Patents

Literature

807 results about "Sandwich type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

There are five main types of sandwich here in the States, 1 and they're all dictated by the type of bread used: hard roll sandwiches, soft bun sandwiches, hero sandwiches, sliced bread sandwiches and every other sandwich which doesn't fit into those other four categories.

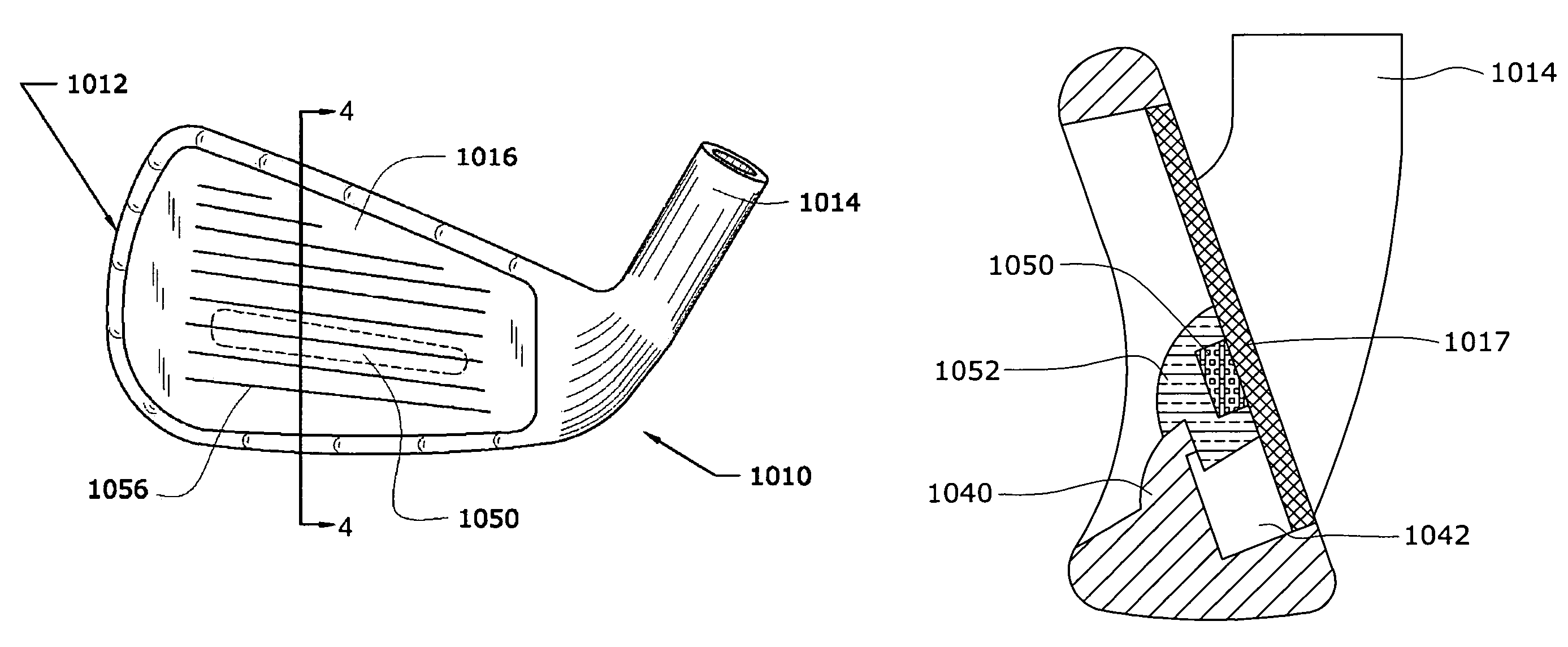

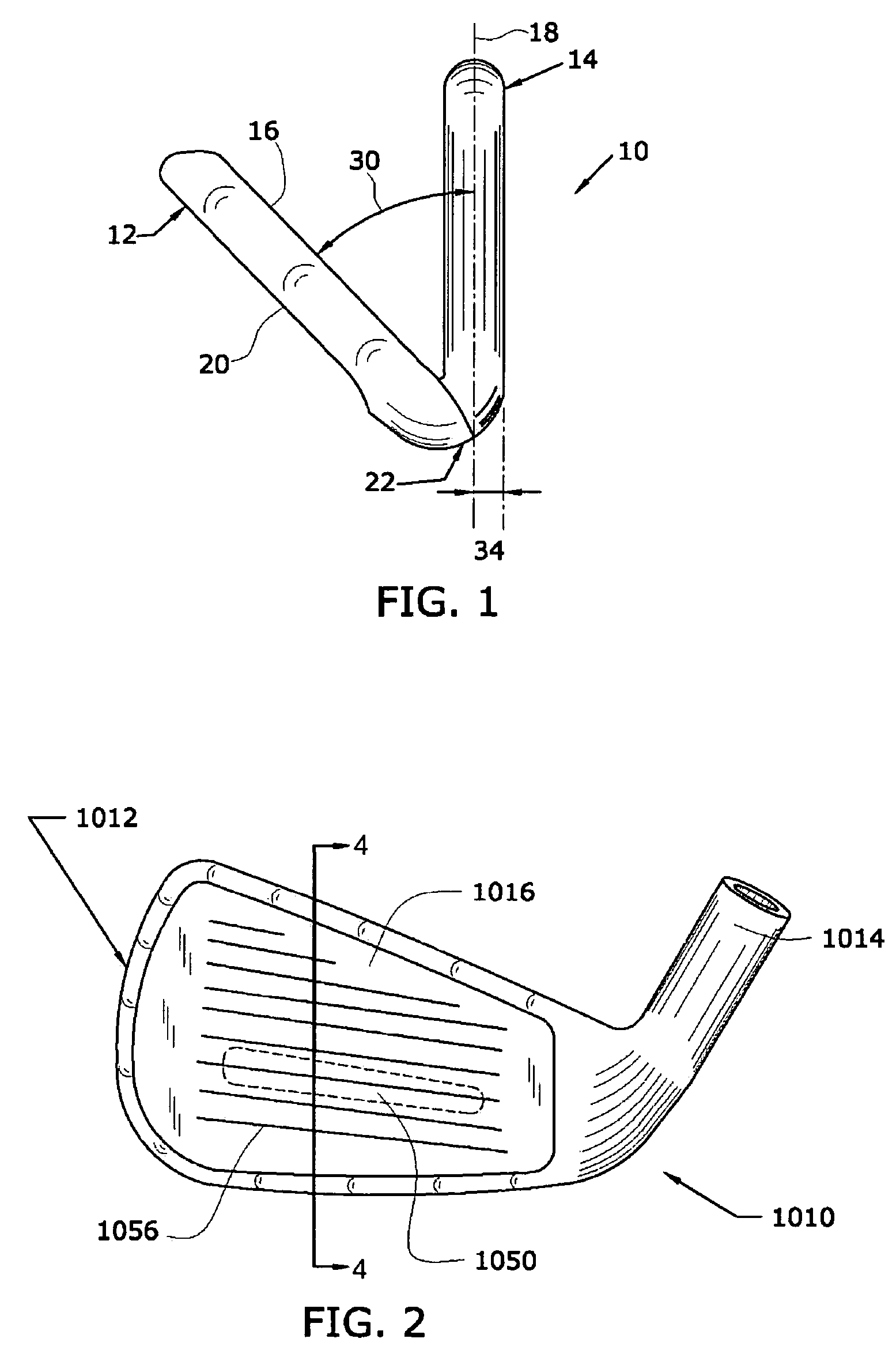

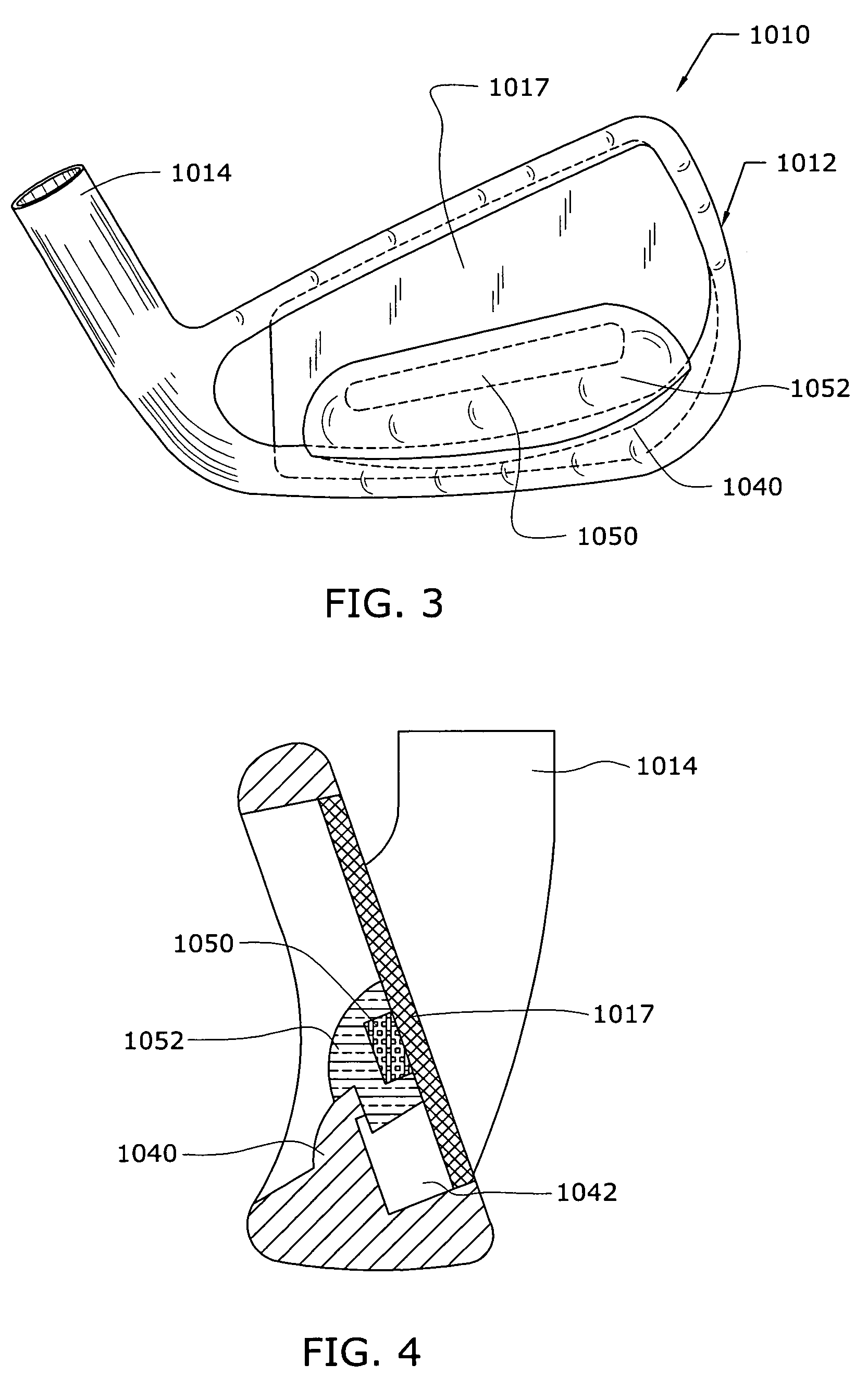

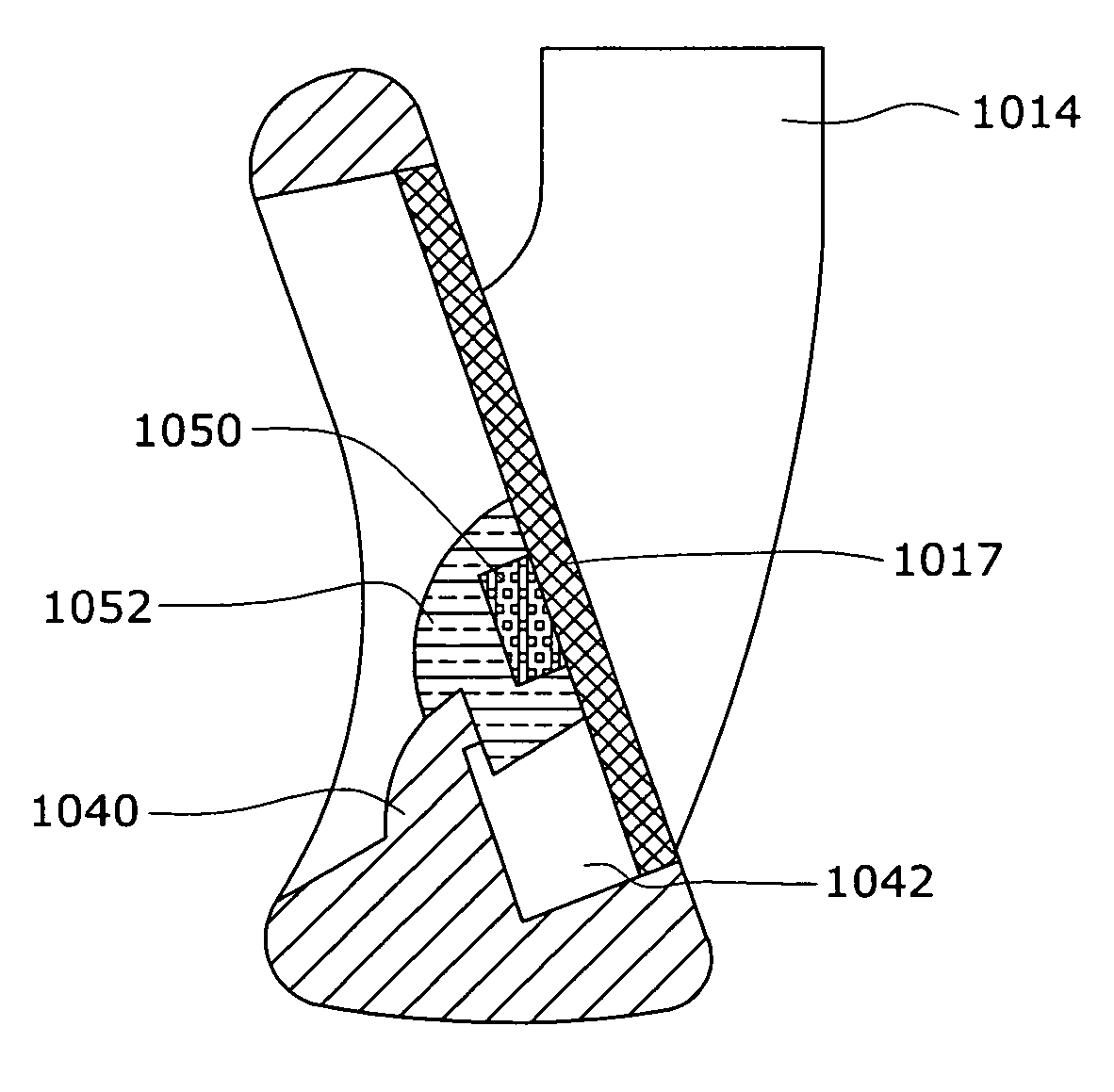

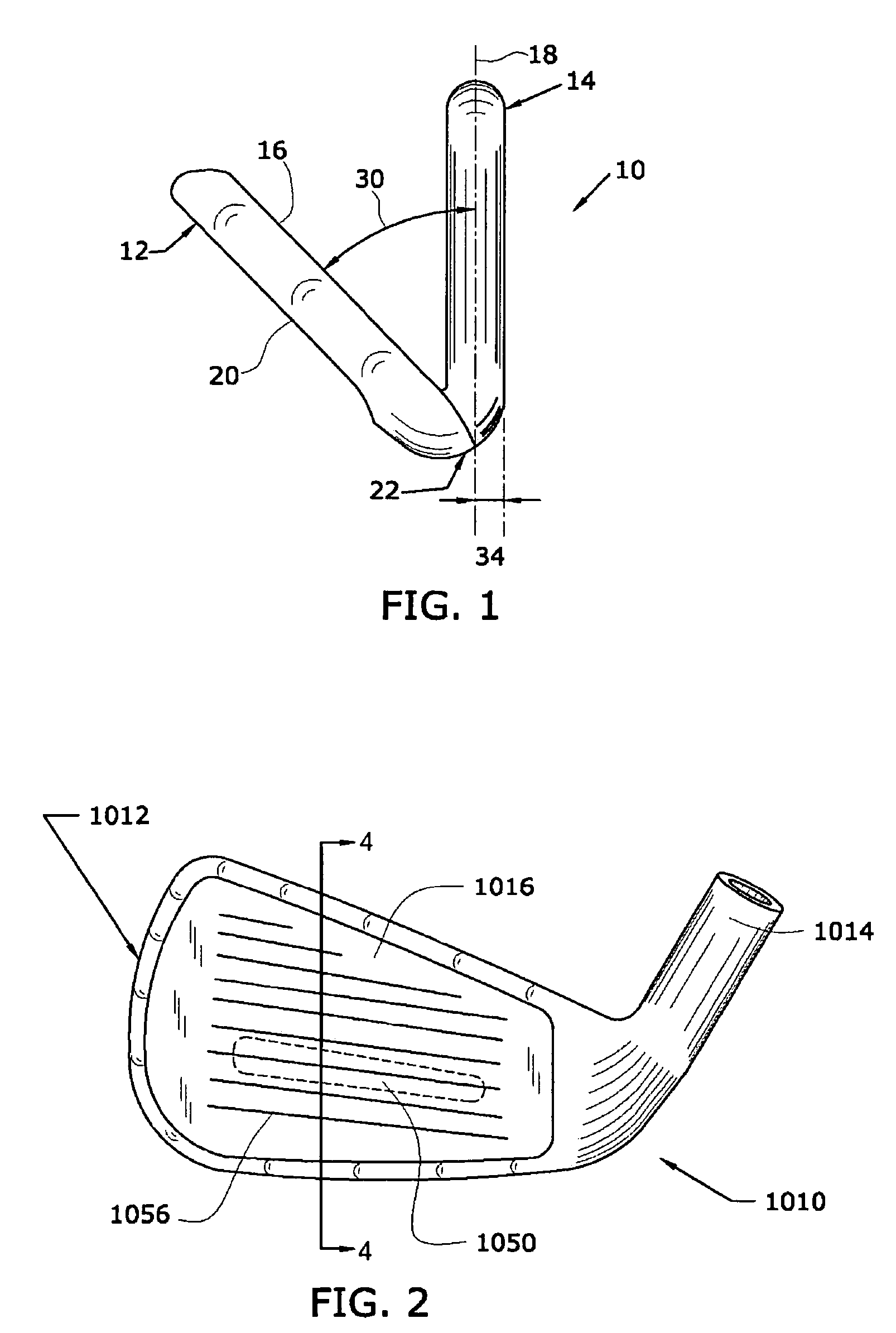

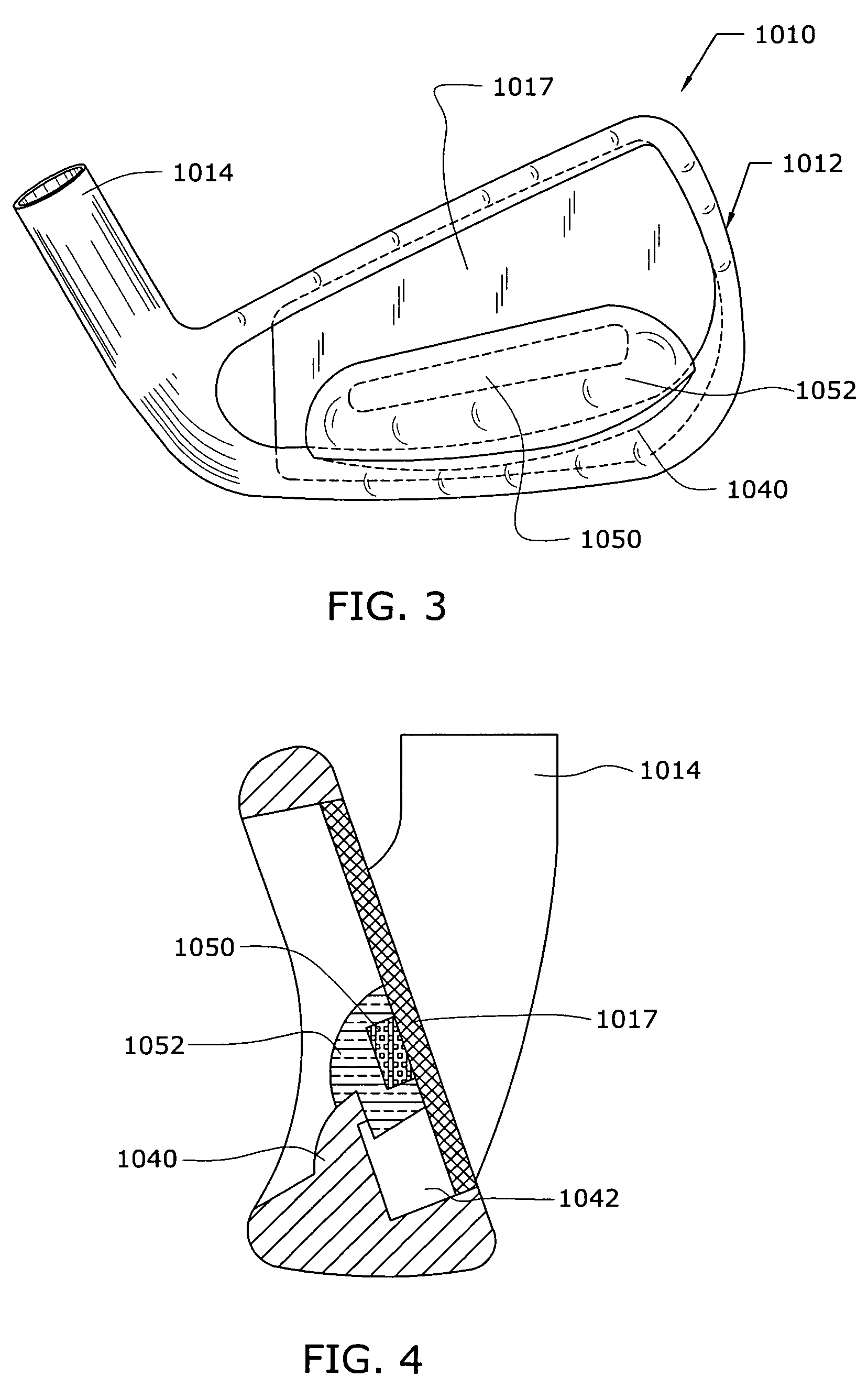

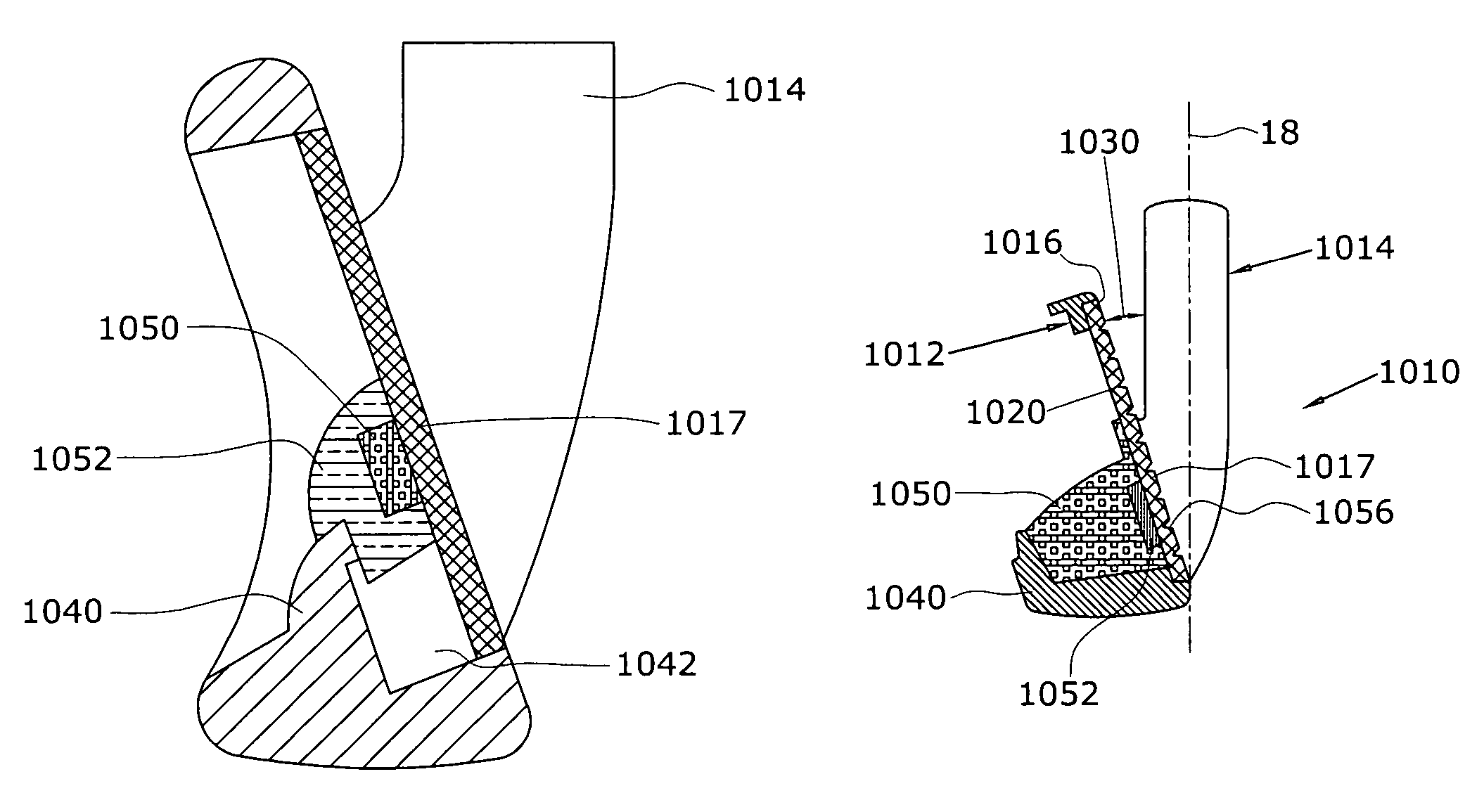

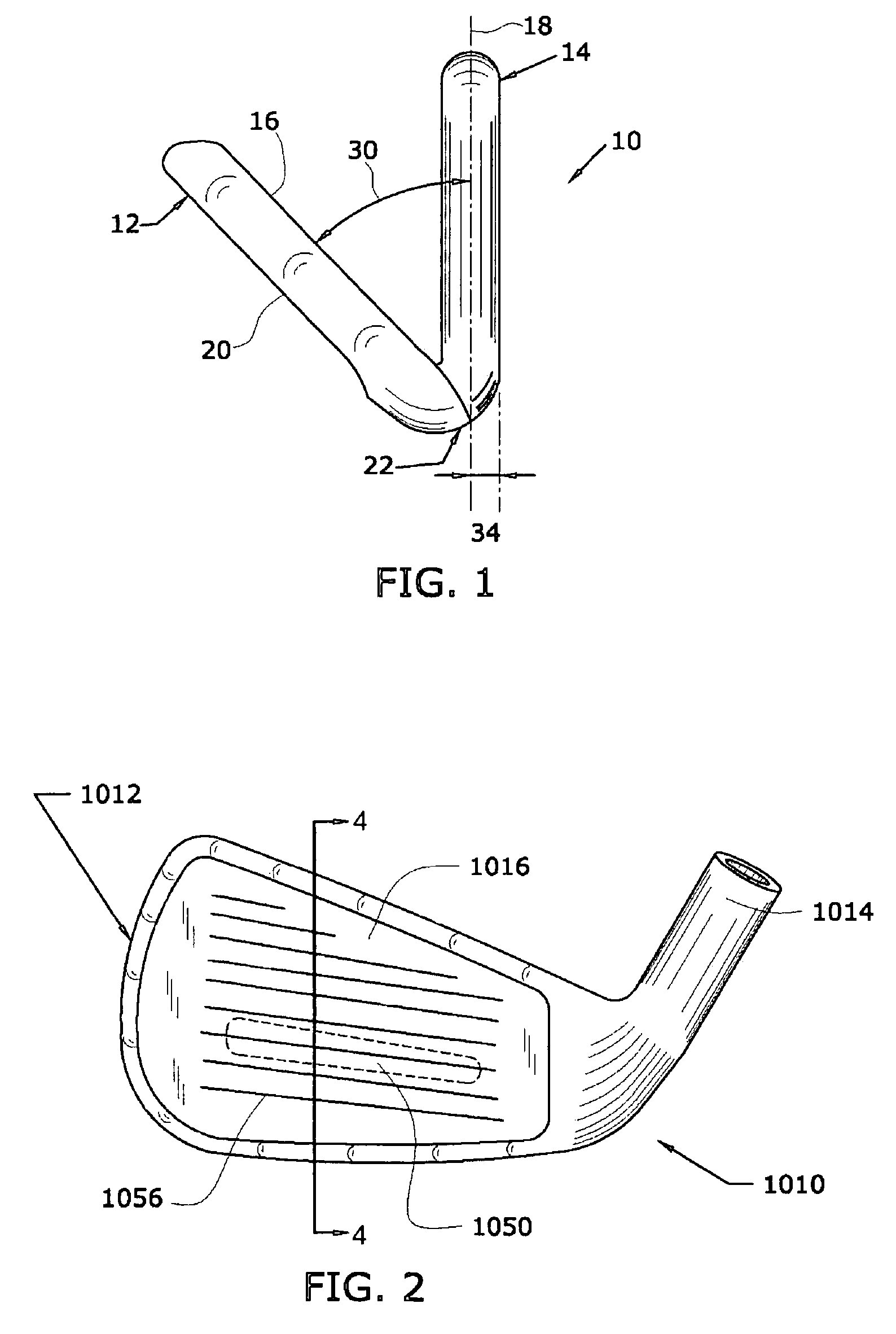

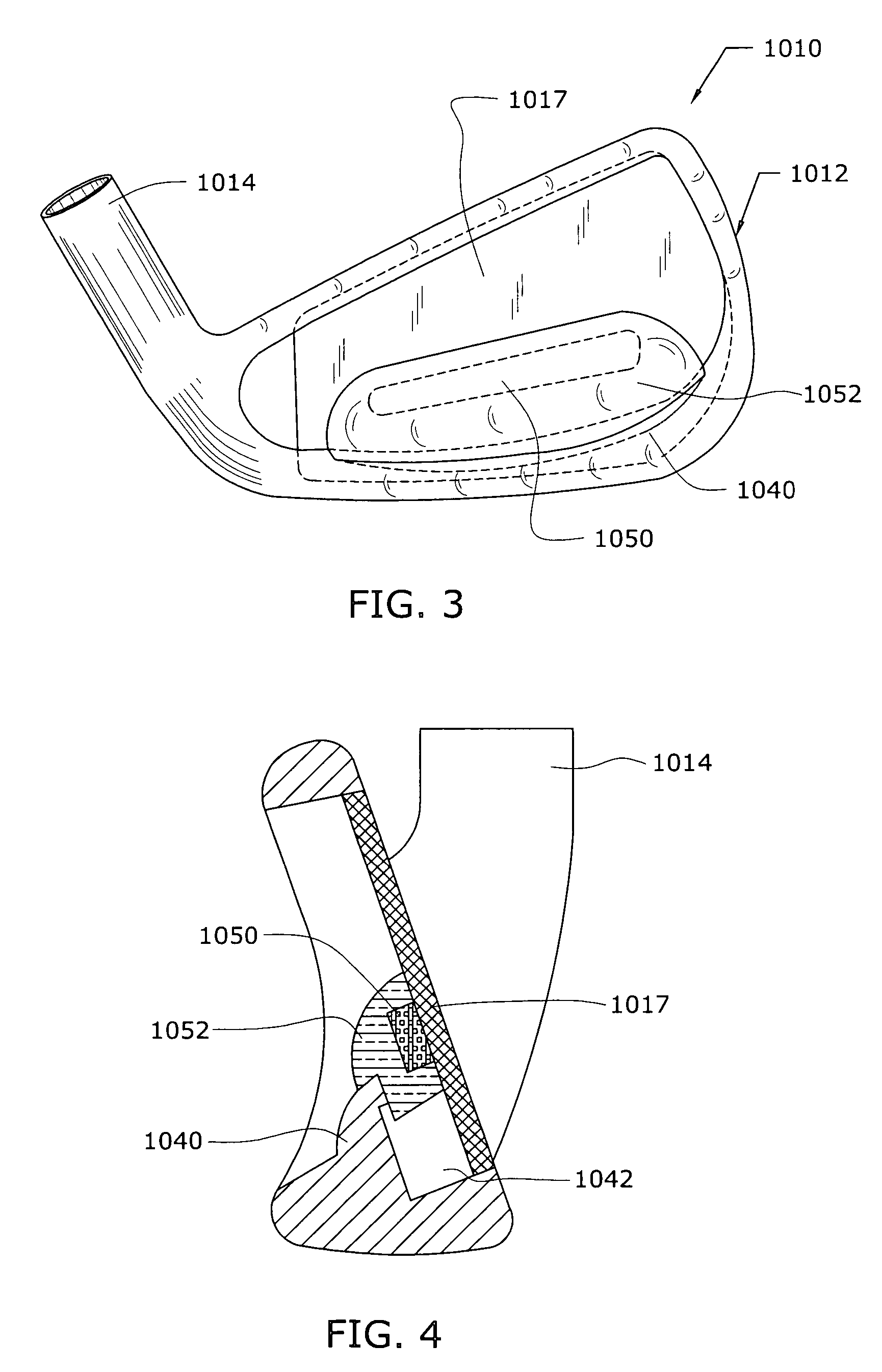

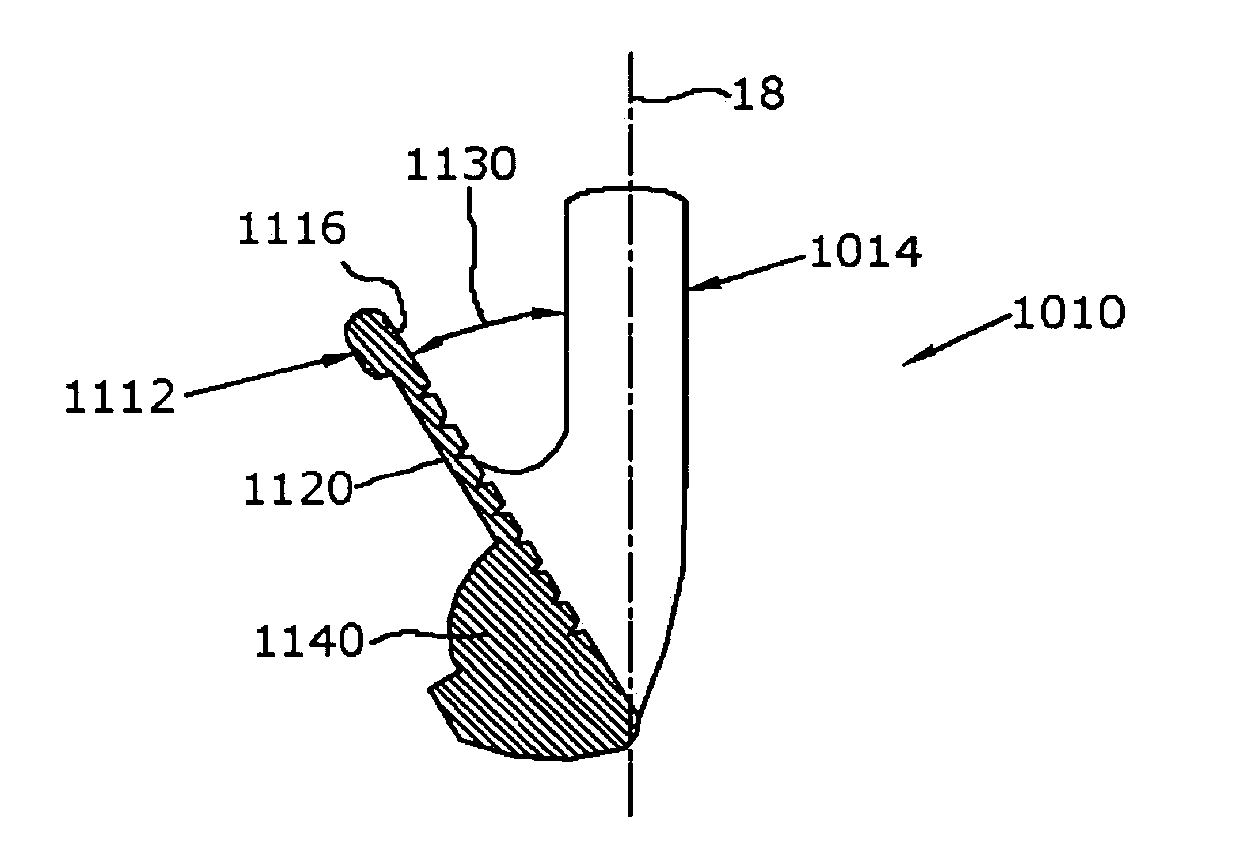

