Patents

Literature

306 results about "Densitometer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A densitometer is a device that measures the degree of darkness (the optical density) of a photographic or semitransparent material or of a reflecting surface. The densitometer is basically a light source aimed at a photoelectric cell. It determines the density of a sample placed between the light source and the photoelectric cell from differences in the readings. Modern densitometers have the same components, but also have electronic integrated circuitry for better reading.

Single tube densitometer

InactiveUS6912904B2Improve accuracyImprove reliabilityVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesMeasurement deviceComputer module

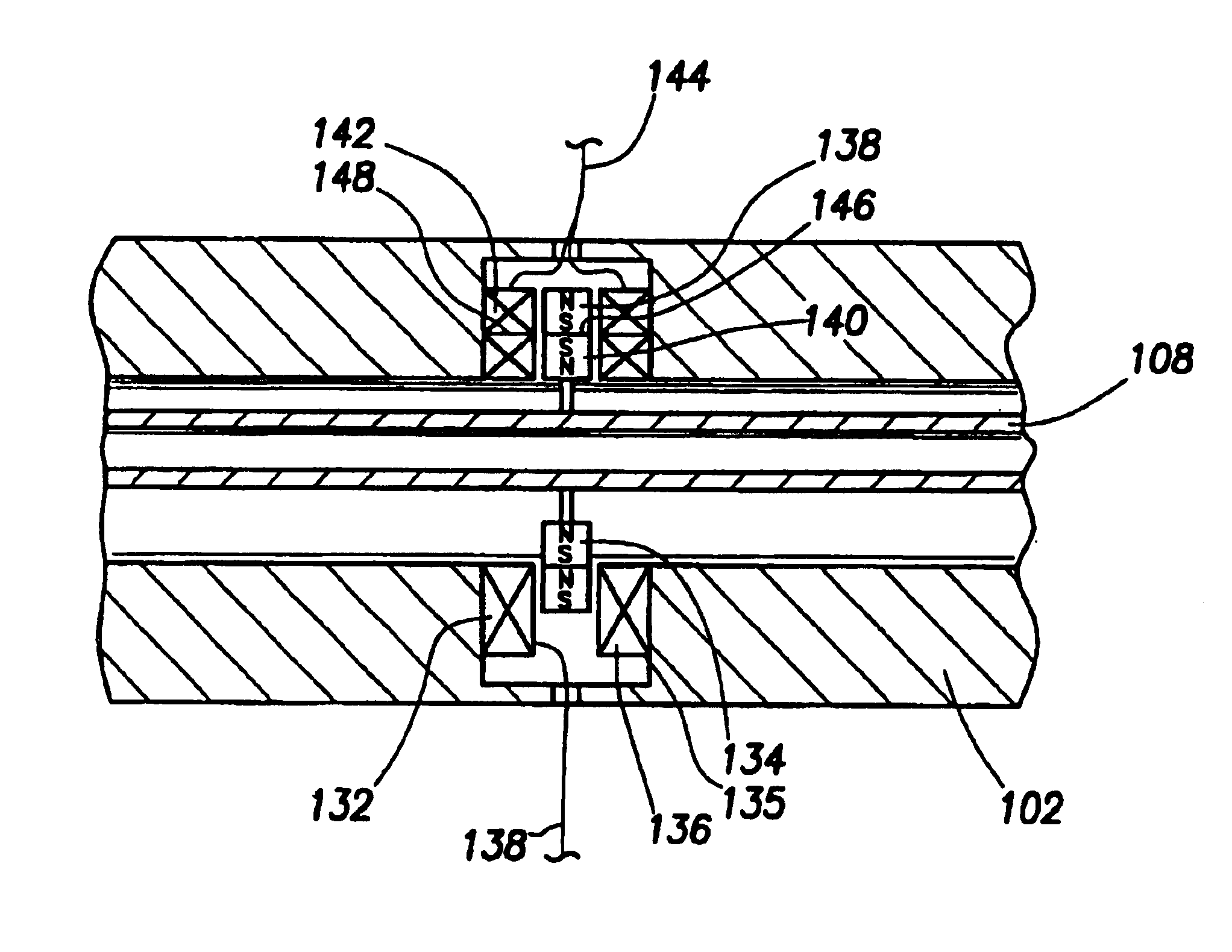

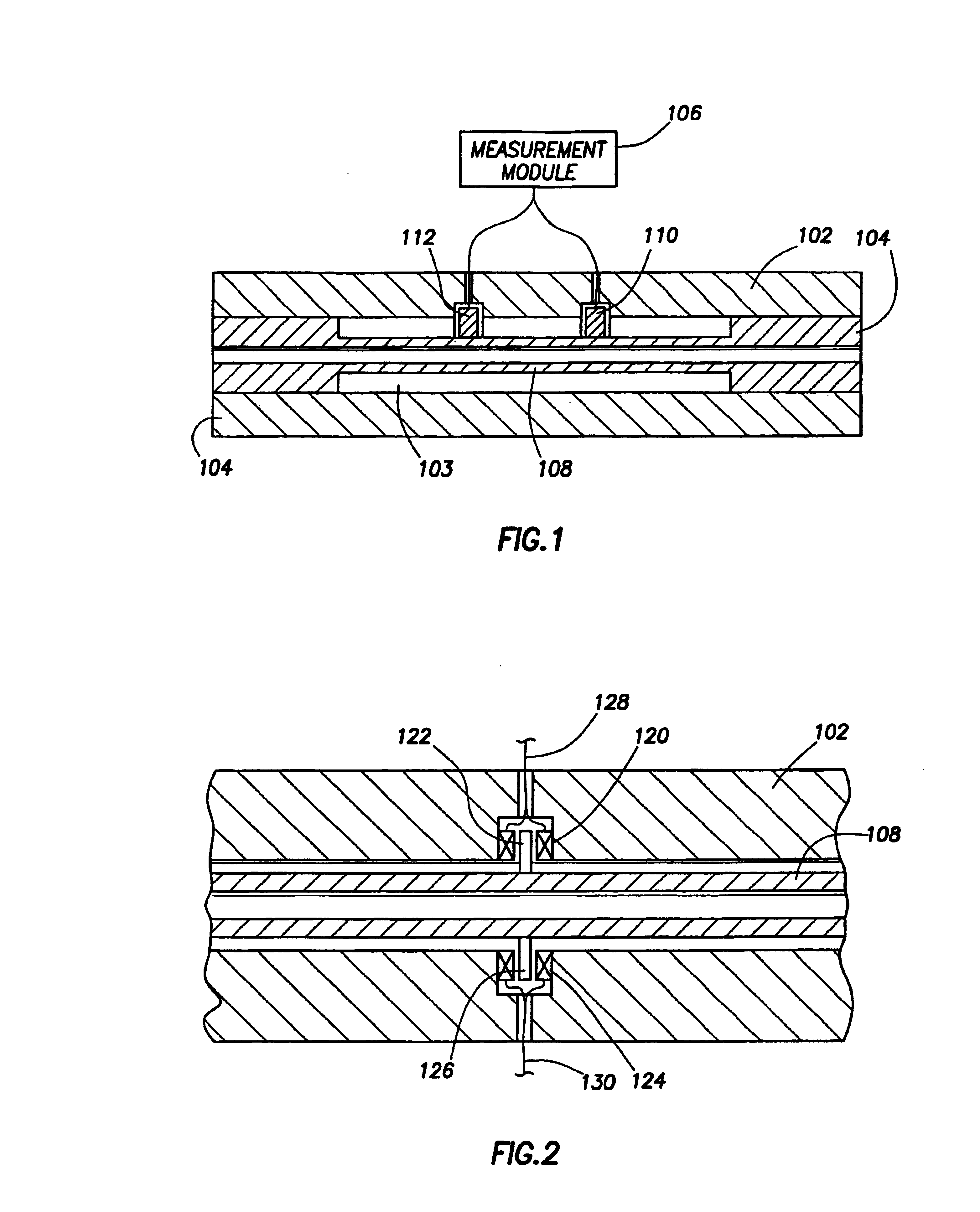

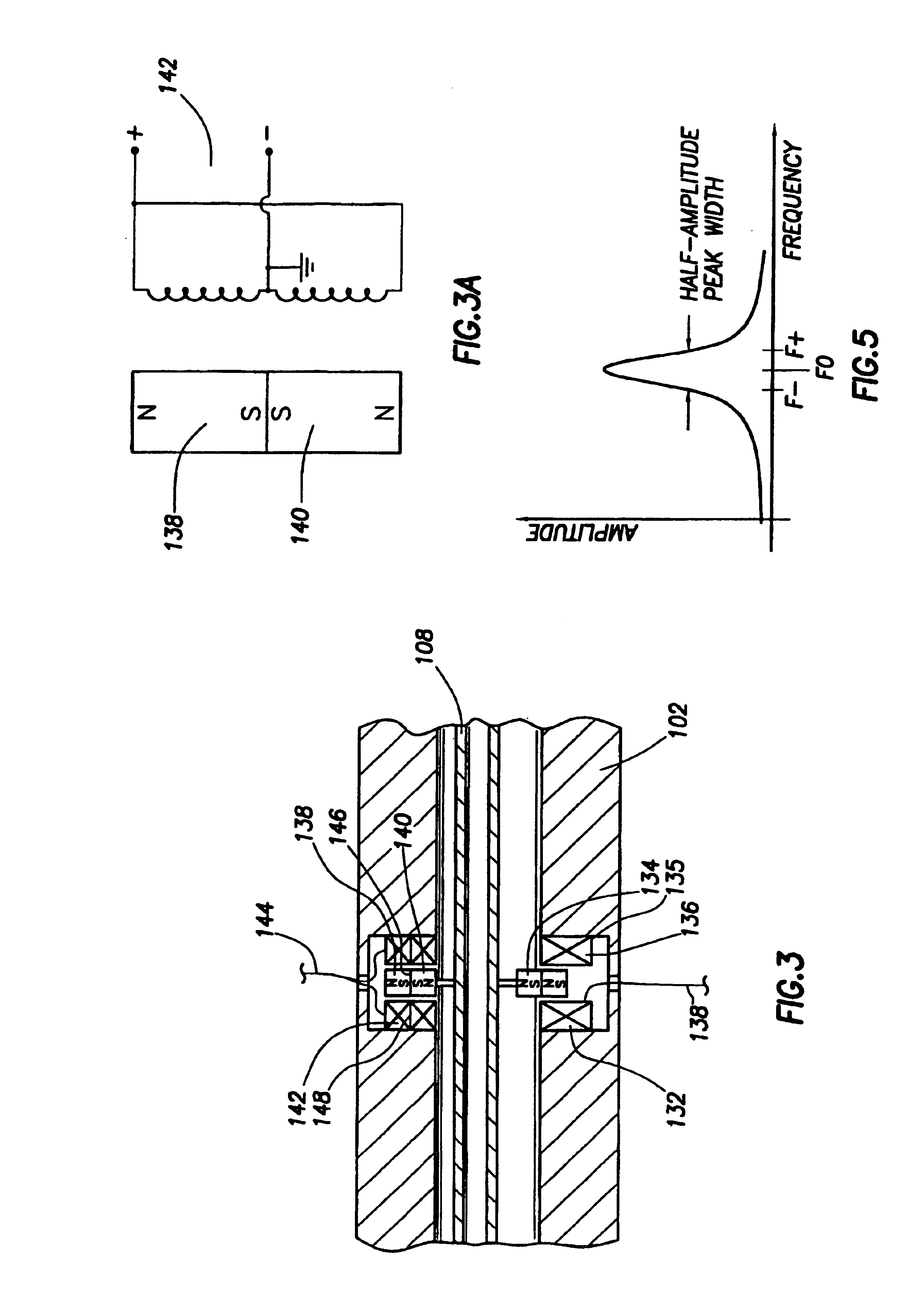

A measurement device is provided that determines fluid properties from vibration frequencies of a sample cavity. In one embodiment, the measurement device includes a sample flow tube, vibration source and detector mounted on the tube, and a measurement module. The sample flow tube receives a flow of sample fluid for characterization. The measurement module employs the vibration sources to generate vibrations in the tube. The measurement module combines the signals from the vibration detector on the tube to determine properties of the sample fluid, such as density, viscosity, compressibility, water fraction, and bubble size. The measurement module may further detect certain flow patterns such as slug flow, for example. To measure the sample fluid density, the measurement module determines the resonant frequency of the sample flow tube. The density can then be calculated according to a formula that compensates for the temperature and pressure of the system.

Owner:HALLIBURTON ENERGY SERVICES INC

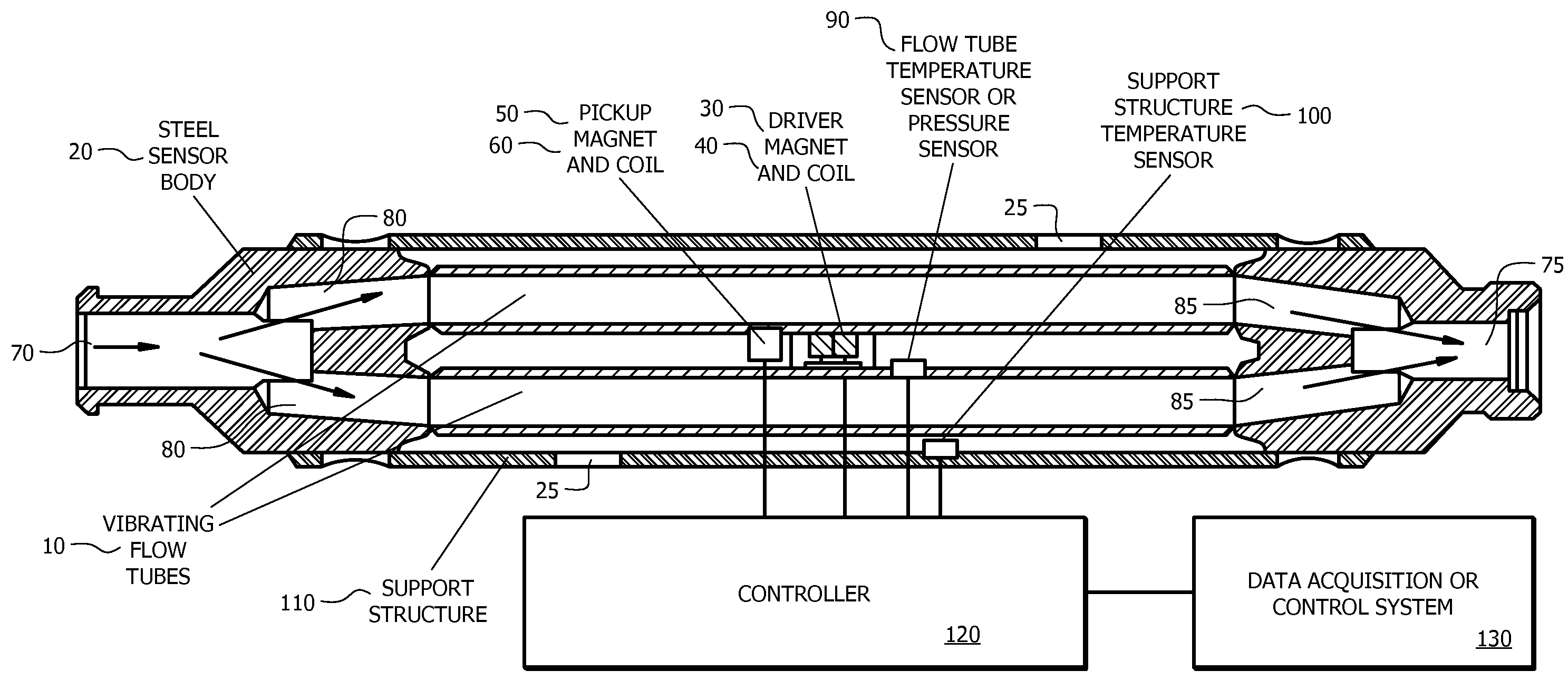

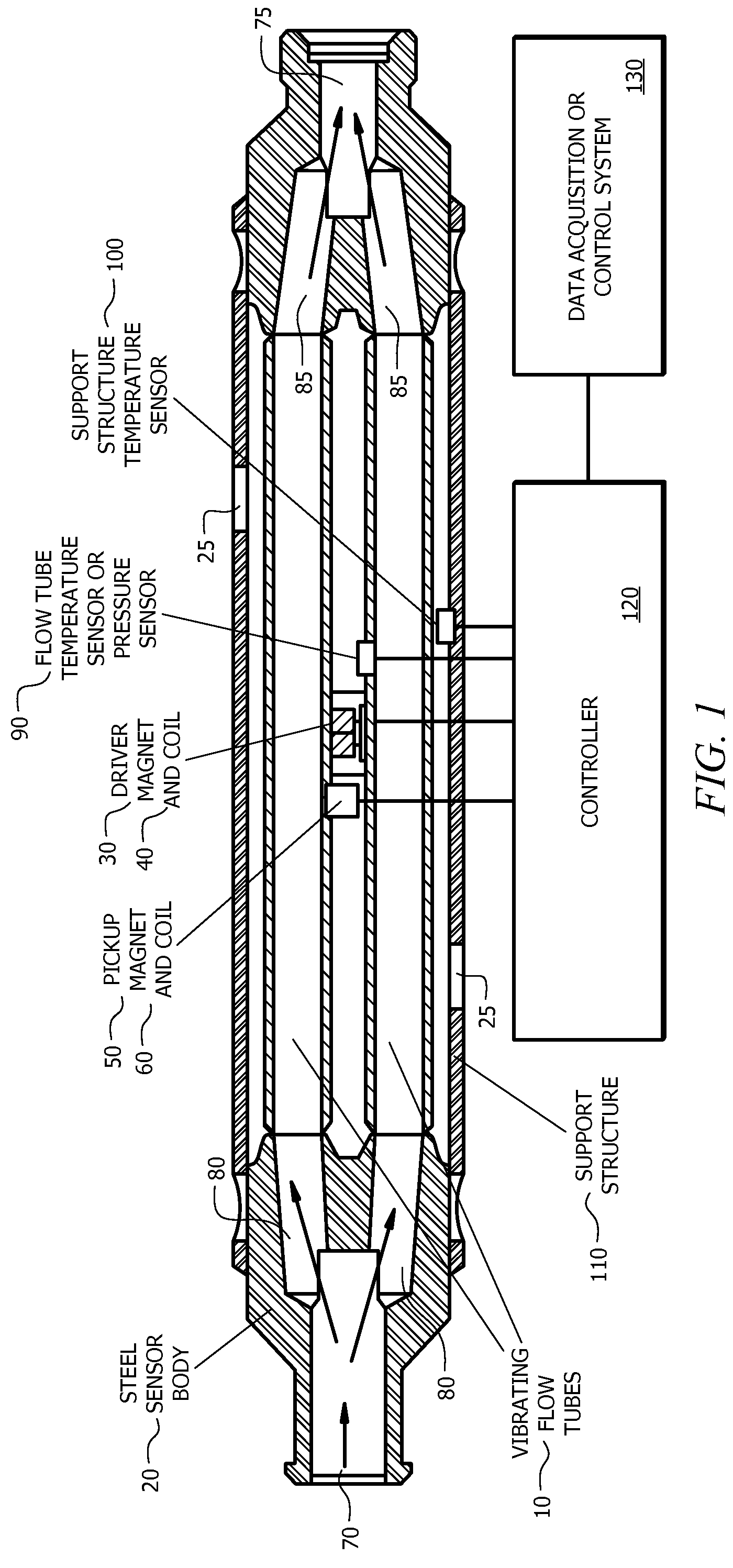

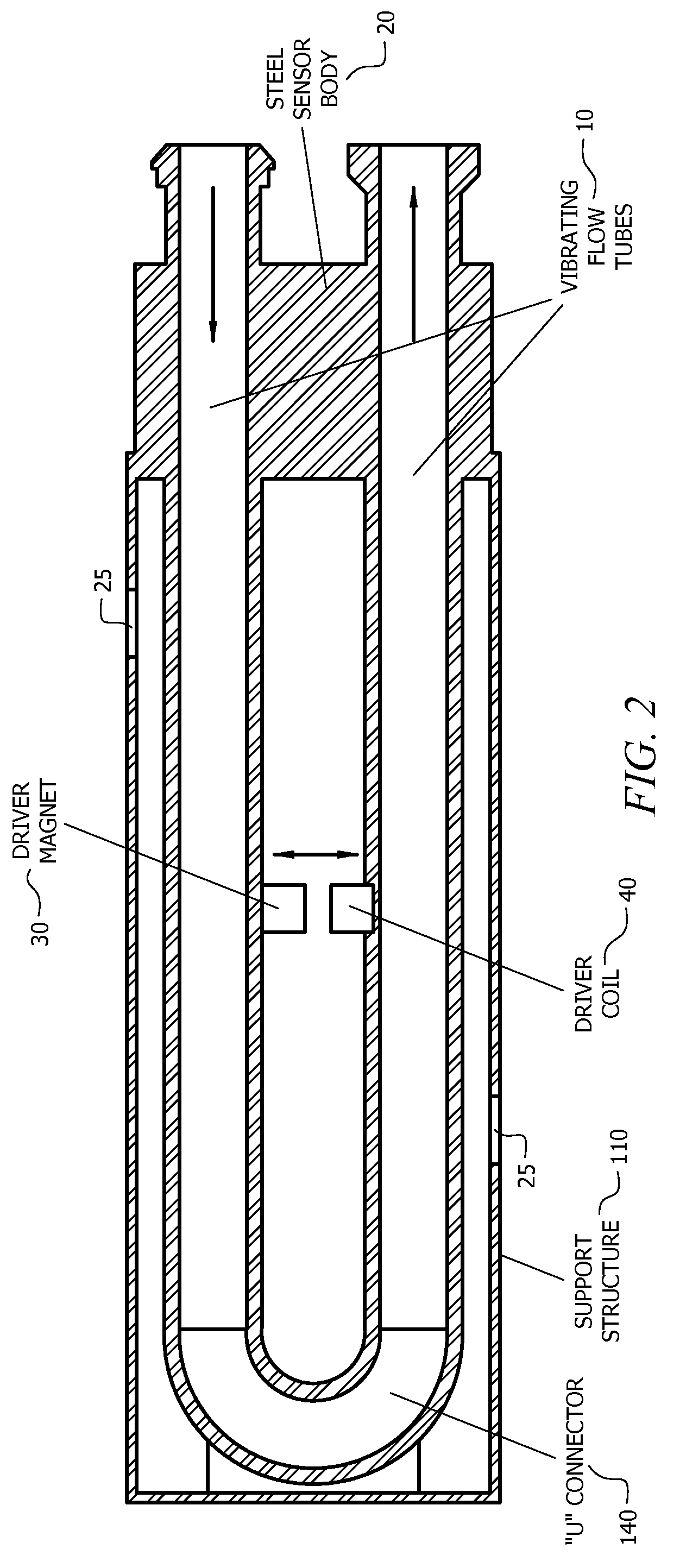

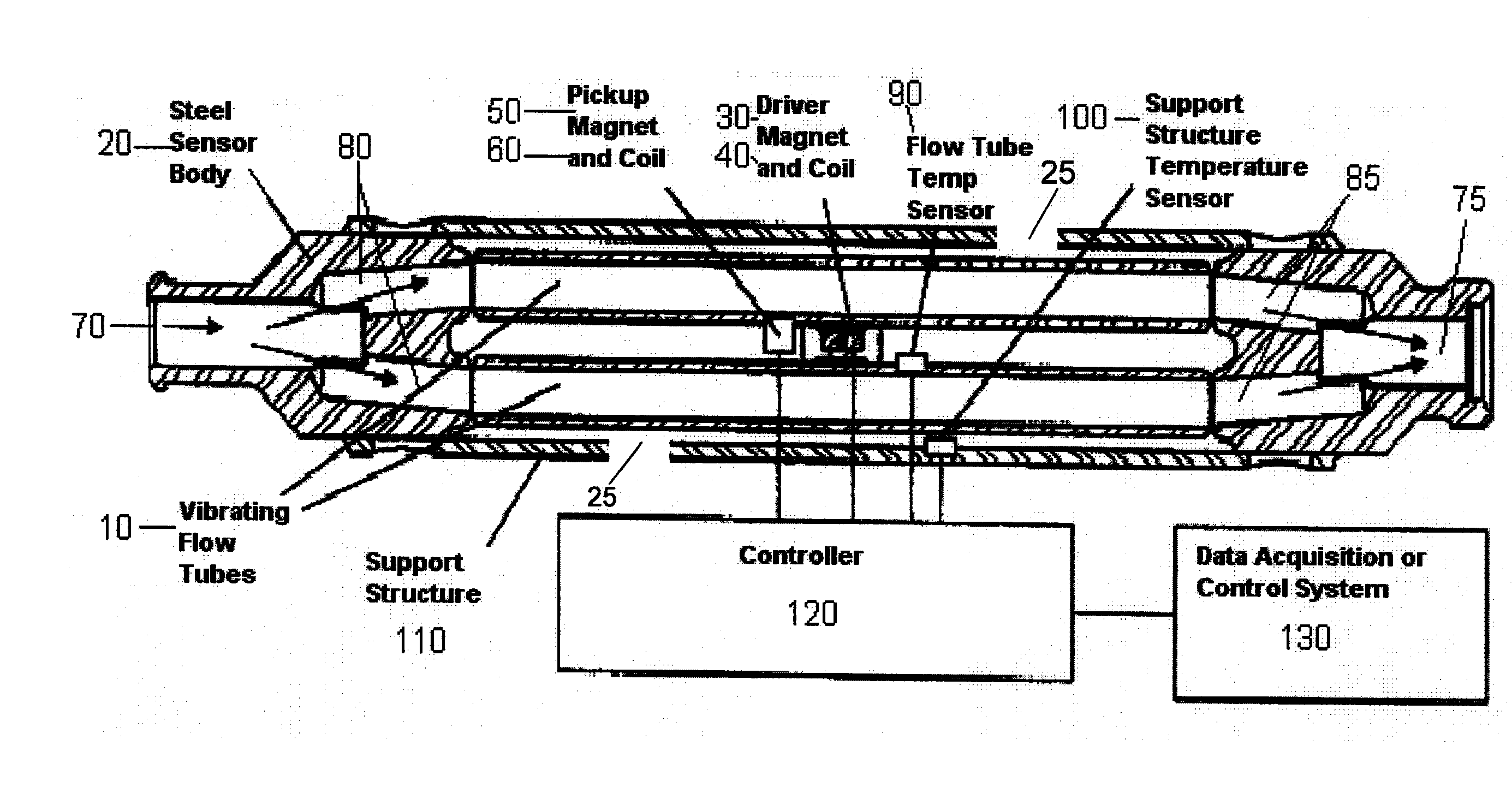

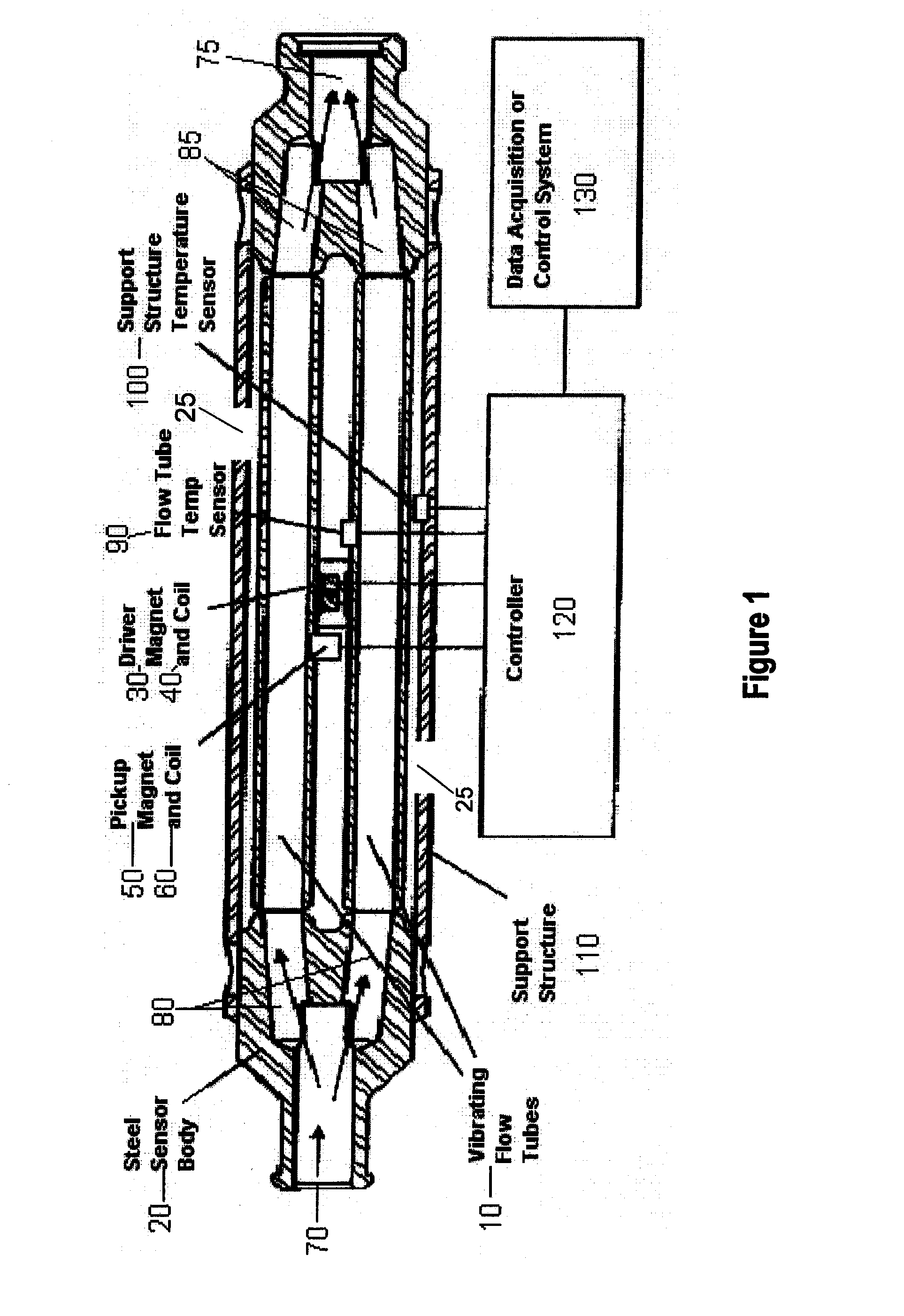

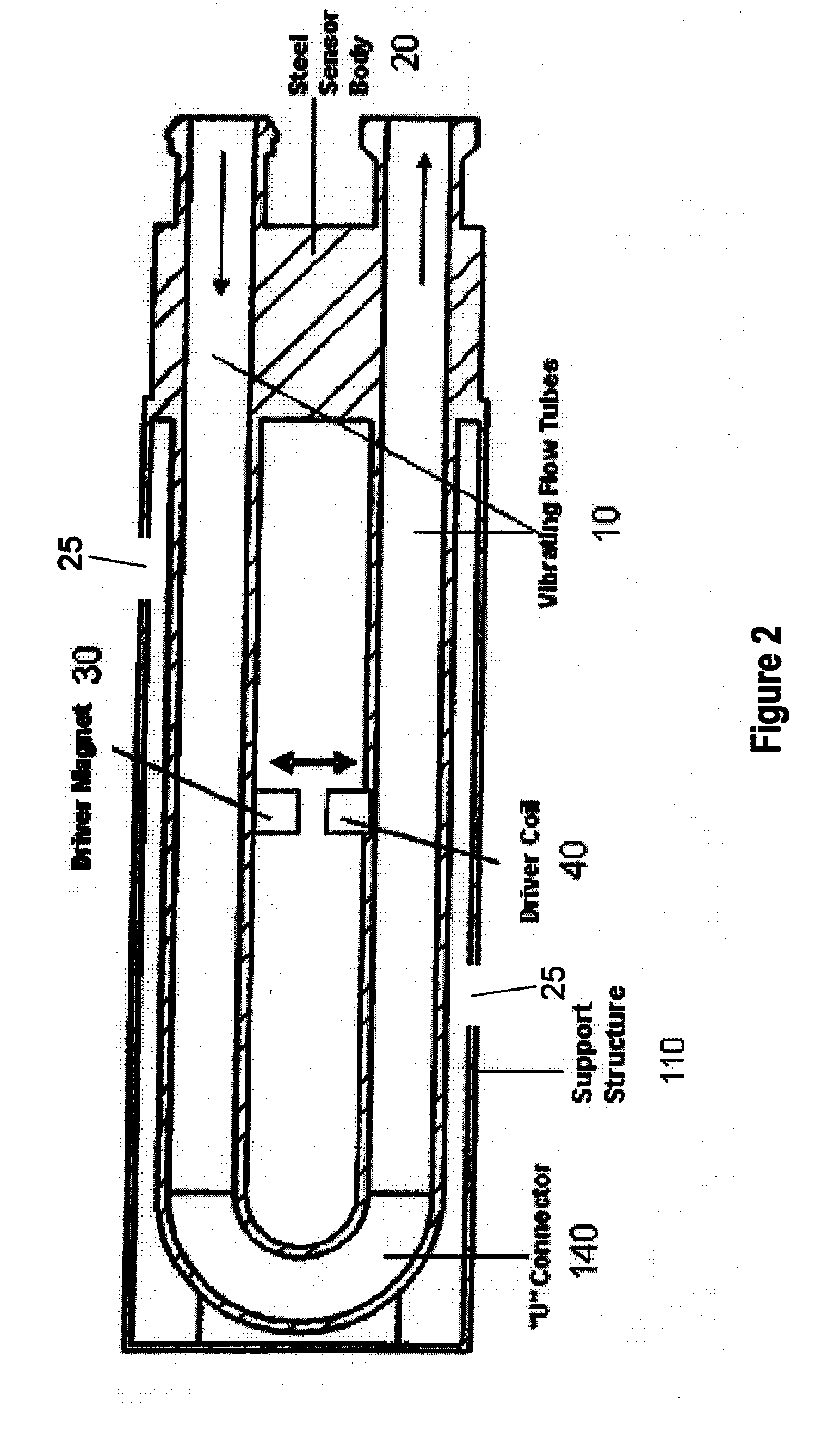

High pressure resonant vibrating-tube densitometer

A method of manufacturing a high pressure vibrating tube densitometer comprising enclosing twin flow tubes within an outer shell, wherein the outer shell comprises portals for the installation or replacement of internal components. A vibrating tube densitometer system for determining the density of a high pressure fluid in a pipeline, the system comprising a densitometer in communication with a controller, the densitometer comprising twin straight flow tubes spaced parallel apart within an outer shell comprising one or more portals for the placement of internal components, wherein the controller is in signal communication with a signal pickup, a tube driver, and the at least one temperature or pressure sensor and calculating the density of a fluid having a pressure of greater than 1500 psi.

