Sandwich liquid core waveguide structure investigating pond

A liquid core waveguide and structure detection technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., to achieve the effect of improving signal-to-noise ratio and reducing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

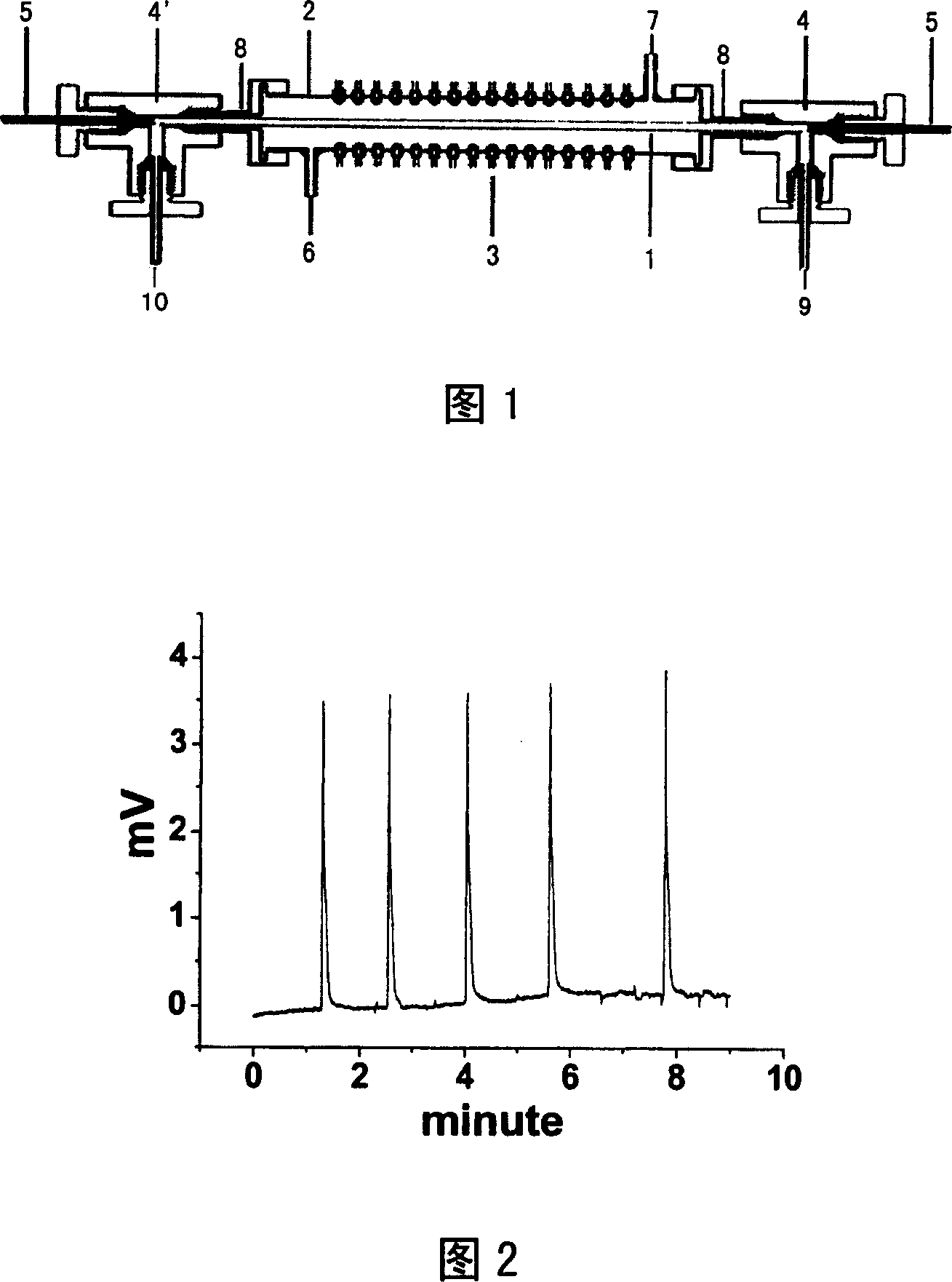

[0034] The sandwich-type liquid core waveguide structure detection cell shown in Figure 1 is mainly composed of liquid core optical fiber, flow cell body, tee joint, ordinary optical fiber and other parts.

[0035] The liquid-core optical fiber 1 is a Teflon AF2400 capillary tube with an outer diameter of 792 μm, an inner diameter of 193 μm, and a length of 18 cm, and is installed in the center of the flow cell body 2; the flow cell body 2 is a stainless steel tube with an outer diameter of 30 mm, an inner diameter of 27 mm, and a length of 160 mm. There are five rows of light source holes in the axial direction, 20 in each row, 100 in total, and each light source hole is equipped with a light-emitting diode 3 with a center wavelength of 470nm; the light-emitting diodes in each row are connected in parallel and powered by a DC stabilized power supply. The voltage is 3.2V, and the working current is 20mA-30mA; the five columns of light-emitting diodes can be controlled separatel...

Embodiment 2

[0039] Use the device shown in embodiment 1, start HPLC infusion system, take fluorescein as sample, methanol is solvent, is made into 10 -6 -10 -9 mol / L fluorescein solution, inject the fluorescein solution into the HPLC system through the injection valve, and detect with the instrument and device described in Example 1, with an injection volume of 10 μl. Figure 2 shows a typical chromatogram. Samples with the same concentration were injected 3 times, and the arithmetic mean value was calculated, and the linear range obtained was: 6.02×10 -9 mol / L-3.01×10 -7 mol / (R 2 = 0.997). It can be seen from the calculation that when the signal-to-noise ratio is 3, the minimum detection concentration of the device for fluorescein is 3.95×10 -10 mol / L.

[0040] Chromatography and detection conditions: PMT working voltage is -730V; mobile phase: methanol; flow rate: 1.0ml / min;

[0041] Fluorescein concentration: 3.01 x 10 -8 mol / L; injection volume: 10μL; LEDs: 100, working voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com