Patents

Literature

238 results about "Assembly automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

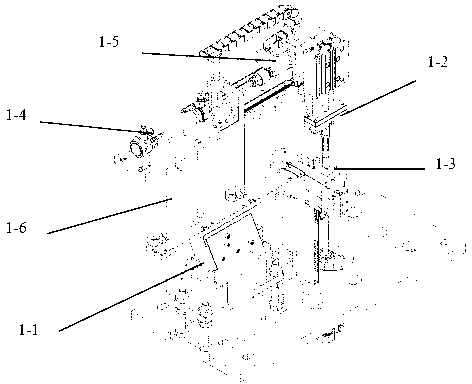

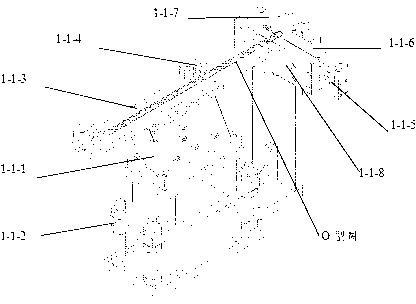

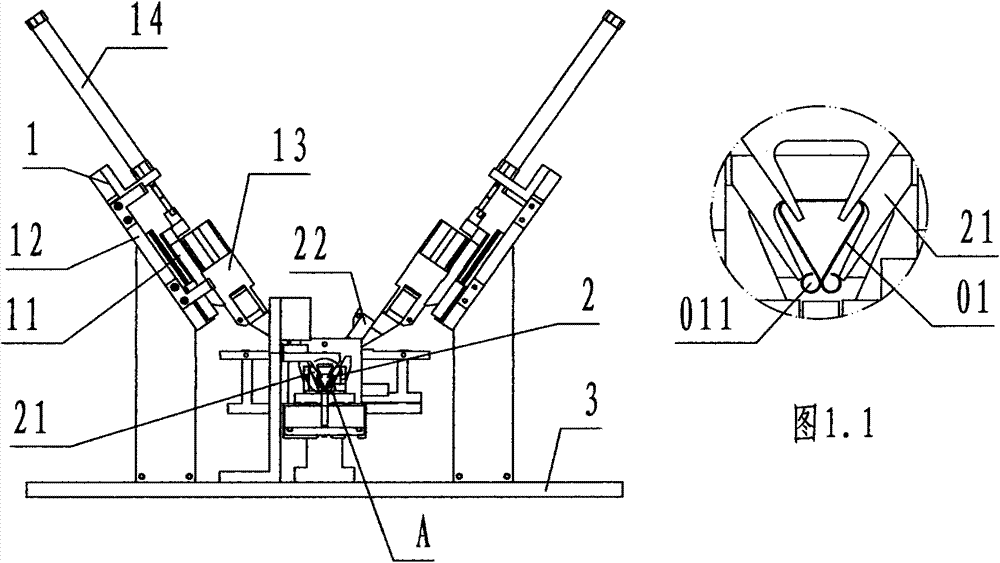

Automatic assembly device and method of O-type sealing ring

InactiveCN103317336ANo damageSmall support ringMetal working apparatusEngineeringUltimate tensile strength

The invention discloses an automatic assembly device of an O-type sealing ring. The automatic assembly device comprises a ring loading and supporting module and a ring moving and releasing module. The ring loading and supporting module forms a feeding station and a ring supporting station, and when a loading device of the O-type sealing ring is located at the feeding station, the O-type sealing ring is delivered to the loading device of the O-type sealing ring by a feeding device of the O-type sealing ring. A loading needle-shaped air cylinder drives the loading device of the O-type sealing ring to move to the ring supporting station, the ring supporting motion is carried out on the O-type sealing ring by a ring supporting device, the O-type sealing ring is delivered to the ring moving and releasing module by the ring supporting device, the ring moving and releasing module enables the supported O-type sealing ring to be delivered to a ring releasing station from the ring supporting station, the ring moving and releasing module breaks away from the supported O-type sealing ring, the supported O-type sealing ring is sleeved at the position of a groove of a workpiece to be assembled, and automatic assembly between the workpiece and the O-type sealing ring is achieved. According to the automatic assembly device, assembly automation of the O-type sealing ring can be achieved, the qualified rate and the assembly efficiency of products are greatly improved, the labor strength is relieved, and the production cost is reduced. The invention further discloses an automatic assembly method of the O-type sealing ring.

Owner:TAIZHOU LIANFANG ELECTROMECHANICAL TECH

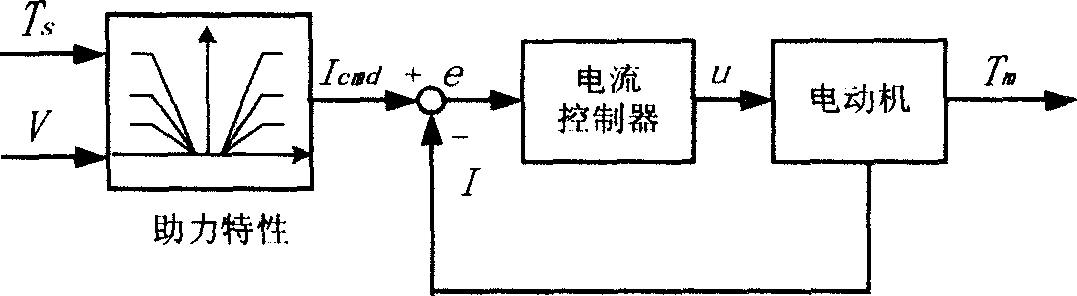

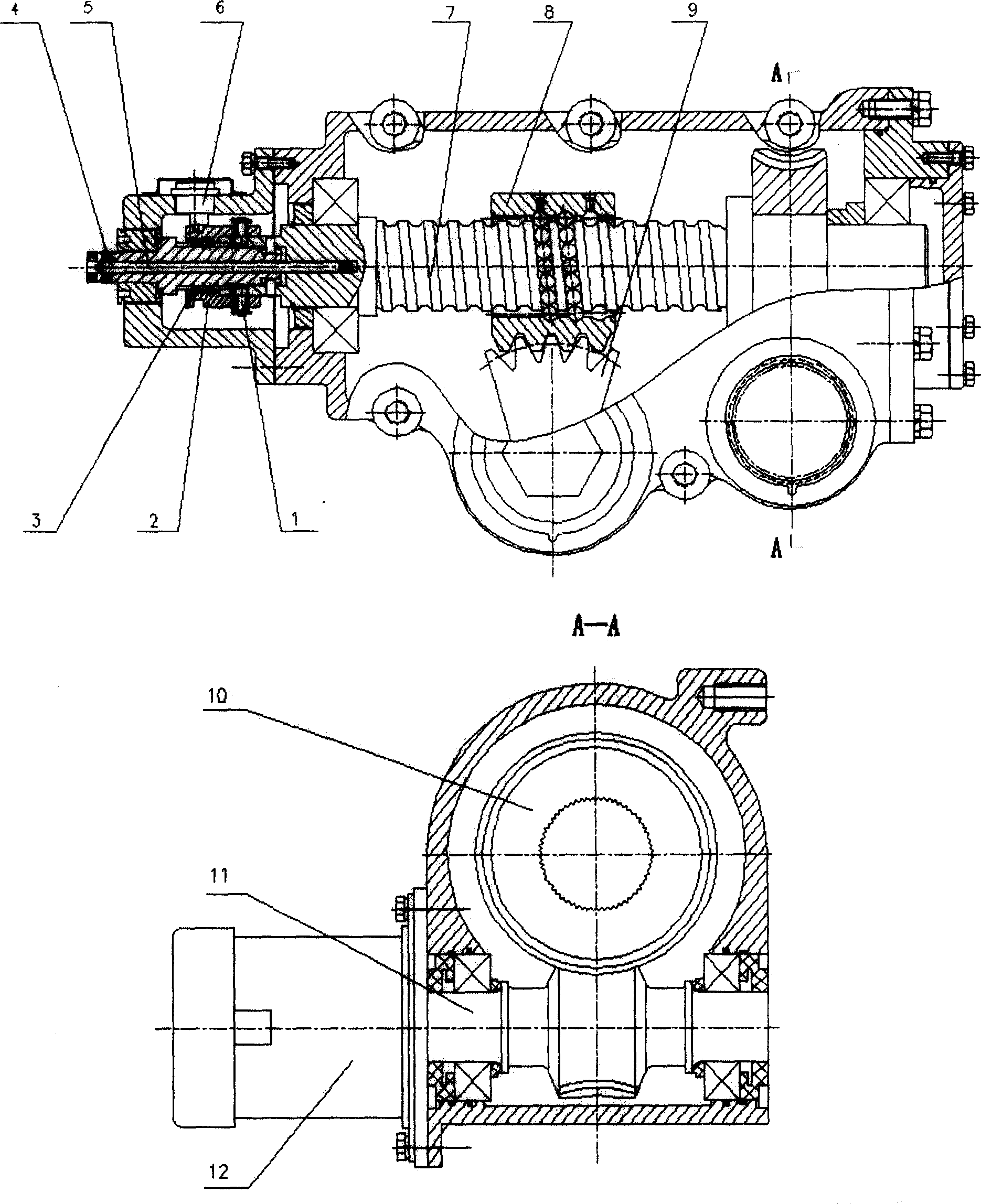

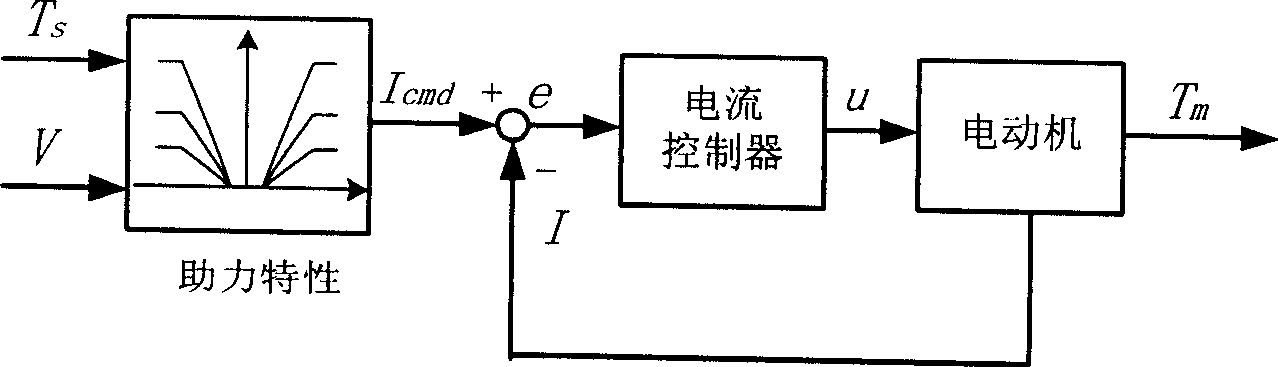

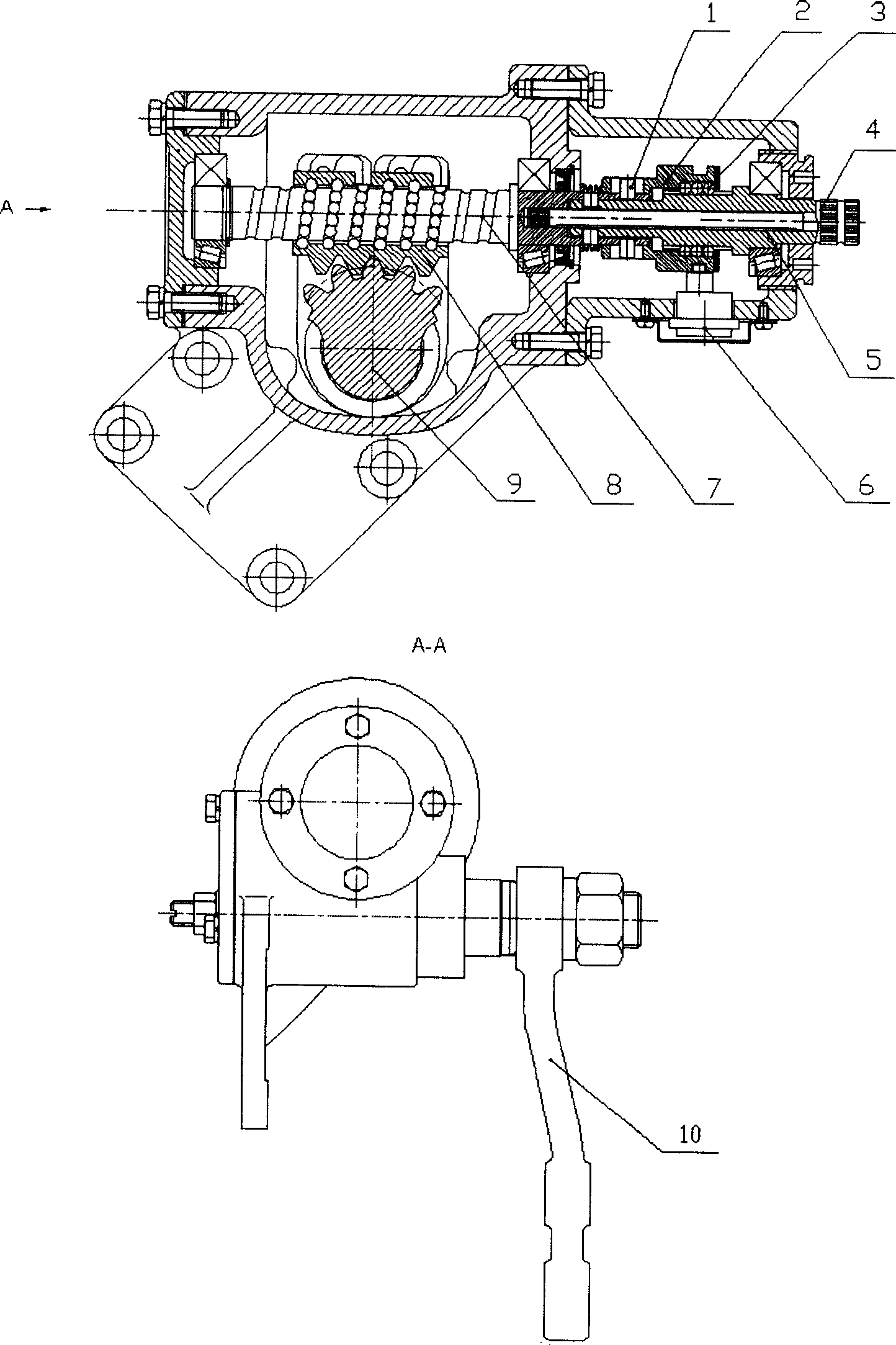

Circular ball type electric booster steering device

ActiveCN1647984AReduce disturbanceReduce pollutionMechanical steering gearsElectrical steeringElectric power steeringElectronic controller

The circular ball type electric booster steering device has, except screw, nut, gear sector, steel ball and other mechanical parts, torque sensor, boosting motor, decelerating mechanism, electronic controller unit, etc. The electronic controller unit determines the target current of the motor based on the steering disc torque and the vehicle speed to complete the feedback tracking control of the motor current. The decelerating mechanism has input connected to the motor and output connected to the screw or gear sector shaft in the circular ball steering unit. The present invention has saving in energy, provides proper power force fitting different running conditions, and has less parts, light weight, compact structure and high automation.