Owner:HALLIBURTON ENERGY SERVICES INC

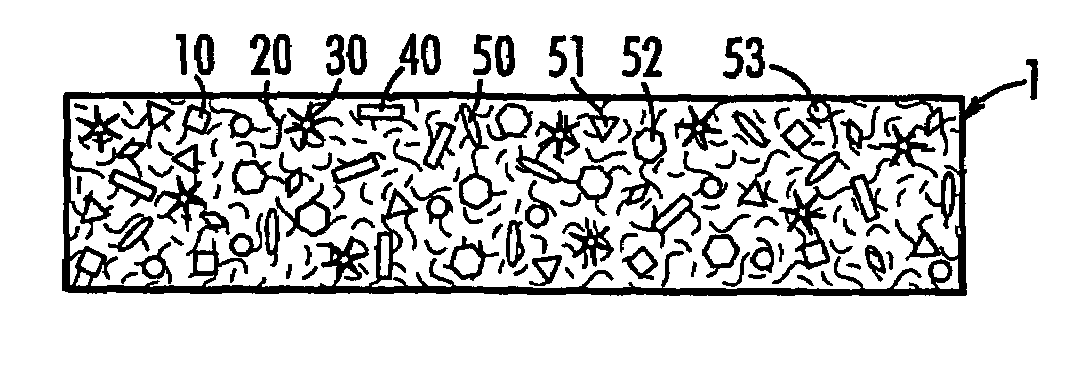

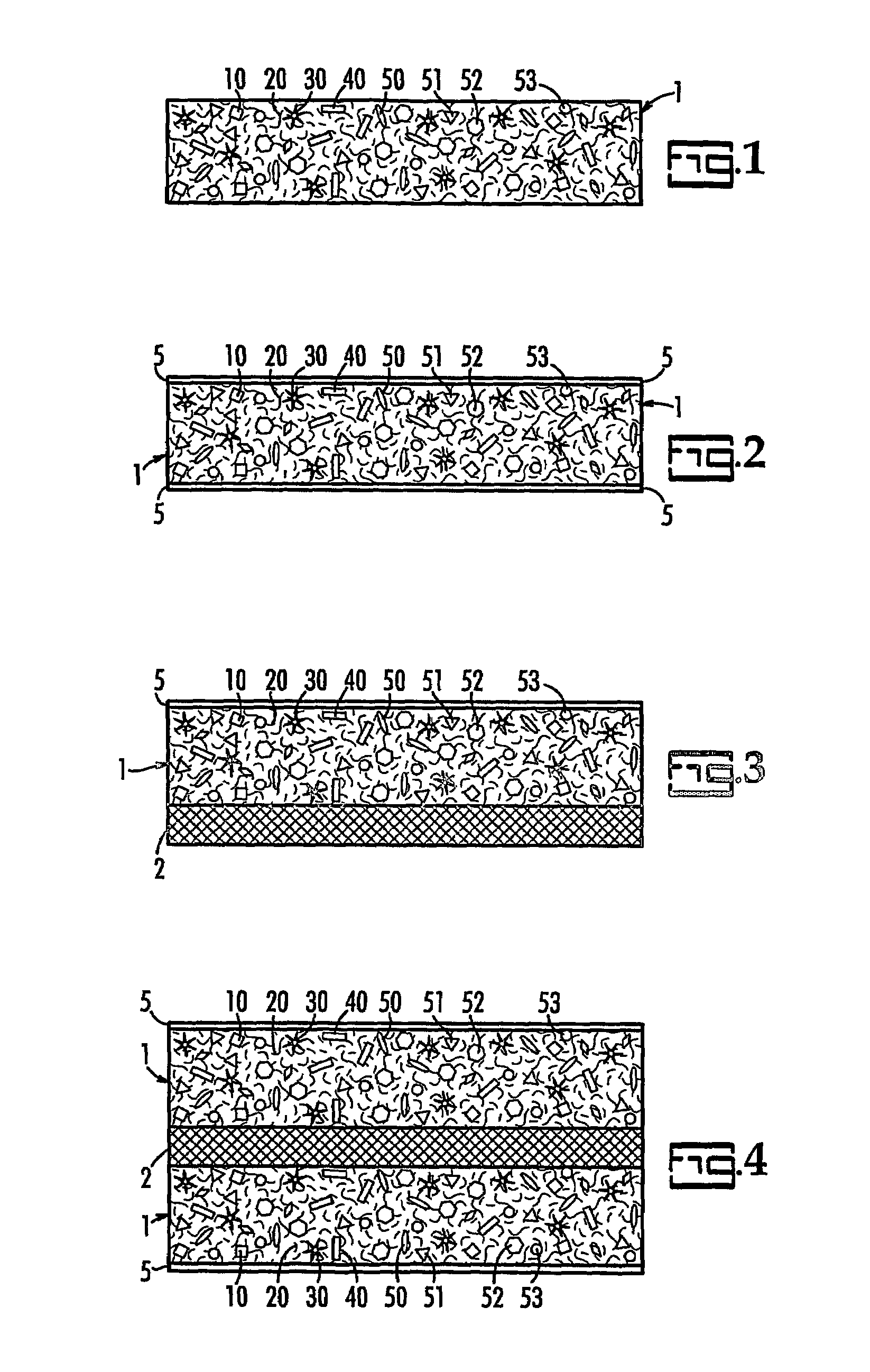

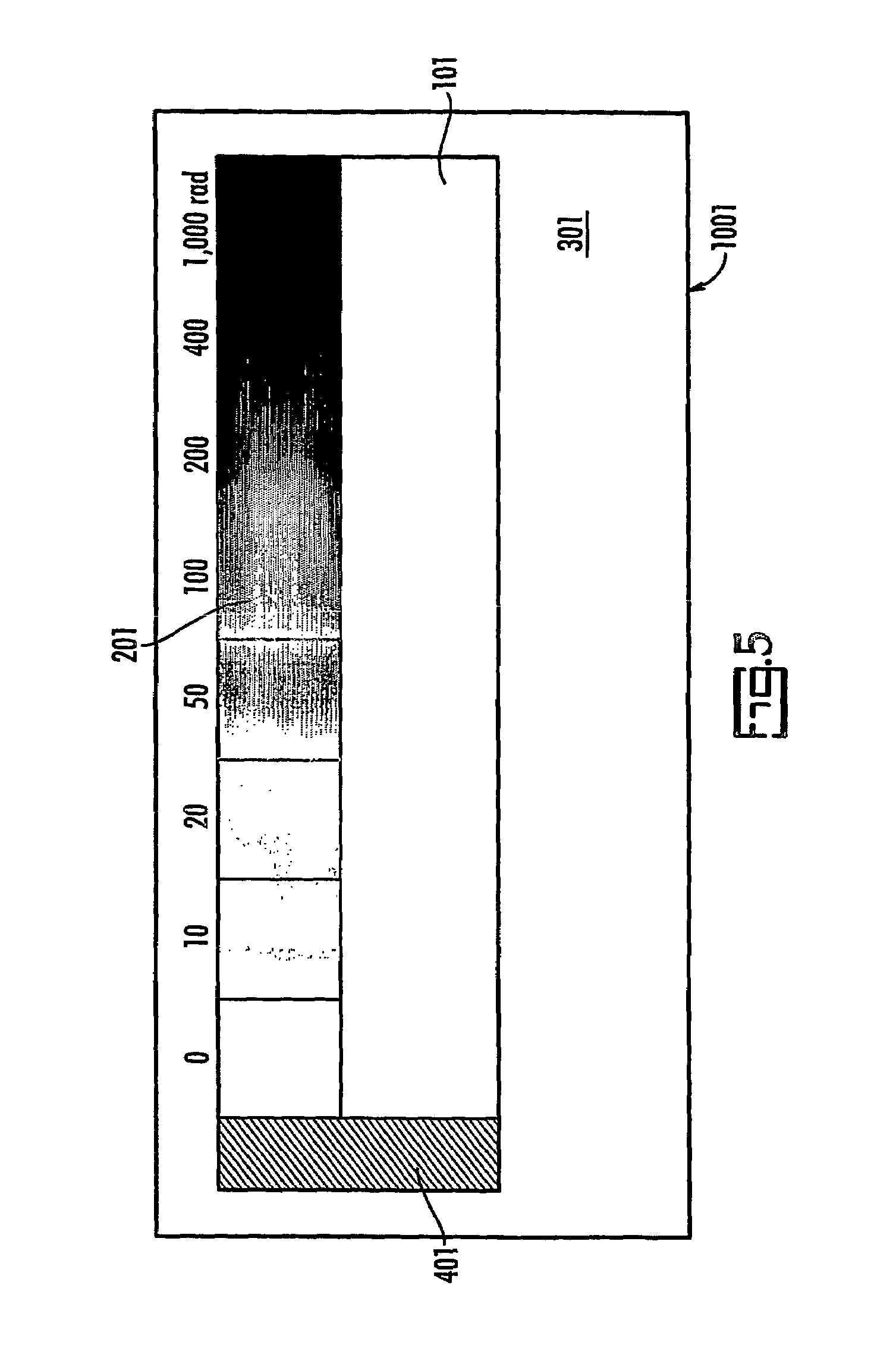

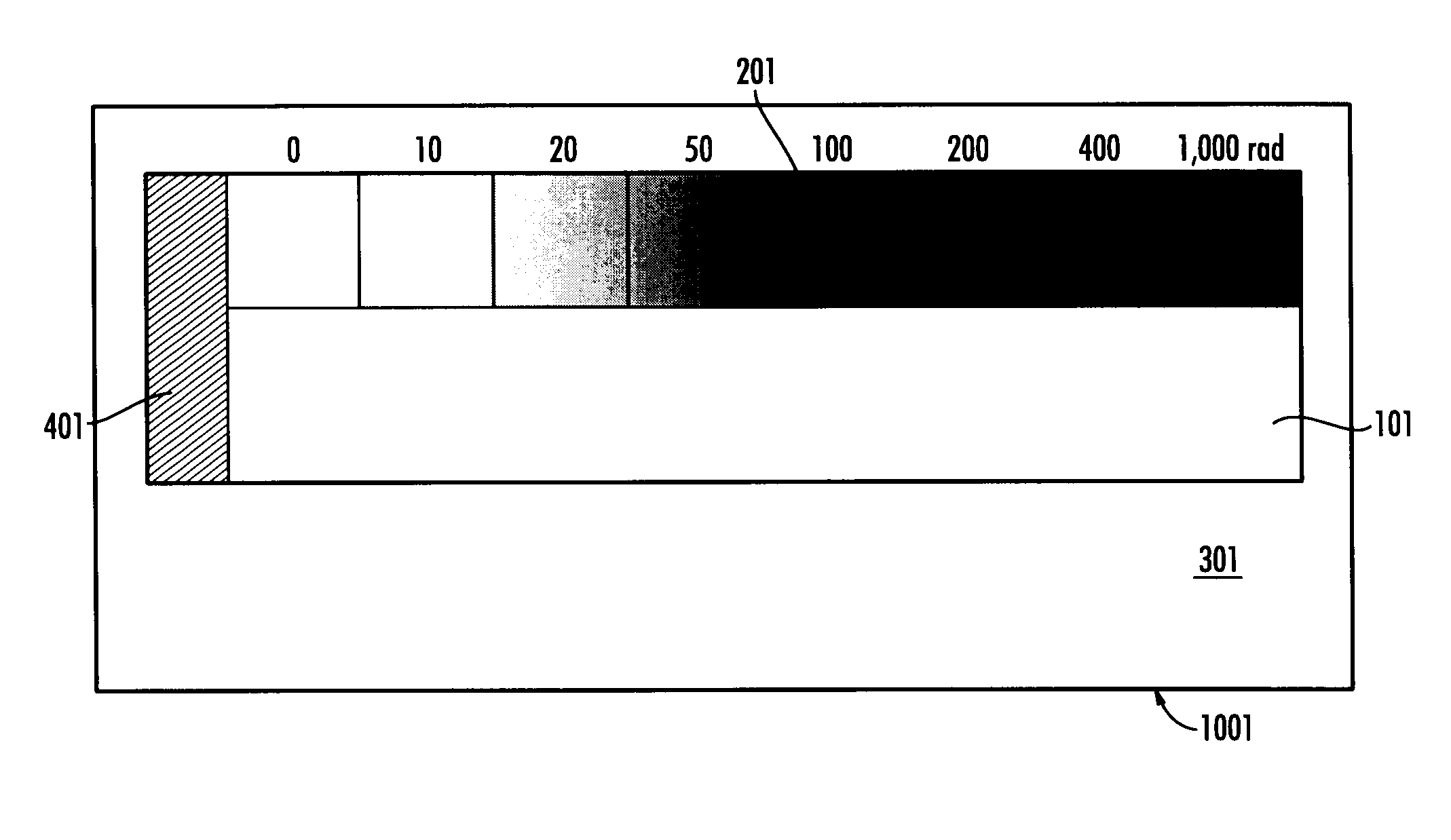

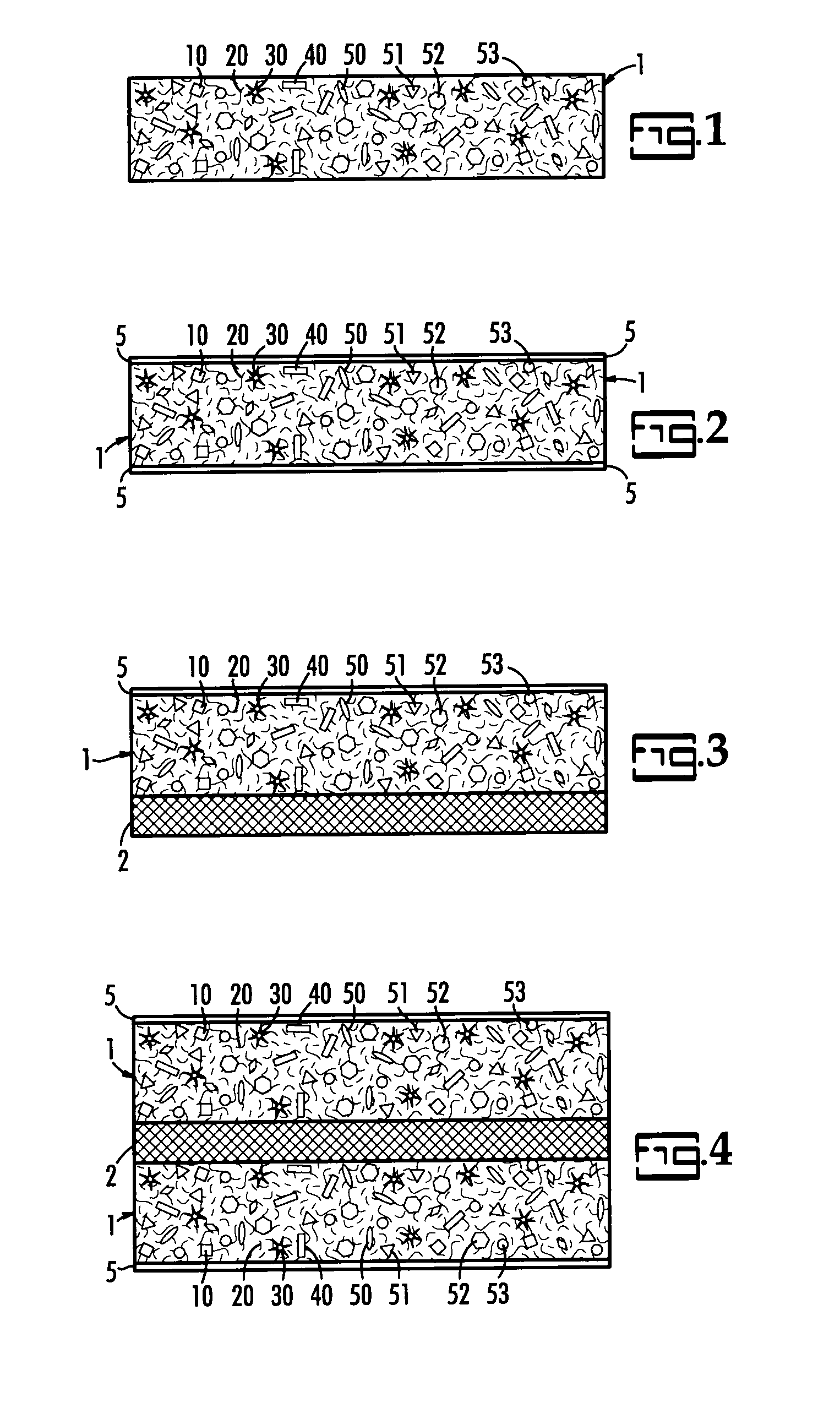

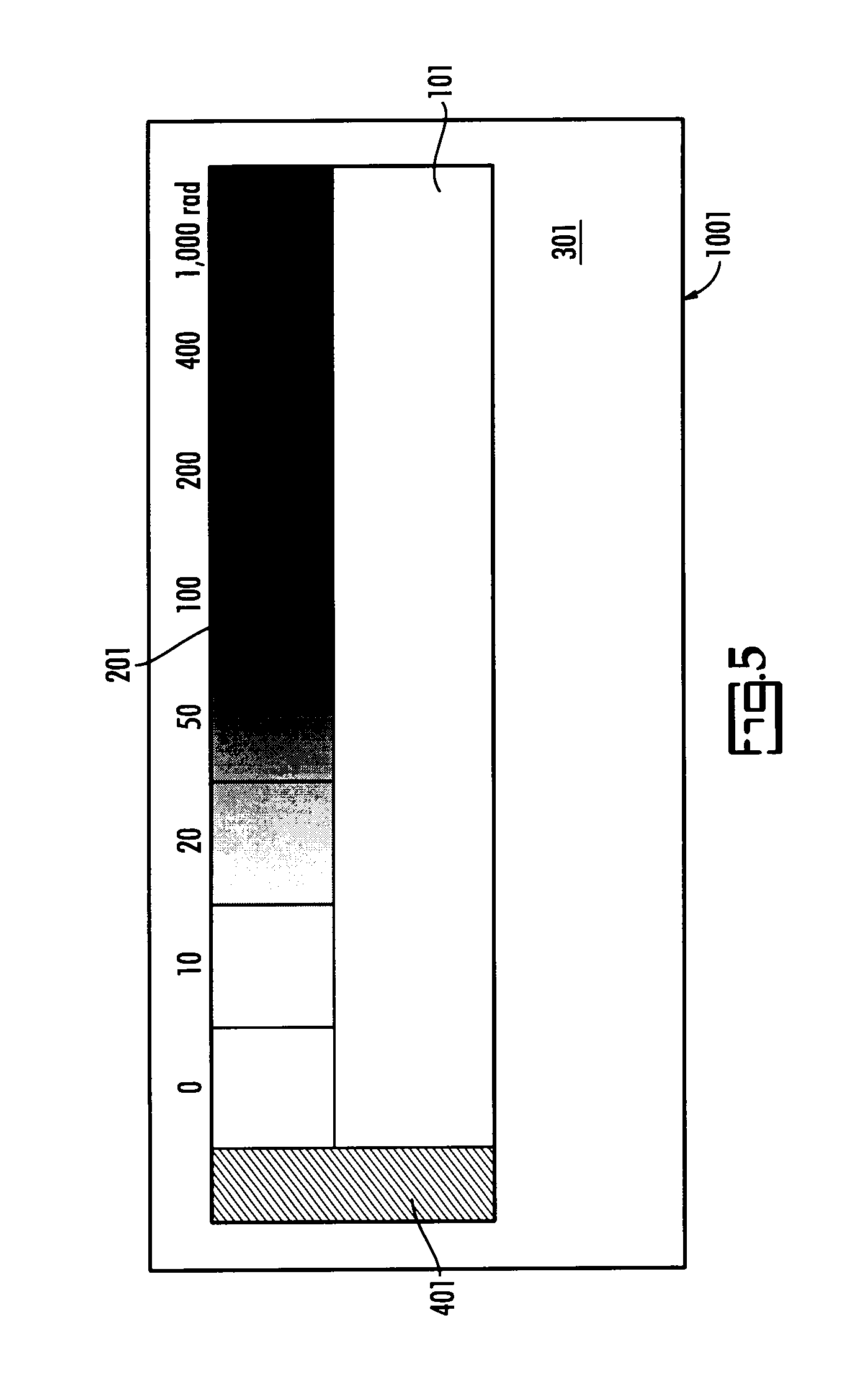

Self indicating radiation alert dosimeter

Described as a self-indicating instant radiation dosimeter (1001) for monitoring high energy radiations, such as X-ray. The dosimeter contains a radiation sensitive, color changing, indicating composition (10), e.g., a diacetylene (R—C≡C—C≡C—R′, where R and R′ are substituents groups) or a radiochromic dye, a polymeric binder (20) and optionally a shelf life extender (50) or an activator (40). The radiation sensitive composition (10) changes color instantly when exposed to high energy radiation. The dose is estimated by comparing the color with a color reference chart or more accurately with a spectrophotometer or an optical densitometer. The radiation sensitive composition (10) is protected from low energy radiation such as UV light, by a layer of low energy absorbing materials, such as UV absorbers.

Owner:JP LAB INC

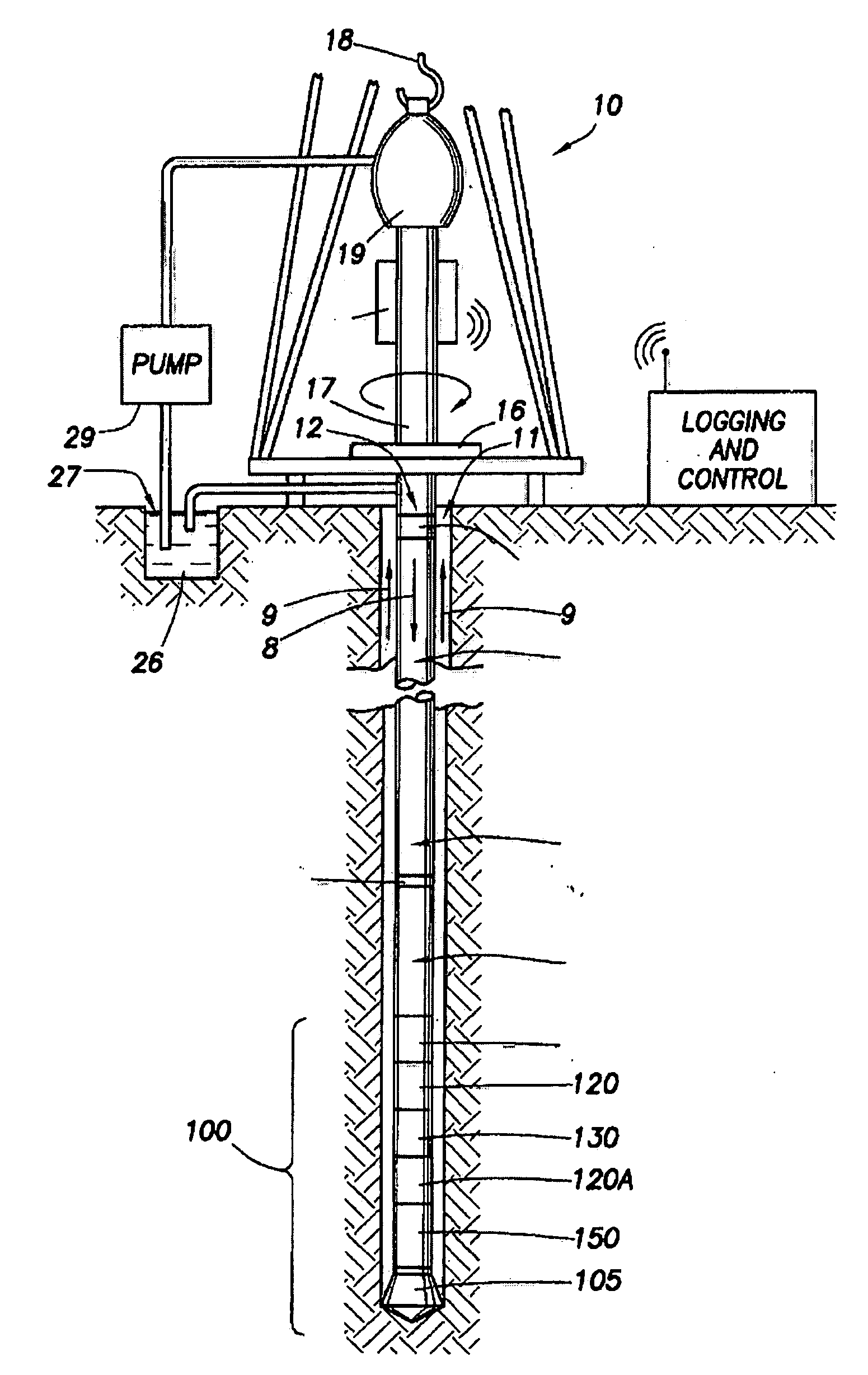

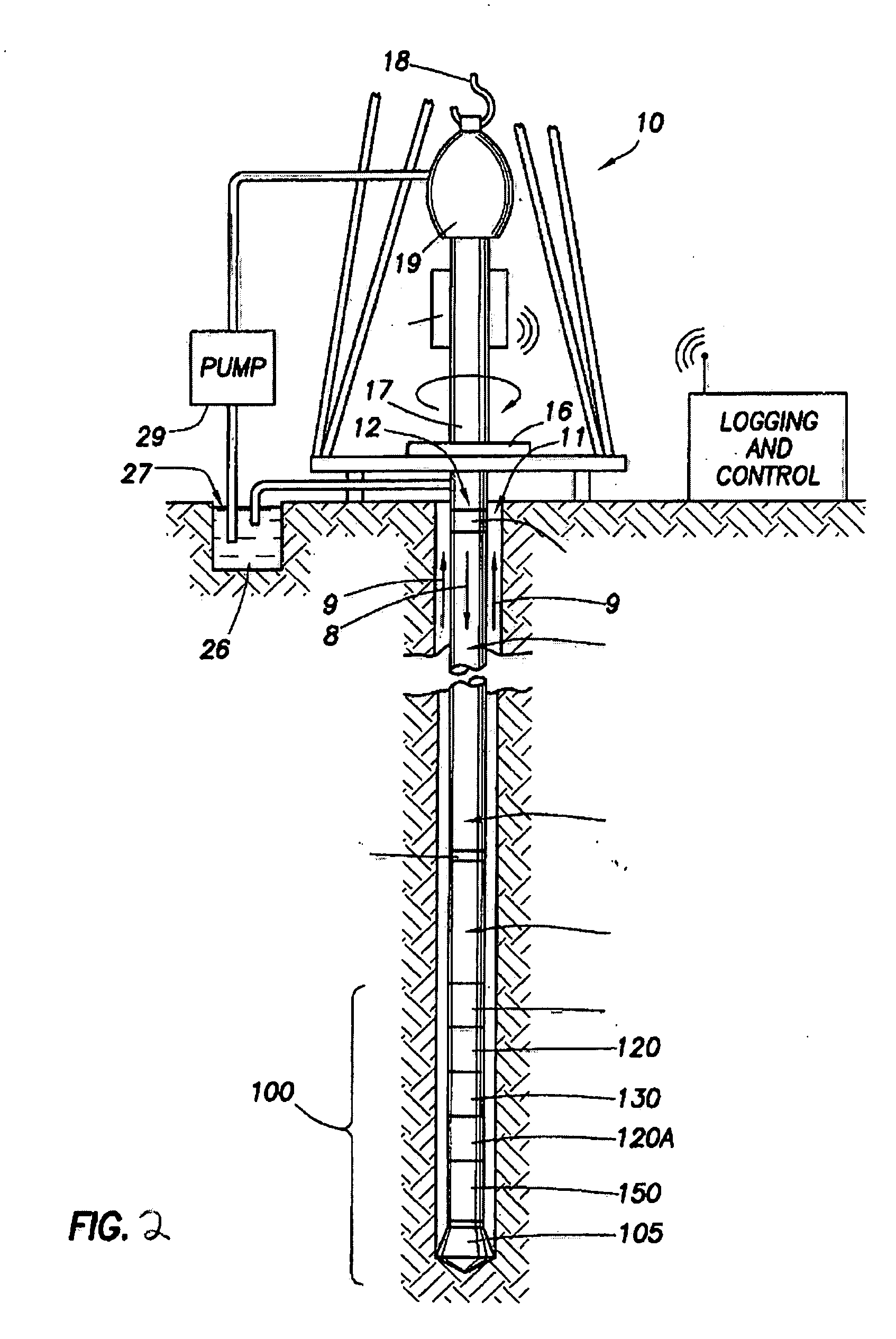

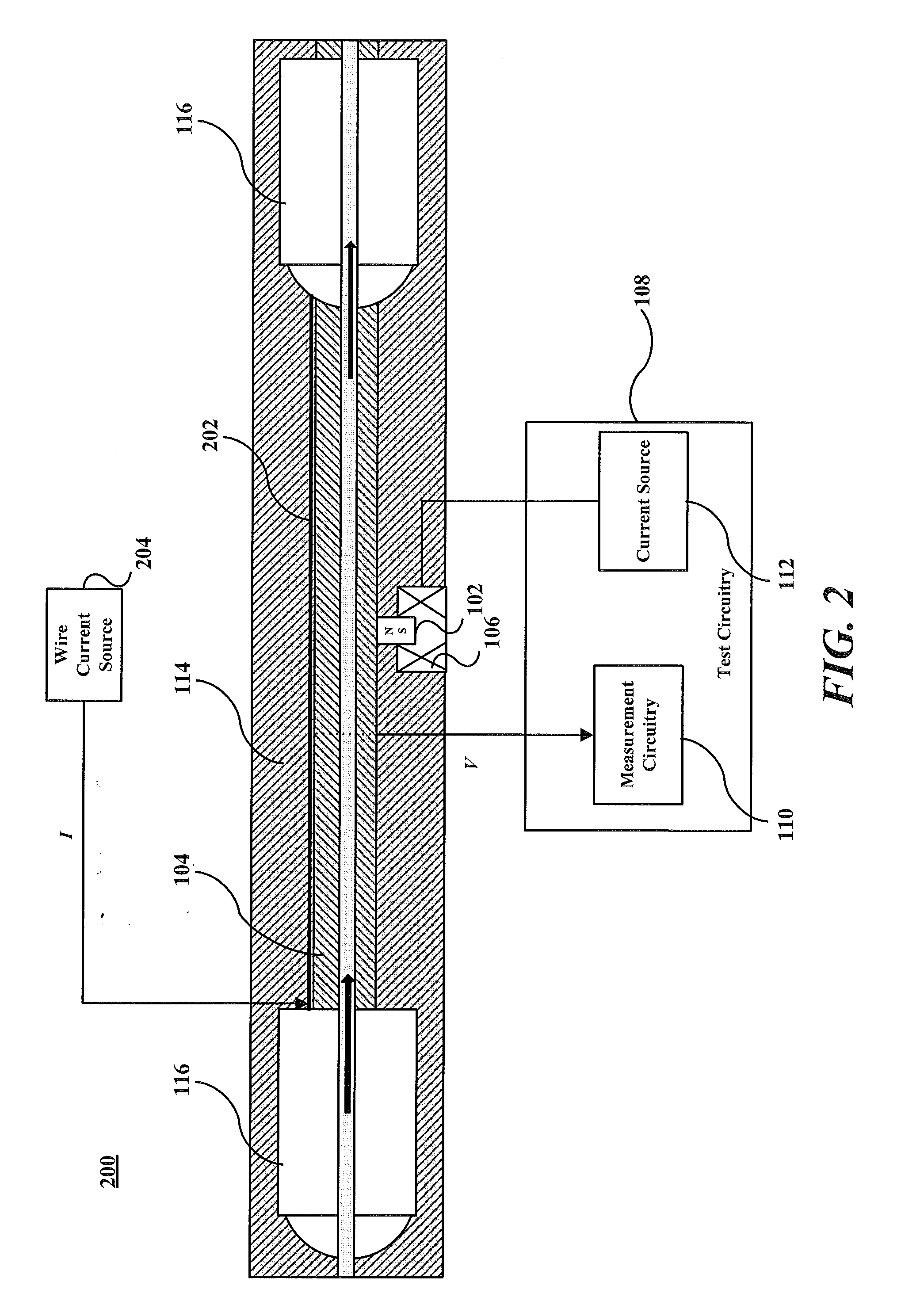

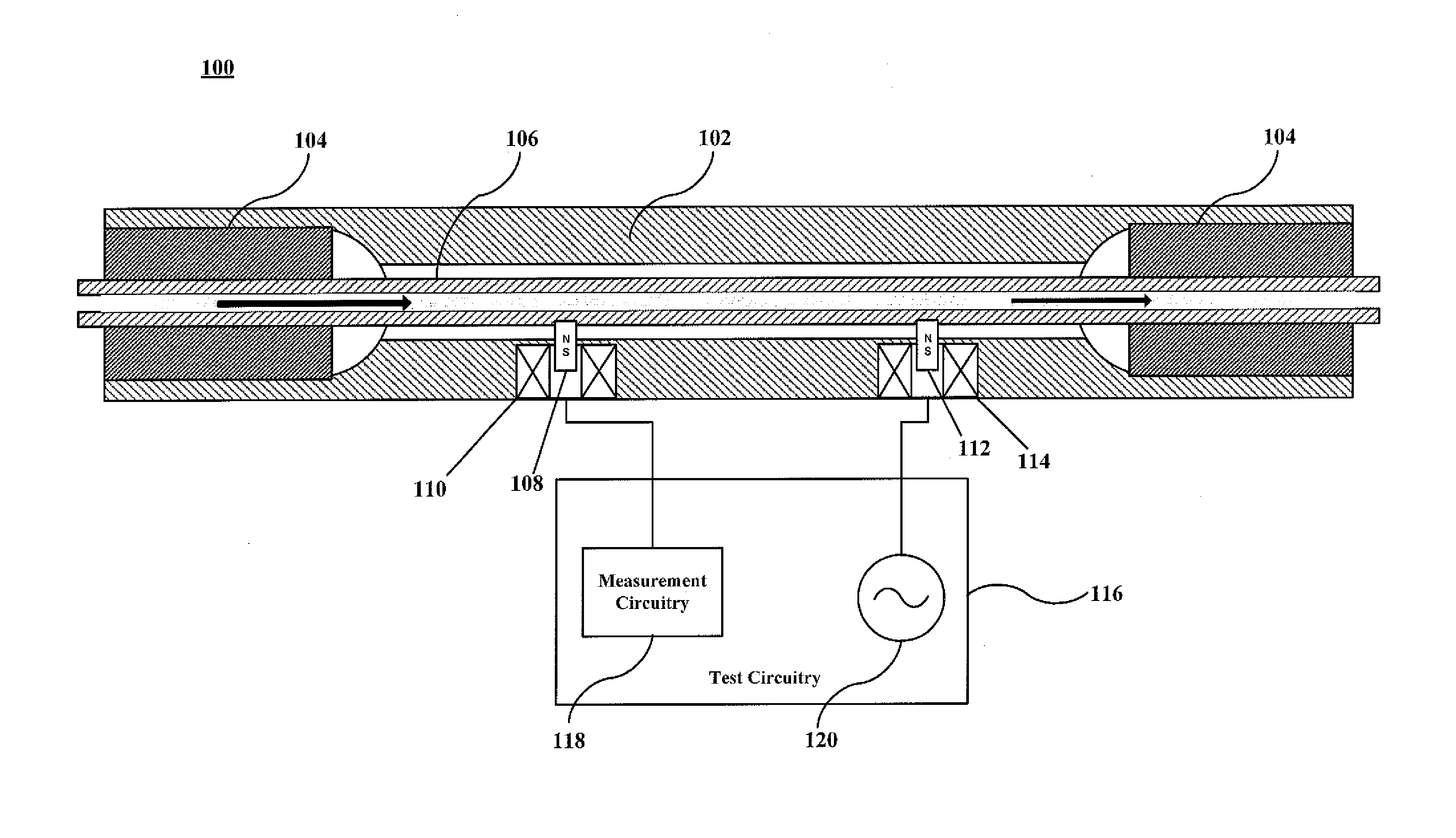

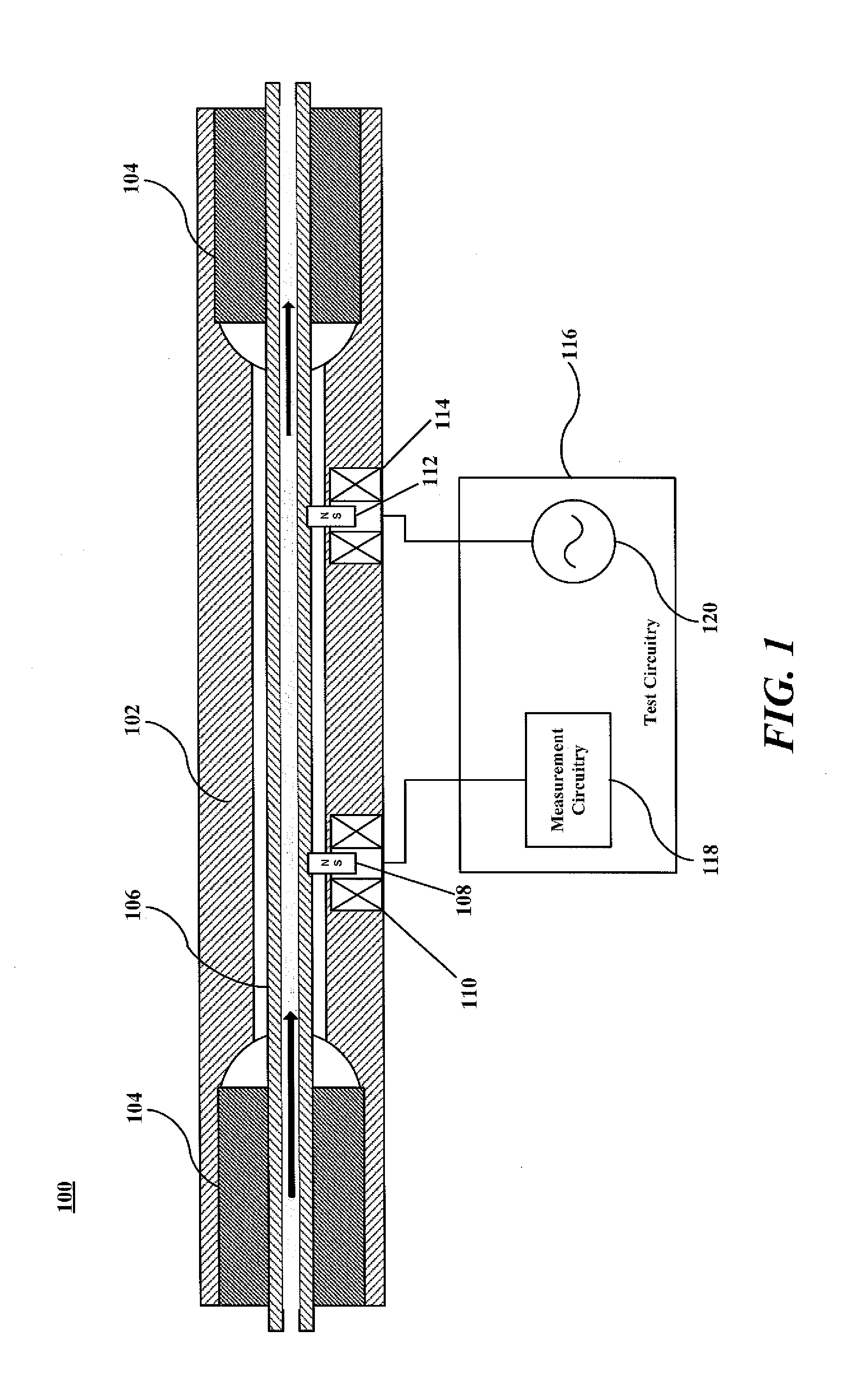

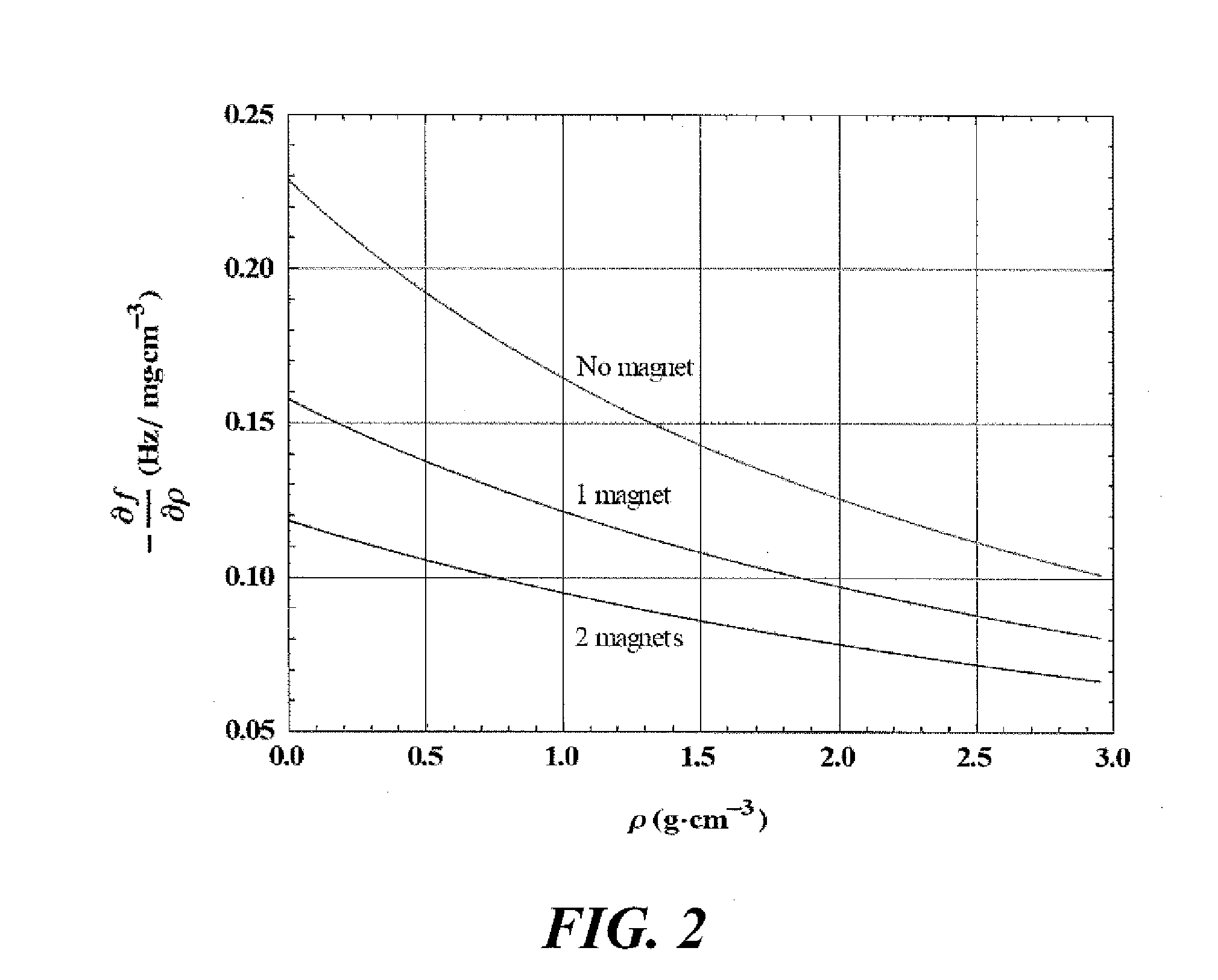

Microfluidic oscillating tube densitometer for downhole applications

ActiveUS20100268469A1Accurately fluid densityQuantity minimizationVibration measurement in solidsResonant frequencyAcousticsAOD use frequency

Devices, methods and systems for determining one or more properties of at least one fluid sample. A tube configured to receive the at least one fluid sample wherein the tube is placed in a pressure housing. Further, an excitation source configured to generate vibration of the tube whereby a circulation of an electrical current along a portion of the tube is subjected to at least one magnetic field produced by at least one magnet. Further still, at least one vibration sensor that converts vibrations of the tube into a measurement signal. Finally, a processor that receives the measurement signal determines a resonant frequency from the measurement signal using a frequency measuring device to determine a property of the one or more properties of the at least one sample fluid.

