Patents

Literature

2790results about "Material weighing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

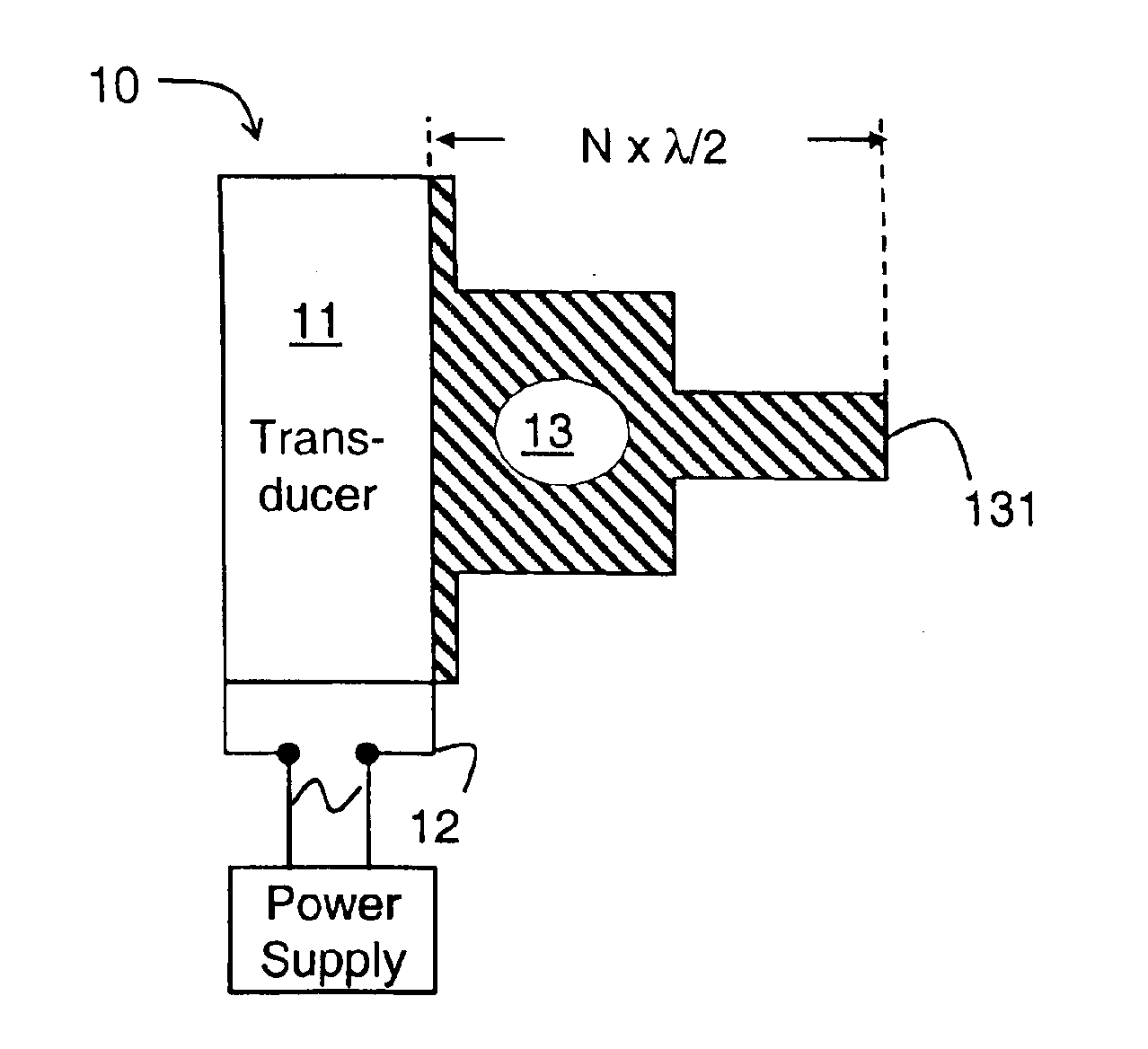

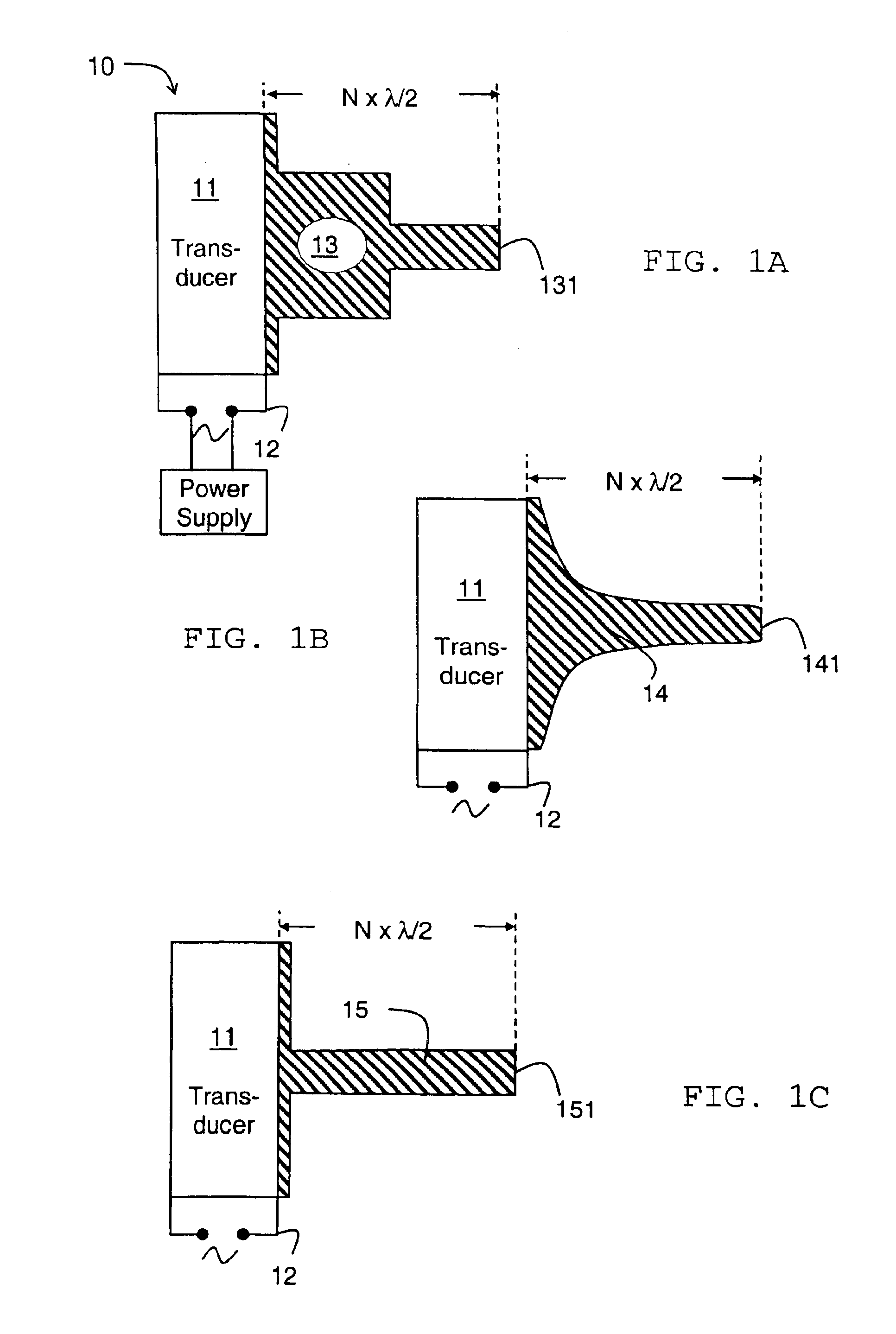

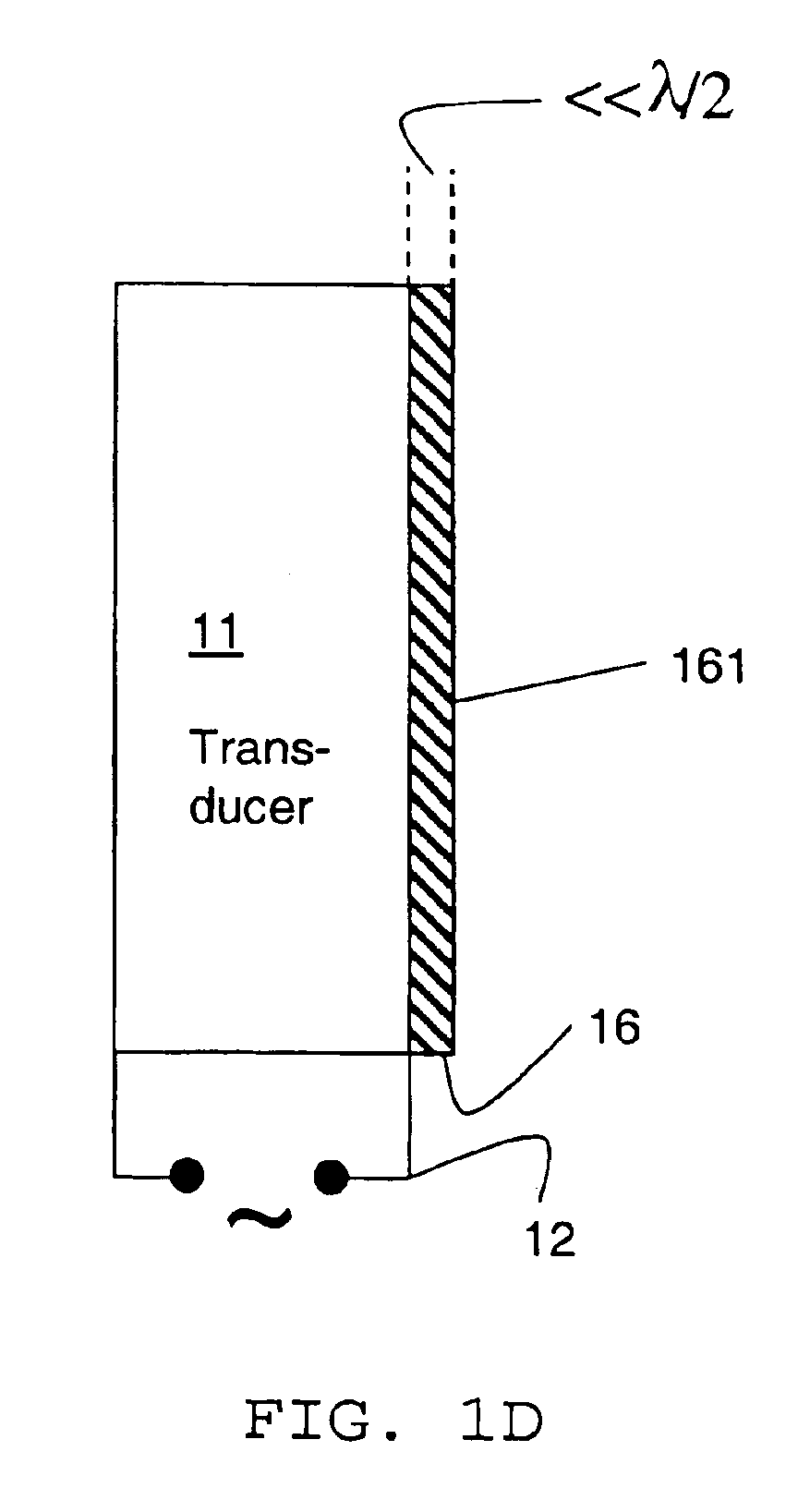

Deposition monitoring system

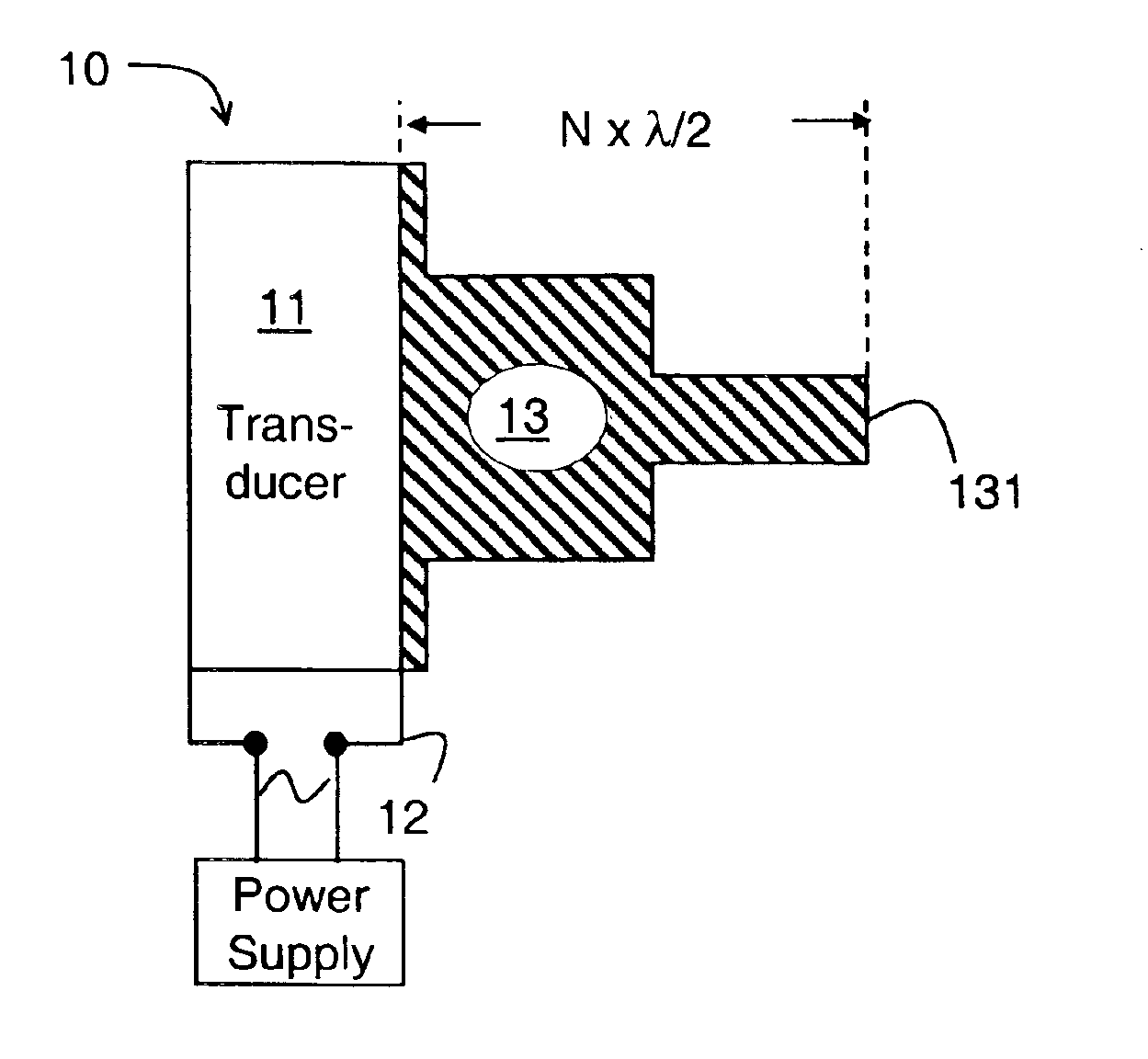

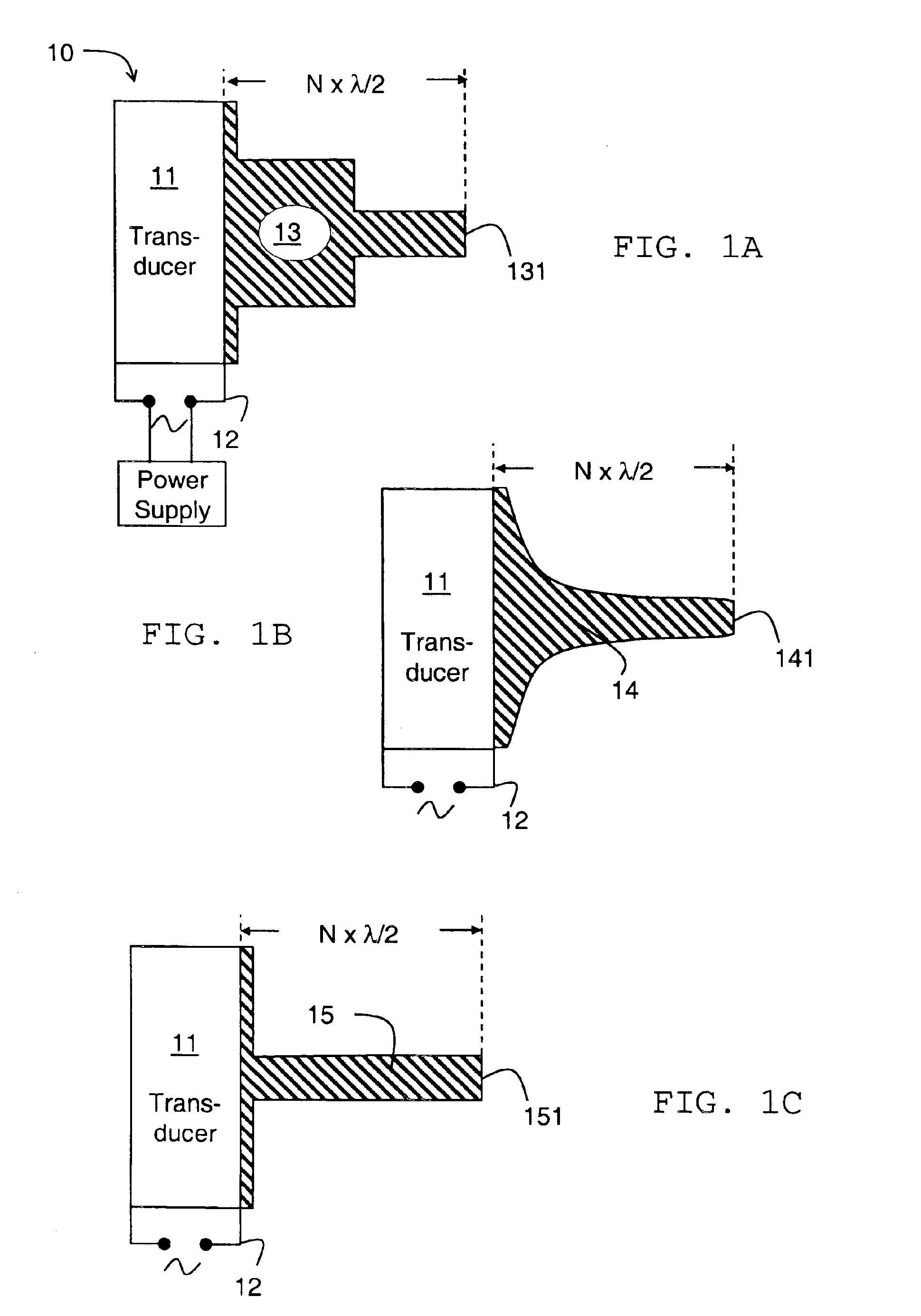

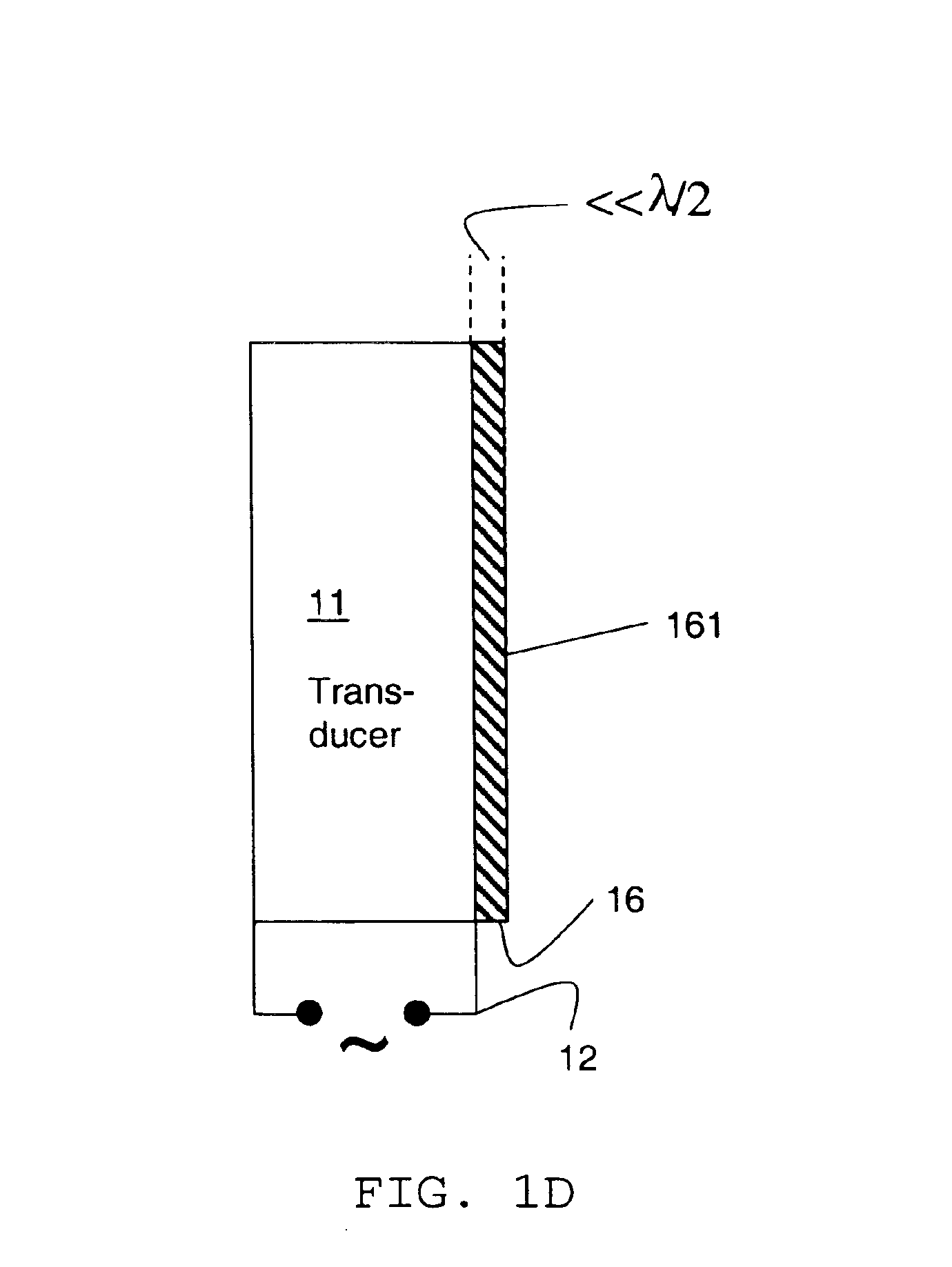

InactiveUS6880402B1Increase deposition thicknessConveniently determinedVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesMonitoring systemOperation mode

Described is an apparatus for detecting and removing deposits from a surface exposed to wellbore fluids. The apparatus can monitor the rate of deposition and subsequently remove the deposited material. The combination of detection apparatus and removal apparatus provides an instrument with self-cleaning operation mode.

Owner:SCHLUMBERGER TECH CORP

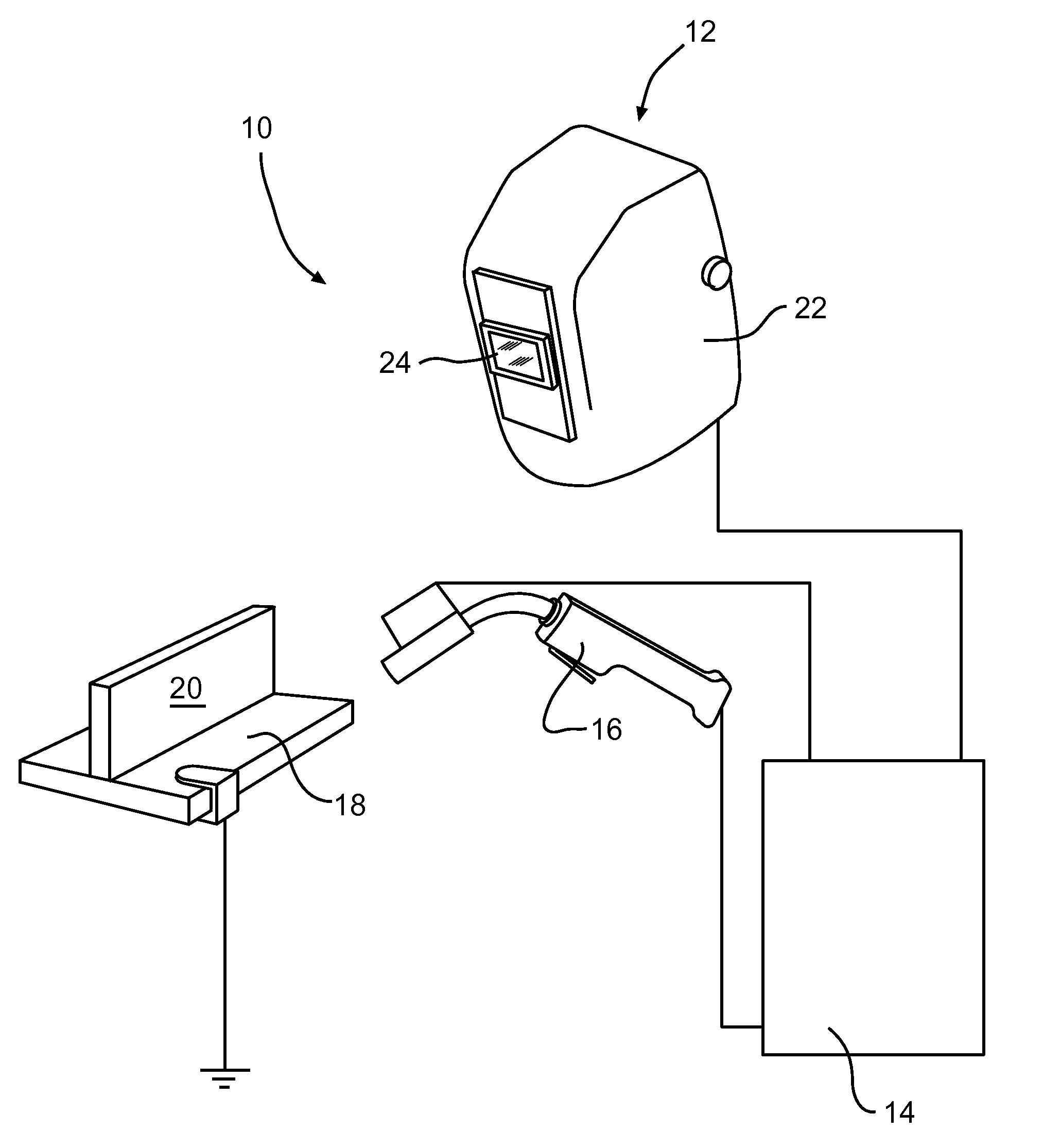

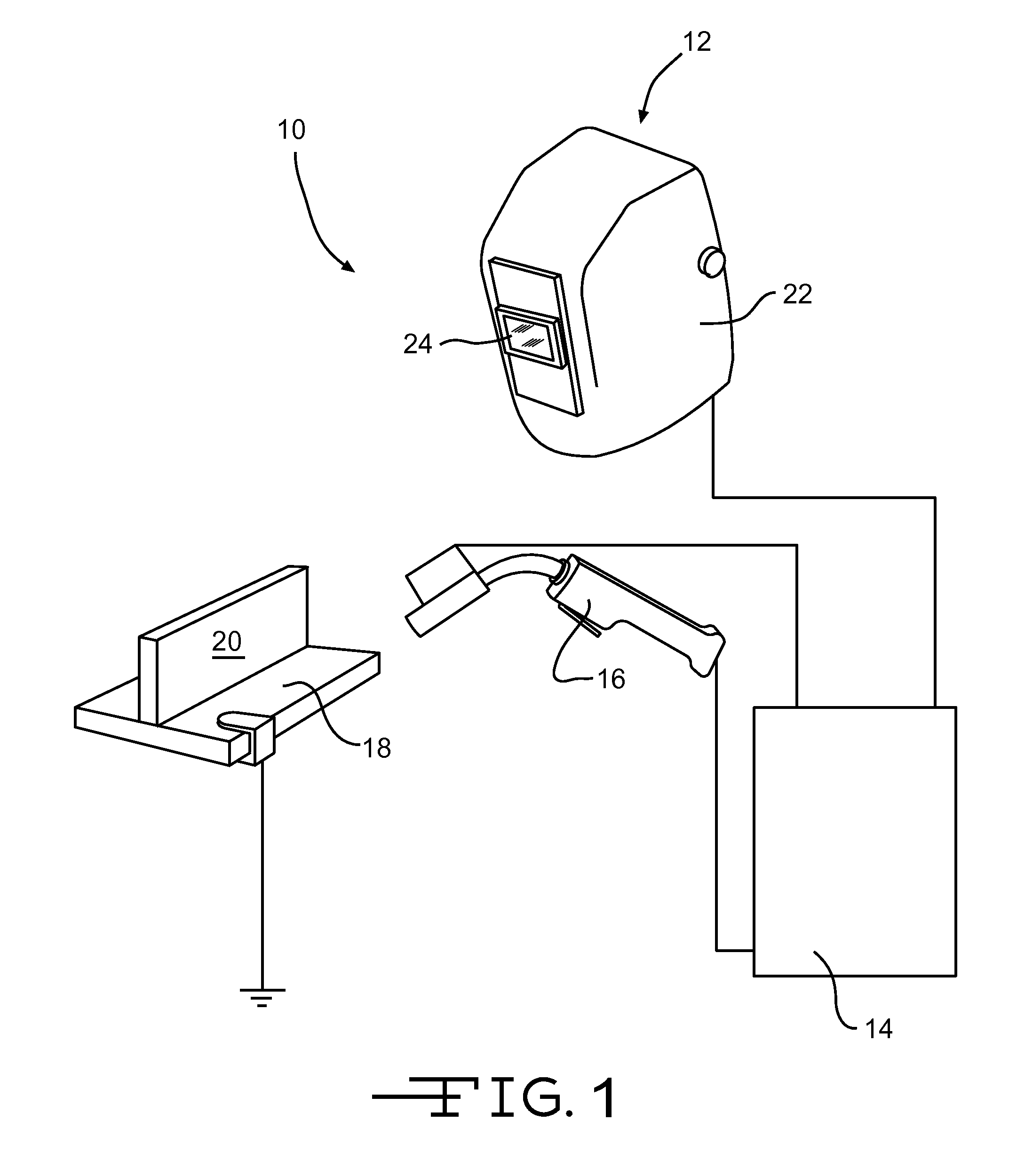

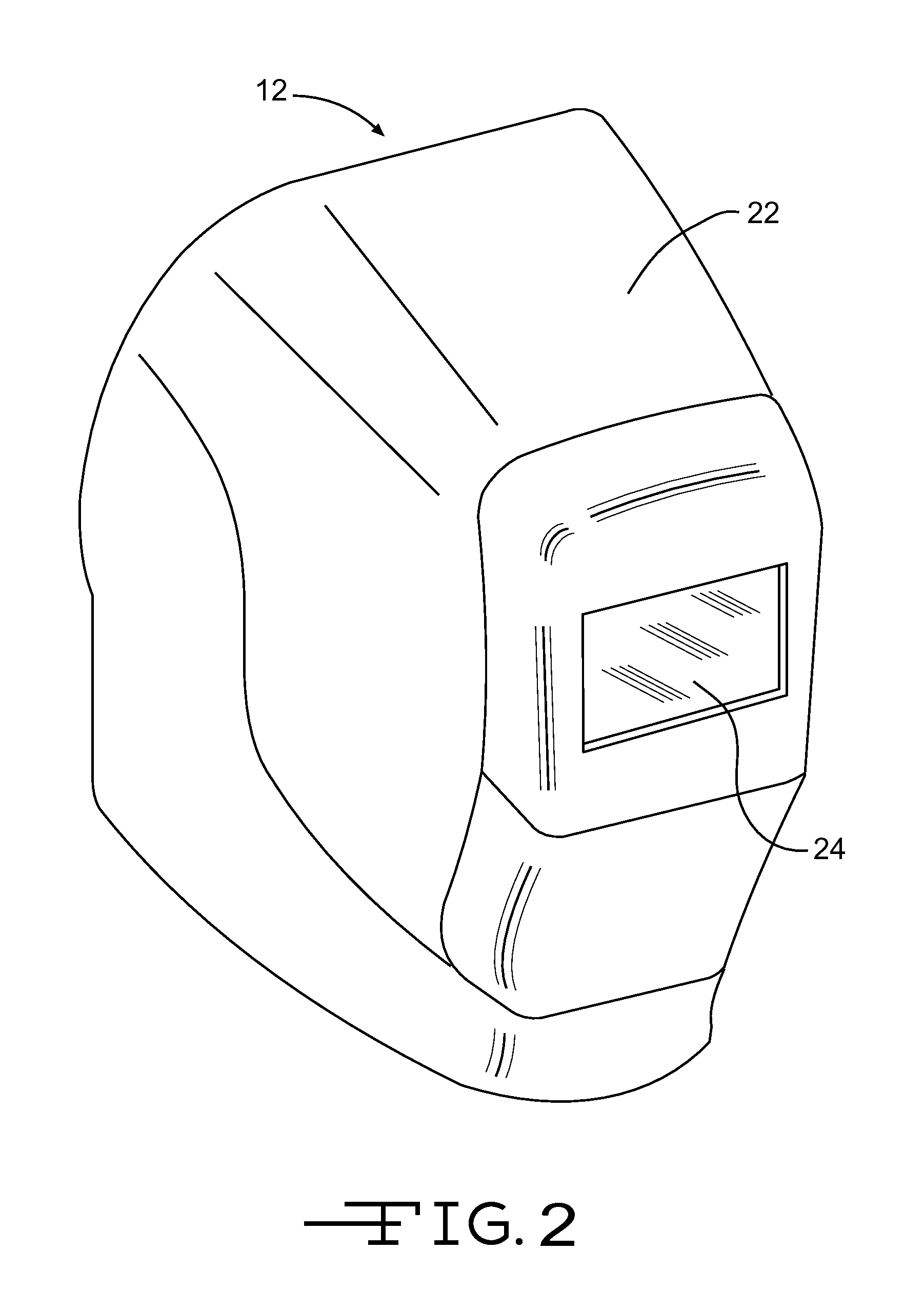

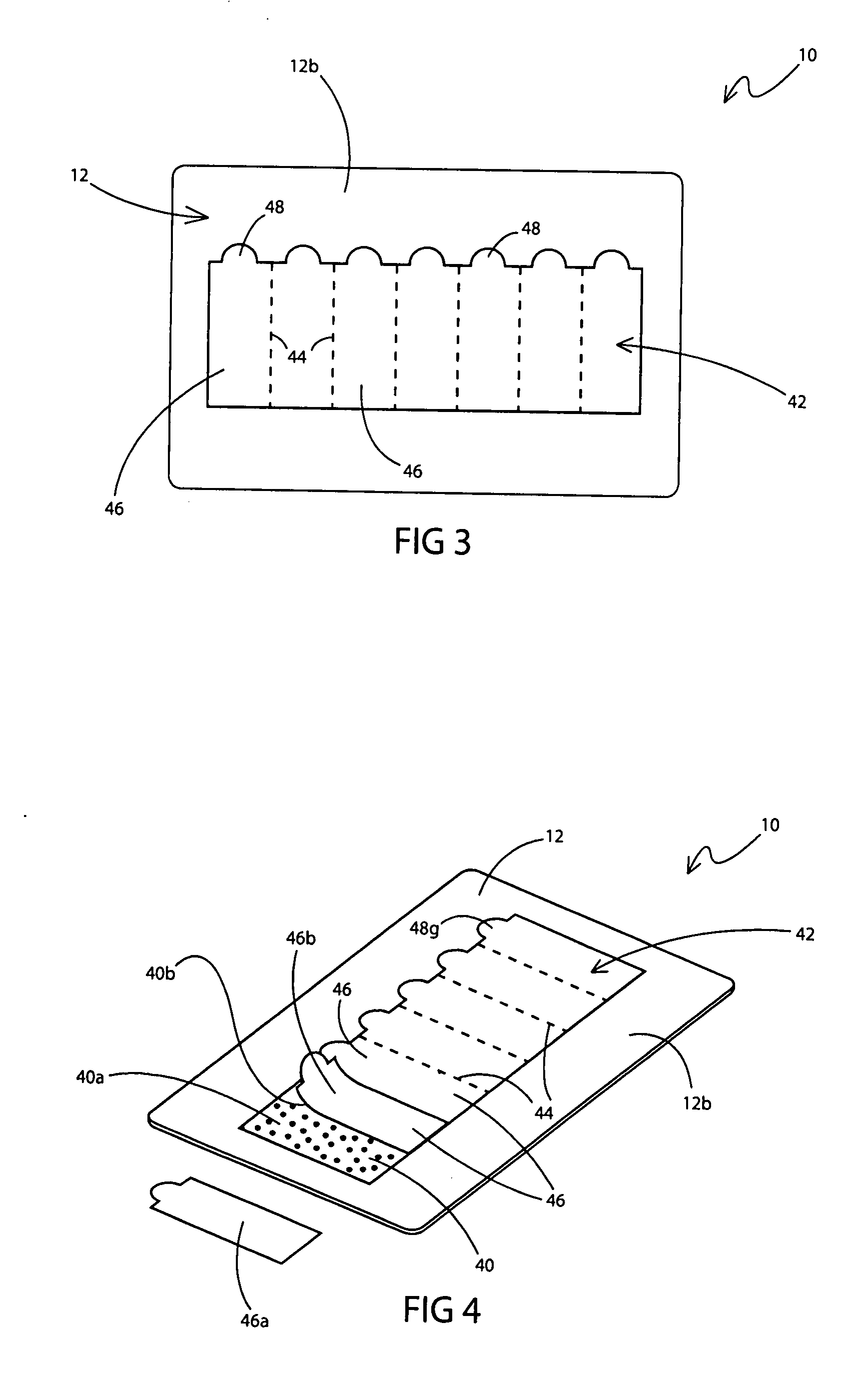

Welding arc apparel with UV activated images

A welding accessory and a system for detecting UV radiation exposure during welding operations are disclosed. The welding accessory may have a surface exposed to UV radiation generated by electric arc welding, a first image visible without exposure to the UV radiation, and a second image formed from UV activated dye that is visible only after exposure to UV radiation generated by the electric welding arc. A system may include a UV exposure indicator with a first state and at least a second state, and include UV activated dye adapted to provide a reversible or persistent visual indication upon exposure to UV radiation. The visual indication may include any combination of symbols, logos, images, text, or other decorative or informational designs as desired.

