Full-automatic well cementation cement slurry quality controlling method and mixing system

A fully automatic technology for cementing cement slurry, which is applied in the direction of control devices, etc., can solve the problems of low work efficiency, high labor intensity, inability to realize fully automatic control of slurry mixing, etc., and achieve the effect of realizing fully automatic control and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

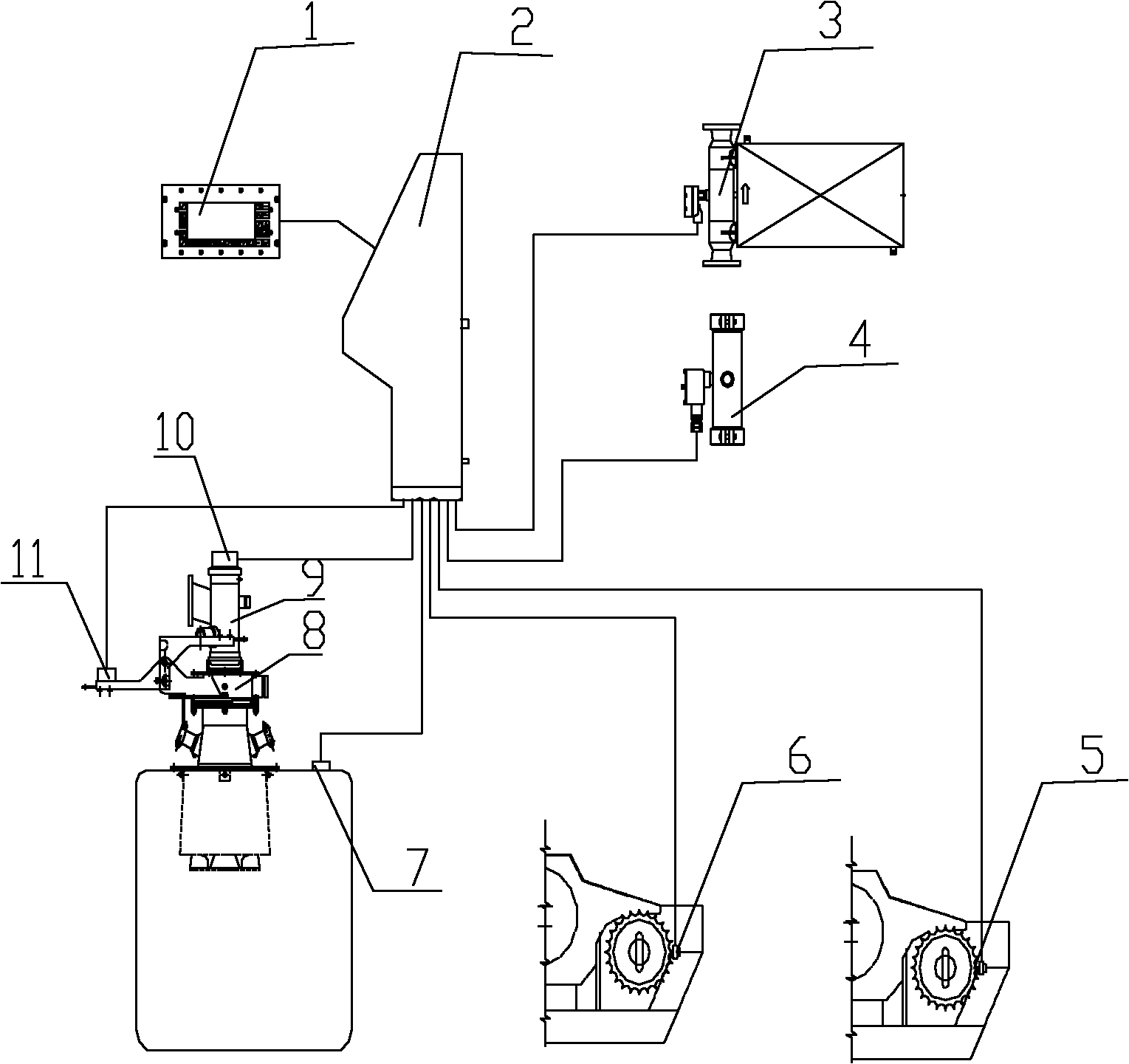

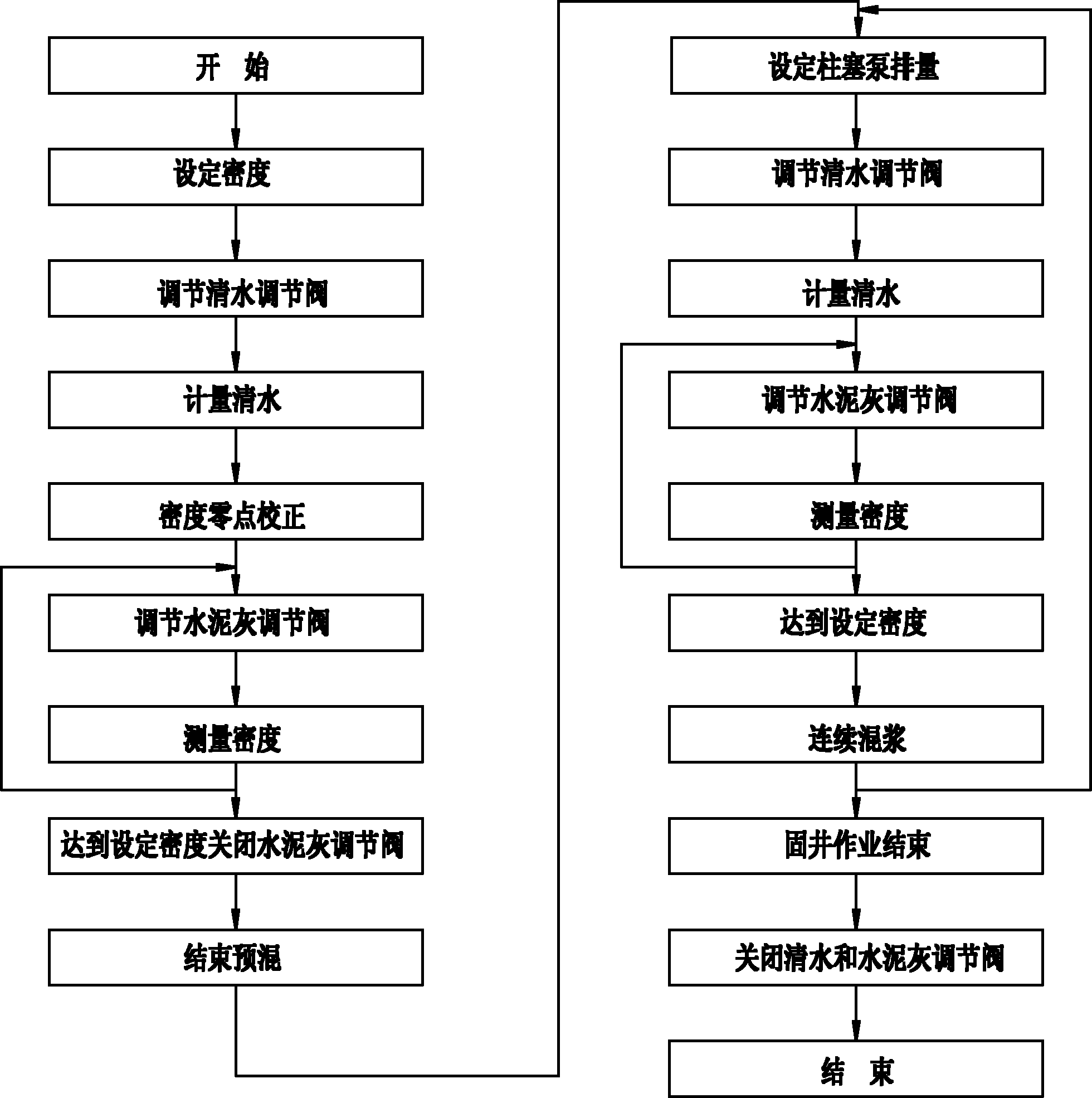

[0019] Attached below figure 1 , 2 , 3 describe an embodiment of the present invention.