Owner:BEIJING AUTONICS TECH

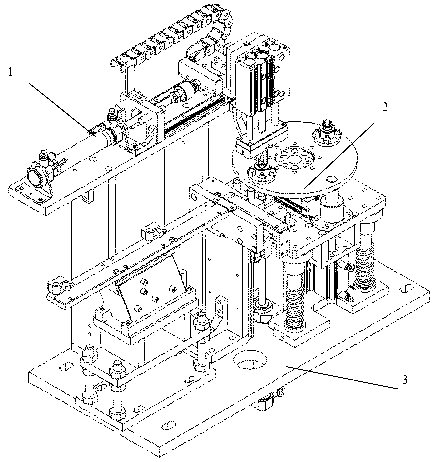

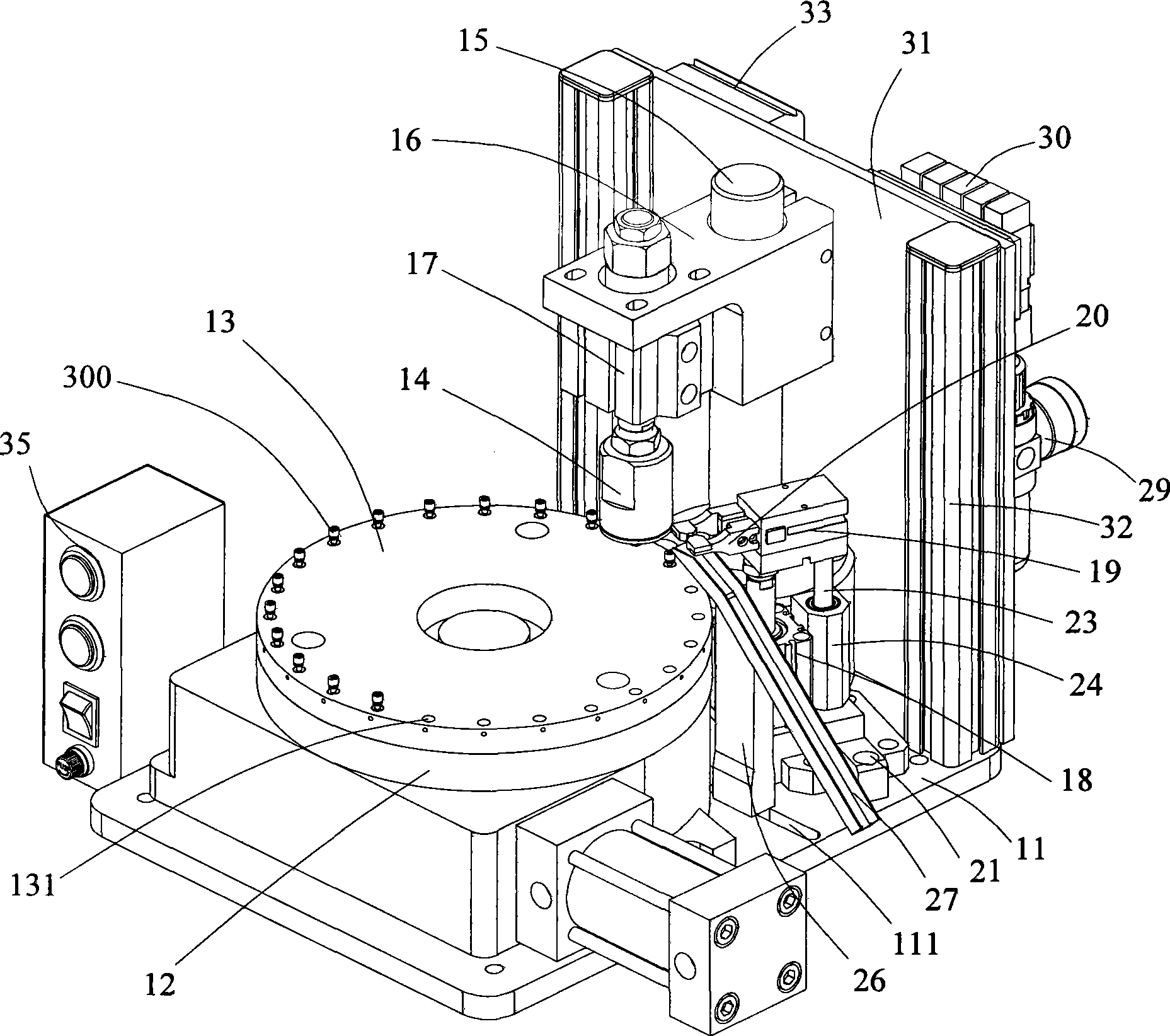

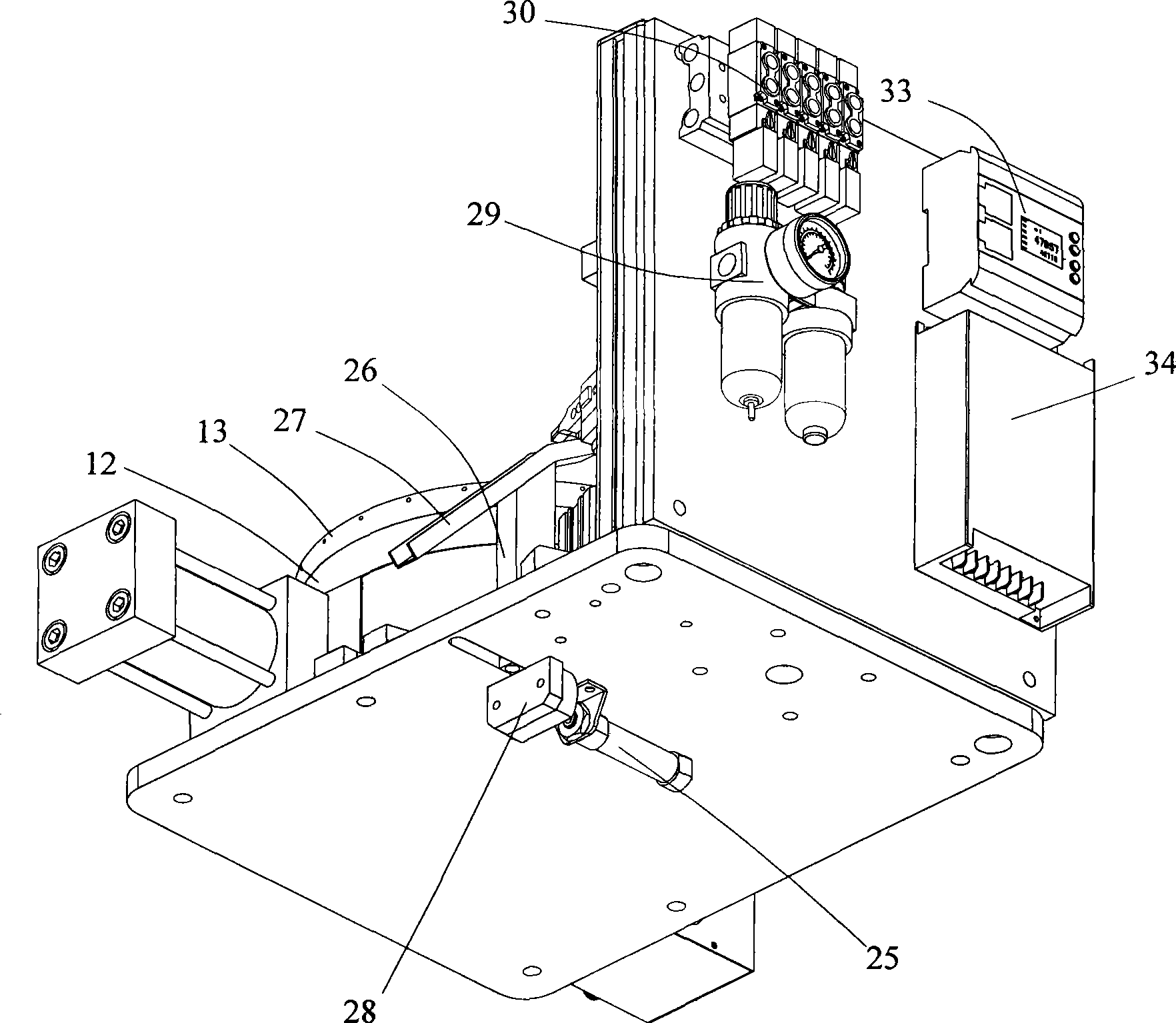

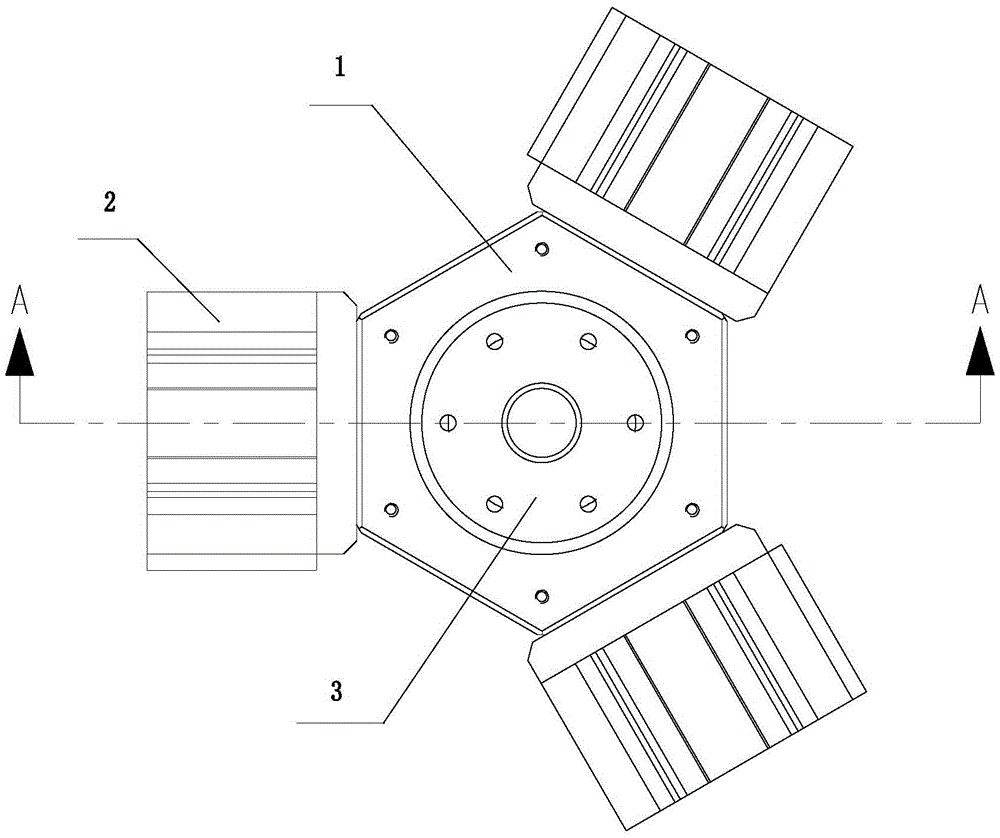

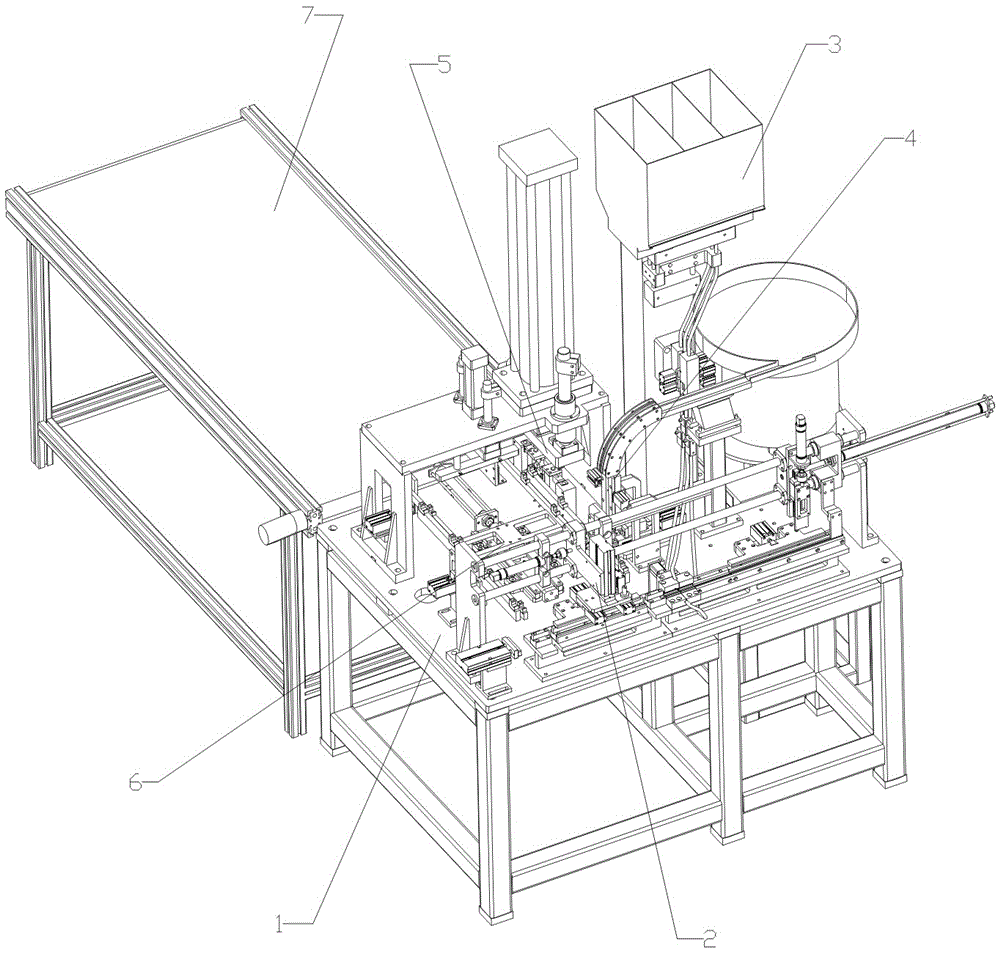

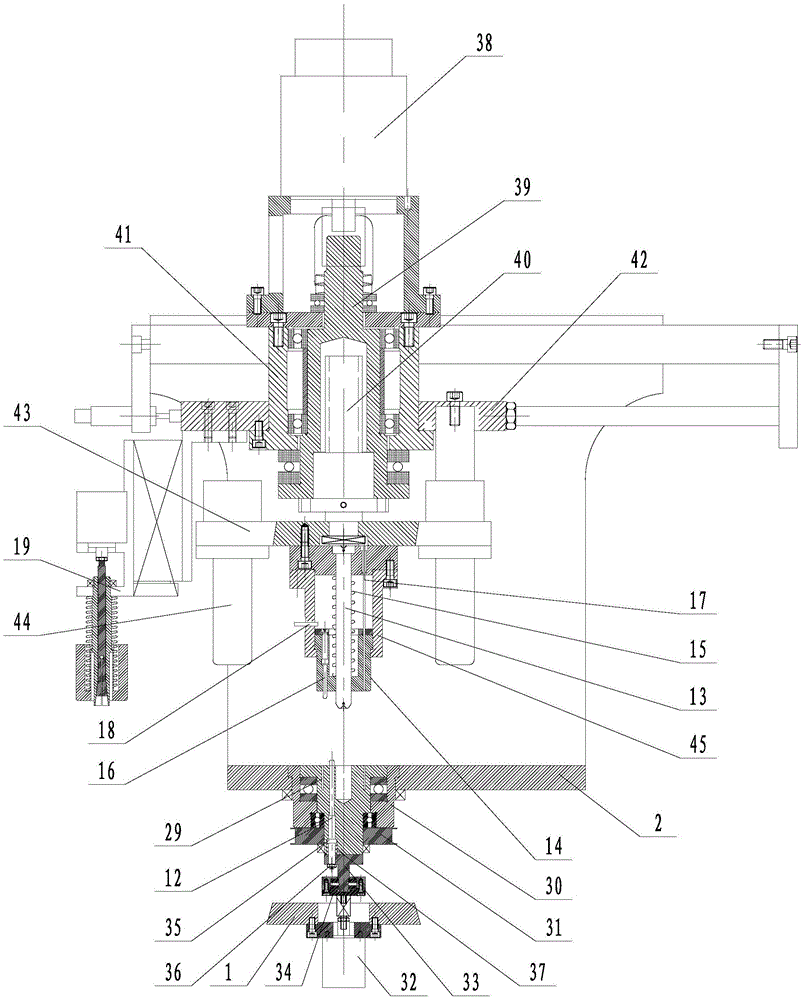

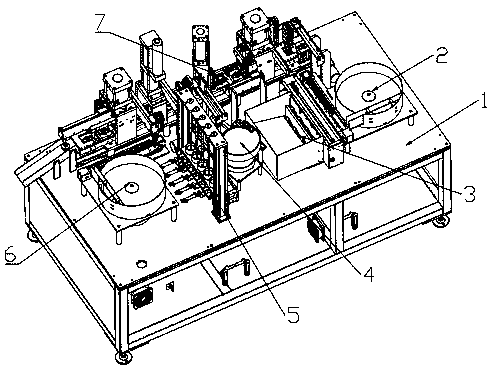

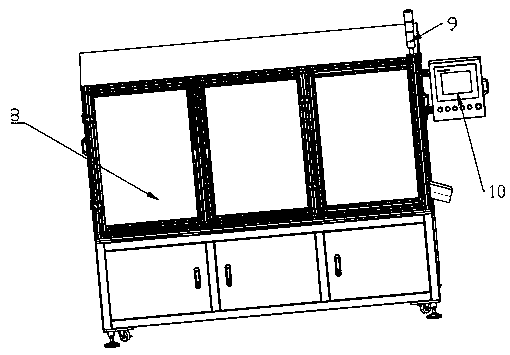

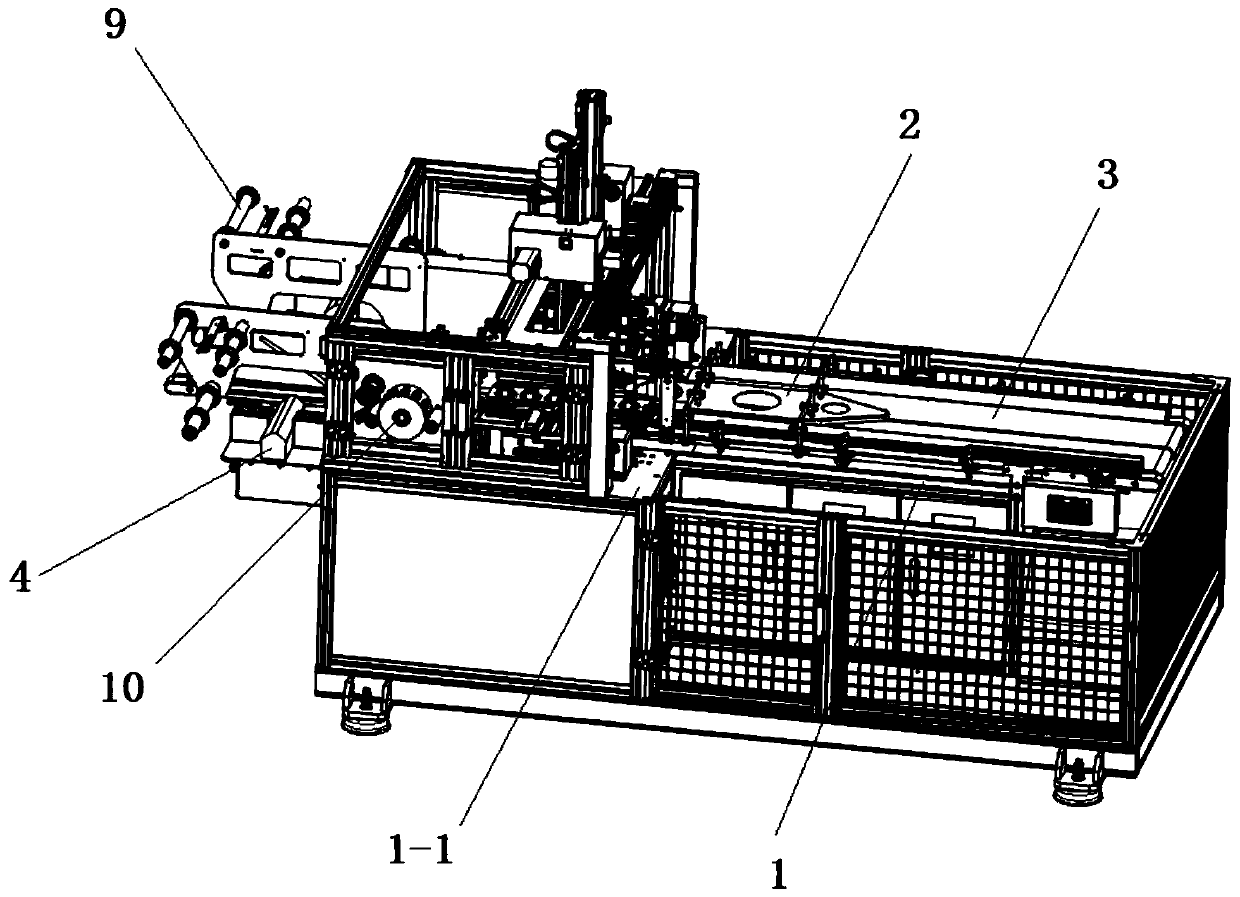

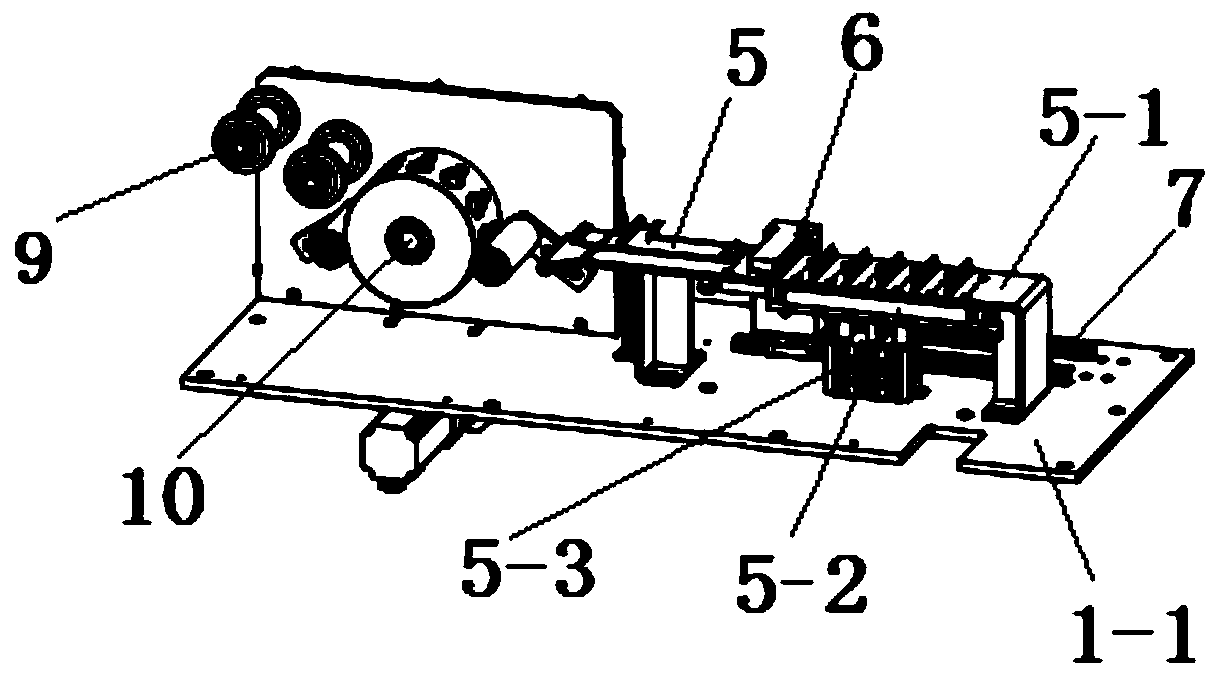

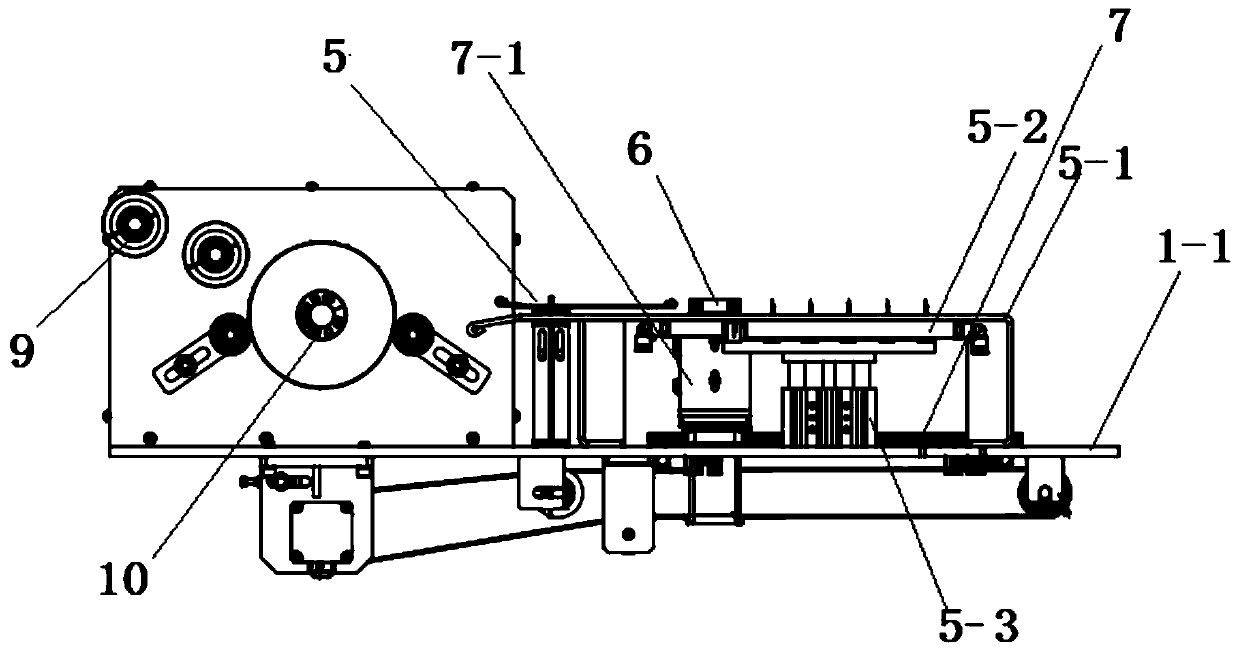

Automatic packaging machine and method for optical fiber ceramic ferrule metal component

InactiveCN101464544AGuaranteed accuracyStable downforceCoupling light guidesMetal working apparatusEngineeringAssembly automation

The invention relates to an automatic packaging machine for metal components in an optical fiber ceramic inserting core. The automatic packaging machine comprises a base, a graduated rotating disc and a clamping device mounted on the base, a workpiece positioning ring mounted on the graduated rotating disc, and a control device for controlling the matching action of the graduated rotating disc and the clamping device. The clamping device comprises a drive mechanism and a pressure head driven and pressed by the drive mechanism; a plurality of workpiece mounting positions are arranged on the circumference of the workpiece positioning ring; and the pressure head is positioned above the workpiece positioning ring. A metal workpiece is driven to the position of the clamping device by utilizing the graduated rotating disc through placing the metal workpiece required to be assembled on the graduated rotating disc; and then the assembly of the metal components in the ceramic inserting core is completed through pressing the pressure head, so that the assembly automation is achieved and the work efficiency is improved. Moreover, the accuracy of assembling the components is ensured due to stable downward pressure of the pressure head, so that the rate of finished products is improved greatly. In addition, the components after being assembled can be automatically taken down from the graduated rotating disc through a blanking device, so that the work efficiency is further improved.