Owner:LINCOLN GLOBAL INC

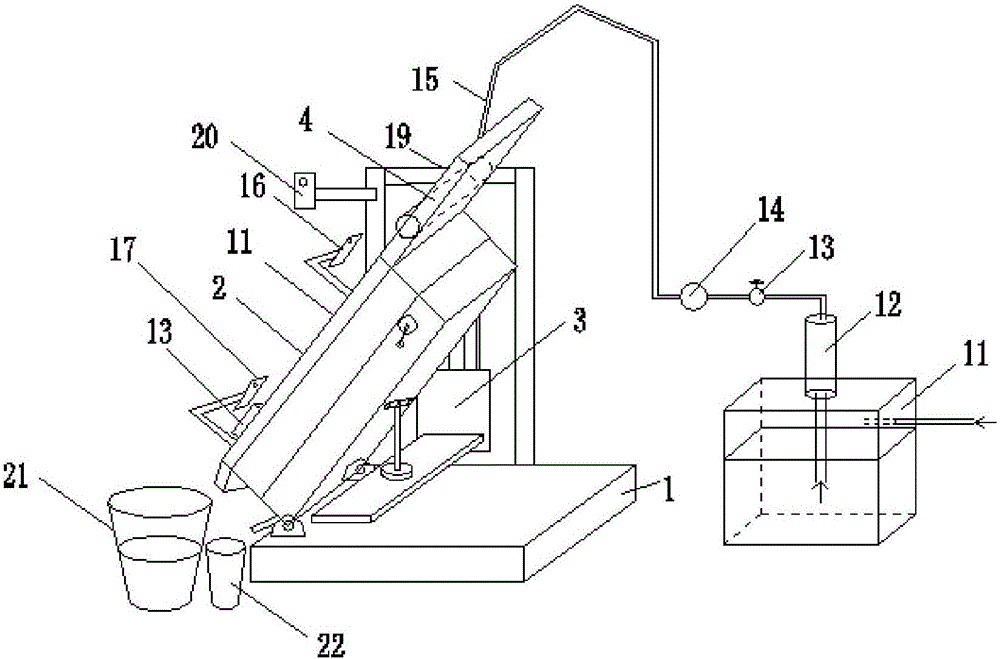

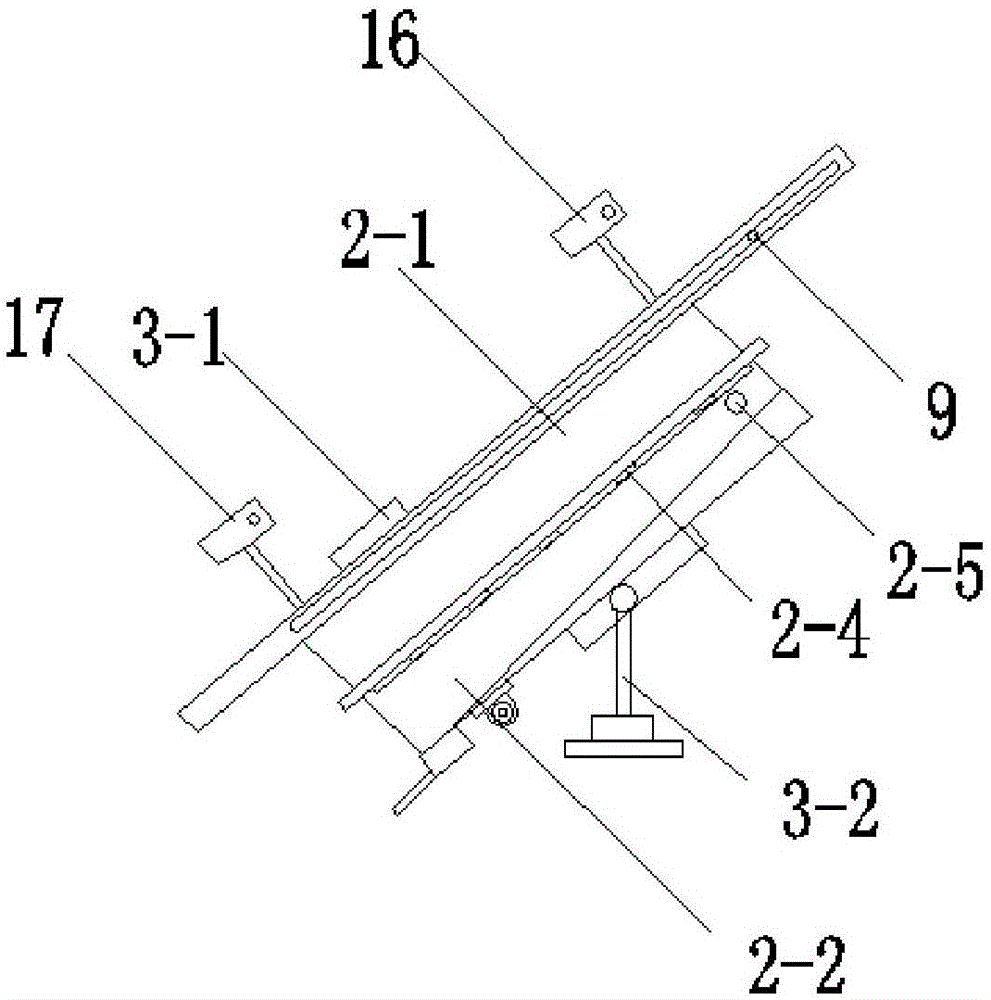

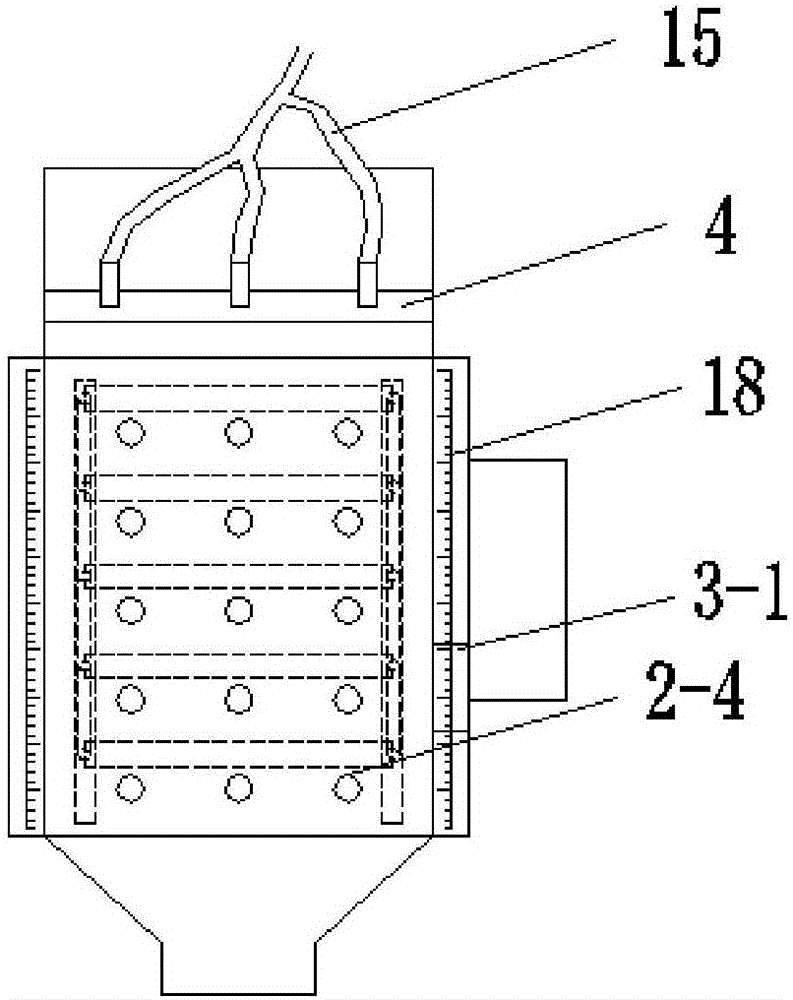

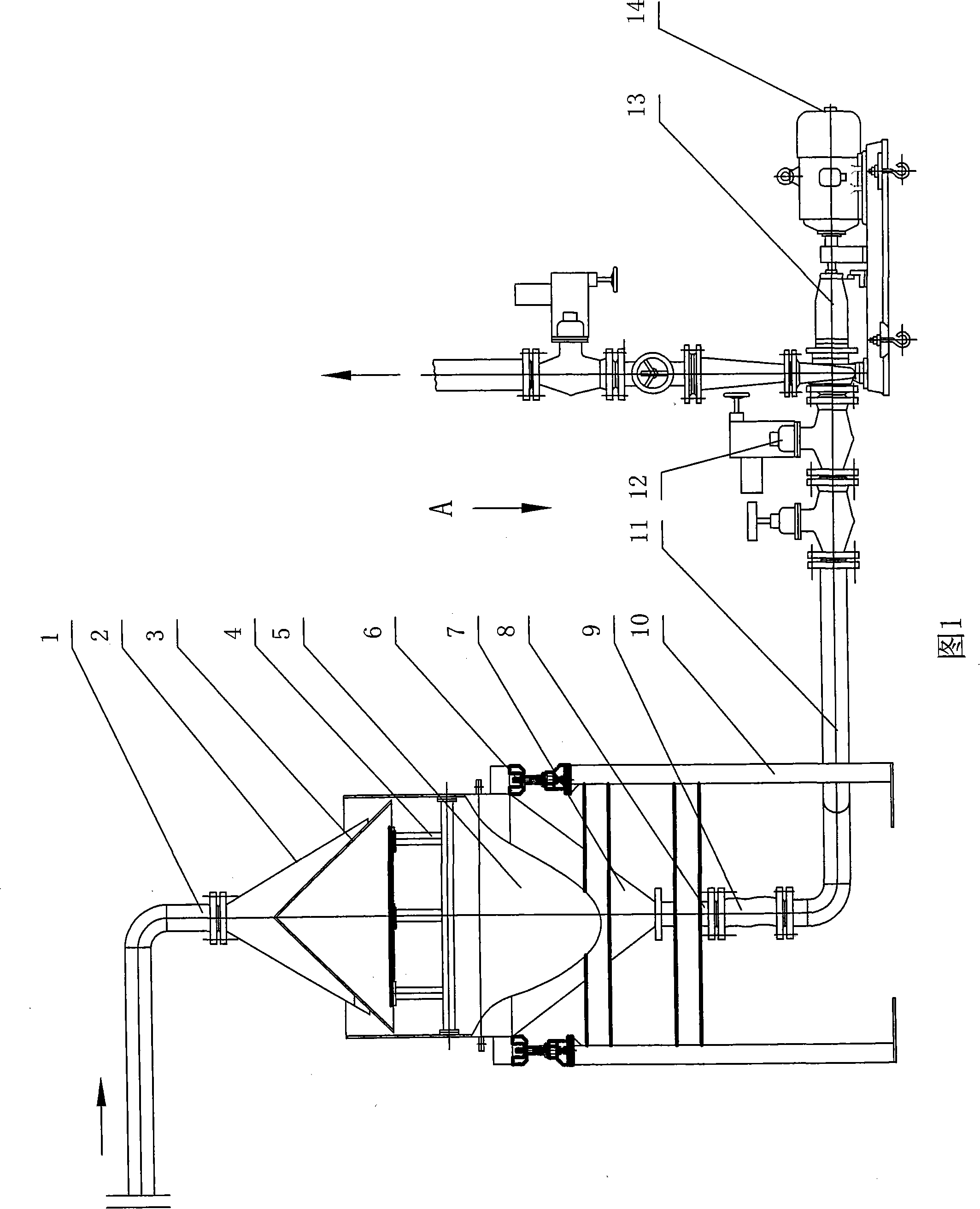

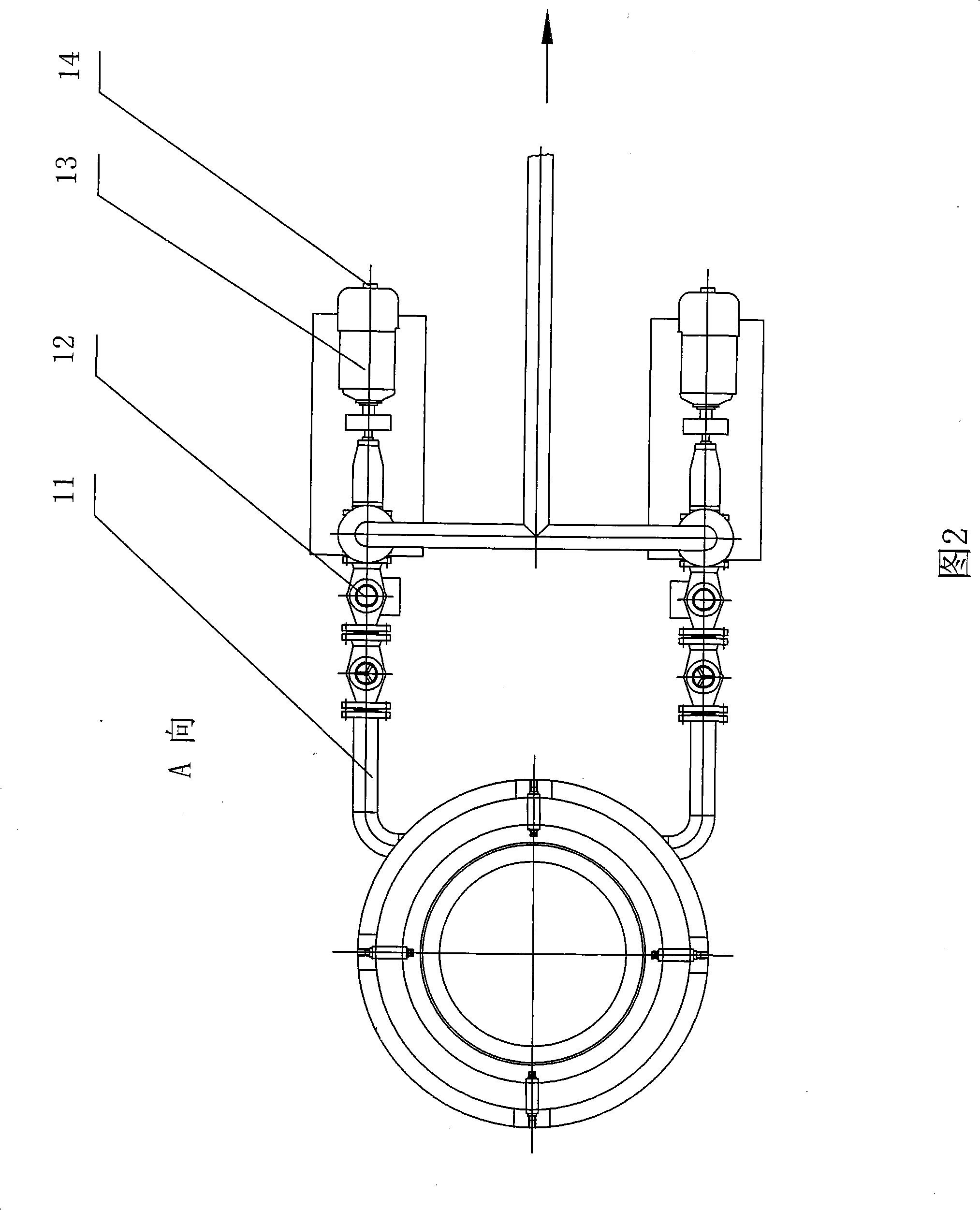

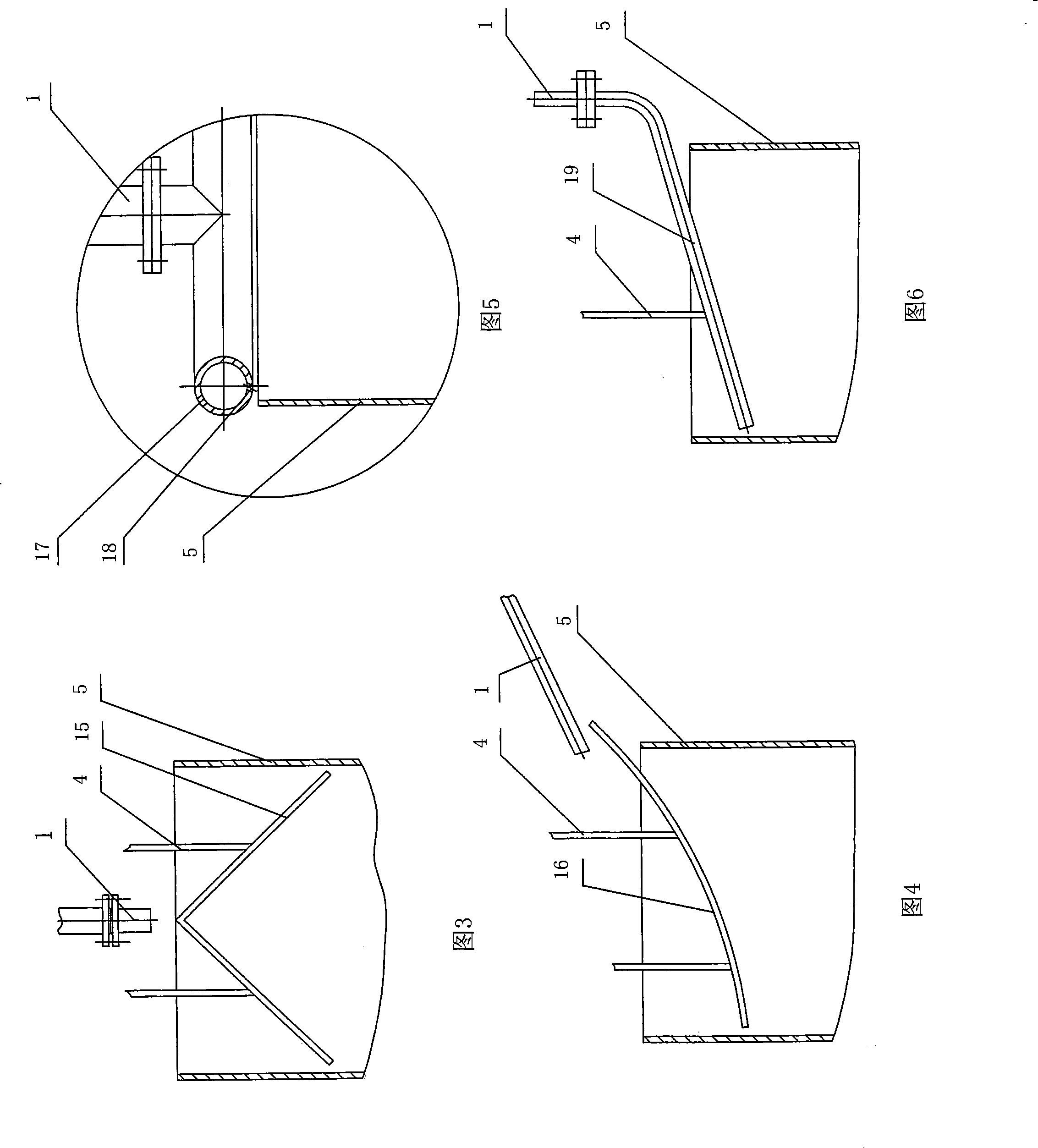

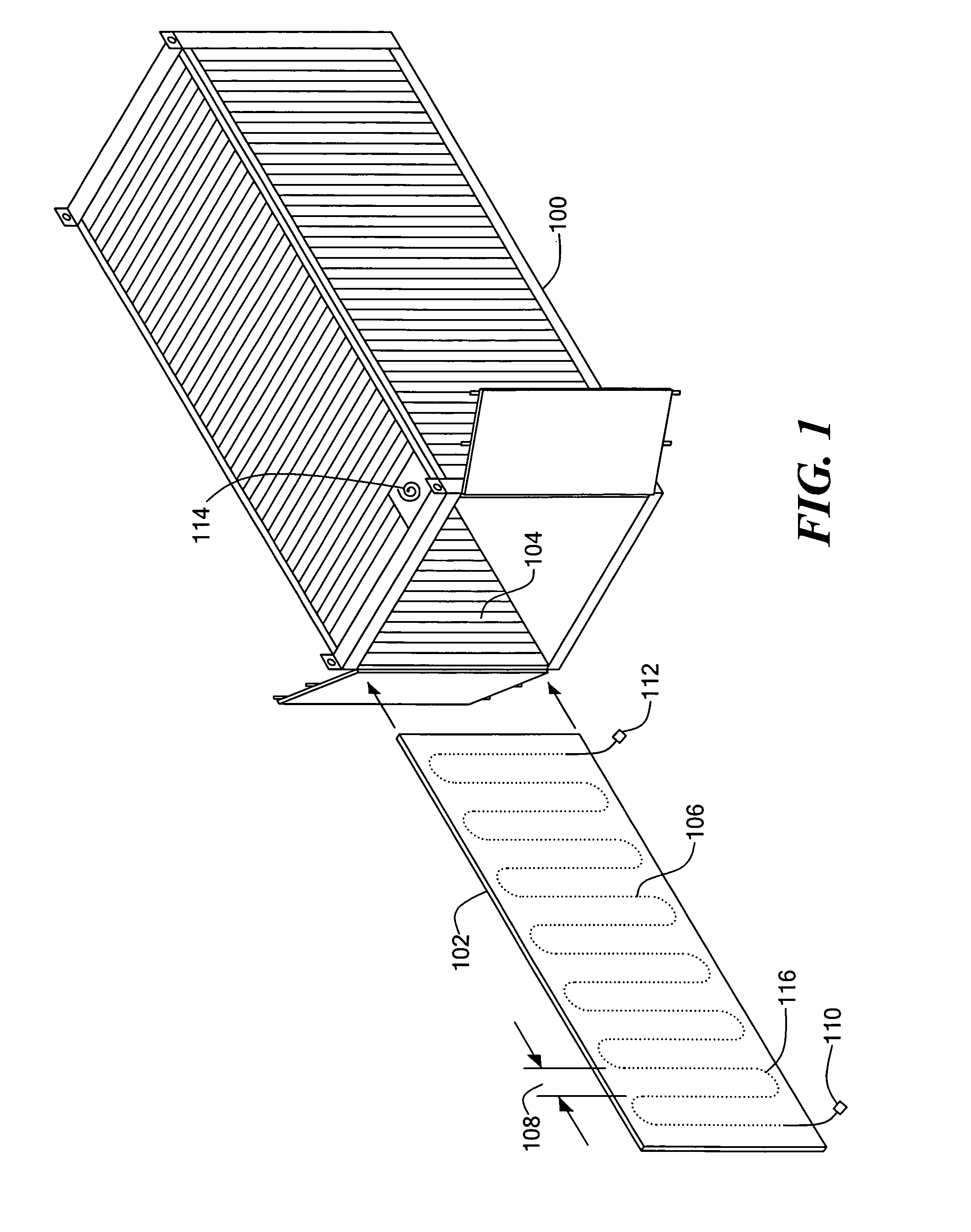

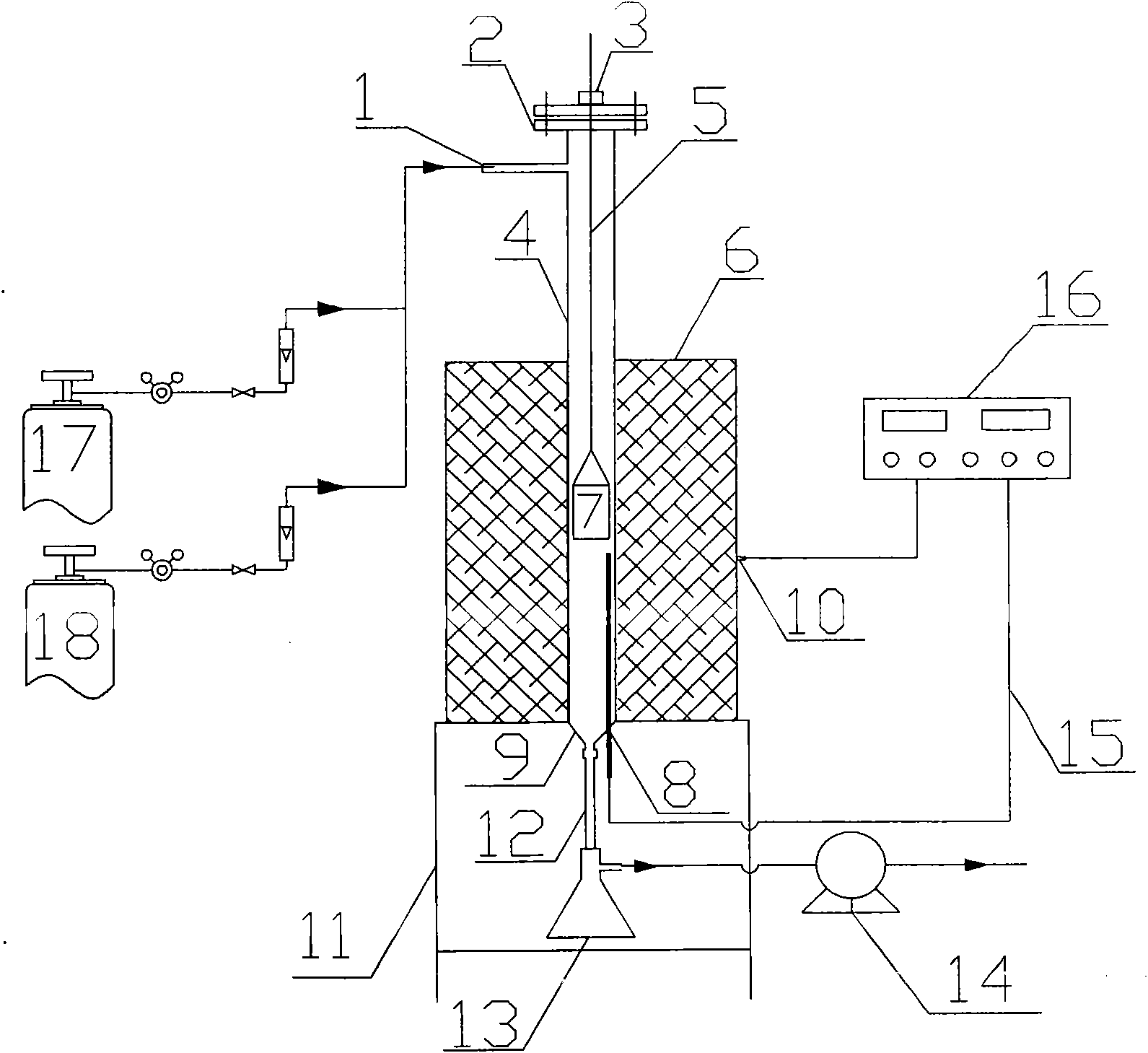

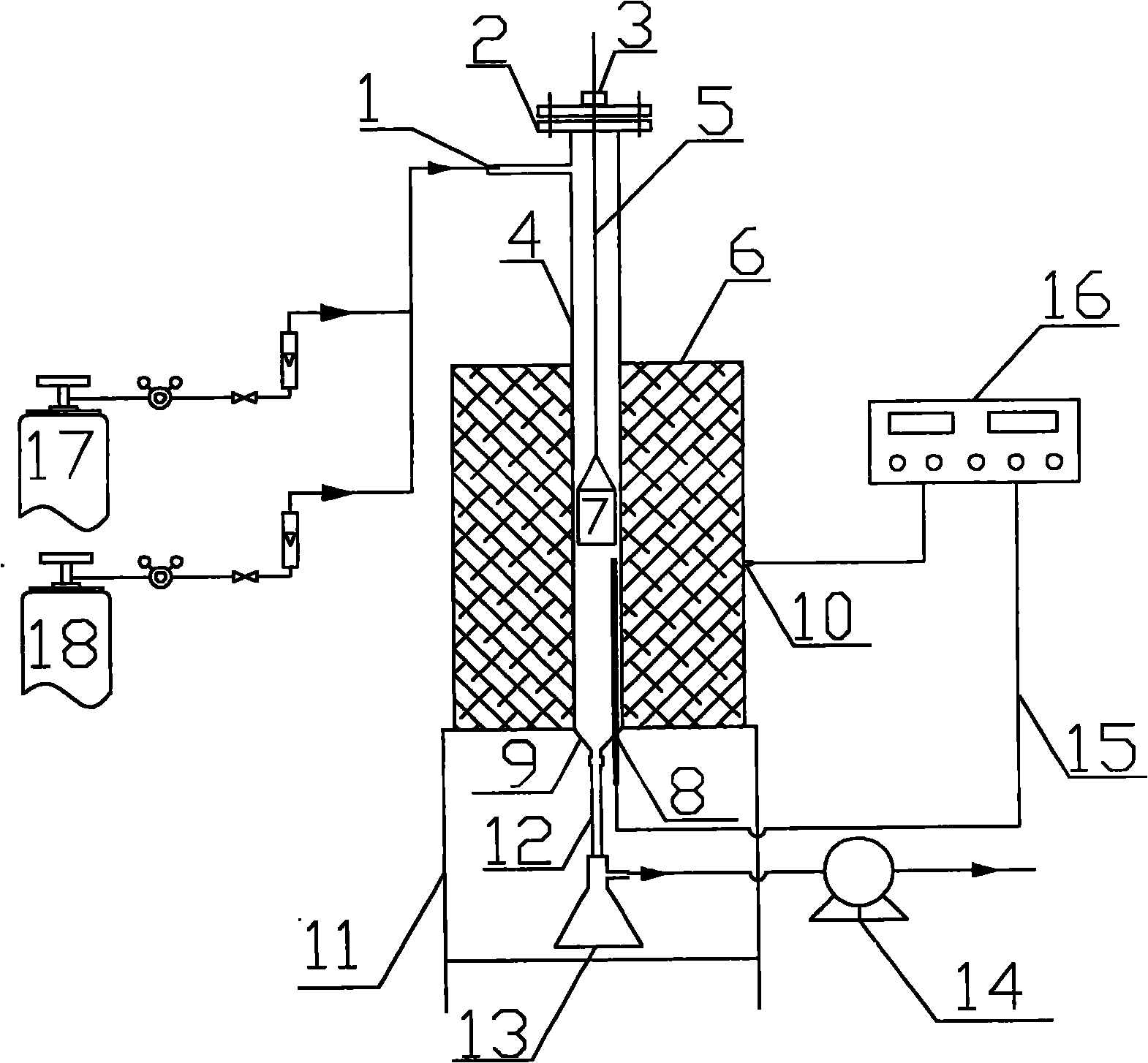

Soil slope water flow erosion resistance simulation test method and device

ActiveCN106290800AIncrease the time to gatherReduce wasteInvestigating moving fluids/granular solidsEarth material testingSoil scienceMaximum depth

The invention relates to a soil slope water flow erosion resistance simulation test method and device. The device comprises a liftable slope simulation device, a sheetflood scouring simulation device, a water and soil collecting device, a flow velocity determining device and a slope surface form camera device. According to the test method, the water flow is controlled, surface flow and seepage are formed, and sheetflood water, seepage water and sediment quantity formed by scouring slopes by sheetflood water are collected. The flow, the flow velocity, the erosion depth, the sand yield and the like of the water flow are measured quantitatively. Compacted soil is soaked in water until saturation for simulation, the efficiency of an indoor simulation test on slope scouring is improved, the test period is shortened, the test result proves the maximum depth of a slope erosion gully and the change rule of the sand yield with time, discloses the relation between the water flow erosion capacity of catchment behind slopes and the slope length, gradient and time and provides a basis for prediction of the water flow erosion scale and the need of slope protection and reinforcement. The device is simple in structure, convenient to operate and suitable for measurement of soil mechanics parameters of slope soil mass.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