Owner:SCHLUMBERGER TECH CORP

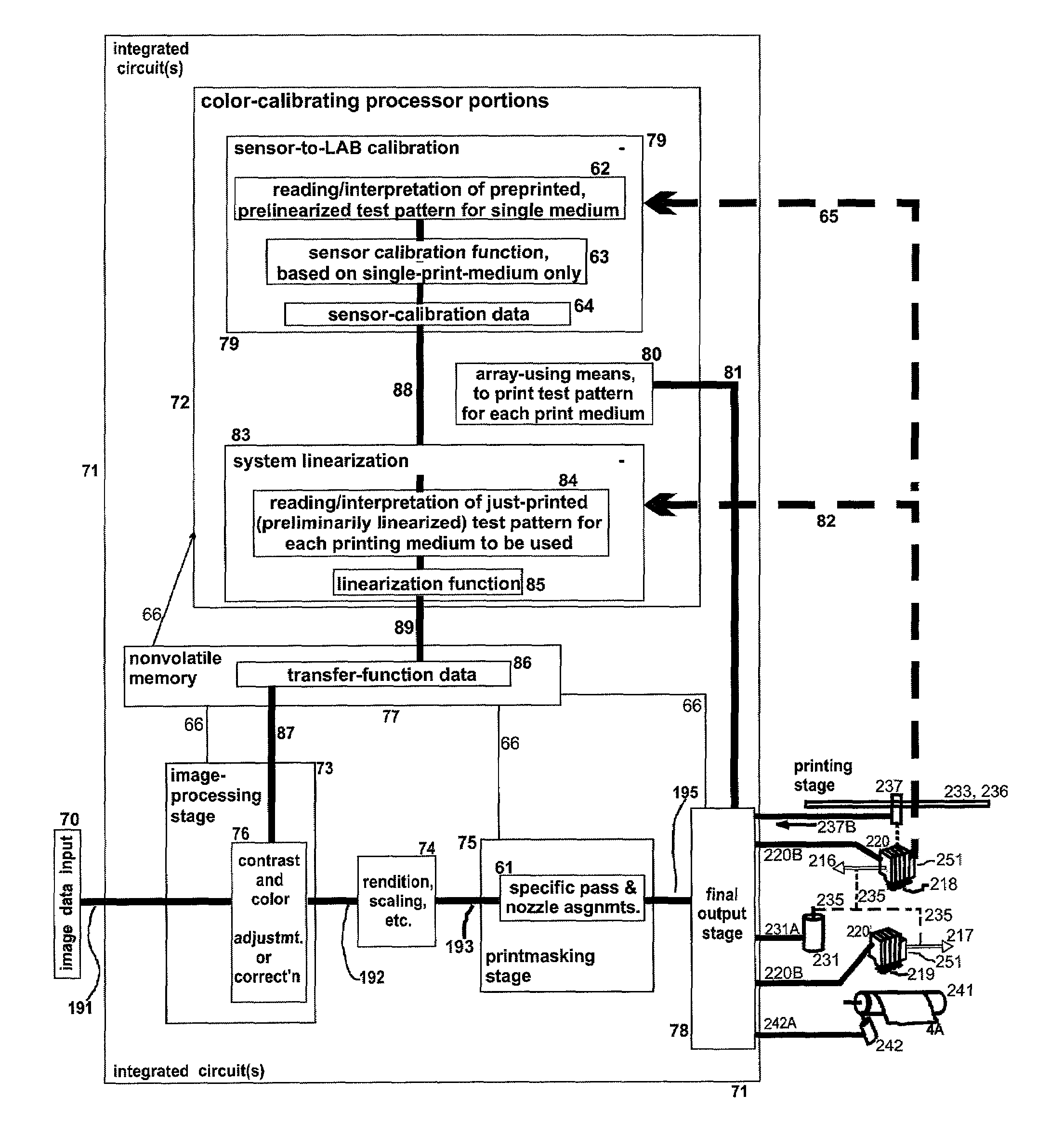

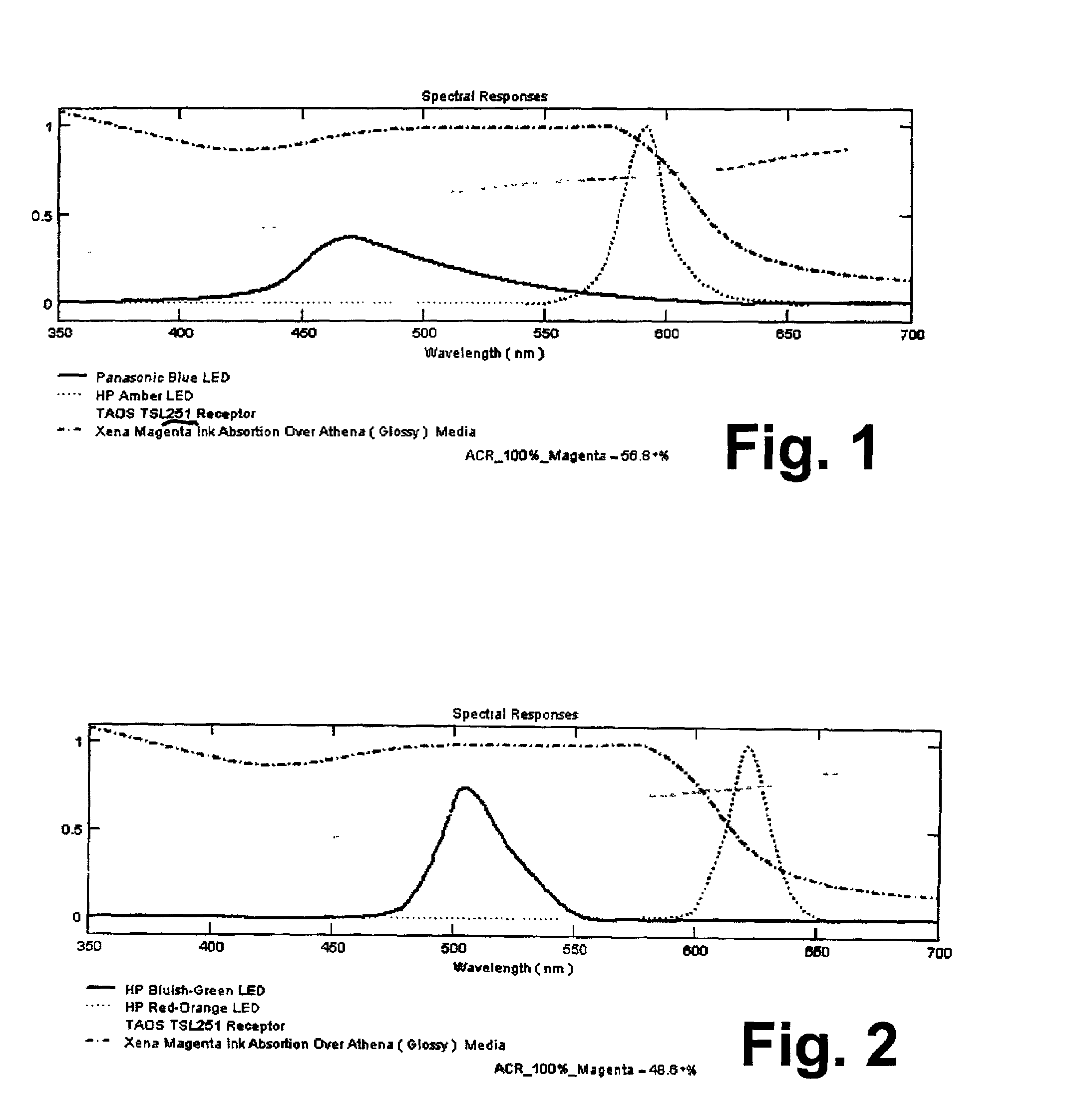

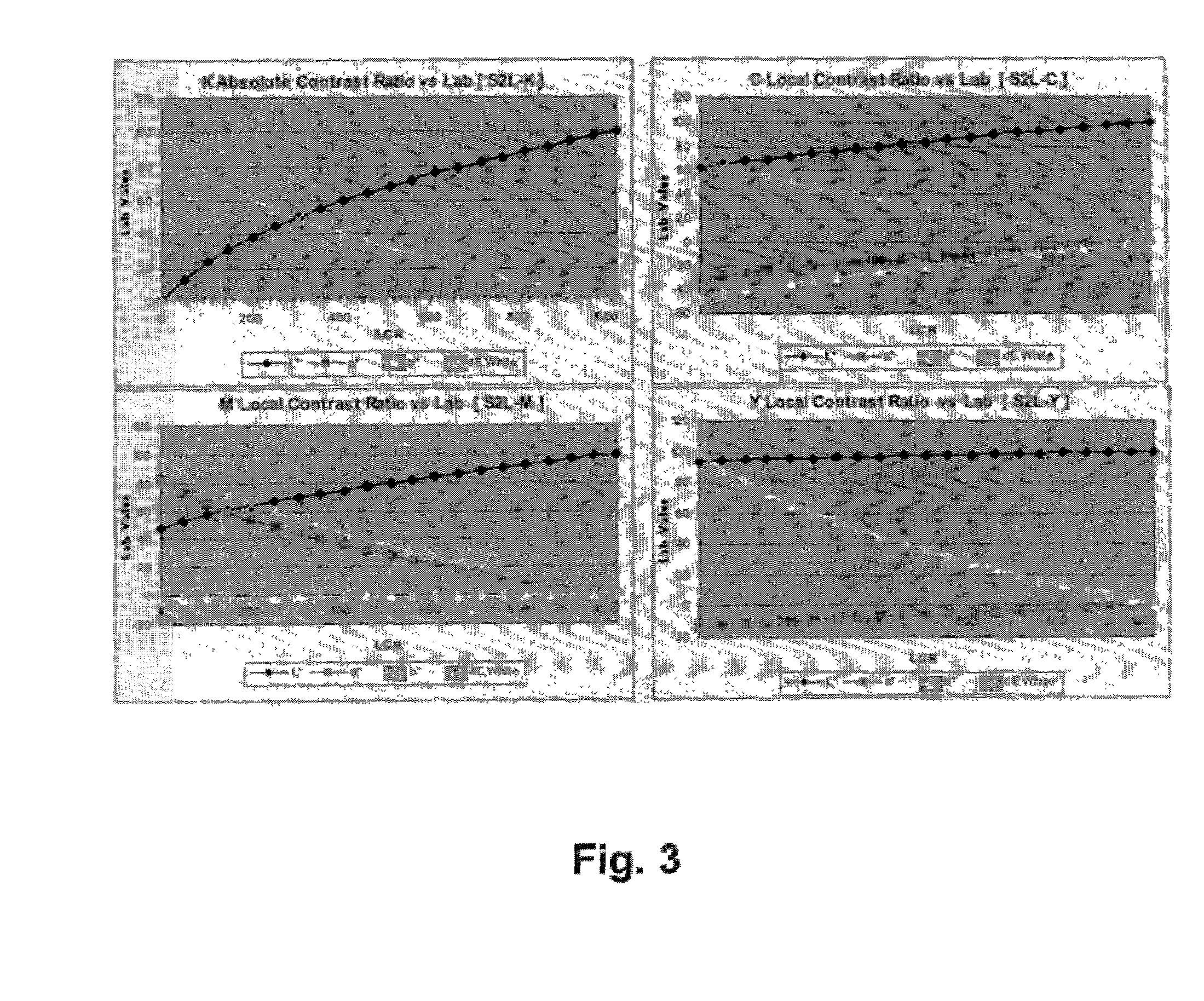

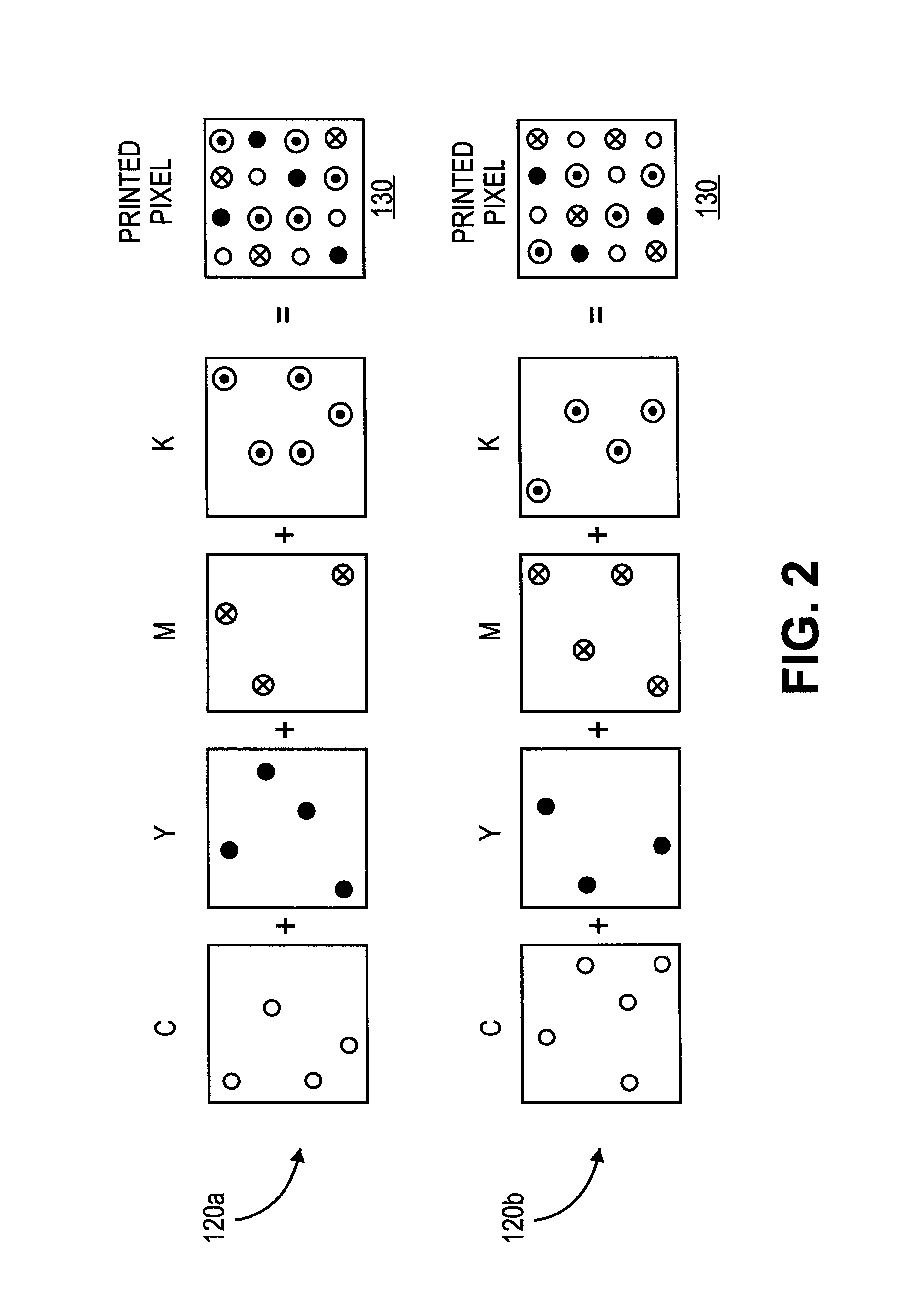

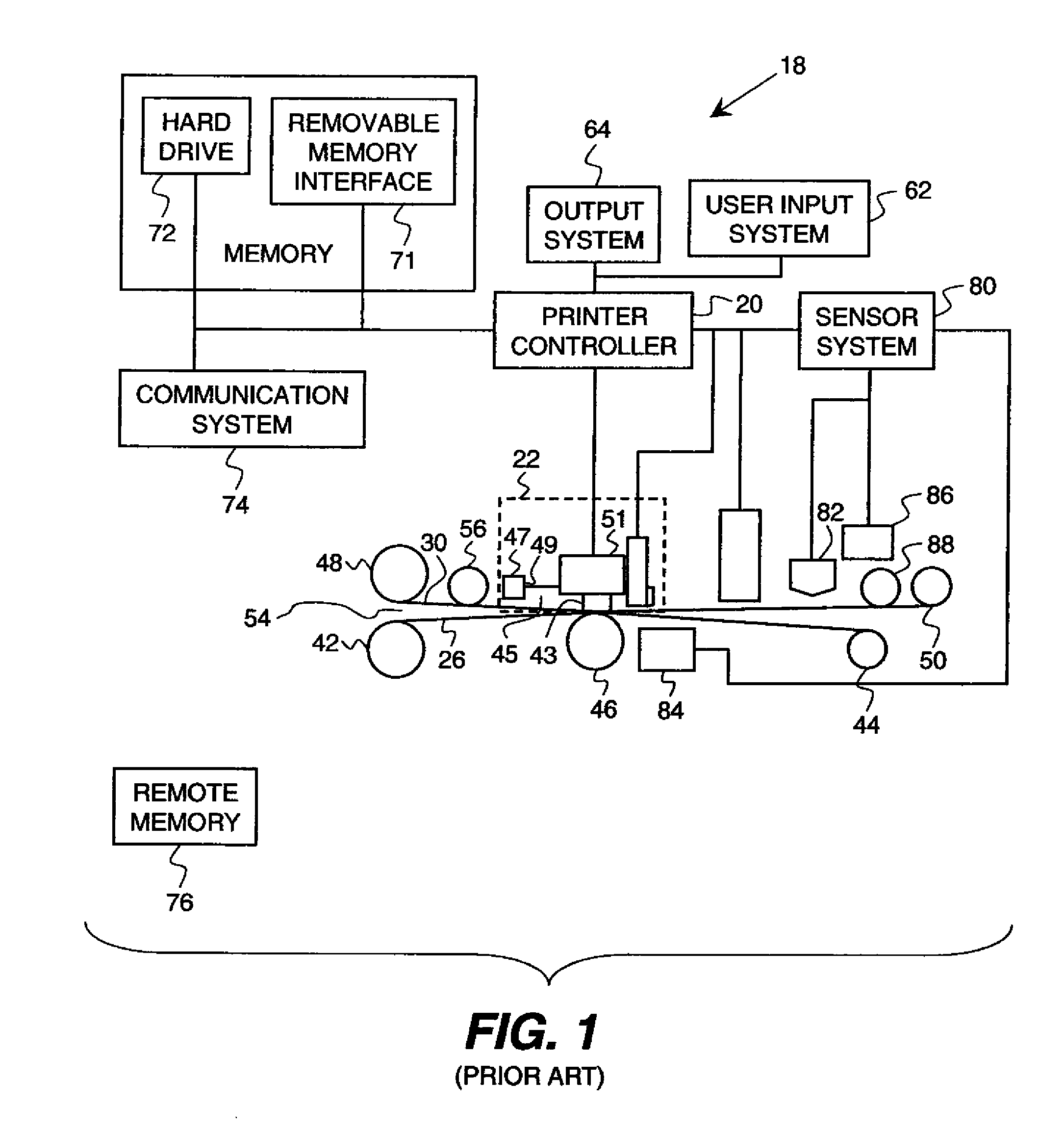

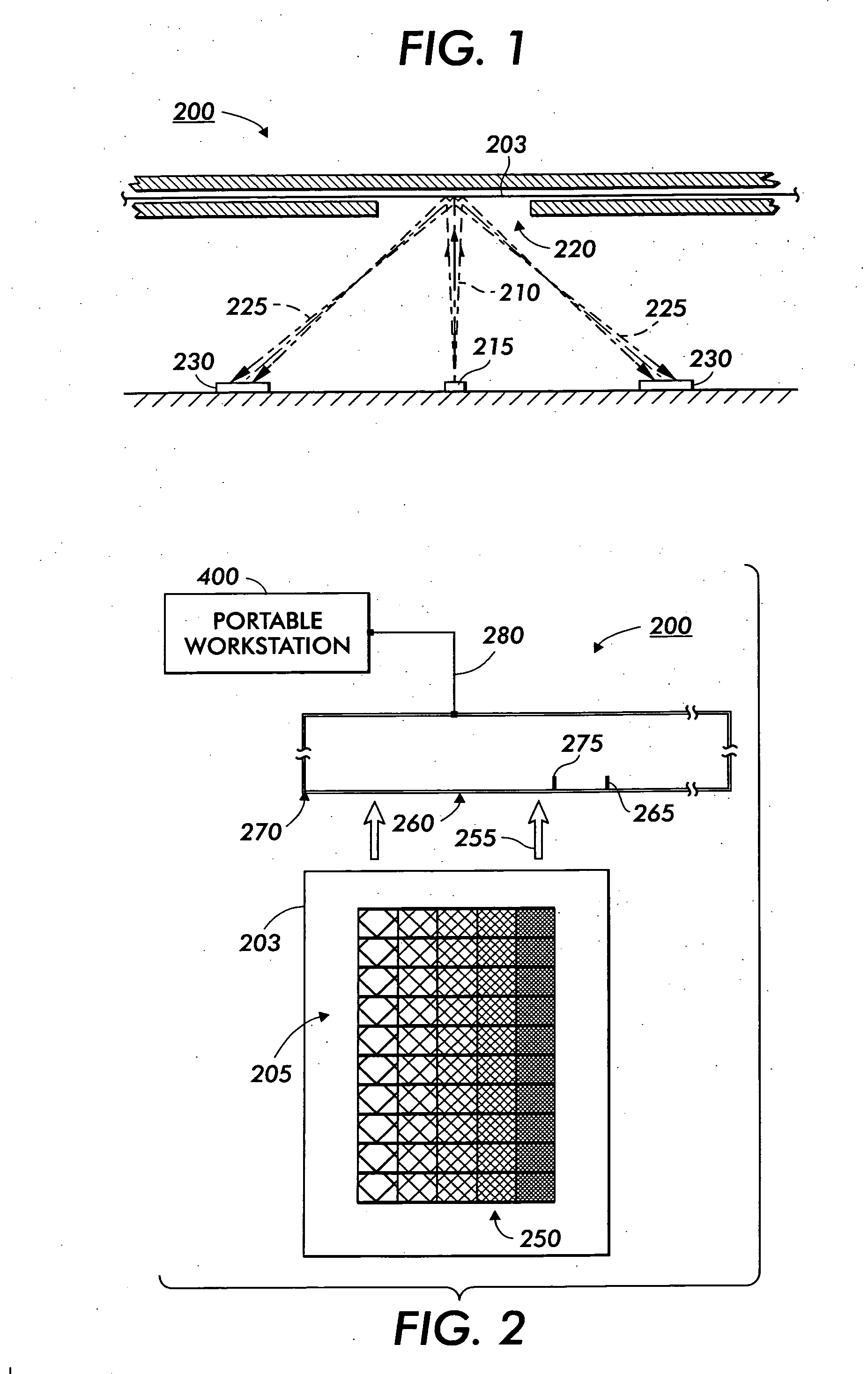

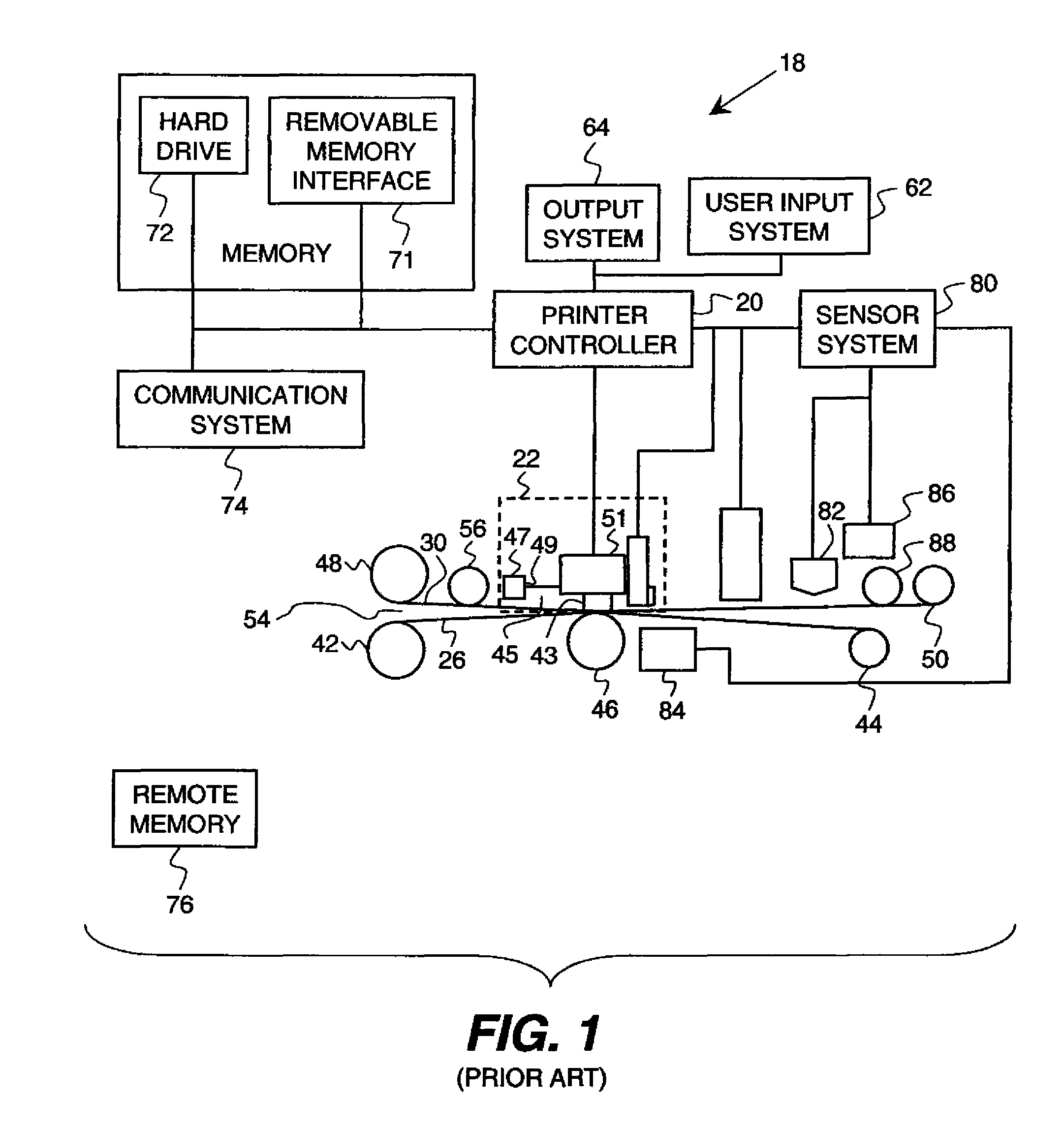

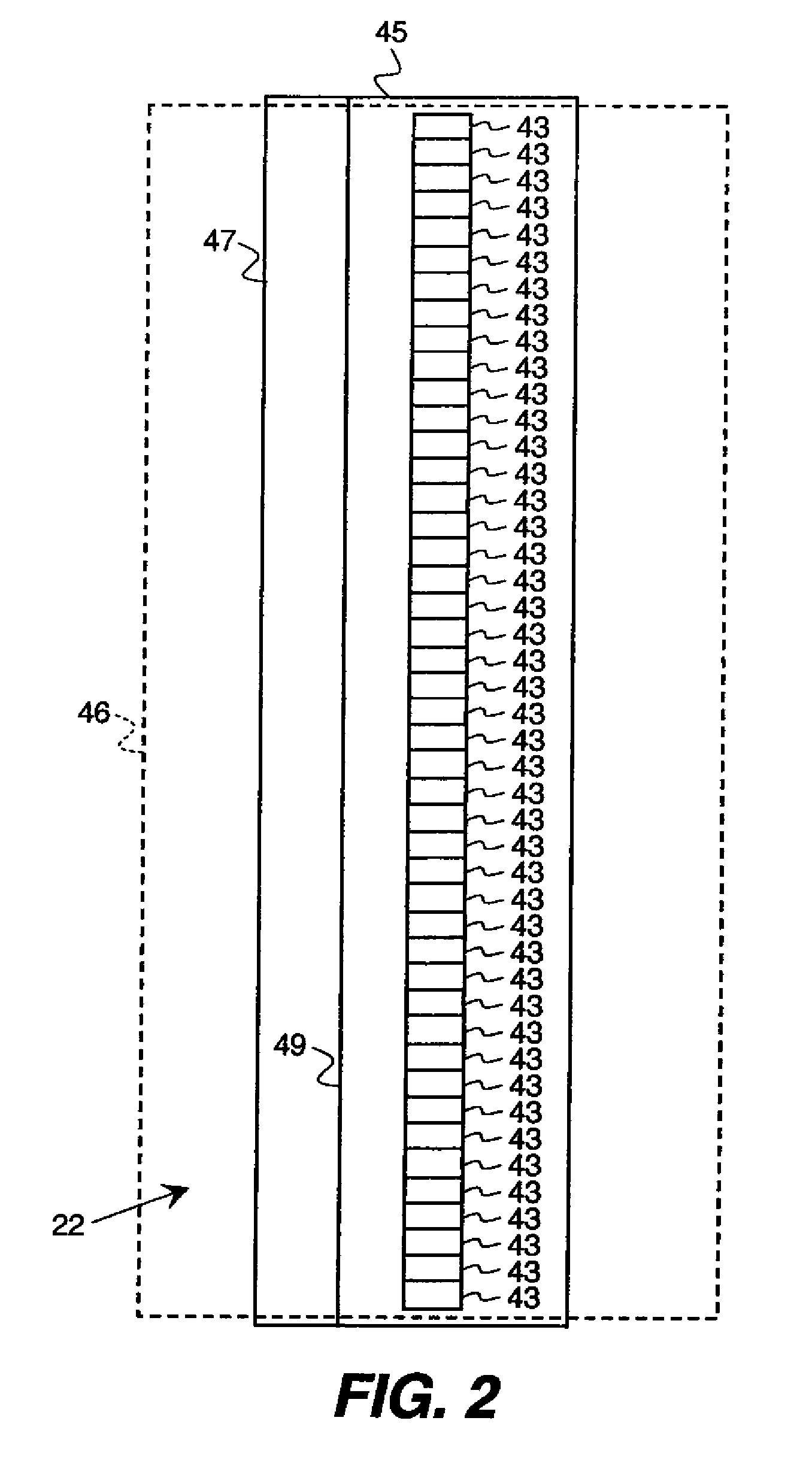

Linearization of an incremental printer by measurements referred to a media-independent sensor calibration

ActiveUS7027185B2Easy CalibrationAvoid necessityDigitally marking record carriersDigital computer detailsLine sensorPrint media

A printing system is linearized automatically using measurements made with a simple optical sensor, such as a line sensor, that is onboard the system. The printing system itself is for forming images on plural printing media. Because the optical sensor is not a calorimeter or even a true densitometer, the sensor requires calibration, preferably based upon measurements using real inks. In the past it has been considered a requirement that such calibration be performed separately using each of the print media that was to be used for printing images. Linearization according to the invention, however, refers to a single calibration of the sensor, that calibration being used in common for essentially all media—even though the single calibration is performed with respect to exclusively a single one of the plural media.

Owner:HEWLETT PACKARD DEV CO LP

Personal and area self-indicating radiation alert dosimeter

Described is a self-indicating instant radiation dosimeter (1001) for monitoring high energy radiations, such as X-ray. The dosimeter contains a radiation sensitive, color changing, indicating composition (10), e.g., a diacetylene (R—C≡C—C≡C—R′, where R and R′ are substituents groups) or a radiochromic dye, a polymeric binder (20) and optionally a shelf life extender (50) or an activator (40). The radiation sensitive composition (10) changes color instantly when exposed to high energy radiation. The dose is estimated by comparing the color with a color reference chart or more accurately with a spectrophotometer or an optical densitometer. The radiation sensitive composition (10) is protected from low energy radiation such as UV light, by a layer of low energy absorbing materials, such as UV absorbers.

Owner:JP LAB INC

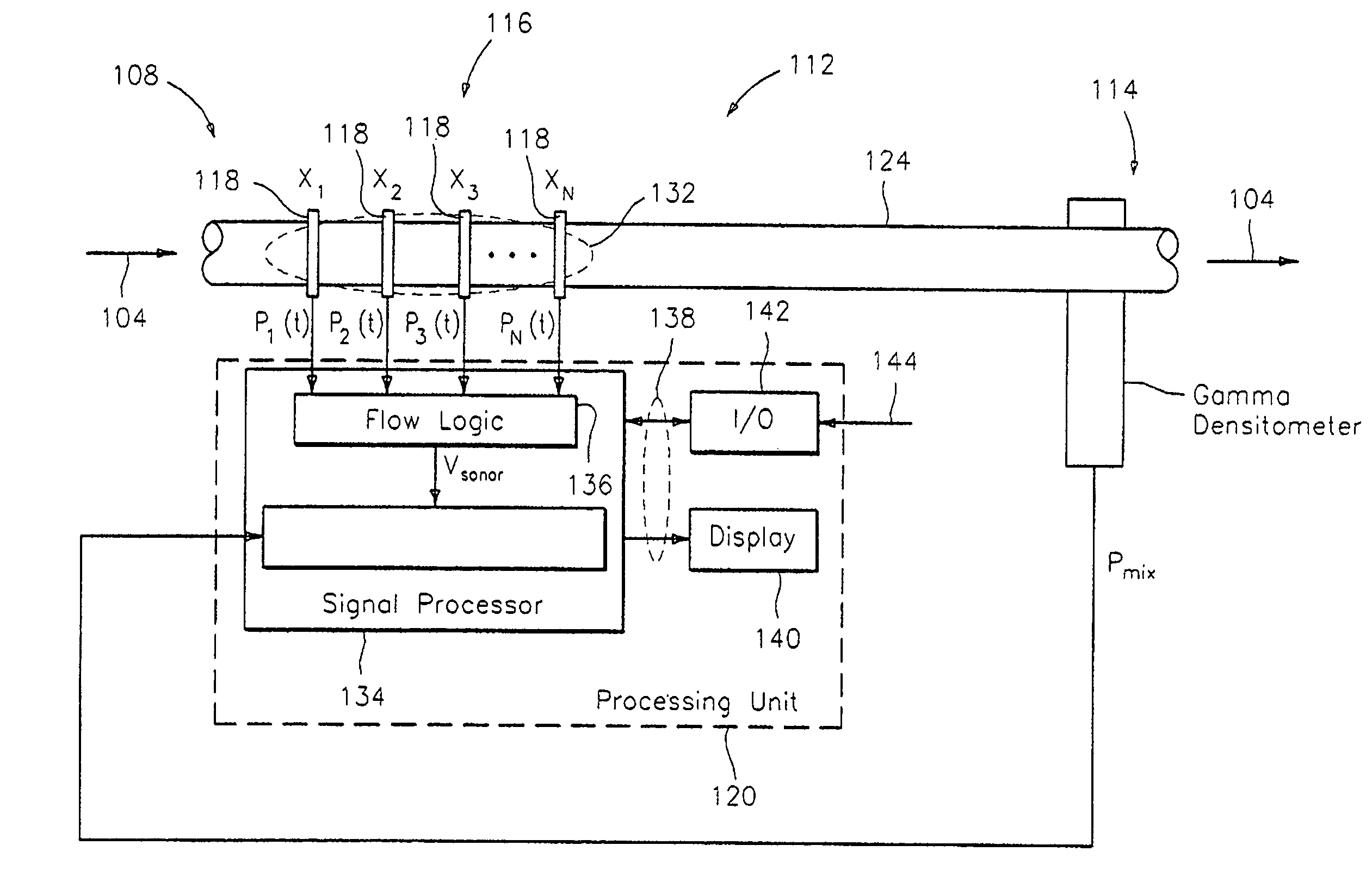

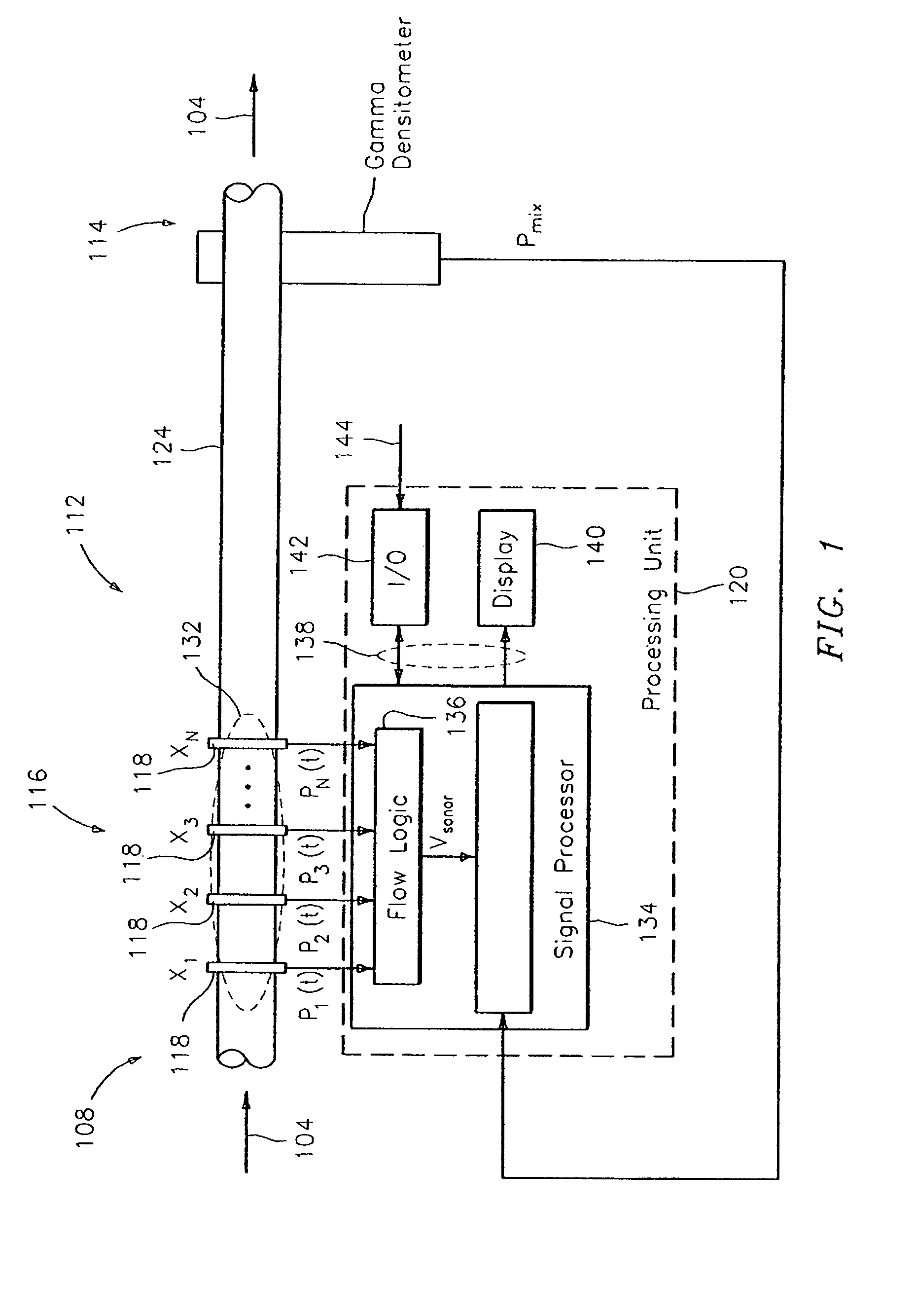

Apparatus and method for determining a parameter in a wet gas flow

ActiveUS7454981B2Volume/mass flow by dynamic fluid flow effectSpecific gravity measurementSonarEngineering

In an apparatus for measuring a parameter of a wet gas flow, a gamma densitometer is provided and configured to non-intrusively measure the density of the wet gas flow. A sonar based flow meter is also provided and configured to non-intrusively determine a flow rate of the gas flow of the wet gas flow. A processing device is in communication with at least one of the gamma densitometer and the sonar based flow meter, the processing device being configured to determine the flow rate of the gas portion and / or liquid portion of the wet gas flow using the measured density and flow rate of the wet gas flow.

Owner:EXPRO METERS

High pressure resonant vibrating-tube densitometer

A method of manufacturing a high pressure vibrating tube densitometer comprising enclosing twin flow tubes within an outer shell, wherein the outer shell comprises portals for the installation or replacement of internal components. A vibrating tube densitometer system for determining the density of a high pressure fluid in a pipeline, the system comprising a densitometer in communication with a controller, the densitometer comprising twin straight flow tubes spaced parallel apart within an outer shell comprising one or more portals for the placement of internal components, wherein the controller is in signal communication with a signal pickup, a tube driver, and the at least one temperature or pressure sensor and calculating the density of a fluid having a pressure of greater than 1500 psi.

Owner:HALLIBURTON ENERGY SERVICES INC

Ultrasonic-densiometer mass flow sensor for use in flow metering units

InactiveUS20070151333A1Accurate mass flow rate informationAccurate informationAerodynamic testingEngine testingFlow transducerEngineering

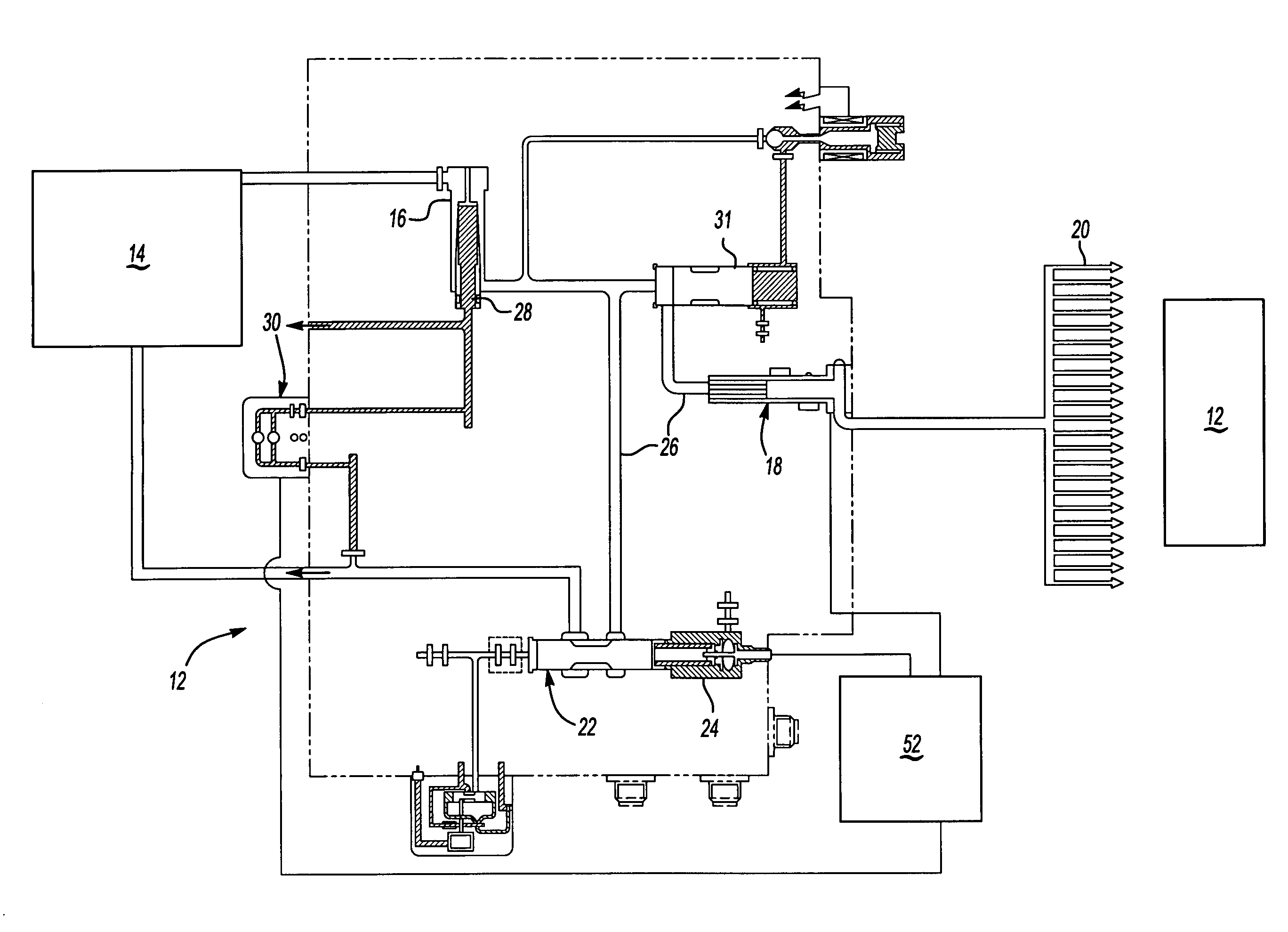

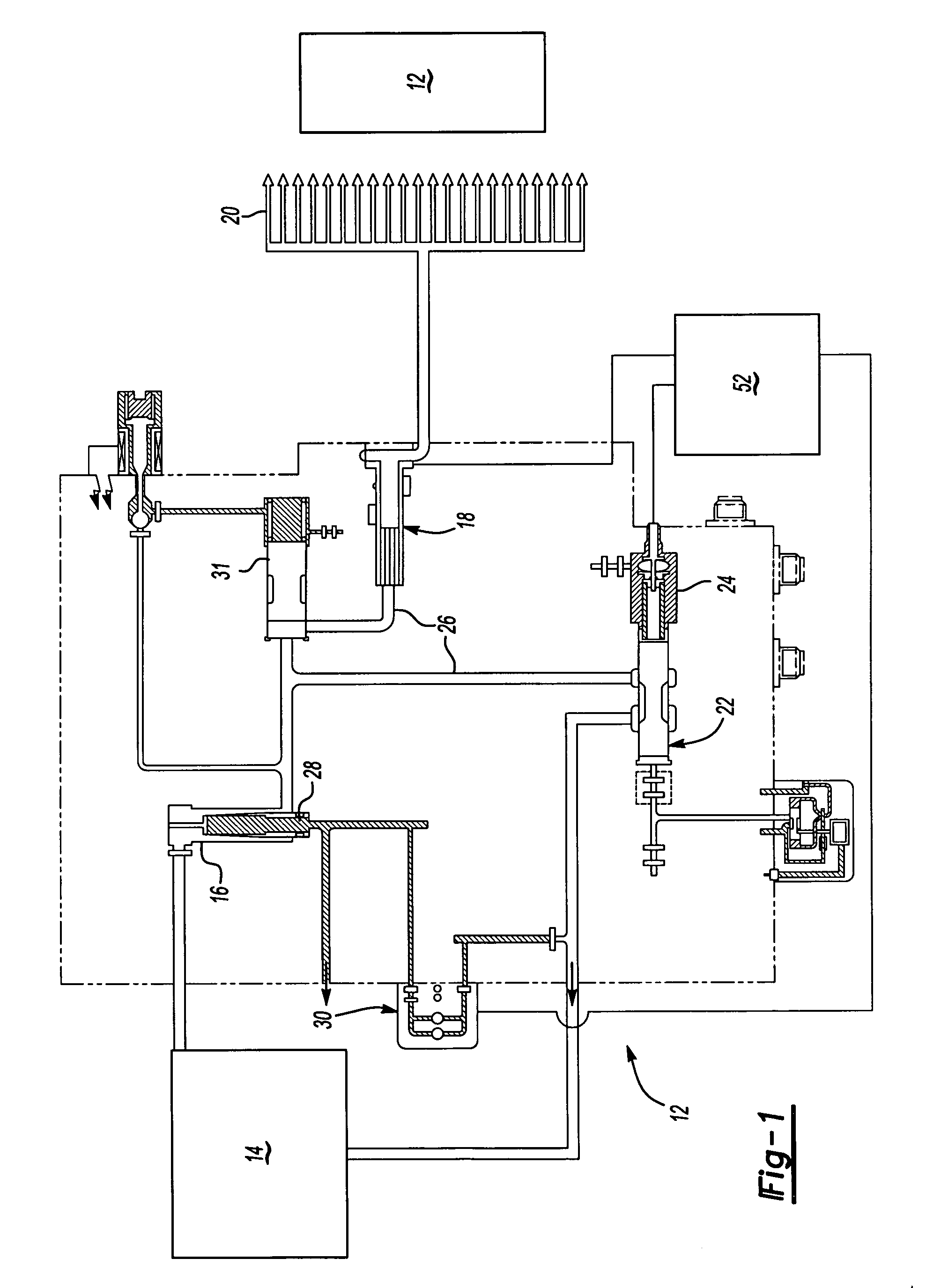

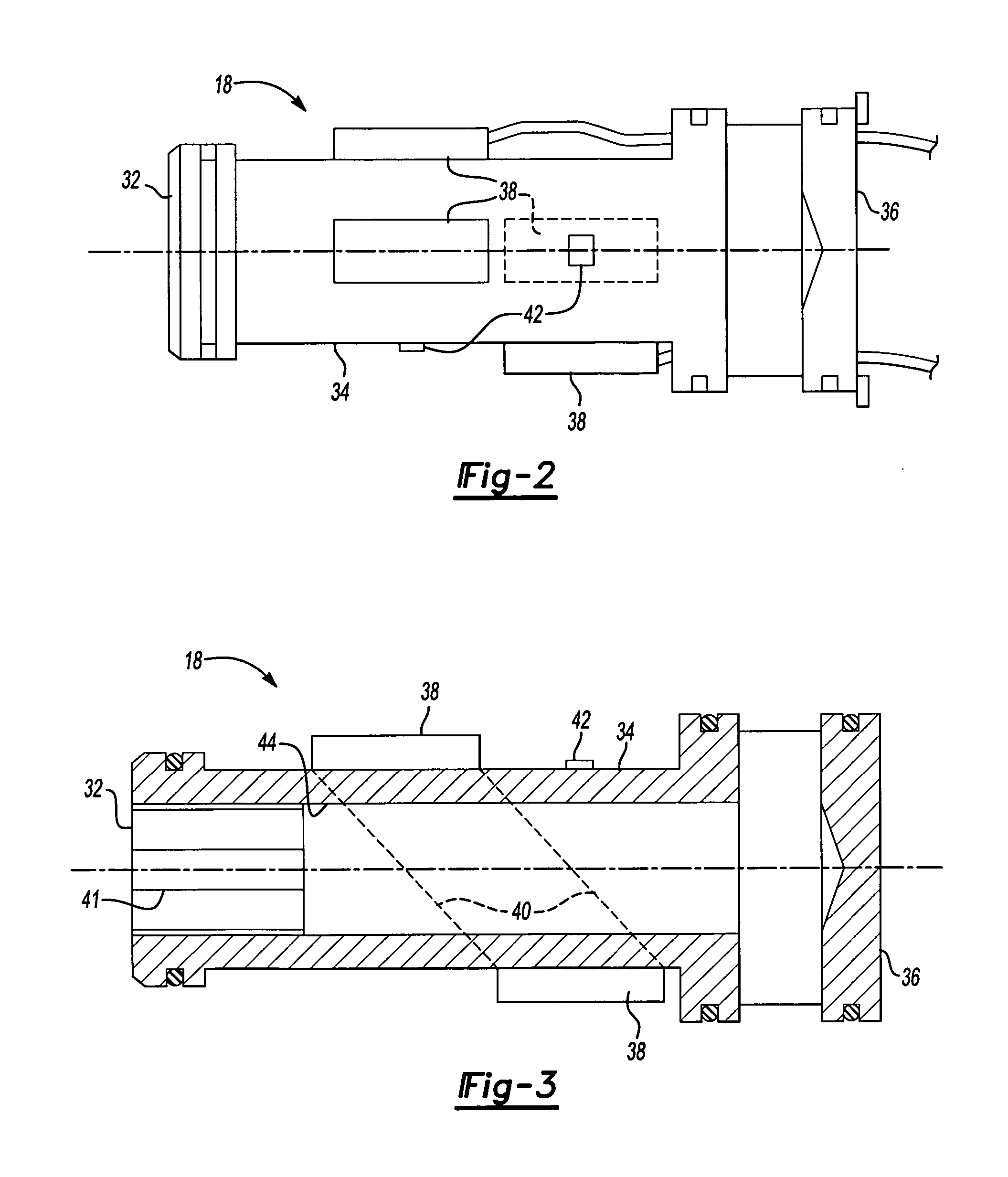

A fuel delivery system uses a volumetric flow sensor and a densiometer to measure a mass flow rate of the fuel. A densiometer may be a coriolis mass flow sensor etched into a small circuit chip. As fuel flows past the densiometer a density of the fuel and characteristic slope as a function of temperature is determined. At least one temperature sensor is also located on the circuit chip to provide accurate temperature of the fuel to correspond to the fuel density reading. Piezoelectric crystals in the volumetric flow sensor generate and receive a sound wave. By analyzing the sound wave signals the volumetric flow rate of fluid through the volumetric flow sensor can be calculated. At least one temperature sensor is also placed on the volumetric flow sensor to correct for any thermal expansion of an inner diameter of the volumetric flow sensor and for final mass flow calculation. The density and temperature information from the densiometer and the volumetric flow and temperature information from the volumetric flow sensor are used to determine the density of the fuel at the volumetric flow sensor. By using the density calculated at the volumetric flow sensor and using the volumetric flow information an accurate mass flow rate of the fuel at the volumetric flow sensor can be calculated.