Owner:SHENZHEN XIANGTONG PHOTOELECTRIC TECH

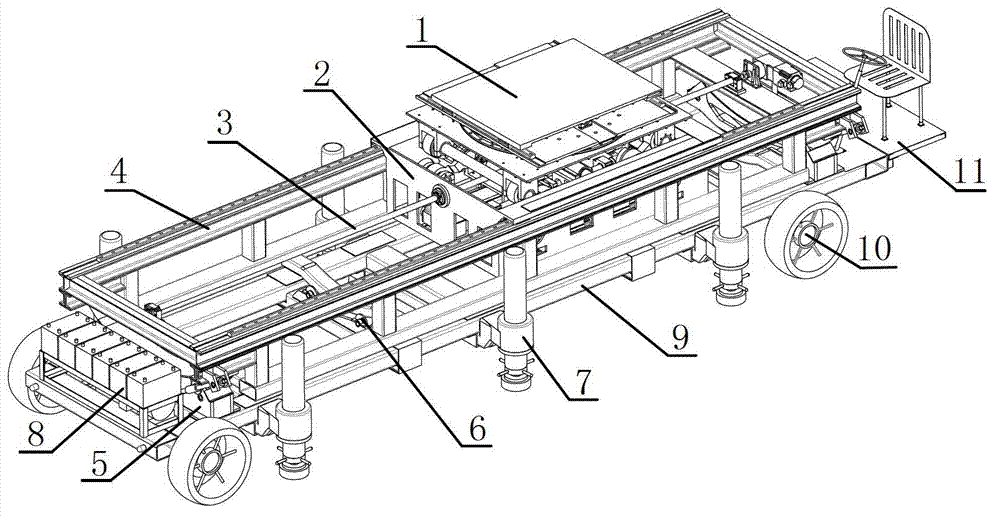

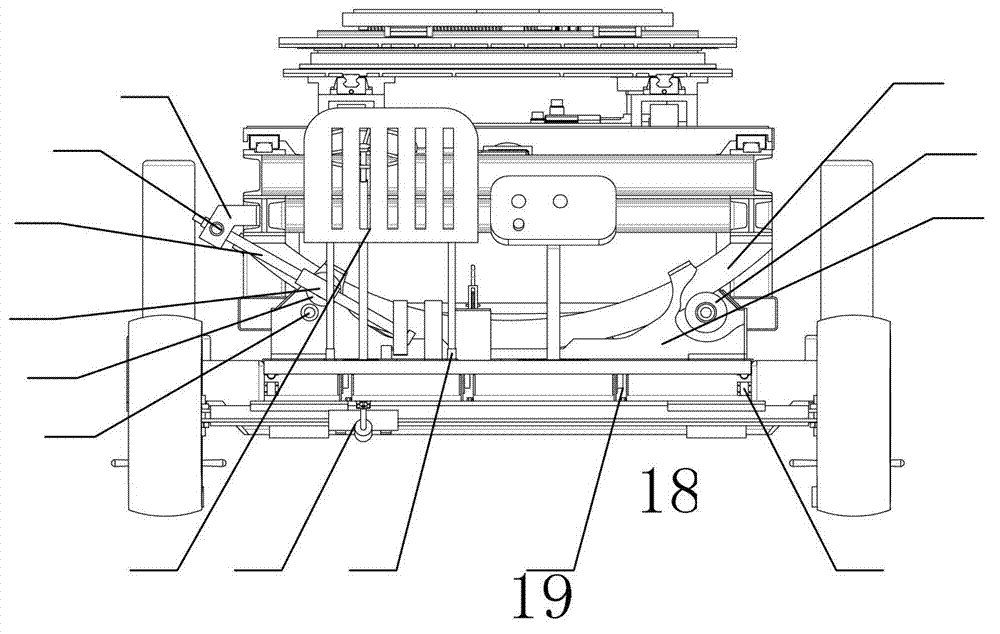

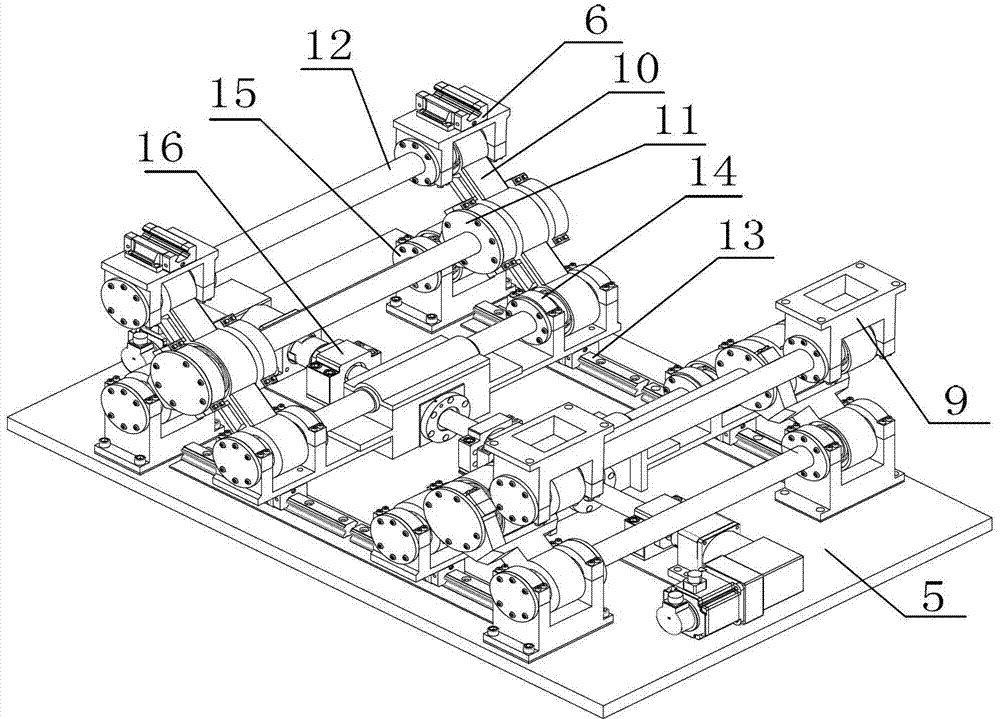

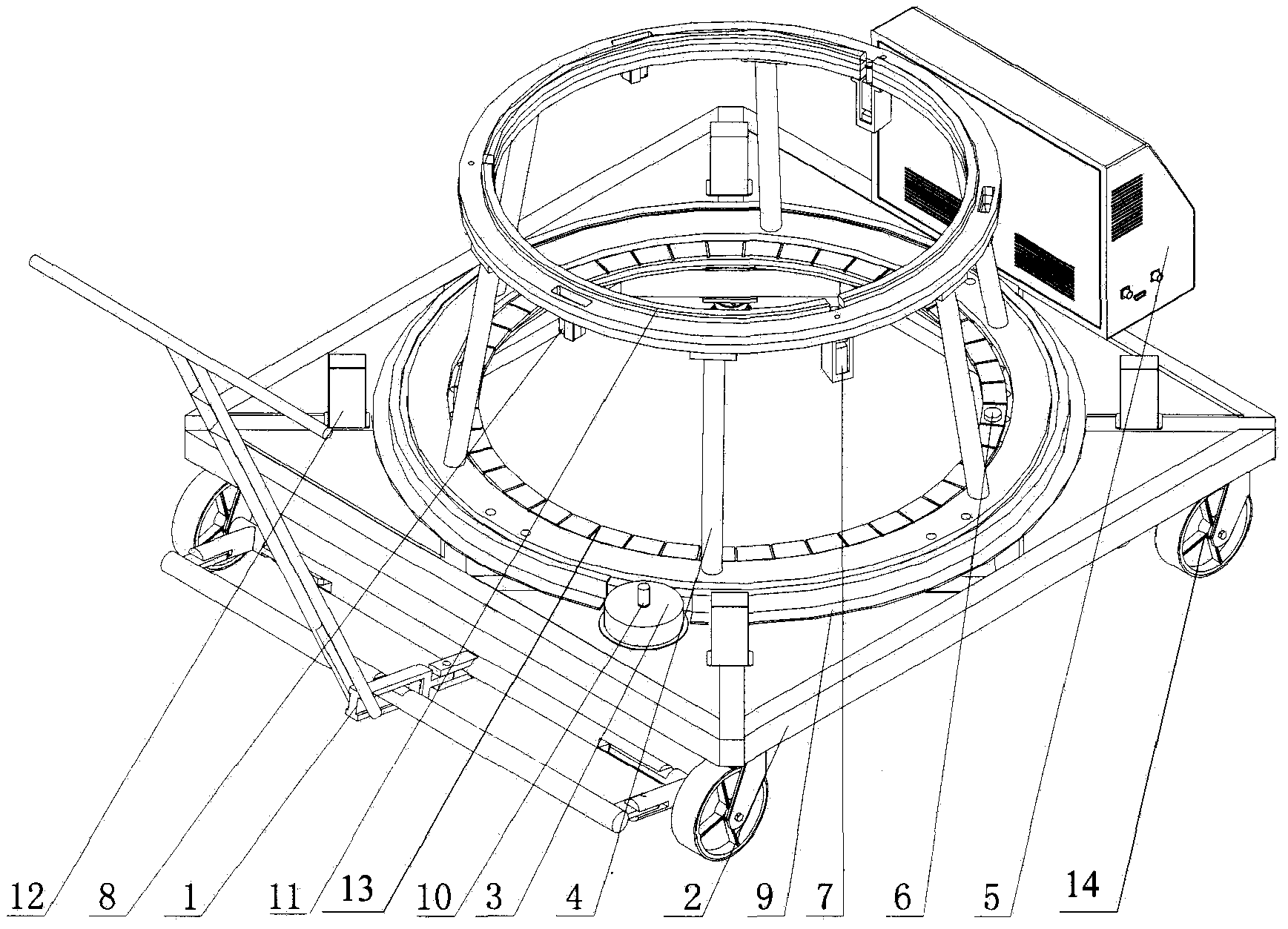

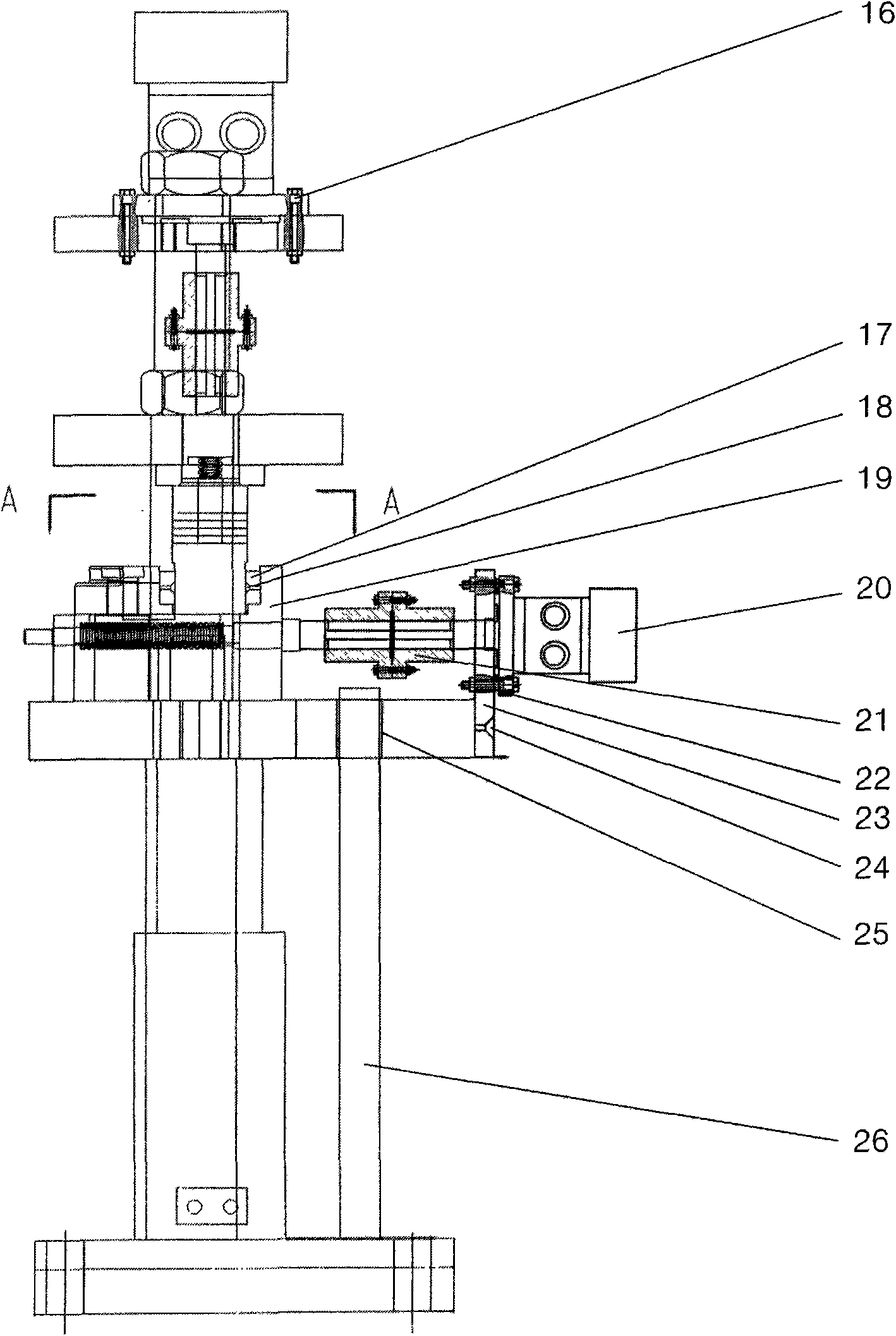

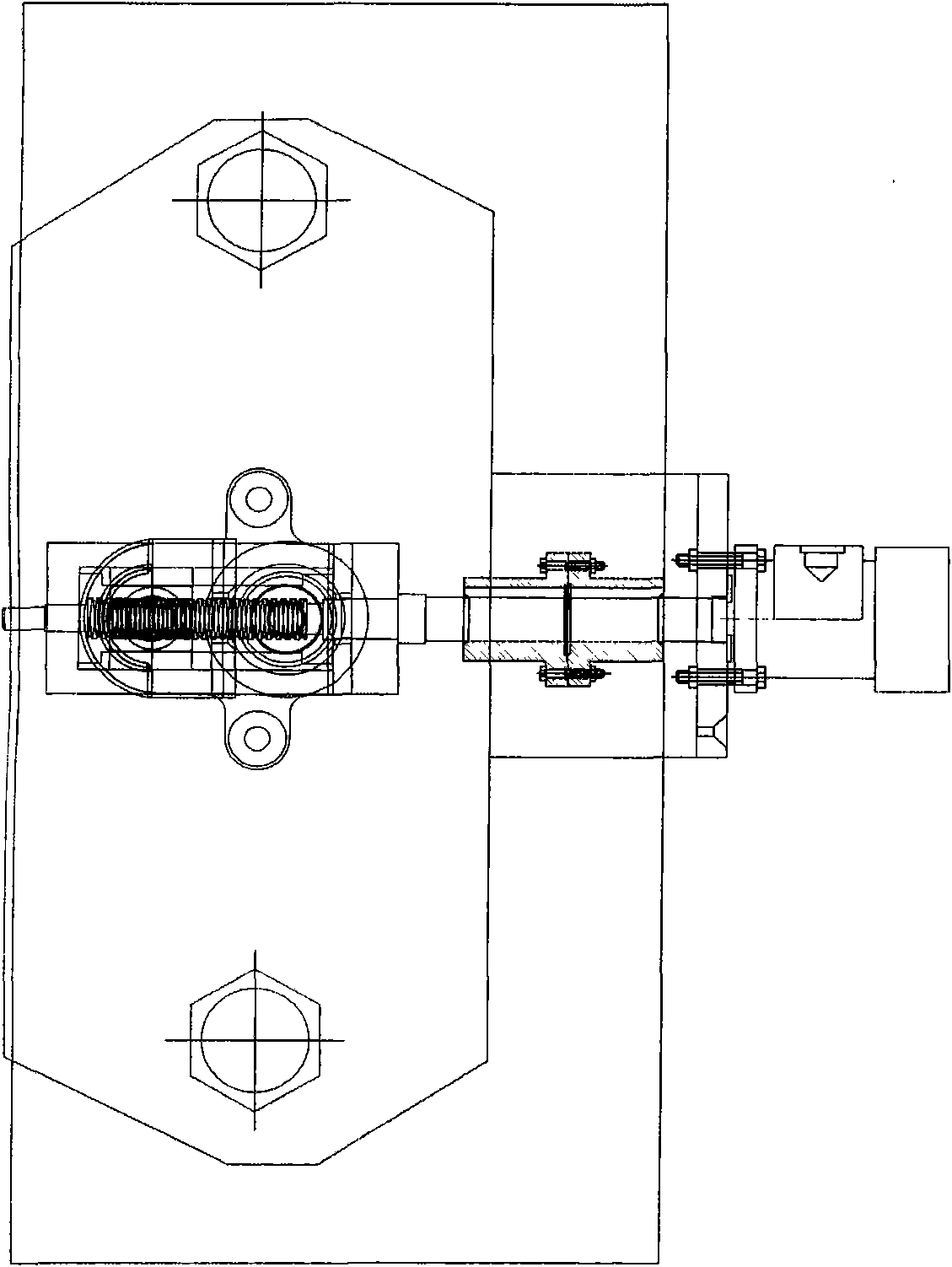

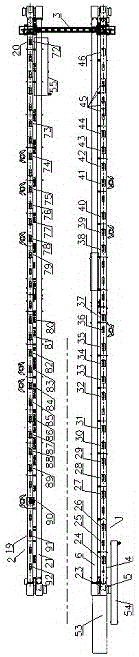

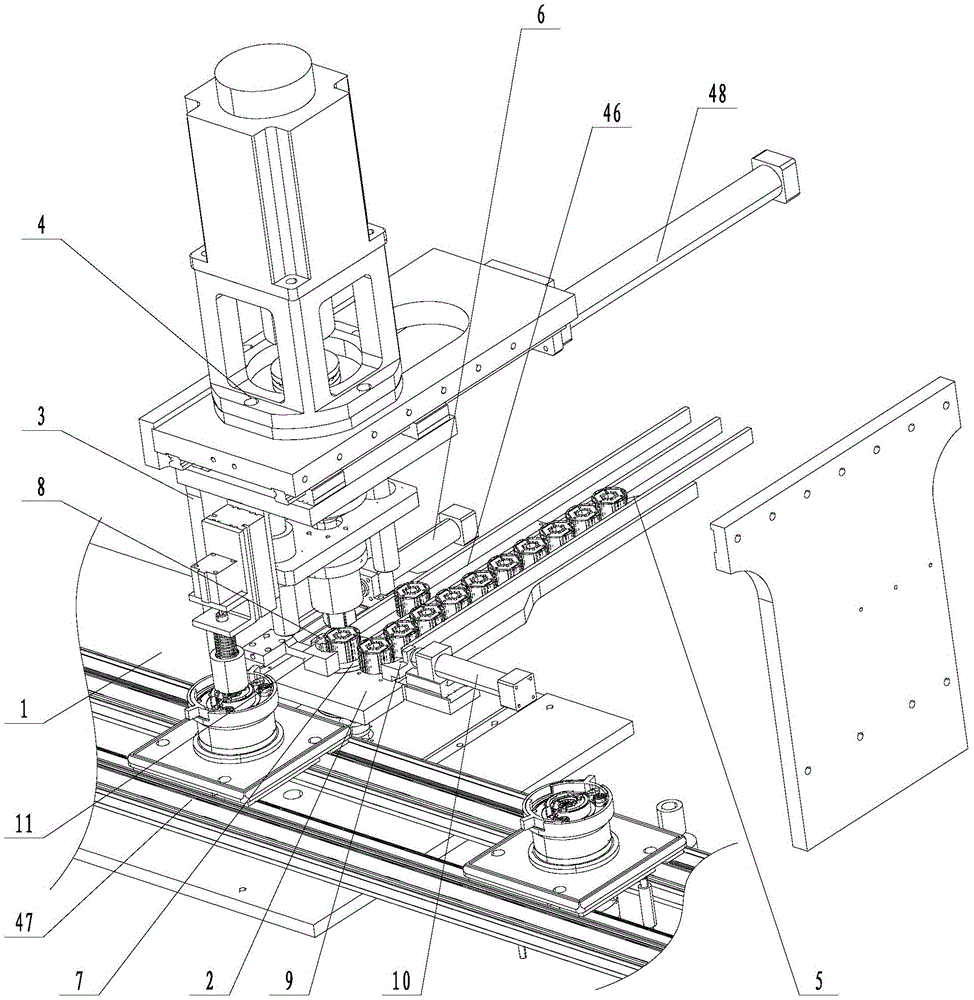

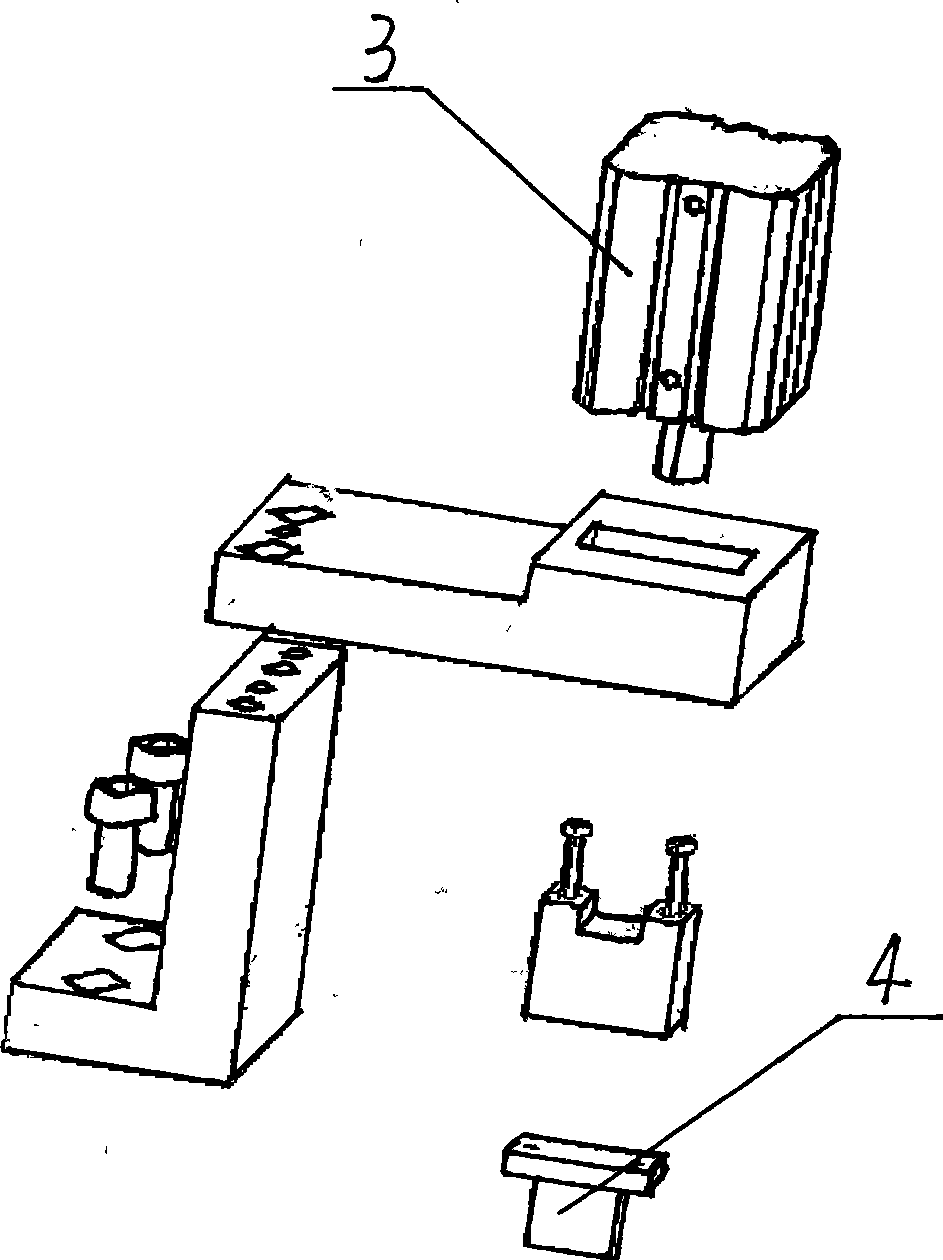

Numerical-control electric frame truck for airplane engine mounting

InactiveCN103204248ARealize the installation workEnable mobilityAircraft assemblyNumerical controlDrive wheel

The invention relates to a numerical-control electric frame truck for airplane engine mounting and belongs to the technical field of assembly automation. The numerical-control electric frame truck is characterized by comprising a multi-shaft posture adjusting platform (1), a posture adjusting platform frame (2), a long-shaft feed mechanism (3), a truck body frame (4), left and right rotation mechanisms (5), an auxiliary support mechanism (6), hydraulic support legs (7), a driving wheel system (8), a truck body underframe (9), steering wheel systems (10), a driving cab (11), a hydraulic control system and a servo control system. Posture of five shafts is driven and adjusted by a servo motor, and posture of the rest one shaft is manually adjusted. Travelling of the frame truck is driven by the mode of electric vehicle. The numerical-control electric frame truck has the advantages that positioning accuracy is high, maneuverability is good, stability is high, engine mounting efficiency is improved, and labor intensity of operators is reduced. Besides, the numerical-control electric frame truck is applicable to automatic mounting operation of heavy complicated shaft parts requiring multi-shaft posture adjustment.

Owner:DALIAN UNIV OF TECH +1

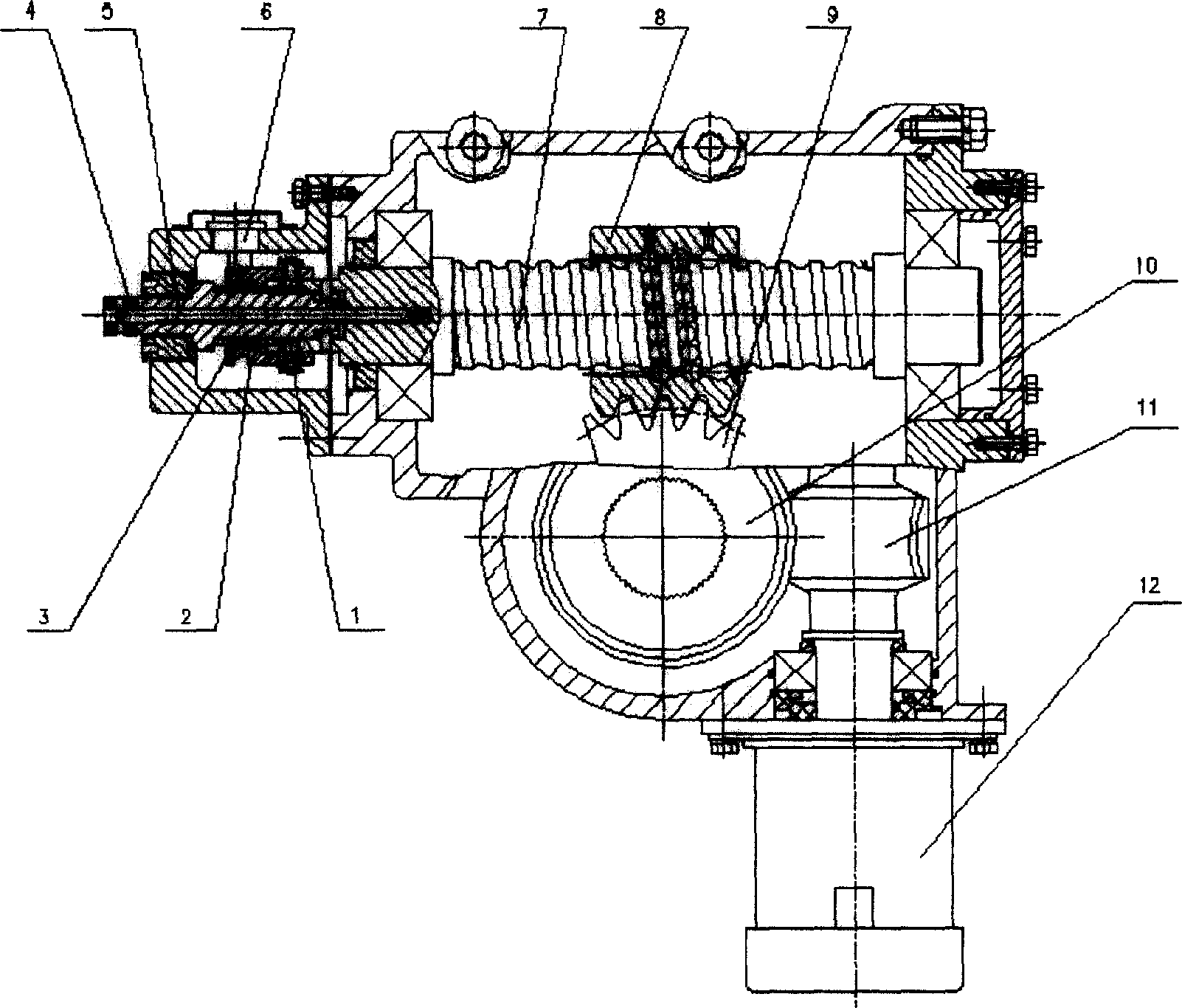

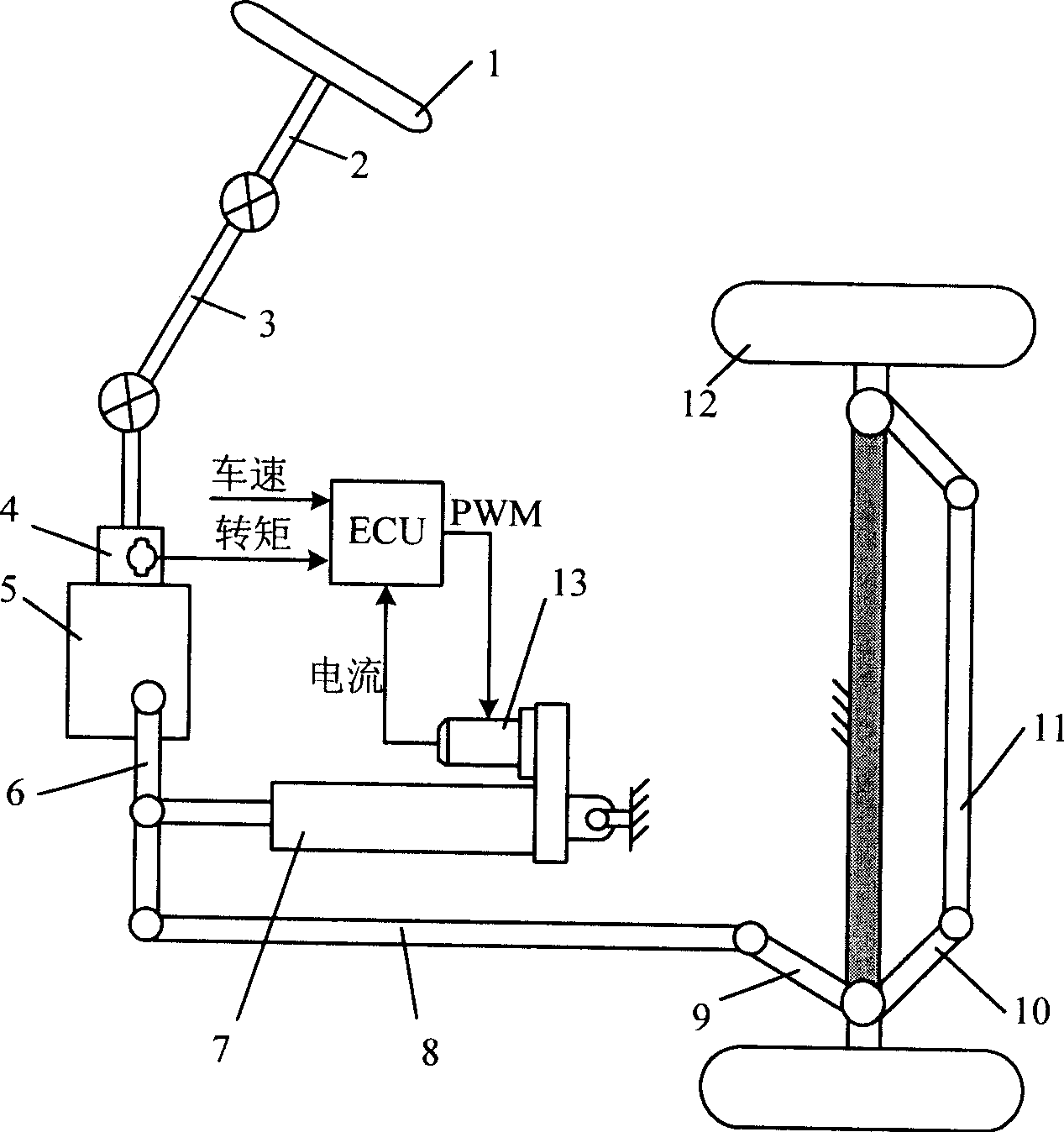

Motor push rod type power-assisted steering apparatus

ActiveCN101450677AReduce disturbanceReduce pollutionElectrical steeringElectric power steeringVehicle frame

The invention relates to an electrical push rod type electrical power-assisted steering device, which comprises a recirculating ball steering gear provided with a torque sensing device, an electrical push rod and an electronic control unit, wherein the torque sensing device is used for detecting moment acted on a steering wheel, and is arranged on an input shaft of the recirculating ball steering gear. One end of the electrical push rod is connected with a steering rock arm, and the other end of the electrical push rod is connected with a vehicle frame. The electrical push rod comprises a power-assisted motor and a speed reducing mechanism, a push rod and so on. An input shaft of the speed reducing mechanism of the power-assisted motor is connected with an output shaft of the power-assisted motor, an output shaft of the speed reducing mechanism is connected with a screw rod of the push rod, and the moment output by the power-assisted motor pushes a rock arm shaft to rotate through a screw nut transmission pair. The electronic control unit is used for controlling the current of the power-assisted motor according to signals of the torque of the steering wheel and the vehicle speed and so on. The steering device can save energy, provide proper power assistance under various running work conditions, has fewer parts, light weight, compact structure and high assembly automatic degree, and is a steering mechanism of vehicle power with energy conservation, safety and environmental protection.

