Patents

Literature

106 results about "Teflon af" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

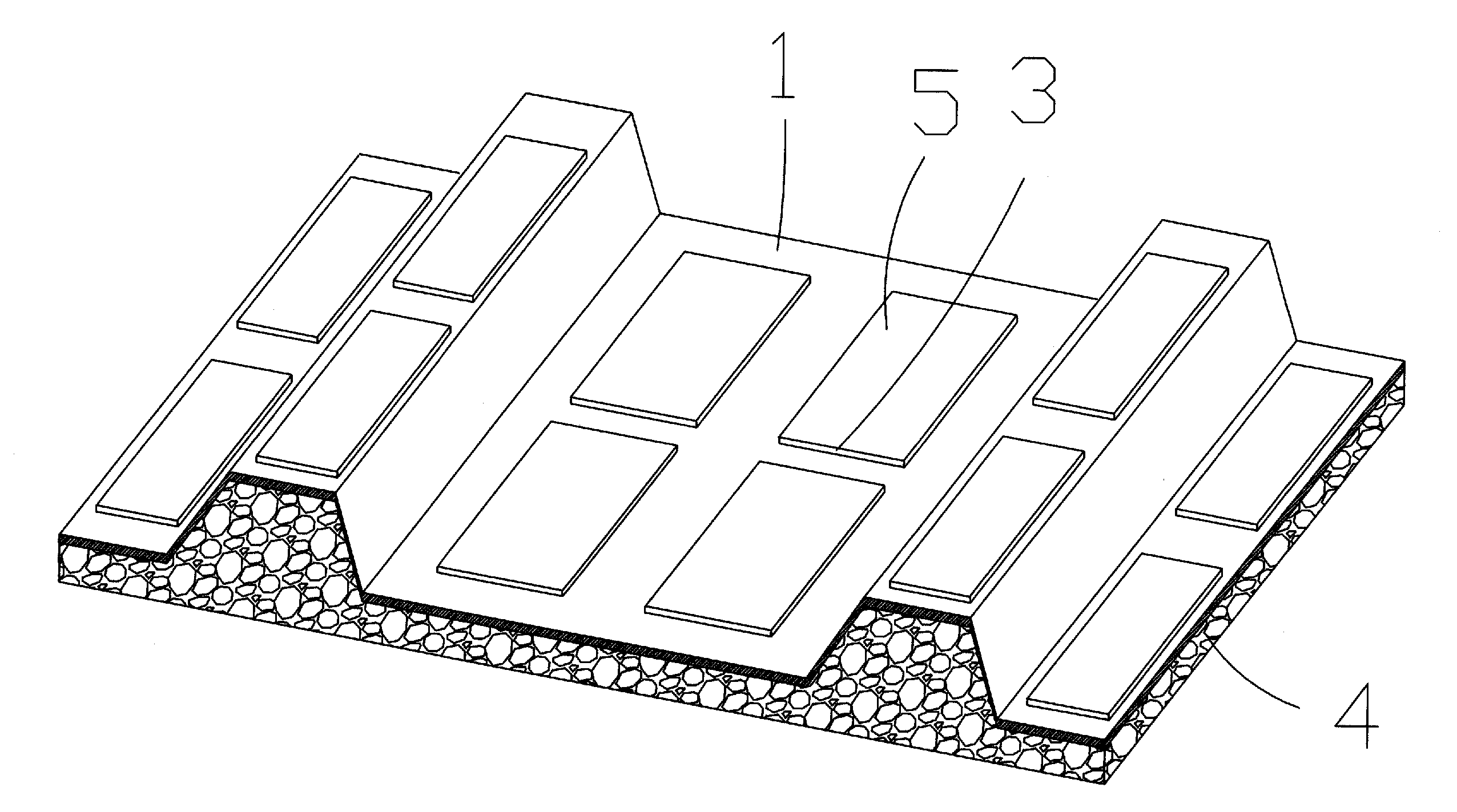

Wear-resistant coating non-stick pan

ActiveCN102835891ASimple designIngenious designCooking-vessel materialsEnvironmental resistanceWear resistant

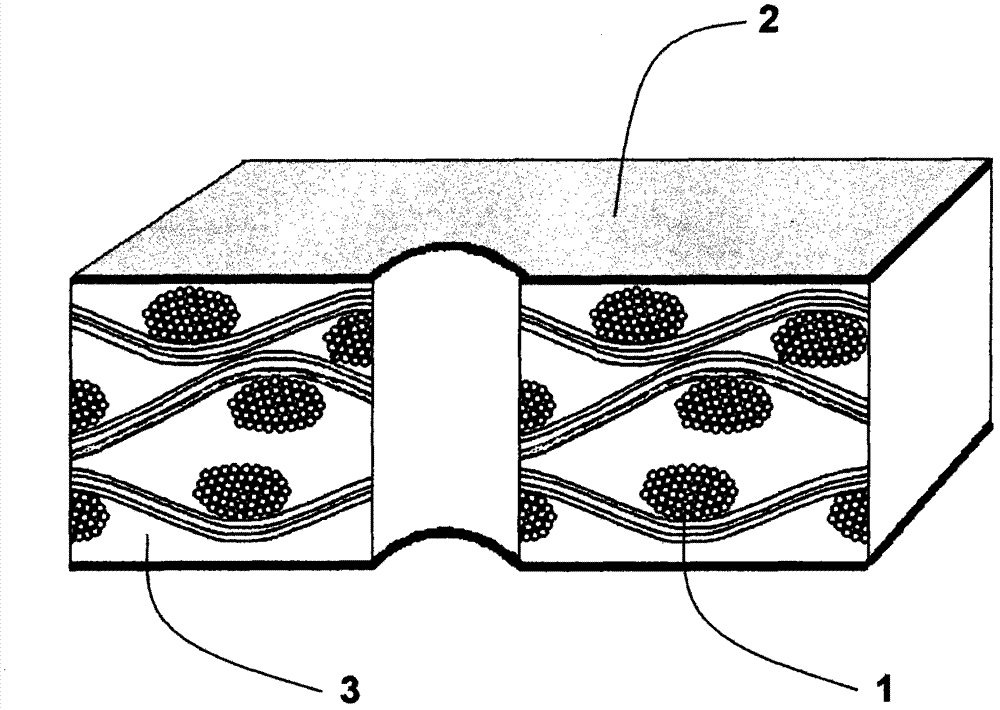

The invention relates to a metal ceramic wear-resistant coating non-stick pan. The non-stick pan comprises a pan body, as well as a graphitic layer and a metal ceramic coating which are positioned on the surface inside the pan, wherein the metal ceramic layer comprises a titanium carbide metal ceramic coating. According to the wear-resistant coating non-stick pan provided by the invention, an uneven bulged structure is arranged on the inner surface of the pan bottom, so that the contact area between the pan bottom and foods can be reduced; and titanium-based metal ceramic has stable characteristics at high temperature and does not pollute foods, and metalized particles are closely combined with a base material along with high adhesion and fine wear resistance, so that the aim of preventing foods from sticking the pan in a high-temperature cooking process can be achieve, and the titanium-based ceramic can replace the existing Teflon non-stick pan. The metal ceramic wear-resistant coating non-stick pan prepared in the invention is smart in design, excellent in performance, and non-toxic and environment-friendly, is more in accordance with the requirements of 'safety, health, energy saving and environmental-friendliness' provided by the World Environmental Organization and nations currently. The process provided by the invention has a simple method, and is suitable for large-scale production.

Owner:FUJIAN HUAXIA VAJRA TECH CO LTD

Preparation method for instant tremella

InactiveCN102669647AKeep appearanceEasy to overflowClimate change adaptationFood preparationBiotechnologyTremella

The invention relates to a preparation method for instant tremella. The method comprises the steps as follows: steeping tremella in cleaning water, breaking up tremella cells with ultrasonic waves, uniformly spreading, placing on a reticular plate coated with Teflon or a plate with water filtering function, curing with high-temperature steam, and then drying to obtain finished instant tremella. By adoption of the method, the instant tremella retains all the natural elements of tremella and has the advantages of quickness in rehydration, good condition, stability in production, high efficiency, low cost and easiness in automatized mass production.

Owner:CHONGQING UNIV

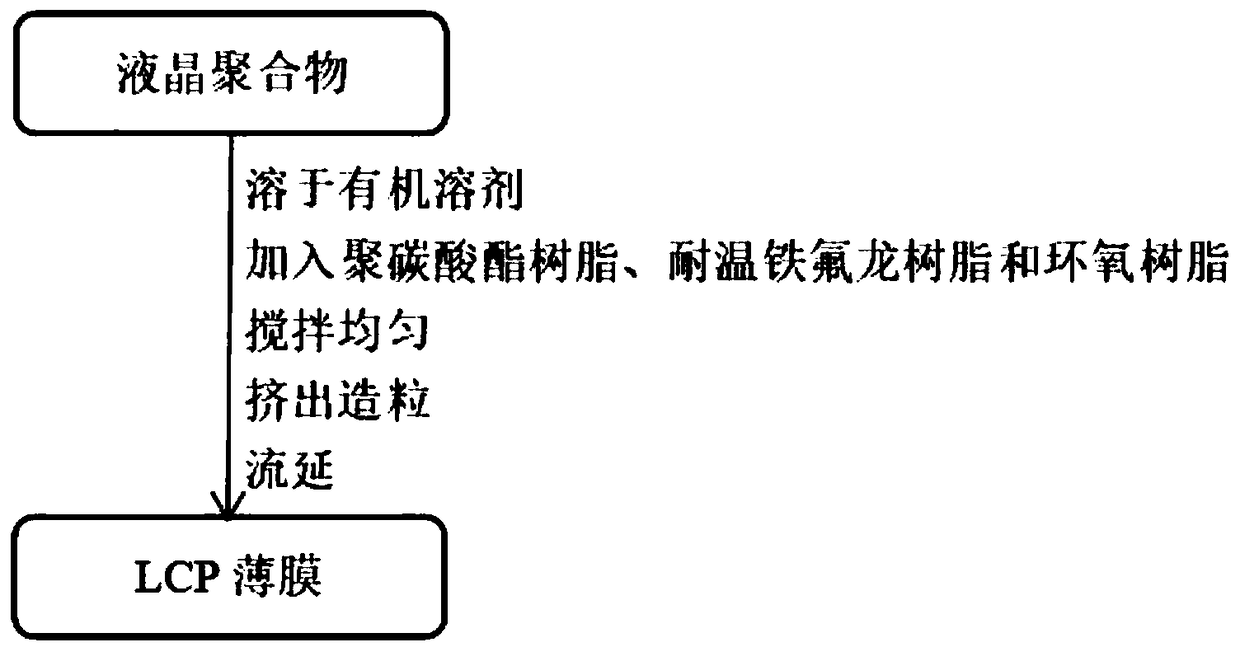

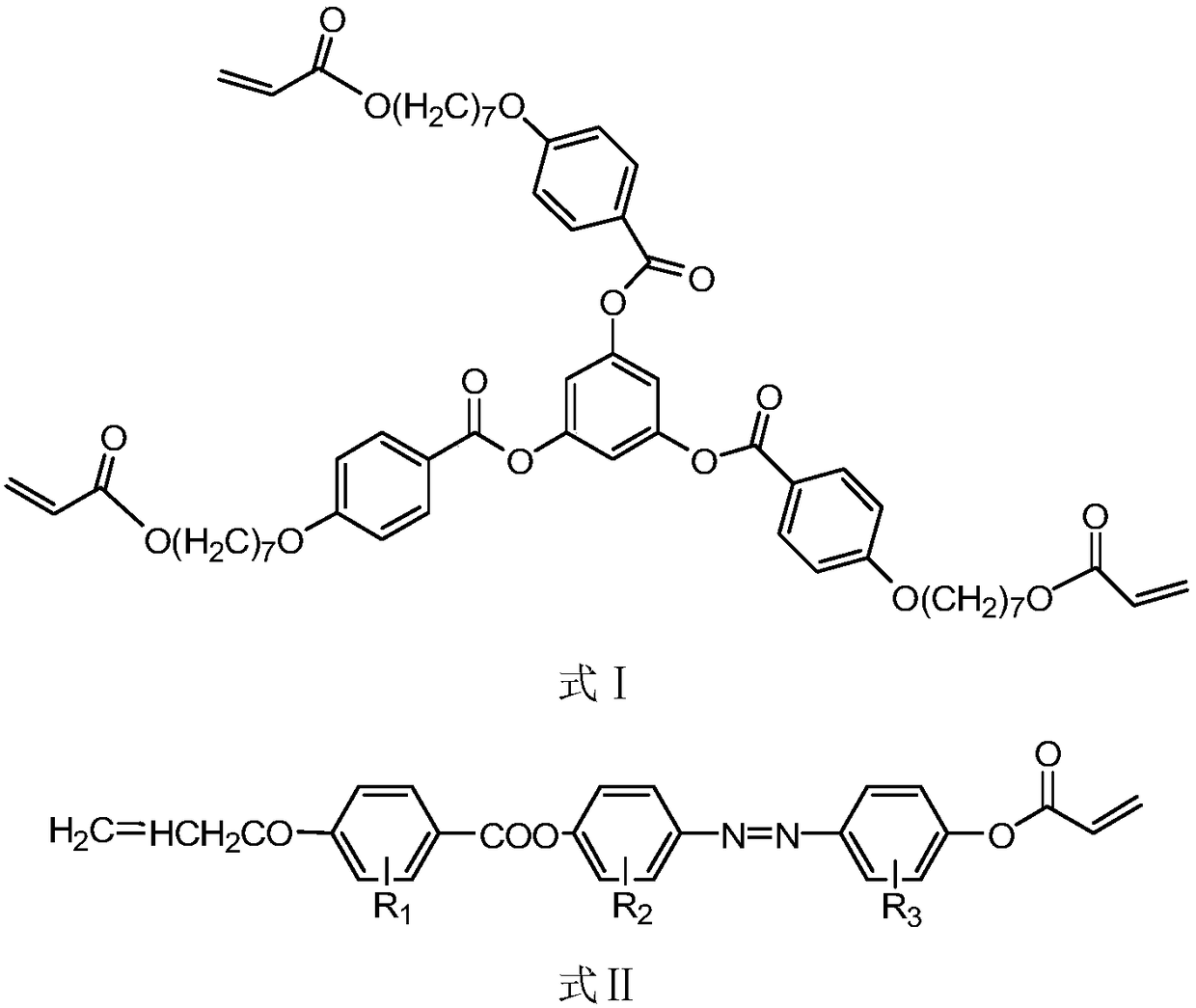

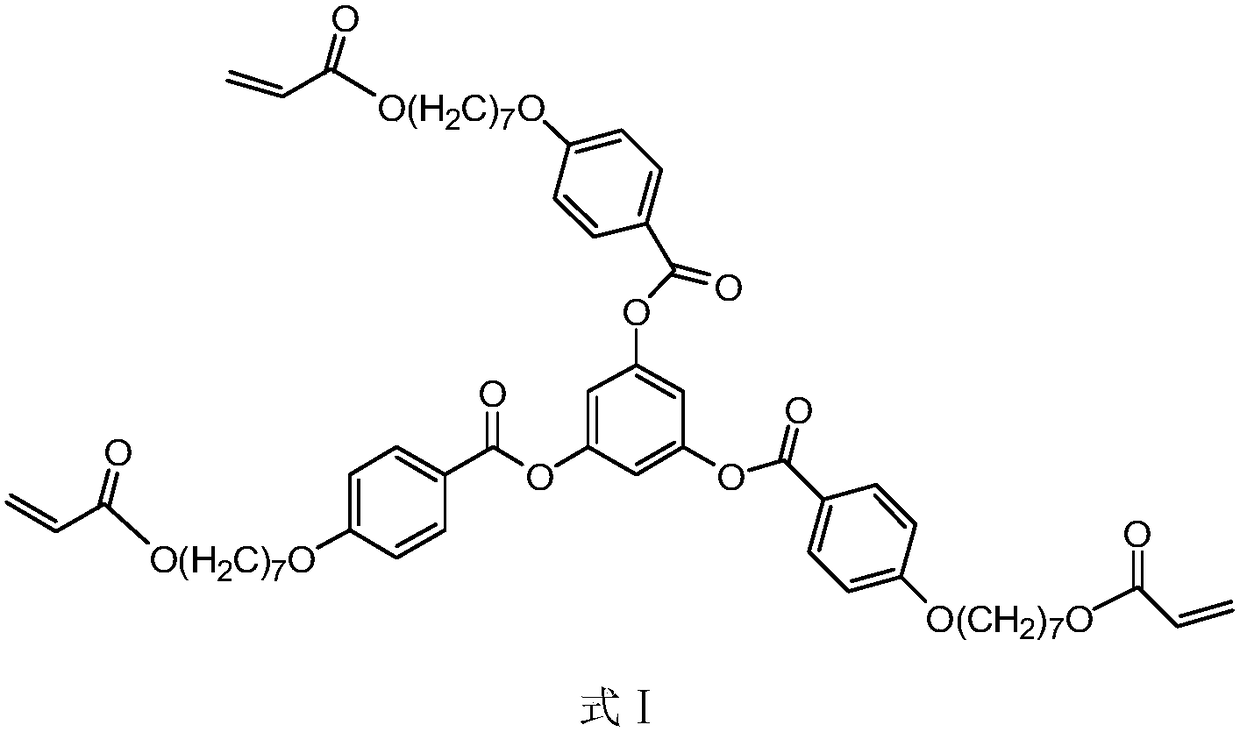

LCP film for FPC industry and preparation method thereof

The invention provides an LCP film for FPC industry and a preparation method thereof. The film is prepared from liquid crystal monomers shown as a formula I and a formula II. The preparation method comprises the following steps: pouring the liquid crystal monomers shown as the formula I and the formula II, a photoinitiator and an ultraviolet absorbent into a liquid crystal box, and inducing polymerization and exposure under ultraviolet light with the intensity of 2 mW / cm<2> and the wavelength of 365 nm at 95 DEG C for 30 min to obtain a liquid crystal polymer; dissolving the liquid crystal polymer in an organic solvent, sequentially adding polycarbonate resin, temperature-resistant Teflon resin and epoxy resin, stirring and mixing uniformly, transferring an obtained reaction liquid to a twin-screw extruder for extrusion granulation, and finally preparing dried particles into the LCP film according to a casting technology. The LCP film has low dielectric constant at high frequency, hasincreased signal transmission speed, and can be widely applied to 5G network.