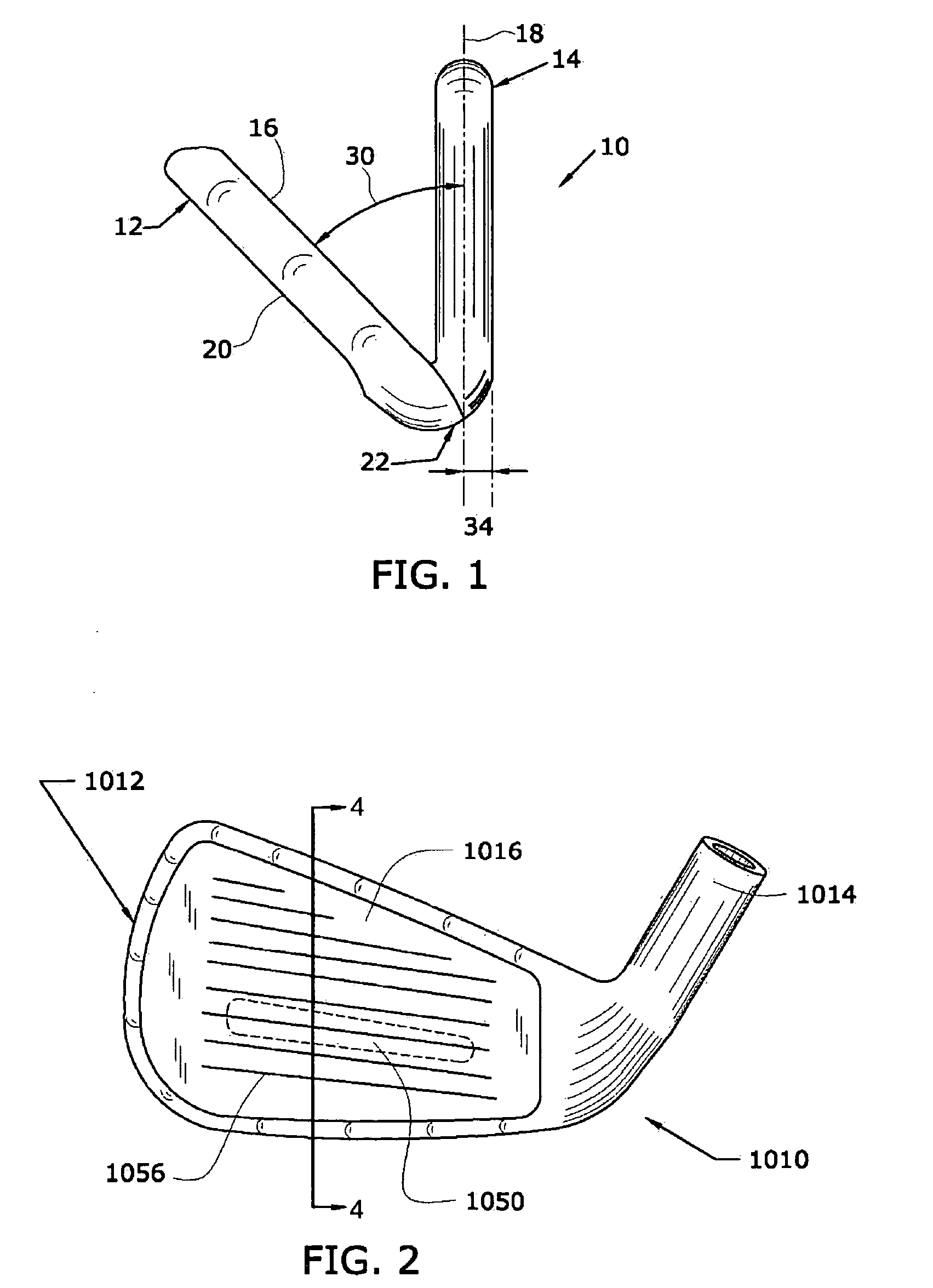

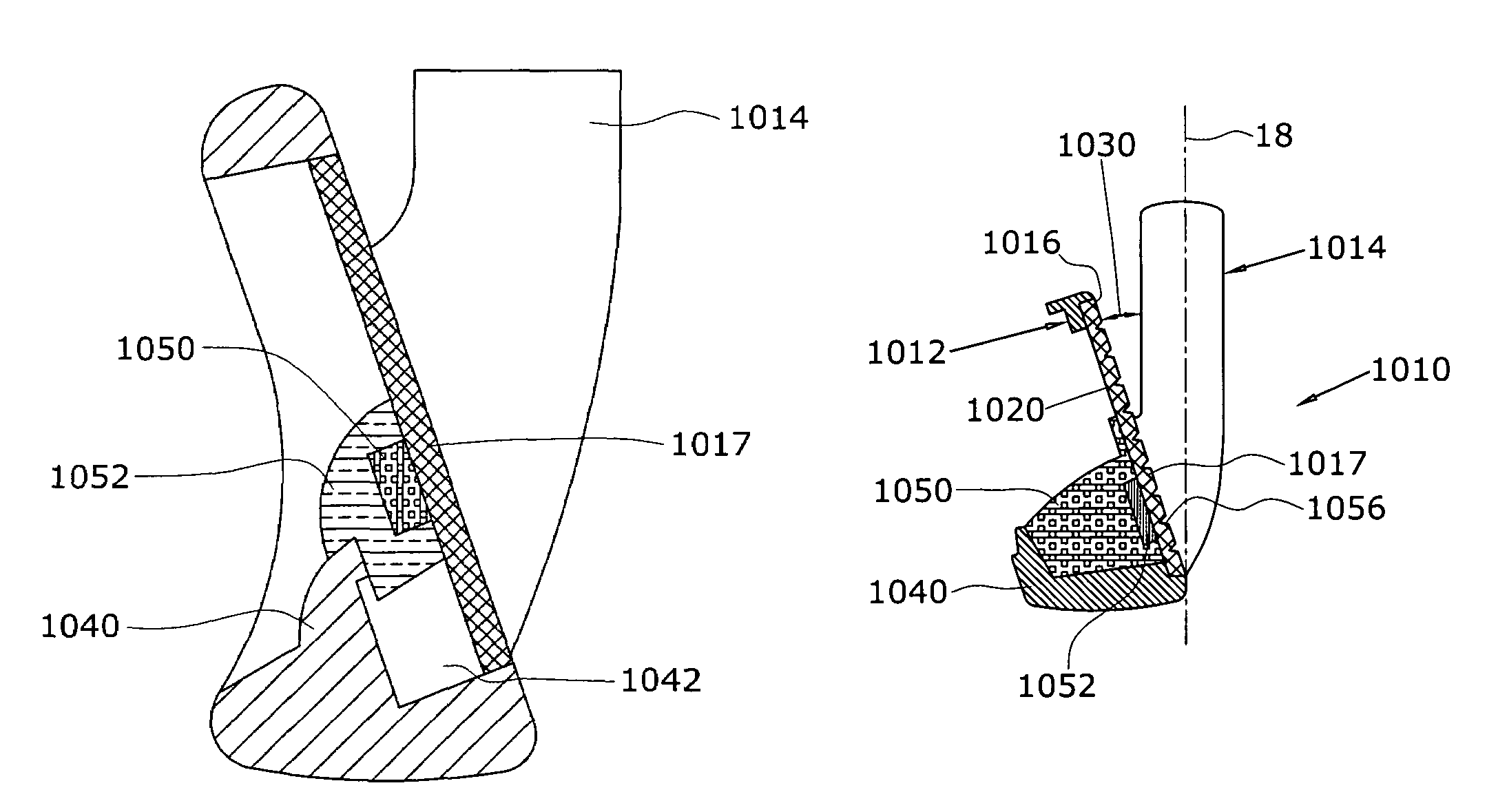

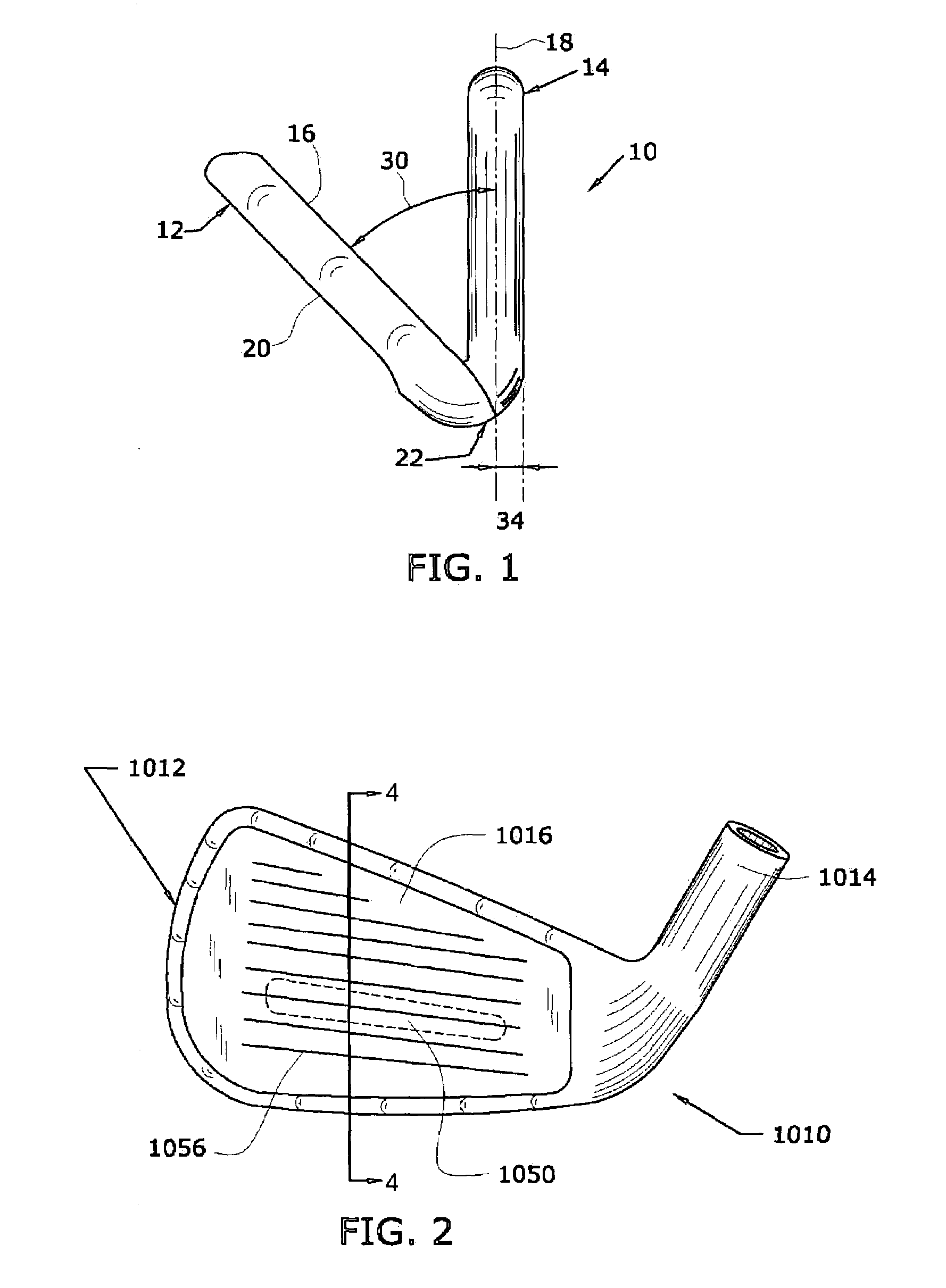

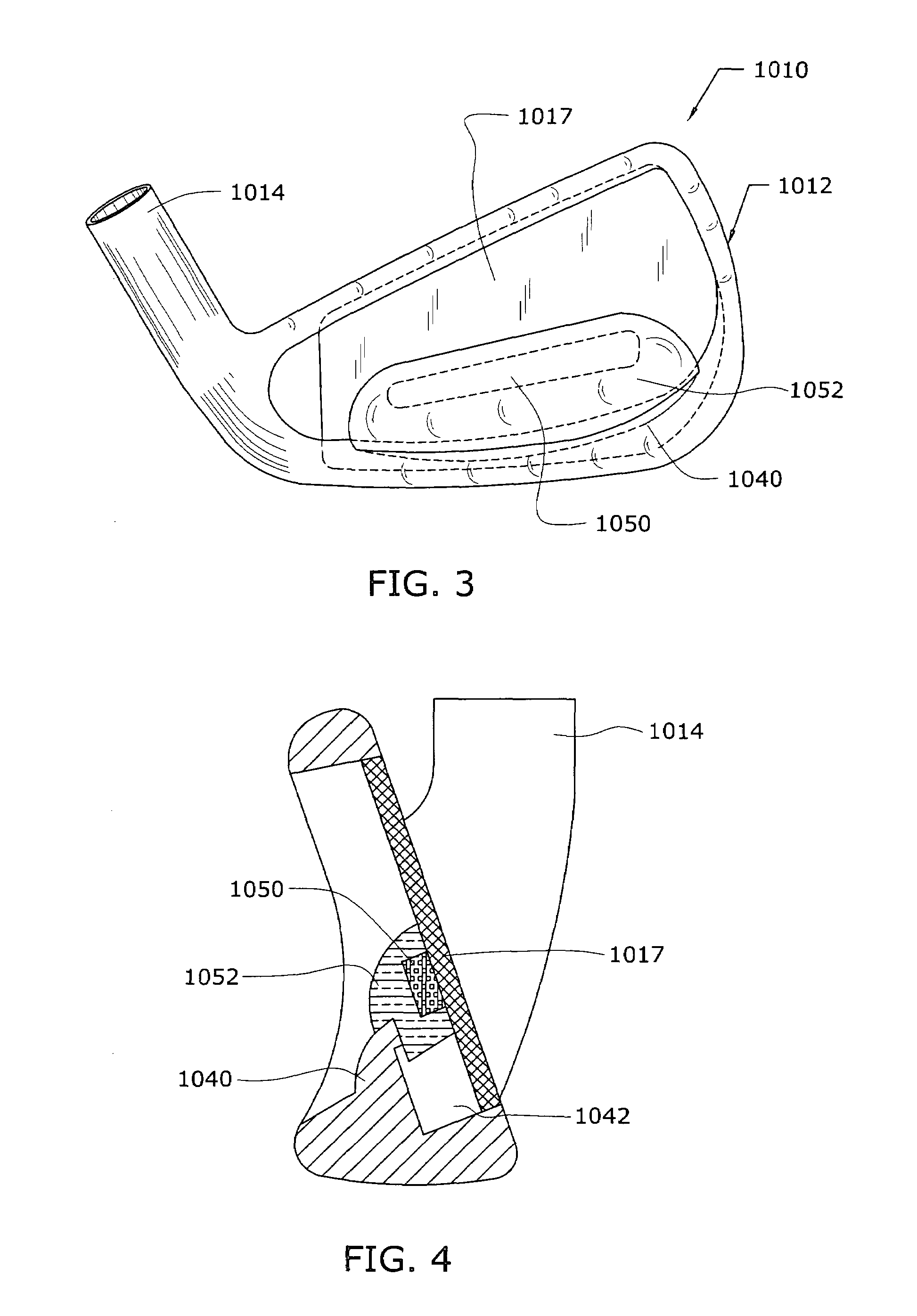

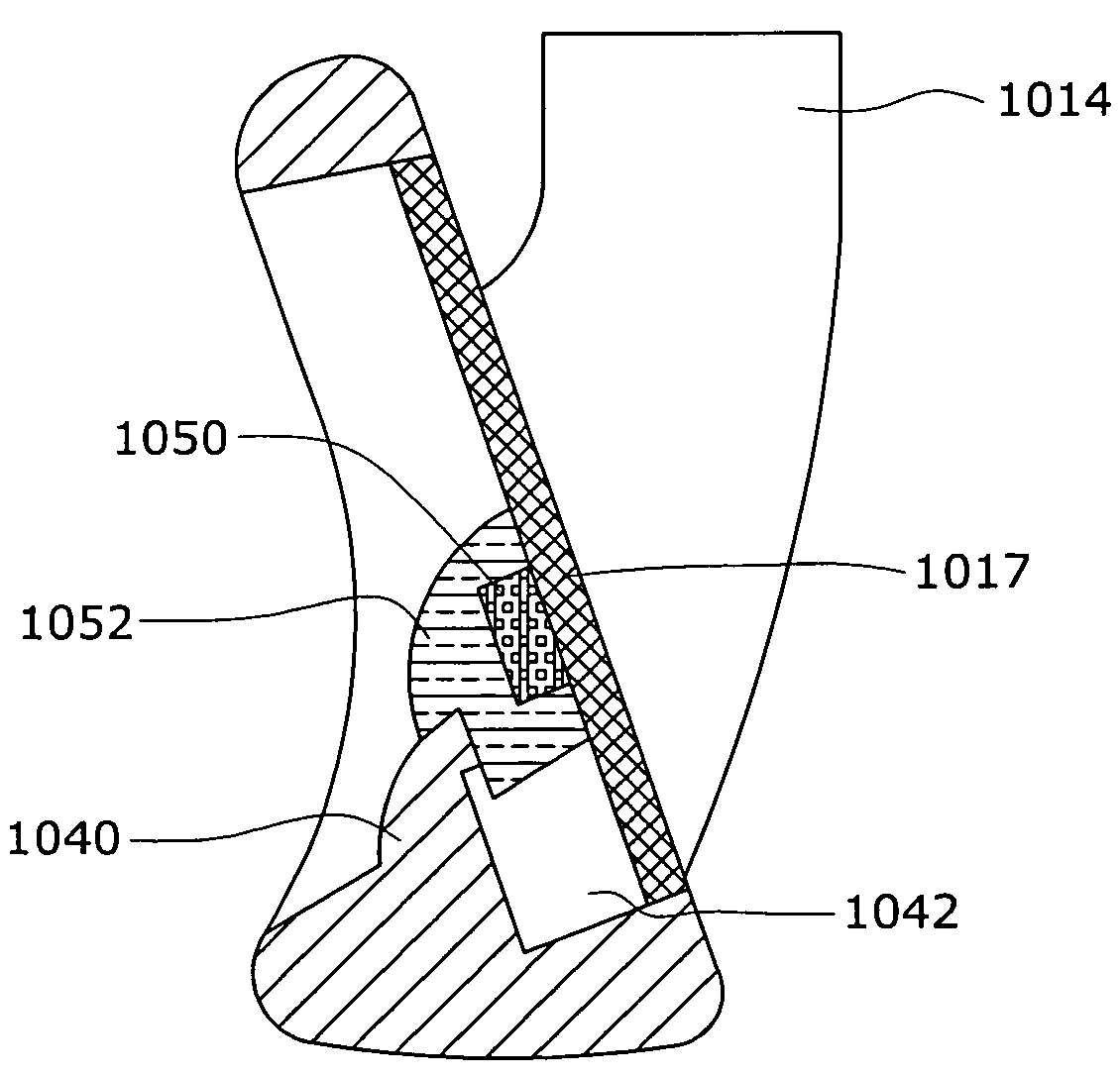

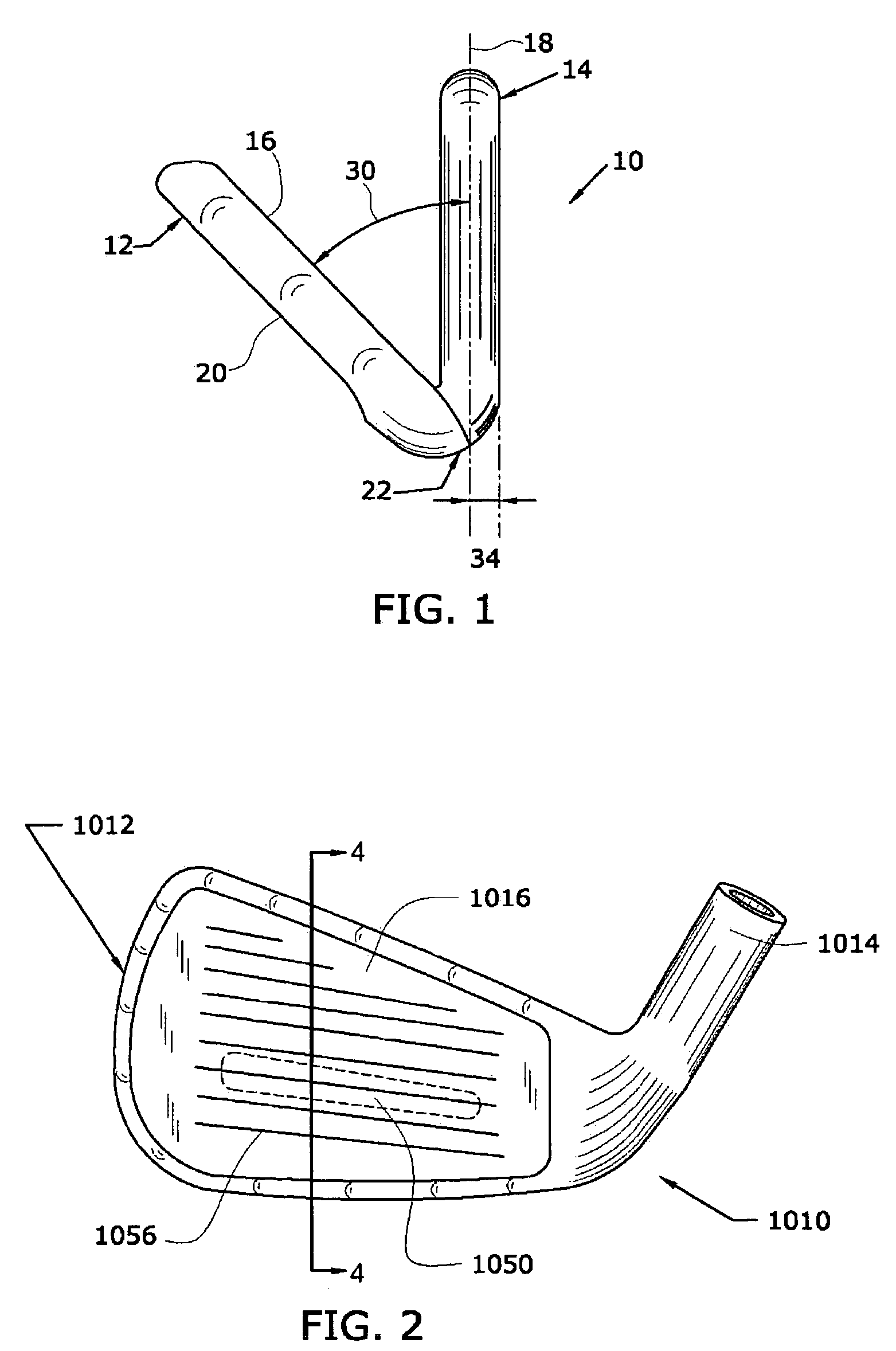

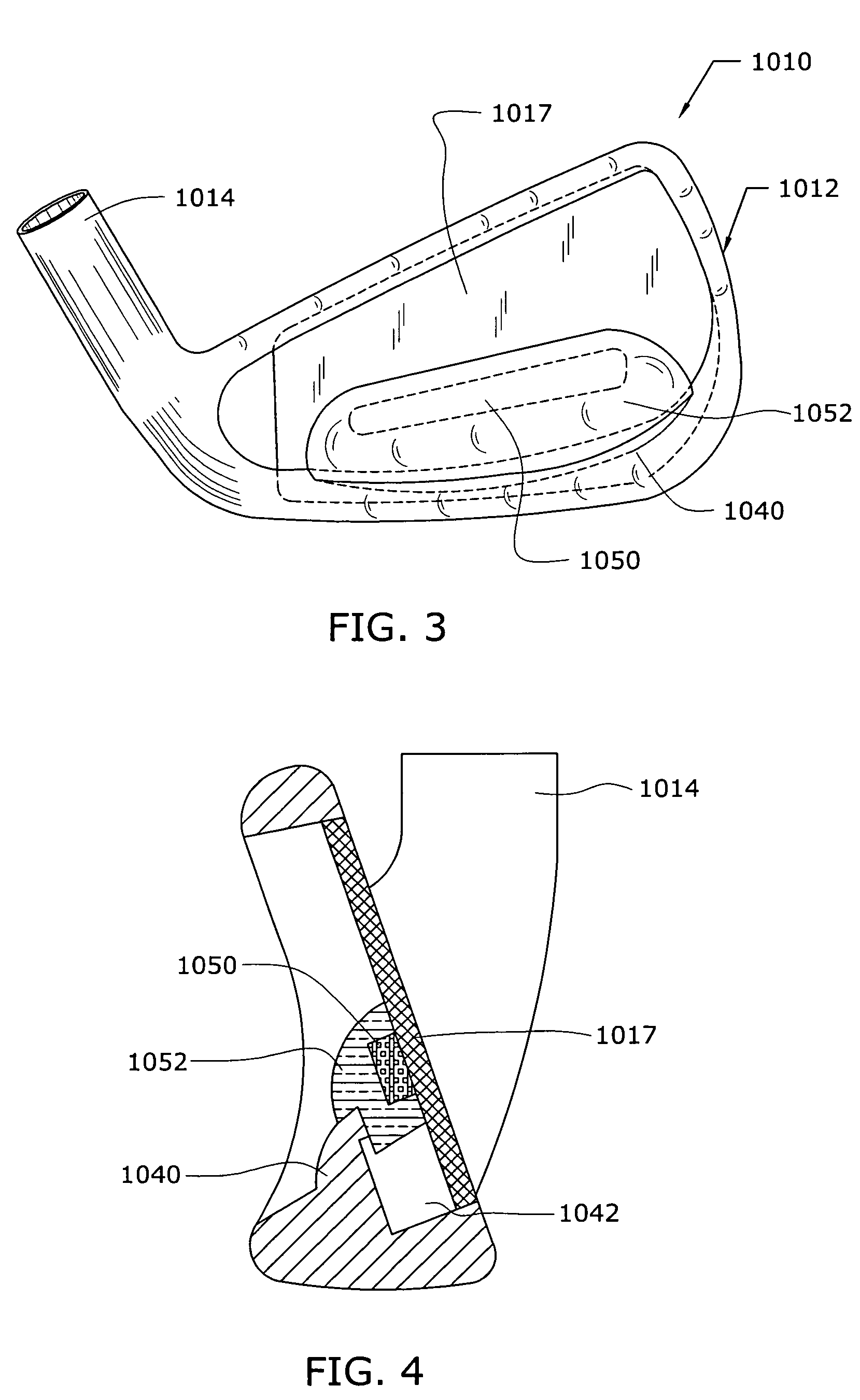

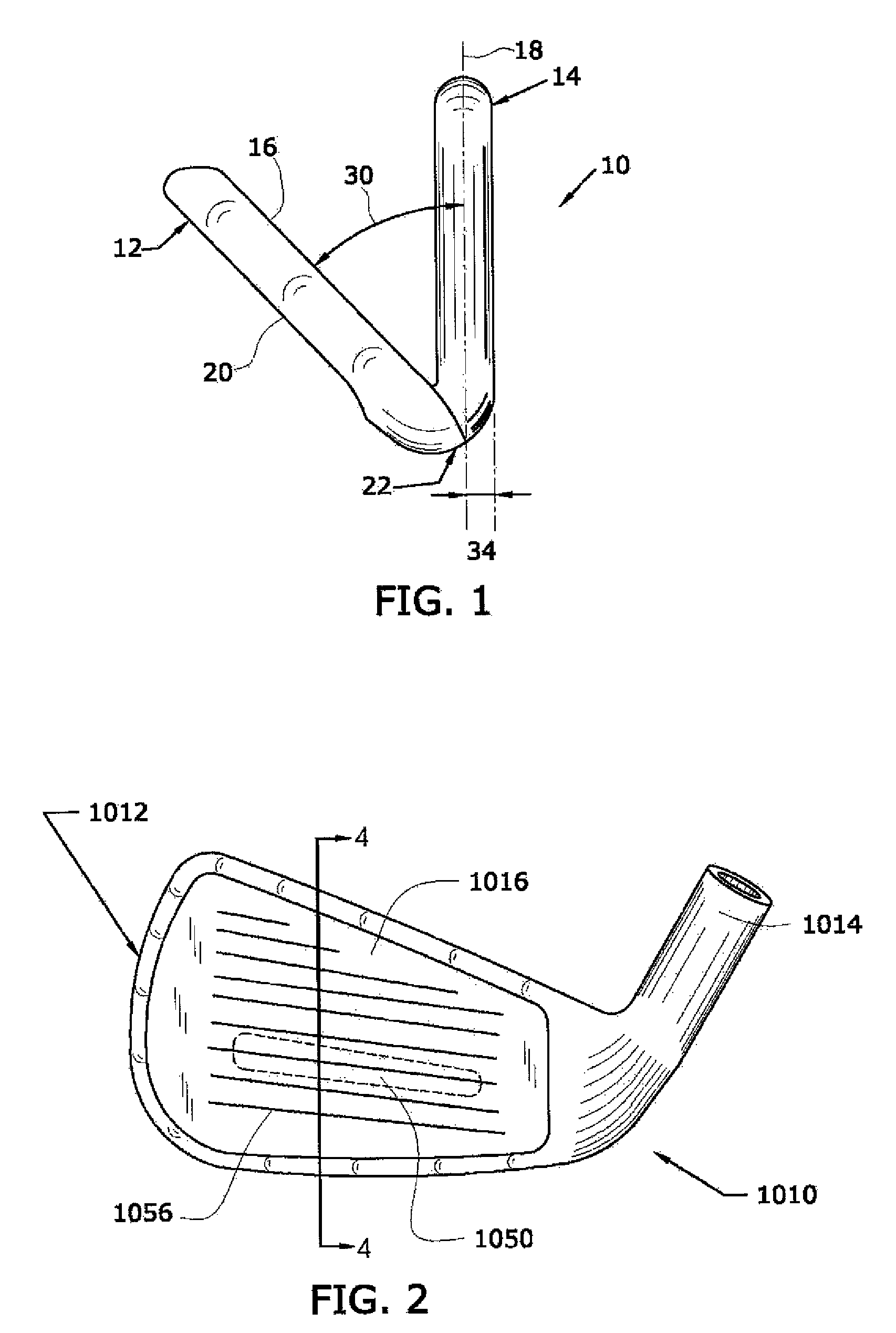

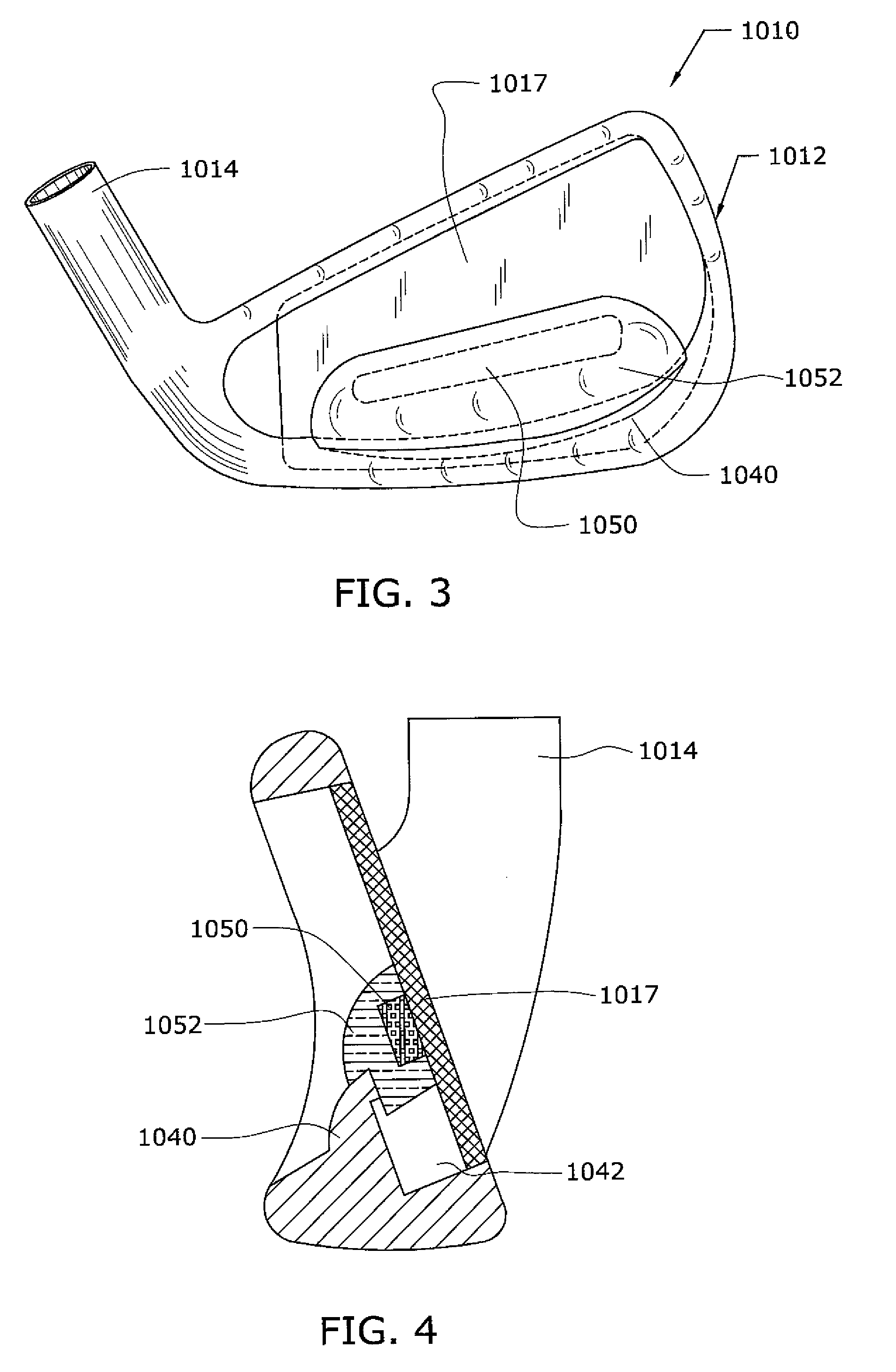

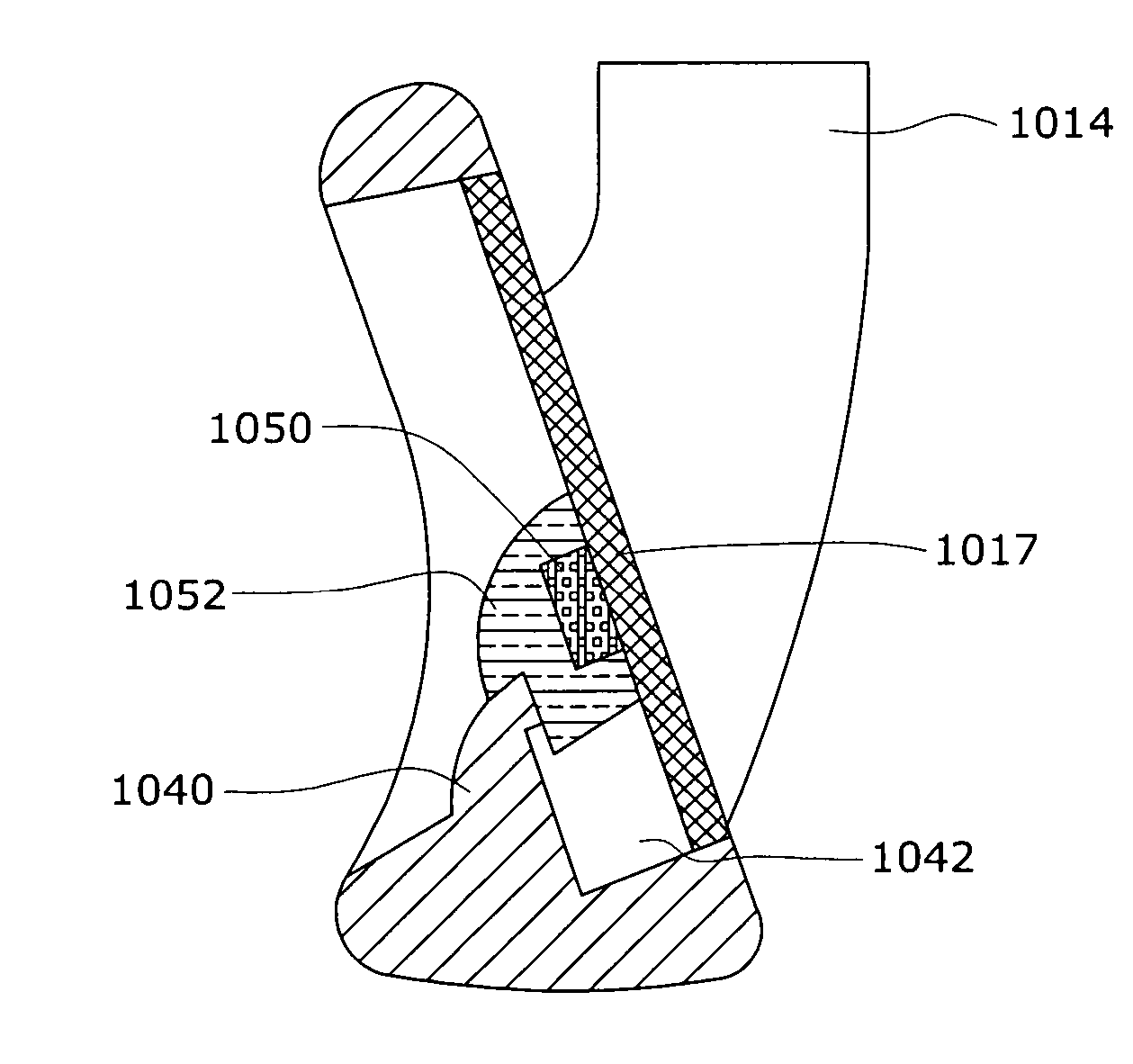

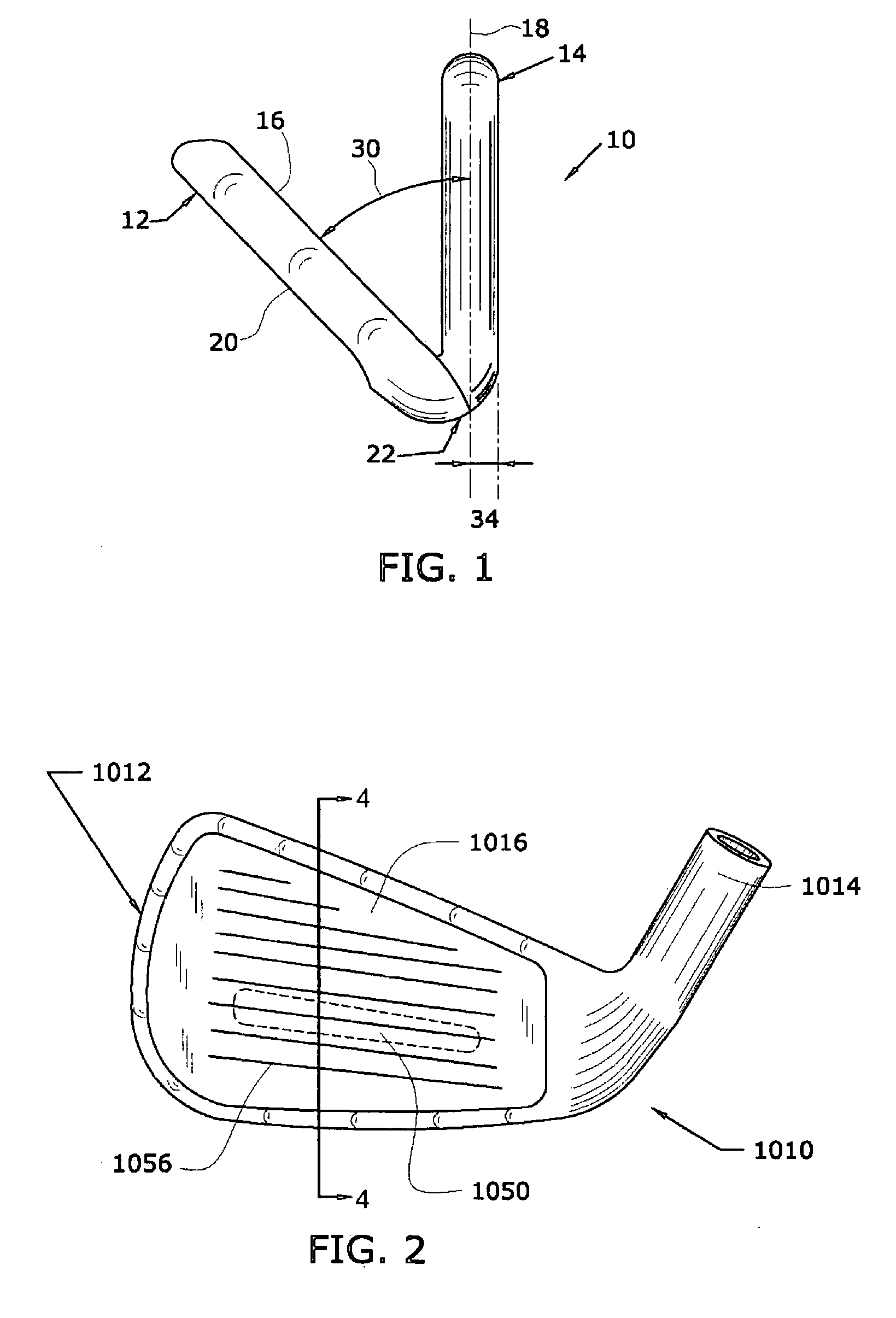

Iron-type golf clubs

Owner:ACUSHNET CO

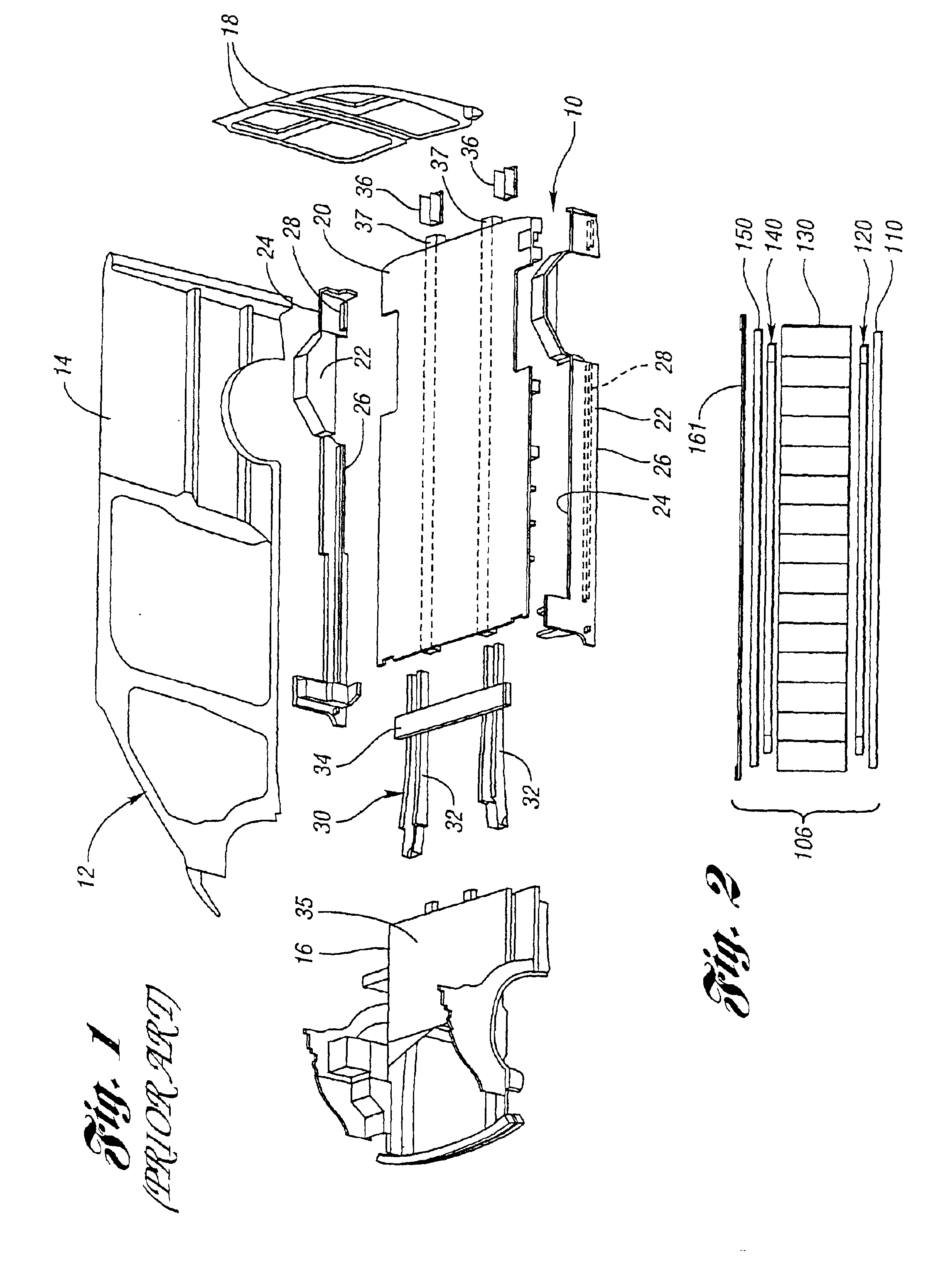

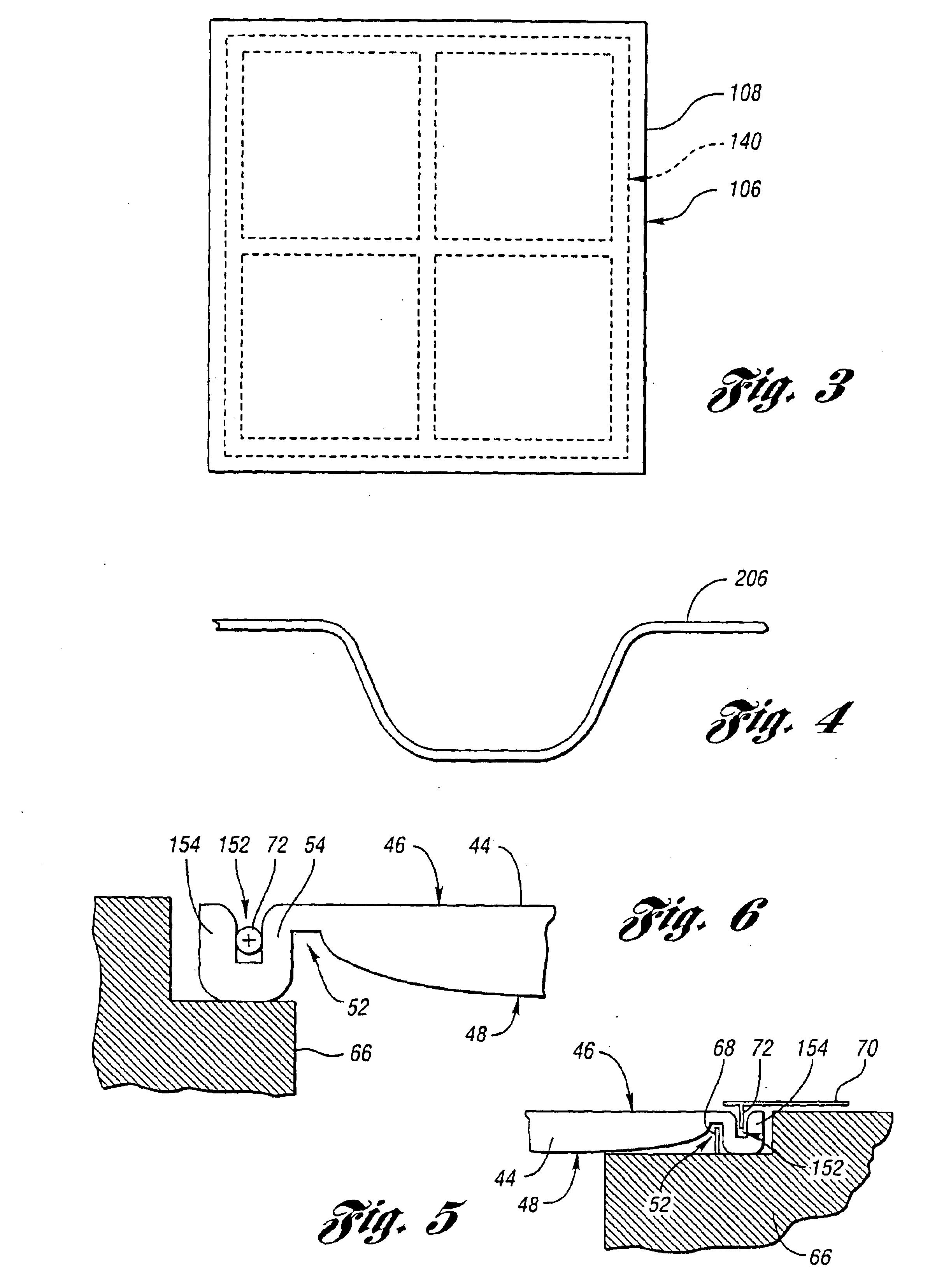

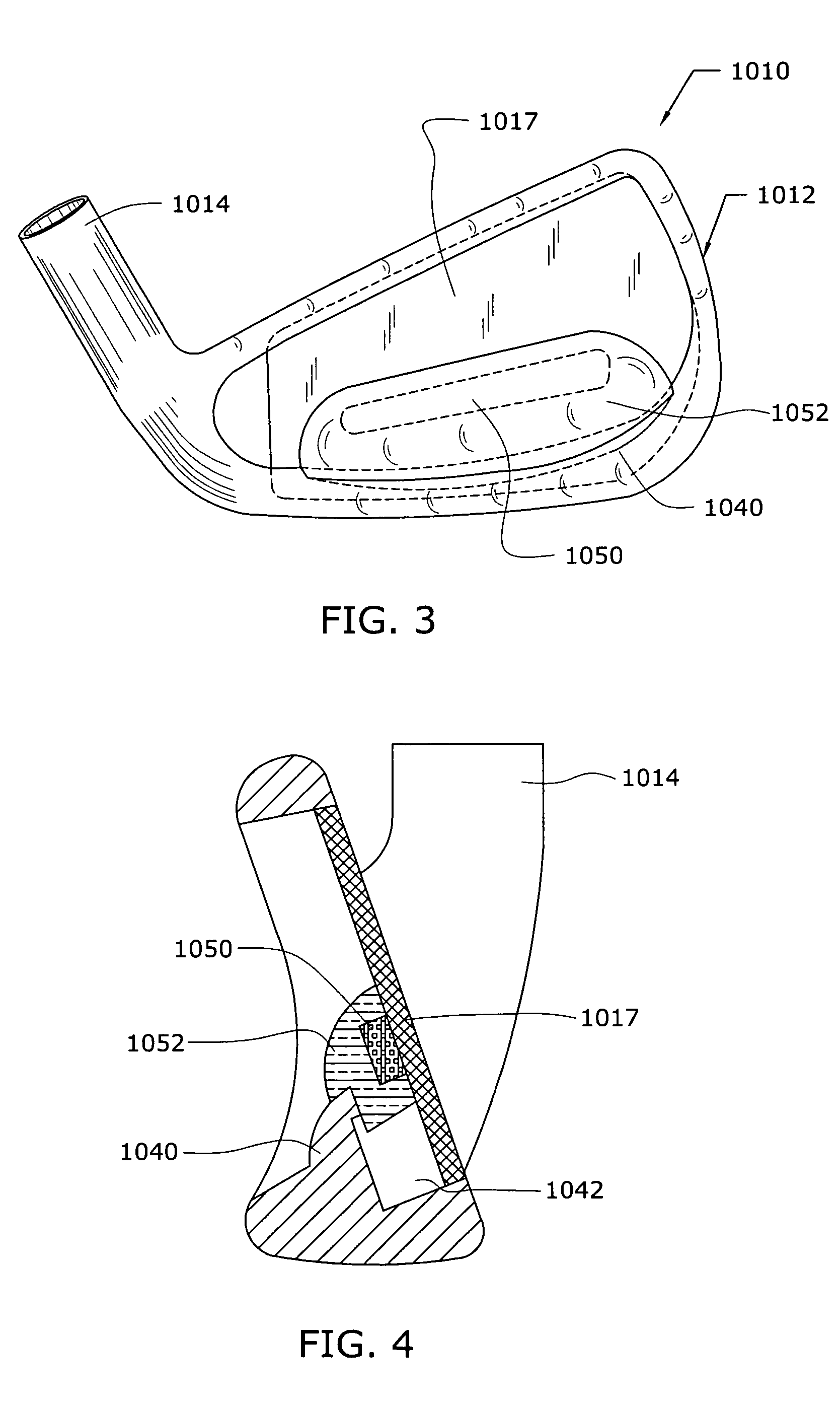

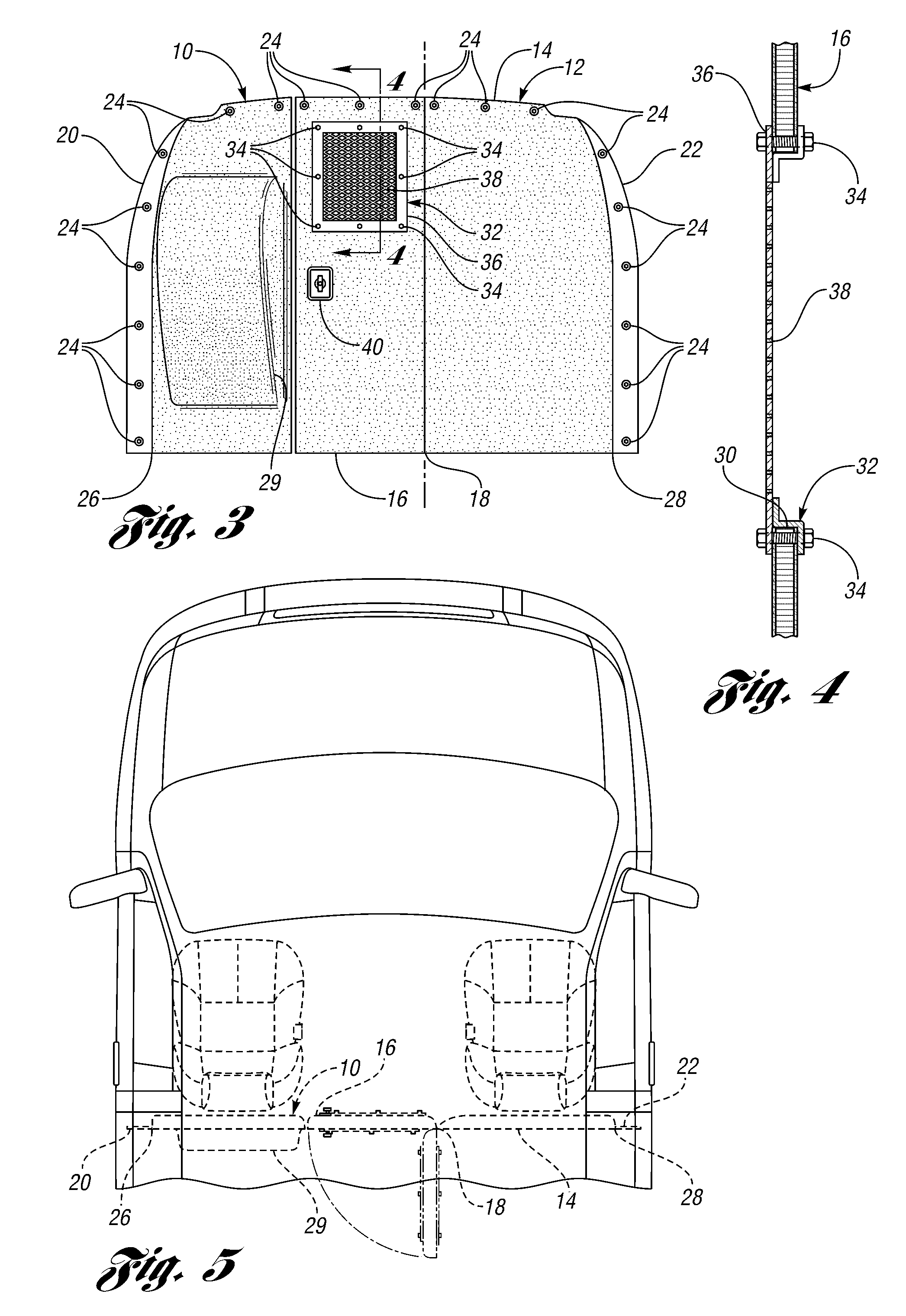

Reinforced composite vehicle load floor of the cellular core sandwich-type

The invention relates to reinforced composite vehicle load floors of the sandwich-type having a cellular core. In a method for making a load floor of the invention, a stack is formed that is made up of: a load-bearing upper skin made of a reinforced thermoplastics material; an upper skeletal frame structure of reinforcing slats each of which is made of a reinforced thermoplastic composite or pultrusion; a cellular core made of a thermoplastic material; a lower skeletal frame structure of reinforcing slats each of which is also made of a reinforced thermoplastic composite or pultrusion; and a bottom skin made of a reinforced thermoplastic material. Each of the frame structures of reinforcing slats has a surface area that is smaller than the surface area of each of the skins. The frame structures of reinforcing slats are positioned symmetrically about a plane formed by the cellular core against the skins.