Owner:BEIJING AUTONICS TECH

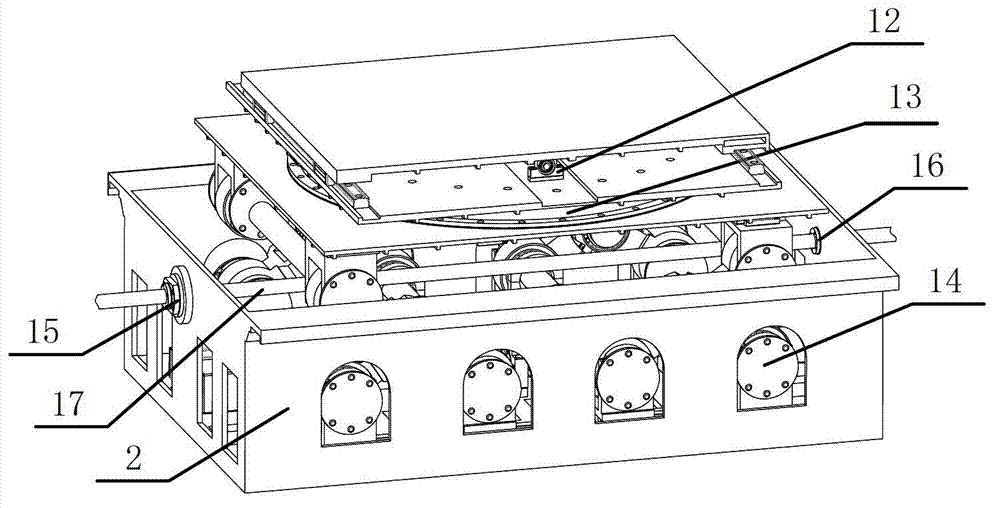

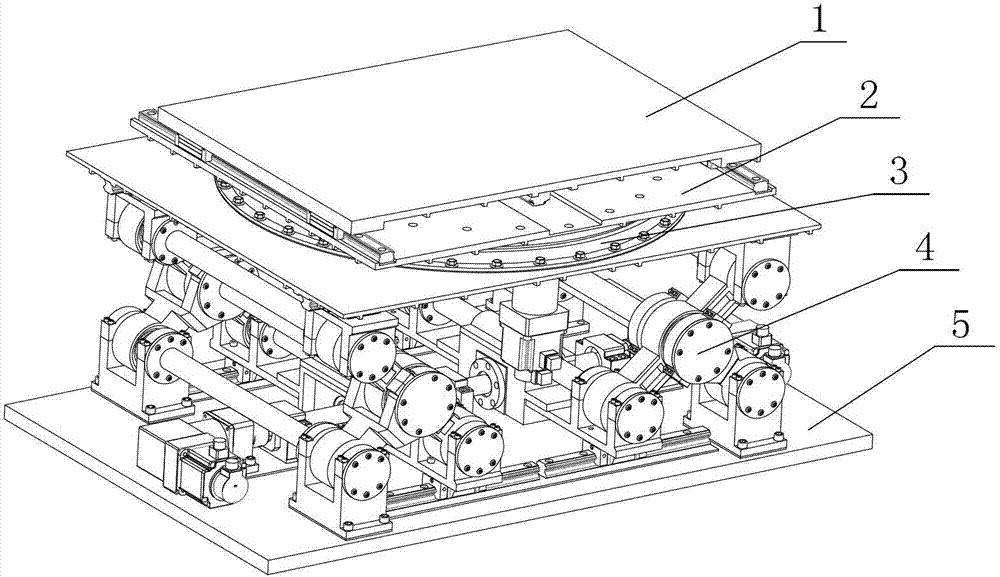

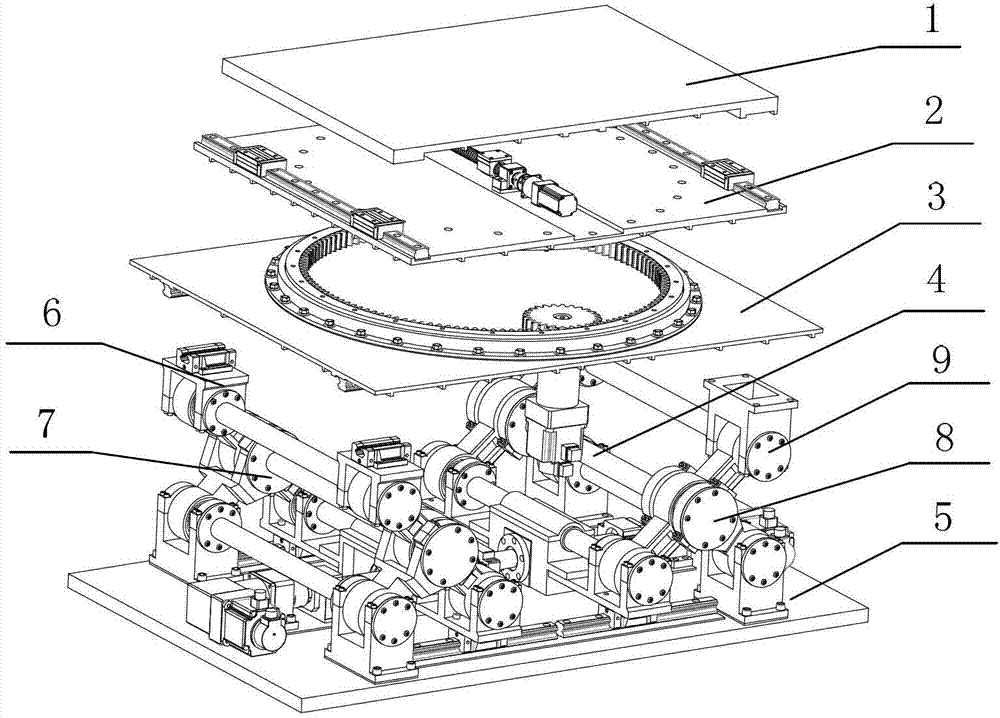

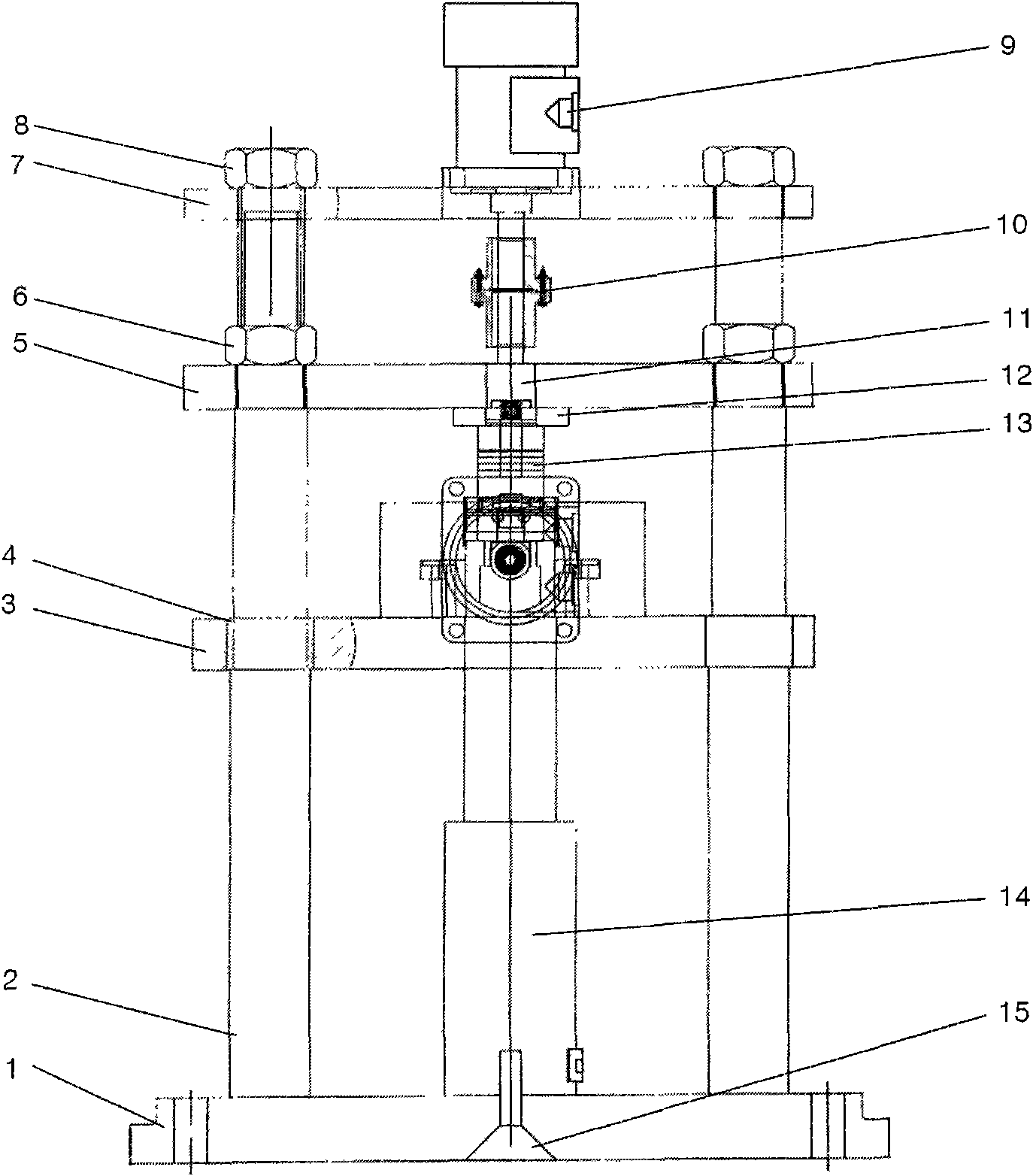

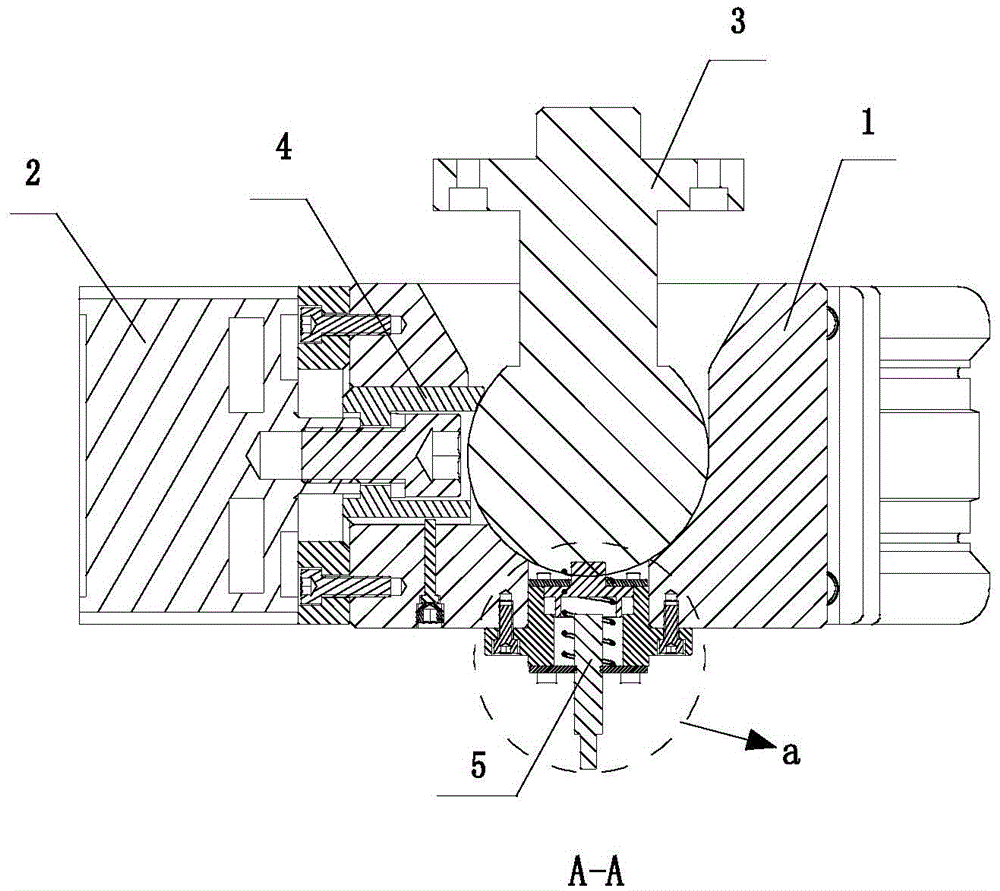

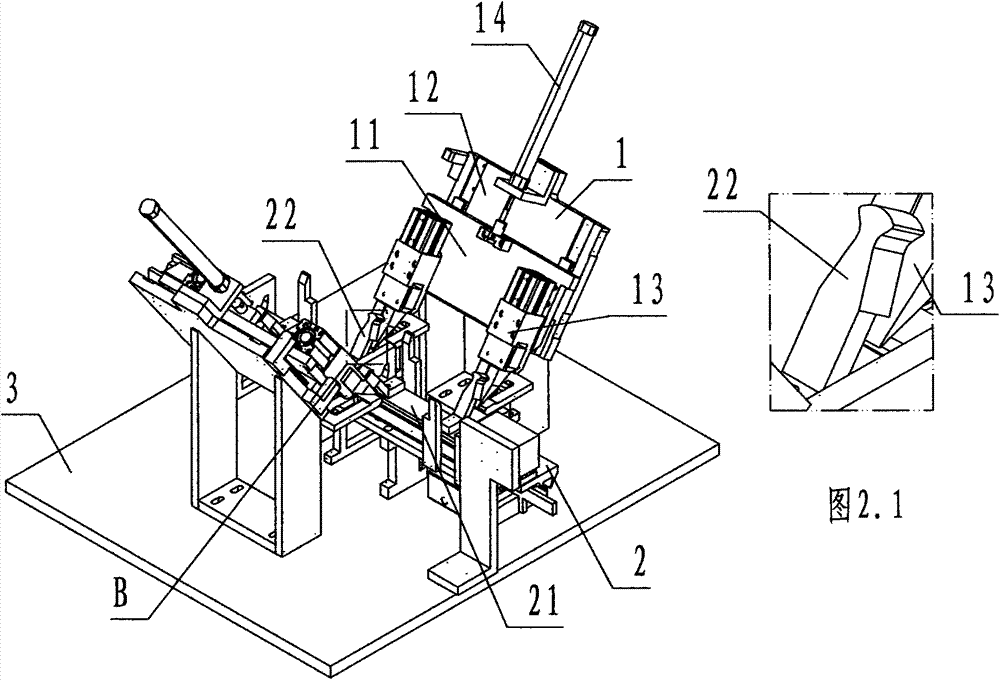

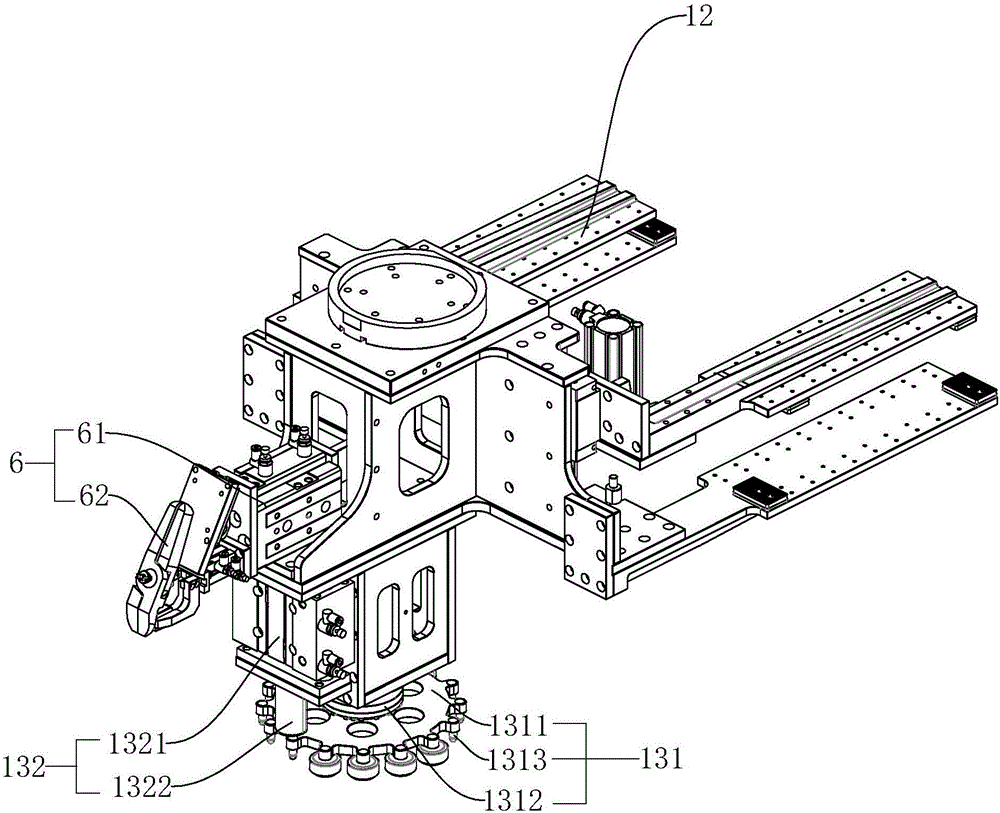

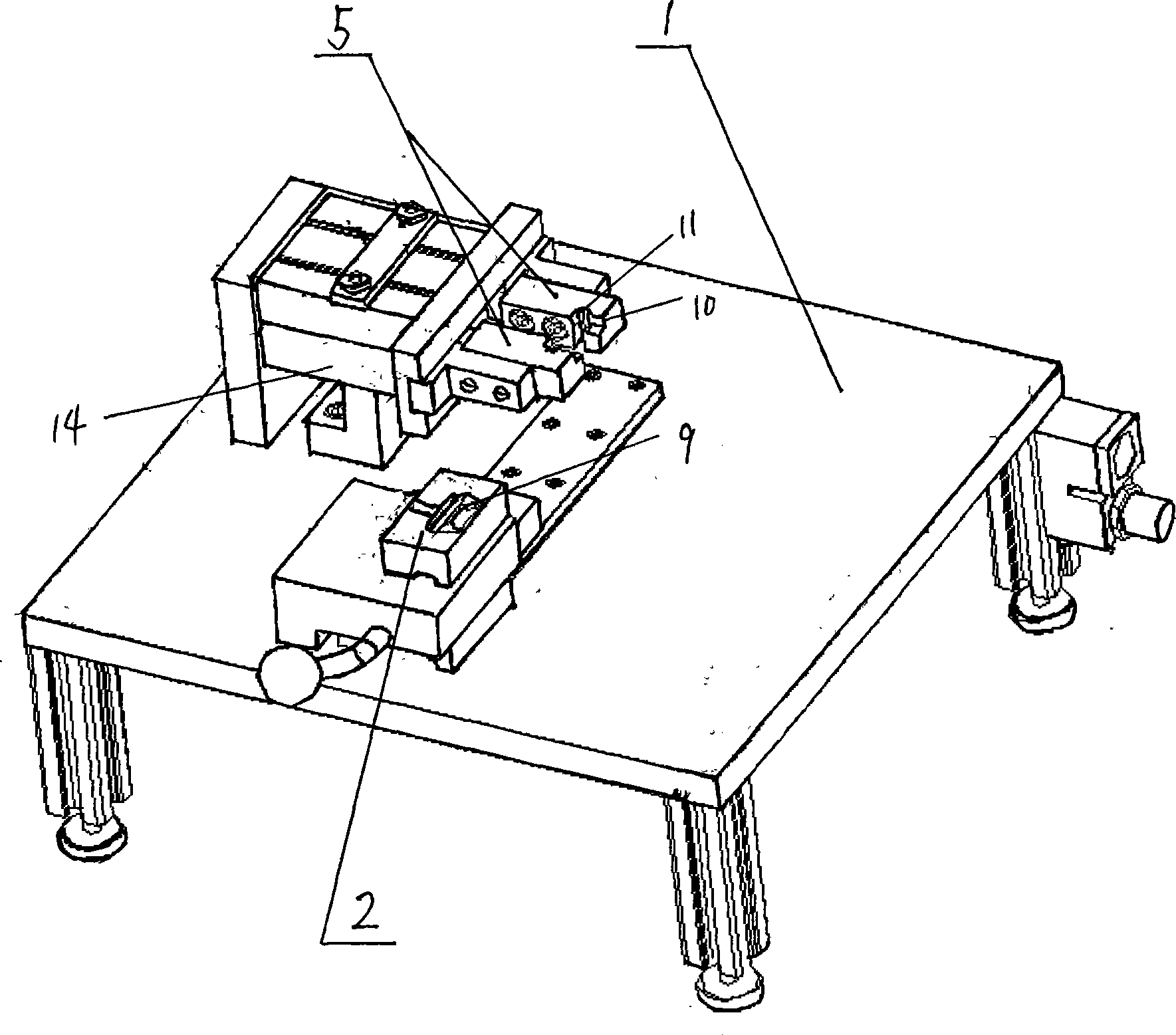

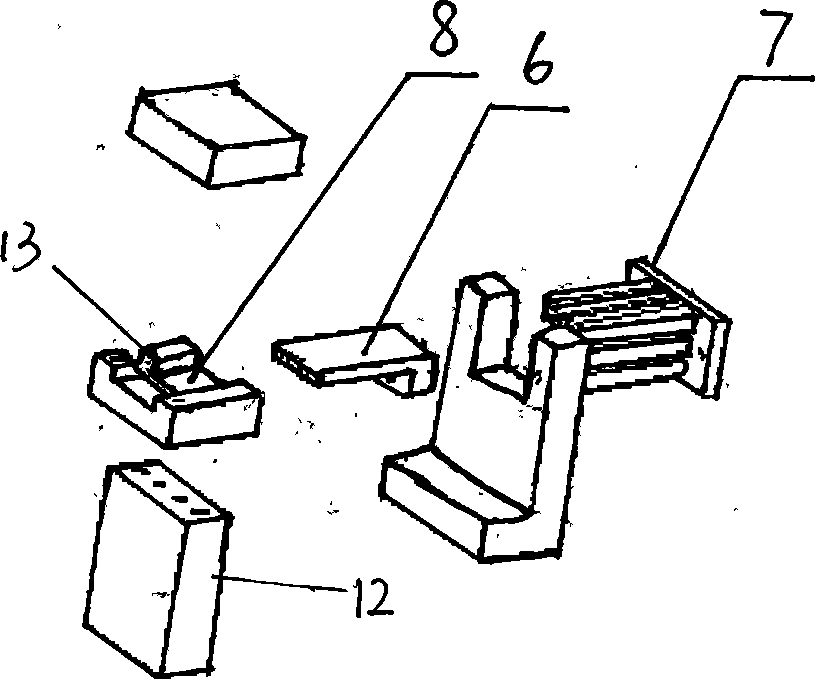

Multi-shaft posture adjusting platform for airplane engine mounting

ActiveCN103204249AAchieve independent controlRealize linkage controlAircraft assemblyJet aeroplaneCarrying capacity

The invention discloses a multi-shaft posture adjusting platform for airplane engine mounting and belongs to the technical field of assembly automation. The multi-shaft posture adjusting platform is characterized by comprising a worktable (1), a translating mechanism (2), a turntable mechanism (3), a lifting and elevating mechanism (4), a platform base (5) and the like. The lifting and elevating mechanism (4) comprises a left upper slide seat (6), a right upper fixing sea (9), a left lifting mechanism (7) and a right lifting mechanism (8), wherein the left lifting mechanism (7) and the right lifting mechanism (8) are of structures conforming to identical operating principles and has a single-side lifting posture adjusting function. All motion mechanisms are of purely mechanical structures driven by a servo motor. The multi-shaft posture adjusting platform has the advantages that carrying capacity is high, mounting accuracy is high, and adjustment range is large; labor intensity of operators is alleviated, and operation efficiency and mounting quality are improved. The multi-shaft posture adjusting platform is widely applicable to accurate assembly of multi-shaft posture adjustment of heavy parts.

Owner:DALIAN UNIV OF TECH

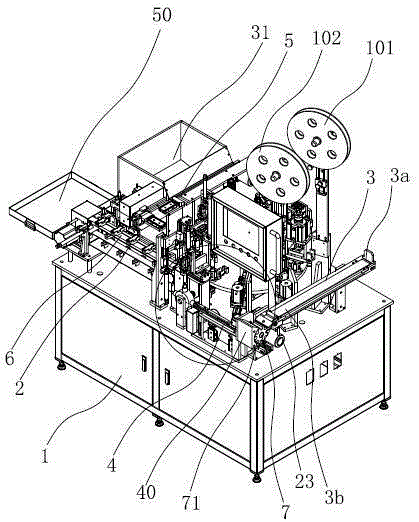

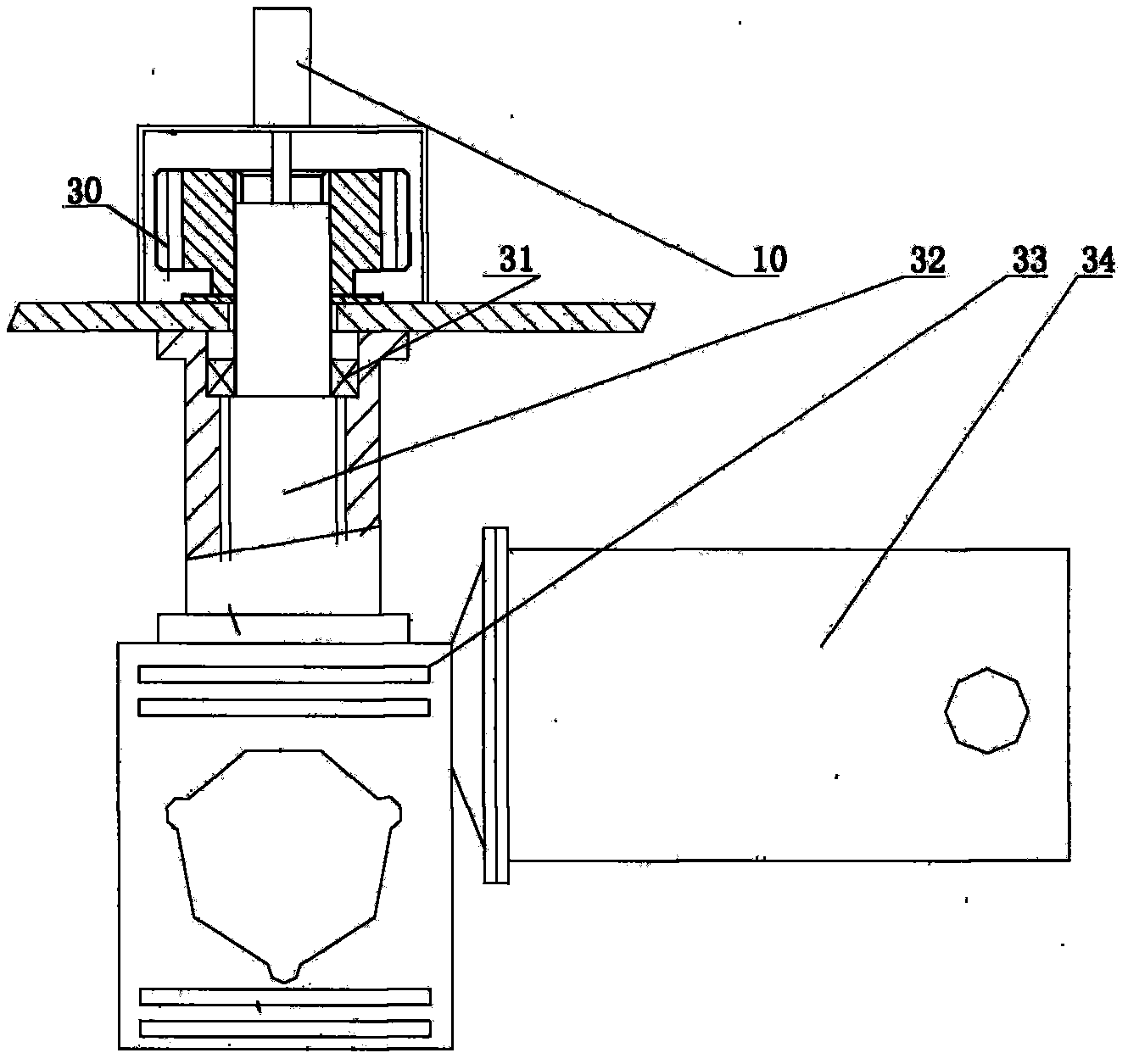

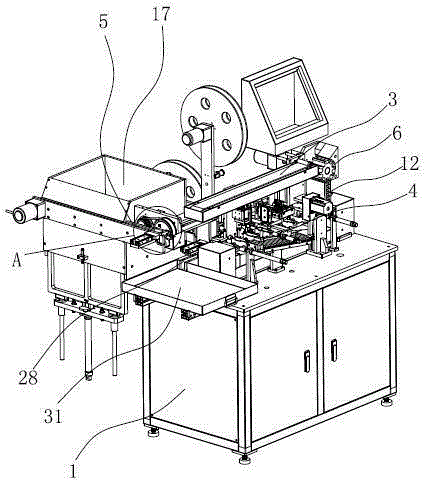

Automatic casing machine of power type cylindrical battery

ActiveCN105304928ASimple structureSmall footprintPrimary cell manufactureAssembling battery machinesCircular discManufacturing technology

The invention provides an automatic casing machine of a power type cylindrical battery, and belongs to the field of a battery manufacture technology. The invention solves the technology problem of low automation degree of present cylindrical battery electrical core casing assembling and the like. The casing machine comprises a rack; the rack is provided with a conveyer belt 1 and a conveyer belt 2 for conveying electrical cores as well as a conveyer belt 3 for conveying casings and a conveyer belt 4 for conveying electrical core carry tools; a rotary disc is horizontally installed on the rack, and several clamping mechanisms for clamping electrical cores are arranged at a circumferential direction of the upper side surface of the rotary disc; an external tab checking apparatus, an internal tab checking apparatus, an upper insulating pad apparatus, an internal tab folding apparatus, an external tab folding apparatus, a defective product detection apparatus and a blanking apparatus are fixedly installed at the circumferential direction of the rotary disc in sequence on the rack, and the external tab checking apparatus, the internal tab checking apparatus, the upper insulating pad apparatus, the internal tab folding apparatus, an external tab measuring apparatus and the external tab folding apparatus are provided. The invention has the advantage of high automation degree.

Owner:深圳市圣瀚宇自动化设备有限公司

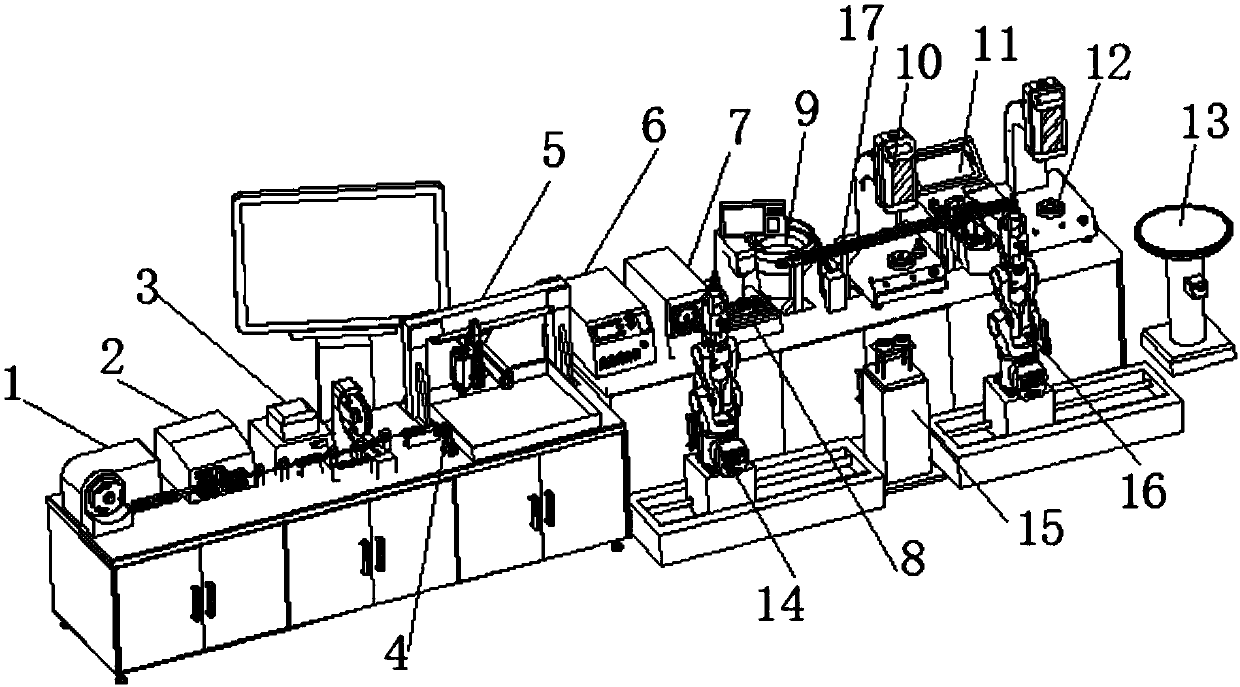

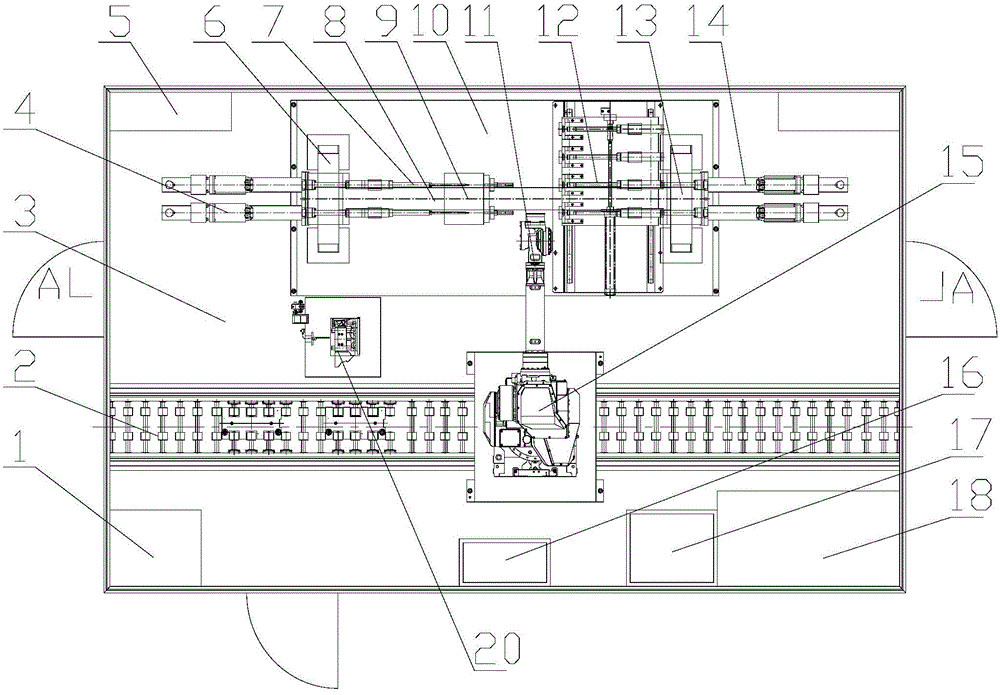

Low-voltage cable assembly intelligent crimping system production line

PendingCN107834338AFully automatedSave spaceConnection formation by deformationLow voltageEngineering

The invention discloses a low-voltage cable assembly intelligent crimping system production line which comprises a fully automatic wire laying marking unit and a wire intelligent crimping unit. The fully automatic wire laying marking unit successively includes an automatic wire laying machine, an automatic wire cutting machine, an automatic cable labeling machine, a label scan gun, and a rectangular coordinate conveying robot from left to right. The wire intelligent crimping unit successively includes, from left to right, a laser wire stripper, a two-axis rotary peeler, a cable detection device, and a vibration plate feeding device, a multi-axis slipway mechanical arm device, a first visual inspection device, a crimping detection device, a second visual inspection device, and a cable collection device. A first electrical apparatus control system six-degree-of-freedom robot and a second electrical apparatus control system six-degree-of-freedom robot are disposed on a side of wire intelligent crimping unit. A conventional apparatus is adjusted and improved so that the high-precision and high-efficiency fully automatic cable assembly automated production line is designed to replace anartificial production method.