Owner:HAMILTON SUNDSTRAND CORP

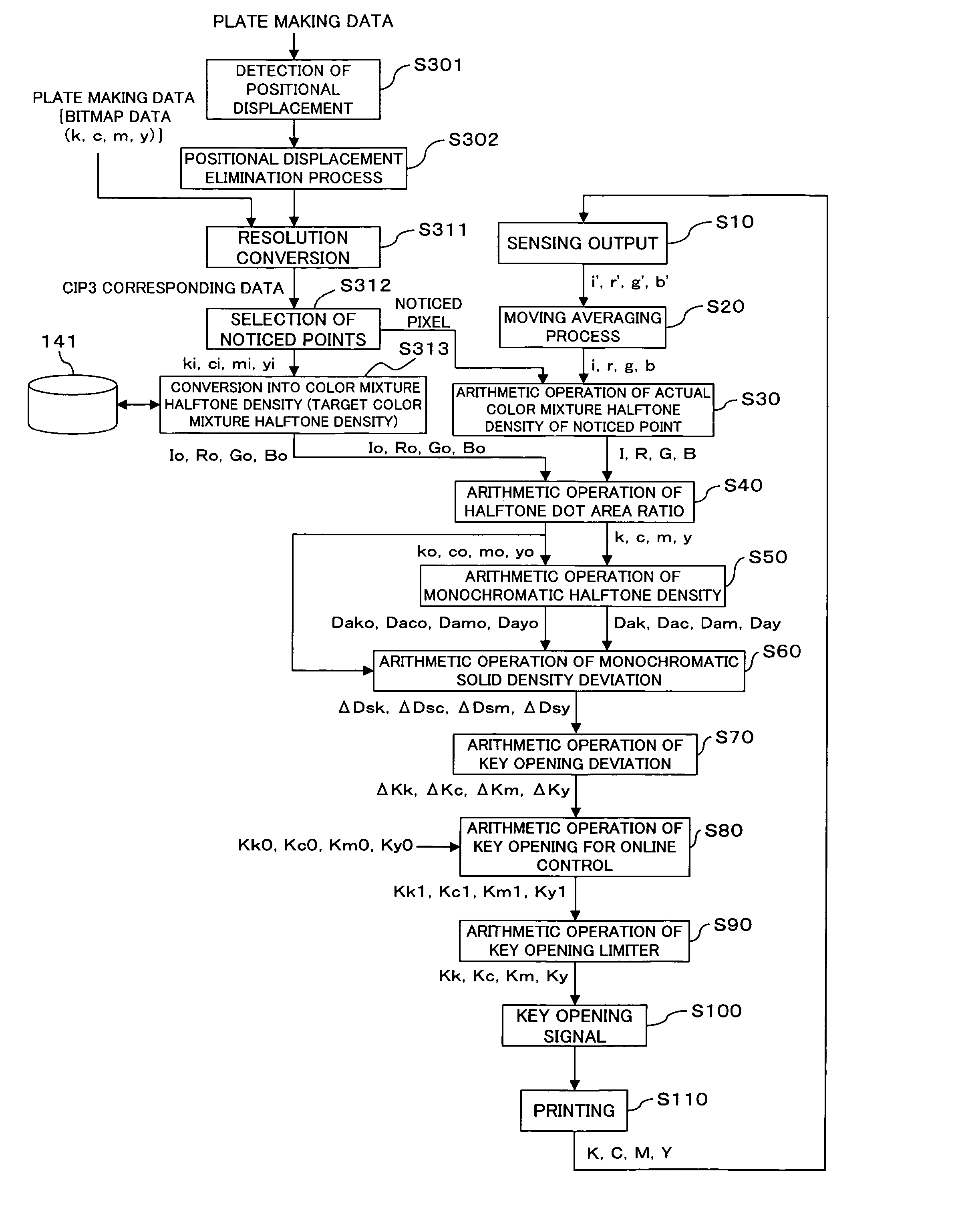

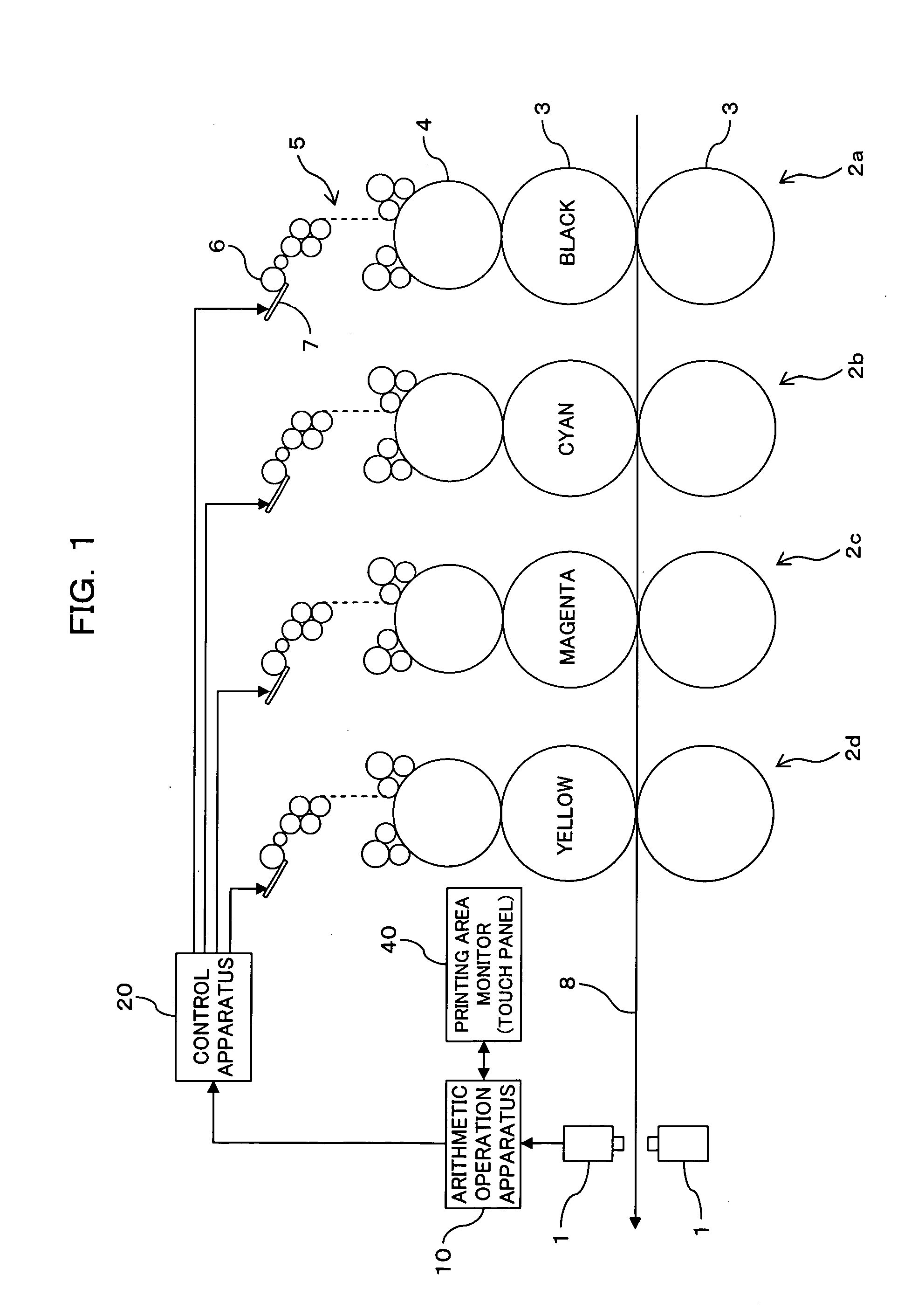

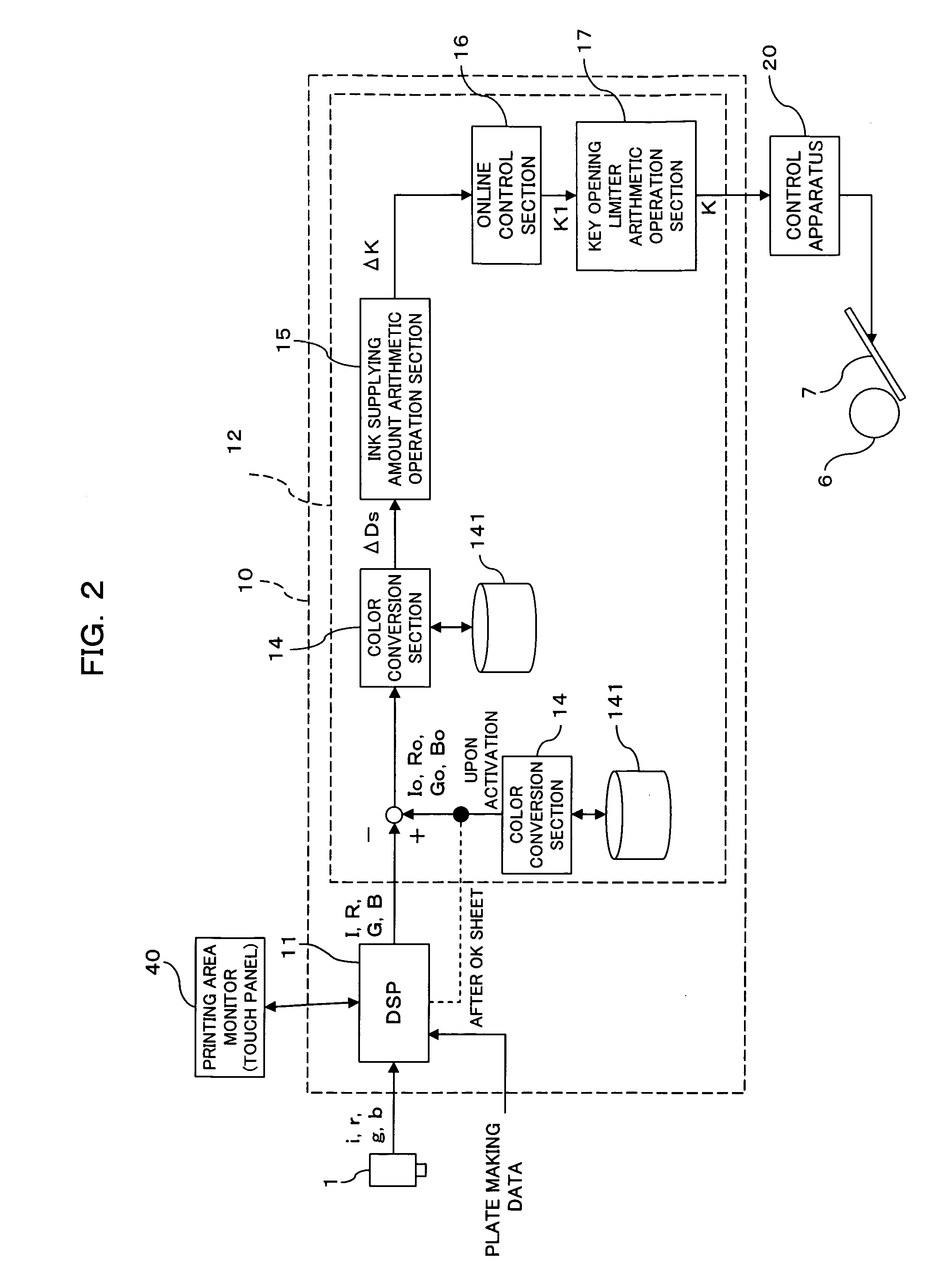

Picture color tone controlling method and apparatus

InactiveUS20060050320A1Low costReadily and rapidly eliminate a positional displacementVisual presentationColor matchingSolid densityComputer graphics (images)

A picture color tone controlling method and apparatus for a printing press is disclosed which can readily and rapidly eliminate a positional displacement between a plate making image and an actual machine image and can appropriately perform color tone control in which an IRGB densitometer is used. A plate making picture position obtained from plate making data is moved so that a positional displacement between the plate making picture position and an actual picture position obtained from a result of actual printing. A target color mixture halftone density for each ink supplying unit width when a printing picture is divided with an ink supplying unit width of an ink supplying apparatus is set. An IRGB densitometer is used to measure the actual color mixture halftone density for each ink supplying unit width of an actually printed sheet obtained by printing. The color mixture halftone densities are individually converted into halftone dot area ratios and further into monochromatic halftone densities. Then, the Yule-Nielsen expression or the like is used to determine a solid density deviation corresponding to a deviation between the target monochromatic halftone density and the actual monochromatic halftone density, and the ink supplying amount is adjusted for each ink supplying unit width in response to the solid density deviation.

Owner:MITSUBISHI HEAVY IND LTD

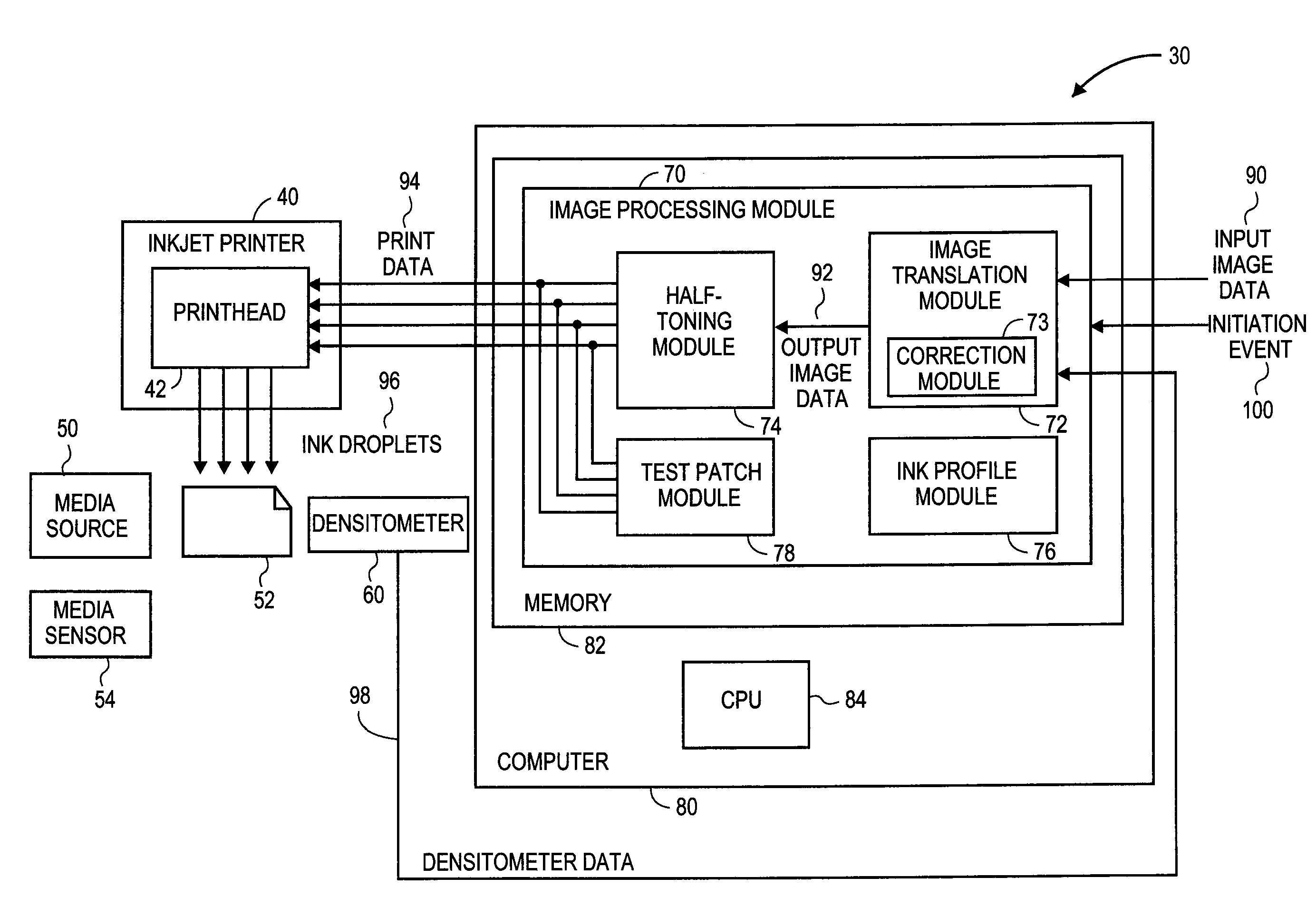

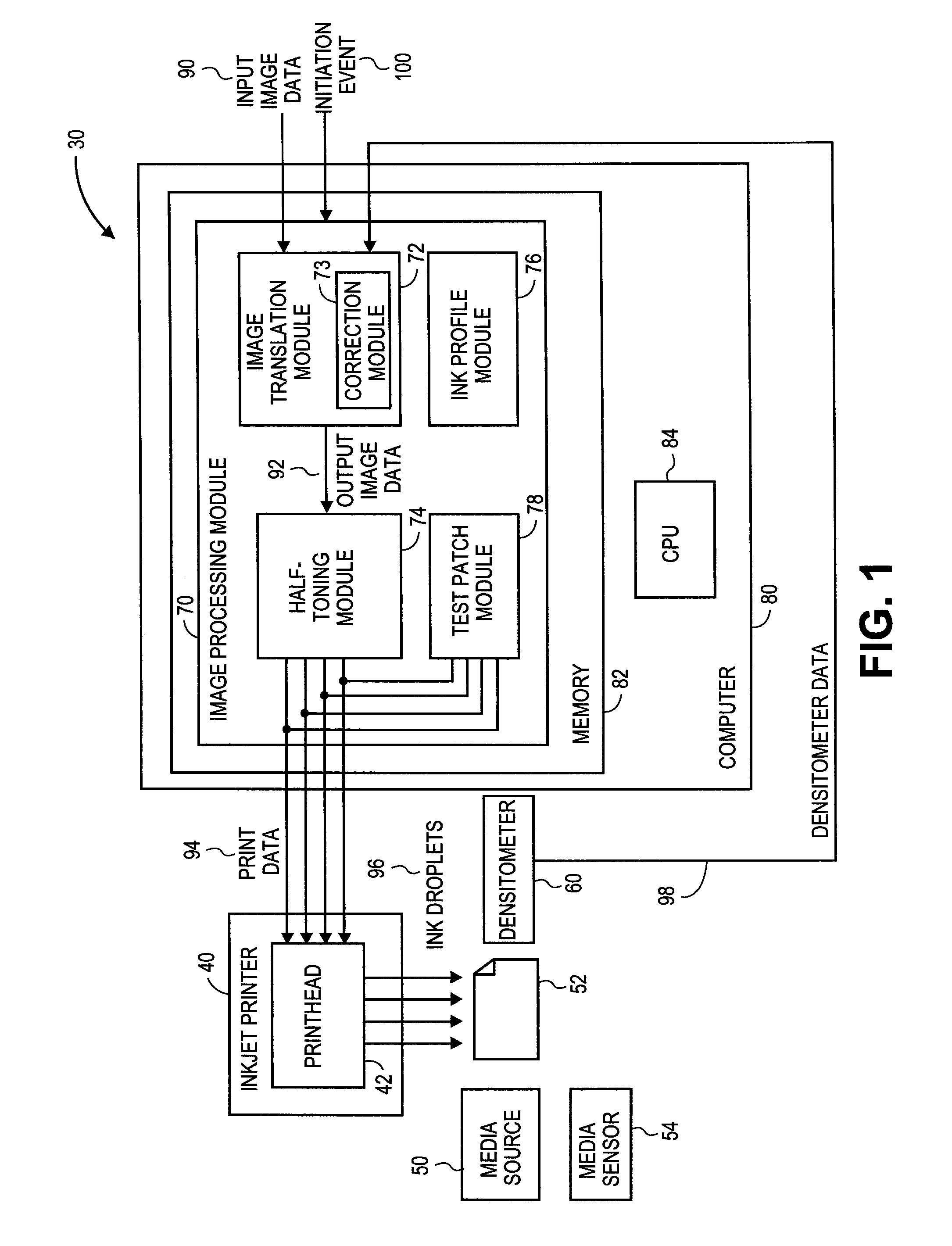

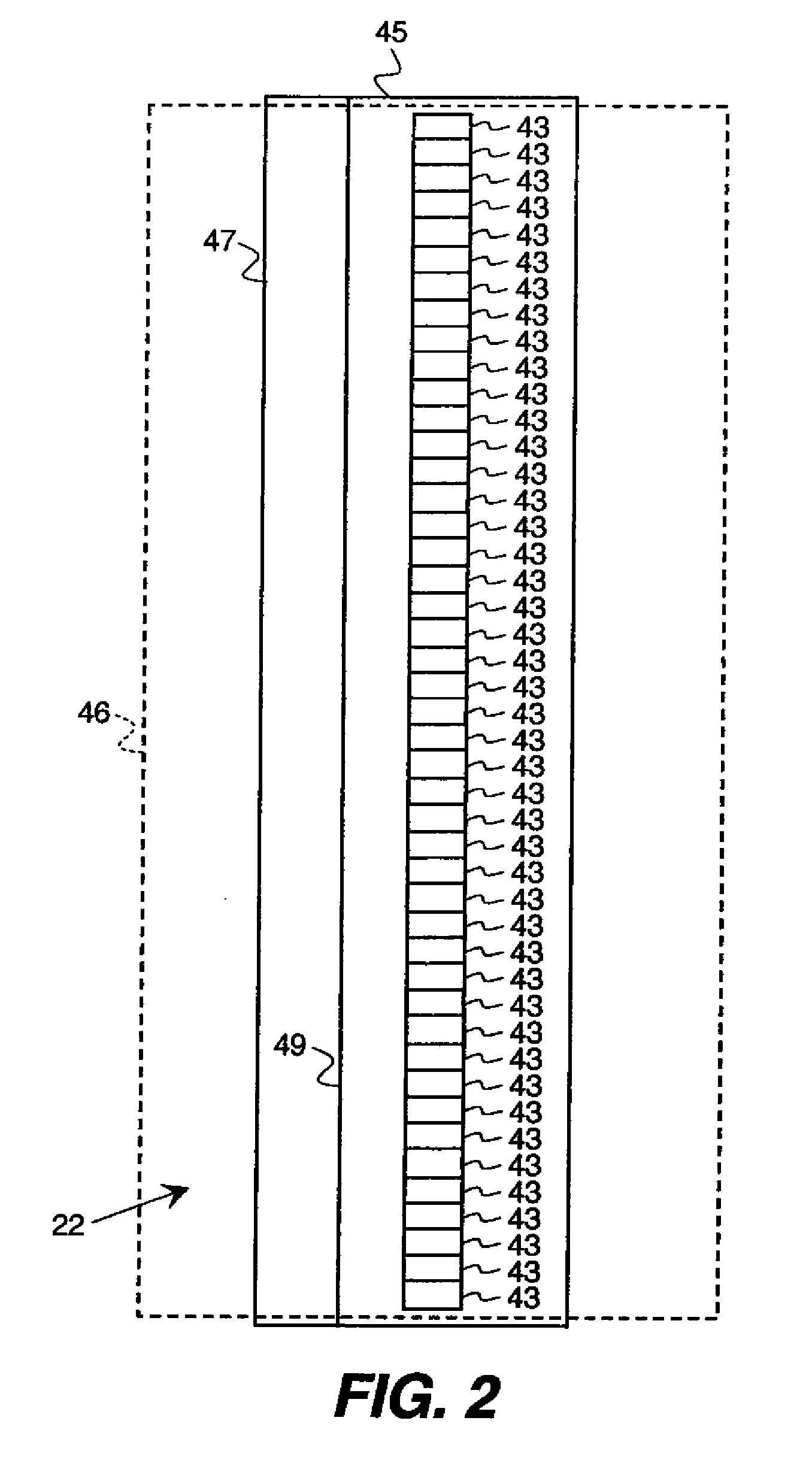

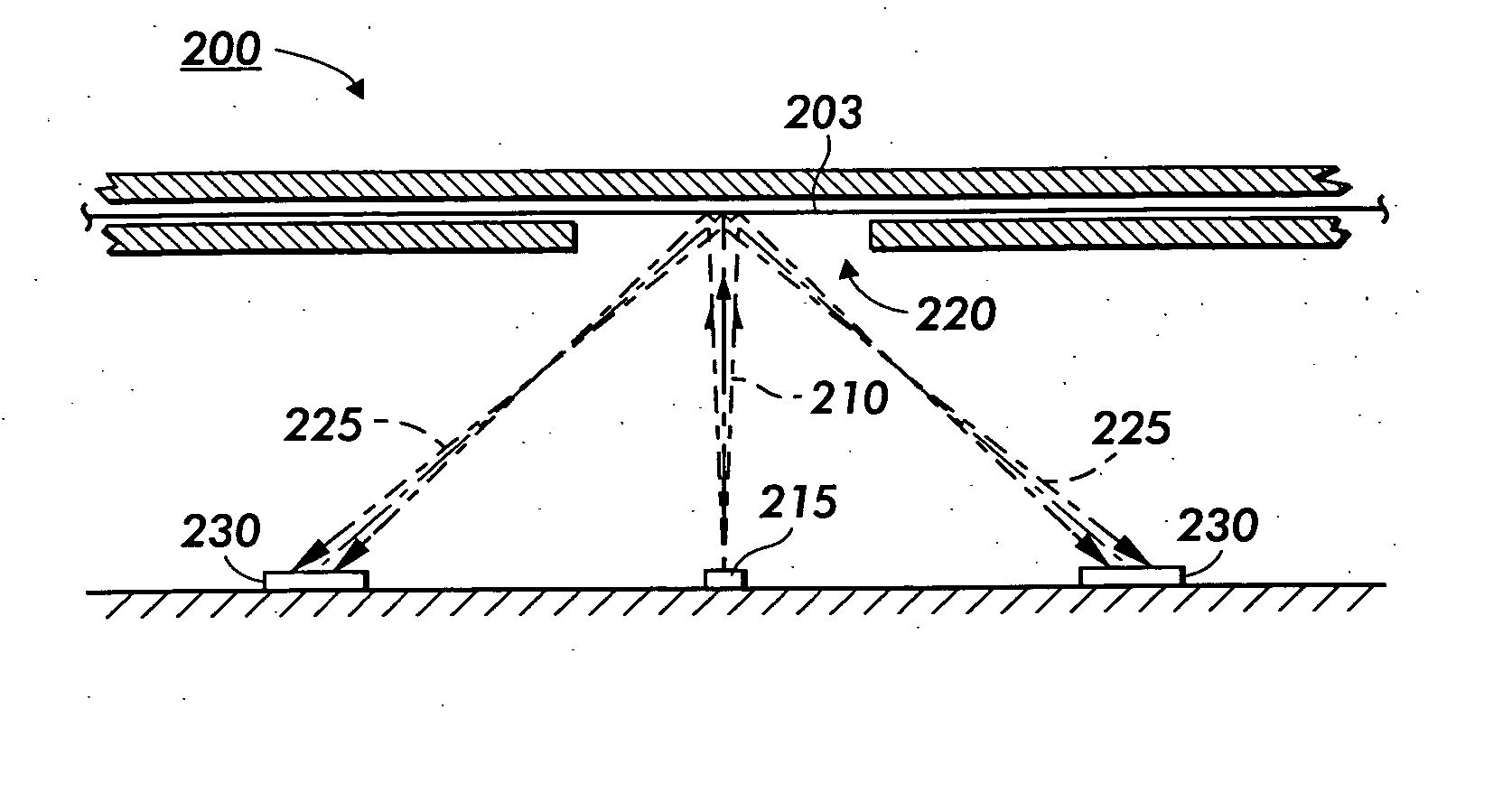

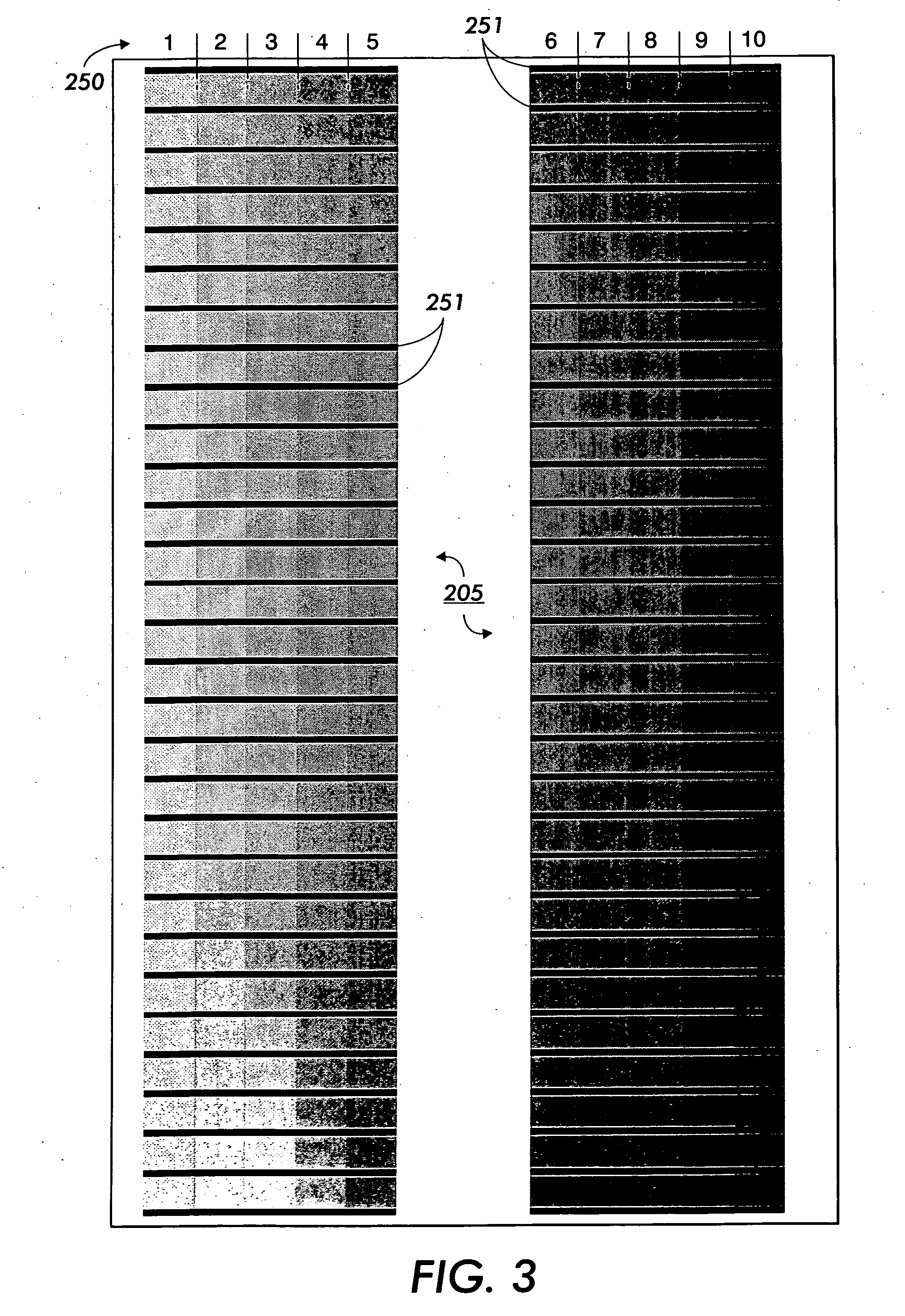

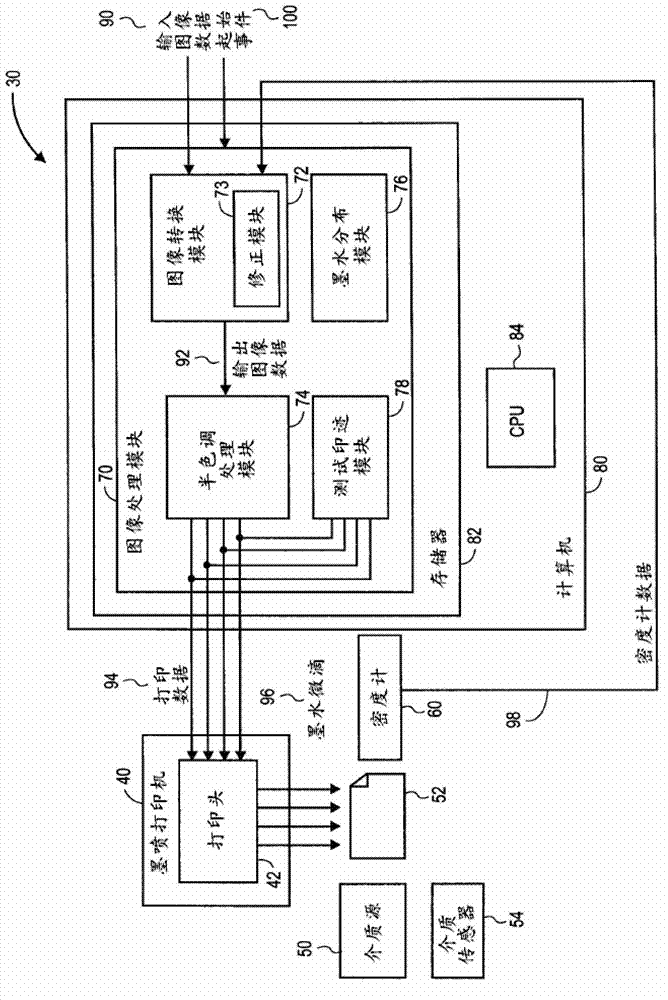

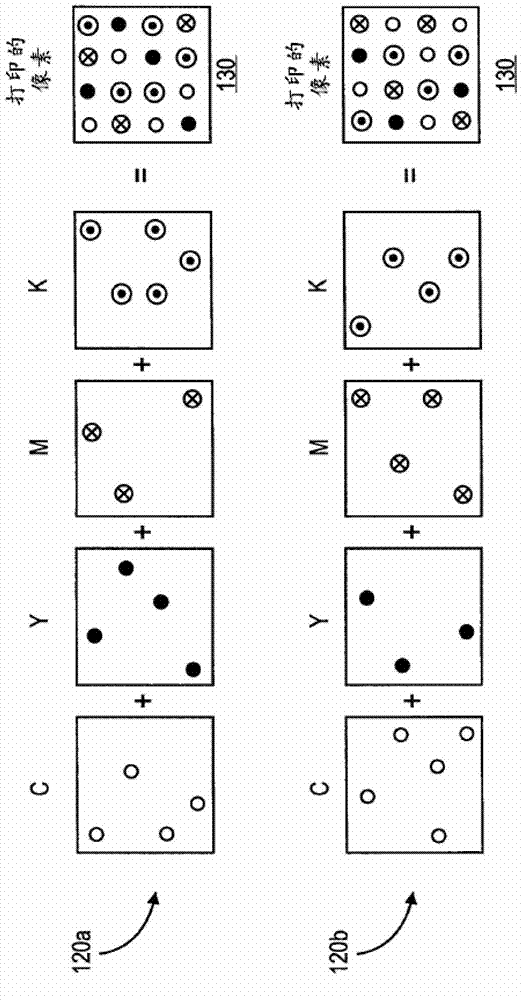

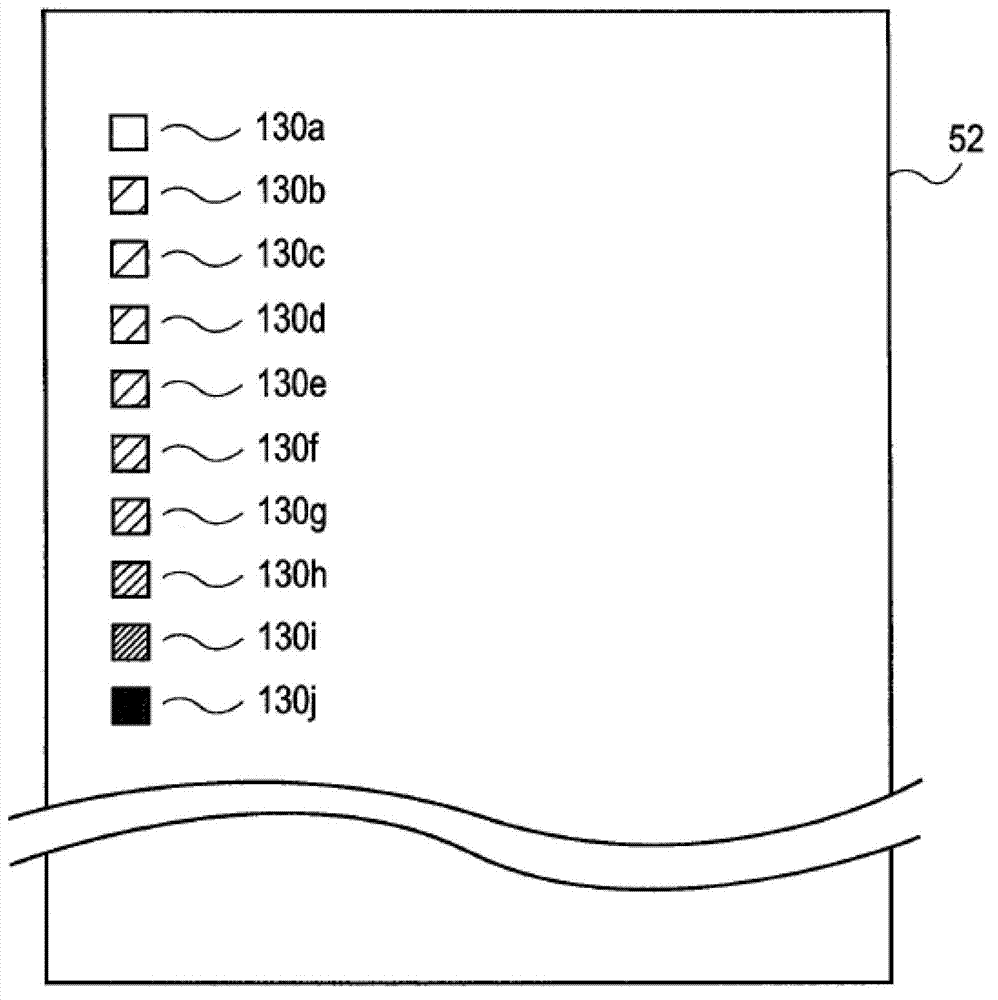

Inkjet print calibration using test patches and densitometer

InactiveUS20130222461A1Affect qualityOther printing apparatusPictoral communicationTest patchVolumetric Mass Density

An inkjet printing system including a media source supplying sheets of transparent film. An image processing module receives and converts input image data to output image data comprising a plurality of output pixels configured to select an ink profile. Predetermined ink profiles are selected representative of a series of test patches each having an expected density. A printhead is configured to eject droplets of available colors of ink onto a sheet of transparent film based on the selected ink profiles to produce the output pixels and an output image thereon, including the series of test patches. A transmissive densitometer measures the actual density value of each of the test patches, wherein the image processing module adjusts the output pixel values based on a deviations between the expected and actual density values of the series of test patches.