Owner:苏州市新广益电子股份有限公司

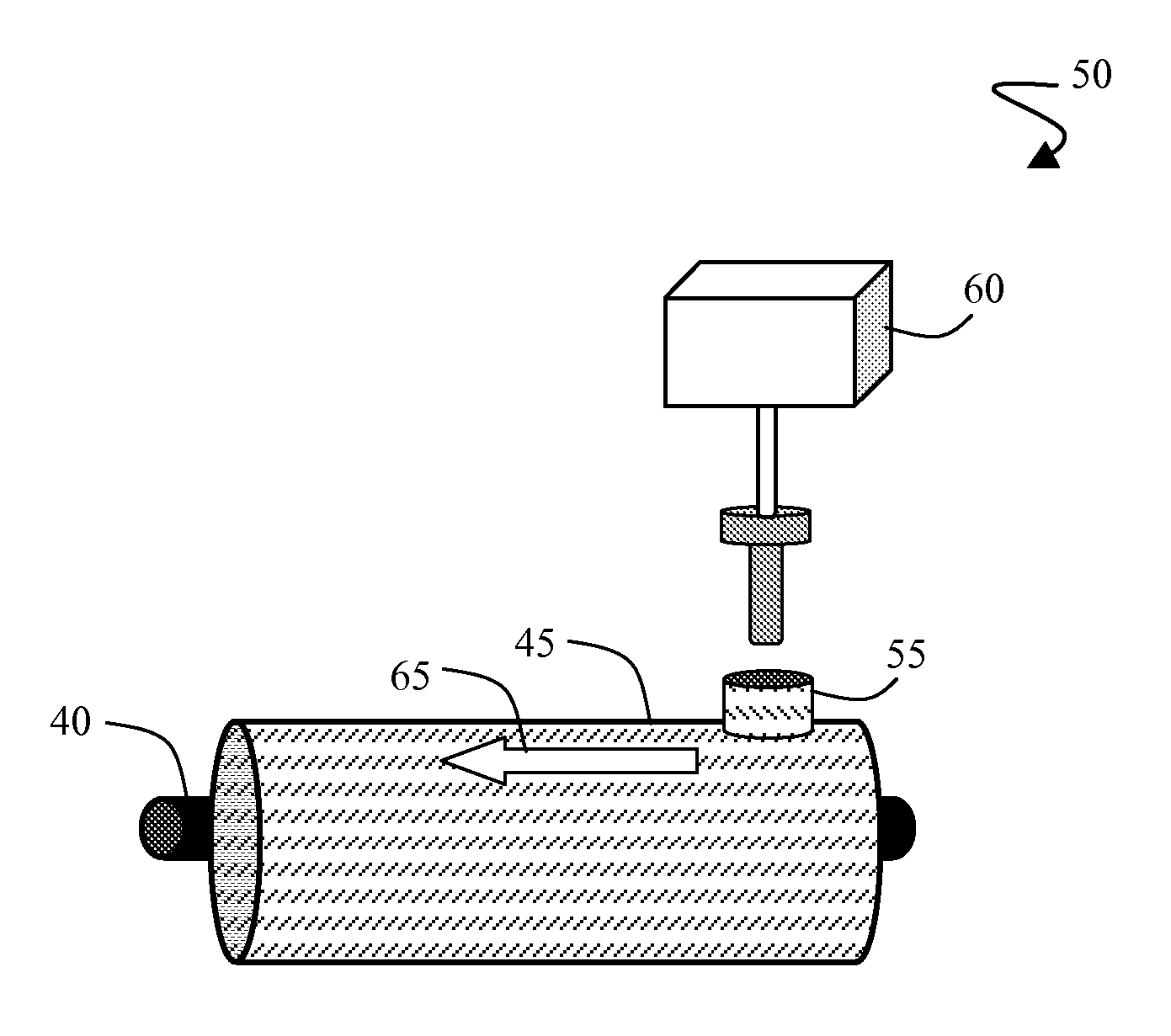

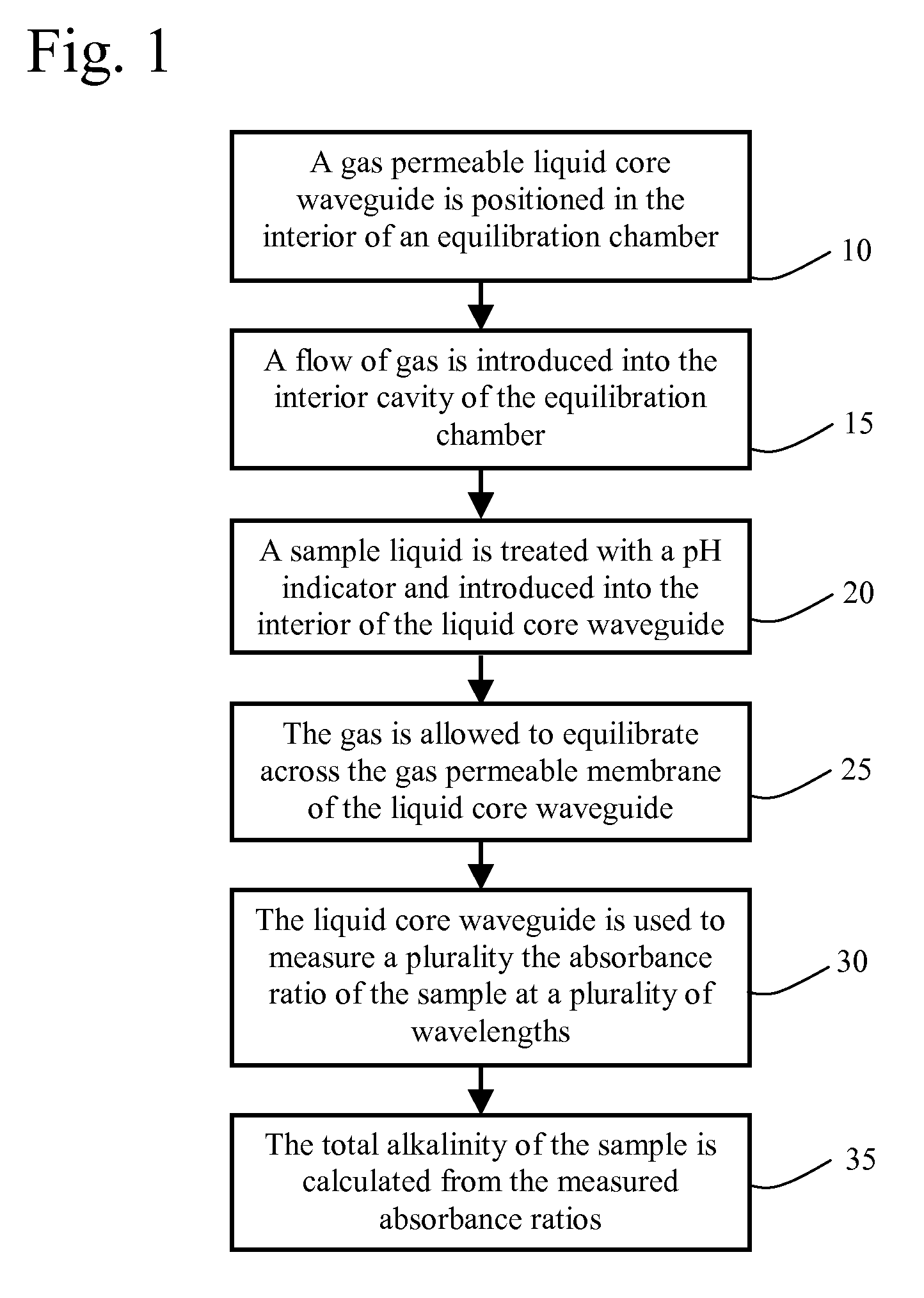

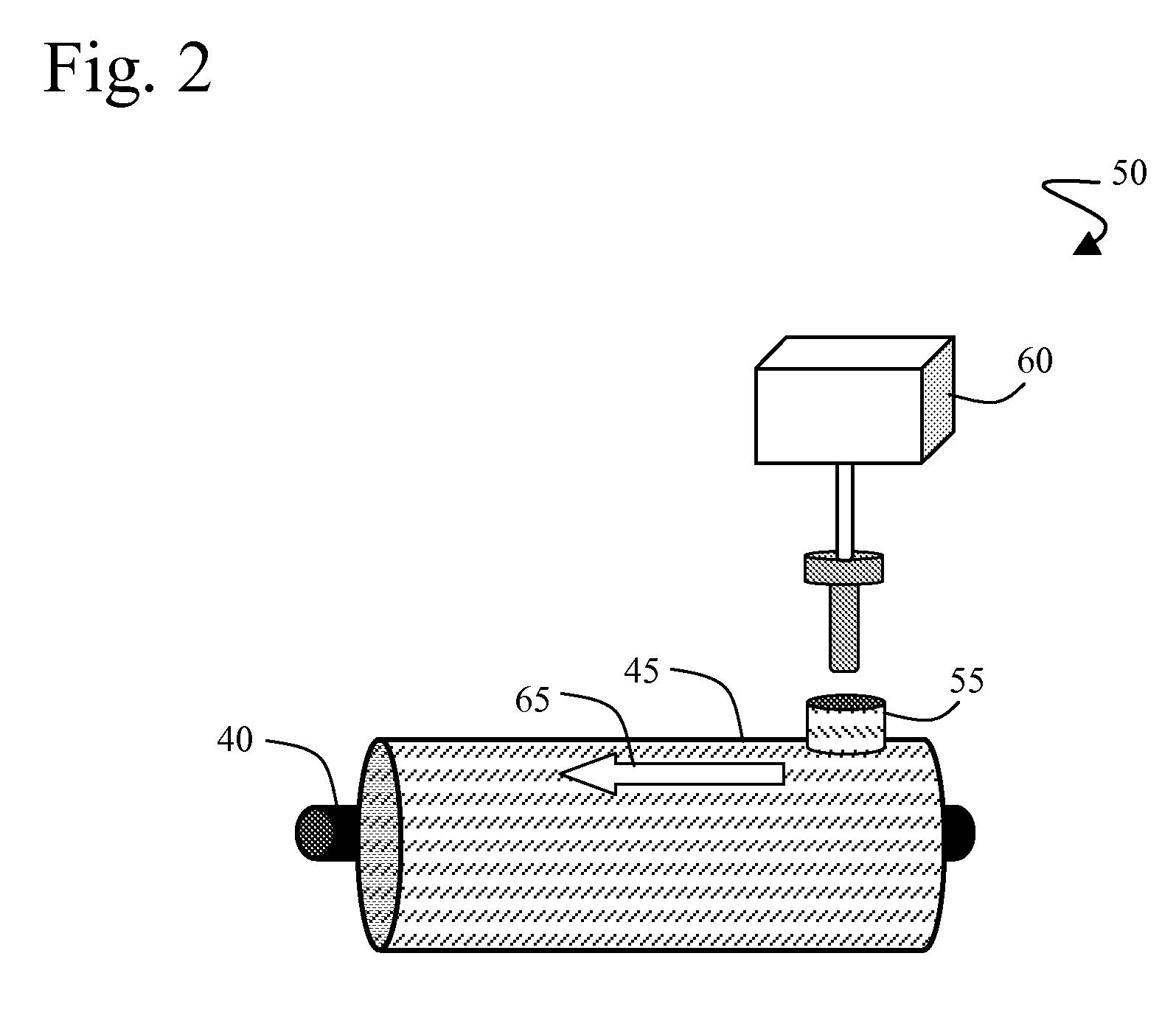

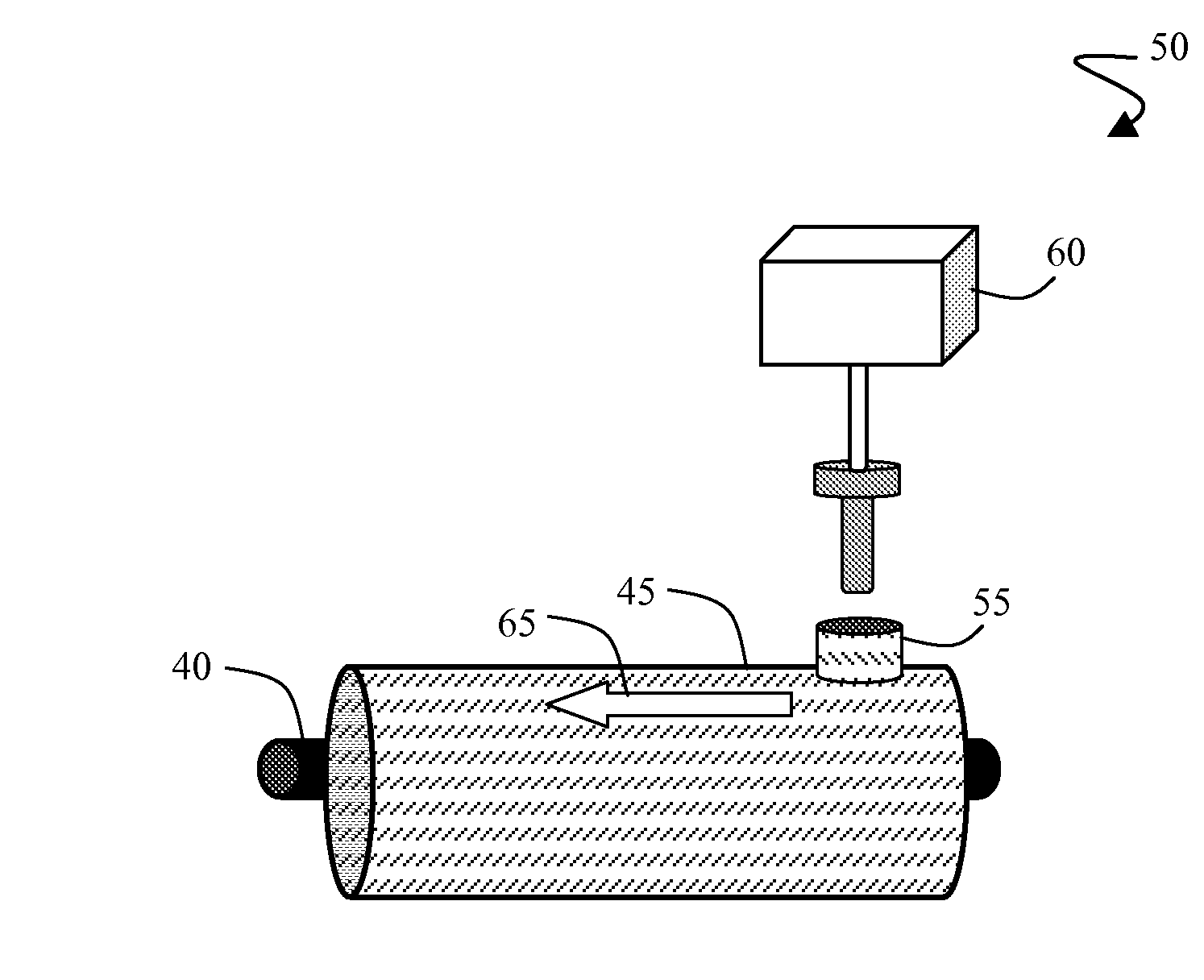

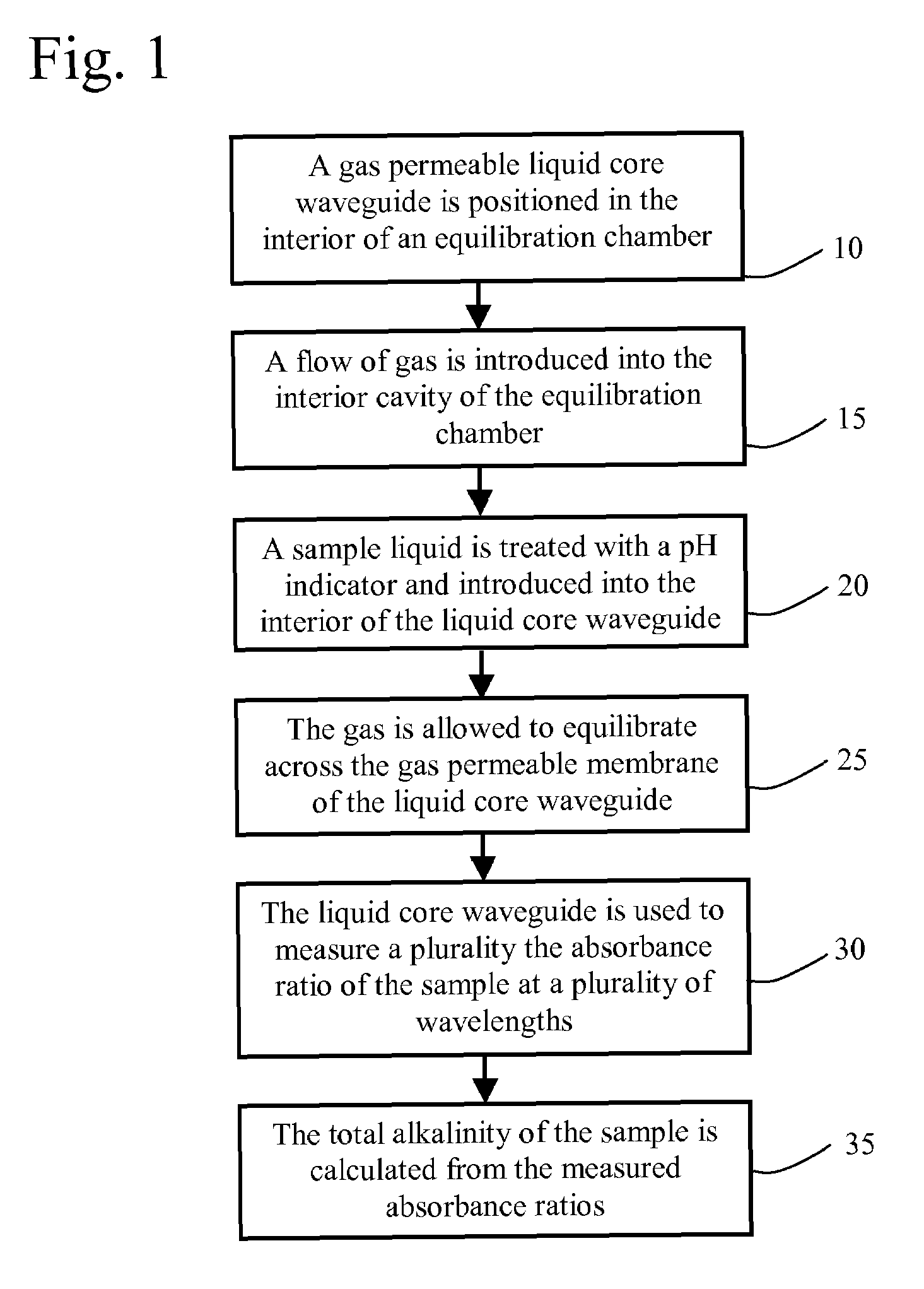

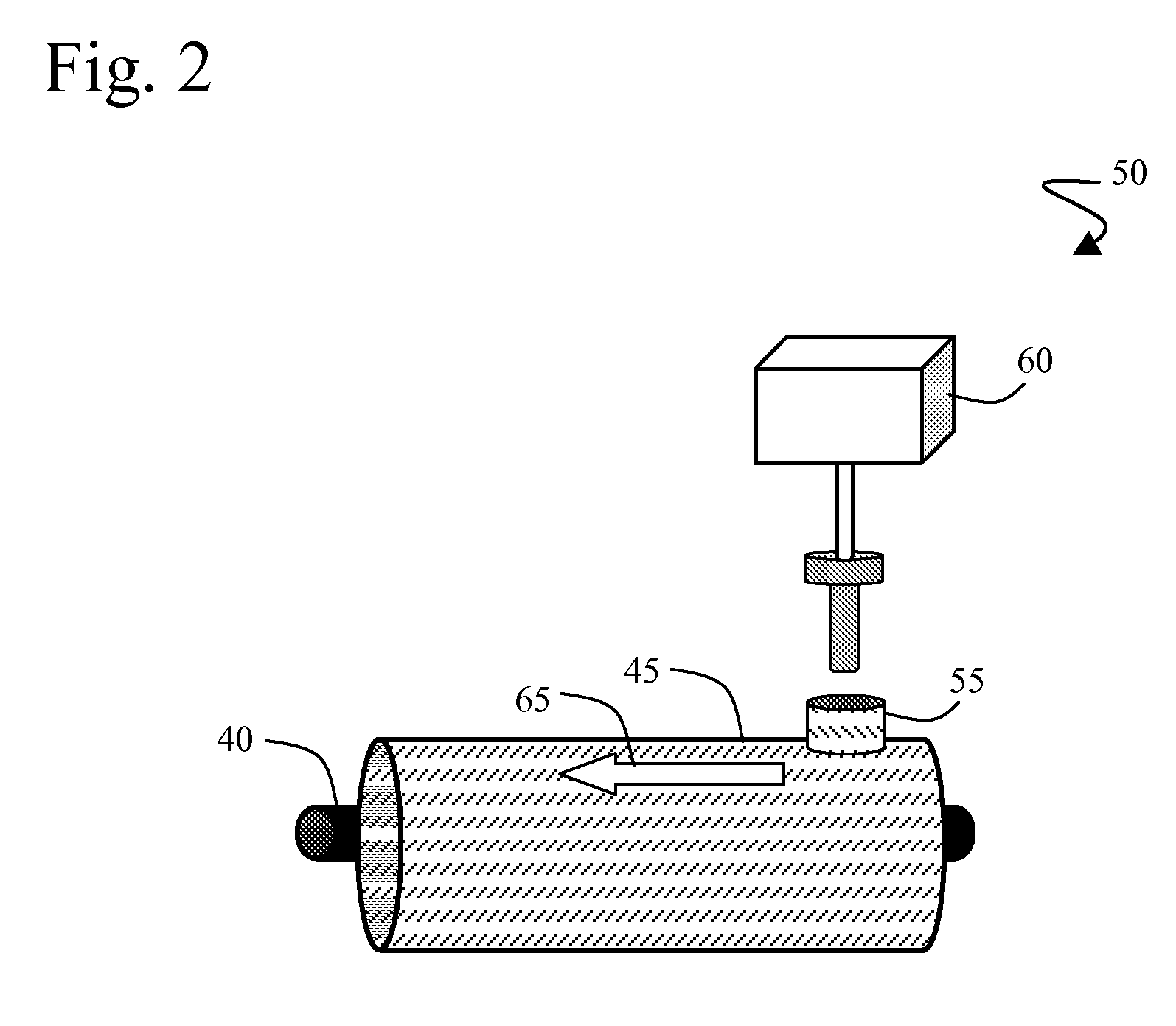

System and Method for Spectrophotometric Measurement of Total Alkalinity Using a Liquid Core Waveguide

InactiveUS20060234389A1Rapid sample throughputEliminate useAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorLiquid coreAlkalinity

A system and method for spectrophotometrically measuring the total alkalinity of a liquid sample. In a particular aspect, the method involves equilibration of a CO2 gas with a sample solution across the permeable walls of a Teflon AF 2400 liquid core waveguide. The waveguide acts as both an equilibration membrane and an optical cell in which spectrophotometric pH measurements are obtained via measurements of absorbance ratios.

Owner:UNIV OF SOUTH FLORIDA

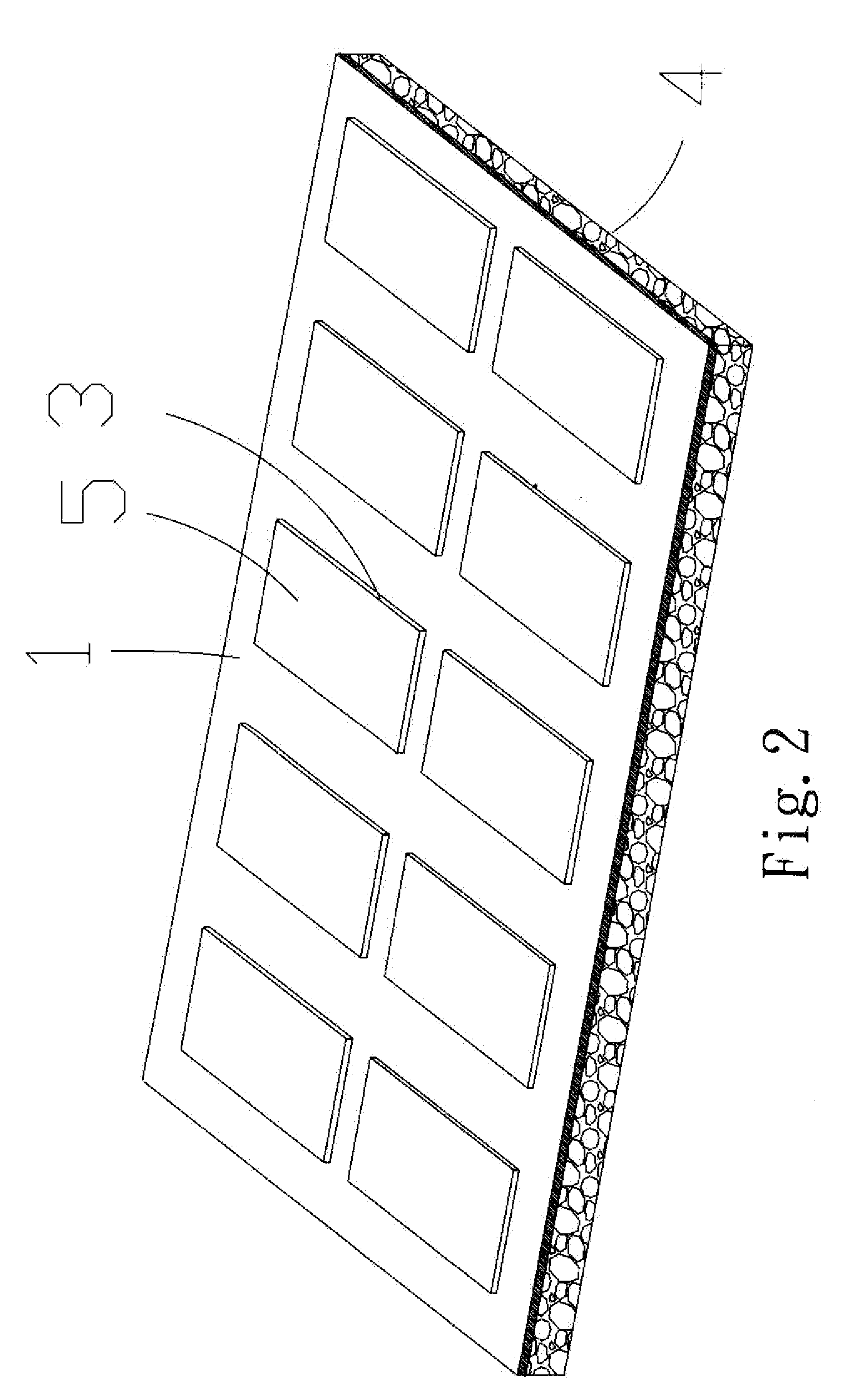

Construction material structure for use with solar power

A construction material structure for use with solar power includes a panel having an outer top side provided thereon with an adhesive element and connected to a bottom side of at least one solar cell via the adhesive element. The panel is a baked enamel steel plate, an aluminum plate, or a plastic plate. A thermal insulation element is disposed on an inner bottom side of the panel. The thermal insulation element is made of polyurethane (PU) foam or gypsum. The adhesive element is an Ethylene Vinyl Acetate (EVA) film or a Polyvinyl Butyral (PVB) film. Another adhesive element is disposed on a top side of the at least one solar cell. A high-transparency high-light-concentration film is disposed on the another adhesive element. A coarse face including projections is disposed on an outer surface of the high-transparency high-light-concentration film. The high-transparency high-light-concentration film is made of Teflon (TEFZEL), Polyester (PET) or Polycarbonate (PC).

Owner:CHANG YAUE SHENG

Feeding throat pipe

Owner:高萌

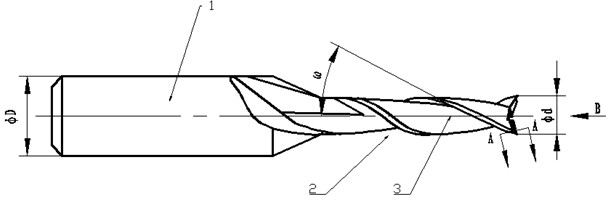

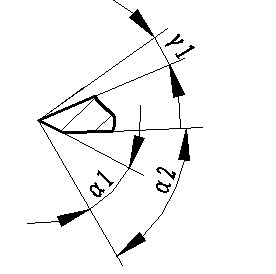

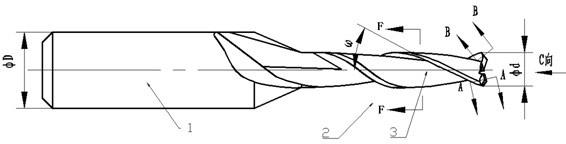

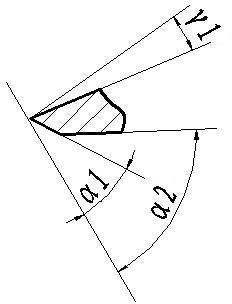

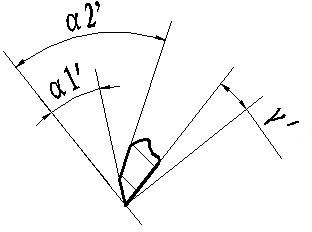

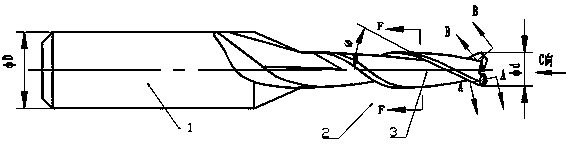

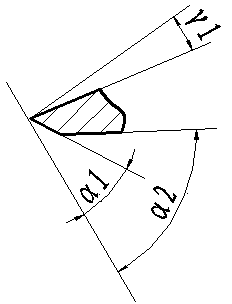

Milling cutter for processing flexible board and forming process thereof

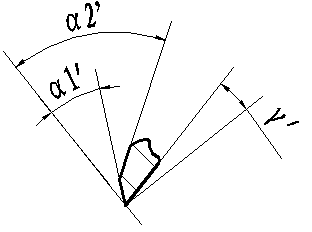

ActiveCN102615326AImprove rigidityImprove processing efficiencyMilling cuttersTool bitMilling cutter

