiece surface qualityVibration measurement in solidsMachine part testingChatter vibrationRotational axis

A stable rotation speed is acquired by finely changing a rotation speed of a rotary shaft 3 based on an expected stable rotation speed, and calculating an amount of change of a k′ number, and the like. Therefore, a more accurate rotation speed can be acquired, and “chatter vibration” generated during machining can be suppressed more effectively than a conventional method. As a result, a quality of a workpiece surface can be improved, and a tool wear and the like can be suppressed.

Owner:OKUMA CORP

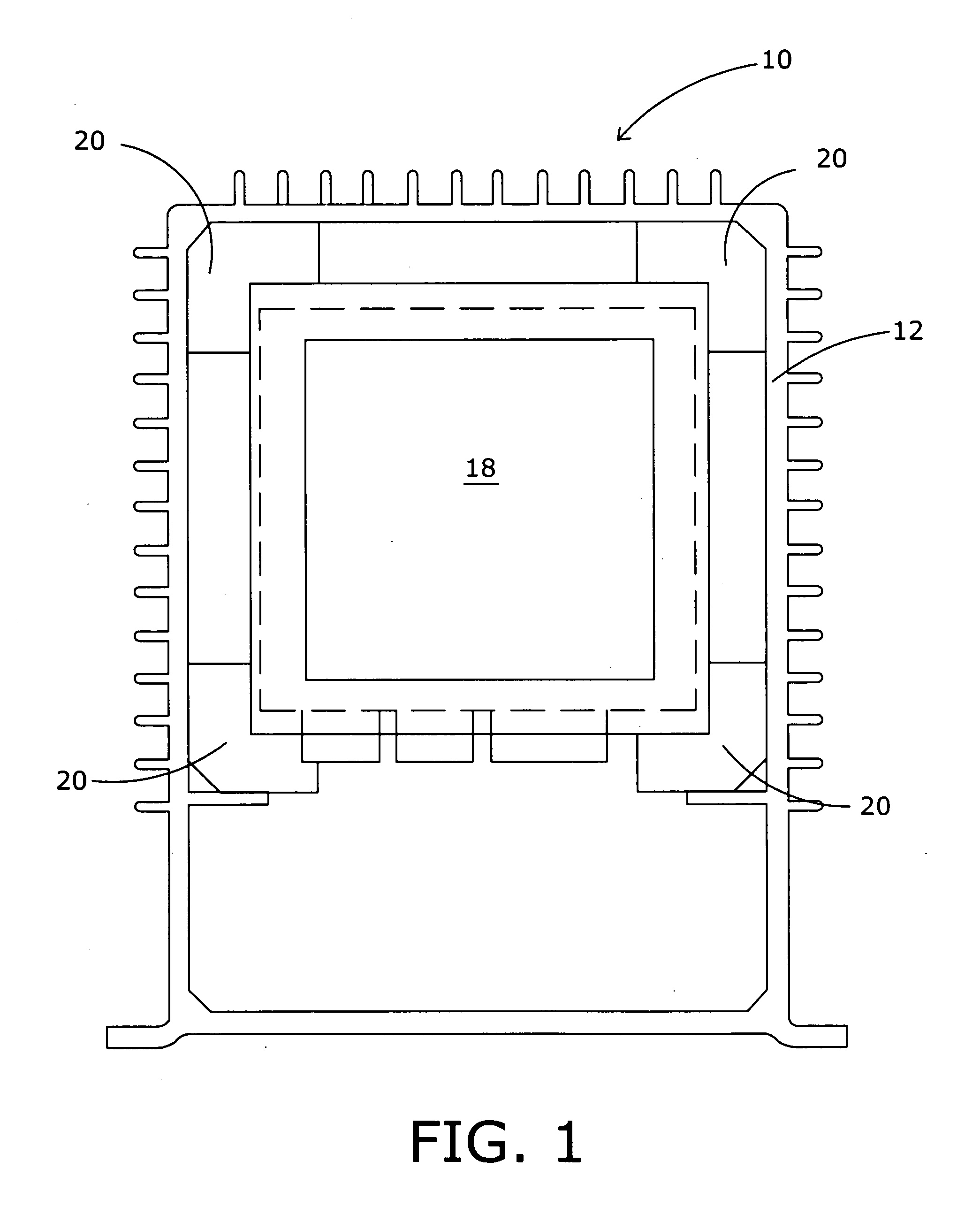

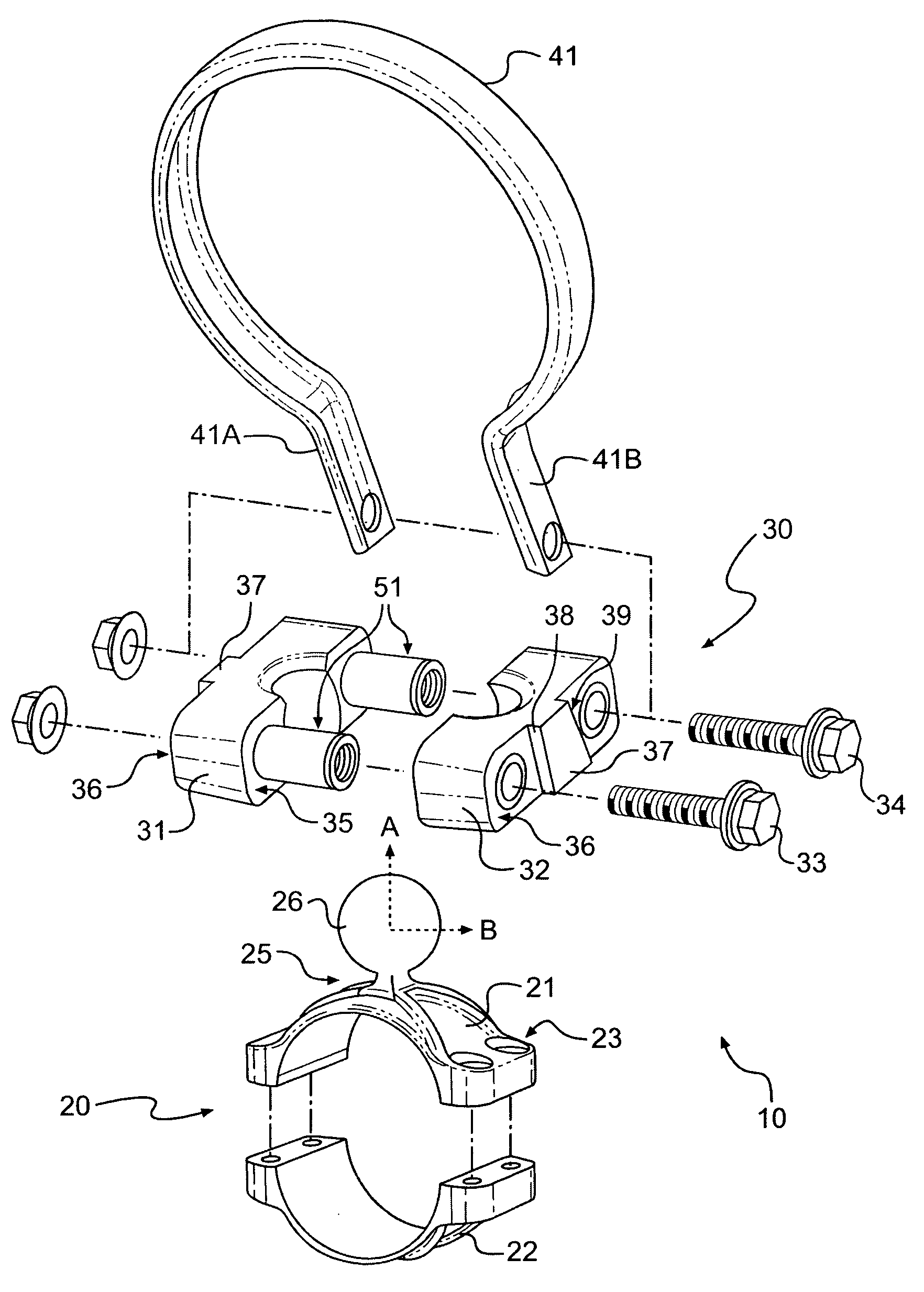