Owner:CARESTREAM HEALTH INC

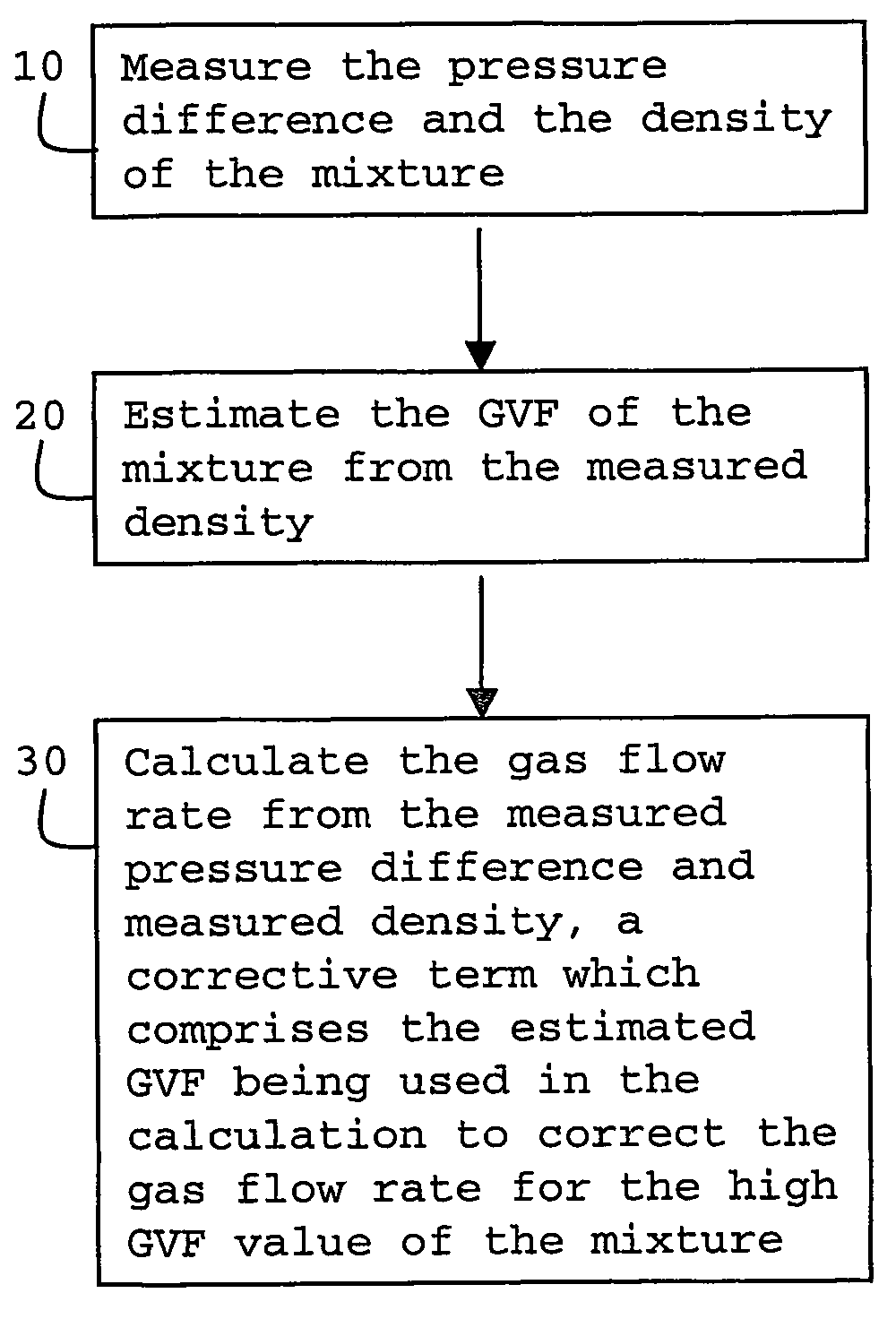

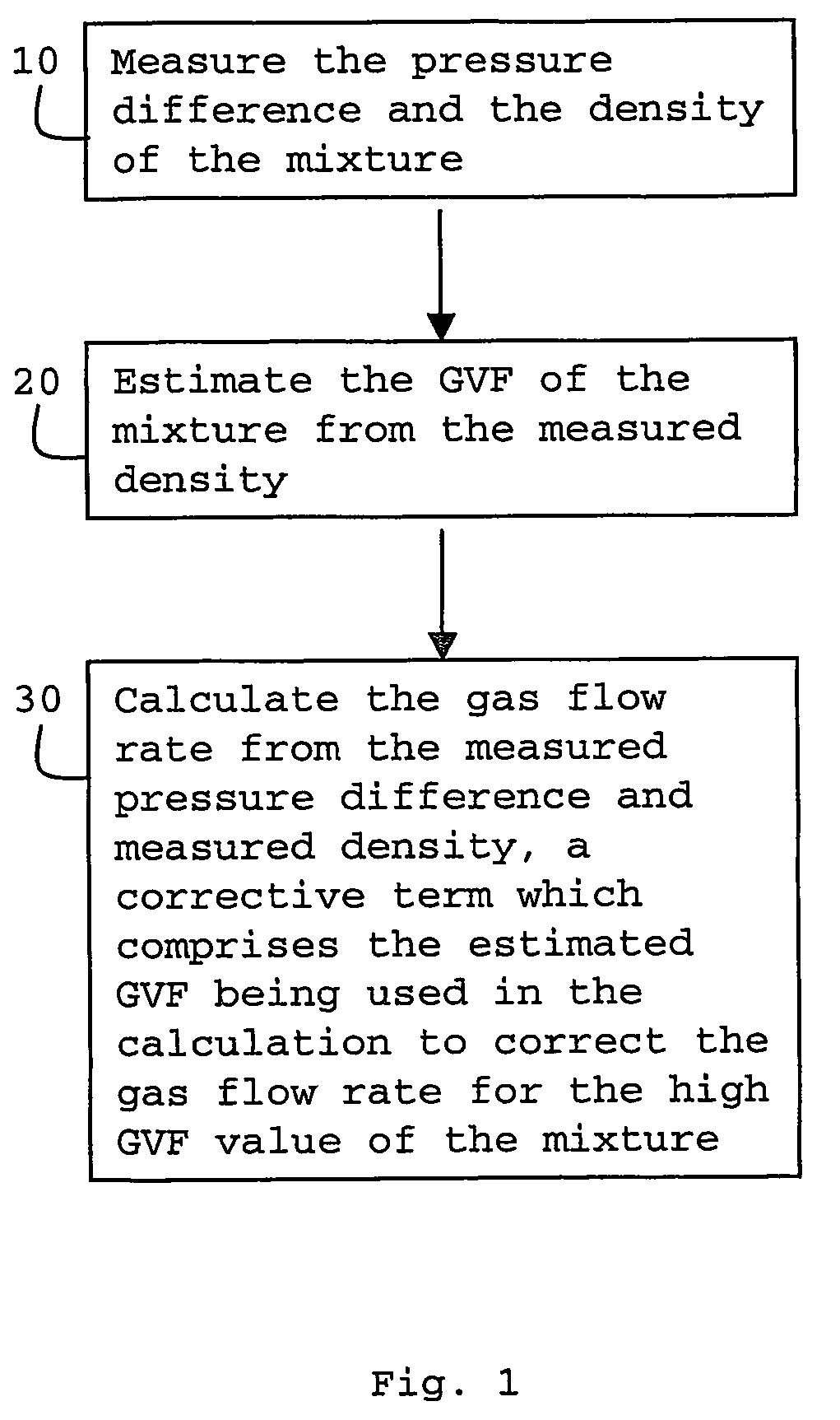

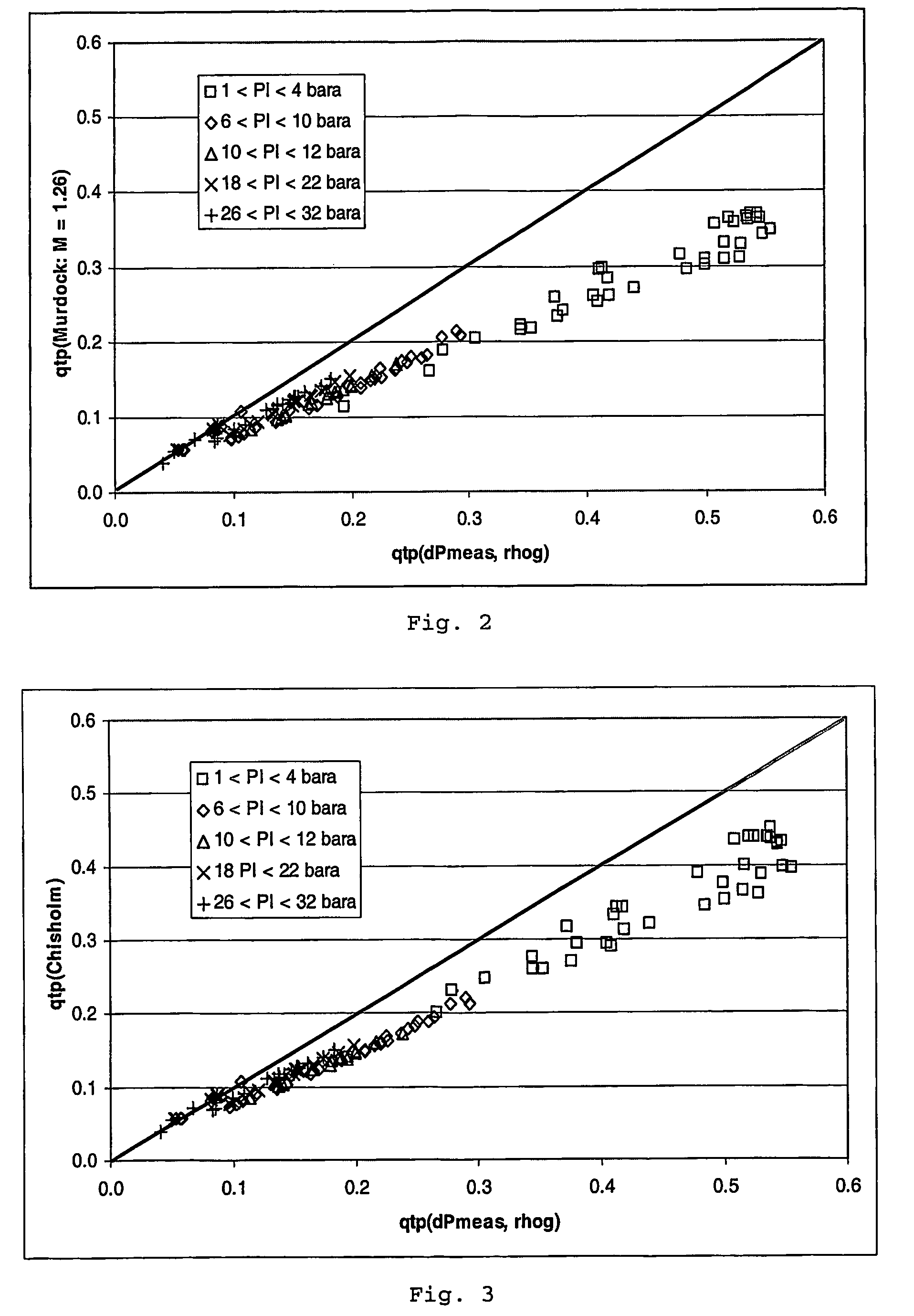

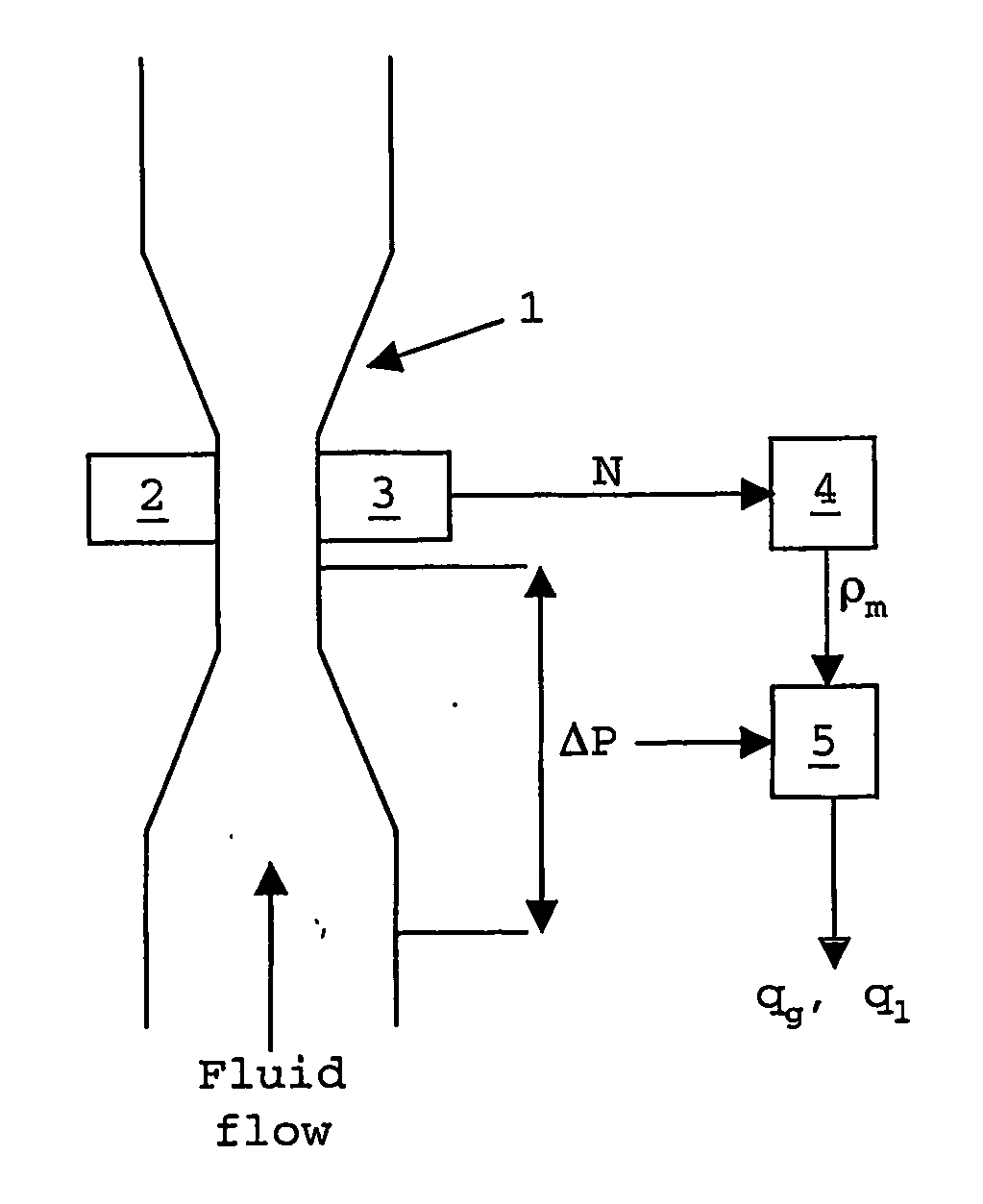

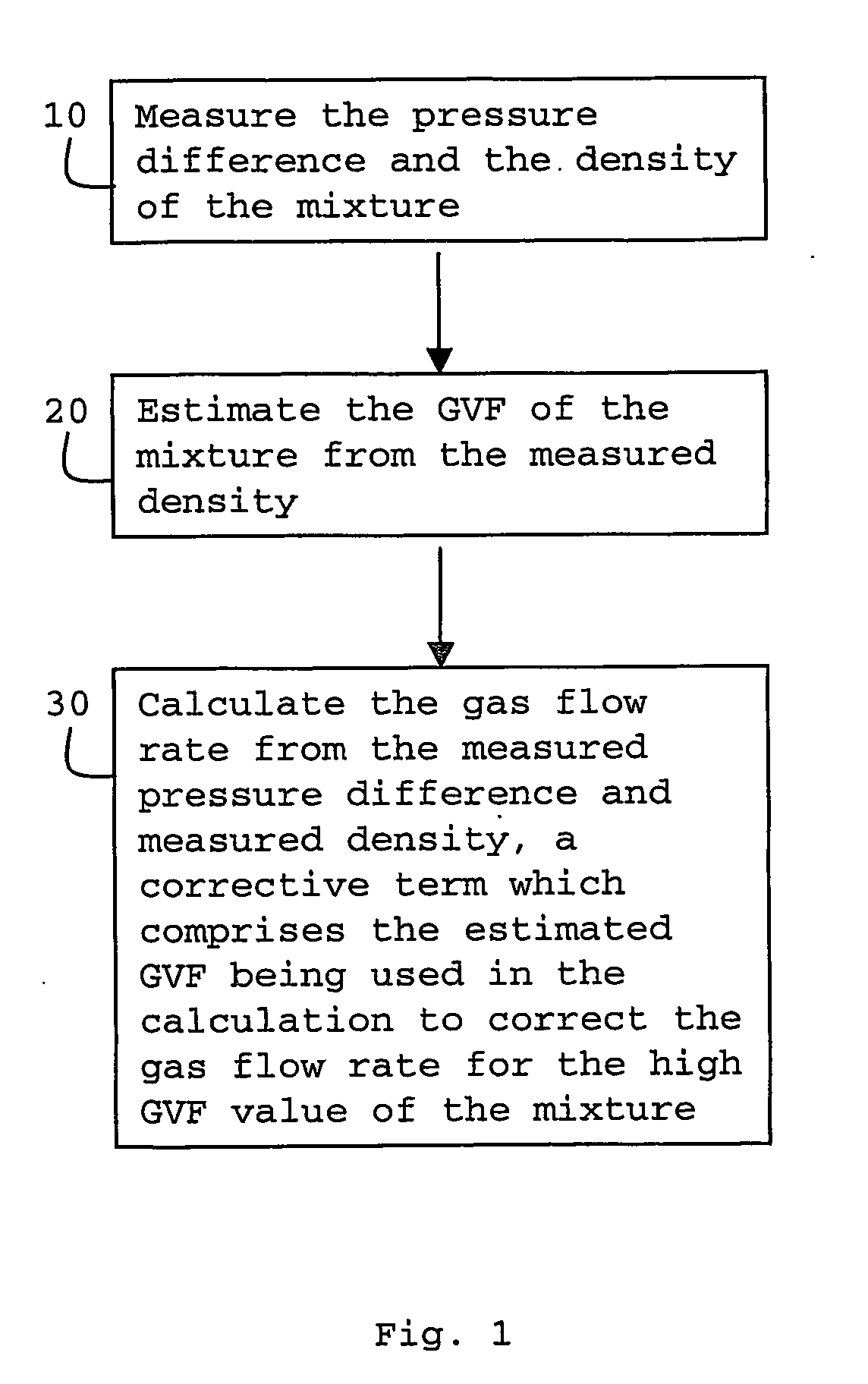

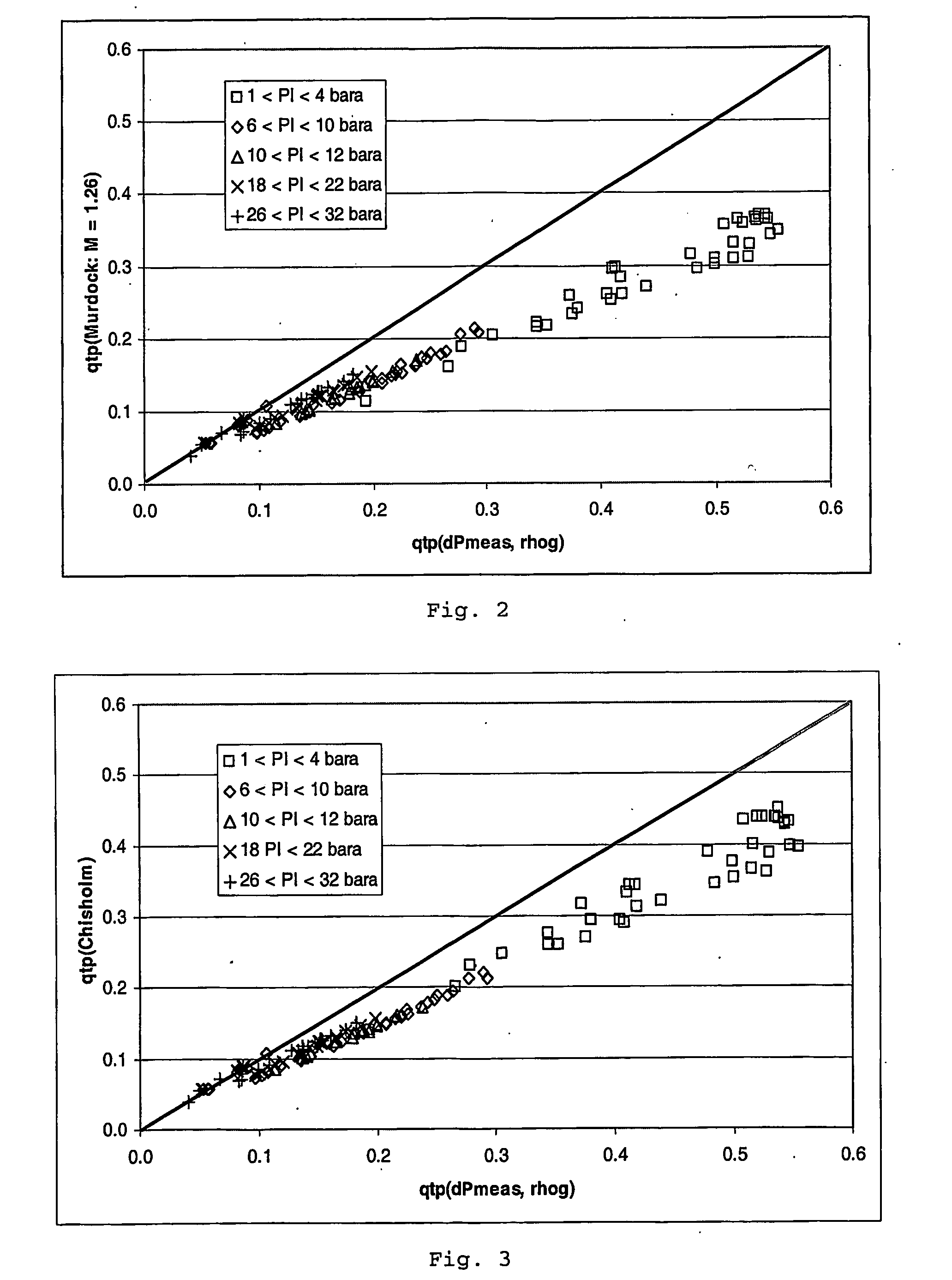

Method and apparatus for determining the gas flow rate of a gas-liquid mixture

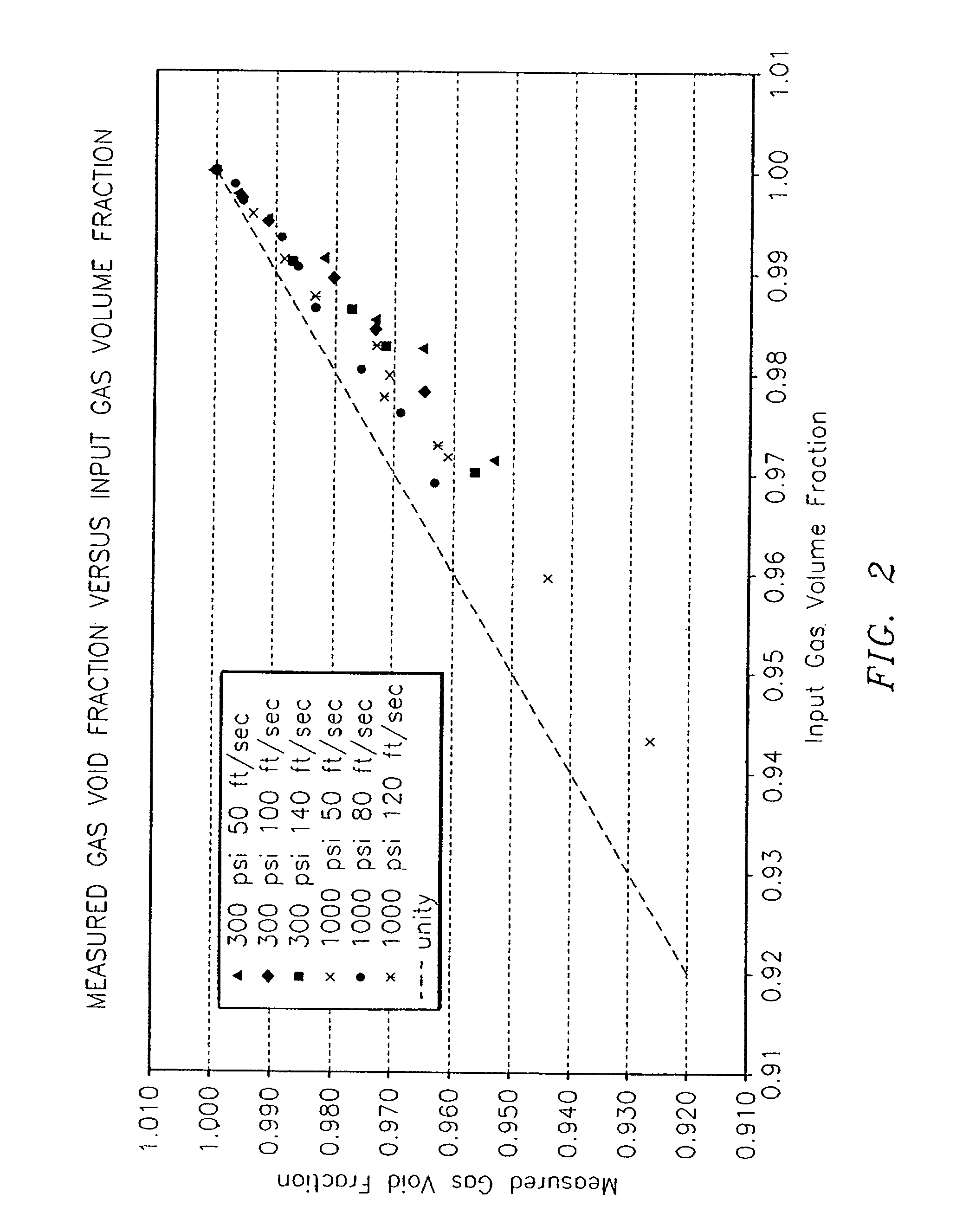

ActiveUS7240568B2Improves mixing)Avoid layeringVolume/mass flow by differential pressureIndirect mass flowmetersDifferential pressureGas volume fraction

A method and apparatus are provided for determining the gas flow rate of a gas-liquid mixture which has a gas volume fraction (GVF) of at least 85% and which is conveyed along a conduit. The conduit is fitted with a differential pressure flow meter and a fluid densitometer. The method comprises: measuring the pressure difference across the differential pressure flow meter and measuring the density of the mixture using the densitometer; estimating the GVF of the mixture from the measured density; and calculating the gas flow rate from the measured pressure difference and measured density. A corrective term which comprises the estimated GVF is used in the calculation to correct the gas flow rate for the high GVF value of the mixture.

Owner:SCHLUMBERGER TECH CORP

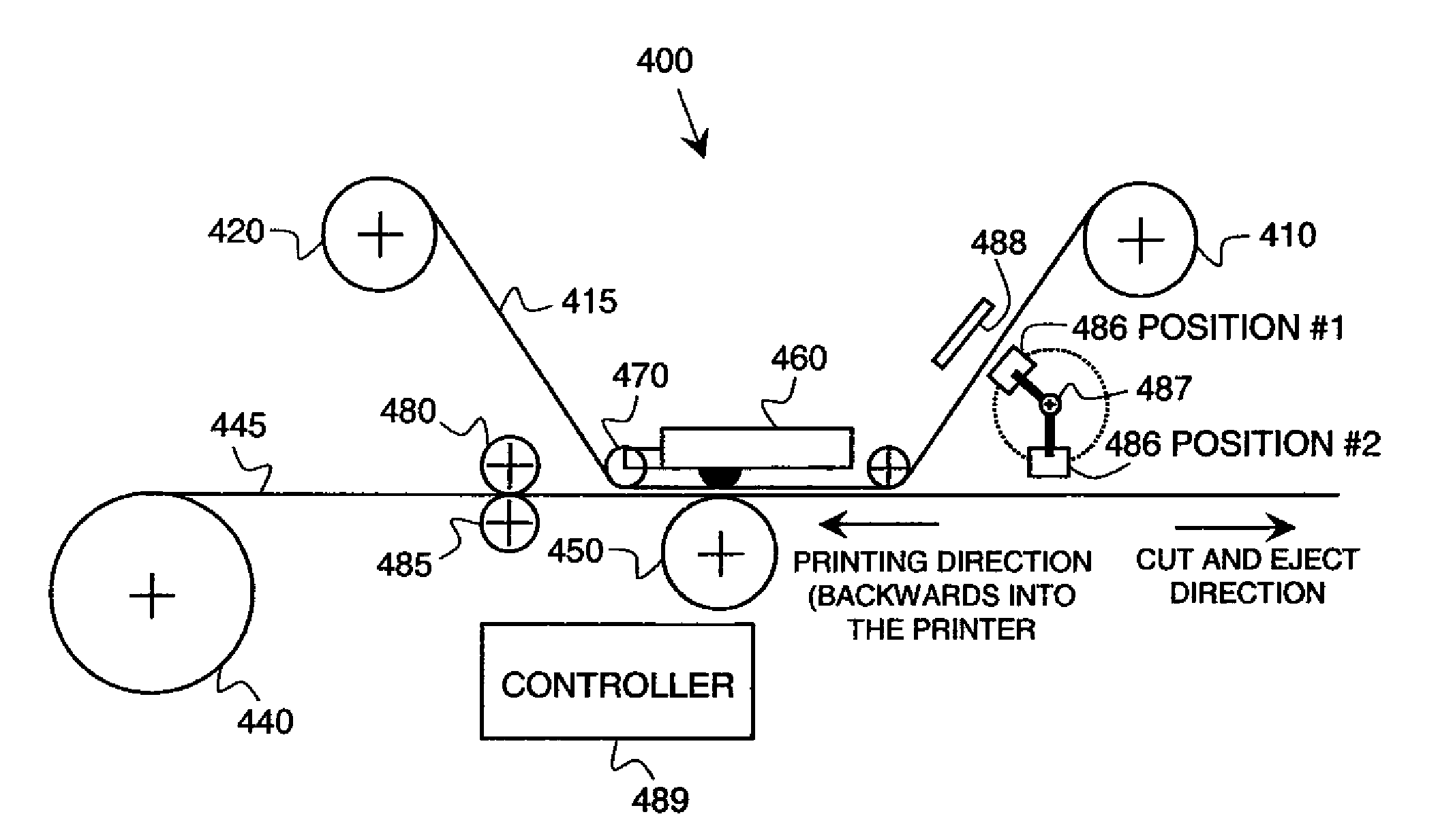

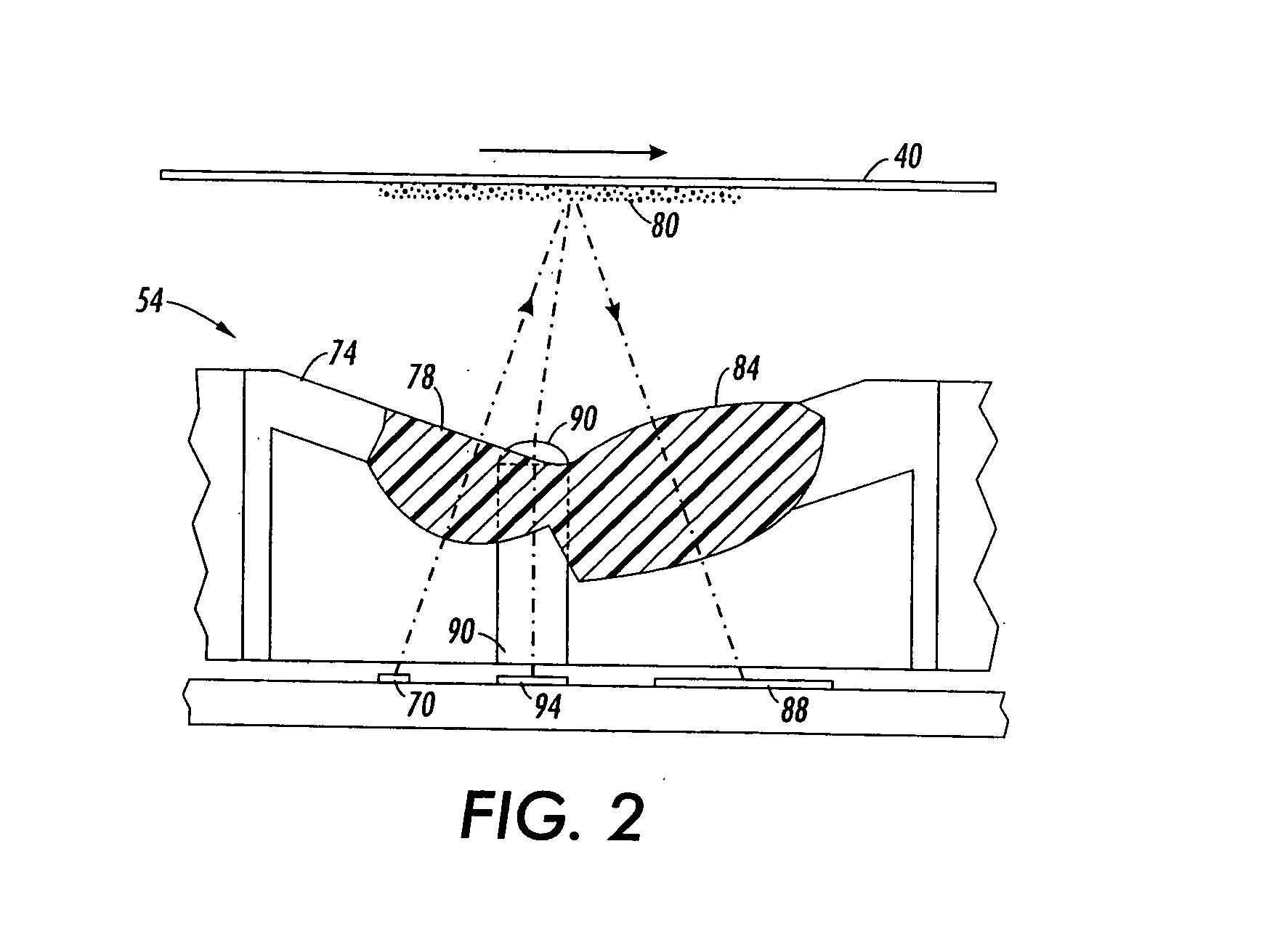

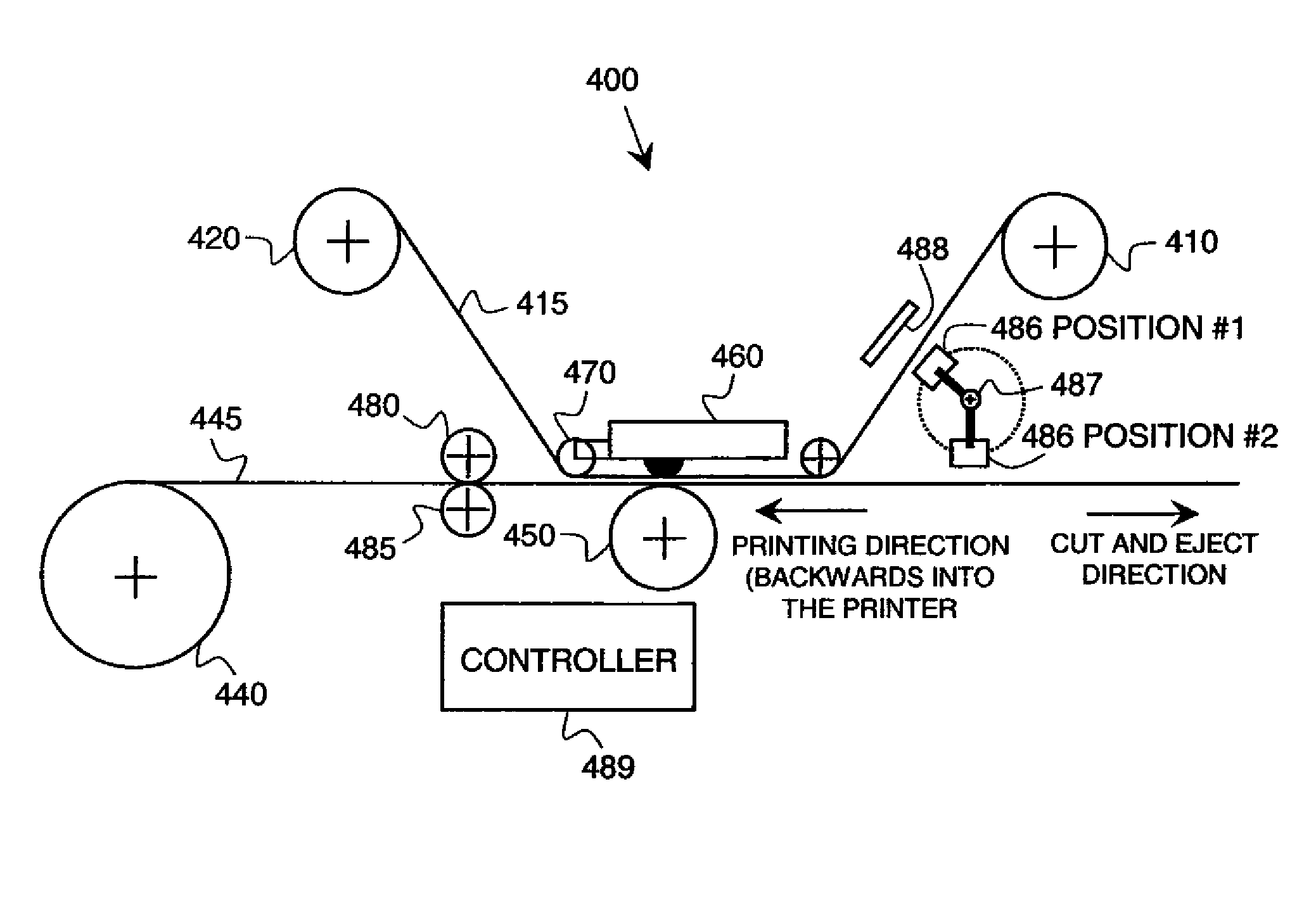

Dual-use sensor assembly for a thermal printer

A sensor apparatus for providing two sensing operations within a thermal printer includes a densitometer with at least one light source that discriminates color and that is positioned in a first position for sensing donor patches within the thermal printer; the densitometer while in a second position provides signals from printed receiver media for internal color calibration of the thermal printer. At least one reflector directs light from the light source to the densitometer through a donor web when the densitometer is in the first position; and a switchable device repositions the densitometer from either the first position or the second position.