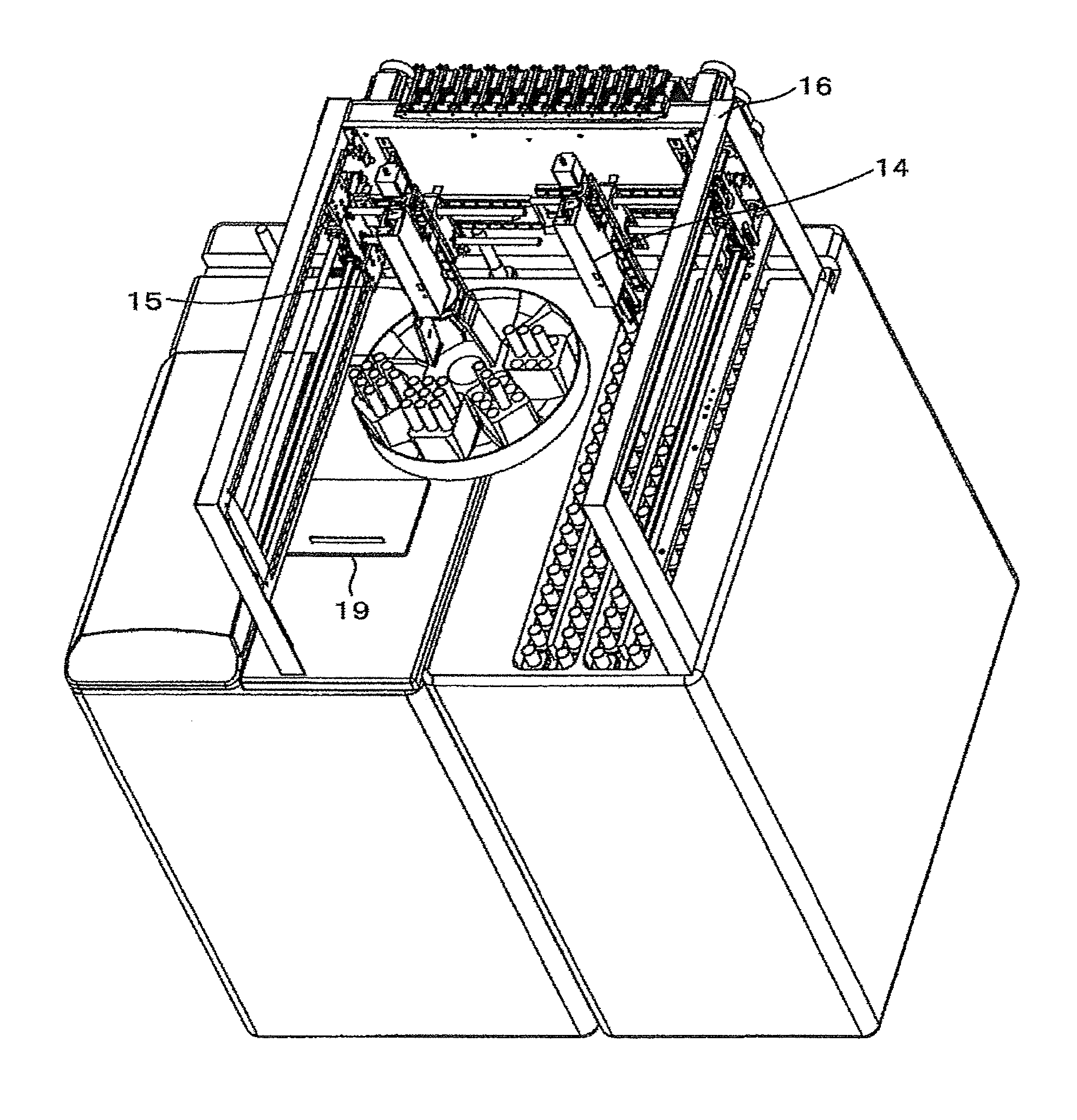

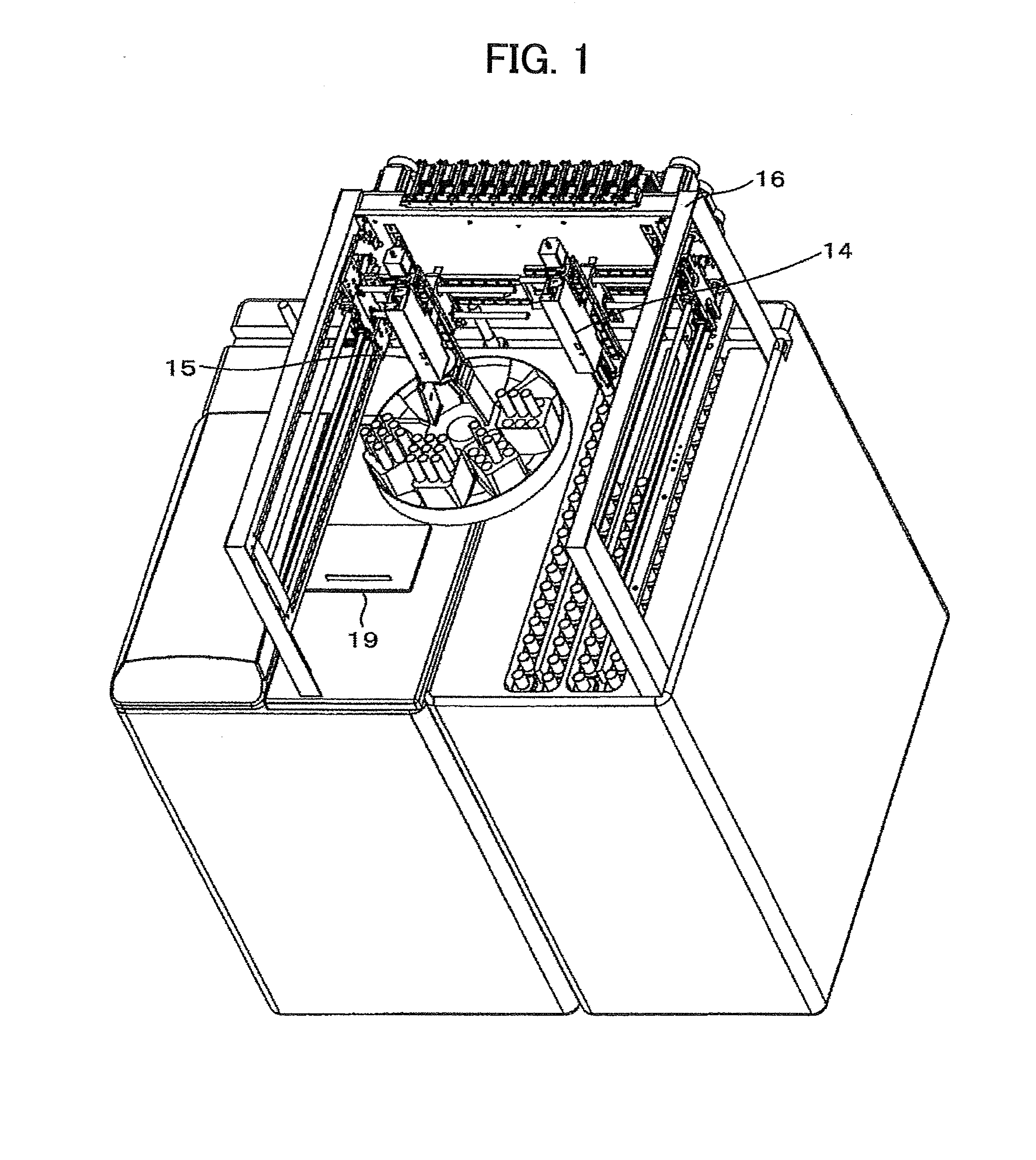

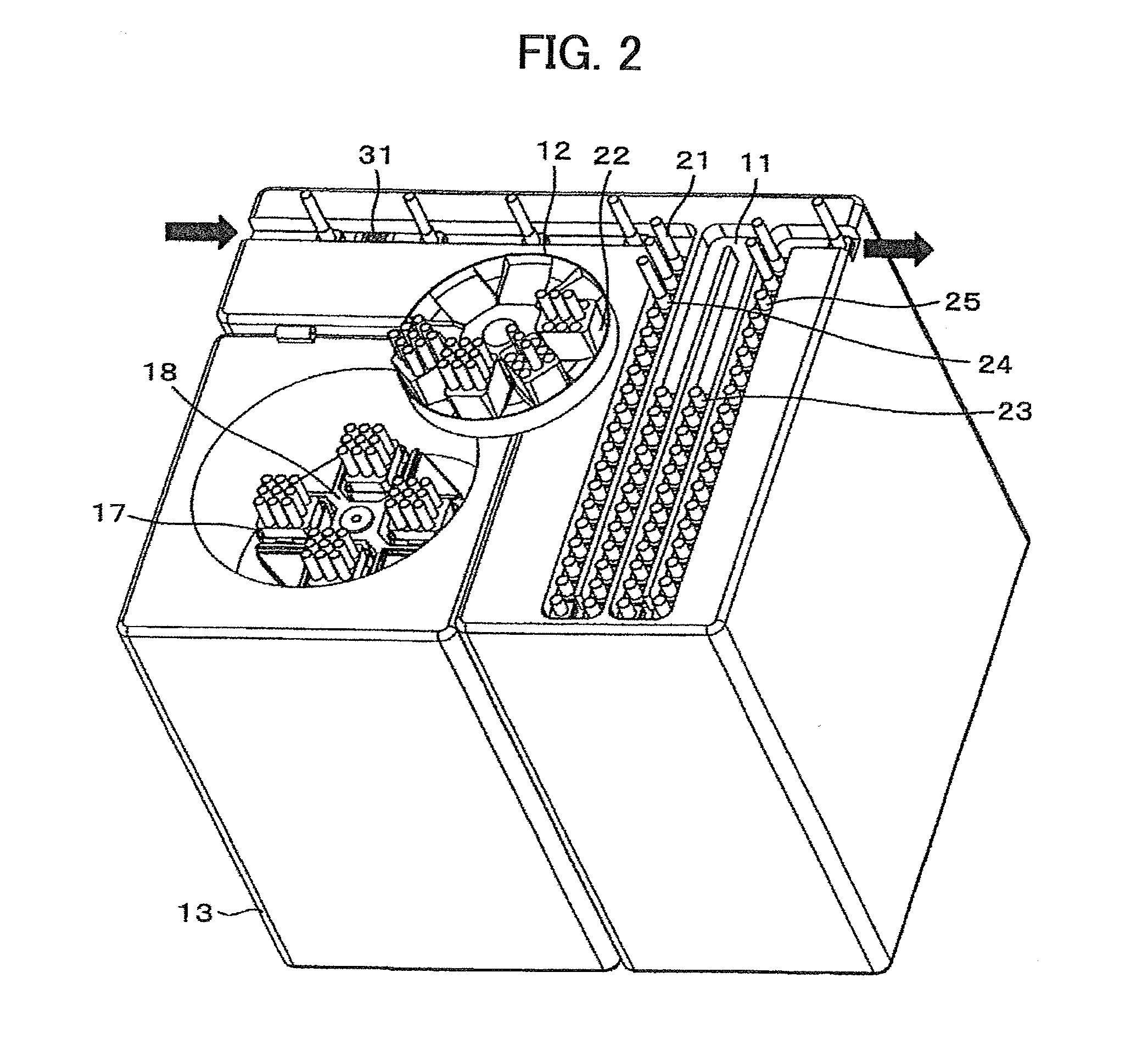

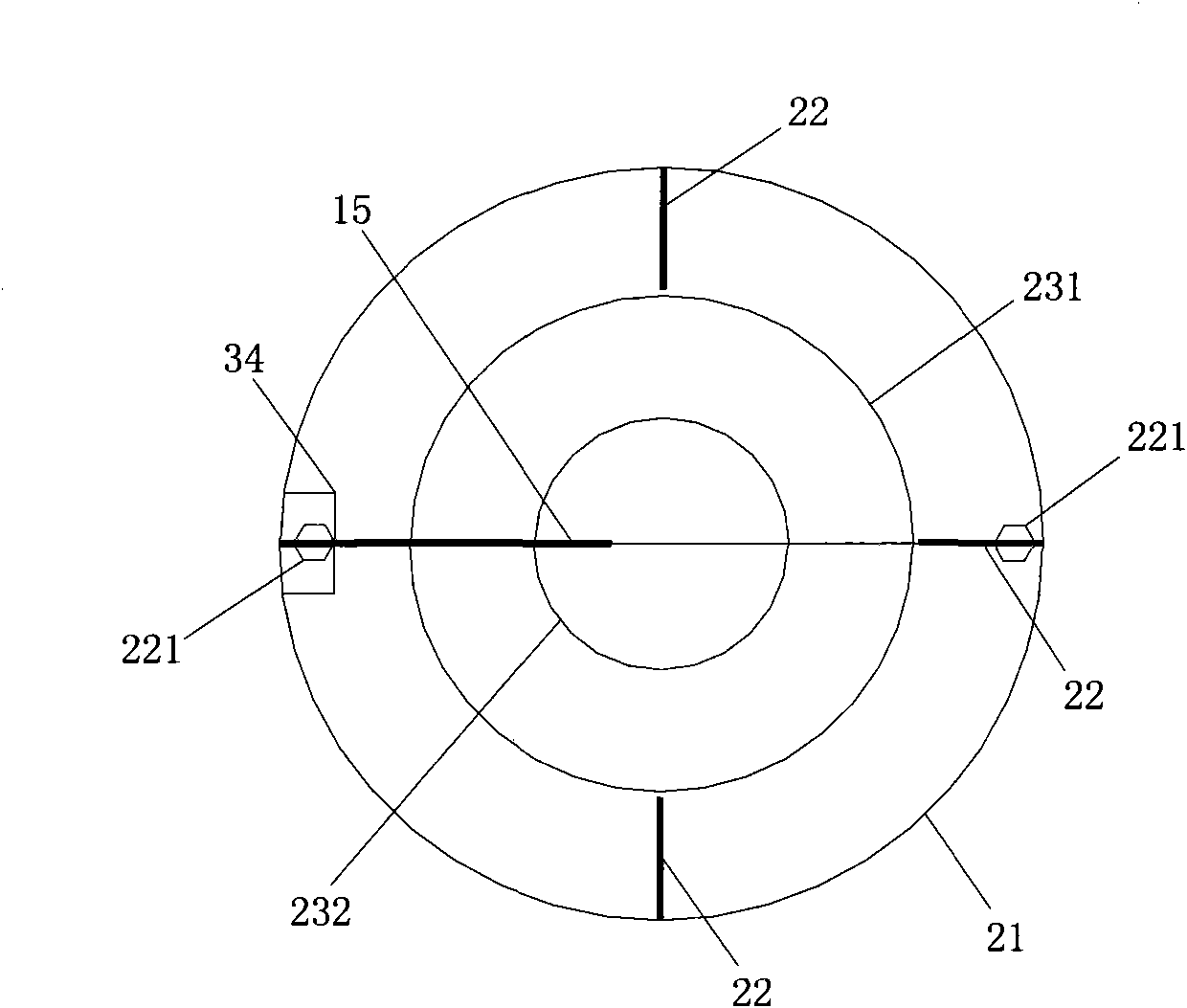

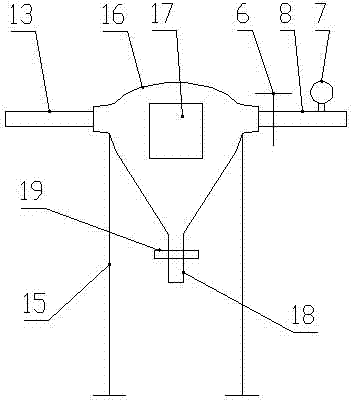

Centrifugal separator

The weight difference is limited between buckets (17) mounted at respective symmetrical positions with respect to a centrifugal separation rotational center and examination of samples is continuously performed in the order in which they are received. In particular, when a sample (21) is carried in a centrifugal buffer line (11), its weight is measured by weight measuring means (31). It is assumed that the names of two adaptors (22) placed at respective symmetrical positions with respect to the centrifugal separation rotational center are defined as an adaptor A and an adaptor B. A first sample is put on the adaptor A and a second sample is put on the adaptor B. Then, a third sample and subsequent ones are each put on the adaptor (22) lighter than the other adaptor after the total weights of samples put on the adaptors are computation-compared with each other.

Owner:HITACHI HIGH-TECH CORP

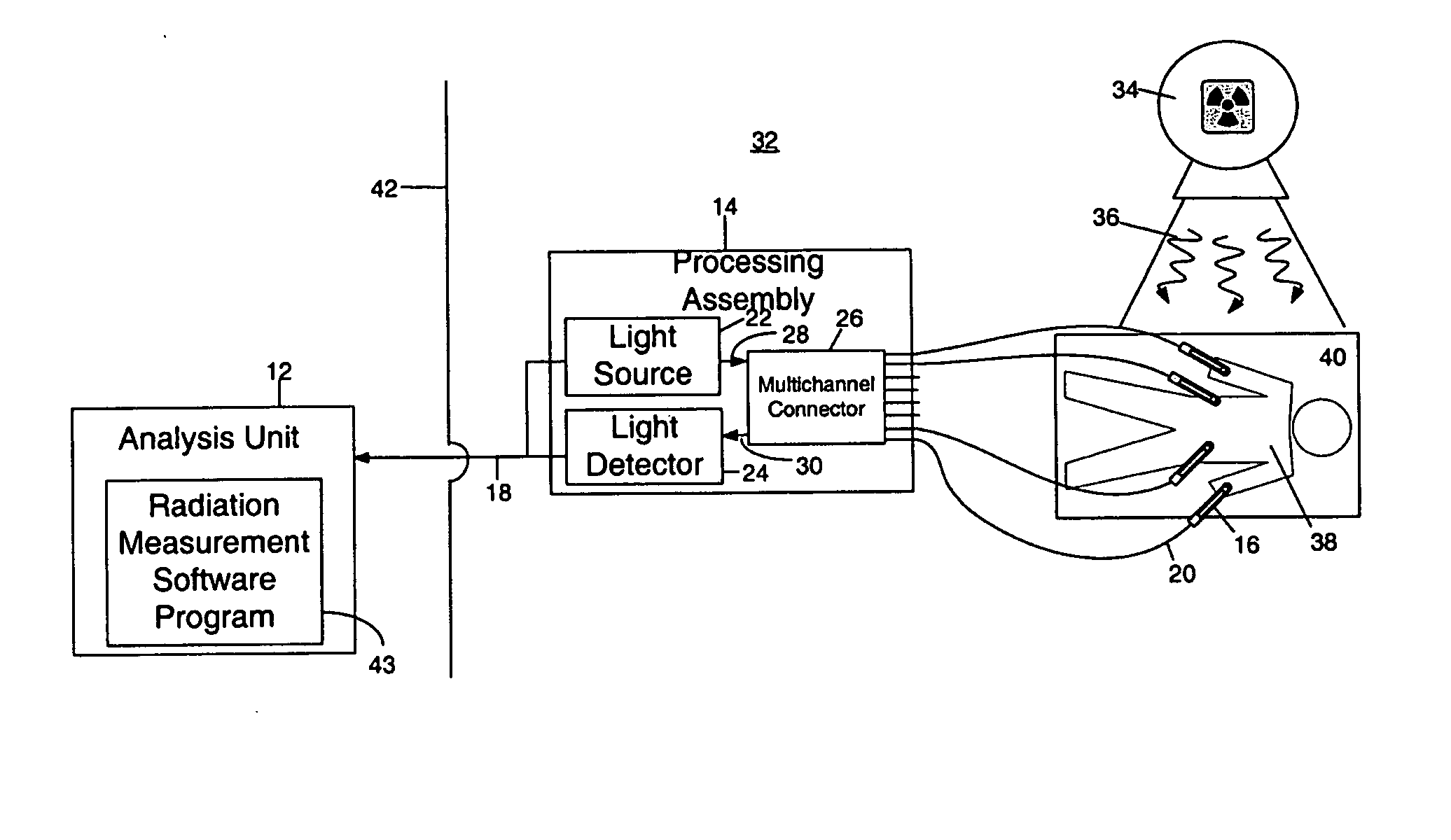

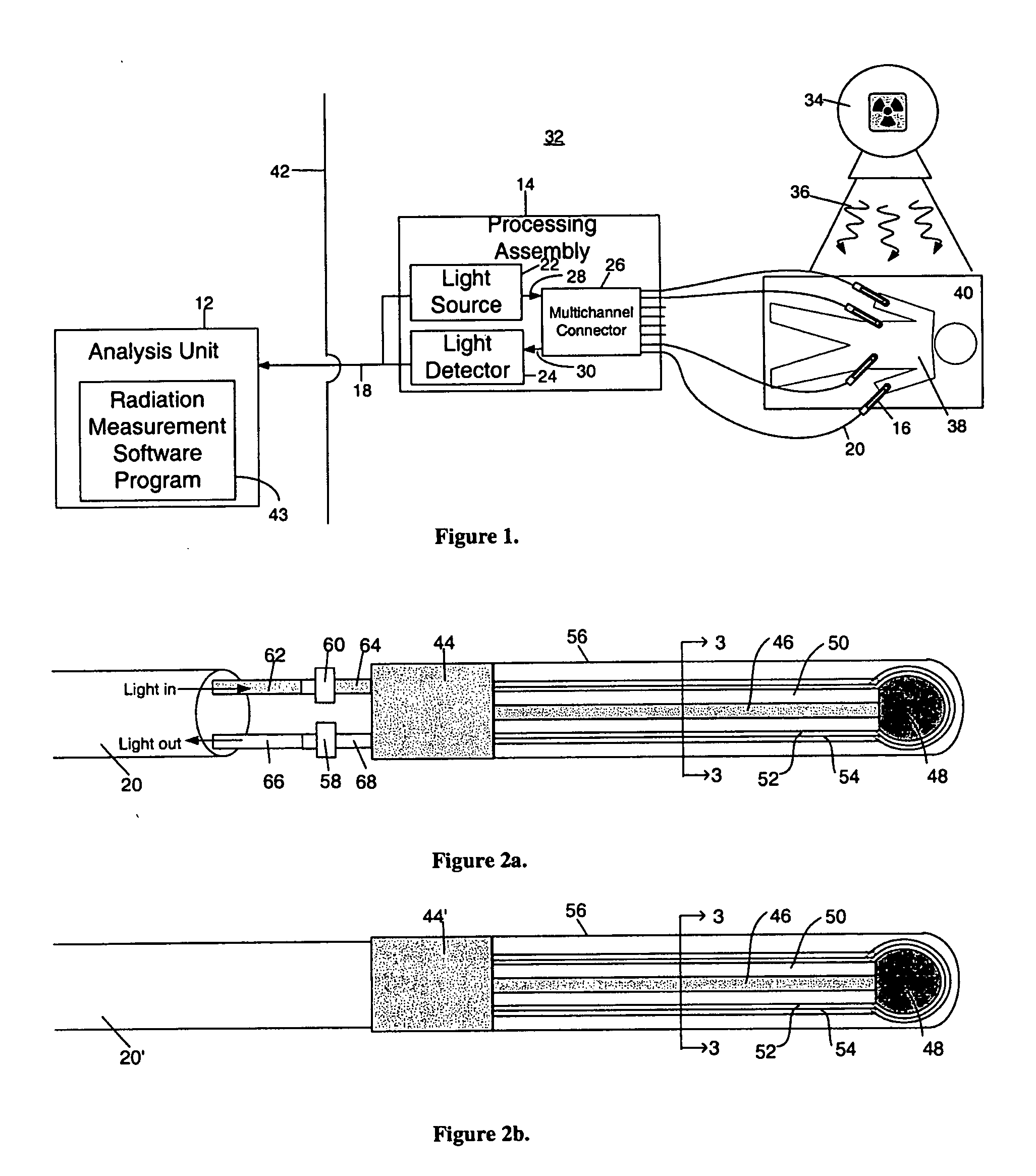

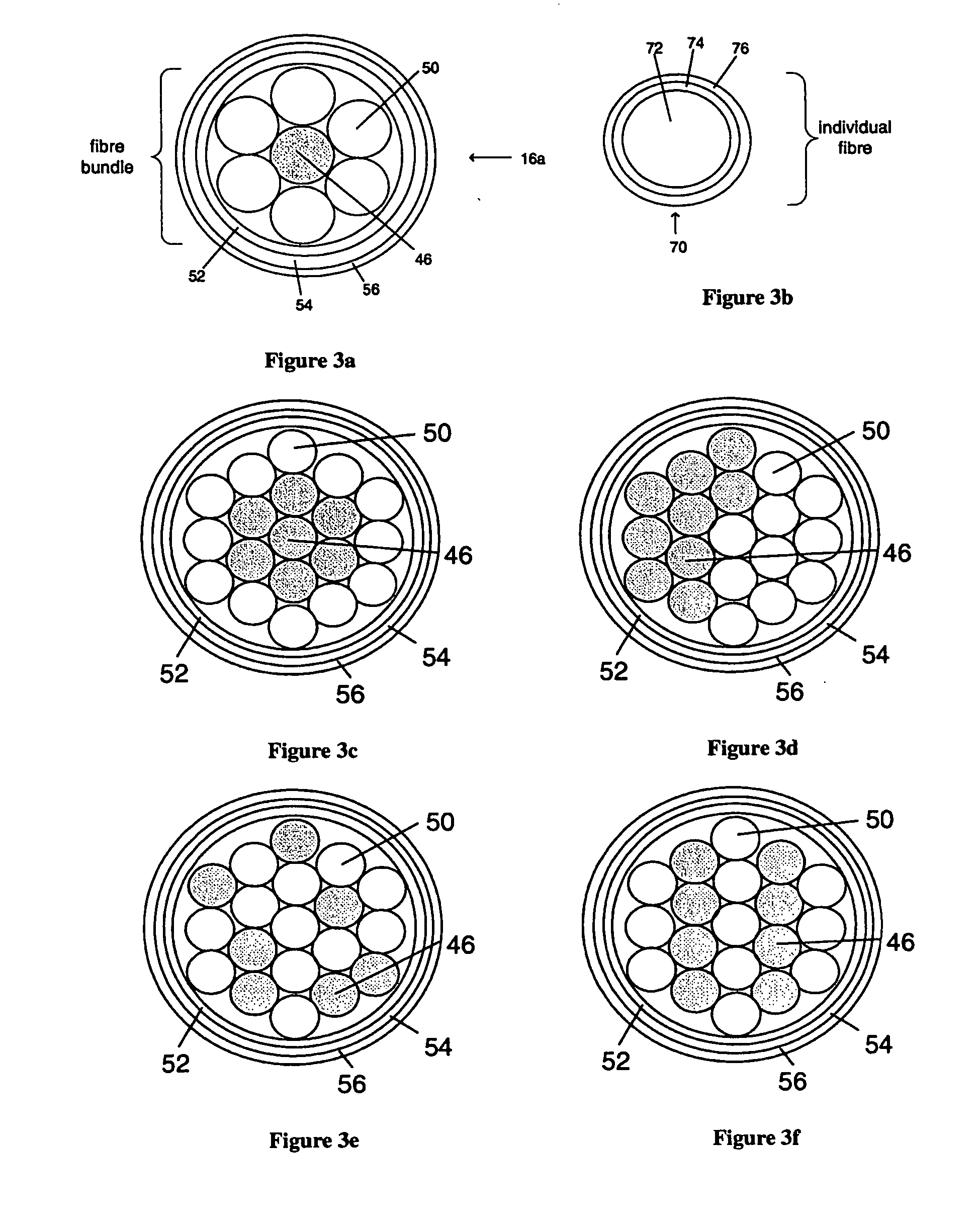

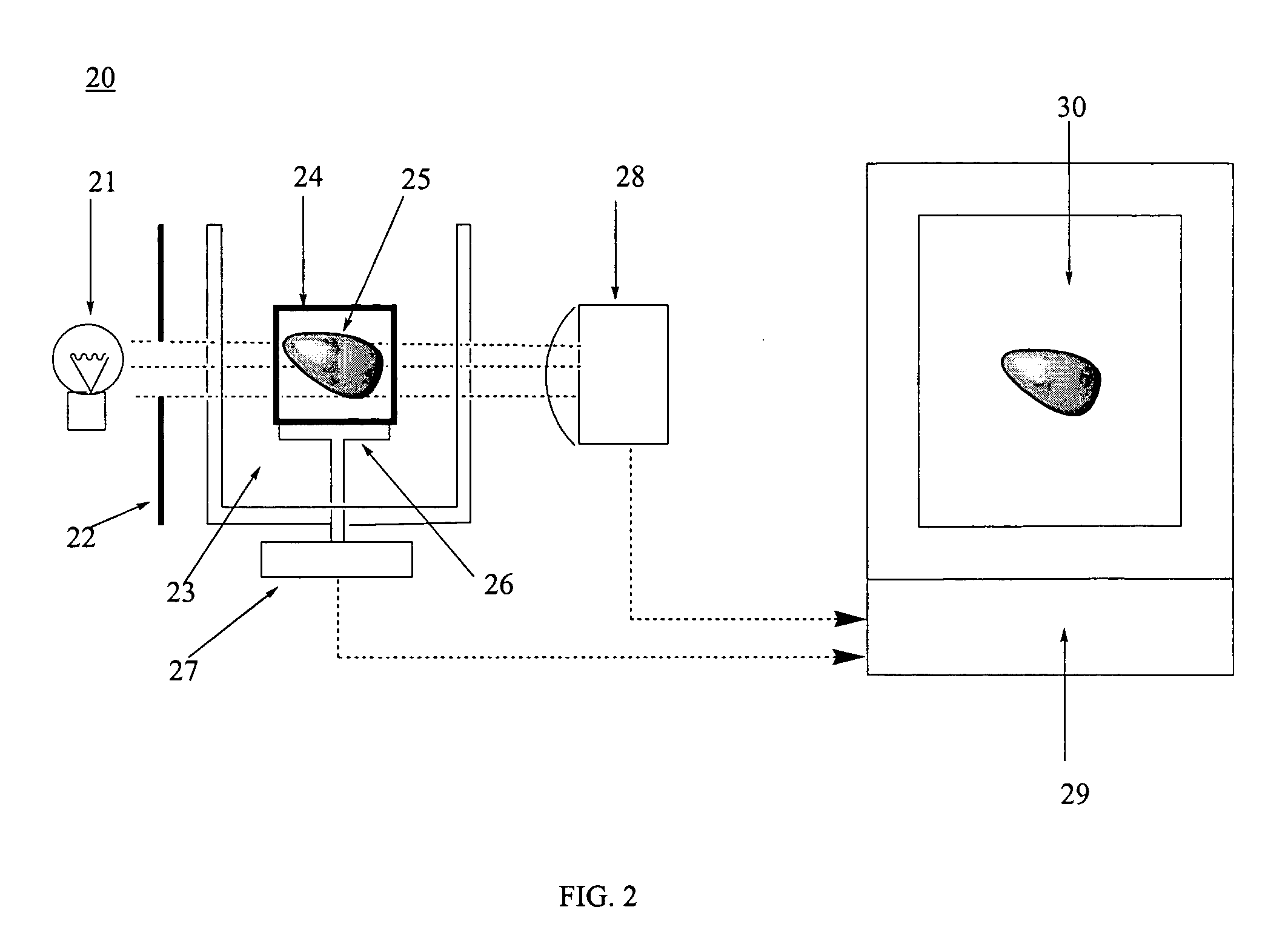

Apparatus and method for determining radiation dose

ActiveUS20060017009A1Minimal disturbanceAct quicklyElectroluminescent light sourcesPhotometryOptical propertyDosimeter

A radiation dosimeter system and method for estimating a deposited radiation dose to an object involves locating at least one radiation dosimeter at the object. The radiation dosimeter includes a radiation sensitive medium having an optical property that changes due to the deposited radiation dose. An optical interrogation signal is provided to the radiation dosimeter via an enclosed optical path for interacting with the radiation sensitive medium. During irradiation, the optical interrogation signal is transformed into an optical information signal that encodes an ionizing radiation induced change in the optical property of the radiation sensitive medium. The radiation dosimeter system then processes the optical information signal for estimating the deposited radiation dose.

Owner:UNIV HEALTH NETWORK

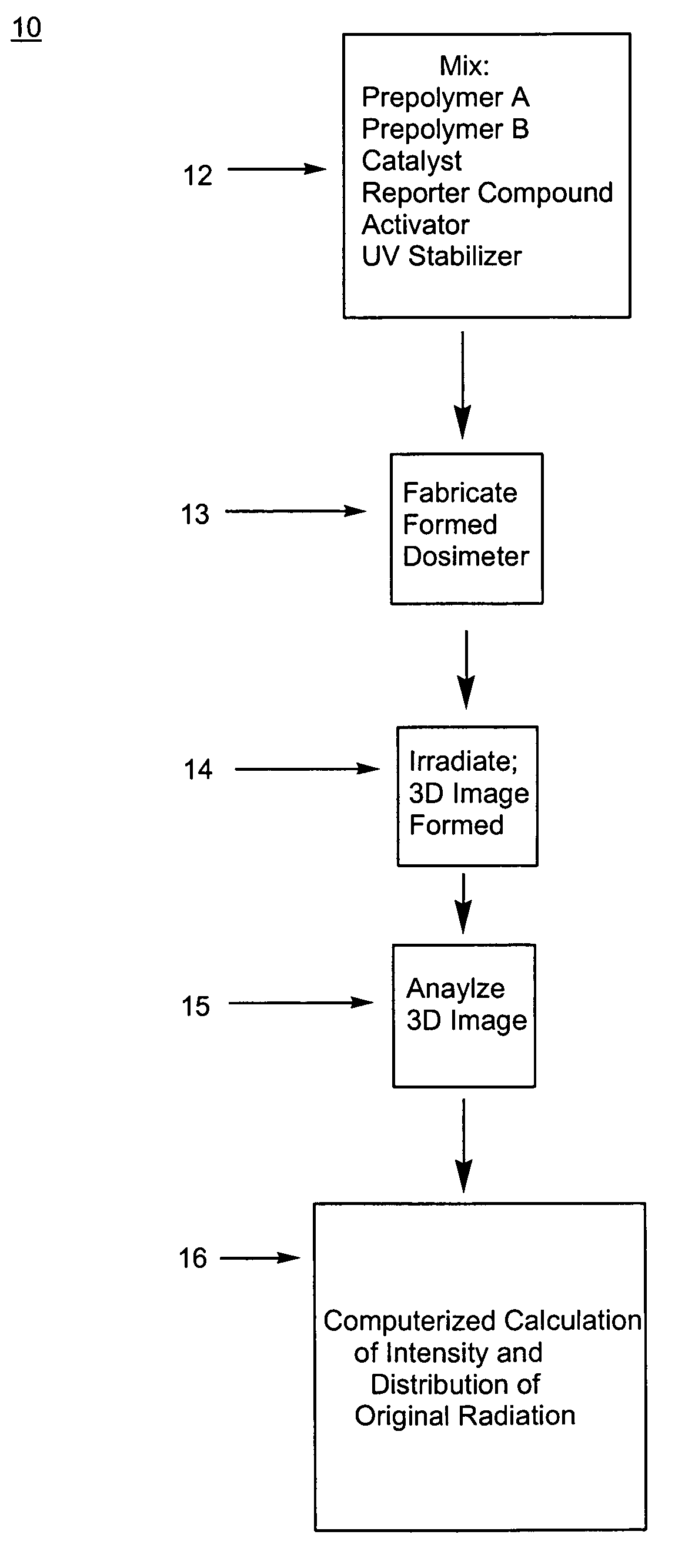

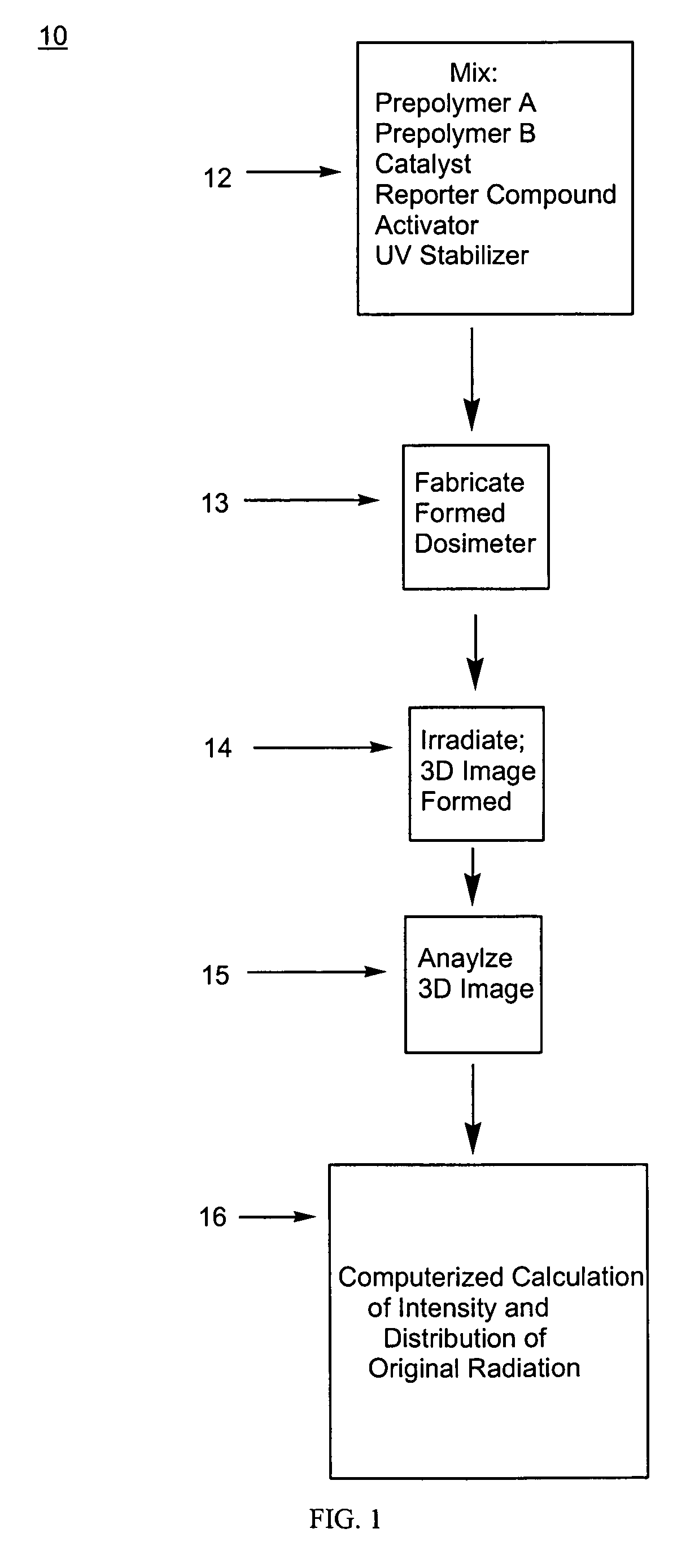

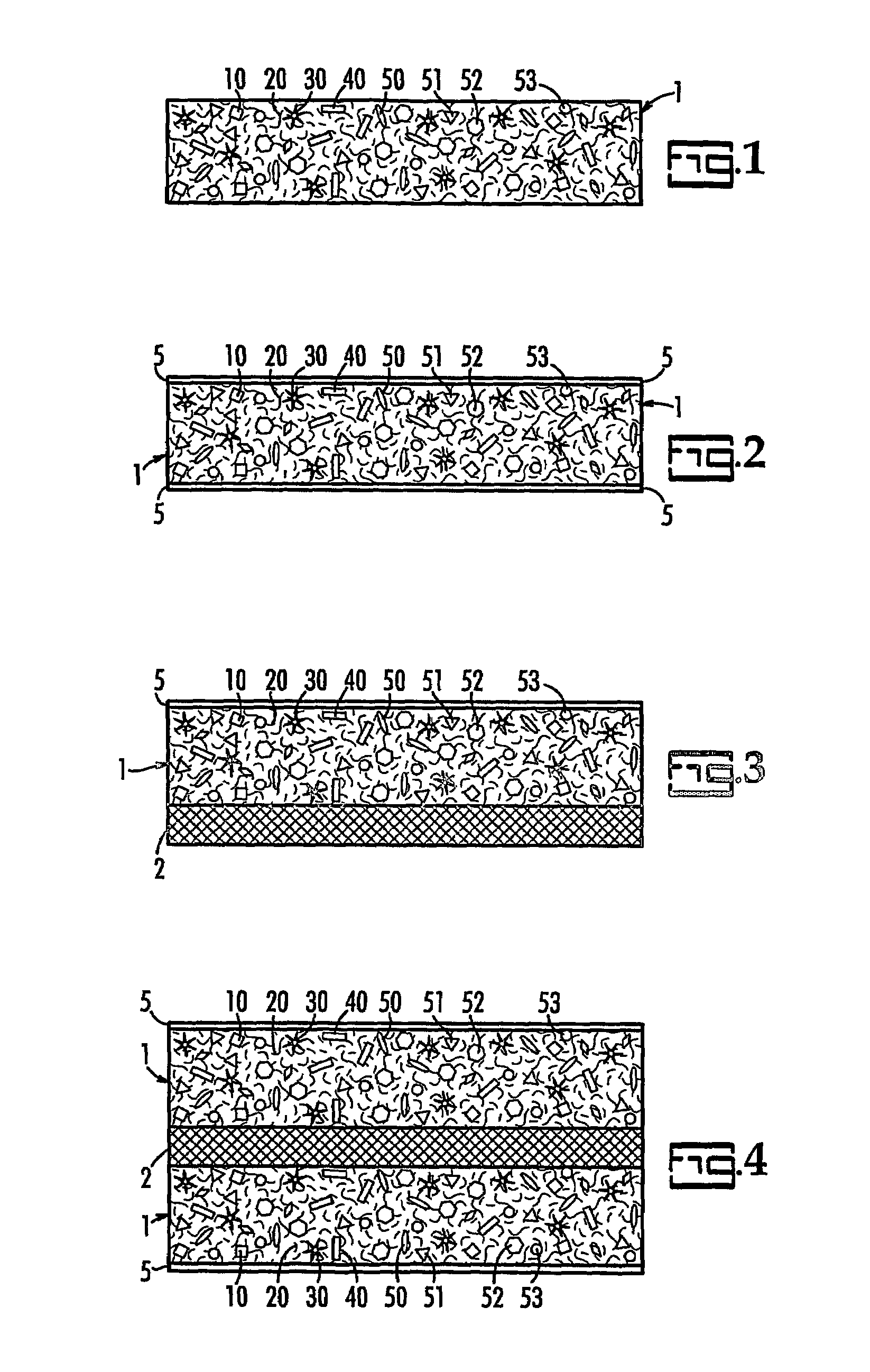

Three-dimensional dosimeter for penetrating radiation and method of use

ActiveUS7098463B2High resolutionRobust and safe processPhotosensitive materialsGlass dosimetersPolymer scienceImage resolution

This invention relates to a method of forming a three-dimensional (3D) dosimetric map in a solid translucent or transparent polymer and to an article of manufacture comprising a polymer formulated to capture data imparted by incident penetrating radiation. The present invention provides a method of preparation of a solid translucent or transparent polymer matrix capable of detecting and displaying a dose or doses of penetrating radiation by forming within the polymeric matrix a 3D dosimetric map which is measurable and quantifiable by various known procedures. The dosimetric map is representative of the 3D distribution of the dose or doses of the penetrating radiation to which the polymer had been exposed and can be quantified at high spatial resolution, thereby providing an accurate, stable, storable record in three dimensions of the radiation exposure or dosing event(s).