Owner:GLOBAL IP HLDG

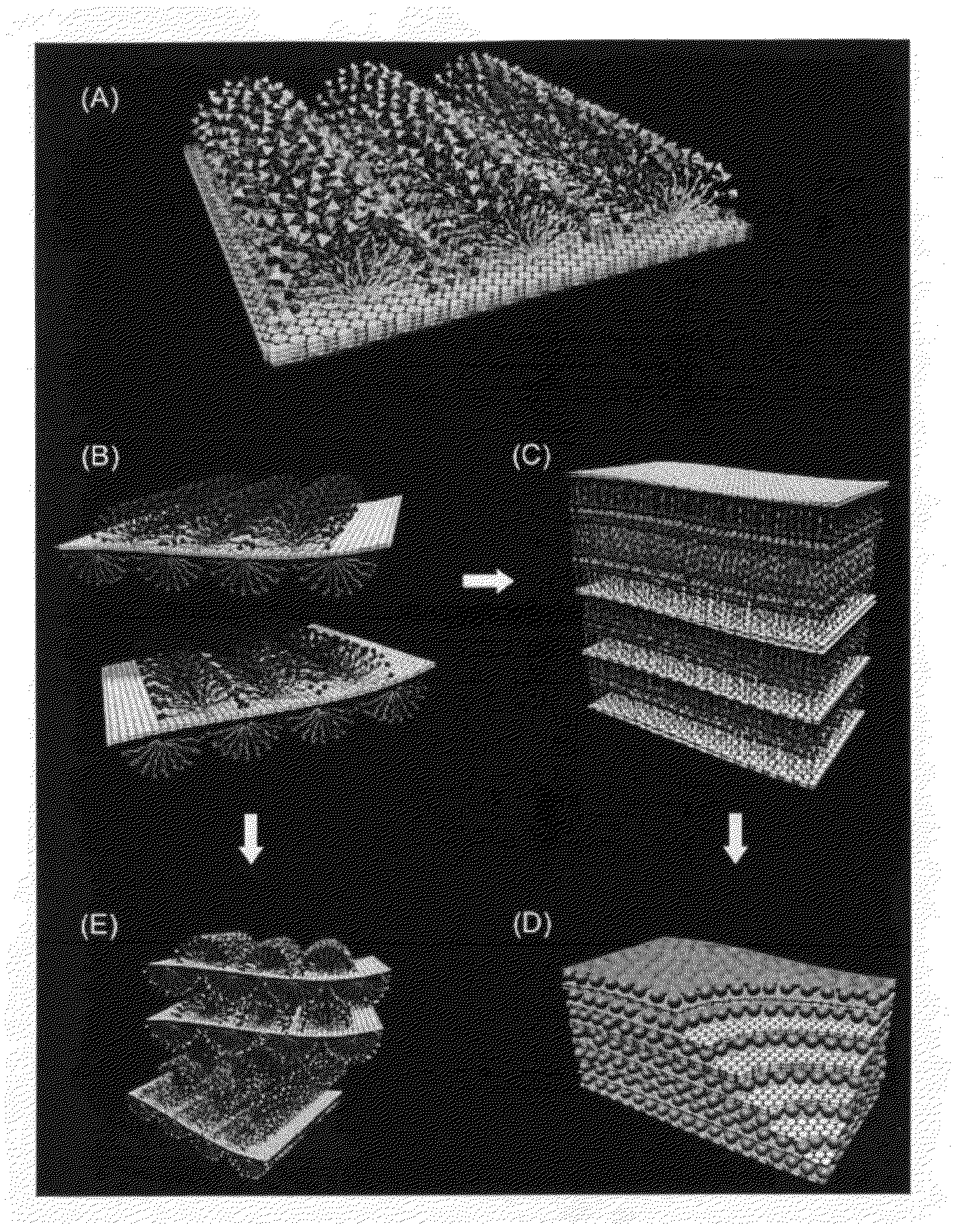

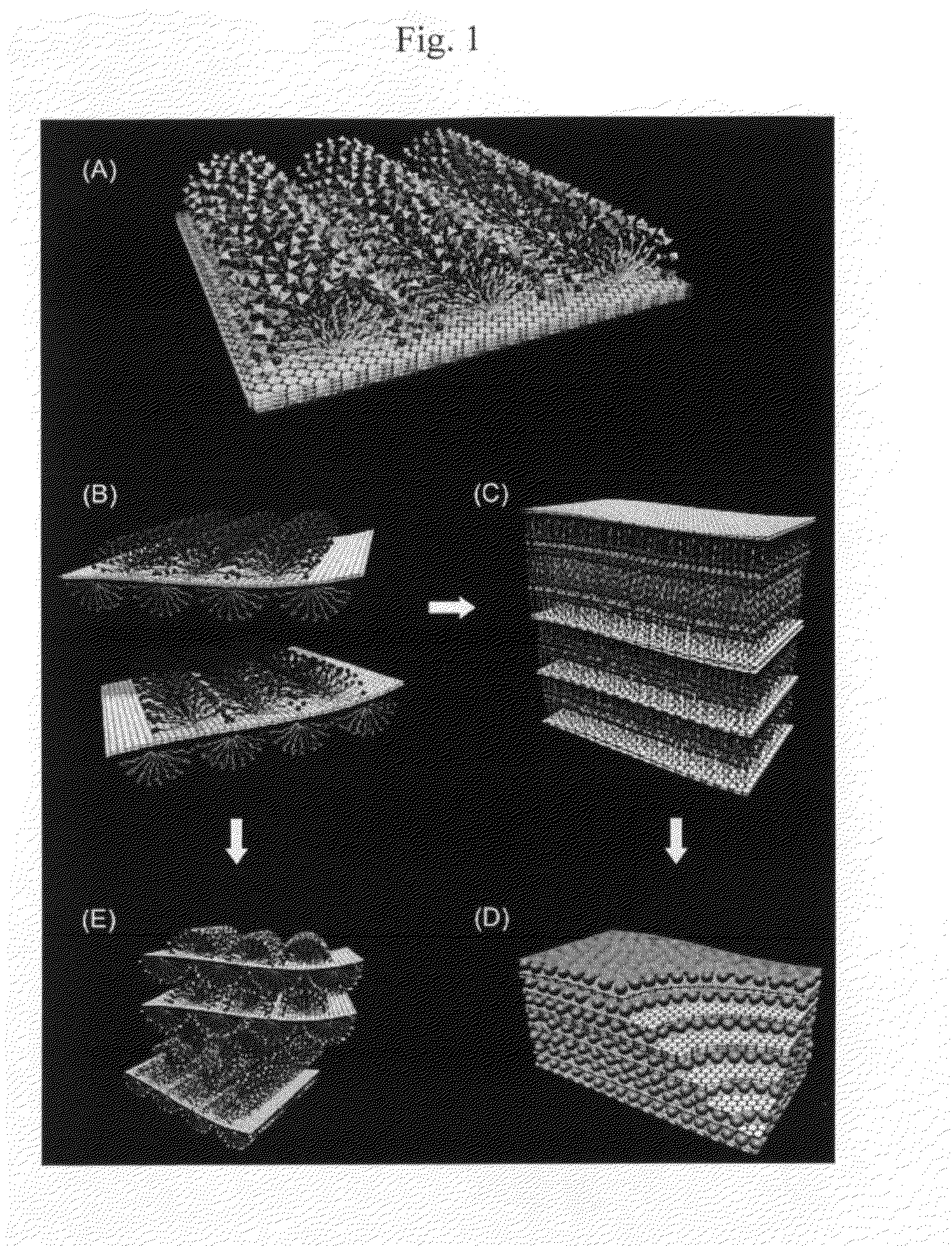

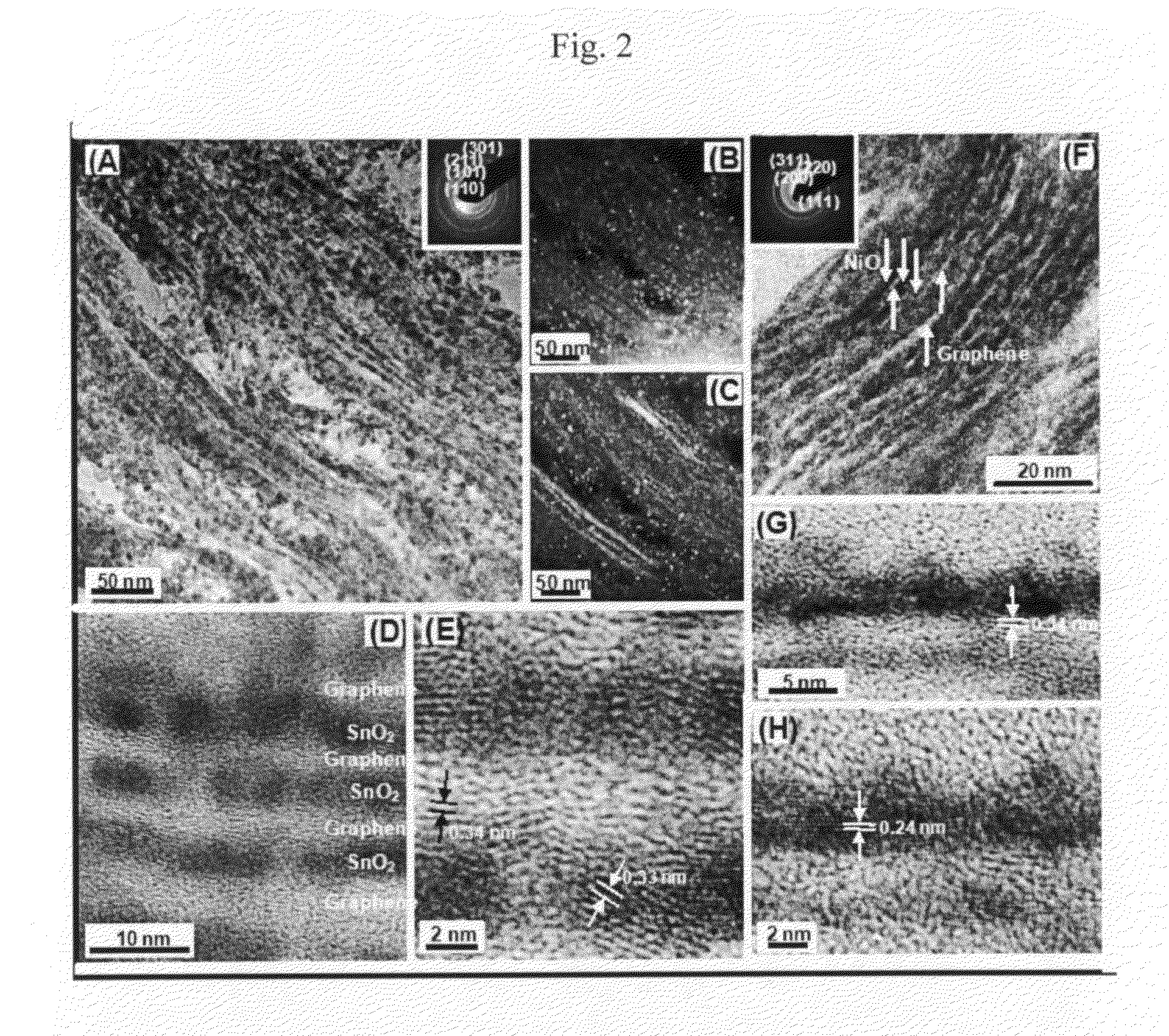

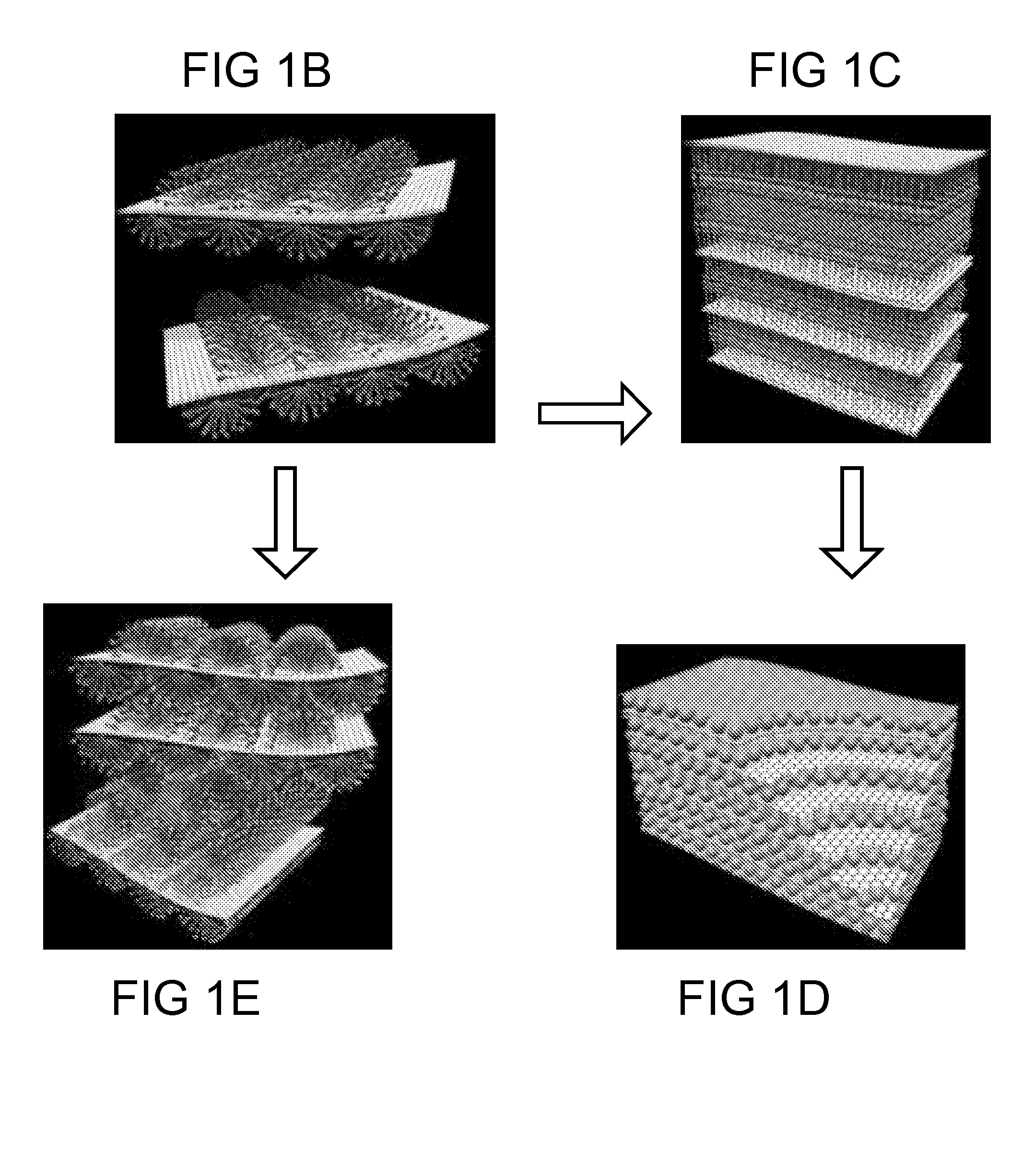

Self assembled multi-layer nanocomposite of graphene and metal oxide materials

Nanocomposite materials having at least two layers, each layer consisting of one metal oxide bonded to at least one graphene layer were developed. The nanocomposite materials will typically have many alternating layers of metal oxides and graphene layers, bonded in a sandwich type construction and will be incorporated into an electrochemical or energy storage device.

Owner:THE TRUSTEES FOR PRINCETON UNIV +1

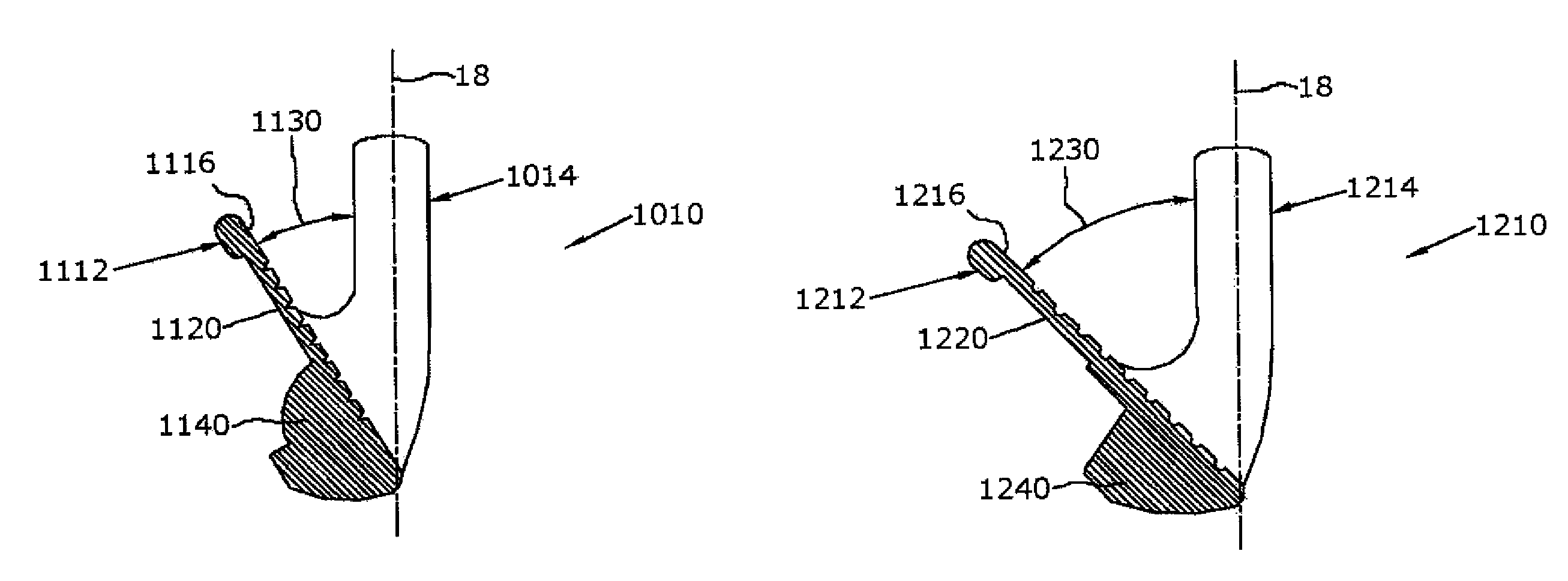

Iron-type golf clubs

Owner:ACUSHNET CO

Iron-type golf clubs

Owner:ACUSHNET CO

Iron-type golf clubs

Owner:ACUSHNET CO

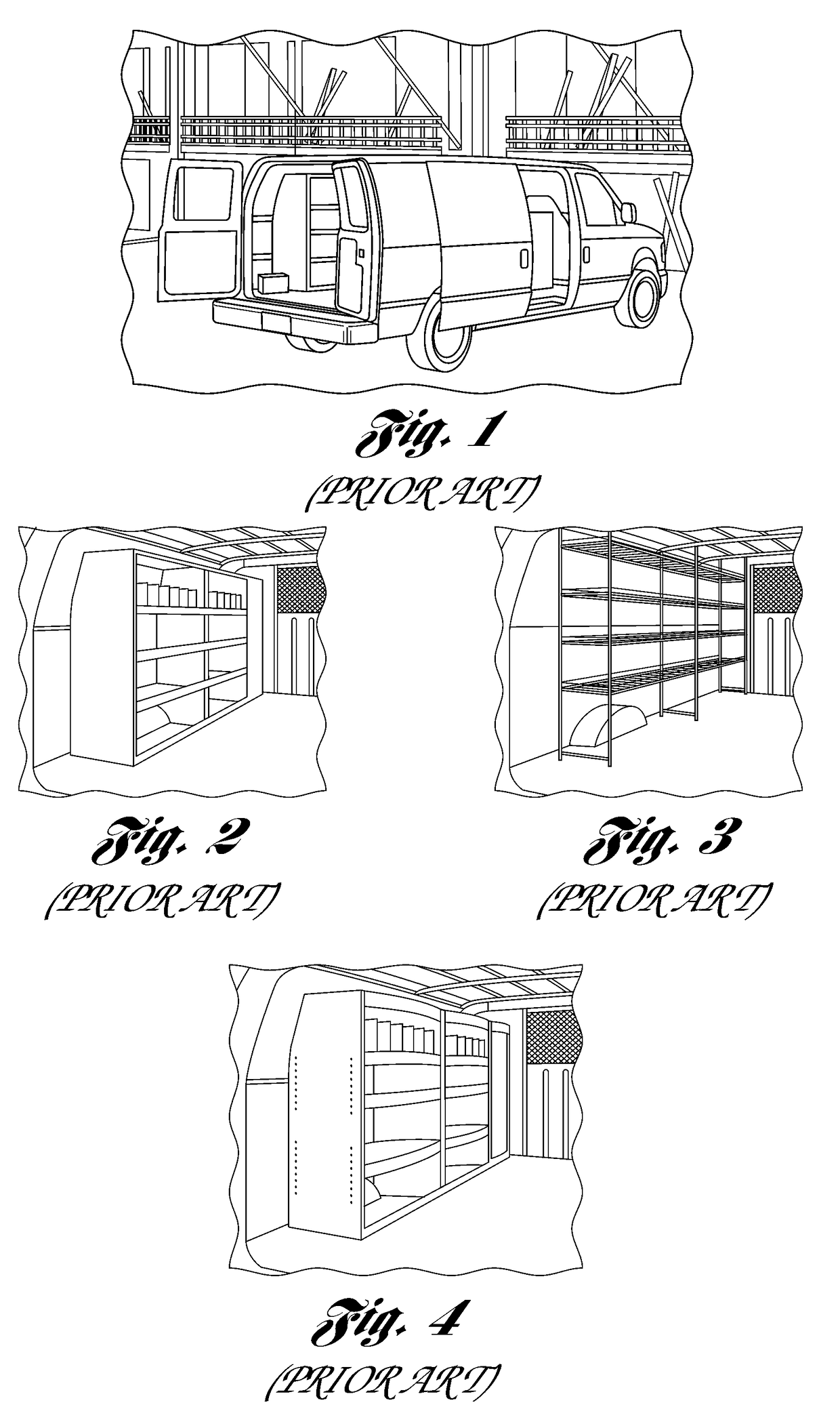

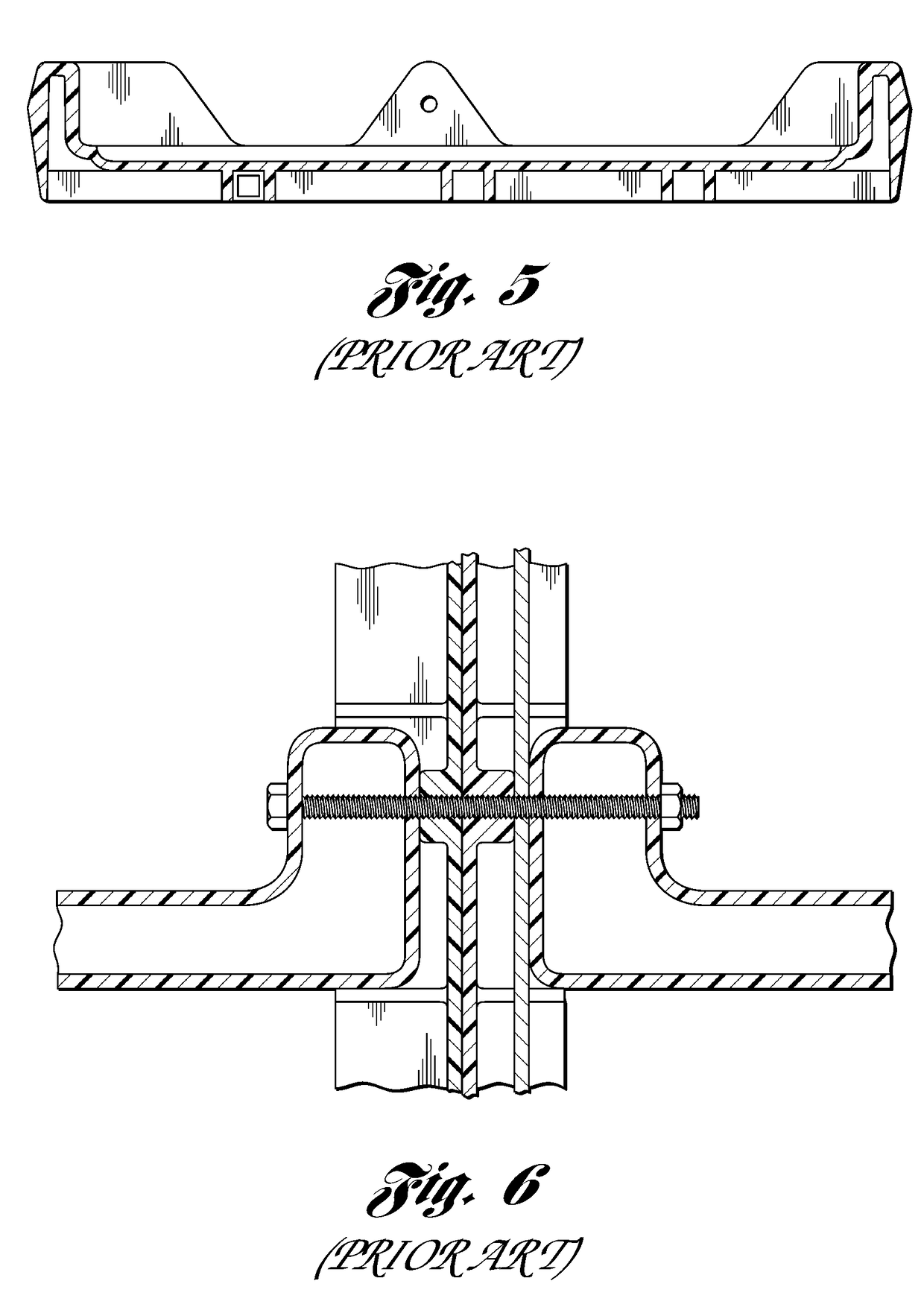

Kit and bulkhead assembly for cargo vehicles

ActiveUS7909379B2Easy to installEasy to removeVehicle arrangementsPedestrian/occupant safety arrangementDriver/operatorFace sheet

A kit from which a plurality of parts are selected and arranged in a cargo vehicle to obtain bulkhead assembly for the cargo vehicle is provided. The assembly partitions or divides a cargo area from a driver area in the vehicle. The kit includes a reinforced composite first panel of a cellular core sandwich-type for positioning proximate a first side of and within the vehicle. The kit also includes a reinforced composite second panel of a cellular core sandwich-type. The second panel includes a first portion for positioning proximate a second side of and within the vehicle, a door portion disposed between the first panel and the first portion and a living hinge portion disposed between the first and door portions to allow the door portion of the second panel to pivot between open and closed positions to allow the driver to move between the areas in the open position of the door portion.

Owner:GLOBAL IP HLDG

Iron-type golf clubs

Owner:ACUSHNET CO

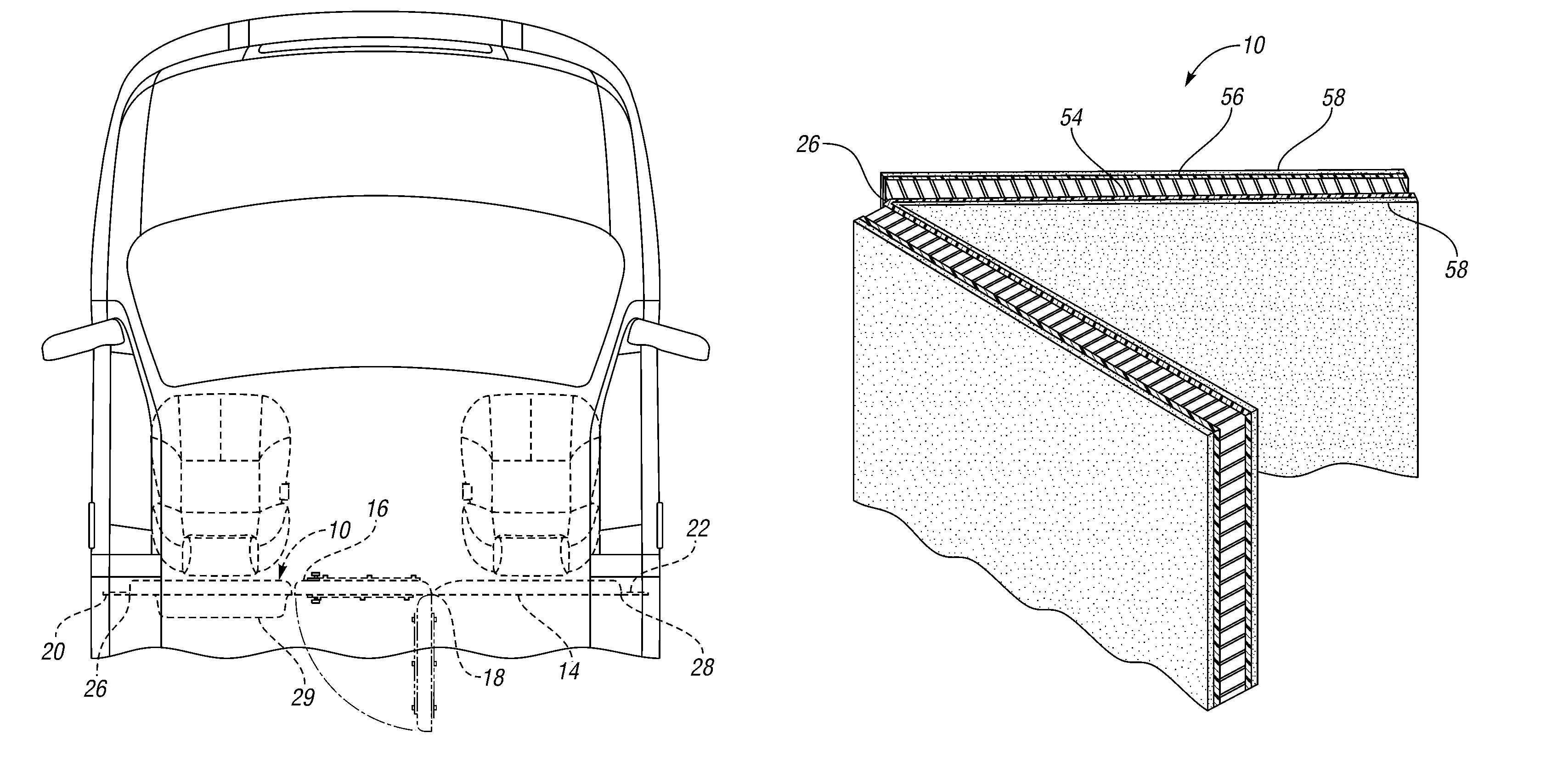

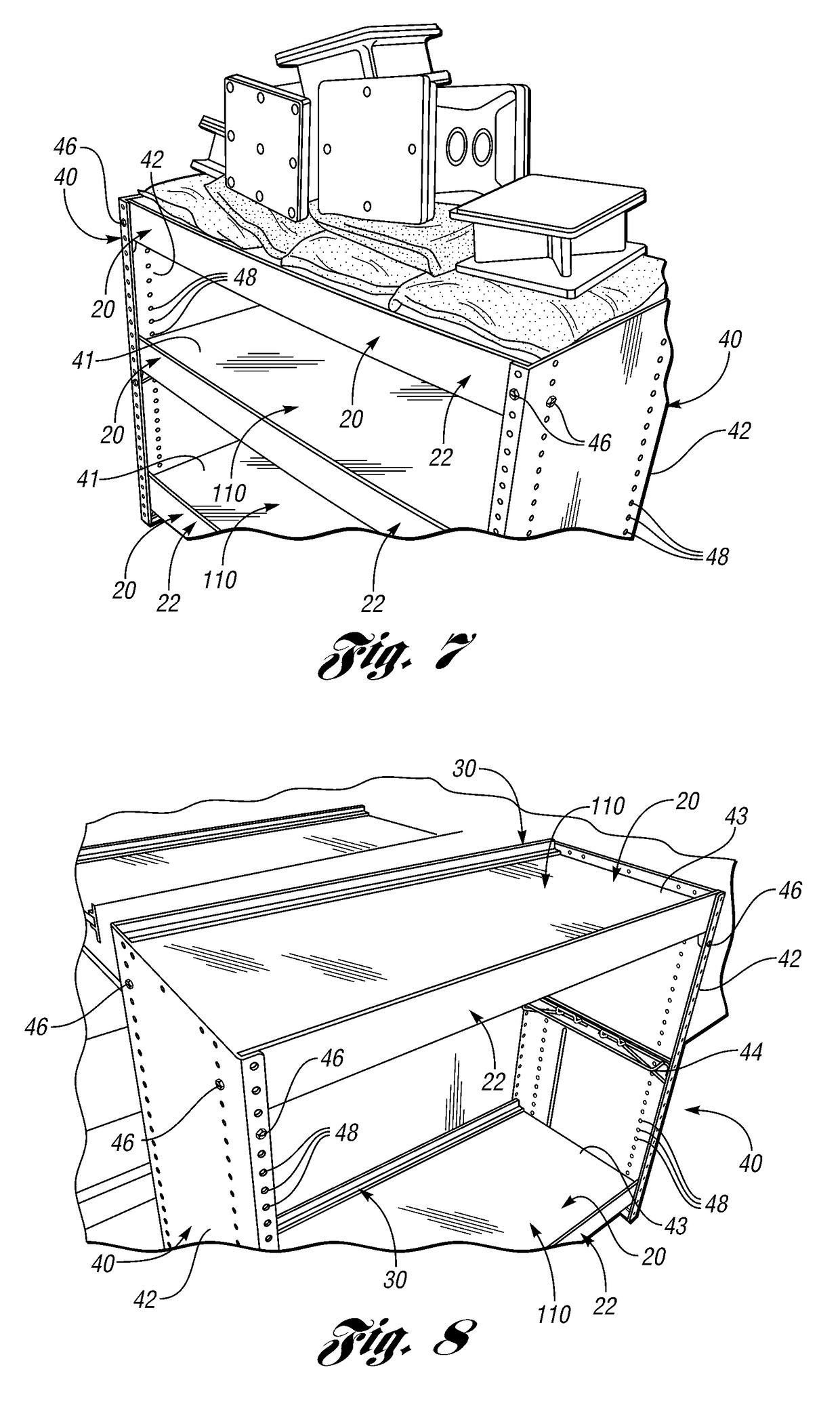

Kit and shelving system to store work tools, equipment and supplies in a motor vehicle and plastic shelf for use therein

ActiveUS8117972B2Easy to installEasy to removeFurniture partsFolding cabinetsMotorized vehicleSandwich type