The invention discloses a milling cutter for processing a flexible board and a forming process thereof. The milling cutter comprises a cutter shank (1), wherein one end of the cutter shank (1) extends to form a milling cutter head (2), two spiral grooves (3) in the same encirclement direction are formed on the surface of the milling cutter head (2) for forming a milling blade, and a V-port cutting surface is arranged at the tail end of the milling cutter head (2); and the angles omega of the spiral angles of the spiral grooves (3) are 28-32 degrees. The invention simultaneously discloses a forming process of the milling cutter for processing the flexible board. The milling cutter can solve the problems of poor rigidity and poor cutting performance of the existing milling cutter for processing a flexible circuit board and is particularly suitable for processing aluminum base boards, copper base boards, the flexible boards, Teflon boards, polytetrafluoroethylene boards and other boards.

Owner:ZHEJIANG DEWEI CEMENTED CARBIDE MFG CO LTD

System and method for spectrophotometric measurement of total alkalinity using a liquid core waveguide

InactiveUS7727770B2Rapid sample throughputEliminate useAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorLiquid coreAlkalinity

A system and method for spectrophotometrically measuring the total alkalinity of a liquid sample. In a particular aspect, the method involves equilibration of a CO2 gas with a sample solution across the permeable walls of a Teflon AF 2400 liquid core waveguide. The waveguide acts as both an equilibration membrane and an optical cell in which spectrophotometric pH measurements are obtained via measurements of absorbance ratios.

Owner:UNIV OF SOUTH FLORIDA

Non-autoclave electroforming composite material method based on carbon nanomaterial

InactiveCN113696513AAvoid problems with storage, etc.Improve molding qualityCapillary pressureElectric energy consumption

The invention provides a non-autoclave electroforming composite material method based on a carbon nanomaterial, which comprises the following steps: laying a carbon nano ultrathin film interlayer between prepregs or dry cloth in a designed product structure, providing interlayer capillary pressure, toughening the structure, and improving the temperature uniformity in the thickness direction. Carbon nano-films wrapped by non-porous Teflon films are arranged on the outer side and the inner side of the structure respectively and serve as resistance heaters, the two ends of the resistance heaters and copper sheets are bonded to be connected into a high-voltage generator, thermocouples are arranged at all positions of the carbon nano-films according to the designed product structure, and real-time temperature monitoring is carried out. The non-porous Teflon films mainly play a role in demolding and insulation. And finally, vacuum bag packaging and heat insulation material wrapping are performed to avoid heat loss, so that electric energy consumption is greatly reduced. And voltage is started after vacuumizing, heating curing is carried out, and in the curing process, the curing temperature change process can be controlled by monitoring the real-time temperature of the thermocouples and adjusting the magnitude of the voltage.