Owner:无锡胜维电气有限公司

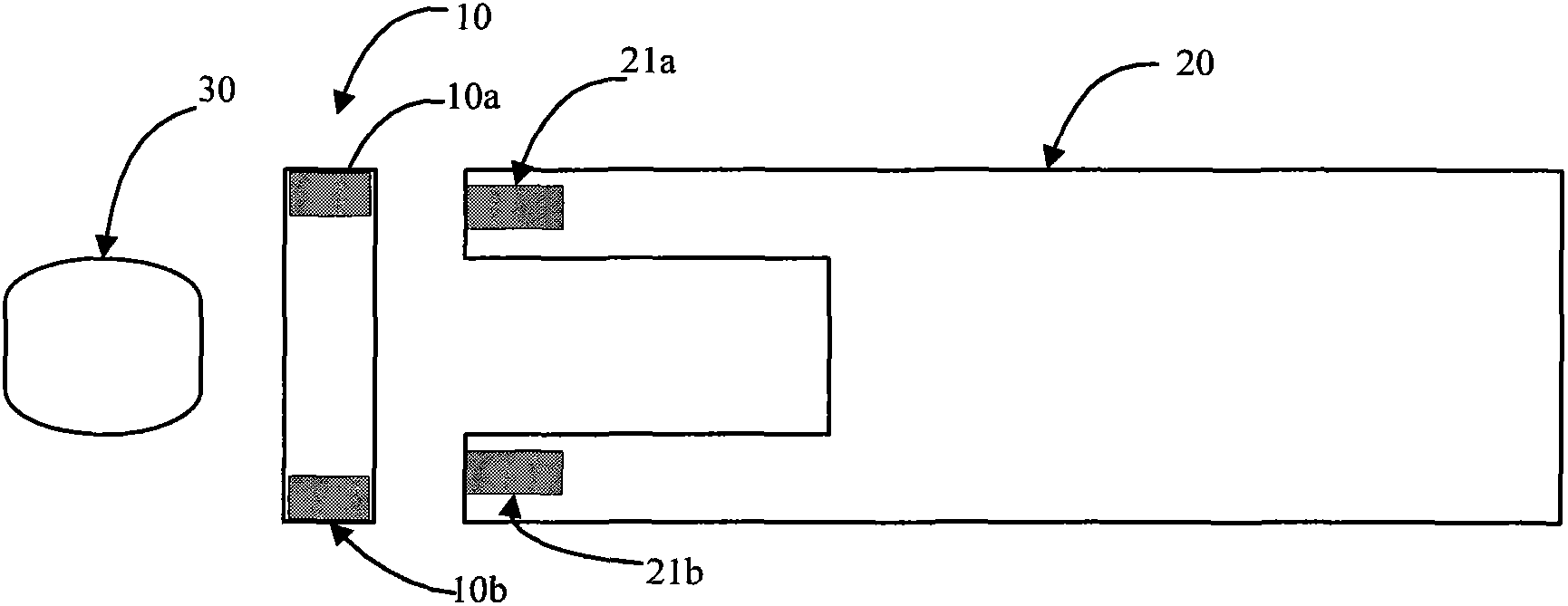

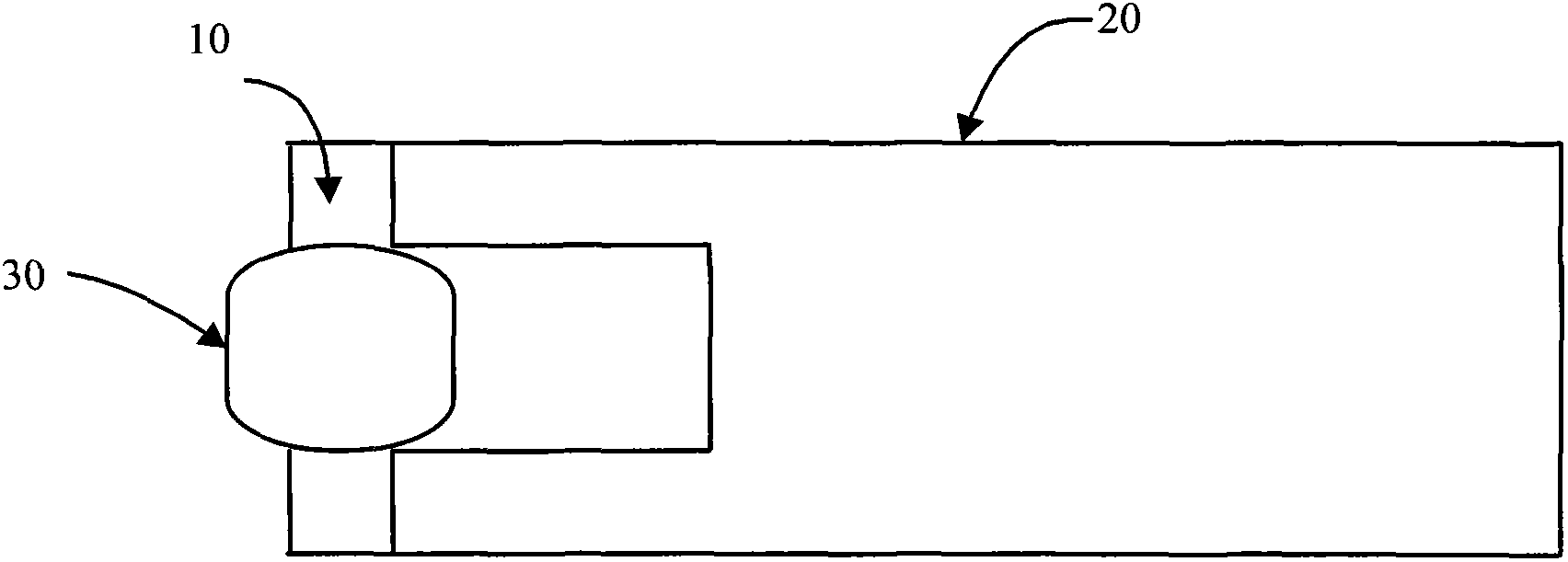

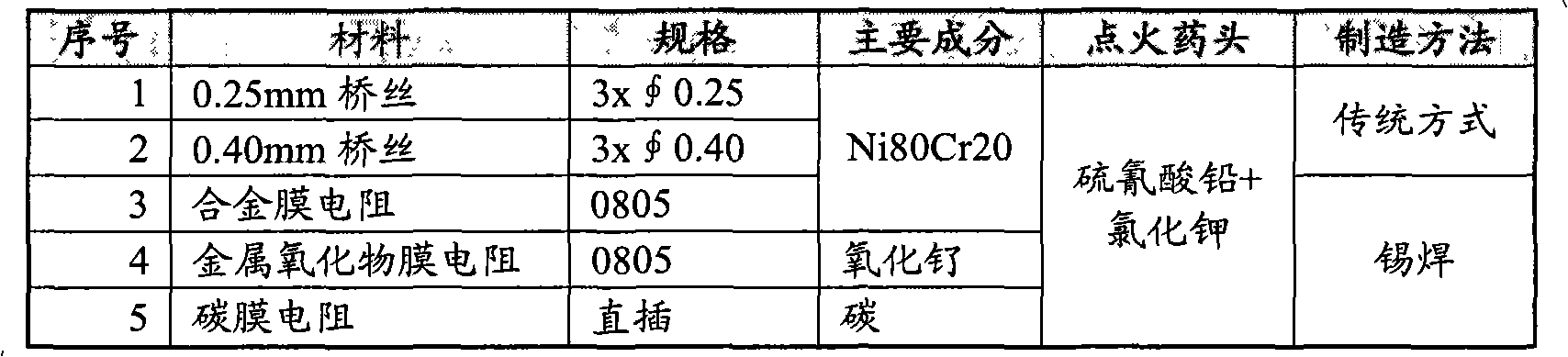

Electric fuse ignition device, electric detonator comprising electric fuse ignition device, electronic detonator comprising electric fuse ignition device, and manufacturing methods for electric detonator and electronic detonator

InactiveCN102878877AEasy to manufactureSimple preparation processBlastingAmmunition fuzesElectrical resistance and conductanceElectricity

The invention provides an electric fuse ignition device. The electric fuse ignition device comprises a film resistor and an ignition explosive head wrapping the film resistor, wherein a power supply device can supply energy to the film resistor so that the film resistor generates enough joule heat and heats the ignition explosive head to a set temperature; and therefore, the ignition explosive head is lighted. The invention also provides an electric detonator comprising the electric fuse ignition device and an electronic detonator comprising the electric fuse ignition device. The invention also provides manufacturing methods for the electric detonator and the electronic detonator. According to the electric fuse ignition device provided by the invention, the film resistor is easy to manufacture, low in cost, high in yield, not easy to break and high in resistance precision, so that the electric detonator comprising the electric fuse ignition device and the electronic detonator comprising the electric fuse ignition device also have the advantages that the manufacturing is simple, the cost is low, the yield is high, the misfire rate is low, and the explosion precision is high. The manufacturing methods for the electric detonator and the electronic detonator are high in assembly automation degree, precise, reliable, high in yield and low in cost.

Owner:XINJIANG CHUANGANDA ELECTRONICS TECH DEV

A satellite automatic assembly platform

ActiveCN106134364BAccurate measurementRealize precision hoisting and docking operationsArtificial satellitesLifting devicesRelative displacementAssembly automation

An automatic satellite assembly platform is composed of three parts: an assembly positioning mechanism, an interface attitude capture device and a control box. In the present invention, the laser displacement sensor uniformly arranged at the satellite docking frame of the interface attitude capture device can accurately measure the relative displacement with the satellite interface adapter when the satellite is hoisted, and the load-bearing sensor uniformly arranged at the satellite docking frame of the interface attitude capture device realizes The measurement of the center of mass of the satellite; the elevator and the inclination sensor set in the assembly positioning mechanism realize the automatic leveling of the platform; the circular slewing support is set in the assembly positioning mechanism so that the satellite automatic assembly platform has the function of a precision turntable, which can make the satellite Precise rotation on the carriage, the accuracy can reach 1'. The satellite automatic assembly platform of the present invention can adapt to the use requirements of different satellites by replacing the satellite interface adapter.

Owner:BEIJING SATELLITE MFG FACTORY

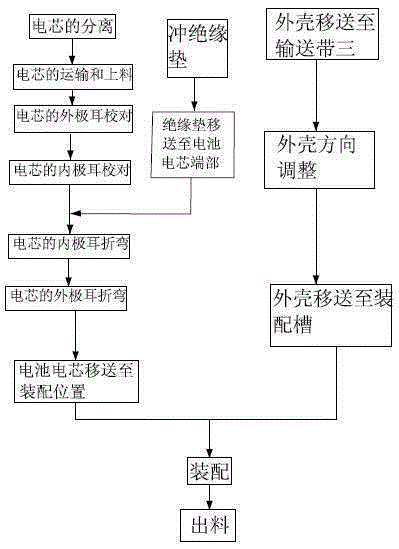

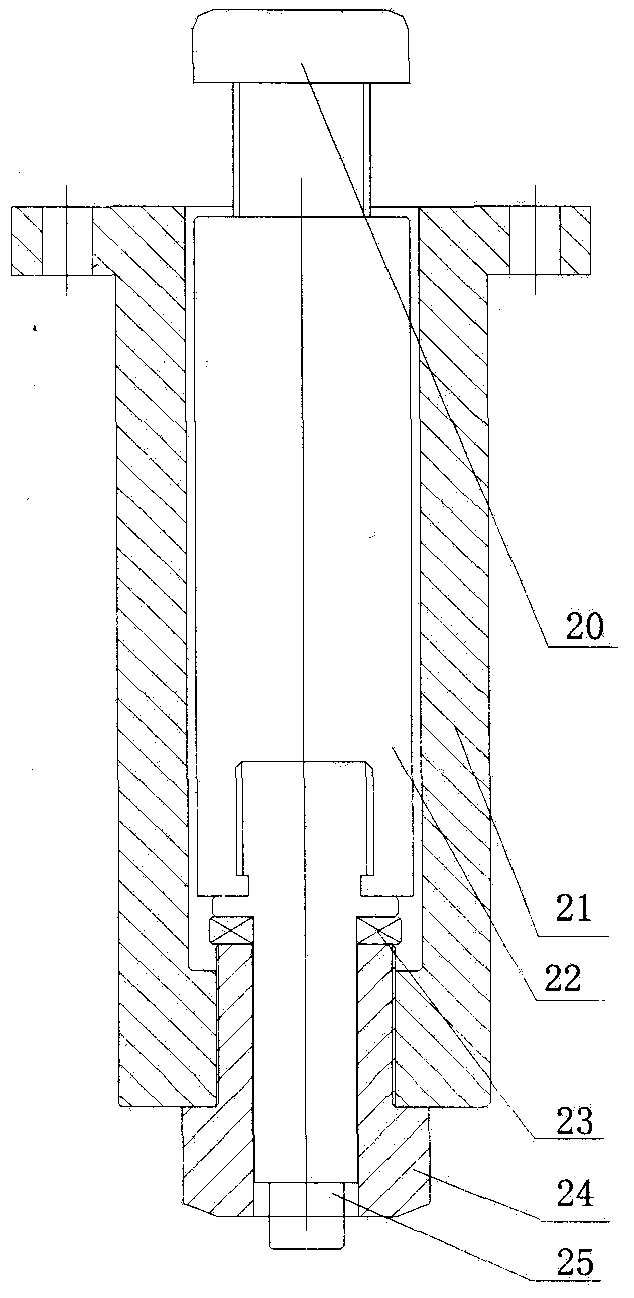

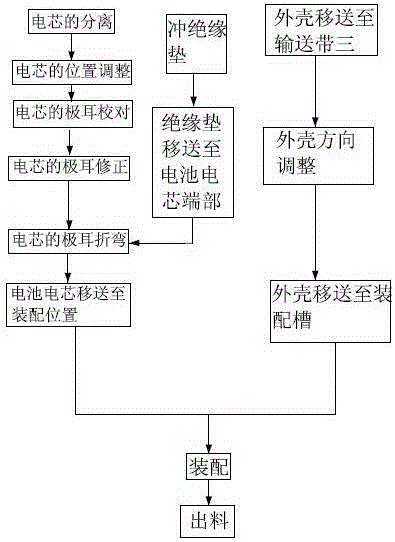

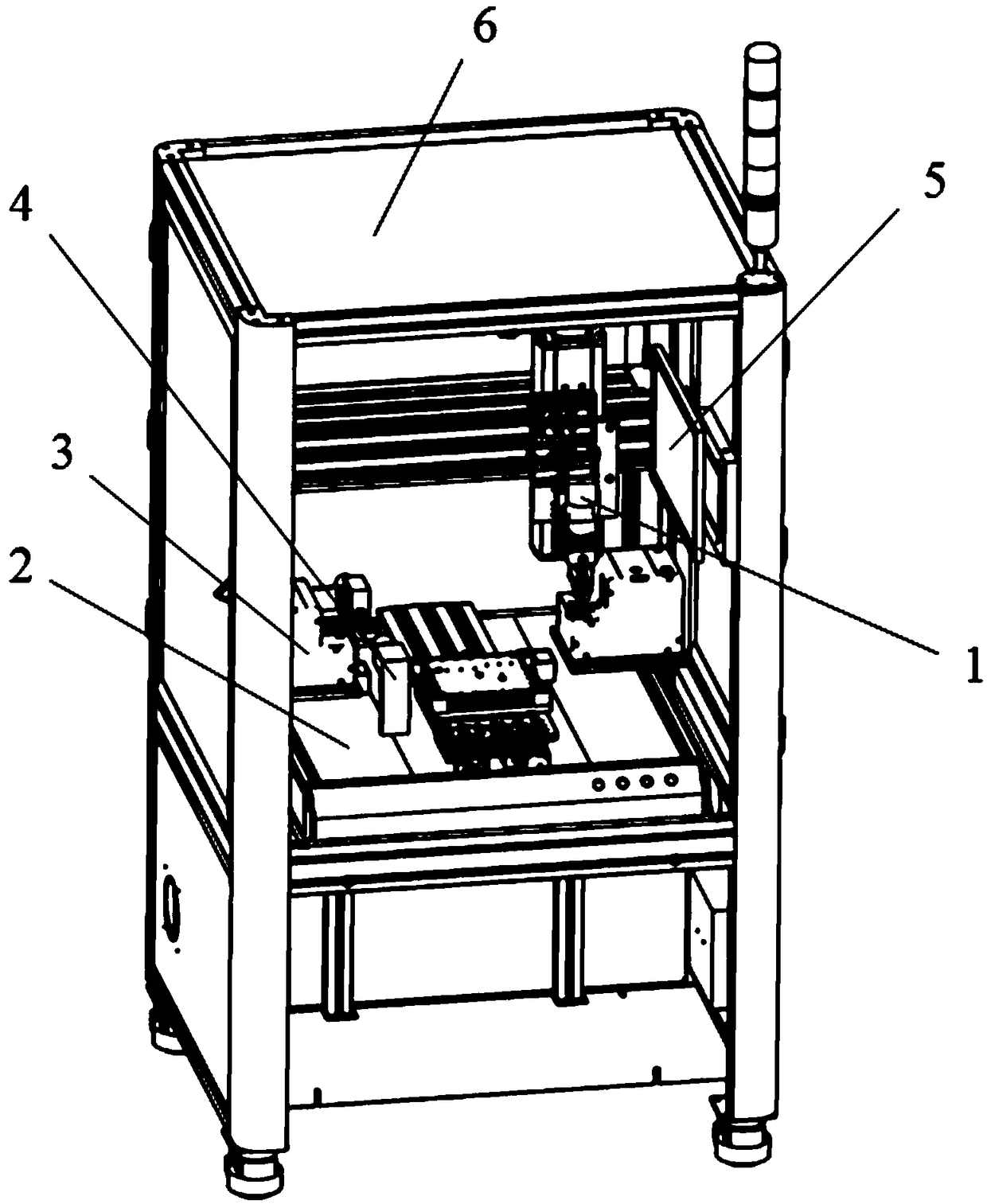

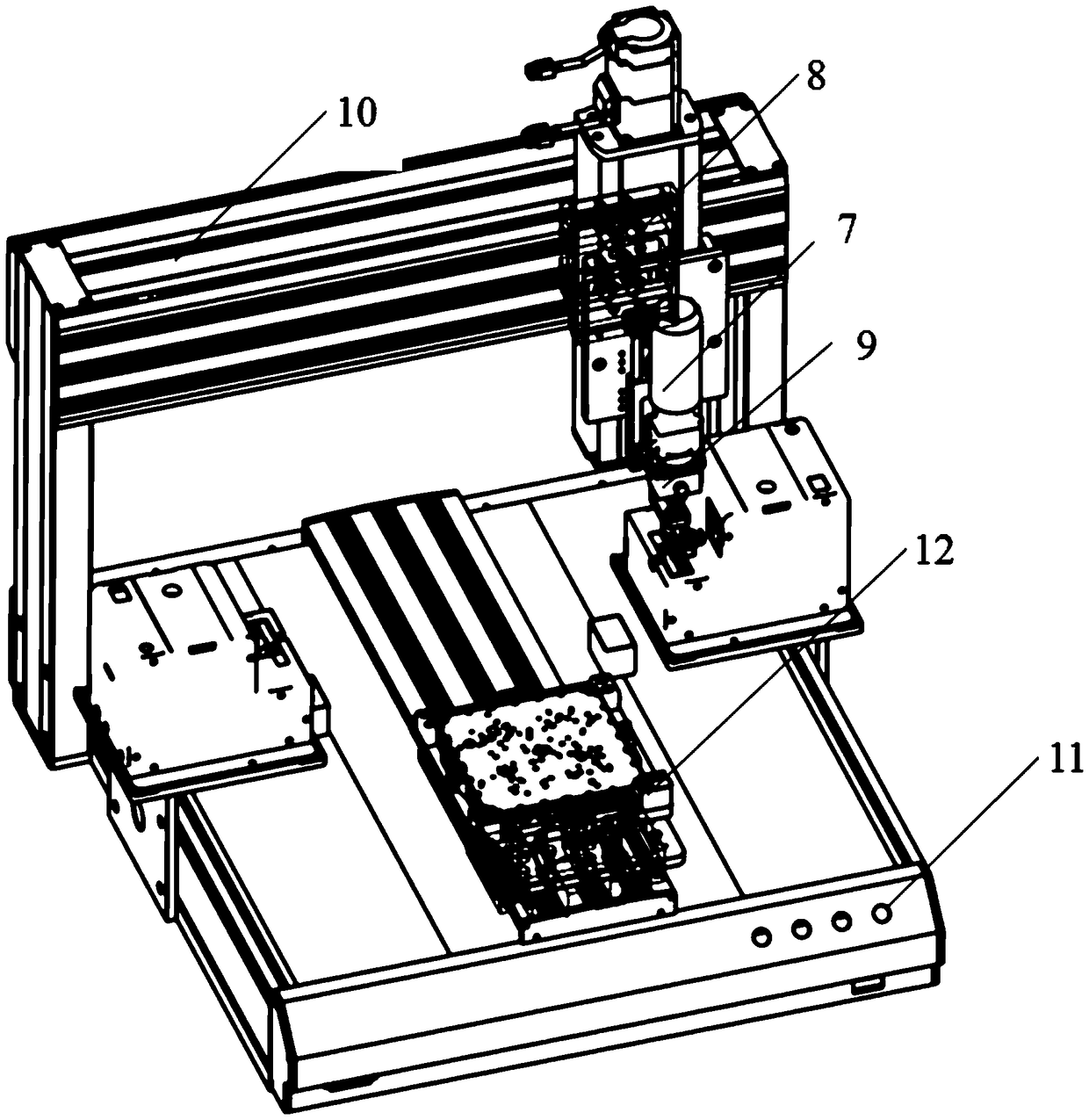

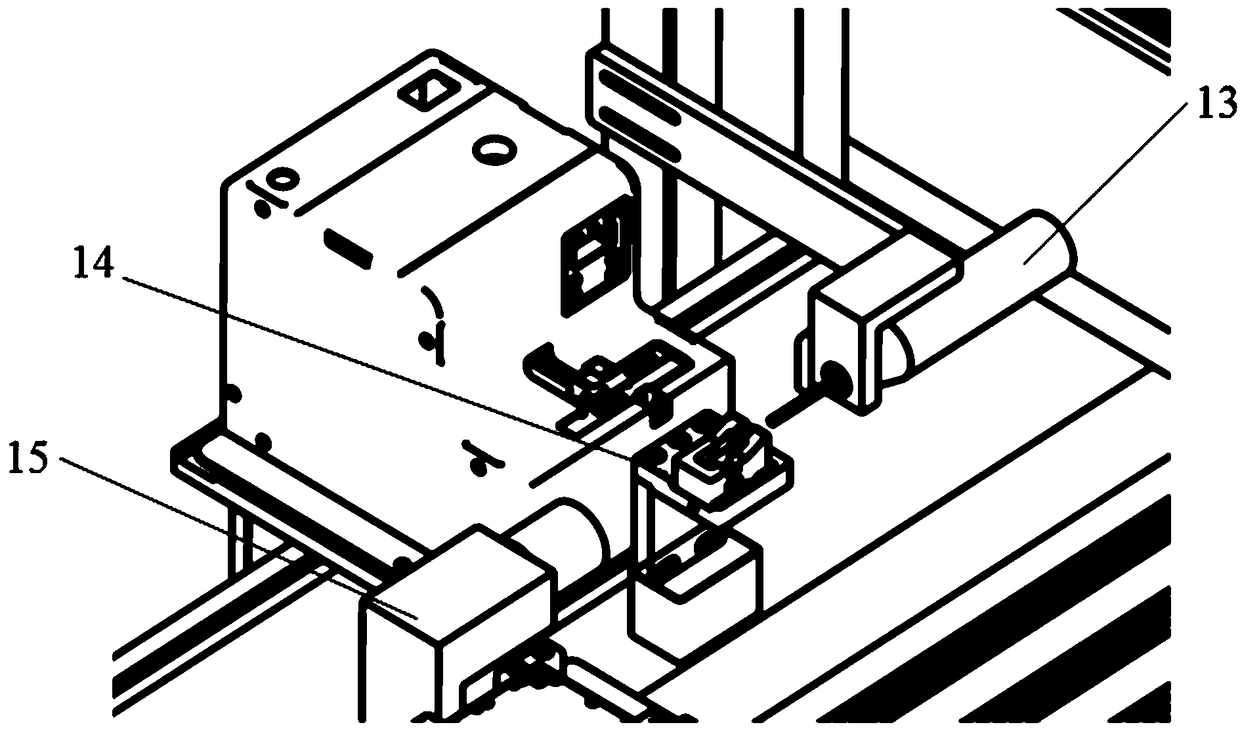

Machine for automatically assembling cylindrical battery into shell

InactiveCN105280932ASimple structureSmall footprintPrimary cell manufactureAssembling battery machinesEngineeringAssembly automation

The invention provides a machine for automatically assembling a cylindrical battery into a shell, and belongs to the technical field of battery manufacturing. The technical problem that the existing operation of assembling a cylindrical battery cell into a shell is low in automation degree and the like is solved. The machine comprises a machine cabinet and a plurality of battery cell carriers capable of carrying battery cells. The machine cabinet is provided with a first conveying belt capable of conveying the battery cells, a second conveying belt capable of conveying the battery cell carriers, and a third conveying belt capable of conveying a shell. A battery cell channel is arranged below the discharge end of the first conveying belt and provided with a separating mechanism capable of separating the battery cells. The second conveying belt is located below the battery cell channel. A battery cell adjustment mechanism, a pole lug proofreading mechanism, a pole lug correcting mechanism and a pole lug bending mechanism are arranged on the two sides of the second conveying belt in sequence. The machine cabinet is provided with an assembly groove. The two ends of the assembly groove are provided with a propulsion air cylinder and a sucking air cylinder. A piston rod of the propulsion air cylinder is provided with a hollow ejector column right opposite to the assembly groove. The machine has the advantages of being simple in structure and high in automation degree.