Owner:KODAK ALARIS INC

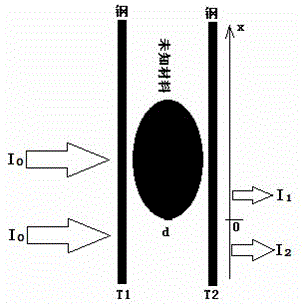

Non-destructive identification method for material of integral coil of distribution transformer

ActiveCN102749342ADoes not affect power supplyTimely claimMaterial analysis by transmitting radiationNon destructiveUltrasound attenuation

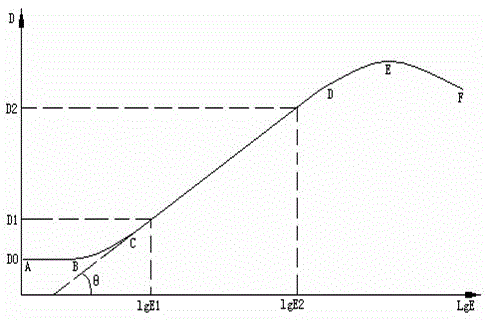

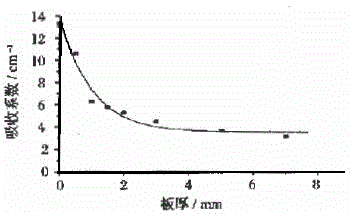

The invention discloses a non-destructive identification method for a material of an integral coil of a distribution transformer. The non-destructive identification method based on the difference of attenuation coefficients of copper, steel and aluminum to X rays includes photographing the distribution transformer in a integral state by the X rays; measuring blackness of photographed negative films of the rays by a black and white densitometer; inputting measured blackness values into a computer; and computing X-ray attenuation coefficient and transillumination thickness curves, which are stored in the computer, of the copper, the steel and the aluminum corresponding to different X-ray tubes and comparing the X-ray attenuation coefficient and transillumination thickness curves with a characteristic curve of the industrial ray films, and judging whether the winding coil of the distribution transformer is made of the aluminum or the copper.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

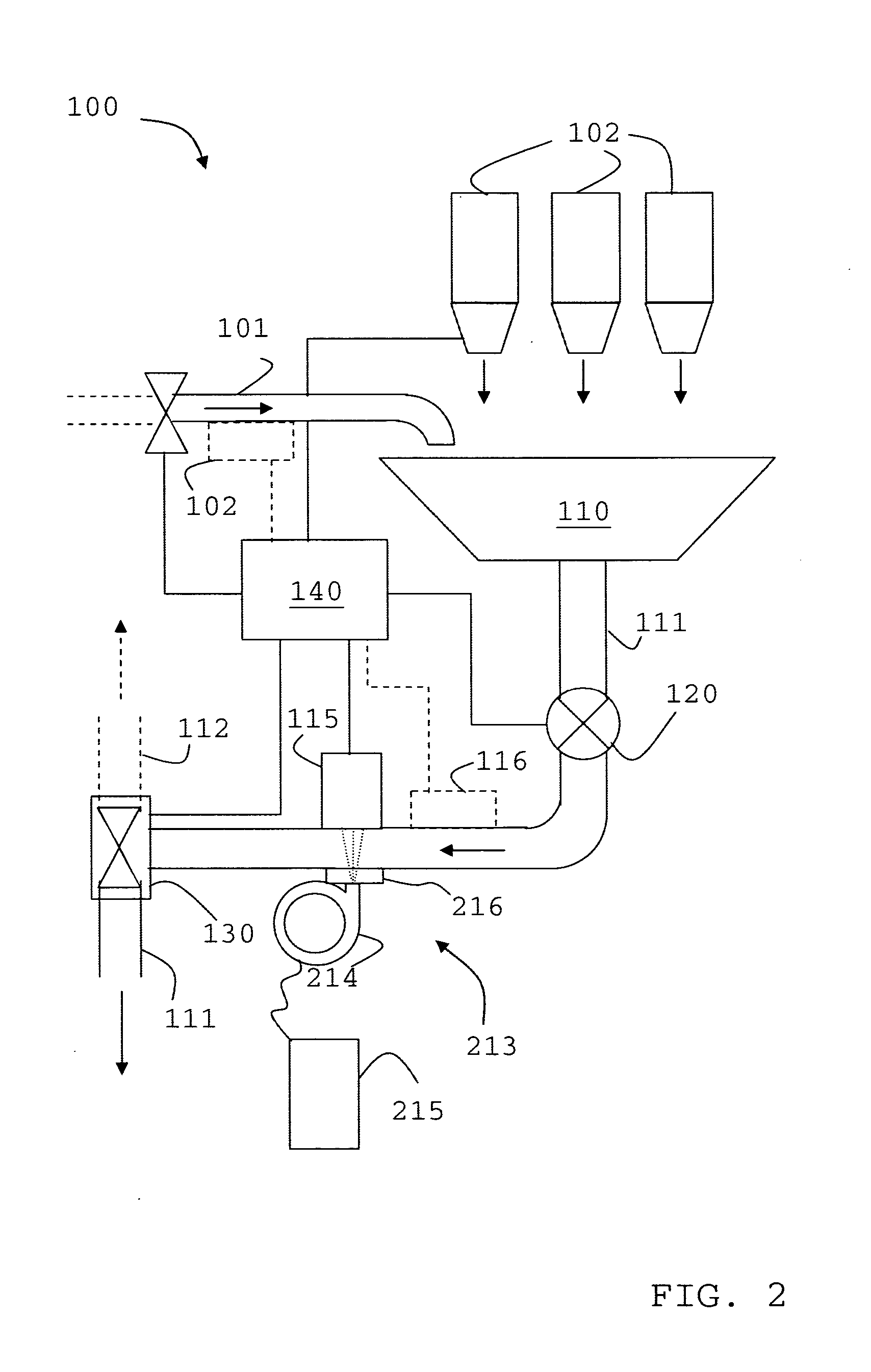

Blending system for solid/fluids mixtures

InactiveUS20070144739A1SurveyMaterial analysis using wave/particle radiationHigh energyRadioactive agent

Methods and system are described for monitoring the composition of a cement slurry or wellbore service fluid, including one or more feeder units for solid particulate material; one or more mixing or blending units adapted to receive material from the feeder units; one or more outlet tubes to direct the cement slurry or wellbore service fluid to a storage facility or into a wellbore; and a control unit connected to at least one densitometer to monitor the density of the cement slurry or wellbore service fluid; wherein the densitometer comprises a generator free of radioactive material and capable of generating high-energy photons based on accelerating or decelerating electrons.

Owner:SCHLUMBERGER TECH CORP

Method and apparatus for determing the gas flow rate of a gas-liquid mixture

ActiveUS20060236779A1Improves mixing)Avoid layeringVolume variation compensation/correction apparatusVolume/mass flow by differential pressureDifferential pressureStream flow

A method and apparatus are provided for determining the gas flow rate of a gas-liquid mixture which has a gas volume fraction (GVF) of at least 85% and which is conveyed along a conduit. The conduit is fitted with a differential pressure flow meter and a fluid densitometer. The method comprises: measuring the pressure difference across the differential pressure flow meter and measuring the density of the mixture using the densitometer; estimating the GVF of the mixture from the measured density; and calculating the gas flow rate from the measured pressure difference and measured is used in the calculation to correct the gas flow rate for the high GVF value of the mixture.

Owner:SCHLUMBERGER TECH CORP

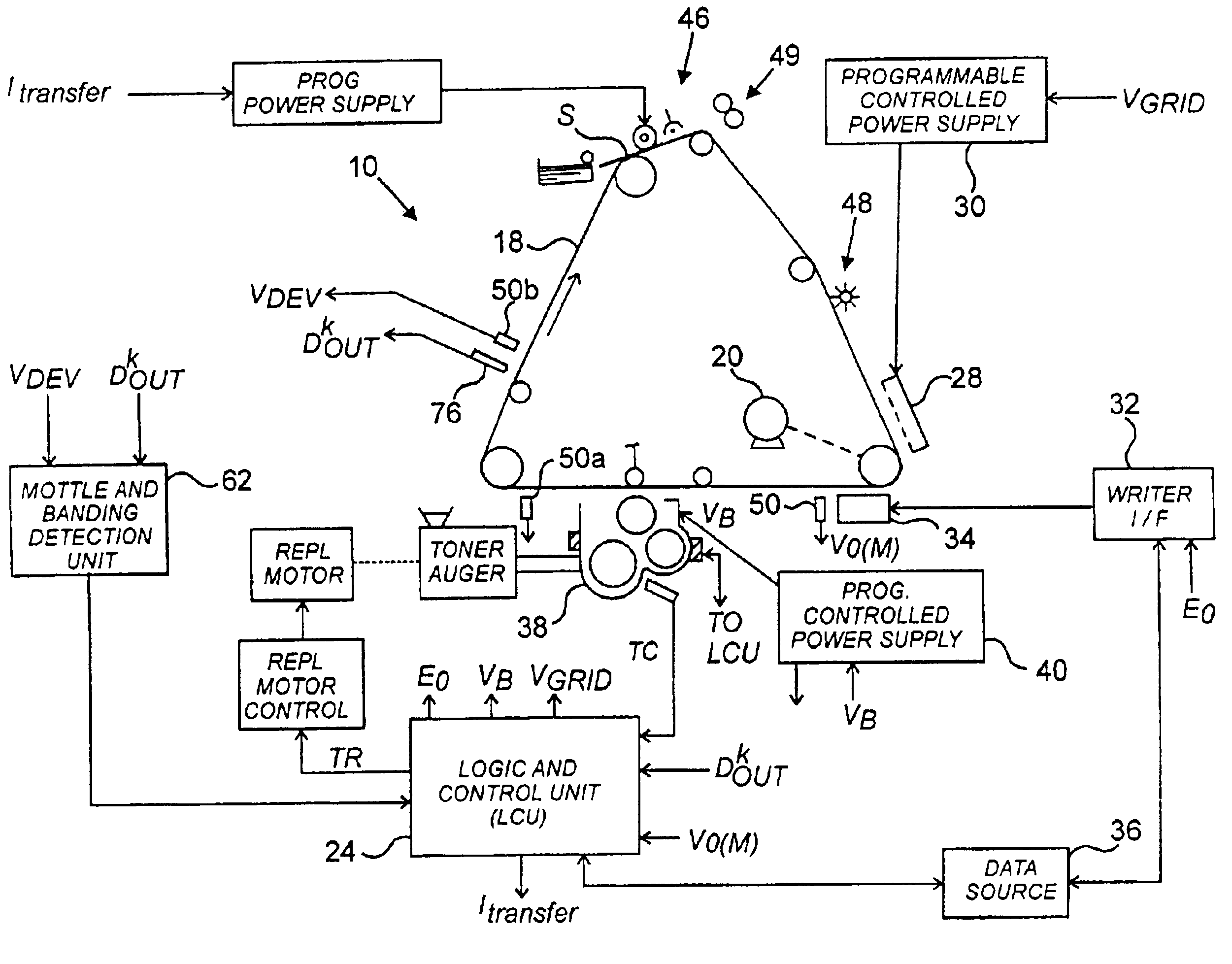

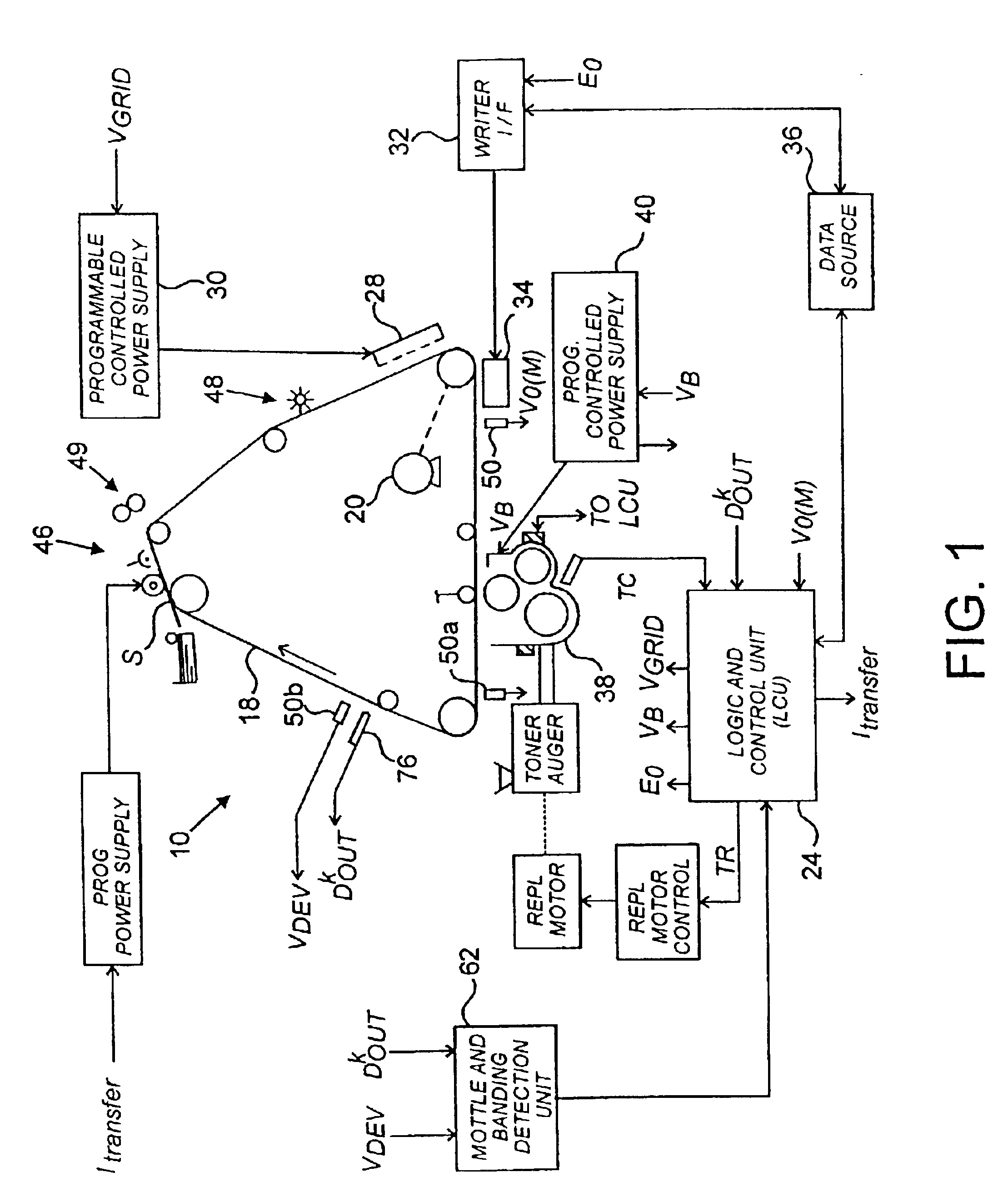

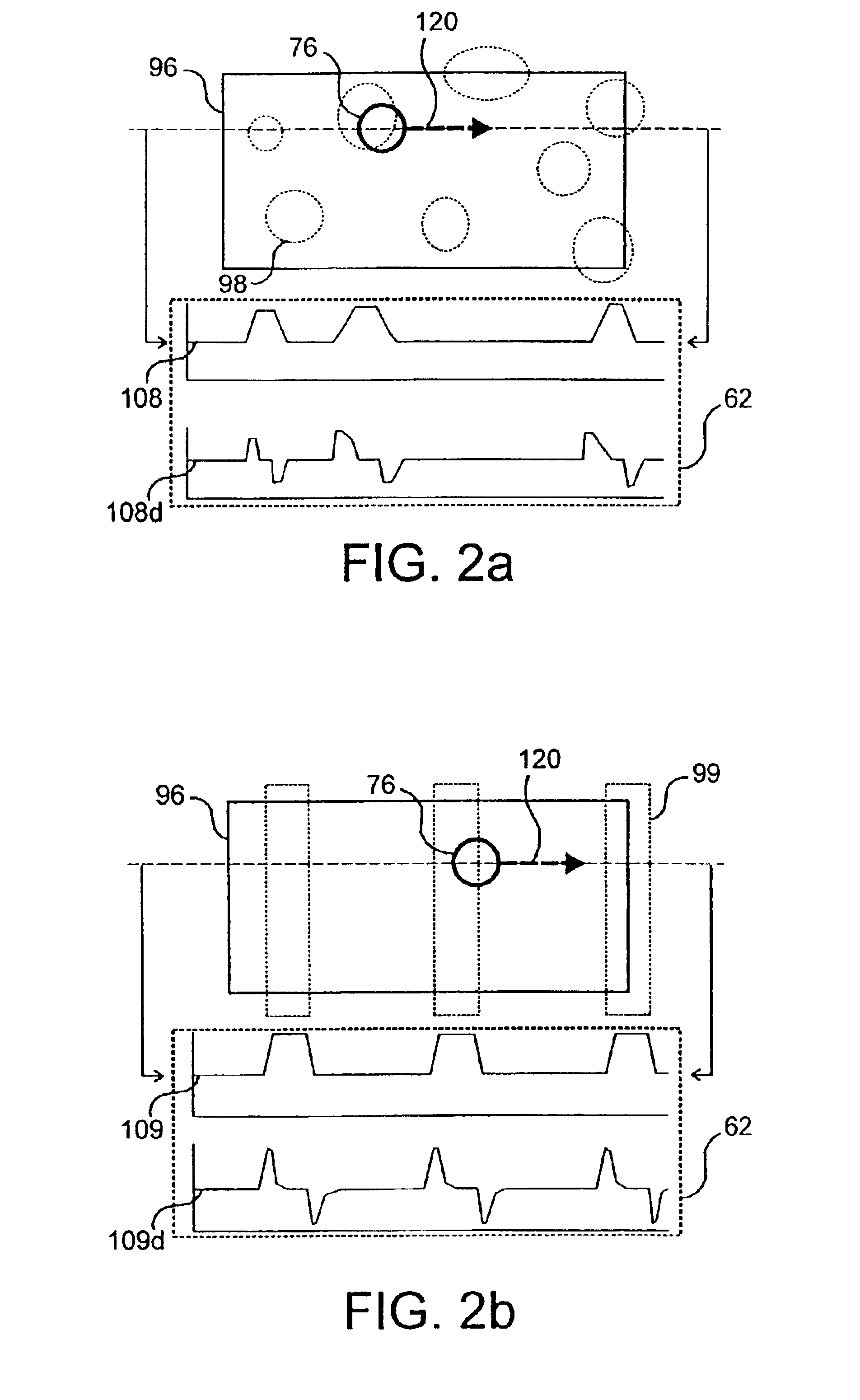

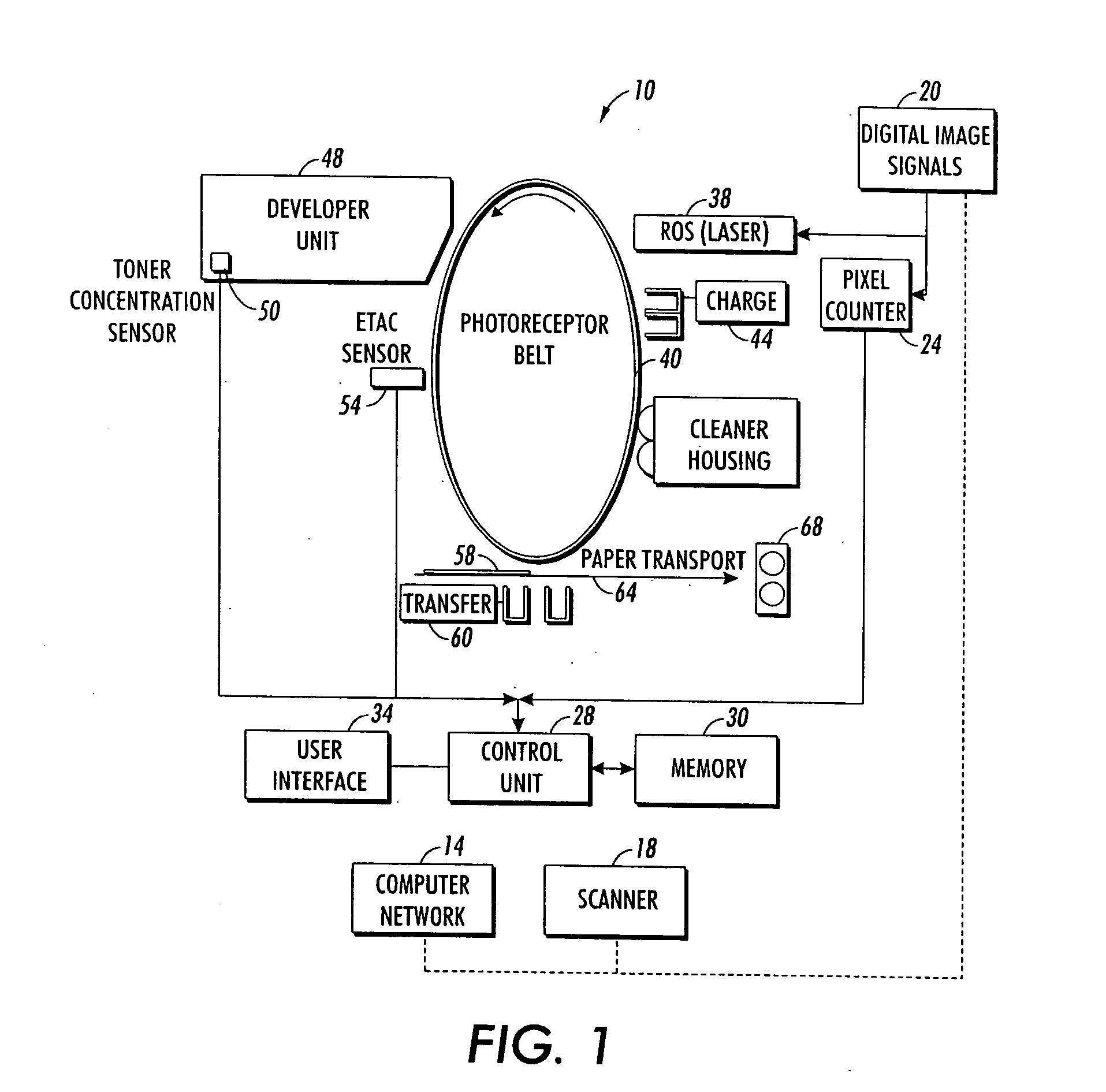

Reduction of banding and mottle in electrophotographic systems

A mechanism and process for detecting mottle or banding in a developed electrophotographic image. Within an electrophotographic reproduction apparatus 10, a photoconductor is used for receiving and developing a latent image. The photoconductor traverses a path that passes a charging station 28, an exposure station 34, a toning station 38, and a transfer station 46. Either a densitometer 76 for measuring the density of the developed image on the photoconductor, or an electrometer 50a or 50b for detecting the voltage of the image on the photoconductor, detects mottle or banding on the developed image. The densitometer 76 or electrometer 50a or 50b has an aperture small enough to detect mottle or banding with wavelengths perceptible by human eyes. A logic and control unit 24 averages the image density or voltage measurements, calculates the variations of the measurements about the average and the periodicities of the measurements, and if the variations or periodicities indicate mottle or banding is present, changes the operation of one or more stations to reduce mottle or banding.

Owner:EASTMAN KODAK CO +1

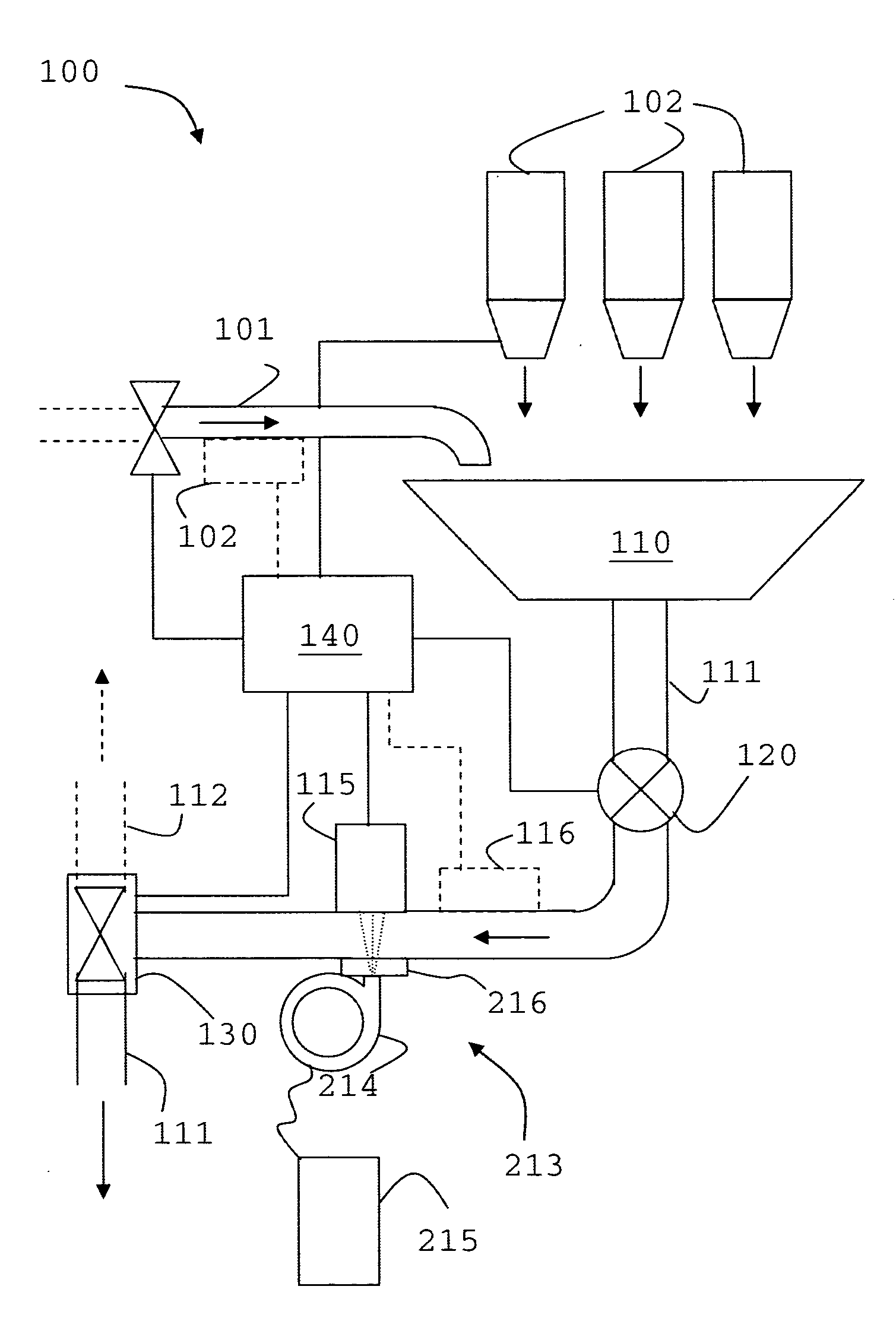

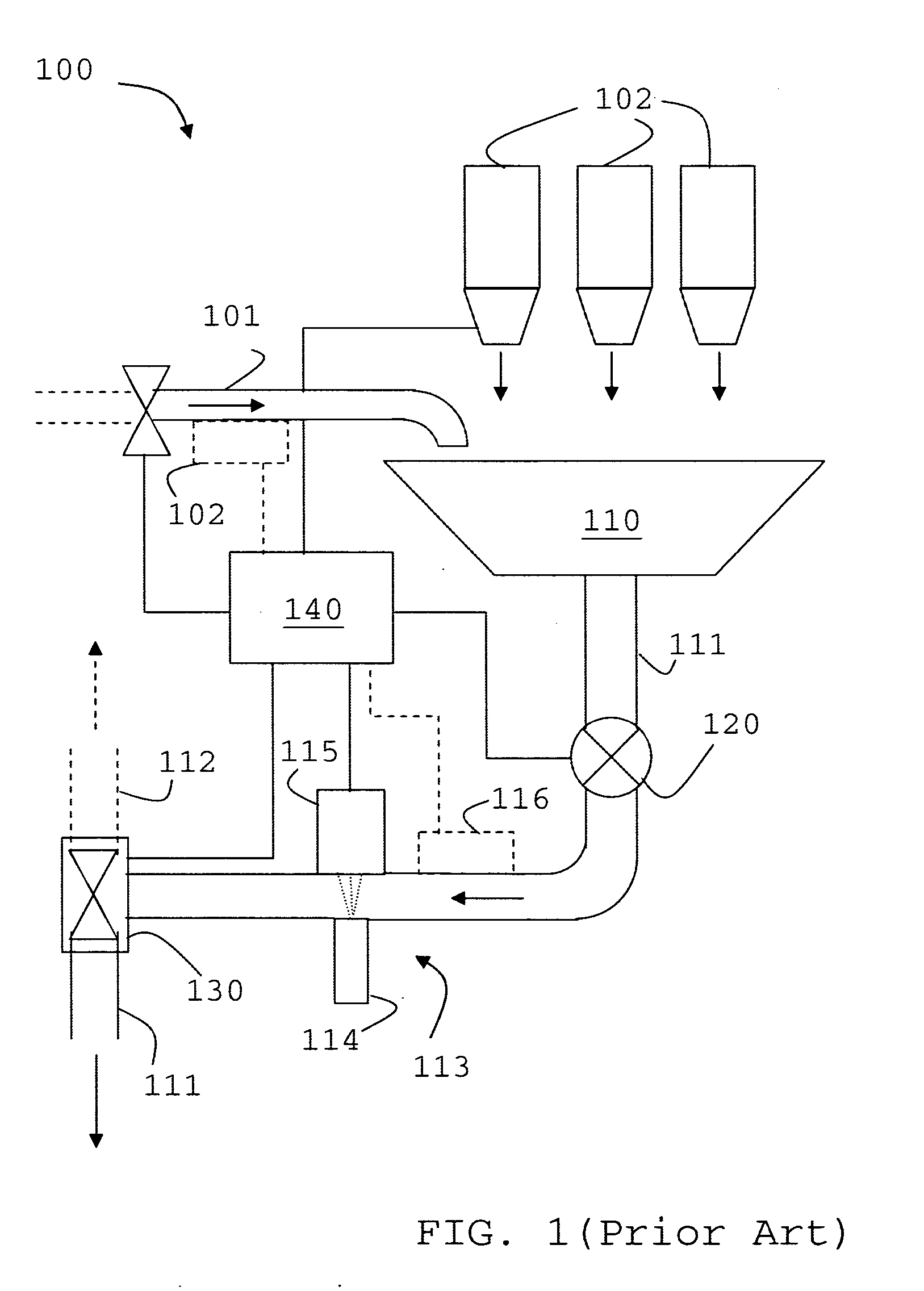

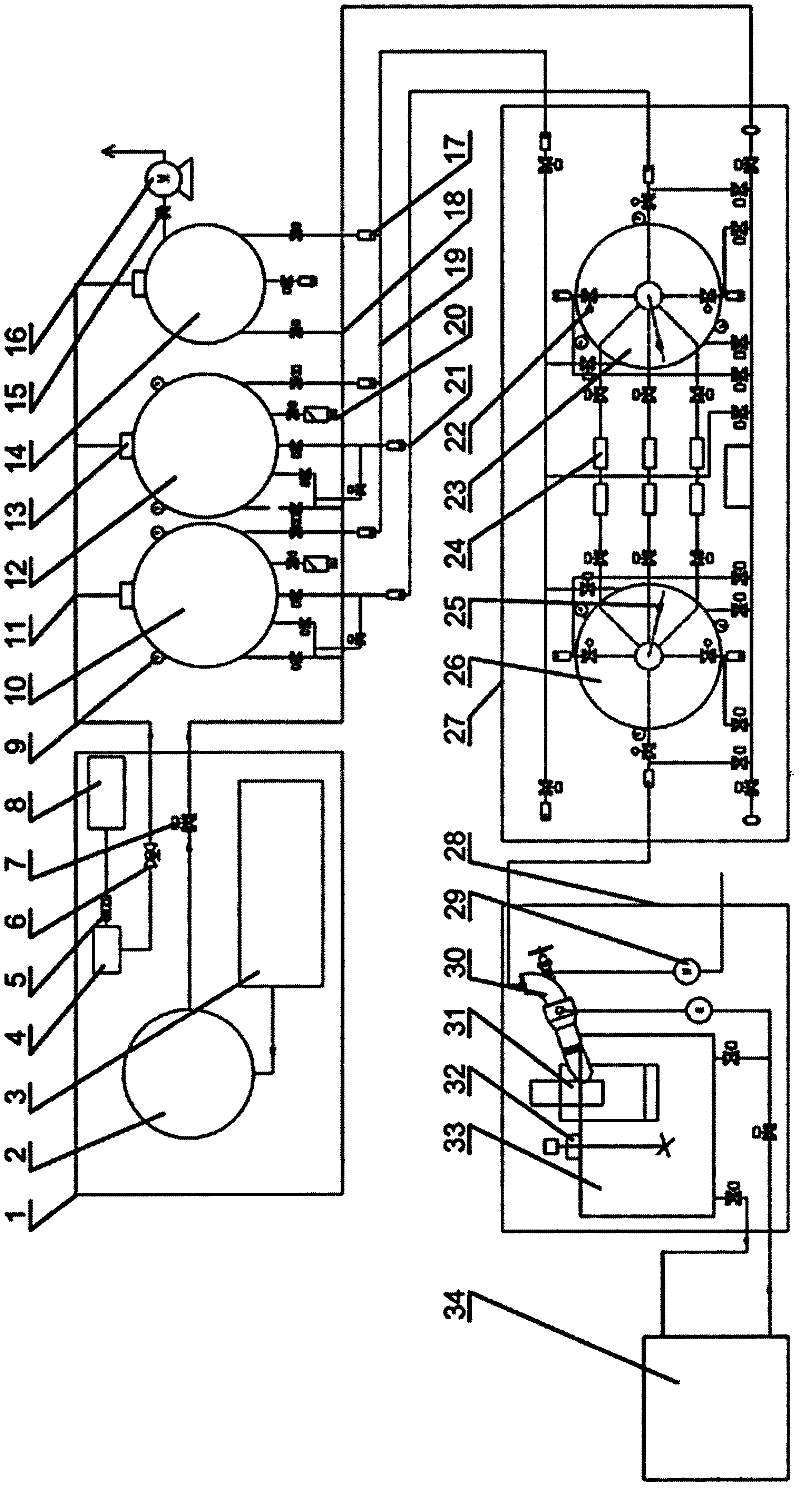

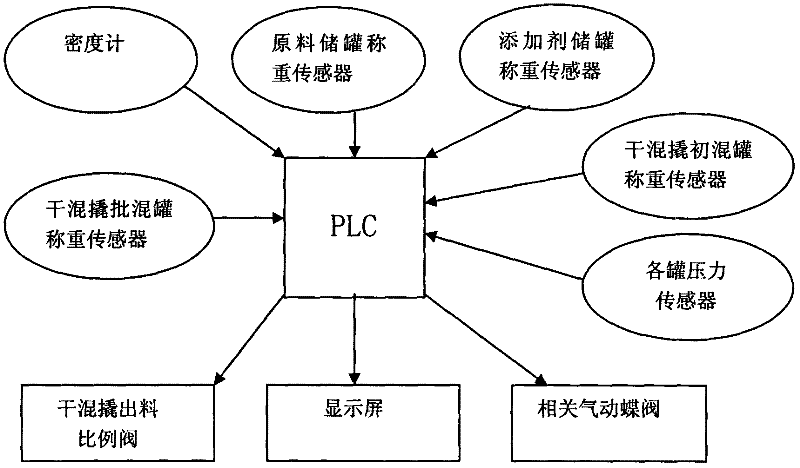

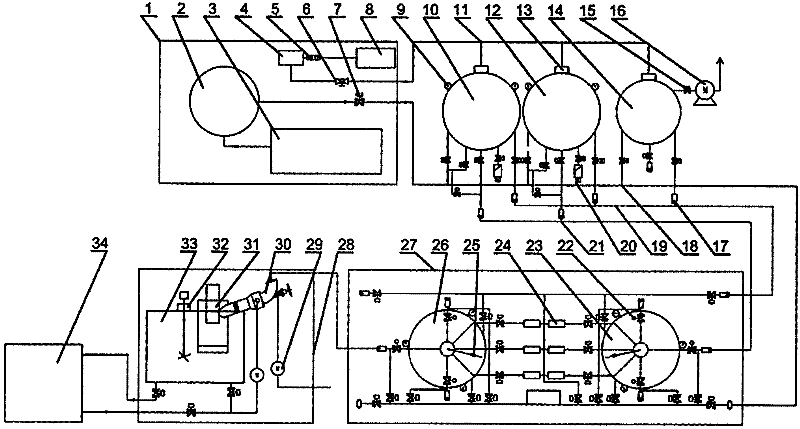

System for automatically and quickly distributing drilling liquid

InactiveCN102418484ASolve precise measurementSolve densityConstructionsMixer accessoriesAutomatic controlHigh energy

The invention discloses a system for automatically and quickly distributing drilling liquid. The system comprises a programmable logic controller (PLC) automatic control system, an air source system, a storage system, a dry mixing system and a slurry mixing system; the air source system comprises an air storage tank, a large-scale air compressor, a dry cooling machine, a small-scale air compressor and an air supply pipeline which are uniformly distributed on a forced draught fan package; the storage system comprises a raw material storage tank, an additive storage tank, a dust removal tank, weighing sensors which are arranged at bottoms of the raw material storage tank and the additive storage tank, a raw material gas conveying pipeline and a dust removal pipeline; the dry mixing system comprises a primary mixing tank and a batch mixing tank which are arranged on a dry mixing package, weighing sensors which are arranged at bottoms of the primary mixing tank and the batch mixing tank, a primary mixing pipeline, a batch mixing pipeline, and a primary mixing tank and batch mixing tank mixing circulation pipeline; and the slurry mixing system comprises a stirring pool, a stirrer which is arranged on the middle part of the stirring pool, a diffusion groove which is formed on one side of the stirrer, a high-energy mixer which is arranged on the upper part of the diffusion groove, a slurry mixing pipeline, a slurry conveying pipeline and a densitometer which is arranged on the slurry conveying pipeline; and all the systems are matched to realize automatic slurry distribution.

Owner:山东胜油固井工程技术有限公司

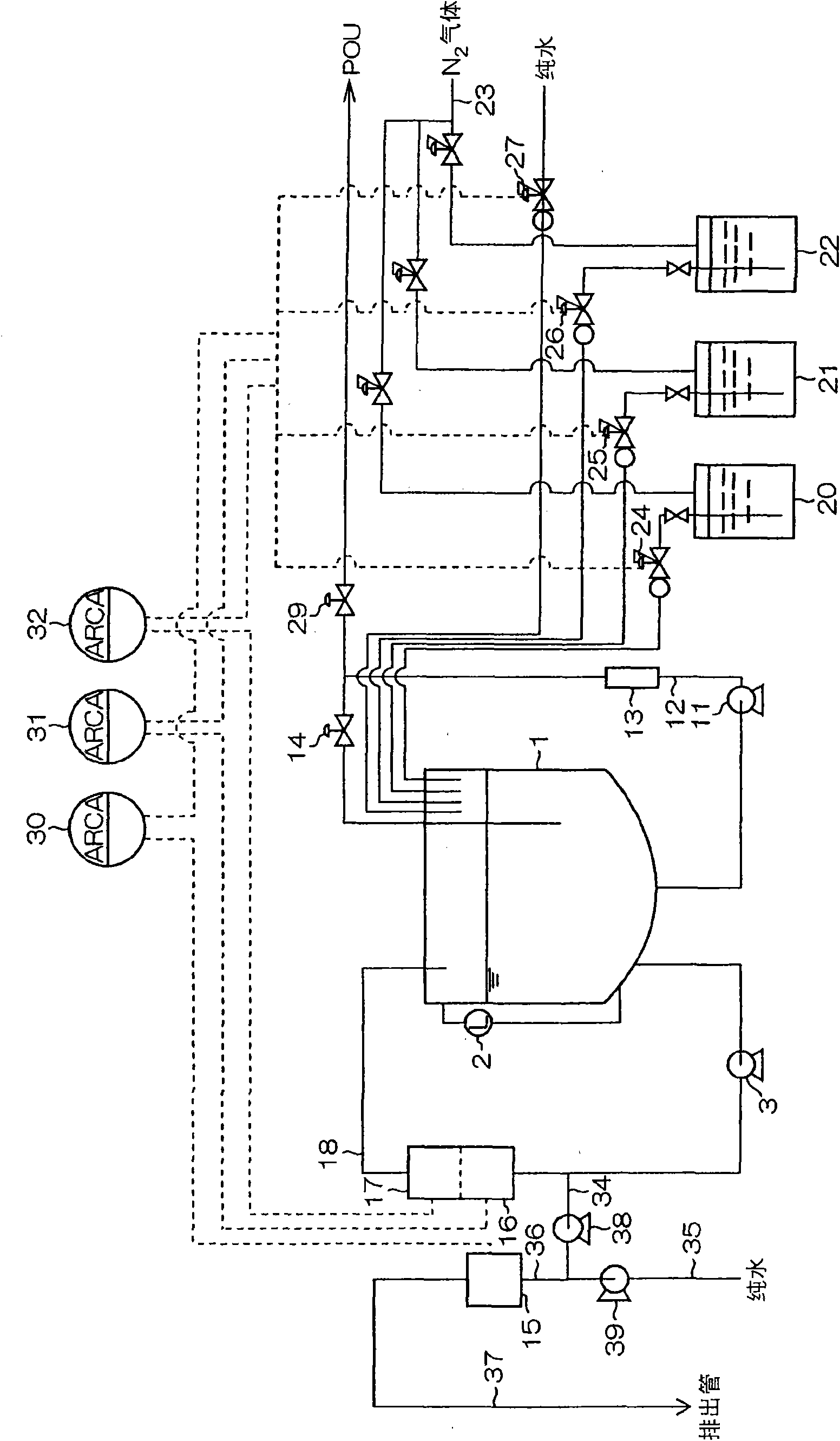

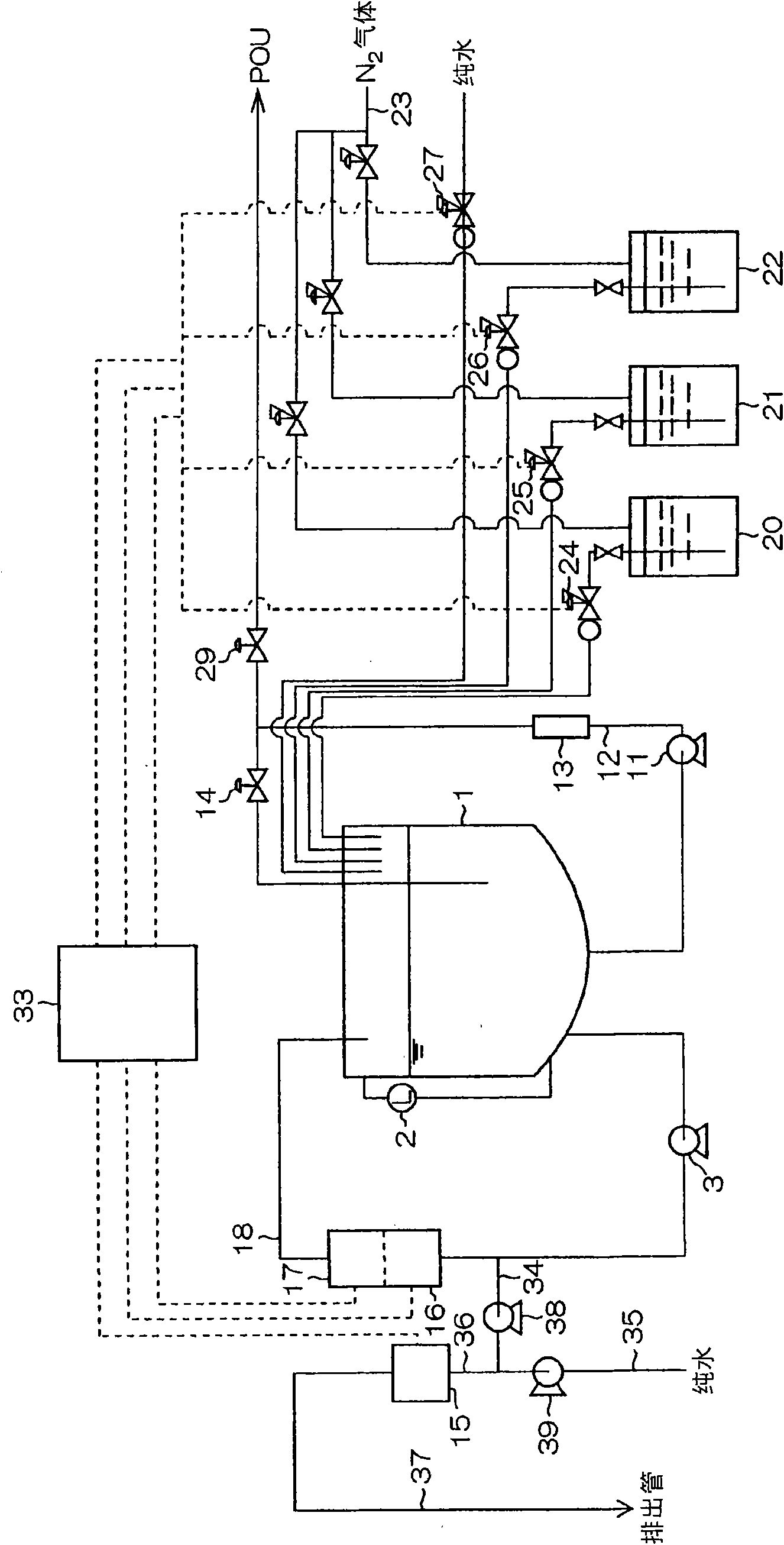

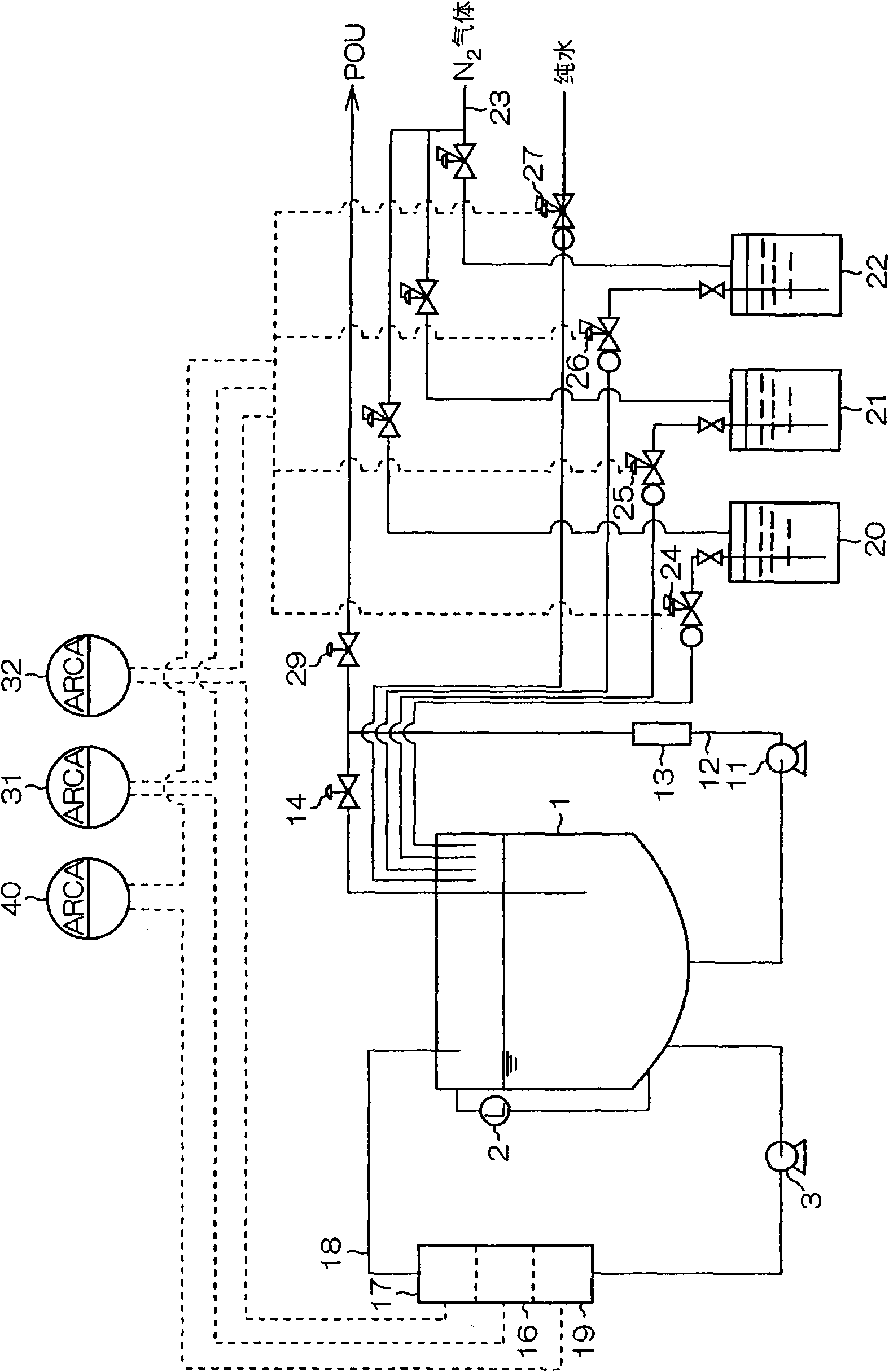

Device for blending etching solution and device for determinating concetration of etching solution

InactiveCN101567309AReal-time continuous determination of nitric acid concentrationGood and constant accuracySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingPhosphoric acidDisplay device

The present invention provides a etching solution blending device which is used in a semiconductor manufacturing works or flat-panel display manufacturing works and is capable of constantly blending nitric acid concentration, moisture concentration, phosphoric acid concentration and acetic acid concentration of the etching solution. The device comprises: an electric conductivity meter for detecting the electric conductivity of the dilution formed by adding pure water into etching solution in a blending tank or an absorption spectrophotometer for detecting the nitric acid concentration of the etching solution, an absorption spectrophotometer for detecting the moisture concentration of the etching solution, an absorption spectrophotometer or a densitometer for detecting the phosphoric acid concentration of the nitric acid, a component concentration operation mechanism for operating the component concentration of the etching solution by multi-component operation method according to the electric conductivity value of the nitric acid concentration conductivity meter, the absorbency value of the moisture concentration absorption spectrophotometer, and the absorbency value of the phosphoric acid concentration absorption spectrophotometer or the density value of the densitometer, and a replenishing mechanism for replenishing at least one of acid original solution, mixed acid original solution and pure water into the blending tank.