Owner:SHANGHAI JIAO TONG UNIV

Anti-static abrasion-resistant polytetrafluoroethylene fibers and preparation technology thereof

InactiveCN108842211AHigh mechanical strengthAntistaticElectroconductive/antistatic filament manufactureMonocomponent halogenated hydrocarbon artificial filamentGlass fiberFiber

The invention discloses anti-static abrasion-resistant polytetrafluoroethylene fibers and a preparation technology thereof. The anti-static abrasion-resistant polytetrafluoroethylene fibers comprise the following raw materials in parts by weight: 55-60 parts of polytetrafluoroethylene, 10-13 parts of polyimide, 6-7 parts of glass fibers, 4-6 parts of carbon fibers, 2-4 parts of aluminum oxide, 3-5parts of graphite, 3-4 parts of copper powder, and 10-15 parts of lubricating oil. The preparation technology comprises the following steps: mixing the raw materials; preparing a cylinder blank through an extruder; performing cold pressing to form a film; drying; sintering; stretching to obtain a fibrotic film; and cutting into silks to obtain the anti-static abrasion-resistant polytetrafluoroethylene fibers. The polytetrafluoroethylene fibers prepared by the method have the advantages of being resistant to static, high in abrasion resistance, and outstanding in mechanical strength.

Owner:ZHONGSHAN LVLANG ADDITIVES CO LTD

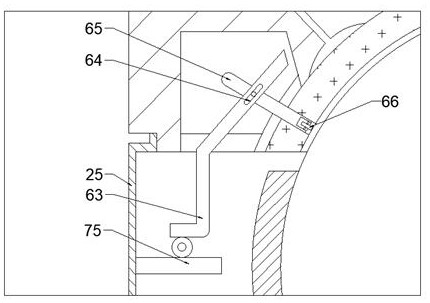

Bearing capable of relieving wear caused by lubricating oil uneven distribution caused by centrifugal force

InactiveCN112576619AControl distribution statusBearing assemblyBall bearingsMagnetic tension forceCentrifugal force

The invention discloses a bearing capable of relieving wear caused by lubricating oil uneven distribution caused by centrifugal force. The bearing comprises an outer ring, a conduction pipeline deviceused for conducting gas is arranged in the outer ring, a Teflon is fixedly connected to the lower side face of the outer ring, balls are slidably connected to the lower side face of the outer ring, the lower side faces of the balls are slidably connected to an inner ring, a rotating shaft is fixedly connected in the inner ring, and transmission space is formed between the outer ring and the innerring. Magnetic fluid is added into lubricating oil so that magnetic force can be applied to the lubricating oil under the action of a magnetic field after the magnetic fluid is electrified and magnetized, and therefore the distribution state of the lubricating oil under the combined action of a centrifugal force field and a magnetic force field is controlled, and by detecting the air pressure change in the bearing, a bearing overload alarm can be given out.

Owner:广州书琴秀科技有限公司

Mesona herb polysaccharide/nano TiO2/hyacinth bean starch multifunctional composite film and preparation method thereof

PendingCN112898615AImprove mechanical propertiesImprove thermal stabilityFlexible coversWrappersComposite filmGlycerol

The invention discloses a mesona chinensis polysaccharide / nano TiO2 / hyacinth bean starch multifunctional composite film and a preparation method thereof, and belongs to the technical field of biodegradable film materials. The composite film is prepared from the following raw materials: 200 to 250 parts of hyacinth bean starch, 60 to 75 parts of glycerol, 2 to 3 parts of mesona chinensis polysaccharide, 4 to 5 parts of nano TiO2 and 2000 to 5000 parts of deionized water. The preparation method comprises the following steps: compounding hyacinth bean starch, glycerin, mesona chinensis benth polysaccharide and a proper amount of deionized water, carrying out water bath heating gelatinization in a water bath kettle, uniformly mixing the gelatinized glue solution with nano TiO2 which is ultrasonically dispersed in the deionized water in advance, carrying out ultrasonic treatment for 30 minutes to remove bubbles, pouring a film-forming solution into a Teflon mold, performing drying in a drying oven, and after the film is formed, performing uncovering from the mold to obtain the composite film. The problems of poor mechanical property, poor thermal stability, poor ultraviolet resistance and the like of a pure starch film are solved, the preparation method of the composite film is simple, and the composite film is good in mechanical property and degradable and has the characteristics of being good in thermal stability, antibacterial, good in hydrophobicity and ultraviolet-proof.