Owner:罗林波

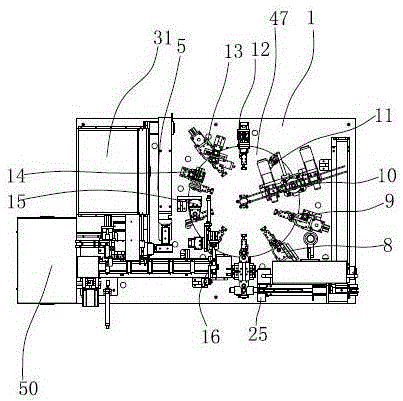

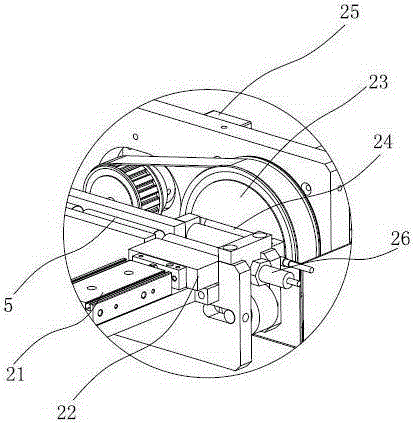

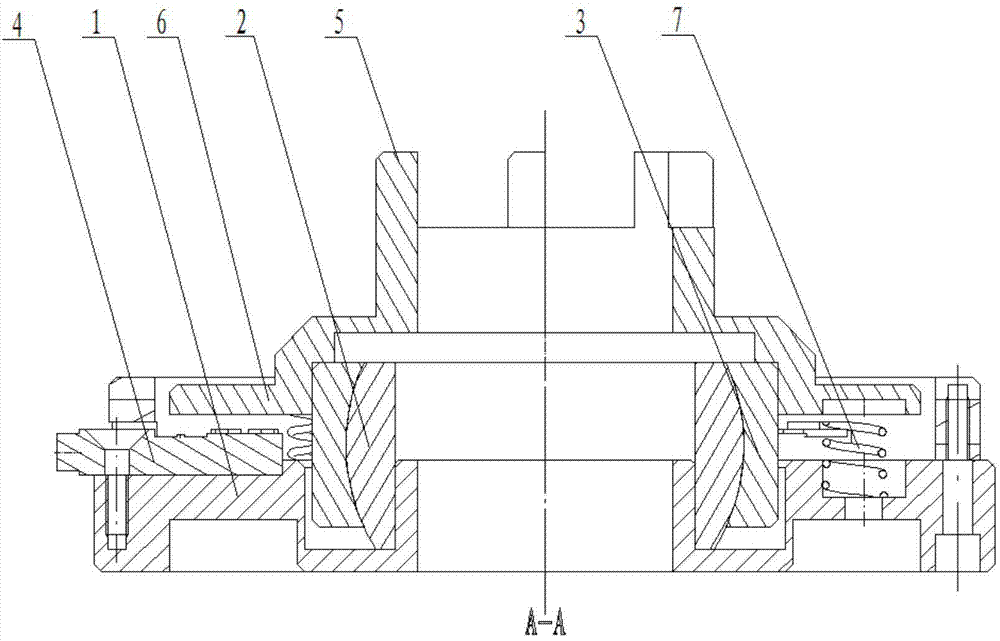

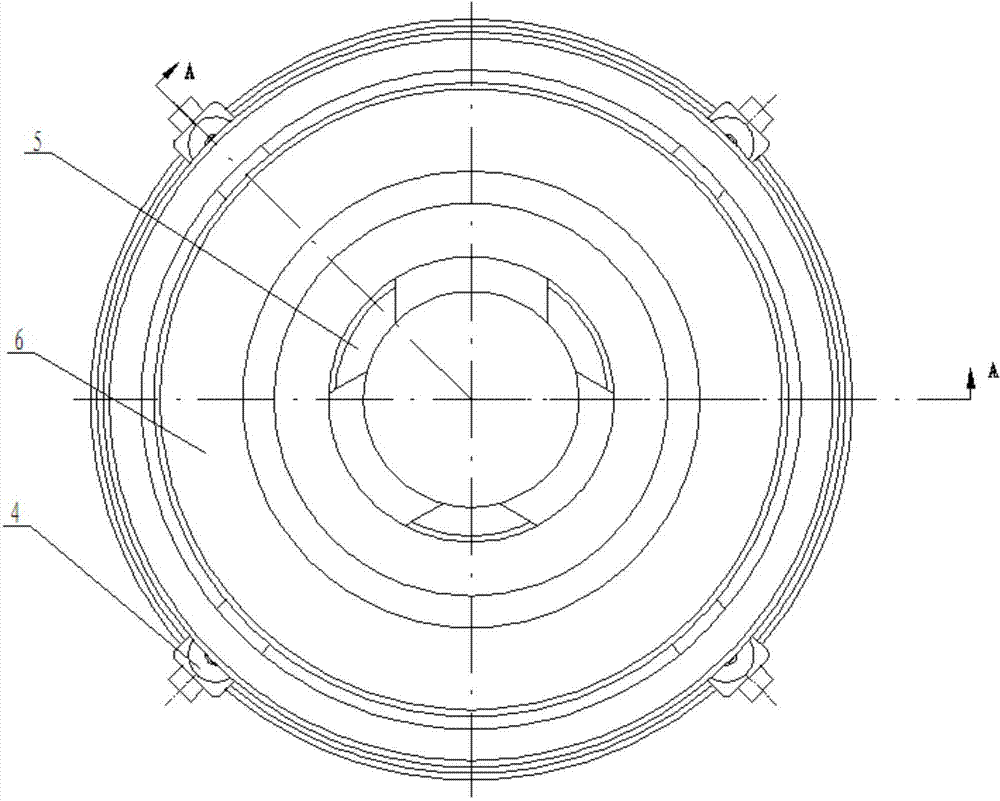

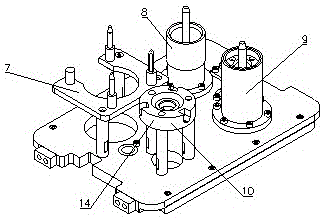

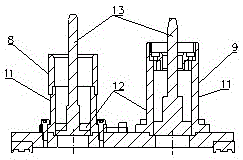

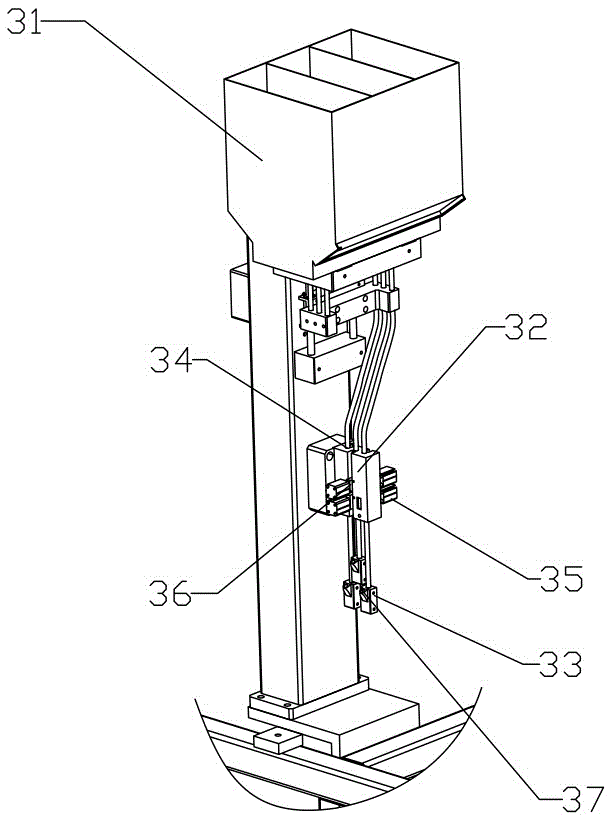

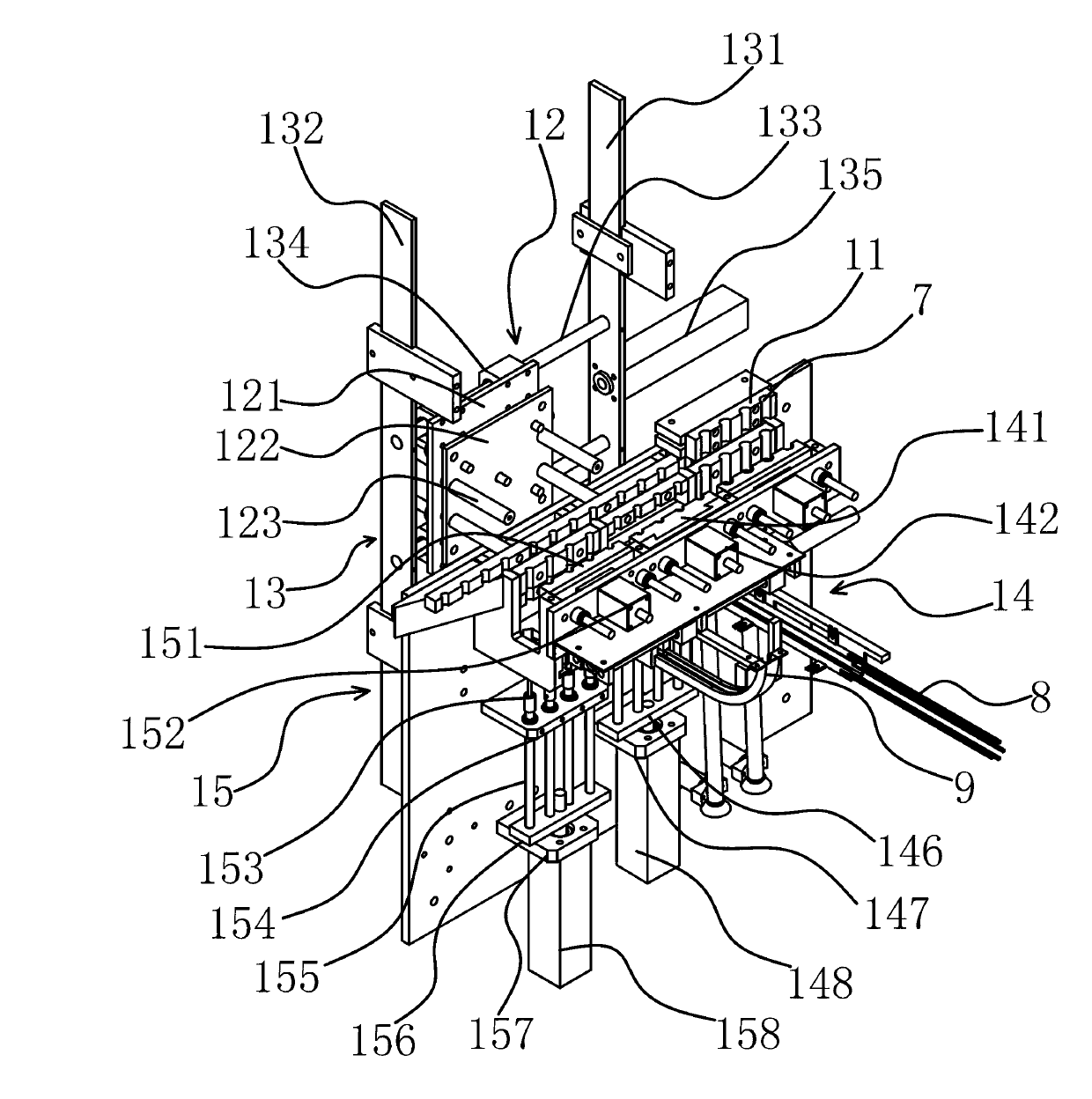

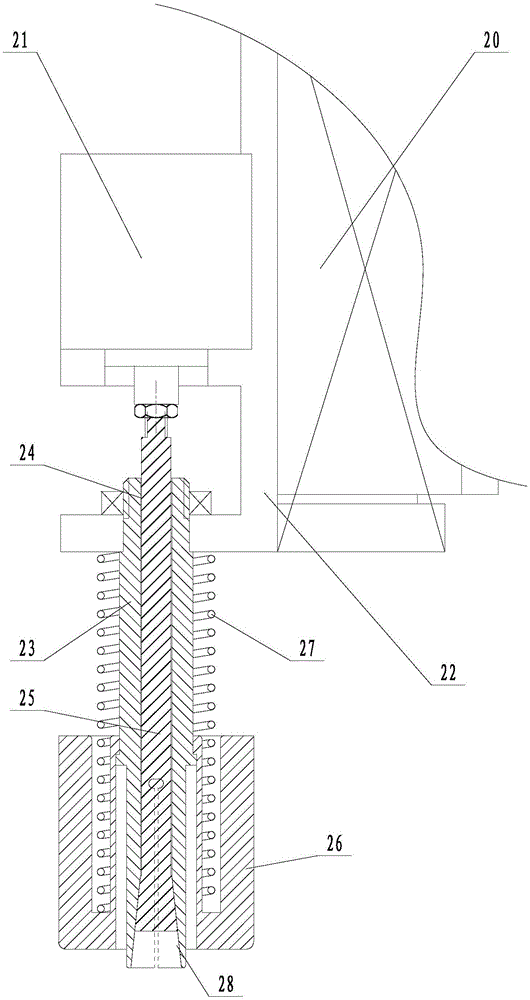

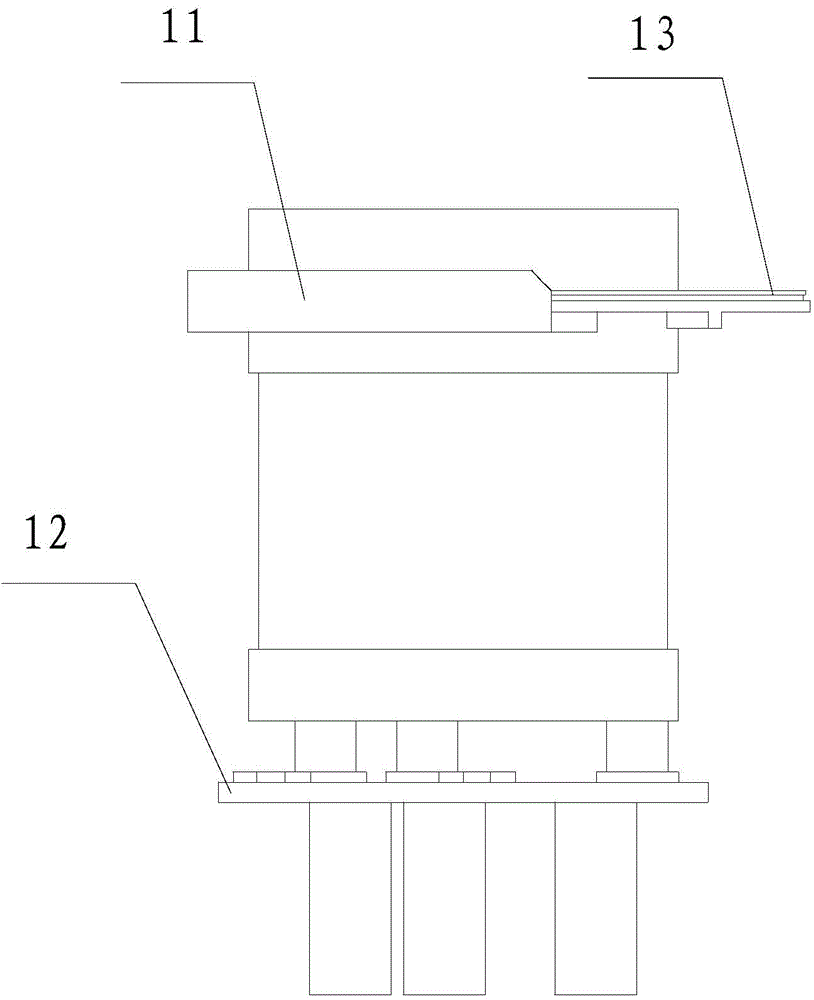

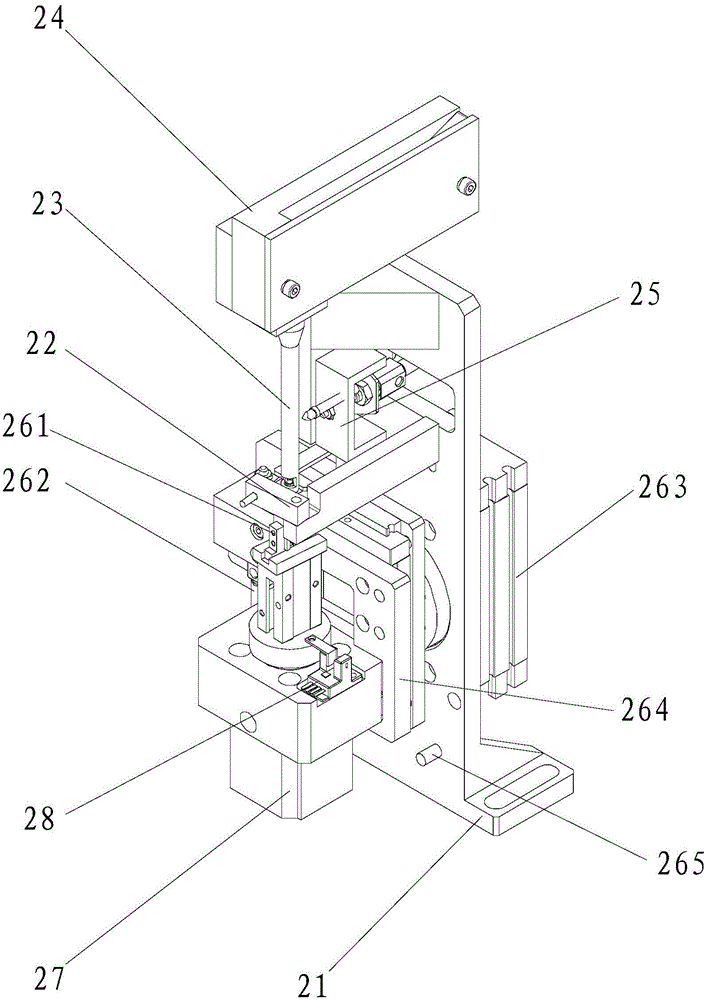

Sandwich type piezoelectric transducer automatic assembly machine

InactiveCN101596673AImprove assembly accuracyImprove assembly efficiencyAssembly machinesAxial pressureFuel tank

The invention discloses a sandwich type piezoelectric transducer automatic assembly machine. A push plate, a pressure plate, a support plate are sleeved on two vertical columns; wherein, the push plate axially slide along the vertical columns through a first copper bush; the pressure plate is fixed on the two vertical columns by a first screw nut to bear the axial pretightening force applied on the sandwich type piezoelectric transducer by a fuel tank; the support plate is fixed on the two columns by a second screw nut to install a first hydraulic motor; a second hydraulic motor is fixed on the push plate by a fourth screw nail, a vertical plate and a fifth screw nail; a jaw vice is fixed on the push plate by a bolt; the push plate axially slide along a guiding shaft through a second copper bush; the guiding shaft is mounted on a base by a screw thread; the first hydraulic motor drives a third screw nut of the sandwich type piezoelectric transducer to rotate by a first coupling and a dedicated sleeve, so as to generate axial pressure and press a piezoelectric ceramics tightly. In the invention, two hydraulic motors are adopted, therefore, the assembly precision and the assembly efficiency are high, the assembly operations is safe, and the assembly automation of the sandwich type piezoelectric transducer is realized.

Owner:HANGZHOU DIANZI UNIV

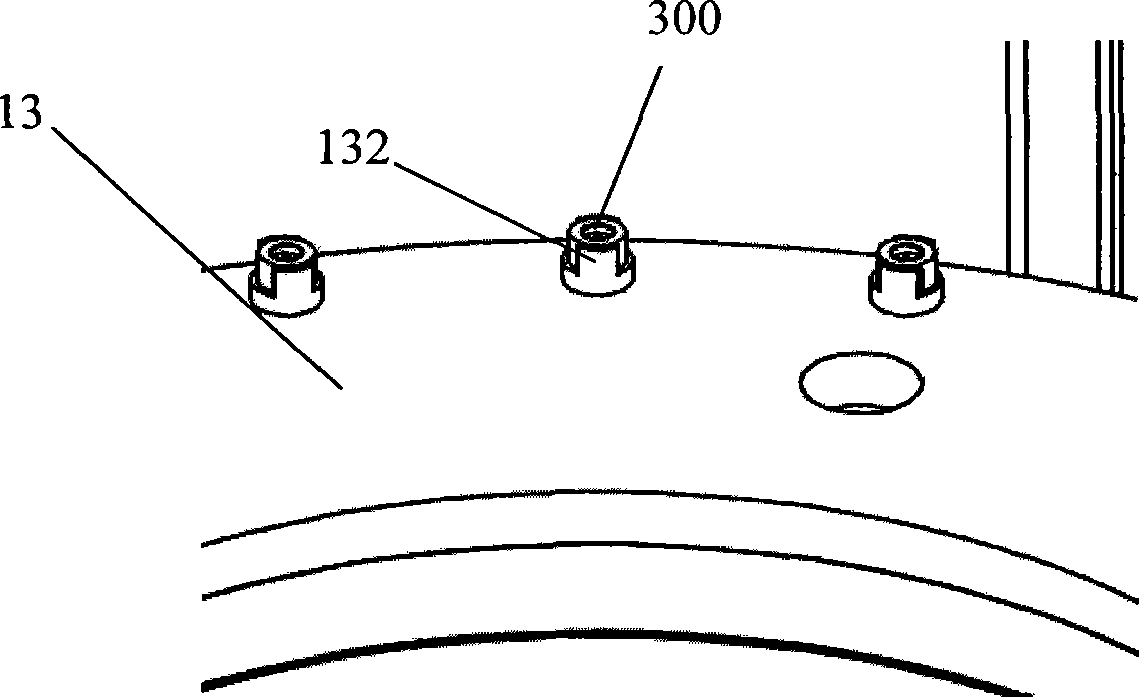

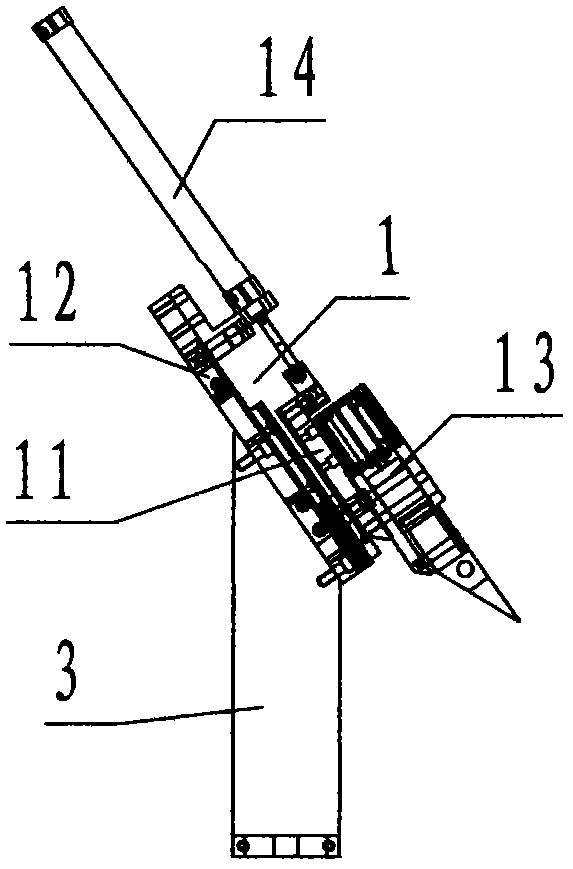

Normal angle measuring unit

ActiveCN103538081AGuaranteed Normal AccuracyGuarantee the quality of hole makingMeasurement/indication equipmentsManipulatorSkin surfaceNormal skin

The invention belongs to aircraft assembly automation technology and relates to a normal angle measuring unit for measuring surface normal skin workpieces in real time. The unit comprises a support plate, a universal mechanism fixing ring, a universal mechanism outer ring, a displacement sensor, a measuring contact end, a measuring plate and a reset spring. The normal angle measuring unit is exquisite in structural design, due to the fact that surface radian of skin workpieces changes along with positions, the normal adjusting unit can automatically adapt to the radian changes on the skin surfaces, deviation value between actual normal and theoretical normal can be measured in real time, deviation angle of the actual normal and the theoretical normal can be adjusted into a preset range according to the deviation value, and perforation normal precision can be guaranteed. By the surface perforation normal measuring unit using the displacement sensor for online measuring, normal deviation of cutter axes and skin surfaces can be adjusted in real time, and perforation quality of skin workpieces can be guaranteed.

Owner:AVIC BEIJING CHANGCHENG AVIATION MEASUREMENT & CONTROL TECH INST +2

Precise locating method for automatic assembly hole making

ActiveCN103522126AGuaranteed positionGuaranteed verticalityMeasurement/indication equipmentsPoint cloudEngineering

The invention discloses a precise locating method for automatic assembly hole making. A hole making system is composed of a five-axis machining machine tool and a laser tracker. A product is mounted on an assembly fixture and made to be in a stable hole making state, the product and the assembly fixture are together moved to the five-axis machining center and fixed, the laser tracker is used for building a coordinate system through datum points of the assembly fixture, the appearance contour of the product is scanned, a solid numerical model is generated from a point cloud obtained by scanning in the reverse direction, measuring software is used for automatically generating a hole site closest to the 3D space of appearance contour mathematical points of the product in space on the surface of the solid numerical model, and the hole site is used as the basis of five-axis machining hole making. The precise locating method has the advantages that machining precision is improved, complex operation and repeated calibration in the hole making process are omitted, precision of the hole making locating degree, the perpendicularity and the reaming cavity depth is better than the requirement of automatic hole making specifications, an expensive end effector is not needed, manufacturing cost is lowered, and production efficiency is maximized.

Owner:航天海鹰(镇江)特种材料有限公司

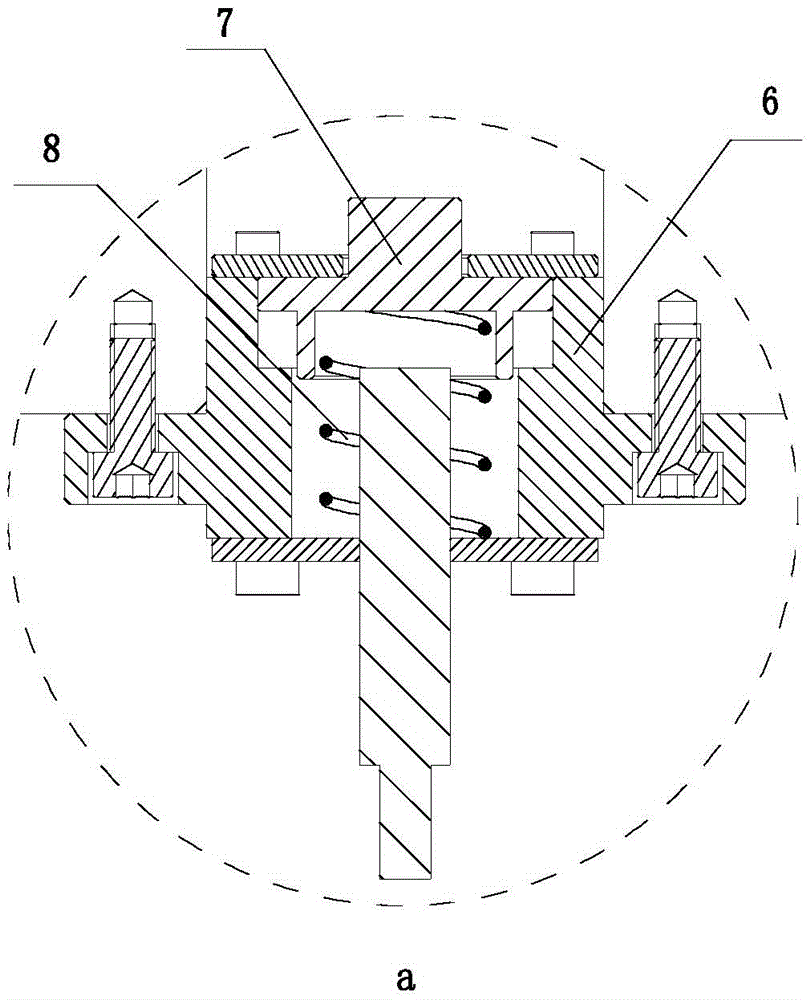

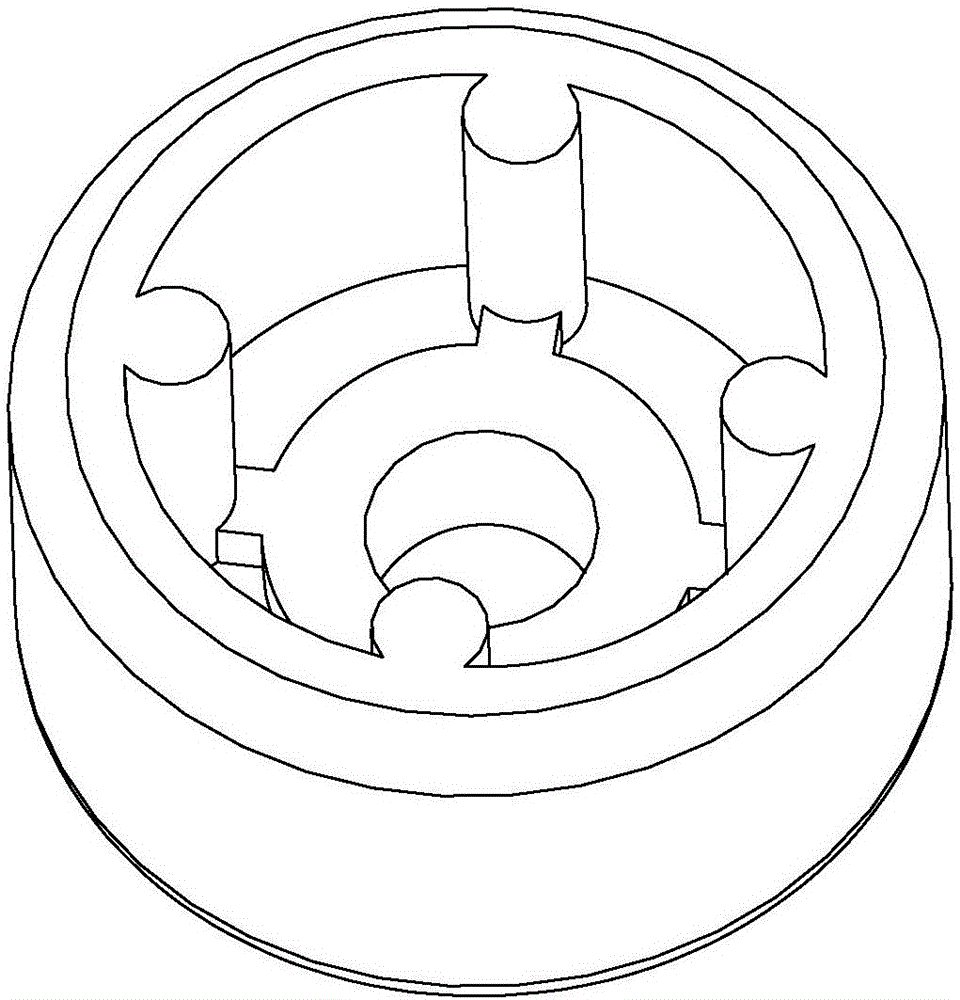

Pose adjusting ball device for airplane assembly

ActiveCN105539876ARealize docking assemblyImprove automationAircraft assemblyNumerical controlEngineering

The invention discloses a pose adjusting ball device for airplane assembly and belongs to the field of airplane manufacturing equipment. The defects that errors are large and the stress of the connecting portion is large exist in the airplane body pose adjustment process due to the adoption of a special fixture or a jack manual operation manner currently. The pose adjusting ball device comprises a ball socket seat and an installation seat used for being connected with and supporting an airplane body. A connecting flange is arranged at the upper portion of the installation seat and the lower portion of the installation seat is fixedly connected with a ball through a connecting rod. An installation seat installation cavity is formed in the center of the ball socket seat. A ball socket corresponding to the ball is arranged at the lower portion of the installation cavity. The installation seat is installed in the ball socket seat. Three clamping devices are evenly arranged on the sides of the ball socket seat in the circumferential direction. An in-position detection switch is arranged at the bottom of the ball socket seat. The pose adjusting ball device is combined with a three-coordinate numerical control locator, accuracy errors existing in manual pose adjustment are effectively avoided, airplane assembly automation and intelligence are improved, and the pose of the airplane body can be better adjusted in six directions.

Owner:ZHEJIANG RIFA AVIATION DIGITAL EQUIP

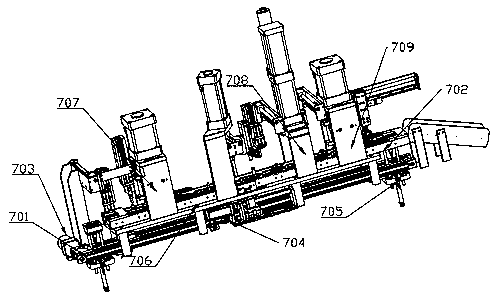

Automatic assembling line for washing machine clutch

InactiveCN105149943AHigh degree of assembly automationReduce demandAssembly machinesEngineeringAssembly automation

The invention relates to an automatic assembling line for a washing machine clutch. The automatic assembling line comprises an automatic shaft assembly assembling line, a clutch final assembly automatic line and a jumper wire transplanting device. The automatic shaft assembly assembling line comprises a shaft assembly assembling conveying line, a shaft assembly assembling carrier and an automatic shaft assembly assembling carrier returning line. The clutch final assembly automatic line comprises a clutch final assembly conveying line, a clutch final assembly carrier and an automatic clutch final assembly carrier returning line. The shaft assembly assembling conveying line and the clutch final assembly conveying line are provided with a plurality of stations sequentially distributed from the initial end to the tail end and online special machines arranged on the stations. The assembling of the washing machine clutch is finished when the shaft assembly assembling carrier and the clutch final assembly carrier pass the stations and the online special machines in sequence. The automatic assembling line has the beneficial effects that the assembling automation rate of the washing machine clutch is greatly increased, the labor intensity of workers is relieved, and the requirement for assembling workers is lowered.

Owner:北自精工机械(常州)有限公司

Automatic assembling machine for slide rail

ActiveCN105643272ARealize automatic rivetingImprove stabilityAssembly machinesEngineeringMechanical engineering

The invention discloses an automatic assembling machine for a slide rail. The machine comprises a frame, and is characterized in that a slide rail cup-joint ball loading mechanism, a ball separating and blowing mechanism, a stopper assembling mechanism and a stopper riveting mechanism are arranged on the frame in sequence; an outlet end of the ball separating and blowing mechanism is connected with the slide rail cup-joint ball loading mechanism; the stopper assembling mechanism is arranged at an outlet end of the slide rail cup-joint ball loading mechanism; and a feeding mechanism is arranged between the stopper assembling mechanism and the stopper riveting mechanism. The automatic assembling machine for the slide rail is high in stability and assembly automation degree.

