Automatic assembly device and method of O-type sealing ring

An automatic assembly device, O-ring technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficulty in adapting to the needs of automatic assembly market competition, inconvenient installation work, low assembly speed, etc., to improve product quality. Qualification rate and assembly efficiency, the effect of reducing production cost and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

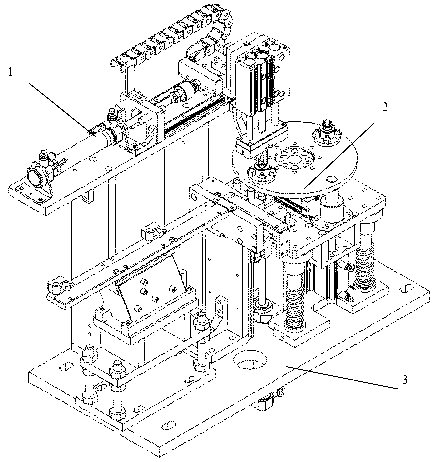

[0079] like figure 1 As shown, the automatic assembly device for the O-shaped sealing ring of the present invention includes an upper ring support module 1, a ring transfer and removal module 2, and a bottom plate 3; the upper ring support module 1 and the transfer and removal module 2 are fixed on the bottom plate 3 Above, the upper ring support module 1 is arranged on one side of the ring transfer and take-off module 2 .

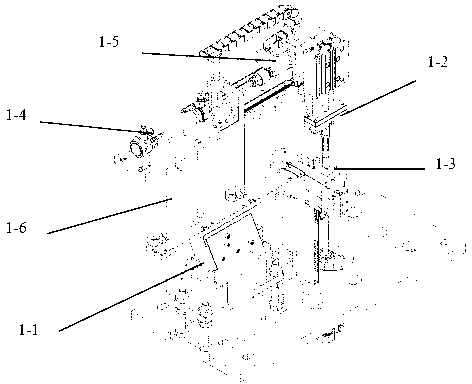

[0080] like figure 2 As shown, the upper ring support ring module 1 includes an O-ring feeding device 1-1, an O-ring feeding device 1-2, a support ring device 1-3, an O-ring feeding device 1-1 and a support ring device 1- 3 are arranged side by side to form the feeding station and the support ring station respectively; the feeding needle cylinder 1-4 is connected to the O-ring feeding device 1-2 through the slider 1-5, and the feeding needle cylinder 1-4 can drive The O-ring feeding device 1-2 makes a reciprocating linear motion, so that the O-ring feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com