Owner:HEURIS PHARMA

Downhole deposition monitoring system

InactiveUS6886406B1Increase deposition thicknessConveniently determinedVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesMonitoring systemEngineering

Described is a downhole apparatus for detecting and removing deposits from a surface exposed to wellbore fluids. The apparatus can monitor the rate of deposition and subsequently remove the deposited material. The combination of detection apparatus and removal apparatus provides a downhole instrument with self-cleaning operation mode.

Owner:SCHLUMBERGER TECH CORP

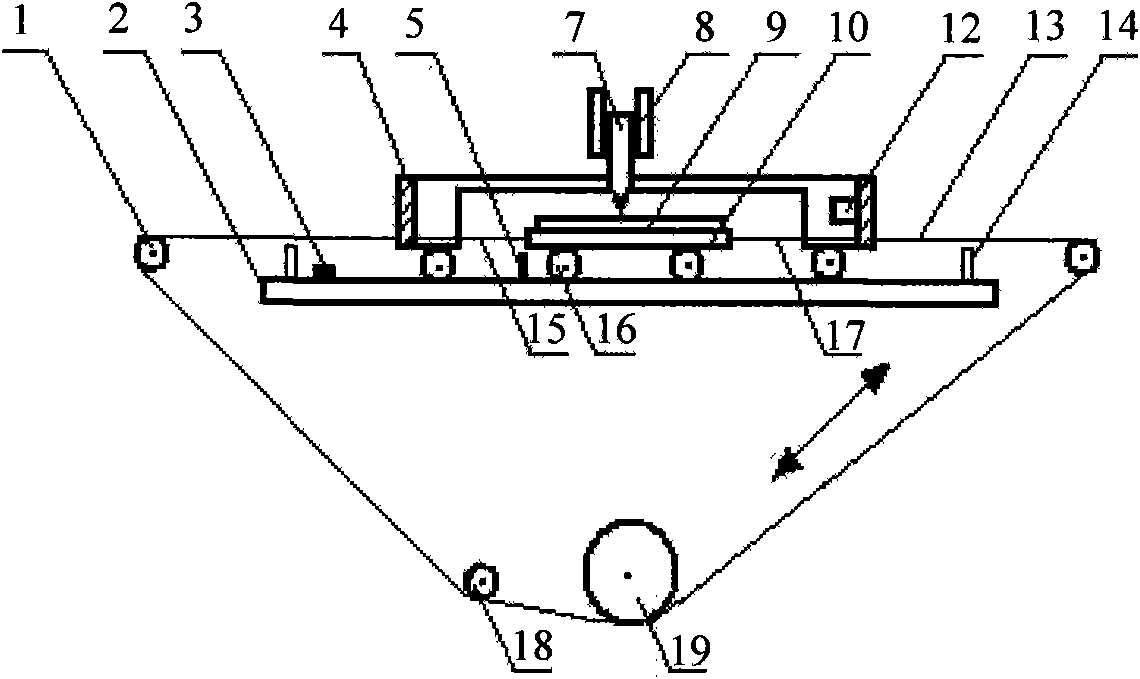

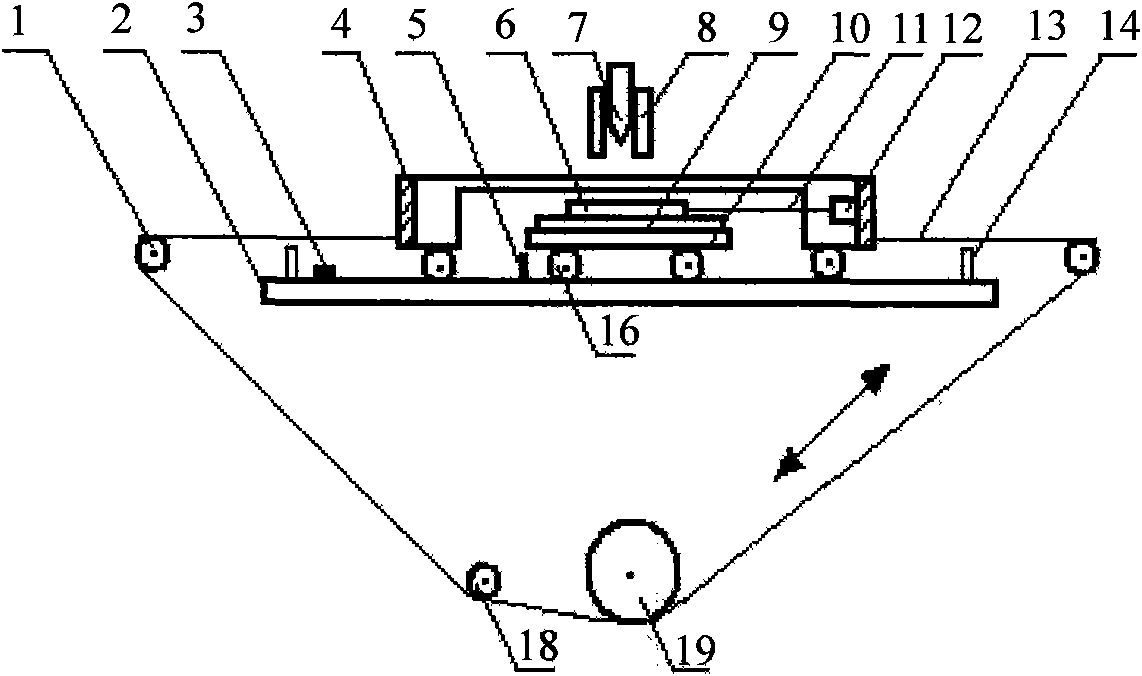

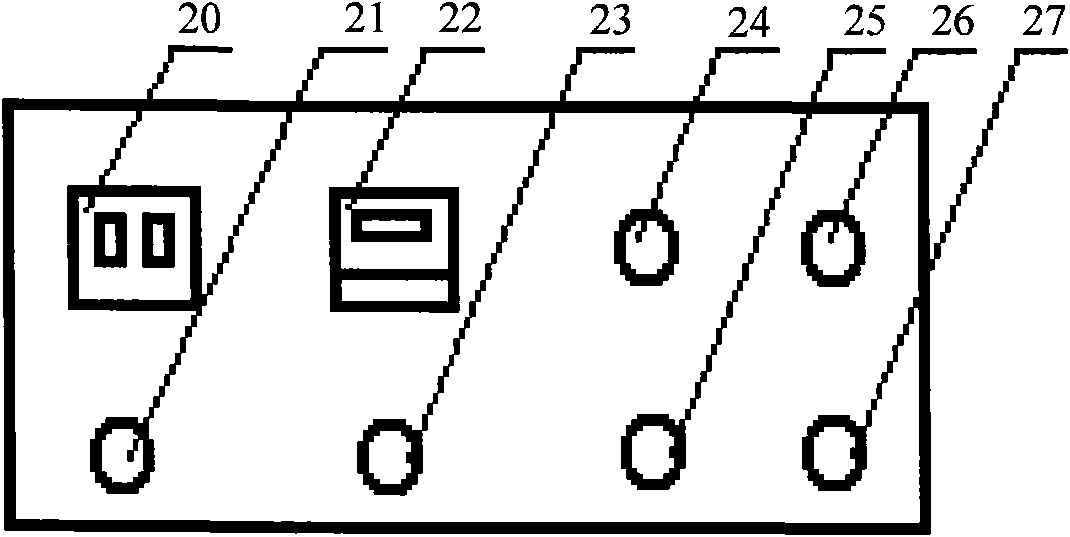

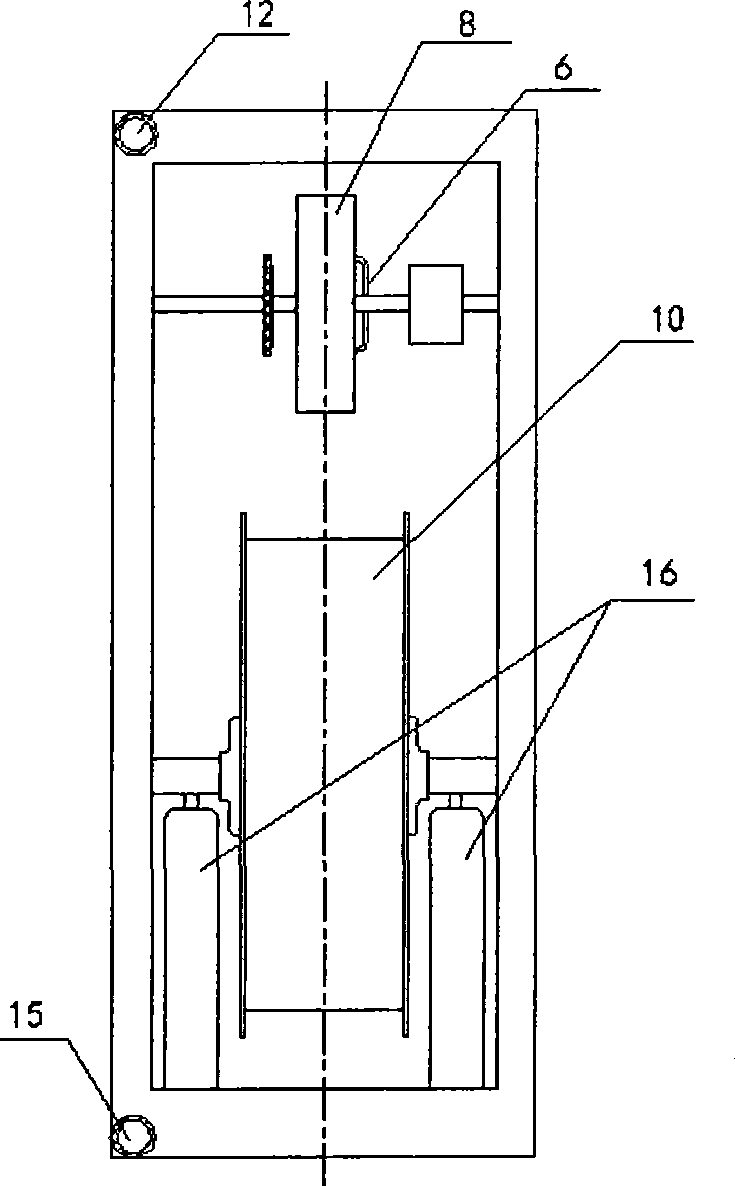

Device and method for testing linear reciprocating sliding friction and abrasion

InactiveCN101556238AAdjustable sliding speedAdjustable loadUsing mechanical meansMaterial weighingPositive pressurePeak value

The invention discloses a device and a method for testing linear reciprocating sliding friction and abrasion; the device consists of a transducer, a workbench, a sample table, a dragging frame, a force sensor, a changeover switch, a counter, a locking device, a guideway, a baffle, a cable wire, a reducer, a peak value stabilizer, a control part and an auxiliary component; the equipment can automatically complete the abrasion test of an arranged period and can manually complete the test to friction coefficient. The testing method comprises the following steps of: leading the friction block and the sample to reciprocate to slide horizontally with constant pressure, obtaining an abrasion weight loss rate after abrading, keeping a certain positive pressure and leading the sliding block to move from stillness to uniform movement, thus obtaining the maximum static friction coefficient and the sliding friction coefficient. The device and the method can realize uniformly linear and reciprocating relative sliding abrasion in long unidirectional journey, test the maximum static friction coefficient between two bodies and the maximum static friction coefficient, the speed, the load and the adjustable journey with other materials, and can be widely applied to the detection of various samples of different materials and different structural forms.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

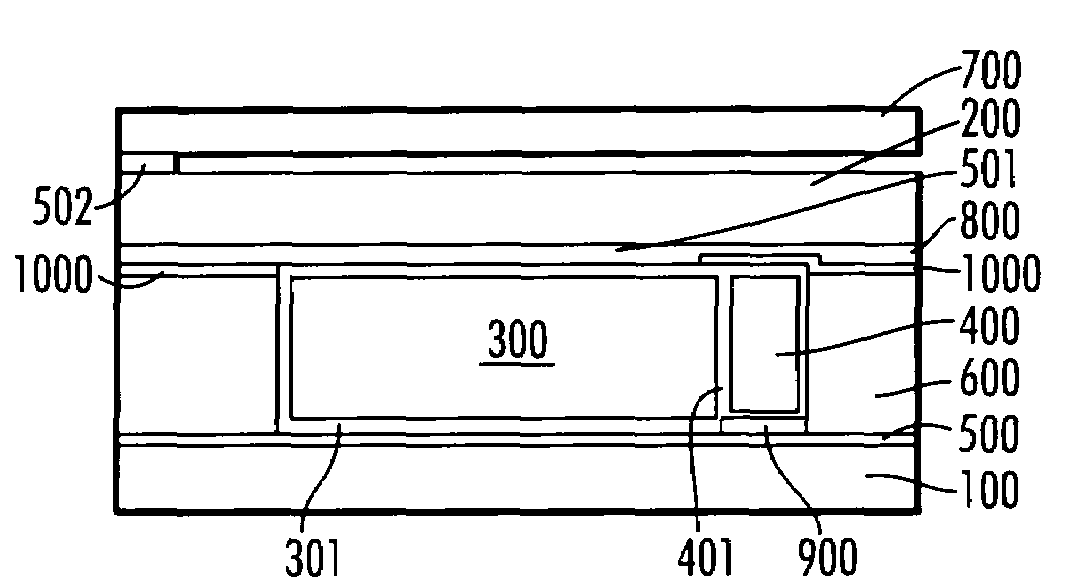

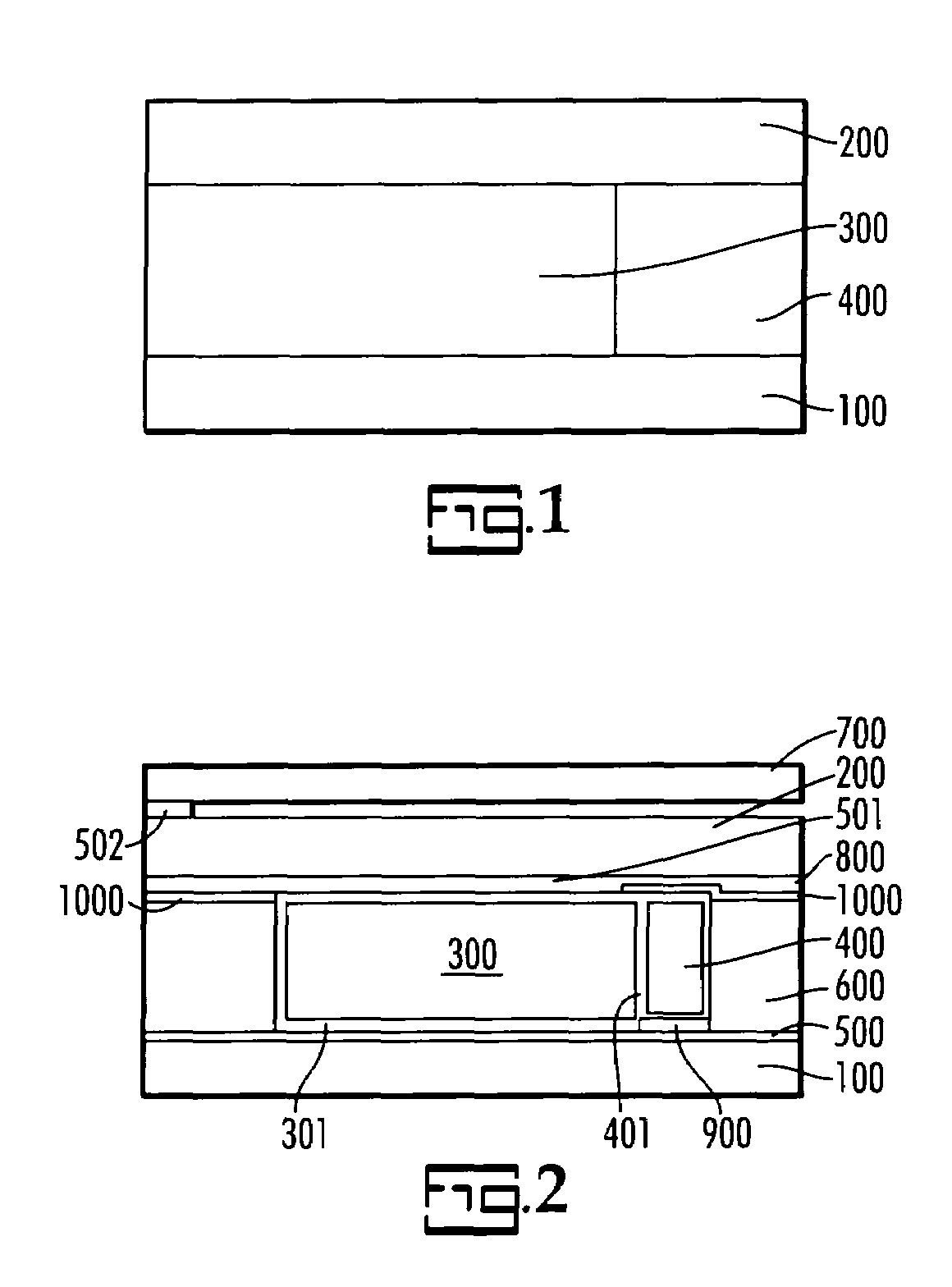

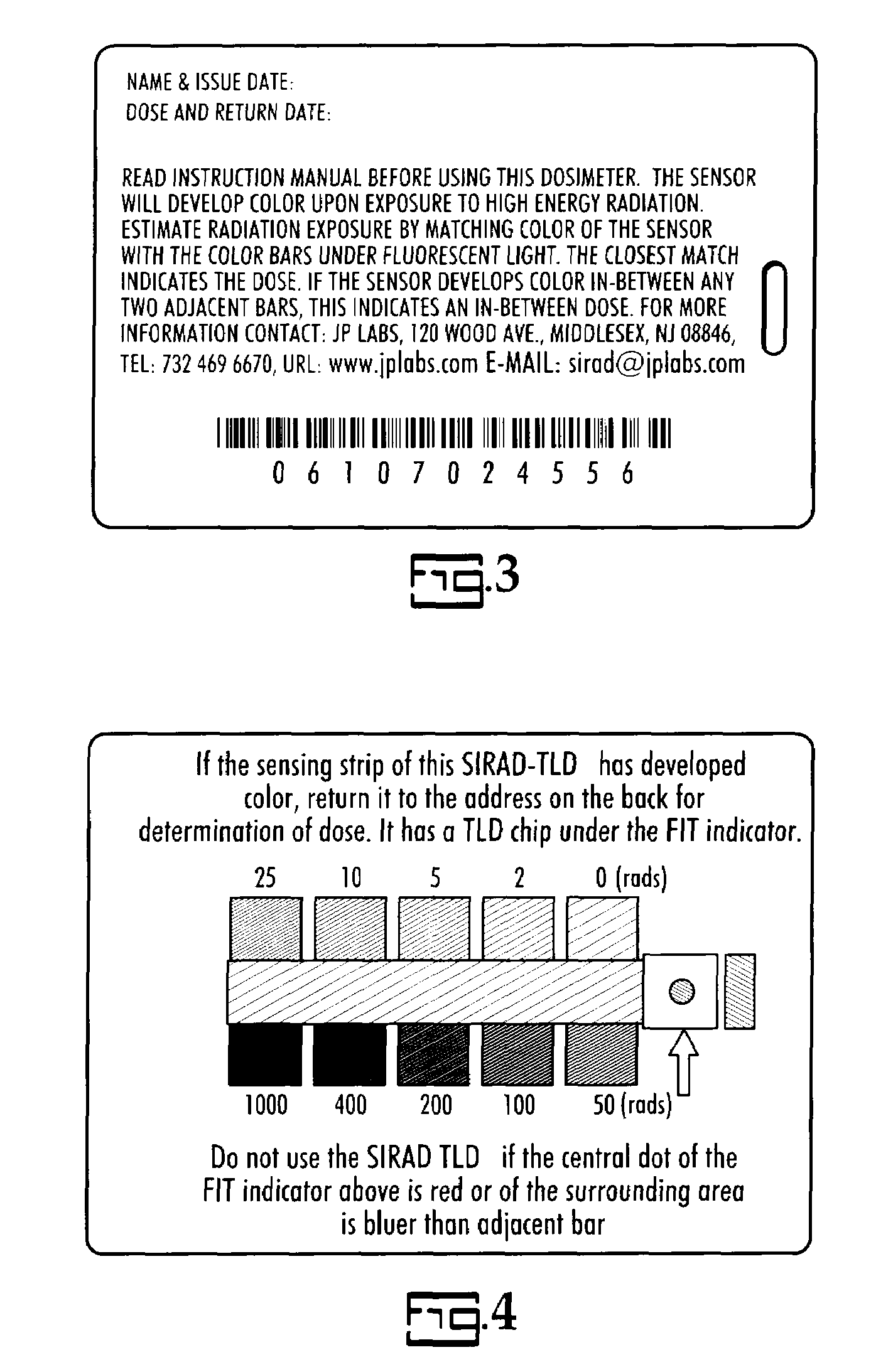

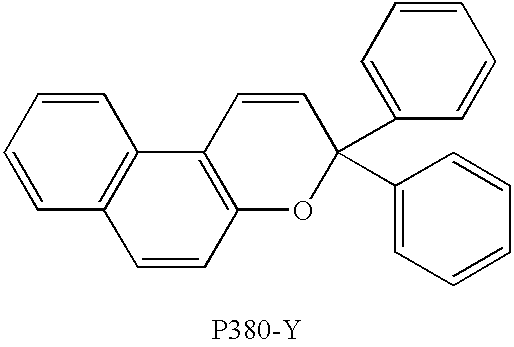

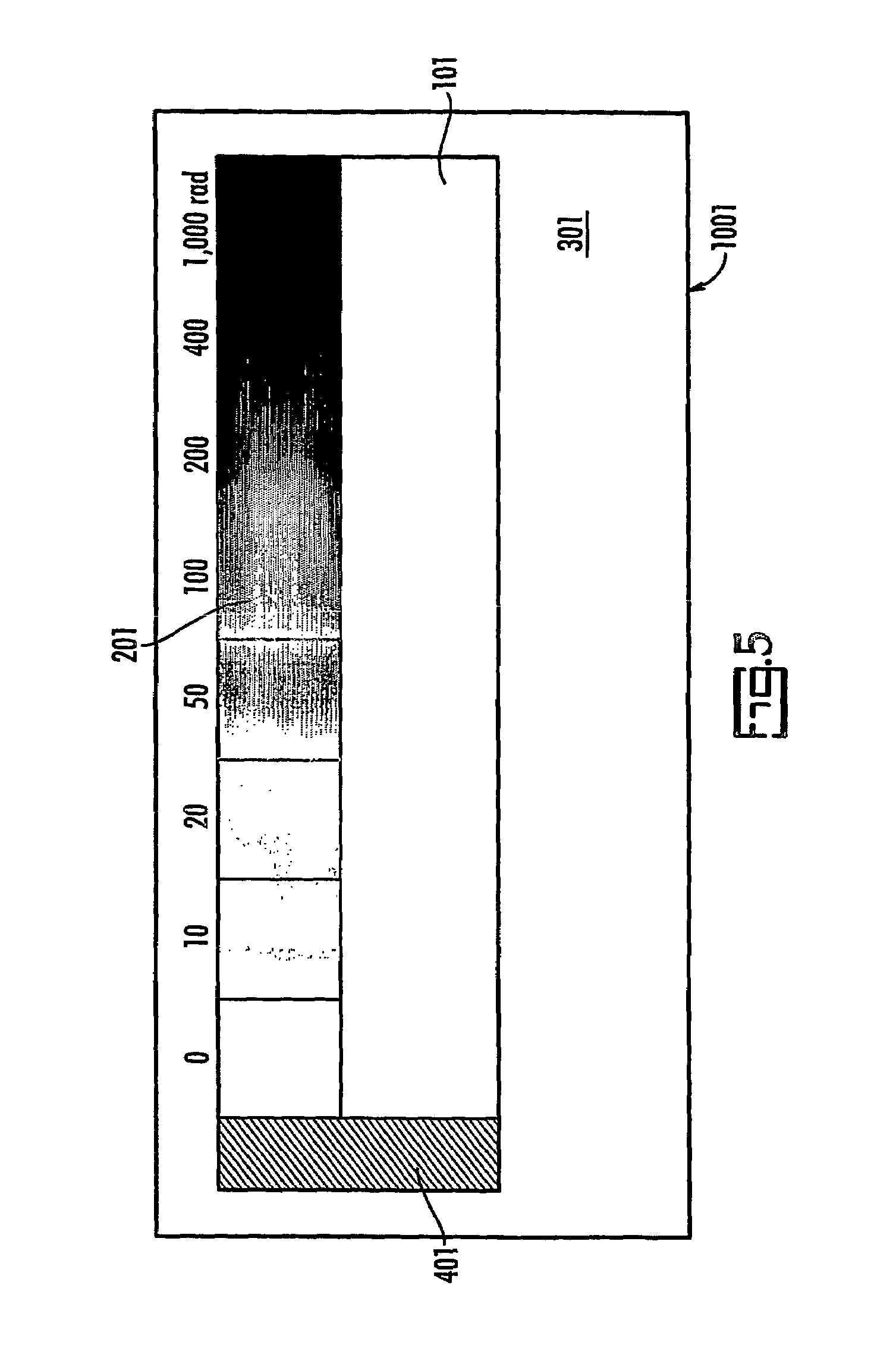

A self indicating multi-sensor radiation dosimeter

InactiveUS20090224176A1Easy to useChemical dosimetersMaterial analysis by optical meansDetonationThermoluminescence

Described is a multi-sensor radiation dosimeter system with (1) a self-indicating, instant radiation sensor and (2) a conventional radiation sensor for monitoring high energy radiations, such as X-ray, electrons and neutrons. Conventional radiation sensors, such as X-ray film, TLD (Thermoluminescence Dosimeters), RLG (Radioluminescence Glass) and OSL (Optically Simulated Luminescence), are highly sensitive but are not instant. In the event of a dirty bomb, nuclear detonation or a radiological accident, one needs to know the exposure instantly so proper precautions can be taken and medical treatment, if required, can be given to the victim. If a self-indicating instant sensor is one of the sensors, one would know the dose instantly, and dose can be determined with higher accuracy than by the traditional methods. This type of device offers the best of both technologies.

Owner:JP LAB INC

Solar blind-UVC photochromic detector and method for calibration

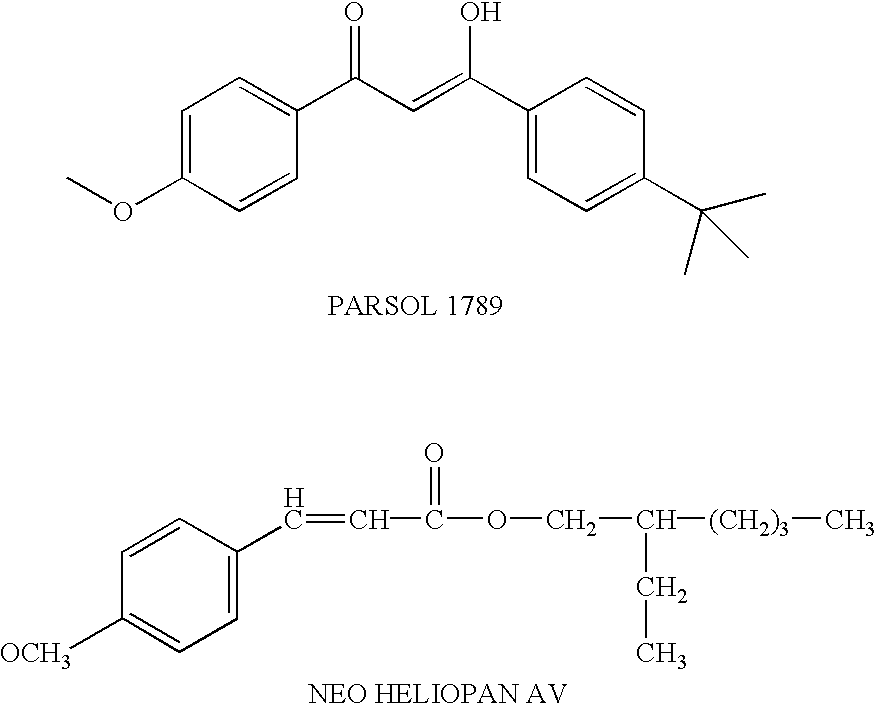

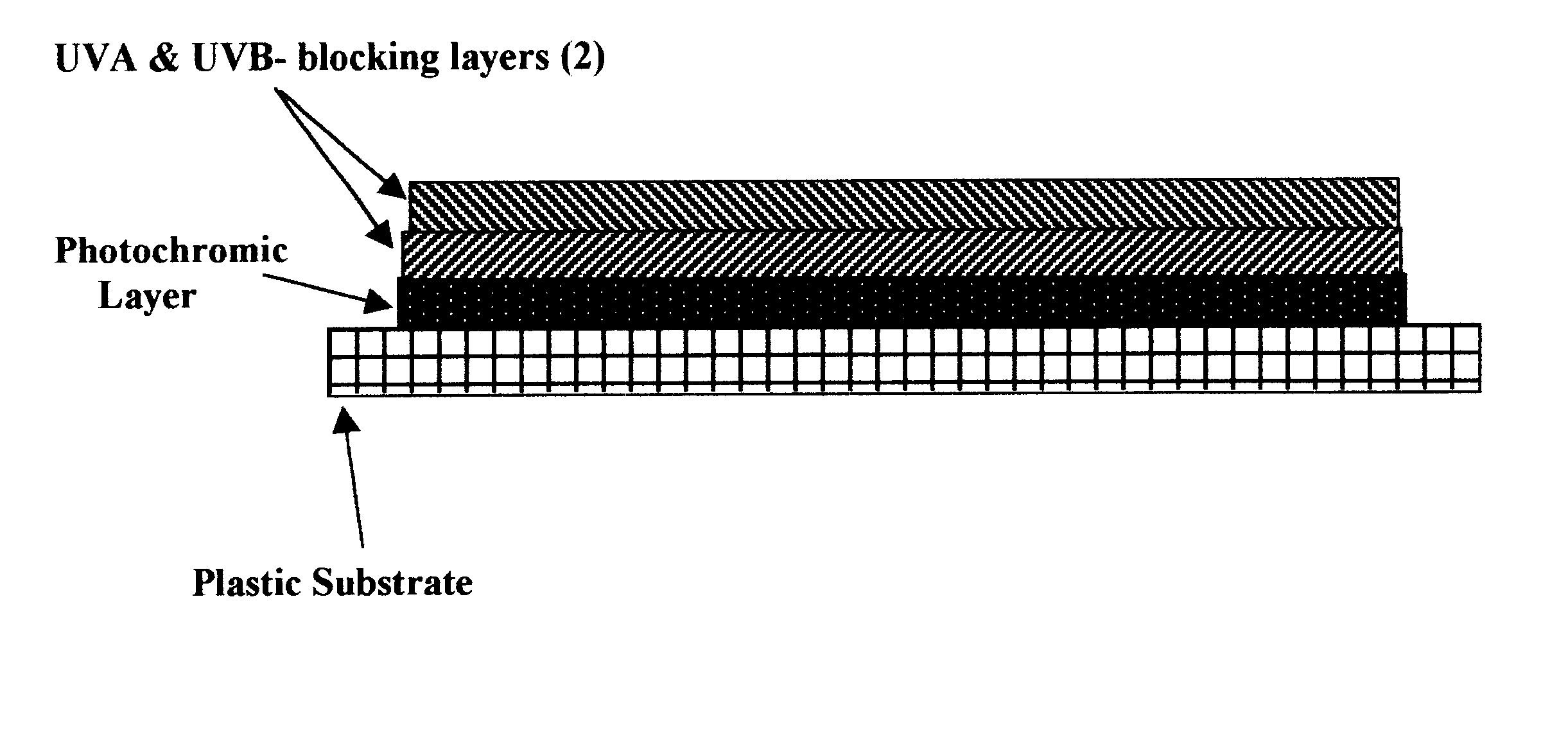

The present invention relates to an ultraviolet radiation detector in general and more specifically to a solar blind ultraviolet radiation detector; that is, a detector insensitive to the radiation of sunlight reaching the earth's surface but sensitive to UVC wavelengths in the spectrum, defined as the interval 200 nm-280 nm. The solar blind detector is base on the use of photochromic compounds in conjunction with ultraviolet wavelength-selective chemical blocks and their incorporation into optically clear polymer matrices. The photochromic compound is selected from the group comprising spiropyran molecules spirooxazine molecules and chromene derivatives. Applications for such device are as numerous as the sources of UVC radiation. An obvious use for such Solar Blind UVC detector is monitoring the output of UVC sources used in the decontamination of water and air (water treatment and air purification) and for sterilization of medical instruments.