Owner:GUANGDONG SACA PRECISION MFG CO LTD

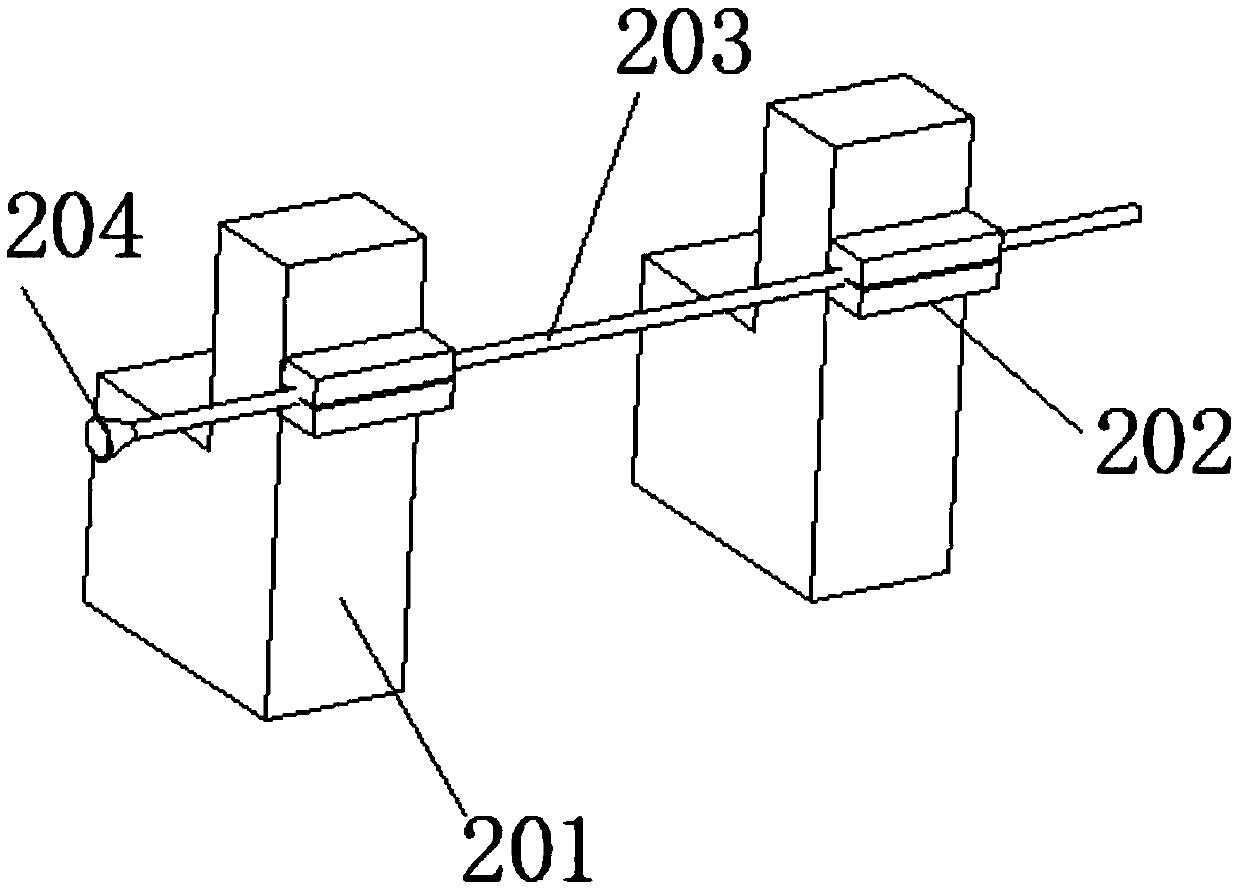

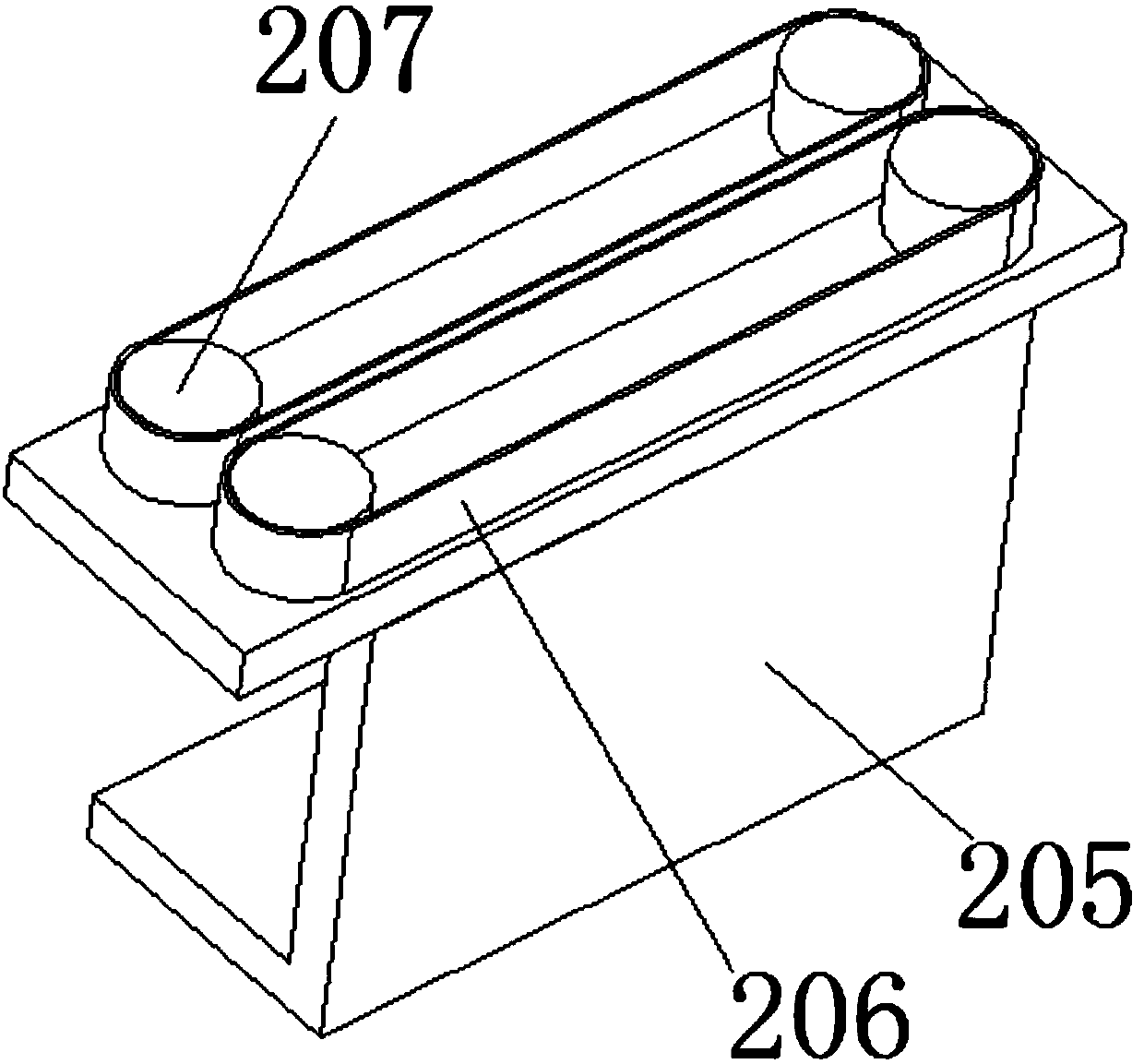

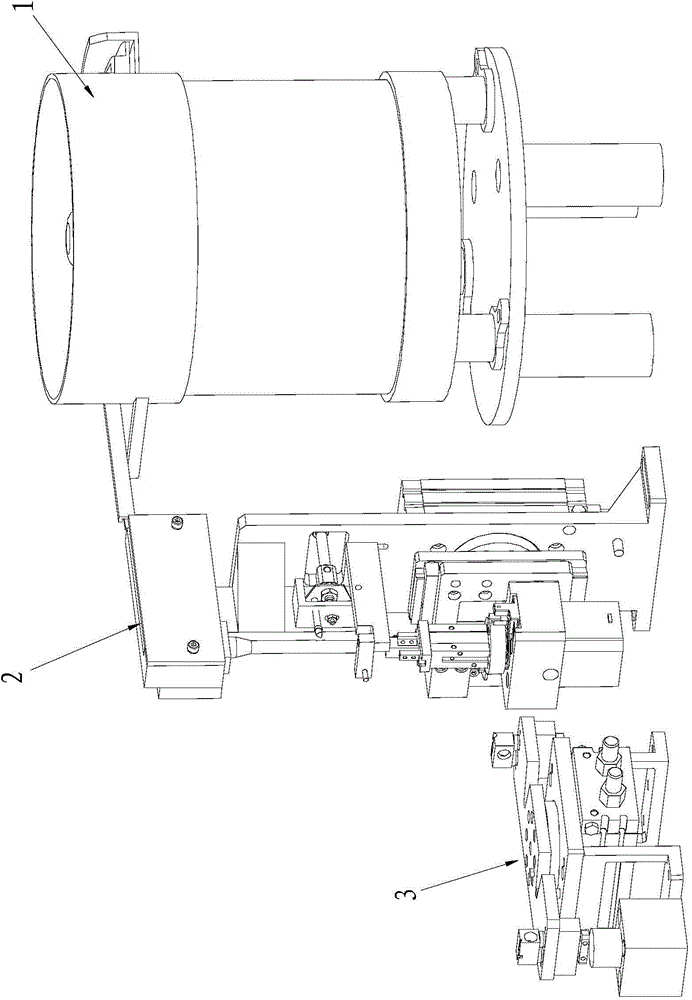

Pneumatic automatic device for assembling binder clips

InactiveCN103586670AAvoid the disadvantages of manual assemblyReduce work intensityMetal working apparatusSlide plateEngineering

The invention discloses a pneumatic automatic device for assembling binder clips. The pneumatic automatic device comprises a mechanical hand (1), a conveying channel (2) and a base (3). The mechanical arm is provided with a sliding plate, a supporting plate, pneumatic gripping devices and a sliding plate air cylinder. The conveying channel comprises a steel clip guide groove, a steel clip air cylinder and a long-tail guide rail. The base comprises a base plate and a support. When the pneumatic automatic device works, steel clips are located in the steel clip guide groove, the steel clip air cylinder drives the steel clips to move backwards along the steel clip guide groove in a queue mode, and the long-tail guide rail is sleeved with long tails in a sliding mode; the long tails are clamped and folded through the pneumatic gripping devices, the pneumatic gripping devices assemble the long tails to the steel clips under the drive of the sliding plate air cylinder, and then the pneumatic gripping devices are reset. According to the pneumatic automatic device for assembling the binder clips, the four pneumatic gripping devices act respectively to assemble the long tails to the steel clips on the basis of the moving stride and speed of the steel clips, so that automatic assembly of the blinder clips is achieved, work strength is reduced, efficiency is improved, and cost is reduced.

Owner:NINGBO LITAI ELECTRONICS TECH

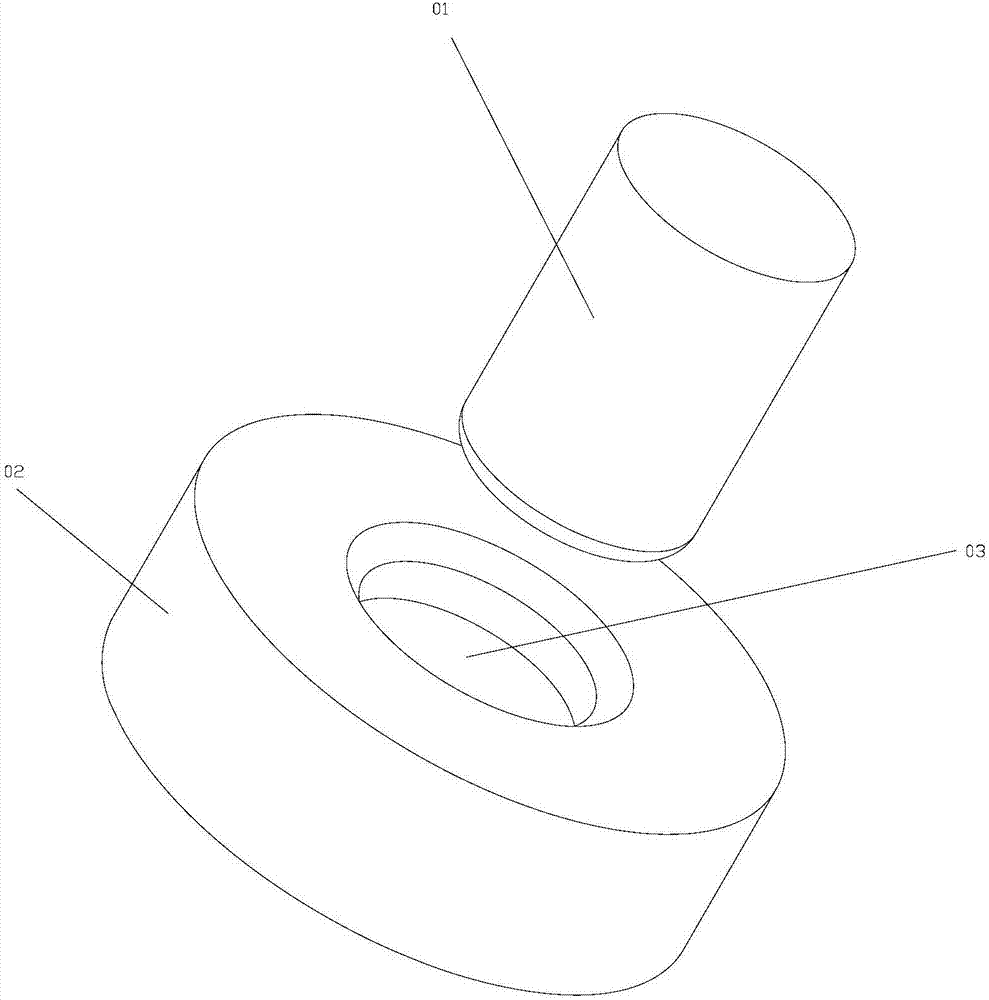

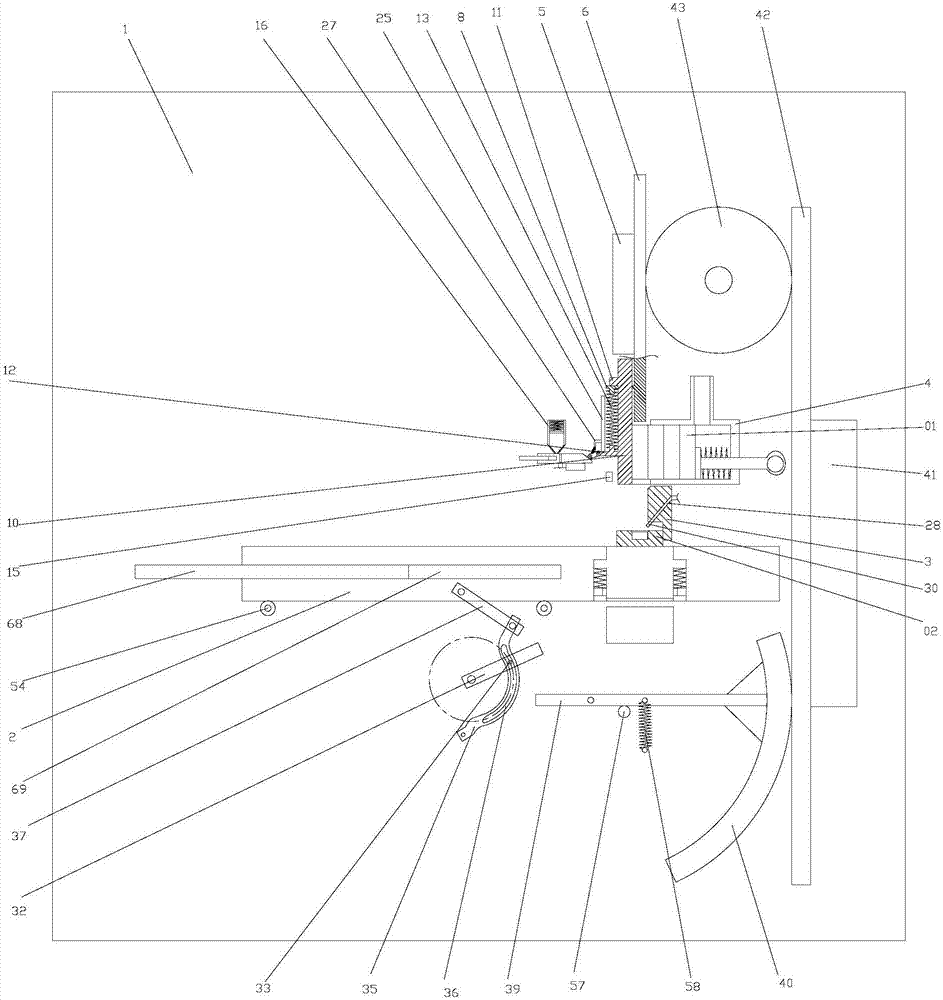

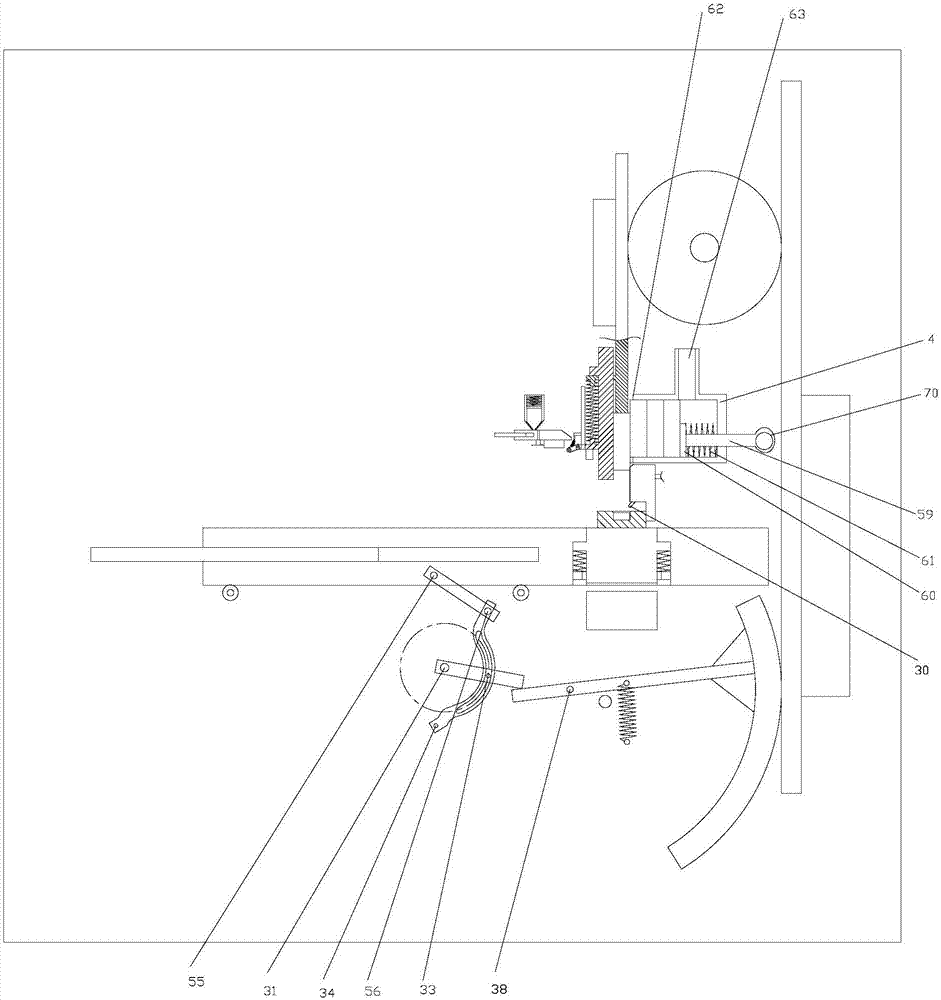

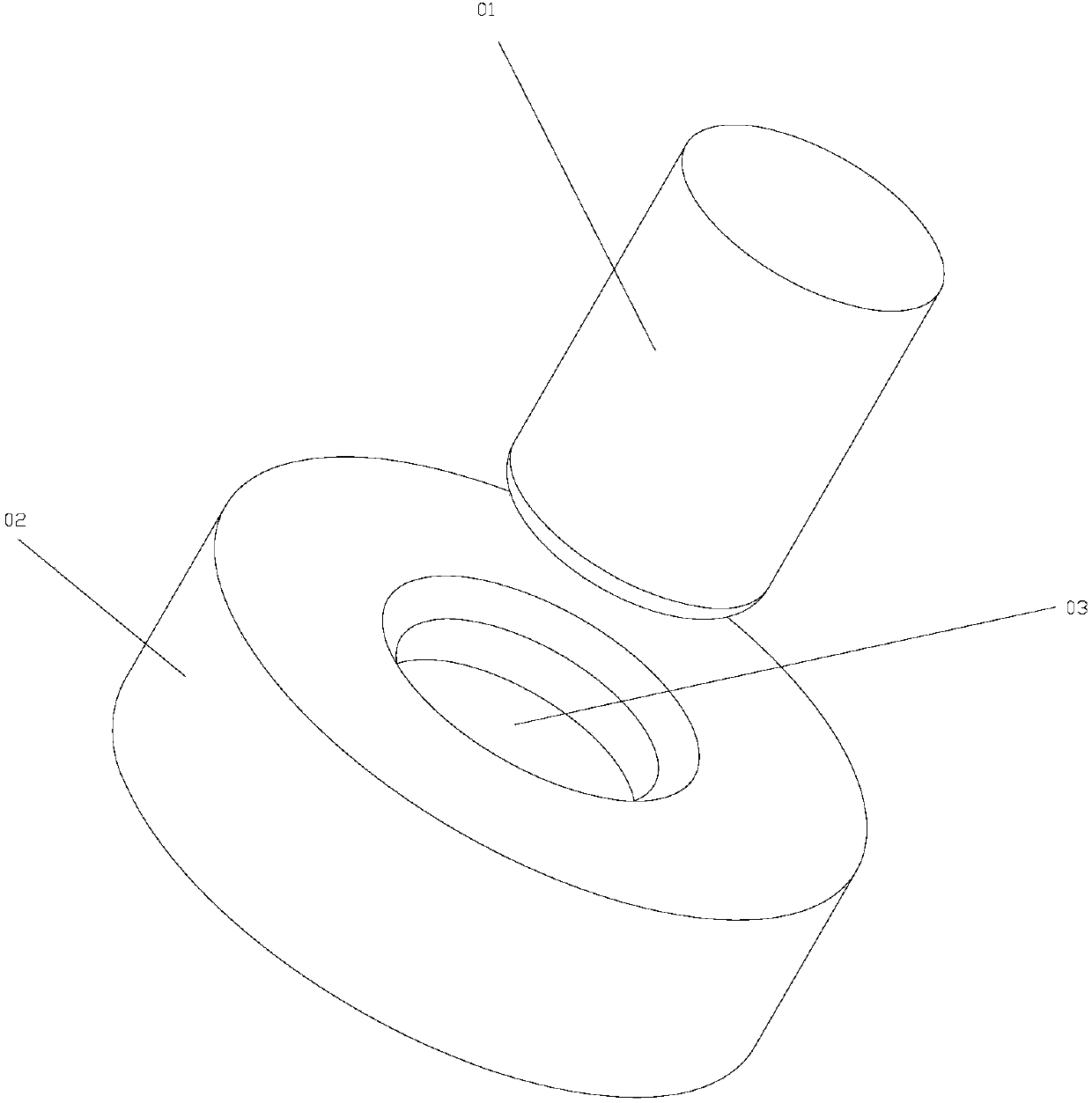

Full-automatic workpiece assembly device

ActiveCN107378449AAvoid transmission instabilityImprove reliabilityMetal working apparatusCircular discEngineering

The invention discloses a full-automatic workpiece assembly device. The full-automatic workpiece assembly device comprises a base (1), and a sliding table (2) is connected with the base (1) in a sliding mode; a stopper (3) is arranged on the base (1) in the moving direction of the sliding table (2), a material barrel (4) used for containing a rotary shaft (1) is arranged on the portion, above the stopper (3), of the base (1), a first linear rack (6) is connected with the portion, above the sliding table (2), of the base (1) in a sliding mode through a first guide block (5), and an ejector pin (7) is arranged at the lower end of the first linear rack (6) and used for pushing the lower end of the rotary shaft (01) to enter an installation hole (03) in a disc (02). By means of the device, operating personnel can be prevented from being injured, continuous assembly work of the rotary shaft and the disc can be conducted, and therefore, the full-automatic workpiece assembly device is higher in assembly automation and safer in assembly.

Owner:嘉兴市华财塑业有限公司

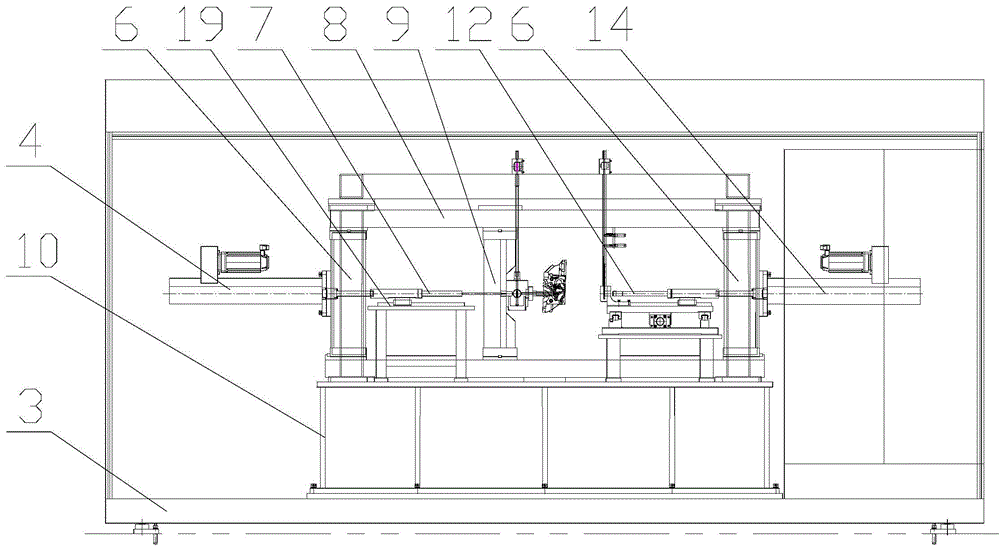

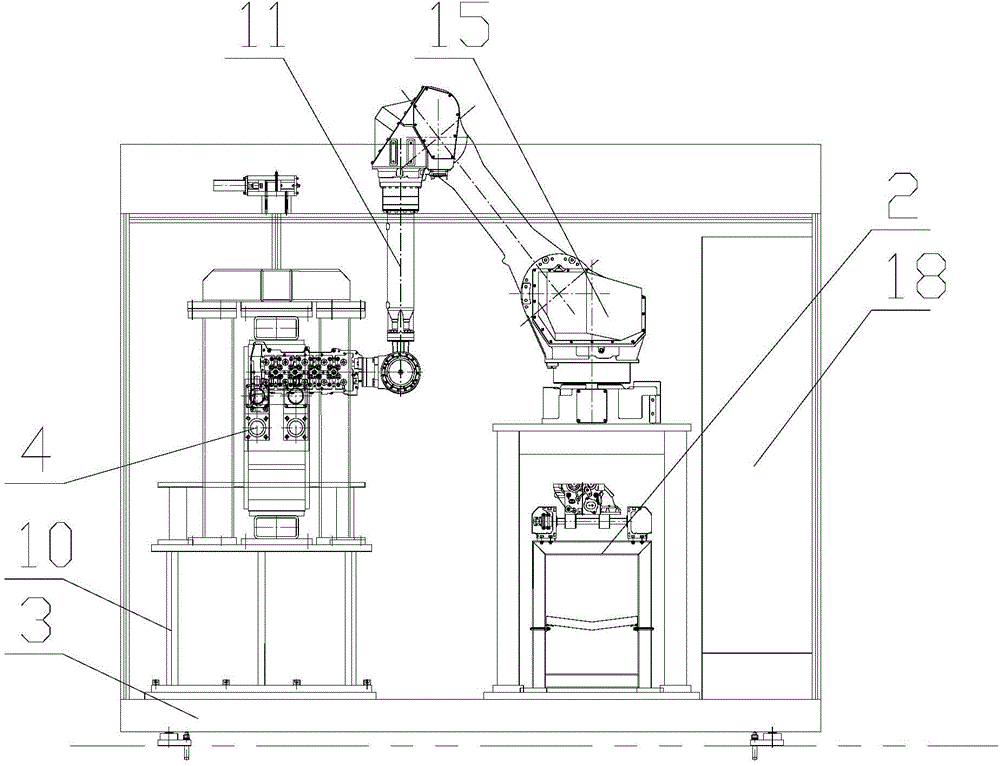

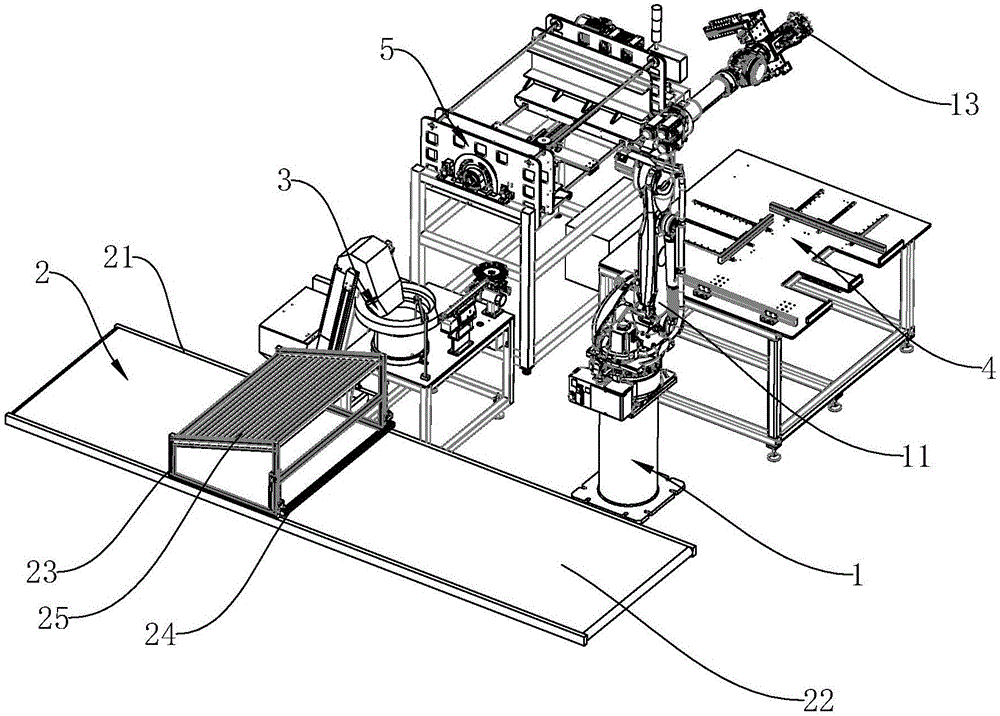

Flexible full-automatic robot guide pipe and seat ring assembling equipment

ActiveCN104148936AIncrease labor costReduce labor productivityAssembly machinesCylinder headEngineering

The invention relates to automatic engine cylinder cover assembling equipment, in particular to flexible full-automatic robot guide pipe and seat ring assembling equipment. The flexible full-automatic robot guide pipe and seat ring assembling equipment comprises a tool frame of a machine tool bottom frame, an automatic logistics roller and an assembly robot, wherein the tool frame is installed on one side of the upper portion of the machine tool bottom frame, and the automatic logistics roller and the assembly robot are installed beside the tool frame. The flexible full-automatic robot guide pipe and seat ring assembling equipment is characterized in that an internal force closed frame type tool body is installed at the upper portion of the tool frame, and a guide pipe pressure head assembling device and a seat ring pressure head assembling device are installed on the internal force closed frame type tool body and are connected with an external automatic feeding device through a guide pipe directed distribution device and a seat ring directed distribution device respectively. The flexible full-automatic robot guide pipe and seat ring assembling equipment has the advantages that the structure is novel, machining is easy and convenient, the production cost is lowered, working efficiency is improved, and automatic assembly is achieved, and therefore the flexible full-automatic robot guide pipe and seat ring assembling equipment is novel and integrates economical efficiency and practicability.