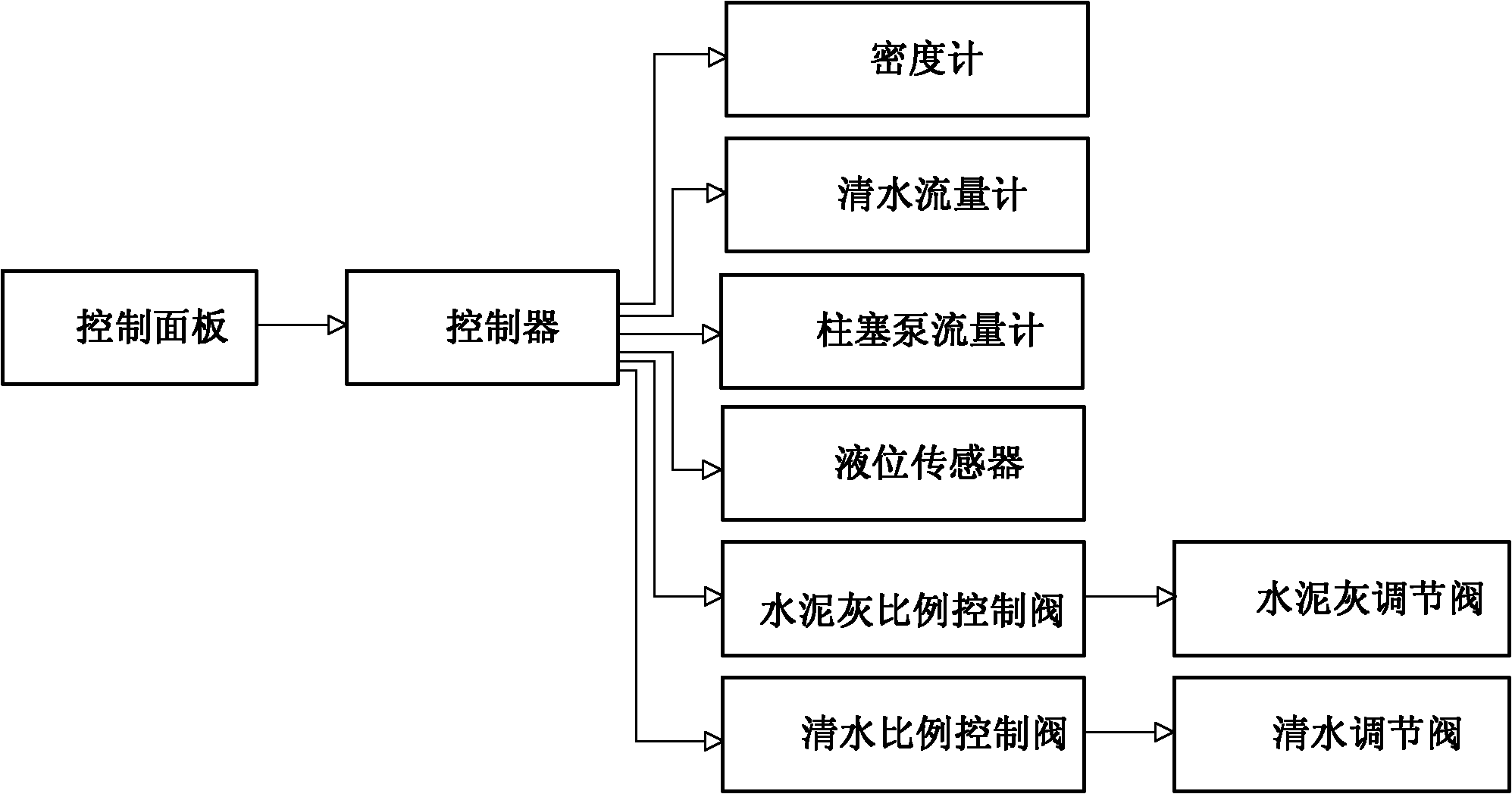

[0020] A fully automatic cementing slurry quality mixing system, which has a solidified controller 2 with a processing program, and the controller 2 communicates with the control panel 1, the density meter 3, the clean water flow meter 4, the plunger pump flow meter I 5, Piston pump flow meter II6, liquid level sensor 7, cement ash proportional control valve 10 and clean water proportional control valve 11 are connected, cement ash proportional control valve 10 is connected with cement ash regulating valve 9, clean water proportional control valve 11 and clean water regulating valve 8 Connection; the plunger pump flowmeter can be set to one or two according to the demand, used to measure the actual flow of the plunger pump, the liquid level sensor 7 is used to measure the liquid level position in the mixing tank, and the clean water flowmeter 4 is used to measure clean water For the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com