Owner:NANCHANG UNIV

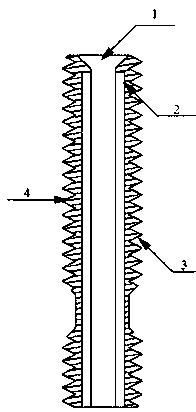

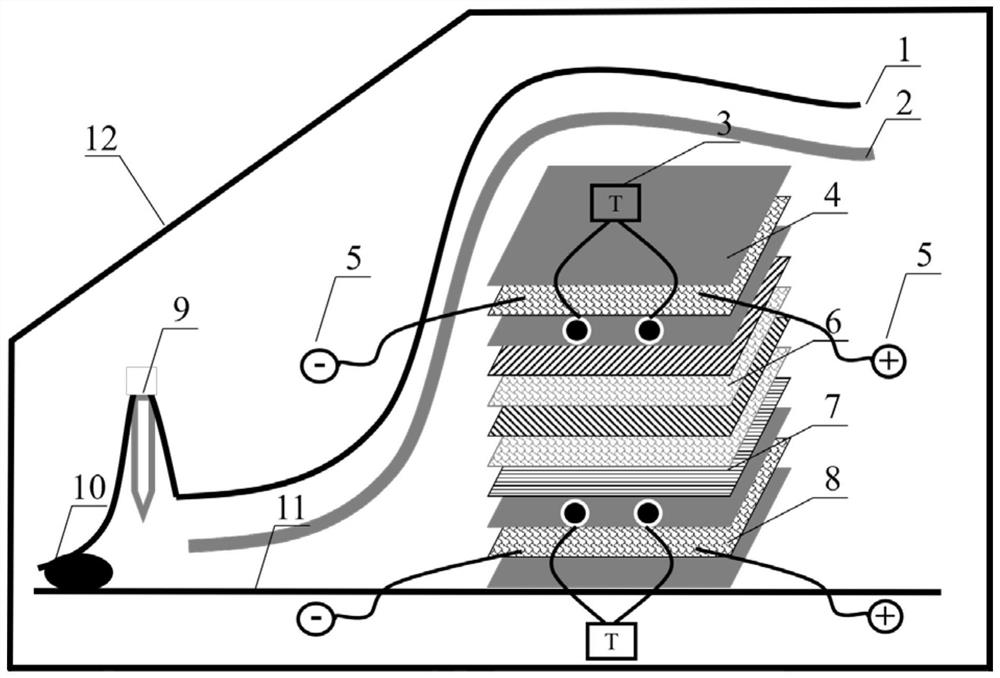

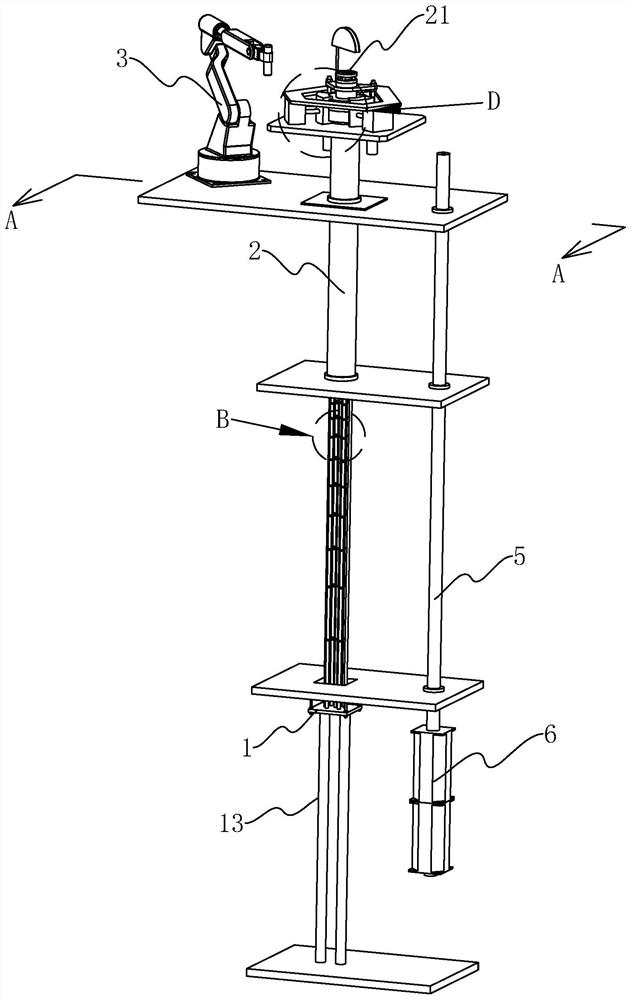

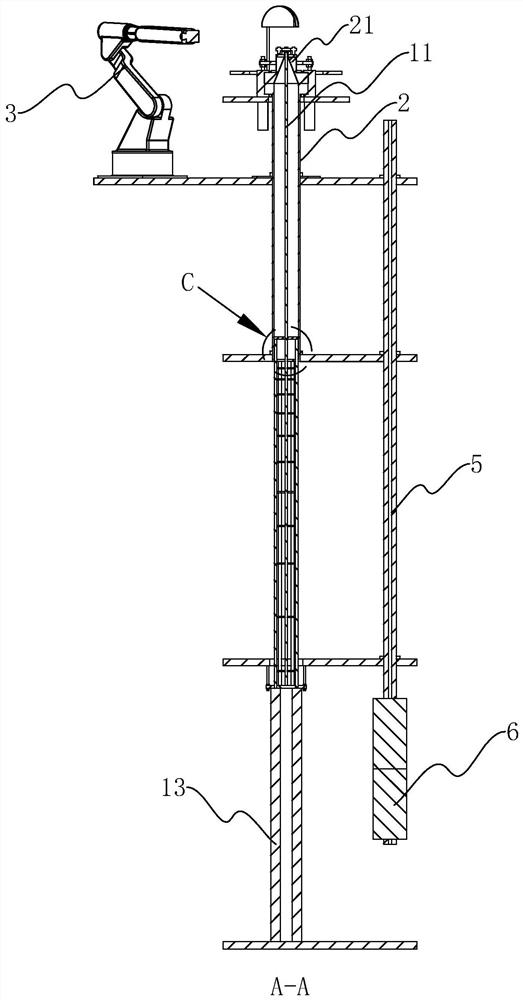

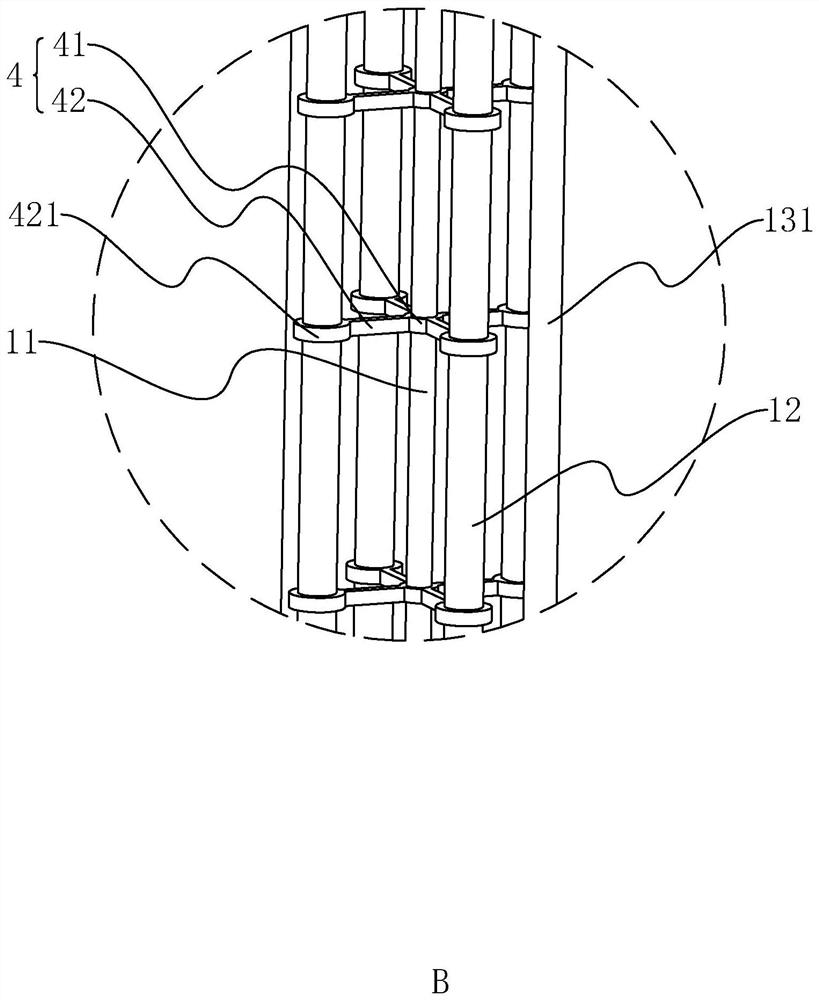

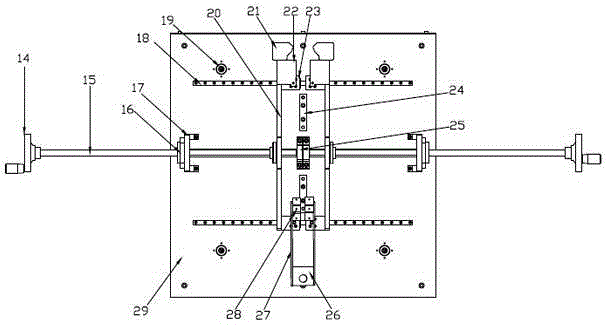

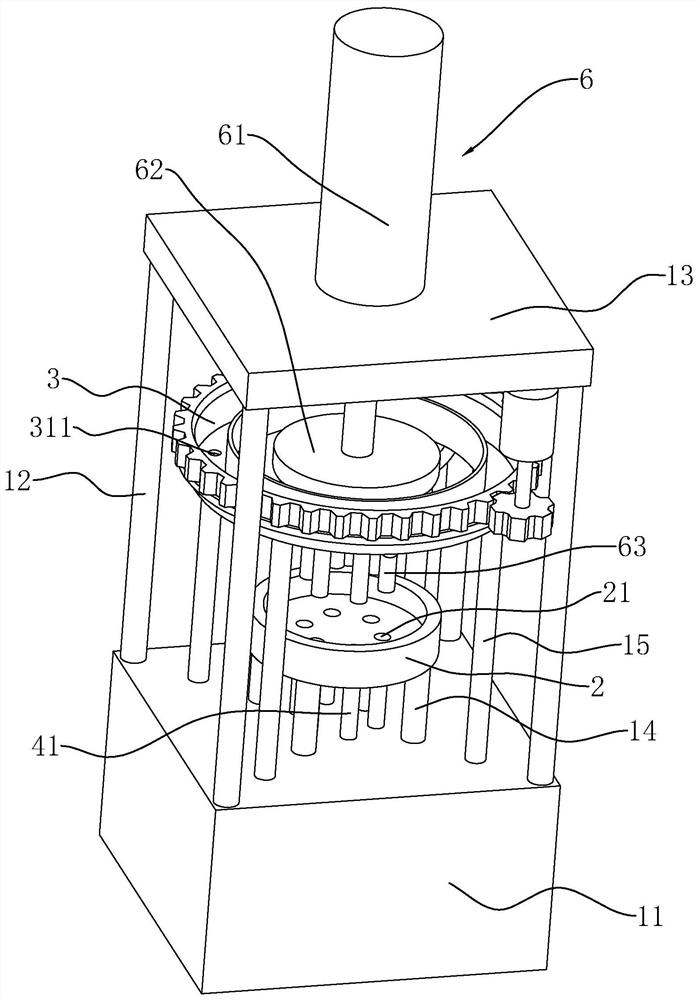

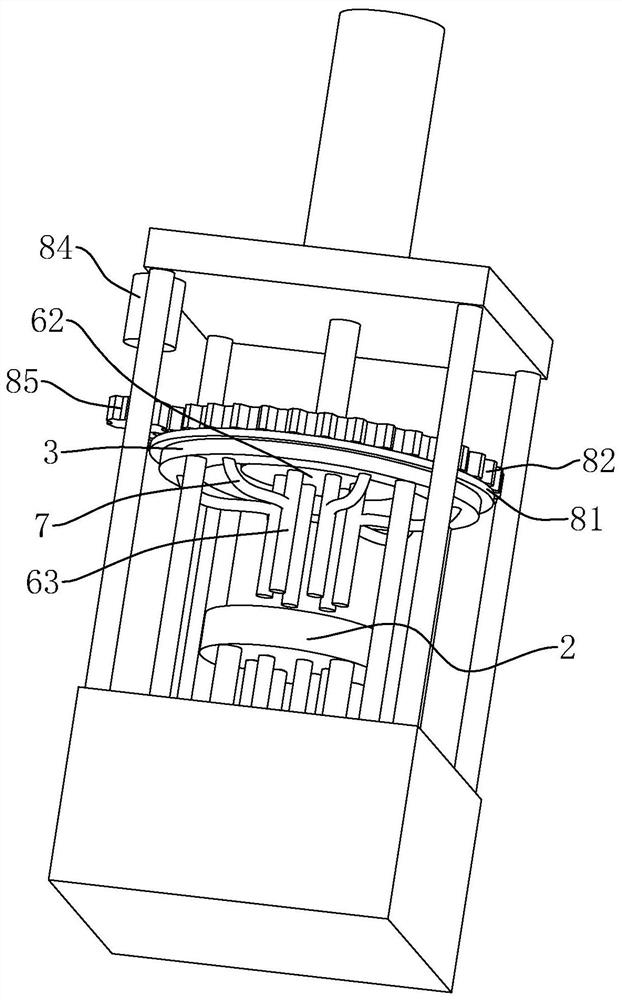

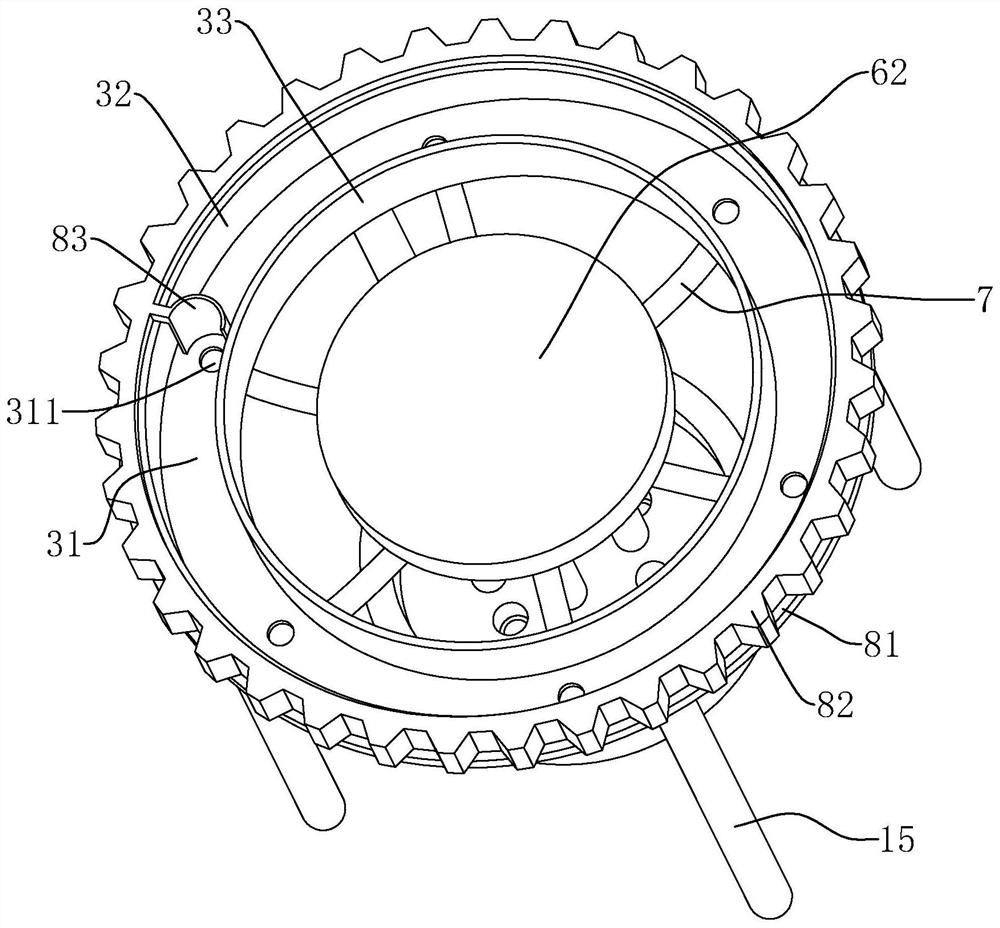

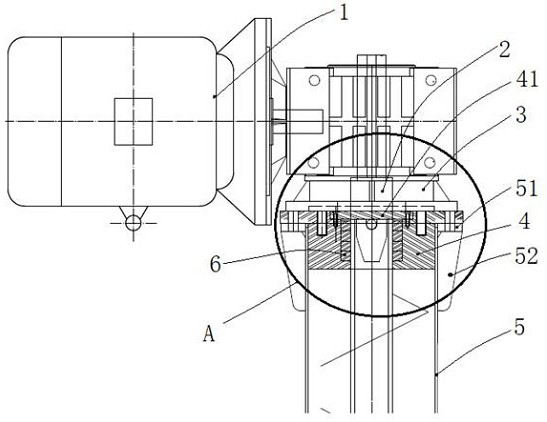

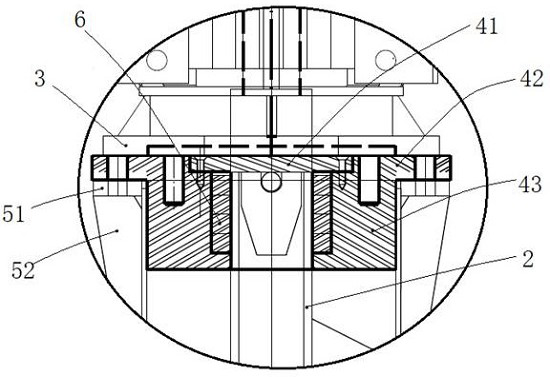

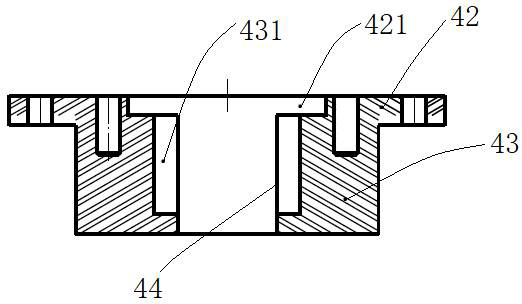

Intelligent super-long paste extruder for production of Teflon insulating tube

The invention discloses an intelligent super-long paste extruder for production of Teflon insulating tube. The intelligent super-long paste extruder comprises a datum plate and a charging barrel erected above the datum plate; a detachable die head is arranged at the end, away from the datum plate, of the charging barrel; a center rod is fixed on the datum plate; the end, away from the datum plate, of the center rod is inserted into the charging barrel; a plurality of guide rods are fixed to the datum plate and are located on the peripheral side of the center rod; the guide rods and the center rod are jointly sleeved with a plurality of sheath assemblies used for correcting the coaxiality of the center rod; an extrusion plate is arranged in the charging barrel in a sliding mode; and a lifting part used for driving the extrusion plate to ascend and descend is arranged on the side, away from the charging barrel, of the datum plate. The extruder has the effect of reducing the deviation of the size of a finished tube, is beneficial to improving the product quality, can increase the length of the Teflon insulating tube manufactured at a time, is beneficial to saving manpower and reducing the waste of raw materials, and further reduces the overall production cost, and the application range of the Teflon insulating tube with a large length size is wider.

Owner:湖北文太新材料有限公司

Method for capping tubular ceramic membrane

ActiveCN110743387AImprove sealingImprove retention efficiencySemi-permeable membranesEndcappingDip-coating

The invention discloses a method for capping a tubular ceramic membrane. The method comprises the following steps: adding a certain amount of membrane layer composition inorganic oxide powder into a Teflon dispersion liquid to fill holes in a Teflon coating layer, and adjusting the aperture size in the coating layer to be consistent with or smaller than the aperture size in a membrane layer, so that the sealing property of the coating layer is improved. According to the invention, firstly, the membrane layer composition inorganic oxide powder is dispersed in a Teflon solution; then the end part of a tubular ceramic membrane is coated with the Teflon solution by adopting a dip coating process; after baking and curing at low temperature, the Teflon coating layer with an average aperture sizeconsistent with the average aperture size of the membrane layer; and the membrane layer composition inorganic oxide powder is introduced into the Teflon coating layer, so that the sealing property ofthe coating layer is improved, interception efficiency of the end part is consistent with interception efficiency of the membrane layer, and overall interception efficiency of the tubular ceramic membrane is improved.

Owner:SANDA FILM SCI & TECH XIAMEN

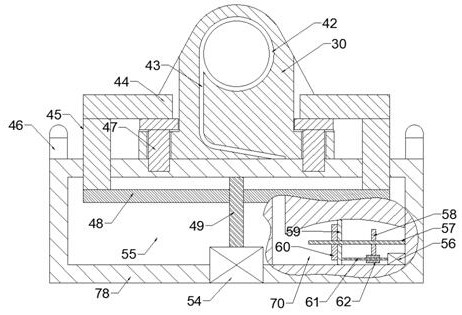

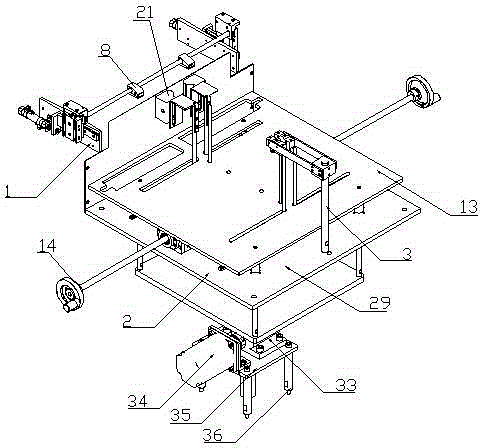

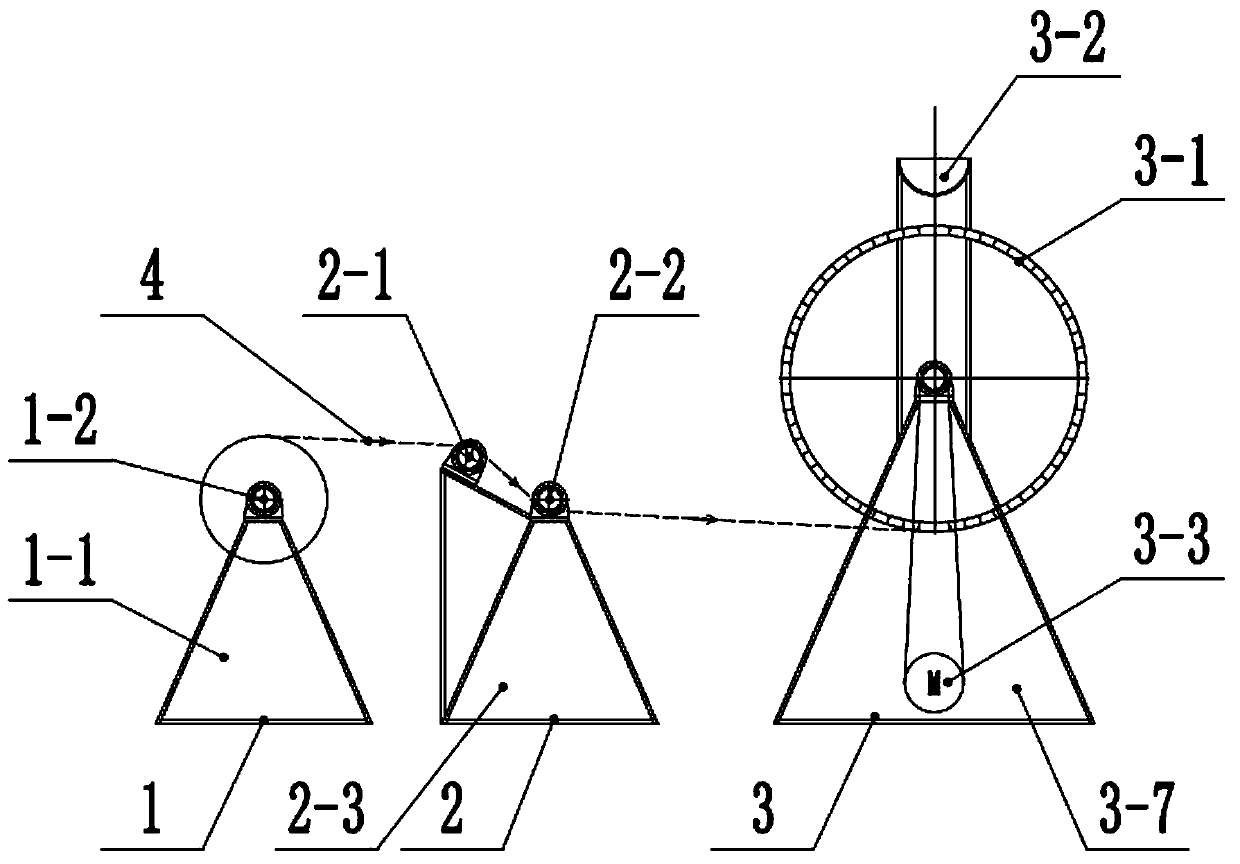

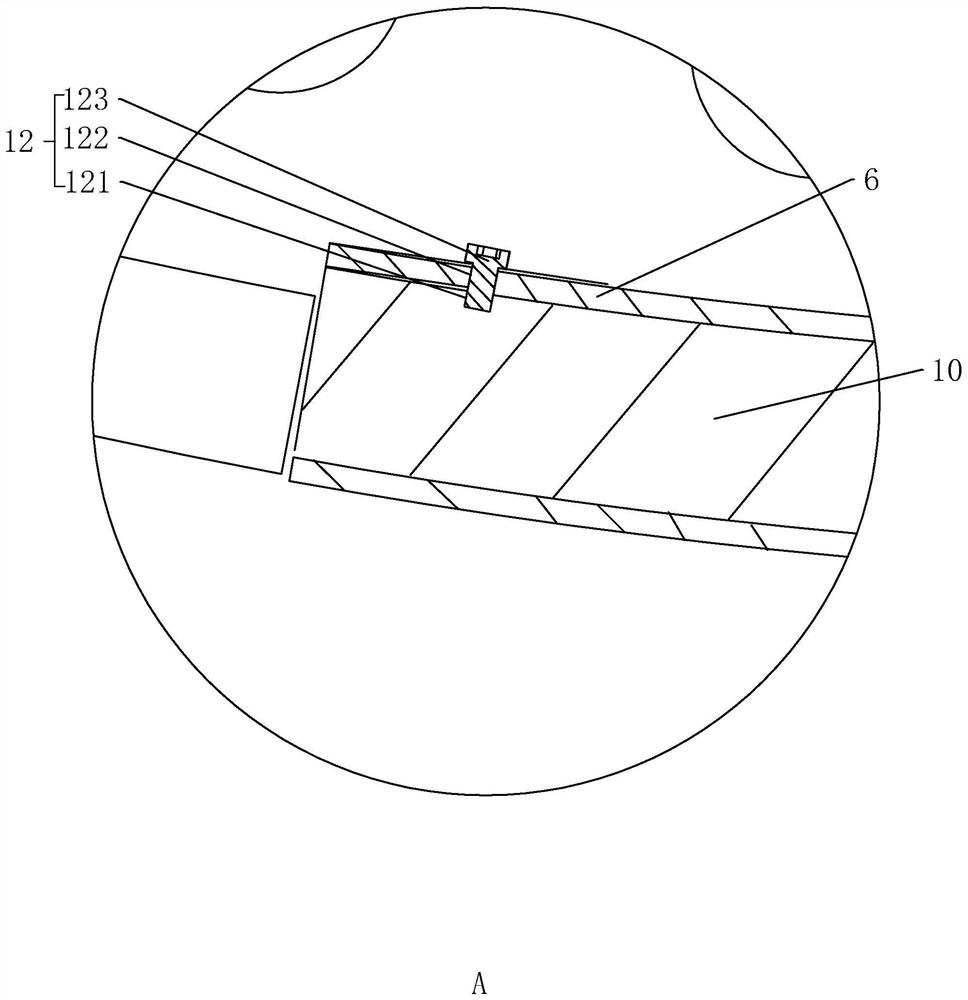

Separating mechanism for flexible teflon cloth

ActiveCN105173802AEasy to separateImprove efficiencyArticle separationStructural engineeringAir knife

The invention relates to a separating mechanism for flexible teflon cloth and belongs to automatic cleaning equipment. The tail end of a feeding bin body mechanism is connected with the separating mechanism. The structures of the left end and the right end of the separating mechanism are symmetric. A fixing seat at the left end serves as an installation plate and is provided with a guide rail. A sliding block installation connecting plate covers a sliding block to be installed on the guide rail with the sliding block together. An air cylinder is fixed to the sliding block installation connecting plate. A lever of the air cylinder is connected with a cross arm installation plate. A cross arm is installed on the cross arm installation plate in an erected manner. A mini air knife is installed on the cross arm. One end of an air cylinder connecting plate is connected with the side edge of the sliding block installation connecting plate, and the other end of the air cylinder connecting plate is connected with an air cylinder rod of a mini air cylinder. The separating mechanism for the flexible teflon cloth has the beneficial effects that the flexible teflon cloth can be conveniently and rapidly separated, even if liquid or sticky substances are left on the flexible teflon cloth, the flexible teflon cloth can be rapidly separated, preparation is made for the next processing procedure, and efficiency is improved.