Owner:DALIAN ZHIYUN AUTOMATION

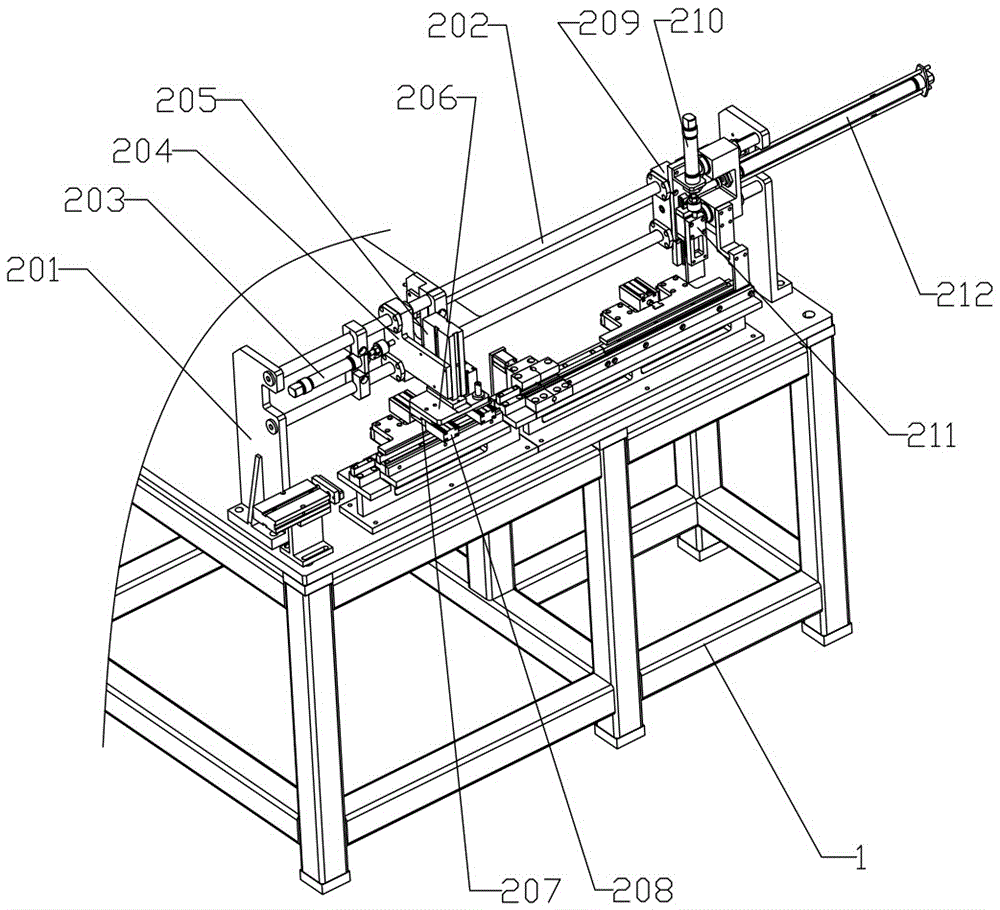

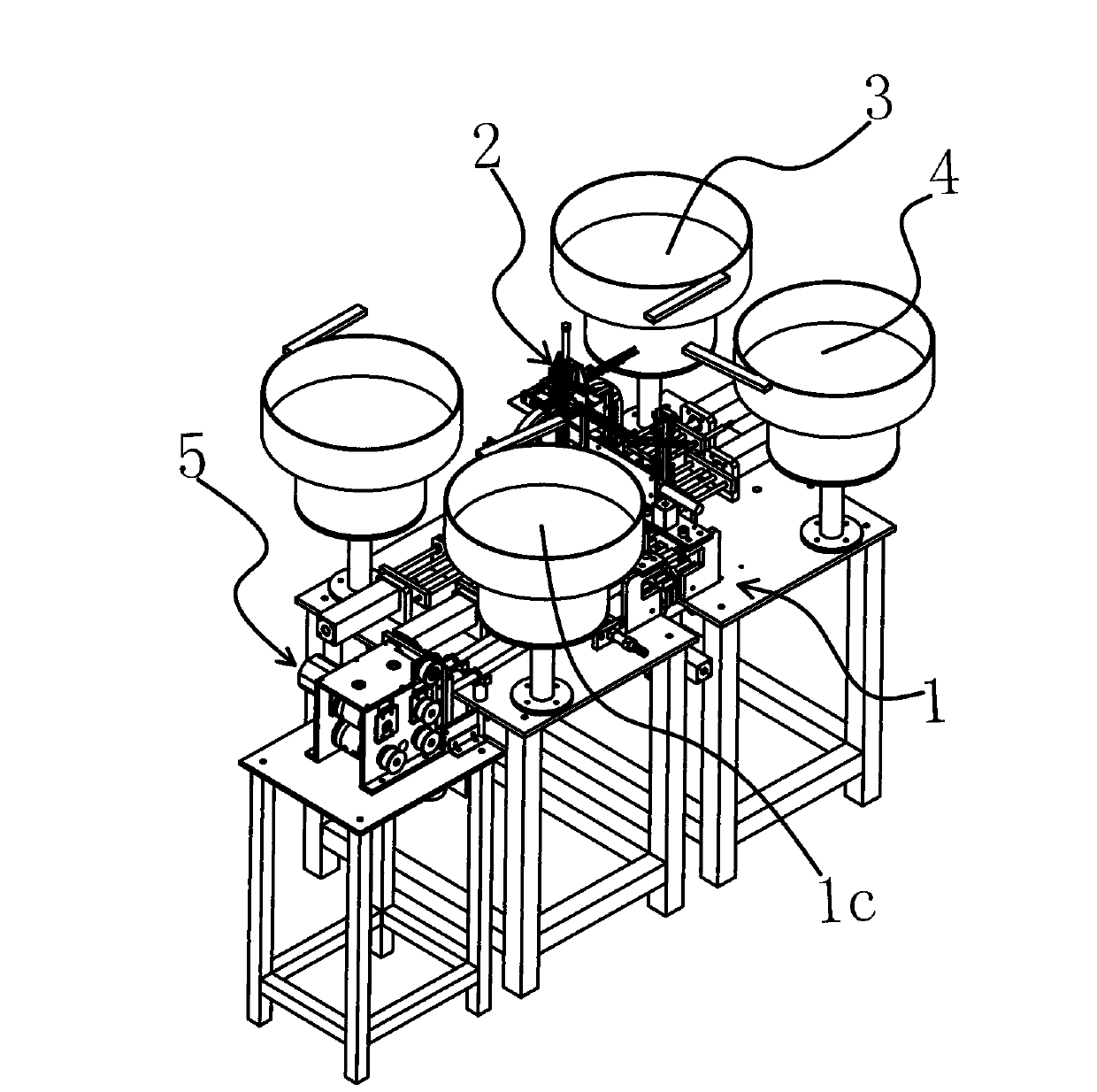

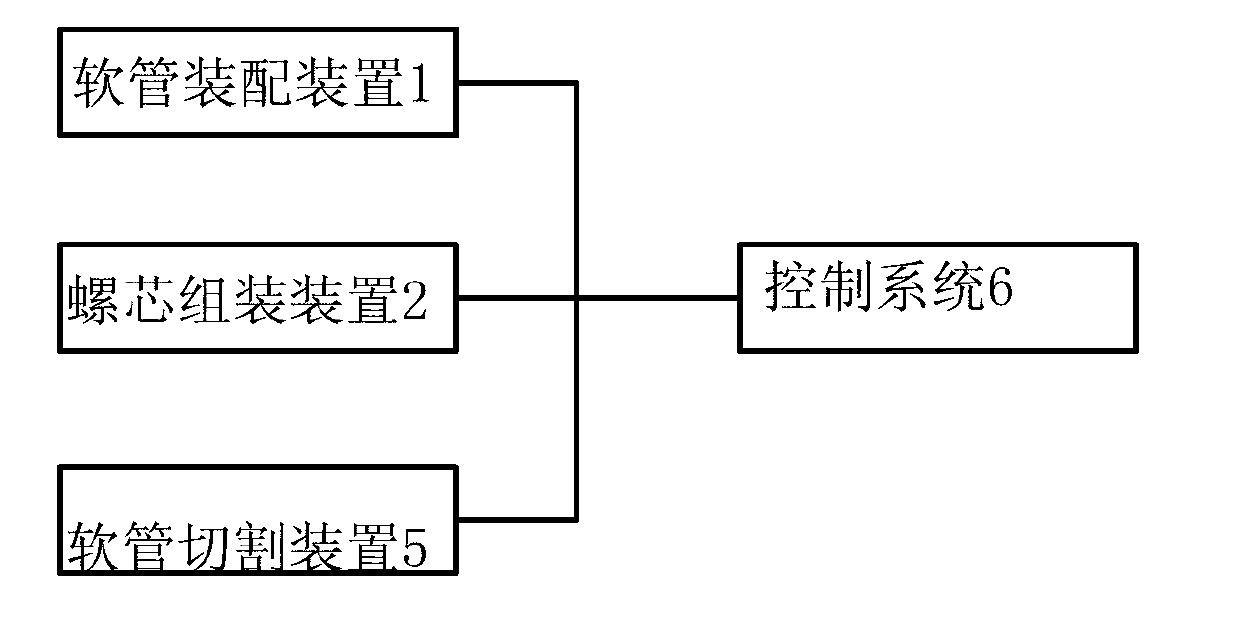

Automatic shearing assembling production line for braided hose

InactiveCN103128547AIncrease productivityReasonable designAssembly machinesProduction lineControl system

The invention belongs to the technical field of production equipment of connecting hoses and particularly relates to an automatic shearing assembling production line for a braided hose. The automatic shearing assembling production line for the braided hose solves the technical problems that working efficiency and automation degree in existing hose cutting and assembling are low and the like. The automatic shearing assembling production line comprises a hose assembling device, the upper portion of the hose assembling device is connected with a screw core assembling device, the screw core assembling device is respectively connected with a nut vibration disk and a core vibration disk, and the hose assembling device is further connected with a hose cutting device. The hose assembling device, the crew core assembling device and the hose cutting device are respectively connected with a control system. Compared with the prior art, the automatic shearing assembling production line for the braided hose has the advantages that the automatic shearing assembling production line is reasonable in design and high in automation degree, automation from screw core assembly to hose cutting and hose assembly is achieved, manual operation is not required in the whole cutting assembling process, two ends of the hose can be assembled simultaneously, production efficiency is greatly improved, production cost is reduced, and product quality is guaranteed.

Owner:XINCHANG COUNTY AOSITE MACHINERY

Automatic assembly line of plastic trays

ActiveCN106738963ARealize production assembly automationReduce labor intensityAssembly lineEngineering

The invention discloses an automatic assembly line of plastic trays. The automatic assembly line comprises a mechanical hand assembly, a conveying device, a pad foot feed device, a tray locating device and a tray turnover device. The mechanical hand assembly is composed of a mechanical arm with six degrees of freedom, a clamping jaw and a pad foot mounting mechanism, wherein the clamping jaw and the pad foot mounting mechanism are arranged on the mechanical arm. The conveying device conveys the plastic trays obtained through injection molding through an injection molding machine so that the plastic trays can be clamped by the clamping jaw, and the conveying device conveys the plastic trays transferred by the clamping jaw, wherein pad feet are mounted on the two faces of each plastic tray. The pad foot feed device provides the pad feet obtained after automatic arrangement so that the pad feet can be acquired by the pad foot mounting mechanism. After the tray locating device clamps the plastic trays provided by the clamping jaw, the pad foot mounting mechanism provides the pad feet, and the pad feet are mounted on the upward surfaces of the plastic trays. The tray locating device clamps the plastic trays provided by the clamping jaw. The automatic assembly line has the beneficial effects that assembly automation is achieved, the work efficiency is improved, and the labor intensity of workers is relieved.

Owner:宁波海天智联科技有限公司

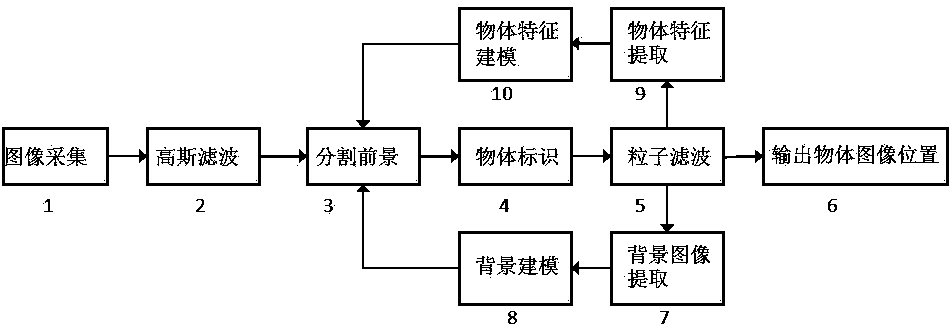

Production line object part motion detection and tracking method based on videos

ActiveCN104299246AAccurate trackingAccurate detectionImage enhancementImage analysisProduction lineImage segmentation

The invention relates to a production line object part motion detection and tracking method based on videos, and belongs to the field of automatic production lines. A single digital camera is adopted for acquiring conveying images of production line objects, modeling is conducted through background subtraction and object characteristics, and then image segmentation of moving objects and a production line background is achieved. In the normal operating process of a production line, through background subtraction, a background region of the production line and a moving object part region are determined, and modeling is conducted through surface characteristics and contour characteristics of the products. In the assembly process of the production line, a Gaussian model of background images is continuously updated, and object parts on the production line are better segmented and are not affected by external environment interference. Meanwhile, motion trails of the objects are matched in multiple images, and therefore the multiple objects can be continuously tracked. By the adoption of the method, the calculation reliability of the positions of the product parts in continuous motion can be improved, the objects can be accurately tracked, and the requirements for product assembly automation can be met.

Owner:南京曼新智能科技有限公司

Assembly device and assembly method for rotor core

ActiveCN105553193AHigh degree of automationImprove assembly efficiencyManufacturing stator/rotor bodiesEngineeringAssembly automation

The invention discloses an assembly device and an assembly method for a rotor core and aims at solving the defect that a disqualified product appears easily due to low assembly automation degree of the rotor core, low positional accuracy of the rotor core and low assembly efficiency. The assembly device comprises a mounting base, a support plate, a support and a compression shaping mechanism, wherein a feed channel and an ejector piston cylinder are arranged on the support plate; a lifting rotary disc is arranged on the support plate; a fixed shaped head and a movable shaped head are arranged on the support plate; the movable shaped head is connected to a feed piston cylinder expansion link; the front end of an ejector piston cylinder expansion link is connected to an ejecting rack; an elastic ejector rod is movably arranged on the rotary disc; a mandrel capable of lifting vertically arranged on the lower end of the compression shaping mechanism; a shaping material return sleeve coats the mandrel; a compression spring coats the mandrel; a plurality of elastic locating core and a plurality of shaping groove shape knives are movably arranged on the shaping material return sleeve; a location sensor is arranged on a position close to the upper ends of the elastic locating cores; and a grab mechanism is arranged at the side of the compression shaping mechanism.

Owner:HANGZHOU FUSHENG ELECTRICAL APPLIANCE

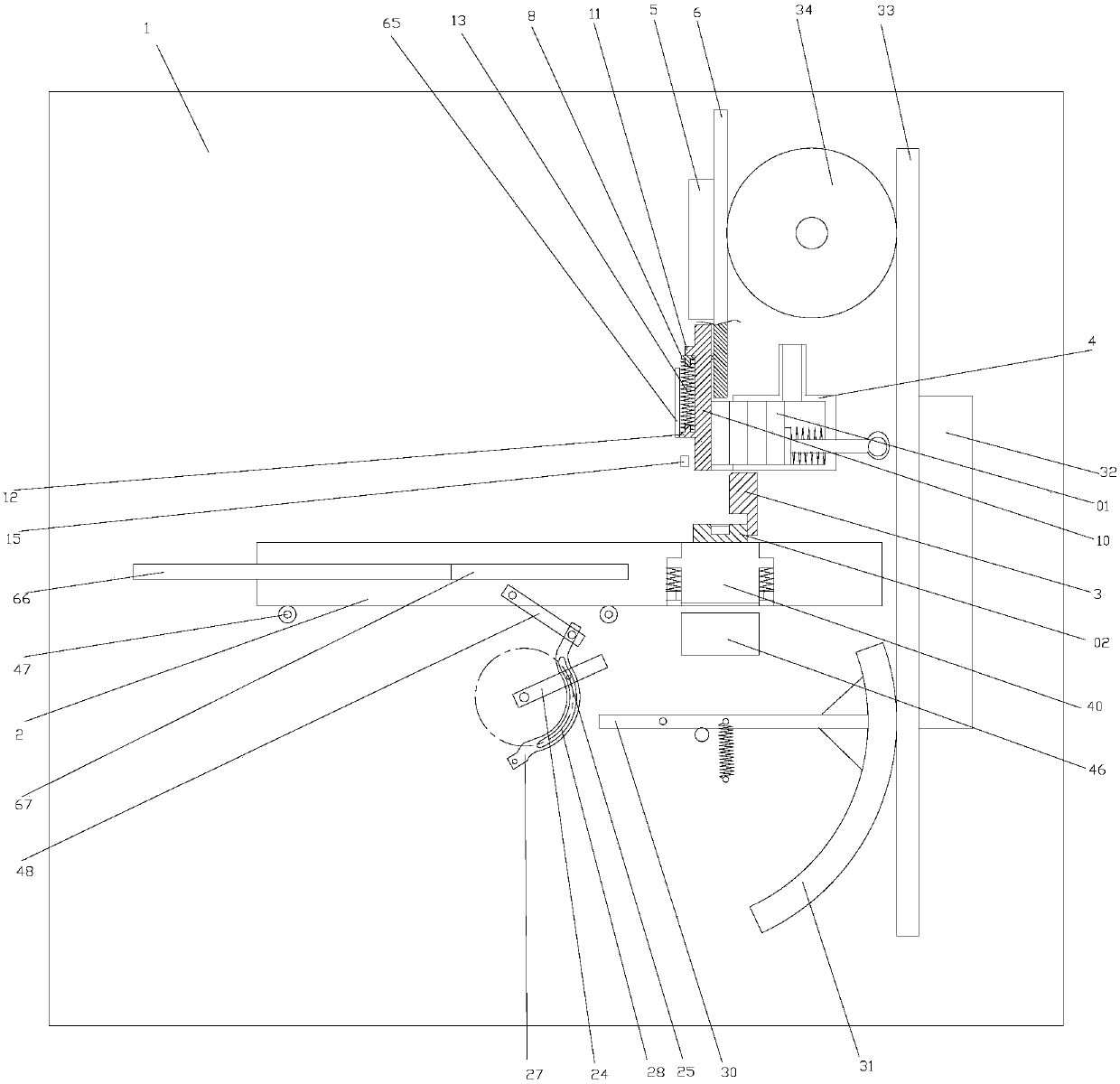

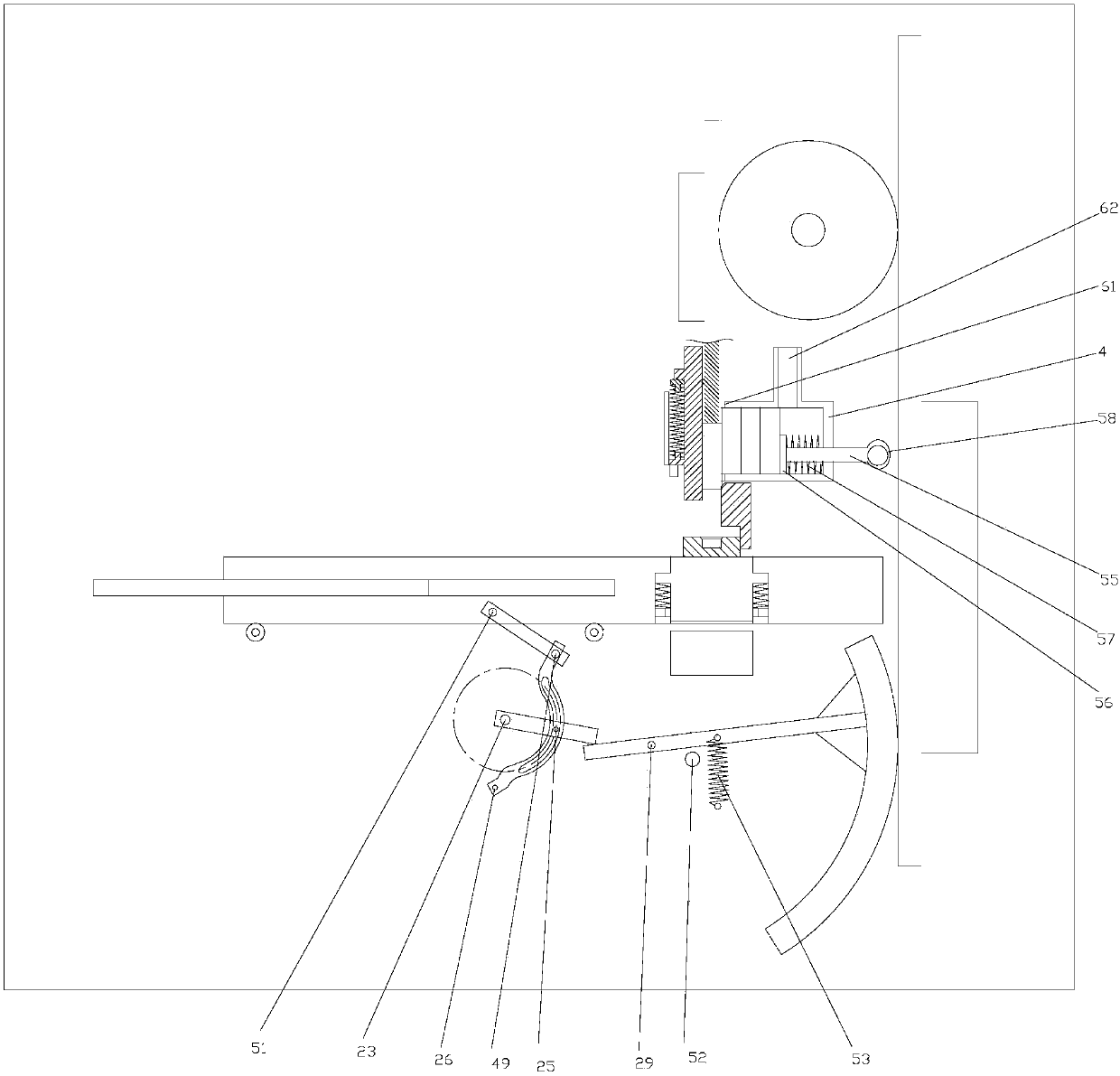

Intelligent continuous assembly blanking device

ActiveCN107671524AStand stillImprove assembly automationMetal working apparatusCircular discEngineering

The invention discloses an intelligent continuous assembly blanking device. The intelligent continuous assembly blanking device comprises a base (1); the base (1) is slidingly connected with a slide table (2); the base (1) is provided with a stopper (3) in a moving direction of the slide table (2); the base (1) is provided with a charging barrel (4) above the stopper (3); the base (1) is slidinglyconnected with a first straight rack (6) above the slide table (2); an ejector rod (7) is arranged at the lower end of the first straight rack (6); a pushing block (8) is arranged on the side wall ofthe first straight rack (6), and is provided with a through hole (9); and a vertical rod (10) is slidingly connected into the through hole (9). The intelligent continuous assembly blanking device canprevent the hand injury of operators, can continuously assemble rotating shafts and discs, and is higher in assembly automation and safer in assembly.

Owner:浙江坤邦机械有限公司

Bearing part assembling automatic equipment

InactiveCN109571007AReduce workloadSave work spaceAssembly machinesMetal working apparatusEngineeringAssembly automation

The invention discloses bearing part assembling automatic equipment. The bearing part assembling automatic equipment comprises a workbench and a protective cover, and the protective cover is arrangedon the workbench; a first oscillation mechanism, a spindle mechanism, a feeding mechanism, a spindle sleeve mechanism, a second oscillation mechanism and a moving mechanism are all fixed to the workbench; the moving mechanism is fixed to the left side of the workbench; the first oscillation mechanism, the spindle mechanism, the spindle sleeve mechanism, the feeding mechanism and the second oscillation mechanism are sequentially arranged on the side face of the moving mechanism from the working end to the finish end; the first oscillation mechanism is used for conveying an inner bearing to themoving mechanism; the spindle mechanism is used for conveying a spindle to the moving mechanism; the spindle sleeve mechanism is used for conveying a spindle sleeve to the moving mechanism; the feeding mechanism is used for conveying an outer bearing to the moving mechanism; and the second oscillation mechanism is used for conveying a clamp spring to the moving mechanism. Therefore, the cost is reduced, the working space is reduced, the working efficiency is improved, and the bearing part assembling automatic equipment is a very good product and has the good market application value.

Owner:深圳市诚盈信科技有限公司

Automatic terminal identification feeding system and automatic terminal identification feeding method

ActiveCN103949810AAchieve deliveryAchieving identifiabilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringColor discrimination

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

Automatic tightening assembly equipment

ActiveCN108080209AGuaranteed relaxationHigh degree of intelligenceLiquid surface applicatorsCoatingsInformatizationSimulation

The invention discloses an automatic tightening assembly device. The automatic tightening assembly device comprises an equipment rack, a high-precision motion execution module mounted on the equipmentrack, and used for realizing rapid servo motion and precise positioning of a screw tightening module, a screw tightening module mounted on the high-precision motion execution module and used for sucking and automatically tightening screws, a screw feeding module mounted on the equipment rack and used for automatically arranging scattered screws and separating uploaded materials one by one, and aglue liquid control and detection module mounted on the equipment rack and used for providing anaerobic thread glue and controlling the liquid level height and automatically detecting the depth of screw dipping glue. The automatic tightening assembly device disclosed by the invention satisfies new requirements for on-line coating of the anaerobic thread glue, realizes automation, informatization and intelligence for the whole process of screw arrangement, screw picking, thread glue dipping, dipping glue testing and screw tightening, solves the automation problem of tightening assembly for thedesign of liquid anaerobic thread glue coating, and has flexibility, high reliability and intelligence to improve production efficiency and product quality.

Owner:SHANGHAI RADIO EQUIP RES INST

Cover and spoon dispensing assembly automatic equipment and production system

PendingCN109760332ARealize automated productionLabor savingPackagingMetal working apparatusManipulatorAssembly automation

The invention discloses a cover and spoon dispensing assembly automatic production system comprising a first operation platform. A conveyor belt is arranged on the first operation platform, a convex splitter plate is arranged on the conveyor belt, and a dispensing device is arranged above a flow dividing channel between the splitter plate and the conveyor belt and is used for sequentially gluing upper covers entering the flow dividing channel in queue; a second operating platform is arranged on one side of the first operating platform, a packaging scoop cutting mechanism is arranged on the second operating platform, and a spoon pulling distribution component is arranged above the packaging scoop cutting mechanism and is used for distributing volumed packaging spoons to the packaging scoopcutting mechanism to be cut; a variable-distance adsorption mechanical arm is arranged above a flow dividing device, the variable-distance adsorption mechanical arm is fixed on a rack, and the variable-distance adsorption mechanical arm is used for sucking the packaging spoons cut by the packaging scoop cutting mechanism, changing the product center distance, doing movement and conducting flow dividing on the glued upper cover. The cover and spoon dispensing assembly automatic production system realizes automatic production throughout the whole process, saves labor and improves efficiency.

Owner:上海珂明注塑系统科技有限公司

Position returning block assembly machine for automobile combined switch

InactiveCN101477905AQuality improvementImprove efficiencyElectric switchesMetal working apparatusEngineeringAssembly automation

The invention discloses an assembly machine for an automobile combined switch homing block, which comprises a bench; a slide block linearly sliding forward and backward is installed on the bench; a homing block fixture is installed on the slide block; a homing block accommodation groove is formed in the homing block fixture; a pressing mechanism is installed at the upper part the homing block fixture; the pressing mechanism consists of a lower air cylinder installed at the upper part the homing block fixture and a punch fixedly connected with the lower end of a piston rod of the lower air cylinder; a gas claw compressing mechanism and a spring feeding mechanism are respectively arranged on the left side and the right side of the homing block fixture; and the gas claw compressing mechanism comprises two horizontal fixture blocks. The assembly machine realizes assembly automation, improves the quality and the efficiency of spring assembly on the automobile combined switch homing block, and satisfies operation requirements of the modern assembly detection line.

Owner:合肥安达数控技术有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com