Owner:GLOBAL IP HLDG

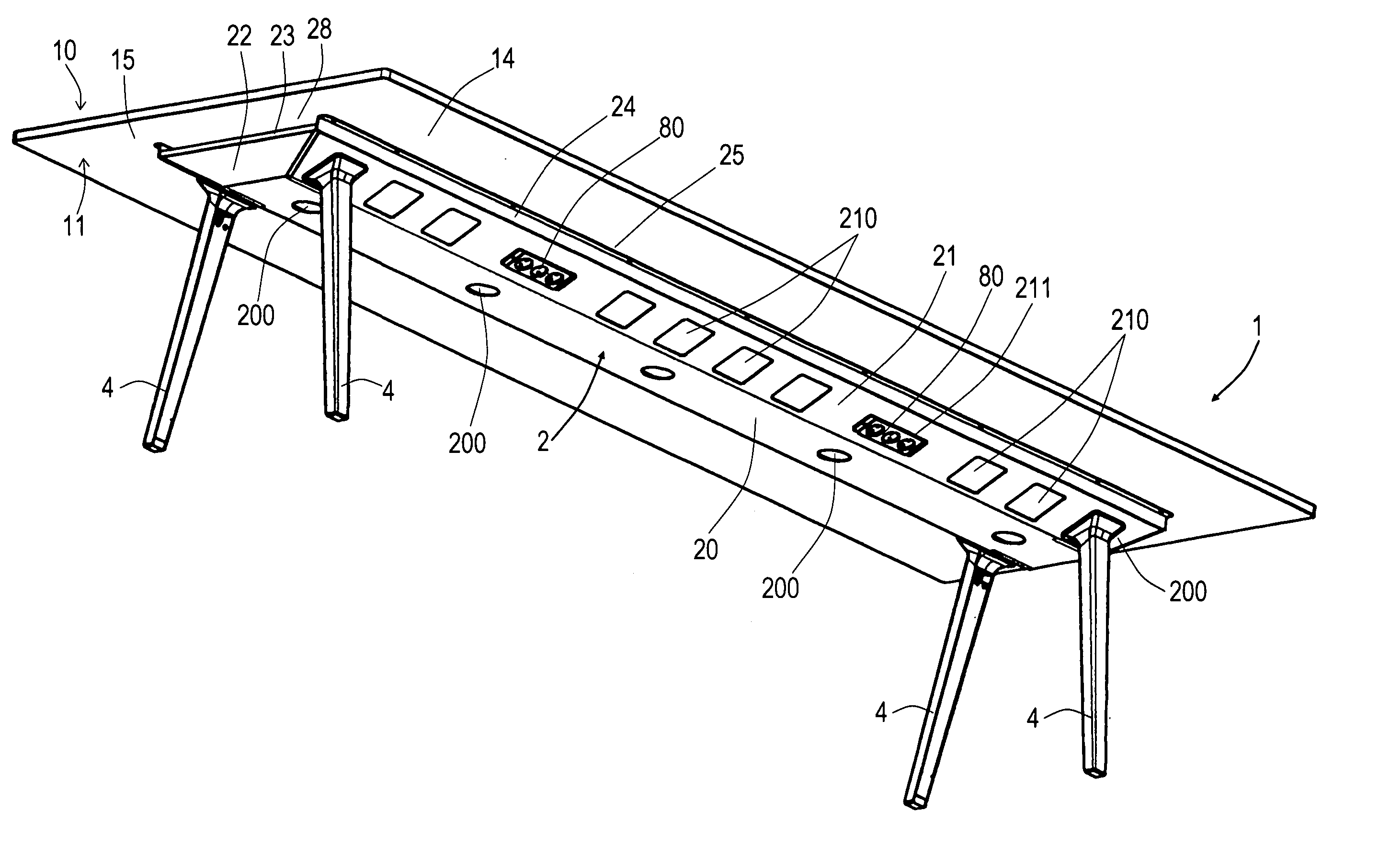

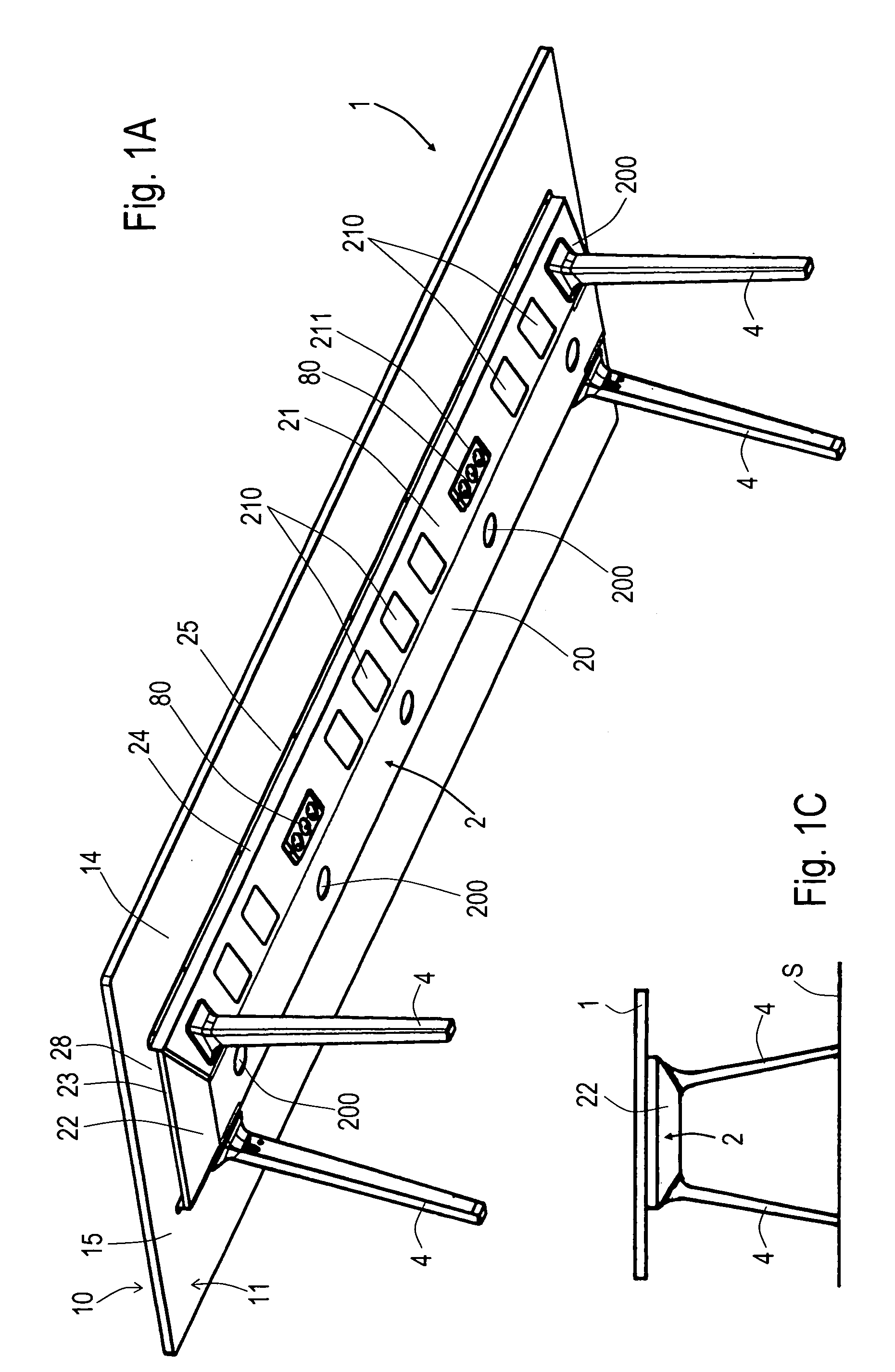

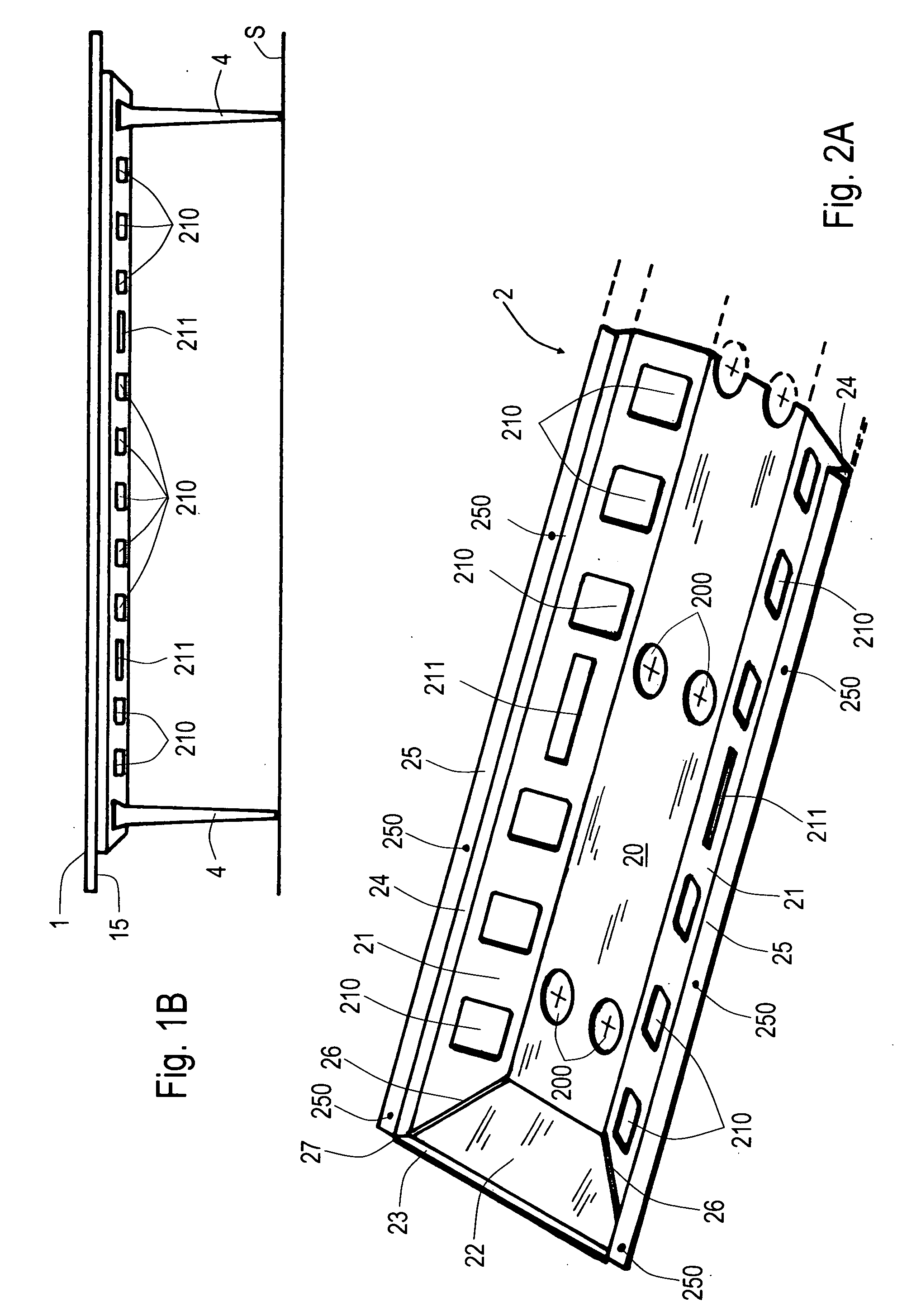

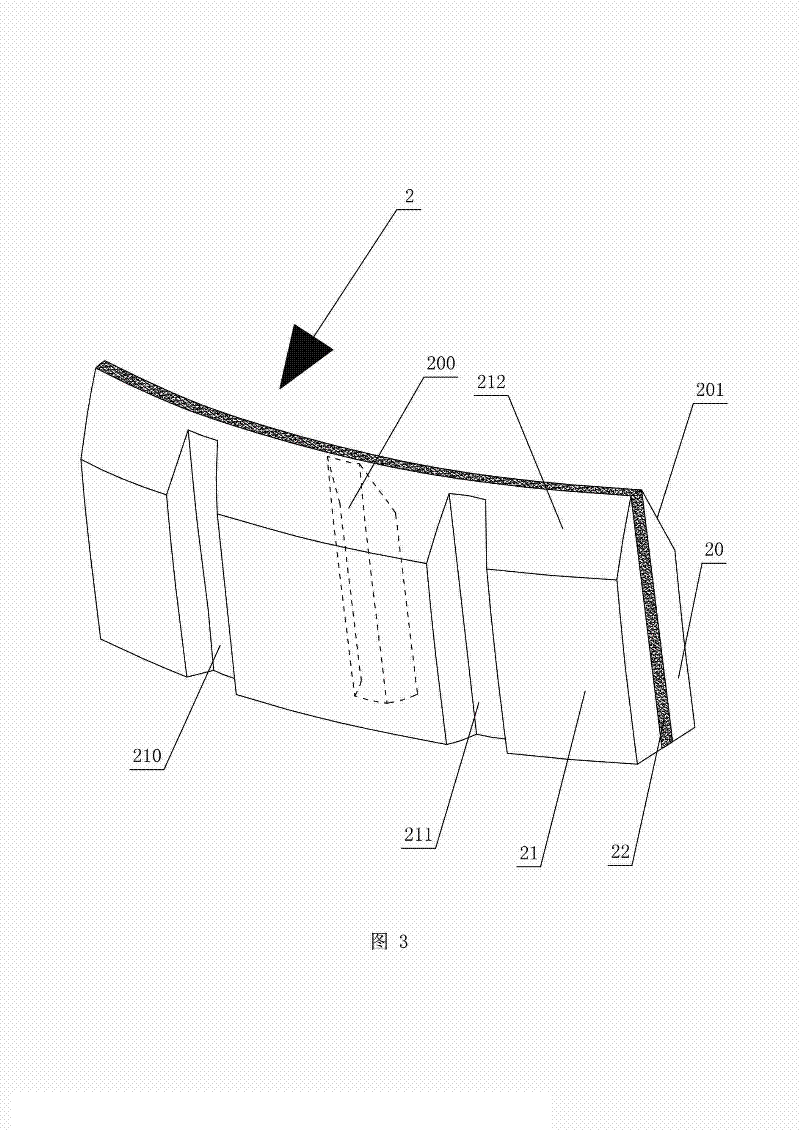

Table, especially office and conference table

The invention relates to a table which is primarily used as an office or conference table, is longer than 2.5 m, and comprises an upwardly open trough (2) as a substructure which is arranged beneath the leaf (1) of the table and preferably consists of sheet metal which is e.g. 2 mm thick. The leaf of the table (1) is connected in a fixed manner to edges (25) which are bent away from the trough (2), creating a sandwich-type structure with mutual reinforcement of the leaf (1) of the table and the trough (2). Especially advantageously, the trough (2) has a trapezoidal cross-section. A grid of openings (210) in the trough (2) enables the feet (4) of the table to be mounted in any position. Additional appliance openings (211) are used to insert socket units (80), while installation openings (200) in the bottom (20) of the trough (2) as used as cable ducts. A height leveling device is provided in each foot (4). A particular advantage of the invention is the stability achieved with a relatively light structure, even for longer tables.

Owner:VITRA PATENTE AG

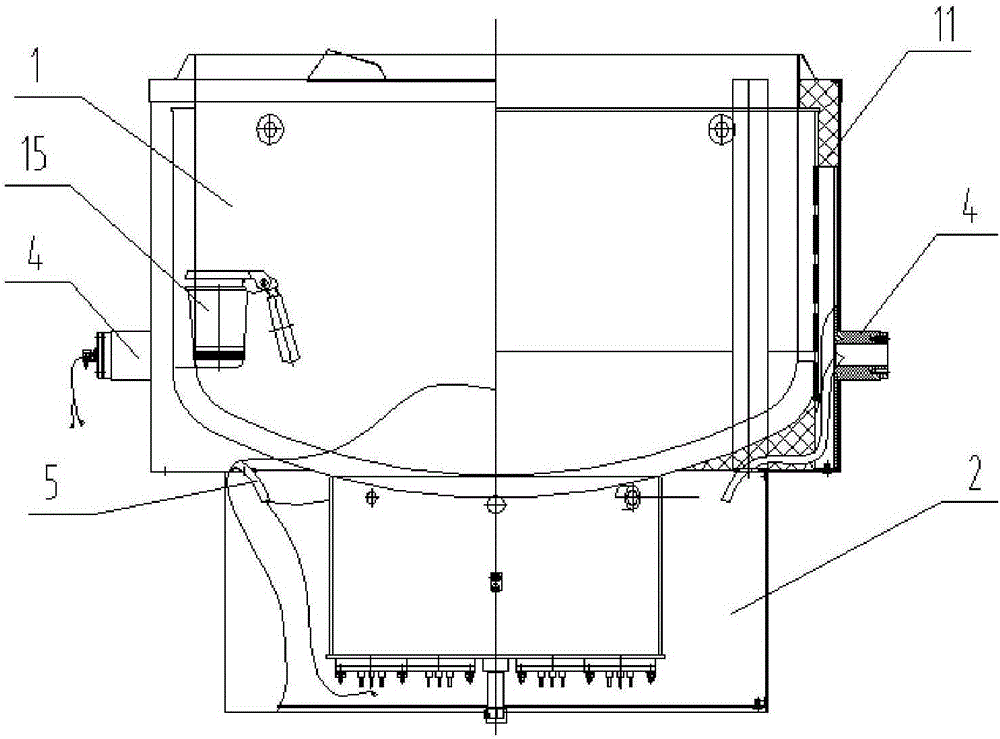

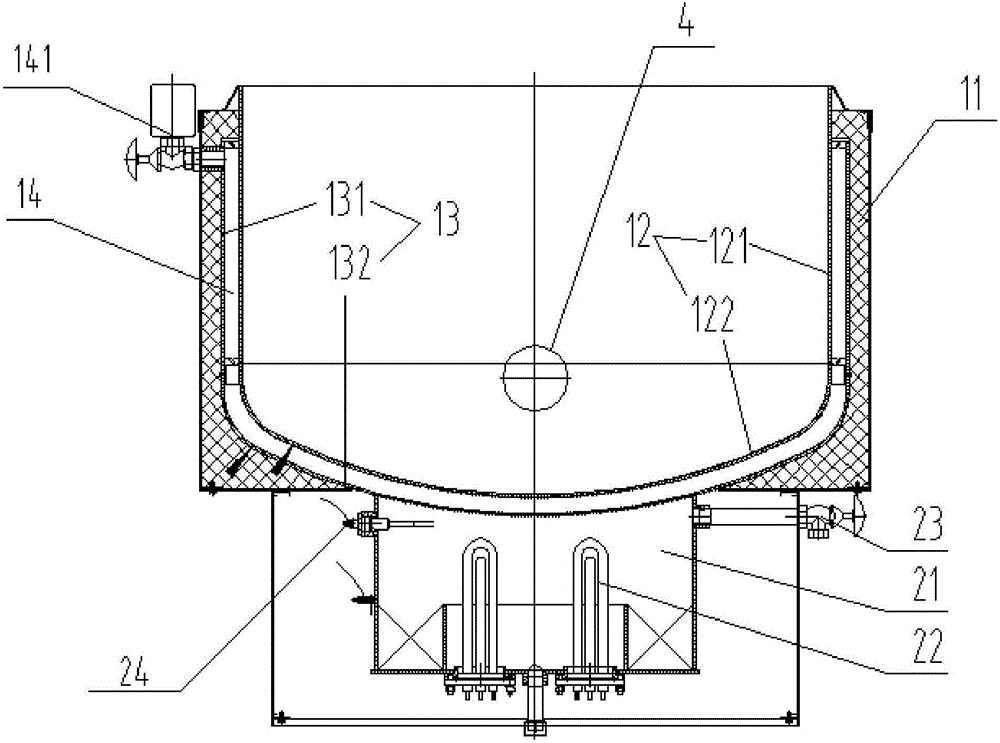

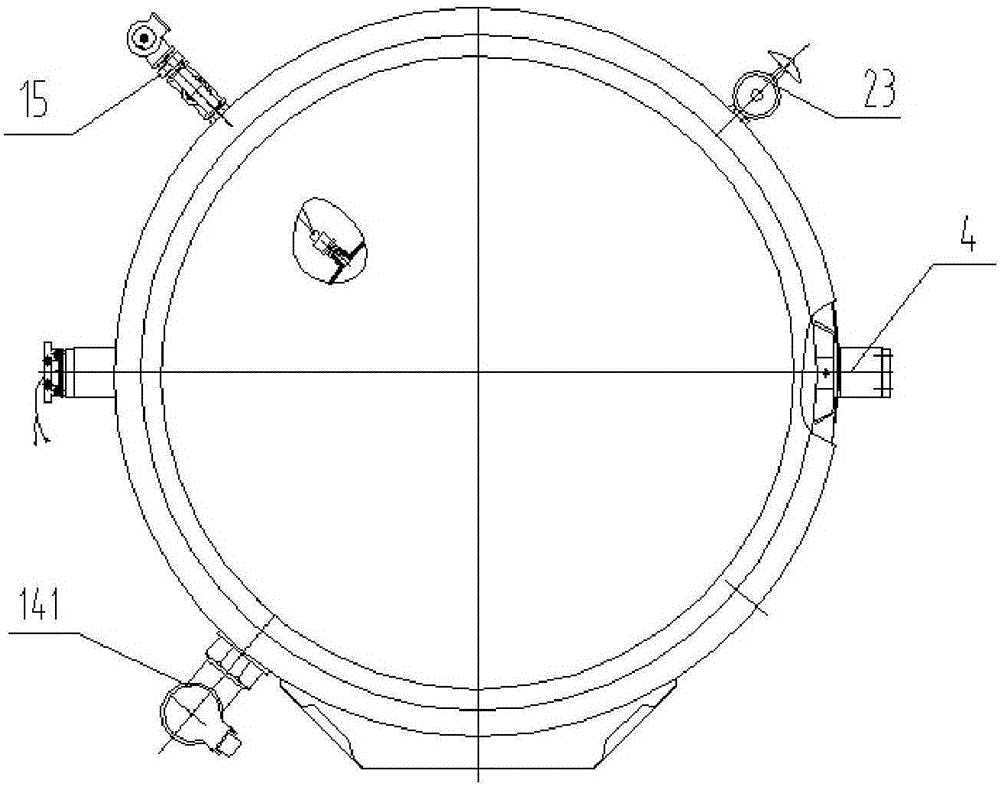

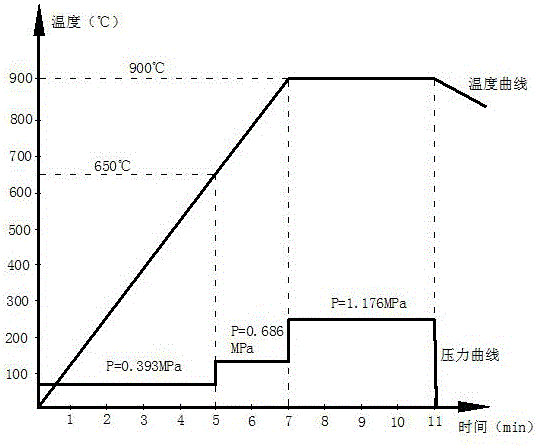

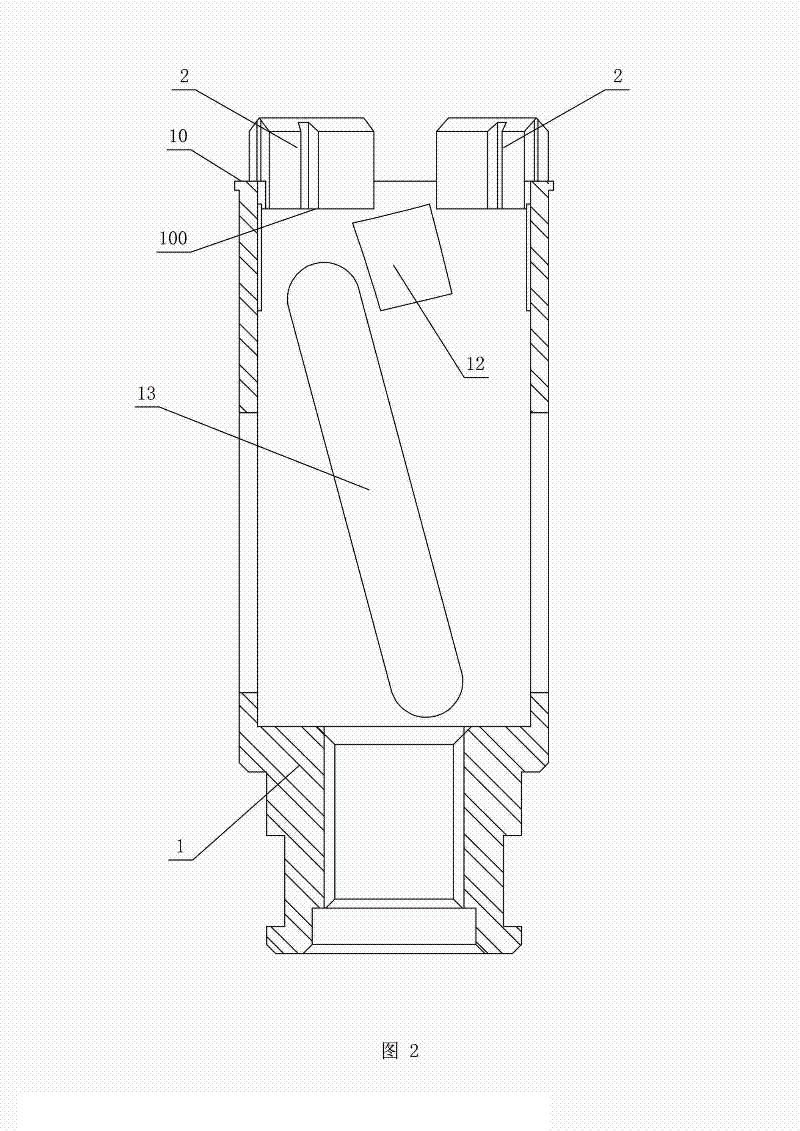

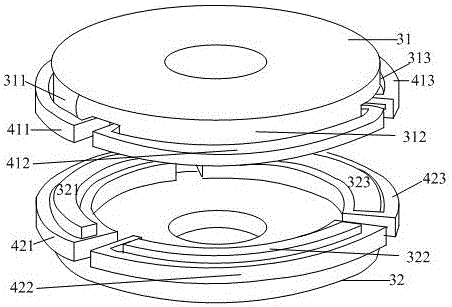

Sandwich type pressure cooker

InactiveCN106388572AEnsure safetyEasy to cleanPressure-cookersWarming devicesFood gradeBoiling point

The invention provides a sandwich type pressure cooker. The pressure cooker comprises a pot body; a heating tank is fixed at the bottom of the pot body; the pot body comprises an inner container and an outer container; a sealed sandwich layer is arranged between the inner container and the outer container to form a steam cavity; a first water inlet is formed in the upper end of the steam cavity; a first water inlet valve is fixed at the first water inlet; the heating tank is provided with a heating cavity which forms a sealed structure with the bottom of the outer container; a second water inlet is formed in a side wall of the heating cavity; a second water inlet valve is fixed at the second water inlet; a water level detector is further arranged on the side wall of the heating cavity; and a controller controls the opening and closing of the second water inlet valve through water level information detected by the water level detector. The pressure cooker is made of the dual-layer food-grade stainless steel pot body, and is easy to wash, corrosion-resistant and high in structural strength; and the sandwich layer is arranged between inner and outer pot bodies and is filled with high-temperature steam by heating, heat is generated by utilizing high pressure and the steam (the temperature of the steam is higher than the boiling point (100 DEG C) of water) of the sandwich layer, and the generated heat is used for heating food in the cooker through heat conduction of metal.