Owner:GOUDJIL KAMAL

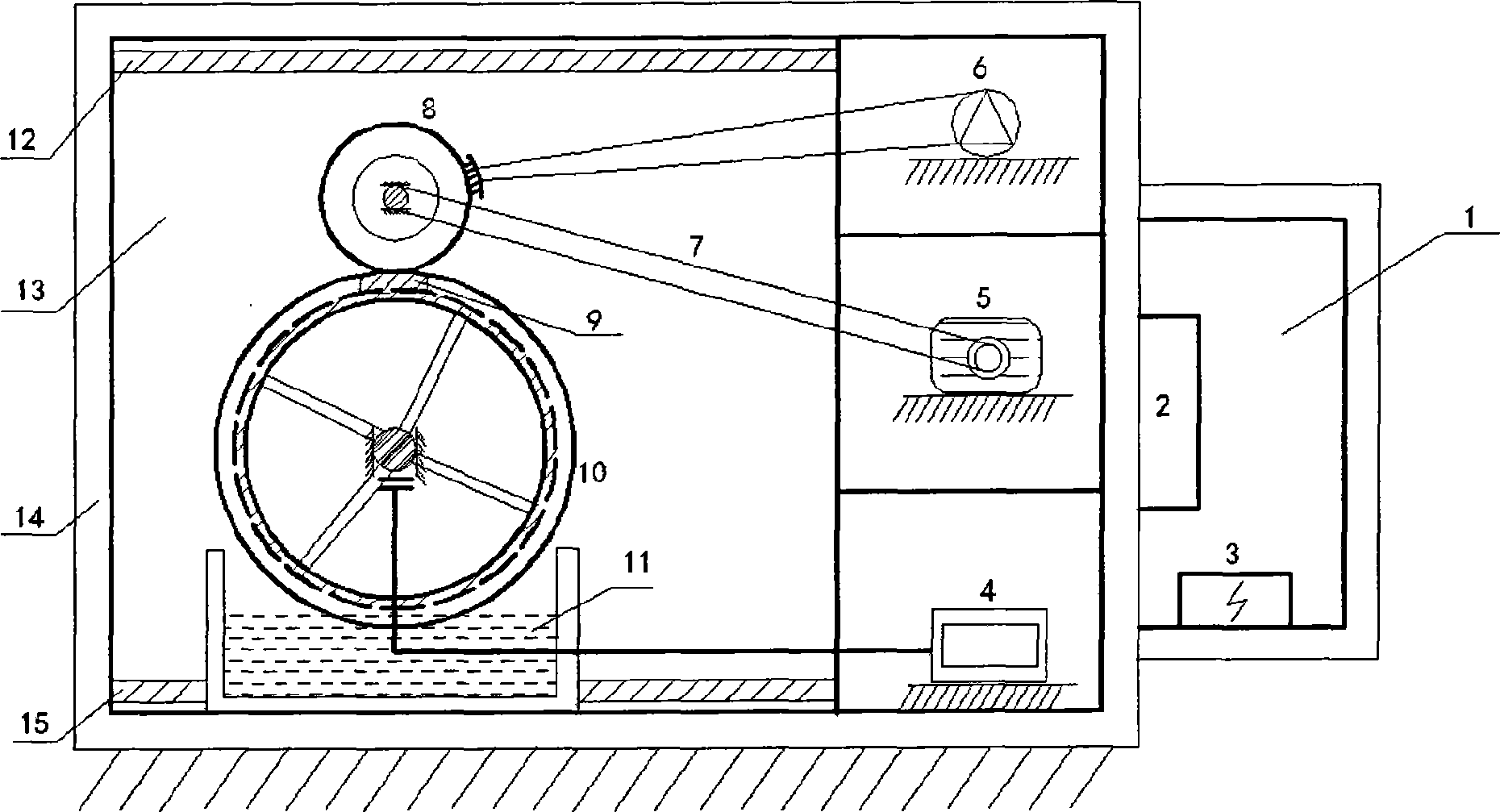

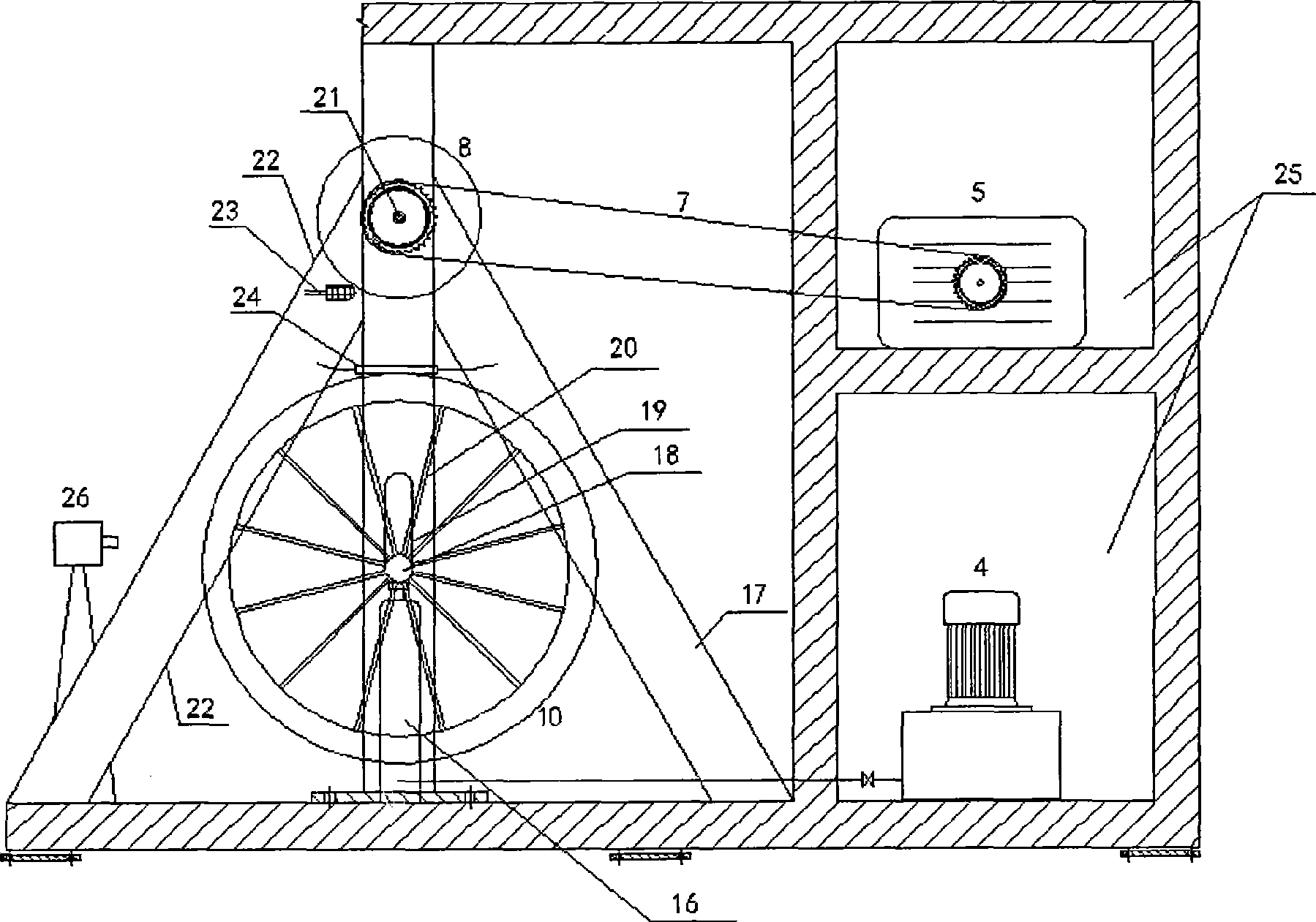

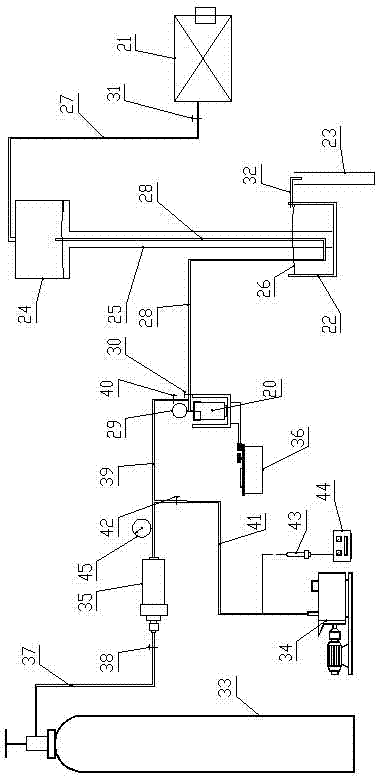

Method for testing accelerating and loading of main drive wheel type pavement materials and device

InactiveCN101532934AImprove guidanceImprove applicabilityMaterial strength using tensile/compressive forcesUsing mechanical meansWater bathsDrive wheel

The invention discloses a method for testing accelerating and loading of main drive wheel type pavement materials and a device thereof. The device comprises a control console, a PLC control box, an electronic box, a hydraulic device, a motor, a brake, a driving chain and chain wheel, a drive wheel, a driven wheel, a water bath tank, a circulated air inlet duct, a thermostatic chamber, a test cabinet and a circulated air outlet duct; the control console is positioned on the outside of the test cabinet; the hydraulic device is connected with the driven wheel; the motor is connected with the drive wheel via the driving chain and chain wheel; the drive wheel is fixed on a bracket; the driven wheel is positioned in a guide slot; the water bath tank is arranged right below the driven wheel; a ranging laser is positioned on one side of the driven wheel; one end of the drive wheel is provided with a microphone and the bottom thereof is provided with a torque sensor; the contact surface of the drive wheel and a test piece is provided with a pressure sensor; two tachometers are fixed on the bracket and are respectively positioned on the outsides of the drive wheel and the driven wheel. The device has simple structure, low prices, flexible use and good reliability.

Owner:SOUTH CHINA UNIV OF TECH

Device and method for measuring permeability coefficient of rock material under action of seepage-stress coupling

InactiveCN101915724AReduce volatilityHigh degree of automationPermeability/surface area analysisMaterial weighingMeasurement deviceCoupling

The invention discloses a device for measuring the permeability coefficient of rock material under the action of seepage-stress coupling, which comprises a triaxial pressure chamber balance system, a permeability coefficient acquisition system and a data acquisition and processing system, wherein the triaxial pressure chamber balance system loads samples axially or laterally through different stress paths; the permeability coefficient acquisition system is connected with the triaxial pressure chamber balance system so as to realize the determination for the quality of penetrating fluid of rock material sample; and the data acquisition and processing system regularly acquires the quality of penetrating fluid of rock material, calculates penetration flow and permeability coefficient, and draws a relationship curve of the permeability coefficient and time, and simultaneously, the data acquisition and processing system also forms a data format of the quality, the penetration flow and the permeability coefficient for storage and display. Such a measurement device can measure the permeability coefficient, as time and stress change, under different stress loading paths, has simple operation and reliable result, and can display the result visually. The invention also discloses a measurement method adopting the measurement device.

Owner:HOHAI UNIV

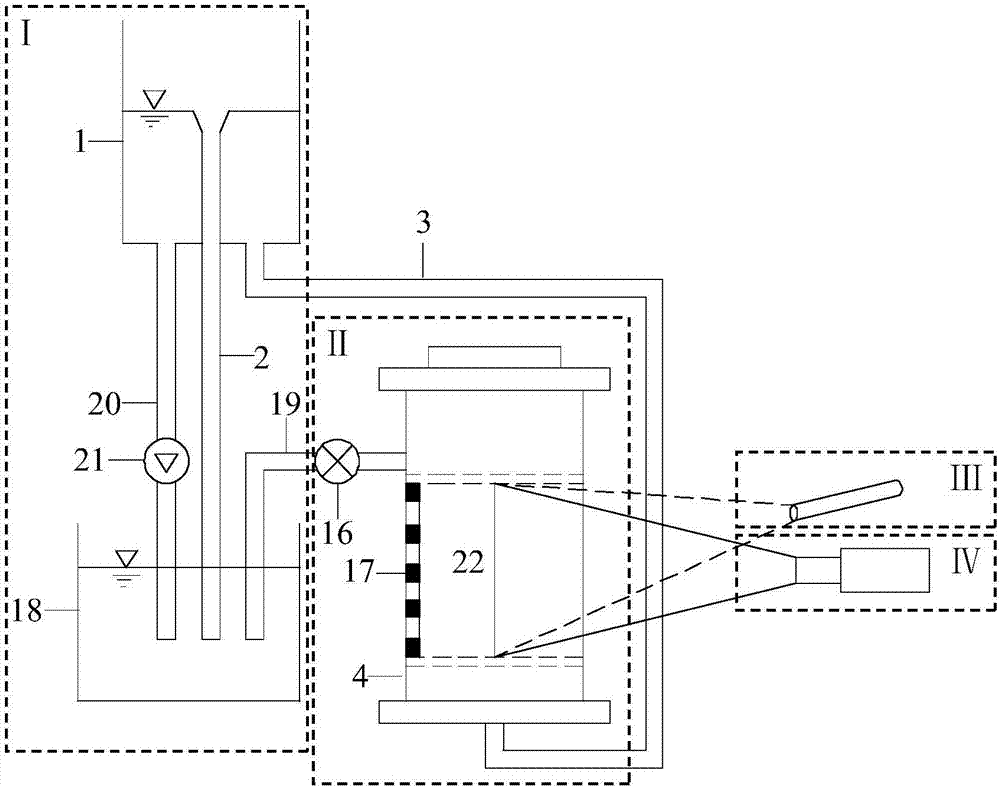

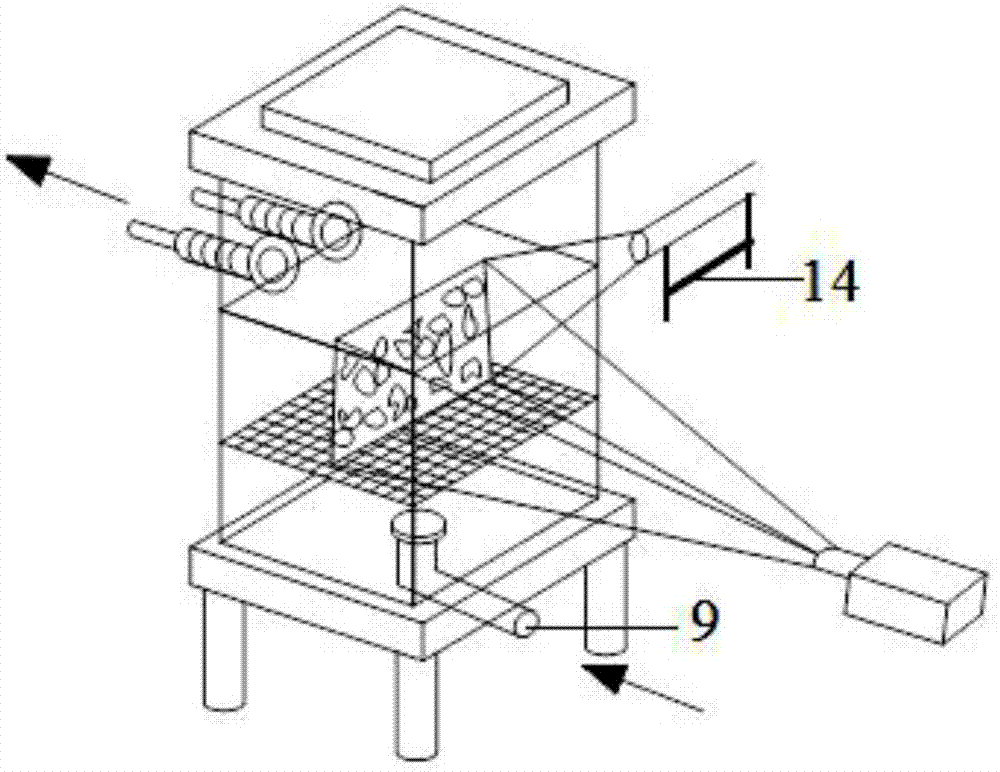

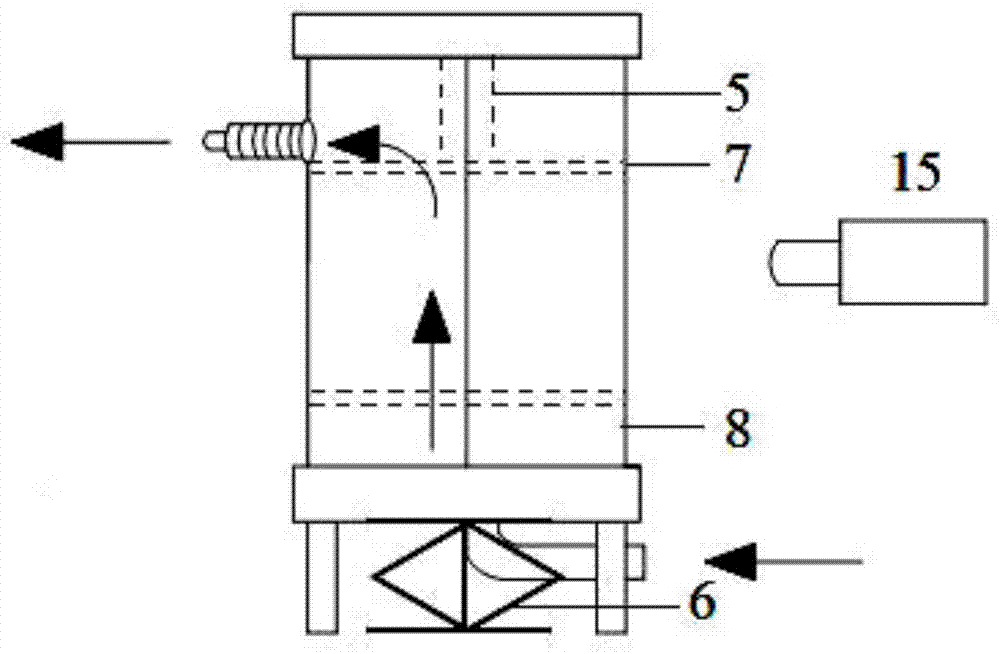

Visual-model testing apparatus and testing method for seepage-stress-coupled internal piping penetration

ActiveCN107167411AEasy to operateEasy to adjustPermeability/surface area analysisHydraulic modelsModel testingControl system

The invention discloses a visual-model testing apparatus and testing method for seepage-stress-coupled internal piping penetration. The testing apparatus is composed of four parts, i.e., a variable-head control and liquid circulation system, a vertical loading and penetration system, a laser control system and an image acquisition system and can carry out experimental study on internal piping penetration of non-steady seepage under the conditions of different stresses, different contents of fines, different grading and the like and research on the characteristics of particle loss and deformation and fracture in the process of seepage. The invention also provides a visual testing method for seepage-stress-coupled simulated erosion-type internal piping. According to the method, head difference is applied to a piping soil sample in a stress field in the vertical loading and penetration system in virtue of the variable-head control and liquid circulation system, so a seepage-erosion-stress three-field coupled internal piping test is realized. The visual-model testing apparatus and testing method provided by the invention are simple in procedure, easy in fabrication, capable of realizing direct and in-depth observation, economic and good in operability, so the meso-scopic mechanism of seepage-stress-coupled internal piping is revealed preliminarily, and a testing foundation is provided for subsequent research.

Owner:HOHAI UNIV

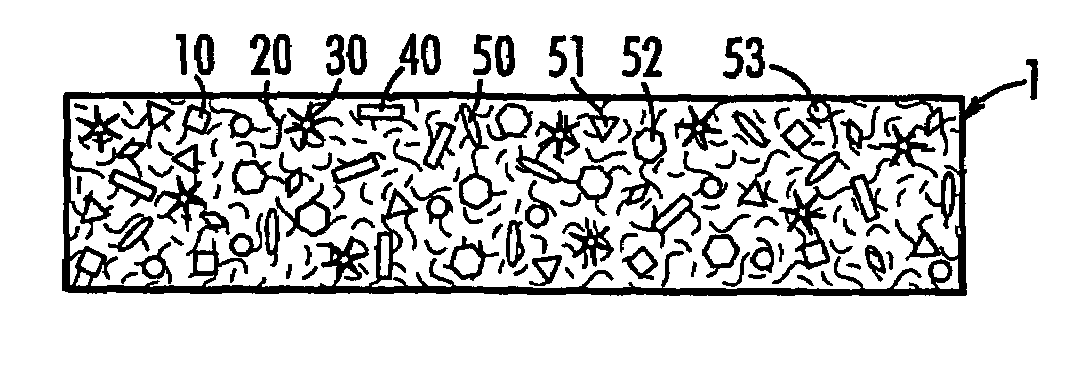

Self indicating radiation alert dosimeter

Described as a self-indicating instant radiation dosimeter (1001) for monitoring high energy radiations, such as X-ray. The dosimeter contains a radiation sensitive, color changing, indicating composition (10), e.g., a diacetylene (R—C≡C—C≡C—R′, where R and R′ are substituents groups) or a radiochromic dye, a polymeric binder (20) and optionally a shelf life extender (50) or an activator (40). The radiation sensitive composition (10) changes color instantly when exposed to high energy radiation. The dose is estimated by comparing the color with a color reference chart or more accurately with a spectrophotometer or an optical densitometer. The radiation sensitive composition (10) is protected from low energy radiation such as UV light, by a layer of low energy absorbing materials, such as UV absorbers.

Owner:JP LAB INC

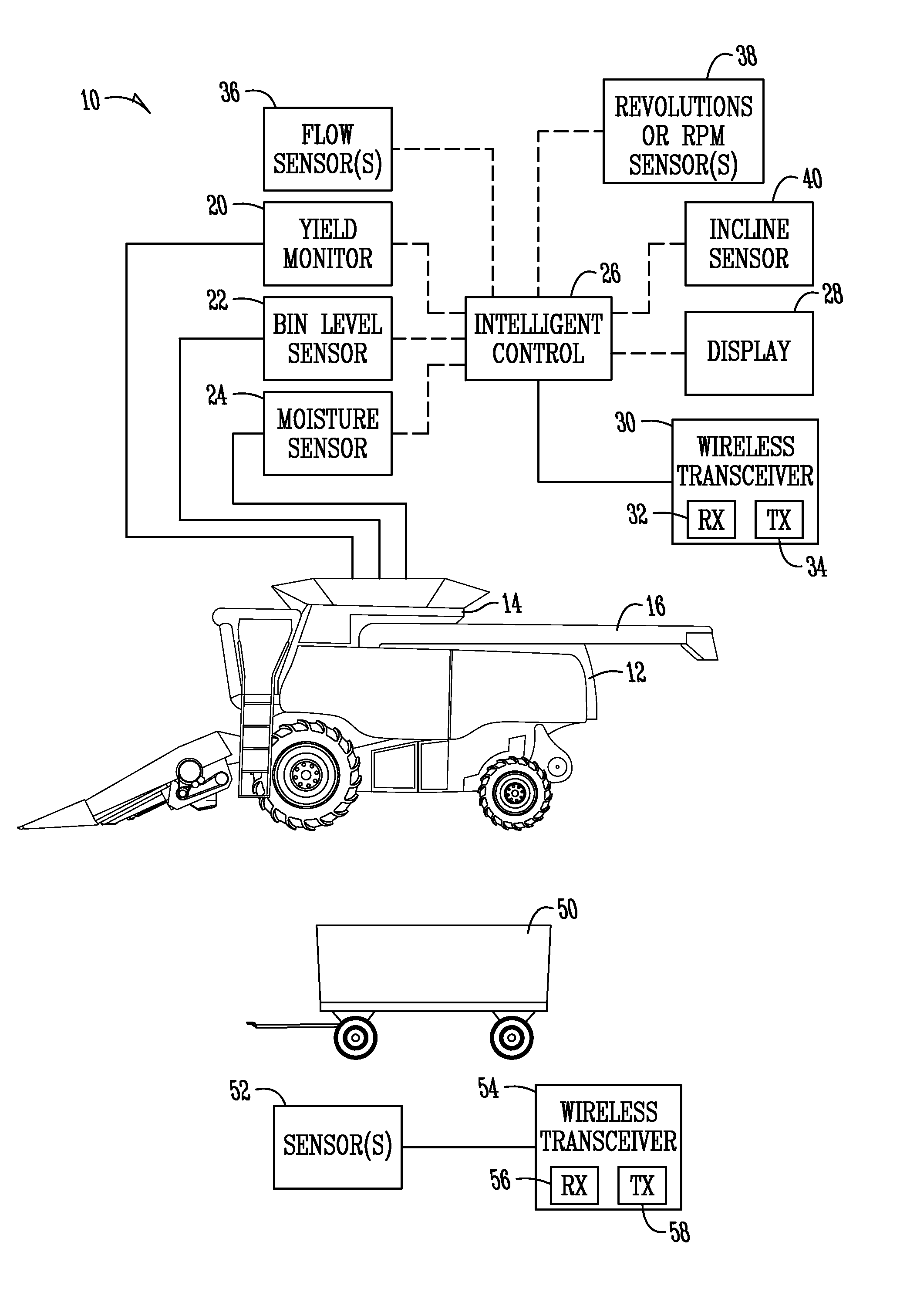

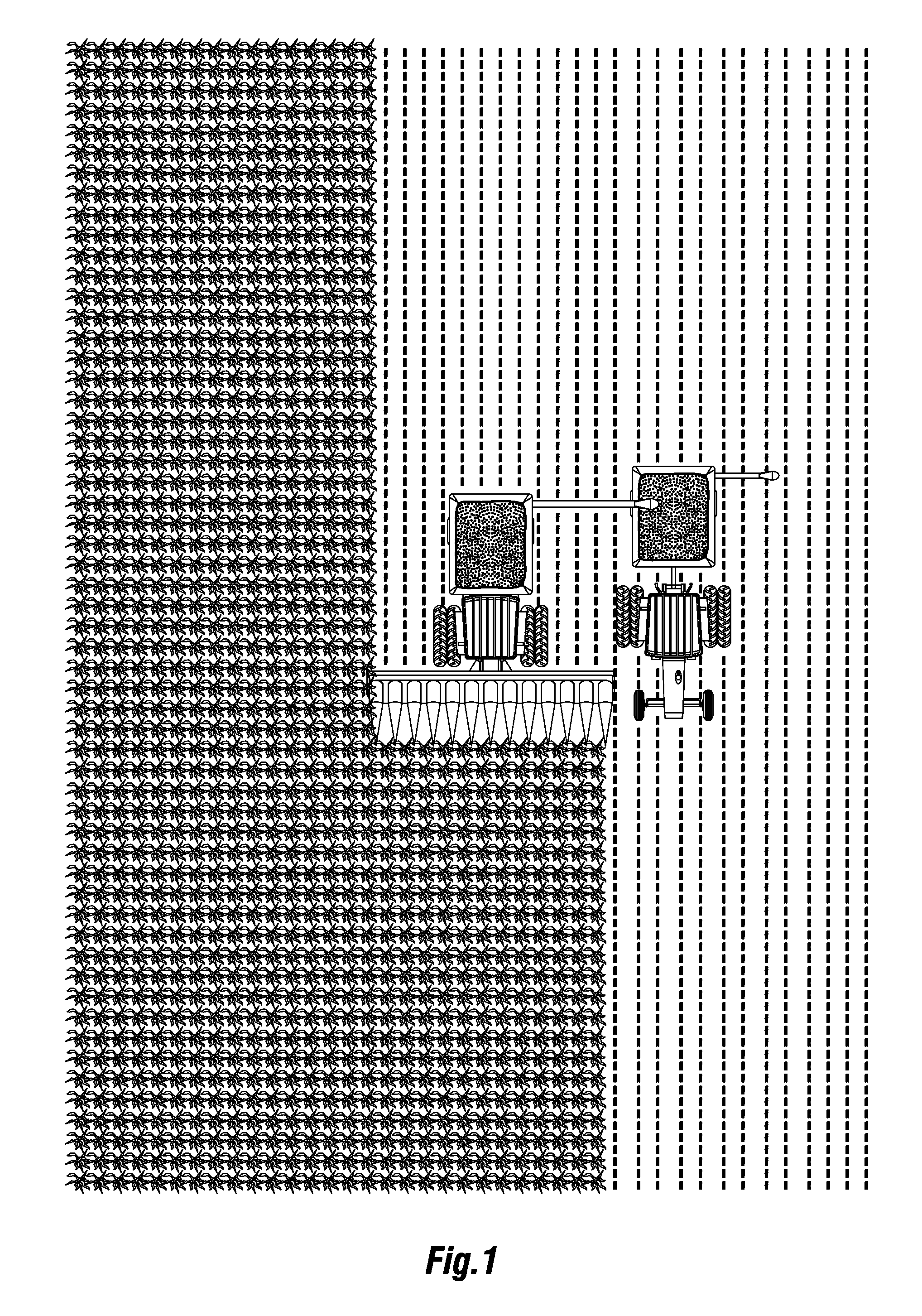

Combine bin level monitoring system

ActiveUS20120253611A1Easy to useEfficient and effectiveAnalogue computers for trafficMowersMonitoring systemEngineering

A combine bin level monitor may include a yield monitor to determine how much grain has been added to the combine tank, a container weighing system (e.g. scales on a grain cart) that measures the amount of grain unloaded from the combine tank and wirelessly transfers the amount to the combine bin level monitoring system. The system further includes a software routine in the combine bin level monitoring system that calculates and displays the bin level by adding grain accumulated by the yield monitor and subtracting grain accumulated by the container weighing system from the last known amount of grain in the combine tank. The accumulated grain is the amount accumulated since the last time the amount of grain in the combine tank was known.

Owner:LEADER TECH

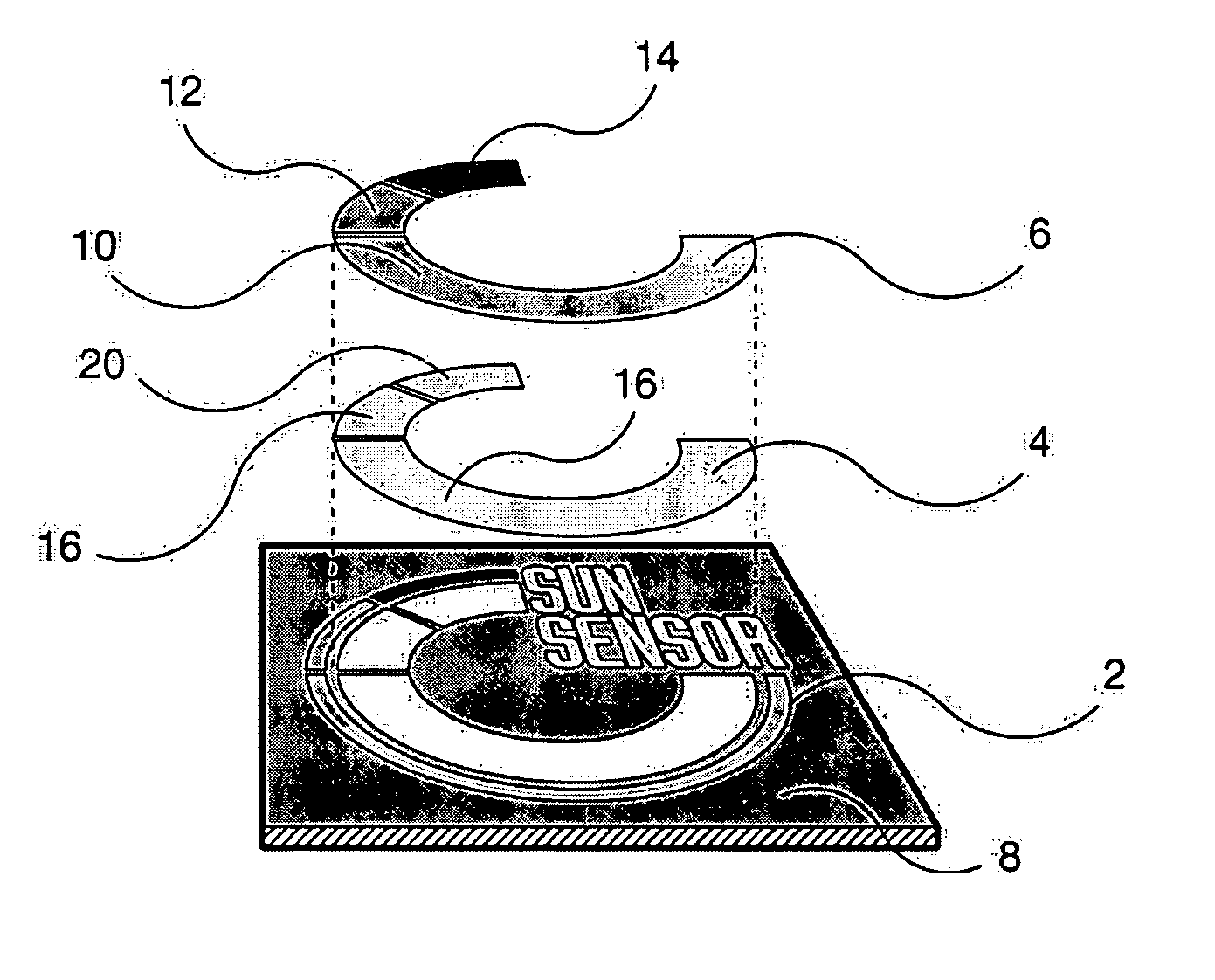

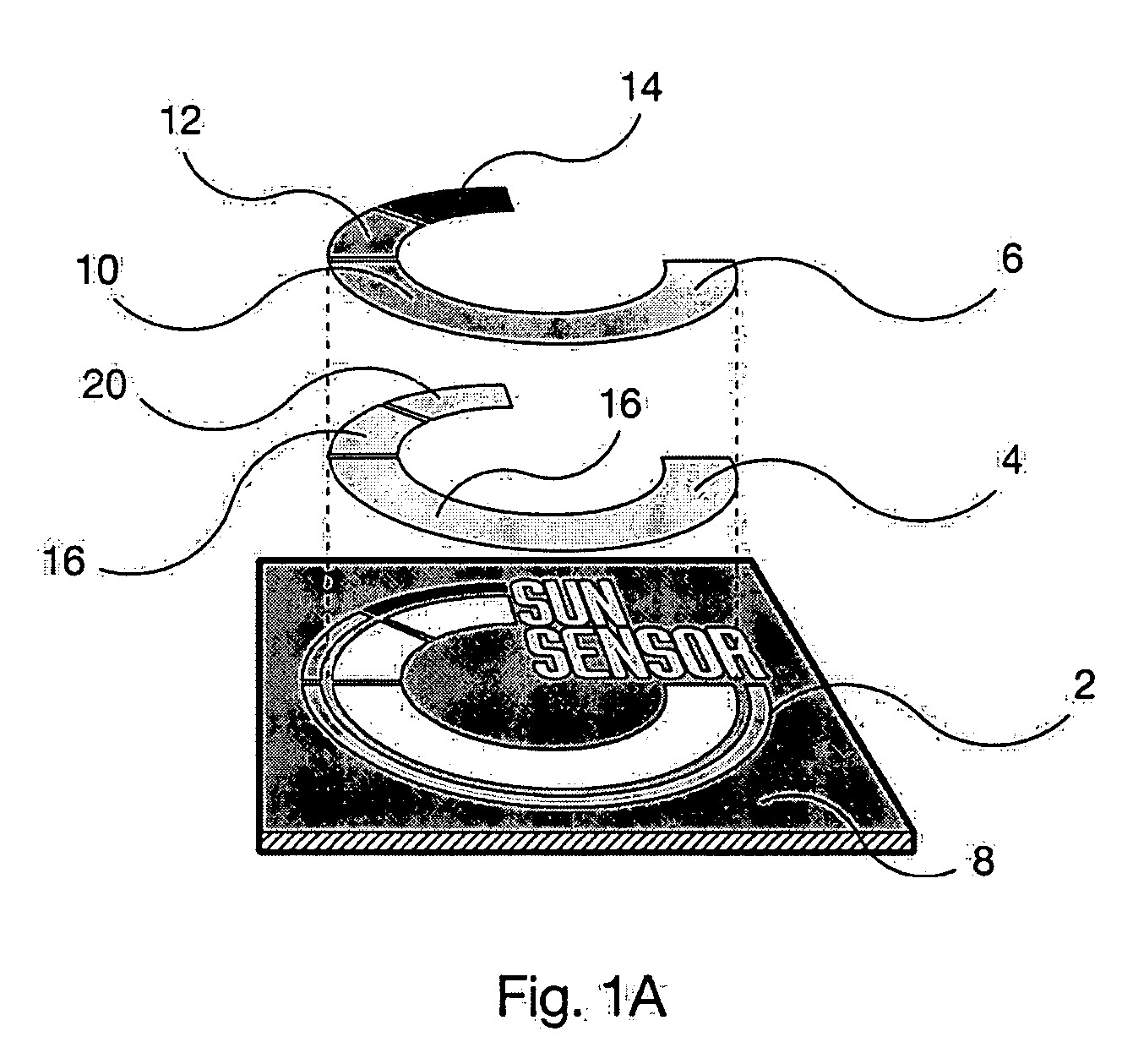

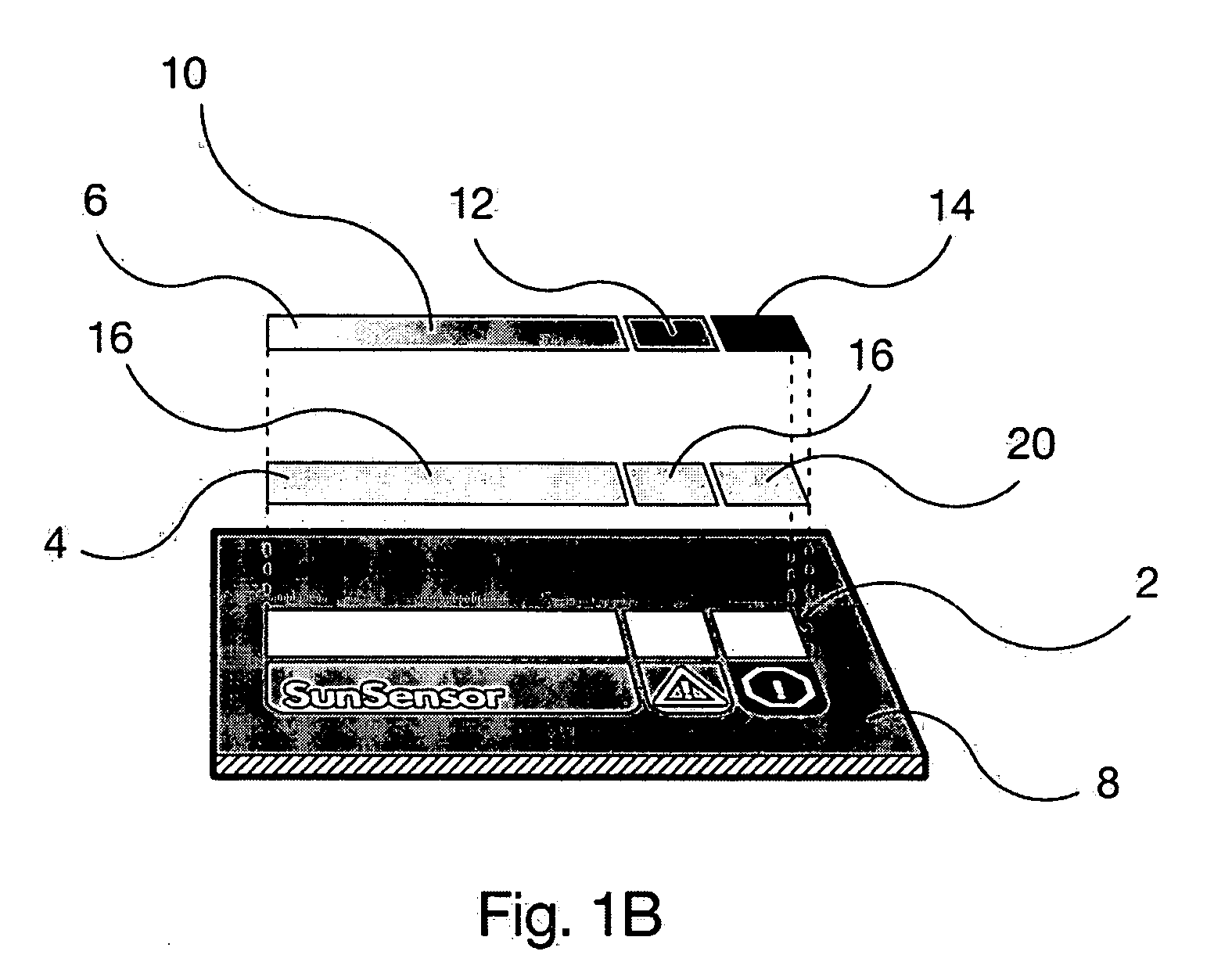

Sun sensor, an article incorporating the sun sensor and methods of preparation and use