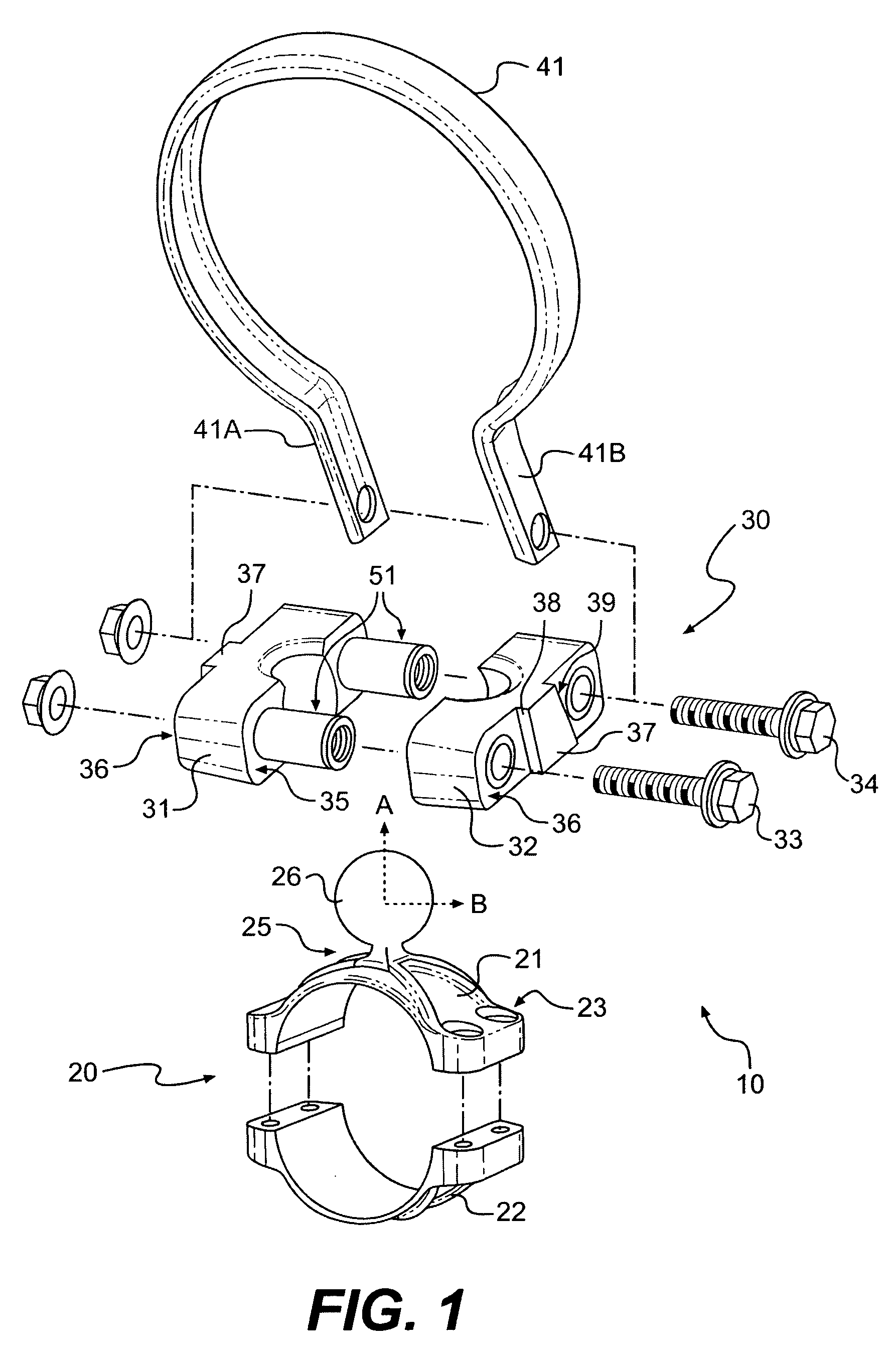

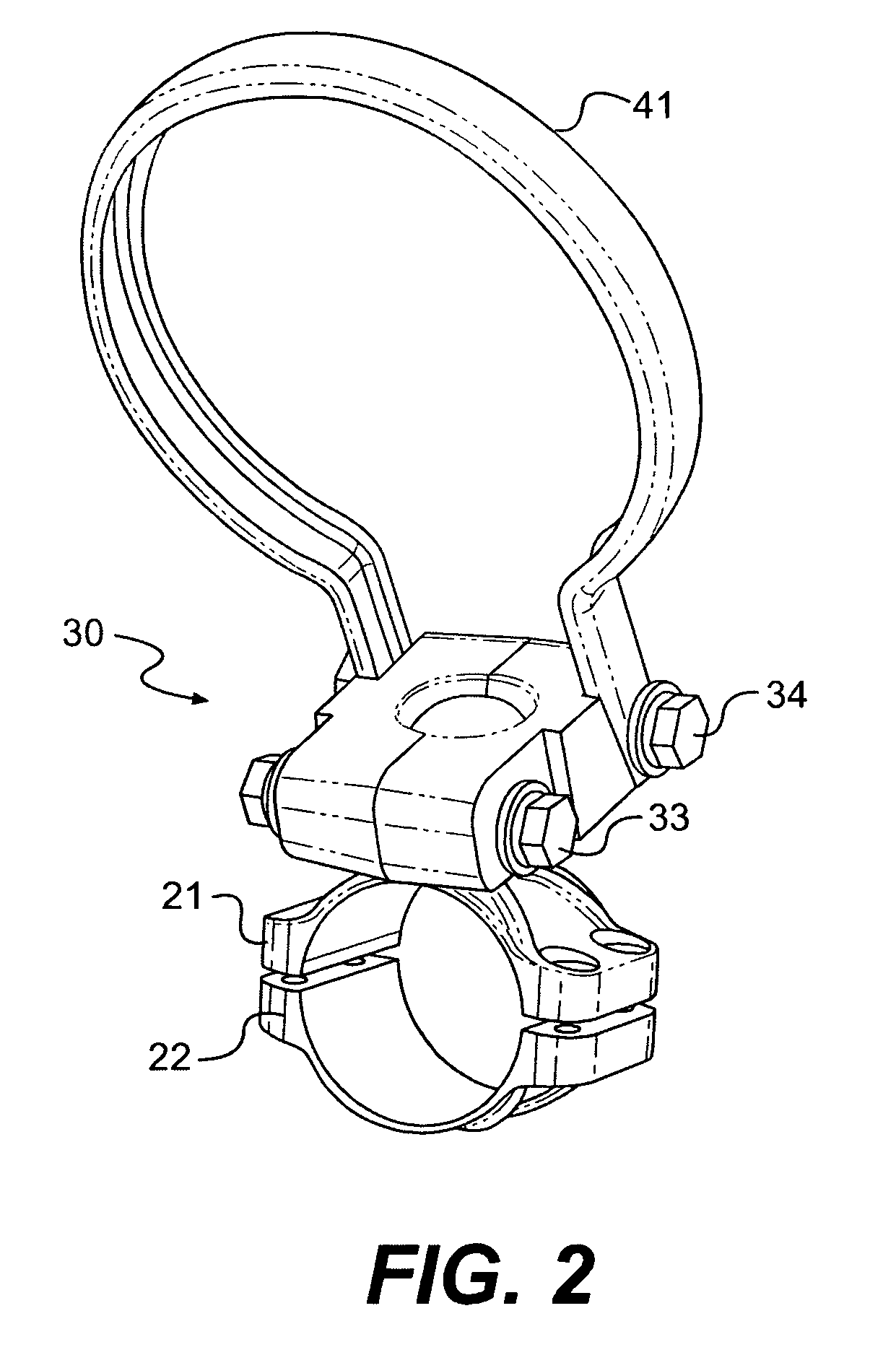

Gauge mounting assembly

InactiveUS6938865B1Increase flexibilityImprove rigidityCandle holdersLighting support devicesEngineeringMechanical engineering