Owner:GUANGZHOU LINKCORE AUTOMATIC EQUIP CO LTD

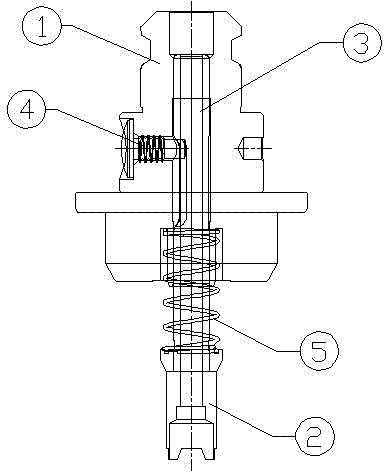

LED (light-emitting diode) series SMT (surface-mount technology) suction nozzle and manufacturing process thereof

InactiveCN103872191AResolve sticky conflictsConsidering Dimensional ErrorsSemiconductor/solid-state device manufacturingSemiconductor devicesInjection mouldingPolypropylene

The invention discloses an LED (light-emitting diode) series SMT (surface-mount technology) suction nozzle and a manufacturing process thereof. The LED series SMT suction nozzle comprises a nozzle head, a nozzle seat, a core, a screw and a spring, wherein the nozzle head is made of anti-adhesive material, i.e. semi-rigidity composite material, and the semi-rigidity composite material comprises Teflon, polyethylene and polypropylene which are configured in a ratio of 65:25:10 in percentage by weight. The manufacturing process of the suction nozzle comprises the steps of manufacturing the nozzle head; burdening the semi-rigidity composite material: configuring the Teflon, the polyethylene and the polypropylene in the ratio of 65:25:10 in percentage by weight; adding the Teflon into a stirrer for baking and melting; adding the polyethylene and the polypropylene into the stirrer for uniformly stirring for forming the semi-rigidity composite material; injection molding, assembling and assembling the nozzle head and the nozzle seat of the suction nozzle in an interference manner. The LED series SMT suction nozzle solves the problem that the LED is easily adhered to the suction nozzle in the SMT process of the LED, has the characteristics of anti-adhesive property, low reject rate, stable mount quality and capability of effectively protecting the surface of the LED against scratch, and easily realizes industrial production.

Owner:JIUJIANG JIAYUAN TECH

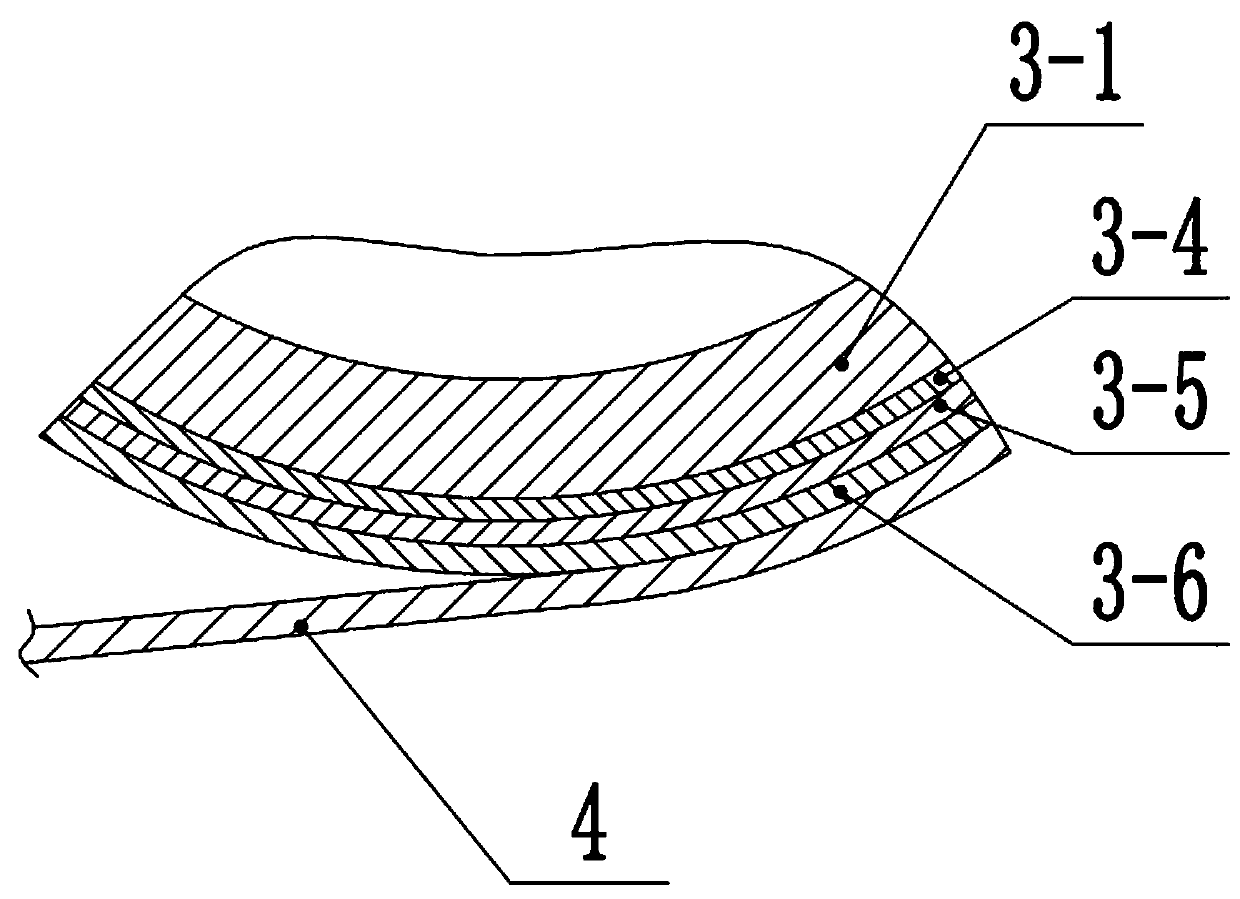

Production equipment and method of carbon cloth drum

PendingCN110745605AEasy to take offIncrease productivityWebs handlingProcess engineeringTeflon membrane

Owner:美尔森银河新材料(烟台)有限公司

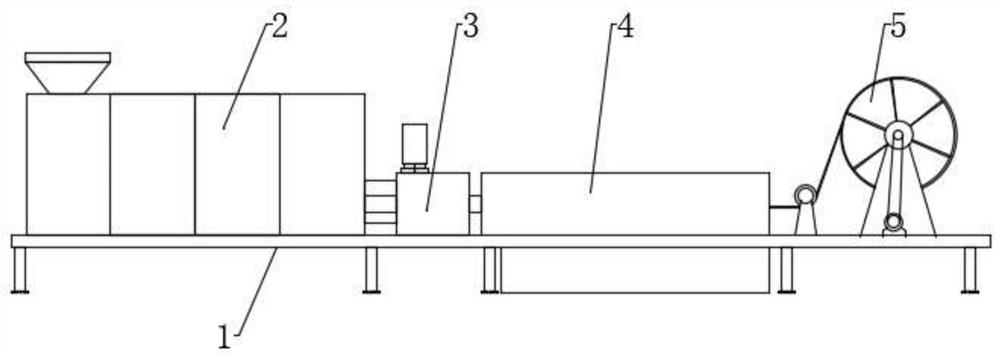

Soluble teflon processing device and processing technology thereof

The invention discloses a soluble teflon processing device and a processing technology thereof. The soluble teflon processing device comprises an extruder, a mold outlet of the extruder is connected with a vacuum mold, the output end of the vacuum mold is connected with a water tank, and the other side of the water tank is provided with a take-up machine; the soluble teflon processing device further comprises a machine frame used for bearing the extruder, the vacuum mold, the water tank and the take-up machine; and a multi-stage temperature control structure is arranged on the extruder, and the temperature of the multi-stage temperature control structure is distributed from low to high in the output direction of the extruder. The soluble teflon processing device and the processing technology thereof have the beneficial effects that sectional temperature control is adopted in the extruder, so that the decomposition phenomenon caused by too fast local temperature rise when soluble polytetrafluoroethylene is heated is avoided, and the stability of the extrusion process is improved; and the high extrusion temperature is adopted, the viscosity of the soluble polytetrafluoroethylene is reduced, the critical shear rate of the soluble polytetrafluoroethylene is increased, the phenomena of rough surface, no gloss or layering are eliminated in the extrusion process, and the extrusion quality of the soluble polytetrafluoroethylene is improved.

Owner:DONGGUAN GODDESS ELECTRONICS

A kind of high hardness composite ceramic non-stick pan and preparation method thereof

ActiveCN109259609BImprove thermal conductivityConsistent temperatureCooking-vessel materialsAntifouling/underwater paintsComposite ceramicBarium carbonate

Owner:NINGBO TAIOOR COOKWARE

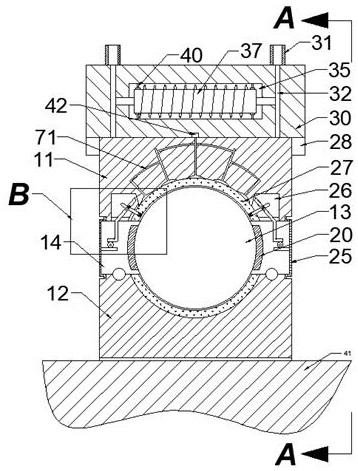

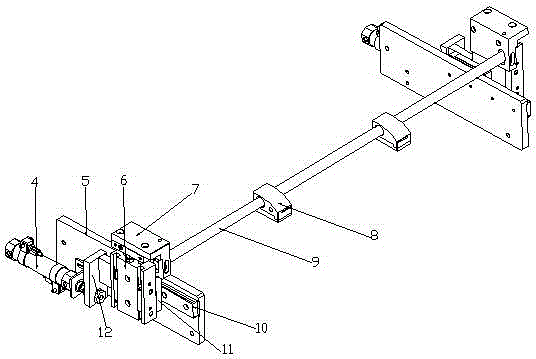

Teflon rod and tube extrusion device

The invention discloses a Teflon rod tube extrusion device and belongs to the field of Teflon rod tube processing. According to the technical scheme, the Teflon rod tube extrusion device comprises a rack, a material tray, a feeding hopper, discharging tubes, heating tubes, a pushing mechanism and a heating assembly, wherein the material tray and the feeding hopper are fixed on the rack; the heating assembly is used for heating the heating tubes; the pushing device comprises an oil cylinder, a disc and pushing tubes; the oil cylinder is fixed on the rack; the disc is fixed toa piston of the oilcylinder; the pushing tubes are fixed on the disc and correspond to dischargingholes; the bottoms of the pushing tubes are through; two guiding blocks are symmetrically arranged inside each pushing tube and close to the bottom position; the bottom of each guiding block is designed to be a slope; an opening-closing block is connected with a sliding block positioned below each guiding block; the contact surface between each opening-closing block and the corresponding guiding block is designed to be a slope; a sliding groove is formed in each guiding block; the groove mouth of each sliding groove is smaller than the groove cavity; each sliding block positioned in the corresponding sliding groove is fixed through the corresponding opening-closing block; the outer diameter of each pushing tubeis the same as the diameter of each discharginghole; and the feeding hopper communicates with the inner cavity of each pushing tube through a corresponding hose. According to the Teflon rod tube extrusion device disclosed by the invention, the descending process of each pushing tube is utilized for supplement, the ascending process of each pushing tube is utilized for feeding, and the working efficiency is effectively improved.

Owner:湖北文太新材料有限公司

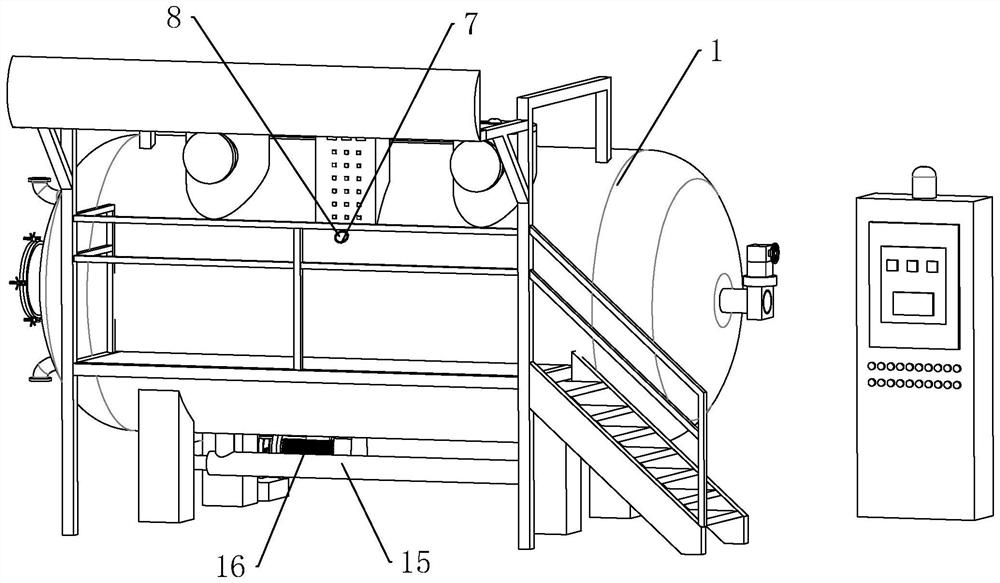

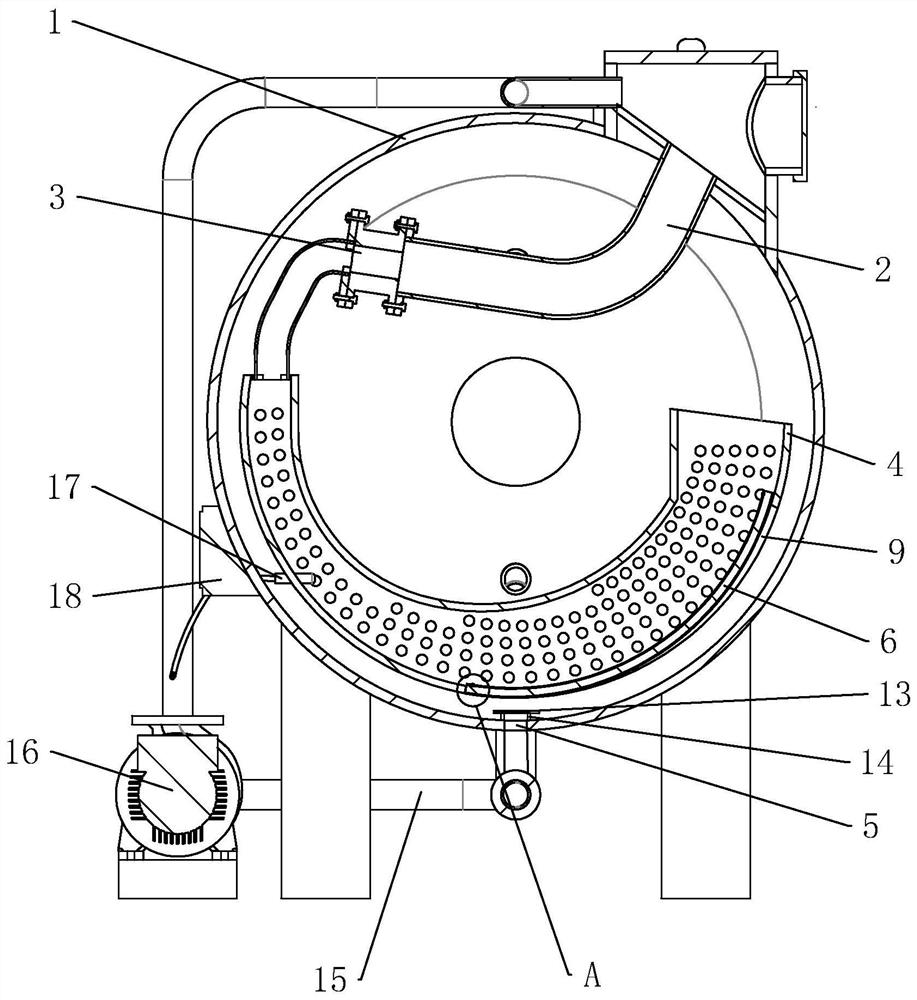

High-temperature high-pressure energy-saving dyeing machine uniform in cloth dyeing and coloring

PendingCN111876945AImprove uniformityImprove dyeing effectTextile treatment containersTextile treatment machine arrangementsPolymer scienceEngineering

The invention relates to a high-temperature high-pressure energy-saving dyeing machine uniform in cloth dyeing and coloring. The machine comprises a cloth moving pipe, a dye vat, a cloth storage tankarranged in the dye vat and a water outlet formed in the dye vat, a through groove is formed in the side wall of the bottom of the cloth storage tank, and a plurality of connecting rods are fixedly connected in the through groove and are arranged in an arc shape. The connecting rods are arranged in the depth direction of an inner cavity of the cloth storage tank and sleeved with Teflon pipes, a seepage groove is formed between every two adjacent Teflon pipes, the water outlet is located below the Teflon pipes, and a rectangular baffle is fixedly connected to the bottom face of the cloth storage tank, is located above the water outlet and shields the water outlet. A gap is reserved between the rectangular baffle and the water outlet, and fixing devices used for fixing the Teflon pipes are arranged on the connecting rods. The dyeing machine has the advantages that the coloring uniformity degree of dyed cloth can be improved, and the final dyeing effect of the dyed cloth is improved.

