High-temperature high-pressure energy-saving dyeing machine uniform in cloth dyeing and coloring

A high-temperature, high-pressure, energy-saving technology, which is applied in the field of dyeing machines, can solve problems such as the twisting and turning of the gray cloth, the irregular arrangement of the gray cloth, and the large amount of water accumulation, so as to improve the uniformity, improve the dyeing effect, and realize The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

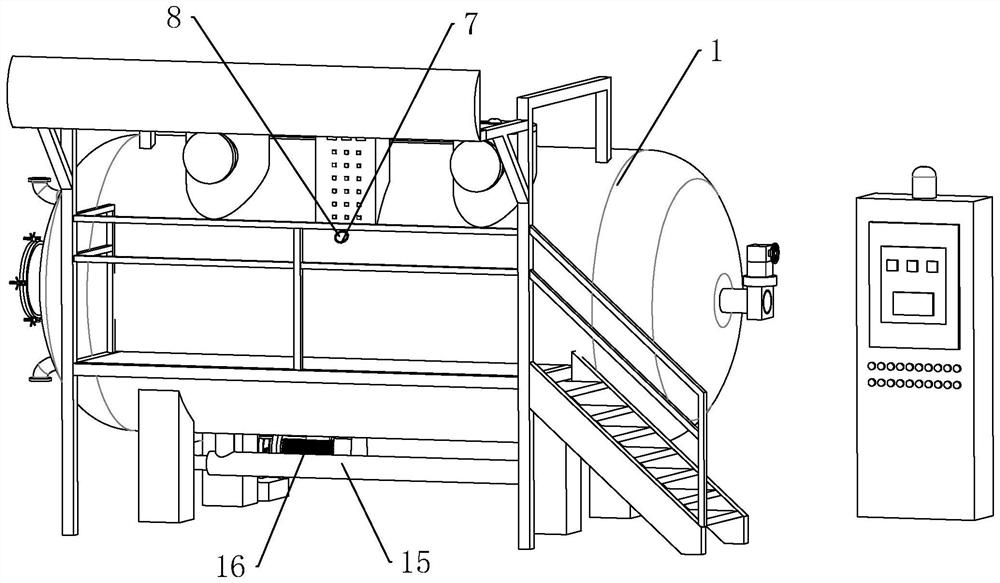

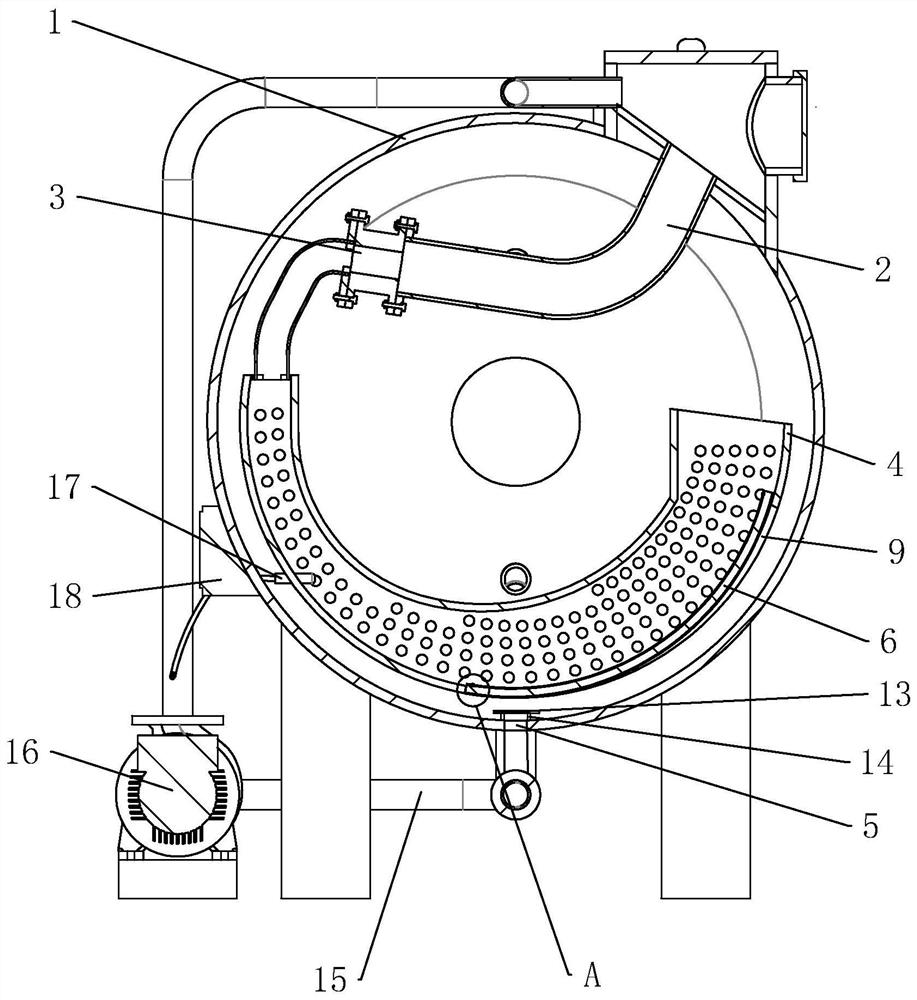

[0034] refer to figure 2 , is a high-temperature, high-pressure, energy-saving dyeing machine with uniform coloring of dyed cloth disclosed in the present invention, comprising a dyeing vat 1, a cloth running pipe 2, a cloth arrangement mechanism 3, a cloth storage tank 4 arranged in the dyeing vat 1, and an opening set on the dyeing vat 1 Outlet 5. Wherein, the cloth storage tank 4 is provided with a Teflon tube 6 for realizing the separation of water and cloth.