An assembly for attaching gauges or other accessories to vehicles provides a base member for securing the assembly to a vehicle surface and a clamp arrangement secured to the base member for superior versatility and customization. The clamp arrangement includes a substantially spherical ball member and a ball clamp, which grips the ball member and allows for the fixed positioning of a gauge frame member to the inner or outer edges of the ball clamp. A tachometer, gauge or other accessory can be secured within the gauge frame member. The ball clamp may be adjusted about the ball member and the gauge frame member can be fixed in different positions to achieve a desired positioning of the gauge. The gauge frame member can be one of a number of designs, including single or double split clamps.

Owner:GAUGE WORKS

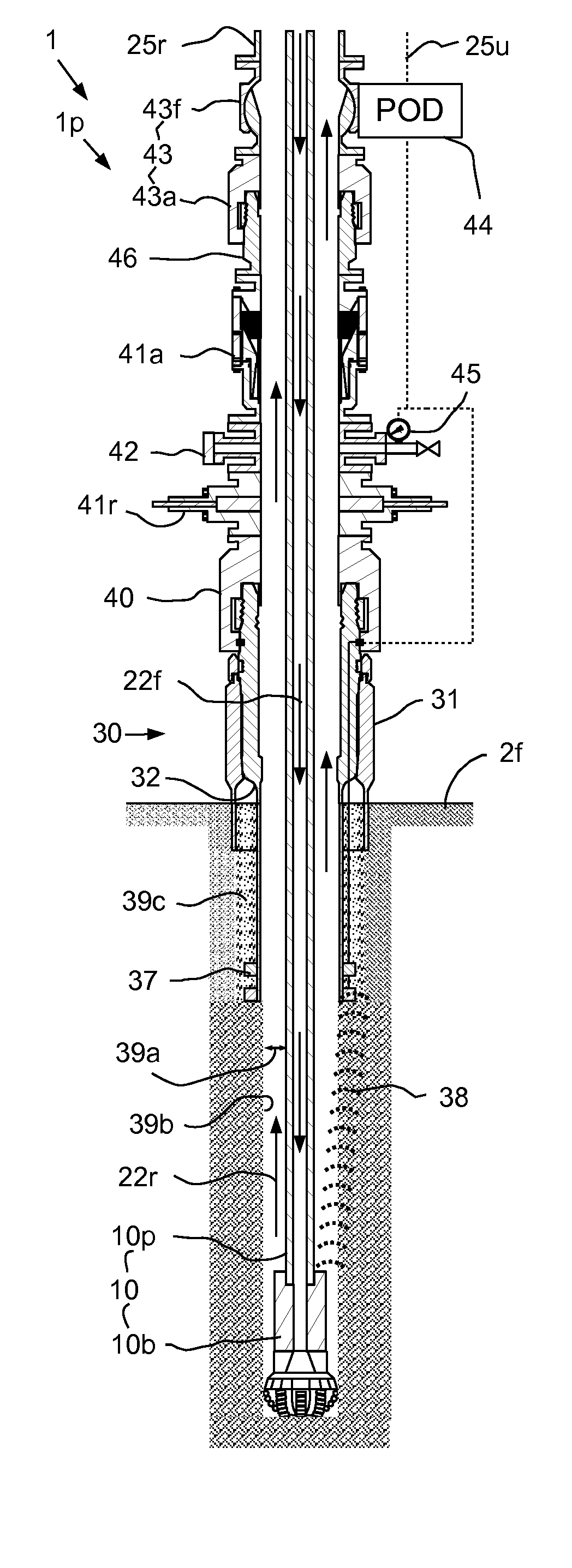

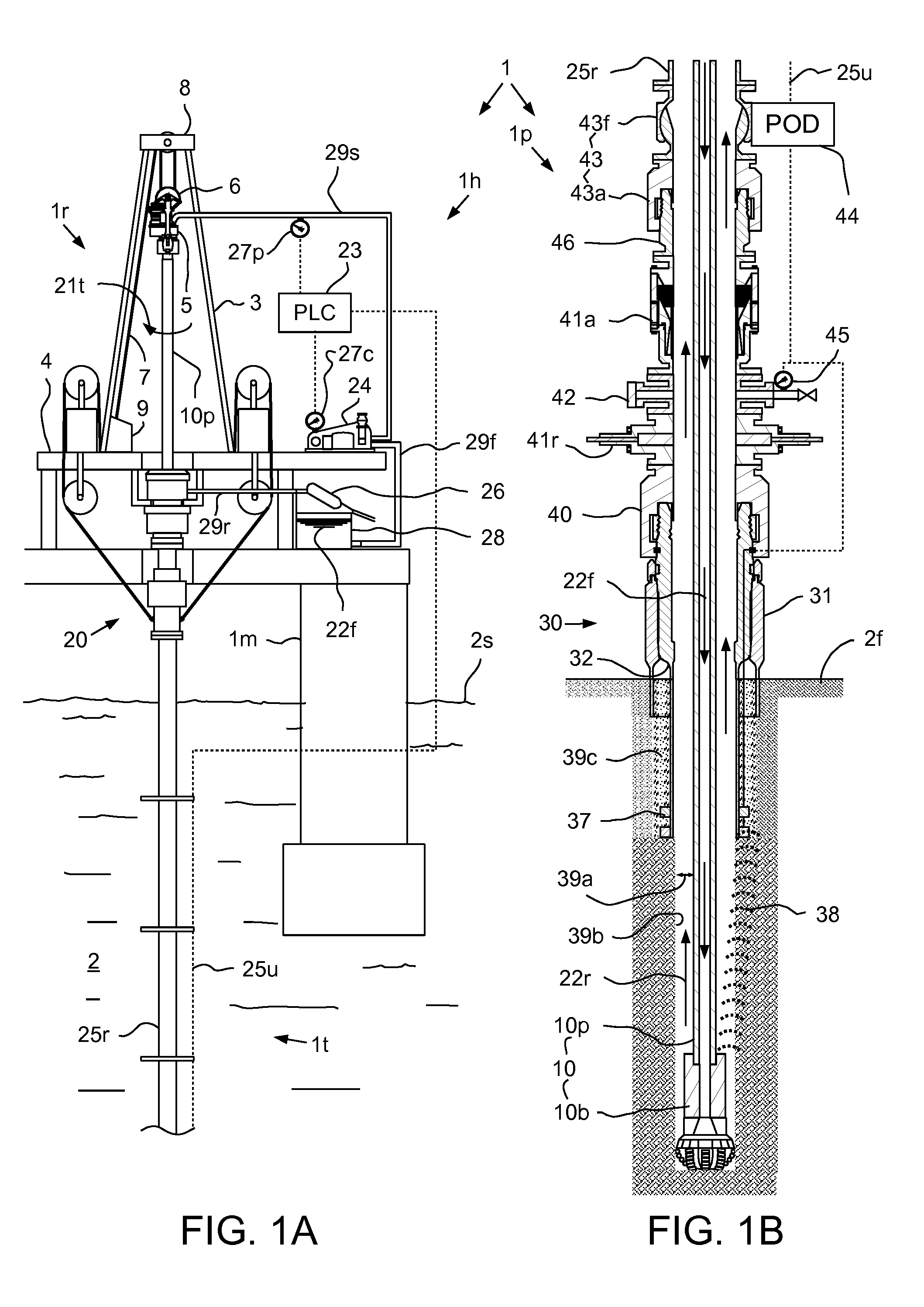

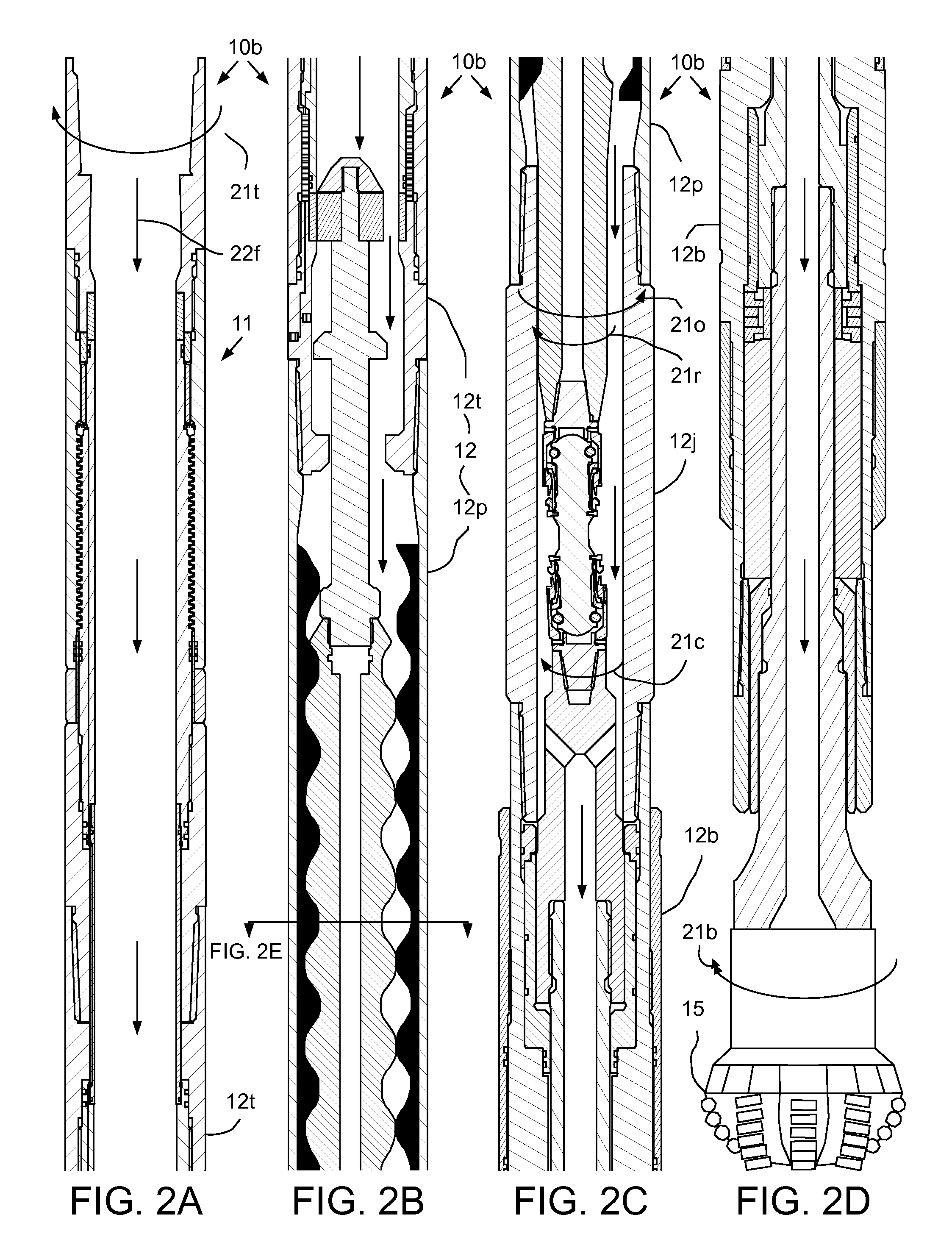

Tachometer for downhole drilling motor

A tachometer for a downhole motor includes: a tubular housing having a coupling for connection to a housing of the motor; and a probe. The probe: has a coupling for connection to a rotor of the motor, is movable relative to the tachometer housing, and has at least a portion disposed in a bore of the tachometer housing. The tachometer further includes electronics disposed in the tachometer housing and including: a battery; one or more proximity sensors for tracking an orbit of the probe; and a programmable logic controller (PLC). The PLC is operable: to receive the tracked orbit, and at least one of: to determine an angular speed of the probe using the tracked orbit, and to forecast a remaining lifespan of the motor using the tracked orbit.

Owner:WEATHERFORD TECH HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com