Owner:ANQING SANWEI ELECTRICAL

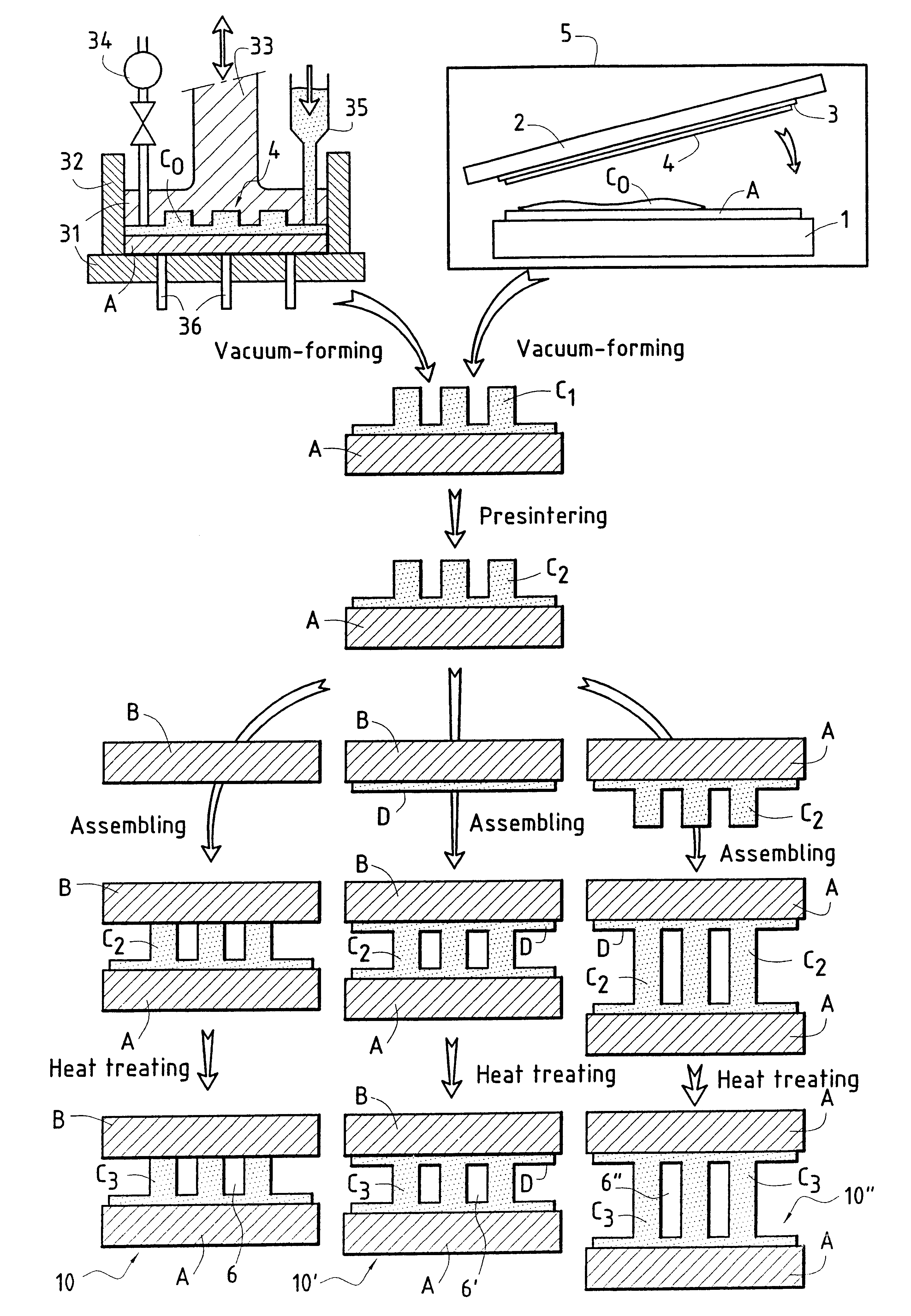

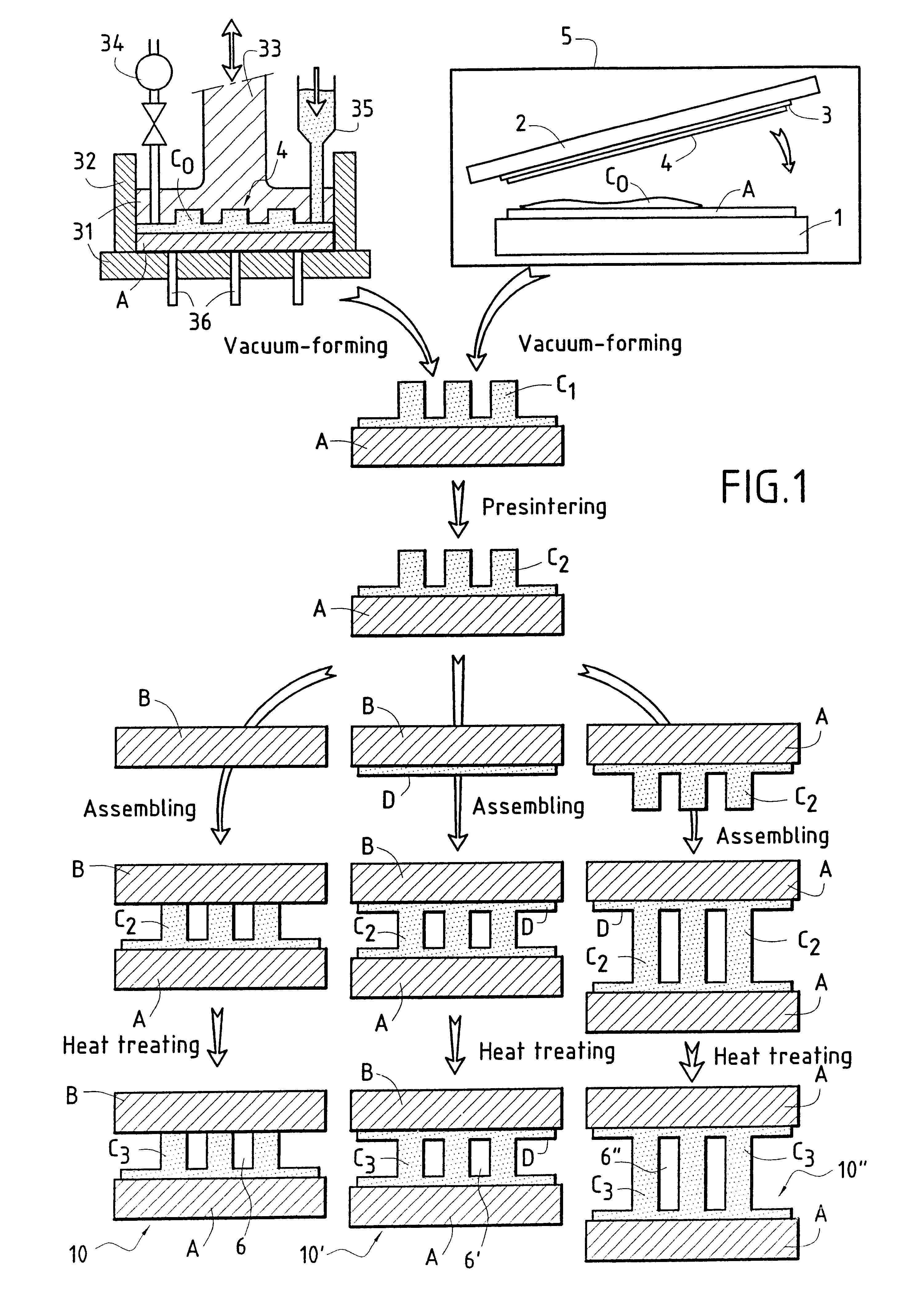

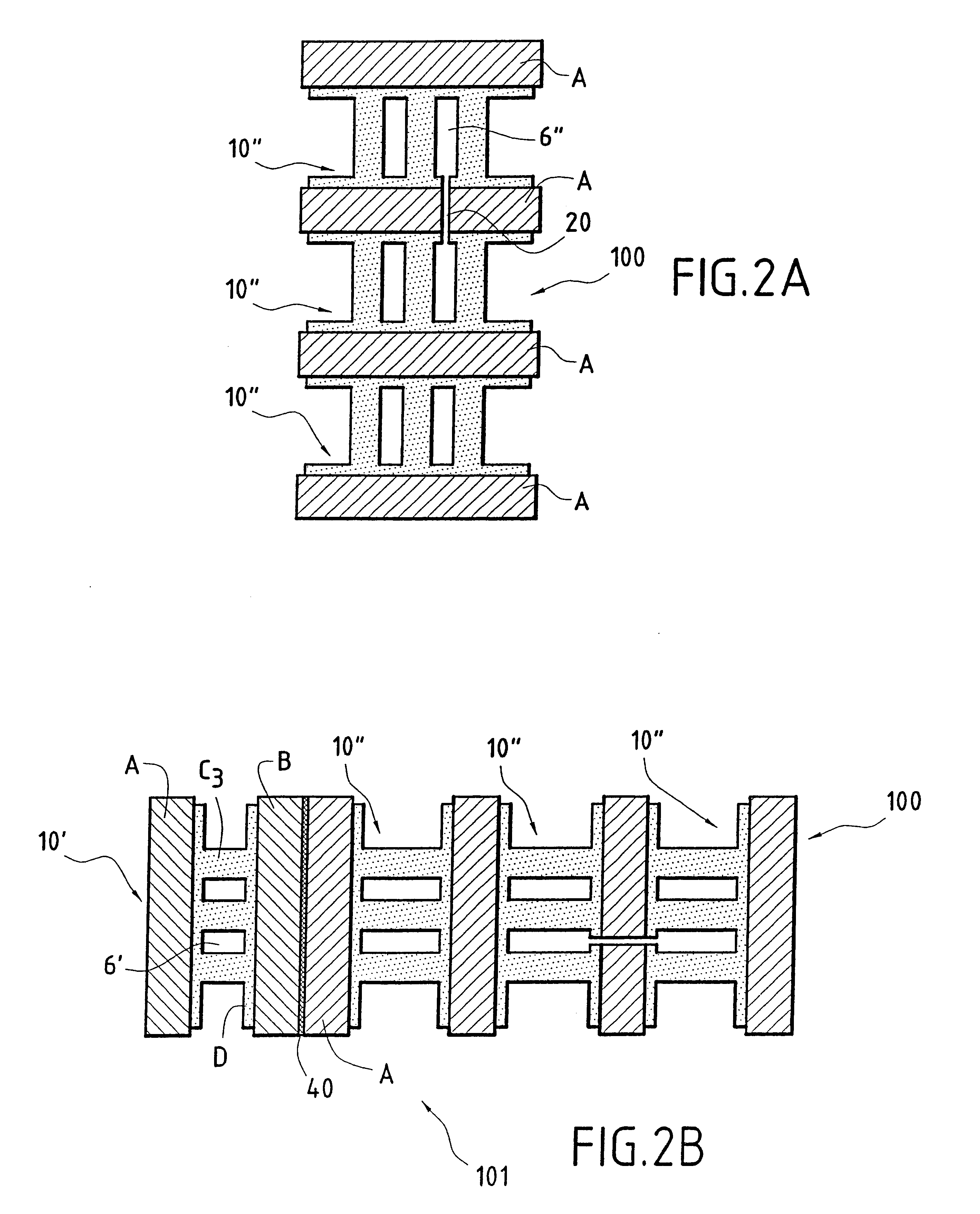

Microfluidic device and manufacture thereof

InactiveUS6595232B2Low cost productionHigh yieldVolume/mass flow measurementFluid pressure measurement by electric/magnetic elementsEngineeringGlass-ceramic

The present invention relates to microfluidic devices and to their method of manufacture. The microfluidic devices are original by their specific structure (of sandwich type) and by the materials from which they are made (mainly glasses, glass ceramics, ceramics), and also by their specific method of manufacture, which is based on a vacuum-forming operation. The microfluidic device includes a first assembly including a microstructure and a first substrate, wherein the microstructure is constructed and arranged on the substrate under vacuum. A second assembly includes a second substrate positioned on the microstructure after the first assembly is presintered and adhered thereto by heat treatment to form a one-piece microstructure defining at least one recess between the first and second substrates.

Owner:CORNING INC

Iron-type golf clubs

Owner:ACUSHNET CO

Self Assembled Multi-Layer Nanocomposite of Graphene and Metal Oxide Materials

Nanocomposite materials having at least two layers, each layer consisting of one metal oxide bonded to at least one graphene layer were developed. The nanocomposite materials will typically have many alternating layers of metal oxides and graphene layers, bonded in a sandwich type construction and will be incorporated into an electrochemical or energy storage device.

Owner:BATTELLE MEMORIAL INST

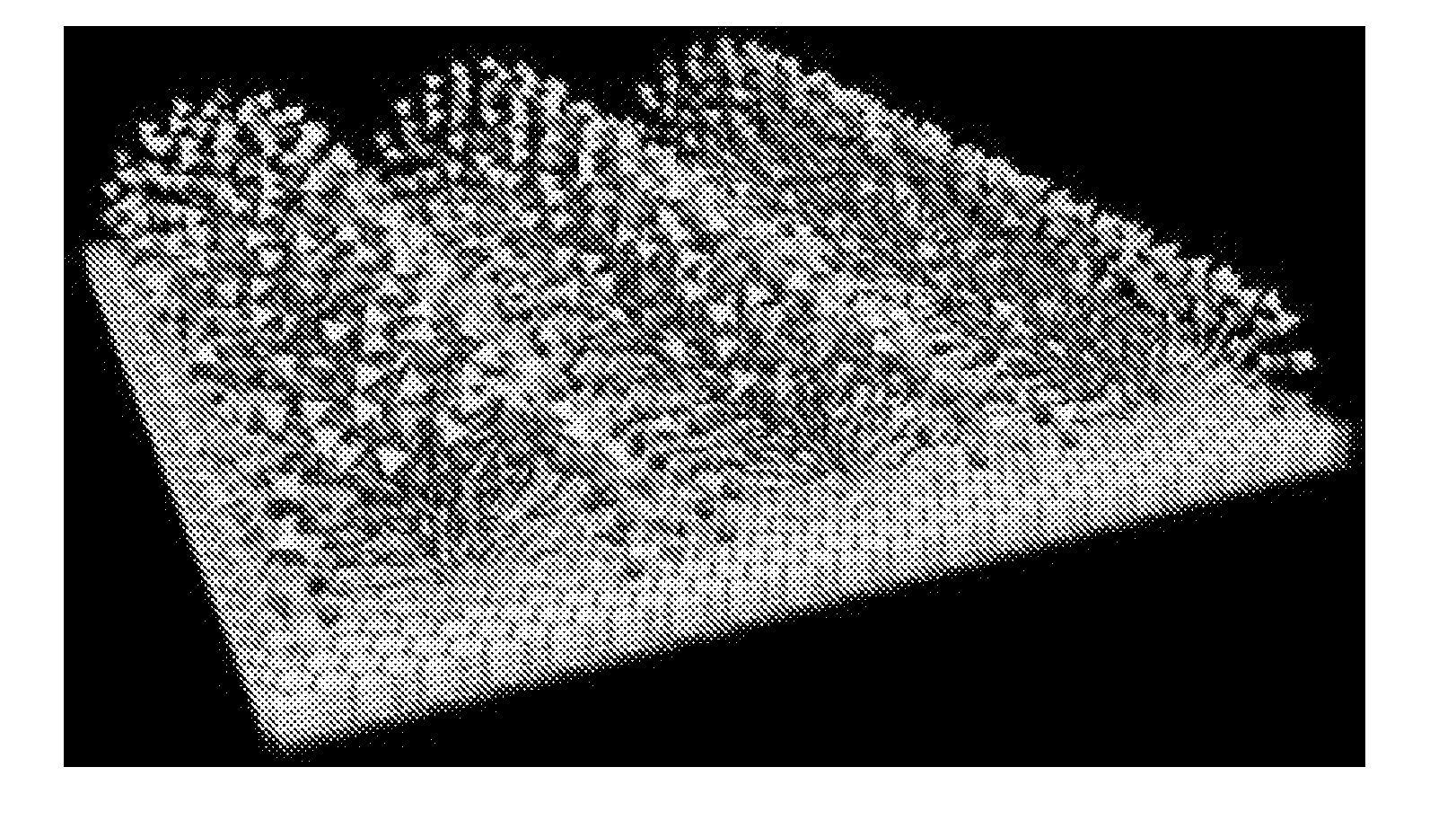

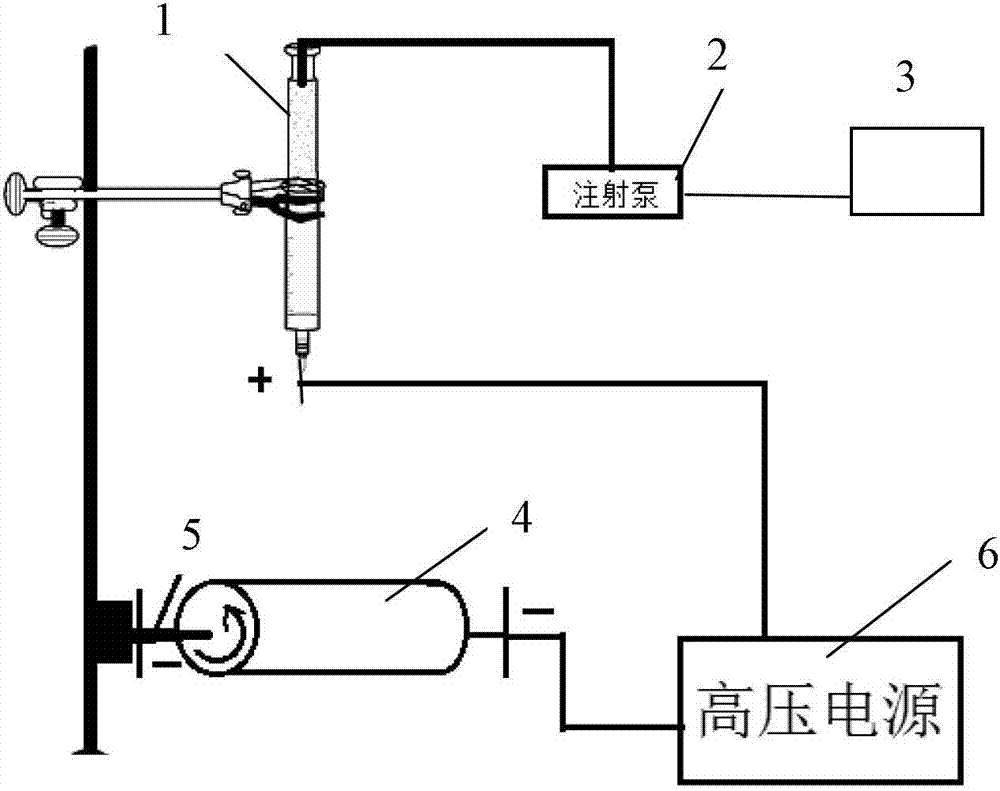

Preparation method of multilayer sandwich type electrostatic-spinning polymer nanofiber composite membrane

ActiveCN103481624AIncrease the areaSimple structureLamination ancillary operationsLaminationFiberPolymer science

The invention discloses a preparation method of a multilayer sandwich type electrostatic-spinning polymer nanofiber composite membrane. The preparation method comprises the steps of firstly, spinning a polymer spinning liquid into a fiber membrane in an electrostatic manner, then spraying a spraying liquid containing inorganic nano-particles to the surface of the electrostatic-spinning fiber membrane by virtue of a jetting technique, continuously spinning the fiber membrane, and repeatedly carrying out the steps according to specific conditions so as to prepare the multilayer sandwich type composite membrane. As the inorganic nano-particles are adhered to the surface of the fiber membrane, not only can the ultrahigh specific area and the specific structural advantage of a nanofiber be brought into full play, but also the selectable ranges of the spraying liquid and the polymer spinning liquid are flexible, so that spraying liquids containing different inorganic nano-particles can be sprayed to electrostatic-spinning fiber membranes made from different raw materials according to actual demands so as to prepare sandwich type composite membranes with different functions, stable structures and good properties, and the application range of the electrostatic-spinning polymer nanofiber composite membranes is expanded.

Owner:河北立格新材料科技股份有限公司

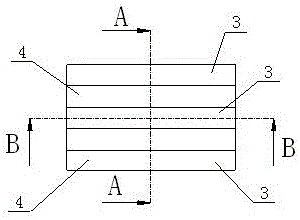

Double layer sandwich foamed concrete composite solid wall plate

InactiveCN1987008AShort demoulding timeIncrease productivityConstruction materialSolid waste managementFiberFoam concrete

A dual-layer sandwich-type solid wall slab is composed of two surficial thin cement slabs and a foam concrete core layer. It is proportionally made of fast hardening sulphoaluminate cement, powdered coal ash, river sand, fibers, hydrogen peroxide as foaming agent, and stabilizer. Its advantages are light weight, high surface strength and high insulating effect.

Owner:贵州华骏集团节能环保材料有限公司

Iron-type golf clubs

Owner:ACUSHNET CO

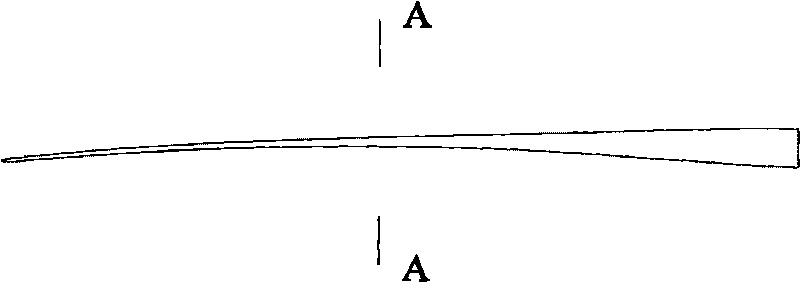

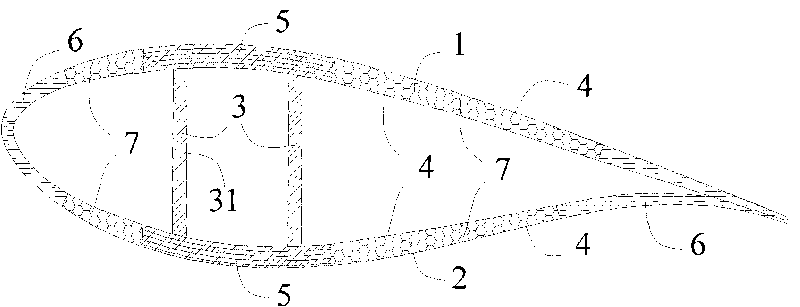

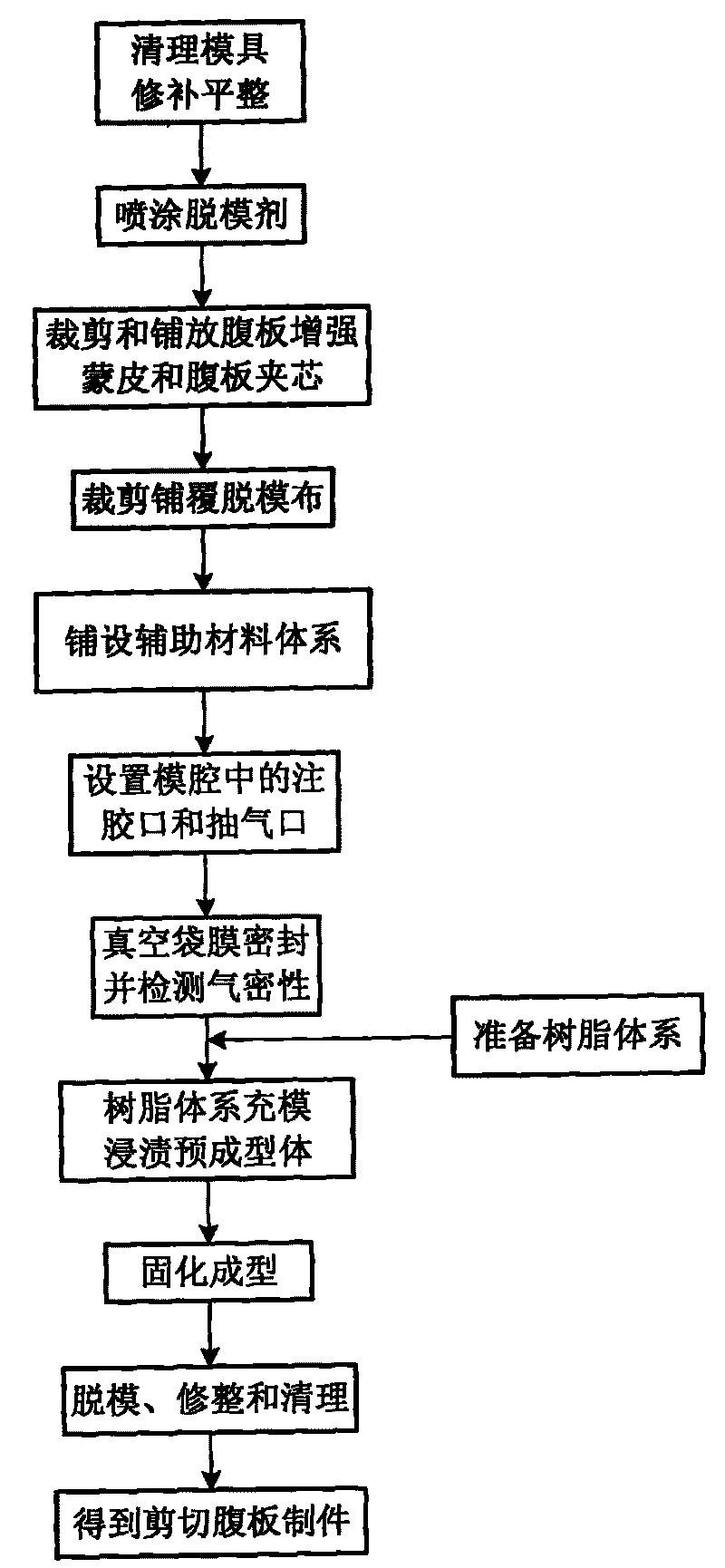

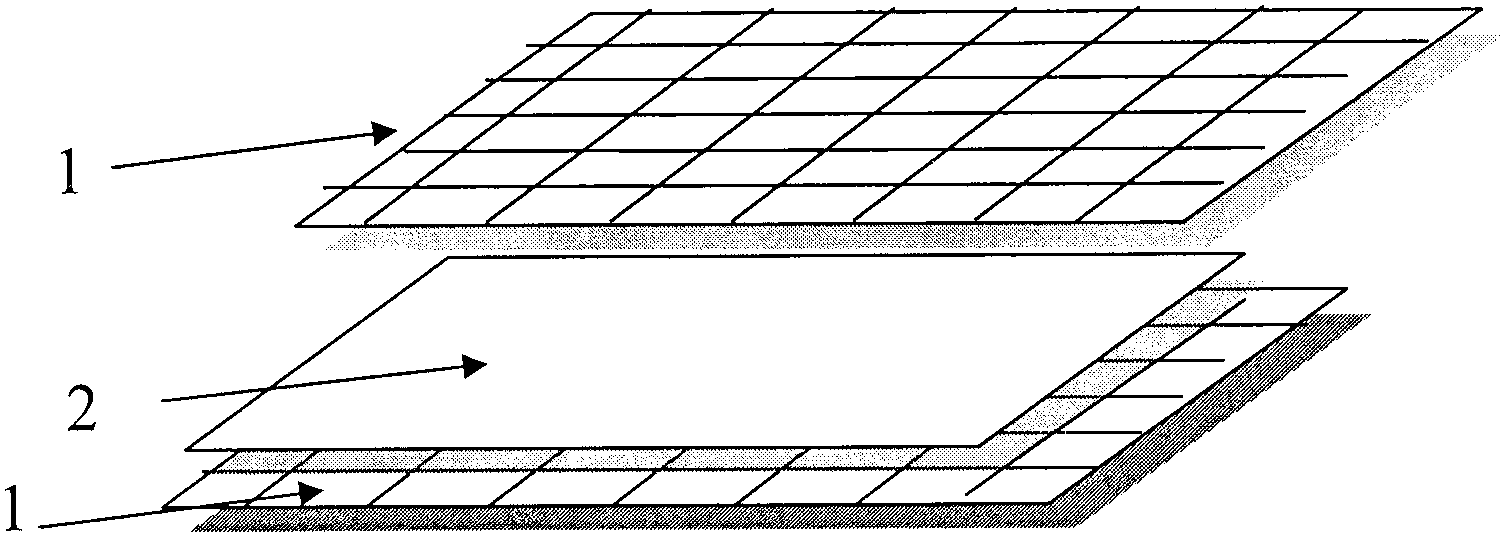

Large-scale composite material wind-power blade and preparation method thereof

ActiveCN101705922ASolve the problem of critical length limitationReduce wasteMachines/enginesWind energy generationElectricityGlass fiber

The invention discloses a large-scale composite material wind-power blade which comprises a suction face shell (1), a pressure face shell (2) and a cutting webplate (3) fixedly connected between the two shells, wherein the suction face shell (1) and the pressure face shell (2) are both sandwich type structural parts of an envelope (4) for covering a core material; the core material comprises a main blade bearing beam (5), a flange reinforcement part (6) of the blade and a filling material (7) arranged between the main blade bearing beam (5) and the reinforcement part (6); and the main blade bearing beam (5) and the reinforcement part (6) both use mixtures of carbon fibers / glass fibers as an reinforcement material. The large-scale composite material wind-power blade has the advantages of light weight, extended critical length, excellent mechanical property, and the like.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

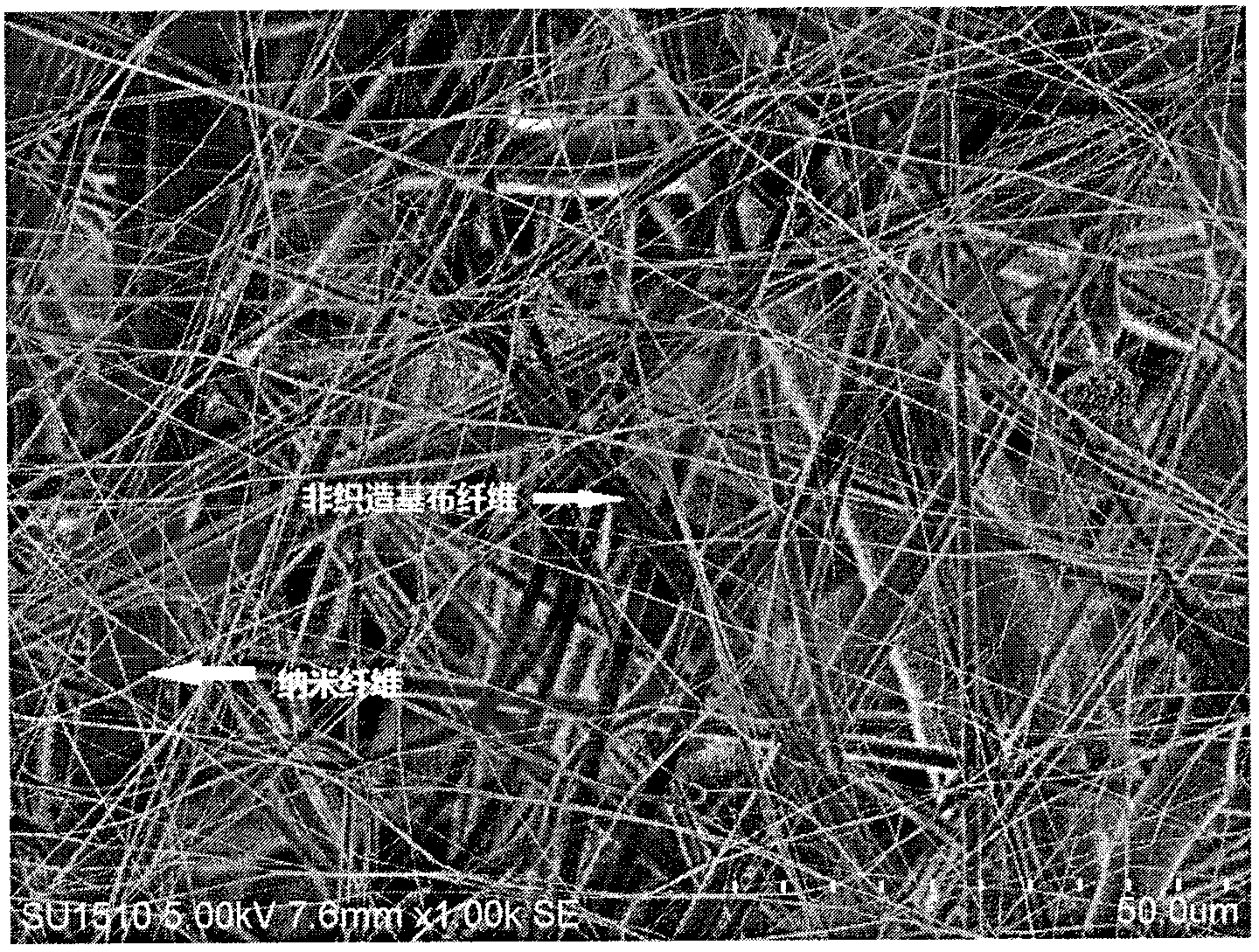

Preparation method of nanofiber sandwich type protective facial mask

InactiveCN102920067AHigh cut-offPromote degradationNon-woven fabricsProtective garmentFiltrationNanofiber

The invention discloses a preparation method of a sandwich type medical protective facial mask and other sandwich type protective facial masks with nanofibers serving as a core layer. The sandwich type protective facial mask is characterized in that a nanofiber film is added in the middle of the conventional protective facial mask which is made of double-layer non-woven fabrics. The preparation method comprises the following steps of: preparing spinning solution in certain mass fraction; transferring the spinning solution into a liquid storing pipe of a spinning device; statically spinning by adopting the common non-woven fabric as an acceptor, so as to obtain the nanofiber film with diameter of 200-600nm; and compositing the obtained nanofiber film with a non-woven material, so as to obtain a sandwich material in a form of 'non-woven fabric-nanofiber film-non-woven fabric'. The preparation method has the advantages that the materials are available and moderate in price; the preparation is quick, simple and convenient; the operation is easy; and the sandwich layer slightly influences the ventilating rate of the material, and plays a remarkable role in the improvement of the bacterial filtration efficiency.