Owner:无锡市天东机械制造有限公司

Application of a fluorine-containing polymer in preparation of transparent frozen soil

InactiveUS20160244545A1High transparencyLow pricePreparing sample for investigationFoundation testingRefractive indexModel test

The present invention discloses the application of a fluorine-containing polymer in the preparation of a transparent frozen soil, which is used as a transparent solid material while in the preparation of a transparent frozen soil, wherein the fluorine-containing polymer is Teflon AF 1600 produced by American DuPont Company, with the refractive index of 1.31 and the density of 2.1-2.3 g / cm3, and are particles with the particle diameter of 0.25-2.0 mm or particles with the particle diameter ≦0.074 mm, and its particles have irregular shape. When said fluorine-containing polymer of the present invention is used as a transparent solid material for preparing a transparent frozen soil, the prepared transparent frozen soil has high transparency, low price, no toxicity and no harm, and good similarity with the properties of the natural frozen soil body, can widely substitute natural frozen soil, is used for simulating complicated geological conditions, and is effectively used in model tests in the geotechnical engineering.

Owner:HOHAI UNIV

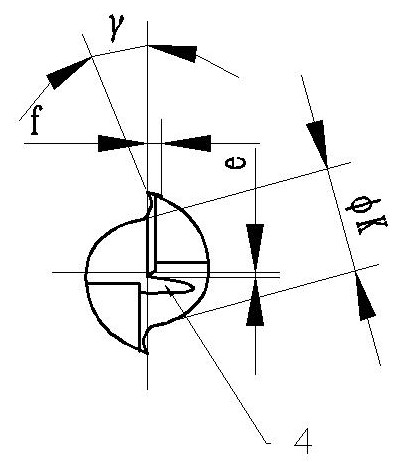

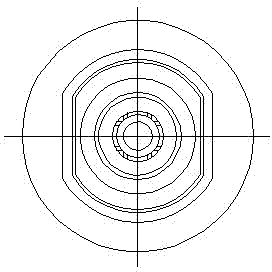

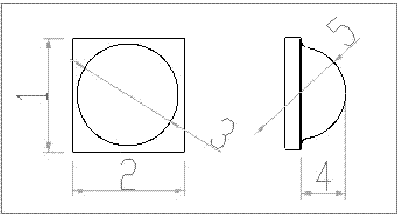

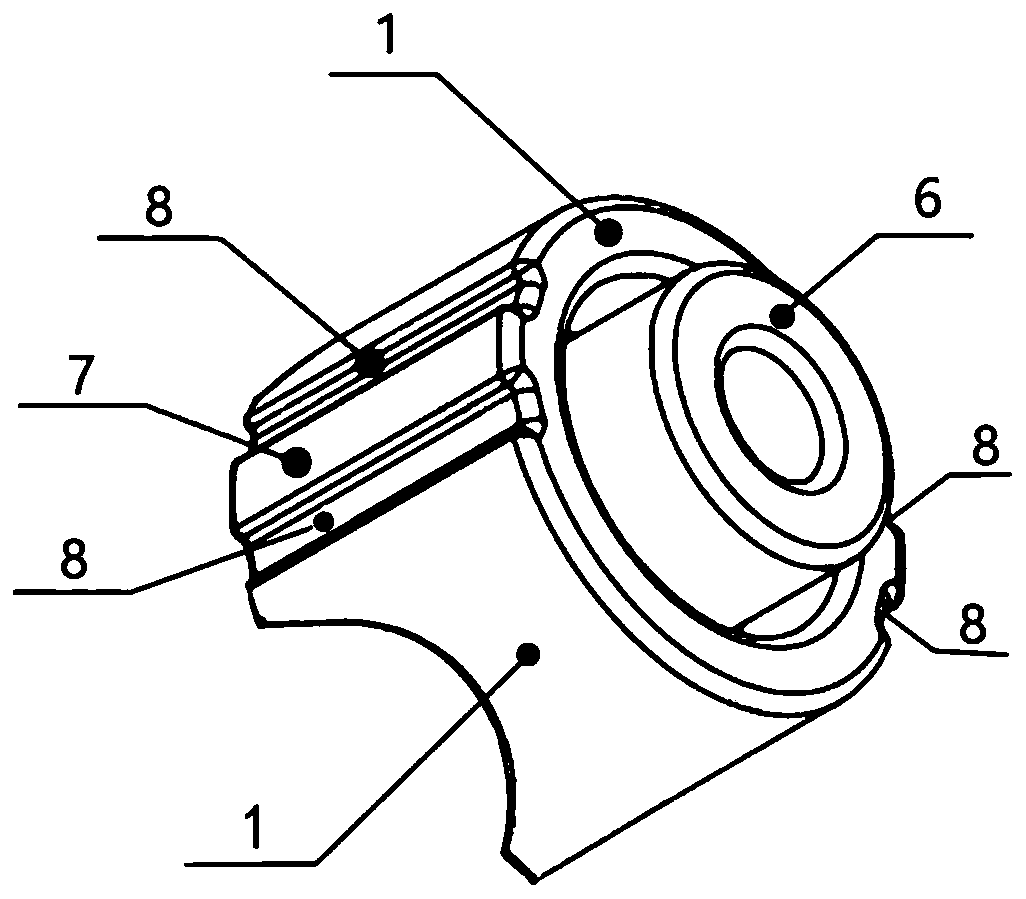

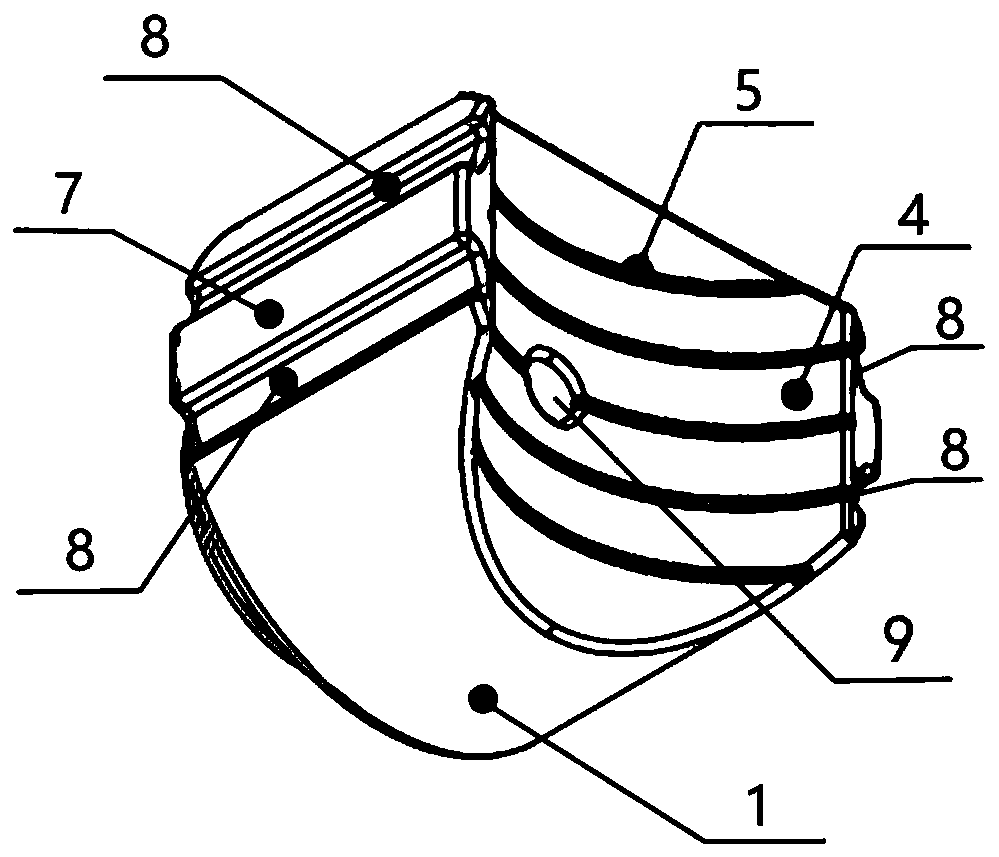

Milling cutter for processing flexible board

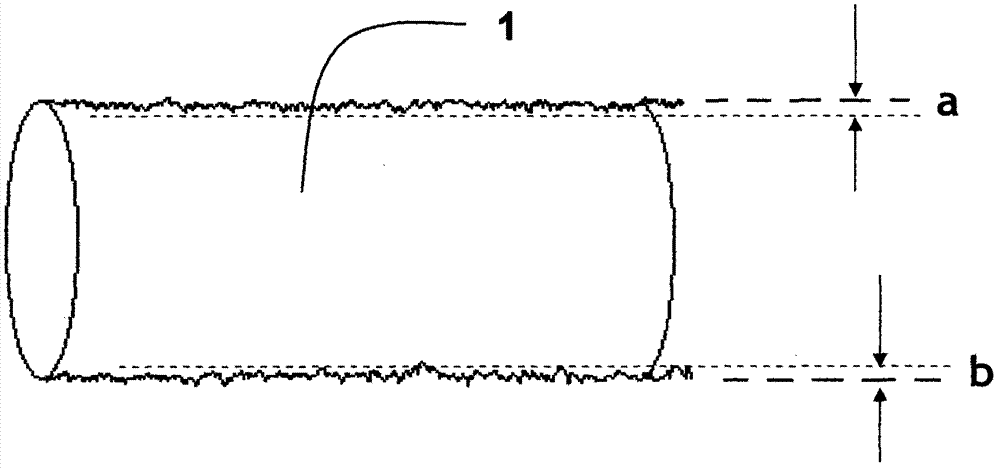

ActiveCN102601437AGuaranteed roughnessGuaranteed dimensional accuracyMilling cuttersTool bitMilling cutter

The invention discloses a milling cutter for a processing flexible board, which comprises a cutter handle (1). One end of the cutter handle (1) extends to form a milling cutter head (2). Two spiral grooves (3) in the same spiral direction are molded on the surface of the milling cutter head (2) to form milling edges. A V-notch cutting surface is arranged at the end of the milling cutter head (2). A chamfer is arranged at the end part of the cutting surface to form a chamfering edge. The spiral angle omega of each spiral groove (3) is 28-32 degrees. The milling cutter solves the problems of poor rigidity and poor cutting performance of the existing milling cutter used for processing flexible circuit boards, and is particularly suitable for processing blind grooves with chamfers on plates such as aluminum substrates, copper substrates, flexible boards, Teflon plates and polytetrafluoroethylene plates.