Owner:HIRAMA LAB

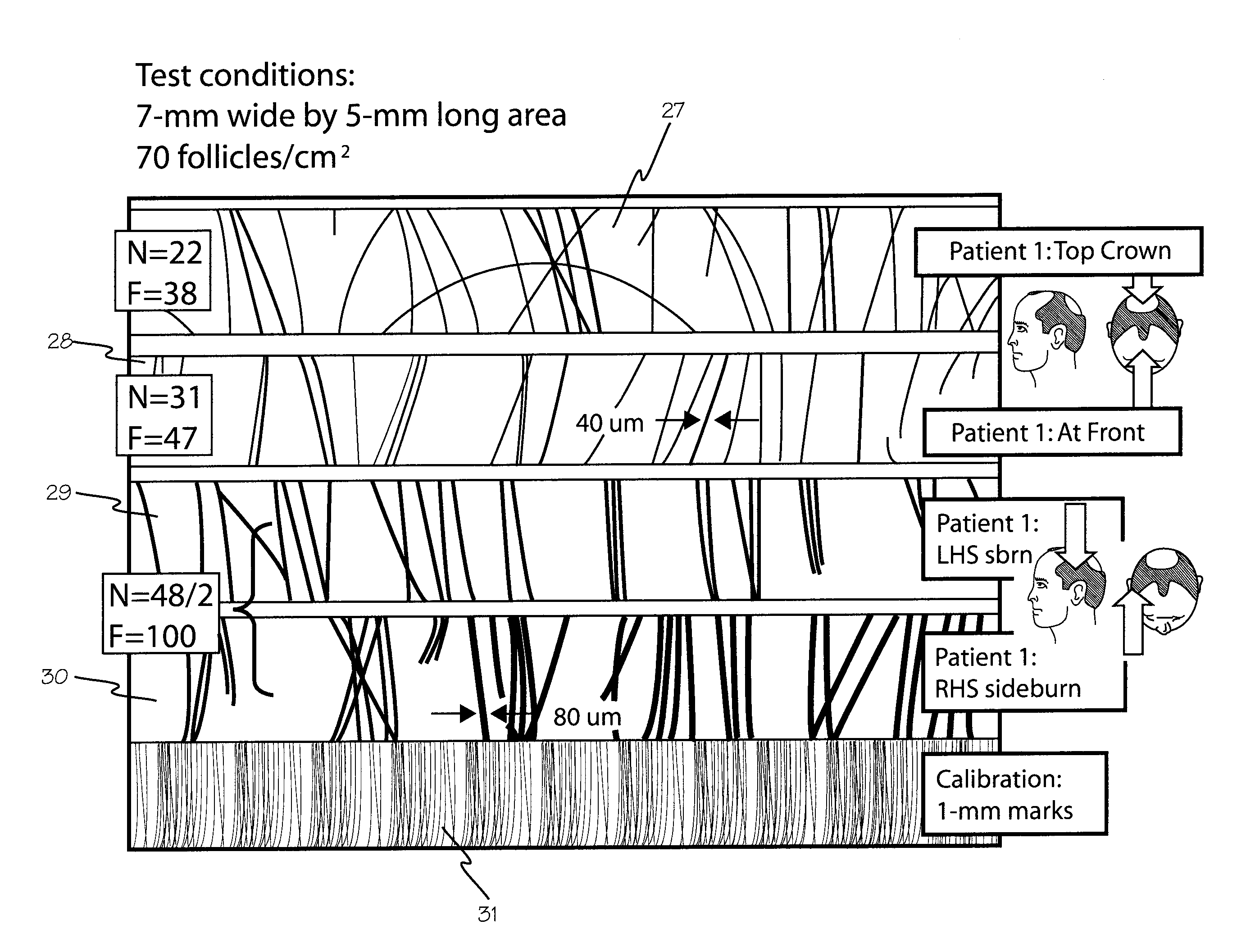

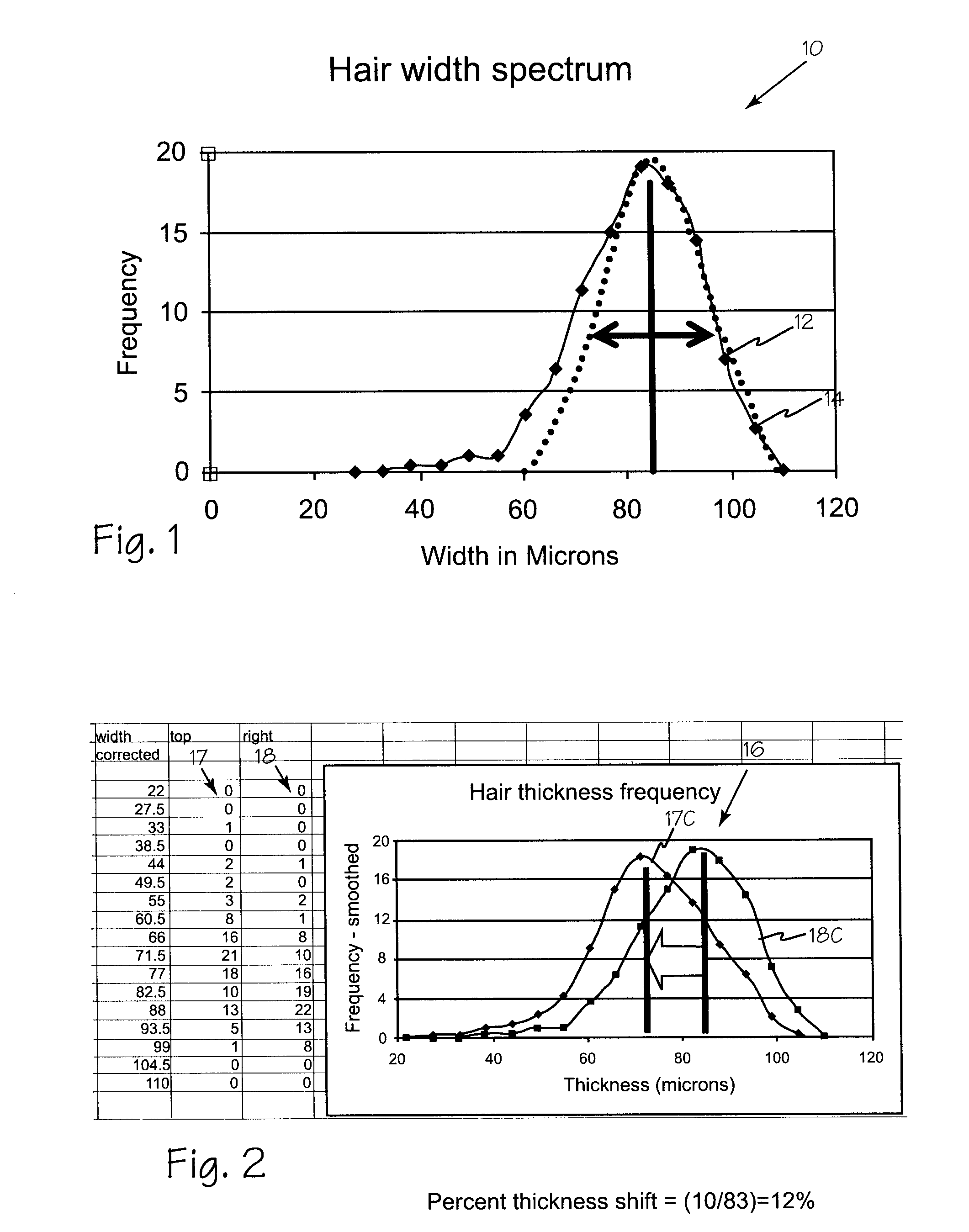

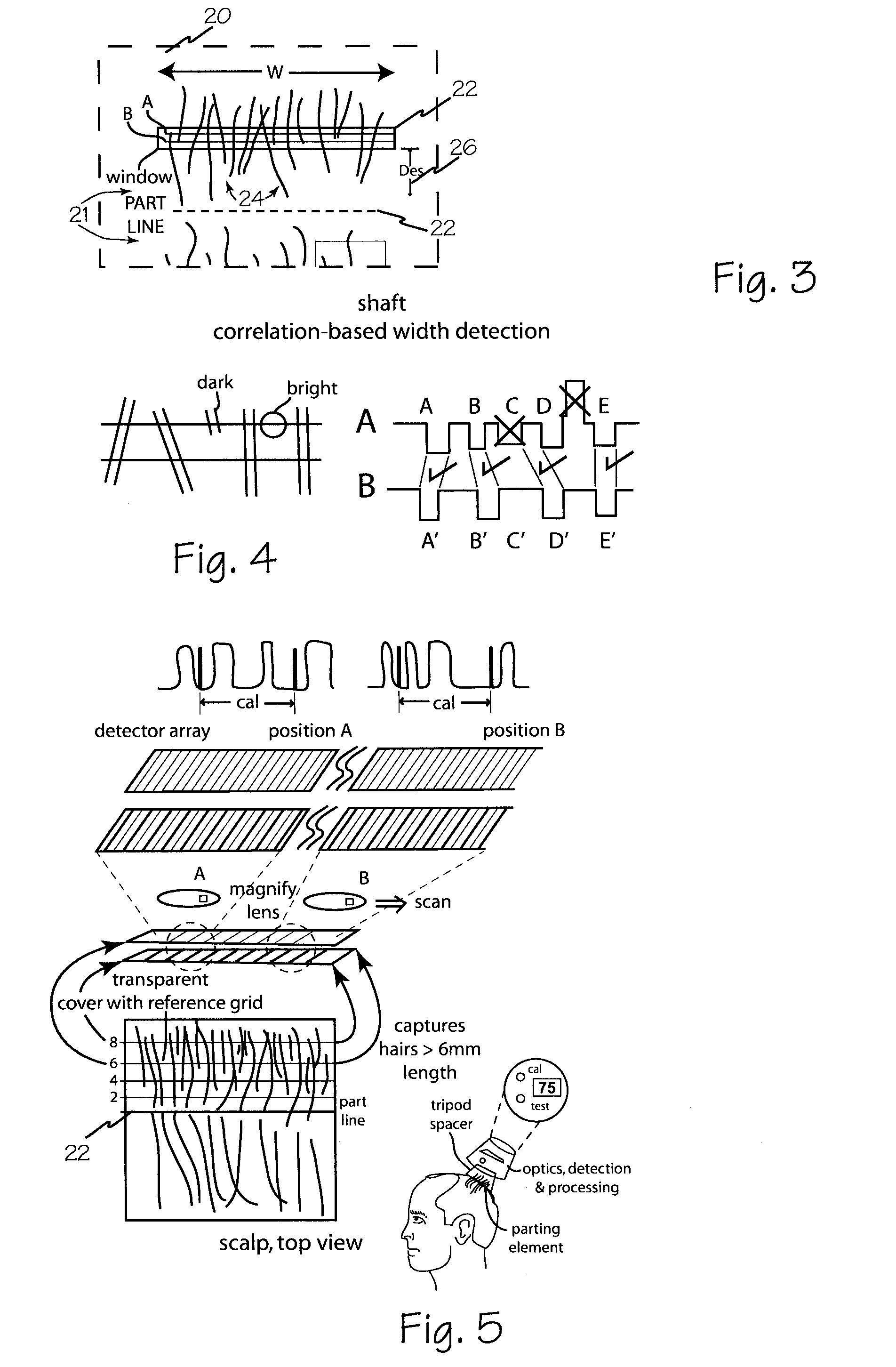

Hair Densitometer

A hair densitometer measures the number of hair shafts in a fixed area and measures the diameters of the counted hair shafts. This is done for two different areas of the head and the comparison results in a quantified measure of the thinning of a persons hair on their head.

Owner:RABIN MICHAEL +2

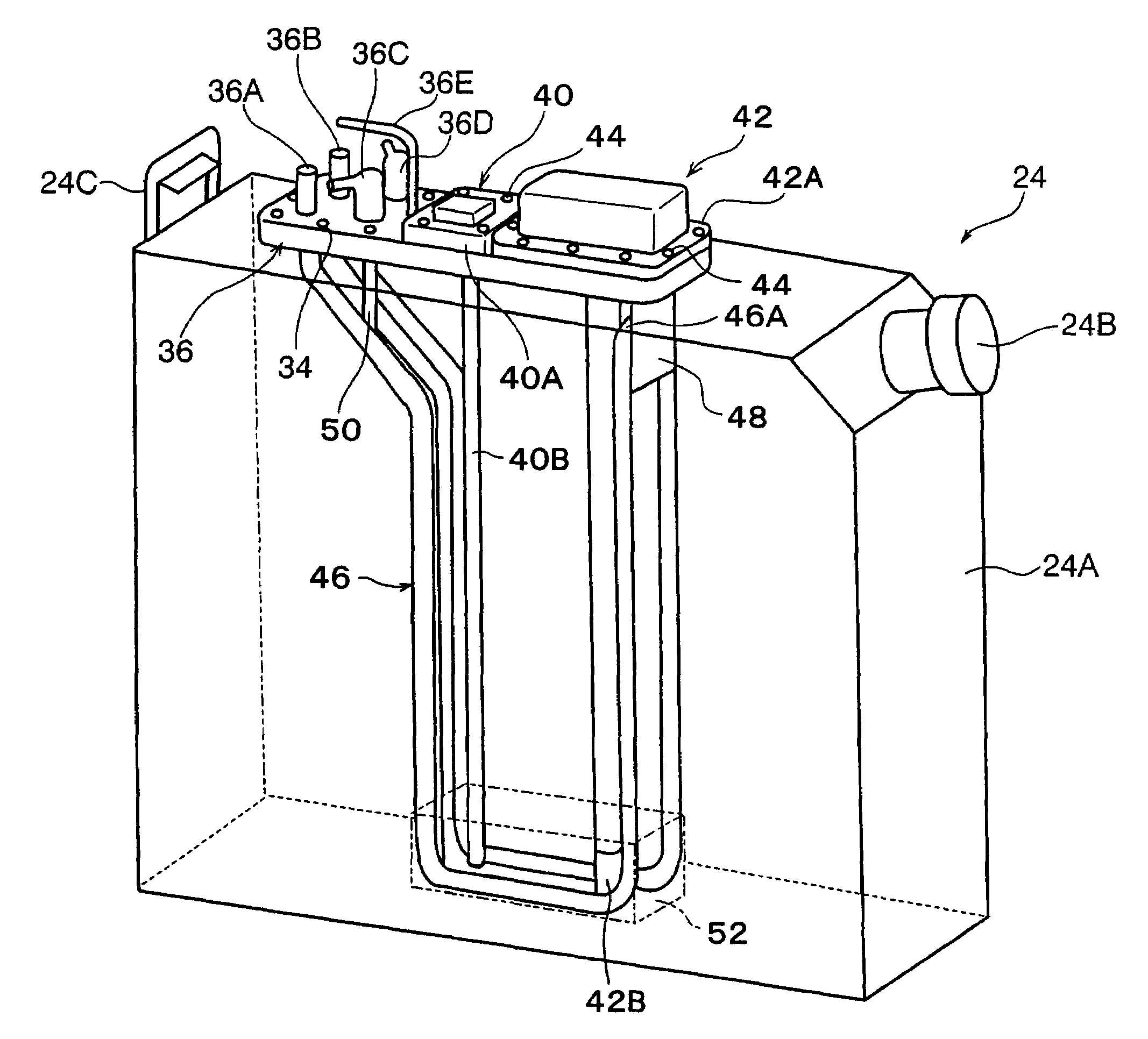

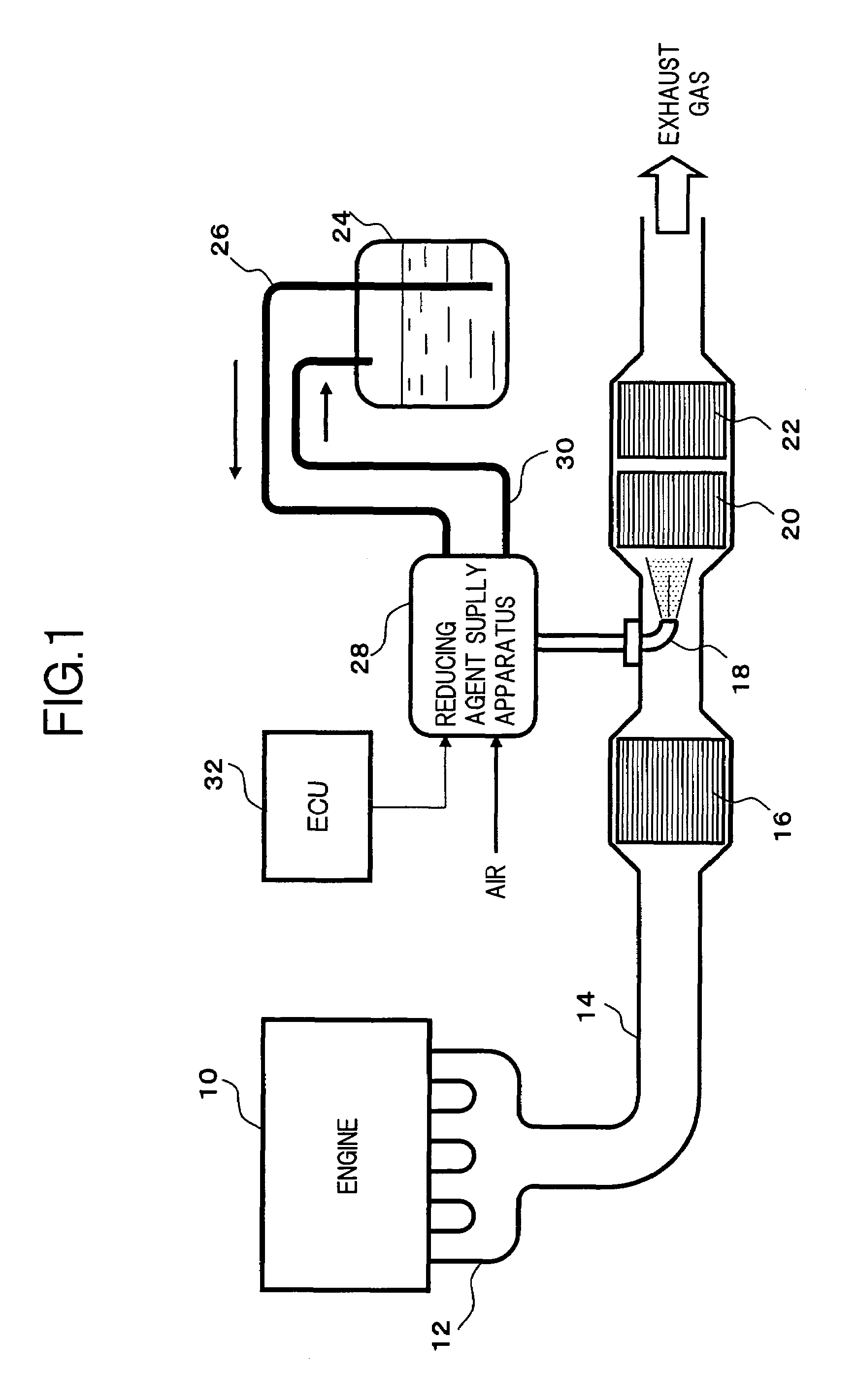

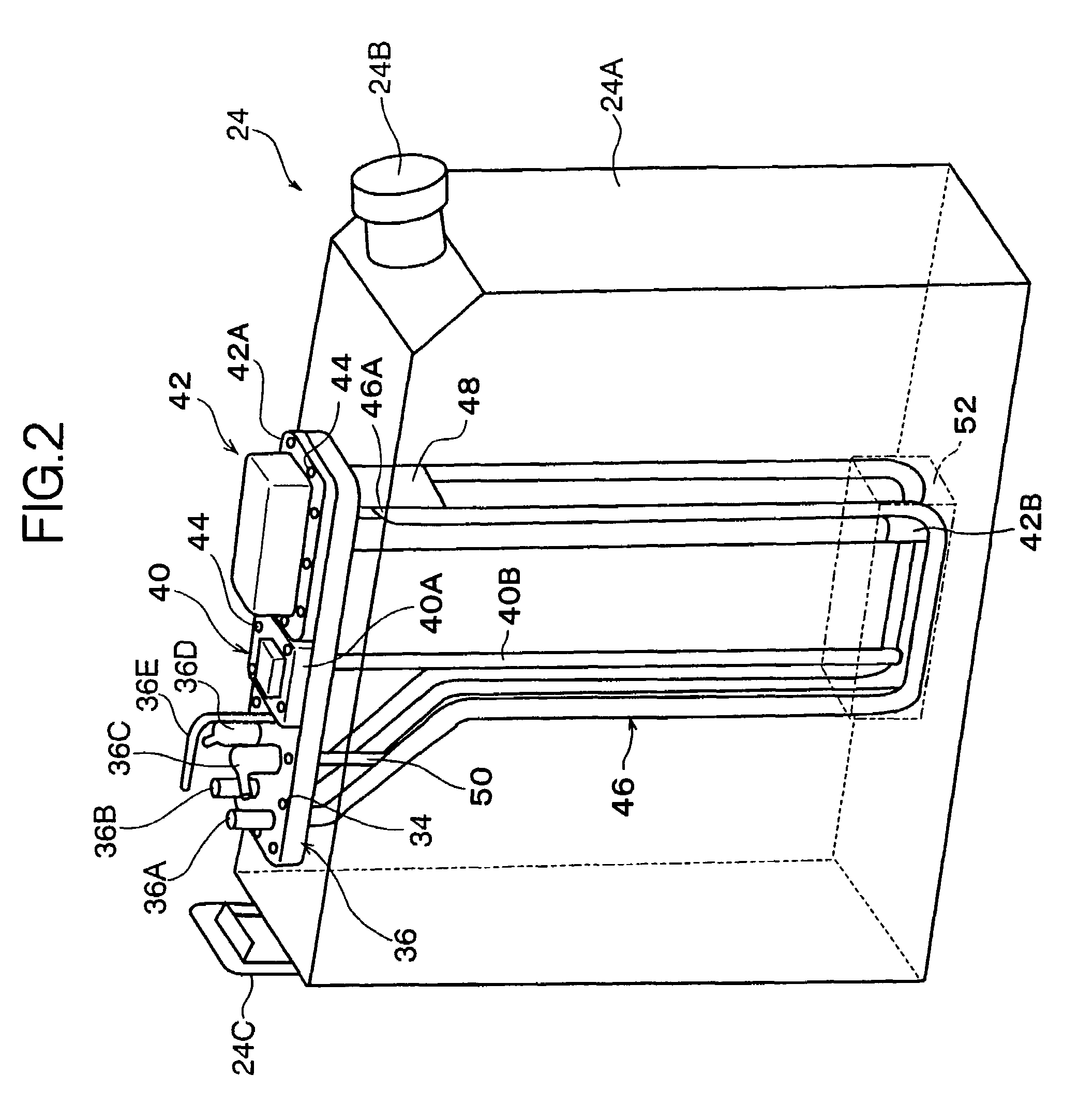

Structure for reducing agent container

ActiveUS7544328B2Reduce inspectionReduce maintenanceTesting/calibration apparatusNitrogen compoundsEngineeringTank container

Owner:NISSAN DIESEL MOTOR CO

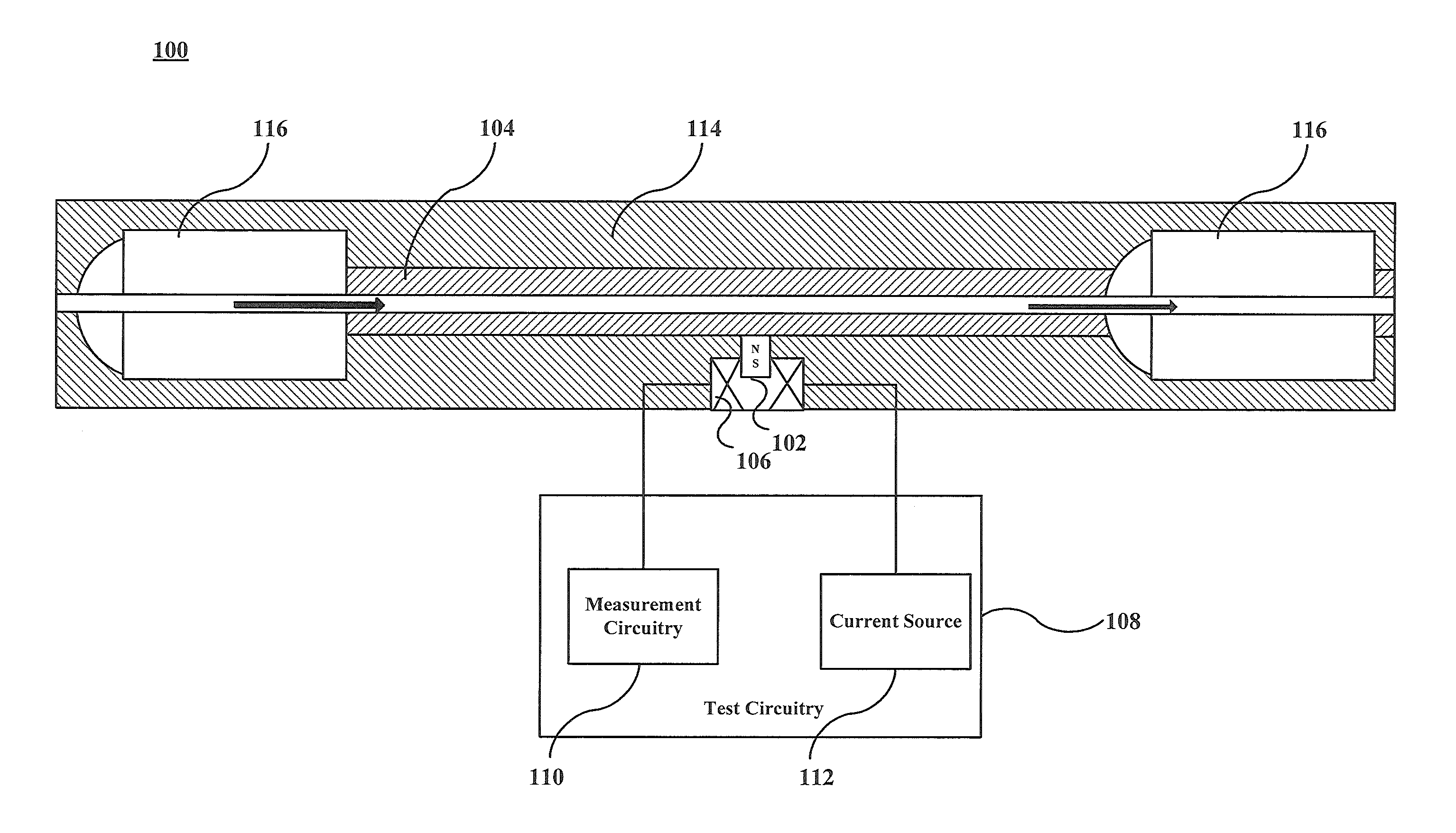

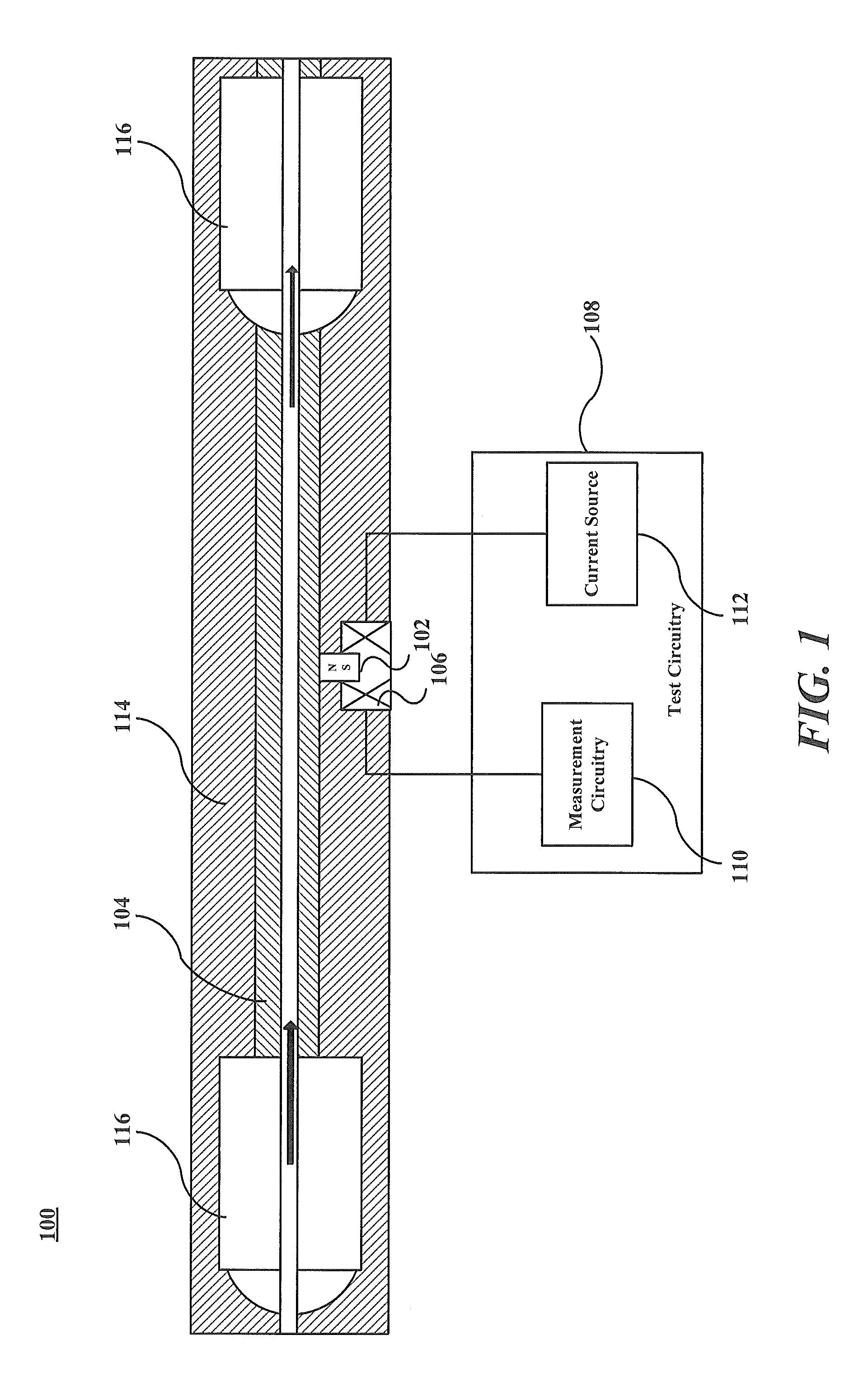

Fluid densitometer with temperature sensor to provide temperature correction

ActiveUS20130180330A1Thermometer detailsSpecific gravity using flow propertiesThermodynamicsFluid density

A sensor for measuring a density of a fluid is provided. The sensor (200) includes a flow tube (104) for receiving the fluid and a vibration driver (102) coupled to the flow tube, the vibration driver configured to drive the flow tube to vibrate. The sensor also includes a vibration detector (106) coupled to the flow tube, the vibration detector detecting characteristics related to the vibrating flow tube, and a distributed temperature sensor (202) coupled to the flow tube, the distributed temperature sensor measuring a temperature of the flow tube as the flow tube vibrates. The sensor further includes measurement circuitry (110) coupled to the vibration detector and the distributed temperature sensor, the measurement circuitry determining a density of the fluid from the detected characteristics related to the vibrating flow tube and the measured temperature of the flow tube.

Owner:HALLIBURTON ENERGY SERVICES INC

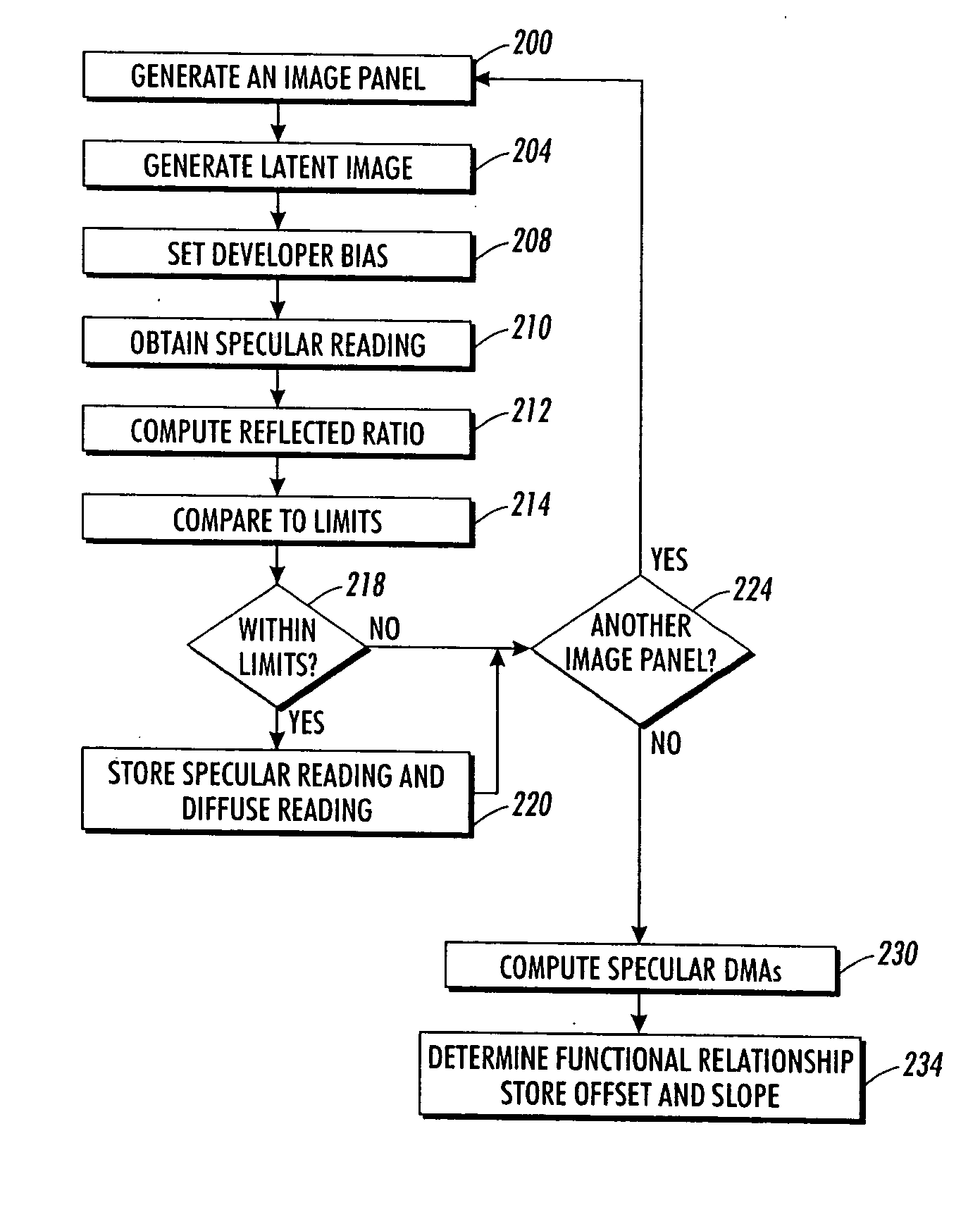

Method and system for calibrating a reflection infrared densitometer in a digital image reproduction machine

ActiveUS20060024077A1Extended Density RangeHigh voltageRadiation pyrometryScattering properties measurementsEngineeringFunctional Relationship

An enhanced toner area coverage (ETAC) sensor may be calibrated to adjust for changes in LED intensity by determining a functional relationship between specular developed mass per unit area (DMA) values and diffuse readings obtained from the sensor. Specular and diffuse readings are obtained from an ETAC sensor that senses reflected light from toner patches generated with incrementally increasing densities on the photoreceptor belt. The specular readings in a particular range and their corresponding diffuse readings are selected for the calibration computations. Reflected ratios are computed from the specular readings and used to determine specular DMAs. The specular DMAs and selected diffuse readings define a set of points for which a functional relationship is determined.