InactiveUS20050285050A1Material analysis by optical meansPhotometry for measuring UV lightChange colorUltraviolet

A container for sunscreen having (a) an alphanumeric indication of a sun protection factor and (b) a solar detector for displaying whether accumulated ultraviolet radiation striking the skin of a user of sunscreen with the indicated sun protection factor has exceeded a threshold level. The solar detector has a sensor layer with a photochromic material that reacts to ultraviolet radiation by changing from a clear state to a colored one, and an ultraviolet absorbing or blocking material covering at least one portion of the sensor layer. The ultraviolet absorbing material covering the at least one portion being present in an amount or concentration such that, upon exposure of the solar detector means to the ultraviolet radiation striking the skin of the user of the sunscreen over the same period of time, blocks sufficient ultraviolet radiation from striking the photochromic material so as to prevent the photochromic material from changing color until the threshold level has been reached at which time the photochromic material changes from the clear state to the colored one.

Owner:SOLATEC

Mineral slurry flux on-line detecting device and multi-parameter on-line detecting integrated system

InactiveCN101251395AAccurate measurementEliminate wear and tearVolume/mass flow measurementMaterial analysis by electric/magnetic meansLiquid productMeasurement device

The invention provides an online detection device for the pulp flow rate and a multi-parameter online detection integration system, which comprise a pulp container which has a feed port and a discharge port and is arranged on a support through a, weighing cell, a pulp flow rate detection device which is provided with a soft connector at the discharge port, and / or a pulp density measuring device, a pulp grain size measuring device and a pulp grade measuring device. The online detection device for the pulp flow rate and a multi-parameter online detection integration system can not only measure any single index of the flow rate, density, grain size and grade of the pulp according to requirements, but also simultaneously measure two or above two or even all of the indexes with high measuring accuracy, good stability and reliability. The online detection device for the pulp flow rate and a multi-parameter online detection integration system also have the advantages of simple structure, high working efficiency, low labor intensity, wide application range, etc., thereby being capable of providing the highly reliable flow rate, density, grain size and grade control parameters for liquid products to ensure product quality, reduce cost and improve working efficiency, and providing a highly guaranteed measuring device and system for full automatic control.

Owner:罗放明

Radiation sensitive film including a measuring scale

An article of manufacture comprising a radiation sensitive material, and a measuring scale that is part of the radiation sensitive material. A method of measuring at least one parameter relating to an irradiated material is also described. A radiation sensitive material including a measuring scale is exposed to radiation and at least one parameter relating to one or more exposed areas of the material is measured by reference to the measuring scale on the material.

Owner:ISP INVESTMENTS LLC

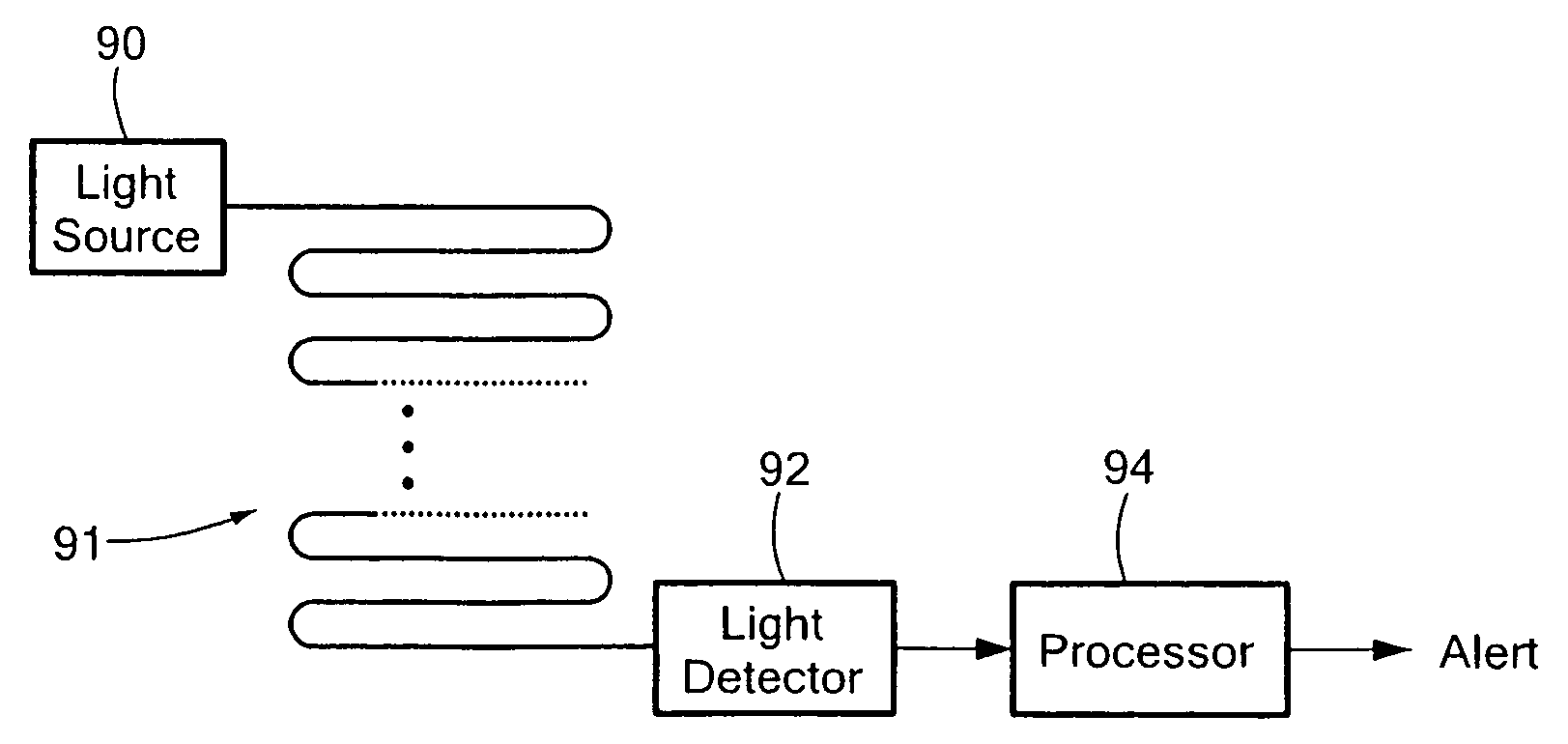

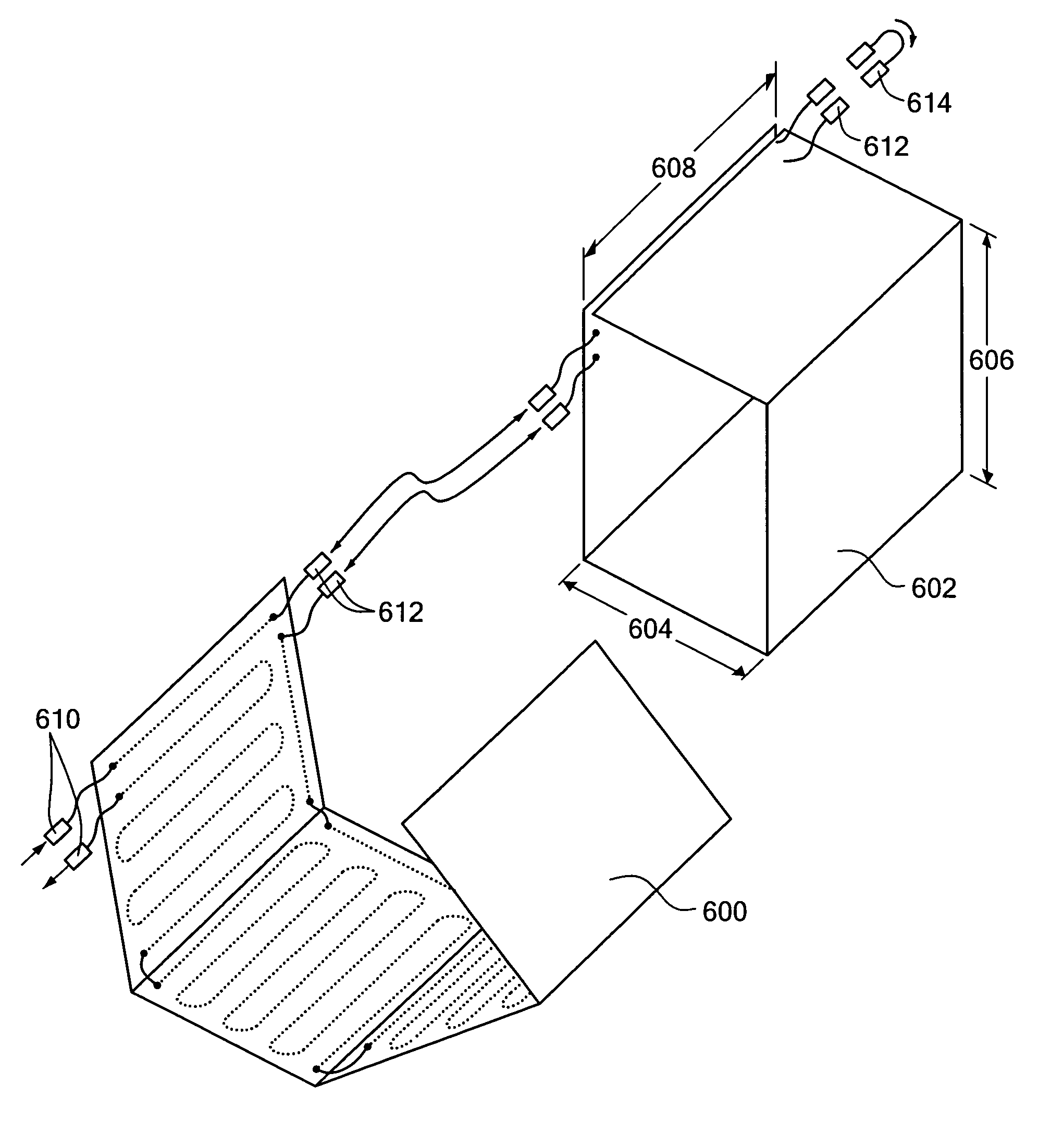

Integrated optical neutron detector

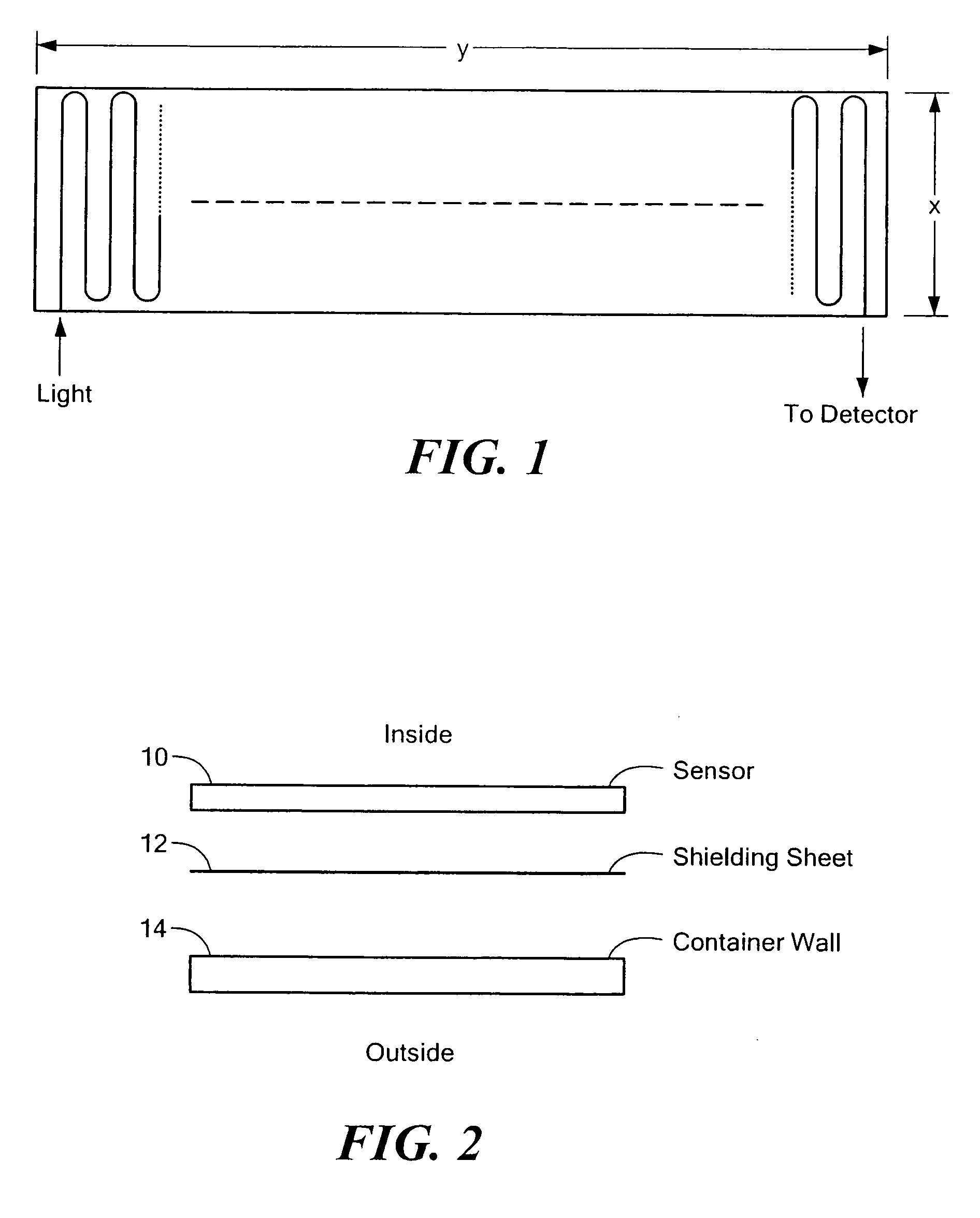

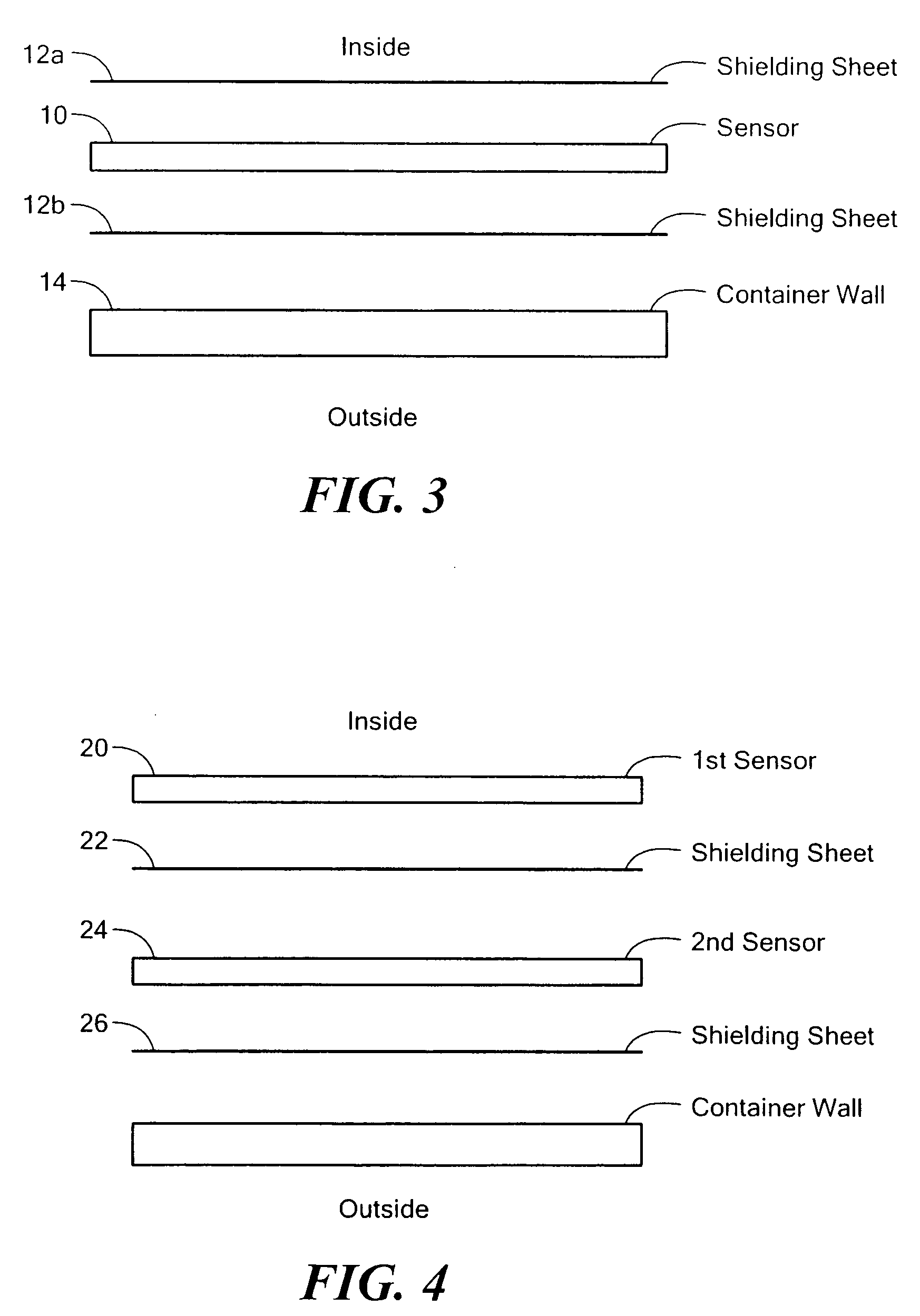

ActiveUS20080237485A1Reduce and alter light transmissibilityMaterial analysis by optical meansX/gamma/cosmic radiation measurmentCarrying capacityFail-safe

A system and method for detecting radiation from a source in a container is disclosed. A continuous optical fiber path is disposed in a medium which is part of or associated with a container and which totally encapsulates the inside volumetric space of the container. The optical fiber path provides a volumetric mass of optical fiber which is reactive to radiation from a radiation source in the container to cause an irreversible change in the light carrying capacity or other characteristic of the optical fiber. A light source is coupled to one end of the optical fiber path for introducing light having a predetermined characteristic. A light detector is coupled to the other end of the optical path for receiving light from the optical path. A circuit is coupled to the light detector and is operative to detect a change in the predetermined characteristic of the light and to provide an indication thereof in a fail-safe manner. The extraction of a radiation signal from background radiation noise is achieved using geometric methodologies. The detection system is operative to facilitate the detection of low level flux of thermalized neutrons.

Owner:3D FUSE TECH

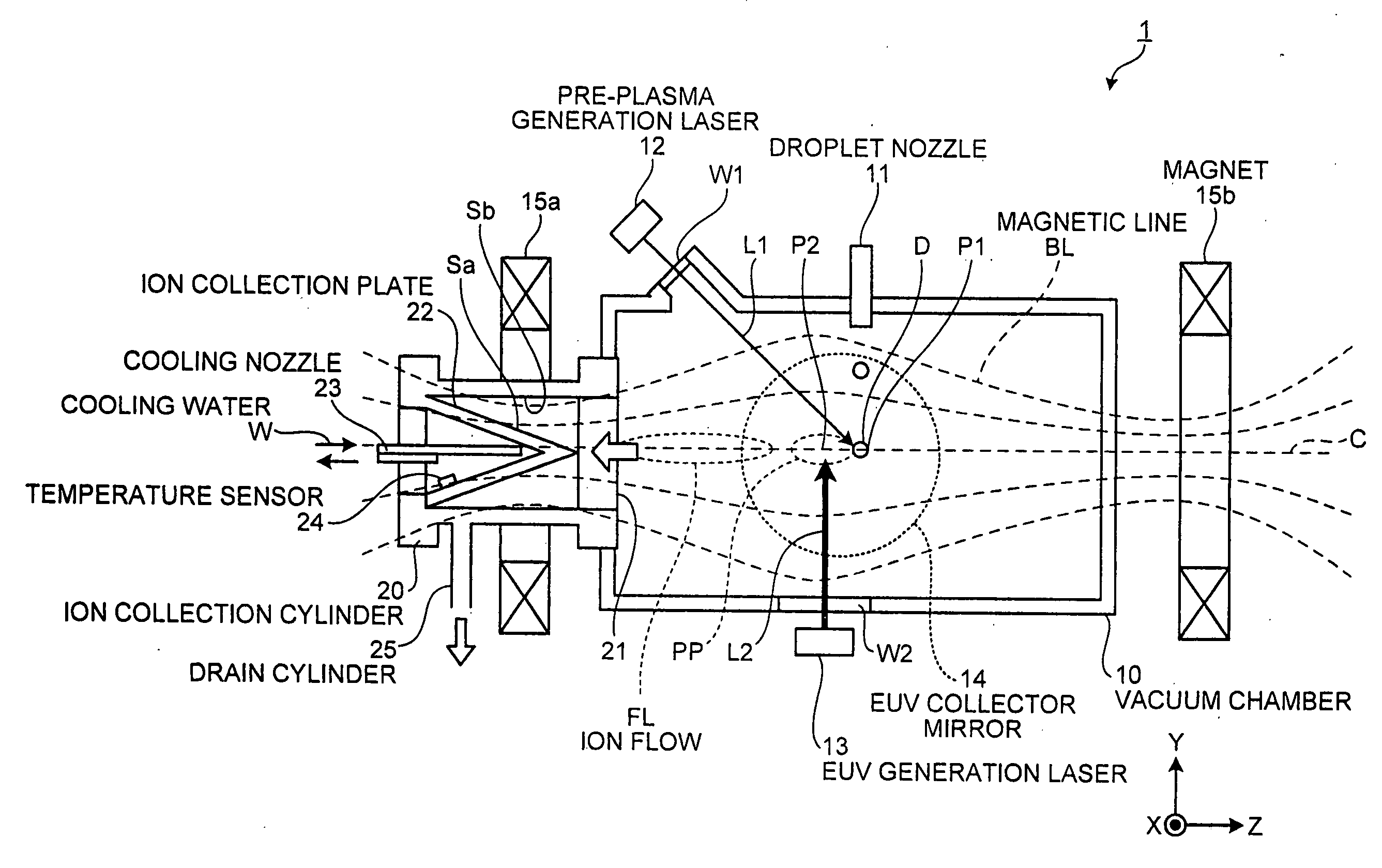

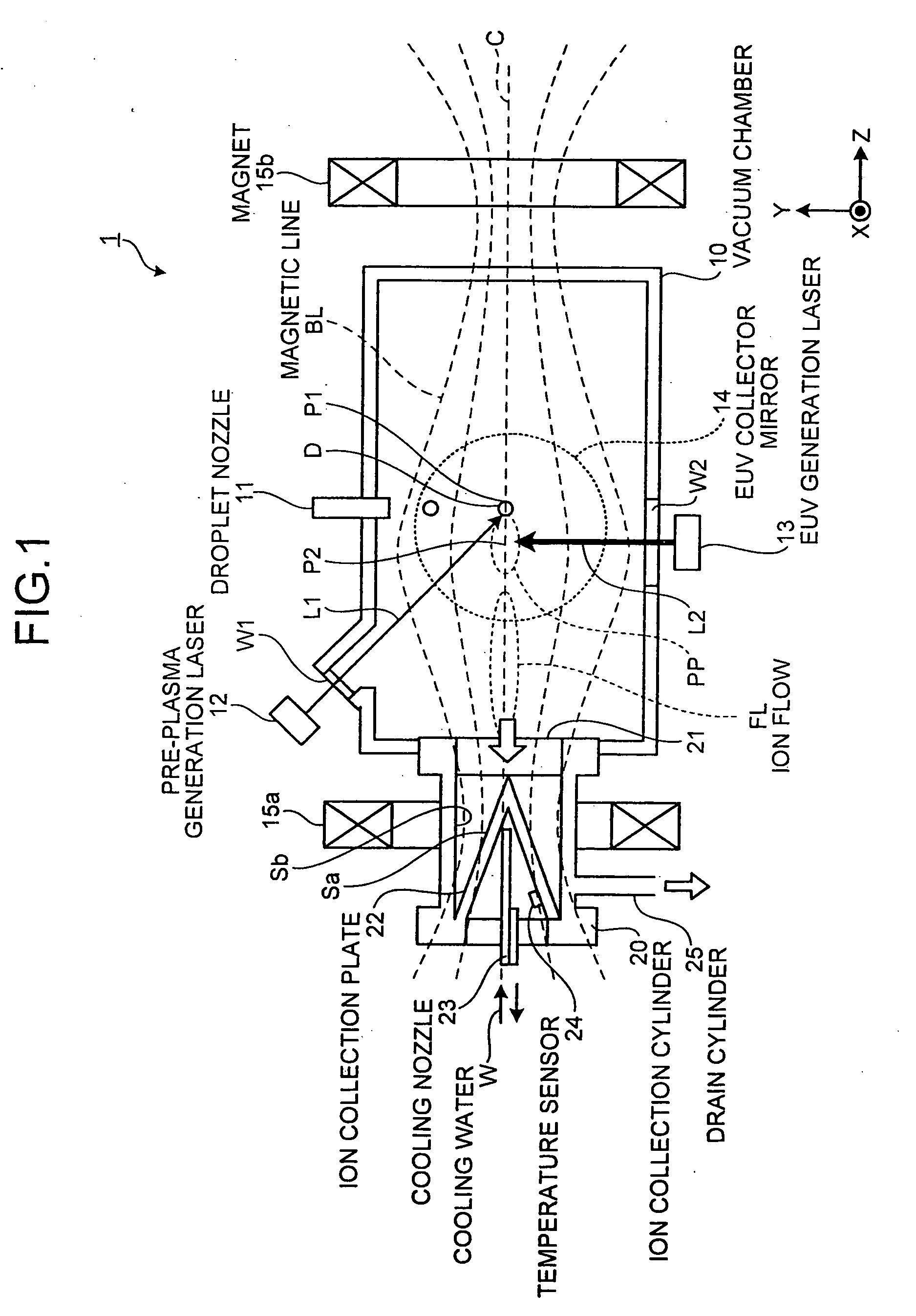

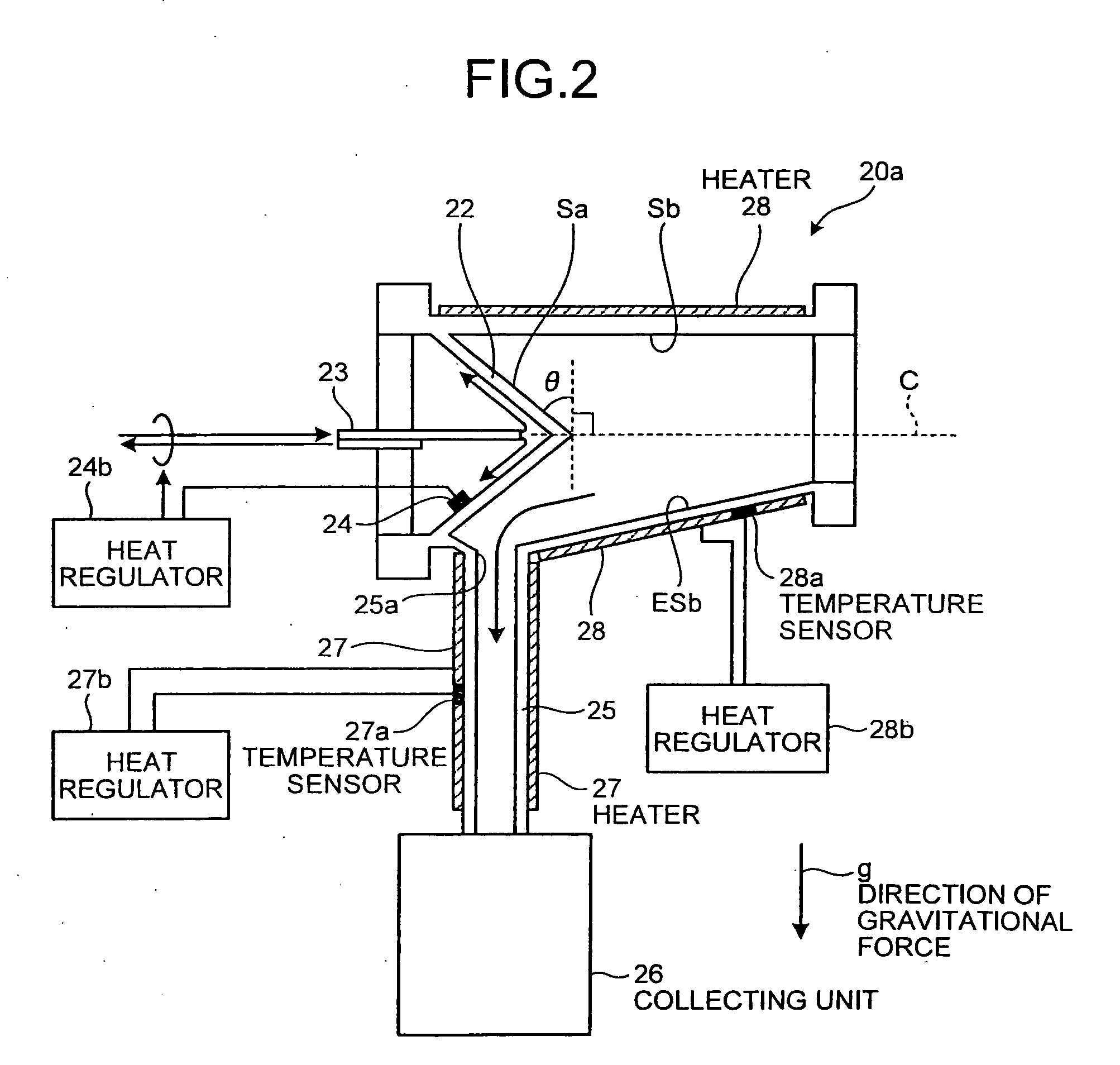

Extreme ultraviolet light source apparatus

In an extreme ultraviolet light source apparatus generating an extreme ultraviolet light from a plasma generated by irradiating a target, which is a droplet D of molten Sn, with a laser light, and controlling the flow direction of ion generated at the generation of the extreme ultraviolet light by a magnetic field or an electric field, an ion collection cylinder 20 is arranged for collecting the ion, and ion collision surfaces Sa and Sb of the ion collection cylinder 20 are provided with or coated with Si, which is a metal whose sputtering rate with respect to the ion is less than one atom / ion.