Owner:ZHEJIANG DEWEI CEMENTED CARBIDE MFG CO LTD

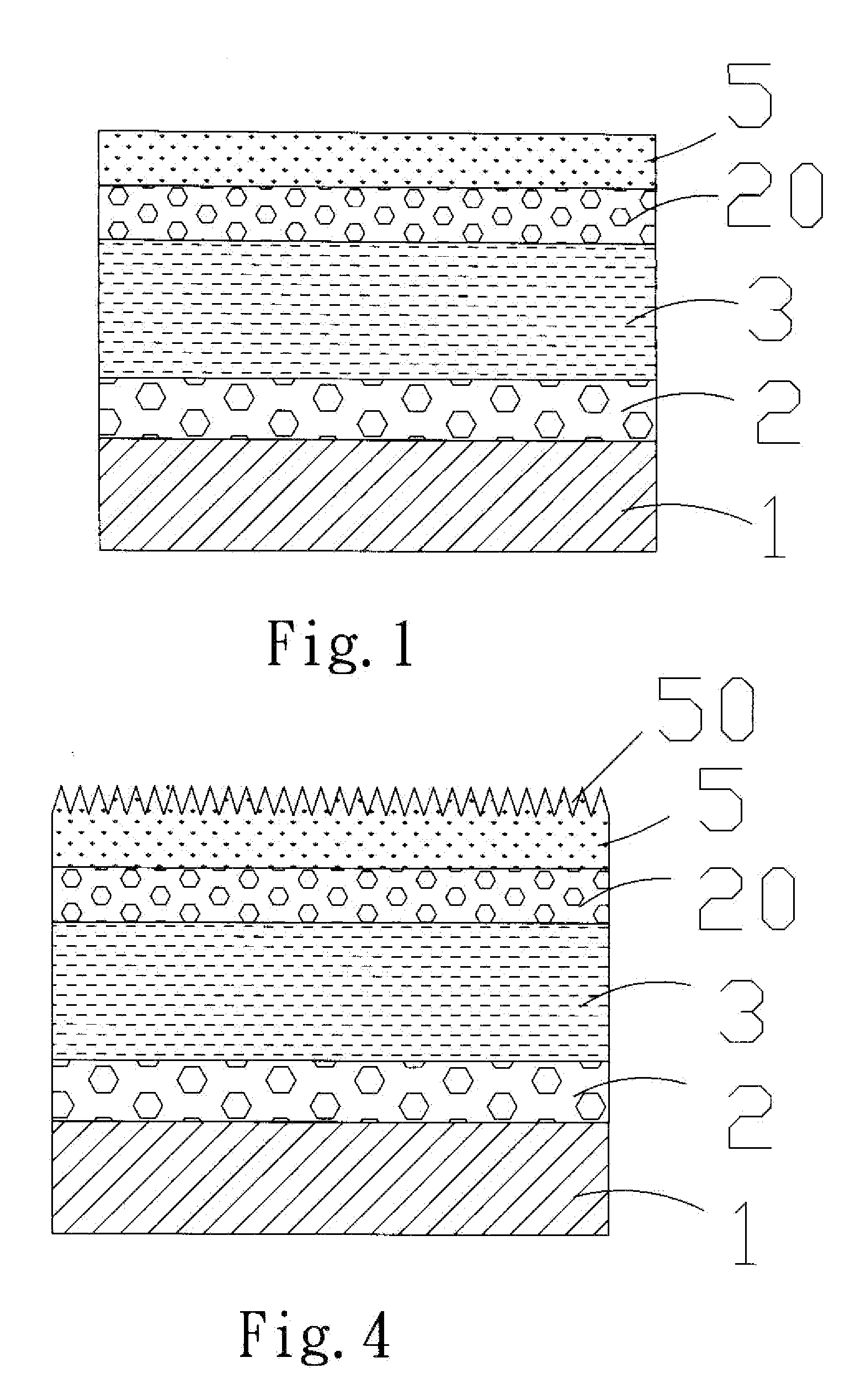

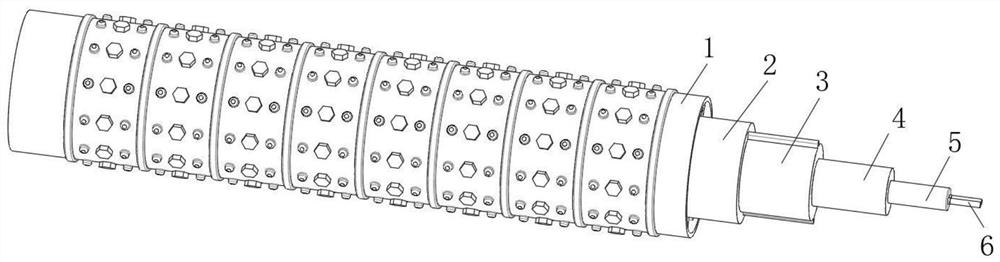

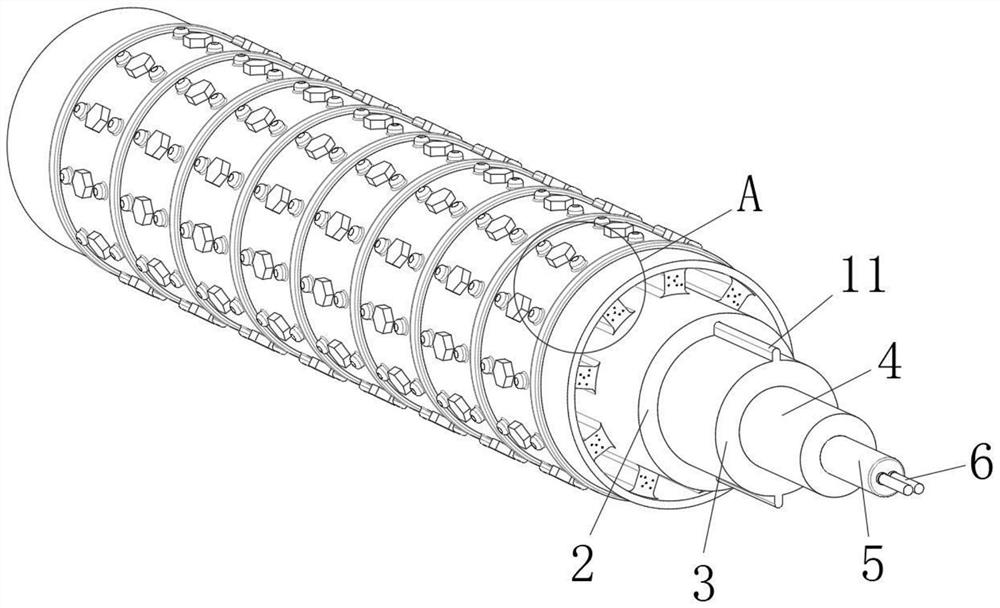

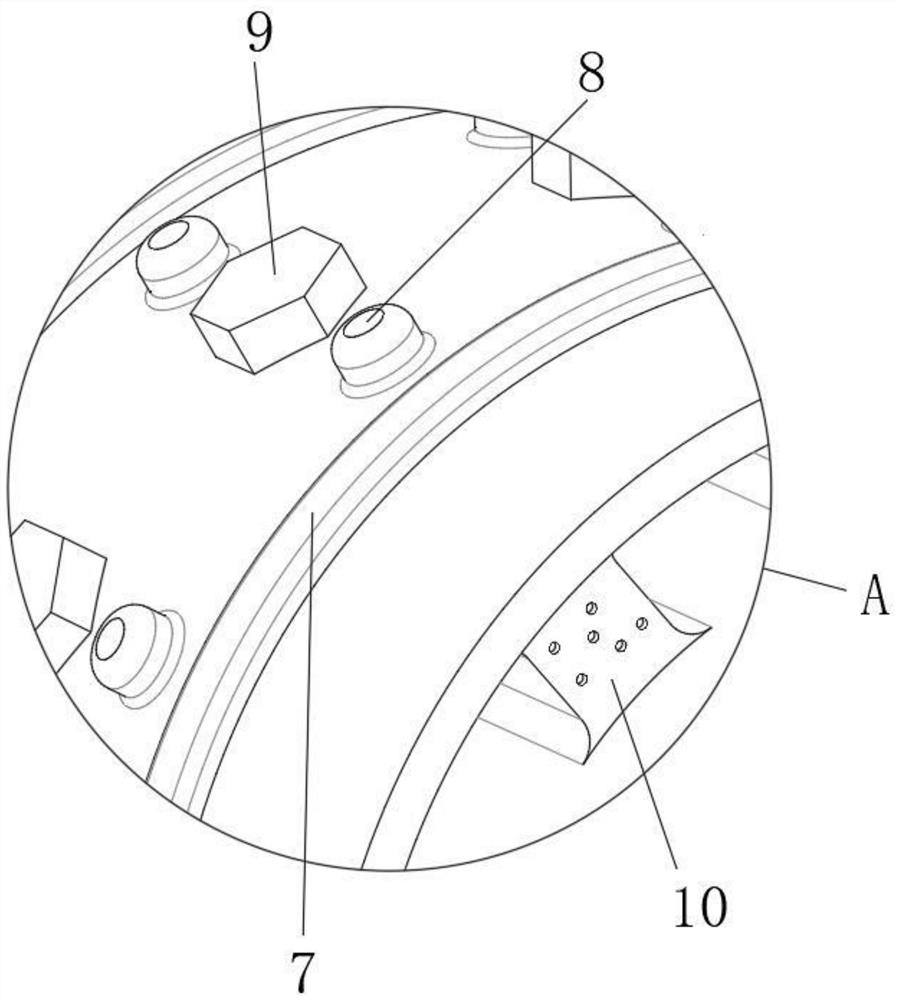

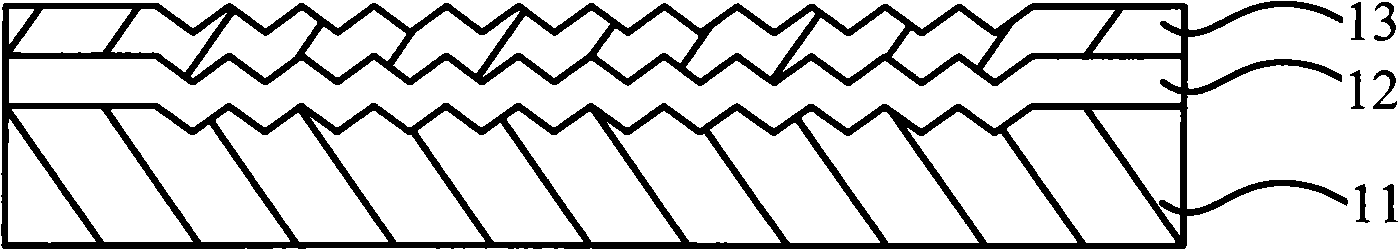

Anti-static teflon wire

InactiveCN113488257AIncrease frictionReduce shakingFlexible cablesFlexible conductorsAdhesive glueEngineering

The invention provides an anti-static teflon electric wire, and relates to the technical field of teflon electric wires. The anti-static teflon electric wire is composed of an outer layer, a teflon layer, a glue layer, an insulating layer, a wire core shielding layer and a wire core body; the teflon layer is fixedly installed on the inner side of the outer layer, the glue layer is fixedly installed on the inner side of the teflon layer, and the insulating layer is fixedly installed on the inner side of the glue layer. An insulating layer is fixedly installed on the inner side of the glue layer, a wire core shielding layer is fixedly installed on the inner side of the insulating layer, and a wire core body is installed in the wire core shielding layer. According to the invention, through the arrangement of the ferrule, the convex particles and the hexagonal blocks, the friction force of the outer layer can be increased, the shaking amplitude of the cable in an electric appliance is reduced, the wear degree is further reduced, the service life is prolonged, and actual use is facilitated; meanwhile, the buffer pad is arranged between the outer layer and the teflon layer, so that when the outer layer is bent, the teflon layer can be prevented from being bent excessively through the buffer pad, and the service life of the teflon layer is further prolonged.

Owner:湖北宇辰新材料有限公司

Structure having high mould-release property

InactiveCN101269558AHighly releasableGood release effectSurface reaction electrolytic coatingMetallic material coating processesRolloverMotherboard

The invention provides a structure of a die with high release property, which comprises a pure nickel metal die motherboard, a stripping film which is formed on the pure nickel metal die motherboard, and an EN-PTFE coating which is formed on the metal die motherboard; the volume percentage content of the Teflon in the EN-PTFE coating is between 10 percent and 35 percent. The structure has the beneficial effect that: the structure of the die with high release property is used for the metal cavity electroforming rollover, the EN-PTFE coating of the die surface does not change the microstructure size of the cavity, at the same time, the release property of the die is increased.

Owner:AU OPTRONICS CORP

Milling cutter for processing flexible board

ActiveCN102601437BGuaranteed roughnessGuaranteed dimensional accuracyMilling cuttersTool bitMilling cutter

The invention discloses a milling cutter for a processing flexible board, which comprises a cutter handle (1). One end of the cutter handle (1) extends to form a milling cutter head (2). Two spiral grooves (3) in the same spiral direction are molded on the surface of the milling cutter head (2) to form milling edges. A V-notch cutting surface is arranged at the end of the milling cutter head (2). A chamfer is arranged at the end part of the cutting surface to form a chamfering edge. The spiral angle omega of each spiral groove (3) is 28-32 degrees. The milling cutter solves the problems of poor rigidity and poor cutting performance of the existing milling cutter used for processing flexible circuit boards, and is particularly suitable for processing blind grooves with chamfers on plates such as aluminum substrates, copper substrates, flexible boards, Teflon plates and polytetrafluoroethylene plates.

Owner:ZHEJIANG DEWEI CEMENTED CARBIDE MFG CO LTD

Manufacture technology for high-frequency material

InactiveCN102774081AChange physical propertiesMeet needsSynthetic resin layered productsGlass/slag layered productsGlass fiberManufacturing technology

The invention relates to a technology for reducing machinery processing problems of printed circuit boards by using a high-frequency material as a basic material. The high-frequency material at least comprises a copper foil, a teflon (polytetrafluoroethylene) resin, glass fiber, and the like, wherein the glass fiber is treated for reducing mechanical strength and is beneficial for processing when machining in subsequent manufacture processes. Materials produced by the method are not changed in material performance and not changed greatly in production cost. However, production yield and production capacity for the subsequently printing circuit boards are improved. The technology can play important role in the development of electronic industry.

Owner:代芳

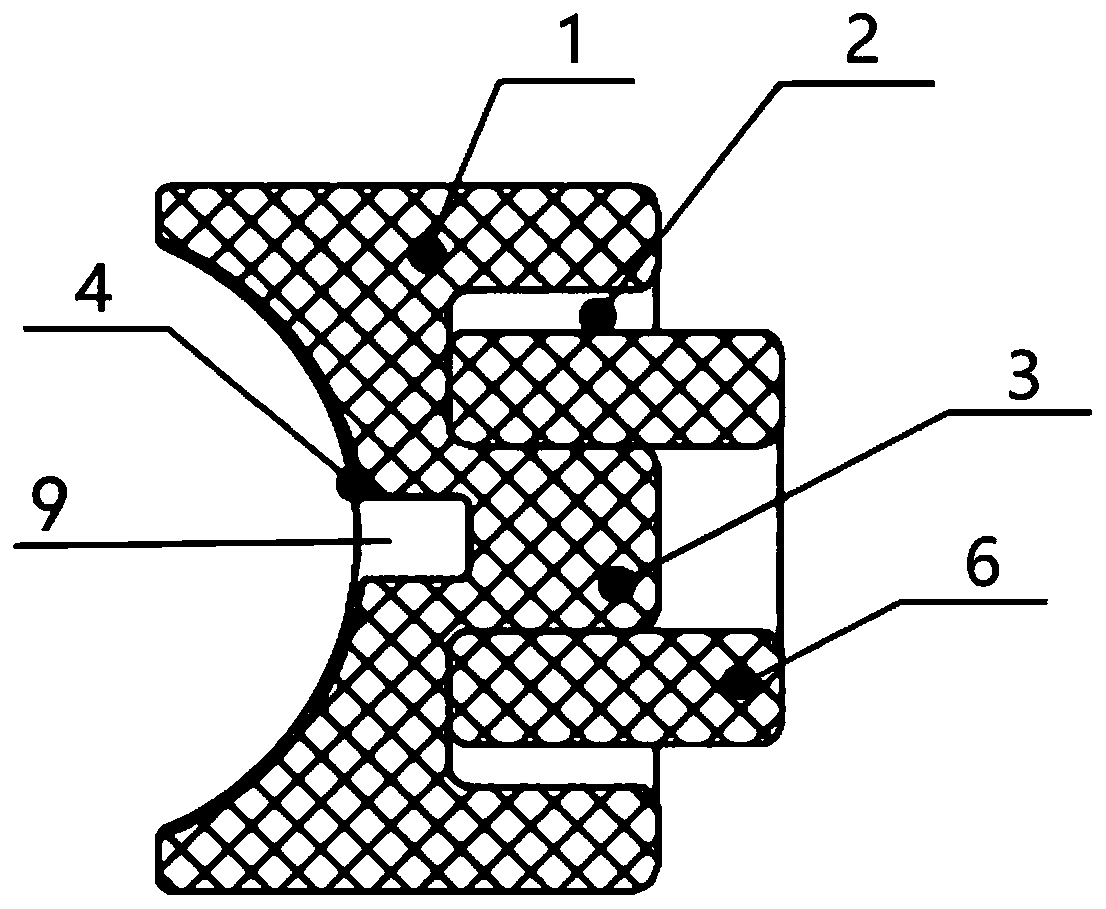

Sealing structure used between shaft and shaft barrel

PendingCN113638972AAchieve sealingGuaranteed coaxialityPackagingBearing unit rigid supportNylon materialInterference fit

The invention provides a sealing structure used between a shaft and a shaft barrel. The sealing structure comprises the shaft and the shaft barrel, wherein the shaft is arranged in the shaft barrel in a penetrating mode and is coaxial with the shaft barrel; a sealing component is arranged at an end opening of the shaft barrel; the sealing component comprises a column type flange and packing; the column type flange is made of nylon materials or Teflon materials; the column type flange comprises a column body part and a flange part which are integrally arranged; the column body part is of a cylinder structure with a through hole; the column body part is arranged between the shaft and the shaft barrel in a sleeving mode and is in interference fit with the shaft and the shaft barrel; the packing is embedded in the column body part and located at the position between the column body part and the shaft; the flange part is of a flange plate structure; the shaft is sleeved with the flange part; the flange part is fixedly connected to the end opening of the shaft barrel; and the flange part is in interference fit with the shaft. A column type flange sealing shaft and the shaft barrel of a special structure are arranged between the shaft and the shaft barrel, so that sealing between the shaft and the shaft barrel is achieved, the coaxiality between the shaft and the shaft barrel is guaranteed, and the duty ratio of the sealing structure is reduced while the structural strength is met.

Owner:河南瑞明尼克筛分机械有限公司

EPS rack clearance buffering stop block assembly

InactiveCN110723196ASimple manufacturing processImprove impact resistanceMechanical steering gearsGlass fiberRubber ring

An EPS rack clearance buffering stop block assembly comprises a pressing block cylinder and a rubber ring. An inward-concave arc rack contact hook face is arranged at the bottom of the pressing blockcylinder, and a concave annular groove is formed in the top of the pressing block cylinder. A protruding rubber ring positioning table is arranged in the middle of the annular groove. The rubber ringis arranged in the annular groove and is limited in the pressing block cylinder through the rubber ring positioning table. The pressing block cylinder is manufactured in the manner that nylon and glass fiber are main materials and subjected to injection molding, and a teflon coating is used for processing plastics; and the rack contact hook face is provided with at least five parallel U-shaped grooves. The EPS rack clearance buffering stop block assembly solves the problems that an EPS stop block assembly on the market is prone to abrasion, abnormal sounds are obvious, the manufacturing manufacturability is poor, and cost is high.

Owner:CHANGHUI AUTOMOBILE STEERING SYST HUANGSHAN

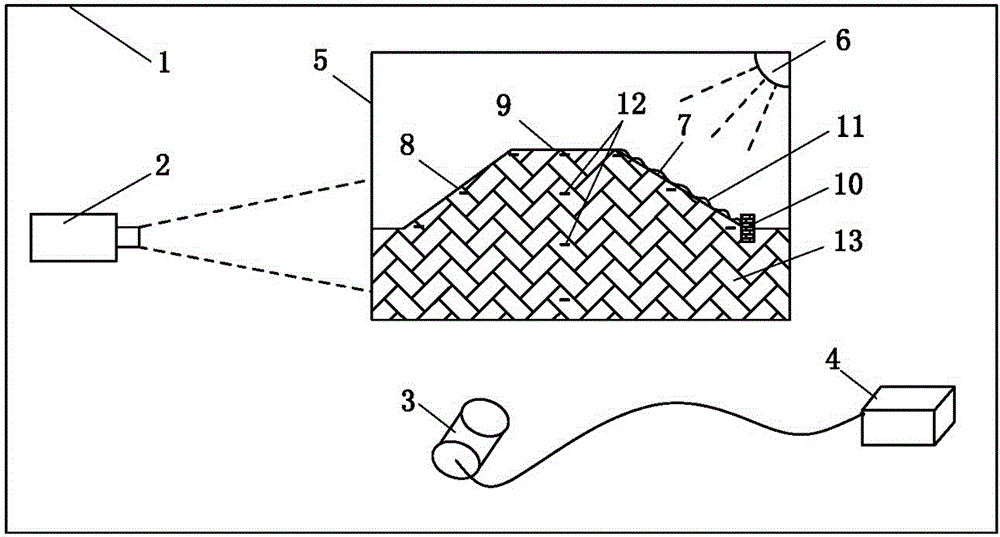

Frozen soil embankment model making and thermal thaw landslide test device and test method of frozen soil embankment model

InactiveCN103926128BHigh transparencyLow pricePreparing sample for investigationMaterial thermal analysisPermafrostSoil properties

The invention discloses a visual frozen soil embankment model making and frozen soil embankment model thermal thaw landslide test device and test method. The transparent frozen soil embankment model is made by using fluorine-containing polymer as a transparent solid material in the transparent frozen soil. The fluorine-containing polymer is a particle with a particle size of 0.25㎜~2.0㎜, which is Teflon AF 1600 produced by DuPont Company of the United States, with a refractive index of 1.31 and a density of 2.1g / ㎝ 3 ~2.3g / ㎝ 3 The test device includes a low-temperature laboratory, and the low-temperature laboratory is provided with simulation devices including transparent model tanks, transparent permafrost embankment models and other simulated embankments and natural environments, including laser sources, recording observation devices and processing devices for digital cameras; The transparent soil prepared by the invention has high transparency and good similarity with natural permafrost soil properties; the test device is easy to realize and has strong repeatability; it can be used to simulate complex geological conditions and is effectively used in model tests in geotechnical engineering .

Owner:HUNAN CITY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com