Owner:XEROX CORP

Methods for automated uniformity assessment and modification of image non-uniformities

InactiveUS20050151974A1Quick feedbackShorten maintenance timeRadiation pyrometryColor measuring devicesFeature evaluationReference image

Methods for automated uniformity assessment and modification of image non-uniformities using an image measurement device capable of determining image reflectance and / or transmitter as a function of position, such as a spectrophotometer, a calorimeter, and / or a densitometer. One or more of these devices scan an image on a substrate, such as a sheet, thereby generating data representing image characteristics, such as, for example, image non-uniformity. The sheet may contain a reference / test pattern including one column, strip or patch intended to have a uniform density. This data generated by the device after the scan of the substrate is analyzed with signal processing algorithms for image characteristics assessment, including image spatial uniformity and compared to reference image characteristics including image spatial uniformity. An image modification profile may be generated to be applied to a marking system to thereby alter subsequent image data and improve image spatial uniformity of the marking system.

Owner:XEROX CORP

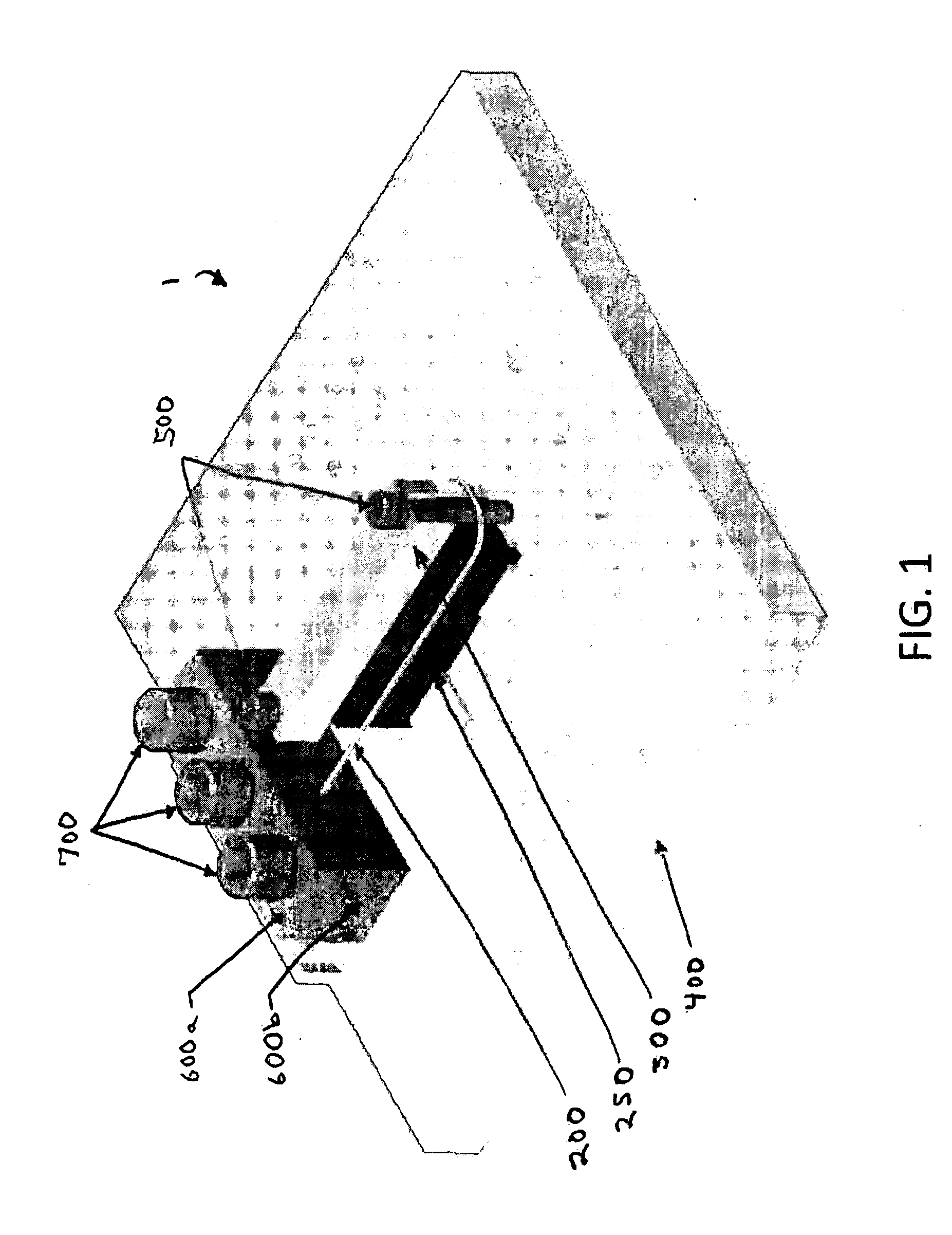

Single magnet fluid densitometer

An instrument for determining fluid properties is provided. The instrument (300) includes a tube (304) receiving the fluid, a single magnet (302) attached to the tube, and a single coil (306) wound around the single magnet. The single coil is coupled to a pulse current source (312) and receives a pulse current that creates a magnetic field in the single coil, the created magnetic field interacting with the single magnet to drive the tube to vibrate. The instrument further includes a detector (306) coupled to the tube, wherein the detector is coupled to measurement circuitry (310) and detects properties of the tube as it vibrates, and the measurement circuitry determines the fluid properties based on the detected properties. The instrument also includes a housing (314) enclosing the tube, the single magnet, and the single coil wound around the single magnet.

Owner:HALLIBURTON ENERGY SERVICES INC

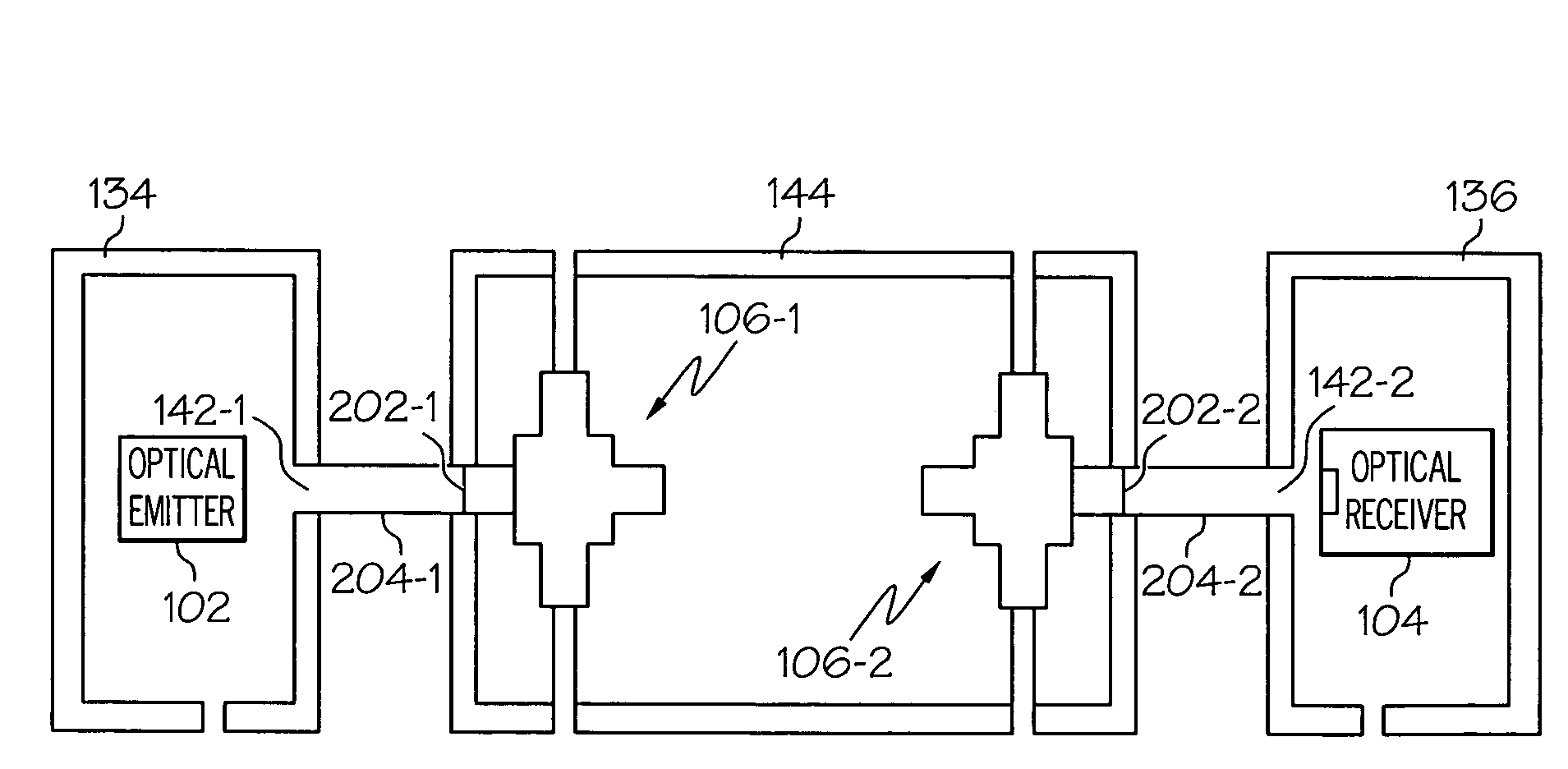

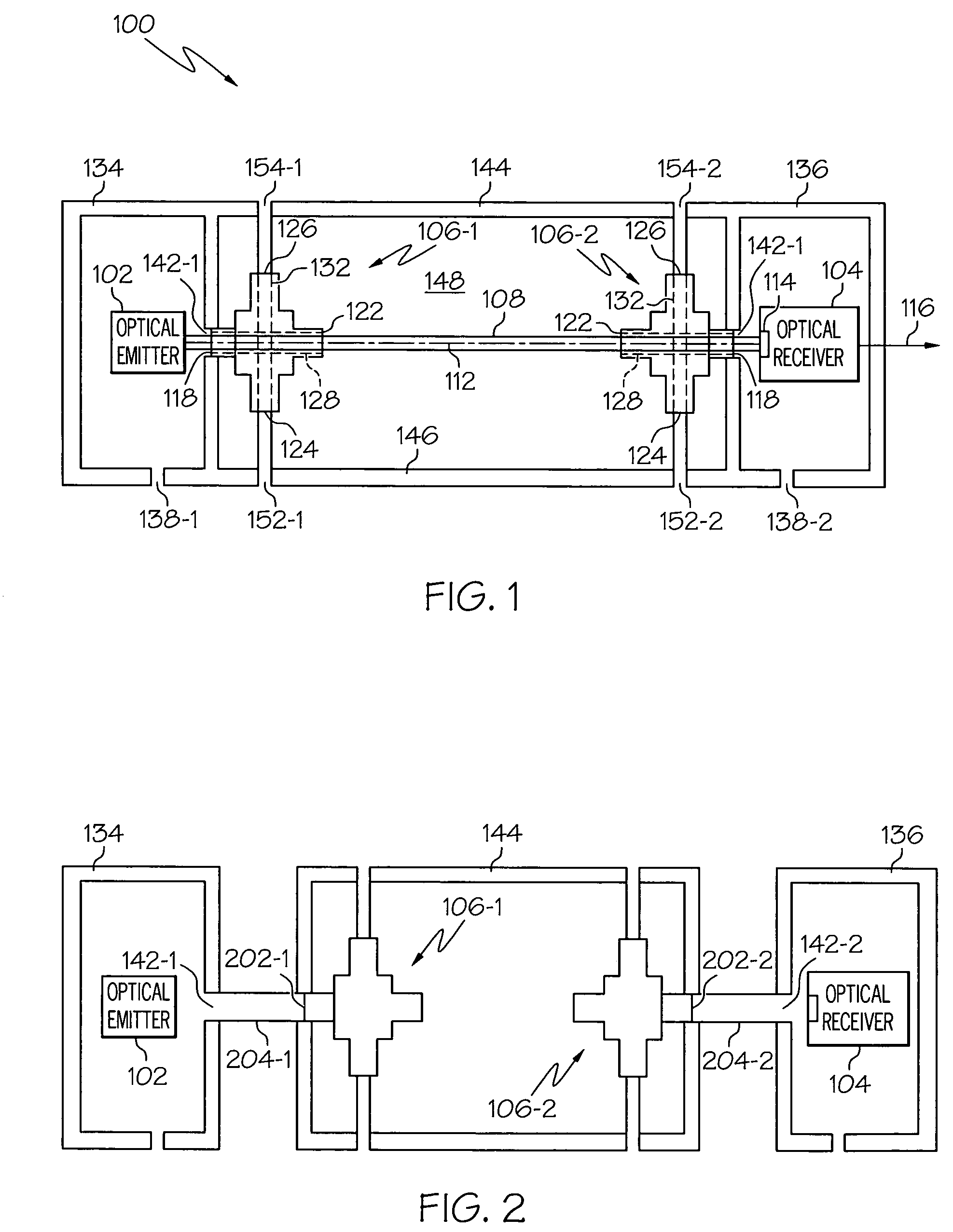

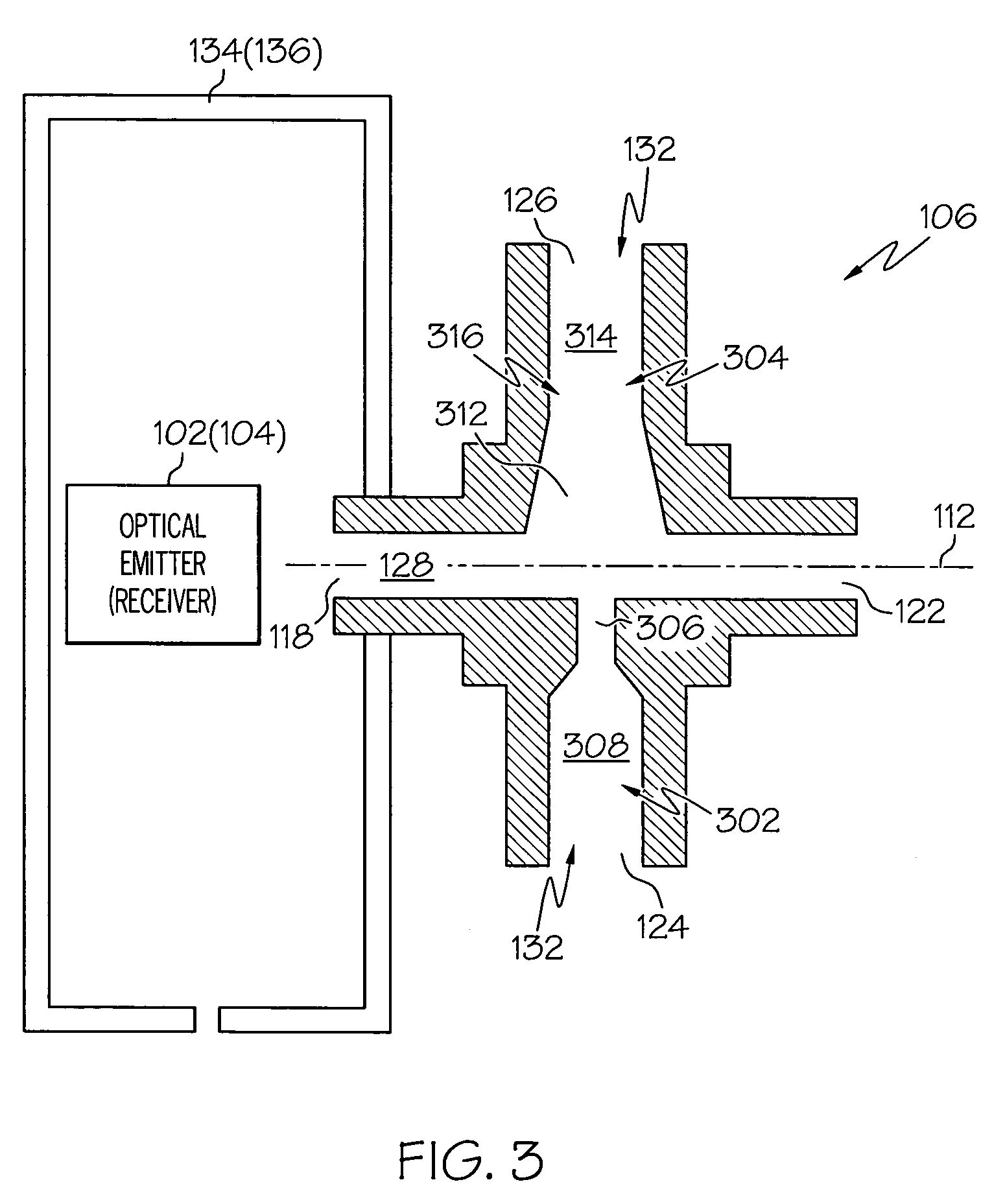

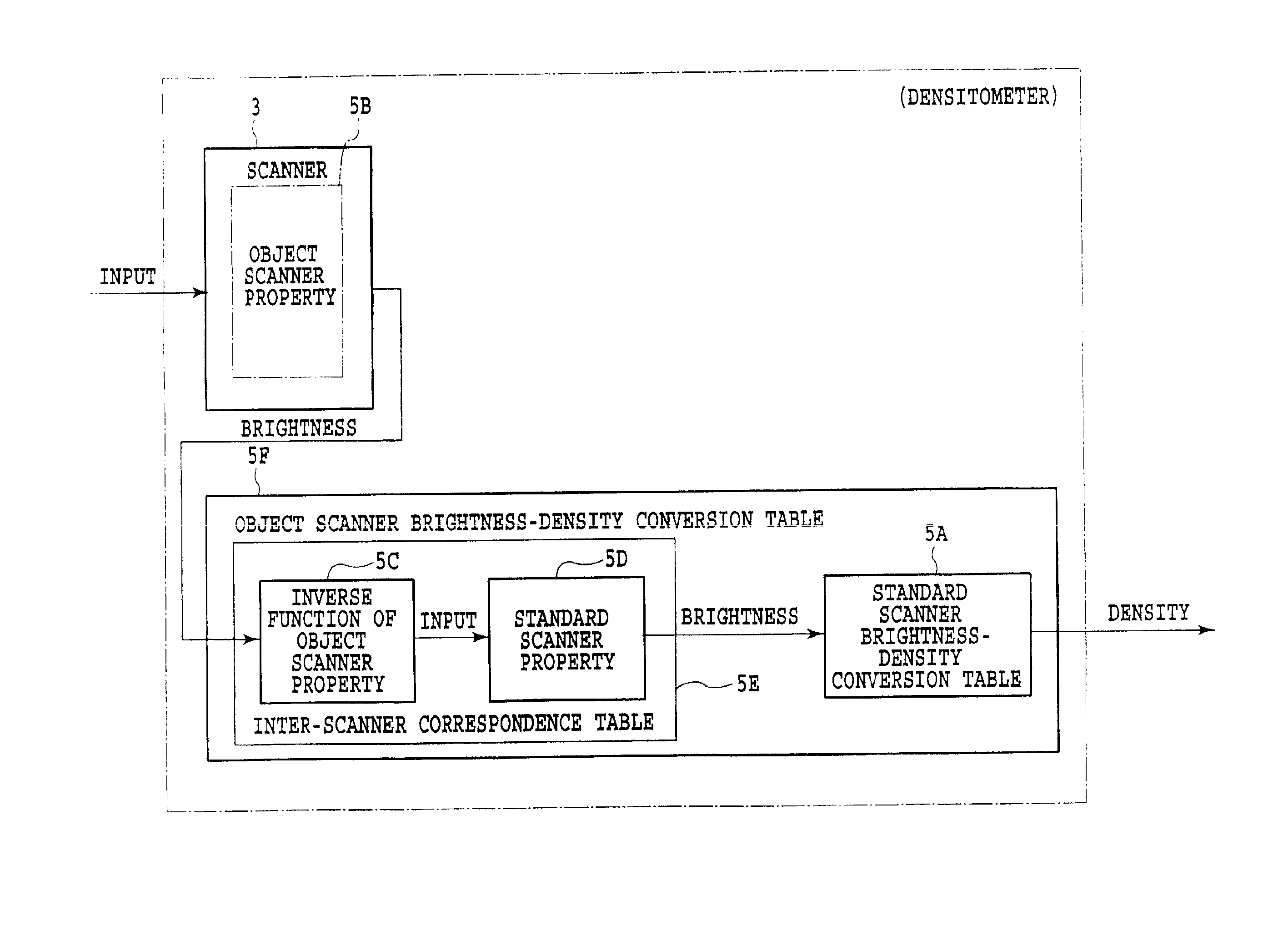

Air purged optical densitometer

An advanced gas purged optical densitometer that significantly decreases the likelihood of optical component contamination and unstable optical path reduction includes an optical emitter, an optical receiver, and an optical path purge device. The optical emitter emits a light beam along an optical axis, through the optical purge path device and a test fluid. The optical receiver receives the light beam after it traverses the optical path purge device and the test fluid, and supplies a signal representative of intensity of the received light beam. The optical path purge device is configured to prevent contamination of the optical emitter and optical receiver, and to maintain a substantially optical path length of the test fluid.

Owner:HONEYWELL INT INC

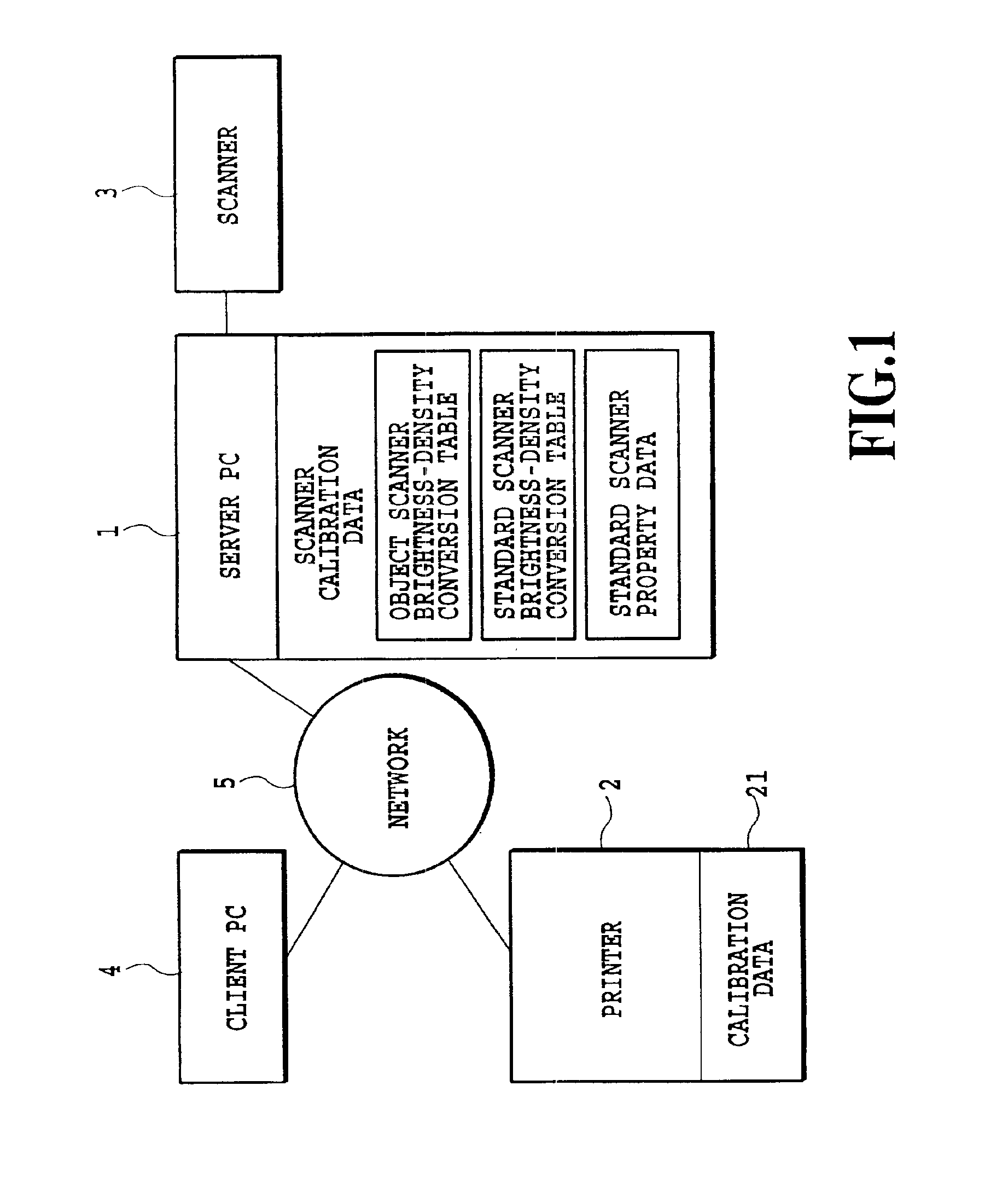

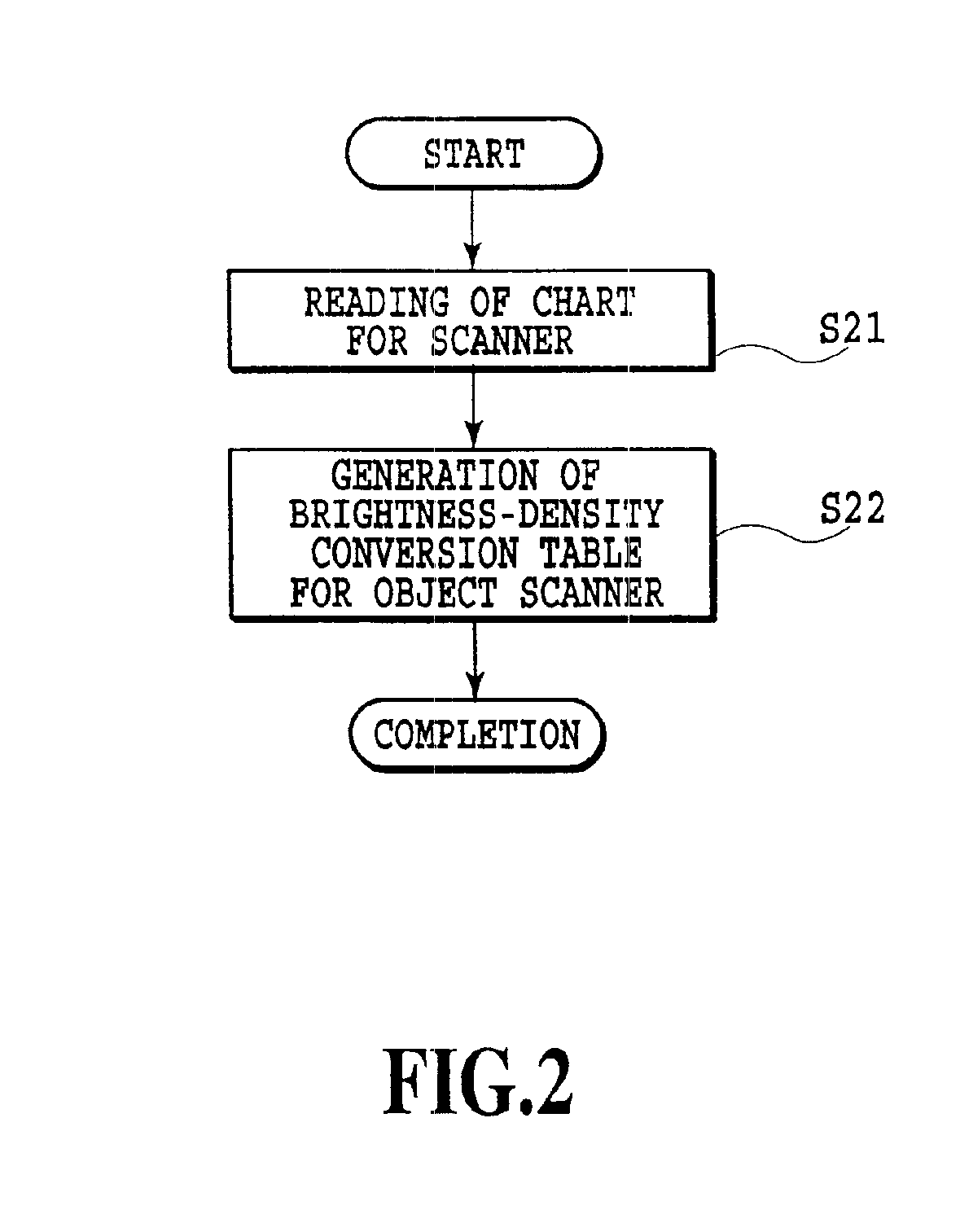

Image processing method of generating conversion data for a scanner and calibration method employing the scanner

InactiveUS6909814B1Improve accuracyReduce loadCharacter and pattern recognitionPictoral communicationImaging processingImaging data

A calibration for a scanner, which is used as a densitometer, is carried out always with high accuracy. More specifically, an image processing method of generating a conversion condition for a scanner which is used for reading an image and generating image data, is provided. The method including the steps of: obtaining a reading property of an object scanner based on image data obtained by that the object scanner reads a chart, and generating the conversion condition for the object scanner based on the reading property of the object scanner, a previously prepared reading property of a standard scanner and a previously prepared brightness-density conversion condition for the standard scanner.

Owner:CANON KK

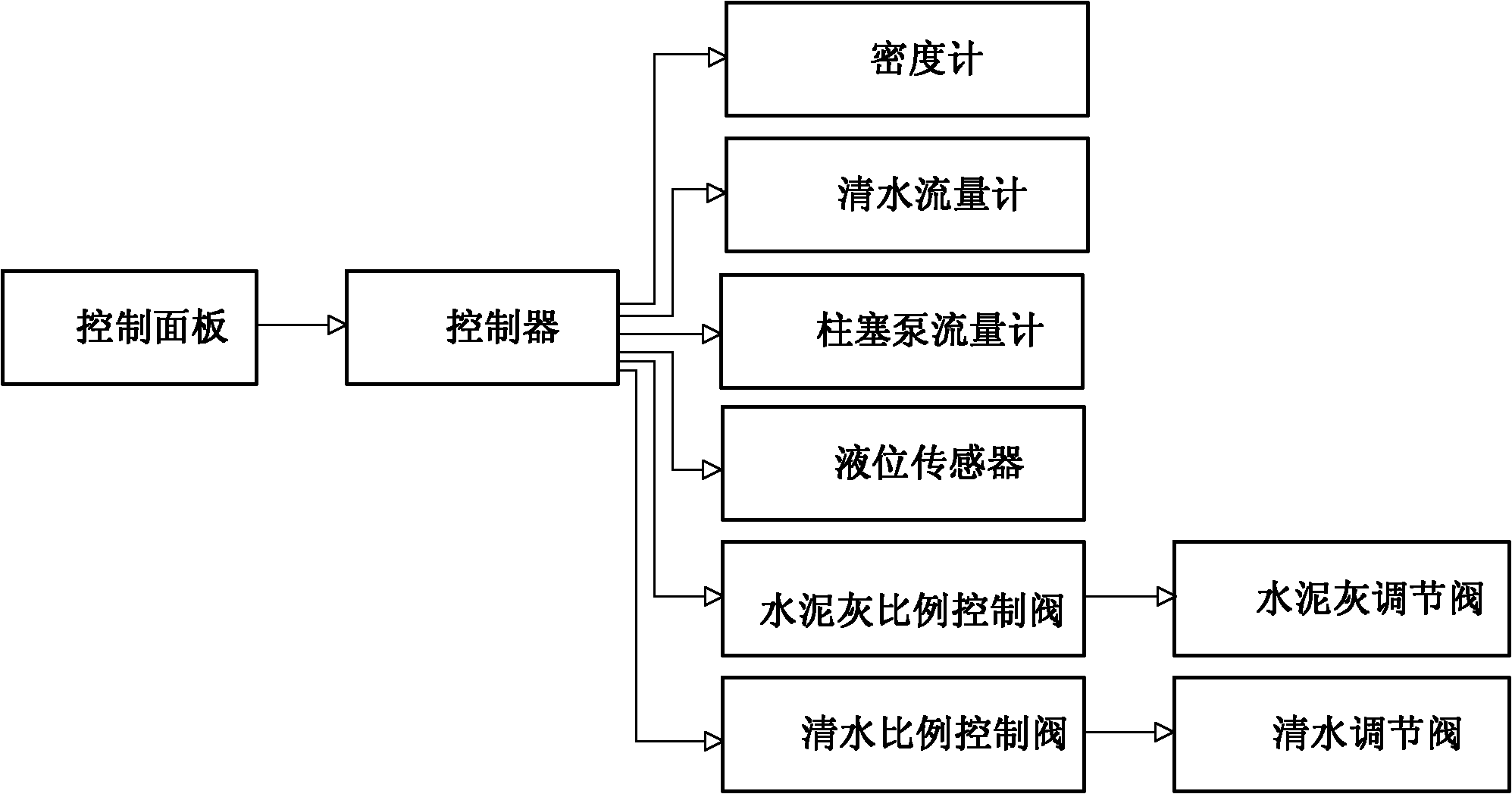

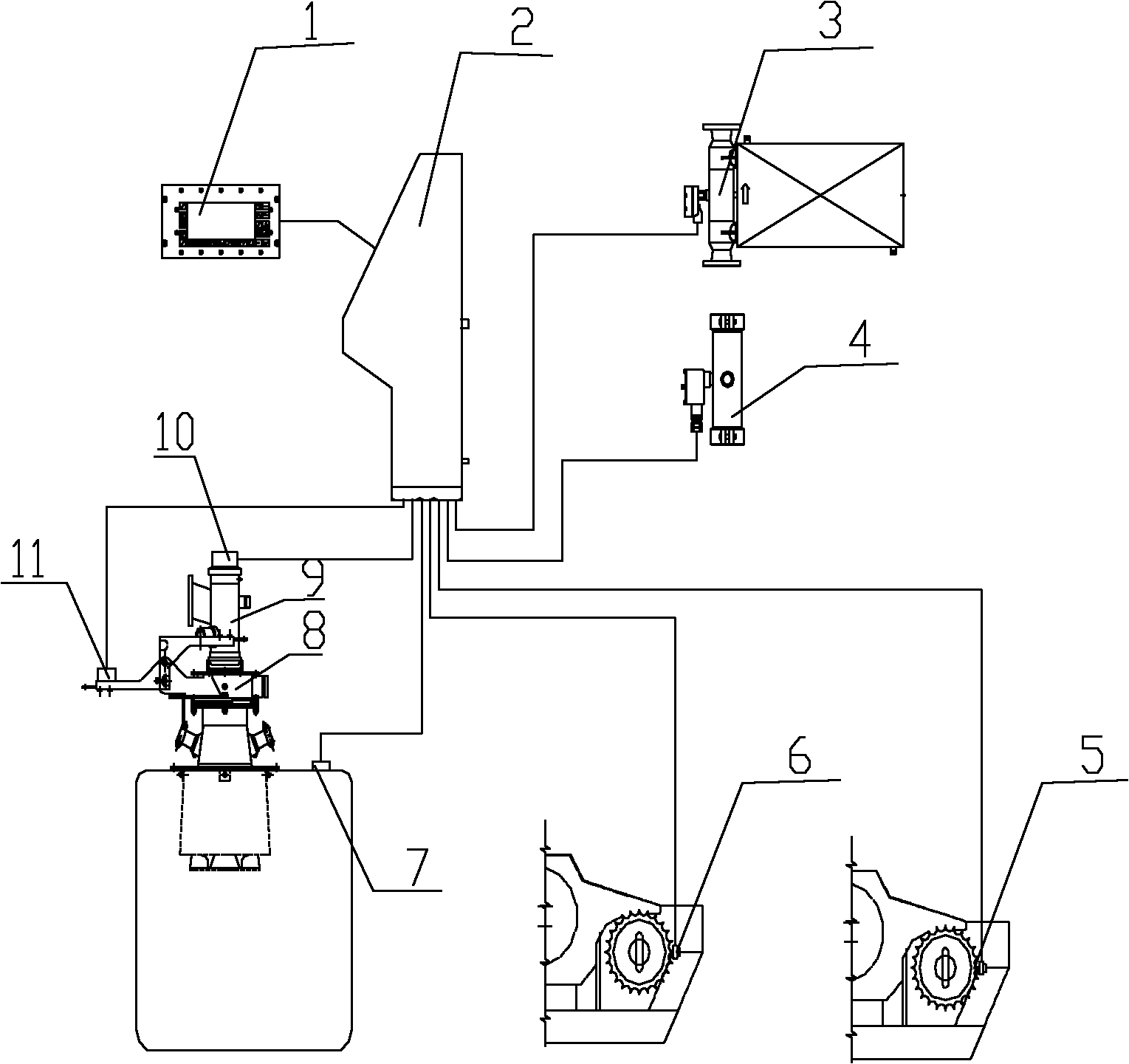

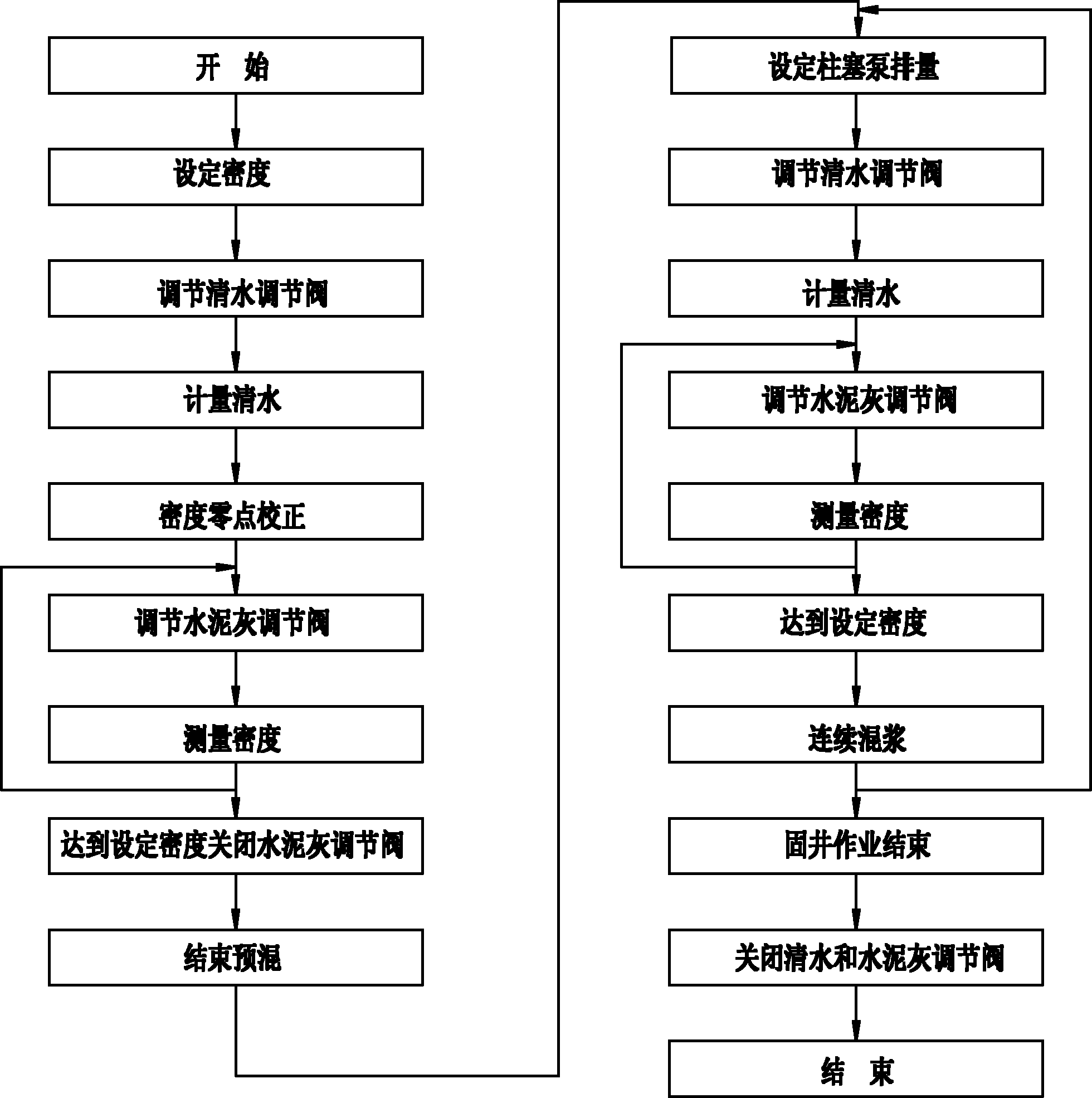

Full-automatic well cementation cement slurry quality controlling method and mixing system

InactiveCN102059743AReduce labor intensityQuality improvementControl apparatusAutomatic controlProportional control

The invention provides a full-automatic well cementation cement slurry quality controlling method and a mixing system. The method comprises the following steps: the density value is determined according to the well cementation required cement slurry; and a control system automatically controls the inlet amount of cement plaster and clean water through a cement plaster proportional control valve and a clean water proportional control valve respectively according to the determined density value. The mixing system comprises a controller, wherein the controller is connected with a control panel, a densitometer, a clean water flow meter, a piston pump flow meter, the cement plaster proportional control valve and the clean water proportional control valve; the cement plaster proportional control valve is connected with a cement plaster adjusting valve; the clean water proportional control valve is connected with a clean water adjusting valve; and the densitometer feeds a collected cement plaster density signal back to the controller, and the cement plaster proportional control valve and the clean water proportional control valve are controlled by the controller. The full-automatic well cementation cement slurry quality controlling method can realize full automatic control on a slurry mixing process in the well cementation operation, so the slurry mixing efficiency and the well cementation cement slurry quality can be improved.

Owner:宝鸡宝石特种车辆有限责任公司

Inkjet print calibration using test patches and densitometer

An inkjet printing system including a media source supplying sheets of transparent film. An image processing module receives and converts input image data to output image data comprising a plurality of output pixels configured to select an ink profile. Predetermined ink profiles are selected representative of a series of test patches each having an expected density. A printhead is configured to eject droplets of available colors of ink onto a sheet of transparent film based on the selected ink profiles to produce the output pixels and an output image thereon, including the series of test patches. A transmissive densitometer measures the actual density value of each of the test patches, wherein the image processing module adjusts the output pixel values based on a deviations between the expected and actual density values of the series of test patches.

Owner:CARESTREAM HEALTH INC

Dual-use sensor assembly for a thermal printer

A sensor apparatus for providing two sensing operations within a thermal printer includes a densitometer with at least one light source that discriminates color and that is positioned in a first position for sensing donor patches within the thermal printer; the densitometer while in a second position provides signals from printed receiver media for internal color calibration of the thermal printer. At least one reflector directs light from the light source to the densitometer through a donor web when the densitometer is in the first position; and a switchable device repositions the densitometer from either the first position or the second position.

Owner:KODAK ALARIS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com