Method for testing accelerating and loading of main drive wheel type pavement materials and device

A pavement material, accelerated loading technology, used in measuring devices, using repetitive force/pulse force to test the strength of materials, analyzing materials, etc. Simple, wide range of application, convenient test operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

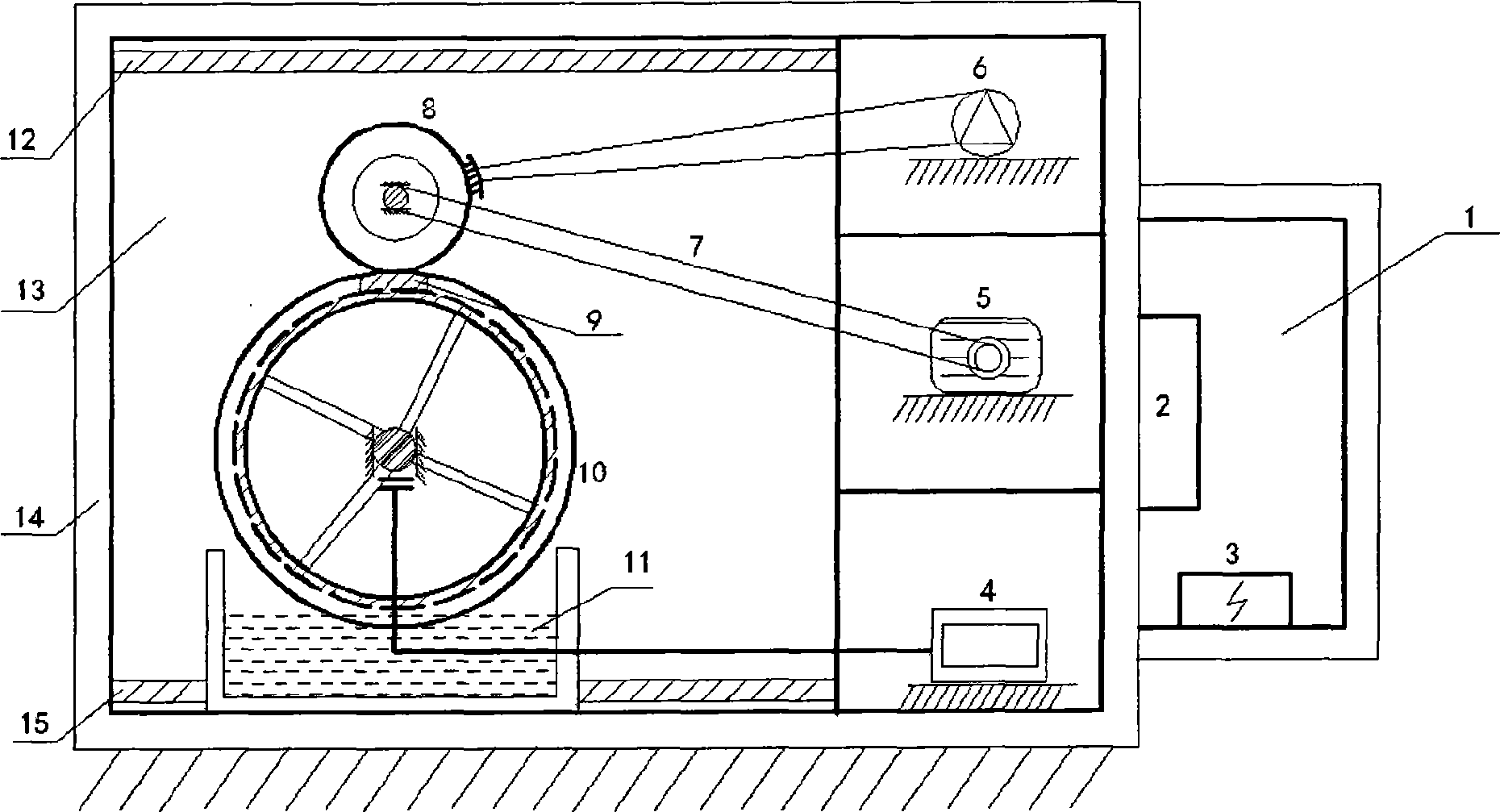

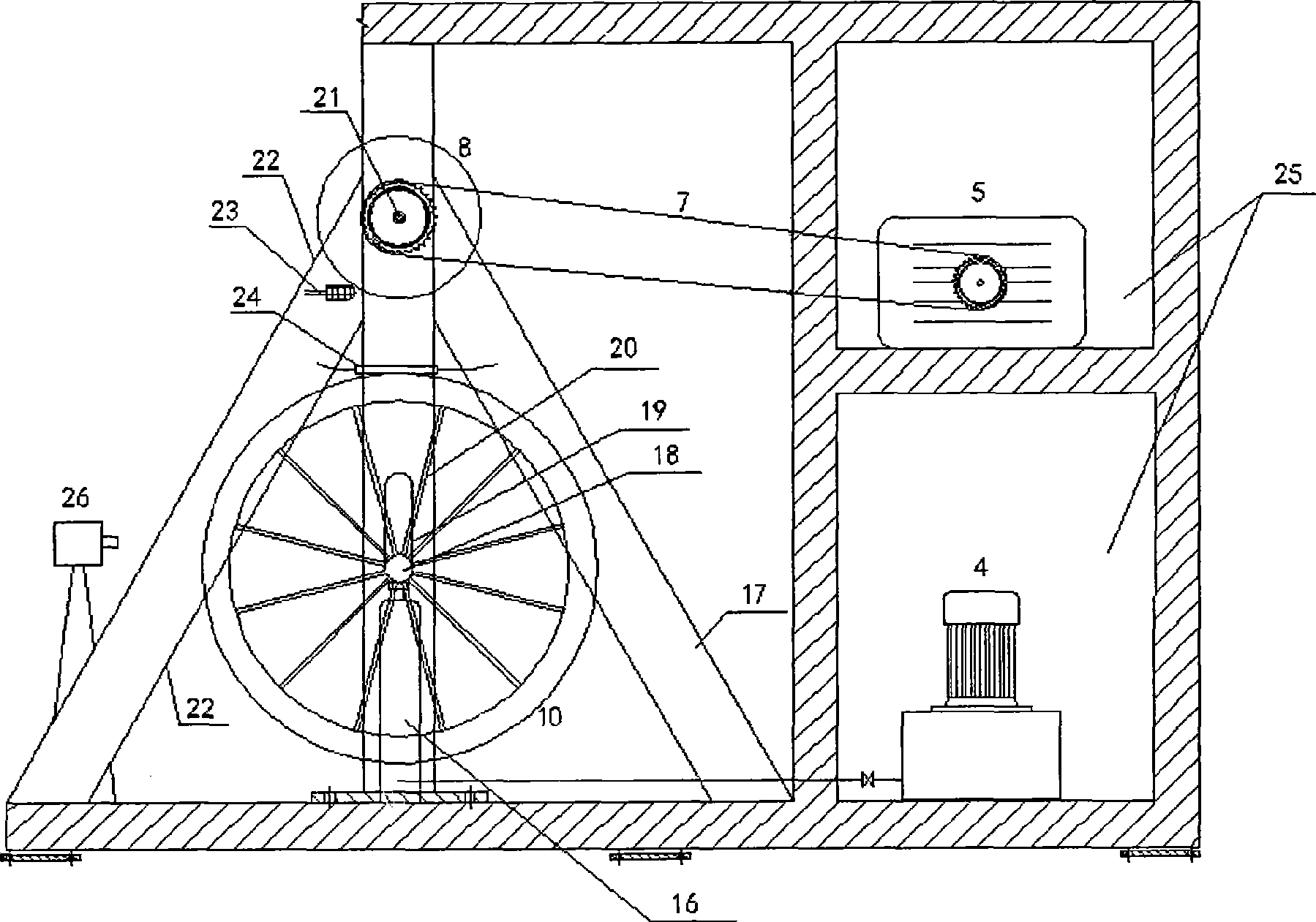

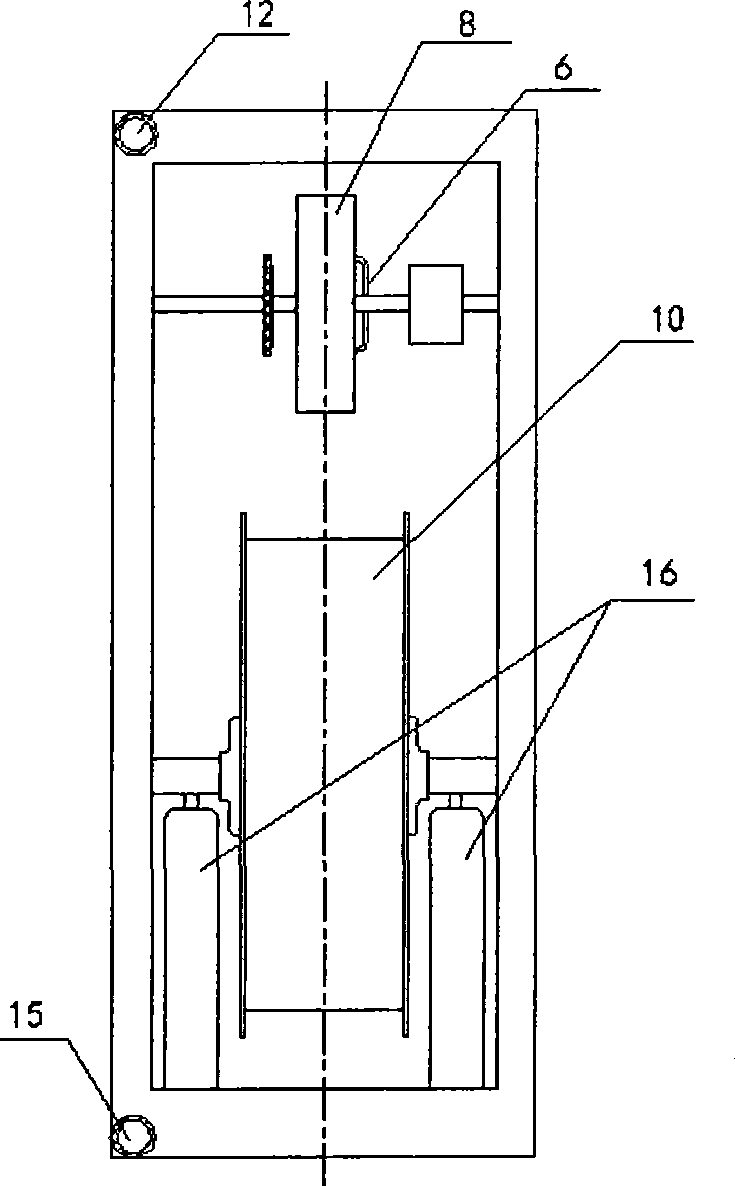

[0038] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0039] Asphalt concrete specimen specification of the present invention is long 300mm * wide 300mm * thick 50mm; Driving wheel adopts 4.00-8 tire, and rotating speed is 0~300r / min; Driven wheel external diameter 1100mm, deep groove 100mm, width is 315mm, so that for Sufficient space is reserved for the lateral deformation of the specimen, and the rotational speed is 0-121r / min; the pressurization range of the hydraulic device is 0-1.0MPa; the temperature range of the constant temperature chamber is 25-70°C.

[0040] Such as Figure 1 to Figure 5 As shown, the main drive wheel type pavement material accelerated loading test device of the present invention includes a console 1, a PLC control box 2, an electric box 3, a hydraulic device 4, a motor 5, a brake 6, a transmission chain and a sprocket 7, and a drive Wheel 8, driven wheel 10, water ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com