[0035] refer to figure 1 The side wall of the dye vat 1 is provided with an observation window 7, and the observation port is arranged in a circular shape. The observation port is connected with the inner cavity of the dye vat 1, and the observation window 7 is fixedly connected with an observation glass 8.

[0036] refer to figure 2 , the vertical section of the distribution pipe 2 is set in a square shape. Compared with the traditional cylindrical distribution pipe 2, this distribution pipe 2 can prevent the ...

Embodiment 2

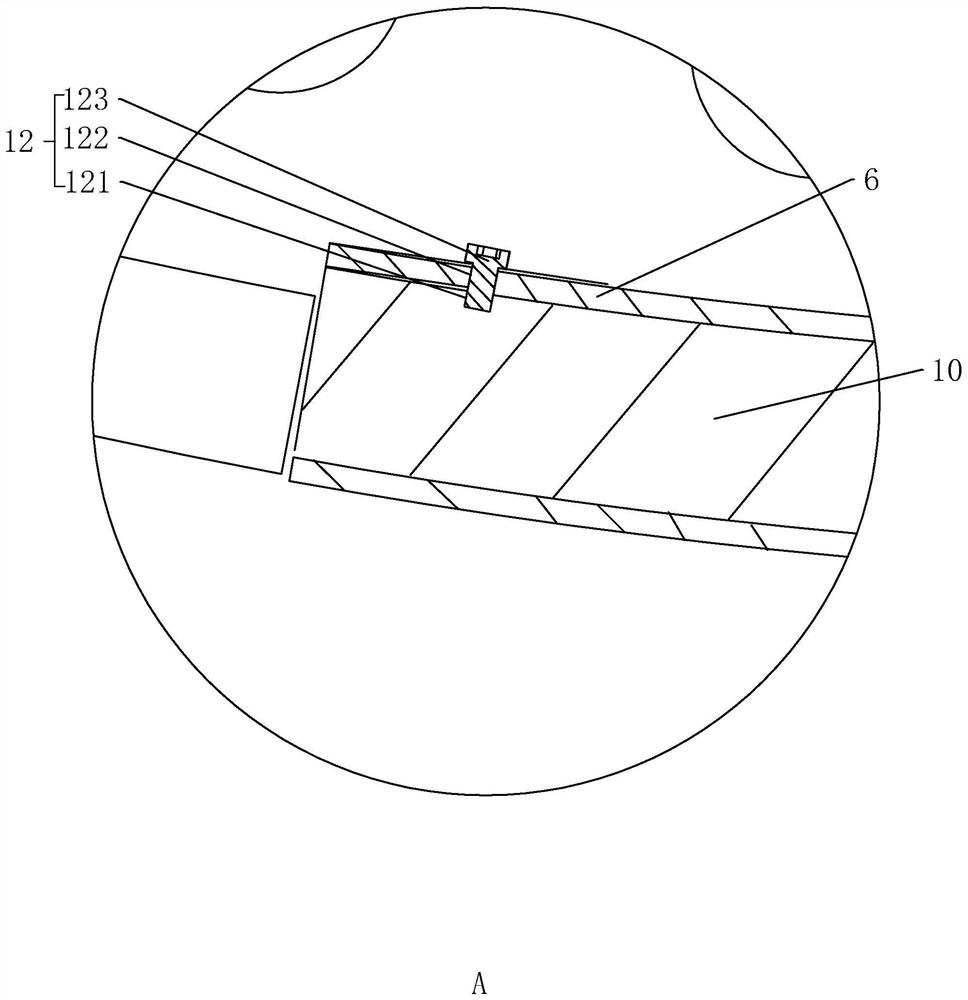

[0047] A high-temperature, high-pressure, energy-saving dyeing machine with uniform coloring of dyed cloth, refer to Figure 5 , the difference from Embodiment 1 is that the fixing device 12 includes a sleeve 124 fixedly connected to the mouth of the Teflon tube 6, a piercing hole 125 provided on the side wall of the sleeve 124, and a sliding connection to the piercing hole. Locating rod 126 in 125, the rotating plate 127 that is connected in locating rod 126 ends in rotation, offers the locating groove 128 that is used for locating rod 126 plugging on connecting rod 10 sidewalls, when Teflon tube 6 is sleeved on connecting After the rod 10 is installed, the sleeve 124 is slidably sleeved on the connecting rod 10 .

[0048] Wherein, the connecting rod 10 is arranged in a cylindrical shape and arranged along a direction perpendicular to the connecting rod 10 . The rotating plate 127 is arranged in a cuboid shape and arranged along a direction perpendicular to the positioning r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com