Owner:GIGAPHOTON

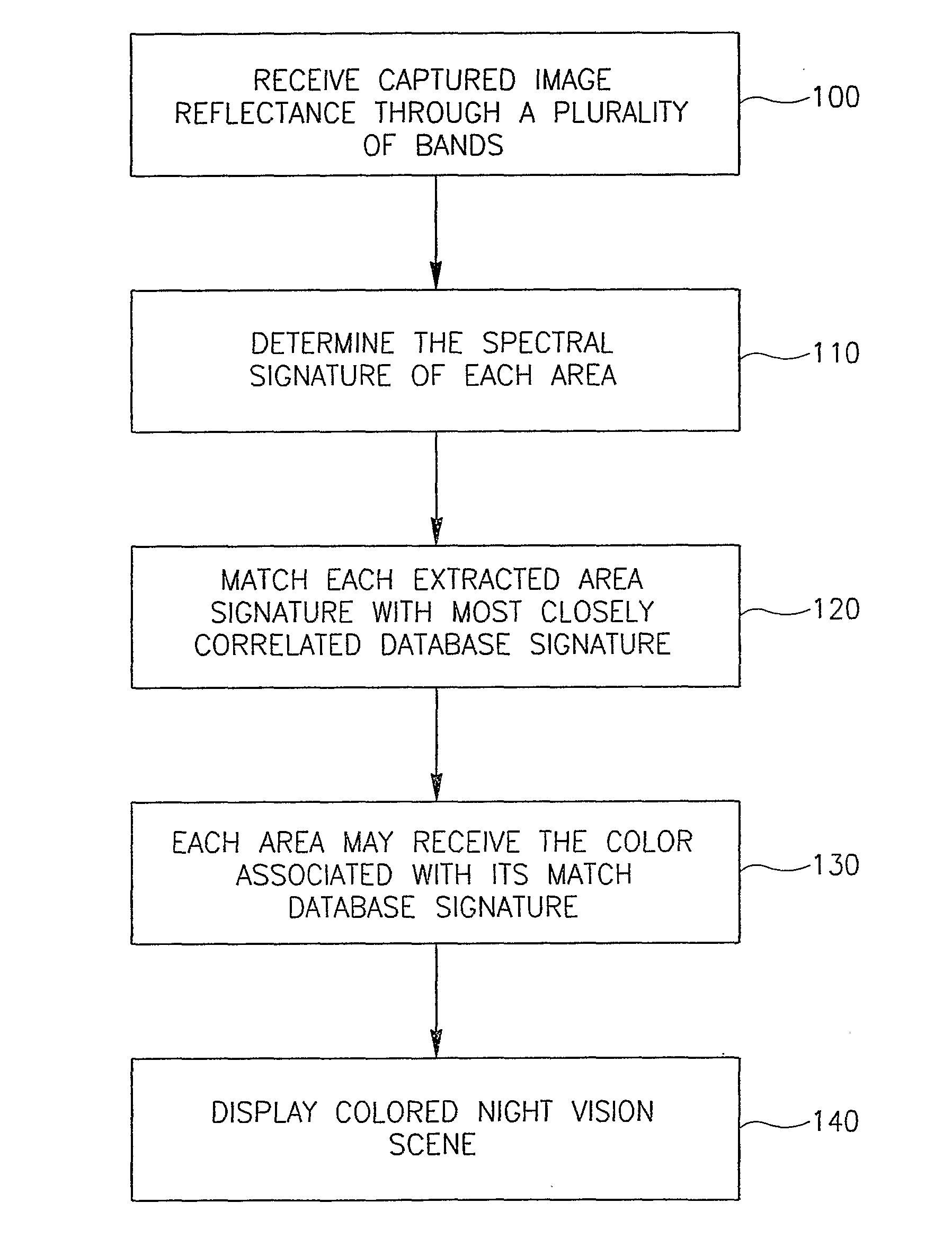

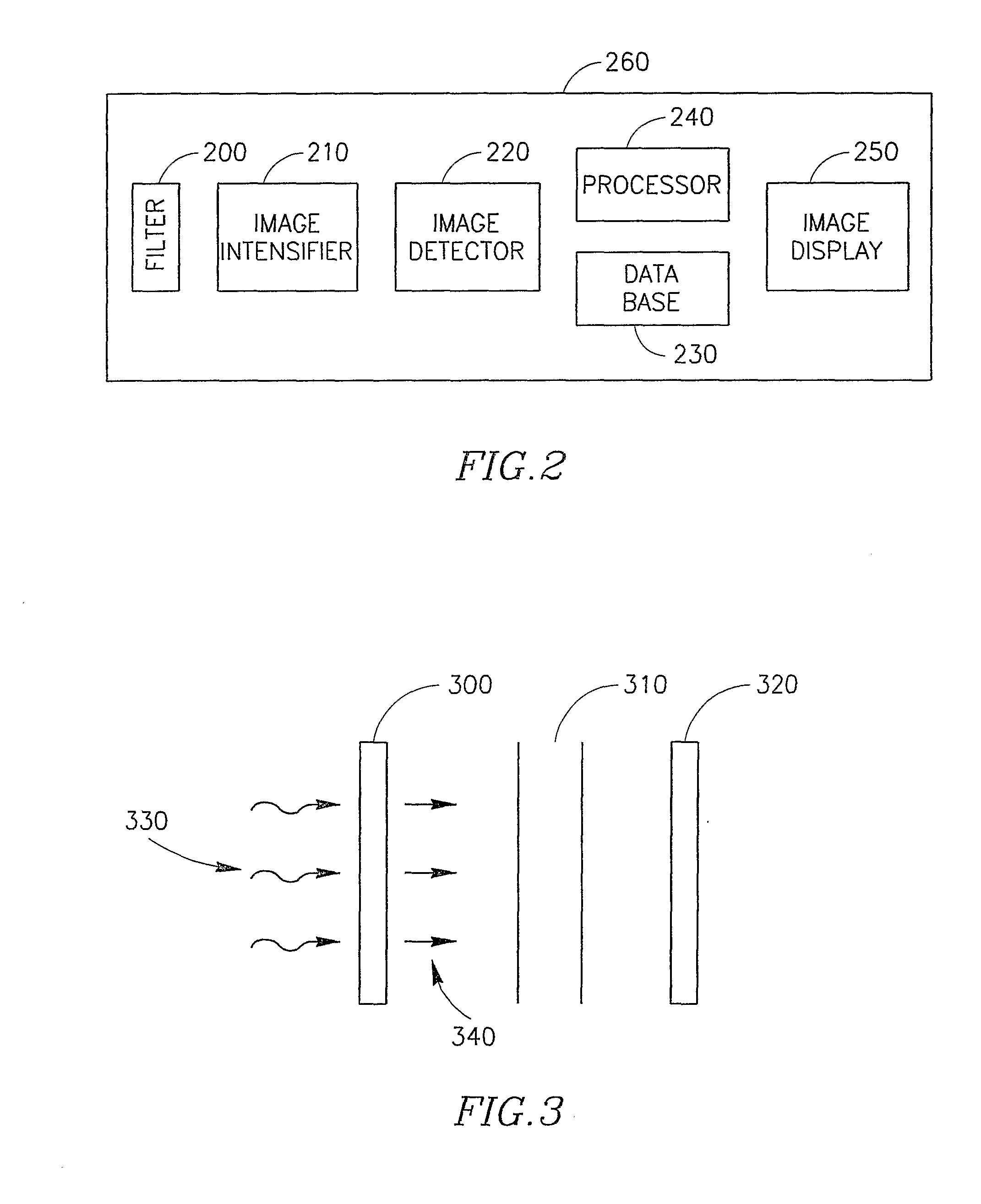

Synthetic Colour Night Vision System

ActiveUS20080157000A1Television system detailsPhotometry using reference valueNight visionSpectral bands

A night vision coloring system may color a scene by extracting the spectral signature of each area in a scene and matching the extracted signature with a predetermined database signature and associated color. The system may comprise a temporal or spatial filtering element that may typically allow the capturing of an image reflection through a plurality of spectral bands, thereby extracting the spectral signature of each area in the image. The color associated with the matched database signature may be used to color each area comprising the image.

Owner:ELBIT SYST LTD

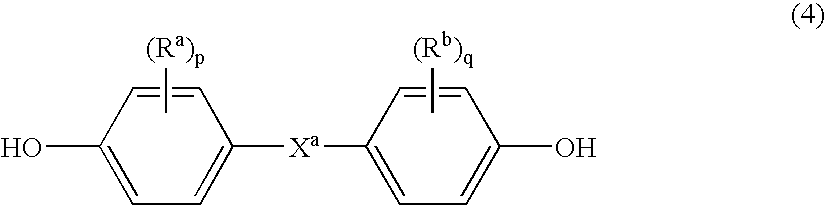

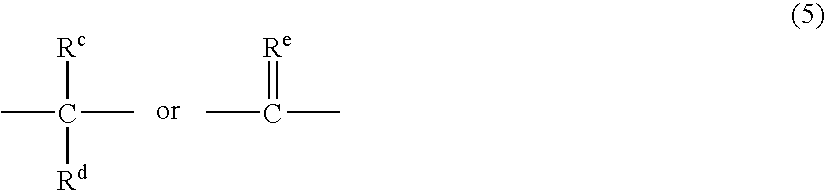

Ionizing radiation stable thermoplastic composition, method of making, and articles formed therefrom

A thermoplastic composition comprises a polycarbonate that is not aryl carboxylate end-capped, and an aryl carboxylate end-capped polycarbonate of formula:Ar1-C(O)—O-(-L-)m-O—C(O)-A1wherein each Ar1 is independently an aryl group, -(-L-)m- is a polycarbonate linking group with m units of linking unit L, and m is at least one; wherein the aryl carboxylate end-capped polycarbonate has aryl carboxylate end groups present in the thermoplastic composition in an amount of 0.01 to 500 mmol / Kg based on the combined weights of the polycarbonate that is not aryl carboxylate end-capped, and the aryl carboxylate end-capped polycarbonate, and wherein a molded article having a thickness of 3.2±0.12 millimeters and consisting of the aryl carboxylate end-capped polycarbonate, the polycarbonate, and less than or equal to 1.0 percent total weight of aliphatic diol, a mold-release agent, and an antioxidant has, after exposure to a total gamma radiation dose of 81 kGy and when measured according to ASTM D1925-70, an increase in yellowness index (dYI) of less than or equal to 24.5, when compared to the unexposed molded article. A method for preparing the aryl carboxylate end-capped polycarbonate that is not aryl carboxylate end-capped, and thermoplastic composition, an article prepared from the thermoplastic composition, are also disclosed.

Owner:SABIC GLOBAL TECH BV

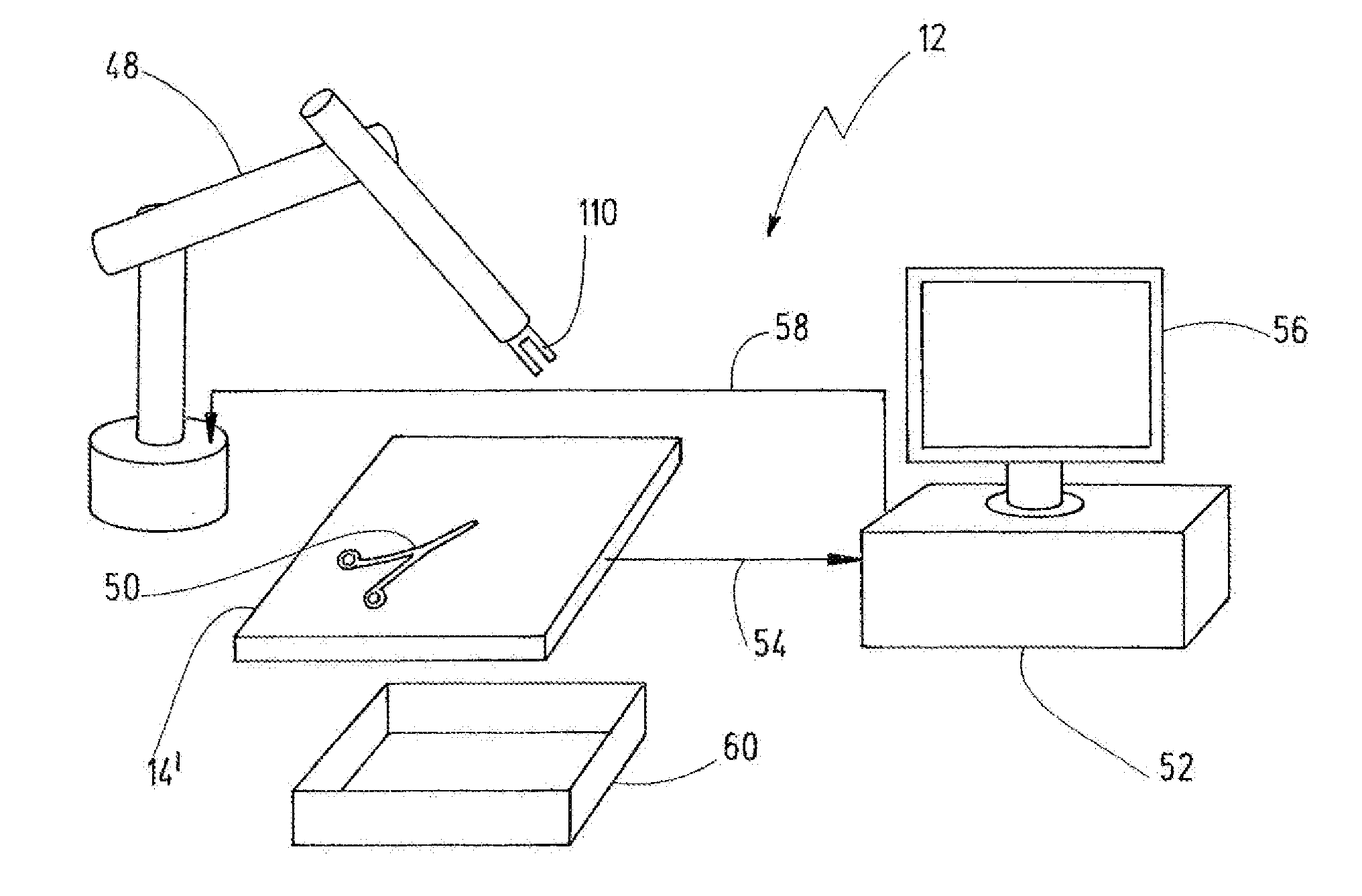

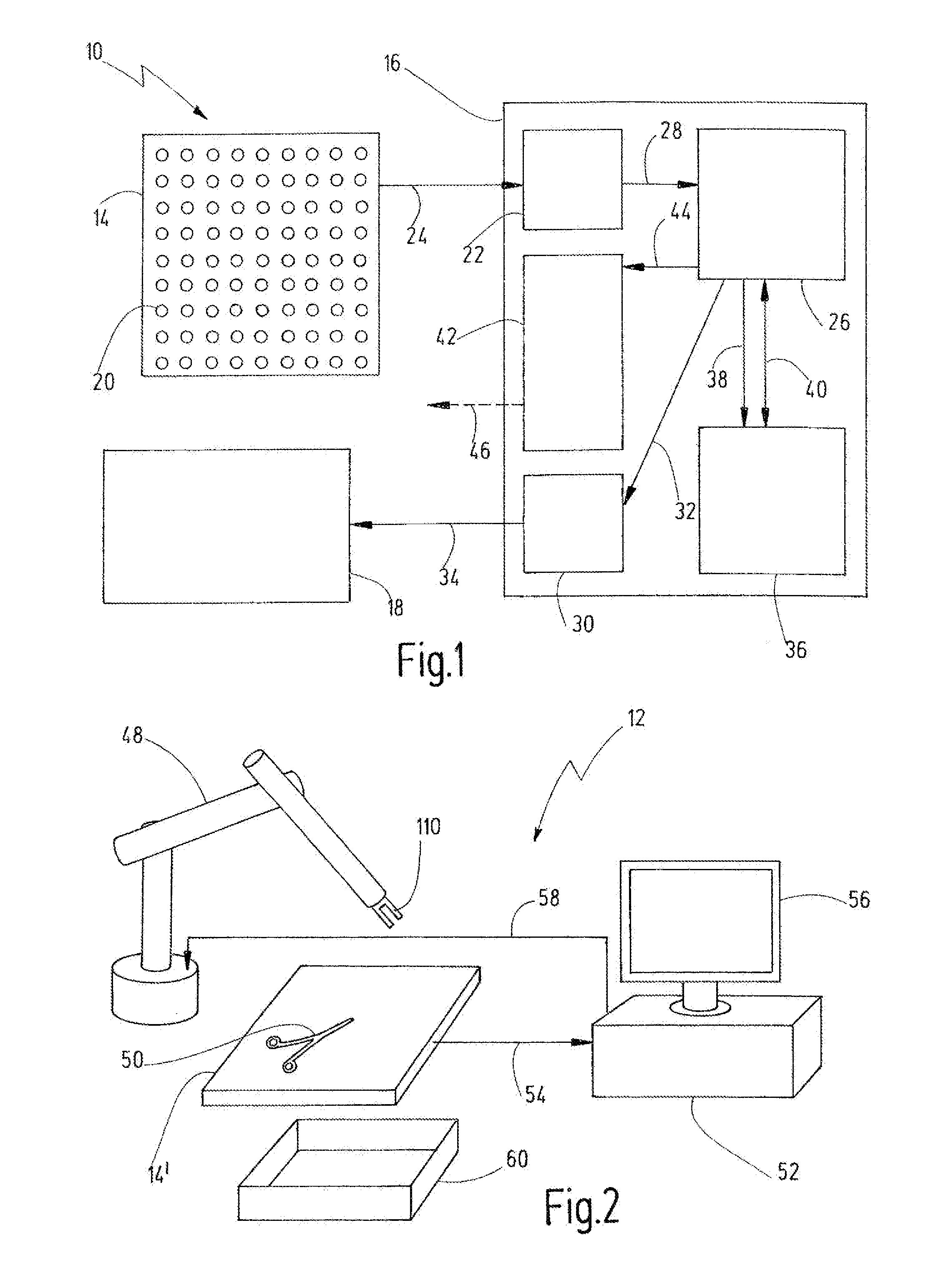

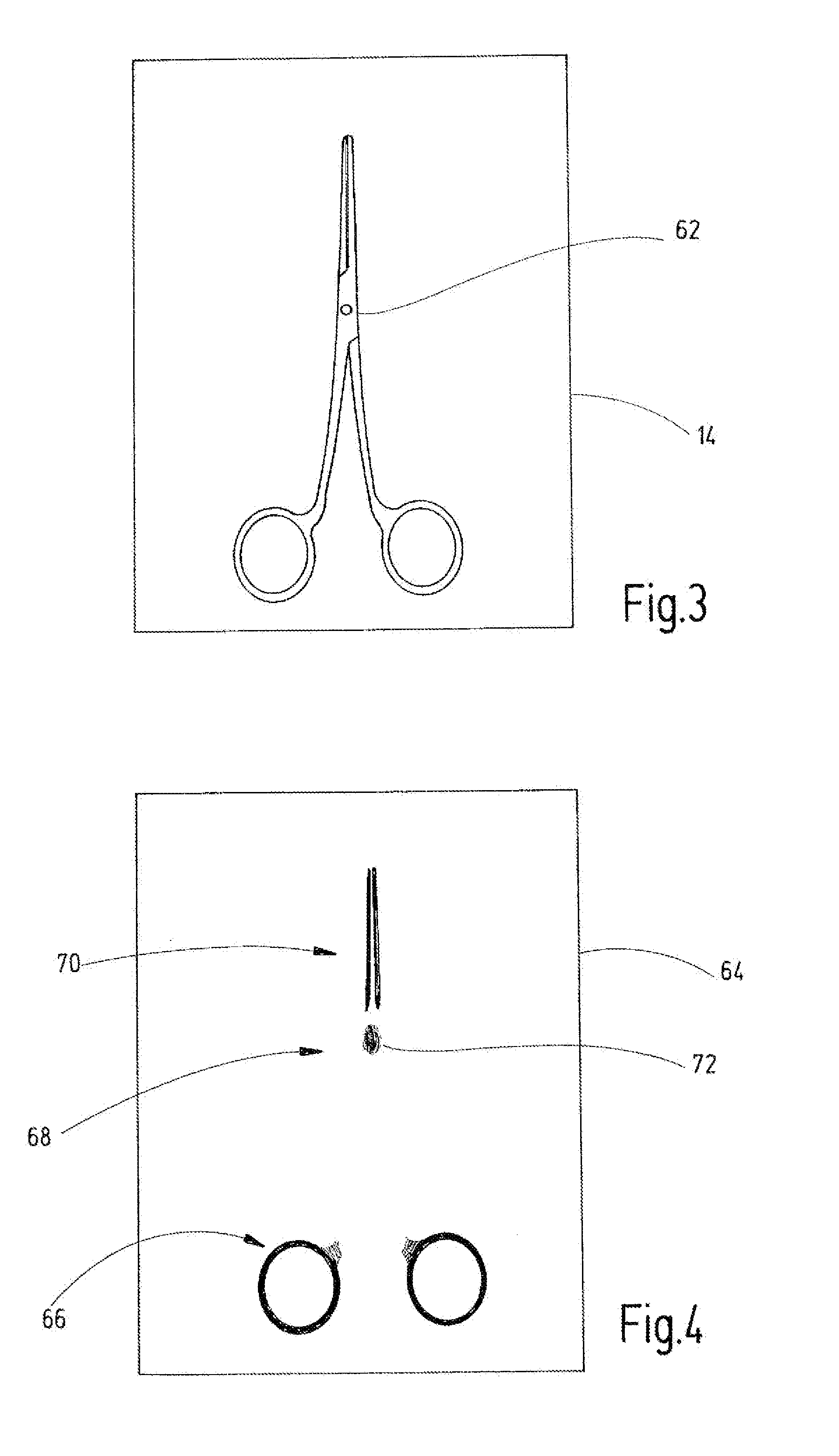

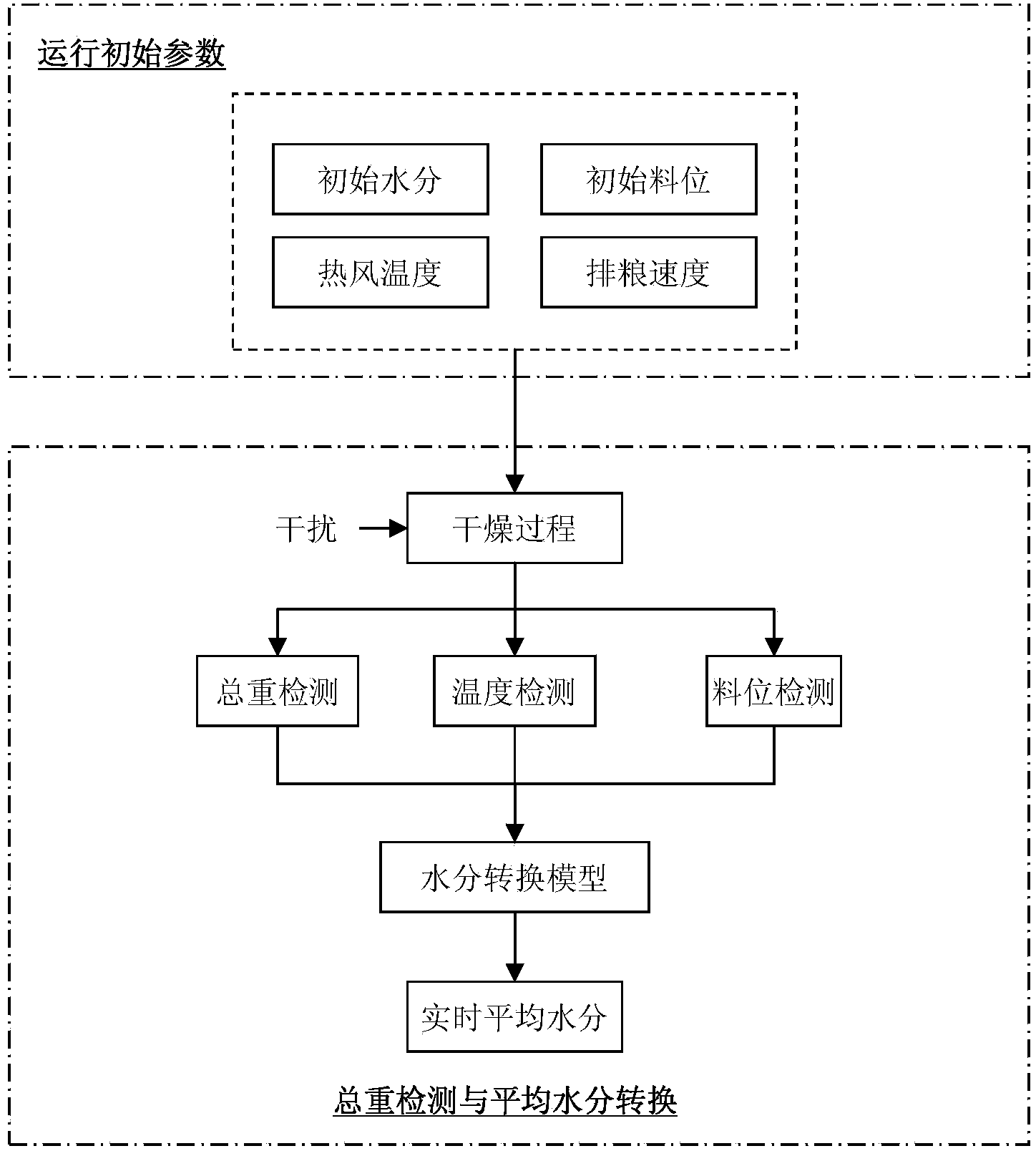

Device And Method For Identifying Instruments

InactiveUS20120259582A1Detectable weight distributionSimplified weightDiagnosticsSurgeryData processing systemComputer science

The invention relates to a device for identifying instruments comprising at least one weight sensor, a data processing system, which has an interface, at least one database and an processing unit, and a visualization unit. Weight distribution data of instruments can be determined and compared by the device. This allows identifying individual instruments. The invention further relates to according methods for detecting a weight distribution of an individual instrument and for identifying an individual instrument, as well as to a method for assembling instrument sets.

Owner:KARL STORZ GMBH & CO KG

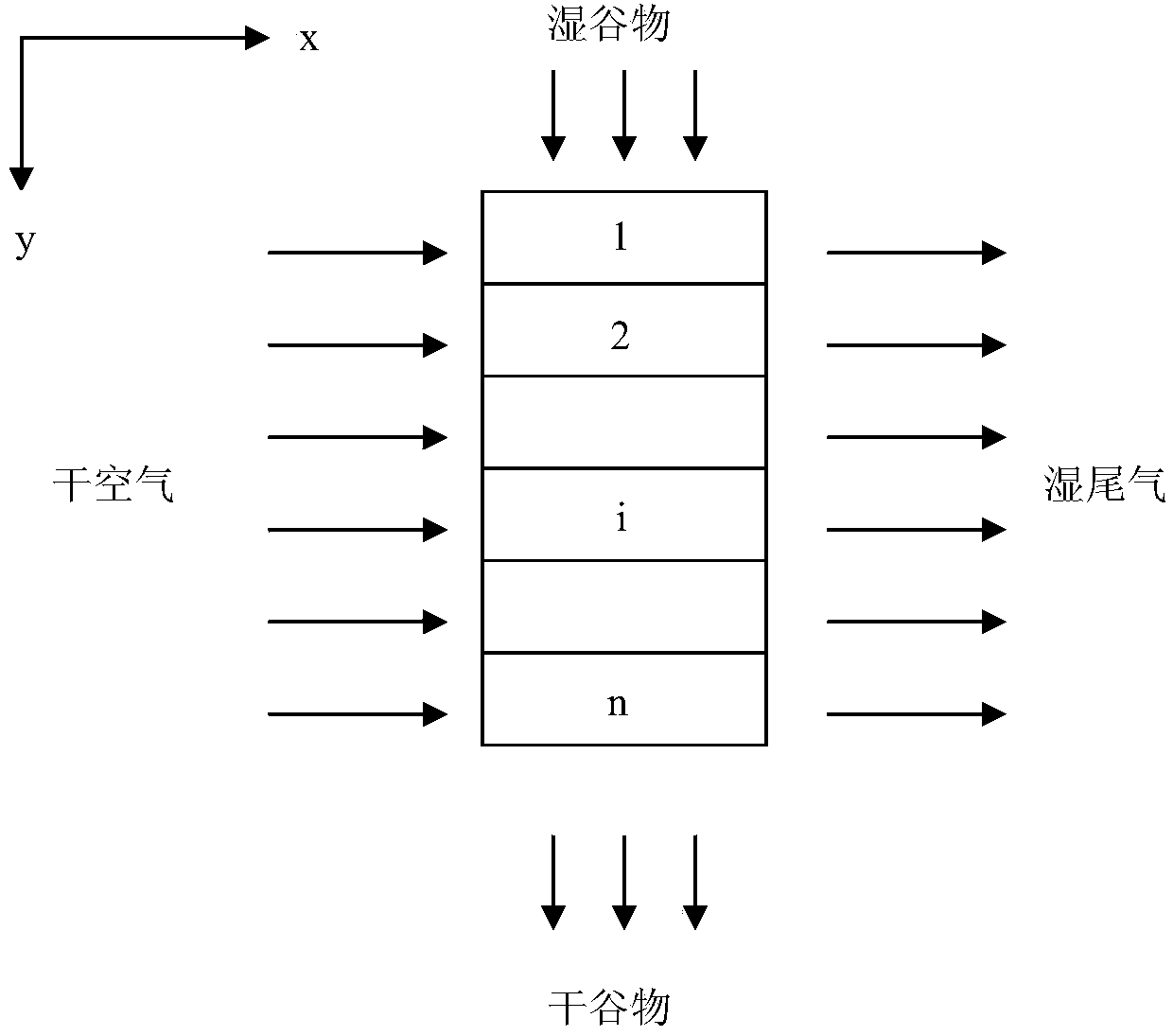

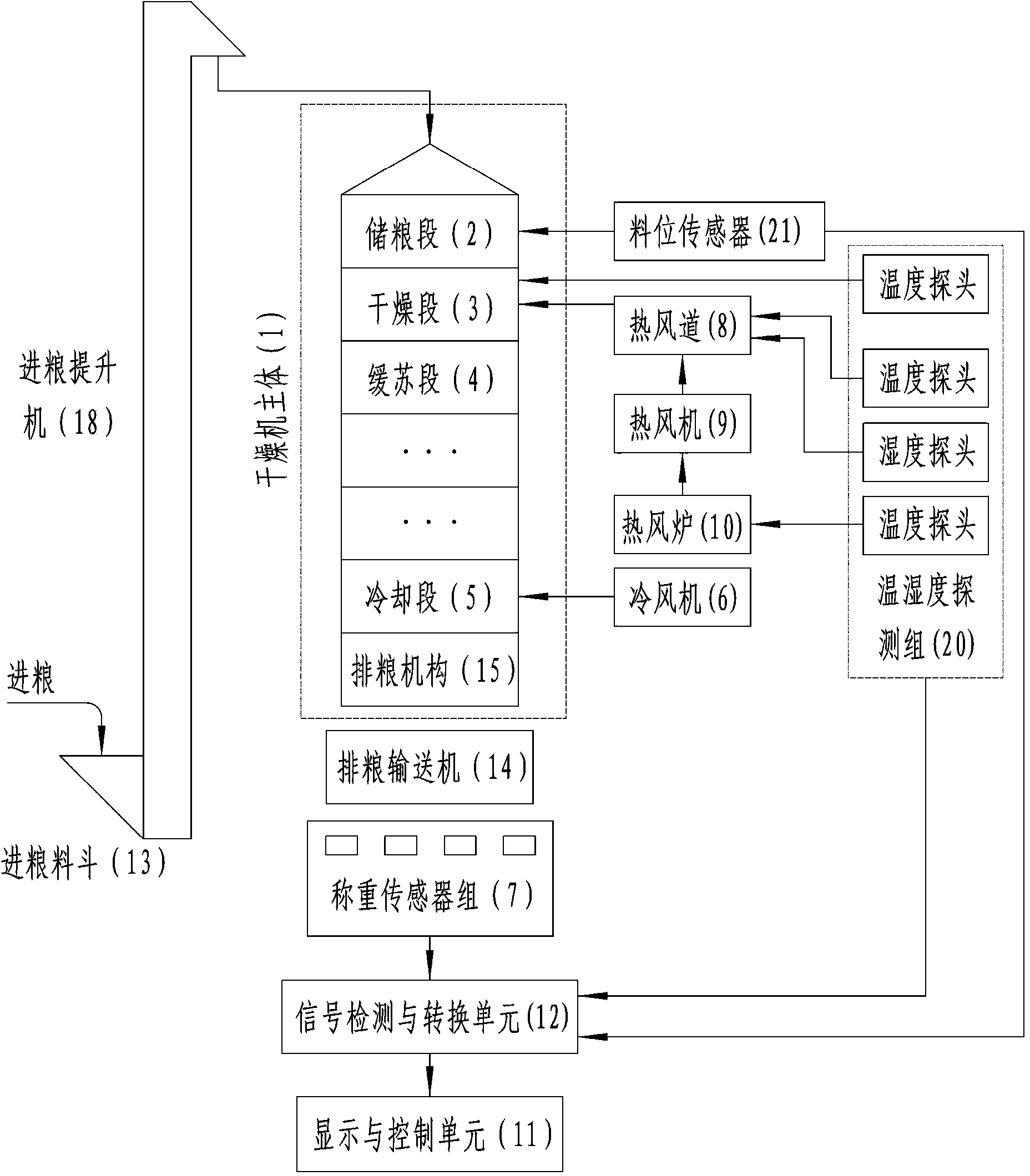

Online detection method for water in continuous grain drying process

ActiveCN103808591AAvoid stabilityAvoid precisionDrying solid materialsDrying machines with local agitationEnvironmental engineeringGrain drying

The invention discloses an online detection method for water in a continuous grain drying process. Water is calculated by using a relation of water and volume weight. The online detection method has the advantages of simple structure, convenience in installation, simplicity in operation, strong interference resisting capacity, good environmental suitability and the like, is suitable for a continuous drying operation of crops such as corns, rice and wheat, and avoids main defects of detection of water in the prior art.

Owner:CHANGCHUN JIDA SCI INSTR EQUIP

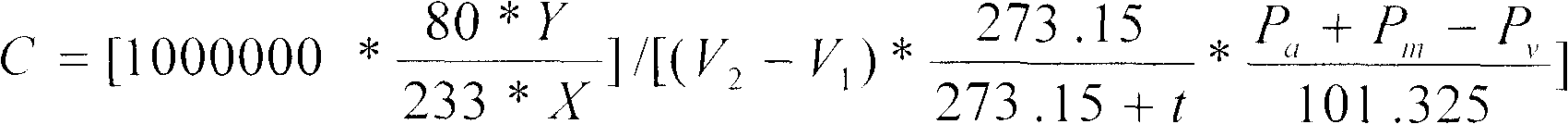

Testing method for content of coal seam methane sampled under negative-pressure environment

ActiveCN103776722AReduce lossesReduced sampling timeWithdrawing sample devicesMaterial weighingDesorptionBall mill

The invention provides a testing method for the content of a coal seam methane sampled under a negative-pressure environment. The testing method comprises the following steps: sampling, namely carrying out in-situ measurement on the methane desorption amount; recording the final in-situ desorption amount V2; determining a methane desorption principle of a coal sample under the negative-pressure environment; carrying out lost methane amount calculation, namely calculating the loss amount V1 according to the measured methane desorption principle of the coal sample under the negative-pressure environment; carrying out residual methane amount laboratory determination, namely heating the coal sample in a sealed state and degassing in vacuum; testing the first-time degassing amount V3; crushing the coal sample by a ball grinding mill and degassing to determine the second-time degassing amount V4; carrying out gas component analysis in the degassing process; and determining the content X of the coal seam methane according to the V1, the V2, the V3 and the V4, and the weight m of the coal sample. The testing method for the content of the coal seam methane sampled under the negative-pressure environment is simple and feasible and particularly has important theoretical values and actual meanings on the desorption amount and the desorption principle of methane under the negative-pressure environment when negative-pressure pumping-out type spot sampling is carried out; the accuracy and the reliability of testing data can be greatly improved and theoretical data are provided for the coal mine safety production.