Owner:JIANGNAN UNIV

Iron-type golf clubs

Owner:ACUSHNET CO

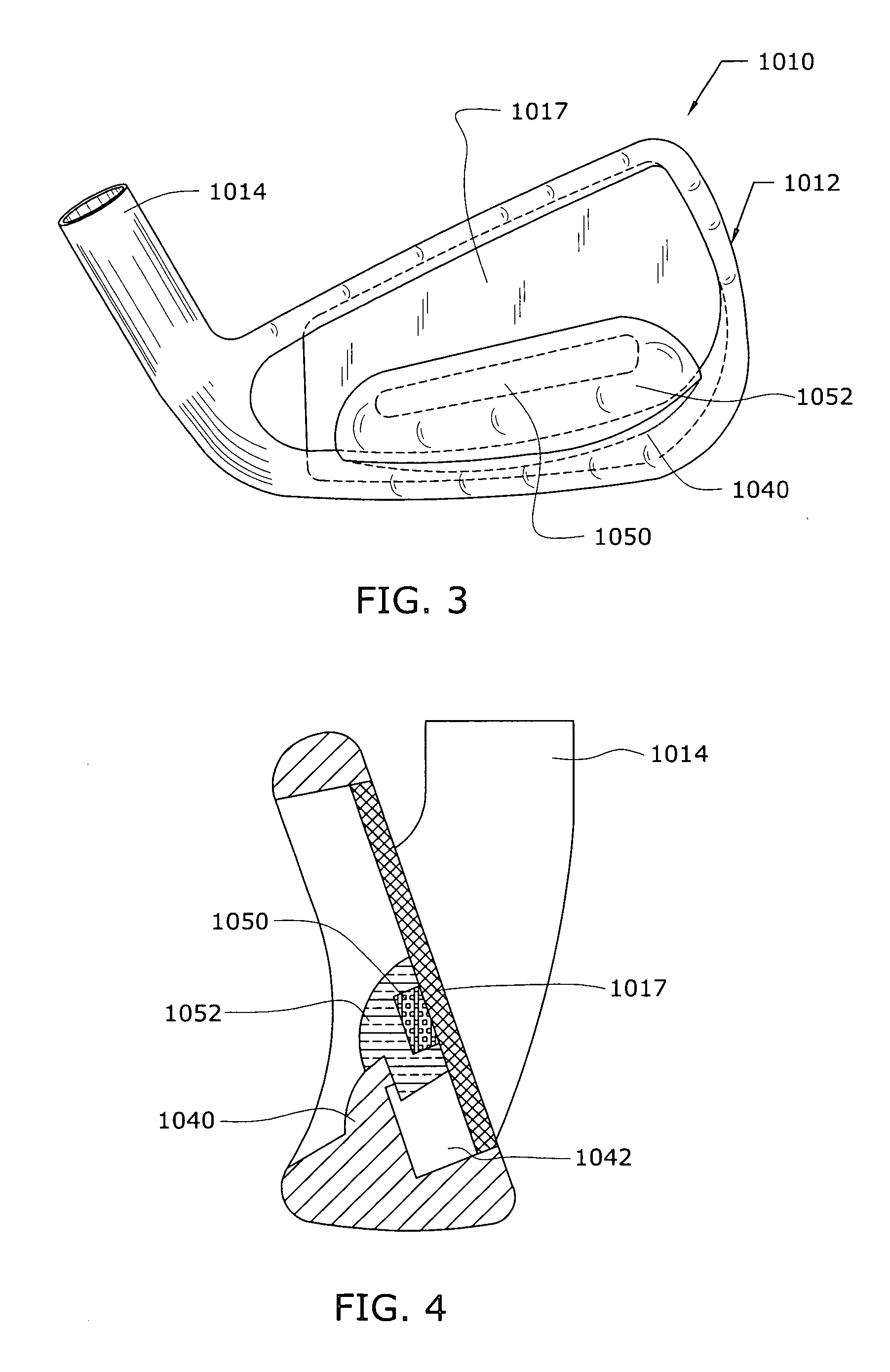

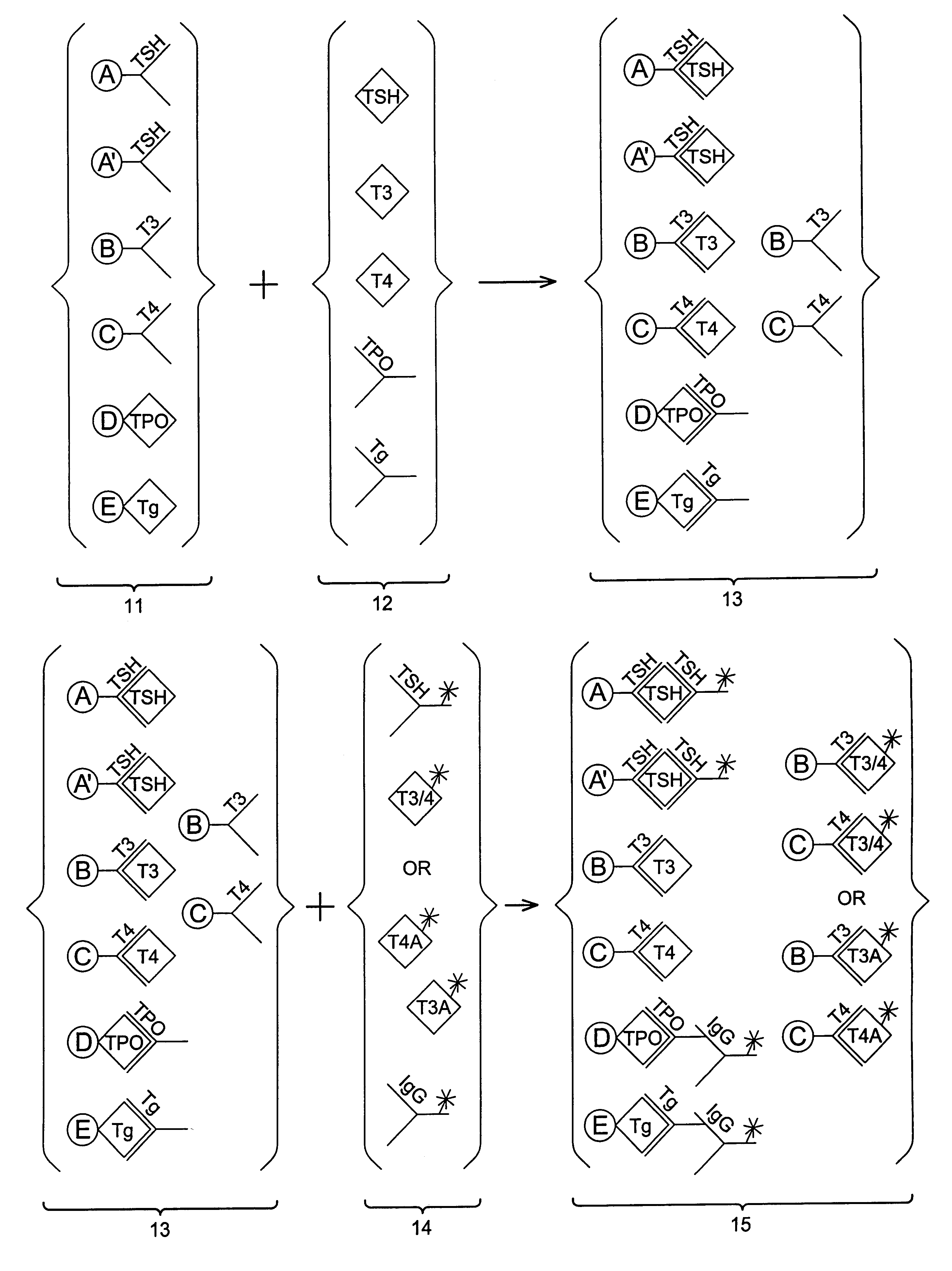

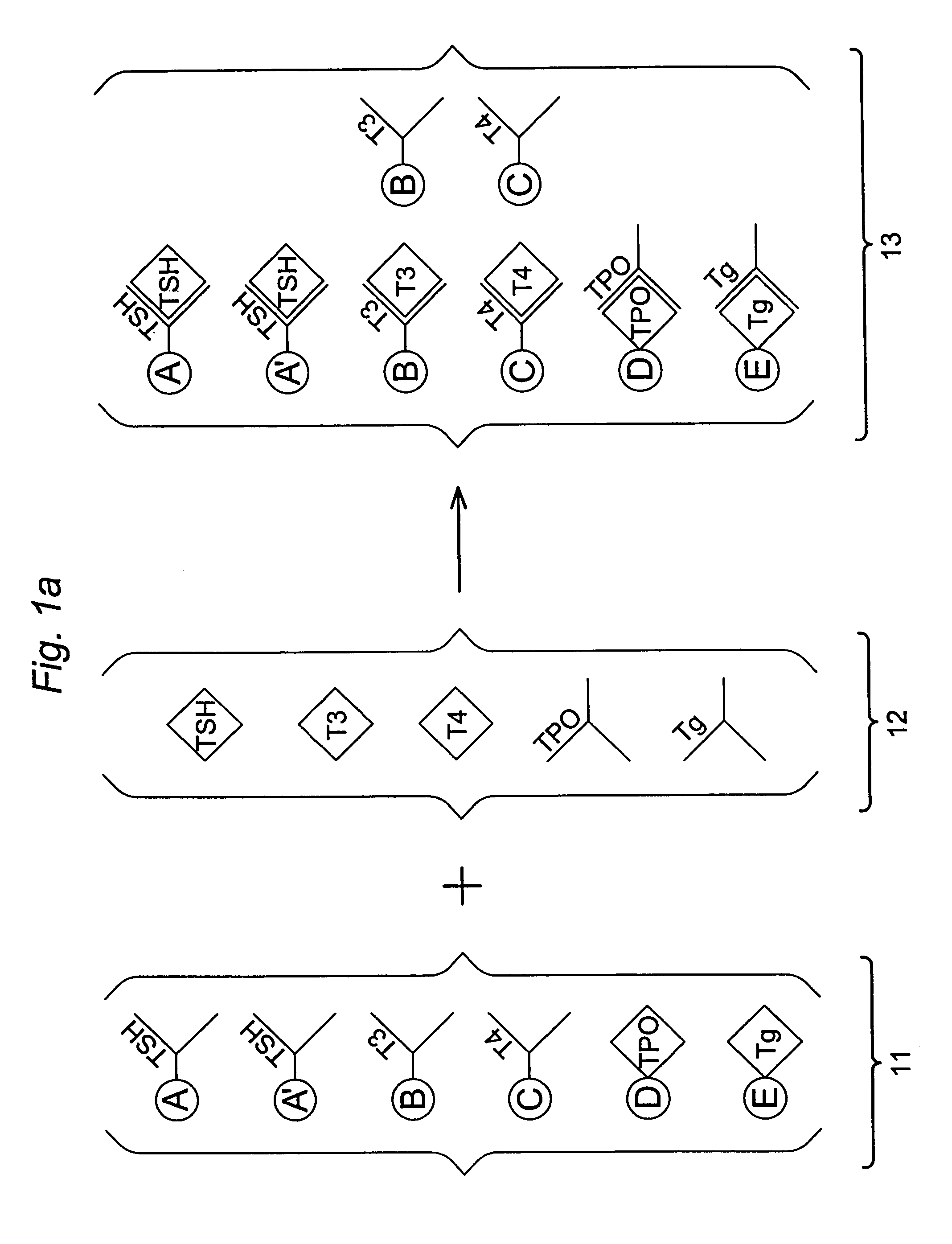

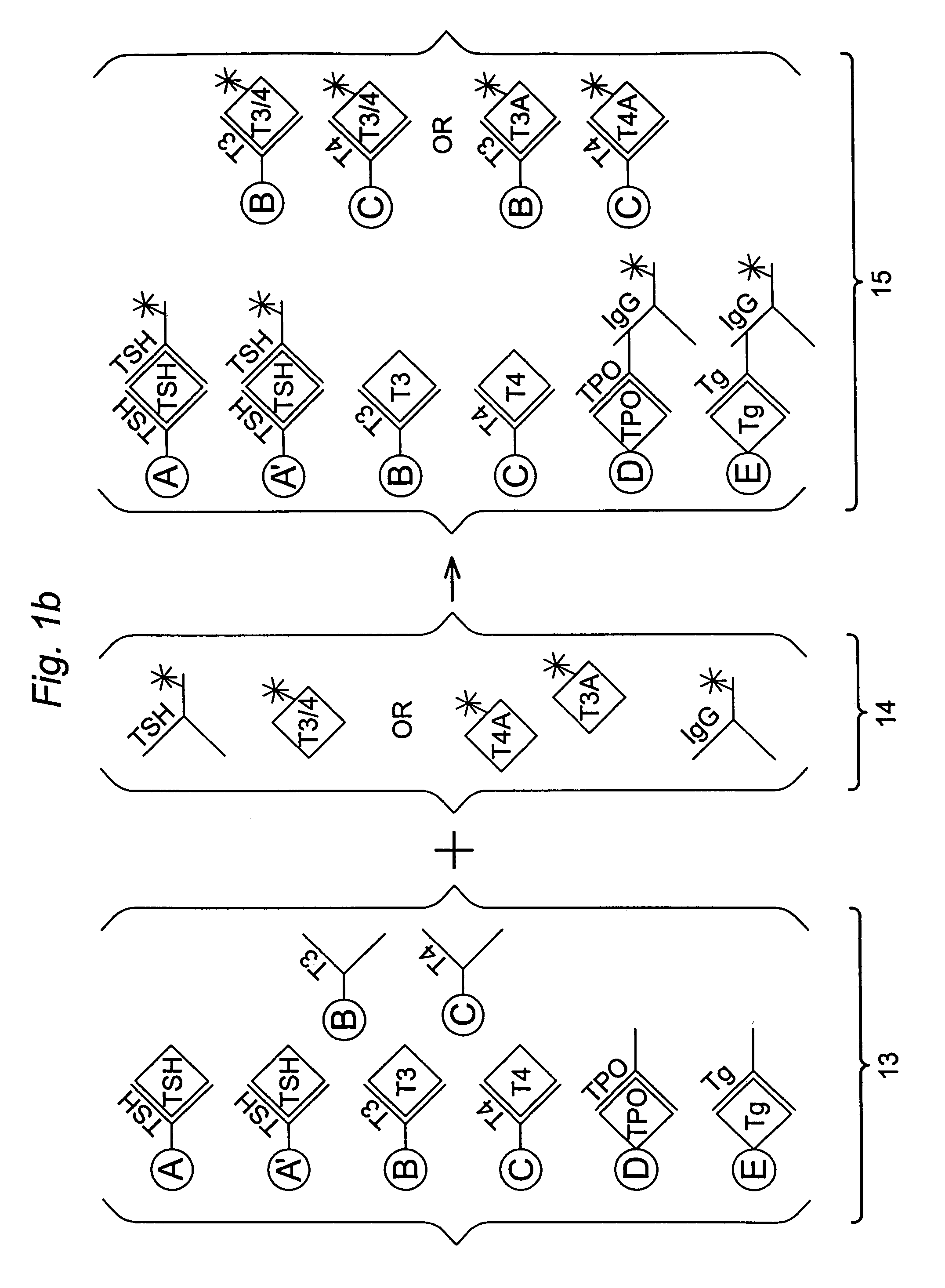

Multi-analyte diagnostic test for thyroid disorders

InactiveUS7271009B1Reduce signalingIncrease ratingsBioreactor/fermenter combinationsBiological substance pretreatmentsDiseaseMulti analyte

Immunological assays for several biological markers for thyroid disorders in a biological sample are performed in a single test with a combination of sandwich-type, sequential competitive, and serological assays by the use of particles classified into groups that are distinguishable by flow cytometry, one group for the assay of each marker. Each group of particles is coated with a different immunological binding member, and coating densities, co-coating materials, and special buffer solutions are used to adjust for differences in the sensitivities and dynamic ranges of each of the markers in the typical sample.

Owner:BIO RAD LAB INC

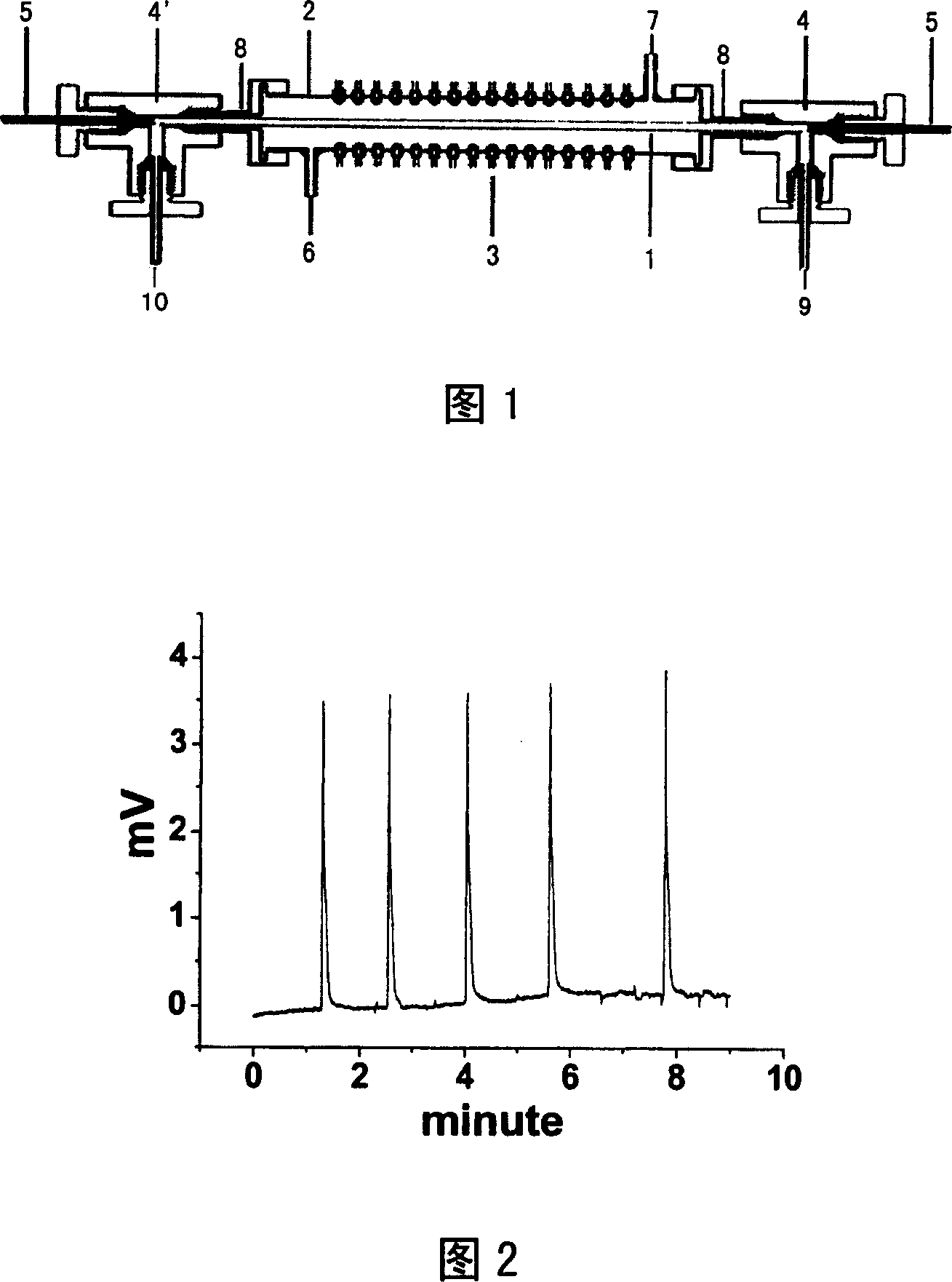

Sandwich liquid core waveguide structure investigating pond

InactiveCN101000299AReduce intensityImprove signal-to-noise ratioMaterial analysis by optical meansLiquid coreTotal internal reflection

The invention relates to sandwich type liquid core wave guide structure detecting pool. It is made up of liquid core optical fiber, circulating pool body, duplex fitting, common optical fiber. The center of the circulating pool body is traversed by one liquid core optical fiber. Its two sides are set liquid inlet and outlet. Its pool wall is set light source hole. And its two ends are respectively connected with one duplex fitting. One of them has circulating pool inlet. And another has outlet to connect with outer separating and analyzing system. The refraction index of the injected liquid is more than 1.31 of the liquid core wave guide to form thick-thin-thick sandwich type structure in the circulating pool that means forming a layer of liquid wall structure with full internal reflection ability at the outer side of the liquid core optical fiber which can prevent side emitting light from entering its inner to reduce scattered light strength, increase detecting signal to noise ratio.

Owner:INST OF CHEM CHINESE ACAD OF SCI

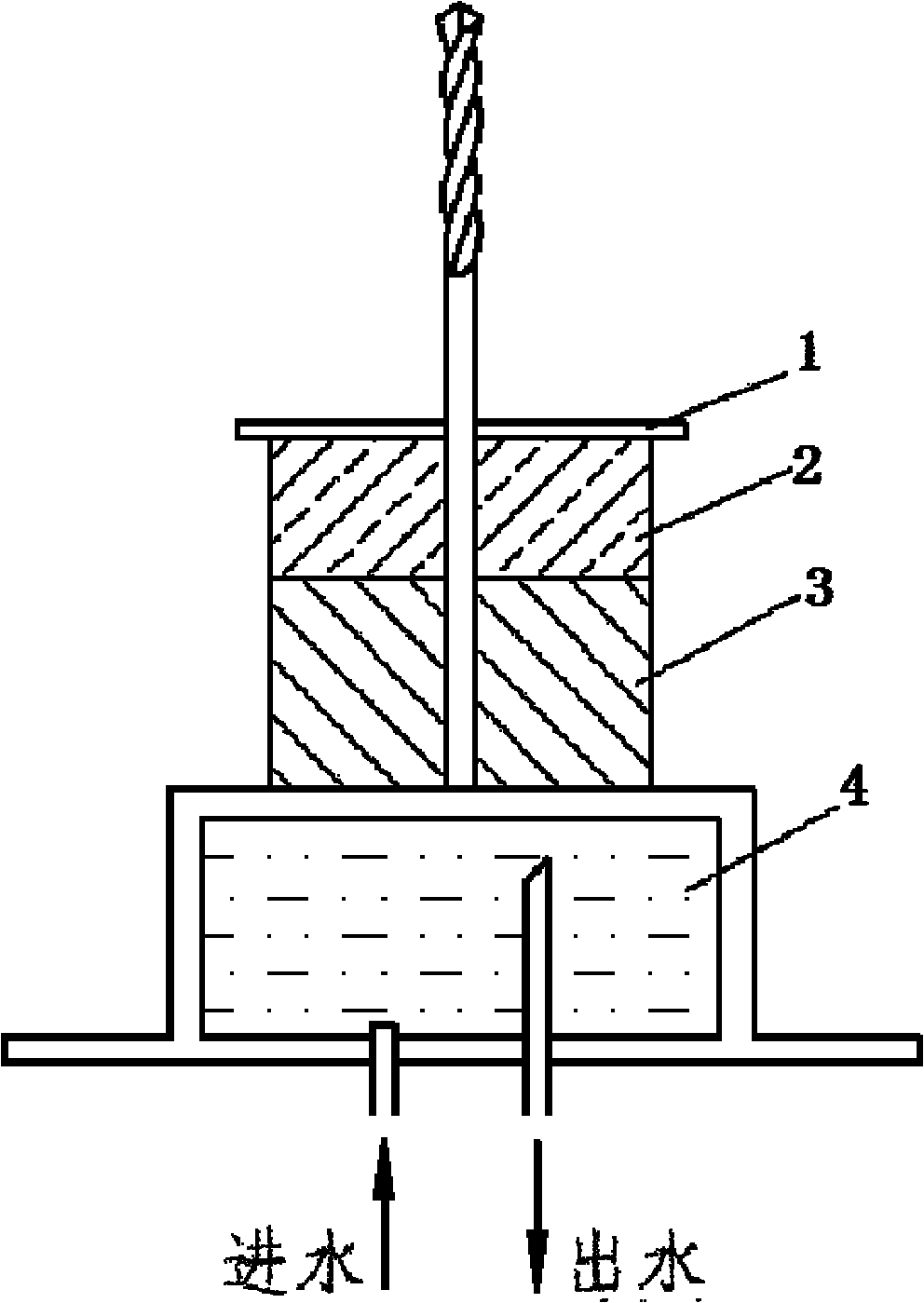

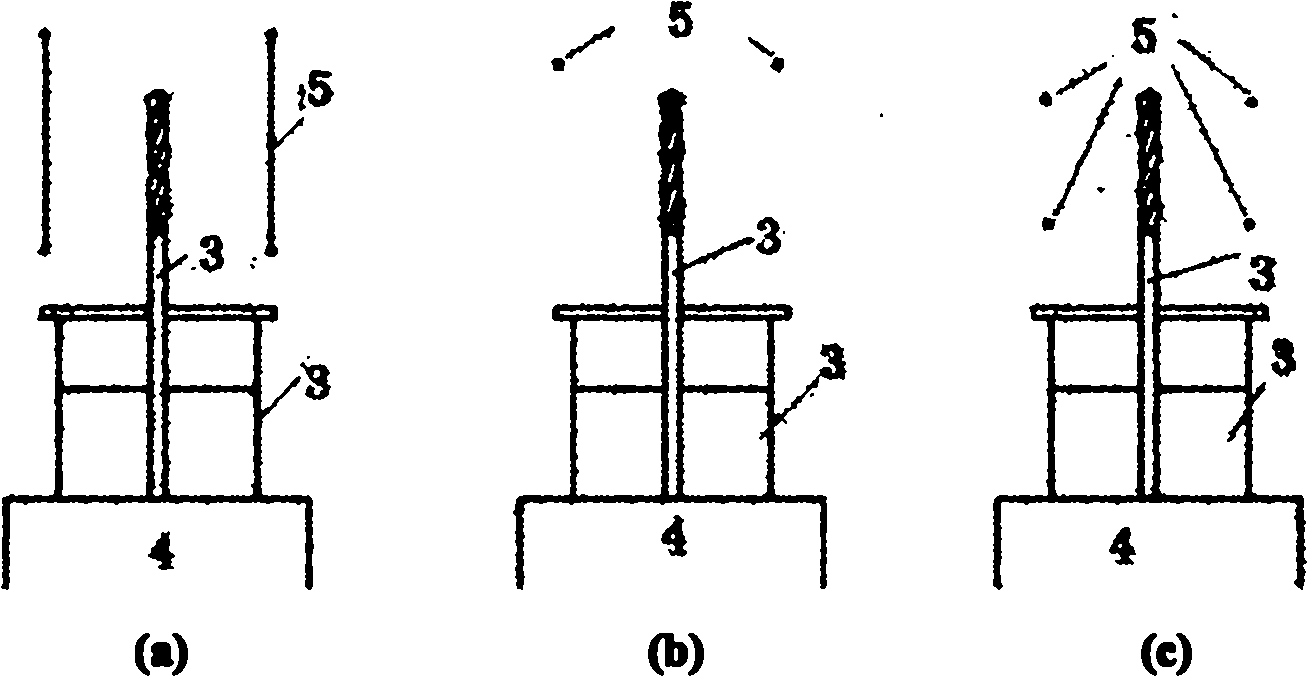

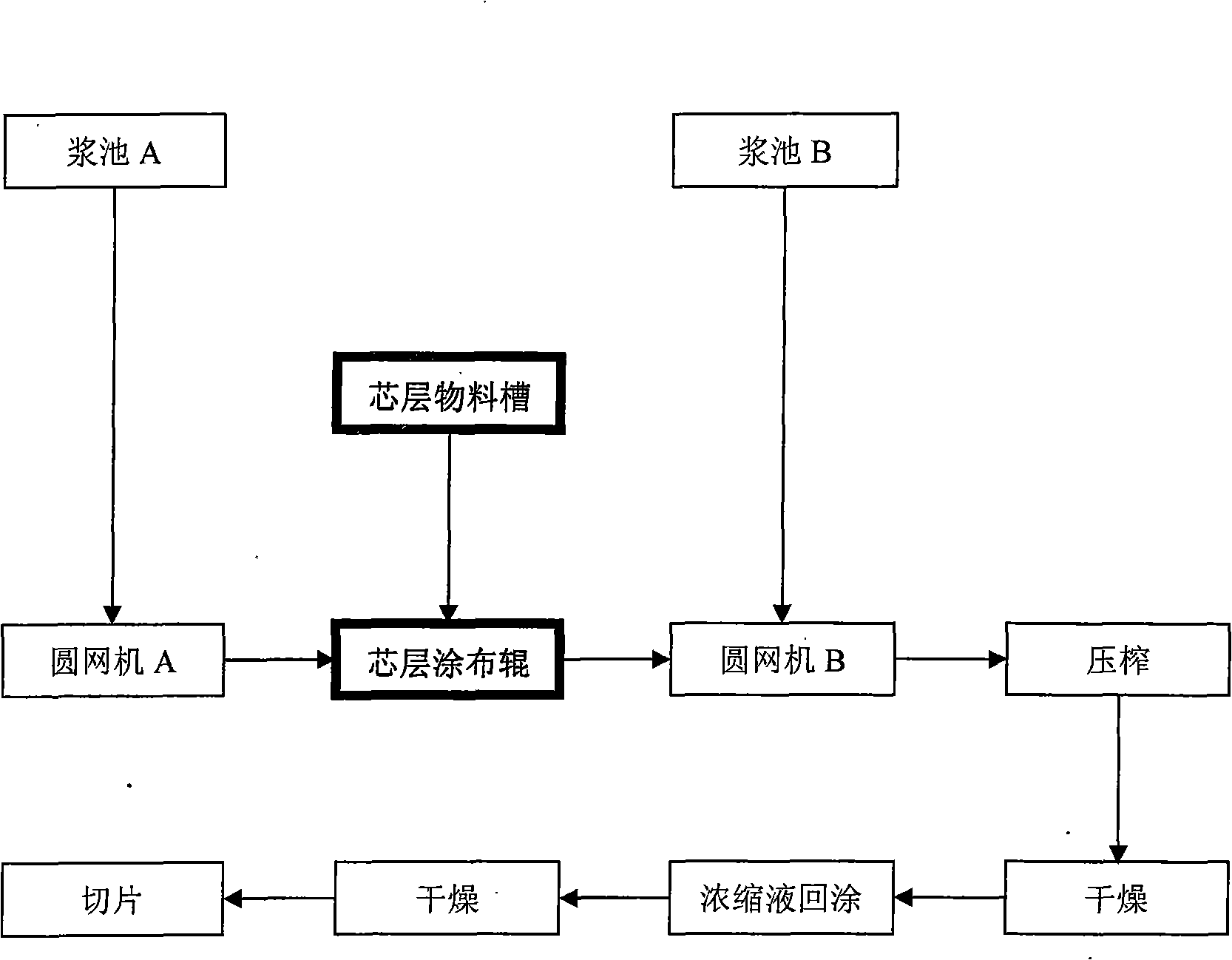

Hot-filament chemical vapor deposition batch preparation method of complicated-shape diamond coated cutting tool

The invention discloses a hot-filament chemical vapor deposition batch preparation method of a complicated-shape diamond coated cutting tool in the technical field of mechanical machining, comprising the steps of: placing a sandwich type foundation on which the cutting tool is arranged on a CVD (Chemical Vapor Deposition) equipment water-cooling worktable through inserting a cutting tool holder of a pretreated complicated-shape hard alloy cutting tool; adopting two lines of hot filaments, wherein the upper line of hot filaments is as high as the nose of the hard alloy cutting tool and the lower line of hot filaments is as high as the bottom of the cutting edge of the cutting tool; and filling hydrogen and acetone and depositing a diamond coating on the surface of the complicated-shape hard alloy cutting tool. According to the the invention, the surface temperature of an underlayer at the cutting edge can be effectively reduced, the rate of the deposition is not decreased and the quality of the diamond coating is improved.

Owner:SHANGHAI JIAO TONG UNIV +1

Preparation method of high-throughput and multilayer sandwich type composite nano-filtration membrane

InactiveCN106390748AHigh retention rateSolve the small gapSemi-permeable membranesMembranesFiltration membraneCationic polyelectrolytes

The invention discloses a preparation method of a high-throughput and multilayer sandwich type composite nano-filtration membrane. The preparation method includes: performing surface modification on an ultrafiltration basement membrane and (zero-dimensional or one-dimensional and two-dimensional) nano materials to allow the ultrafiltration basement membrane and the nano materials to be electronegative, and using cationic polyelectrolyte as the bridge to alternatively assemble the one-dimensional or zero-dimensional nano materials and two-dimensional sheet layers onto the ultrafiltration basement membrane to obtain the high-throughput composite nano-filtration membrane with a functional layer being two-dimensional nano materials sandwiched with one-dimensional or zero-dimensional nano materials. The preparation method has the advantages that the difficulty that the interlayer spacing of a two-dimensional nano layered membrane is small and the two-dimensional nano layered membrane is easy to deform during high-pressure filtration is solved effectively by the prepared functional layer, membrane throughput can be increased evidently, and the long-term stability of the membrane structure can be kept at the same time; the preparation method is simple in preparation process, and the prepared nano-filtration membrane is high in throughput and promising in application prospect in fields such as dye removing.

Owner:TIANJIN POLYTECHNIC UNIV

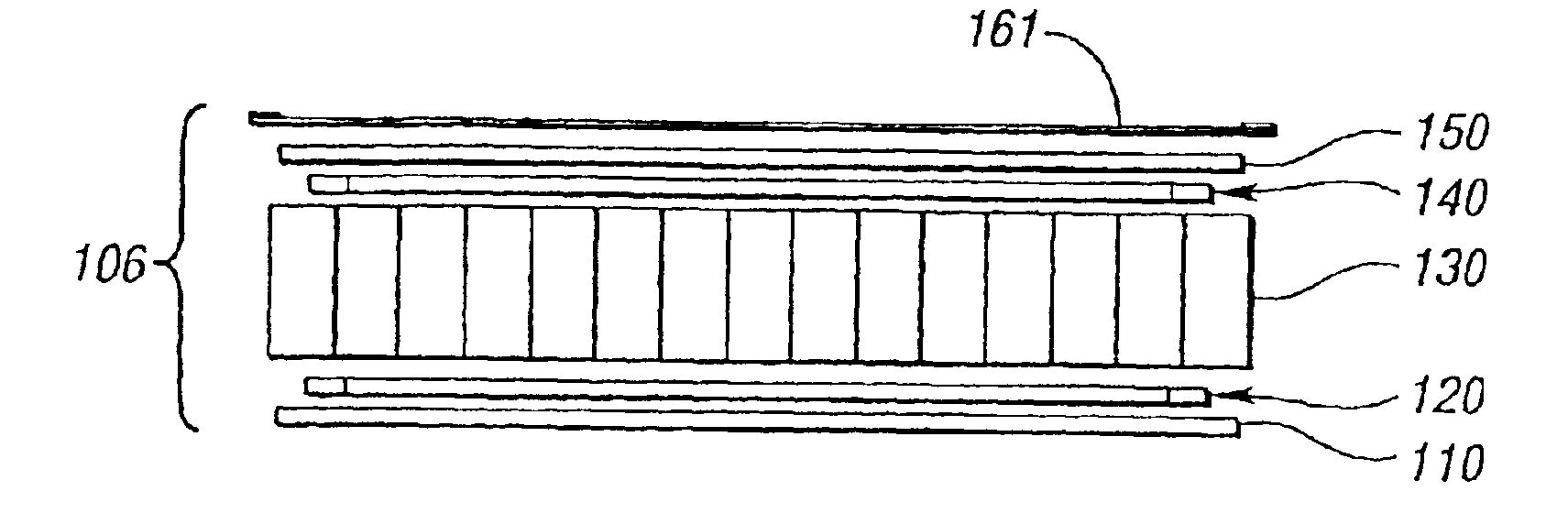

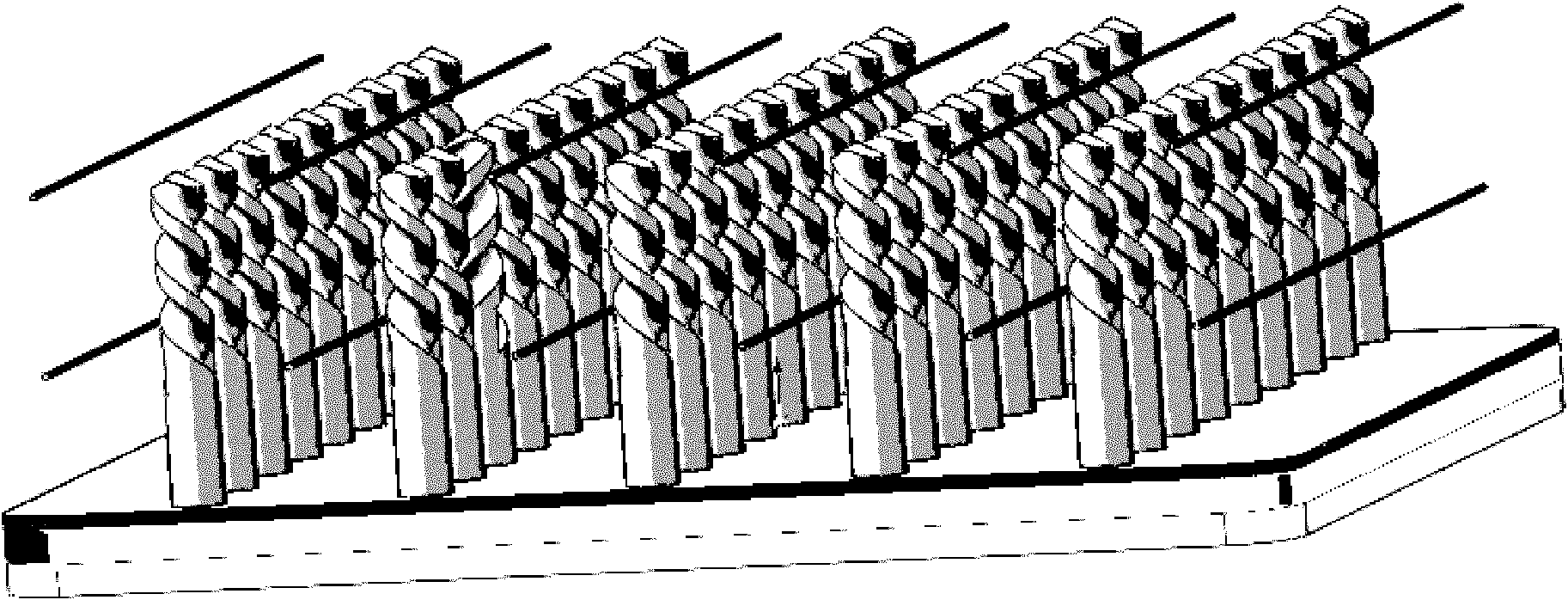

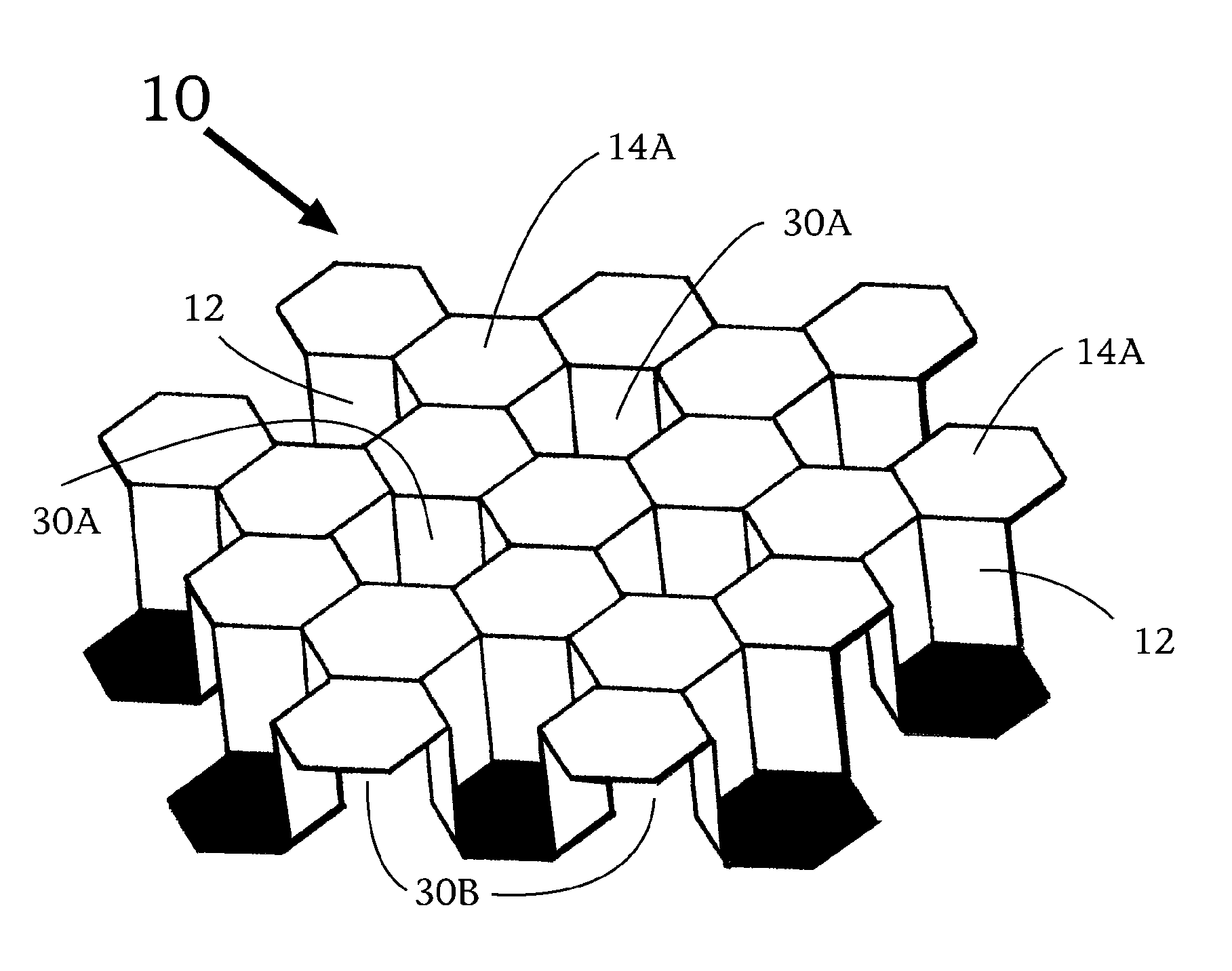

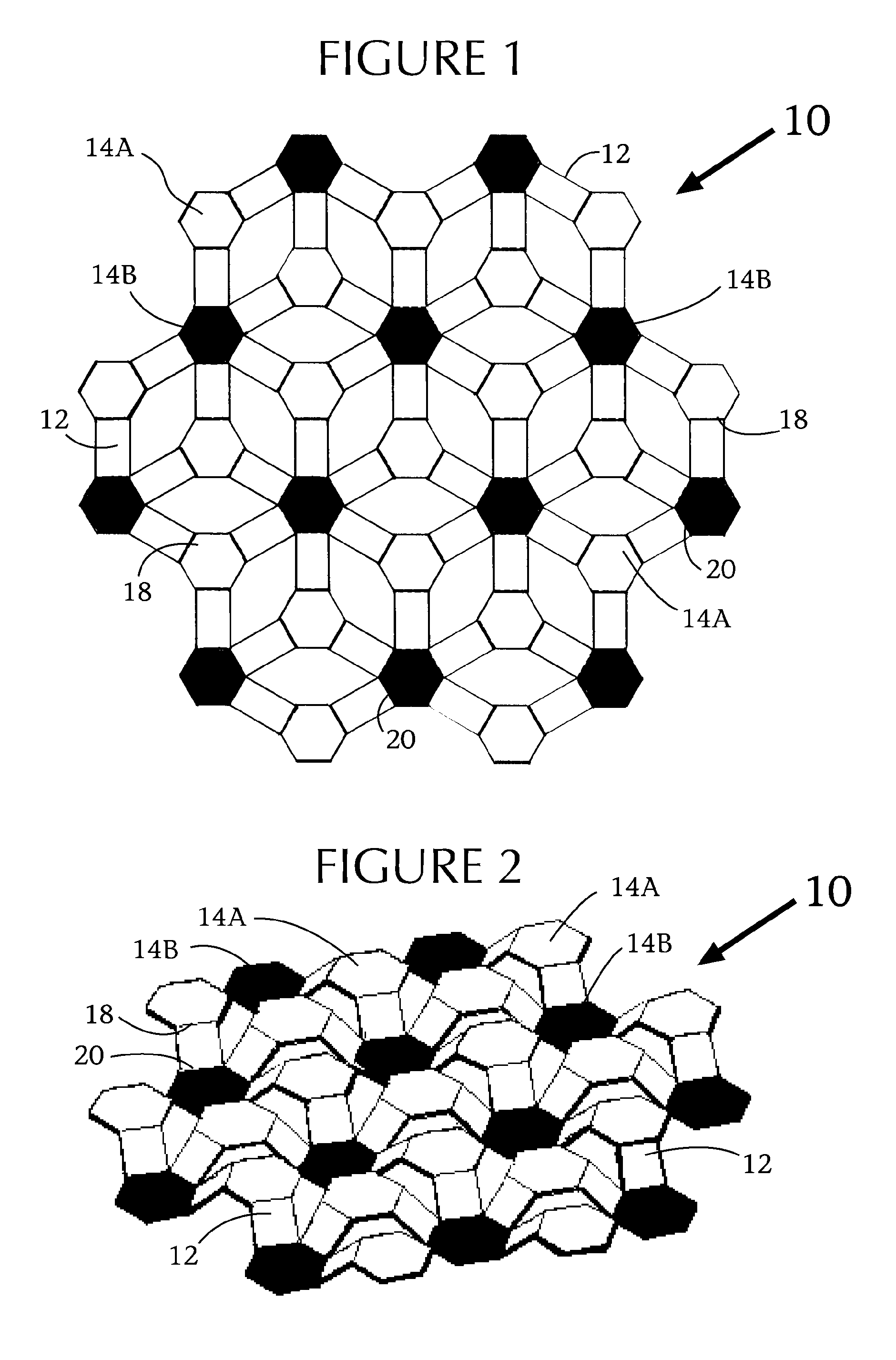

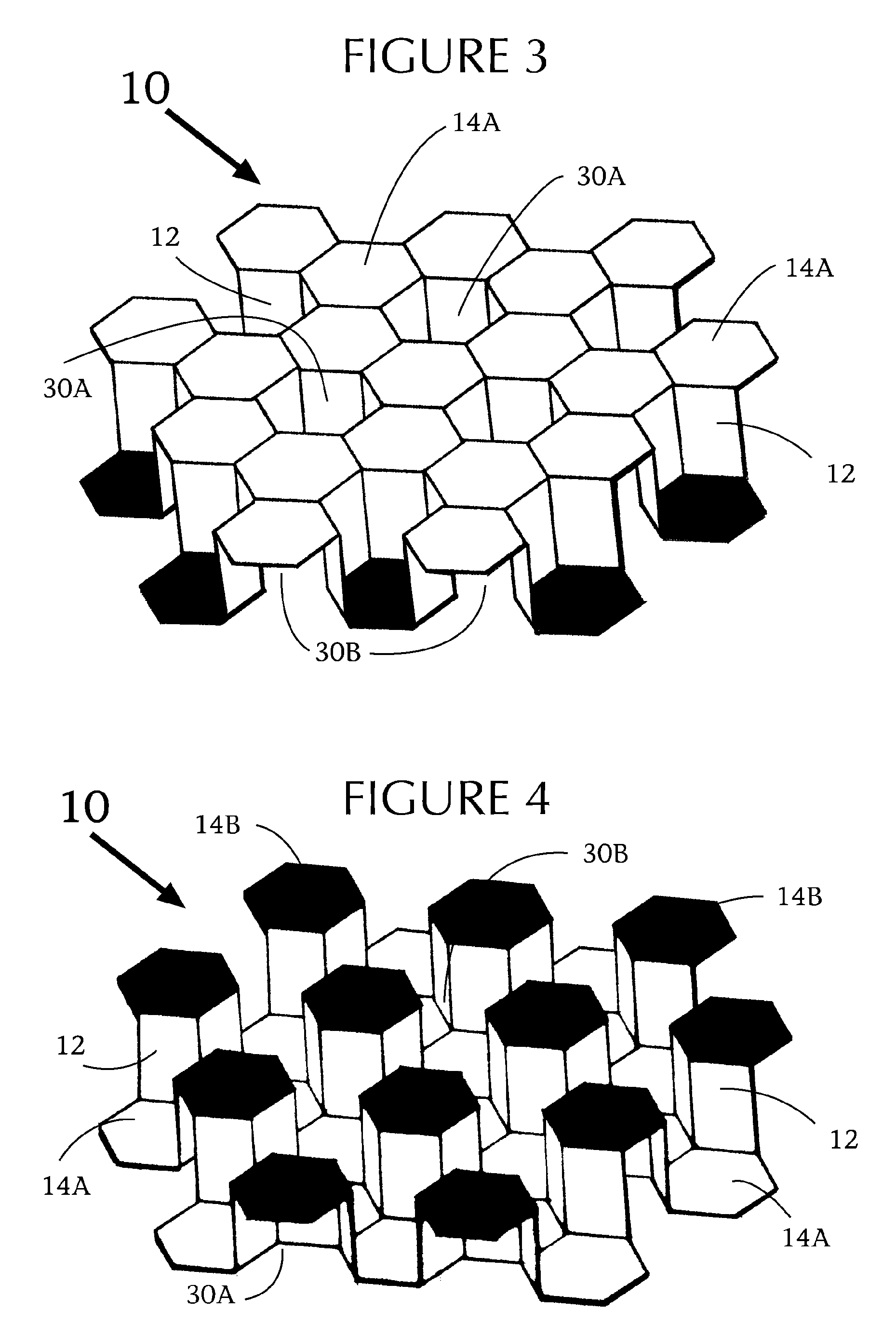

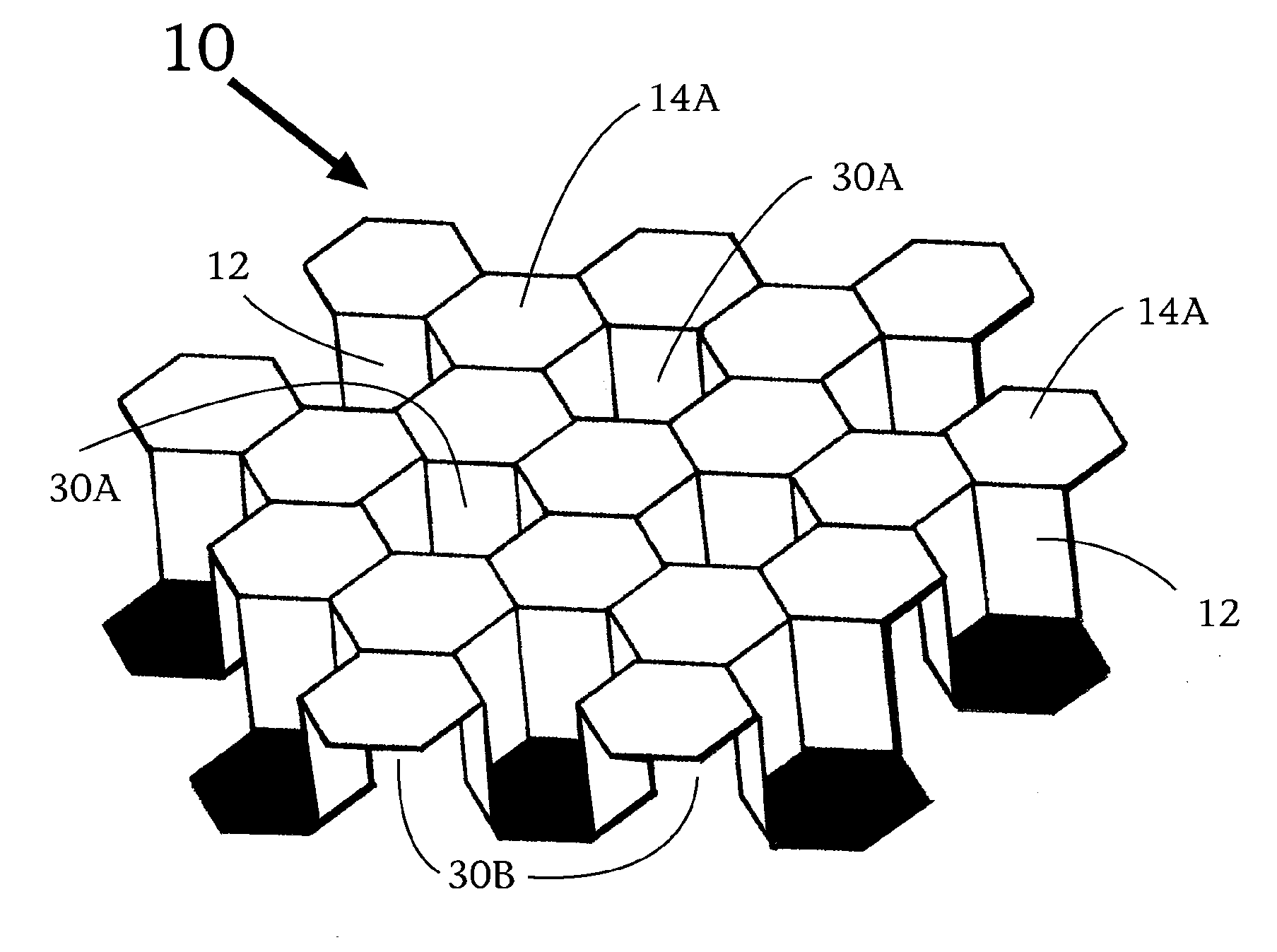

Flexible construction element with large bonding surface area and method of manufacture

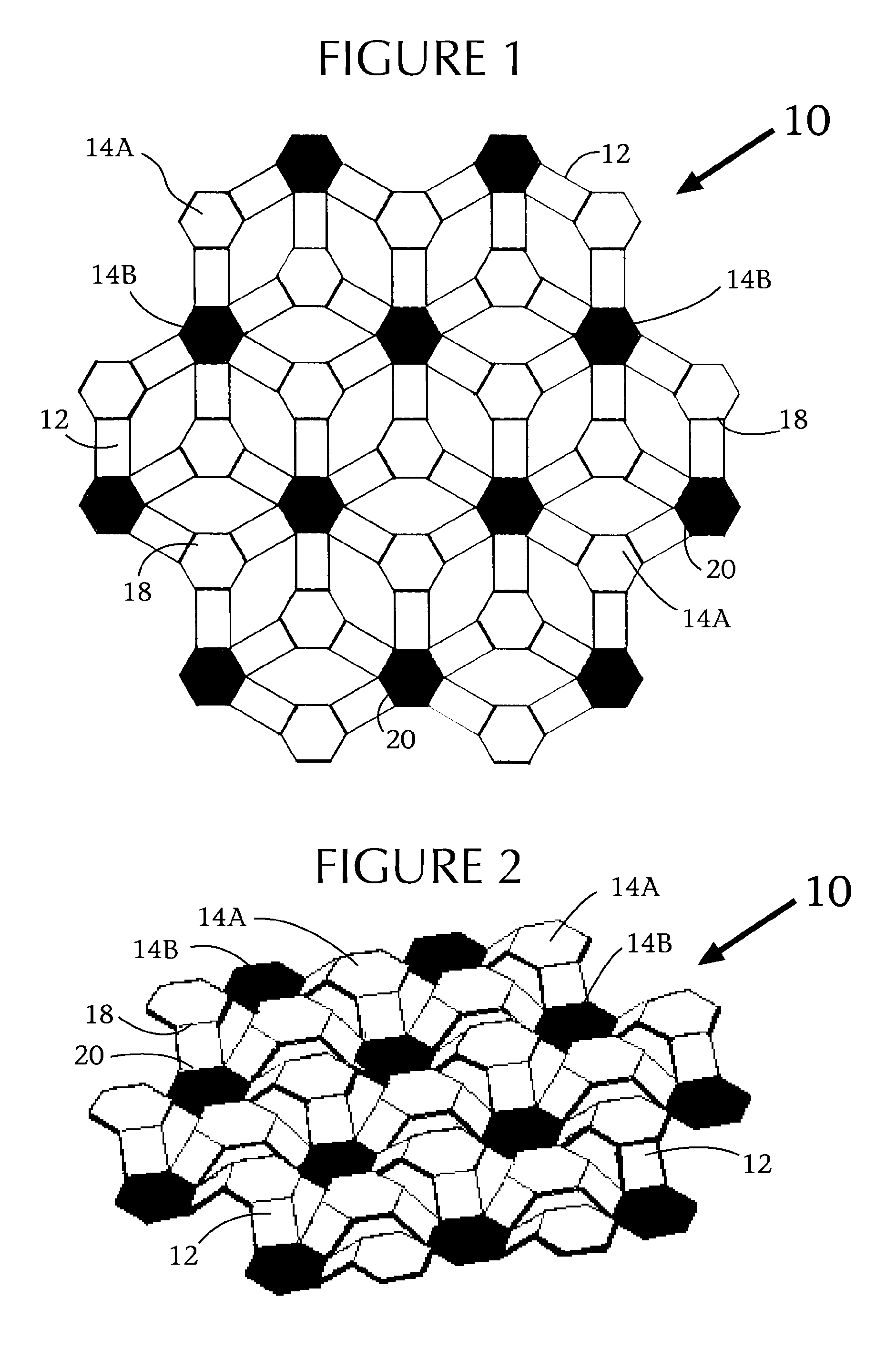

ActiveUS7541085B2Increase the areaIncreased shear strengthPaper/cardboard articlesLaminationHexagonal cellGeometric design

A flexible core element having a large bonding surface area suitable for sandwich type construction comprising a plurality of first hexagonal nodes defining a first surface, a plurality of second hexagonal nodes defining a second surface spaced apart from and parallel to the first surface, and a plurality of rectangular wall members which interconnect said first hexagonal nodes to said second hexagonal nodes and define the depth of the core element. Each hexagonal node corresponds to an open hexagonal cell on its obverse surface and serves as a bonding surface. The core element is fabricated from a continuous sheet of material that has been die-cut with a repeating geometrical design, creased and folded, concertina style, in upon itself to make a double-sided core material that is flexible, able to vent, exhibits good bend and shear strength, and has a large surface bonding area rendering it suitable in the construction of lightweight sandwich panels and offering a wide array of other applications.

Owner:BURDON ROBERT L J

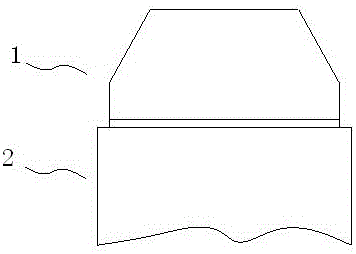

Sandwich type frame saw tool bit and manufacturing method thereof

ActiveCN106182448AImprove wear resistanceHigh sharpnessStone-like material working toolsGranularityHardness

The invention provides a sandwich type frame saw tool bit and a manufacturing method thereof. The tool bit can keep good cutting performance all the time in the use process, and therefore the machining quality and the service life are ensured. The sandwich type frame saw tool bit is provided with a cutting part which is made of diamond powder and functional metal powder. The cutting part comprises at least two work layers, a transition layer is arranged between every two adjacent work layers, and the two sides of the sandwich type frame saw tool bit are the corresponding work layers. The granularity of the diamond powder in the work layers is smaller than that of the diamond powder in the transition layers; the concentration of the diamond powder in the work layers is larger than that of the diamond powder in the transition layers; and the hardness of alloy matrixes in the work layers is larger than that of alloy matrixes in the transition layers. By means of the manufacturing method for the tool bit, the components and the shapes of the work layers and the transition layers can be accurately controlled, and therefore sharpness of the tool bit is maintained all the time in the use process, the guidance property of the tool bit is improved, the cutting quality is improved, and the service life of the tool bit is prolonged.

Owner:GUANGZHOU CRYSTAL TECH

Flexible construction element with large bonding surface area and method of manufacture

ActiveUS20070015000A1Large surface bonding areaEasy to bendPaper/cardboard articlesLaminationHexagonal cellGeometric design

A flexible core element having a large bonding surface area suitable for sandwich type construction comprising a plurality of first hexagonal nodes defining a first surface, a plurality of second hexagonal nodes defining a second surface spaced apart from and parallel to the first surface, and a plurality of rectangular wall members which interconnect said first hexagonal nodes to said second hexagonal nodes and define the depth of the core element. Each hexagonal node corresponds to an open hexagonal cell on its obverse surface and serves as a bonding surface. The core element is fabricated from a continuous sheet of material that has been die-cut with a repeating geometrical design, creased and folded, concertina style, in upon itself to make a double-sided core material that is flexible, able to vent, exhibits good bend and shear strength, and has a large surface bonding area rendering it suitable in the construction of lightweight sandwich panels and offering a wide array of other applications.

Owner:BURDON ROBERT L J

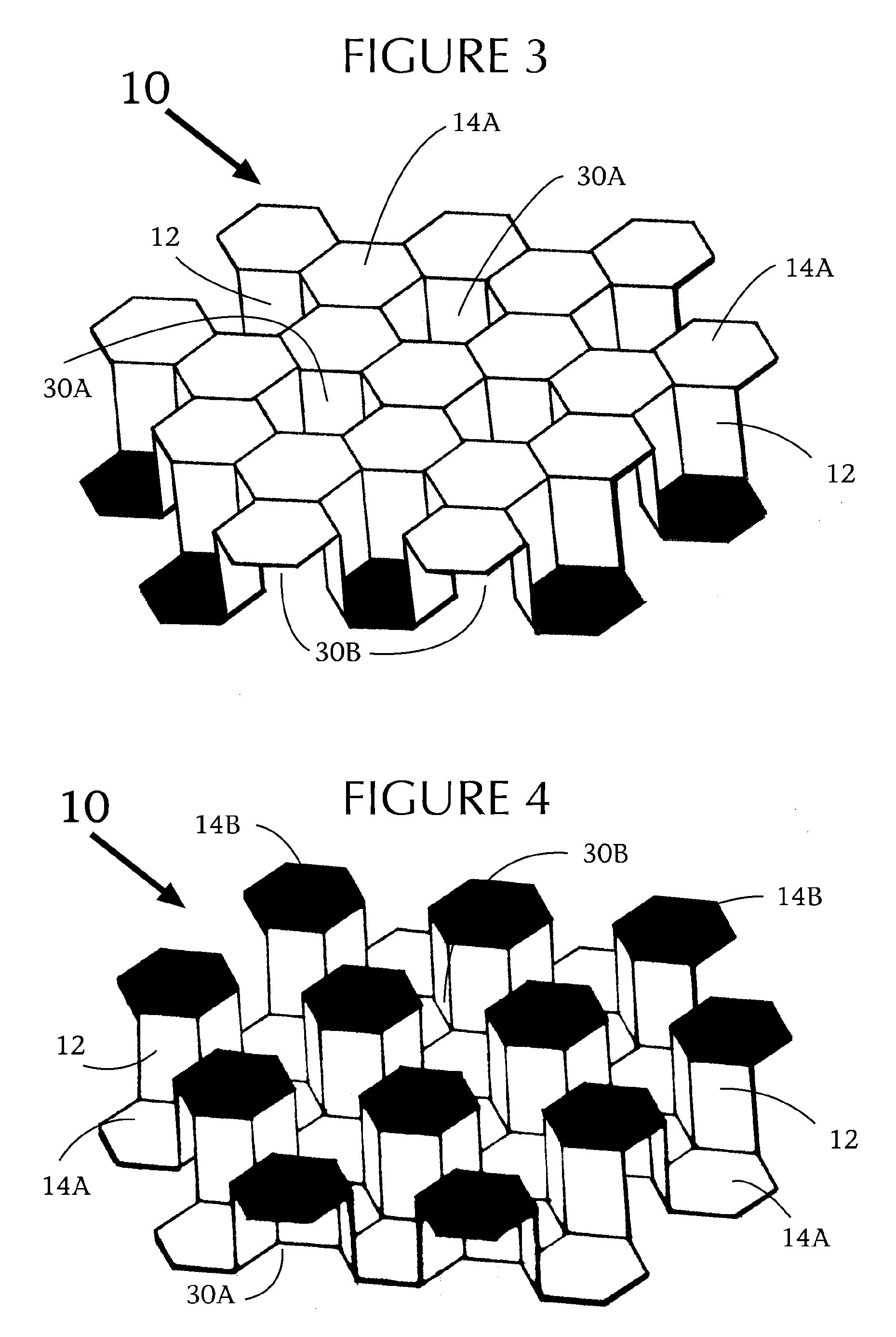

Production method of sandwich type paper-making method reconstructed tobacco leaf

ActiveCN101491369AGuaranteed uniformityGuaranteed stabilityTobacco preparationNon-woody plant/crop pulpFiberFilm base

The invention discloses a method for producing reconstituted tobacco by a sandwich type paper making method. The method comprises the following steps that: tobacco raw materials and non-tobacco fiber materials are subjected to soaking extraction by clean water, the soluble matter is prepared into a concentrated solution for standby, the insoluble matter is pulped, and the upper layer of the insoluble matter is paper-made by a cylinder paper machine; tobacco powder is mixed with clean water, a binder and an additive for tobacco and evenly stirred to prepare a sandwich layer coating material; by adopting a roller coating mode, the coating material is evenly coated on the surface of the upper layer to form a sandwich layer; the lower layer is paper-made on the surface of the sandwich layer and pressed to form a film base; and the concentrated solution is coated back on the film base, and subjected to drying and parting cut to prepare the finished product. The method has the advantages of effectively ensuring the even and stable distribution of the middle sandwich layer, improving the utilization rate of the tobacco raw materials and having active actions on the energy conservation and emission reduction in the production of the reconstituted tobacco, along with simple method, low cost and complete utilization of the raw materials.

Owner:CHINA TOBACCO YUNNAN REMFG TOBACCO CO LTD +1

High-efficiency diamond bit and production process thereof

ActiveCN102528942ANot easy to fall offImprove performanceStone-like material working toolsWear resistantHardness

A high-efficiency diamond bit comprises a base and a tool bit fixedly disposed on the base. The tool bit consists of an inner sharp blank, an outer sharp blank and a wear-resistant hard blank sandwiched between the inner sharp blank and the outer sharp blank, and diamond particles and pre-alloyed powder are sintered after being mixed to form each of the inner sharp blank, the outer sharp blank and the wear-resistant hard blank. The tool bit is a sandwich type structure, namely, the wear-resistant hard blank is sandwiched between the inner sharp blank and the outer sharp blank, and excellent sharpness of the top of the tool bit is improved. In addition, when the tool bit grinds, the hardness of the inner sharp blank and the hardness of the outer sharp blank are lower than the hardness of the wear-resistant hard blank, accordingly, a triangular pointed edge can be constantly formed on the top of the tool bit, an excellent self-sharpening performance and excellent sharpness of the cutting head are constantly kept, and cutting force is high.

Owner:福建省泉州万龙石业有限公司

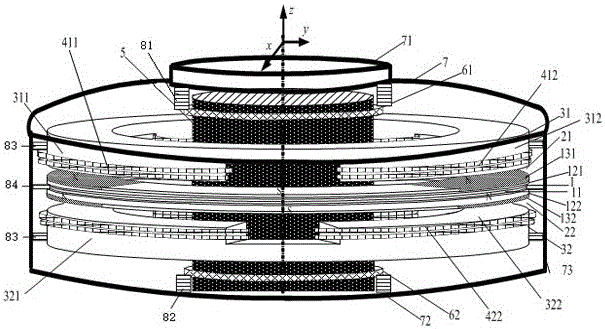

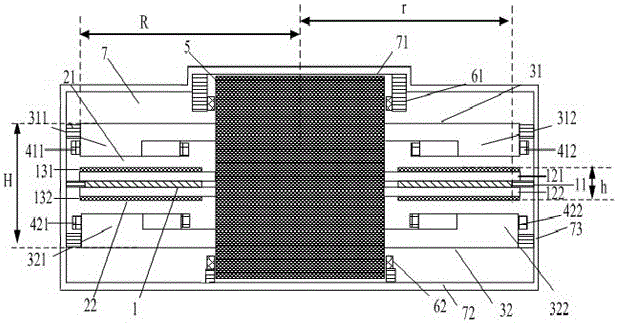

Magnetic suspension flywheel battery for sandwich-type electric car and work method thereof

ActiveCN106655605AStrong gyro effectSuppress gyro effectElectric machinesMechanical energy handlingMagnetic bearingElectric cars

The present invention discloses a magnetic suspension flywheel battery for a sandwich-type electric car and a work method thereof. A vertical rotation shaft is arranged at the center of the internal portion of a vacuum chamber, a disc-type flywheel motor is coaxially arranged at the center of the axial direction of the vertical rotation shaft, disc-type magnetic bearings having the same structure, being arranged at the axial direction in the longitudinal symmetry mode relative to the disc-type flywheel motor and being sleeved at the outer portion of the vertical rotation shaft are coaxially arranged at the upper portion and the lower portion of the disc-type flywheel motor, and each disc-type magnetic bearing is wound with a set of radial control coils; the disc-type flywheel motor is composed of a stator, two rotors and two sets of permanent magnets, the stator is located at the center of the disc-type flywheel motor and coaxially arranged at the outer portion of the vertical rotation shaft, and the two rotors are respectively and symmetrically arranged at upper and lower sides of the stator and coaxially and fixedly sleeved on the vertical rotation shaft; and the two sets of the permanent magnets are respectively pasted on the surfaces, back to the stator, of the two rotors along the peripheral directions, the whole structure of the flywheel battery is a disc-type structure, the disc-type magnetic bearings and the disc-type flywheel motor are both the flat structures to inhibit the gyroscopic effect of the rotors.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com