Owner:HENAN POLYTECHNIC UNIV

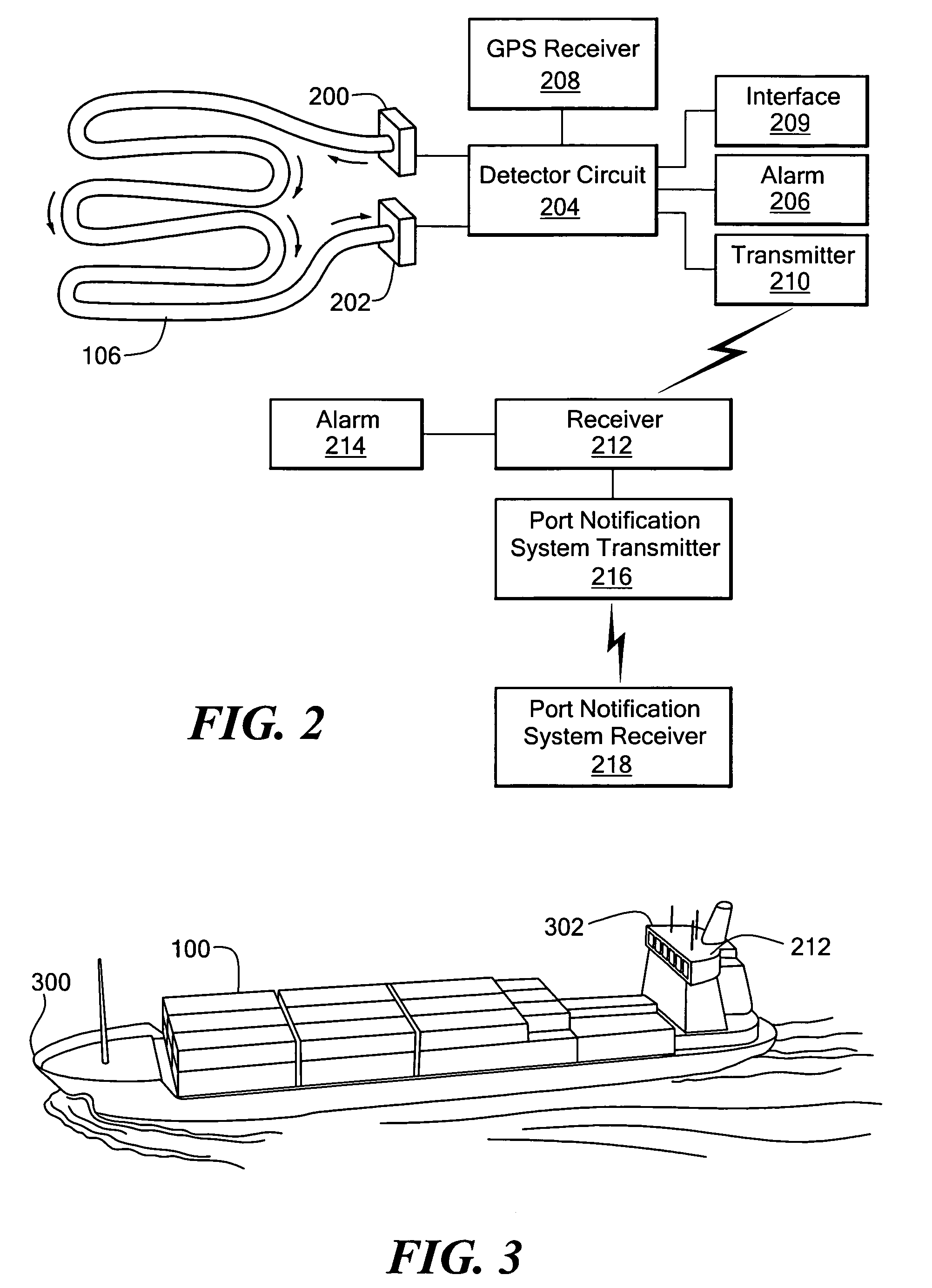

Tamper proof container

InactiveUS7098444B2Radiation pyrometryMaterial analysis by optical meansTamper resistanceOptical property

A liner sheet lines at least a portion of an interior surface of a shipping container or box and defines an optical path extending across at least a portion of the sheet, such that a breach of the interior surface also alters an optical characteristic of the optical path. For example, an optical fiber can be woven into, or sandwiched between layers of, the liner sheet. The optical path is monitored for a change in an optical characteristic. If the container or box interior surface is breached, one or more portions of the optical fiber are severed or otherwise damaged, and the optical path is altered. The detected change in the optical path can be used to trigger an alarm, such as an annunciator, or to send a message that includes information concerning the container's contents or time or location of the container when the breach occurred to a central location, such as a ship's control room or a port notification system.

Owner:3D FUSE TECH

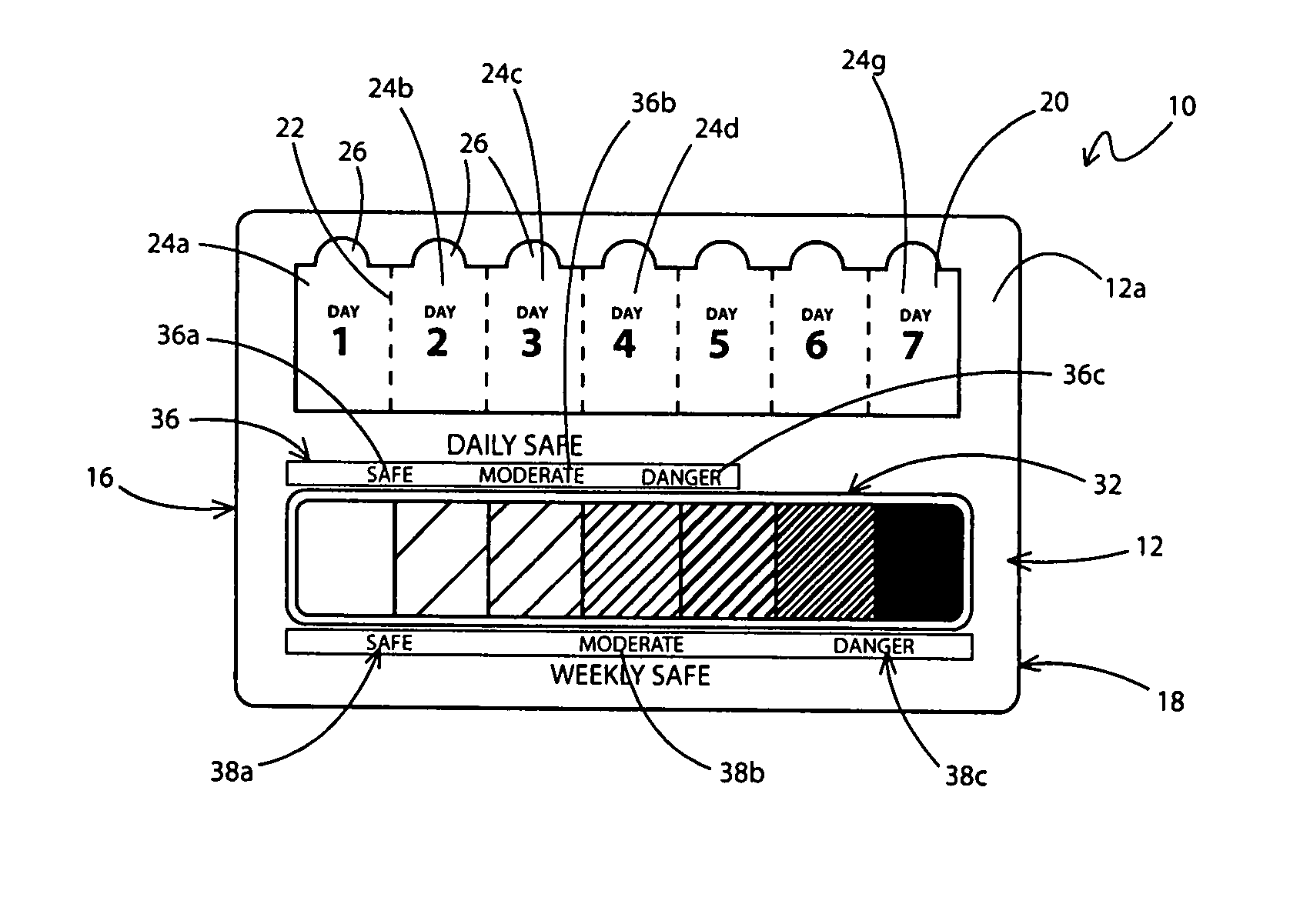

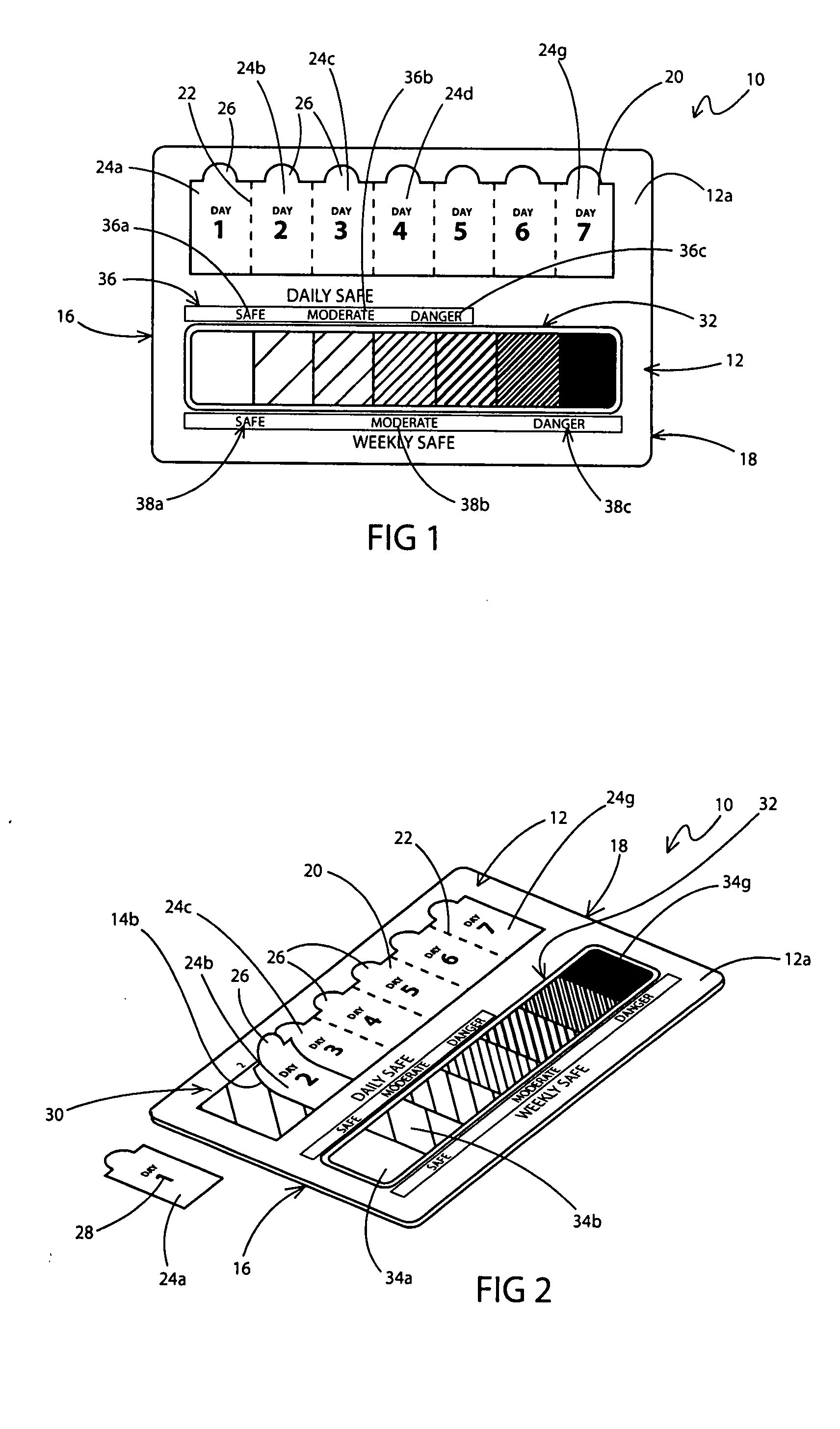

Ultraviolet radiation monitoring device and a method of using the same

InactiveUS20080185534A1Material analysis by observing effect on chemical indicatorGlass dosimetersUltraviolet radiationUltraviolet

A disposable device for monitoring exposure to ultraviolet radiation (UVR) over a single period of time and a cumulative period of time. The device includes a base upon which is applied a UVR sensitive material that irreversibly changes after exposure to UVR. A protective covering is applied over the UVR sensitive material and includes segments that are individually removable to reveal a portion of the UVR sensitive material thereunder. A UVR exposure scale and first and second keys are provided on the base. A first segment of the covering is removed and the base is placed in an appropriate location. After a period of time, the change in the UVR sensitive material is compared to the scale and first key to determine if the level of exposure is safe for that time period. The procedure may be repeated over a number of time periods with a new segment of the protective covering being removed for each time period. The cumulative UVR exposure is determined by comparing the change in the first time period's UVR sensitive material to the scale and a second key associated therewith.

Owner:BARRINGTON L SIMON

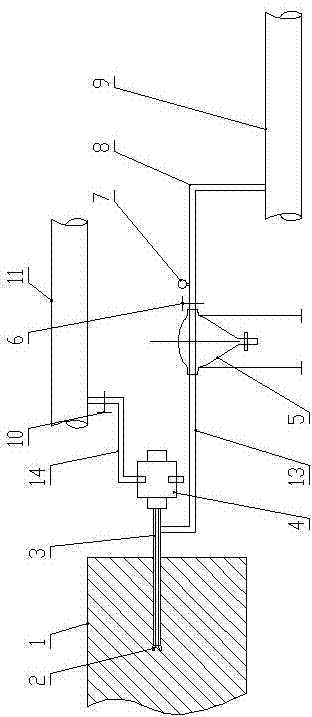

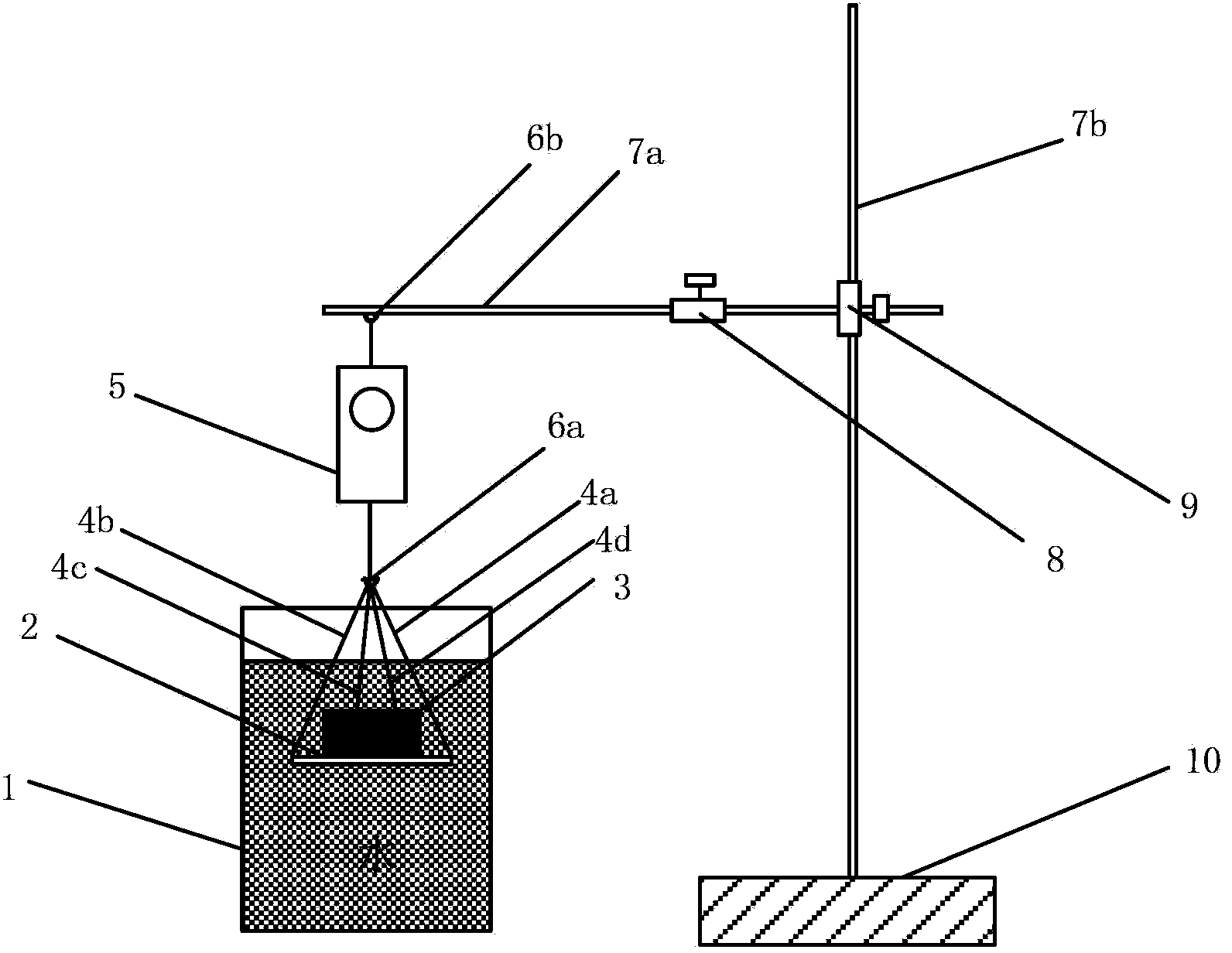

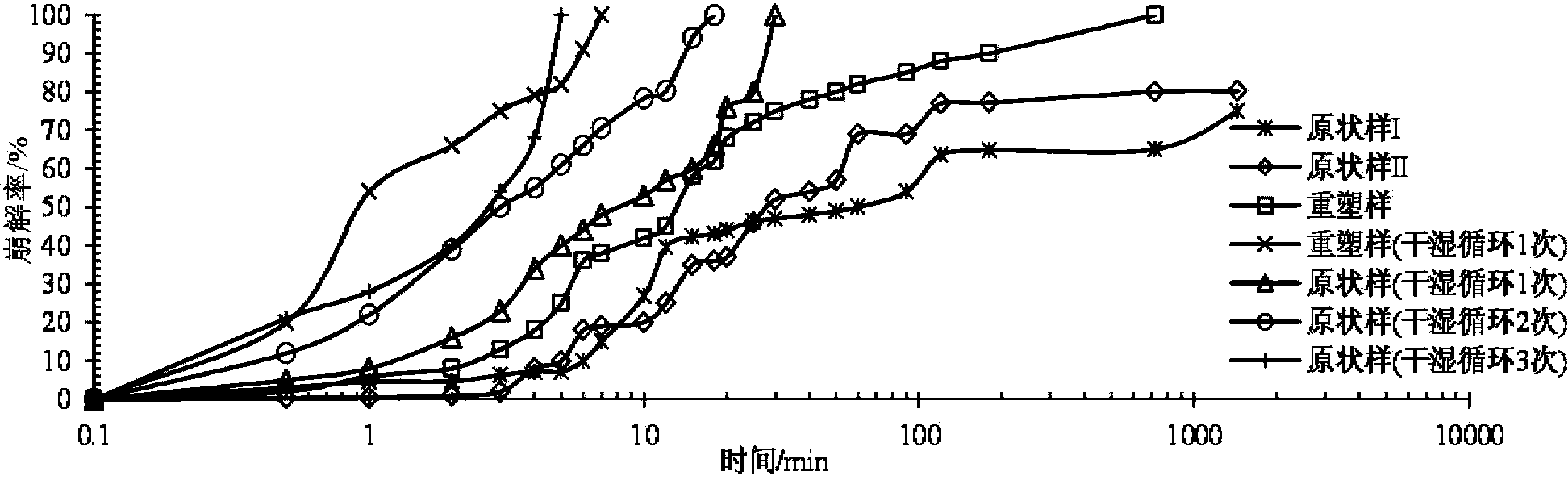

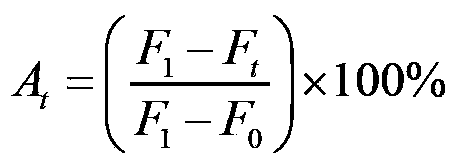

Rock and soil disintegration test device as well as using method

InactiveCN103399140AThe principle is matureSimple structureEarth material testingParticle size analysisTest sampleCopper wire

The invention discloses a rock and soil disintegration test device as well as a using method. A base is connected with fulcrum bars; a vertical stretching valve is connected with the fulcrum bars respectively; a fulcrum bar is provided with a horizontal stretching valve, and a second hook is hung on the fulcrum bar; one end of a spring-loaded thrust meter is connected with the second hook; the lower part of the other end of the spring-loaded thrust meter is connected with the hook; copper wires are fastened to four edge corners of a metal grid net, and at the other end, the copper wires are twisted into a strand to be hung on the hook; rock and soil test samples are placed on the metal grid net, and then are immersed into a flask. The using method of the rock and soil disintegration test device comprises the following steps: (1) a no-load test, namely pouring distilled water into the flask, and recording the reading number F0 on the spring-loaded thrust meter; (2) rock and soil test sample manufacture, namely manufacturing a soil test sample and a rock test sample respectively by a cutting ring and a cutter; (3) a disintegration test, namely placing the rock and soil test samples on the metal grid net, and immersing into water, thus completing the test; (4) data processing. The rock and soil disintegration test device is simple in structure, easy to assemble and debug, low in cost, high in precision, good in stability and high in applicability, and can be widely applied to rock and soil engineering science research.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

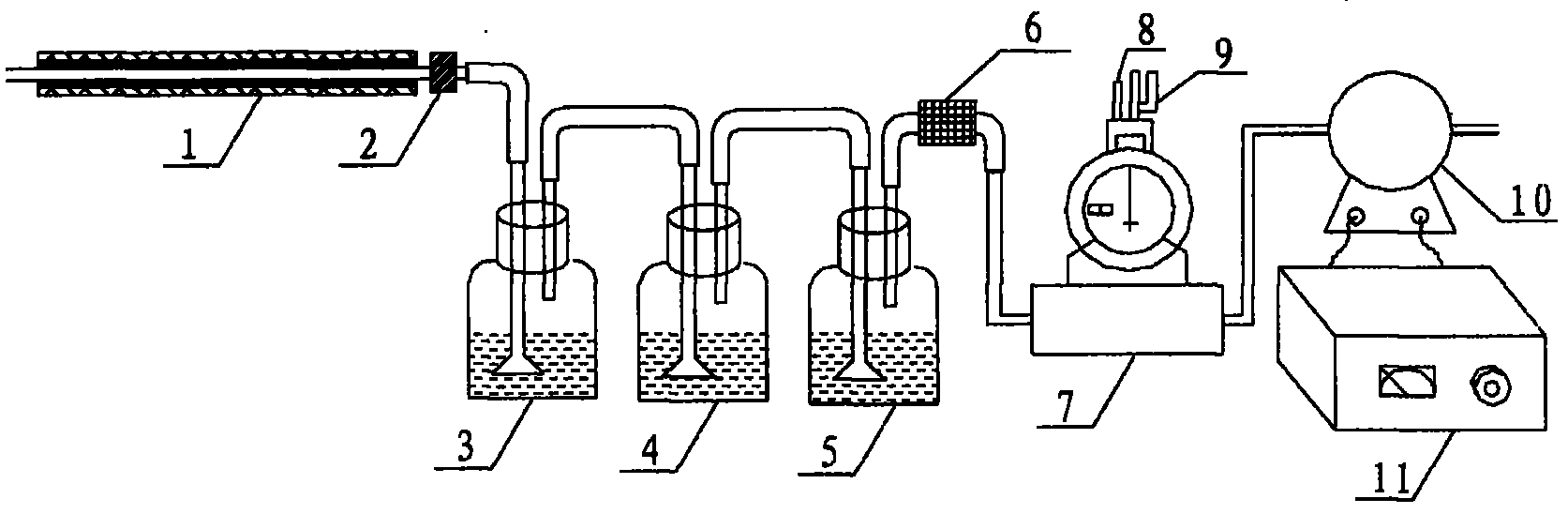

System for determining SO3 in flue gas

InactiveCN102419292AAvoid the impact of determinationAccurate measurementPreparing sample for investigationMaterial weighingFlue gasProcess engineering

The invention discloses a system for determining SO3 in flue gas, comprises the following parts: a sampler which has the function of heating the flue gas that passes through the sampler; an absorber with an aqueous solution of isopropanol, wherein, the inlet of the absorber is connected with the outlet of the sampler to let the flue gas pass through the aqueous solution of isopropanol; a gas flowmeter, wherein, the inlet of the gas flowmeter is connected with the outlet of the absorber; and a vavuum pump which is connected with the outlet of the gas flowmeter.

Owner:PANZHIHUA IRON AND STEEL +2

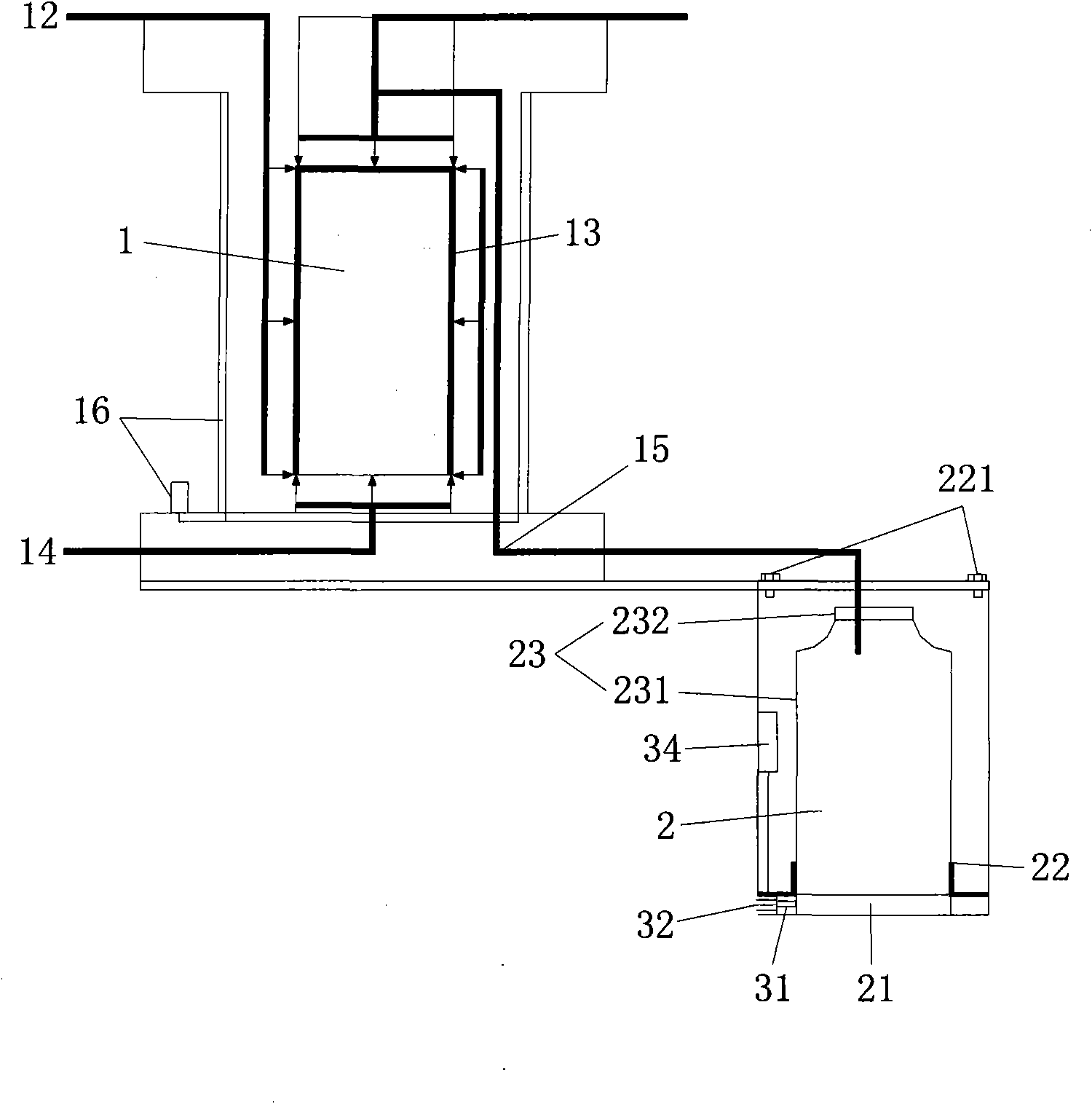

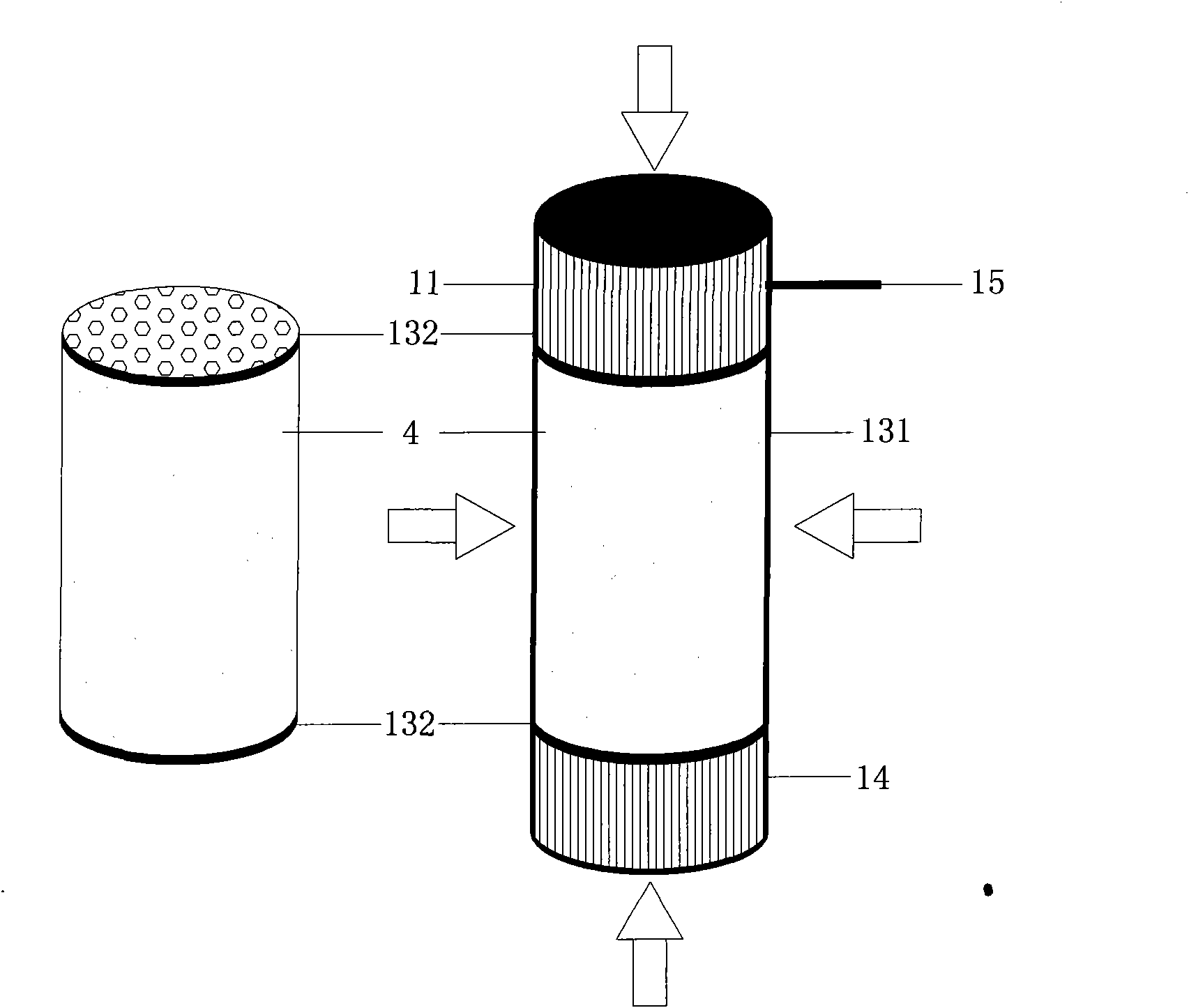

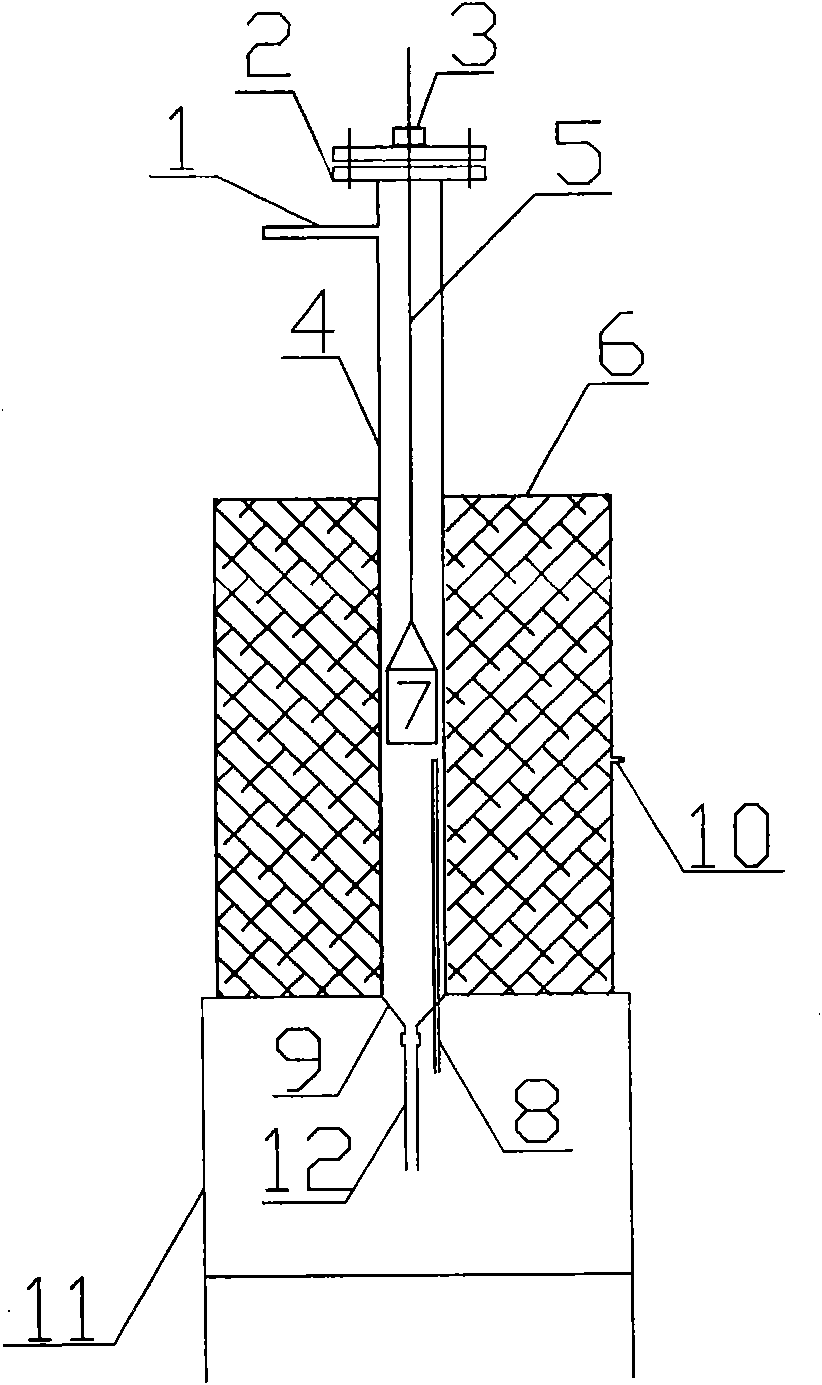

Fast pyrolytic test device and application

InactiveCN101846642AFast pyrolysisGood value for moneyMaterial weighingInvestigating phase/state changeTarEngineering

The invention relates to a fast pyrolytic test device, which consists of a tubular electric heating furnace (6), an object carrying frame (11), a temperature test and control opening (8), a reaction tube (4), an air inlet opening (1) and an oil air outlet opening (9). The invention is characterized in that the air inlet opening (1) is arranged at the upper part of the reaction tube (4), the top of the reaction tube (4) is provided with an adjustable sealing element (3), a stainless steel rod (5) is arranged in the reaction tube (4), the top end of the stainless steel rod (5) is connected with the adjustable sealing element (3), the lower end of the stainless steel rod (5) is connected with a sample hanging basket (7), the middle lower part of the reaction tube (4) is positioned inside the tubular electric heating furnace (6), the bottom of the reaction tube (4) is provided with the temperature test and control opening (8) and the conical oil air outlet opening (9), the conical oil air outlet opening (9) is connected with an oil air outlet tube (12), and the tubular electric heating furnace (6) is positioned on the object carrying frame (11). The invention has the advantages of high performance price ratio, simple and convenient operation, simple structure and low equipment cost, can realize slow temperature rise and fast pyrolysis under the condition of simulated work conditions, can realize fast cooling, and can accurately measure the tar amount generated by the pyrolysis.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com